Technology and device for manufacturing gypsum lightweight cavity wallboard and building block

A hollow wallboard, light-weight technology, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of increased investment, equipment for producing wallboards that cannot produce blocks, labor waste, etc., to reduce investment Low cost, excellent sound insulation performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

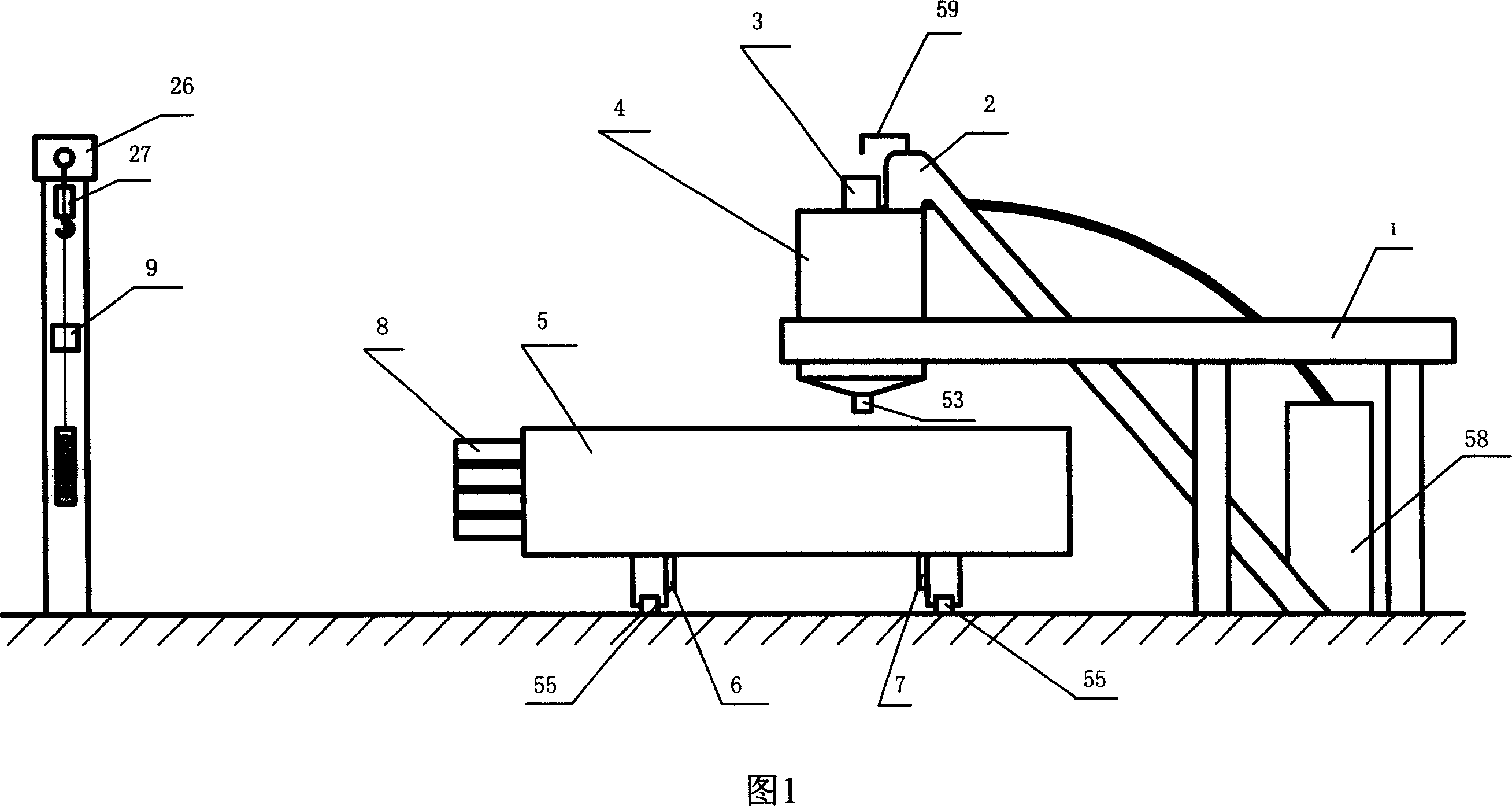

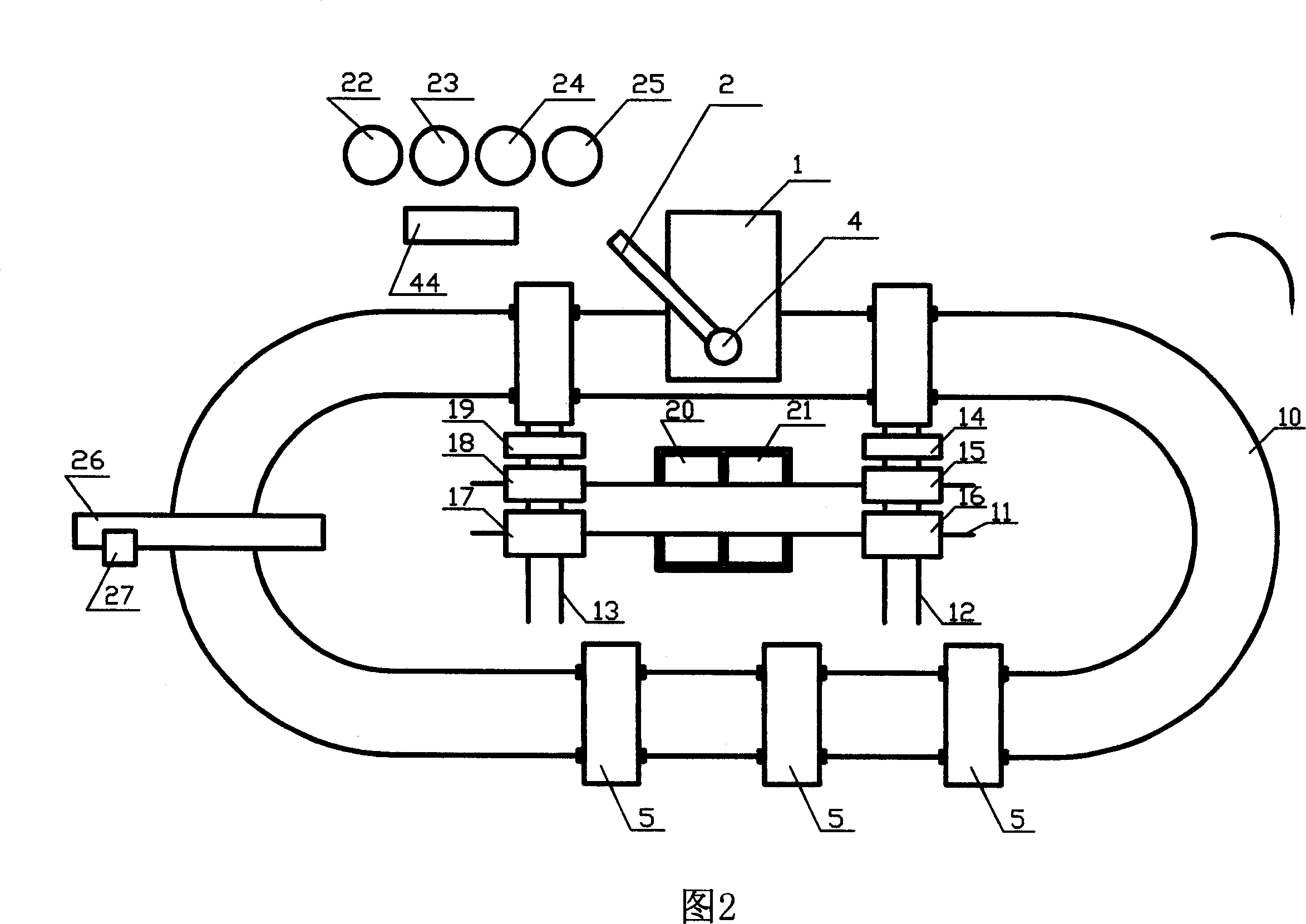

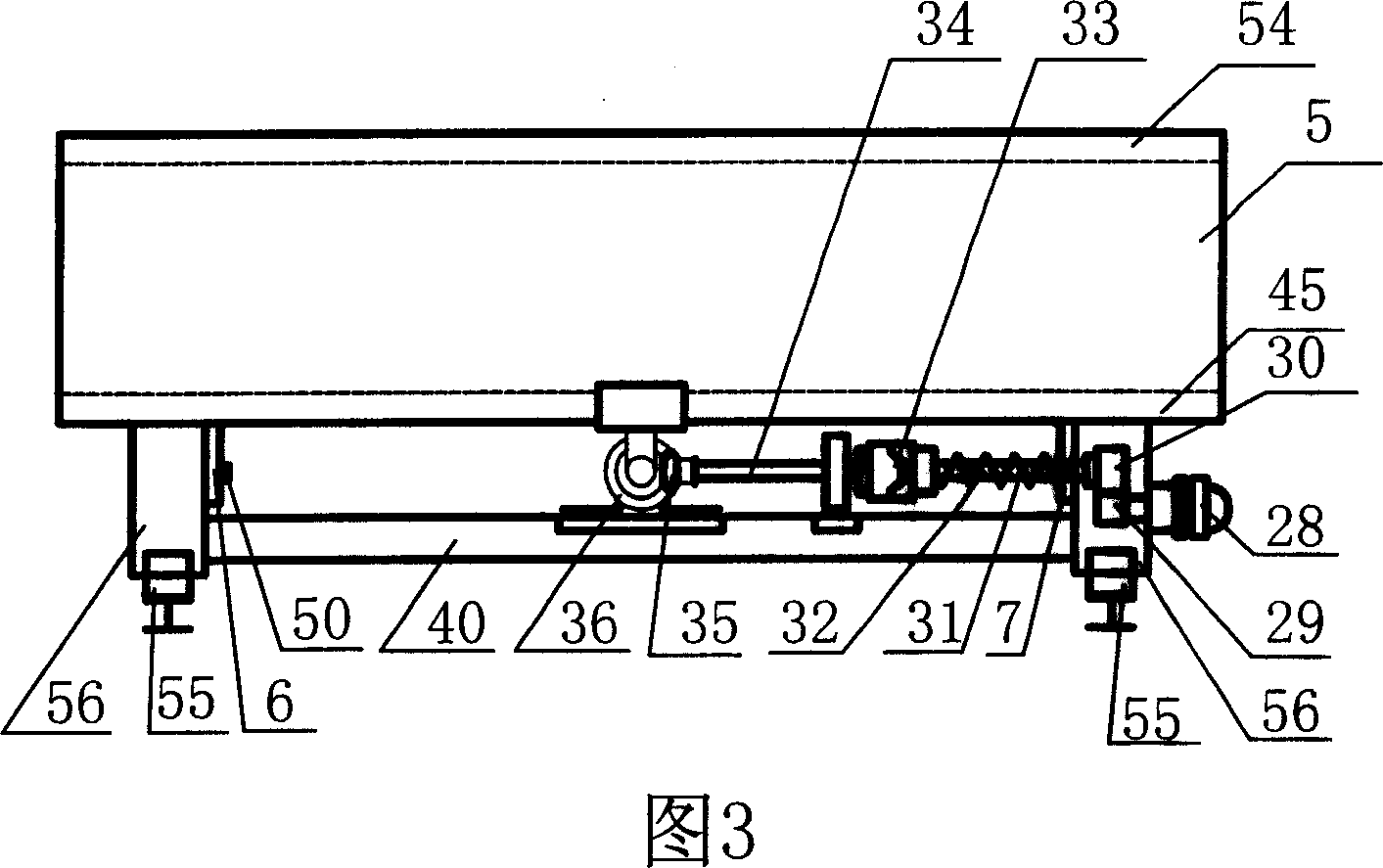

[0037] A multi-functional automatic gypsum lightweight hollow wall panel and block production line, which consists of the following parts:

[0038] ① Feeding equipment: including storage tanks 22, 23, 24, 25, automatic meter 44, feeding hoist 2 and water tank 58.

[0039] According to the quantity of raw materials, 1 to 5 storage tanks can be set up, and the lower part of each storage tank is equipped with an independent small hopper. The raw materials in each storage tank are weighed by the automatic meter 44 at the same time and enter their respective small hoppers, and then are transported to the lower common hopper 60 by the small hoppers at the same time, and then transported to the mixing tank 4 by the feeding mechanism 2 for feeding; Simultaneously water tank 58 is filled with water after metering by automatic metering system. The matching of weighing and delivery time with stirring and pouring time can make the automatic metering system work continuously in a cycle. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com