Patents

Literature

82 results about "Biodegradable copolymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wound healing polymer compositions and methods for use thereof

The present invention provides bioactive polymer compositions that can be formulated to release a wound healing agent at a controlled rate by adjusting the various components of the composition. The composition can be used in an external wound dressing, as a polymer implant for delivery of the wound healing agent to an internal body site, or as a coating on the surface of an implantable surgical device to deliver wound healing agents that are covalently attached to a biocompatible, biodegradable polymer and / or embedded within a hydrogel. Methods of using the invention bioactive polymer compositions to promote natural healing of wounds, especially chronic wounds, are also provided. Examples of biodegradable copolymer polyesters useful in forming the blood-compatible, hydrophilic layer or coating include copolyester amides, copolyester urethanes, glycolide-lactide copolymers, glycolide-caprolactone copolymers, poly-3-hydroxy butyrate-valerate copolymers, and copolymers of the cyclic diester monomer, 3-(S)[(alkyloxycarbonyl)methyl]-1,4-dioxane-2,5-dione, with L-lactide. The glycolide-lactide copolymers include poly(glycolide-L-lactide) copolymers formed utilizing a monomer mole ratio of glycolic acid to L-lactic acid ranging from 5:95 to 95:5 and preferably a monomer mole ratio of glycolic acid to L-lactic acid ranging from 45:65 to 95:5. The glycolide-caprolactone copolymers include glycolide and ε-caprolactone block copolymer, e.g., Monocryl or Poliglecaprone.

Owner:MEDIVAS LLC

Biodegradable copolymers

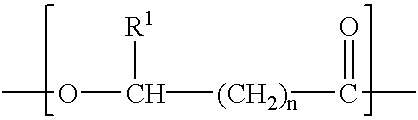

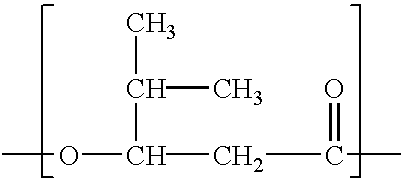

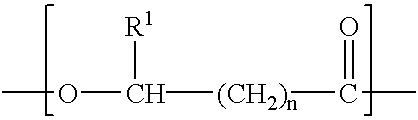

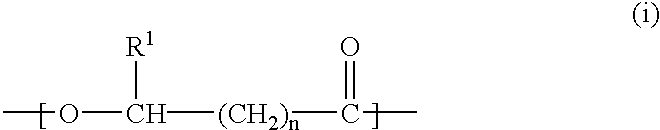

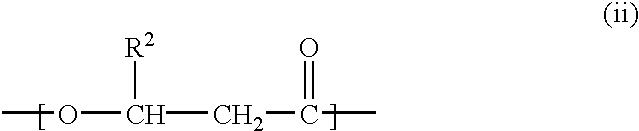

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure wherein R2 is a C4-C19 alkyl or alkenyl; and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

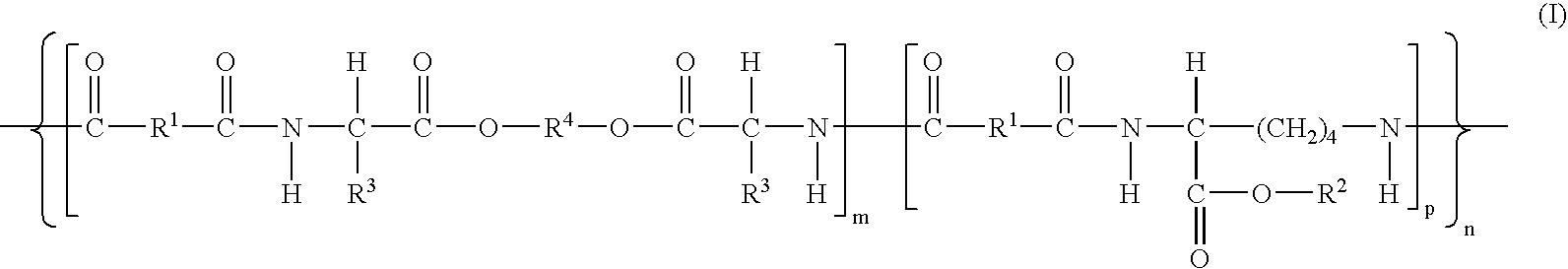

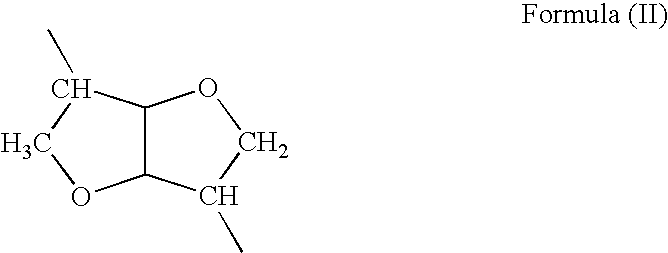

Polymers for implantable devices exhibiting shape-memory effects

InactiveUS20090035350A1Promote tissue regenerationMaintaining vascular patencyBiocideOrganic active ingredientsBiodegradable copolymersDevice form

Owner:ABBOTT CARDIOVASCULAR

Polymers For Implantable Devices Exhibiting Shape-Memory Effects

InactiveUS20140010858A1Improve mechanical propertiesImprove adhesionCosmetic preparationsBiocideBiodegradable copolymersDevice form

The present invention is directed to polymeric compositions comprising a biodegradable copolymer that possesses shape-memory properties and implantable devices (e.g., drug-delivery stents) formed of materials (e.g., a coating) containing such compositions. The polymeric compositions can also contain at least one non-fouling moiety, at least additional biocompatible polymer, at least one biobeneficial material, at least one bioactive agent, or a combination thereof. The polymeric compositions are formulated to possess good mechanical, physical and biological properties. Moreover, implantable devices formed of materials comprising such compositions can be delivered to the treatment site in a conveniently compressed size and then can expand to dimensions appropriate for their medical functions.

Owner:ABBOTT CARDIOVASCULAR

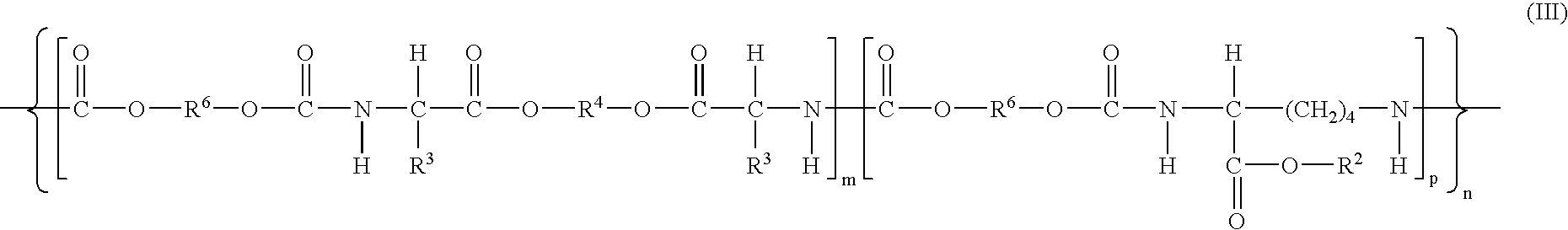

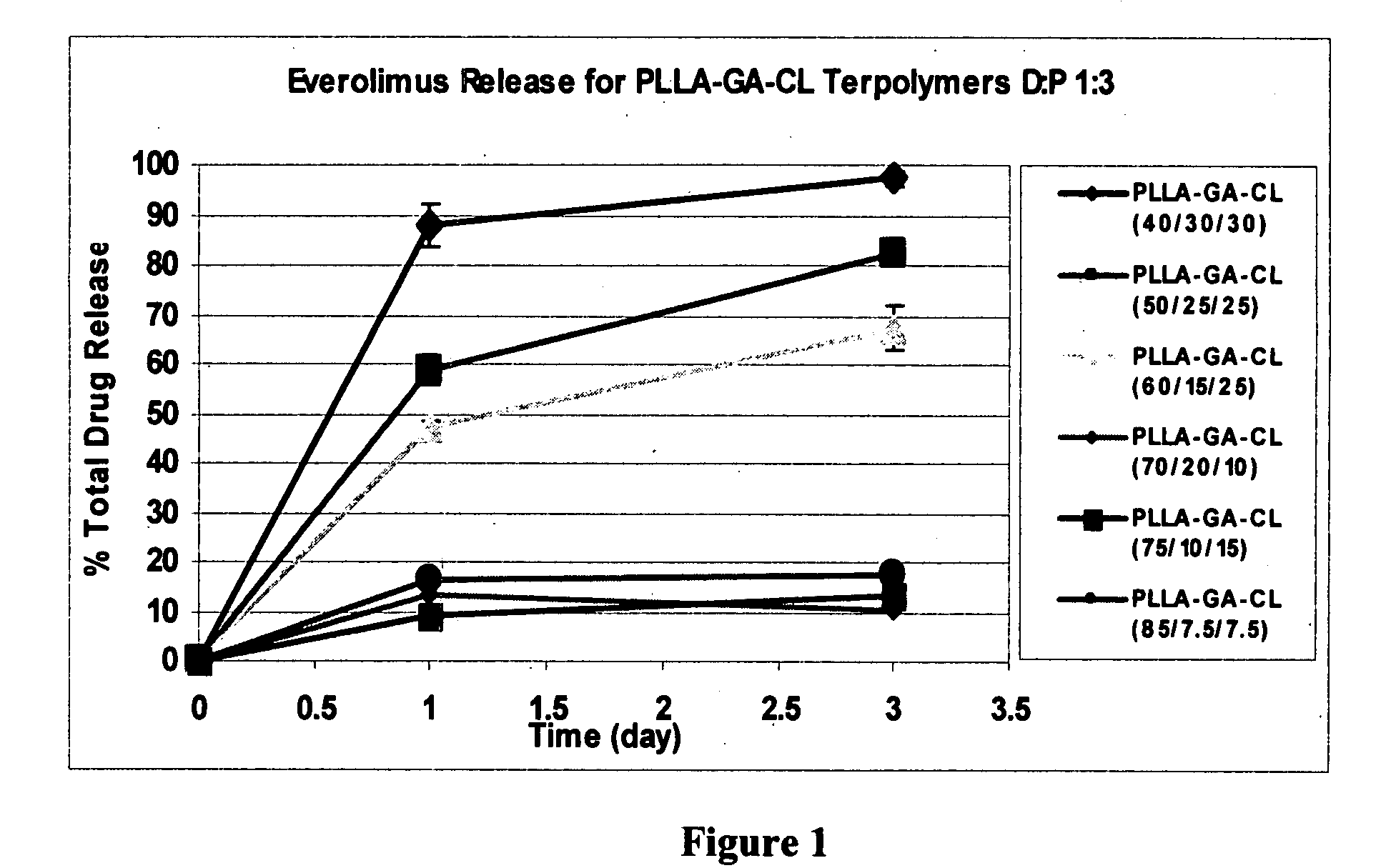

Biodegradable polymeric materials providing controlled release of hydrophobic drugs from implantable devices

InactiveUS20090110713A1Good miscibilityImprove breathabilityBiocideCosmetic preparationsBiological propertyControl release

The present invention is directed to polymeric materials (e.g., coatings) comprising biodegradable copolymers and implantable devices (e.g., drug-delivery stents) formed of such materials. The biodegradable copolymers are derived from at least two relatively polar monomers and at least one relatively nonpolar monomer. Incorporation of at least one relatively nonpolar monomer into the copolymer improves controlled release of a hydrophobic drug from the polymeric material by increasing the copolymer's miscibility with and permeability to the hydrophobic drug. The polymeric materials can also contain at least one biocompatible moiety, at least one non-fouling moiety, at least one biobeneficial material, at least one bioactive agent, or a combination thereof. The polymeric materials are designed to improve the mechanical, physical and biological properties of implantable devices formed thereof.

Owner:ABBOTT CARDIOVASCULAR

Absorbent articles comprising biodegradable PHA copolymers

InactiveUS6160199AProtect and promote and control plant growthRaise the ratioSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Polyester blend compositions and biodegradable films produced therefrom

ActiveUS7388058B2SoftnessImprove mechanical propertiesHollow articlesPolyesterBiodegradable copolymers

A polyester blend composition that comprises at least two copolymers selected from certain copolymers, particularly blends of branched and linear biodegradable copolymers. Also provided is a blown film that is produced from the polyester blend composition, and a process for producing the polyester blend composition and the film. The film is biodegradable, transparent, and has excellent mechanical properties.

Owner:DUPONT DKK +1

Fibers, nonwoven fabrics, and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate

InactiveUS6013590AProtect and promote and control plant growthHigh elongationBaby linensAdhesivesPolymer scienceBiodegradable copolymers

The present invention relates to fibers, and nonwovens comprising said fibers, comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid previous topsheet, a biodegradable liquid impervious backsheet comprising the above fibers and / or nonwovens, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

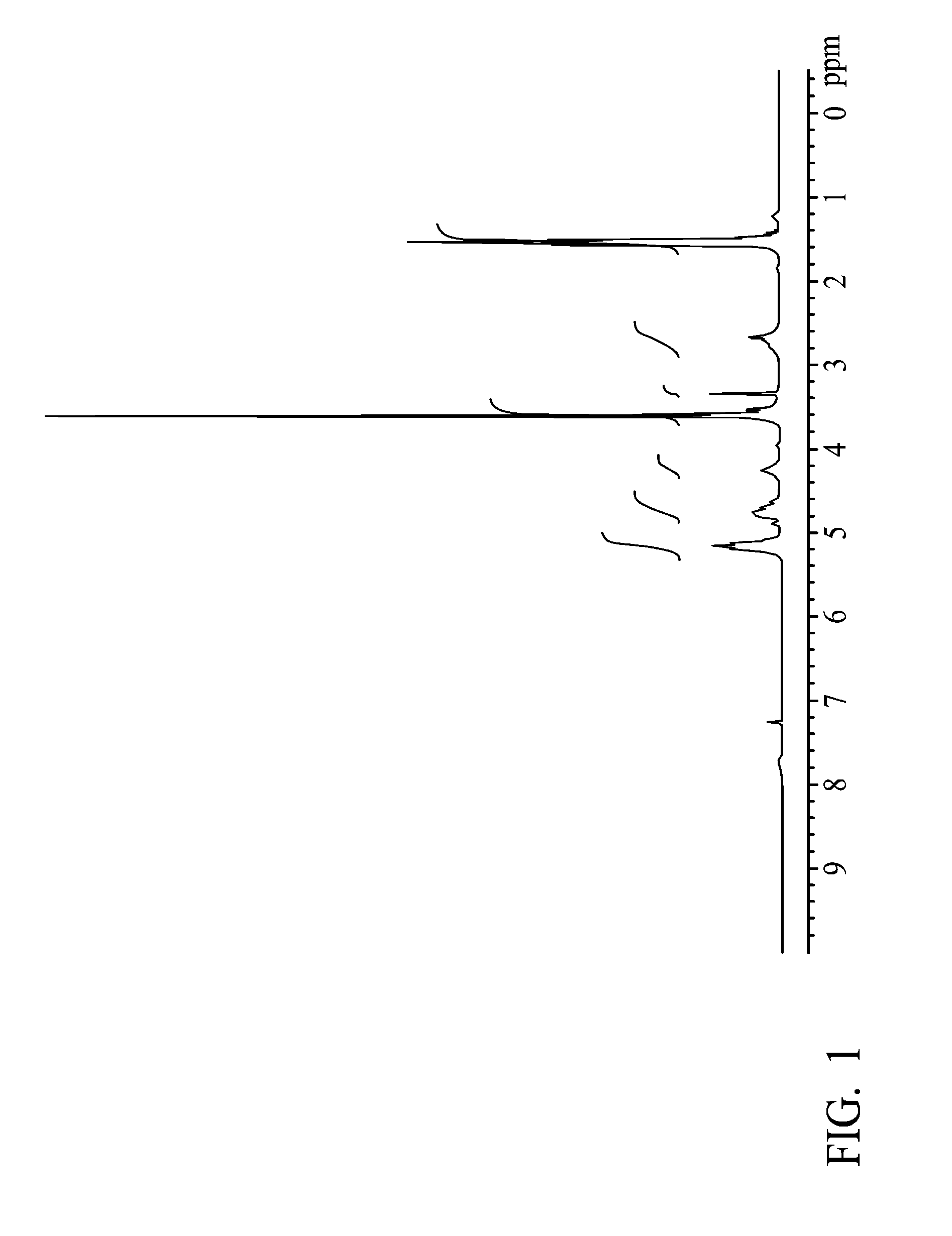

Biodegradable copolymer and thermosensitive material

The disclosed is a biodegradable copolymer, an amphiphilic diblock copolymer, composed of a hydrophilic segment and a hydrophobic segment. The hydrophilic segment is an endcapped PEG or derivatives thereof. The hydrophilic segment is a random polymer polymerized of lactone or cyclic C3-C6 molecule and lactic acid / glycolic acid. There is no coupling agent between the hydrophilic and hydrophobic segments, and the biodegradable copolymer is formed by one-pot ring-opening polymerization. The biodegradable copolymer can be dissolved in water to form a thermosensitive material having a phase transfer temperature of 25 to 50° C., thereby being applied to biological activity factor delivery, tissue engineering, cell culture and biological glue.

Owner:IND TECH RES INST

Plastic articles comprising biodegradable PHA copolymers

InactiveUS6569990B1Easy to processDifficult to processFlexible coversWrappersBiodegradable copolymersBiodegradable polymer

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structurewherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structureand wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Fibers, nonwoven fabrics and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate

InactiveUS6143947AProtect and promote and control plant growthHigh elongationEngine sealsBaby linensPolymer scienceBiodegradable copolymers

The present invention relates to fibers, and nonwovens comprising said fibers, comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above fibers and / or nonwovens, and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

Films and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate comonomer units

InactiveUS6027787AEasily processed into filmPromote degradationSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to a film comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above film, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

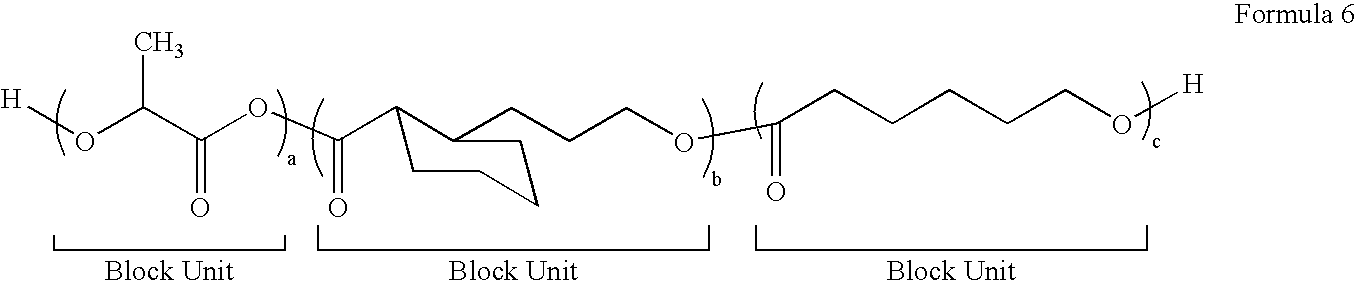

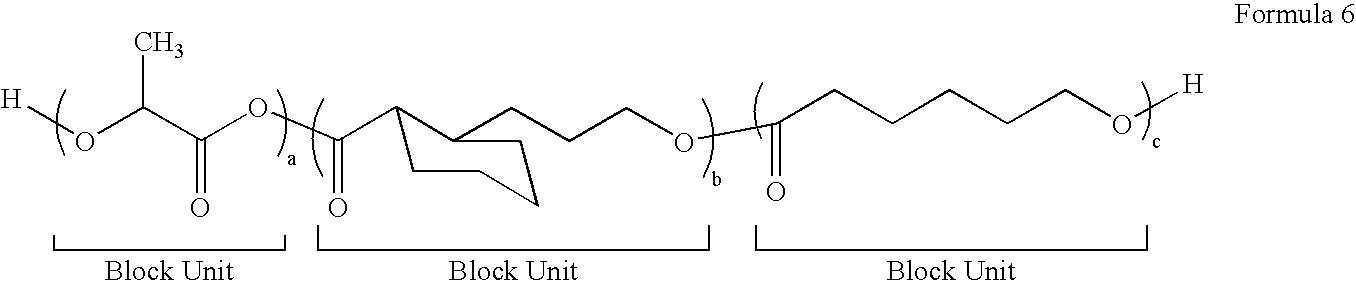

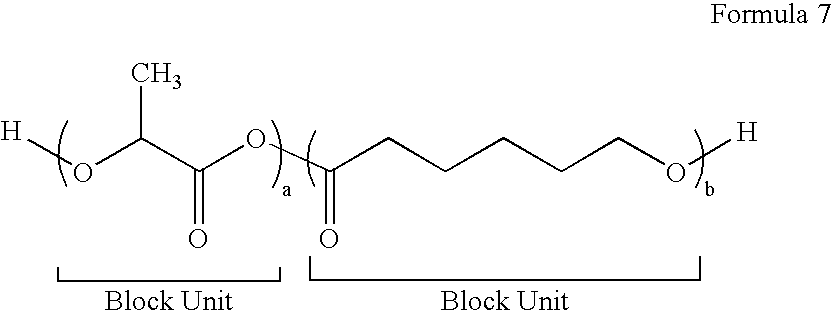

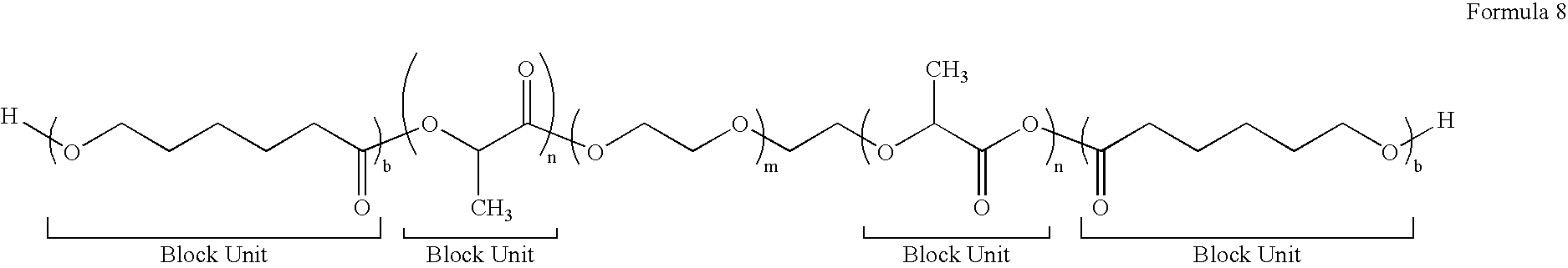

Block Biodegradable Copolymers for Medical Devices

Disclosed herein are implantable medical devices comprising controlled release biodegradable block copolymers or coated with controlled release block copolymers and at least one drug releasable from the block copolymer. The controlled release block copolymers comprise least two blocks selected from the group consisting of polyesters, polyethers, and polyurethanes.

Owner:MEDTRONIC VASCULAR INC

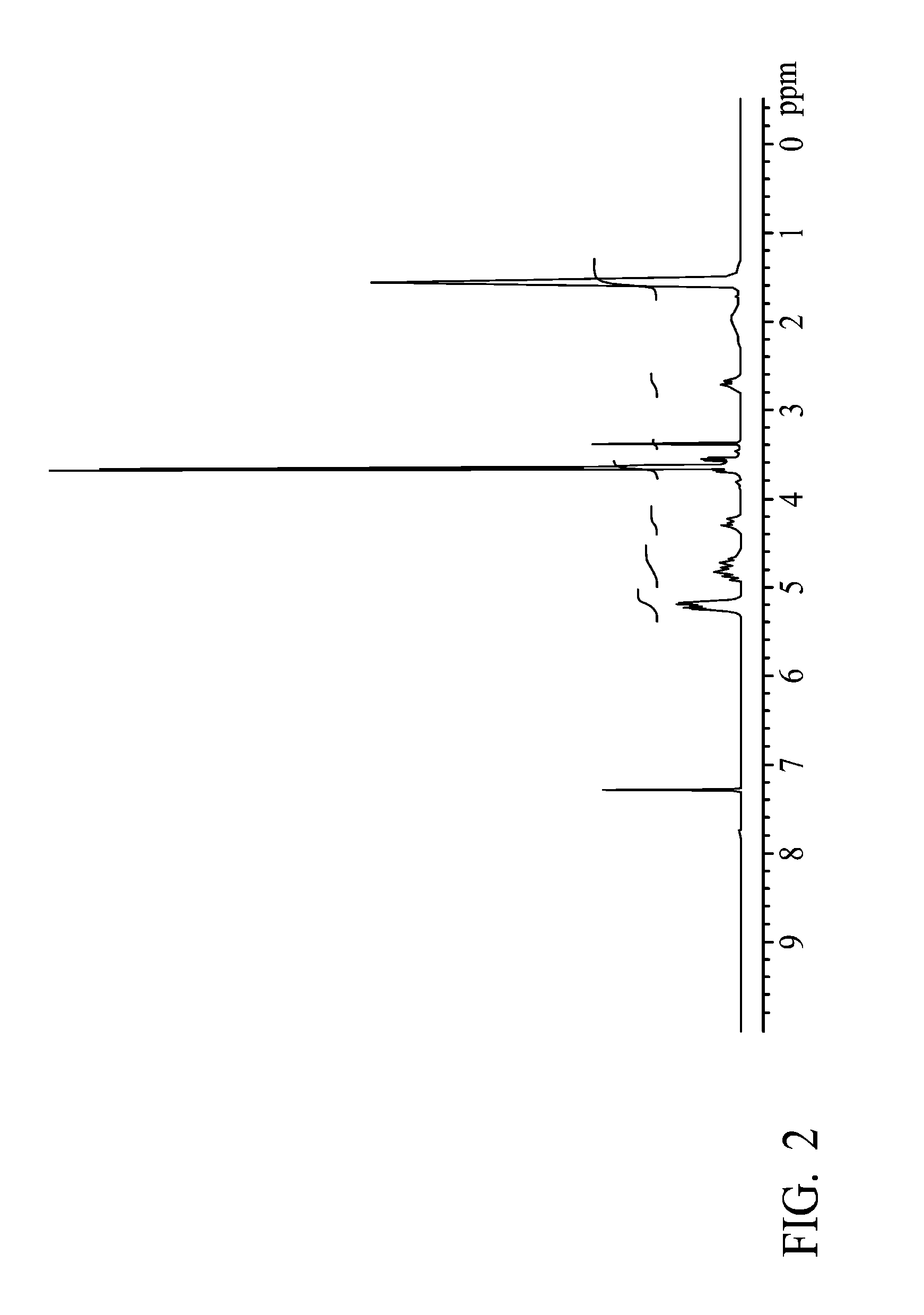

Thermosensitive biodegradable copolymer

ActiveUS20050113531A1Simplify implantation procedureSimple manufacturing processSurgical adhesivesPharmaceutical delivery mechanismHydrogenBiodegradable copolymers

A thermo-sensitve copolymer of following formula; is disclosed; wherein R1 is hydrogen, or —C(═O)—R2; R2 is C7-30 alkyl substituted or unsubstituted with functional groups; R3 is hydrogen, or C1-6 alkyl; and x, y or z individually is an integer greater than 0. The thermo-sensitive copolymers disclosed here are easy to be implanted into a human body through injection. The biodegradability is greatly improved and the cytotoxicity of the copolymers is low.

Owner:IND TECH RES INST

Agricultural items and agricultural methods comprising biodegradable copolymers

InactiveUS6903053B2Easy to handlePromotes worker safetyBiocideDrug compositionsBiodegradable copolymersMonomer

An agricultural item comprising a biodegradable polyhydroxyalkanoate copolymer comprising two randomly repeating monomer units. The first randomly repeating monomer unit has the structure: wherein R1 is H or a C1-2 alkyl, and n is 1 or 2; and the second randomly repeating monomer unit has the structure: wherein R2 is a C3-19 alkyl or a C3-19 alkenyl. At least 50% of the randomly repeating monomer units have the structure of the first randomly repeating monomer unit.

Owner:DANIMER IPCO LLC

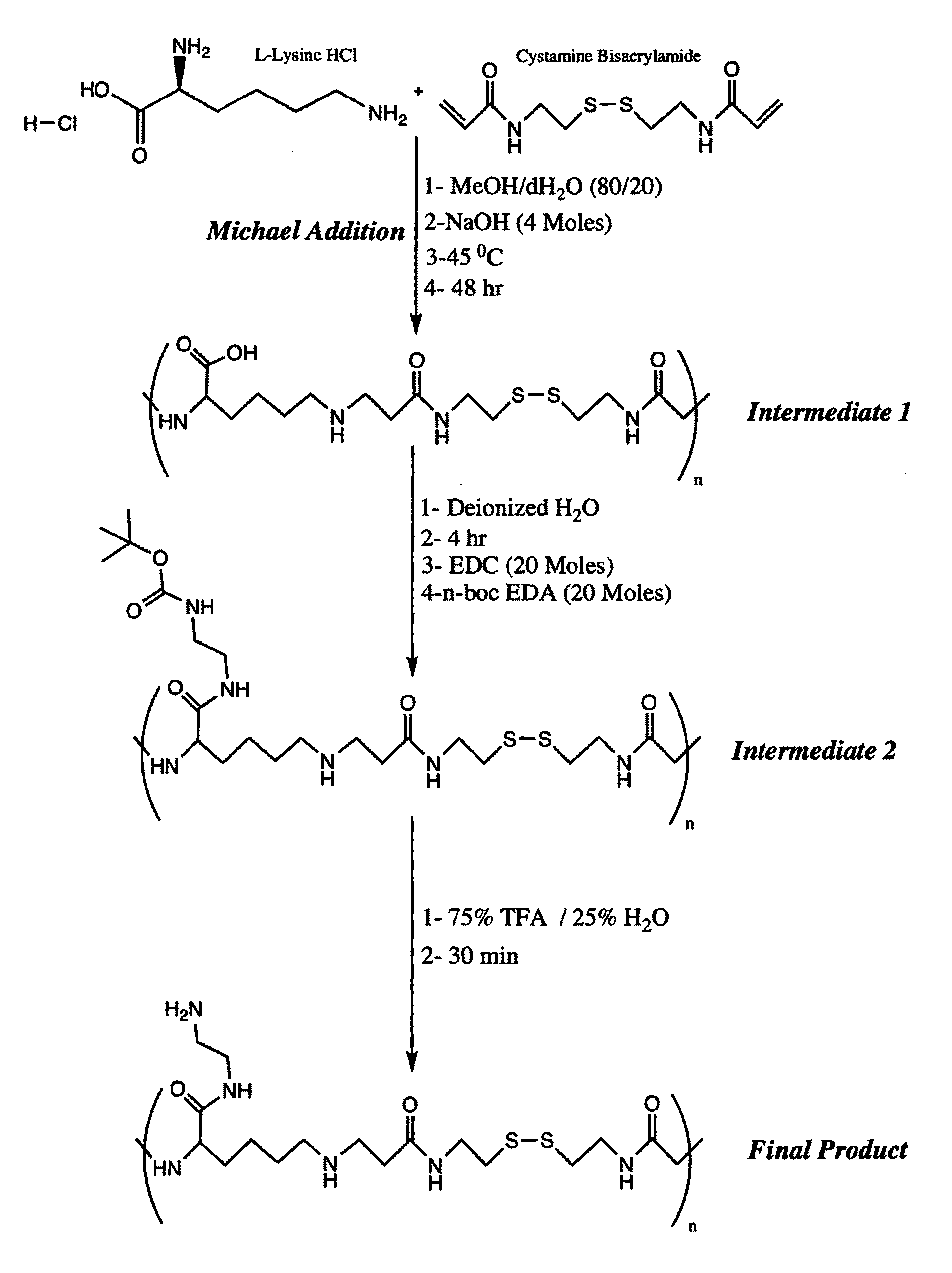

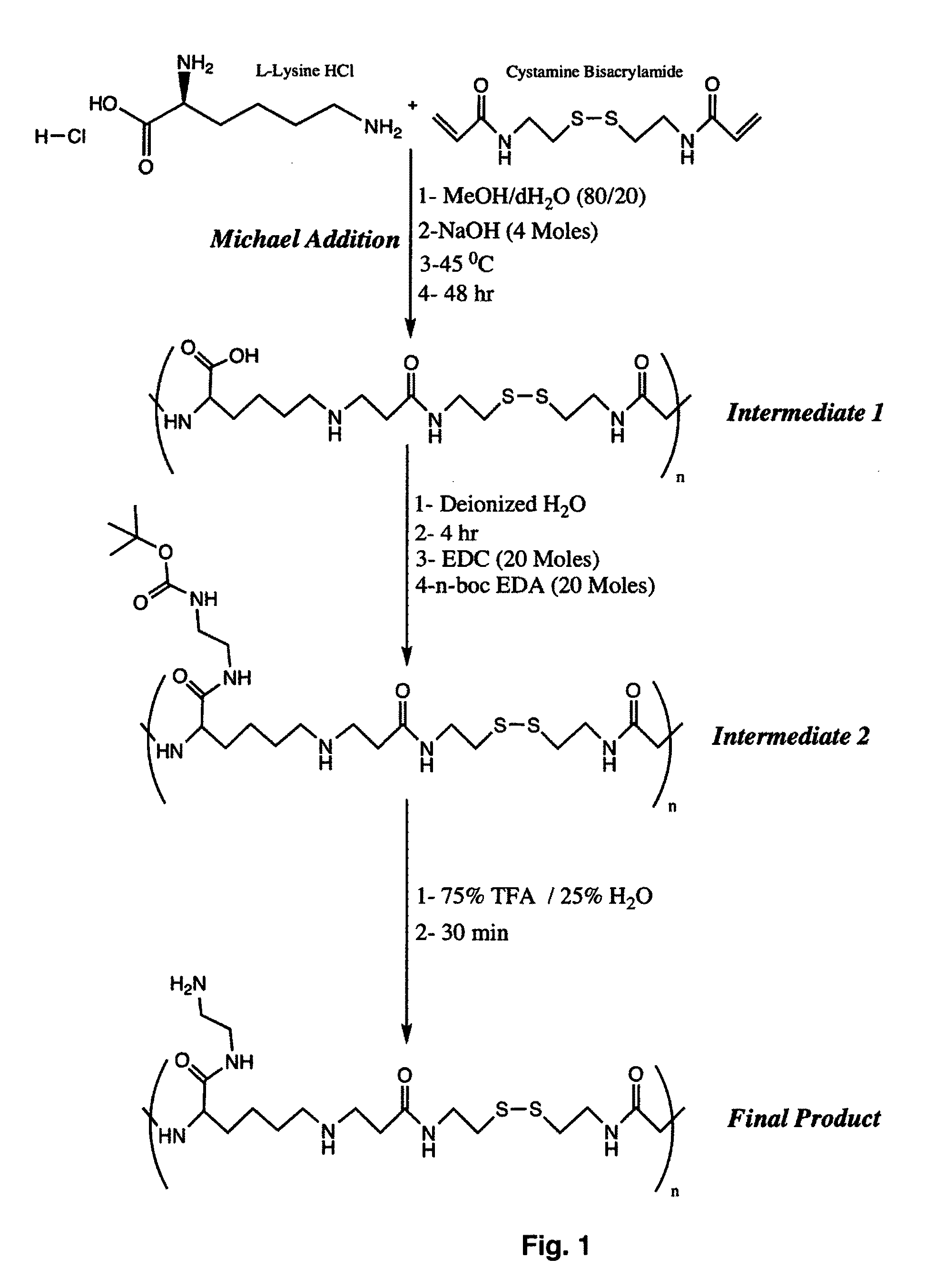

Reducible polymers for nonviral gene delivery

ActiveUS20100204301A1Good biocompatibilityPromote escapeGenetic material ingredientsSaccharide peptide ingredientsGene deliveryBiodegradable copolymers

Provided herein are biodegradable copolymers and nanoplex delivery systems comprising the same and a cargo molecule, such as a nucleic acid, a polynucleotide or other biomolecule. The biodegradable copolymers may comprise a reducible polymer linearly modified with lysine, such as a linear lysine-modified N,N′-cystamine bisacrylamide. The biodegradable copolymers also may be conjugated to a sequestering moiety, such as dietheylamine. The biodegradable copolymers also may comprise one or both of a targeting moiety and one or more moieties to facilitate endosomal escape. Also provided are methods for treating a pathophysiological condition and for increasing biocompatibility of a polymeric delivery system upon delivery to a subject using the biodegradable copolymers and nanoplexes.

Owner:UNIV HOUSTON SYST

Thermosensitive biodegradable copolymer

ActiveUS7179867B2Reduce harm to tissuesSolve lowSurgical adhesivesPharmaceutical delivery mechanismBiodegradable copolymersChemistry

A thermo-sensitve copolymer of following formula;is disclosed; wherein R1 is hydrogen, or —C(═O)—R2; R2 is C7-30 alkyl substituted or unsubstituted with functional groups; R3 is hydrogen, or C1-6 alkyl; and x, y or z individually is an integer greater than 0. The thermo-sensitive copolymers disclosed here are easy to be implanted into a human body through injection. The biodegradability is greatly improved and the cytotoxicity of the copolymers is low.

Owner:IND TECH RES INST

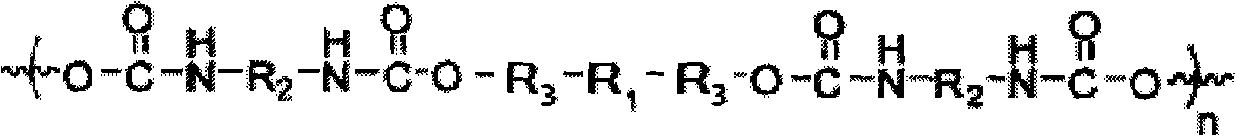

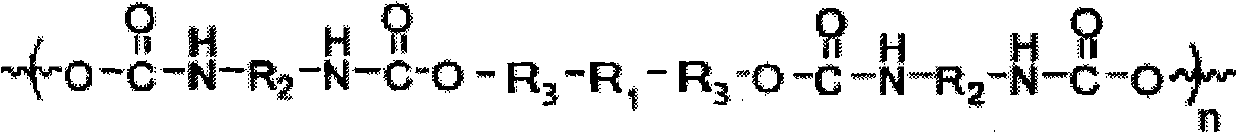

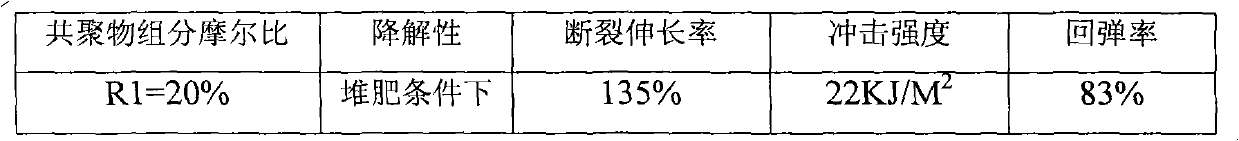

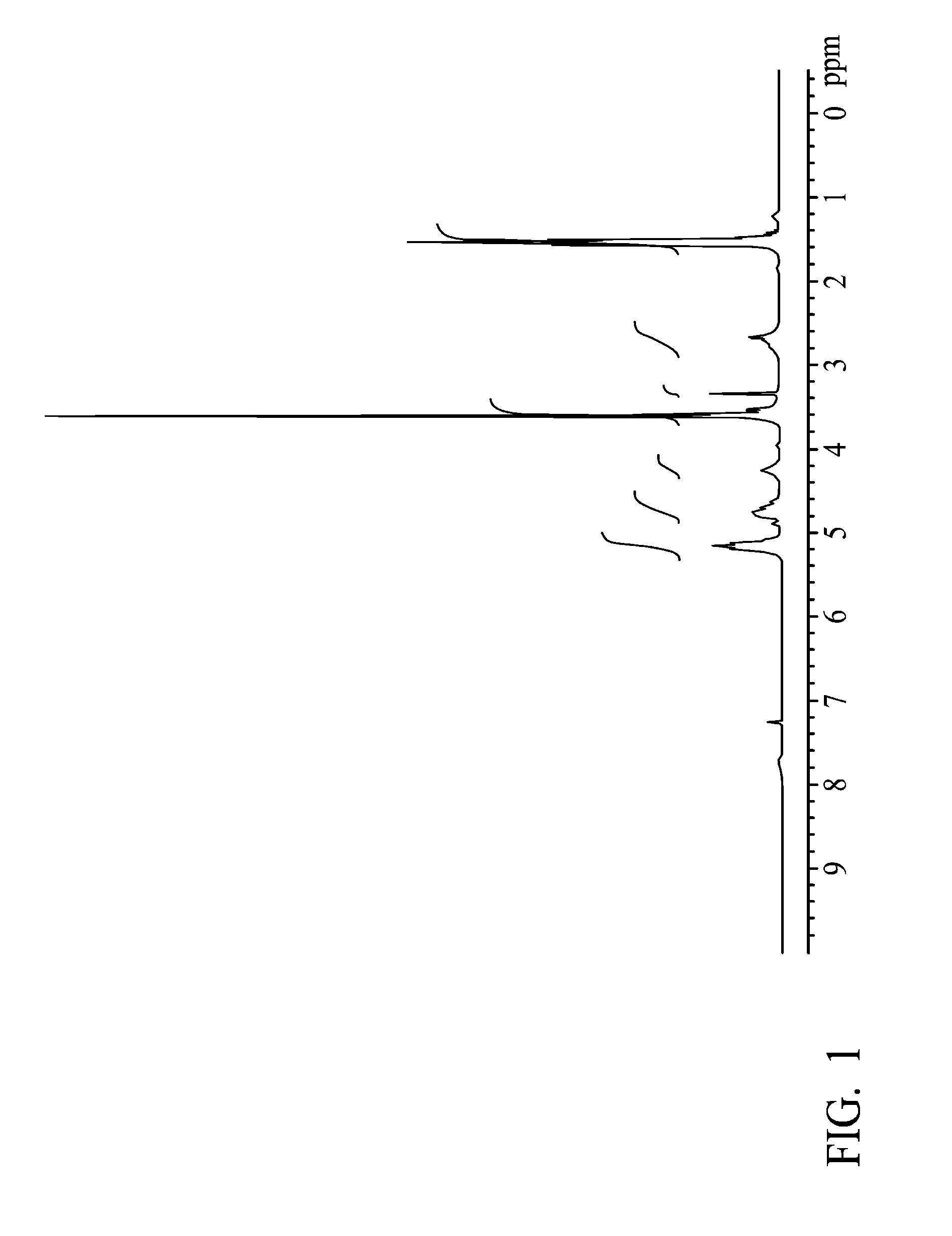

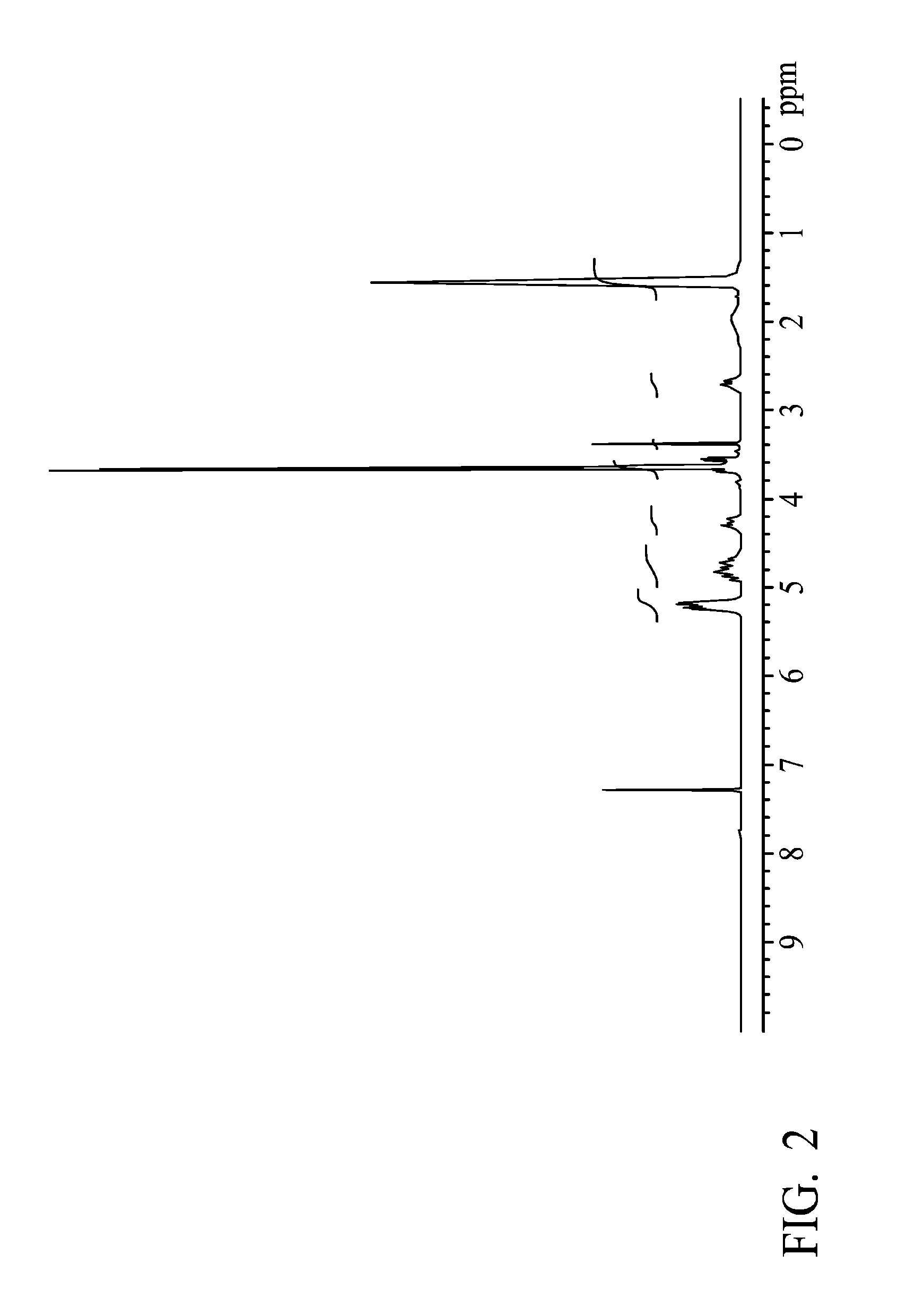

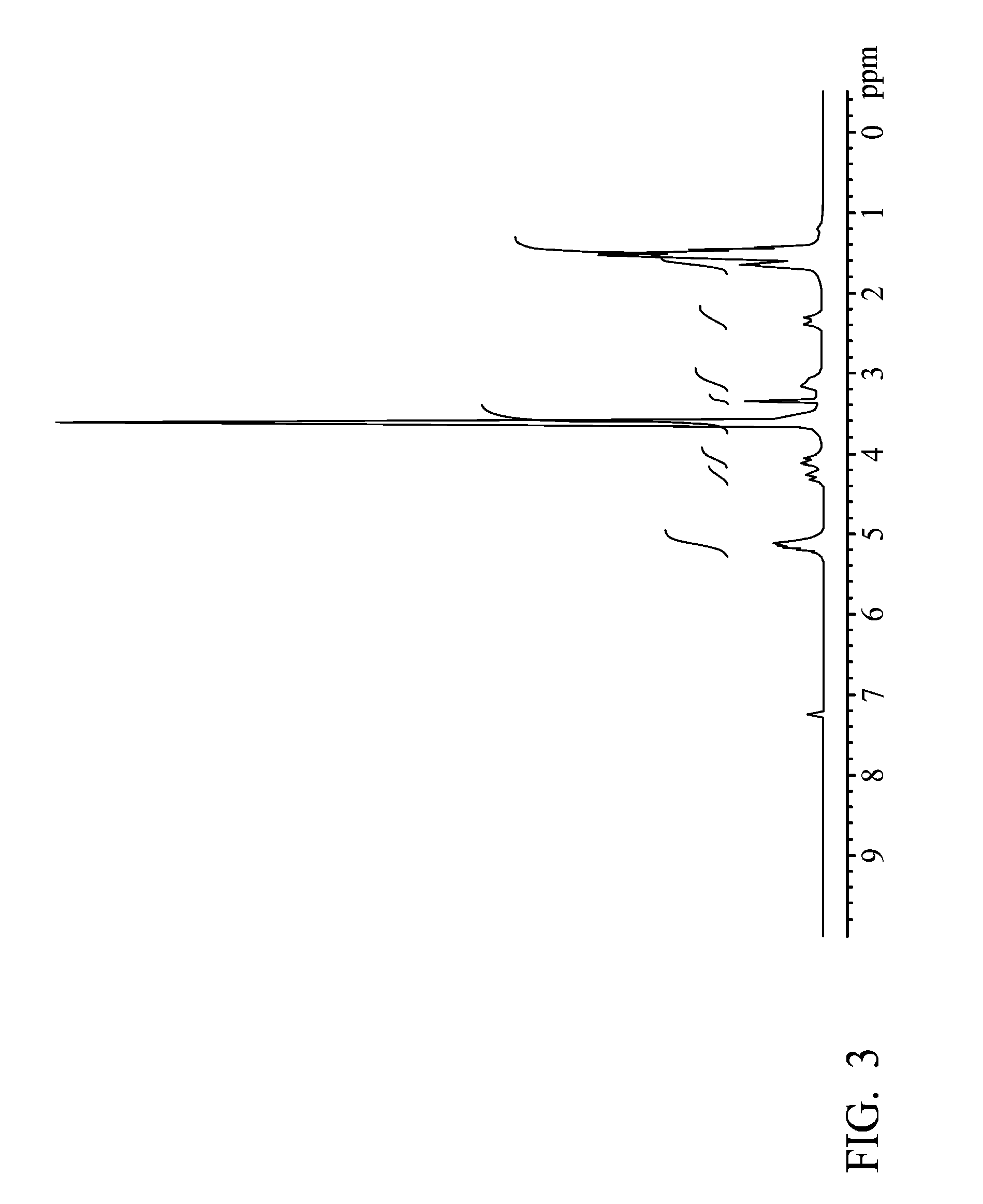

Biodegradable copolymer

The invention belongs to the technical field of materials, and particularly relates to a biodegradable copolymer. In the general structural formula of the copolymer, R1 is polyether or polyester polyol, polyether or polyester polyamine, and polyester or polyether polybasic acid; R2 is CnH2n+1, n is 1 to 5, phenyl and substituted phenyl; and R3 is poly alcohol acid or polyamino acid. The copolymer can comprise less than or equal to 30 molar percent of benzene ring structure. By changing the proportions and composition of R1, R2 and R3, the degradability, heat stability, hydrolysis stability, breaking elongation, flexural strength, tensile strength, impact strength, Young modulus, and rebound resilience of the copolymer can be changed. The biodegradable copolymer can be applied to the fields of automobiles, electronics, spinning, furniture, interior decoration, leather, papermaking, packaging, machinery, building and the like. The biodegradable copolymer is simple and economic, the raw materials are abundant and can be obtained easily, industrial production can be realized easily, the prepared copolymer is biodegradable, and environment-friendly, and has a wide application rang, and the components and the raw materials are easy to recycle.

Owner:TONGJI UNIV

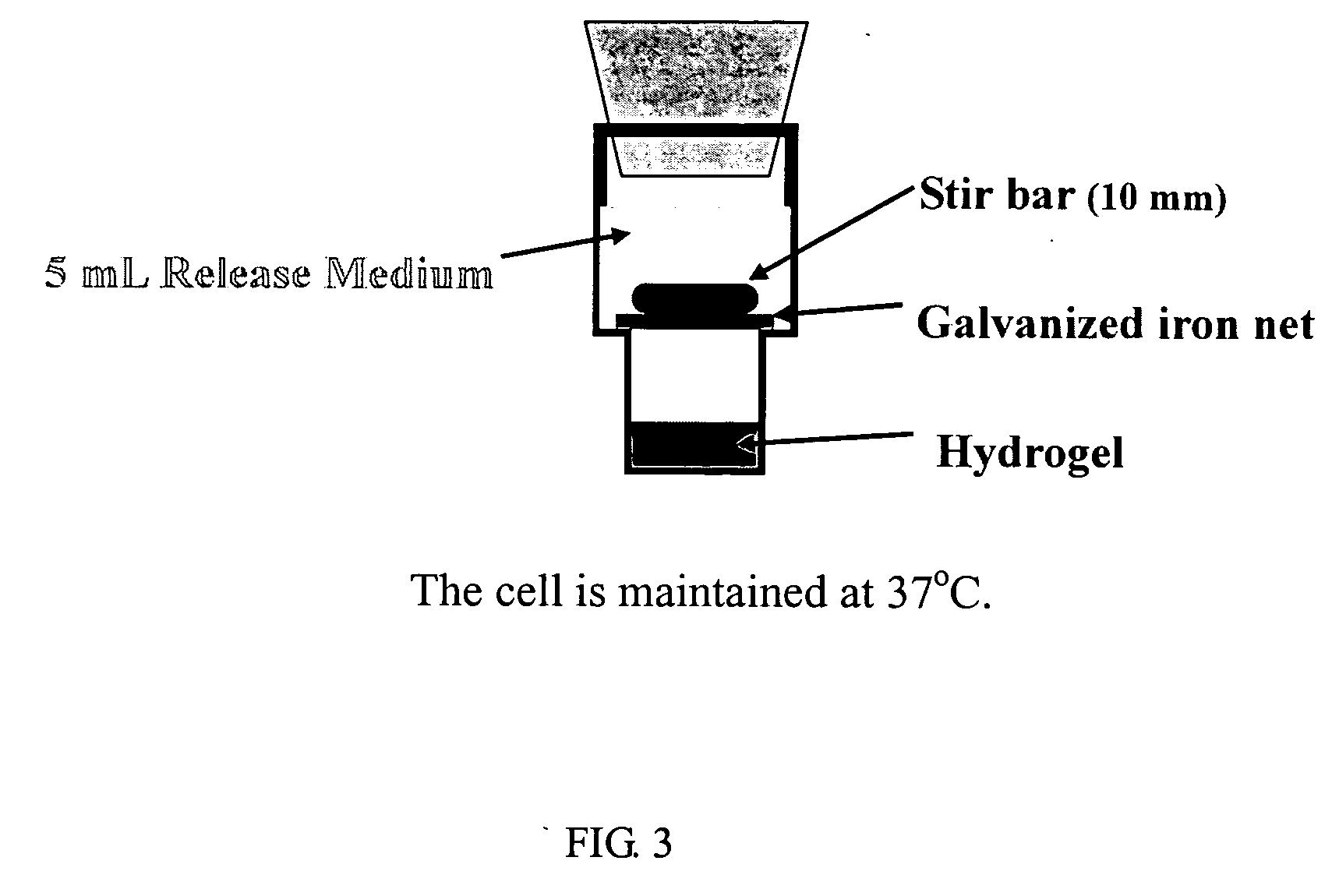

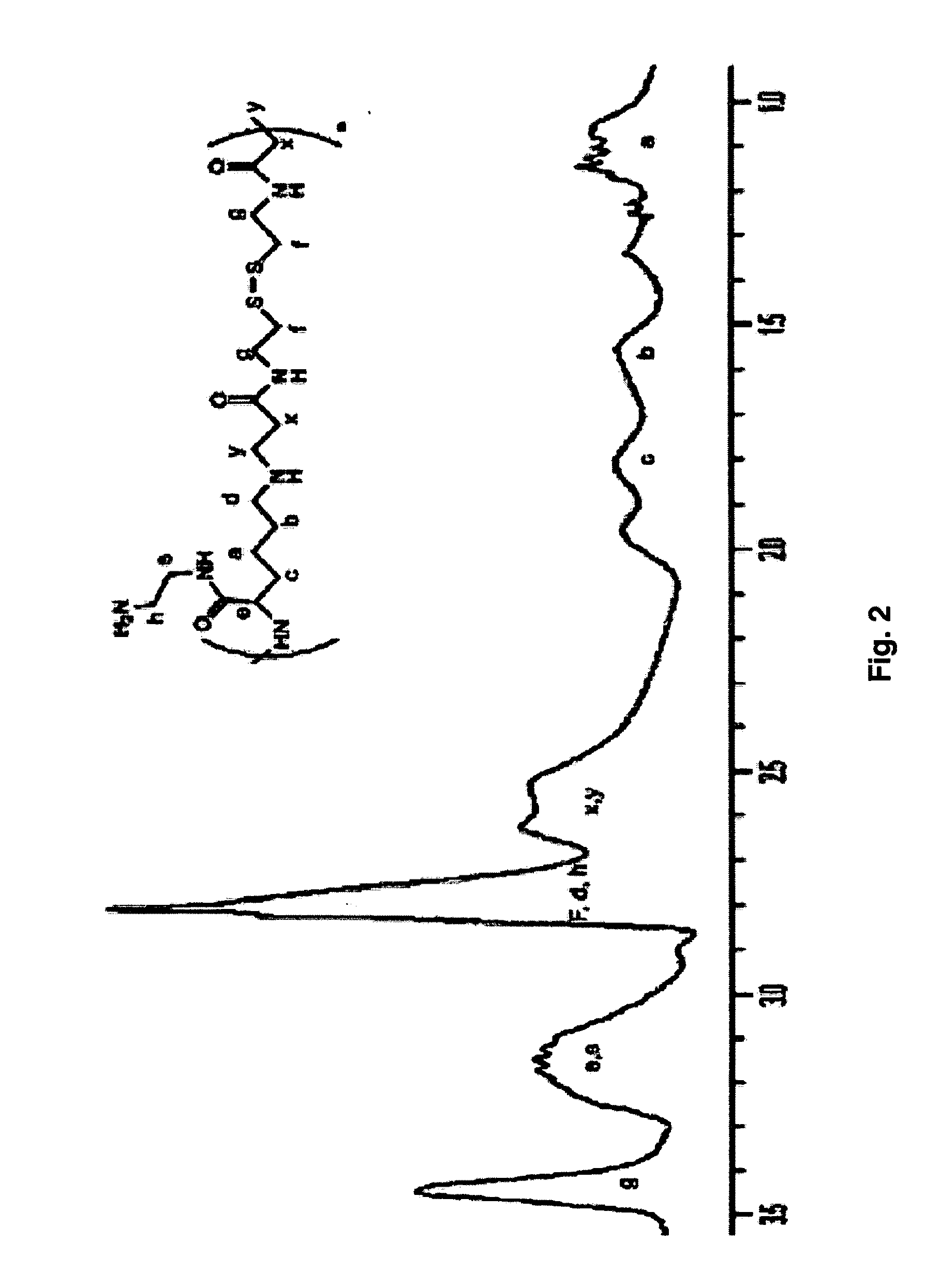

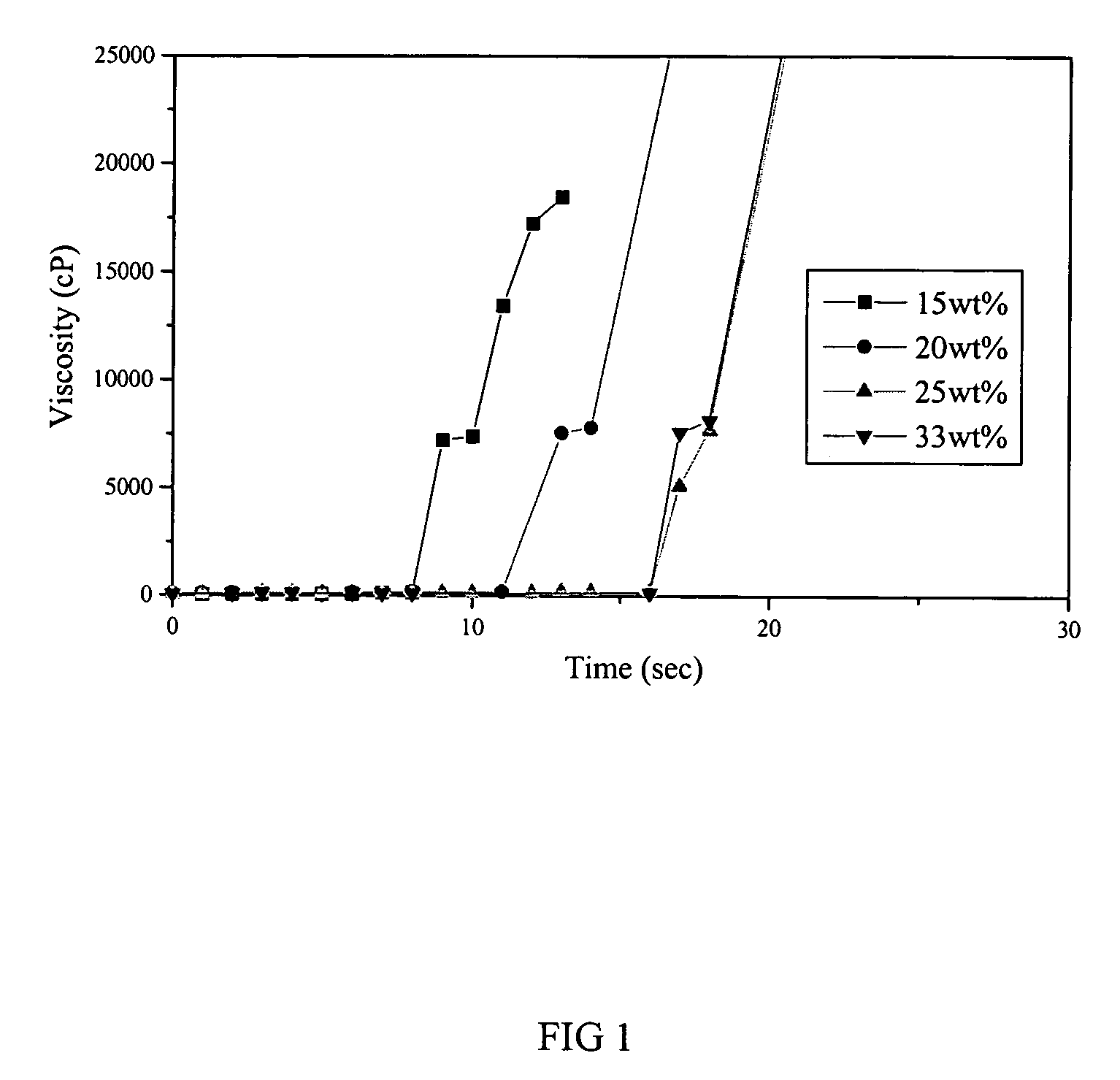

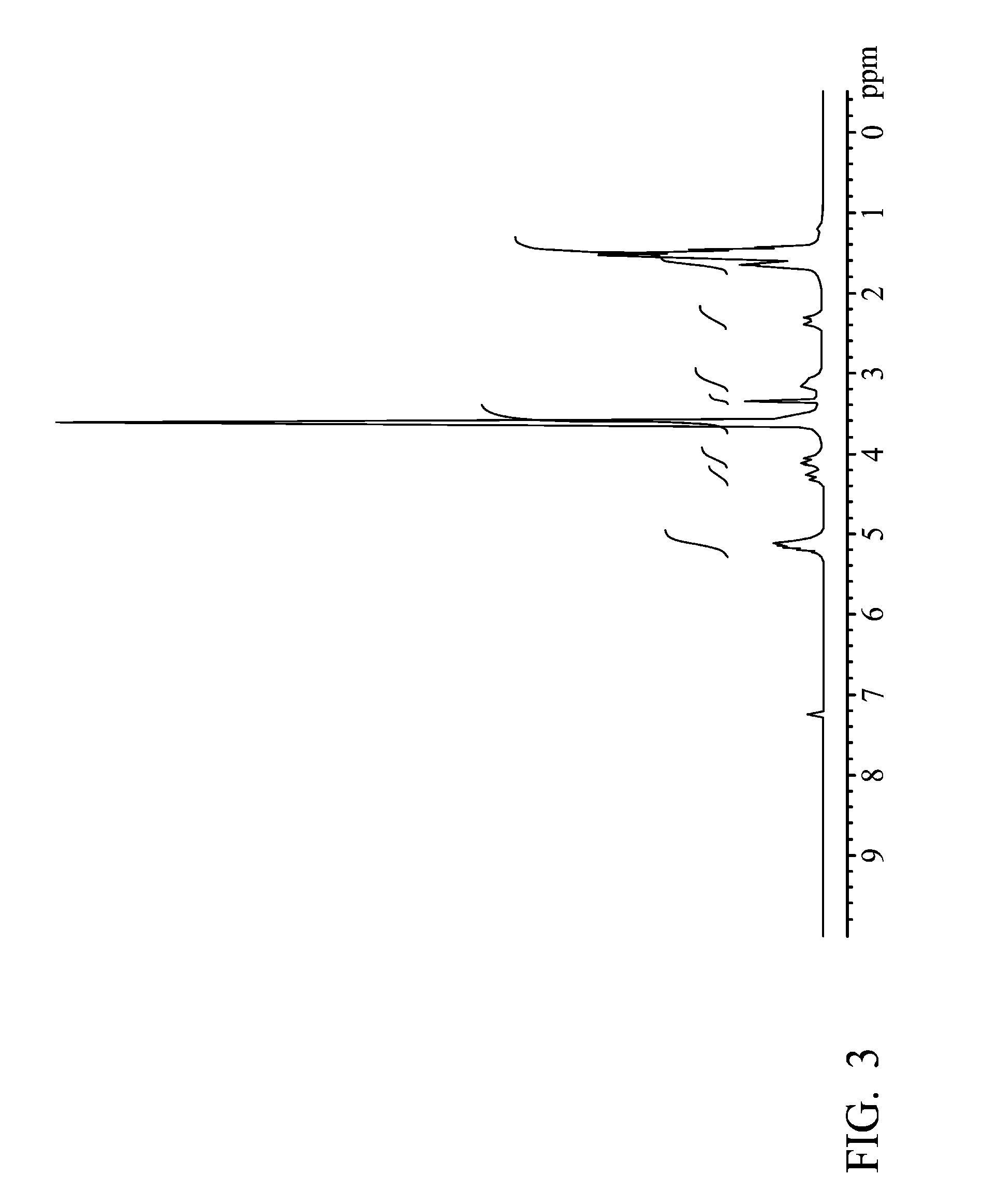

Biodegradable copolymer hydrogels

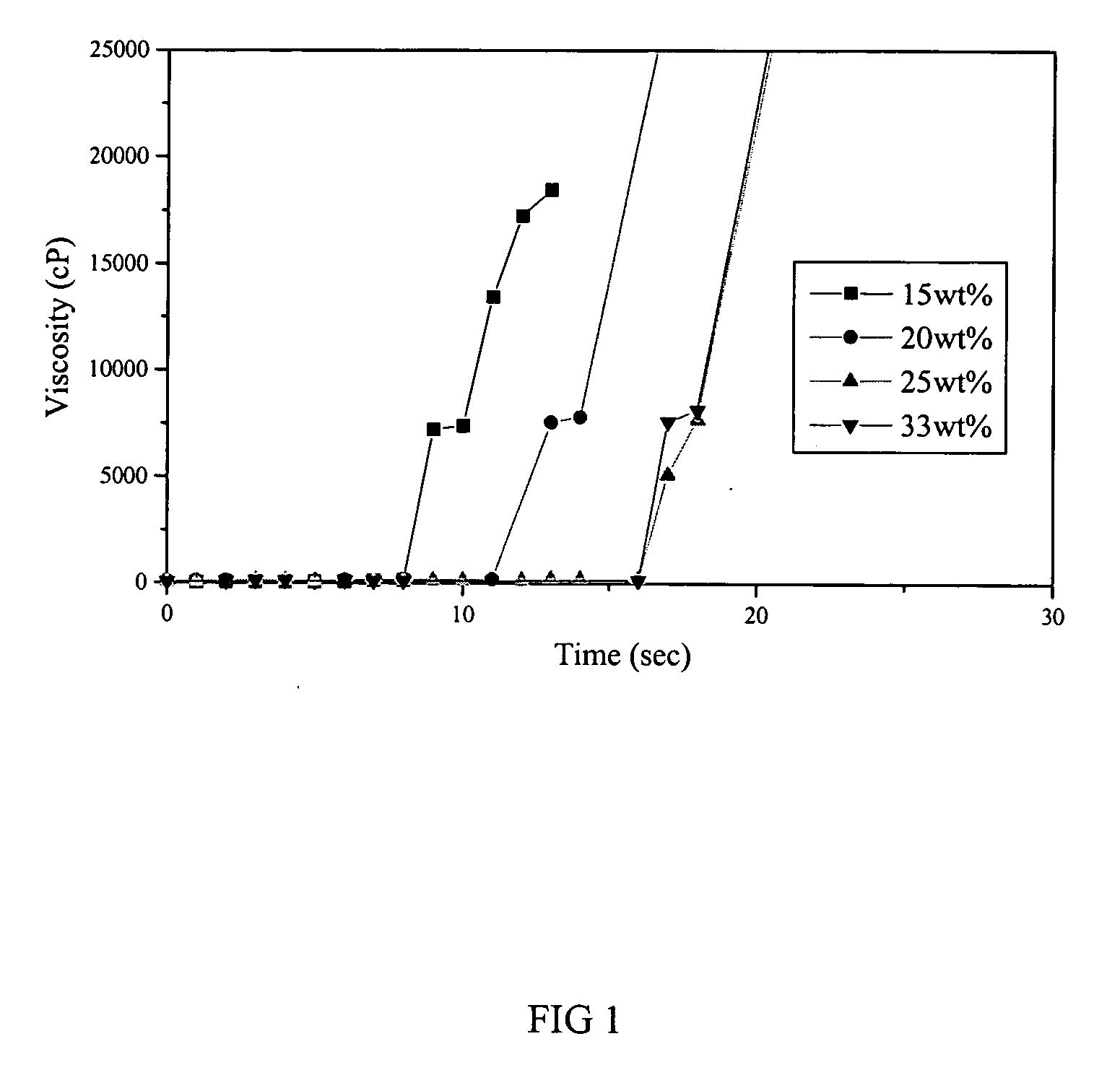

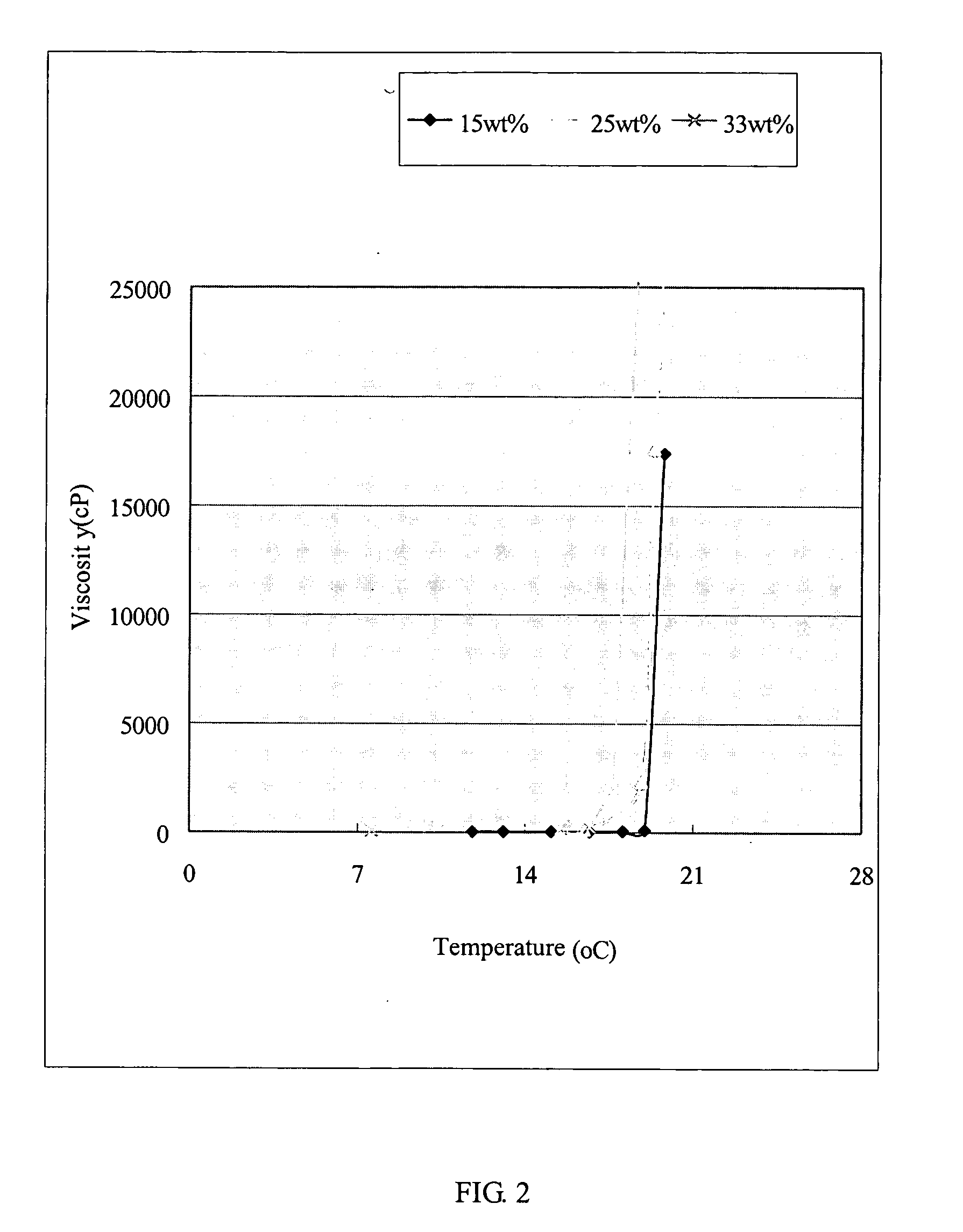

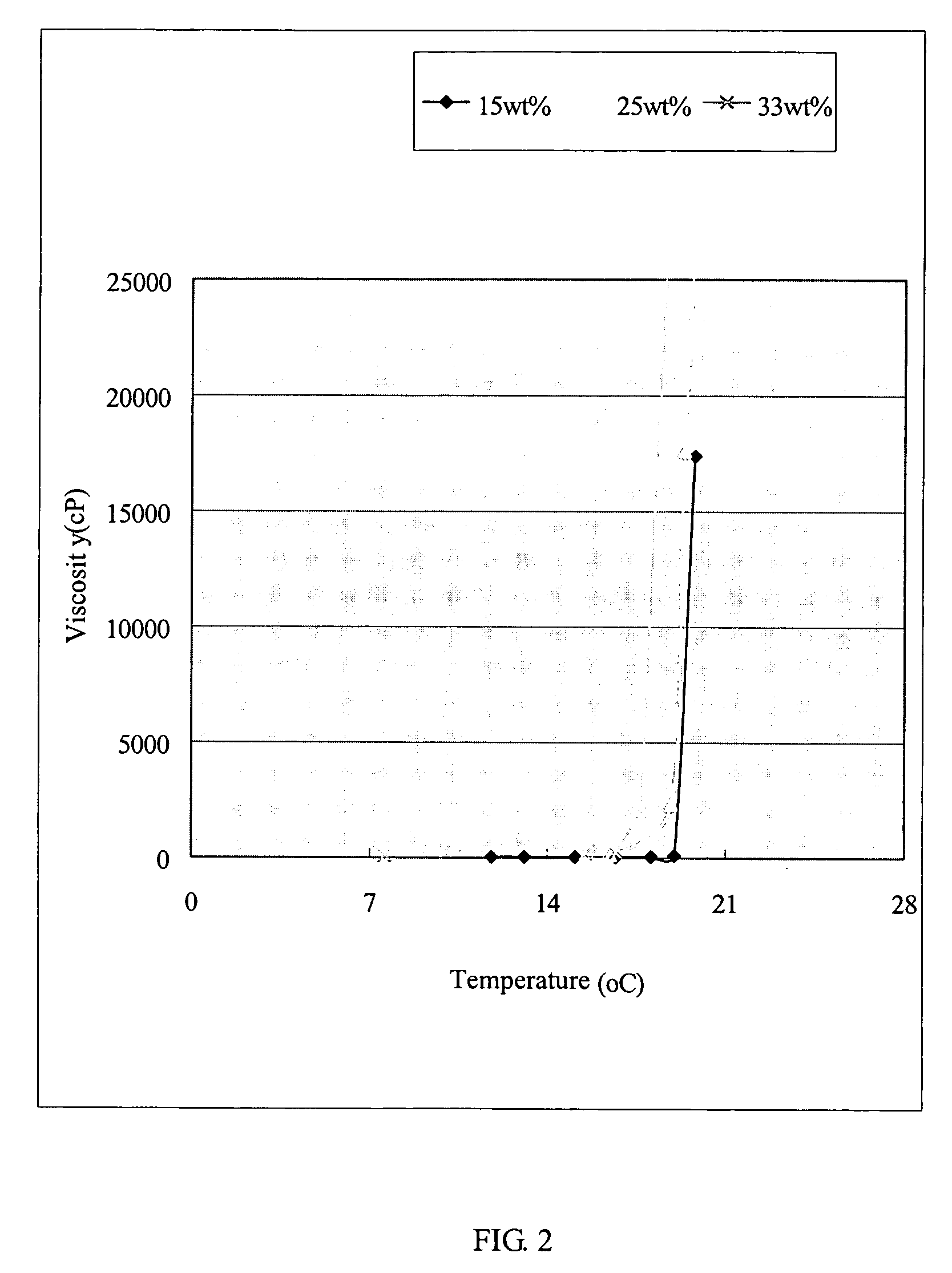

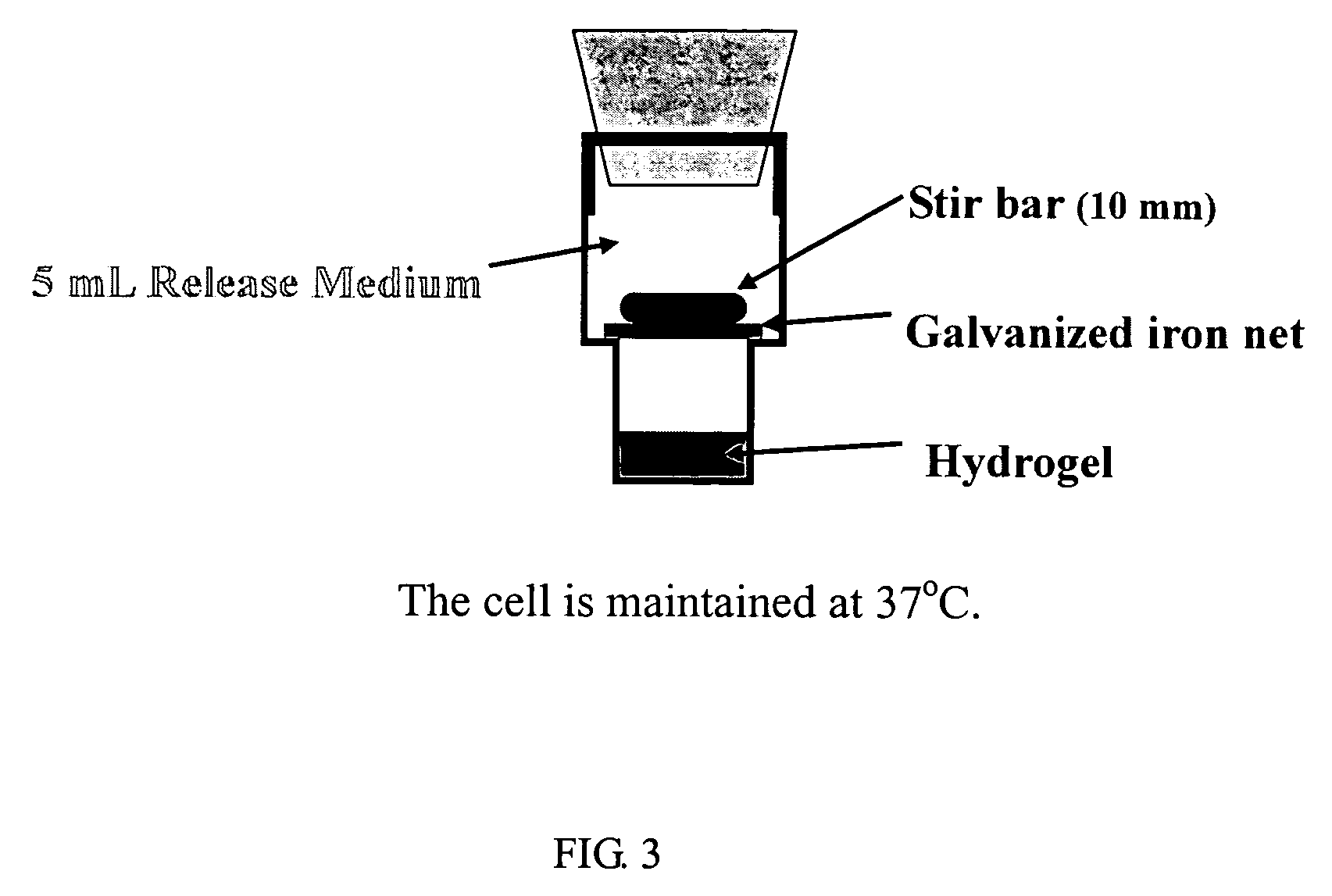

ActiveUS20100166863A1Low viscosityHigh viscosityPowder deliveryEmulsion deliveryPolyesterPolymer science

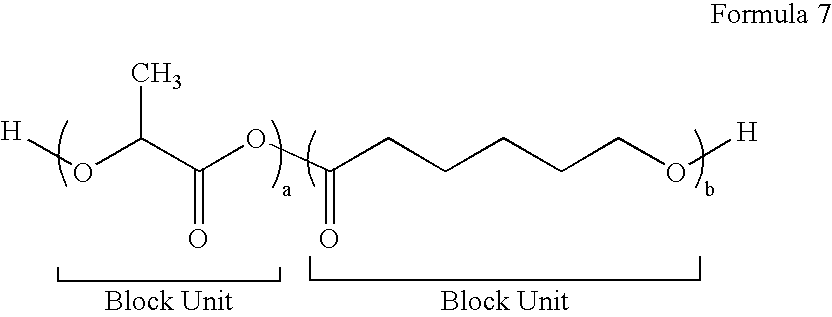

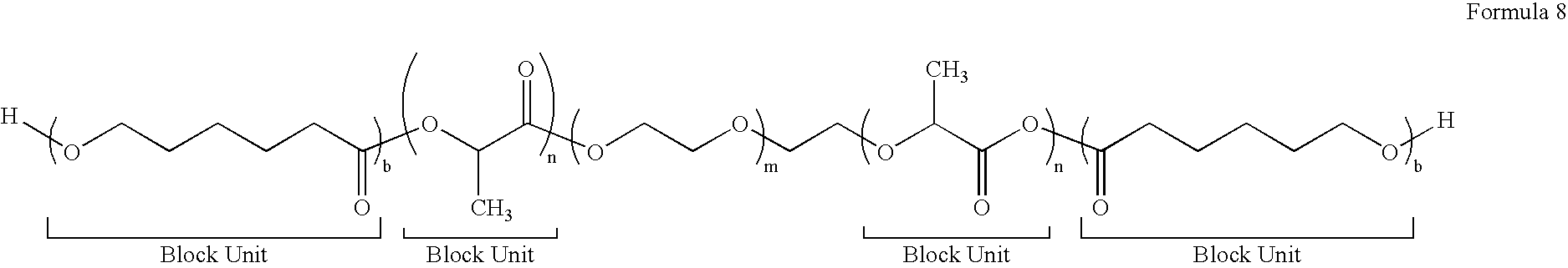

Biodegradable copolymer hydrogels are provided. The biodegradable copolymer hydrogels have a structure of Formula (I) or Formula (II)A-B—BOX—B-A Formula (I)B-A-B—(BOX—B-A-B)n-BOX—B-A-B Formula (II), wherein, A comprises a hydrophilic polyethylene glycol polymer (A); B comprises a hydrophobic polyester polymer (B); BOX is bifunctional group monomer of 2,2′-Bis(2-oxazoline) and used for coupling the blocks A-B or B-A-B; and n is an integer, equal to or greater than 0.

Owner:IND TECH RES INST

Biodegradable plastics

InactiveUS20080167436A1Promote absorptionReduce the amount requiredPharmaceutical non-active ingredientsBiodegradable copolymersSide chain

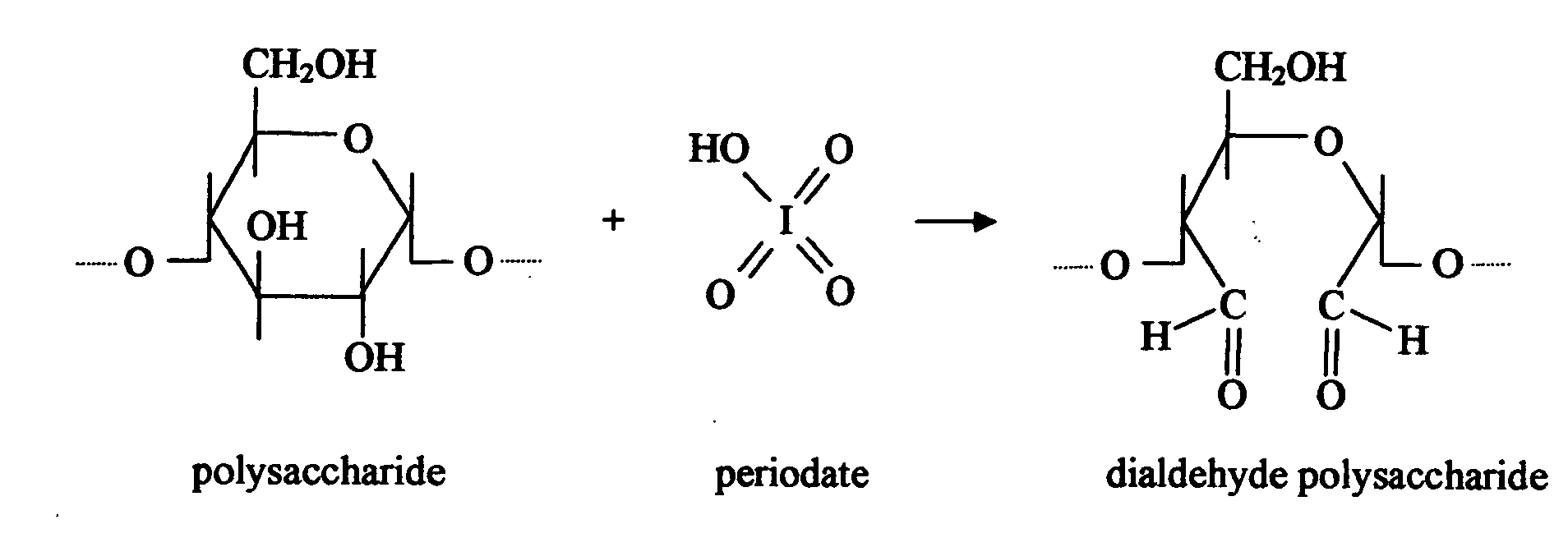

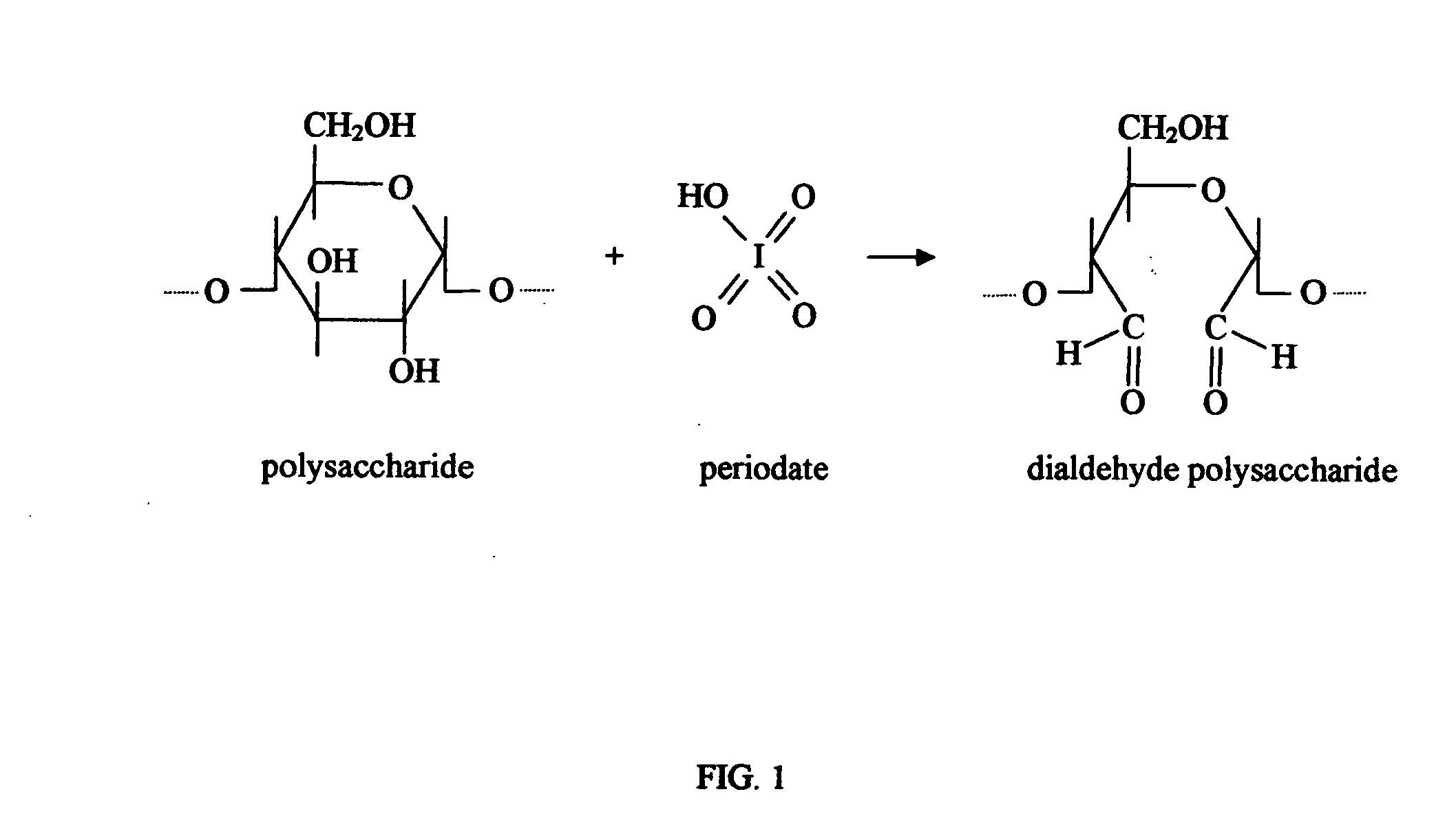

A method for producing biodegradable plastic from natural materials containing polysaccharides by treating the polysaccharide-containing materials with a basic aqueous solution, subsequently treating the mixture with a modifying material that converts pendant hydroxyl groups at any carbon atom of the anhydroglucose units of the saccharide to create polysaccharide carboxylate, and then reacting the product with proteins to produce a biodegradable copolymer with electrostatic chemical bonds between protein and polysaccharide carboxylate molecules. The process provides relatively inexpensive methods for preparing biodegradable plastics that are useful for manufacturing various articles.

Owner:SAGINAW VALLEY STATE UNIV

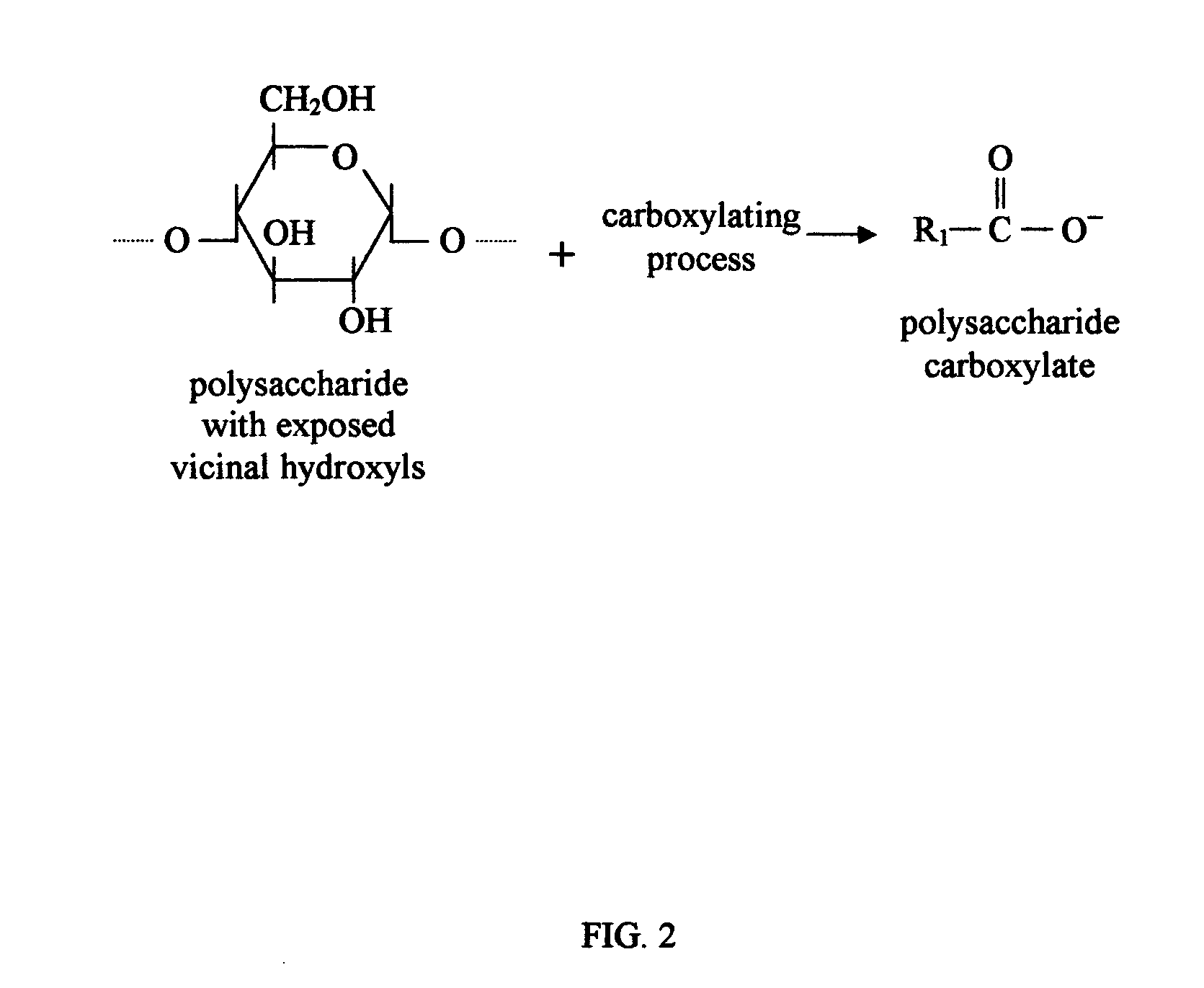

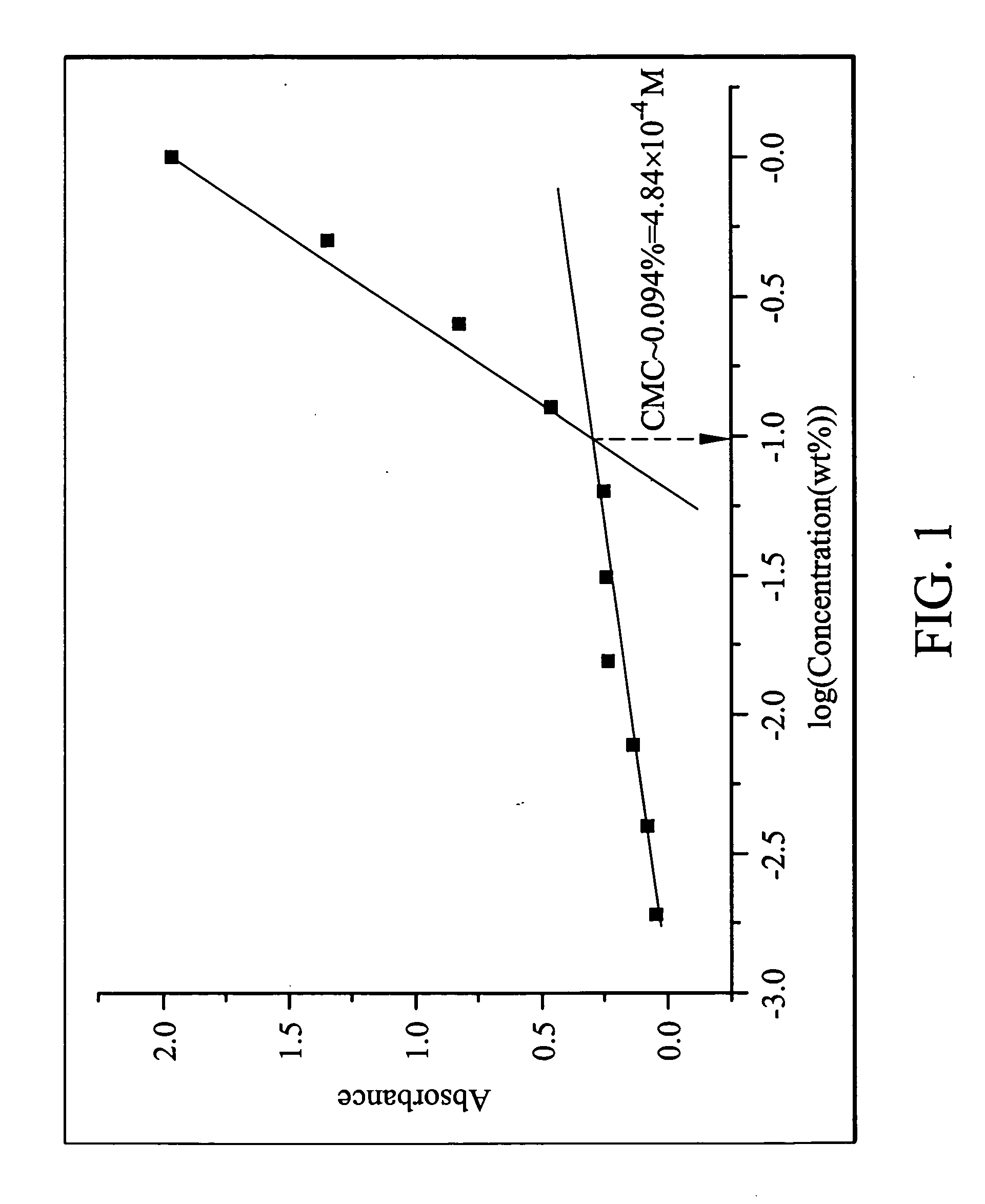

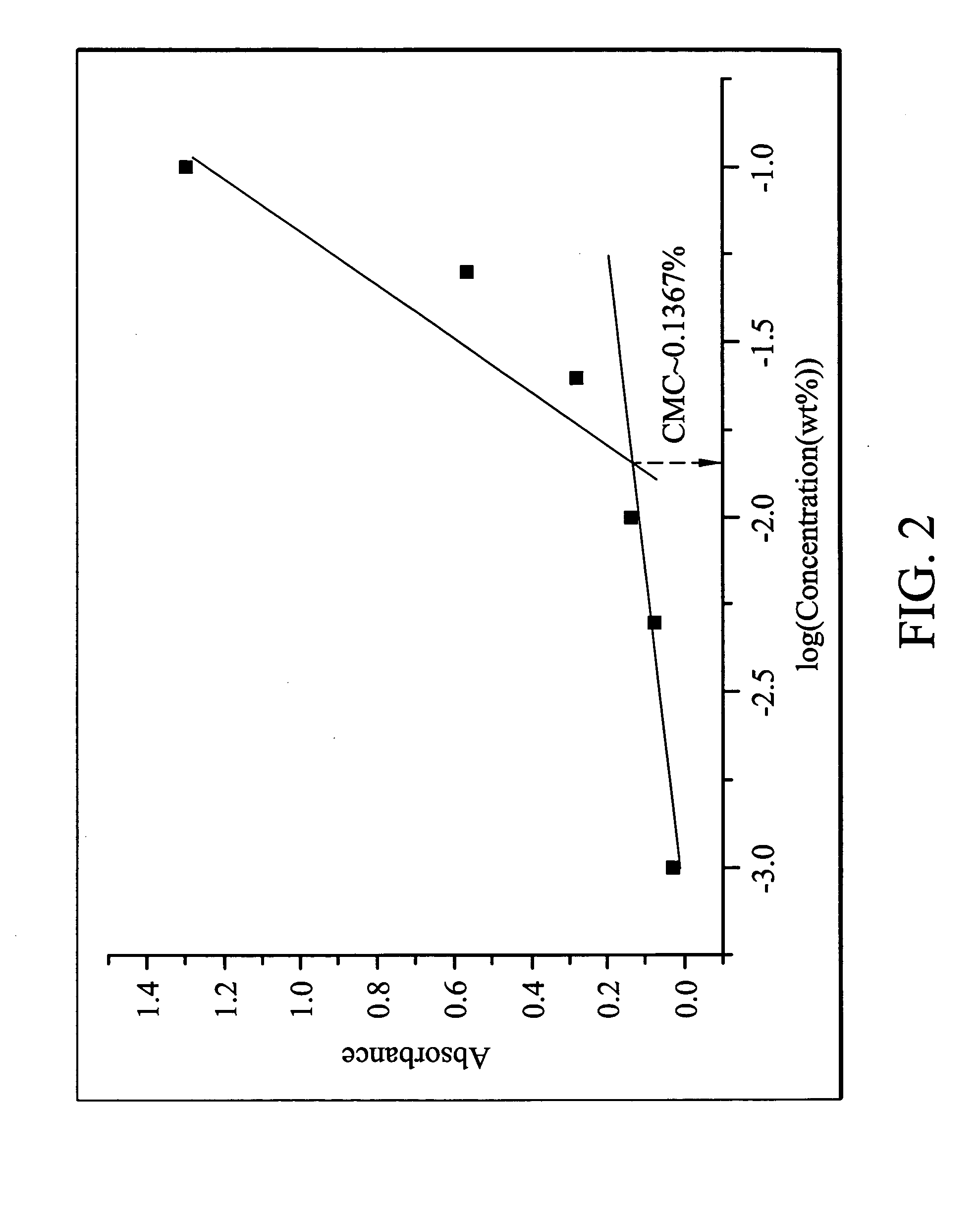

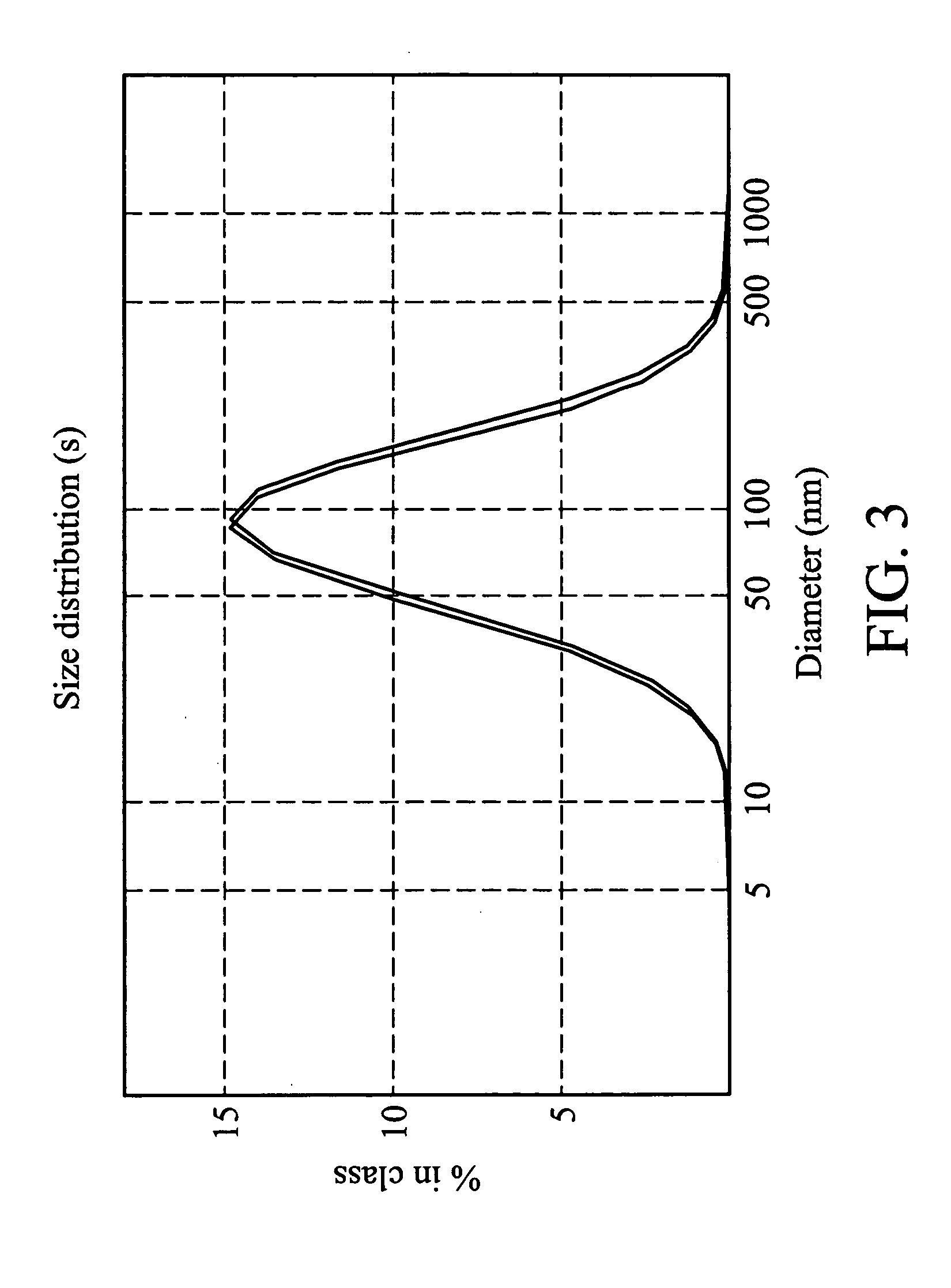

Biodegradable copolymer, and polymeric micelle composition containing the same

ActiveUS20050019303A1High molecular weightImprove hydrophobicityPowder deliverySynthetic polymeric active ingredientsPolyesterBiodegradable copolymers

A biodegradable copolymer with a core block comprising bioresorbable hydrophobic polyester segment and from 3 to 10 shell blocks comprising hydrophilic polyethylene glycol segment. The hydrophobic polyester segment and each of the hydrophilic polyethylene glycol segments are linked by a urethane linkage. A polymeric micelle composition containing the copolymer is also provided. The copolymer forms micelles when the concentration of the copolymer in a dispersing medium reaches or exceeds the critical micelle concentration. The micelles possess good drug and bioactive agent delivery characteristics and are suitable for use in drug delivery or cosmetic applications.

Owner:IND TECH RES INST

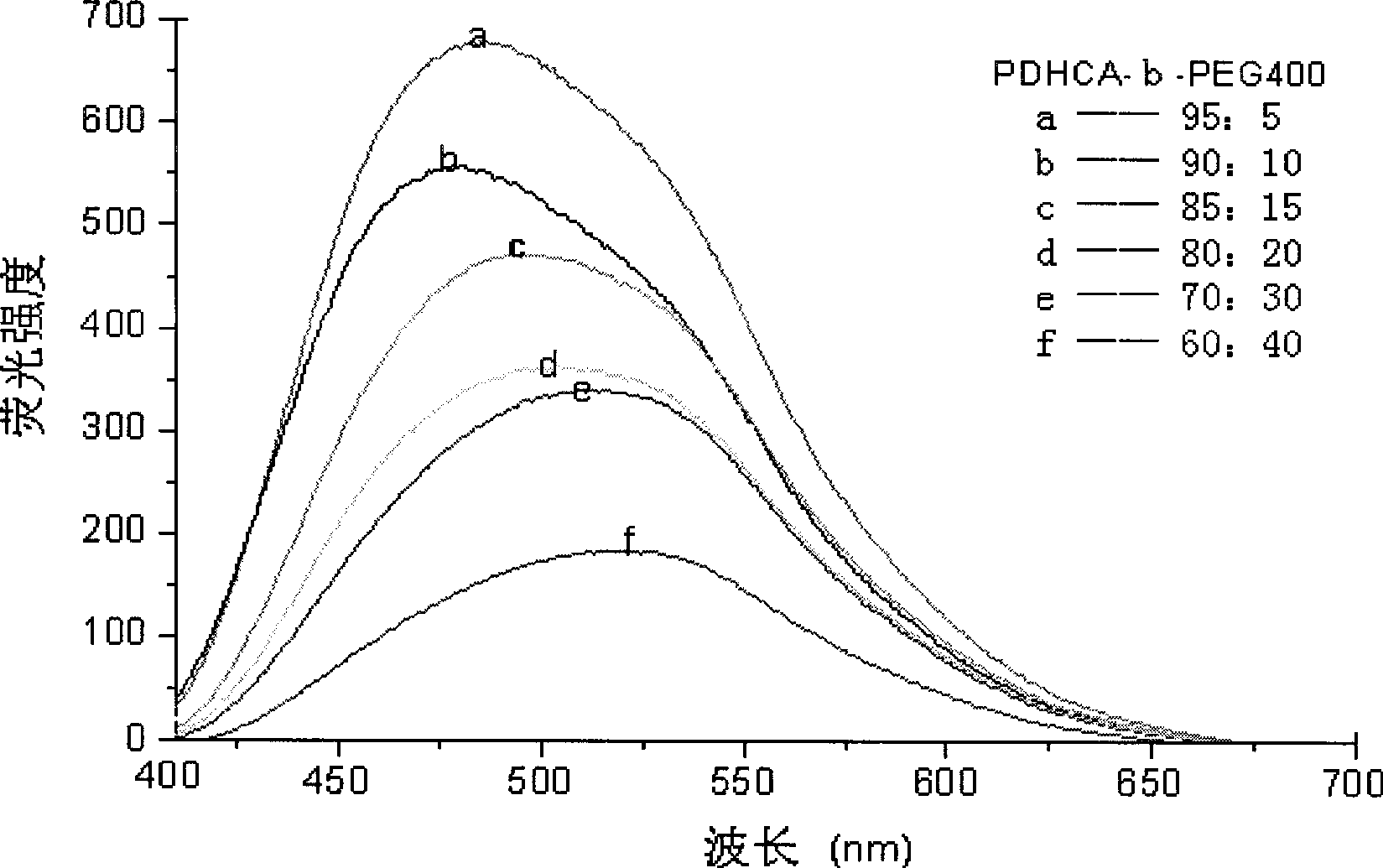

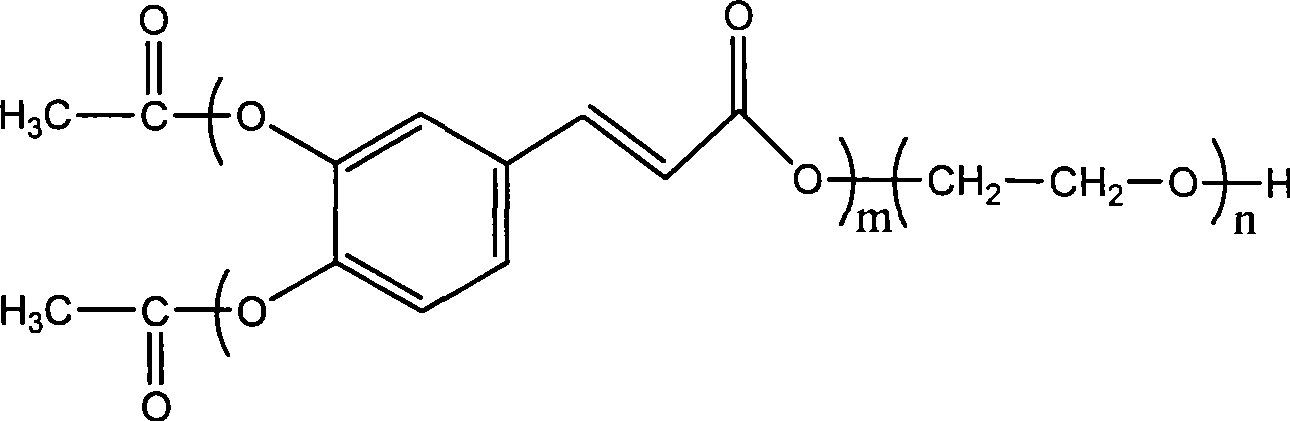

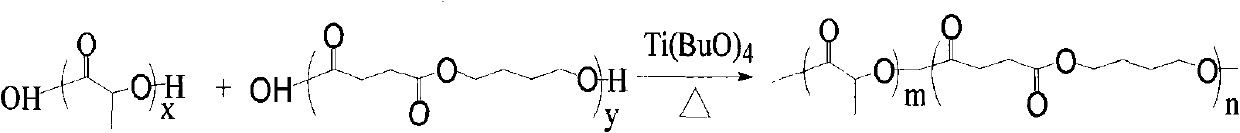

Preparation method for biodegradable fluorescent polyester multipolymer

InactiveCN101544749AMolecular weight controllableControllable glass transition temperatureSodium acetatePolyester

The invention relates to a preparation method for a biodegradable fluorescent polyester copolymer, belonging to the field of functional materials. The method comprises the following steps: using 3,4-dihydroxy cinnamic acid as a main monomer, using PEG400, PEG1000, PEG2000, PEG4000 and PEG6000 with different molecular weights, lactic acid, p-hydroxybenzoic acid or lithocholic acid as functional monomers and using sodium acetate as a catalyzer and acetic anhydride as a solvent; and adopting a two-step melting polycondensation method to obtain a caffeic acid ester copolymer with controllable molecular weight, glass transition temperature, fluorescence intensity, degradation speed, and the like so that the caffeic acid ester copolymer can be used as a degradation material or a fluorescent probe and applied to the fields of organizational projects, biological medicines, environmental protection, and the like. The invention provides a simple convenient high-efficiency method for preparing the biodegradable copolymer which has fluorescent performance.

Owner:JIANGNAN UNIV

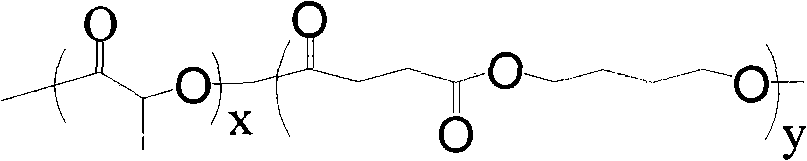

Biodegradable copolymer hydrogels

ActiveUS8211959B2High temperature sensitivityNo cytotoxicityPowder deliveryPolyesterBiodegradable copolymers

Biodegradable copolymer hydrogels are provided. The biodegradable copolymer hydrogels have a structure of Formula (I) or Formula (II)A-B—BOX—B-A Formula (I)B-A-B—(BOX—B-A-B)n-BOX—B-A-B Formula (II),wherein, A comprises a hydrophilic polyethylene glycol polymer (A); B comprises a hydrophobic polyester polymer (B); BOX is bifunctional group monomer of 2,2′-Bis(2-oxazoline) and used for coupling the blocks A-B or B-A-B; and n is an integer, equal to or greater than 0.

Owner:IND TECH RES INST

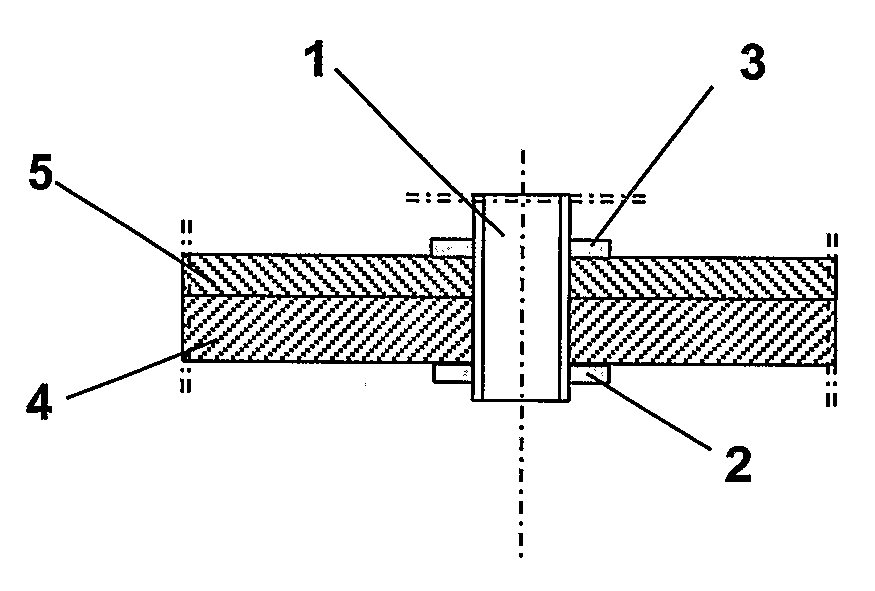

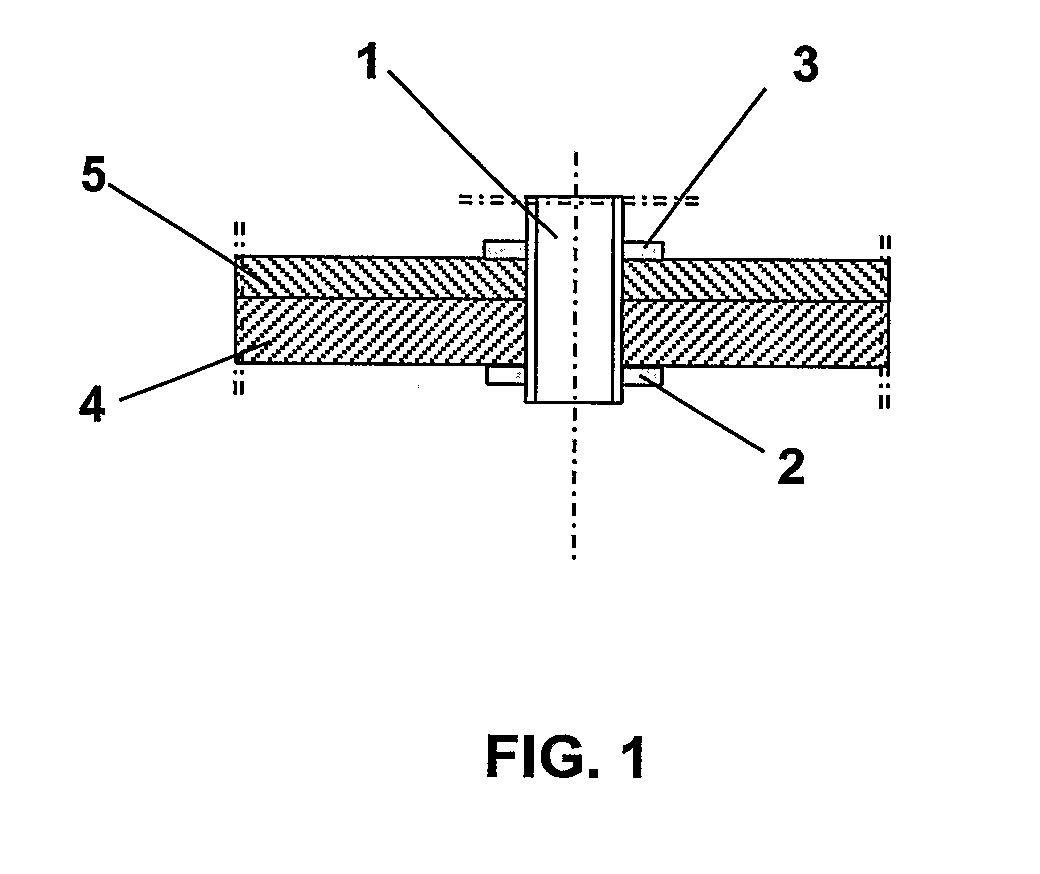

Percutaneous gastrostomy catheter including a single biodegradable internal flange

The invention relates to a percutaneous gastrostomy probe including a tube (1), an internal retaining means (2) and an external flange (3), essentially characterised in that the internal retaining means is formed by a single flange (2) made entirely from a biodegradable copolymer The type of polymers used, the dose and molar mass in number thereof and the thickness of the flange are determined so as to produce (i) a retaining means that combines flexibility and elastomer properties and (ii) a connection between the flange (2) and the tube (1), having a tearing threshold that is a function of the stoma creation time.

Owner:ELEPHENT TECH

Completely biodegradable resin made of non-staple grain plant modified starch and its preparation method

ActiveCN102408588AIncrease the amount addedHigh resource substitutionBiodegradable copolymersTemperature and pressure

The invention discloses a preparation method of a completely biodegradable resin made of non-staple grain plant modified starch. The method comprises the steps of: first putting non-staple grain plant starch into a reaction vessel, adding water to prepare it into starch milk, and heating it to a proper temperature, conducting stirring and washing, then adding chemicals into a water solution for modification grafting treatment, and then separating water and starch through centrifugation, and conveying the separated modified starch to an airflow drying system for dewatering and drying, then taking 100 parts of dried modified starch, adding 5-50 parts of a compatilizer, 2-15 parts of an anti-block agent, 0-100 parts of polylactic acid, and 150-250 parts of a completely biodegradable copolymer of dibasic acid and dibasic alcohol, and mixing them uniformly, carrying out extrusion granulating or tabletting under an appropriate temperature and pressure, thus obtaining a resin material or sheet special for complete biodegradation. The resin of the invention has both the usage function similar to ordinary plastic products and a complete biodegradability. And after being used and abandoned, the resin can be degraded into carbon dioxide and water that can be consumed by the environment.

Owner:SUZHOU HANFENG NEW MATERIAL

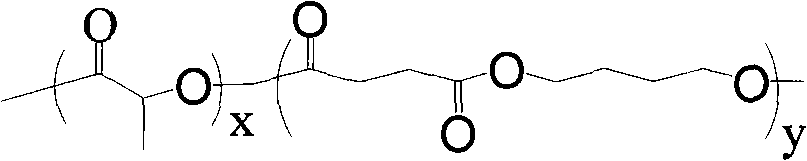

Biodegradable copolymer and preparation method thereof

InactiveCN102020773AGood physical and mechanical propertiesNo pollution in the processPolymer scienceBiodegradable copolymers

The invention discloses a biodegradable copolymer of PLA-co-PBS (Poly Lactic Acid-co-Poly Butylenes Succinate) and a preparation method thereof. The copolymer is a binary copolymer prepared through a melt polycondensation reaction of a low PBS polymer and a low PLA polymer under a catalytic system and a stabilized system. Measured by GPC (Gel Permeation Chromatography), the copolymer has the weight-average molecular weight ranging from 4.25*104 g / mol to 7.34*104 g / mol and the molecular weight distribution MW / MN ranging from 1.47 to 1.84 as well favorable physical and mechanical performance, is completely degradable and is widely applied to sheets, membranes, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

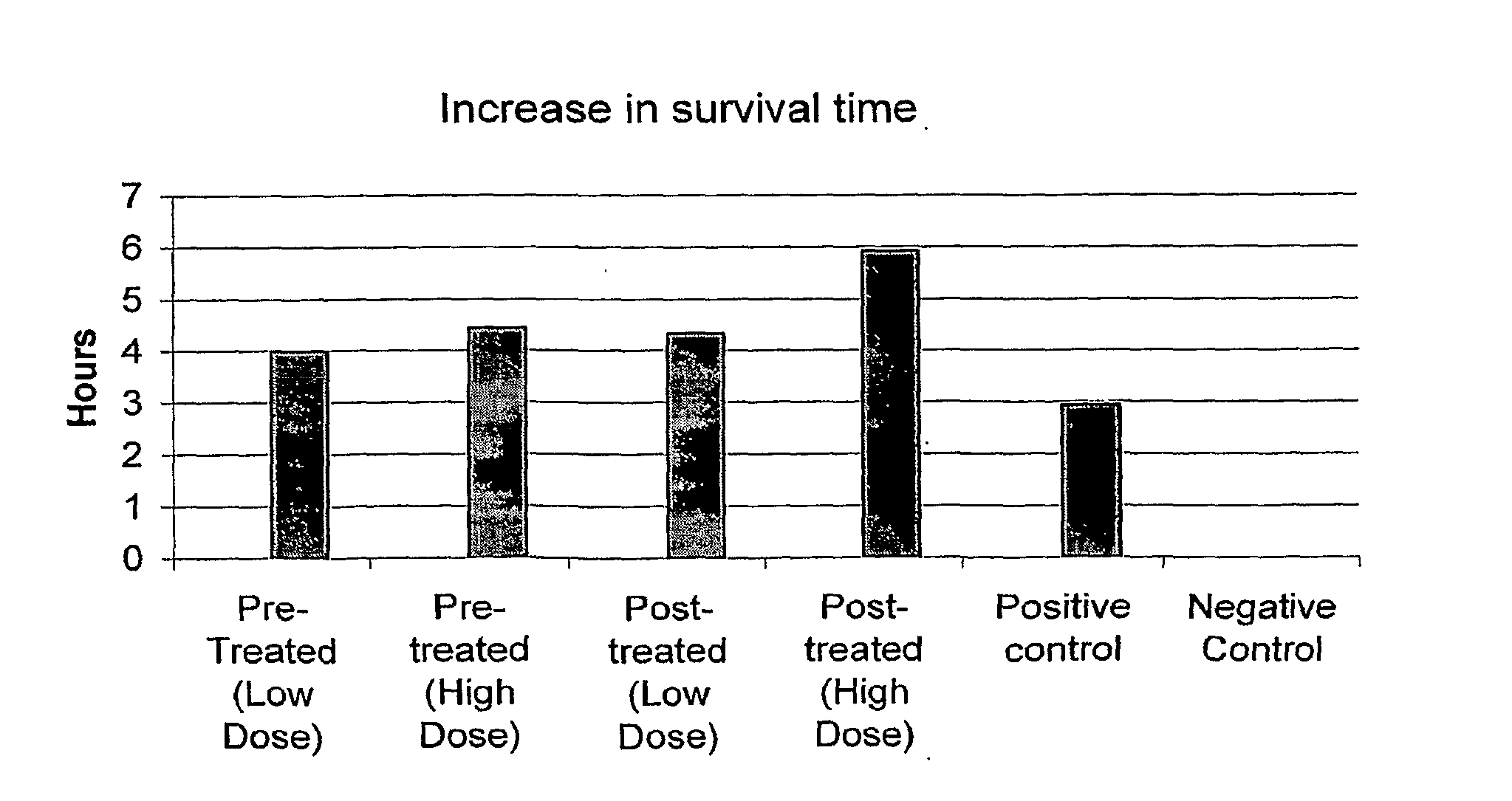

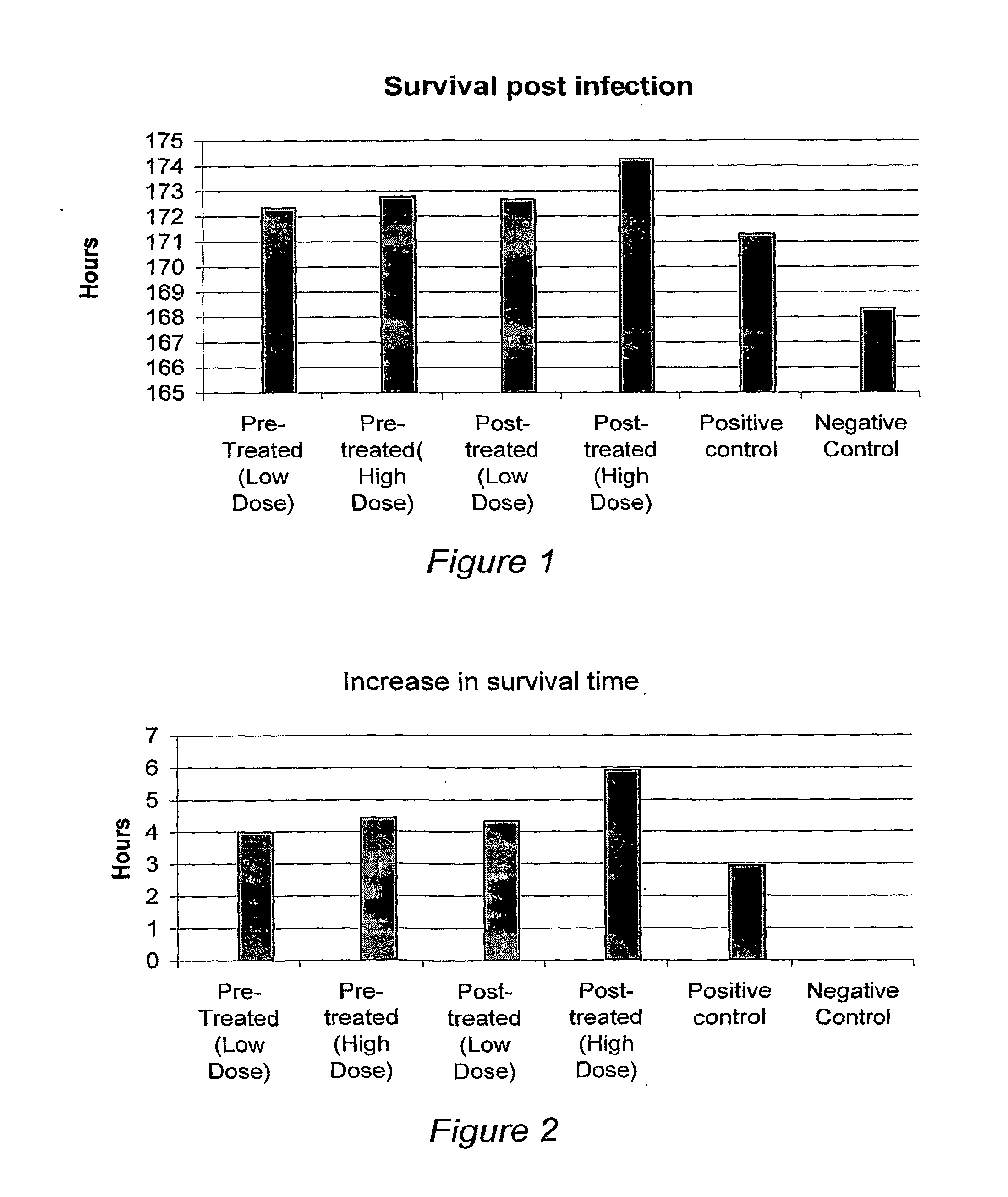

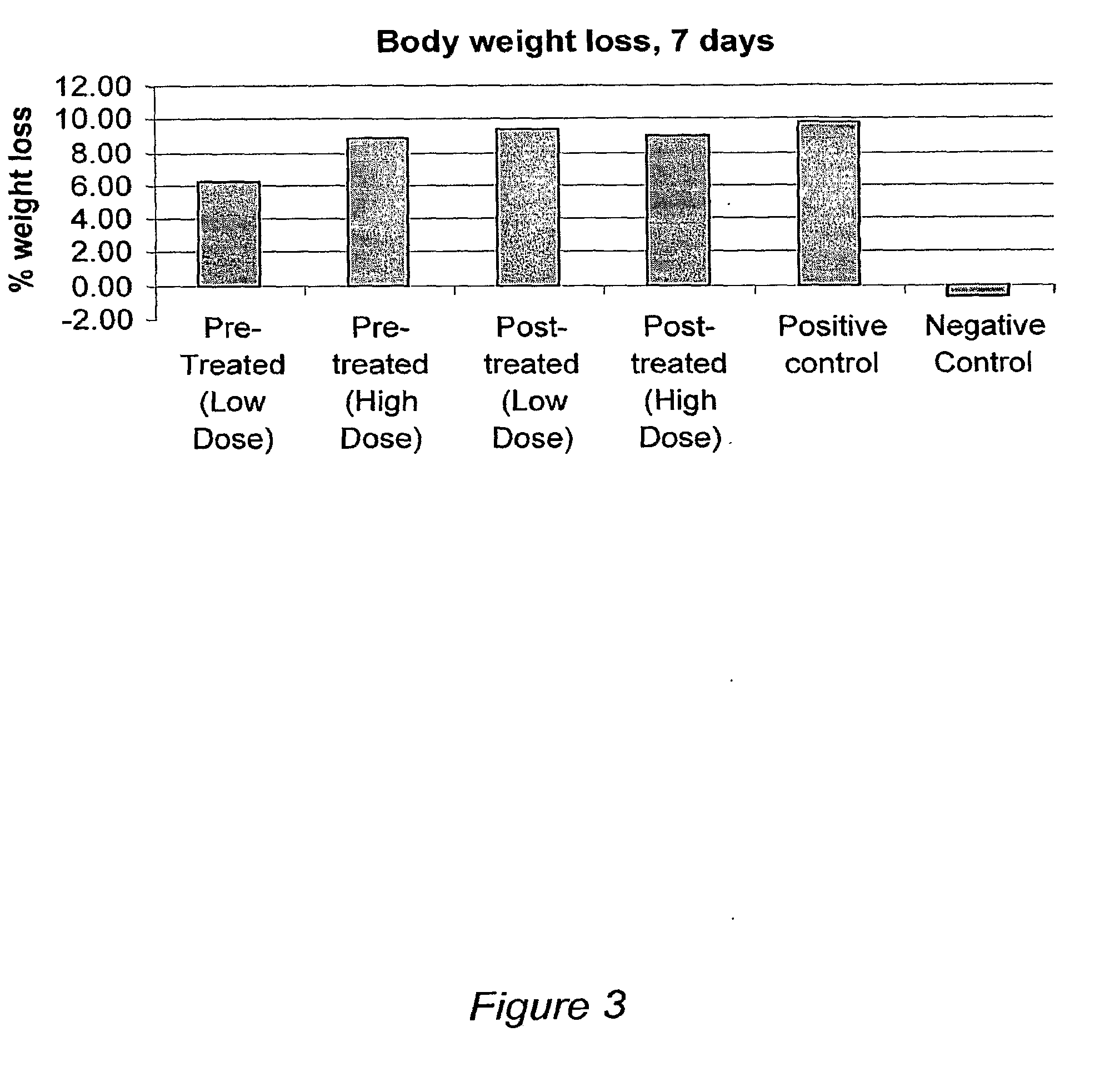

Self assembling amphiphilic polymers as antiviral agents

InactiveUS20100008938A1Inherent propertyStrong antiviral activityOrganic active ingredientsNanostructure manufactureBiodegradable copolymersBackbone chain

There are provided amphiphilic biodegradable copolymers comprising a hydrophilic backbone with pendant aliphatic groups as the hydrophobic component. The polymers form nanoscale molecular aggregates in aqueous environments, which have hydrophobic interiors that are capable of solubilizing insoluble organic compounds and disrupting viral coat proteins. The polymers optionally feature reactive functional groups that provide attachment points for antibodies, ligands, and other targeting moieties which mediate adherence of the aggregate to a viral target.

Owner:ALLEXCEL INC

Block biodegradable copolymers for medical devices

Disclosed herein are implantable medical devices comprising controlled release biodegradable block copolymers or coated with controlled release block copolymers and at least one drug releasable from the block copolymer. The controlled release block copolymers comprise least two blocks selected from the group consisting of polyesters, polyethers, and polyurethanes.

Owner:MEDTRONIC VASCULAR INC

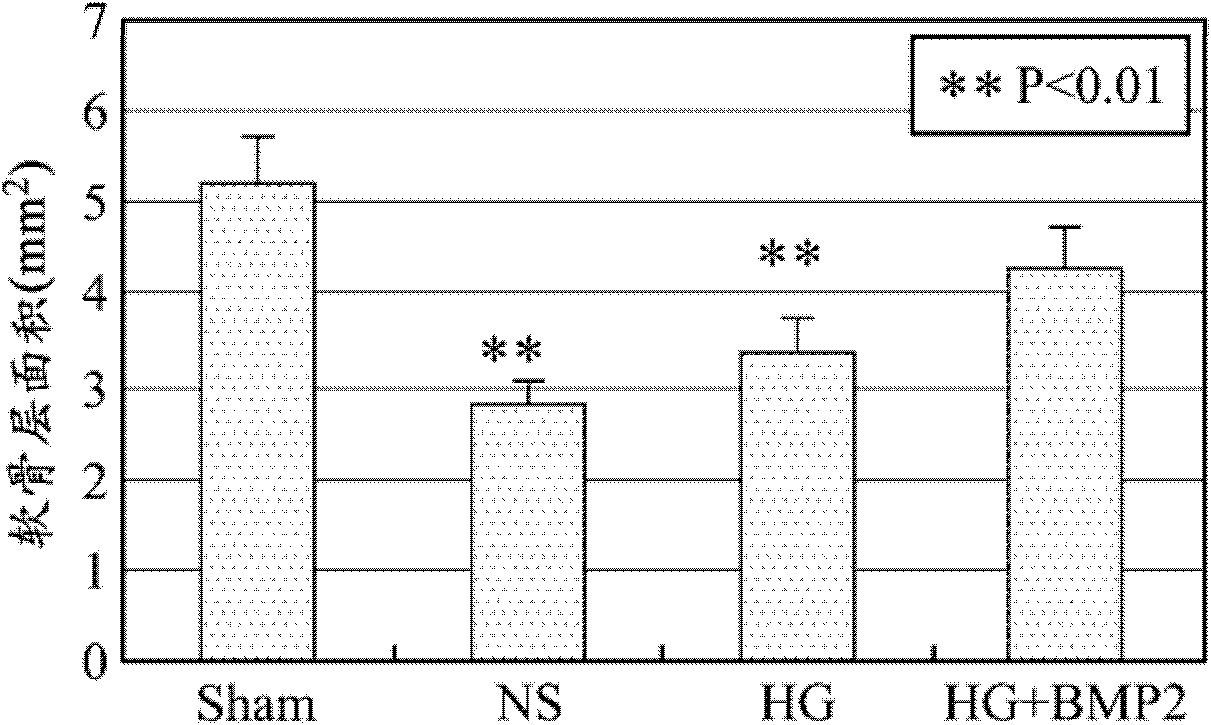

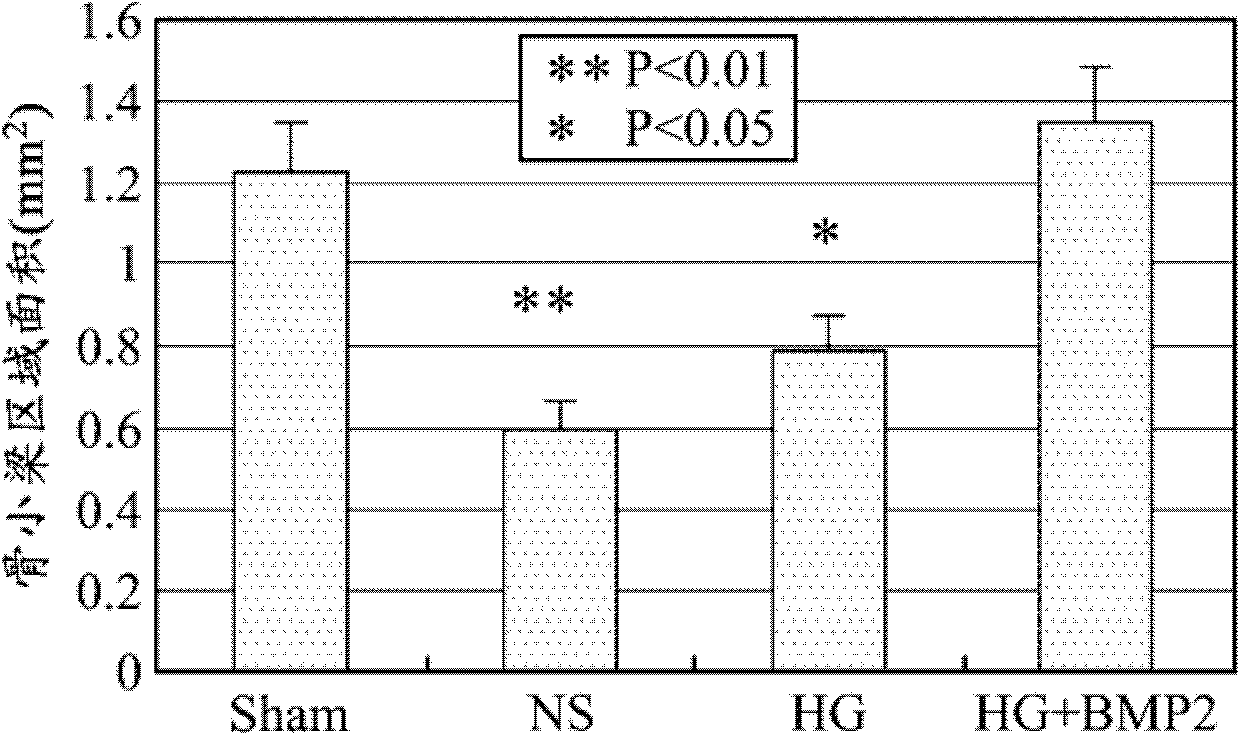

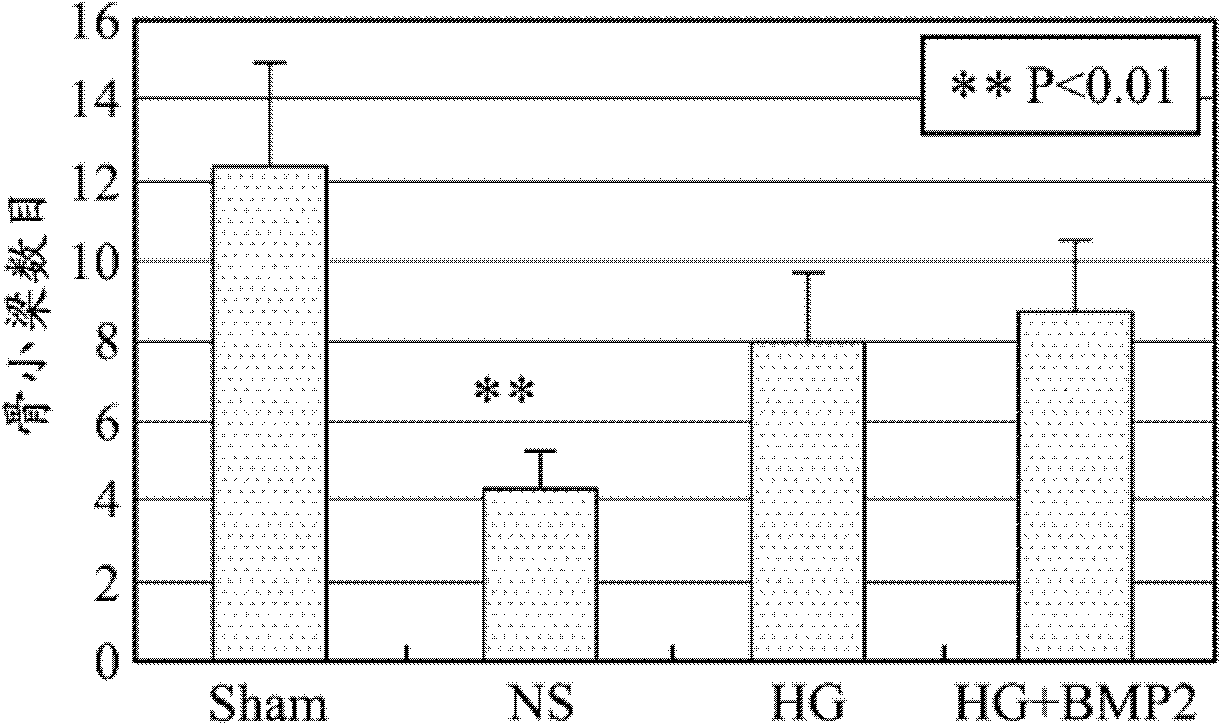

Thermal responsive composition for treating bone diseases

Thermal responsive compositions for treating bone diseases are provided. The thermal responsive composition for treating bone diseases includes a bone growth factor and a biodegradable copolymer, wherein the biodegradable copolymer is provided with an A high polymer and a B high polymer, and satisfies Formula (I) or Formula (II): A-B-BOX-B-A (Formula I) and B-A-B-(BOX-B-A-B)n-BOX-B-A-B Formula (II), wherein, A includes a hydrophilic polyethylene glycol polymer, B includes a hydrophobic polyester polymer, BOX is a bifunctional group monomer of 2,2'-Bis(2-oxazoline) and used for coupling the blocks A-B or B-A-B, and n is an integer and the same or more than 0.

Owner:IND TECH RES INST

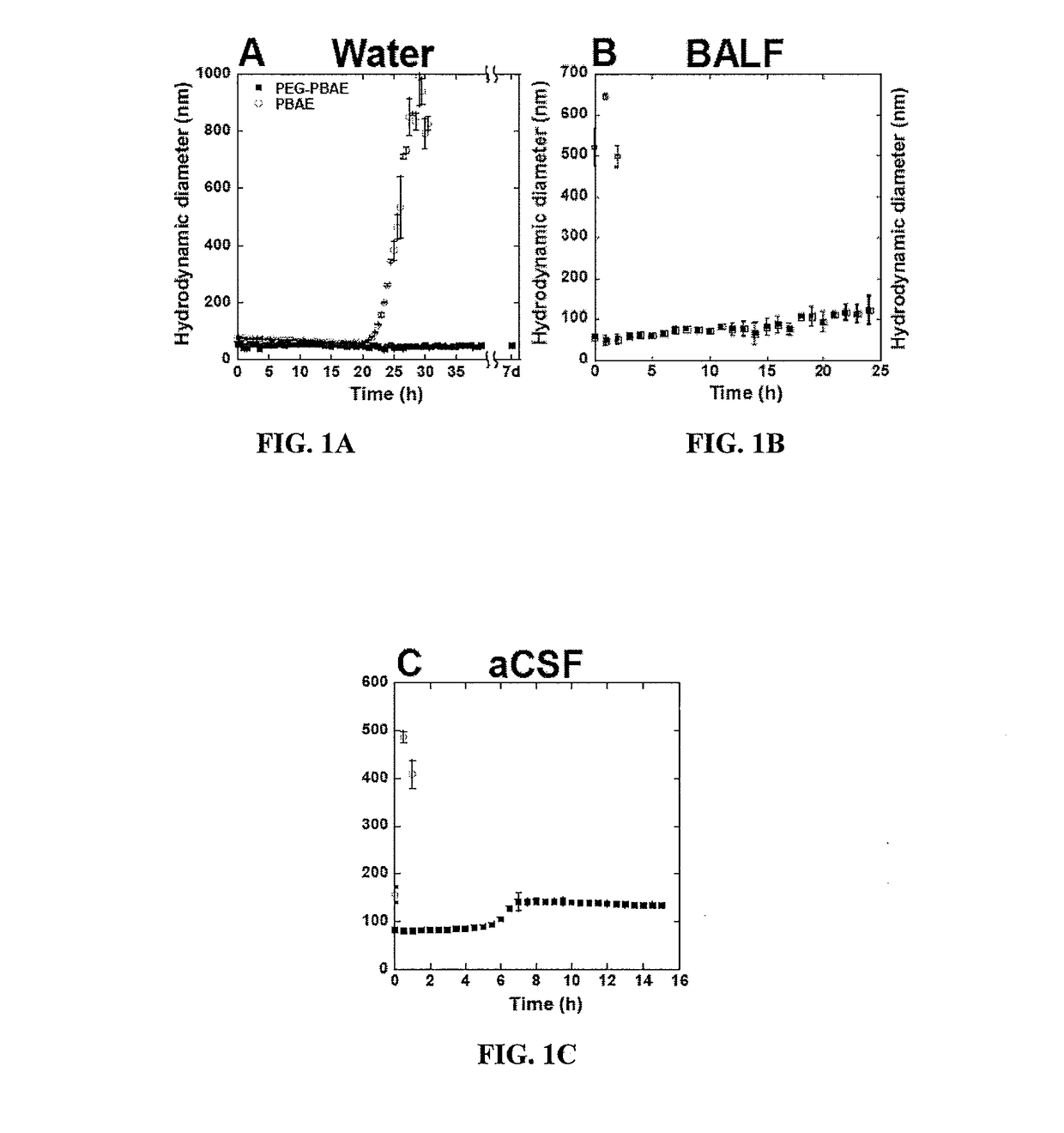

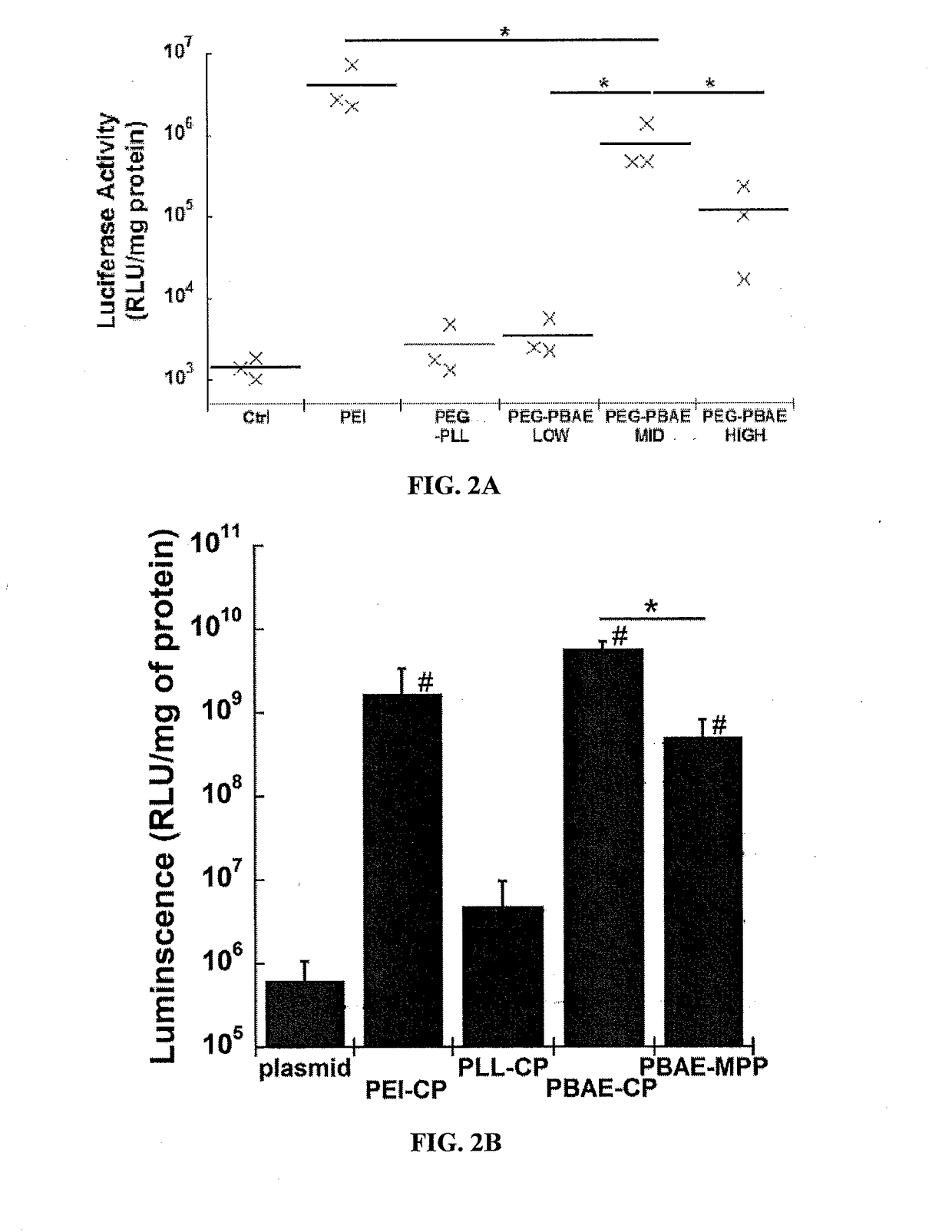

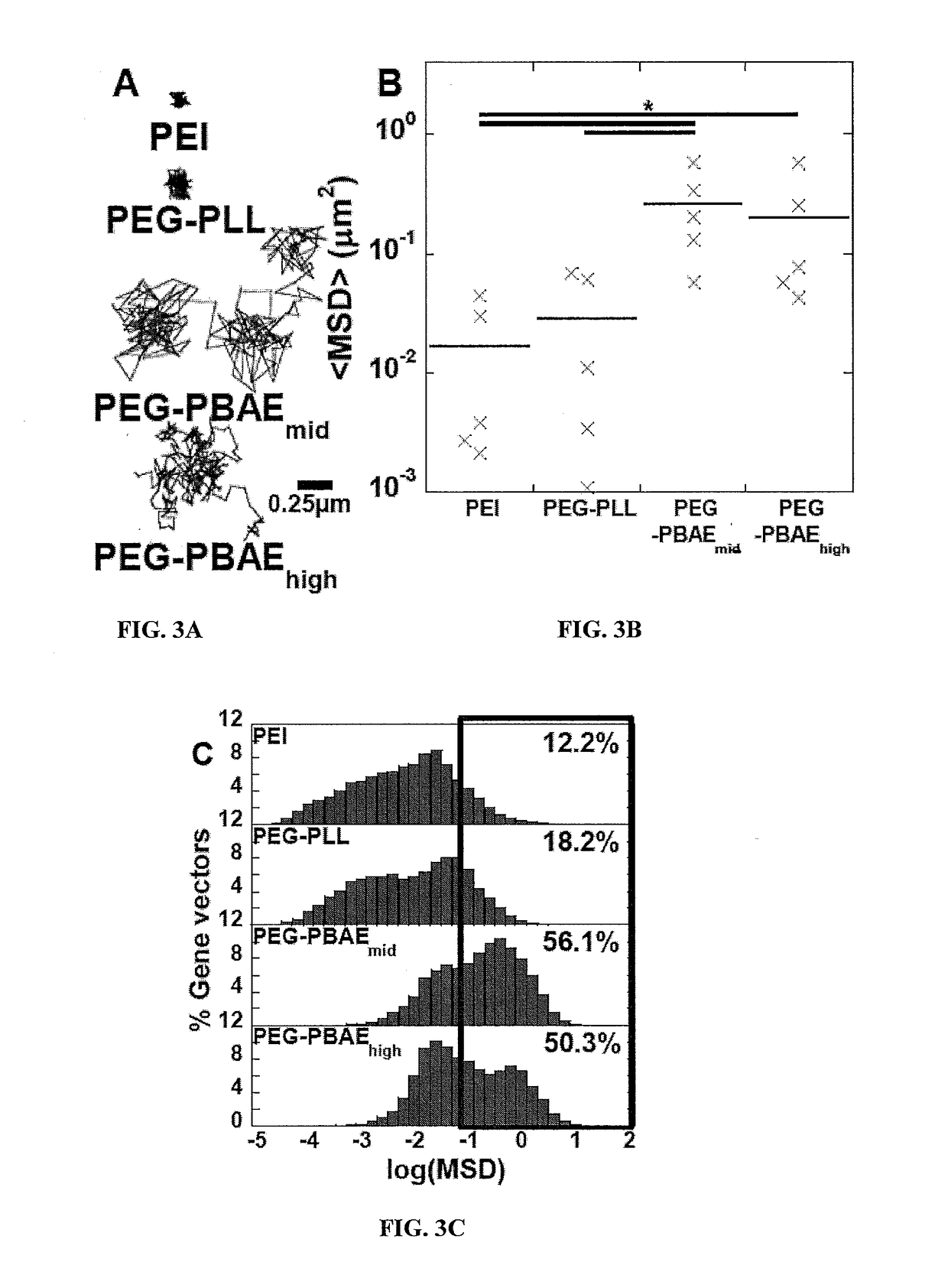

Highly stable biodegradable gene vector platforms for overcoming biological barriers

ActiveUS20170072064A1Solution stableHigh expressionPowder deliveryMicroencapsulation basedCell-Extracellular MatrixBiodegradable copolymers

A major challenge in non-viral gene delivery remains finding a safe and effective delivery system. Colloidally stable non-viral gene vector delivery systems capable of overcoming various biological barriers, are disclosed. The gene vectors are biodegradable, non-toxic and highly tailorable for use in specific applications. The vectors include a mixture of biodegradable copolymers, such as PBAE, and biodegradable polymers conjugated with hydrophilic, neutrally charged polymer, such as PEG. The gene vectors demonstrate broad vector distribution and high transgene delivery in vivo, providing an efficient non-viral gene delivery system for localized therapeutic gene transfer. Methods of using the vectors to overcome biological barriers including mucus gel and extracellular matrix are provided. Methods of formulating the vectors are also provided.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com