Patents

Literature

314 results about "Pigment printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

POSS/polyurethane aqueous composite paint and preparation method thereof

ActiveCN101250375ANo subsidenceEasy to storePolyurea/polyurethane coatingsEmulsion paintsPolyurethane dispersionHeat resistance

The invention relates to a POSS / polyurethane water compound paint and the process for preparation, the water compound paint is prepared by the following process, firstly, preparing POSS which is not capped with a hydrolysis method, secondly, adopting silane coupling agent KH-550 to cap and get a POSS which contains amido group, and finally, chemically compounding POSS and water polyurethane dispersion to prepare a POSS / polyurethane water compound paint. The water compound paint of the invention has the advantages of excellent indoor temperature storage property, degree of hardness and waterproof property, and fire-resisting property and anti-ultraviolet light property are excellent. The process for preparation of the invention has the advantages of convenient and simple technique, high film coating quality, low production cost and extend application prospect and the like, which has no pollution to environment, the water paint is a new generation environmental-friendly high-performance chemical product, which can be applied in the fields such as automobile coating, wood coating, construction, office furniture, leather, textile finishing, pigment printing and mechanical equipment.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Nano hollow silica dioxide micro-sphere/polyurethane composite aqueous paint and preparation method thereof

InactiveCN101250374AIncrease the degree of cross-linkingExcellent thermodynamic propertiesPolyurea/polyurethane coatingsEmulsion paintsMechanical equipmentSilicon dioxide

The invention belongs to the technical filed of water paint, which particularly relates to nanometer hollow silica sphere / polyurethane compound water paint and the process for preparation thereof. The water compound paint is chemically compounded by hollow SiO2 sphere, whose dimension is 50-250 nanometers, isocyanate terminated polyurethane prepolymer, catalyst and other auxiliary agents. Indoor temperature storage stability of the compound water paint is excellent, nanometer hollow SiO2 sphere and water polyurethane have excellent compatibility, hardness and compatibility of the water compound coating layer are greatly improved, and fire-resisting property and ultraviolet resistant performance are excellent. The process for preparation of the invention has the advantages of convenient and simple technique, high film coating quality, low production cost and extensive application prospect and the like, which has no pollution to environment, the water paint is a new generation environmental-friendly high-performance chemical product, which can be applied in the fields such as automobile coating, wood coating, construction, office furniture, leather, textile finishing, pigment printing and mechanical equipment.

Owner:TONGJI UNIV

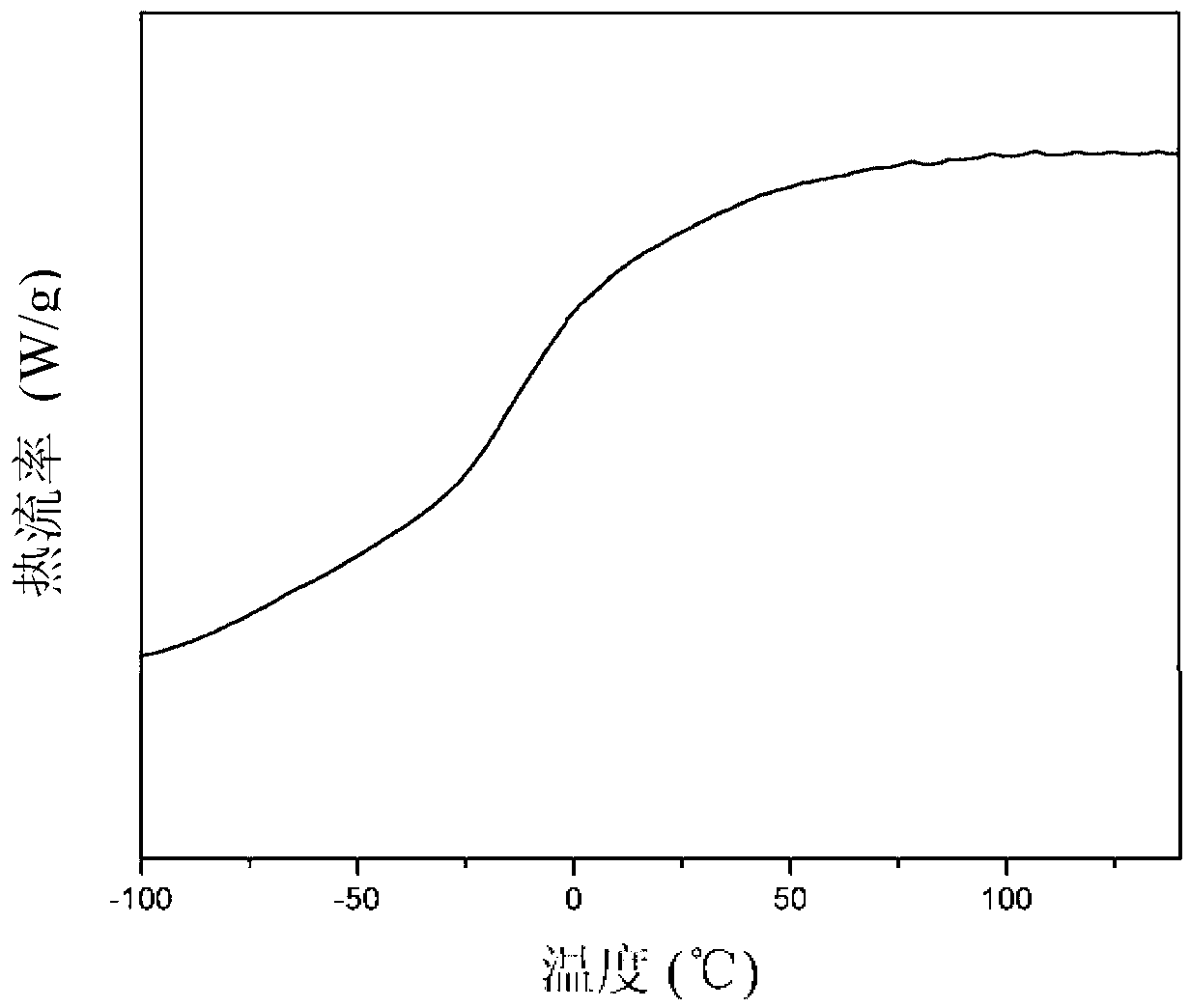

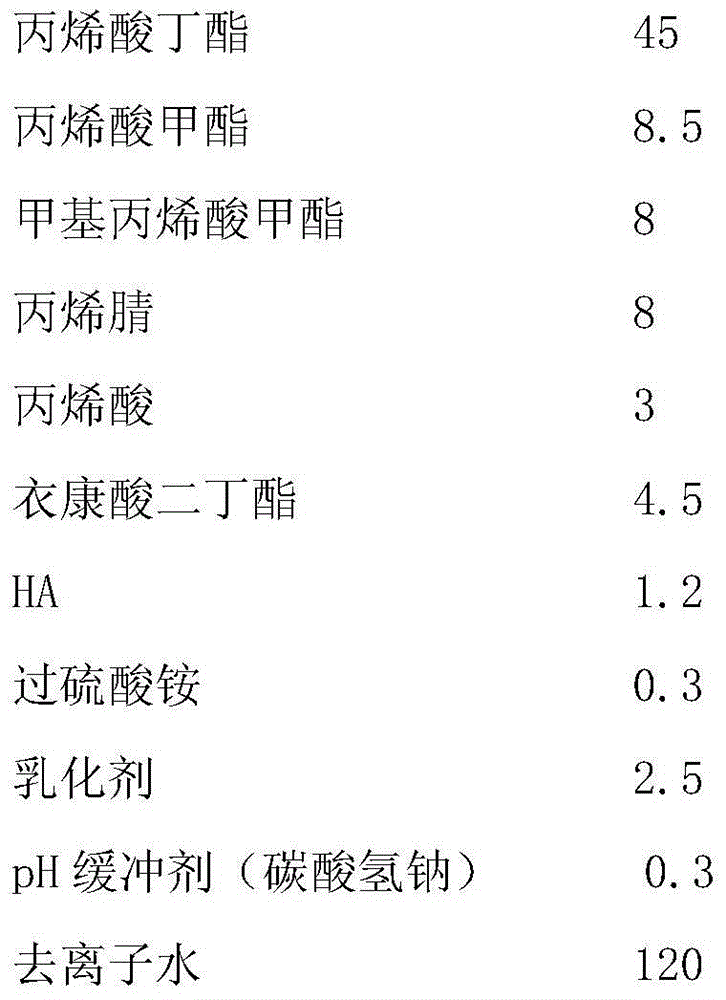

Environment protection type pigment resin printing adhesive agent capable of self crosslinking at low-temperature, and preparation thereof

InactiveCN101220563ASimple processLow costEster polymer adhesivesDyeing processPolyesterSodium bicarbonate

The invention belongs to the water-base adhesive technical field, in particular to an environment-protecting pigment printing binder which auto-crosslinks in the low temperature and a preparation method thereof which includes a polymeric monomer is added into the water solution of the composite emulsifier and the sodium bicarbonate, and the mixture is stirred so as to obtain the pre-emulsion; the pre-emulsion is added into a reaction vessel in lots, a polymerization is initiated, and a styrene-acrylic emulsion base which crosslinks in the low temperature is obtained; the pH value is adjusted, a crosslinking agent is added and the needed binder is obtained. The pigment printing binder obtained by the preparation of the method does not comprise formalin, alkyl phenol polyoxyethylene ether and other harmful substances. The finished textile printing obtained by using the binder has the advantages of soft hand feeling, brilliant color, wear resistant, and high soaping fastness, etc.; the textile printing used for the cotton cloth, polyester-cotton can get better effect. The mixture of the binder and the synthetic thickener can modulate the proper textile printing pulp, and is applicable to plate printing and net-tube printing.

Owner:FUDAN UNIV

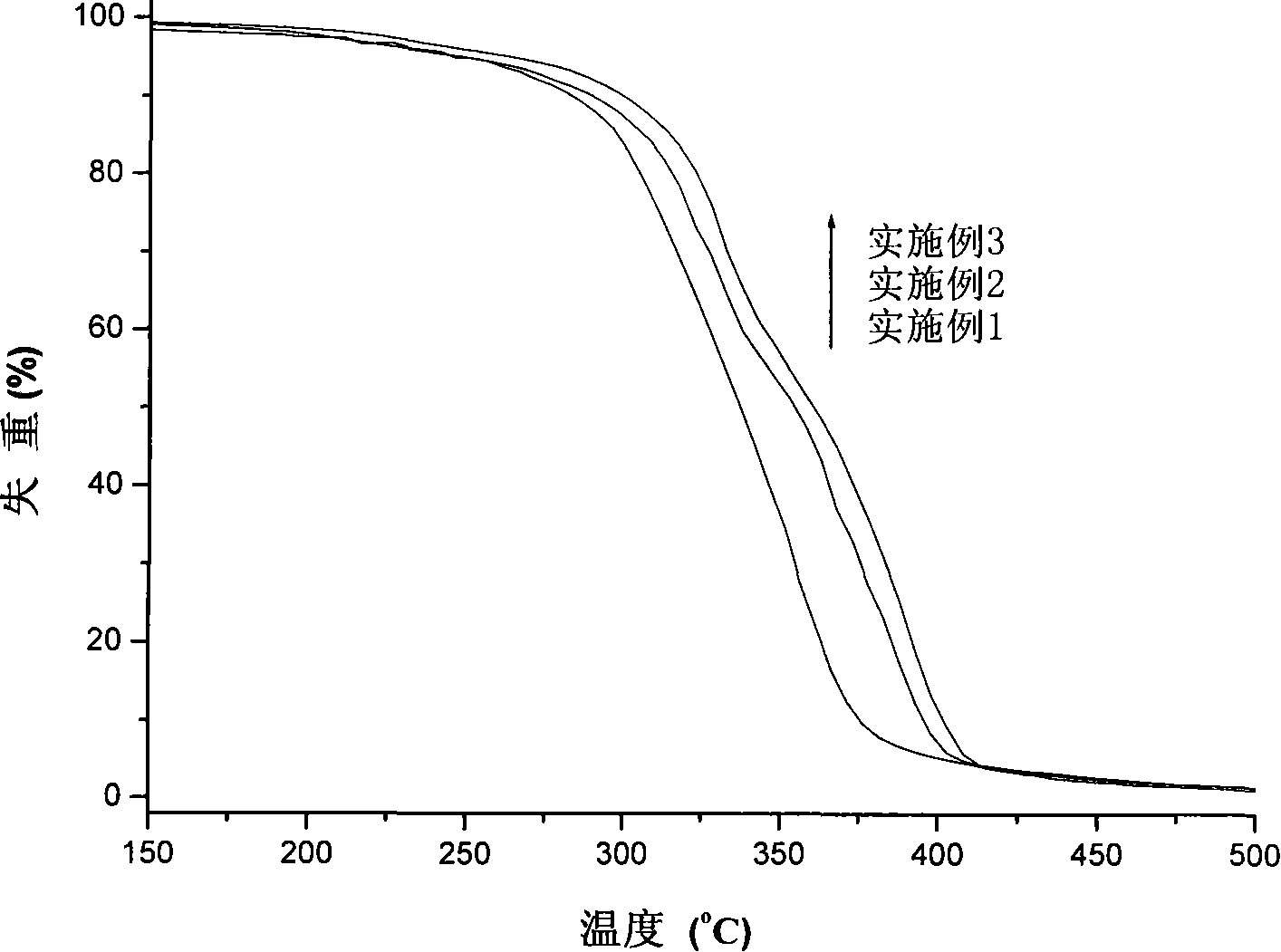

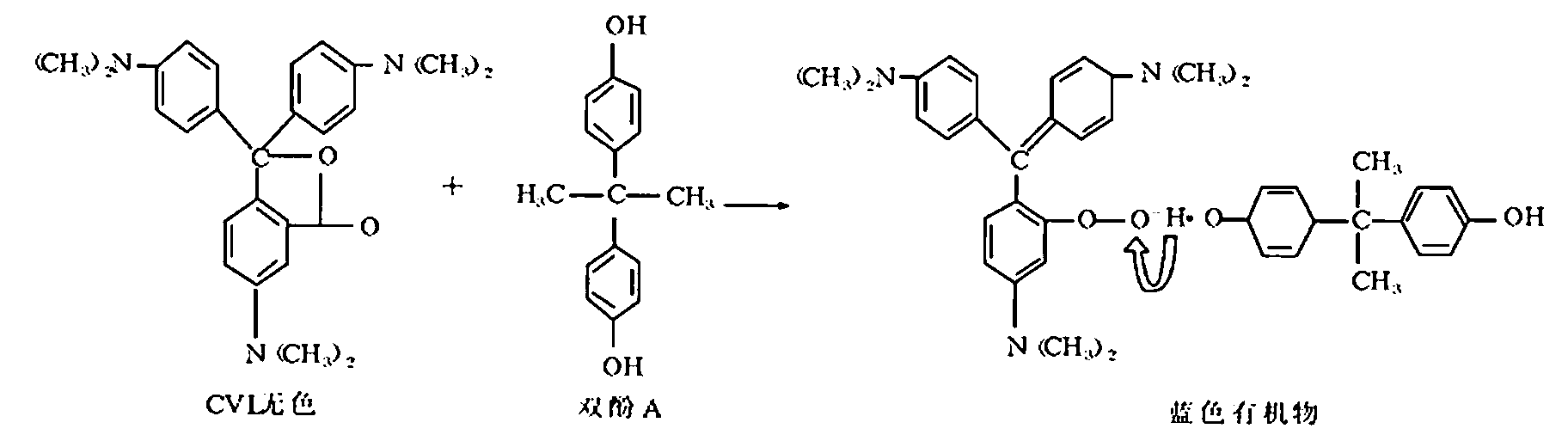

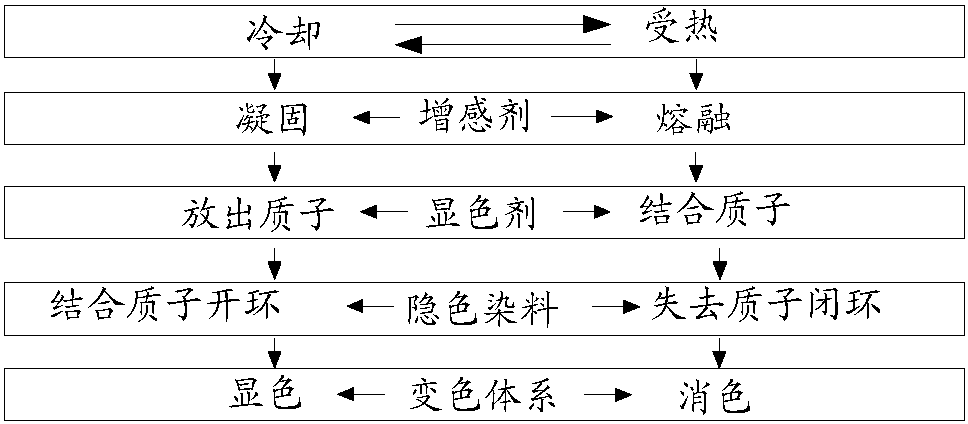

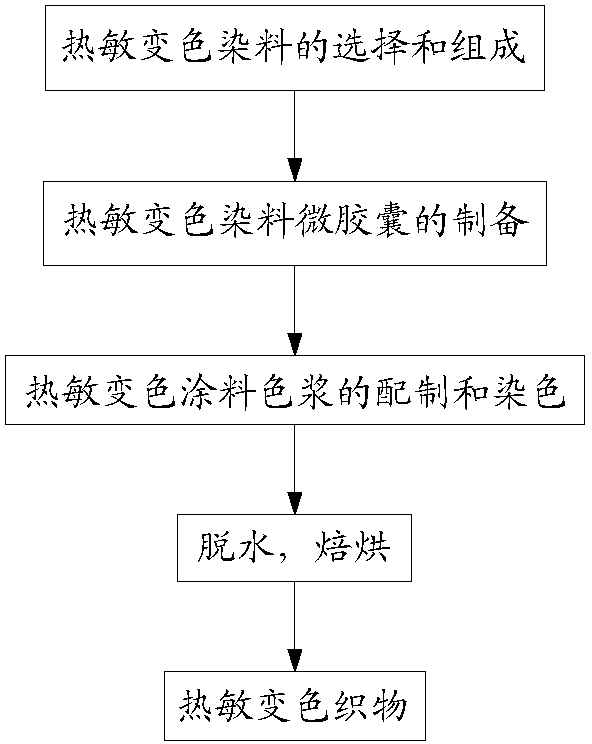

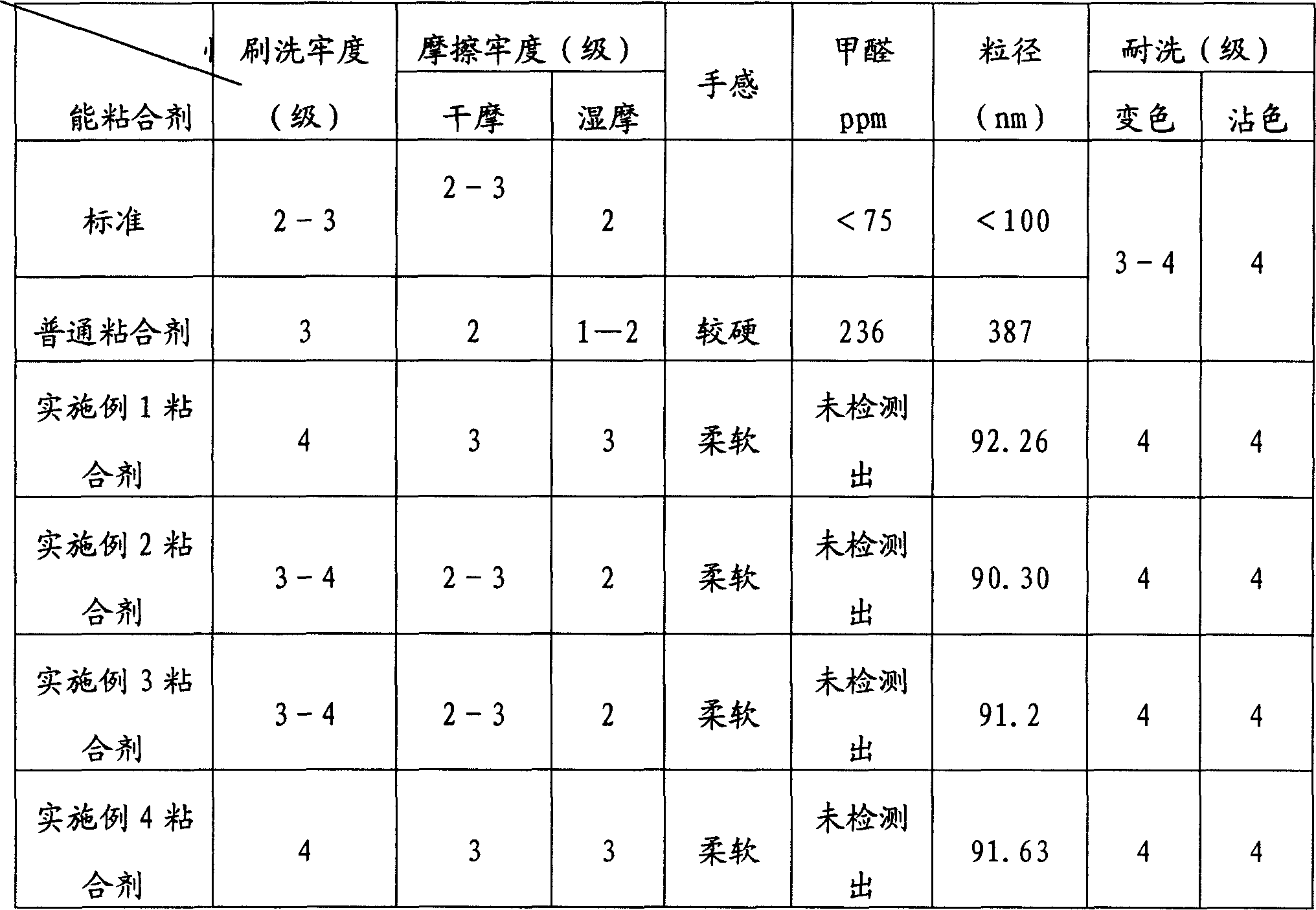

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

Environment protection type microemulsion interpenetrating network pigment resin printing adhesive agent and manufacturing method

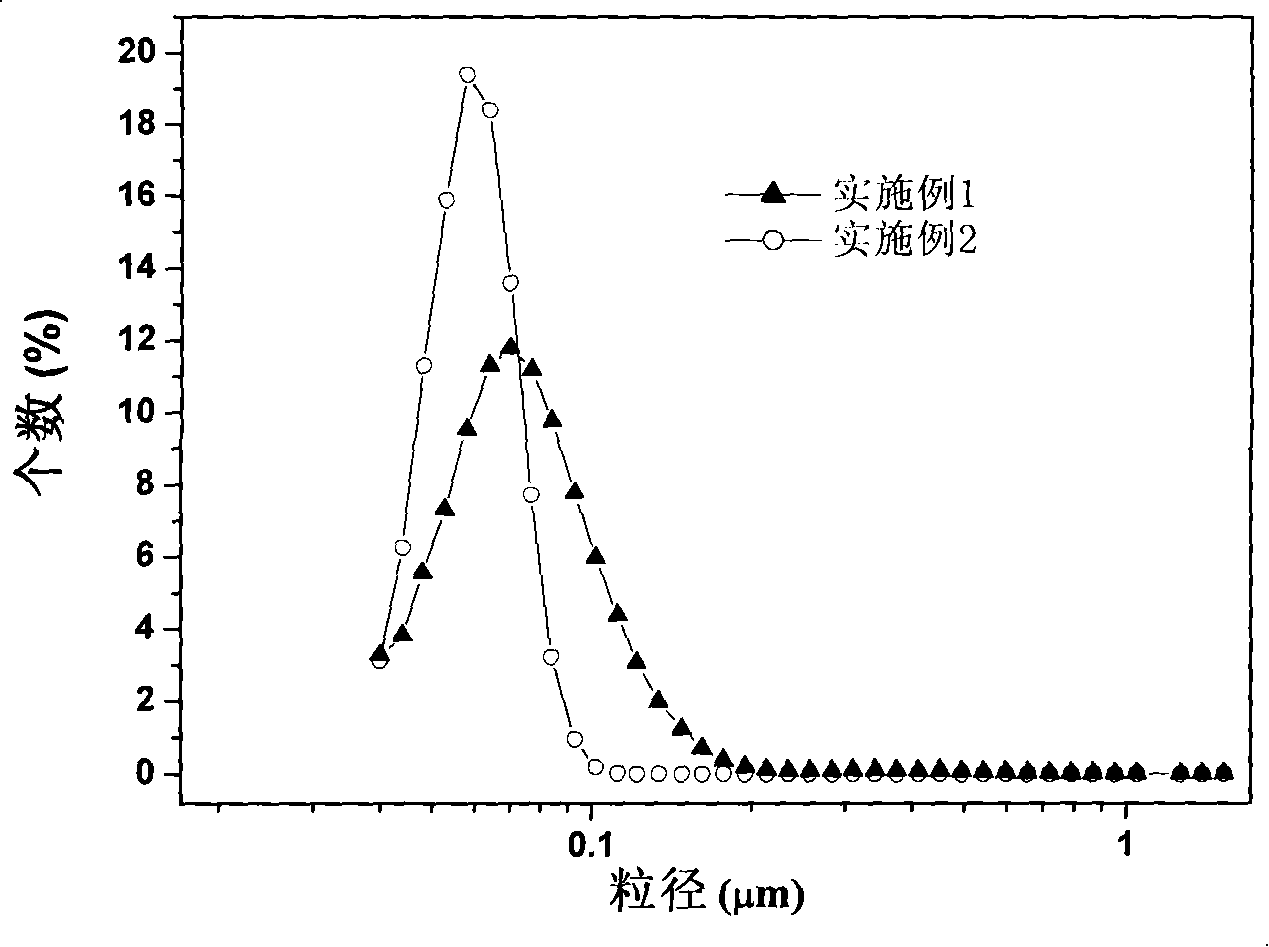

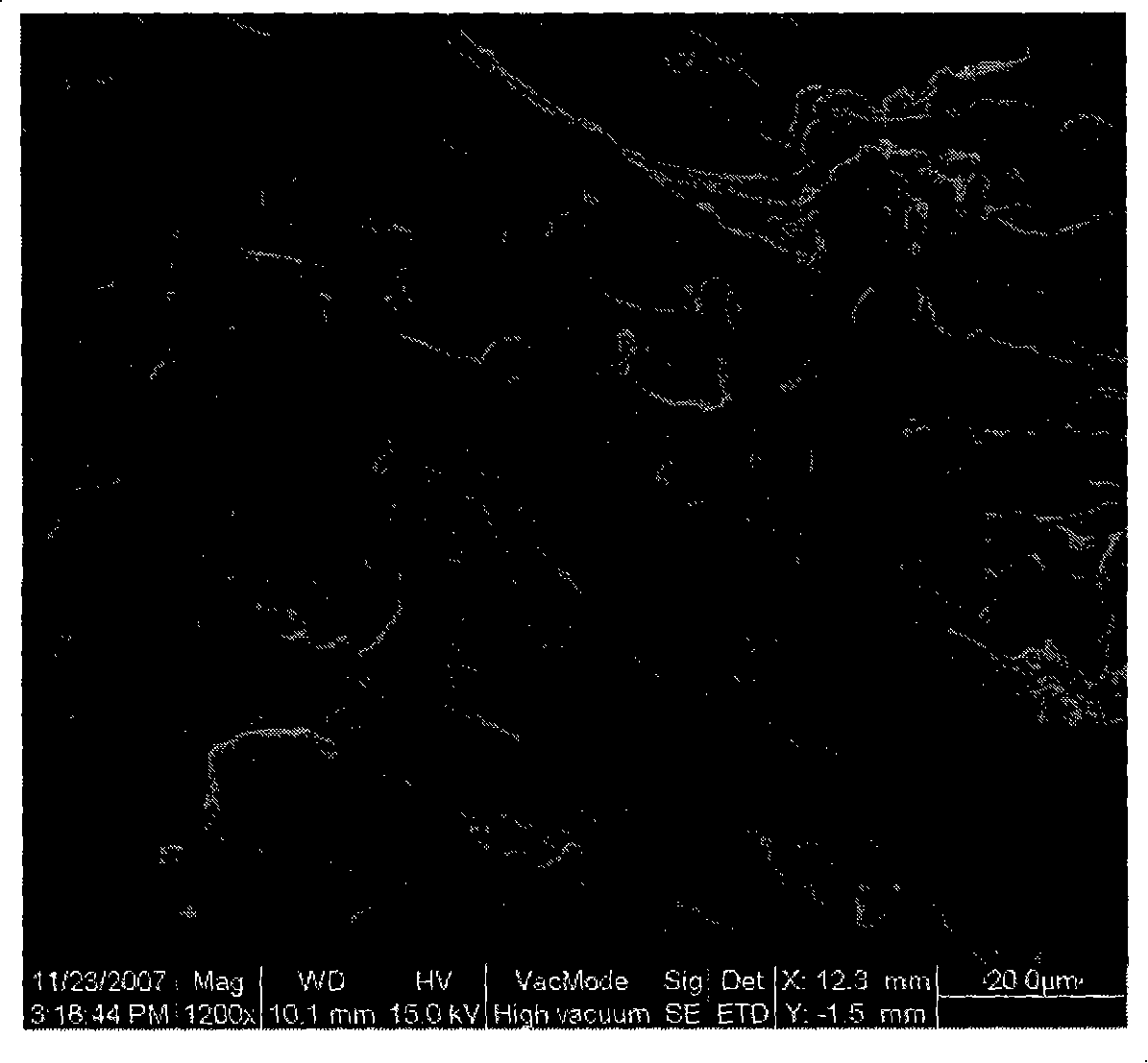

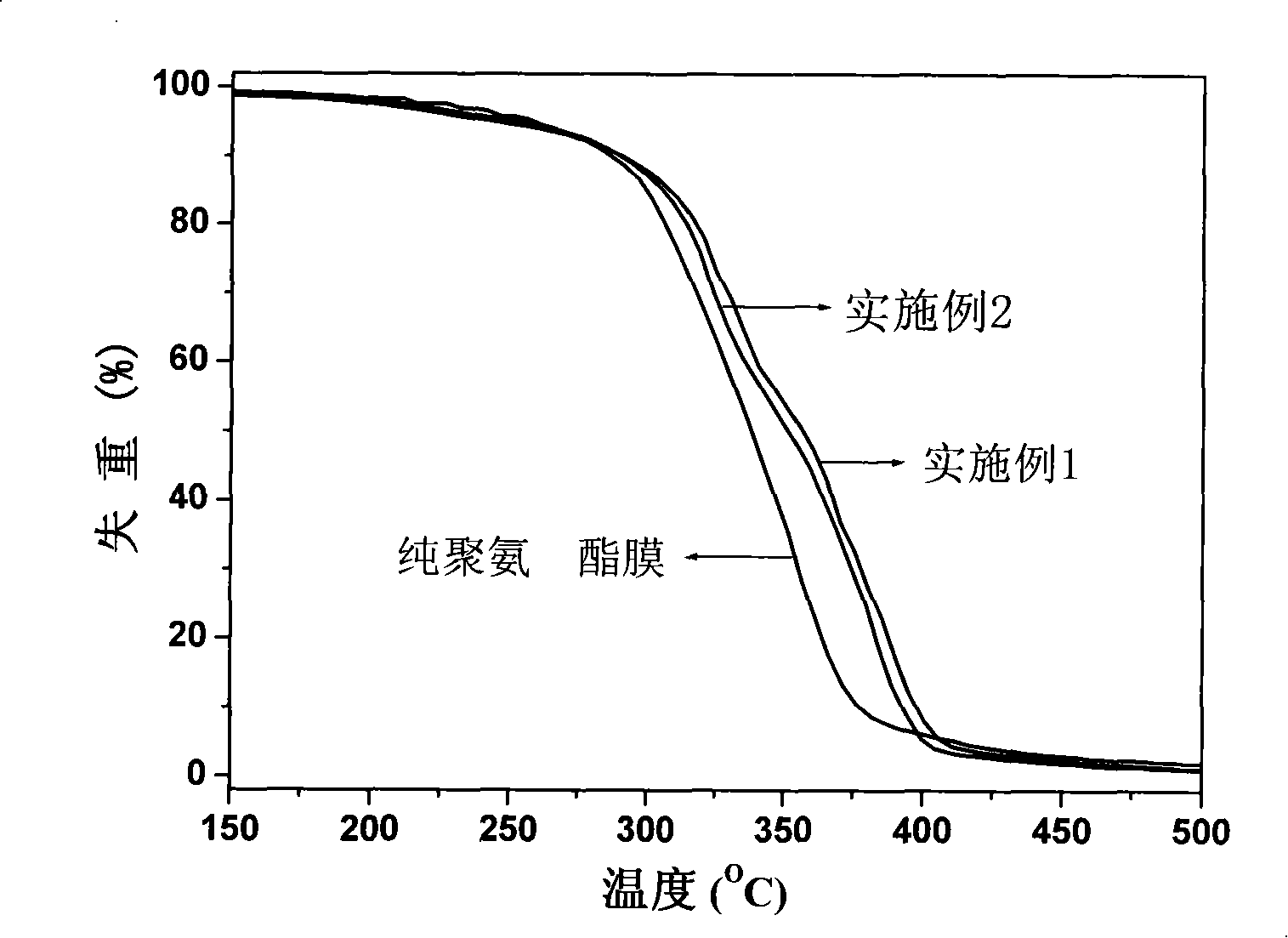

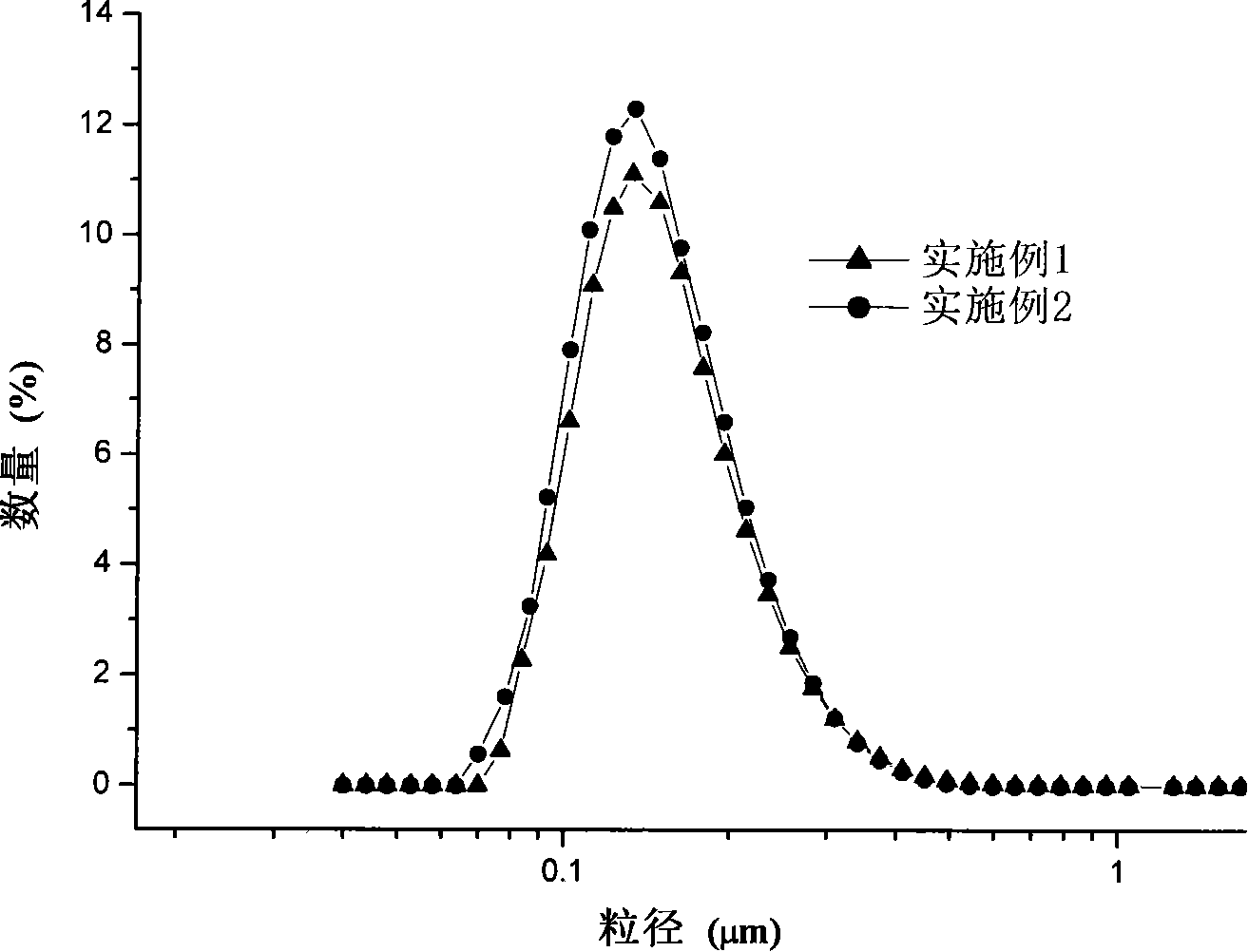

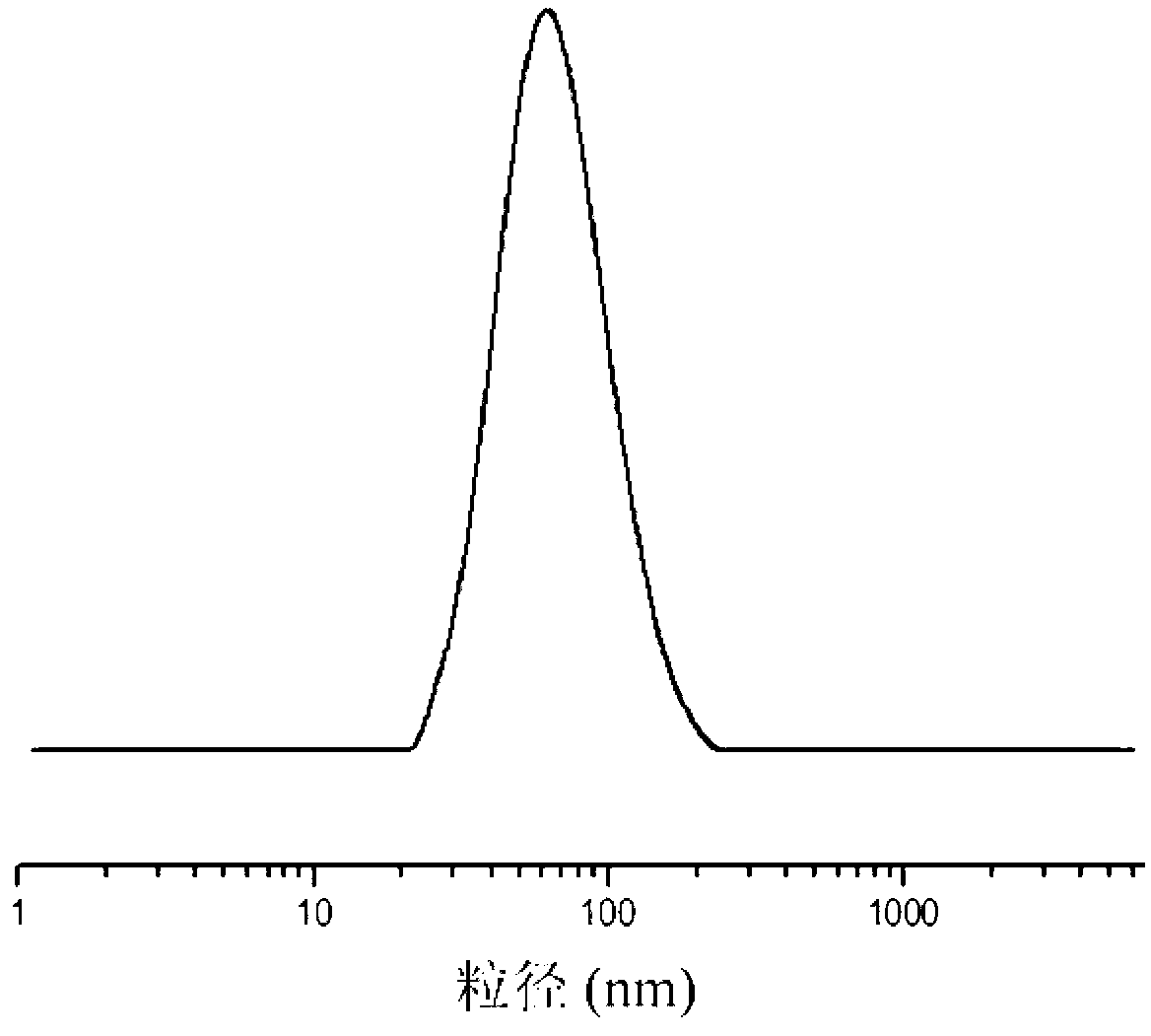

InactiveCN101245561AEvenly distributedImprove product qualityEster polymer adhesivesDyeing processFunctional monomerLatex particle

The invention discloses an environmental-friendly microemulsion interpenetrating network pigment printing binding agent and a manufacturing method, and is made of a soft monomer, a hard monomer, a functional monomer, an emulsifying agent, an initiator and deionized water; latex particle of the interpenetrating network pigment printing environmental-friendly binding agent manufactured by the invention is distributed evenly and the product quality is stable; by using the binding agent to carry out pigment printing, the feel is good and the color fastness is high; formaldehyde is not released in the process of subsequent processing, thus meeting the requirement of environmental protection.

Owner:JIANGSU GEMEIGAO DEV CO LTD

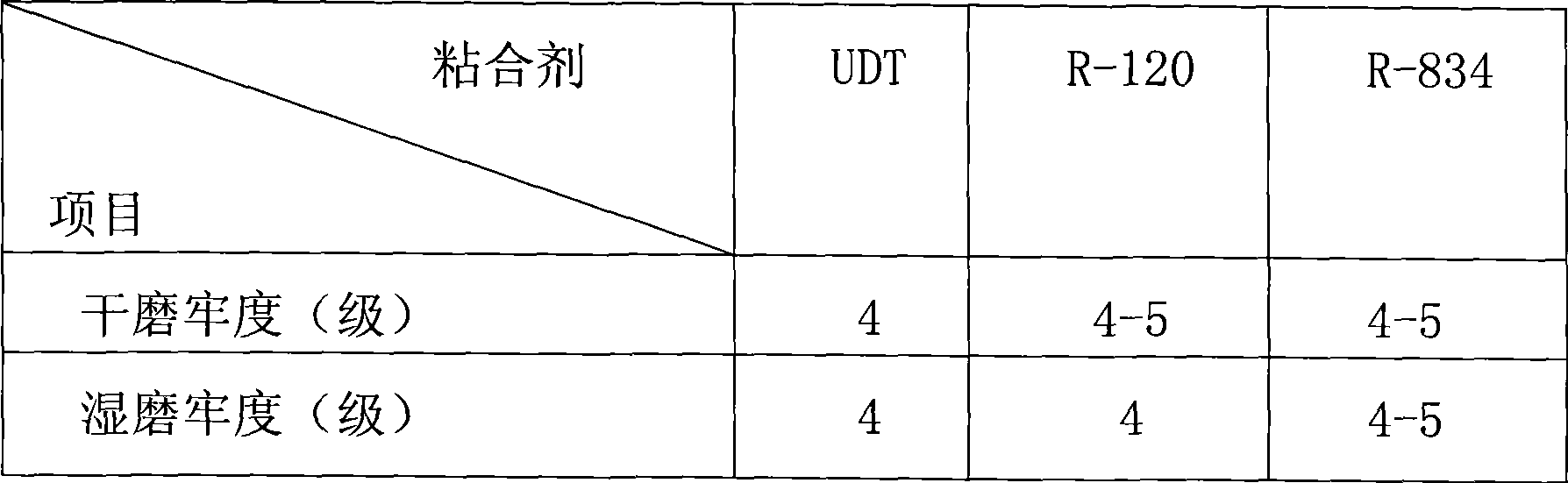

Textile water-based pigment printing binding agent and preparation method

ActiveCN102605648AMeet printing requirementsHigh fastnessEster polymer adhesivesDyeing processTextile printerPolymer science

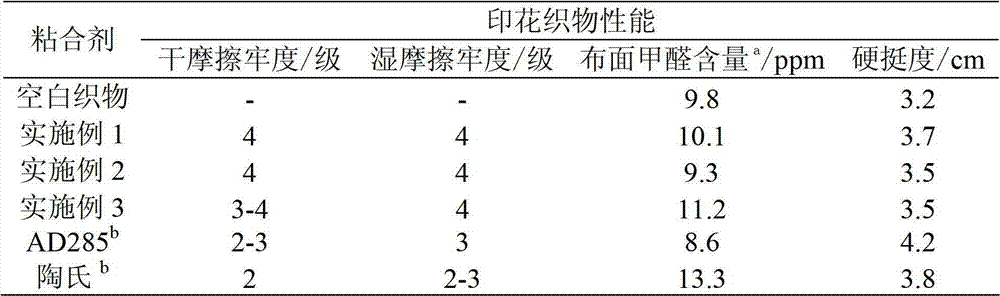

The invention relates to a textile water-based pigment printing binding agent and a preparation method. The textile water-based pigment printing binding agent is prepared in a way that acrylonitrile, ethyl acrylate, butyl acrylate, crylic acid, hydroxyethyl methacrylate, acrylamide, sodium dodecyl sulfate, alcohol dodecyl polyoxyethylene (10) ether, deionized water, ammonium persulfate and sodiumhydrogen sulfite are subjected to emulsion polymerization and then are mixed with pyrolysis closed polyurethane crosslinking agent according to proportion. The product is cured in low temperature condition, has remarkable advantages in the aspects of dry rubbing fastness, wet rubbing fastness, soaping fastness and the like, is simple and easily-controllable in production operation, and is energy-saving and environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

Nano-level formaldehyde-free coating printing-dyeing adhesvie, and its preparing method and use

The invention discloses a nano-level formaldehyde-free paint dye printing adhesive and the preparing method and application thereof. And it comprises N-epoxy propyl acrylamide cross-linking monomer, butyl acrylate, isooctyl acrylate, ethyl acrylate, methyl methacrylate, styrene, vinyl acetic acid, crylic acid, methacrylic acid, reactive surface active agent, unsaturated strongly hydrophilic monomer, vinyl- containing organosilicon monomer, etc. and its grain size can reach nano level and it does not comprise formaldehyde. And it can be used for paint printing and for paint dyeing, as well as for other fields, such as building field.

Owner:SICHUAN TEXTILE SCI RES INST +1

Environment-protection coating printing adhesive and its preparing method

InactiveCN1936172AGood compatibilityUniform sizePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSal ammoniacPolymer science

The invention relates to an environment protecting resin-bonded pigment printing adhesive that is made up according the following steps: adding 0.5-1% polyacrylic acid salt into polyurethane acrylic ester emulsion, adjusting pH value to 7-8 to gain cream, and the viscosity is 30-60Pa.S. The preparation of polyurethane acrylic ester emulsion includes the following steps: gaining end ethenyl polyurethane performed polymer from polyether glycol, isocyanic ester and auxiliary agent, mixing the preformed polymer with acrylic ester monomer and water to make dispersing liquid, irradiating for 30-50 minutes at 1.5-2.5KGy radiation dose. The content of formaldehyde is below 5ppm and APEO below 5ppm in the adhesive. The product is environment protection.

Owner:合肥安大天辐新材料有限公司 +1

Method for preparing pigment printing binder from oxidized graphene modified polyacrylate

ActiveCN103554346AImprove mechanical propertiesImprove performanceNon-macromolecular adhesive additivesEster polymer adhesivesEmulsionGraphene

A method for preparing a pigment printing binder from oxidized graphene modified polyacrylate comprises the following steps: dissolving ammonium persulfate in deionized water and placing the mixture in a reactor of 75-80 DEG C; adding an emulsion A and an initiator aqueous solution A, adding an emulsion B and an initiator aqueous solution B, keeping warm at 75-80 DEG C and reacting for 2 hours after dripping, cooling, adjusting pH to 4.0-6.5 by the use of an ammoniacal liquor, and discharging to prepare a polyacrylate emulsion; stirring an oxidized graphene aqueous solution and adding the oxidized graphene aqueous solution into the polyacrylate emulsion so as to obtain the pigment printing binder. The pigment printing binder is prepared by introducing oxidized graphene in modification of the polyacrylate emulsion. Under the condition of the same dosage of the binder, oxidized graphene is added to raise dry and wet rub fastness of a printed fabric, and softness and washing fastness of the fabric are basically unchanged.

Owner:威海联桥新材料科技股份有限公司

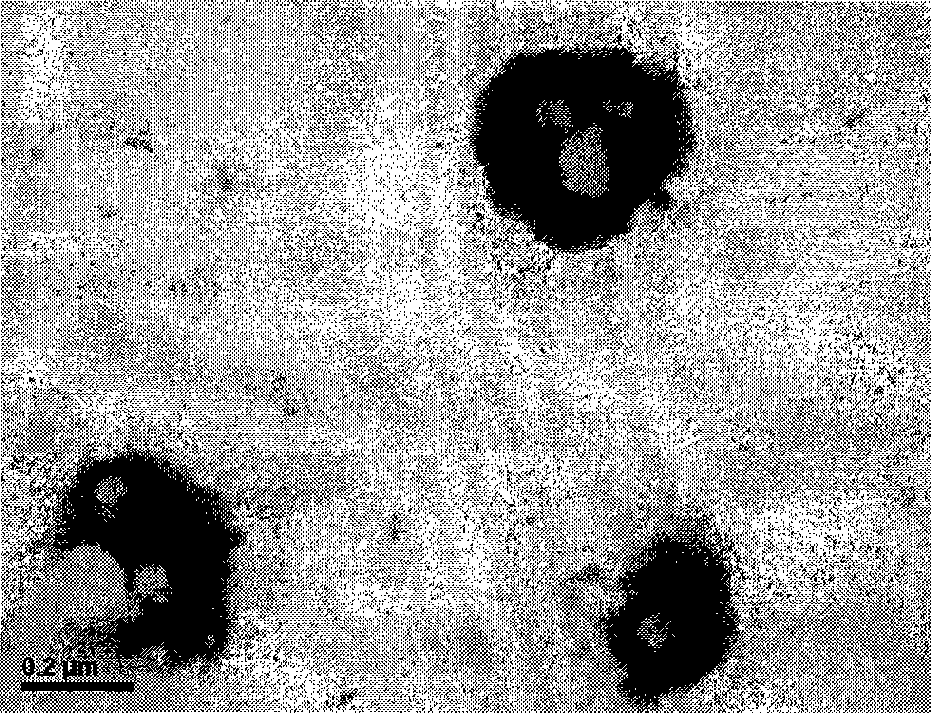

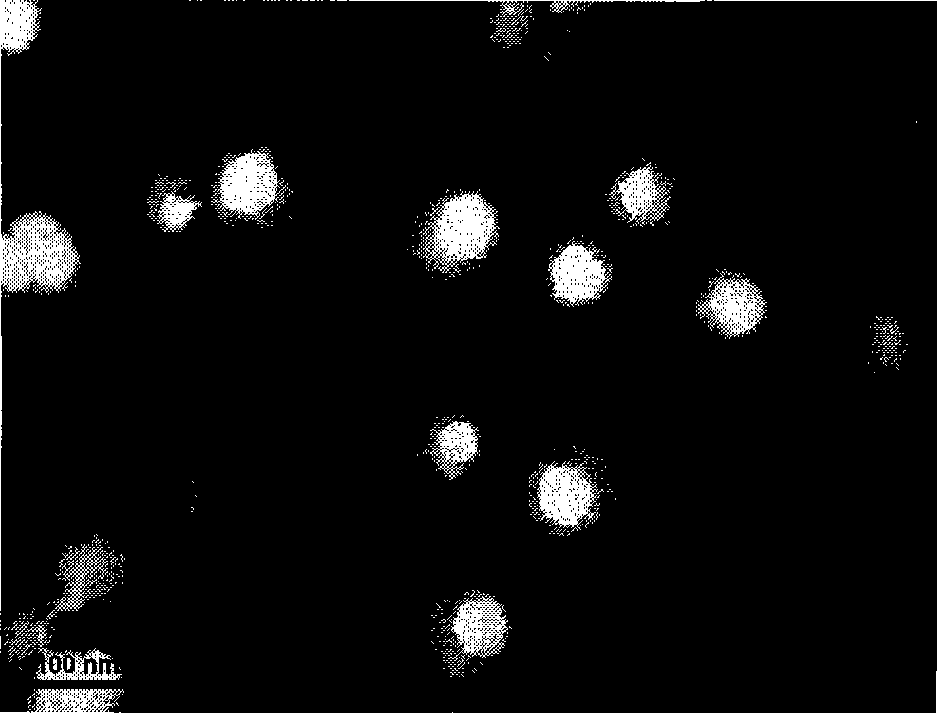

Core-shell type paint dyeing and printing adhesive agent emulsion and preparation method thereof

InactiveCN101368342AImprove bonding fastnessImprove stabilityDyeing processPotassium persulfatePolymer science

The invention discloses a method for preparing core-shell emulsion type adhesive which is modified by hydroxyl-terminated acrylic ester and is used in fabric printing and dyeing processes. The adhesive is prepared through the following steps: soft monomers copolymerize with crosslinking monomers and portions of hard monomers to produce core-shell particles; then a small portion of soft monomers and a large portion of crosslinking monomers copolymerize with hard monomers to coat the surface of the core layer, thus obtaining a shell layer and forming stable core-shell type emulsion. One or the mixture of two or more from 2-hydroxyethyl acrylate, hydroxypropyl acrylate, hydrobutyl acrylate and hydrohexyl acrylate is taken as a portion of soft monomers and crosslinking monomers; one or the mixture of two or more from hydroxylmethyl methacrylic acid, 2-hydroxyethyl acrylate methacrylic acid and hydroxypropyl methacrylic acid is taken as a portion of hard monomers and crosslinking monomers; one from butyl acrylate, ethyl acrylate and 2 ethylhexyl acrylate is taken as main soft monomers; one or the mixture of two or more from methyl methacrylate, crylic acid, cinnamene, acrylonitrile and methacrylic acid is taken as the hard monomers; surfactant sodium dodecyl sulfate, sodium dodecyl benzene sulfonate and octyl phenol polyethylene glycol are taken as emulsifying agent; potassium persulfate or ammonium persulfate is taken as initiator; and the copolymer emulsion is produced through emulsion copolymerization. Observed by transmission electron microscopy, the particles of the emulsion have visible core-shell structure and are even in distribution; the emulsion is stable, absolutely has no formaldehyde release both during the machining and using processes; the emulsion can be used both for pigment printing and for pigment dyeing.

Owner:JIANGNAN UNIV

Method for transferring pattern of textile fabric

InactiveCN101974859ABreak through the idea of transfer printingReduce processing timeDyeing processMolten stateOrganic solvent

The invention discloses a method for transferring a pattern of a textile fabric. The method comprises the following steps of: dissolving polyoxyethylene or polypropylene oxide in water, an organic solvent or mixed solution of the water and the organic solvent, coating paper or plastic film, drying and rolling for later use, or heating the polyoxyethylene or polypropylene oxide to a molten state, coating the paper or the plastic film, and rolling after the coating for later use; printing the paper or the plastic film by utilizing dye ink or Chinese dye ink to prepare transfer paper or transfer film; attaching the printing surface of the transfer paper or transfer film to a to-be-transferred textile fabric, feeding into a transfer machine together, heating and pressing to realize printing; stripping off the transfer paper or transfer film and fixing the dye, or fixing the dye and stripping off the transfer paper or the transfer film; and washing the textile fabric and forming to finish the transfer printing. By the transfer printing method of the invention, the inherent transfer printing idea is broken through, a damping step is saved, the processing time is saved, the production cost is reduced and the difficulty of pigment printing is reduced.

Owner:常州涵源新印花有限公司

Pigment printing binding agent and synthesizing method thereof

ActiveCN102182080AGood flexibilityImprove breathabilityDyeing processHazardous substanceALLYL SUCROSE

The invention provides a pigment printing binding agent and a synthesizing method thereof. The binding agent is prepared from silicone-acrylate copolymer, aqueous polyurethane, liquid rubber, an emulsifying agent and the like. By taking advantage of the high film-forming property of polyacrylic acid, the high flexibility of organic silicone, the high air permeability of polyurethane and the high elasticity of the liquid rubber, the high-fastness and super-soft pigment printing binding agent is prepared by a complex synergistic technology. The binding agent has high film-forming property, air permeability, flexibility and elasticity, good handfeel and high color fastness. After the binding agent is applied to a printing fabric, the release amount of a harmful substance, namely formaldehyde, is small.

Owner:成都德美精英化工有限公司

Pigment dyeing method of denim yarn

The invention relates to a pigment dyeing method of a denim yarn. The method comprises the following steps of: pretreating pigment printing paste by adopting a cationic binder; and continuously performing pad dyeing on the denim yarn by using the treated pigment printing paste. The denim yarn produced by the method has high color fastness and good handfeel, does not require steps such as water washing, and can be directly applied to sizing and weaving; and the process flow is shortened greatly, the energy consumption is lowered, and the production cost is saved.

Owner:CHANGZHOU UNIV +1

Method for preparing polyacrylic ester/nanoSiO2 coating printing adhesive by using Pickering emulsion polymerization method

The invention relates to a method for preparing a polyacrylic ester / nanoSiO2 coating printing adhesive by using a Pickering emulsion polymerization method. During preparation of a polyacrylic acid emulsion, the problems of poor washing fastness and poor wet rubbing fastness are caused by adding a surfactant. The method comprises the following steps: mixing and stirring nanoSiO2 sol with water, and dropwise adding methyl methacrylate, glycidyl methacrylate, butyl acrylate and acrylic acid; and raising the temperature, adding an ammonium persulfate solution, preserving heat for reacting, naturally cooling a reaction product, filtering the cooled reaction product, and discharging the filtered reaction product. The polyacrylic ester / nanoSiO2 coating printing adhesive is prepared by taking the nanoSiO2 sol, an acrylic acid monomer and the glycidyl methacrylate as raw materials through Pickering emulsion polymerization. The method has the advantages of simple process, avoidance of the use of the surfactant and environmental friendliness. Meanwhile, nanoparticles are introduced, so that a film is prevented from sticking at a high temperature.

Owner:广州麦吉高分子新材料科技有限公司

Method for preparing ketohydrazine cross-linked acrylic ester-polyurethane composite weaving emulsion and use thereof

InactiveCN101240101AFeel goodSoft touchPolyureas/polyurethane adhesivesEster polymer adhesivesCross-linkHydrazine compound

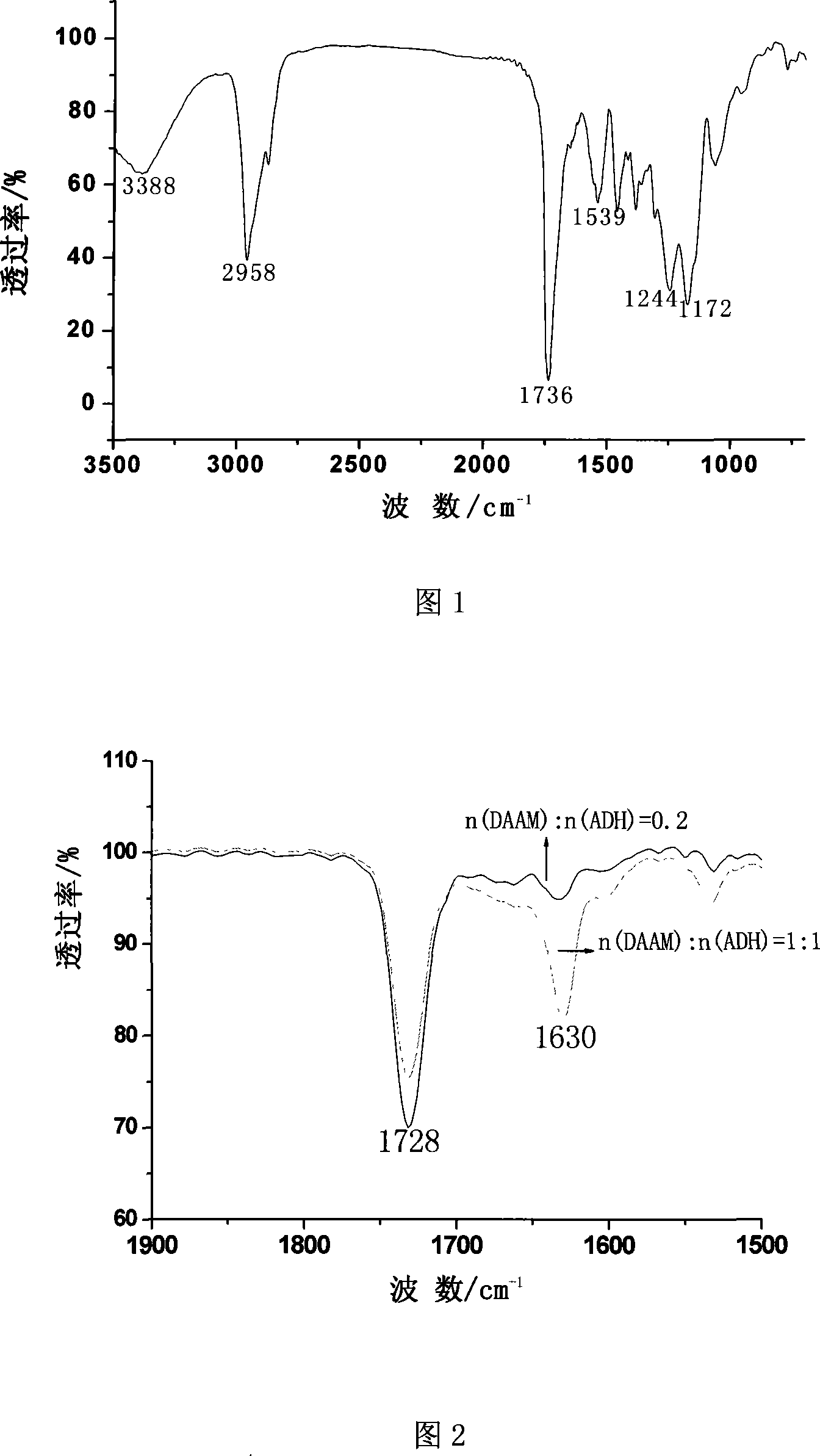

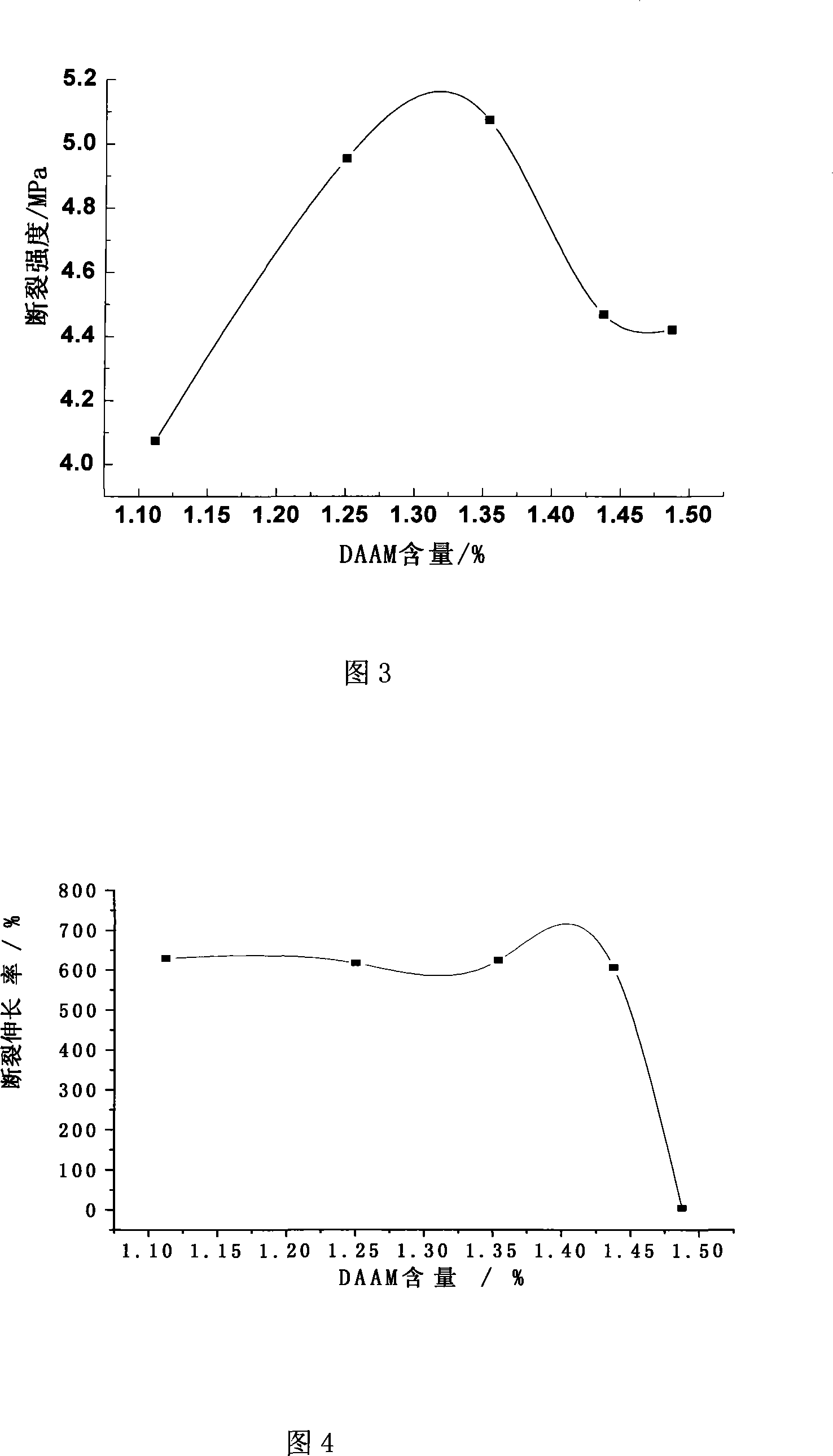

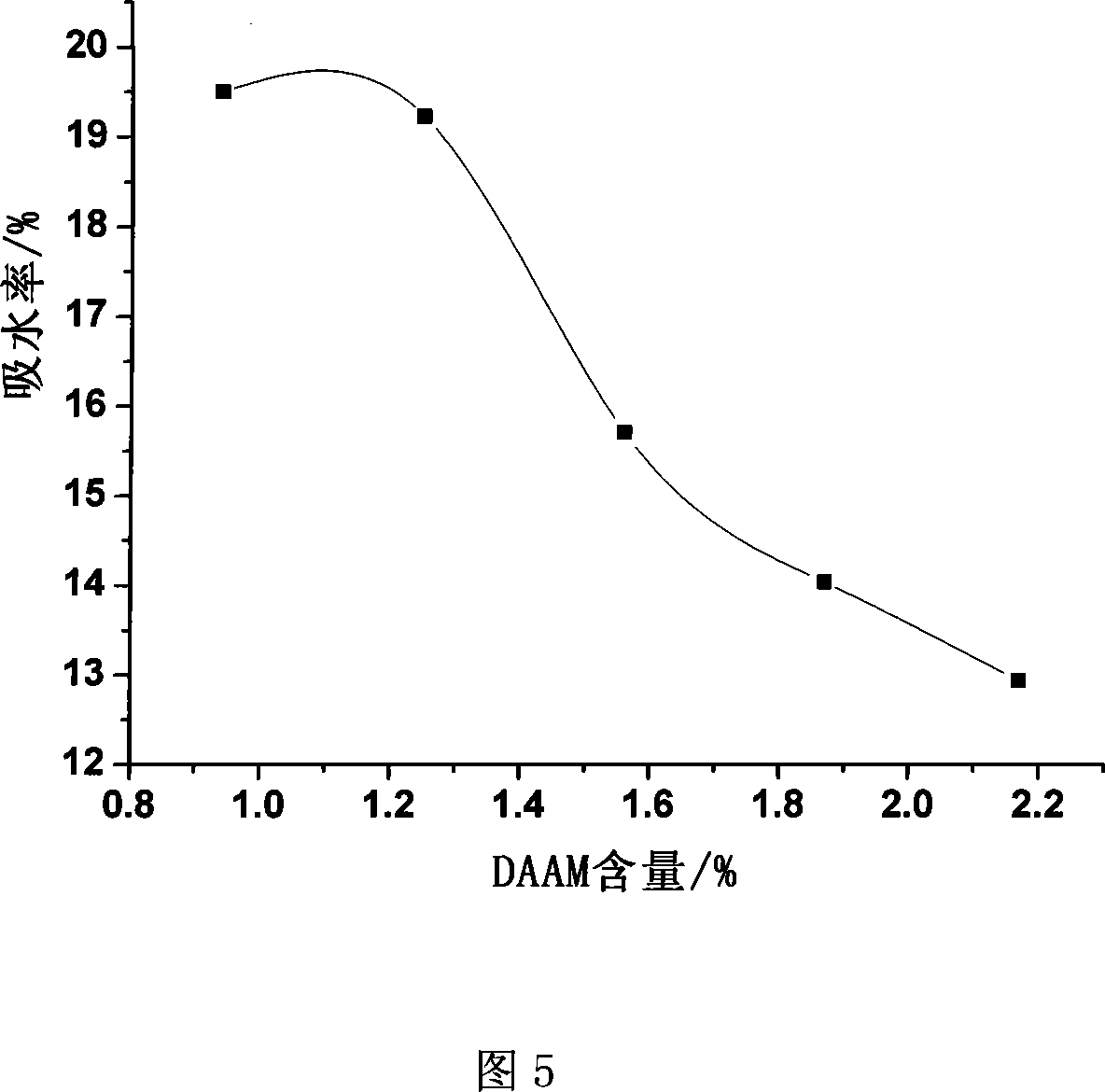

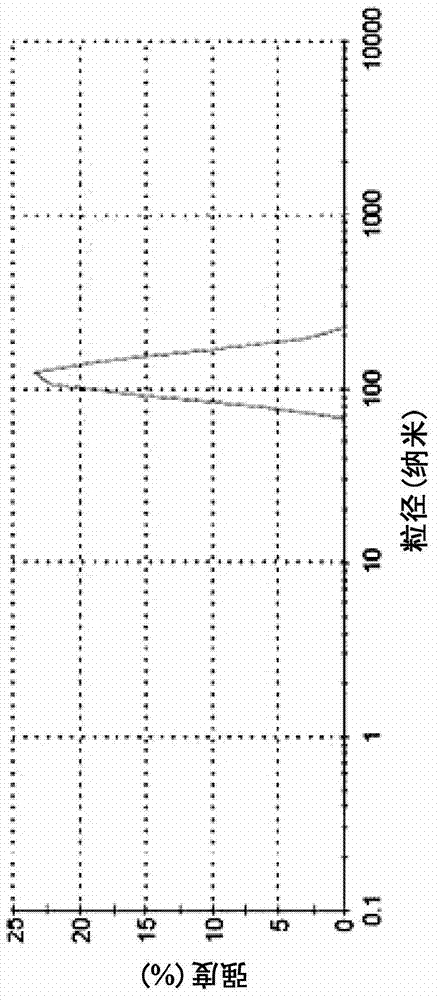

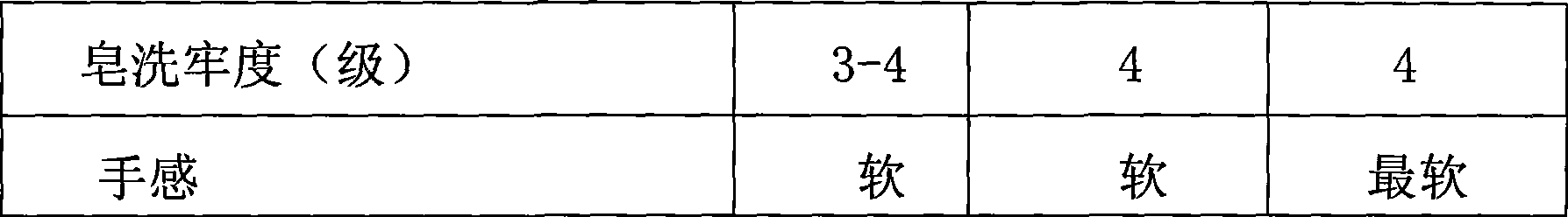

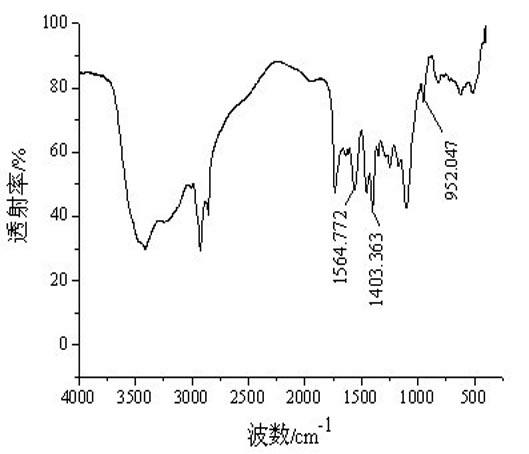

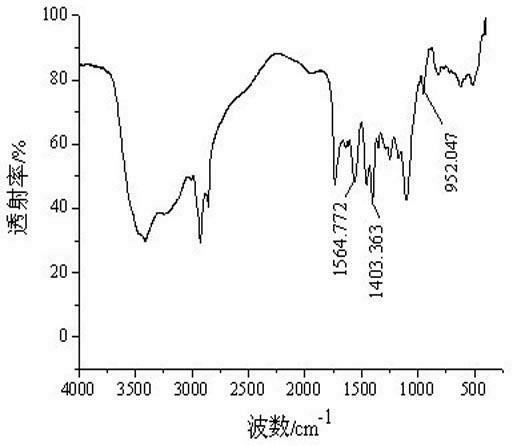

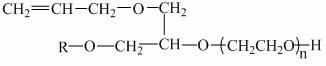

The invention discloses a preparation method and use of a ketone hydrazine crosslinkable acrylic ester and polyurethane composite textile emulsion. Cobalt 60 - gamma radiation method polymerization process is used for overcoming low color fastness and high aldehyde content of the bond of resinfixed pigment printing. Acrylic ester emulsion incorporating active ketone carbonyl is synthesized by acrylic ester mixxed with monomer and diacetone acrylamide(DAAM). The ketone hydrazine crosslinkable acrylic ester and polyurethane (PUA) composite textile emulsion is prepared by mixxing the acrylic ester emulsion with polyurethane emulsion incorporating diazanyl in definite proportions. Infra-red spectrum(IR), mechanical property and hydrolytic resistance deo tecting methods are used to analyze the composite textile emulsion and to detect the color fastness and environmental protection of the bond of resinfixed pigment printing. The result indicates when the content of DMMA is between 1.3 and 1.4 percent, the performance of the PUA composite textile emulsion is good and the bond based on the emulsion is an environmentally friendly product which is aldehydeless and without APEO, the aldehyde content satisfy infant clothing, and colour fastnes to brush-washing and crocking fastness are improved.

Owner:ANHUI UNIVERSITY +1

Environmental-friendly pigment printing binding agent and preparation method thereof

ActiveCN102757525ASimple preparation processReduce production energy consumptionDyeing processCross-linkFunctional monomer

The invention relates to an environmentally-friendly pigment printing binding agent and a preparation method thereof. The preparation method includes the steps as follows: (1), monomers are provided, and include 45-85% of soft monomers, 10-35% of hard monomers, 2-7% of functional monomers, and 3-13% of cross linking monomers according to the total mass of monomers; (2), an emulsion polymerization reaction is carried out on part of soft monomers, hard monomers and functional monomers at the temperature of 60-90 DEG C and in the presence of an radical initiator; and (3), an emulsion polymerization reaction is carried out on the rest of soft monomers, hard monomers and functional monomers as well as cross linking monomers at the temperature of 25-45 DEG C, and in the presence of an intermediate product obtained in the step (2), the radical initiator and co-initiator compounds, thereby obtaining the pigment printing binding agent product. The binding agent is used for extra deep coloured printings, and solves the problem that the rubbing fastness is insufficient when the existing environmental-friendly binding agent is used for theextra deep coloured printings.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

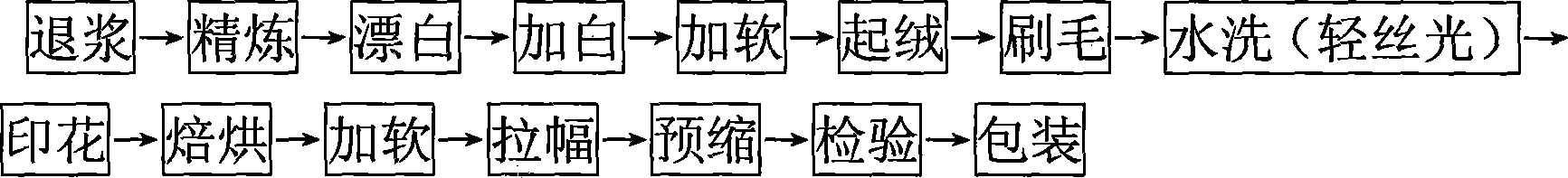

Method for producing energy-saving and environment-friendly type soft resin-bonded pigment printing nap cloth

InactiveCN101418523ASimple processShort processSucessive textile treatmentsFibre treatmentAdhesiveSlurry

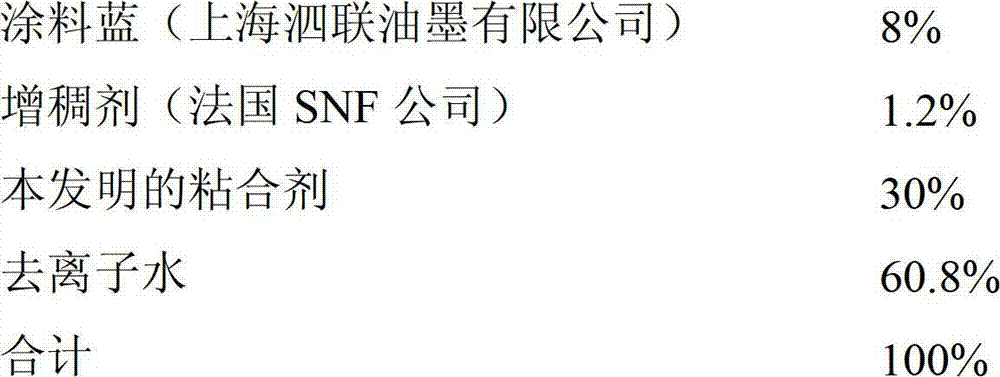

The invention relates to a method for textile production. The method for producing an energy-saving environment-friendly soft paint printing fleece comprises the following steps: step one: destarch, refining and bleaching; step two: whitening, softening and carding; step three: performing treatment before printing by water washing or mercerization; step four, printing: firstly, preparing a color slurry mixed solution and performing printing through a circular screen printer with the drying temperature of lower than 120 DEG C, the vehicle speed of between 30 and 35 m / min, the roasting temperature of 150 DEG C, and the roasting time of between 3 and 5 minutes; and step five, afterfinishing.. A color slurry aqueous solution for pigment printing has the following formula: the viscosity of the prepared color slurry is between 50 and 80 dPa.S; printing paint is between 0.01 and 8 percent; an adhesive for pigment printing is between 8 and 20 percent; a thickening agent for pigment printing is between 3 and 6 percent. Compared with dye printing, the pigment printing has the advantages of simple process, short process course, convenient color match of products, small pollution, low cost and the like.

Owner:辽宁宏丰印染有限公司 +2

Salt-resistive thickening agent as well as preparation method and application thereof

InactiveCN102675558AImprove salt toleranceStable salt toleranceDyeing processHydrophilic monomerTextile printer

The invention relates to a salt-resistive thickening agent and a preparation method thereof. The preparation method comprises the following steps of: adding a certain mass of acrylic acid and N,N-methylene bisacrylamide into a reaction container; adjusting pH (Potential of Hydrogen) to 6.5-7.0 by using liquid ammonia or a sodium hydroxide solution; adding a mixed solution of Span-80 and kerosene or tasteless kerosene to be completely and uniformly mixed; slowly adding a salt-resistive monomer and a catalyst and sufficiently emulsifying to obtain sticky liquid; introducing nitrogen gas and heating; after the reaction is finished, reducing the temperature to a room temperature; and addingTween-80 and uniformly mixing to obtain the salt-resistive thickening agent which is used for pigment printing and dispersed printing of textiles. The salt-resistive thickening agent takes a polyoxyethylene ether non-ionic hydrophilic monomer containing allyl and a long-chain fatty alcohol chain section as a functional monomer to improve the salt-resistive performance of the thickening agent; the source of raw materials is wide, and a preparation process is simple and easy to be control, so that the salt-resistive thickening agent is suitable for industrial production.

Owner:SUZHOU UNIV

Water-based resin-free pigment printing paste

InactiveCN103572619AGuaranteed stabilityImprove water resistanceDyeing processPolyesterTextile printer

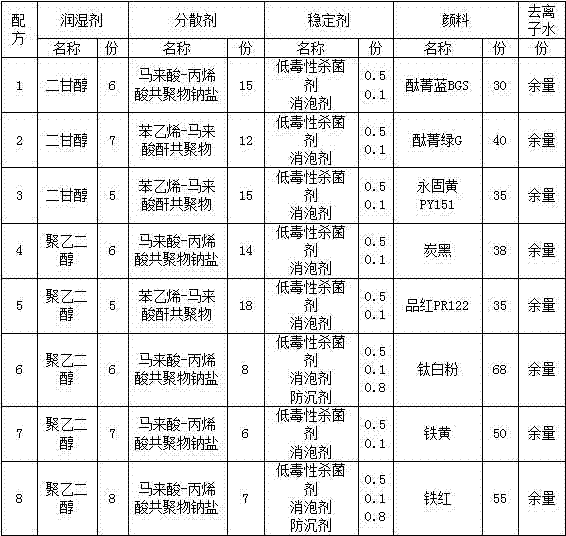

The invention relates to water-based resin-free pigment printing paste and provides pigment printing paste applicable to coloring of water-based leather coatings and pigment printing of pure cotton, polyester cotton and blended fabric. The water-based resin-free pigment printing paste comprises the following components by weight: 2 to 20 percent of wetting agent, 1 to 20 percent of dispersing agent, 1 to 10 percent of stabilizing agent, 25 to 70 percent of pigment and the balance of deionized water, wherein the wetting agent is one of dibasic alcohol or condensed poly diols; the dispersing agent comprises one or more of sodium salt or ammonium salt of an acrylic copolymer and a multi-anchor multi-chain macromolecular polymer; the stabilizing agent comprises one or more of a low-toxicity anti-corrosion bactericide, a defoaming agent and an anti-settling agent. The water-based resin-free pigment printing paste is applicable to coloring of leather coatings and pigment printing of pure cotton, polyester cotton and blended fabric, and is wide in application range; a paint film has high water resistance and high dyeing rate.

Owner:HUNAN XINLIHUA NANO TECH

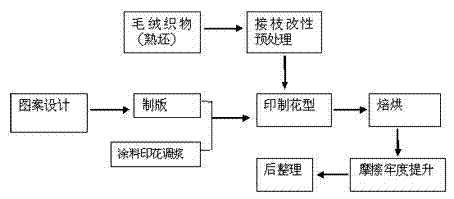

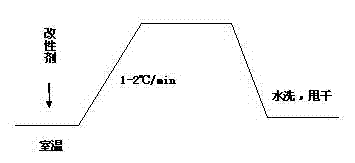

Processing method for pigment printing of plush product

InactiveCN102191685ASolve the problems of poor printing fastness and bad hand feelingEasy to printDyeing processAnimal fibresAdhesiveChemistry

The invention discloses a processing method for pigment printing of a plush product. The processing method comprises the following steps of: carrying out modifying pretreatment by adopting a grafting agent before printing, drying and naturally airing after grafting and modifying treatment, adding a color fixing agent and a softening agent into a printing paste formula to prepare pigment printing paste and carrying out a printing technology. The processing method comprises the following process flow of: making a ripe blank of a plush fabric, pretreating by grafting and modifying, blending the pigment printing paste, printing patterns, drying, increasing crocking fastness and after-treating. A technical formula of the processing method is characterized in that: firstly, in the grafting and modifying technology and formula for the plush fabric, the plush fabric is soaked for 20-30min in the grafting agent of 5-20 percent (o.w.f: on weight the fabric) in a bath ratio of (1:20)-(1:100) at the temperature of 60-70 DEG C, is continuously stirred and then is dried; and secondly, in the pigment printing paste technology and formula, the pigment printing paste comprises the following components in percentage by weight: 0.01-6 percent of pigment, 5-15 percent of adhesive, 2-5 percent of thickening agent, 0.5-5 percent of softening agent, 2-10 percent of color fixing agent, 0.5-5 percent of glycerin and 1-5 percent of urea. The processing method for the pigment printing is convenient to operate, and a pigment printing product has good fastness and good hand feel.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

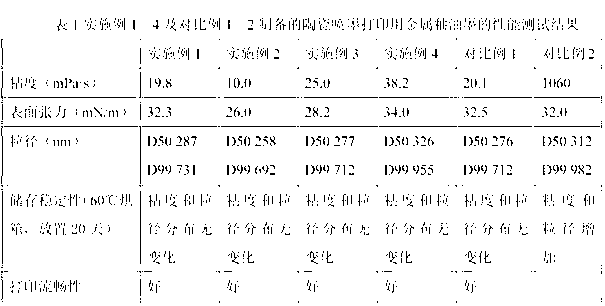

Metal glaze printing ink for ceramic ink-jet printing and preparation method thereof

ActiveCN103224724AGood quality and stabilityGood inkjet printing performanceInksPrinting inkDefoaming Agents

The invention discloses a metal glaze printing ink for ceramic ink-jet printing and preparation method thereof, wherein the printing ink comprises, based on the mass percentage: 40-60% of metal glaze, 2- 5% of resin, 4 - 8% of dispersant, 0.1-0.2% of flatting agent, 0.2 - 0.5% of defoamer, 0.08 - 0.12% of anti-settling agent, and the balance for solvent; wherein the metal glaze contains the following components of SiO2, Al2O3, K2O, Na2O, CaO, MgO style, Fe2O3, P2O5, ZnO. The metal glaze printing ink for ceramic ink-jet printing is provided with advantages of good quality stability, long preservation, and good performance of ink-jet printing. The metal glaze printing ink prepared by the invention has low viscosity, even particle size distribution, simple and efficient preparation. The metal glaze printing ink prepared by the invention can be used with pigment printing ink for ceramic ink-jet printing, and can further improve the decoration effect of the ceramic tiles.

Owner:FOSHAN DOWSTONG TECH

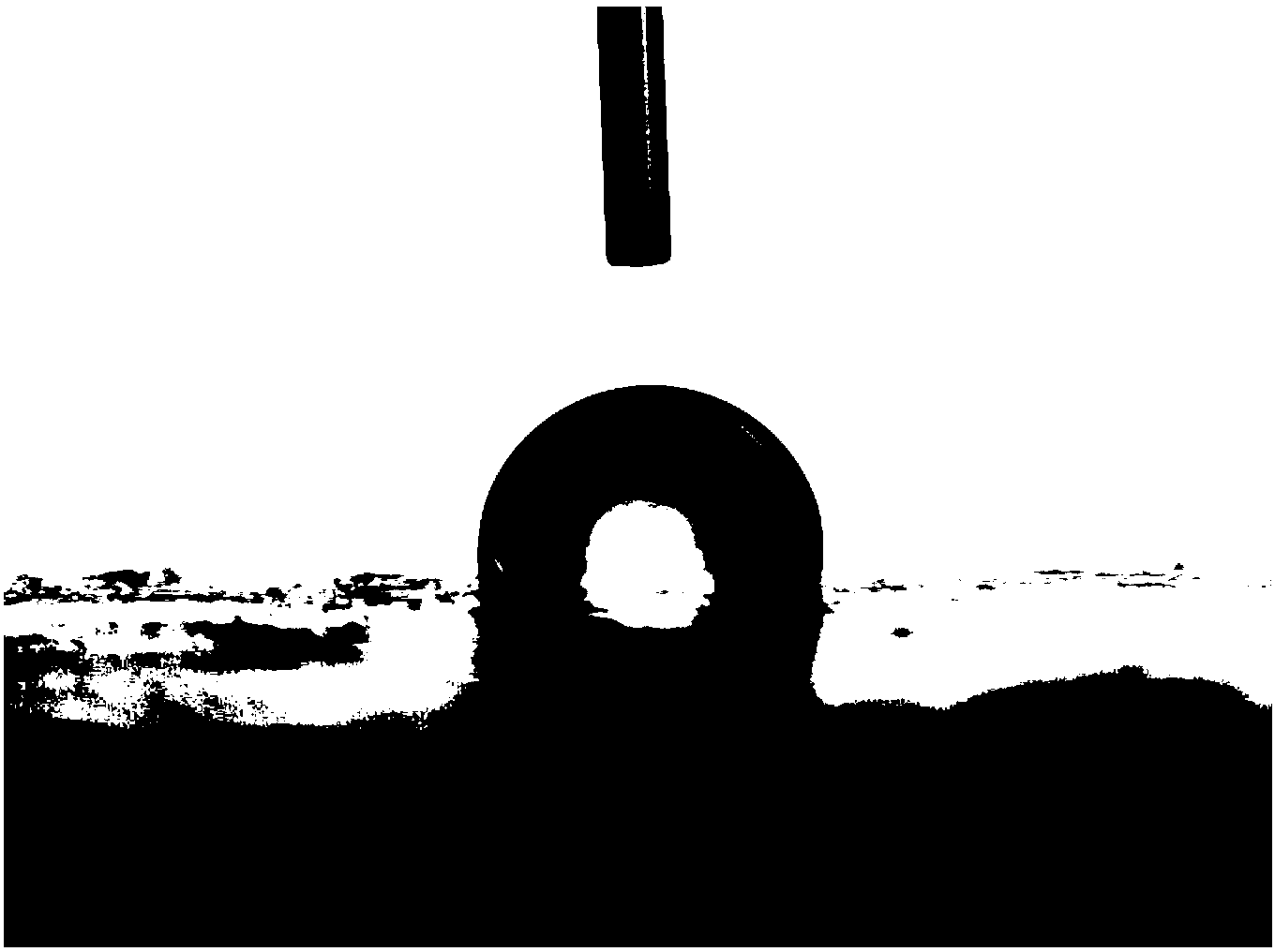

Fluorine-silicon-modified acrylate adhesive, preparation method and application thereof

ActiveCN103224765ASolve the feelSolve the fastnessEster polymer adhesivesDyeing processEmulsionAdhesive

The invention discloses a fluorine-silicon-modified acrylate adhesive which is prepared by the following raw materials by weight parts: 50 parts of water, 0.1-1 part of an anionic emulsifier, 10-20 parts of acrylate polymerizable monomers, 0.2-1 part of acrylic acid, 0.5-5 parts of fluorine containing organosilicon monomers, 0.1-2 parts of co-emulsifier and 0.1-1 part of an initiator. The fluorine-silicon-modified acrylate adhesive is a stable fluorine-silicon-modified acrylate emulsion, can be used for pigment printing, is soft in touch, high is color fastness, good in system stability and stable in product quality, and effectively solves problems of incompatible touch and fastness, and hot sticking and cold shortness existing in present acrylate adhesives. The invention further discloses a preparation method of the fluorine-silicon-modified acrylate adhesive. According to the method, stable fluorine-silicon-modified acrylate emulsion is prepared through miniemulsion polymerization. The method is simple in preparation, easy to implement and operate, and easy for industrial production, and has wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

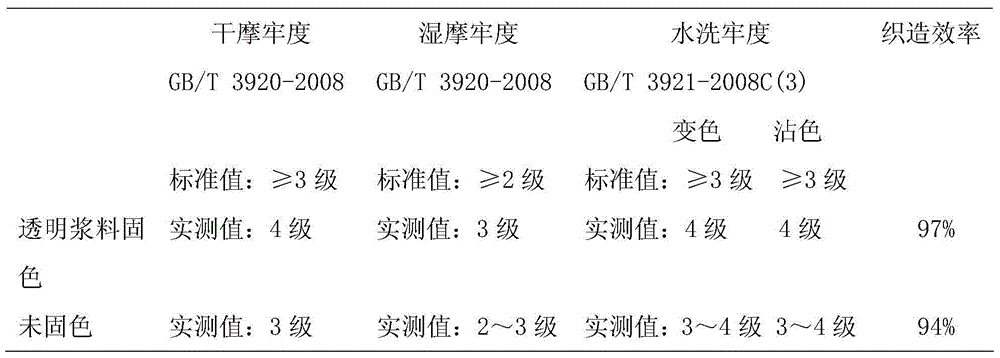

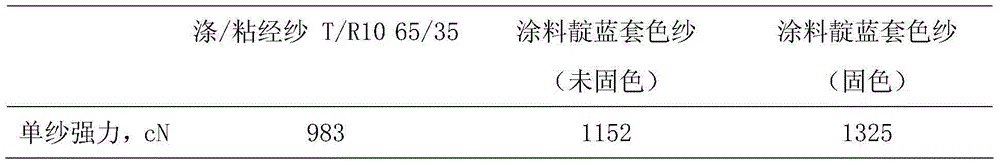

Paint-indigo stereo overdyeing and fixation desizing-free sizing and dyeing process for jean blended warps

The invention discloses a paint-indigo stereo overdyeing and fixation desizing-free sizing and dyeing process for jean blended warps. The process comprises the following steps: diluting self-crosslinking polyacrylate emulsion slurry containing color paste with water, carrying out uniform mixing with stirring, carrying out slurry groove dip-dyeing sizing and roller pad dyeing sizing on the jean blended warps so as to realize sizing and dyeing, drying the jean blended warps having undergone sizing and dyeing with a drying drum, then carrying out self-crosslinking and solidification, then further carrying out sizing coating and dye fixation on the jean blended warps by using self-crosslinking polyacrylate emulsion slurry not containing color paste, carrying out drying with the drying drum, self-crosslinking and solidification and then carrying out overdyeing with indigo; and further carrying out sizing coating and dye fixation on the jean blended warps having undergone overdyeing with indigo by using the self-crosslinking polyacrylate emulsion slurry not containing color paste again. According to the invention, pigment printing paste and indigo are respectively coated by a layer of a transparent self-crosslinking polyacrylate emulsion slurry membrane for dye fixation, so color fastness of two colors are substantially improved, new colored light hardly forms, and good stereoscopic sensation or layering sensation is obtained.

Owner:广州市唯佳安达新材料科技有限公司 +1

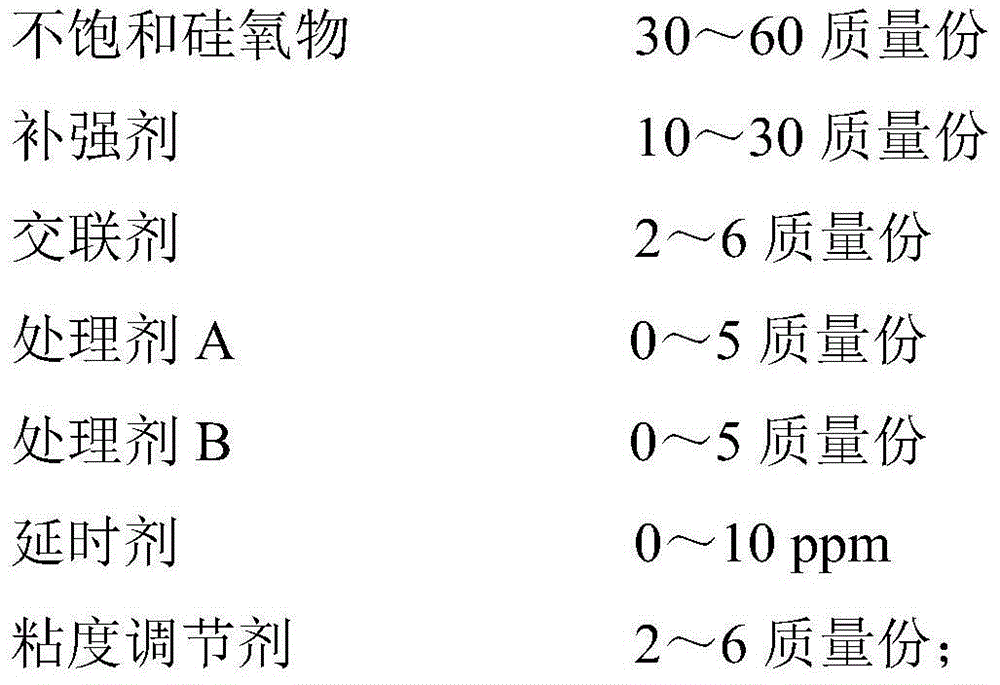

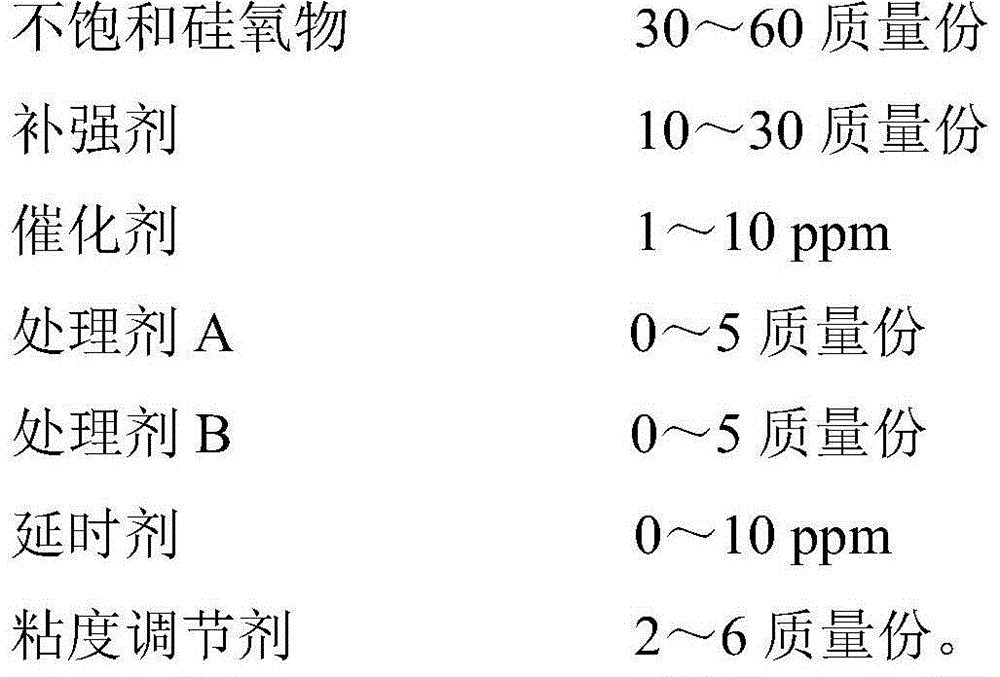

Machine printing silica gel for pigment printing as well as preparation method and application thereof

ActiveCN104480748ARealize continuous use of machinesIncrease productivityDyeing processTextile printerReaction temperature

The invention belongs to the technical field of organic silicon, and discloses a machine printing silica gel, which can be used for performing continuous machine printing and is excellent in performance, for pigment printing, a preparation method of the machine printing silica gel and an application of the machine printing silica gel in the field of textile printing. The machine printing silica gel for pigment printing comprises unsaturated silicon oxide, a crosslinking agent containing silicon hydrogen bonds, silicon hydrogen addition catalyst and a reinforcing agent, wherein the reinforcing agent comprises an inorganic substance reinforcing agent and an organic substance reinforcing agent. A composite enhancing system is creatively used, so that the product silicone gel is surely good in network passing property and good in ink returning property; siloxane with a certain structure, MQ resin and hydrogen-containing organic substances are designed and used to ensure that the reaction temperature and operation time of the product have relatively wide ranges, glue dying mesh clogging is avoided after 4 hours of continuous machine printing, and the production efficiency is improved; and the preparation method disclosed by the invention is simple, environmentally friendly and energy-saving, and the obtained silica gel is stable in storage and excellent in performance, has advantages of less bubbles, easy leveling, good fastness, good slip resistance and the like, and can be widely applied to the field of textile printing.

Owner:GUANGZHOU HUMAN CHEM

Ink jet recording method for printing pigment

ActiveUS20140240399A1Contamination is suppressedIncrease drying speedInksPower drive mechanismsEngineeringColoring agents

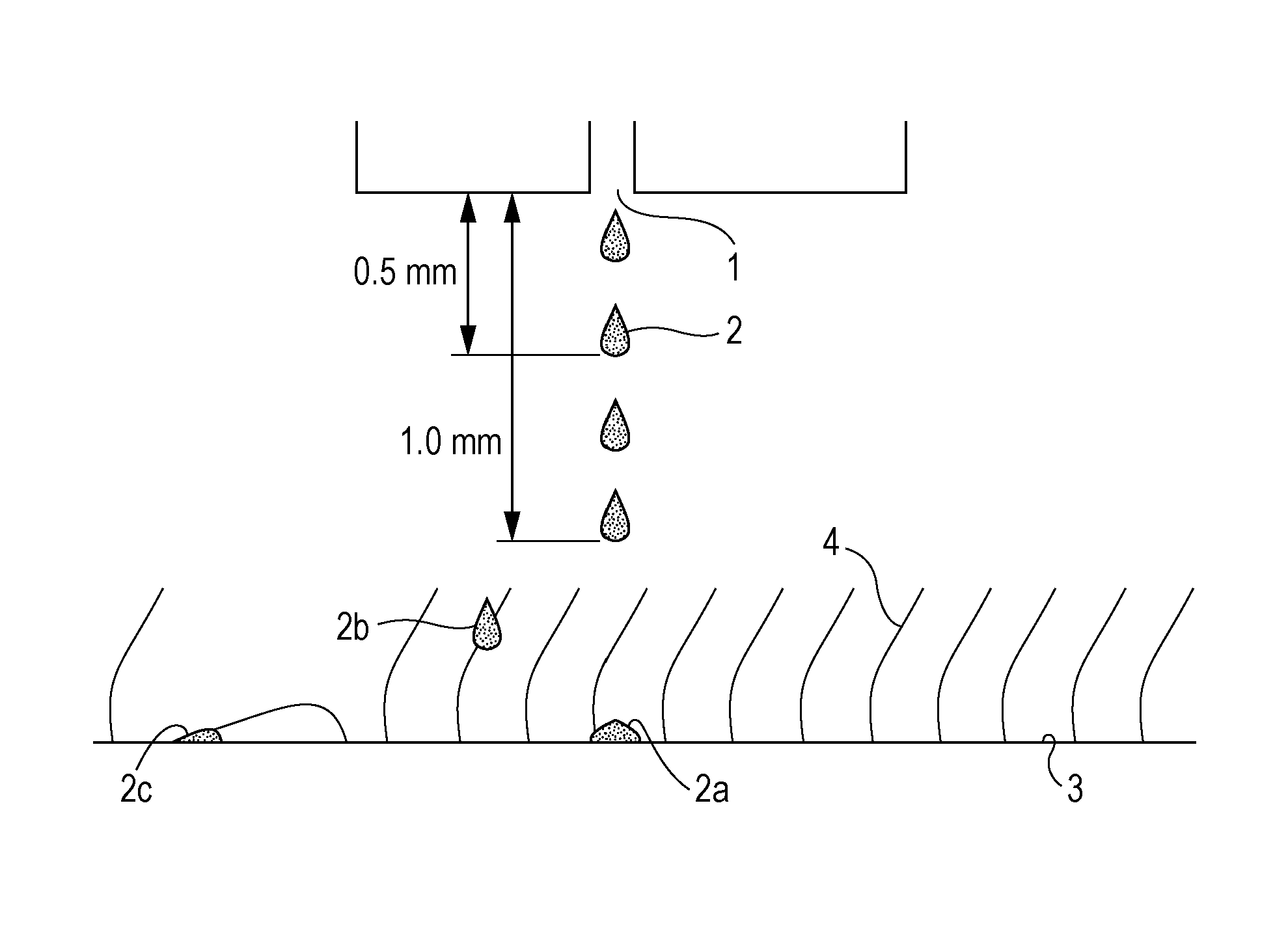

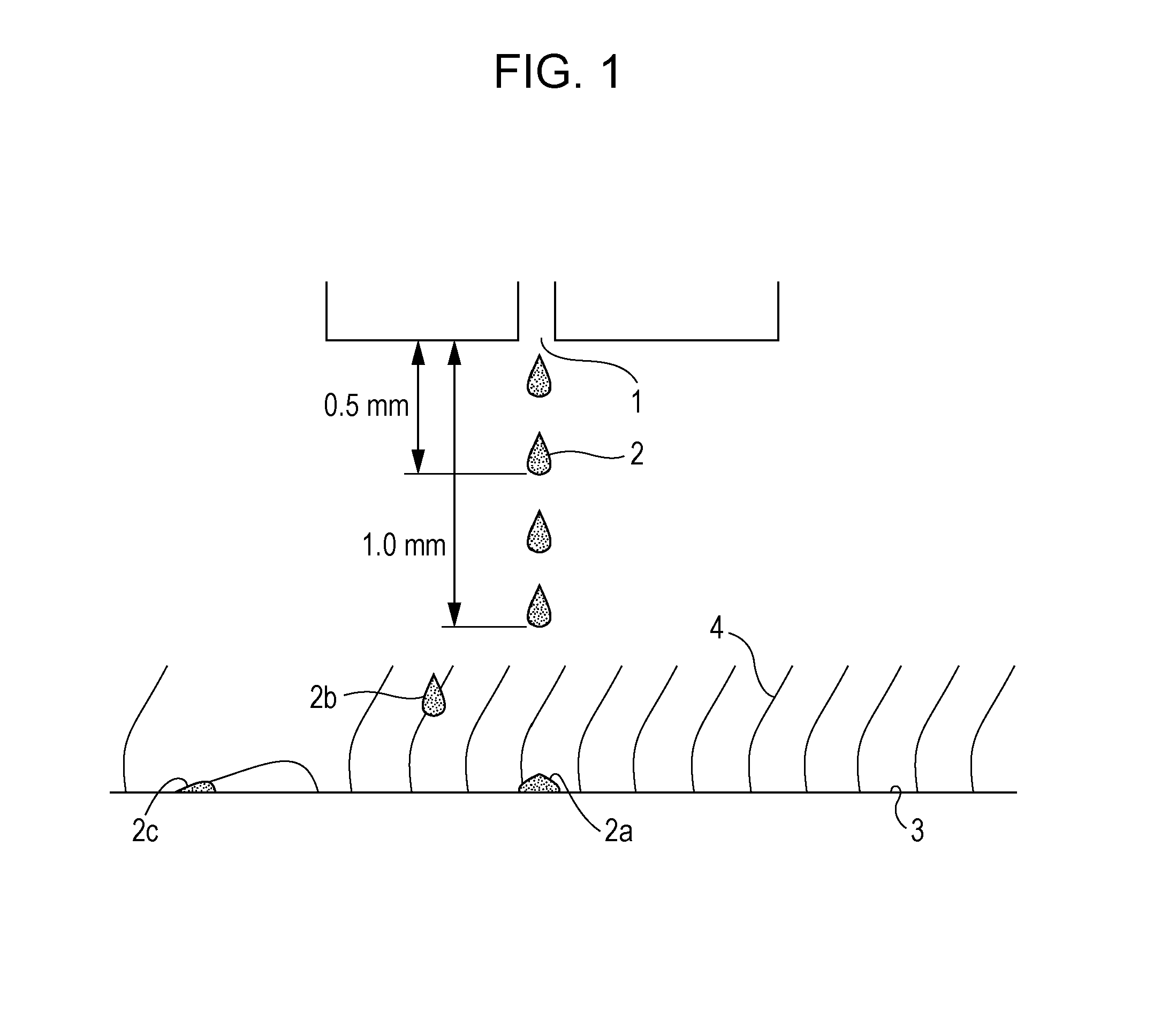

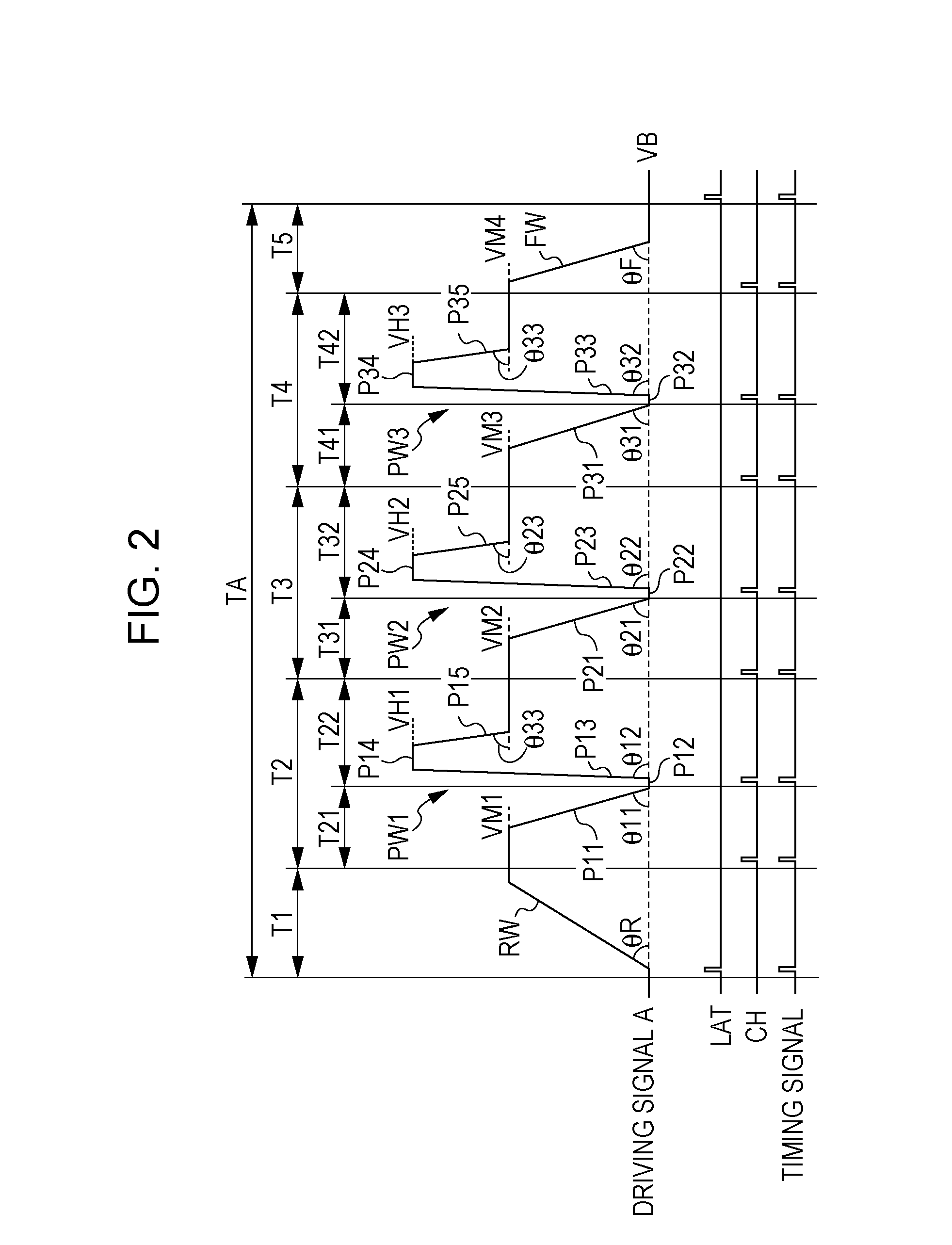

There is provided an ink jet recording method for printing a pigment in which a pigment printing ink composition including at least pigment as a colorant is discharged from a nozzle opening as an ink droplet having an amount of the ink of the ink droplet of 9 ng or less with an average discharging speed V of 5 m / s or greater at a distance in the range of 0.5 mm to 1.0 mm in the direction from the nozzle opening to cloth, and whereby the pigment printing ink composition is adhered to the cloth.

Owner:SEIKO EPSON CORP

Electrolyte resistant antipermeation synthetic printing thickener and its preparation method and application

This invention discloses an ionization resistant, impervious composite printing thickener and its manufacturing method and application, which is got through co polymerization of such unsaturated acids as a-alkyl acrylic acid polyoxyethylene ester, acrylic acid, methacrylic acid and such unsaturated monomers as acrylamide and butyl acrylate in mixed solution of water and solvent naphtha by antiphase latex. When the thickener in this invention is applied in pigment printing color paste, it assumes advantages of high thickening ability, strong ionization resistance and no oozing, and besides it can be applied in thickening white coat, black coat and color paste, the prepared printing color paste not oozing or gelling.

Owner:SICHUAN TEXTILE SCI RES INST +1

Pigment printing thickener and method for preparing same

The invention provides a pigment printing thickener and a method for preparing the same. The method comprises the following steps of: preparing a water phase containing monomers, a crosslinking agent and an initiator and an oil phase containing solvent oil and an activator; shearing-emulsifying the water phase and the oil phase at a high speed in an atmosphere of argon gas; initializing the solution by sulfur dioxide, heating the solution to the temperature of between 50 and 60 DEG C, keeping the solution warm, adding an emulsifier, stirring the mixed solution for 10 to 30 minutes, adding the mixed solution to the solvent oil containing sodium polyacrylate and the activator, and evenly stirring the mixed solution to obtain the finished product of the pigment printing thickener. The pigment printing thickener has the advantages of small dosage, strong thickening effect and good thixotropic property, has a simple preparation process and is suitable for mass industrialized production.

Owner:荆州市天翼精细化工开发有限公司

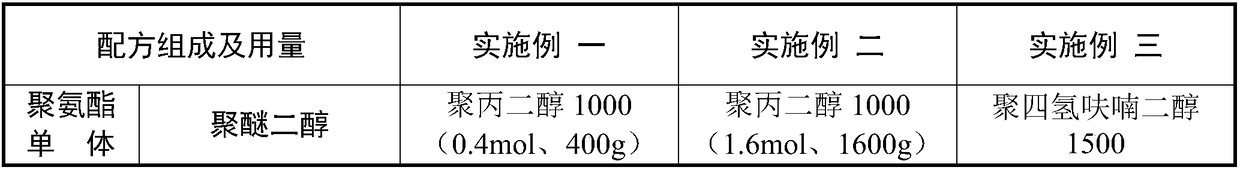

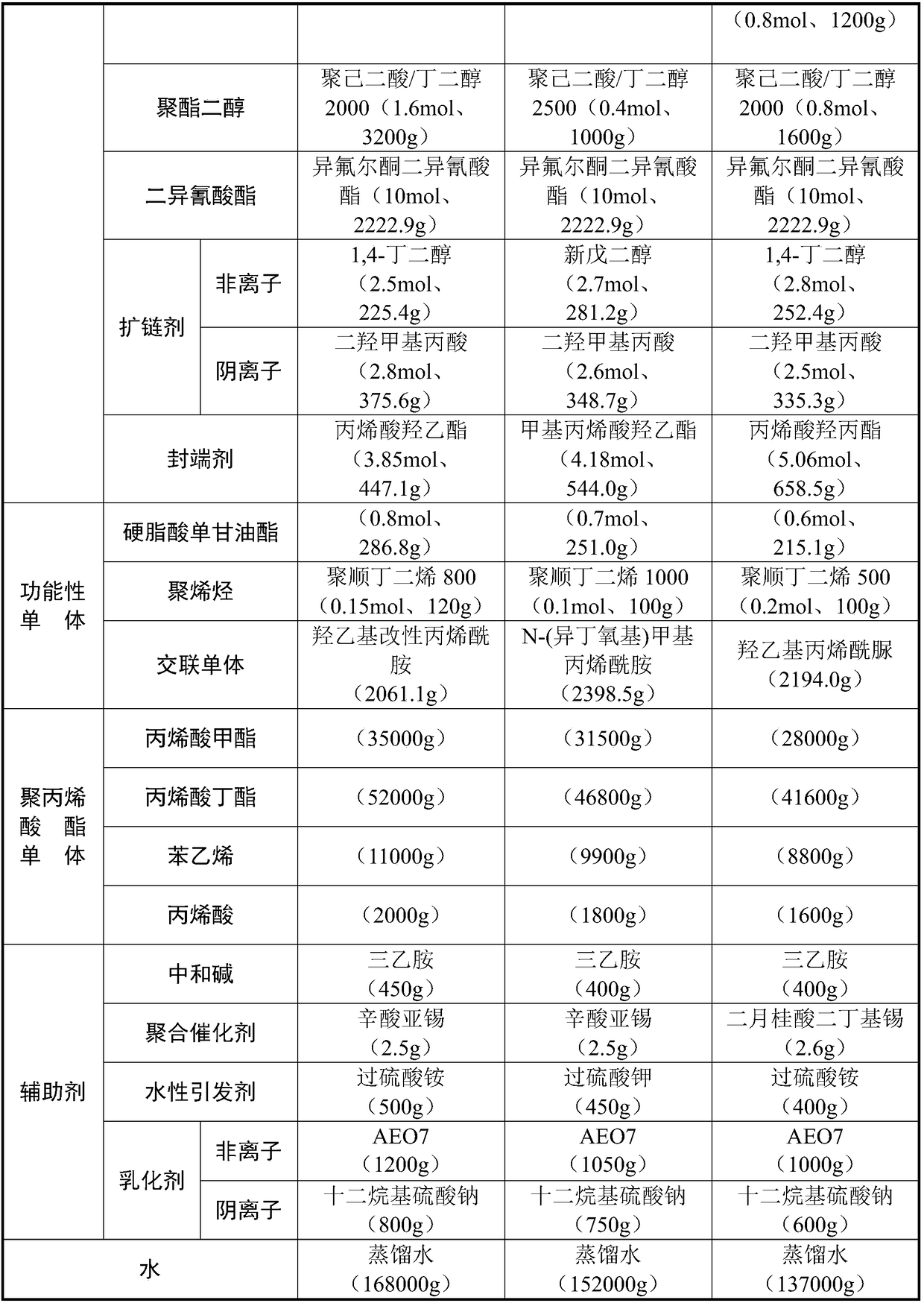

Preparation method of elastically-crosslinked water-fast polyurethane modified polyacrylate emulsion and product prepared by using preparation method

The invention relates to a preparation method of an elastically-crosslinked water-fast polyurethane modified polyacrylate emulsion and a product prepared by using the preparation method. The preparation method comprises the following steps: preparing for raw materials including a polyurethane monomer, a polyacrylate monomer, a functional monomer, an adjuvant and water; carrying out bulk polymerization; carrying out blocking; carrying out emulsion; and carrying out emulsion polymerization to prepare the elastically-crosslinked water-fast polyurethane modified polyacrylate emulsion. A polyurethane long-chain crosslink with a certain density, a moderate amount of crosslinked active groups and a water-repellent side long chain are introduced into a molecule of the material, so that various textile coatings or pigment printing glue films have excellent water fastness, good color fastness, remarkable flexibility as well as certain water repellency and antifouling ability, so that the elastically-crosslinked water-fast polyurethane modified polyacrylate emulsion has a good market prospect; and the product is safe, environment-friendly and convenient to use and can be used for the field ofvarious substrate processing such as coating, textile adhesion, pigment printing and pigment dyeing.

Owner:广东奕美化工科技有限公司

Method for preparing noctilucent printed fabric

The invention provides a method for preparing a noctilucent printed fabric, comprising the following steps of: fully mixing golden and silver powder binder with water; then adding a rare earth aluminate luminescent material and fully mixing; then adding a pigment printing thickening agent HIT and fully mixing to obtain printing paste; printing a raw material fabric in a plate screan printing mode by using the printing paste, and then baking; and carrying out tentering softening treatment to prepare the noctilucent printed fabric. The noctilucent printed fabric prepared with the method is suitable for manufacturing decorations and children products. The adopted noctilucent material is a rare-earth activated aluminate luminescent material and has a stable crystal structure; and for the luminescence performance, the processes of light absorption, energy storage and luminescence can be permanently kept on the premise that the crystal structure is not damaged. The material does not contain any radioactive element and has the characteristics of rapidness of light absorption, high start brightness, long afterglow time, safety, practicability and the like.

Owner:SHANDONG WEIQIAO PIONEERING GROUP

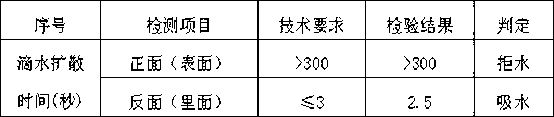

Sweat stain resisting tidying method of hygroscopic and sweat releasing knit goods

ActiveCN103161045AAchieve anti-sweat effectStay flexibleSucessive textile treatmentsTwo or more solvent application treatmentEngineeringMoisture

The invention provides a sweat stain resisting tidying method of hygroscopic and sweat releasing knit goods. The sweat stain resisting tidying method is characterized by comprising the following process procedures of mild finishing of the knit goods, size mixing, sweat stain resisting processing on front faces of the knit goods, sweat stain resisting detection and stoving. Sweat can be instantly absorbed or volatilized through the hygroscopic and sweat releasing mild finishing of the knit goods; a pigment printing mode is then used for forming a film coating with a plurality of ventilation minuteness air holes on the surfaces of the knit goods, each minuteness hole is smaller than sweat liquid and bigger than sweat molecules of a human body, and the sweat is spread out in a mode of the sweat liquid to enable sweat stains to leave no trace on the surface of clothes. Therefore, the sweat stain resisting tidying method has the effects of sweat stain resistance, the reverse sides of the knit goods after the sweat stain resisting processing can absorb moisture and rapidly dry, the surfaces of the knit goods have the effects of sweat stain resistance, and the knit goods are good in air permeability, can be comfortably wore and are favorable for popularization and use.

Owner:QINGDAO XUEDA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com