Casting powder for medium carbon peritectic steel continuous casting crystallizer

A continuous casting crystallizer and medium carbon sub-laden technology, which is applied in the field of iron and steel smelting and continuous casting, can solve problems such as cracks and low melting points, and achieve the effects of preventing molten steel from oxidation, preventing absorption of inclusions, and weakening heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Lime, silica, boric anhydride, lithium oxide, corundum powder and boron nitride are used as raw materials, fully dried and dehydrated at 200°C, ground into fine powder, weighed ingredients, pre-melted at 1300°C, cooled in a mill Grind internally until it passes through a 200 mesh sieve (particle size less than 0.074mm), and make hollow particles in a spray granulation tower, and the particle size of mold powder ranges from 0.1-0.4mm.

[0024] The composition analysis results of the prepared mold flux are as follows (mass percentage):

[0025] CaO 44%, SiO 2 45%, B 2 o 3 3%, Li 2 O 2%, Al 2 o 3 2%, BN 3%, the balance is impurities, of which S 0.02%, P 0.02%.

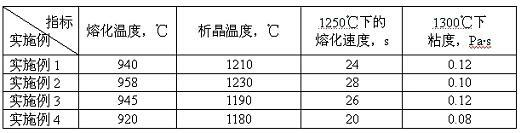

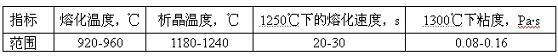

[0026] The main physical and chemical performance indicators of this embodiment are shown in Table 2.

Embodiment 2

[0028] Lime, silica, boric anhydride, lithium oxide, corundum powder and boron nitride are used as raw materials, fully dried and dehydrated at 200°C, ground into fine powder, weighed ingredients, pre-melted at 1300°C, cooled in a mill Grind internally until it passes through a 200 mesh sieve (particle size less than 0.074mm), and make hollow particles in a spray granulation tower, and the particle size of mold powder ranges from 0.1-0.4mm.

[0029] The composition analysis results of the prepared mold flux are as follows (mass percentage):

[0030] CaO 50%, SiO 2 40%, B 2 o 3 2%, Li 2 O 2%, Al 2 o 32%, BN 3%, the balance is impurities, of which S 0.02%, P 0.02%.

[0031] The main physical and chemical performance indicators of this embodiment are shown in Table 2.

Embodiment 3

[0033] Lime, silica, boric anhydride, lithium oxide, corundum powder and boron nitride are used as raw materials, fully dried and dehydrated at 200°C, ground into fine powder, weighed ingredients, pre-melted at 1300°C, cooled in a mill Grind internally until it passes through a 200 mesh sieve (particle size less than 0.074mm), and make hollow particles in a spray granulation tower, and the particle size of mold powder ranges from 0.1-0.4mm.

[0034] The composition analysis results of the prepared mold flux are as follows (mass percentage):

[0035] CaO 40%, SiO 2 50%, B 2 o 3 1%, Li 2 O 3%, Al 2 o 3 1%, BN 4%, the balance is impurities, of which S 0.02%, P 0.02%.

[0036] The main physical and chemical performance indicators of this embodiment are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com