Cascade reboiling of ethylbenzene/styrene columns

A technology of reboiler and distillation tower, which is applied in the field of separation of styrene products and unreacted ethylbenzene, and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] This example is according to prior art (rather than the present invention), adopts single packed distillation column to separate ethylbenzene from styrene monomer. This is used for comparison with the results of the subsequent practice of the present invention.

[0031] Using a single packed column under normal industrial conditions, 85-100 theoretical stages are required to obtain the required separation. Ethylbenzene is recovered as an overhead and styrene is recovered as a bottoms product. A typical design uses a top pressure of 70 mmHg (absolute) and a bottom pressure of 145 mmHg absolute. Under this pressure profile, the temperatures at the top and bottom of the column are about 66°C and 92°C, respectively. Heat is fed into the column via a thermosiphon type reboiler. Typically, a low pressure stream, cooled between about 115-130°C, is used as the heat source. The overhead vapor from the top of the tower can be condensed in cooling water or air-fin heat exchang...

example 2

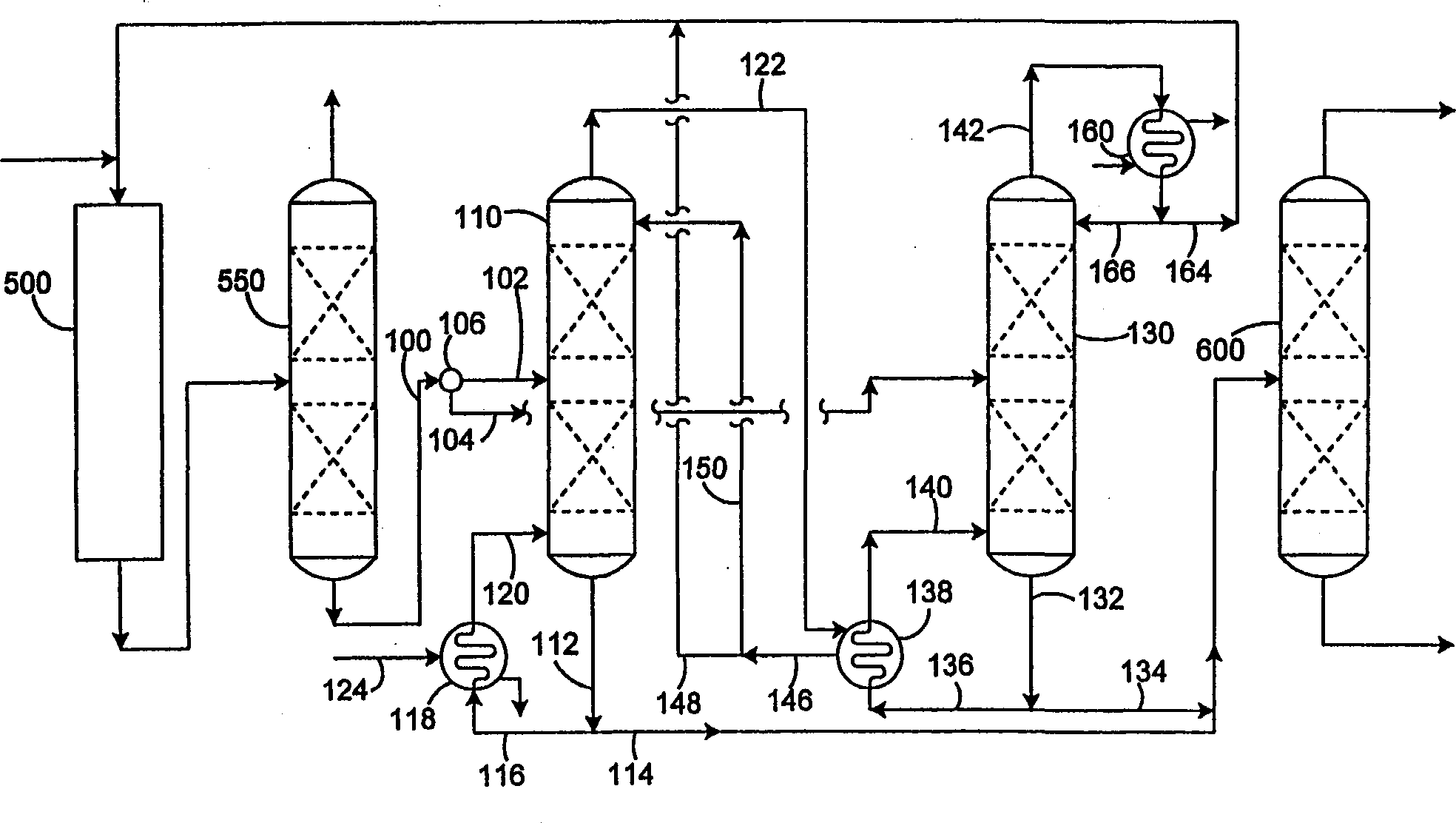

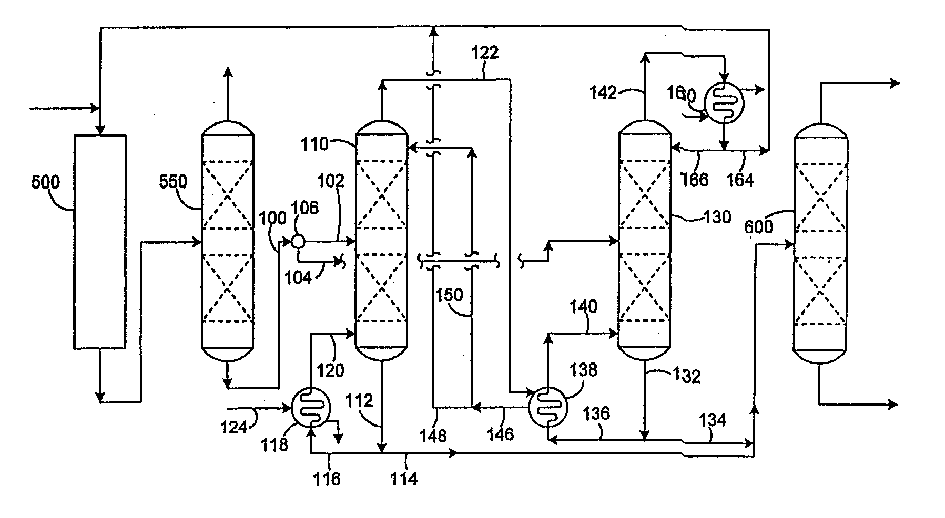

[0060] This example is a representative embodiment according to the present invention, such as figure 1 As shown, wherein, the mixed feed stream containing ethylbenzene and styrene monomer is divided into two process streams, which are distilled in two series distillation columns operated under different pressure and temperature conditions. The pressure of the columns is set such that the condensation temperature at the top of one column is higher than the bottom temperature of the other column. Because the overhead vapor from the higher pressure column is condensed at a temperature higher than the bottom temperature of the lower pressure column, this vapor stream can be used as a heat source for the lower pressure column with surprising process efficiencies and synergies.

[0061] In this example of the invention, the low pressure column was operated at an overhead pressure of 36 mmHg absolute (0.677 psia) and a bottom pressure of 100 mmHg absolute (1.934 psia). Under this p...

example 3

[0110] As mentioned earlier, in a styrene monomer (SM) plant for the dehydrogenation of ethylbenzene (EB) to produce styrene, the reactant ethylbenzene is fed and the conversion per pass through the reactor is typically 50-70%. Unreacted ethylbenzene must then be recovered and separated from the styrene product before it can be recycled back to the reaction system. In the reaction zone, components lighter than EB and components heavier than styrene are also formed. A mixture of light ends, ethylbenzene, styrene, and heavies is usually fed to a distillation train to purify SM and recover EB. Common practice is to use a three-step distillation process to achieve these purifications.

[0111] In order to separate the above-mentioned components, the distillation section of a styrene plant usually consists of three separate column systems. The first tower in this tower series recovers light components such as benzene and toluene (B / T tower), such as figure 1 Shown in the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com