Magnetized-and-demagnetized Lyocell fiber high-quality textile process

A high-quality fiber technology, applied in the fields of textile, fiber treatment, textiles and papermaking, etc., can solve the problems of increasing yarn breaking strength, reducing roving breakage rate, and low quality, so as to increase breaking strength and improve shed clarity The effect of reducing hairiness and hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

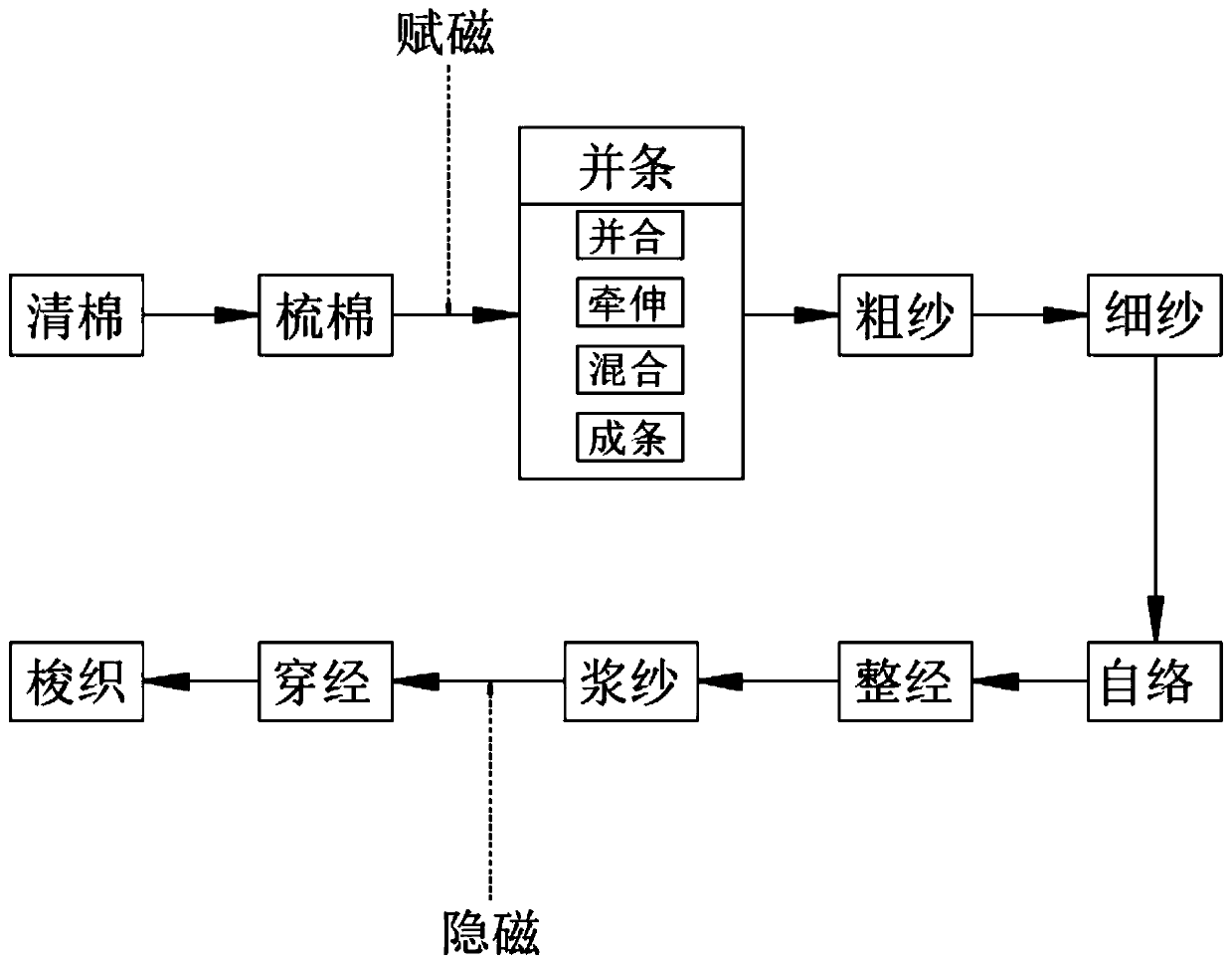

[0056] see figure 1 , a high-quality textile process for magnetically hidden lyocell fibers, comprising the following steps:

[0057] S1. Cotton cleaning: remove most of the impurities, defects and short fibers that are not suitable for spinning in the lyocell fiber raw material, and then make the cleaned lyocell fiber raw material into a lap with uniform thickness and good shape;

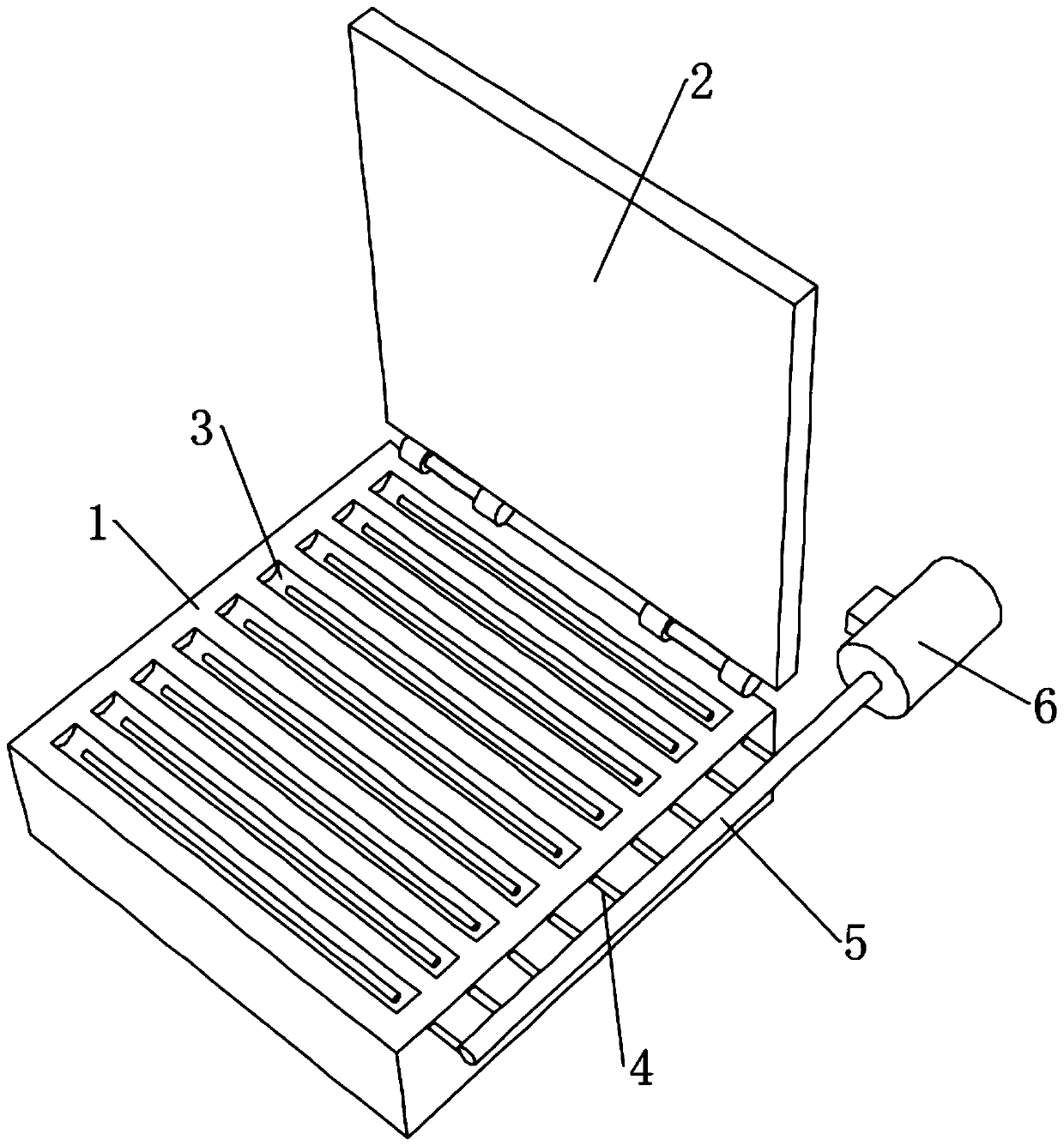

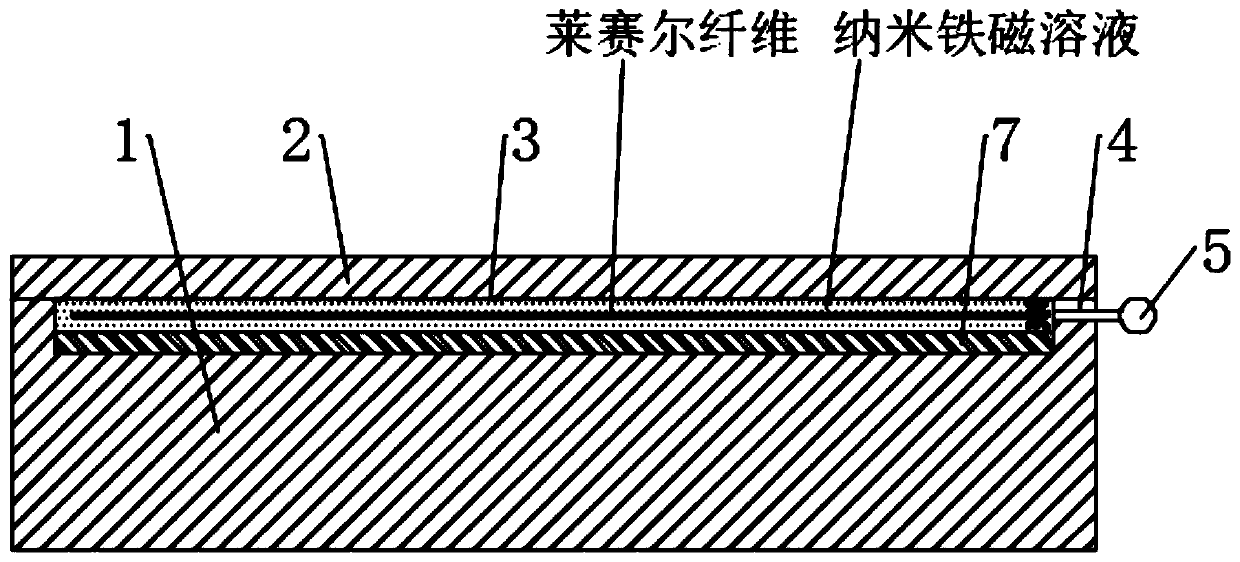

[0058] S2. Carding: separate the cotton laps into fibers, and remove the fine impurities in the cotton laps, and then use a split magnetizing device for processing, place the lyocell fibers and pour nano-ferromagnetic solution to submerge 1-2mm , after the treatment is completed, a sliver that meets the requirements is made;

[0059] S3, drawing: 1) merging: merging with 6-8 slivers to improve uneven length of sliver;

[0060] 2) Drafting: stretch the sliver to the specified weight, please refer to Figure 5 , and hang it vertically in a windless environment for setting and stretching, and a str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com