Apparatus for positioning and cooling lining layer of damaged LWR nuclear reactor

A technology for reactors and linings, applied in the fields of reactors, nuclear engineering, nuclear power generation, etc., can solve the problems of destroying melts, lack of guiding devices for melting linings, and inability to ensure the effective flow of melts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

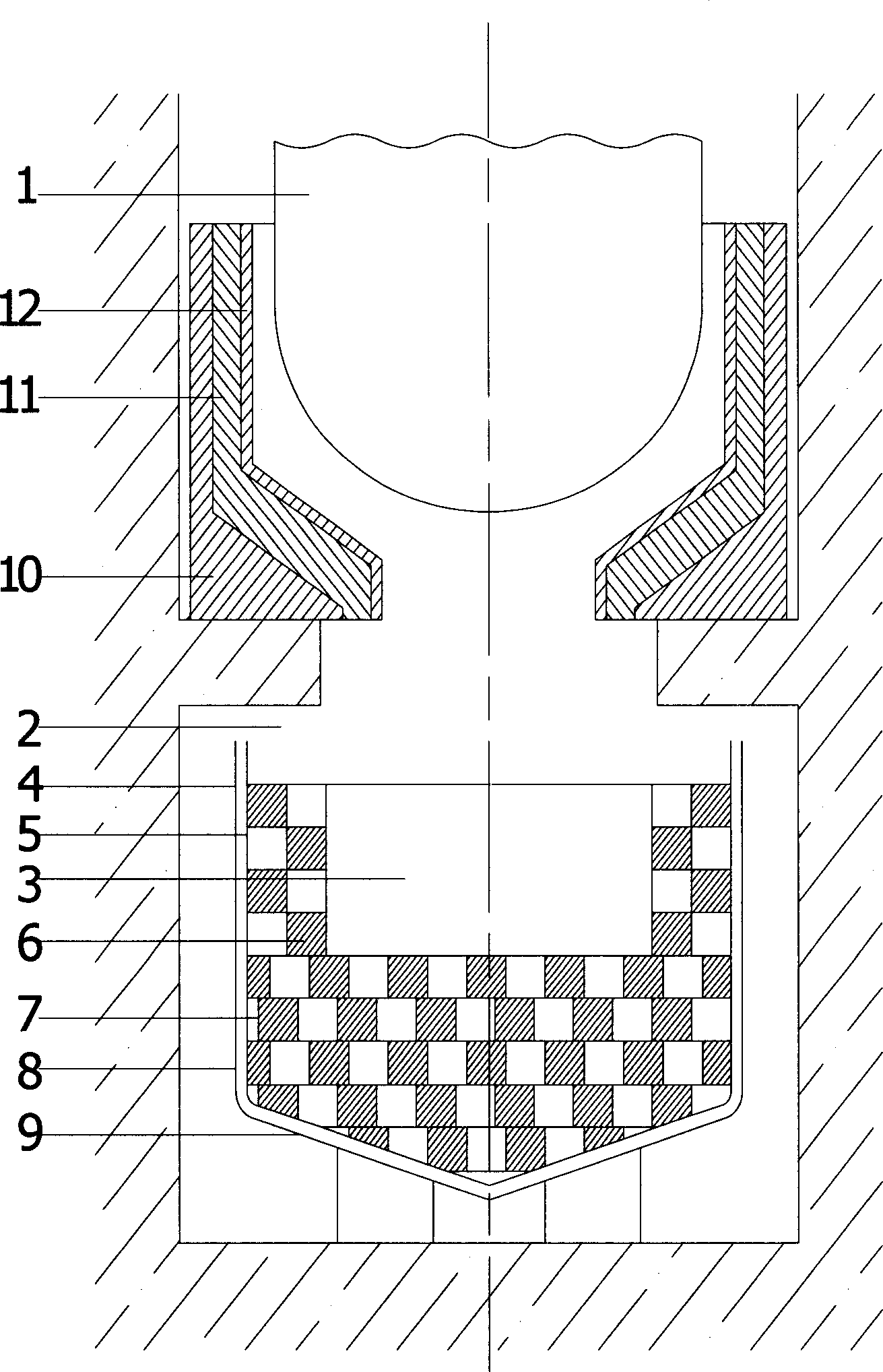

[0062] refer to figure 1 , the system includes a nuclear reactor 1 located in a concrete well 2 . The sub-compartment of the concrete well houses the core catcher 3 and inside the cooled jacket 4 is a steel basket 5 containing a mass of diluent sacrificial material 6 enclosed in a steel shell 7 . The cooled jacket comprises side walls 8 and a bottom 9 . Between the reactor and the core catcher there is a guide 10 whose walls are covered with refractory concrete 11 and whose surface has a coating of meltable concrete 12 .

[0063] The working principle of the system is given below. The process begins with the shell of the reactor 1 melting through and the molten lining flowing into the sub-compartments of the concrete well 2 . To guide the melt flow, below the reactor is a guide 10 , which is, for example, funnel-shaped. In order to protect the bearing portion of the guide, its surface is covered with refractory concrete 11 . In order to prevent the molten lining from soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com