Weaving process of Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarn fabric

A moisture-absorbing and perspiration-wicking filament fabric technology, which is applied in textiles and papermaking, liquid/gas/steam yarn/filament processing, fabrics, etc., can solve the problems of inability to produce hemp-moisture-absorbing and perspiration-wicking polyester filament fabrics, etc. Achieve the effect of improving the opening efficiency, reducing fabric surface weaving defects, and ensuring product quality

Inactive Publication Date: 2014-05-07

JIHUA 3542 TEXTILE CO LTD

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the deficiencies in the prior art, the object of the present invention is to provide a weaving process of hemp-moisture-absorbing and perspiration-wicking polyester filament cloth, through a special sizing process to improve the formation of yarn braids and the extra-large tension of the loom and the The cooperation of technology solves the problem that traditional weaving technology cannot produce hemp-moisture-absorbing and sweat-wicking polyester filament fabric

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

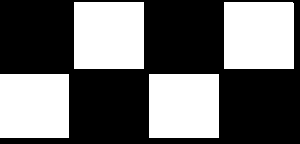

[0017] Embodiment 1: as figure 1 Shown, hemp - plain weave of moisture wicking polyester filament cloth.

Embodiment 2

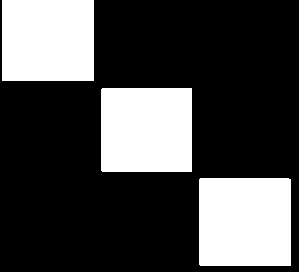

[0018] Embodiment 2: as figure 2 Shown, Hemp - 2 / 1 twill weave of moisture-wicking polyester filament cloth.

Embodiment 3

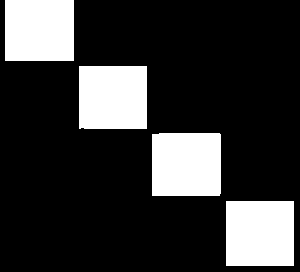

[0019] Embodiment 3: as image 3 Shown, Hemp - 3 / 1 twill weave of moisture-wicking polyester filament cloth.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a weaving process of a Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarn fabric and relates to the technical field of textile production and weaving. The weaving process comprises the steps of spooling, warping, warp sizing, denting, weaving and arrangement. A tension piece is added during warping, a single-soaking dual-pressure sizing mode is adopted for warp sizing, a fabric weaving machine adopts a 'large tension and small opening' production process, the problem that two of the Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarns are not identical in tension and tangled to form a small braid is solved, accordingly the purpose of weaving the Chinese-hemp-hygroscopic and sweat-releasing polyester filament yarn fabric is achieved, the activation efficiency is improved, fabric cover knitting faults are decreased, and the product quality is ensured.

Description

technical field [0001] The invention relates to the technical field of textile production and weaving, in particular to a weaving process of hemp-moisture-absorbing and sweat-wicking polyester filament cloth. Background technique [0002] Hemp-moisture-absorbing and sweat-wicking polyester filament fabric has many functions such as moisture absorption, breathability, comfort, heat dissipation, mildew resistance, antibacterial, sound absorption, radiation resistance, and ultraviolet protection, and is favored by people. At present, in the prior art, hemp-moisture-absorbing and perspiration-wicking polyester filament cloth generally adopts hemp and moisture-absorbing and perspiration-wicking polyester filaments to form strands through double twisting, but this kind of hemp and moisture-absorbing and perspiration-wicking polyester filaments Due to the difference in tension between the hemp yarn and the polyester filament, the strands made of two-fold twisting are prone to small...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D15/00D06B3/04D03D15/217D03D15/283D03D15/50

Inventor 左攀峰张慧霞

Owner JIHUA 3542 TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com