Patents

Literature

920 results about "Biodegradable plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable plastics are plastics that can be decomposed by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. Biodegradable plastics are commonly produced with renewable raw materials, micro-organisms, petrochemicals, or combinations of all three.

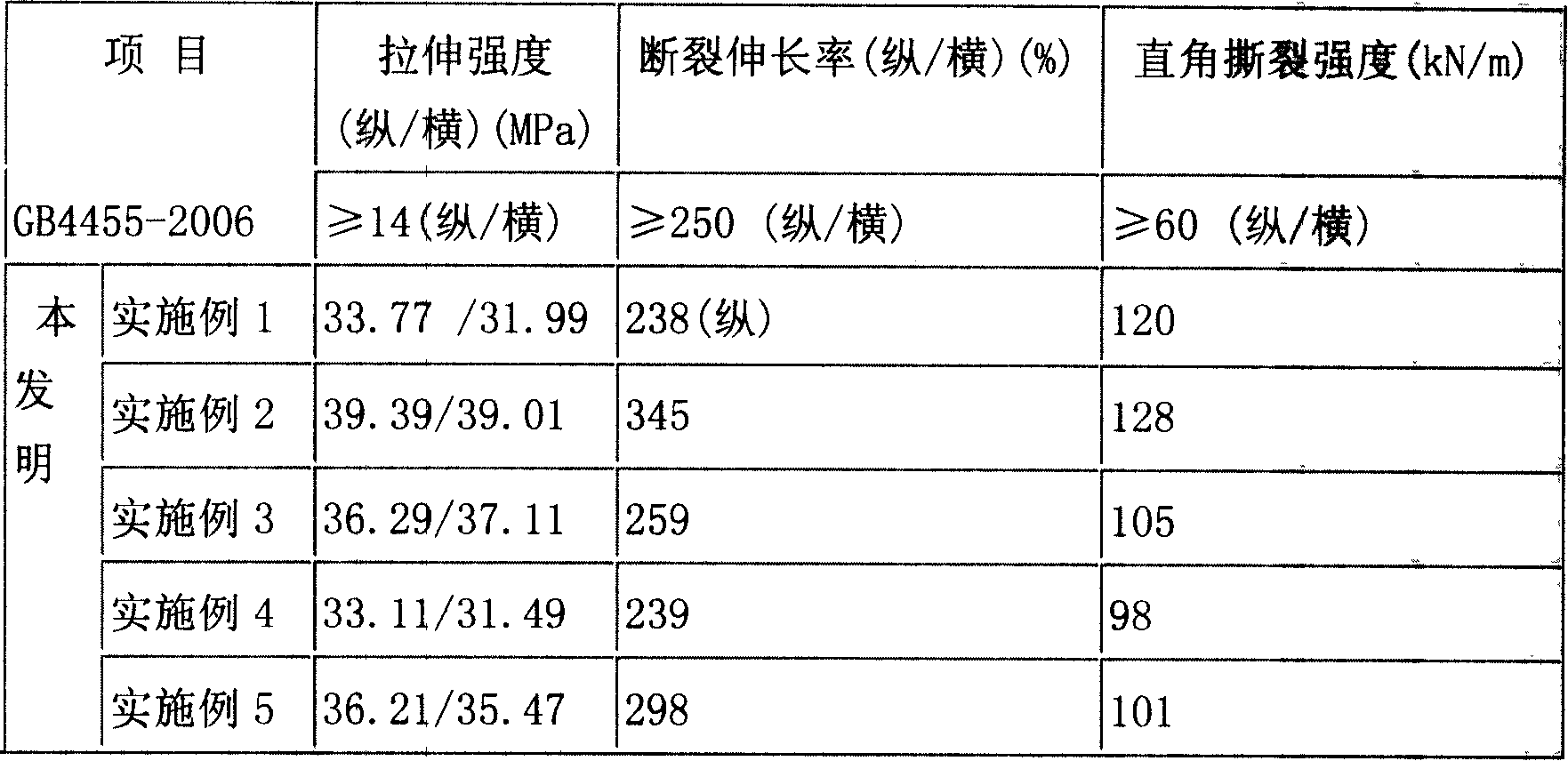

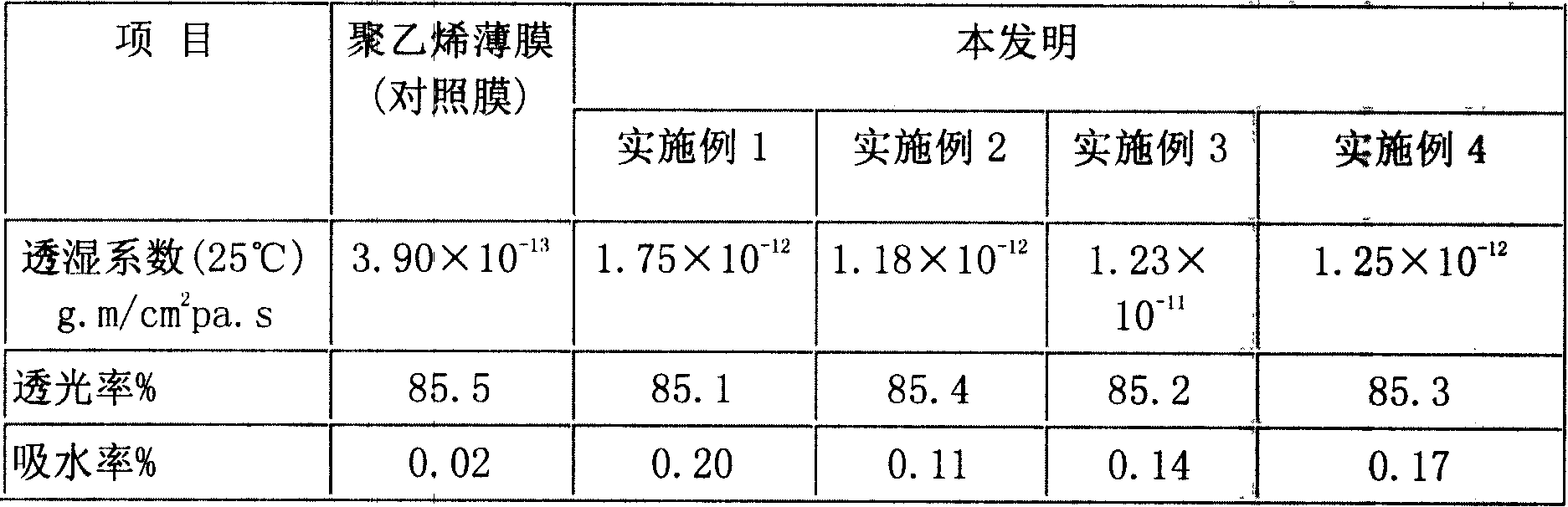

Total-biodegradation plastic film and preparation method thereof

InactiveCN101240086AQuality improvementImprove performanceFlat articlesPlastic filmMechanical property

A full-biodegradable plastic membrane, which uses thermoplastic starch with diameter of 1-9 mu m, biodegradable polymer and auxiliary component as raw material, processed by screw extruding apparatus and membrane producing apparatus. The raw material comprises 30-70 parts by weight of thermoplastic starch with diameter of 1-9 mu m, 10-40 parts by weight of biodegradable polymer, 5-10 parts by weight of compatible modified component, 3-5 parts by weight of complex plasticized component, 10-30 parts by weight of lubricant. These materials are mixed and processed by screw extruding apparatus and membrane producing apparatus, wherein the lubricant is at least adding into other materials for mixture before process by screw extruding apparatus and during melt blending, and the adding amount of lubricant before process by screw extruding apparatus is not more than 1 / 3 of the total amount thereof. By highly increasing dosage of lubricant and changing mixing way, thermoplastic degree of starch is increased, rheological property of the system and processing quality of product are dramatically improved, mechanical property of the product is enhanced.

Owner:上海悦仕生物材料有限公司 +1

Fully degradable polylactic acid sheet material with high strength and high-temperature resistance, and preparation method thereof

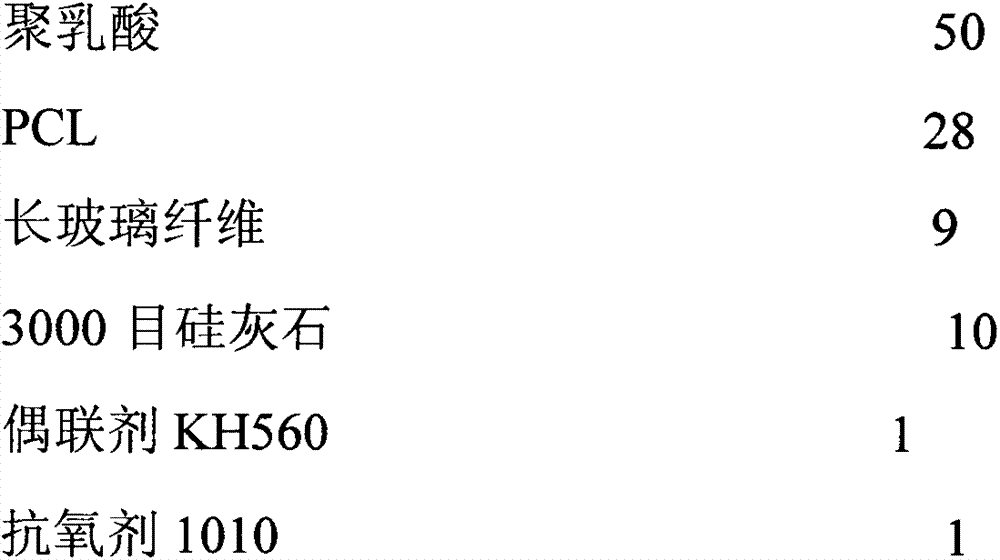

The invention discloses a fully degradable polylactic acid sheet material with high strength and high-temperature resistance, and a preparation method thereof. The preparation method of the fully degradable polylactic acid sheet material comprises following steps: by mass, 50 to 78% of polylactic acid, 10 to 30% of a flexibilizer, 10 to 30% of an inorganic filling material, and 1 to 3% of other auxiliary agents are mixed uniformly; a mixed master batch is prepared by an extruder; and then the fully degradable polylactic acid sheet material is obtained using the extruder. According to the preparation method, polylactic acid is taken as a basic resin material, a fully biodegradable plastic with excellent flexibility is taken as the flexibilizer, the inorganic filling material is taken as a reinforcing agent, the other auxiliary agents comprise a coupling agent, an antioxidant, a lubricant and the like, so that heat resistance and toughness of polylactic acid are improved. The fully degradable polylactic acid sheet material can be used in packaging fields of foodstuff, cosmetic and electronic product. Compared with traditional petroleum based high-molecular materials, the fully degradable polylactic acid sheet material is friendly to the environment, and the base material is renewable; compared with common polylactic acid materials, the fully degradable polylactic acid sheet material possesses excellent toughness and heat resistance.

Owner:深圳市江之源实业有限公司

Biodegradable nanometer filling function master batch and preparation method and application thereof

The invention relates to a biodegradable nanometer filling function master batch and a preparation method and application thereof, and belongs to the technical field of biodegradable plastic master batch preparation.The master batch is prepared from, by weight, 10-50 parts of biodegradable polyester, 40-80 parts of nanometer filler, 1-5 parts of dispersing agent, 1-5 parts of lubricant, 0.5-2.5 parts of coupling agent and 0.1-0.5 part of antioxidant.Mixing and plasticizing are conducted through an internal mixer, and extruding and die surface hot cutting are conducted through a single-screw extruder to obtain the biodegradable nanometer filling function master batch.The master batch is prepared with biodegradable polyester as the carrier and nanoscale powder as the filler and with the aid of various additives; on one hand, the compatibility and dispersity of the master batch and biodegradable plastic are improved, and the processing performance and processing environment of the material are improved; on the other hand, by introducing nanometer filler and adding the master batch to biodegradable plastic, the mechanical property of biodegradable plastic products can be improved, production cost can be reduced, and environment pollution is reduced.

Owner:JIANGXI PINGXIANG XUANPIN PLASTIC PROD CO LTD

Biodegradable supertough polylactic acid (PLA) blend material and preparation method thereof

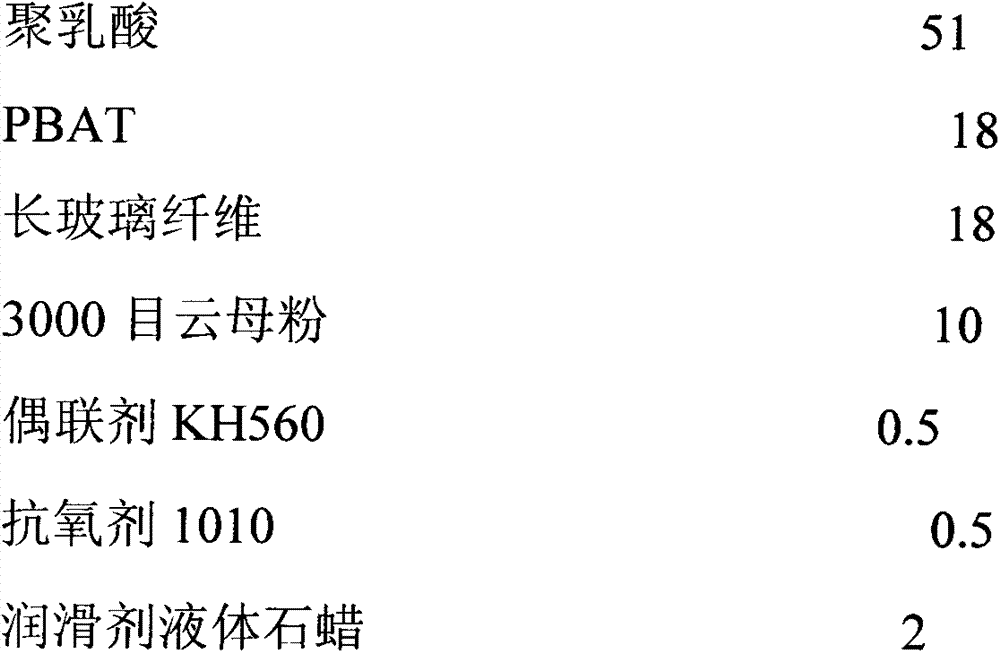

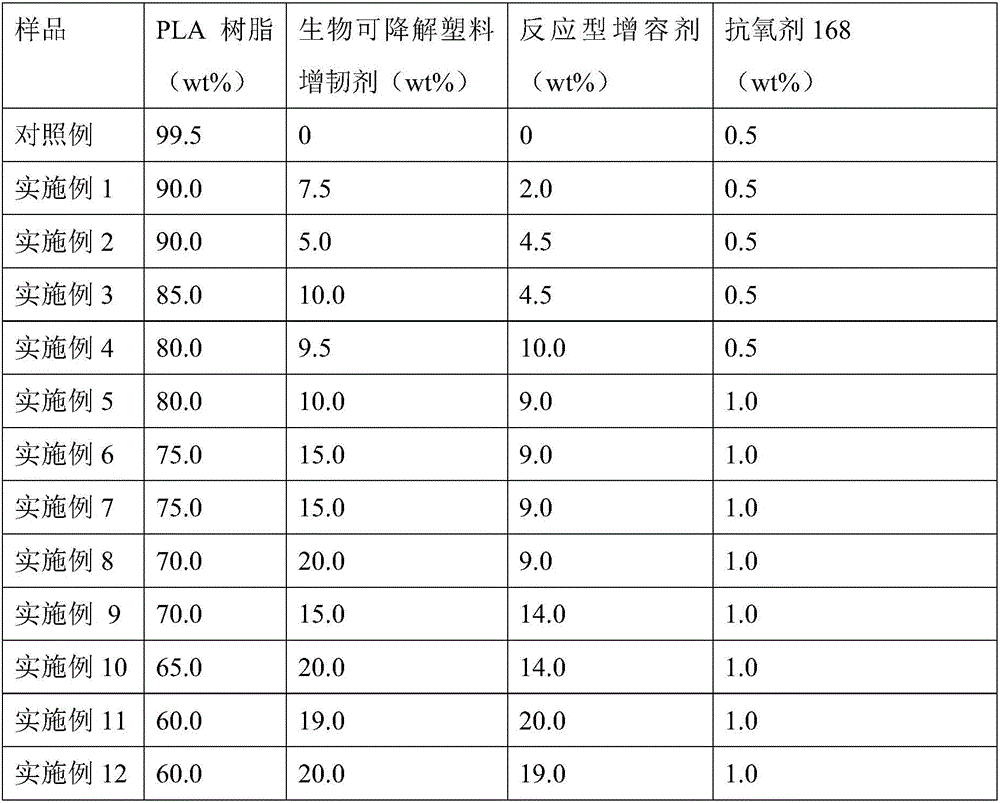

The invention relates to a biodegradable supertough polylactic acid (PLA) blend material which is mainly composed of 60.0-90.0 wt% of PLA resin, 5.0-20.0 wt% of biodegradable plastic toughener, 2.0-20.0 wt% of reactive compatibilizer and 0.2-1.0 wt% of antioxidant. Fusion reaction blending is carried out to prepare the supertough PLA three-element blend material, thereby greatly enhancing the impact property and ductility of the PLA. The biodegradable supertough PLA blend material has the advantages of excellent impact strength and excellent elongation at break, does not greatly influence the bending strength and tensile strength of the PLA, and can be used in the fields of packaging, automobile industry and the like.

Owner:QINGDAO UNIV OF SCI & TECH

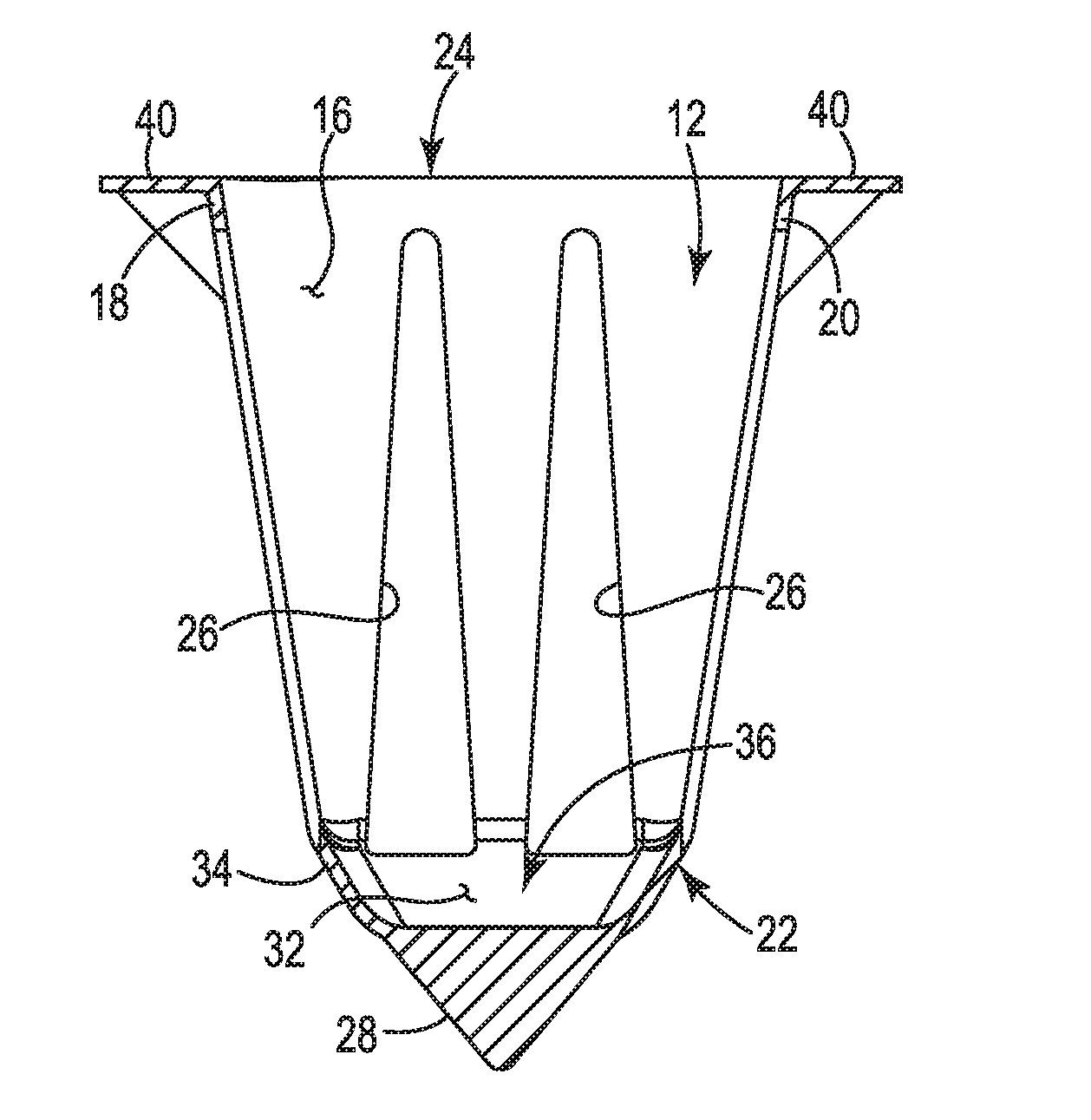

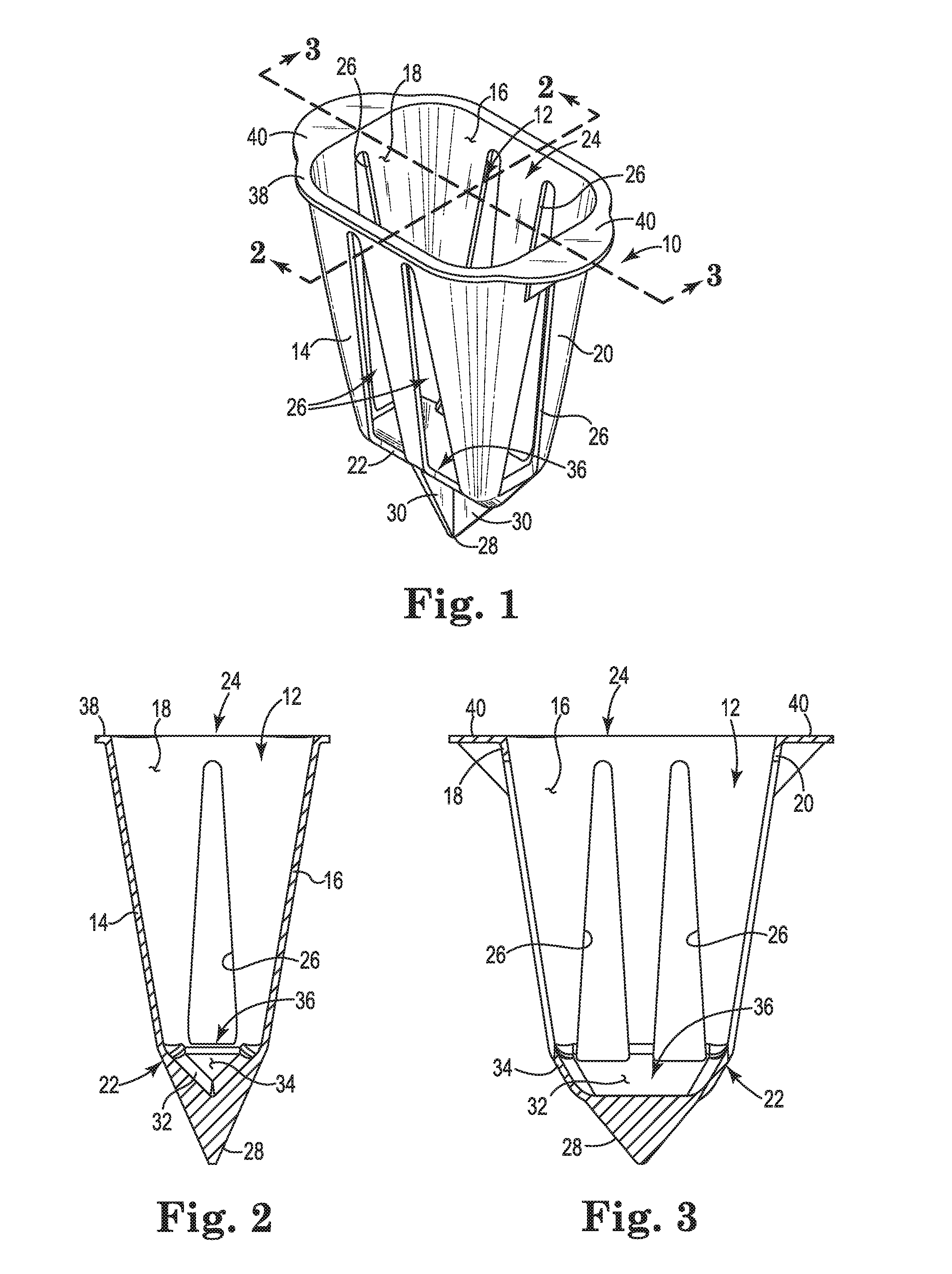

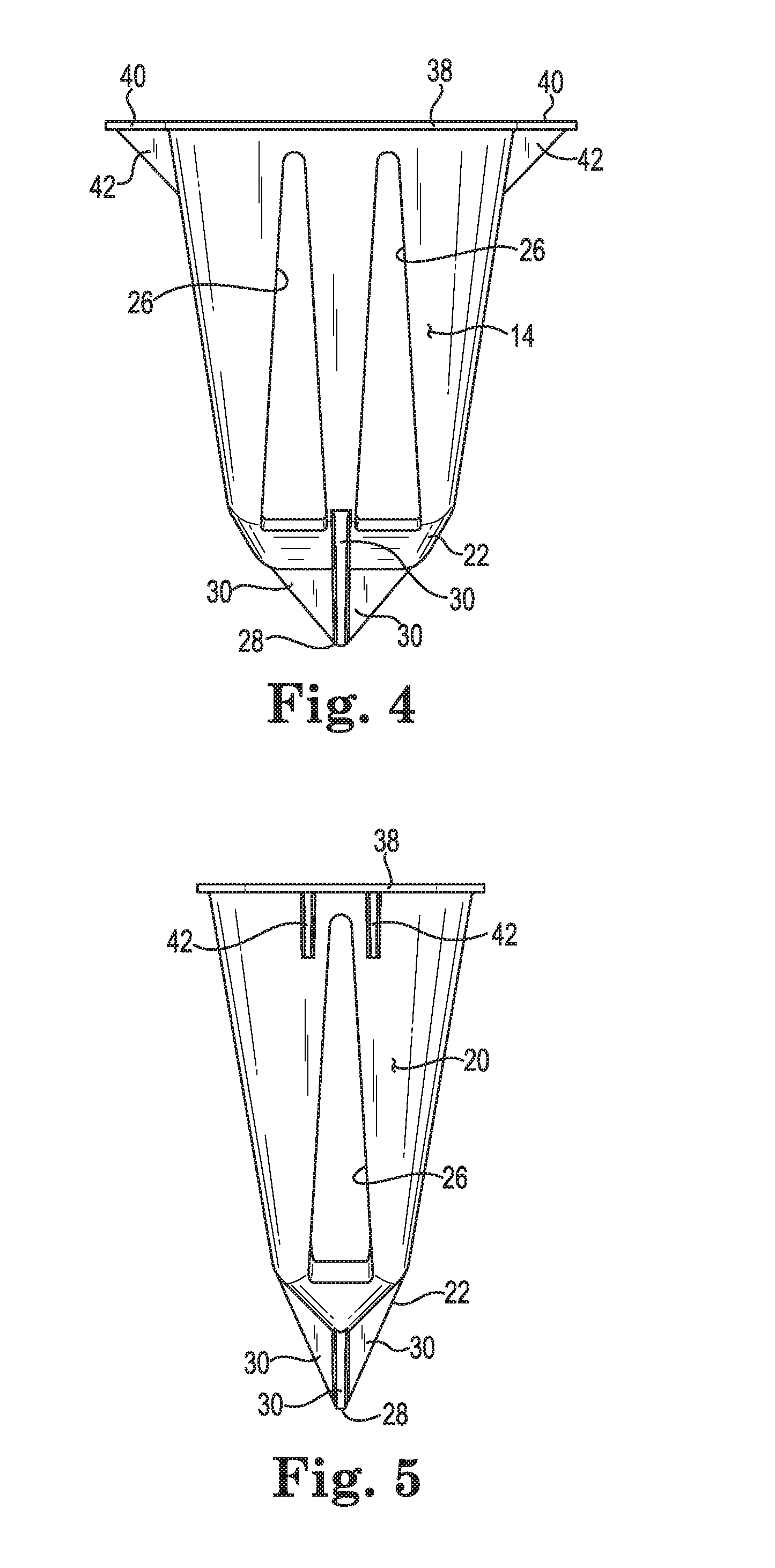

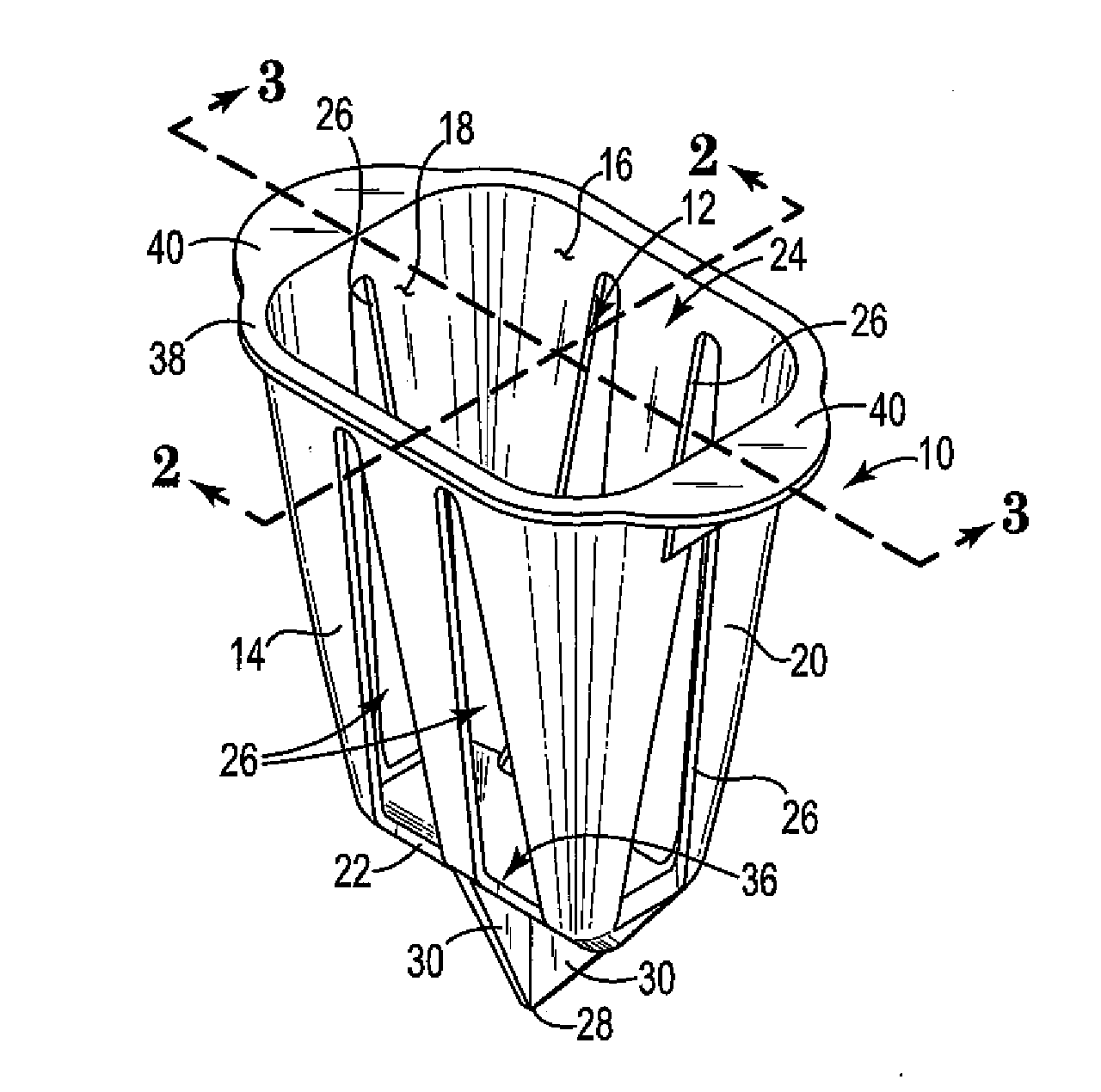

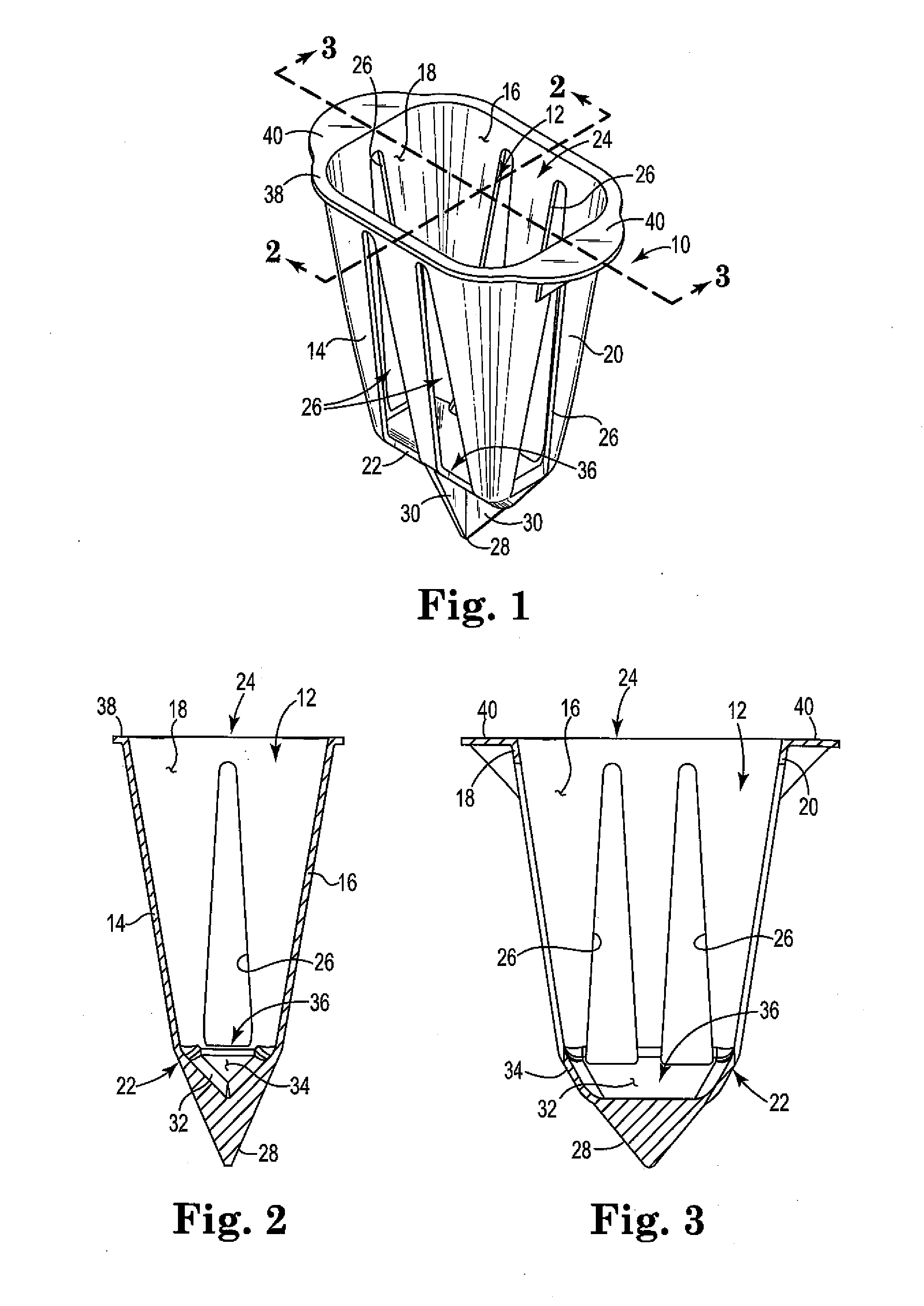

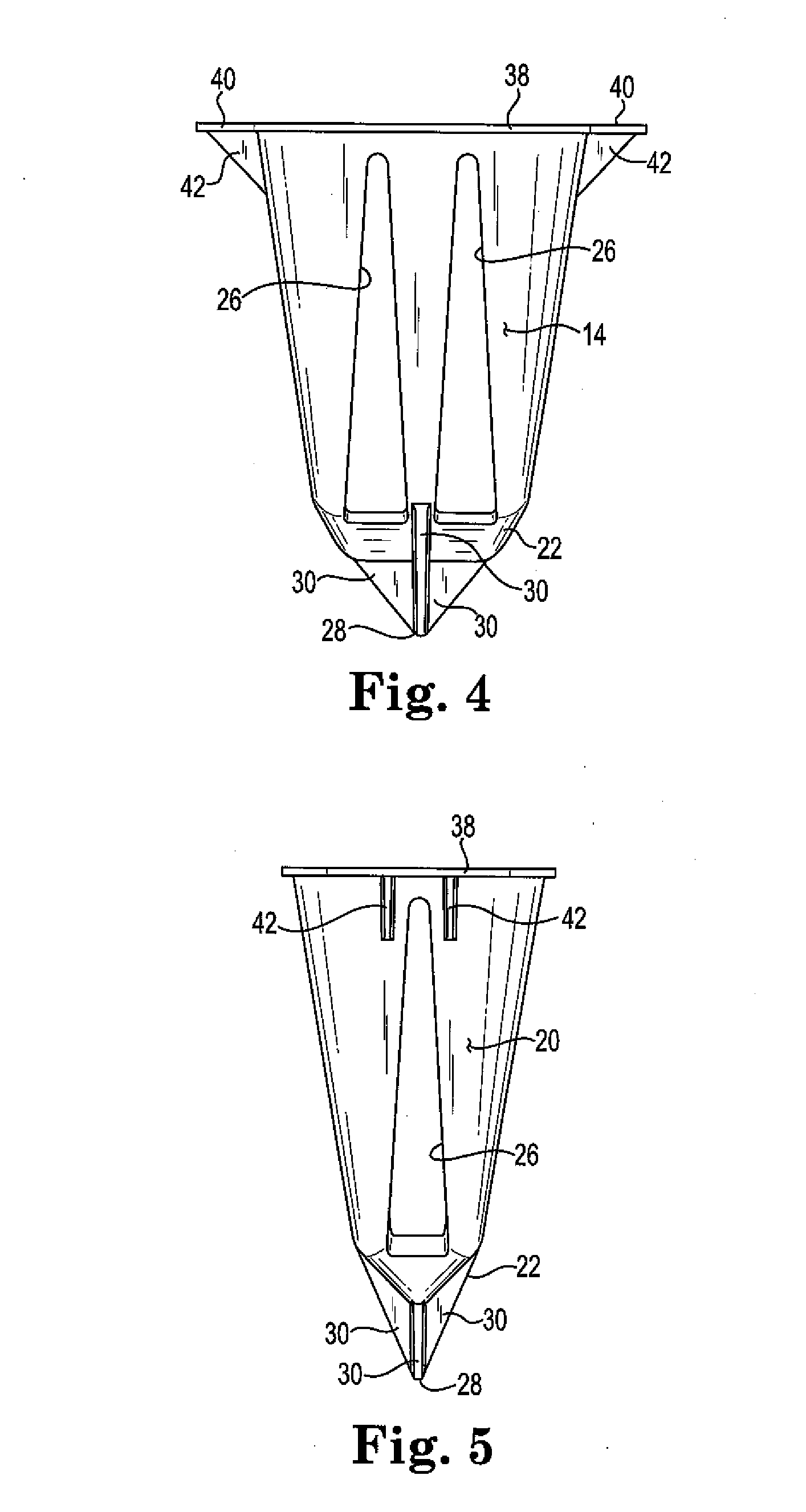

Biodegradable horticulture container

ActiveUS20160174470A1Decrease containment volumeProvide nutritionCultivating equipmentsReceptacle cultivationTime aspectEngineering

The containment of plants and seedlings as such plants or seedlings are grown, transported, displayed and planted is provided. Containers are comprised of biodegradable materials that have the advantage of being formed into containers with various features, such as by an injection molding process, but that can be buried within the soil along with a plant's roots. Such containers allow for plant or seedling transplanting without having to separate the container from the plant's root system. More preferably, biodegradable plastics utilized in accordance with the present invention have properties such that the plastic can be injection molded and yet provide a stable structural container that will last in accordance with predetermined set needs, which needs may include environmental aspects, timing aspects and decompositional aspects. By utilizing injection molding, containers can be formed with many advantageous features.

Owner:SELFECO LLC

Biodegradable plastic composition and producing method thereof

InactiveUS20050288399A1Simple chemical compositionEasy to makePaper coatingCoatingsSynthetic resinAlkene

A biodegradable plastic composition is provided. The biodegradable plastic composition includes a starch in a range from about 25% to about 50% by weight of the composition, a synthetic biodegradable resin in a range from about 10% to about 40% by weight of the composition, a synthetic resin with linear alkenes in a range from about 5% to about 15% by weight of the composition, an affinity agent in a range from about 8% to about 20% by weight of the composition, a coupling agent in a range from about 1% to about 3% by weight of the composition, and an additives in a range from about 1% to about 15% by weight of the composition. Further, a producing method of the biodegradable plastic also is provided.

Owner:CHEN MING TUNG

Green biodegradable plastic film and processing technology thereof

The invention discloses a green biodegradable plastic film. The green biodegradable plastic film is prepared from, by weight, 60-70 parts of butylene polyadipate / terephthalate, 20-30 parts of polylactic acid, 16-24 parts of modified starch, 4-7 parts of a reinforcing filler, 5-8 parts of a plasticizer, 2-3 parts of a lubricant and 1-2 parts of a light stabilizer. The invention also discloses a processing technology of the green biodegradable plastic film. The butylene polyadipate / terephthalate and polylactic acid, adopted as the matrix in the invention, are completely biodegradable plastics, are green and environmentally friendly, and are mixed according to a certain ratio to form a film matrix, so the respective defects are compensated, and the mutual complementation of the mechanical performances and the barrier performance is achieved; addition of the proper amount of the modified starch can improve the mechanical properties of the film and obtain the completely degraded plastic ofPBAT; and the strength and the barrier property of the film can be improved under the assistance of a tiny amount of the reinforcing filler in order to obtain the green biodegradable plastic film withexcellent performances.

Owner:谷水英

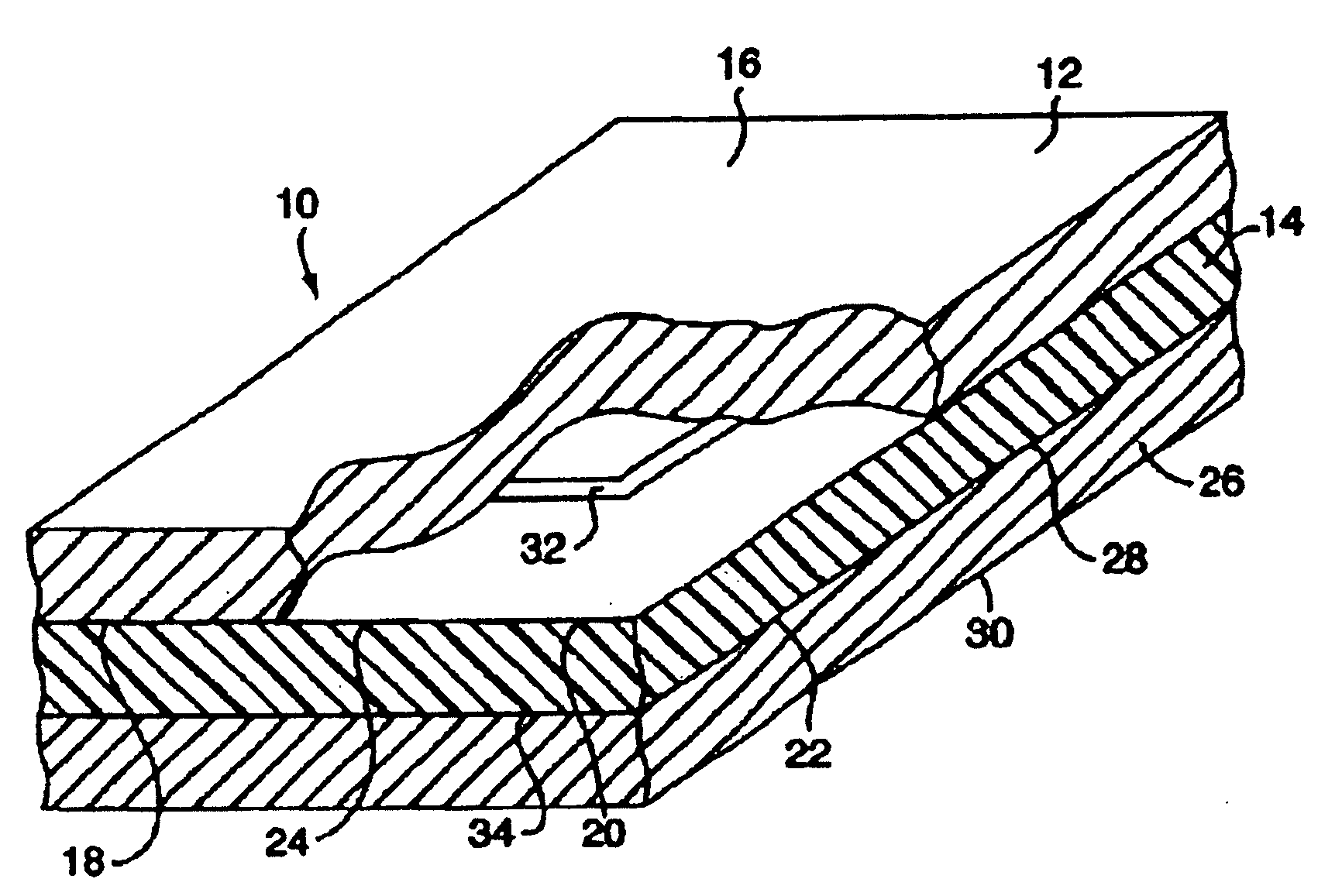

Biodegradable molded article, manufacturing method thereof, and composition for expansion molding

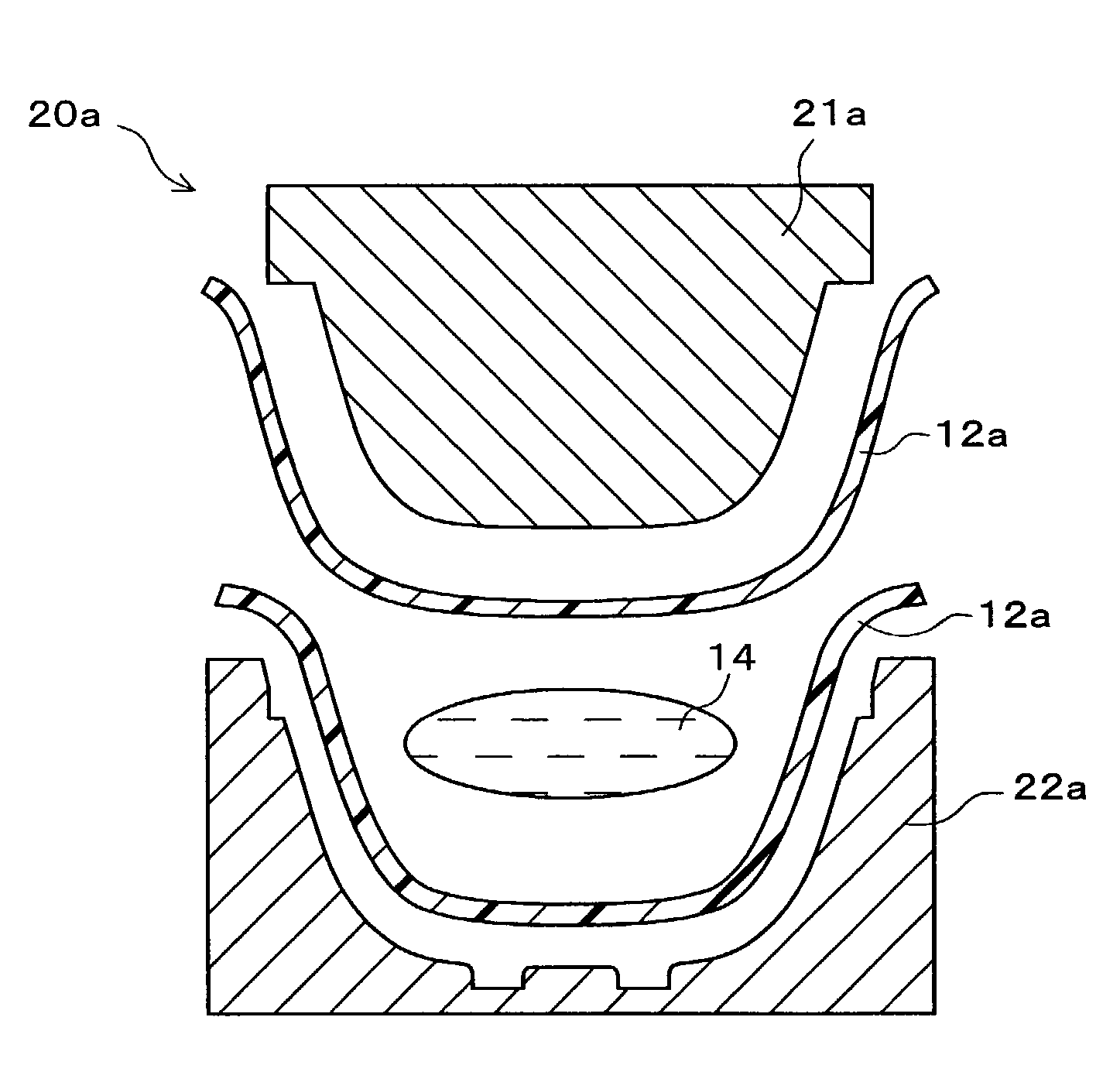

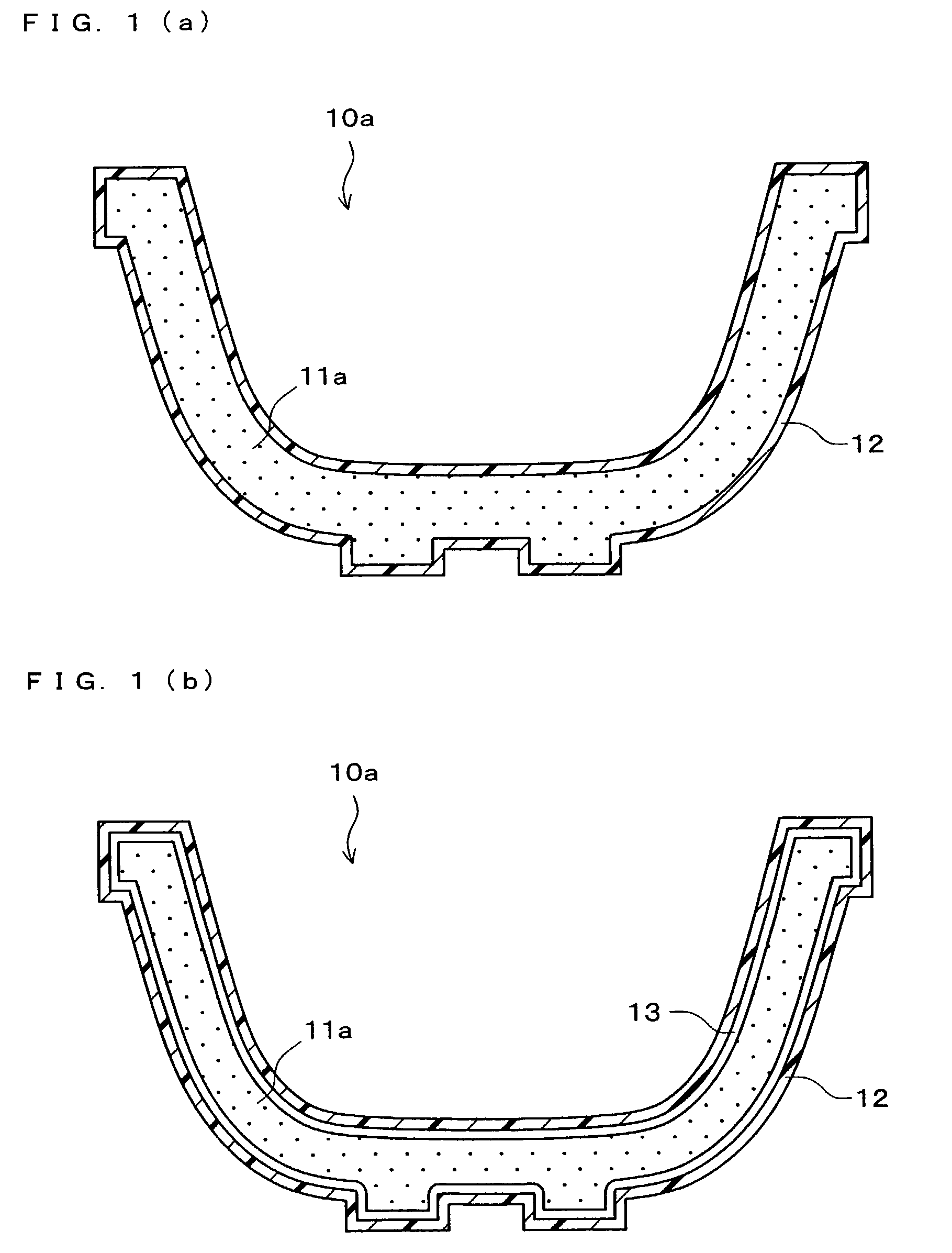

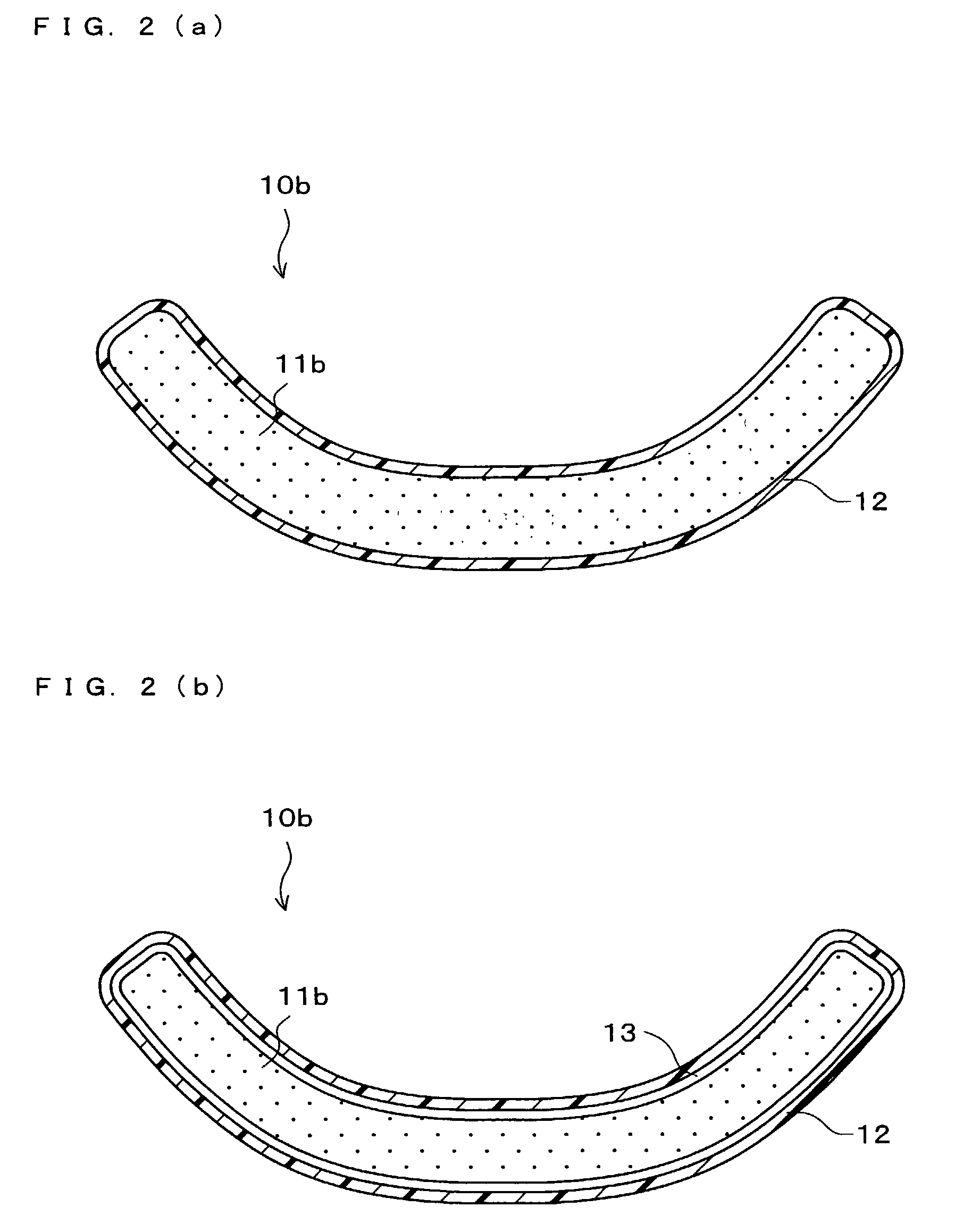

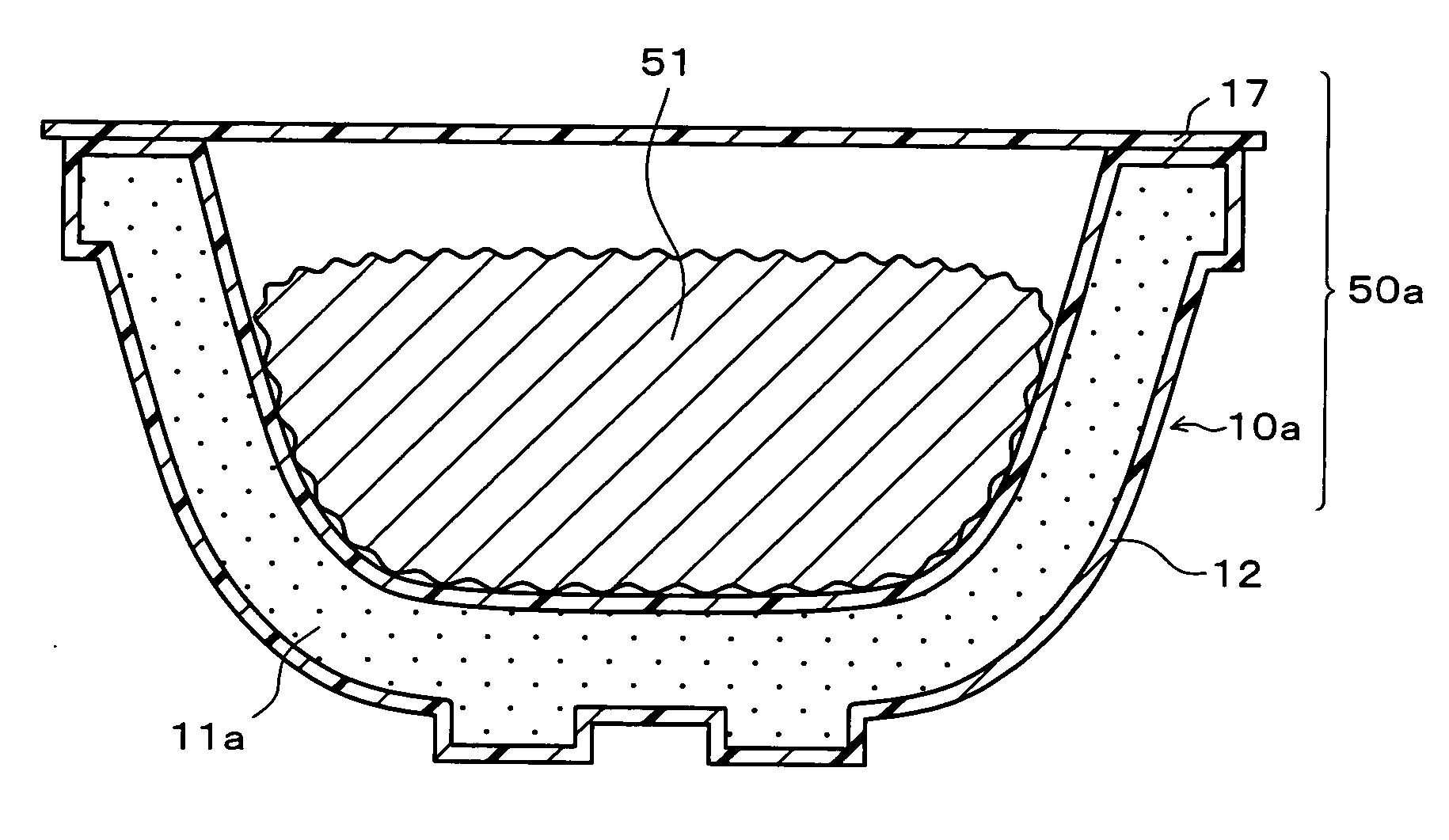

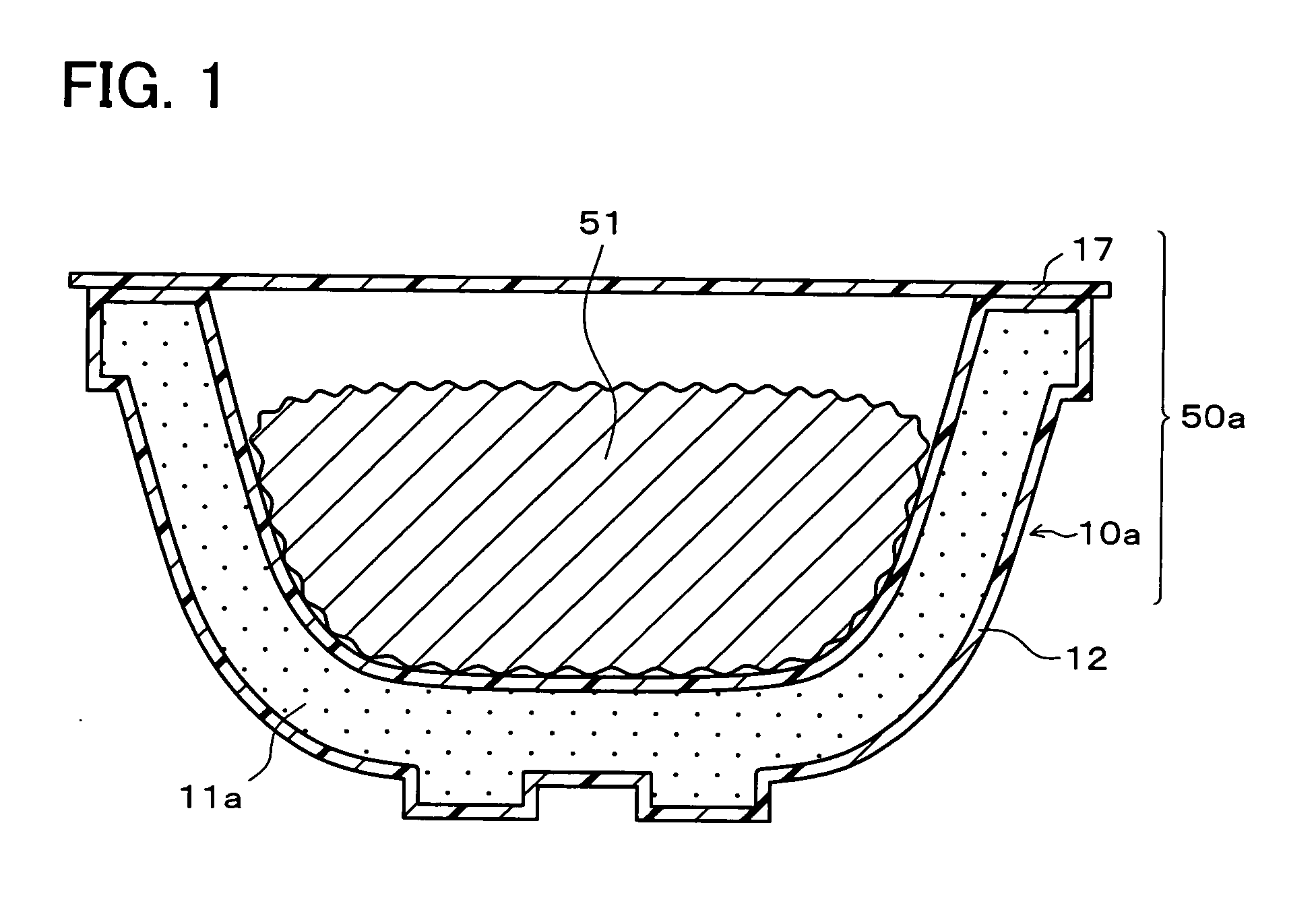

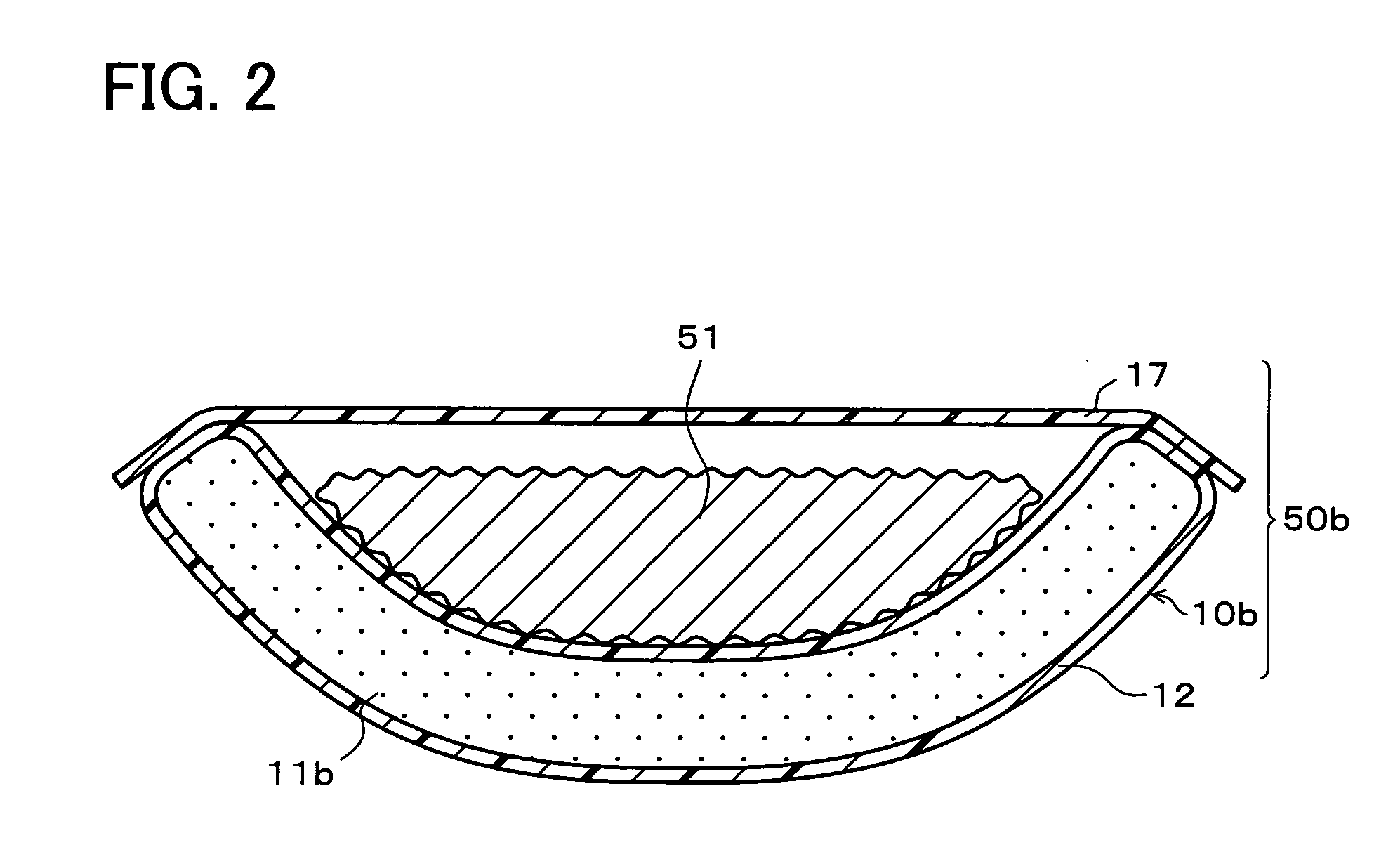

InactiveUS7332214B2Improve adhesionAvoid insufficient heatingFlexible coversWrappersPolymer scienceShell molding

Biodegradable molded articles; a process for producing the same: and compositions for foam molding packed in a packaging film bag to be used in the production. A bowl-type container(10a), which is one of the biodegradable molded articles as described above, consists of a bowl body(11a) comprising starch as the main component and a coating film(12) having at least hydrophobic properties and comprising a biodegradable plastic as the main component which is bonded to the surface of the bowl body(11a). This bowl body(11a) is formed by steam-foaming molding a material to be molded which is in the form of a slurry or a dough containing starch and water. The coating film(12) is closely bonded to the surface of the bowl body(11a) either directly or via an adhesive layer. Compositions for foam molding packed in such packaging film bags can be easily stored and molded.

Owner:NISSEI KK

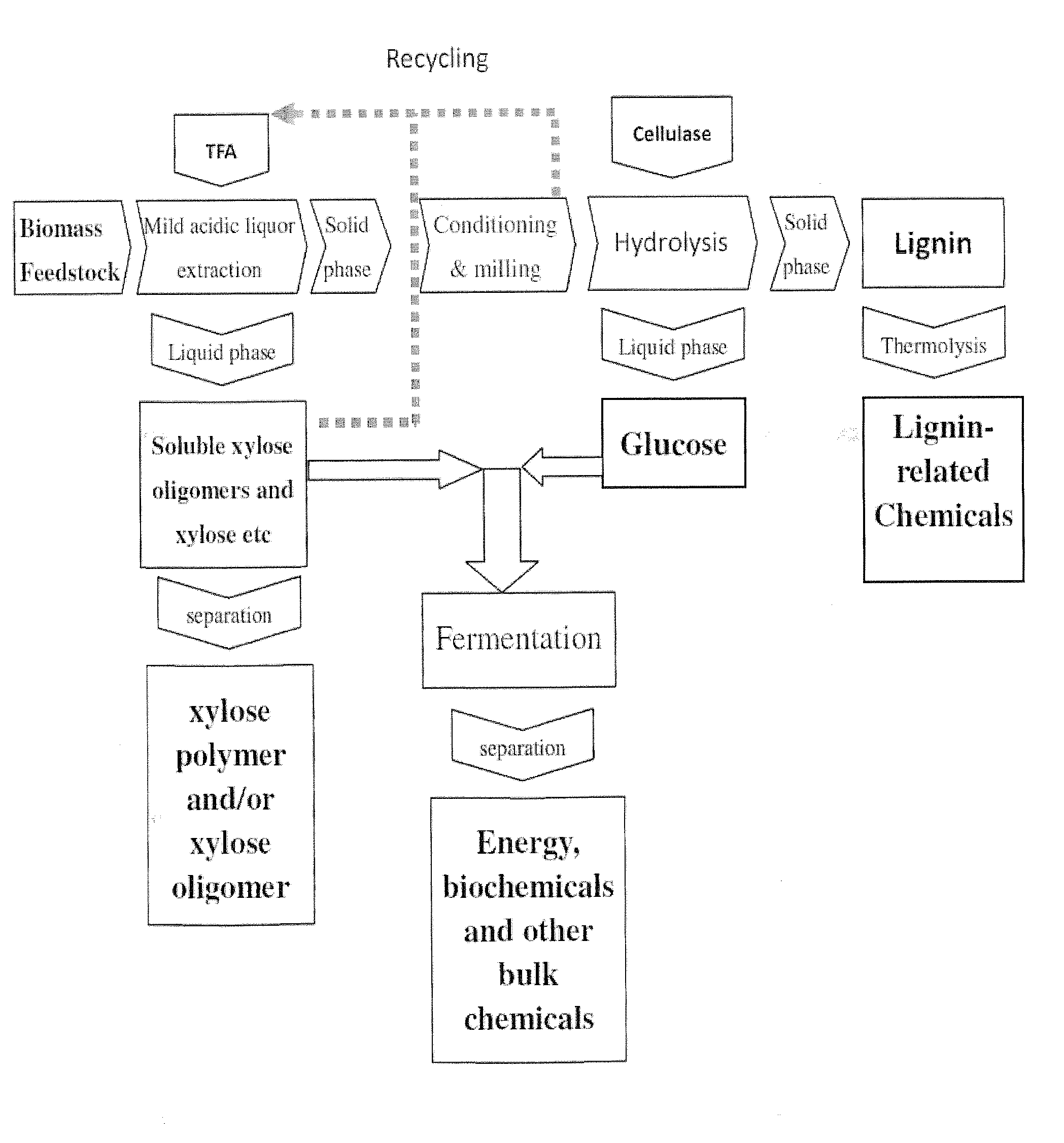

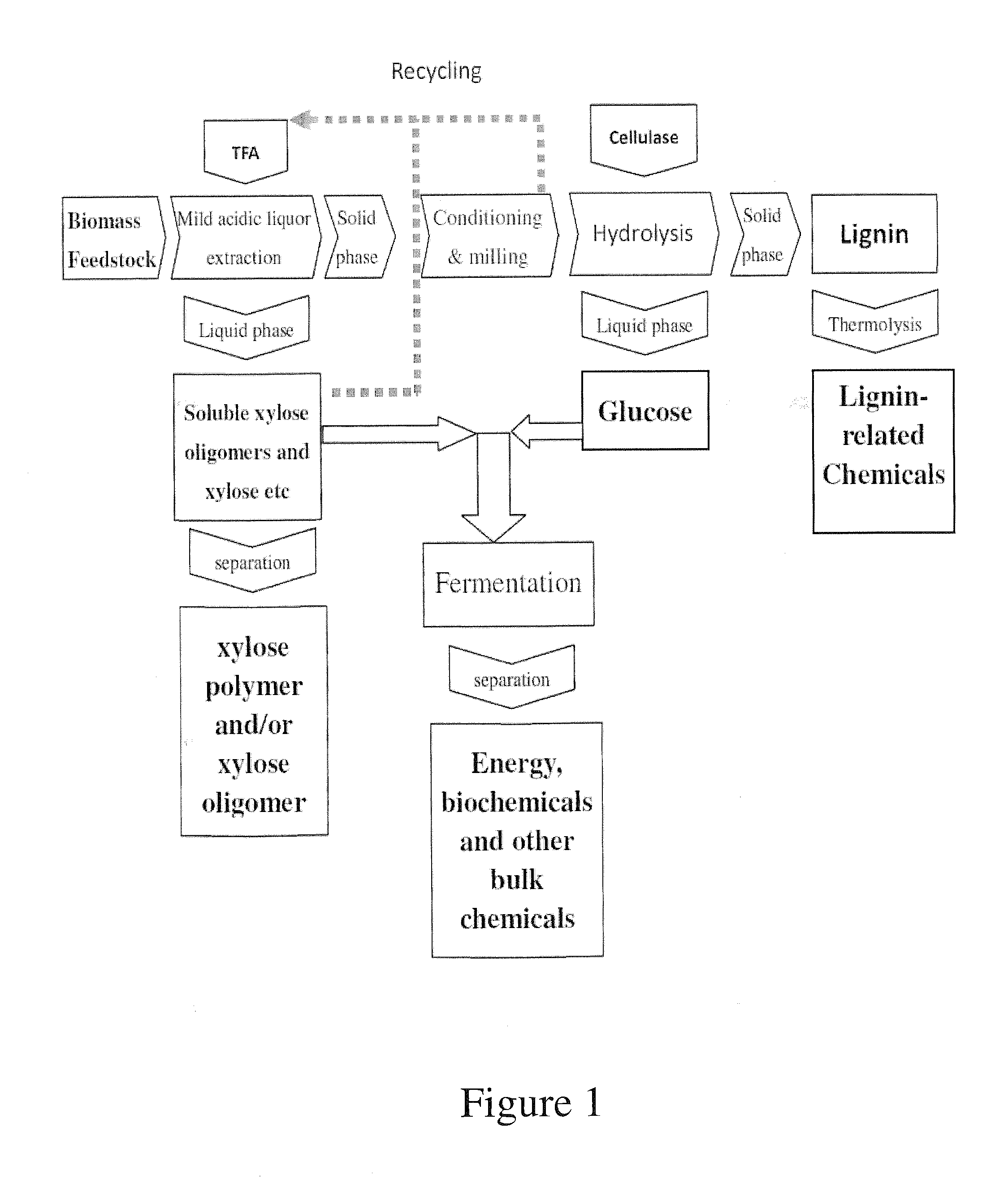

Process for biomass conversion

InactiveUS20100297704A1Easy to GrindIncrease ratingsSugar productsPretreatment with acid reacting compoundsPolymer scienceEnergy products

The present invention relates to a clean process of preparing high grade biomass products, and their use in the production of health care products, bio-energy products, biochemicals, bio-originated chemicals and biodegradable plastics.

Owner:LI RONGXIU

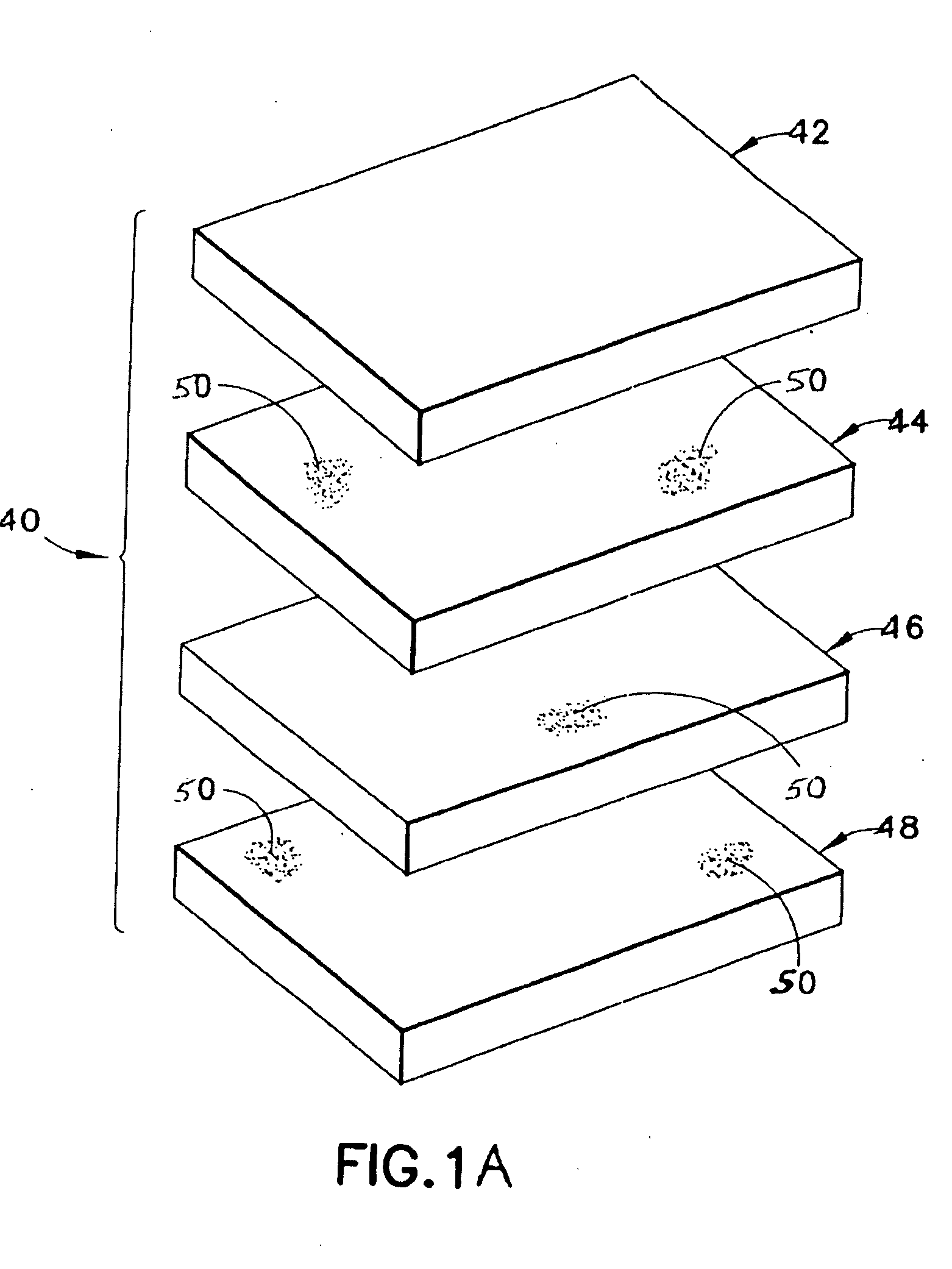

Paper/biodegradable plastic laminate and electromagnetic shielding material

A paper / plastic laminate suitable for use in laser and digital copiers and printers etc. that use heat set fuser toner adhesion as the method for fusing / bonding an ink to a paper. The laminate includes a paper web laminated to a polymeric film using 100% solids, or solventless, adhesives. The polymeric film is made from a biodegradable polymeric material such as a polylactide or a biodegradable polyolefin. An electromagnetic shielding material includes a paper web, a biodegradable polymeric material; and a conductive layer in a laminate structure that, when interposed between a receiving antenna of an RFID smart chip and a transmitting antenna of a signal generator, prevents the reading of the chip.

Owner:CHASE CORP

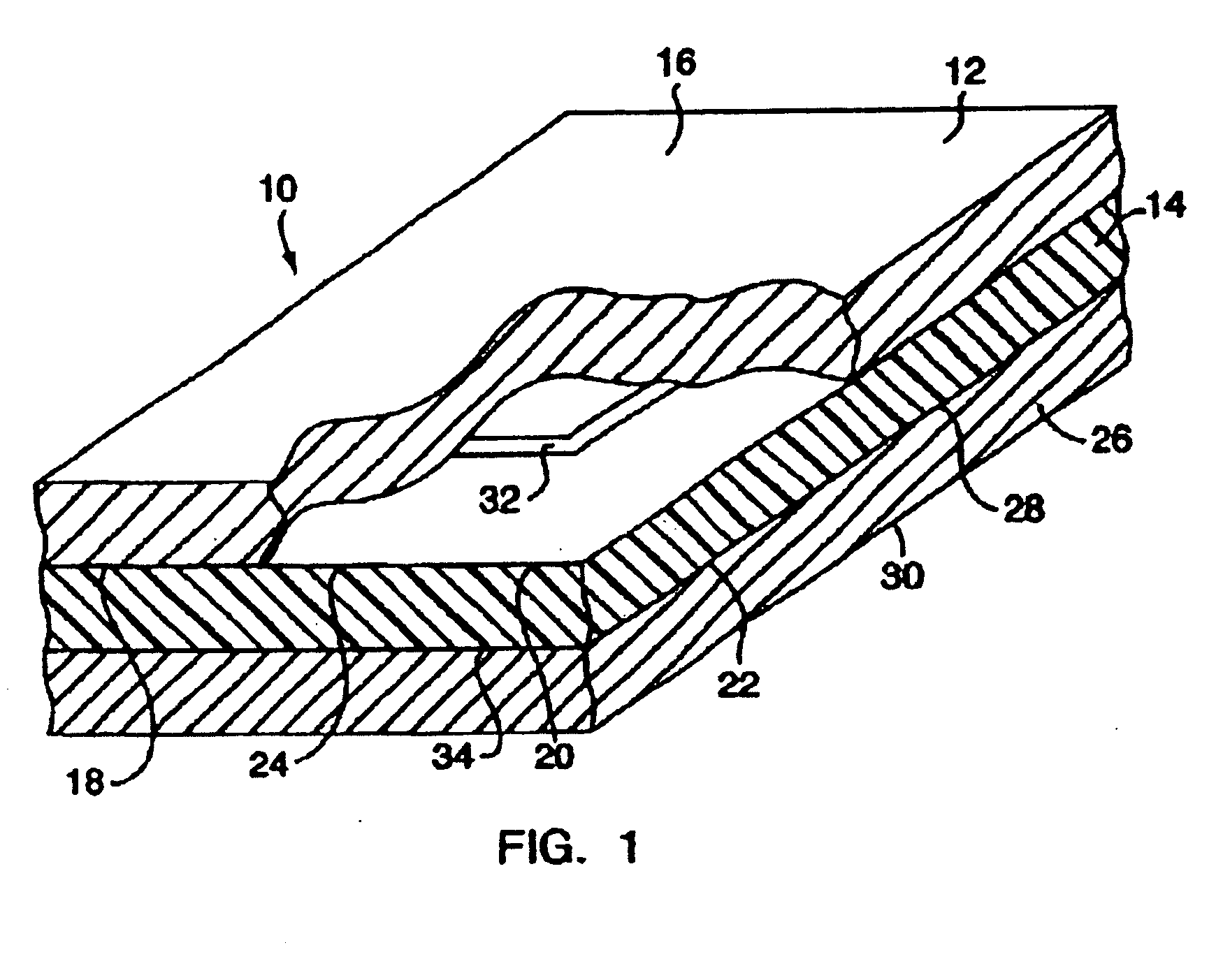

Hermetically sealed container

InactiveUS20050236415A1High strengthPromote biodegradationFlexible coversWrappersShell moldingEngineering

A bowl-shaped container (10a) which is as a hermetically sealed container includes a bowl-shaped container (10a) having a space to contain contents (51) at the inside and an opening to take in and out the contents (51), and a lid (17) mainly made of plastic to seal the opening of the bowl-shaped container (10a), which is heat-sealed to a rim of the opening of the bowl-shaped container (10a). The bowl-shaped container (10a) adheres a coating film (12) mainly made of biodegradable plastic and having at least hydrophobicity to the surface of the main body (11a) of the container mainly made of starch. The main body (11a) is molded through steam expansion of a slurry or dough molding material containing starch and water. For these reasons, it is possible to provide a hermetically sealed container mainly made of starch having sufficient strength and at least sufficient water resistance, and a very excellent biodegradability.

Owner:NISSEI CO LTD

Chemical heating combinations and heating bag

ActiveCN101338182AImprove barrier propertiesEasy to useExothermal chemical reaction heat productionBio-packagingNonwoven fabricMaterials science

The invention belongs to the heating material field and in particular discloses a chemical heating composition which comprises iron powder, bamboo carbon powder, non-sodium soluble inorganic salt, water, inorganic porous water retention agent and super absorbent resin. In air, the heating composition can be used as heating material, and wastes of the heating composition can be reused as fertilizer and soil amendments. In addition, a heating bag which is provided with double-layer structure is also disclosed by the invention. The internal layer is a permeable package bag which is full of the chemical heating composition. The external layer is non-permeable package bag. The permeable package bag of the internal layer is processed from biodegradable nonwoven fabrics and biodegradable plastics. After being abandoned, the permeable package bag of the internal layer can be biodegradable, and pollutions to the environment are avoided.

Owner:上海超迪科技有限公司

Degradable plastic packaging bag

InactiveCN104927318AHigh tensile strengthLow moisture permeabilityFlexible coversWrappersArray data structurePolyvinyl alcohol

The present invention belongs to the field of plastic products, and particularly relates to a biodegradable plastic packaging bag which is characterized by comprising the following components by weight: 5-15 parts of ethyl cellulose, 10-20 parts of polyethylene, 15-30 parts of modified starch, 15-30 parts of corn starch, 15-30 parts of sweet potato starch, 20-40 parts of polylactic acid, 2-10 parts of calcium carbonate powder, 1-5 parts of a lubricant, 1-5 parts of a plasticizer, 1-3 parts of a toughening agent, 1-10 parts of a degradation accelerator, 1-5 parts of polyvinyl alcohol, 2-5parts of chitosan, 1-5 parts of a compatibilizing agent and 2-6 parts of polycaprolactone. The biodegradable plastic packaging bag begins to thin, lose in weight, reduce in strength, then gradually splits into fragments after being exposed to the environment for two months, when these fragments are buried in garbage or soil, the degradation effect is very obvious; by addition of the plasticizer and the calcium carbonate powder, the added ingredients may enhance the tensile strength of the plastic packing tape, reduce the air and moisture permeability, and maintain the original characteristics of the plastic packaging bag.

Owner:TIANJIN YOUZHI TECH CO LTD

Starchlike biological degradatable plastic mother material and its preparation method

InactiveCN1640919APromote degradationGood compatibilityGraft polymer adhesivesMasterbatchPolymer science

The present invention is biodegradable plastic mother material and its preparation process, and has the features of simple production process, low cost, etc. The biodegradable plastic mother material is prepared with material including starch, starch grafting modifier, bonding resin, bonding resin grafting modifier, bonding resin grafting initiator, lubricating plasticizer, stabilizer, dispersant and degradation assistant. The preparation process includes starch grafting modification, bonding resin grafting modification and other steps. The biodegradable plastic mother material has excellent biocompatibility, high starch content and high biodegrading performance.

Owner:SUZHOU HANFENG NEW MATERIAL

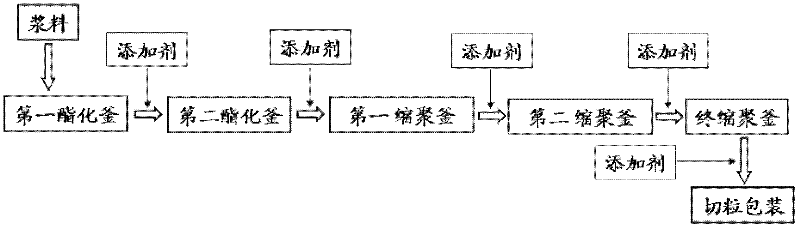

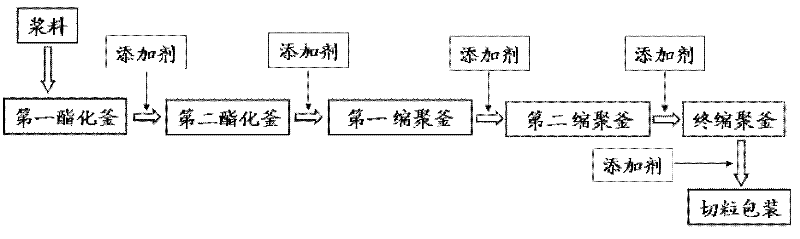

Method for continuously preparing biodegradable plastic

The invention discloses a method for continuously preparing biodegradable plastic, which consists mainly of the steps of continuously adding slurry prepared from one or more dibasic acid and one or more diol into a first esterification kettle, allowing esterification to obtain homopolyester or copolyester oligomer, allowing further esterification in a second esterification kettle to obtain an esterified substance, continuously introducing the esterified substance to a first condensation kettle, allowing condensation to remove small molecule under the condition of low vacuum and obtain prepolymer, continuously introducing the prepolymer to a high-vacuum second condensation kettle, allowing condensation to remove small molecule and obtain polymer, and subjecting the polymer to continuous thickening and polymerization in a final condensation kettle having a thickening function to obtain biodegradable plastic sections with high molecular weight and melting index smaller than 5. The inventive process has simple operation and high automation degree, and the obtained biodegradable plastic sections have uniform quality and no batch difference.

Owner:SHANGHAI JUYOU CHEM ENG

Full biodegradation plastic material and preparation method thereof

The invention discloses a full biodegradation plastic material, which comprises, by weight, the polylactic acid 20-40%, the long-chain branch aliphatic polyester or long-chain branch aliphatic series-aromatic copolyesters 50-60%, the chain extender 0.1-3%, the filler 1-10%, the plasticizer 5-10%, the antioxygen 0.1-1%, the lubricant 0.1-1%, the stabilizer 0.1-1% and the nucleating agent 0.1-1%. A preparation method of the full biodegradation plastic material comprises the steps of enabling all components to be mixed in a high speed mixer, feeding in a twin-screw extruder after accurate measurement by means of a measurement scale to conduct squeezing-out and prilling to obtain the full biodegradation plastic material. The full biodegradation plastic material improves mechanical property of biodegradable plastic (PBSA) products by adjusting screw combination and extruding through reaction mixing and improves suppleness and degradation rate of the polylactic acid simultaneously, the obtained full biodegradation plastic material has not only excellent biodegradation performance and aging quality, but also excellent mechanical property and blow-film processability.

Owner:KINGFA SCI & TECH CO LTD +2

Filling masterbatch used in biodegradable plastic, and preparation method thereof

InactiveCN102516723AGuaranteed DispersionAvoid reunionArtifical filament manufactureMasterbatchPolymer science

The invention discloses a filling masterbatch used in biodegradable plastic. The masterbatch is composed of components of, by mass: (A) 20.0-80.0% of biodegradable polyester, (B) 1.0-80.0% of a filling material, (C) 0.1-10.0% of a lubricating agent, (D) 0.1-5.0% of a high-temperature-resistant agent, and (E) 0.1-5.0% of a hydrolysis-resisting agent. The masterbatch is advantaged in that: (1) compatibility of the carrier is consistent with that of the biodegradable plastic, such that the filling masterbatch has excellent dispersity in the biodegradable plastic; (2) the obtained filling masterbatch satisfies an application requirement of biodegradable plastic En13432; when the filling masterbatch is mixed with biodegradable plastic, the biodegradation performance of the original material is completely maintained; (3) high temperature and hydrolysis resistances of the filling masterbatch are good, and the filling masterbatch has high physical mechanical properties; (4) with the filling masterbatch, while the cost of biodegradable plastic is reduced, physical chemical properties especially the biodegradation performance of the filled material are maintained.

Owner:KINGFA SCI & TECH CO LTD +2

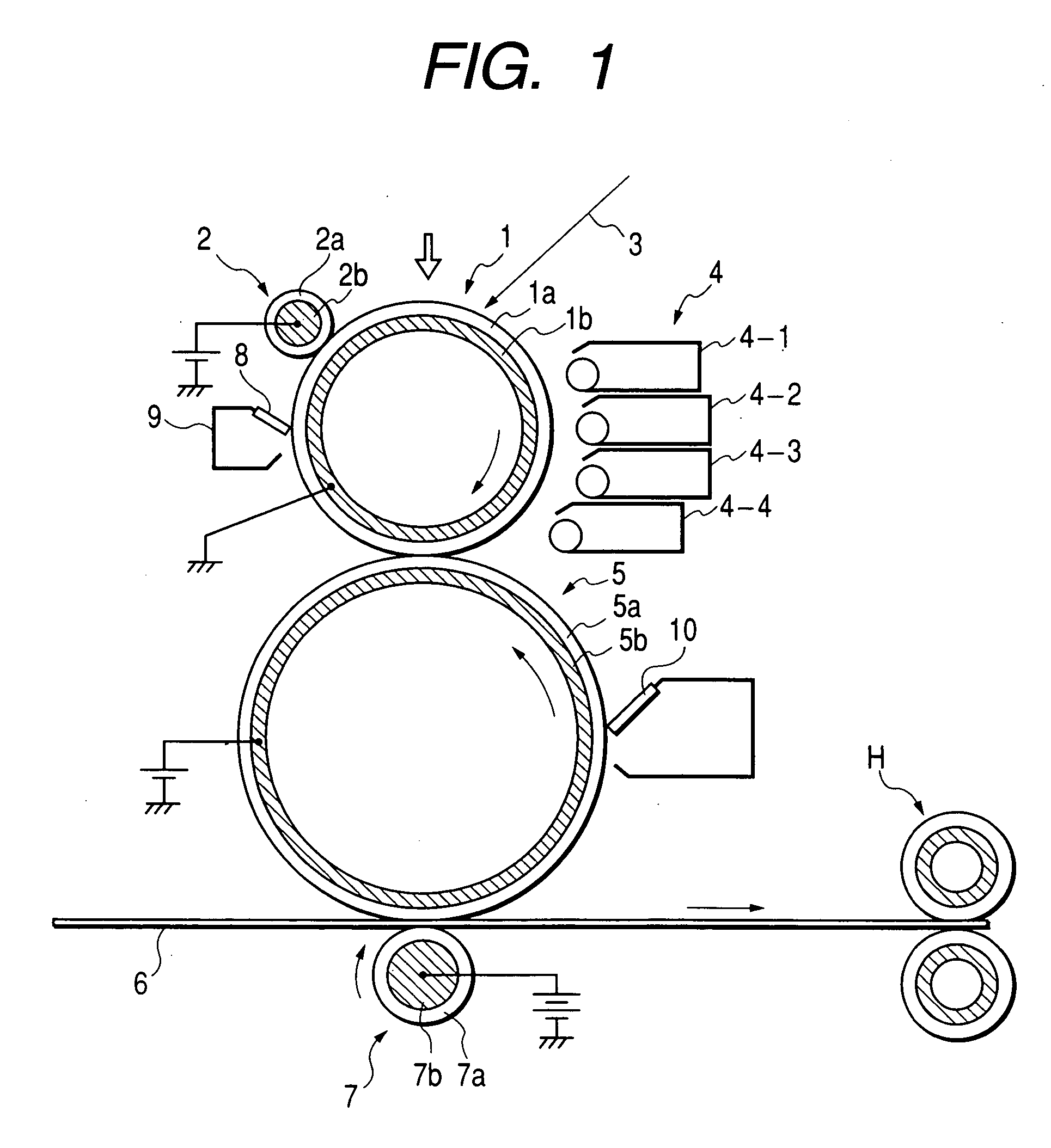

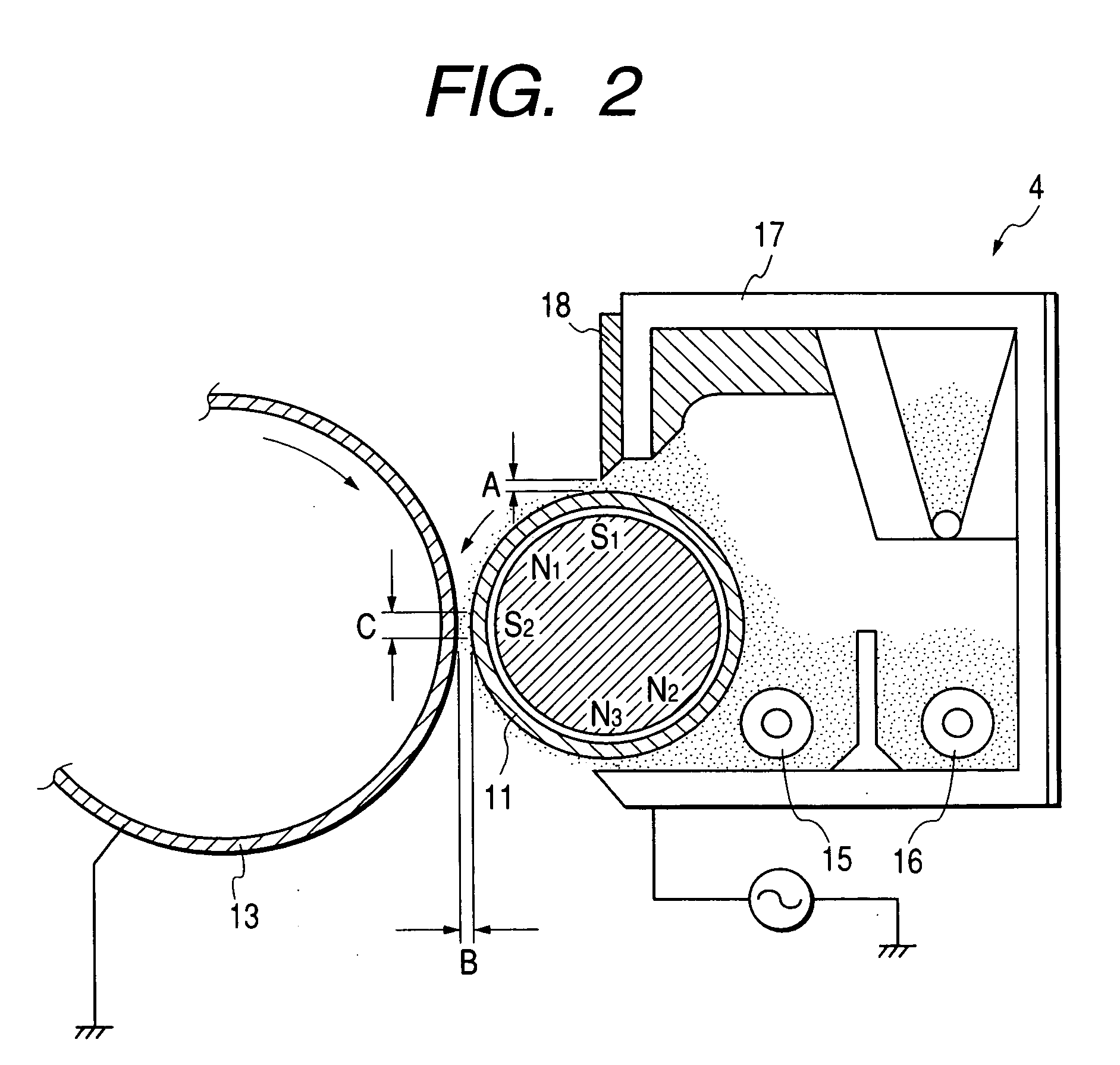

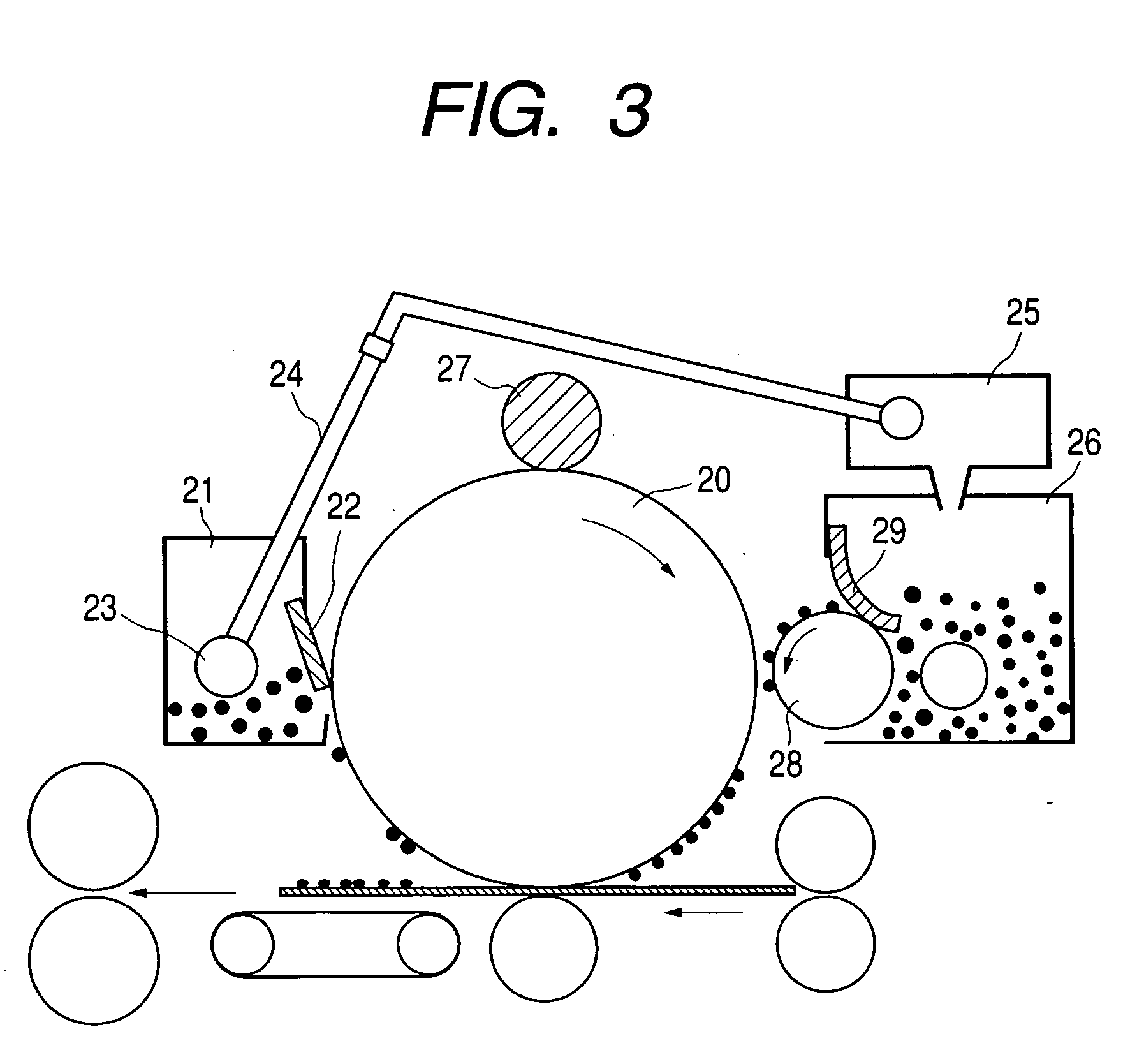

Polyhydroxyalkanoate containing amide group, sulfonic group, and sulfonate ester group, method for producing the same, and charge control agent, toner, image forming method, and image forming apparatus

InactiveUS20060014921A1Improved melt processabilityHigh crystallinityOrganic active ingredientsDevelopersHalogenAliphatic hydrocarbon

A polyhydroxyalkanoate containing in a molecule at least one unit represented by the chemical formula (1). The polyhydroxyalkanoate is a biodegradable plastic with enhanced melt-processability and exhibits excellent charging stability, high chargeability, and enhanced dispersibility when used as a charge control agent of a toner in an electrophotographic process. (R denotes -A1(—SO2R1)x. R1 is selected from OH, a halogen atom, ONa, OK, and OR1a. R1a and A1 are selected from a substituted or unsubstituted aliphatic hydrocarbon structure, a substituted or unsubstituted aromatic ring structure, and a substituted or unsubstituted heterocyclic structure. Further, m and x are integers selected from 1 to 8, and when two or more units exist, each of R, R1 R1a, A1, m, and x is defined as above independently for each of the units.)

Owner:CANON KK

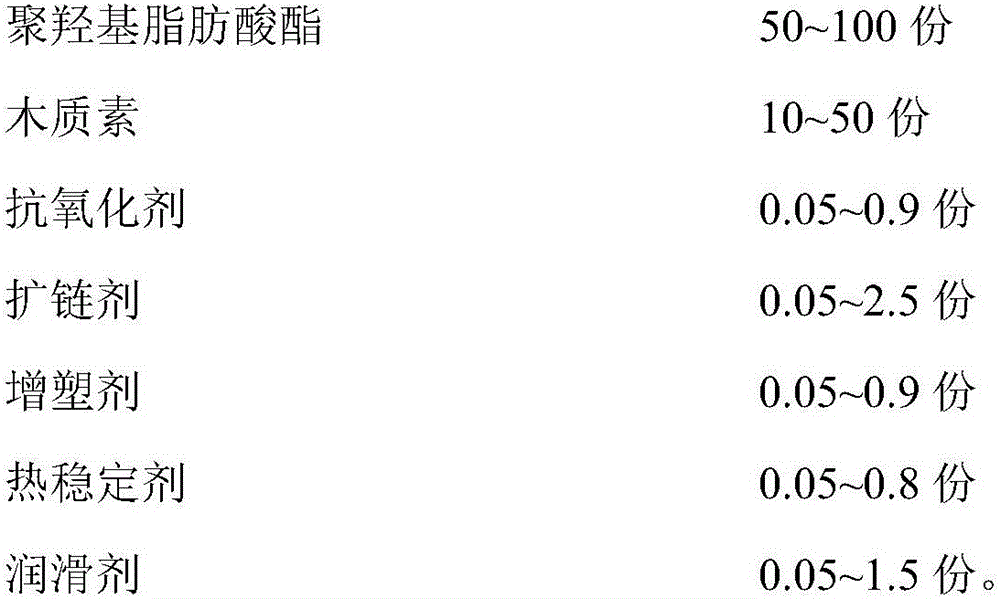

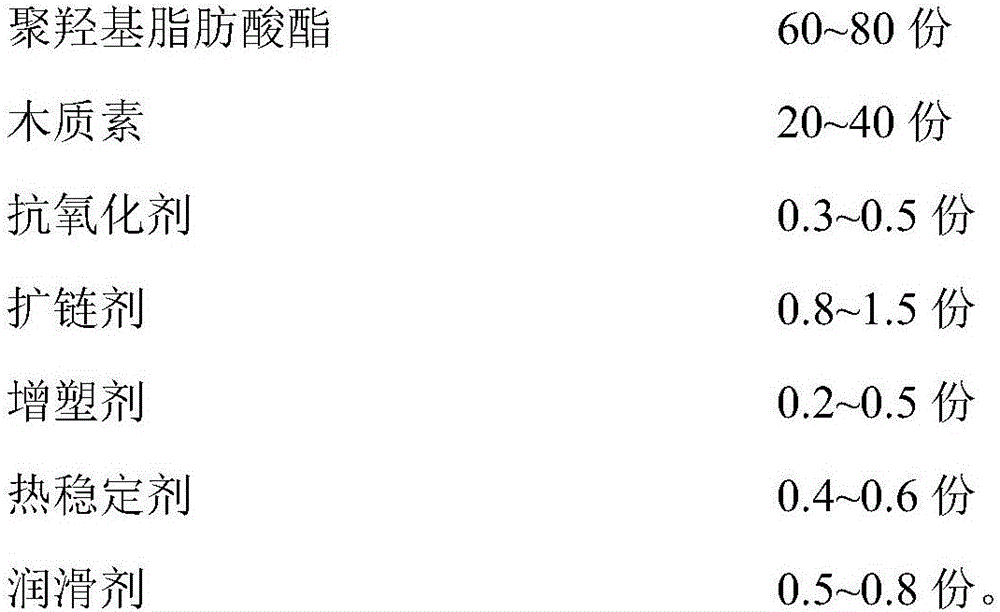

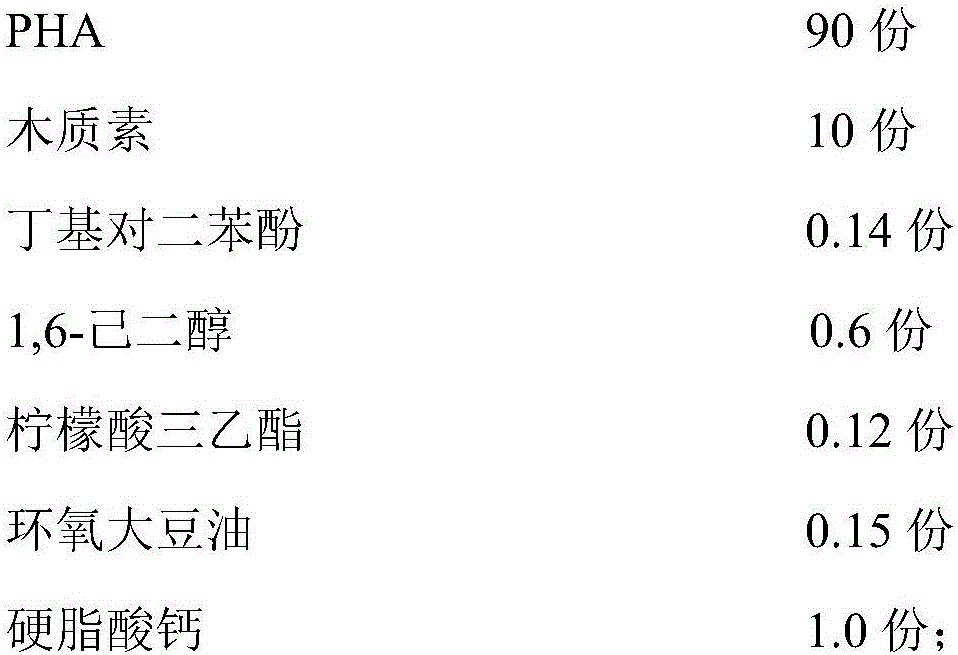

Lignin modified PHA biodegradable plastic and preparing method thereof

The invention discloses a preparing method of a lignin modified PHA biodegradable plastic. The preparing method comprises the steps of 1, conducting vacuum drying on a certain amount of polyhydroxyalkanoate and lignin for certain time; 2, adding dried polyhydroxyalkanoate, lignin, chain extender, antioxidant, plasticizer, lubricant and heat stabilizer in a high mixing machine, and conducting full mixing; 3, extruding the mixed materials into granules through a twin-screw extruder; 4, conducting membrane blowing on the obtained lignin-PHA composite plastic at certain temperature to prepare the lignin modified PHA biodegradable plastic. According to the preparing method of the lignin modified PHA biodegradable plastic, by introducing a biologic material lignin, the lignin-PHA composite plastic prepared through compound modification meets the demand for complete degradation, meanwhile, the mechanical property of pure PHA resin is strengthened, the cost of the plastic is effectively reduced, and the plastic is more beneficial to market popularization.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Biodegradable plastic with antibacterial property and preparation method thereof

ActiveCN101880446AImprove antibacterial propertiesChange in crystallization propertiesNatural dyesPolymer scienceSludge

The invention provides a biodegradable plastic with antibacterial property and a preparation method thereof. The biodegradable plastic with antibacterial property comprises biodegradable plastic matrix and antibacterial plant source dyes which are dispersed in the biodegradable plastic matrix, wherein the mass ratio of the antibacterial plant source dyes to the biodegradable plastic matrix is (0.01-10):100. The invention simply and fast extracts various antibacterial plant source dyes and prepares the biodegradable plastic which is the effective constituent of the various antibacterial plant source dyes, so that the plastic not only is biodegradable but also has good antibacterial property. The biodegradable plastic changes the crystallization property of the existing plastic since the dyes play a part in nucleating agent, is more easily degraded after the plastic product is abandoned, is environment-friendly, and has the degradation rate which is more than 90% after being putted in compost, active sludge and soil for 6 months.

Owner:浙江温州轻工研究院

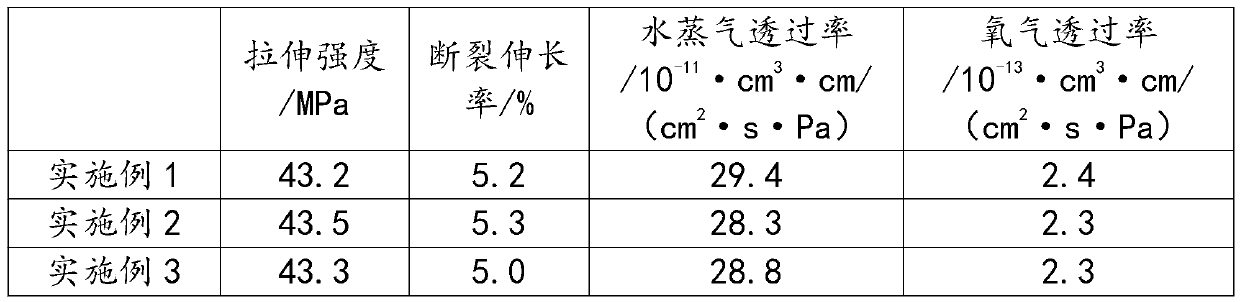

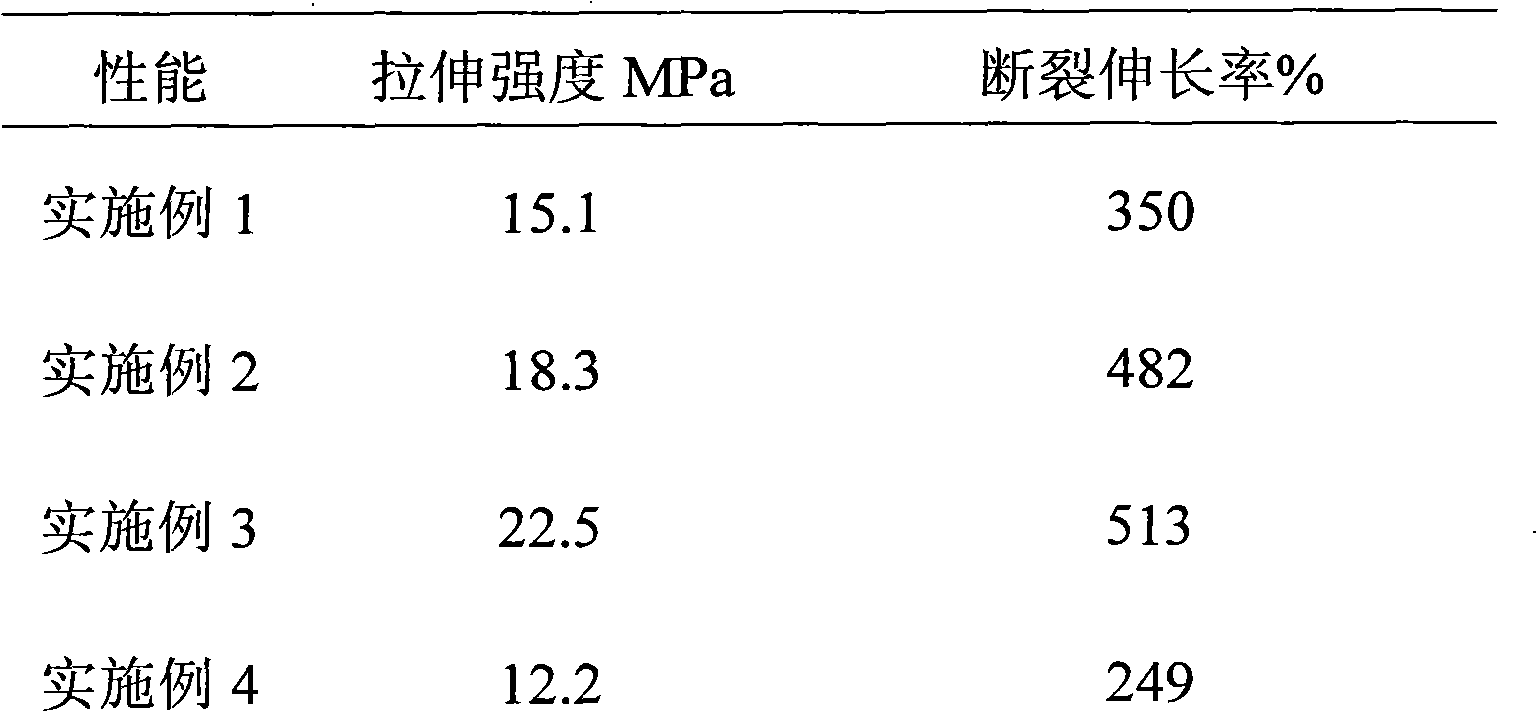

Preparation method of completely biodegradable plastic resin and film products thereof

The invention relates to a preparation method of a completely biodegradable plastic resin and film products thereof. The preparation method is realized through the following steps: conducting surface treatment on starch with content controlled to be 90% by taking corn starch, sweet potato starch, tapioca, konjac starch, poly(butylene succinate) (PBS), various plastic additives and the like as raw materials, and blending the starch with biodegradable synthetic resin (PBS, PLA (polylactic acid)) for modification; and adopting film blowing, extrusion and other technologies to obtain corresponding products. The preparation method has the beneficial effects that on the premise of maintaining the product to be completely biodegradable, the tensile strength and elongation at break of the product can be improved, so that the product truly conforms to the market demand.

Owner:上海可伊实业有限公司

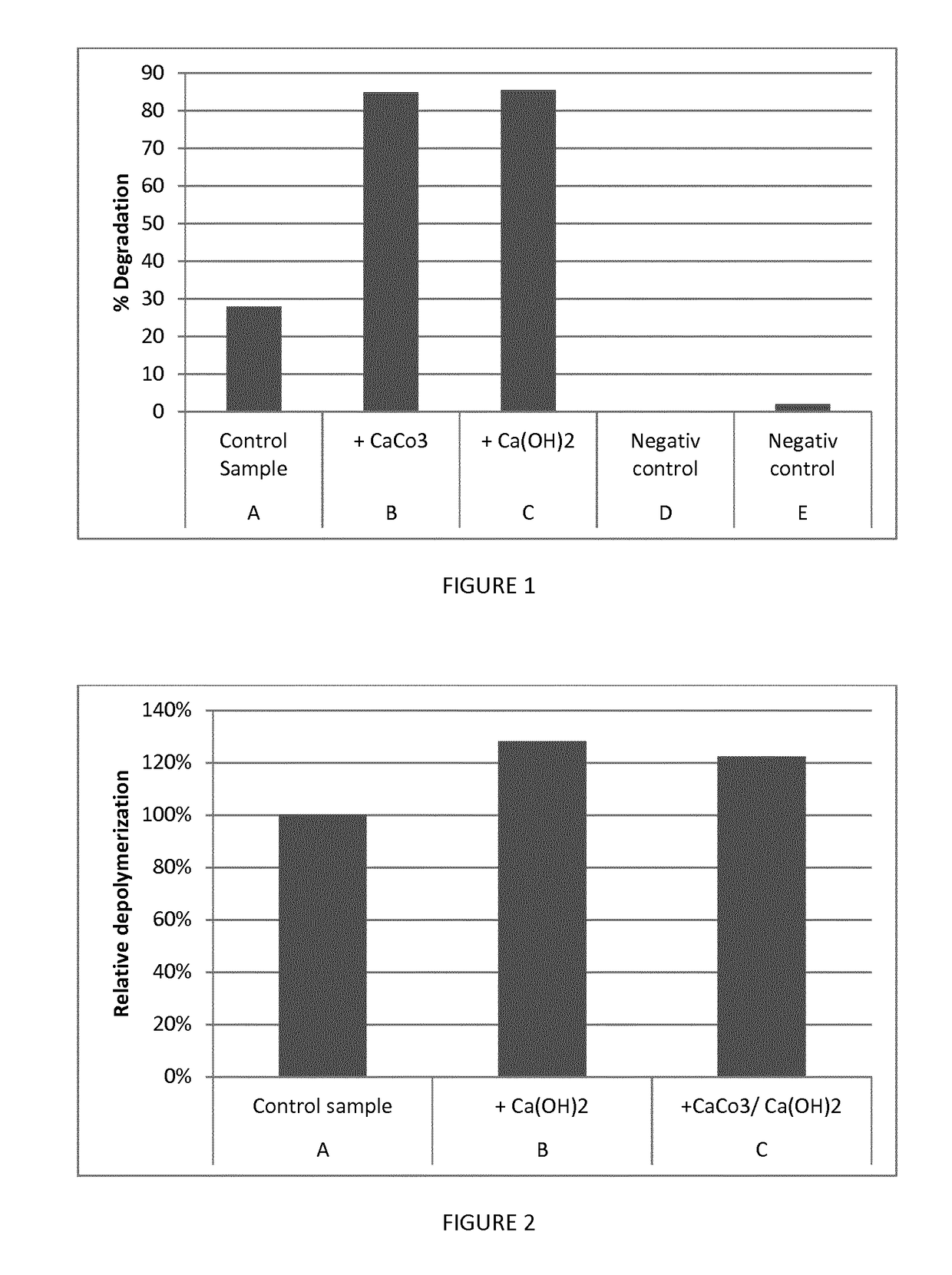

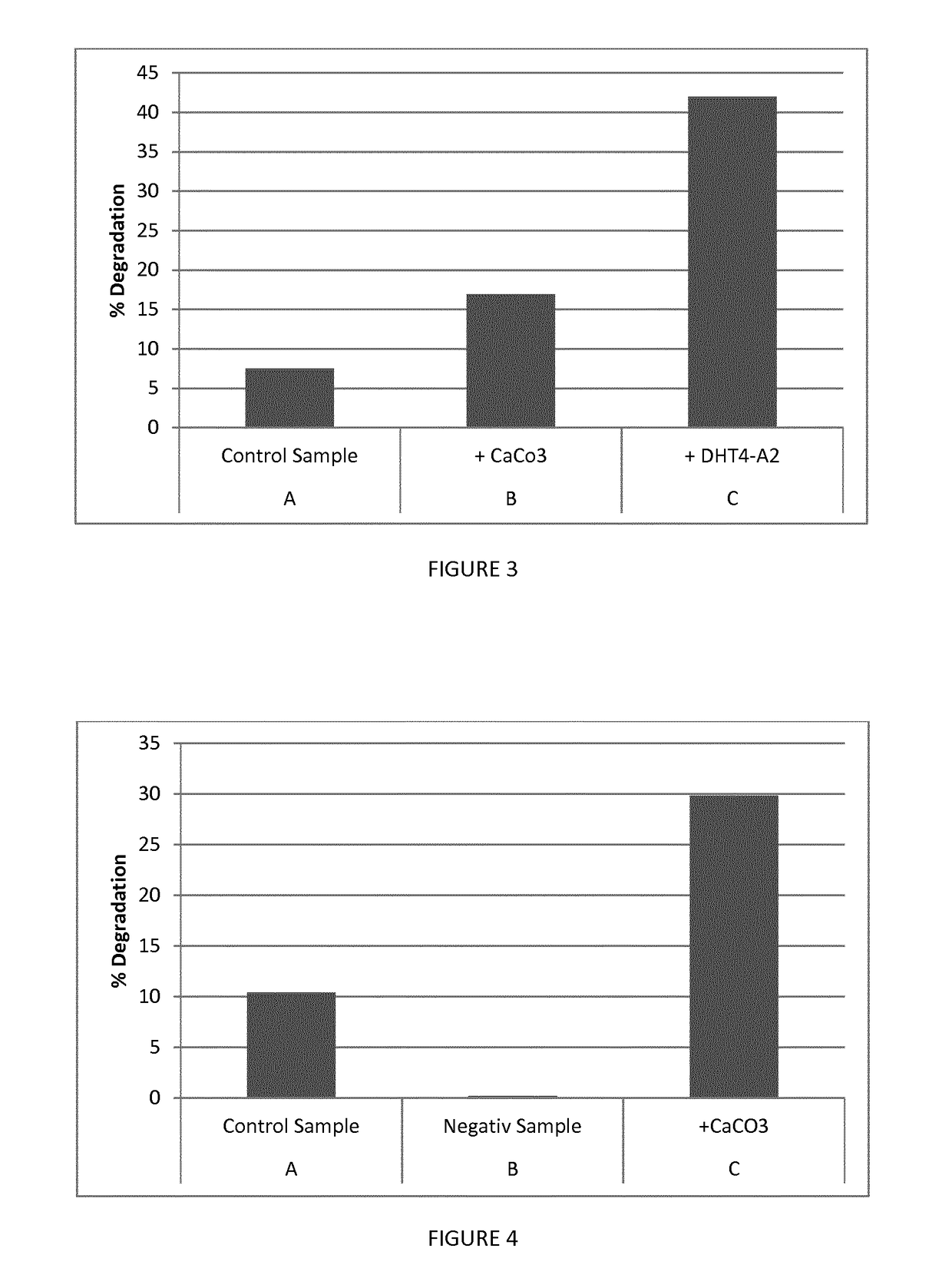

Biodegradable polyester composition and uses thereof

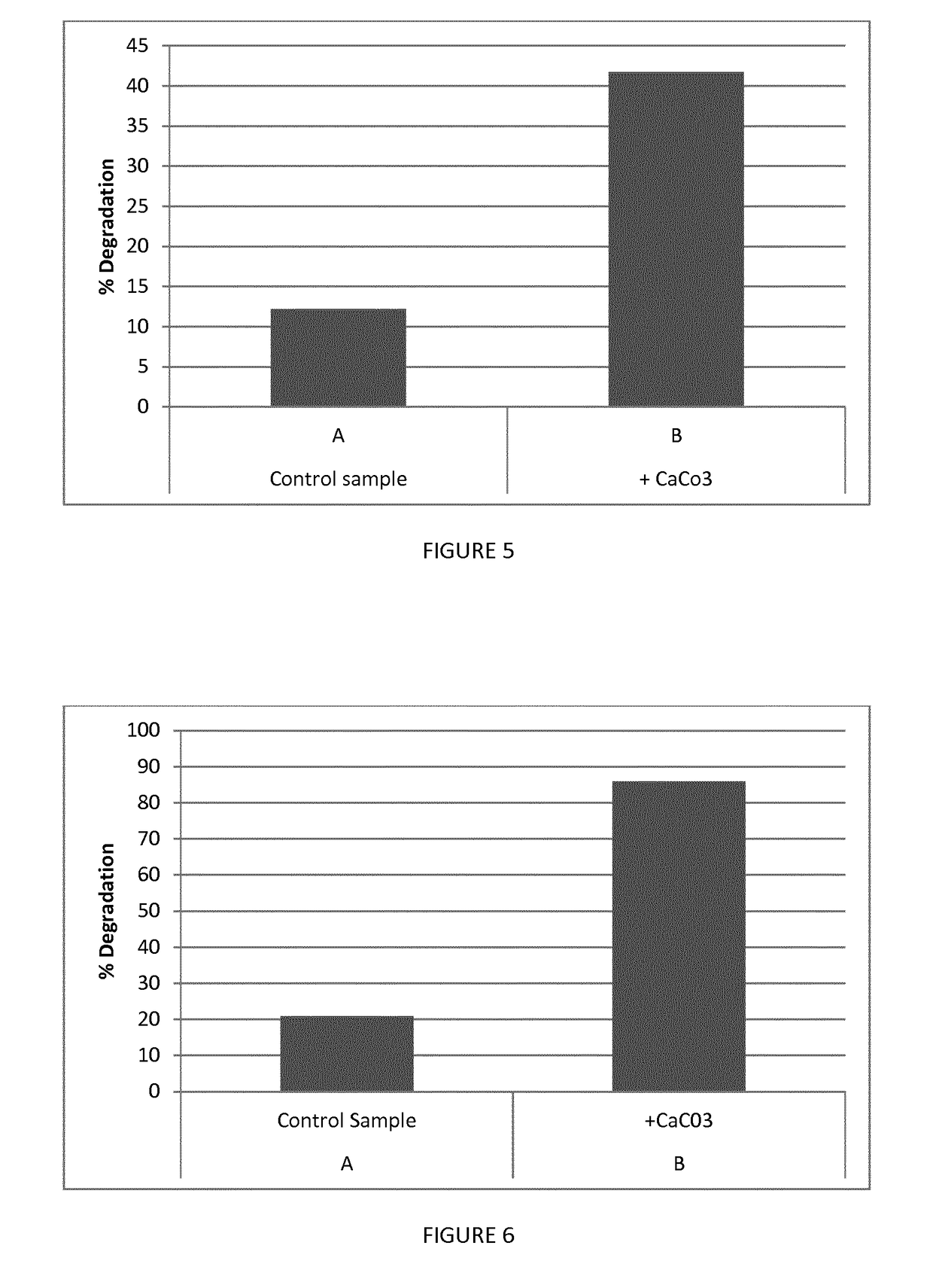

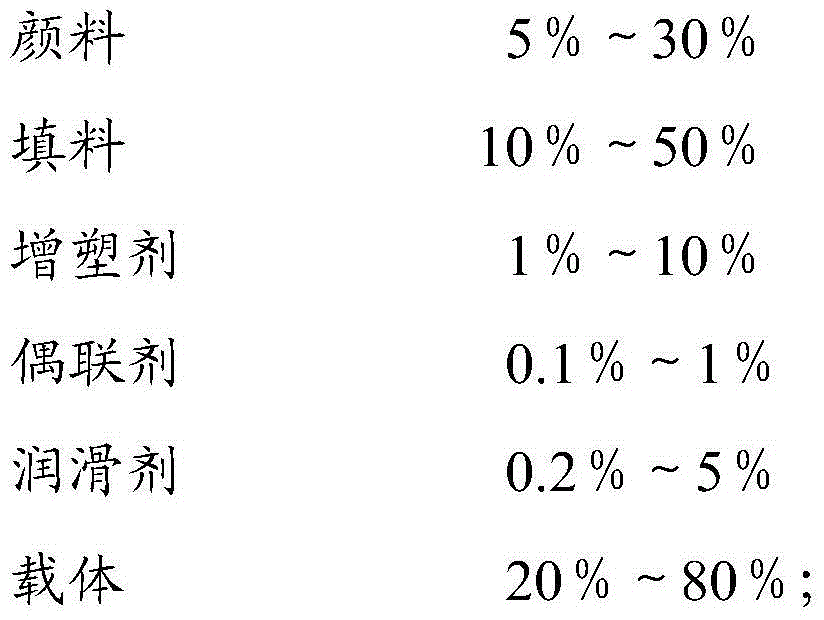

ActiveUS20180142097A1Enhance polyester degrading activityPromote degradationPlastic recyclingOxidoreductasesPolymer scienceBiodegradable polyester

The present invention relates to plastic composition comprising at least one polyester, biological entities having a polyester-degrading activity and at least an anti-acid filler, wherein the biological entities represent less than 11% by weight, based on the total weight of the plastic composition, and uses thereof for manufacturing biodegradable plastic articles.

Owner:CARBIOS

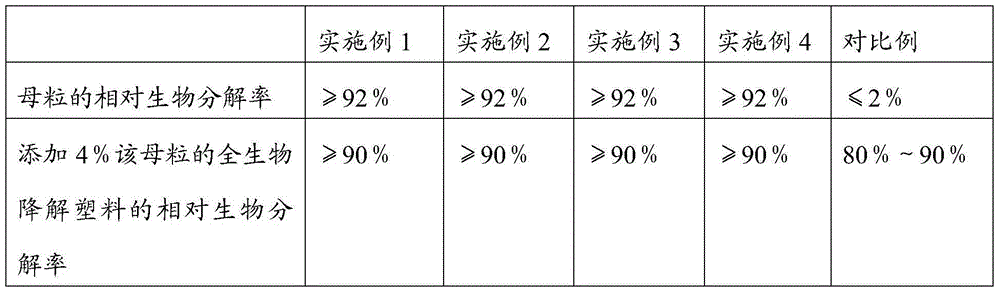

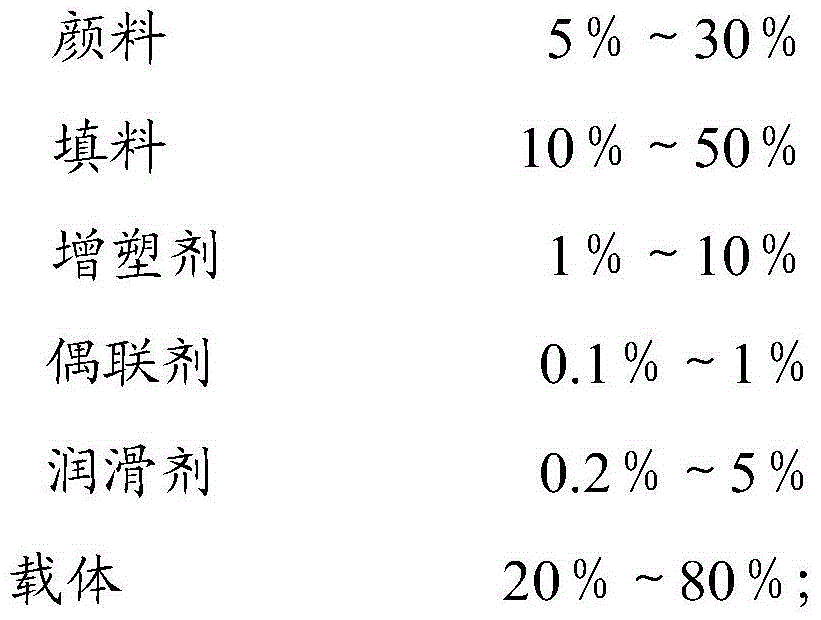

Biodegradable plastic color master batch and making method thereof

The invention relates to the technical field of plastic, and especially relates to a biodegradable plastic color master batch and a making method thereof. The biodegradable plastic color master batch comprises the following raw materials by weight percentages: 5-30% of pigment, 10-50% of filling material, 1-10% of plasticizer, 0.1-1% of coupling agent, 0.2-5% of lubricant and 20-80% of carrier. The biodegradable plastic color master batch has excellent physicochemical performance as common color master batch, and can avoid the disadvantages of time consuming and labor consuming for granulation and coloring of the biodegradable plastic color master batch and the influence to physical property; the biodegradable plastic color master batch can substitute the usage of the nondegradable plastic color master batch, and mixing of a nondegradable plastic component in the biodegradable plastic can be avoided.

Owner:东莞市普凯塑料科技有限公司

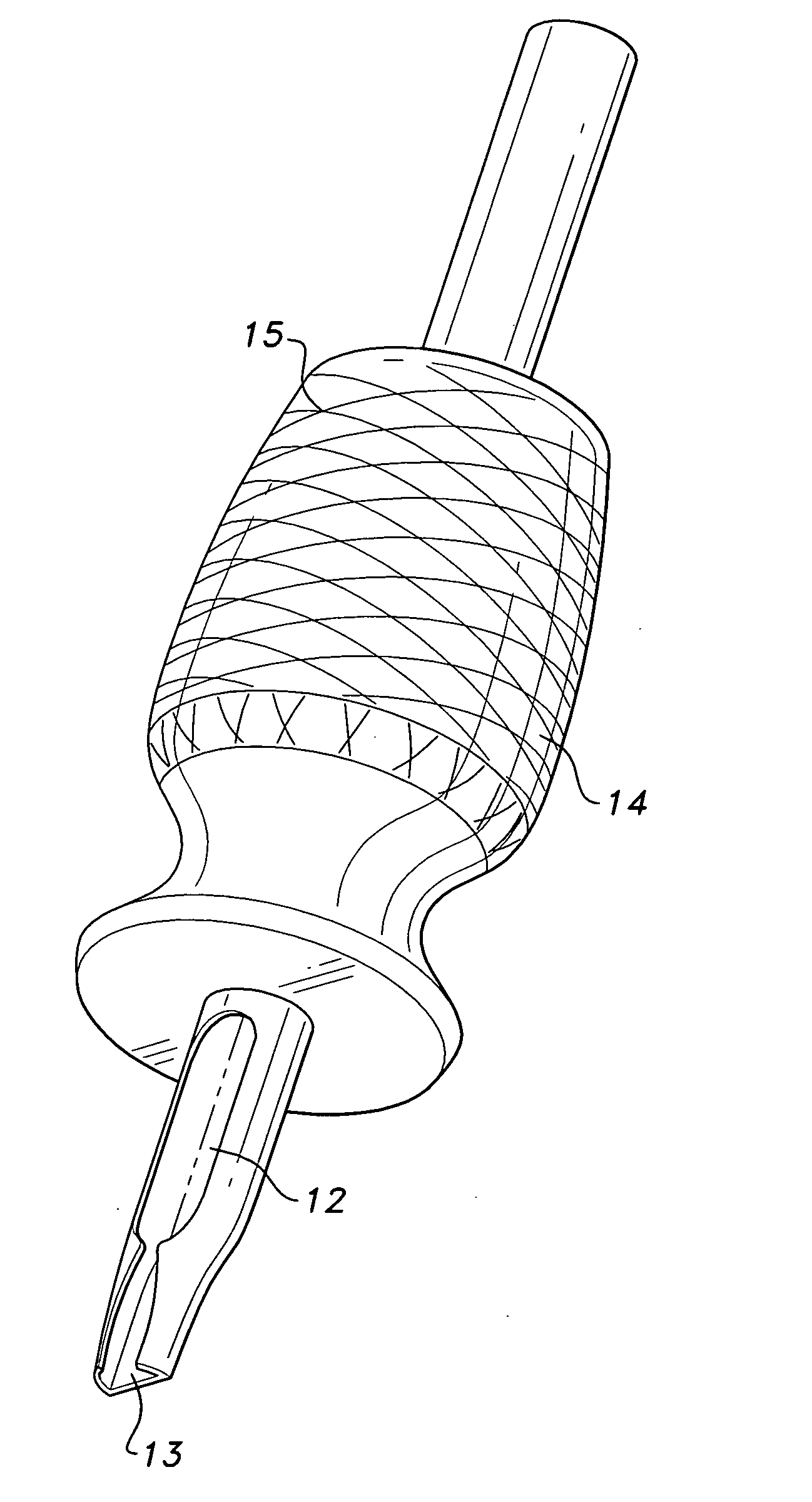

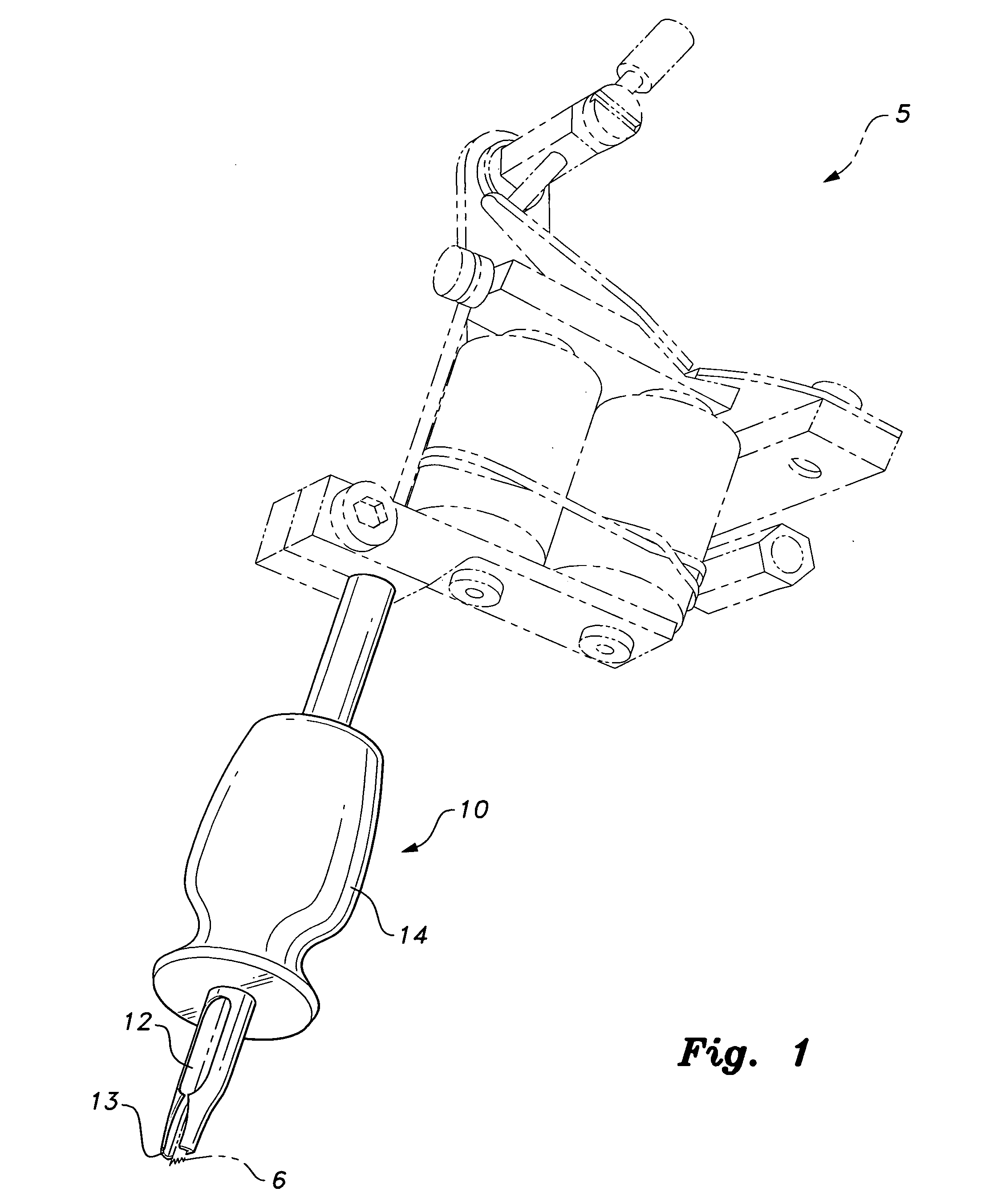

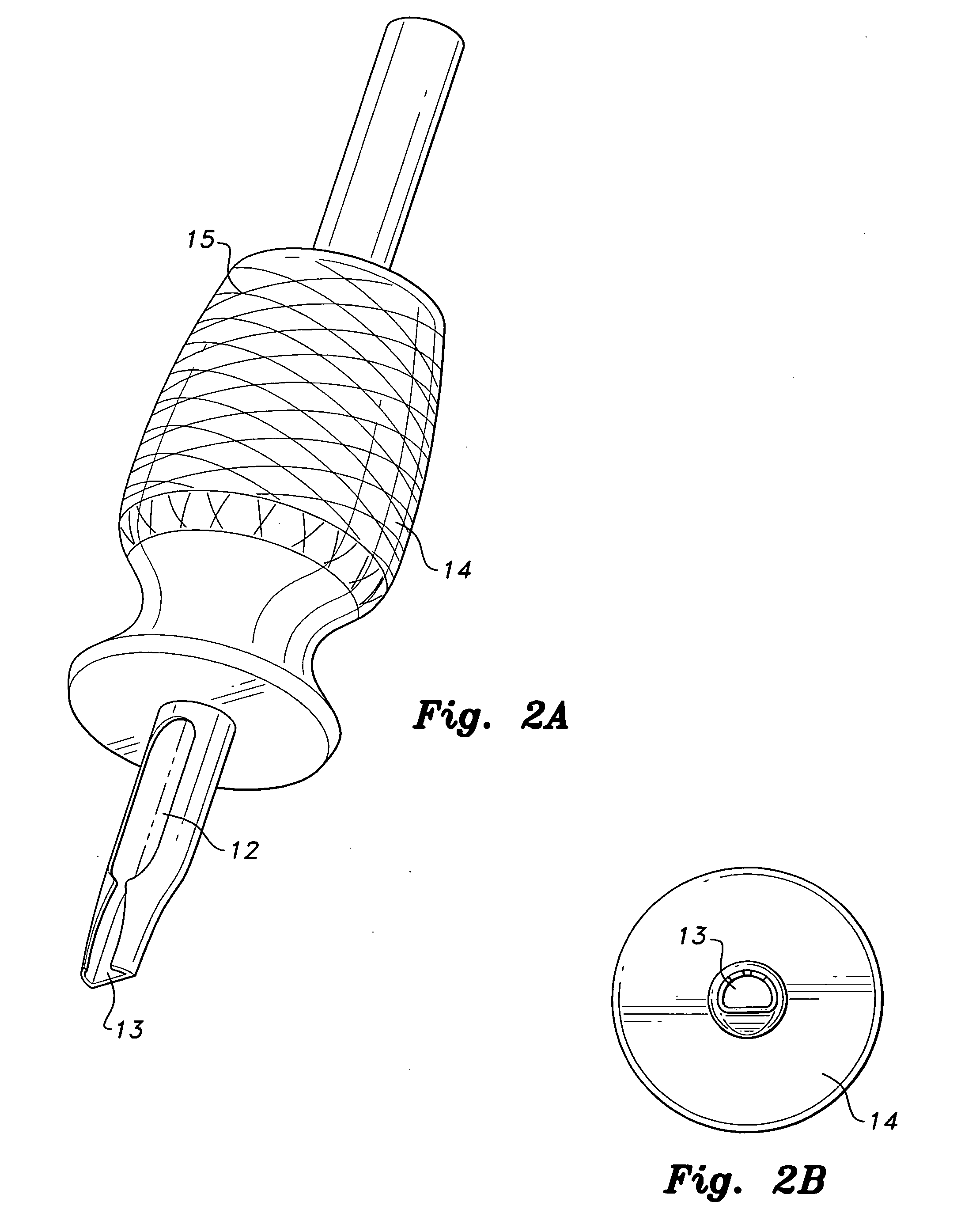

Biodegradable, disposable tattoo tube

InactiveUS20100206138A1Readily apparentMedical devicesInk reservoir pensBiomedical engineeringBiodegradable plastic

The biodegradable, disposable tattoo tube includes an elongated plastic tube adapted to be releasably attached to a tattooing device, a shaped tip at one end of the tube, an open ink reservoir adjacent the tip, and an ergonomic grip disposed between opposing ends of the tube. The tattoo tube is made from biodegradable plastic material that may be recycled naturally or in any other conventional manner.

Owner:CLARK JOSEPH B

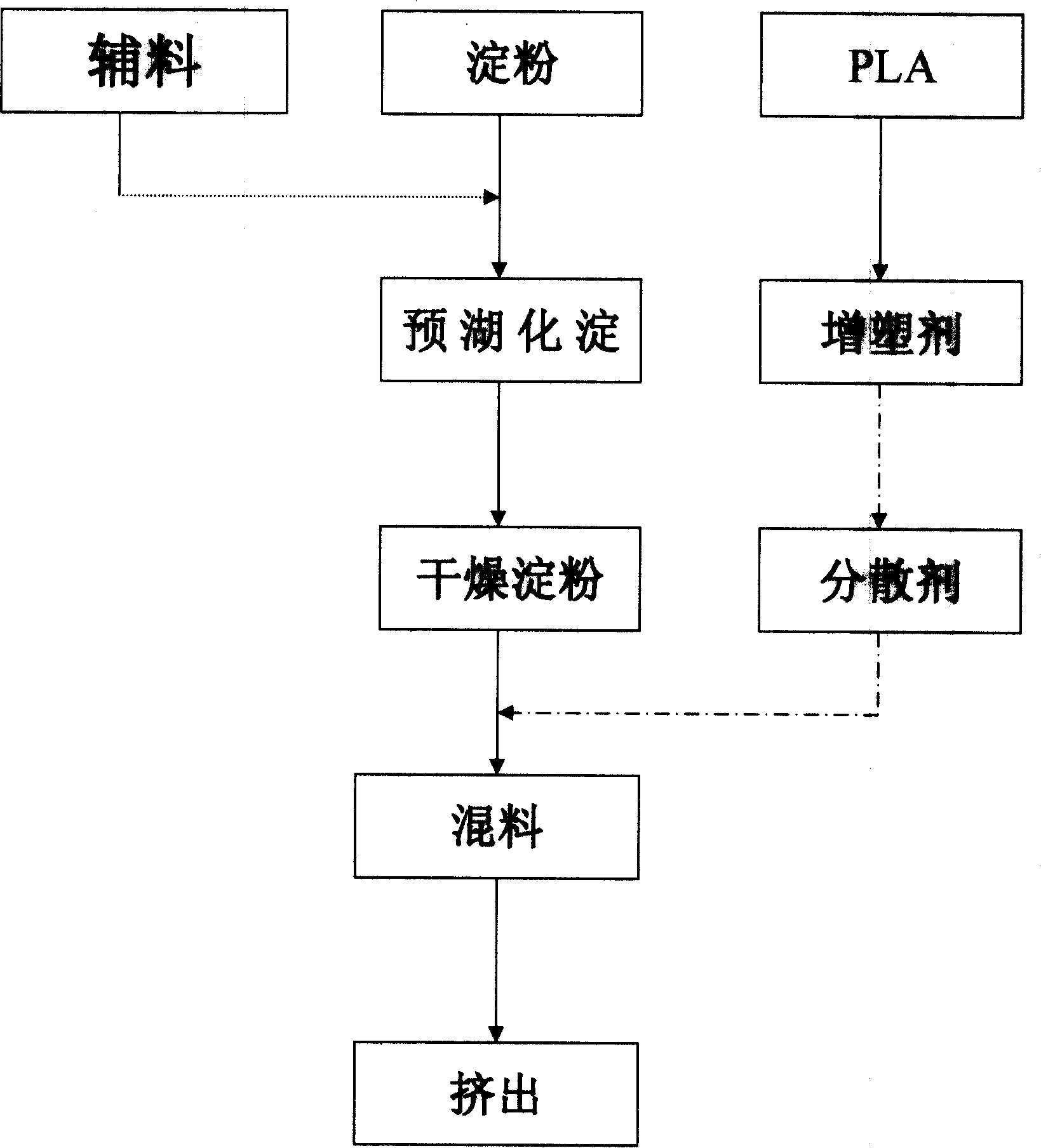

Nano composite biological degradation plastic and preparing method thereof

The present invention discloses one kind of nanometer composite biodegradable plastic and its preparation process. The nanometer composite biodegradable plastic consists of polylactic acid 200-600 weight portions, modified starch 300-700 weight portions, nanometer montmorillonite 200-400 weight portions, plasticizer 25-55 weight portions and dispersant 10-70 weight portions. The modified starch is polyglycol and glycerin modified pregelatinized starch comprising starch 100 weight portions, polyglycol 0.1-10 weight portions and glycerin 0.1-10 weight portions. The nanometer composite biodegradable plastic may be applied in producing high quality agricultural film and packing film with obvious biodegradability, high mechanical and physical performance.

Owner:LUDE GASOLINEEUM CHEM BEIJING

Biodegradable plastic line for three-dimensional (3D) printing

The invention discloses a biodegradable plastic line for three-dimensional (3D) printing. The biodegradable plastic line comprises polylactic acid, impact modifier, plasticizer and an aid, wherein the impact modifier is compounded by one or more of acrylate impact modifiers and thermoplastic elastomer impact modifiers; the plasticizer is compounded by one or more of phthalic acid ester plasticizers, citrate plasticizers, epoxy plasticizers and lactate plasticizers; the aid comprises one or a mixture of more of a lubricating agent, an antioxidant and a chain extender. The material has high liquidity and dimensional stability, the requirements of a 3D printer on printing fluency and dimensional stability of the material are met, and the material is biodegradable, high in degradation rate, environmental friendly and pollution-free. Meanwhile, the material has a certain transparency, and the product printed by the 3D printer has semipermeability and is attractive in appearance and bright in color.

Owner:芜湖瀚博电子科技有限公司

Epoxy functionalized chain extender, and preparation method and application thereof

ActiveCN102936307ANarrow molecular weight distributionHigh glass transition temperatureBiodegradable plasticSolvent

The invention discloses an epoxy functionalized chain extender for bio-base and biodegradation-base polymers, and a preparation method and application thereof. The chain extender is prepared from the following raw materials in parts by mass: 50-75 parts of styrene monomer, 25-50 parts of acrylic acid glyceride monomer and 2-12 parts of initiator. The preparation method of the epoxy functionalized chain extender, which comprises the following steps: selecting the reaction monomers and initiator, adding the reaction monomers and initiator into a reaction kettle in a preset sequence, copolymerizing at proper temperature and mixing speed, removing the solvent from the reaction product, and granulating to obtain the product. The epoxy functionalized chain extender can be used for extending and crosslinking bio-base and biodegradable plastic molecular chains of which polylactic acid (PLA) and polypropylene carbonate (PPC) have fatty group polyester structure. The epoxy functionalized chain extender has the characteristics of narrow molecular weight distribution, high glass transition temperature, simple preparation process, and shorter reaction time since all the raw materials are mixed to react at the solvent reflux temperature.

Owner:SHANXI CHEM RES INST

Biodegradable horticulture container

ActiveUS20160174469A1Decrease containment volumeProvide nutritionCultivating equipmentsReceptacle cultivationTime aspectEngineering

The containment of plants and seedlings as such plants or seedlings are grown, transported, displayed and planted is provided. Containers are comprised of biodegradable materials that have the advantage of being formed into containers with various features, such as by an injection molding process, but that can be buried within the soil along with a plant's roots. Such containers allow for plant or seedling transplanting without having to separate the container from the plant's root system. More preferably, biodegradable plastics utilized in accordance with the present invention have properties such that the plastic can be injection molded and yet provide a stable structural container that will last in accordance with predetermined set needs, which needs may include environmental aspects, timing aspects and decompositional aspects. By utilizing injection molding, containers can be formed with many advantageous features.

Owner:SELFECO LLC

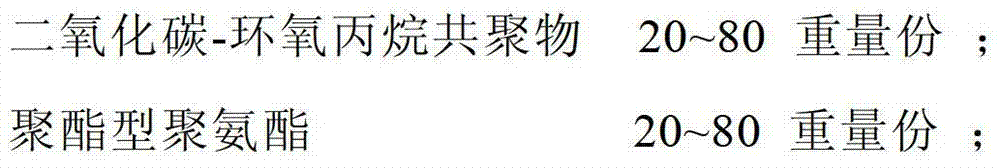

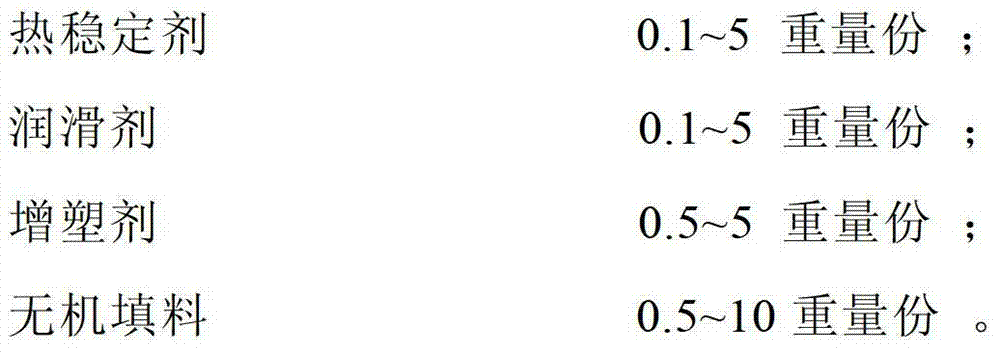

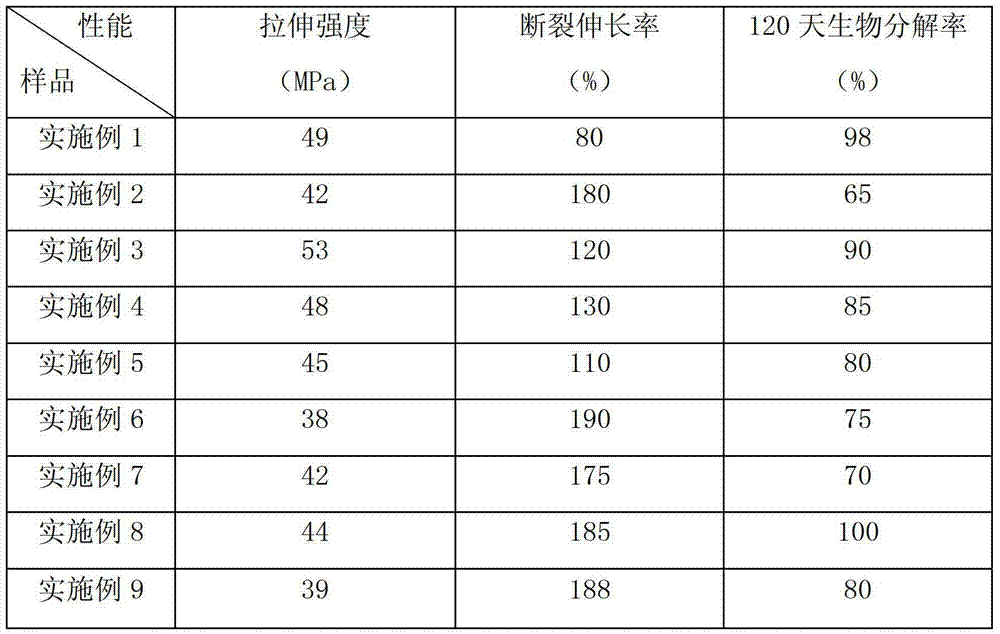

Biodegradable resin composition

The invention provides a biodegradable resin composition. The biodegradable resin composite comprises the following components in parts by weight: 20-80 parts of carbon dioxide-propylene epoxide copolymer, 20-80 parts of polyester type polyurethane, 0.1-5 parts of a thermal stabilizer, 0.1-5 parts of a lubricant, 0.5-5 parts of a plasticizer and 0.5-10 parts of inorganic filler. The invention also relates to an application of the biodegradable resin composition in preparation of films, sheets, molded goods or fibers. The biodegradable resin composition solves the problem that a general polyurethane material which has a higher melting point cannot be melted with the carbon dioxide-propylene epoxide copolymer easily at the same time; moreover, a product prepared from the biodegradable resin composition provided by the invention has good mechanical properties, is beneficial for long-term storage and long-distance transport, increases the degradation velocity under a composting condition, shortens the composting time after use, and is suitable for preparing biodegradable plastics.

Owner:南通华盛高聚物科技股份有限公司

Full-biodegradable plastic film and preparation method thereof

The invention discloses a full-biodegradable plastic film, which takes poly ethylene carbonate polyurethane as the base. The material is composed of the following components in parts by weight: 20-90 parts of poly ethylene carbonate polyurethane, 1-50 parts of thermoplastic starch, 5-10 parts of compatible modified component, 3-5 parts of nanometer inorganic reinforced component, 2-20 parts of compound plastification component and 10-30 parts of lubrication component. The full-biodegradable plastic film prepared by the method of the invention has favourable biodegradable performance and can be completely biodegradated within 180 days under the condition of compost; the film has favourable toughness, higher anti-tearing strength and wide using temperature range, can satisfy the performance requirements of various plastic products in the market, in particular to the plastic products, such as disposable packages, tableware, plastic shopping bags and the like which have severe white pollution, so that the film is the full-biodegradable material with wide market prospect.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com