Patents

Literature

142results about "Stereotype plates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

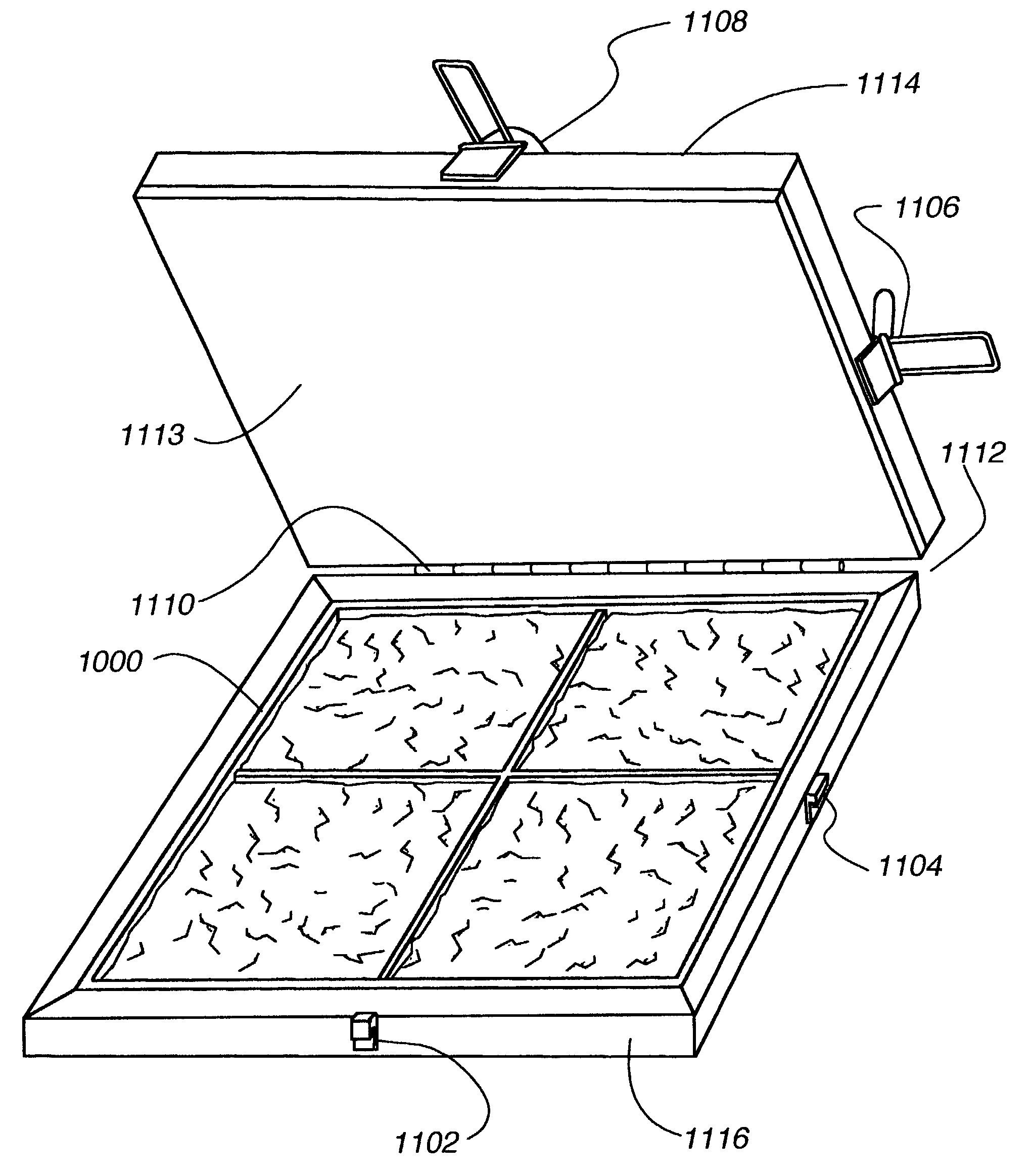

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

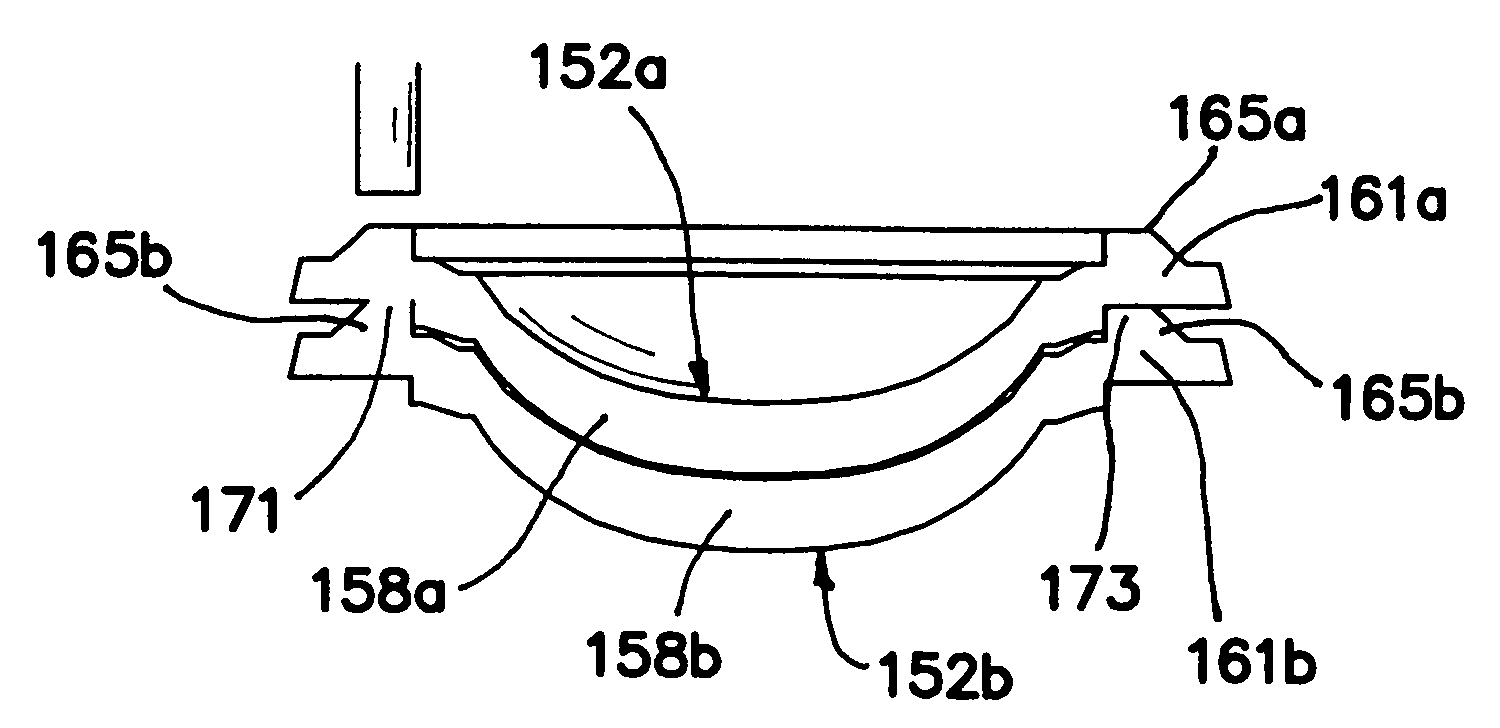

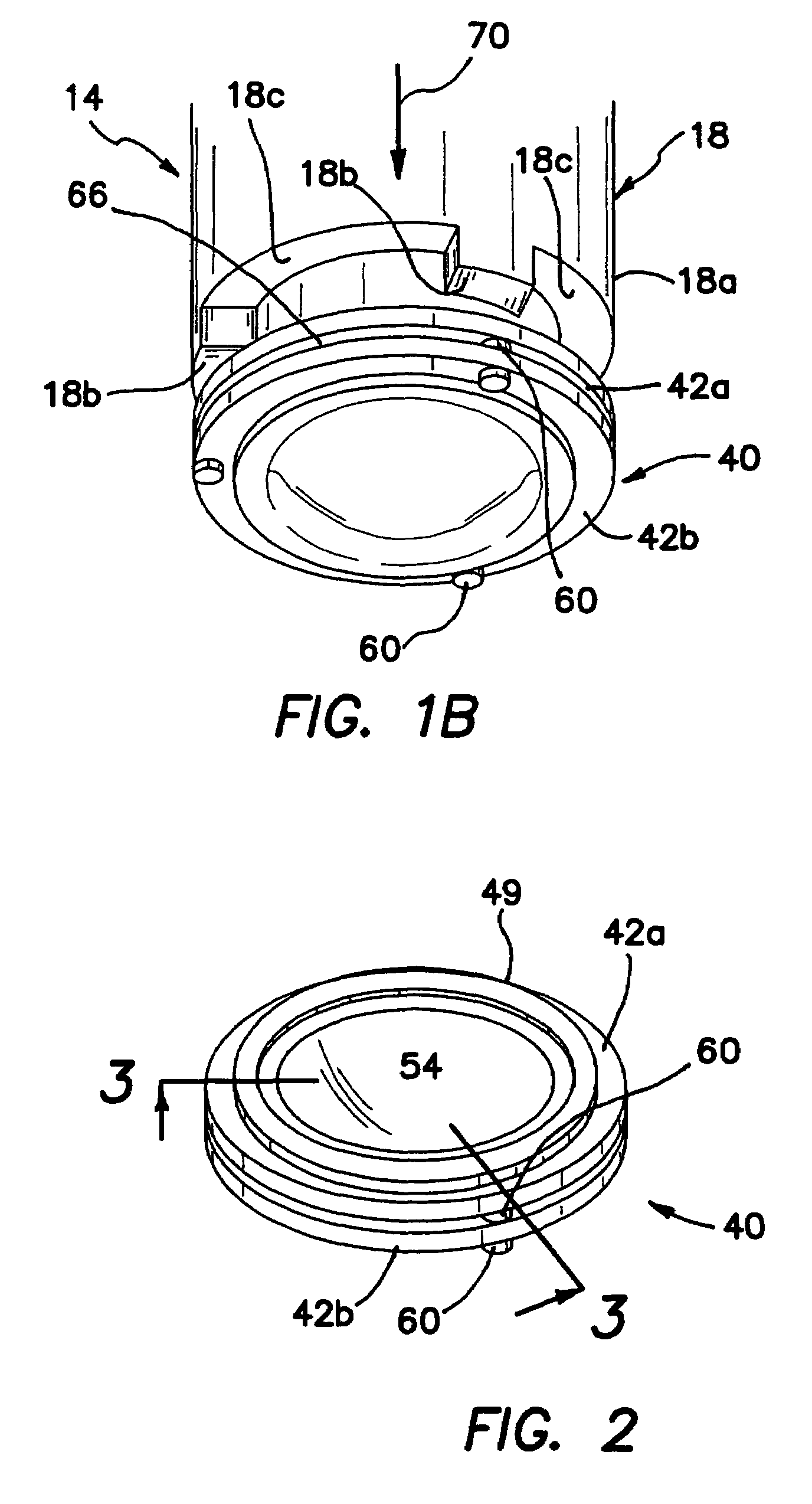

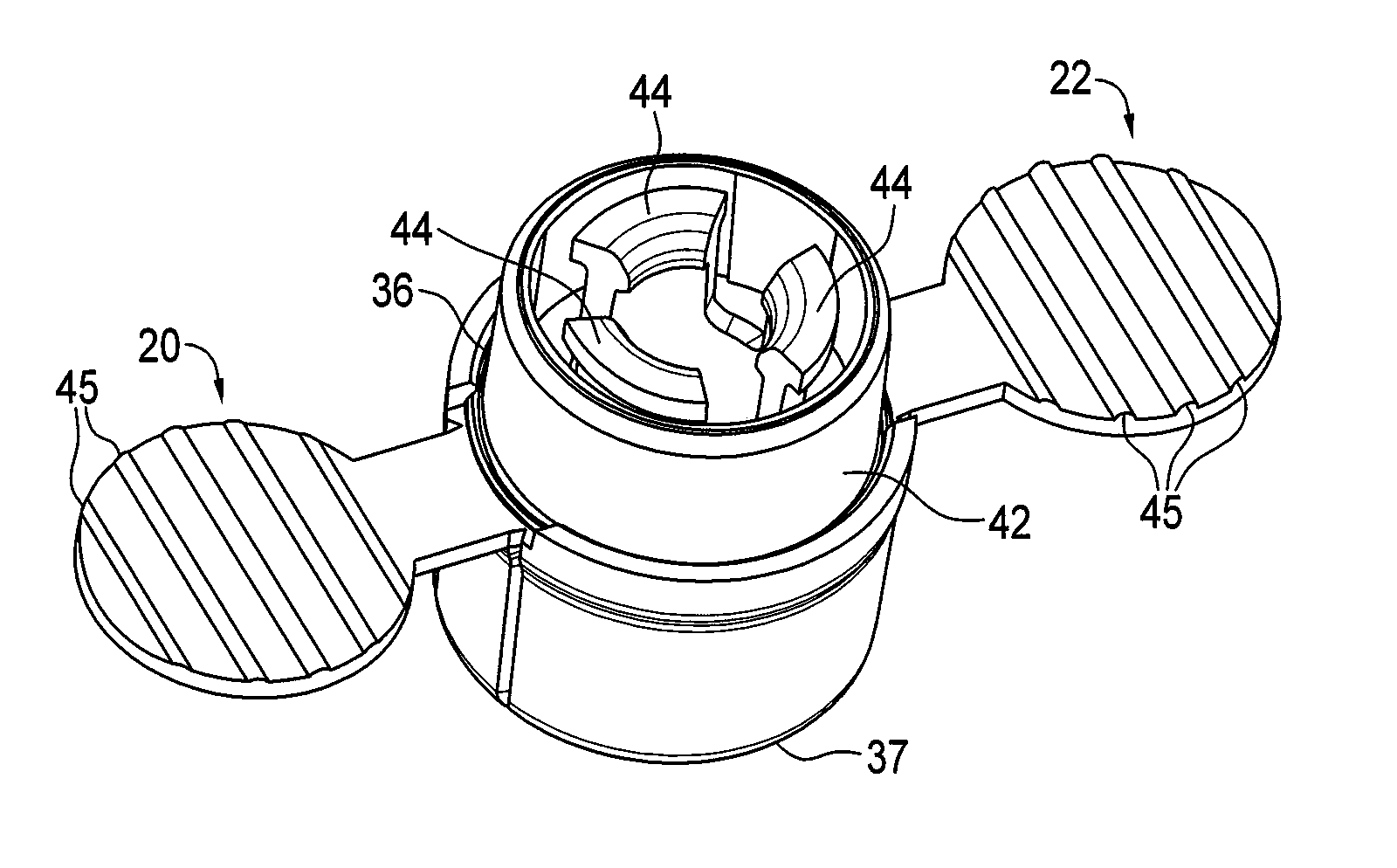

Contact lens mold assemblies and systems and methods of producing same

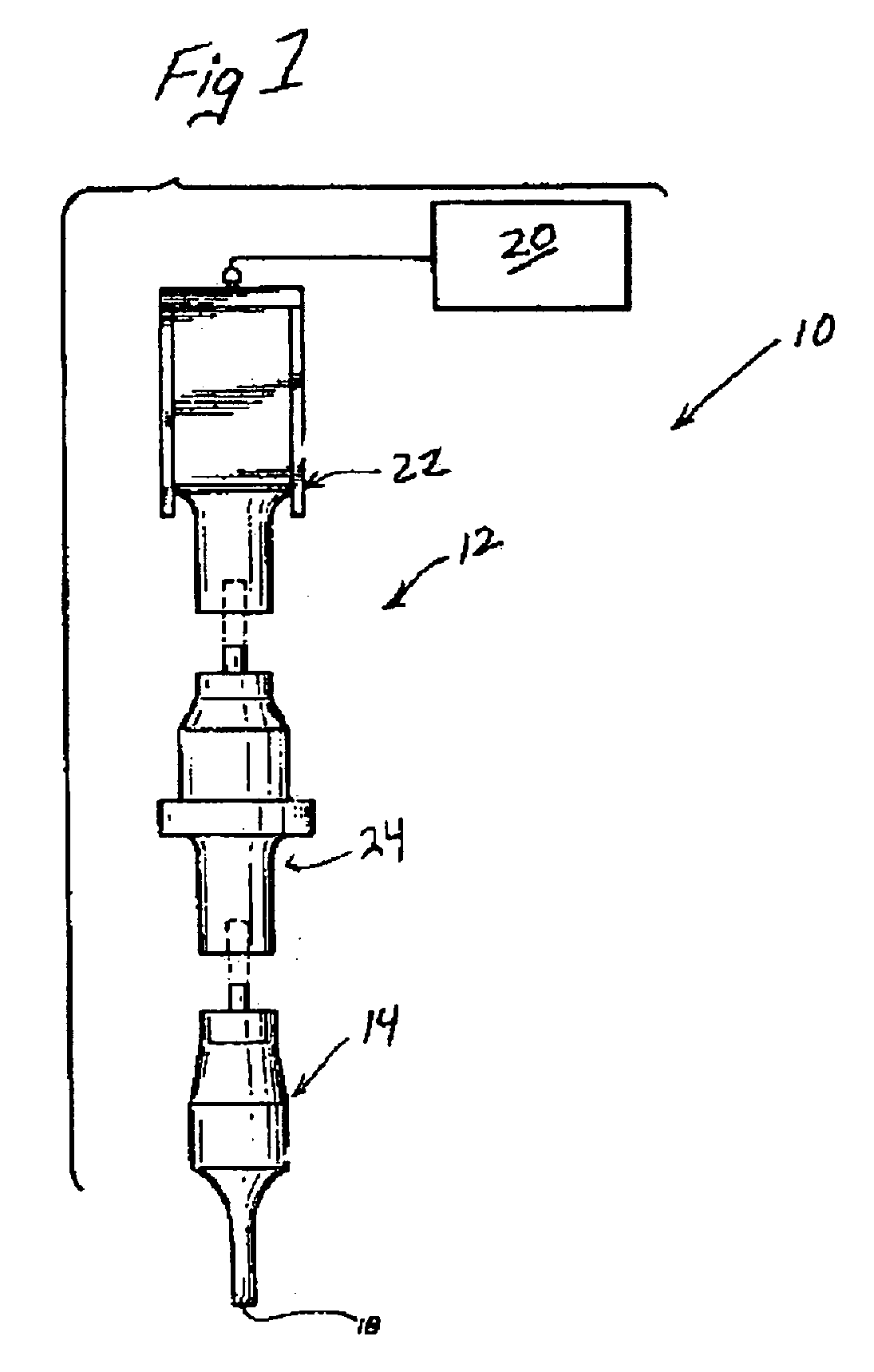

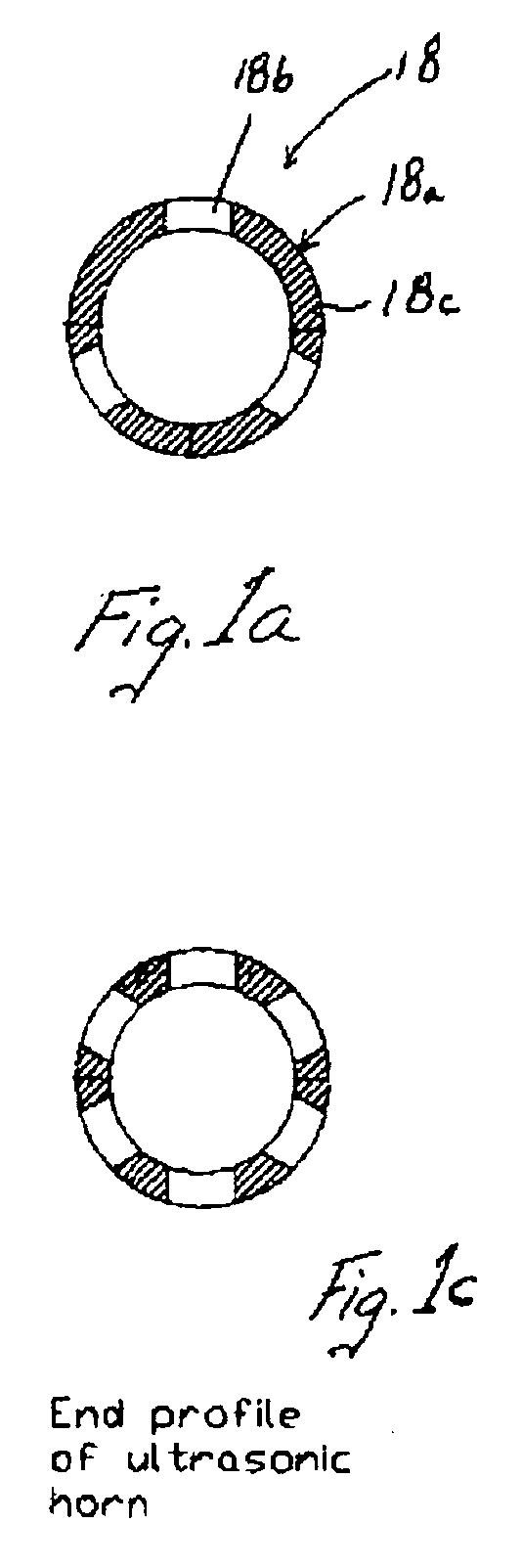

ActiveUS20070035051A1Prevent materialEnhanced cavitationOptical articlesStereotype platesEngineeringContact lens

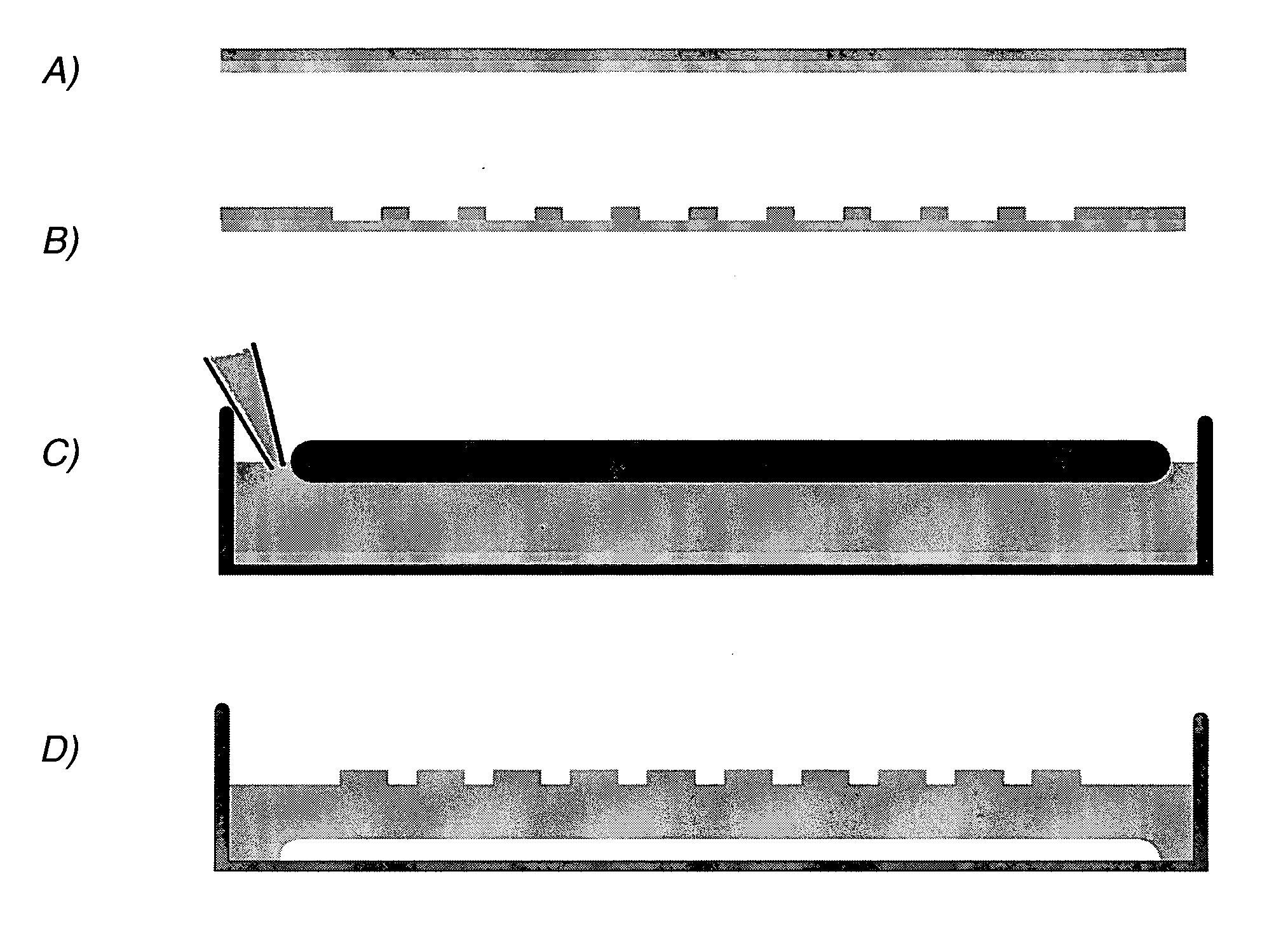

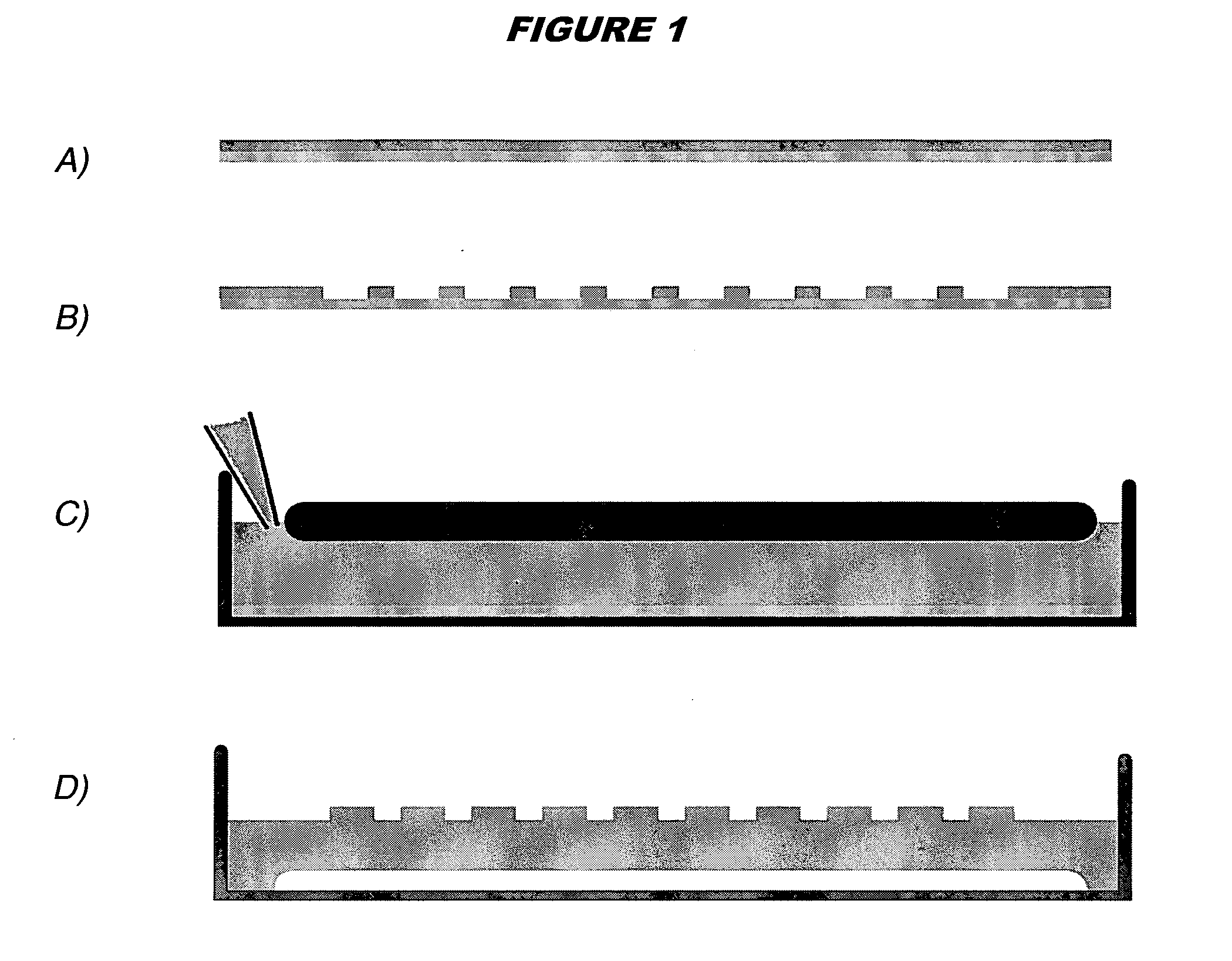

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which when coupled together are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by means of focused ultrasound energy.

Owner:COOPERVISION INT LTD

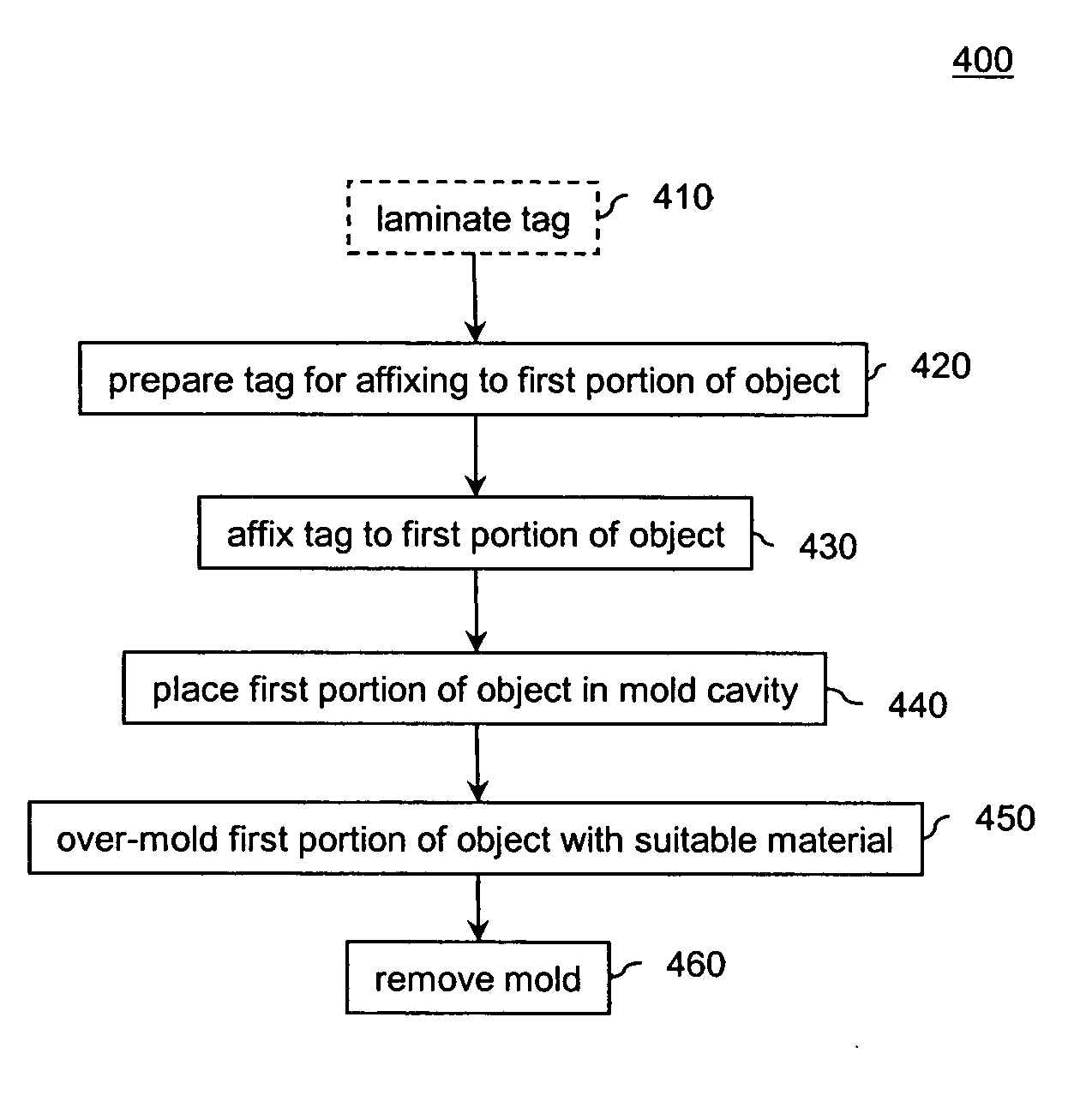

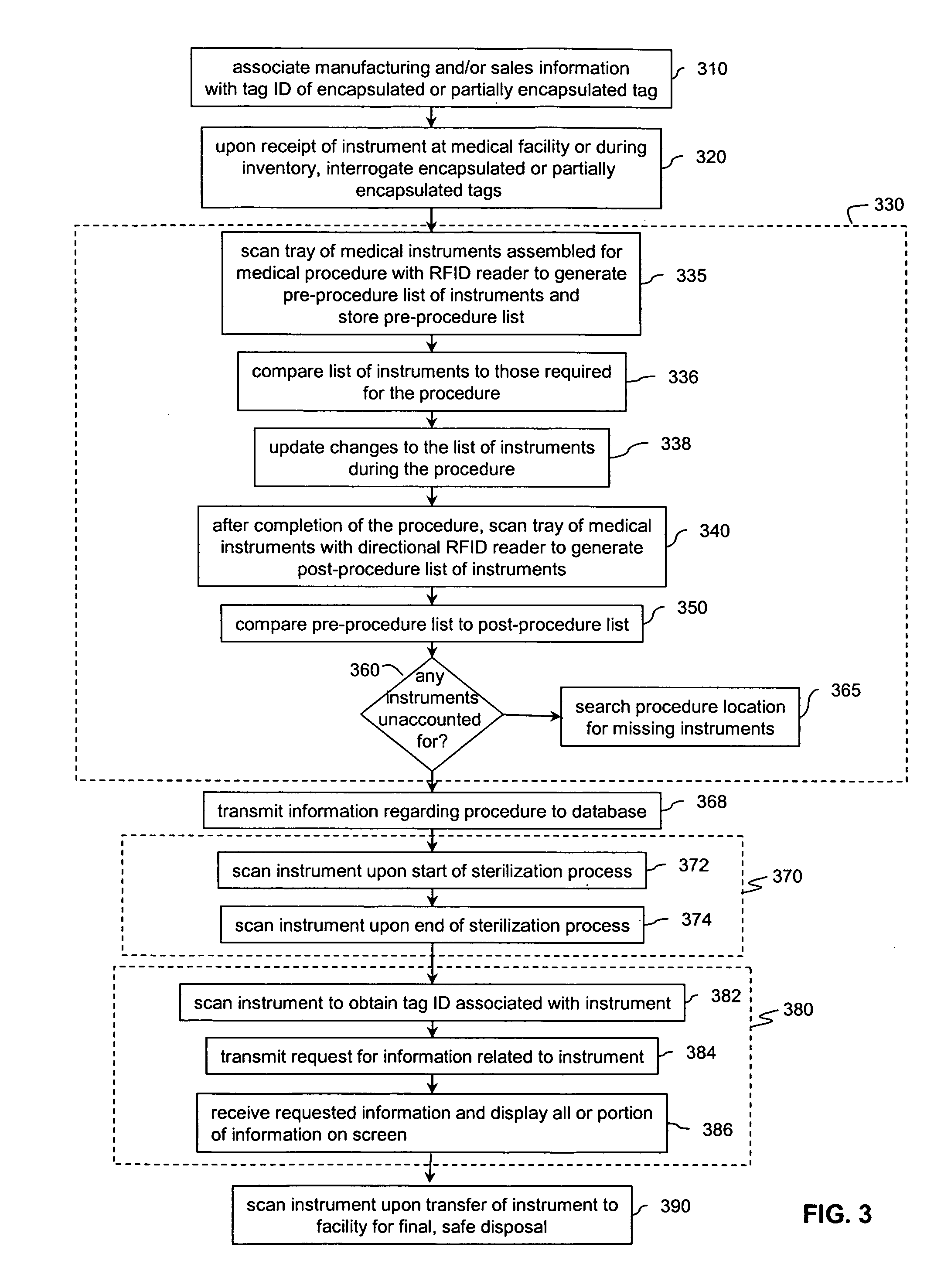

Radio frequency identification (RFID) solution to lost time spent on instrument inventory

A method for manufacturing an object having an encapsulated radio frequency identification (RFID) tag is provided. An RFID tag is mechanically or chemically affixed to a first portion of the object being manufactured. The first portion of the object, with the RFID tag affixed is placed in a cavity of a mold. The first portion is then over-molded with a first material such as high temperature thermoplastic or low temperature thermoset to generate a seamless object. A method for manufacturing an object having a partially encapsulated RFID tag is also provided. An RFID tag is laminated with a lamination material, such as high temperature thermoplastic. The laminated RFID tag is affixed to a mold. The laminated RFID tag is then over-molded with a first material to generate a seamless object. Methods for tracking medical instruments having encapsulated or partially encapsulated RFID tags are also provided.

Owner:SYMBOL TECH INC

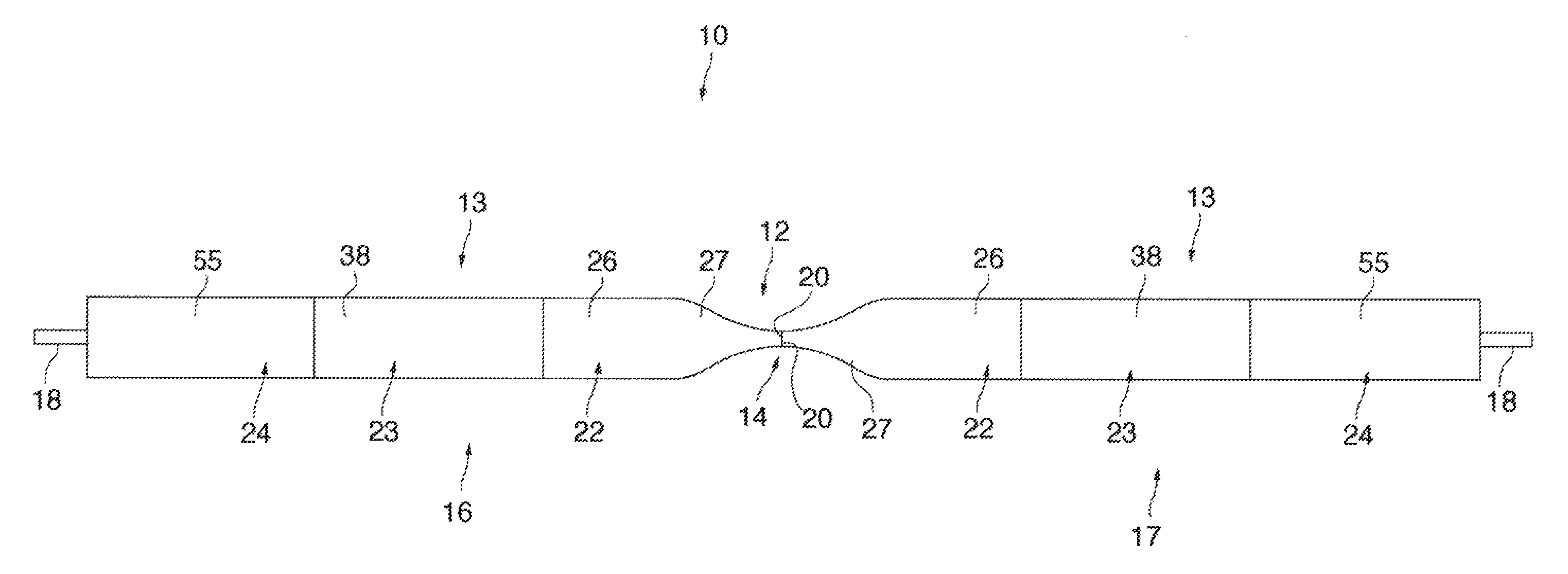

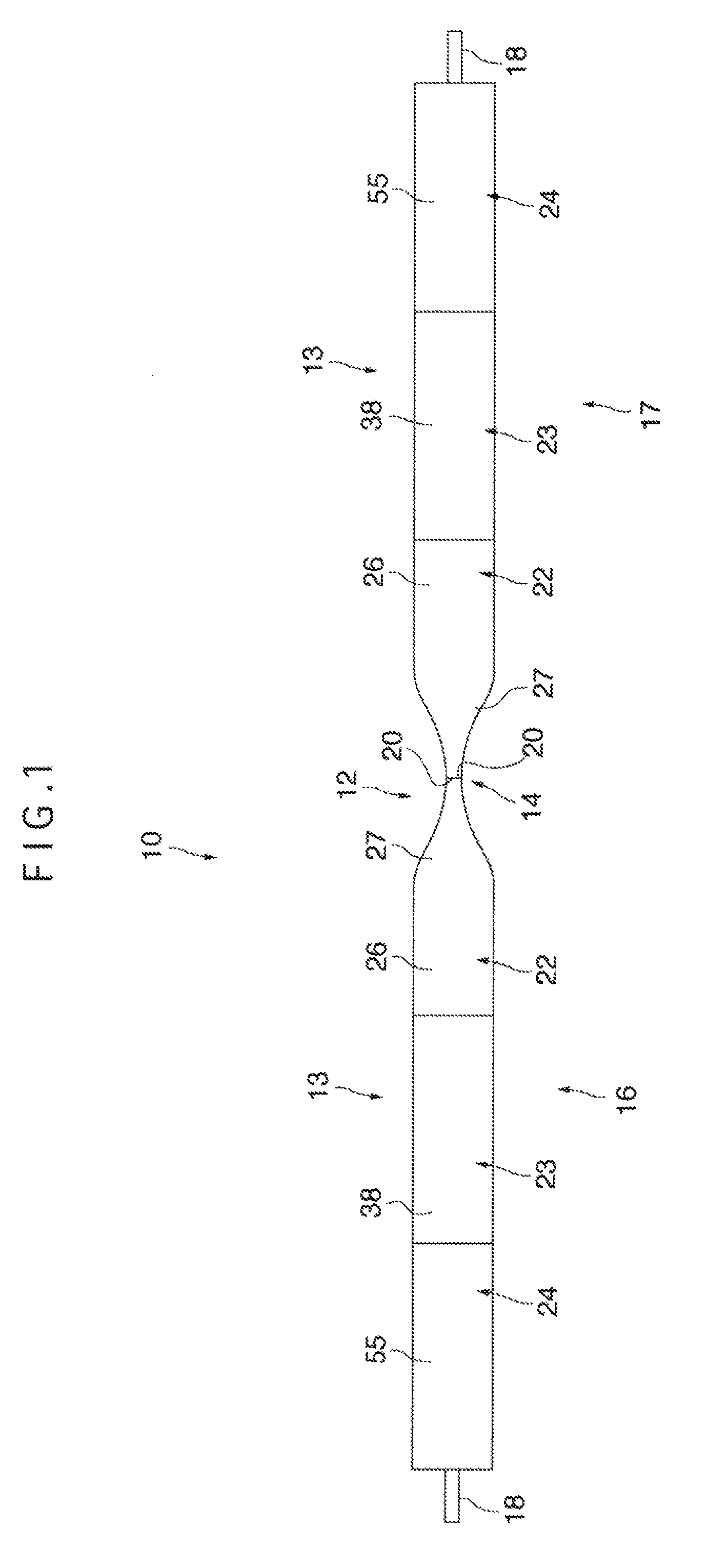

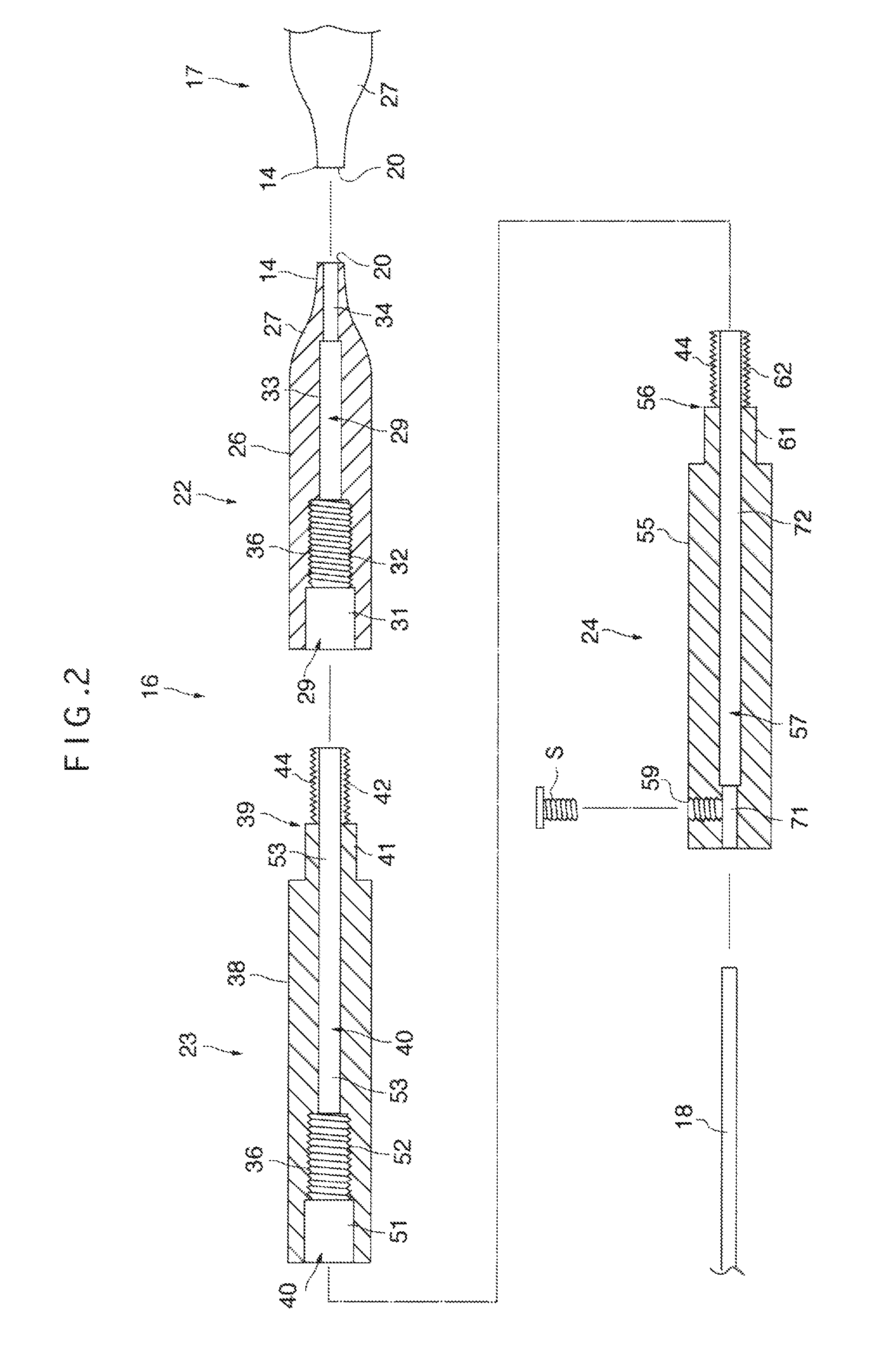

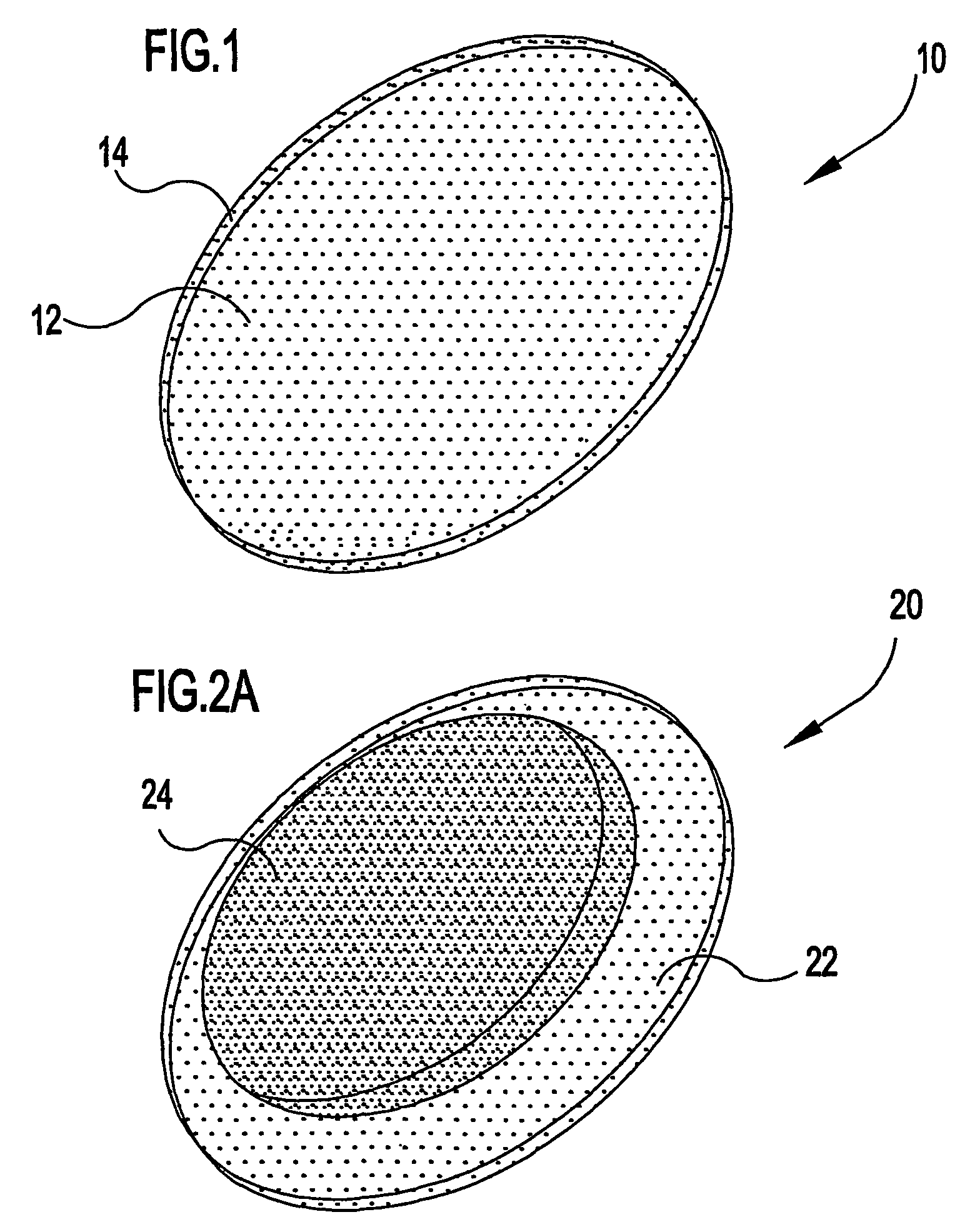

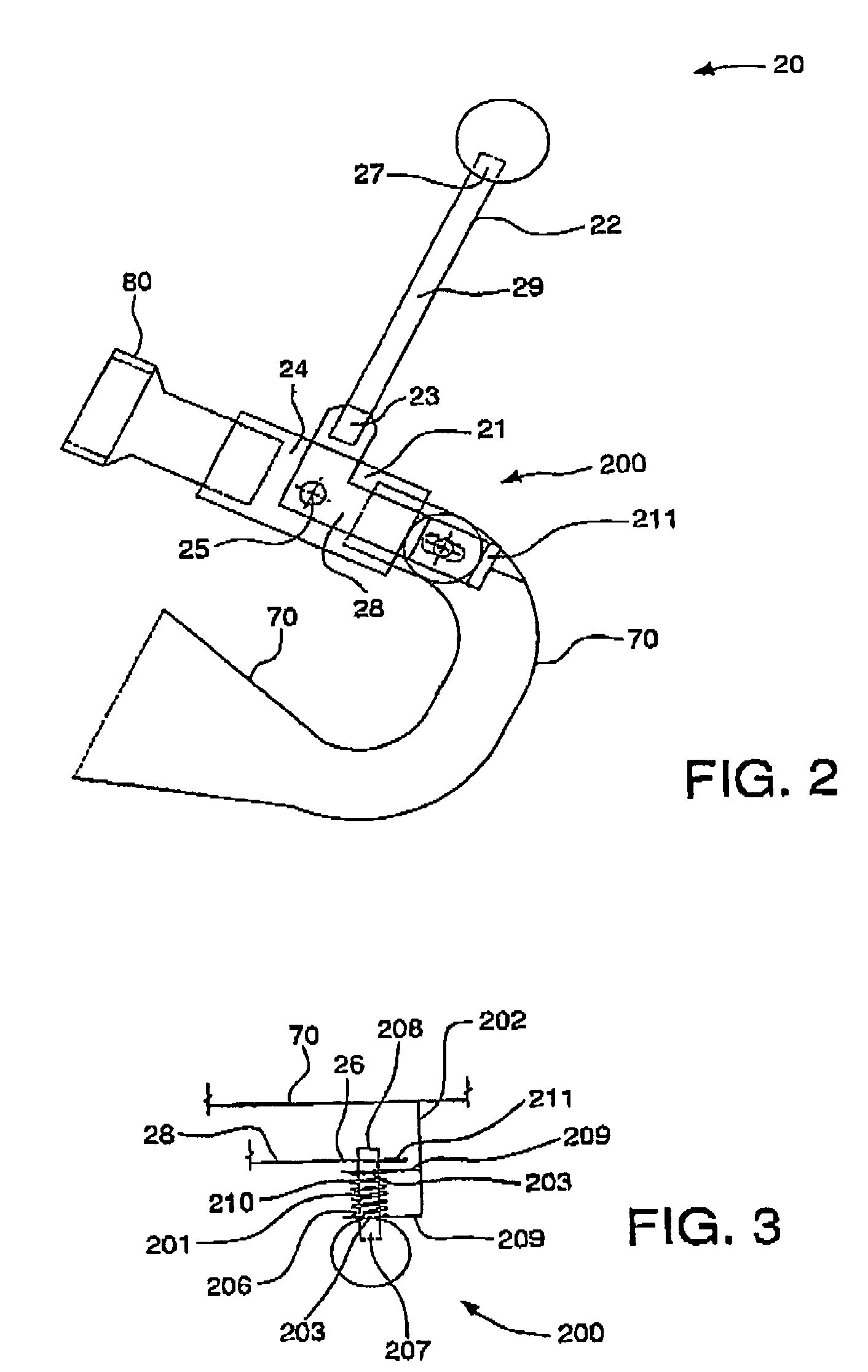

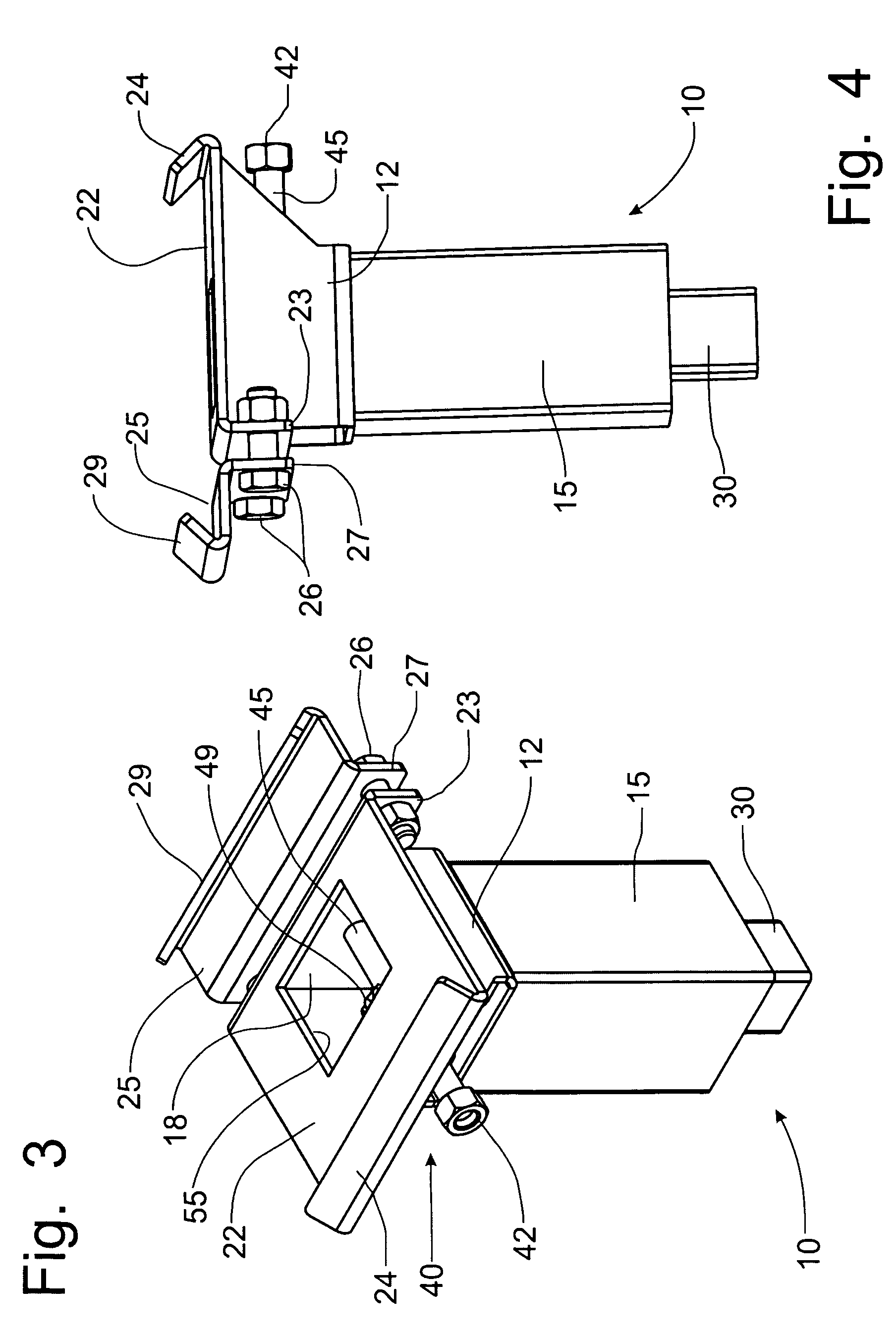

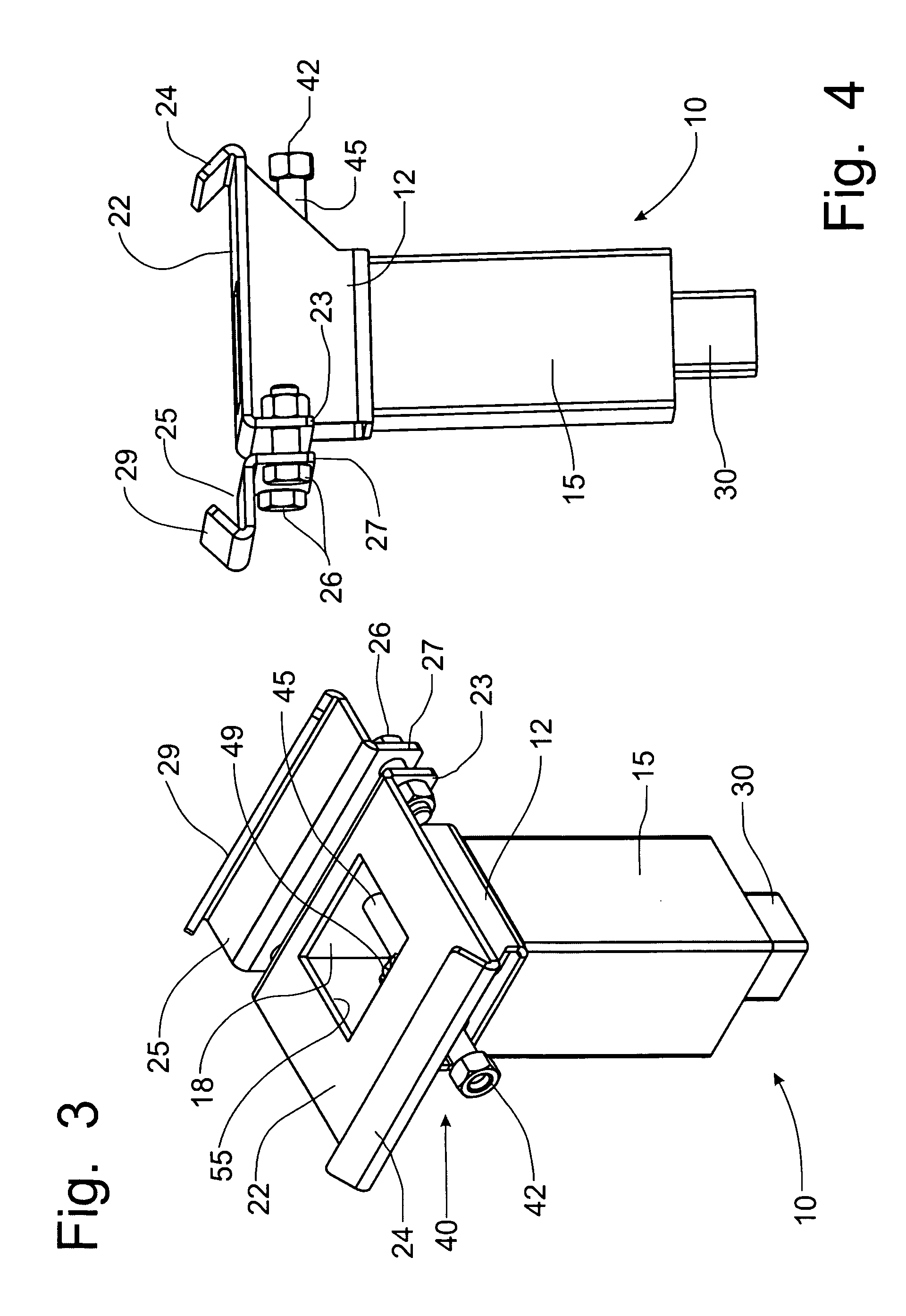

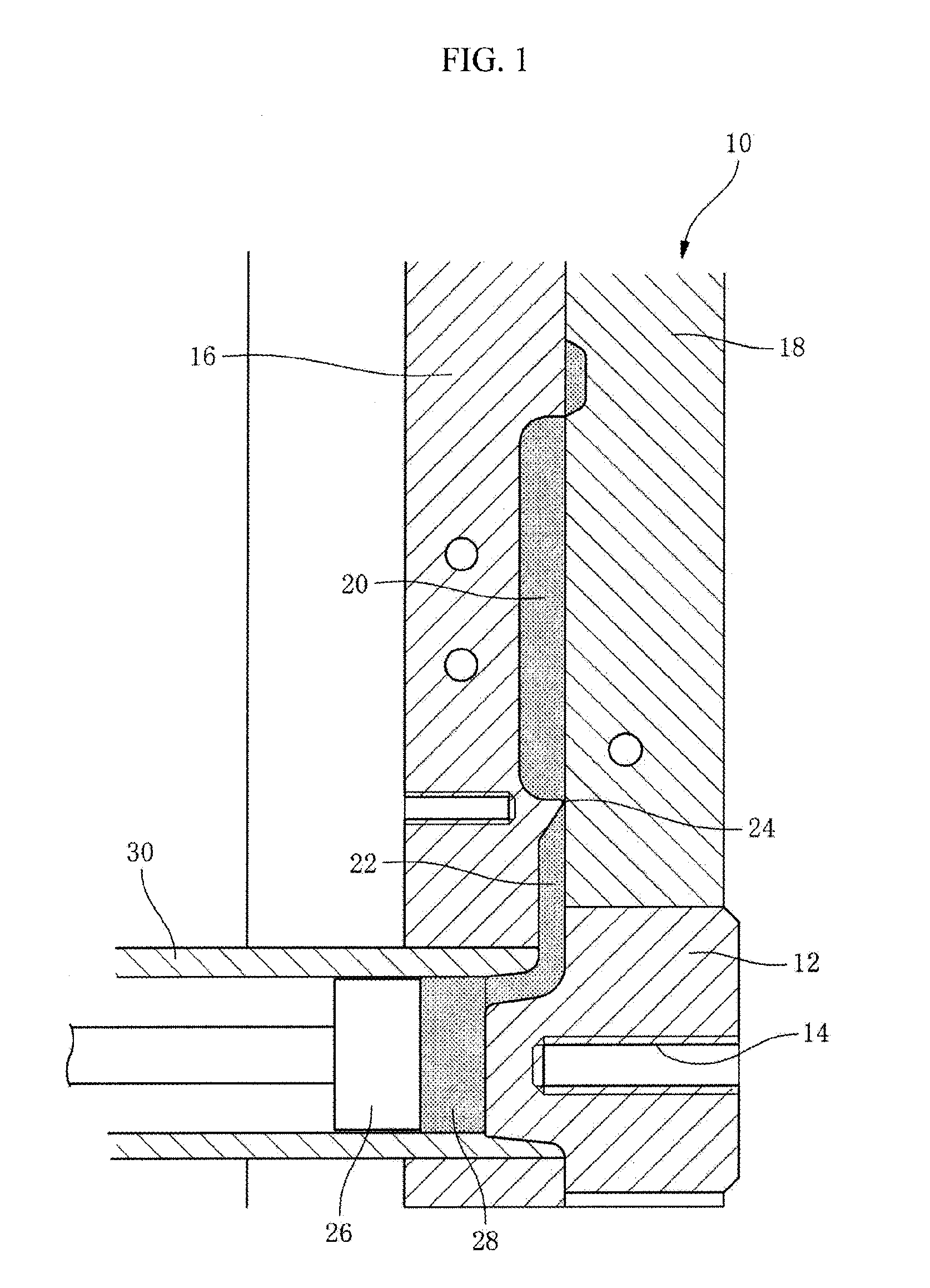

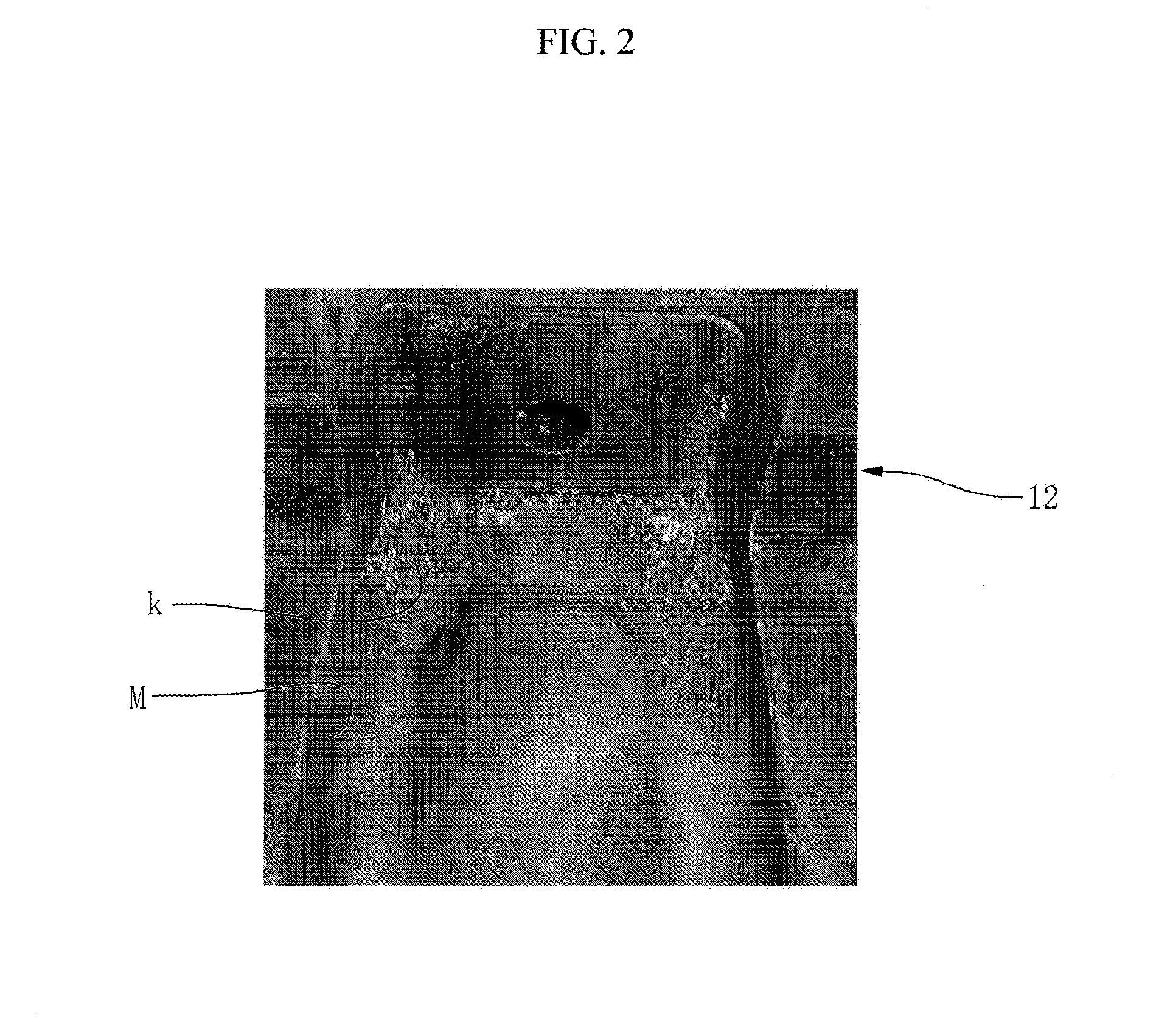

Mold for producing simulated blood vessel, method of producing simulated blood vessel and simulated blood vessel

Disclosed is a method whereby a narrowed part similar to an actual lesioned blood vessel can be easily obtained. A mold (10) comprises first and second molded members (16, 17) having inner spaces (29, 40, 57) passing through in the axial direction and an axial member (18) detachably inserted through the individual inner spaces (29, 40, 57) of the individual molded members (16, 17). The molded members (16, 17) have tapered front parts (27, 27) respectively. In the state of facing the front ends (20) of the tapered front parts (27) to each other and thus forming a concave (12), the axial member (18) is attached. A first material (75) made of a mixed material comprising calcium carbonate or the like and silicone or the like is applied to the concave (12). A second material (76) such as silicone is applied to the entire outer periphery of the mold (10). After hardening the materials (75, 76), the mold (10) is withdrawn by detaching the axial member (18) and dividing the concave (12). Thus, a simulated blood vessel (78) having a simulated narrowed part of the blood vessel caused by calcification can be obtained.

Owner:WASEDA UNIV

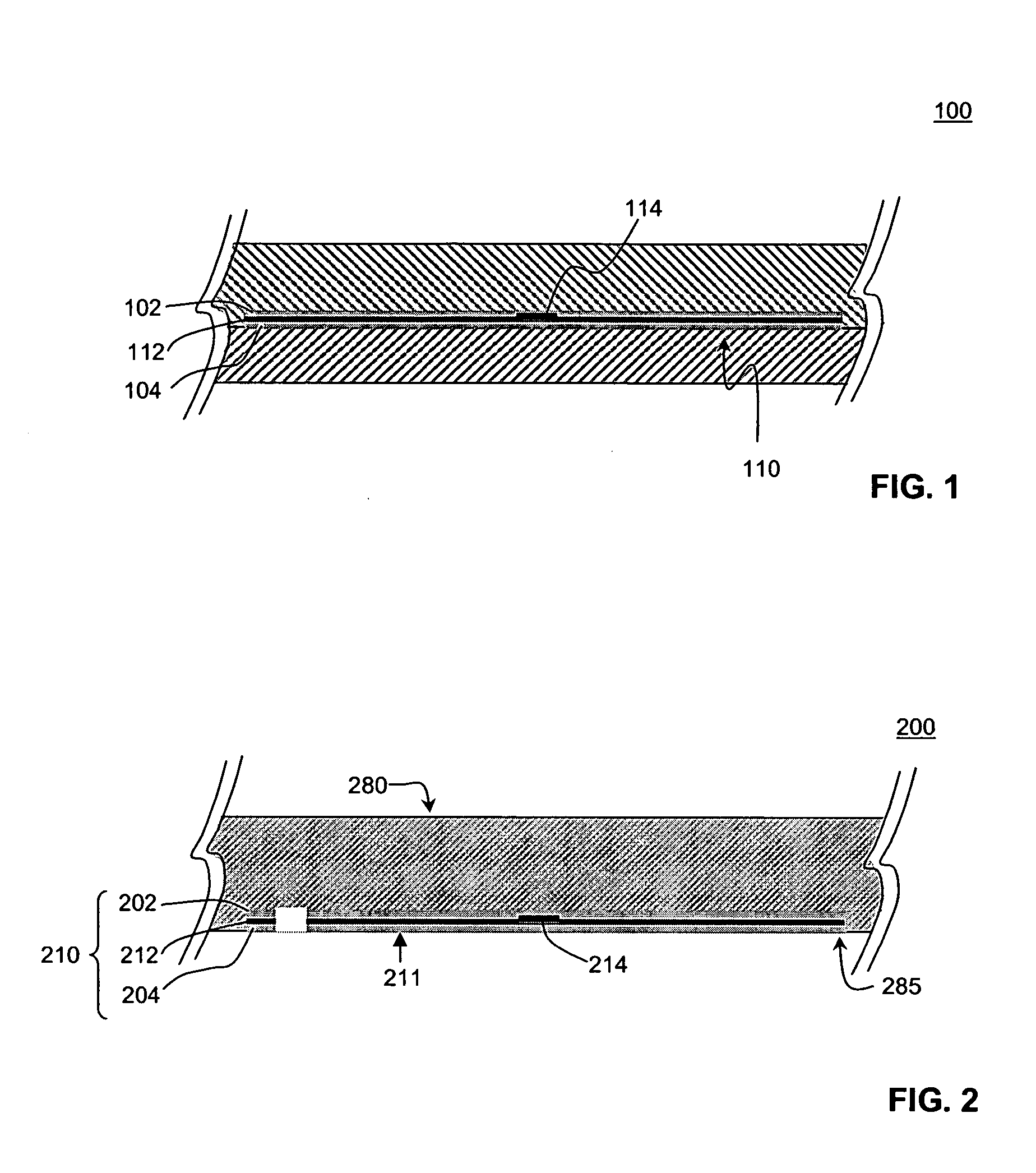

Ocular therapeutic agent delivery devices and methods for making and using such devices

ActiveUS7658364B2Increase release rateReached efficientlyOrganic active ingredientsSenses disorderDual modeOcular implant

Owner:UNITED STATES OF AMERICA

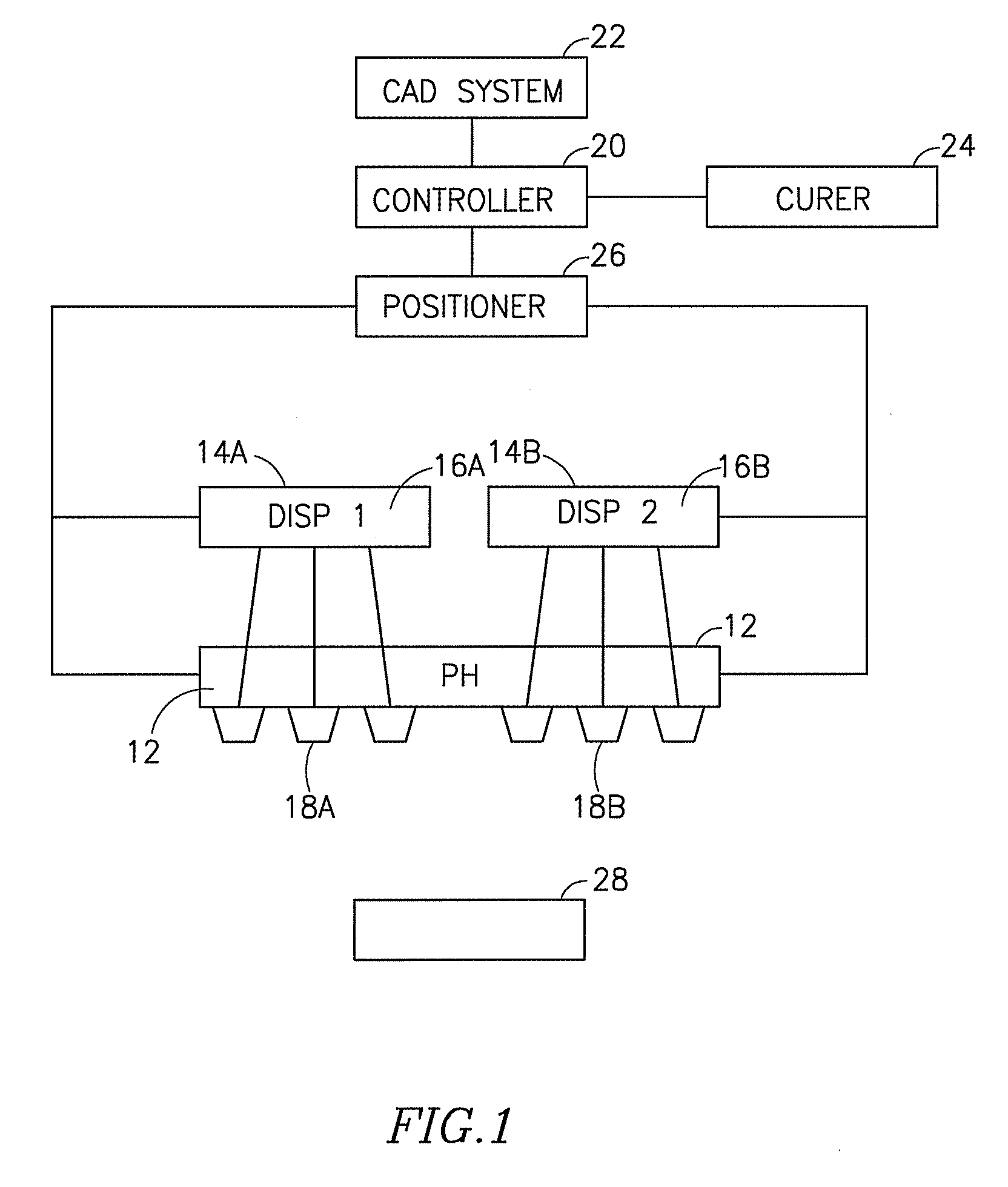

Compositions and methods for use in three dimensional model printing

InactiveUS20080105818A1Similar elasticitySimilar strengthButtonsRecord carriersInvestment castingMaterials science

Embodiments of the invention are directed to a method of producing three-dimensional prototype molds for use in investment casting. The method includes dispensing modeling material and support material in a predetermined arrangement, in layers, to produce a three-dimensional mold having an outer shell. Generally, the out shell includes modeling material and the interior of the mold includes support material. Then the mold is cured.

Owner:OBJET GEOMETRIES

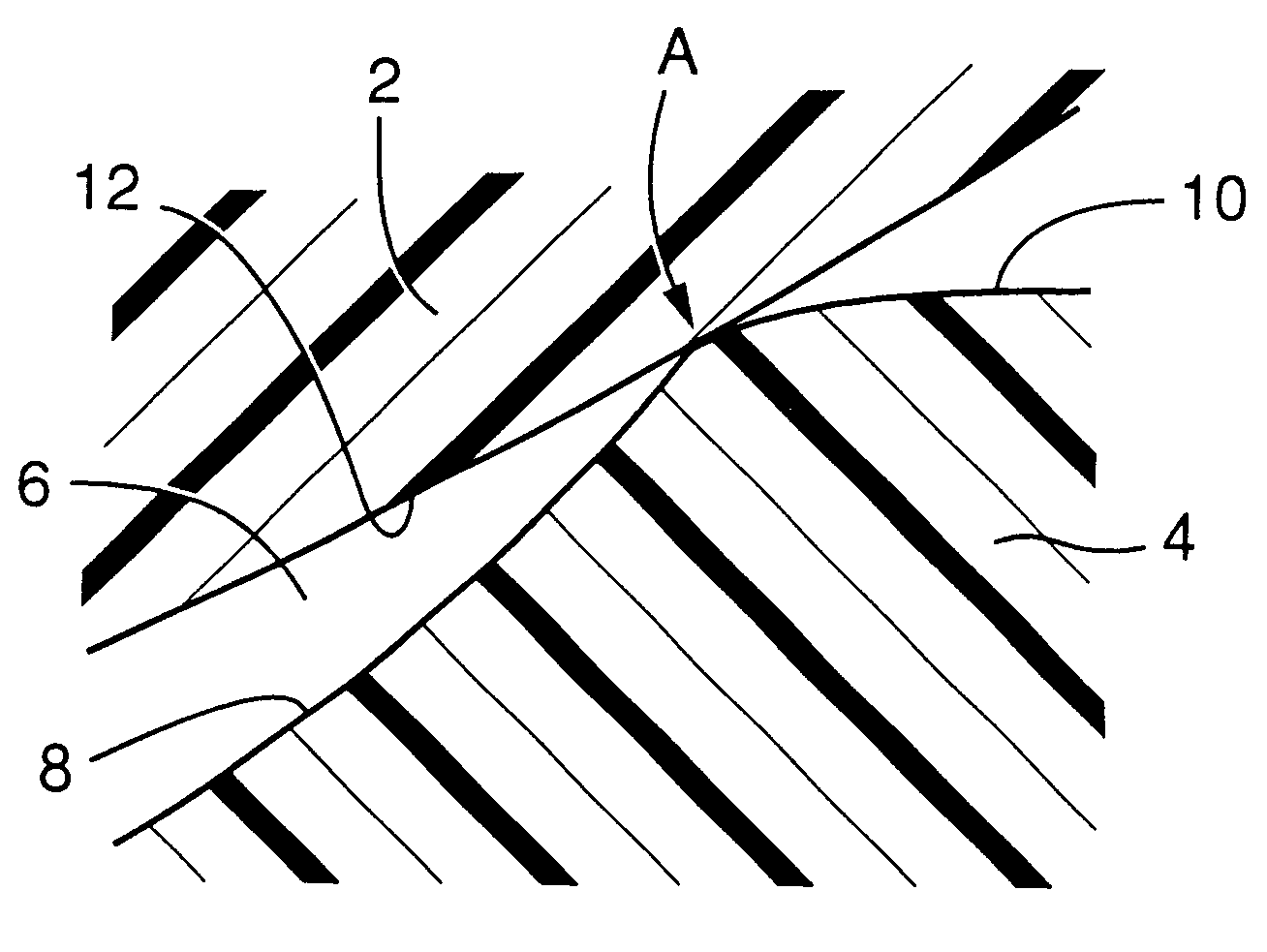

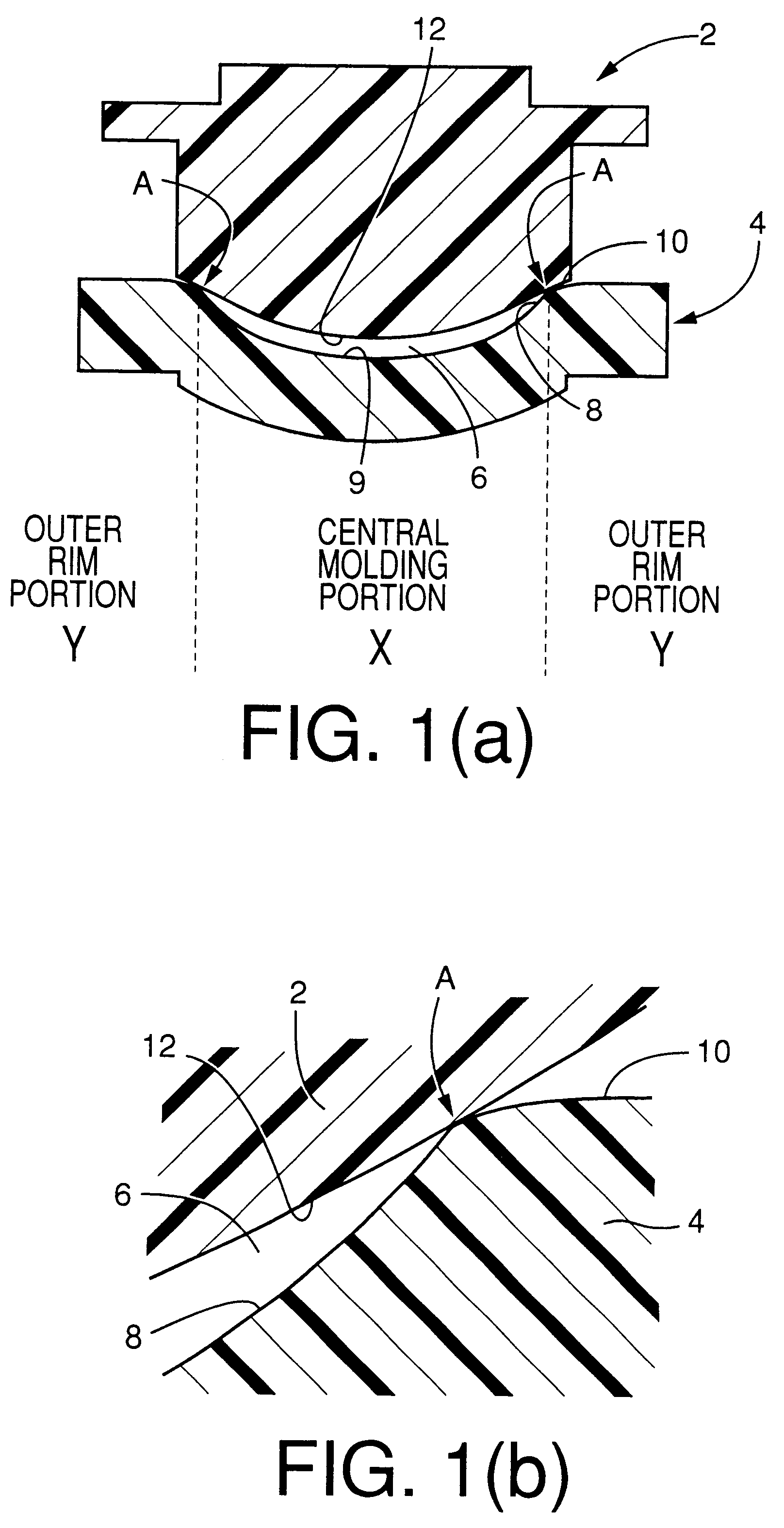

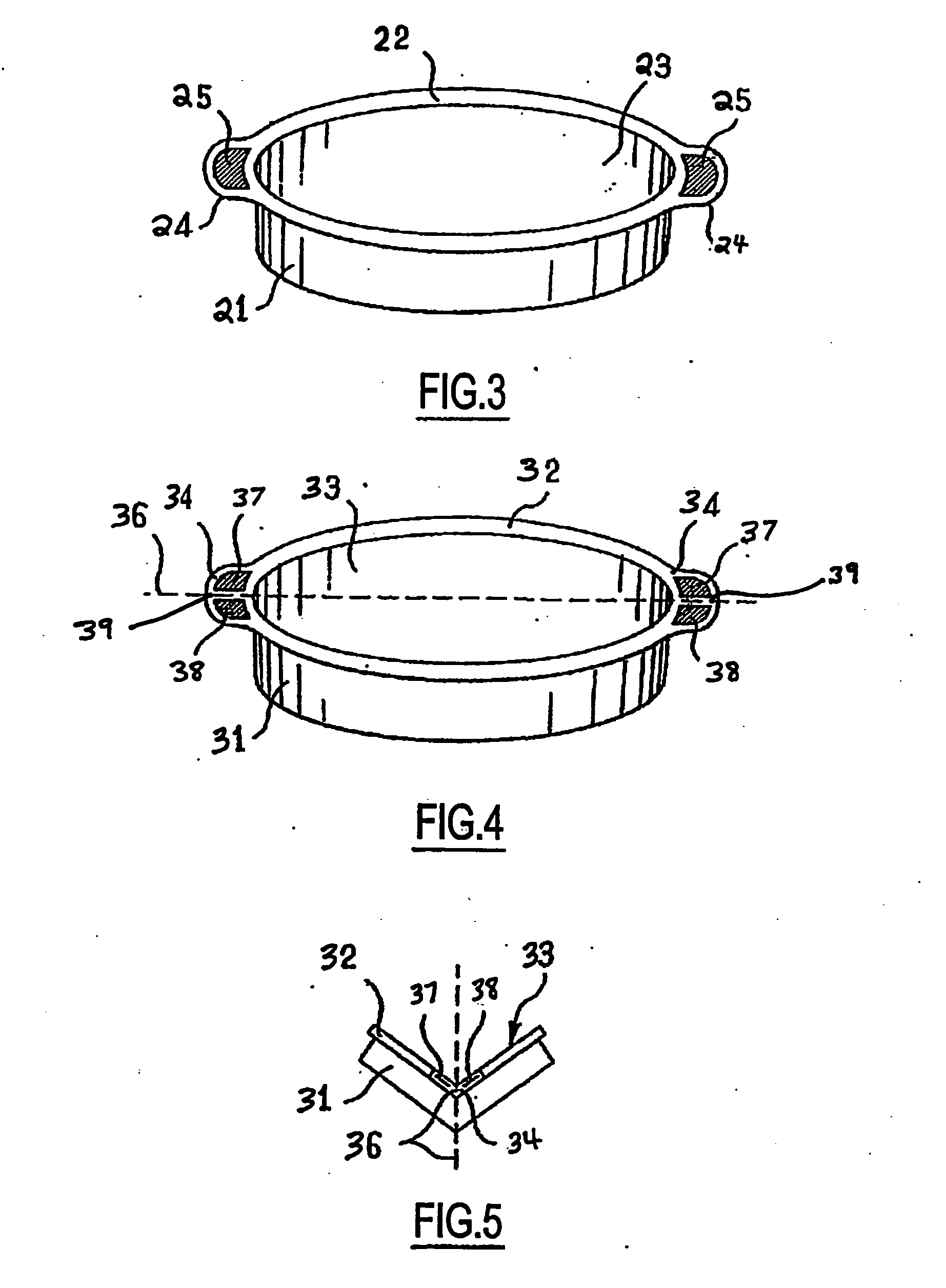

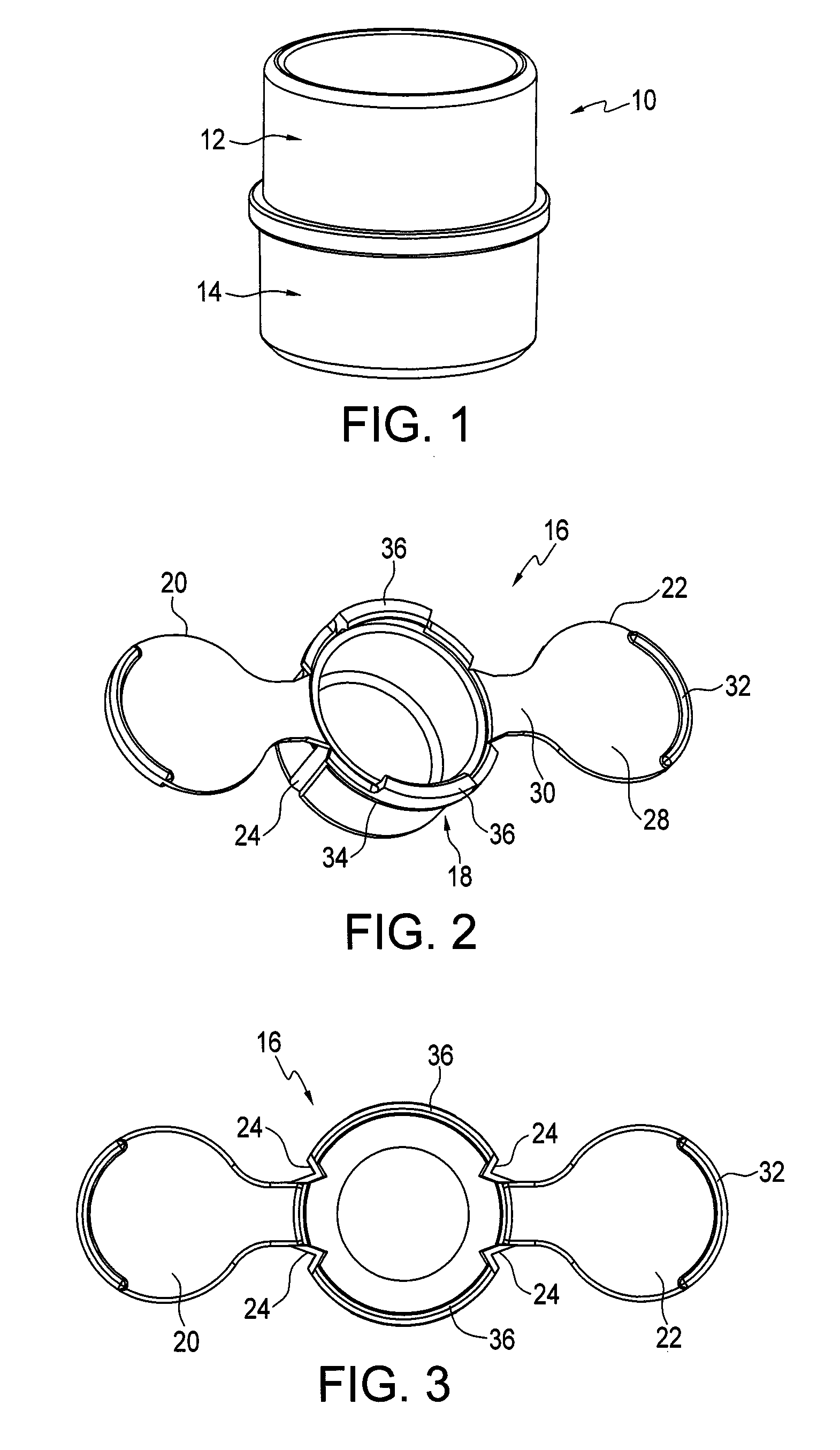

Mold assembly for forming ophthalmic lens

InactiveUS6257547B1Avoid Insufficient SealingImprove stabilityFoundry mouldsOptical articlesEntocentric lensRadial position

Lens mold assembly including a first and a second mold cooperating with each other to define a mold cavity for molding an ophthalmic lens with the first and second molds being held in line contact with each other at a radial position, wherein at least one of the two molds consists of a central molding portion located radially inwardly of the radial position, and an outer rim portion located radially outwardly of the radial position, the central molding portion cooperating with the other mold to define the mold cavity, the above-indicated at least one mold having a mold surface which is opposed to a mold surface of the other mold when the two molds are assembled together, the mold surface of the at least one mold consisting of a central lens-forming region in the central molding portion, and an outer peripheral non lens-forming region in the outer rim portion, at least a part of the lens-forming region adjacent to the radial position providing a concave portion, while at least a part of the outer peripheral non lens-forming region adjacent to the radial position providing a convex portion.

Owner:MENICON CO LTD

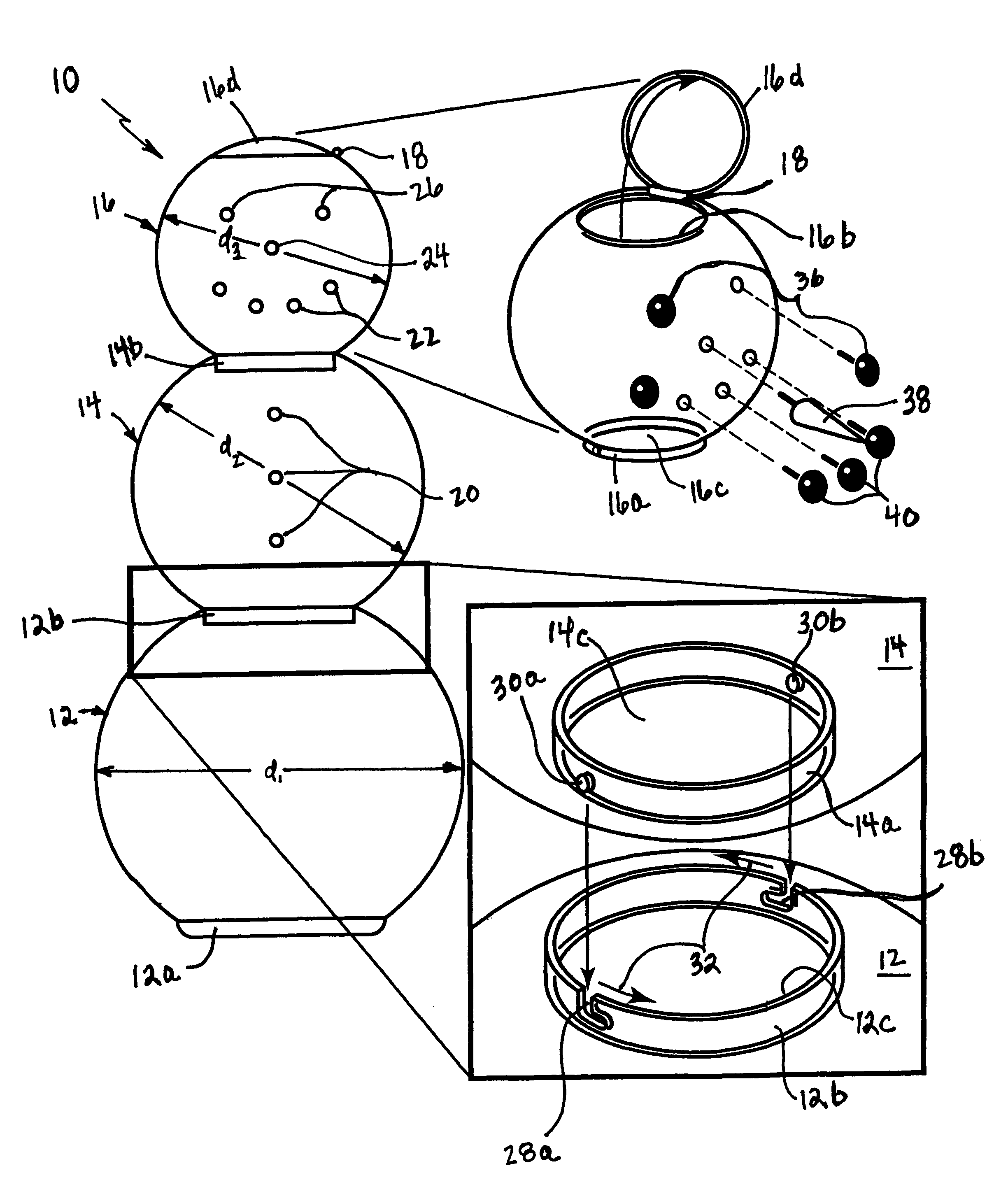

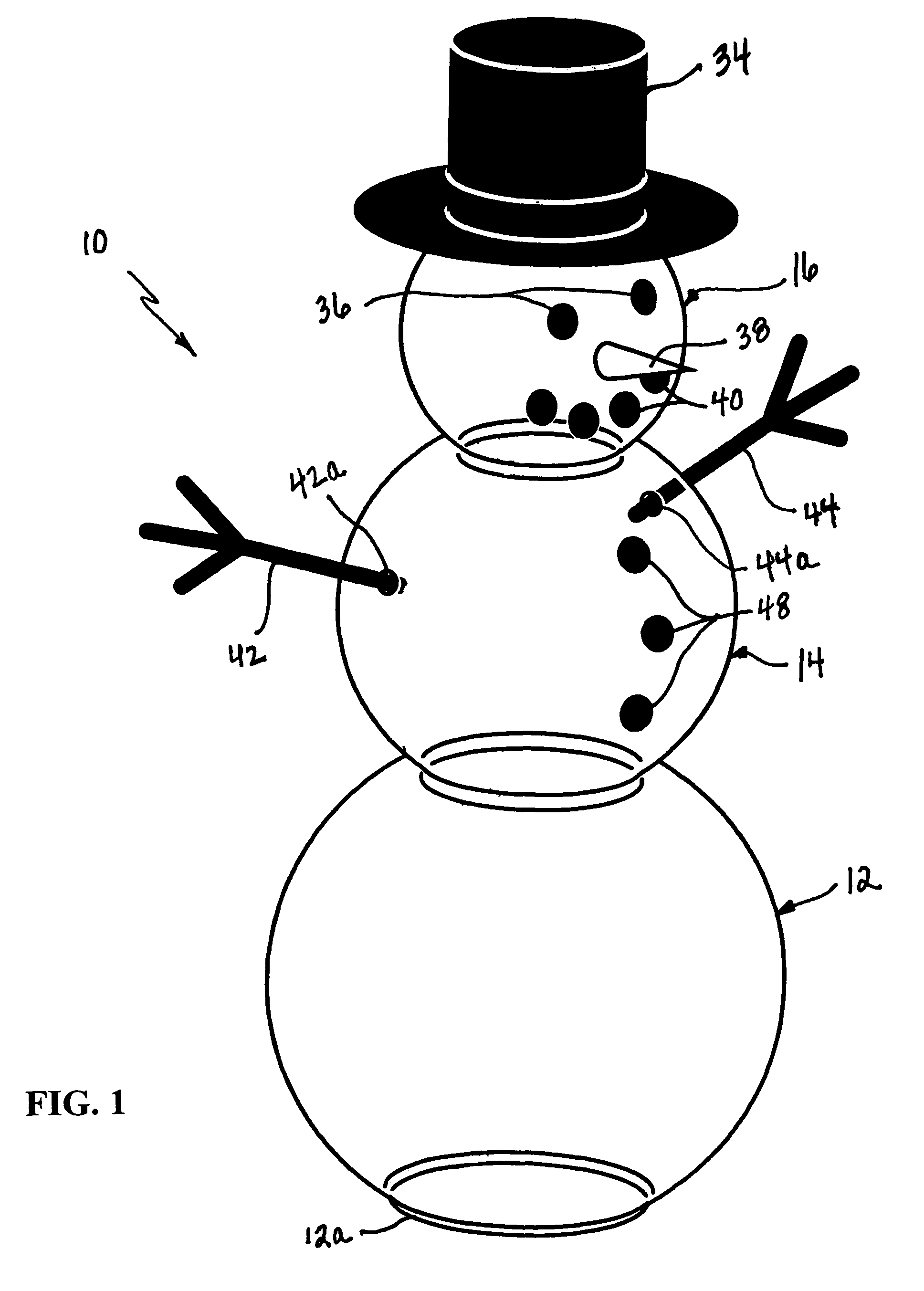

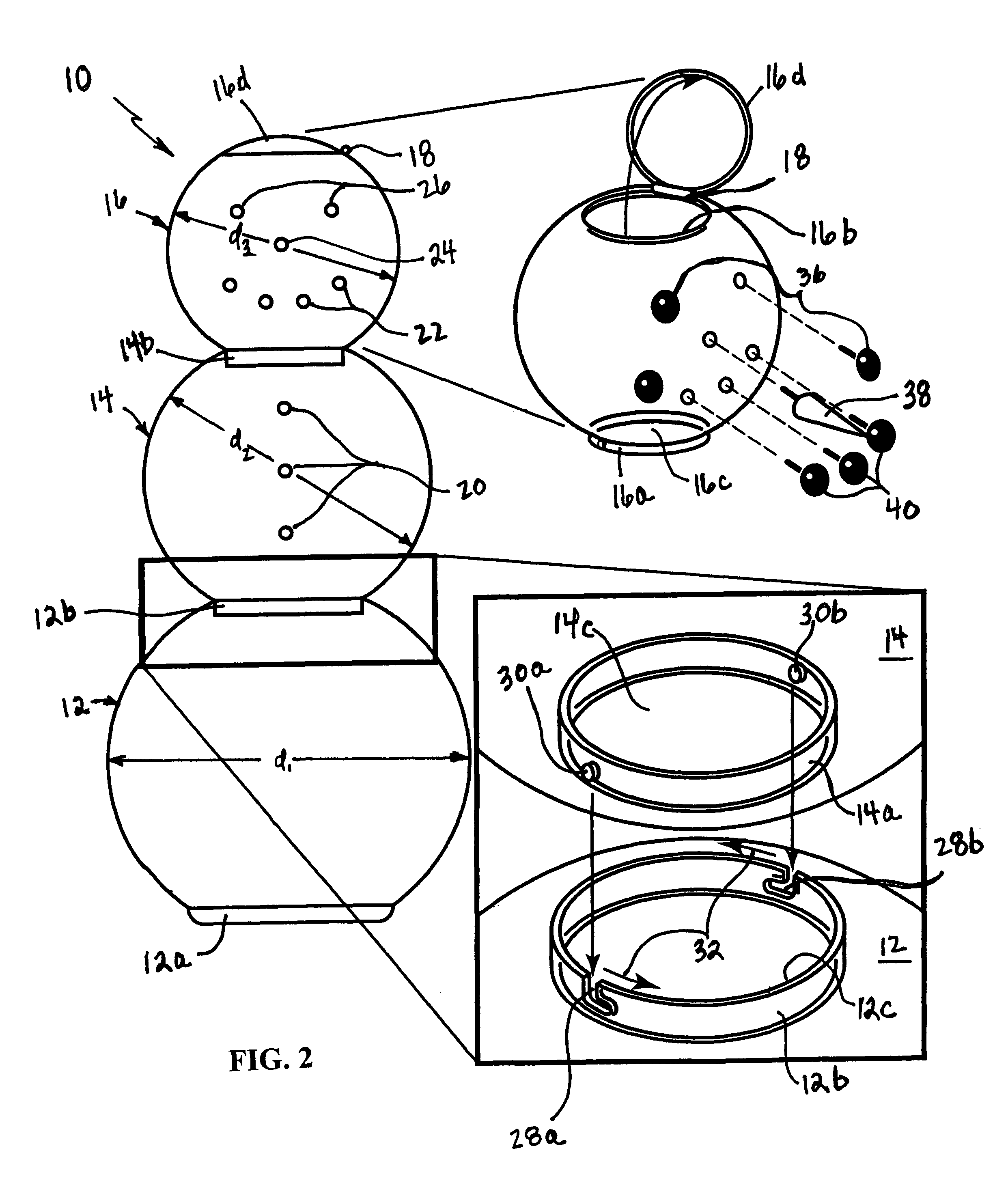

Snowman mold

ActiveUS7963500B1Easy to shapeReliable wayMould separation apparatusLighting and heating apparatusCouplingEngineering

A mold for forming a snowman includes lower, intermediate and upper generally spherical, hollow members comprised of clear plastic. Each plastic member includes an upper aperture for filling the member with snow. The lower member includes a generally flat base portion for positioning stability and an upper connection ring adapted for secure coupling to a lower connection ring on the intermediate member. The intermediate member also includes an upper connection ring adapted for secure coupling to a lower connection ring on the upper member. The three connected members form a hollow, vertical structure which when filled with snow provides a snowman of classic shape, symmetry and proportions. The individual spherical hollow members are easily connected and disconnected, with the intermediate and upper members having apertures for receiving eye, nose, mouth and arm indicia, with the upper member further including a hat mounting arrangement in one embodiment.

Owner:HOLIDAY ANGELA C

Non ionic groups of amphoteric polysaccharide linear or branched alkyl or acid and base distillation reservoir liquid or gas mechanically refined and Nano particle dispersion and recovery basin in vacuum processing for Building Materials and High Wear-Heat Resistant Parts Brushes; Windings; Coils; Battery Cells; Brake Pads; Bushings; 2.5 Phase Extrusions Die Cast Molding; Refrigeration; Polarized Glass; and Central Processing Unit Processors.

Manufacture process scientific formula mechanically refined and nanoparticle dispersion preform slurry non ionic or electrolyte carbon nanofoam CNFs with or without ionic suspension elements manufactured, Preform slurry high wear-heat resistant parts electronic component composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension element enhanced composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, capacitors, battery cells, rheostats, electronic resistors, transformers, transducers, rectifiers, power supplies, or heat sinks, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, washers, spacers, and bushings, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts precision casting molds manufacturing highly pure metal, Super Alloy, acid-solid, alkaline, glass, acrylic, halide, alkalide, or ceramics specializing in 2.5 phase die cast molding.

Owner:MATTHEWS ROBERT RICHARD

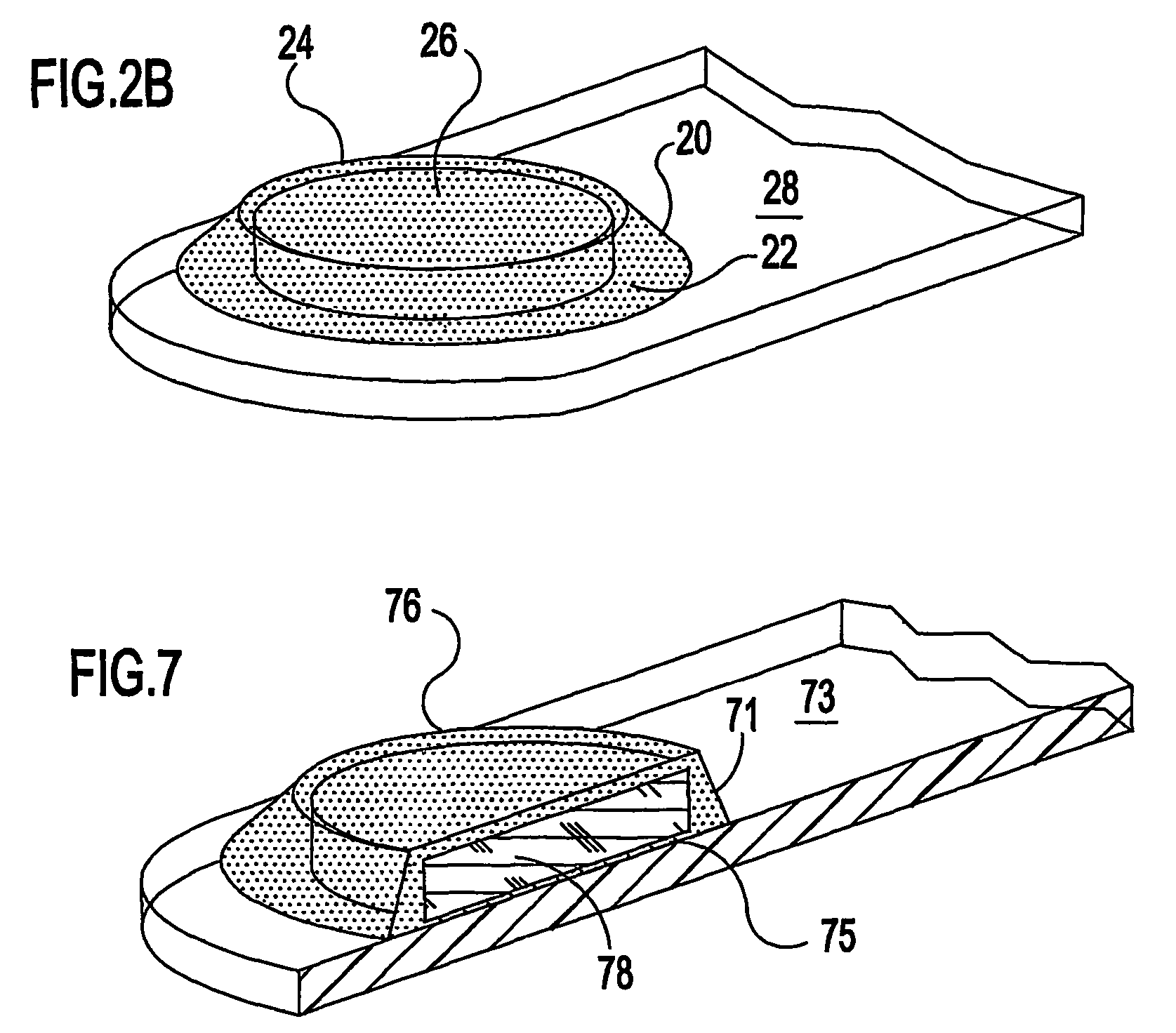

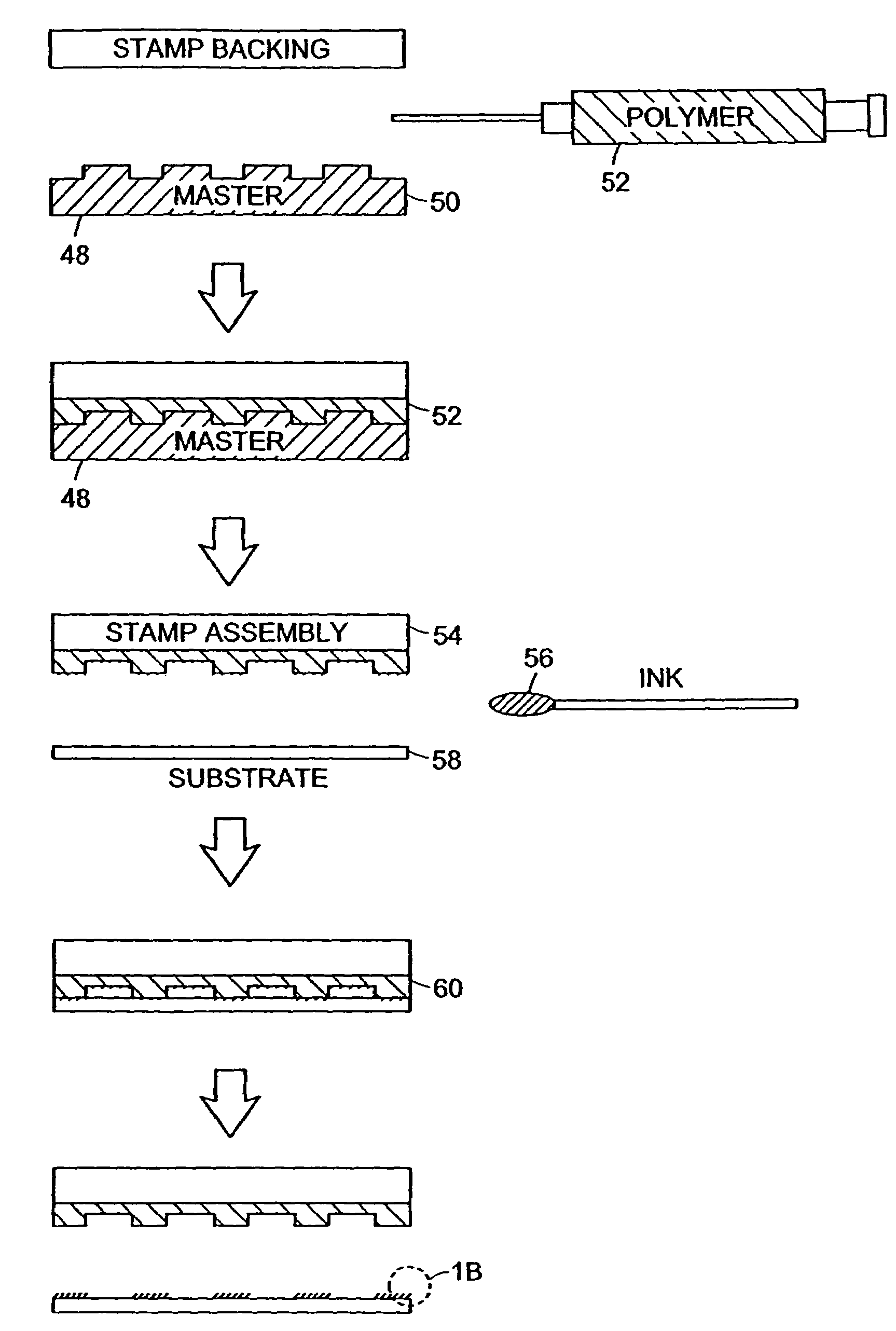

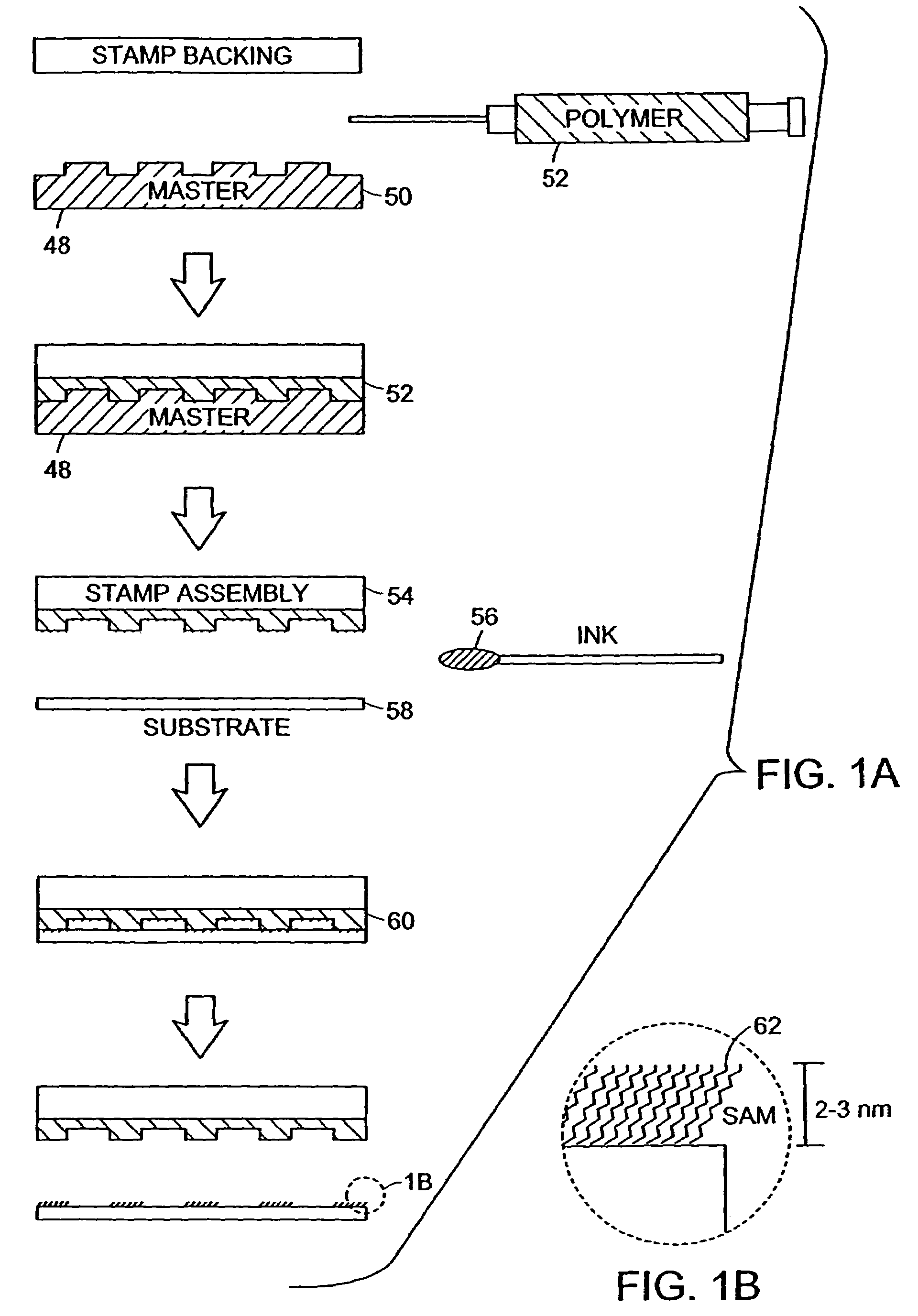

Microcontact printing

InactiveUS20070261574A1Generate undesired patterning resultsControl distortionMaterial nanotechnologyMechanical working/deformationMicrocontact printingEngineering

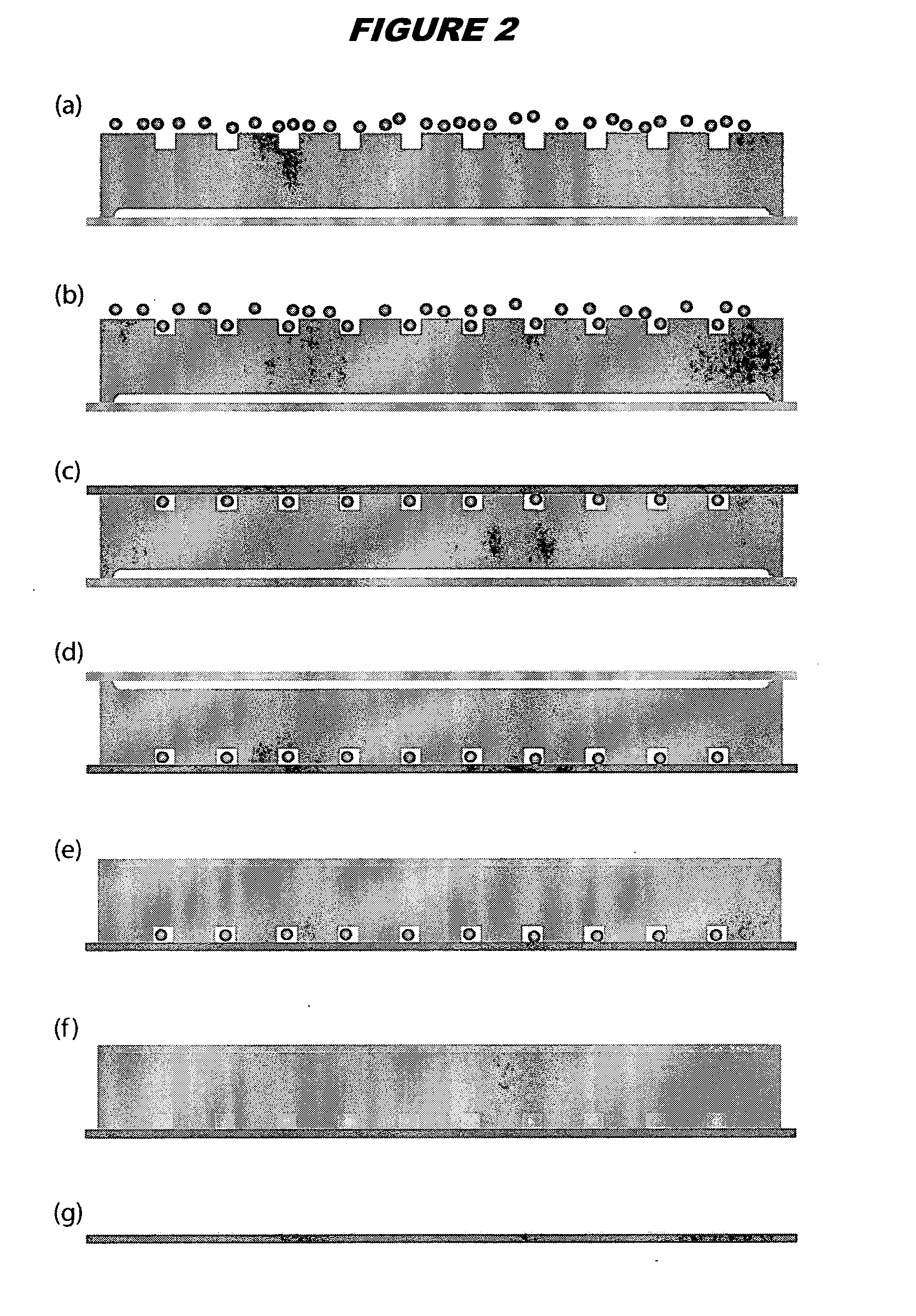

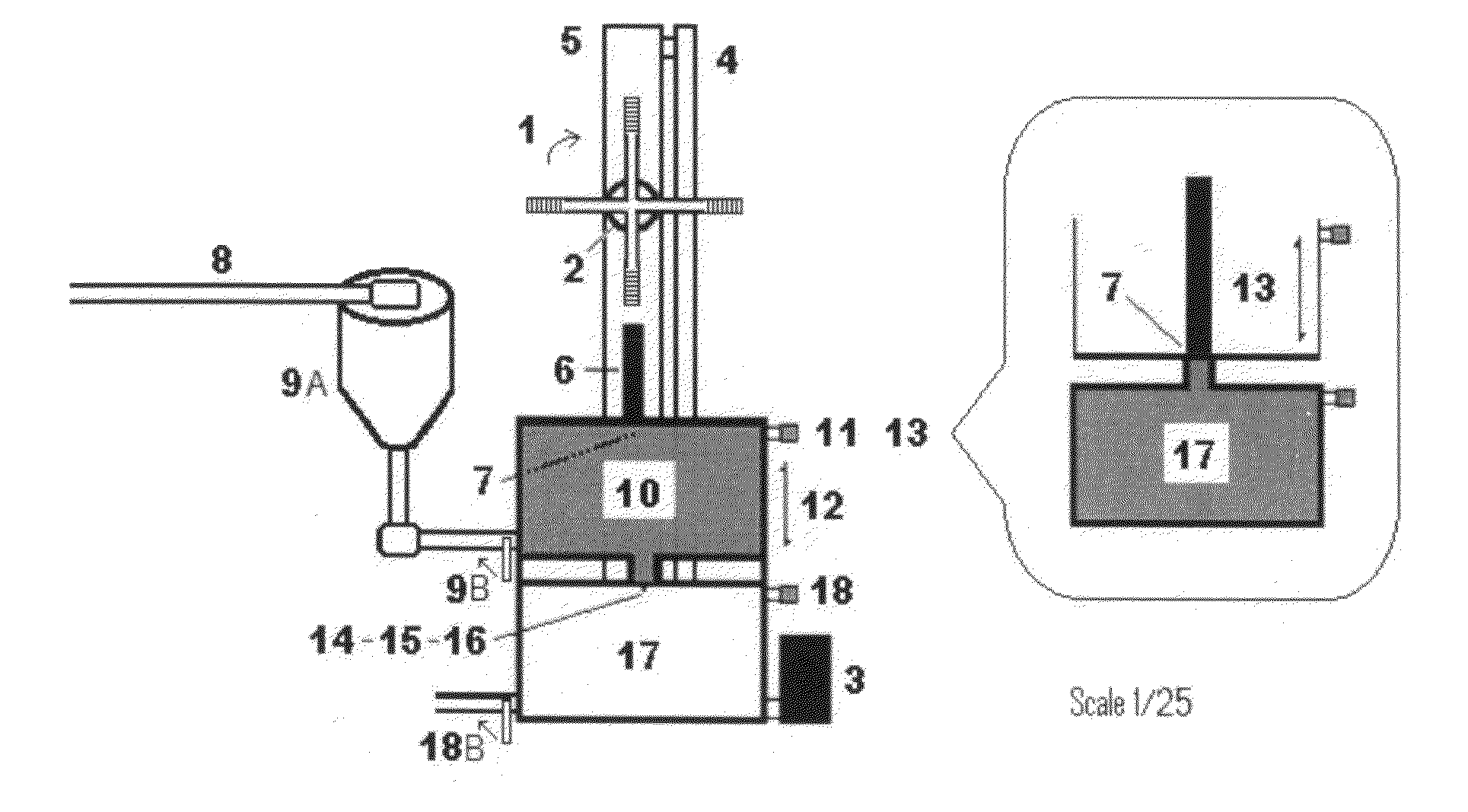

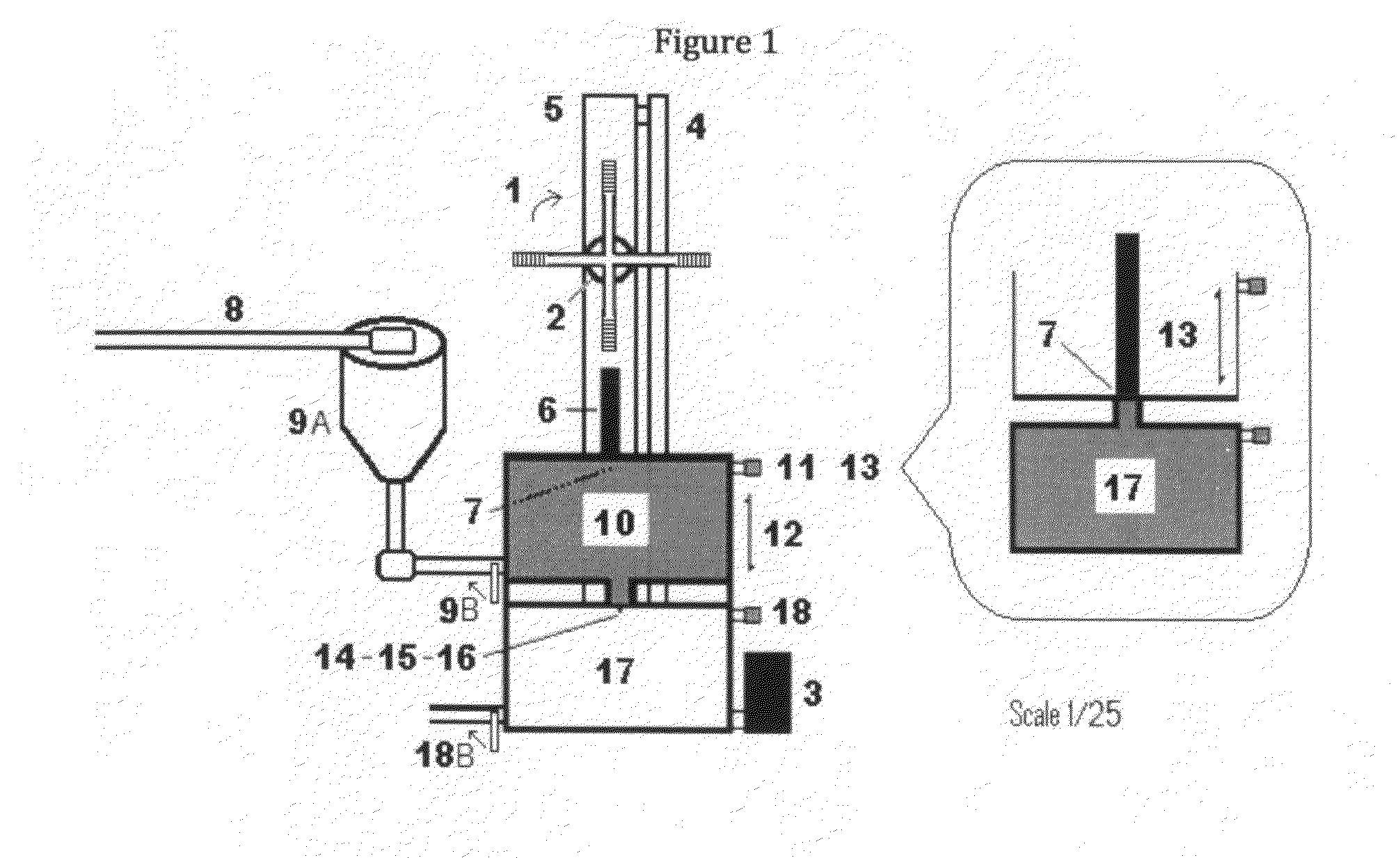

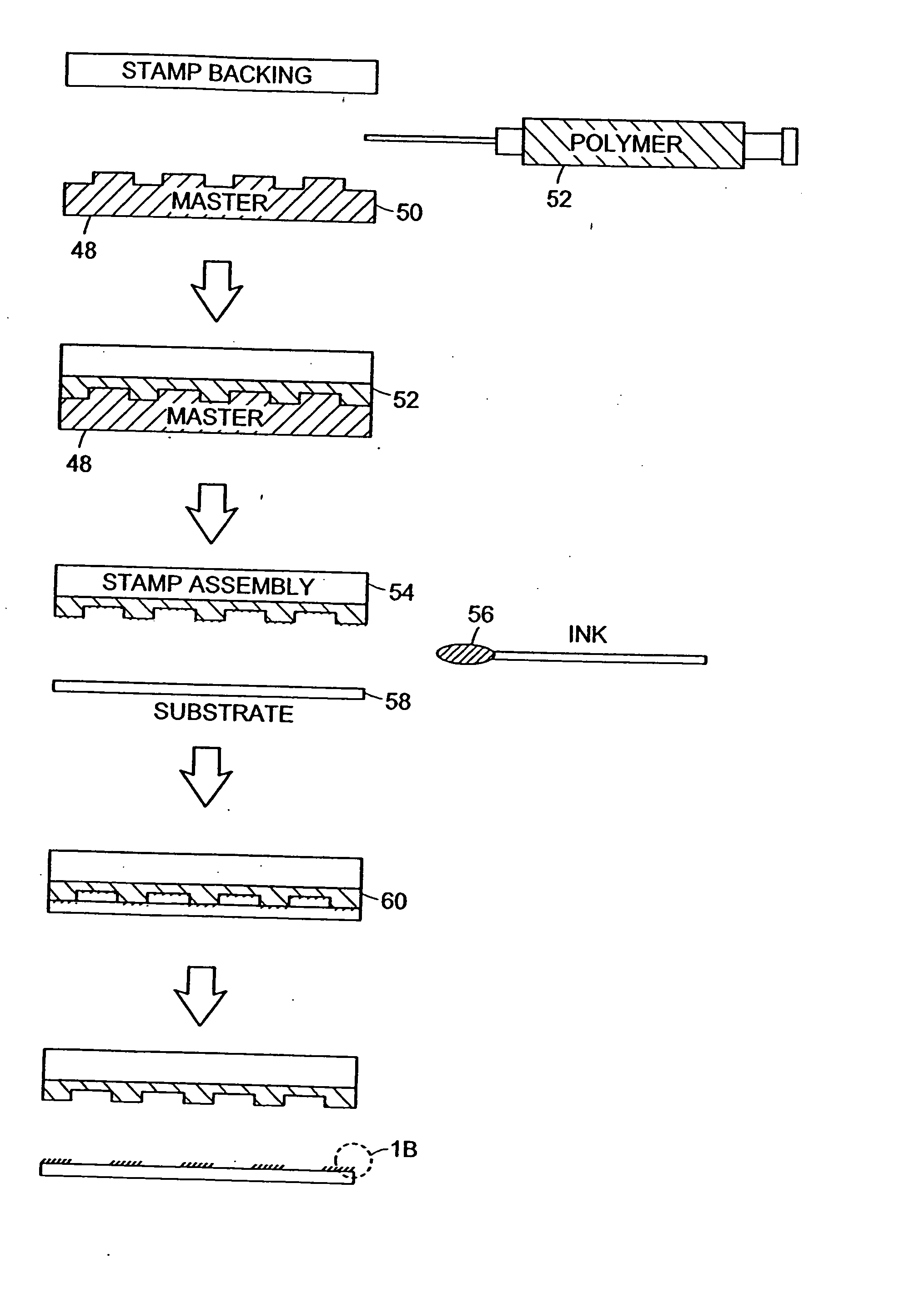

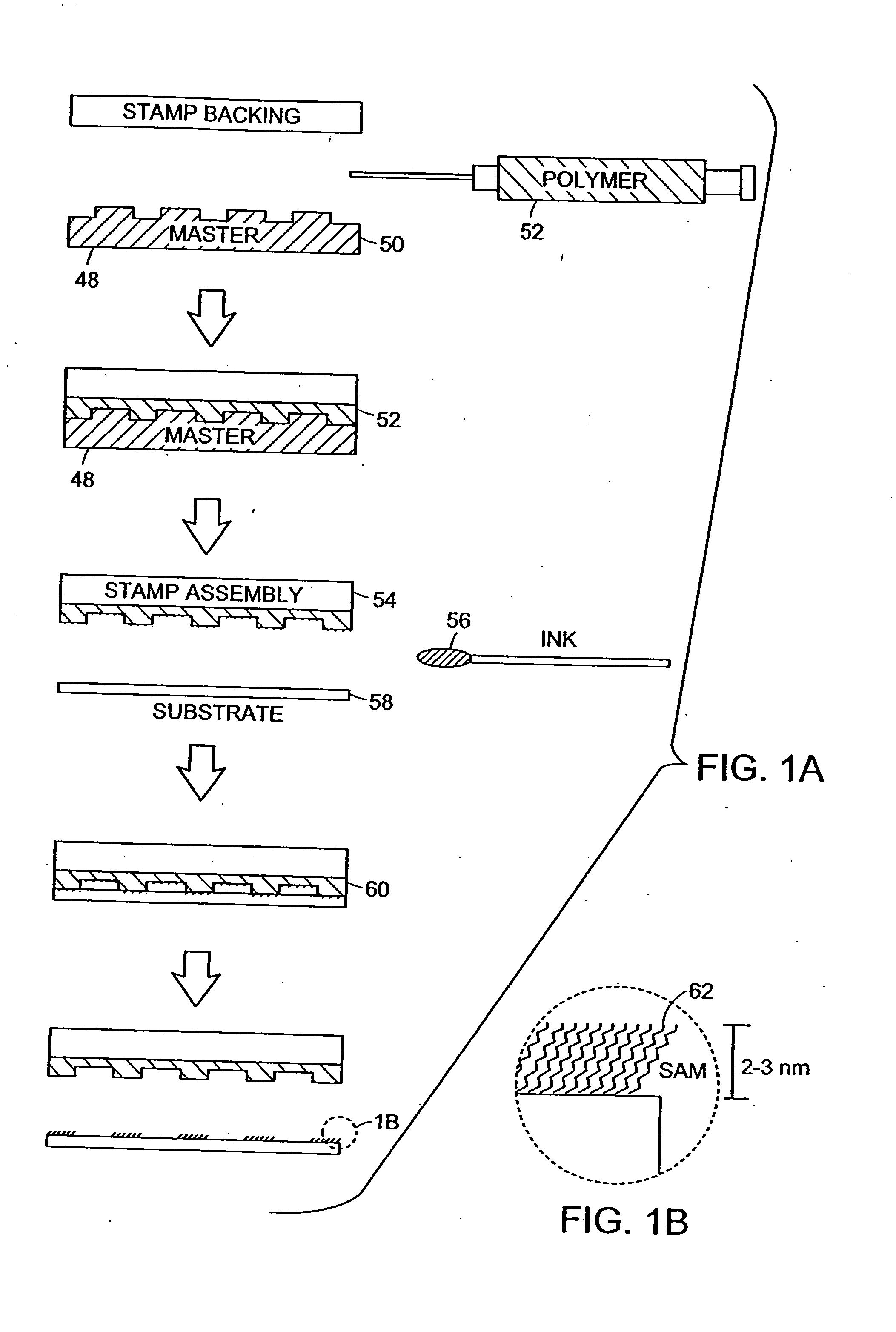

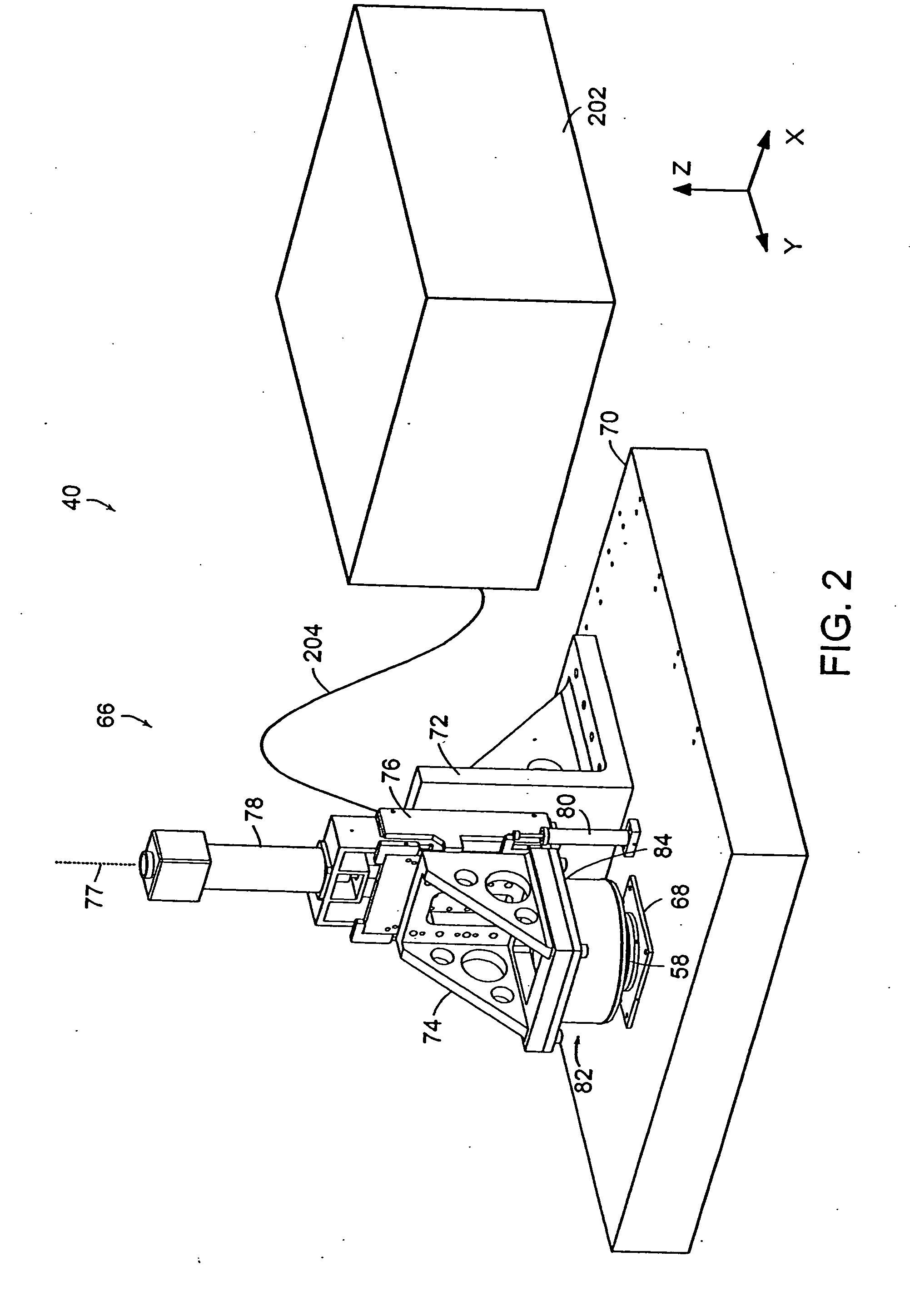

A microcontact printing tool having a print unit including a stamp head with a stamp and a wafer chuck for retaining a substrate. The stamp contained by the stamped head movable relative to the substrate by an actuator and a stage. A plurality of sensors detect the position of the stamp relative to substrate. A method of using the printing tool that includes a real-time feedback for consistent and accurate application of force during the printing of the substrate. The stamp head includes a pressure chamber carrying the stamp. The stamp backing is deflected prior to contact of the stamp with the substrate to form a minimum point and the stamp backing and the stamp is returned to a plane to create a printing propagation contact. An apparatus has a master backing and a stamping backing in close proximity and the stamp material drawn in through a vacuum. The stamp is separated from the master by use of a parting fluid.

Owner:MASSACHUSETTS INST OF TECH

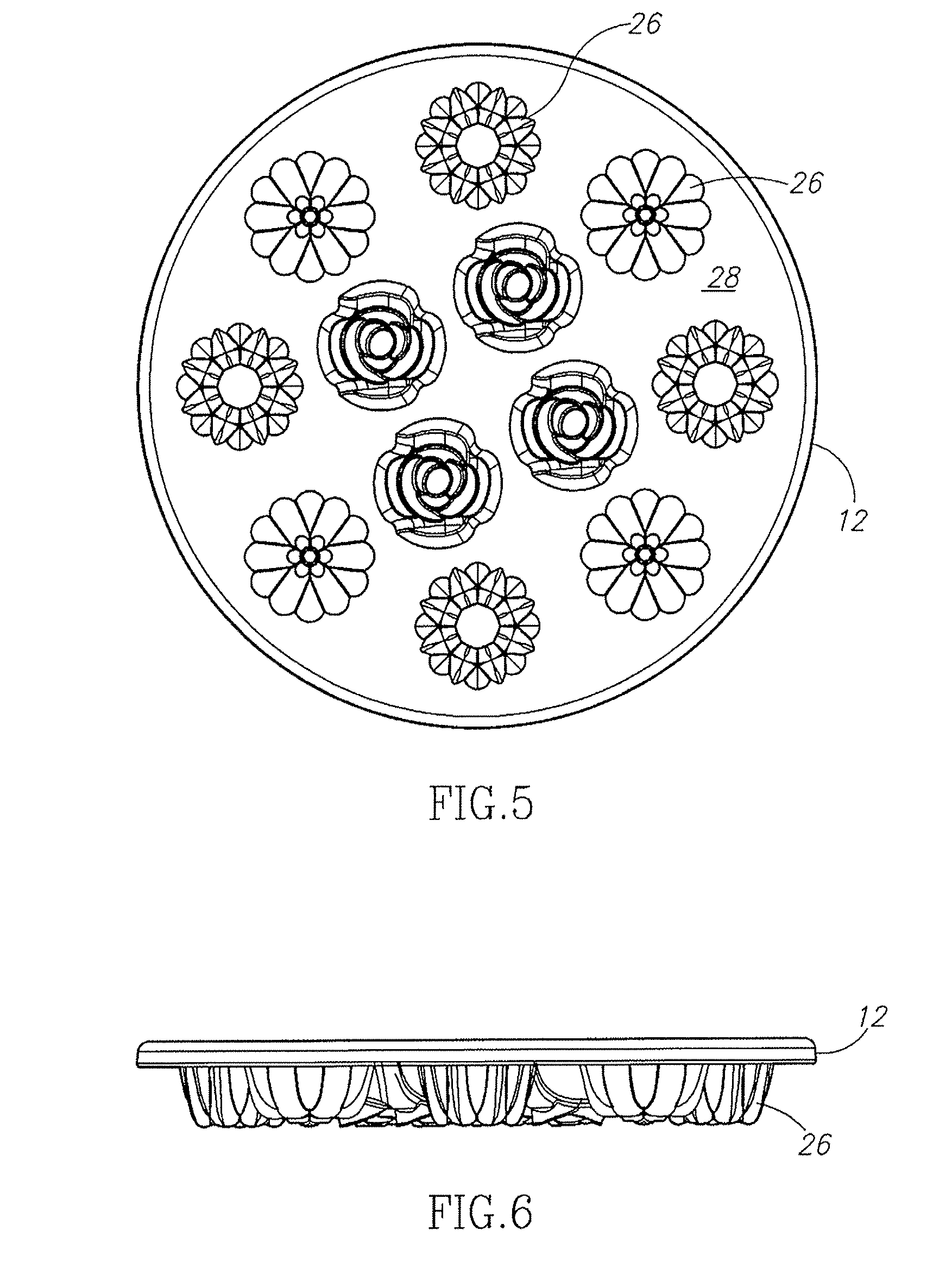

Method And Packaging For Baked, Thaw And Serve, Or Microwavable Goods

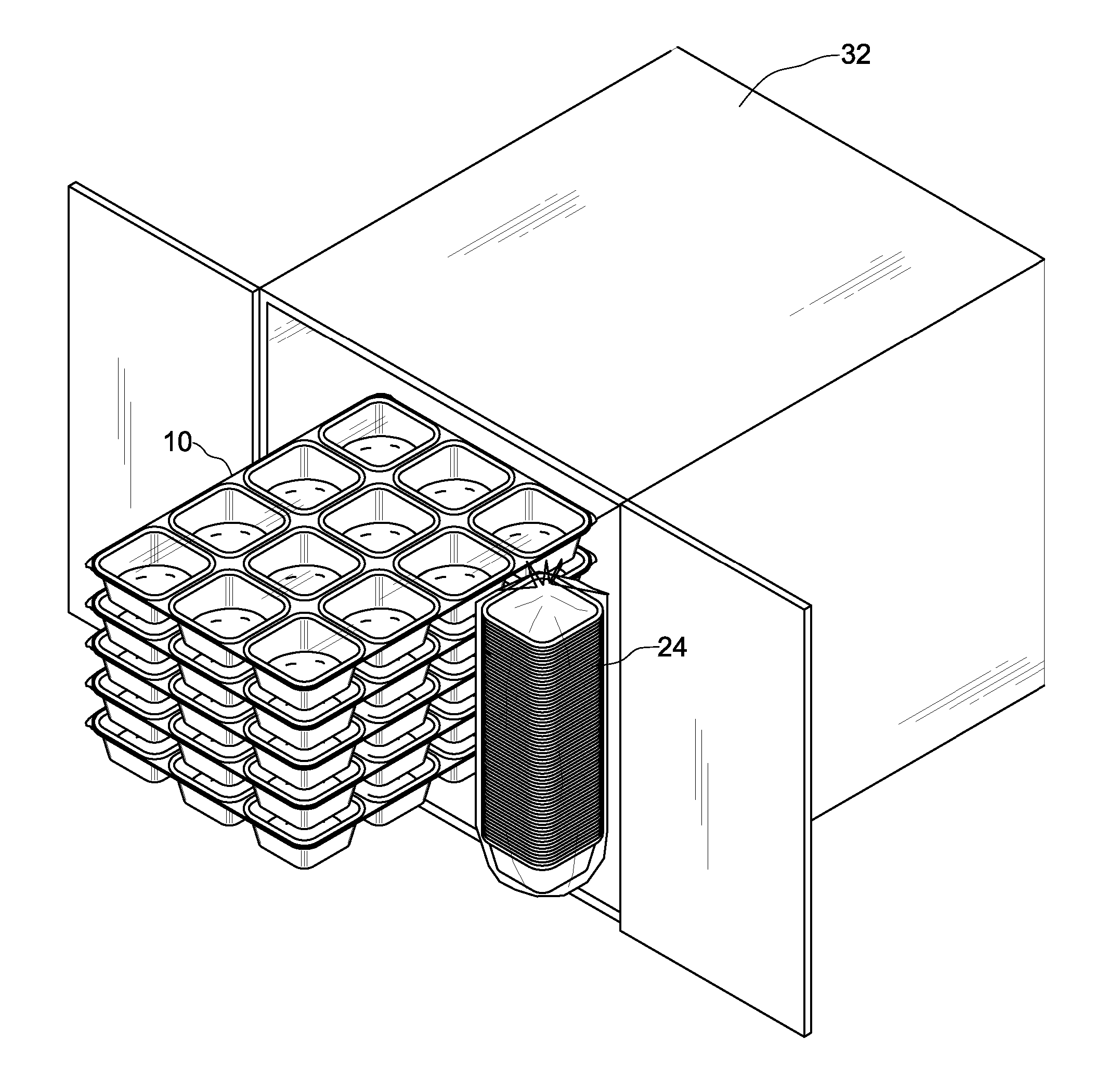

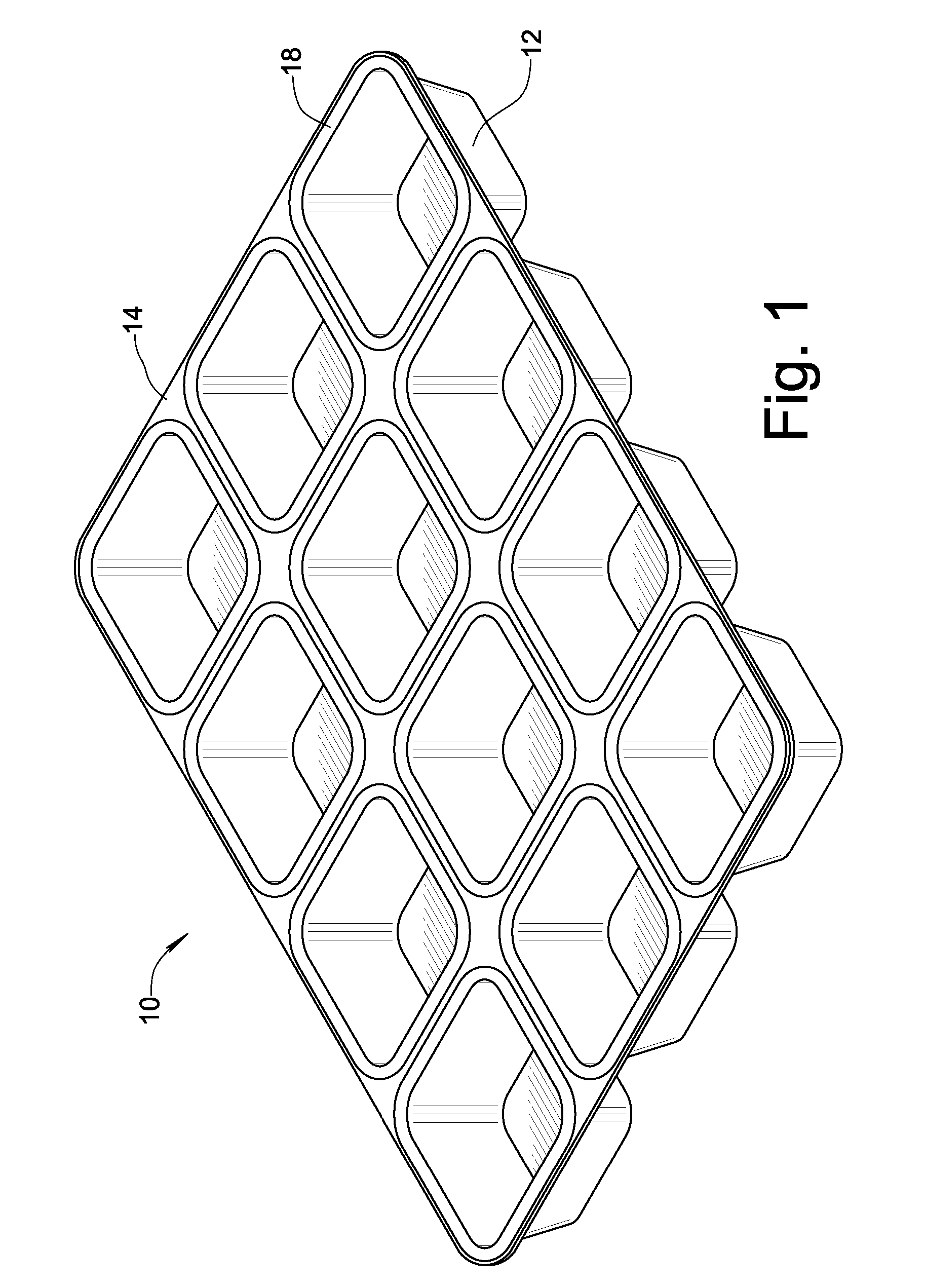

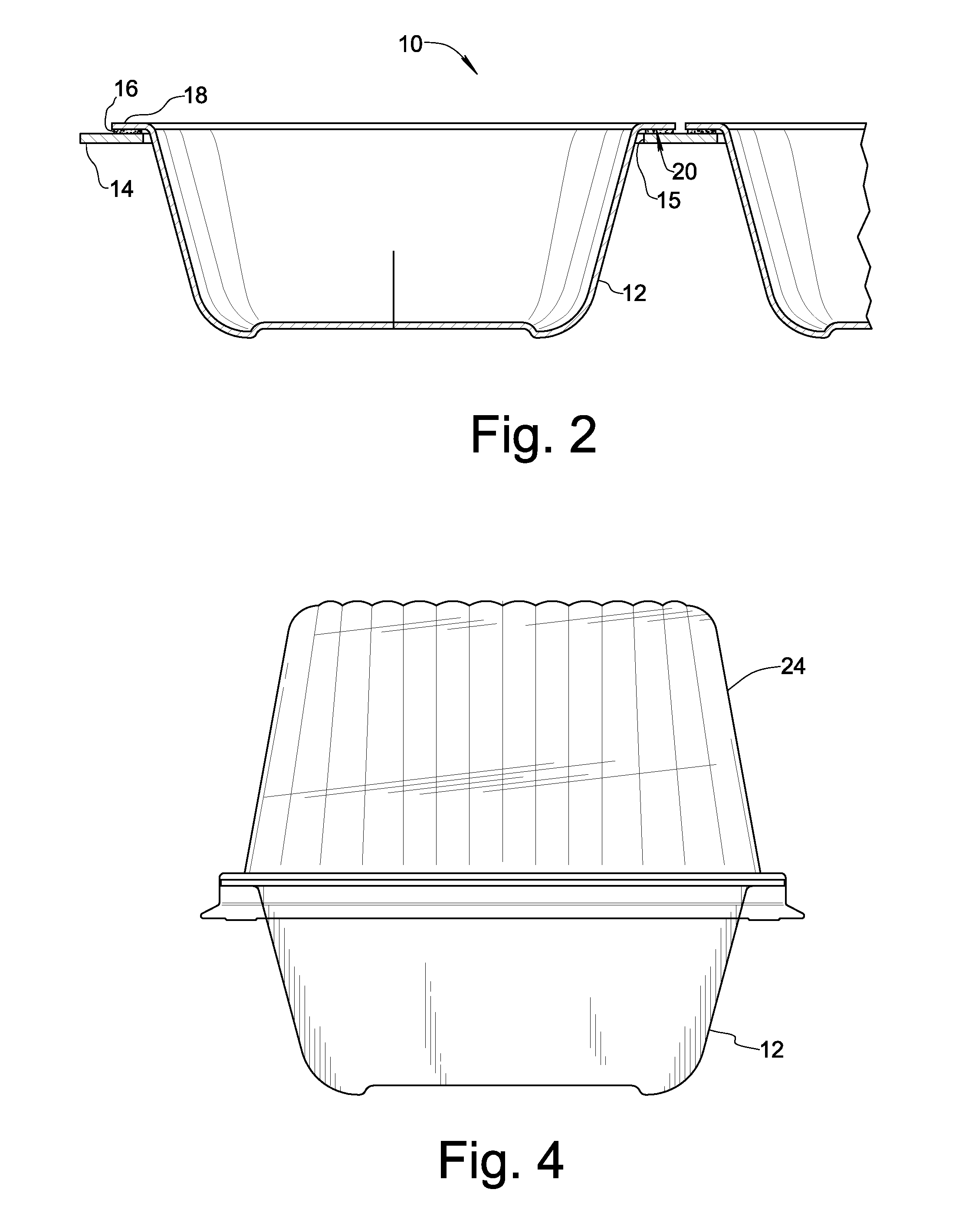

InactiveUS20070108089A1Envelopes/bags making machineryMould separation apparatusMicrowaveSupport matrix

Packaging for heatable food portions comprises an ovenable tray including a plurality of serving containers connected by a detachable support matrix. In one embodiment, the support matrix is attached to the serving containers by hot melt glue which melts during baking or heating to automatically release the support matrix from the serving containers. Pre-filled trays are shipped with display covers fitted to the serving containers, such that the covers may be placed on the individual serving containers after the food portions are baked and the serving containers are separated from the support matrix to provide individually packaged, freshly baked food portions for display.

Owner:RICH PRODUCTS

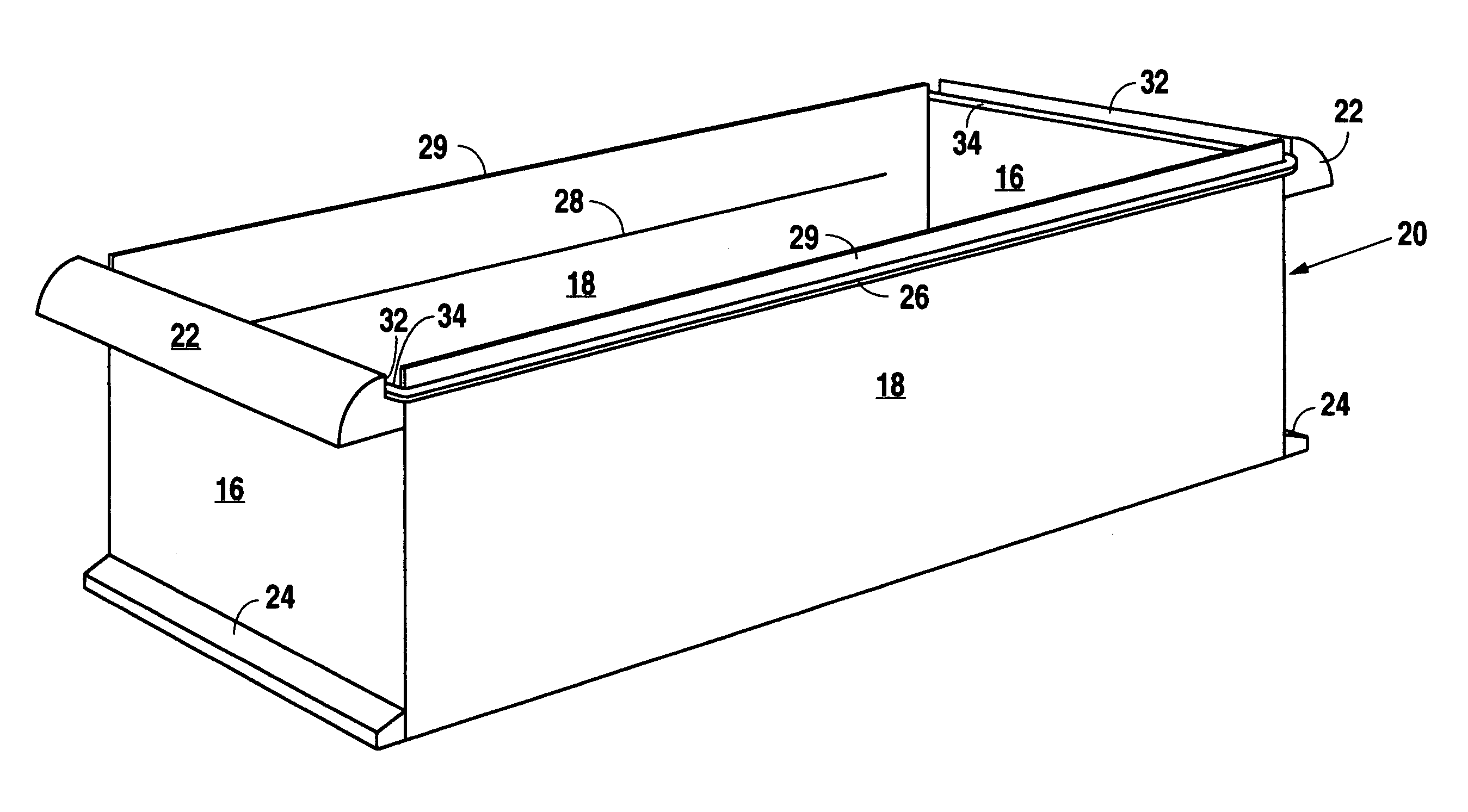

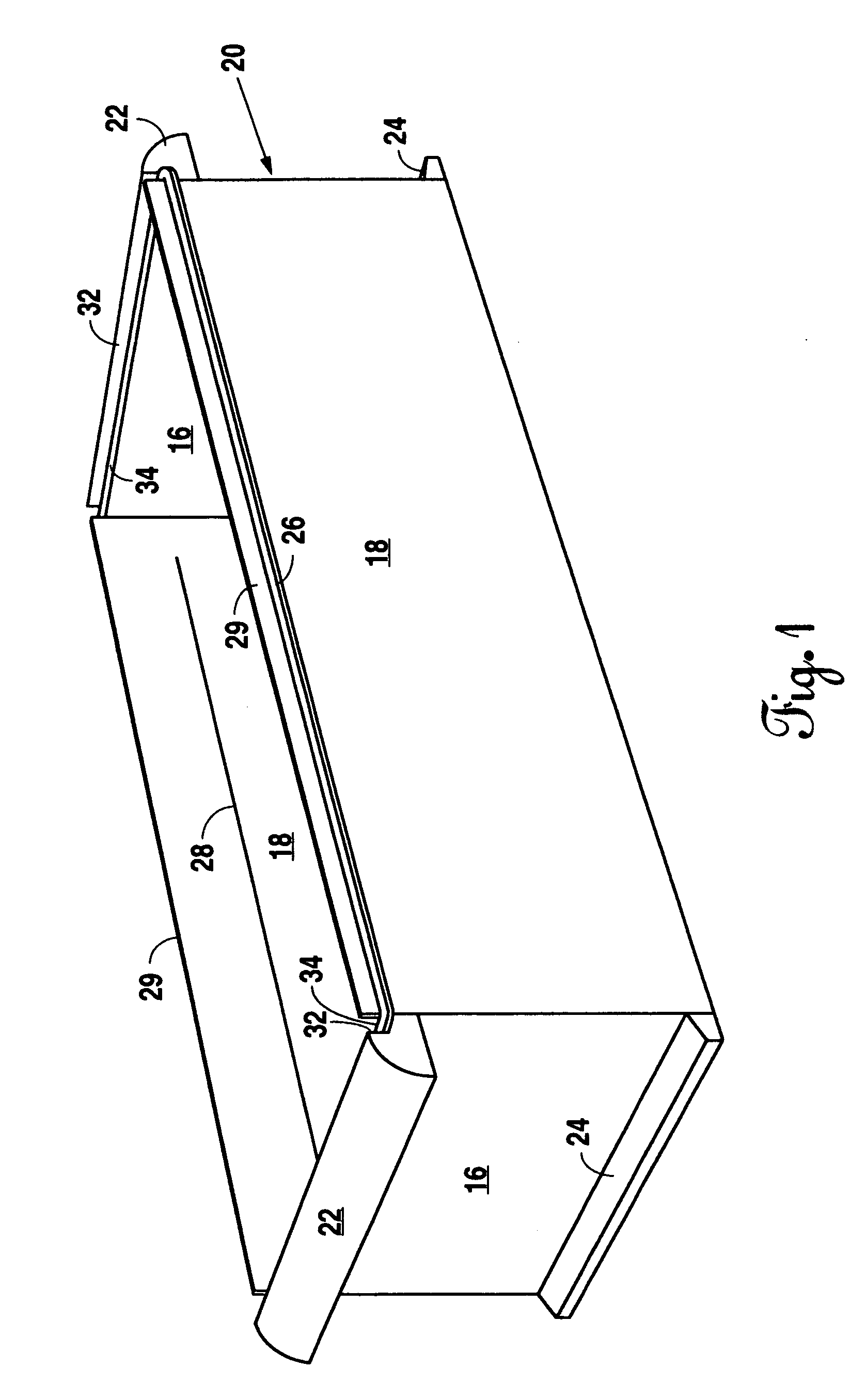

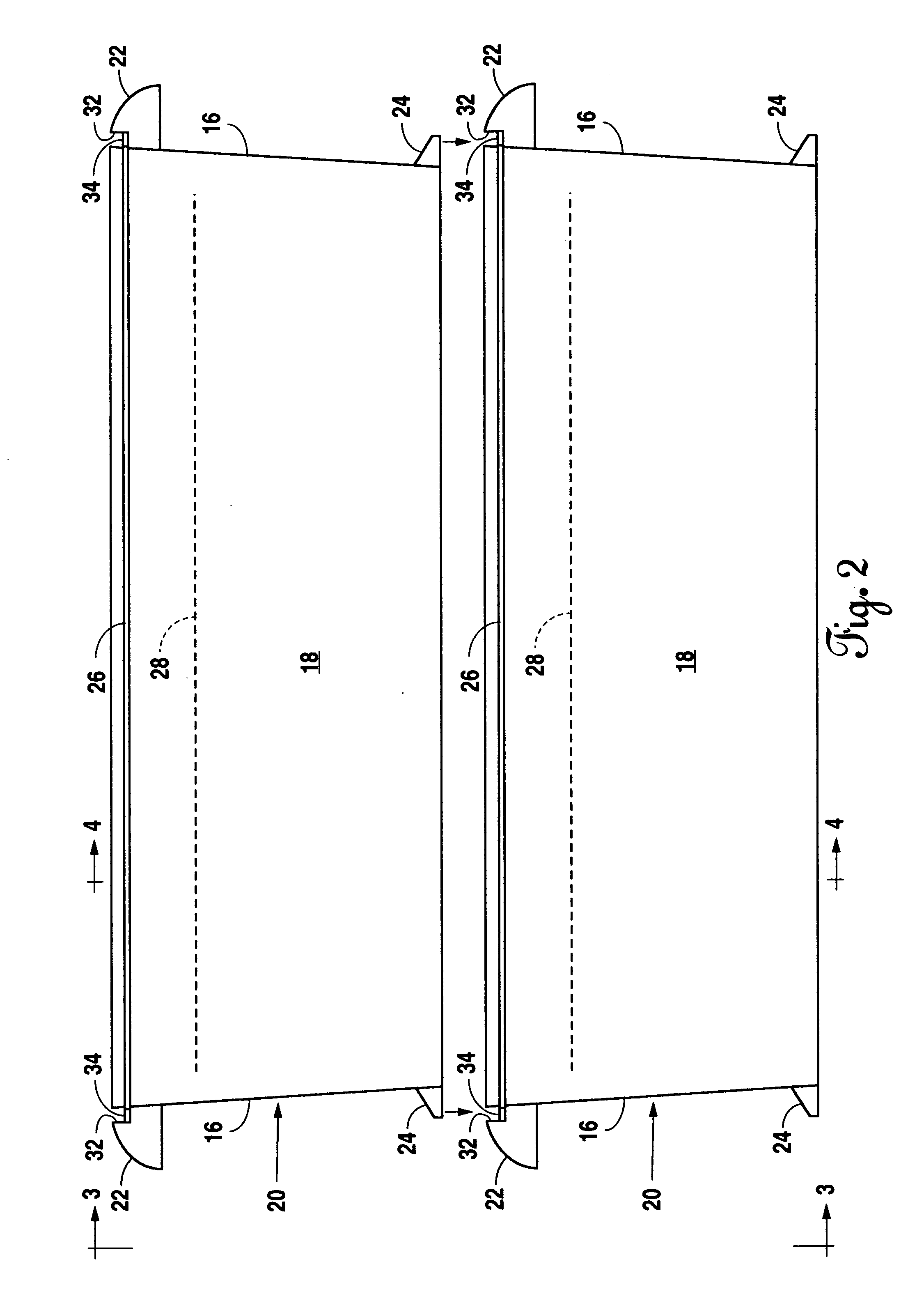

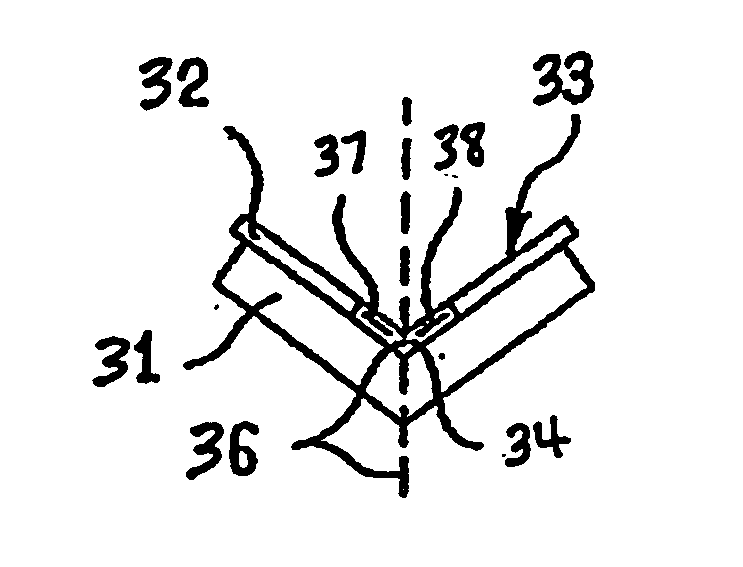

Stackable mold for making block ice

InactiveUS20070262230A1Efficient freezingHigh strengthMould separation apparatusLighting and heating apparatusEngineeringAirflow

A stackable mold for making block ice is disclosed. The bottom edges of the sidewall of the mold have stacking lips and the top edges of the sidewall have stacking ledges. The stacking ledges of a lower mold mate with the stacking lips of an upper mold, thereby allowing multiple molds to be stacked on top of one another. Guide lips along the sidewalls of the mold prevent slipping and shifting of the stacked molds. The tapered property of the molds creates space between the bottom of an upper mold and the top of a lower mold to allow airflow through the lower mold. A reinforcing lip extends along the top of the long sides for reinforcement.

Owner:MCDERMOTT CARLOS TOMAS JR

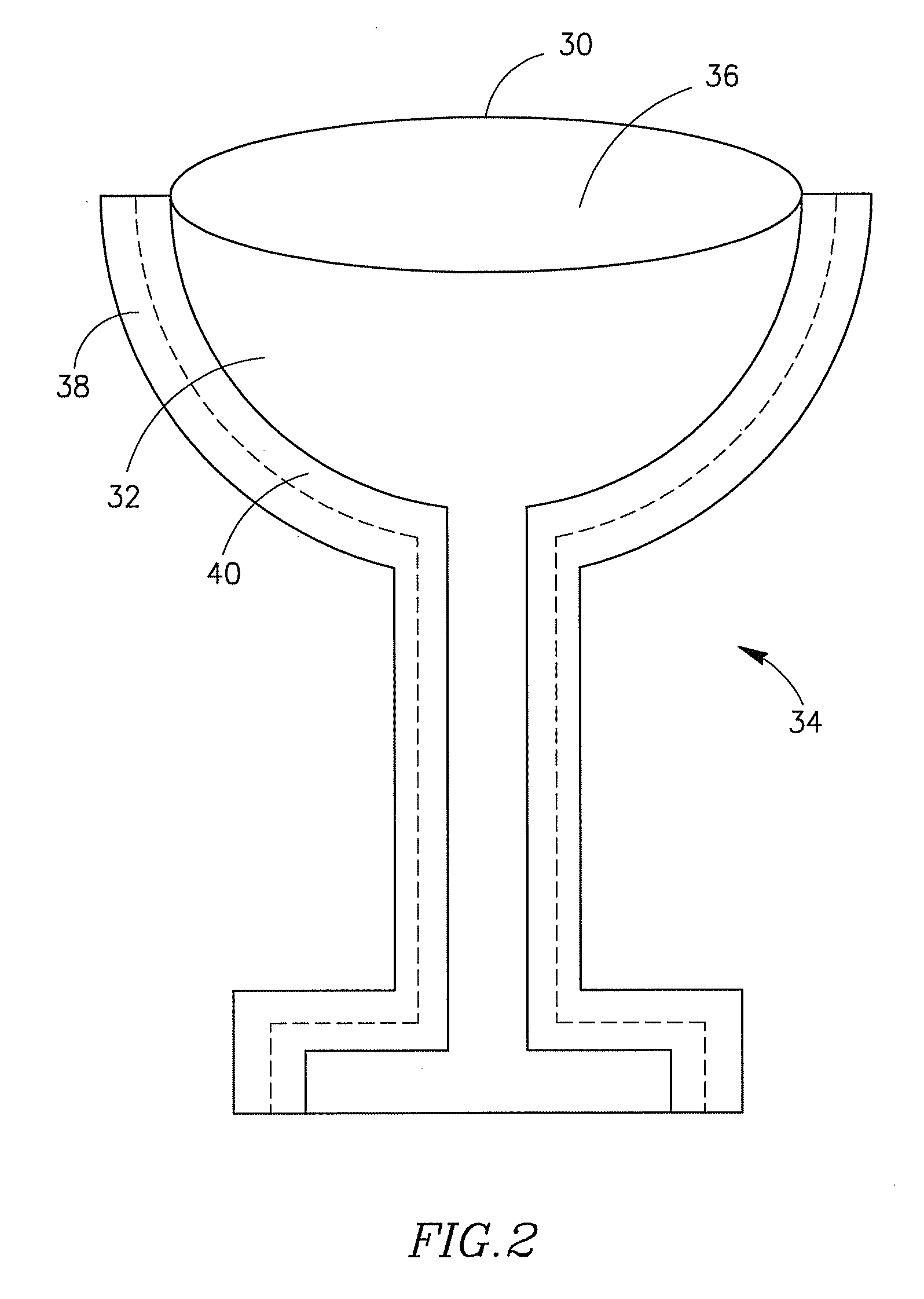

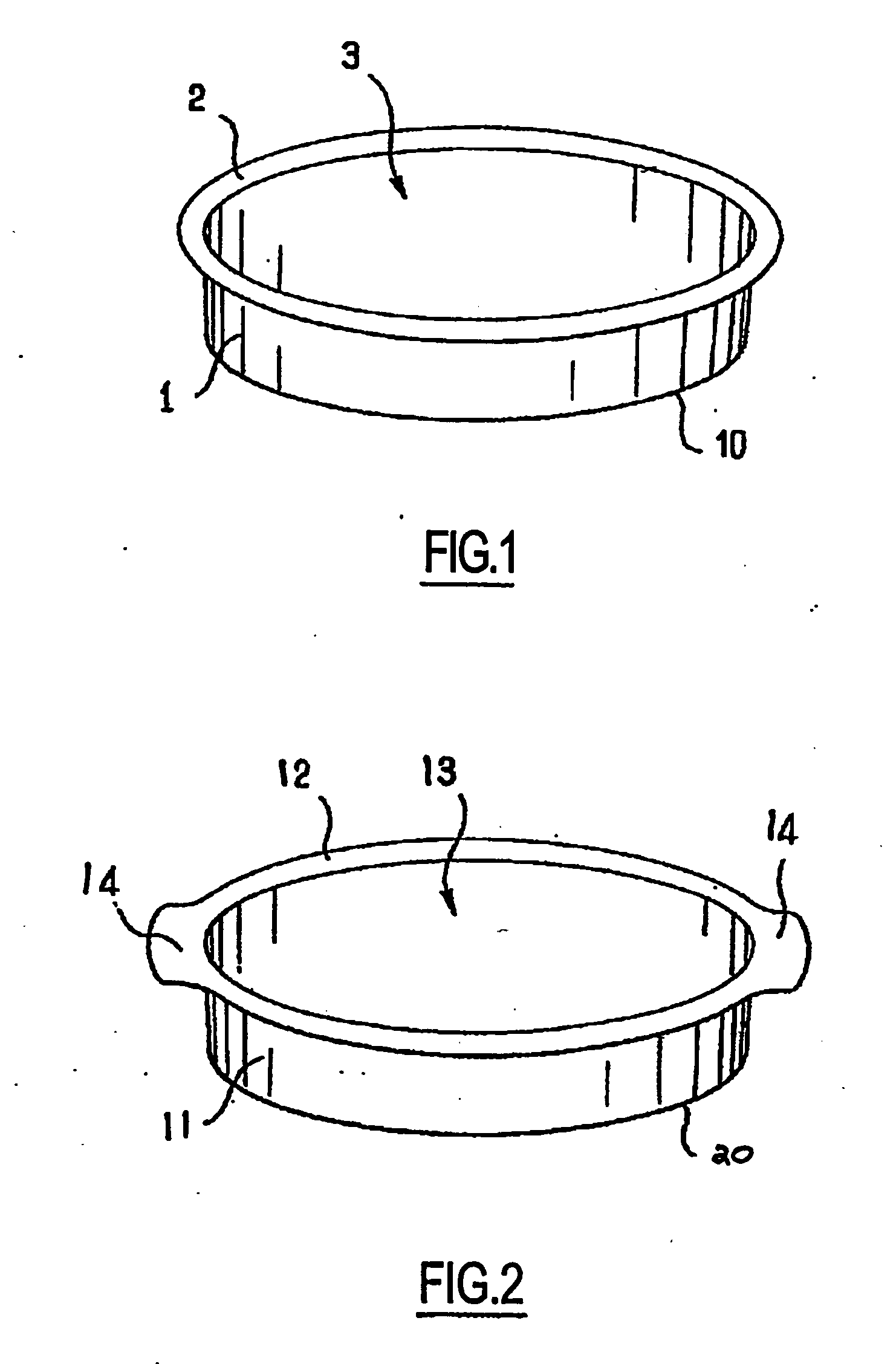

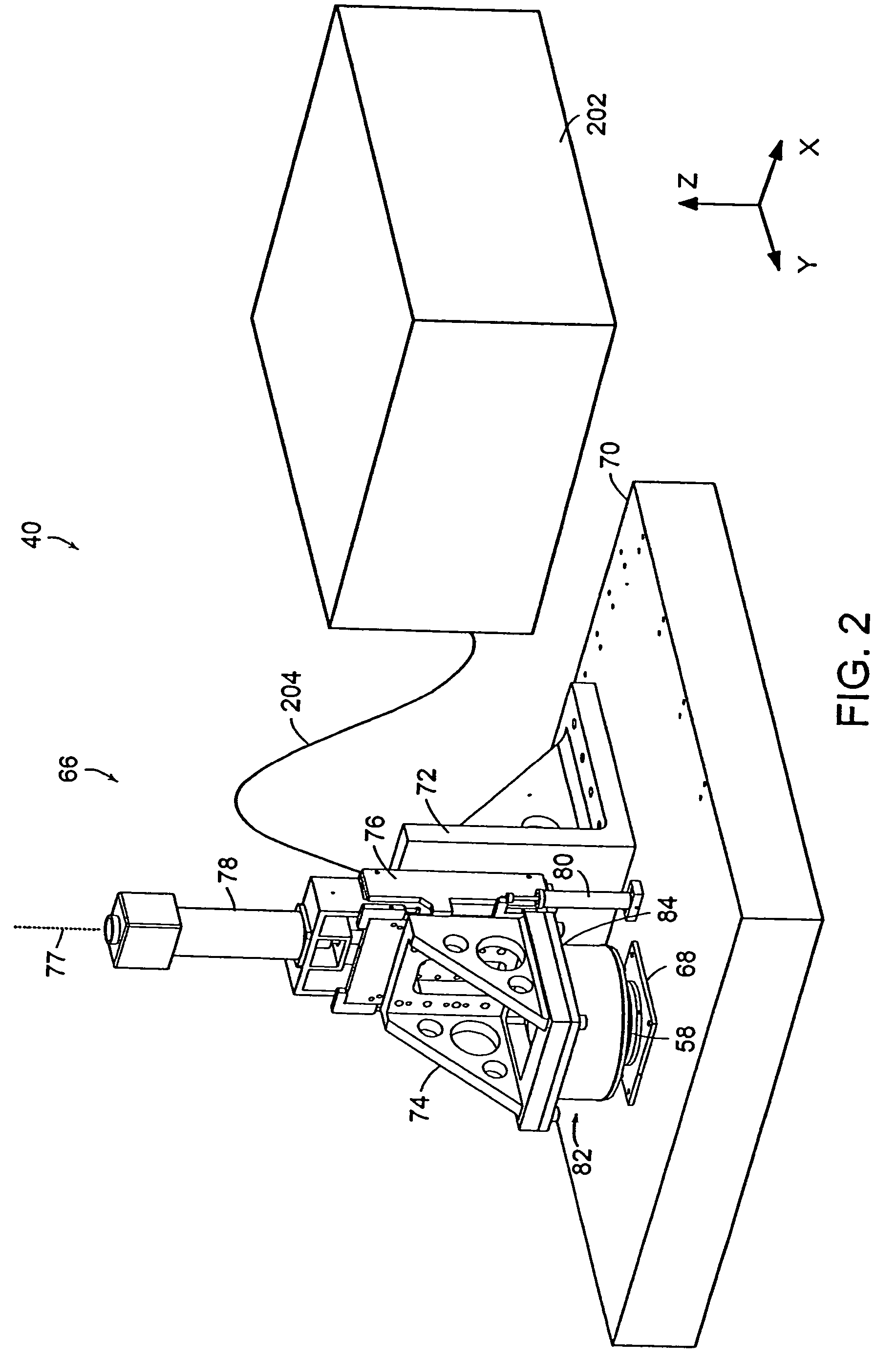

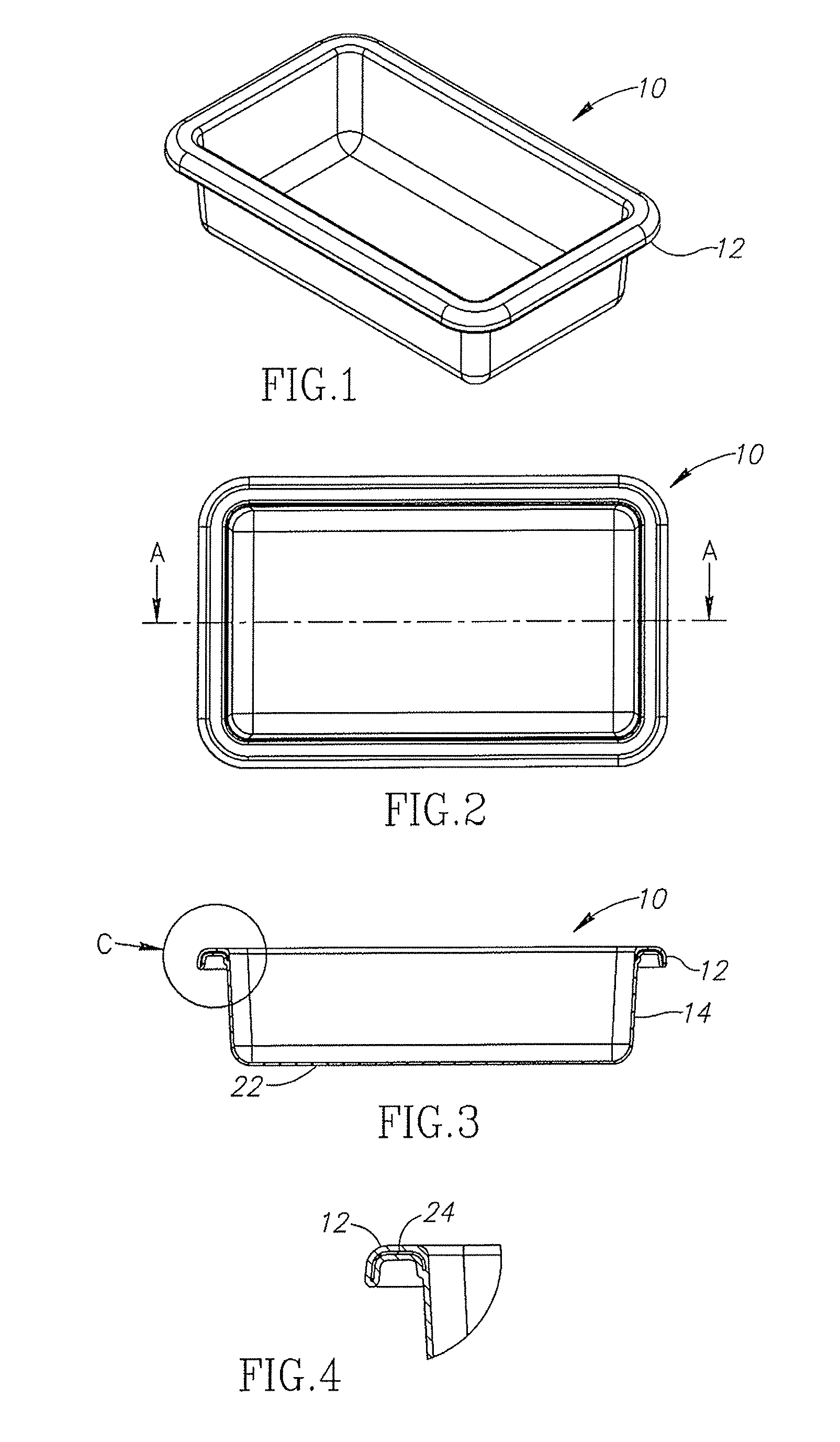

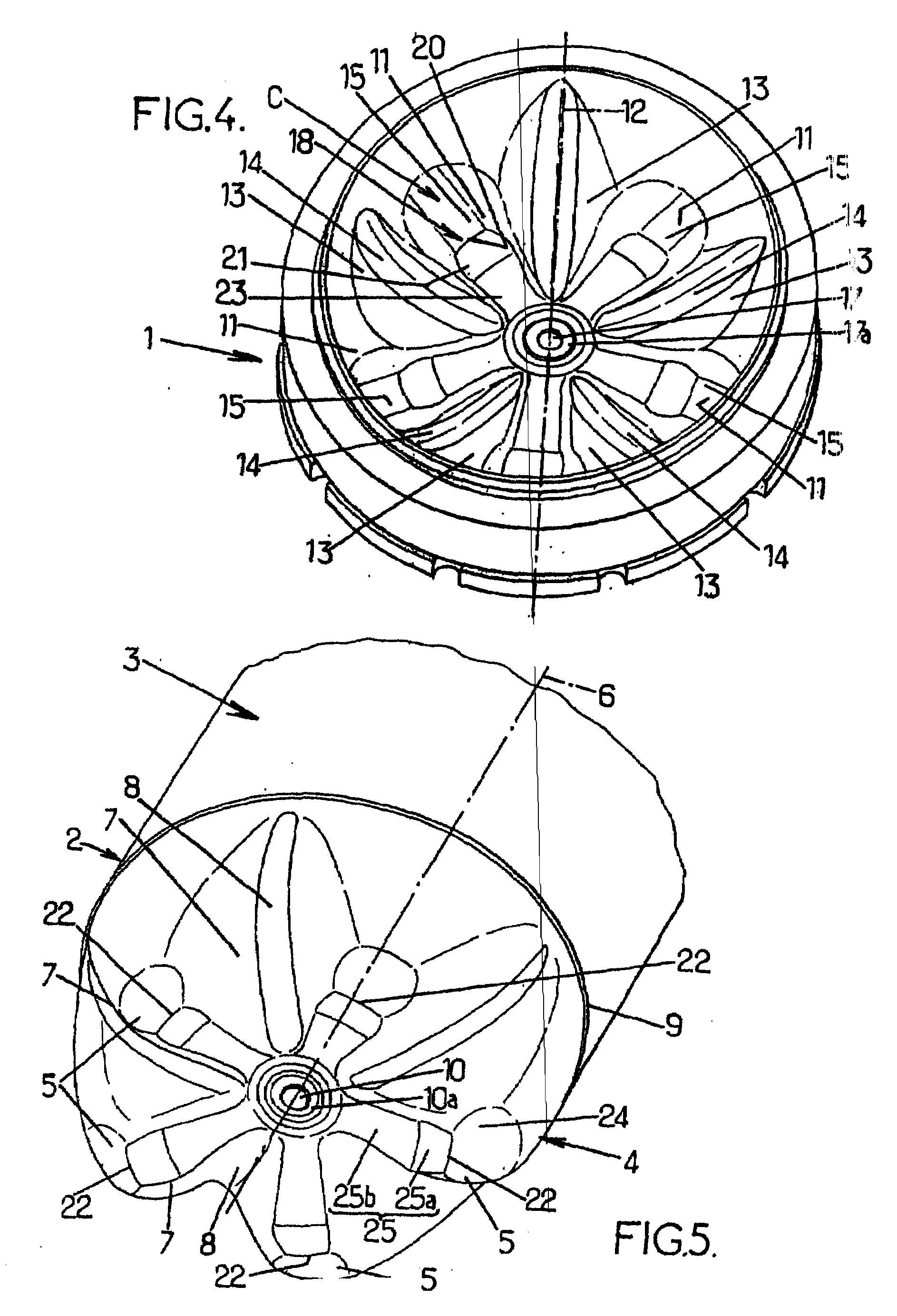

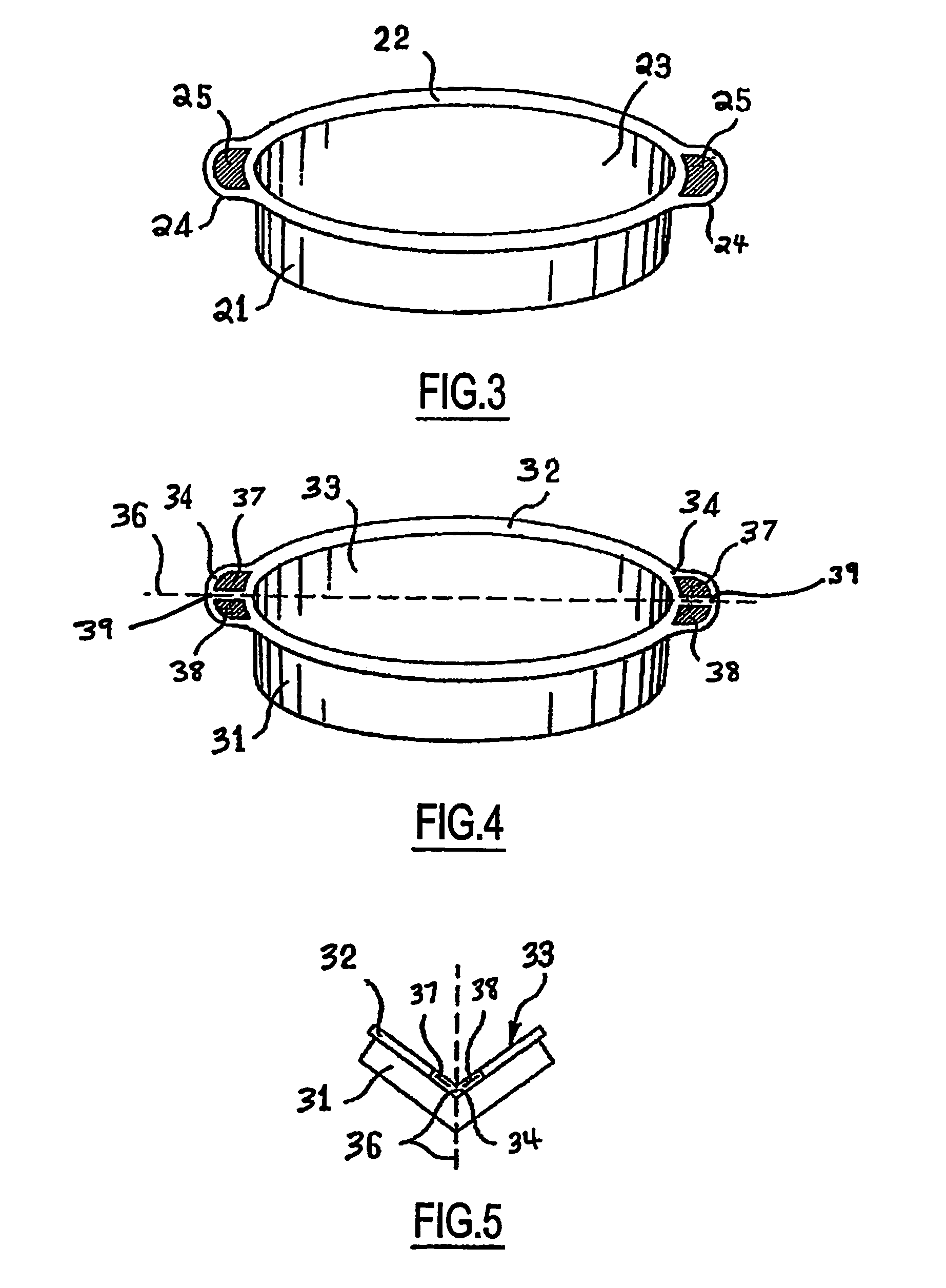

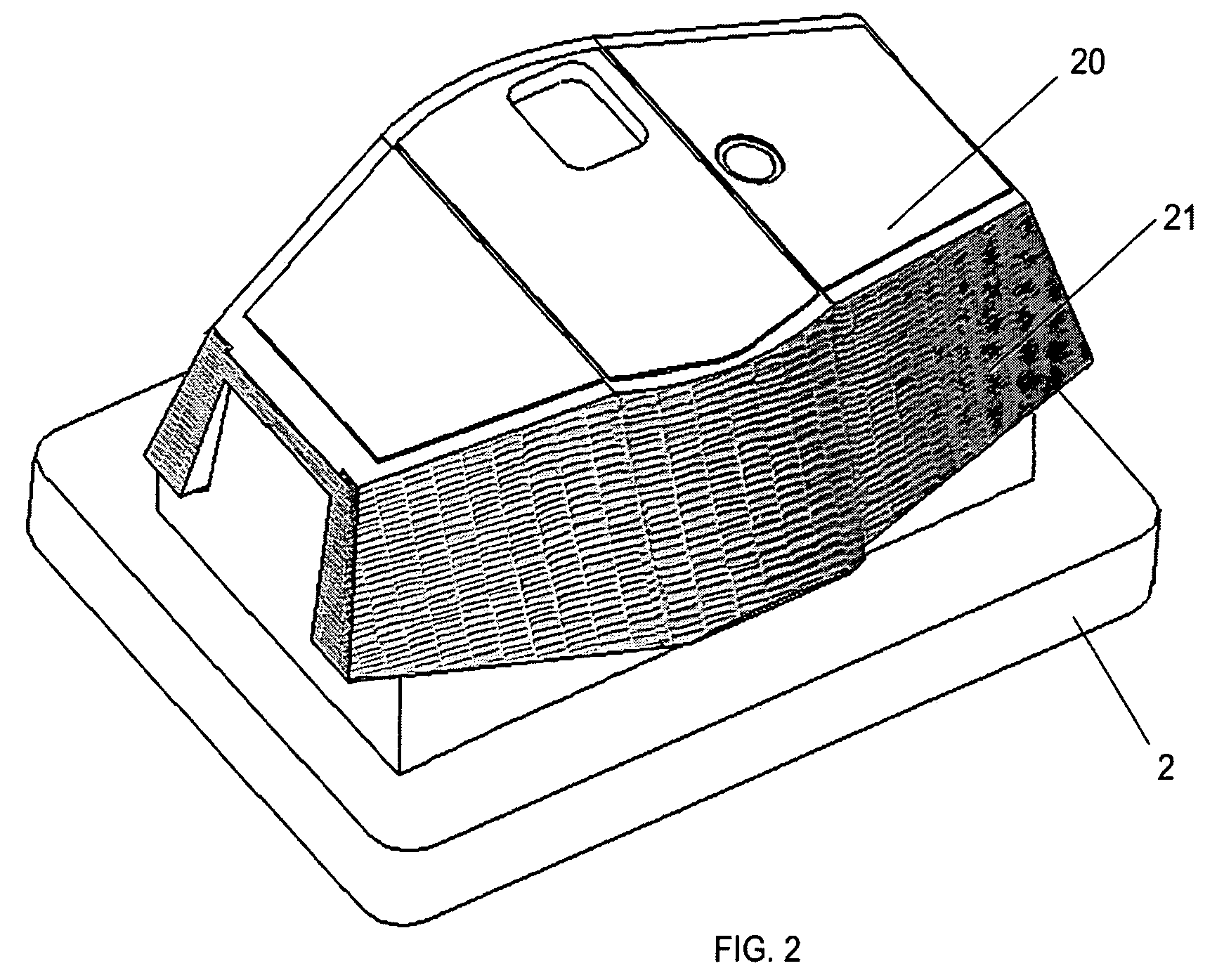

Flexible mold with grasping handles

InactiveUS20050056642A1Simple and safe operationEasy to handleStereotype platesSealingEngineeringMechanical engineering

A flexible, silicone mold having a bowl and a peripheral rim that defines an opening to the bowl. Two substantially flat grasping zones are disposed along substantially opposite ends of the rim and the grasping zones have sufficient dimensions to permit control of the geometry of the rim and also to permit control of the horizontal positions of the two grasping zones.

Owner:MASTRAD

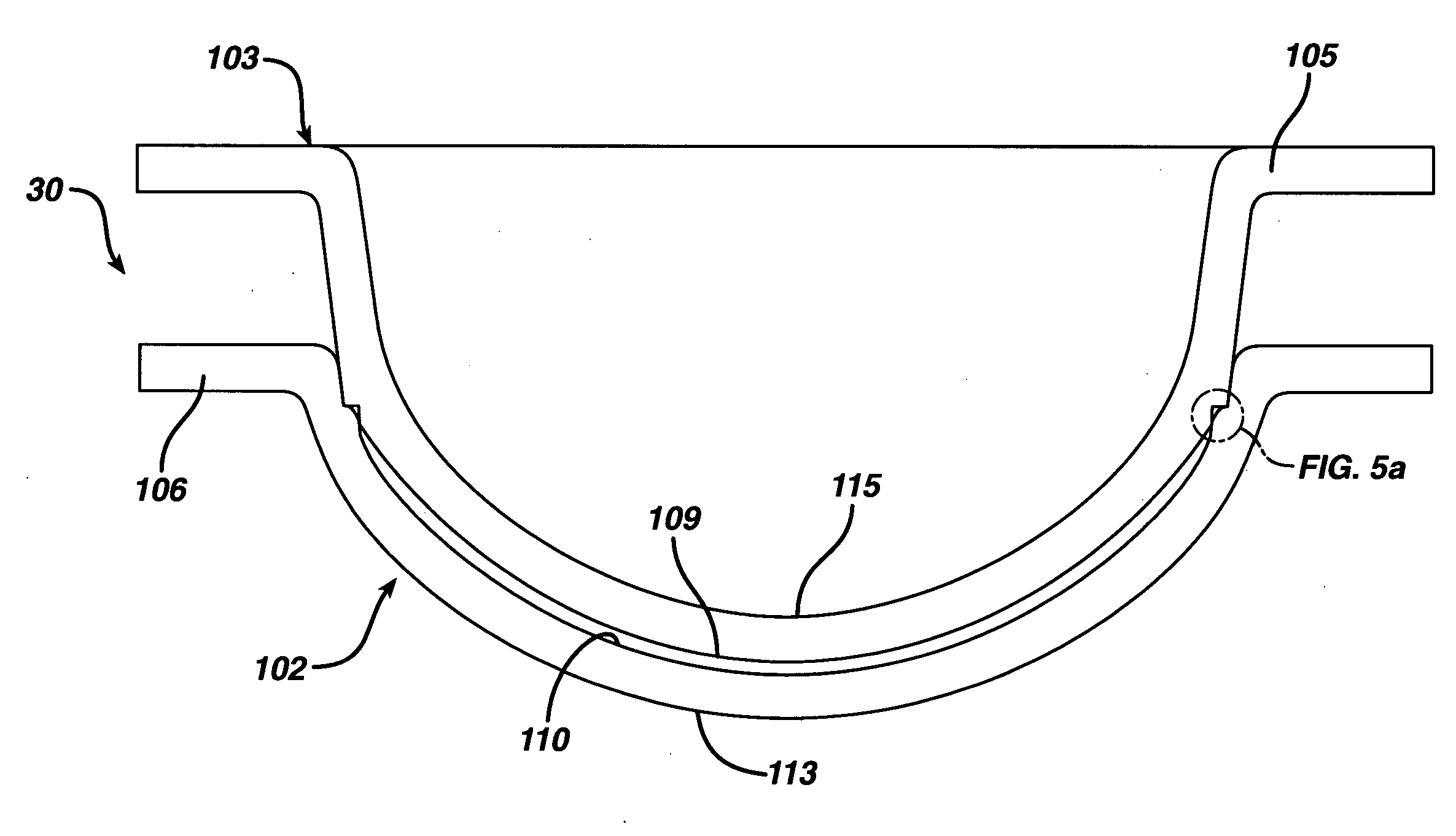

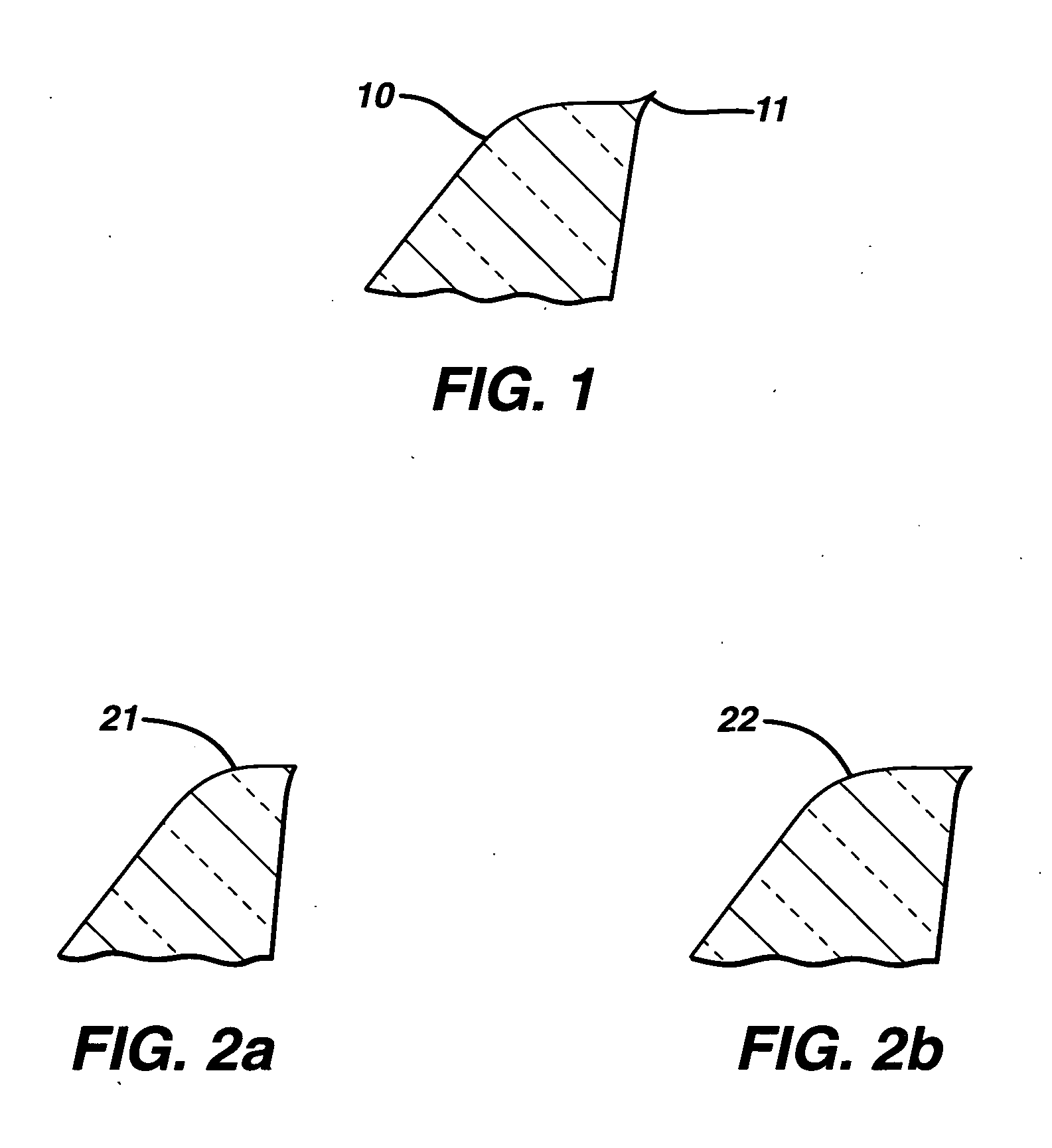

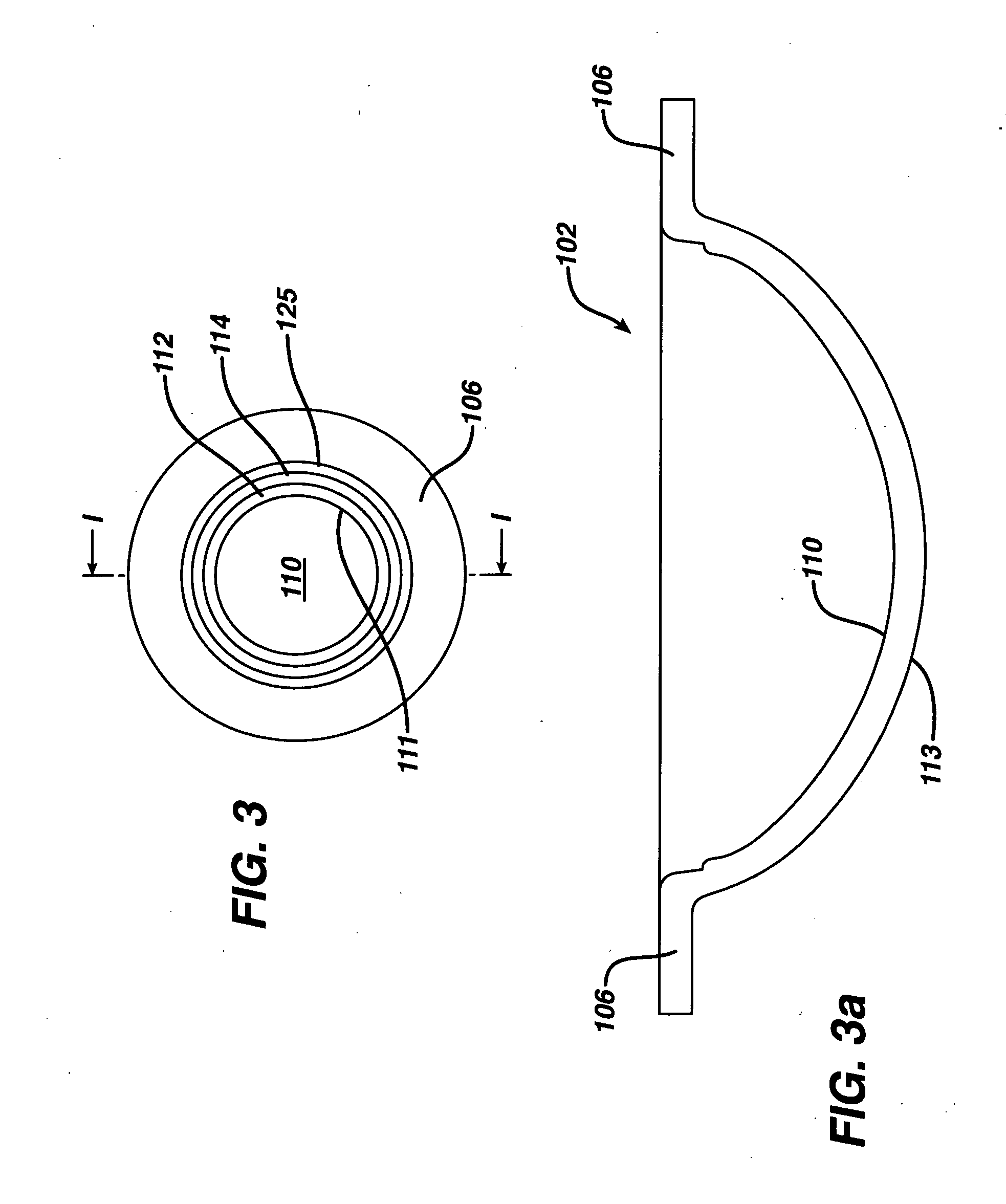

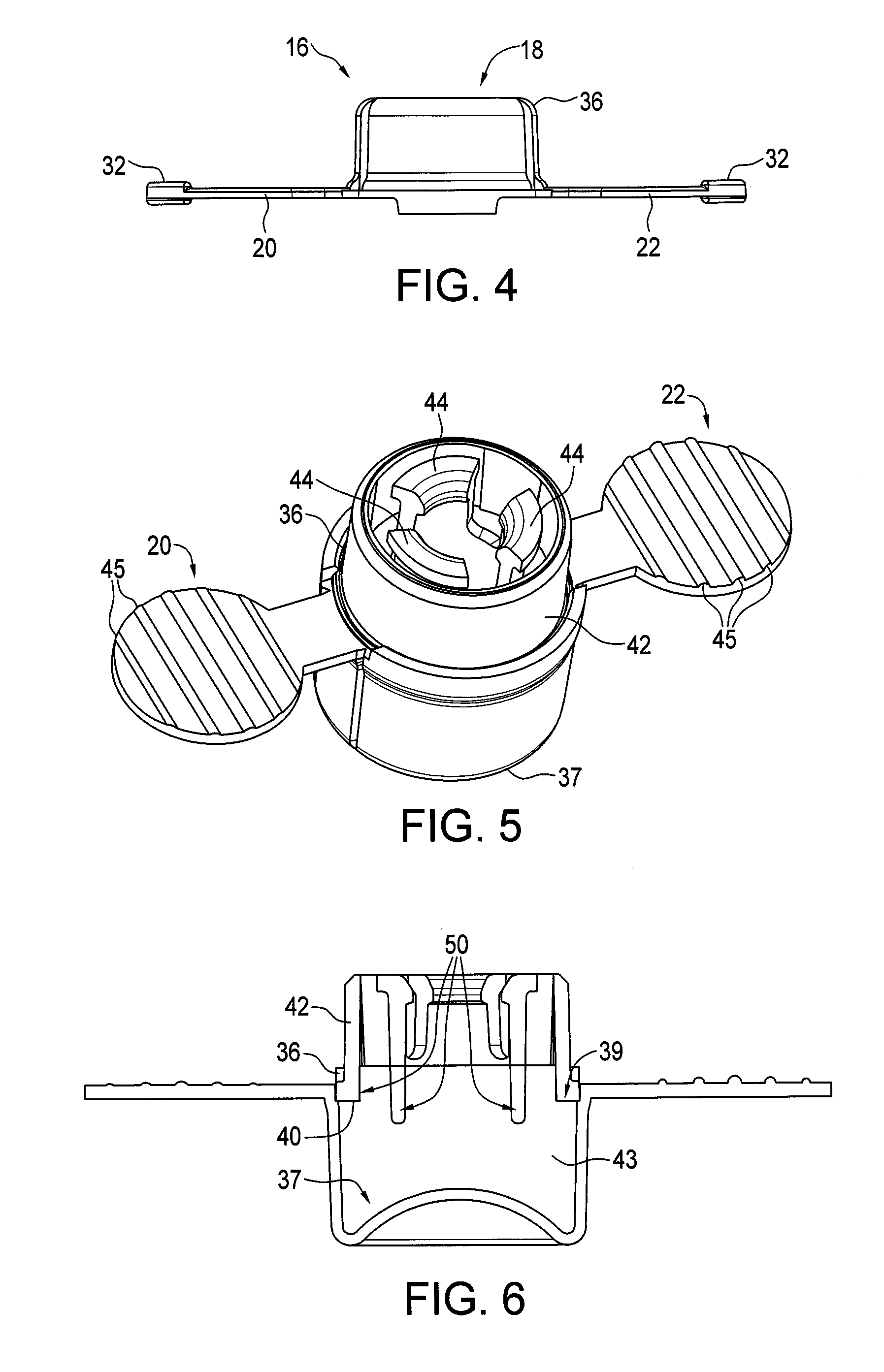

Contact lens mold assemblies and systems and methods of producing same

ActiveUS7731873B2For quick replacementPrecise and accurate amountOptical articlesStereotype platesEngineeringLens plate

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which, when coupled together, are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by focused ultrasound energy.

Owner:COOPERVISION INT LTD

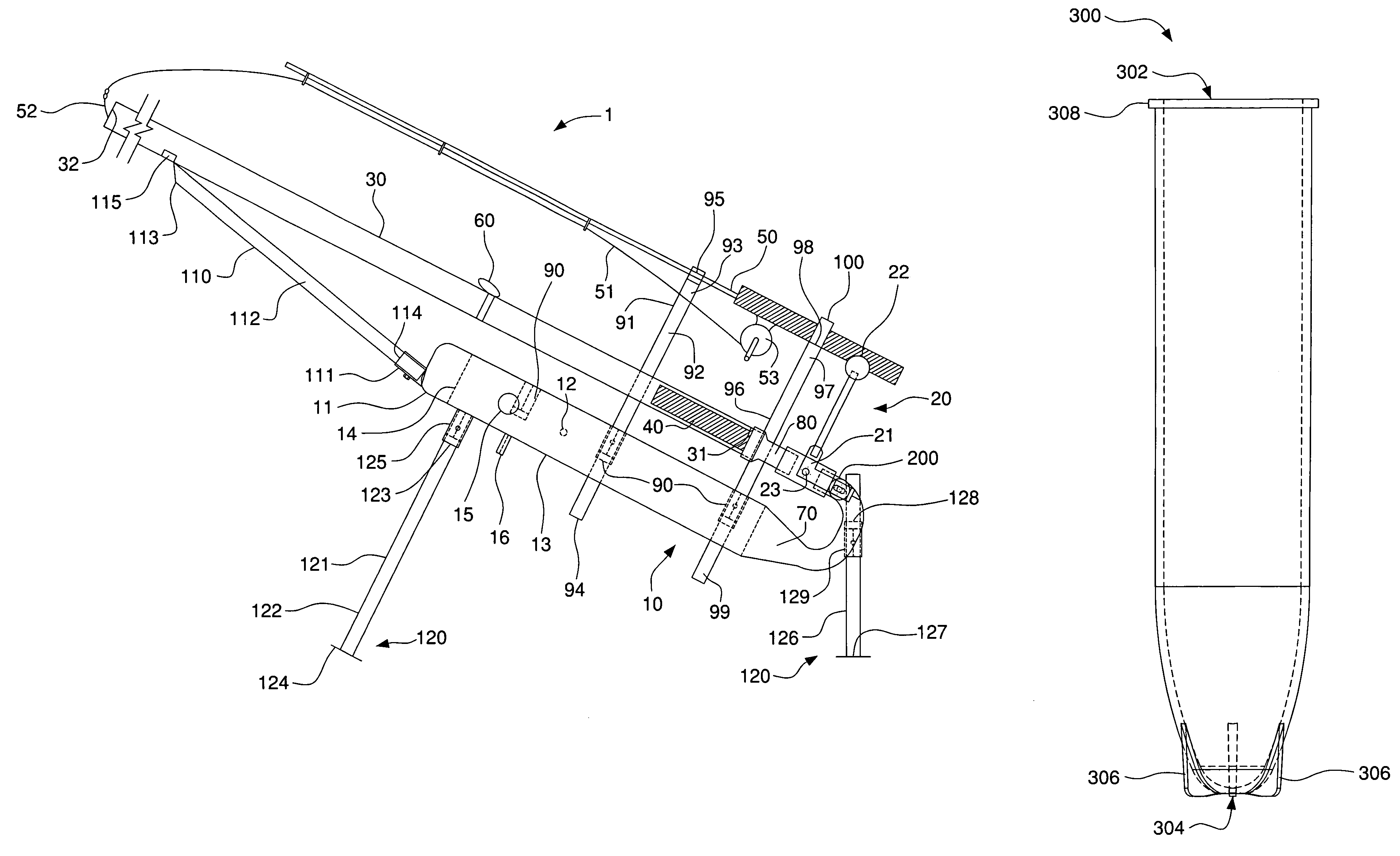

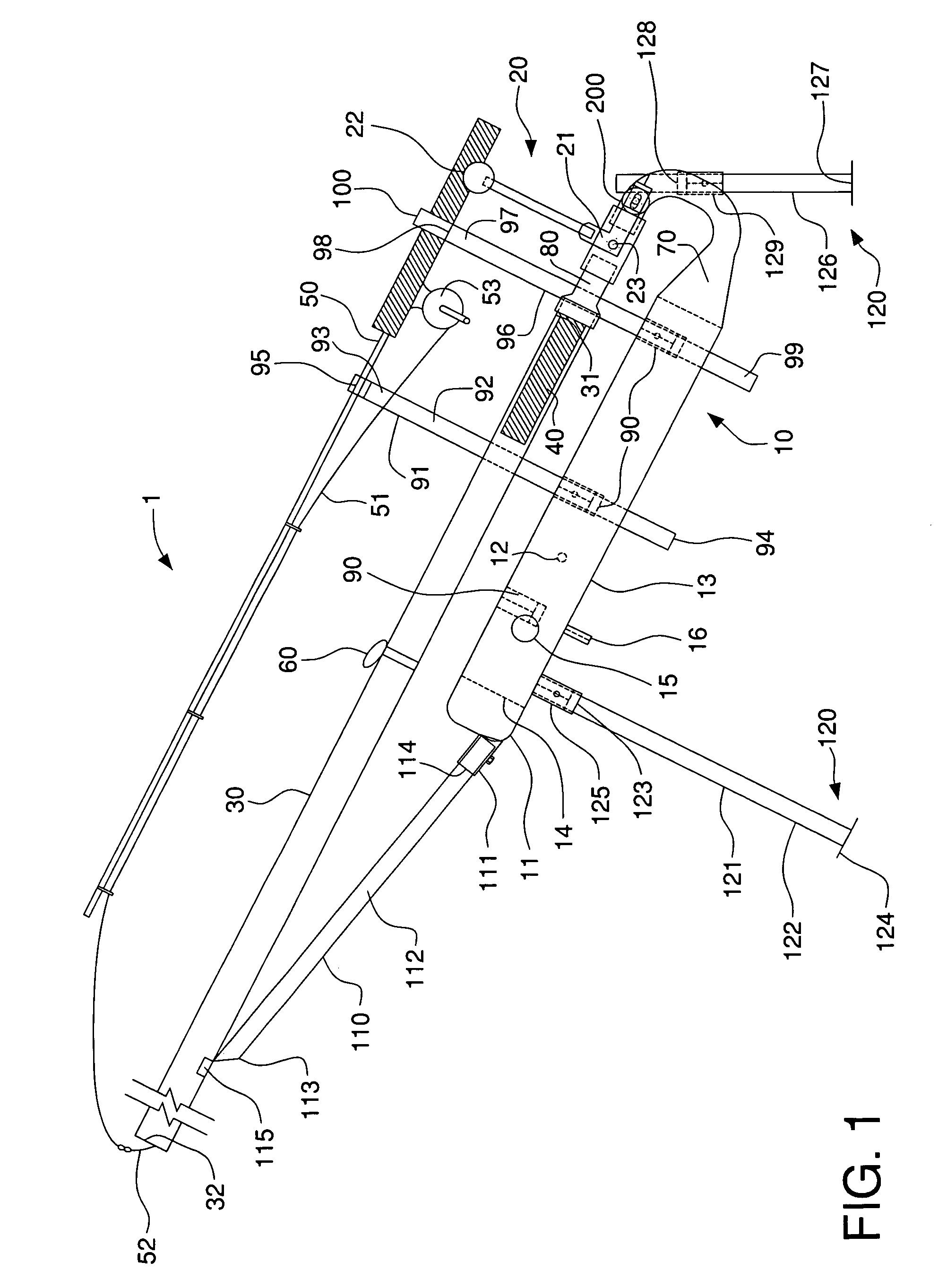

Fishing line casting and bait projectile system

ActiveUS7409794B2Easy constructionEasy to operateMould separation apparatusLighting and heating apparatusDecoyReduction drive

A powered fishing line casting system utilizing compressed air is provided to cast a projectile provided with fishhooks and bait, and to which the fishing line to be cast is attached, to greater distances than could be achieved using conventional casting methods. The system includes a hollow launch tube sized to accommodate insertion of the projectile. A reducer is disposed adjacent to one end of the launch tube and is adapted to receive a flow of compressed gas from an accumulator tank and to discharge a stream of high-velocity air that impinges upon the projectile disposed within the launch tube in order to launch the projectile. A manually-operable valve is interposed between the reducer and the accumulator tank to control the flow of air to the reducer. Spaced-apart front and rear support legs provide stable support for the system during and between launches of a fishing line carrying projectile.

Owner:M DOOLEY PROD LLC

Microcontact printing

InactiveUS7665983B2Generate undesired patterning resultsControl distortionMaterial nanotechnologyMechanical working/deformationMicrocontact printingActuator

A microcontact printing tool having a print unit including a stamp head with a stamp and a wafer chuck for retaining a substrate. The stamp contained by the stamped head movable relative to the substrate by an actuator and a stage. A plurality of sensors detect the position of the stamp relative to substrate. A method of using the printing tool that includes a real-time feedback for consistent and accurate application of force during the printing of the substrate. The stamp head includes a pressure chamber carrying the stamp. The stamp backing is deflected prior to contact of the stamp with the substrate to form a minimum point and the stamp backing and the stamp is returned to a plane to create a printing propagation contact. An apparatus has a master backing and a stamping backing in close proximity and the stamp material drawn in through a vacuum. The stamp is separated from the master by use of a parting fluid.

Owner:MASSACHUSETTS INST OF TECH

Silicone baking pan

A mold is integrally formed from a flexible material that is suitable for baking or molding food products, such as food grade silicone. In one example, the mold includes a rim at the top and a wall extending between the rim and a base at the bottom. The wall is sufficiently thick that the pan can support its own weight while holding a food item. The mold may include an interior or exterior relief pattern that is imparted onto the food item. In some forms, an upper portion of the mold is relatively smooth and more flexible than a lower portion having a relief pattern. An internal U-shaped stiffening element helps to prevent the mold from collapsing and improves handling of the mold.

Owner:PROGRESSIVE INT

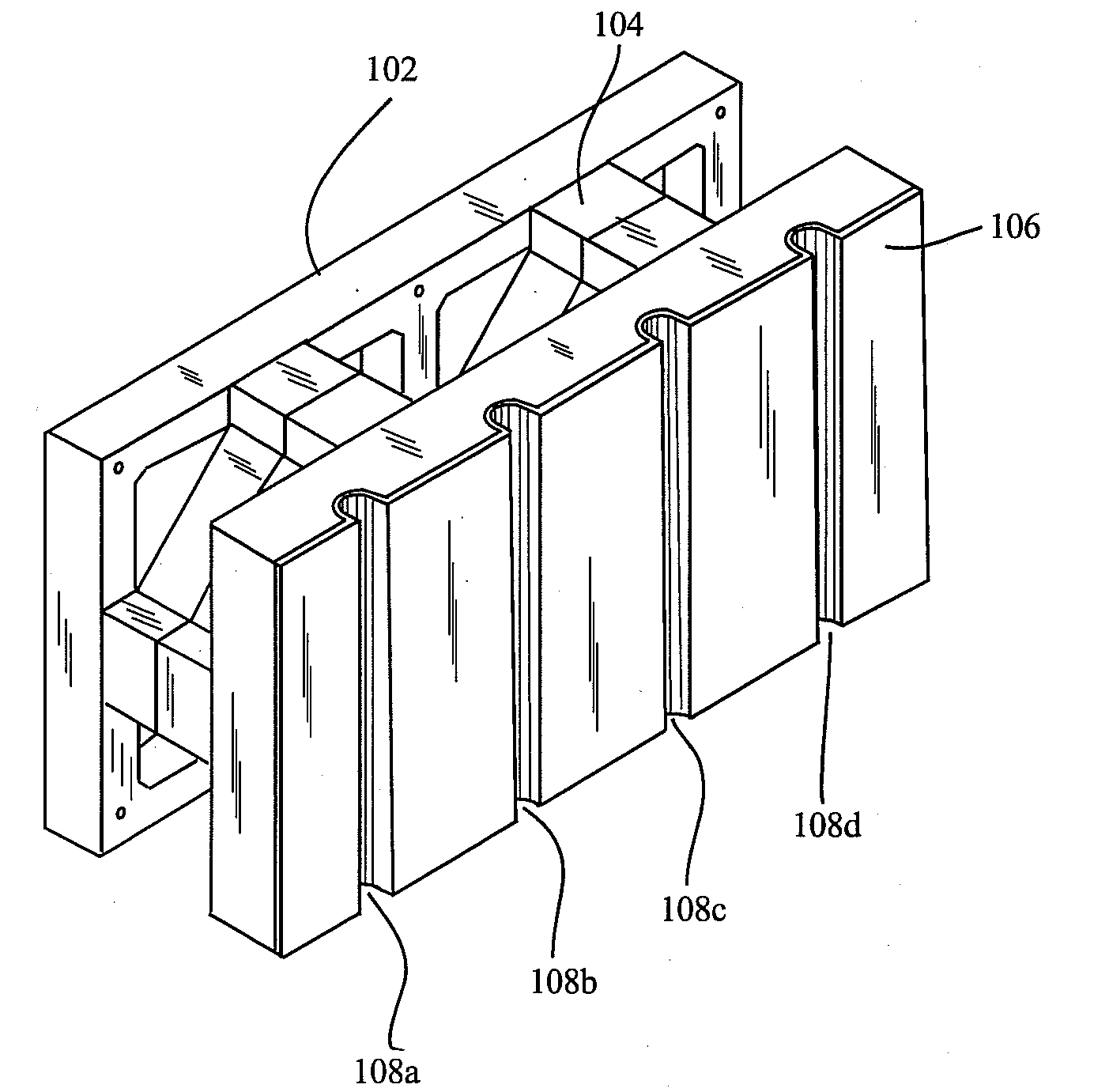

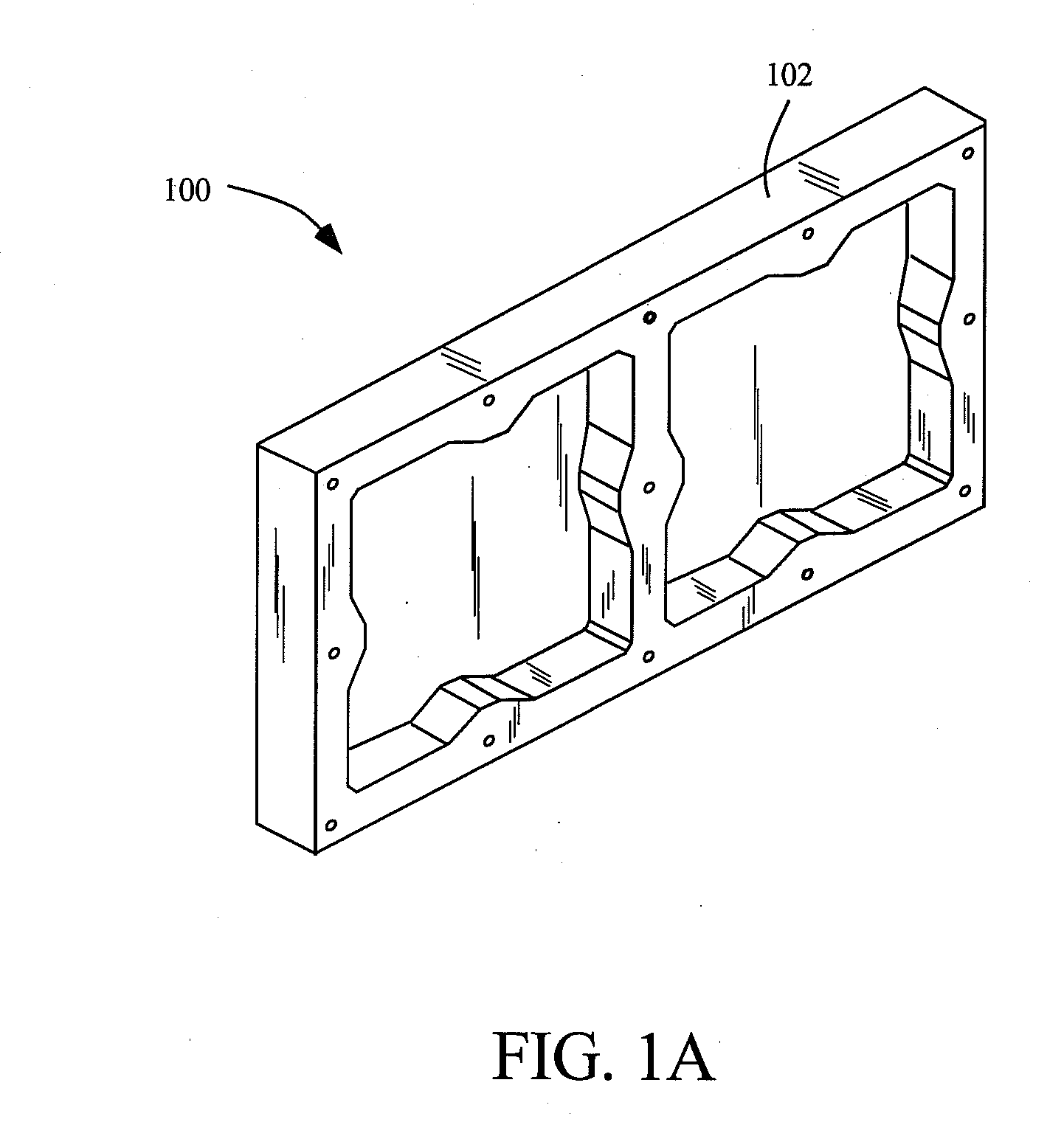

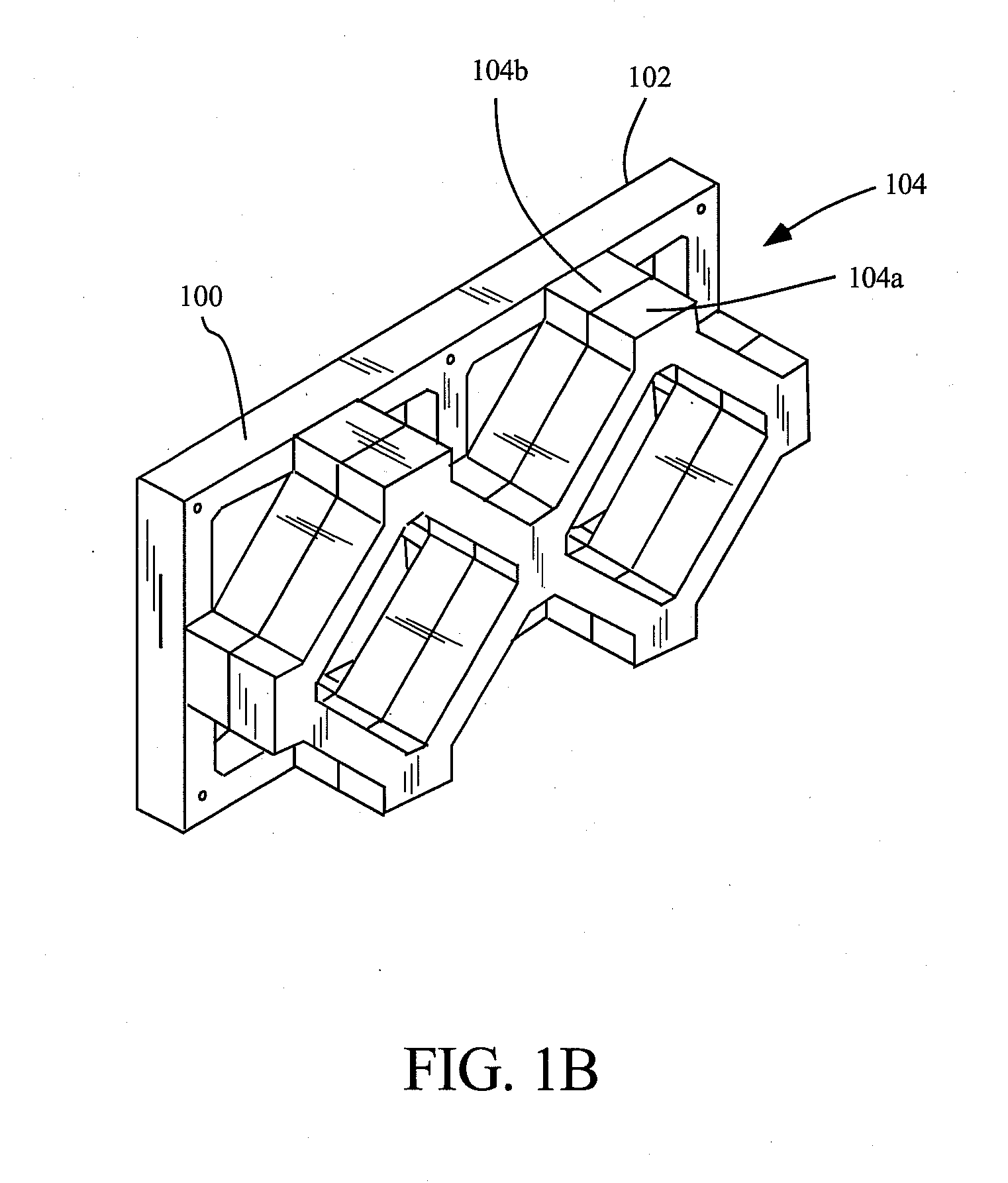

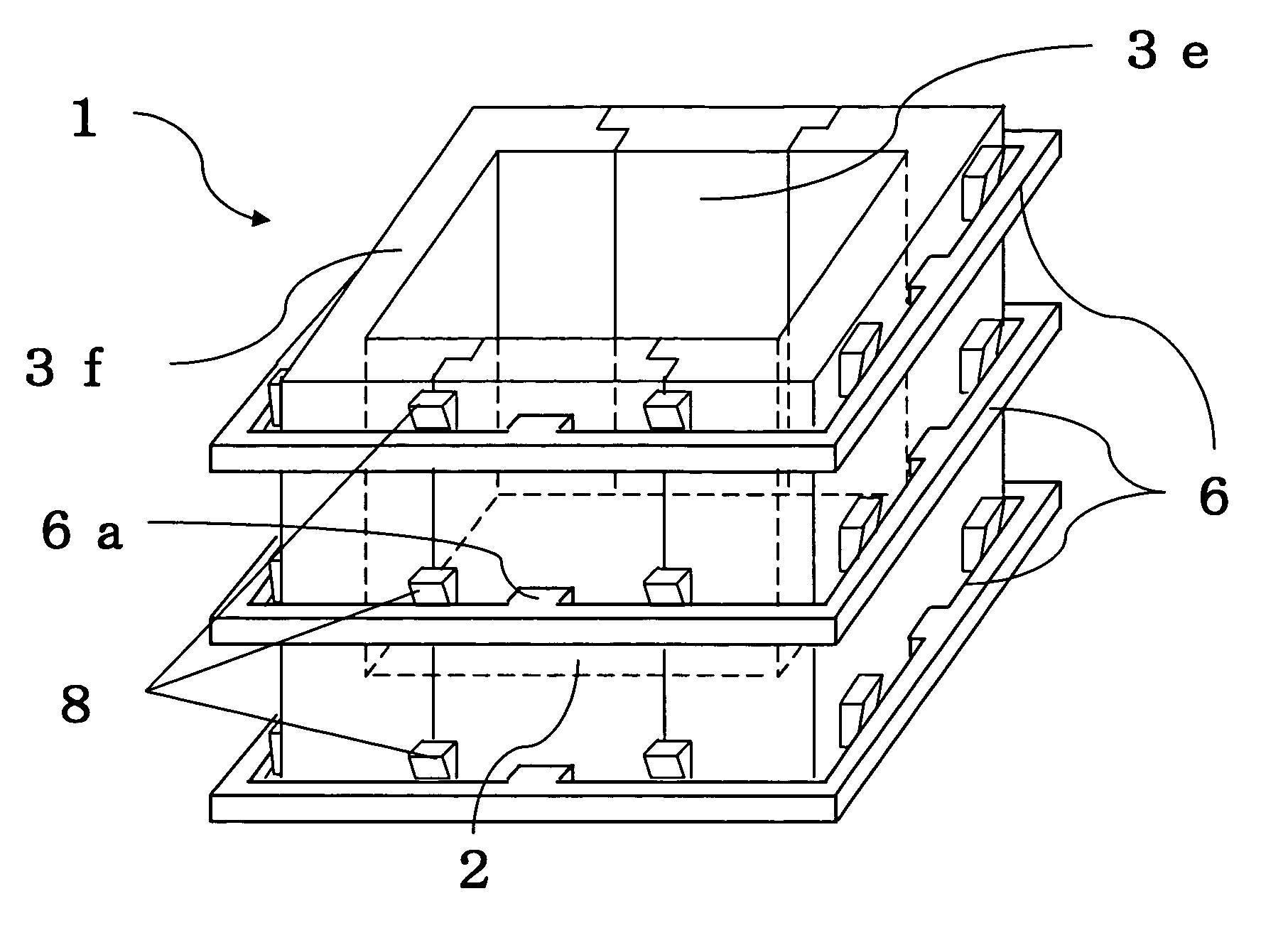

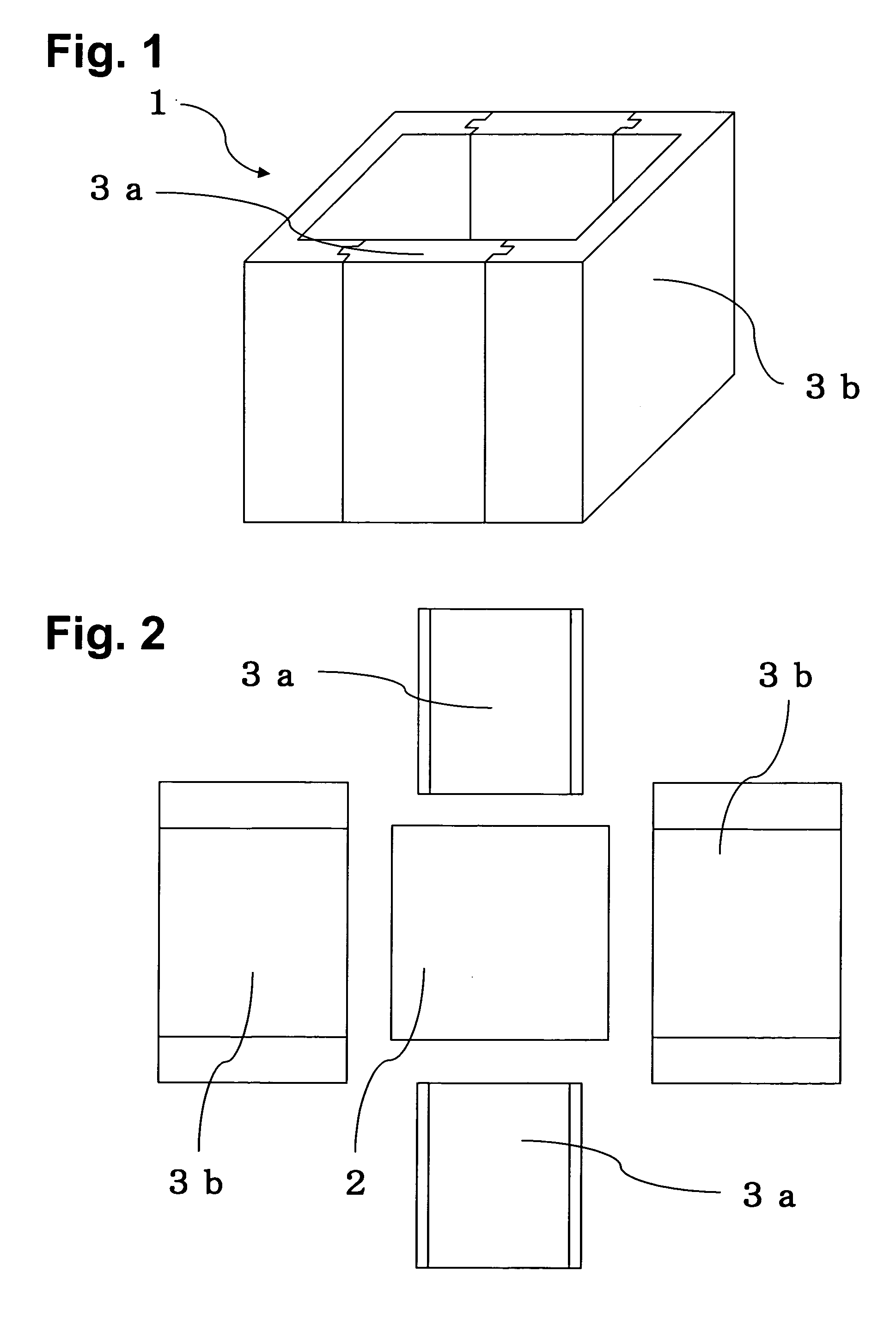

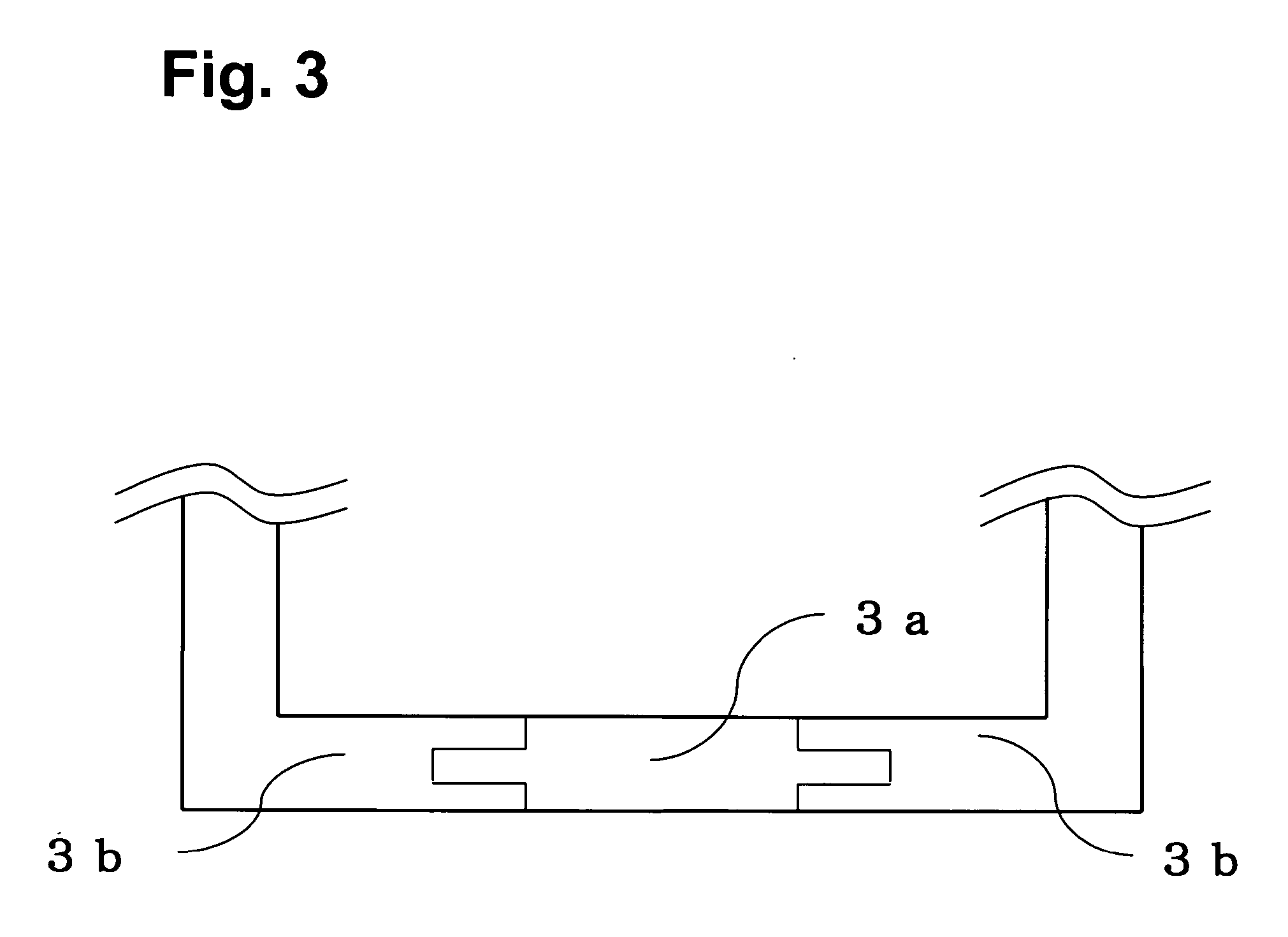

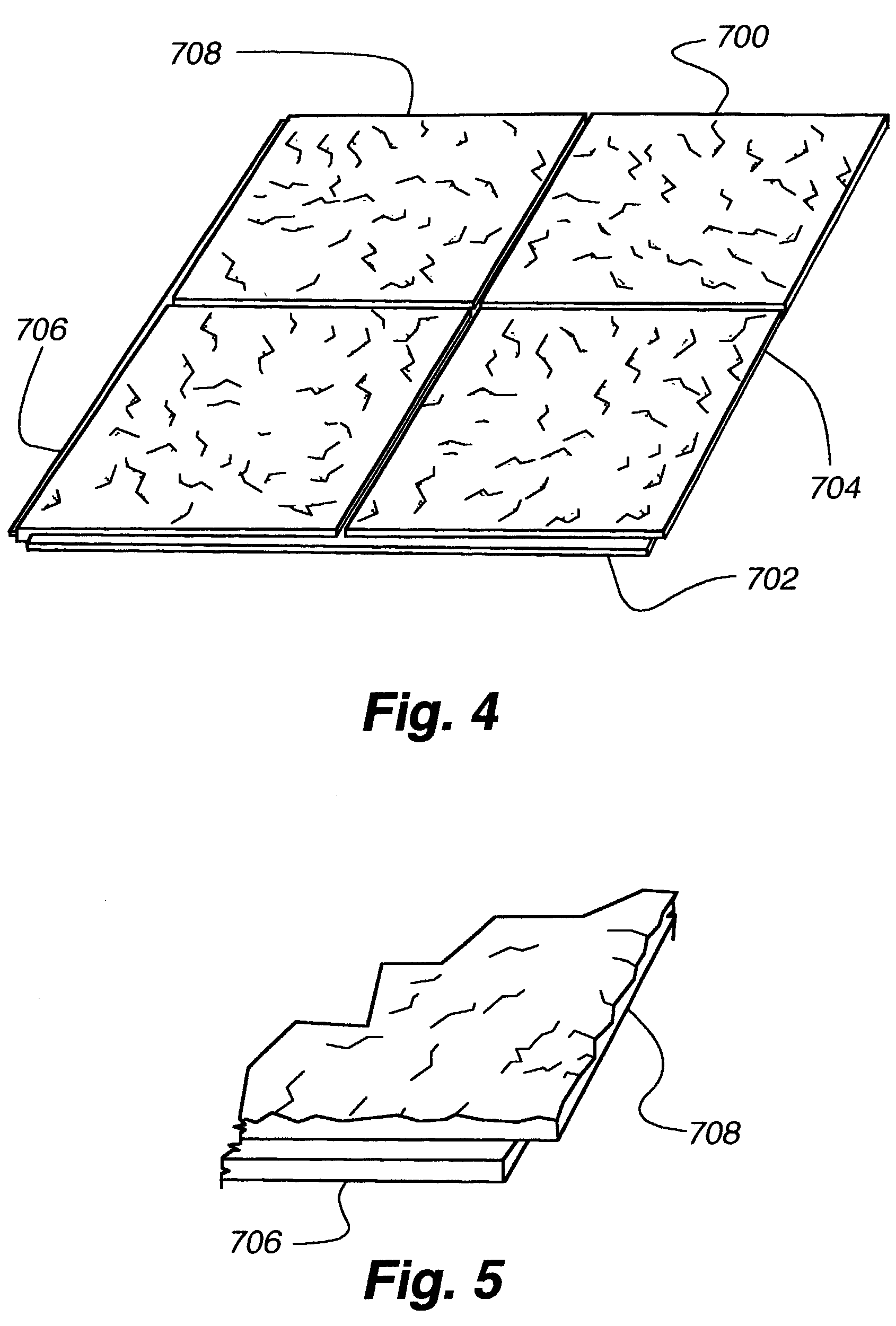

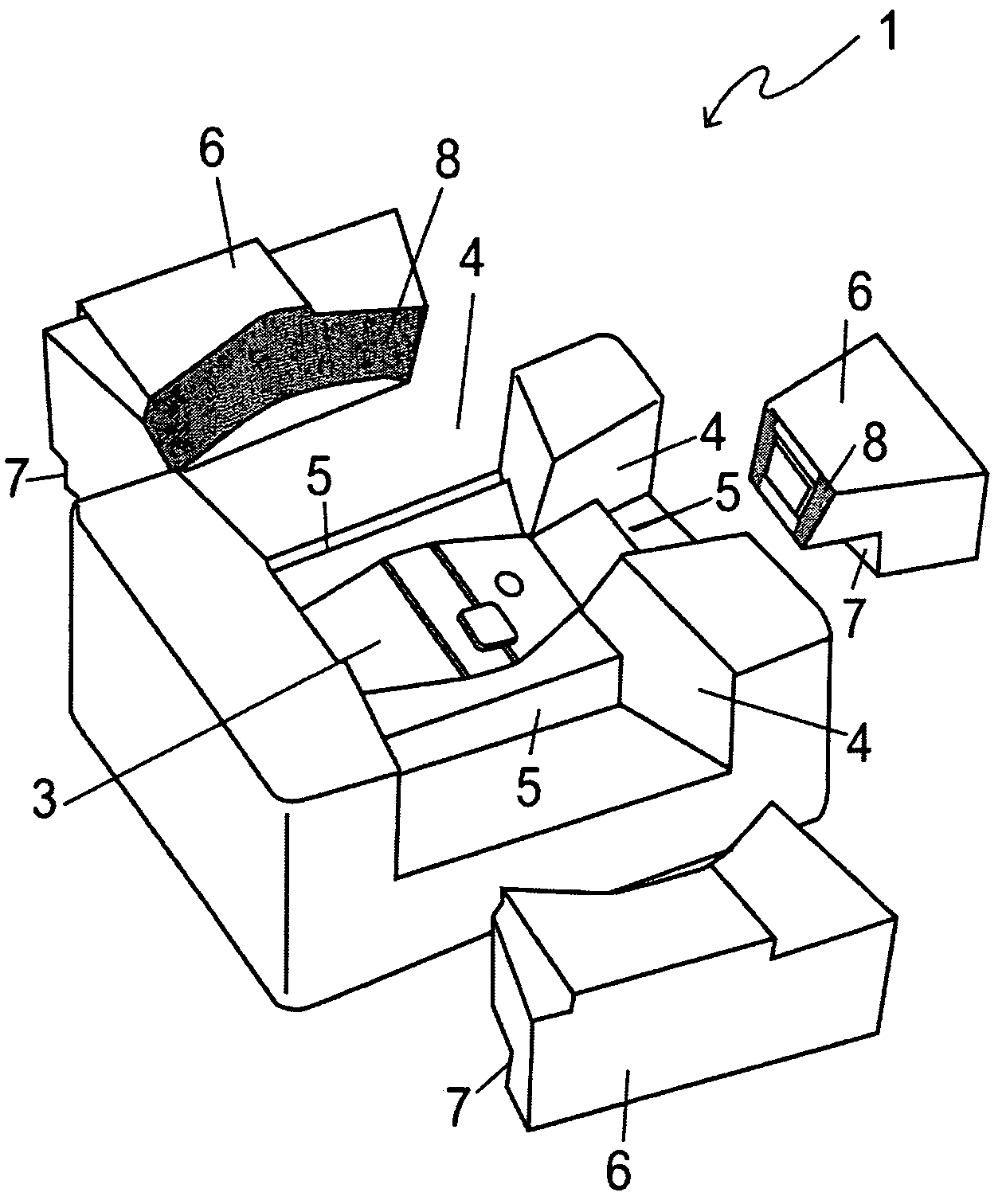

Modular building block system and method of manufacture

InactiveUS20080104906A1High degree of designHigh degree of structural flexibilityWallsStereotype platesService provisionCoupling

A first load bearing component is adapted to provide load bearing strength when the modular building block is used in a building panel. A second load bearing component is coupled to the first load bearing component via a first coupling arrangement and is adapted to provide load bearing strength when the modular building block is used in the building panel. A building services component is positioned between the first load bearing component and the second load bearing component for providing a conduit for at least one building service. The first and second load bearing components and the building services component are adapted to be configurable in a plurality of positions relative to the other.

Owner:PYO JOHN M

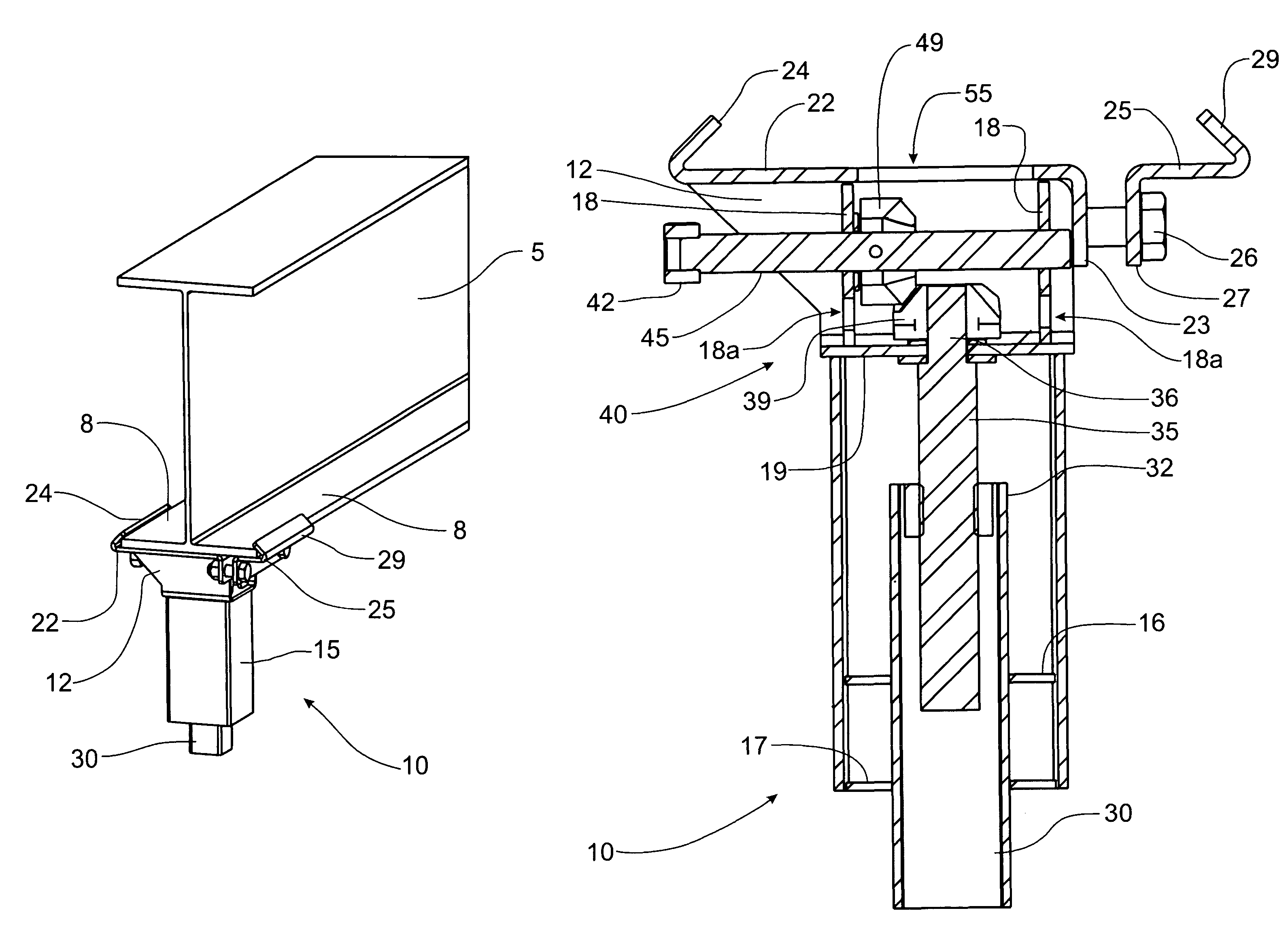

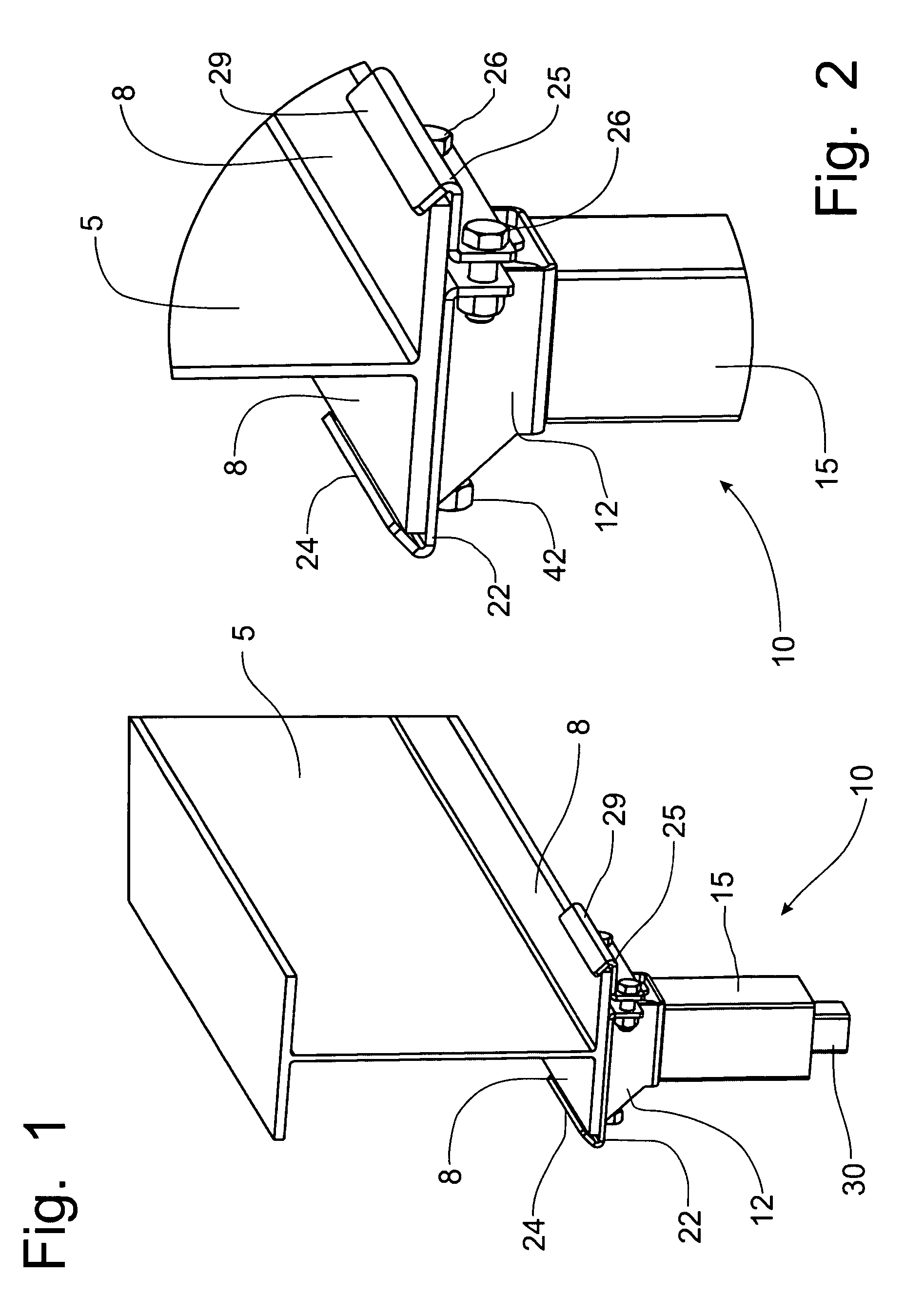

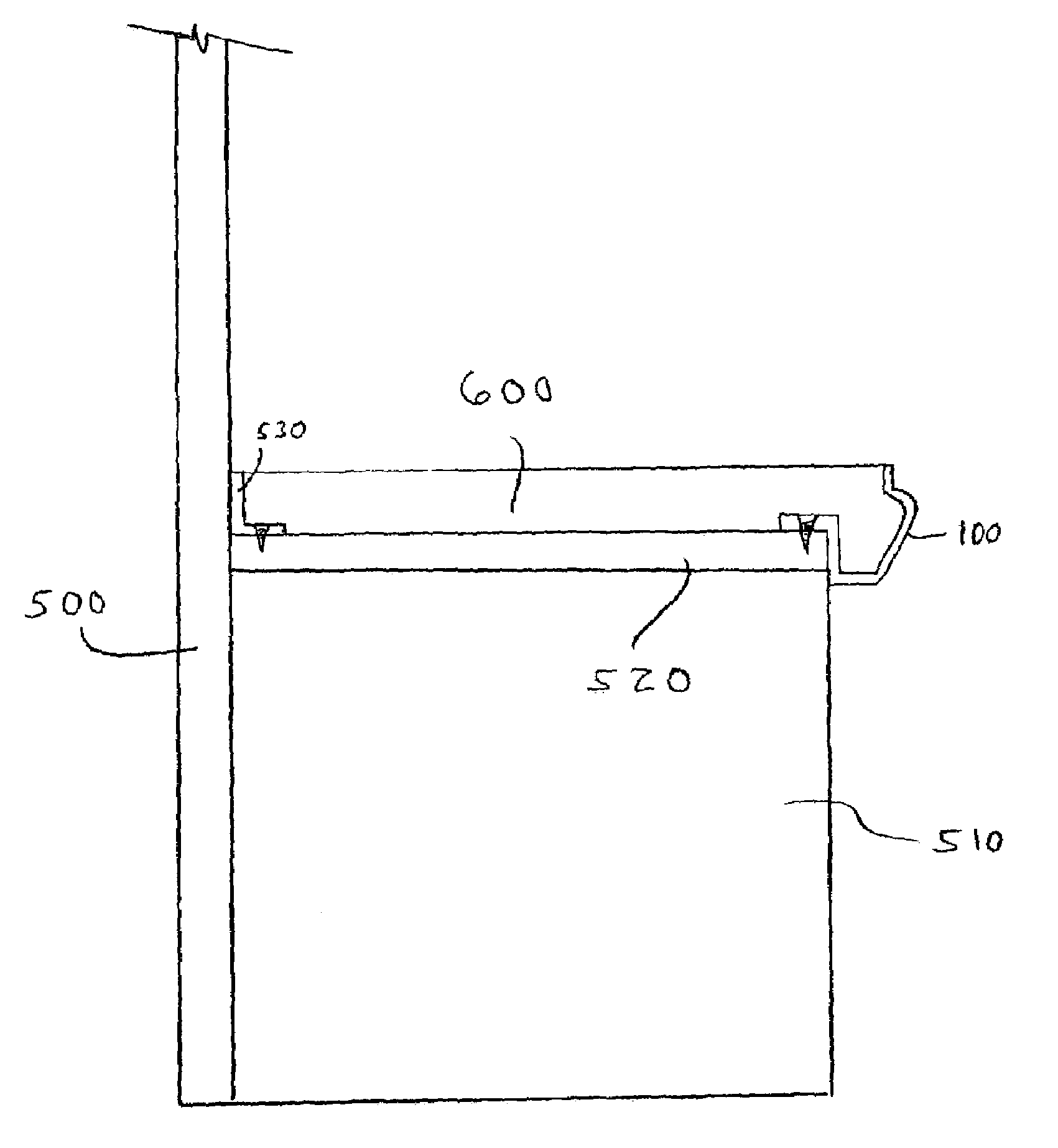

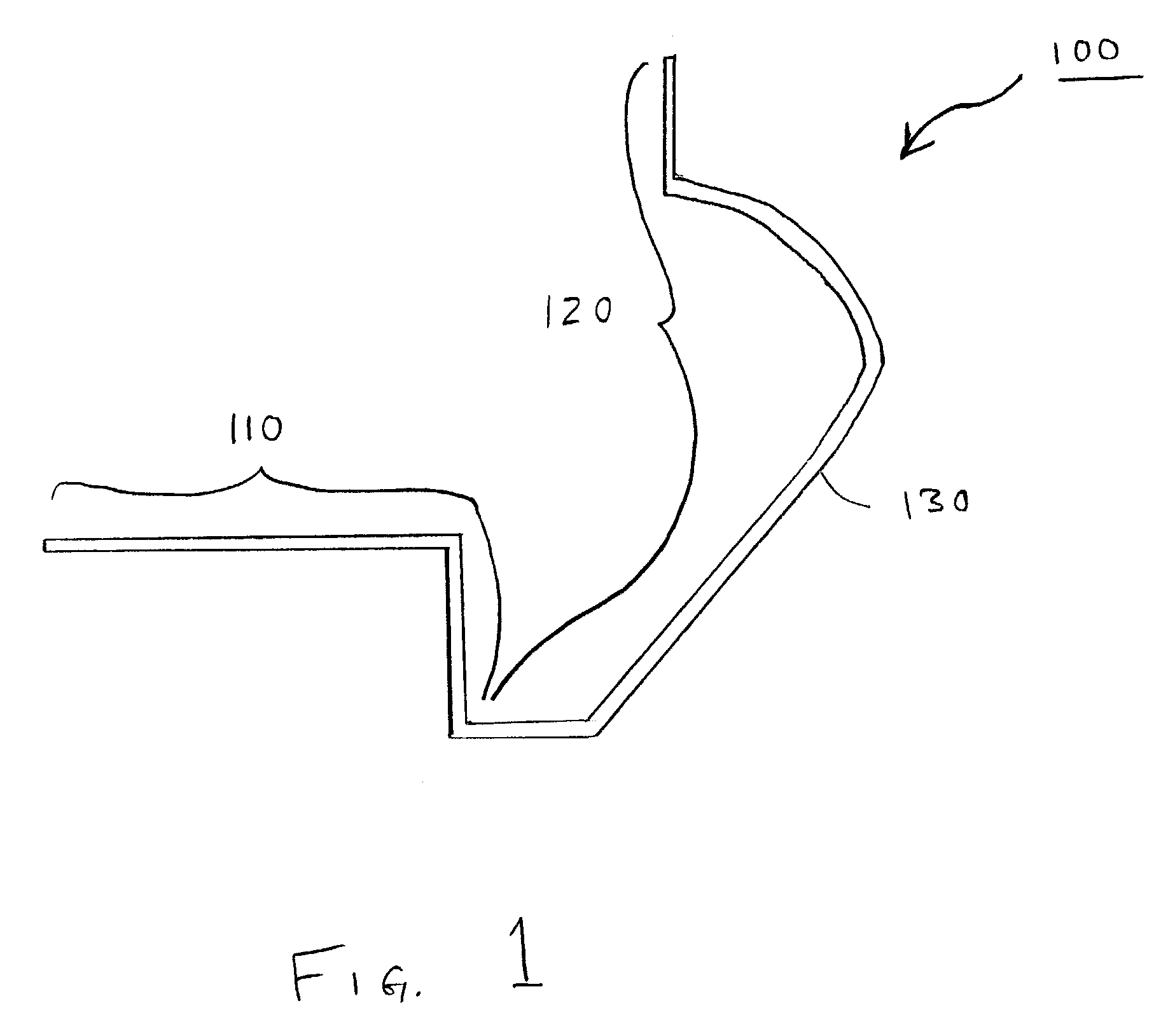

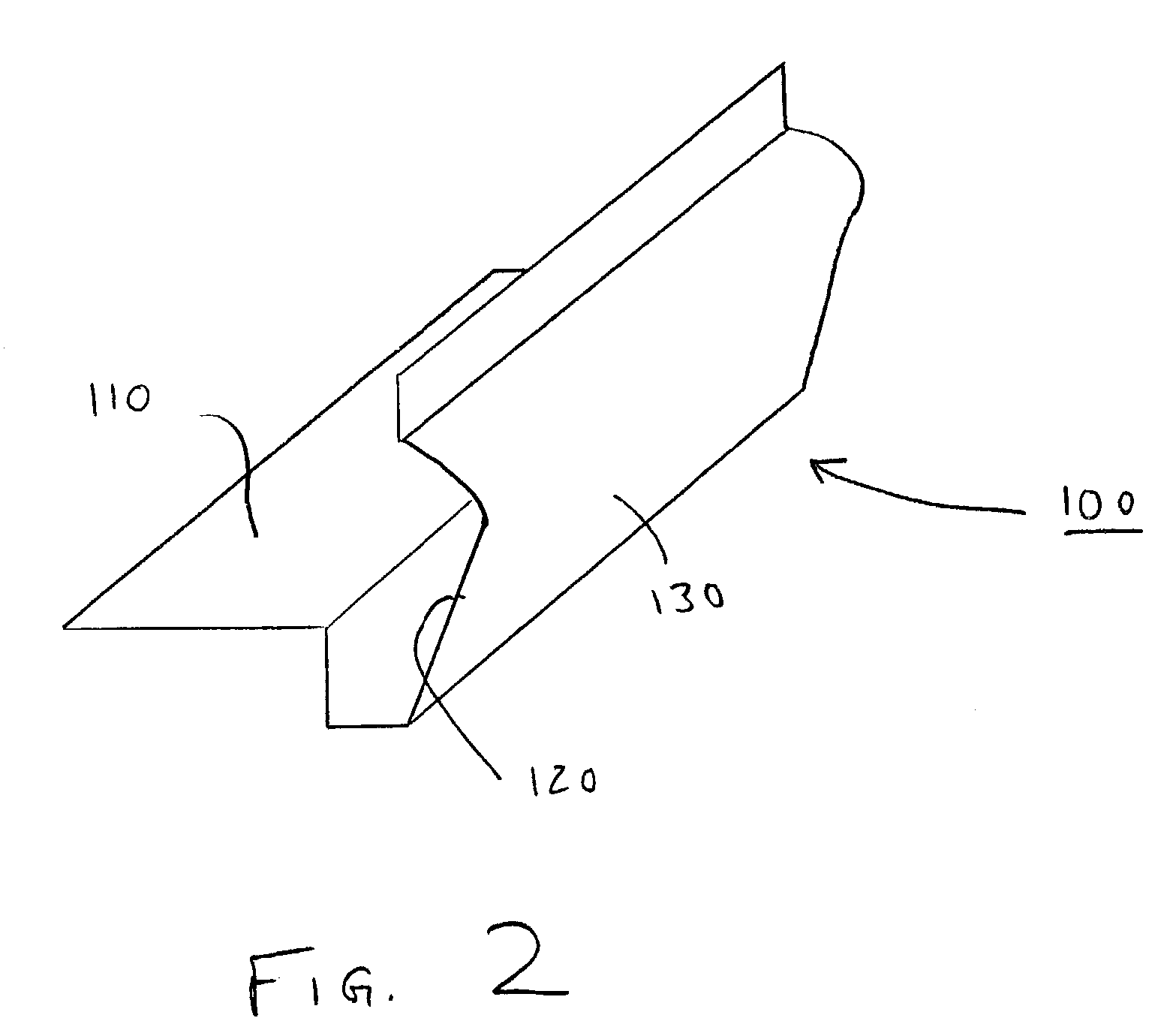

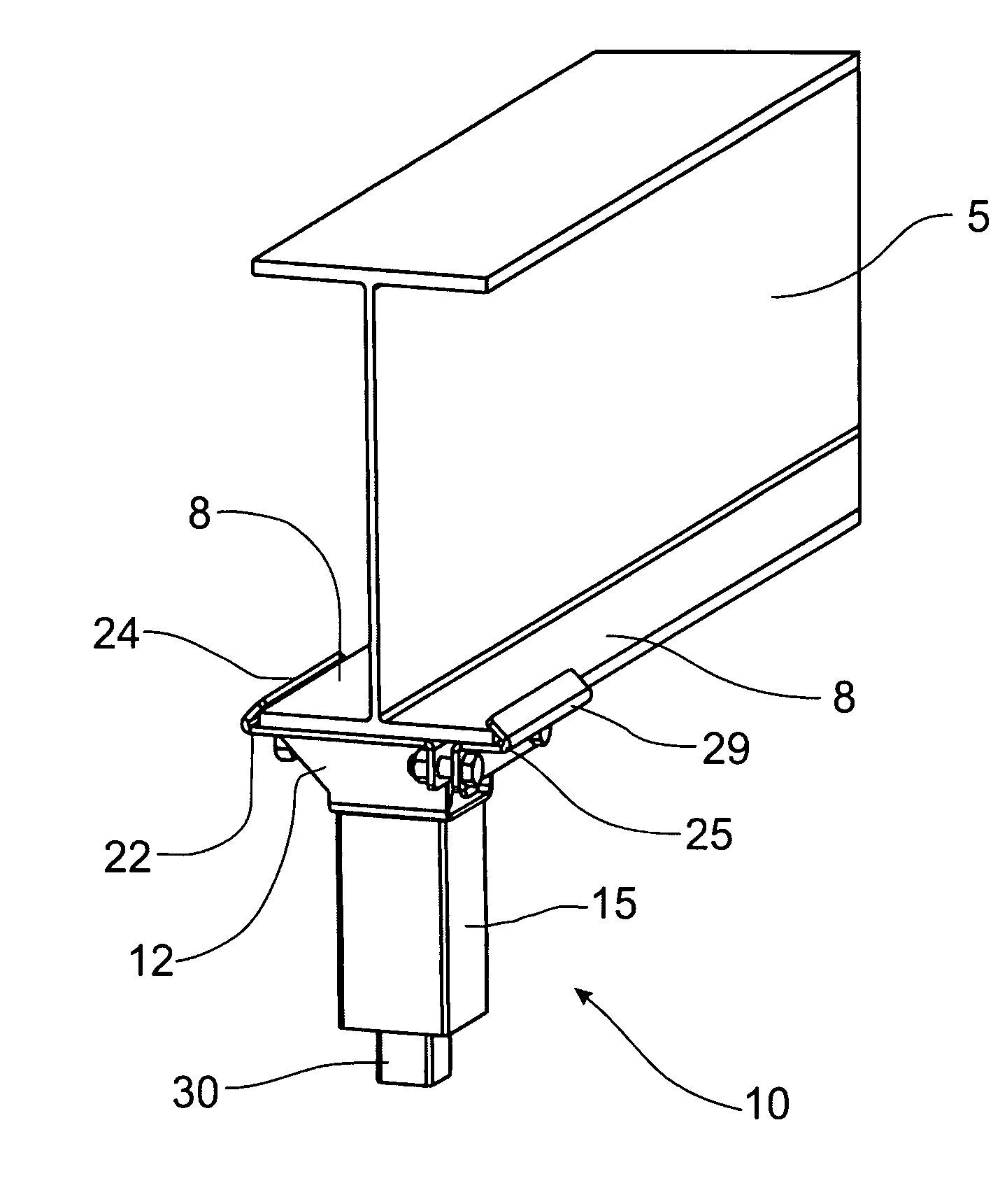

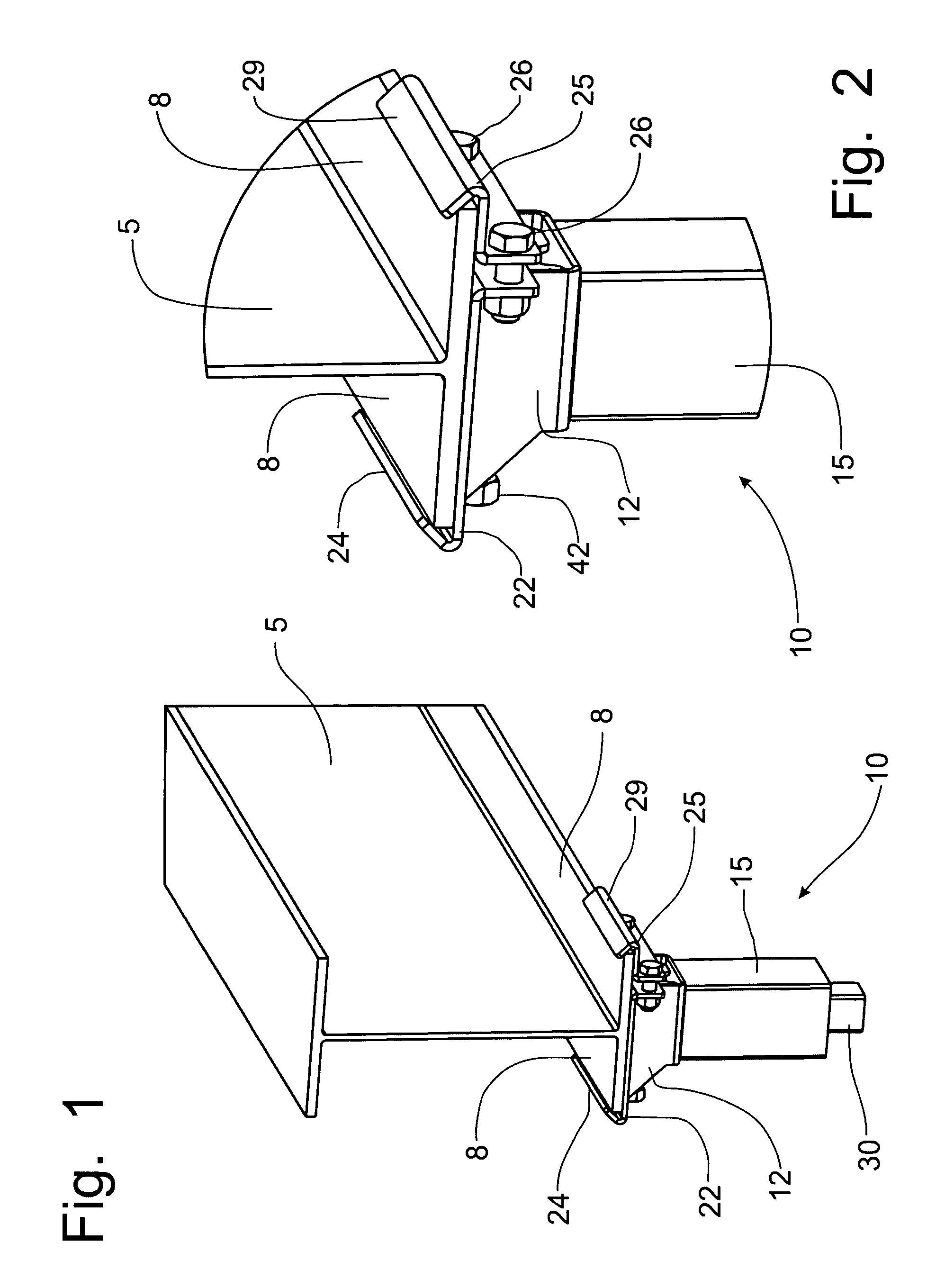

Adjustable support stand for pre-cast concrete wall forms

ActiveUS7922145B2Durable in constructionReduce manufacturing costMoulding surfacesMould separation apparatusDrive shaftEngineering

An adjustable support stand is mounted on a pre-cast concrete wall panel form to facilitate the leveling of the form and the support of the form about the production plant floor. The adjustable support stand includes a frame portion that houses a threaded rod positional fixed for rotation within the frame portion to drive a vertical movement of the leg member in response to rotation of the threaded rod. The adjustable support stand further includes a clamping apparatus that detachably mounts the frame portion to the flanges of a steel beam frame member. The actuator member can be a nut welded to the top of the threaded rod to affect movement of the engaged leg member in response to manipulation with a powered or manually operated hand tool, or a gear set and an orthogonal drive shaft that transfers rotation from a hand tool to the threaded rod.

Owner:SUPERIOR WALLS OF AMERICA

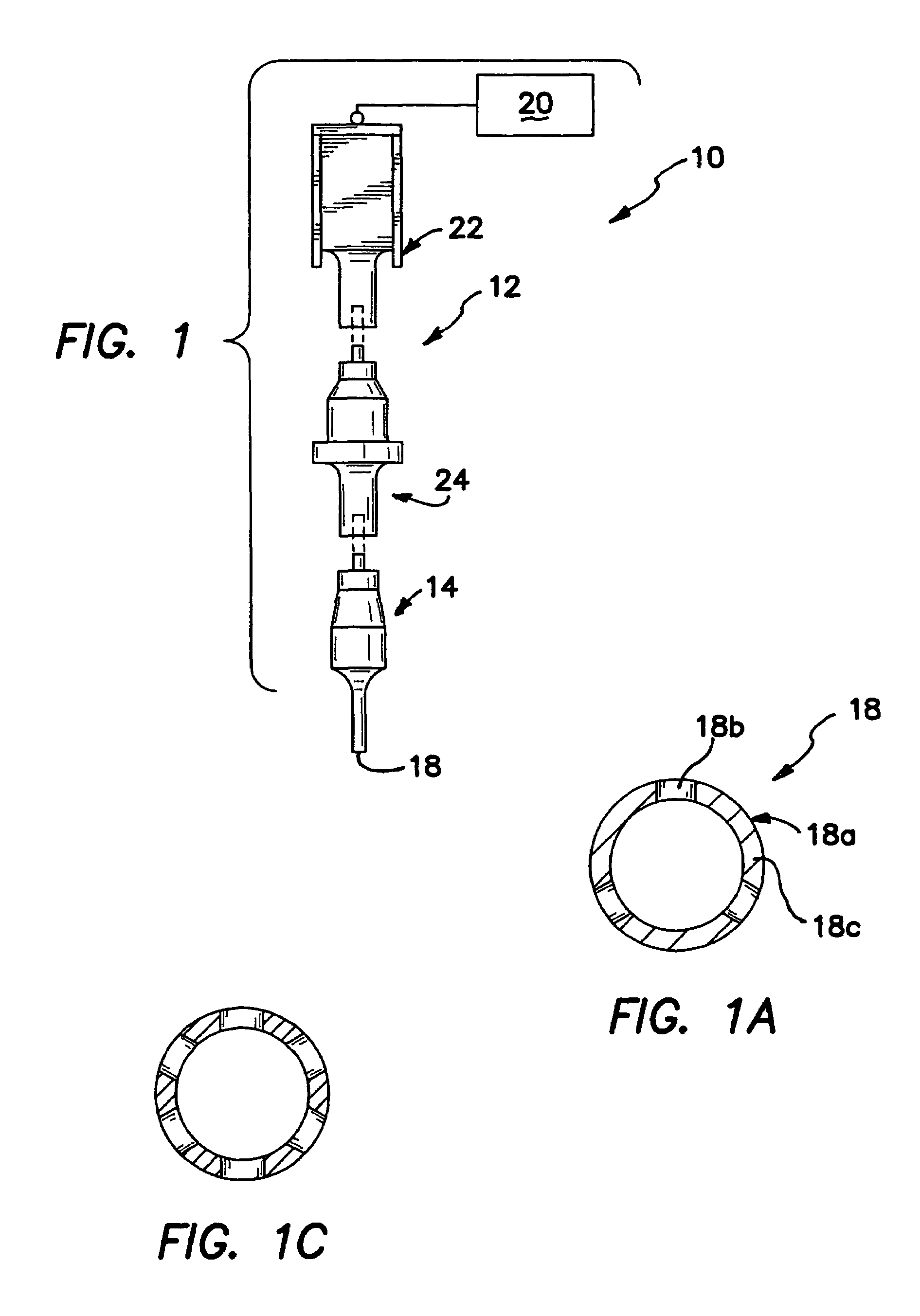

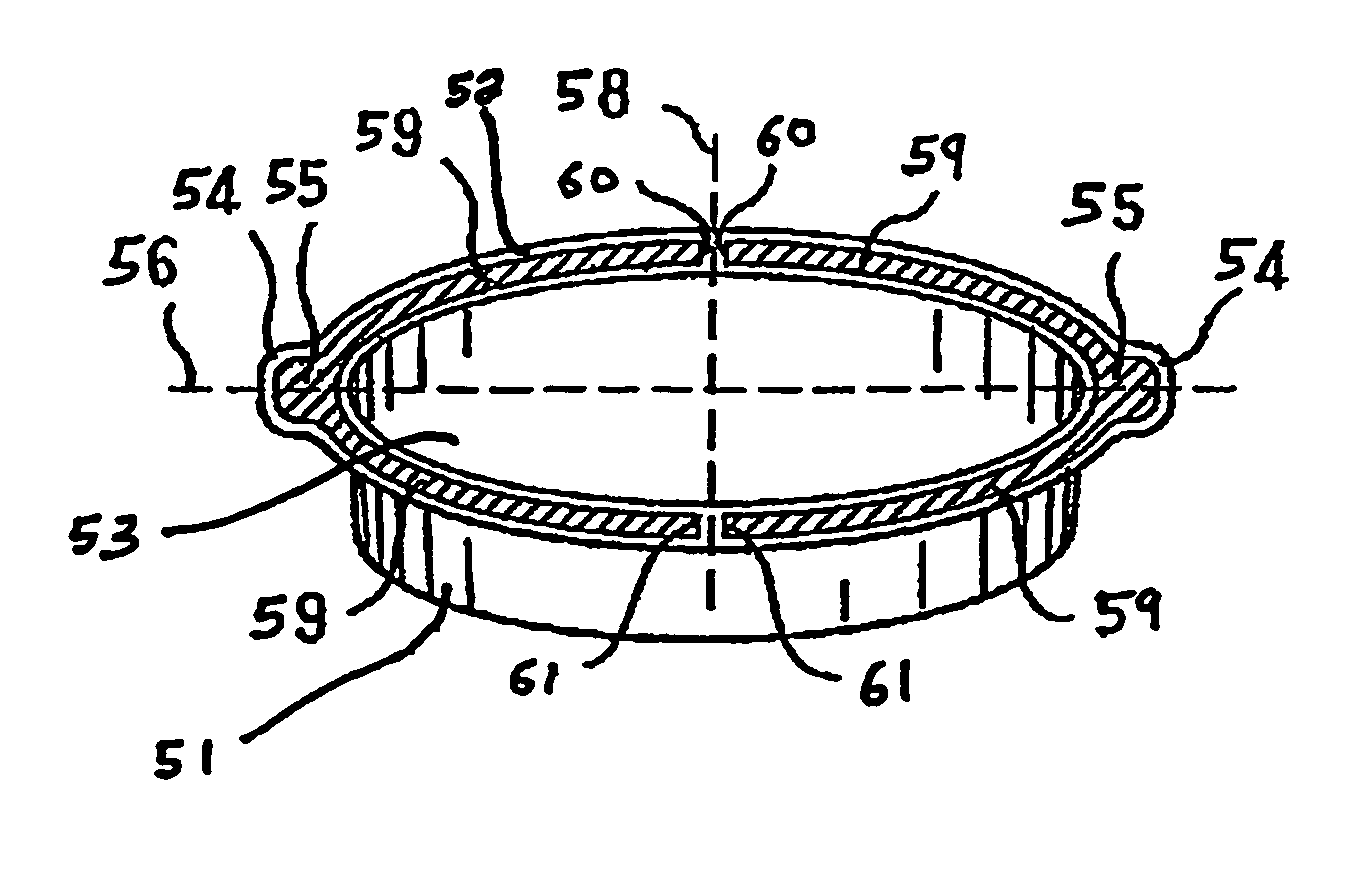

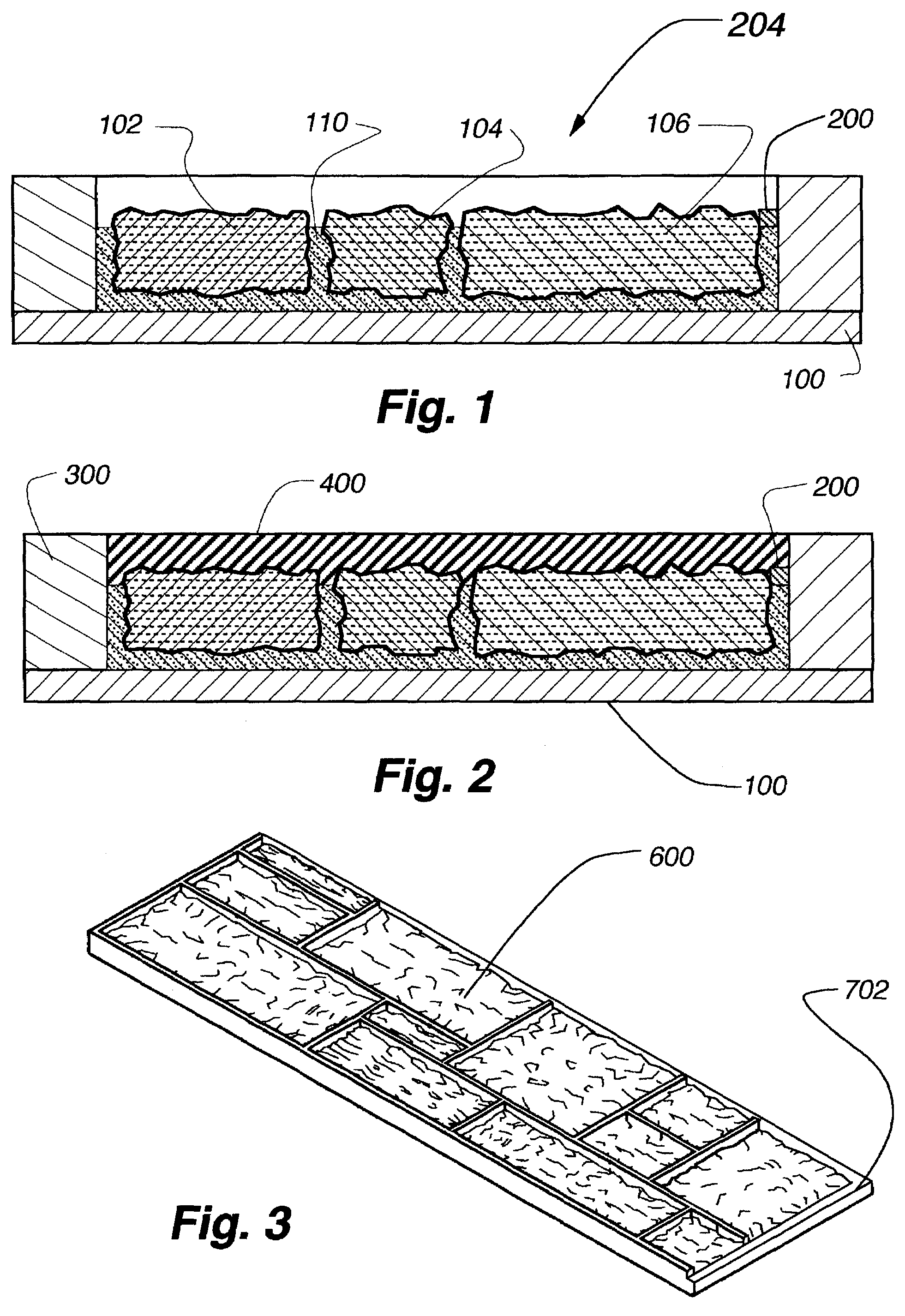

Molds for use in contact lens production

Owner:JOHNSON & JOHNSON VISION CARE INC

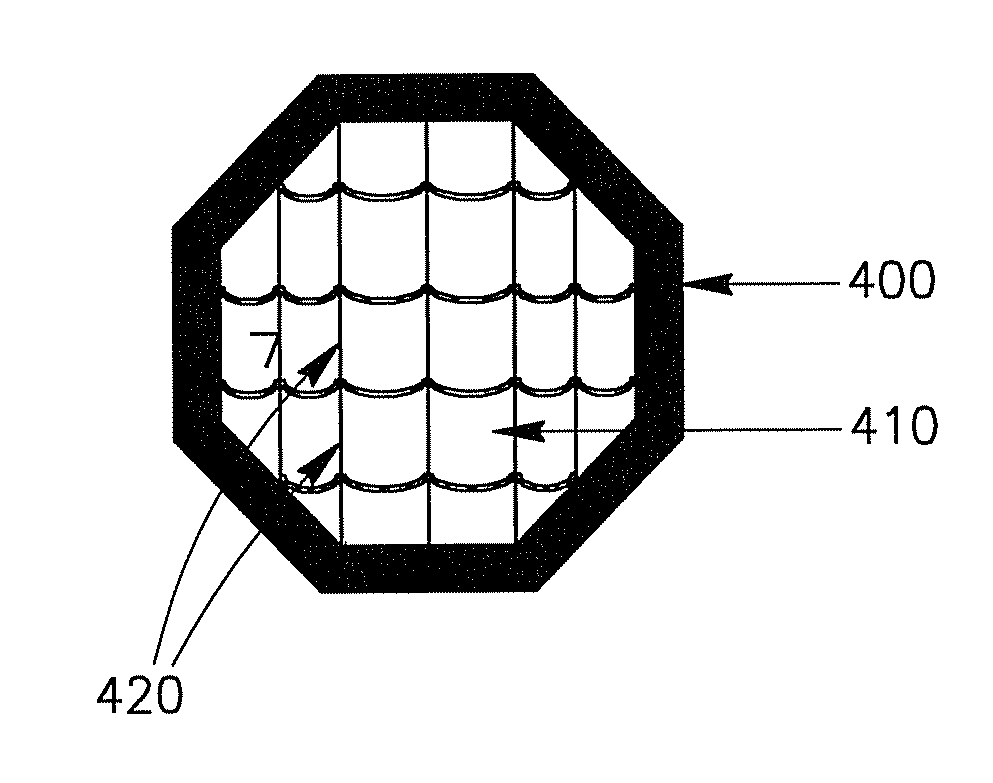

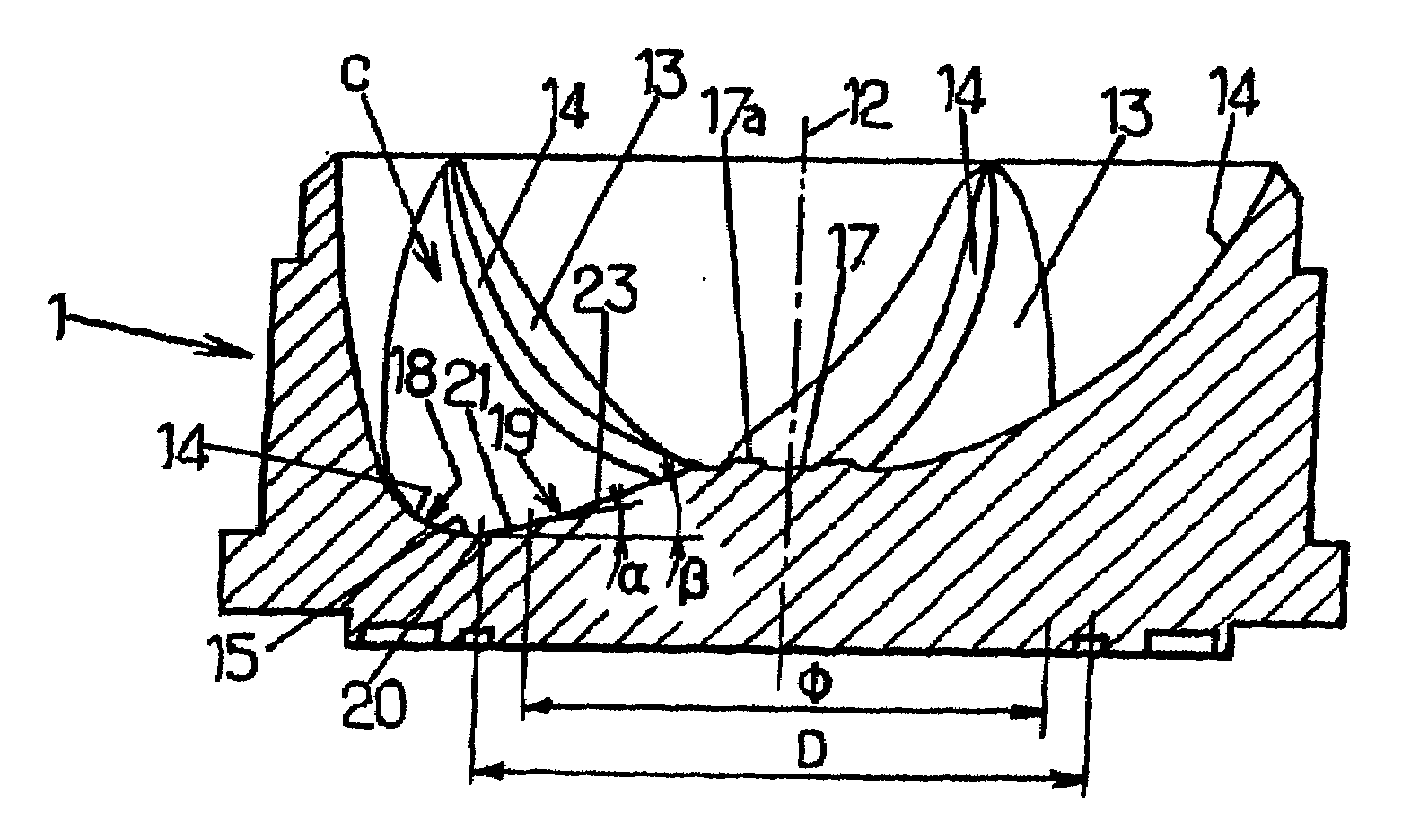

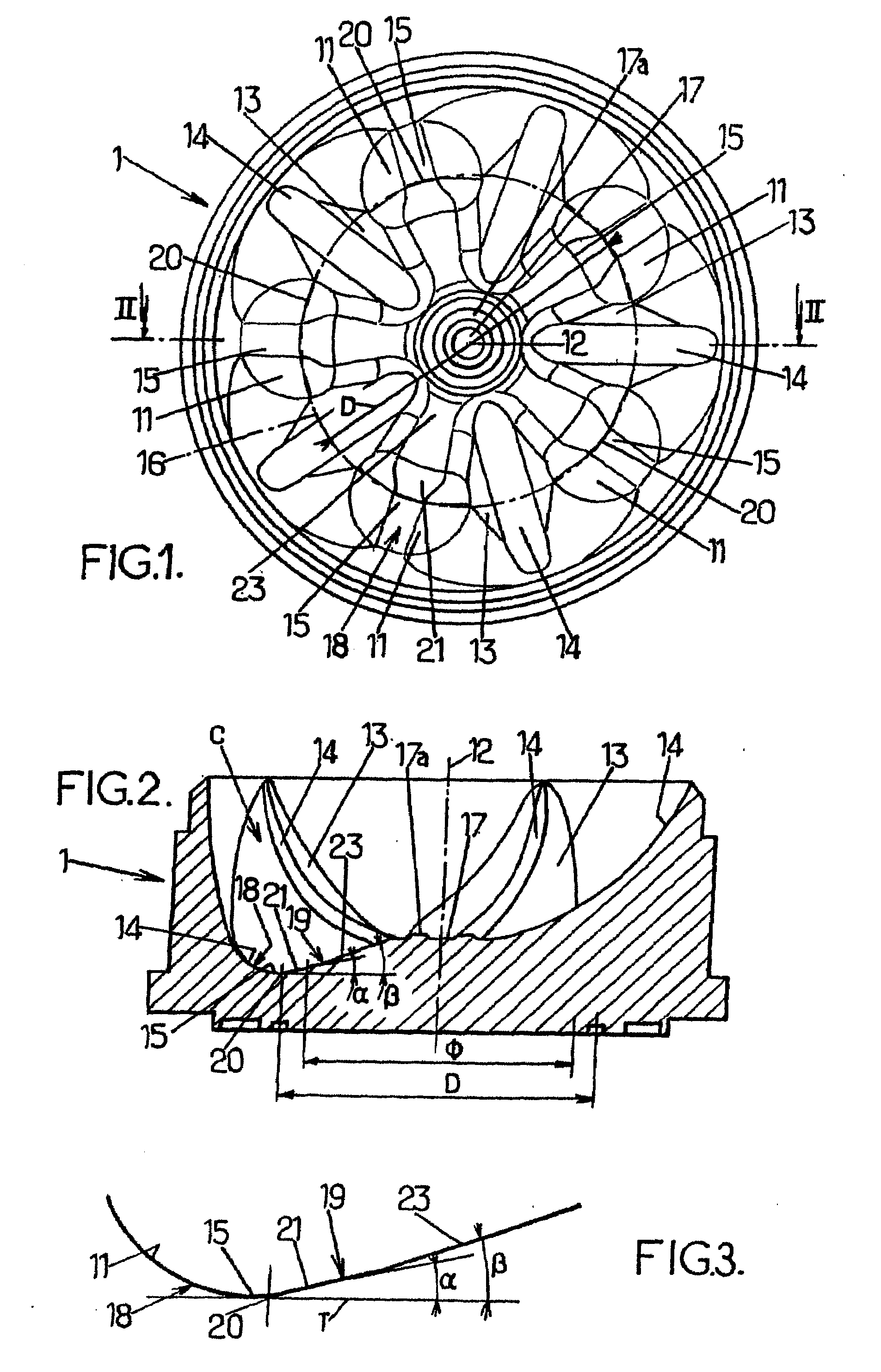

Mould base for moulds for manufacturing thermoplastic containers and moulding device equipped with at least one mould equipped with such a base

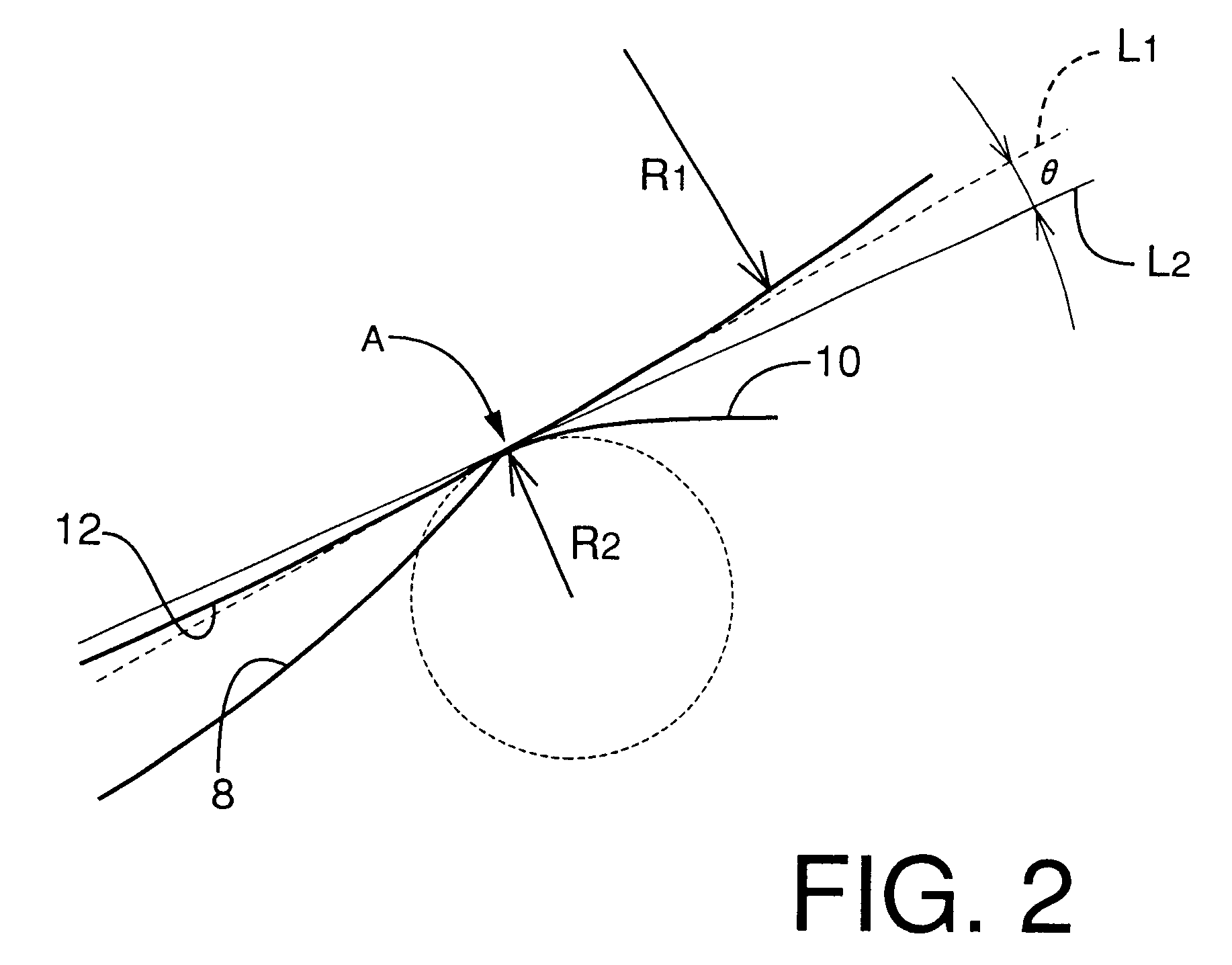

ActiveUS20090020682A1Improve stabilityWithout affecting production rateFoundry mouldsStereotype platesMechanical engineeringRidge

The invention relates to a mould base (1) for a mould that is used for the blow moulding or stretch-blow moulding of thermoplastic containers (2) having a petaloid-shaped base. The mould base (1) includes several cavities (11) separated by radiating ridges (13) with concave crests (14), the bases (15) of the cavities (11) being distributed along a circular contour. As seen radially on either side of the deepest point thereof, each cavity (11) is defined towards the exterior by a curved surface portion (18) having a circular arc radial cross-section and towards the interior by a broken-plane surface portion (19) with at least two slopes that intersect the curved surface portion (18) at a straight edge (20). The plane (T) which contains the aforementioned edge (2) and which is tangent to the curved surface portion (18) is perpendicular to the axis (12) of the mould base. Moreover, the portion of plane (21) adjacent to the curved surface portion (18) has a slope (a) of between 12° and 8° in relation to the tangent plane (T).

Owner:SIDEL PARTICIPATIONS SAS

Flexible mold with grasping handles

InactiveUS7419071B2Simple and safe operationEasy to handleStereotype platesSealingMechanical engineeringSilicone

A flexible, silicone mold having a bowl and a peripheral rim that defines an opening to the bowl. Two substantially flat grasping zones are disposed along substantially opposite ends of the rim and the grasping zones have sufficient dimensions to permit control of the geometry of the rim and also to permit control of the horizontal positions of the two grasping zones.

Owner:MASTRAD

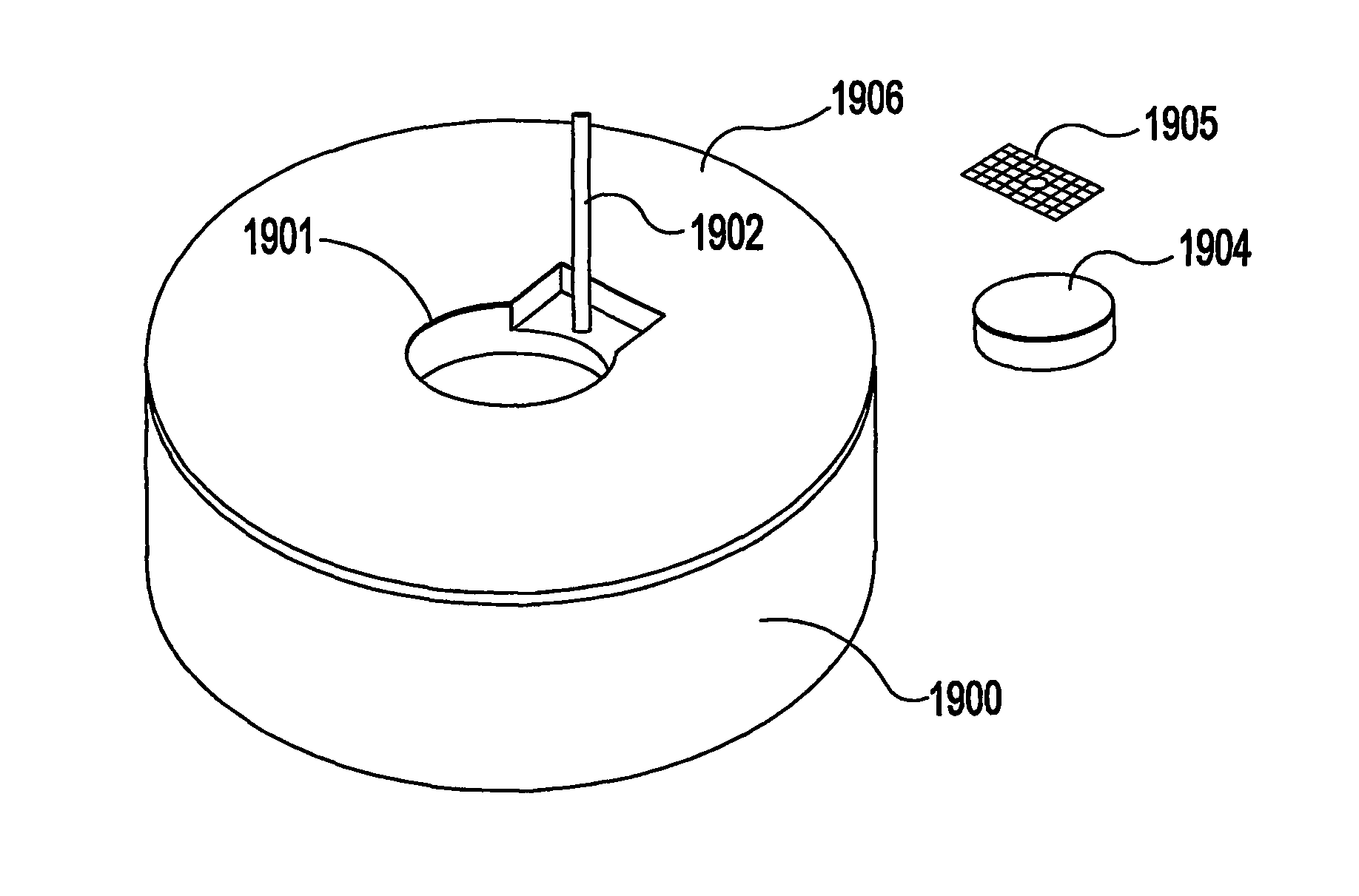

Molding assembly for forming ingot and a method of forming ingot

A molding assembly for forming an ingot, including side members each having engaging end portions, the engaging end portions of the side members being engaged with respective ones of the side members such that the side members form a polygonal prism having sides, corners, a top opening and a bottom opening, the engaging end portions of the side members engaging to form connecting portions positioned in the sides, and a bottom member fitted to close the bottom opening of the polygonal prism so as to form a molding device for molding a molten material into an ingot.

Owner:KYOCERA CORP

Counter top mold and method of using same

ActiveUS7001558B2Easy to useQuick pourConfectioneryStereotype platesMechanical engineeringEngineering

Owner:BALDONI EDWIN

Adjustable Support Stand for Pre-Cast Concrete Wall Forms

ActiveUS20090194665A1Durable in constructionReduce manufacturing costMoulding surfacesMould separation apparatusDrive shaftGear wheel

An adjustable support stand is mounted on a pre-cast concrete wall panel form to facilitate the leveling of the form and the support of the form about the production plant floor. The adjustable support stand includes a frame portion that houses a threaded rod positional fixed for rotation within the frame portion to drive a vertical movement of the leg member in response to rotation of the threaded rod. The adjustable support stand further includes a clamping apparatus that detachably mounts the frame portion to the flanges of a steel beam frame member. The actuator member can be a nut welded to the top of the threaded rod to affect movement of the engaged leg member in response to manipulation with a powered or manually operated hand tool, or a gear set and an orthogonal drive shaft that transfers rotation from a hand tool to the threaded rod.

Owner:SUPERIOR WALLS OF AMERICA

Methods and apparatus for replicating original objects

Owner:SD4 PANEL TECH L L C

Steel for mold, and mold

InactiveUS20150314366A1Improved coefficientImprove high temperature strengthAdditive manufacturing apparatusFoundry mouldsMetallurgyImpurity

The present invention relates to a steel for a mold, having a composition containing, on a % by mass basis, 0.25%<C<0.38%, 0.01%<Si<0.30%, 0.92%<Mn<1.80%, 0.8%<Cr<2.2%, 0.8%<Mo<1.4%, and 0.25%<V<0.58%, with the balance being Fe and inevitable impurities, and a mold manufactured by additive manufacturing by using the steel for a mold.

Owner:DAIDO STEEL CO LTD

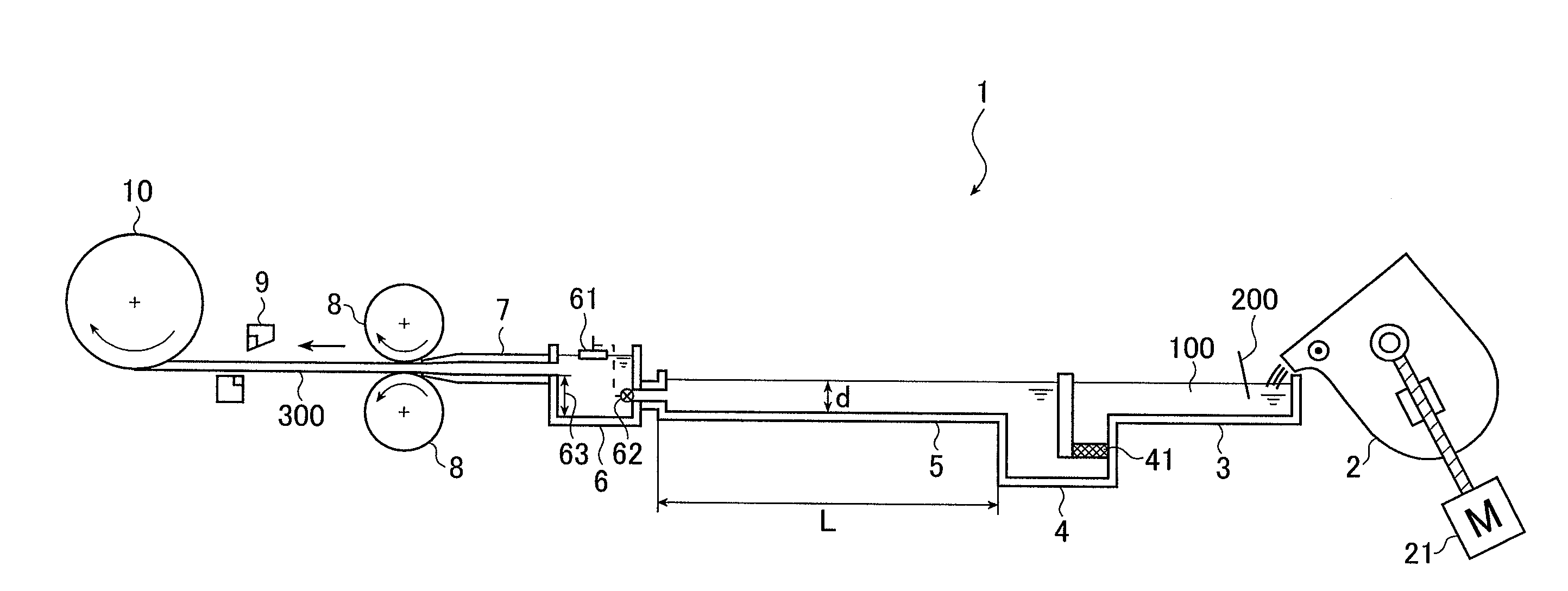

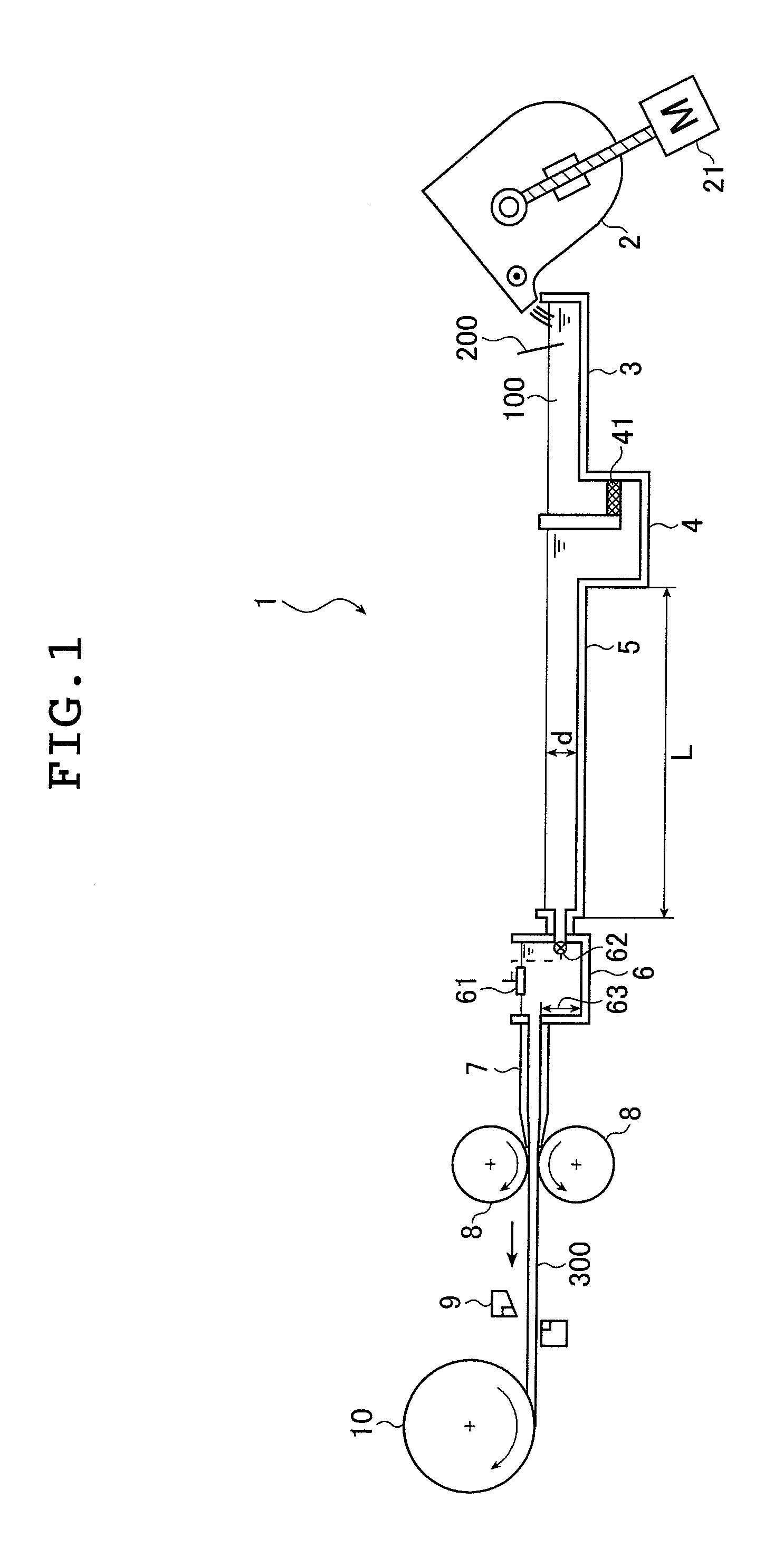

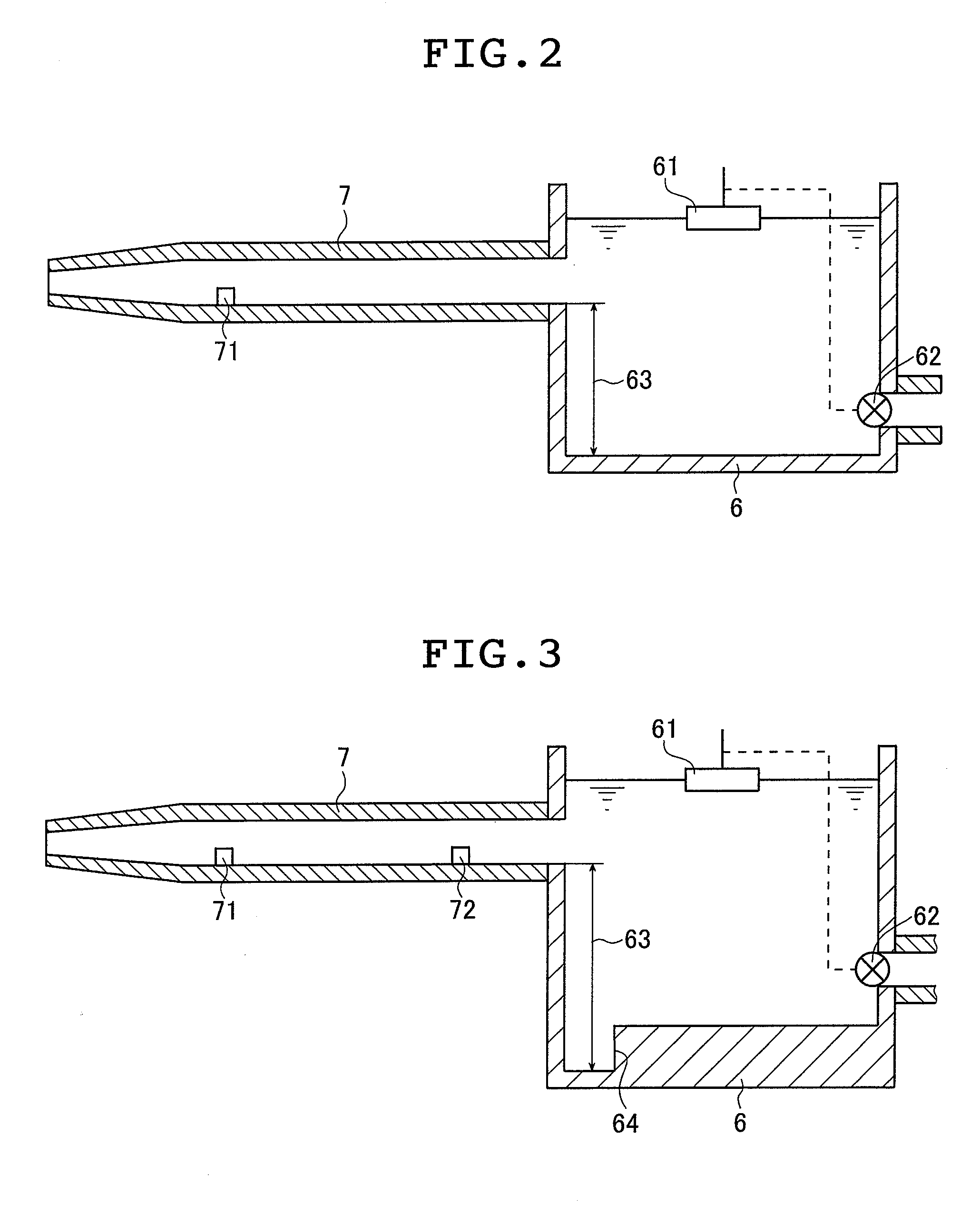

Method and apparatus for manufacturing aluminum alloy strip for lithographic printing plates

InactiveUS20090004044A1Inhibition formationStereotype platesBlast furnace detailsTitaniumPlanographic printing

Disclosed is a method of manufacturing, by a continuous casting process, aluminum alloy strip for use in the production of supports for lithographic printing plates, comprising the step of passing an aluminum melt successively through a filtering means, a launder connected to the filtering means, a liquid level controlling means connected to the launder, and a melt feed nozzle connected to the liquid level controlling means, wherein the aluminum melt is obtained by melting an aluminum starting material, then adding to and melting in the molten aluminum starting material a titanium and boron-containing aluminum alloy, and the time t in seconds required for the aluminum melt to pass through the launder satisfies the following condition (1):t≧270×1.2×D , (1)where D is the depth in meters of the melt in the launder.The method is able to prevent the formation of black streaks even when casting is carried out for an extended period of time.

Owner:FUJIFILM CORP

Article and method for fabricating an applicator tip assembly for a skin formulation applicator

The article and corresponding method include a casting fixture for a part of a skin formulation applicator which is otherwise difficult to cast. The casting fixture includes a central cup section and two opposing tear-away sections. A rigid base portion of an applicator tip assembly is mounted into an upper rim of the cup section and liquid silicone material is poured into the volume defined in the cup section portion beneath the base portion. The silicone cures and bonds to extending elements from the base portion, providing a firm connection between the cast tip portion and the base portion. When the combined part is ready for use, the tear-away sections are removed by the user, which results in an easy ejection of the part, which can then be installed by the user in the formulation applicator.

Owner:LOREAL SA

Plastics moulding

Owner:DRAGON MODELS LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com