Patents

Literature

2654results about "Ceramic shaping plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

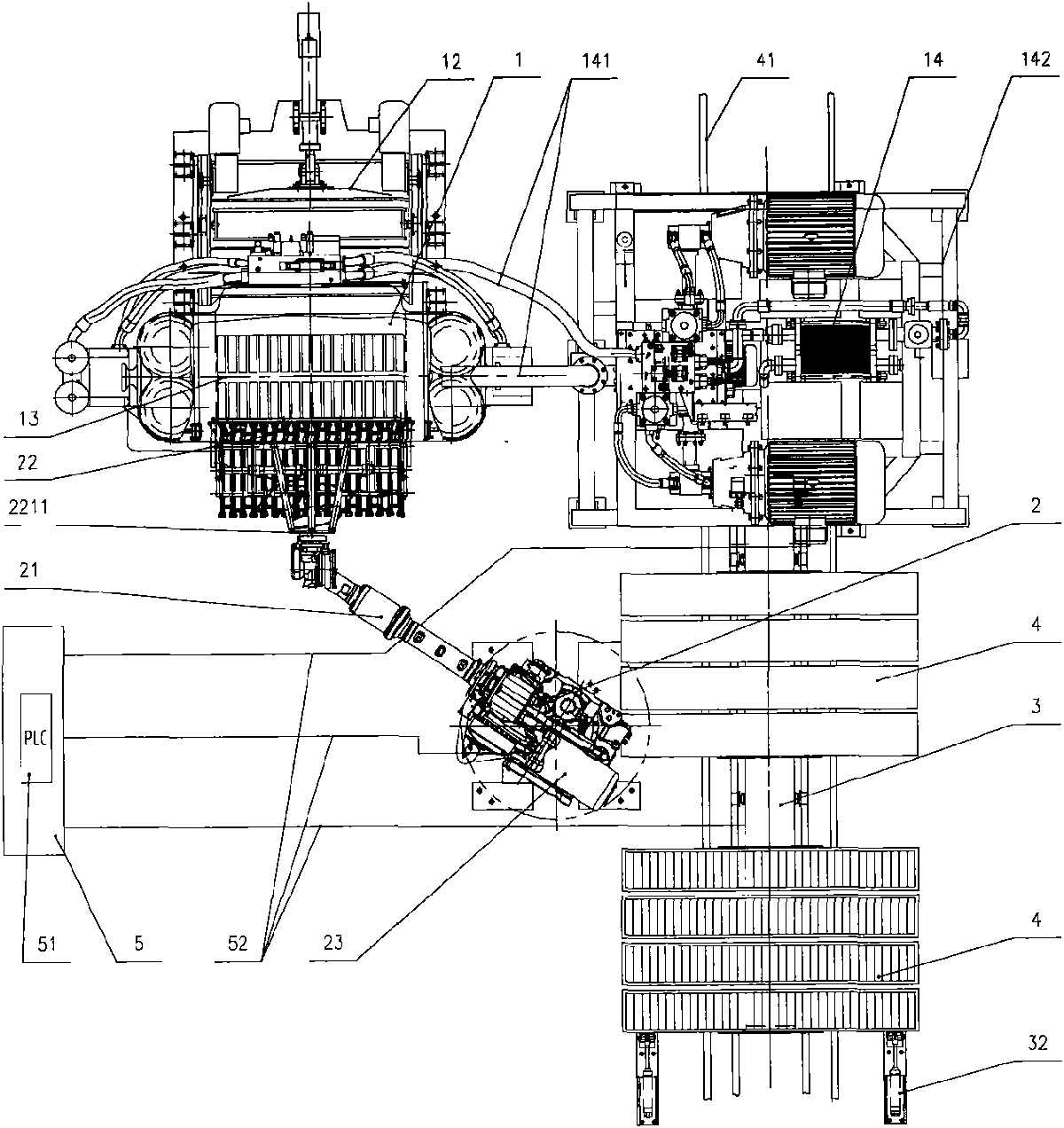

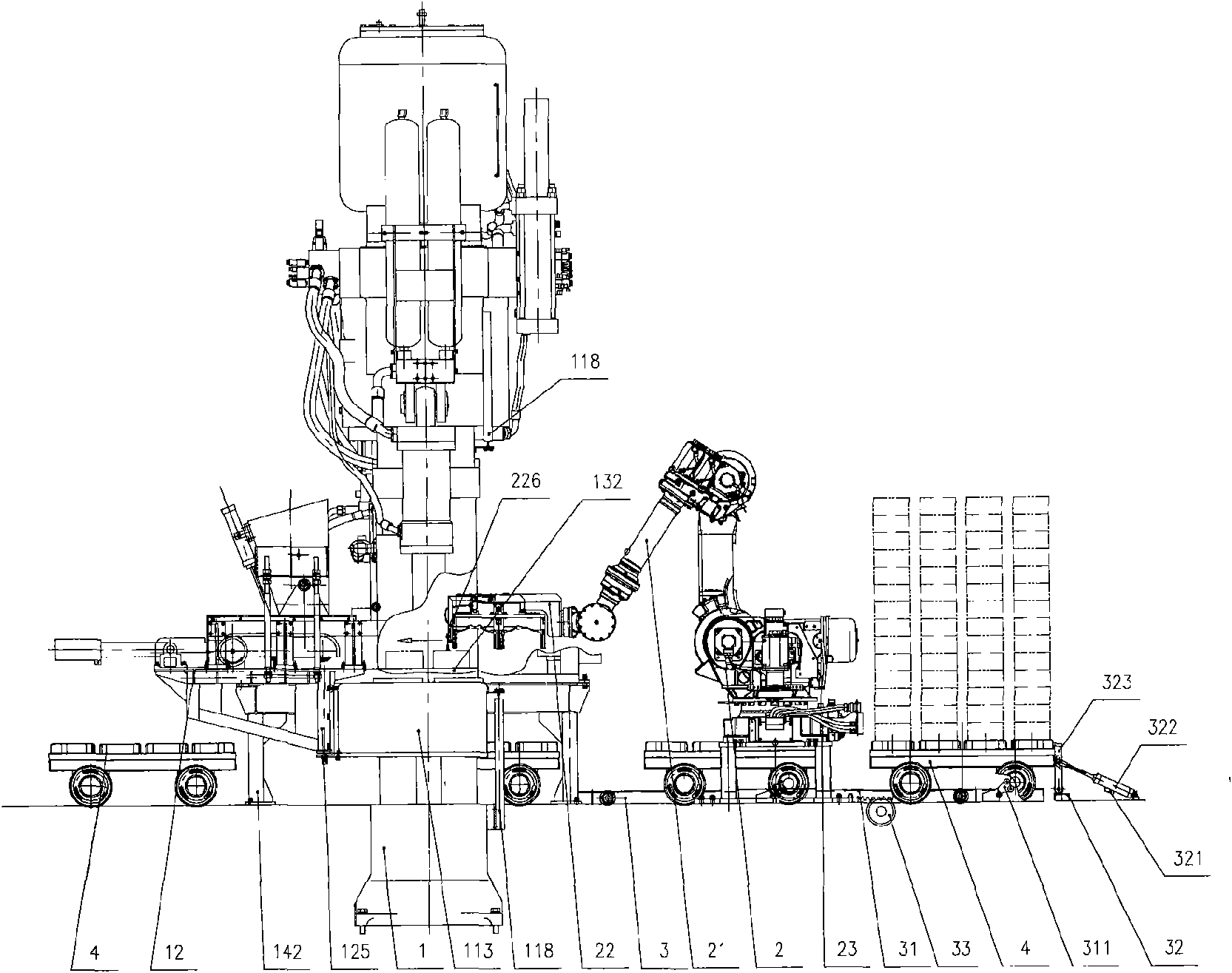

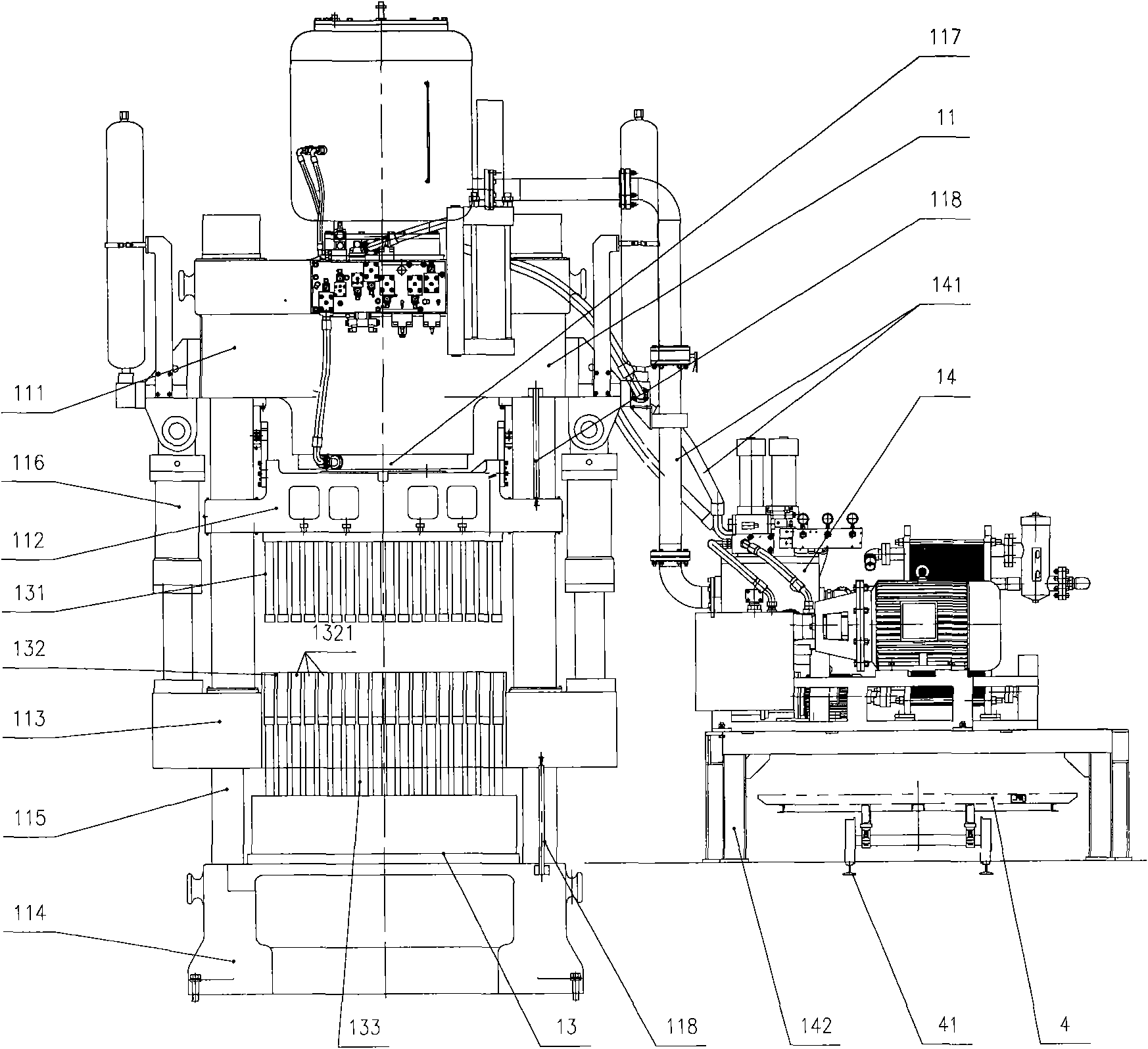

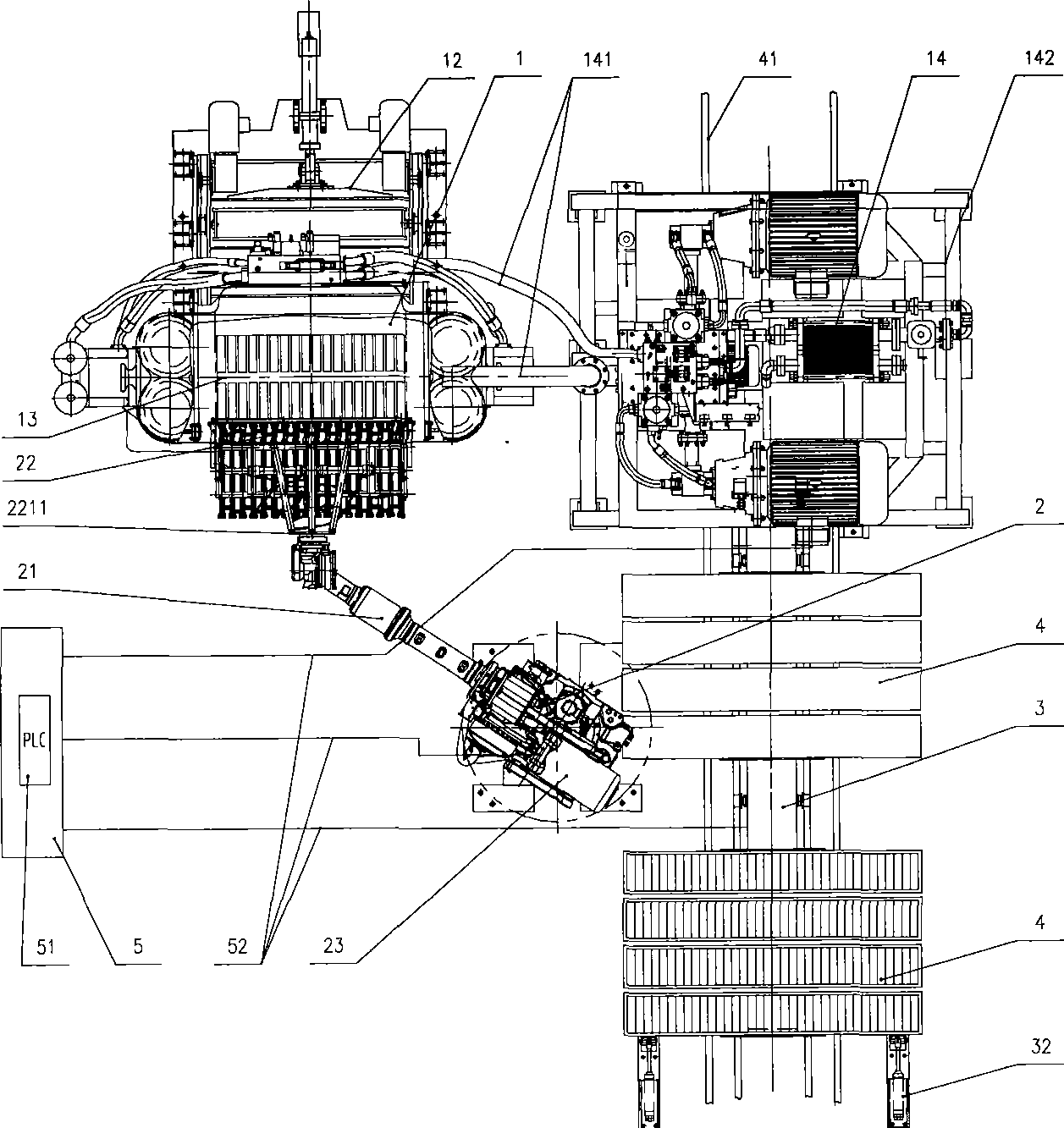

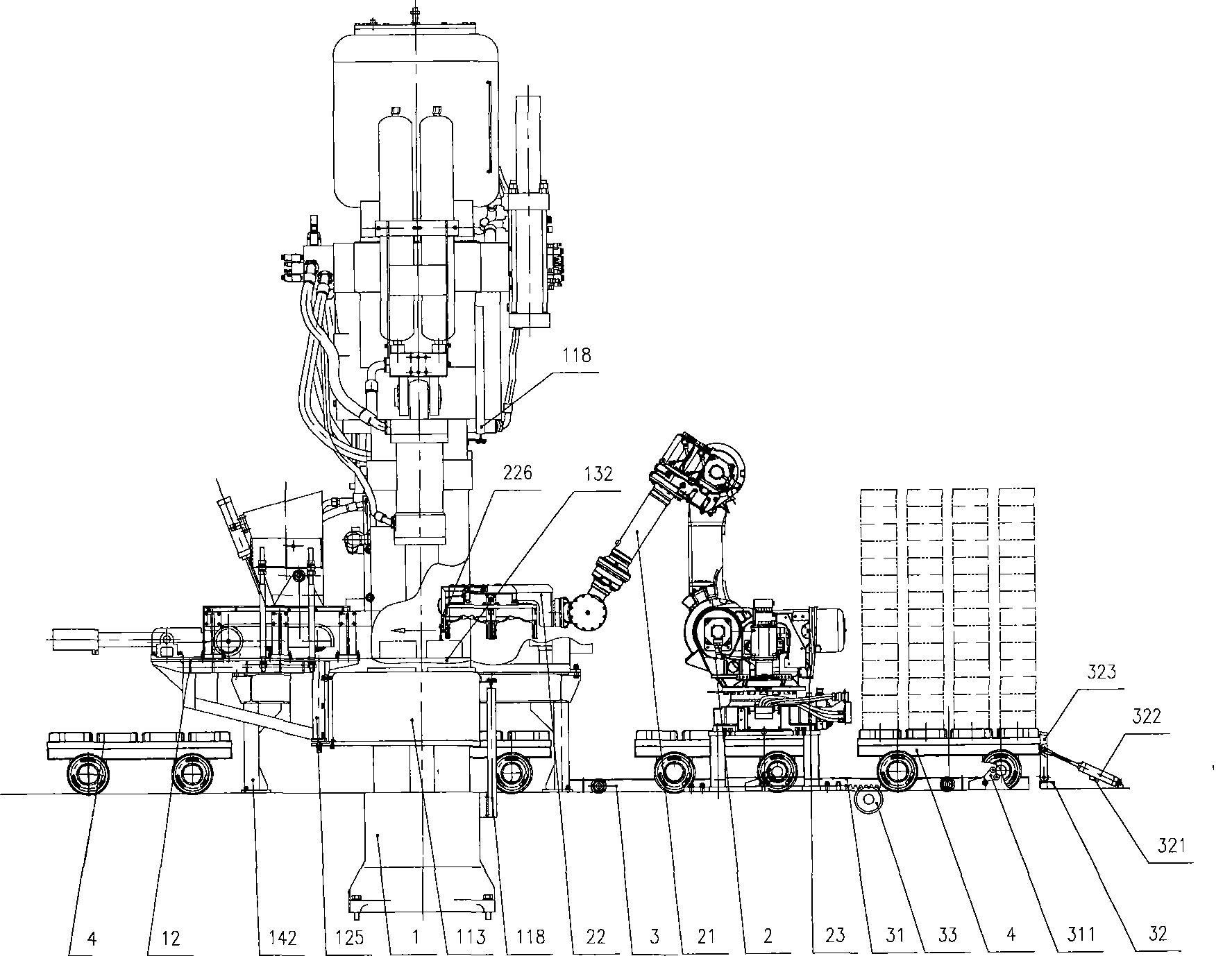

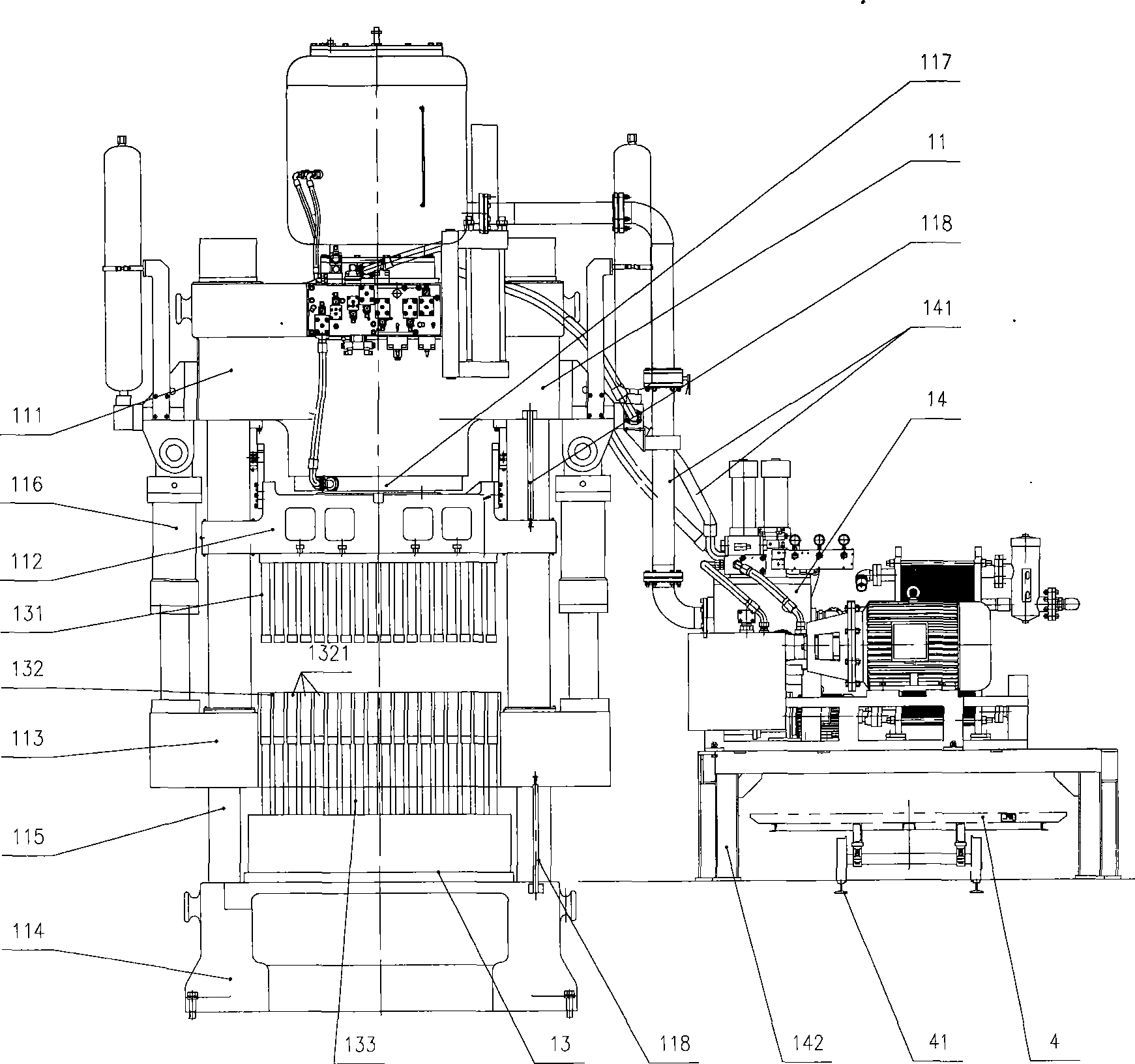

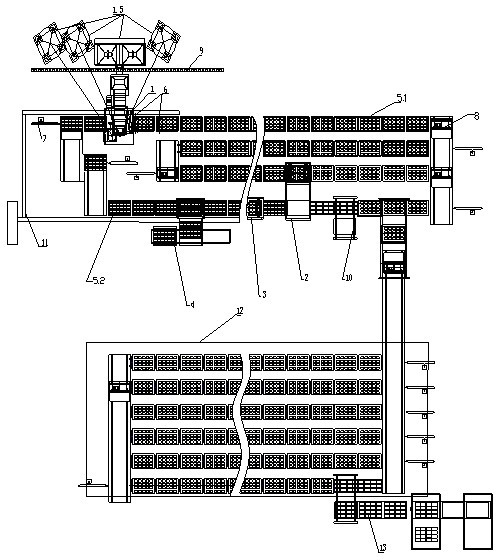

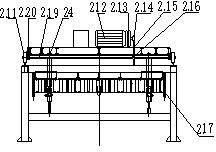

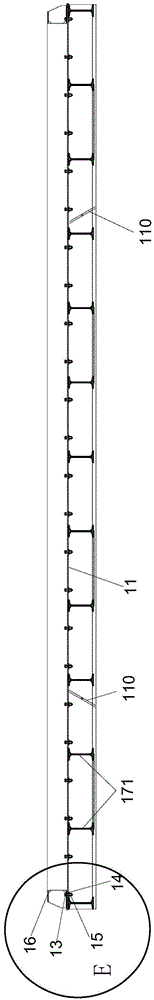

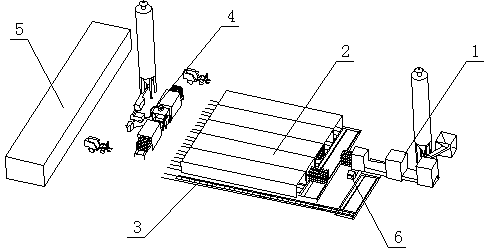

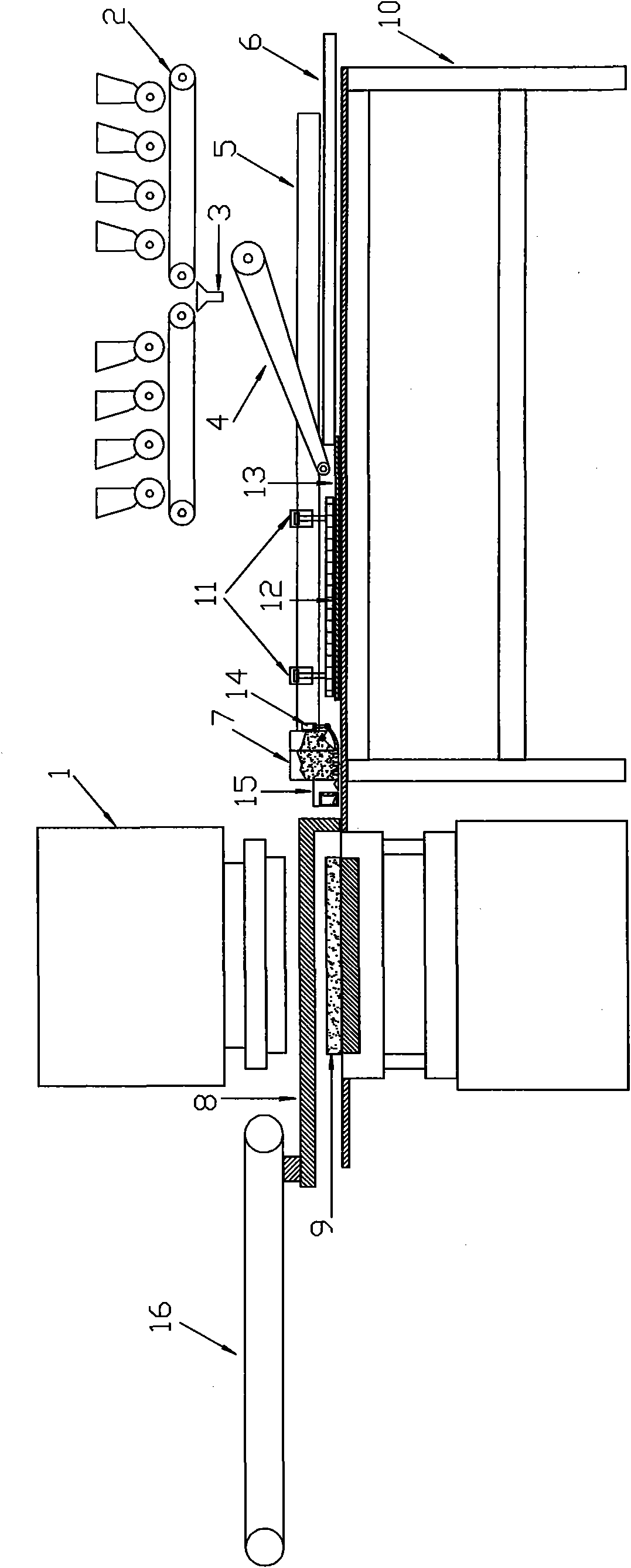

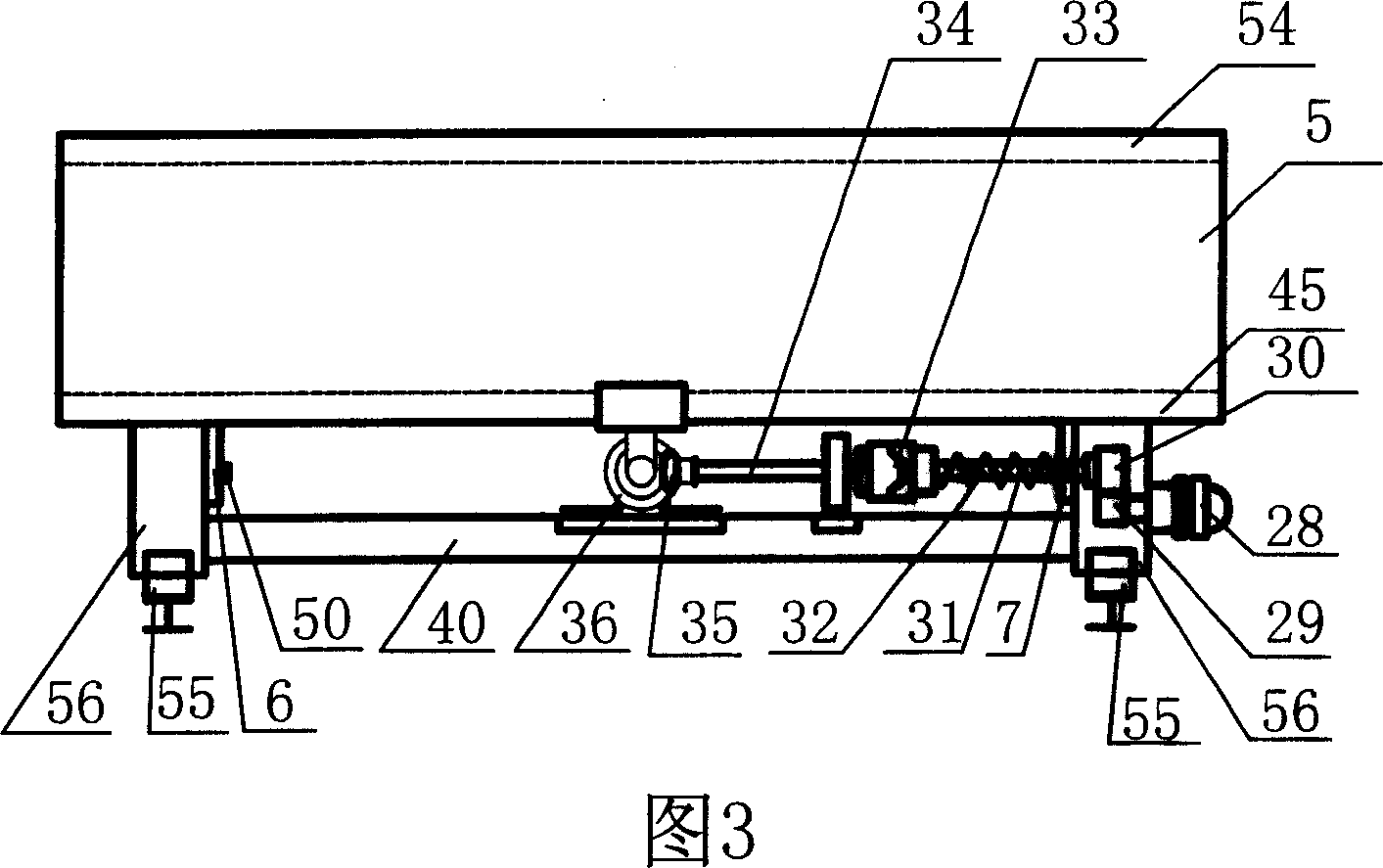

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

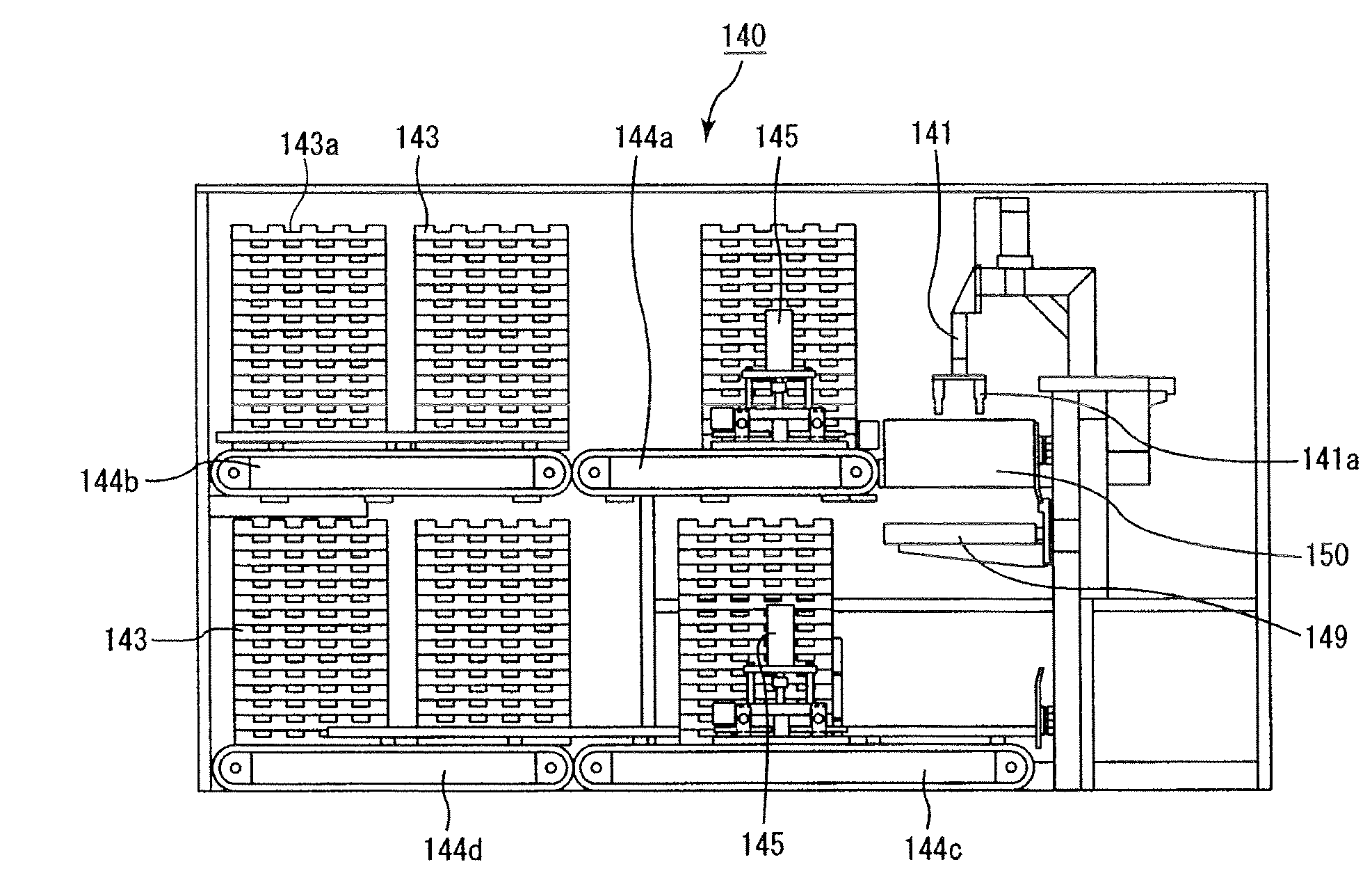

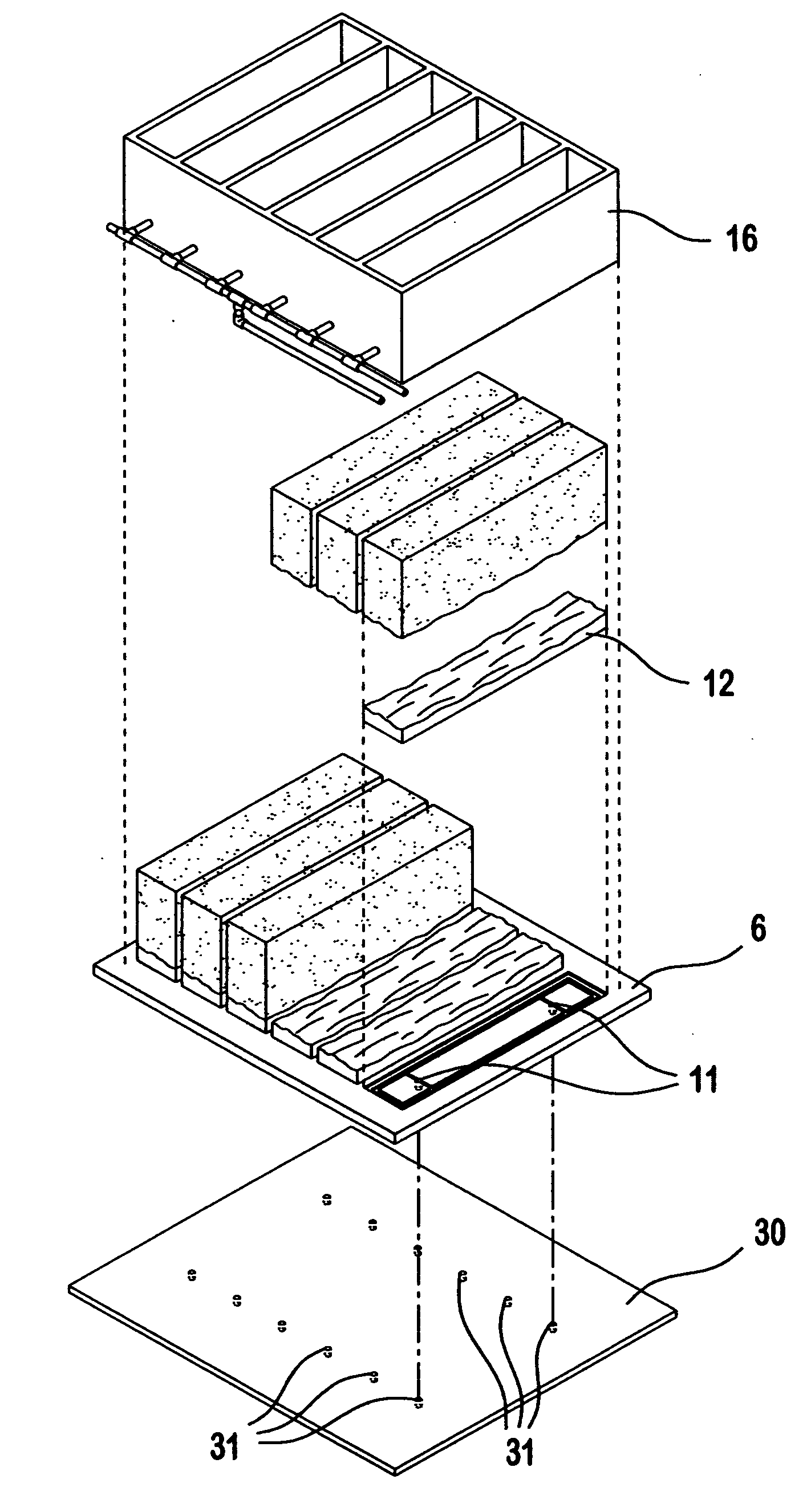

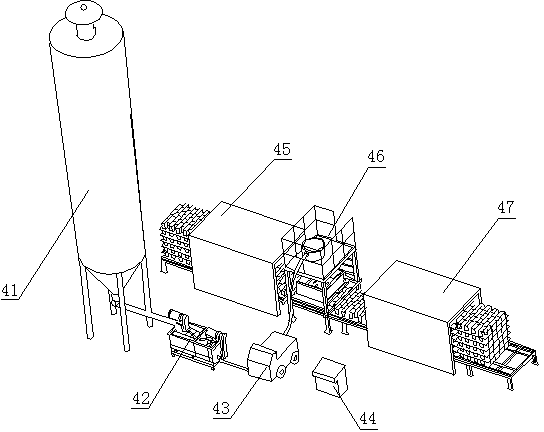

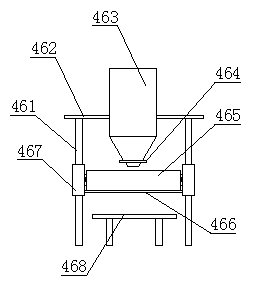

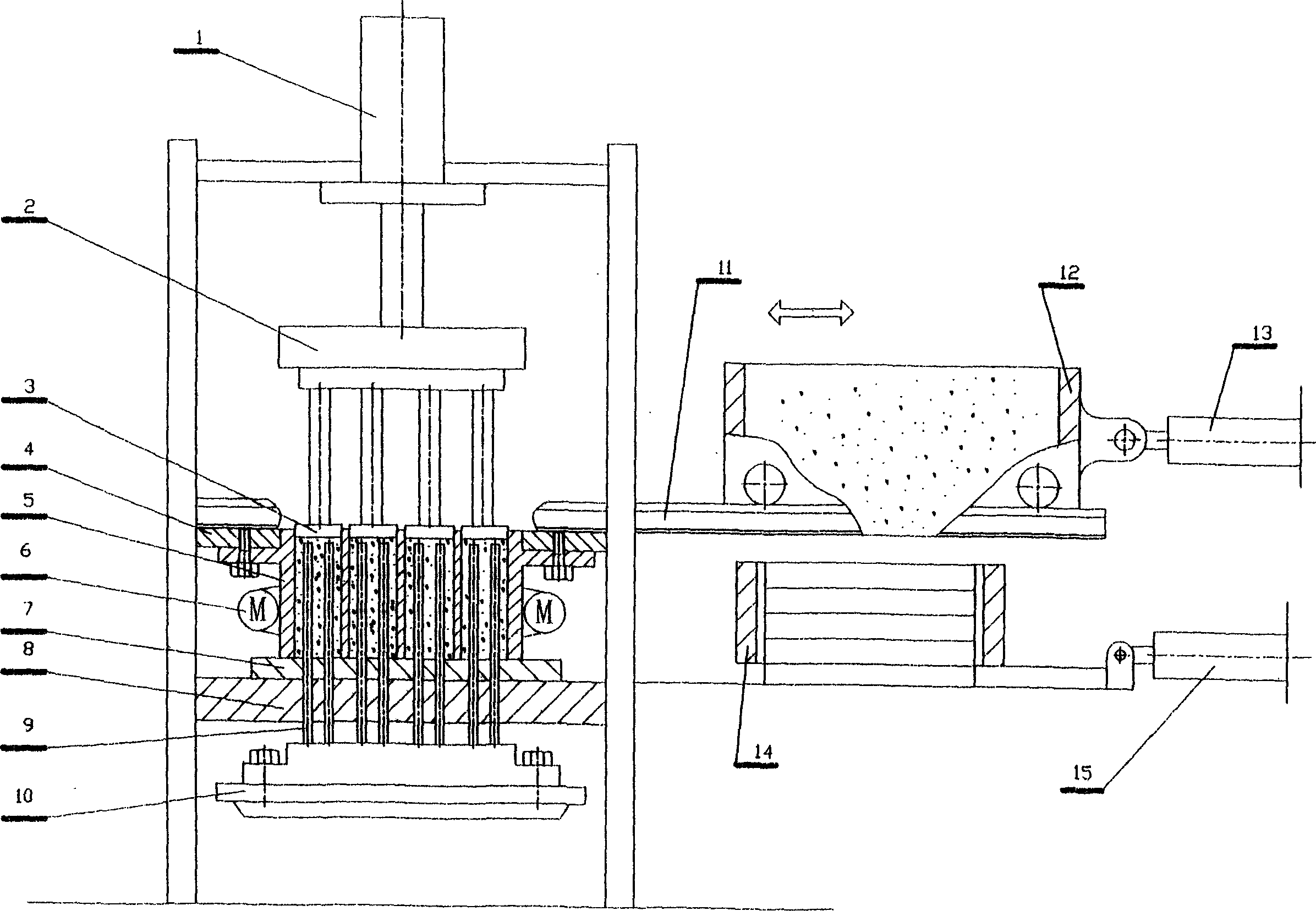

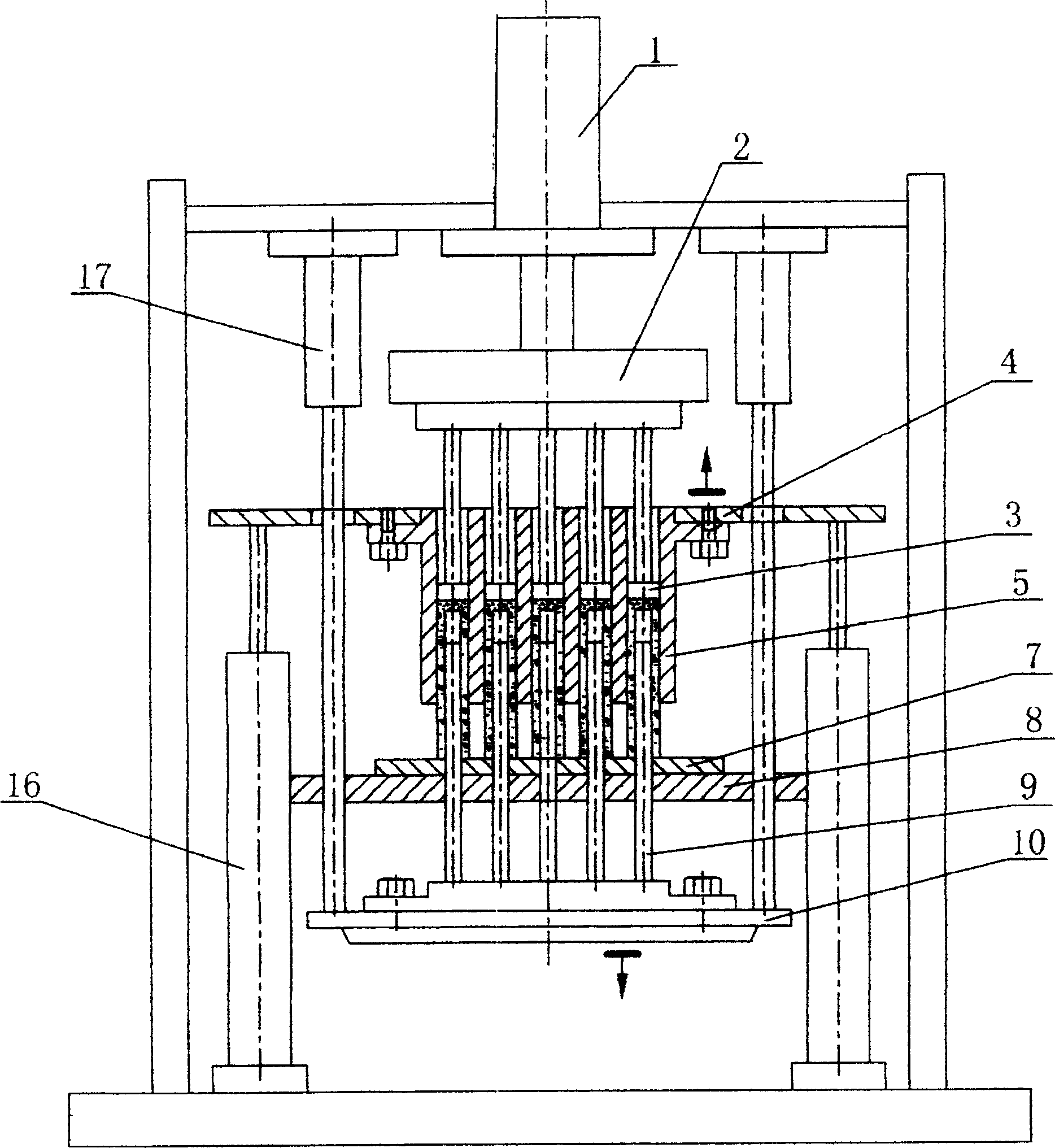

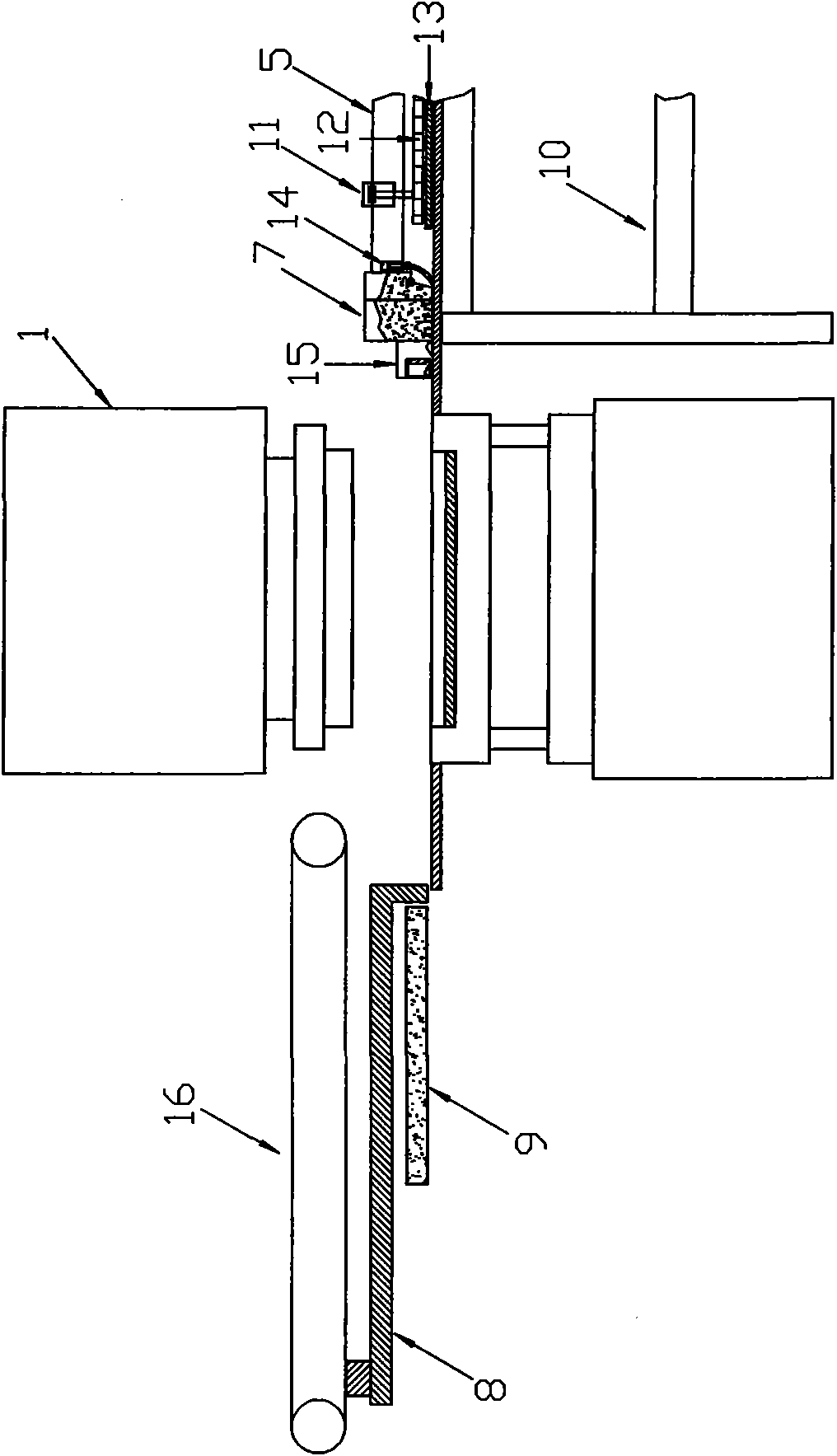

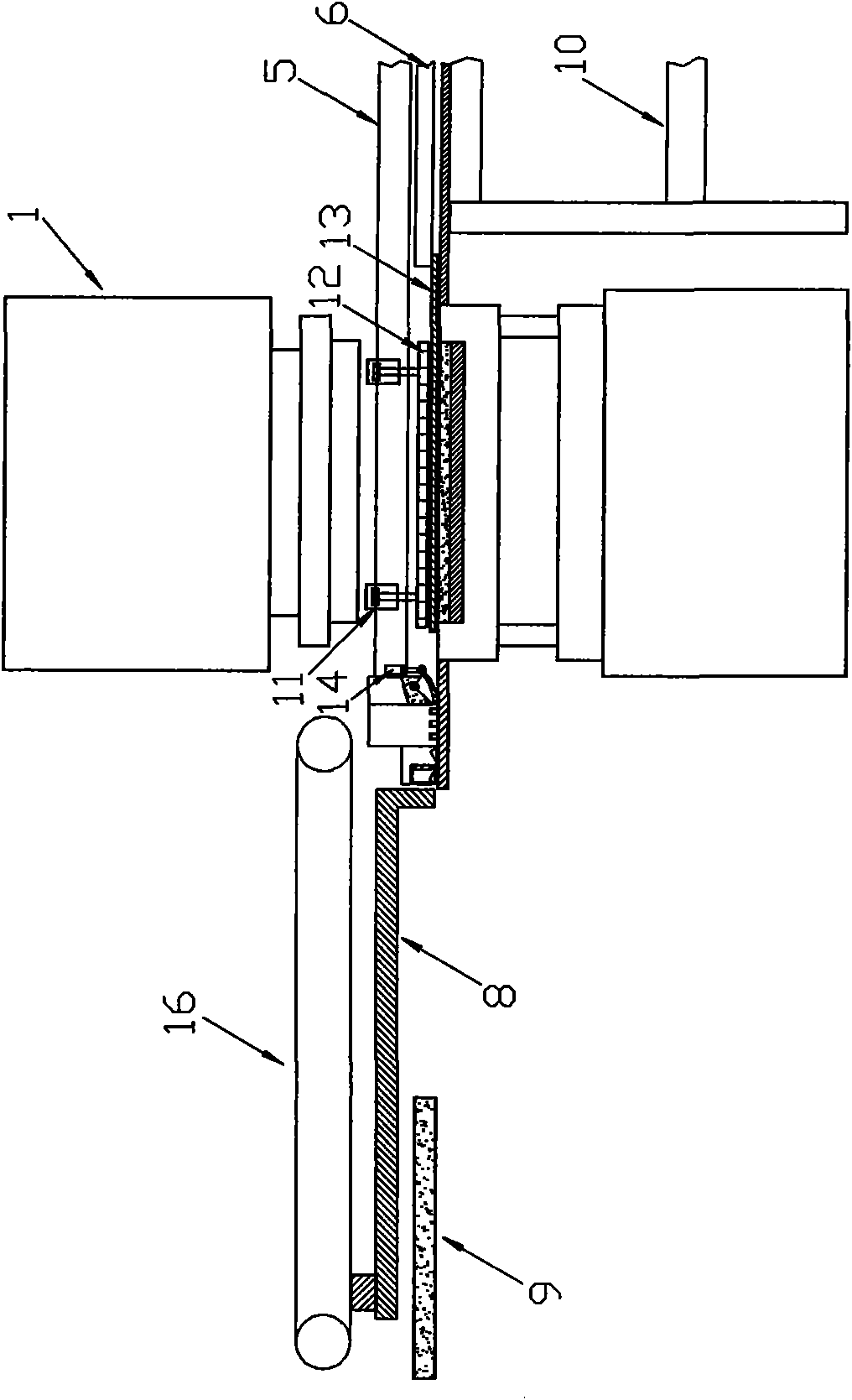

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

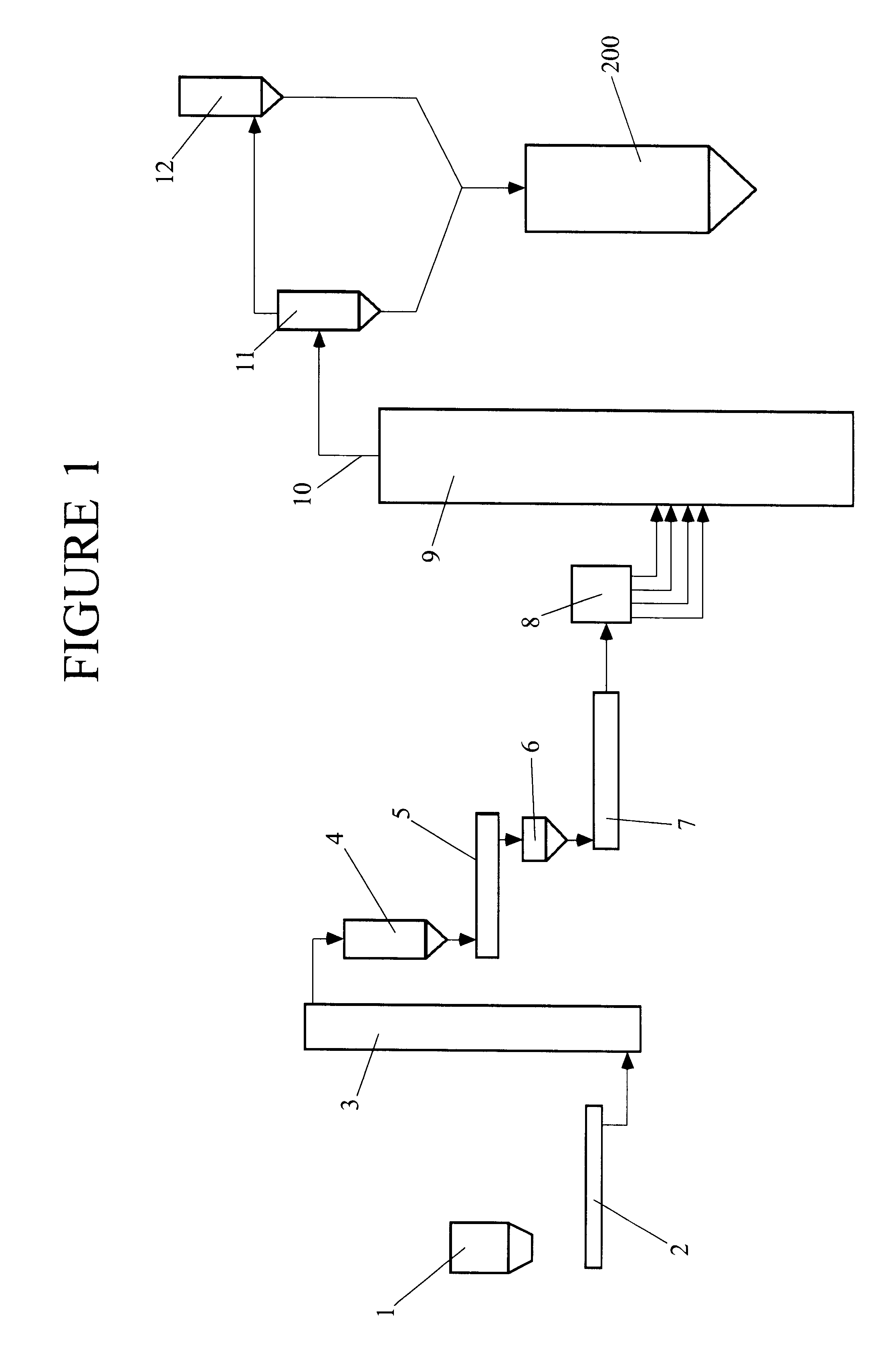

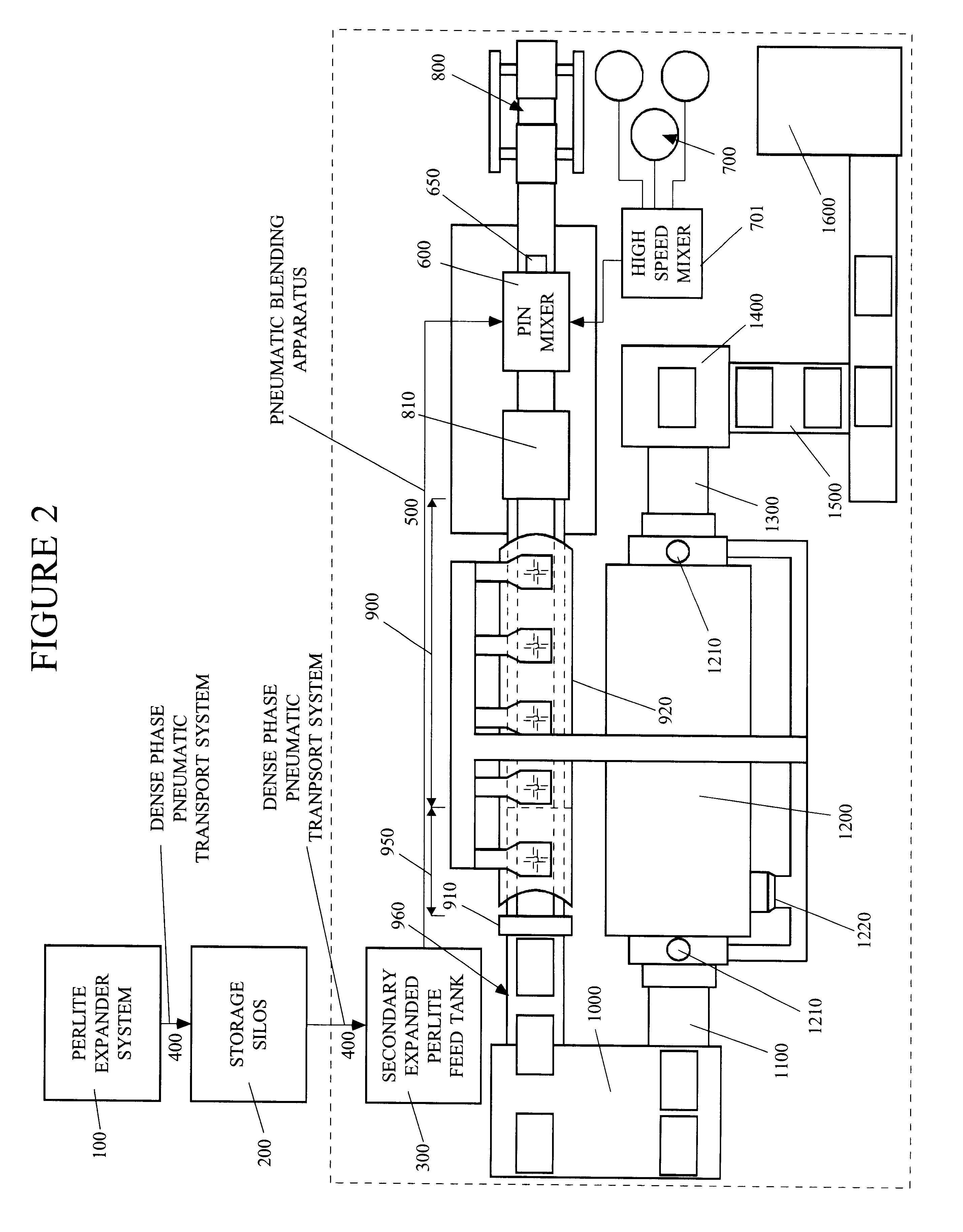

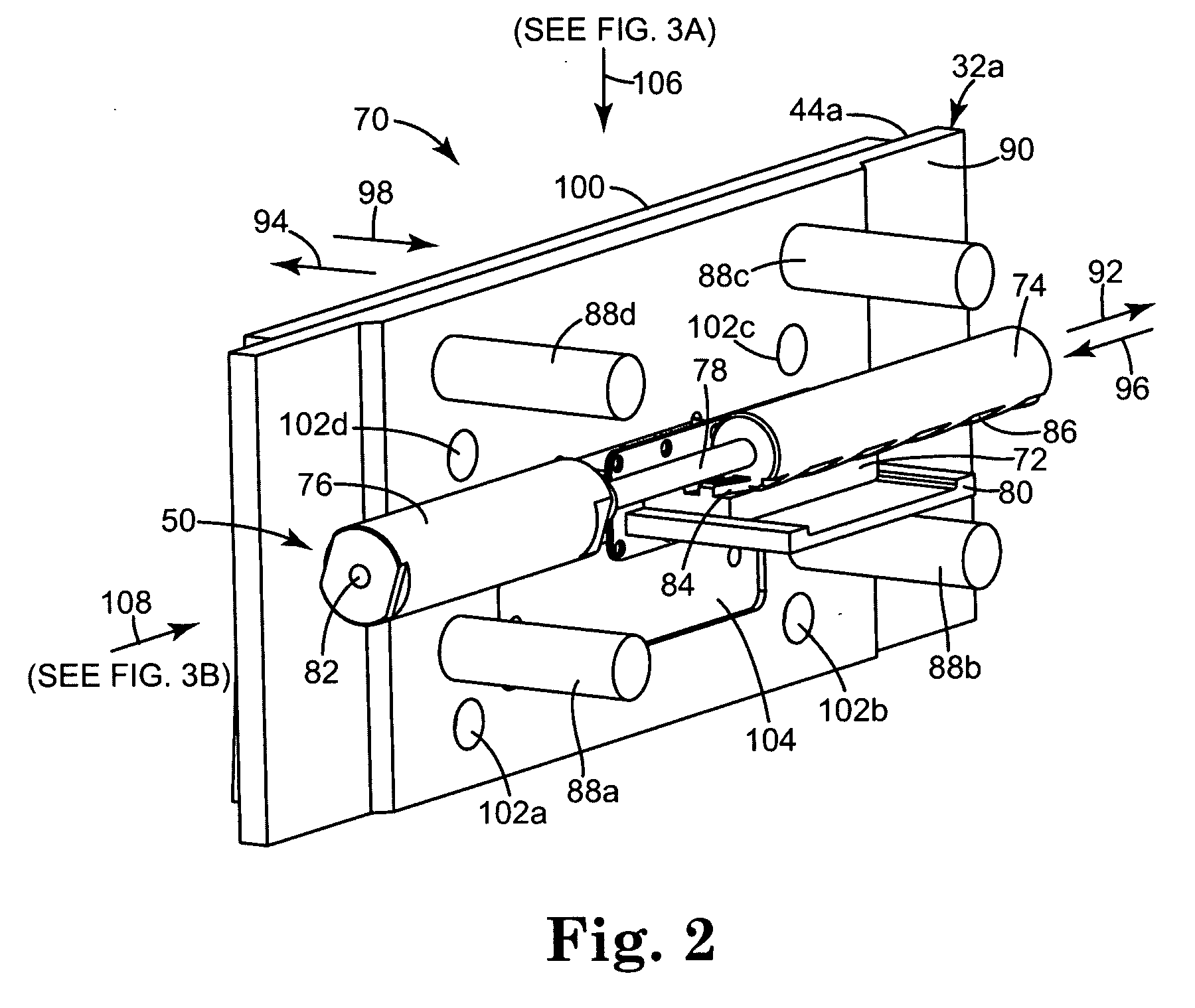

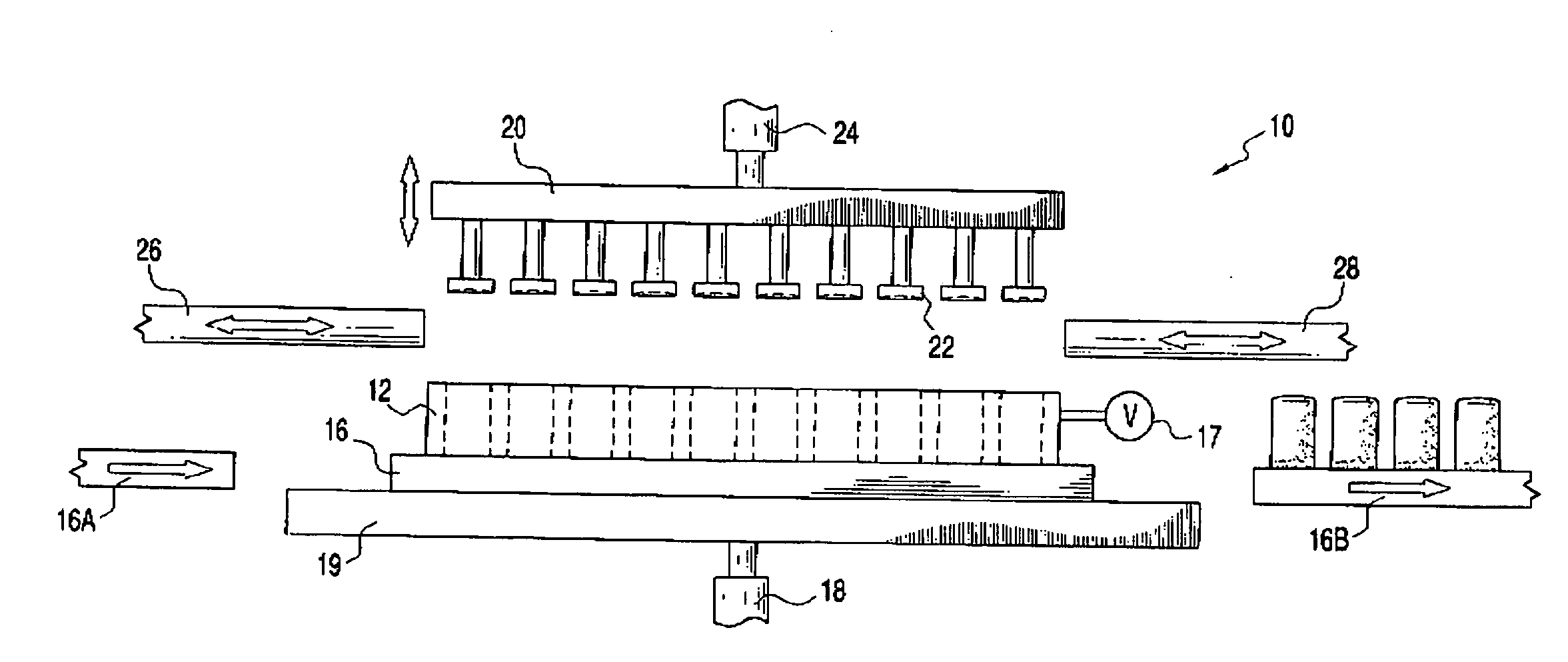

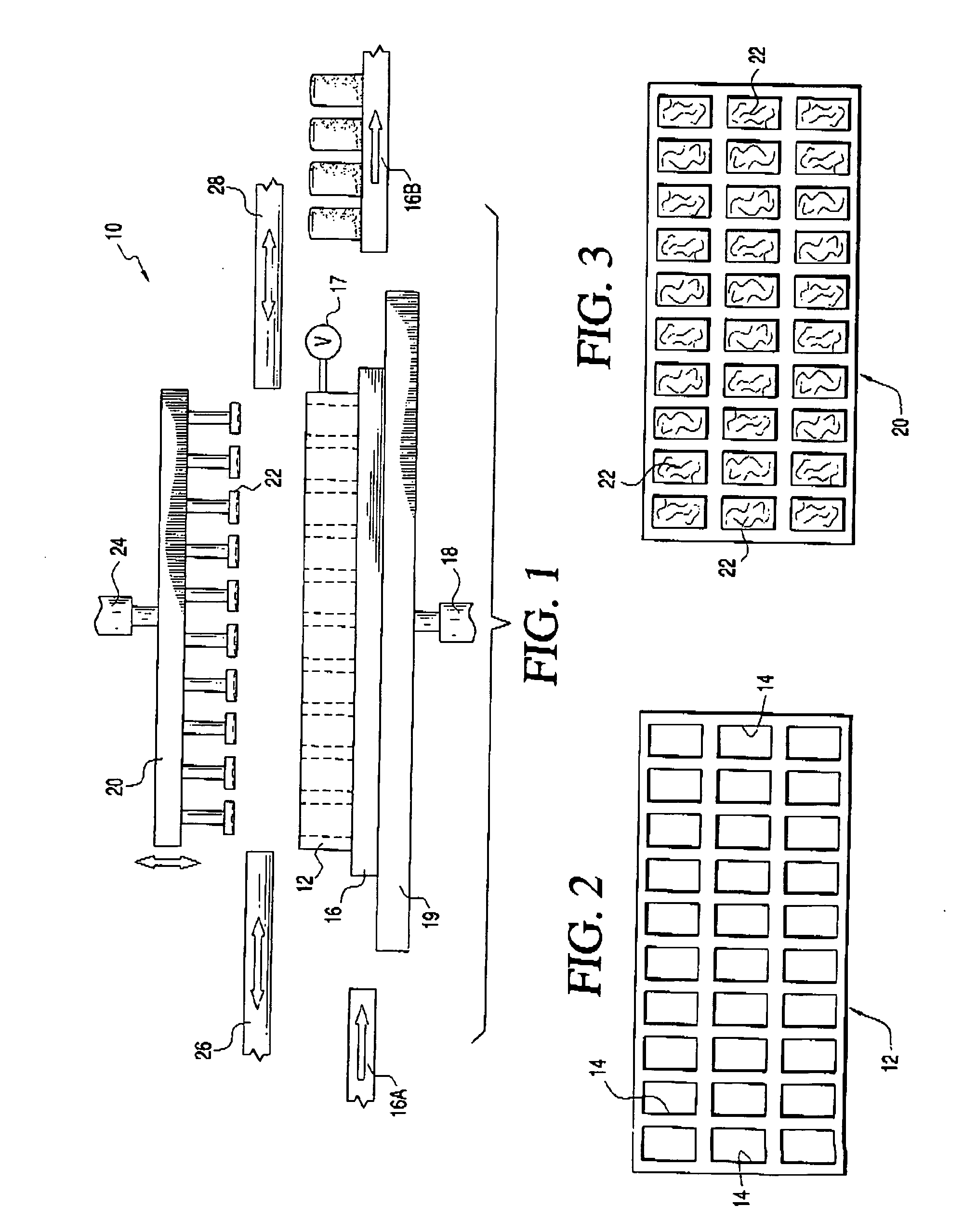

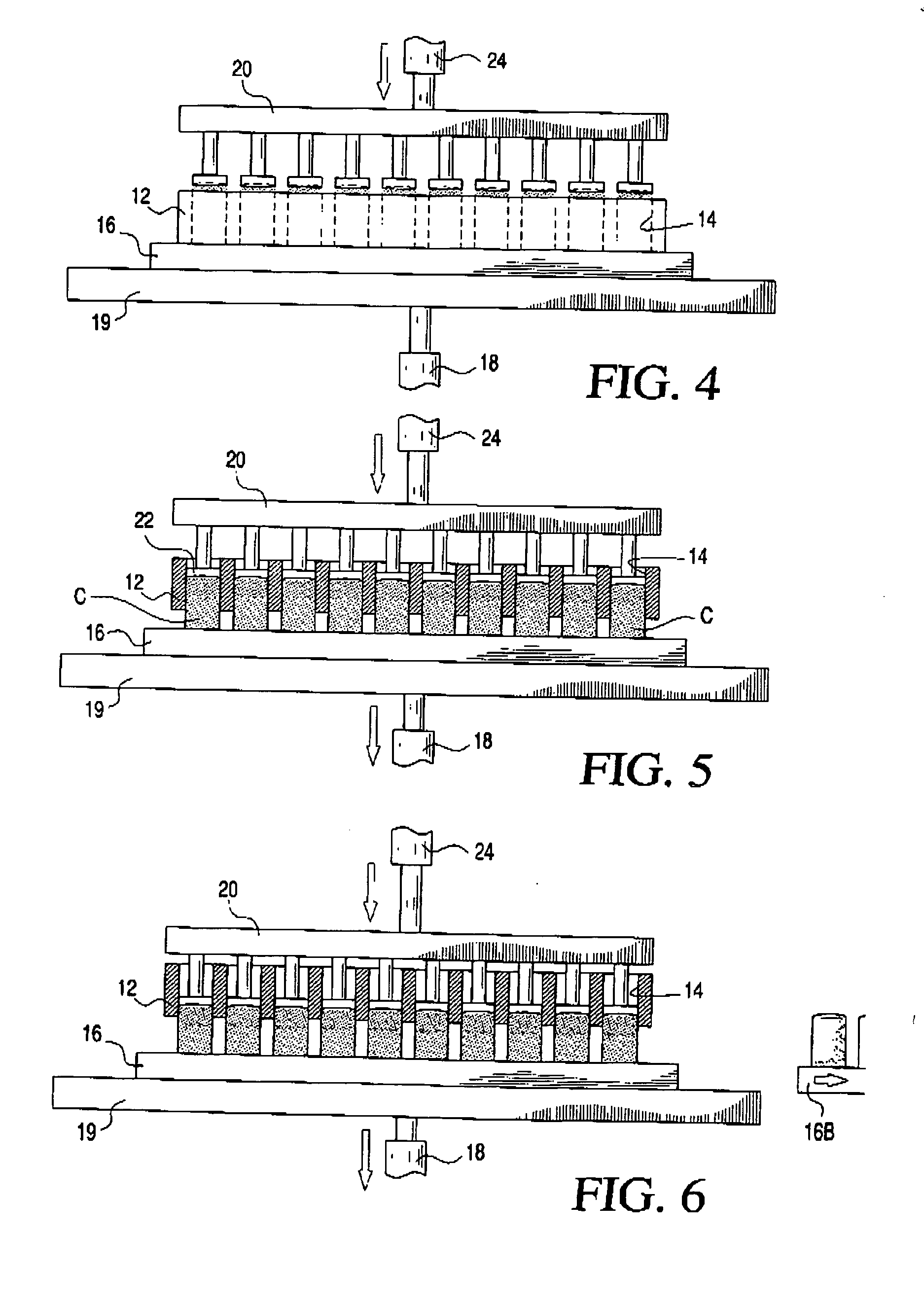

Strengthened, light weight wallboard and method and apparatus for making the same

InactiveUS6319312B1Easy to optimizeReduce amountConstruction materialCeramic shaping plantsSingle plateFlexural strength

A novel wallboard composition is disclosed comprising a unique combination of synthetic binders selected for their ability to establish a strengthened permanent bond in the final dry state for use in a wallboard composition comprising primarily gypsum, and in a wallboard composition comprising an expanded mineral such as Perlite which largely reduces the amount of gypsum over current gypsum wallboard formulations, thus reducing the weight while maintaining the strength of the wallboard structure. In a preferred embodiment, the lightweight, strengthened wallboard of the present invention also comprises an optional covering veneer that is applied to the top ply of the face paper to provide increased strength, moisture resistance, and fire retardency, and the back paper top ply is treated to provide increased flexural strength. Additionally, this invention relates to the unique manufacturing process to produce the wallboard composition of the present invention in order to create a lightweight, strengthened, moisture resistant, and fire retardant wallboard used to cover walls and ceilings in construction applications. Still further, this invention relates to the apparatus for manufacturing the wallboard composition of the present invention, including a method and apparatus for economically converting a standard gypsum wallboard manufacturing facility into a facility for manufacturing wallboard of the present invention.

Owner:INNOVATIVE TECH ENTERPRISES

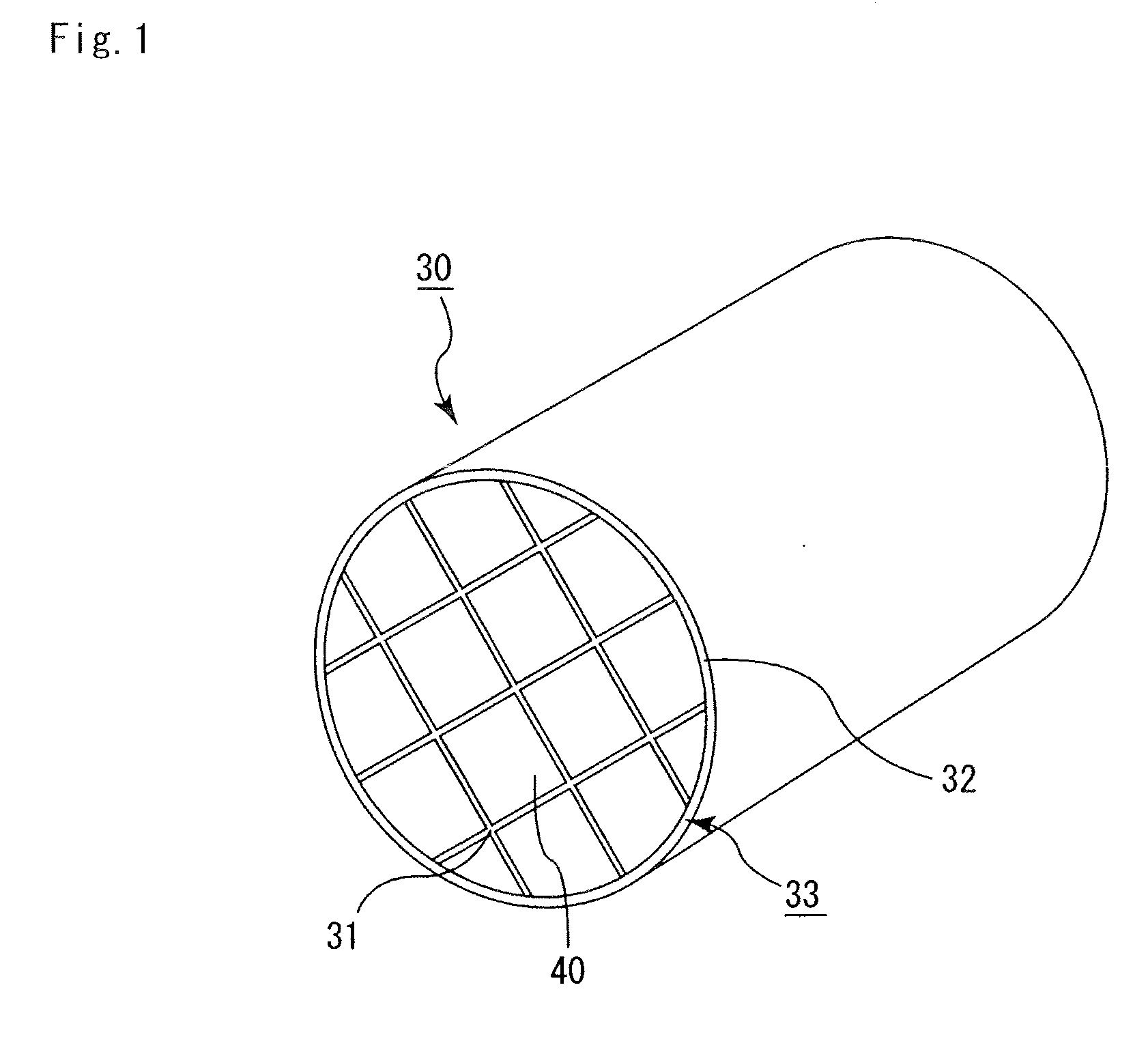

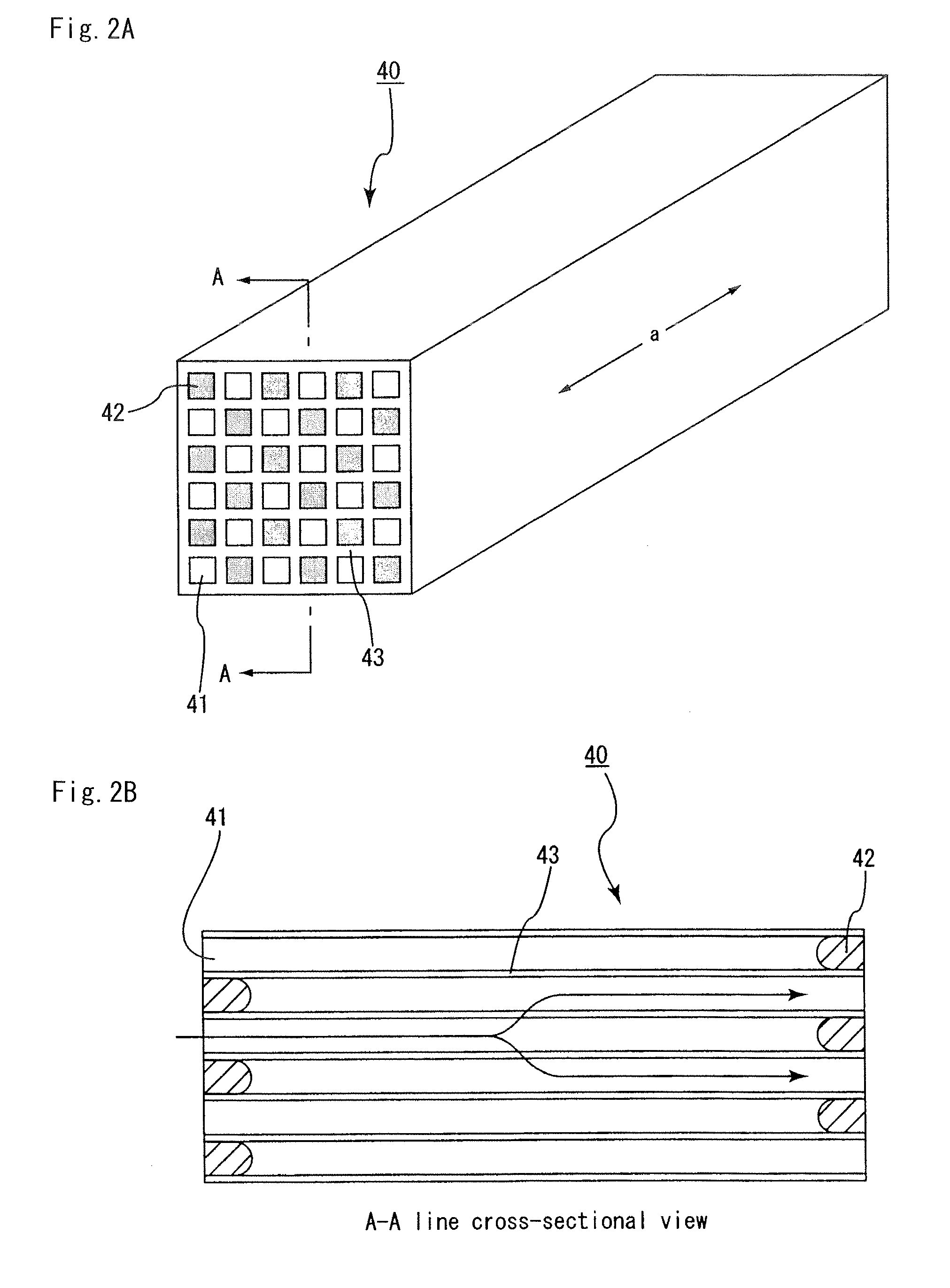

Method for manufacturing a honeycomb structure, honeycomb molded body receiving apparatus, honeycomb molded body taking-out apparatus

InactiveUS20080116200A1Discharging arrangementCeramic shaping plantsHoneycomb structureMaterials science

A method for manufacturing a honeycomb structure includes producing a pillar-shaped honeycomb molded body in which a plurality of cells are placed in parallel with one another in a longitudinal direction with a cell wall therebetween by molding a ceramic raw material; and producing a honeycomb fired body by carrying out a single or a plurality of treatments including at least a firing treatment on the honeycomb molded body. The method further includes temporarily storing the treated honeycomb molded body on which the single or plurality of treatments have been carried out in a molded body storage container; taking out the treated honeycomb molded body placed in the molded body storage container from the molded body storage container; and conveying the taken-out honeycomb molded body to a subsequent process.

Owner:IBIDEN CO LTD

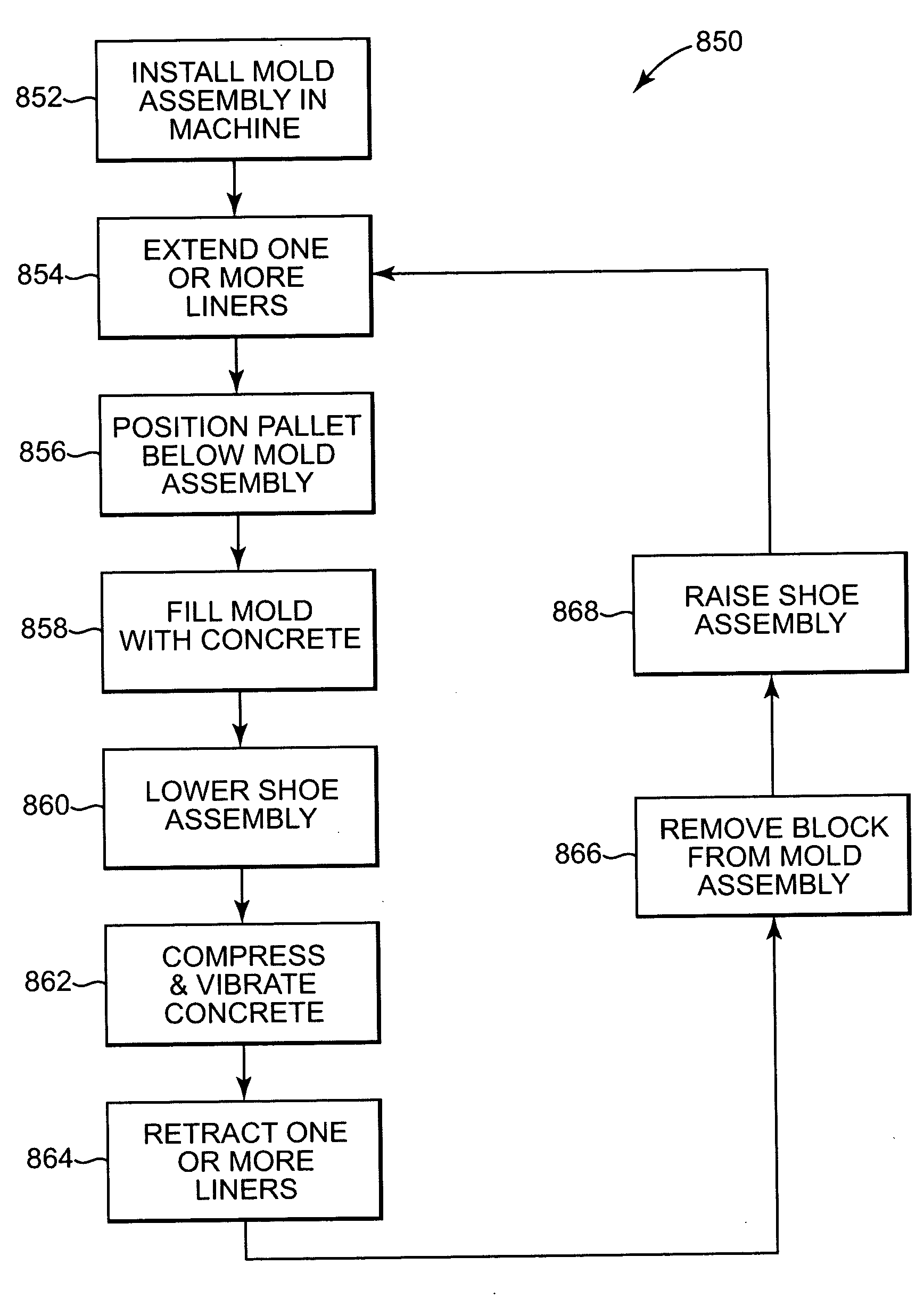

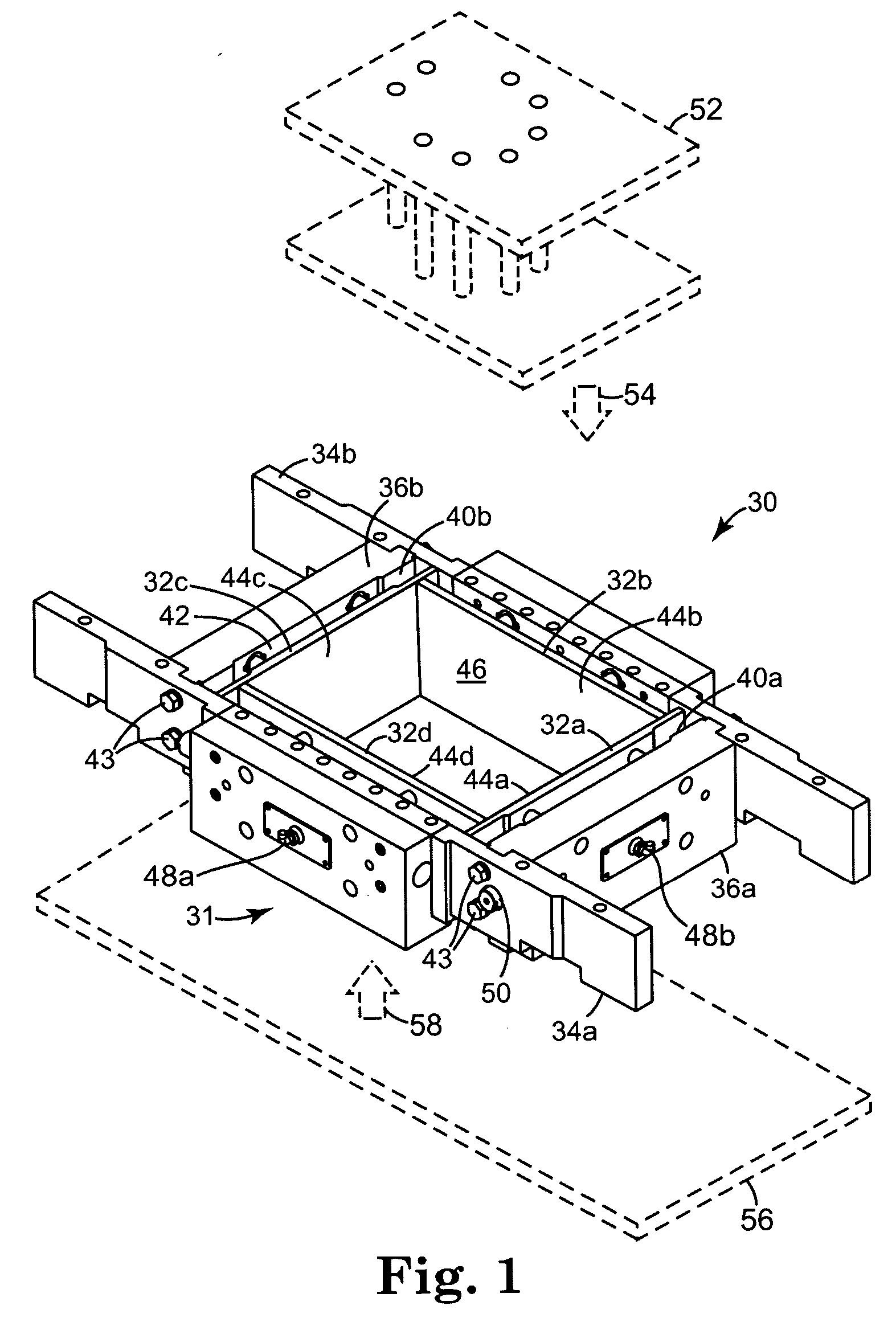

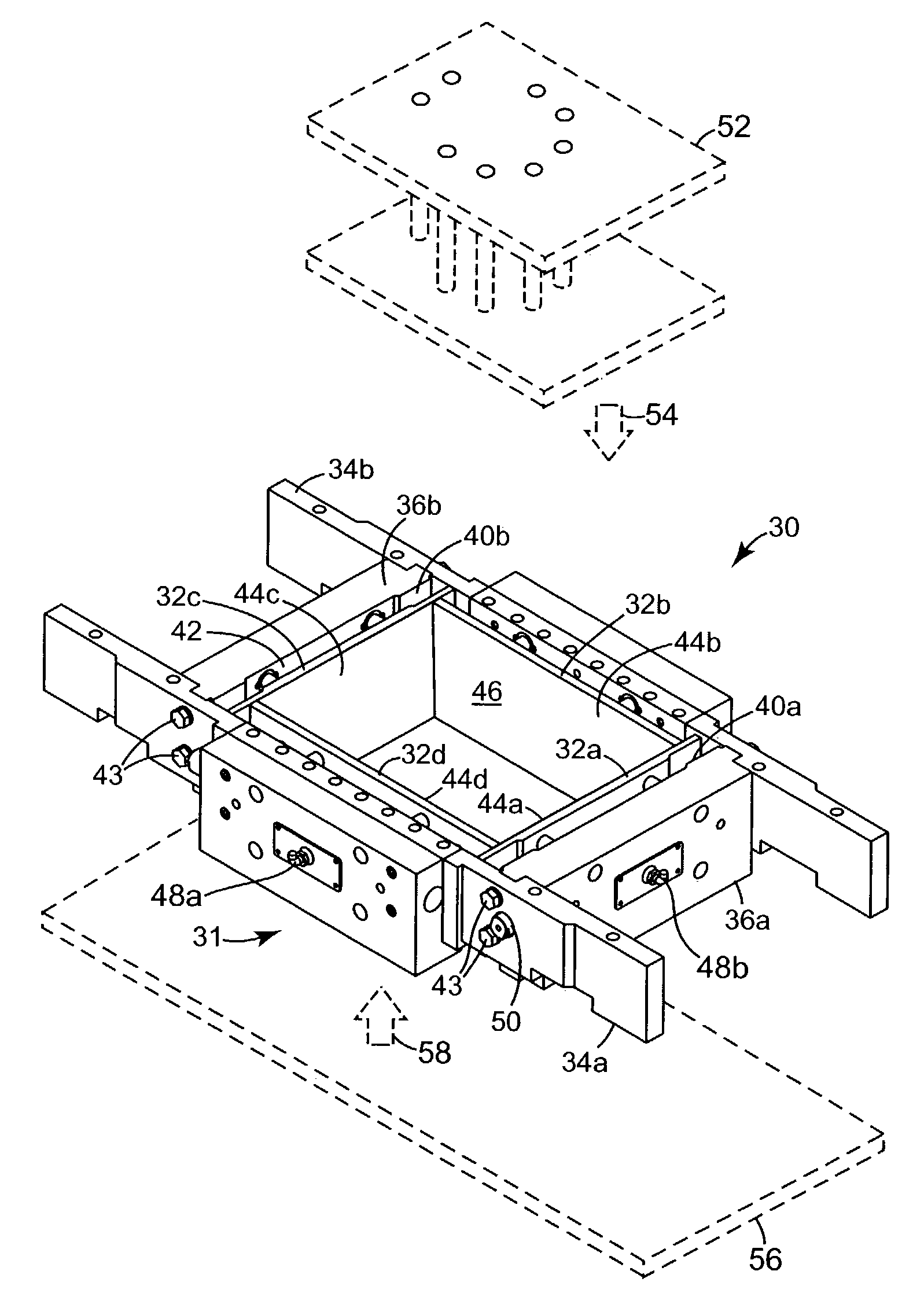

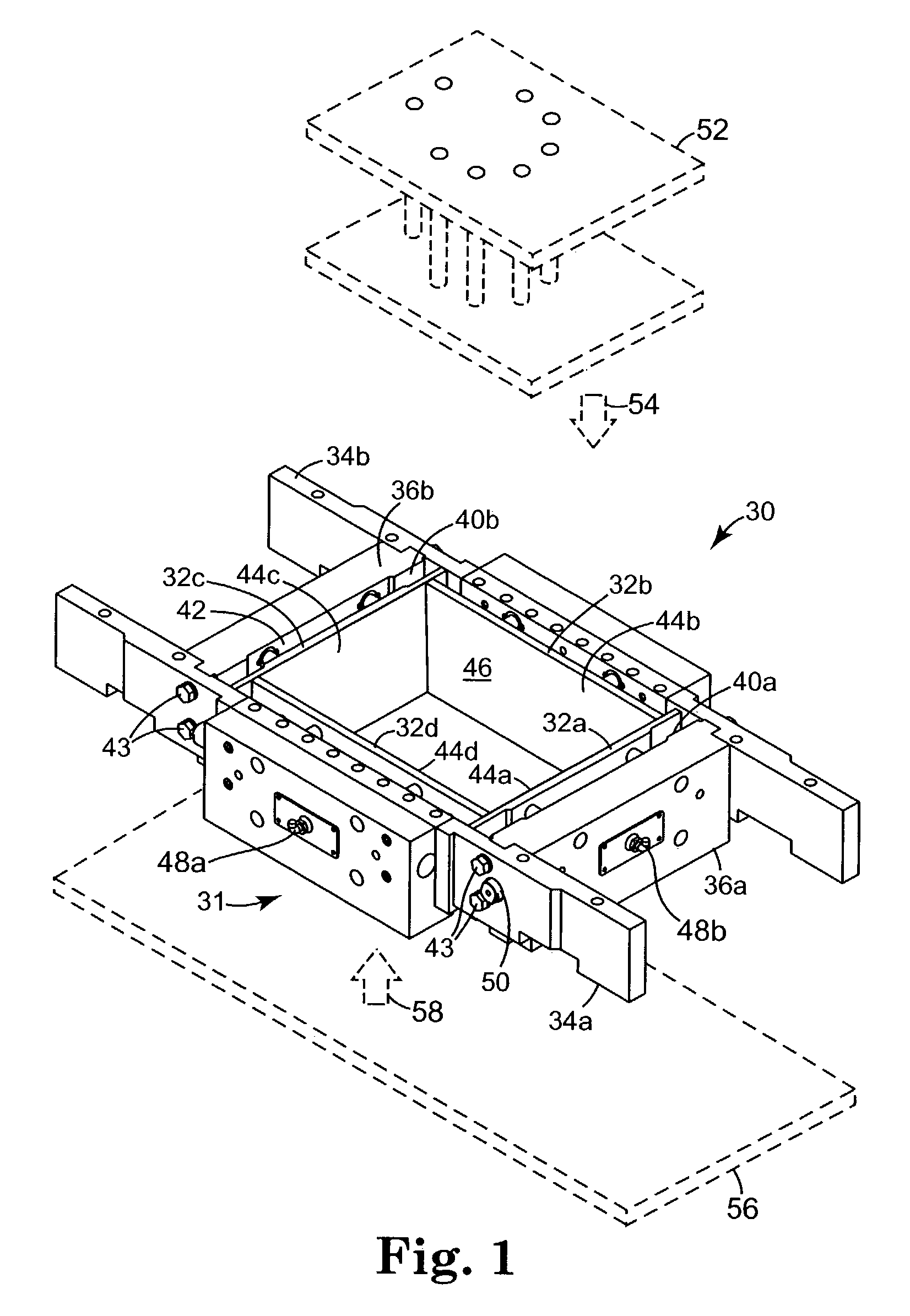

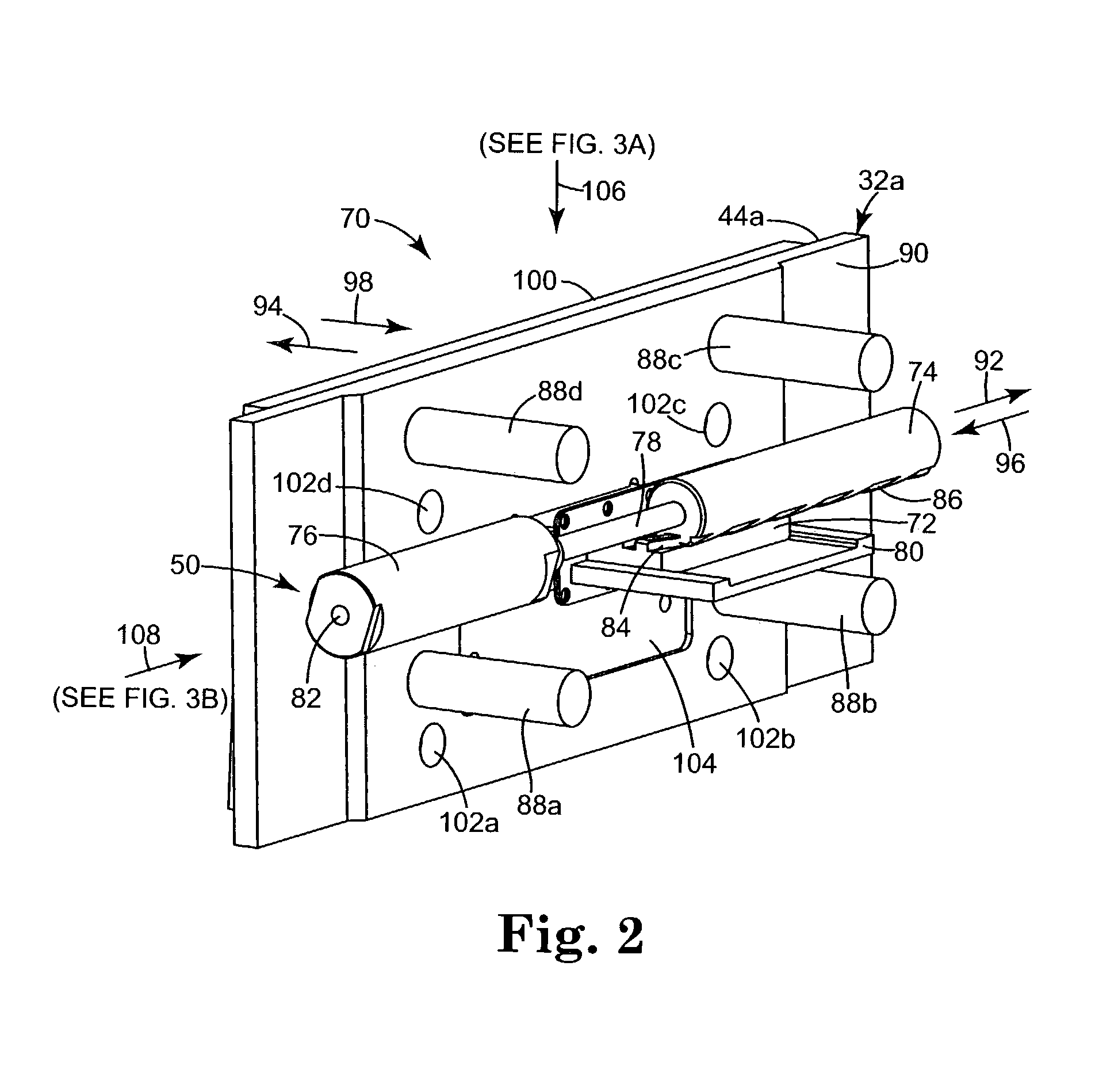

Masonry blocks and method and system of making masonry blocks

A method of producing a masonry block including providing a mold assembly having a plurality of liner plates that together form a mold cavity having an open top and an open bottom, wherein at least one of the liner plates is moveable between a retracted position and a desired extend position relative to an interior of the mold cavity with a gear drive assembly. The at least one moveable liner plate is moved to the desired extended position, the bottom of the mold cavity is closed with a pallet, dry cast concrete is placed in the mold cavity via the open top, the top of the mold cavity is closed with a moveable head shoe assembly, and the dry cast concrete is compacted to form a pre-cured masonry block. The at least one moveable liner plate is moved to the retracted position, the pre-cured masonry block is expelled from the mold cavity and cured.

Owner:NESS INVENTIONS

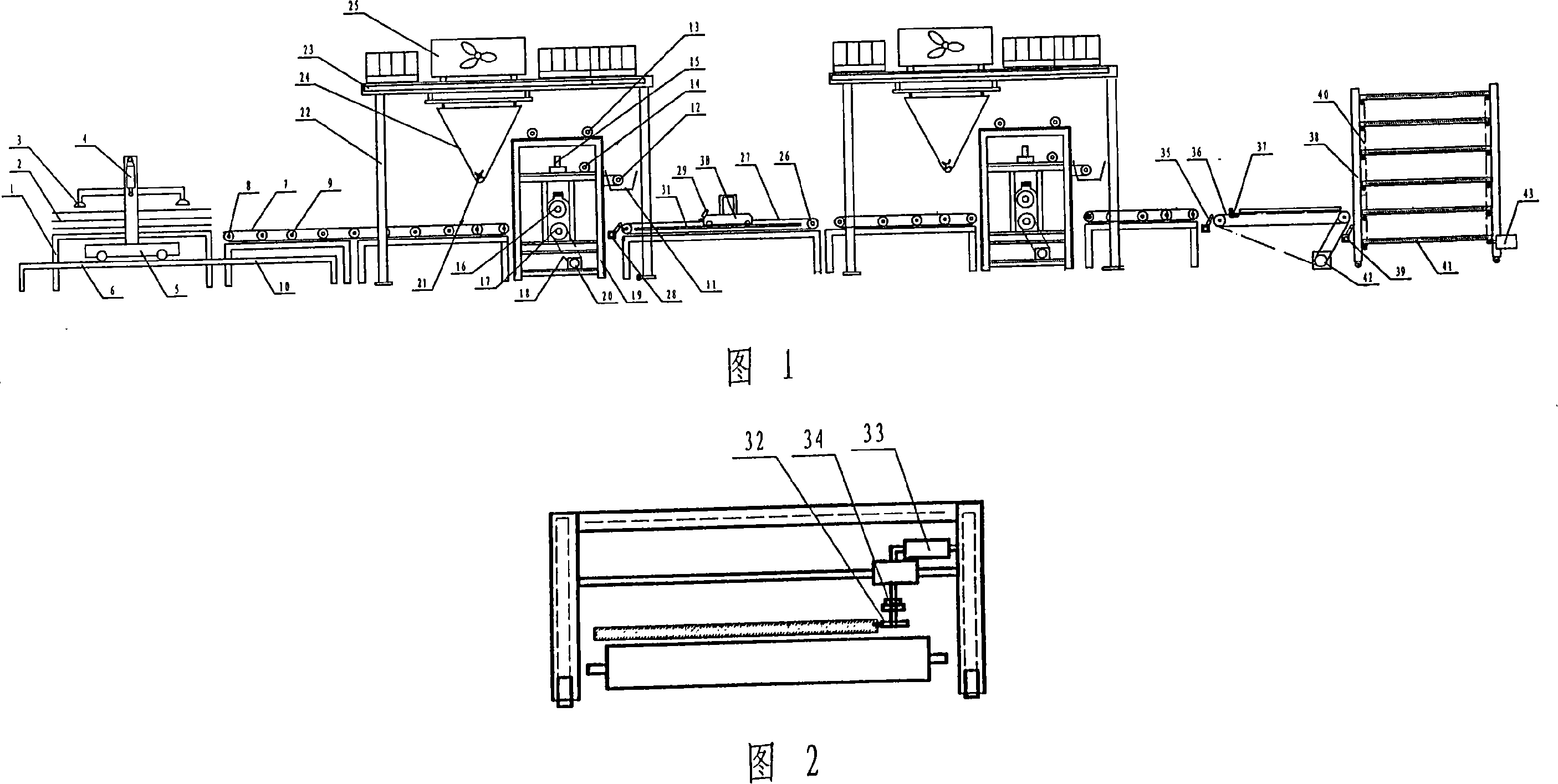

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

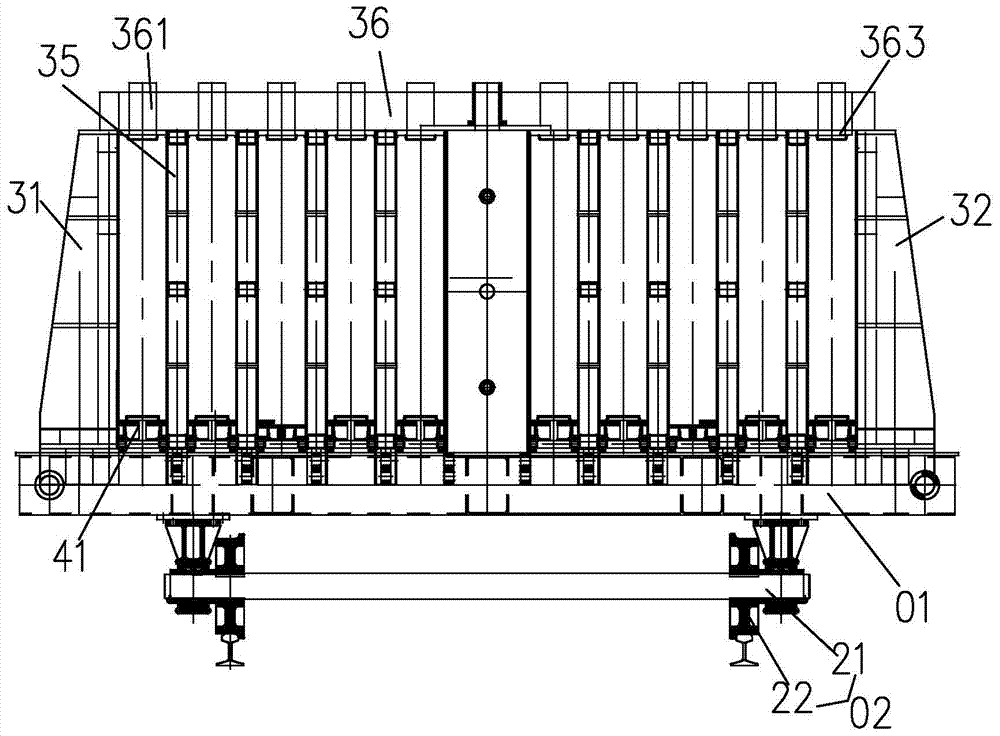

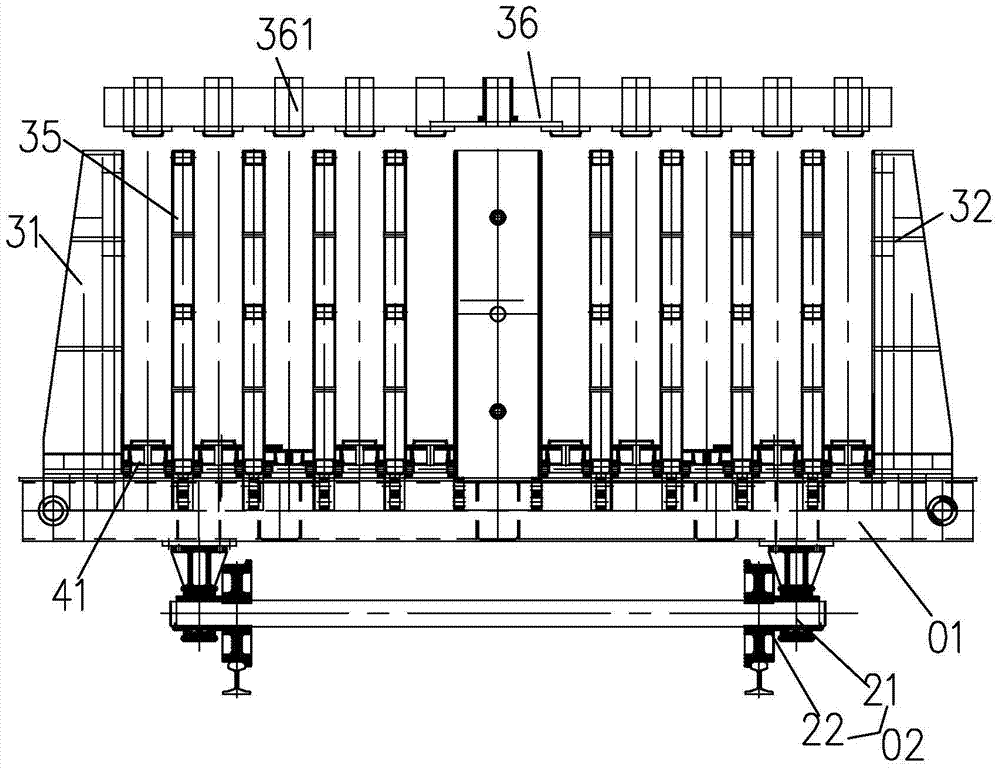

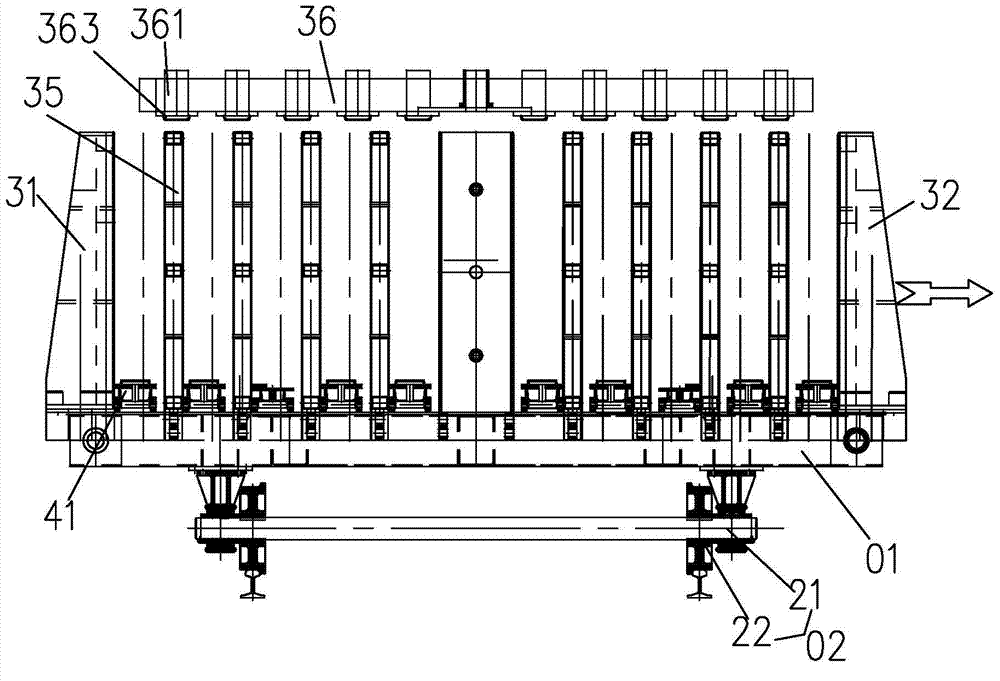

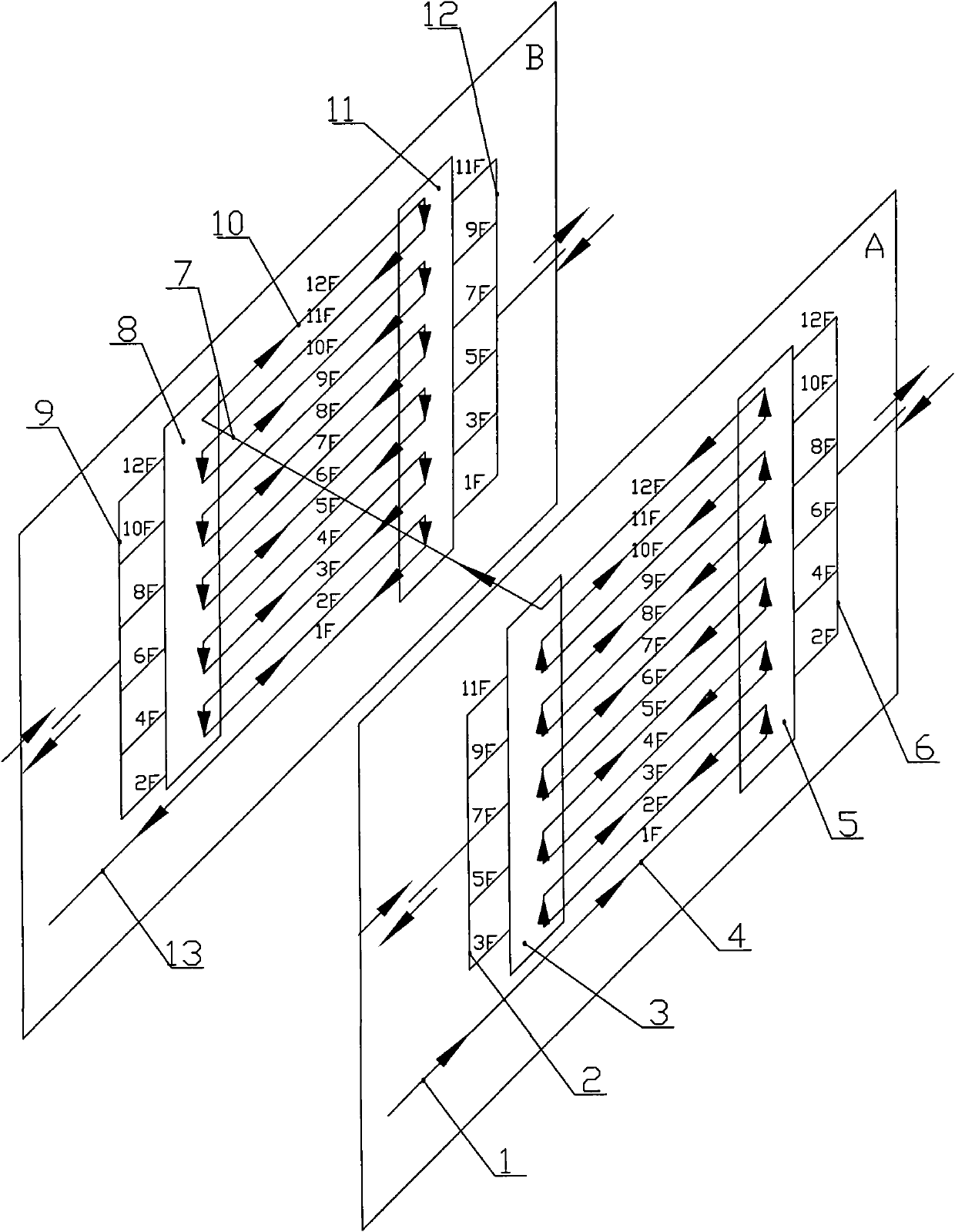

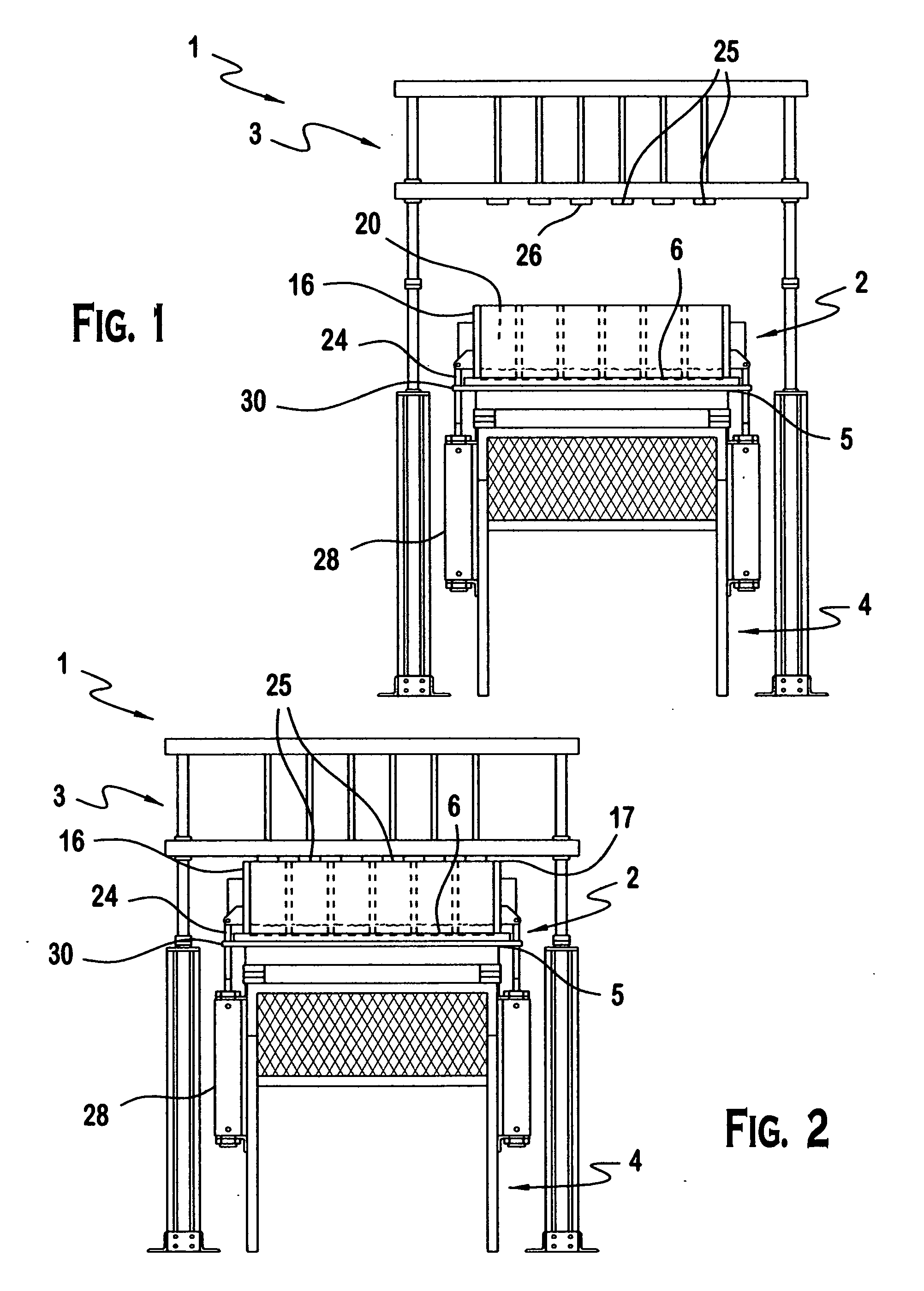

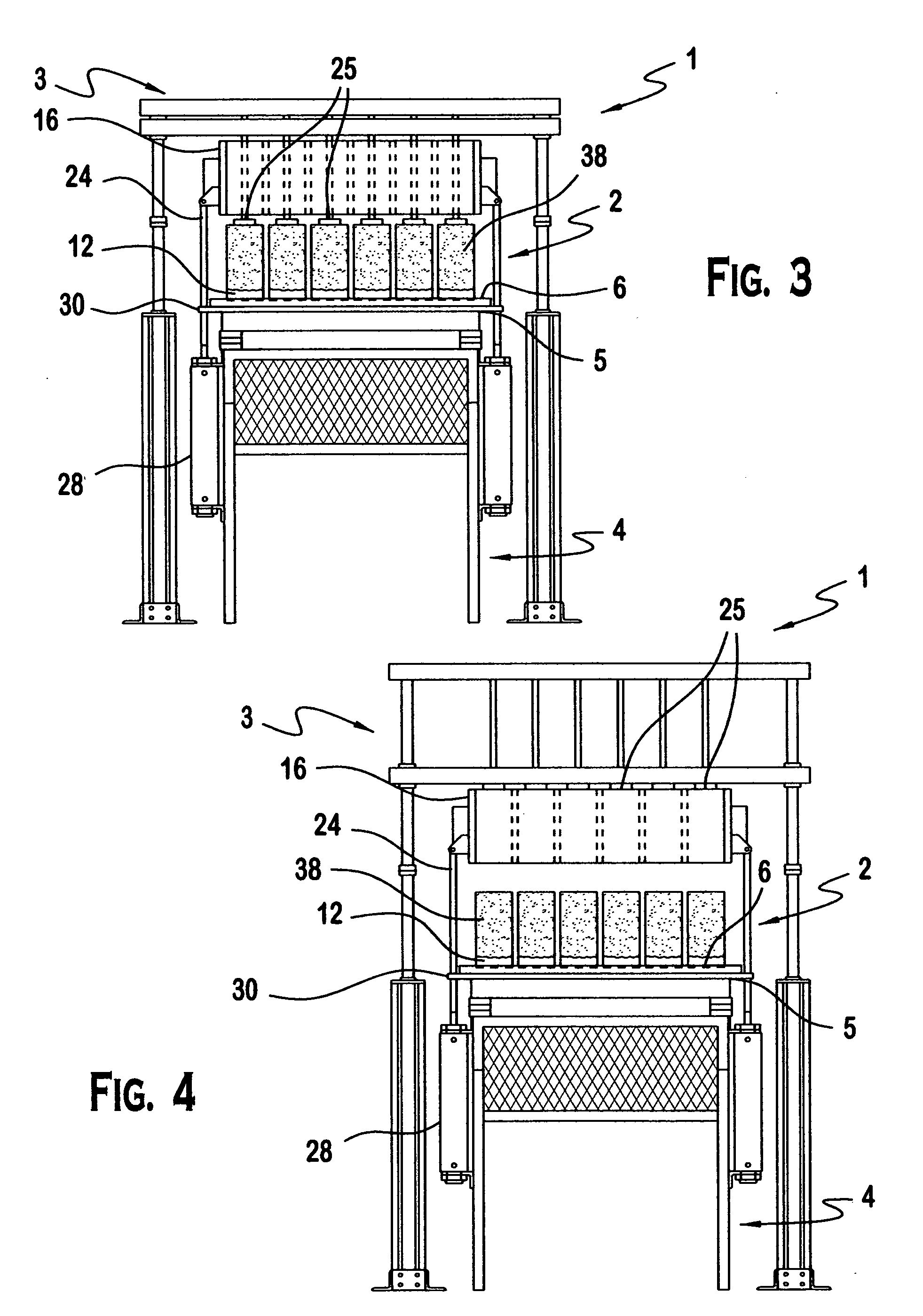

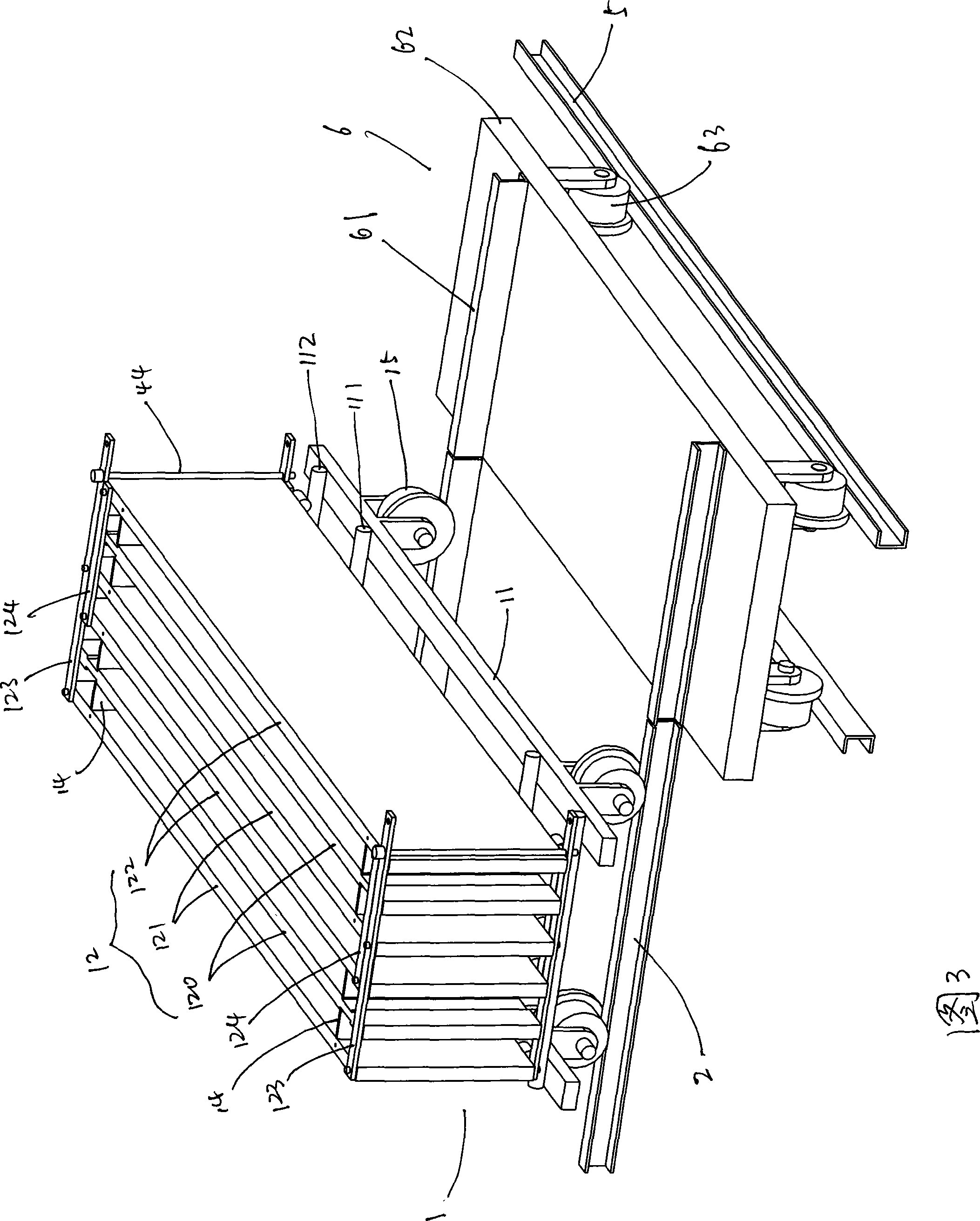

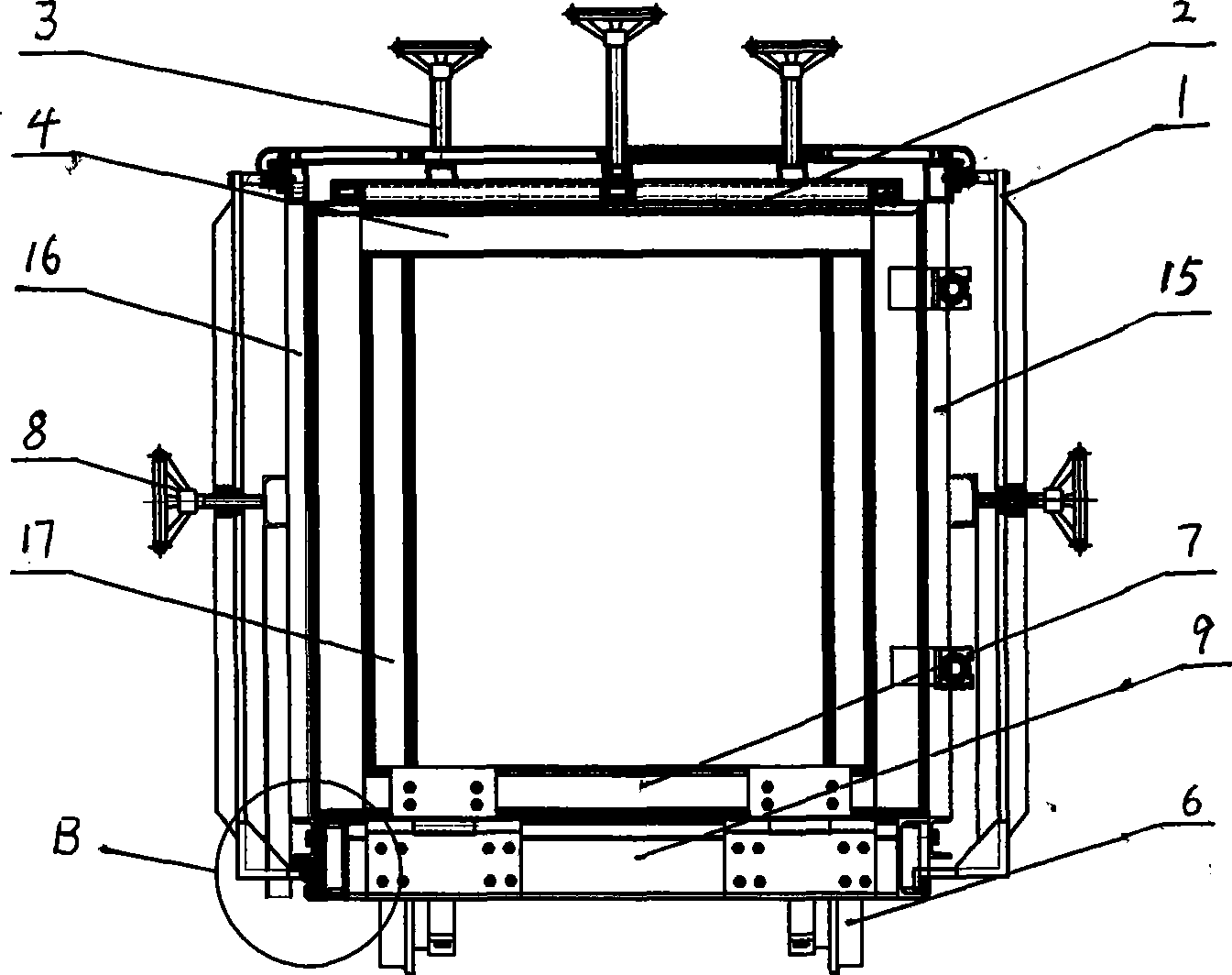

Multi-function concrete prefabricated part group vertical framework production equipment and production line

ActiveCN104260185ALow costReduce labor intensityMouldsCeramic shaping plantsProduction lineEngineering

The invention discloses multi-function concrete prefabricated part group vertical framework production equipment and production line. The multi-function concrete prefabricated part group vertical framework production equipment comprise a chassis, a travelling device, a first side framework, a second side framework, a first end framework, a second end framework, a plurality of separating walls, a top framework and a plurality of bottom supports; the first end framework and the second end framework are provided with a core pipe hole respectively; the first side framework, the second side framework, the first end framework, the second end framework and the separating walls can move on the chassis; a cavity is formed between the first side framework and the separating wall which is arranged at the left end, a cavity is formed between the second side framework and the separating wall which is arranged at the right end, and a cavity is formed between every two adjacent separating walls; every bottom support is placed at a chassis position which is located in every cavity; the top framework is arranged at the top of the first side framework, the second side framework, the first end framework, the second end framework and the plurality of separating walls; the top framework is provided with a grouting pipe and a overflow pipe; the multi-function concrete prefabricated part group vertical framework production equipment also comprise a plurality of top liner templates and a plurality of bottom liner templates; every top liner template can be placed at the top of the corresponding cavity; every bottom liner template can be placed at the bottom of the corresponding cavity. According to the multi-function concrete prefabricated part group vertical framework production equipment, the production efficiency is greatly improved and the cost is low.

Owner:BEIJING EVEREST GREEN BUILDING TECH

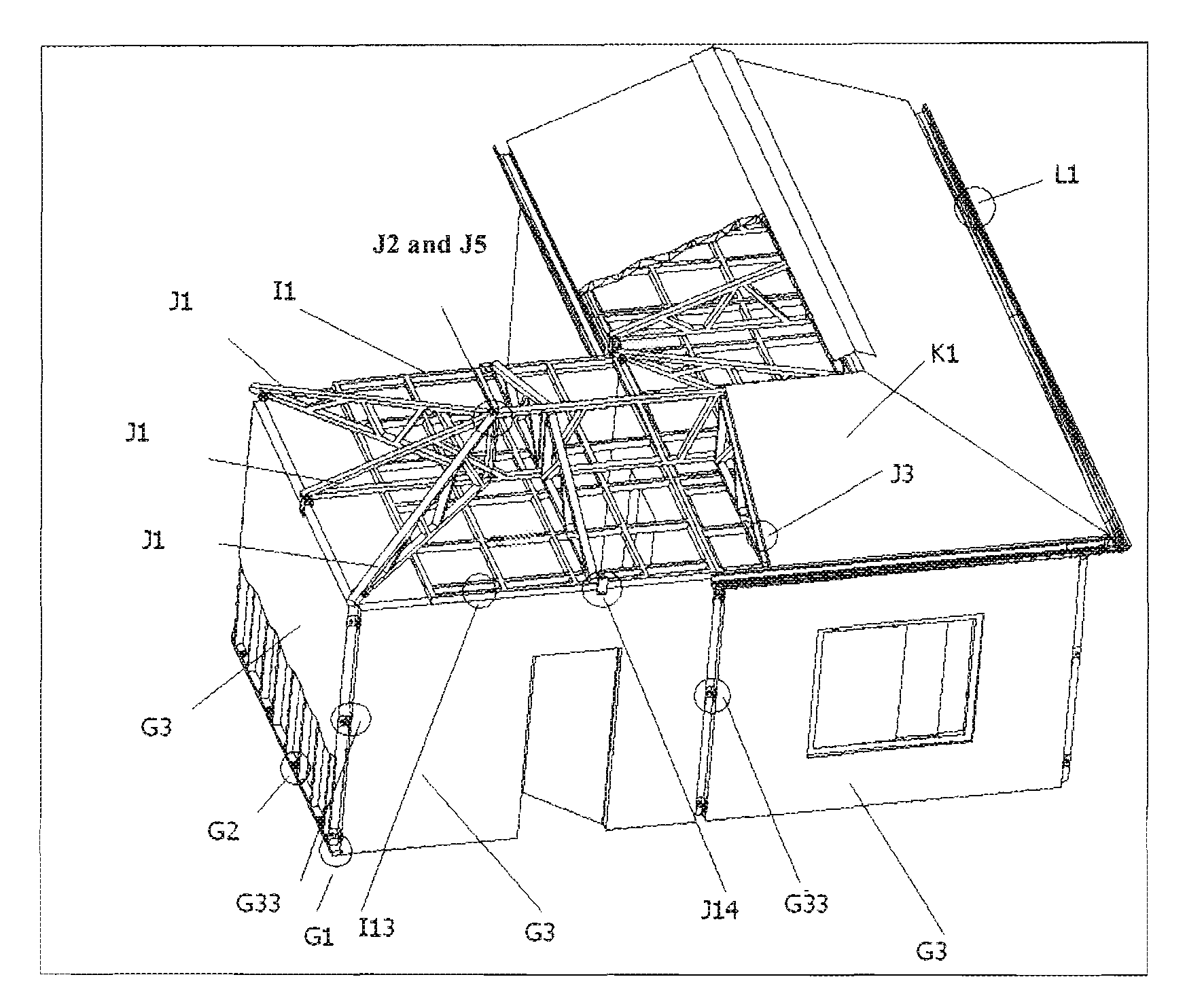

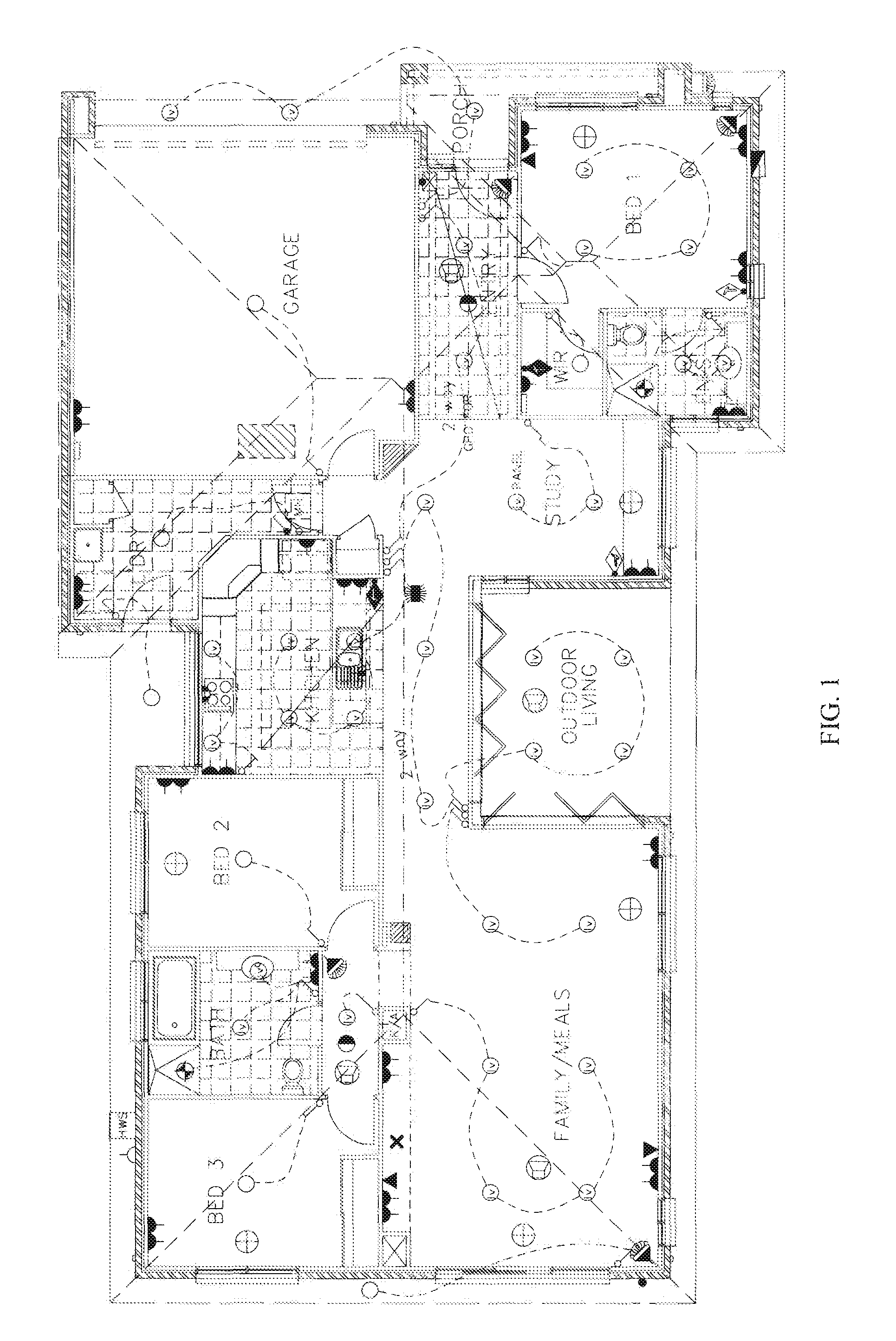

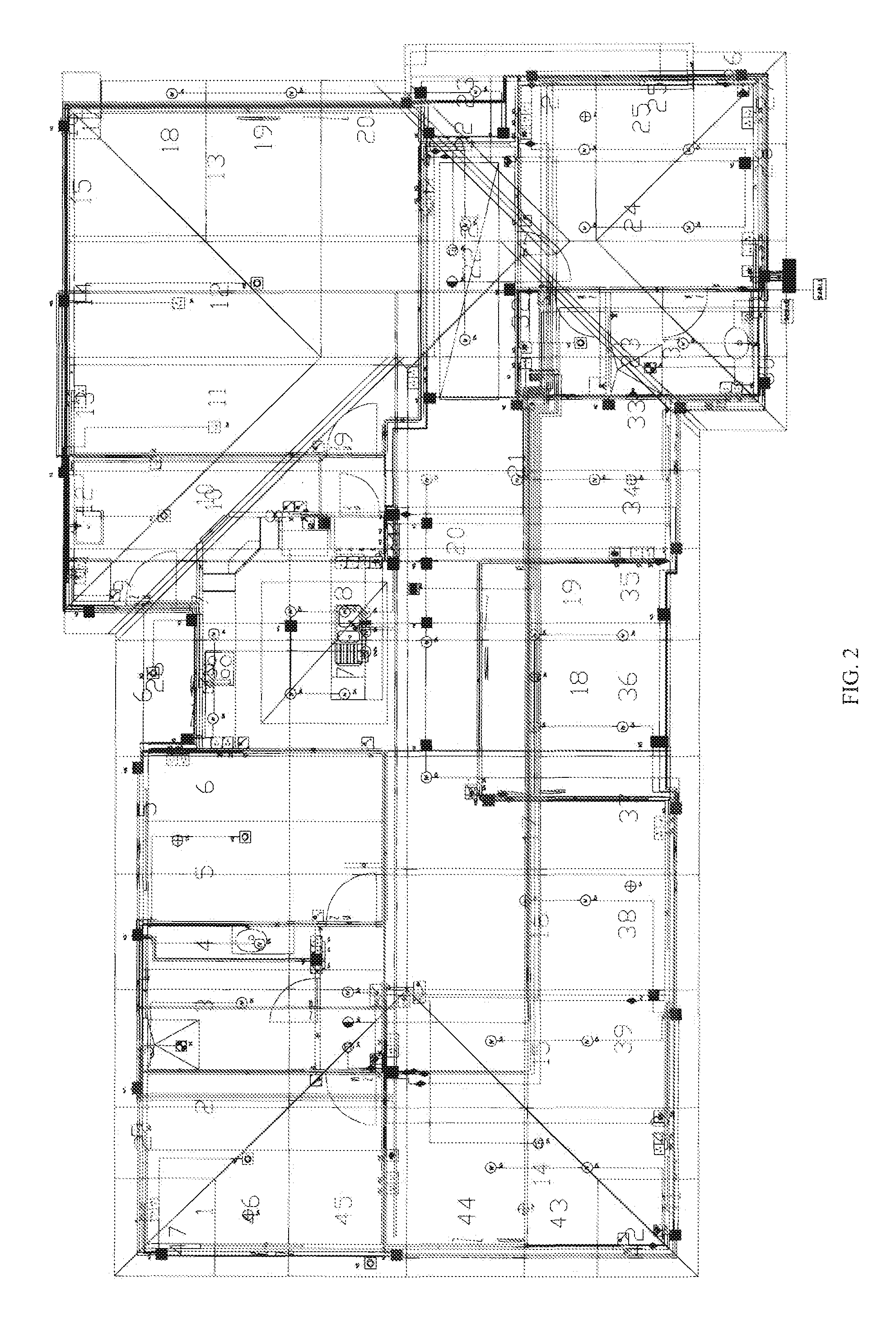

Prefab system, structure and assembling method for all-functional framed buildings

InactiveUS20100024318A1Precision and efficiency and speedMade preciselyGeometric CADBuilding roofsElectricityFloor plan

A computerized prefab architect design system (CPAD) and method for the fabrication of frame-structured buildings with all functions, including an integrating device for integrating building design elements including customer acknowledged floor plans, plumbing layouts, electricity wiring layouts and structure / strength parameters into an assembly drawing; a dividing device for forming segments and layouts of wall panels, floor / ceiling panels and roof panels, layouts of roof trusses, and segments and layouts of plumbing, wiring and jointers in accordance with a segmentation rule for buildings comprising a local building specification, segmentation based on a loading size of a shipping container, strength and structural requirements of buildings, requirements for convenient on-site work and flexible assembly lines at factories; a generating device for generating a polygon stencil for components of the prefab architect based on said segments and layouts, said stencil including building frames, functional boards to be mounted onto the frames and functional accessories and appliances; and an outputting device for forming data including a list of materials, an electronic guide display, CAM files, container loading plans and assembly drawings for on-site work in accordance with requirements for the fabrication in said stencil. This invention comprises also a computer controlled fabrication system and method, with CPAD system and method included, for all-functional prefab framed buildings, an all-functional prefab framed building structure fabricated by utilizing the described system and method, and a quick method to assembly on site the described all-functional prefab framed buildings.

Owner:SHANGHAI PRECISION HOUSES MFG

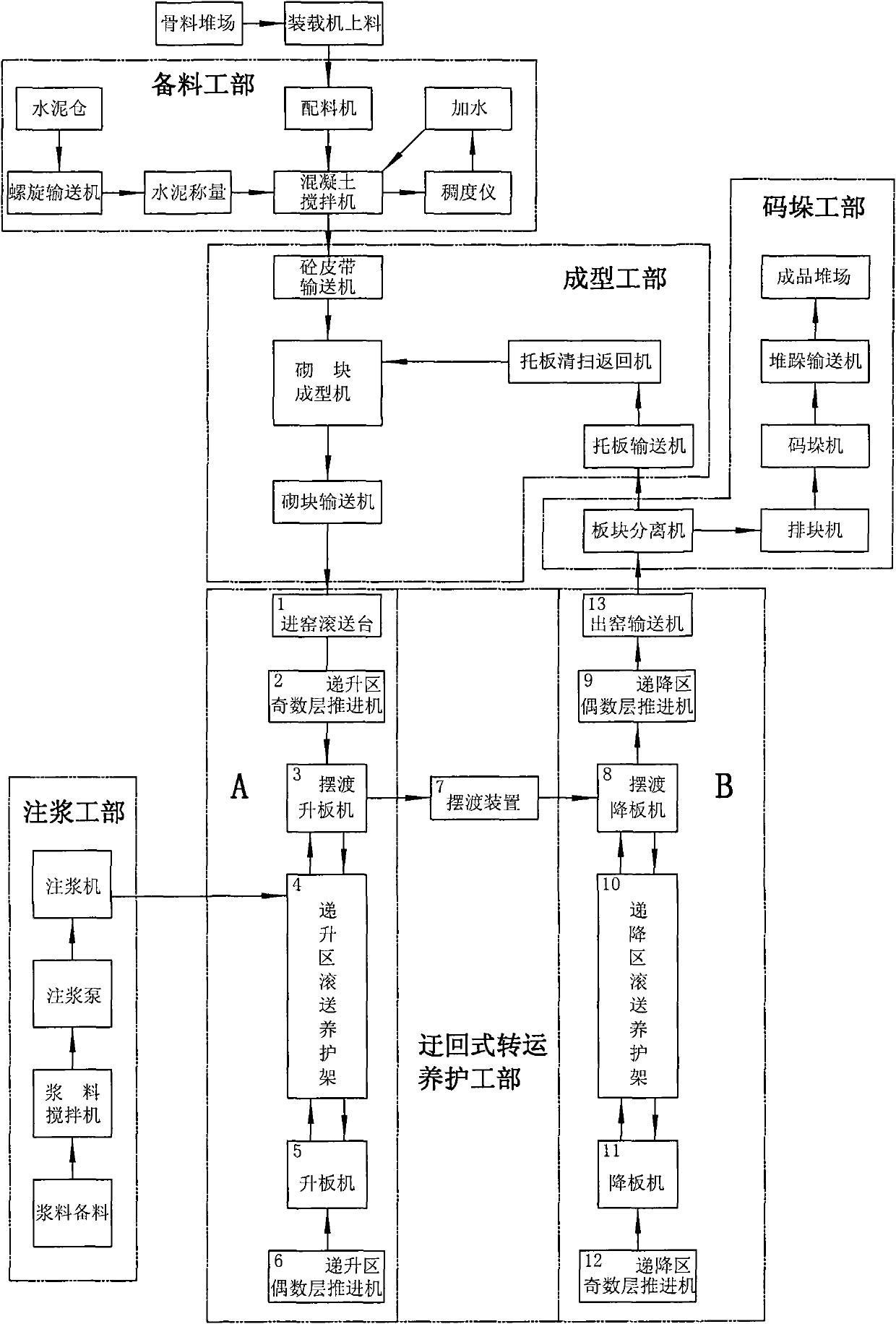

Production method of concrete grouting compound heat-insulating building block

InactiveCN101767365AAvoid manual operationIncrease productivityCeramic shaping plantsProduction lineMaterials preparation

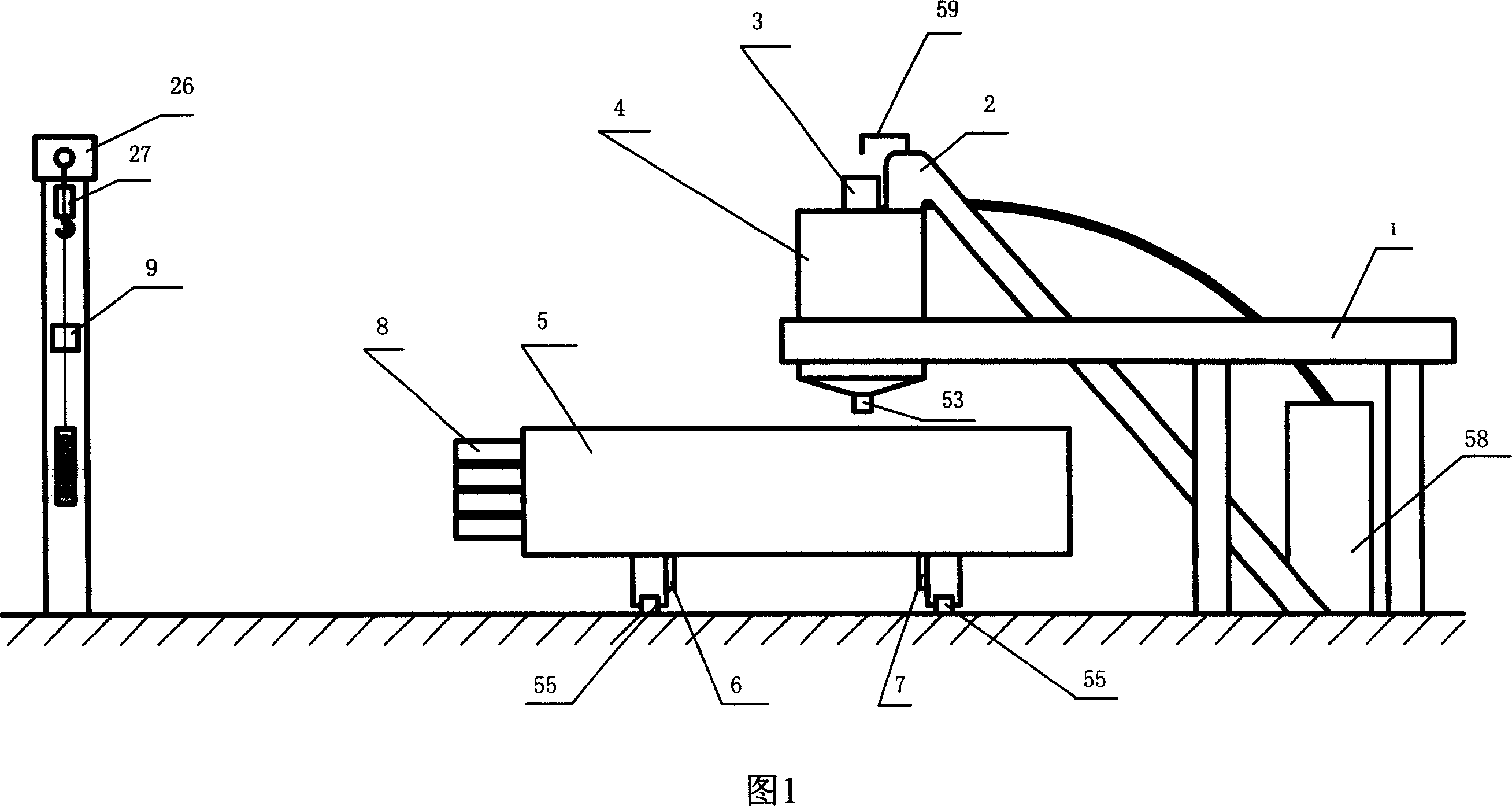

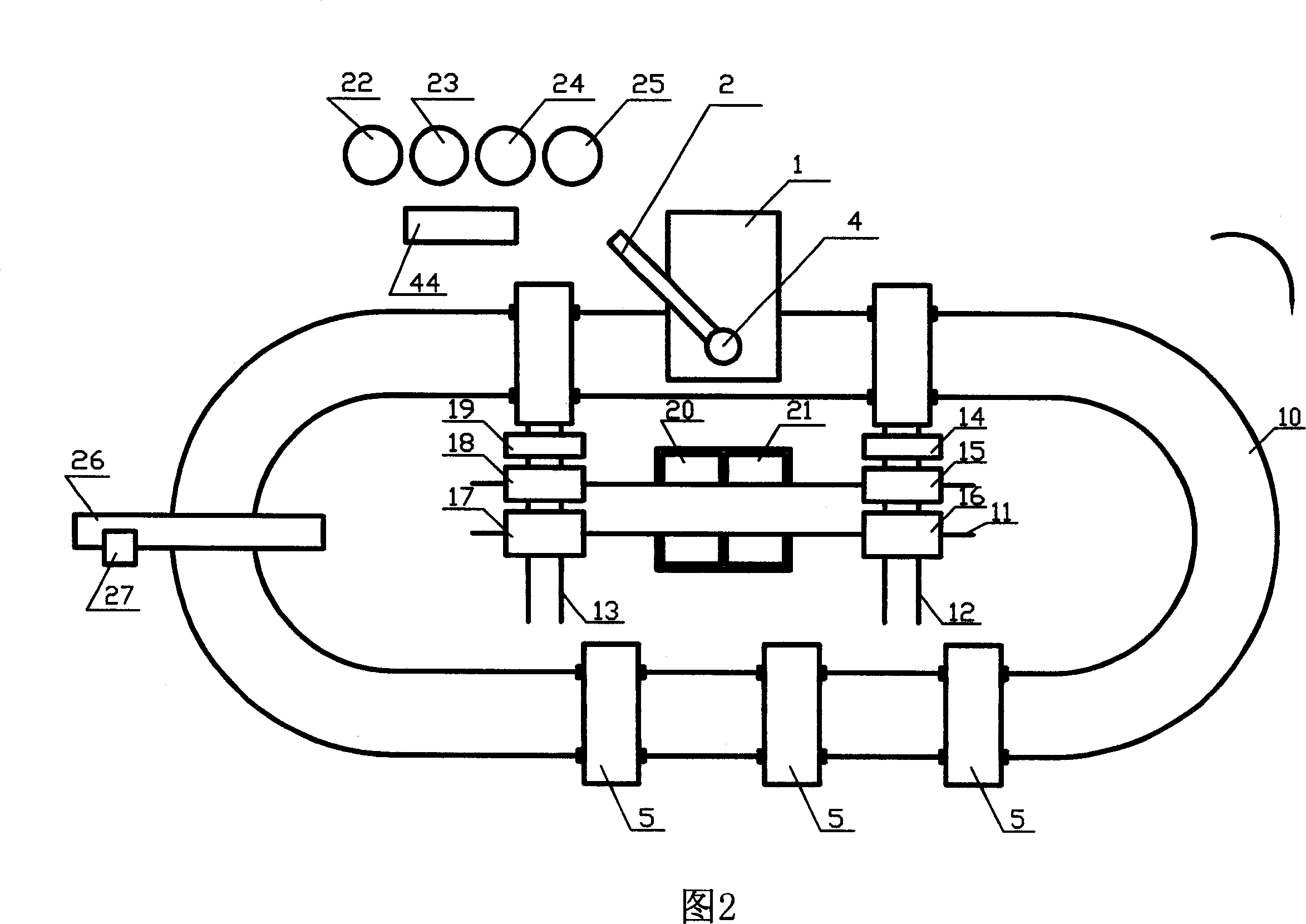

The invention discloses a production method of a concrete grouting compound heat-insulating building block, which belongs to the field of building material machines and comprises a material preparation part, a forming part, a roundabout type transfer curing part, a grouting part and a stacking part, wherein the material preparation part is used for evenly stirring raw materials of building blocks and conveying the stirred raw materials to the forming part; the forming part is used for forming hollow building blocks by a building block forming machine and placing the hollow building blocks on a support plate; the hollow building blocks enter the roundabout type transfer curing part and are cured while being transferred; in the process of transferring and curing, the grouting part is used for grouting the hollow building blocks, so that the hollow building blocks become heat-insulating building blocks; and the cured compound heat-insulating building blocks are stacked into piles by the stacking part. By using the method, the transferring and the curing are combined into a whole, the curing is carried out in the process of the transferring, the transferring is carried out in the process of curing, any idle stroke does not exist and the production efficiency is greatly improved. In addition, in the curing process, the hollow building blocks can be grouted, so that the filling of a heat-insulating material can be finished in the production line and the manual operation can be avoided.

Owner:扬州威奥重工机械有限公司 +1

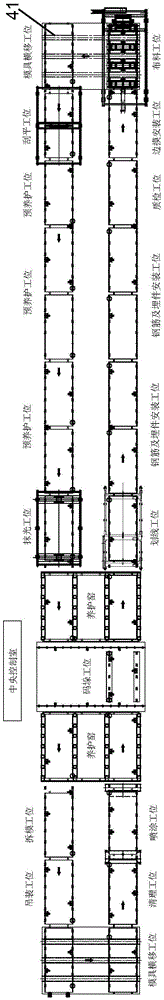

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

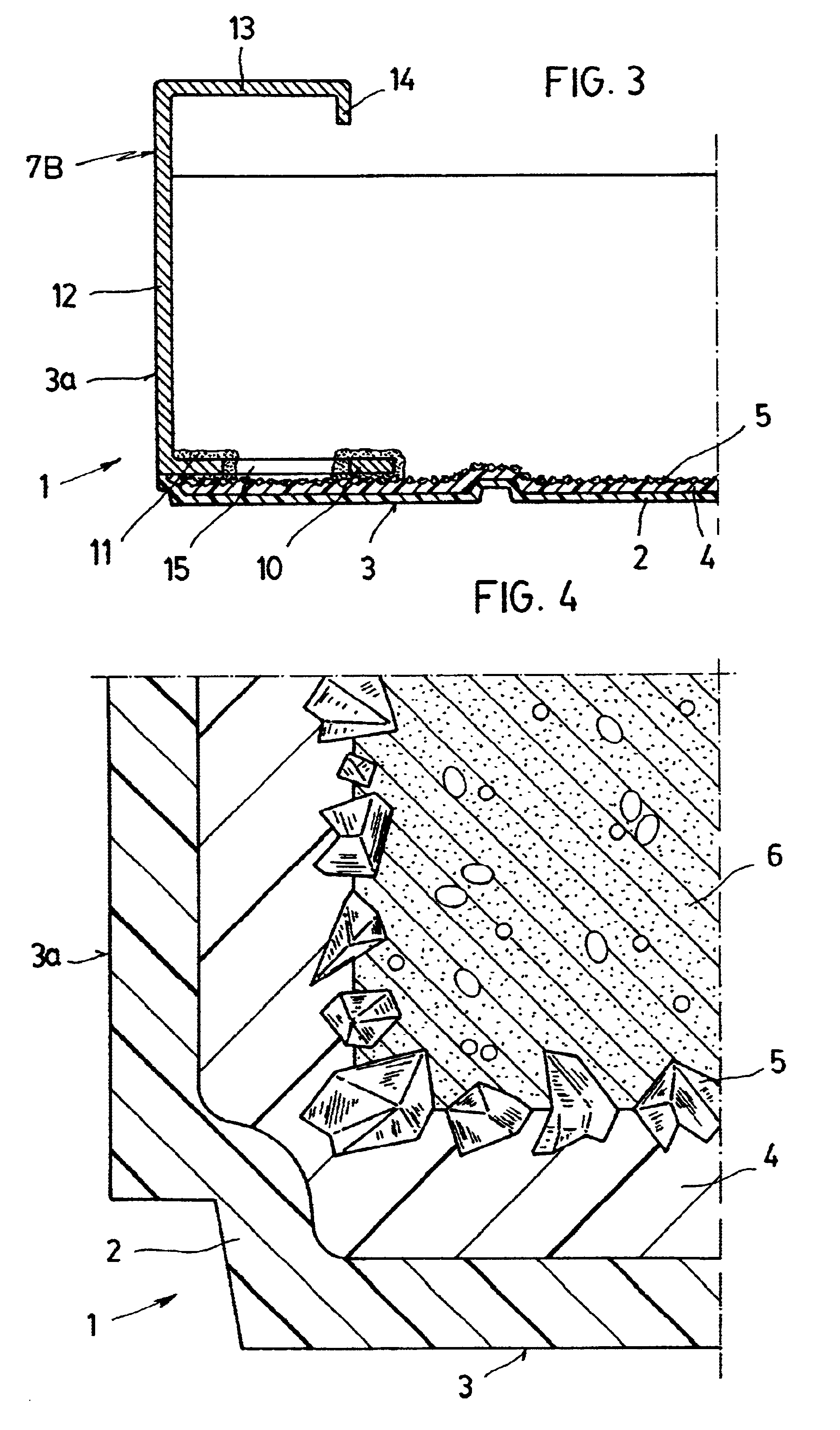

Paving block and molding process therefor

InactiveUS20070216058A1Produce multipleHigh strengthConfectionerySweetmeatsEngineeringUltimate tensile strength

A paving block that closely resembles a used mined cobblestone. The blocks are manufactured by a bi-layer concept that is subjected to processes that cause the layers to structurally integrate. The process and composition permit the mass production of blocks having independent top topographies that emulate the surfaces of original cobblestones and with a comparable strength.

Owner:ECOLOGICA CARMELO

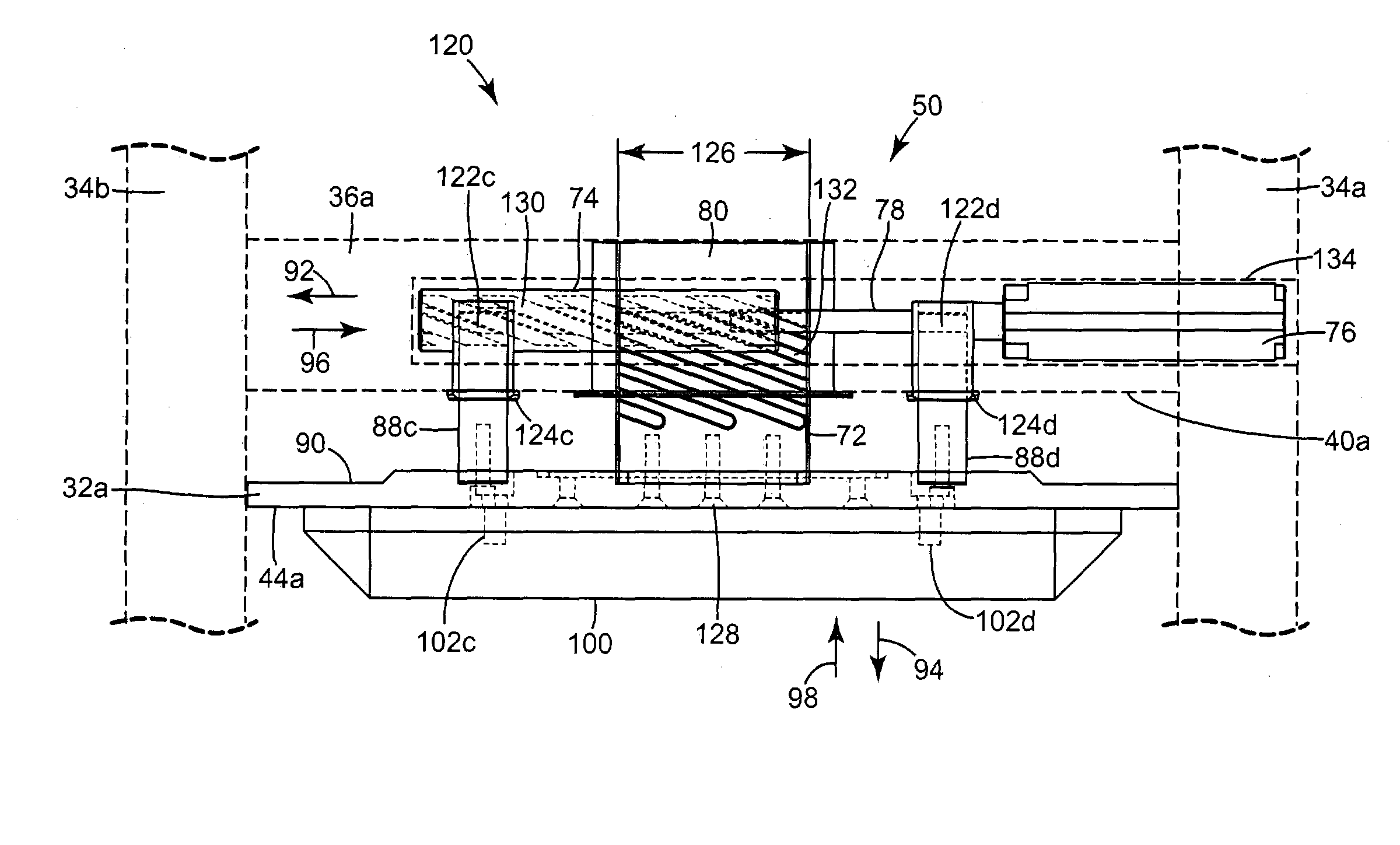

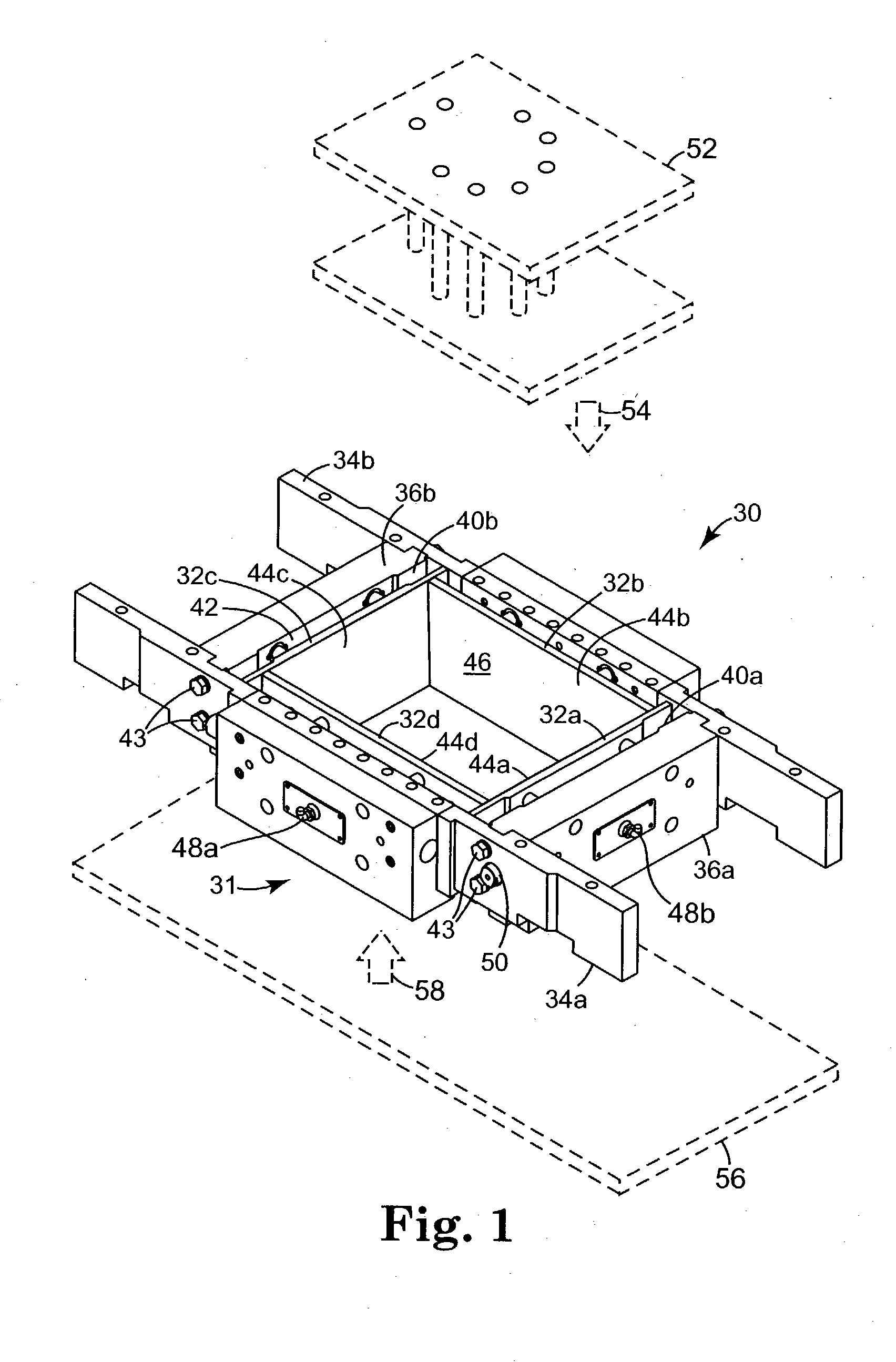

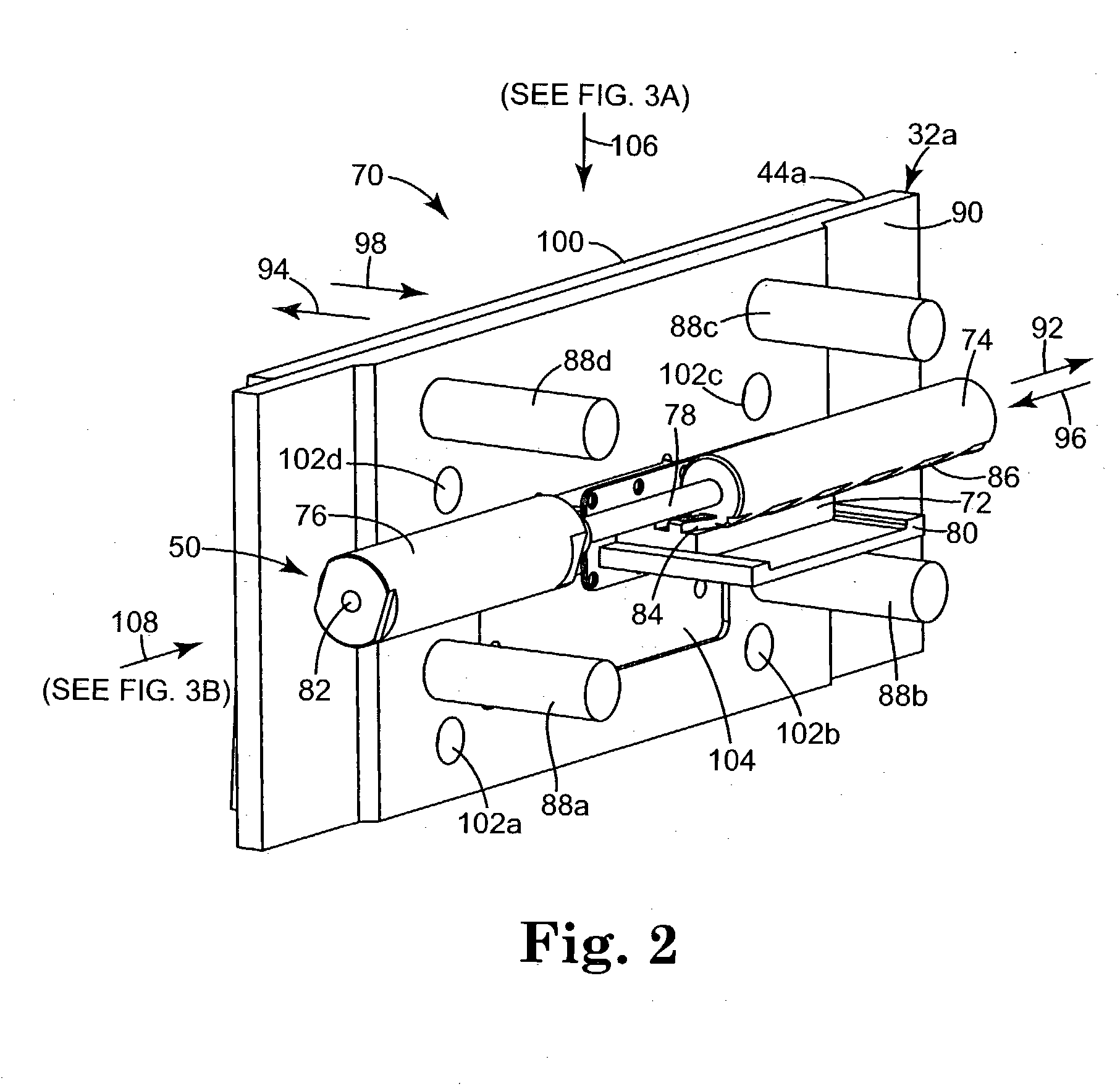

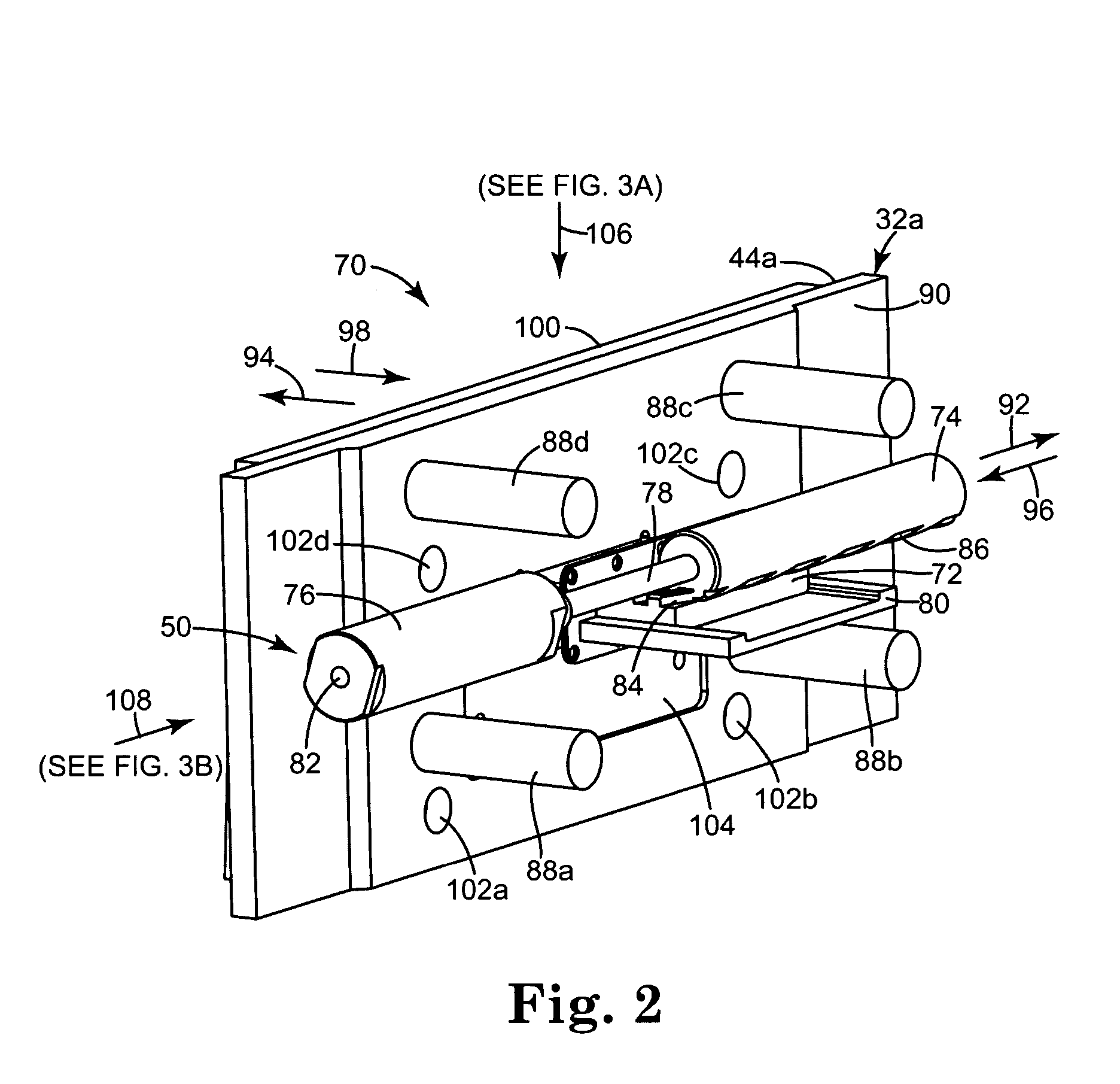

Concrete block mold with moveable liner

One aspect of the present invention provides a mold assembly for manufacturing concrete blocks that is adapted for use in a concrete block machine. The mold assembly comprises a plurality of liner plates and a gear drive assembly. Each liner plate has a major surface and the liner plates are configured such that the major surfaces form a mold cavity, wherein at least one of the liner plates is moveable. The gear drive assembly is selectively coupled to the at least one moveable liner plate and is configured to move the at least one moveable liner plate in a first direction toward an interior of the mold cavity by applying a force in a second direction different from the first direction, and to move the liner plate in a direction away from the interior of the mold cavity by applying a force in a direction opposite the second direction.

Owner:NESS INVENTIONS

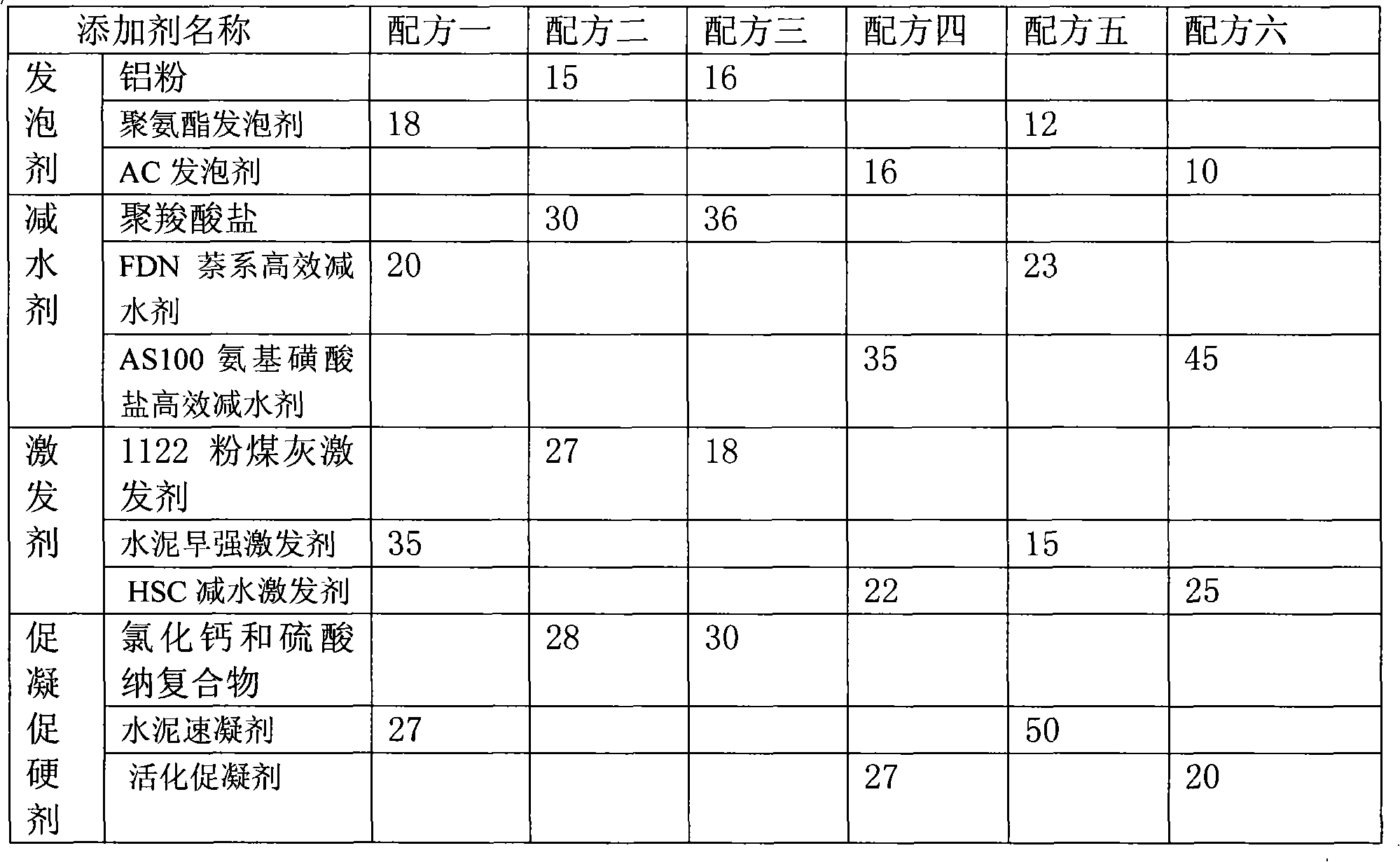

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

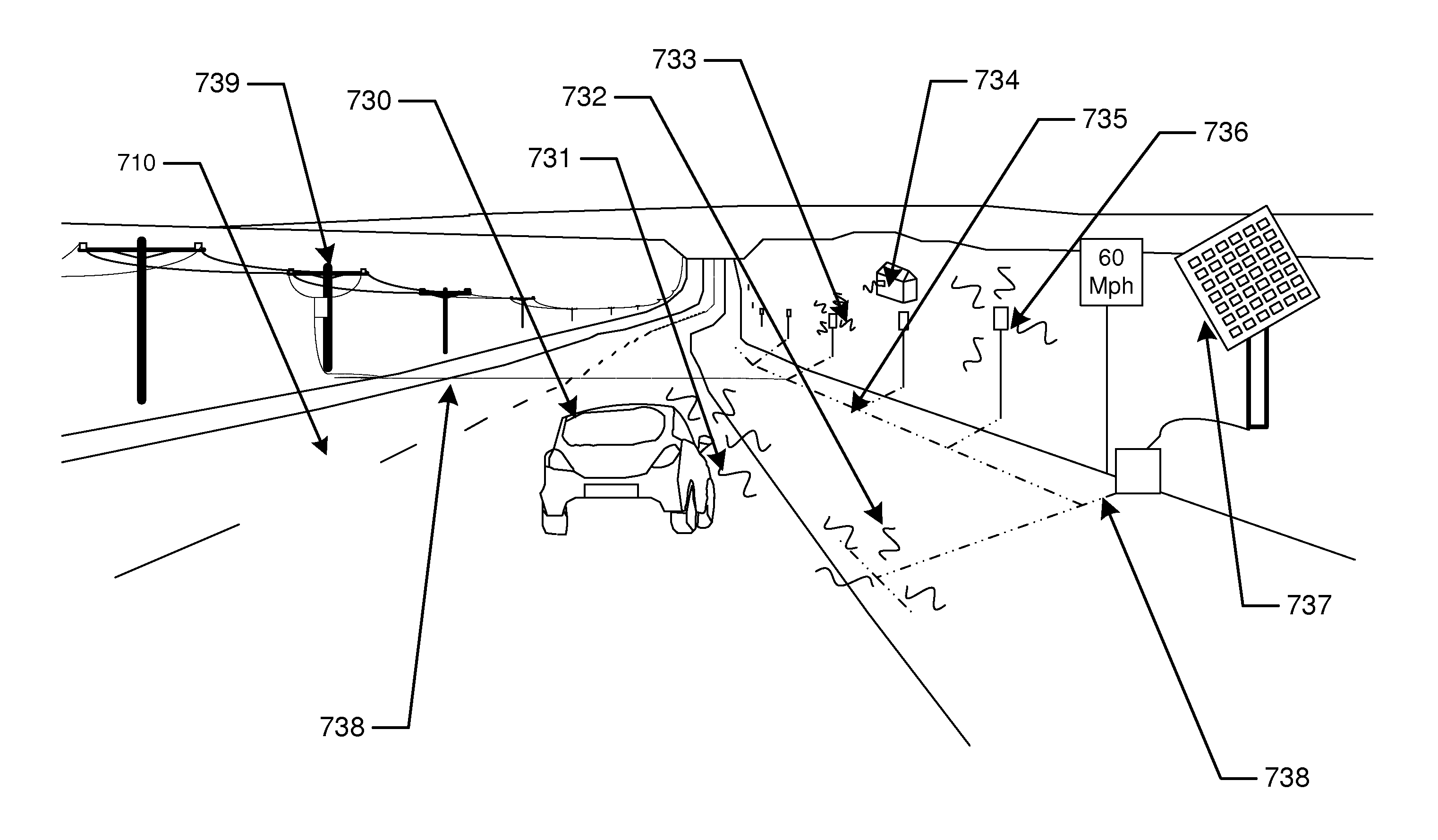

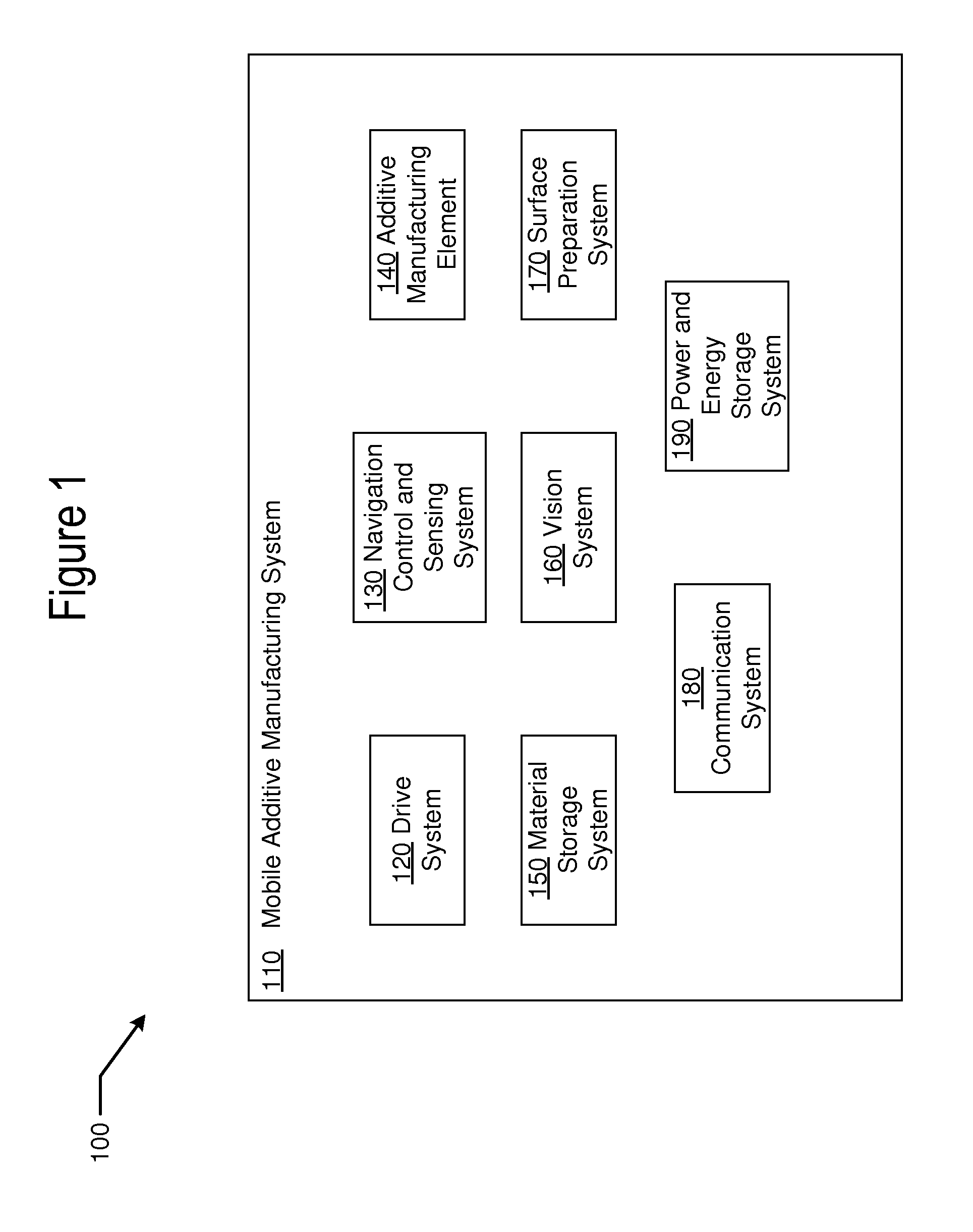

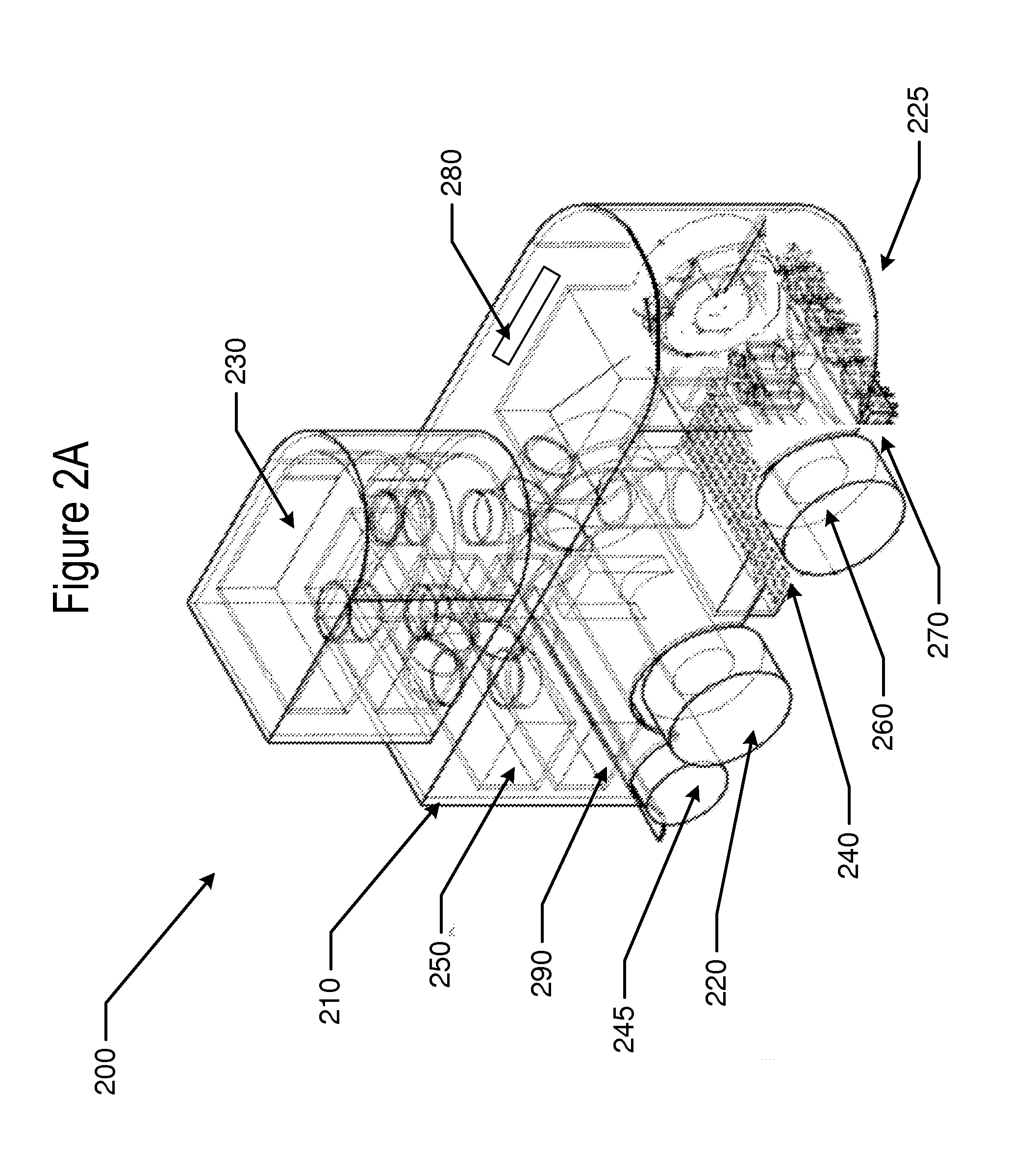

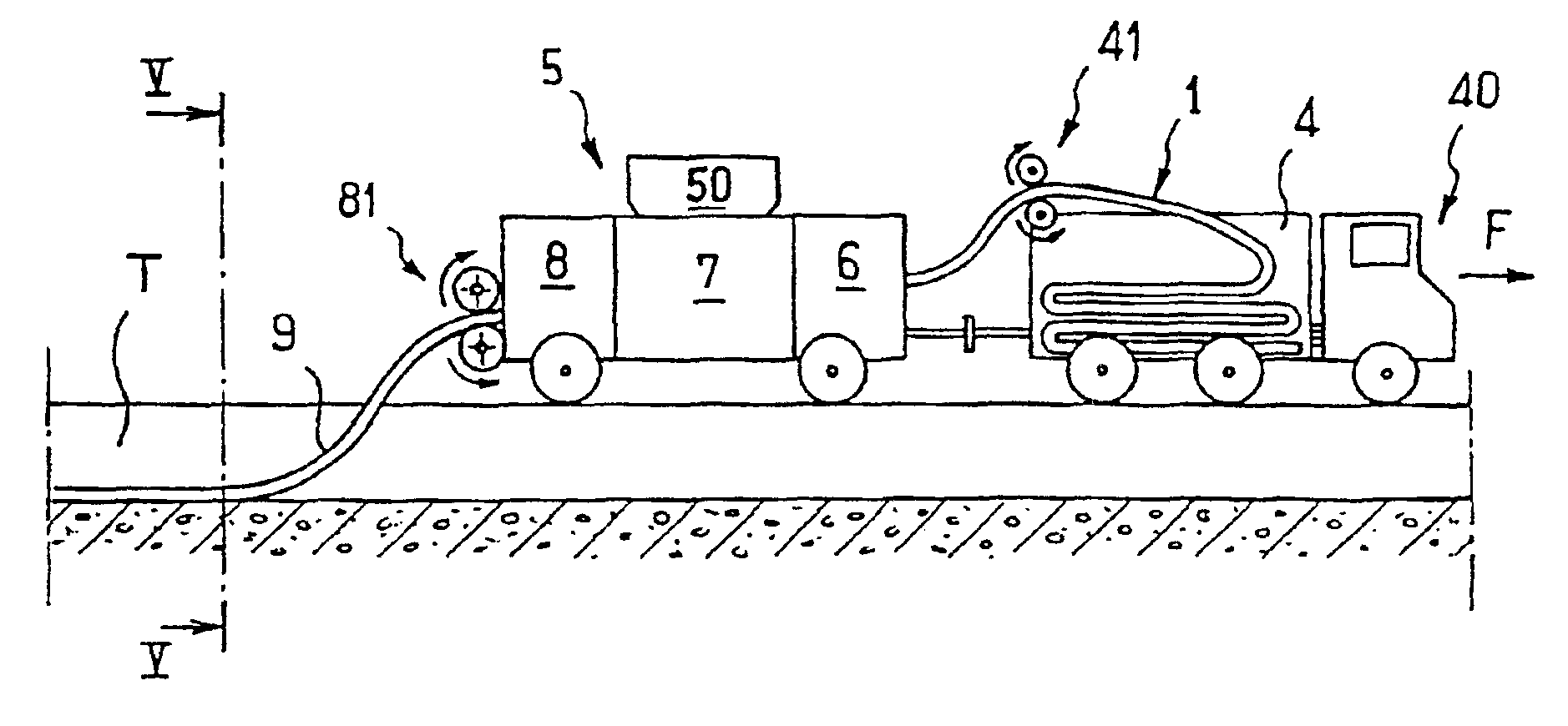

Methods and apparatus for mobile additive manufacturing of advanced structures and roadways

ActiveUS20140374933A1Manufacturing platforms/substratesManufacturing driving meansAdditive layer manufacturingManufacturing engineering

The present disclosure provides various aspects for mobile and automated processing utilizing additive manufacturing and the methods for their utilization. In some examples, the mobile additive manufacturing apparatus may perform surface treatments that support the building of walls. Other examples may involve the support of creating and repairing advanced roadways.

Owner:ADDIBOTS

Concrete block making machine and method

A method for manufacturing decorative concrete blocks for decorative garden walls is presented, along with a machine suitable for practicing the method.

Owner:FIREDMAN DOUGLAS KELLER +1

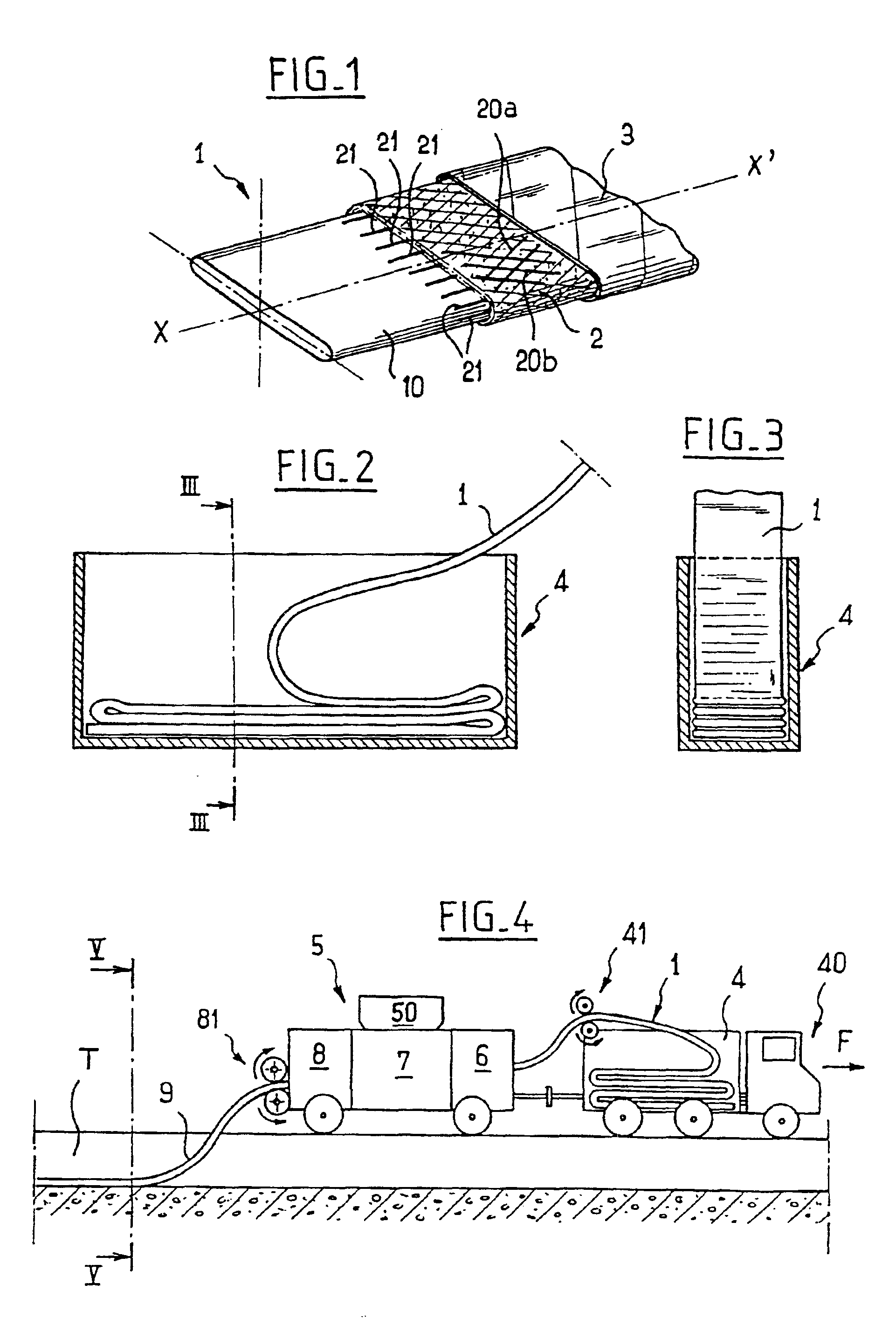

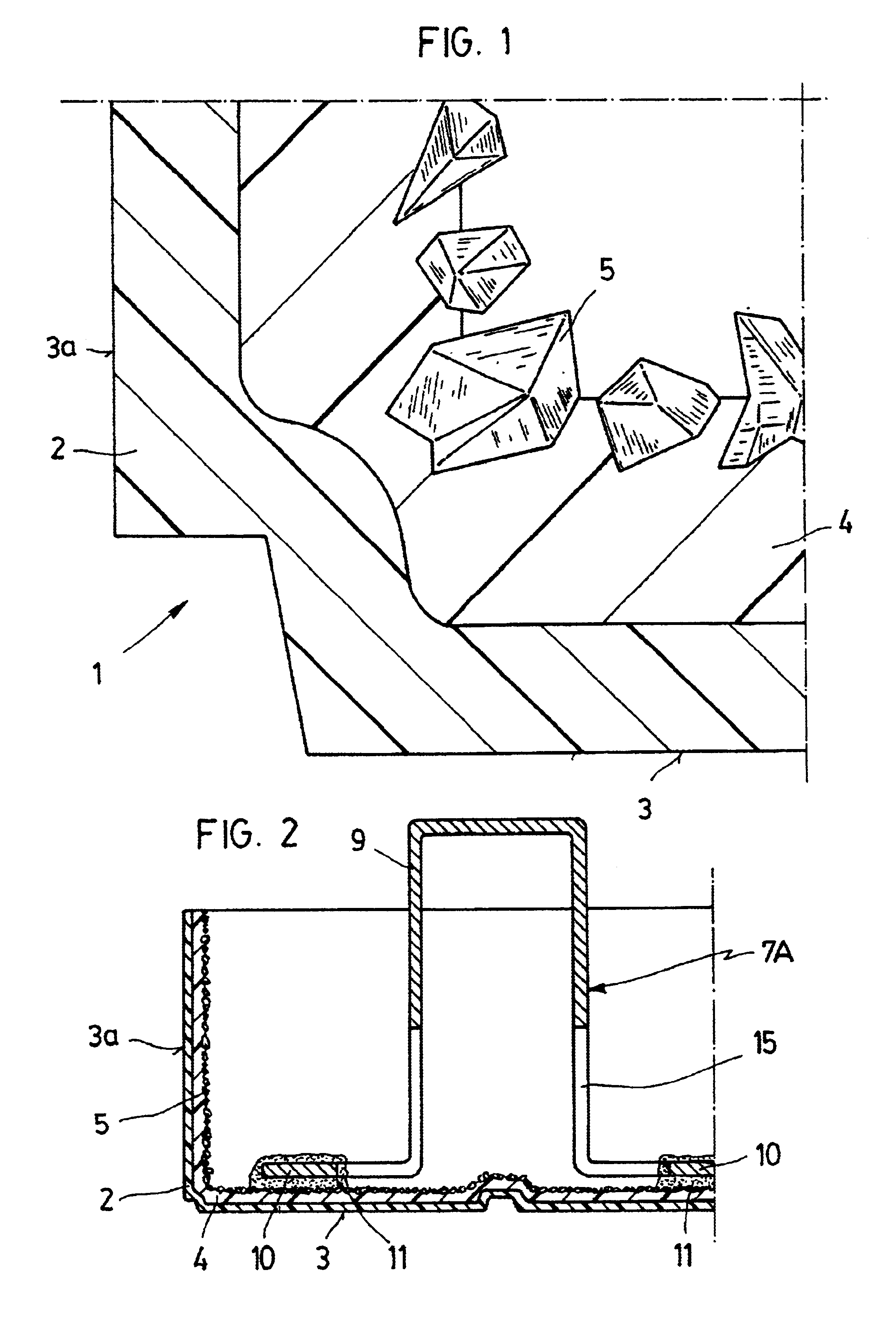

Method and installation for laying a cylindrical pipe on a support

InactiveUS6899842B1Simple and inexpensive implementationAvoid radial expansionUnderground chambersButter manufactureWaste managementStructural engineering

Owner:SERVICES PETROLIERS SCHLUMBERGER SA

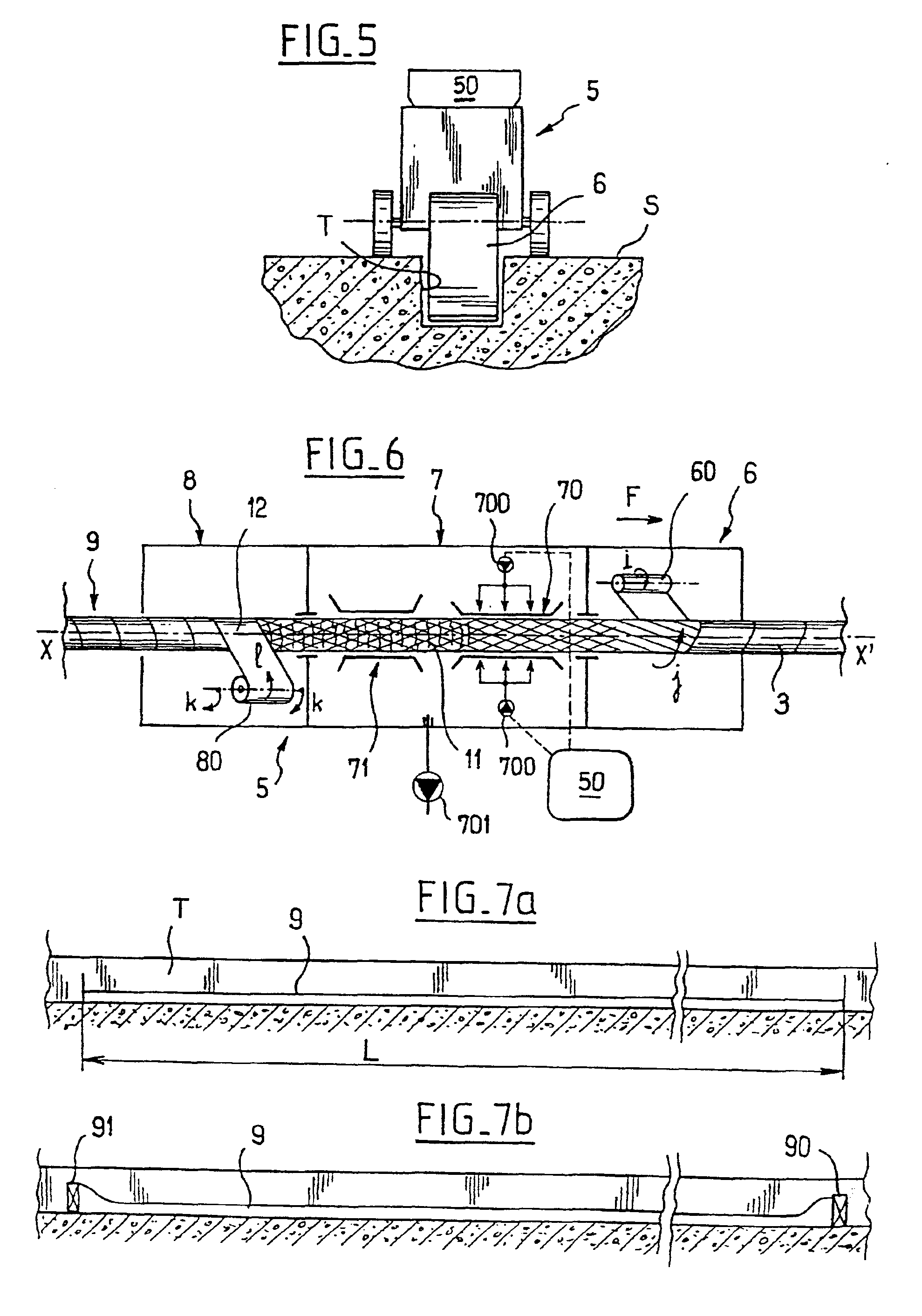

Building panel and plant for the manufacture thereof

InactiveUS6857241B1Easy to produceAccurate locationArtificial islandsConstruction materialThin layerSynthetic resin

This building panel consists of lightweight panel for external or internal closures of latticework support structures, which is constituted by slabs of air-setting resistant material. The slabs are reinforced in the facade panels for external closures and unreinforced for the dividing panels for internal closures. They are provided with a patterned surface on the visible face and are smooth or shaped at the edges. The visible face is formed by a thin layer of molded synthetic resin or fine mortar paste. When the layer is molded synthetic resin and is disposed as a shell for the panel, it comprises over the whole of the inner surface thereof an internal synthetic resin layer, the entire free surface of which is covered with a solid bulk material, the components of which firmly partially anchored in said internal layer and afford a substantial free surface for anchorage of the air-setting material forming the resistant body poured thereover. This material fills the entire volume of said panel shell, at the same time as it includes therein reinforcement means provided with points directly accessible from the outside of the concealed face of the panel.

Owner:PELLICER CARLOS FRADERA

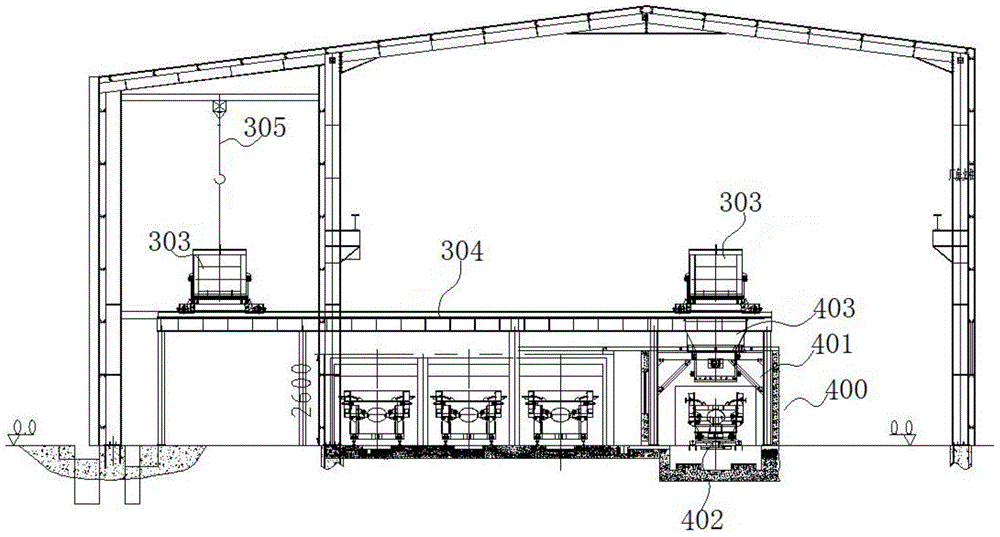

Production line for self-heat-insulation building blocks for walls

ActiveCN103128848AReduce waste lossEasy maintenanceCeramic shaping plantsProduction lineFoam concrete

The invention discloses an equipment production line for self-heat-insulation building blocks for walls. The equipment production line comprises a hollow brick production system, a steam curing system, a transfer system, a foam concrete pouring system and an automatic control system. The steam curing system is respectively connected with the hollow brick production system and the foam concrete pouring system by the transfer system, and the automatic control system is connected with the hollow brick production system, the steam curing system, the foam concrete pouring system and the transfer system by control circuits. Compared with the traditional production line, the equipment production line has the advantages that the steam curing efficiency is greatly improved, the energy cost is greatly saved, and the production cost is reduced; and distances from a filling plate and a filling groove to hollow bricks can be adjusted via lifting mechanisms, so that slurry can be effectively prevented from flowing out of the hollow bricks during pouring when the quantity of slurry in the filling groove is excessively high, waste of the slurry is reduced, and accordingly the production cost is saved.

Owner:河南华泰新材科技股份有限公司

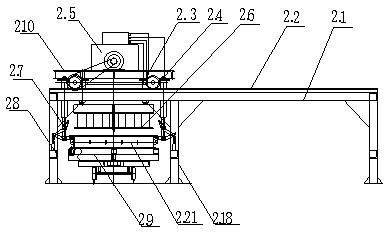

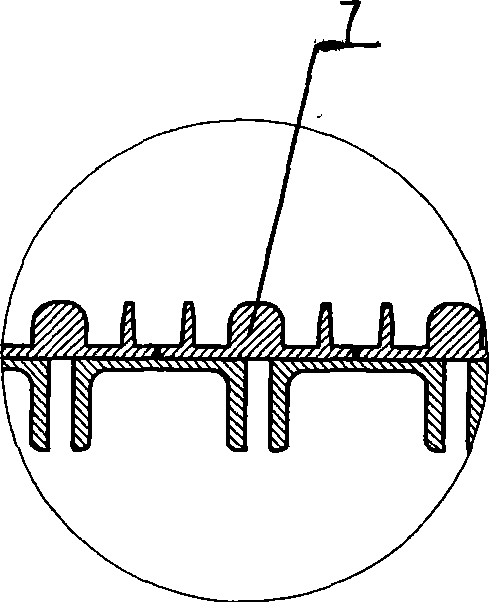

Automatic shaping method and equipment for load-bearing hollow brick

InactiveCN1657251ALiberate labor intensitySpeed up the flowDischarging arrangementMouldsBrickEngineering

A method for automatically shaping the load-bearing hollow brick includes such steps as preparing concrete, stirring, filling in mould, inserting core mould while vibrating, hydraulic pressing, and demoulding. Its apparatus is composed of electric power control box, control mechanism, motor, concrete preparing system, shaping system, feeding unit, and discharging unit.

Owner:广西金瓯建材机械有限公司

Compound thermal insulation wall plate and external wall heat-insulation board producing line

InactiveCN101138866AIncrease productivityEasy to operateDischarging arrangementCeramic shaping plantsProduction lineThermal insulation

The present invention discloses a production line of a composite heat proof wall plate and an external heat proof plate of an external wall. The production line includes an automatic mounting moulding board mechanism, cloth-net roll mechanisms, a reseau cloth automatic cutting mechanism and an automatic plate-sending, shelf-installing and shelf-sending mechanism which are orderly linked by a belt feeding production chain. Mixing and material-dropping mechanisms are arranged above a section of belt feeding production chain between the automatic mounting moulding board mechanism and a first group of cloth-net roll mechanism and between a forward group of cloth-net roll mechanism and a next group of cloth-net roll mechanism. At least two groups of matched mixing and material-dropping mechanisms and the cloth-net roll mechanisms are arranged. The production line can produce the composite heat proof wall plate and at the same time can also produce the external heat proof plate of an external wall and has the characteristics of high production efficiency, simple and convenient operation and high quality of processing.

Owner:泰安鲍文特科技有限公司

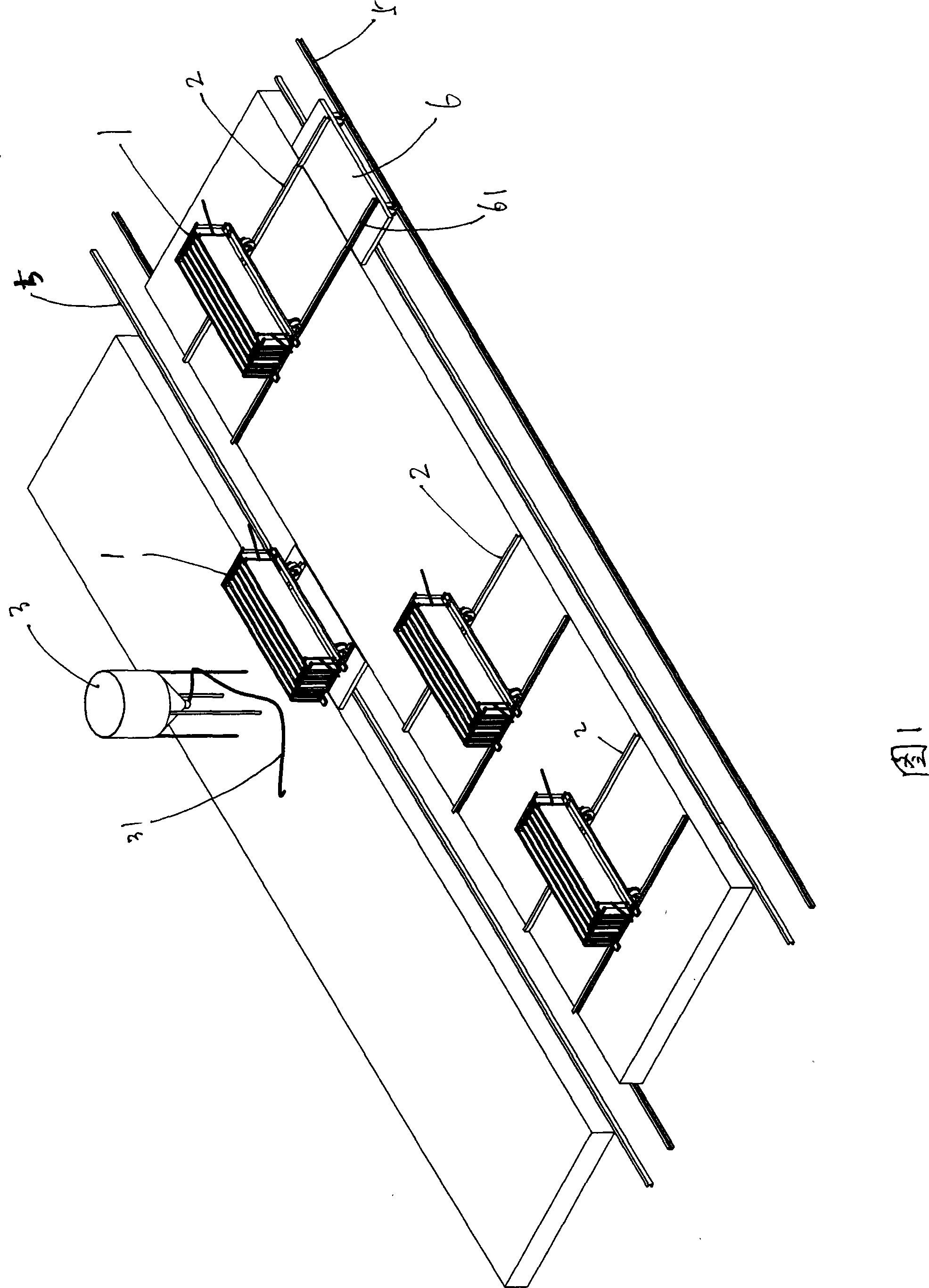

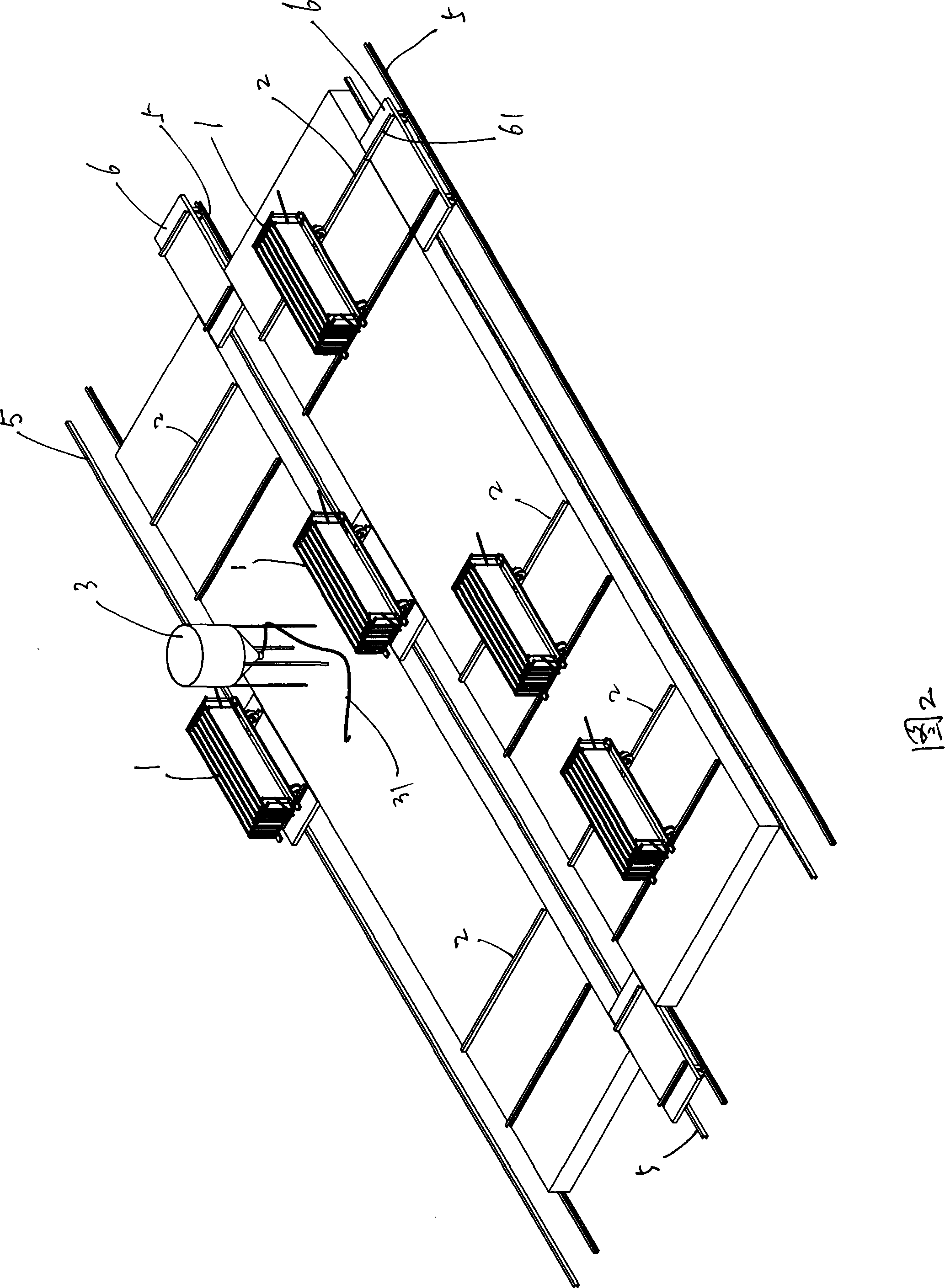

Lightweight composite wall panel moulding apparatus and product line

ActiveCN101244581ASignificant progressFix fixMouldsCeramic shaping plantsProduction lineVehicle frame

The invention provides a forming machine for a lightweight composite wallboard, which is characterized in that three side vertical templates are classified as a group; one template in the center of each group is the fixed template; two templates at two sides of each group are respectively the left moving template and right moving template; the fixed template is fixed at a frame; the left moving template, the right moving template, a left bed die band and a right bed die band are flexibly connected with the beams of the frame; each left moving template, right moving template, left bed die band and right die band are respectively connected with a plurality of link bars. The invention still provides a production line for lightweight composite wallboard. The production line is provided with a die car track and a sinking transfer orbit; a transfer wheelbarrow is arranged at the orbit; the forming machine can be arranged at the transfer wheelbarrow through a connection orbit or can enter into a die car orbit from the transfer wheelbarrow. The forming machine for a lightweight composite wallboard has the advantages of simple equipment and light weight, overcoming the defect that traditional wallboard forming machine is so big that the machine can not be moved; the side vertical template and bed die band adopt the grouping connection design, solving the problem of the heeling and opening of the side vertical template and the fixation of the bed die band; the open die facility is classified and the operation becomes very convenient; the wallboard production line uses flow shop and the forming machine is handled movably according to the working procedure, improving work efficiency.

Owner:广州市建筑材料工业研究所有限公司

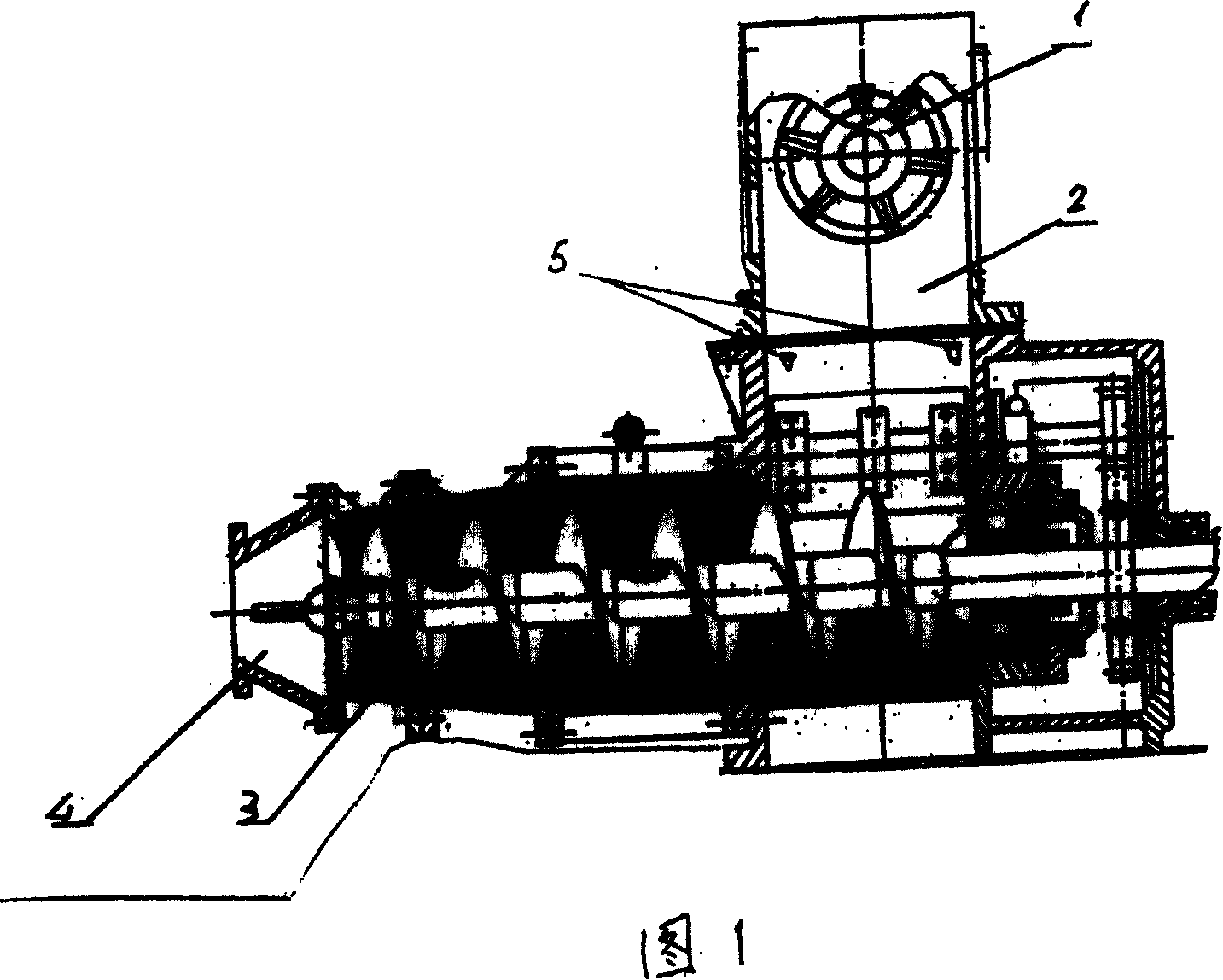

Method for producing gypsum building products by using expressing technique

InactiveCN101138863AReduce production energy consumptionFast productionSolid waste managementCeramic shaping plantsBuilding productPresent method

The present invention provides a process method for producing a gypsum building product, namely an extruding method which is energy-saving and time-saving and which can rapidly produce a gypsum building product with excellent quality. The process method mainly consists of three major parts: the preparation of a gypsum extrusion material, an extruder group and a production process procedure. The structure of the extruder consists of four parts: a mixing segment 1, a buffer segment 2, an extruding segment 3 and a forming machine head 4. The extruding method produces a gypsum building product mainly through the following procedures: a material, which is mainly gypsum and to which a small amount of mixing water added, is extruded and formed by the extruder group, smeared into a specified size by a cutting machine head and becomes a finished product after a finishing processing. The gypsum building product of the present process method has the following advantages: (1) that the product substrate with a compressive strength one to two times as strong as that of the ordinary product by a pouring method is compact and has strong strength, (2) that the product without too much free moisture and does not need a heat drying or drying process, thus greatly reducing production energy consumption, (3) and that the present method with a rapid production speed and a short production cycle is a quick process for producing gypsum building products.

Owner:方承仕

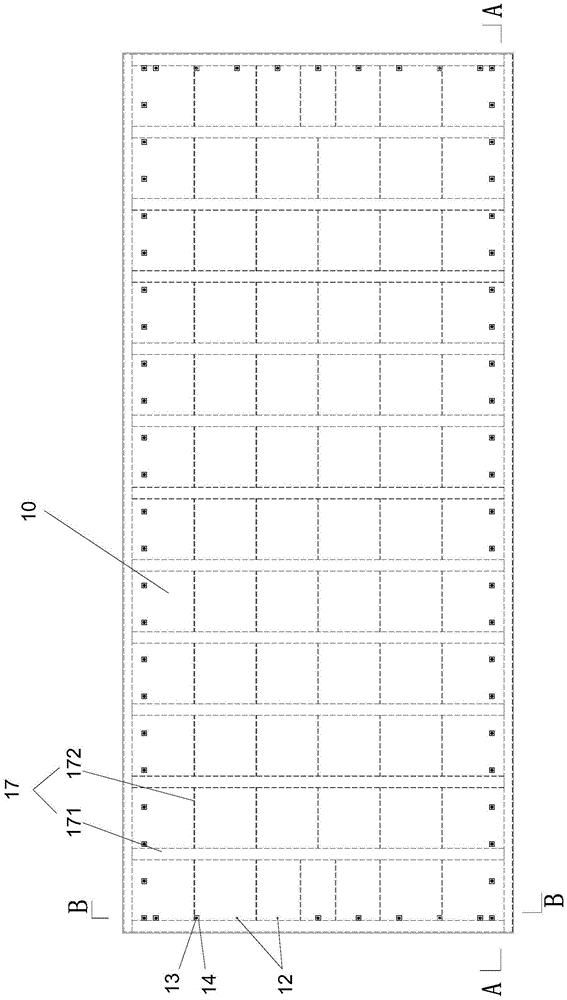

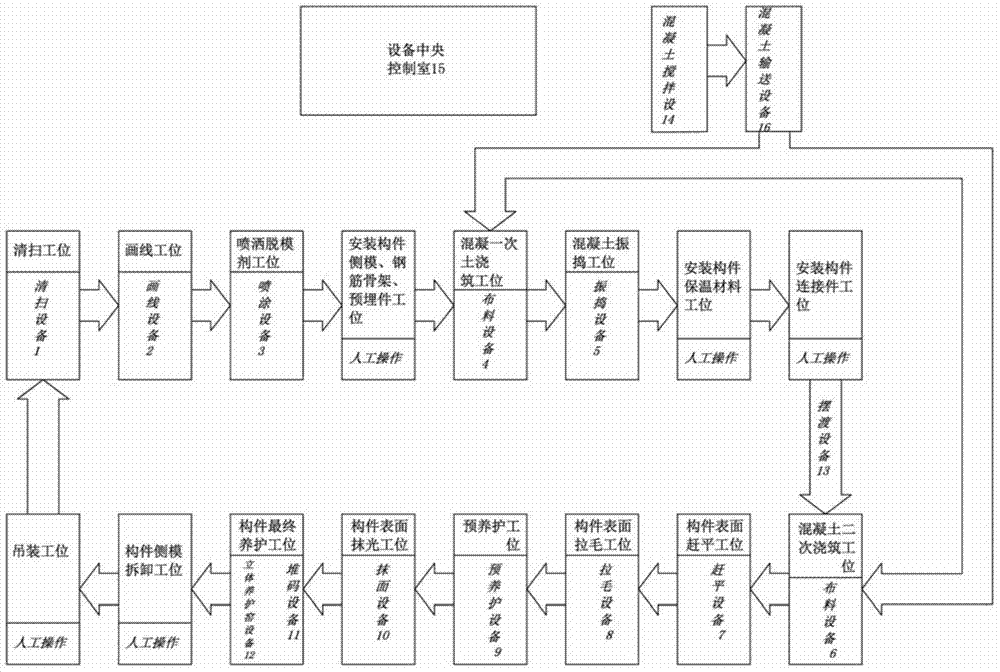

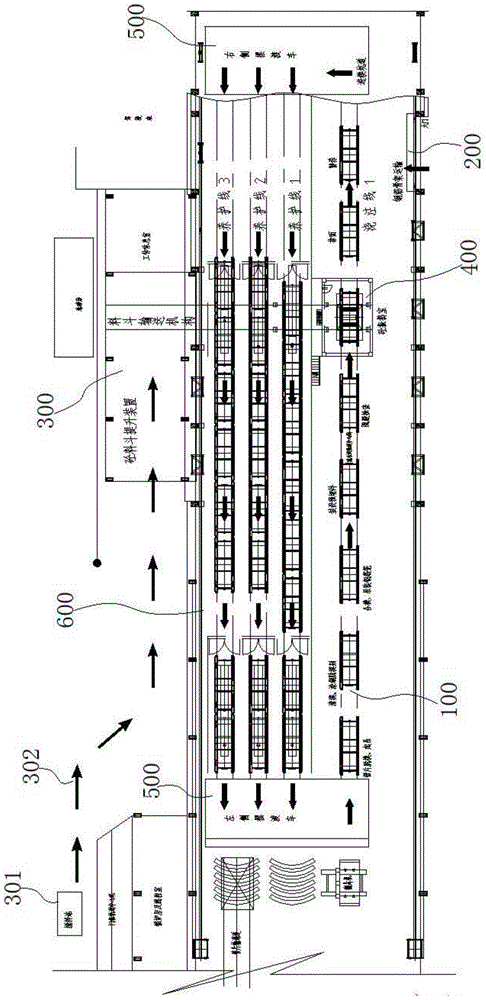

Automatic production line of building industrialization concrete precast members

ActiveCN104723449ARealize centralized maintenanceRealize program controlCeramic shaping plantsProduction lineEngineering

The invention discloses an automatic production line of building industrialization concrete precast members. The automatic production line comprises a member bottom die sweeping station, a member bottom die line drawing station, a member bottom die release agent spraying station, a member side die, steel reinforcement framework and embedded part installing station, a member concrete primary pouring station, a member concrete vibrating station, a member heat insulating material installing station, a member connecting part installing station, a member concrete secondary pouring station, a member surface flattening station, a member surface galling station, a member pre-curing station, a member surface troweling station, a member final maintenance station, a member side die detaching station and a member hoisting station which are sequentially and cyclically connected. Centralized maintenance is achieved, energy is saved, energy consumption is reduced, and the mechanical degree is high. Procedures are compactly linked, worker employment is low, and production efficiency can be improved. Production cost of products is low, production can be flexibly arranged according to the demand ratio of the market for different members, and the requirements for a large amount of material supply of different products of different projects are met.

Owner:沈阳宝力德科技有限公司

Method for pouring and molding large scale disposal wallboard and mould carriage thereof

InactiveCN101439553AHigh strengthImprove product qualityDischarging arrangementMould separation apparatusWire cuttingSlurry

The invention discloses a method for one-time wallboard perfusion moulding on a large scale and a pan car thereof. A die of the bottom plate of a wallboard is fixed inward the internal part of the bottom plate of the pan car at equal distance; dies of the side wall of the wallboard are respectively fixed inward the front side plate and the back side plate of the pan car at equal distance; therefore, after the case of the pan car is fully filled with pasty slurries, a vibrator leads to the vibration of the whole case on the front side plate and the back side plate; after the vibration, a finished product is obtained after initial setting, wallboard cutting, steam curing, pan car removal of shuttering and other processes; therefore, 20-200 wallboards are processed in one time. The wallboard cutting is realized in the form of steel wire cutting or clapboard partition; a steel wire netting is embedded in the wallboard, so as to greatly enhance the strength of the wallboard; therefore, the invention has the advantages that the inner wallboard of the pan car is formed by large-scale one-time injection moulding by using the die, the precision of the die is high, the product quality is reliable, the injection amount is large, the production efficiency is greatly improved and the cost is saved.

Owner:朱春生

Concrete block mold with moveable liner

Owner:NESS INVENTIONS

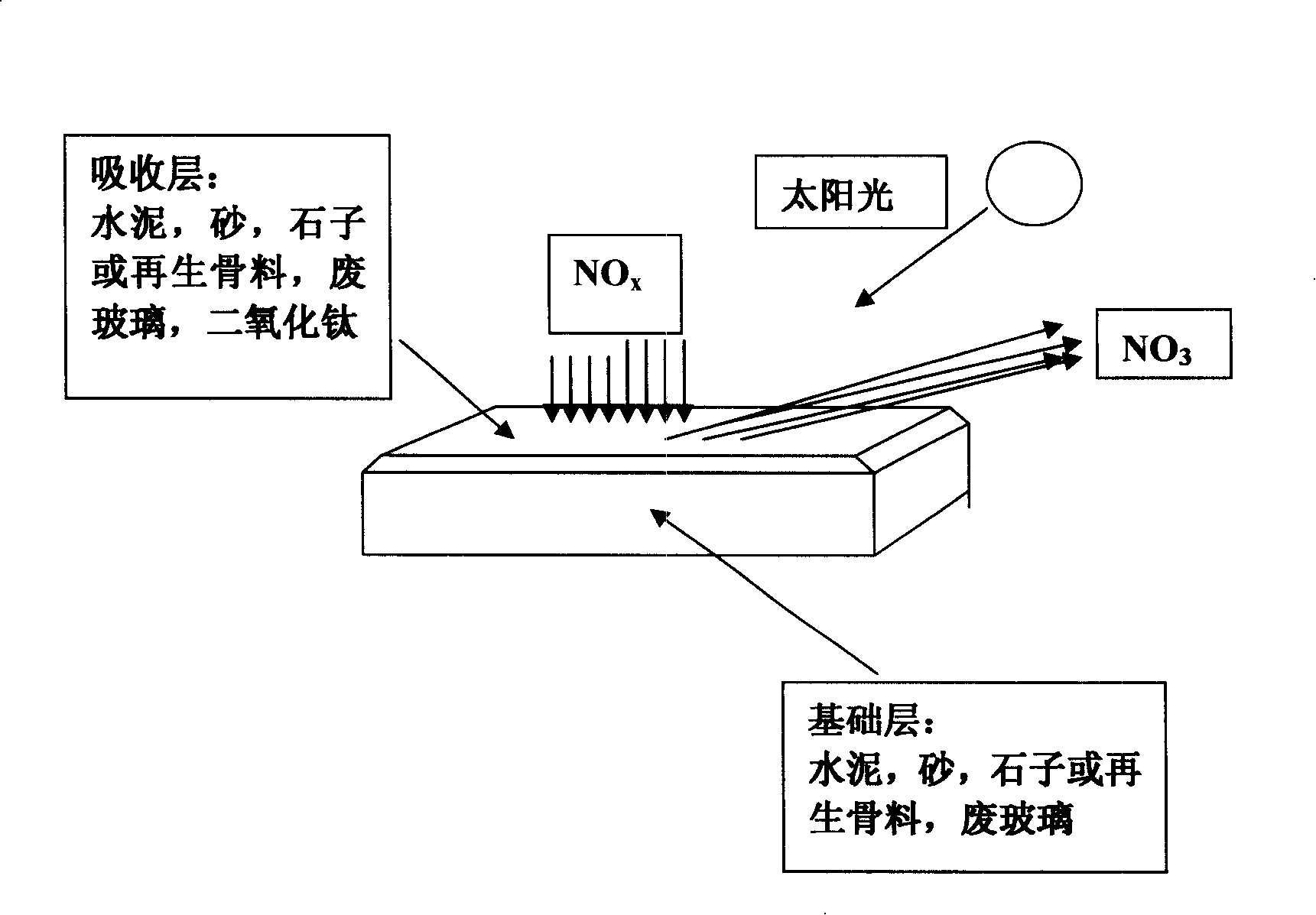

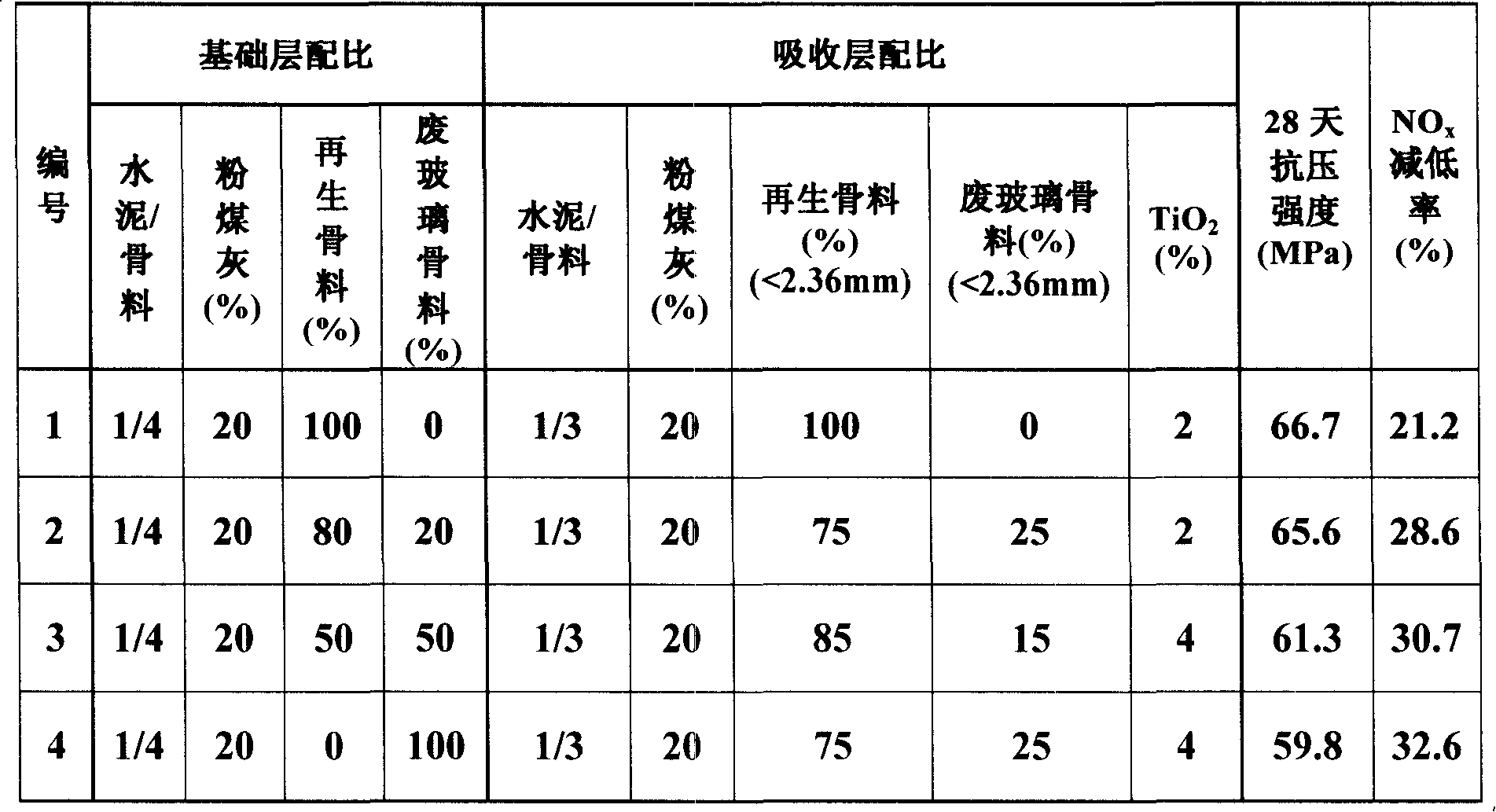

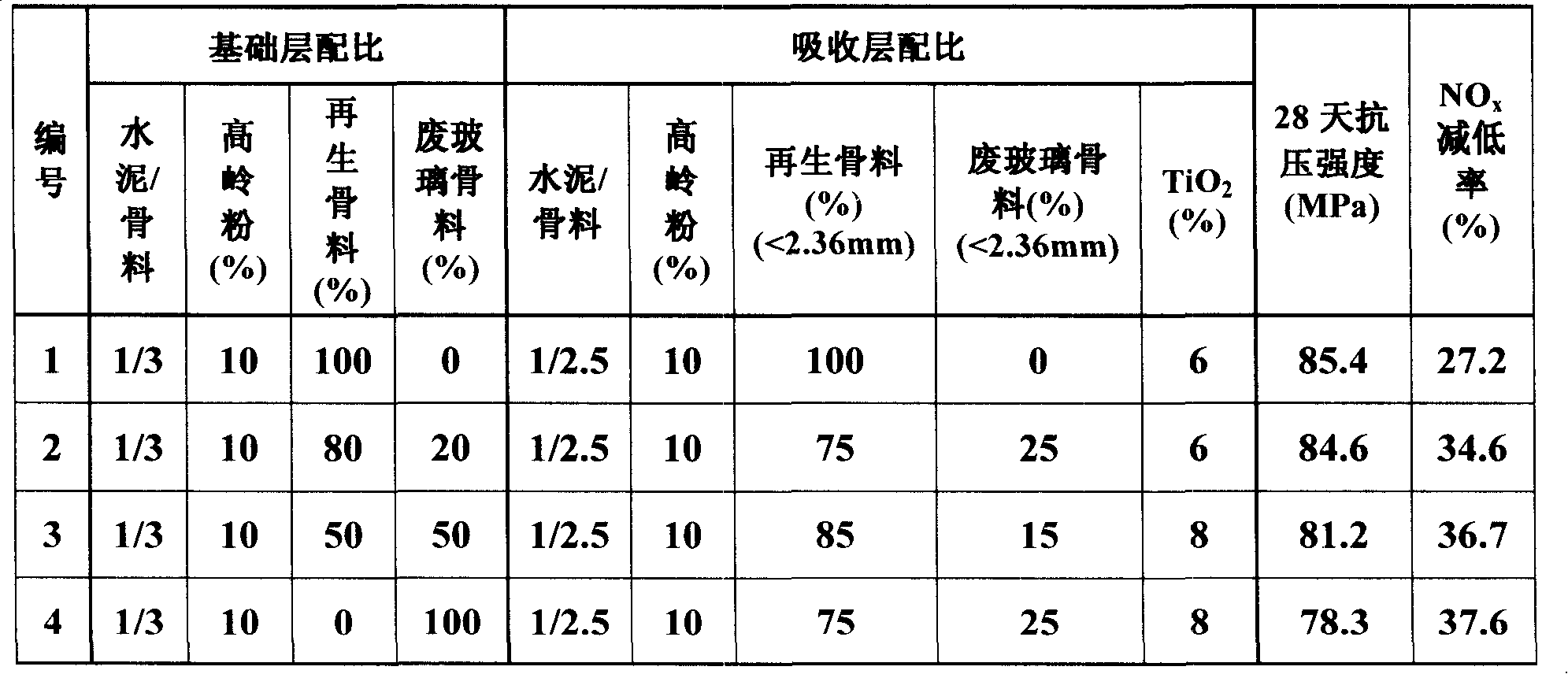

Concrete paving brick capable of purifying air and method for manufacturing the same

The invention provides a concrete paving brick capable of clarifying air produced by using building waste and recycled glass and the manufacturing method thereof. The paving brick comprises an absorption layer and a foundation layer, the absorption layer comprises cement, aggregate, titanium oxide and coal ash or kaolinite powder, the aggregate of the absorption layer comprises recycled aggregate, waste glass aggregate and sand or stones; the foundation layer comprises cement, aggregate and coal ash or kaolinite powder, the aggregate of the foundation layer comprises recycled aggregate, waste glass aggregate and sand or stones. The paving brick of the invention has good function of absorbing exhaust gas and good strength.

Owner:THE HONG KONG POLYTECHNIC UNIV

Equipment and method for producing imitation stone-texture ceramic tile

The invention relates to equipment and a method for producing an imitation stone-texture ceramic tile. The equipment comprises a hydraulic machine, a tile pulling rod, a material pushing frame of a secondary material spreader and a composite base material hopper, wherein the tile pulling rod is arranged at the front end of the composite base material hopper on the material pushing frame of a secondary material spreader and consists of two tile pulling arms and a transverse rod. The equipment is characterized by also comprising a tile pulling mechanism driving the tile pulling rod and a powder removing mechanism which is used for removing powder and arranged between the hydraulic machine and the composite material hopper. The invention also provides a secondary material spreading device and a method thereof, which not only can solve the problem of directly producing a ceramic tile with a clear texture effect pattern imitating a natural stone without a polishing working procedure difficult to be realized in a counter steer mode, particularly a rough surface or dull surface micro powder ceramic tile with the texture effect pattern imitating the natural stone, but also can ensure that the texture effect pattern imitating the natural stone in a micro powder material can be kept more complete.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD

Technology and device for manufacturing gypsum lightweight cavity wallboard and building block

InactiveCN1927560AIncrease productivityRealize continuous pouring moldingCeramic shaping plantsCeramic shaping liningsProduction lineBrick

The invention relates to a method for producing gupse hollow wall plate and brick, which can demould without rotating core tube. Wherein, said method comprises combining mould, mounting core tube, irrigating, taking out core tube and opening mould; before combining mould, plating demoulding agent on the template and plating set retarder on the core tube to retard the slurry contacted with the core tube; and it can demould without rotating core tube. The inventive product line comprises feeding device, mixing irrigator, mould machine, installer, core taking device and lifter; the mixing pot of mixing irrigator is fixed on the platform of mixer; the material of storage pot via feeding device is fed to the mixing pot; the bottom of irrigate valve of mixing pot is opposite to the mould chamber of mould machine; the mould machine moves on annular track. The invention has high efficiency and low cost.

Owner:长沙归一新材料科技股份有限公司

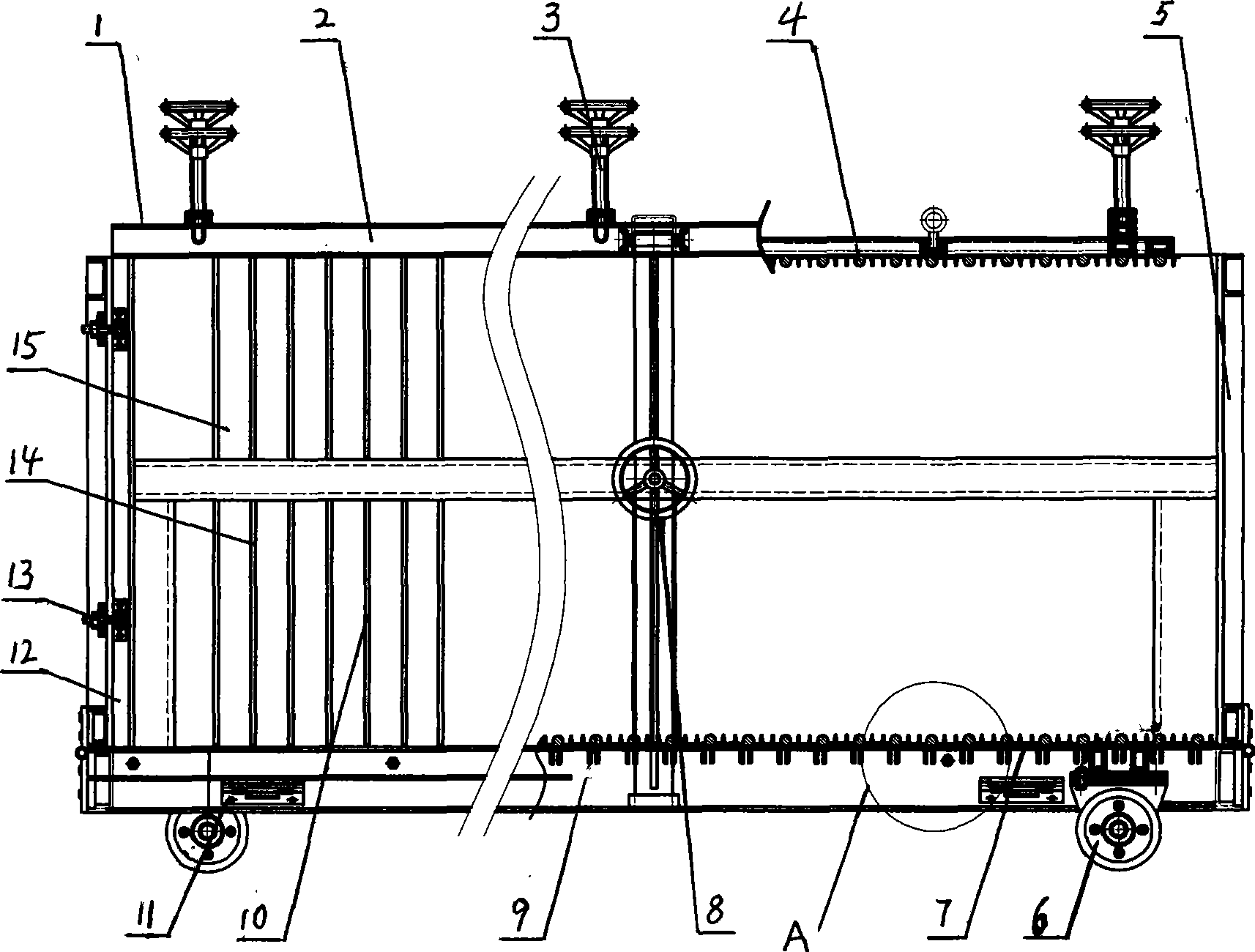

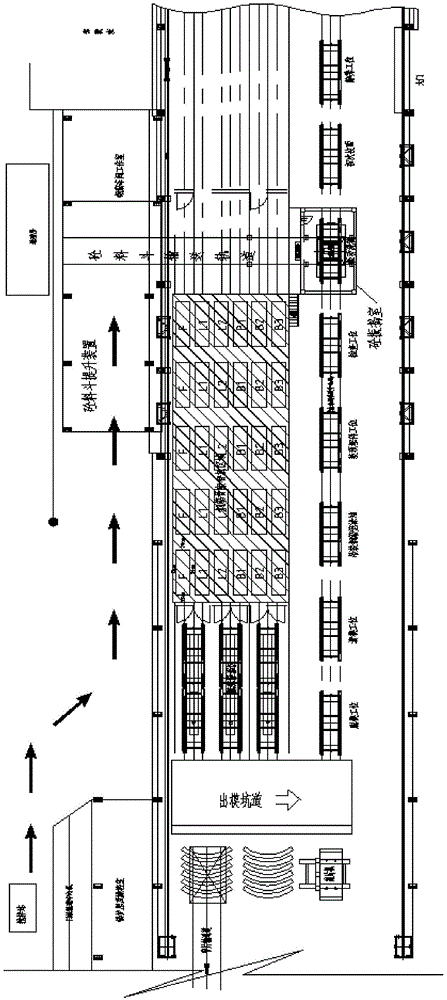

Intelligent flow production line for shield segment prefabrication

ActiveCN105082346AImprove precast production efficiencyReduce labor intensityCeramic shaping plantsProduction lineAutomatic control

The invention discloses an intelligent flow production line for shield segment prefabrication. Mold propelling systems in the production line are arranged on a pouring production line body and curing production line bodies respectively and push segment molds on the production line bodies to move. Transverse moving ferrying systems are matched with the pouring production line body and the curing production line bodies and used for conveying the molds from the pouring production line body to the curing production line bodies or conveying the molds from the curing production line bodies to the pouring production line body. A concrete feeding system is matched with a concrete pouring system and used for conveying concrete to the concrete pouring system. The concrete pouring system is arranged on the pouring production line body and used for completing segment pouring forming. An intelligent steam curing control system is used for conducting steam curing control on segments on the curing production line bodies. A programmable logic controller (PLC) automatic control system coordinates mutual matching among the systems, so that automation of shield segment prefabrication is achieved. The intelligent flow production line is stable in performance, good in reliability, easy to maintain and good in safety performance and meanwhile has the characteristics of being automatic and high in informationization degree and production efficiency.

Owner:CCCC THIRD HARBOR ENG +1

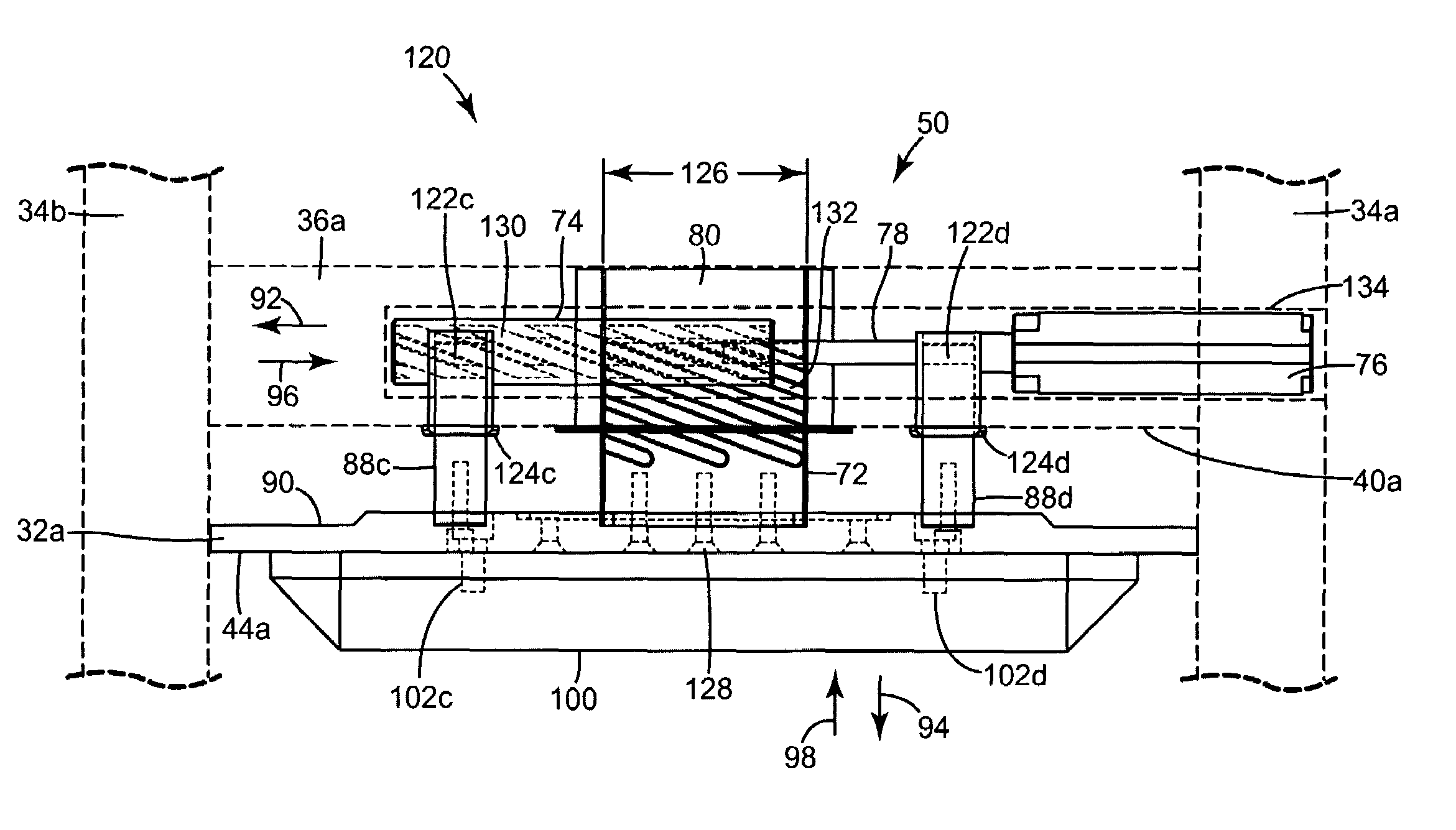

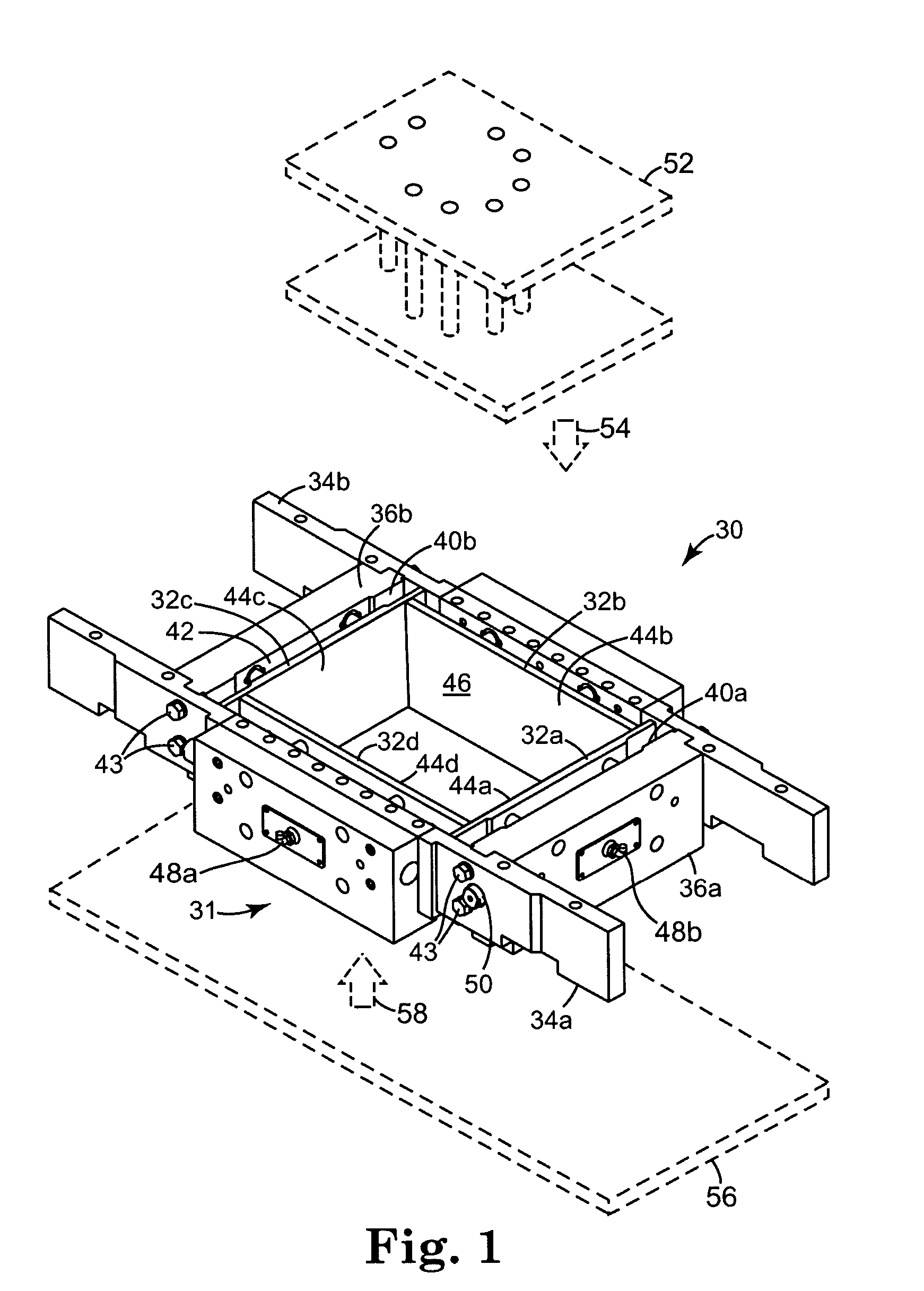

Block mold having moveable liner

A mold assembly for producing masonry blocks and adapted for use in a masonry block machine. The mold assembly includes a plurality of liner plates, each liner plate having a major surface, the liner plates positioned within a mold box and configured such that the major surfaces form a mold cavity having a desired form, wherein at least one of the liner plates is moveable between a retracted position and a desired extended position toward an interior of the mold cavity. A gear drive assembly selectively coupled to the at least one moveable liner plate and configured to move the at least one moveable liner plate between the retracted position and the extended position, wherein the gear drive assembly is positioned substantially external to the mold box when the at least one moveable liner plate is in the retracted position.

Owner:NESS INVENTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com