Patents

Literature

1004 results about "Textile production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile production is the process by which fibers, filaments, yarn, and thread - both natural and synthetic - are made. It also comprises the production of objects made with these materials. Both processes have their own steps for production. Let's examine them both.

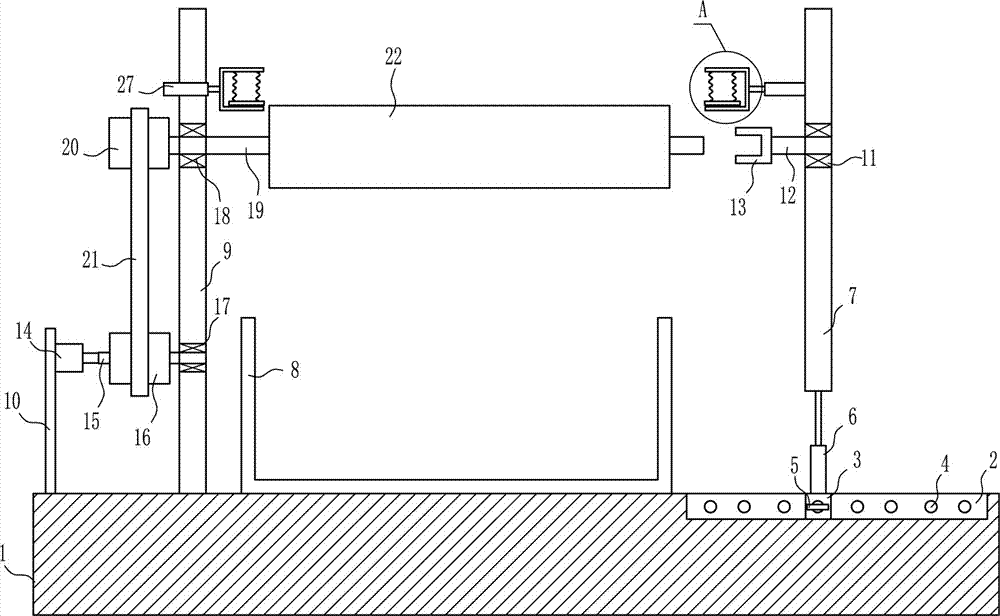

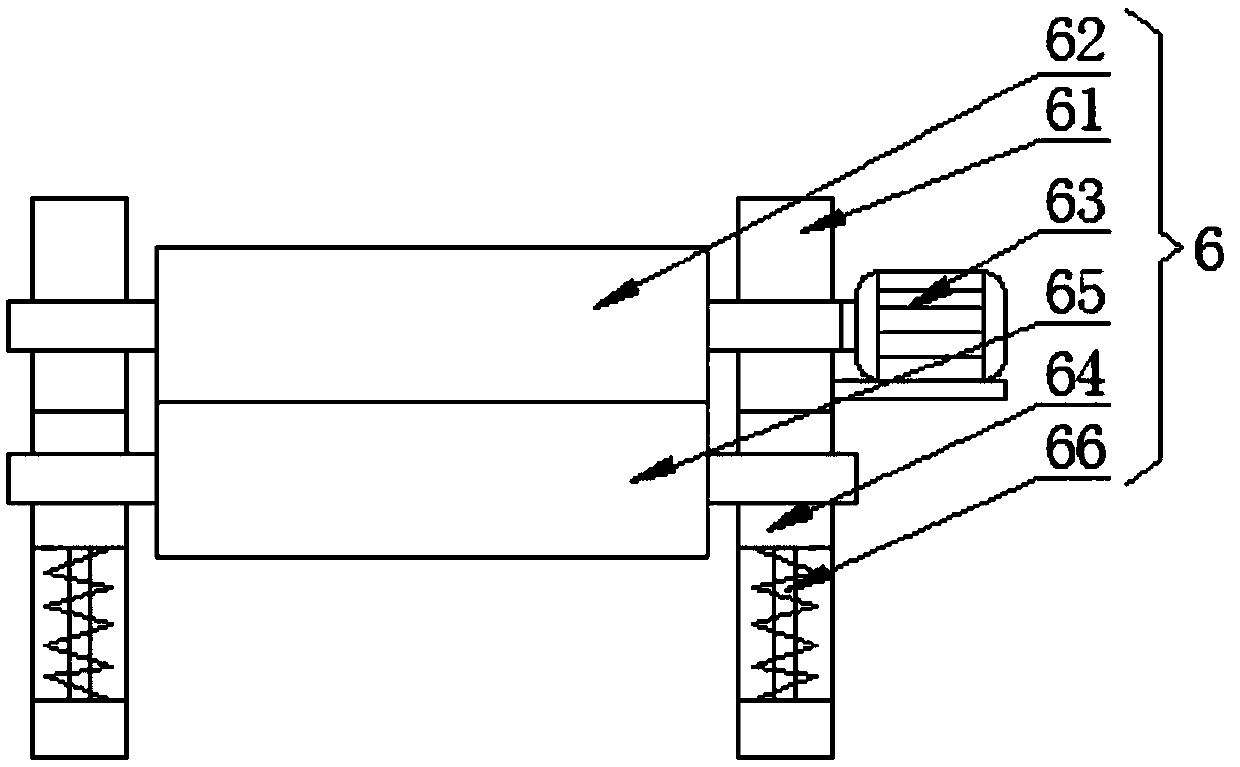

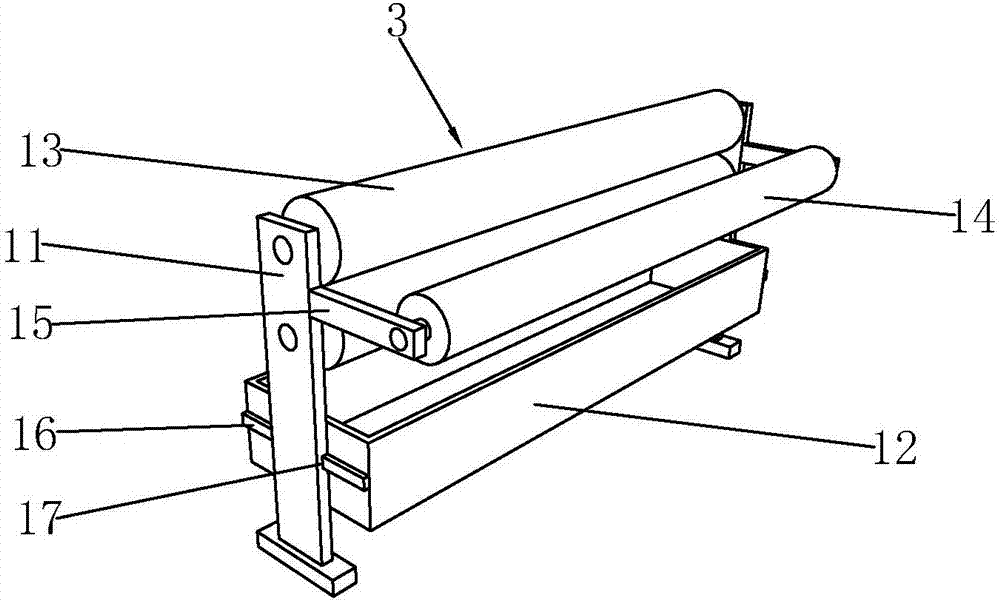

Cloth rolling device for textile production

The invention relates to a cloth rolling device, in particular to a cloth rolling device for textile production. The cloth rolling device for textile production aims to achieve the technical effects of being convenient to use, easy to operate, capable of achieving flat rolling and flat shearing and high in shearing speed and improves the work speed. The cloth rolling device for textile production comprises a base, a first sliding block, a threaded rod, a first air cylinder, a right side plate, a holding frame, a left side plate, a fixed plate, a first bearing seat, a first bearing, a thumb cylinder and the like. The right side of the base is provided with a sliding groove. The first sliding block is arranged inside the sliding groove in a sliding manner. The middle portion of the first sliding block and the front side of the portion, located in front of the sliding groove, of the base are provided with threaded holes at equal intervals. The threaded rod is connected into the corresponding threaded hole in a threaded manner. According to the cloth rolling device for textile production, through rotation of a first roller, cloth is rolled, and the cloth is cut through a cutter.

Owner:浙江云中马股份有限公司

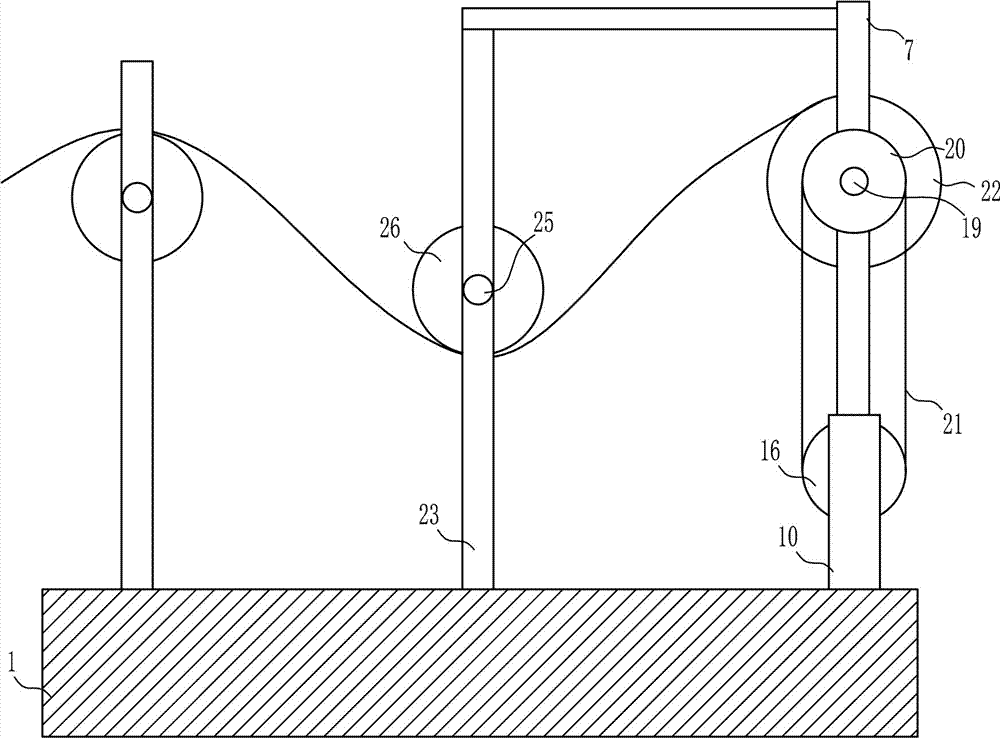

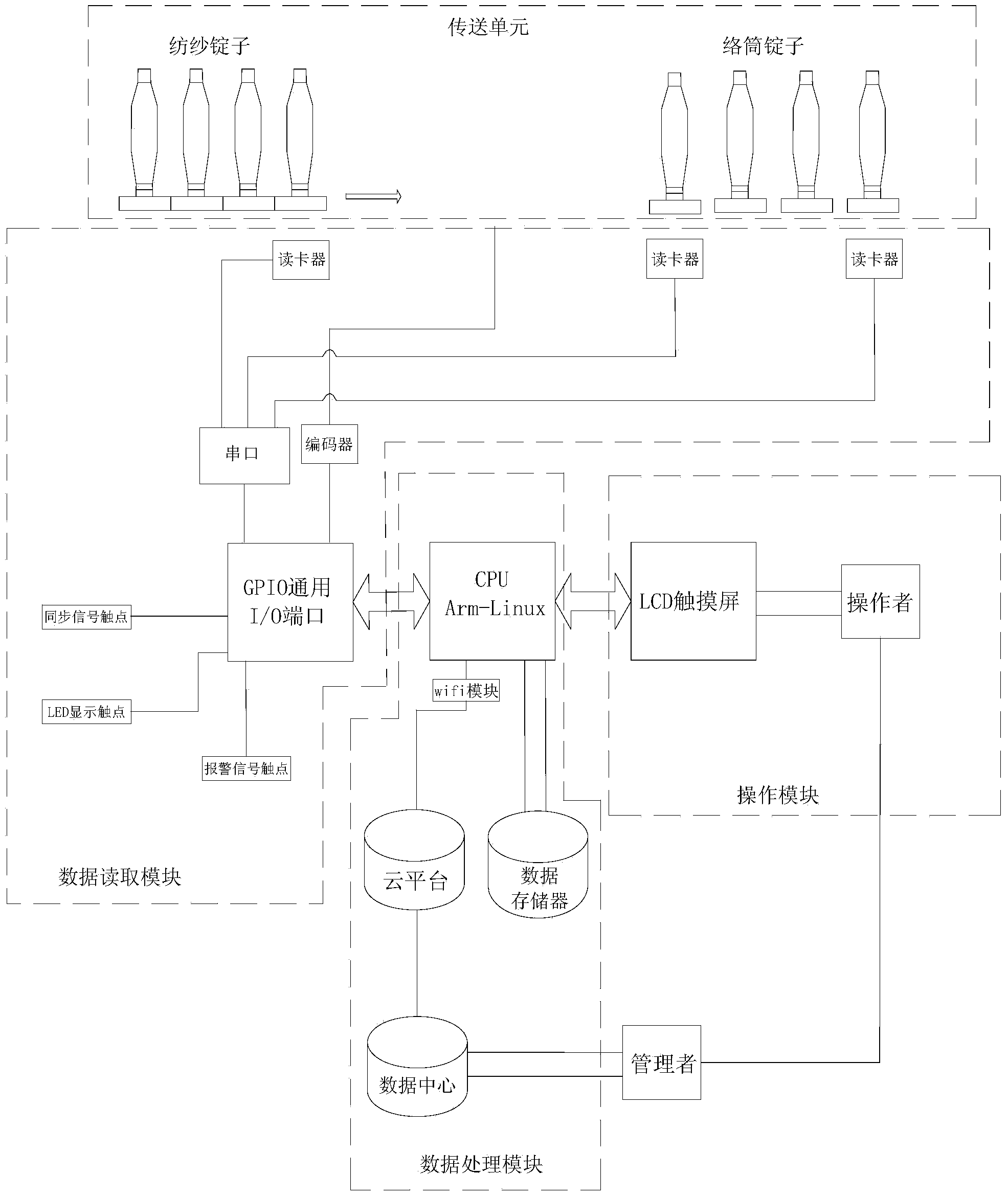

Textile production automated management system and management method thereof

InactiveCN104049615AFind out exactlyImprove spinning qualityTextiles and paperTotal factory controlYarnBobbin

The invention discloses a textile production automated management system and a management method thereof. The management method includes the steps that each spinning spindle and / or spooling spindle of a transport unit are respectively provided with an RFID radio frequency tag module with coded message, the RFID radio frequency tag modules corresponding to each specific spinning spindle position and / or each specific spooling spindle position are respectively provided with a card reader, and therefore tag information and working condition information corresponding to all spinning spindles and / or spooling spindles are obtained and transmitted to a data processing module to be stored, analyzed and processed. According to the system and method, bobbin positioning and quality online monitoring can be carried out rapidly, quality conditions of spun yarn can be checked in real time, the production automation level is improved, labor intensity is relieved, labor productivity is raised, and automated management of quality of spun yarn is achieved.

Owner:ZHANJIANG ZHONGZHAN TEXTILE

Methods and systems for processing cellulose-containing materials and isolating cellulose molecules; methods for regenerating cellulosic fibers

InactiveUS20160369456A1Reduce environmental impactPretreatment with water/steamPulp properties modificationPost-consumer wastePre treatment

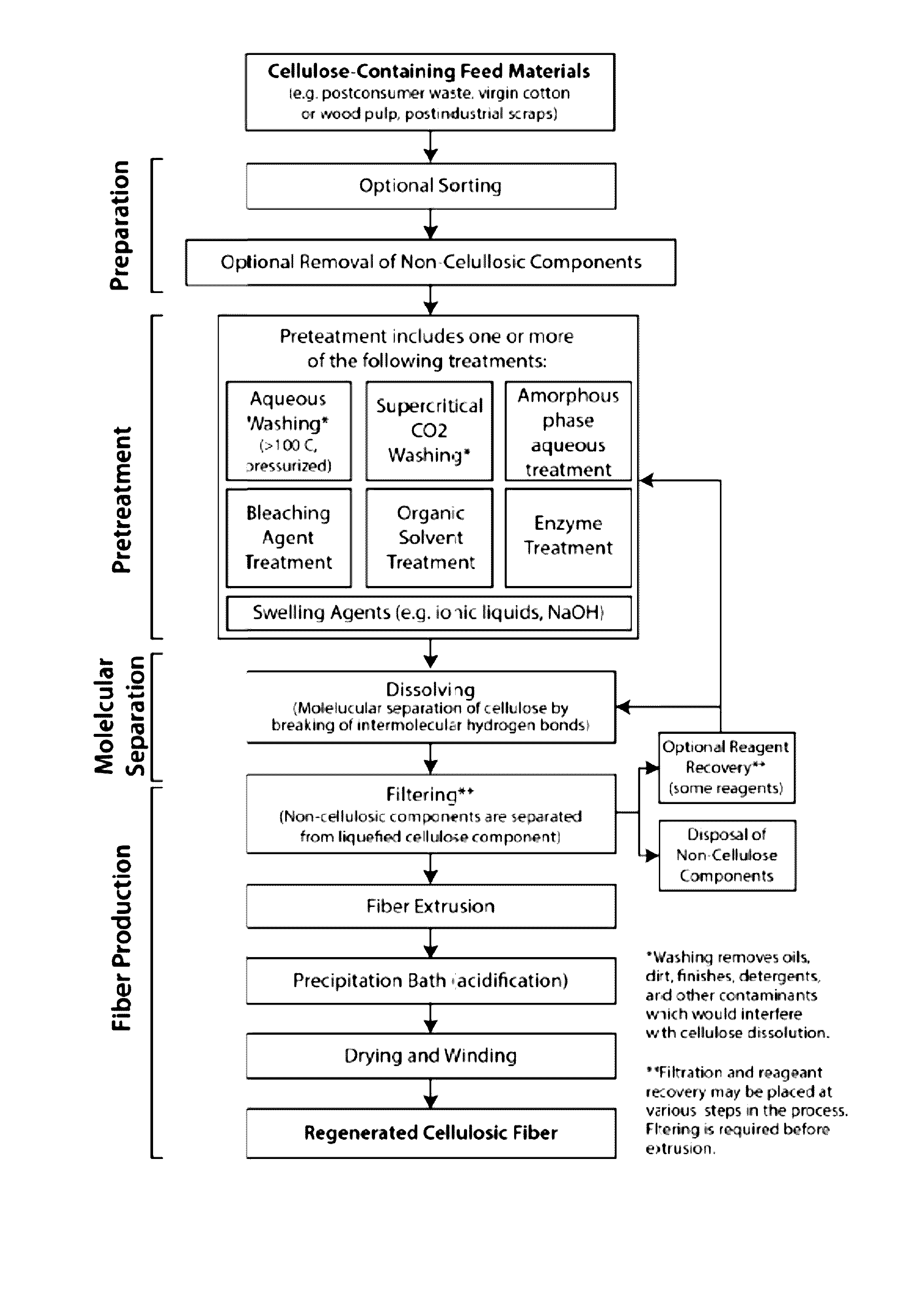

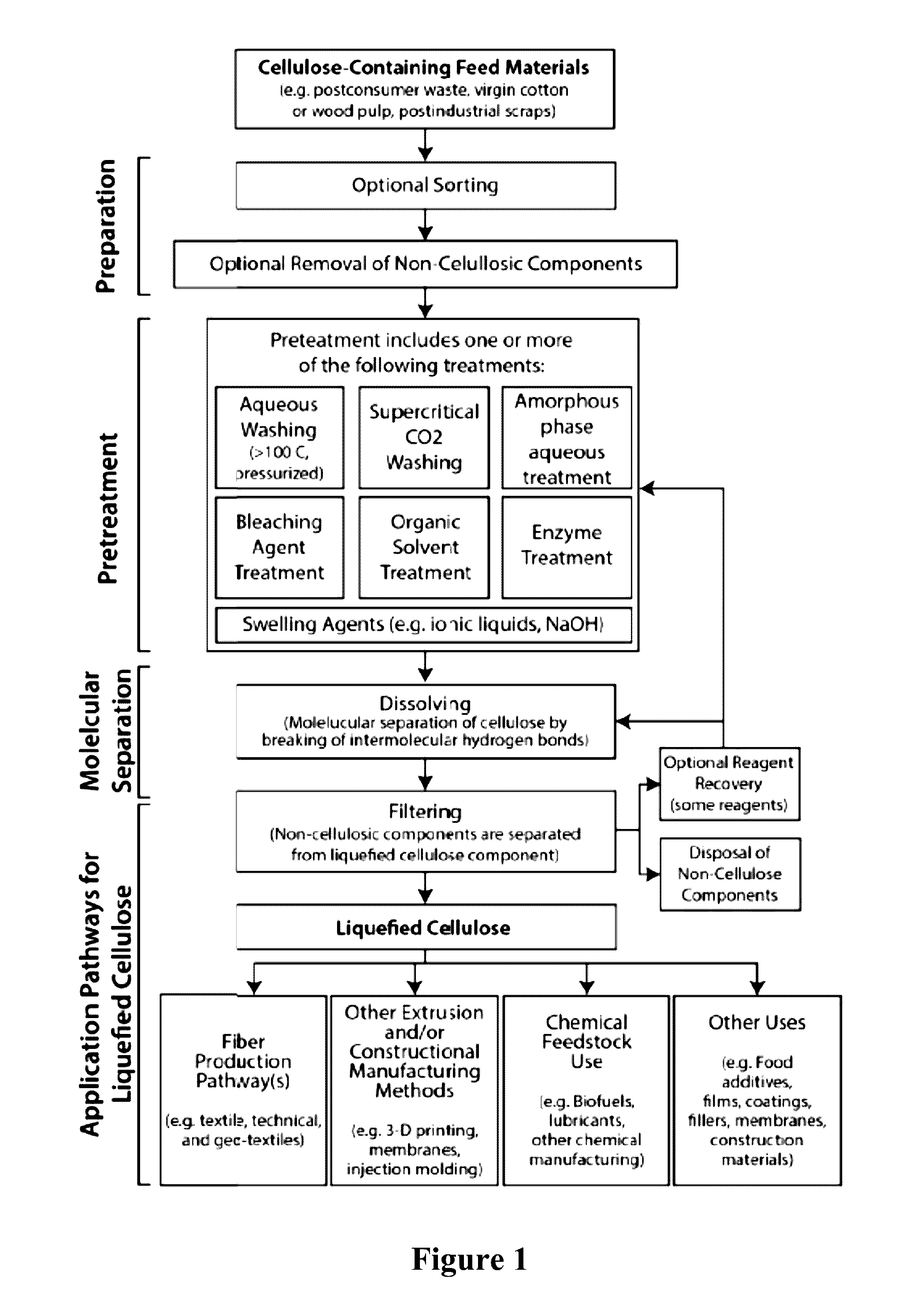

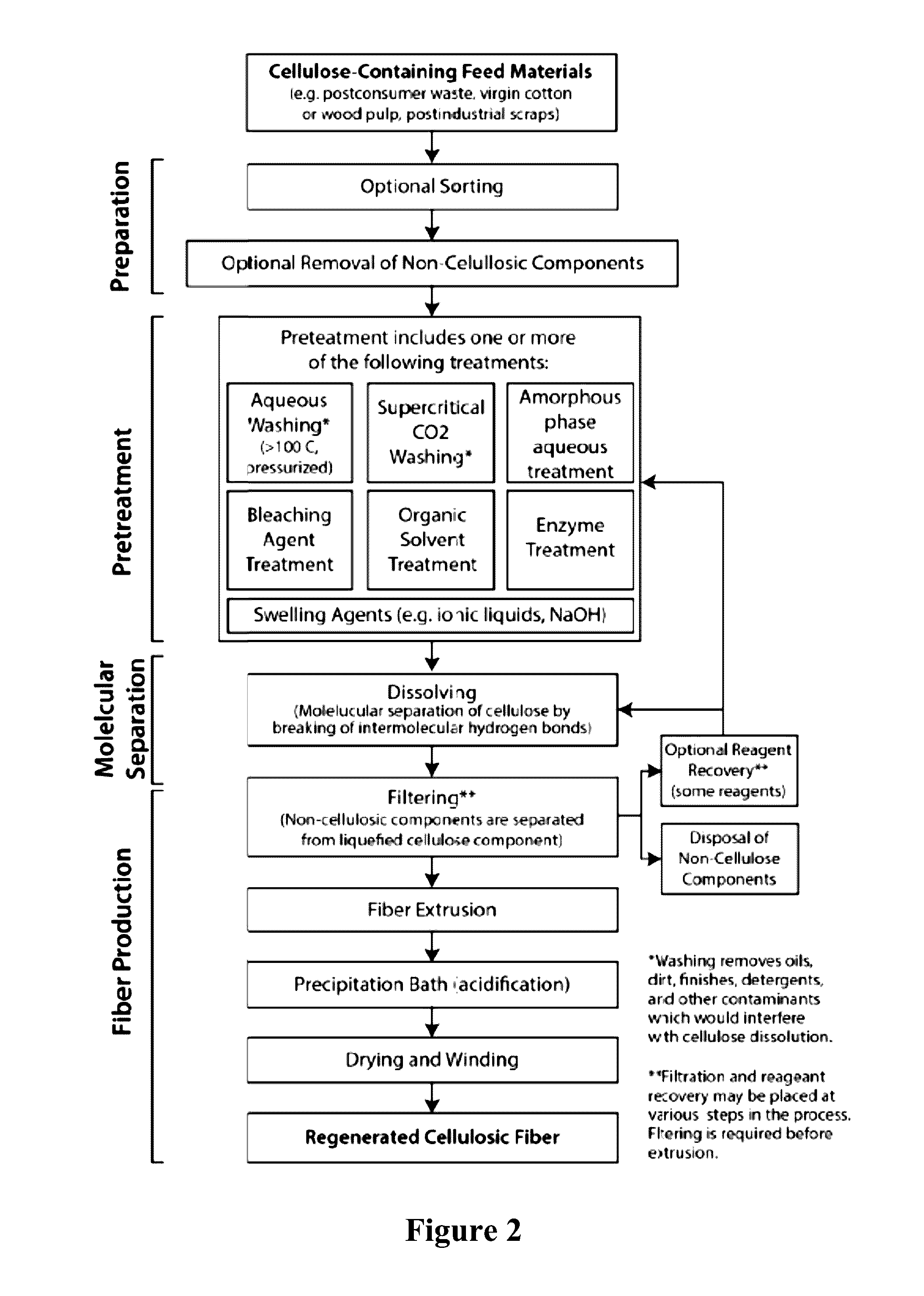

Methods and systems of the present invention use cellulose-containing materials, which may include post-consumer waste garments, scrap fabric and / or various biomass materials as a raw feed material to produce isolated cellulose molecules having desirable properties that can be used in the textile and apparel industries, and in other industries. A multi-stage process is provided, in which cellulose-containing feed material is subjected to one or more pretreatment stages, followed by a pulping treatment, to isolate cellulose molecules. The isolated cellulose molecules may be used in a variety of downstream applications. In one application, isolated cellulose molecules are extruded to provide regenerated cellulose fibers having desirable (and selectable) properties that are usable in various industrial applications, including textile production.

Owner:EVRNU SPC

Recovery method for NMMO solvent in fibre production by solvent method

ActiveCN101280476AReduce concentrationHigh recovery rateArtificial filament recoveryTextile/flexible product manufactureFiberRecovery method

The invention relates to a recycling method of NMMO waste liquor, which provides a recycling method of NMMO in the waste liquor of fiber production with solvent method. According to the specific method of the invention, after passes through in sequence the cation resin exchange column and the anion resin exchange column, the NMMO waste liquor is in decompression and evaporation to the refractive index of 1.480 and cooled, thus the NMMO containing a crystallization water is produced. The cation resin is the macroreticular type or gel-type strong acid polystyrene cation exchange resin, and the anion resin is the macroreticular type or gel-type alkalescence acrylic acid anion resin. Compared with the prior recycling method, in the method of the invention, the recovery rate of the NMMP waste liquor is increased from 95% to 99.5%. In the discharged wastewater after the recycling, the concentration of NMMO is reduced and the steam is saved. Therefore, the textile production costs are greatly reduced.

Owner:YIBIN GRACE GROUP CO LTD

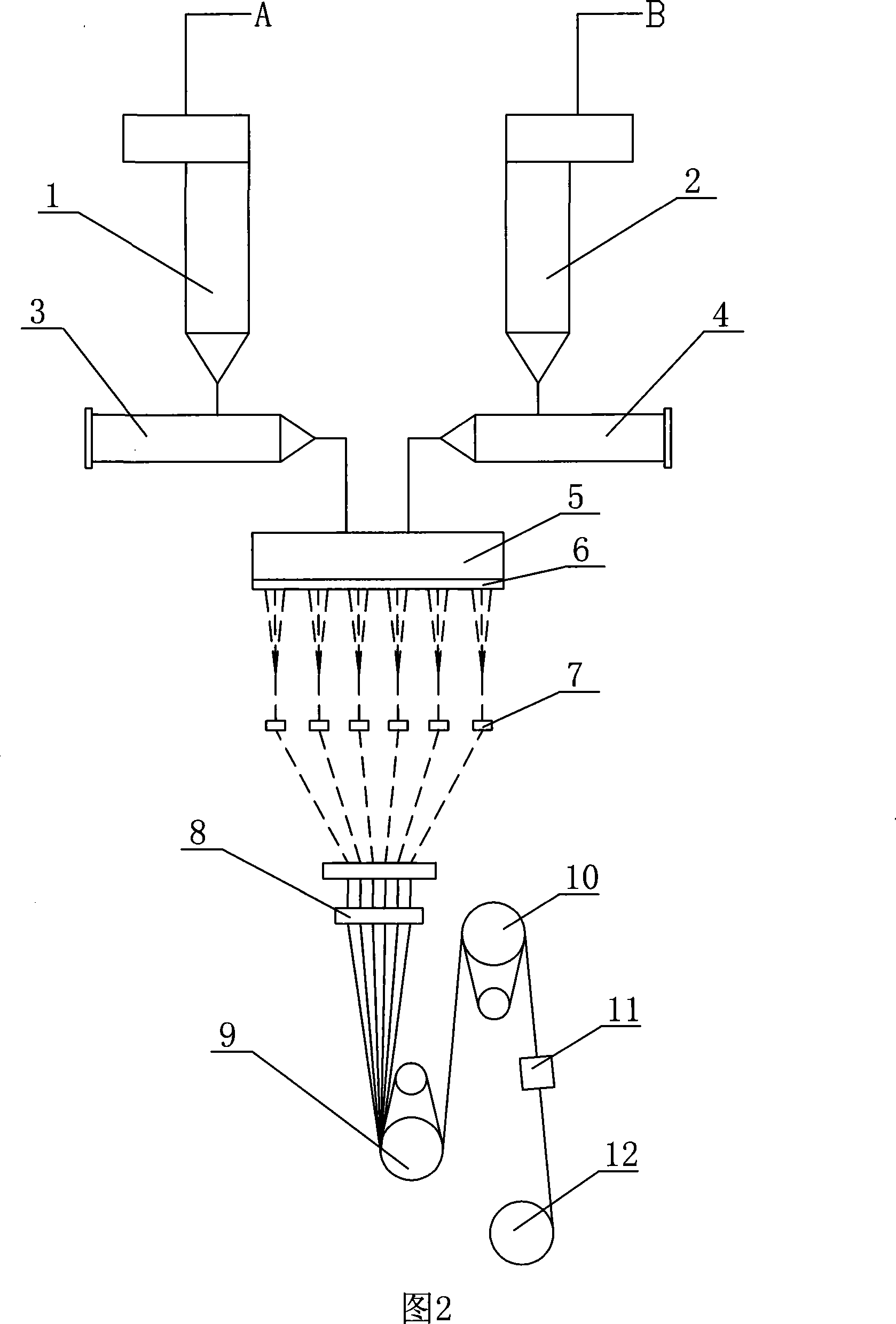

Double-component polyester-nylon superthin drafting thread and its production method

InactiveCN101086087ABeautiful appearanceAvoid disadvantagesFilament/thread formingMonocomponent polyesters artificial filamentPolyesterYarn

The invention discloses a bi-component polyester-brocade ultrafine drawing yarn which has beautiful appearance, excellent performance, simple process and easy operation and its production method; among them the components of brocade includes polyamide 6 slicers in optical fiber grade which are distributed in '*'shape, the component of polyester includes polyester slicers in optical fiber grade which are distributed in other spaces; said production method is: drying, melting and squeezing said two raw materials, then transporting them into the '*'shape polyester-brocade composite assemblies in spinning box, squeezing out two components in composite assemblies at the same time, drying and shaping by lateral blowing, oiling by oiling system, then guiding them to the first and second heat roller through pre-network nozzle blowing network, last winding-up tows through winding head and preparing the desired bi-component polyester-brocade ultrafine drawing yarn, the rolling speed when winding-up is 3900-5300m / min. Said products can be used in the high-grade textiles productions of artificial chamois skin, peachskin suede, super-high density textiles and other textiles widely.

Owner:张家港保税区长江塑化有限公司

Wetting, drying, and ironing device for textile production

InactiveCN108060543AReduce defective rateGuaranteed qualityLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingWater dischargeEngineering

Owner:石小英

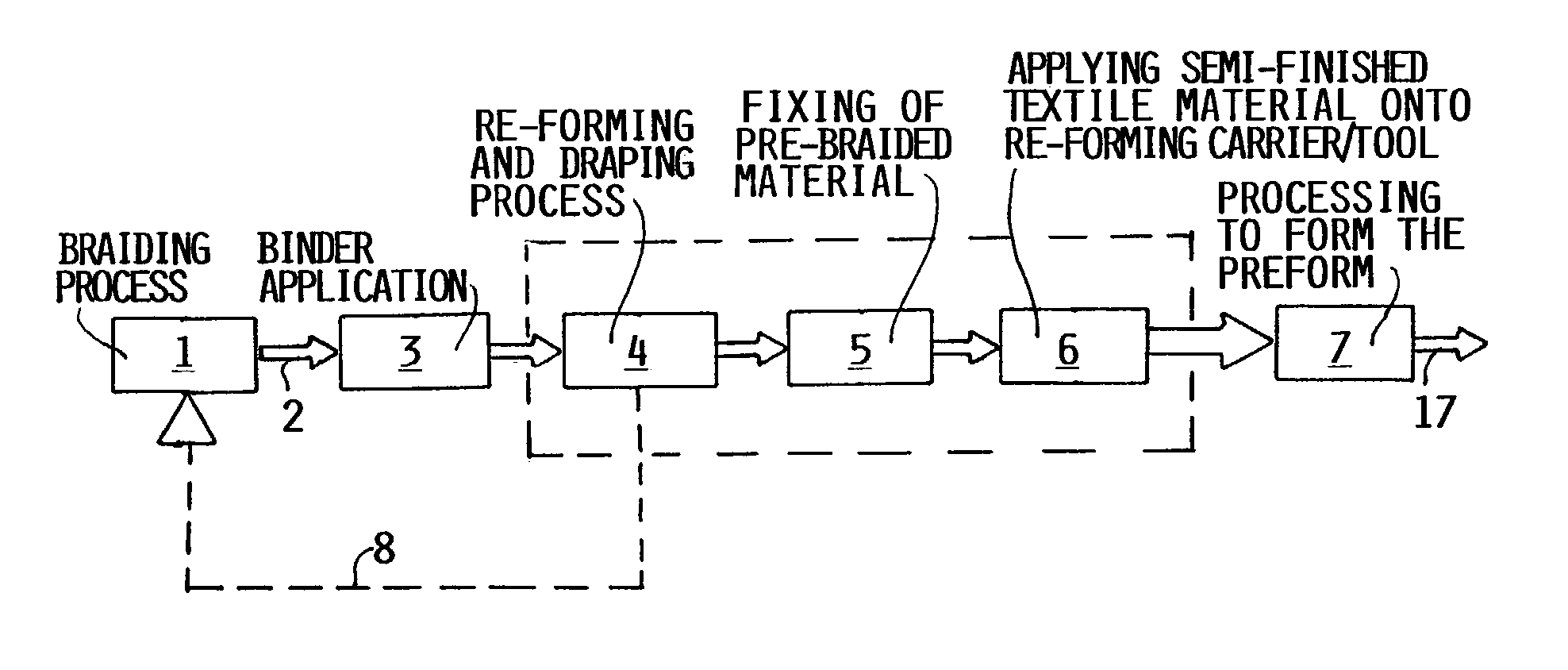

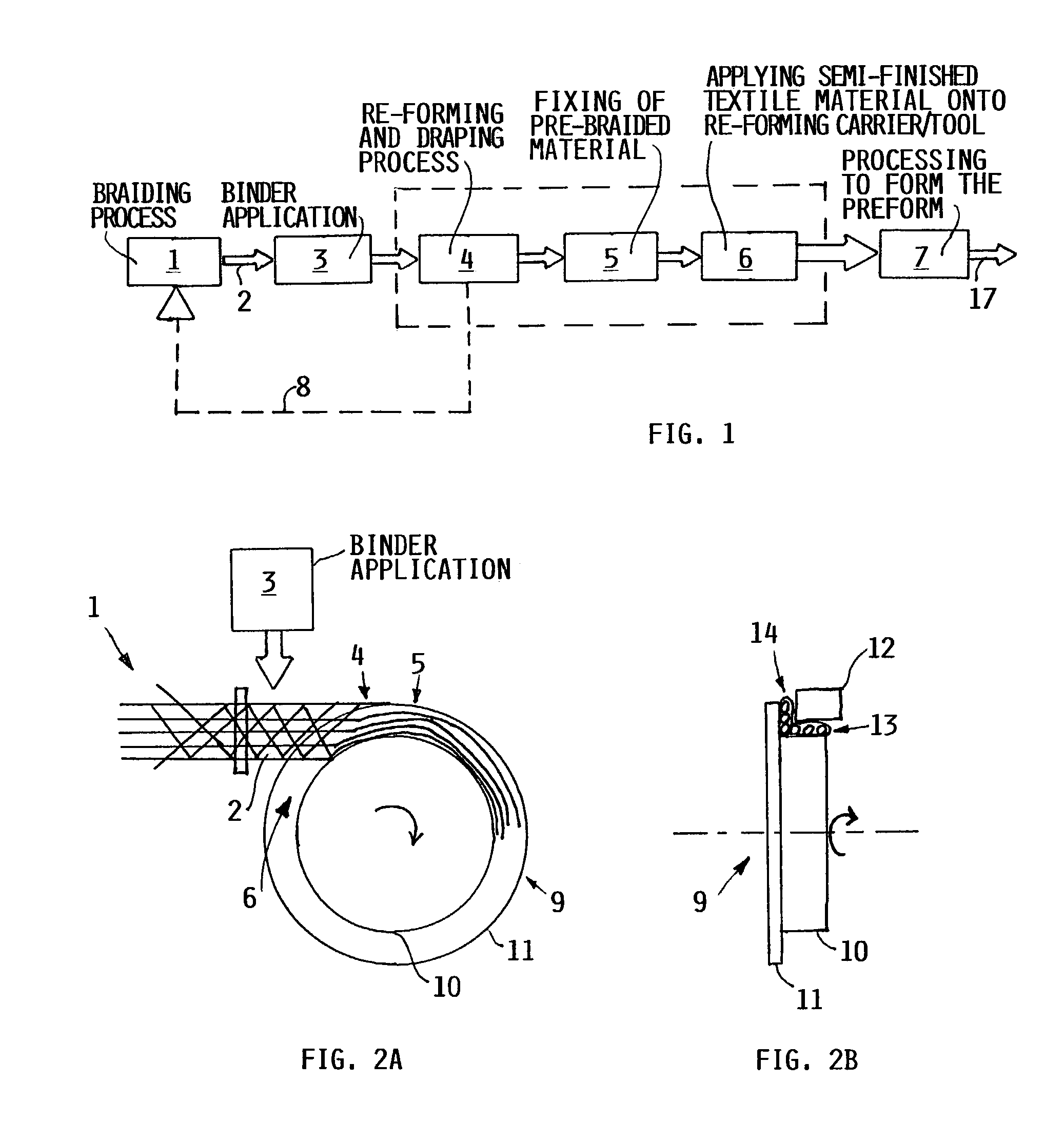

Method of producing textile preforms for fiber reinforced composite products from textile semi-finished articles

InactiveUS7008580B2Reducing damage and undulationAvoid displacementLamination ancillary operationsLaminationPolymer scienceFiber-reinforced composite

A method of producing a textile preform to be used for making a fiber reinforced plastic composite product involves the following steps. A two- or three-dimensional semi-finished textile material or article is produced by essentially any textile production process, such as weaving, knitting or braiding. A binder is applied to the textile material, which is then subjected to a reforming and / or draping process by being applied onto a carrier and reforming tool having a contour or geometry adapted to that of the desired preform that is to be produced. Thereby, the previously unfixed fibers of the textile material are brought into the desired finished orientation and are then fixed, and the cross-sectional shape of the material is changed. This produces the preform having the desired contour, geometry and fiber orientation. The preform may then be subjected to further processing steps to form the finished composite product.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

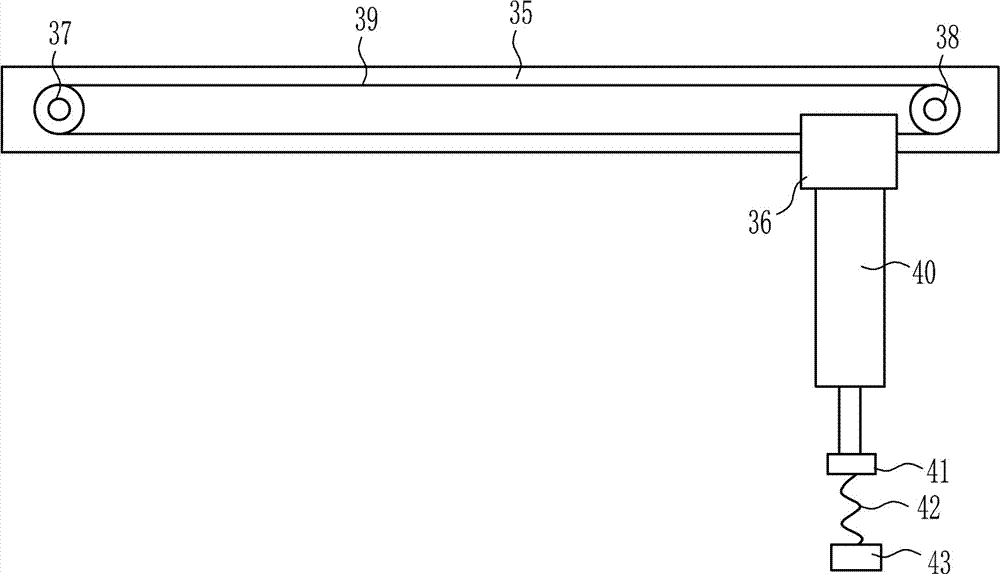

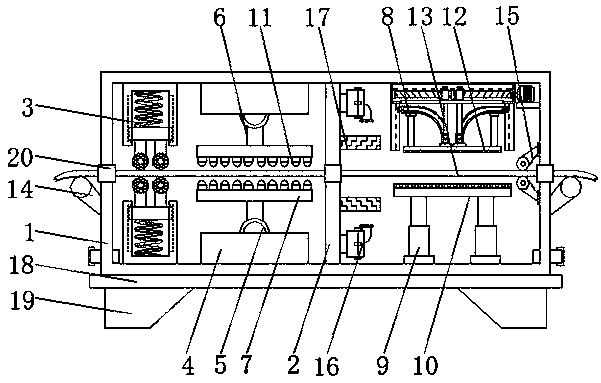

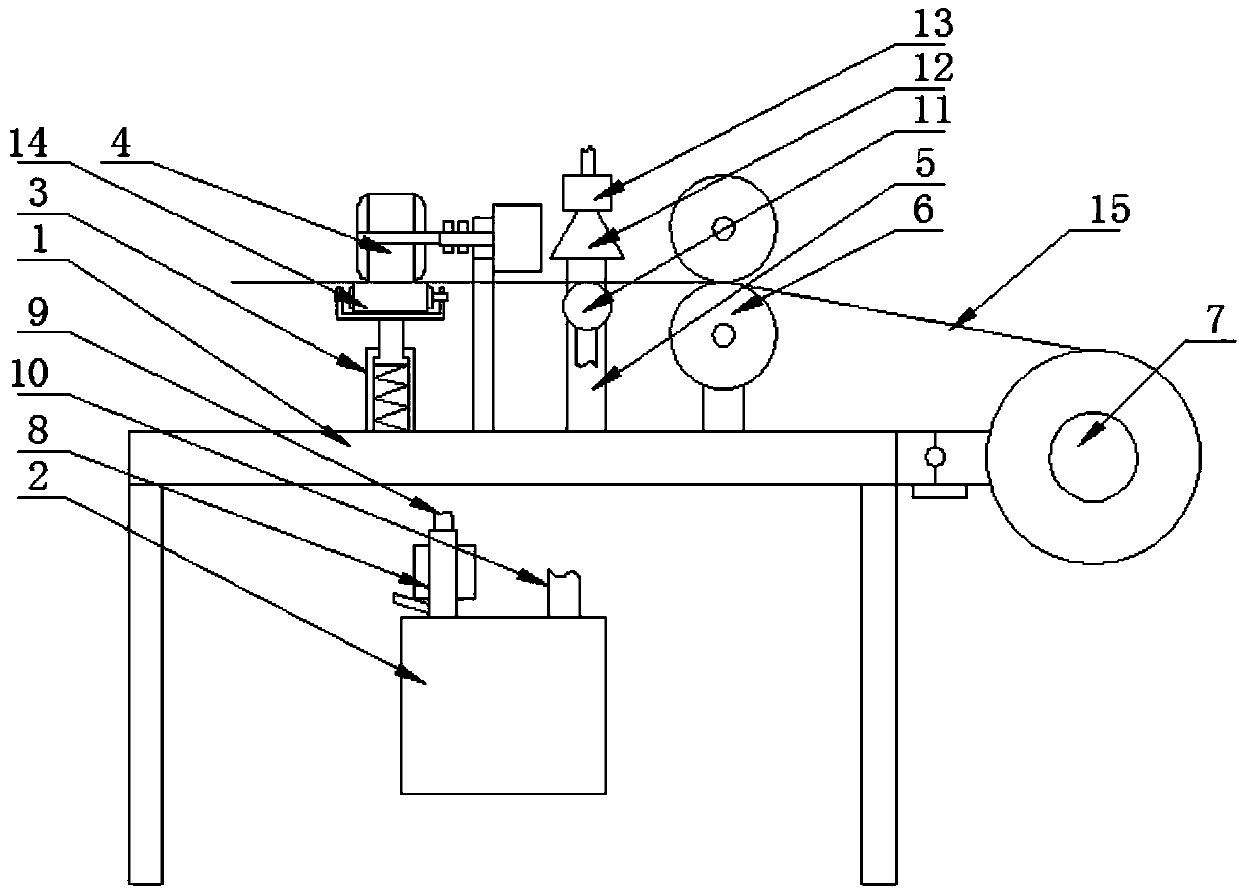

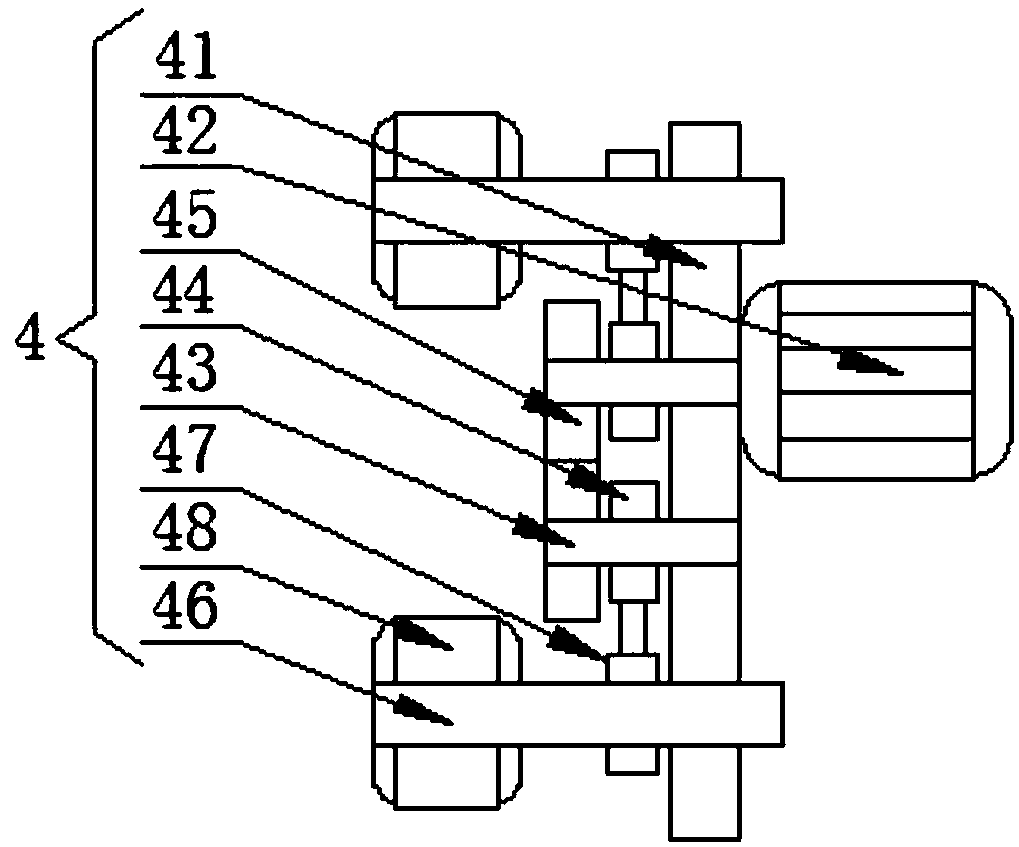

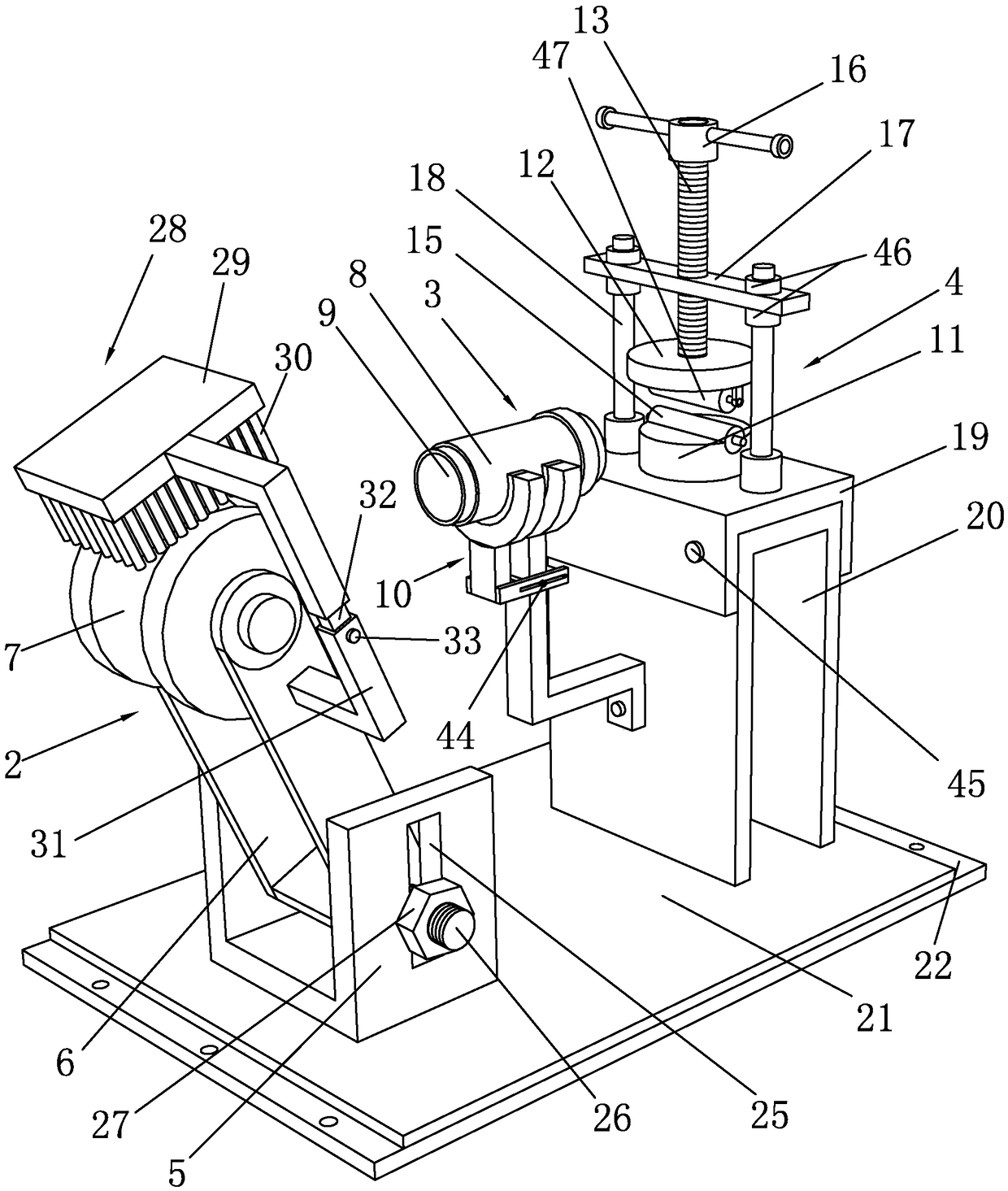

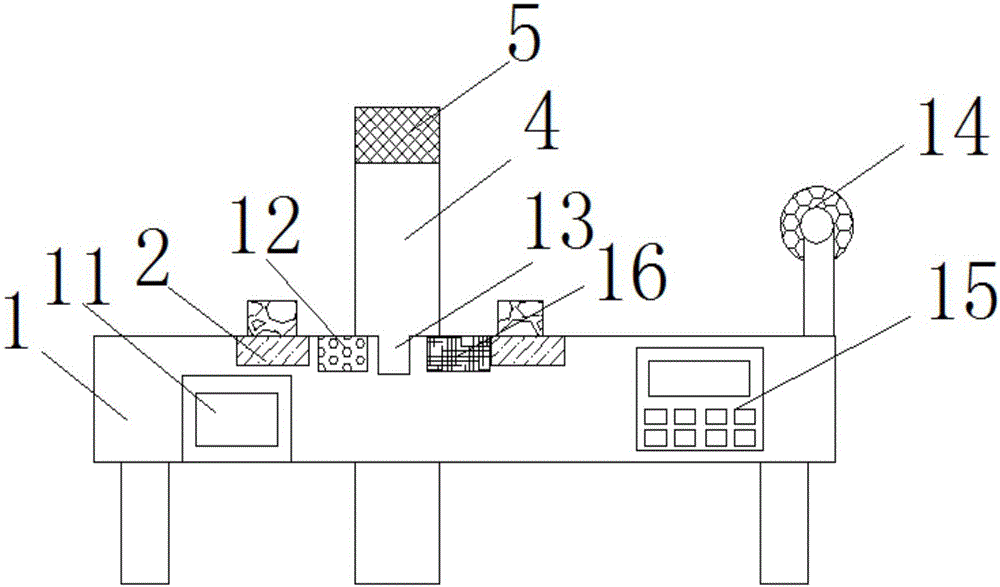

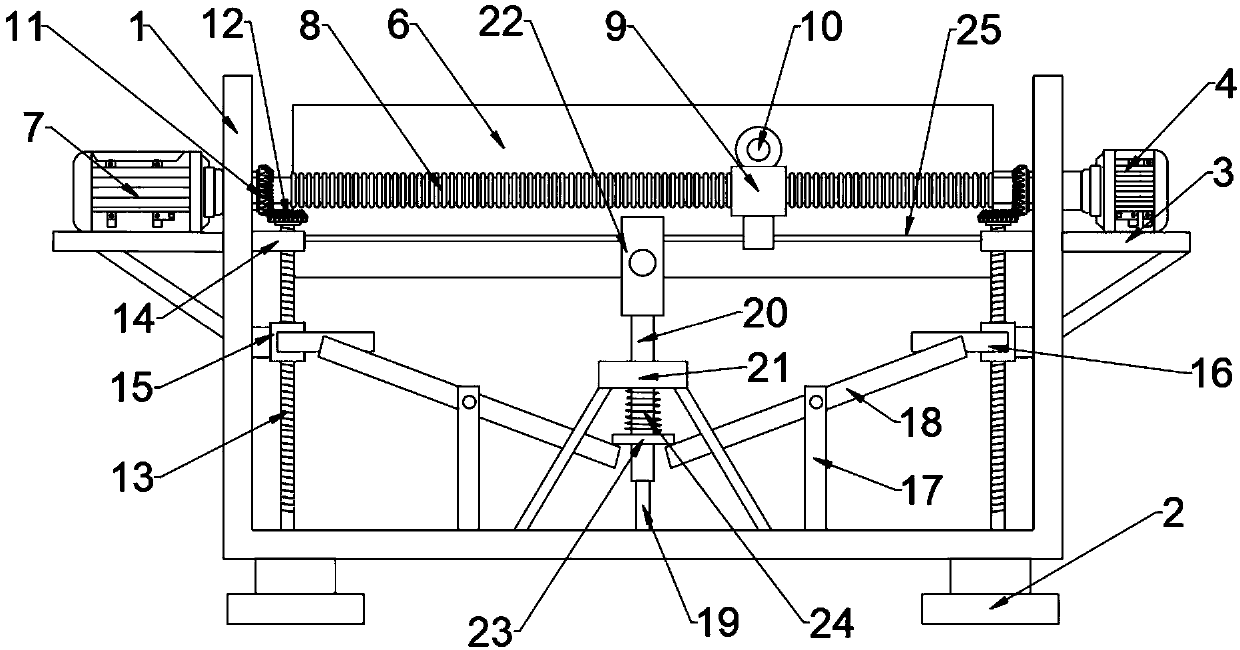

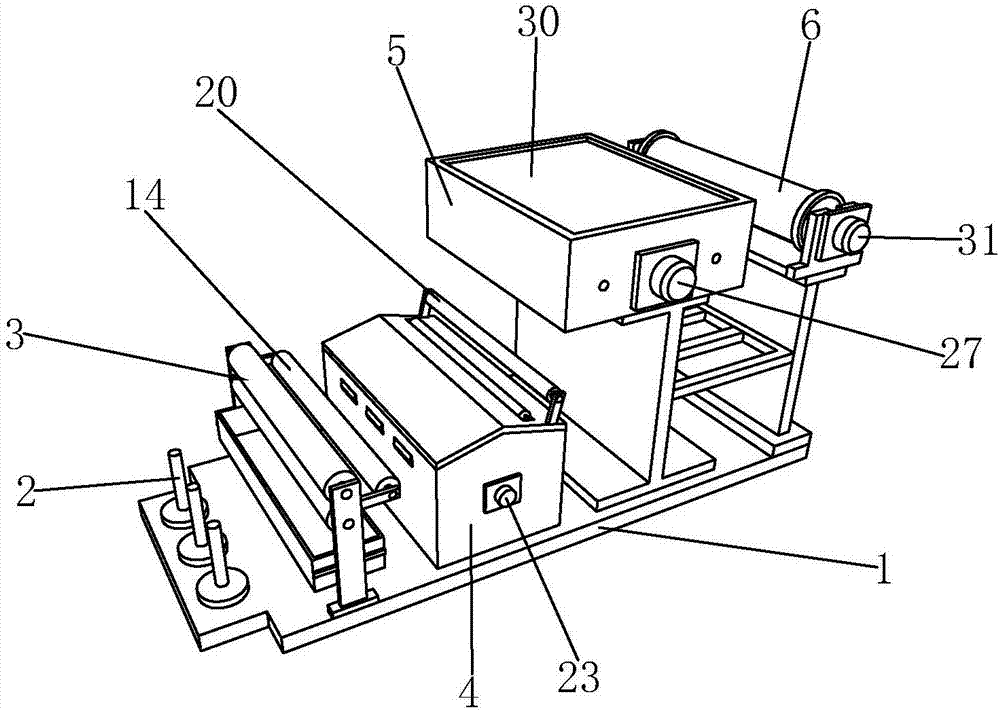

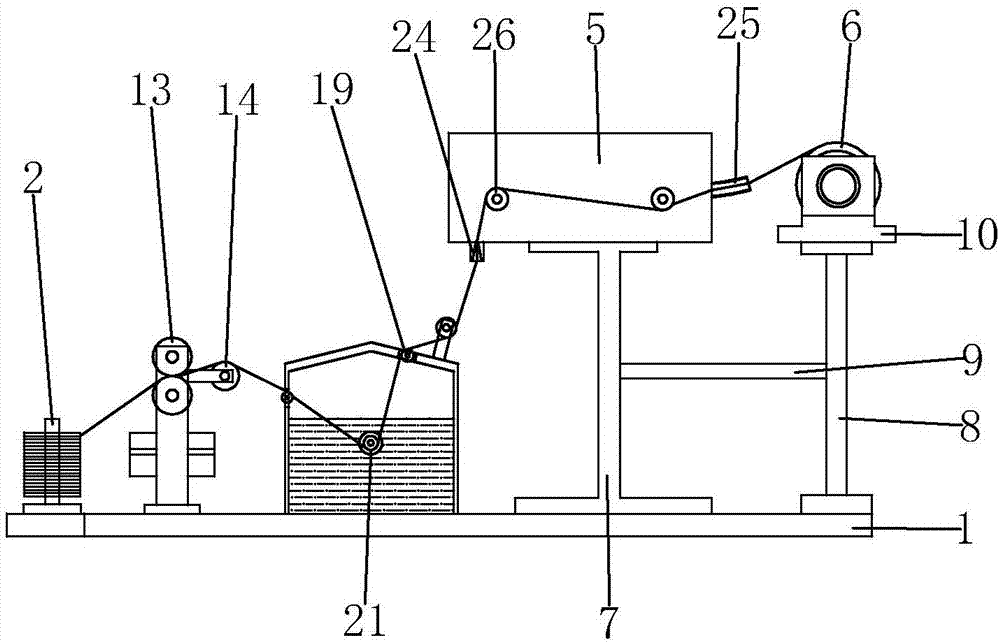

Winding device applied to textile production and having ironing function and working method of winding device

ActiveCN109677983AQuality assuranceTo remove wrinklesTextile shapingWebs handlingWrinkle skinWater resources

The invention discloses a winding device applied to textile production and having an ironing function, and the winding device belongs to the technical field of textile production. The winding device comprises a worktable, a steam generator and a textile fabric; the top sidewall of the worktable is sequentially provided with a supporting rod, an extension device, a bracket and a pressing device from left to right; the right sidewall of the worktable is provided with a winding device part; the top of a first water inlet is provided with a cooling device; the middle f the rear sidewall of the bracket is provided with a spraying pipe; the top sidewall of a cover body is provided with a draught fan; in the winding device, two groups of rolling wheels rotate to drive the front and rear ends of the textile fabric to leave away from each other so as to flatten the wrinkle parts of the textile fabric; subsequently steam is sprayed to the textile fabric via spraying holes of a spraying pipe so as to iron the textile fabric, thus the wrinkles can be removed, amd the quality of the textile fabric is guaranteed; the steam is quickly condensed into water drops after making contact with a coolingpipe and an inserting plate; the water drops enter the steam generator via the first water inlet so as to achieve a water resource recycling effect, and the drying of the surrounding space is guaranteed.

Owner:晋江市天守服装织造有限公司

Towel treating process

InactiveCN102121197AReduce dosageSimple processBiochemical fibre treatmentDyeing processElectricityTextile production

The invention provides a towel treating process which belongs to the technical field of textile production processes. The process comprises steps of pretreatment scouring and bleaching, neutralizing, deoxidizing, dyeing, soap boiling, polishing, softening and the like. The process is characterized in that deoxidizing, dyeing and polishing steps in the conventional process are completed in one step. The process is simple. By adopting the process, the consumption of water, electricity and steam is greatly reduced and the production efficiency is increased.

Owner:LOFTEX INDS

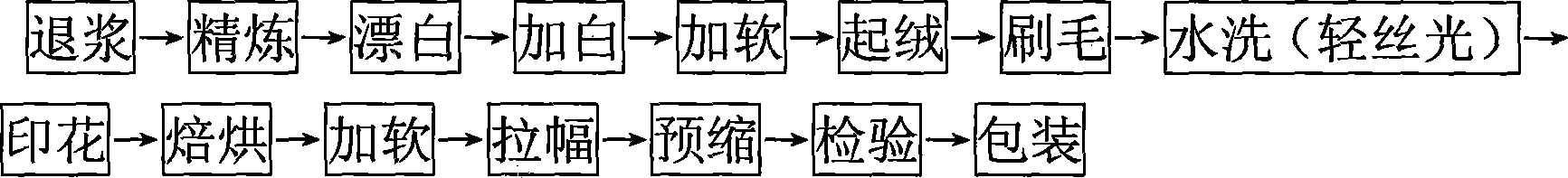

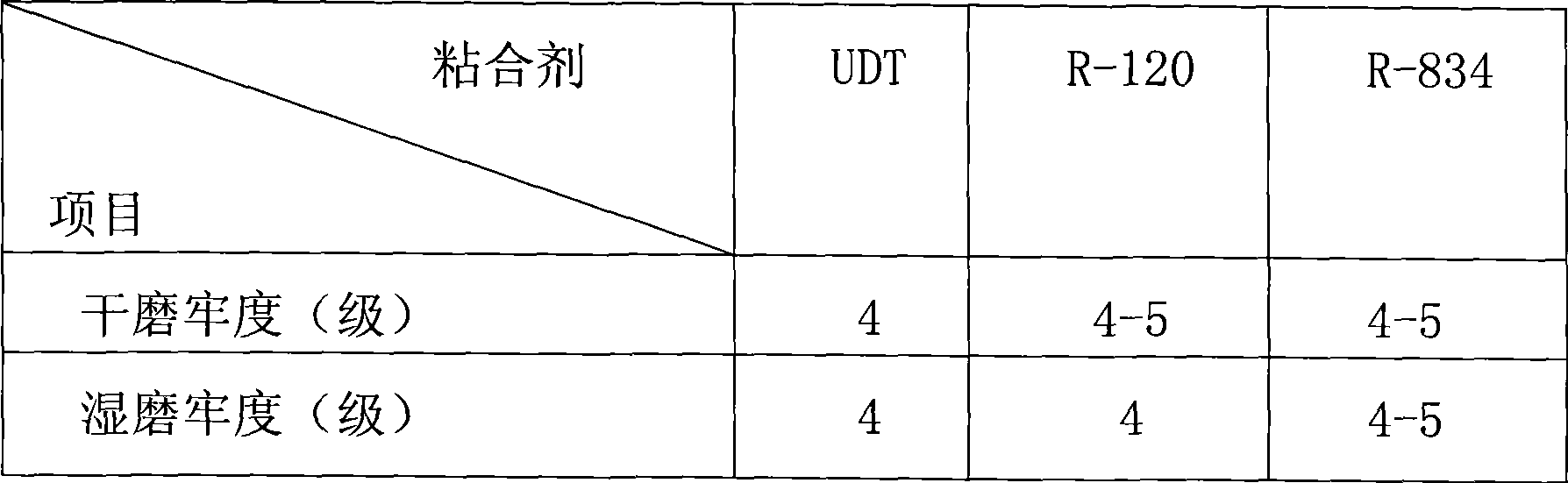

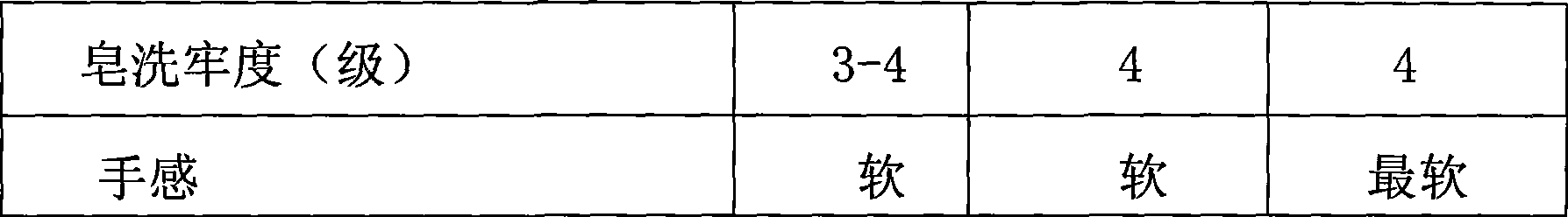

Method for producing energy-saving and environment-friendly type soft resin-bonded pigment printing nap cloth

InactiveCN101418523ASimple processShort processSucessive textile treatmentsFibre treatmentAdhesiveSlurry

The invention relates to a method for textile production. The method for producing an energy-saving environment-friendly soft paint printing fleece comprises the following steps: step one: destarch, refining and bleaching; step two: whitening, softening and carding; step three: performing treatment before printing by water washing or mercerization; step four, printing: firstly, preparing a color slurry mixed solution and performing printing through a circular screen printer with the drying temperature of lower than 120 DEG C, the vehicle speed of between 30 and 35 m / min, the roasting temperature of 150 DEG C, and the roasting time of between 3 and 5 minutes; and step five, afterfinishing.. A color slurry aqueous solution for pigment printing has the following formula: the viscosity of the prepared color slurry is between 50 and 80 dPa.S; printing paint is between 0.01 and 8 percent; an adhesive for pigment printing is between 8 and 20 percent; a thickening agent for pigment printing is between 3 and 6 percent. Compared with dye printing, the pigment printing has the advantages of simple process, short process course, convenient color match of products, small pollution, low cost and the like.

Owner:辽宁宏丰印染有限公司 +2

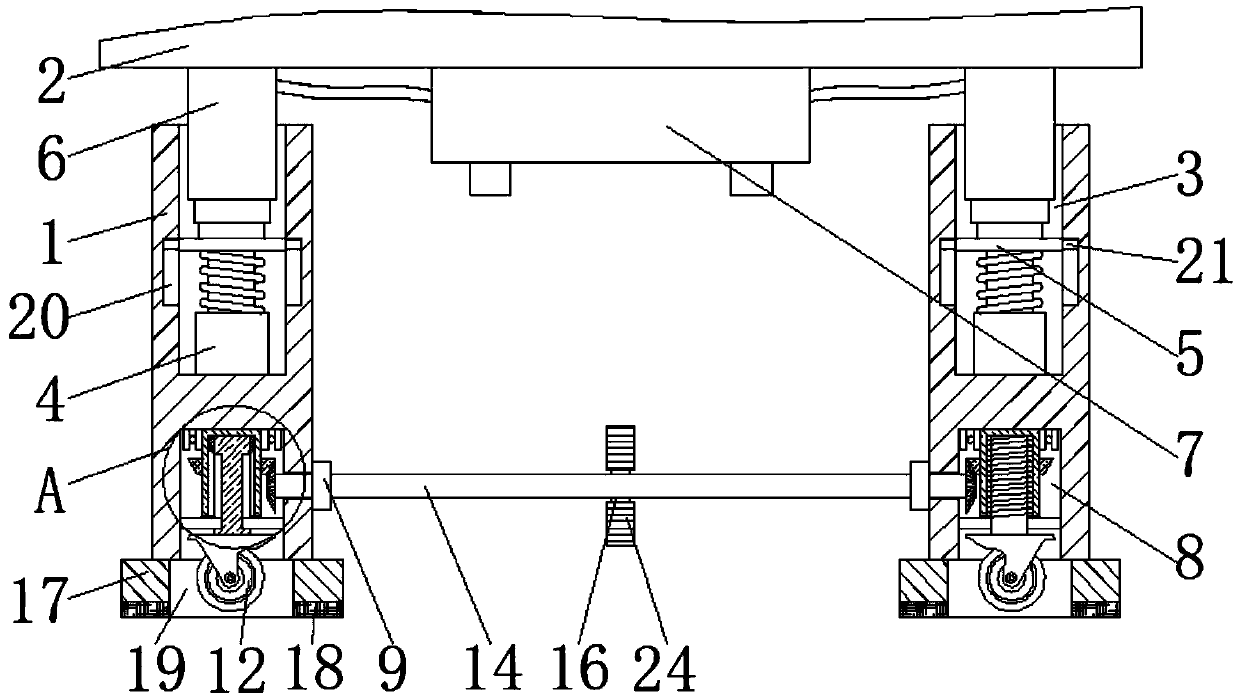

Auxiliary transferring equipment for textile production

InactiveCN108945052AGuaranteed firmnessPrevent dumpingSupporting partsHand carts with multiple axesEngineeringTextile production

The invention provides auxiliary transferring equipment for textile production, and relates to the field of textile equipment. The auxiliary transferring equipment comprises a base, a fixing seat is fixedly mounted at the top of the base, a working table is arranged on the upper side of the fixing seat, a first supporting column is arranged on the left side of the fixing seat, a motor is fixedly mounted on the left side of the first supporting column, a driving gear is arranged on the left side of the first supporting column, a rotating shaft of the motor is in transmission connection with thedriving gear, and a threaded rod is arranged in the first supporting column. According to the auxiliary transferring equipment for textile production, textile cloth can be clamped and fixed through clamping plates, the firming effect on the cloth is ensured during transporting of the textile cloth, the textile cloth is prevented from toppling, the quality of the textile cloth is improved, and damage to the textile cloth is reduced; and the buffering effect can be achieved through a first buffering spring and a second buffering spring, bumping in the transporting process is reduced, and the damage to the textile cloth is greatly reduced.

Owner:湖州南浔富龙纺织有限公司

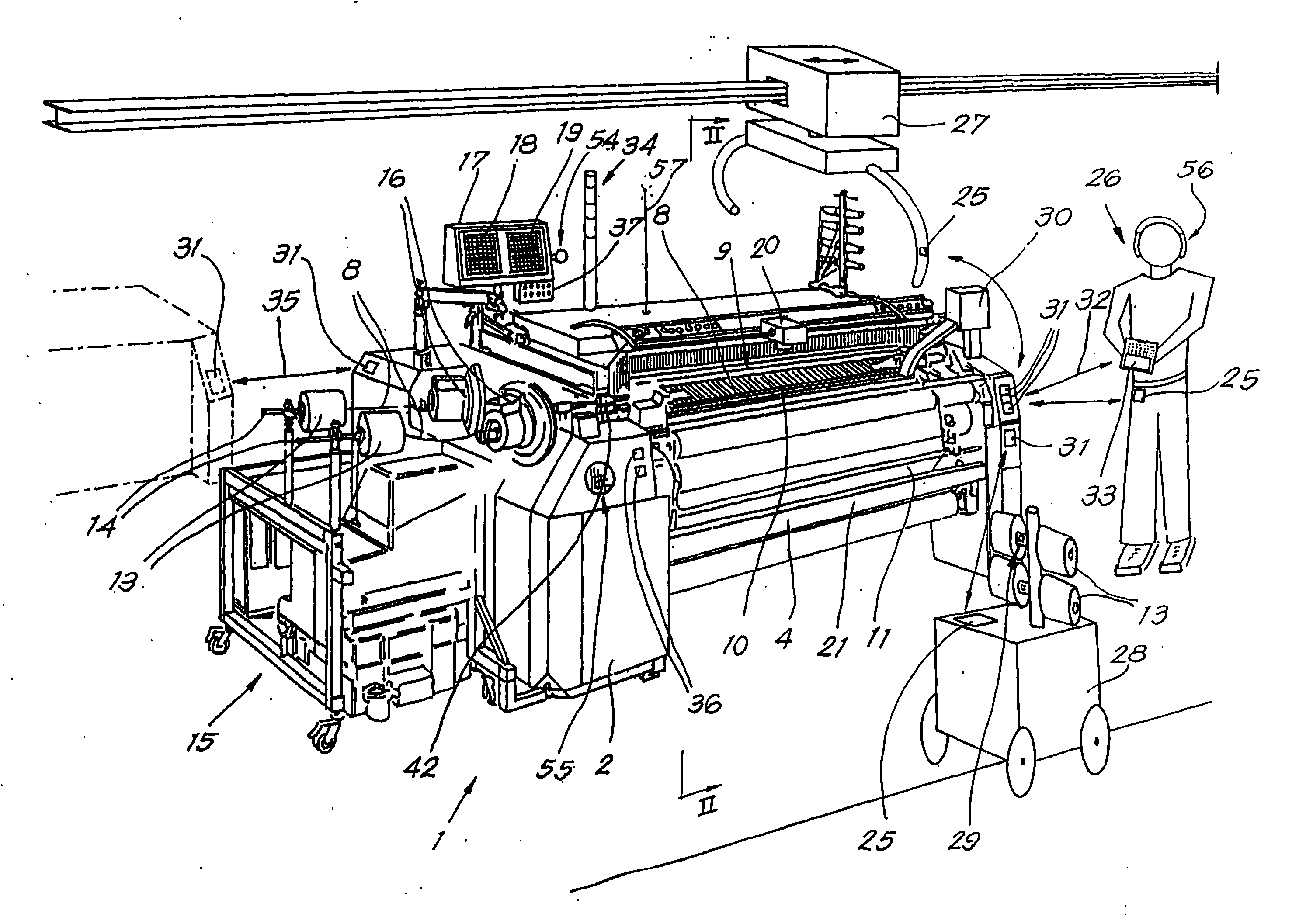

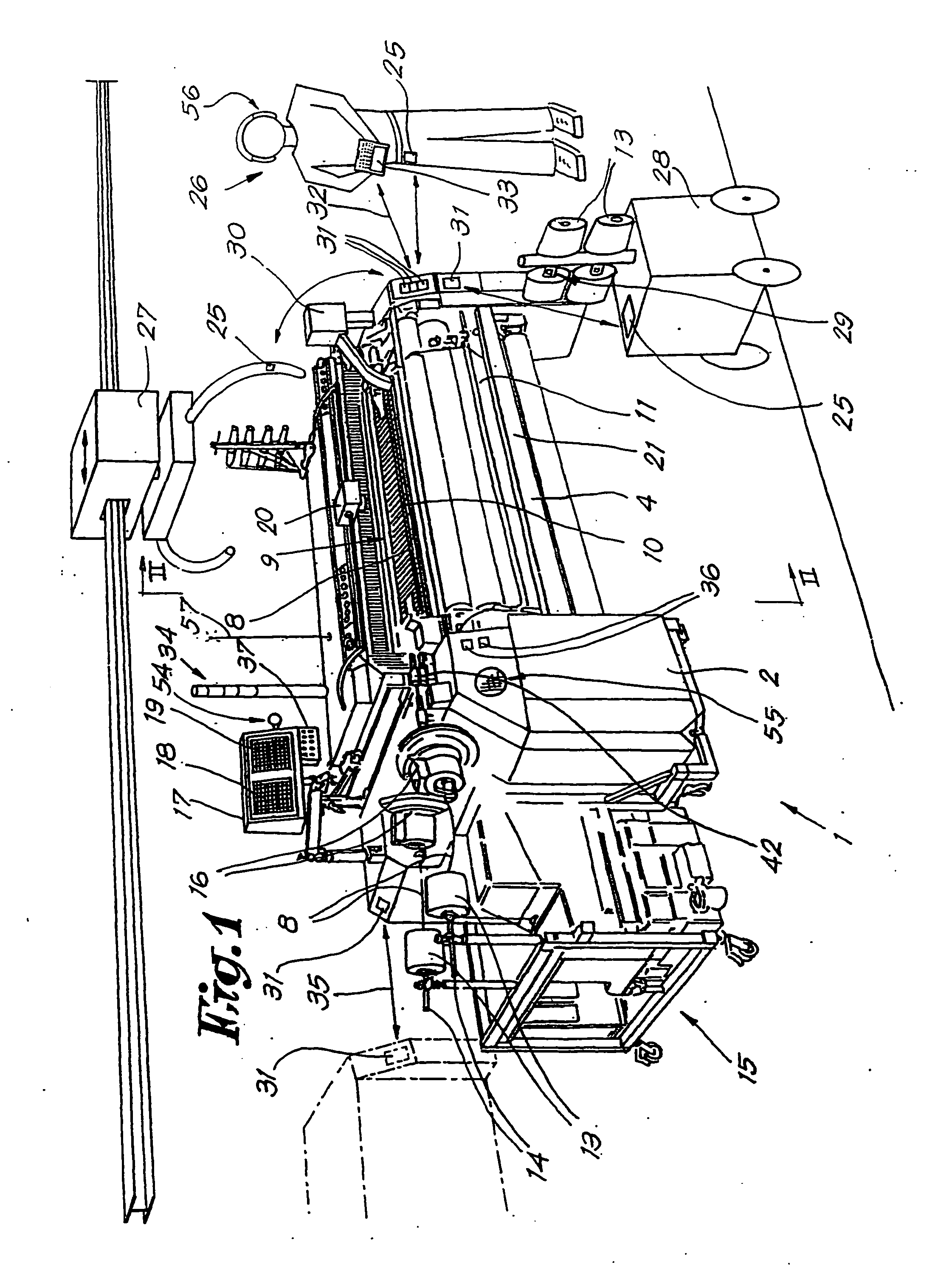

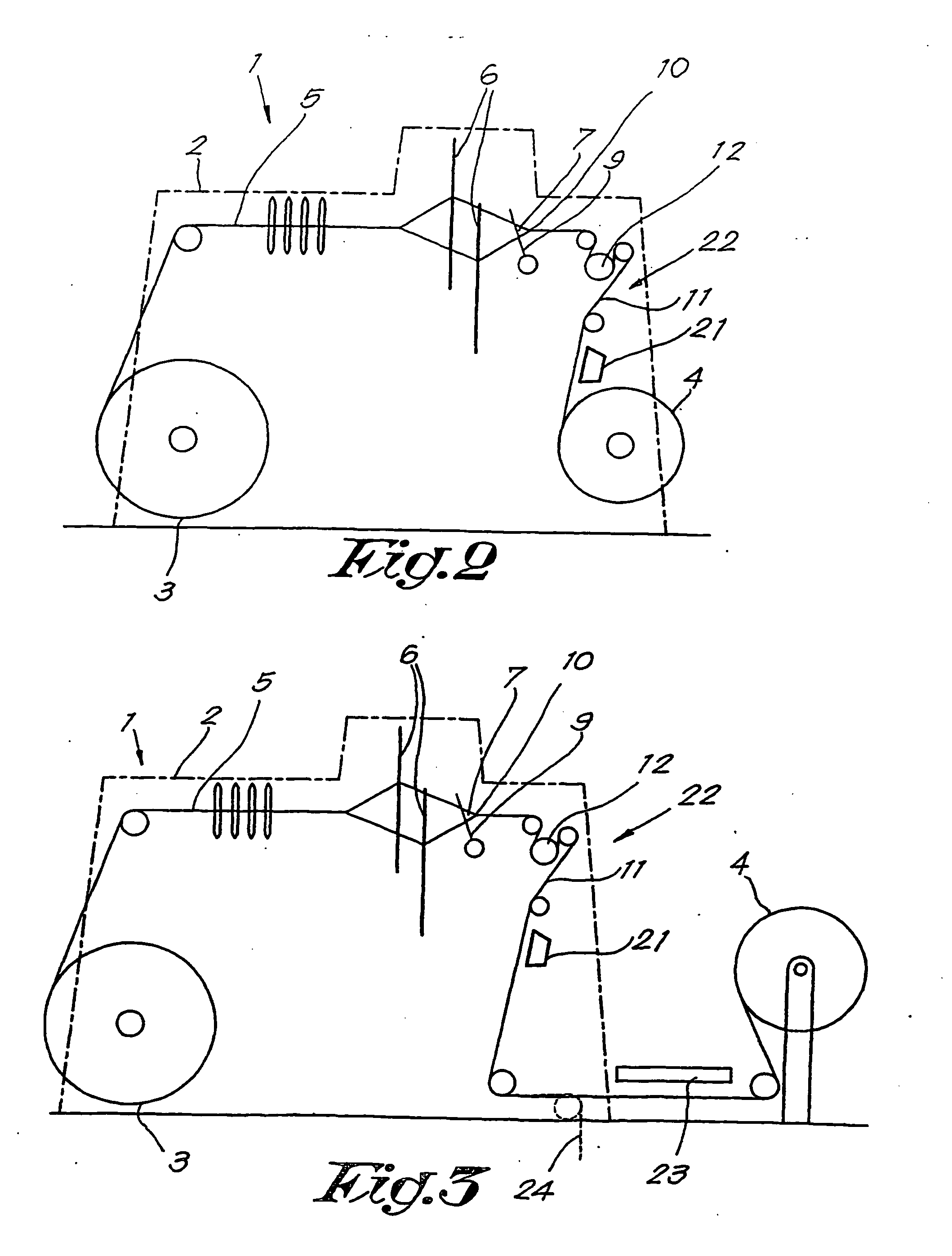

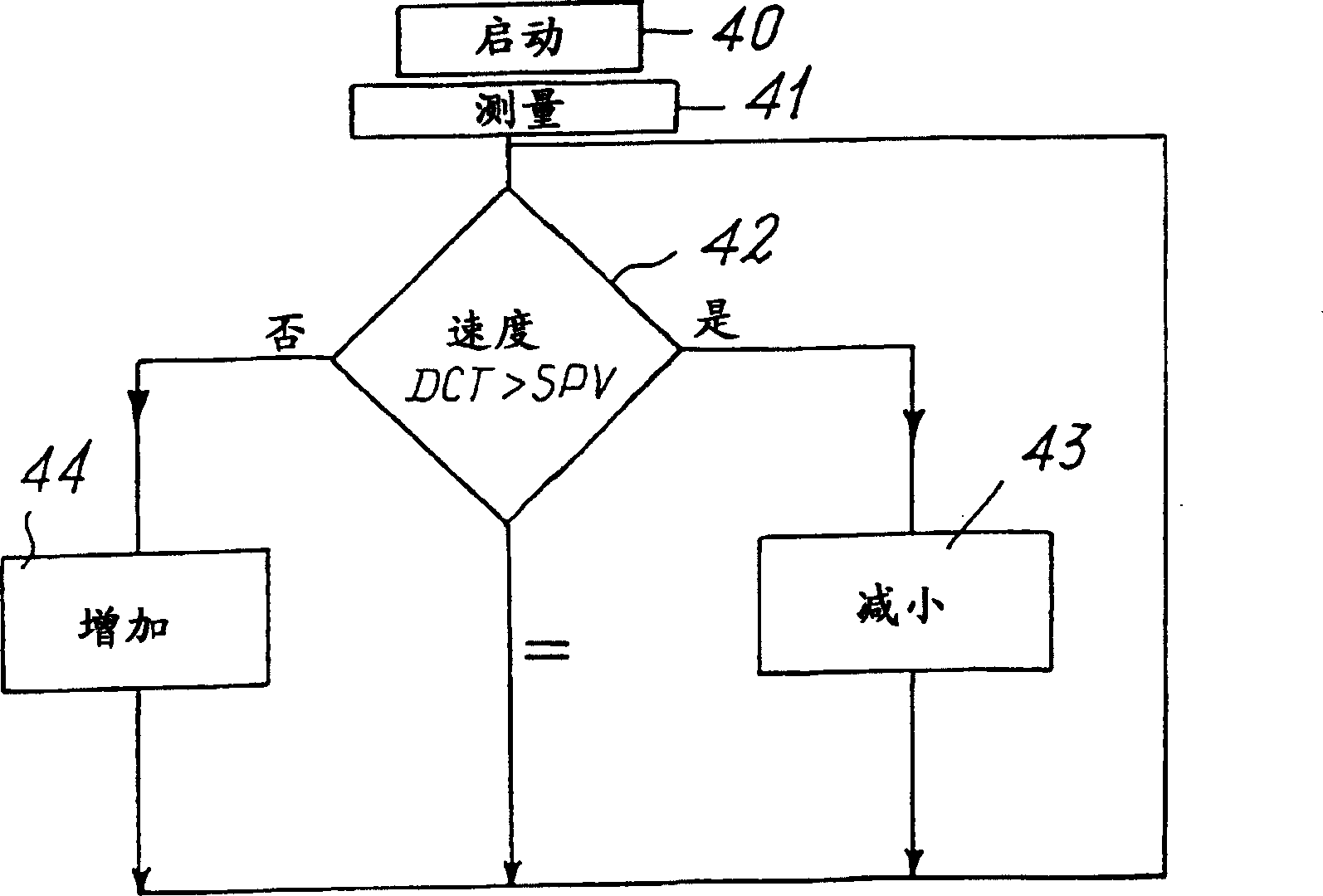

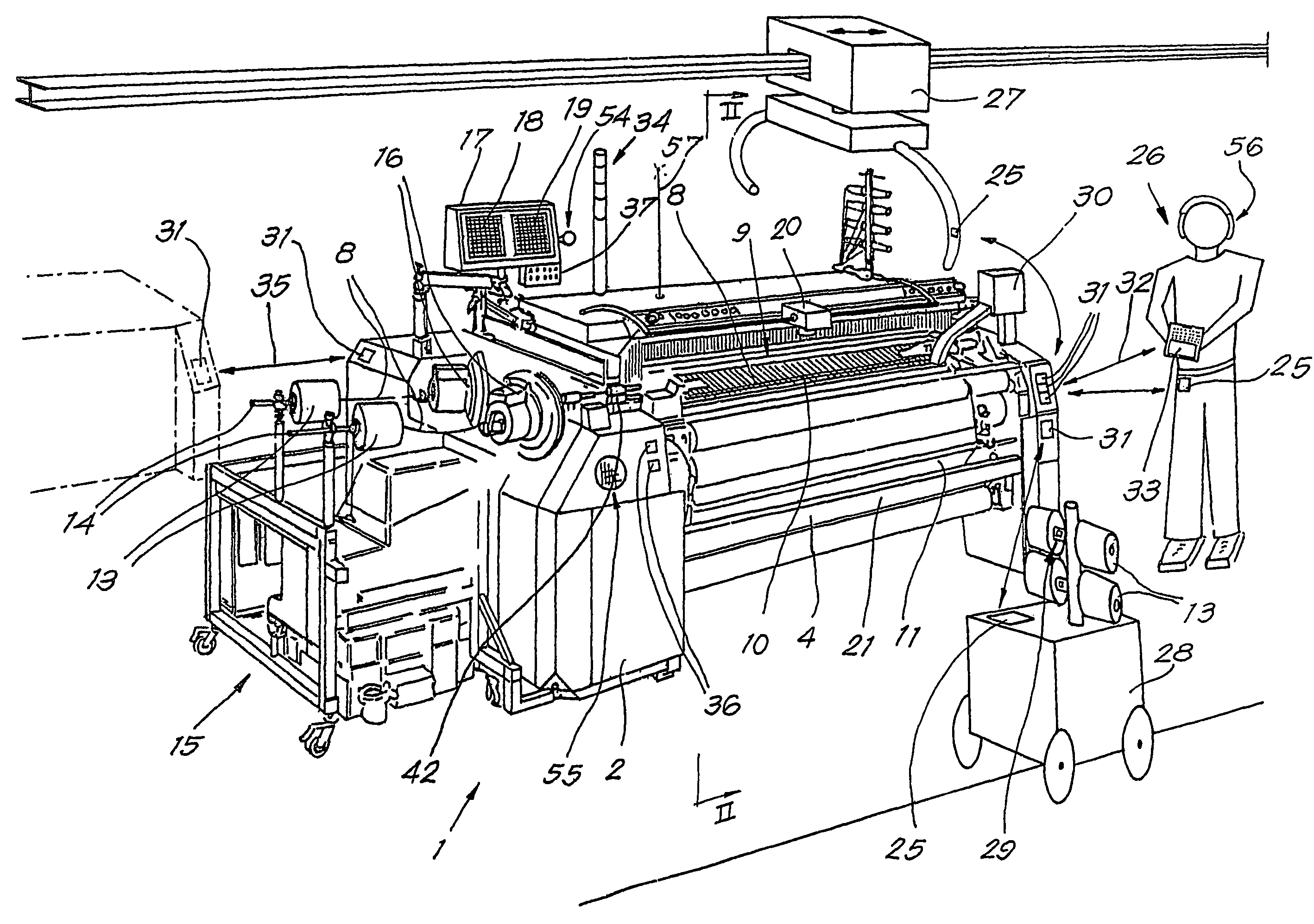

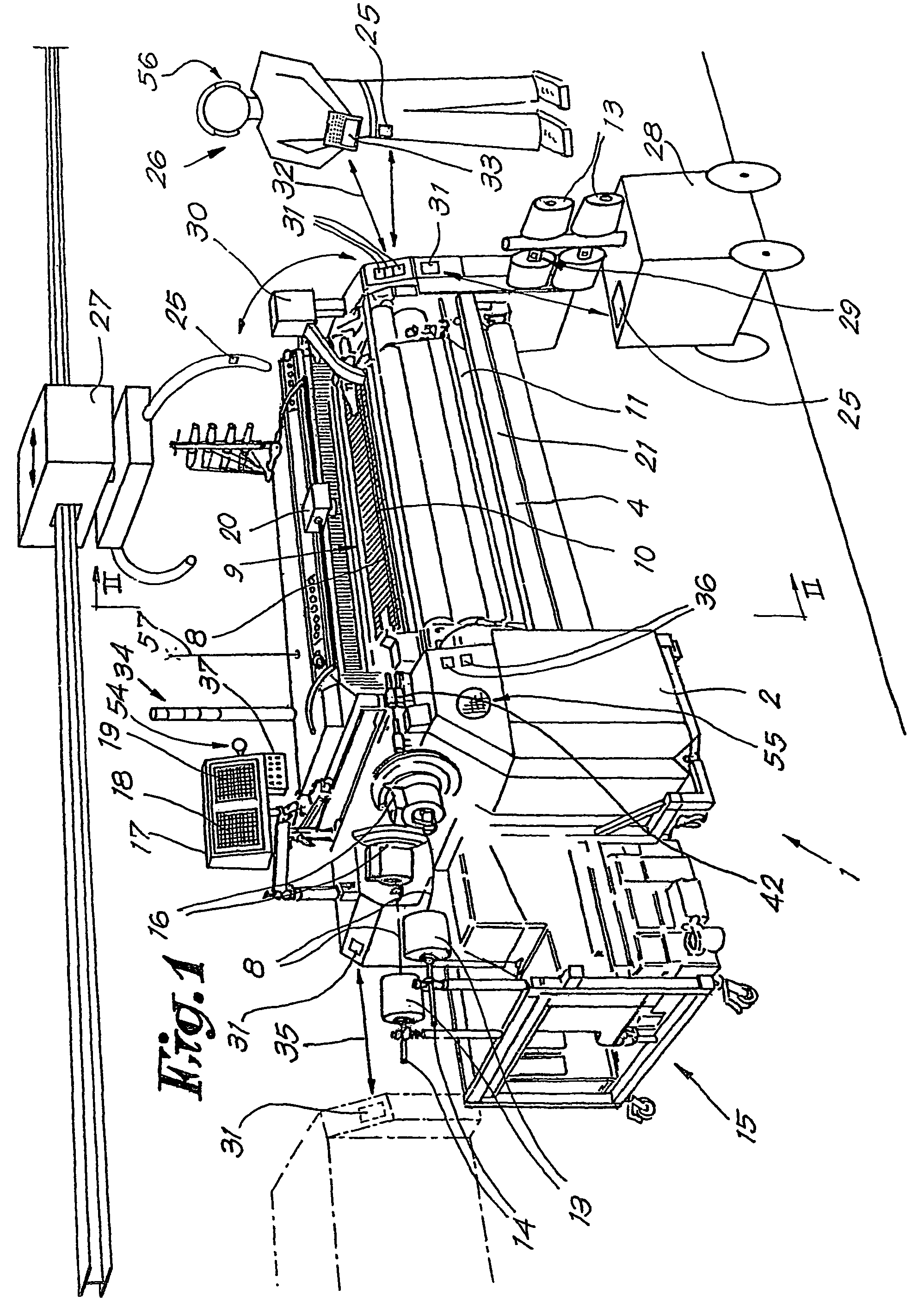

Method for optimizing a textile production process

InactiveUS20060144457A1Easy operator controlEasy visual controlInspecting textilesLoomsTextile productionManufacturing engineering

Owner:PICANOL NV

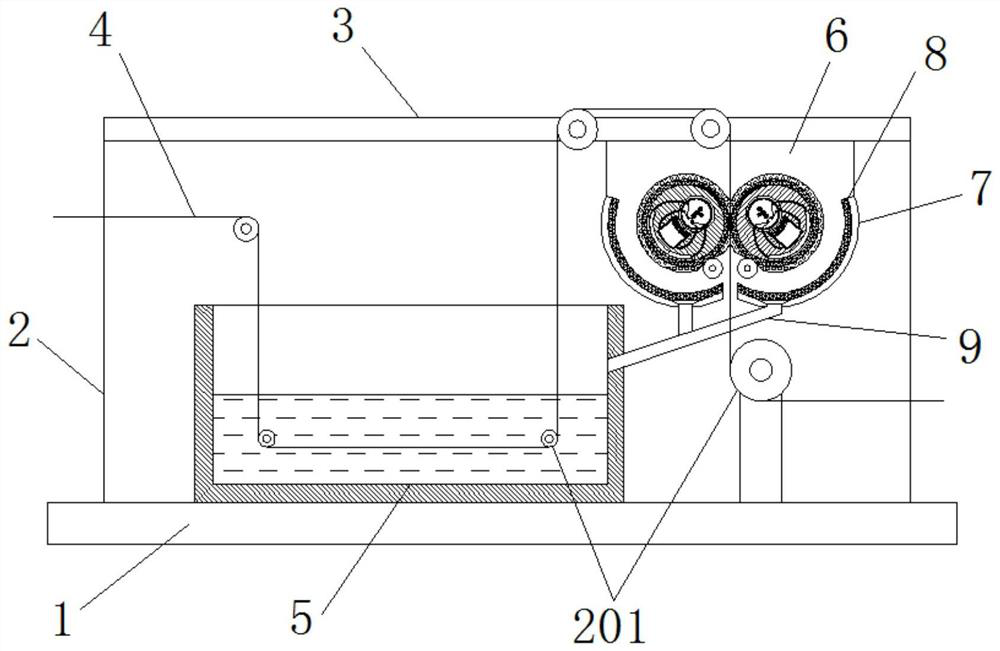

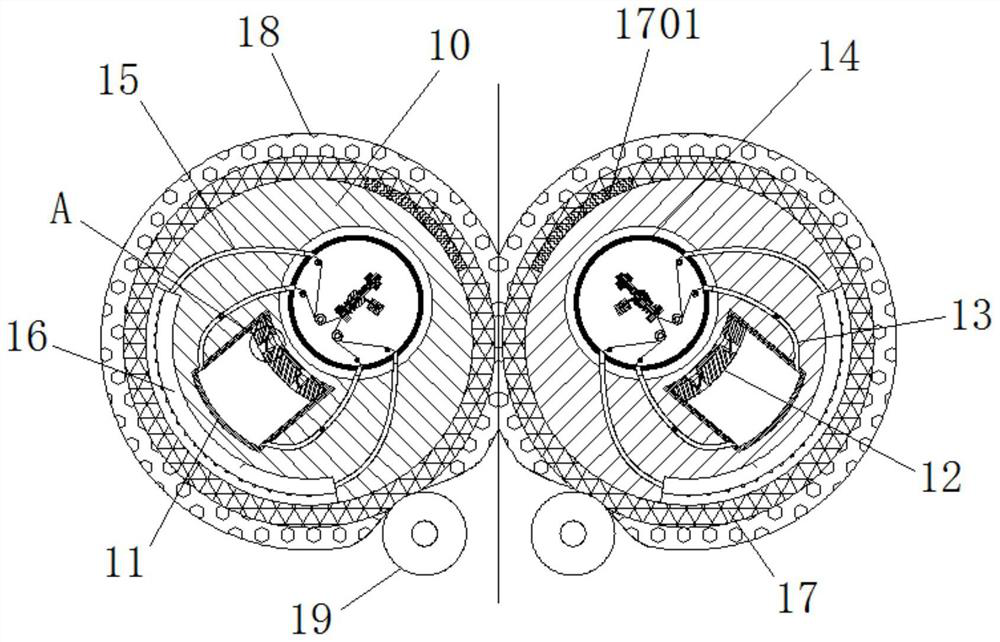

Non-woven fabric rapid cleaning, dewatering and clearing device for textile production

InactiveCN111748941ASolve efficiency problemsResolution timeLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionStructural engineeringNonwoven fabric

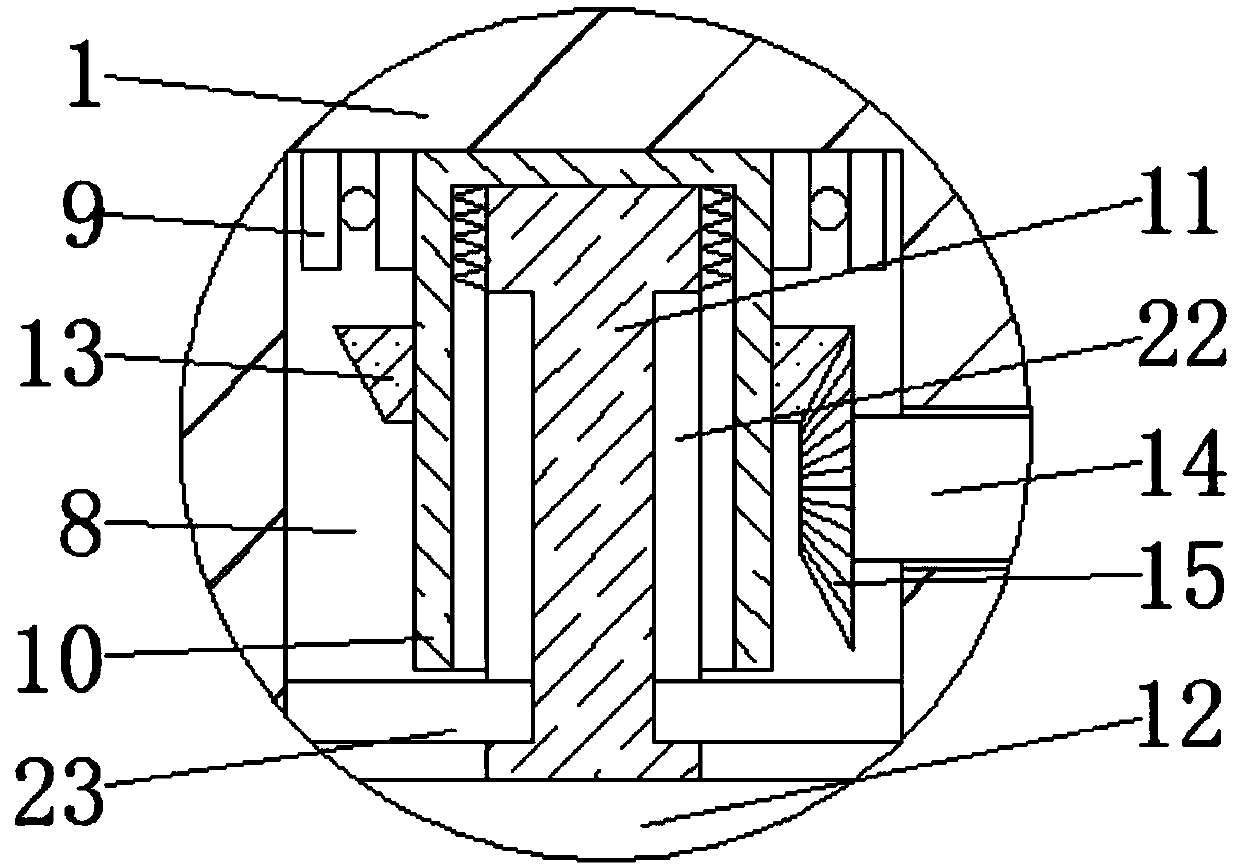

The invention relates to the technical field of non-woven fabric processing equipment, and discloses a non-woven fabric rapid cleaning, dewatering and clearing device for textile production. The non-woven fabric rapid cleaning, dewatering and clearing device comprises a fixing plate, wherein the fixing plate comprises a guide block, a fixing block, a sliding rod, a third spring and a second guideroller; a magnet piston comprises a vent groove, an arc-shaped groove and a swing plate; an arc-shaped magnetic block is arranged on the inner wall of a driving roller; a T-shaped magnetic block is connected to the interior of the guide block in a sliding mode; and a rubber ball is connected to the outer side end of a rope. The arc-shaped magnetic block moves upwards, the arc-shaped magnetic blockadsorbs the magnet piston to move downwards, and gas in the magnet piston enters an air bag through an air inlet pipe; and when the arc-shaped magnetic block moves to the upper side, the arc-shaped magnetic block adsorbs the magnet piston to move upwards, the lower part of the T-shaped magnetic block drives the rope to pull the rubber ball through the second guide roller, and the gas in the air bag clears fluff on sponge, so that the fluff on the sponge is prevented from being adhered to the non-woven fabric again or accumulated on the sponge again.

Owner:池志琴

Process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material

InactiveCN101550634AHigh strengthHigh strength retentionFiltration separationNon-woven fabricsFiberSulfide

The invention relates to a process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material, belongs to the fibrous raw material textile production technology field. The process uses polyphenylene sulfide fiber as raw material, has the following steps: processing raw material by checking, weighing, feeding, feeding into long certain, mixing cotton and fine loosing; layering and carding respectively by a first carding machine and a second carding machine; putting respectively into mesh placing machine for placing mesh; debatching, congruent, superposing and prewetting; spunlacing by a plurality of spunlacing machine, dewatering, drying and reeling. The advantages of the invention is that: the invention adopts polyphenylene sulfide high-performance fiber as raw material, the raw material is adapted to high efficient high speed carding production for its self physical and chemical properties, structure and adaptability to meshing and reinforcing process; improves spunlacing entanglement effect to fiber; improves the mechanical strength of spunlaced composite filtering material significantly, and ensures the end product to achieve excellent mechanical properties, filtering quality and chemical resistance property.

Owner:SHAOXING RONGLIDA TEXTILE TECH

Textile fabric cleaning device and method for textile fabric production

InactiveCN107938206AAchieve precipitationAchieve recyclingMechanical cleaningPressure cleaningArchitectural engineeringTextile production

The invention discloses a textile fabric cleaning device for textile fabric production in the technical field of textile fabrics. A fixed supporting rod is installed on the left side of the top of a work table, a telescopic rod is inserted at the top of the fixed supporting rod, a fastening bolt is inserted in the outer wall of the fixed supporting rod, and a tension regulating roller is mounted at the top of the telescopic rod through a bearing. A cleaning tank is disposed on the right side of the fixed supporting rod, and through a pipe, the top of the work table is provided with a setting tank communicated with the bottom of the cleaning tank. Through a pipe, the left side of the setting tank is connected with a water tank disposed at the bottom of the work table. The bottom of the water tank is connected with a water inlet of a water pump through a pipe. A water outlet on the left side of the water pump is connected with a water feeding pipe. The device is simple to operate, the height of the tension regulating roller is adjusted by adjustment of the heights of both the fixed supporting rod and the telescopic rod, so that the tension of a to-be-cleaned textile fabric can be setaccording to different requirements, and it is ensured that the textile fabric cleaning operation is completed efficiently.

Owner:石卫祥

Ice-cold polyester functional fabric and production method thereof

InactiveCN106567175AHigh strengthReduce the temperatureFibre treatmentWoven fabricsPolyesterPulp and paper industry

The invention belongs to the technical field of textile production and specifically relates to ice-cold polyester functional fabric and a production method thereof. The fabric is satin fabric which is formed by warp yarn and weft yarn, wherein the wrap yarn is blended yarn formed by ice-cold polyester fiber and tencel fiber and the weft yarn is doubling yarn formed by doubled bamboo fiber. The production method comprises following steps: 1) beam-warping process; 2) sizing process; 3) denting; 4) weaving process. The yarn strength is increased by adopting blended yarn; the yarn feather is reduced so as to facilitate later sizing and weaving; the blended yarn is processed with sizing agent, which can effectively reduce the shrinkage of ice-cold polyester fiber and is convenient for weaving; doubled bamboo fiber is used as weft yarn; the cross sectional area of the weft yarn is doubled so that the weft direction strength is increased so as to facilitate the later high speed weaving; the production method is simple and efficient. The ice-cold polyester functional fabric has smooth hand feel, high strength and good anti-static-electricity performance and color fastness performance; the fabric is quick in cooling and heat dissipating.

Owner:JIHUA 3509 TEXTILE

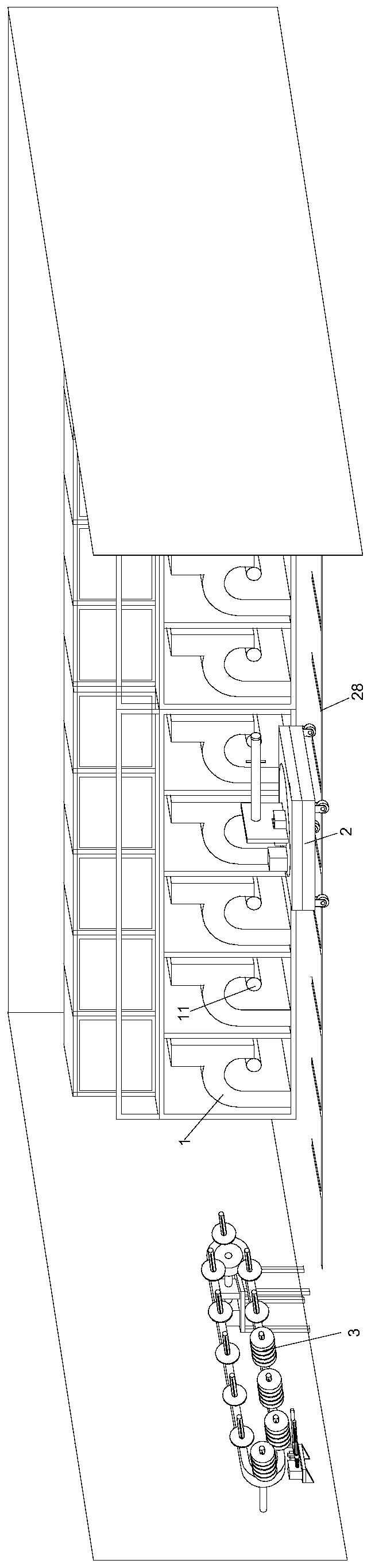

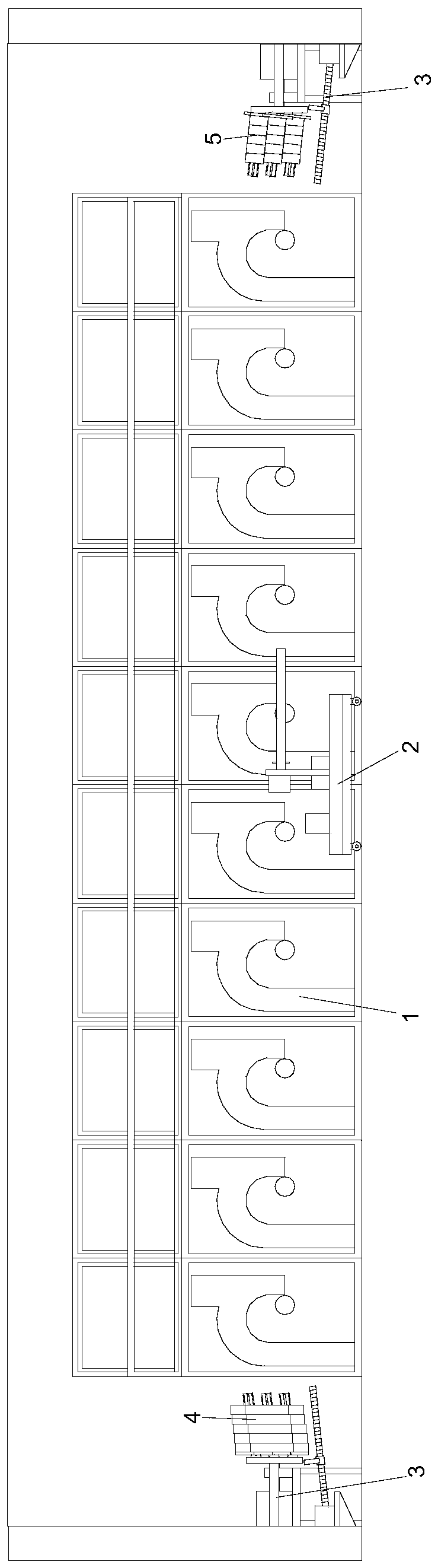

Intelligent textile production system based on automatic guided vehicle (AGV)

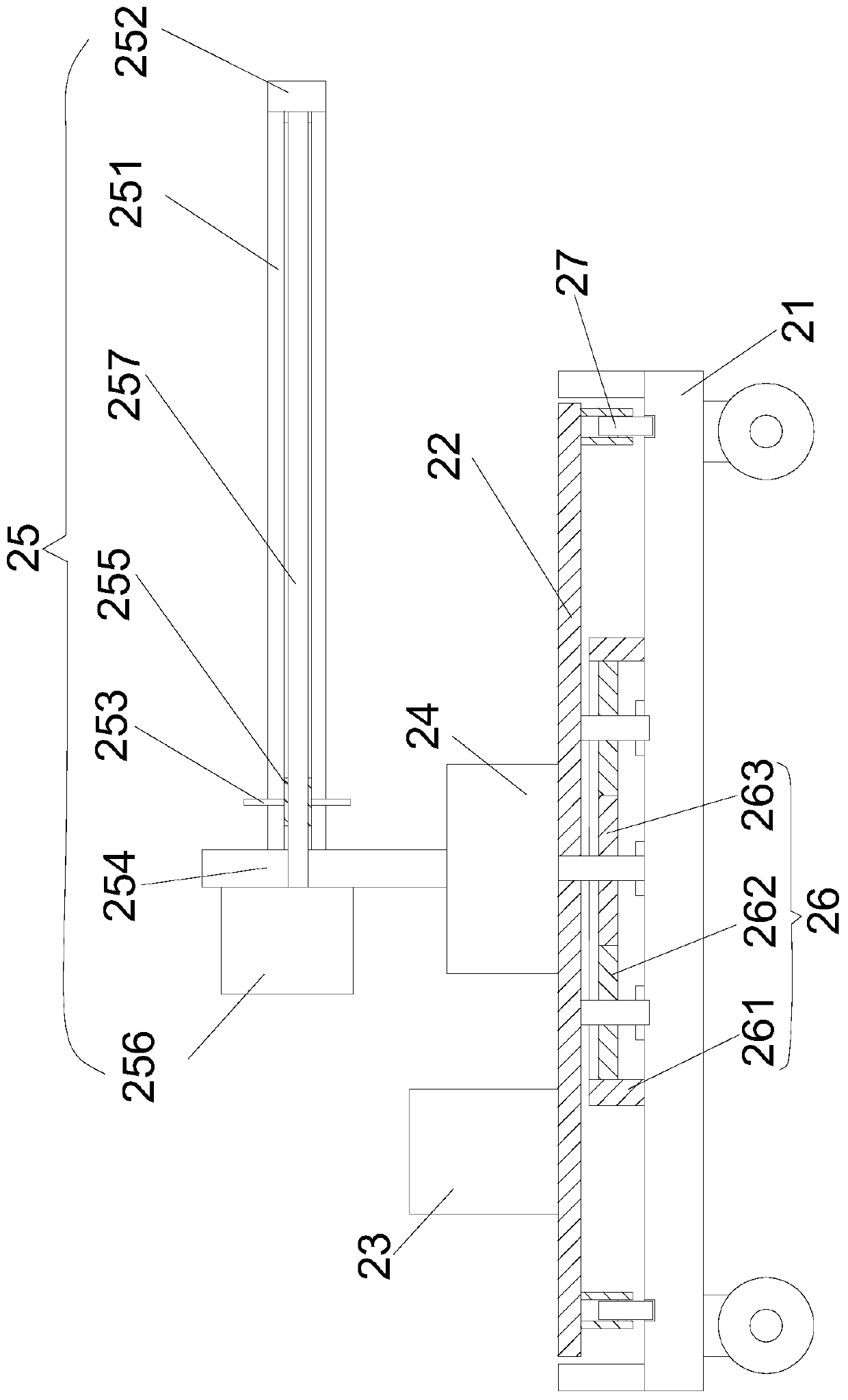

PendingCN110407030AImprove installation efficiencyReduce complexityFilament handlingElectric/hybrid propulsionProduction lineWinding machine

The invention relates to an intelligent textile production system based on an automatic guided vehicle (AGV). The intelligent textile production system based on the AGV comprises ACWW5T, a JRT type full-automatic winding machine and the AGV arranged in a spinning and winding workshop, and a paper tube or spinning cake temporary storage mechanism, wherein a rotary table is arranged on the upper surface of the AGV; an ejecting mechanism is installed on the upper surface of the rotary table, and the ejecting mechanism comprises a sleeve pipe, a first screw rod, a first screw rod nut, a second drive motor and a support panel; the paper tube or spinning cake temporary storage mechanism comprises a support frame, a conveyor chain, a driving chain wheel, a driven chain wheel and an ejecting unit;and the support frame is installed on the wall at the left side or the right side of the spinning and winding workshop. By utilizing the function of the AVG running along a specified track, the rotary table and the ejecting mechanism are additionally installed, so that paper tubes are automatically installed, spinning cakes are automatically unloaded, the complexity in working is greatly reduced,the working intensity is reduced, and the installation efficiency of the paper tubes and the unloading efficiency of the spinning cakes are improved; and the automatic improvement cost and the improvement time of a production line are reduced.

Owner:MINJIANG UNIV

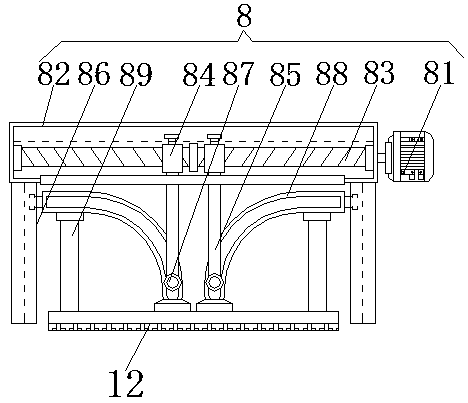

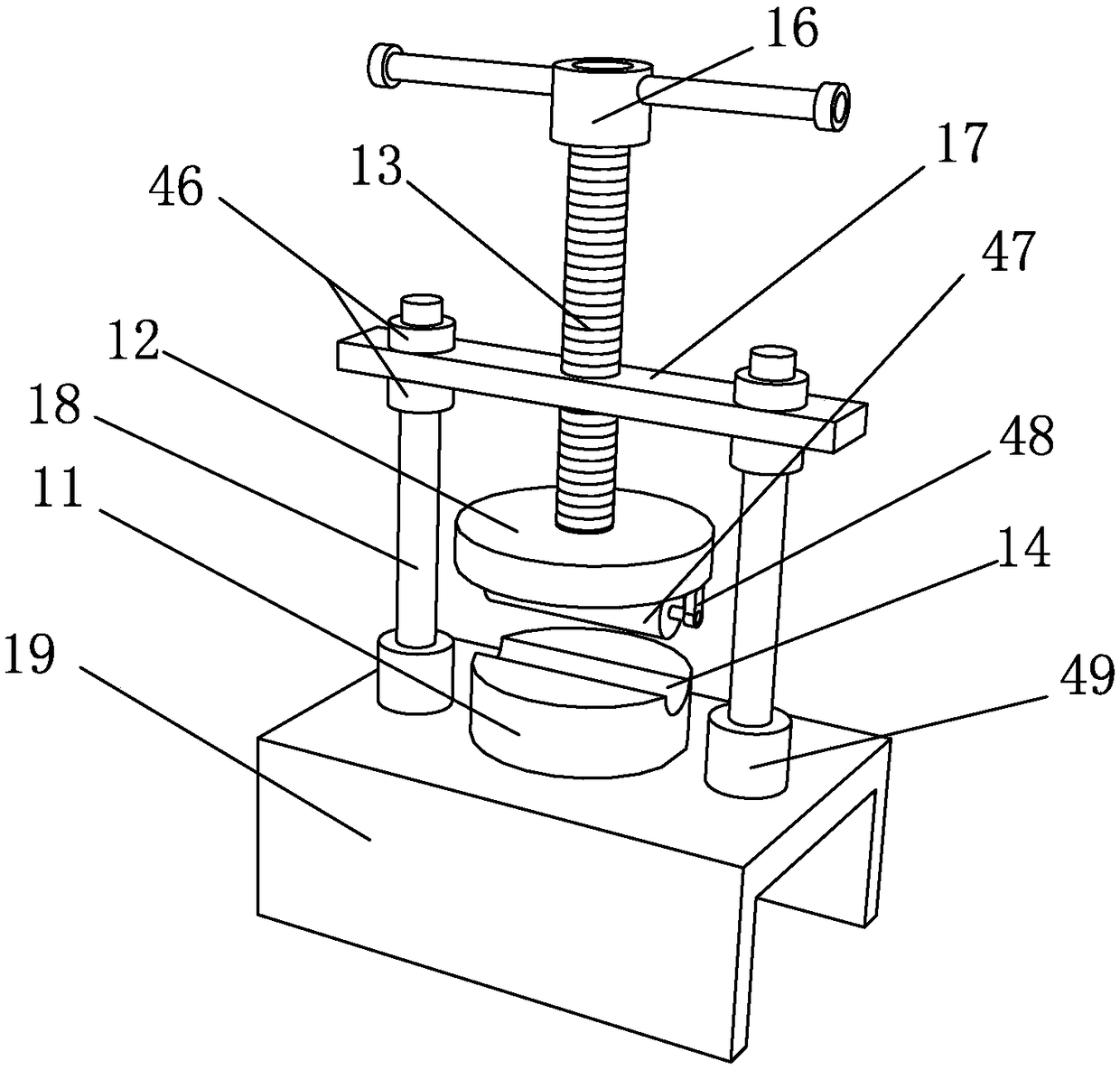

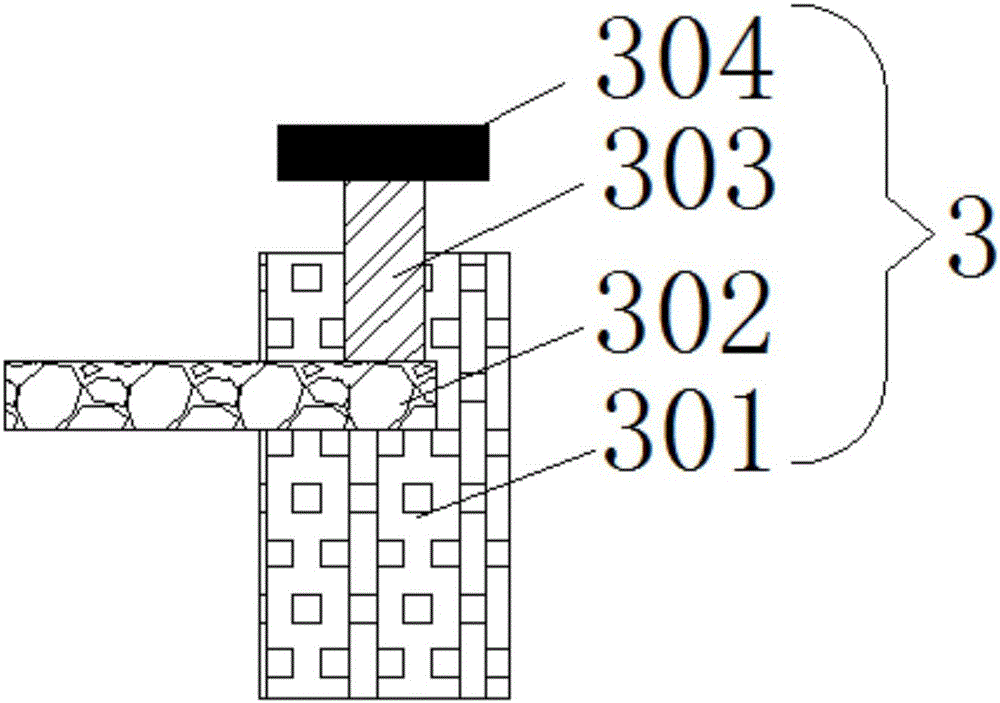

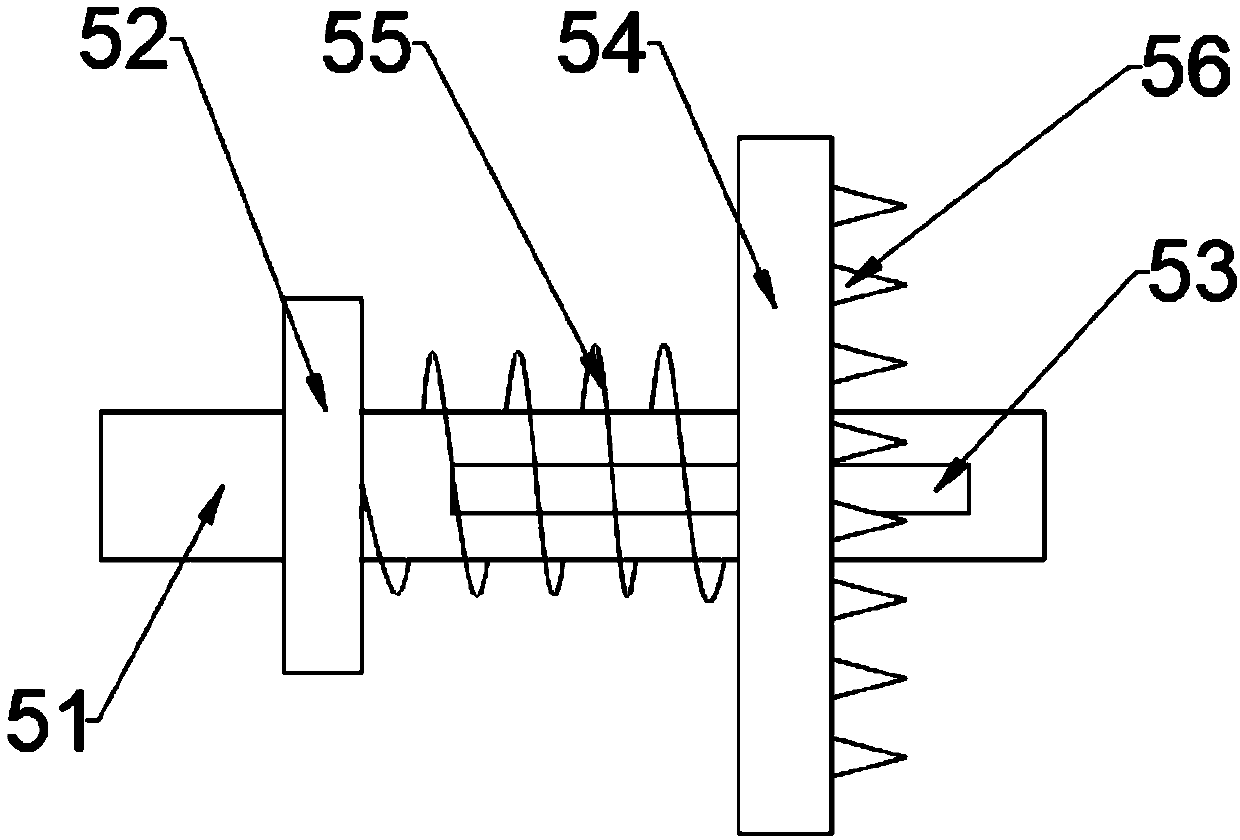

Yarn guiding device for textile product production

InactiveCN109281021AReduce mechanical vibrationEasy to assemble and disassembleYarnYarnPulp and paper industry

The invention discloses a yarn guiding device for textile product production. The device comprises a fixing bottom plate, a guiding assembly, a burr removing assembly and an adjusting assembly, the burr removing assembly comprises a guiding tube, a heating sleeve tube and a supporting frame, the heating sleeve tube is sleeved with the guiding wire, a heating wire is arranged in the heating tube, the adjusting assembly comprises a fixing plate, an adjusting plate and a pressurizing screw rod, the fixing plate is located on the limiting frame, a tensioning roller is arranged below the bottom ofthe adjusting plate, and the pressurizing screw rod is sleeved with the limiting plate. According to the yarn guiding device, yarns can be welled guided to prevent the yarns from breaking in the conveying process, the adjustment of the angle of the yarns can be conducted according to the conveying angle of the yarns, the using range of the guiding device is expanded, burrs, impurities and the likeon the yarns are removed through the burr removing mechanism to improve the quality of the yarns, and tensioning force in the yarn conveying process can be conducted by the adjusting assembly according to the conveying demands of the yarns to help the conveying of the yarns.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

Weaving process of Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarn fabric

InactiveCN103774321AReduce weave defectsImprove opening efficiencyWoven fabricsLiquid/gas/vapor yarns/filaments treatmentEngineeringBiological activation

The invention provides a weaving process of a Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarn fabric and relates to the technical field of textile production and weaving. The weaving process comprises the steps of spooling, warping, warp sizing, denting, weaving and arrangement. A tension piece is added during warping, a single-soaking dual-pressure sizing mode is adopted for warp sizing, a fabric weaving machine adopts a 'large tension and small opening' production process, the problem that two of the Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarns are not identical in tension and tangled to form a small braid is solved, accordingly the purpose of weaving the Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarn fabric is achieved, the activation efficiency is improved, fabric cover knitting faults are decreased, and the product quality is ensured.

Owner:JIHUA 3542 TEXTILE CO LTD

Production method of long-term soft and fluffy and hydroscopic and fast dry looped fabric

The invention belongs to the technical field of textile production processes and particularly relates to a production method of long-term soft and fluffy and hydroscopic and fast dry looped fabric. The production method includes the steps of spinning, warping, sizing, weaving and dyeing and finishing treatment. During weaving, low-hot-water-shrinkage yarn and high-hot-water-shrinkage yarn are adopted as looped yarn, and weaving is carried out according to a specific yarn arrangement sequence. The looped fabric has the advantages of being soft after being washed multiple times and being hydroscopic and fast dry and low in hair, the drying time is 5 min or longer shorter than that of a towel of the same weight, and the pile retention is smaller than 0.5%. The limitation of raw material use is broken through, it is unnecessary to use superfine fiber yarn or superfine fiber filaments, and the product quality of the looped fabric can be remarkably improved. The product structure range to which the technical method is applicable is wider, and no double-hair structure is needed; the manufactured towel is better in style, and loops are smoother. A splitting process (dacron alkali peeling process) is not adopted, dyeing energy consumption is effectively reduced, and meanwhile environmental pollution caused by the splitting process is reduced.

Owner:LOFTEX CHINA LTD

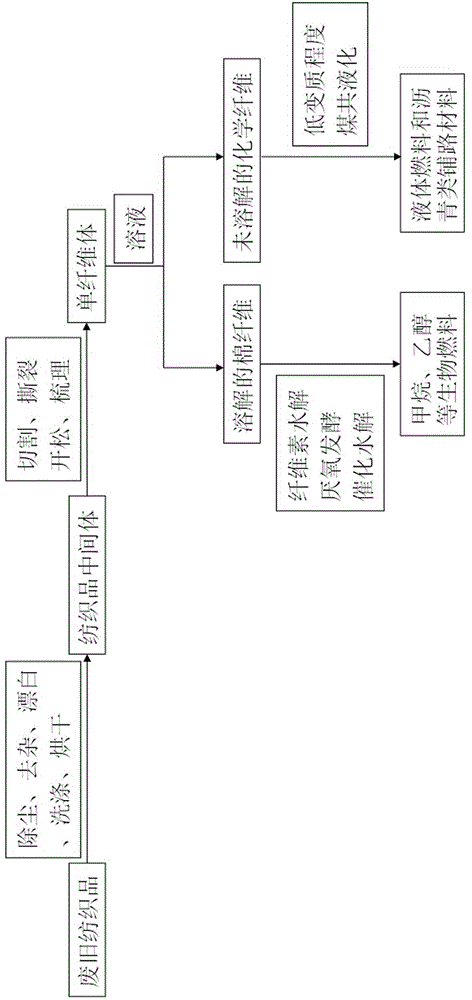

Method for producing fuel and road asphalt modifier by utilizing waste and old textiles

ActiveCN104531234ASolve processing problemsIncrease profitSolid waste disposalLiquid carbonaceous fuelsPtru catalystSingle fibre

A disclosed method for producing a fuel and a road asphalt modifier by utilizing waste and old textiles comprises the following steps: (1) pre-treating waste and old textiles, namely, successively performing dedusting, impurity removal, bleaching, washing and baking processing on waste and old textiles, and then performing cutting, tearing, loosening and carding to obtain single fibrous body; (2) dissolving the single fibrous body obtained in the step (1) by using an alkali solution, and performing solid-liquid separation to obtain a gossypin solution and undissolved chemical fiber; (3) adding cellulase into the gossypin solution for hydrolyzing, or adding a catalyst for hydrolyzing, or performing anaerobic fermentation, so as to prepare a biological fuel; and (4) adding low-coalification-degree coal, a catalyst and a solvent into the undissolved chemical fiber obtained in the step (2) for coliquefaction, so as to prepare a liquid fuel and the road asphalt modifier. The method converts waste and old textiles into the fuel and prepares the road asphalt modifier, comprehensively utilizes coal and waste and old textiles, and reduces environmental pollution.

Owner:河南卓谷科技有限公司

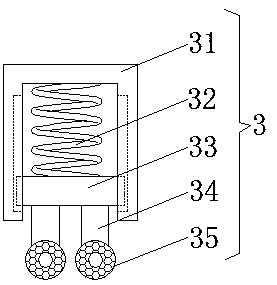

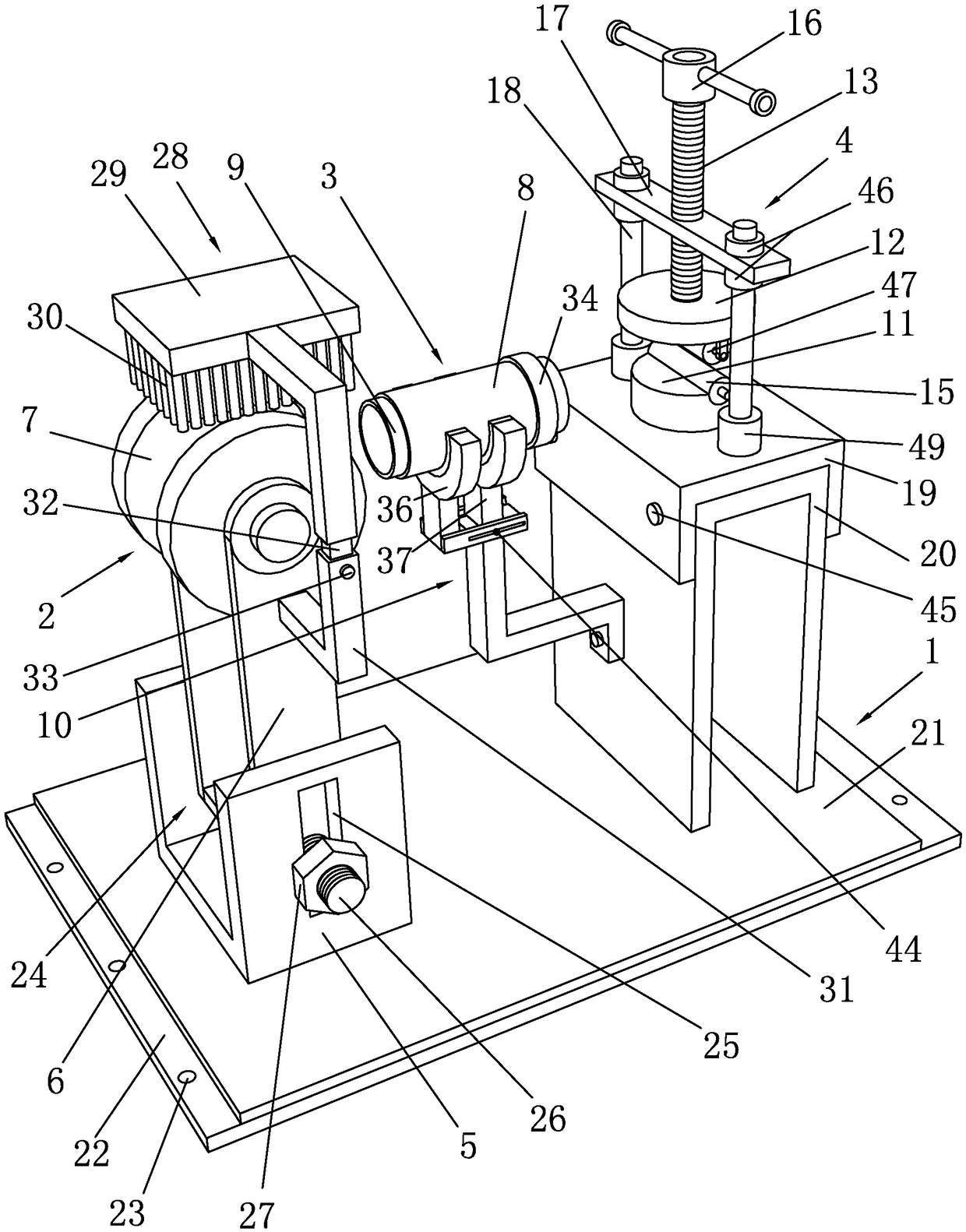

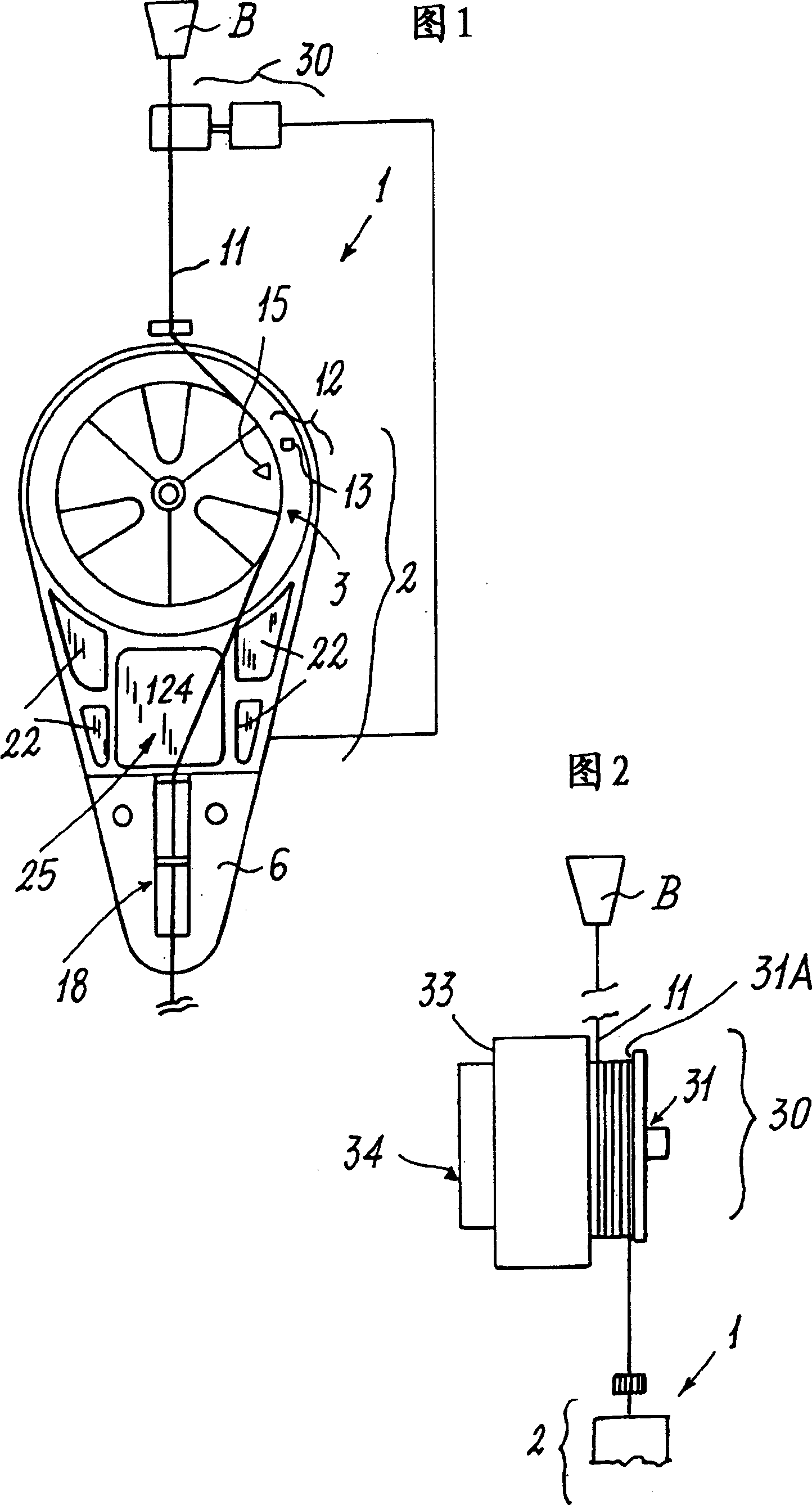

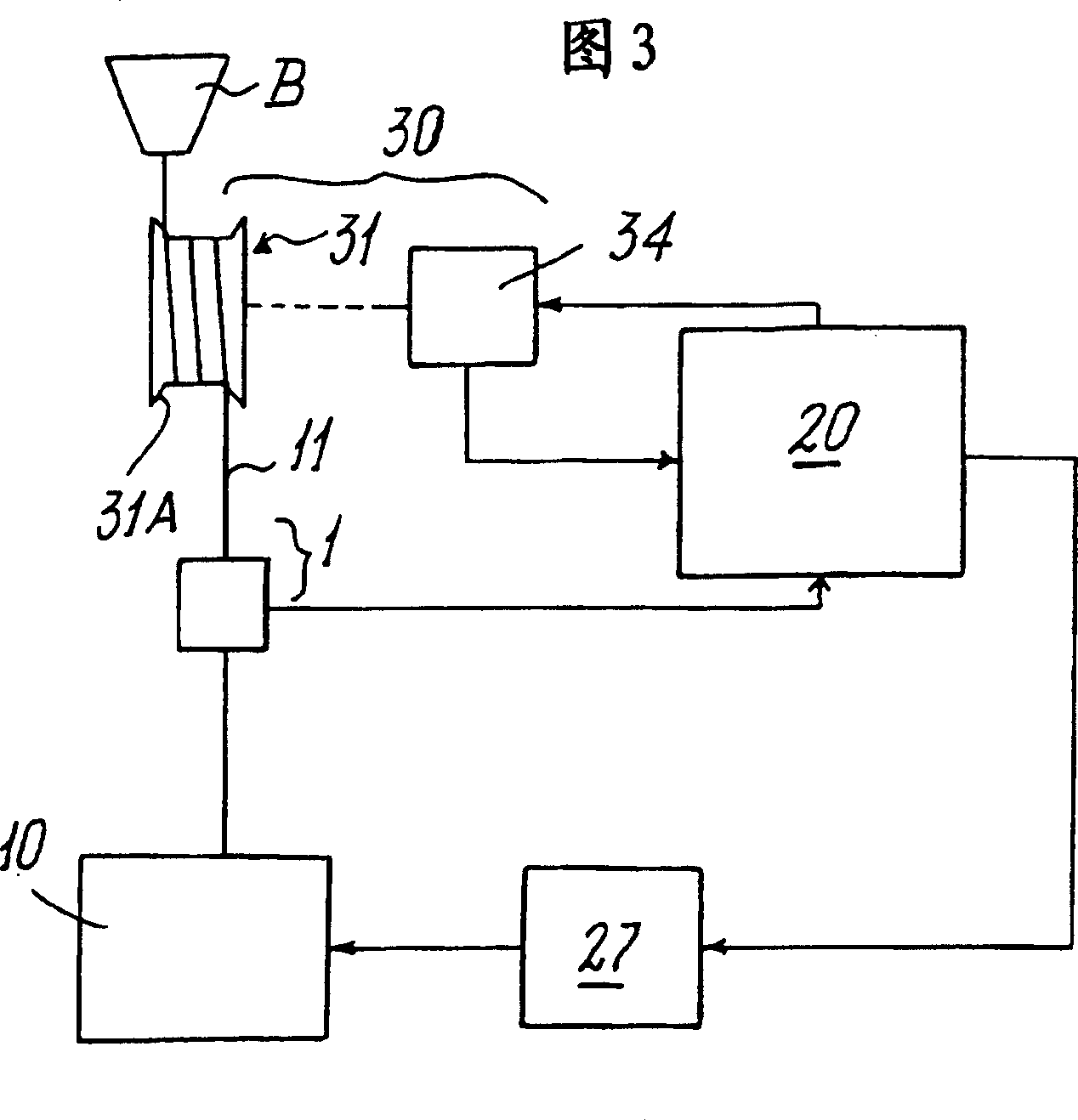

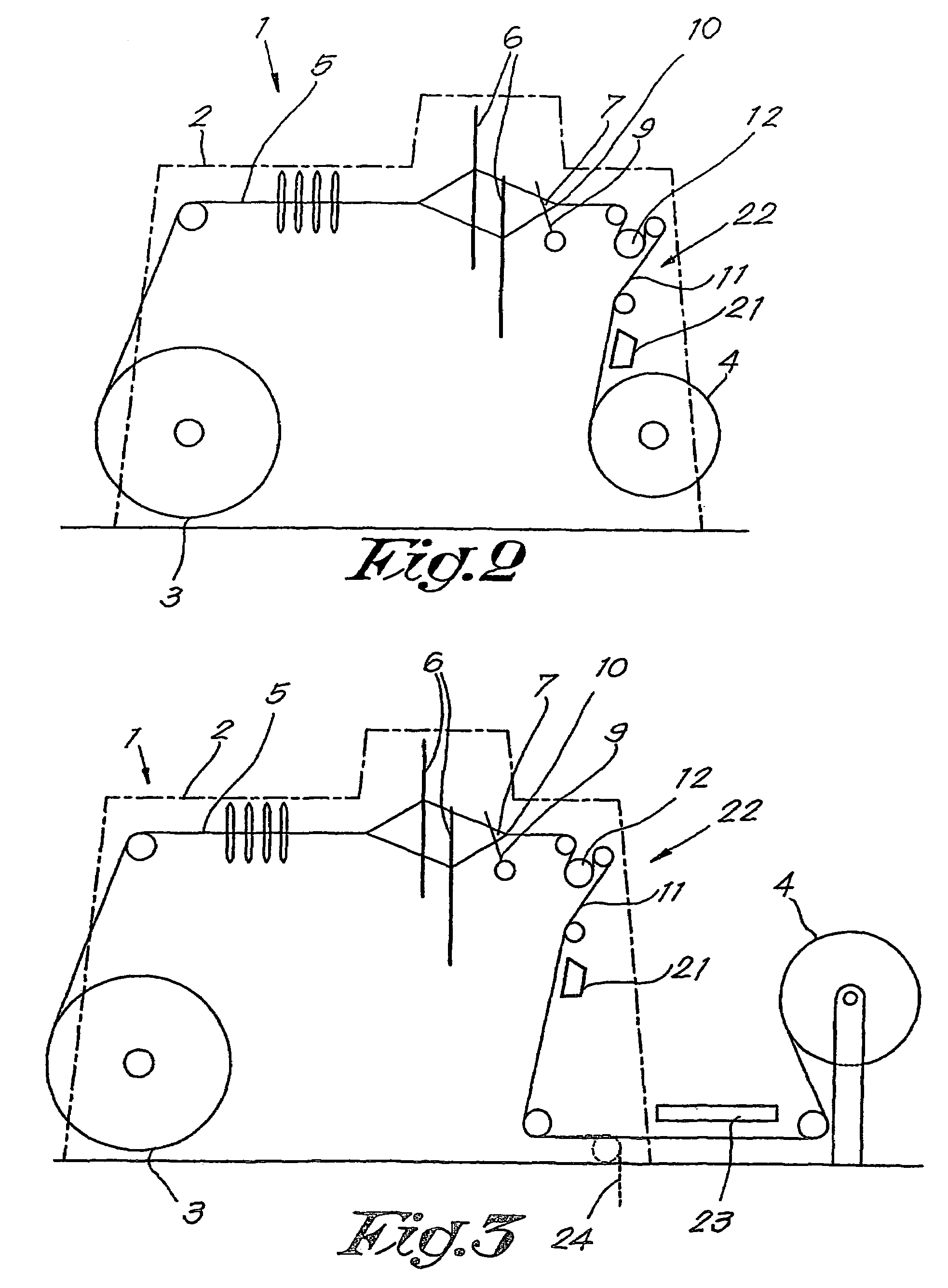

Device and method for feeding an elastomeric yarn to a textile machine

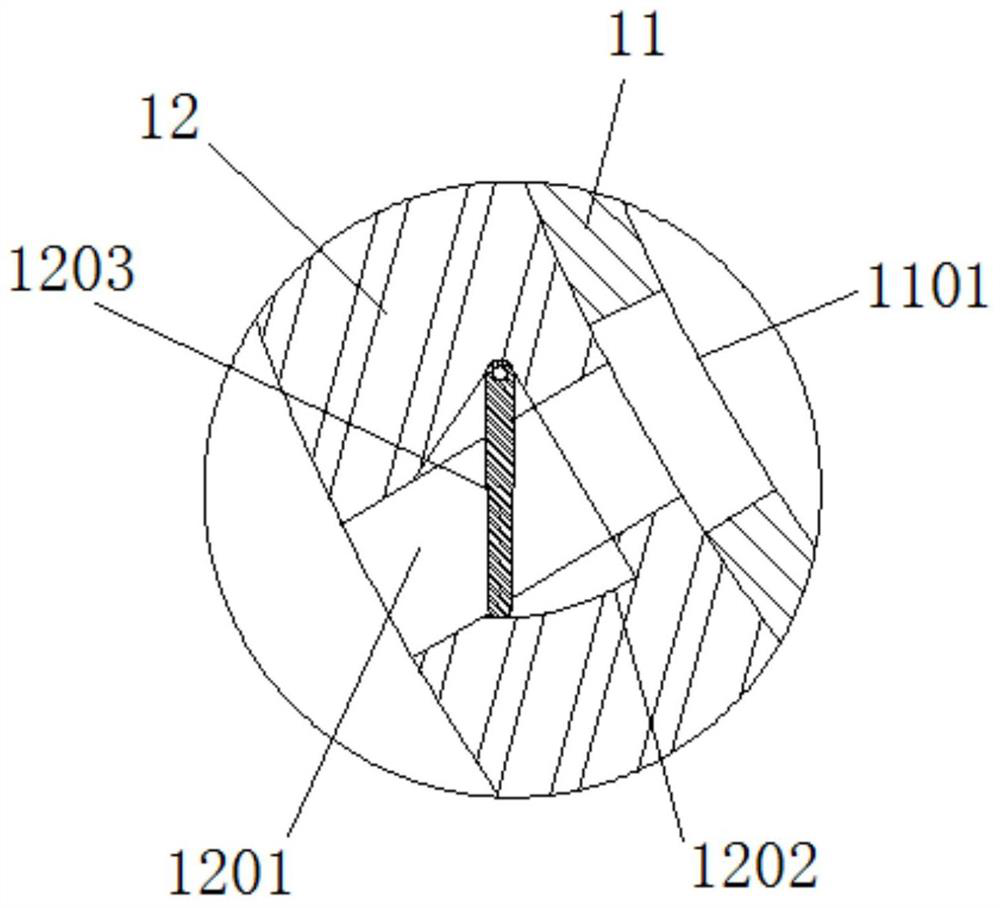

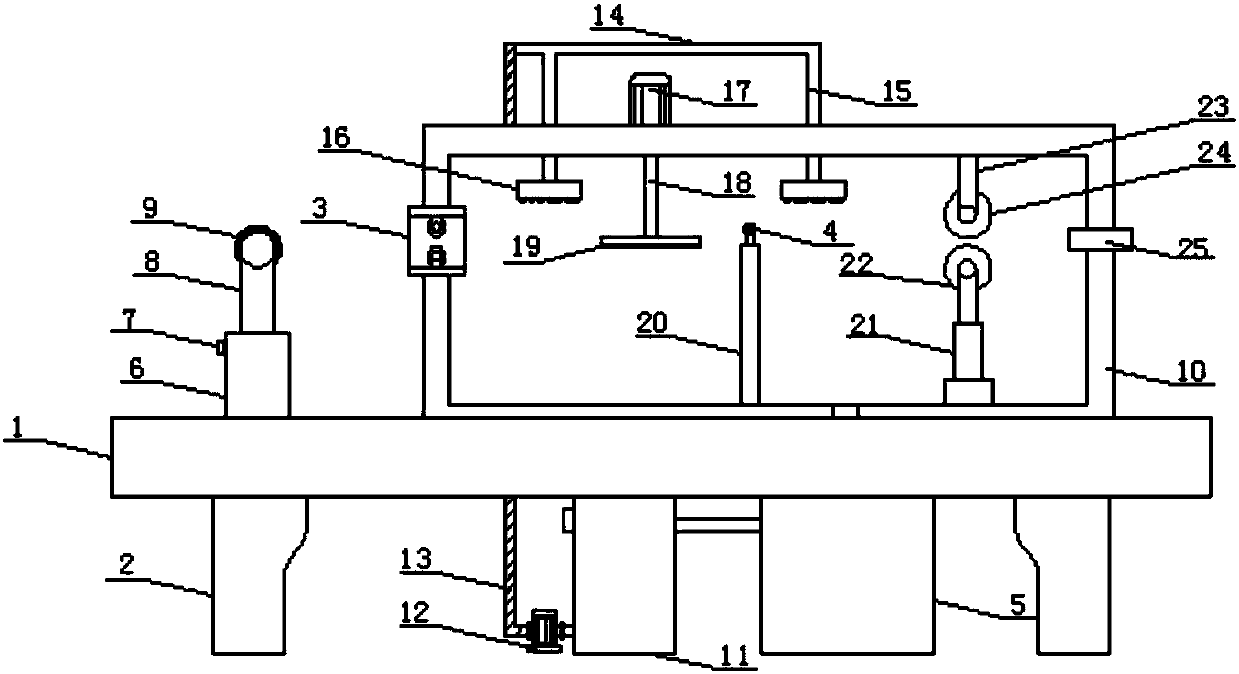

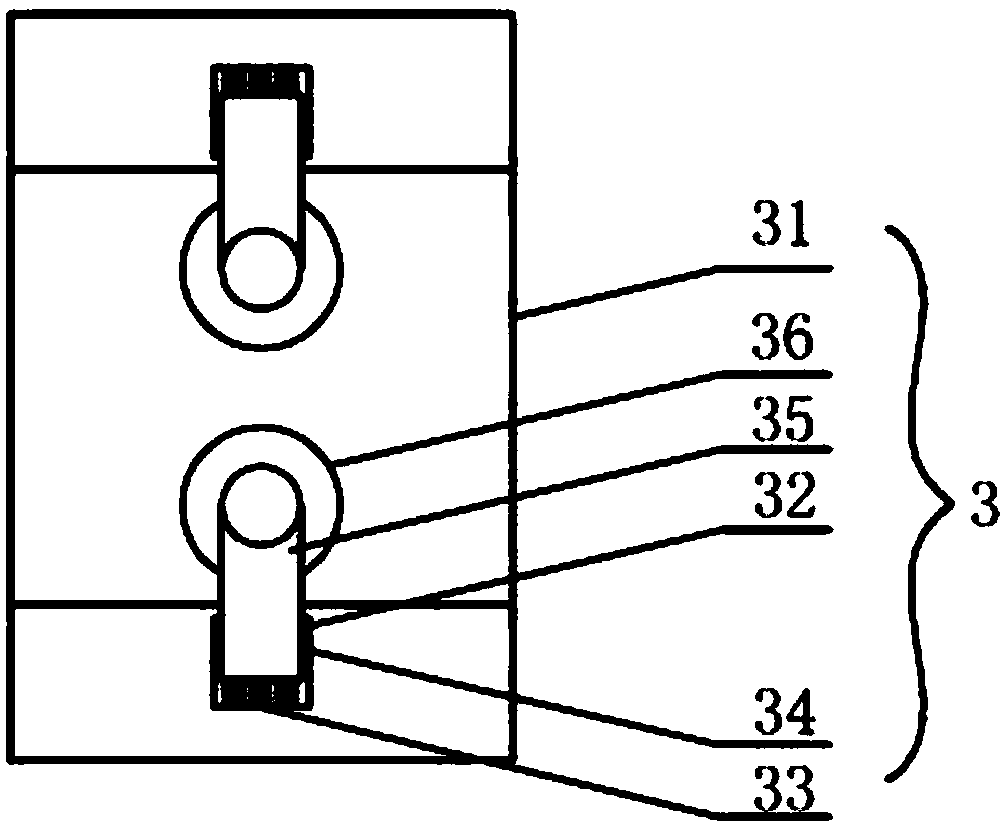

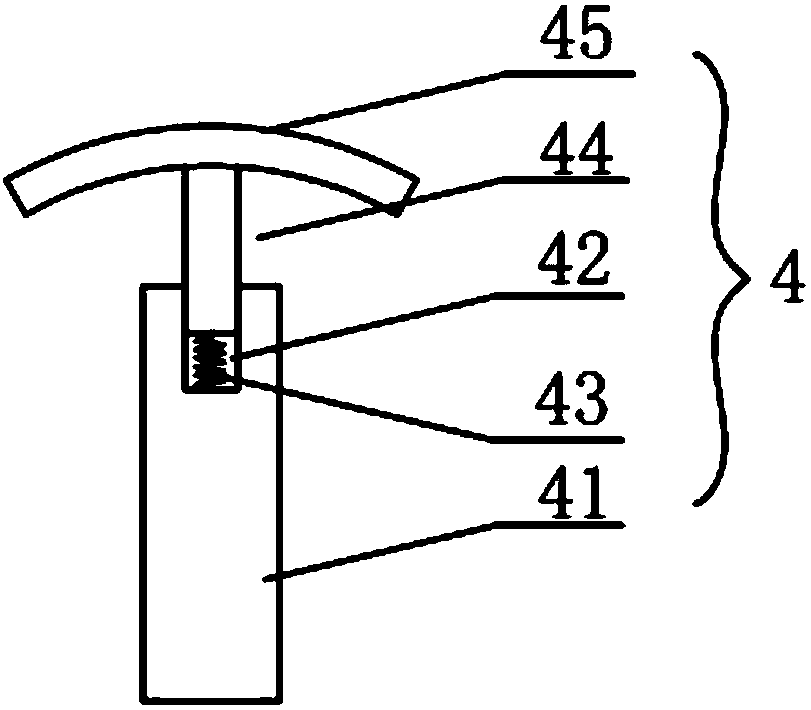

A device for controlling the feeding of elastic yarn (11) having known elasticity and withdrawing from the yarn bobbin (B) to feed textile machines (10) such as knitting machines, hosiery machines, winding machines In a machine, or other textile machine, the yarn has inherent elasticity and is fed into the textile machine at an inherent speed, a device (18) for detecting the tension of the yarn (11) and a device (18) for measuring and a device (3, 12) for changing the yarn speed, the detection device (18) and the measuring and changing device (3, 12) are connected to the device (20) for controlling and adjusting the tension and speed parameters ), the control and adjustment device (20) continuously measures the values of two parameters during the process of feeding the yarn (11) to the textile machine, and is characterized in that it also includes a compensation device (30), which compensates for the deviation from the yarn bobbin. (B) The dimensional characteristics of the withdrawn elastic yarn (11) before cooperating with the tension detection device (18) and the speed measurement device (3, 12), thereby enabling the yarn to be fed into the textile with constant dimensional characteristics The entire production of textiles is provided in the machine (10). A method implemented by the above device is also disclosed.

Owner:蒂齐亚诺・巴里亚

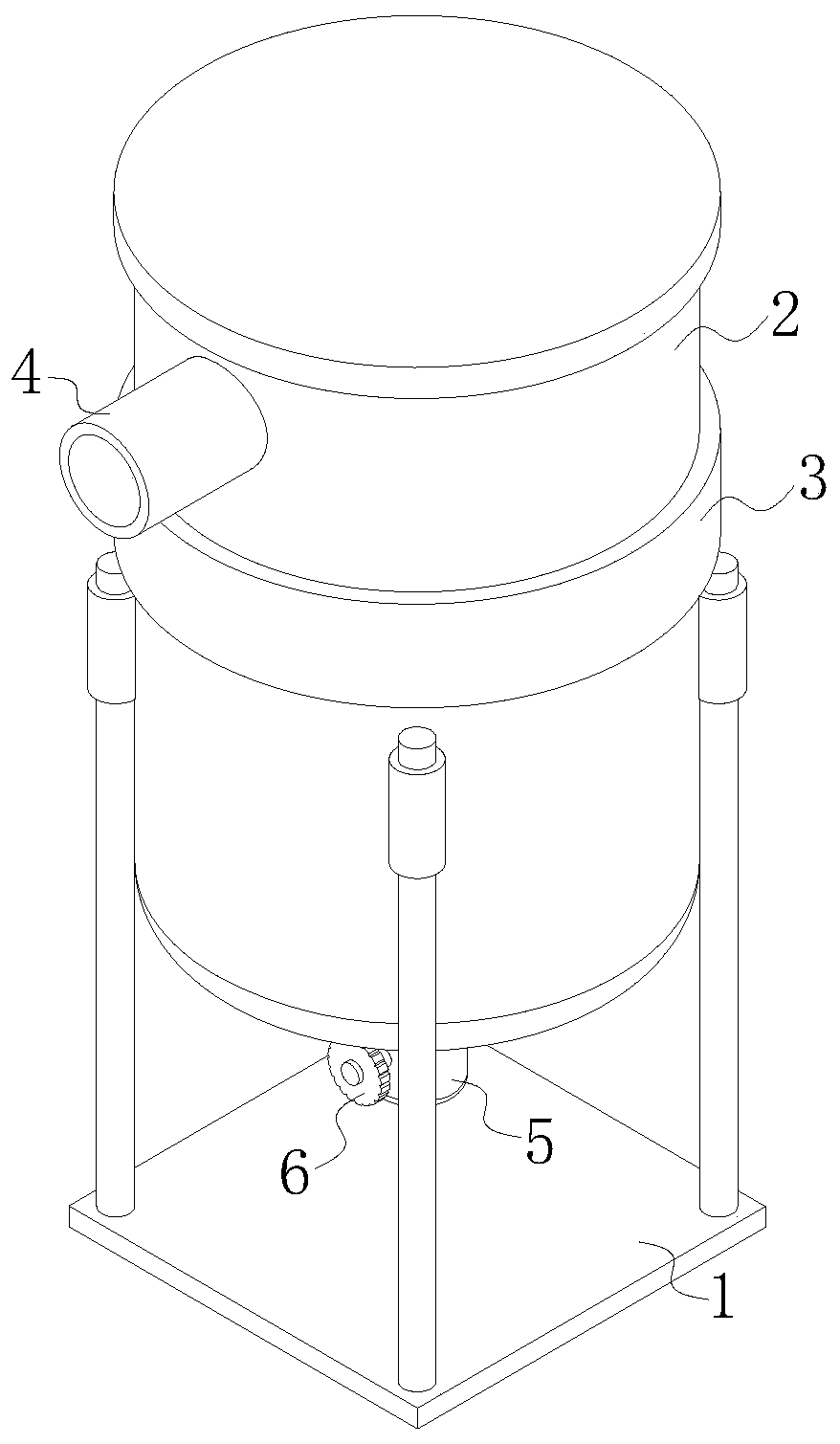

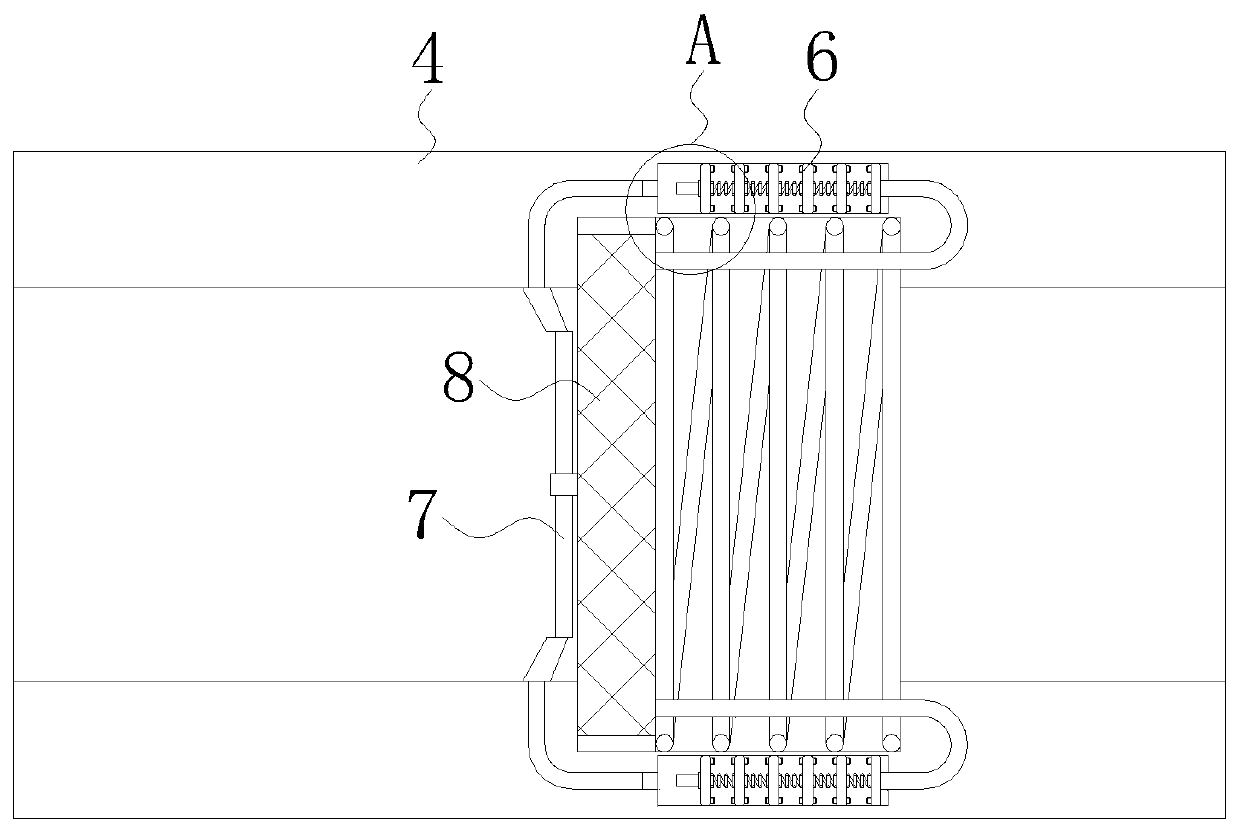

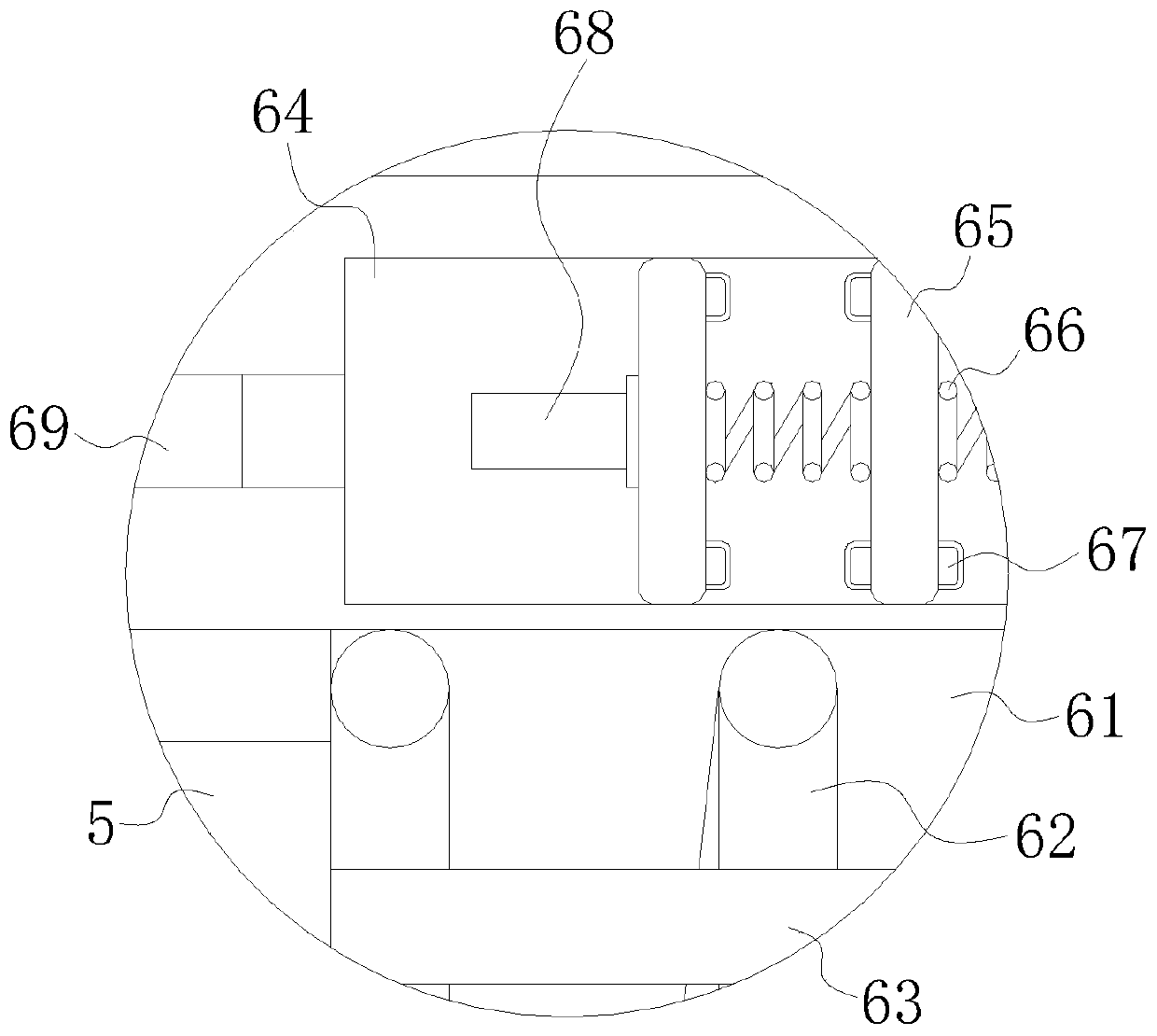

Sewage treatment equipment for textile production

ActiveCN110975364AEasy to handleHandle the device, effectively cleared by turning on theFiltration circuitsStationary filtering element filtersWater flowSewage treatment

The invention discloses sewage treatment equipment for textile production, and relates to the technical field of sewage treatment. The sewage treatment equipment for textile production comprises a mounting rack. A cylinder body is fixedly mounted on the mounting frame, and a quick filtering layer is embedded in the upper half part of the inner cavity of the cylinder body. A water inlet pipe communicated with the inner cavity of the cylinder body is inserted into the top of the front face of the cylinder body. A water drainage pipe communicated with the inner cavity of the cylinder body is welded to the middle of the bottom of the cylinder body, and a water drainage valve is fixedly installed on the water drainage pipe. A filter screen is connected in a sliding manner into the water inlet pipe, and a detection mechanism is arranged on the rear side of the filter screen. According to the sewage treatment equipment for textile production, the detection mechanism is arranged in a filter tank, and along with the increase of the service time of the filter screen, floccules and particles accumulated on the surface of the filter screen are gradually increased, the water flux of the filterscreen is reduced after the floccules and the particles are intertwined, then the impact force of water flow on the filter screen is gradually increased, and the change state serves as the detection standard of the detection mechanism, so that the blockage degree of the filter screen can be detected in real time.

Owner:肇庆中彩机电技术研发有限公司

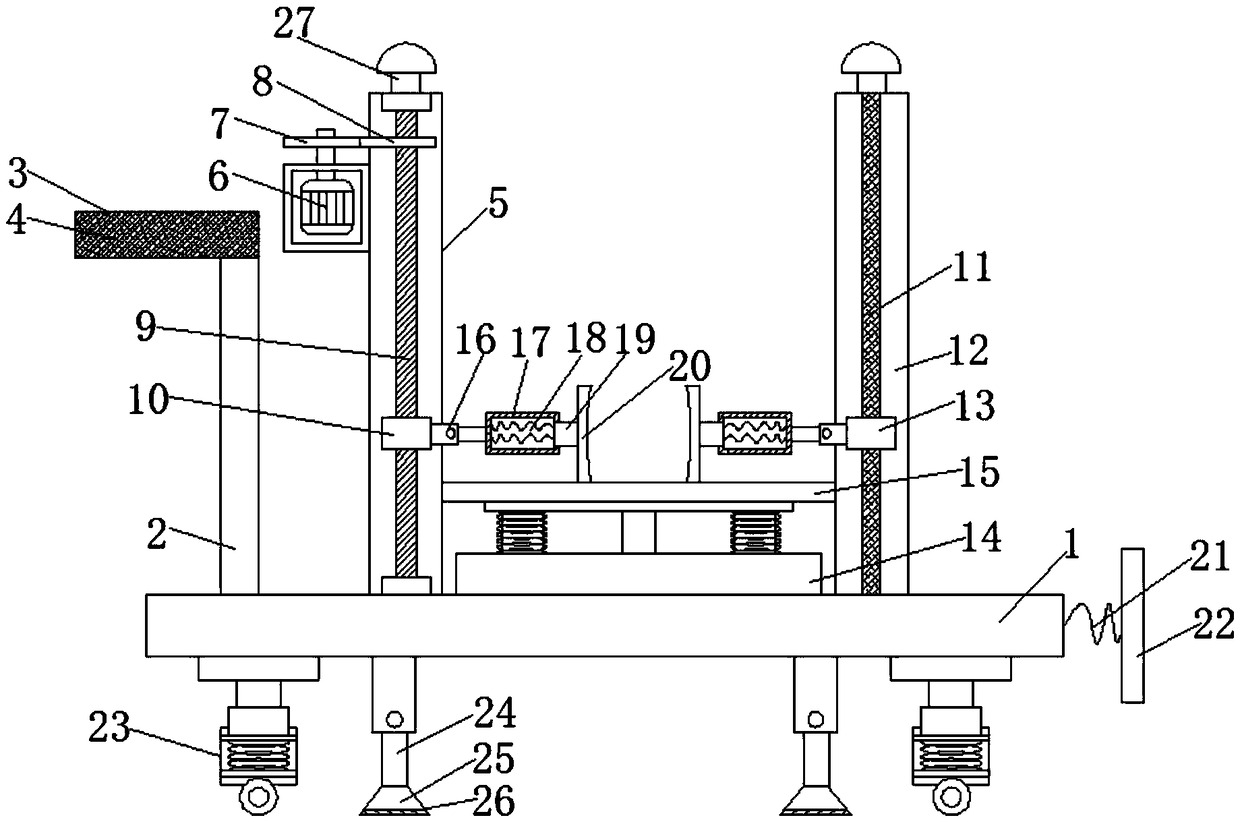

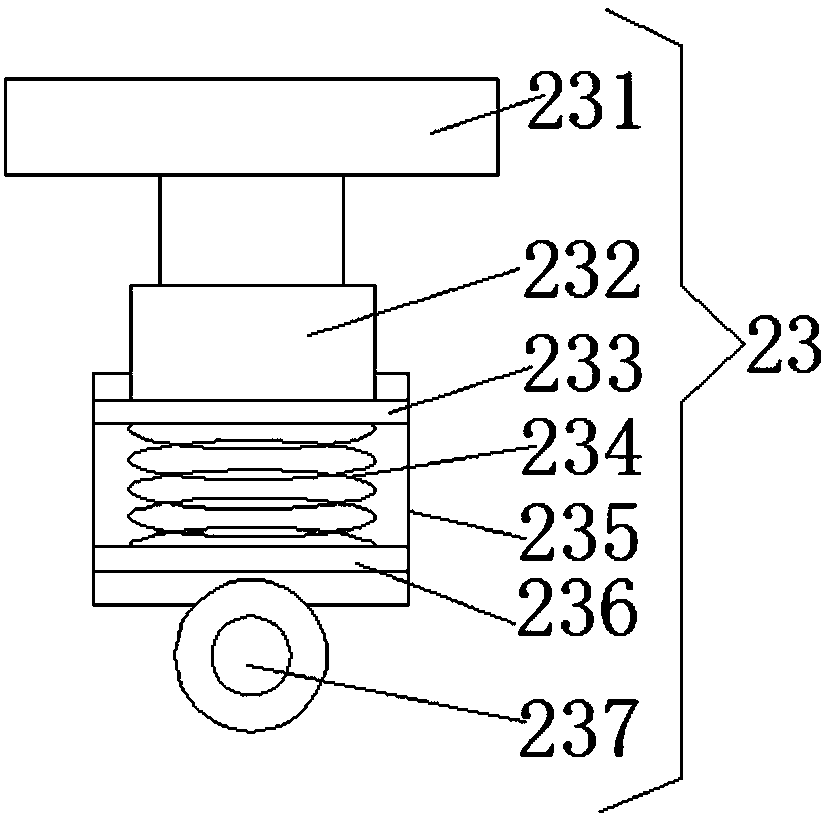

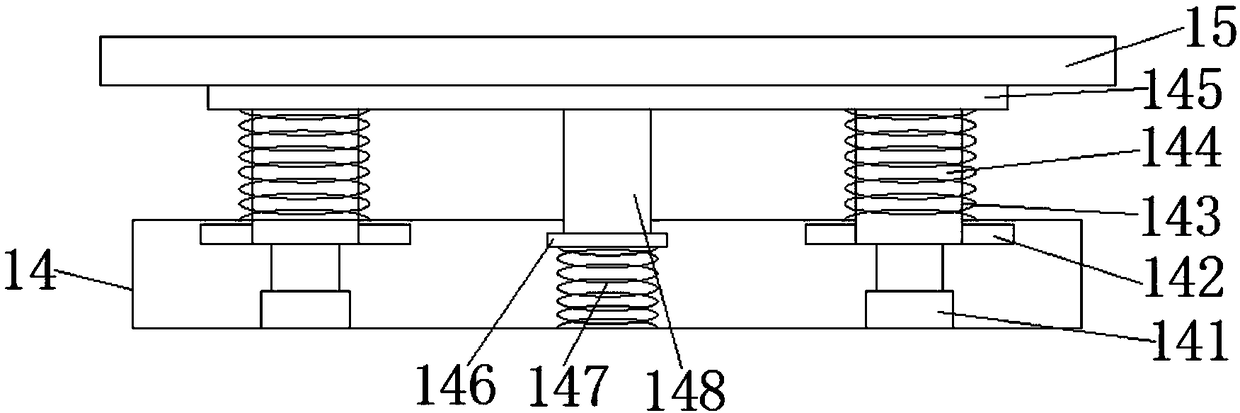

Textile machine supporting device convenient to adjust

InactiveCN108679375AImprove work efficiencyGuaranteed stabilityPortable framesLoomsHydraulic control unitThreaded pipe

The invention discloses a textile machine supporting device convenient to adjust. The textile machine supporting device convenient to adjust comprises supporting legs and a textile machine. The top ofeach supporting leg is provided with a deep groove. Dampers are fixedly connected with the bottoms of the inner cavities of the deep grooves. The tops of the dampers are fixedly connected with a supporting plate. The two sides of the supporting plate are connected with the inner cavities of the deep grooves in a sliding manner. Hydraulic telescopic rods are fixedly connected with the top of the supporting plate. According to the textile machine supporting device convenient to adjust, through cooperative use of the supporting legs, the textile machine, the deep grooves, the dampers, the supporting plate, the hydraulic telescopic rods, a hydraulic control unit, grooves, bearings, threaded pipes, threaded rods, universal wheels, driven bevel gears, a transmission rod, driving bevel gears anda handle, the height of the supporting device can be easily, conveniently and rapidly adjusted according to the height demand of an operator, so that the work efficiency is improved; and besides, when not used, the universal wheels can be retracted, the stability of the textile machine supporting device is better guaranteed, and great convenience is brought to textile production work.

Owner:SUZHOU BAIBI TEXTILE TECH CO LTD

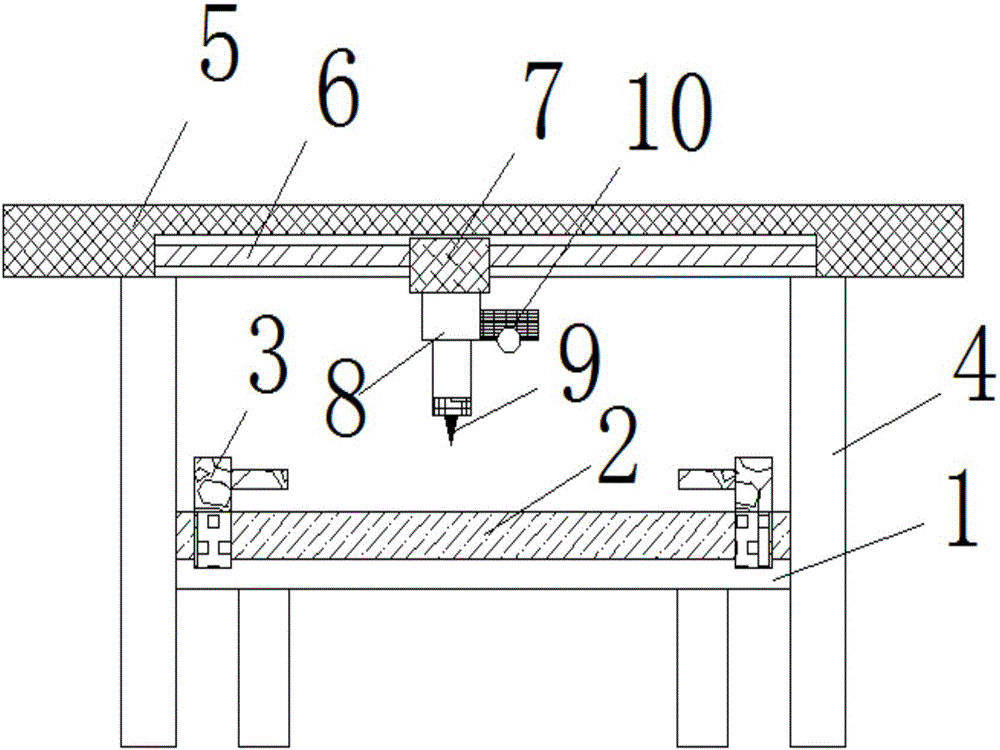

Fabric cutting device for textile production

InactiveCN106337272AGuaranteed qualityEasy to rollSevering textilesWinding machineArchitectural engineering

The invention discloses a fabric cutting device for textile production. The fabric cutting device comprises a machine stand, wherein the top of the machine stand is provided with two groups of sliding chutes along the horizontal direction; two sides of the interiors of the sliding chutes are slidably connected with limiting devices; two sides of the machine table are symmetrically provided with upright columns; the tops of the upright column are fixedly provided with a cross beam; the bottom of the cross beam is provided with a sliding rail; the sliding rail is slidably connected with an electric sliding block; the bottom of the electric sliding block is fixedly provided with an electric telescopic link; the bottom of the electric telescopic link is in threaded connection with a cutting tool; one side of the top end of the electric telescopic link is provided with a camera; the left side of the top end of the interior of the machine stand is provided with a fabric inspection device; the right side of the top end of the interior of the machine stand is provided with a distance measuring sensor; one side of the front surface of the machine table is provided with a controller; one end of the top of the machine table is provided with a fabric winding machine through a connection rod. The fabric cutting device is simple in structure, reasonable in design, convenient to operate, low in manufacturing cost and wise in use range, is capable of saving time and labor and improving the working efficiency, and is convenient to popularize and generalize.

Owner:泉州市知产茂业工业设计有限公司

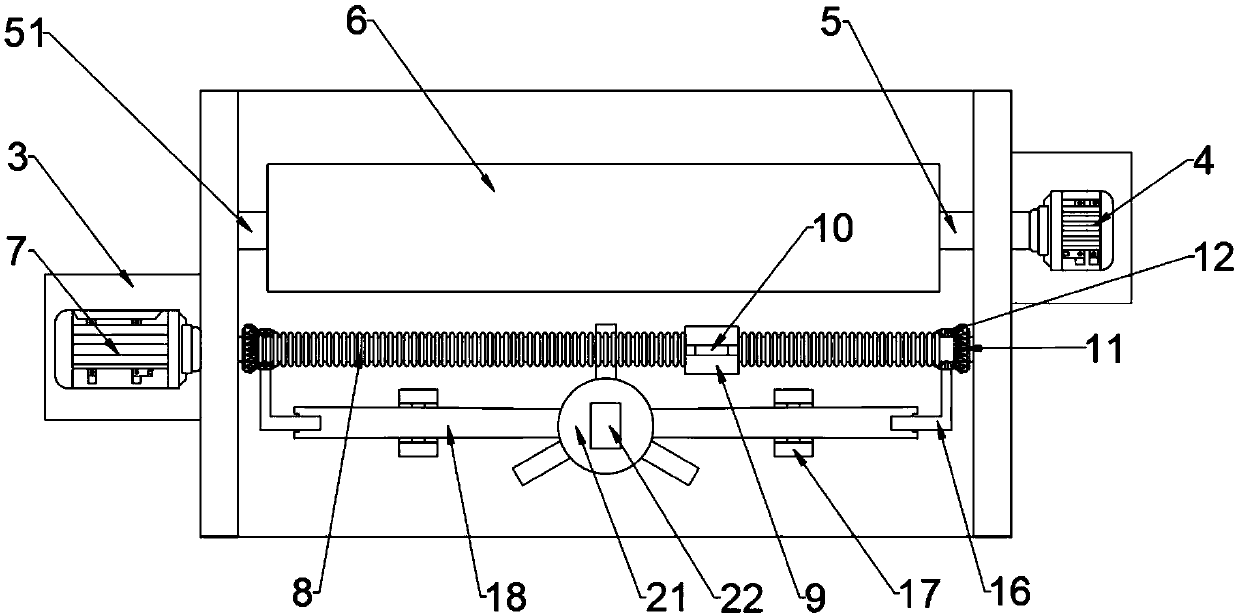

Winding machine for textile production and facilitating tensity adjustment

ActiveCN109626118AGuaranteed tensionConvenient and even coilingFilament handlingWinding machinePhysical pendulum

The invention discloses a winding machine for textile production and facilitating tensity adjustment, and belongs to the technical field of textile production. The winding machine comprises a U-shapedframe, wherein supporting legs are arranged at four corners of the bottom of the U-shaped frame, motor mounting frames are arranged on the outer walls of the left side and the right side of the U-shaped frame, a swinging coil is arranged at the top of a moving block, driving bevel gears are arranged on the left side and the right side of the outer wall of a lead screw, the bottom of the moving block sleeves the outer wall of a guide rod through holes, the top of a movable lifting rod is movably connected with a tensioning guide device through a triangular supporting table, a limiting convex edge is arranged on the outer wall, located below the triangular supporting table, of the movable lifting rod, the left side and the right side of the bottom of the limiting convex edge are in lap joint with the ends of the left group of rotating rods and the right group of rotating rods correspondingly, and a compression spring is arranged on the outer wall of the movable lifting rod between the limiting convex edge and the triangular supporting table. According to the winding machine, the tensity of a wire can be kept all the time through synchronous automatic adjustment while winding is uniform when winding needs physical pendulum.

Owner:常山航翔纺织有限公司

Method for optimizing a textile production process and devices applying this method

InactiveUS7310565B2Easy to controlEasily interpretableInspecting textilesLoomsTextile productionManufacturing engineering

Owner:PICANOL NV

Anti-static flame-retardant fabric and production method thereof

InactiveCN106283329AHigh strengthSoft touchWarping machinesHeat resistant fibresPulp and paper industryTextile production

The invention belongs to the technical field of production of textiles and particularly relates to anti-static flame-retardant fabric and a production method thereof. The fabric is twill consisting of warp and weft, wherein the warp consists of folded yarns of double blended yarn and conductive yarn, the blended yarn is formed by blending flame-retardant viscose, aramid fibers and acrylic fibers, and the conductive yarn is formed by doubling polyester filament yarn and polyester conductive filaments; the weft consists of folded yarns of double blended yarn, and the blended yarn is formed by blending flame-retardant viscose, aramid fibers and acrylic fibers. The production method of the fabric comprises steps as follows: 1) a warping process; 2) a sizing process; 3) reeding; 4) a weaving process. Two pieces of warp of the anti-static flame-retardant fabric are spaced reasonably, and the fabric touches soft, is good in breathability, good in anti-static property and high in strength and has better wearing comfort.

Owner:JIHUA 3509 TEXTILE

Aramid fiber blended yarn and preparation technology thereof

The invention relates to the field of textile production, in particular to aramid fiber blended yarn and a preparation technology thereof. The aramid fiber blended yarn is characterized in that 1414.Kevlar aramid fiber, 1313.T450 aramid fiber, flame retardant glue, modacrylic, combed cotton, conducting fiber, chinlon and tencel are adopted as raw materials, fineness degrees of the materials are respectively 1.7, 2.2 and 3 deniers, any four materials in the raw materials are selected as main raw materials, the length of the four materials selected as the main materials at will is 48-51 millimeters, the lengths of the remaining auxiliary raw materials are respectively 28 millimeters and 38 millimeters. Compared with the prior art, the processing technology is simple in process, produced products have good performance such as high strength, high modulus, high-temperature resistance, acid resistance, alkali resistance and light weight, are high in strength, and can solve the problem that a machine part is damaged easily. The development of the aramid fiber blended yarn and the success of matched military supplies can bring markets for enterprises and innovation conceptions. Meanwhile, firmness, flame-retarding performance and anti-static electricity capacity of the military supplies are changed in nature compared with prior fiber blended yarn.

Owner:SHANGHAI SHENAN TEXTILE

Yarn dyeing device for textile production

InactiveCN106930024AFlexible connectionEasy to cleanTextile treatment containersSucessive textile treatmentsYarnEngineering

The invention discloses a yarn dyeing device for textile production, which comprises a supporting platform, on which a bobbin holder, a yarn feeding mechanism, a dye box, an air-drying box and a take-up roller are respectively arranged, and on the yarn feeding mechanism, there are Waste box, one side of the dye box is provided with a feeding trough, the top surface of the dye box is provided with an outlet slot, the inside of the dye box is provided with a dyeing roller, the dyeing roller is evenly distributed with wire grooves, and the outside of the dye box is provided with a drive motor. The driving motor is connected to the dyeing roller. There is an inlet hose at the bottom of the air-drying box. The lead roller is connected with a take-up motor on one side of the take-up roller. The invention has the advantages of simple structure, flexible connection, multi-strand yarn dyeing at one time, and winding together, high working efficiency, good dyeing effect, and high quality and good performance of the obtained yarn product.

Owner:嵊州市靖洁纺织机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com