Patents

Literature

1050results about "Ceramic shaping linings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

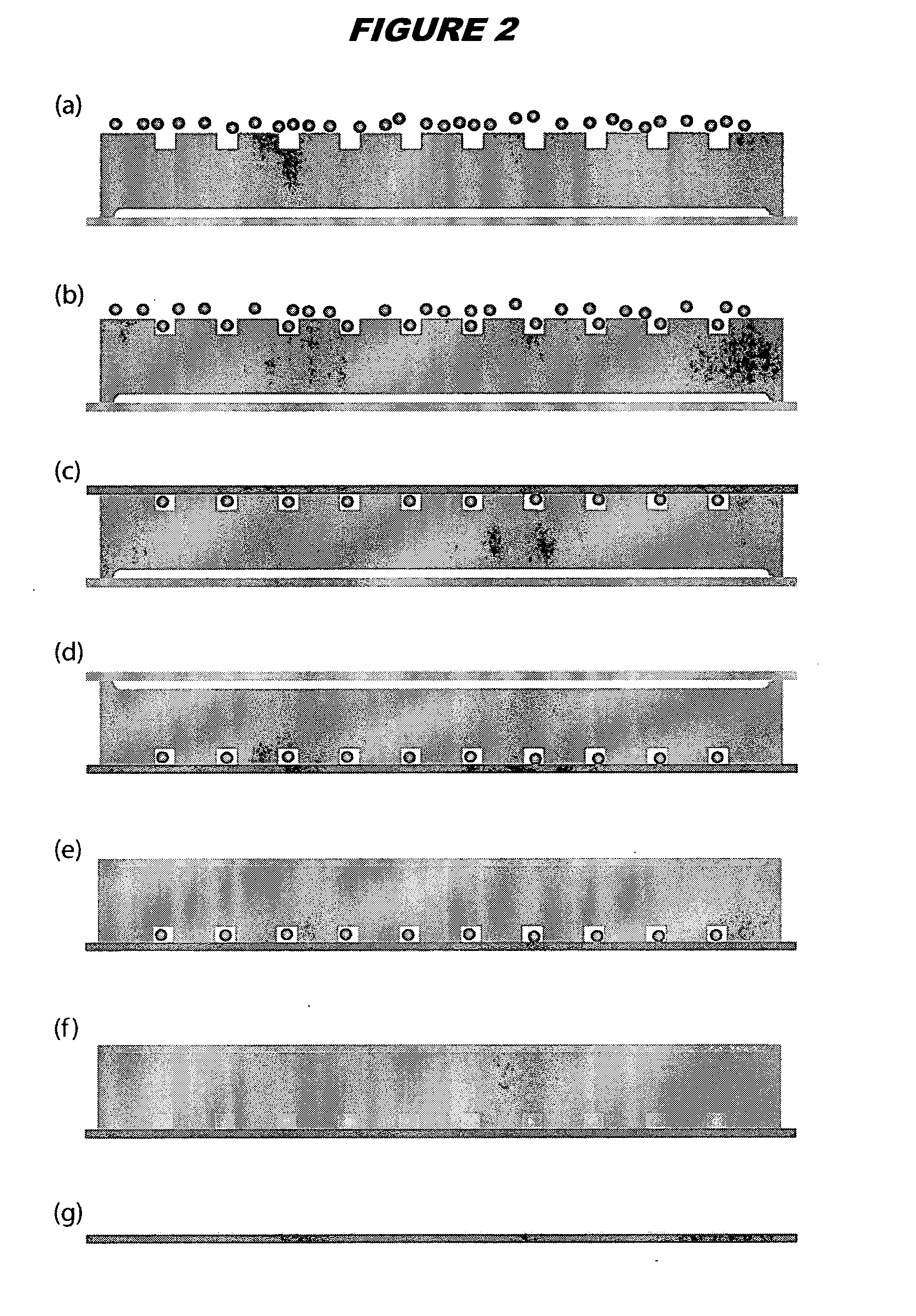

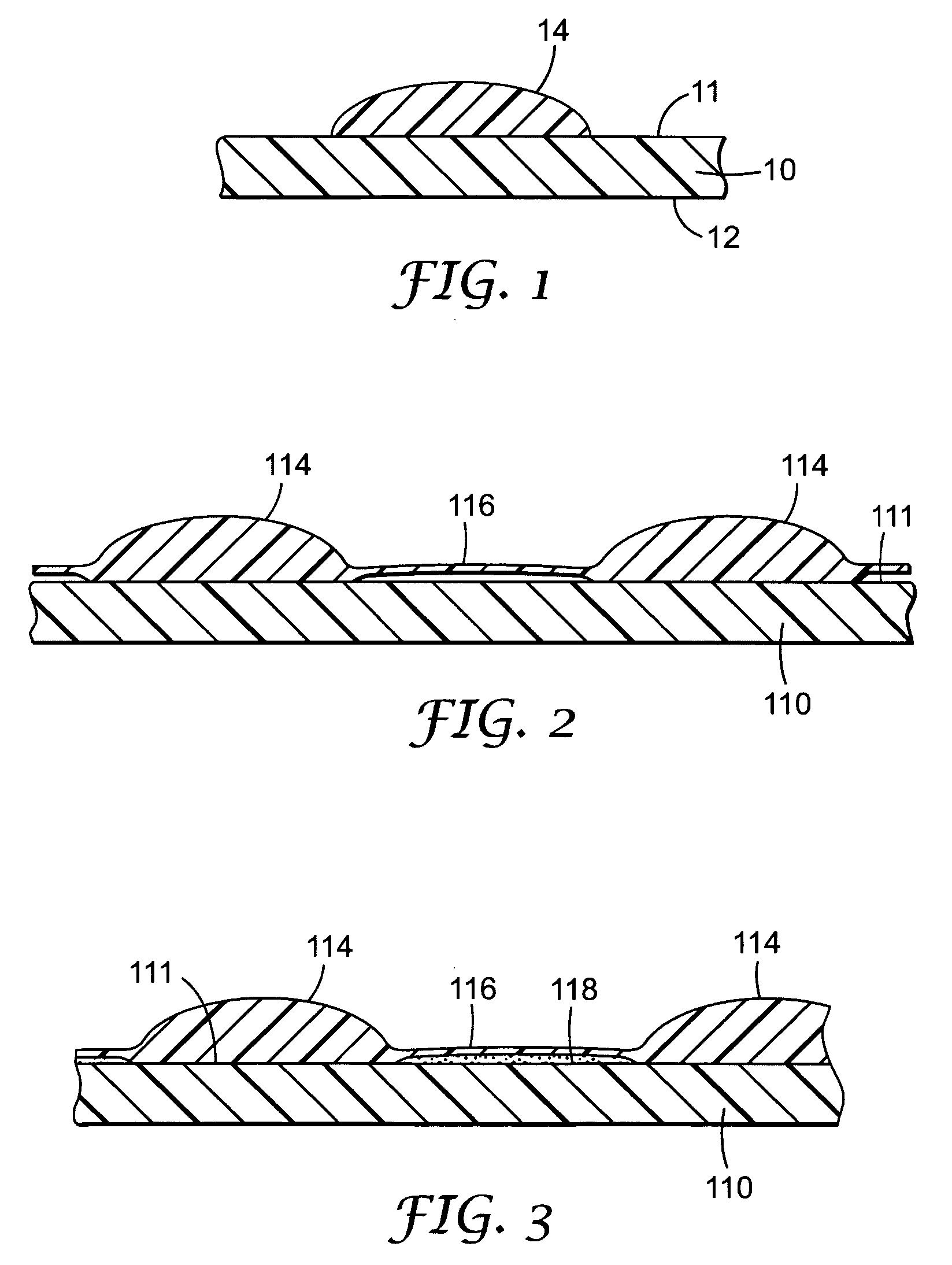

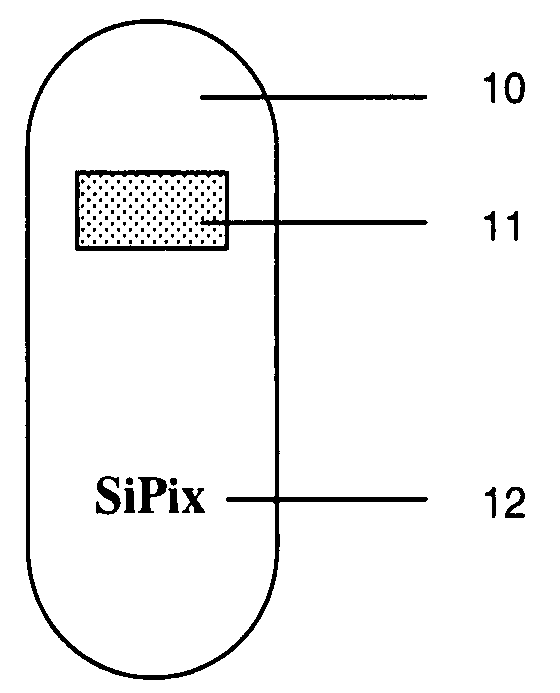

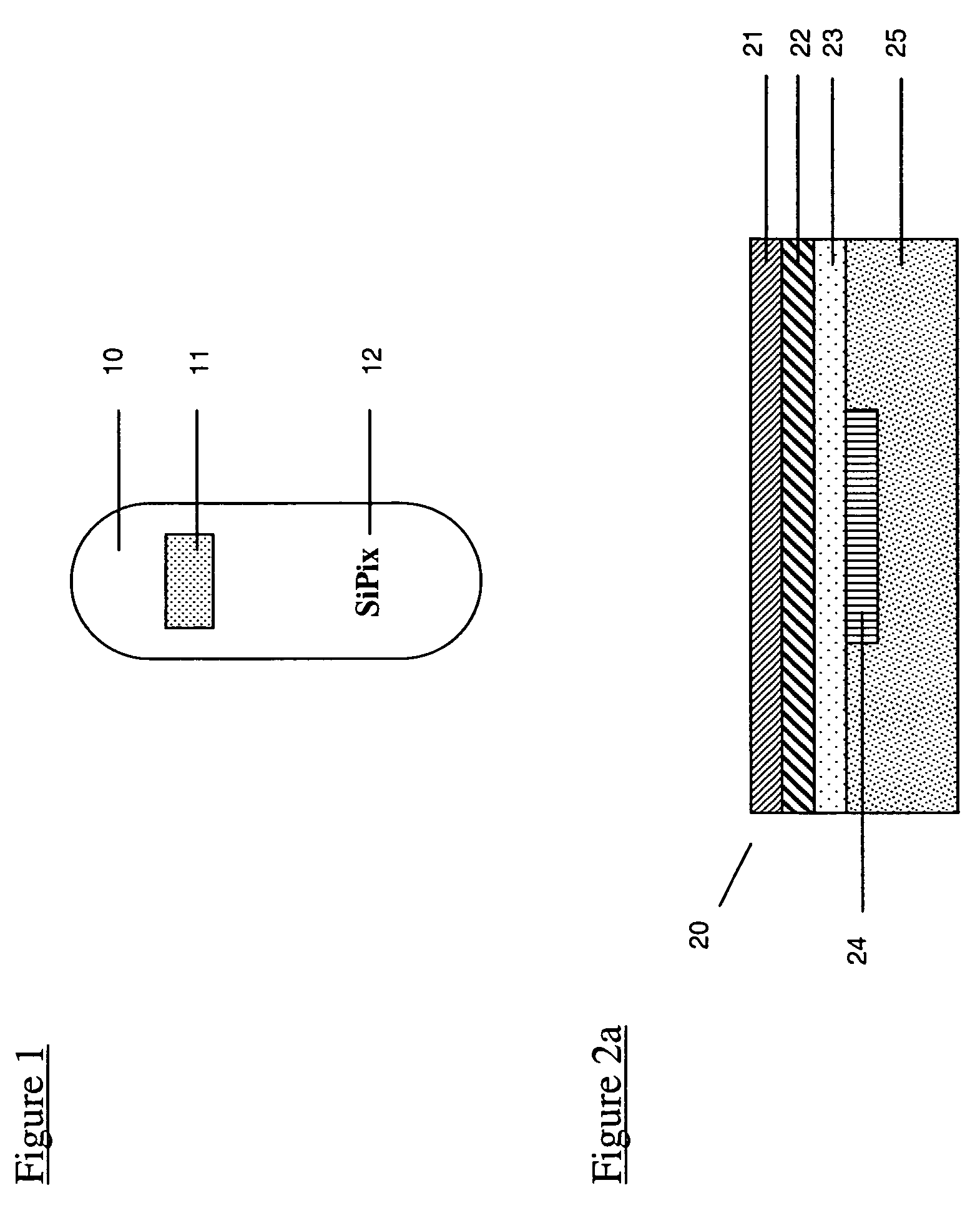

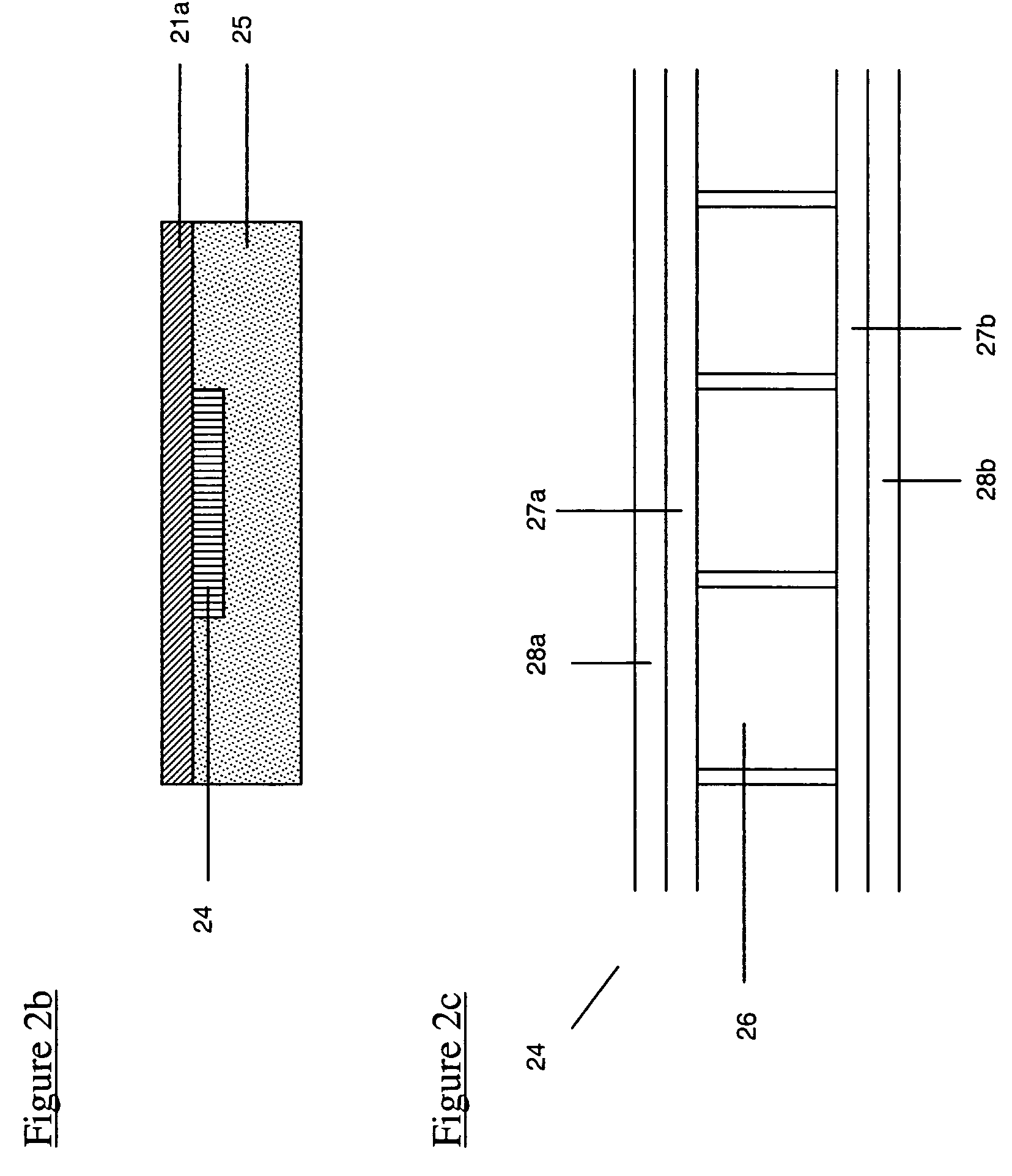

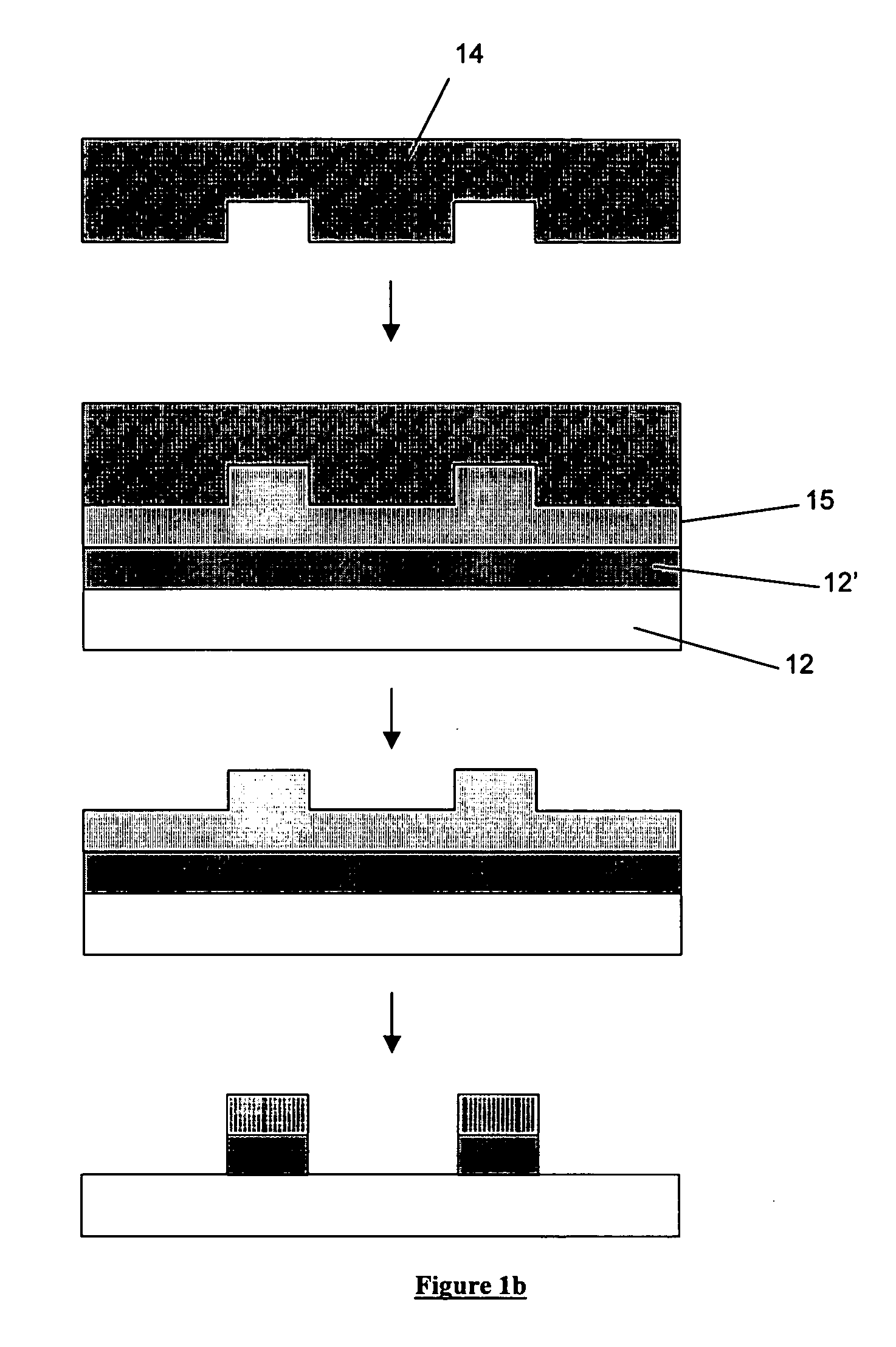

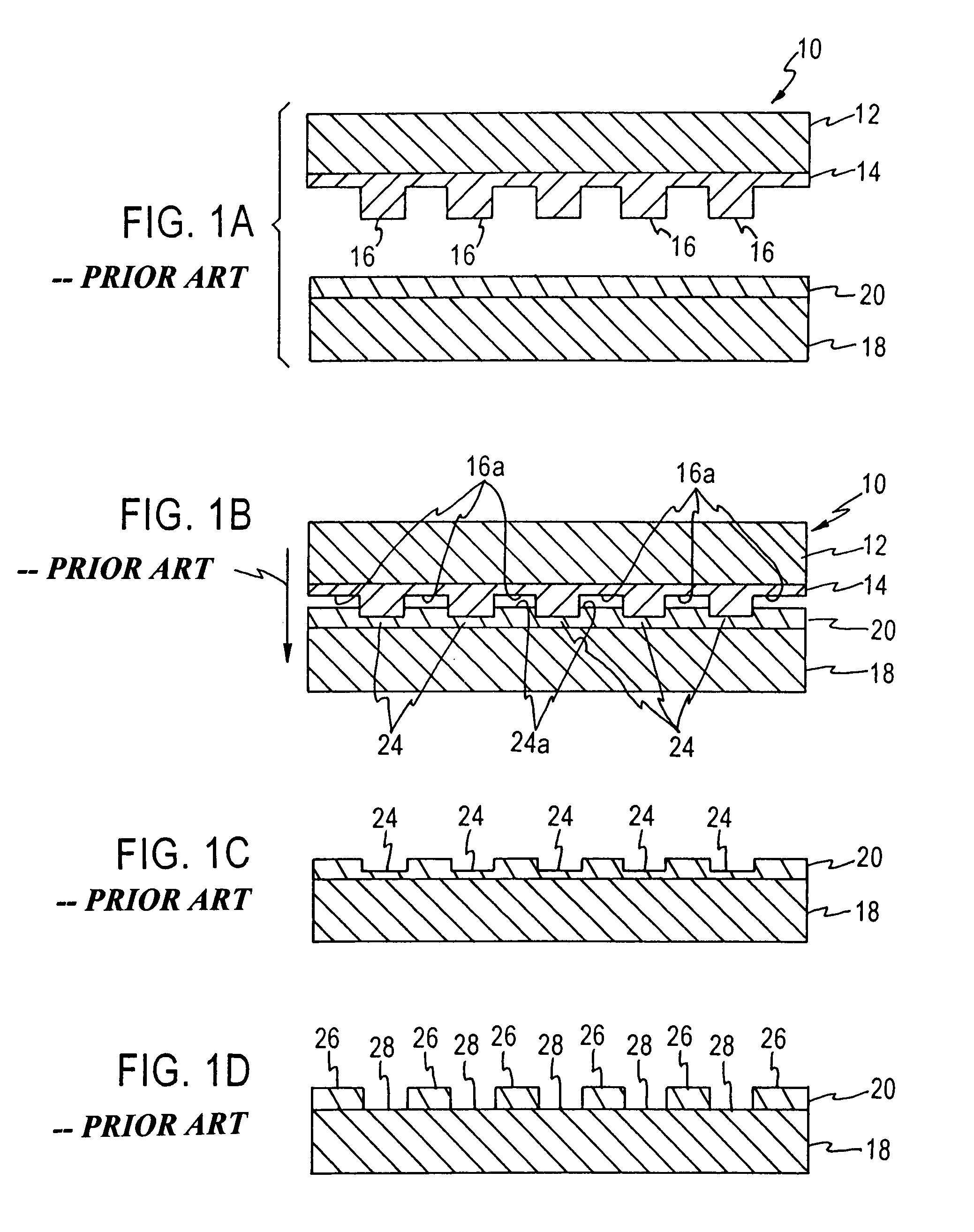

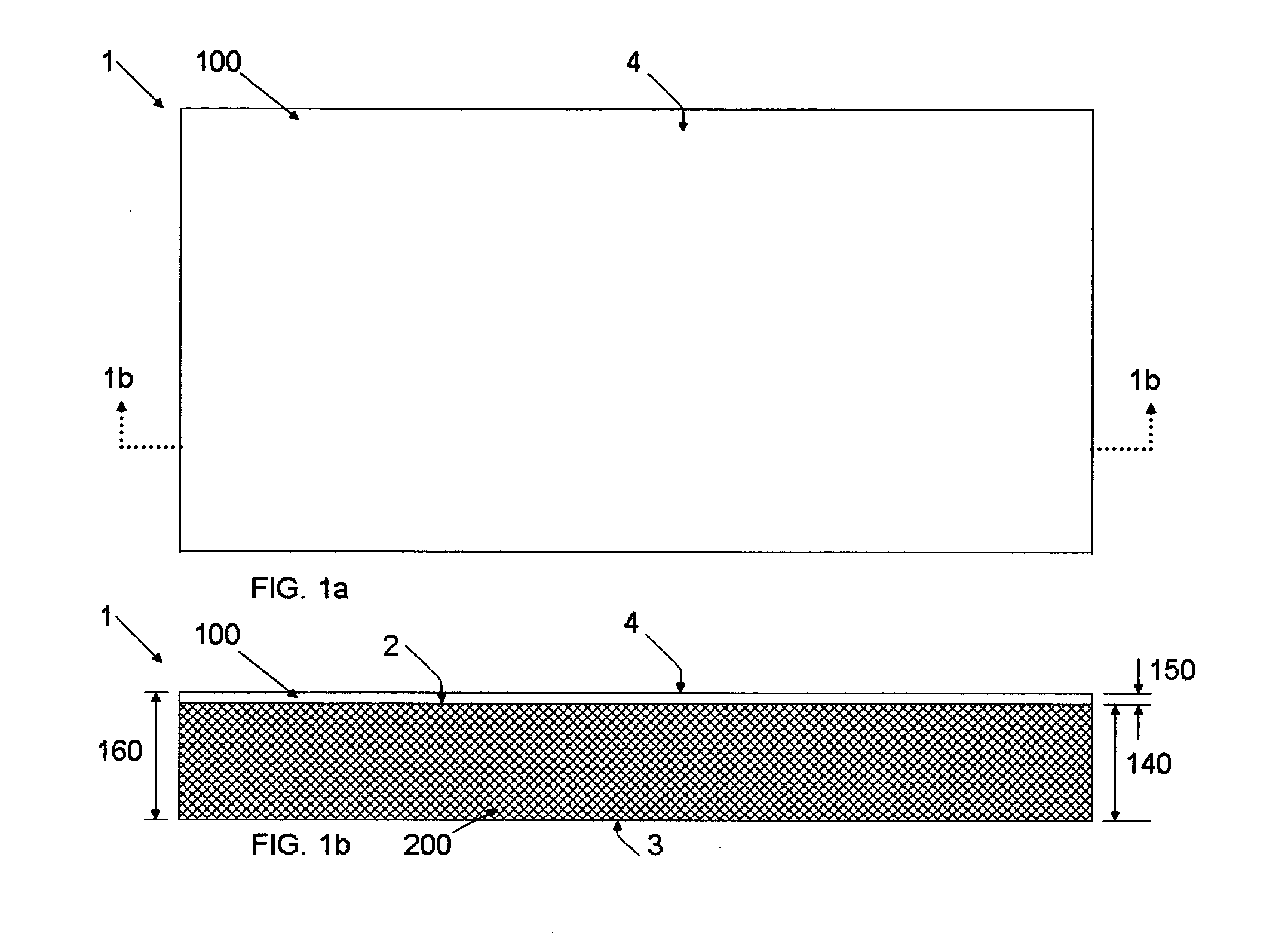

Formation of discontinuous films during an imprint lithography process

ActiveUS6932934B2Low viscosityMaterial nanotechnologyDecorative surface effectsLithography processLithographic artist

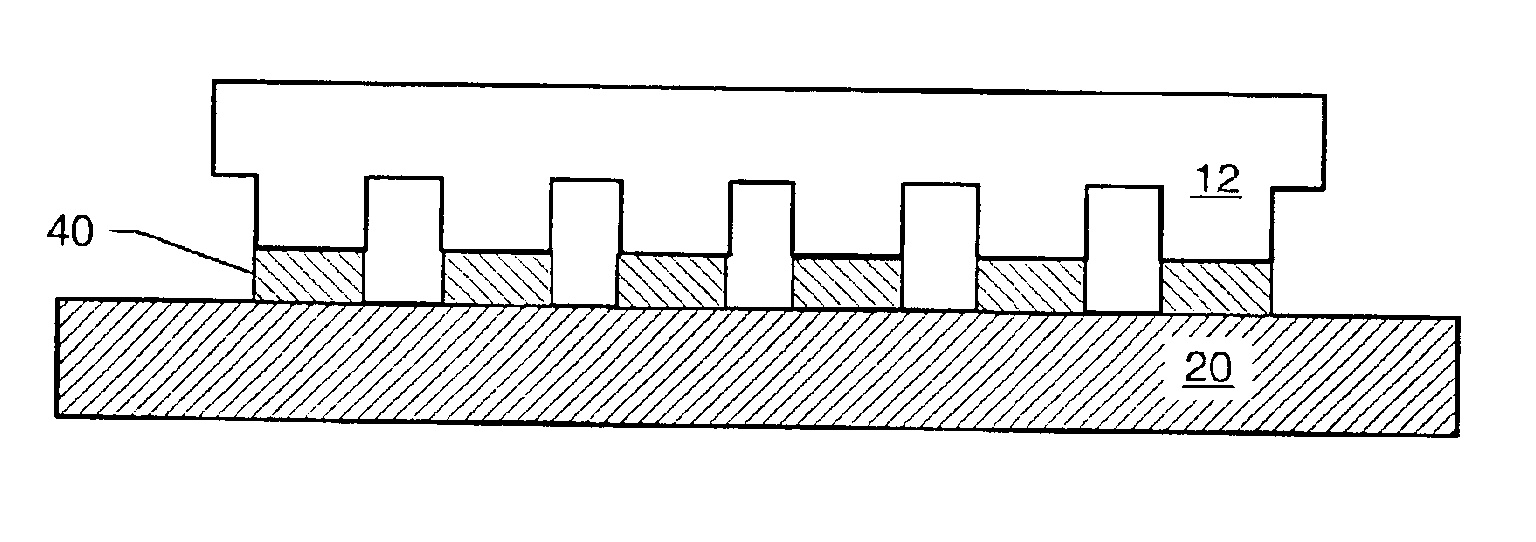

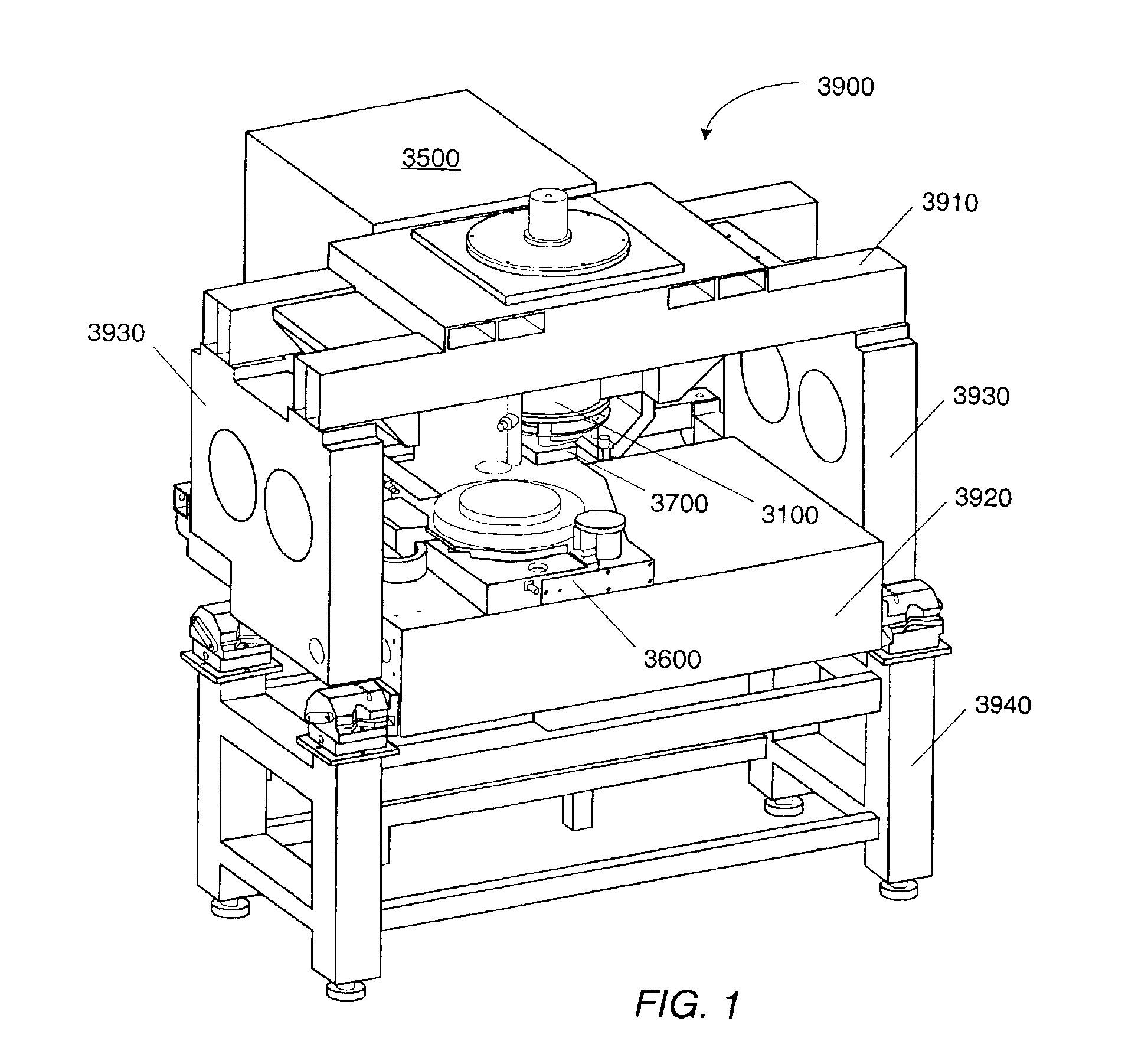

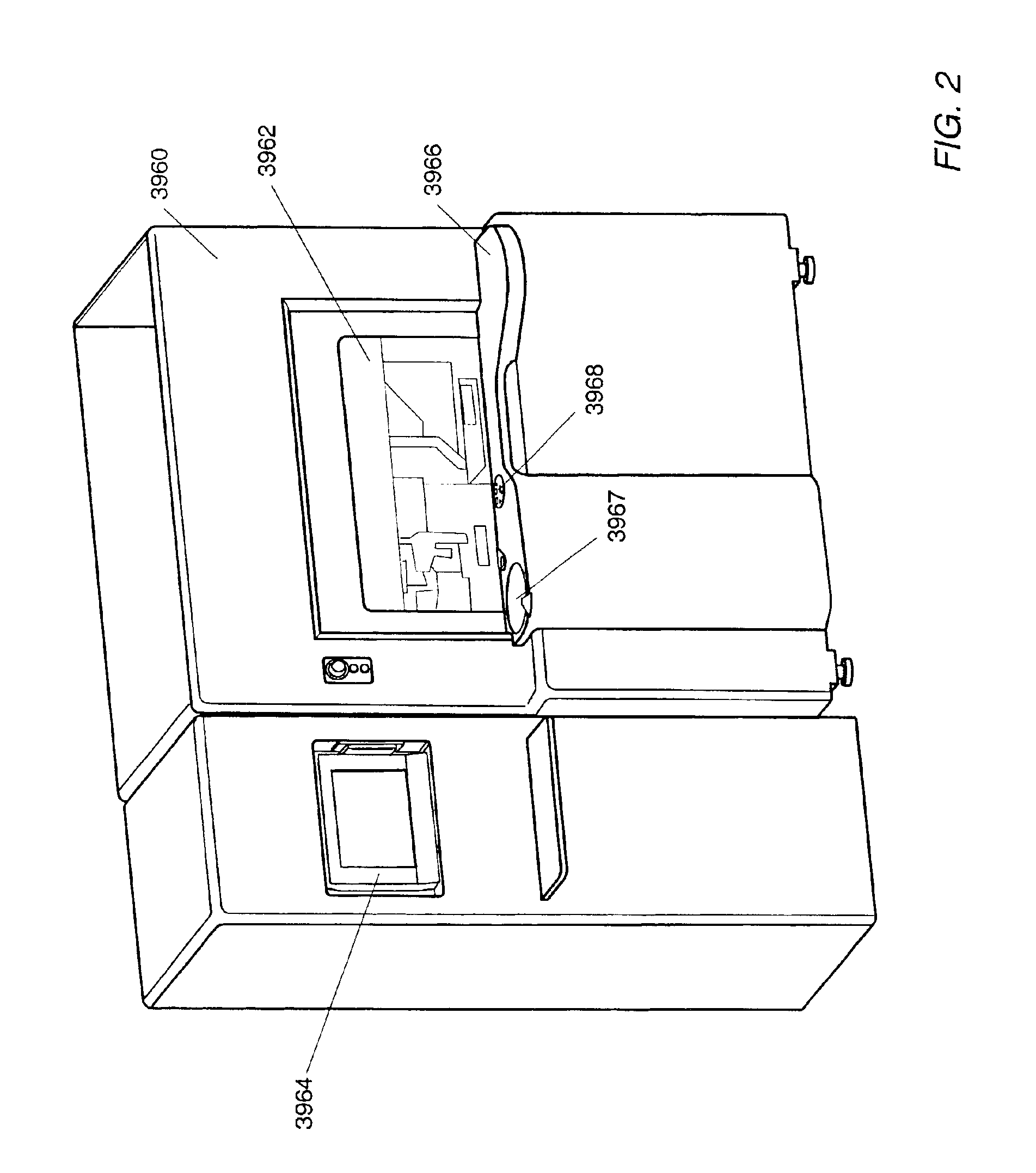

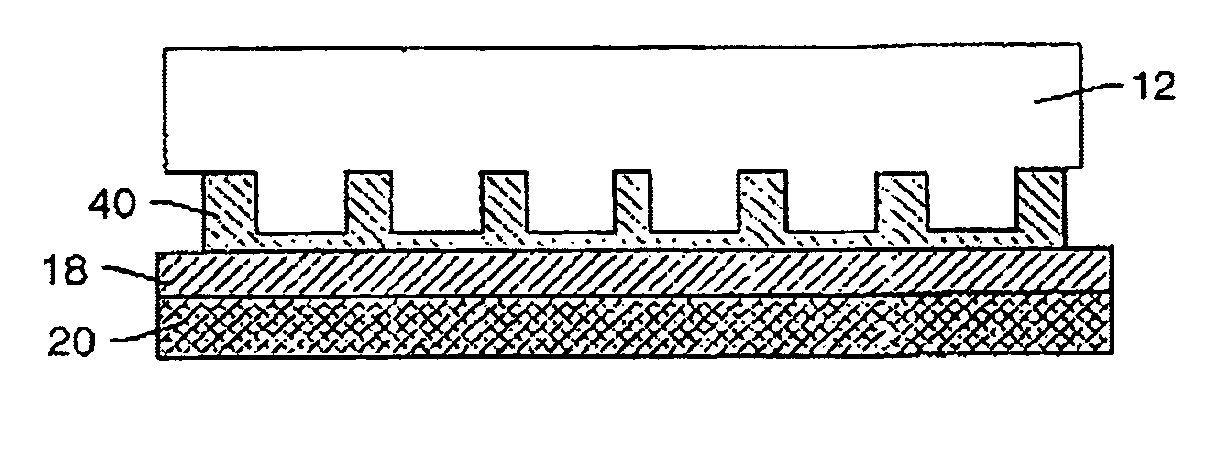

The present invention is directed to methods for patterning a substrate by imprint lithography. An imprint lithography method includes placing a curable liquid on a substrate. A template may be contacted with the curable liquid. Surface forces at the interface of the curable liquid and the template cause the curable liquid to gather in an area defined by a lower surface of the template. Alternately, the curable liquid may fill one or more relatively shallow recesses in the template and the area under the template lower surface. Activating light is applied to the curable liquid to form a patterned layer on the substrate.

Owner:CANON KK

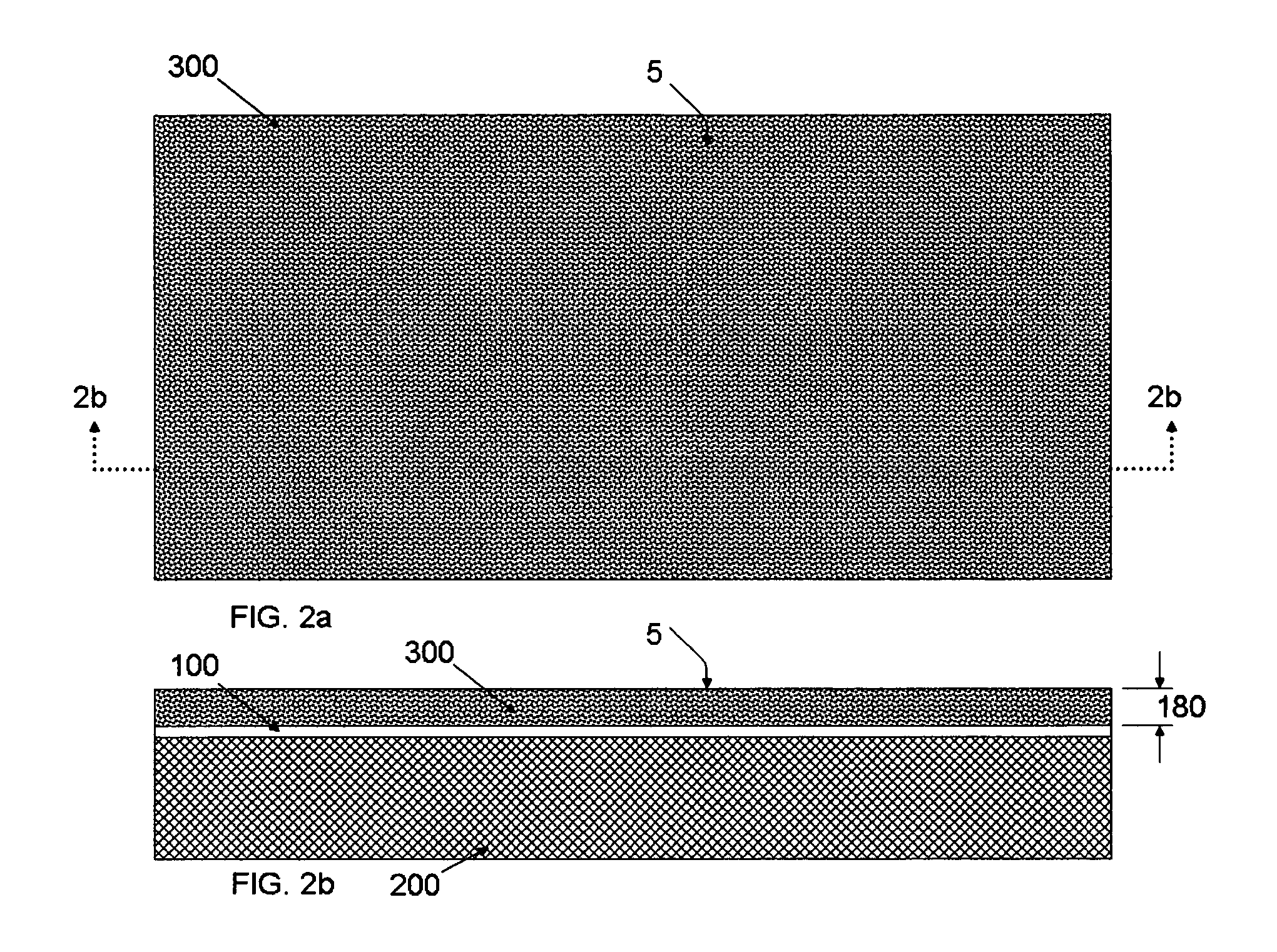

Step and repeat imprint lithography processes

The present invention is directed to methods for patterning a substrate by imprint lithography. Imprint lithography is a process in which a liquid is dispensed onto a substrate. A template is brought into contact with the liquid and the liquid is cured. The cured liquid includes an imprint of any patterns formed in the template. In one embodiment, the imprint process is designed to imprint only a portion of the substrate. The remainder of the substrate is imprinted by moving the template to a different portion of the template and repeating the imprint lithography process.

Owner:CANON KK

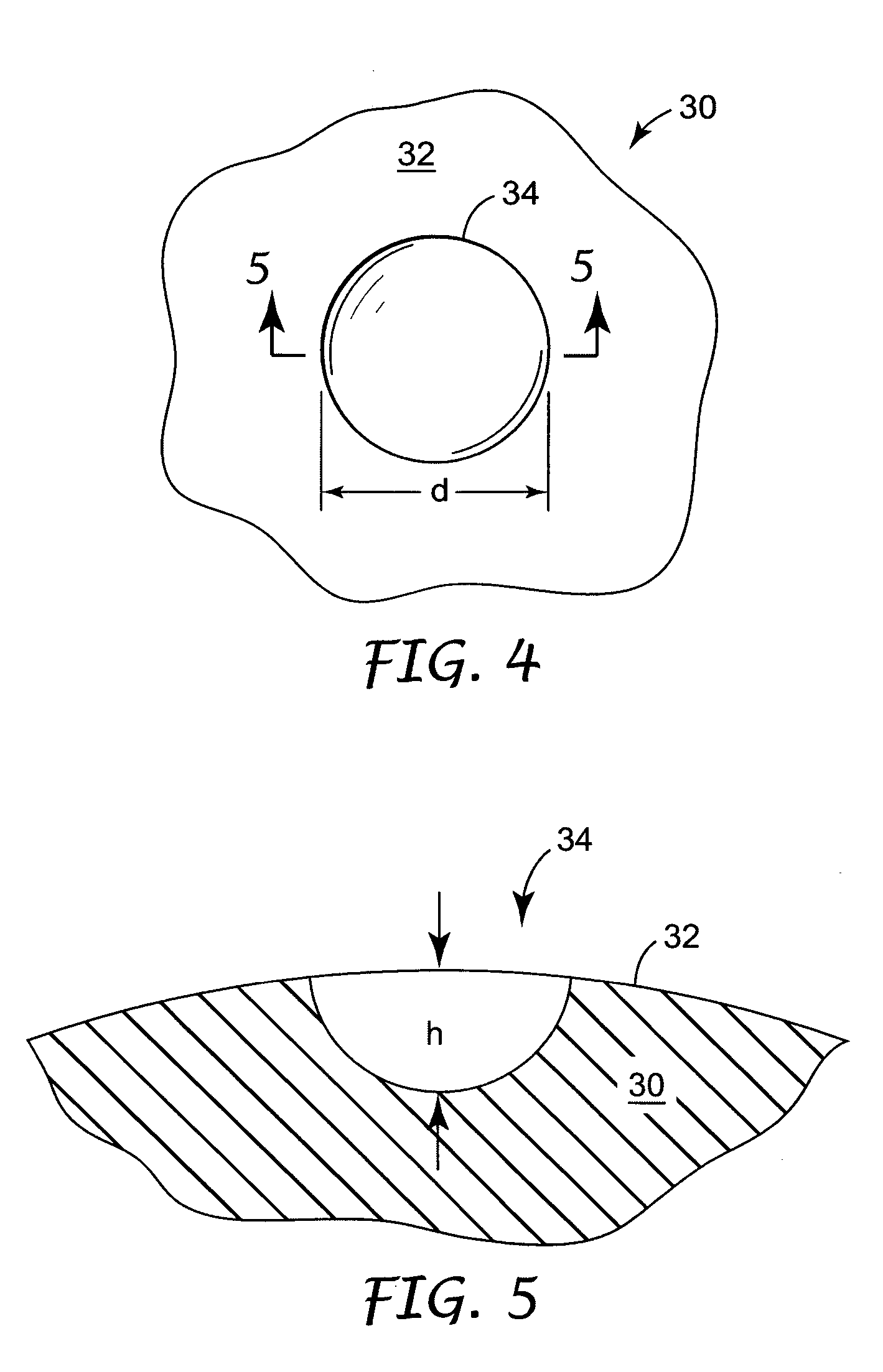

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

Casting preforms for optical fibres

InactiveUS20050089670A1Difficult and expensive to produceButtonsCladded optical fibreOptoelectronicsPolymer

This invention relates to a method of preparing a preform for an optical fibre, and more particularly to a method of preparing a preform for a polymer holey optical fibre. The invention provides a method of preparing a preform for manufacture of a polymer holey optical fibre comprising casting a preform body in a mould from a suitable material, said mould including at least one protrusion adapted to form a corresponding hole within the preform, and subsequently separating the preform body and mould. The invention also provides a method of preparing a preform for manufacture of a polymeric holey optical fibre comprising separately casting one or more elements of a preform in respective mould(s) from a suitable material, and separating said elements from said respective mould(s) and combining said elements to construct a preform having a plurality of holes therein, each hole being formed in an element or formed by the combination of two or more elements.

Owner:THE UNIV OF SYDNEY +2

Matrix and method of producing said matrix

The invention relates to a matrix suitable for use in the replication of a plastic element having a positive microstructure, comprising a first wear-resistant layer that is supported by a carrier element, wherein the matrix comprises a heating means for supplying electrical heat energy through the wear-resistant layer or carrier element. The invention further relates to a plastic element producing machine and a method for the manufacture of a plastic element having a surface with a positive microstructure.

Owner:GYROS

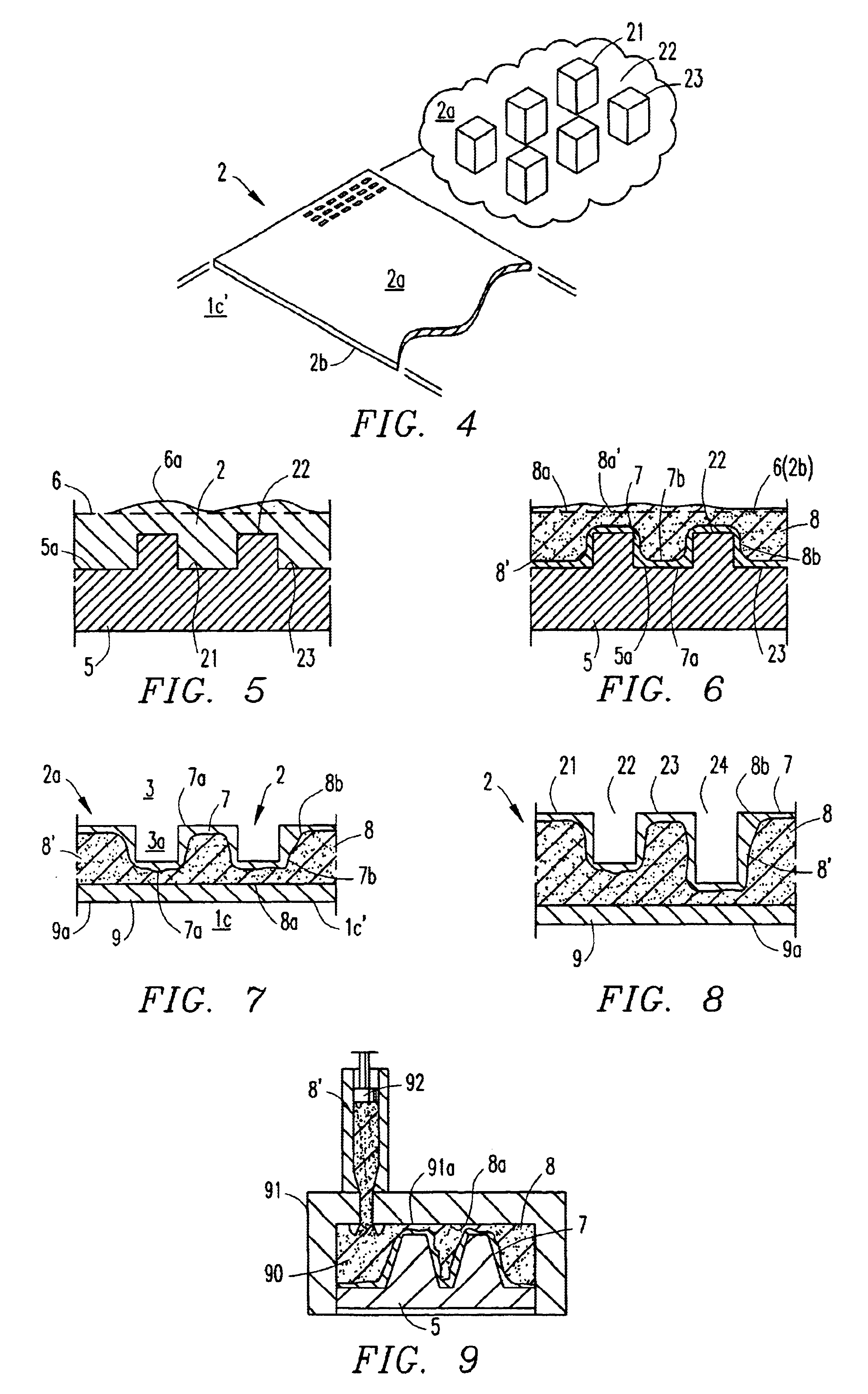

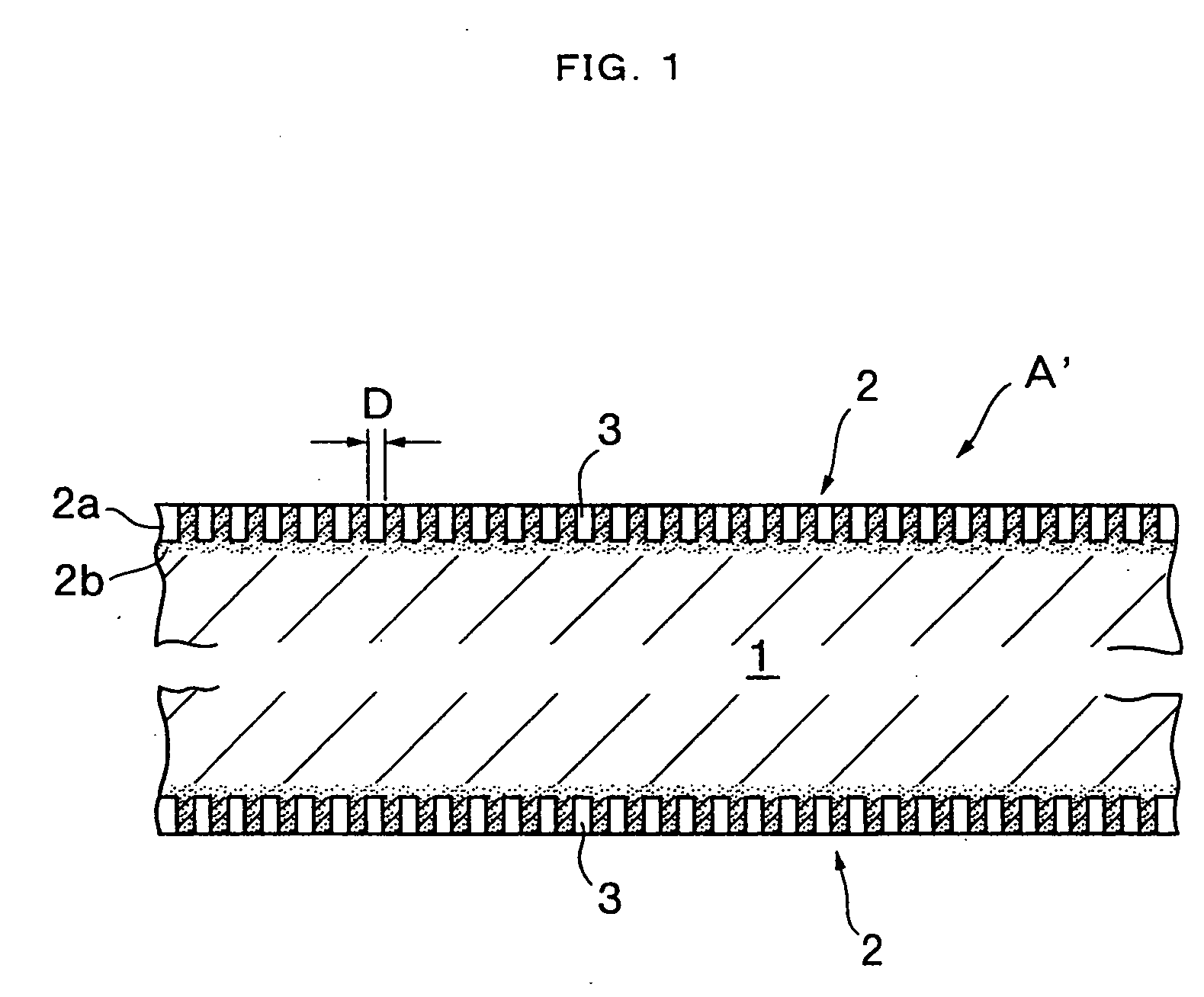

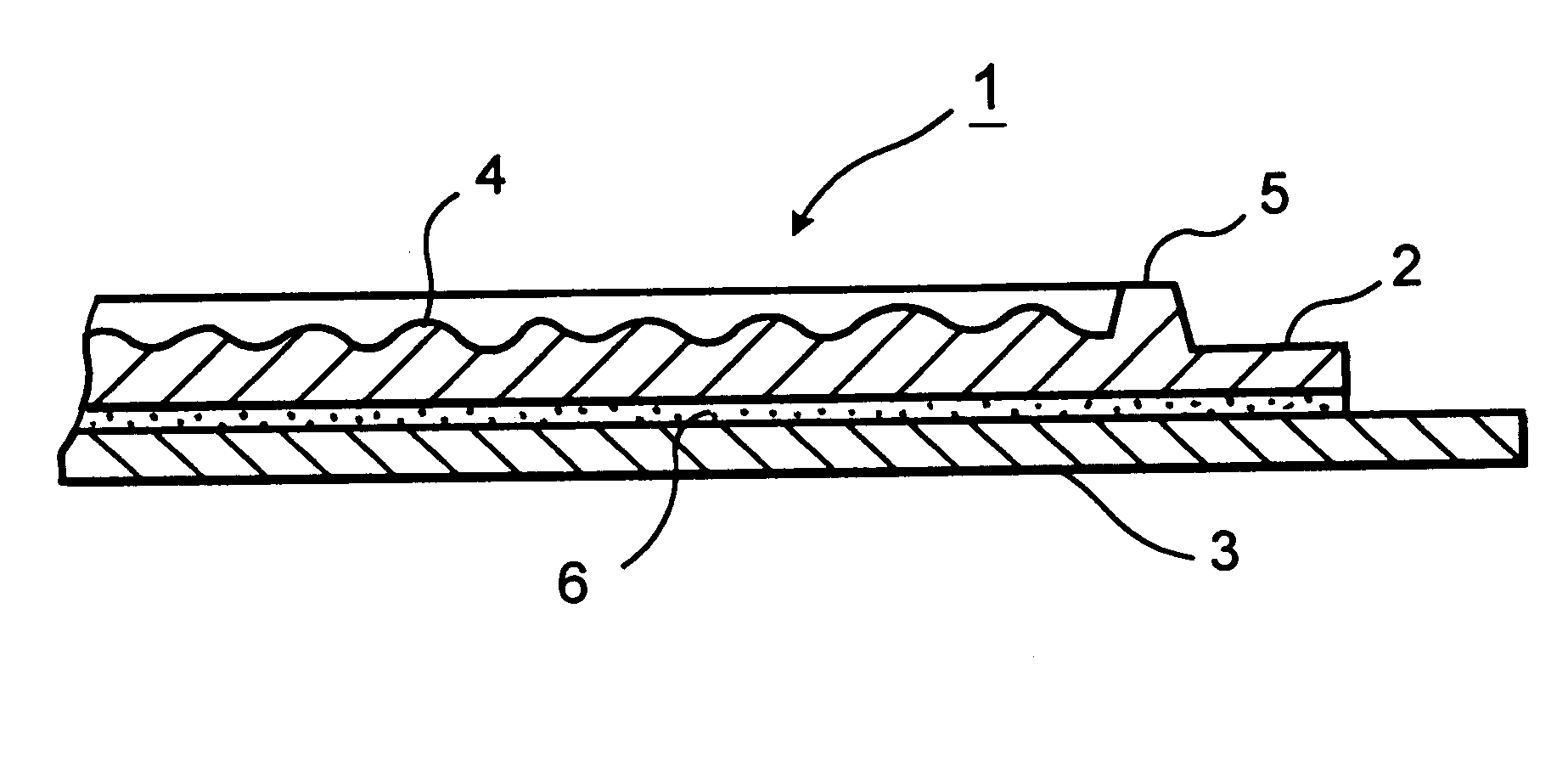

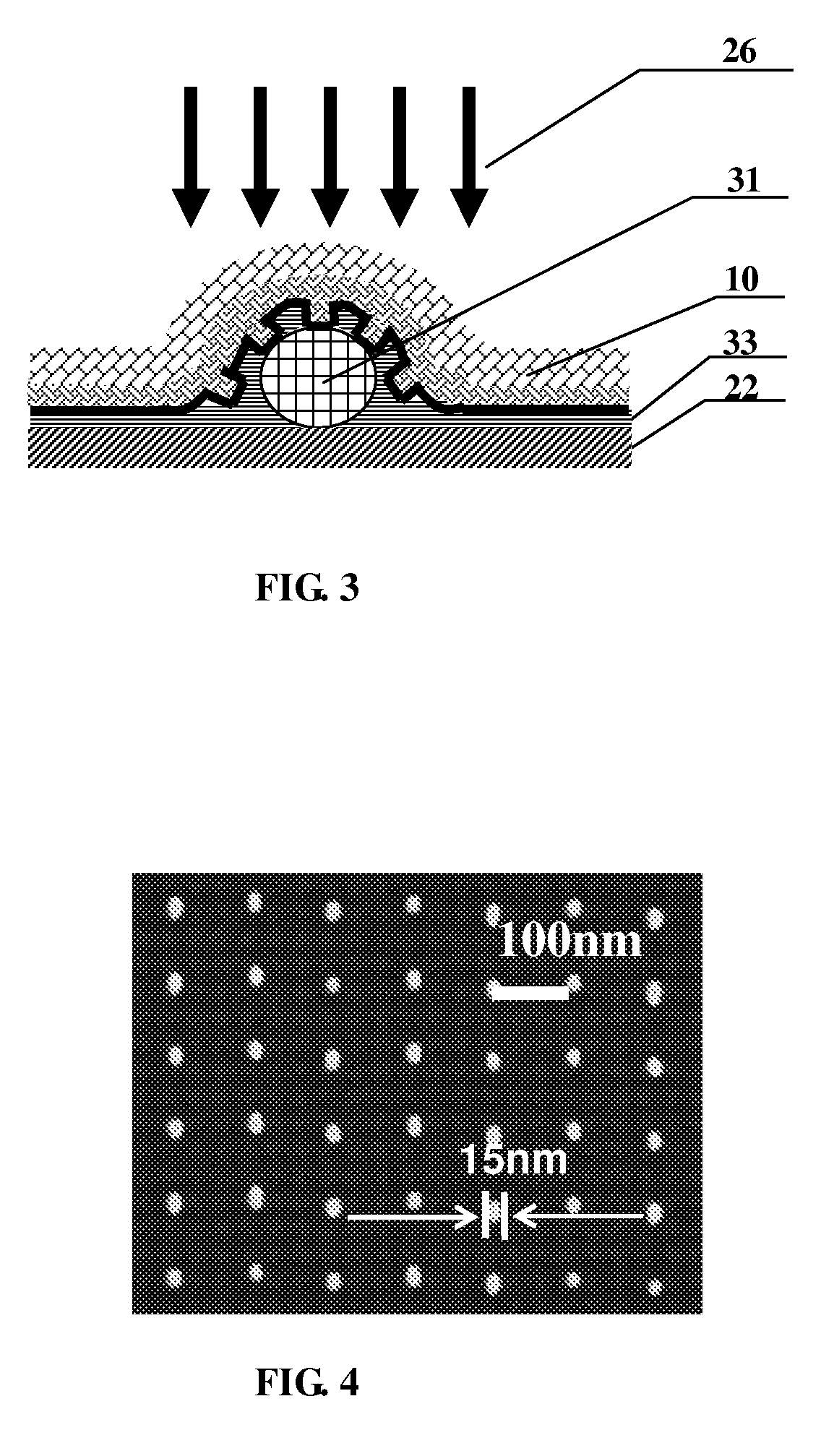

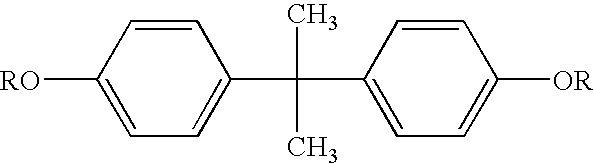

Composite of aluminium material and synthetic resin molding and process for producing the same

ActiveUS20060055084A1Stable and fast compositeHigh tensile strengthAnodisationNatural mineral layered productsO-Phosphoric AcidSynthetic resin

The present invention is to provide a process for producing a composite of an aluminum material and a synthetic resin molding that can be produced at a high efficiency and to provide a stable and fast composite that is large in a peel strength and a mechanical strength. The process for producing a composite according to the present invention is characterized in that an aluminum raw material is oxidized in an electrolytic bath of phosphoric acid or sodium hydride, thereby an anodic oxidation coating provided with innumerable pores 3 having a diameter of 25 nm or more made open in the surface thereof is formed thereon, and a synthetic resin mold 6 is coupled with the anodic oxidation coating 2 in such a condition that the part 6a thereof is intruded in the innumerable pores.

Owner:CHERRY CHIEF MAF CORP

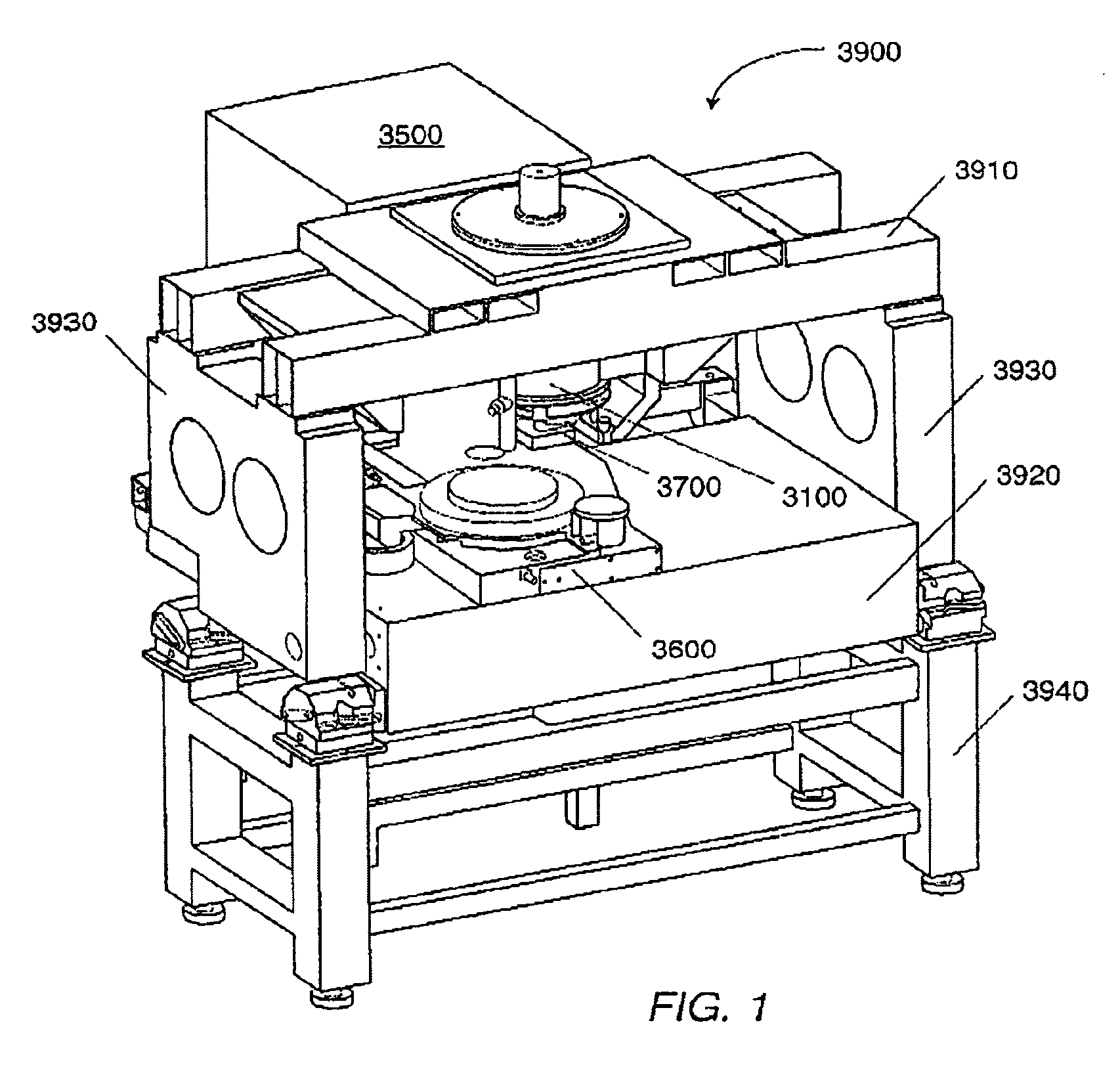

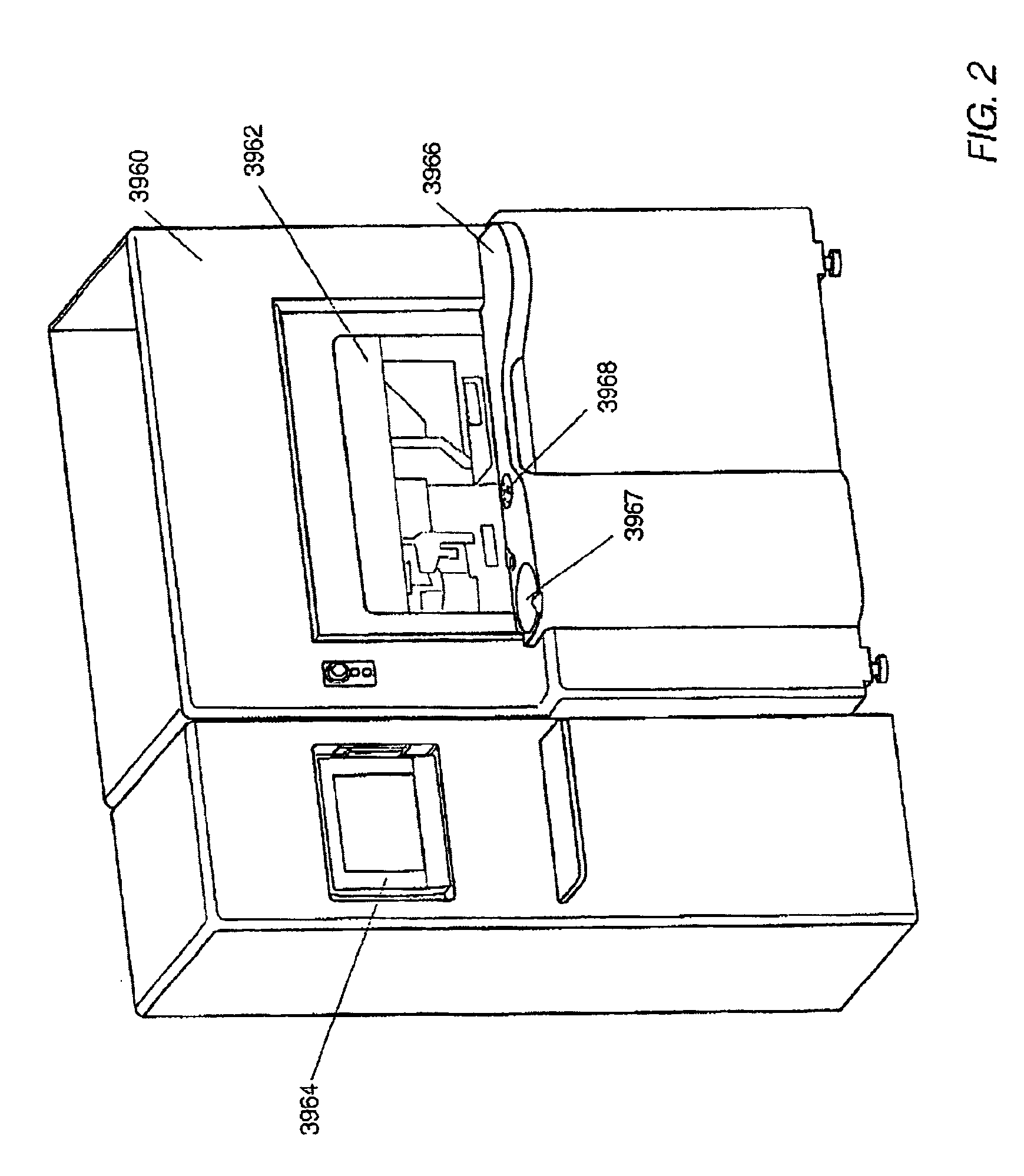

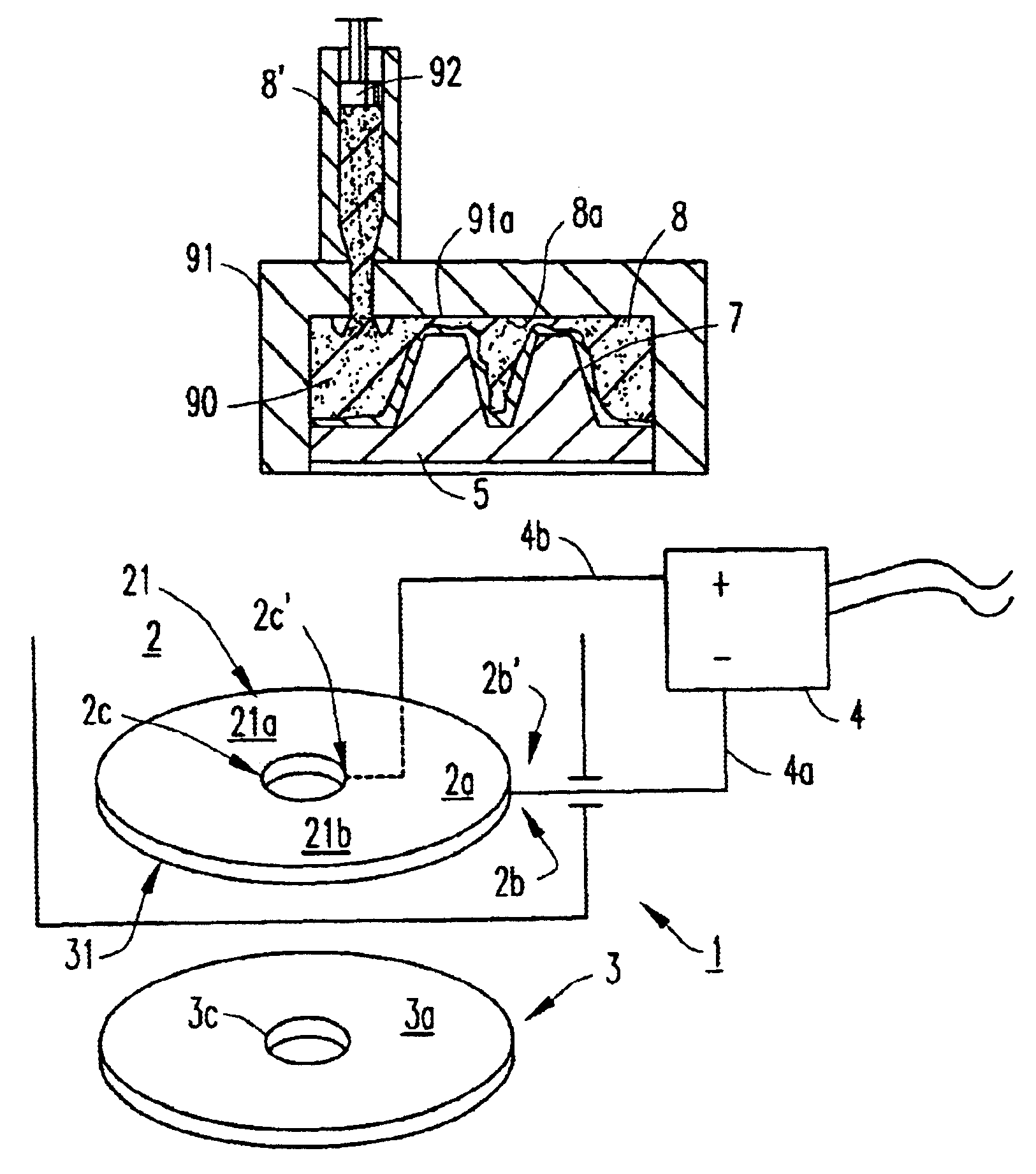

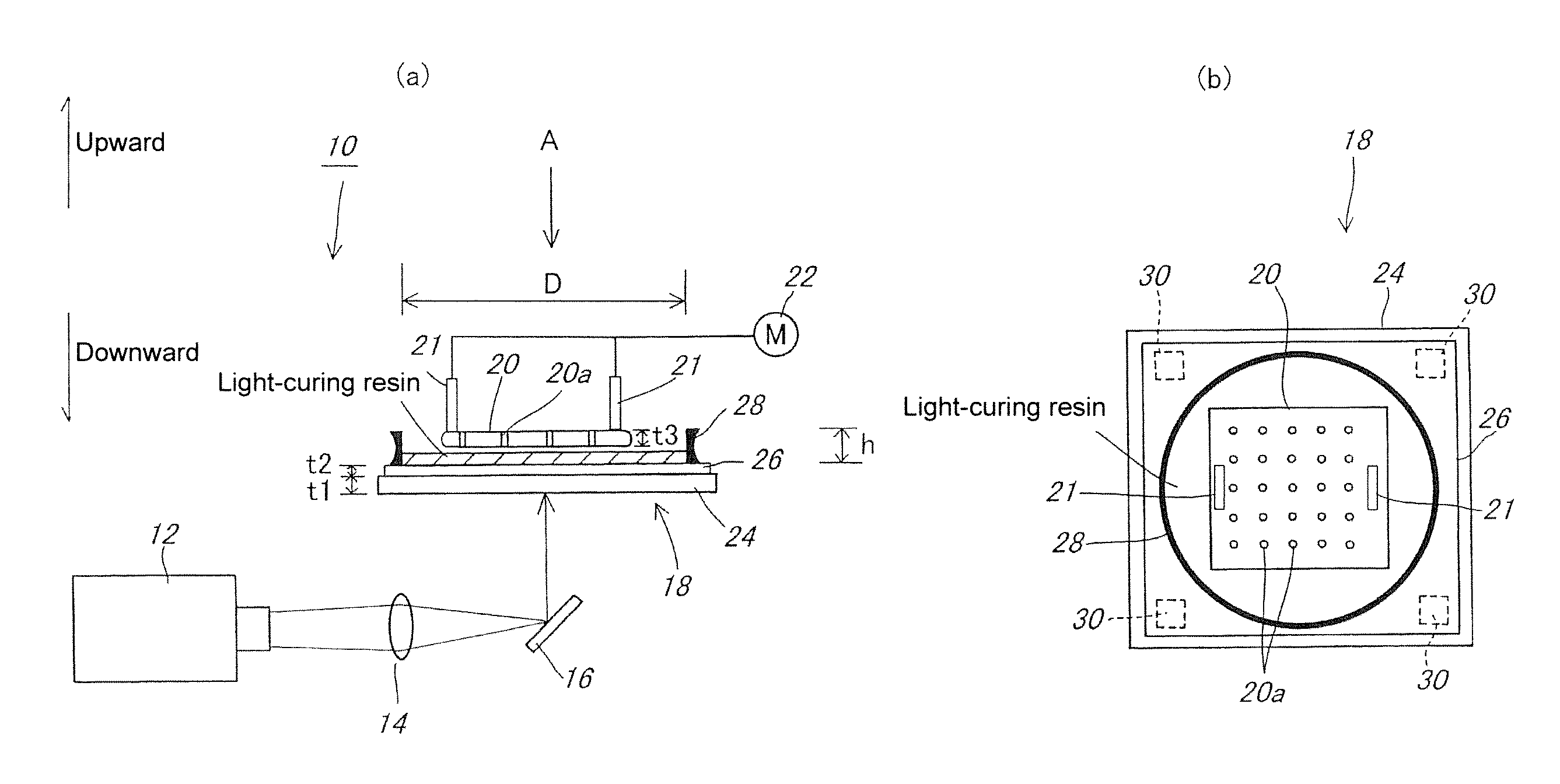

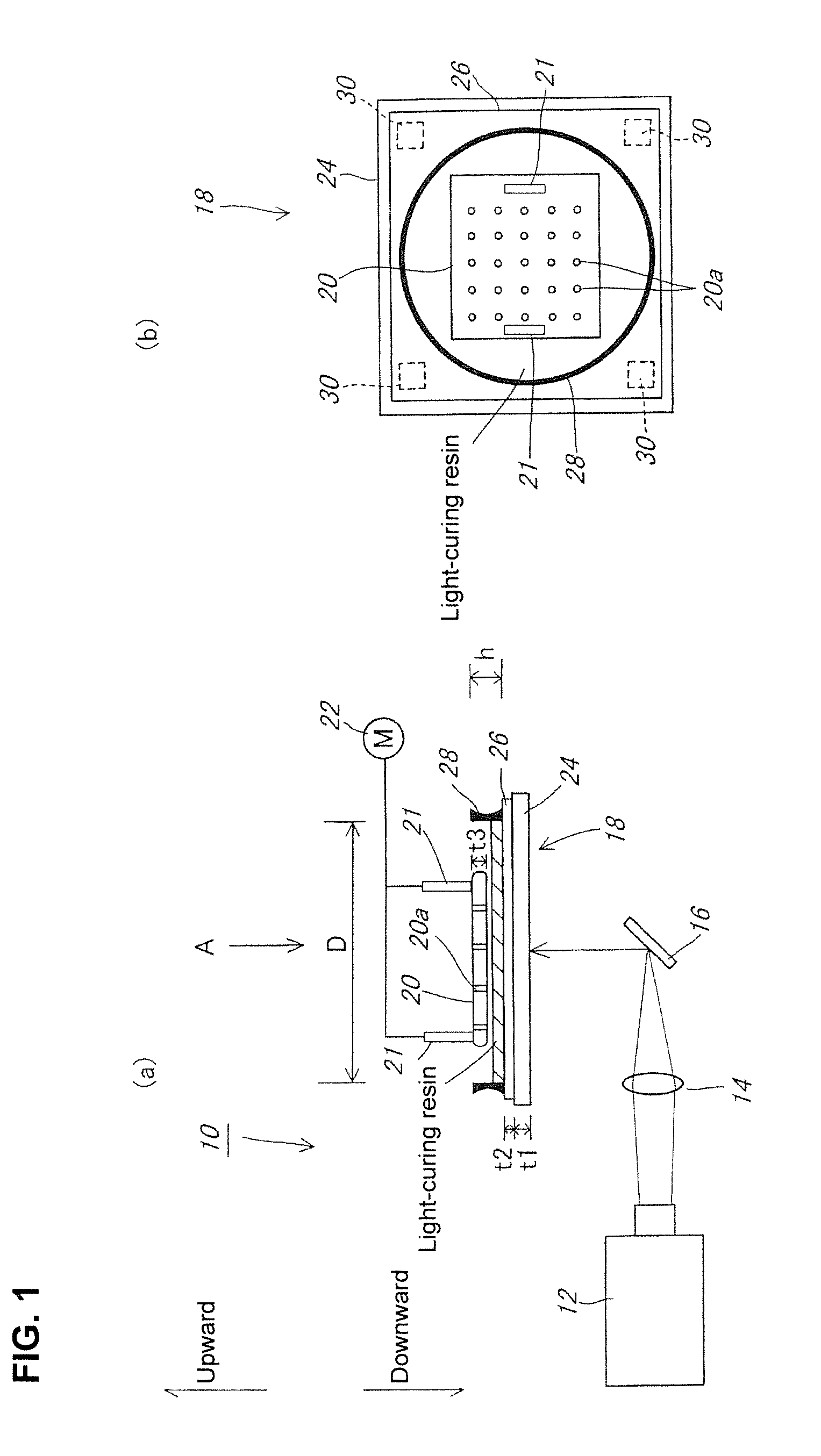

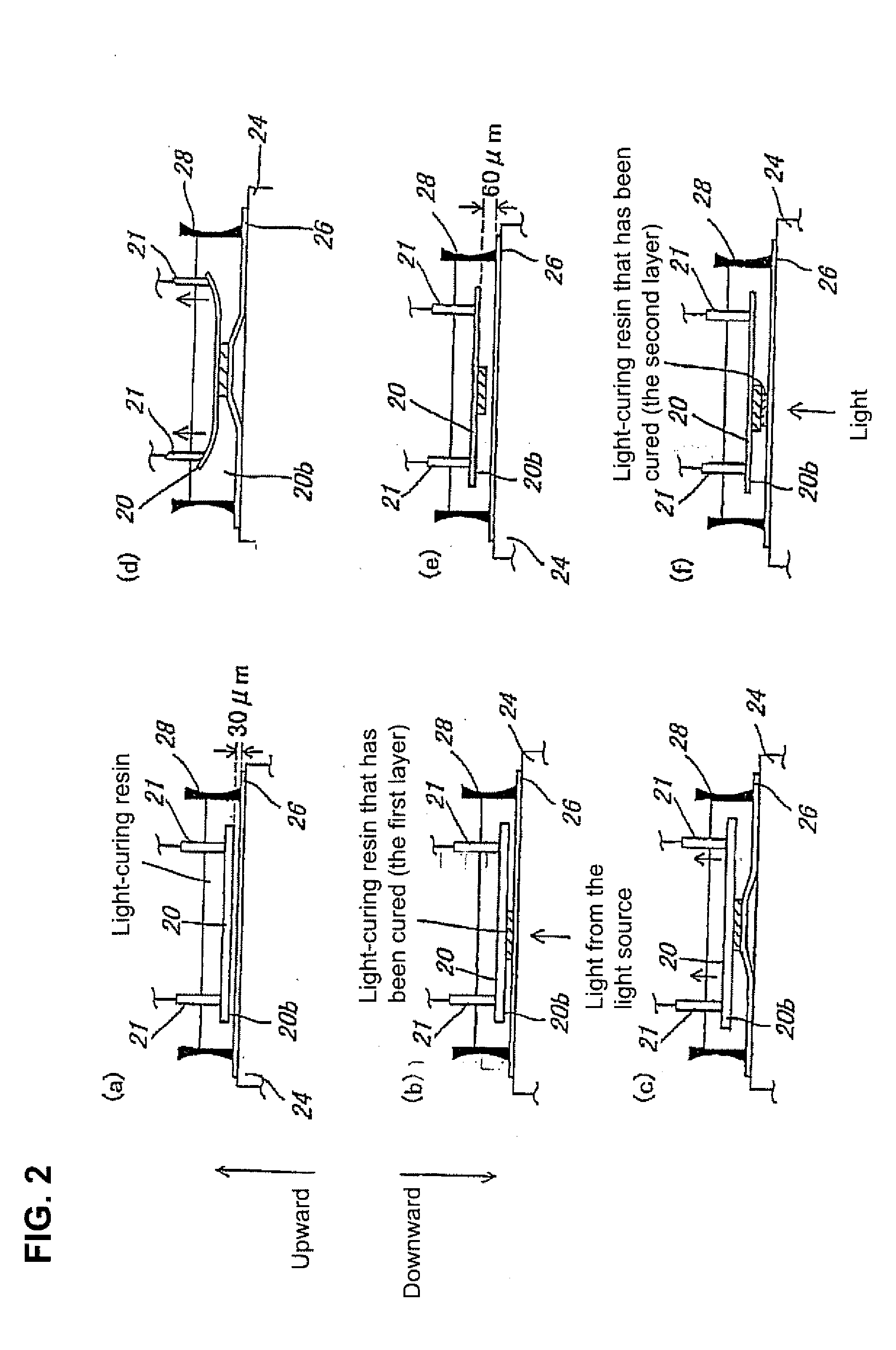

Three-dimensional molding device

InactiveUS20080174050A1Manufacturing platforms/substratesConfectioneryPolymer chemistryMaterials science

The present invention relates to a three-dimensional molding device for producing a three-dimensional molded object. The three-dimensional molding device comprises a receptacle for retaining a light-curing resin, a light source for irradiating light to cure the light- curing resin retained inside the receptacle, wherein the three-dimensional molded object is produced by curing the light-curing resin, and a flexible three-dimensional molded object holding plate, which adheres to the light-curing resin and holds the three-dimensional molded object when the resin in the receptacle is cured.

Owner:LG ELECTRONICS INC

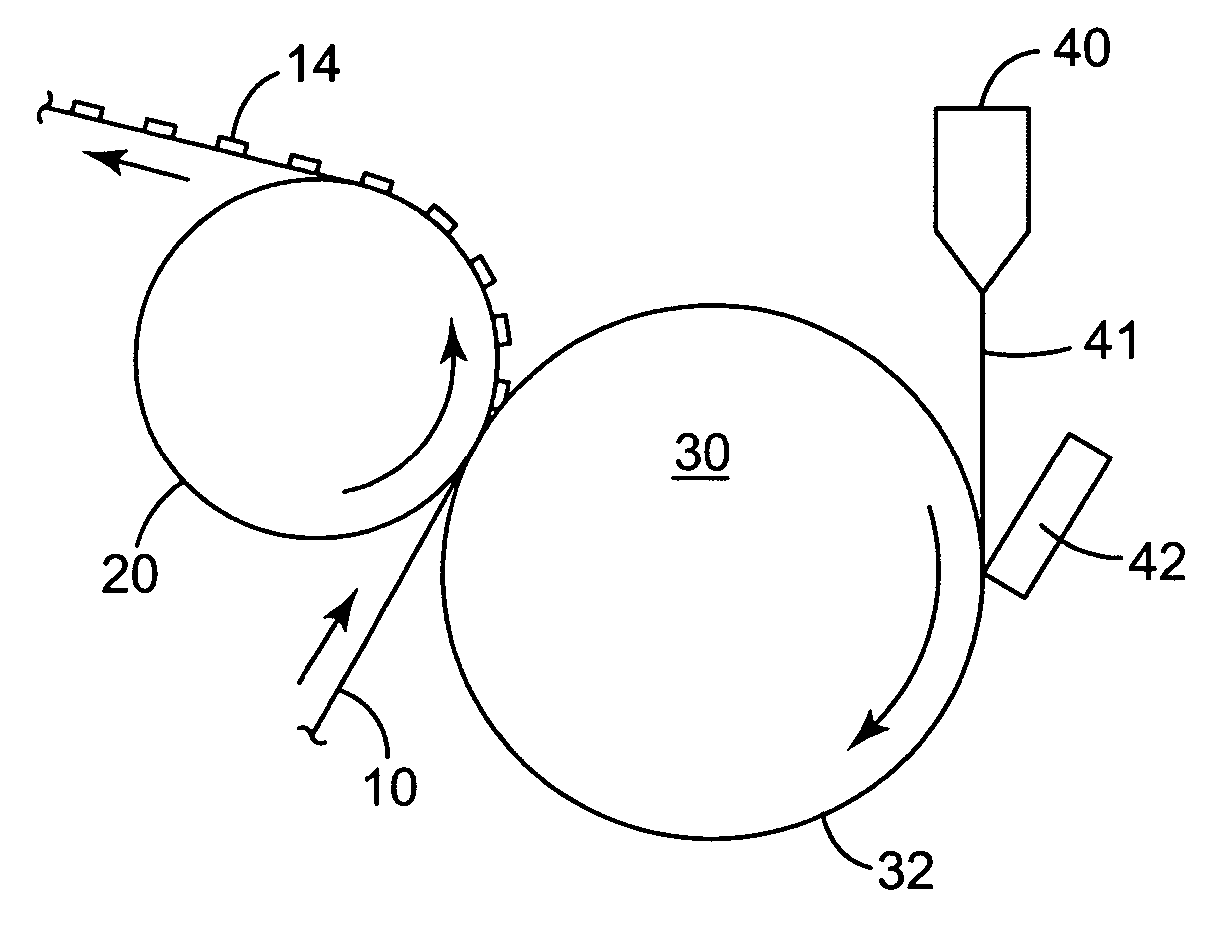

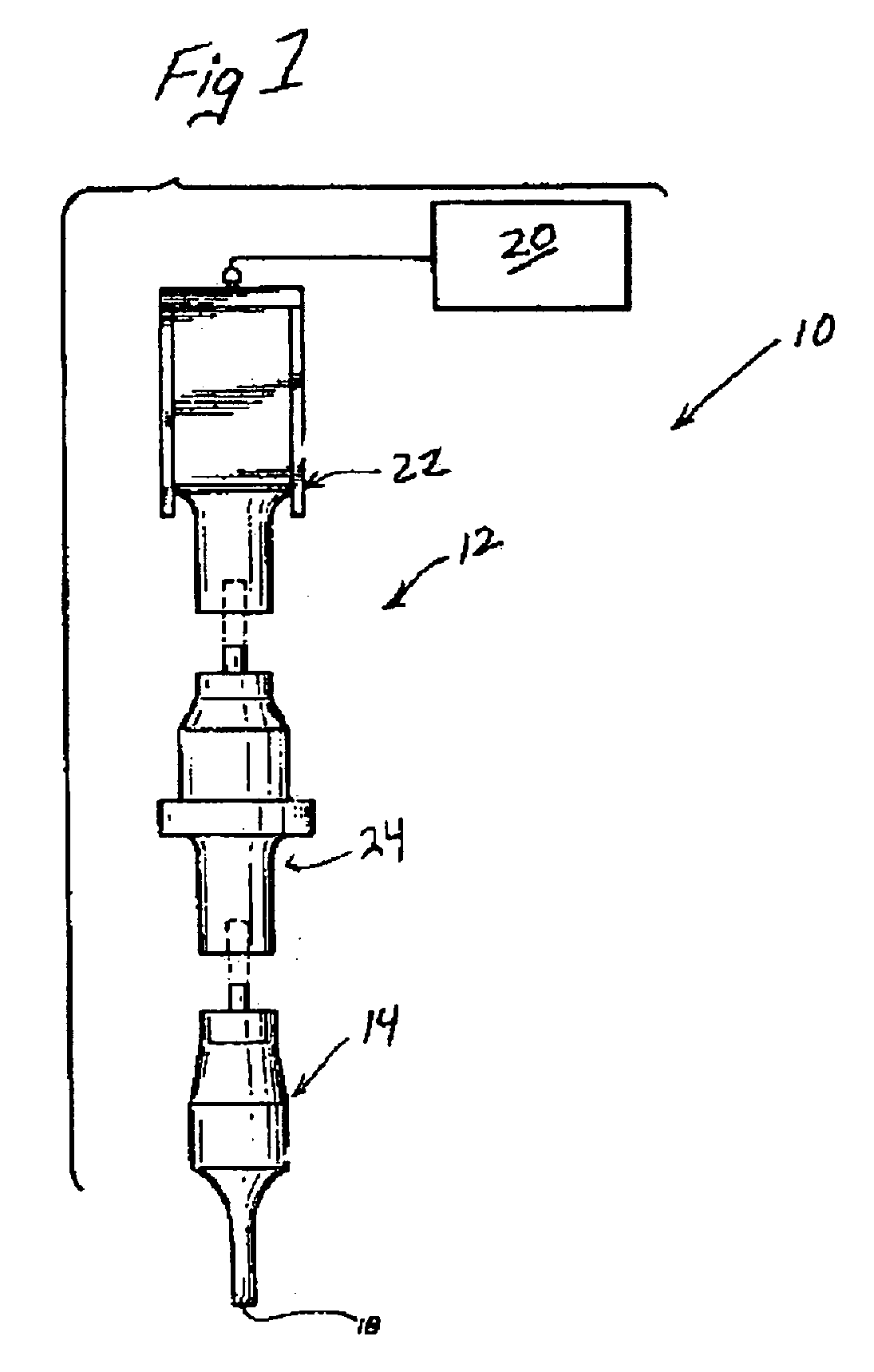

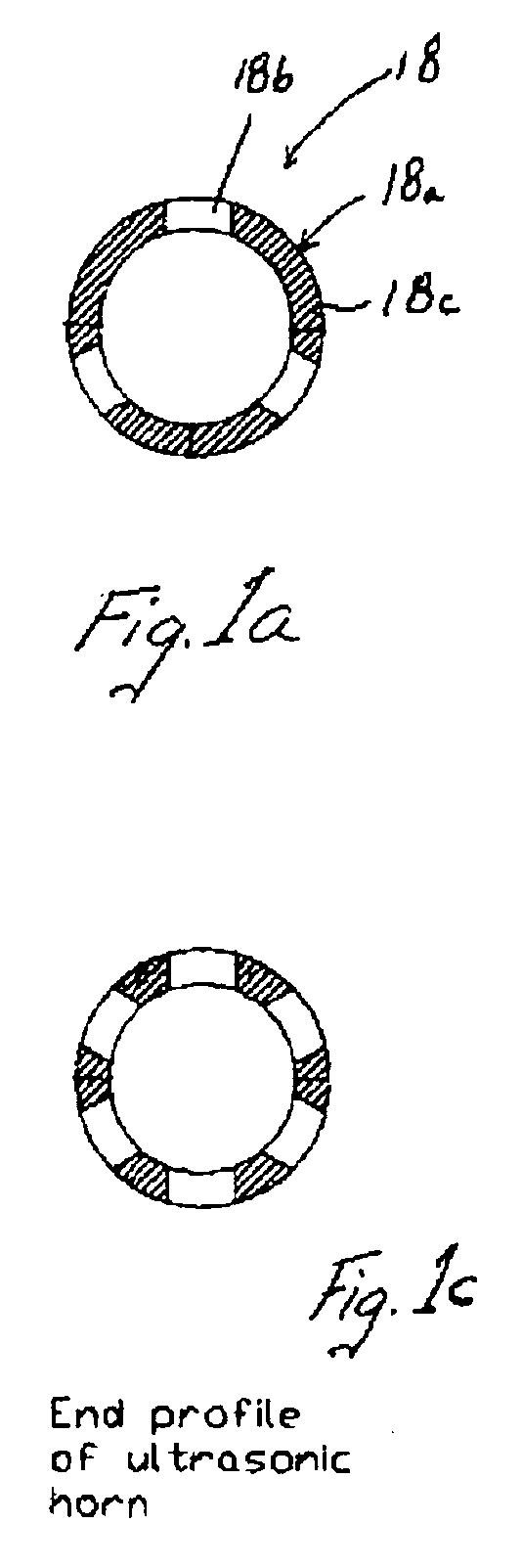

Ultrasonic assisted deposition of anti-stick films on metal oxides

InactiveUS20020130441A1Inhibit entry and adhesionLiquid surface applicatorsOptical articlesUltrasonic assistedCasting mold

A method and apparatus for ultrasonic assisted deposition of a release agent onto a workpiece is disclosed. The release agent can be any fluorinated or non-fluorinated phosphorous-containing organic acid. The workpiece can be any workpiece desired to be coated with the release agent, such as a surface needing an anti-stick coating required in a plastic casting or injection mold. Metal oxide workpiece surfaces strongly bond to fluorinated phosphorus-containing organic acids. In particular, the present invention can deposit anti-stick coatings onto smooth or porous surfaces, such as anodized aluminum and its alloys, using ultrasonic assisted deposition

Owner:KORRY ELECTRONICS

Composite webs and closure systems

InactiveUS7195729B2Increase the lengthDifferent compositionWood working apparatusCeramic layered productsMaterials sciencePolymer architecture

Composite webs having one or more polymeric structures located on a substrate, closure systems comprising composite webs, and methods of attaching articles are disclosed. The polymeric structures are formed using thermoplastic compositions and are attached to a surface of a substrate. The polymeric structures include an area that is attached to the substrate and a detached area that is not attached to a surface of a substrate.

Owner:3M INNOVATIVE PROPERTIES CO

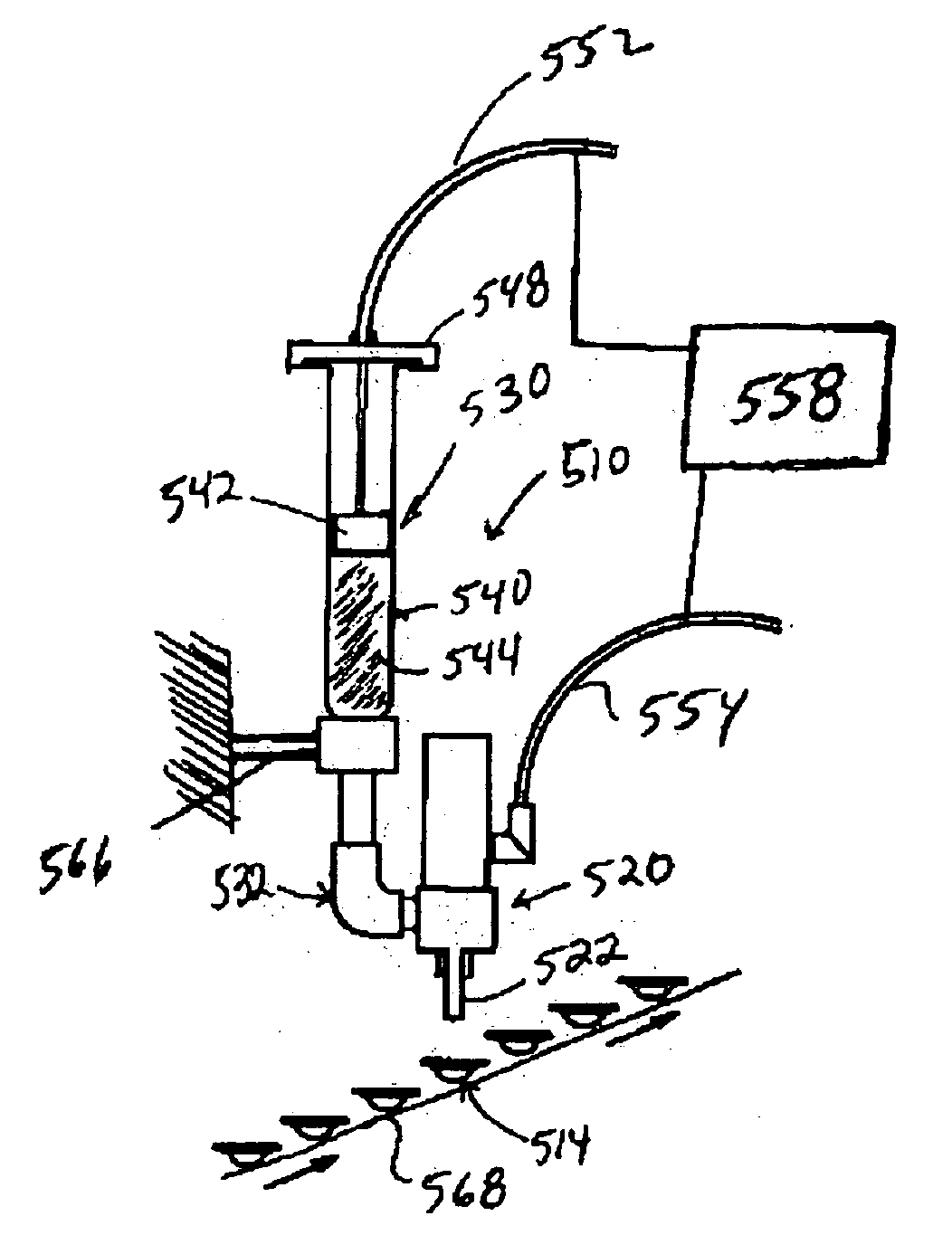

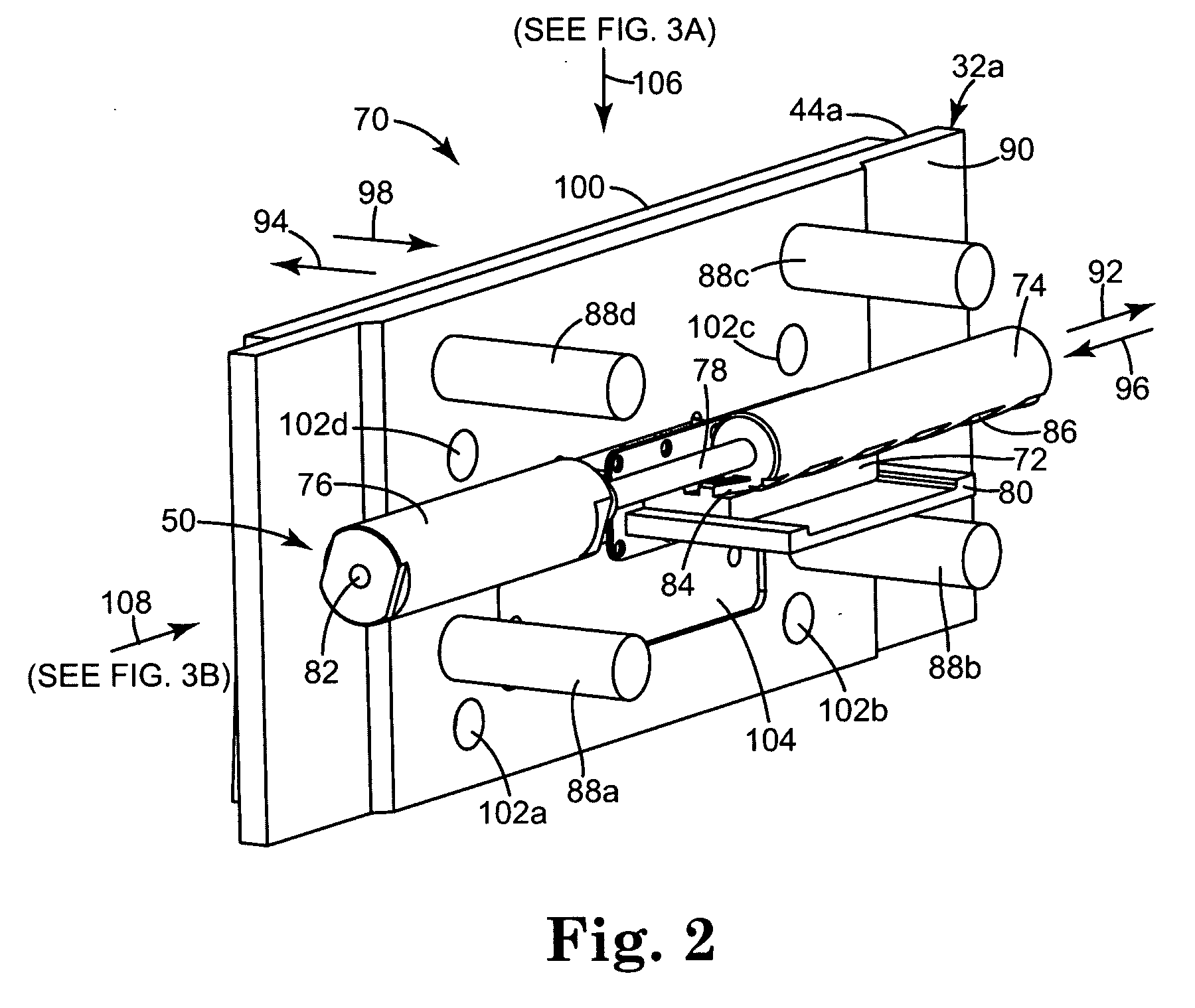

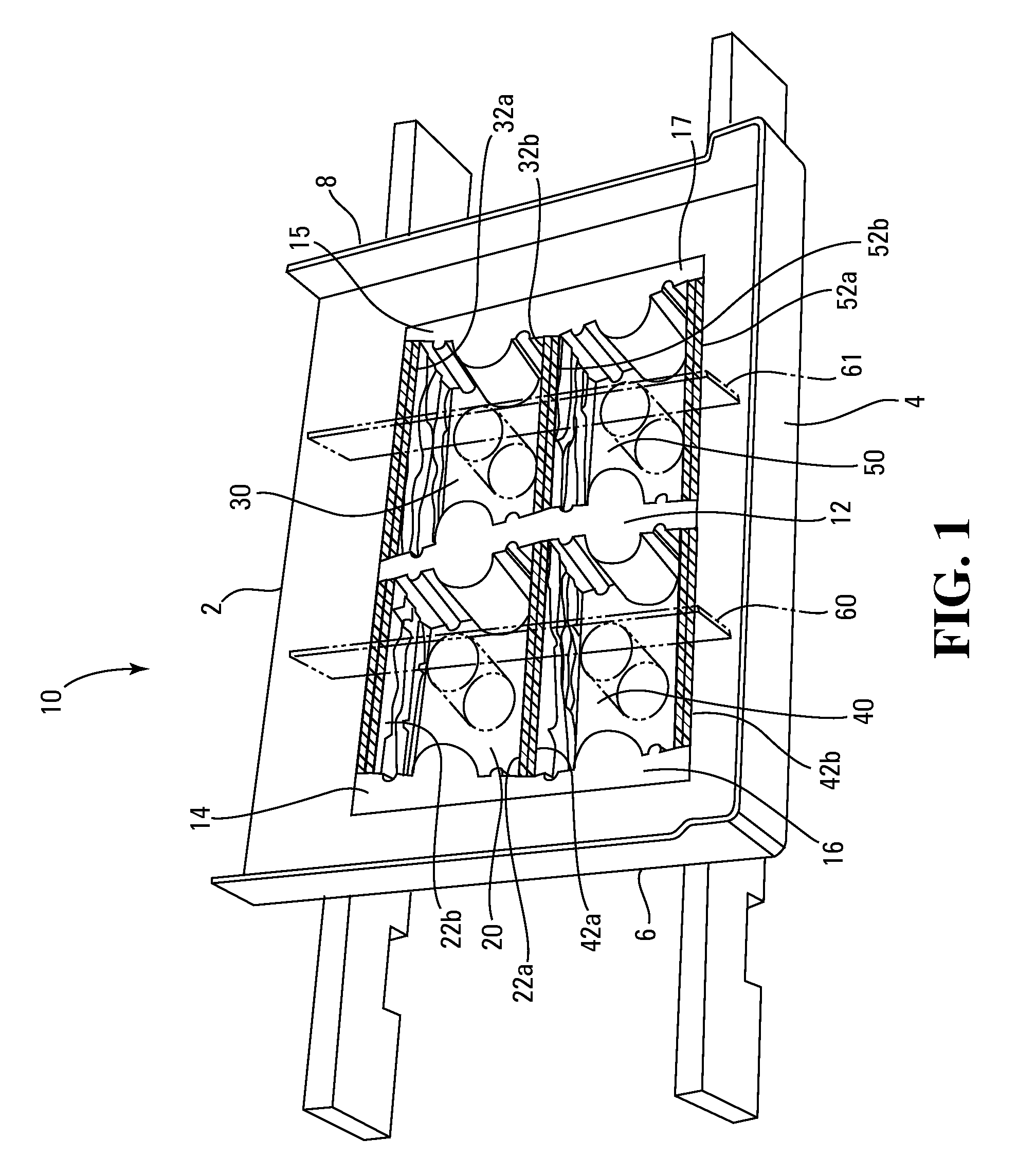

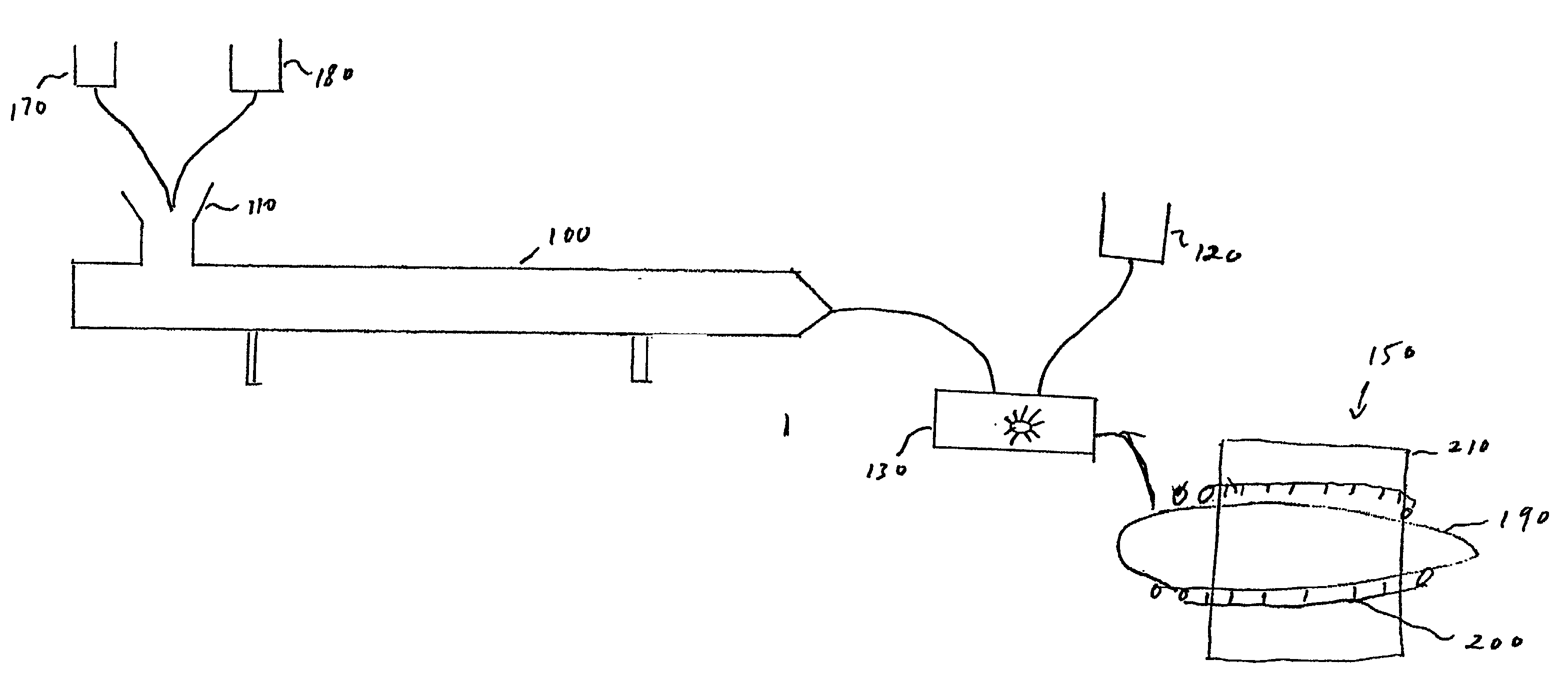

Contact lens mold assemblies and systems and methods of producing same

ActiveUS20070035051A1Prevent materialEnhanced cavitationOptical articlesStereotype platesEngineeringContact lens

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which when coupled together are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by means of focused ultrasound energy.

Owner:COOPERVISION INT LTD

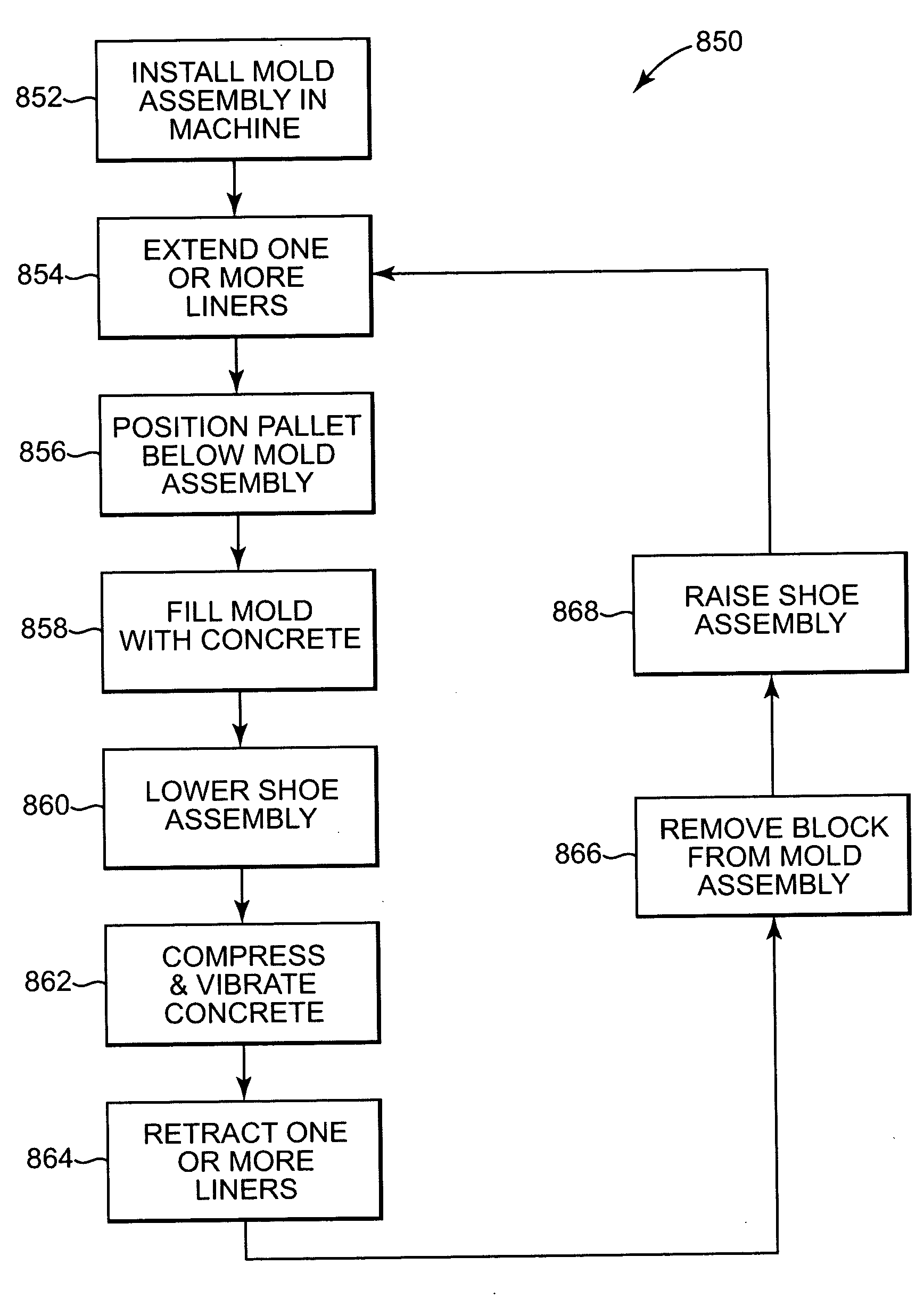

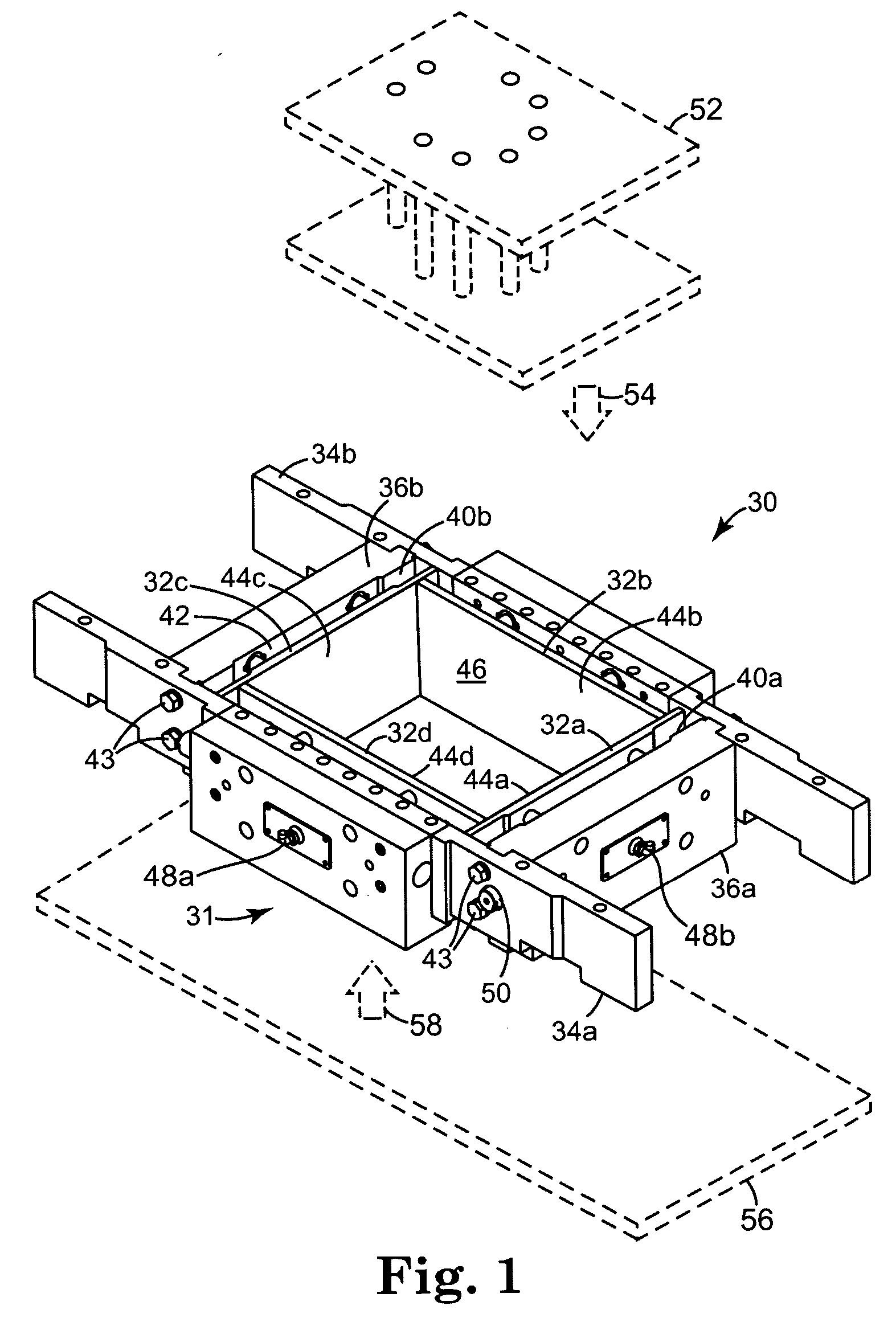

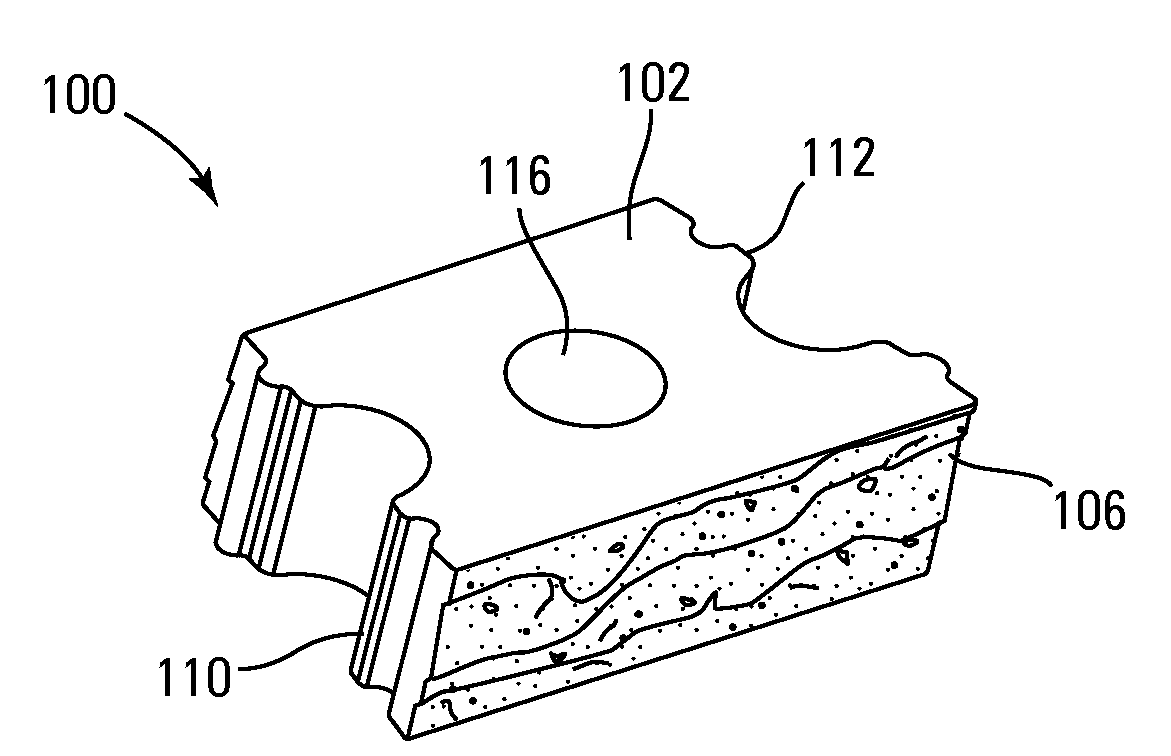

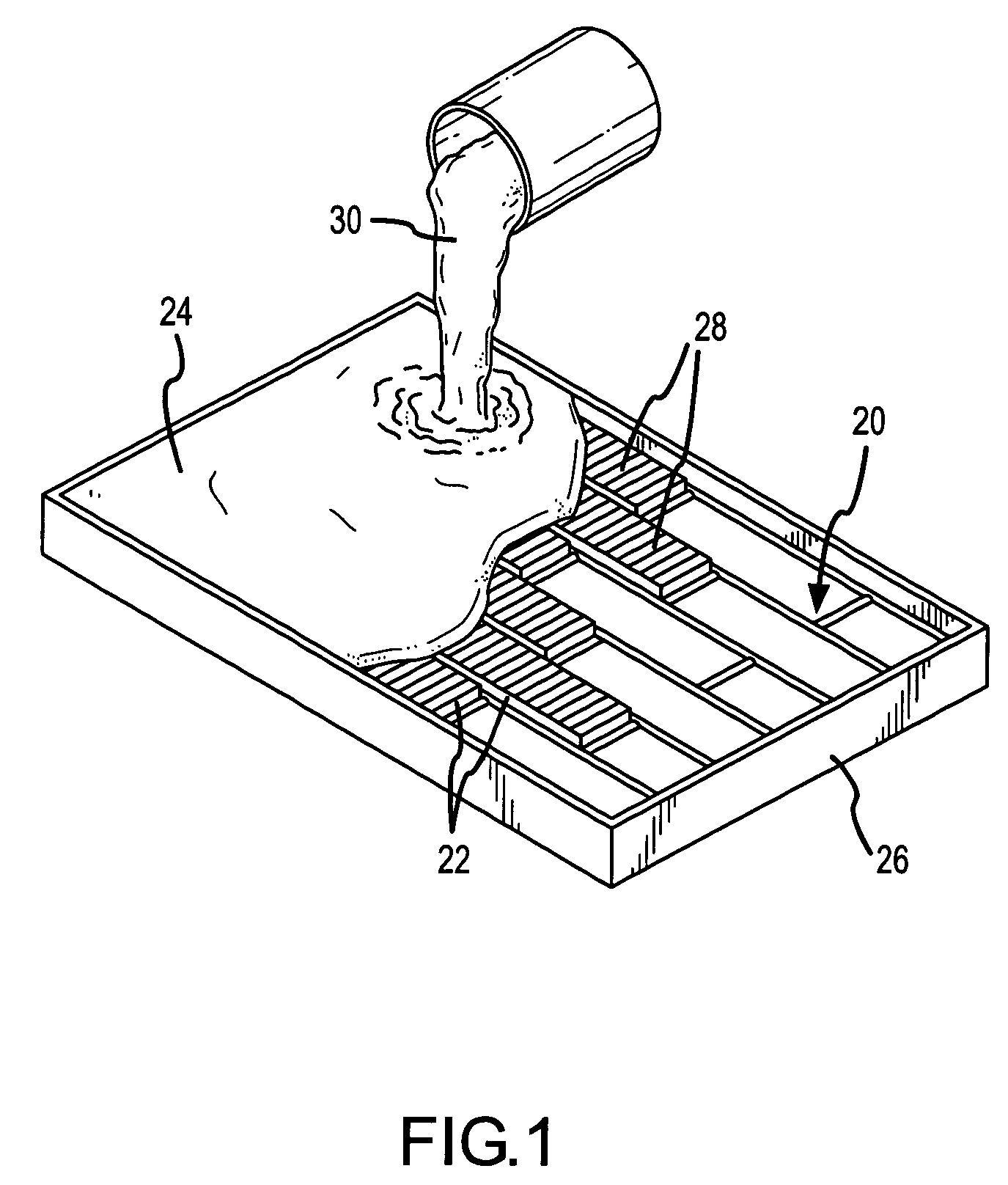

Masonry blocks and method and system of making masonry blocks

A method of producing a masonry block including providing a mold assembly having a plurality of liner plates that together form a mold cavity having an open top and an open bottom, wherein at least one of the liner plates is moveable between a retracted position and a desired extend position relative to an interior of the mold cavity with a gear drive assembly. The at least one moveable liner plate is moved to the desired extended position, the bottom of the mold cavity is closed with a pallet, dry cast concrete is placed in the mold cavity via the open top, the top of the mold cavity is closed with a moveable head shoe assembly, and the dry cast concrete is compacted to form a pre-cured masonry block. The at least one moveable liner plate is moved to the retracted position, the pre-cured masonry block is expelled from the mold cavity and cured.

Owner:NESS INVENTIONS

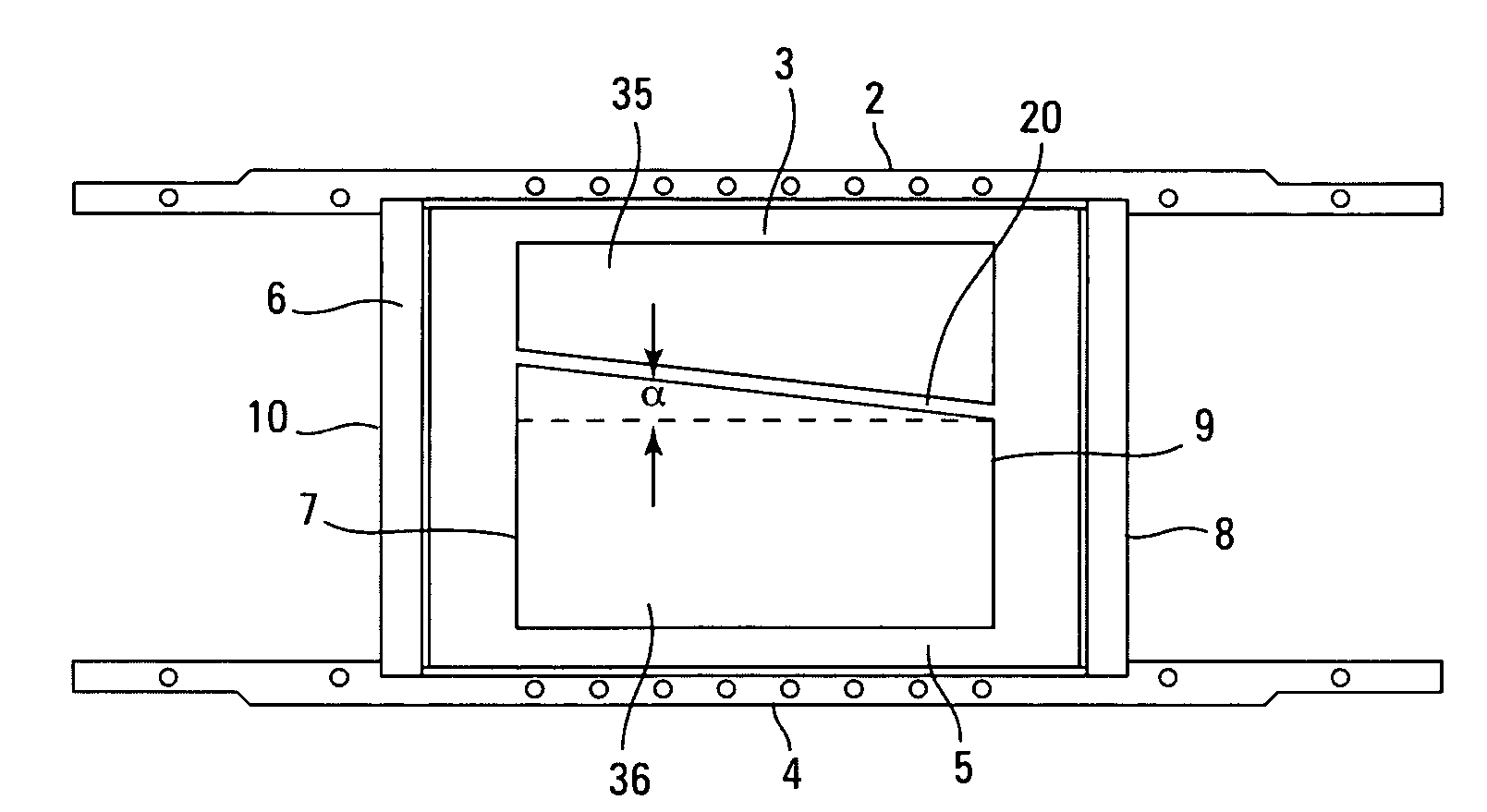

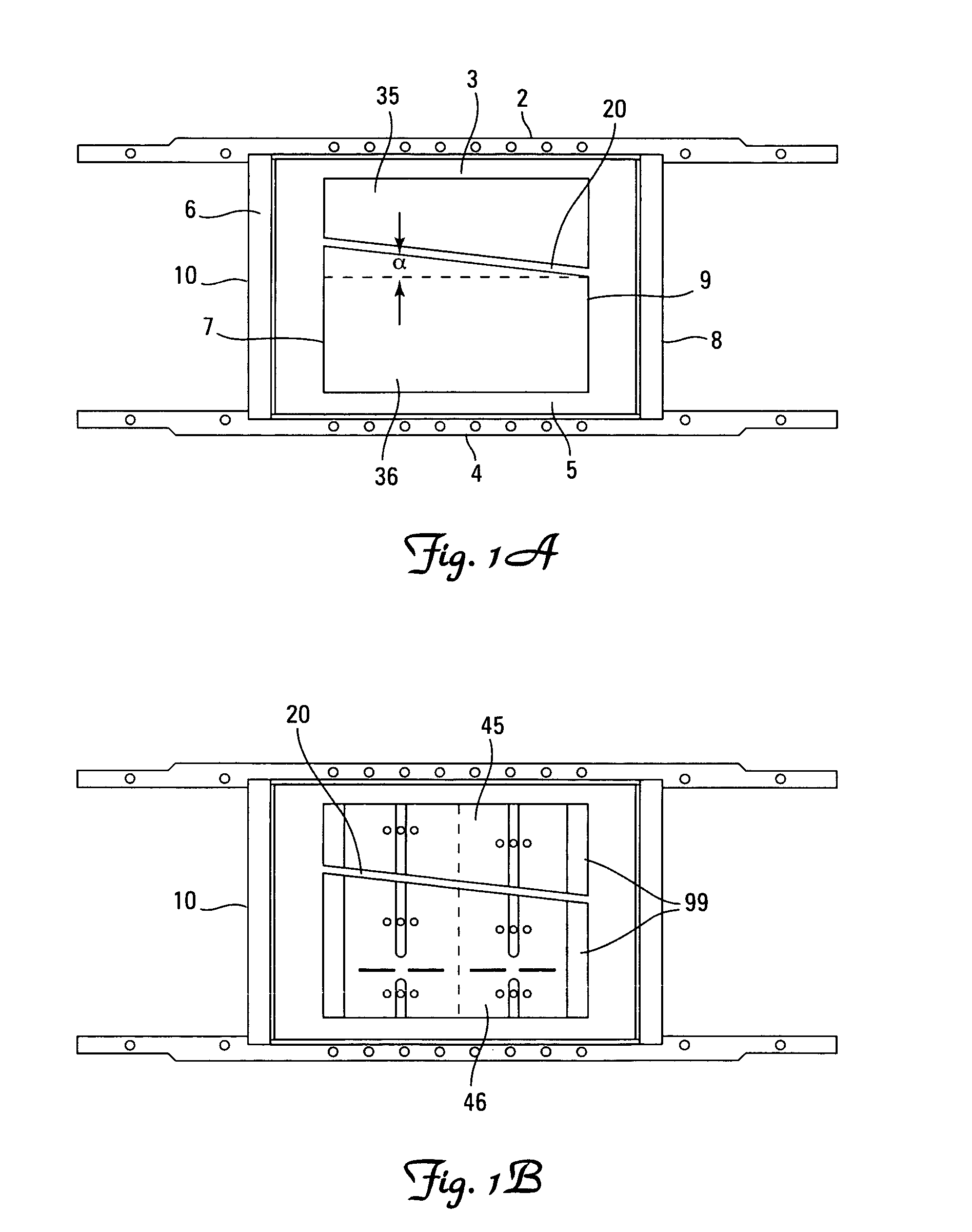

In mold manufacture of an object with embedded display panel

This invention relates to an object having a display panel embedded in its top surface and processes for its manufacture. This invention also relates to an in-mold display transfer film or foil, which comprises a temporary carrier film, a release layer, a display panel, an adhesive or tie layer and optionally a durable layer.

Owner:E INK CORPORATION

Method of manufacturing an inorganic board

A mold used for manufacturing an inorganic board and a method of manufacturing an inorganic board by employing said mold are provided in the present invention. Said mold consists of a mold part made of a fiber reinforced plastic and a metal part attached to the back of said mold part, and because of said metal part, the difference in the coefficient of thermal expansion between said mold and an inorganic board manufactured on said mold is small.

Owner:NICHIHA CORP

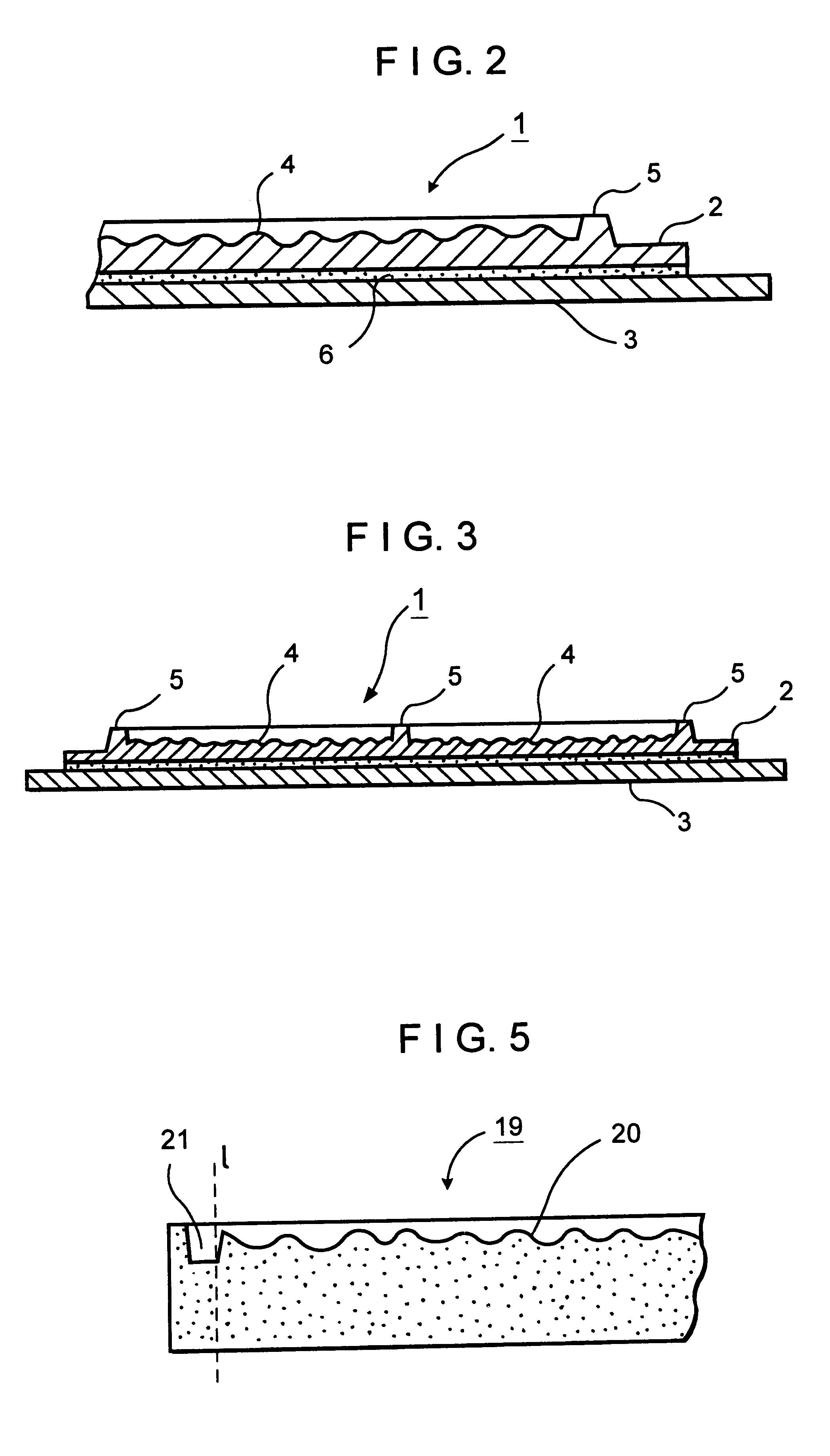

Imprint lithography

A method of making an imprint lithography template includes applying a curable material to a patterned surface of a master imprint template, allowing the curable material to cure and thereby forming a second imprint template having a patterned surface which is the inverse of the patterned surface of the master imprint template; removing the second imprint template from the master imprint template; applying inorganic sol-gel to a substrate; imprinting the inorganic sol-gel with the second imprint template; allowing the inorganic sol-gel to cure; and removing the second imprint template from the cured inorganic sol-gel, such that the inorganic sol-gel forms a third imprint template having a patterned surface which corresponds with the patterned surface of the master imprint template.

Owner:ASML NETHERLANDS BV +1

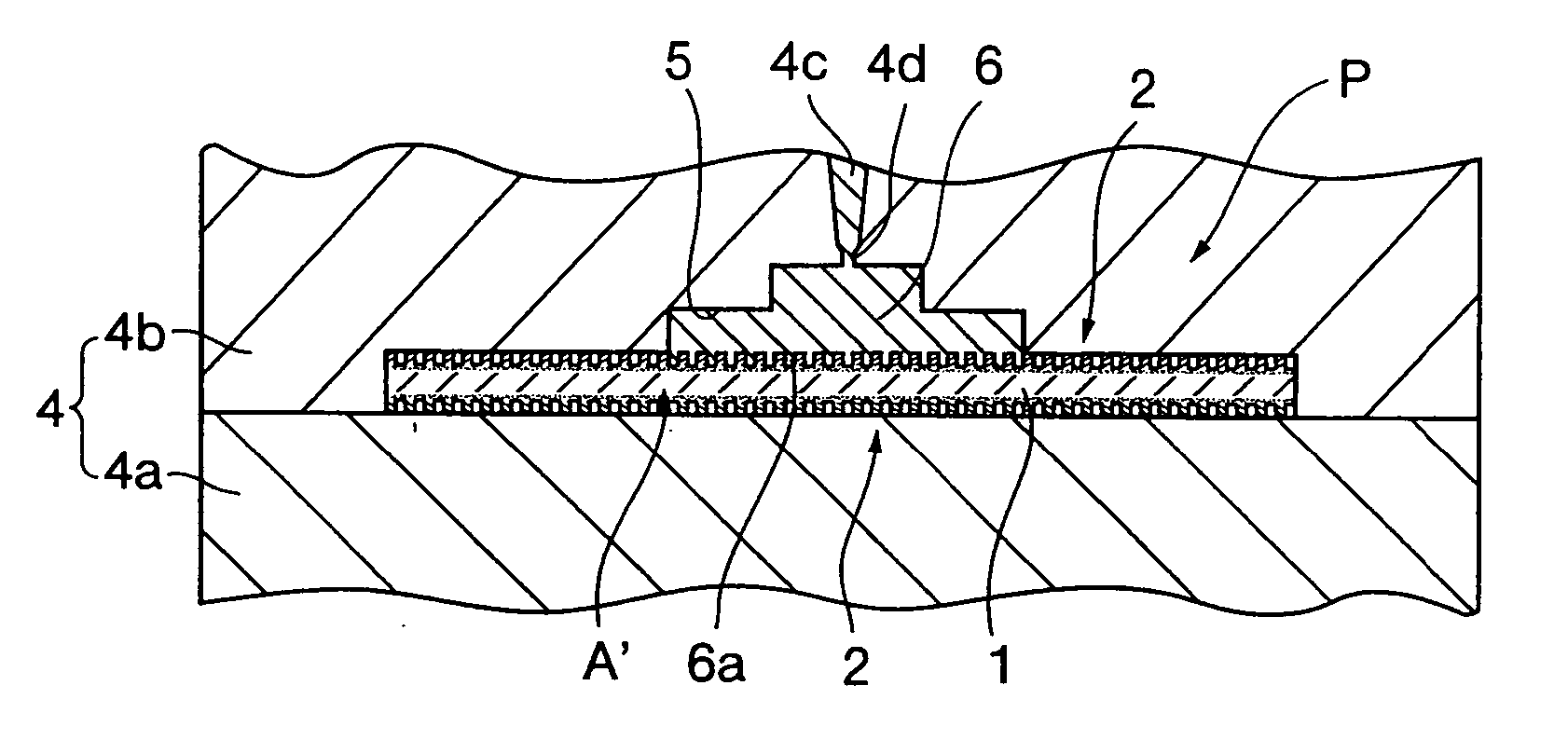

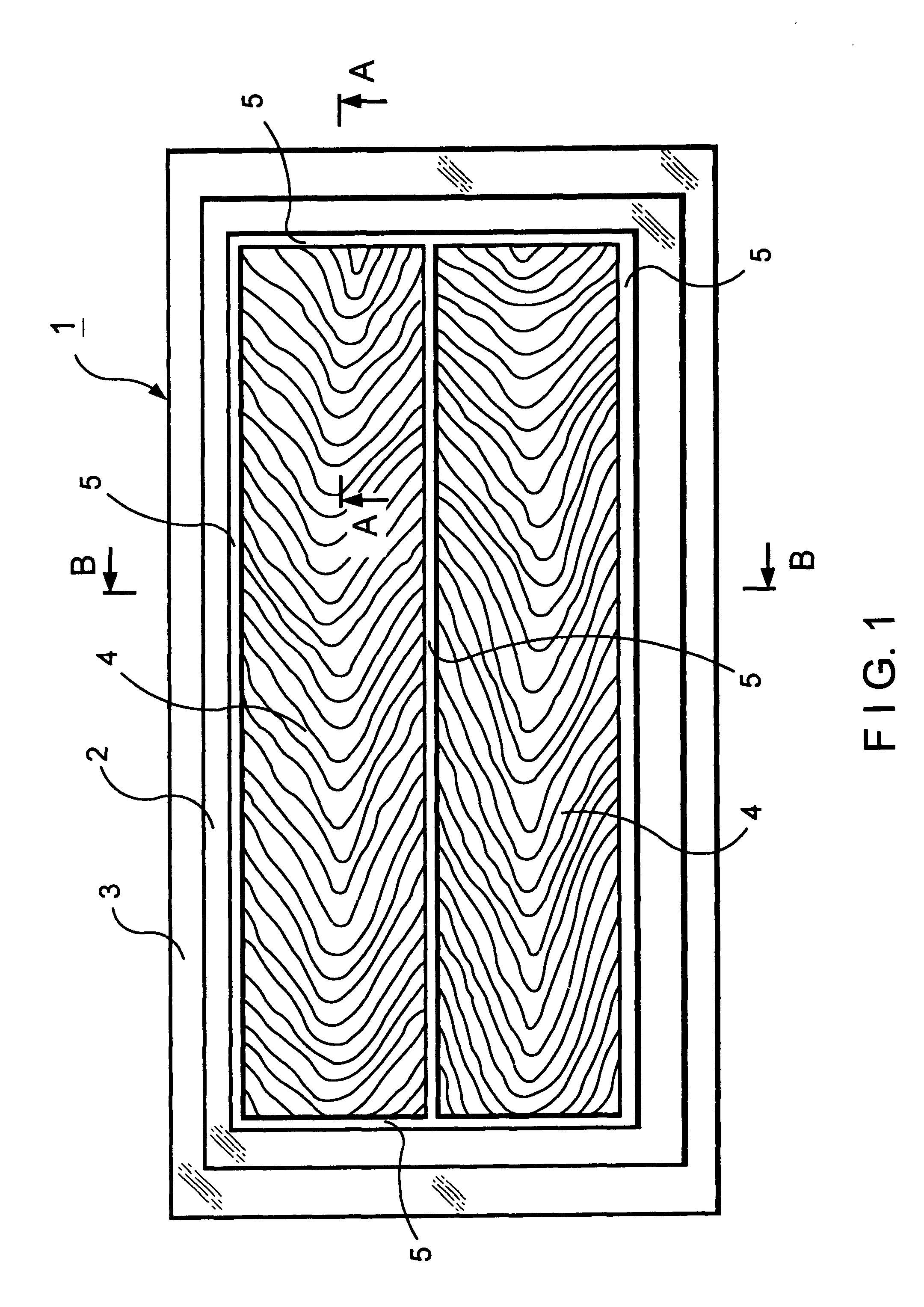

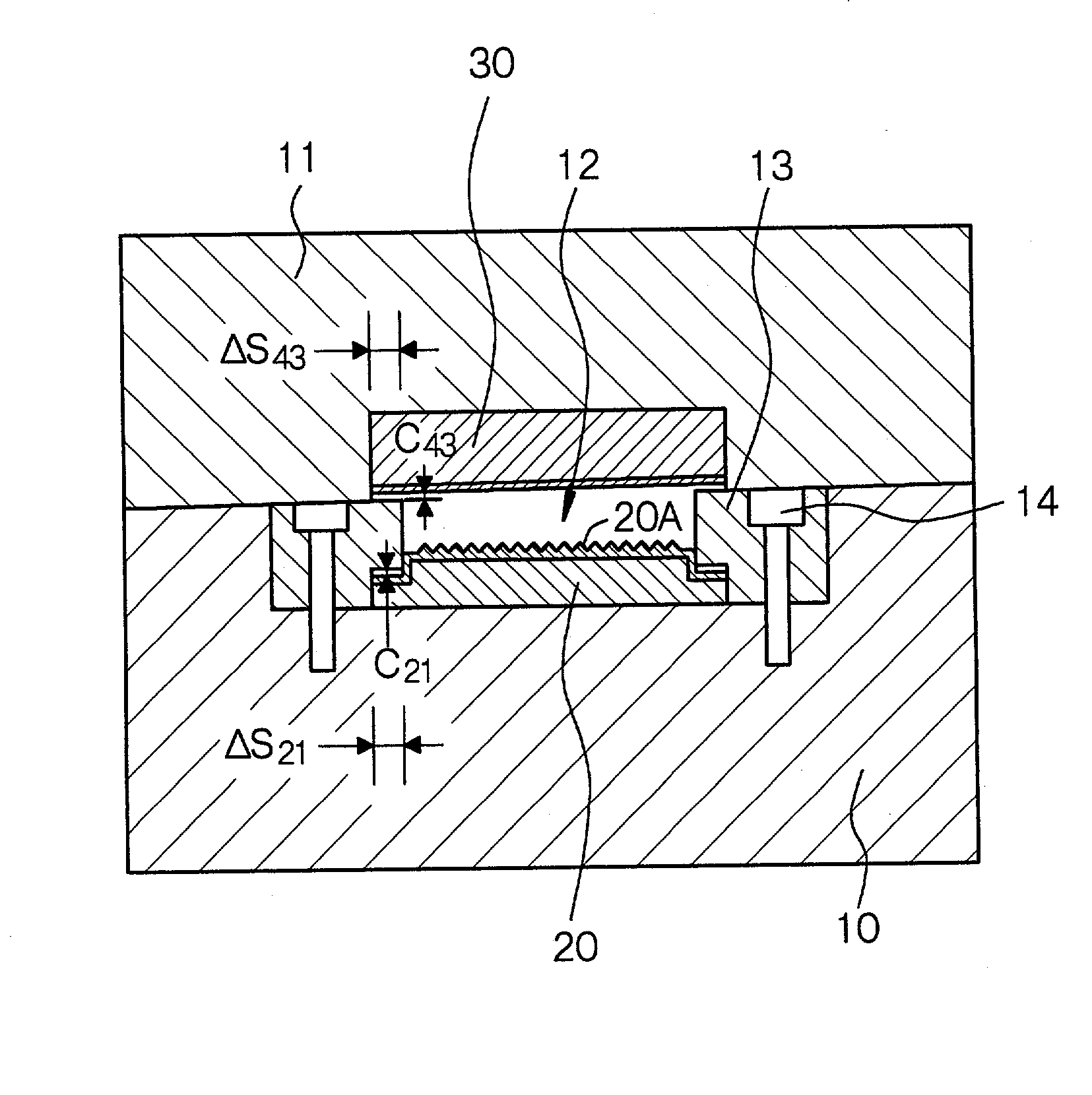

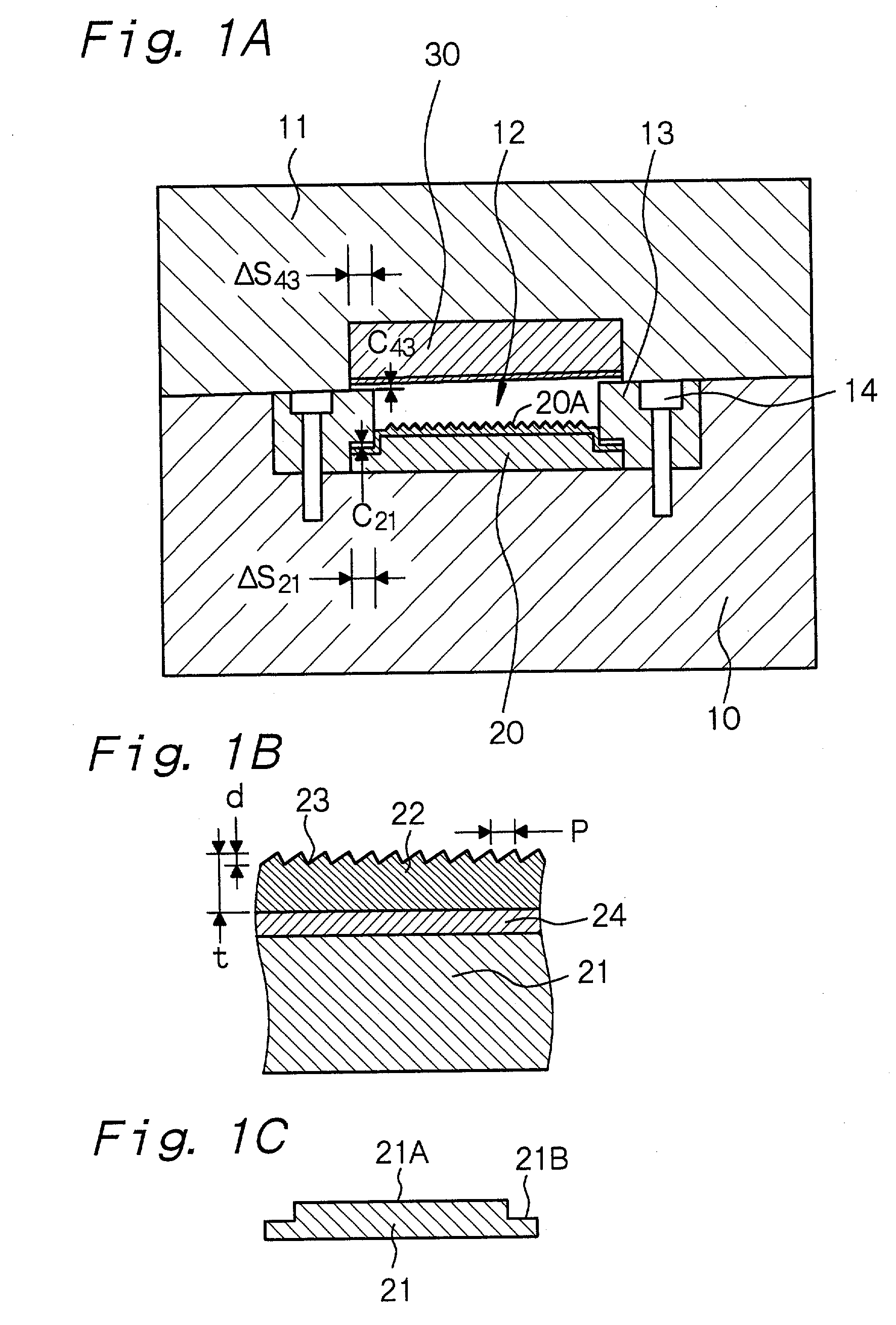

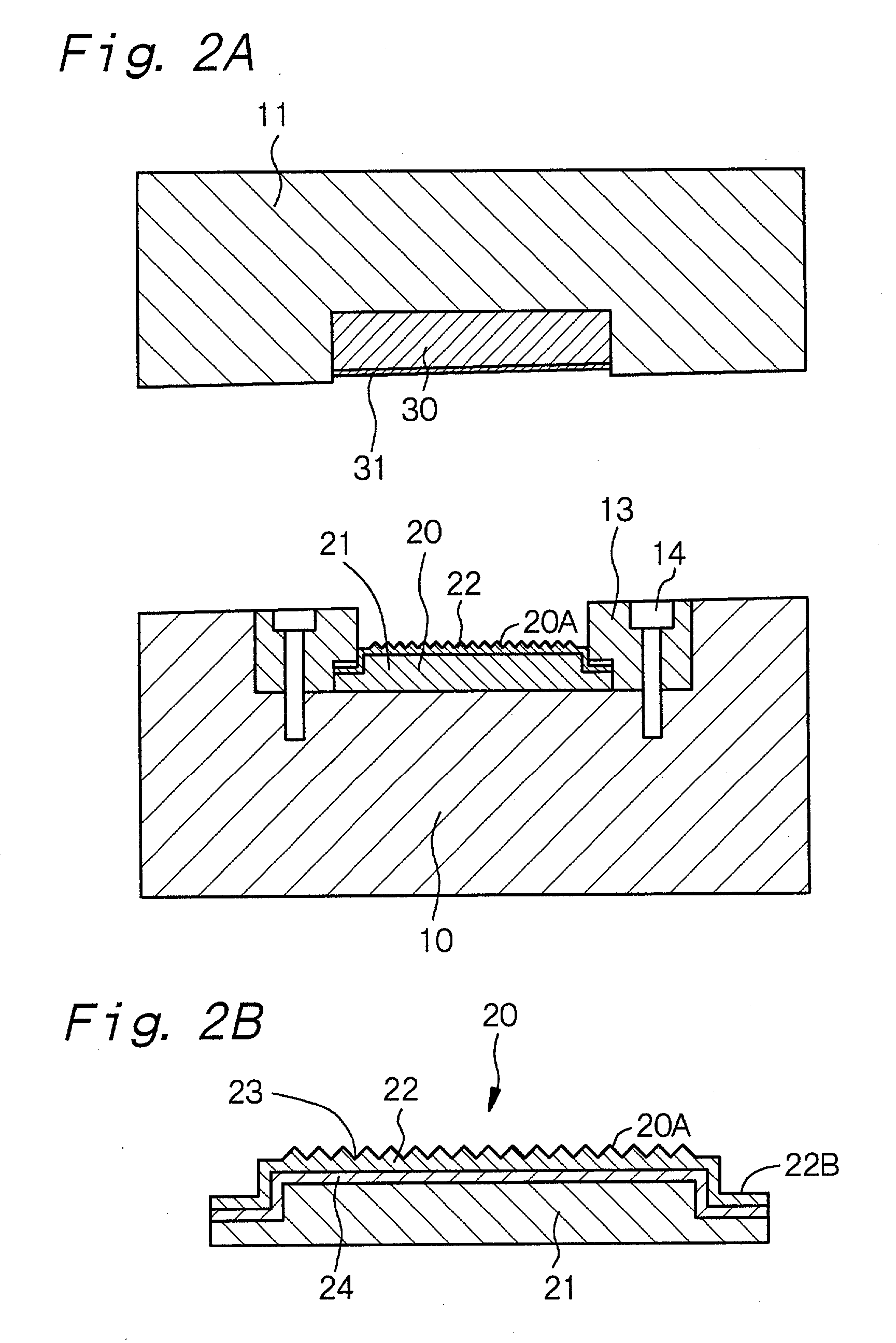

Light guide plate made of transparent resin, molding method thereof, insert block, mold assembly, and area light apparatus

InactiveUS20020181224A1Accurately reliably formedCorrect formatMechanical apparatusMouldsLight guideMechanical engineering

A light guide plate which is made of a transparent resin and has a first main surface and a second main surface opposite to said first main surface, said first main surface having a surface portion provided with convex portions having a height of 5x10-7 m to 6x10-5 m each and a pitch of 5x10-7 m to 4x10-4 m, each convex portion having a tip portion, and the convex portions of at least 80% of the total convex portions having the tip portions having a radius of curvature of 2x10-6 m or less.

Owner:MITSUBISHI ENG PLASTICS CORP

Mold box and method of manufacturing multiple blocks

Owner:KEYSTONE RETAINING WALL SYST

Heated build platform and system for three dimensional printing methods

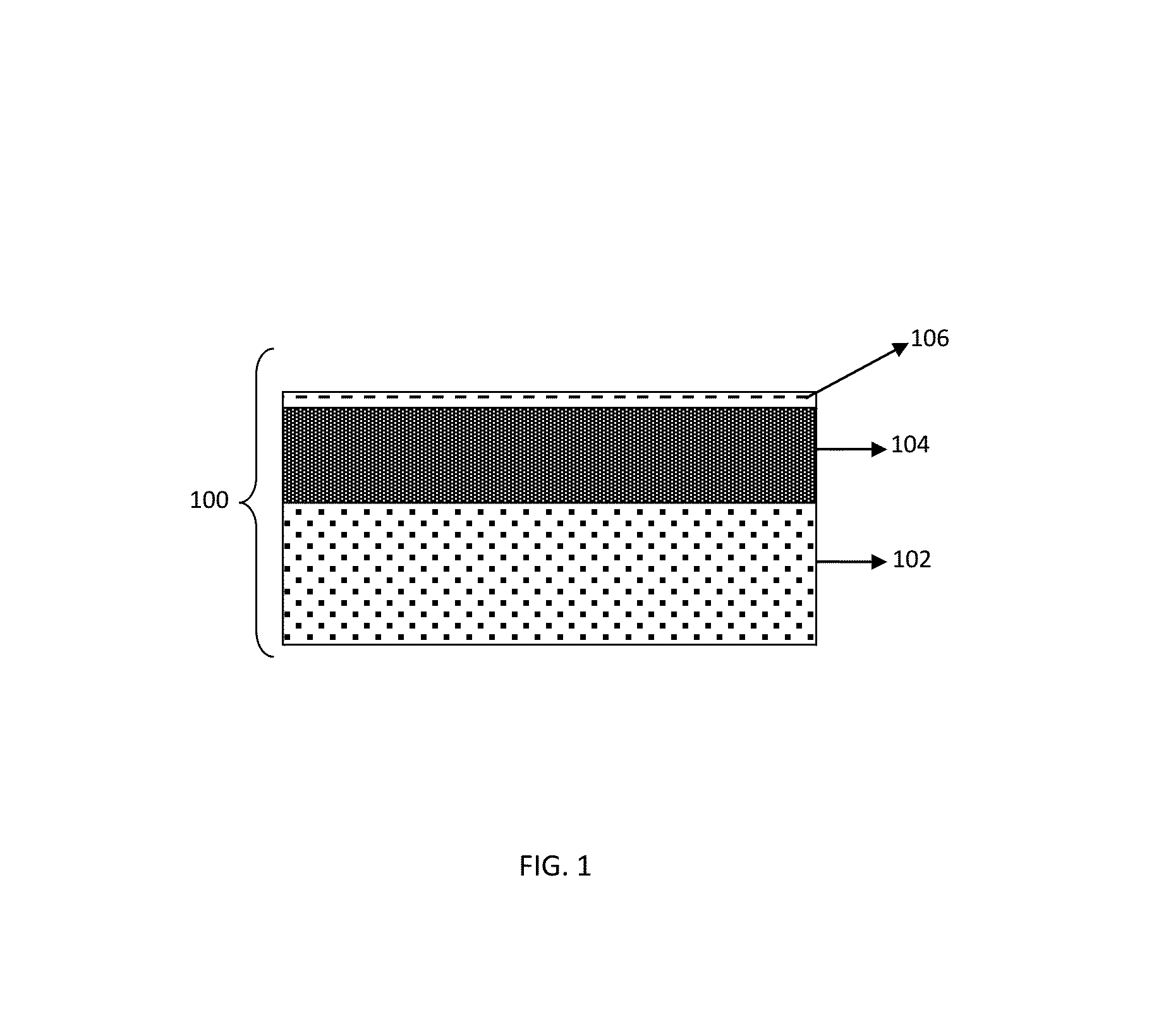

ActiveUS20160176118A1Quick installationQuick releaseManufacturing platforms/substratesManufacturing heating elementsThermoplasticPolymer science

An apparatus performing as a base for printing 3D objects using high temperature thermoplastics employing additive manufacturing methods is provided. The apparatus comprises a heated build platform, a thin removable plate secured on top of the build platform, a high temperature polymer coating applied over the removable plate, and surface treatment of high temperature polymer coating to maintain adhesion between 3D object and printing surface. Also, the removable plate has low coefficient of thermal expansion compared to build platform below it, for avoiding bowing of the plate as it is heated due to heated build platform, hence providing flat printing surface. The thin removable plate allows 3D objects to pop off the plate upon cooling, without damaging the polymer coating, the plate, or the object. It also allows for continuous operation of printing, while the plate is released for cooling, a new plate is installed for printing.

Owner:AREVO INC

Cement retarder and cement retardative sheet

A saturated polyester obtained by a reaction of a polycarboxylic acid component comprising a polycarboxylic acid having 2 to 6 carbon atoms in the main chain (e.g. maleic anhydride), and a polyol component comprising a polyhydric alcohol having 2 to 4 carbon atoms or its condensate is used as a cement retarder. A retardative sheet can be formed by applying or impregnating a composition comprising the retarder and a tacky adhesive to a base sheet. By forming a predetermined pattern with the use of the retarder or sheet in a form, depositing a mortar composition, washing a surface of the hardened concrete, and washing out uncured mortar, a figure or a washing finished surface is formed on a surface of a concrete product.

Owner:DAICEL HULS

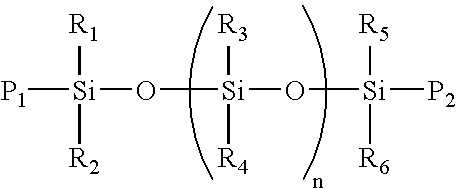

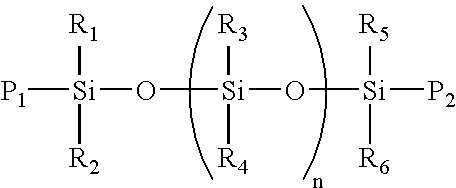

Dental impression composition on functionalized polyethers

A dental impression composition comprises a polyether derivative functionalized via the hydroxyl groups of a polyether polyol with groups such as aziridine, epoxide and unsaturated substituents including (meth)acrylic, allyl, vinyl, vinyl ether or maleate groups, wherein the level of cyclic oligomeric polyethers is less than 5.0 weight percent.

Owner:3M DEUTLAND

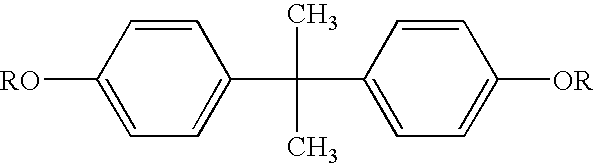

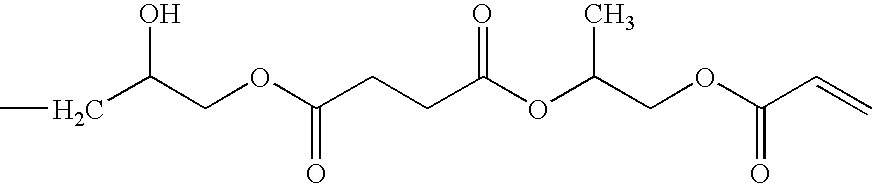

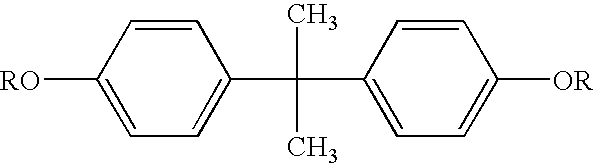

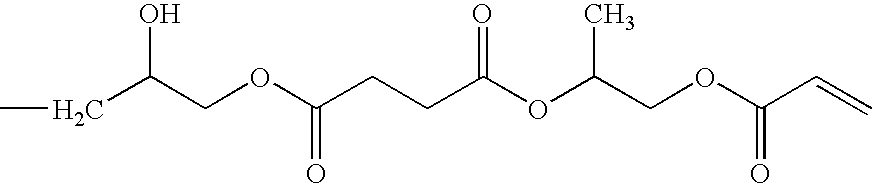

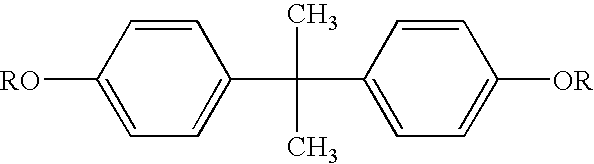

Abrasion resistant coatings

InactiveUS7375144B2Enhanced resistance to abrasion and chemicalImprove clarityOrganic chemistryMixing methodsDiacrylate esterUrethane acrylate

Disclosed are radiation-curable, abrasion resistant coating compositions for thermoplastic substrates which provides superior abrasion, chemical, and impact resistance properties. The coating composition includes at least one flexible diacrylate component, at least one aromatic diacrylate component, and at least one urethane acrylate. Also disclosed are shaped articles having the coating composition applied to at least one surface and cured by exposure to radiation.

Owner:EASTMAN CHEM CO

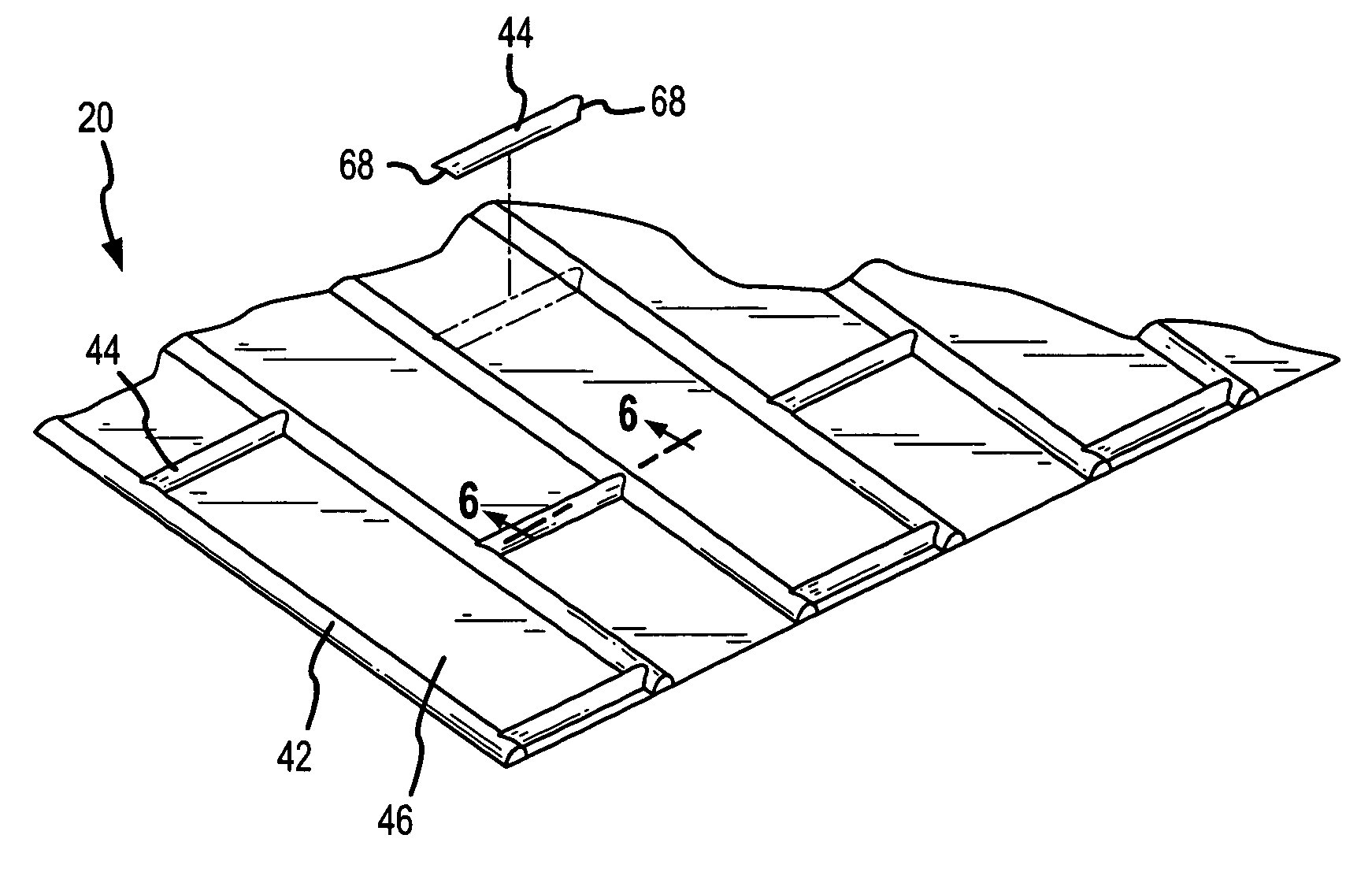

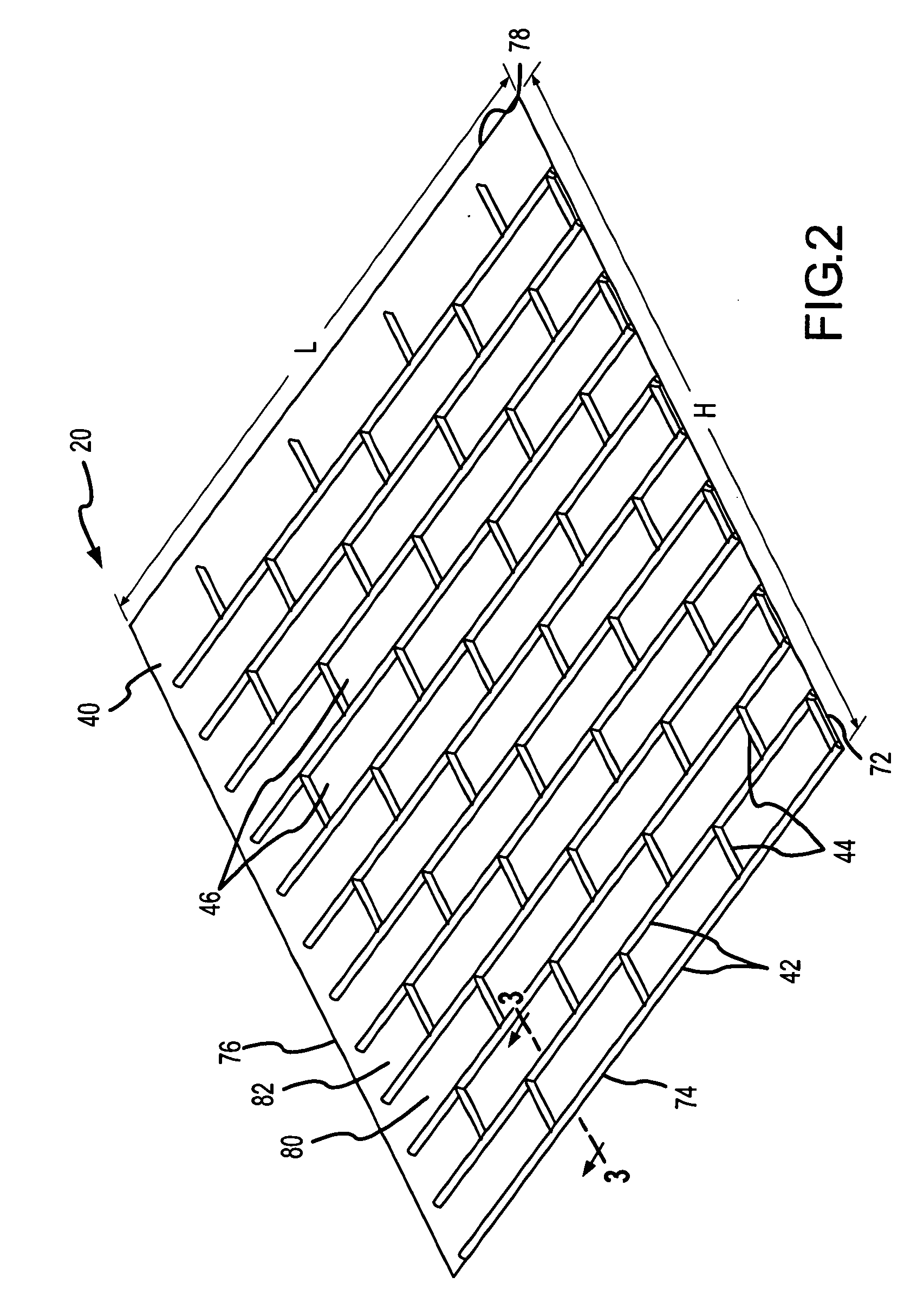

Mold box and method of manufacturing a block

The present invention relates a mold box method of manufacturing a block, and a wall block with a stepped-back strata and ledges imprinted on one or more faces of the block. A mold box is provided with a block face liner that is machine cut to create a particular strata and ledge pattern that is widest at the top of the liner and steps back over a plurality of planes to a narrower width at the bottom of the liner. Masonry material is allowed to form in the mold box around the liner to produce the strata and ledges imprint onto one or more faces of the block. The invention also relates to the mold box, multiple embodiments of the block face liner with differing strata and ledge patterns, and to blocks formed in the mold box and methods of constructing walls with the blocks.

Owner:KEYSTONE RETAINING WALL SYST

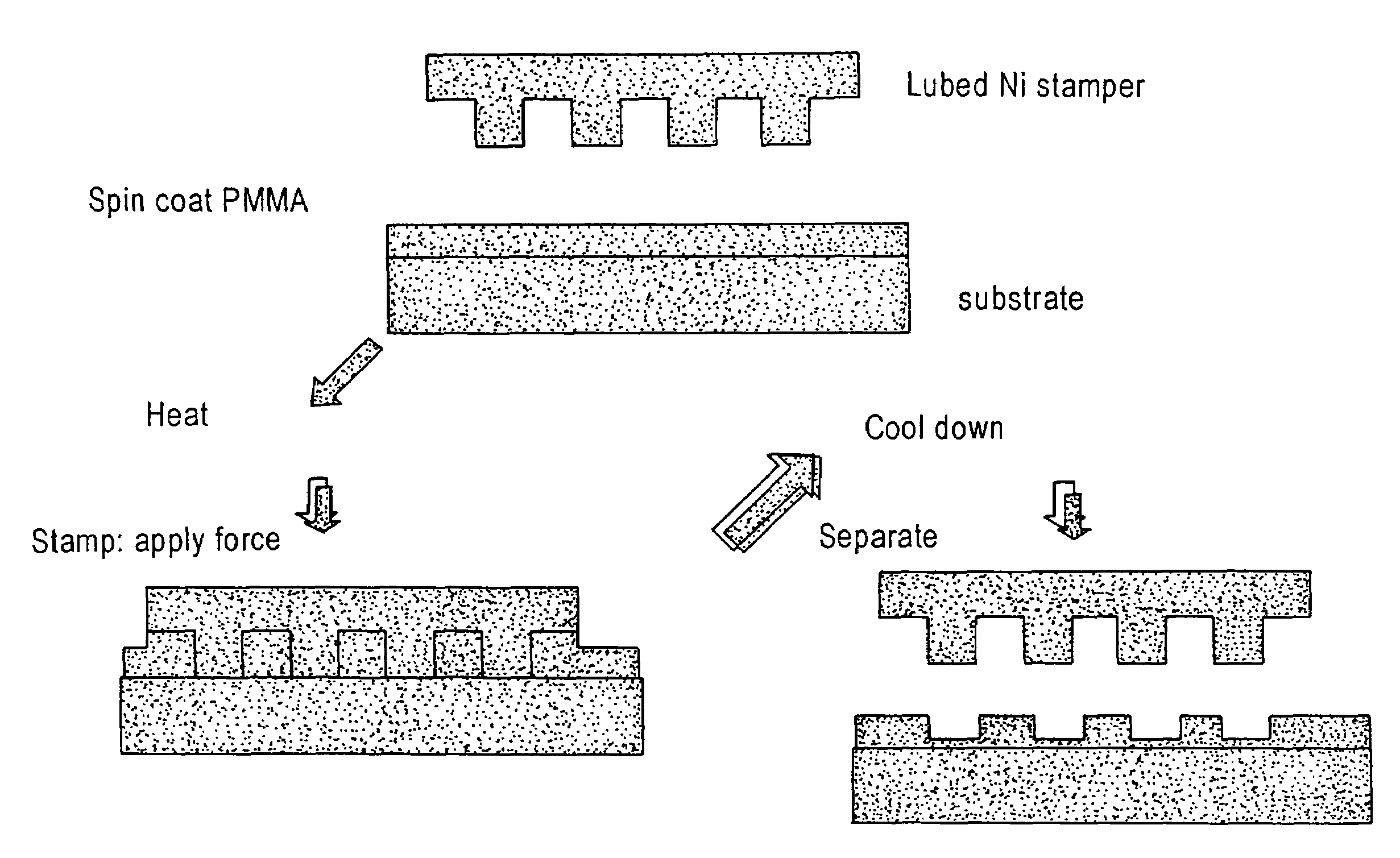

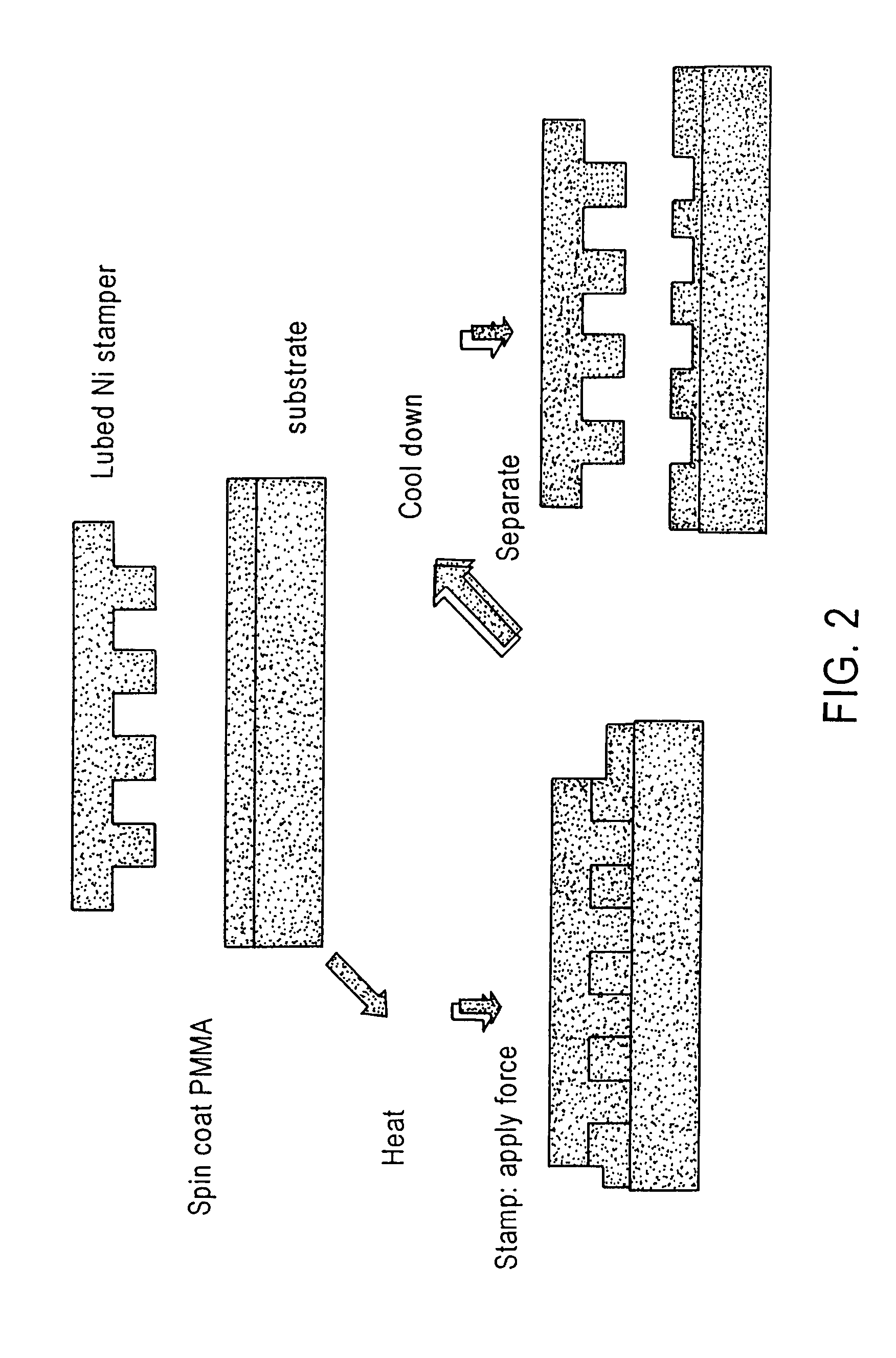

Surface modified stamper for imprint lithography

InactiveUS7294294B1Good release effectMinimize peelingRecord carriersNanoinformaticsLithographic artistEngineering

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH LLC

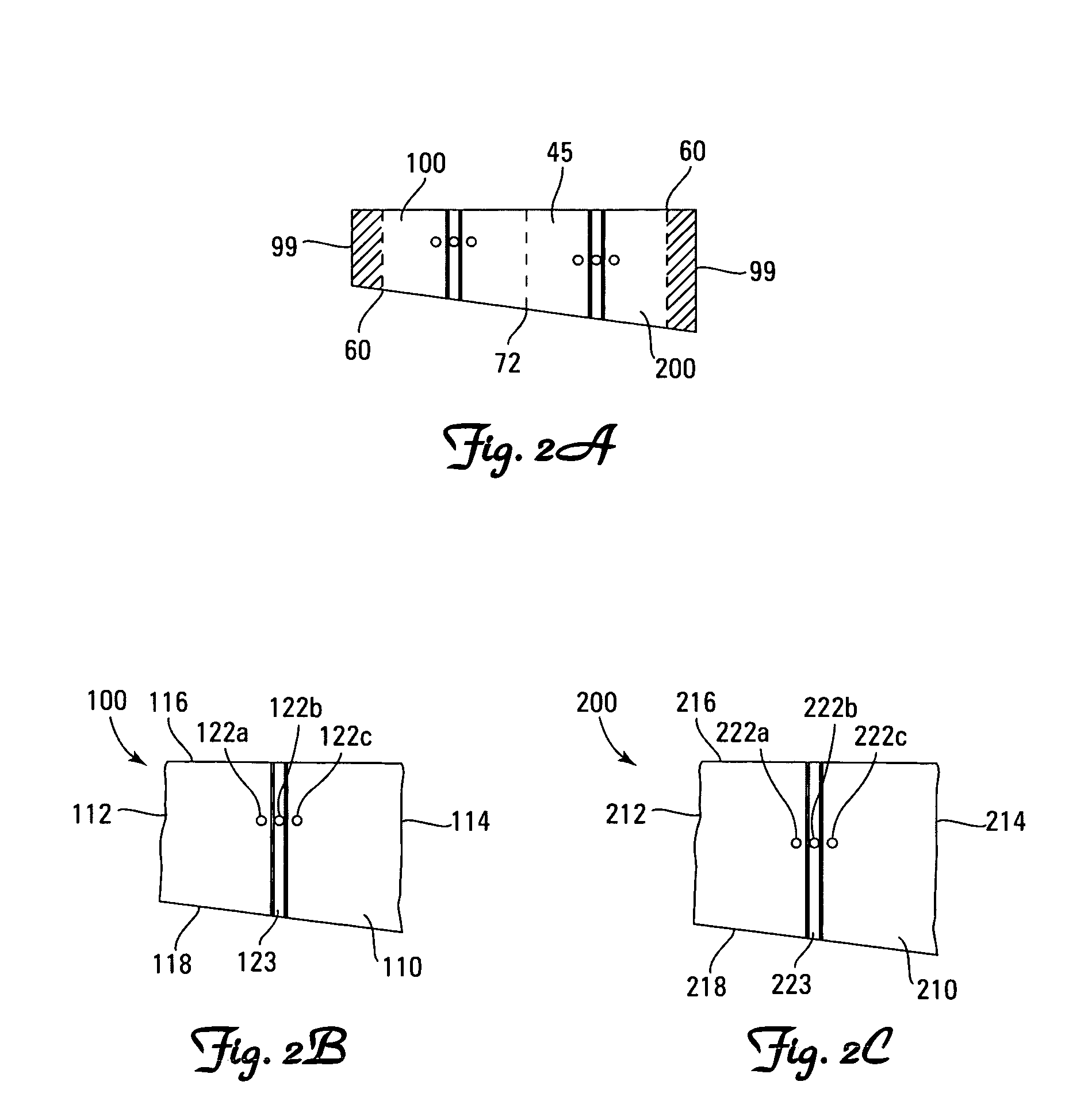

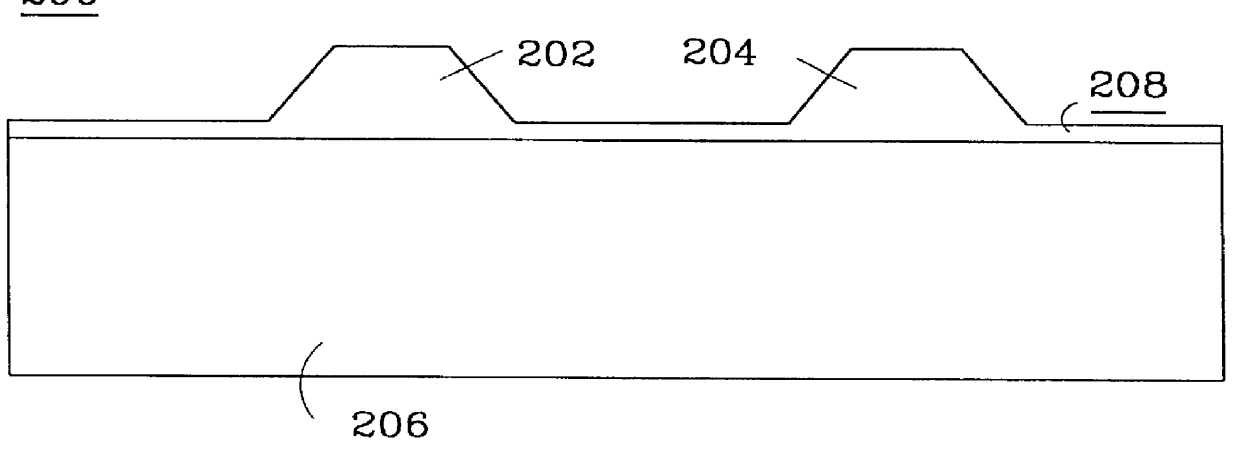

Method for making elastic bumps from a wafer mold having grooves

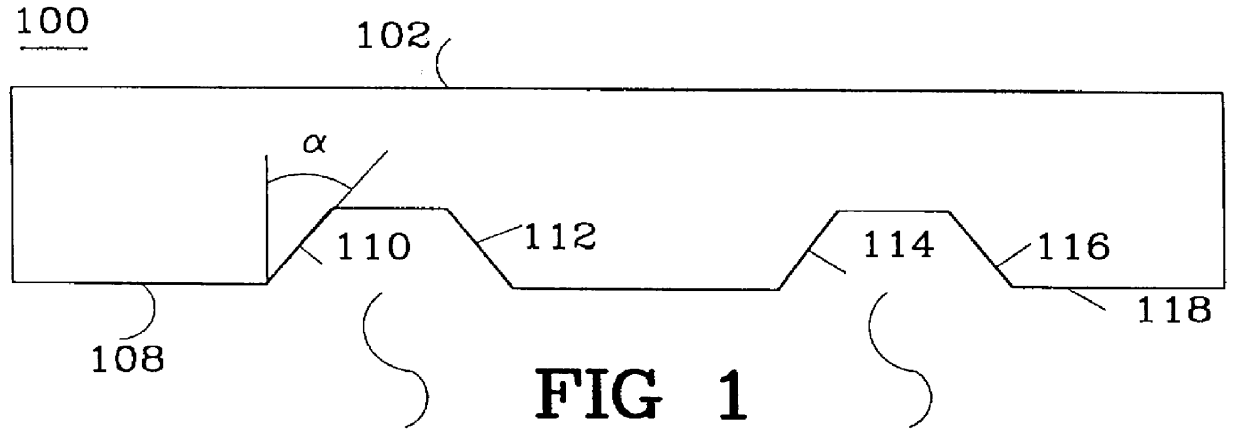

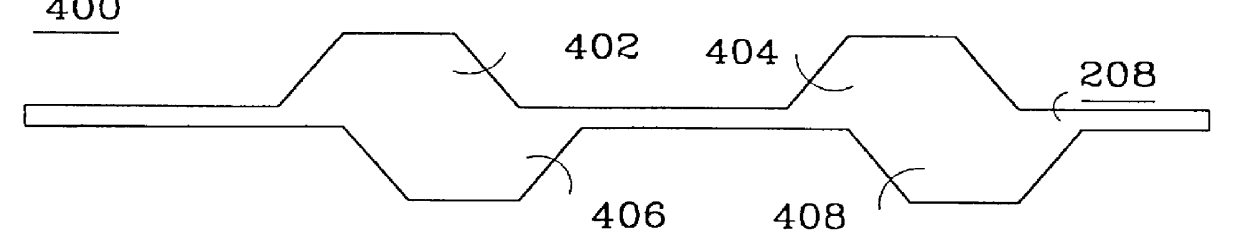

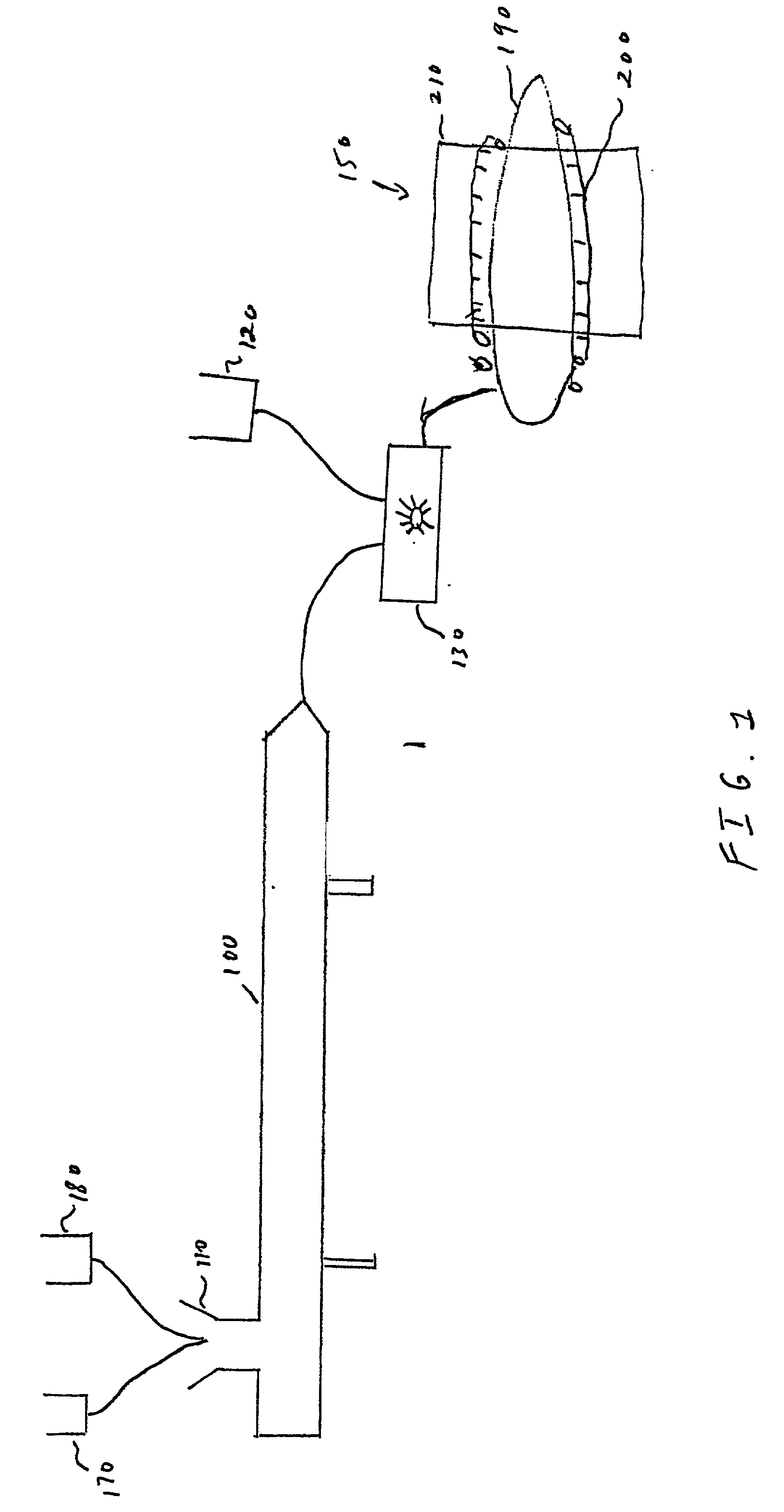

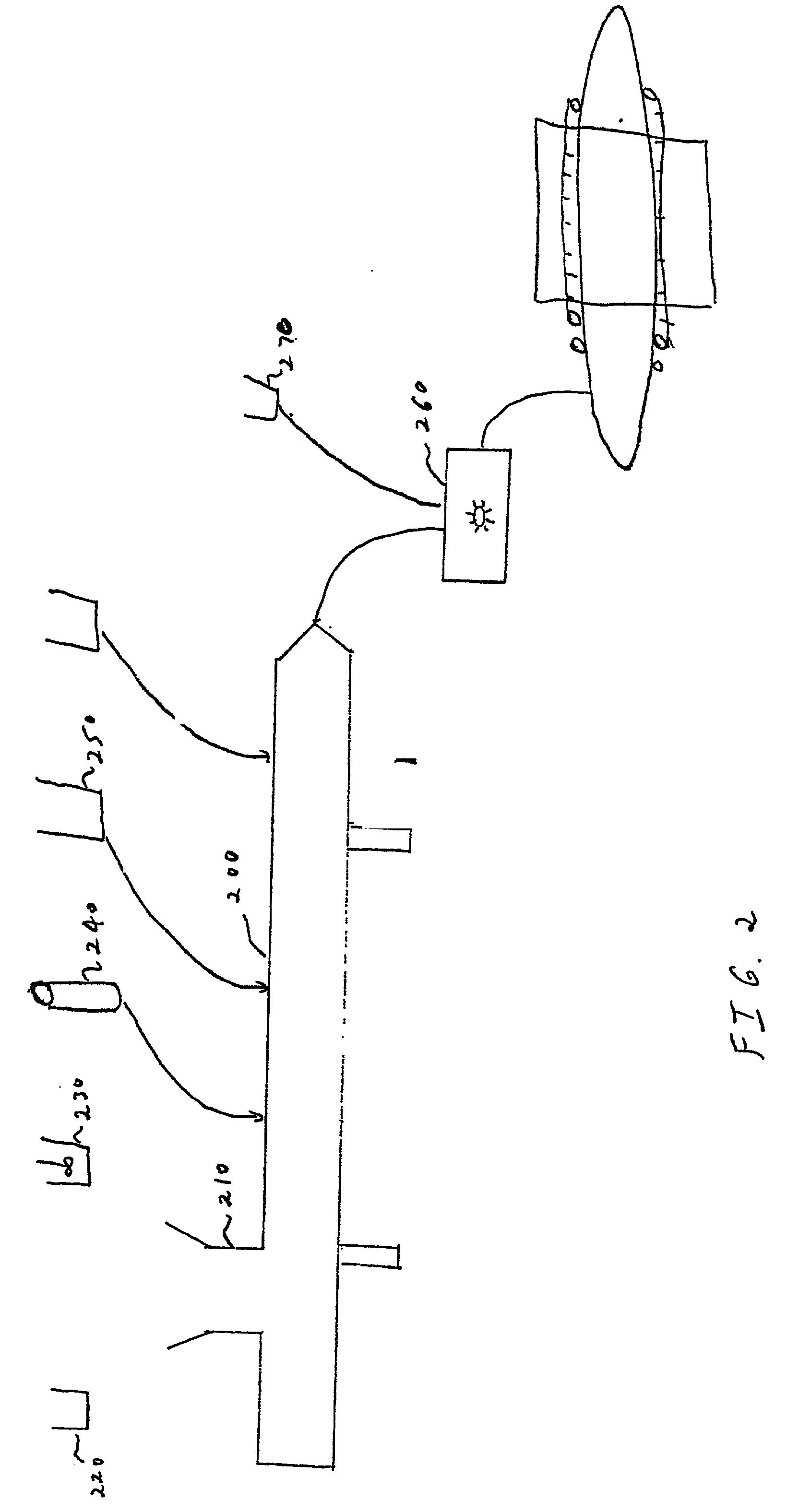

This invention relates to a manufacturing process for making elastic bumps in the micro-electronic field. It solves the problem to mould micrometer sized elastic features by means of a micro-machined mould. The method is a reproducible moulding technology to achieve elastic bumps being a perfect replication of the mould. The mould is made of one or several grooves etched in a silicon wafer. The method includes the steps of: cleaning the surface of the mould (100) from dust and other particles; depositing a release agent on the mould and the release agent, e.g. Parylene or silane, forming a conformal self-assembled layer (118) on the surface of the mould; putting on a curable elastomer, to form an elastomeric structure (208) on the mould; curing the mould and the structure; and separating the structure from the mould.

Owner:INFINEON TECH AG

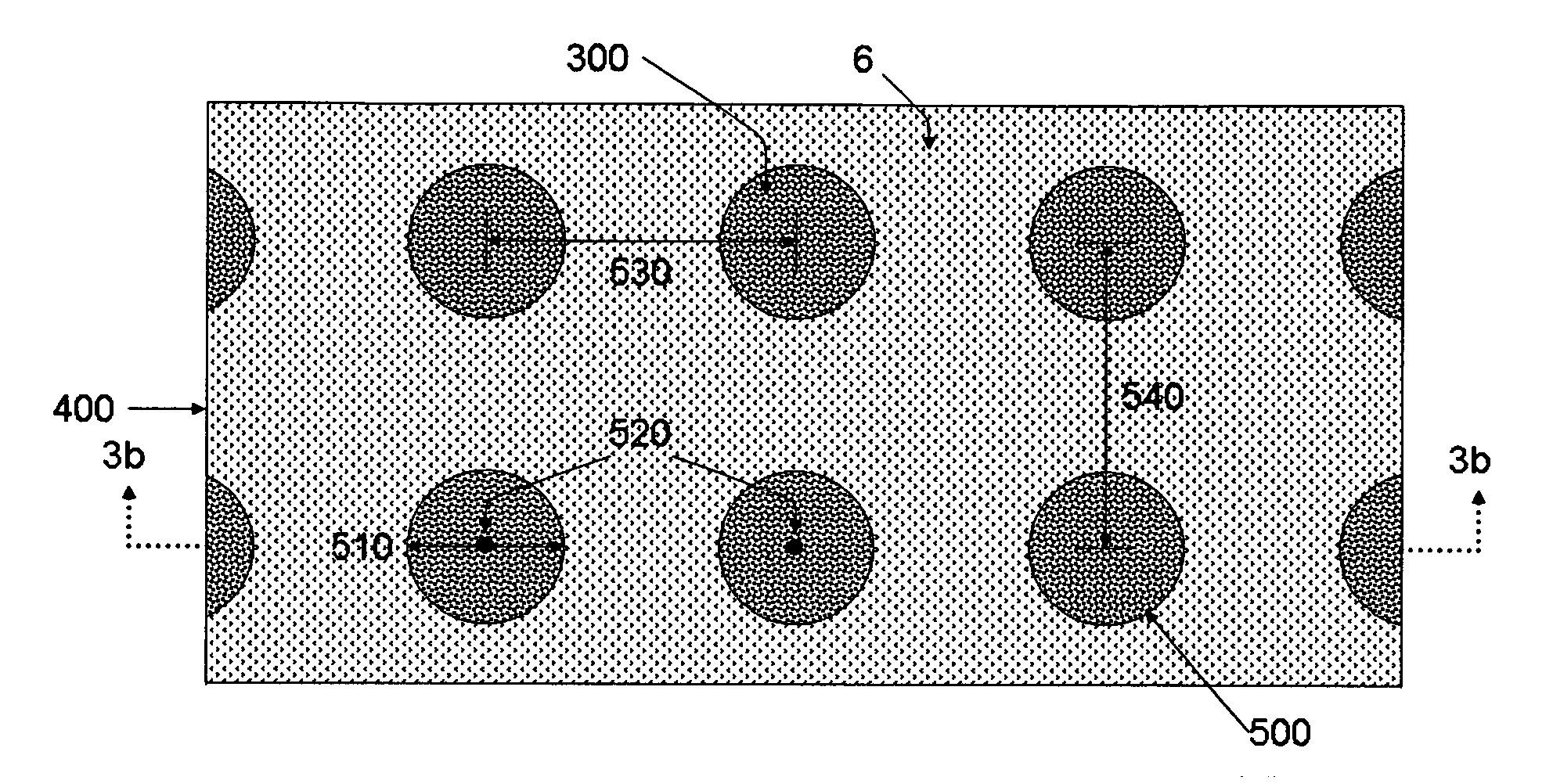

Foam liner for casting objects in poured walls

A liner holds objects in place within a form for a poured wall. The liner includes a backing sheet and a plurality of foam bed joints arranged in a substantially parallel fashion along a length dimension. A plurality of separate foam head joints are attached along a height dimension, wherein opposing ends of the foam head joints engage adjacent bed joints to define a plurality of regions on the backing sheet for receiving the objects to be cast in the poured wall. Each foam joint has a rounded cross section to form a curved grout line between the objects cast in the poured wall. The foam joints include an outer protective skin to prevent the poured wall material from bonding with the foam cells. A method of forming the liner includes aligning the separate foam bed joints and head joints in a grid and then pressing an adhesive-backed paper sheet against the foam joints.

Owner:SCOTT WILLIAM CLARE +1

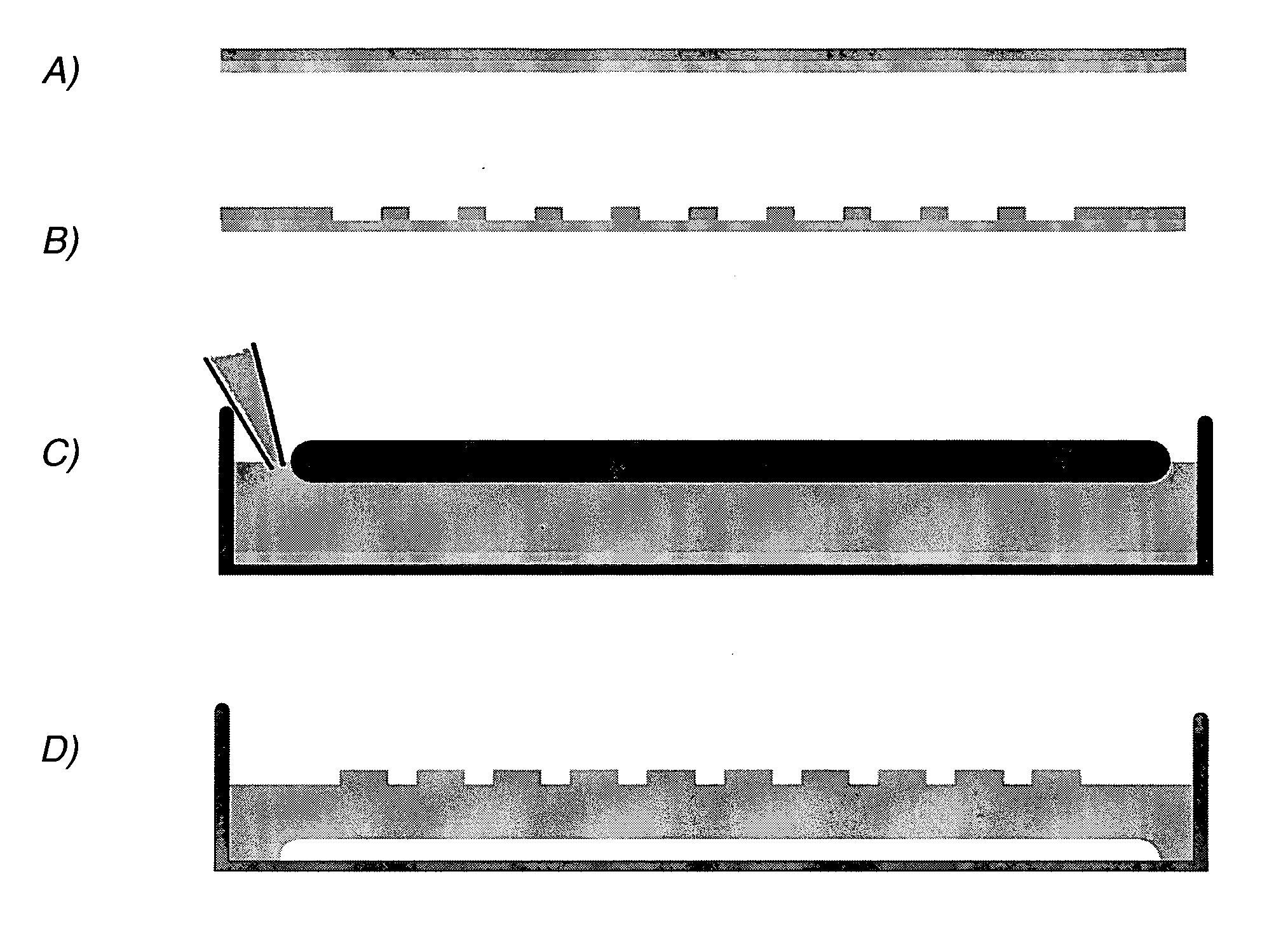

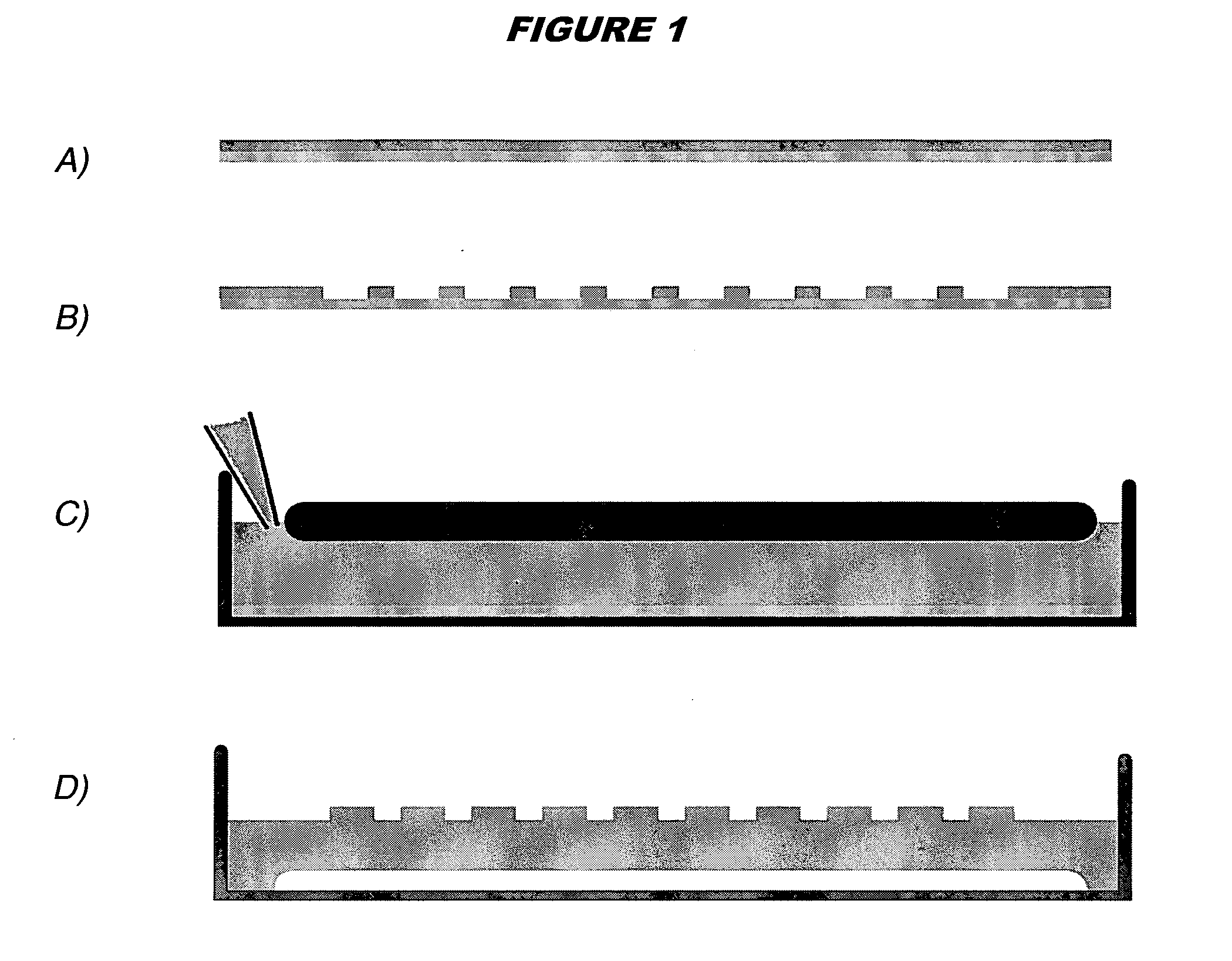

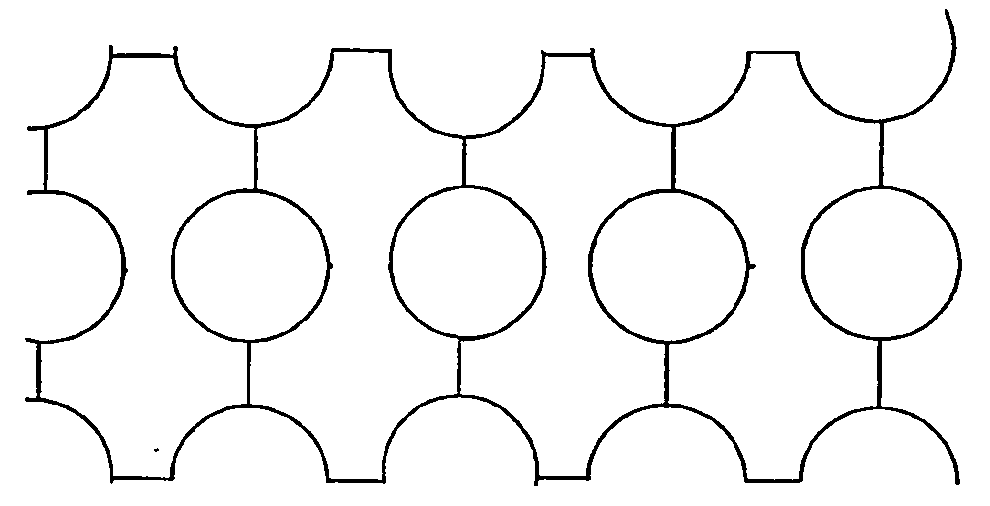

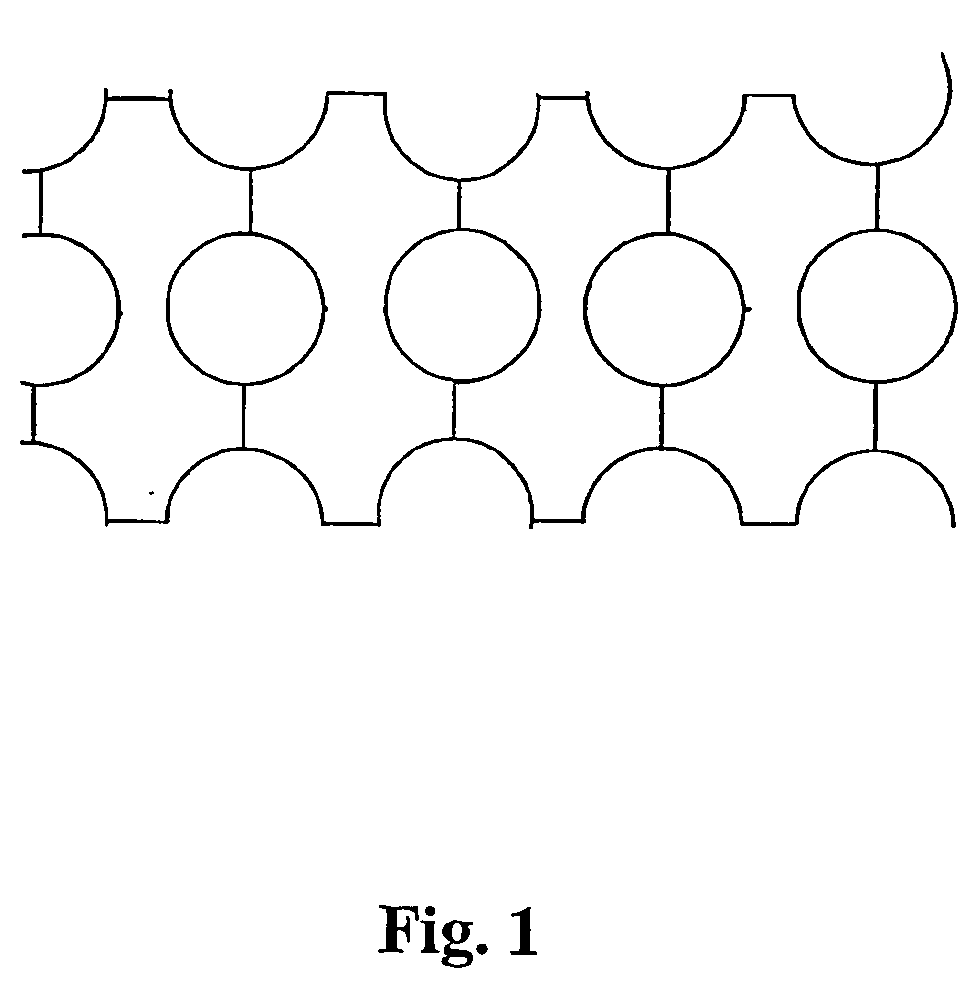

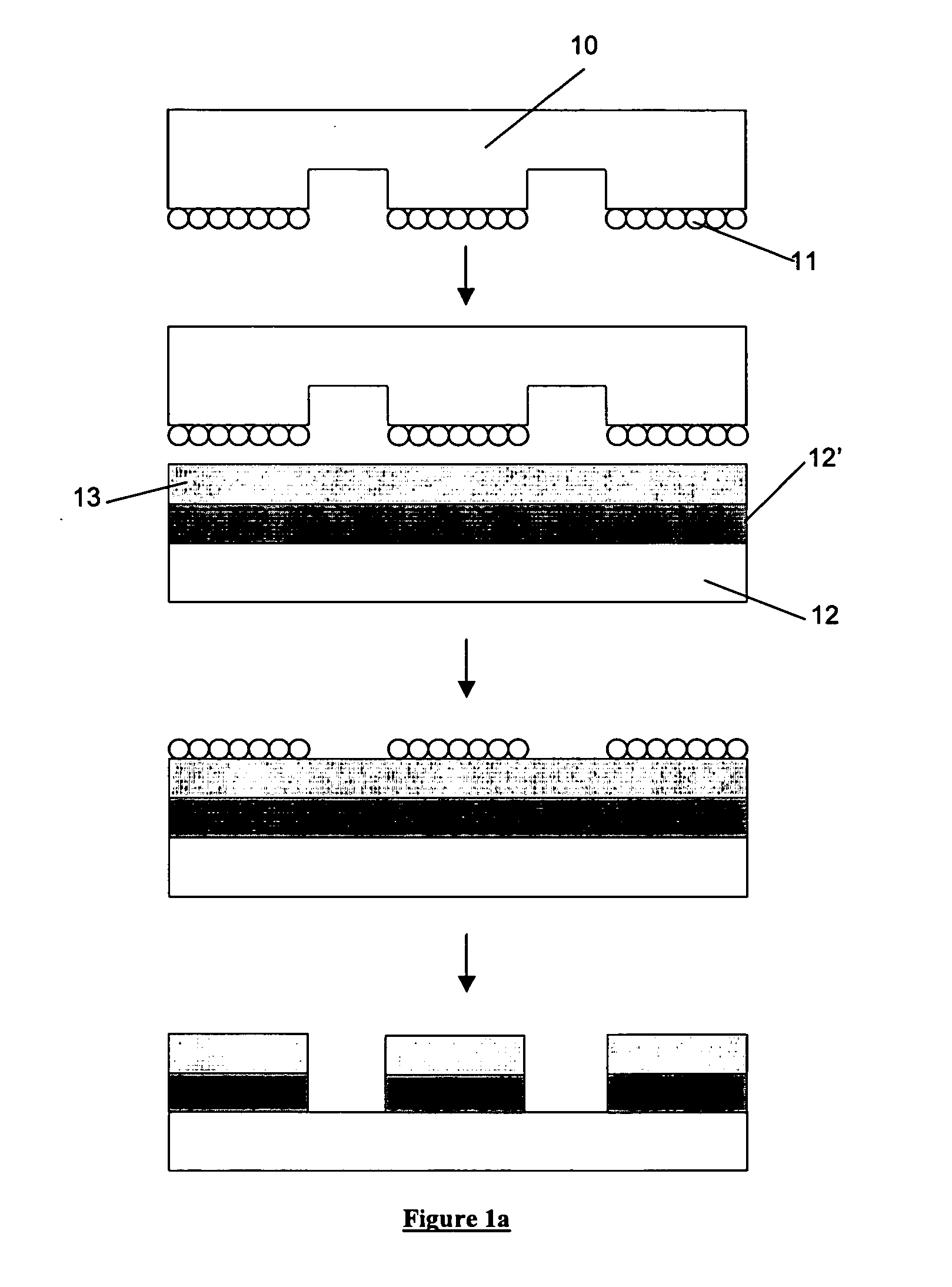

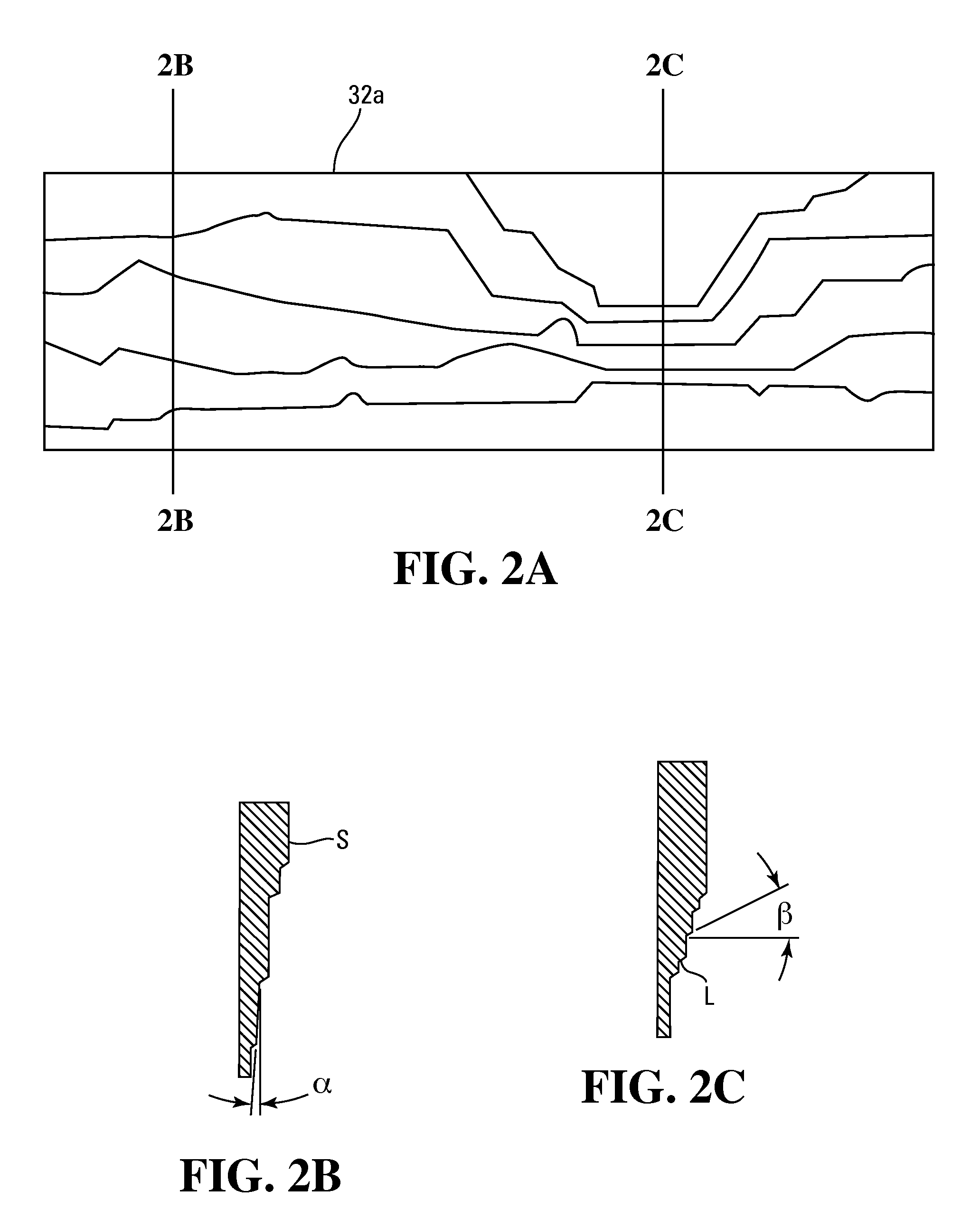

Reusable template for creation of thin films; method of making and using template; and thin films produced from template

ActiveUS20060277778A1Easy to controlFormation of thinElectric discharge tubesUsing mechanical meansCarbon filmElectron

The present invention is directed generally to templates used in the creation of thin-film replicas, for example, the creation of thin films, such as carbon films, for use as specimen support in electron-beam specimen analysis. More specifically, the present invention is directed to novel reusable patterned templates, the methodology of making these reusable templates, the templates made from such methodologies, the use and reuse of these templates to make thin films of any type for any purpose, and the thin films made from these templates. A feature of the novel template of the present invention is in its employment of one or more zones of discontinuity, or undercuts, associated with the patterns transferred into the template to allow for the removal of the thin film from the template without sacrificing the structural integrity of the template to prevent at least one re-use of the template.

Owner:EMS ACQUISITION CORP

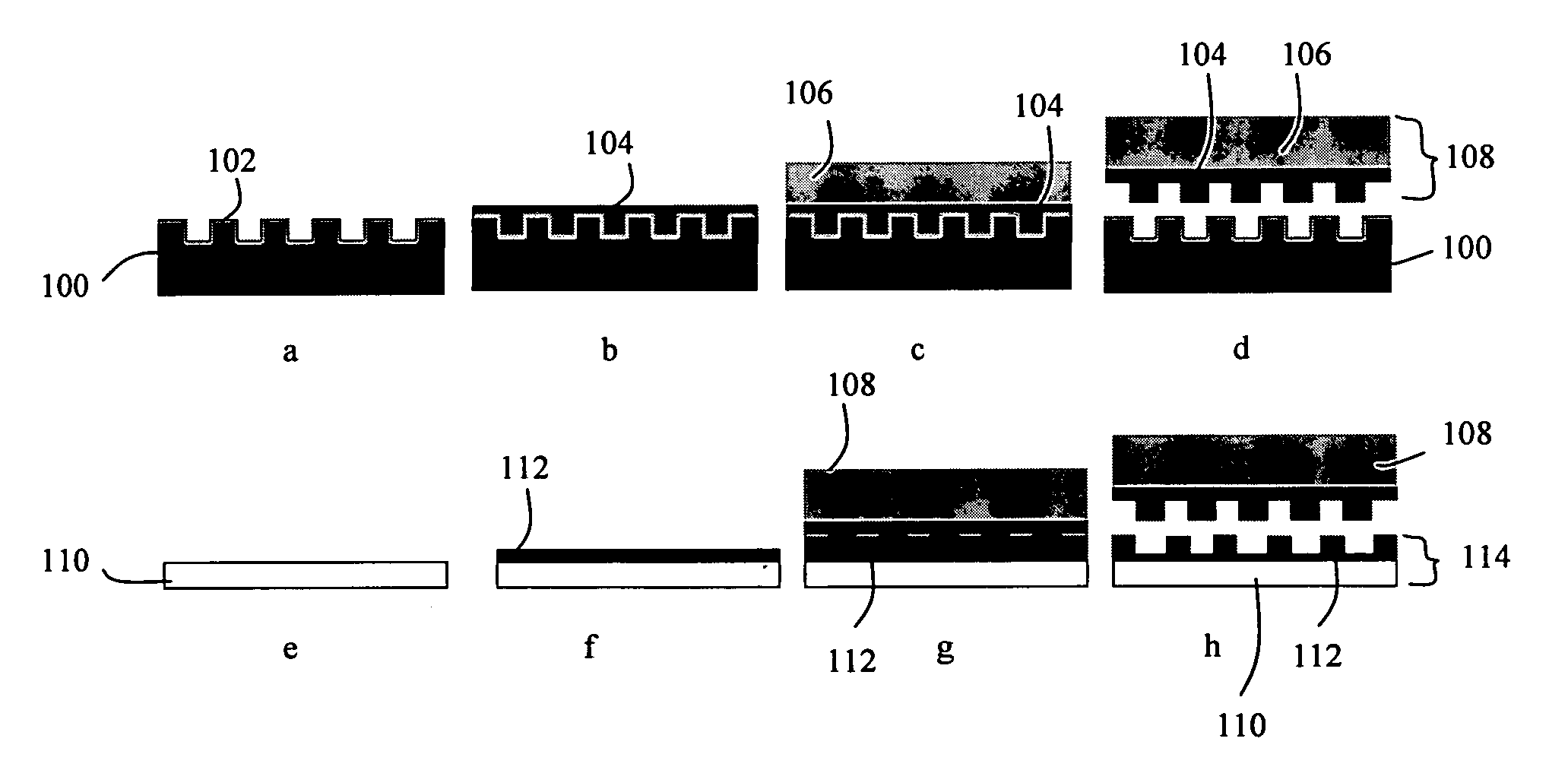

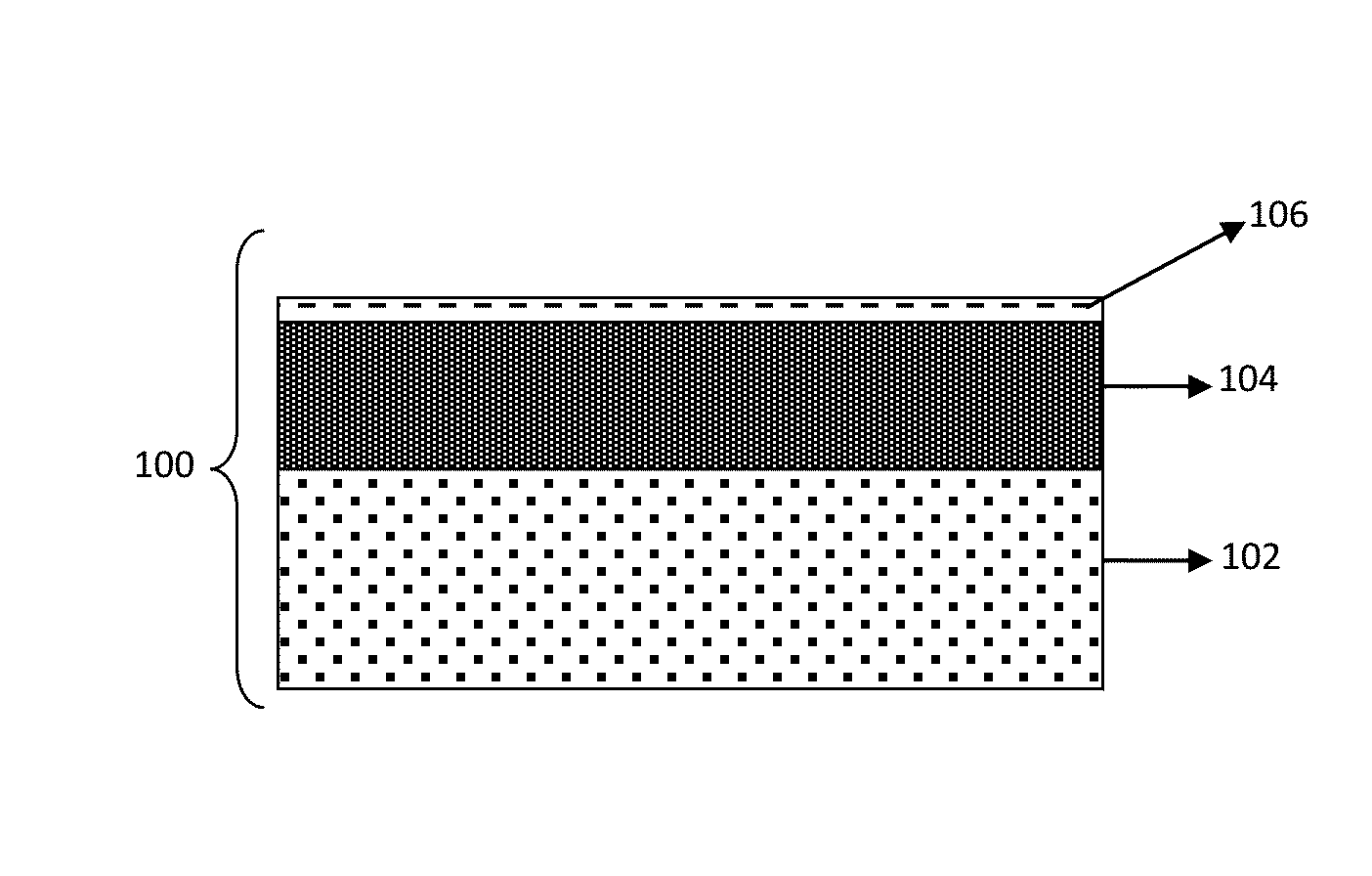

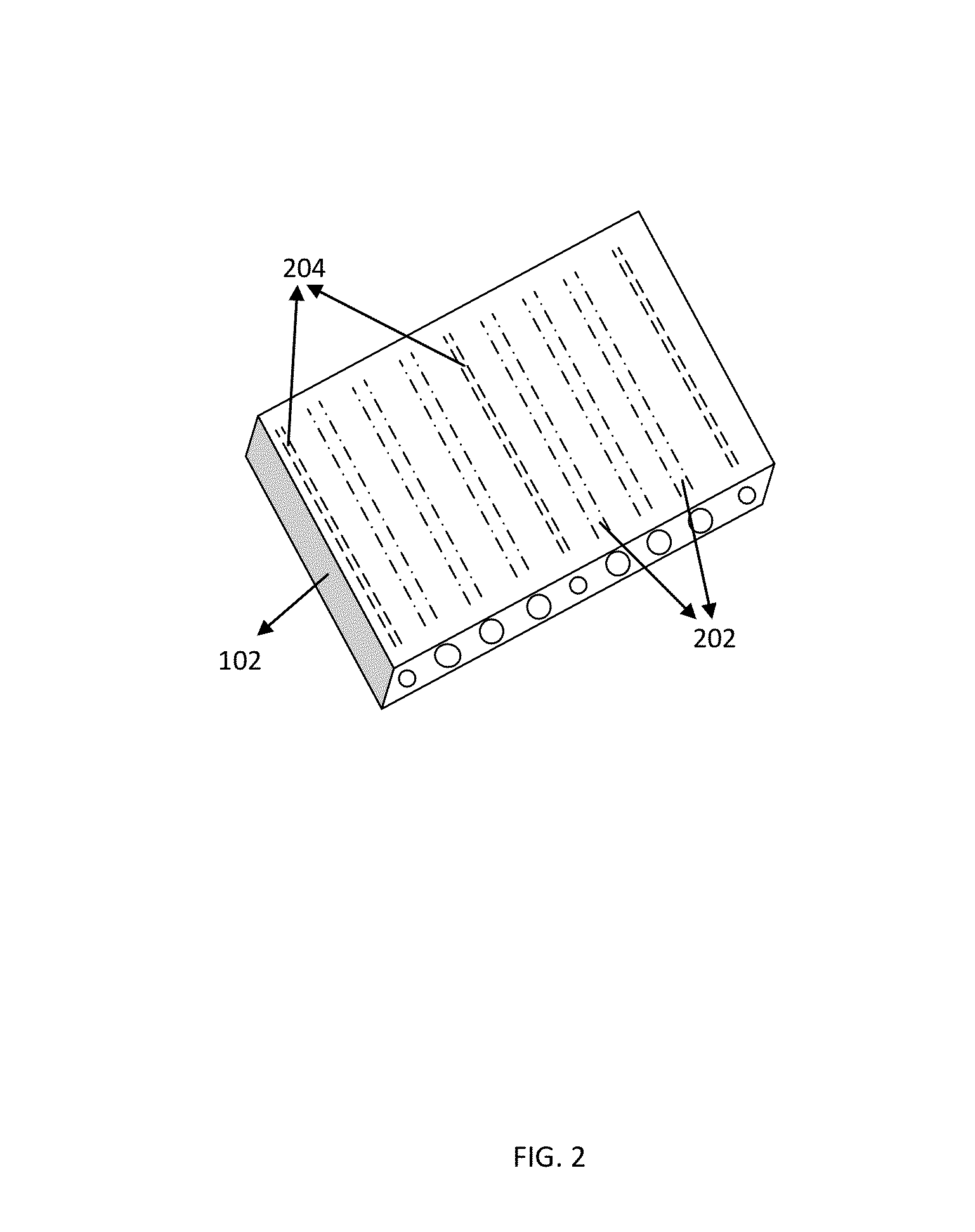

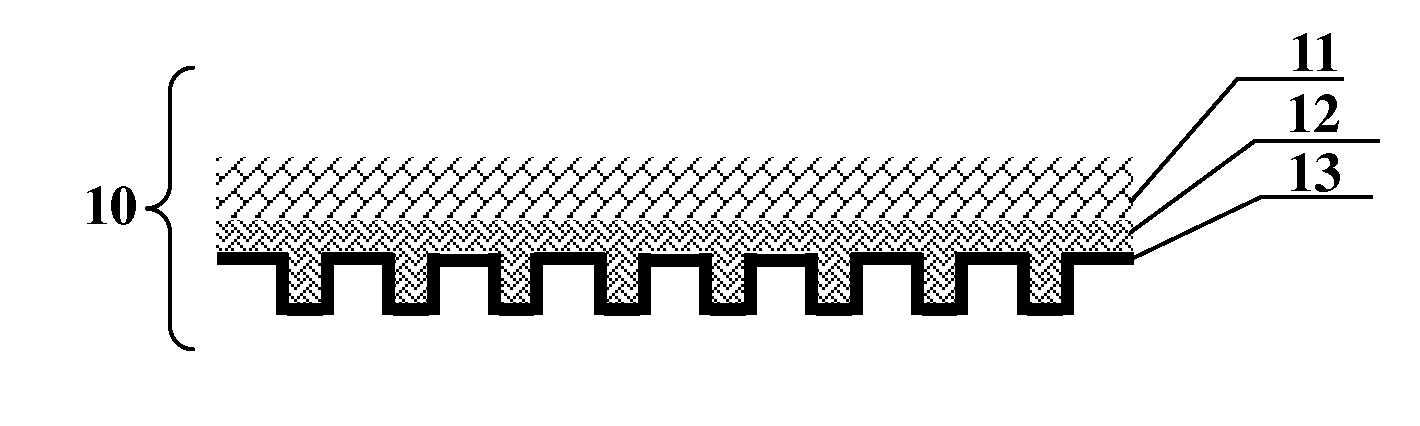

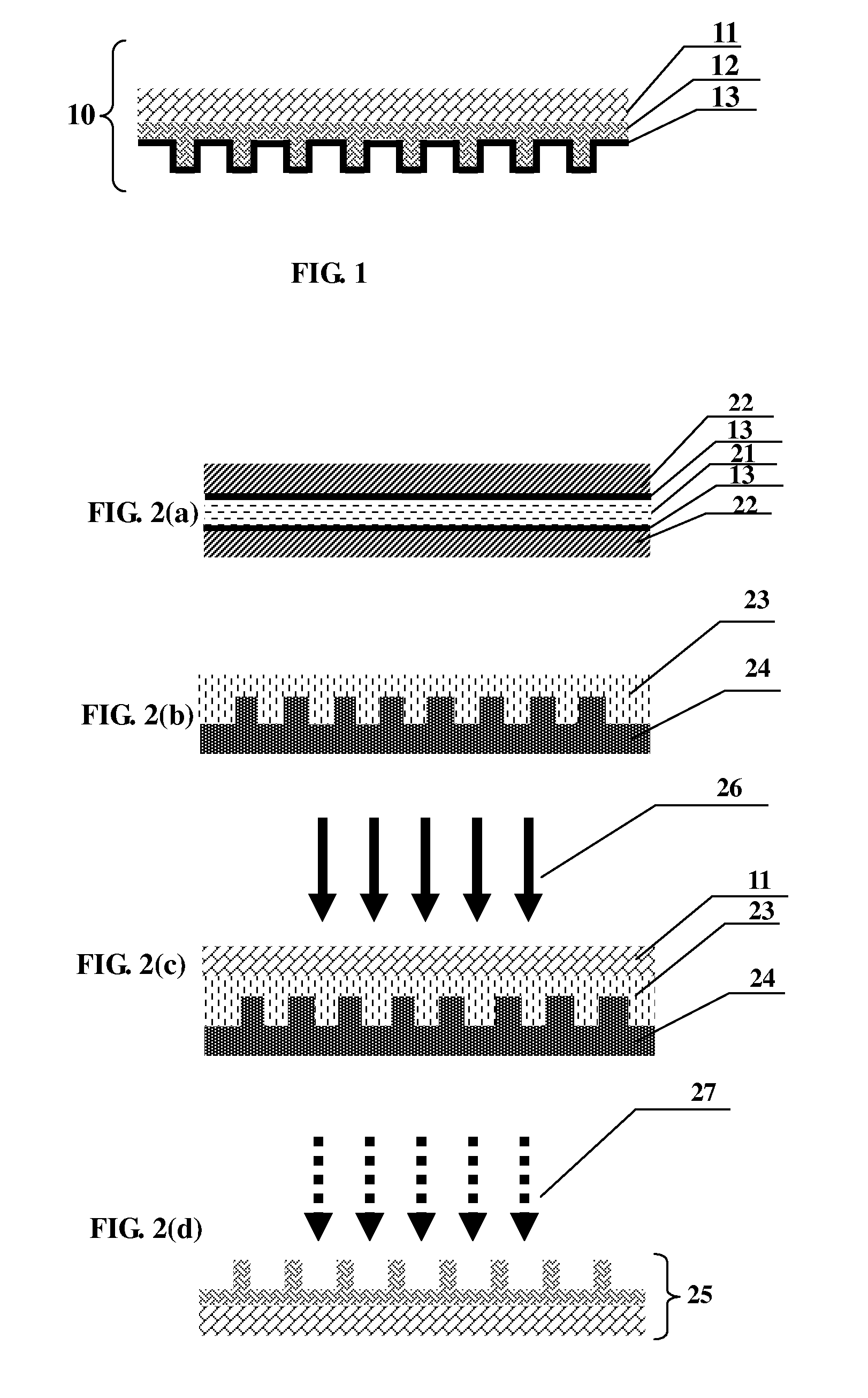

Flexible nanoimprint mold, method for fabricating the same, and mold usage on planar and curved substrate

ActiveUS20100109203A1High contactHigh resolutionLiquid surface applicatorsNanoinformaticsChemical LinkageElastomer

The present invention provides a flexible nanoimprint mold which can fabricate sub-15 nm ultra fine structures on either planar or curved substrates. The mold comprises a top ultra-thin rigid layer of imprint patterning features and a bottom thick flexible layer of polymer elastomer. The two distinct layers are preferably integrated via chemically bonding. The top layer of the mold enables a sub-15 nm resolution of pattern fabrication and the bottom layer affords a conformal contact to planar or curved surface of substrates. The methods for fabricating the same are disclosed.

Owner:NANJING UNIV

Abrasion resistant coatings

InactiveUS20060286383A1Enhanced resistance to abrasion and chemicalImprove clarityOrganic chemistryMixing methodsPolymer scienceDiacrylate ester

Disclosed are radiation-curable, abrasion resistant coating compositions for thermoplastic substrates which provides superior abrasion, chemical, and impact resistance properties. The coating composition includes at least one flexible diacrylate component, at least one aromatic diacrylate component, and at least one urethane acrylate. Also disclosed are shaped articles having the coating composition applied to at least one surface and cured by exposure to radiation.

Owner:EASTMAN CHEM CO

Room temperature curable water-based mold release agent for composite materials

InactiveUS20060074159A1Effective regulationGroup 4/14 element organic compoundsOther chemical processesEpoxyWater based

A room temperature curable water-based mold release agent that is useful for demolding composite parts, such as epoxy and polyester based polymer materials. The mold release agent is curable at low temperatures, such as room temperature, but is thermally stable up to conventional epoxy based composite molding temperatures, e.g., greater than 200 or 280° C. The mold release agent is useful for demolding large composite parts that are cured in large ovens at high temperature when the molds themselves are prepped at room temperature before placing in the oven. The mold release agent is also useful for demolding polyester composite parts that are prepared and cured at low temperature such as room temperature.

Owner:HENKEL IP & HOLDING GMBH

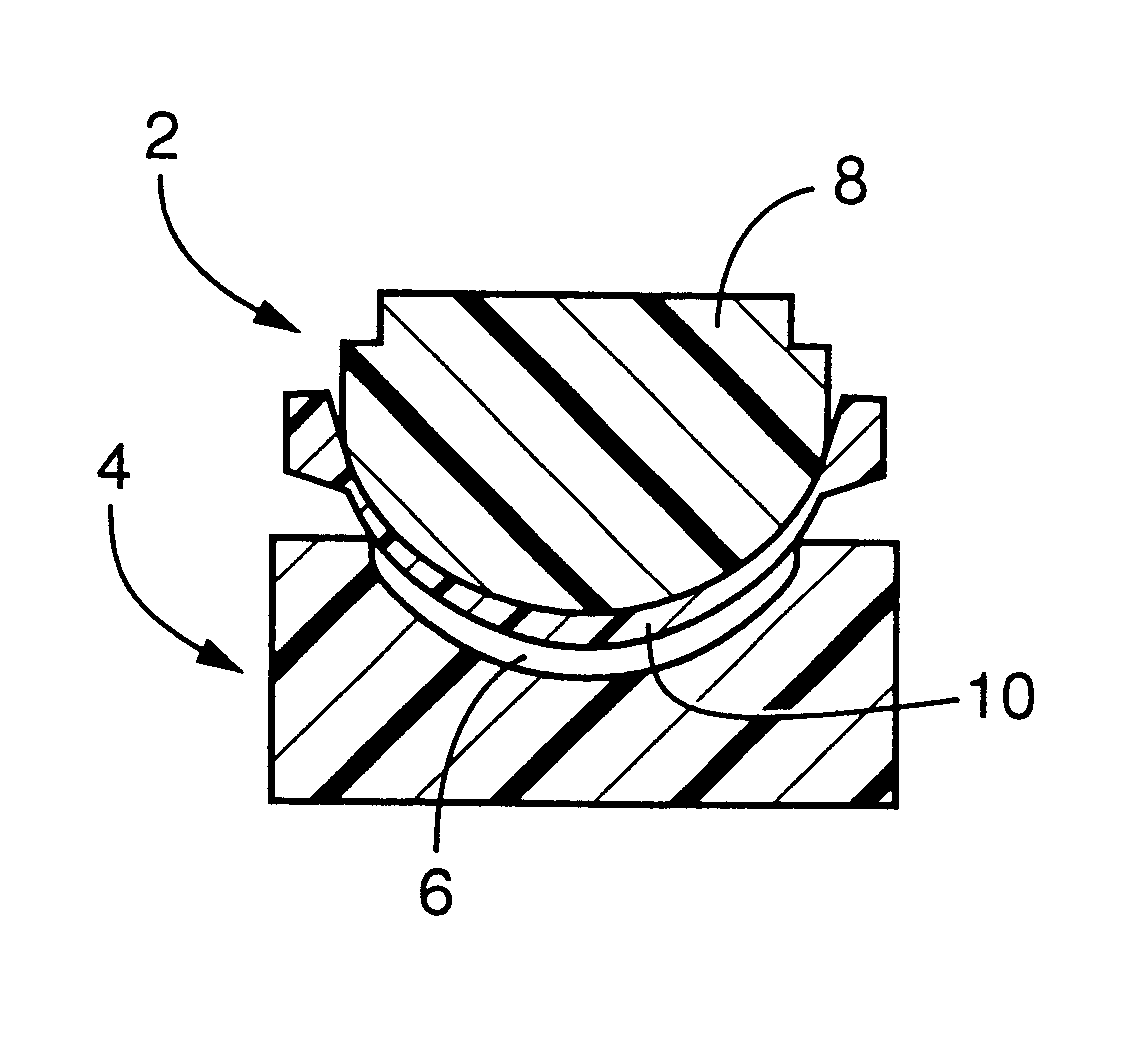

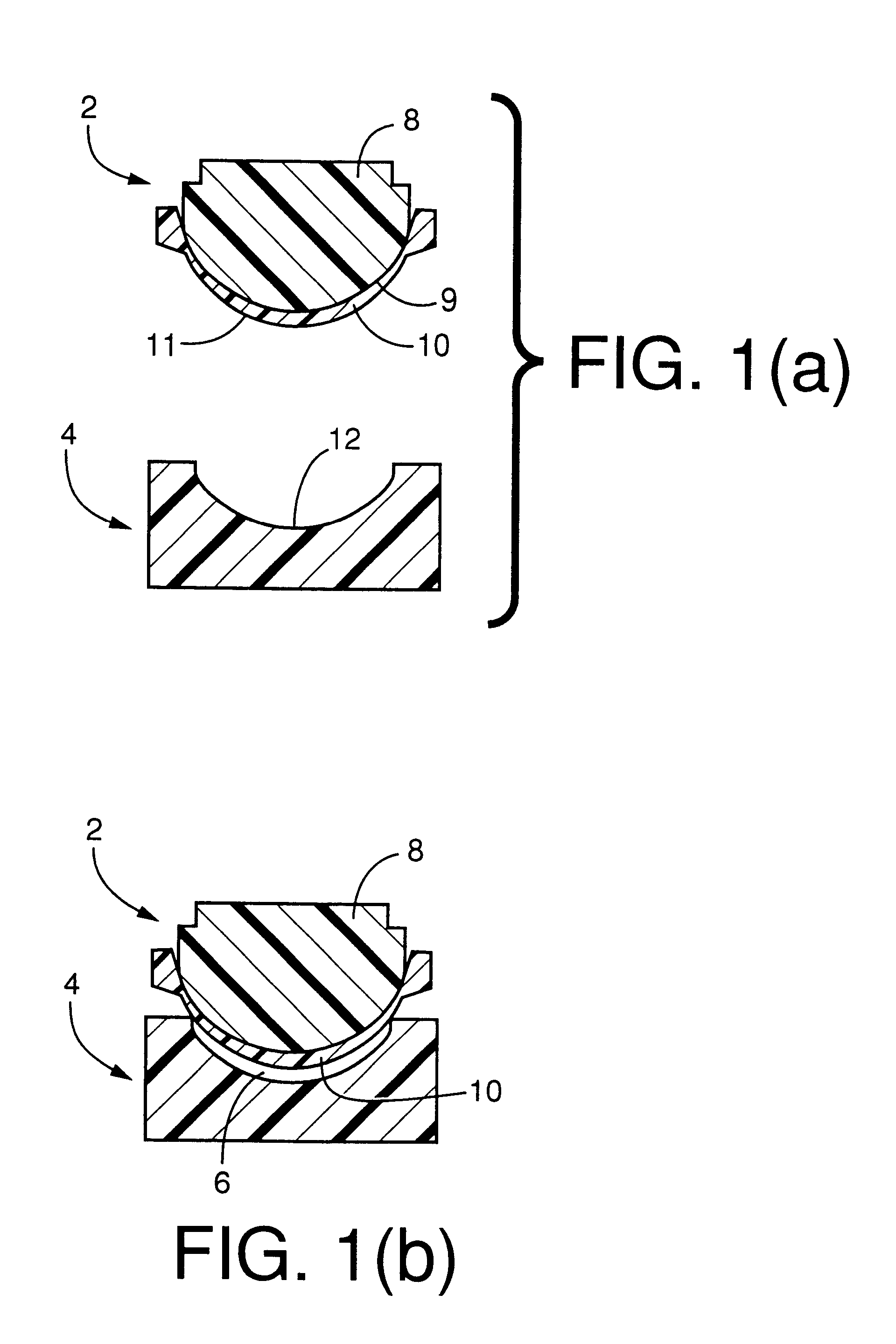

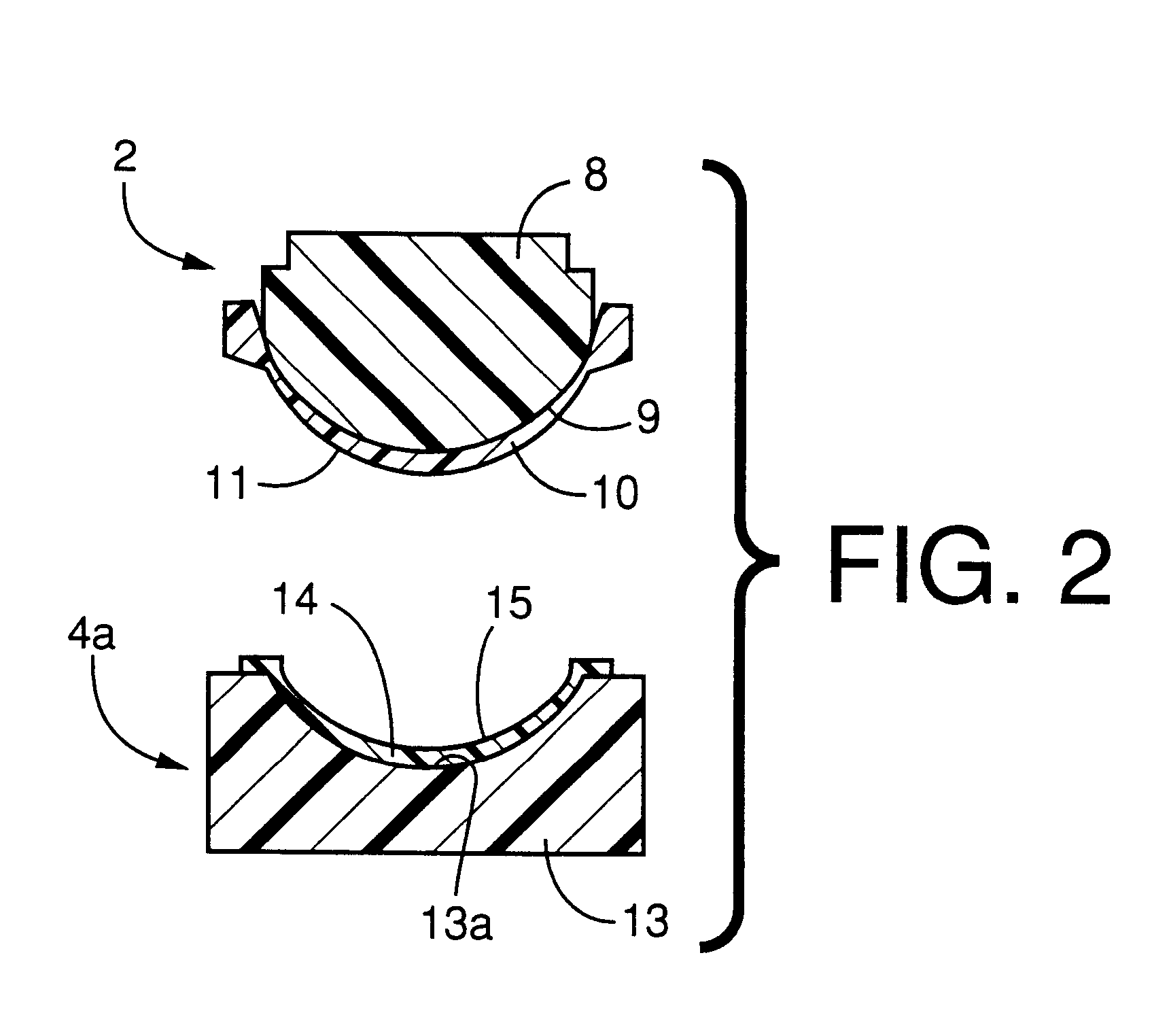

Mold assembly for forming ophthalmic lens, method of producing the same, and method of producing ophthalmic lens using the mold assembly

InactiveUS6315929B1Simple and cheap equipmentAccurate configurationOptical articlesDomestic articlesShell moldingMaterials science

A mold assembly for forming an ophthalmic lens, the mold assembly comprising a first mold and a second mold which cooperate with each other to define therebetween a mold cavity having a profile following that of the ophthalmic lens, wherein the improvement comprises: at least one of the first and second molds being a coated mold consisting of a body portion including a backing surface having rigidity and mechanical strength enough to withstand a molding operation for forming the ophthalmic lens in the mold cavity, and a thermoplastic film retained on the body portion such that the thermoplastic film covers the backing surface of the body portion, the thermoplastic film having a molding surface which partially defines the mold cavity and which gives a corresponding one of opposite surfaces of the ophthalmic lens.

Owner:MENICON CO LTD

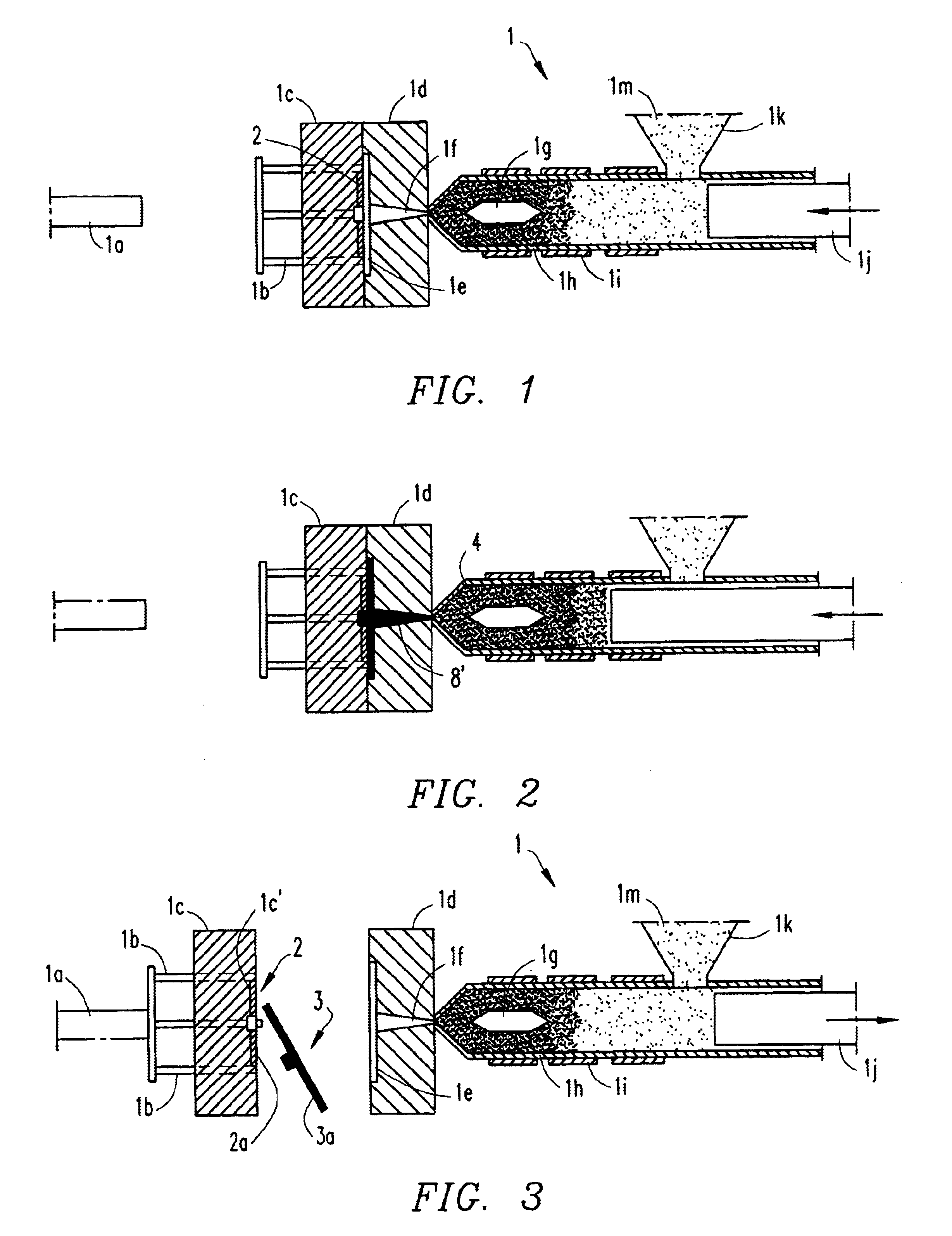

Process and apparatus for making a thermoset foam

InactiveUS20020171164A1Avoid squeezingAvoid deathDough-sheeters/rolling-machines/rolling-pinsConfectioneryPolymer scienceExtrusion

A thermosetting foam, preferably a polyurethane foam is prepare by mixing all the components in one or more extruders and directing the chemical streams to a mixing head where the catalyst is added. Thus, the reaction can be controlled in a facile manner, whereby clogging of the extrusion head is avoided.

Owner:JOHNS MANVILLE INT INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com