Patents

Literature

710results about How to "Improve melt fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-diffusion modified polypropylene composite material and preparation method thereof

ActiveCN101817953AHigh surface glossImprove impact resistancePolypropylene compositesMolecular sieve

The invention belongs to the field of modified polypropylene composite materials and relates to a low-odor and low-diffusion modified polypropylene composite material suitable for manufacturing interior decorative parts of automobiles. The composite material comprises the following components in part by weight: 60 to 90 parts of polypropylene, 0 to 40 parts of mineral filler, 1 to 5 parts of odor adsorbent and 0.1 to 1 part of assistant, wherein the odor adsorbent is a mixture of three types of clay, bentonite, porous silicon dioxide, activated aluminum oxide or molecular sieve. The prepared modified polypropylene composite material has the characteristics of high surface glossiness, high shock resistance and intensity, melt flowing property and mechanical property; due to the adoption of various gas adsorbents, the product has low odor diffusion property and a total carbon value of between 13.7 and 24.5 mu gC / g; simultaneously, needed raw materials have wide sources and are readily available.

Owner:SUZHOU SUNWAY POLYMER

Thermoplastic resin composition and engineering plastic composition

InactiveUS20050159533A1Improve liquidityImprove melt fluiditySpecial tyresEngineering plasticTape recorder

Owner:MITSUBISHI CHEM CORP

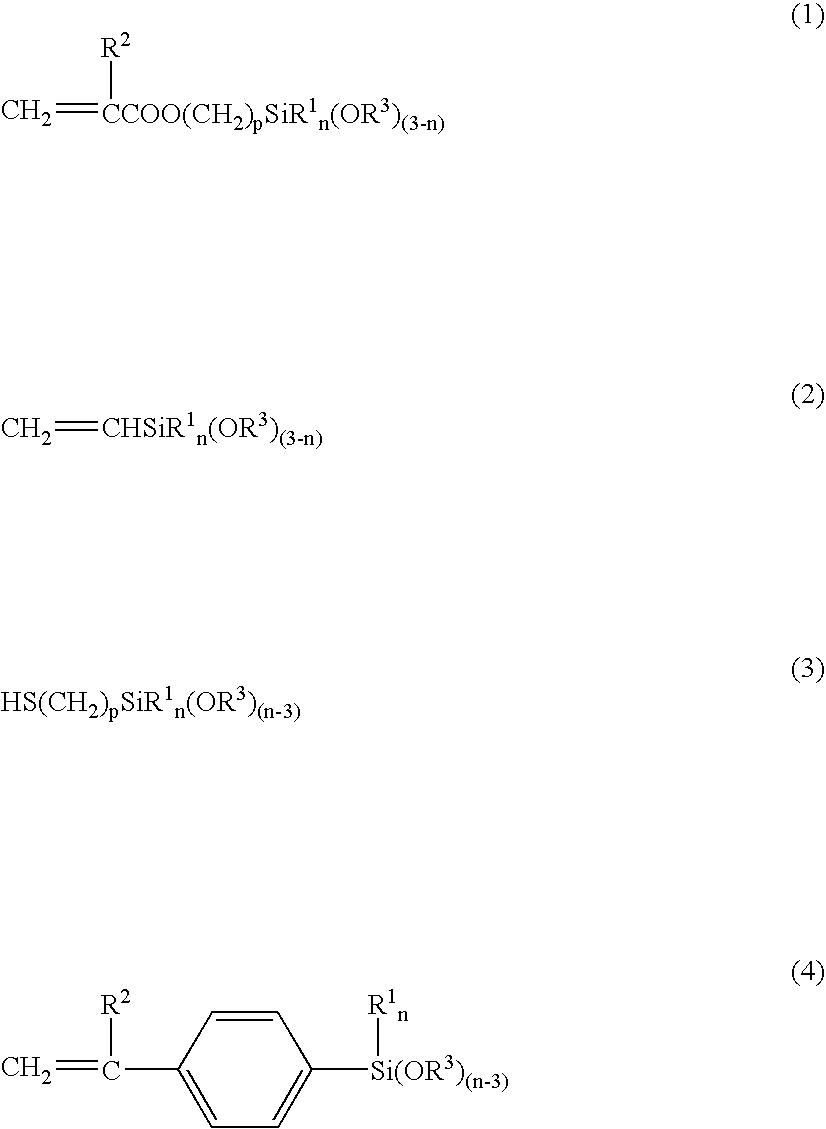

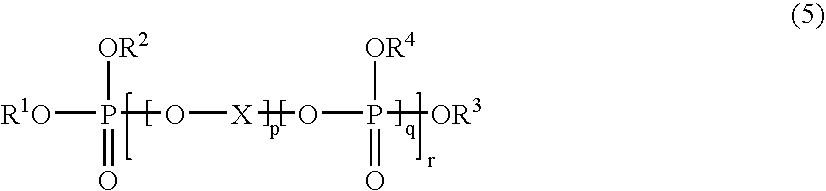

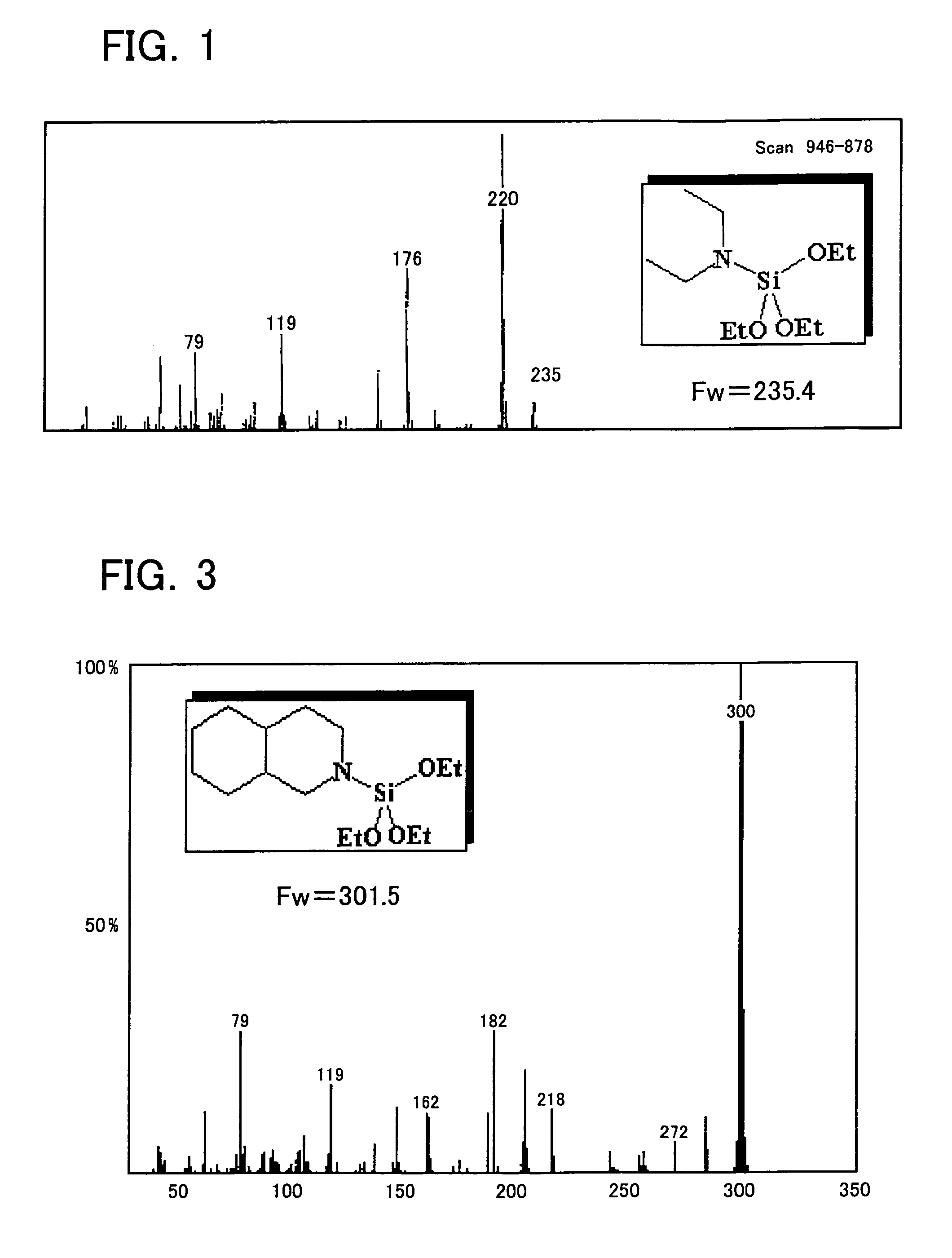

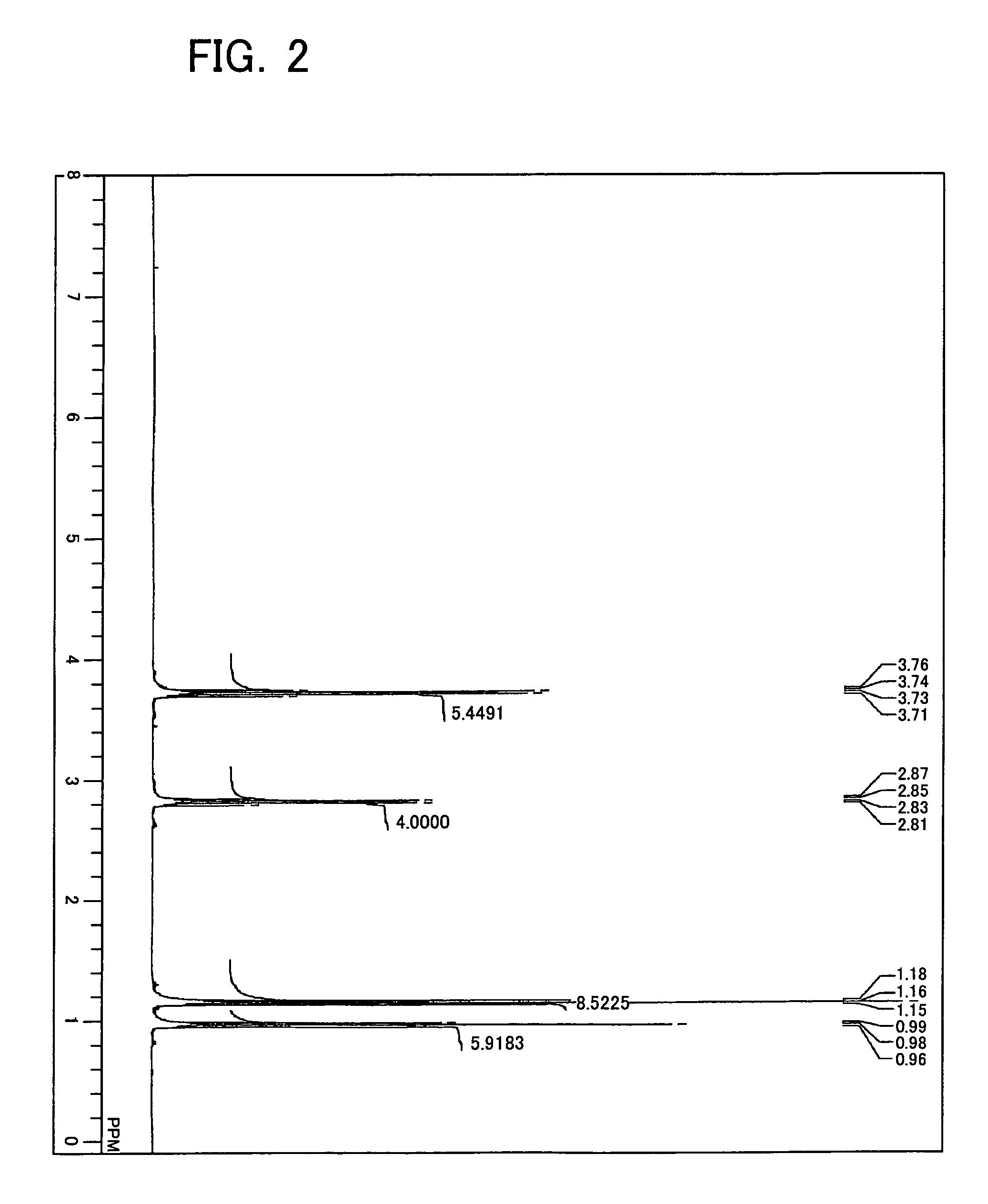

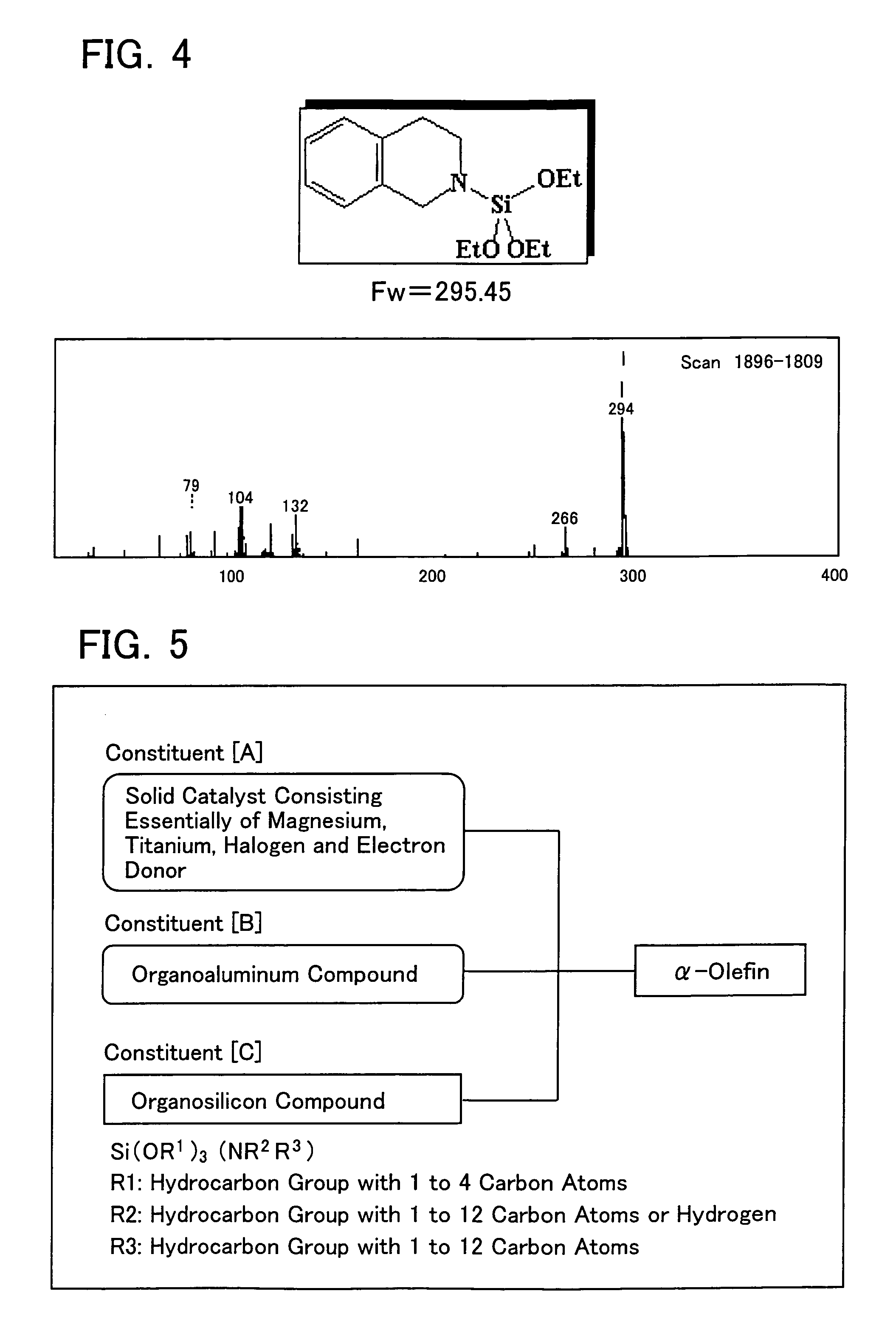

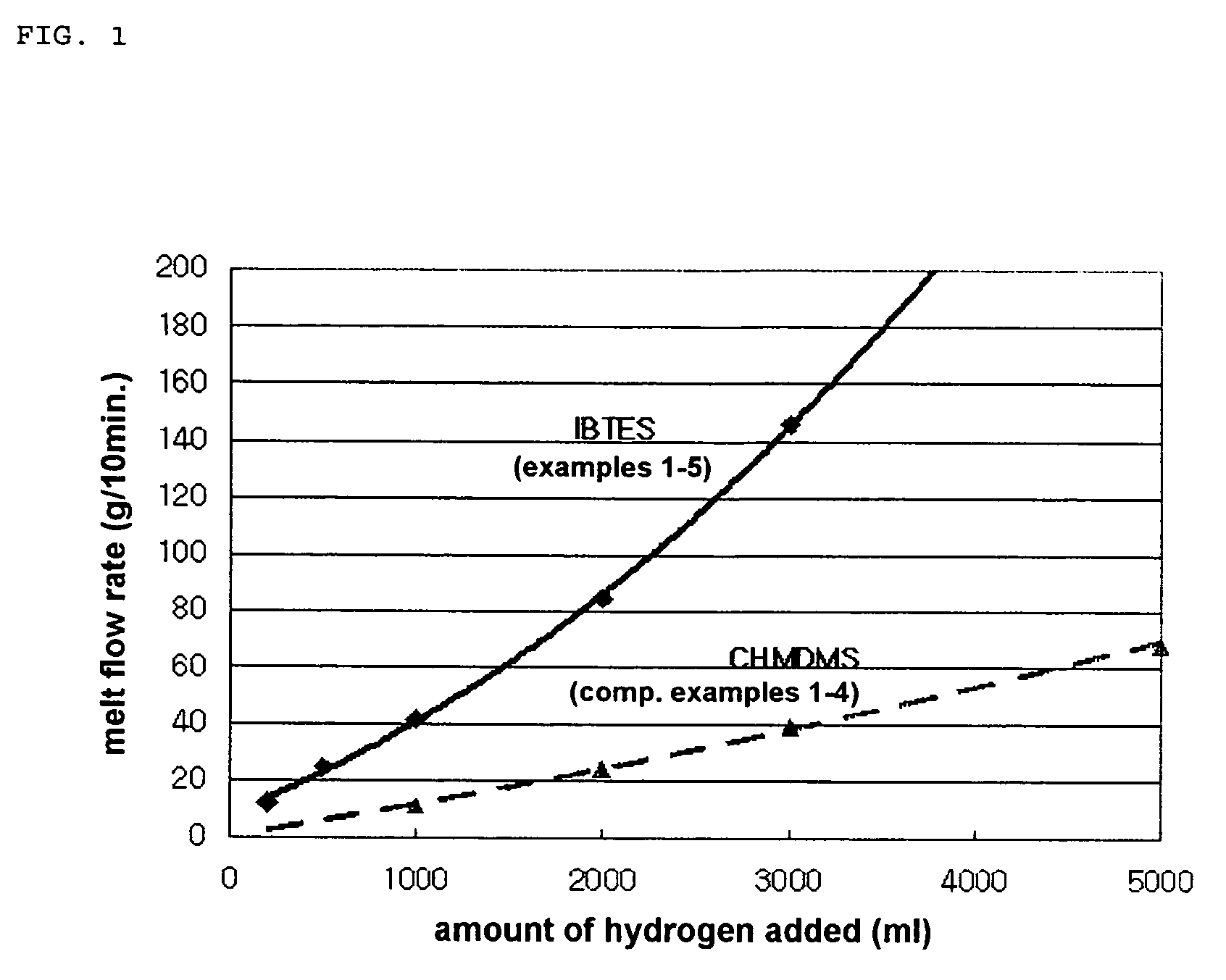

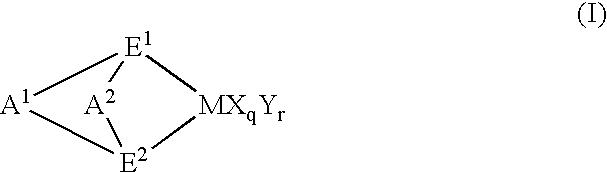

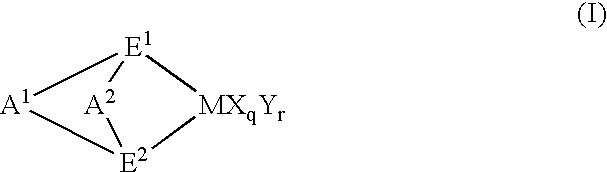

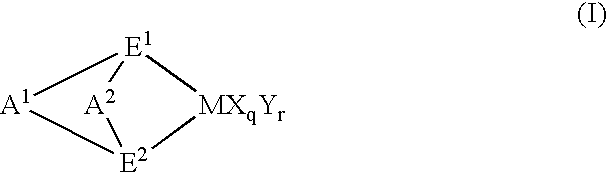

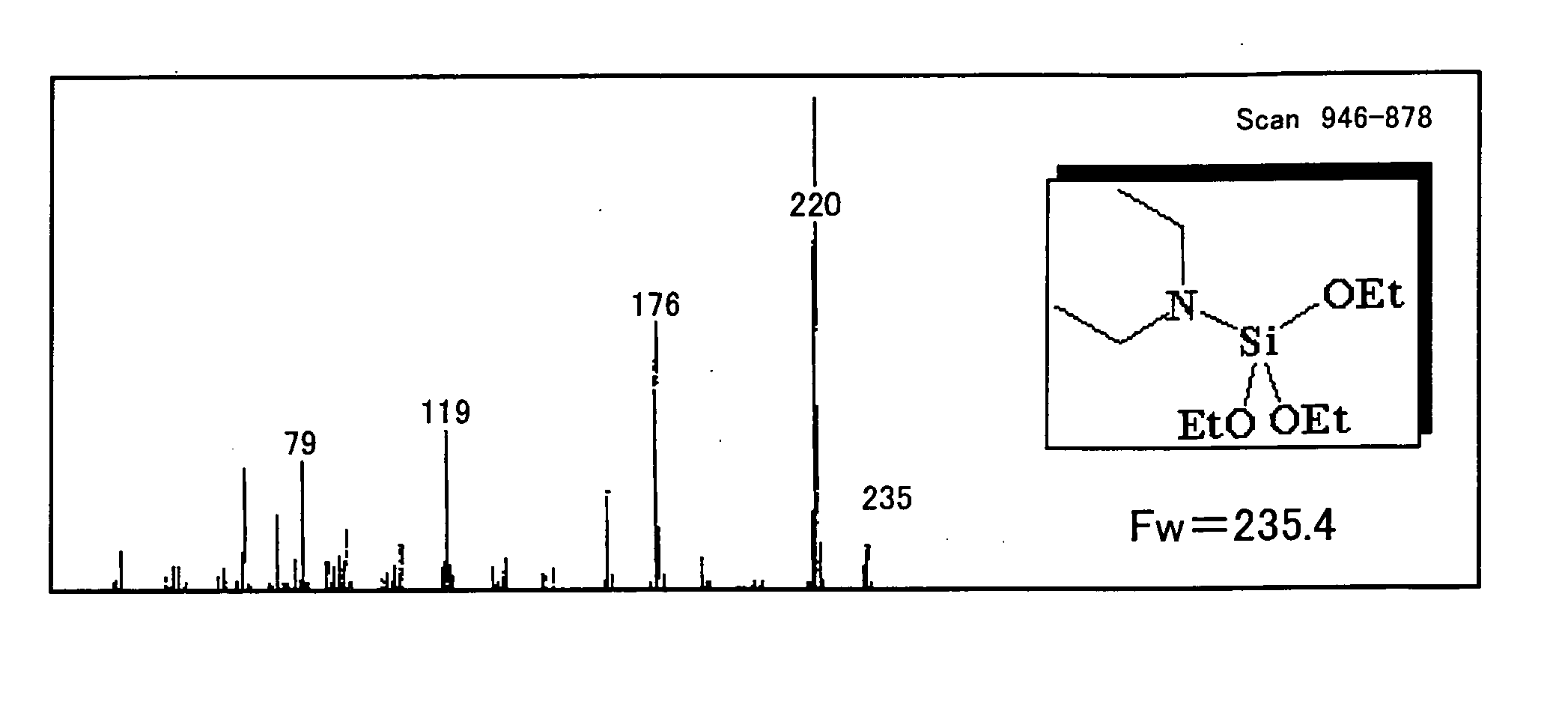

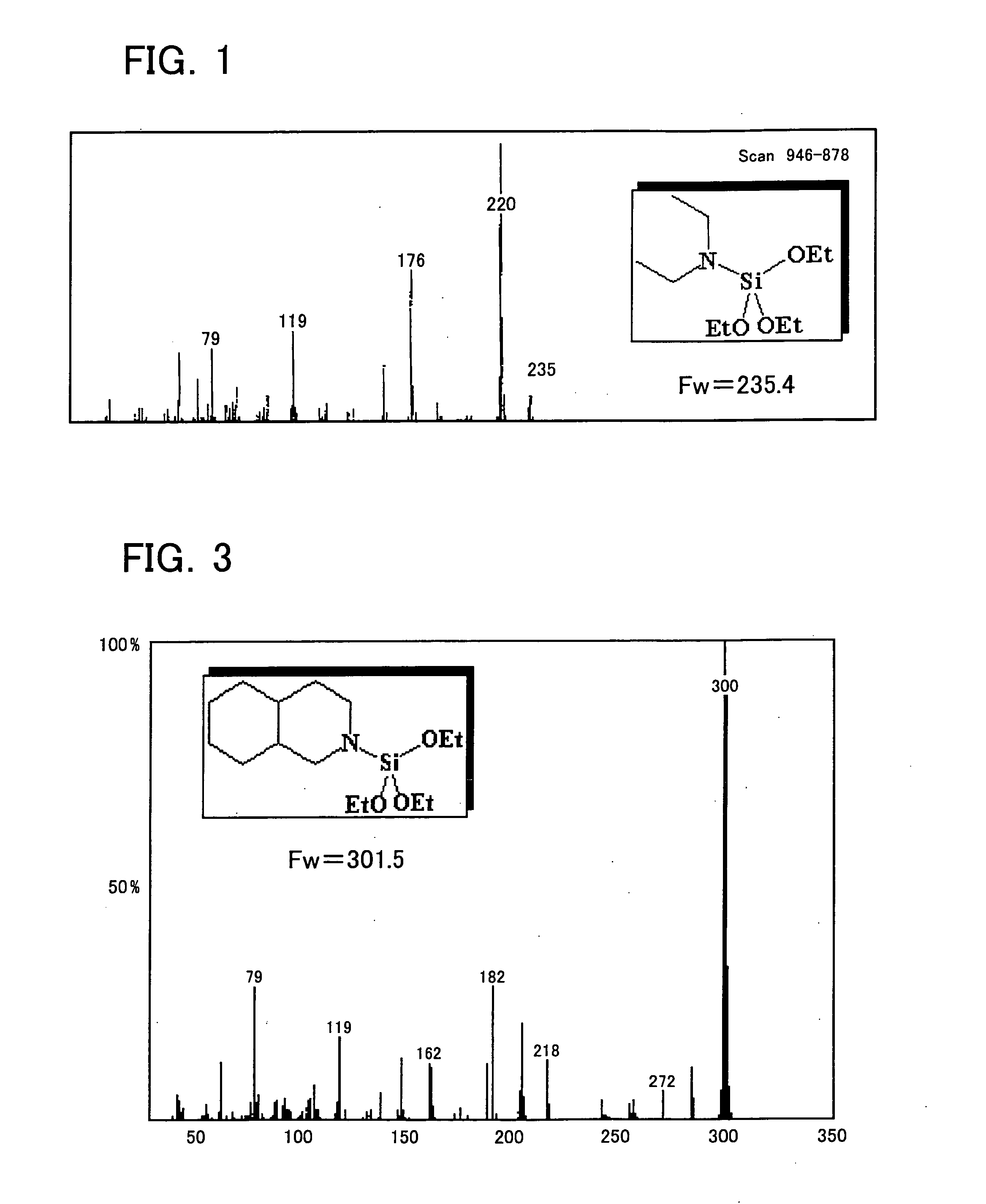

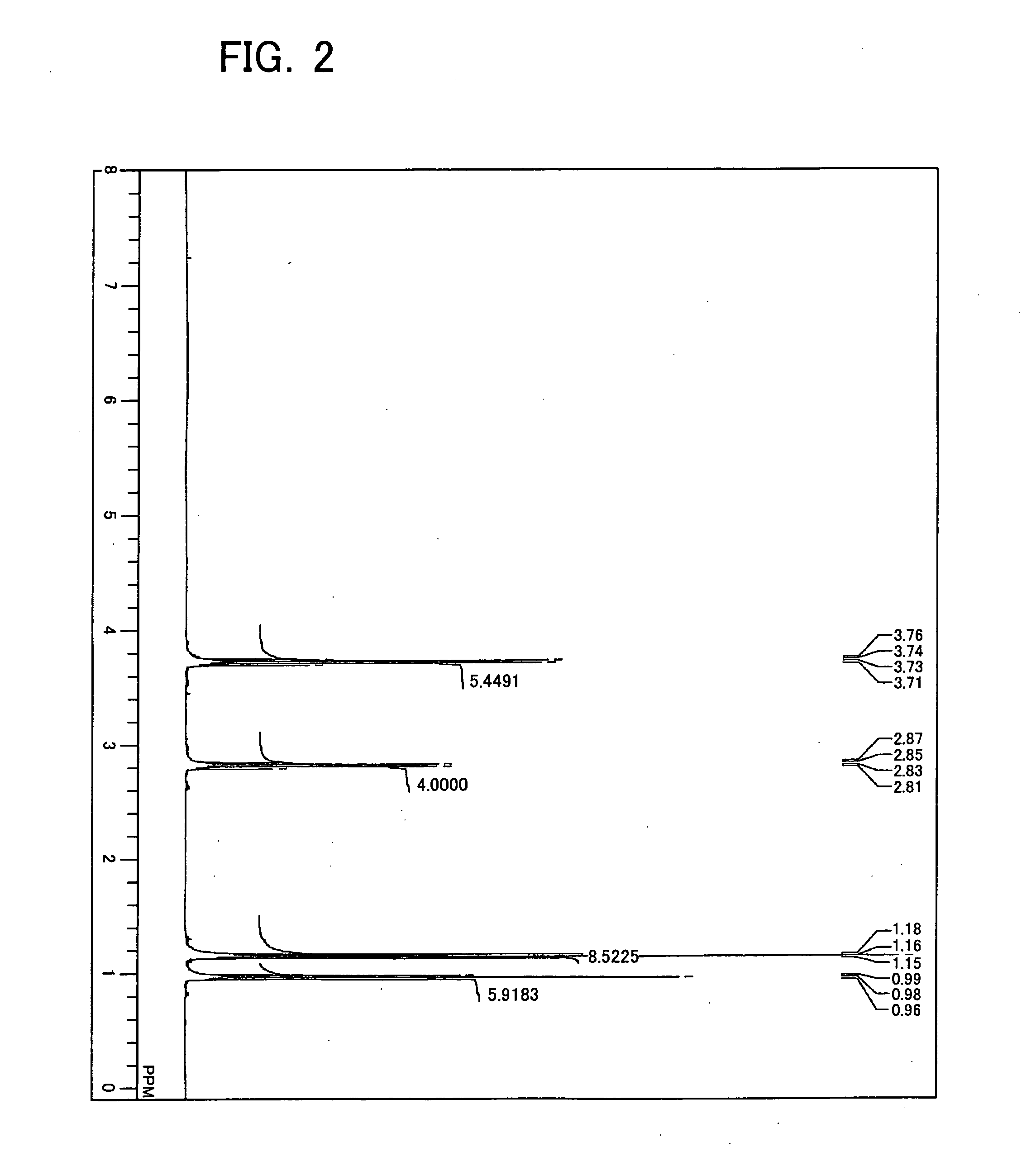

Catalysts for polymerization or copolymerization of α-olefins, catalyst components thereof, and processes for polymerization of α-olefins with the catalysts

InactiveUS7238758B2Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenReaction rate

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38:Si(OR1)3(NR2R3)Formula 37(where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms)RNSi(OR1)3Formula 38(where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

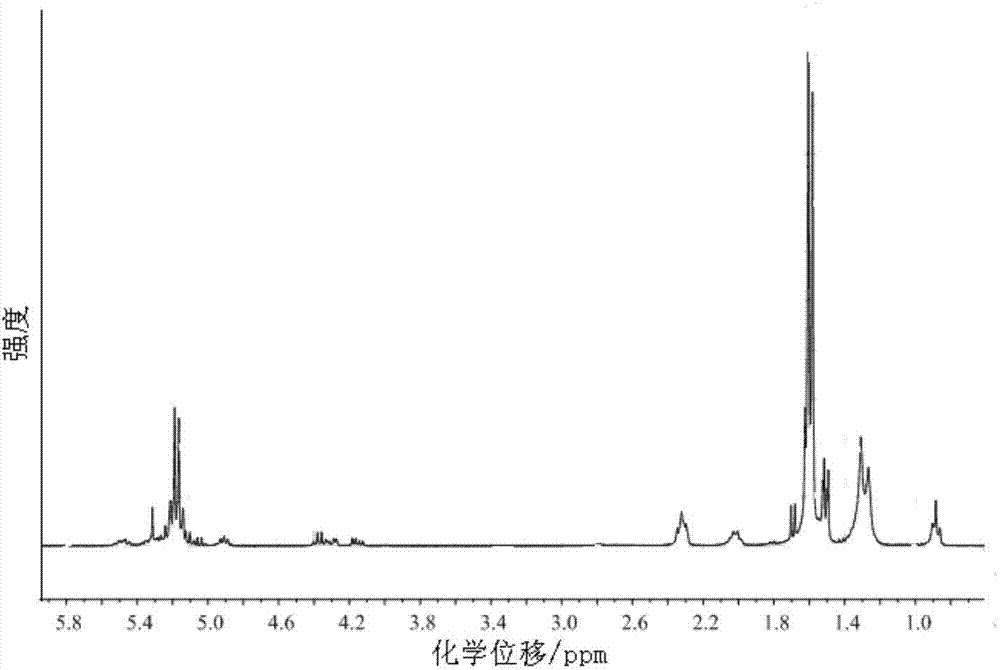

Method for producing propylene polymer having a very high melt-flowability

ActiveUS7244794B2Ensure effective applicationHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

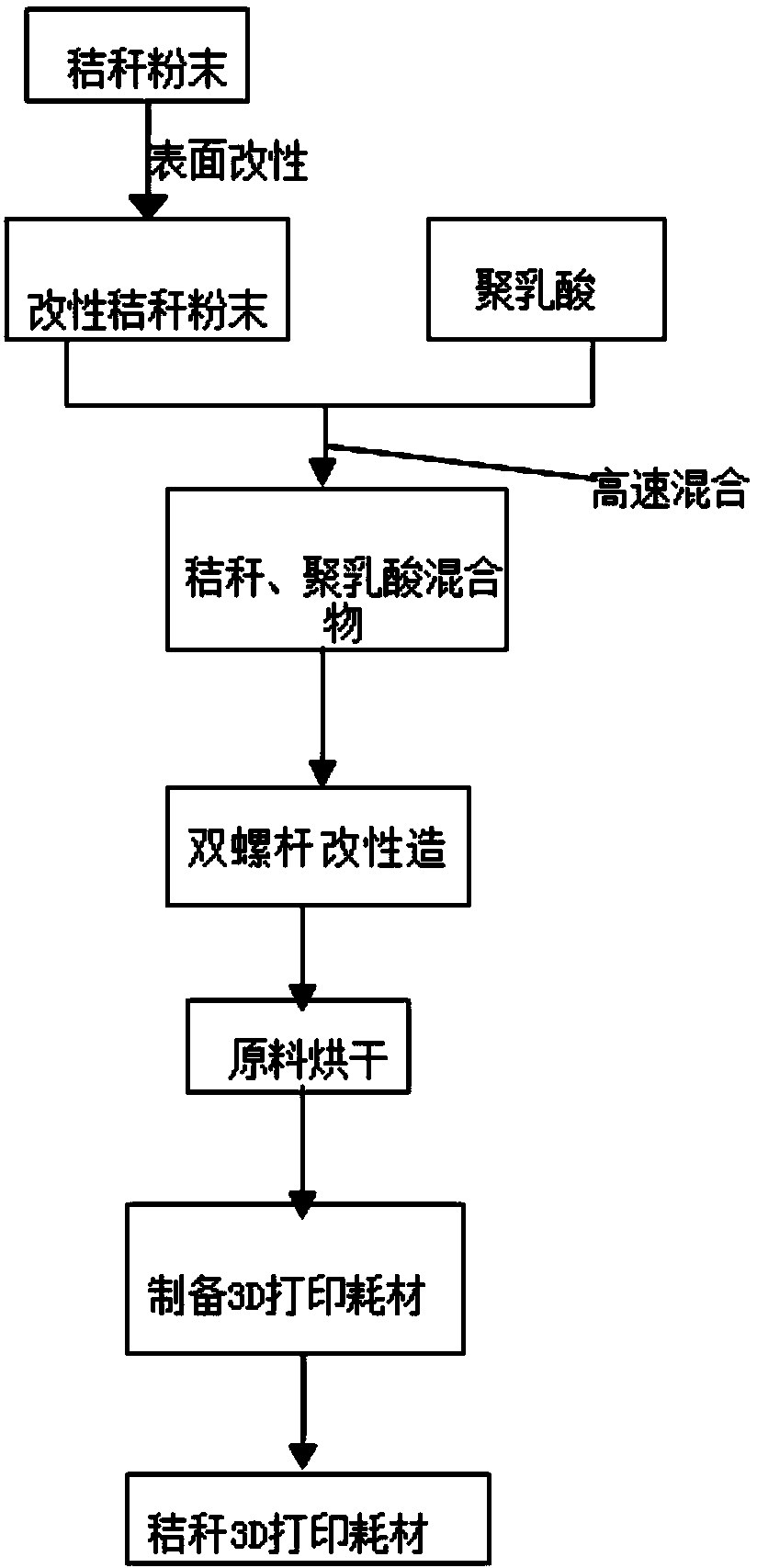

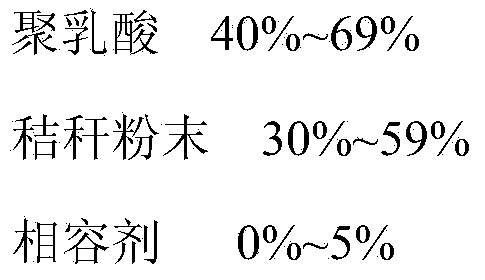

Straw 3D printing consumable and preparation method thereof

The invention provides a straw 3D printing consumable and a preparation method thereof. The formula includes the following raw materials in mass percentage: 40 to 69 percent of polylactic acid, 30 to 59 percent of straw powder, 0 to 5 percent of a compatilizer, and 0.2 to 3 percent of other additives. Straws, a crop byproduct, are fully utilized by the straw 3D printing consumable for surface modification, and the degradable material polylactic acid is added for melt blending. Compared with the prior art, the 3D printing material provided by the invention has stable performances, can replace common 3D plastic consumables in 3D printing, is non-toxic, low-carbon and environment-friendly, and has superior comprehensive performances, thereby achieving considerable economic value and broad market prospects.

Owner:芜湖瀚博电子科技有限公司

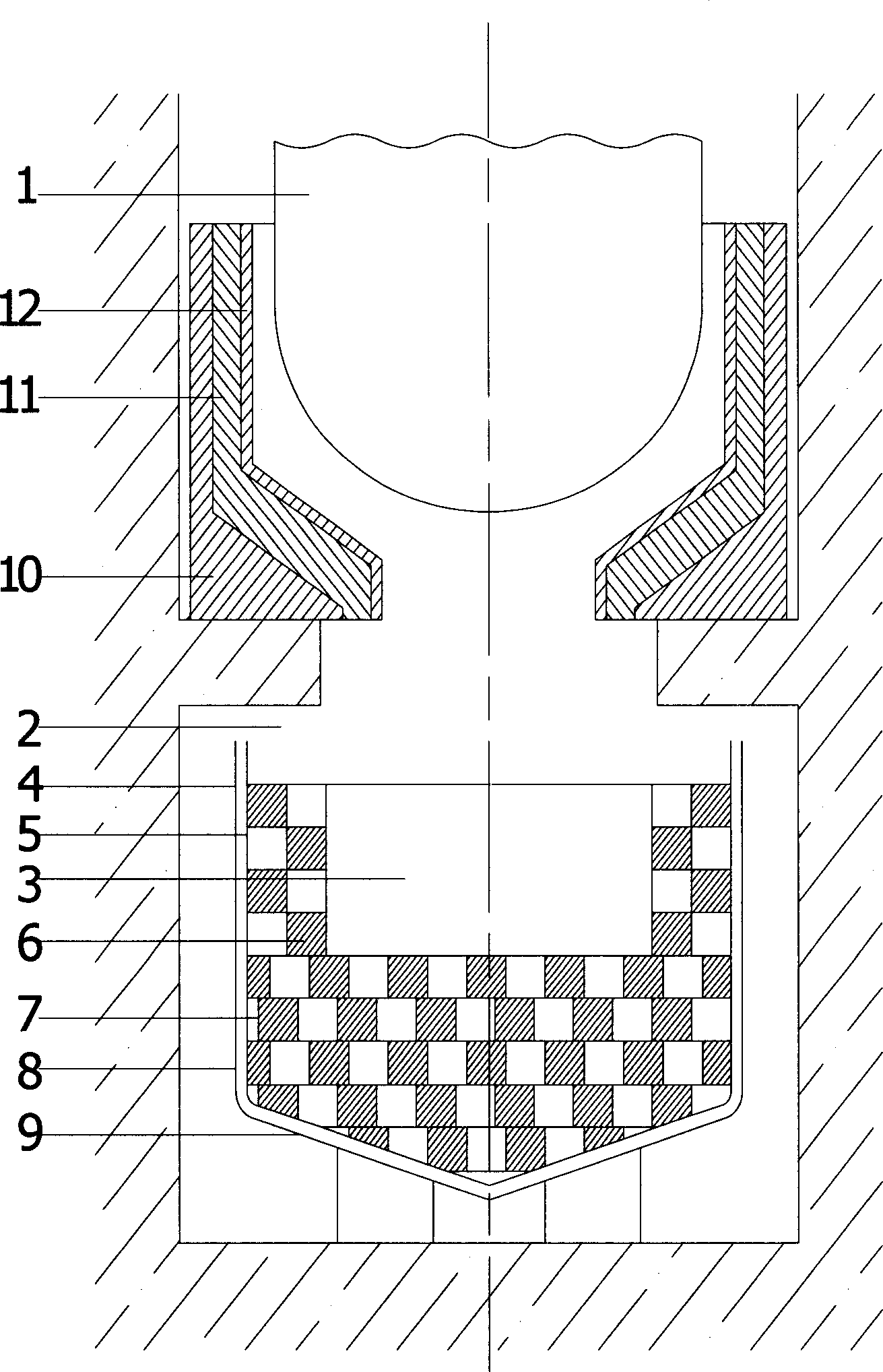

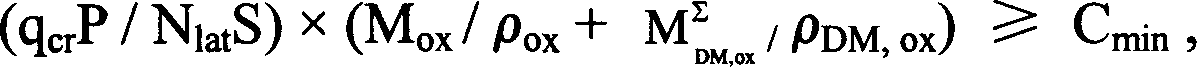

Apparatus for positioning and cooling lining layer of damaged LWR nuclear reactor

InactiveCN1585034AImprove melt fluidityImprove cooling conditionsNuclear energy generationEmergency protection arrangementsCore catcherNuclear reactor

The invention relates to apparatus for positioning and cooling melting lining layer when the melting lining layer flows out of the reactor shell during accident. The improvements of invention are described as following: the design of the cooling lining layer trap which has steel basket shell and arranged in sub-reactor, wherein sacrifice material is filled in the steel basket for diluting the component containing uranium and steel component of the lining layer; the shape (arrangement) of the sacrifice material in reactor core; the choice for optimum number of the sacrifice material; installation of guiding device used for the lining layer flowing into the reactor core trap. Especially, the thickness of bottom of the cooling jacket is larger than the thickness of the side wall thereof for no less than 30%, and the cooling jacket inclines to its center for 10 to 20 degree; the diluent and sacrifice material is made into blocks packed in steel shell.

Owner:V·B·哈本斯基 +17

Application of hyperbranched polyester to plastic processing

The invention discloses an application of hyperbranched polyester to plastic processing, and belongs to the technical field of plastic processing assistants. The application of the hyperbranched polyester to plastic processing includes the steps that by mass, 0.1% to 5% of the hydroxyl-terminated hyperbranched polyester is added into plastic; the mixture is mixed to be even, extruded, prilled and dried, and a modified plastic product is obtained. According to the application, the plastic such as PPC and the hyperbranched polyester are melted and blended, and the plastic such PPC is modified through a double-screw extruder; after the hyperbranched polyester is added into a base material of the plastic such as PPC, the effective melt viscosity of the plastic such as PPC can be remarkably reduced; in other words, processing temperature and thermal degradation are reduced; in addition, melting fluidity improved in this way can also be achieved through the small adding amount,, and extruding film forming can be more easily achieved; the tensile strength of the modified plastic such as PPC is up to 30 MPa, and the strength can be higher than the strength of thin-film-level LLDPE and the strength of thin-film-level PVC.

Owner:WEIHAI CY DENDRIMER TECH

Multi-element heat-resistant aluminum alloy material with high strength and preparation method thereof

ActiveUS20120152414A1Improve mechanical propertiesImprove corrosion resistanceTransportation and packagingMetal-working apparatusHeat resistanceUltimate tensile strength

A heat-resistant aluminum alloy material with high strength and preparation method thereof are provided. The aluminum alloy material comprises (by weight %): Cu: 1.0˜10.0, Mn: 0.05˜1.5, Cd: 0.01˜0.5, Ti: 0.01˜0.5%, B: 0.01˜0.2 or C: 0.0001˜0.15, Zr: 0.01˜1.0, R: 0.001˜3 or (R1+R2): 0.001˜3, RE: 0.05˜5, and balance Al:, wherein, R, R1, and R2 include Be, Co, Cr, Li, Mo, Nb, Ni, W. The Al alloy has the advantages of narrow quasi-solid phases temperature range of alloys, low hot cracking liability during casting improved high temperature strength and high heat resistance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Low-emanation automobile inner fitting special-purpose material and preparation thereof

The invention relates to a kind of low emission type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, organic expellent of low molecule 1.0-3.0 parts, antioxidant 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and organic expellent of low molecule, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 3) three-stage vacuum extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

Block copolymer

A block copolymer is obtained by anionic polymerization, includes two or more polymer blocks A miscible with each other, and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A, has a ratio [Mn(Amax) / Mn(Amin)] of 2 or more, wherein the ratio [Mn(Amax) / Mn(Amin)] is the ratio of the largest number average molecular weight [Mn(Amax)] to the smallest number average molecular weight [Mn(Amin)] among the polymer blocks A, has at least one block bonding including polymer block Amax-polymer block B-polymer block Amin, and has a total content of the polymer blocks A ranging from 20 wt % to 45 wt % based on the total mass of the block copolymer.This invention provides block copolymers having two or more polymer blocks A miscible with each other and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A and exhibiting satisfactory flexibility, melt fluidity, moldability, coatability, mechanical properties, and other properties. The block copolymers of the present invention can yield molded articles having reduced anisotropy and surface stickiness and excellent mechanical properties and pressure-sensitive adhesive compositions having excellent adhesive properties.

Owner:KURARAY CO LTD

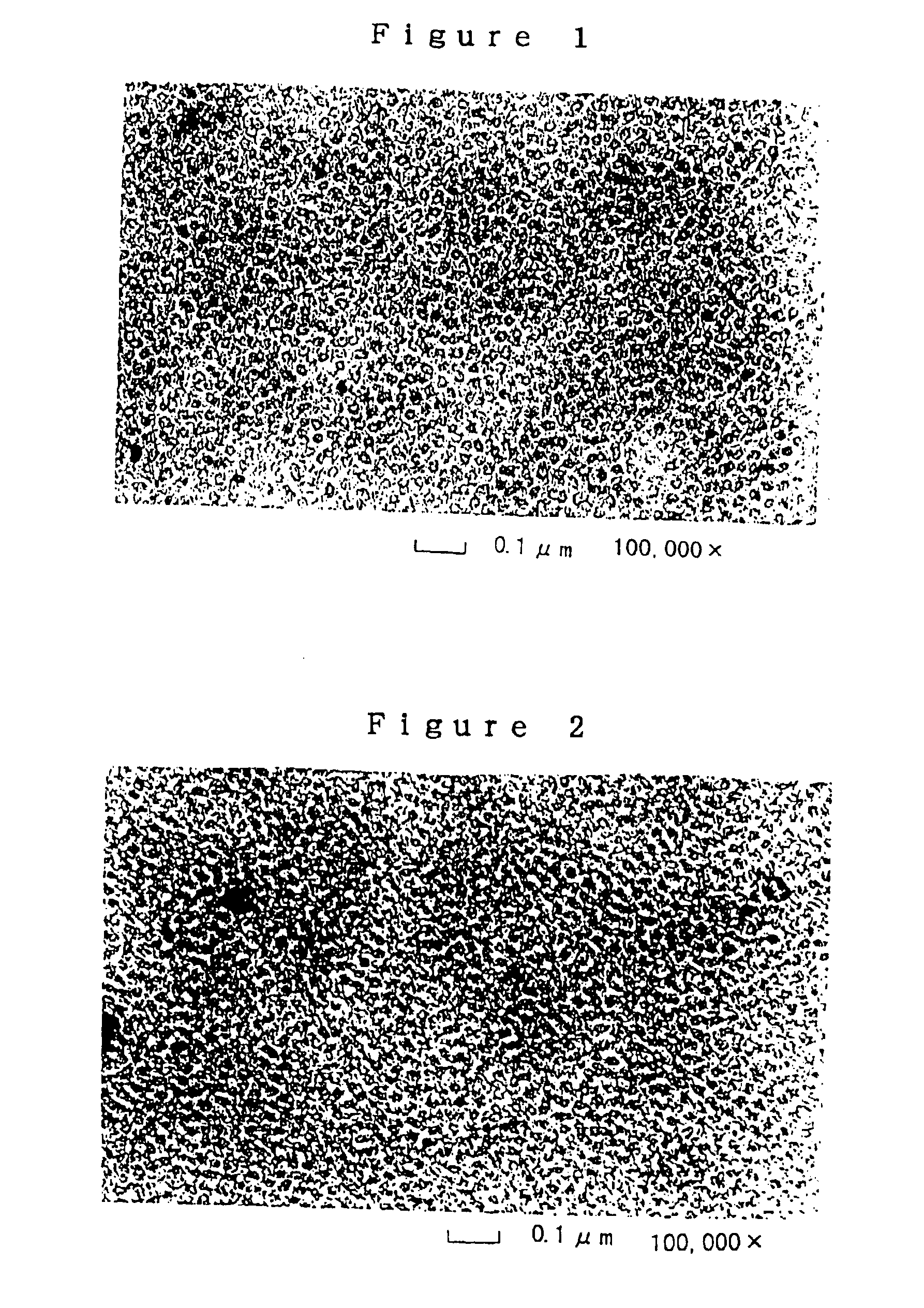

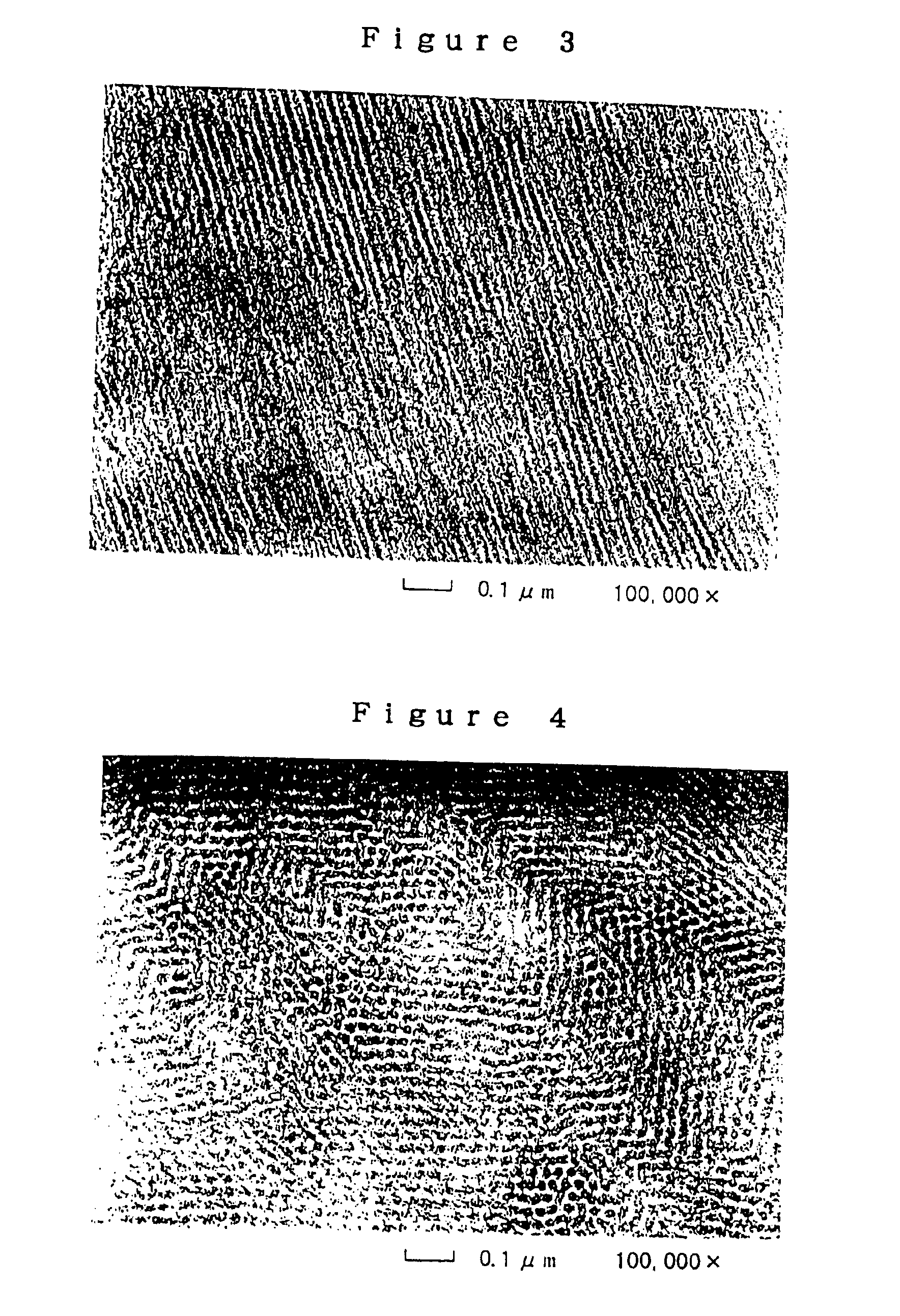

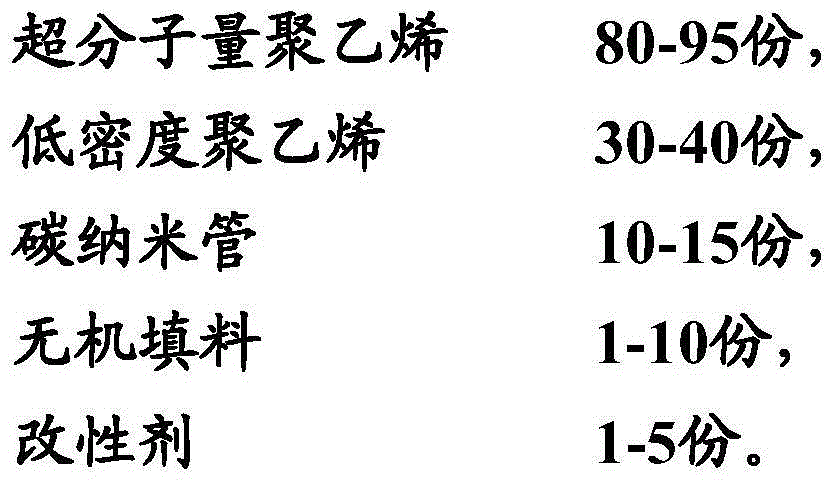

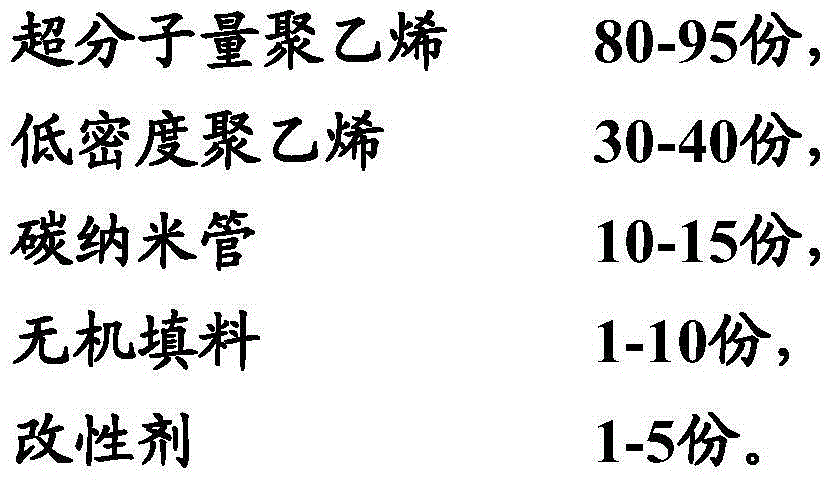

Modified ultrahigh molecular polyethylene for 3D printing and preparation method thereof

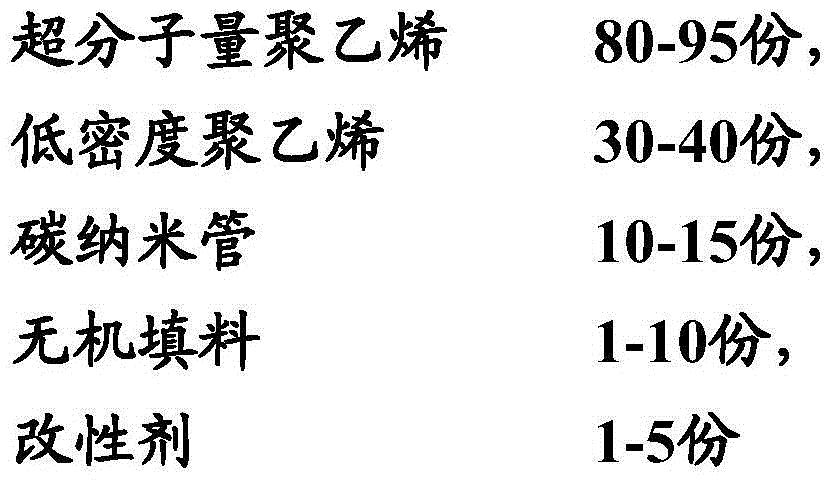

ActiveCN103980595AImprove melt fluiditySuitable for 3D printingLow-density polyethylenePolymer science

A modified ultrahigh molecular polyethylene material for 3D printing comprises the following components, by weight, 80-95 parts of ultrahigh molecular polyethylene, 30-40 parts of low-density polyethylene, 10-15 parts of carbon nanotube, 1-10 parts of an inorganic filling material, 1-5 parts of a modifier, 0.1-0.5 part of an antioxidant and 0.1-0.5 part of a coupling agent. The modified UHMWPE material provided by the invention has good melt fluidity, heat resistance and abrasion resistance. By the preparation method, the ultrahigh molecular polyethylene is more in line with characteristics of a 3D printing material, and the ultrahigh molecular polyethylene has a wide application prospect in the 3D printing technology.

Owner:INST OF CHEM CHINESE ACAD OF SCI

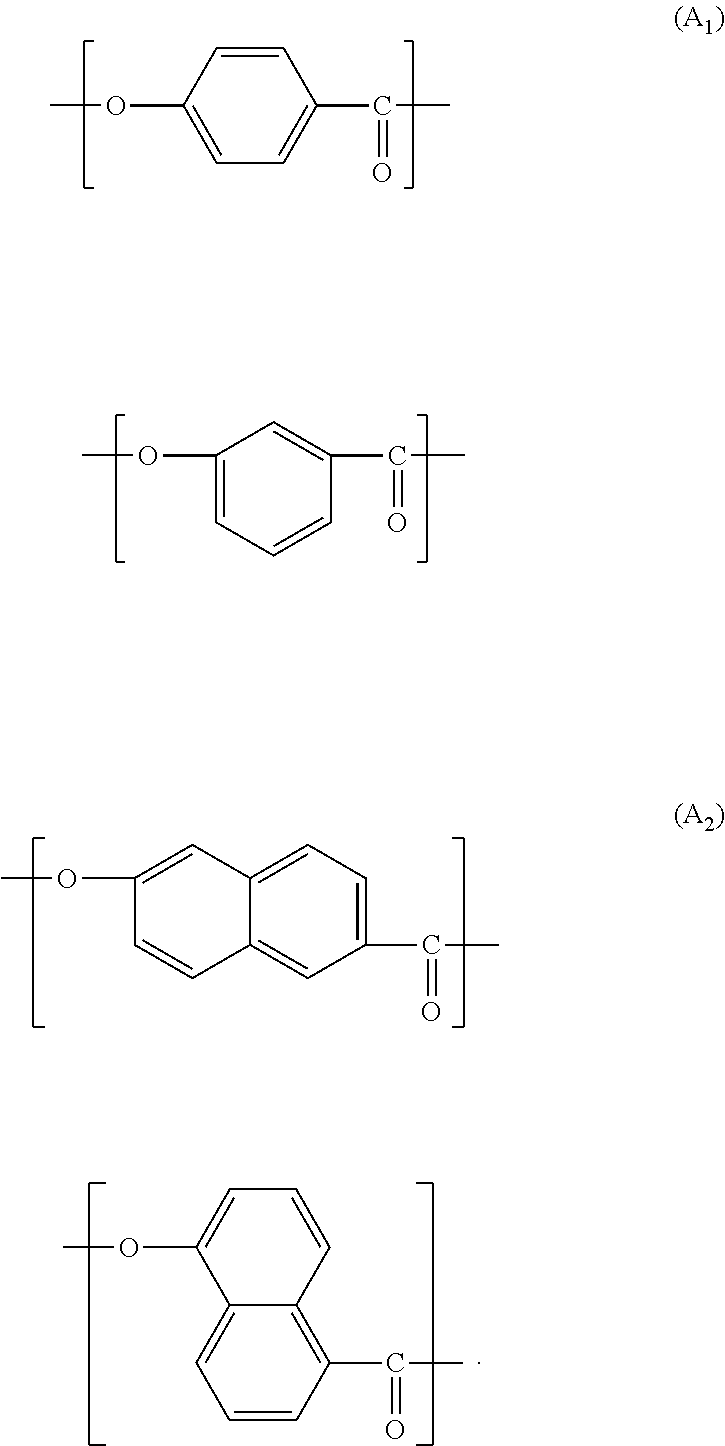

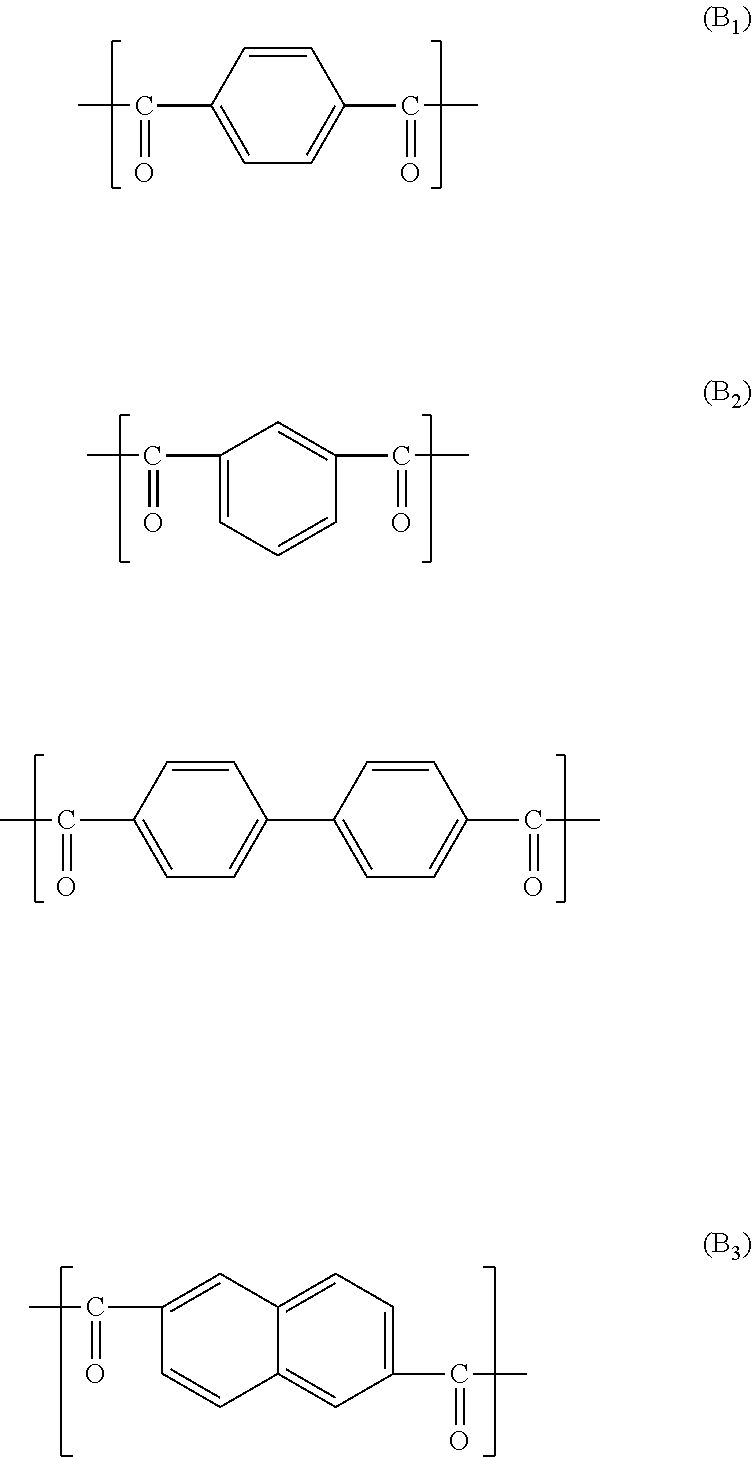

Liquid crystalline polyester composition, method for producing the same, and connector

InactiveUS20110189454A1InhibitionHigh mechanical strengthSynthetic resin layered productsSpecial tyresCrystallographyLiquid crystalline

The present invention provides a composition comprising a liquid crystalline polyester, a plate-like filler and a carbon black having a number average particle size of more than 20 nm and 45 nm or less. The composition is less likely to cause blister even at a high temperature.

Owner:SUMITOMO CHEM CO LTD

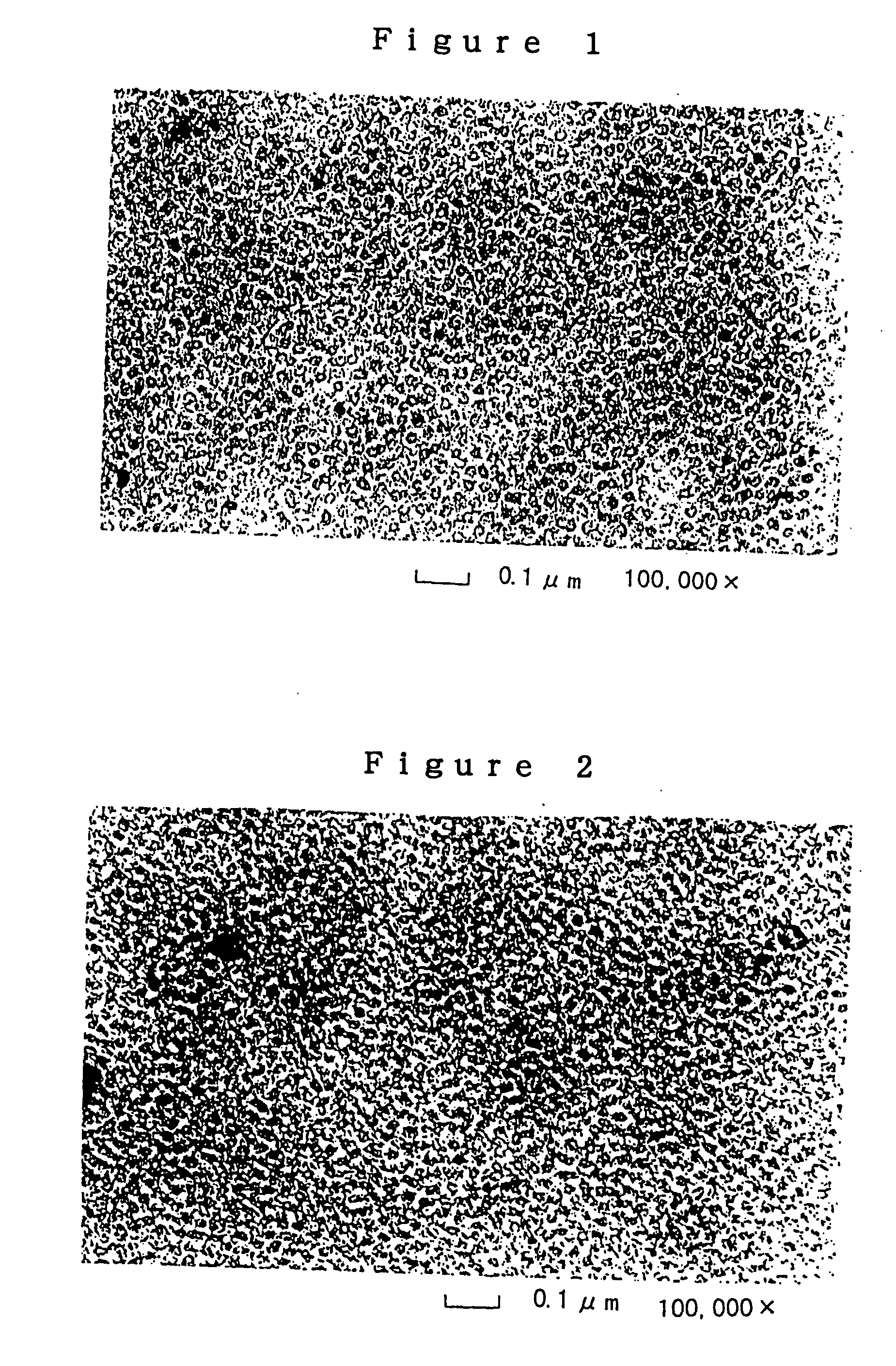

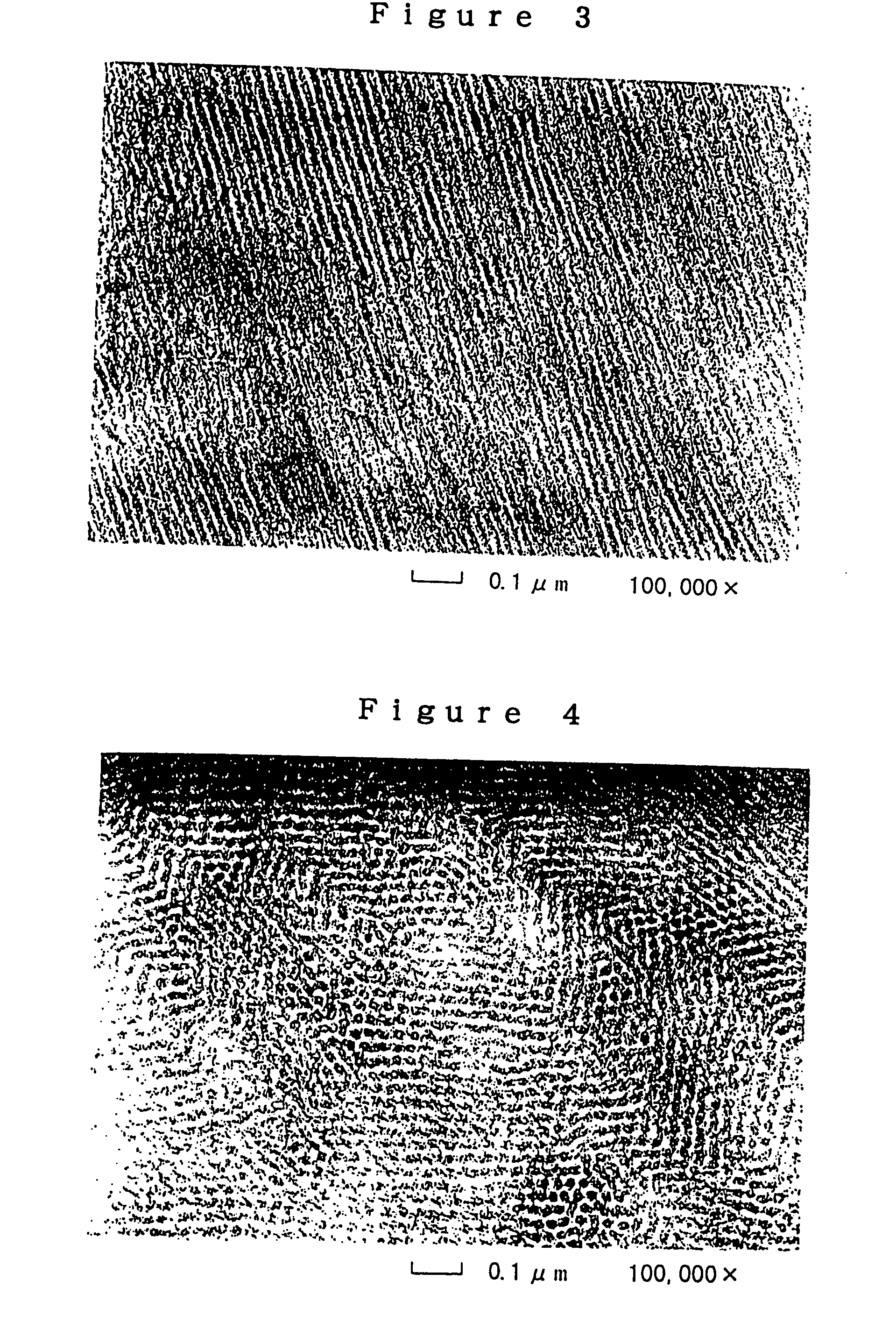

Preparation method of PTFE (polytetrafluoroethylene) copper-clad plate with high elastic modulus

InactiveCN102166852ALow dielectric constantLow elastic modulusGlass/slag layered productsMetal layered productsGlass fiberPolymer science

The invention provides a preparation method of a PTFE (polytetrafluoroethylene) copper-clad plate with a high elastic modulus, which comprises the following steps of: preparing copper foil and glass fiber cloth with a low dielectric constant, and preparing a fluororesin mixture; soaking the glass fiber cloth with the prepared fluororesin mixture, transferring the soaked glass fiber cloth into a baking oven for baking and drying, and repeating the steps to enable the glass fiber cloth to be soaked, baked and dried many times, thereby obtaining soaking pieces the resin content of which is about 60-70%; and superposing the soaking pieces, coating the copper foil on two sides, and laminating to obtain the PTFE copper-clad plate. The baking and drying process comprises three stages, wherein the temperature of the baking oven in the first stage is 50-100 DEG C, the temperature of the baking oven in the second stage is 200-320 DEG C, and the temperature of the baking oven in the third stage is 380-400 DEG C. The plate prepared by the method provided by the invention not only has a lower dielectric constant but also has a higher elastic modulus, and the plate has the advantages of consistent internal structure and good dimensional stability.

Owner:GUANGDONG SHENGYI SCI TECH

Low-diffusion modified polypropylene composite material and preparation method thereof

ActiveCN101817953BHigh surface glossImprove impact resistancePolypropylene compositesMolecular sieve

Owner:SUZHOU SUNWAY POLYMER

Scraping-resistant automobile inner fitting special-purpose material and preparation thereof

ActiveCN101255253AExcellent surface scratch resistanceLow costUltimate tensile strengthPolypropylene

The invention relates to a kind of scraping tolerance type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, lubricant 0.5-3.0 parts, antioxidant1010 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and lubricant, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes; 3) stirring and mixing at rotate speed of 1500-2000 rpm for 10-15 minutes; 4) stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 5) extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

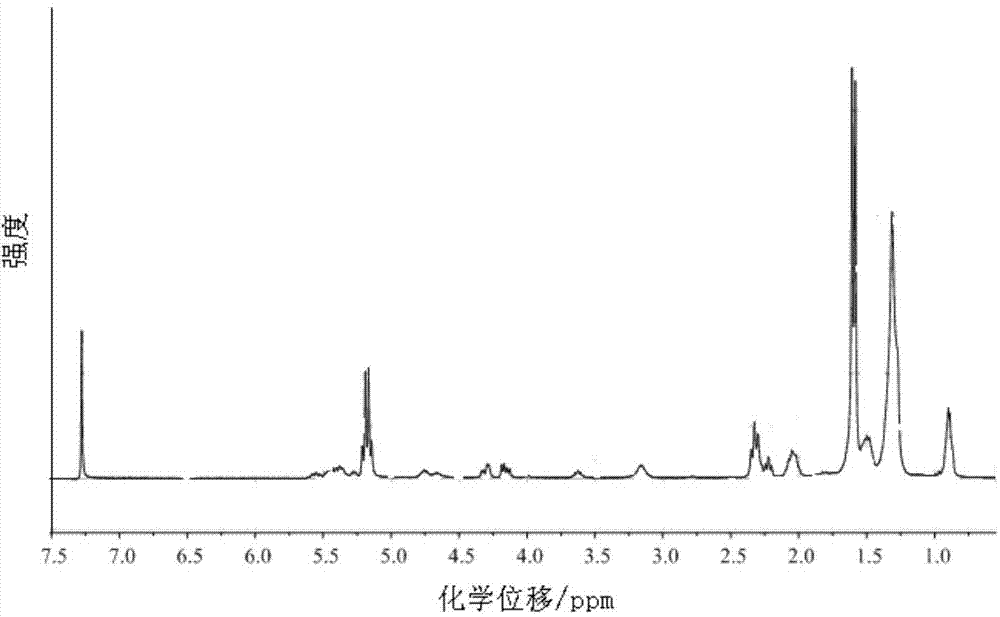

Propylene polymer and composition containing the same, molded object and laminate comprising these, and processes for producing propylene polymer and composition containing the same

InactiveUS6906155B1Improve melt fluidityLess amountOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPliabilityPropylene Polymers

A propylenic polymer according to the present invention or a composition thereof have an excellent melt flowability and contains a less amount of stickiness-causing components, and also has a low modulus and is pliable, and is capable of providing a transparent molded article, thus being useful as a substitute for a pliable vinyl chloride resin. In addition, a molded article made therefrom exhibits an excellent heat seal performance at a low temperature, and is excellent in terms of transparency and rigidity. Specifically, it has an isotactic pentad fraction (mmmm), which indicates a stereoregulariry, of 30 to 80%, a molecular weight distribution (Mw / Mn) of 3.5 or less and an intrinsic viscosity [η] of 0.8 to 5 dl / g.

Owner:IDEMITSU KOSAN CO LTD

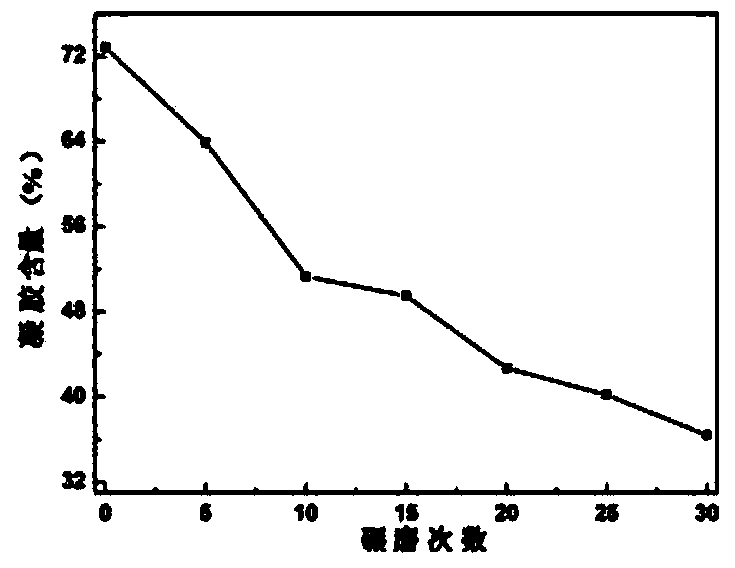

Waste crosslinked polyethylene recovered material and recovery method thereof

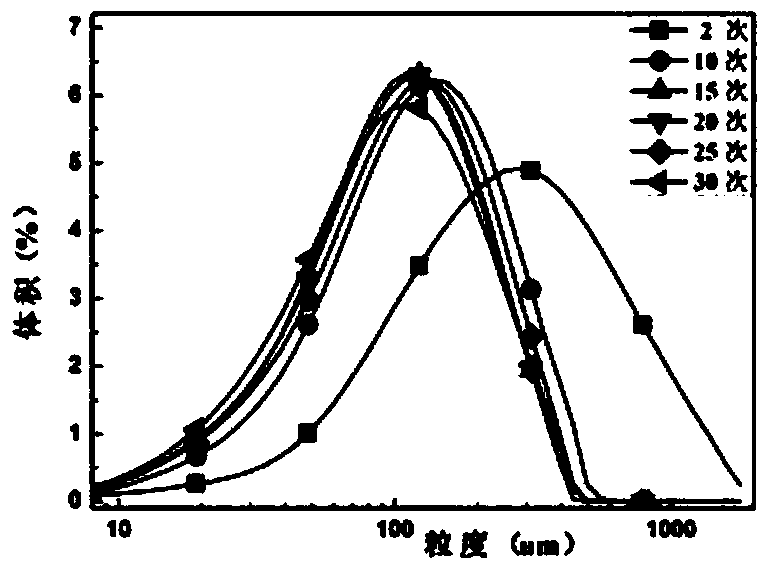

InactiveCN104385485AImprove melt fluidityImprove performancePlastic recyclingRecovery methodThermoplastic

The invention discloses a waste crosslinked polyethylene recovered material and a recovery method thereof. The waste crosslinked polyethylene recovered material comprises the following steps of crushing waste crosslinked polyethylene to obtain particles with sizes of 0.5-2cm, and grinding the particles by a solid-state mechanochemical reactor to obtain powder of 100-500 meshes, wherein in grinding, a cooling cycle water temperature is controlled in a range of 5-30 DEG C, grinding pressure is controlled in a range of 10-50MPa, a grinding rotation rate is controlled in a range of 10-1000rpm and grinding frequency is 5-30. A Soxhlet extraction device test result shows that the powder has gel content less than 60%. The recovery method can selectively cut out C-O bonds and Si-O bonds in waste crosslinked polyethylene, cut out cross bonds of a three dimensional crosslinking structure, change the original insoluble and non-melting characteristic, improve material thermoplastic and fusion fluidity, and provides thermoplastic processability for the waste crosslinked polyethylene recovered material. The waste crosslinked polyethylene recovered material can be processed to form high-value recovered materials and products with excellent performances by conventional thermoplastic processing processes such as extrusion and rolling.

Owner:SICHUAN UNIV

Powerful three-dimensional crimp memory fibers and production method thereof

InactiveCN103590139AAccurate measurementEasy to curlMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberMetallurgy

The invention relates to a powerful three-dimensional crimp memory fiber and a production method thereof. Raw materials employed include Poly(1,4-cyclohexylene dimethylene terephthalate) (PCT for short) and poly(trimethylene terephthalate) (PTT for short); and the raw materials are melted, mixed and subjected to blend spinning. According to the invention, a blend melt which is formed by melting and blending the polymers and even and stable in dispersion is subjected to spinning, drafting and the like, so that three-dimensional short fibers with very excellent crimp and memory properties can be obtained. On one hand, the PCT has very good crimp and compression reversion properties, and more easily form lots of dense crimps under the synergistic effect of the high elasticity performance of the PTT, and the PTT has extremely good memory performance and is capable of locking the crimps formed; and as a result, the powerful three-dimensional crimp memory fibers are capable of always keeping the oringinal crimp state.

Owner:YANGZHOU GUANGTAI CHEM FIBER

Polyarylether carbonitrile industrial production method

The industrial process of polyarylethernitrile, this invention relates to the Synthesis of polyarylethernitrile. Adding 2, 6-dichlorocyanobenzene, polyhydric phenol, anhydrous potassium carbonate, solvent NMPA, toluene in autoclave, heating-up the autoclave to 100-200 deg C in the condition of 2. 0-2. 5MPa in autoclave, heating-up the autoclave to 150-300deg C after 2-6h heat preservation, taking out the fixed object of autoclave after 1-6h heat preservation, getting the polyarylethernitrile after washing by boiling-water, desiccation and granulation. The production condition of this invention is easy to realize, the industrial process is easy to control, and the produced polyarylethernitrile is low in cost and suit to use of multirealm.

Owner:YANGZHOU TIANCHEN FINE CHEM

Block copolymer

A block copolymer is obtained by anionic polymerization, includes two or more polymer blocks A miscible with each other, and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A, has a ratio [Mn(Amax) / Mn(Amin)] of 2 or more, wherein the ratio [Mn(Amax) / Mn(Amin)] is the ratio of the largest number average molecular weight [Mn(Amax)] to the smallest number average molecular weight [Mn(Amin)] among the polymer blocks A, has at least one block bonding including polymer block Amax-polymer block B-polymer block Amin, and has a total content of the polymer blocks A ranging from 20 wt % to 45 wt % based on the total mass of the block copolymer. This invention provides block copolymers having two or more polymer blocks A miscible with each other and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A and exhibiting satisfactory flexibility, melt fluidity, moldability, coatability, mechanical properties, and other properties. The block copolymers of the present invention can yield molded articles having reduced anisotropy and surface stickiness and excellent mechanical properties and pressure-sensitive adhesive compositions having excellent adhesive properties.

Owner:KURARAY CO LTD

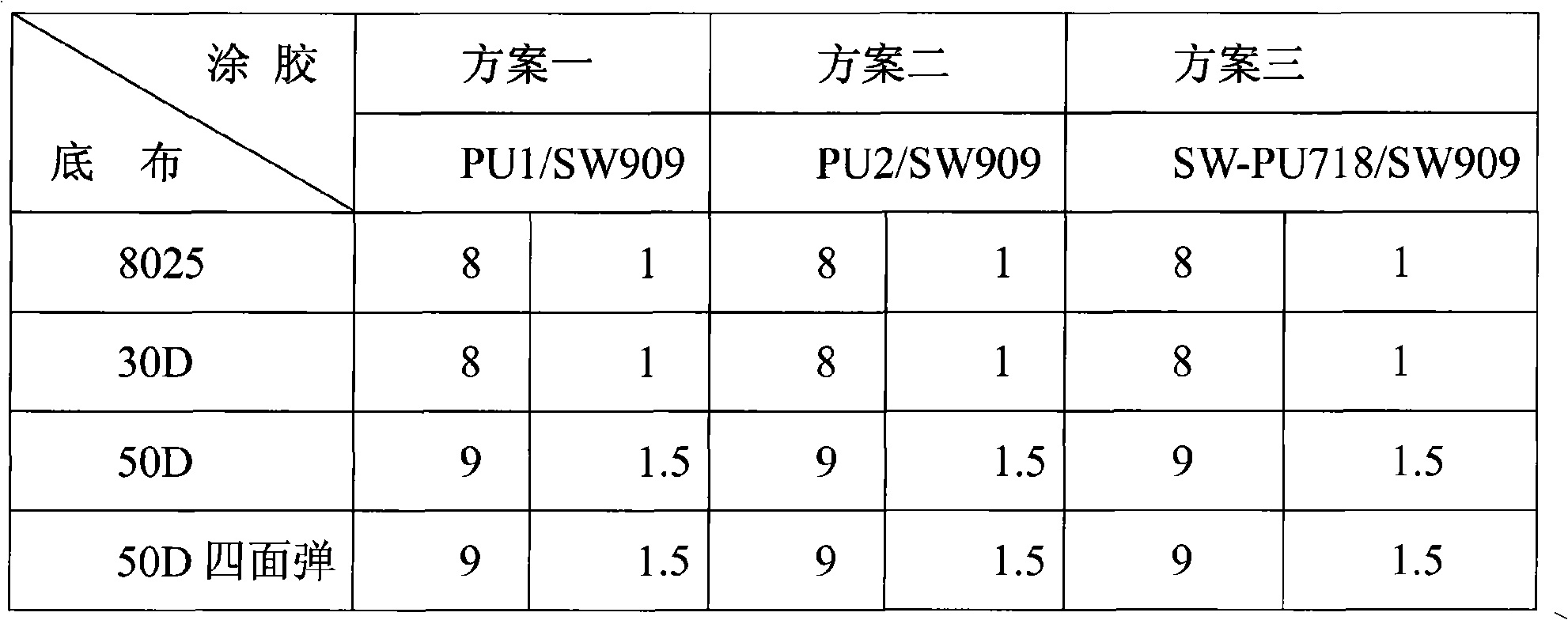

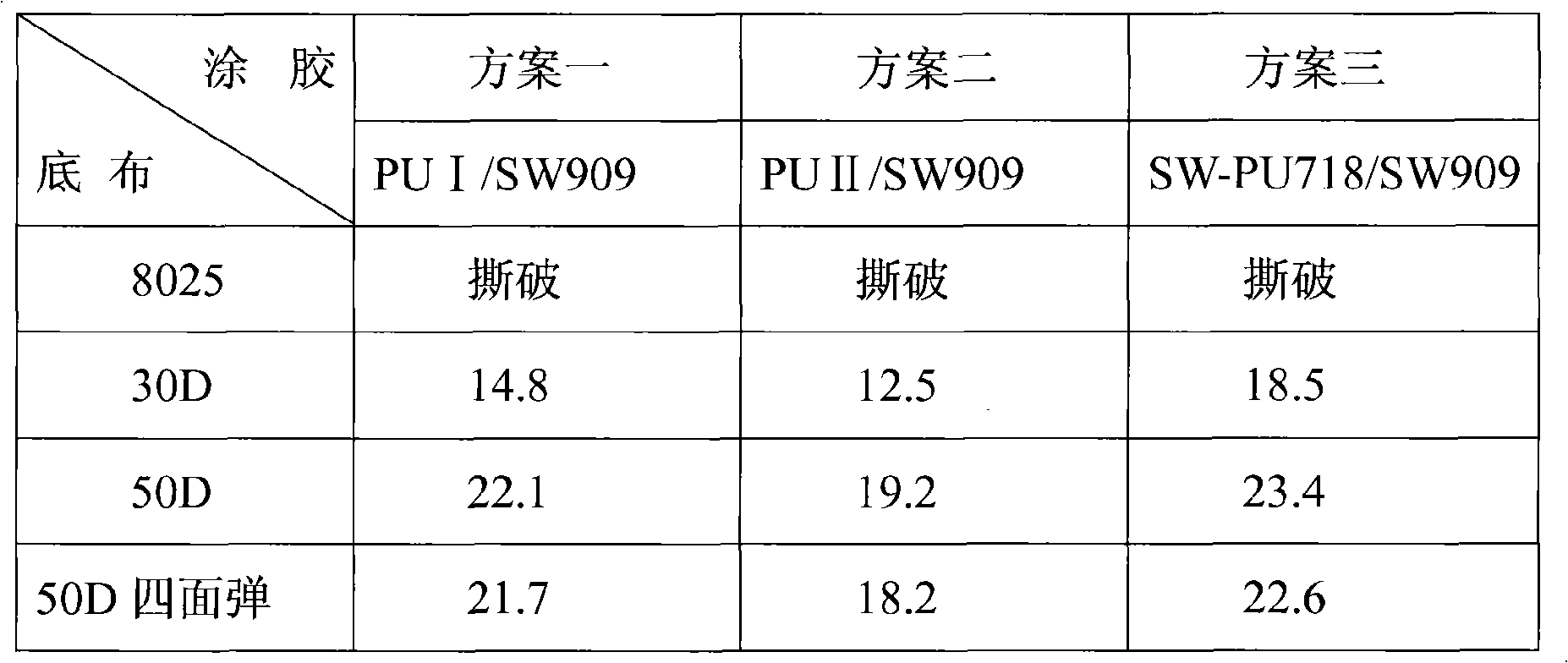

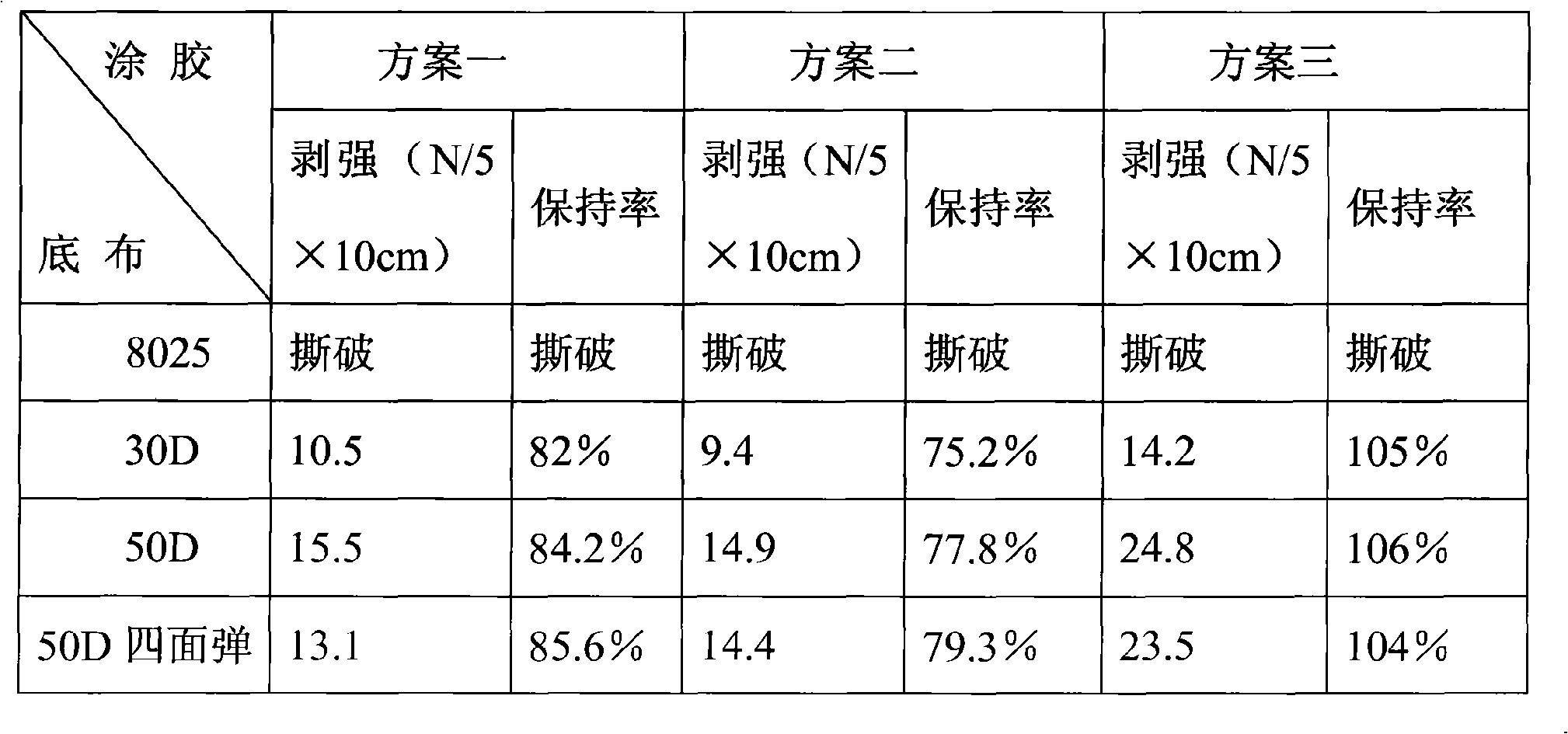

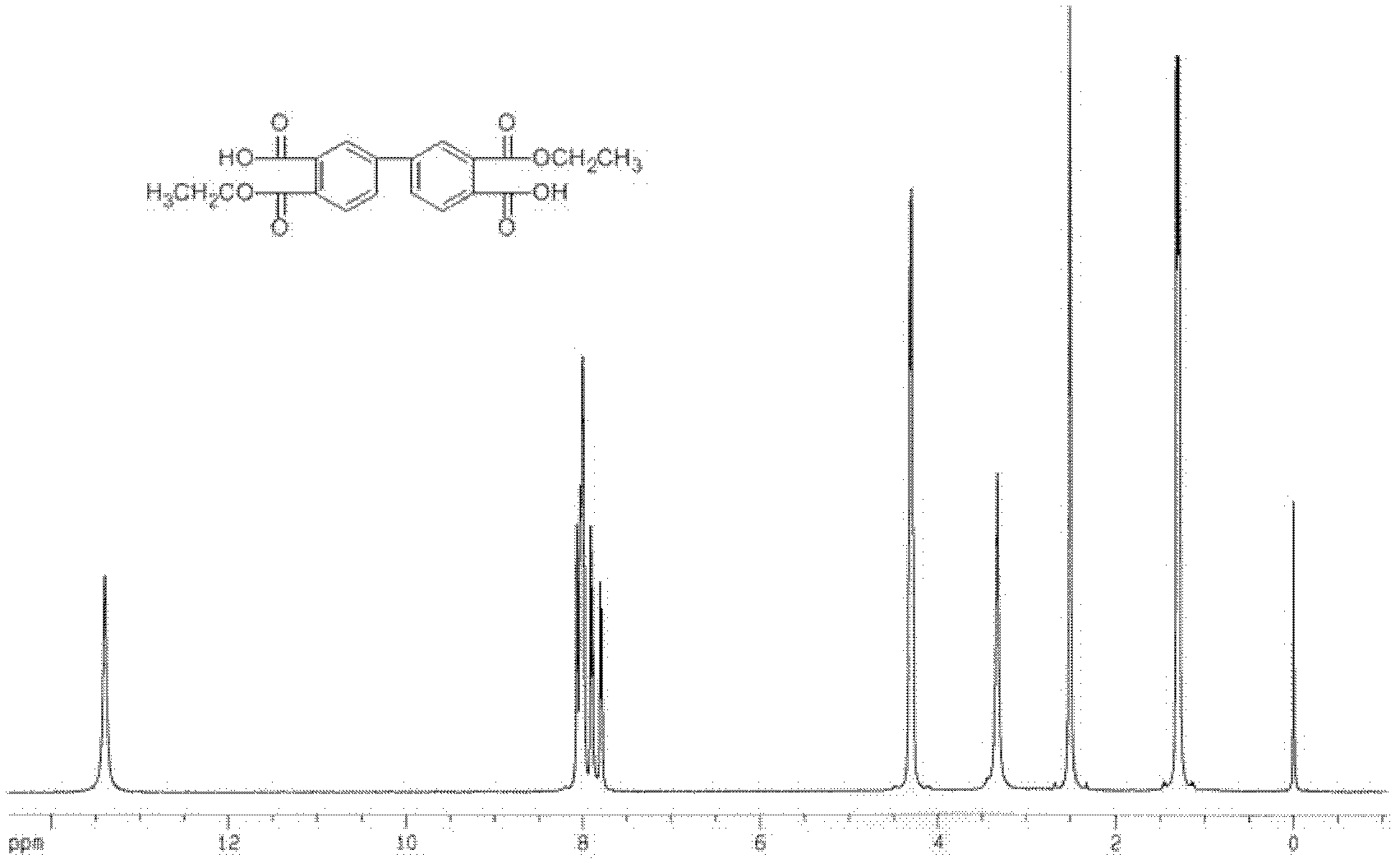

Polyurethane hot melt adhesive for high-grade lining cloth and preparation method thereof

InactiveCN101570676AOvercome difficult bonding problemsDoes not affect damagePolyureas/polyurethane adhesivesPolyesterToluene diisocyanate

The invention discloses the polyurethane hot melt adhesive for high-grade lining cloth, which is obtained through the reaction among polyester polyols with the relative molecular weight thereof being 2,000 to 2,200, 4,4-diphenylmethane diisocyanate (MDI), toluene diisocyanate (TDI), 1,4-butanediol (1,4-BDO) and aromatic diamine extender, wherein, the molecular weight of the polyurethane hot melt adhesive is 85,000 to 95,000. The polyurethane hot melt adhesive has the advantages of low thermal-bonding temperature and rapid crystallization, thereby facilitating the machining operations, preventing the polyurethane hot melt adhesive from being stuck to cloth and further preventing the polyurethane hot melt adhesive from penetrating and bleeding on ultra-thin loose base cloth; furthermore, the polyurethane hot melt adhesive has outstanding resistance to dry-cleaning and washing as well as washing under various caustic conditions. The invention further discloses a method for preparing the polyurethane hot melt adhesive for high-grade lining cloth.

Owner:长兴三伟热熔胶有限公司

Halogen-free flame-retardant glassfiber reinforced PC/PBT alloy material and preparation method thereof

The invention discloses a halogen-free flame-retardant glassfiber reinforced polycarbonate / polybutylene terephthalate (PC / PBT) alloy material and a preparation method thereof. The halogen-free flame-retardant glassfiber reinforced PC / PBT alloy material consists of the following components in percentage by weight: 53 to 66.6 percent of PC resin, 10 to 20 percent of PBT resin, 1 to 2 percent of compatilizer, 3 to 5 percent of toughening agent, 1 to 5 percent of halogen-free flame retardant, 10 to 20 percent of glass fiber, 0.3 to 0.8 percent of coupling agent, 0.6 to 1 percent of lubricant and 0.2 to 0.5 percent of antioxidant. The halogen-free flame-retardant glassfiber reinforced PC / PBT alloy material of the invention has the advantages of high melt fluidity, bright and clean surface of product, and good comprehensive performance and can be used for manufacturing liquid crystal inner frames, television modules and some external products having high surface requirements.

Owner:SHENZHEN KEJU NEW MATERIAL

Environment-friendly polyvinyl chloride resin composition and preparation method thereof

ActiveCN103571105ADoes not affect basic mechanical propertiesImprove toughnessPolyvinyl chlorideToughness

The invention discloses an environment-friendly polyvinyl chloride resin composition and a preparation method thereof. The environment-friendly polyvinyl chloride resin composition is prepared from the following raw materials in parts by weight: 80-100 parts of polyvinyl chloride resin, 20-80 parts of ester polymer, 1-5 parts of thermal stabilizer and 1-10 parts of auxiliary thermal stabilizer. The environment-friendly polyvinyl chloride resin composition obtained according to the preparation method can be used for obviously improving the toughness and melt fluidity of the polyvinyl chloride resin. The polyvinyl chloride resin composition is environment-friendly and has superior comprehensive performance; the preparation method of the composition is simple and is easy for realizing industrialization.

Owner:JIANGNAN UNIV

Polyimide resin as well as preparation method and application thereof

The invention discloses polyimide resin with low melt viscosity and high toughness as well as a preparation method of a composite material of the polyimide resin. The resin is high in solid content, low in solution viscosity and is easy to steep carbon fibers to prepare a high-quality carbon fiber prepreg (a belt or cloth); a melt resin formed by heating and melting the resin has the characteristics of low melt viscosity and wide melting temperature; a resin condensate formed by heating and solidifying is high in toughness and high in Tg (glass-transition temperature). The resin is suitable for steeping reinforced fibers to prepare prepregs, and a carbon fiber reinforced composite material prepared by the autoclave and the hot hubbing forming process is excellent in impact-resistant toughness, comprehensive mechanical property and high-temperature resistant performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyesterimide enamelled wire paint capable of straightly soldering and method for preparing same

InactiveCN101338157AShort synthesis timeReduce energy consumptionPlastic/resin/waxes insulatorsCoatingsPolyesterLacquer

The invention discloses direct welding polyester imine enamel wire paint and a preparation method thereof. Firstly, polyester imine resin generates from monacid, aromatic dicarboxylic acid, 4-methacryoxypropyl, 4, 4'-diaminodiphenyl-methane, trihydric alcohol, triethanolamine, dihydric alcohol and monoethanolamine through the melt copolycondensation under the function of catalyst; secondly, modified etherifying amino resin is prepared from melamine, urea, benzoguanamine, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; thirdly, modified etherified phenolic resin is prepared from technical xylenol, isopropylidene diphenol, boric acid, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; finally, three products obtained through the three steps are mixed with mixed environmental solvent according to the quality ratio of 1-1.9 to 0.2-0.9 to 0.2-0.9 to 8 to obtain the direct welding polyester imine enamel wire paint. The enamel wire painted through the enamel wire paint of the invention can be welded directly under the condition of not higher than 400 DEG C and the stretch of the enamel wire paint or the fluting of zero pinhole can be realized.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

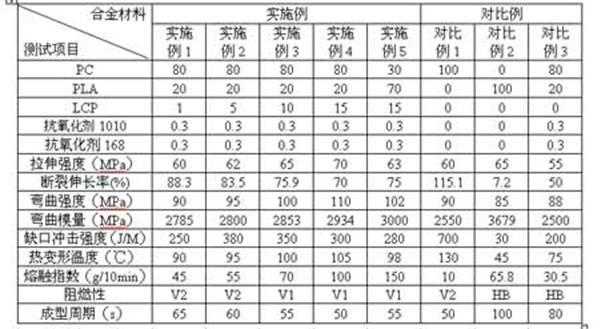

Polyactic acid/polycarbonate alloy material, and preparation method and application thereof

The invention discloses a polyactic acid / polycarbonate alloy material, and a preparation method and application thereof. The polyactic acid / polycarbonate alloy material comprises the following raw materials in part by weight: 10 to 90 parts of polycarbonate, 10 to 90 parts of polyactic acid, 1 to 20 parts of liquid crystal high polymer and 1 to 25 parts of flexibilizer. The polyactic acid / polycarbonate alloy material is prepared by adding the raw materials into a double-screw extruder to be melted and blended. The polyactic acid / polycarbonate alloy material provided by the invention has environmentally-friendly characteristics and excellent physical and mechanical properties, and greatly improves impact strength, bending modulus and heat distortion temperature. The liquid crystal high polymer is added to promote the quick crystallization of the polyactic acid, so that the prepared polyactic acid / polycarbonate alloy can be formed quickly, the forming cycle is reduced from 80 seconds to50 seconds, processing cost is reduced, flowability and fire resistance are improved, and the polyactic acid / polycarbonate alloy material is applicable in the fields of office automation (OA) equipment, communication equipment, automobile parts, domestic appliances and the like.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

Recycled material for preparing vehicle bumper and preparation method of such recycled material

The invention relates to a recycled material for preparing vehicle bumper and a preparation method of the recycled material. The recycled material is prepared from recycled polypropylene, recycled polyethylene, an elastomer, an inorganic mineral filter, kieselguhr, a compatilizer, an antioxidant and a lubricant. The preparation method of the recycled material provided by the invention is reasonable, simple in technology, safe and environment-friendly, can obviously improve the strength, the rigidity, the flexibility and the size stability of the recycled plastic, and simultaneously, can greatly eliminate the pungent smell caused by degrading and the like of the recycled plastic; and moreover, in comparison with new materials, the recycled material can reduce the cost under the condition of low performance loss, and can be used for low- and mid-range vehicle bumpers.

Owner:HEFEI GENIUS NEW MATERIALS

Functional nylon-6 fiber and preparation method thereof

ActiveCN103774271AStrong persistenceEvenly distributedMelt spinning methodsArtifical filament manufactureIn situ polymerizationNylon 6

The invention relates to a functional nylon-6 fiber and a preparation method thereof. The fiber comprises branched-chain nylon-6 functional master batches and conventional nylon-6 chips, wherein the branched-chain nylon-6 functional master batches account for 6-10% in weight percentage; the preparation method comprises the steps of firstly, preparing the branched-chain nylon-6 functional master batches with an in-situ polymerization method or a blending method; secondly, crystallizing and drying the branched-chain nylon-6 functional master batches and the conventional nylon-6 chips respectively, and mixing, and then performing vacuum drying to obtain blended chips; and finally, performing melt spinning to the blended chips. The using amount of functional additives is reduced properly under a condition that the functionality is improved or kept, the production cost is reduced and the fiber spinnability is improved.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Polylactic acid base composite material and preparation method thereof

The invention discloses a polylactic acid base composite material prepared by 50.0wt%-80.0wt% of polylactic acid, 5.0wt%-20.0wt% of polylactic acid-castor oil copolymer, 5.0et%-30.0wt% of polylactic acid-polyurethane copolymer. The polylactic acid-castor oil copolymer and the polylactic acid-polyurethane copolymer with branched or hyperbranched structure are guided in the polylactic acid resin for obviously improving the melt strength of the polylactic acid, realizing stable blow molding machining and raising the processing ability of the polylactic acid base composite material; the branched structure and the toughness polyurethane can raise the mechanical property of the polylactic acid base composite material product. According to the experimental result, the tearing strength of the composite material product is greater than 20MPa, the elongation at break is greater than 100%, and the thickness of the film is controllable in the range of 20 microns to 50 microns. The preparation method for polylactic acid base composite material is also provided.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

InactiveUS20050202958A1Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenOlefin polymerization

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38: Si(OR1)3(NR2R3) Formula 37 (where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms) RNSi(OR1)3 Formula 38 (where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com