Printing adhesive and preparation method thereof, printing paste and clothing

An adhesive and printing technology, applied in the field of light industrial textiles, can solve the problems of limited performance improvement and environmental protection, and achieve the effect of clear flower shape, low environmental pollution and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

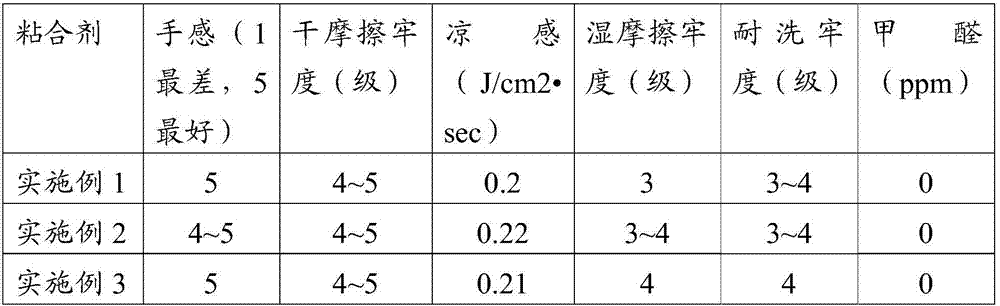

Examples

Embodiment 1

[0073] Heat up 40.0g of cooling silicone oil emulsion SOFTEXS-585, 0.6g of emulsifier, and 60g of deionized water to 40°C, and stir evenly for 2 hours to obtain the first component; 30.0g of butyl acrylate, 20.0g of isooctyl acrylate, Methyl methacrylate 10.0g, acrylonitrile 5.0g, pH buffer 0.5g, emulsifier 1.5g, deionized water 50g, stir evenly to make acrylate pre-emulsion; 0.4g potassium persulfate in 8.0g deionized water Dissolve and prepare initiator solution; Add 100g of the above-mentioned polymer silicone emulsion, 30.0g of butyl acrylate, 20.0g of isooctyl acrylate, 10.0g of methyl methacrylate, 5.0g of acrylonitrile, di 1.5 g of ethylene glycol methacrylate was heated up to 30°C. Swell under stirring for 12 hours; heat up to 50°C, add 6g of the above-mentioned initiator solution, and heat up to 78°C, after the emulsion in the polymerization reactor has blue light, then continuously add the remaining pre-emulsion to the polymerization reactor for 2 hours. After the a...

Embodiment 2

[0076] Heat up 62.0g of cooling silicone oil emulsion H-424, 30g of deionized water to 40°C, and stir evenly for 2 hours to obtain the first component; 40.0g of butyl acrylate, 10.0g of ethyl acrylate, and 10.0g of methyl methacrylate g, acrylonitrile 3.0g, styrene 2.0g, pH buffer 0.5g, emulsifier 1.5g, deionized water 50g, stir evenly to make acrylate pre-emulsion; dissolve 0.35g potassium persulfate in 7.0g deionized water , to prepare an initiator solution; add 90 g of the above-mentioned polymer silicone emulsion, 40.0 g of butyl acrylate, 10.0 g of ethyl acrylate, 10.0 g of methyl methacrylate, 3.0 g of acrylonitrile, and 2.0 g of styrene in the polymerization reactor. g, 1.5 g of ethylene glycol dimethacrylate, heated up to 30°C. Swell under stirring for 12 hours; raise the temperature to 50°C, add 4.5g of the above-mentioned initiator solution, and raise the temperature to 78°C, after the emulsion in the polymerization reactor has blue light, then continuously drop the ...

Embodiment 3

[0080] Heat up 50.0g of cooling silicone oil emulsion SOFTEX S-009, 1.5g of emulsifier, and 50.0g of deionized water to 40°C, and stir evenly for 2 hours to obtain the first component; 40.0g of butyl acrylate, 5.0 g of isooctyl acrylate g, methyl methacrylate 5.0g, styrene 3.0g, methylenebisacrylamide 1.5g, pH buffer 0.5g, emulsifier 1.6g, deionized water 50g, stir evenly to make acrylate pre-emulsion; 0.5g potassium persulfate is dissolved in 9.0g deionized water, and is mixed with initiator solution; Add above-mentioned polymer silicone emulsion 100g, butyl acrylate 40.0g, isooctyl acrylate 5.0g, methacrylic acid in polymerization reactor Methyl ester 5.0g, styrene 3.0g, methylenebisacrylamide 1.0g, heat up to 30°C, swell for 12h under stirring; heat up to 50°C, add 6g of the above-mentioned initiator solution, heat up to 80°C, wait for polymerization After the blue light appeared in the emulsion in the kettle, add the remaining pre-emulsion to the polymerization reaction ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com