Patents

Literature

187 results about "Conventional casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

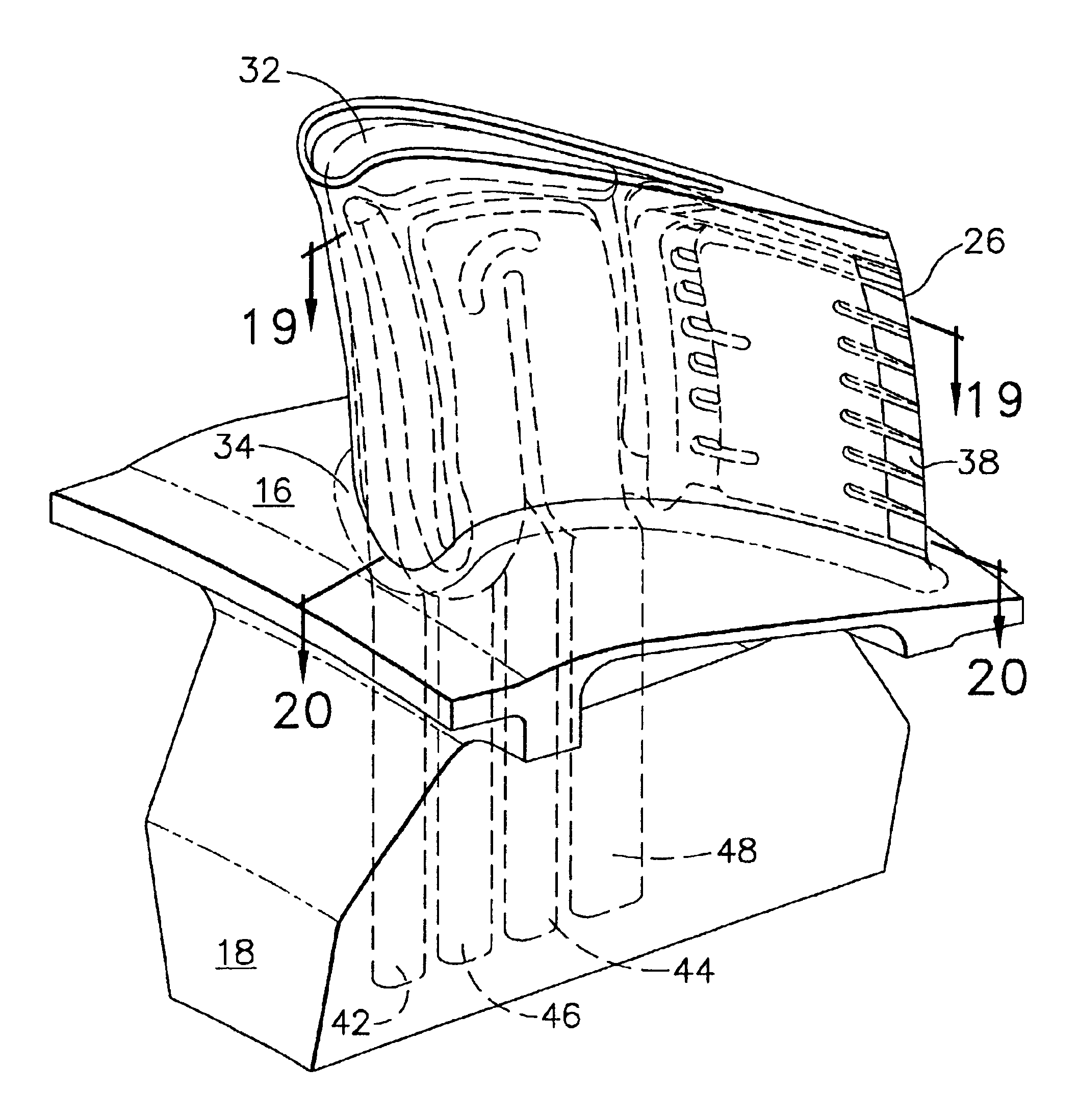

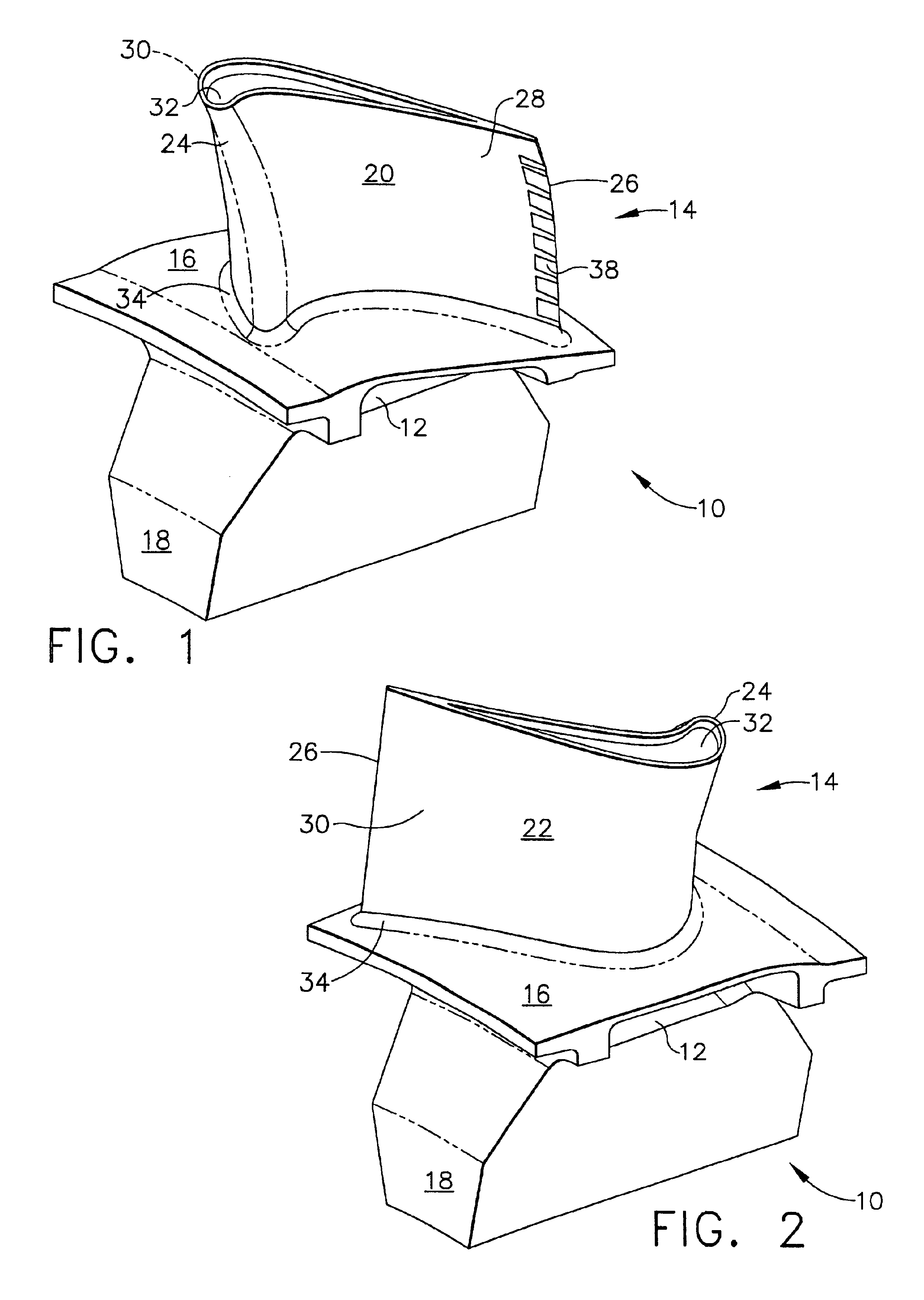

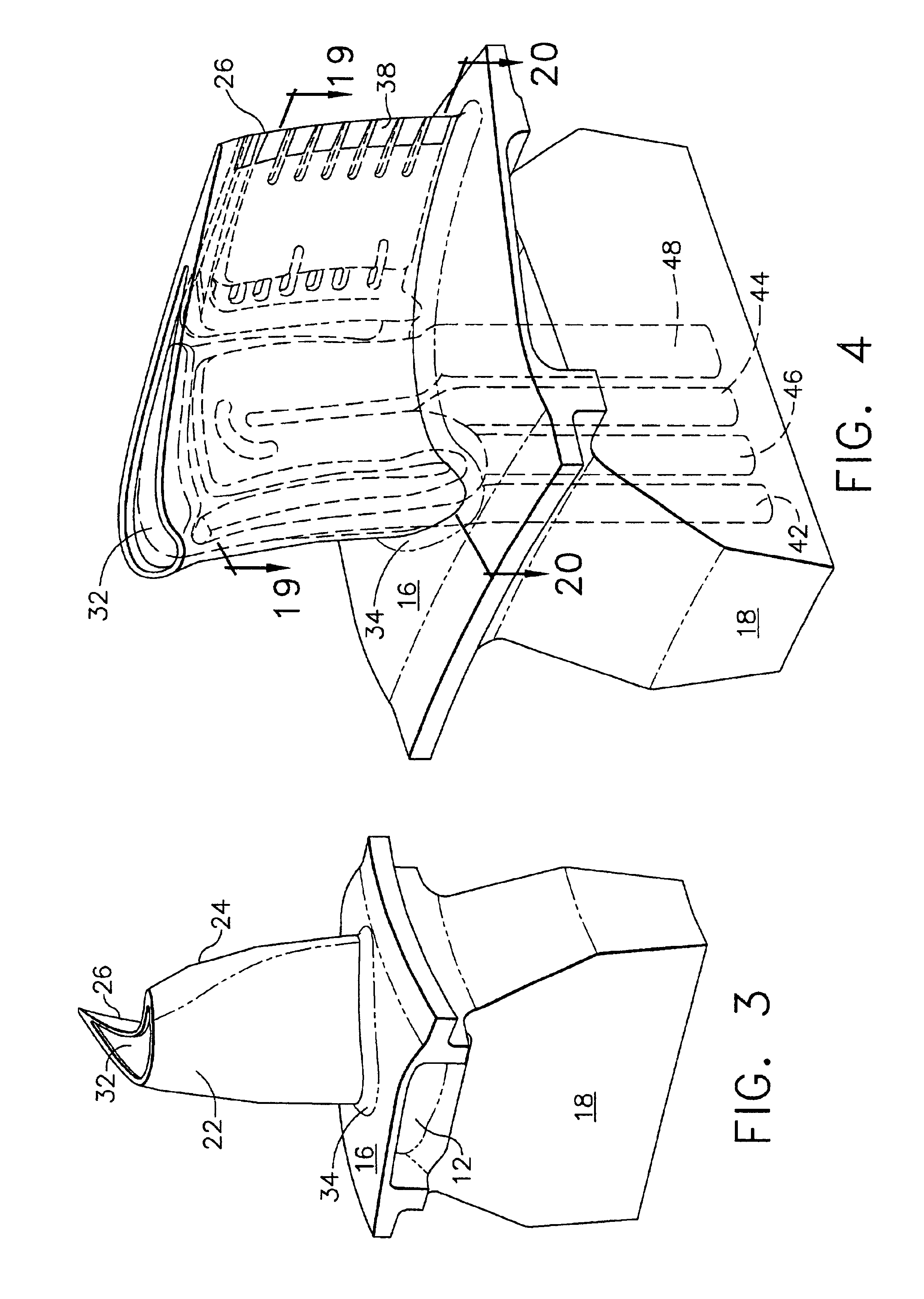

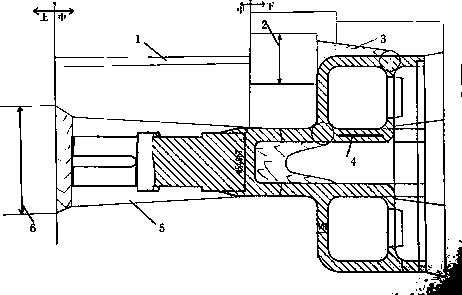

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

Anticorrosion cast multi-element Cu-alloy simulating golden colour and its preparing process

An anticorrosion golden Cu-alloy contains Cu (60-84 wt.%), Zn (0-35 wt.%), Al (0.5-10 wt.%), Ni (0.5-1.5 wt.%), Mn (0.1-8 wt.%), Fe (0-5 wt.%), Ti (0.01-15 wt.%), Ce (0.001-5 wt.%), and Sn (0-8 wt.%)and is prepared by conventional casting. Its advantages are golden colour without decolouring, and high resistance to atmosphere corrosion, NaCl solution, and sulfuric acid solution.

Owner:ZHEJIANG UNIV

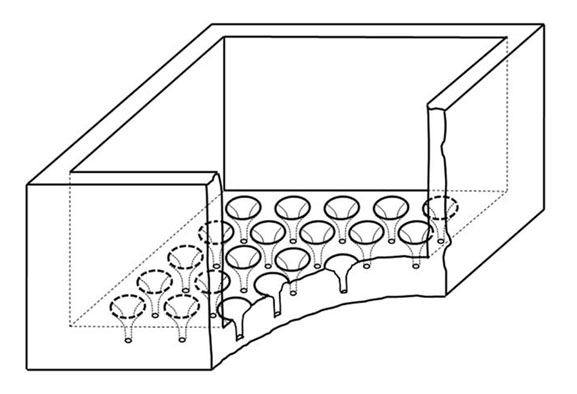

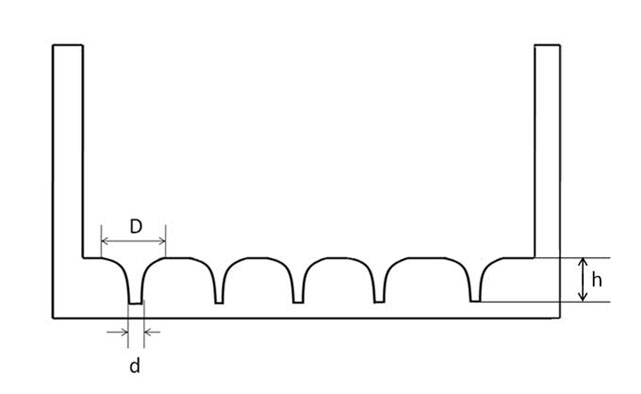

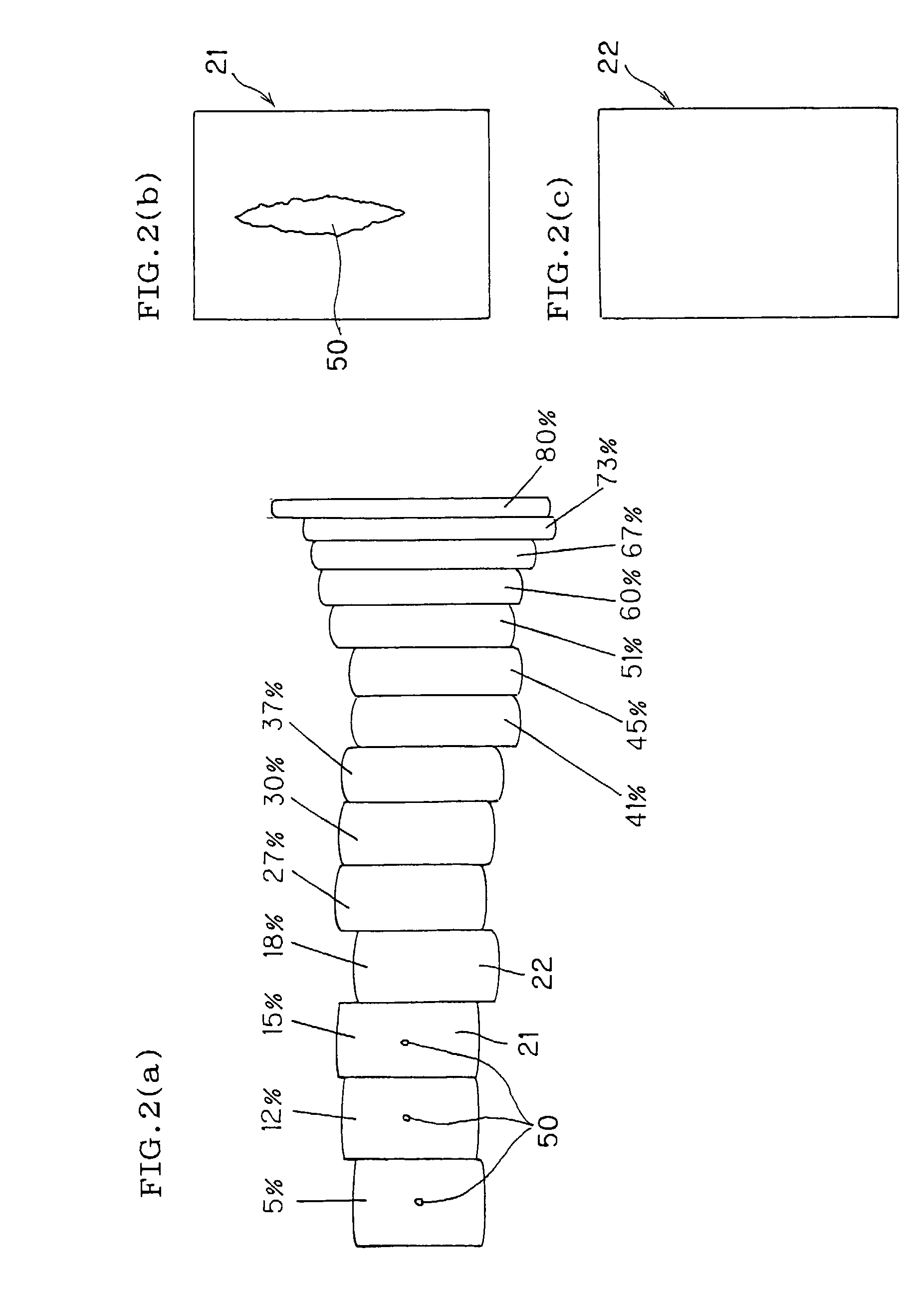

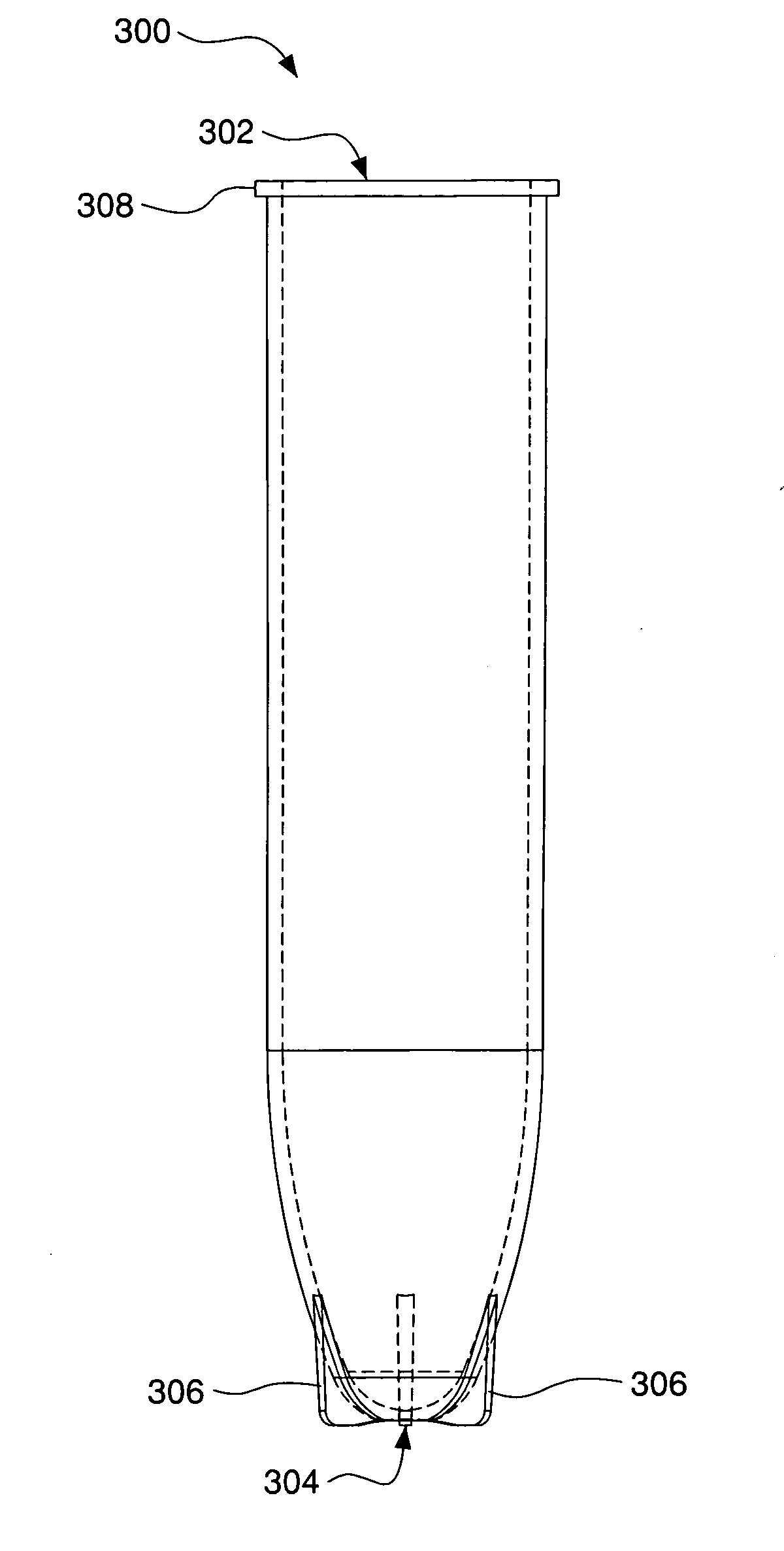

Quartz crucible and method for casting quasi-single crystal

InactiveCN101979718AQuality improvementImprove electrical performanceFrom frozen solutionsConventional castingElectrical performance

The invention discloses a quartz crucible. The bottom of the quartz crucible is provided with a pit which is spontaneously generated by inducing seed crystal. The invention also discloses a method for casting quasi-single crystal by using the quartz crucible. By using the quartz crucible of the invention, the quality of grown cast crystalline silicon is effectively improved so as to improve the electrical performance of a solar cell. By the method for casting the quasi-single crystal in the invention, the diameter of the obtained crystal grain is about 5 to 10cm, tests show that the dislocation density is about 10<3>cm<-2> which is far less than a number range of 10<4> to 10<5>cm<-2> of silicon crystal obtained by the conventional casting method under the same condition; and accordingly, the minority carrier lifetime value of a silicon slice obtained by the method of the invention is about 18us which is greater than the minority carrier lifetime value of 11us of the silicon slice prepared from the same raw material by the conventional casting method.

Owner:ALTUSVIA ENERGY TAICANG

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

Plastic compositions having mineral-like appearance

Composite plastic compositions based on the dispersion of selected crosslinked polymers in certain thermoplastic matrices are disclosed. The composite compositions are readily formed and processed by thermal extrusion processes versus conventional casting processes. Preferred composite plastic compositions based on crosslinked poly(alkyl (meth)acrylate) polymers and modified poly(alkyl (meth)acrylate) thermoplastics are especially useful in the preparation of synthetic architectural materials having a mineral-like appearance, such as that of granite.

Owner:ARKEMA FRANCE SA

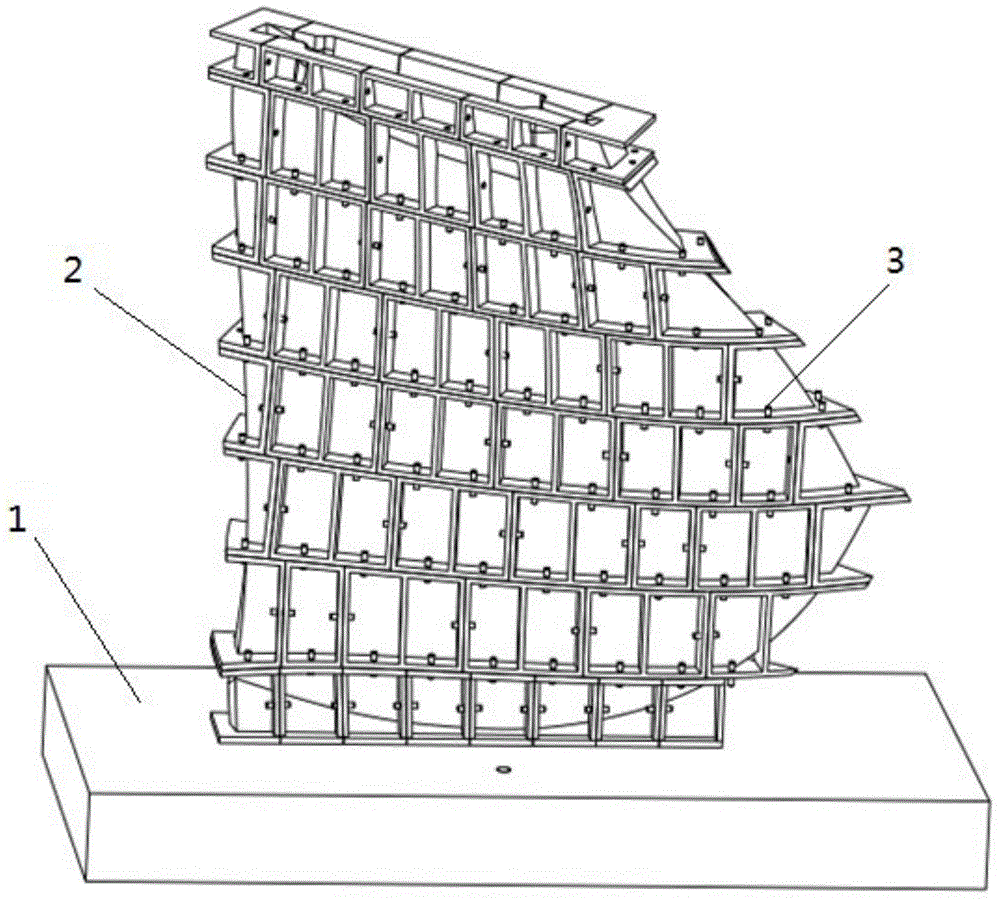

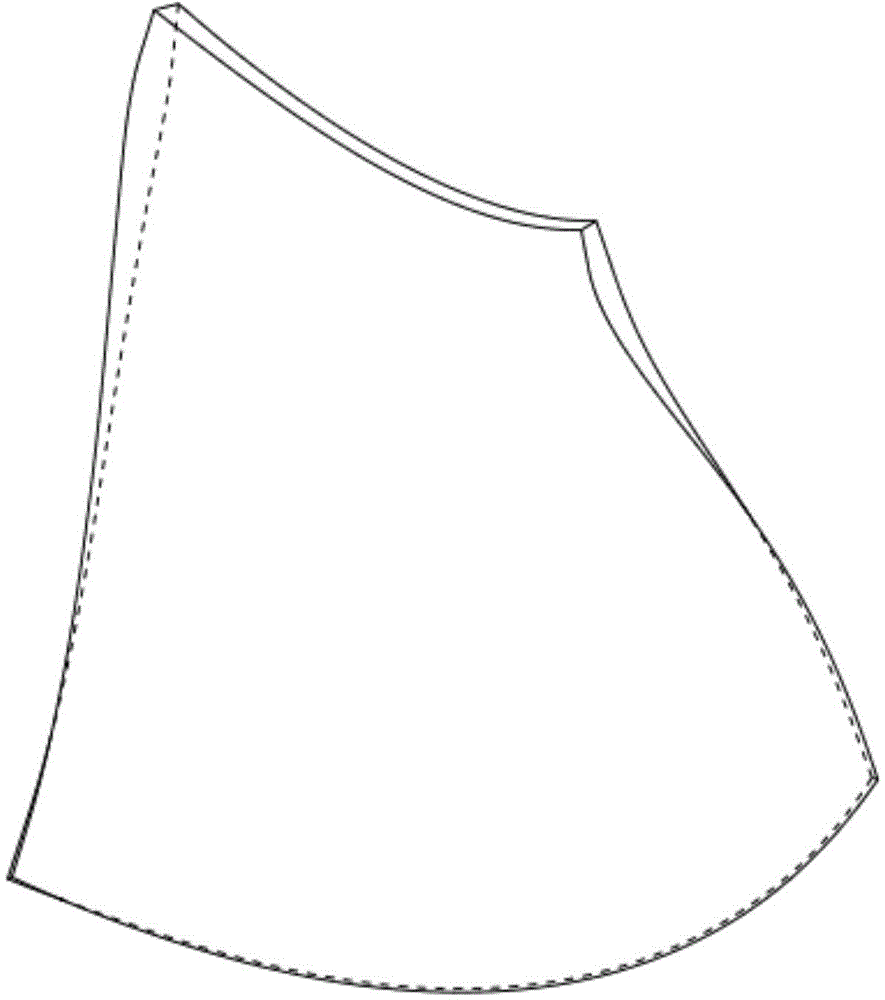

3D-printing sand core moulding method of large-scale hydraulic turbine blade

InactiveCN104416120AImprove product qualityReduce labor intensityFoundry mouldsFoundry coresConventional castingUltimate tensile strength

The invention relates to a 3D-printing sand core moulding method of a large-scale hydraulic turbine blade. In the method, a wood mould manufacturing process in a conventional casting production process is free while a plurality of moulds of sand cores are designed in 3D-cartographic software. The sand cores are directly printed and moulded by a 3D printer and finally the sand cores are assembled layer-by-layer to complete the moulding process. In the method, the conventional mould manufacturing process is omitted so that the 3D-printing sand core moulding method is significantly reduced in production period, is reduced in production cost, is high in moulding accuracy, is low in labor intensity, is low in environmental pollution and is especially suitable for large-scale hydraulic turbine blade production in various models and in large production scale.

Owner:北京瑞泓翔宏大科技发展有限公司

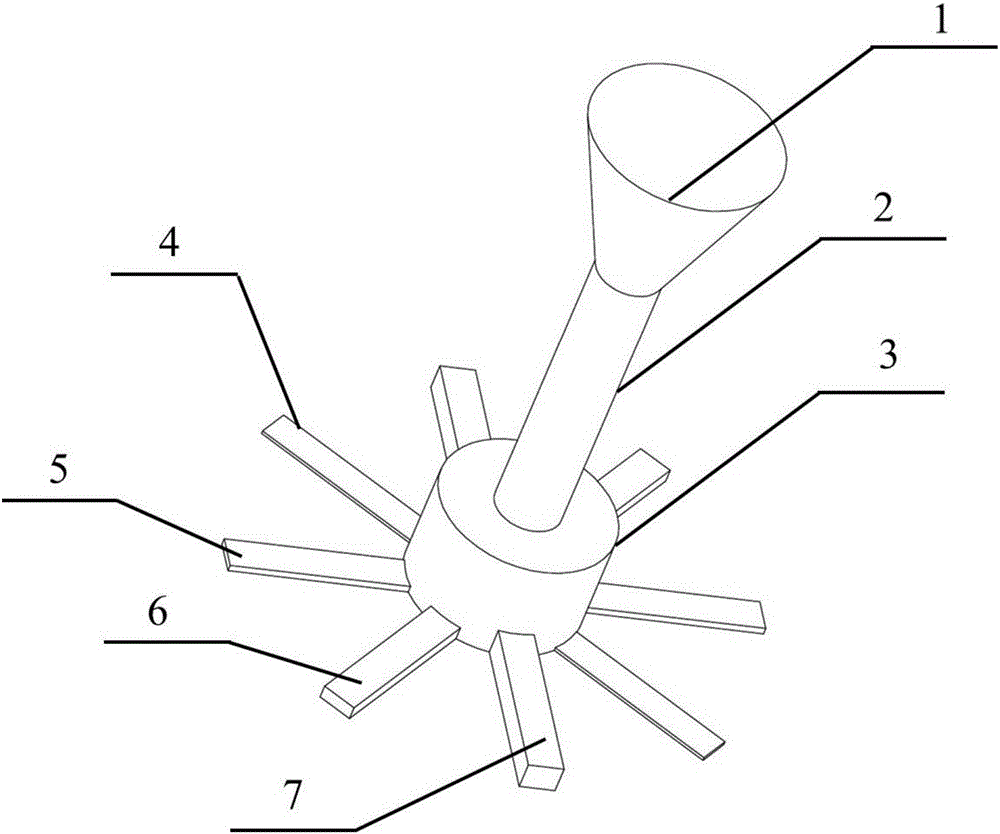

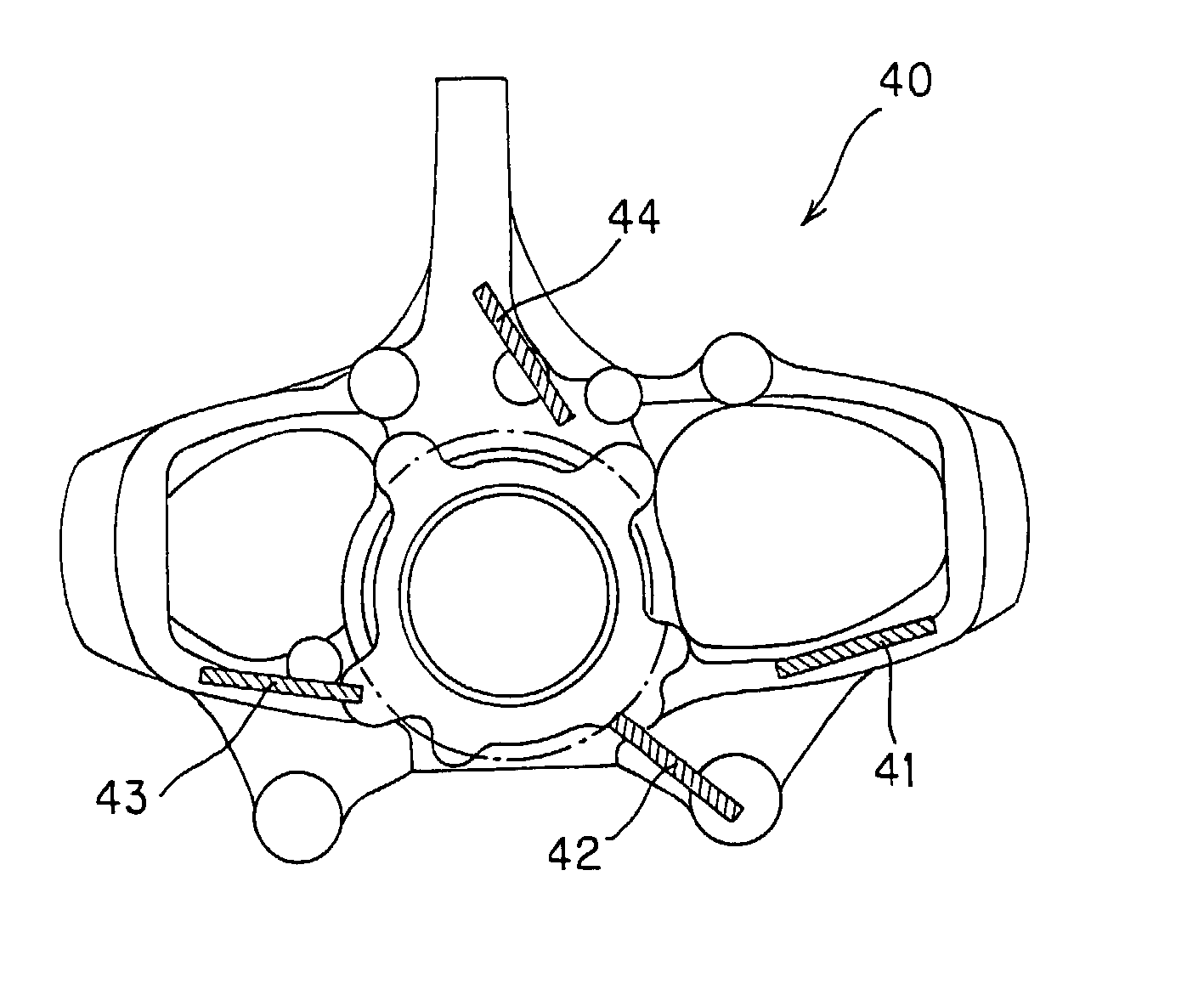

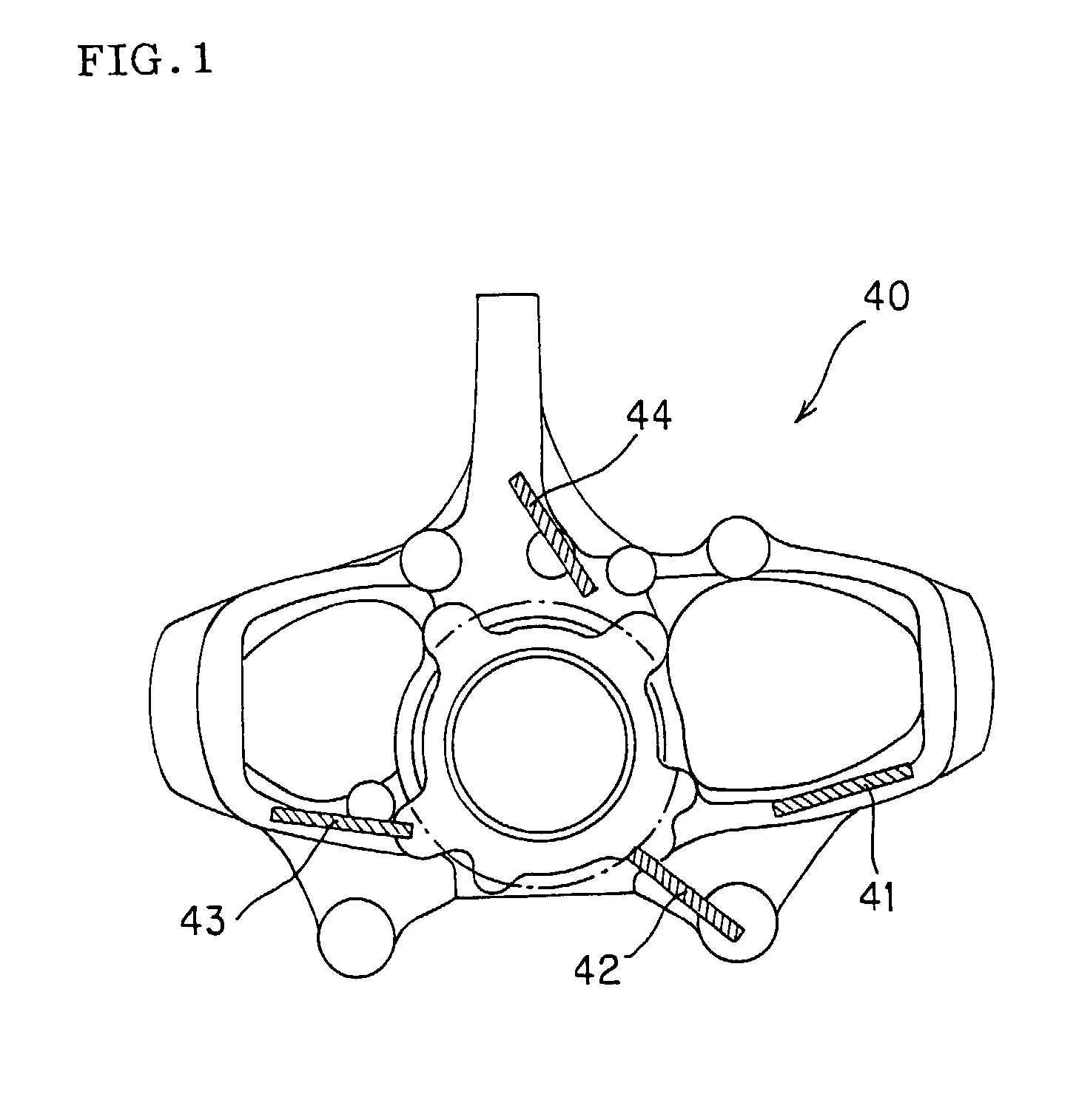

Casting and method for evaluating hot crack tendency of high temperature alloy investment casting process

ActiveCN104999032AReduced tendency to form hot cracksFoundry mouldsFoundry coresConventional castingInvestment casting

The invention provides a casting and method for evaluating the hot crack tendency of the high temperature alloy investment casting process. The investment casting adopts a step test model with an extra large variable-section coefficient; the model comprises a cylinder, the bottom of the cylinder is connected with four pairs of thin plates of different thickness, the top center of the cylinder is connected to the bottom of a sprue, and the top of the sprue is connected with a truncated cone-shaped pouring gate. After adopting the casting and method, the hot crack tendency condition of the high temperature alloy investment casting under the conventional casting processing conditions is found out, the improvement of the casting technology is guided, reasonable advice can be supplied for the structural design of the casting, so that the hot-crack forming tendency of the high temperature alloy investment casting is expected to be reduced from the source, and the other existing hot crack evaluation methods cannot be compared with the advantages.

Owner:ZHONGCHAO HANGYU INVESTMENT CASTING S&T CO

Mg-gd-y-zn-zr alloy and process for preparing the same

A Mg—Gd—Y—Zn—Zr alloy with high strength and toughness, corrosion resistance and anti-flammability and a process for preparation thereof are disclosed. The components and the mass percentages thereof in the Mg—Gd—Y—Zn—Zr alloy are: 3.0%≤Gd≤9.0%, 1.0%≤Y≤6.0%, 0.5%≤Zn≤3.0%, 0.2%≤Zr≤1.5%, the balance being Mg and inevitable impurities. The process for preparation thereof comprises: adding pure Mg into a smelting furnace for heating, then introducing mixed gases of CO2 and SF6 into the furnace for protection; adding other raw materials in sequence when the pure Mg is completely melted; preparing an ingot; conducting a homogenization treatment on the ingot prior to extrusion; conducting an aging treatment on the extruded alloy. A wrought magnesium alloy having superior overall performances and good fracture toughness, corrosion resistance and anti-flammability, with a small amount of rare earth element is obtained by adjusting the proportion of the alloy elements and by conventional casting, extrusion and heat treatment processes. The cost of the alloy is reduced while the strength of the alloy is maintained.

Owner:THE BOEING CO

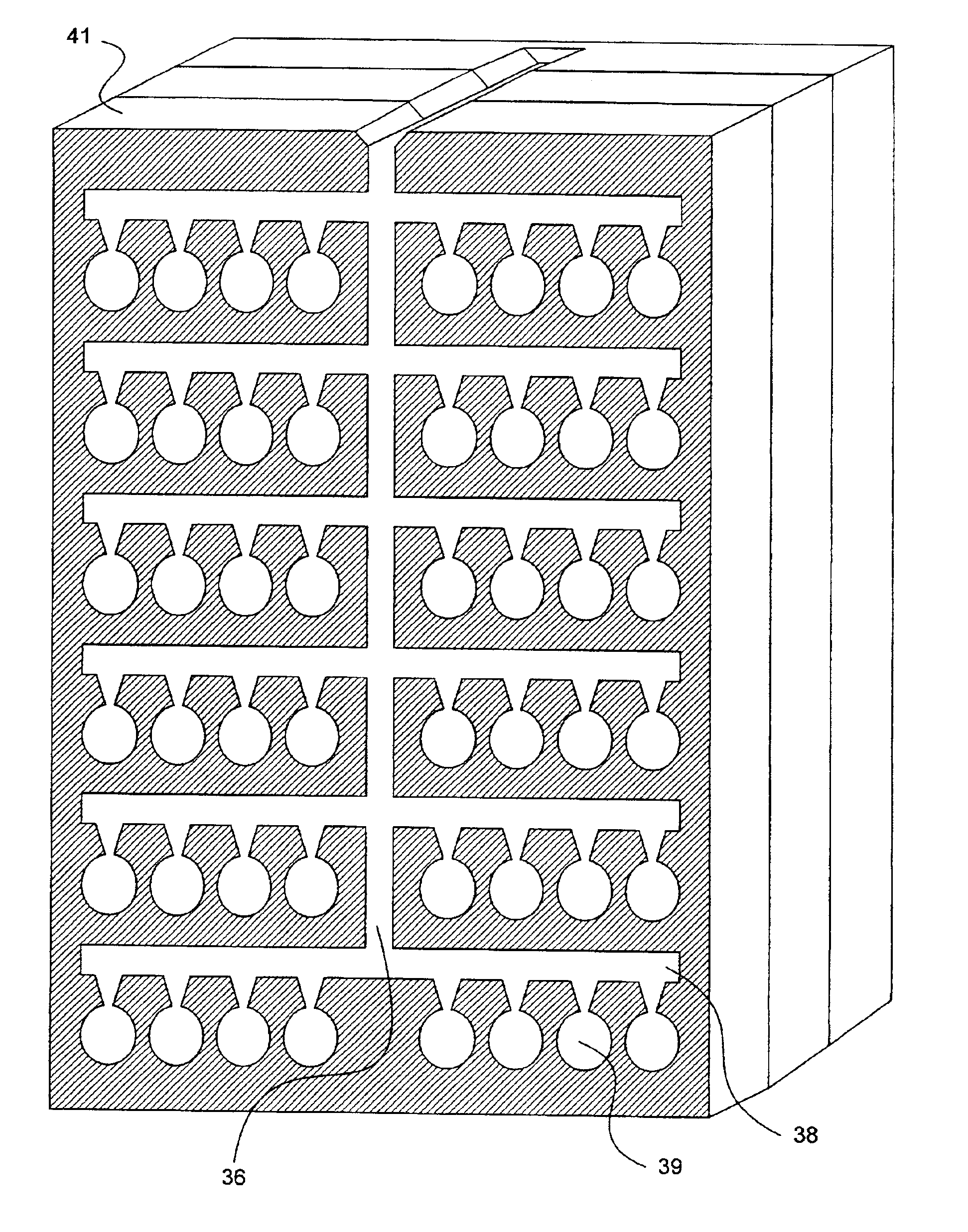

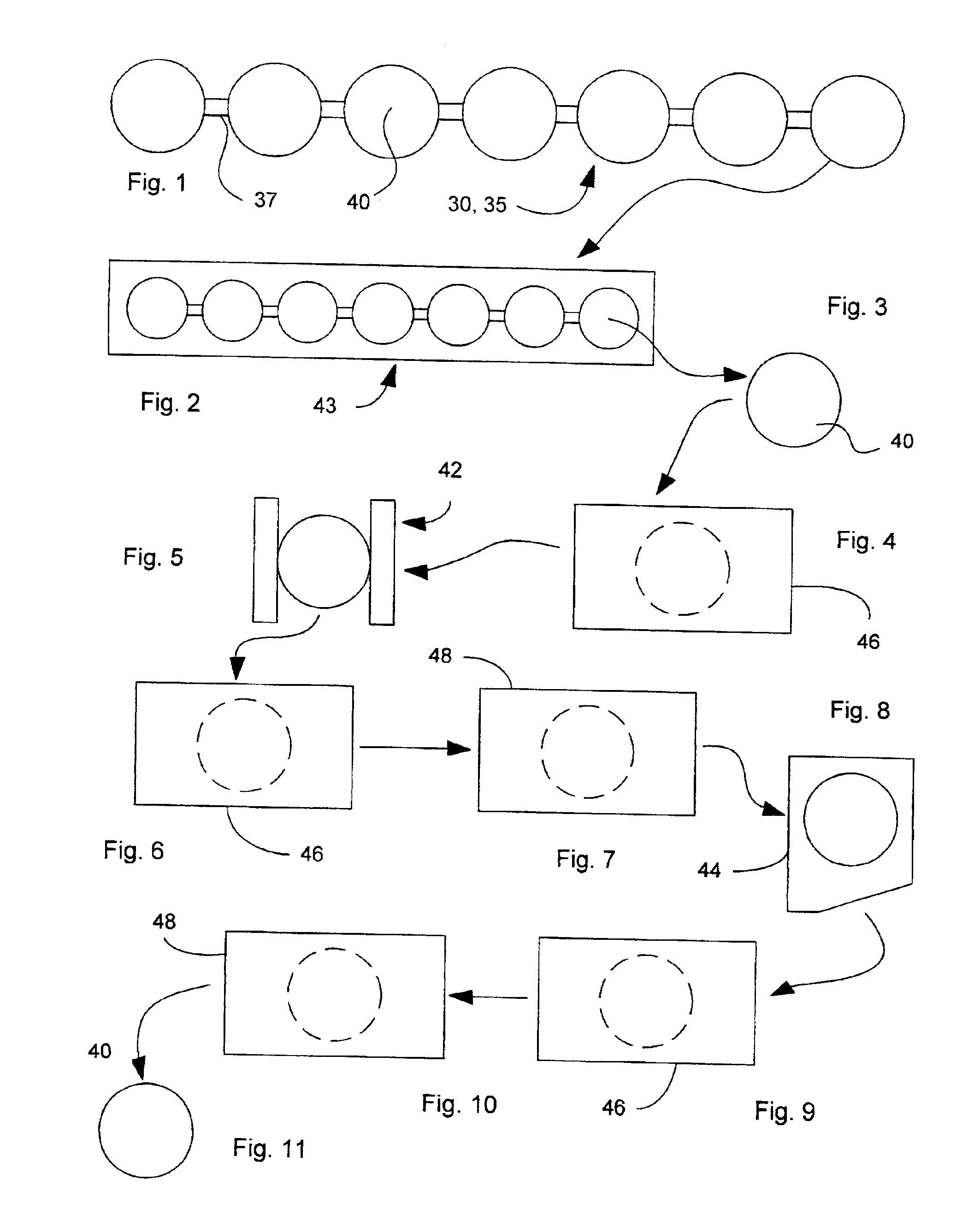

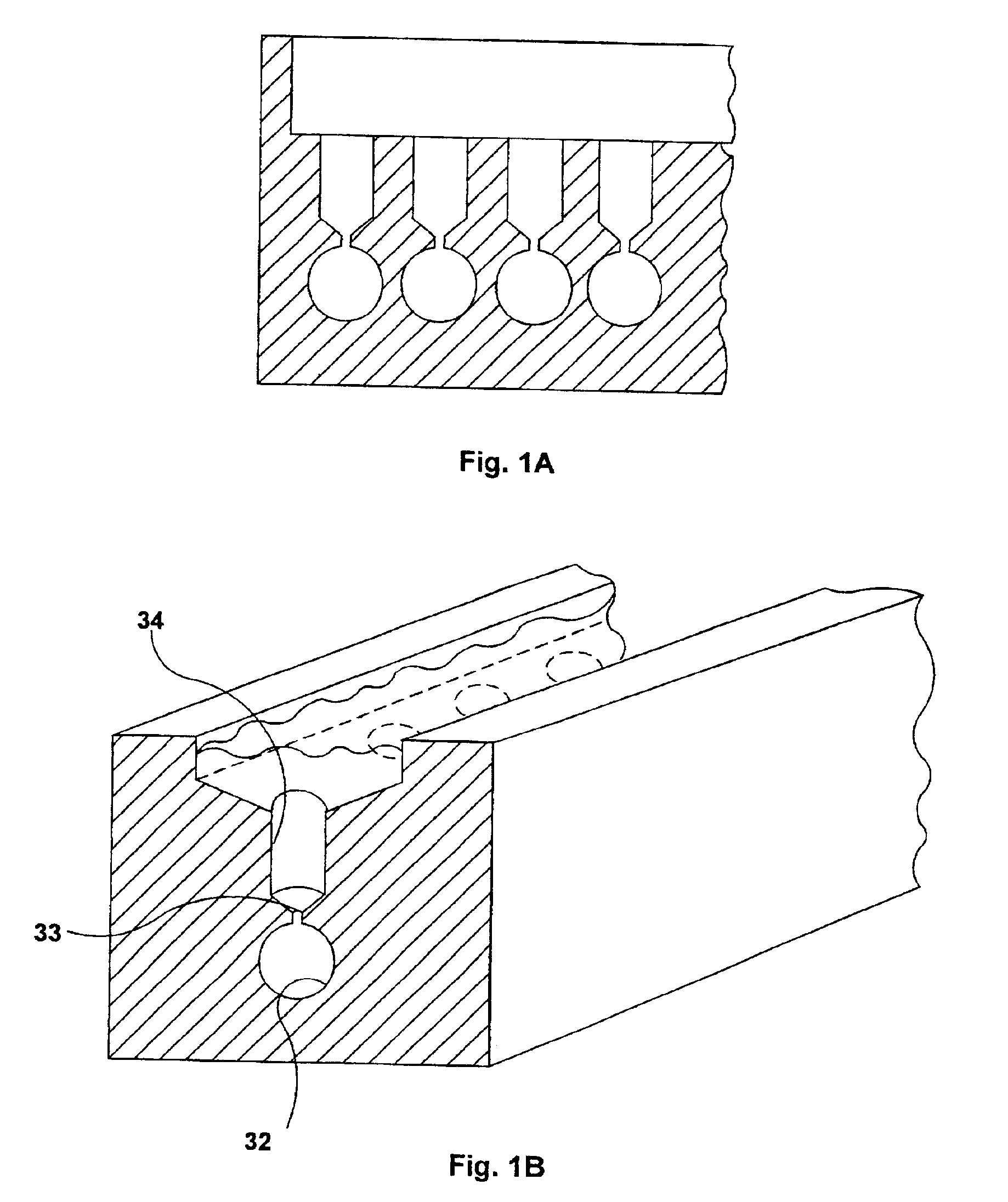

Nitinol ball bearing element and process for making

InactiveUS6886986B1High strengthImprove damping performanceRevolution surface grinding machinesSpherical surface grinding machinesBall bearingConventional casting

A bearing having bearing elements made of Type 60 Nitinol made by an investment casting process for producing near net shape parts of Nitinol includes making a ceramic mold having a series of spherical cavities, pouring molten Nitinol into the mold cavities, cooling the mold and the Nitinol in the cavities to produce solidified Nitinol balls, and breaking the mold away from the Nitinol balls. Nitinol rods for roller bearings can be made by conventional casting directly from the crucible in a draw-down oven. The bars are hot machined or hot rotary swaged and then centerless ground and laser cut to length, or are first cut to length and then centerless ground individually for crowned roller elements. The balls are broken or cut from the risers, leaving the gates attached, and are consolidated by healing under pressure in a hot isostatic press, then ground to the desired size. The balls or rollers are polished, then treated to create an integral ceramic finish. They are then repolished to produce an extremely smooth finish. The balls can also be cut from a sheet or plate of the ball material as cubes or cylinders and processed in an abrasive tumbler to round off the corners and edges, and the rounded cubes or cylinders can hen be ground to spherical form in conventional ball grinder.

Owner:NITINOL TECH

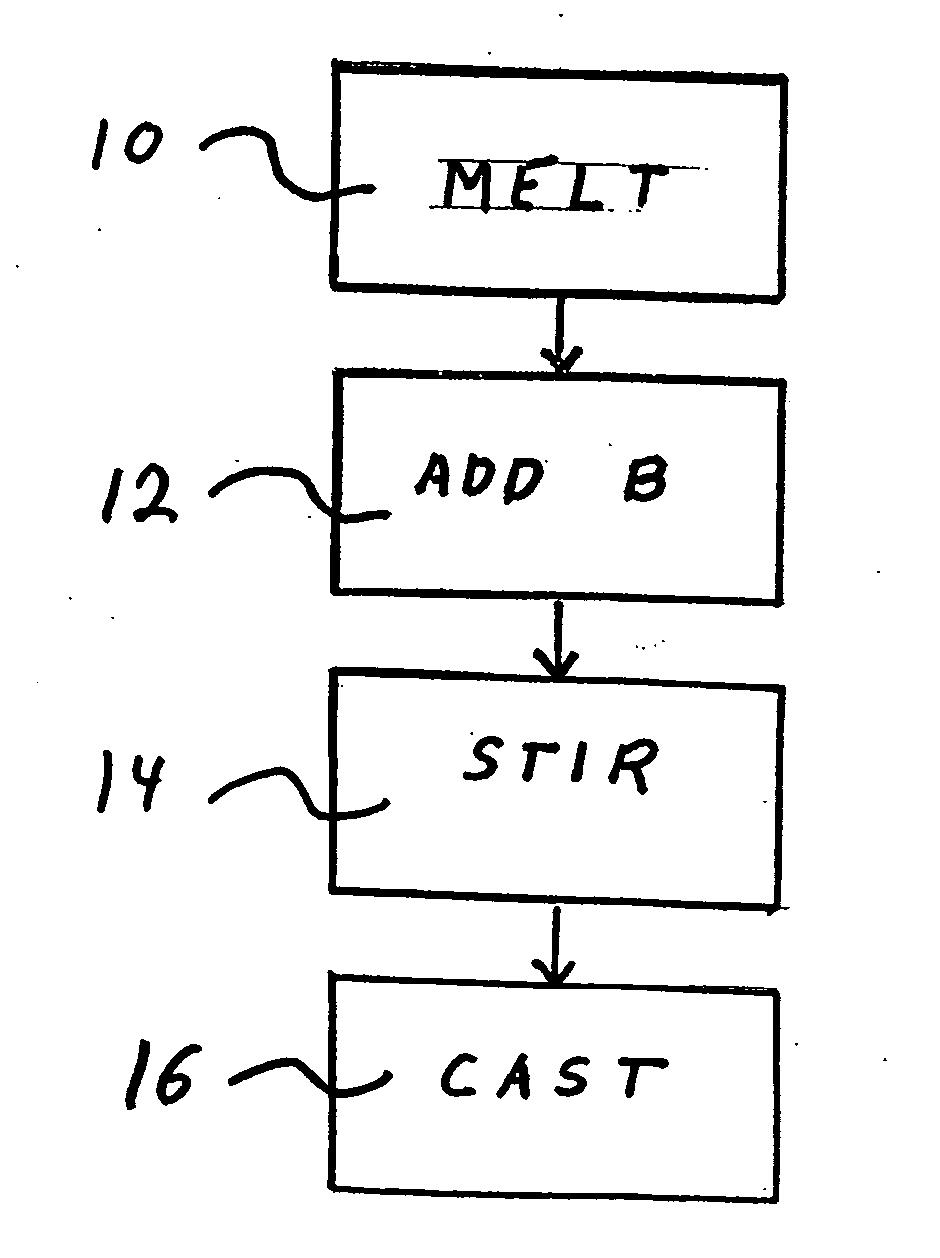

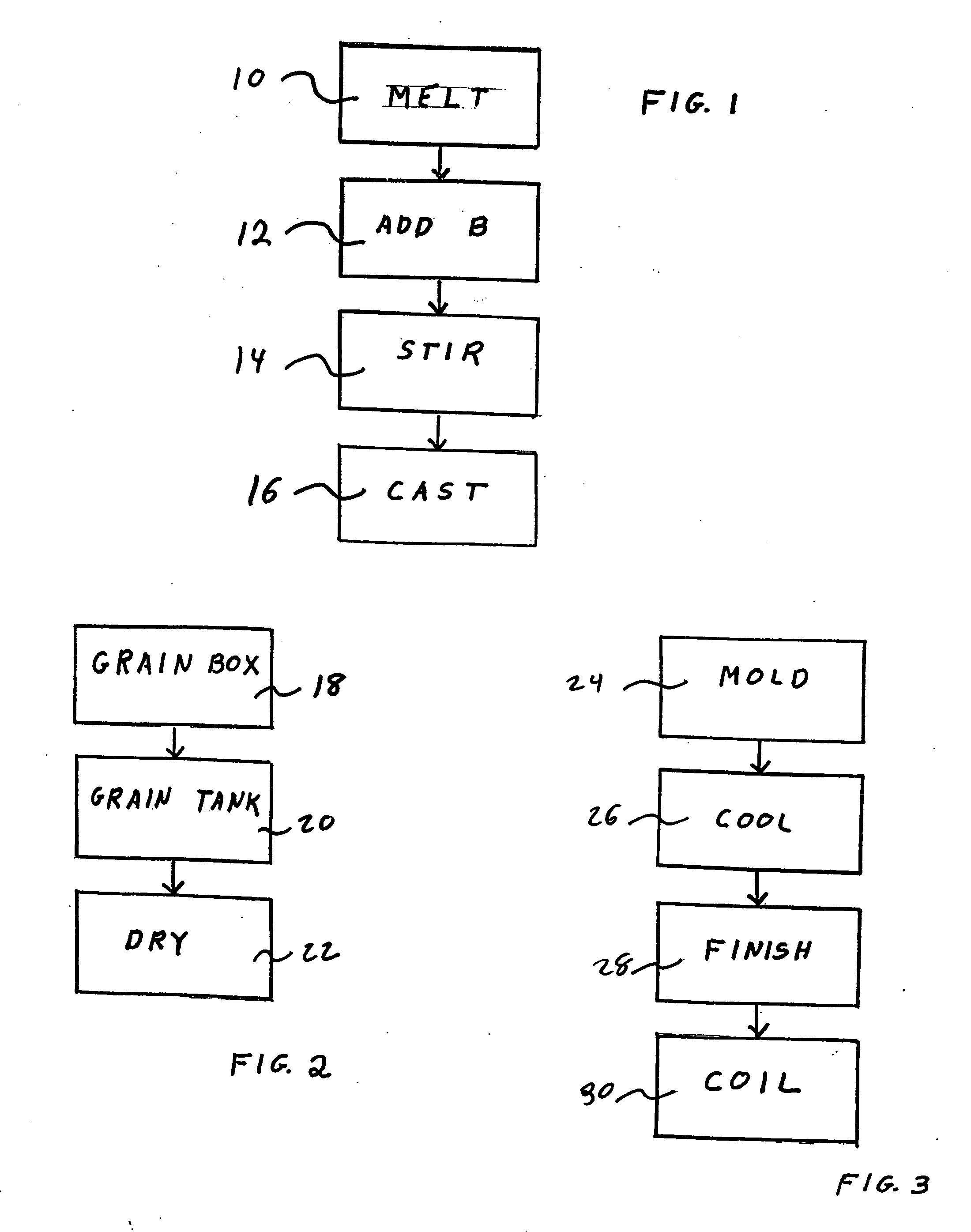

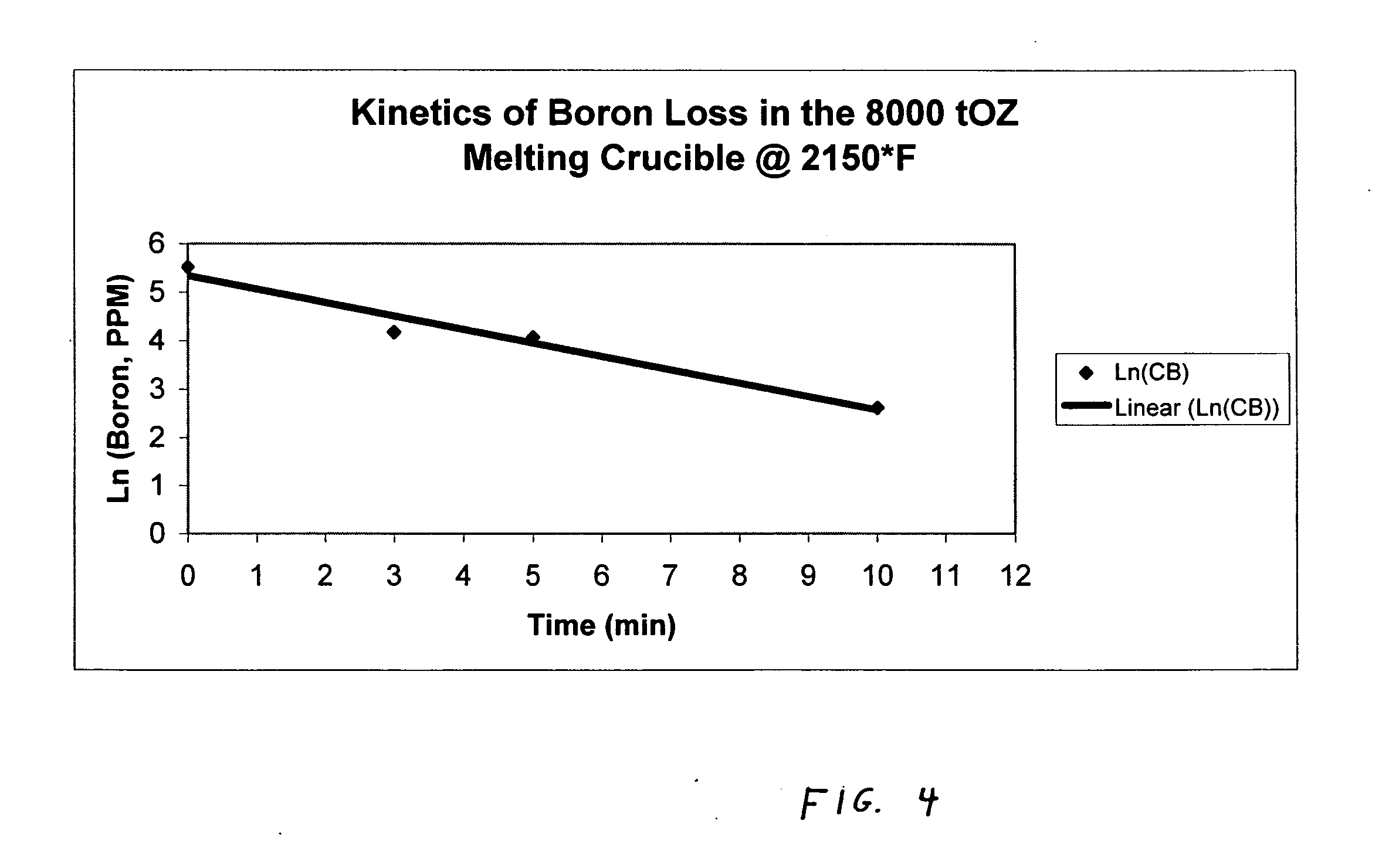

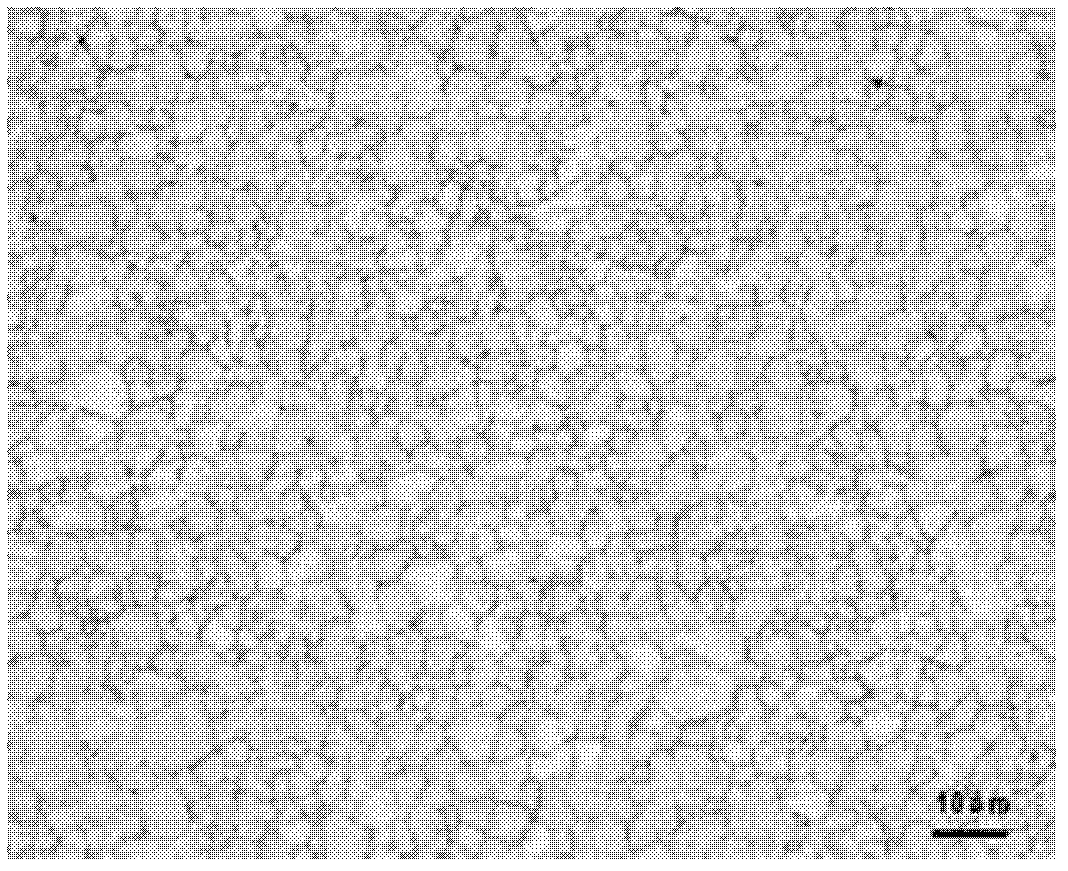

Method for adding boron to metal alloys

A method to grain refine and deoxidize a precious metal alloy or a master alloy includes the steps of (a) forming a precursor melt consisting essentially of constituents of the precious metal alloy or master alloy and inevitable impurities; (b) dispersing a compound selected from the group consisting of boron containing metal hydrides, boron containing metal fluorides and mixtures thereof throughout the precursor melt; and (c) solidifying the boron containing precious melt alloy or master alloy. One suitable compound is solid sodium borohydride (sodium tetrahydroborate). To minimize evaporation of the boron on contact with the precursor alloy melt, the sodium borohydride may be wrapped in a metal foil formed from constituents of the precious metal alloy or master alloy. The cast precious metal alloy or master alloy has been found to have a reduced number of hard spots and reduced silicon contamination when compared to conventional casting methods.

Owner:STERN LEACH CO

Method for manufacturing magnesium alloy thin plate

ActiveCN102304654ASolve the problem of bulky organizationHigh surface finishLower yieldConventional casting

The invention relates to a method for manufacturing a magnesium alloy thin plate. The invention aims to solve the problems of low yield strength, low tensile strength and low elongation percentage in the magnesium alloy thin plate manufactured by the conventional casting method or machining method and the problem of thick tissues of magnesium alloy products. The method comprises the following steps of: 1, melting; 2, casting; 3, annealing; 4, extruding; 5, performing hot rolling; and 6, performing cold rolling. The method is mainly used for manufacturing the magnesium alloy thin plates.

Owner:NORTHEAST LIGHT ALLOY CO LTD

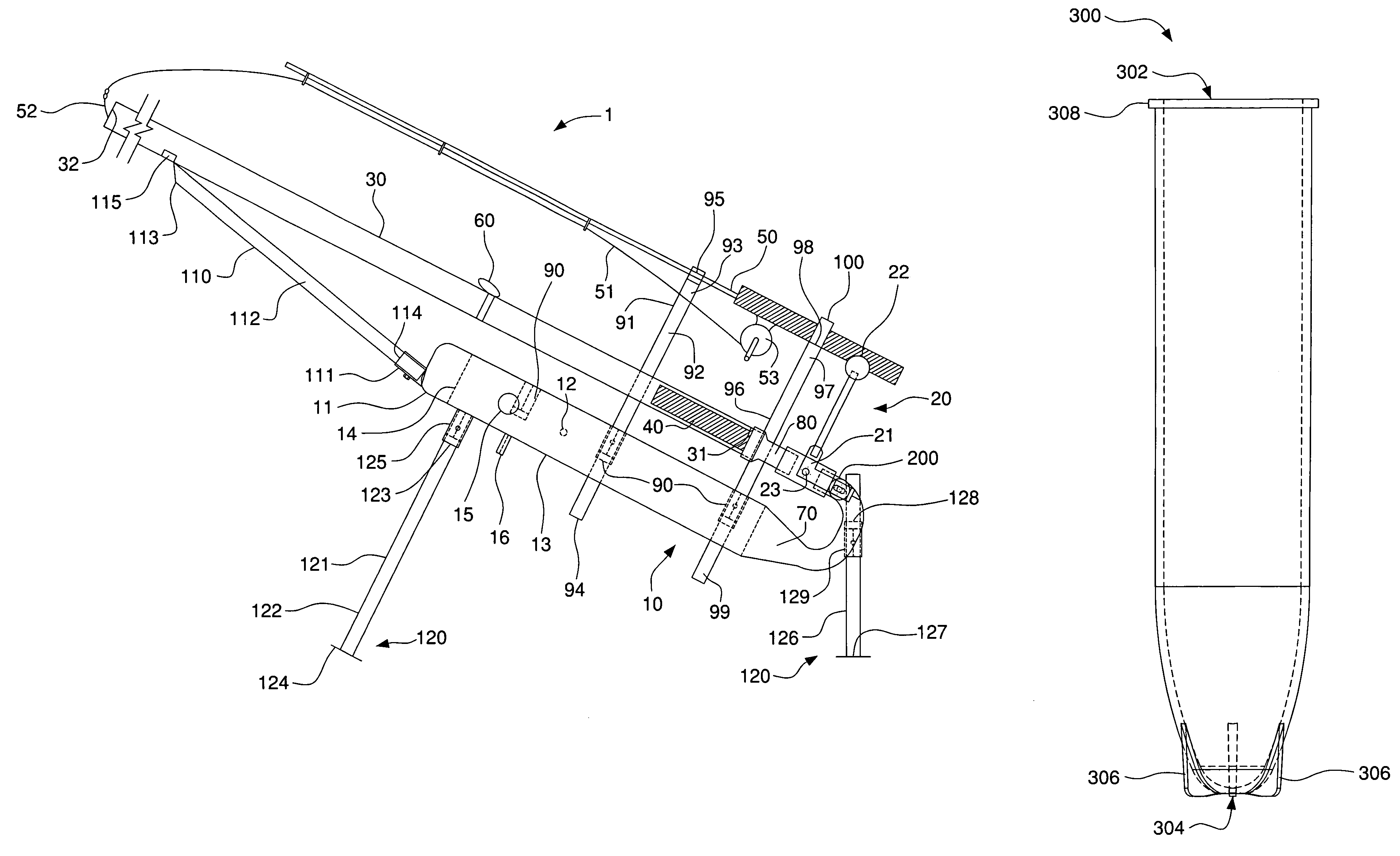

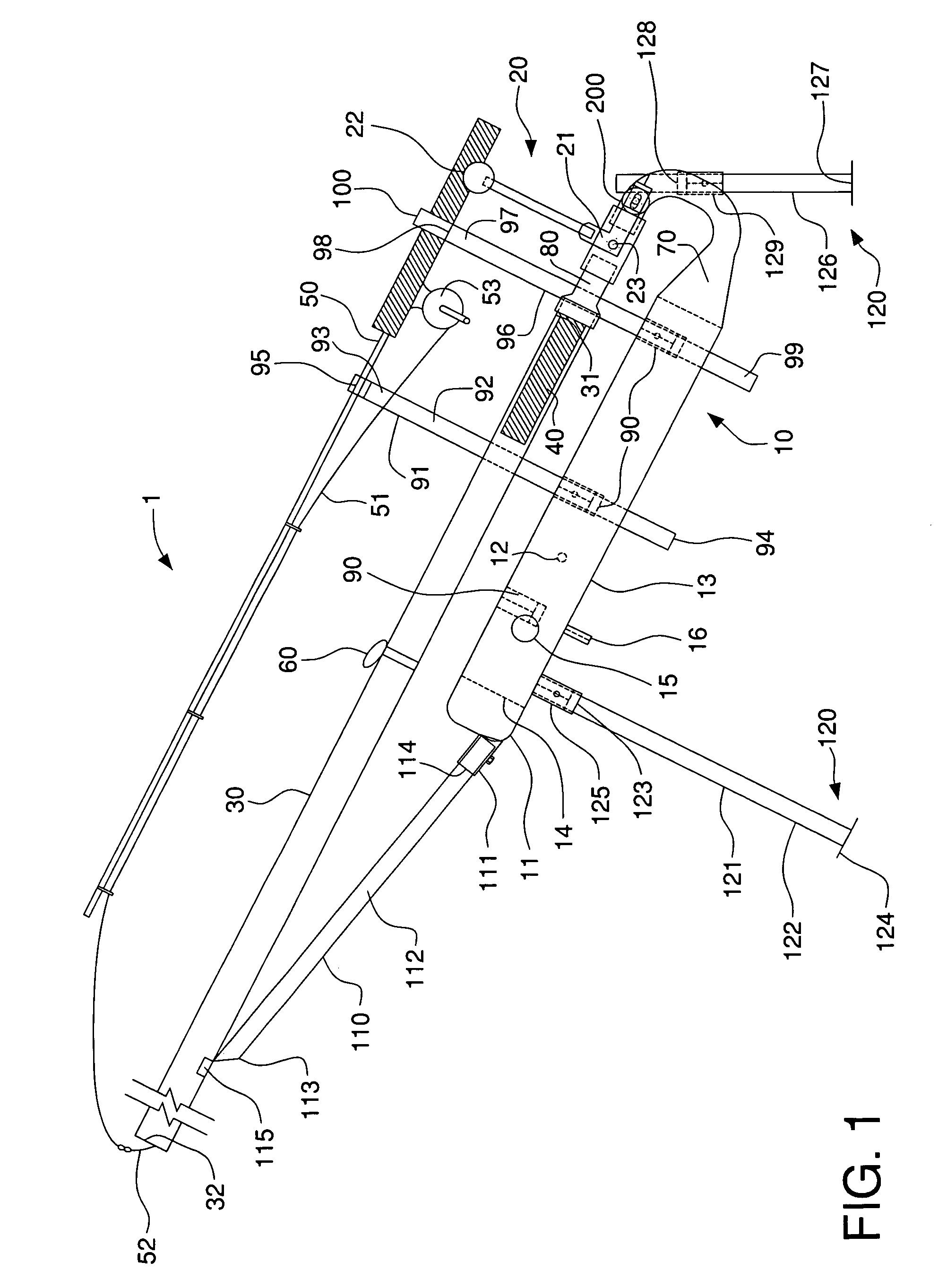

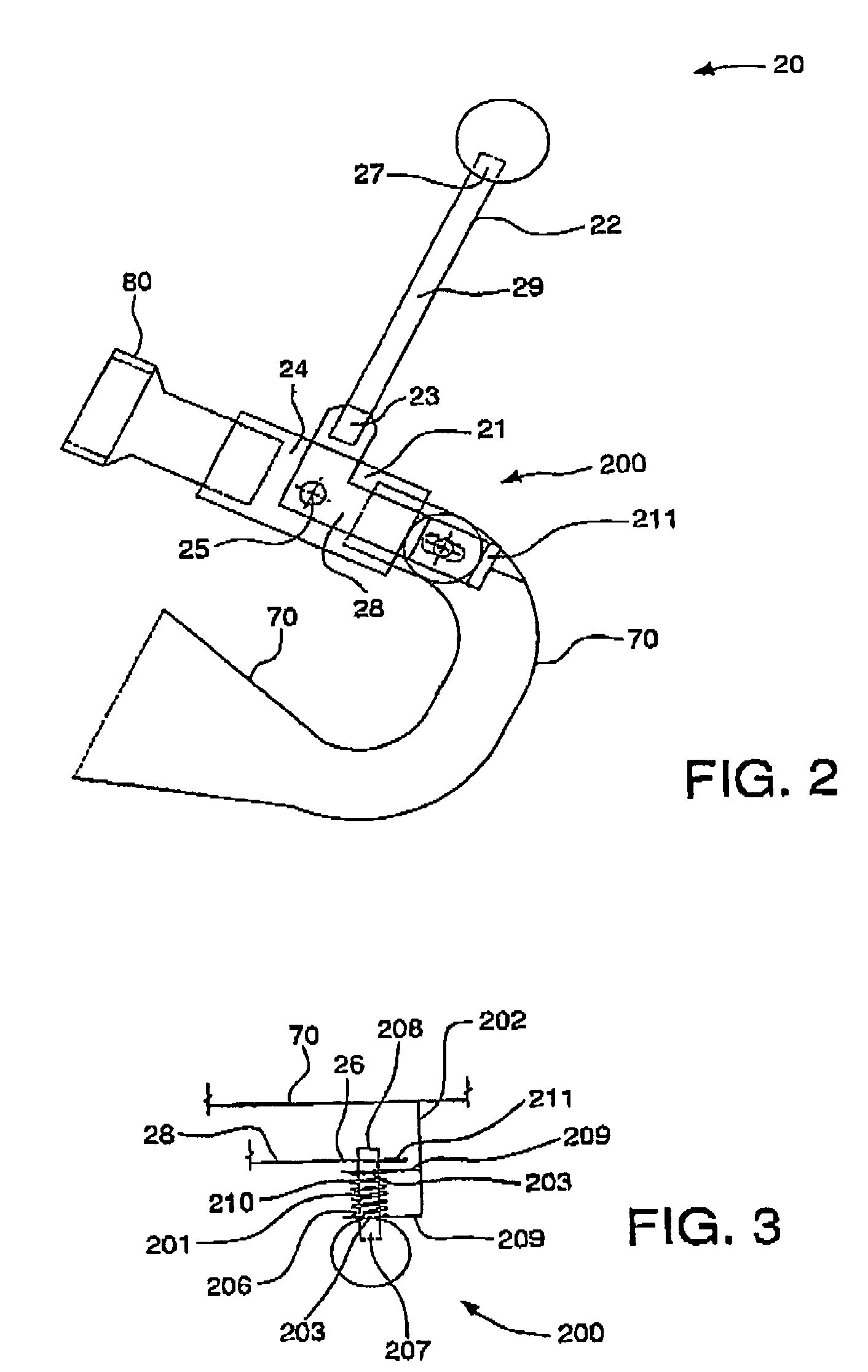

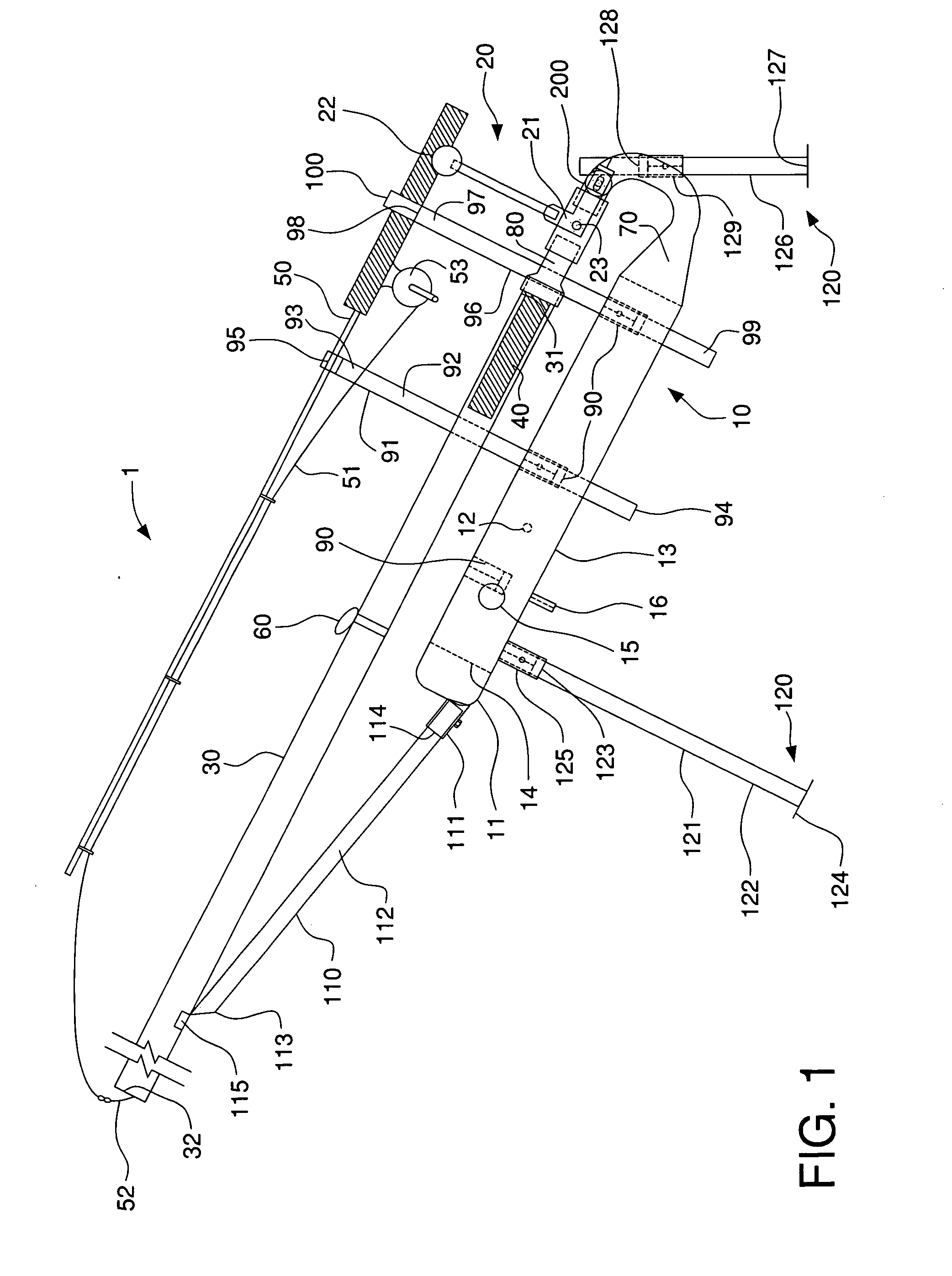

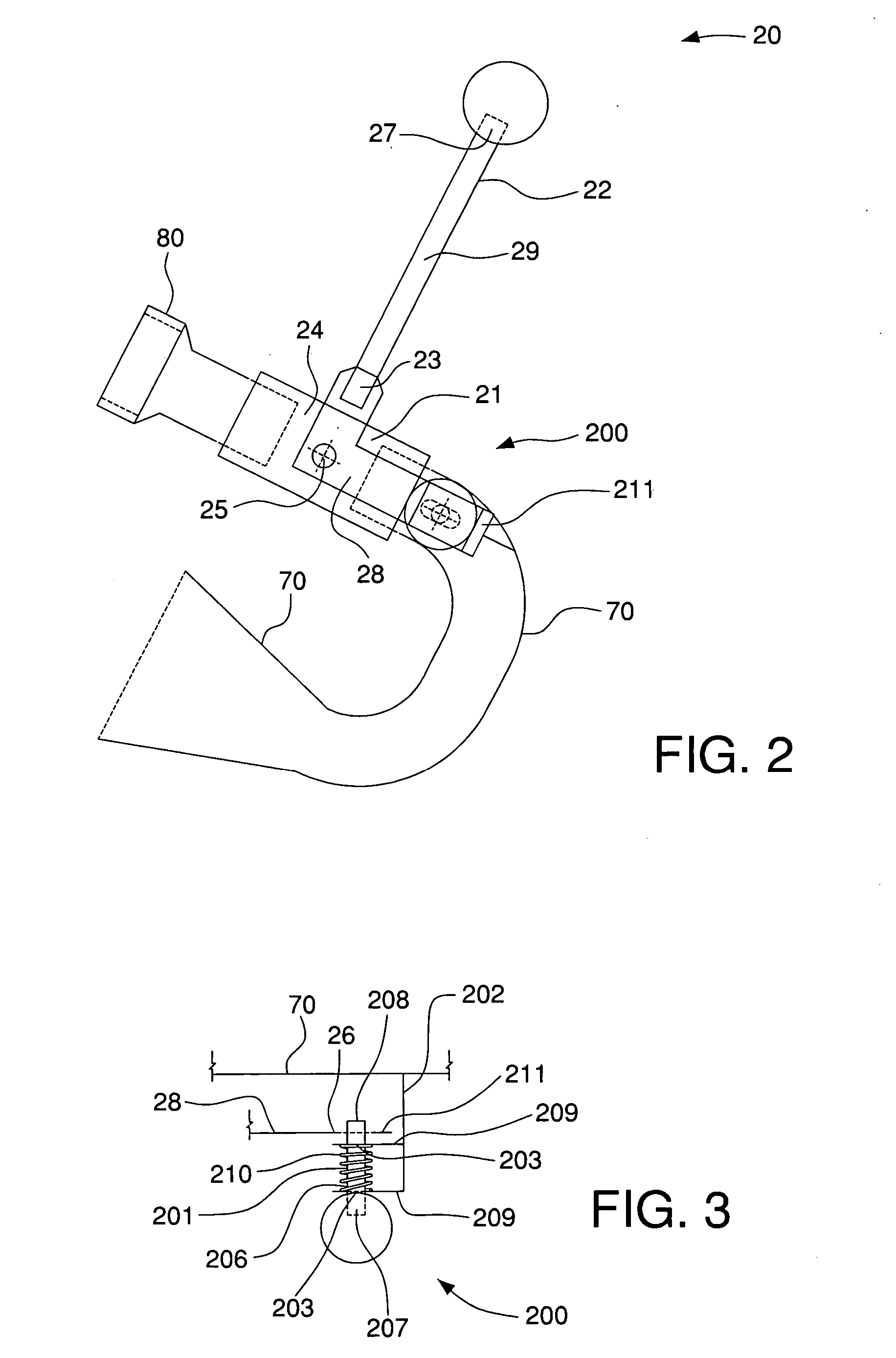

Fishing line casting and bait projectile system

ActiveUS7409794B2Easy constructionEasy to operateMould separation apparatusLighting and heating apparatusDecoyReduction drive

A powered fishing line casting system utilizing compressed air is provided to cast a projectile provided with fishhooks and bait, and to which the fishing line to be cast is attached, to greater distances than could be achieved using conventional casting methods. The system includes a hollow launch tube sized to accommodate insertion of the projectile. A reducer is disposed adjacent to one end of the launch tube and is adapted to receive a flow of compressed gas from an accumulator tank and to discharge a stream of high-velocity air that impinges upon the projectile disposed within the launch tube in order to launch the projectile. A manually-operable valve is interposed between the reducer and the accumulator tank to control the flow of air to the reducer. Spaced-apart front and rear support legs provide stable support for the system during and between launches of a fishing line carrying projectile.

Owner:M DOOLEY PROD LLC

Aluminum alloy for casting-forge, and aluminum casting forged product and manufacturing method therefor

InactiveUS20030010412A1High strengthLow costSuspensionsSteering linkagesConventional castingManganese

An aluminum casting forged product is provided by using an aluminum alloy for casting forge including a useless raw material for forging such as flash as a raw material and by controlling a weight percentage of an alloy element such as silicon, magnesium, copper, and manganese; the product having an enhanced fluidity, and an improved castability, with retaining a sufficient strength, preventing useless intermetallic compounds from forming, restraining deterioration due to oxidation and corrosion, and further improved strength by a forging effect: and there is also provided a simple manufacturing method, with a high yield and high productivity. An aluminum casting forged product of high tensile strength, high proof, and elongation, higher mechanical properties than those of the conventional casting forged product, high corrosion resistance, and high quality without defects, and being low in cost is also obtainable as a thick-wall aluminum product.

Owner:ASAHI TEC CORP +1

Plastic compositions having mineral-like appearance

Composite plastic compositions based on the dispersion of selected crosslinked polymers in certain thermoplastic matrices are disclosed. The composite compositions are readily formed and processed by thermal extrusion processes versus conventional casting processes. Preferred composite plastic compositions based on crosslinked poly(alkyl (meth)acrylate) polymers and modified poly(alkyl (meth)acrylate) thermoplastics are especially useful in the preparation of synthetic architectural materials having a mineral-like appearance, such as that of granite.

Owner:ARKEMA FRANCE SA

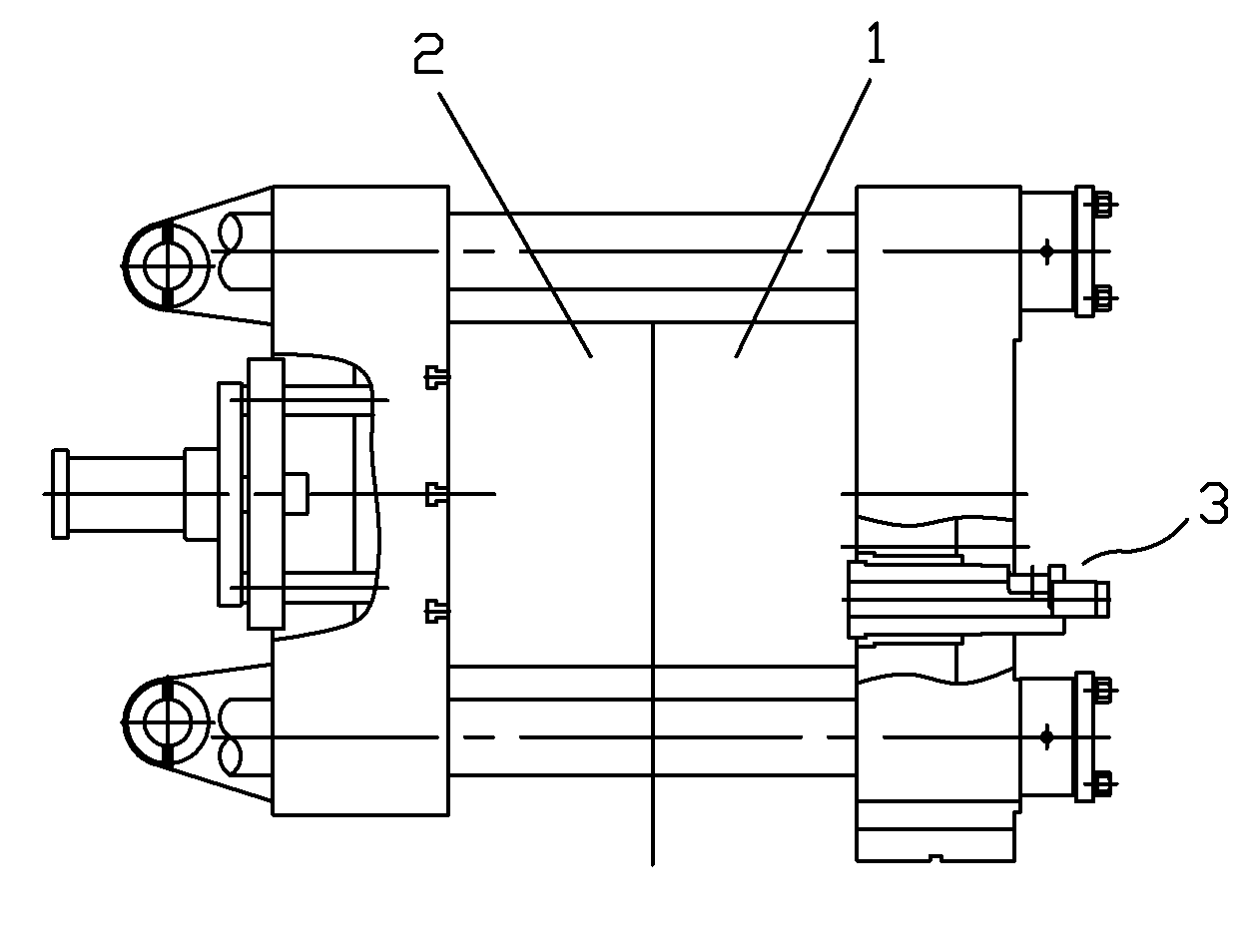

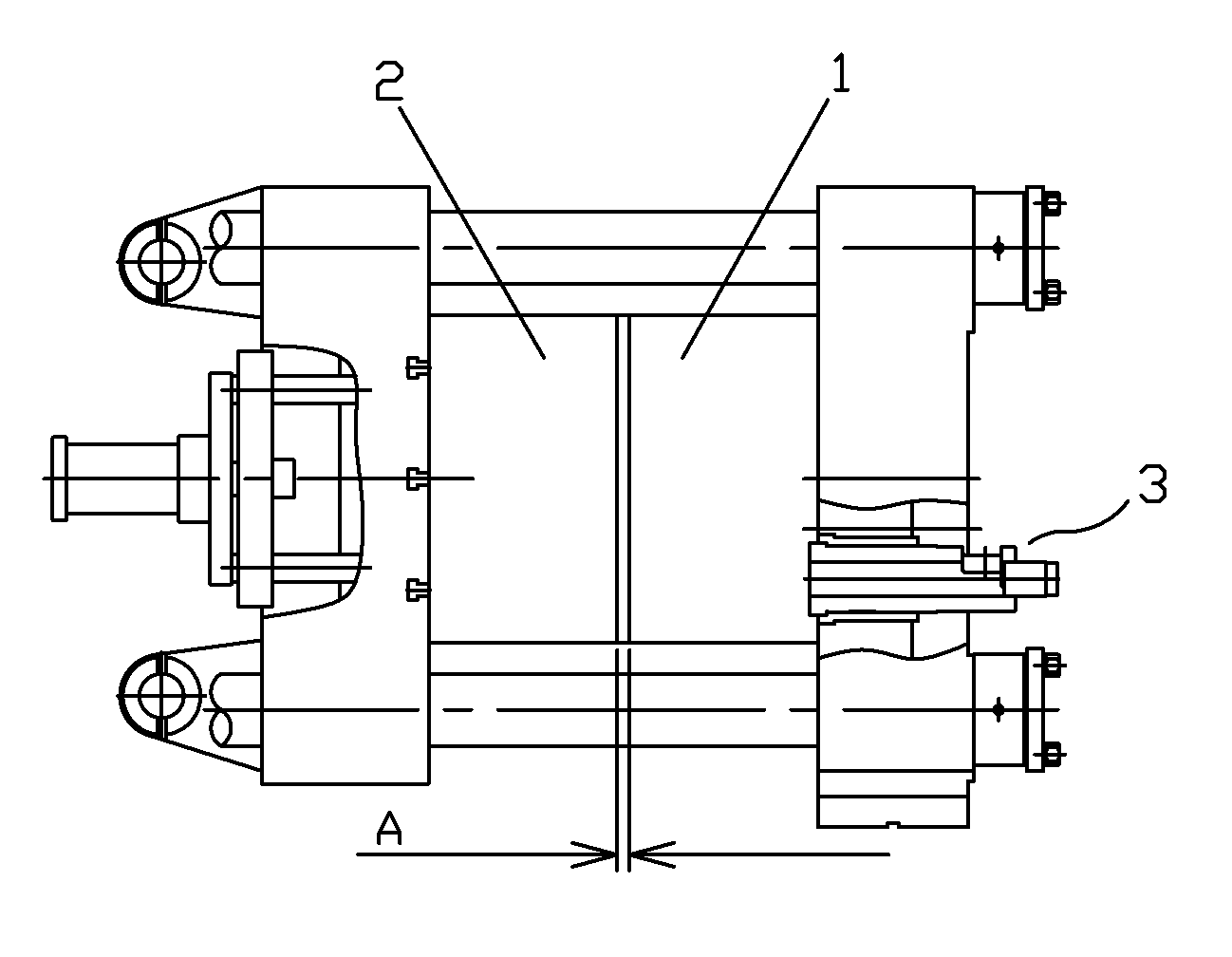

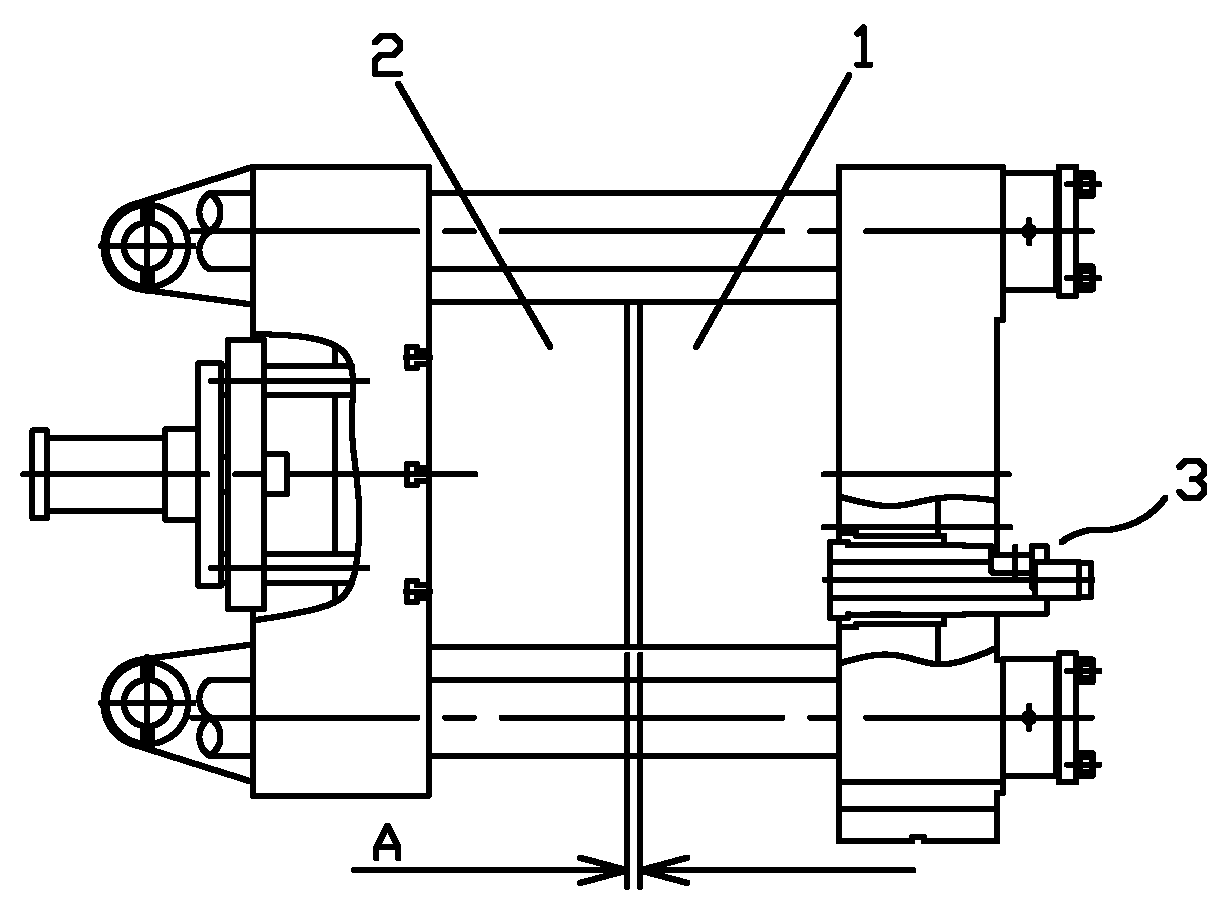

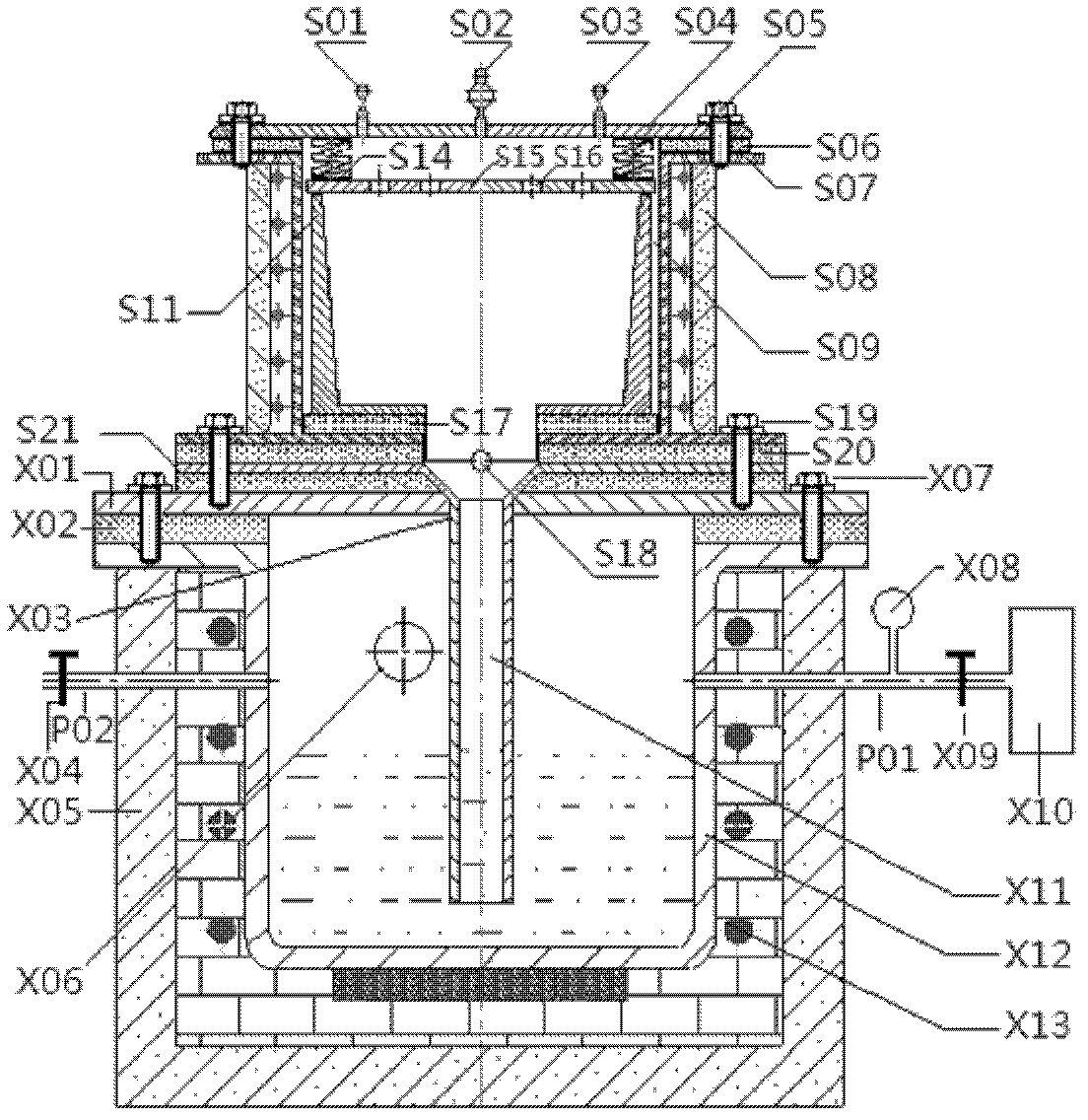

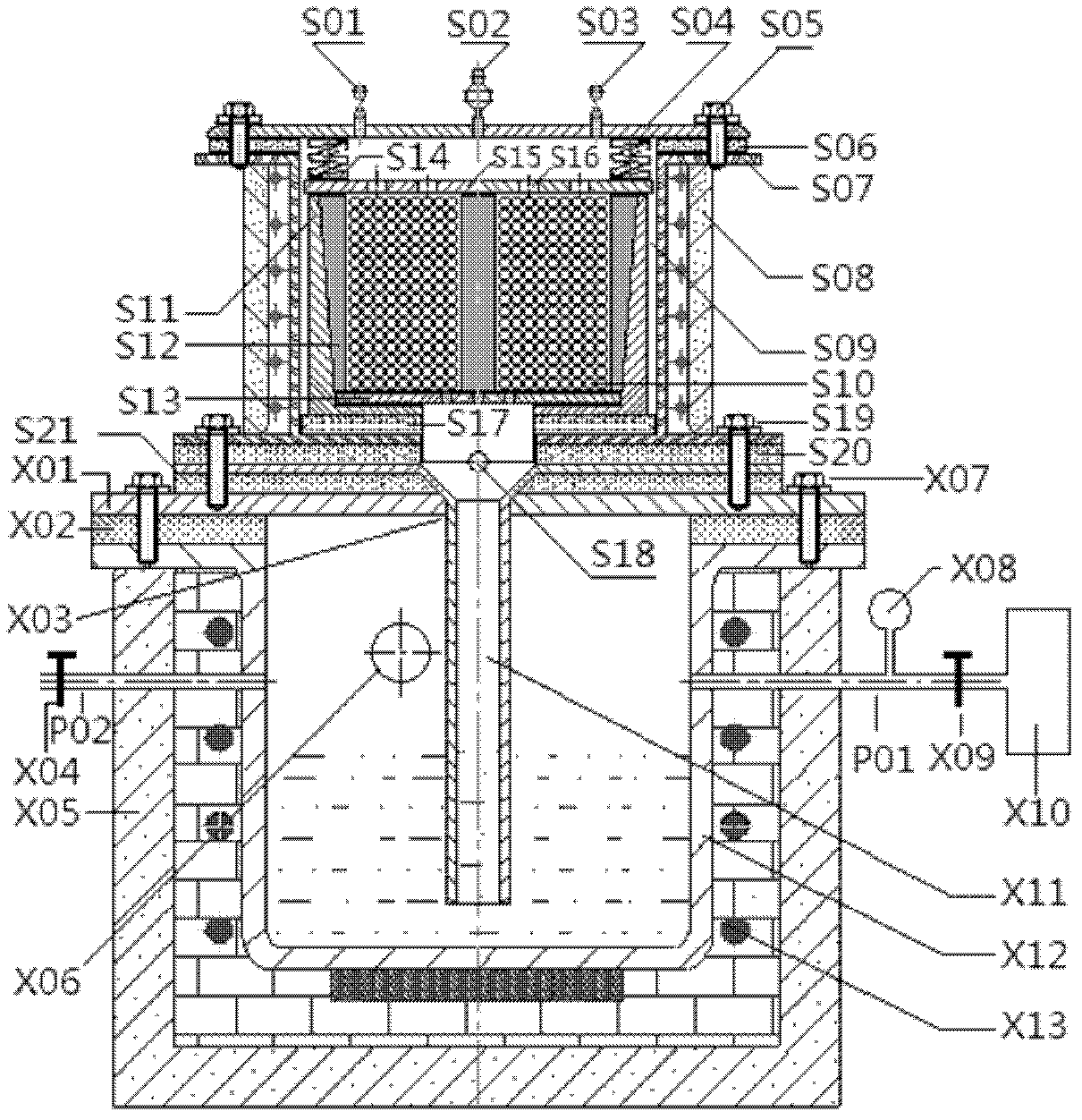

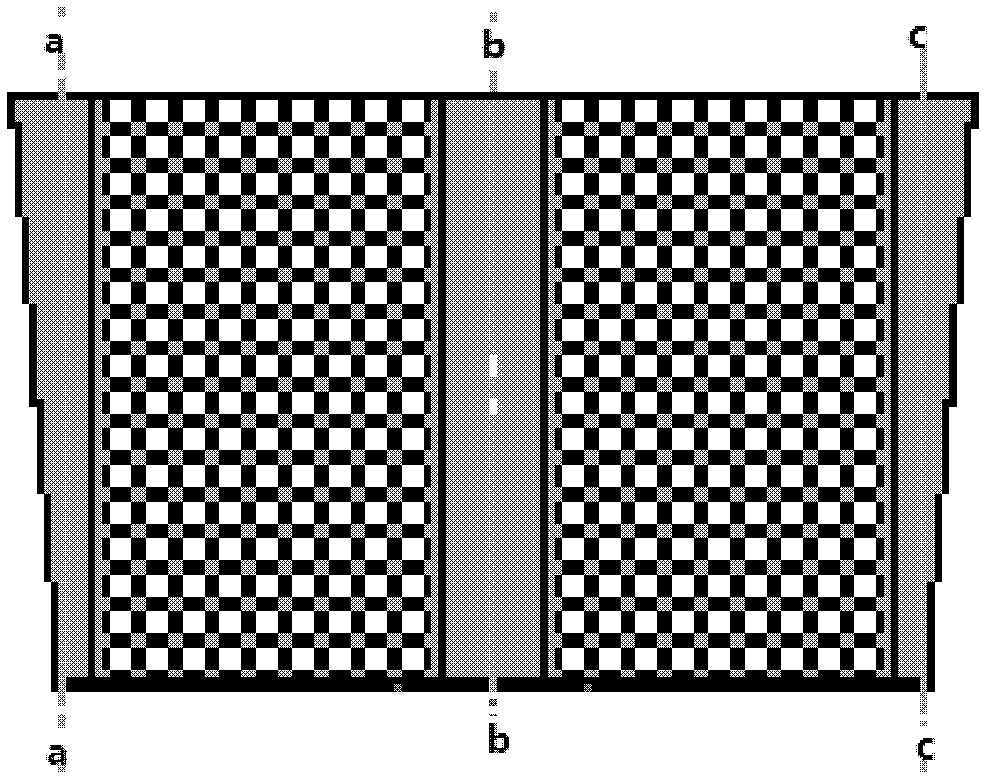

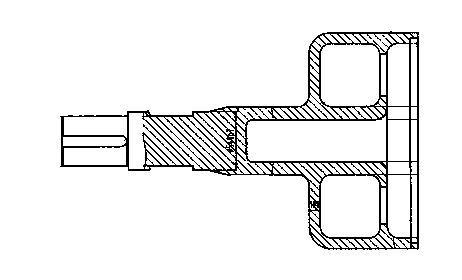

Squeeze casting machine and squeeze casting method thereof

The invention provides a squeeze casting machine, which comprises a base, a mold closing and locking mechanism, an injection mechanism and a hydraulic control system, wherein the mold closing and locking mechanism comprises a static mold, a movable mold, a main cylinder and a main cylinder piston rod; a seal safety belt is arranged in a seal matching structure between the static mold and the movable mold; the mold closing and locking mechanism comprises a monitoring control device which is used for monitoring a distance between the static mold and the movable mold and ensures that the static mold and the movable mold have a safe distance in the seal safety belt; and the hydraulic control system comprises a main cylinder feeding oil path which ensures that the movable mold and the static mold are driven by the main cylinder and completely closed after injection mold filling of the injection mechanism is completed. The squeeze feeding pressure is about 5 to 10 times that of the conventional casting injection pressure. The squeeze casting machine can realize 'common casting mold filling, squeeze casting and feeding' which is remarkably superior to 'common casting mold filling, high-speed punch squeeze' of the conventional casting machine.

Owner:马保庆

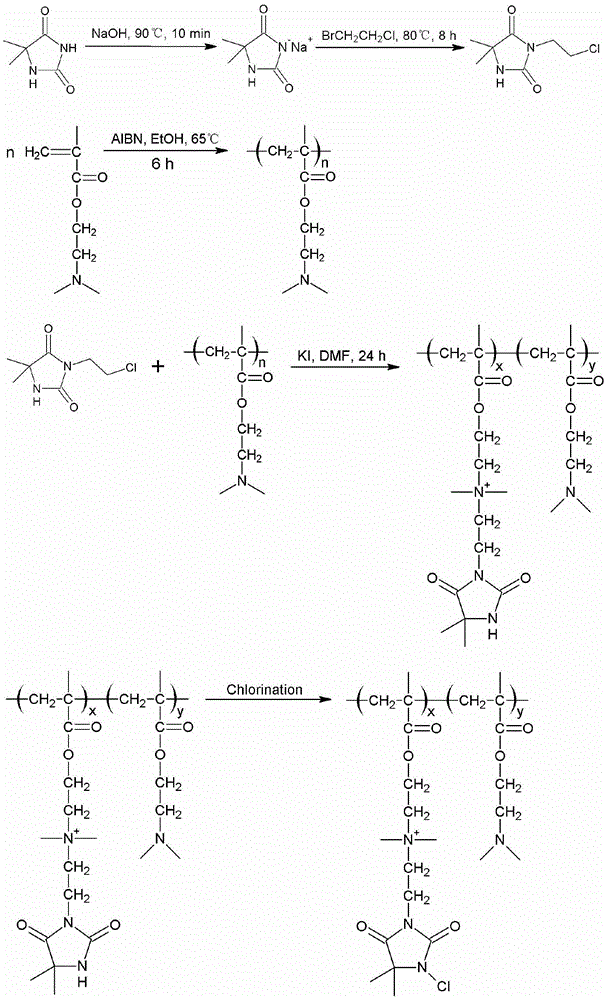

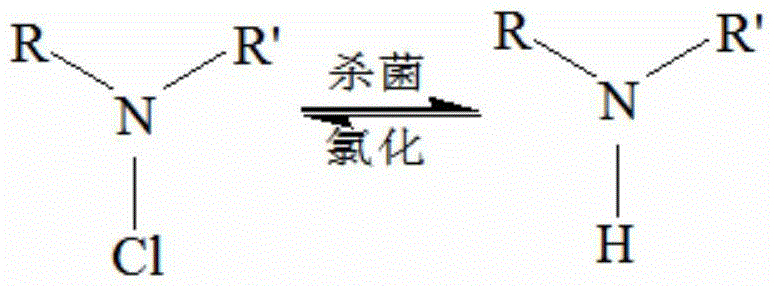

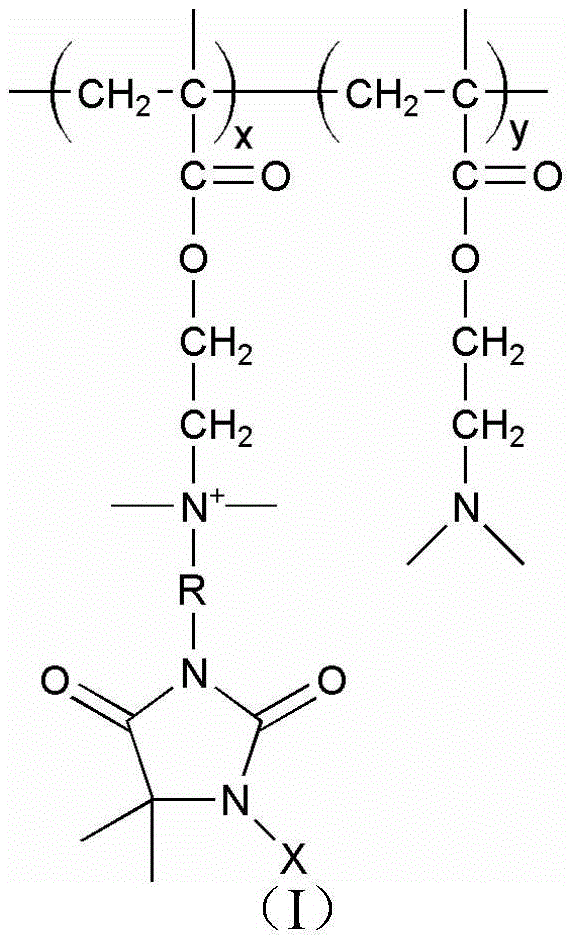

Annular halamine type polymeric antibacterial agent containing quaternary ammonium group and preparation method and application of polymeric antibacterial agent

ActiveCN105601778AFast sterilizationImprove antibacterial propertiesBiocideFungicidesHalogenConventional casting

The invention provides an annular halamine type polymeric antibacterial agent containing quaternary ammonium group and preparation method and application of the polymeric antibacterial agent. The preparation method includes: synthesizing an annular micromolecular halamine type polymeric antibacterial agent precursor and a polymeric autopolymer; enabling the precursor and the polymeric autopolymer to be in substitution reaction to obtain a polymeric antibacterial agent precursor; halogenating to obtain the annular halamine type polymeric antibacterial agent. The application includes: dissolving the polymeric antibacterial agent precursor in N, N-dimethyl formamide, and mixing with a base material; adopting electrostatic spinning technology or conventional casting dissolving process to obtain a membrane containing the antibacterial agent precursor; soaking the membrane in a solution containing active halogen for halogenating reaction; taking the membrane out for water washing, and drying to obtain an antibacterial material. The preparation method is mild in reaction condition, raw materials are low in cost and easy to get, production cost is low, equipment is simple and convenient, and process operation is simple; the antibacterial agent prepared by the method has excellent antibacterial performance and is stable, safe and nontoxic.

Owner:JIANGNAN UNIV

Preparation method for special casting material of ferronickel rotary kiln discharge opening

InactiveCN104150926AImprove corrosion resistanceImprove thermal shock resistanceConventional castingZirconate

The invention discloses a preparation method for a special casting material of a ferronickel rotary kiln discharge opening. The special casting material is prepared from the following materials in percentage: 40-80% of material bauxite or / and adamantine spar aggregate, 5-20% of electric smelting mullite or / and adamantine spar fine powder, 3-10% of alumina micro powder, 3-10% of silicone micro powder, 1-8% of pure calcium aluminate cement and 3-30% of calcium zirconate or / and zirconite. The preparation method has the advantages that corrosion resistance, thermal shock resistance and performance in moderate-temperature intensity can be improved greatly; utilization requirements of the ferronickel rotary kiln discharge opening are met. Compared with the conventional casting materials used by cement kiln discharge openings, the service life of the casting material can be prolonged by three months.

Owner:ZHENGZHOU DONGFANG CERAMIC ENG

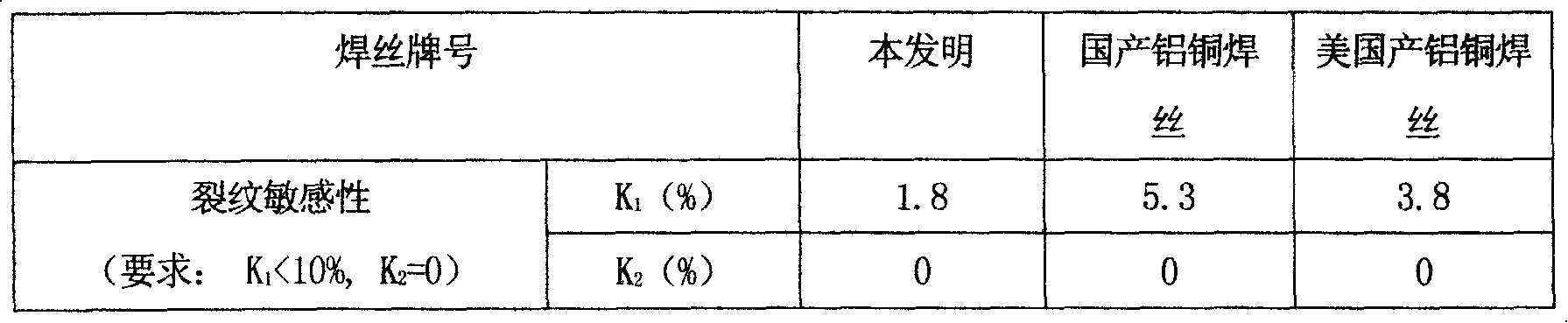

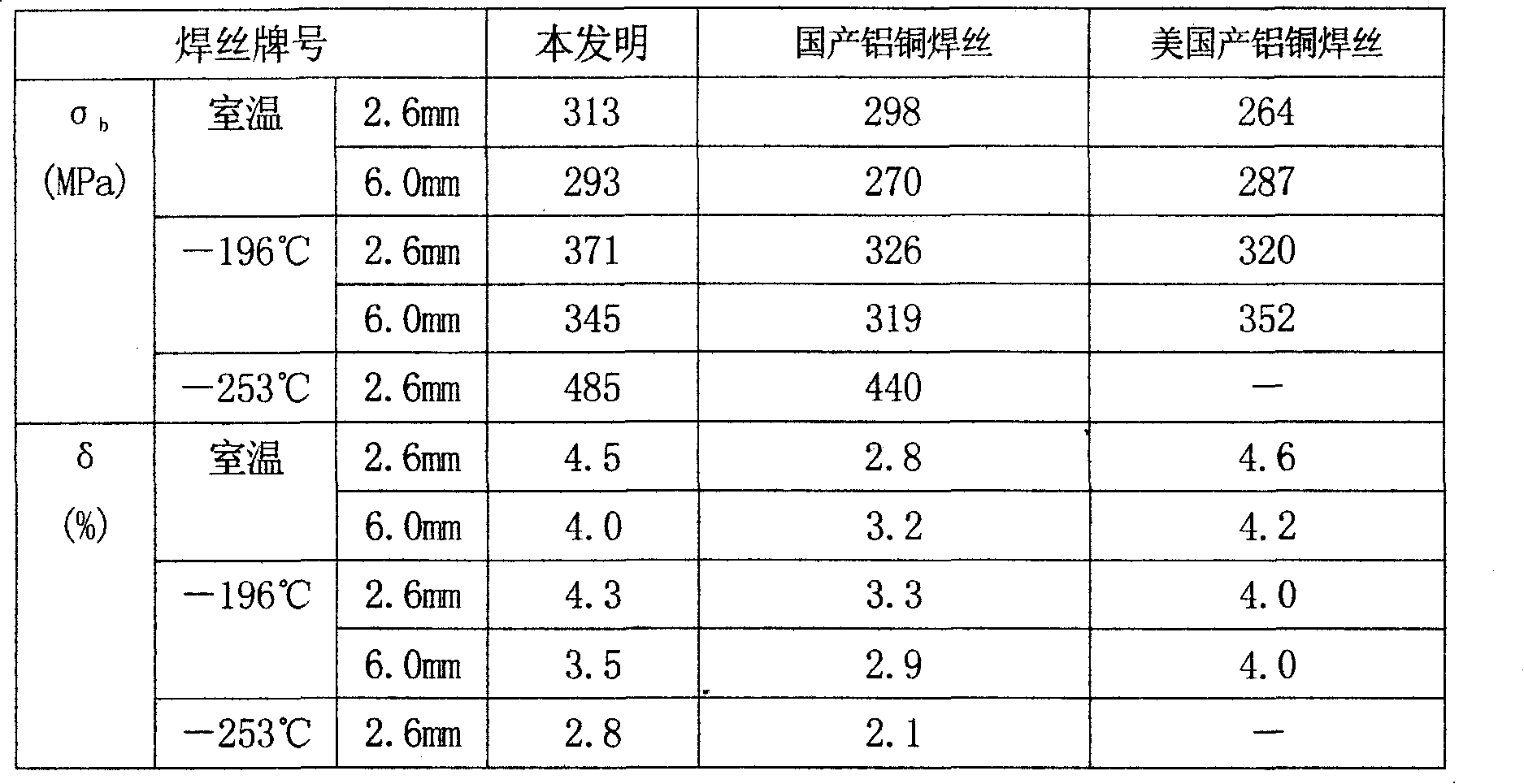

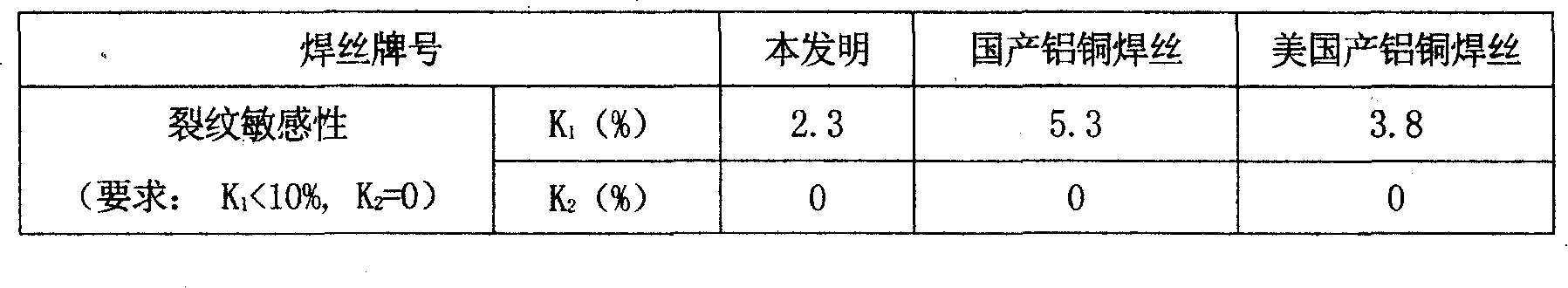

Soldering wire for high-strength aluminum copper alloy

ActiveCN101176955AReduce sensitivityStrengthening effect is goodWelding/cutting media/materialsSoldering mediaPorosityChemical composition

The invention belongs to the field of material science and engineering, and its chemical composition is as follows: (wt%): Cu 5.8~6.8, Mn 0.2~0.4, Ti 0.05~0.2, Zr 0.05~0.25, V 0.01~0.20, Cr 0.01~0.25, Fe 0.15, Si 0.08, Zn 0.05, Mg 0.02, and the balance is Al; the welding wire is refined by traditional melting and casting process according to the formula. The invention satisfies the manufacturing problem of high-strength aluminum-copper alloy matched welding wire by controlling the components. The welding wire of the invention has low sensitivity to welding cracks, small weld seam porosity sensitivity, and excellent joint mechanical properties.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

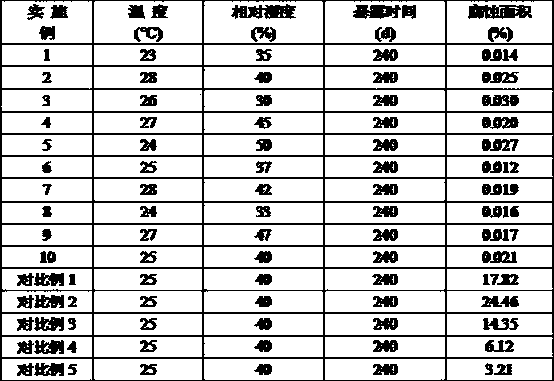

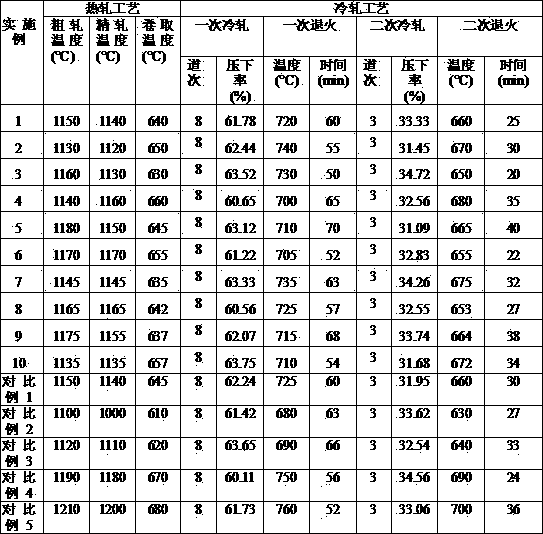

Decorative bundling belt with tensile strength of more than or equal to 950MPa and production method thereof

The invention discloses a decorative bundling belt with the tensile strength of more than or equal to 950MPa. The decorative bundling belt comprises the following components in percentage by weight: 0.08-0.18% of C, 0.60-1.20% of Mn, less than or equal to 0.010% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.30-0.60% of Nb, 0.30-0.60% of Cr and 0.040-0.070% of Als. The production steps comprise smelting, continuous casting for forming a blank, conventional casting blank heating, hot rolling, conventional acid washing, secondary cold rolling, secondary annealing and belt making. The thickness of the bundling belt is 0.8mm, the tensile strength is not less than 950MPa, the elongation is not less than 10%, the repeated bending times is not less than 10 times (R=5mm), and a uniform, compact, strong-adhesion and bright coating with the thickness of 1.5-2.5mu m is produced on the surface of the bundling belt. The bundling belt, which is not obviously rusted when being placed in an indoor atmospheric environment for 240 days, completely meets the requirements for bundling and packing high-quality commodities.

Owner:武汉钢铁有限公司

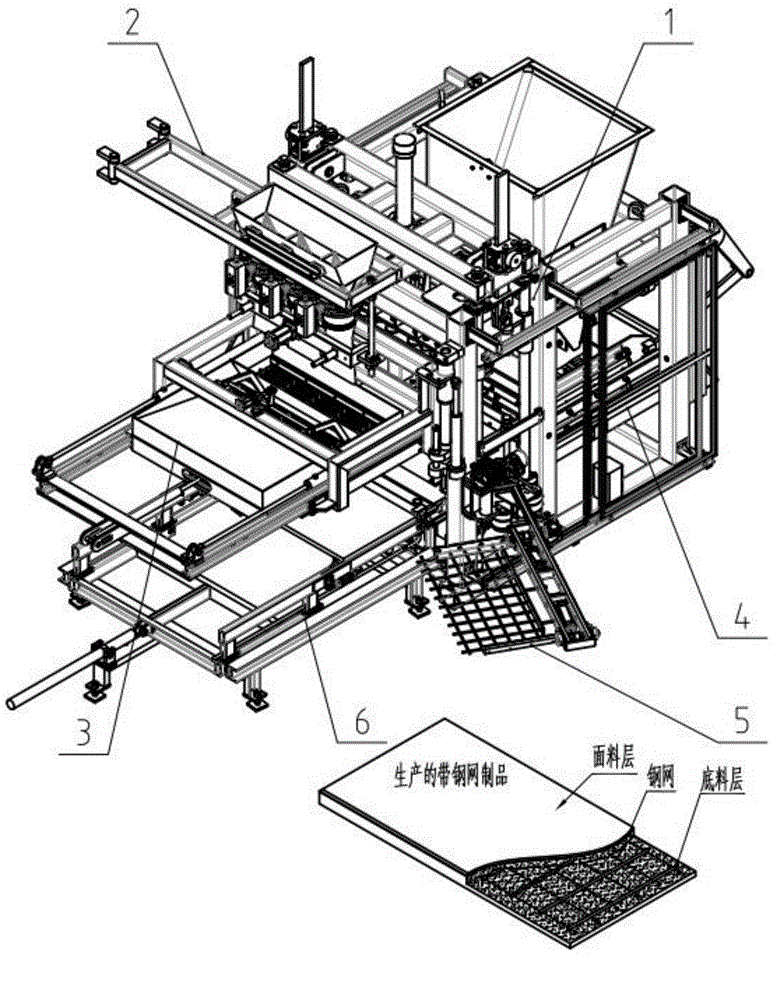

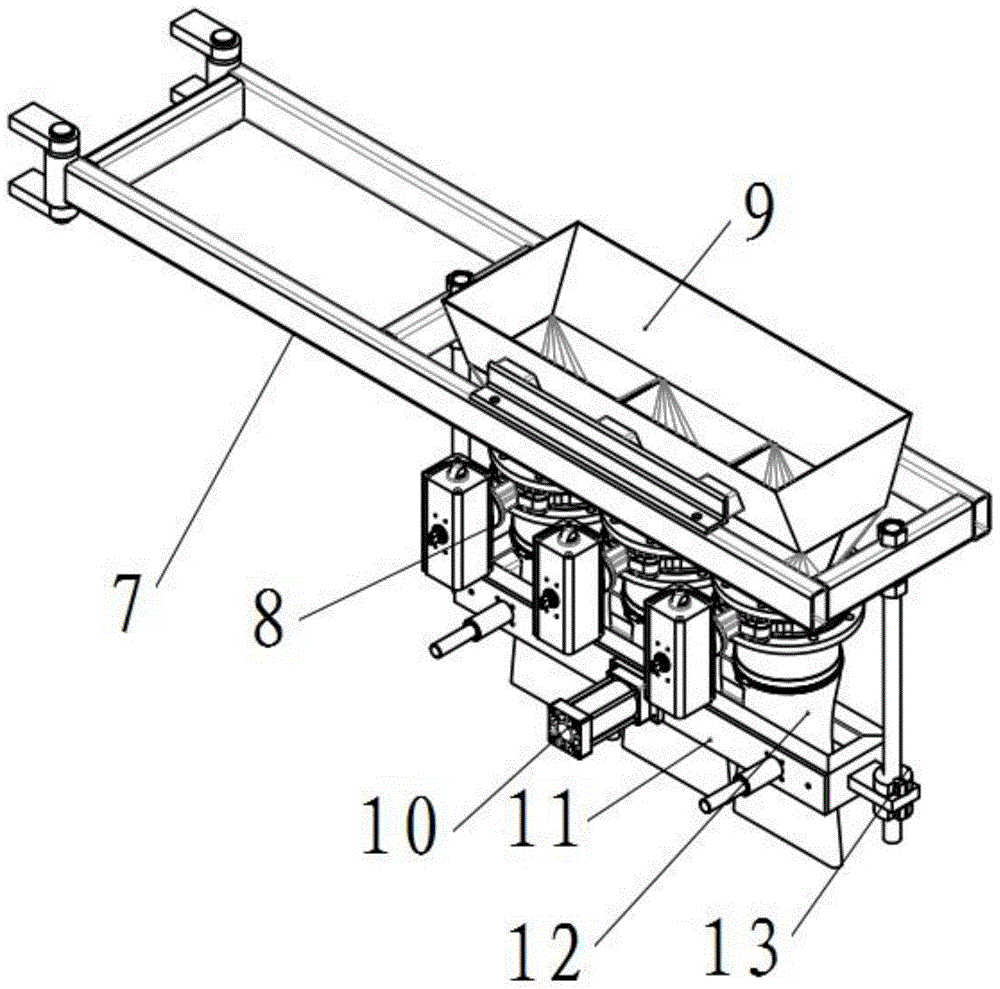

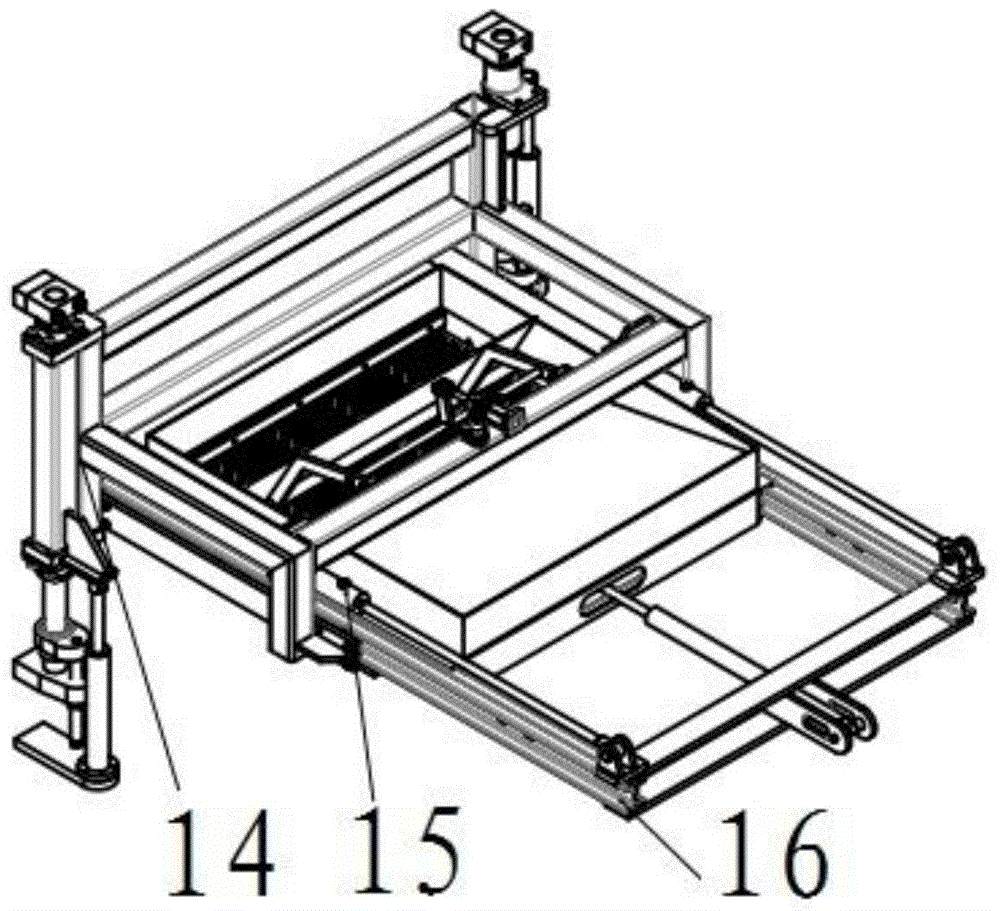

High-compactness concrete product molding machine

InactiveCN104552596AImprove compactnessHigh strengthCeramic shaping apparatusHigh strength concreteSocial benefits

The invention discloses a high-compactness concrete product molding machine. The machine comprises a bracket I, wherein the upper end of the brake I is provided with a vacuum vibration molding device; the front end of the vacuum vibration molding device is provided with a matching quantitative feeder; the lower end of the quantitative feeder is provided with a spreading surface material distributing machine; a matching bottom material distributing device is arranged at the rear end of the spreading fabric distributing machine and on the lower side of the vacuum vibration molding device; a steel mesh automatic laying device is arranged at the front end of the bottom material distributing device and at the lower end of the spreading surface material distributing machine; the front of the steel mesh laying device is provided with a matching brick receiver. The machine has the beneficial effects that high-compactness high-strength concrete products can be produced by using a vibration compression molding principle; particularly the conventional casting process is changed, the natural stone imitation concrete products are mechanically produced on a large scale, and extremely high economic benefit and social benefit are realized; the products are more compact, higher in strength, delicate, bright and clean in appearance and can be further deep-processed into decorative concrete products.

Owner:BEIJING REIT TECH DEV

Preparation method for U-shaped hole in casting

The invention relates to the casting field, and especially relates to a preparation method for a U-shaped hole in casting. Molding is carried out according to a designed casting structure. A U-shaped hole core is prepared from fibers with high temperature resistance and a metal skeleton, or painting for casting is painted uniformly on a metal skeleton to prepare a U-shaped hole core. The size of the U-shaped hole core is the same as the size of the shaped hole. The U-shaped hole core is placed in the mold during the pouring process. After the casting is taken out, the U-shaped hole core is drawn out, and a U-shaped hole meeting the curvature radius of design requirements can be obtained. The preparation method is advantageous in that, the problem that a U-shaped hole cannot be cast through a conventional casting method is solved.

Owner:SHENYANG POLYTECHNIC UNIV

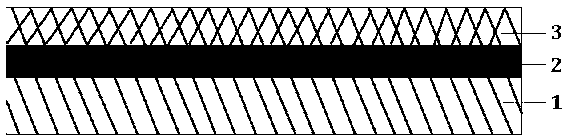

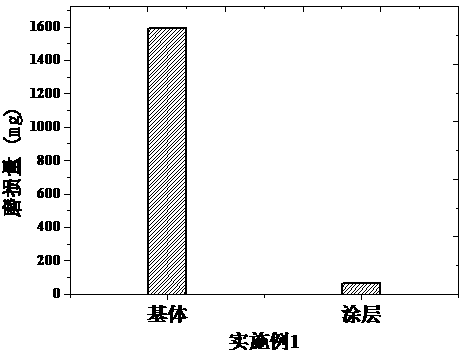

Composite wear-resistant liner of sandwich structure

InactiveCN103057207AAvoid consumptionImprove toughnessCeramic layered productsMetal layered productsConventional castingMetallic materials

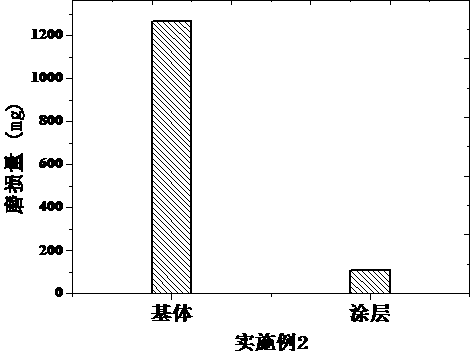

The invention discloses a multi-layer composite super-wear-resistant liner of sandwich structure and a preparation process of the liner, belonging to the field of preparation of wear-resistant liners. The wear-resistant liner is composed of a substrate support layer, a bonding transition layer and a hard surface wear-resistant layer by compositing functionally graded materials, wherein the substrate support layer is formed by compression instead of conventional casting; the bonding transition layer is formed by flame remelting with self-fluxing alloy material, having good substrate invasion and high bonding strength; and the hard surface wear-resistant layer is formed by flame remelting with ceramic alloy material, having excellent bonding performance and high abrasive resistance. Compared to the prior art, by gathering the advantages of high toughness of the metal material and high abrasive resistance of the ceramic alloy material, the multi-layer composite super wear-resistant liner of sandwich structure and the preparation process thereof disclosed by the invention have the advantages of simple substrate forming process, low cost, and strong controllability of coating material and process, so that complicated technology for heating processing during an alloy casting process is avoided and the service life is prolonged by more than 10 times compared with that of ordinary steel liners.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

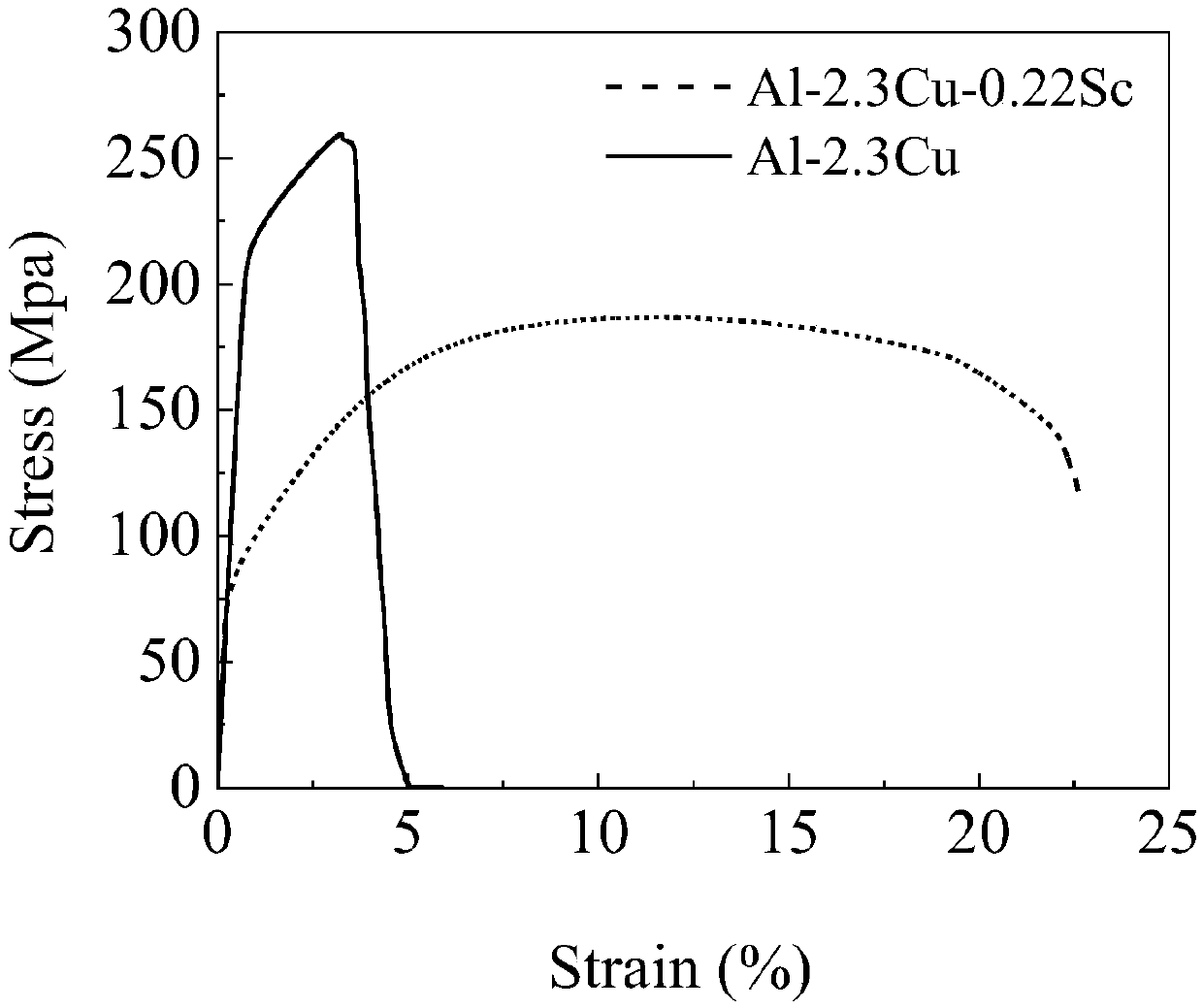

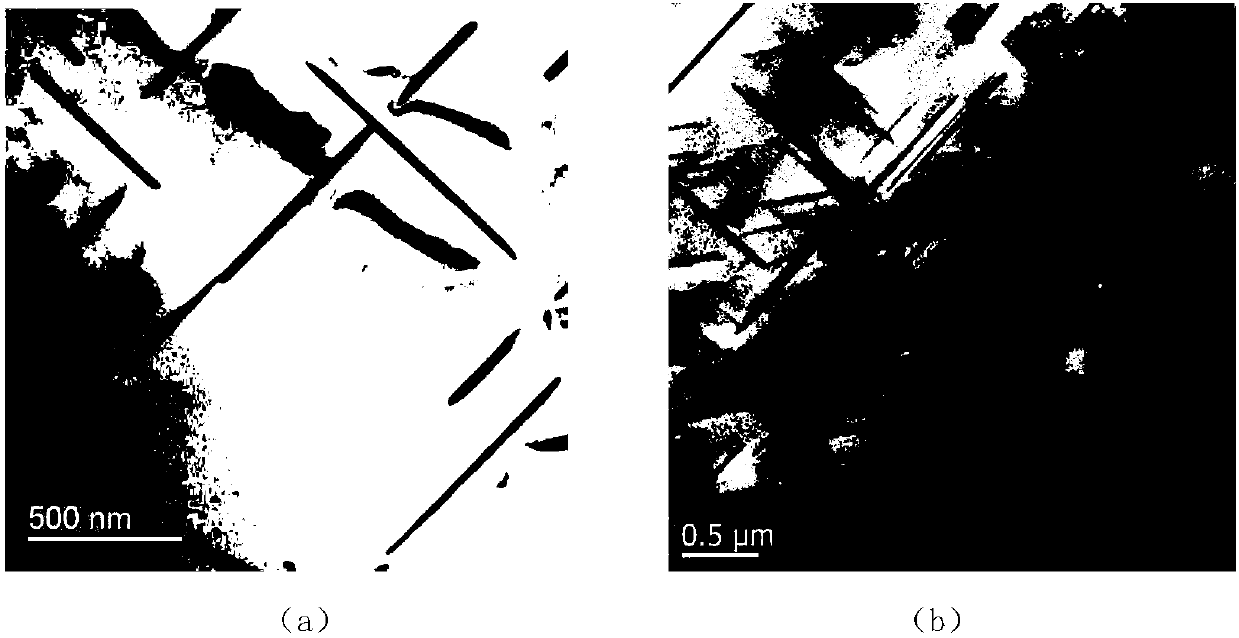

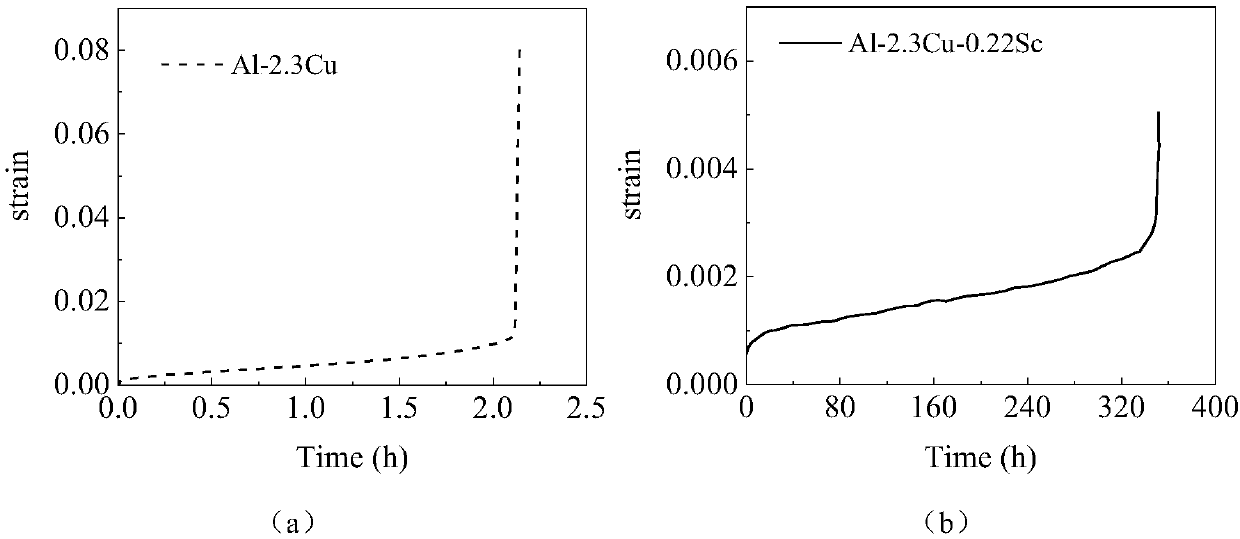

High-strength creep-resistant scandium-containing Al-Cu series aluminum alloy and casting and heat treatment processes

The invention discloses a high-strength creep-resistant scandium-containing Al-Cu series aluminum alloy and a casting and a heat treatment processes. The alloy comprises the components of, the mass percent of Cu are 2.0-5.0%, the mass percent of Sc is 0.1-0.5%, the mass percent of Si is 0.01-0.03%, the mass percent of Ti is 0.01-0.03%, the balance Al and inevitable impurities, and conventional casting is carried out. The aging heat treatment process comprises the steps of homogenizing treatment, a heat preservation is carried out for 3 hours to 50 hours, and air cooling is carried out; carrying out solid solution treatment, the heat preservation is carried out for 30 minutes to 15 hours, and water quenching is carried out; aging treatment, the heat preservation is carried out for 1 hours to 20 hours. According to the high-strength creep-resistant scandium-containing the Al-Cu series aluminum alloy and the casting and the heat treatment processes, a small amount of Sc elements are addedinto the Al-Cu alloy, the result shows that the Sc not only can obviously be refined the theta'-Al2Cu precipitation phase, but also improve a precipitation density of the precipitated phase of the theta'-Al2Cu, and a room temperature strength of the Al-Cu alloy is obviously further improved.

Owner:XI AN JIAOTONG UNIV

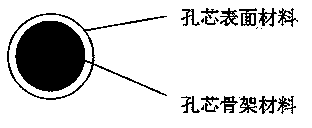

Device for preparing special-shaped metal-based porous composite material

ActiveCN102601342AEvenly distributedEasy to manufactureFoundry mouldsFoundry coresPorous compositeConventional casting

The invention discloses a device for preparing a special-shaped metal-based porous composite material. The device comprises a melt preparation system, a pressurization system, a diversion component, a casting system and a vacuumizing system, wherein the diversion component is communicated with the melt preparation system and the casting system, and a melting crucible in the melt preparation system is directly communicated with the pressurization system; and a casting chamber in the casting system is connected with the vacuumizing system. After negative pressure is formed in the casting chamber by vacummizing, a metal melt in the melting crucible enters a casting chamber mold filled with pore-forming particles through the diversion component; and after the melt in the casting chamber mold reaches the preset height, the melt in the casting chamber mold is condensed under the dual functions of the negative pressure in the casting chamber and the positive pressure in the melting crucible. By the method, complex special-shaped porous metal members can be prepared, and the defects of common insufficient seepage, excessive seepage and the like in the conventional casting method, and the defects of crystallization porosity inside castings and the like can be effectively overcome.

Owner:元泰达新材料江苏有限公司

Casting process of cylinder body casting with shaft

InactiveCN103447469AReduce defectsMeet internal quality requirementsFoundry mouldsFoundry coresBox modelingConventional casting

A casting process of a cylinder body casting with a shaft overcomes disadvantages of sand holes, pores, unstable quality, lower finished product rate and higher production cost exiting in a product produced by a conventional casting process. The invention provides the casting process of the cylinder body casting with the shaft, and the casting process effectively reduces appearance of the defects such as the casting sand holes, the pores and the like, meets the inner quality requirements of the casting, improves the casting quality, and reduces the production cost. A three-box modeling method is employed, a small end face of a shaft head is a top surface and used as an upper box parting surface; a middle box parting surface is arranged at a position of 600 mm on a cylinder body; an upper box is a riser cover box, a middle box is a solid sample model, and a lower box adopts a core assembly method.

Owner:LUOYANG LUOBEI HEAVY IND MACHINERY

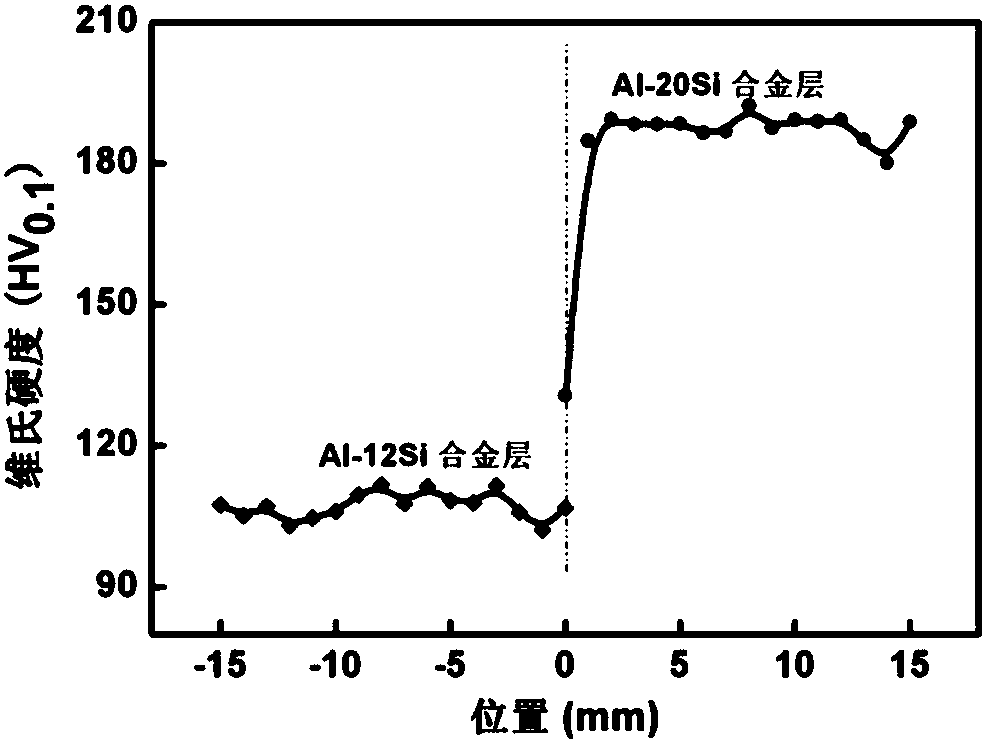

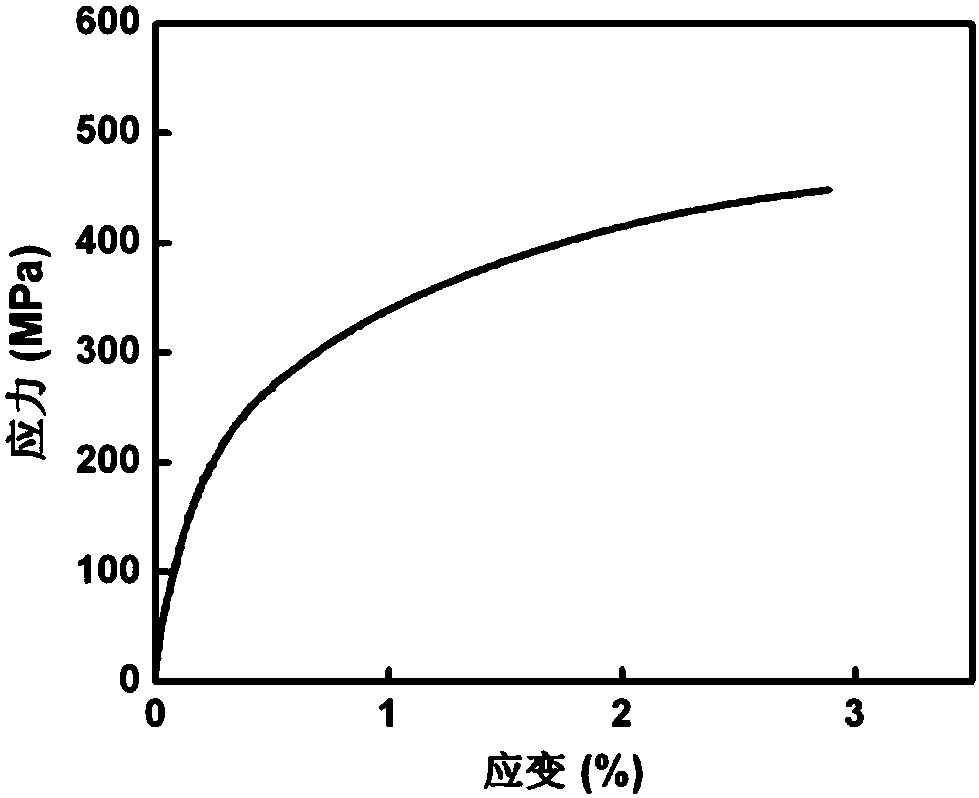

Multi-layer Al-Si alloy and preparation method thereof

InactiveCN108103366AAdditive manufacturingIncreasing energy efficiencySelective laser meltingConventional casting

The invention relates to a preparation method of a multi-layer Al-Si alloy and belongs to the technical field of material processing. In the invention, according to a formula, a master alloy ingot isprepared through fusion blending via a conventional casting method, then alloy powder is prepared via a gas atomization process; then the multi-layer material is prepared through a selective laser fusion technology; finally the mechanical performances of the multi-layer material are adjusted through subsequent thermal treatment, thereby preparing the multi-layer material having microstructure uniformity and high-performances. Being different from methods, with hot press sintering and casting, for preparing the multi-layer Al-Si alloy, the method, for the first time, employs the selective laserfusion technology to prepare the alloy, then employs thermal treatment for further adjusting the strength and ductility of the alloy. The method not only has practical value to development of high-performance light alloys, but also supplies a new way for laser rapid shaping and technical optimization of complex and fine structural members.

Owner:SHANGHAI UNIV OF ENG SCI

Fishing line casting and bait projectile system

ActiveUS20060059764A1Prevented from launchingEasy constructionMould separation apparatusLighting and heating apparatusDecoyConventional casting

A powered fishing line casting system utilizing compressed air is provided to cast a projectile provided with fishhooks and bait, and to which the fishing line to be cast is attached, to greater distances than could be achieved using conventional casting methods. The system includes a hollow launch tube sized to accommodate insertion of the projectile. A reducer is disposed adjacent to one end of the launch tube and is adapted to receive a flow of compressed gas from an accumulator tank and to discharge a stream of high-velocity air that impinges upon the projectile disposed within the launch tube in order to launch the projectile. A manually-operable valve is interposed between the reducer and the accumulator tank to control the flow of air to the reducer. Spaced-apart front and rear support legs provide stable support for the system during and between launches of a fishing line carrying projectile.

Owner:M DOOLEY PROD LLC

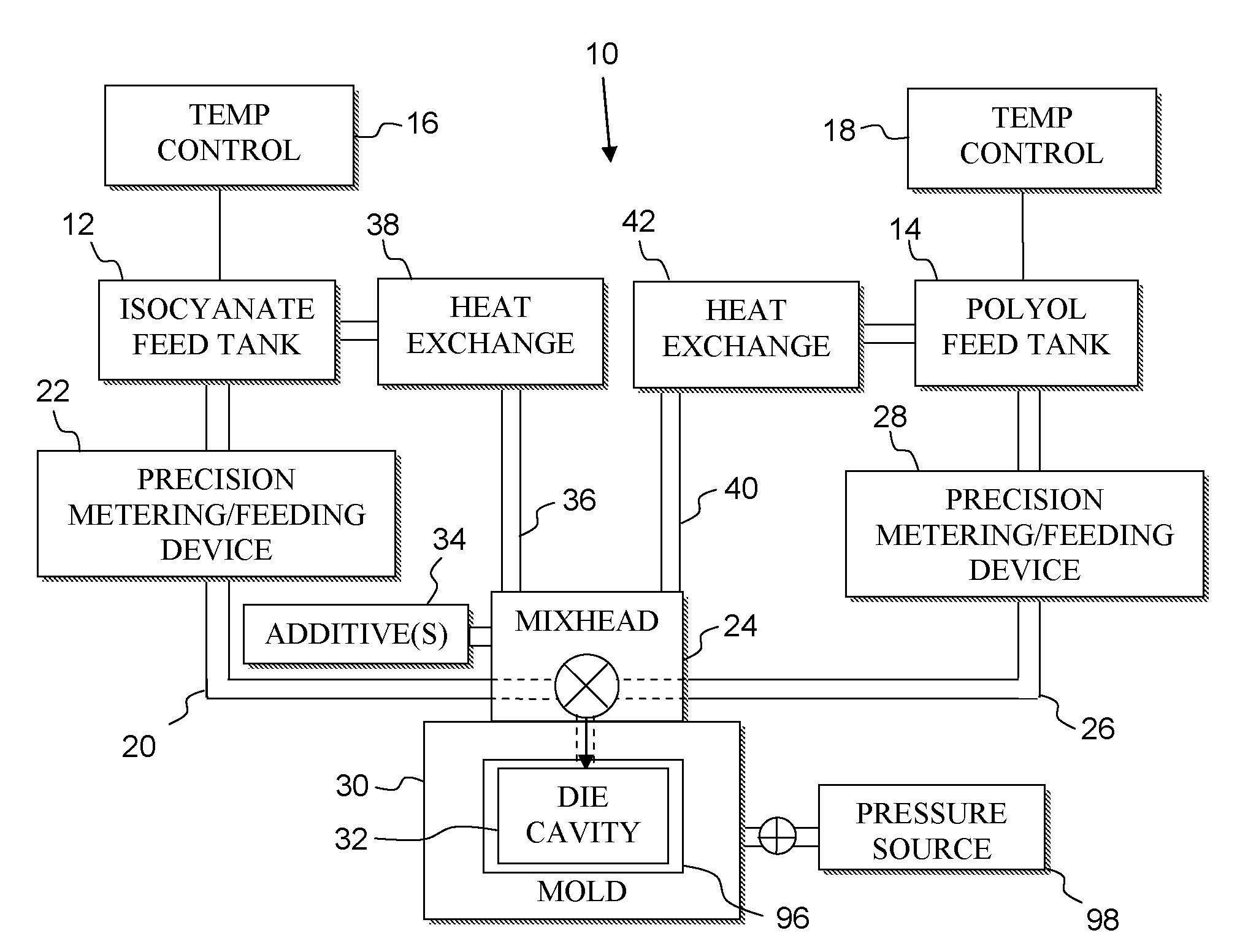

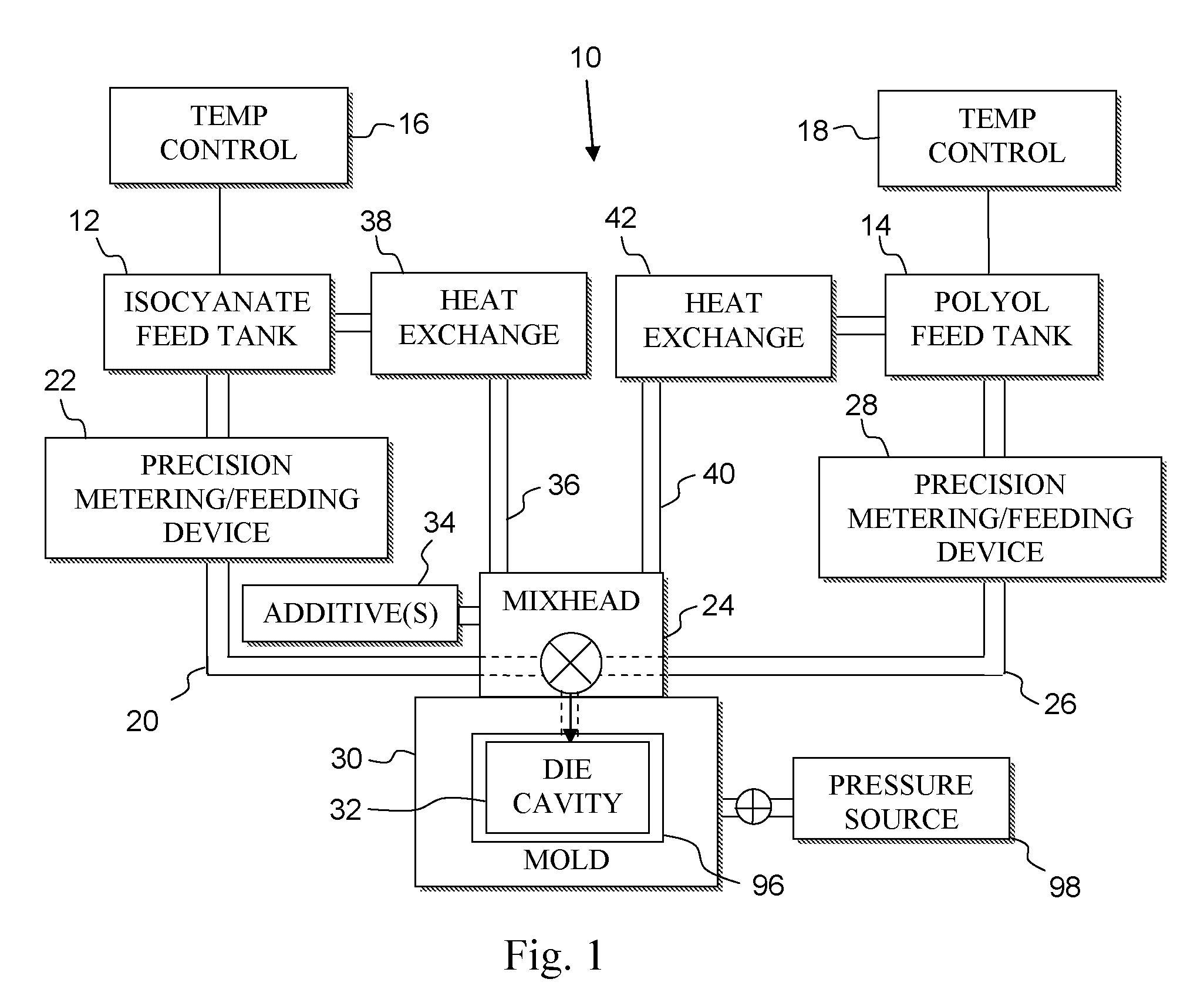

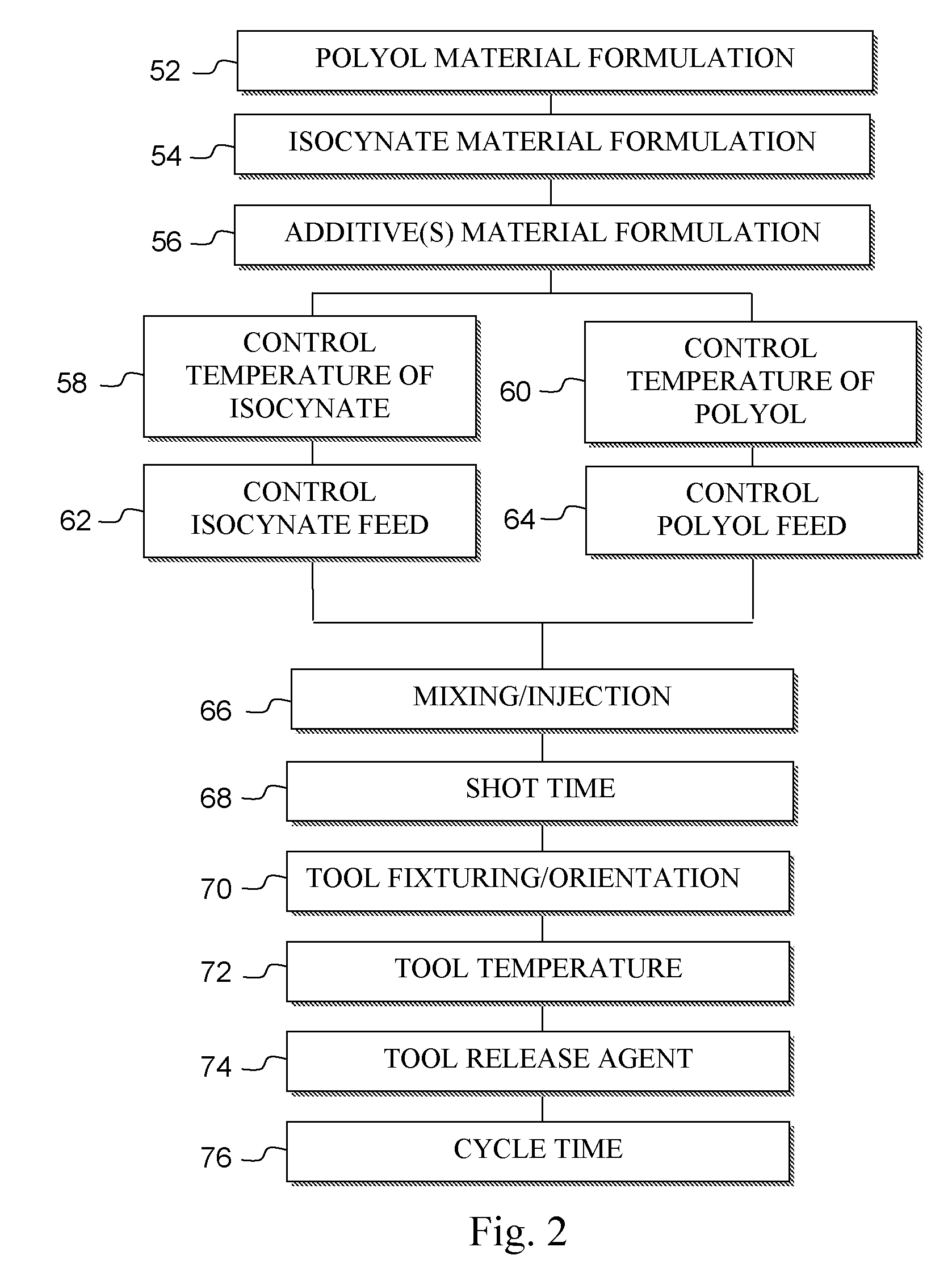

Casting materials

ActiveUS20090008058A1Solve the lack of stiffnessSolve the lack of rigidityAdditive manufacturing apparatusCasting safety devicesConventional castingMaterials science

A foam material comprises a liquid polymer and a liquid isocyanate which is mixed to make a solution that is poured, injected or otherwise deposited into a corresponding mold. A reaction from the mixture of the liquid polymer and liquid isocyanate inside the mold forms a thermally collapsible foam structure having a shape that corresponds to the inside surface configuration of the mold and a skin that is continuous and unbroken. Once the reaction is complete, the foam pattern is removed from the mold and may be used as a pattern in any number of conventional casting processes.

Owner:PCC STRUCTURALS

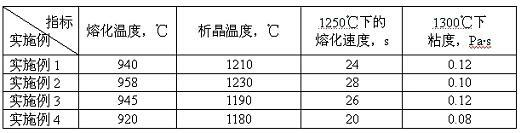

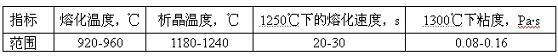

Casting powder for medium carbon peritectic steel continuous casting crystallizer

The invention belongs to the technical field of steel melting continuous casting production, and particularly relates to casting powder for a medium carbon peritectic steel continuous casting crystallizer sensitive to cracks. The casting powder comprises the following components by weight percentage: 40 to 50 percent of CaO, 40 to 50 percent of SiO2, 1 to 6 percent of B2O, 1 to 4 percent of Li2O, 1 to 5 percent of Al2O3, 1 to 6 percent of BN1 and 1 to 2 percent of inevitable impurities, wherein the impurities comprise 0.03 percent of S and 0.03 percent of P. The preparation method comprises the steps of: fully drying and dehydrating raw materials, weighing and mixing according to weight parts, grinding and uniformly mixing, pre-melting, cooling, powdering, and adopting the conventional casting powder preparing and molding process to obtain granular finished casting powder. The casting powder has relatively low melting temperature and relatively high crystallization temperature, particularly has the advantages of good lubrication and anti-oxidization effects of glass powder and high impurity absorption capacity and the advantages of high heat preservation performance of the powder with the high crystallization temperature and casting blank crack control, and is suitable for pouring medium carbon peritectic steel sensitive to the cracks.

Owner:JIANGSU UNIV

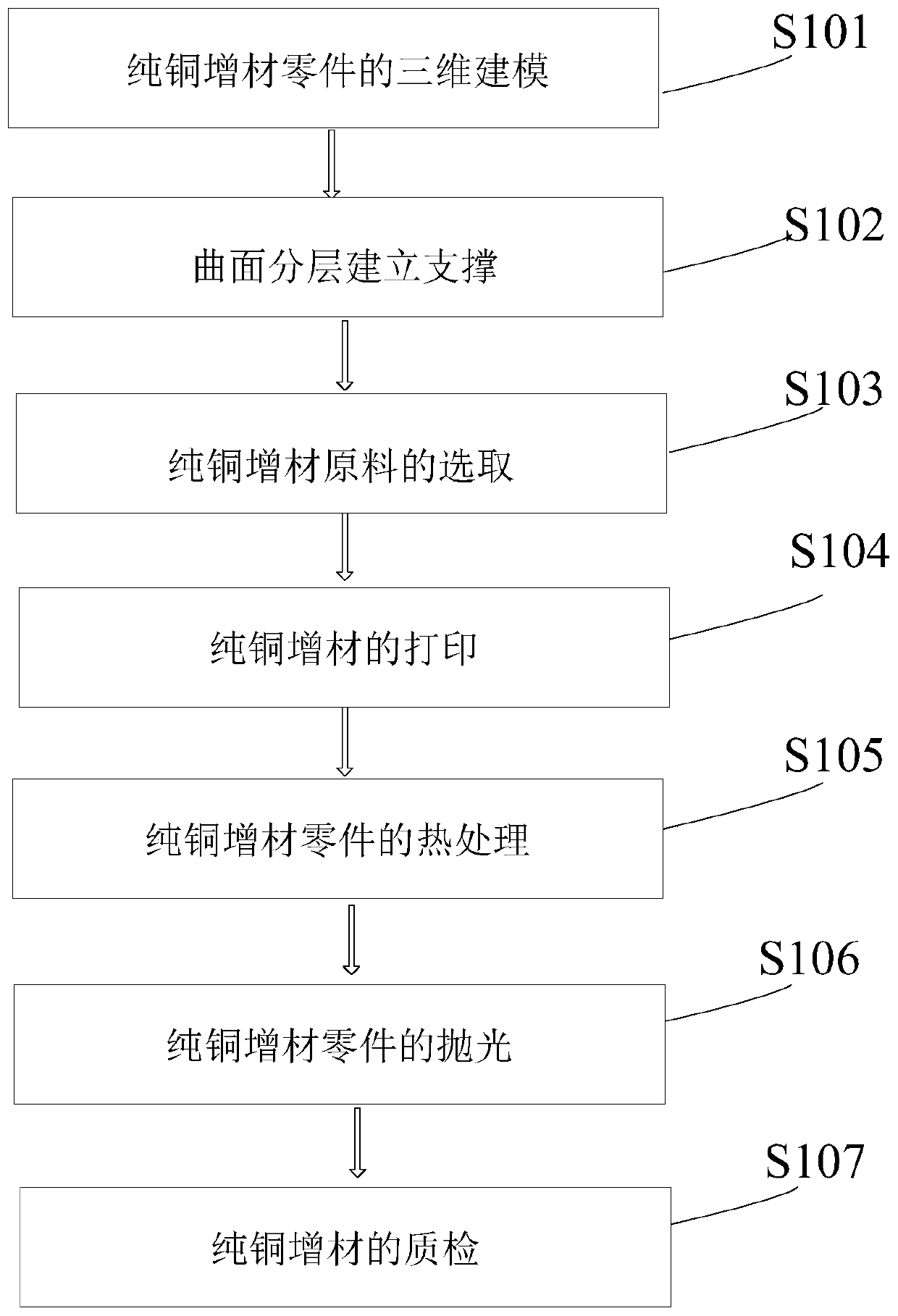

Manufacturing method of pure copper 3D printing additive material

InactiveCN109759589ALow costShorten the production cycleAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyConventional casting

The invention provides a manufacturing method of a pure copper 3D printing additive material, and belongs to the technical field of 3D printing additive material manufacturing. The manufacturing method of the pure copper 3D printing additive material specifically comprises the following steps of three-dimensional modeling of a pure copper additive material part; layering of a curved surface and support establishment; selection of pure copper additive material raw materials; printing of the pure copper additive material; thermal treatment of the pure copper additive material part; polishing ofthe pure copper additive material part; and quality inspection of the pure copper additive material. By the adoption of the manufacturing method, no mold is required, particularly, the cost is not increased when a complex object is manufactured, the part manufacturing cost can be substantially reduced, and the production cycle of the part is shortened; meanwhile, the internal stress of the thin-walled part can be eliminated, and the deformation of the part is avoided; the 3D printing also has the advantages that the dimensional accuracy is high, the surface quality is high, and the performanceof formed parts is excellent; and the defect that according to a conventional casting method, when the processing operation is conducted, the crystal grain is large is overcome, the process of the laser 3D printing belongs to the fast-heating and rapid-cooling machining process, and the crystal grain of the part is refined. As a result, the part which is processed by the laser 3D printing is highin accuracy, good in forming property and high in comprehensive mechanical property.

Owner:SHAANXI SCI TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com