Preparation method of cationic polyacrylamide sludge dehydrant

A technology of sludge dehydrating agent and polyacrylamide, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of CPAM introducing oligomer templates, etc., achieve low cost, high monomer conversion rate, and less initiator dose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

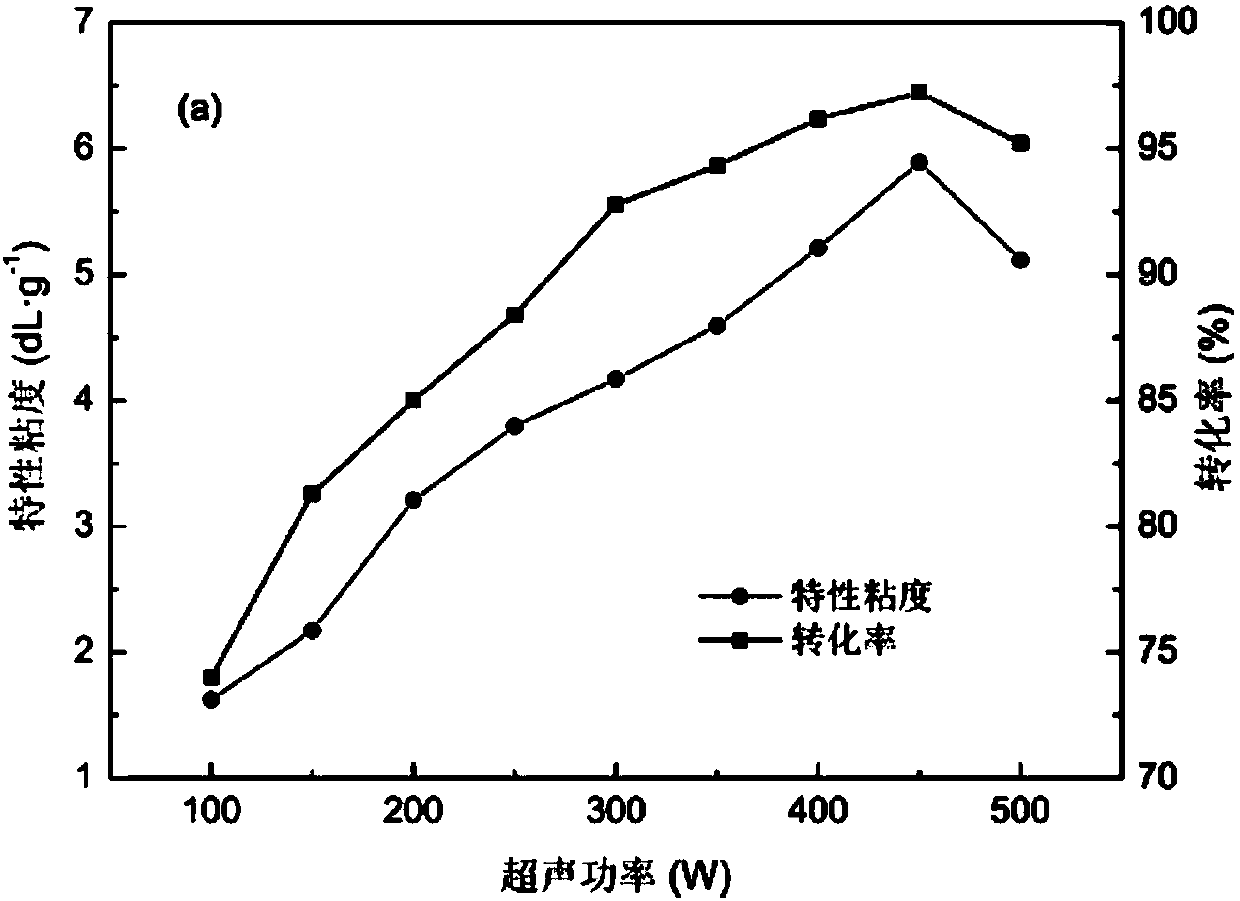

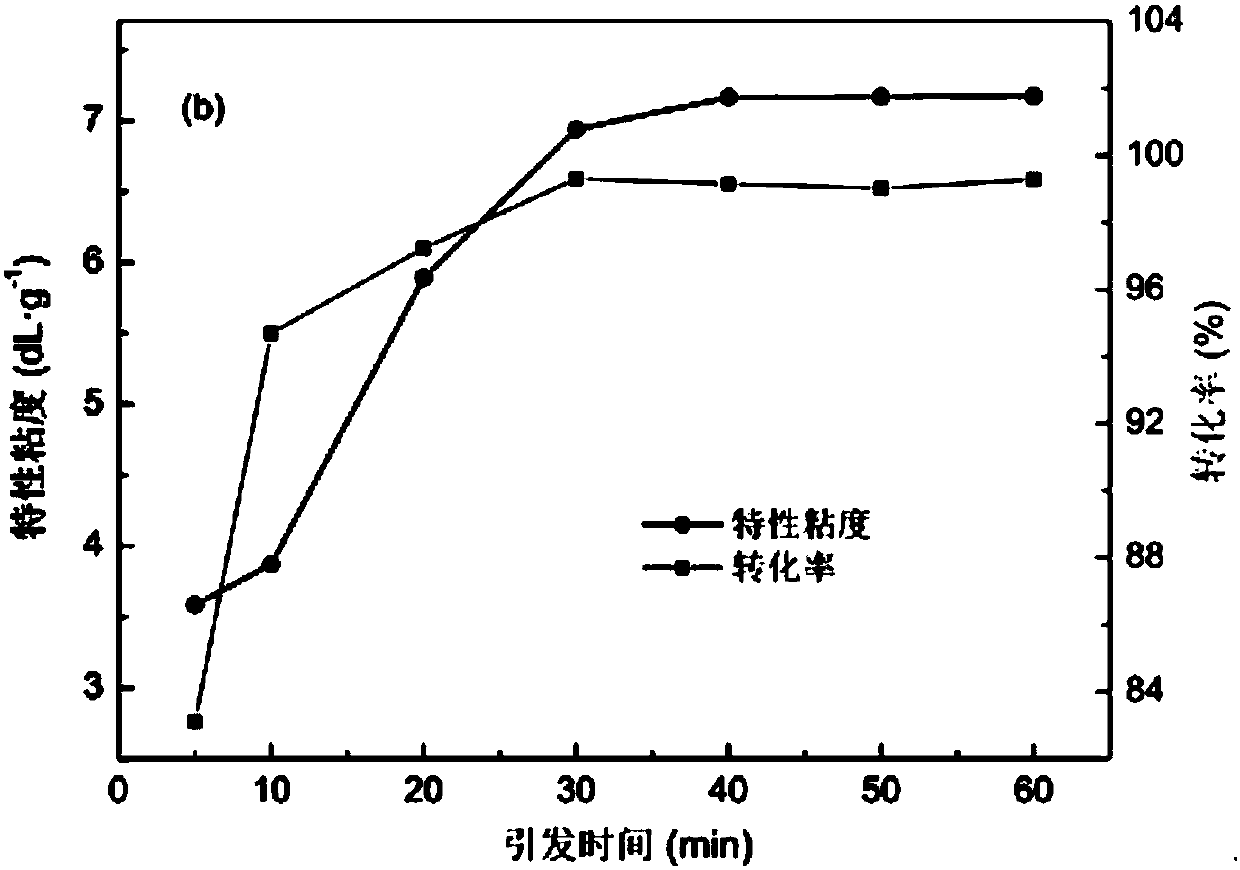

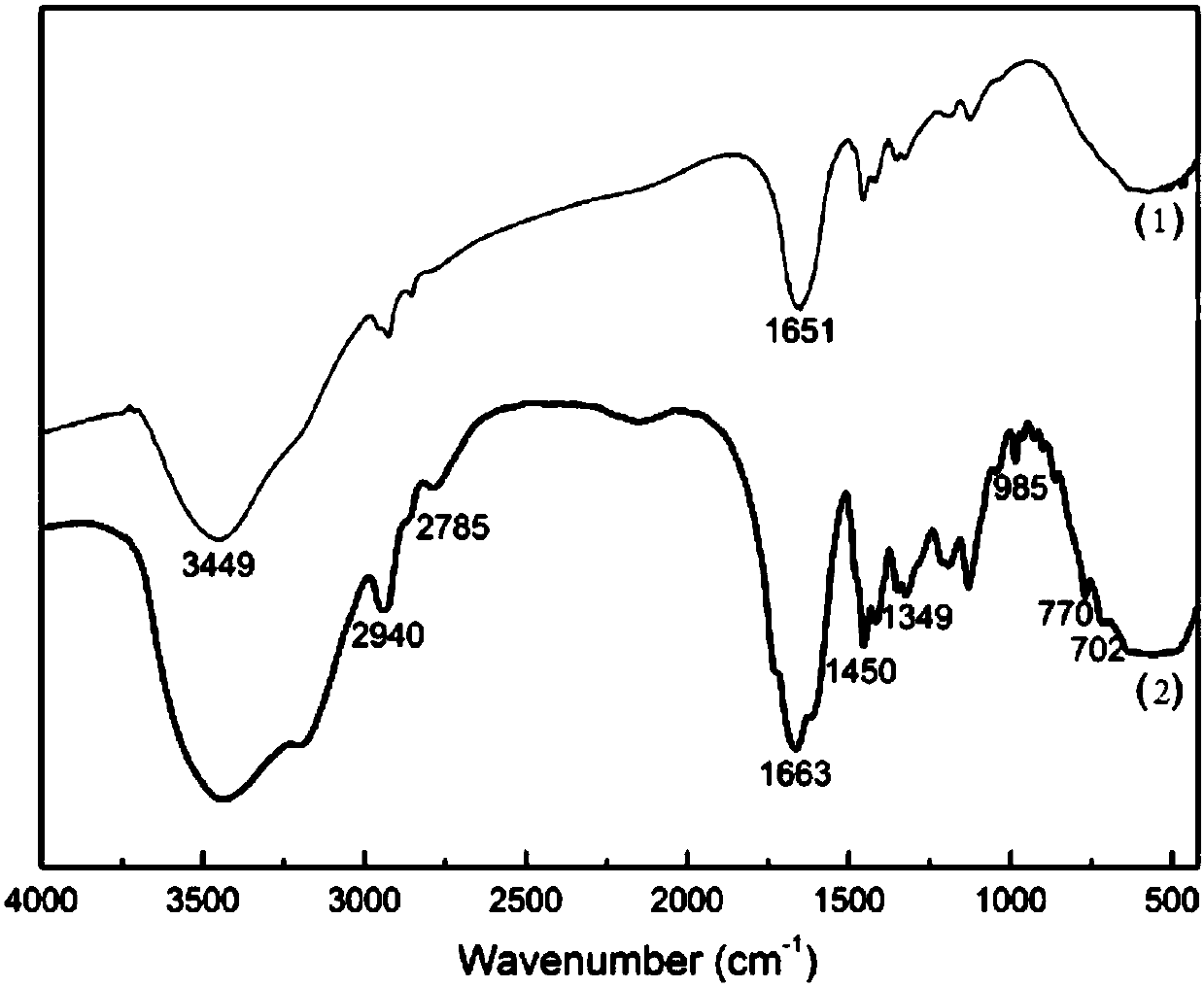

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the present embodiment cationic polyacrylamide sludge dewatering agent comprises the following steps:

[0036] (1) Add 5g AM monomer, 0.072g complexing agent EDTA-2Na (the mass fraction of EDTA-2Na is 0.4%) and 0.36g solubilizer urea (the mass fraction of urea is 2.0%) into the reactor, and then pass through the pipette Draw 2.21g of surface-active monomer DMBAC (the sum of the mass fraction of AM and DMBAC monomer is 40%, n(DMBAC):n(AM)=1:9) and 10.38g of distilled water are added to the reactor, and use a glass rod to fully Stir until completely dissolved to form a mixed solution.

[0037] (2) Use 0.1mol / L hydrochloric acid or sodium hydroxide to adjust the pH value of the mixed solution to 4, and fill it with N with a purity > 99.9%. 2, 2.2 mg of initiator V was added after 6 min 50 (V 50 0.03% of the total mass of AM and DMBAC); continue to pass N 2 After 10 min, the reactor was quickly sealed with the reactor bottle cap to form a seale...

Embodiment 2

[0040] The preparation method of this implementation cationic polyacrylamide sludge dewatering agent, the steps are as follows:

[0041] (1) Add 5g AM monomer, 0.06g complexing agent EDTA-2Na (the mass fraction of EDTA-2Na is 0.3%) and 0.3g solubilizer urea (the mass fraction of urea is 1.5%) into the reactor, and then pass through the pipette Draw 1.99g of surface active monomer DMBAC (the sum of the mass fraction of AM and DMBAC monomer is 35%, n(DMBAC):n(AM)=1:10) and 12.62g of distilled water are added to the reactor, and the glass rod is used to fully Stir until completely dissolved to form a mixed solution.

[0042] (2) Use 0.1mol / L hydrochloric acid or sodium hydroxide to adjust the pH of the mixed solution to 3, and fill it with N with a purity > 99.9%. 2 , after 6 min, add 1.4mg initiator V 50 (V 50 0.02% of the total mass of AM and DMBAC); continue to pass N 2 After 10 min, the reactor was quickly sealed with the reactor bottle cap to form a sealed reaction syste...

Embodiment 3

[0045] The preparation method of this implementation cationic polyacrylamide sludge dewatering agent, the steps are as follows:

[0046] (1) Add 5g AM monomer, 0.11g complexing agent EDTA-2Na (0.5% EDTA-2Na mass fraction) and 0.55g solubilizer urea (2.5% urea mass fraction) into the reactor, and then pass through the pipette Draw 4.96g of surface-active monomer DMBAC (the sum of the mass fraction of AM and DMBAC monomer is 45%, n(DMBAC):n(AM)=1:4) and 11.5g of distilled water are added to the reactor, and the glass rod is used to fully Stir until completely dissolved to form a mixed solution.

[0047] (2) Use 0.1mol / L hydrochloric acid or sodium hydroxide to adjust the pH value of the mixed solution to 5. After it dissolves, fill it with N with a purity > 99.9%. 2 , after 6 min, add 4mg initiator V 50 (V 50 Concentration is 0.04%); continue to pass N 2 After 10 min, the reactor was quickly sealed with the reactor cap covered with plastic wrap to form a sealed reaction syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com