Patents

Literature

96results about How to "Increase the rate of polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature self-crosslinking polyacrylate pigment printing binding agent and preparation method thereof

InactiveCN102391411ALow viscosityIncrease the rate of polymerizationEster polymer adhesivesDyeing processKetoneCarbonyl group

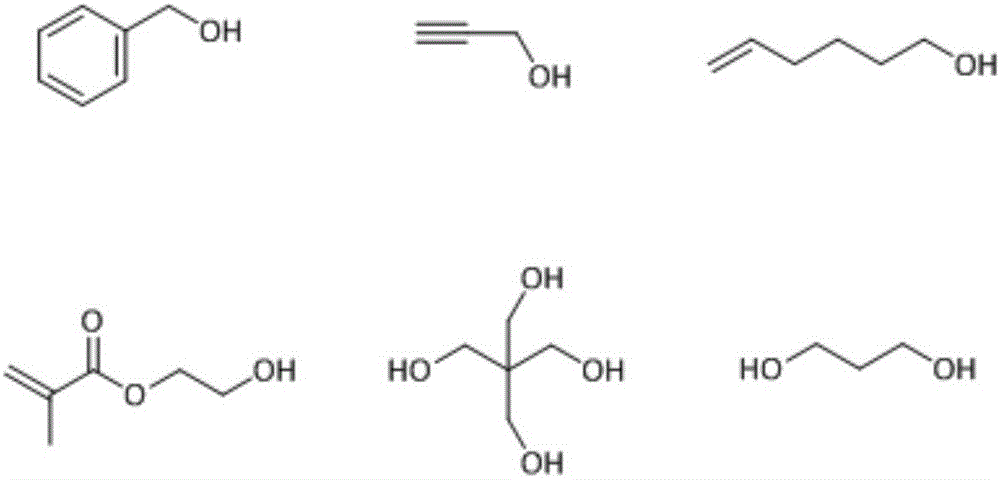

The invention discloses a low-temperature self-crosslinking polyacrylate pigment printing binding agent and a preparation method thereof. The method comprises the following steps of: based on part by mass, preparing pre-emulsion from 70-90 parts of soft monomer, 10-30 parts of hard monomer, 5-10 parts of crosslinking monomer, 2-5 parts of ketone-containing carbonyl monomer, 0.6-3.0 parts of emulsifier and 50-70 parts of de-ionized water; adding 25-33 parts of de-ionized water, 0.2-1.0 part of emulsifier and 0.2-0.6 part of pH buffer; adding 14-16 parts of pre-emulsion and 2-2.5 parts of initiator solution; heating to 78-82 DEG C; dropwise adding remaining pre-emulsion and initiator solution after blue light occurs; heating to 85-90 DEG C and preserving heat for 0.5-1 hour; then cooling to be below 40 DEG C; adjusting pH value to be 6.5-7.0; and finally adding solution formed by dissolving 1-3 parts of hydrazide based monomer in 4-5 parts of de-ionized water. The agent is a formaldehyde-free environmentally-friendly product.

Owner:SOUTH CHINA UNIV OF TECH

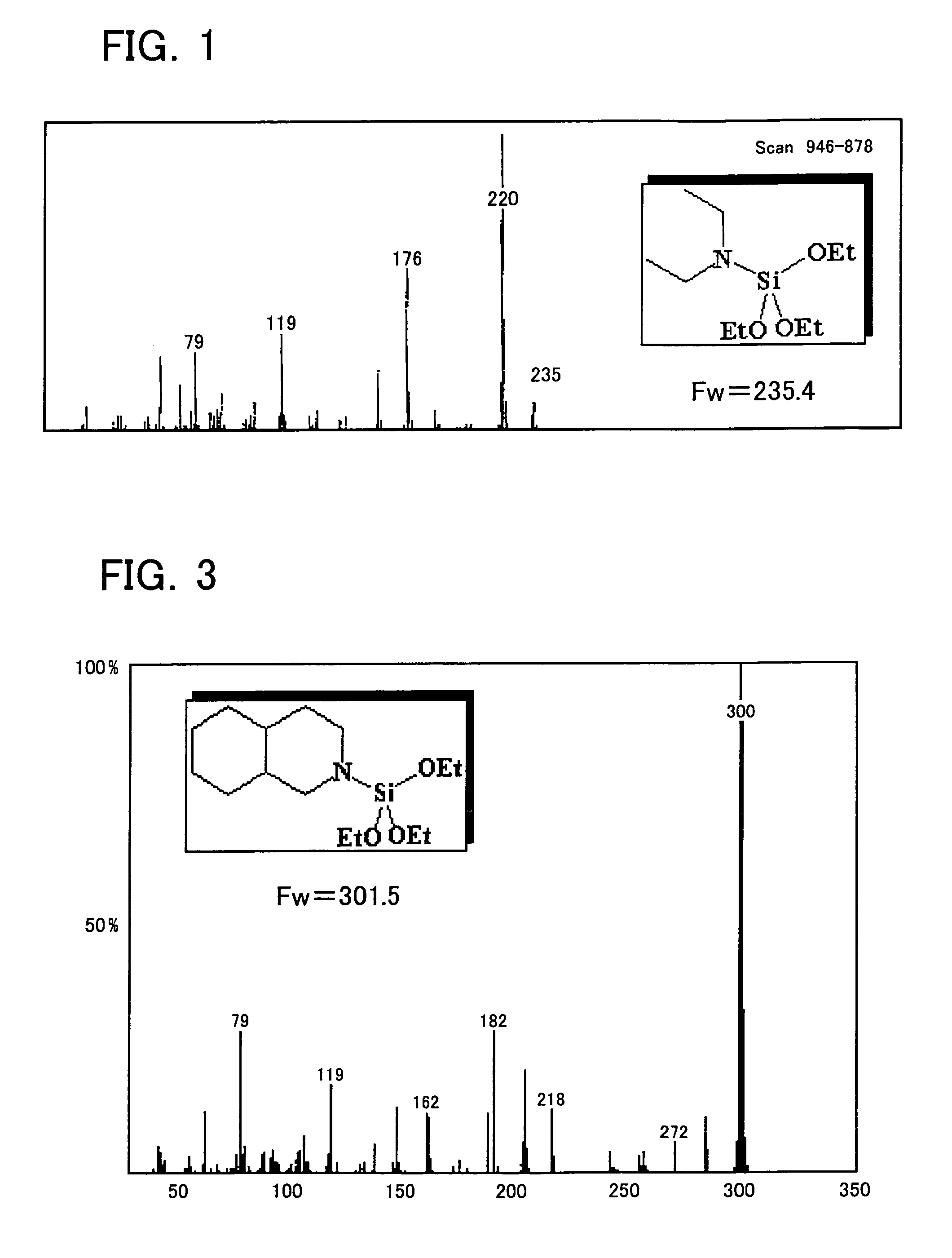

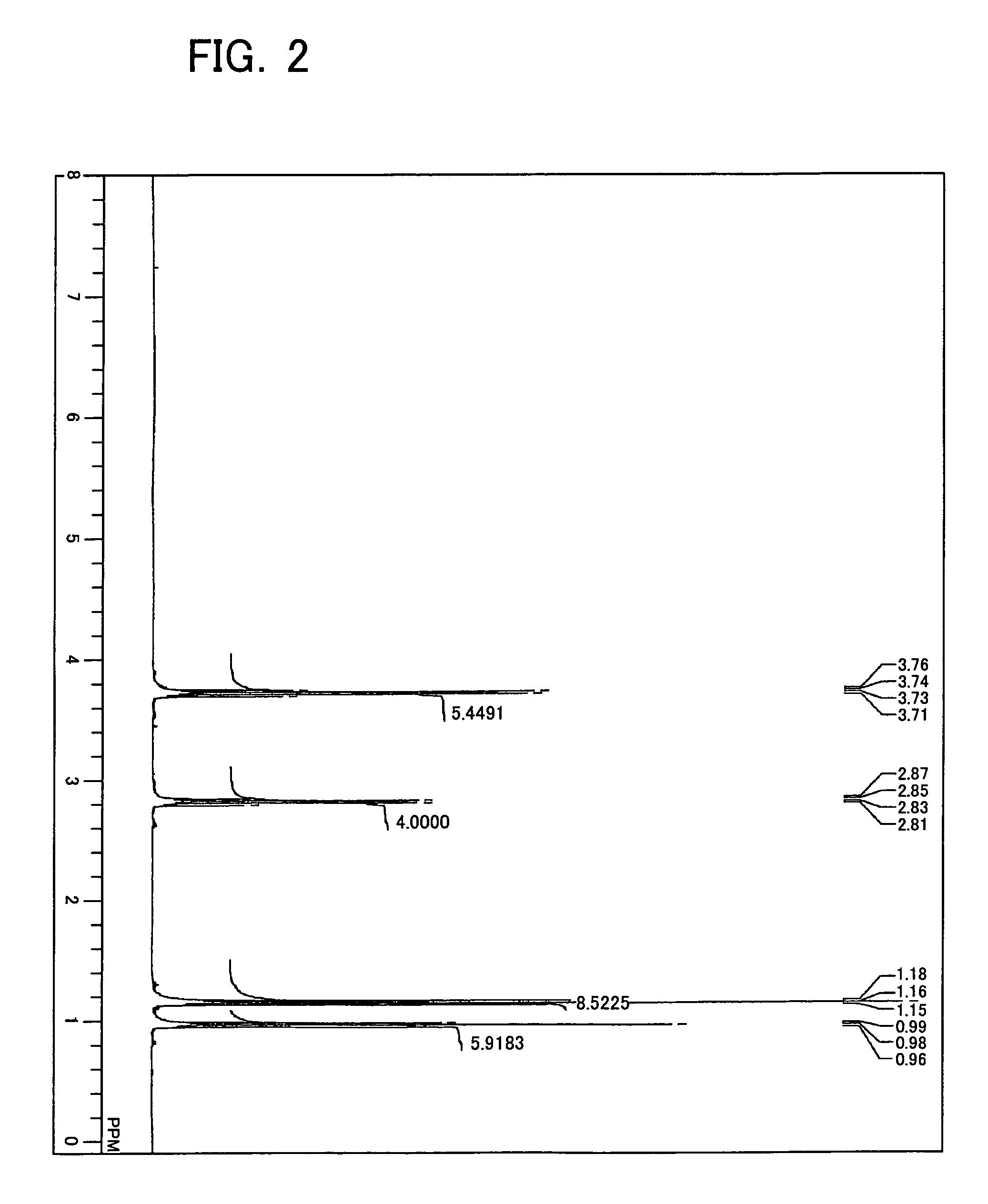

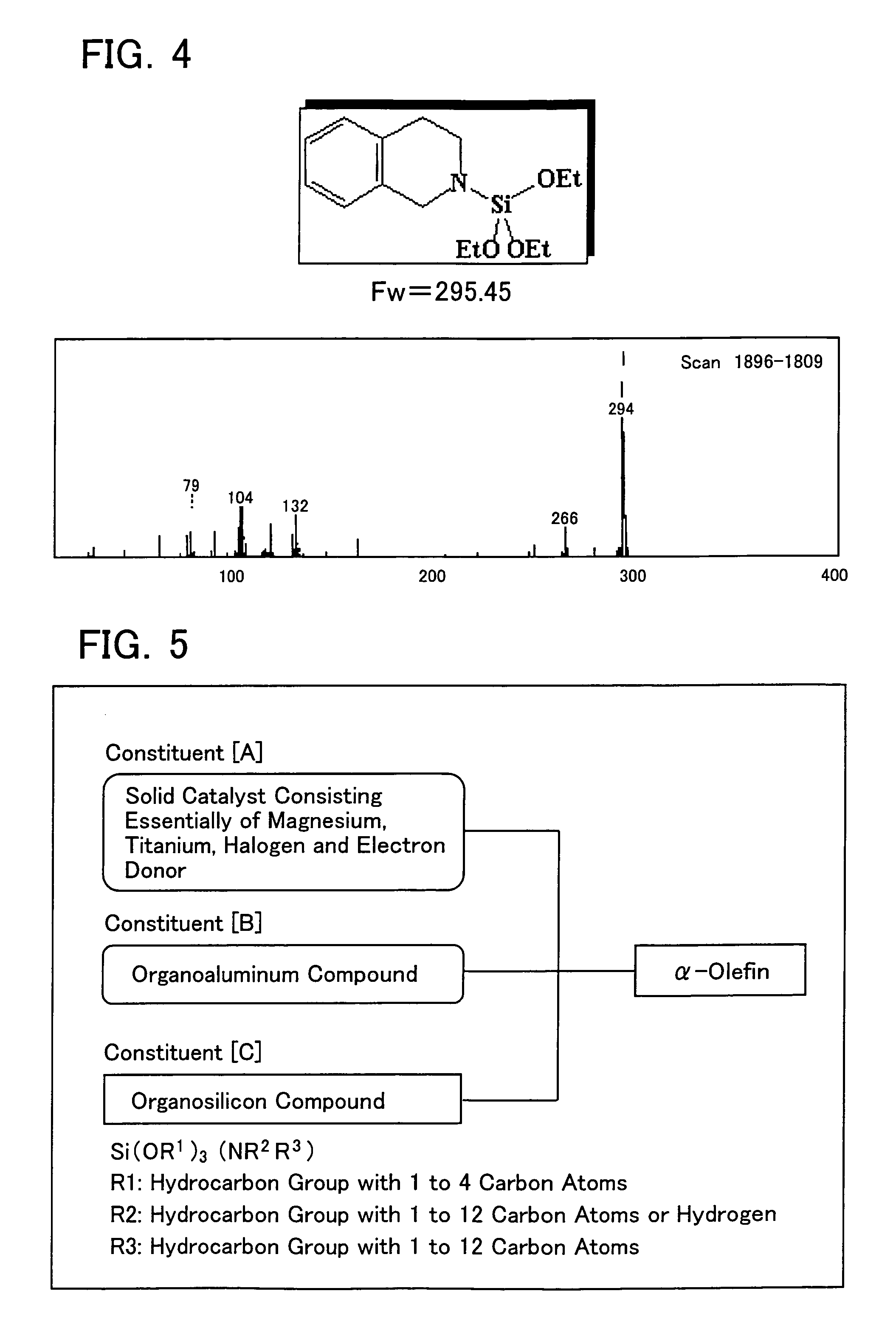

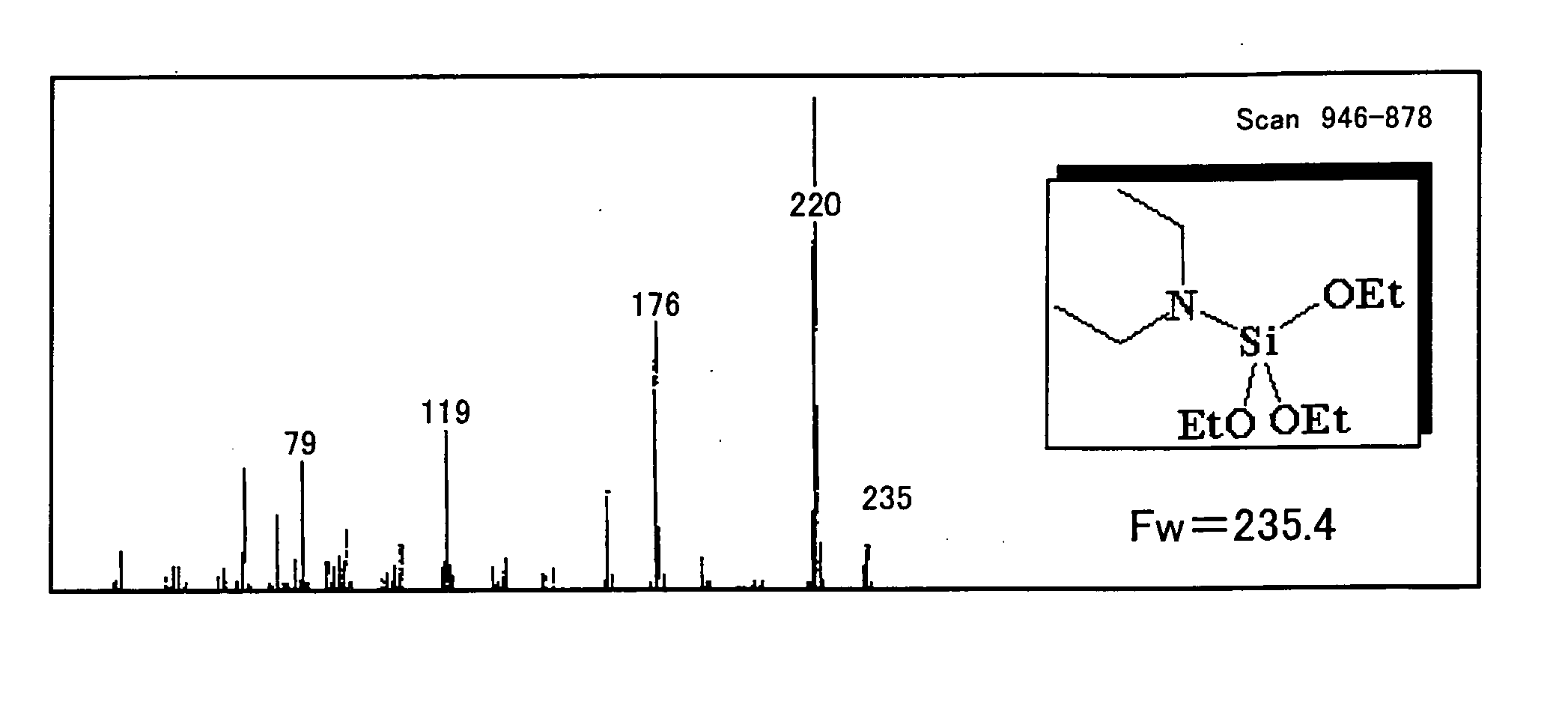

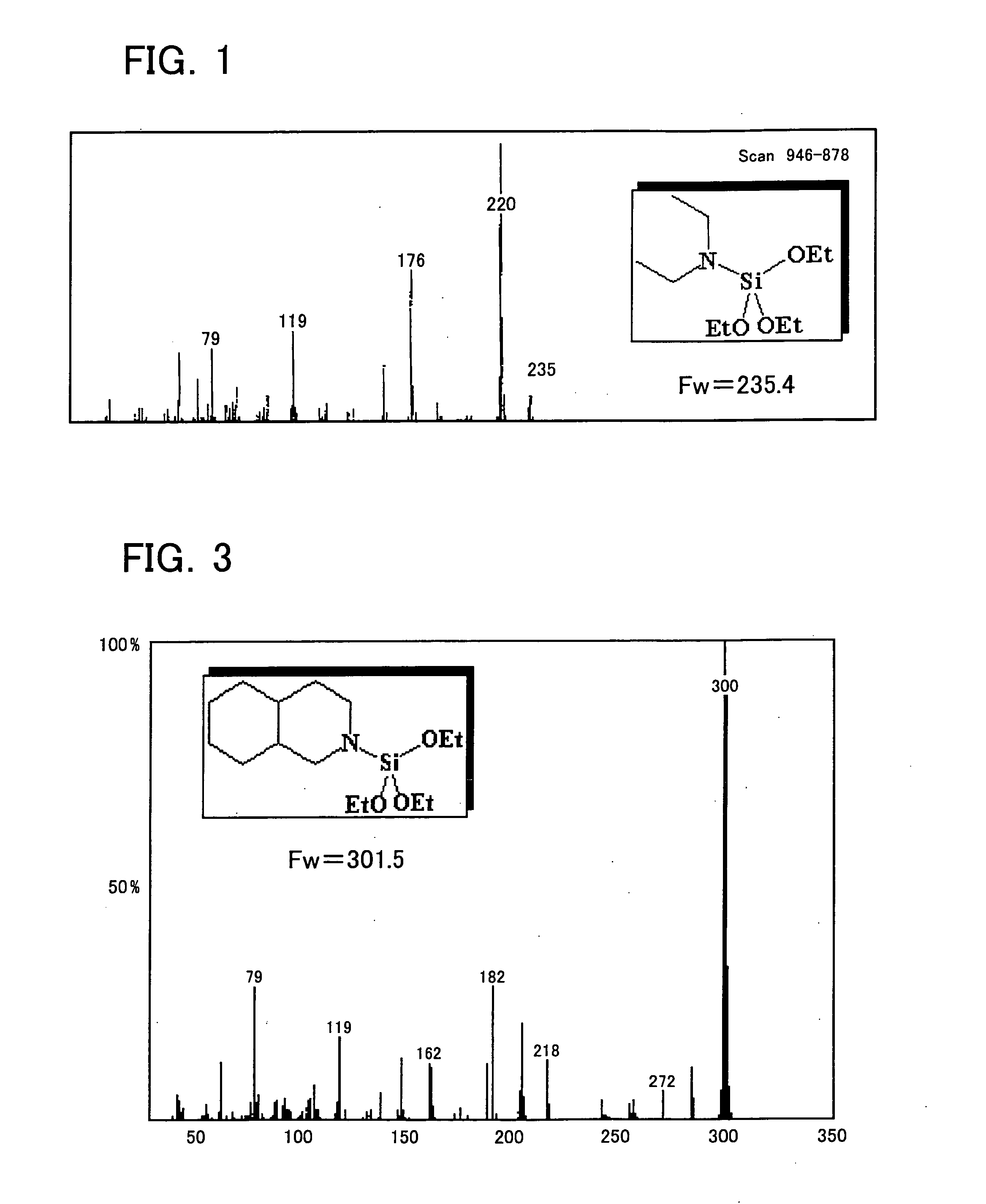

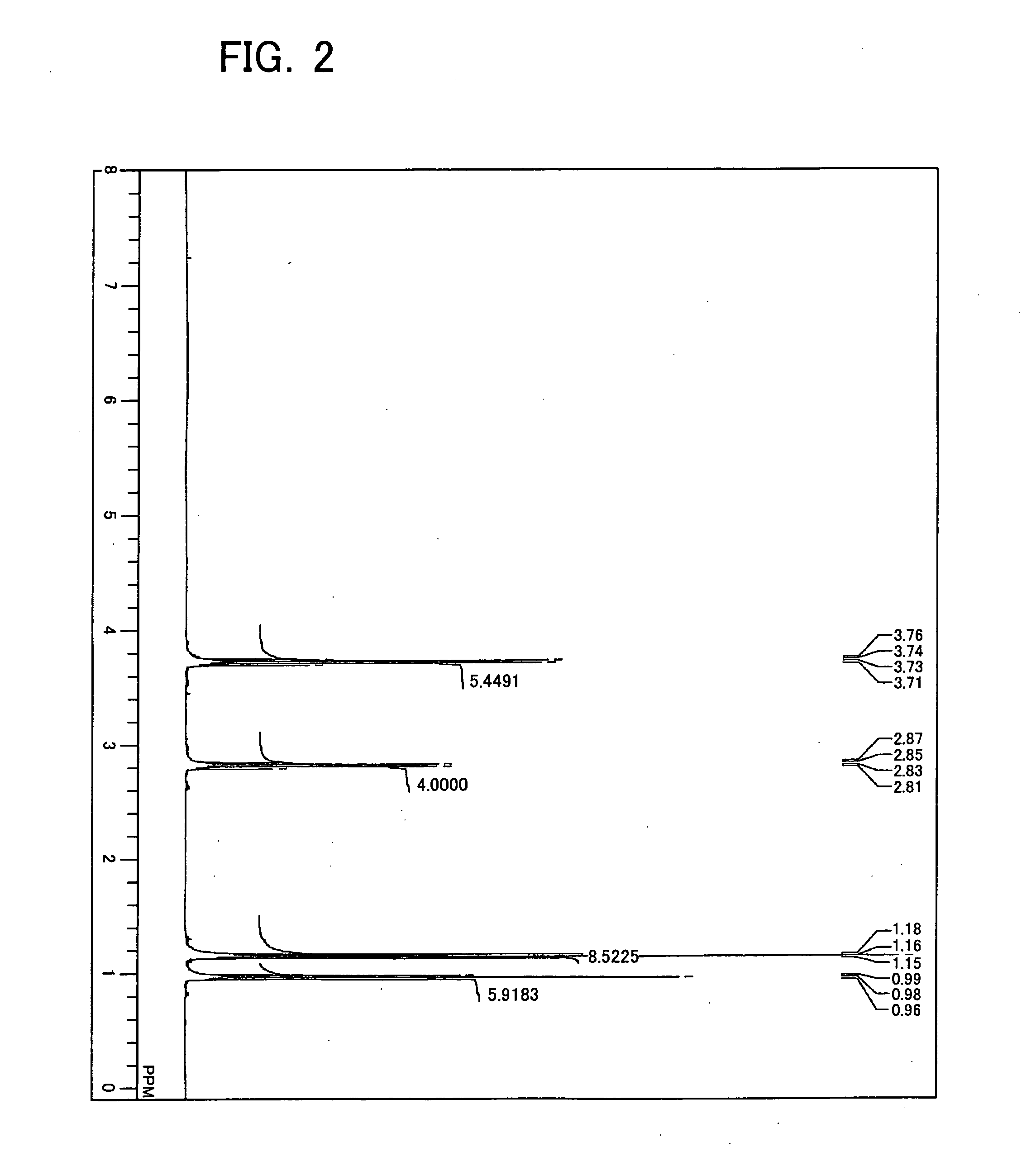

Catalysts for polymerization or copolymerization of α-olefins, catalyst components thereof, and processes for polymerization of α-olefins with the catalysts

InactiveUS7238758B2Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenReaction rate

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38:Si(OR1)3(NR2R3)Formula 37(where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms)RNSi(OR1)3Formula 38(where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

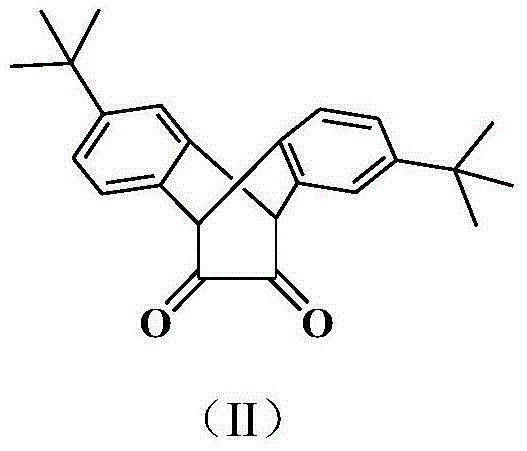

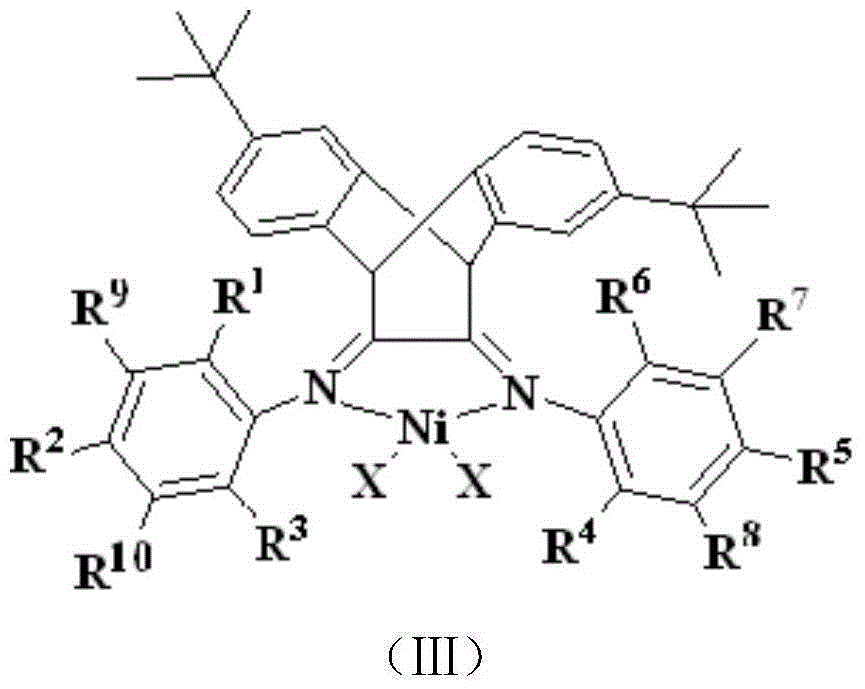

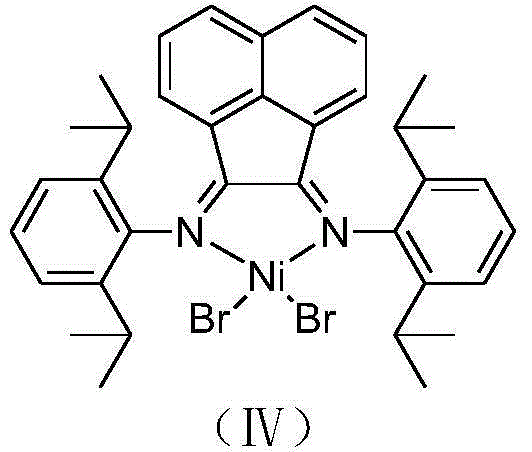

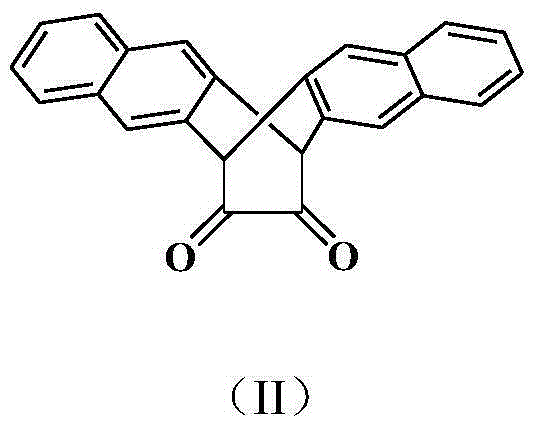

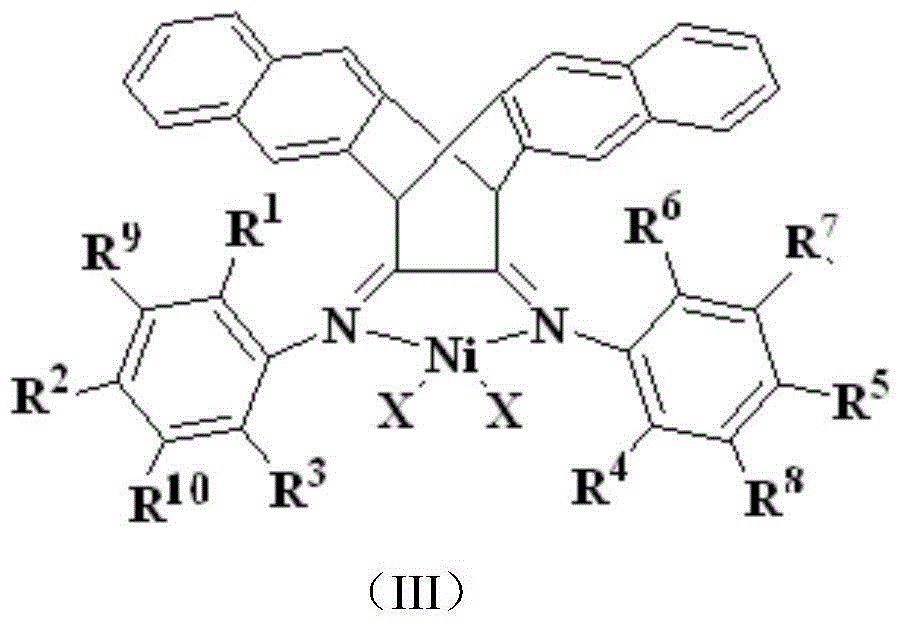

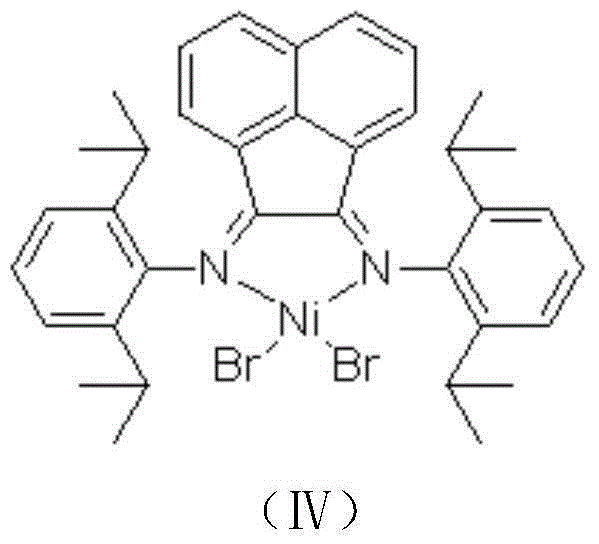

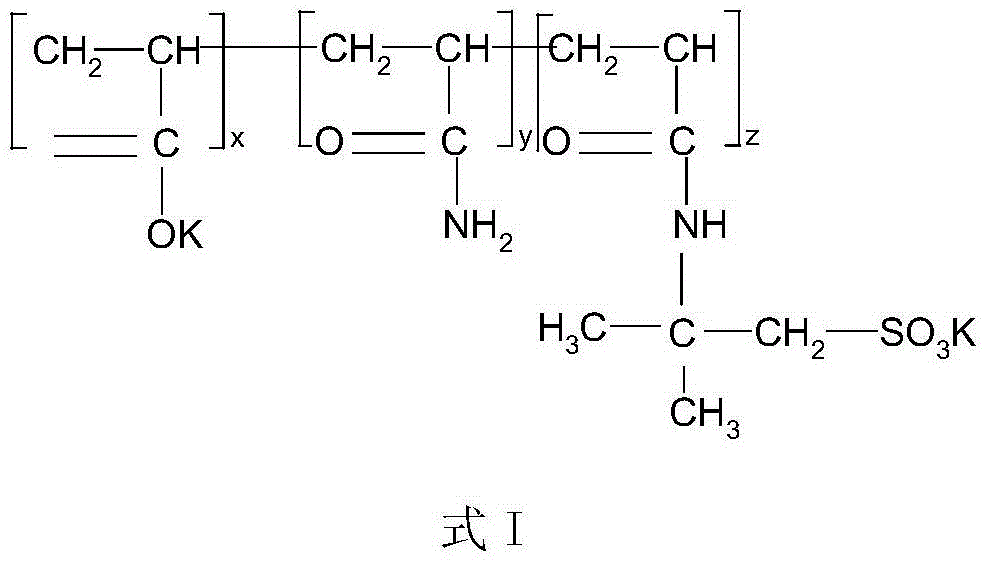

Diimine ligand compound, and complex and application thereof

ActiveCN106397264AHigh molecular weightIncrease the rate of polymerizationNickel organic compoundsImino compound preparationHydrogenHalogen

The invention provides a diimine ligand compound as shown in a formula (I) which is defined in the specification and a preparation method thereof. In the formula I, R1 to R10 are same or different and are independently selected from a group consisting of hydrogen, saturated or unsaturated alkyl groups, oxyl groups and halogen. The invention also relates to the preparation method for the diimine ligand compound, a complex containinging the diimine ligand compound, and a preparation method and application of the complex. As a catalyst composition obtained in the invention is applied to ethylene homopolymerization, polymerization activity is high under a high-temperature polymerization condition (50 to 100 DEG C); and an obtained polymer has high molecular weight and narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

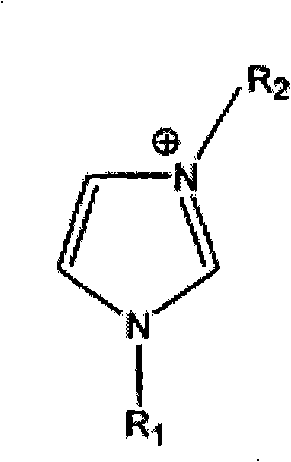

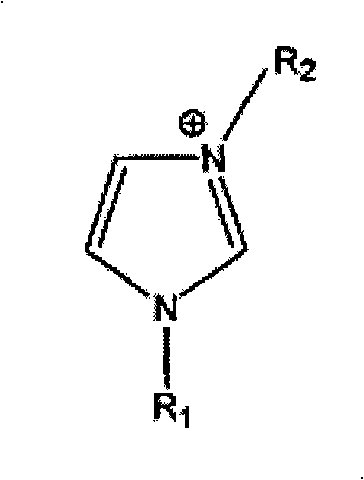

Method for preparing polyacrylonitrile/carbon nano tube composite material by taking ionic liquid as solvent

InactiveCN101864015AEvenly dispersedHigh molecular weightElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentIn situ polymerizationCarbon nanotube

The invention relates to a method for preparing a polyacrylonitrile / carbon nano tube composite material by taking ionic liquid as a solvent. The method comprises the following steps of: dispersing carbon nano tubes to the ionic liquid; adding monomers and an initiator into the ionic liquid for polymerizing to obtain stock solution of the polyacrylonitrile / carbon nano tube composite material; and obtaining the polyacrylonitrile / carbon nano tube composite material by washing and drying the obtained stock solution. The polyacrylonitrile / carbon nano tube composite material is prepared into a polyacrylonitrile / carbon nano tube composite membrane by adopting a coating method or is prepared into polyacrylonitrile / carbon nano tube composite fibers by adopting a wet spinning process or a dry-jet wet spinning process. The adopted solvent ionic liquid can make the carbon nano tubes disperse uniformly, and has no volatility and environmental-friendliness. In the preparation method, an in-site polymerization method is adopted, so the preparation method is simple and convenient to operate. The composite material can be used in the fields such as the enhancement, the conductivity, the anti-static property, the electromagnetic shielding and the like of a material.

Owner:DONGHUA UNIV

Diimine ligand compound, and complex and application thereof

ActiveCN106397261ANarrow molecular weight distributionIncrease the rate of polymerizationNickel organic compoundsImino compound preparationHalogenDiimine

The invention provides a diimine ligand compound as shown in a formula (I) which is defined in the specification and a preparation method thereof. In the formula I, R1 to R10 are same or different and are independently selected from a group consisting of hydrogen, saturated or unsaturated alkyl groups, oxyl groups and halogen. The invention also relates to the preparation method for the diimine ligand compound, a complex containinging the diimine ligand compound, and a preparation method and application of the complex. As a catalyst composition obtained in the invention is applied to ethylene homopolymerization, polymerization activity is as high as 3.84 * 10<6> g / mol(Ni) / h under a high-temperature polymerization condition (50 to 100 DEG C); and an obtained polymer has high molecular weight and narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

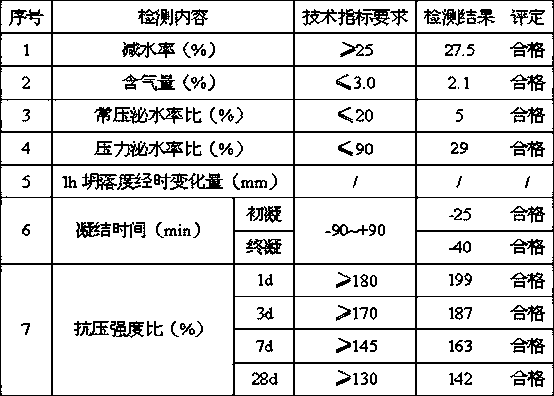

A kind of preparation method of high performance water reducer

InactiveCN102286134AHigh priming activityIncrease the rate of polymerizationHigh strength concreteChemistry

A preparation method of a polycarboxylate high-performance water reducer, under the protection of an inert gas and under the action of an oxidation-reduction initiation system and a chain transfer agent, the active macromonomer A (methallyl poly Oxyethylene ether), small molecule monomer B (methacrylic acid or acrylic acid) and small molecule monomer C (sodium methacrylate, sodium propylene sulfonate or sodium styrene sulfonate) are prepared by copolymerization in water. The invention adopts a highly active oxidation-reduction initiation system, which can increase the polymerization reaction rate, lower the polymerization temperature and shorten the reaction time, and the polymer has an ideal molecular structure. The water reducing agent prepared by the invention has excellent properties such as high water reducing rate, good dispersibility, no loss of slump over time, and high concrete strength; at the same time, the method of the invention adopts copolymerization reaction in water, the preparation process is simple, and it also has green Environmental protection, low energy consumption, low cost and other characteristics.

Owner:江苏天音化工有限公司 +1

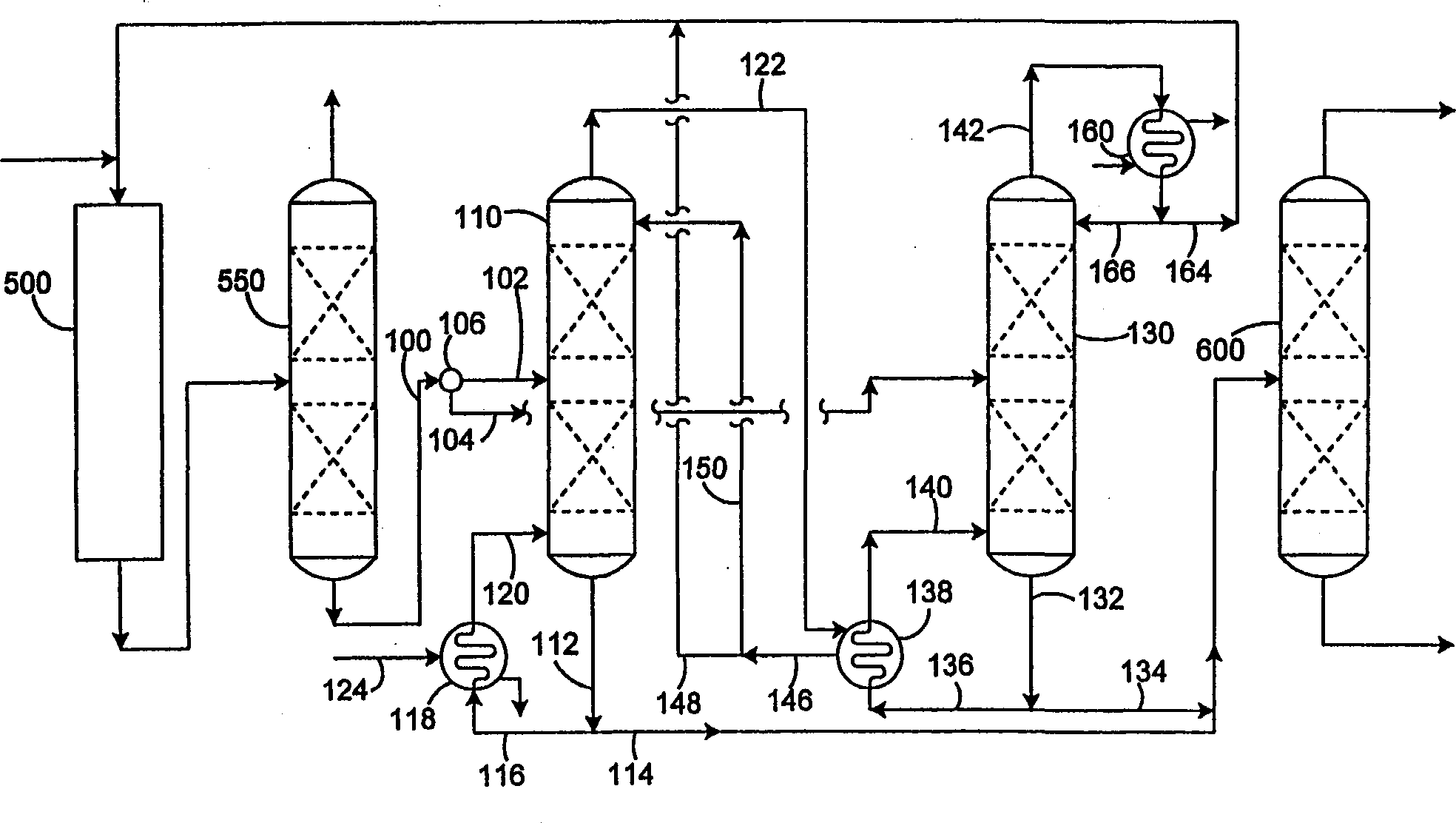

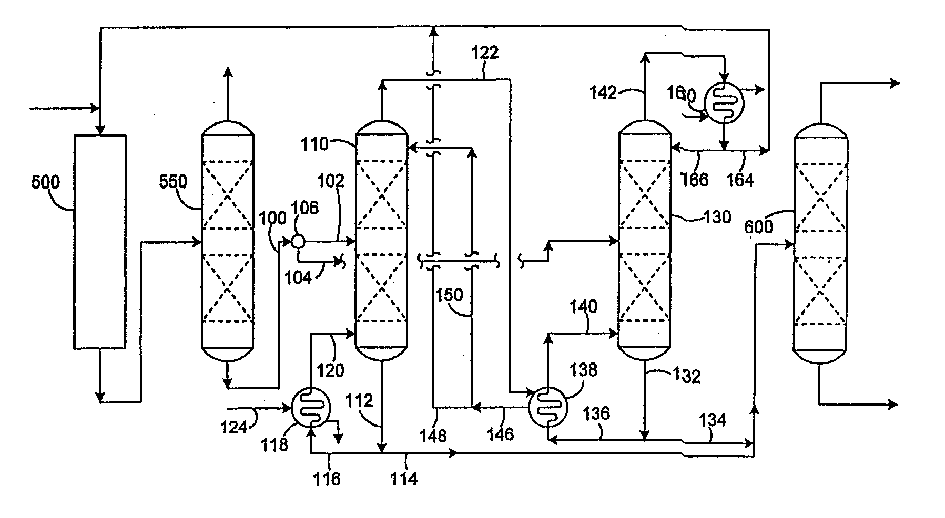

Cascade reboiling of ethylbenzene/styrene columns

InactiveCN1309578AIncrease lossIncrease the rate of polymerizationDistillation regulation/controlDistillation purification/separationThermal energyFractionating column

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

Synthesis method and application of water soluble chitosan-based flocculant

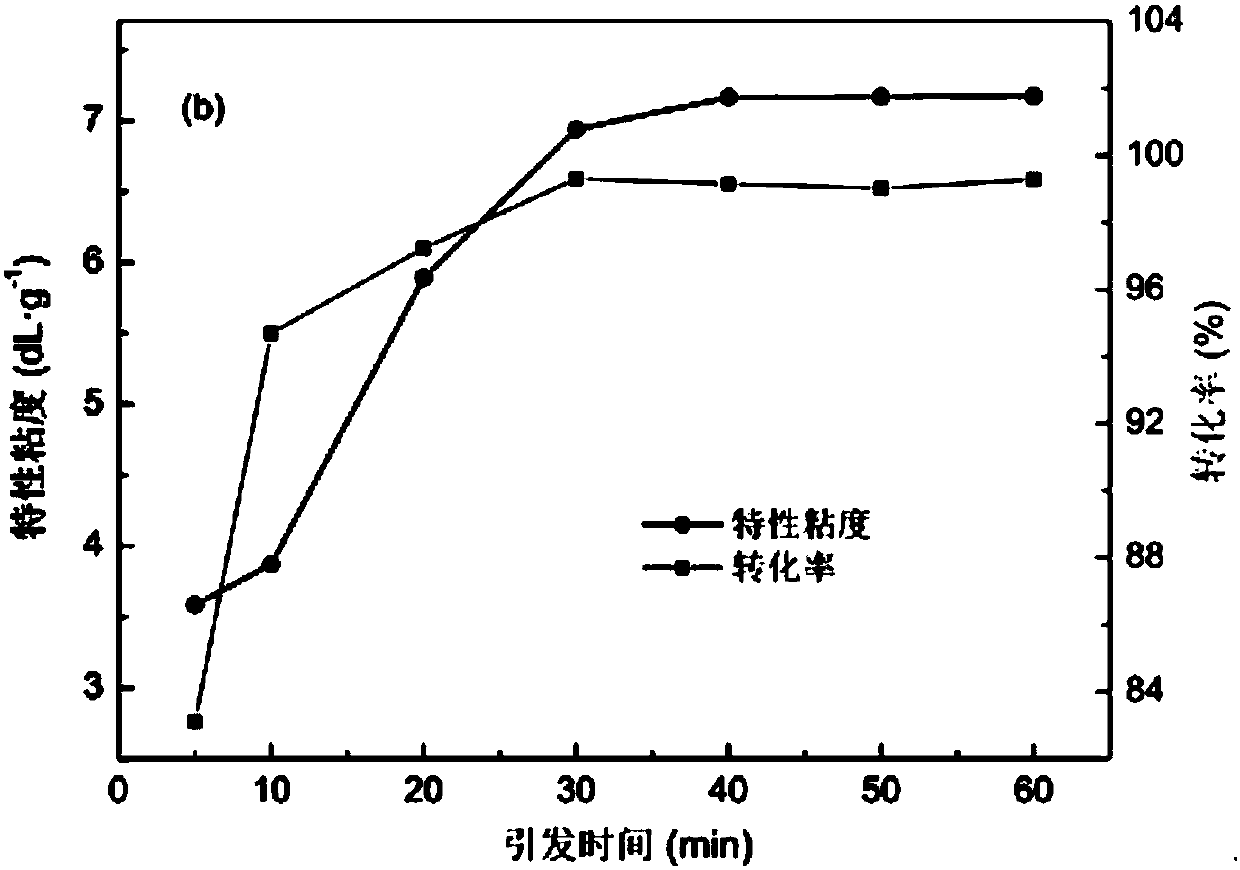

ActiveCN105622847ASpeed up homolysisThe polymerization reaction is fastWater/sewage treatment by flocculation/precipitationFunctional monomerAlcohol ethyl

The invention provides a synthesis method and application of a water soluble chitosan-based flocculant. The method comprises the steps of adding chitosan into acid solution, adding acylated monomer aqueous solution into the acid solution, uniformly stirring and mixing, performing vibration reaction for 1 to 10 h at 5 to 60 DEG C, performing precipitation and purification through ethyl alcohol and acetone, drying, and obtaining N-acylated chitosan; sequentially adding the N-acylated chitosan, deionized water, acrylamide and strong cation functional monomer into a reactor, uniformly stirring, leading nitrogen into homogenous solution to remove oxygen, adding a photoinitiator and a cosolvent, uniformly stirring and mixing, putting the raw materials into an ultraviolet light reaction device to perform polymerization reaction, drying, performing granulation and powder process, and obtaining the water soluble chitosan-based flocculant; the flocculant can be used for the removal treatment of alga in source water. The flocculant is good in solubility property, high in viscosity coefficient and short in synthesis time, does not need temperature reduction control, simplifies the production technology, reduces energy consumption, and reduces the production cost.

Owner:NANJING UNIV OF TECH

Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

InactiveUS20050202958A1Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenOlefin polymerization

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38: Si(OR1)3(NR2R3) Formula 37 (where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms) RNSi(OR1)3 Formula 38 (where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Tetrafluoroethylene-propylene fluorine-containing elastic body and preparing method thereof

An tetrafluoroethylene-propylene fluorine-containing elastomer and its preparation method includes: (1) providing an aqueous dispersions of comonomer, which includes: (a) tetrafluoroethylene, propylene and one or more kind of other comonomers, (b) oxidation-reduction system, which includes: water-soluble inorganic peroxide initiator, water-soluble iron salt reductant, coordination agent, water-soluble inorganic aid reducer, (c) water-soluble metal hydroxide pH modifier, and (d) emulsifier. Its characteristic is (2) under the polymerization temperature of 10~50deg.C and polymerization pressure of 3.1~8MPa, the monomers take polymerization.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

Reduced shrinkage early strength polycarboxylic acid water reducing agent mother liquid and preparation process thereof

The invention discloses a reduced shrinkage early strength polycarboxylic acid water reducing agent mother liquid and a preparation process thereof. The water reducing agent mother liquid is preparedby the free radical copolymerization reaction of a polyether macro-monomer, an anionic active monomer, a cationic active monomer, a shrinkage reducing monomer, a chain transfer agent and an initiator;wherein the polyether macro-monomer is isopentenyl polyoxyethylene ether and / or methyl allyl polyoxyethylene ether; the anionic active monomer is acrylic acid; the cationic active monomer is methacrylatoethyl trimethyl ammonium chloride; the shrinkage reducing monomer is an esterification reaction product of a phenyl alcohol or a methyl phenyl alcohol with acrylic acid; the chain transfer agent is 2-methyl-2-propene-1-sulfonic acid sodium salt; and the initiator comprises an initiator system A and an initiator system B, the initiator system A comprises organic hydrogen peroxide and vitamin C,and the initiator system B comprises sodium bisulfite and a ferrous salt. According to the preparation process, different functional monomers are grafted to the high-performance polycarboxylic acid water reducing agent, and the length of the main chain is adjusted, so that the polycarboxylic acid water reducing agent has excellent water reducing rate, and also has early strength and reduced shrinkage.

Owner:WUHAN SUBO NEW BUILDING MATERIAL CO LTD

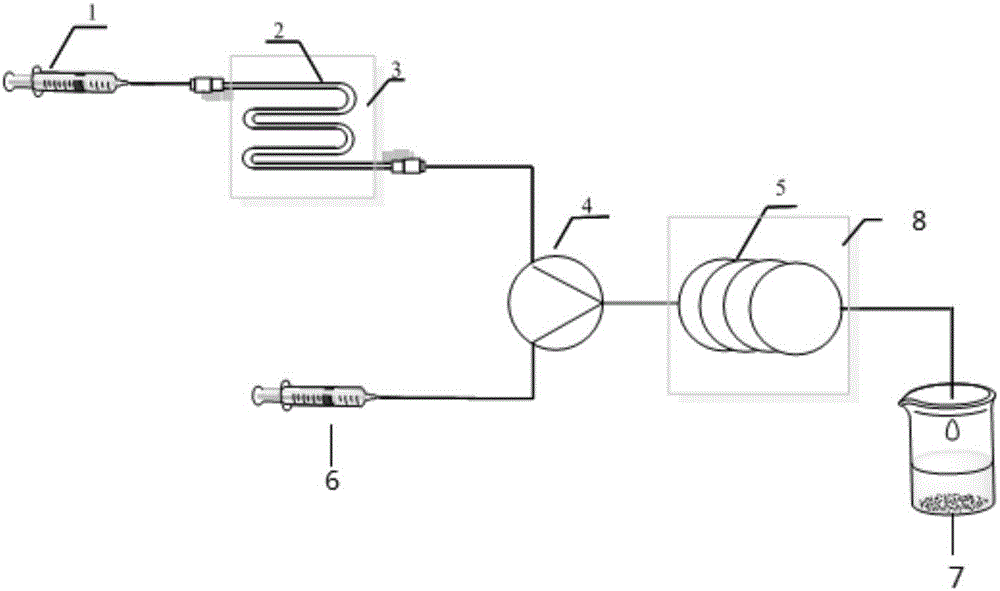

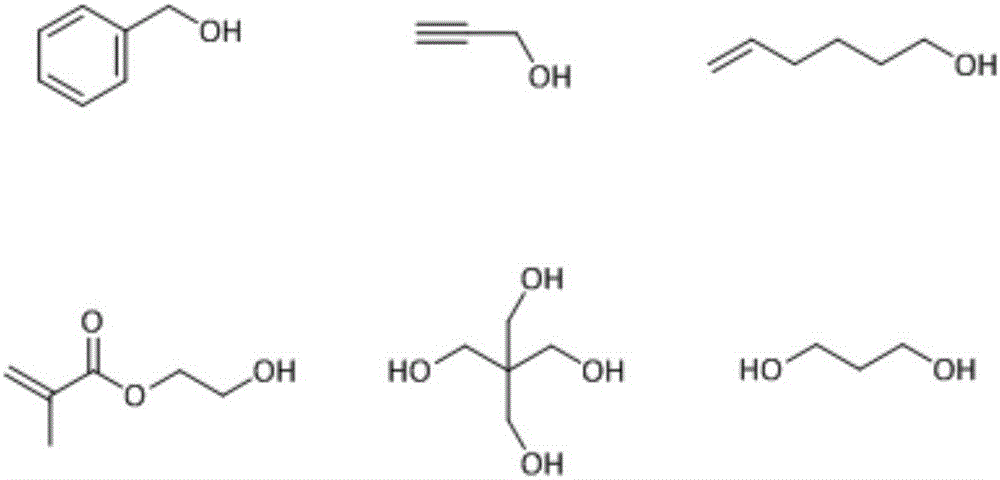

Method for synthesizing polyether glycol in microstructure reactor

The invention relates to a method for synthesizing polyether glycol in a microstructure reactor, which comprises the following steps: respectively pumping oxyalkylene and a catalyst liquid generated by reacting an alkaline catalyst and an initiator into the microstructure reactor composed of a micro-mixer and a retention time prolonging pipe, reacting while controlling the reaction temperature and pressure, neutralizing the reaction solution, adsorbing, degassing and filtering to obtain the refined polyether glycol. The hydroxyl value of the refined polyether glycol is 50-550 mgKOH / g, and the relative molecular mass is 300-3300 g / mol. The method overcomes the defects of long initiation time and low operational efficiency in the intermitted technique, solves the problems of complex equipment, high requirements for technological condition control and long retention time in the continuous technique, implements quick and continuous production, and has the advantages of short reaction time, simple technique, high safety, high controllability, high adjustment flexibility, continuous operation and the like.

Owner:上海睿瓦科技有限公司

Controllable free-radical polymerization method by using organic-inorganic composite material as photoinitiator

InactiveCN104910308AReduce dosageIncrease the rate of polymerizationAtom-transfer radical-polymerizationRoom temperature

The invention relates to an initiator for atom transfer free-radical polymerization and application thereof. The initiator uses an organic-inorganic composite material as the atom transfer free-radical polymerization photoinitiator. The photoinitiator performs photo-control atom transfer free-radical polymerization on monomers for atom transfer free-radical polymerization, an atom free-radical initiator, a catalyst and a ligand at room temperature. The reaction has the characteristic of active polymerization. The method can perform atom transfer free-radical reaction under ultraviolet irradiation, and can also perform atom transfer free-radical reaction under visible light irradiation. The method obviously lowers the catalyst consumption. The photoinitiator is recyclable, and has the advantages of simple technique, environment friendliness and the like.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Preparation method of PVDF-PAA (polyvinylidene fluoride-polyacrylic acid) block copolymer

ActiveCN104610518AIncrease the rate of polymerizationSimple processPolyvinylidene fluorideComposite material

The invention discloses a preparation method of a PVDF-PAA (polyvinylidene fluoride-polyacrylic acid) block copolymer. The method comprises steps as follows: firstly, preparing a PVDF seed emulsion through iodine transfer active free-radical miniemulsion polymerization, then adding acrylonitrile monomers to continue polymerization to obtain a PVDF-PAN (polyacrylonitrile) block copolymer, and finally, hydrolyzing the PVDF-PAN block copolymer under an alkaline condition to obtain the PVDF-PAA block copolymer. The method is simple in process, the molecular weight of PVDF and PAA blocks as well as components of the block copolymer are convenient to control, and the prepared PVDF-PAA block copolymer can be applied to preparation of porous PVDF membranes with excellent stain resistance and stable membrane flux for sewage treatment.

Owner:JUHUA GROUP TECH CENT +1

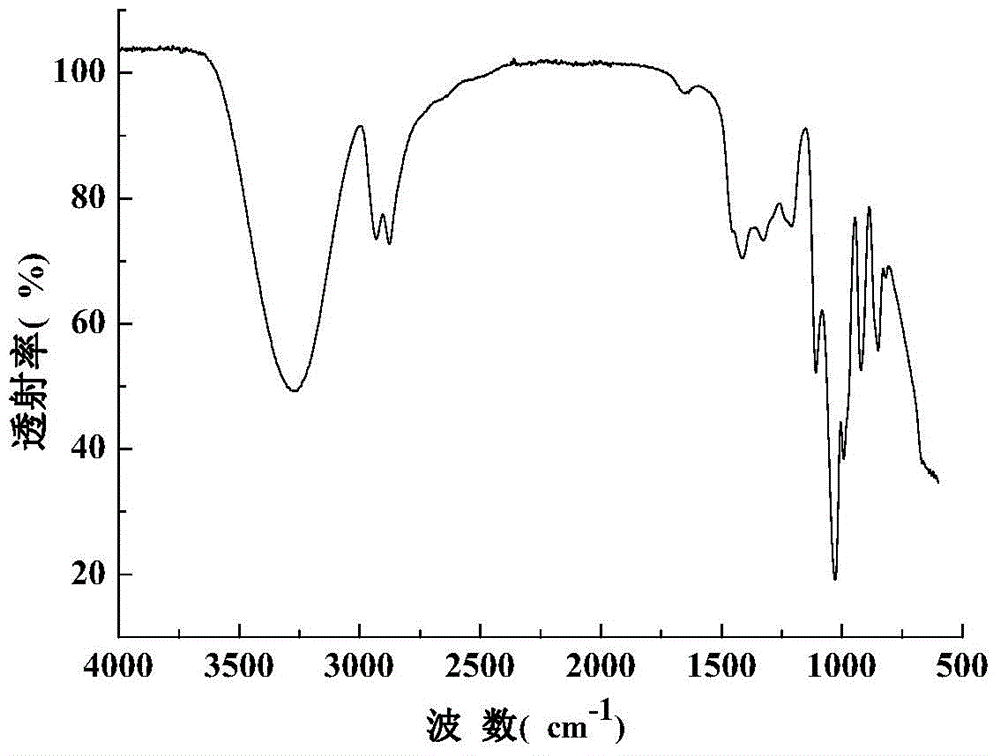

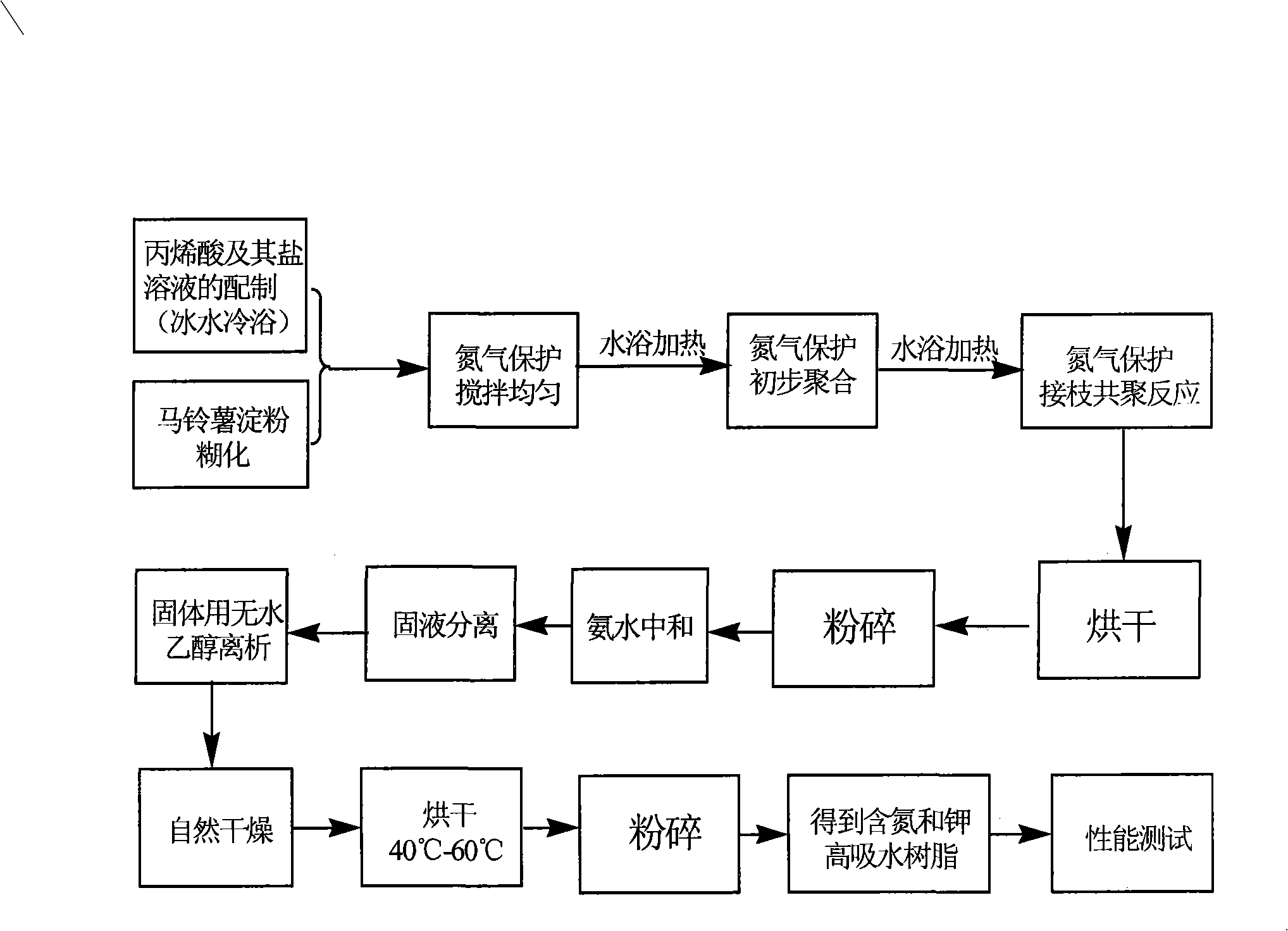

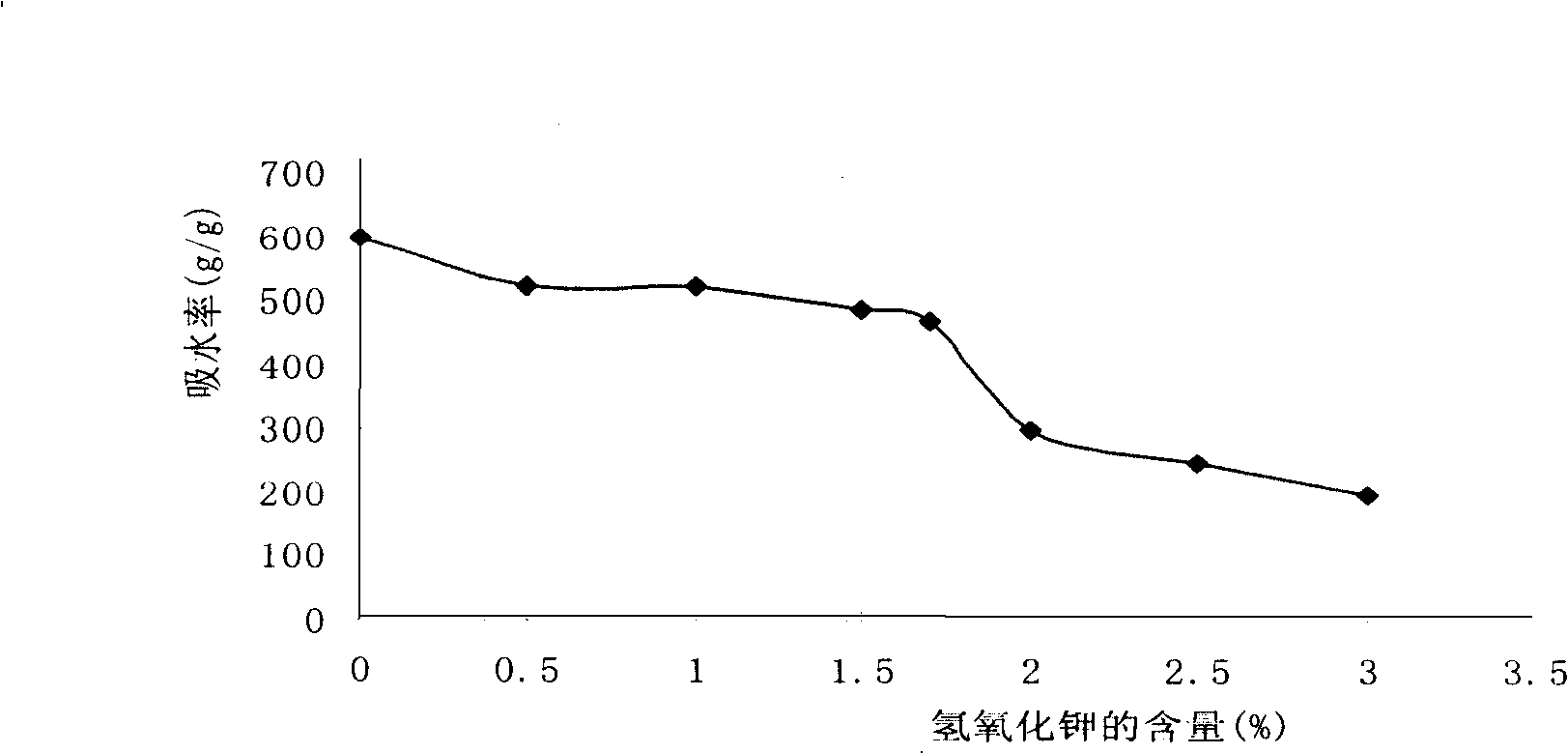

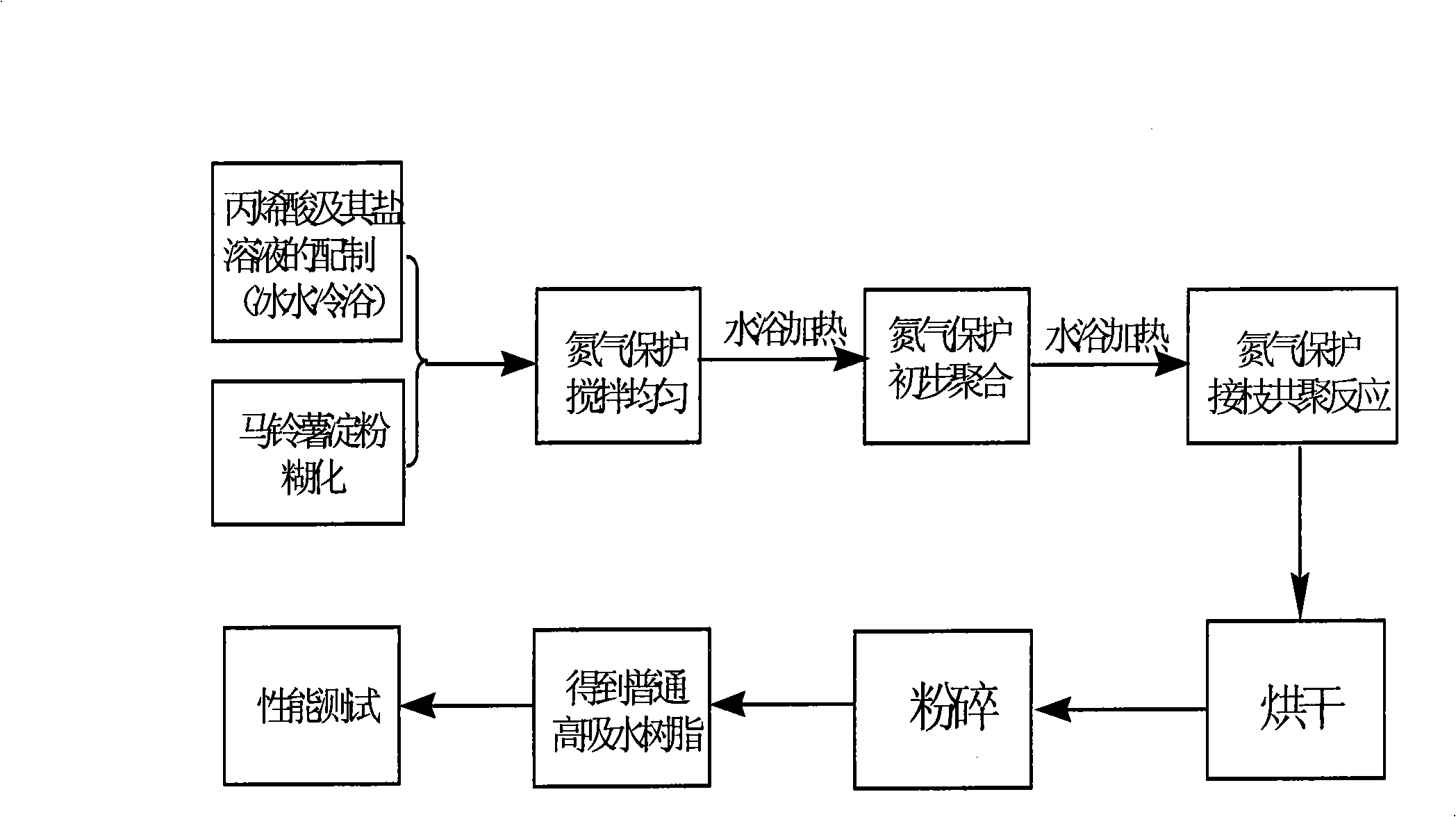

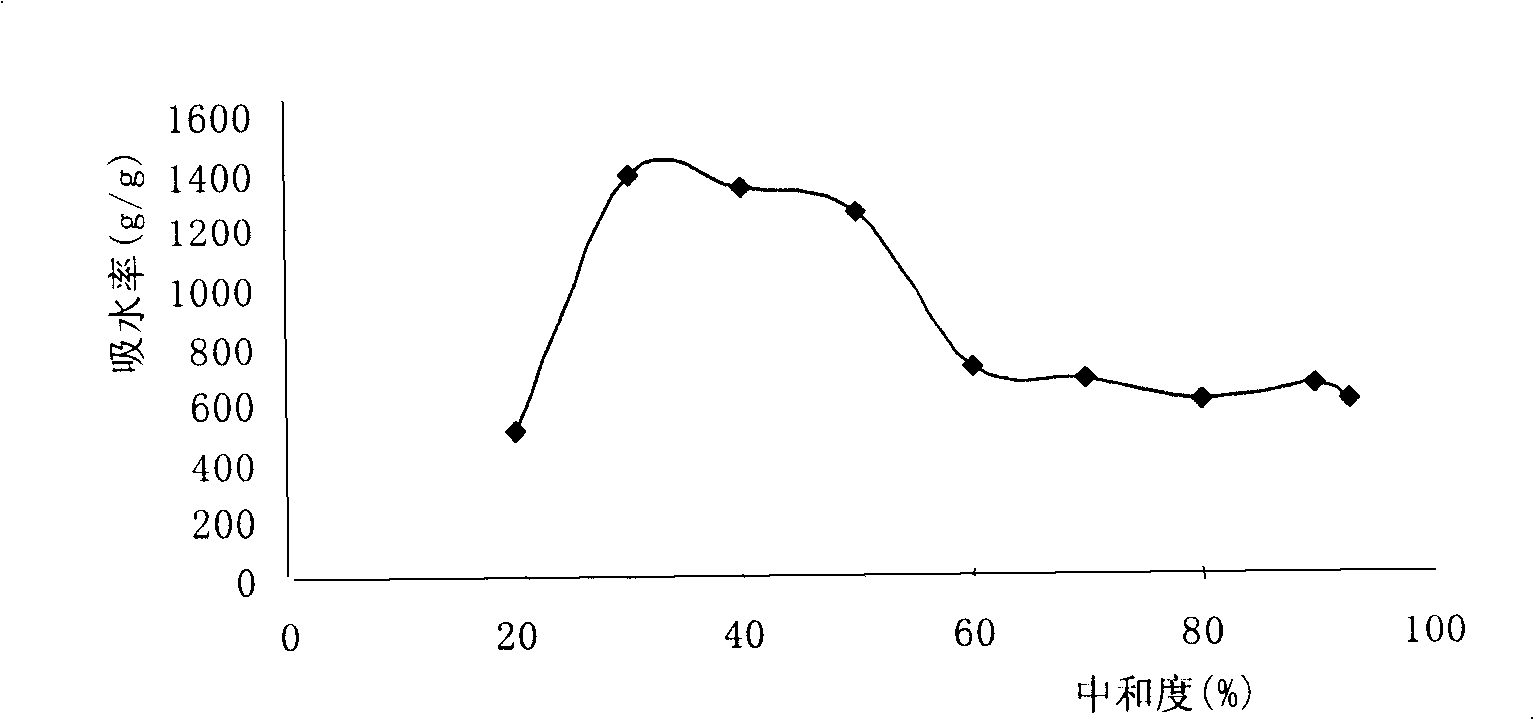

Preparation of super absorbent resin containing potassium and nitrogen

The invention discloses a method for making super absorbent resin containing kalium and nitrogen. The method comprises the following main technological processes that: acrylic acid is adopted to pass through a neutral aluminum oxide chromatographic column so as to remove polymerization inhibitor; a mixed solution of sodium hydroxide and potassium hydroxide and acrylic acid undergo neutralization reaction in ice-water bath, and potato starch is mixed with deionized water so as to carry out gelatinization; the neutralized acrylic acid and the salt solution of the acrylic acid are mixed with the gelatinized potato starch, and then initiator potassium persulphate is added in; the mixture is stirred evenly under the protection of nitrogen and then is heated by water bath so as to ensure that potato starch, acrylic acid and the salt of the acrylic acid undergo graft copolymerization reaction under the protection of nitrogen; moreover, the mixture undergoes heat-preservation reaction and then is dried and crushed and dipped in ammonia water; then, the mixture is separated by anhydrous alcohol and then is dried and crushed again so as to obtain the super absorbent resin containing kalium and nitrogen. The super absorbent resin made by the method has greatly increased water-absorbing capacity and contains kalium and nitrogen nutrient element as compared with similar products; moreover, the super absorbent resin plays an important role in soil water conservation, desert control and plant growth, etc. in arid areas.

Owner:INNER MONGOLIA UNIVERSITY

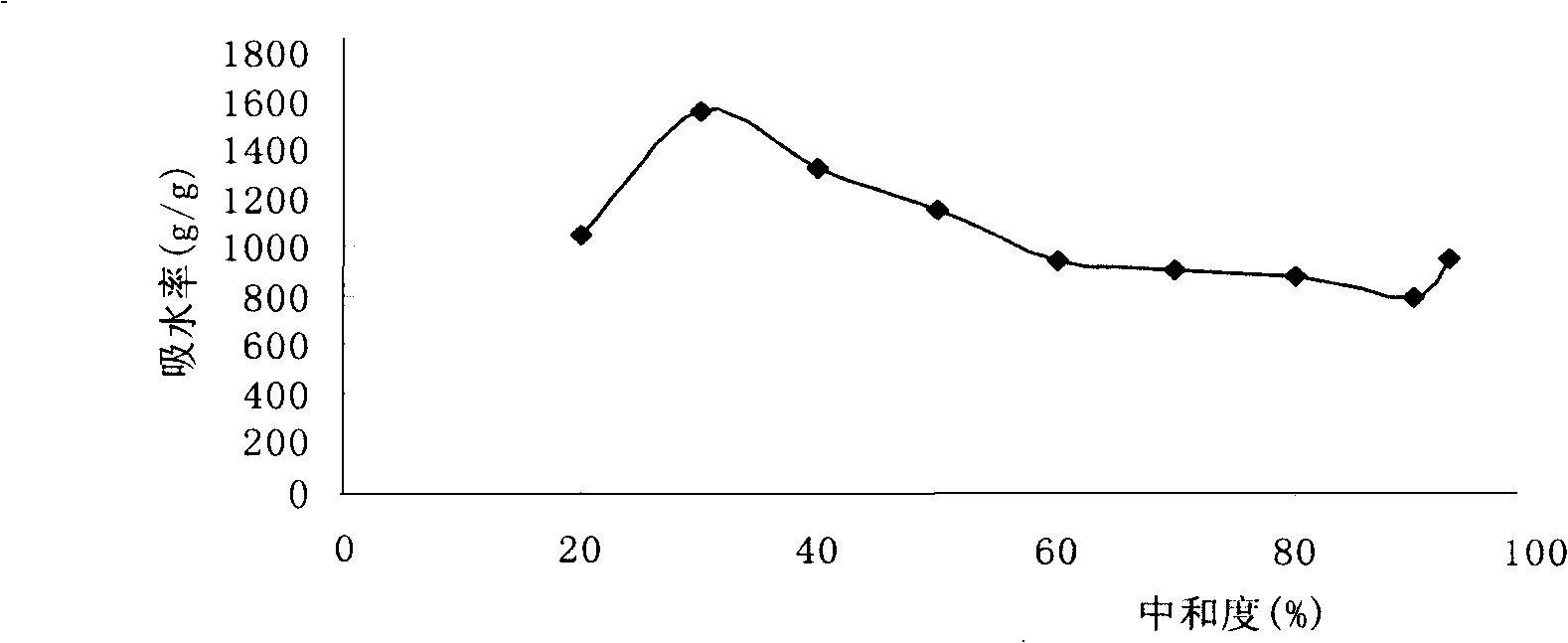

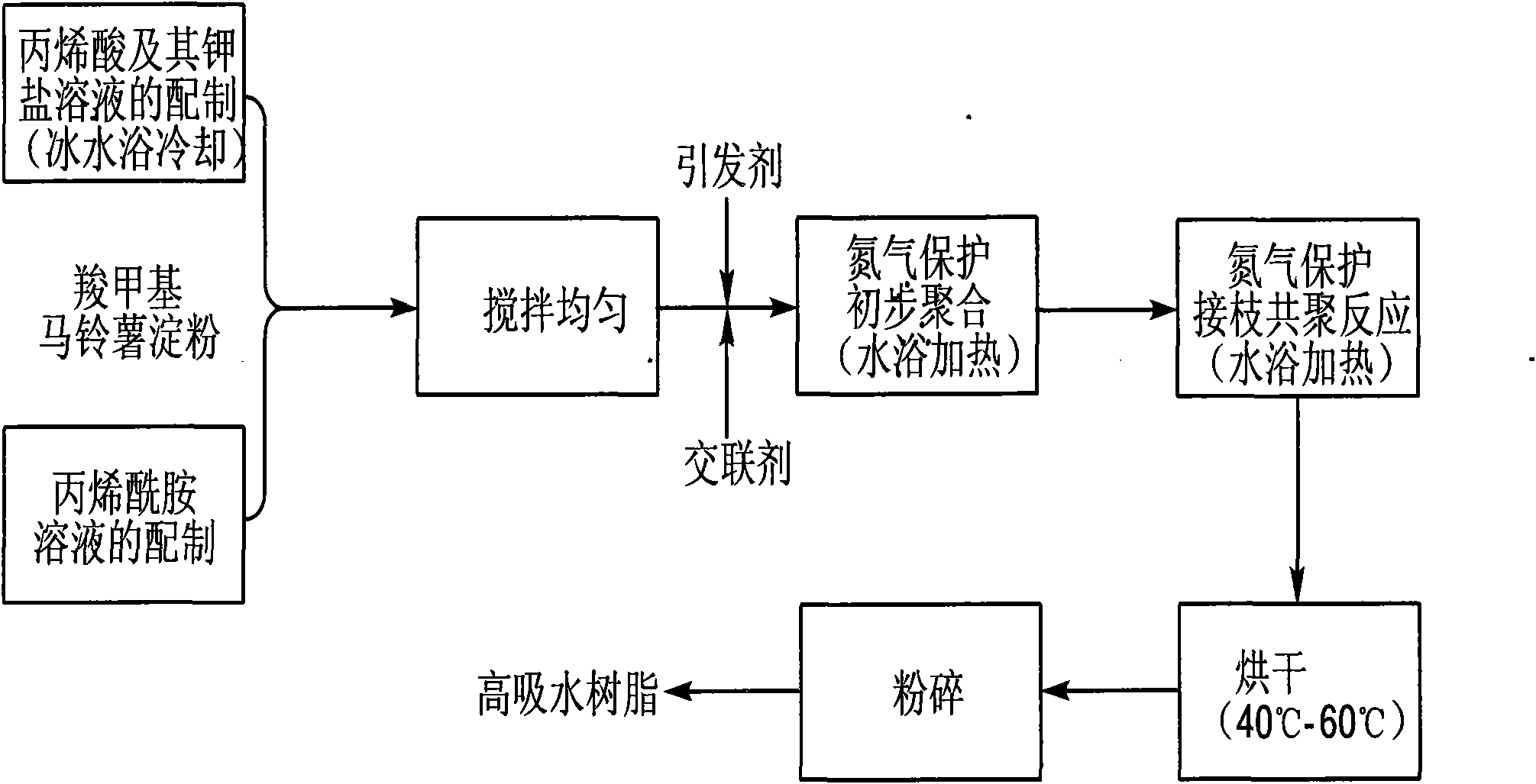

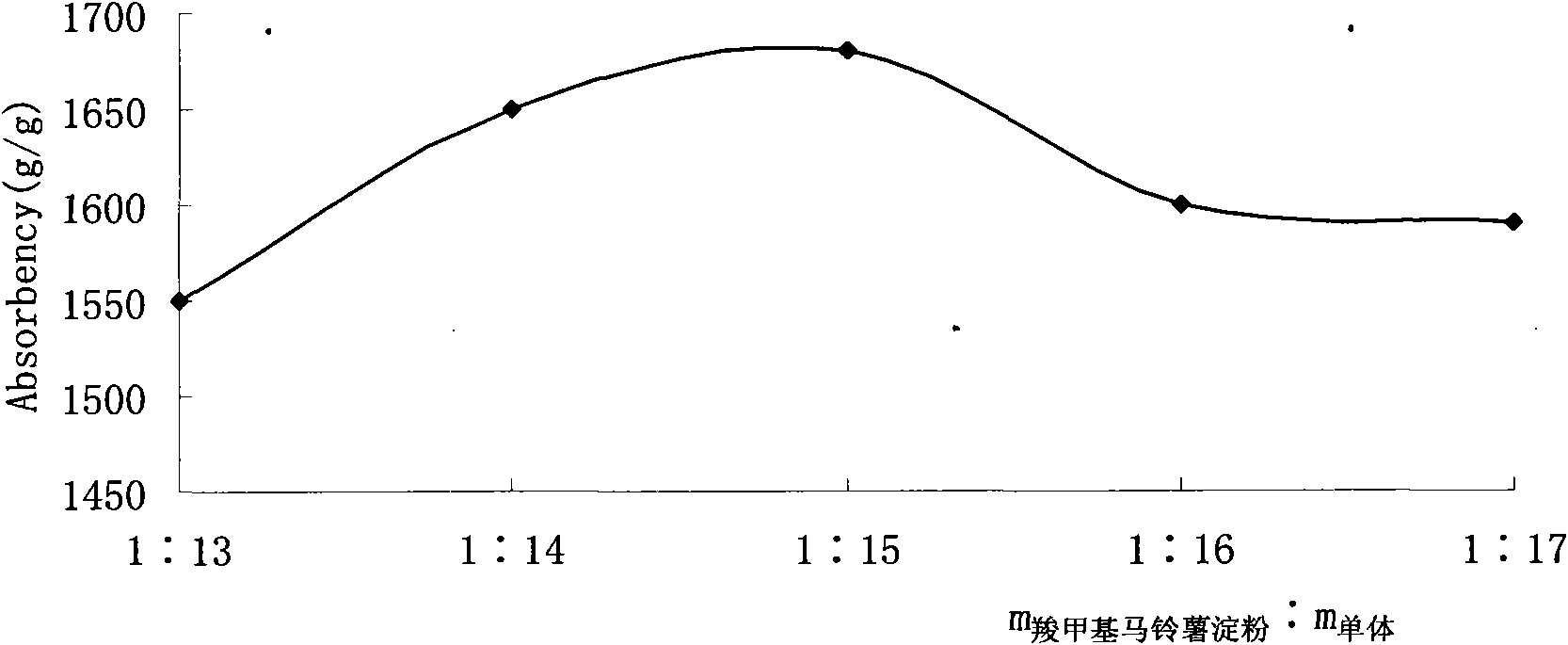

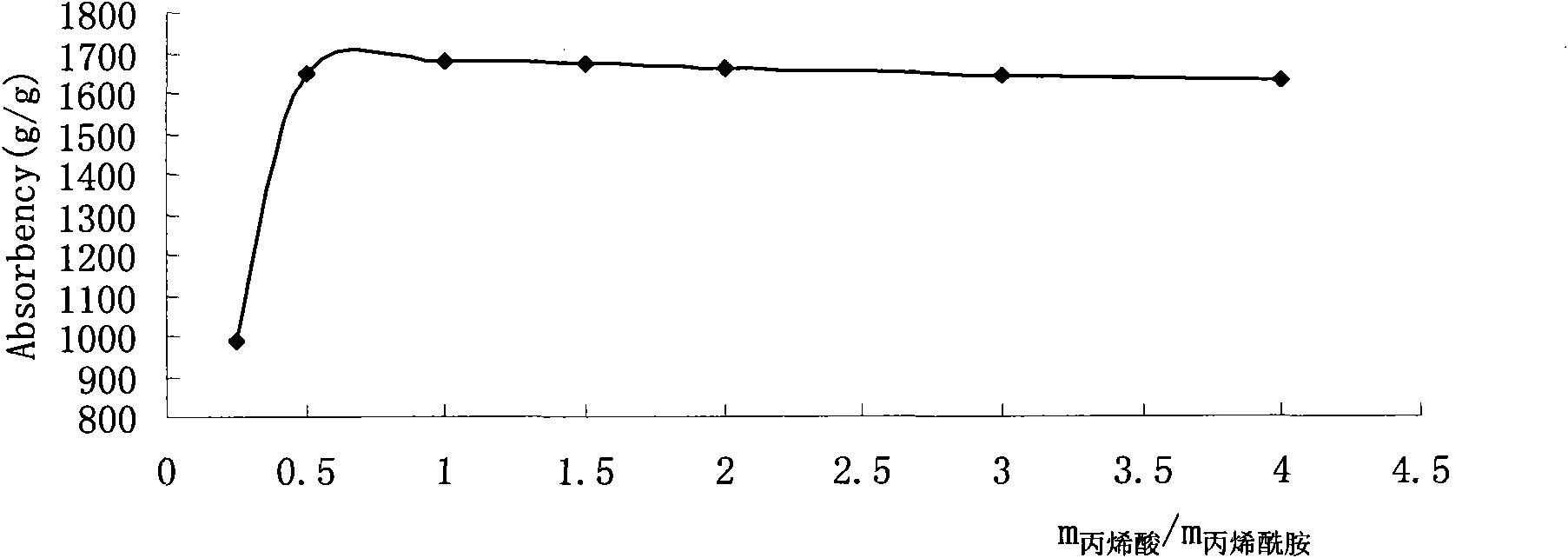

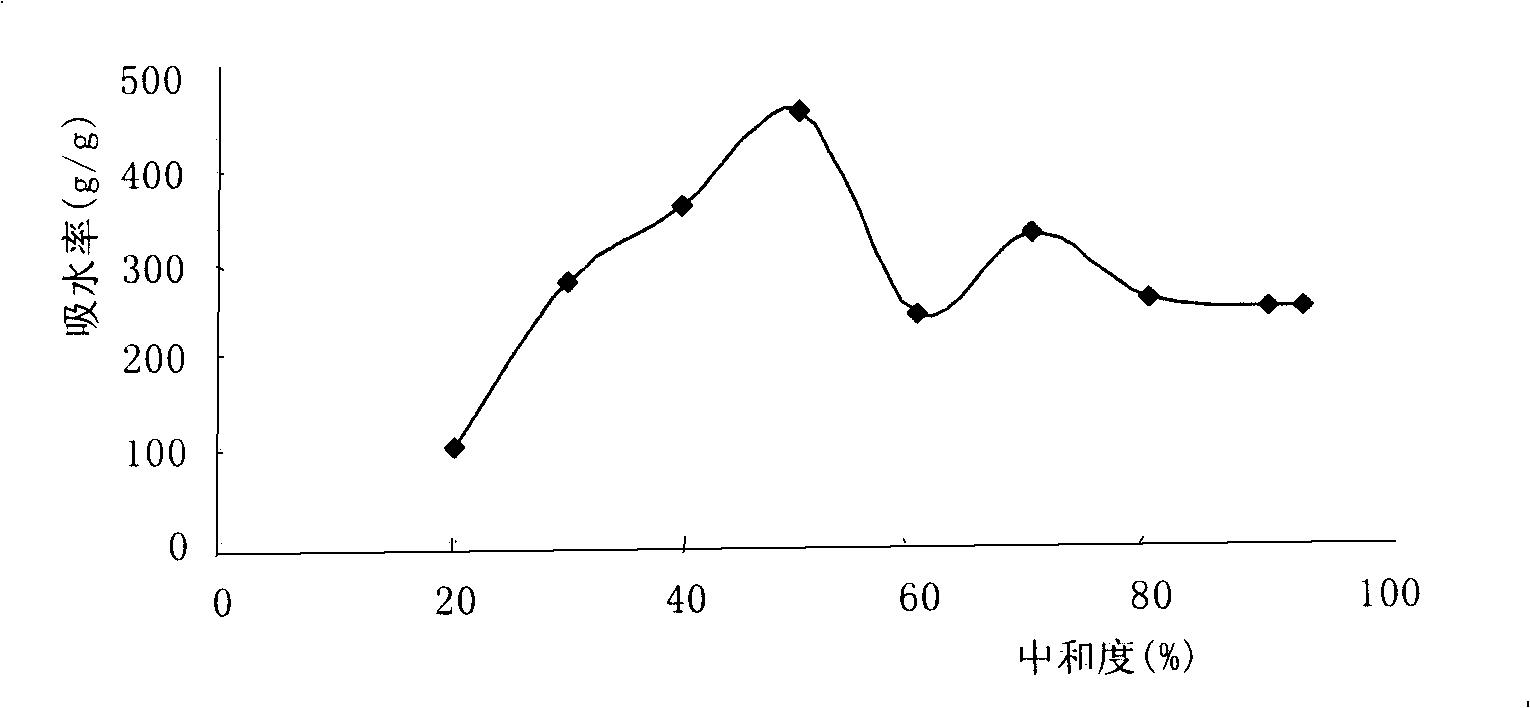

Method for preparing potassium- and nitrogen-containing high water-absorbent resin from carboxymethyl potato starch serving as raw material

The invention discloses a method for preparing potassium- and nitrogen-containing high water-absorbent resin from carboxymethyl potato starch serving as a raw material. The product is prepared from the carboxymethyl potato starch serving as the raw material; and the carboxymethyl potato starch is water soluble, so compared with starch serving as the raw material, the carboxymethyl potato starch does not need gelatinization, and the preparation process is greatly simplified. Compared with like products, the high water-absorbent resin prepared by the method has the advantages of high water absorbing and retaining capability and high gel strength, contains potassium and nitrogen necessary for plant growth, and has great effects of resisting drought and keeping seedlings, increasing both production and income, promoting plant growth and the like for the soil in arid regions.

Owner:广西珅信科技有限公司

Method for preparing butyl rubber by catalytic polymerization

ActiveCN102140147AThe synthesis process is stableHigh molecular weightPolymer scienceCationic polymerization

The invention relates to a method for preparing butyl rubber by catalytic polymerization. The method comprises the following steps: contacting an isobutene monomer with an isoprene monomer at the temperature of minus 75 DEG C-minus 50 DEG C in the presence of an aliphatic series hydrocarbon diluent and a catalyst composite so as to carry out a cationic polymerization reaction, wherein the amount of added isobutene is 80-85% of the total volume, and the weight of added isoprene is 2.90-2.97% of that of isobutene, the allowance is the aliphatic series hydrocarbon diluent based on volume, the content of aluminium diethyl monochloride in the added catalyst composite is 0.13-0.23% of the mass of isobutene, the addition weight of ethylaluminum dichloride is 8.2% of that of aluminium diethyl monochloride, and the addition mass of water is 10-16% of that of the added diethylaluminum. The catalyst composite is stable in property, and butyl rubber with high dialkene content and molecular weight is formed at the polymerization reaction rate.

Owner:PETROCHINA CO LTD

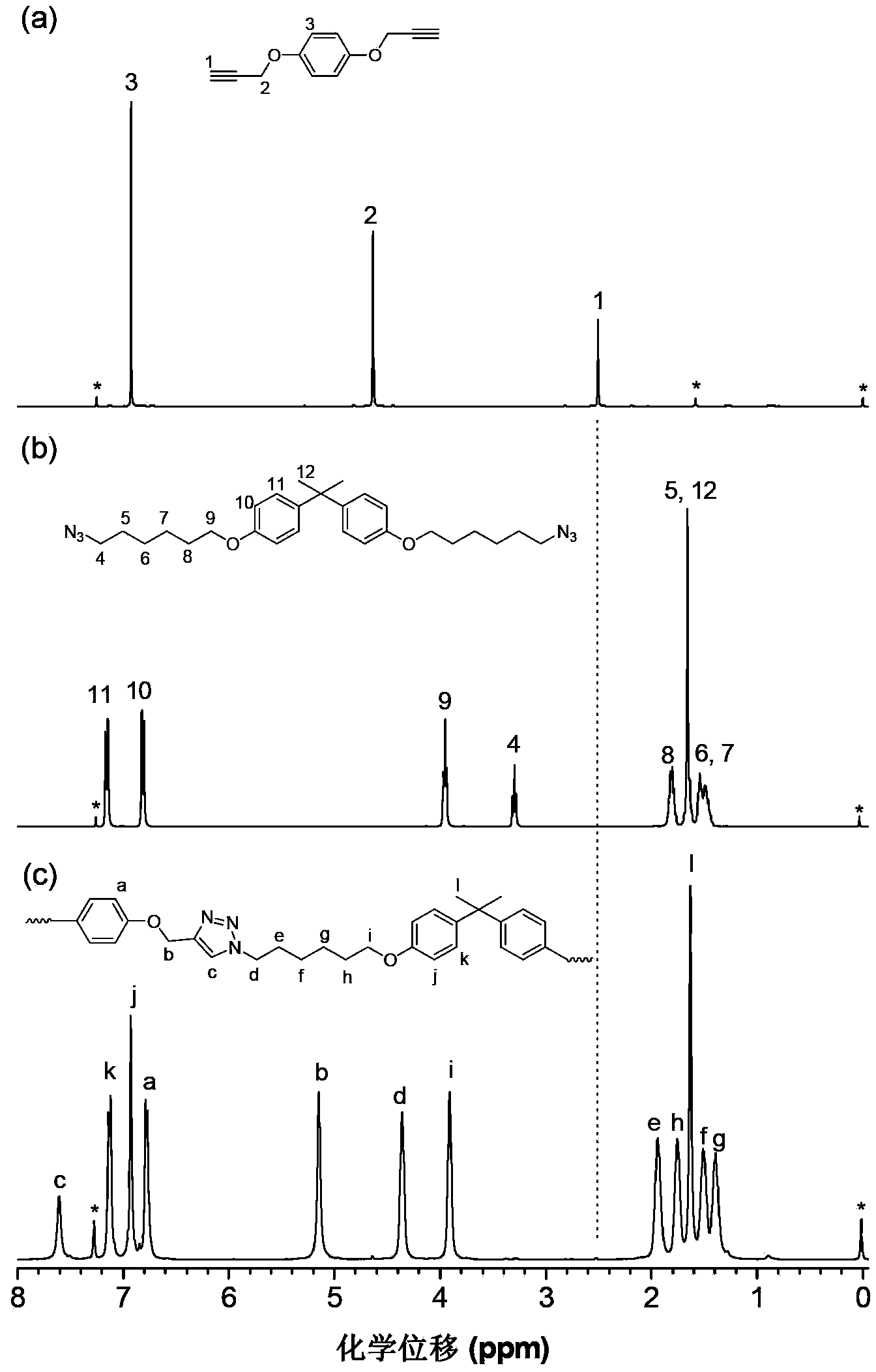

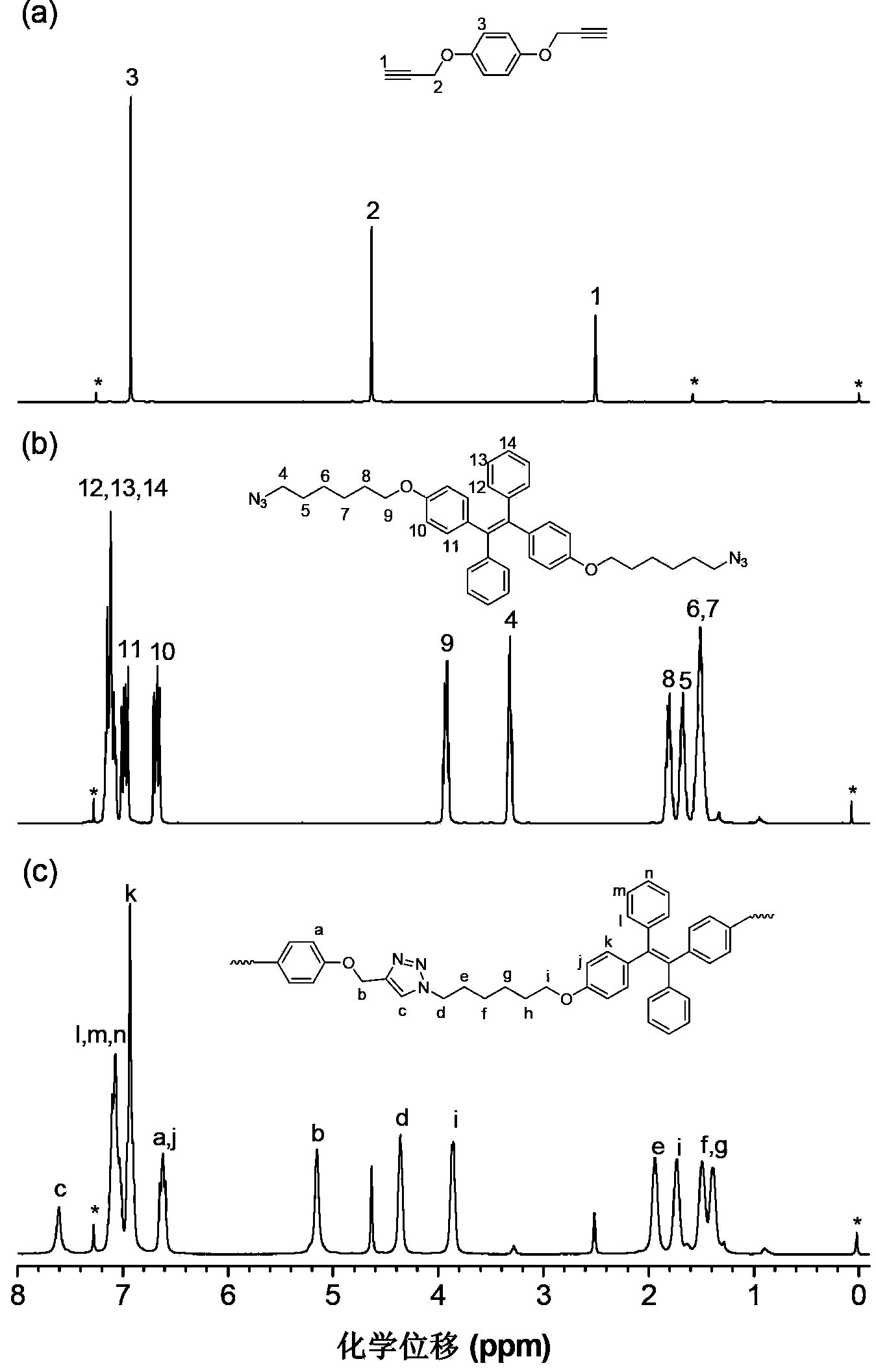

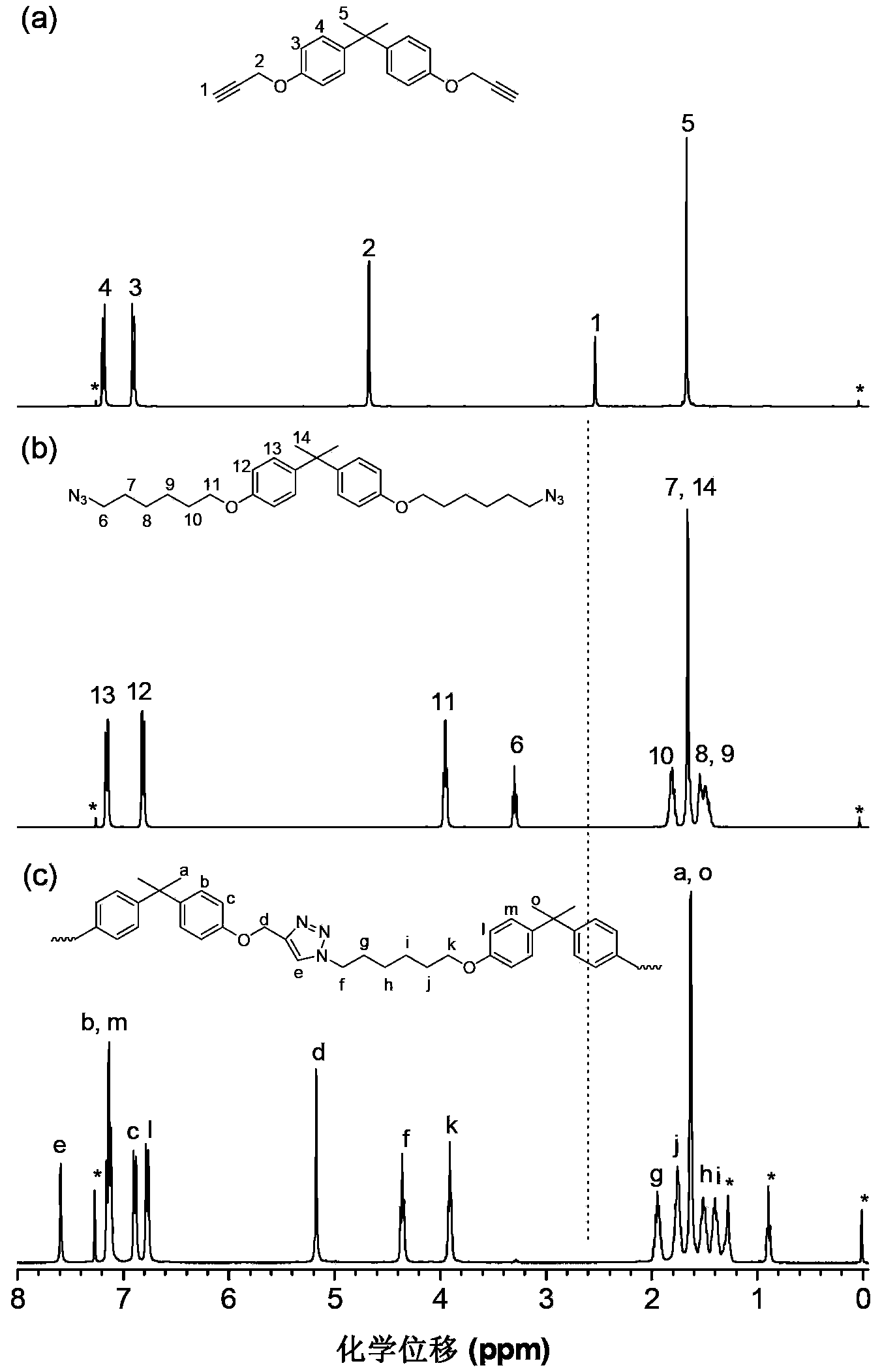

Method for preparing polytriazole through catalysis of recyclable supported cuprous catalyst and prepared polytriazole

InactiveCN103408756AIncrease contact areaIncrease the rate of polymerizationChemical recyclingPolymer dissolutionSolubility

The invention discloses a method for preparing polytriazole through catalysis of a recyclable supported cuprous catalyst and prepared polytriazole. The method comprises the following steps: under the catalysis of a supported click polymerization catalyst, a nitrine monomer and an alkyne monomer are subjected to click polymerization reaction in an organic solvent so as to form polytriazole. The method realizes the click polymerization reaction through catalysis of the supported cuprous catalyst, and has the advantages that the activity is high, the condition is gentle, the stereoselectivity is high, and the solubility of polymer is excellent, and the copper content of the polymer prepared by utilizing the reaction is low. In addition, after the supported cuprous catalyst used by the reaction is recycled for 4 times, the reaction activity of the supported cuprous catalyst is not subjected to obvious change.

Owner:ZHEJIANG UNIV

Preparation method for polycarboxylate high-performance water reducer

Provided is a preparation method for a polycarboxylate high-performance water reducer. The water reducer is prepared by copolymerization reaction of macromolecule monomer methoxy polyethylene glycol mono(meth) acrylate ester, small molecule monomer (meth)acrylic acid and sodium styrene sulfonate in an aqueous solution under the protection of inert gas and the action of a redox initiation system and a chain transferring agent. According to the invention, a high-activity redox initiation system is employed, which enhances the polymerization rate, reduces polymerization temperature, shortens reaction time, ensures non-hydrolysis of macro-molecular polyester monomers in the process of polymerization and a high conversion rate of raw materials, and guarantees that polymers have long side chains arraying at uniform intervals and an ideal comb shaped molecular structure. The water reducer prepared in the invention has the characteristics of a high water-reducing rate, a small slump loss and the like, and enables concrete with the water reducer to have high strength; simultaneously, the copolymerization reaction is carried out in water in the method, and therefore the method has the characteristics of simple preparation technology, environmental protection, low cost, etc.

Owner:江苏天音化工有限公司 +1

Synthetic method of lubricating fluid loss additive and application method thereof

InactiveCN104479070AGood molecular weightHigh molecular weightDrilling compositionWater soluble polymersChemistry

The invention relates to the technical field of oil-gas well engineering, specifically to a lubricating fluid loss additive and its synthetic process and application method. The technical scheme is as follows: the synthetic method of the lubricating fluid loss additive comprises the following steps: 1) preparing an aqueous phase solution; 2) preparing an oil phase solution; and 3) slowly adding the aqueous phase solution drop by drop into the oil phase solution for 10-20 min, introducing nitrogen, stirring, and polymerizing for 15min-1h by water bath of 40-65 DEG C after adding dropwise, so as to obtain the lubricating fluid loss additive. By the technical scheme, introduction of the oil phase endows the lubricating fluid loss additive water-soluble polymer with good lubricating property.

Owner:SINOPEC SSC +1

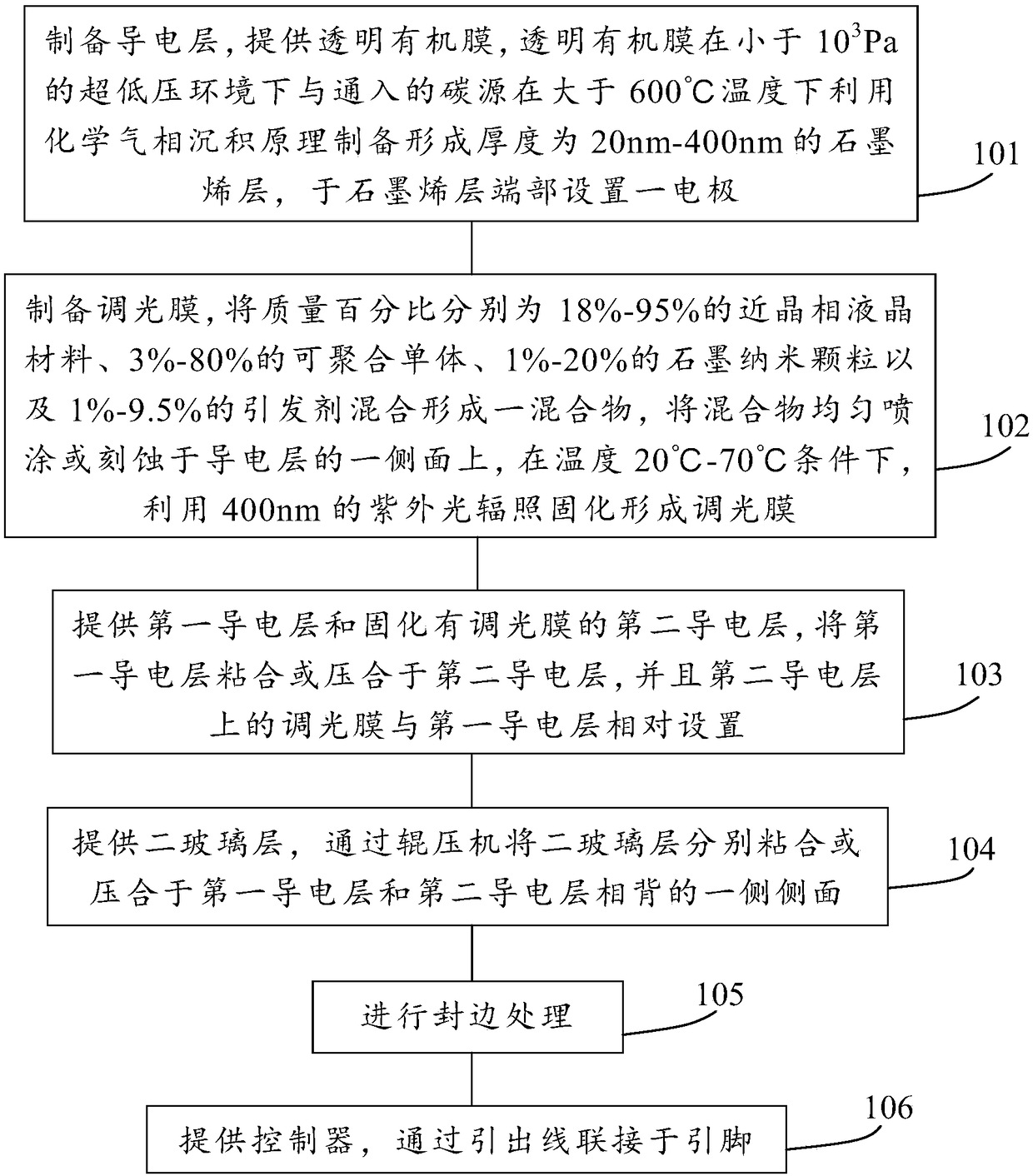

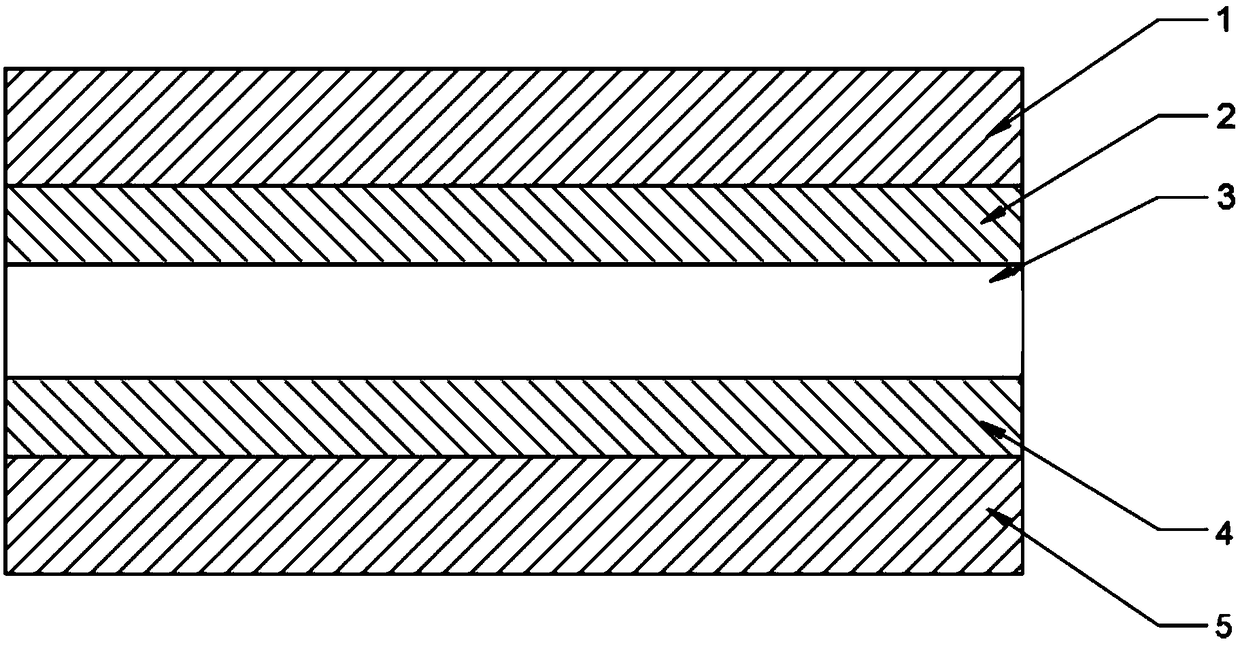

Automobile smart glass and manufacture method thereof

The invention provides automobile smart glass and a manufacture method thereof. The manufacture method comprises steps of preparing a conductive layer, wherein a transparent organic film and an introduced carbon source are prepared into a graphene layer through chemical vapor deposition at over 600DEG C in a less than 103Pa environment; preparing a smart film, wherein graphite nano particles, a smectic liquid crystal material, a polymerizable monomer and an initiator are mixed and blended uniformly, then a mixture is sprayed or etched at the side of the graphene layer in the conductive layer,and then is radiated by 400nm ultraviolet light for 10-30 minutes at 20-70DEG C so as to be cured to form the smart film; providing a first conductive layer and a second conductive layer, on which thesmart film is cured, bonding or laminating the first conductive layer onto the second conductive layer; and providing two glass layers, bonding or laminating the two glass layers on opposite sides ofthe first conductive layer and the second conductive layer respectively, and sealing the edge. Automobile smart glass prepared by the manufacture method can well protect privacy of users, and has high shock resistance and soundproof effect.

Owner:扬州晶彩光电科技有限公司

Method for synthesizing segmented copolymer by coupling enzymatic catalysis and organic catalysis by virtue of micro reactor

ActiveCN106520851ATo achieve high-efficiency copolymerizationIncrease the rate of polymerizationBioreactor/fermenter combinationsBiological substance pretreatmentsReaction rateOrganocatalysis

The invention discloses a method for synthesizing a segmented copolymer by coupling enzymatic catalysis and organic catalysis by virtue of a micro reactor, and relates to the field of the synthesis of polymers. The method comprises the following steps: (a) dissolving a monomer 1 and an initiating agent in an organic solvent, pumping an obtained solution into an immobilized enzyme micro reactor, and conducting a full reaction; (b) dissolving a monomer 2 and an organic catalyst in an organic solvent, mixing an obtained solution and reaction liquid outputted from the step (a) in a mixer 4, pumping a mixed solution into a micro-channel reactor 5 and conducting a full reaction; and (c) adding a quenching agent and a third organic solvent to reaction liquid collected from the step (b), and conducting separating and purifying, so as to obtain the pure poly-monomer 1-poly-monomer 2 segmented copolymer. According to the method provided by the invention, the processes of the enzymatic catalysis and the organic catalysis are coupled by virtue of the micro reactor, so that advantages of the enzymatic catalysis and the organic catalysis are integrated, and subsequently reaction efficiency is greatly improved, reaction time is shortened an continuous production is achieved; and the method has the advantages of being safe, efficient, low in energy consumption, high in reaction rate, moderate in reaction conditions and the like.

Owner:NANJING UNIV OF TECH

Waterborne binder and food-contact waterborne printing ink prepared by using waterborne binder

The invention relates to the technical field of printing ink, and particularly relates to a waterborne binder and food-contact waterborne printing ink prepared by using the waterborne binder. The waterborne binder comprises the following raw materials in parts by weight: 15-20 parts of modified rosin, 5-15 parts of starch, 0.5-5 parts of emulsifying monomers, 0.5-5 parts of an initiator, 0.1-2 parts of a pH regulator and 40-60 parts of water, wherein each part of the emulsifying monomers is prepared by the following method: stirring 70-90 parts of acrylic monomers and / or styrene monomers, 0.5-5 parts of an emulsifier and 20-30 parts of water at a temperature of 30-45 DEG C to obtain the emulsifying monomers. According to the waterborne binder, the harm of the use of organic solvents to thehealth of human bodies is avoided, and compared with the existing waterborne acrylic resin, the waterborne binder is more environmentally friendly and is harmless to the human bodies.

Owner:GUANGDONG YINGKE GRP CO LTD

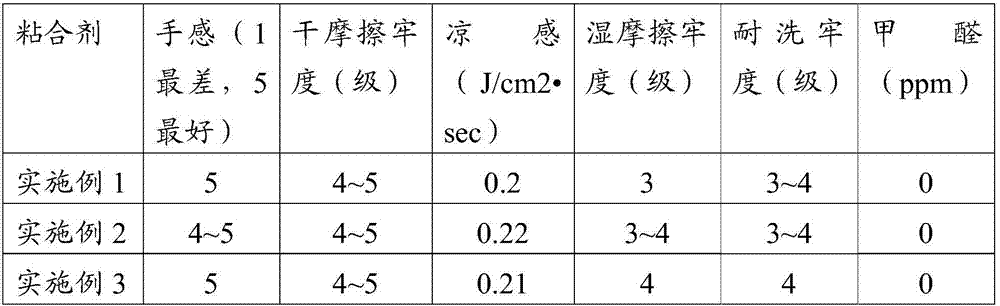

Printing adhesive and preparation method thereof, printing paste and clothing

The invention discloses a printing adhesive and a preparation method thereof, printing paste and clothing. The printing adhesive is prepared from the following components in parts by weight: 40-70 parts of a cool silicone emulsion, 0.6-1.0 part of an emulsifier, 36-59 parts of deionized water, 80-100 parts of soft monomer, 10-30 parts of a hard monomer, 0.6-3.0 parts of an emulsifier, 0.2-0.6 part of a pH buffer agent, 50-60 parts of deionized water, 0.2-0.6 part of an initiator and 1-4 parts of a cross-linking monomer. The printing adhesive has the advantages of low viscosity and good heat dispersion and has a relatively high polymerization reaction rate, and the obtained polymer is high in molecular weight.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

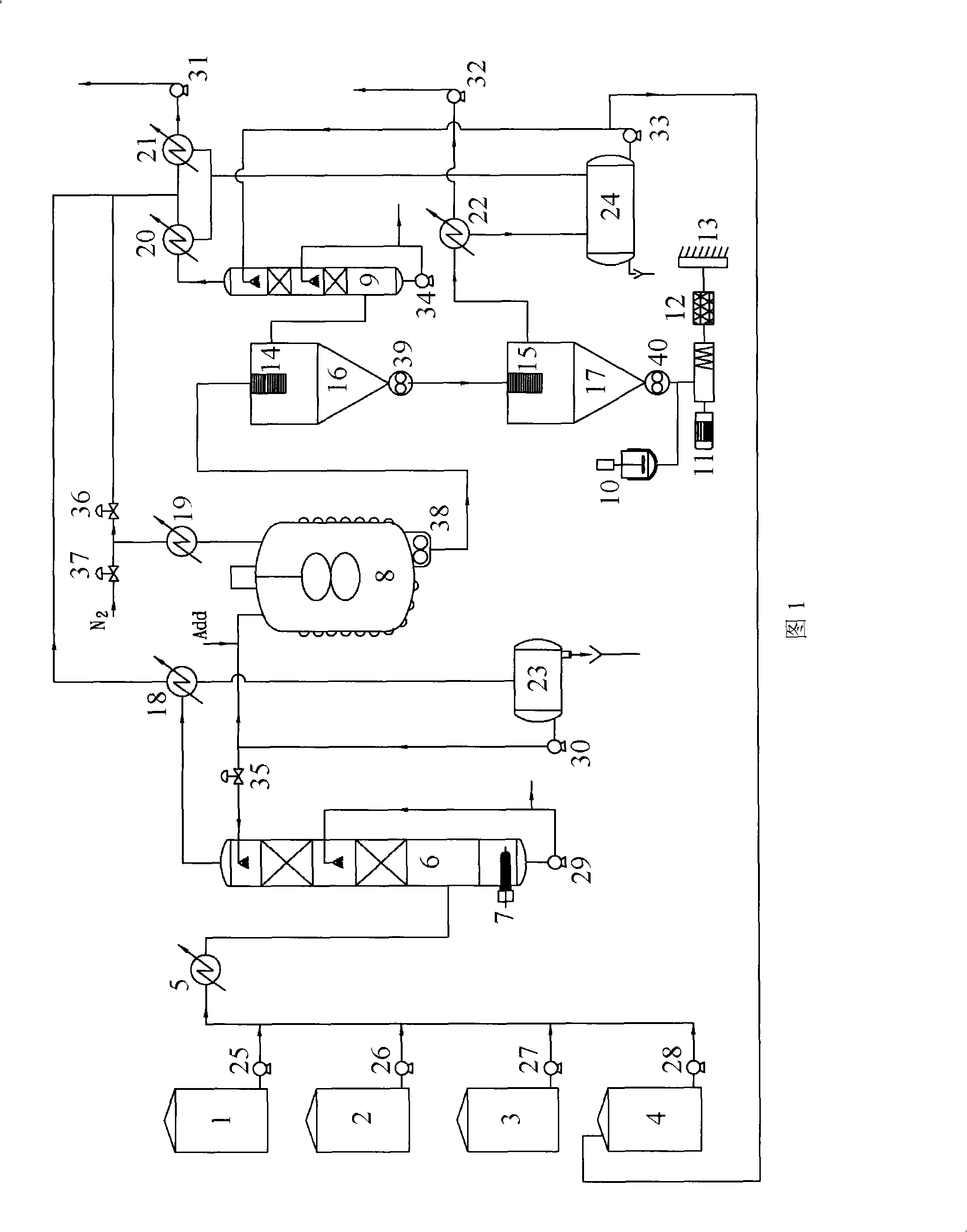

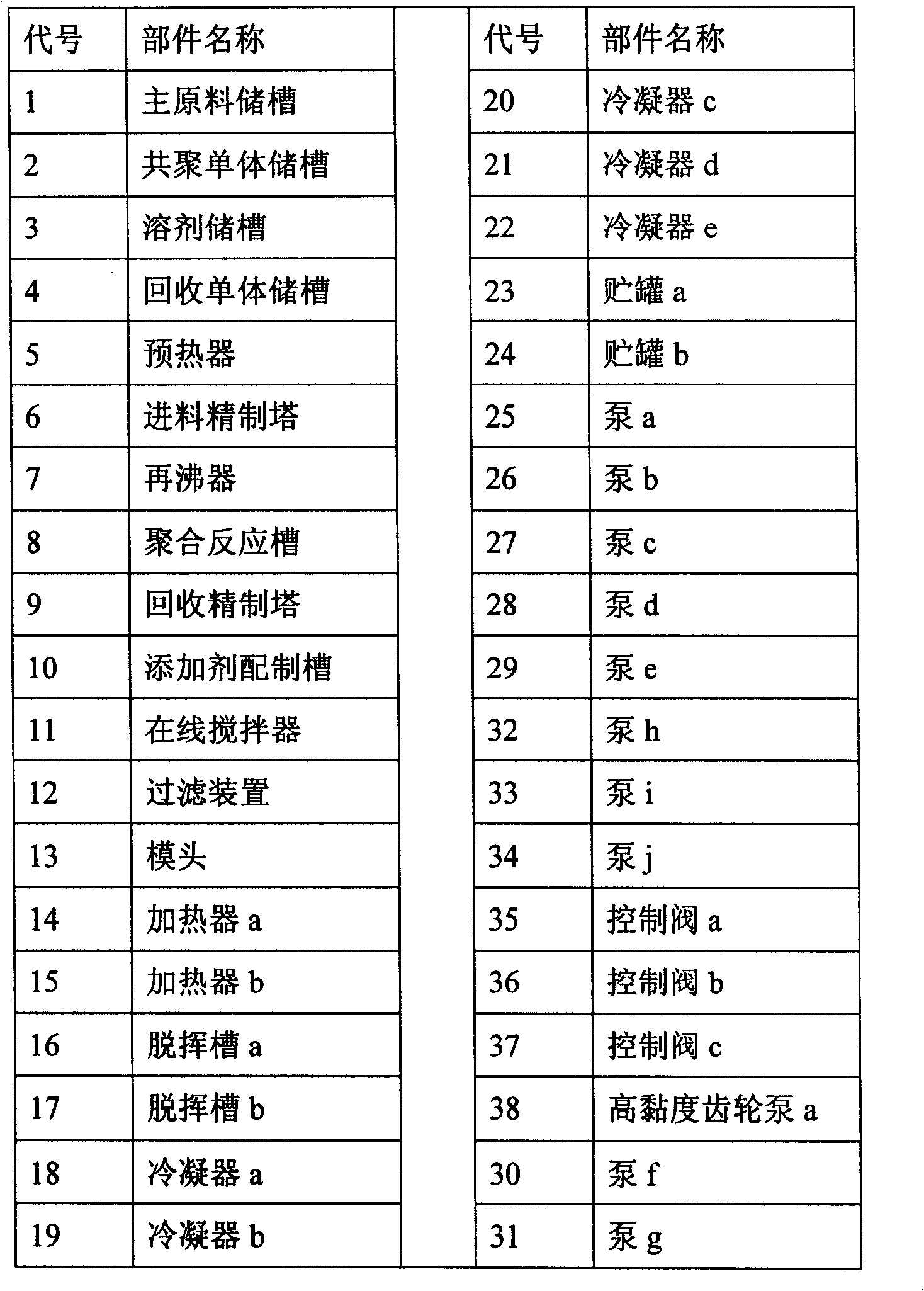

Optical-grade polymethylmethacrylate continuous solution polymerization process and equipment thereof

The invention relates to the preparation method of a polymer compound and a plant used therefor, in particular to a continuous solution polymerization process of optical-grade poly(methyl methacrylate) and the plant used therefor. The plant used for the continuous solution polymerization process of optical-grade poly(methyl methacrylate) comprises a refining and distillation device, a polymerization reaction device, a two-stage devolatilization device, and a wire-drawing and granulation device connected with each other in series, and specifically comprises a feed refining tower, a polymerization reaction groove, a recovering and refining tower, heaters a and b, and devolatilization tanks a and b. The continuous solution polymerization process can prepare optical-grade poly(methyl methacrylate) from monomers, a copolymer, a stabilizing agent, a molecular weight regulator, an initiator and a solvent according to the following four steps: (1) refining and distillation, (2) polymerization reaction, (3) flash devotilization and (4) wire drawing and granulation. The PMAA produced by the process has the advantages of high safety, no gel accumulation, improved physical properties and color of the produt, low energy consumption, environmental protection, clean production, good weathering resistance of the product, anhydrous polymerization, no black spots on the product, etc.

Owner:SHANGHAI JINGQI POLYMER MATERIAL

Preparation of super absorbent resin

InactiveCN101302269AImprove performanceReduce dosageOrganic chemistryWater bathsPotassium persulfate

The invention discloses a method for making super absorbent resin. The method comprises the following main technological processes that: acrylic acid is adopted to pass through a neutral aluminum oxide chromatographic column so as to remove polymerization inhibitor; sodium hydroxide and acrylic acid undergo neutralization reaction in ice-water bath, and potato starch is mixed with deionized water so as to carry out gelatinization; the neutralized acrylic acid and the salt solution of the acrylic acid are mixed with the gelatinized potato starch, and then initiator potassium persulphate is added in; the mixture is stirred evenly under the protection of nitrogen and then is heated to ensure that potato starch, acrylic acid and the salt of the acrylic acid undergo graft copolymerization reaction under the protection of nitrogen; then, the mixture undergoes heat-preservation reaction and then is dried and crushed so as to obtain the super absorbent resin. The super absorbent resin made by the method has excellent properties as well as greatly increased water-absorbing capacity as compared with similar products; the method takes potato starch as a raw material, thereby opening a path for the deep processing of farm products; moreover, the super absorbent resin can be used in disposable sanitary products, and can also change soil aggregate structure so as to increase soil water permeability and gas permeability; therefore, the super absorbent resin plays an important role in soil water conservation and desert control in arid areas.

Owner:内蒙古永业生物技术有限责任公司

Method for preparing isotropic coke through catalytic carbonization

InactiveCN104293366ALow reaction temperatureShorten the production cycleWorking-up pitch/asphalt/bitumen by chemical meansCoking carbonaceous materialsChemistryCoal

The invention relates to a method for preparing isotropic coke through catalytic carbonization. The method comprises the following steps: by taking coal tar (or coal pitch) as a raw material, adding a certain ratio of lewis acid catalyst, mixing to be uniform, putting the mixture into an autoclave, and performing catalytic carbonization under a certain temperature and pressure, thereby obtaining the isotropic coke. Compared with the traditional process for coking carbon precursors at high temperature through reactions such as thermal initiated free radical polymerization and cracking, the catalytic carbonization method has the advantages that the needed heating temperature is low, and low-cost coal tar (or coal pitch) is selected. Therefore, the manufacturing cost of the isotropic coke is greatly reduced on aspects of the raw materials and the process.

Owner:HUAQIAO UNIVERSITY

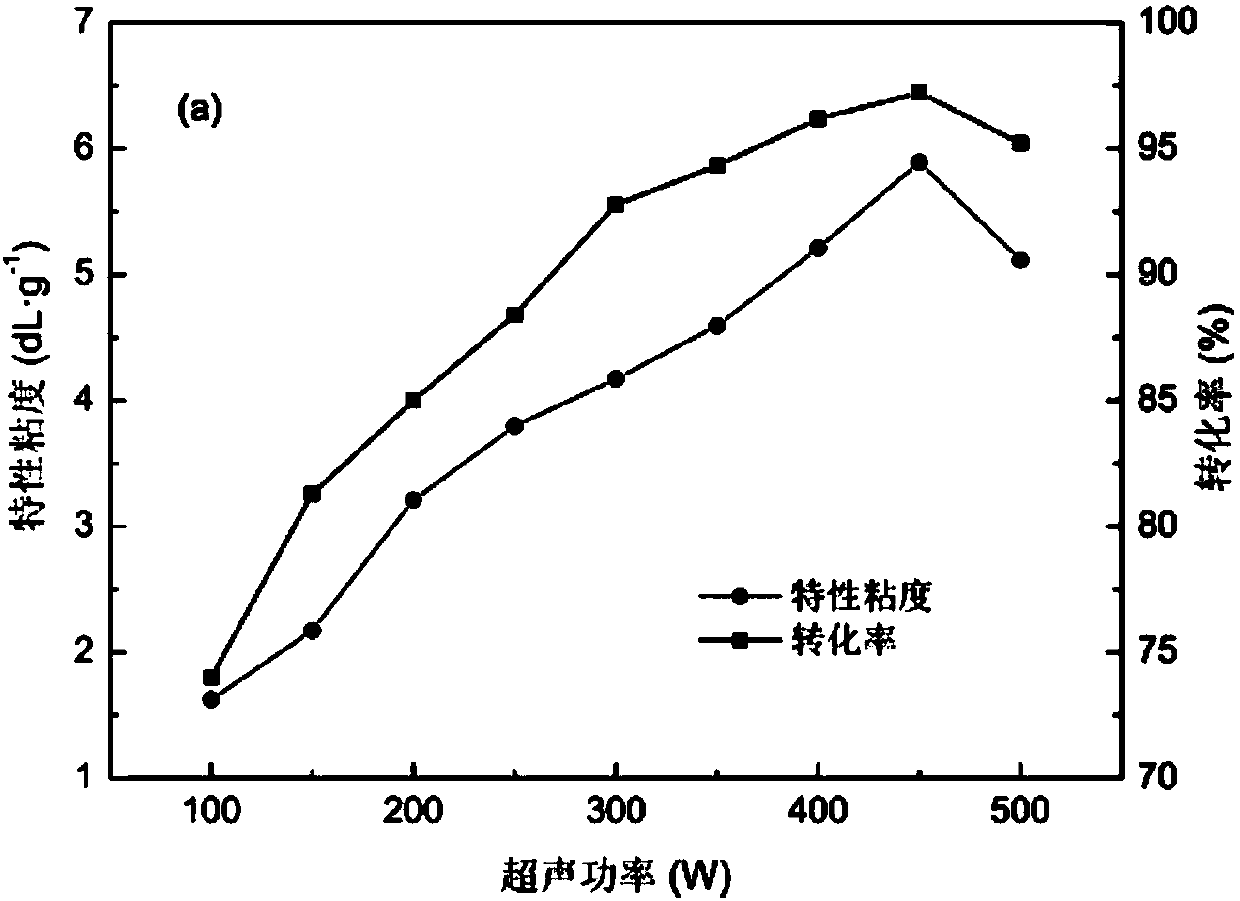

Preparation method of cationic polyacrylamide sludge dehydrant

ActiveCN107601820ACapable of "self-assembly"Improve conversion rateSludge treatment by de-watering/drying/thickeningSludgeDouble bond

The invention discloses a preparation method of a cationic polyacrylamide sludge dehydrant. The preparation method comprises the steps of dissolving acrylamide, a complexing agent EDTA-2Na, solubilizer urine and methylacryloyl yloxyethyl dimethyl benzyl ammonium chloride into water to be prepared into a mixed solution; adjusting a pH of the mixed solution to 3 to 5, adding an initiator V50 and then performing ultrasonic reaction on the mixed solution in a nitrogen atmosphere; after the ultrasonic reaction finishes, standing and curing the mixed solution, then taking a polymer obtained from reaction out, purifying and grinding into powder to obtain the cationic polyacrylamide sludge dehydrant. According to the preparation method disclosed by the invention, soap-free emulsion polymerizationis utilized, and a surface active monomer with amphipathy is utilized to replace an original cationic monomer and a template; since the surface active monomer not only has a self-assembling function,but also can polymerize double bonds, the surface active monomer can generate copolymerization directly with the acrylamide monomer; thus, the problem that an oligomer template is introduced by CPAM for preparing a block structure in a traditional method is avoided.

Owner:洛阳市誉龙净水材料有限公司

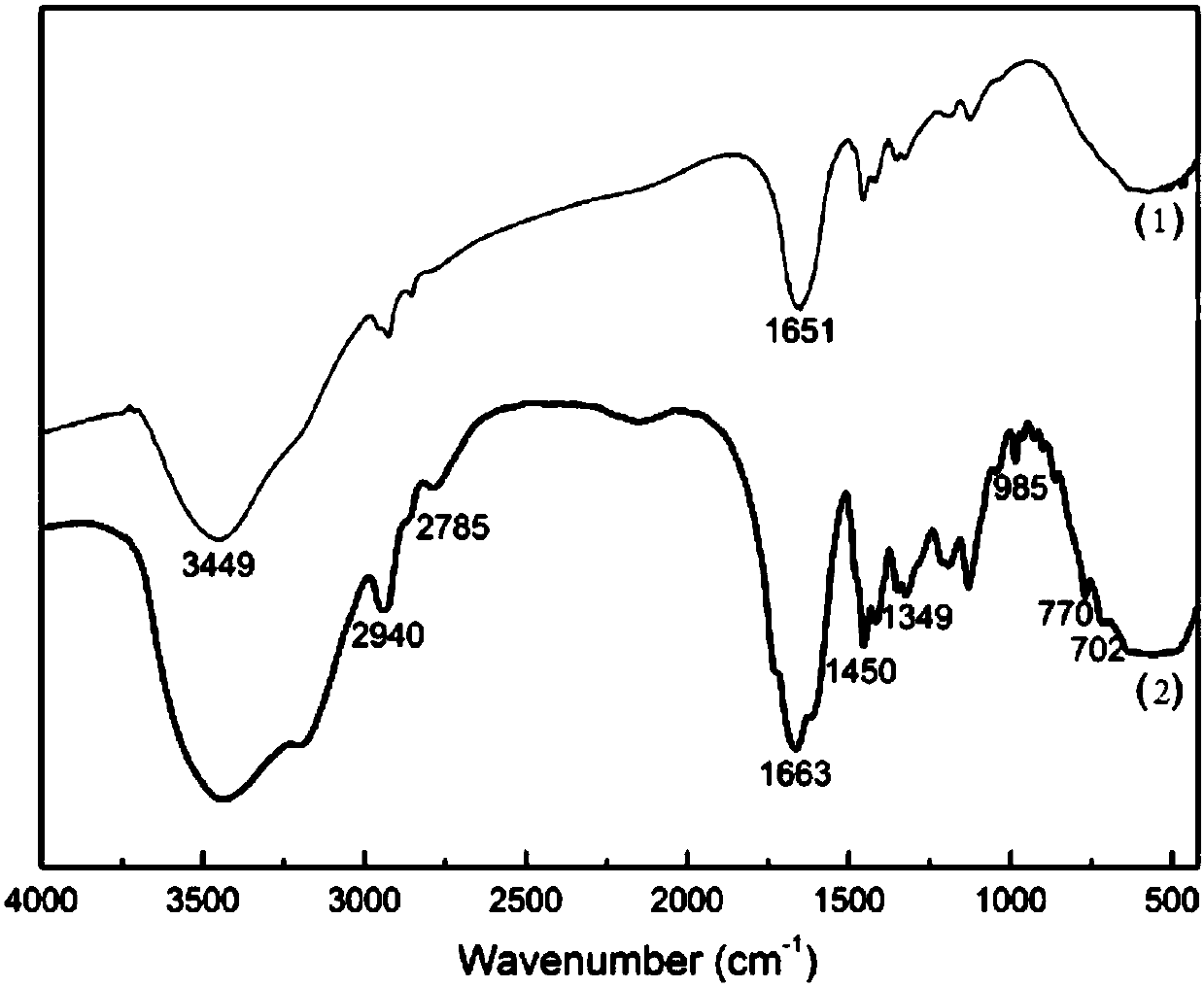

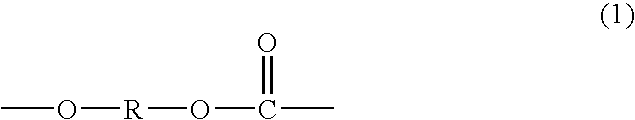

Polycarbonate diol having high proportion of primary terminal OH

InactiveUS7005495B2Satisfactory polymerization reaction rateReduced responseOrganic chemistryEnd-groupThermoplastic polyurethane

Disclosed is a polycarbonate diol having diol monomer units and carbonate monomer units, wherein the amount of at least one diol monomer unit selected from the group consisting of a 1,5-pentanediol unit and a 1,6-hexanediol unit is from 50 to 100% by mole, based on the total molar amount of the diol monomer units, and wherein the ratio of primary hydroxyl groups in all terminal groups of the polycarbonate diol is in a specific range. Also disclosed is a thermoplastic polyurethane obtained by copolymerizing the above-mentioned polycarbonate diol and a polyisocyanate.

Owner:ASAHI KASEI KK

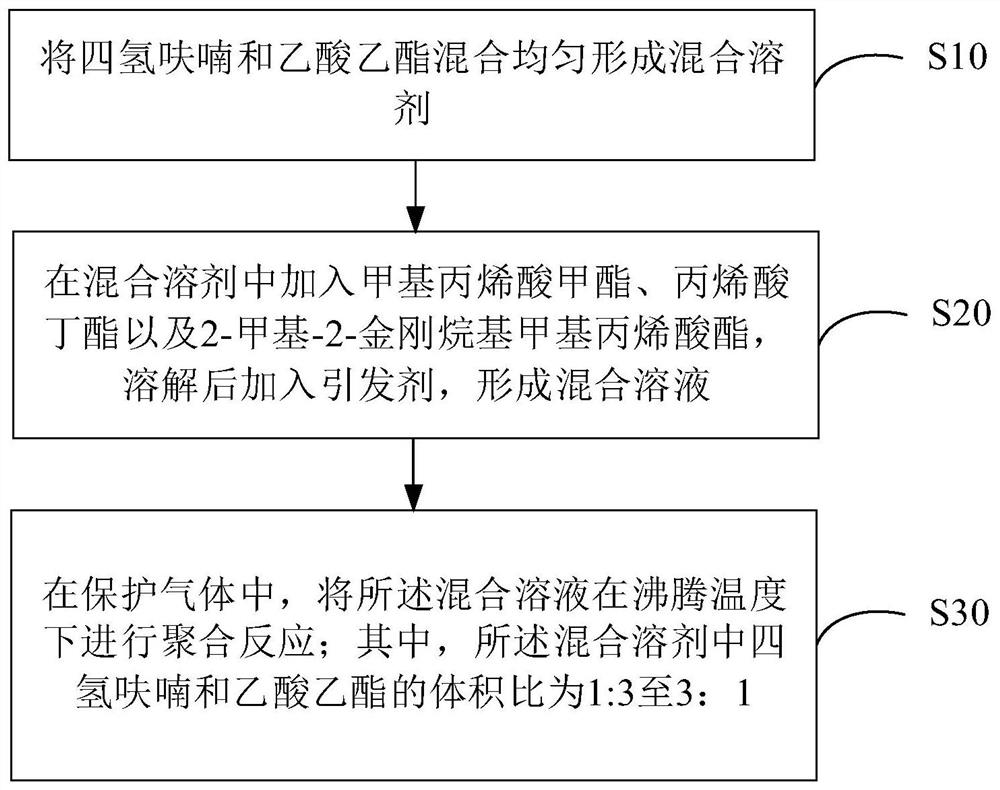

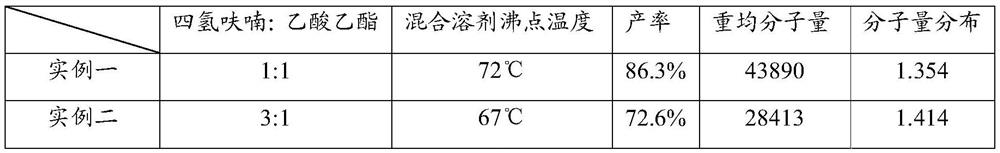

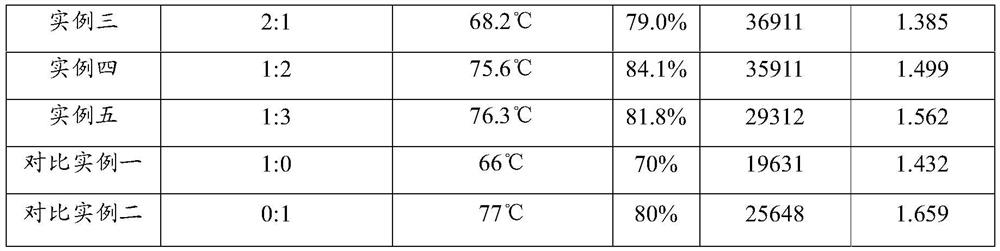

Methacrylic resin, preparation method thereof and photoresist

ActiveCN112778449AIncrease profitControl molecular weightPhotosensitive materials for photomechanical apparatusPolymer scienceMeth-

The invention provides a preparation method of methacrylic resin. The method comprises the steps of uniformly mixing tetrahydrofuran and ethyl acetate to form a mixed solvent; adding methyl methacrylate, butyl acrylate and 2-methyl-2-adamantyl methacrylate into the mixed solvent, dissolving, and adding an initiator to form a mixed solution; and carrying out polymerization reaction on the mixed solution at boiling temperature in protective gas, wherein the volume ratio of tetrahydrofuran to ethyl acetate in the mixed solvent is 1: 3 to 3: 1. The invention also provides methacrylic resin. The boiling point of the mixed solution is adjusted by adjusting the ratio of tetrahydrofuran to ethyl acetate in the mixed solvent, so that the purpose of controlling the reaction temperature is achieved, and then the decomposition rate of an initiator is controlled through different reaction temperatures, the polymerization reaction rate is increased, and the molecular weight of a polymerization product is controlled.

Owner:NINGBO NATA OPTO ELECTRONICS MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com