Method for producing energy-saving and environment-friendly type soft resin-bonded pigment printing nap cloth

A paint printing, energy-saving and environmental protection technology, applied in the processing of textile materials, continuous processing of textile materials, dyeing methods, etc., can solve the problems of many reactive dye printing processes, poor color fastness, hard hand feeling, etc. Good fastness and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

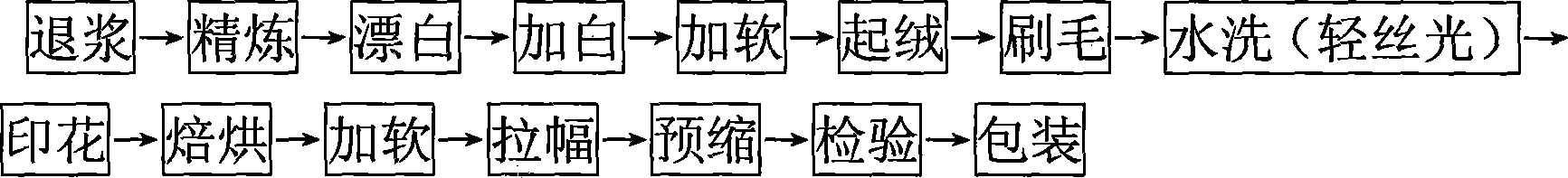

[0031] The production method of the energy-saving and environment-friendly soft paint printing brushed cloth, the specific process steps are:

[0032] The first step of desizing, refining, and bleaching: using the alkali-oxygen one-bath process, performing two dipping and two rolling in the padding solution, with a surplus rate of 110%, and steaming at 100°C for 60 minutes; the padding solution is made of the following raw materials: The prepared mixture:

[0033] NaOH (100%) 40g / l

[0034] h 2 o 2 (100%) 13g / l

[0035] Stabilizer GJ101 (Shijiazhuang Huancheng) 7g / l

[0036] Efficient scouring agent 22ECO (Shanghai Henkel) 7g / l;

[0037] The second step is whitening, softening, and napping: perform one dipping and one rolling in the following padding solution, dry at 120°C, and raise the napping machine with four positive and three reverse methods; the padding liquid is prepared from the following two raw materials , where the concentration of whitening agent VBL is 3.5g...

Embodiment 2

[0056] The first step of desizing, refining, and bleaching: alkali-oxygen one-bath process, two dipping and two rolling, with a 100% excess rolling rate, steaming at 100°C for 60 minutes; the specific formula of the padding solution is:

[0057] NaOH (100%) 38g / l

[0058] h 2 o 2 (100%) 15g / l

[0059] Stabilizer GJ101 8g / l

[0060] Efficient scouring agent 22ECO 8g / l;

[0061] The second step is whitening, softening, and napping: the following mixed solution is used for napping, one soaking and one padding, drying at 110°C, four positive and three reverse napping machines, and the specific padding solution is:

[0062] VBL 3.5g / l

[0063] LD-10 40g / l;

[0064] The third step is pre-press washing and pre-press mercerizing: after mercerizing cotton fibers, the fiber alignment is improved, and the fibers are closely attached to each other, which improves the uniform bearing capacity of the fibers to external forces, but the slippage between fibers is also relatively reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com