Patents

Literature

1974results about "Auxillary apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

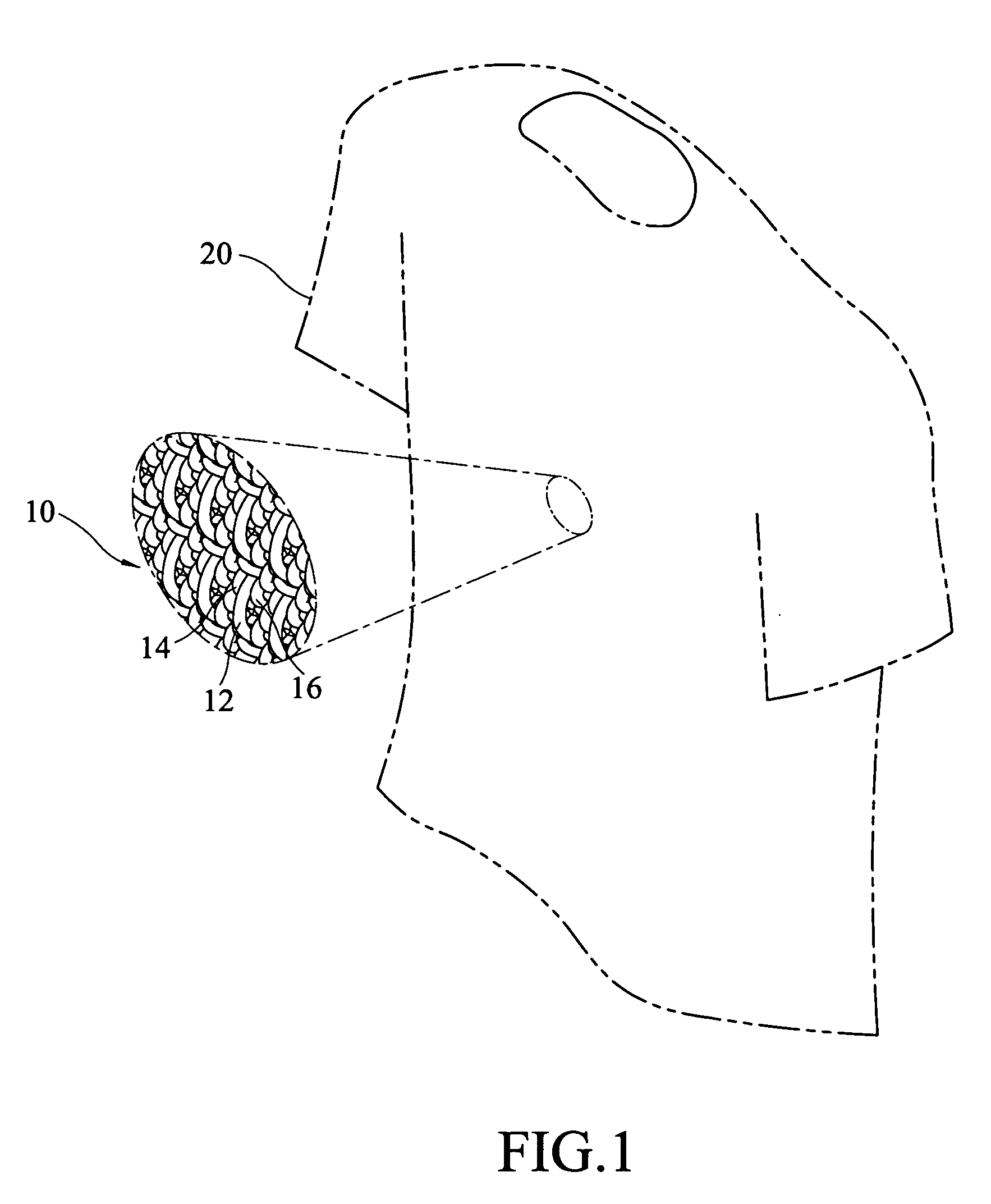

Protection product

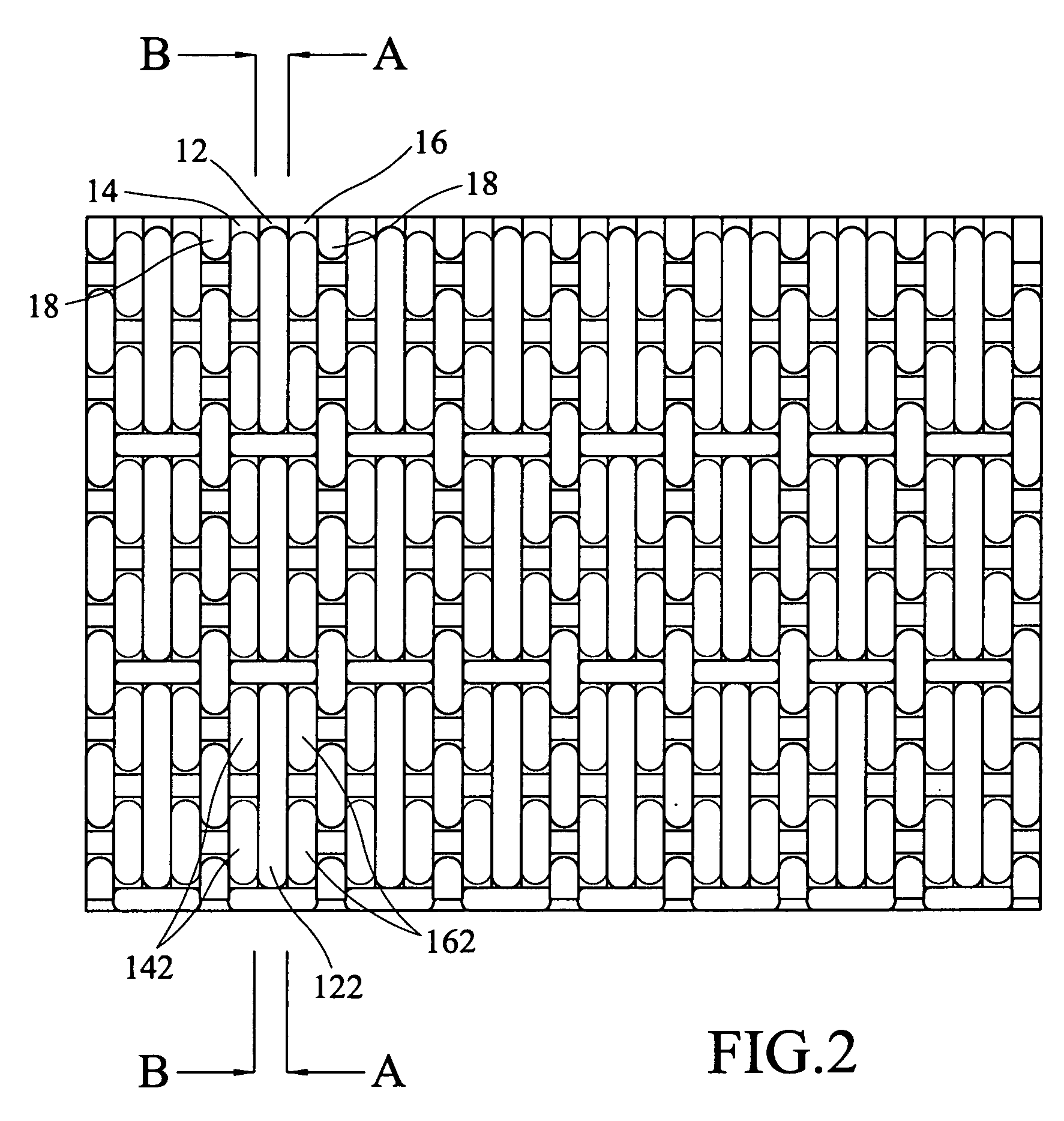

A protection product made of (i) a woven fabric woven with a high-performance fiber, in which the opening rate of thread-opening treatment is 0 to 5%, and the width of a thread constituting the woven fabric is 10-fold or more relative to the thread thickness, (ii) a woven fabric in which the cross-sectional shape of a thread constituting the woven fabric is thinner on an edge side of both ends as compared with an intermediate part in the width direction, or (iii) a woven fabric woven with a twistless high-performance fiber having a fineness of 200 to 15,000 dtex, in which the ratio of the thread width to the thread thickness of at least one of a warp and a weft is 10 to 100, and the opening rate is 0 to 5%.

Owner:SOWA TEXTILE +2

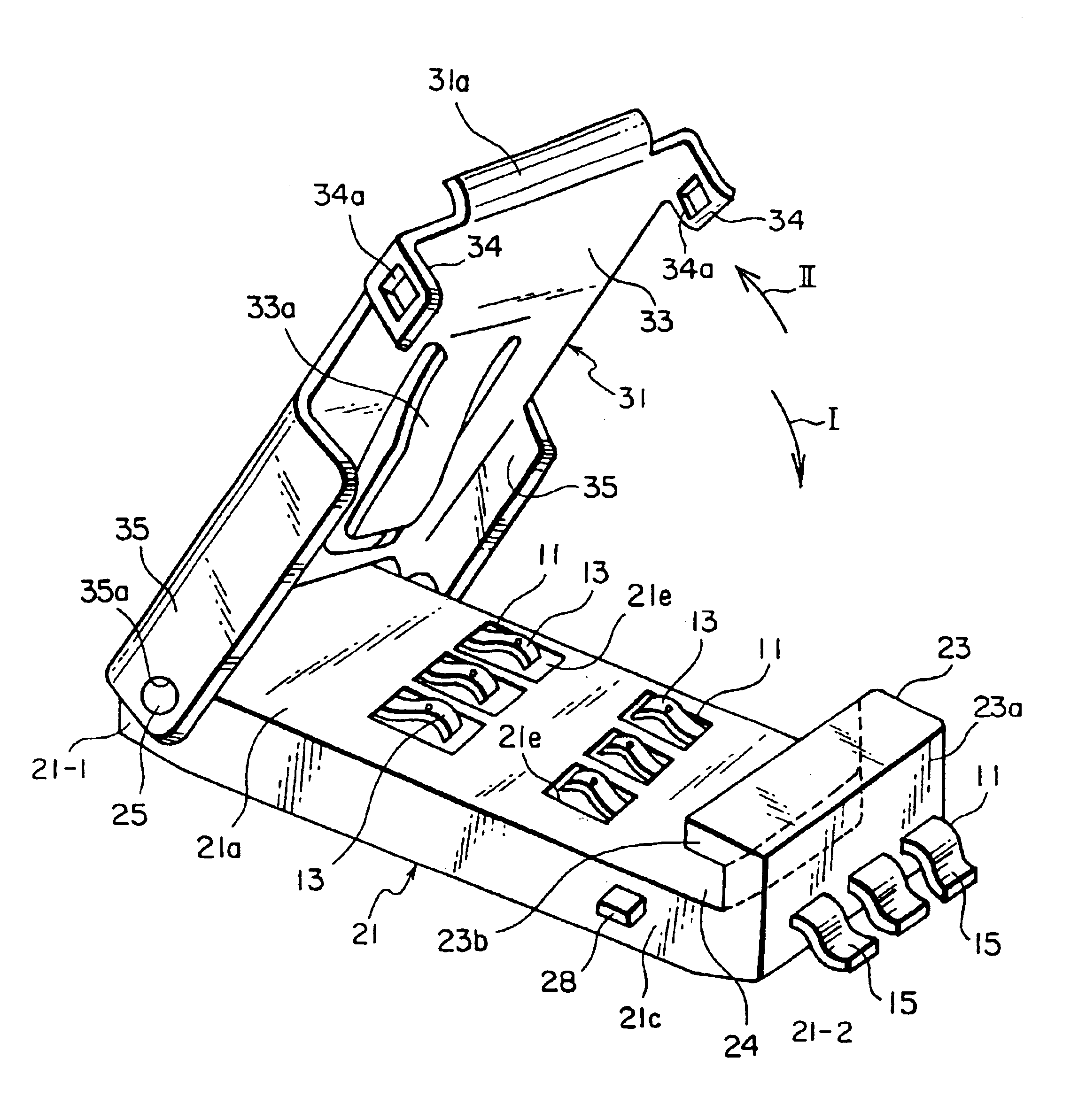

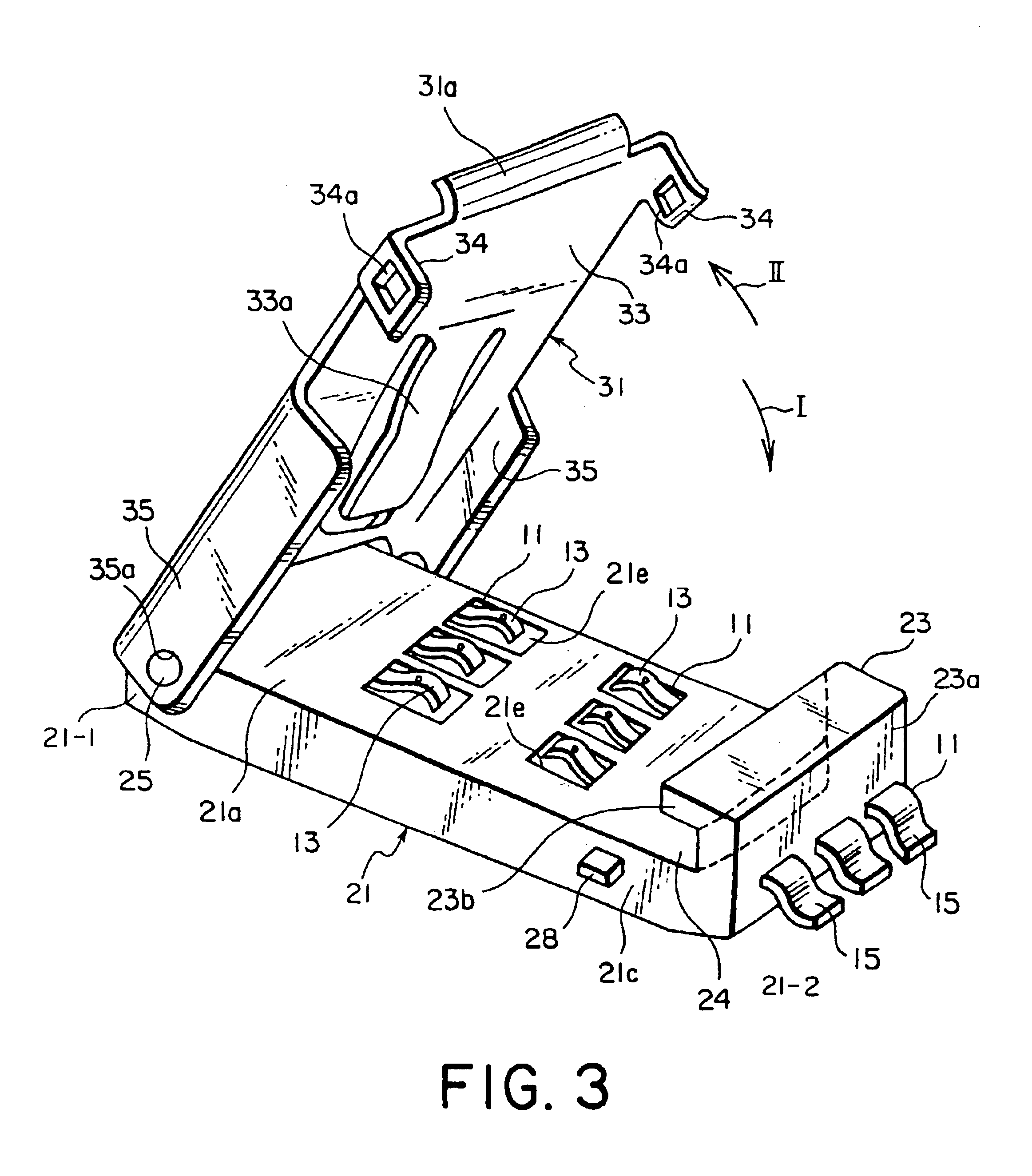

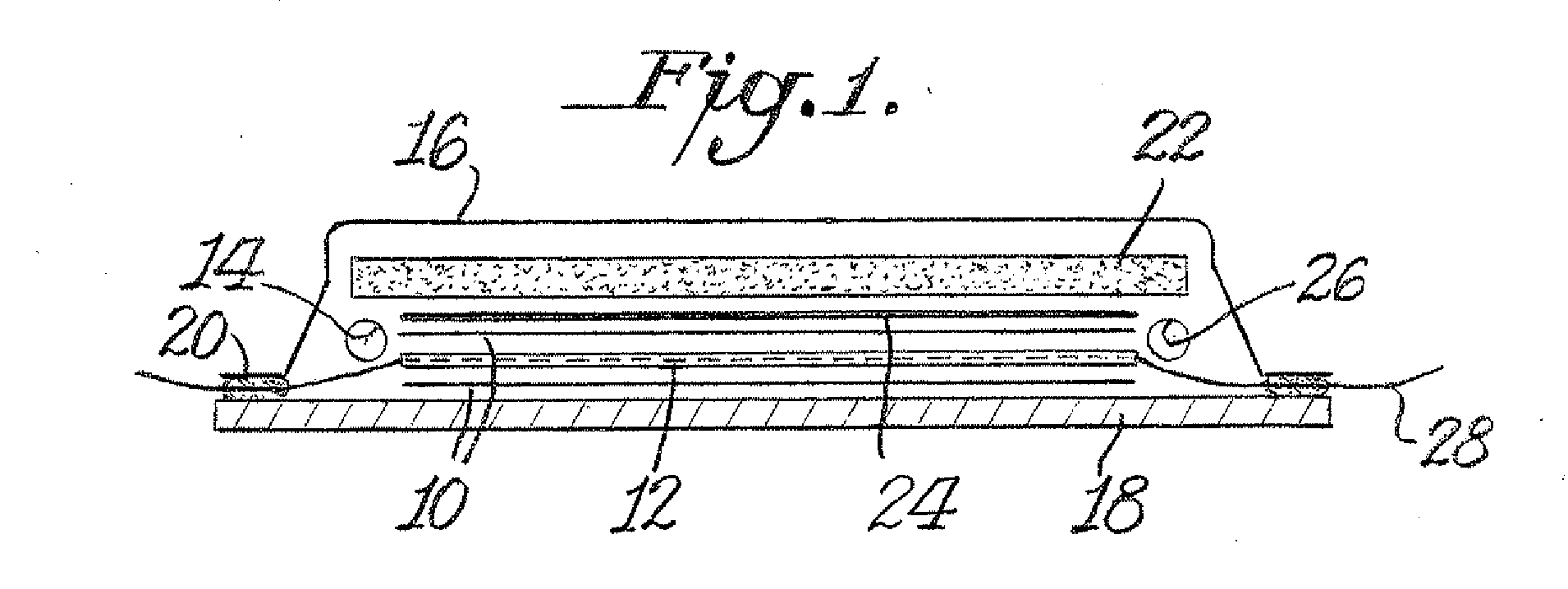

Card connector reduced in operating force

InactiveUS6890203B2Reduce operating forceReduce forceEngagement/disengagement of coupling partsConveying record carriersEngineeringMechanical engineering

Owner:JAPAN AVIATION ELECTRONICS IND LTD

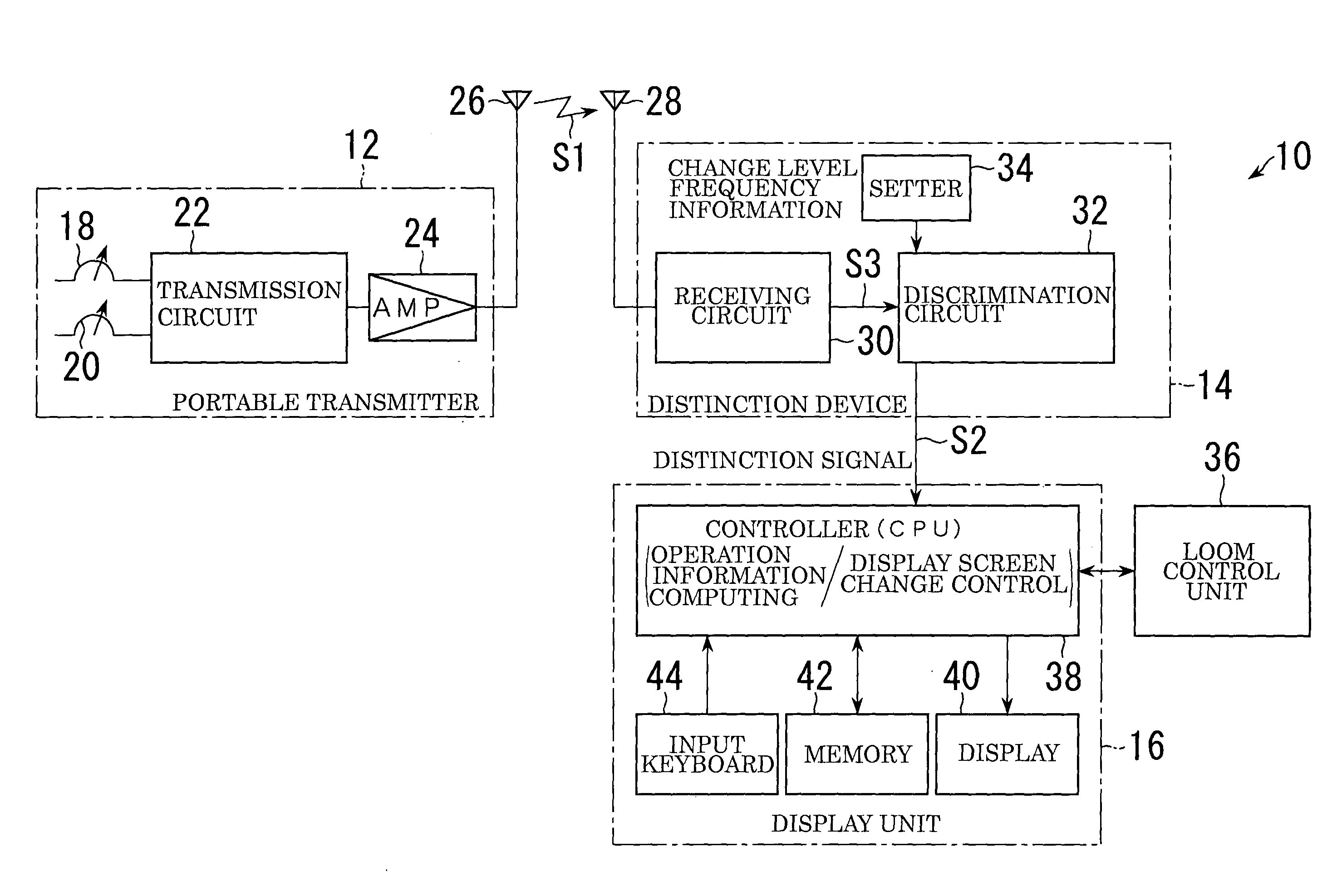

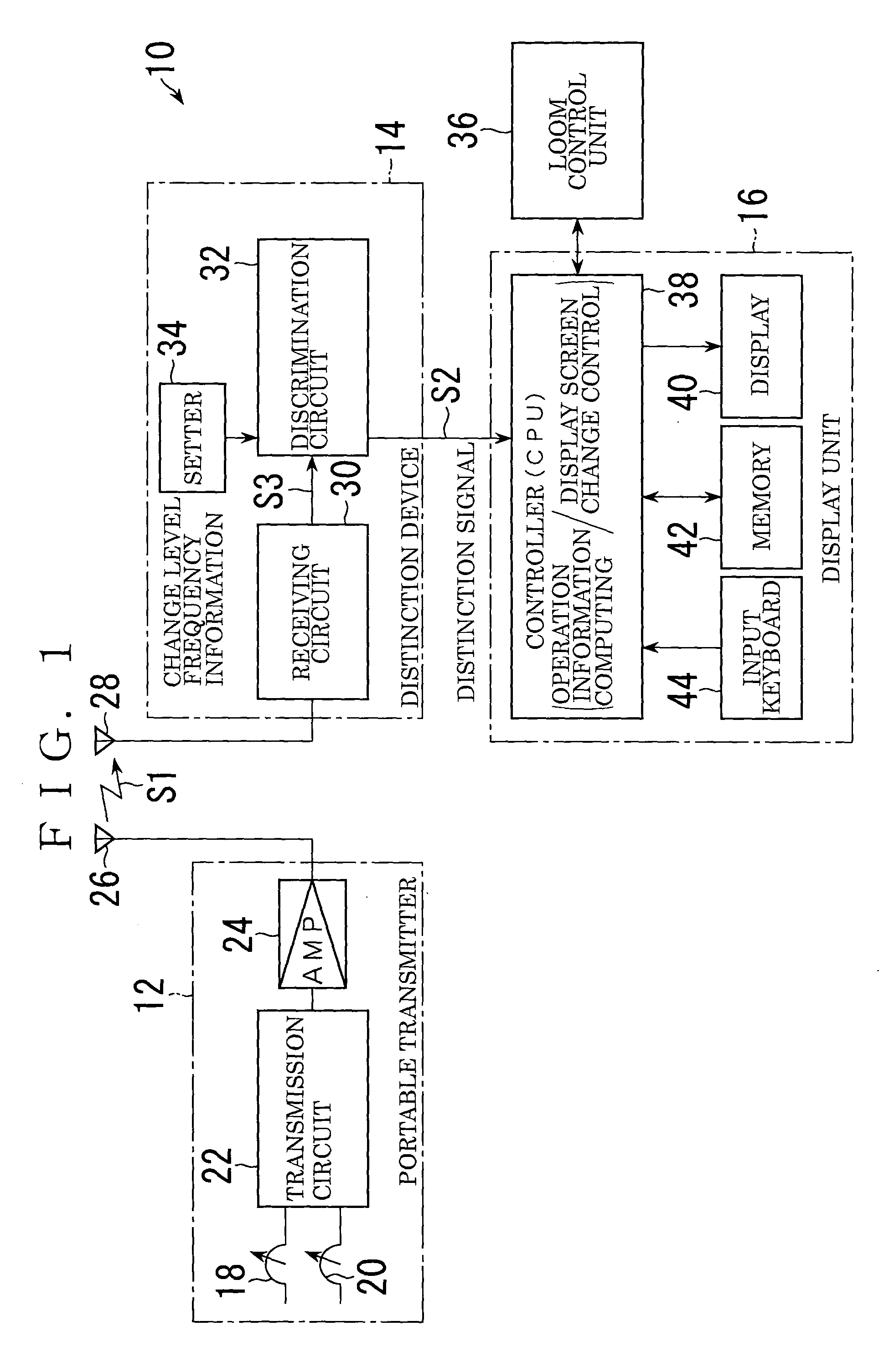

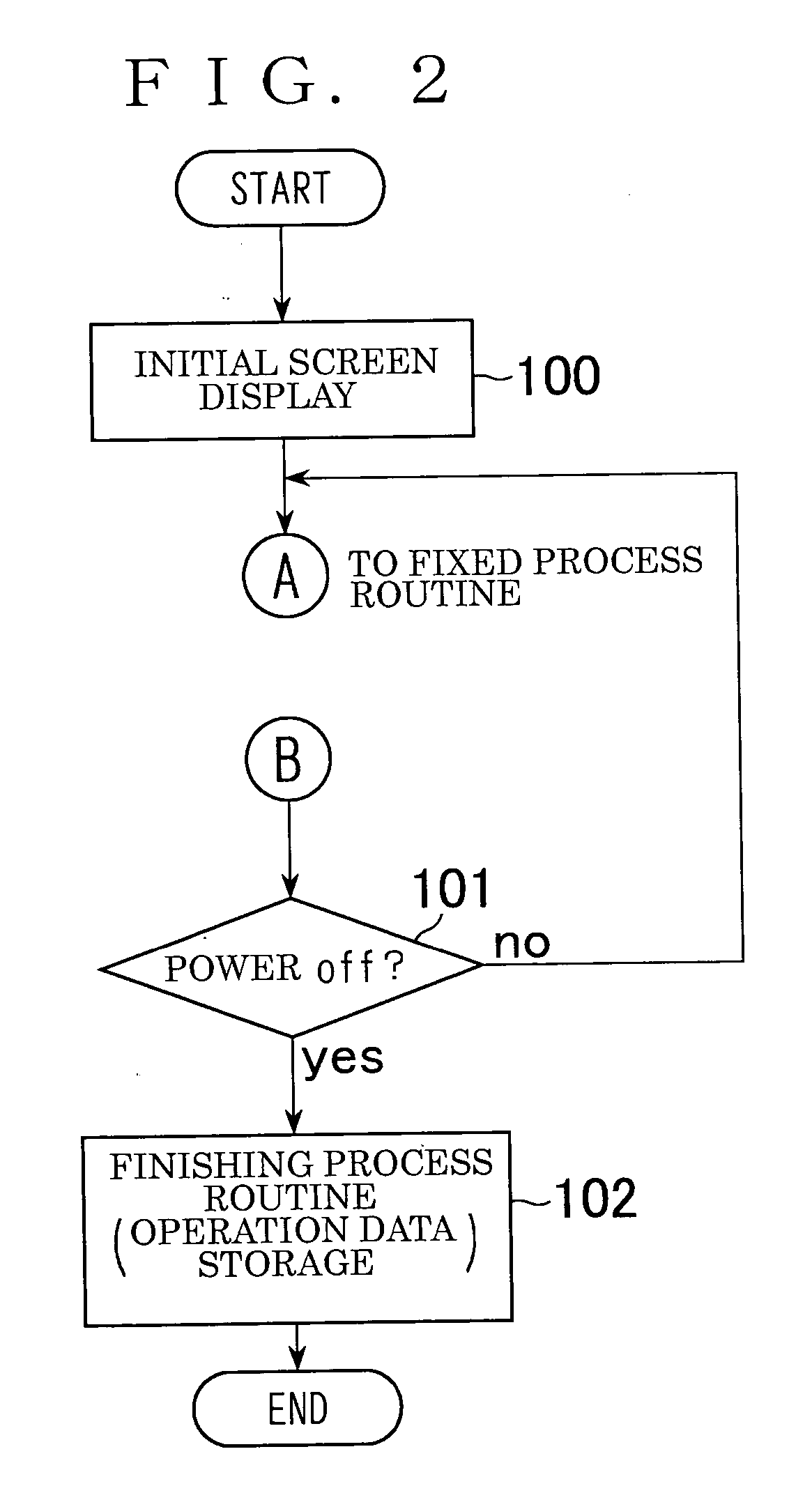

Information display apparatus of a loom

The information display apparatus is characterized by storing at least plural pieces of loom information, by comprising: data control means capable of outputting the stored loom information; display means for displaying in a screen the loom information outputted from data control means; and distinction means for distinguishing a kind of a person engaged in weaving and outputting a distinction result in the data control means, and by presetting in the data control means the item for display corresponding to the distinction result, thereby outputting the loom information relative to the item for display corresponding to the distinction result from the data control means to the display means.

Owner:TSUDAKOMA KOGYO KK

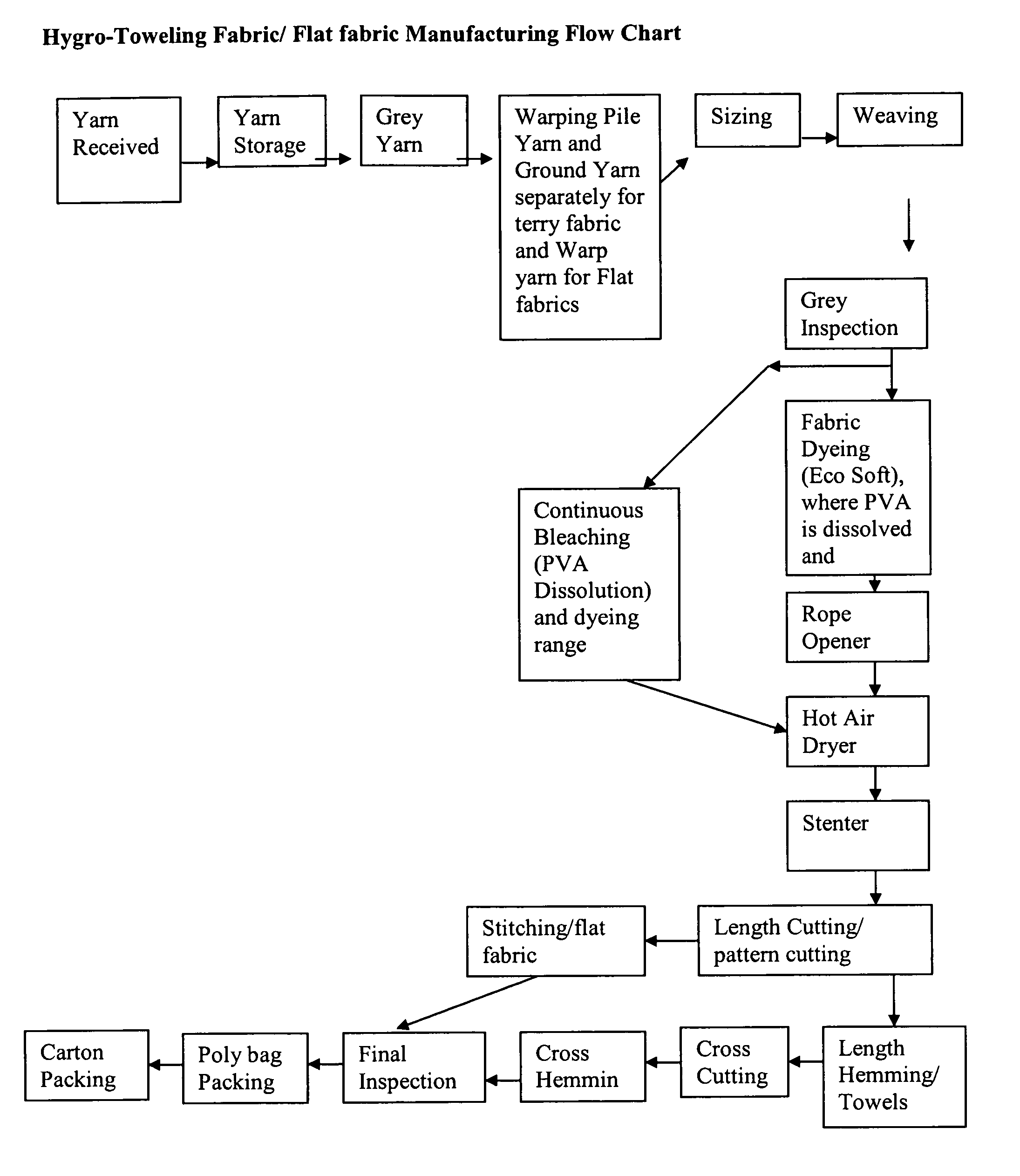

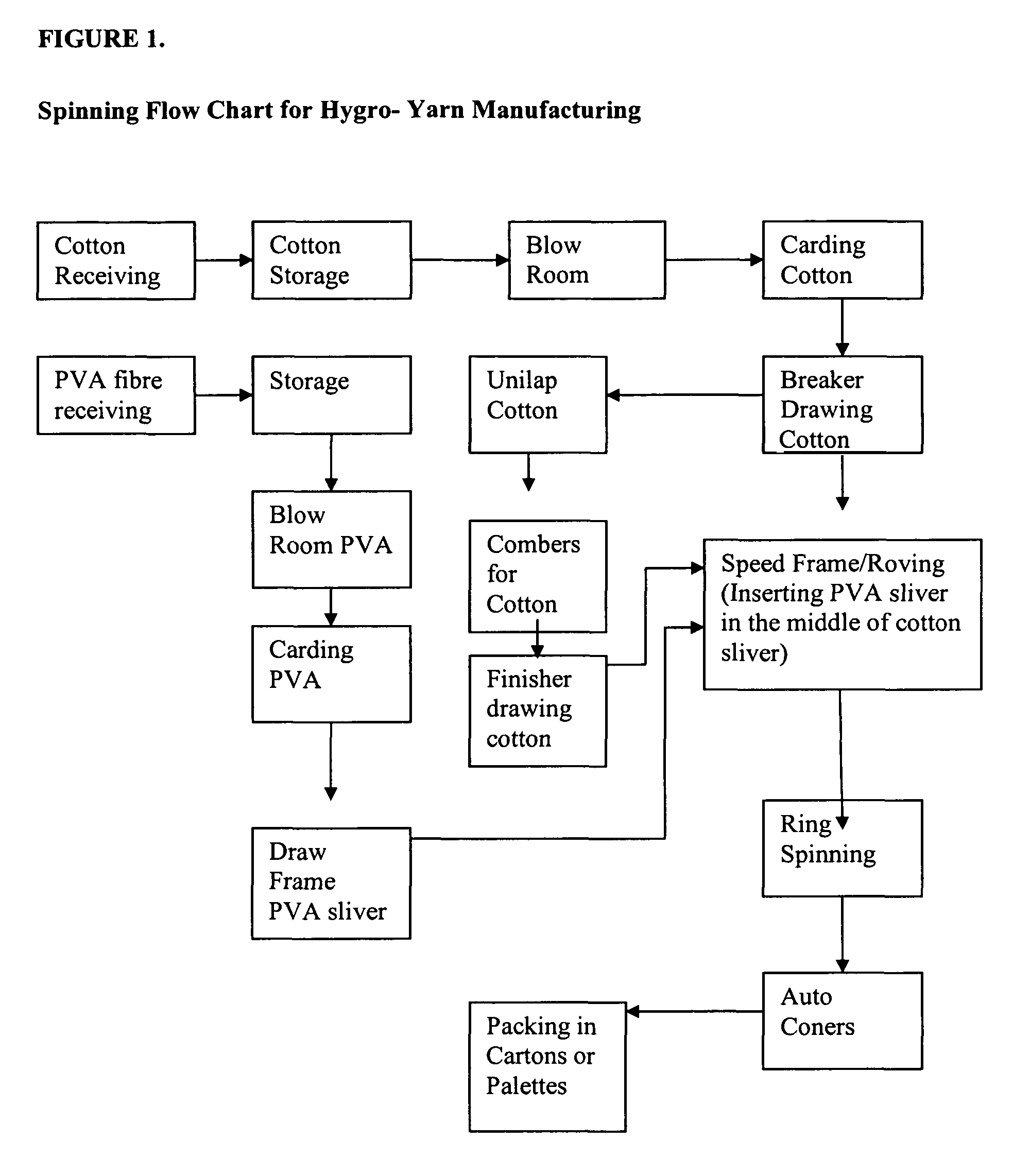

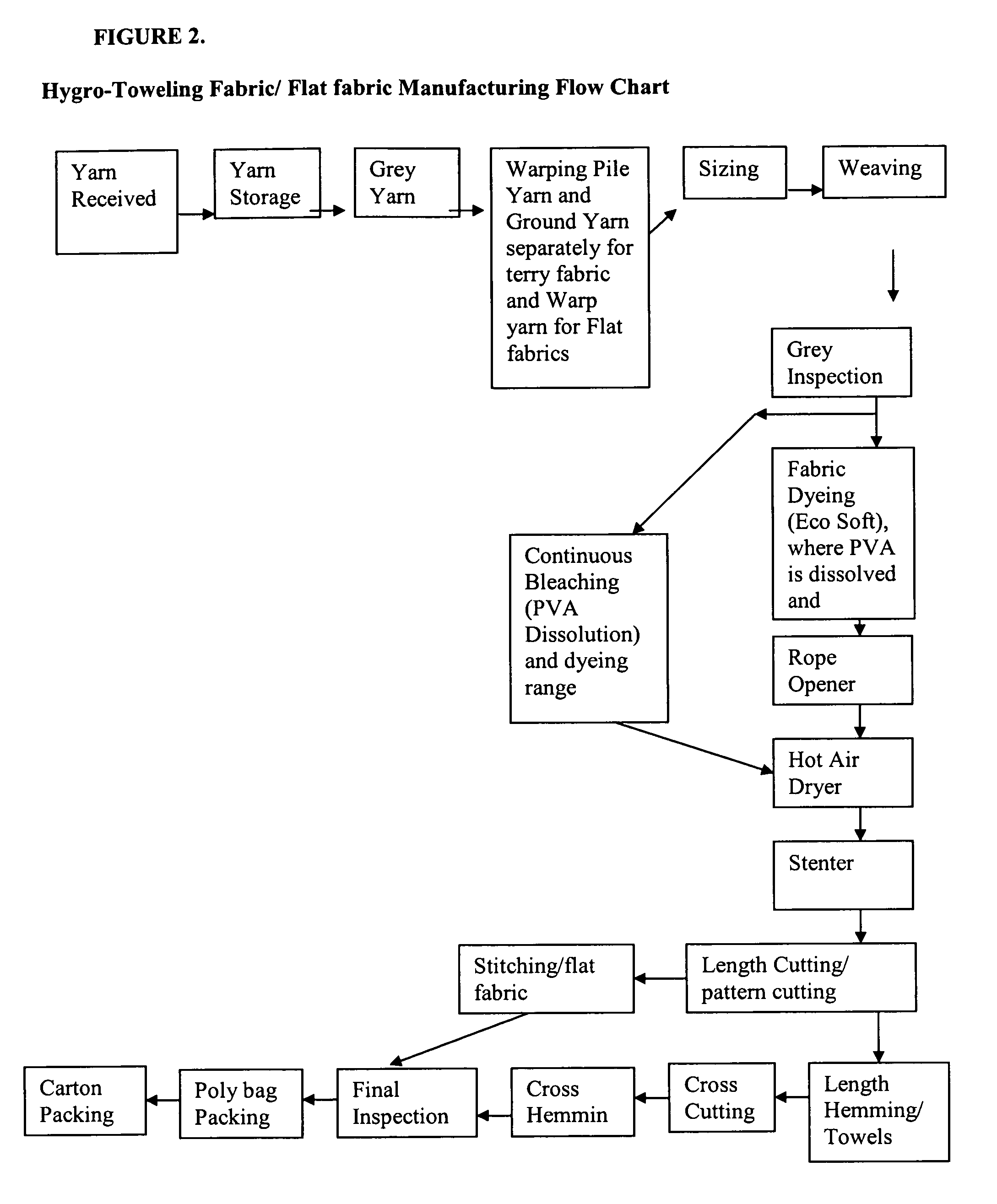

Hygro materials for use in making yarns and fabrics

ActiveUS8733075B2Fast dryingIncrease in sizeFabric breaking/softeningLayered productsFiberWarm water

A process is described wherein pile yarn is woven with cotton weft and warp yarns to produce terry fabrics, such as towels. The fabric is then washed in warm water to dissolve the PVA fibers. The amount of fibers dissolved, depends upon the count of the yarn or yarns used. By dissolving the PVA fibers, a hollow air space is produced throughout the pile yarn, corresponding to an increase in the air space in the pile yarn. By increasing the air space in the pile yarn, the resulting towels are softer and bulkier than standard cotton towels. The present invention further relates to pile yarn in terry woven fabric (warp yarn), or weft yarn, in the case of flat fabrics.

Owner:WELSPUN INDIA LTD

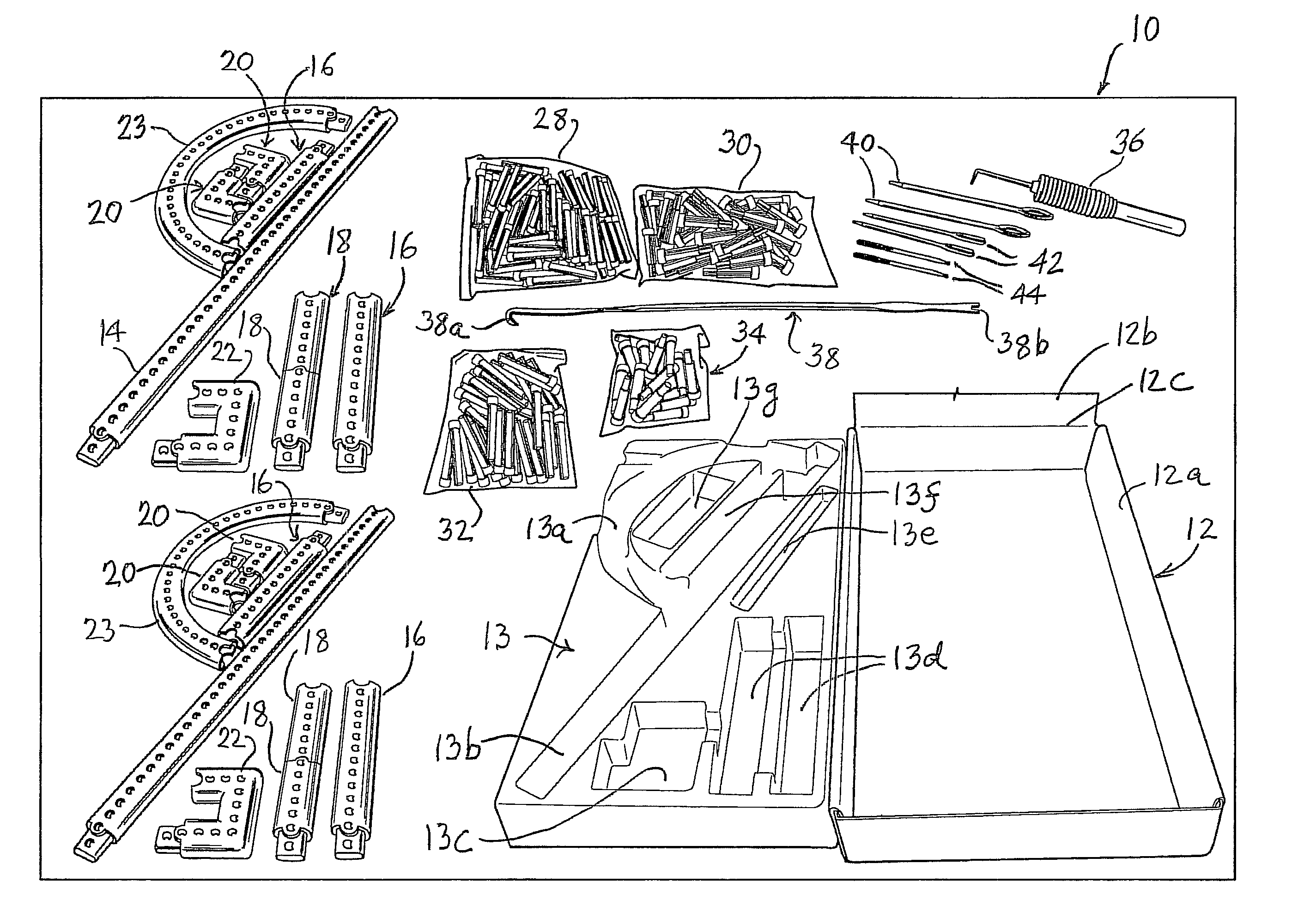

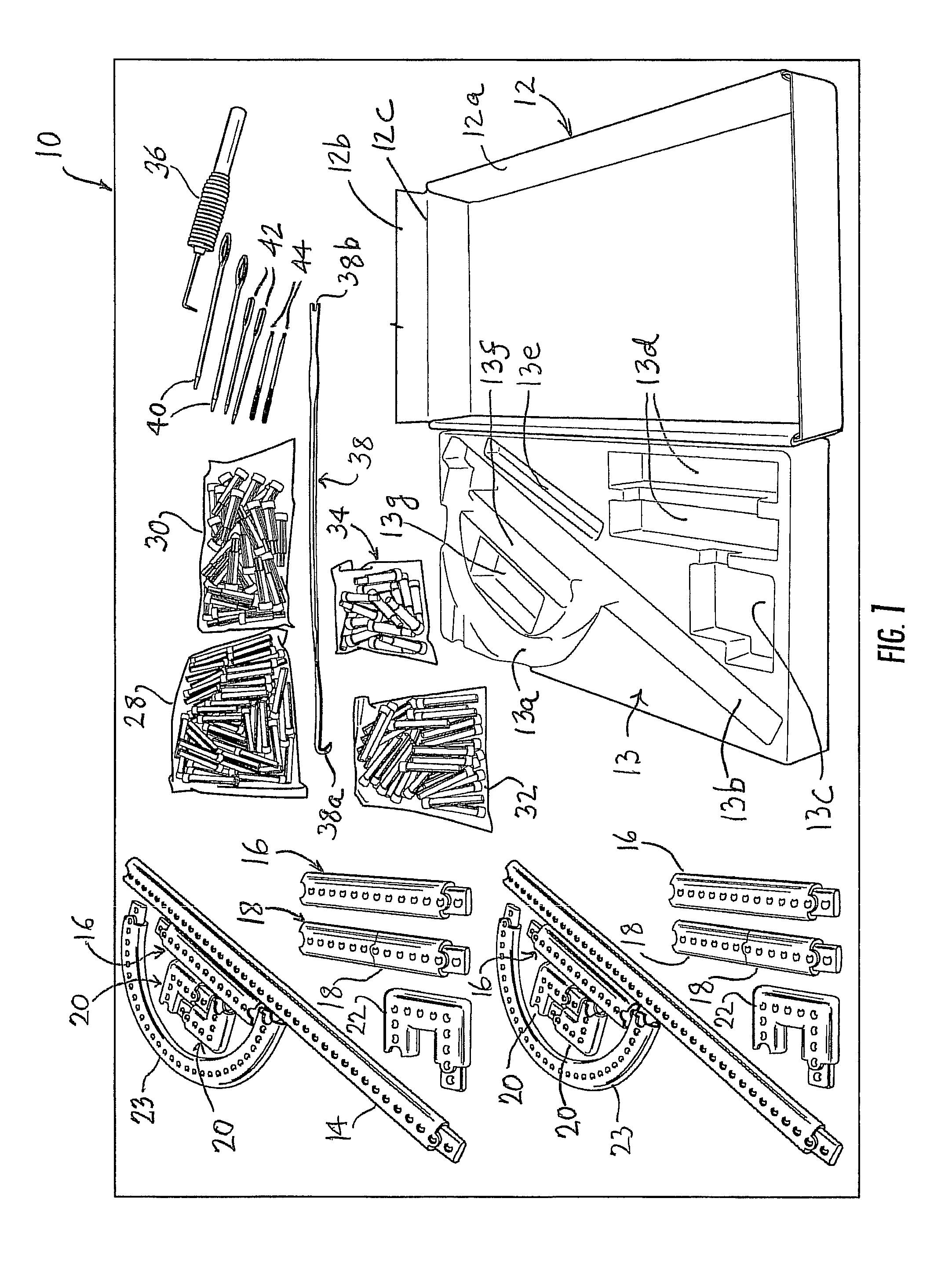

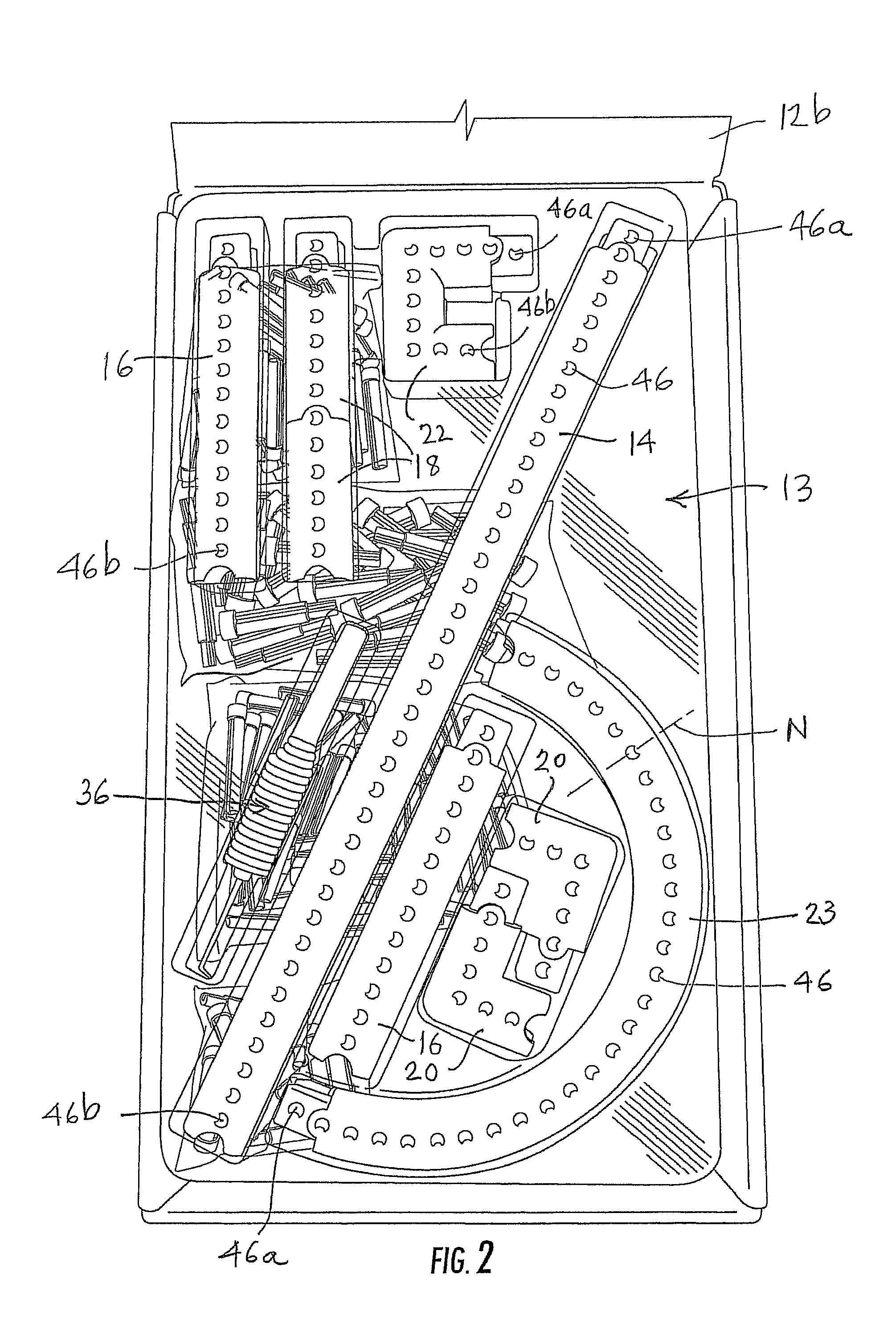

Modular adjustable frame hand loom

ActiveUS8316894B2Easy constructionReduce manufacturing costAuxillary apparatusContainer/bottle contructionYarnAbutment

An adjustable knitting and weaving hand loom includes differently shaped elongate sections. Tabs and channels connect the sections to form a closed frame by connecting adjoining sections in end-to-end abutment. The tabs and mating channels form sliding joints between adjoining sections. Each of the sections is provided with a series of substantially uniformly spaced holes or bores. End-most holes through the tabs and the channels are aligned when the axial tabs are fully slidably mated within associated axial channels. Pegs are dimensioned to be received both within aligned end-most holes at each slip joint and intermediate holes. The pegs are inserted into aligned end-most bores or holes function both to secure yarn during knitting and to lock the axial tabs from inadvertently separating from mating axial channels by movements along the direction of insertion.

Owner:SCHAUB RENE

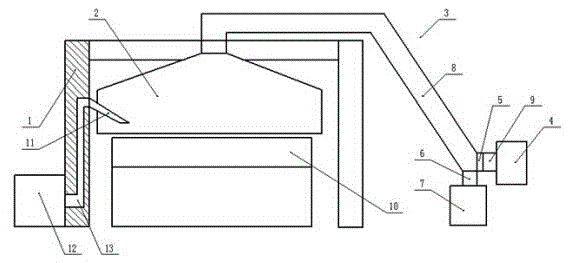

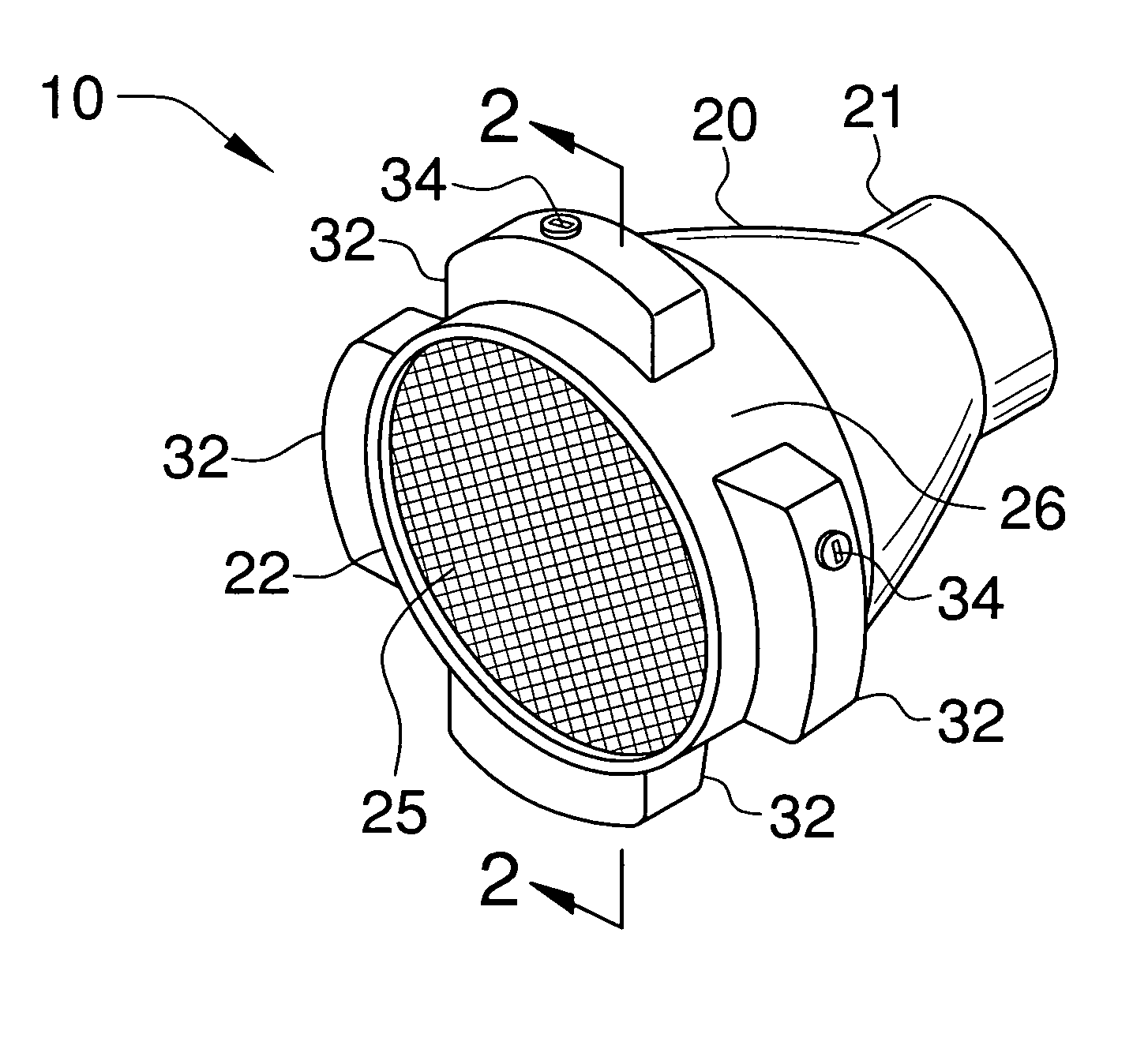

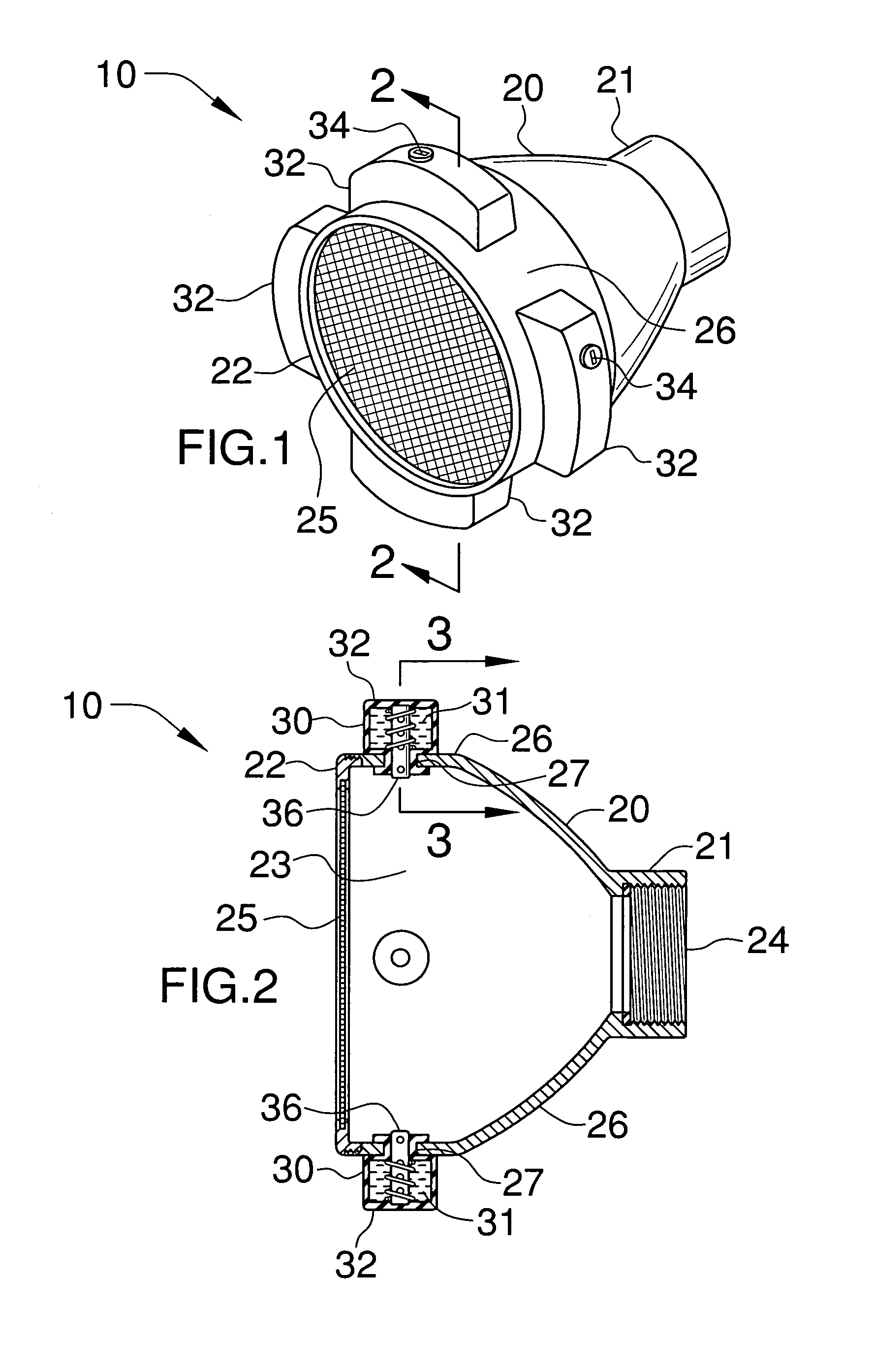

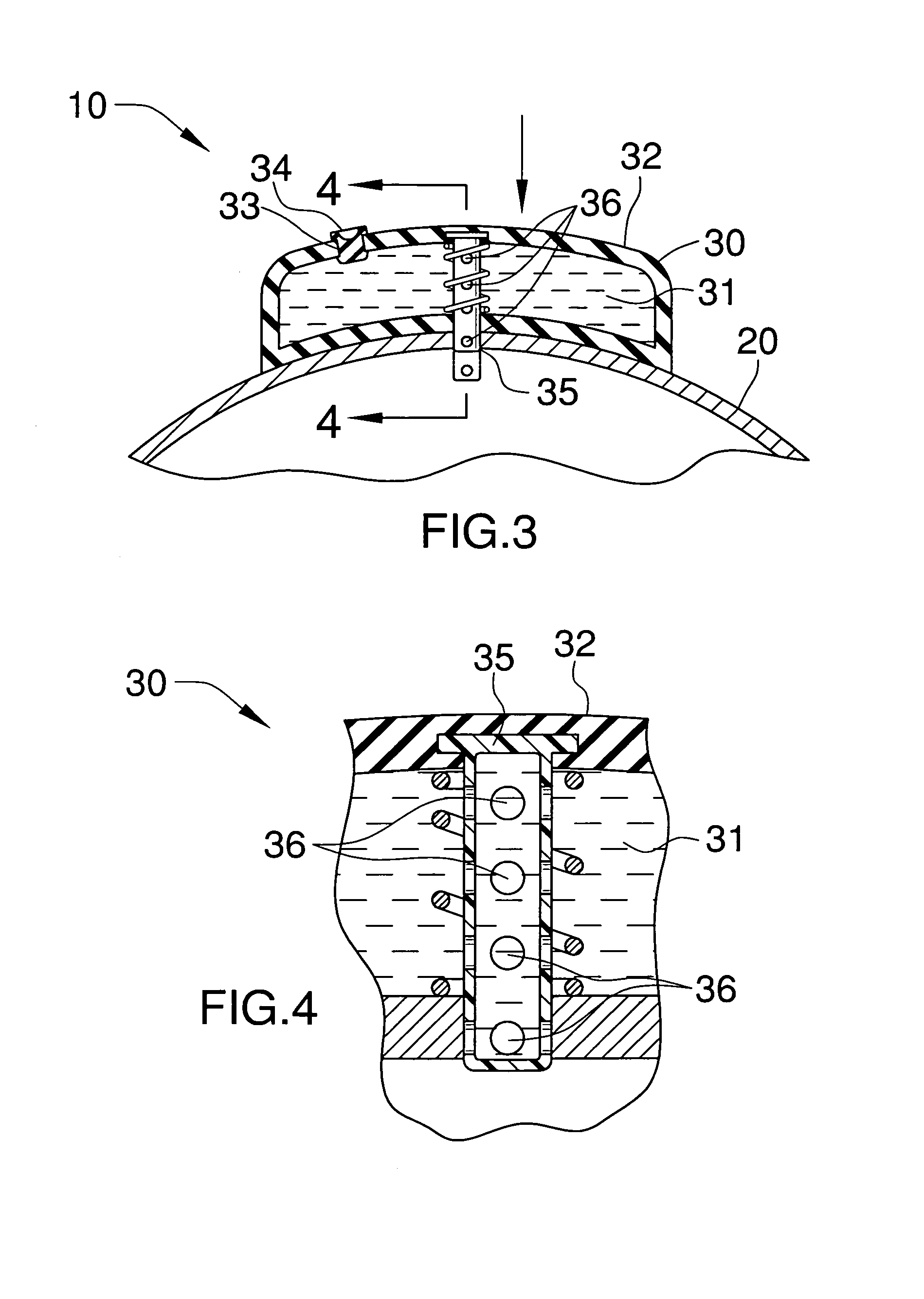

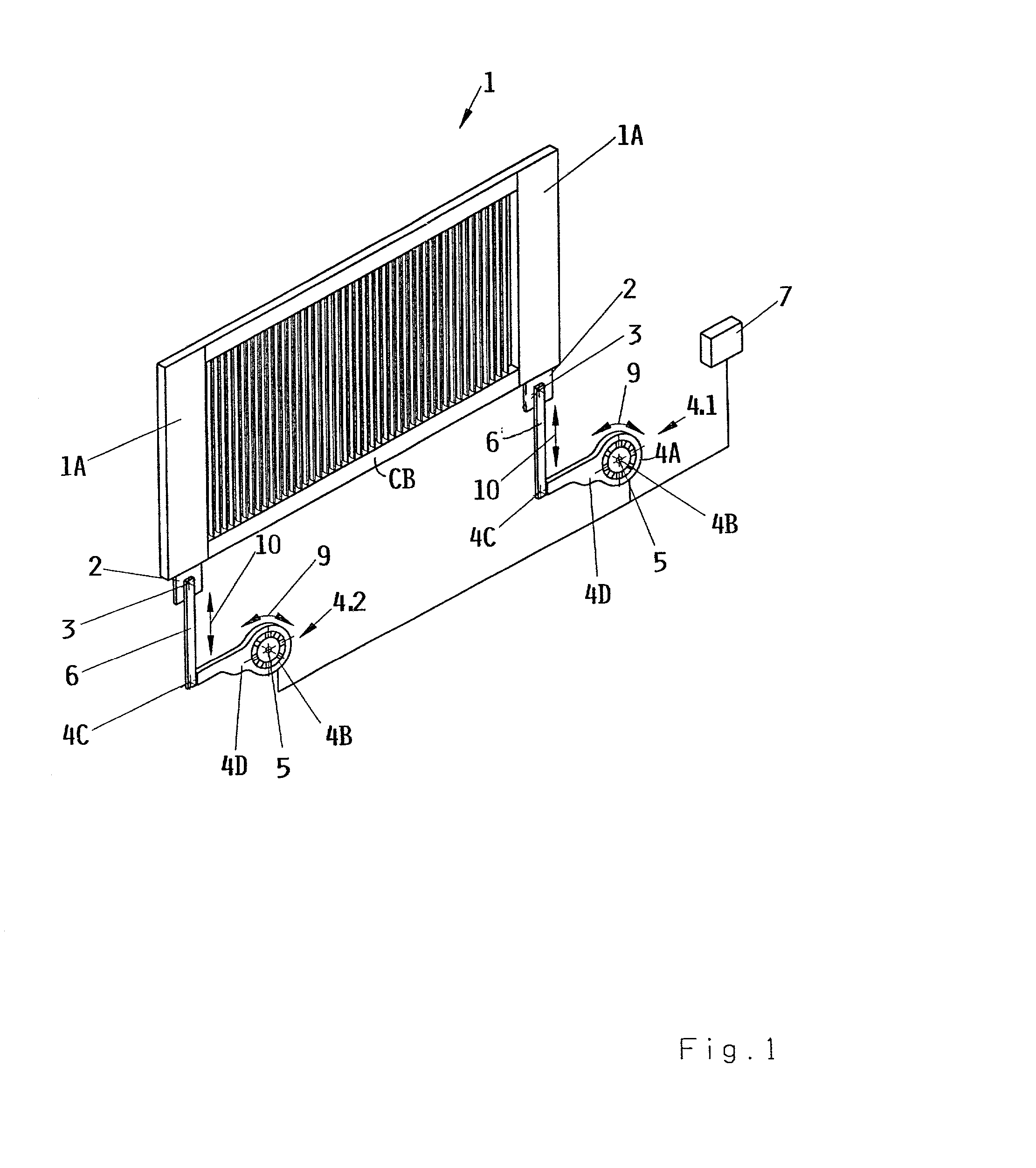

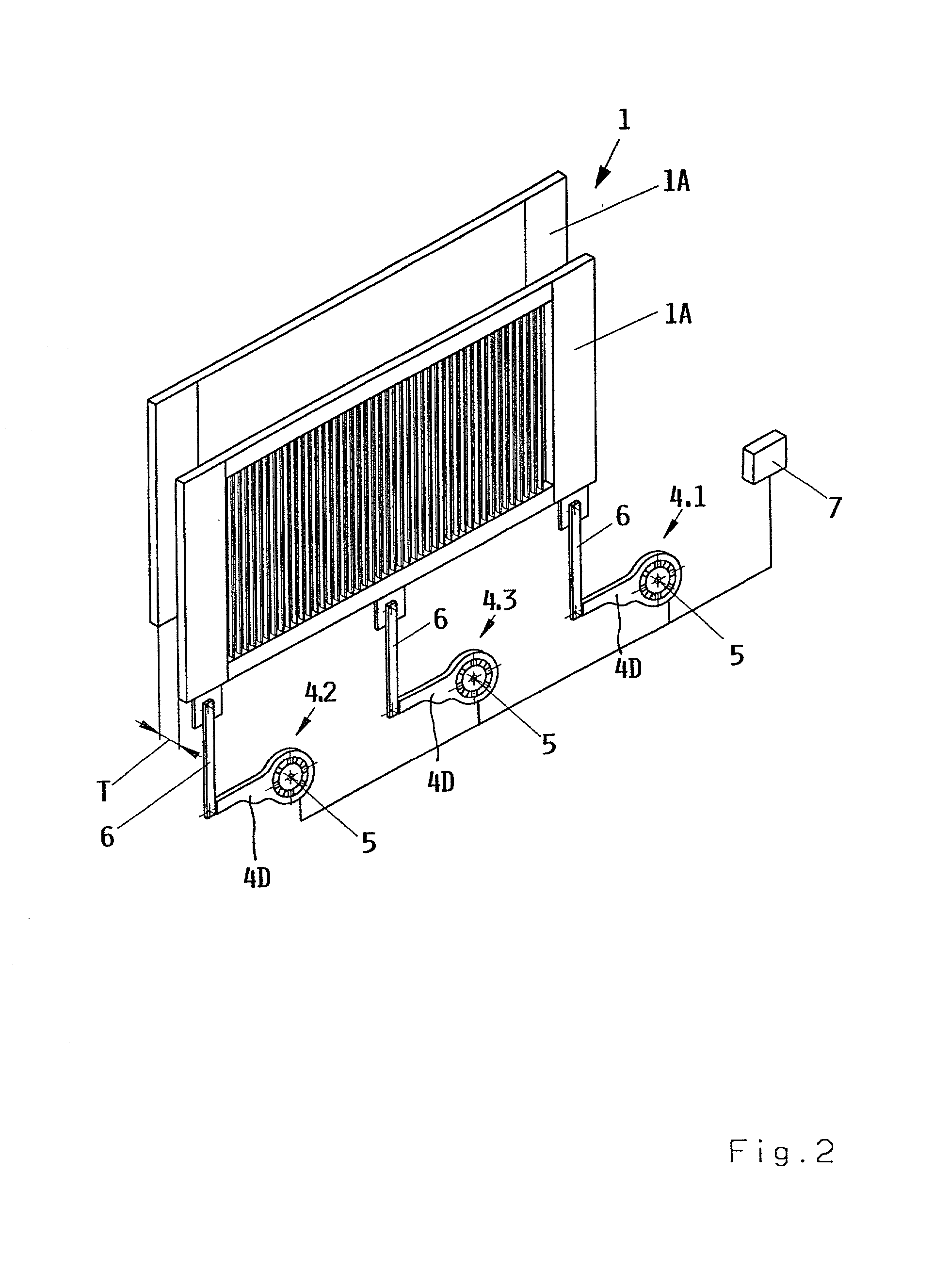

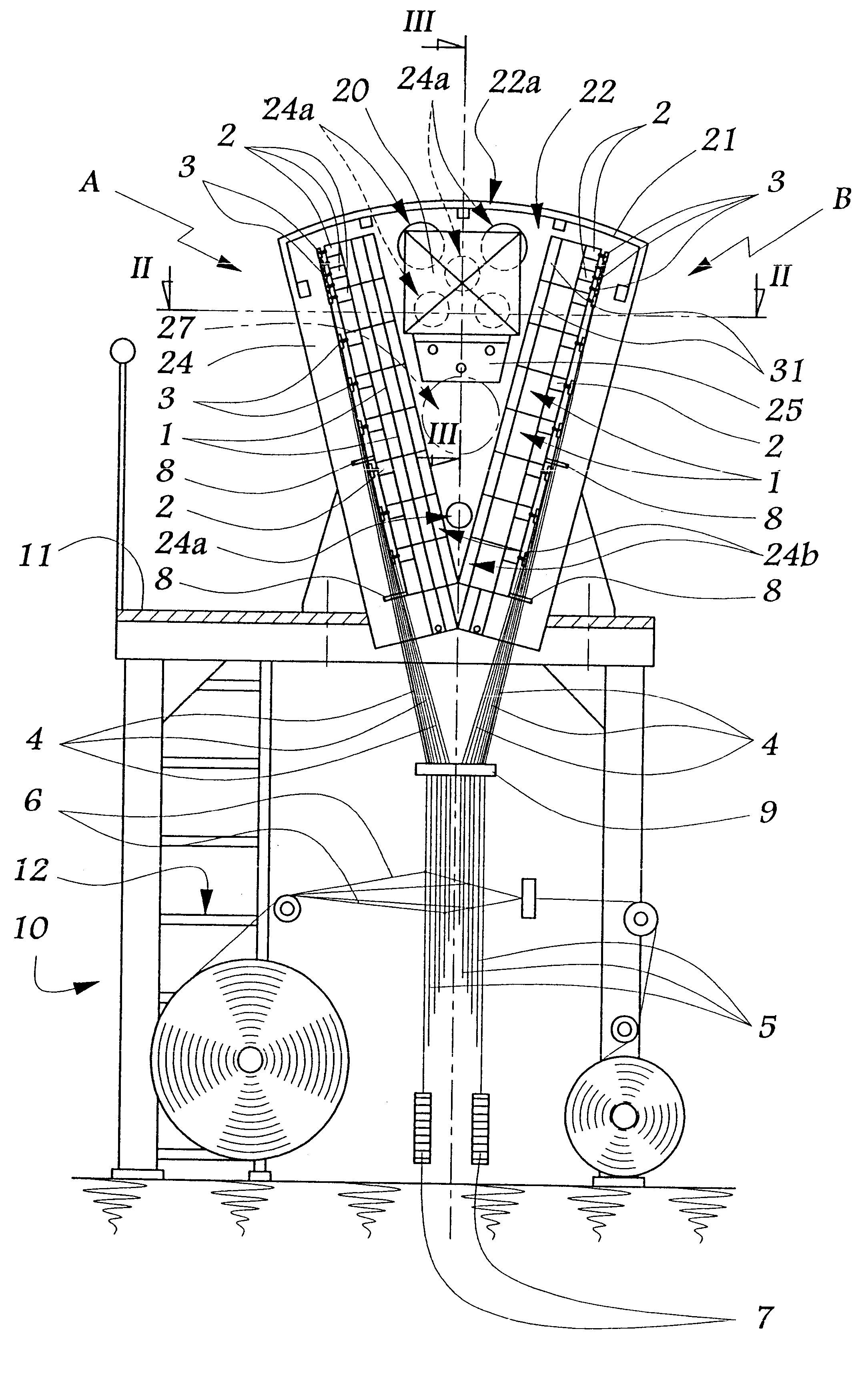

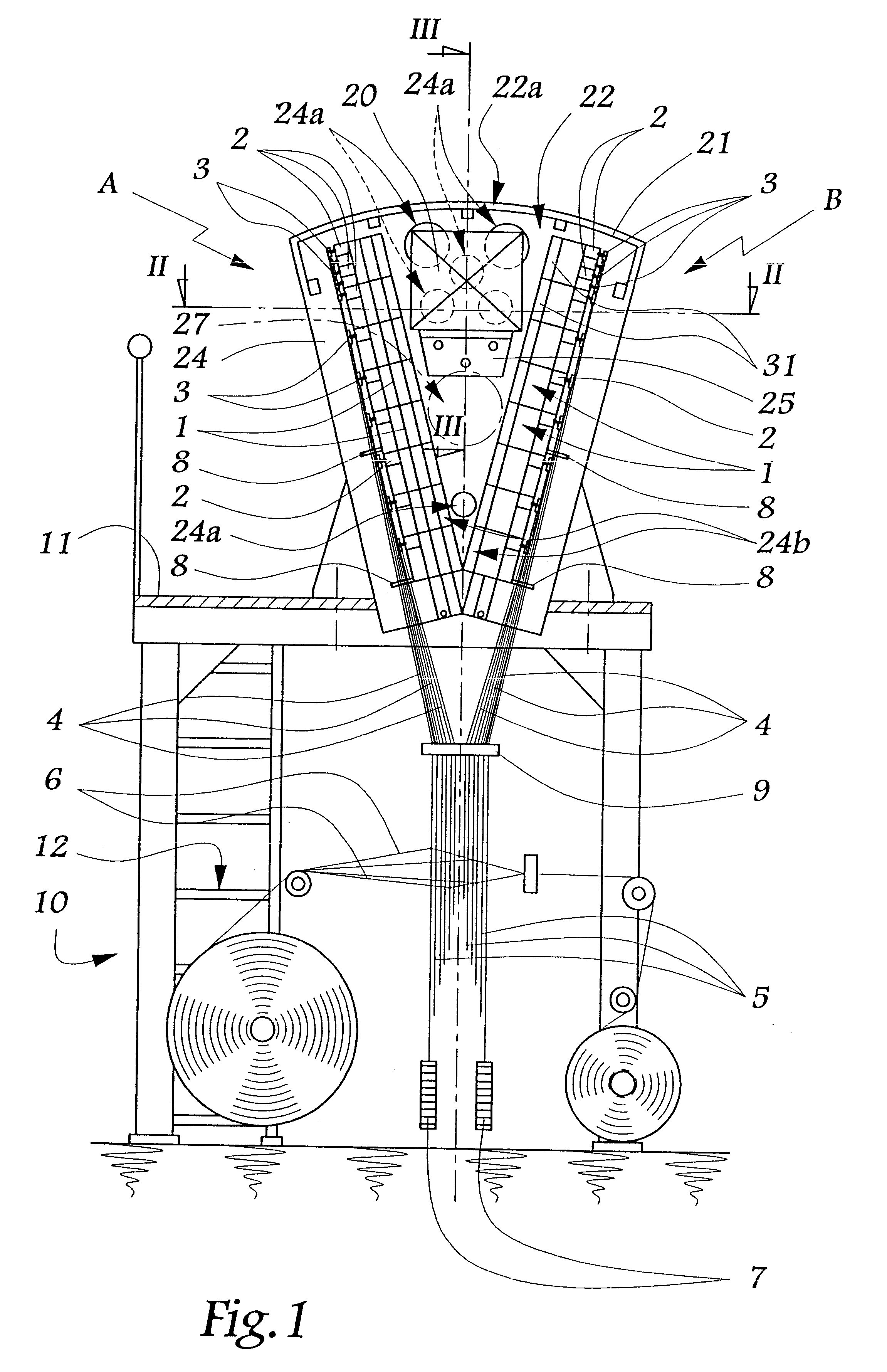

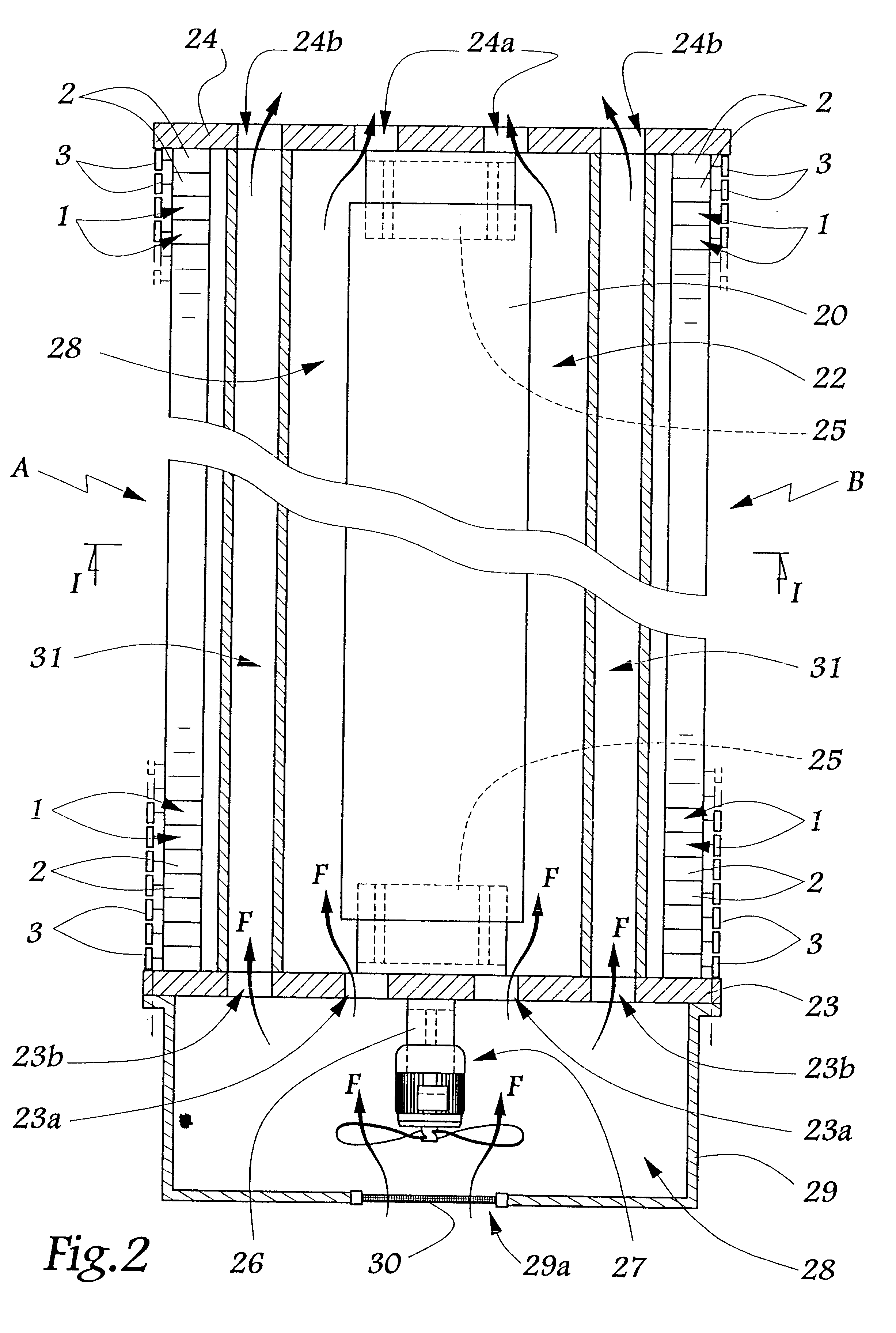

Textile machine dust removal device

InactiveCN104404698AImprove cleanlinessPhysical health threatAuxillary apparatusKnittingEngineeringAir blower

The invention discloses a textile machine dust removal device. The textile machine dust removal device comprises a support, a filter screen and a spinning device; a collection bucket is arranged on the support; the lower end of the collection bucket can rightly cover above the spinning device; a collection pipe which is communicated with a collection chamber of the collection bucket is arranged on the collection bucket; the collection pipe is communicated with an input end of an exhaust fan; the collection pipe comprises an inclined pipe; the inclined pipe is communicated with a straight pipe; the filter screen is arranged inside the collection pipe; the collection pipe at the front end of the filter screen is communicated with a dust outlet pipe; an outlet end of the dust outlet pipe is arranged inside a collection bag; an air blower is arranged outside the left side of a machine frame; the air blower is connected with an air channel which is formed inside the machine frame; an outlet of the air channel is provided with a dust blowing opening. According to the textile machine dust removal device, the structure is simple, dust can be blocked through the filter screen, then the dust falls into the collection bag through the dust outlet pipe, and accordingly collection of the dust is achieved, the clean and tidy degree of a workshop is guaranteed, and meanwhile threat to health of workers from the dust is avoided.

Owner:SUQIAN CITY SUYU DISTRICT ZHUOWEI SILK

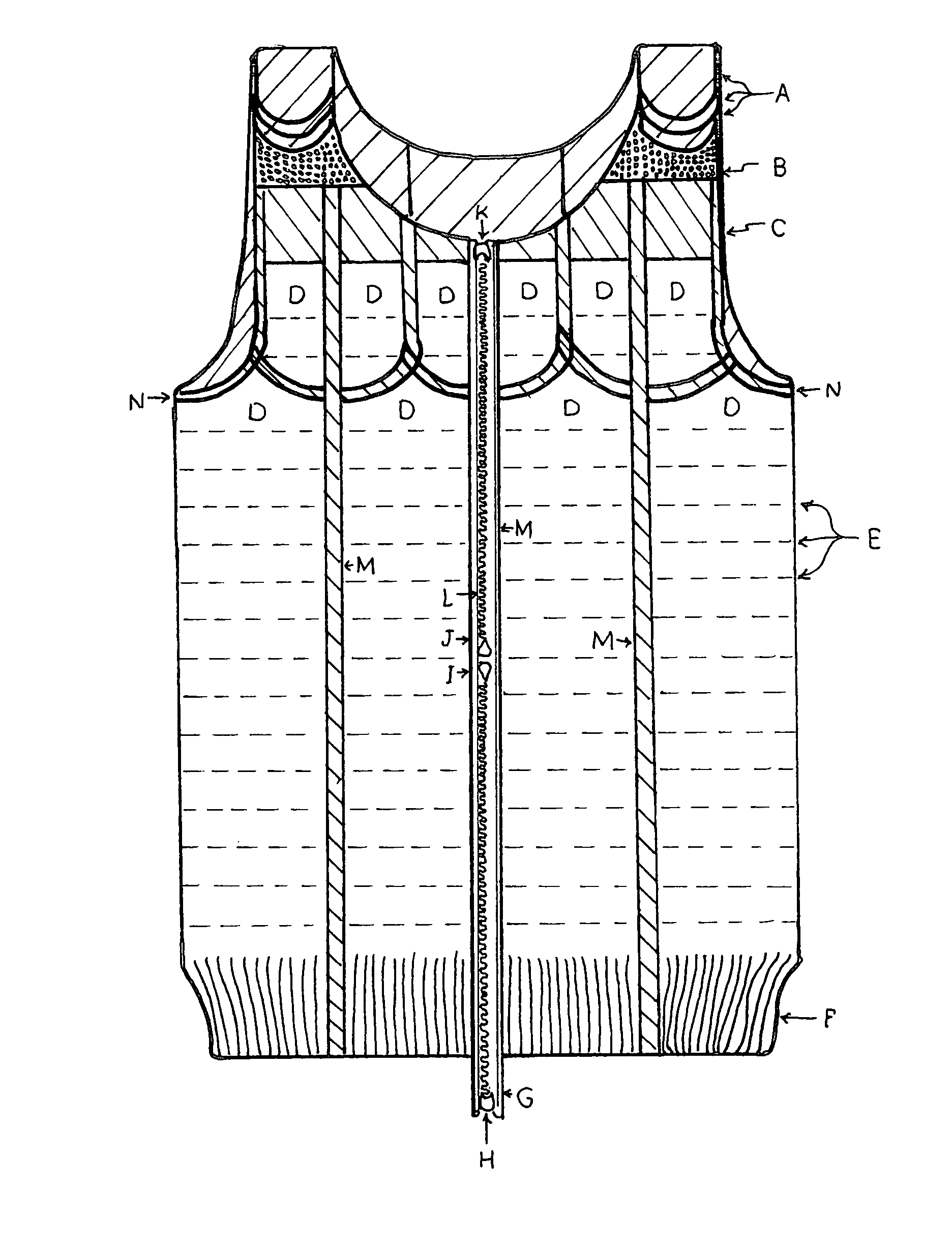

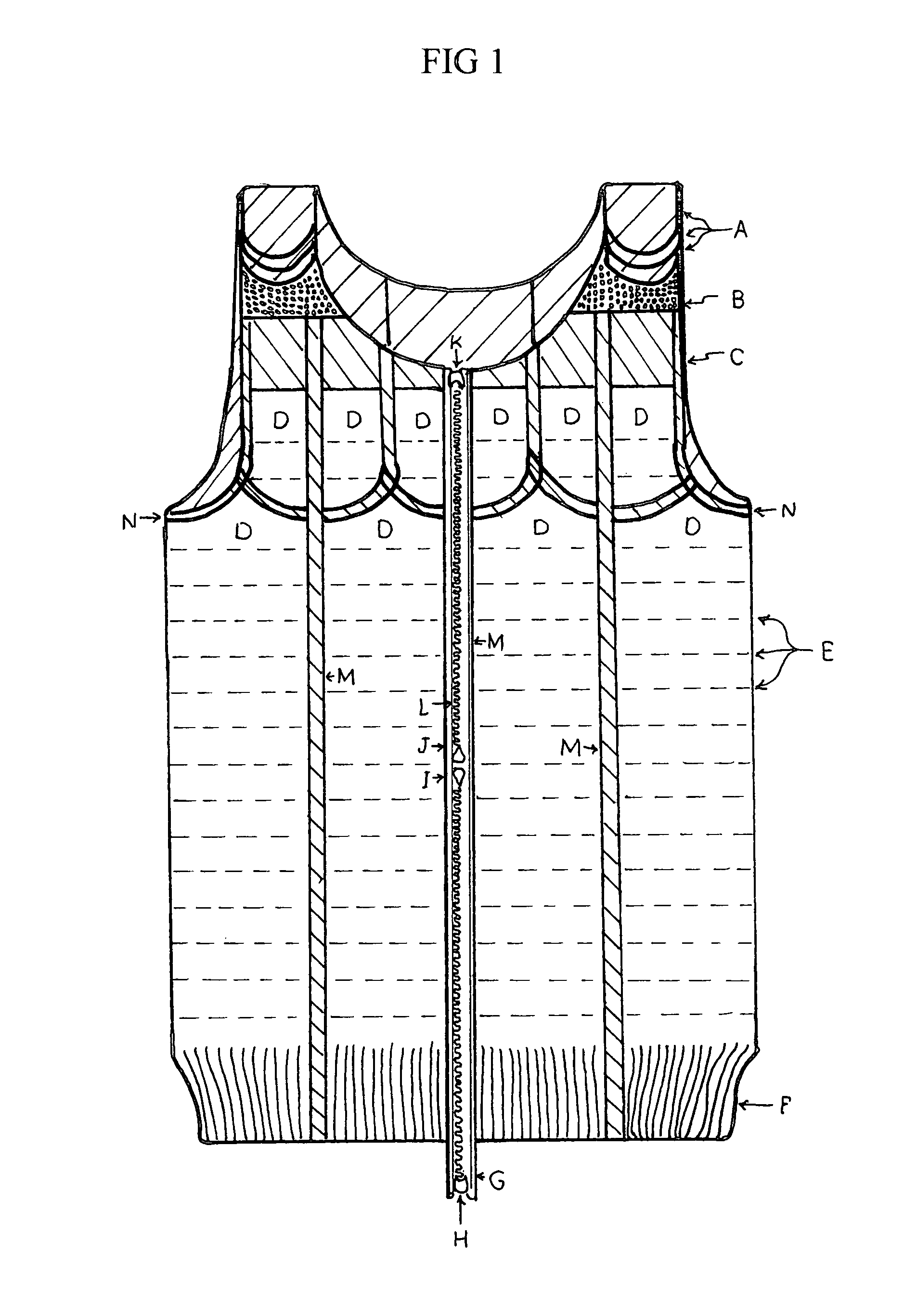

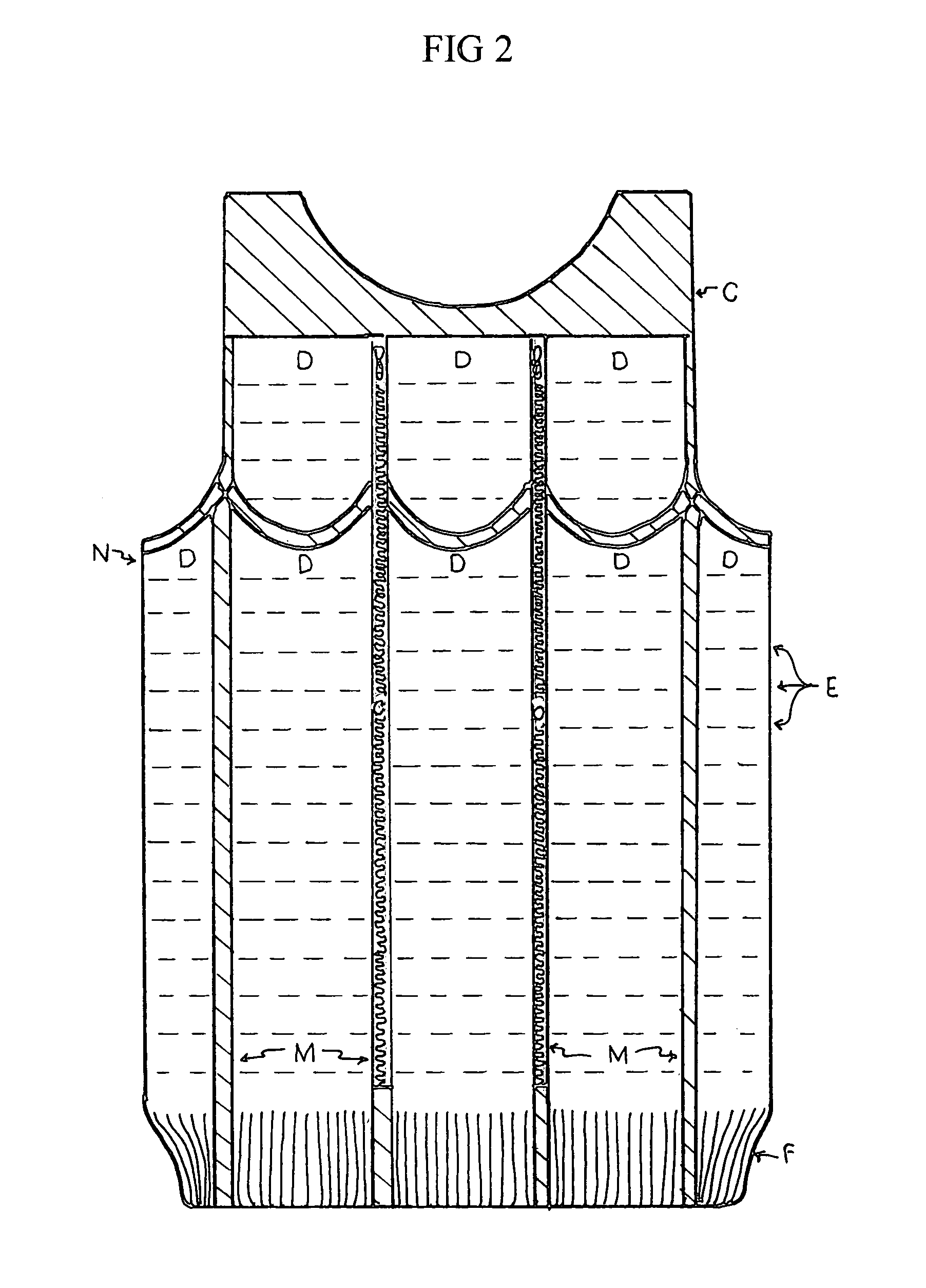

Weaving process for production of a full fashioned woven stretch garment with load carriage capability

InactiveUS7841369B1Easy to useHigher compressive forceJacquardsLoomsPulp and paper industryLoad carriage

A weaving process for constructing weft stretch full fashioned utility garments using a jacquard machine, an electronic loom and highly stretchable elastomeric fill yarns.

Owner:V PARADOX

Fragrance-dispensing shower head

InactiveUS7093775B1Precise positioningSustained beneficialPiezoelectric/electrostriction/magnetostriction machinesLoomsWater flowEngineering

A fragrance dispensing shower head apparatus includes a shower head including proximal and distal end portions and a central bore extending therebetween. The proximal end portion has a threaded inner surface. The shower head further includes a wire-mesh screen traversing water flow such that foreign debris can be sustained upstream of the distal end portion. A mechanism is included for ejecting a quantity of the fragrance into the bore and includes a plurality of reservoirs for holding the fragrance. The reservoirs introduce the fragrance adjacent to the distal end portion and have substantially similar shapes.

Owner:BINGHAM TRAVIS D

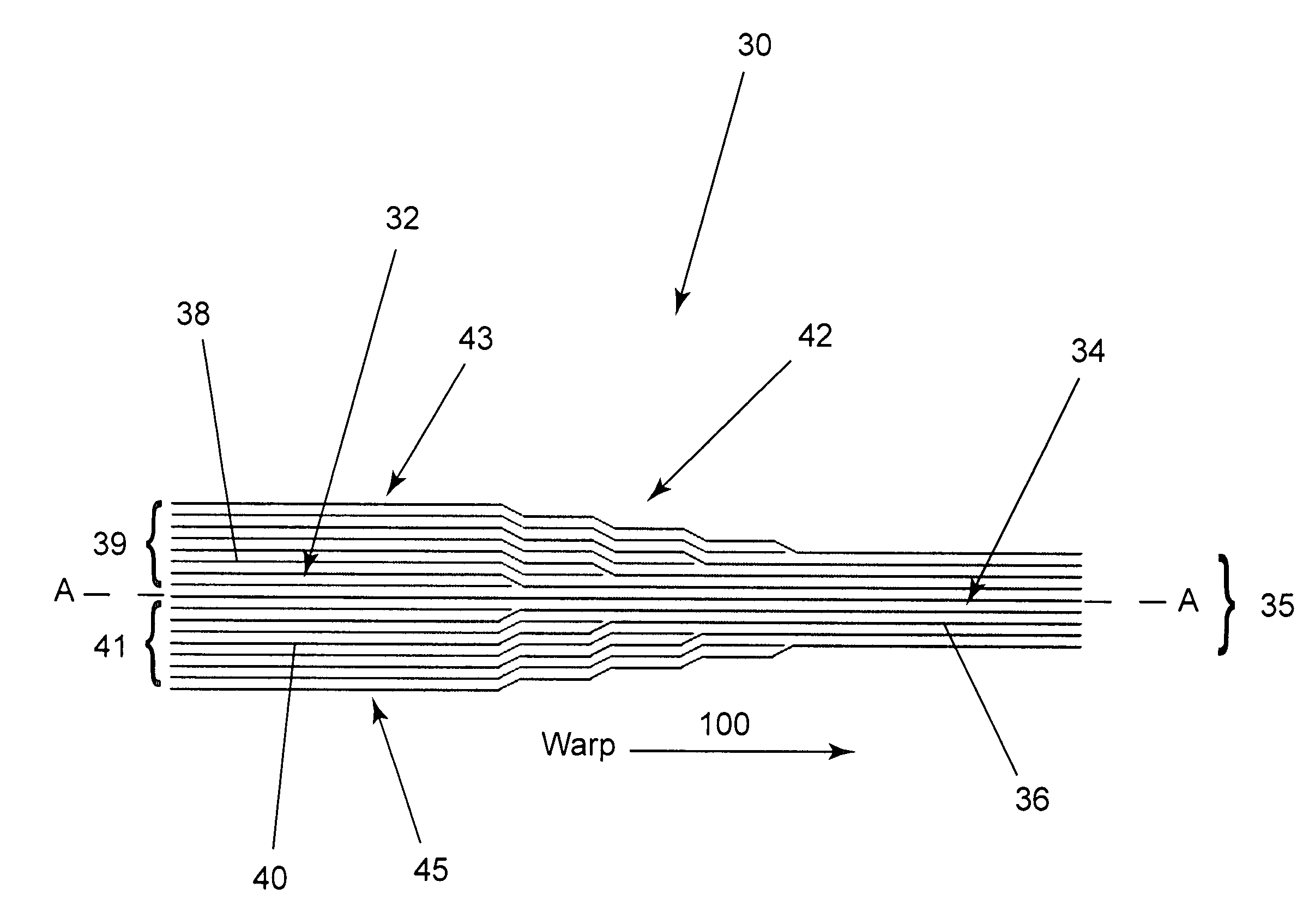

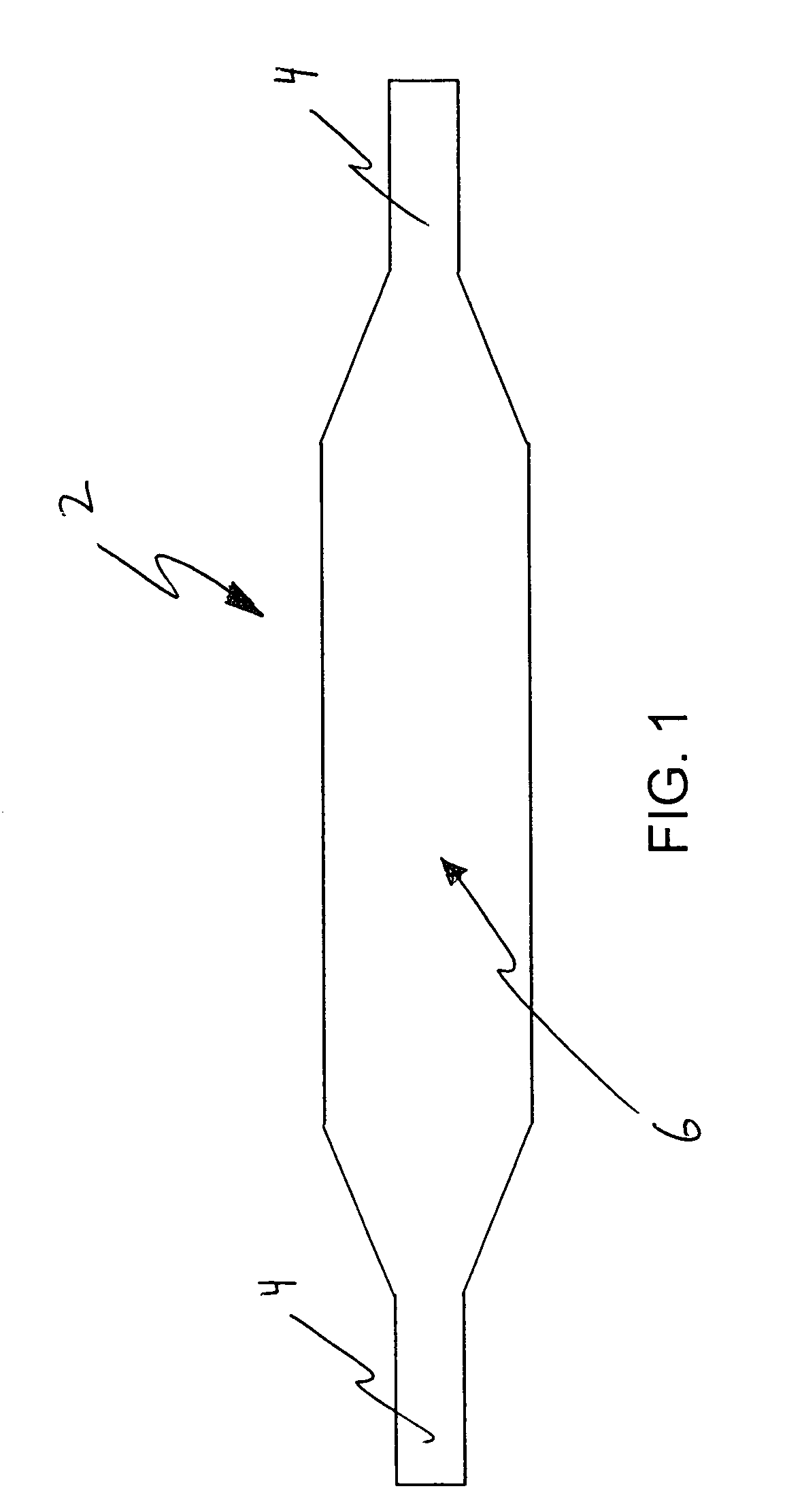

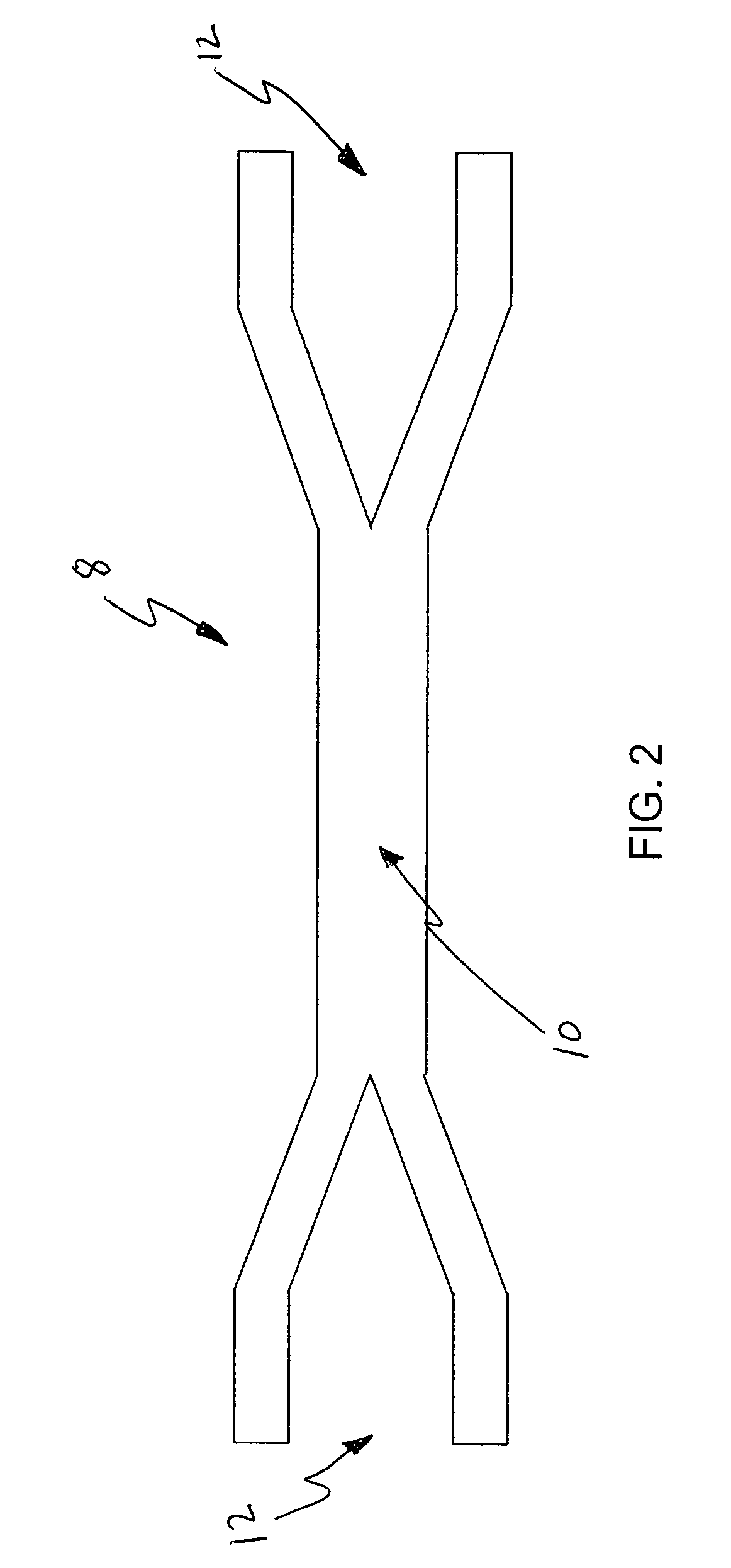

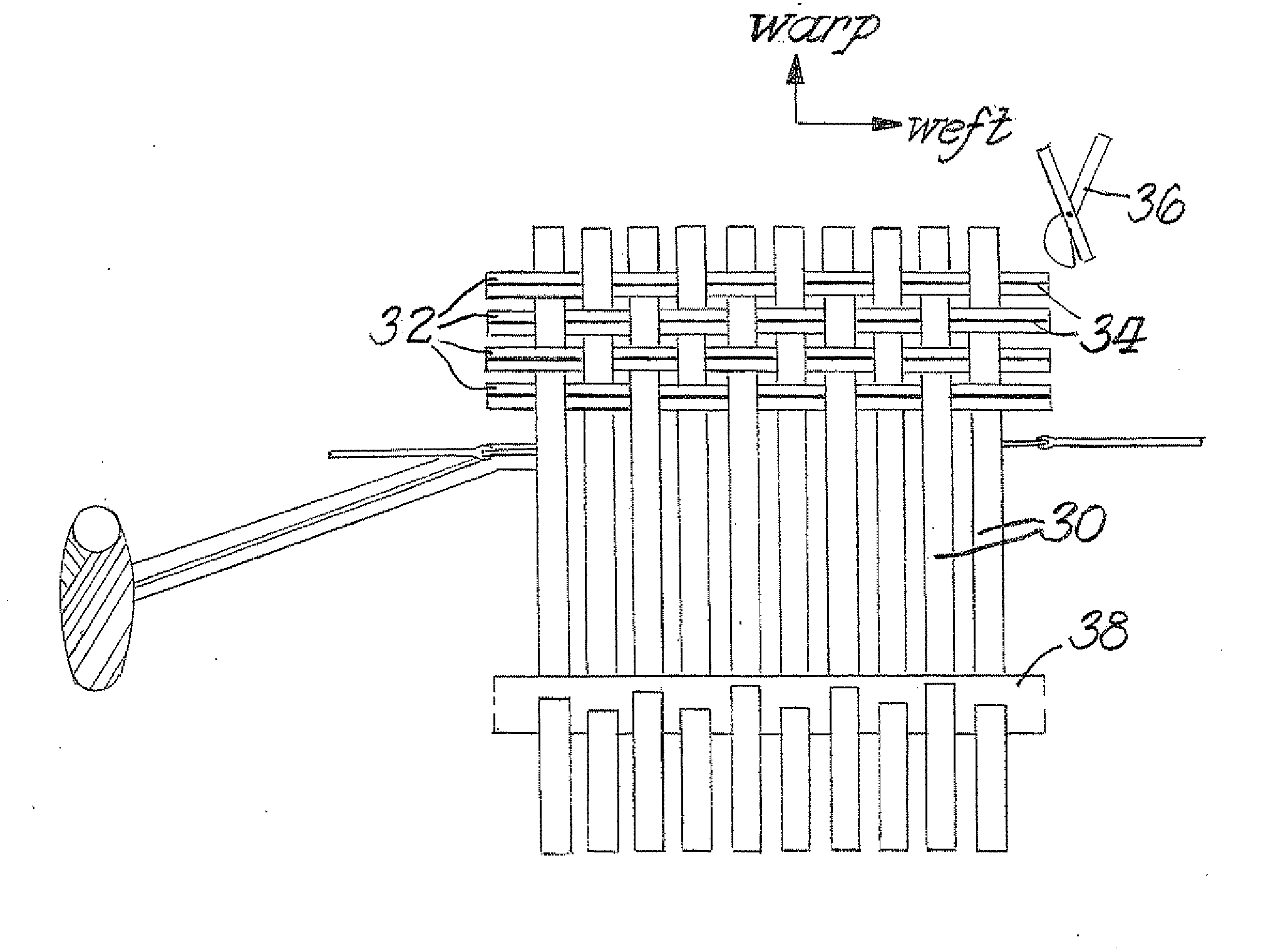

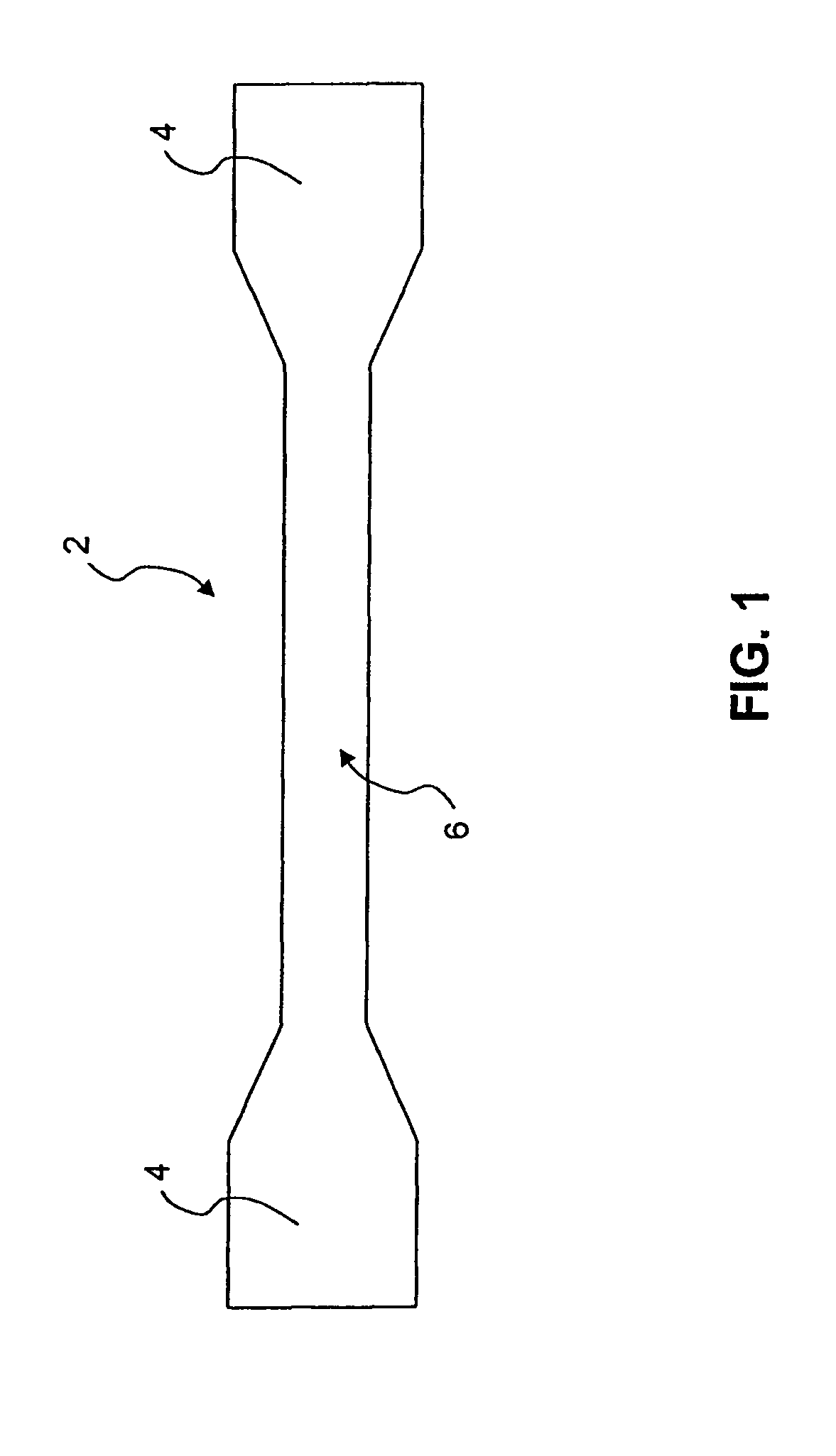

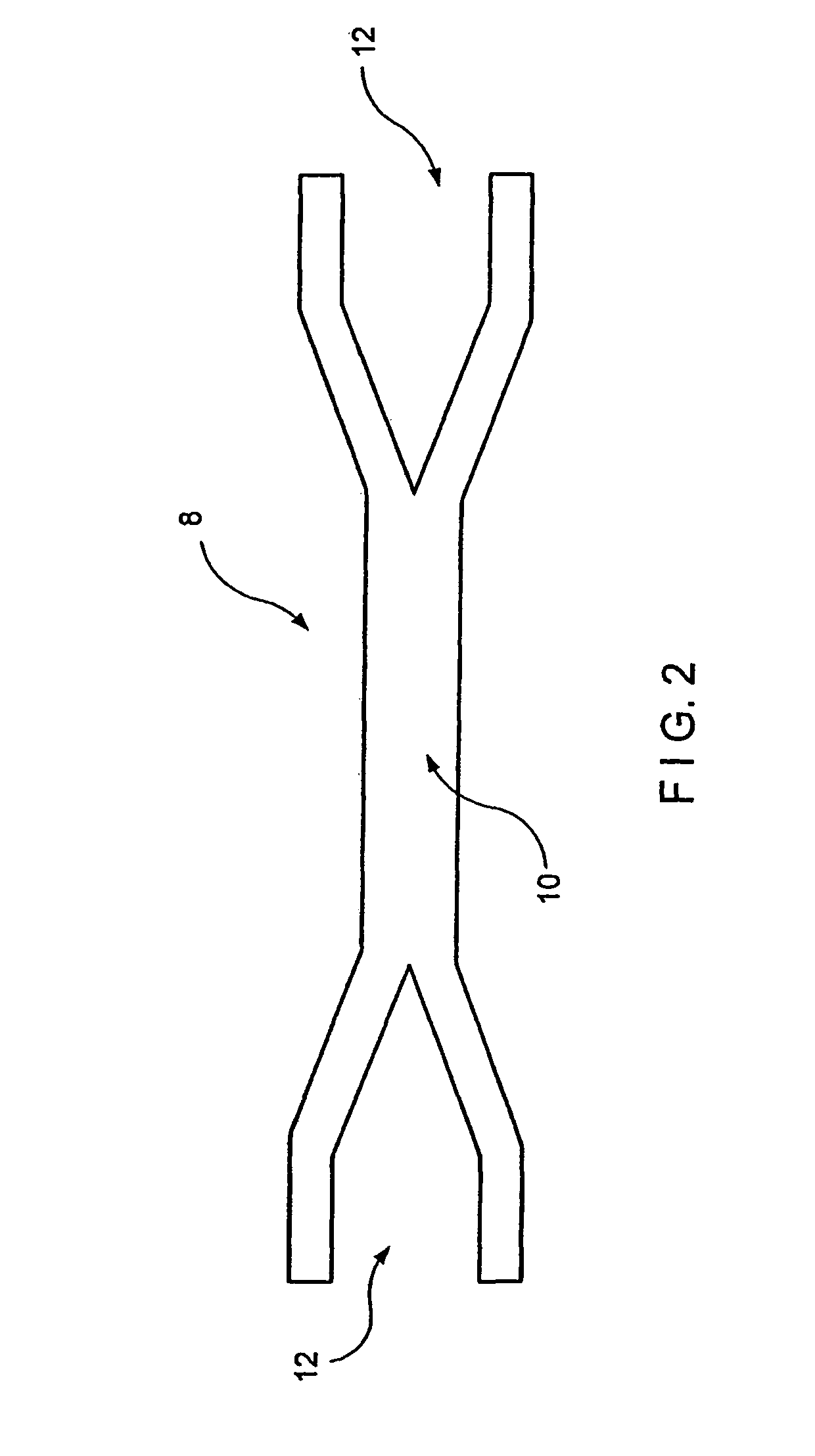

Hybrid three-dimensional woven/laminated struts for composite structural applications

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies.

Owner:ALBANY ENGINEERED COMPOSITES

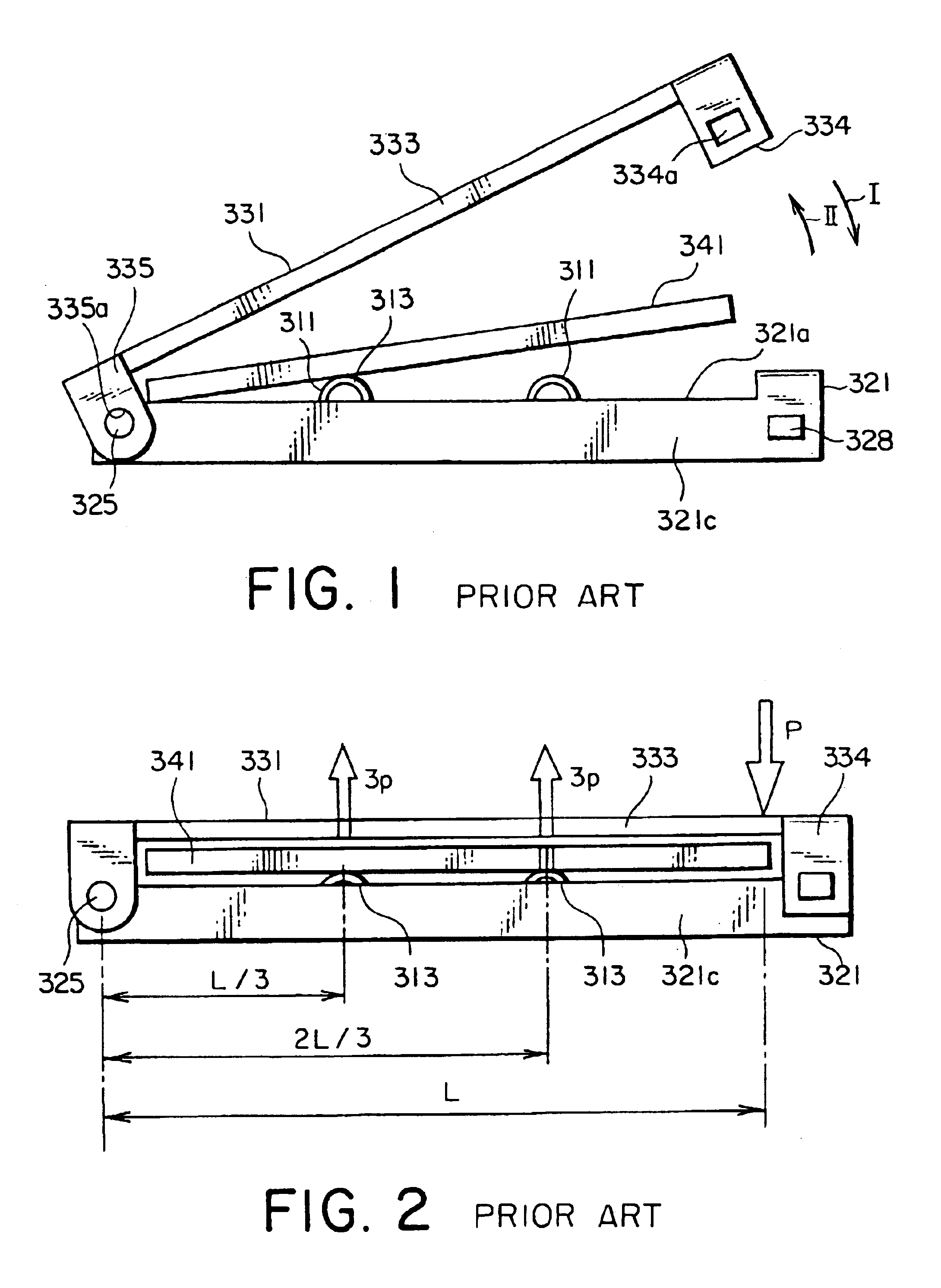

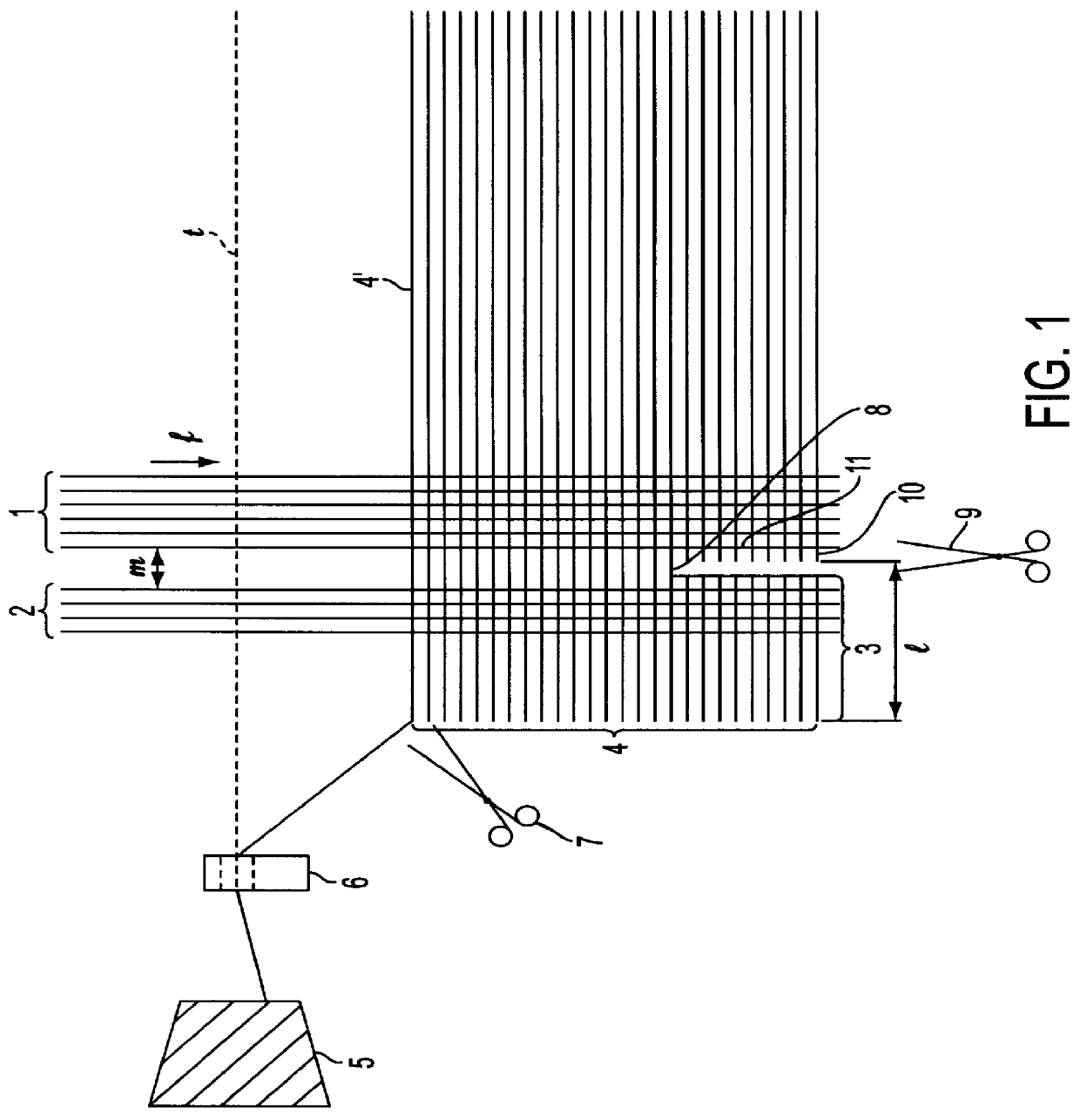

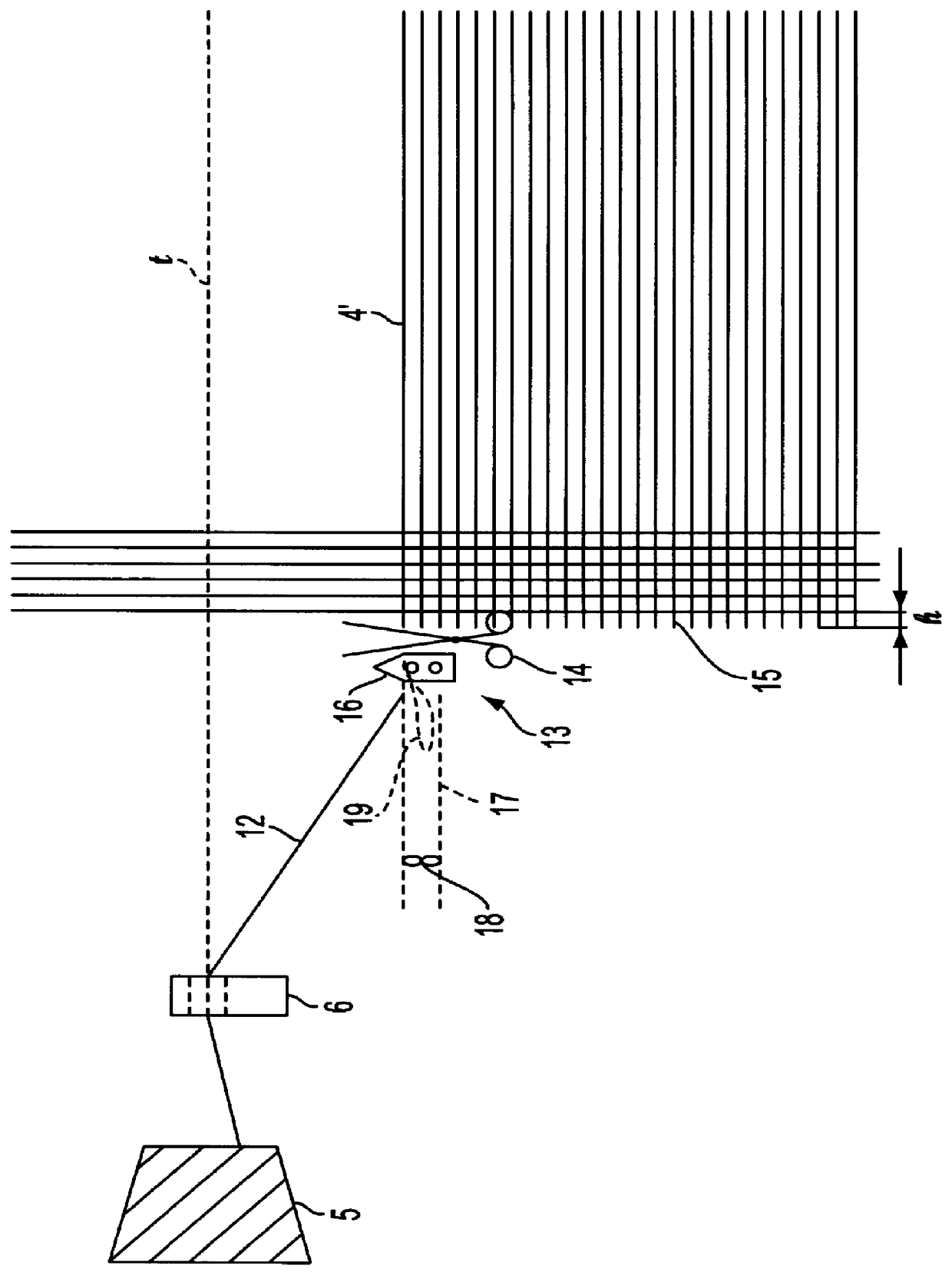

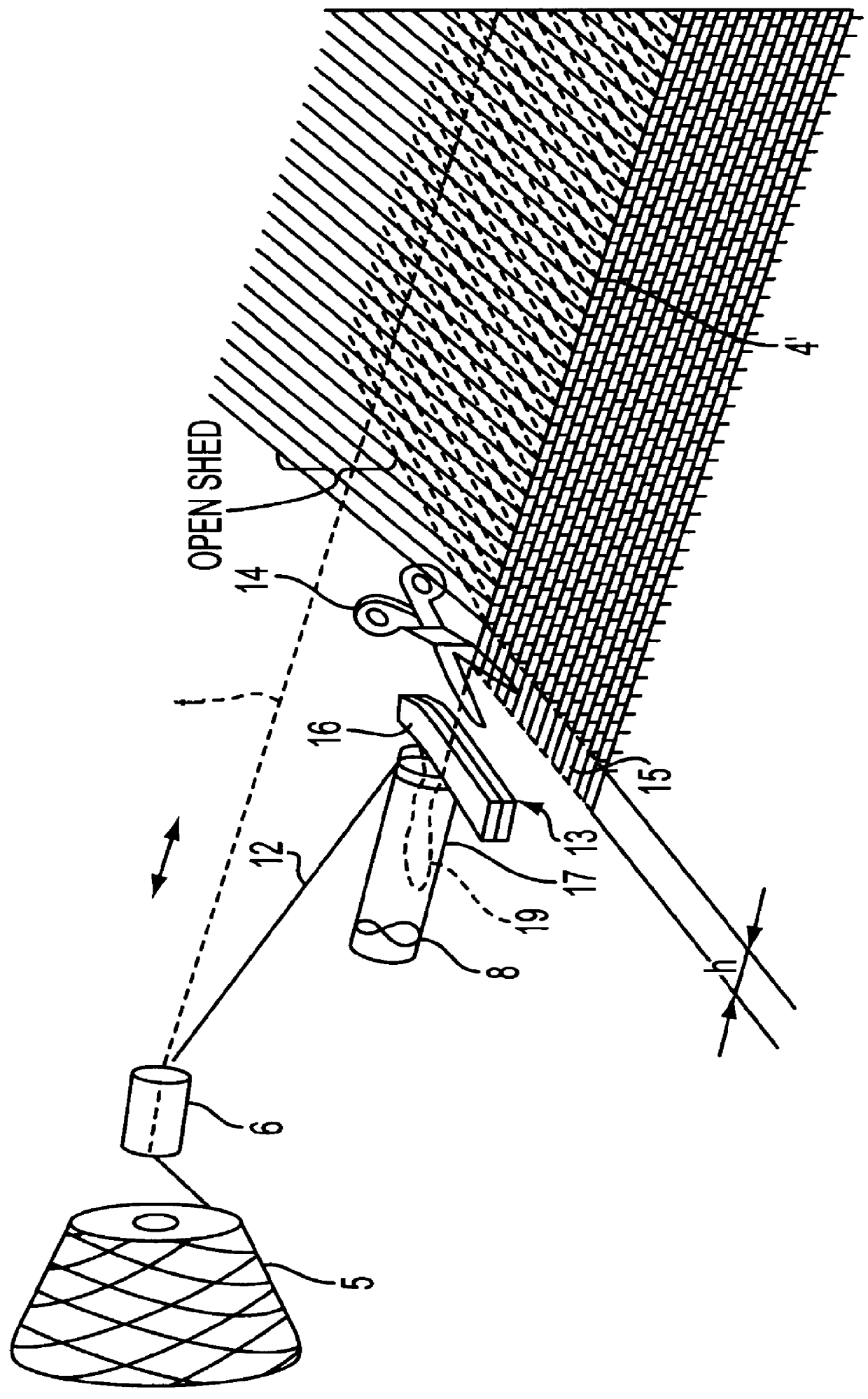

Method for cutting a selvedge of a weft insertion side of a rapier loom

A method for cutting a selvedge on a weft thread insertion side of a rapier loom equipped with a weft thread supply by creating a free space of warp threads arranged separately from a main warp body. The weft thread is inserted through an open shed of the warp body. The inserted weft thread is beaten, and inserted into a holding device which subjects it tension. The wet thread is cut after being beaten and while subject to tension. The end of the weft thread is inserted it into the open shed of the warp after the cutting.

Owner:ISOLA FABRICS SRL

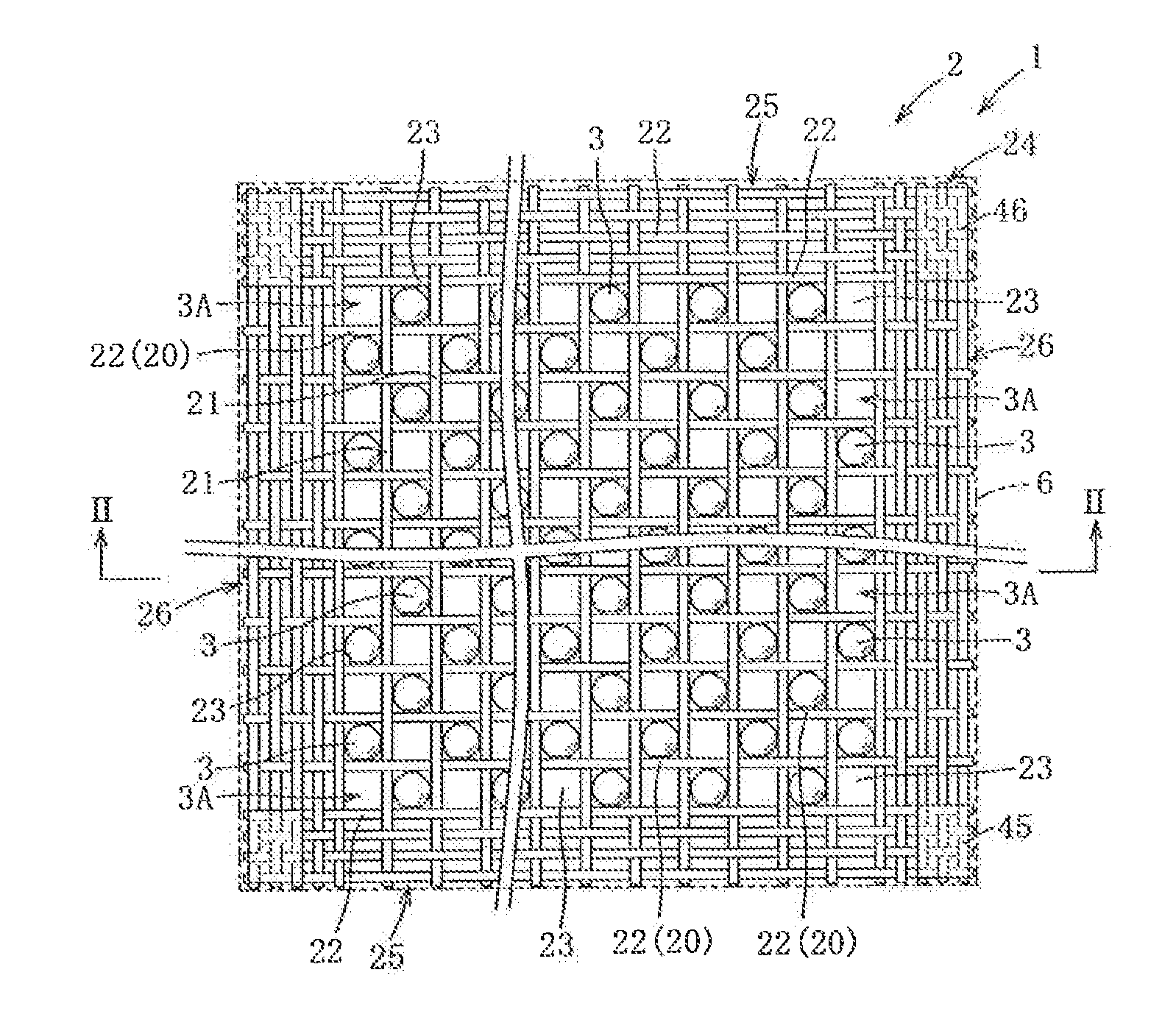

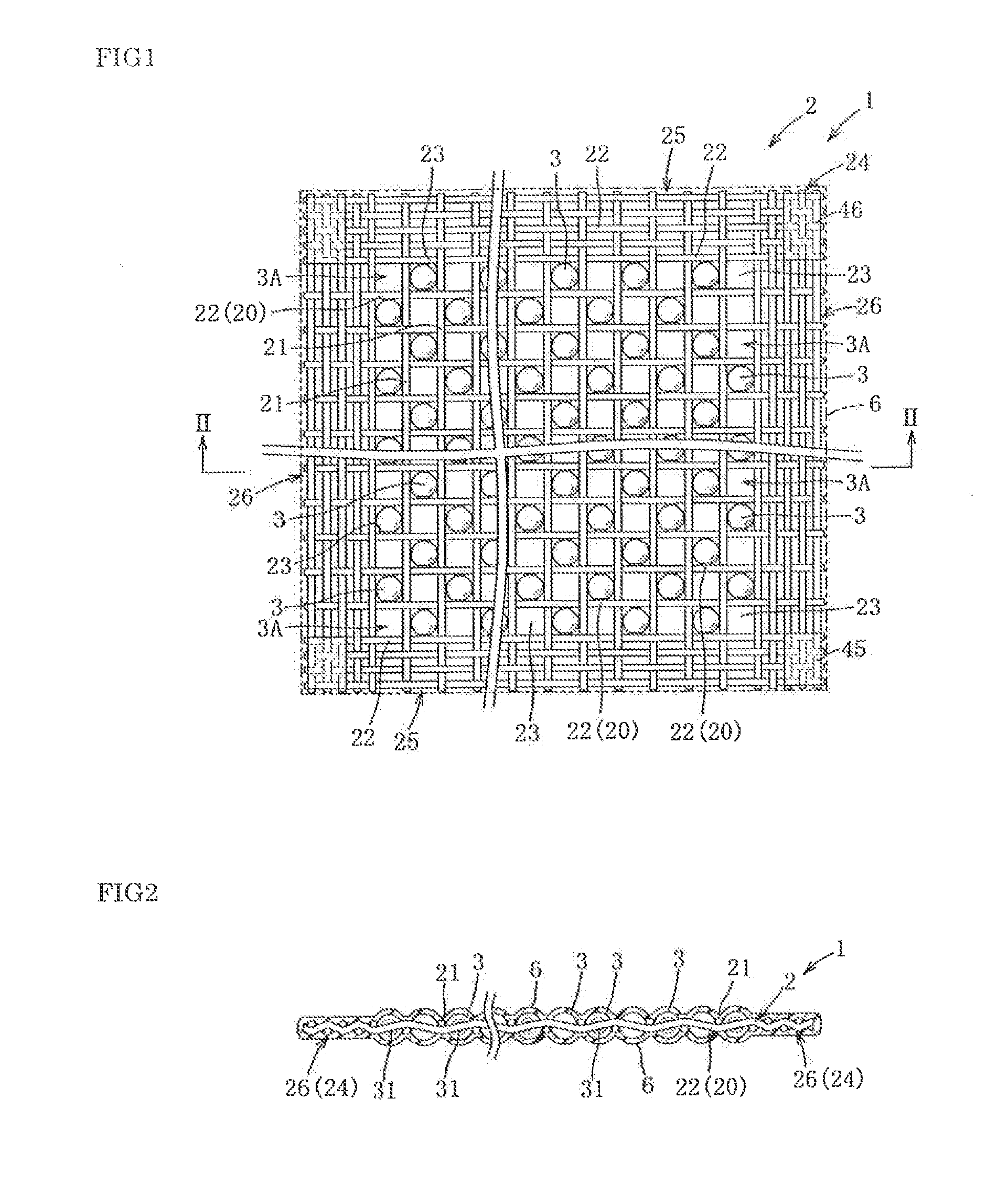

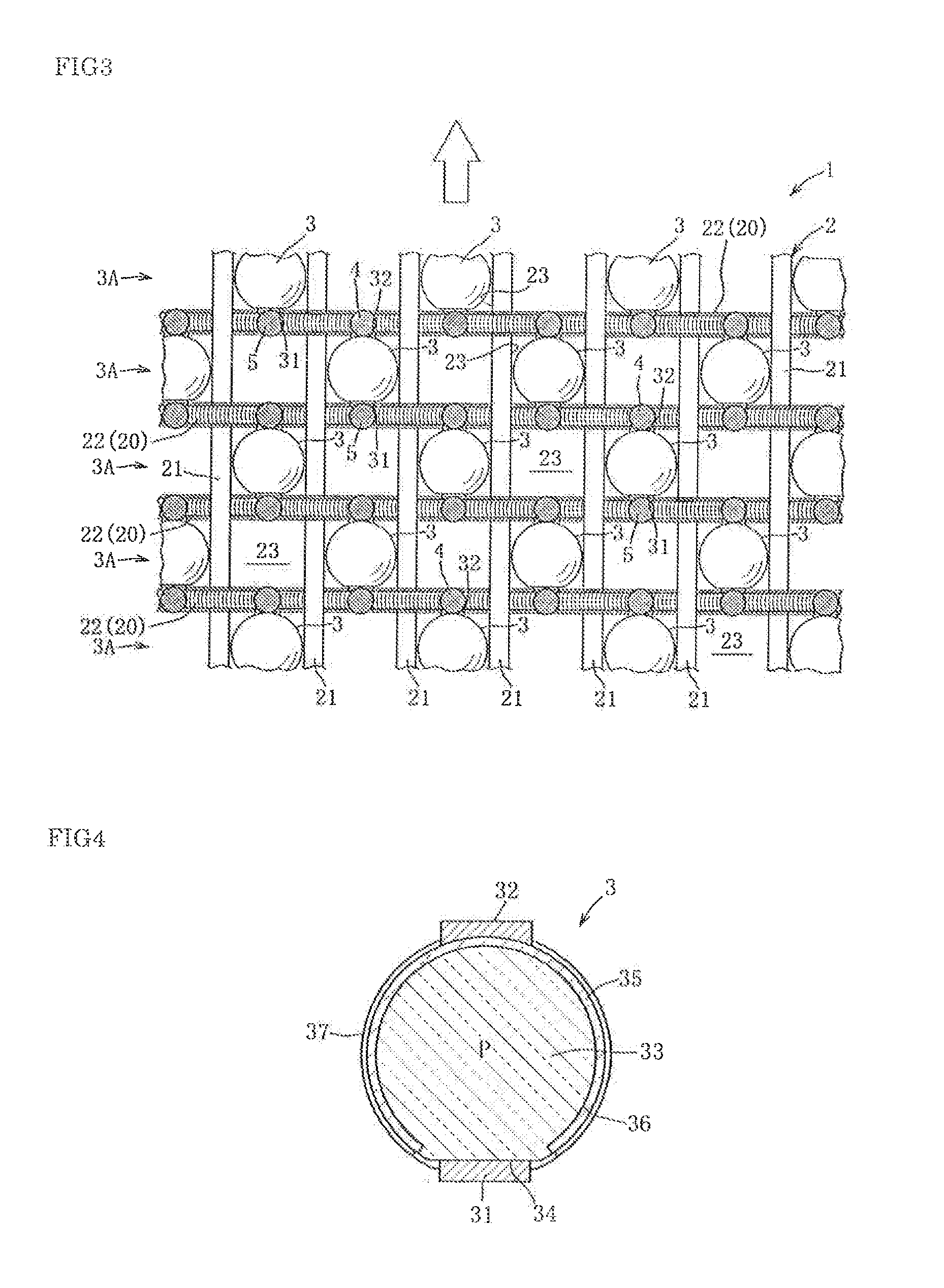

Woven mesh substrate with semiconductor elements, and method and device for manufacturing the same

A woven mesh substrate with semiconductor elements and a method and a device for manufacturing such a substrate, and more particularly a technique that makes it possible to exploit a woven mesh substrate with semiconductor elements in which a plurality of spherical semiconductor elements having a light receiving function or a light-emitting function are installed on a woven mesh substrate in net form that is made up from a plurality of vertical strands that are insulating and a plurality of horizontal strands that are conductive.

Owner:SPHELAR POWER

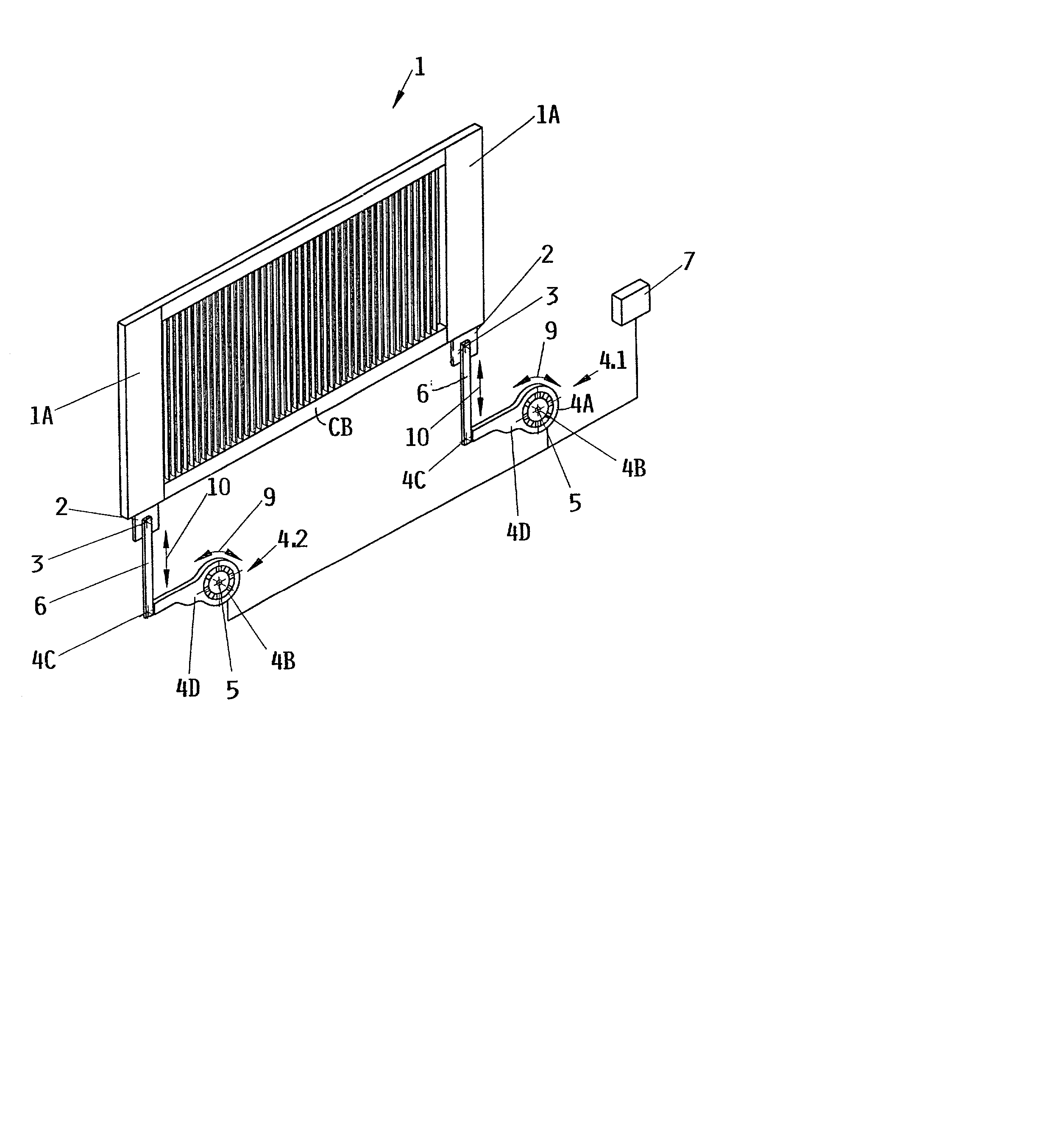

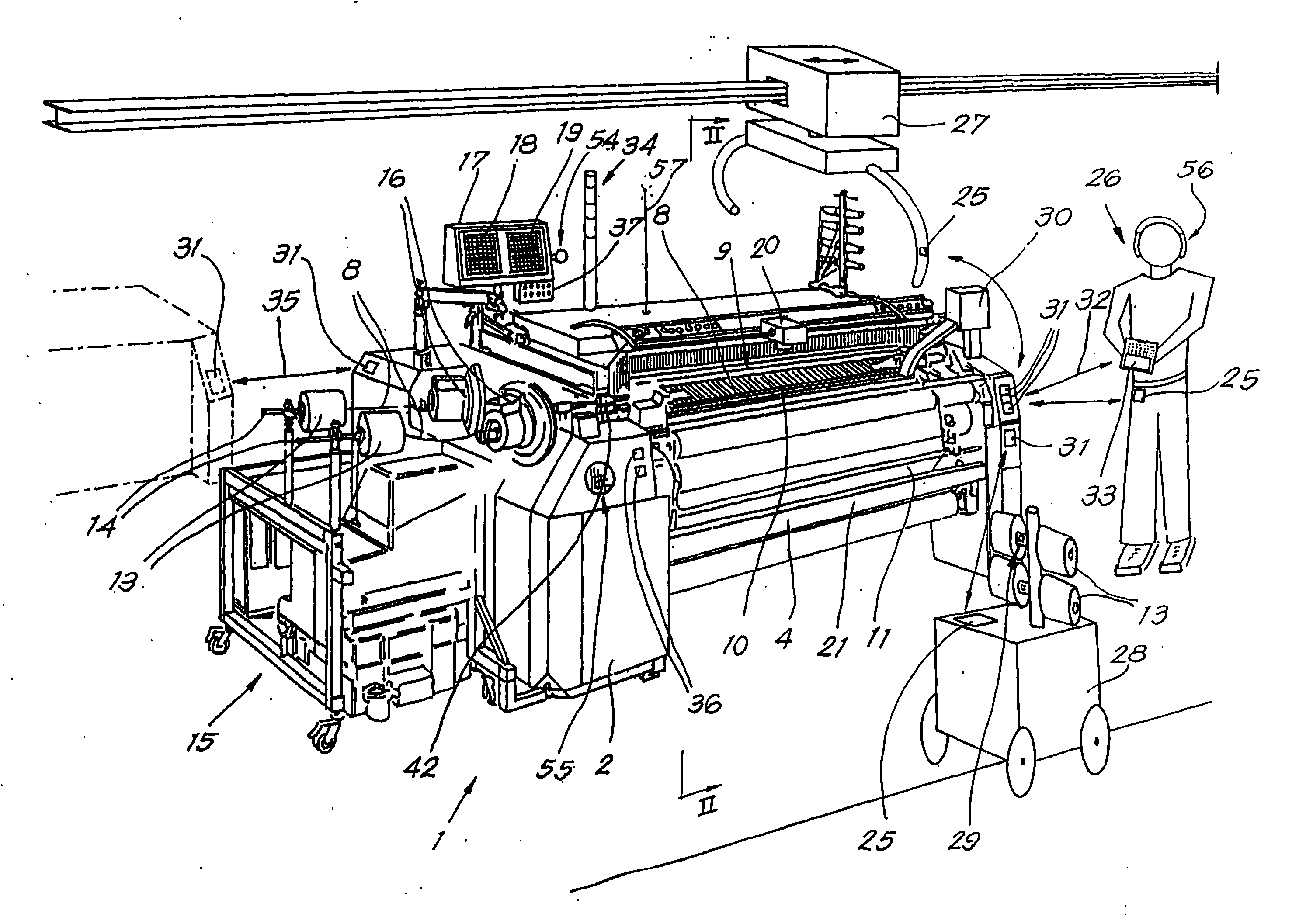

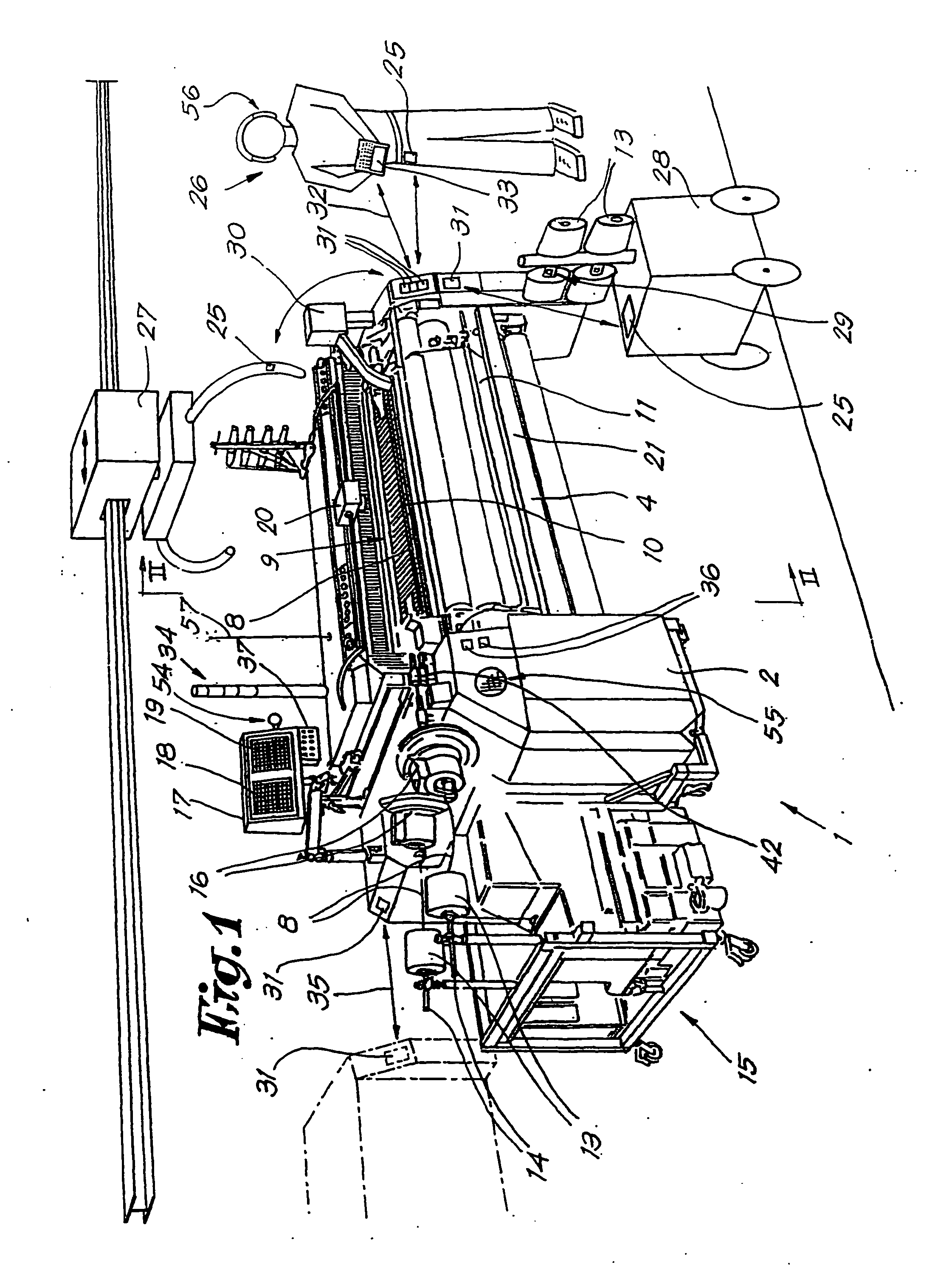

Drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have a external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

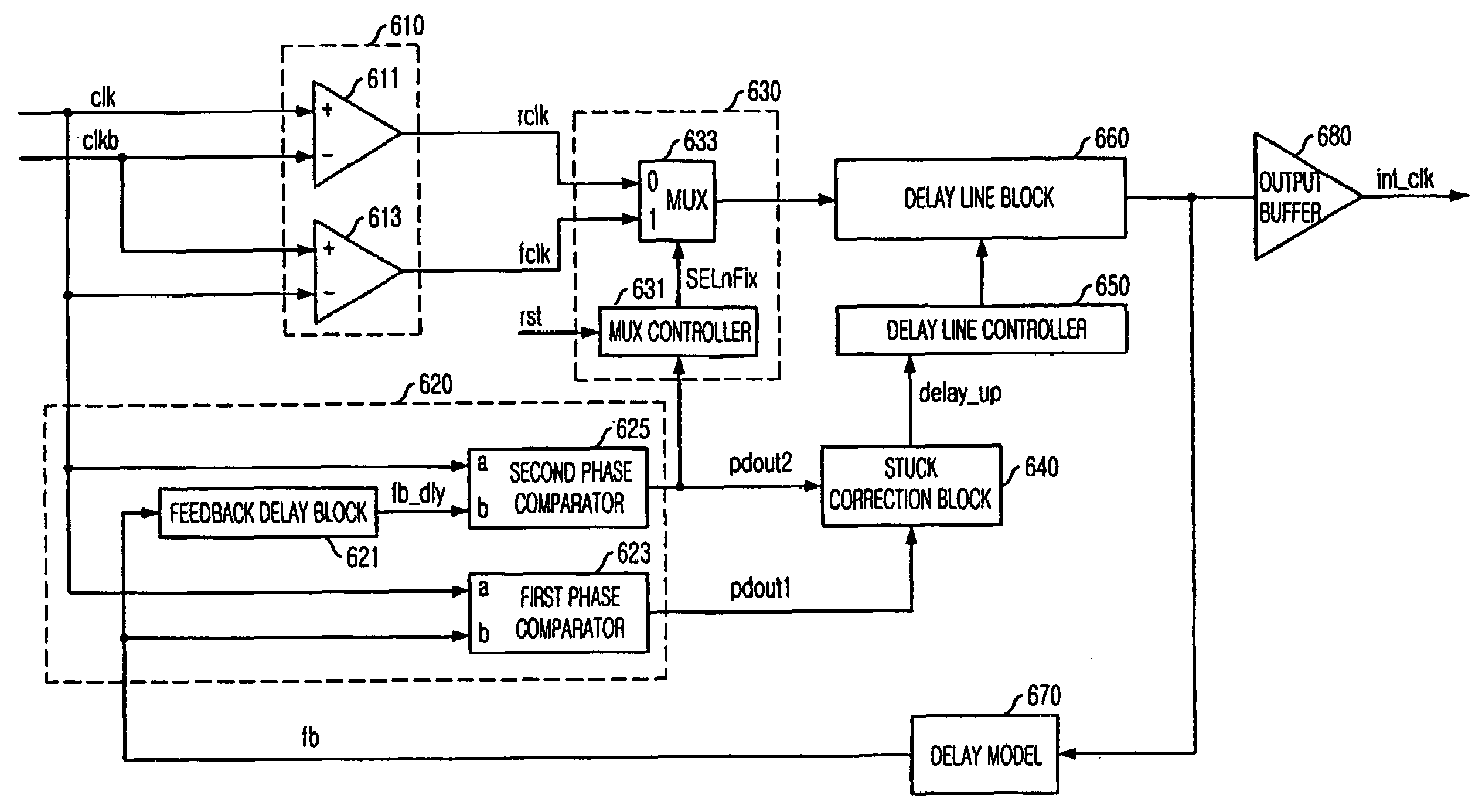

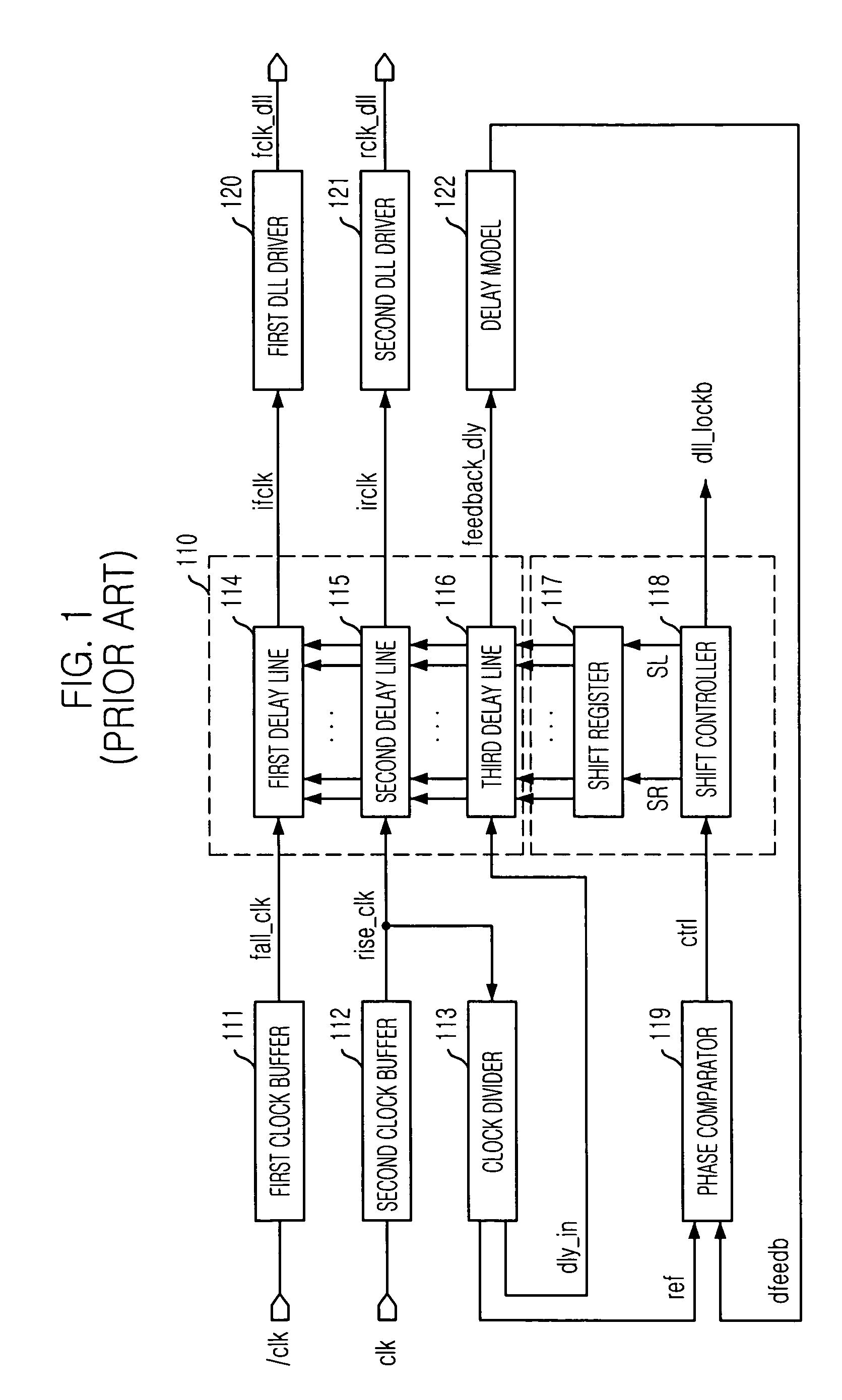

Delay locked loop in semiconductor memory device

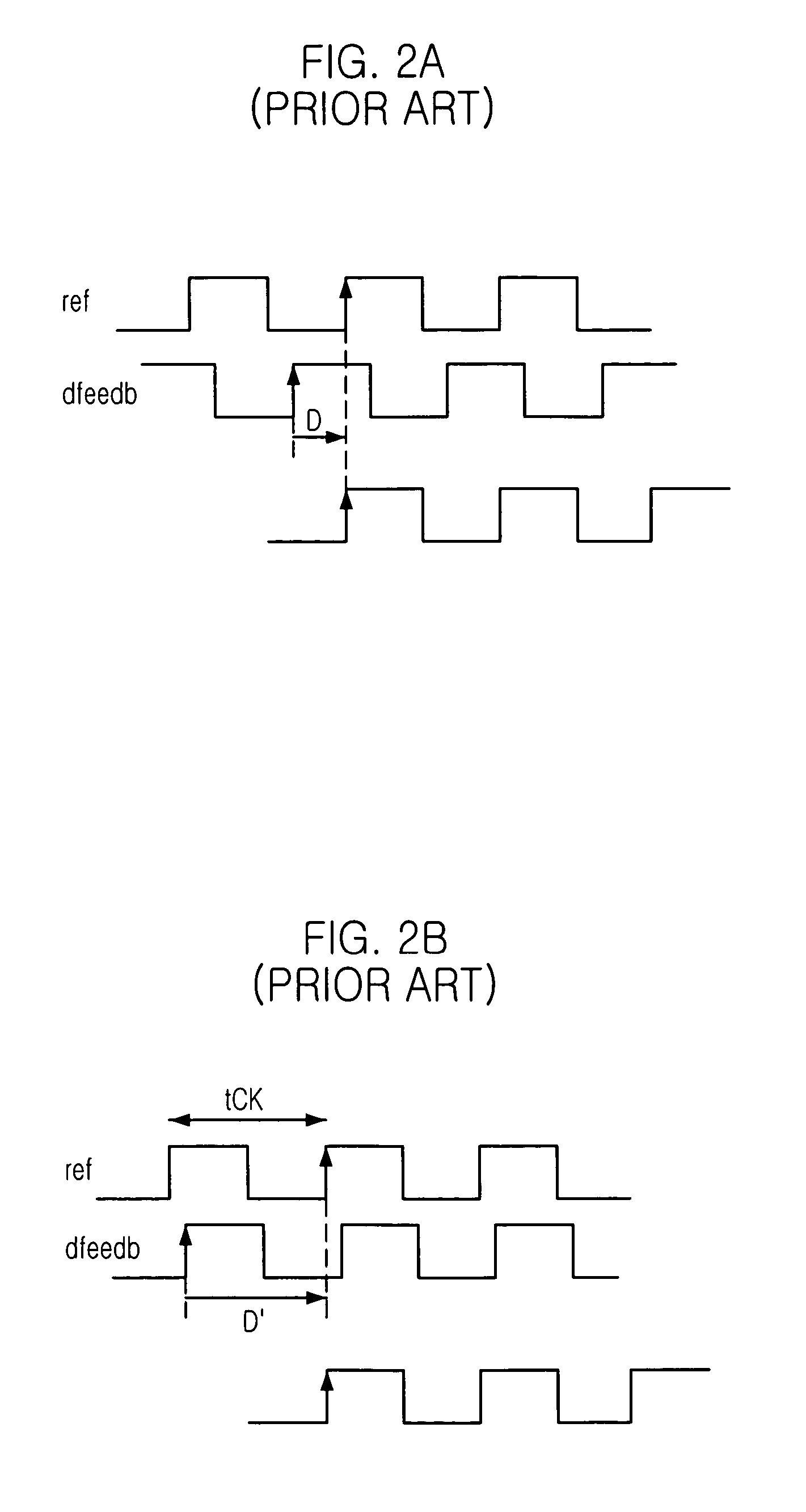

A delayed lock loop for preventing a stuck fail in a dead-zone includes a clock buffering block for generating a first and a second internal clock signals; a phase comparison block for delaying a feedback signal by a first predetermined value and for respectively comparing a phase of a delayed feedback signal and a phase of the feedback signal with a phase of the external clock signal; a clock selecting block for selecting one of the first and second internal clock signals based on one comparison result to thereby generate a selected internal clock signal; a stuck checking block for determining a delay value based on the other comparison result; a delay line block for delaying the selected internal clock signal by the delay value; and an output buffer for buffering an outputted signal from the delay line block to thereby generating a DLL clock signal.

Owner:INTELLECTUAL DISCOVERY CO LTD

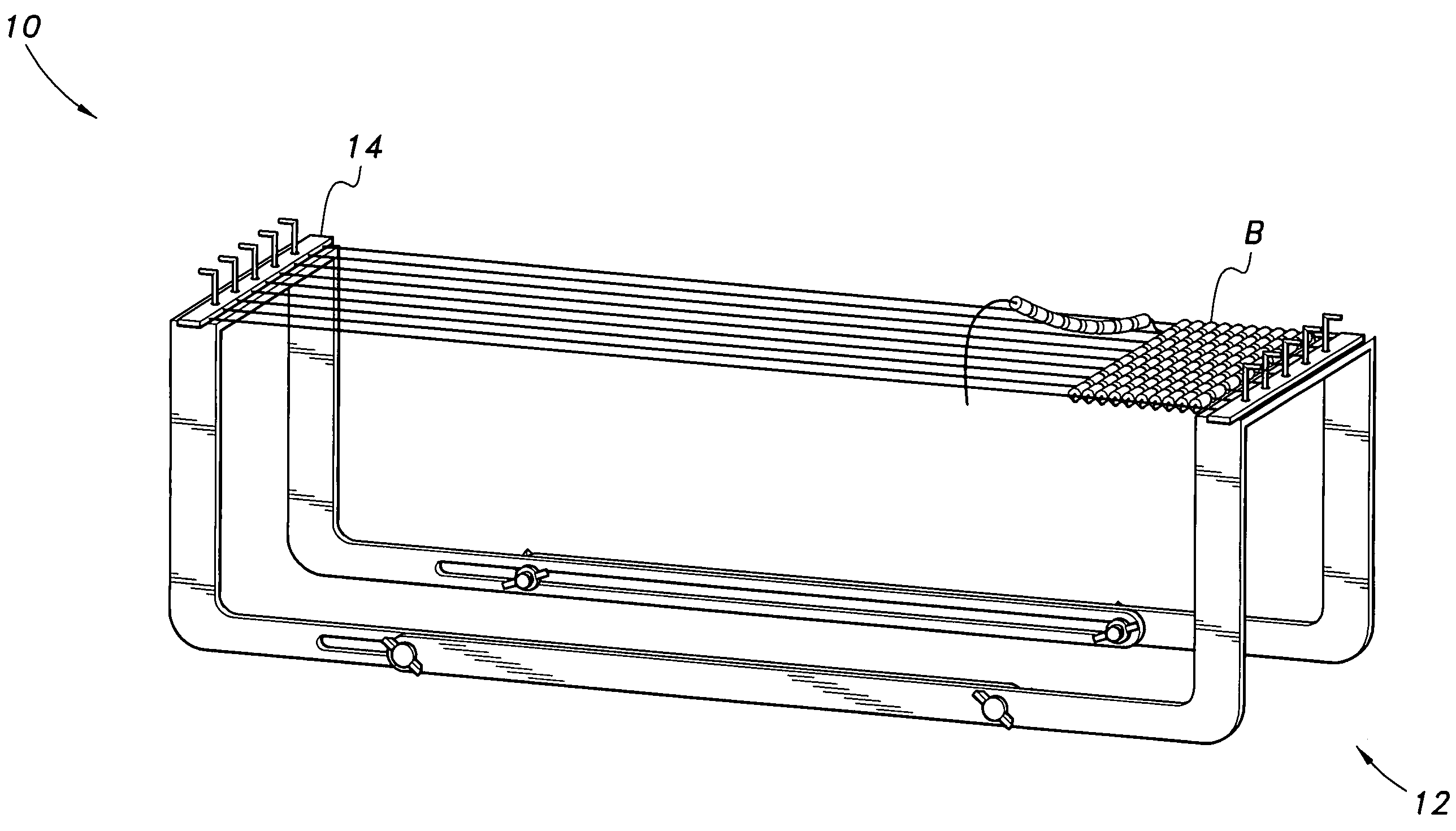

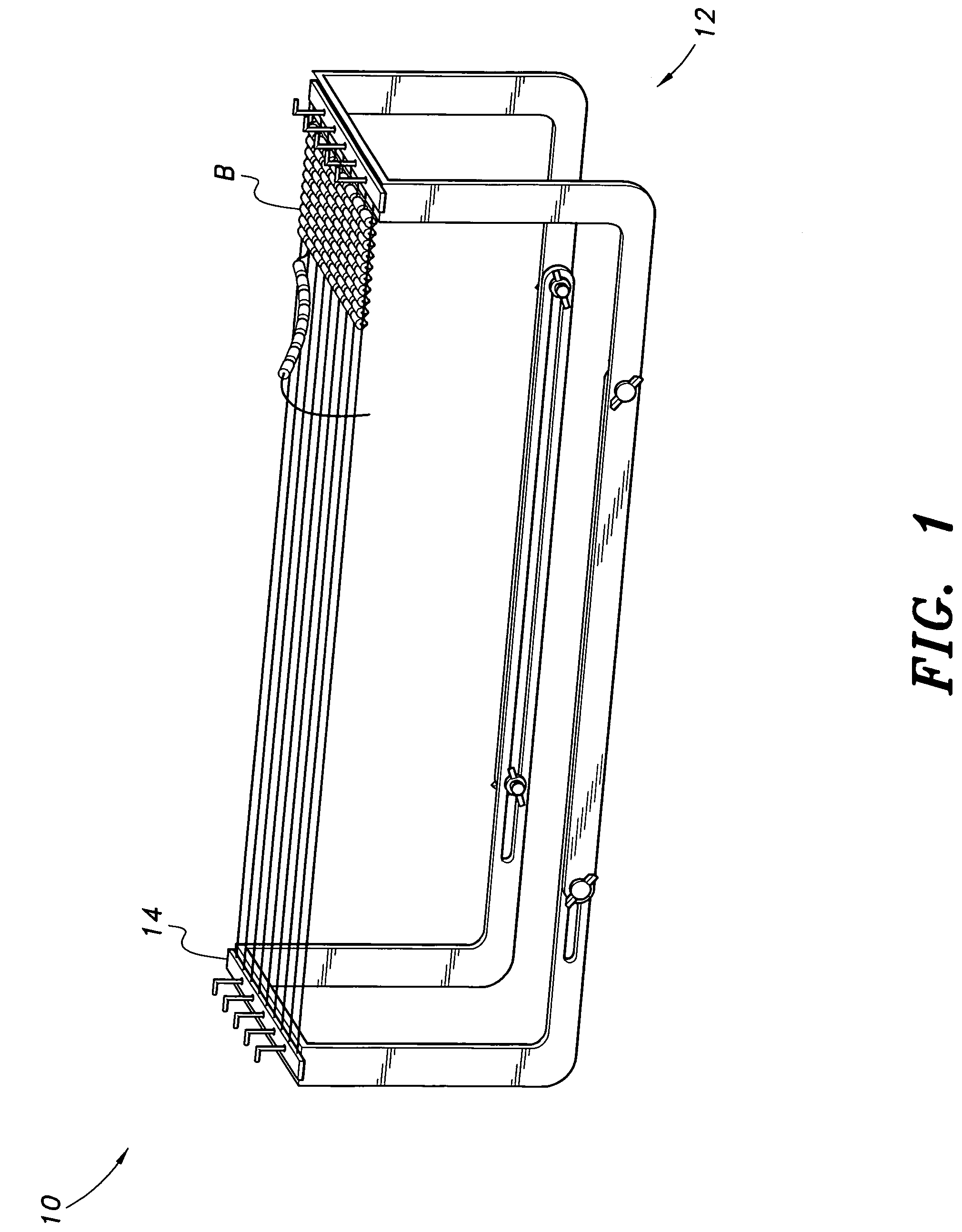

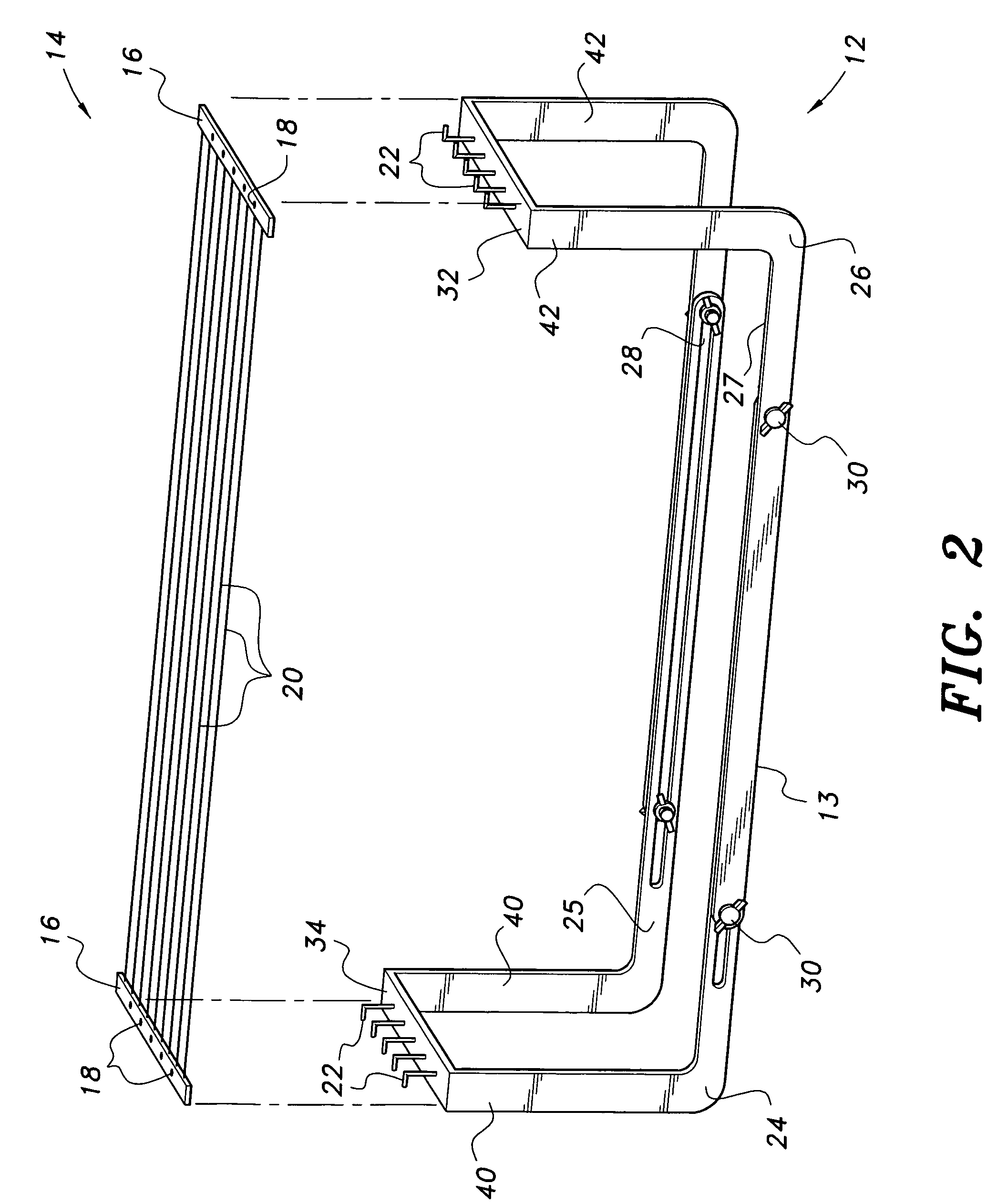

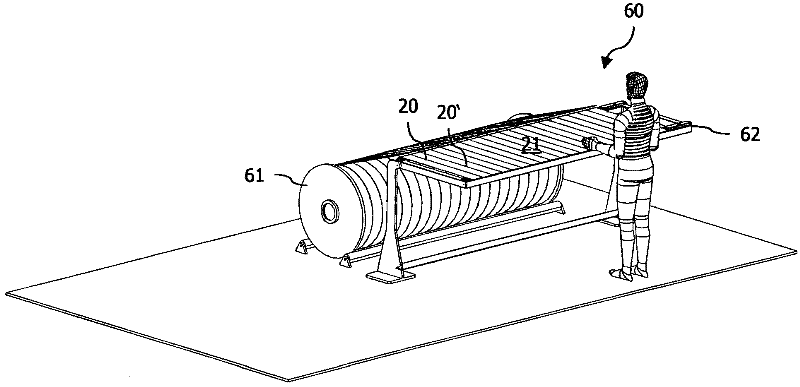

Beading loom with removable warp thread cartridge

The beading loom with a removable warp thread cartridge has warp threads mounted in a cartridge that is removably received in a frame of the loom, allowing the user to bead the threads in a conventional manner, but without having to wrap the threads on the loom manually. Once finished with one beading product, the user may then remove the cartridge from the loom and replace the beaded project with a fresh cartridge of warp threads. The frame has an elongated base having an adjustable length along the longitudinal direction.

Owner:SKAFLESTAD KRISTINE K

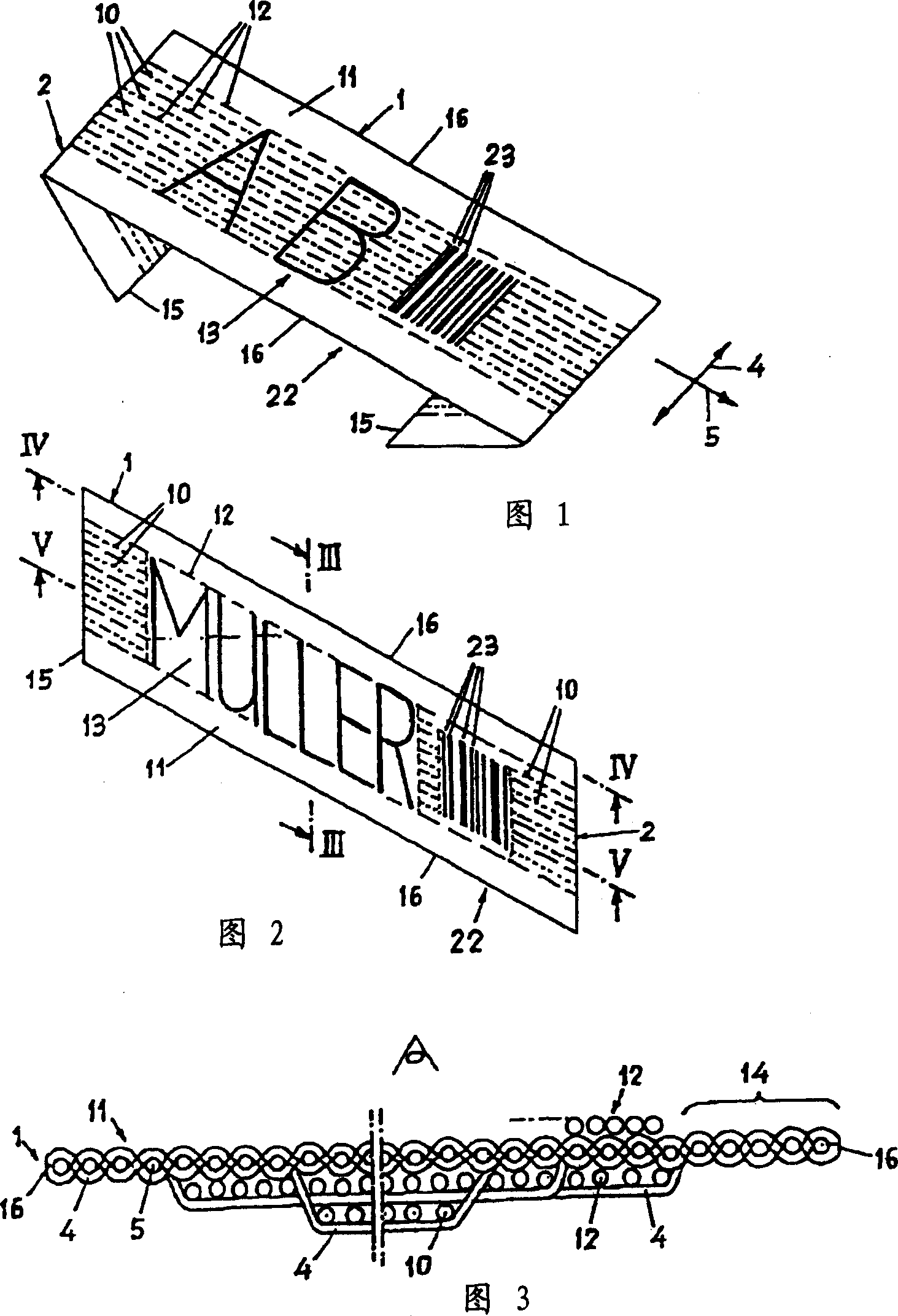

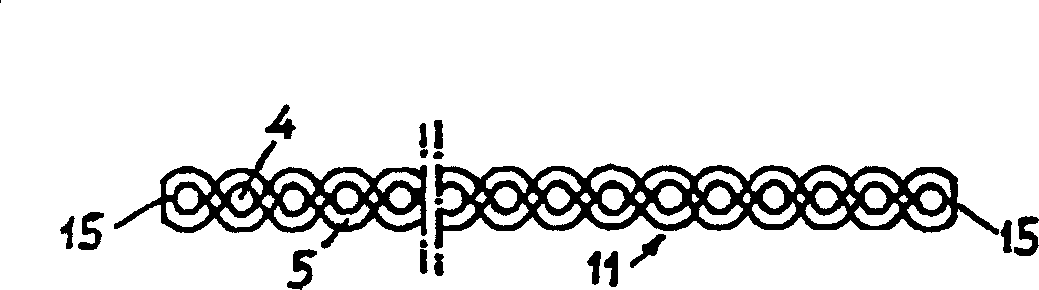

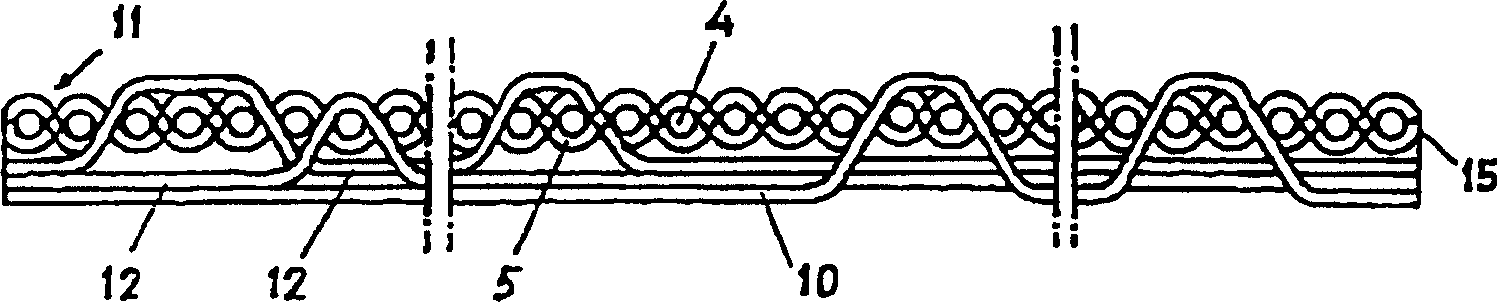

Method for producing in visible barcode and barcode thus produced

The label has two non-folded longitudinal sides (1) and two foldable narrow sides (2) and consists of a backing fabric (11) with warp threads (4) and basic picks (5), in addition to embroidery picks (12) made of a fusible thread material forming the pattern. The embroidery picks (12) forming the pattern extend parallel and at a distance to the unfolded longitudinal sides (1) of the backing fabric (11). The non-folded longitudinal side (1) is an edge of a cut formed in the backing fabric outside the area (13) of the pattern. The label has the advantage that the edges of the cuts on the longitudinal sides are soft and skin friendly thereby substantially improving wearing comfort. Due to the fact that the edge of the cuts produced by the basic picks have practically no brows and the picks extend parallel in relation to the longitudinal side of the labels, and even appearance is achieved on the entire length of the label since the picks cover evenly the back part.

Owner:TEXTILMA AG

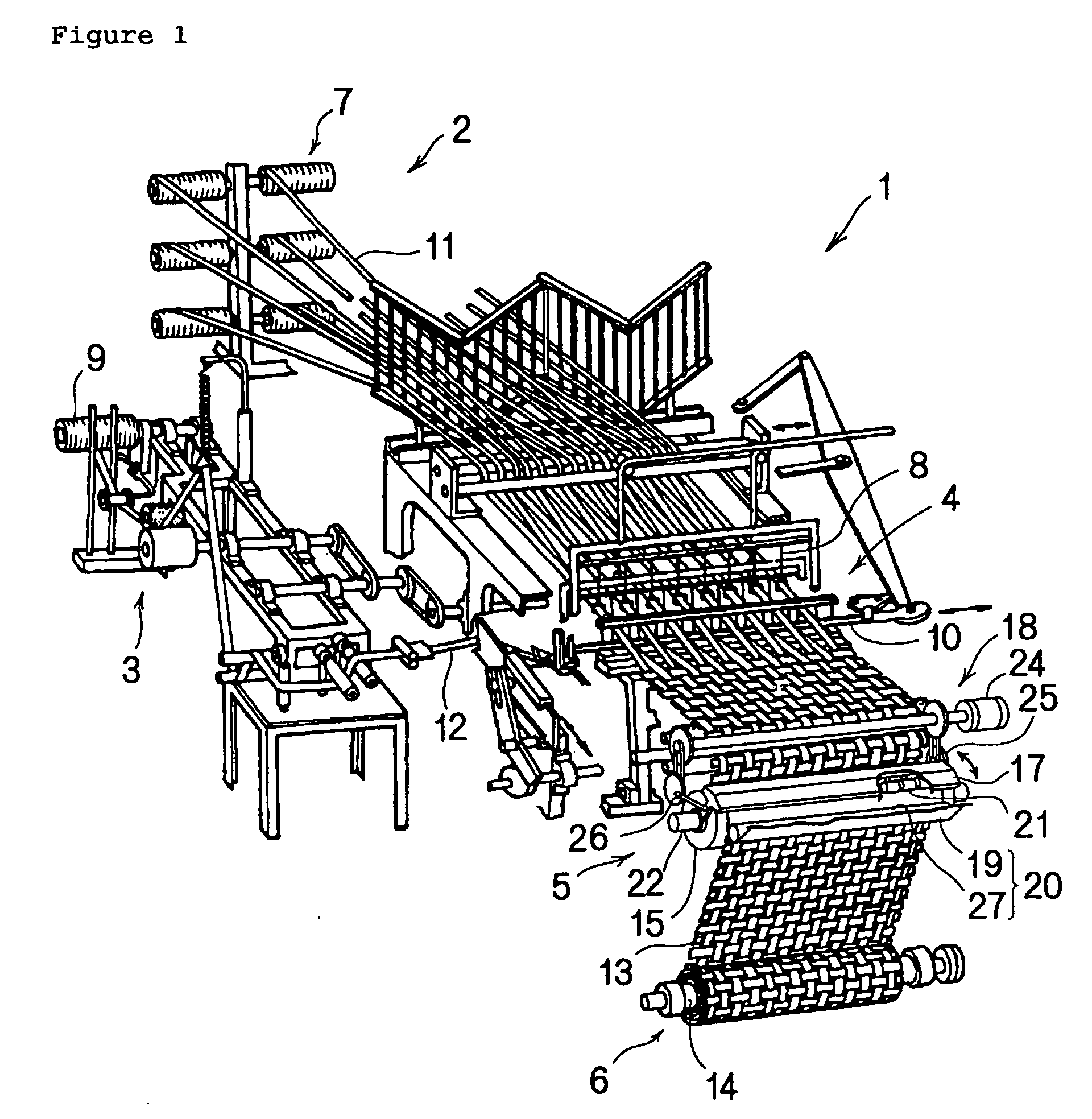

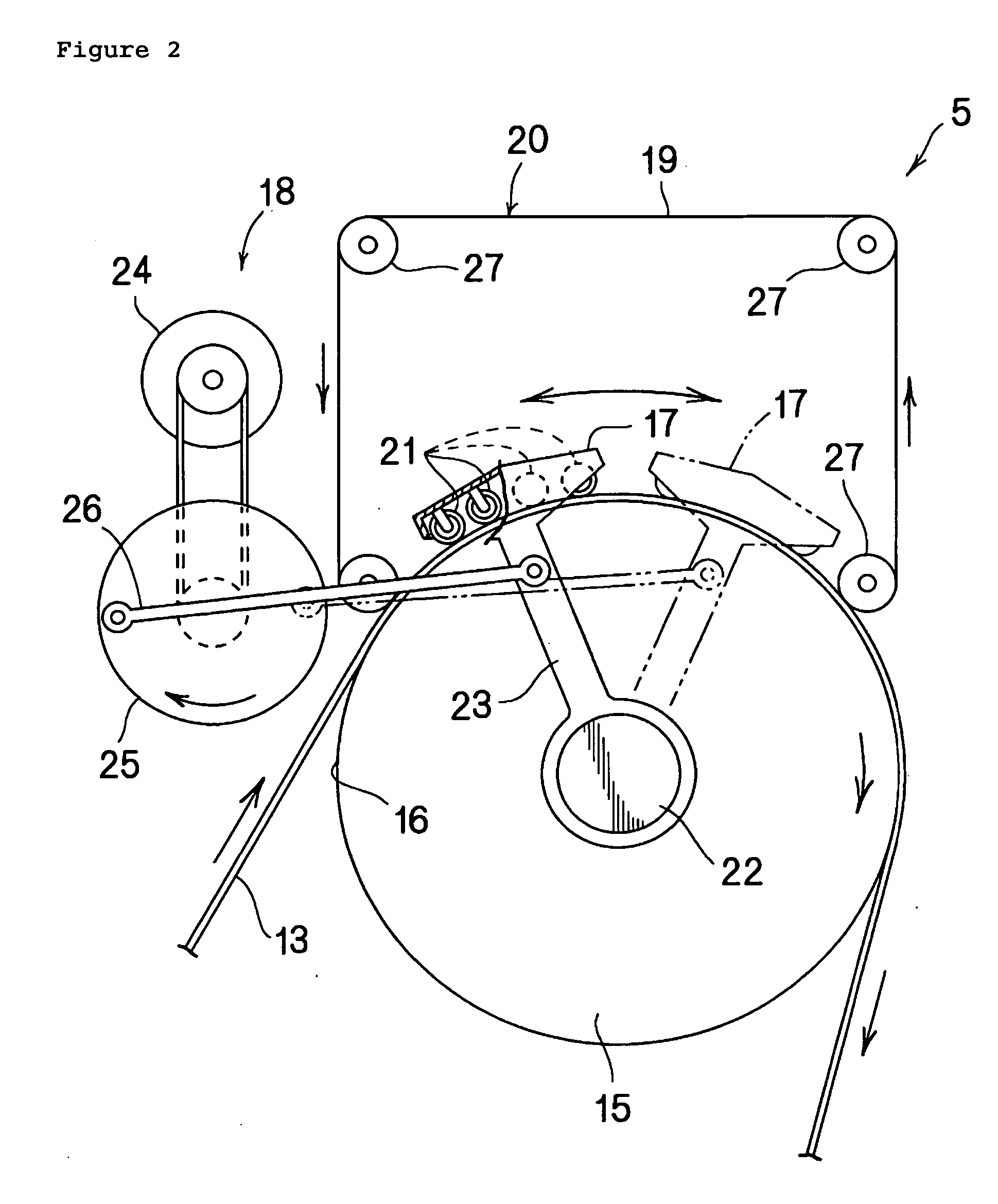

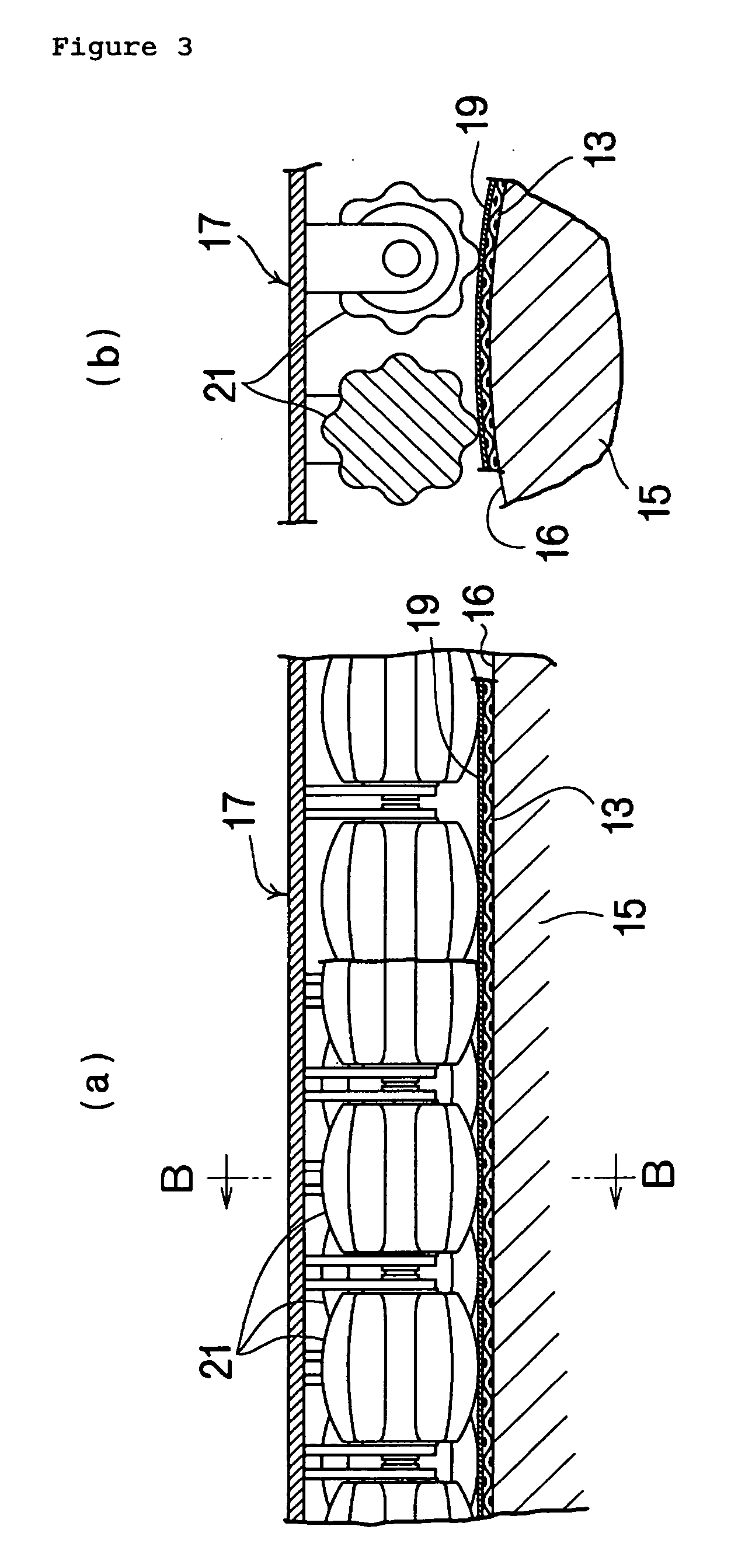

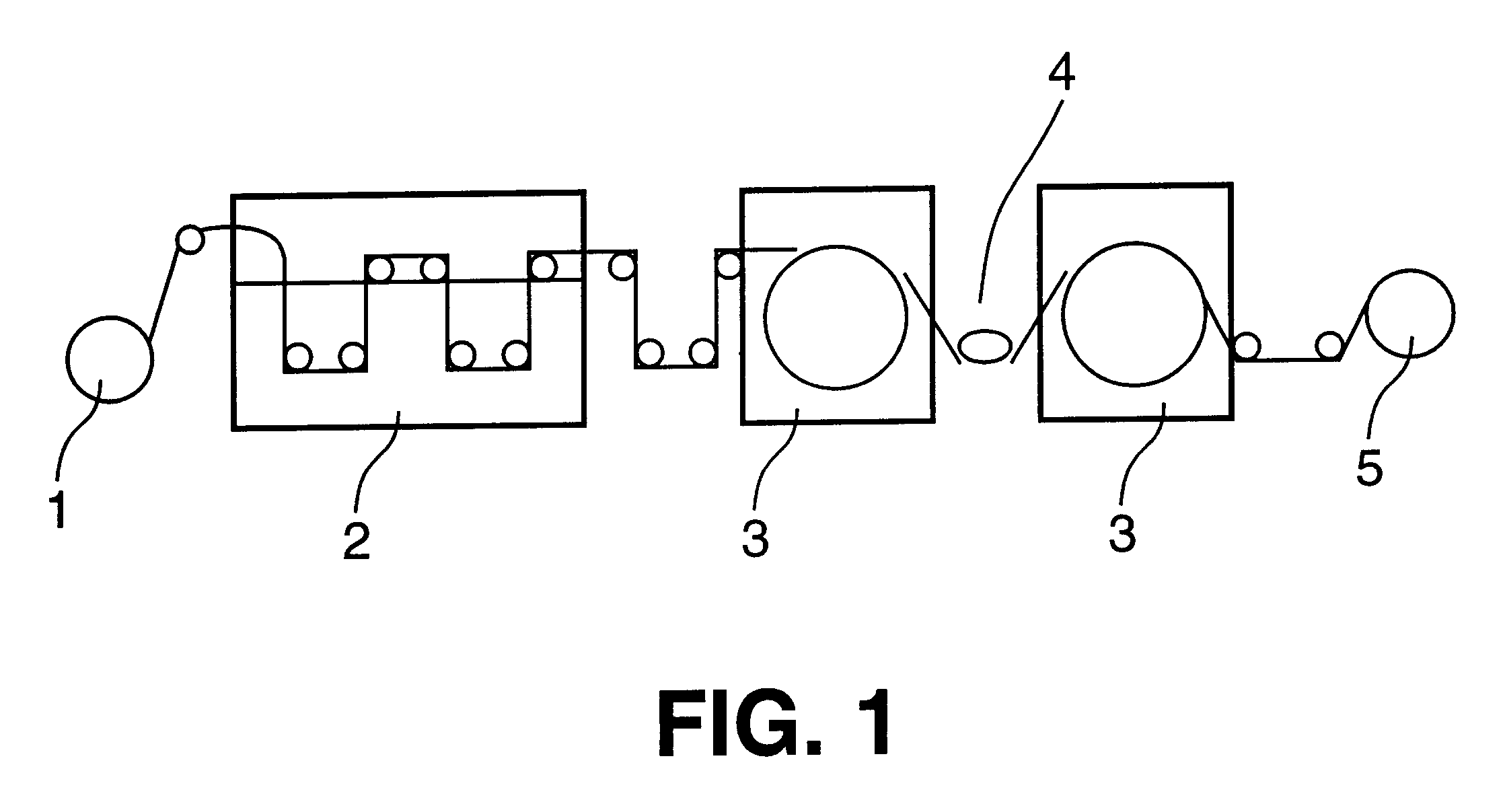

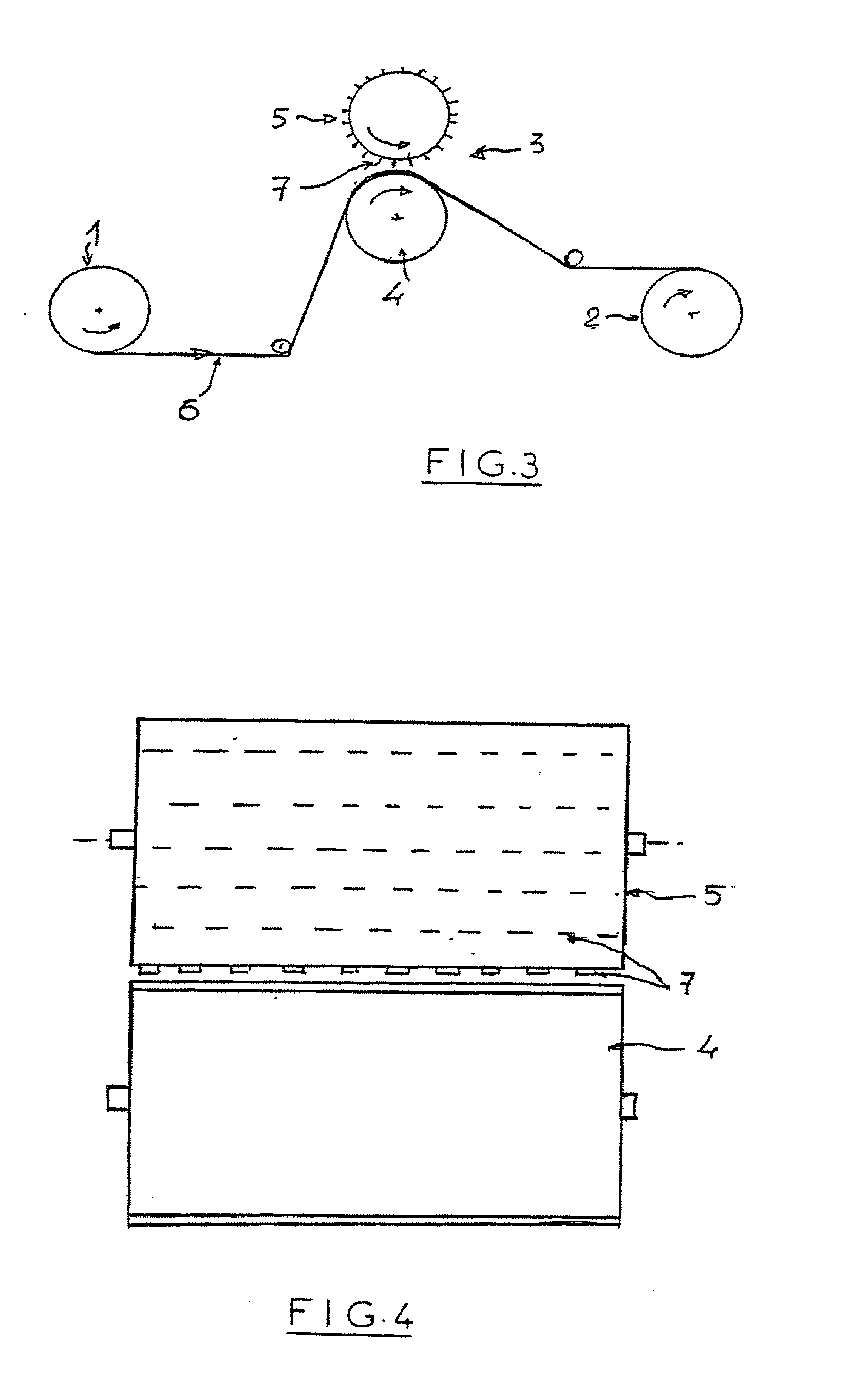

Uncoated woven fabric for air bags, and its production process and system

InactiveUS6182709B1Improve mechanical propertiesImproving of pliabilityPedestrian/occupant safety arrangementLoomsPulp and paper industryWoven fabric

Owner:TOYO TOYOBO CO LTD

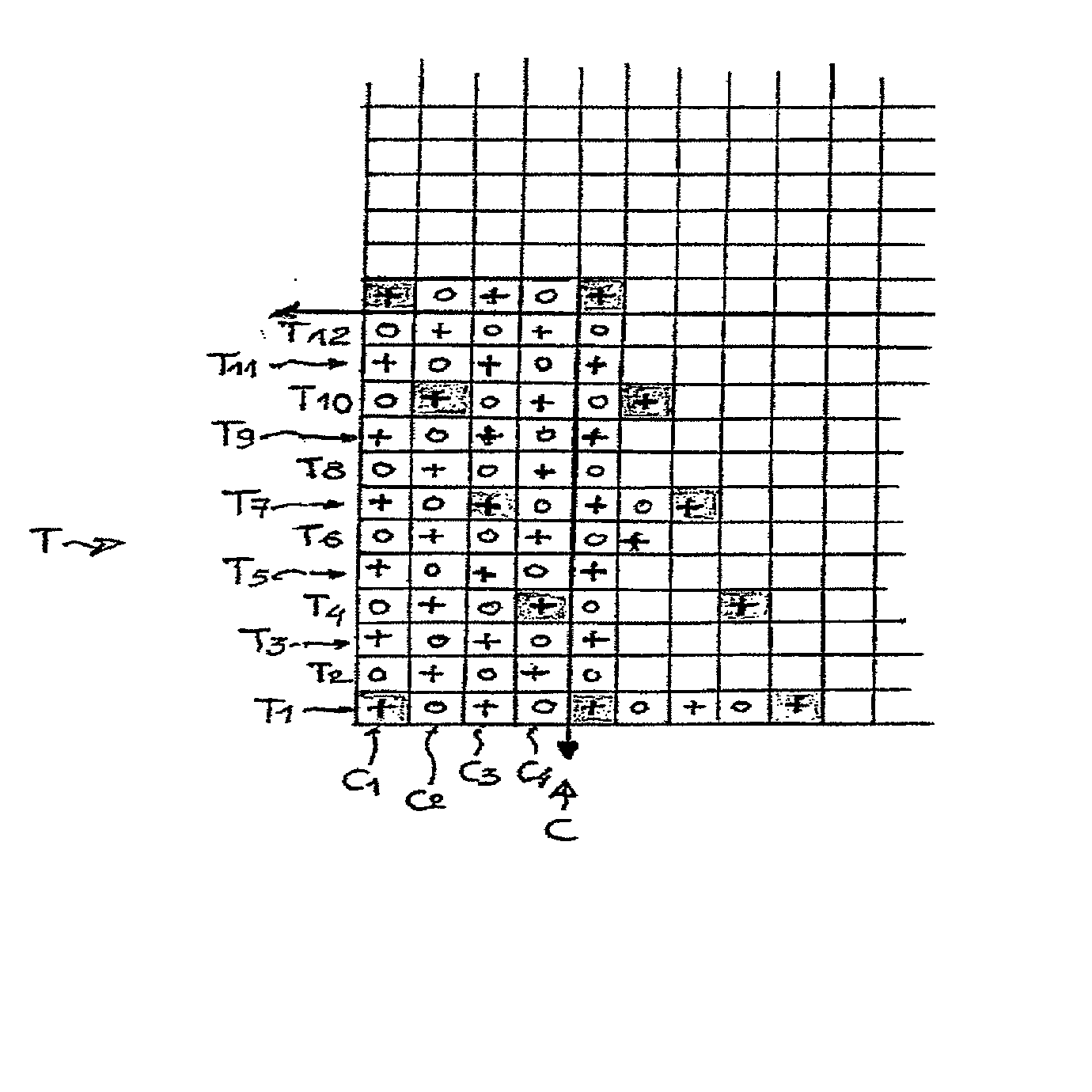

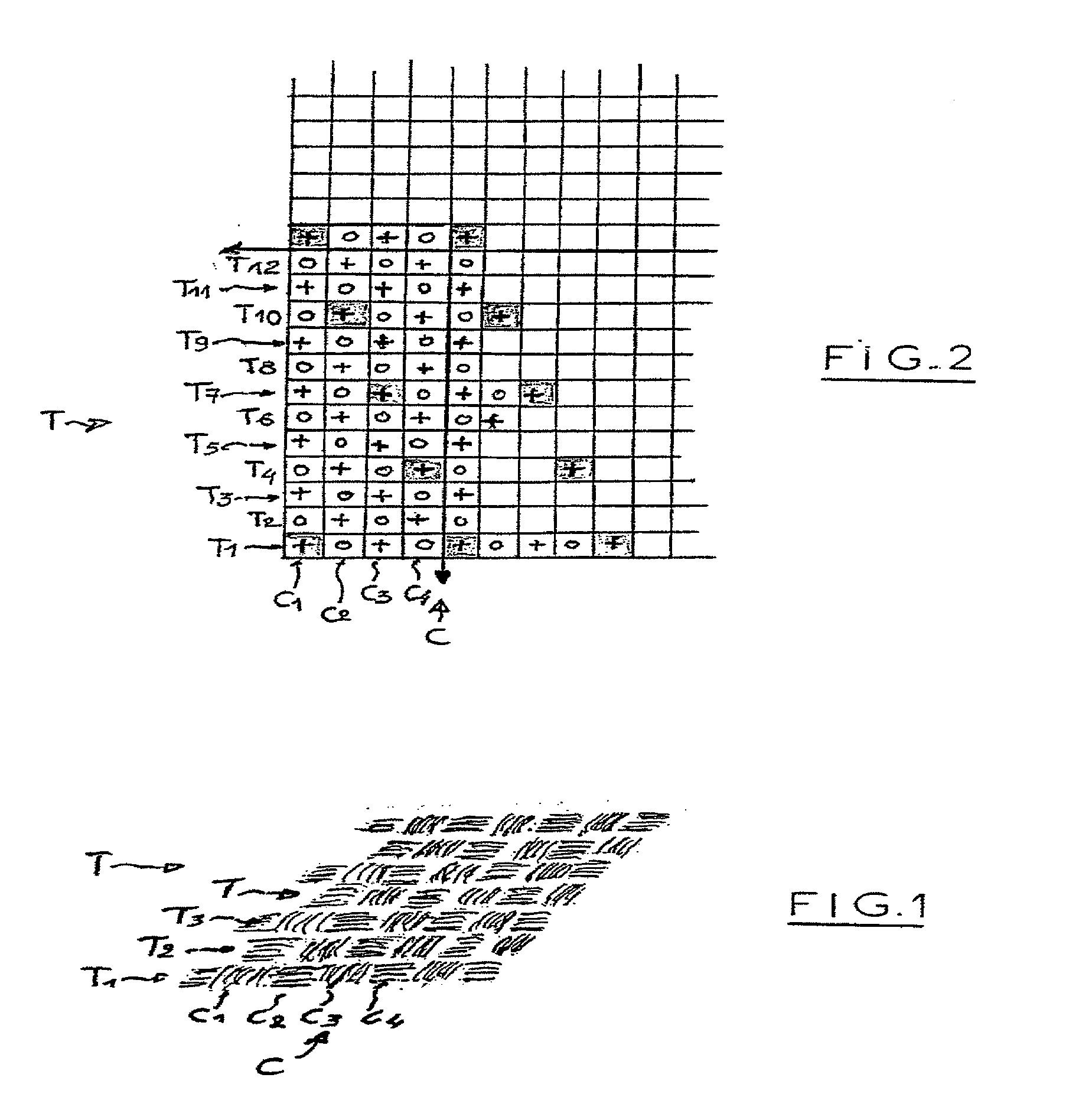

Textile material in sheet form for technical uses

The invention relates to a textile material in sheet form, consisting of a warp and weft fabric produced by rovings of continuous technical filaments (glass, carbon, aramide) without torsion. The invention is characterized in that the fabric is produced according to a plain weave or derivative thereof, the density of the warp (C) and the weft (T) being balanced; the warp threads (C) or weft threads (T) are weakened or cut individually at predetermined intervals without any noticeable deterioration in the characteristics of the weft or warp threads situated beneath the weakening or cutting area; and the areas in which a series of threads of the fabric (C) or (T) are weakened or cut are produced with a lateral and vertical thread course between two consecutive threads.

Owner:ESTAB LES FILS DAUGUSTE CHOMARAT & CO SA

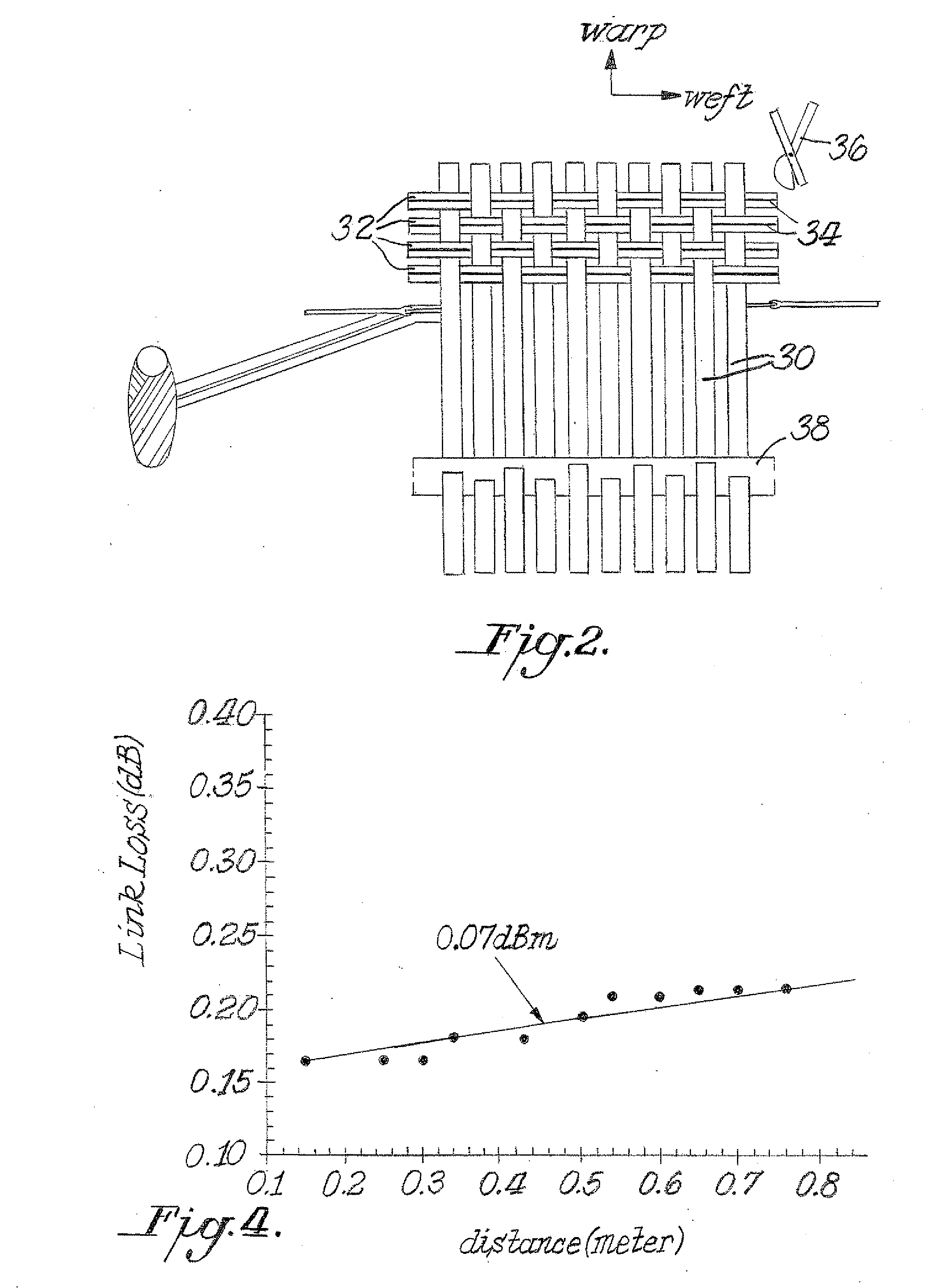

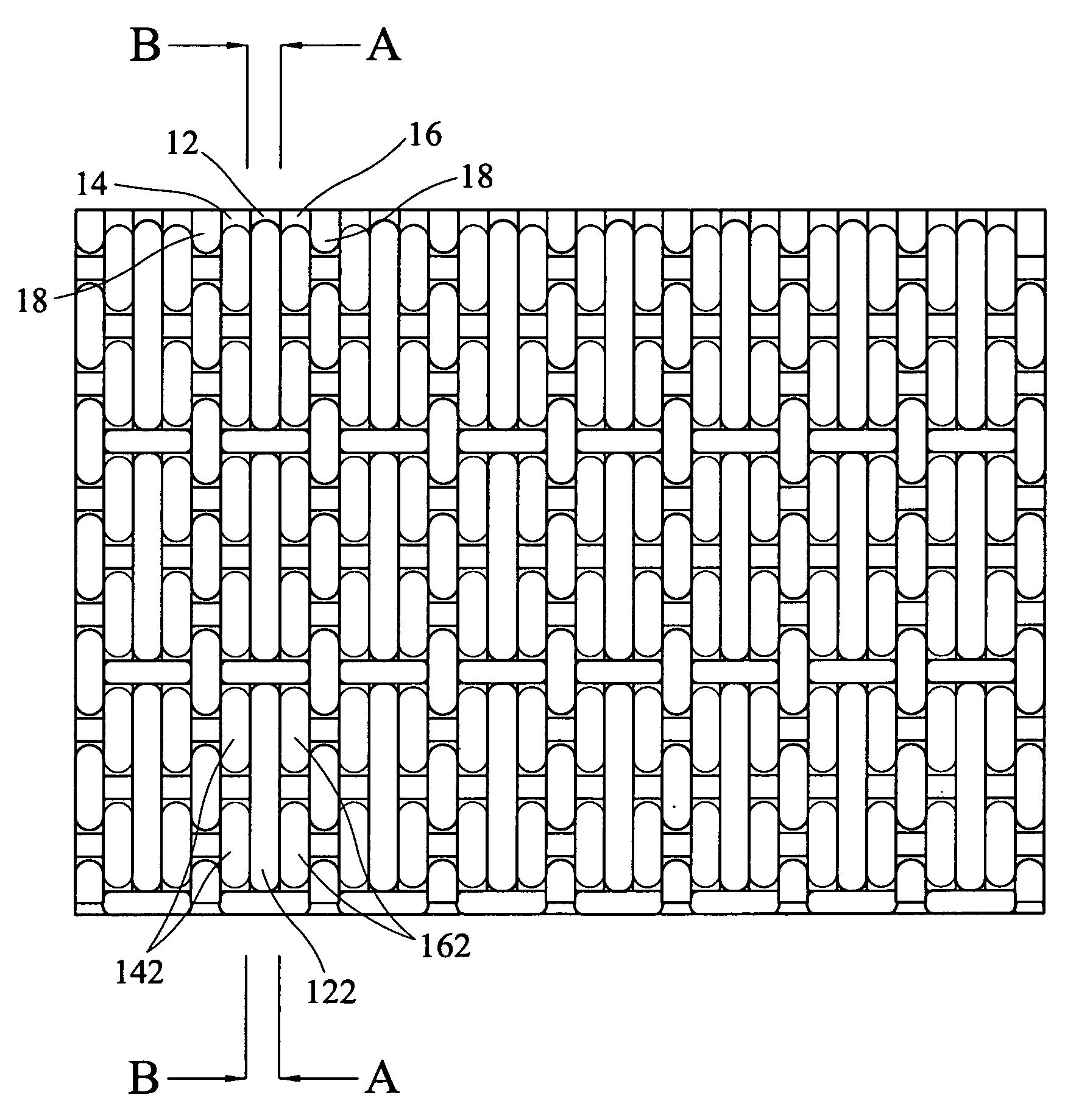

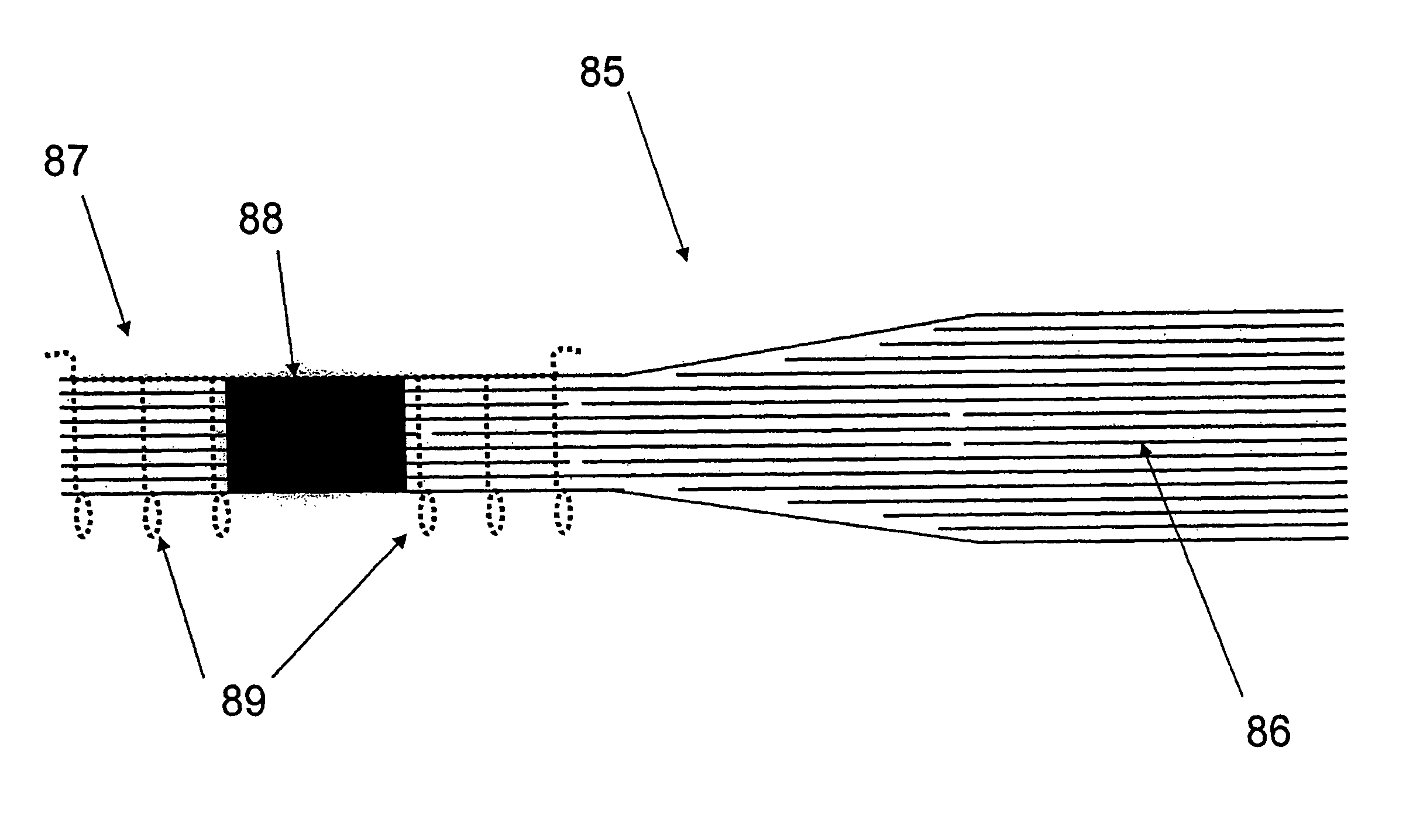

Automated process for embedding optical fibers in woven composites

InactiveUS20070103928A1Increased complexityIncrease laborProtective fabricsAuxillary apparatusEngineeringOptical fiber

An automated process for embedding optical fiber in woven composites includes embedding a woven fabric in resin using a vacuum infusion process to create a structural composite with integrated optical conduit with less than 0.8413 optical loss. The optical fiber is embedded in the woven fabric in both warp and weft directions. Optical fiber connectorization is done without polishing.

Owner:UNITED STATES OF AMERICA +1

Weave with visual color variation

The present invention relates to a weave with a visual color variation, which is interlaced by a plurality of longitudinal yarns and a plurality of latitudinal yarns. One of the longitudinal yarns and latitudinal yarns includes at least one protruding yarn and two color yarns with different colors. The protruding yarn has a plurality of protruding portions presenting on the surface of the weave. The two color yarns are arranged beside the protruding yarn respectively, and the two color yarns have a plurality of color portions presenting on the surface of the weave respectively. If the weave is observed from different viewing angles, the color portions are interfered by the protruding portion to make the weave show various visual color variations.

Owner:HUANG MIN SAN

Method for optimizing a textile production process

InactiveUS20060144457A1Easy operator controlEasy visual controlInspecting textilesLoomsTextile productionManufacturing engineering

Owner:PICANOL NV

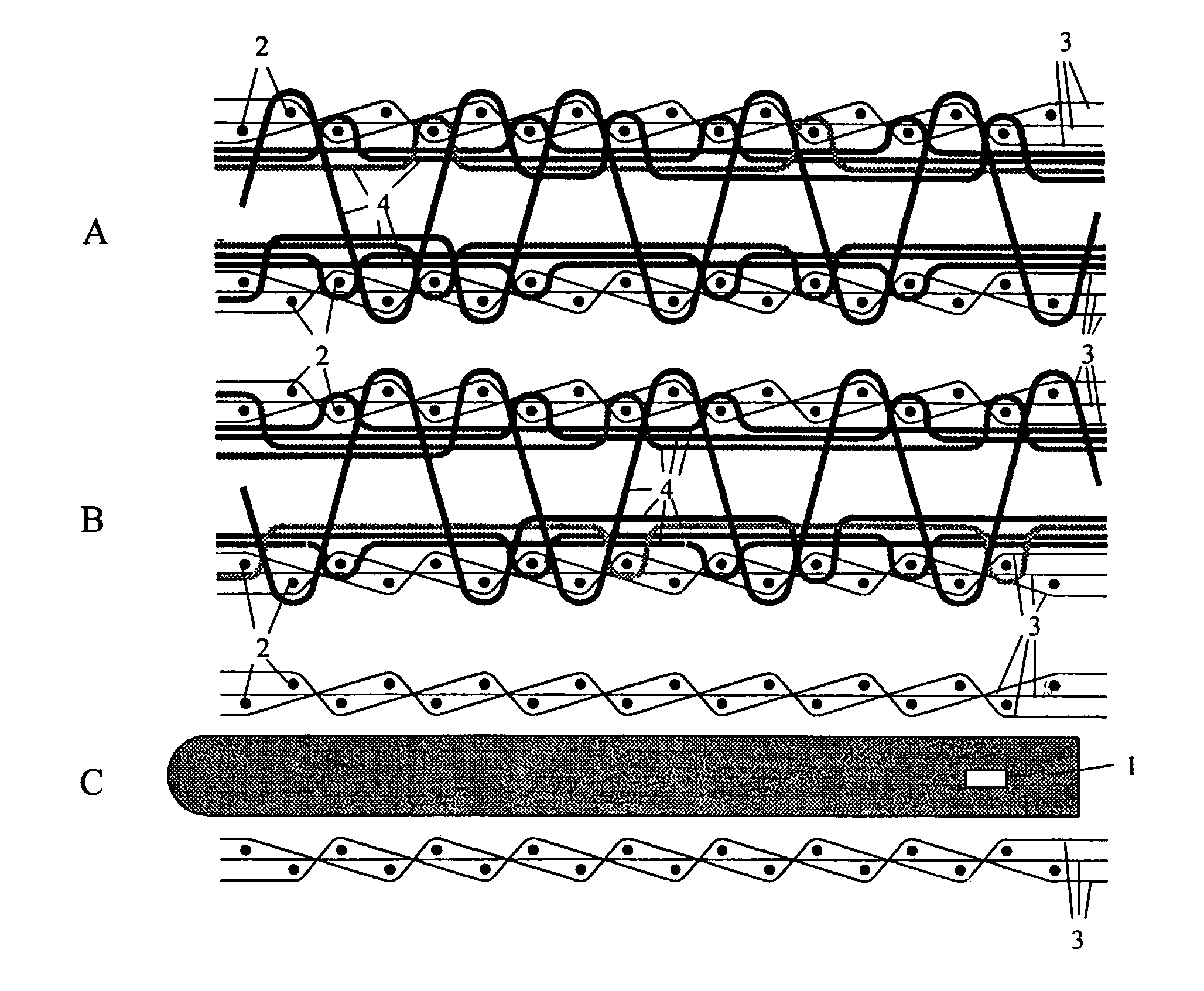

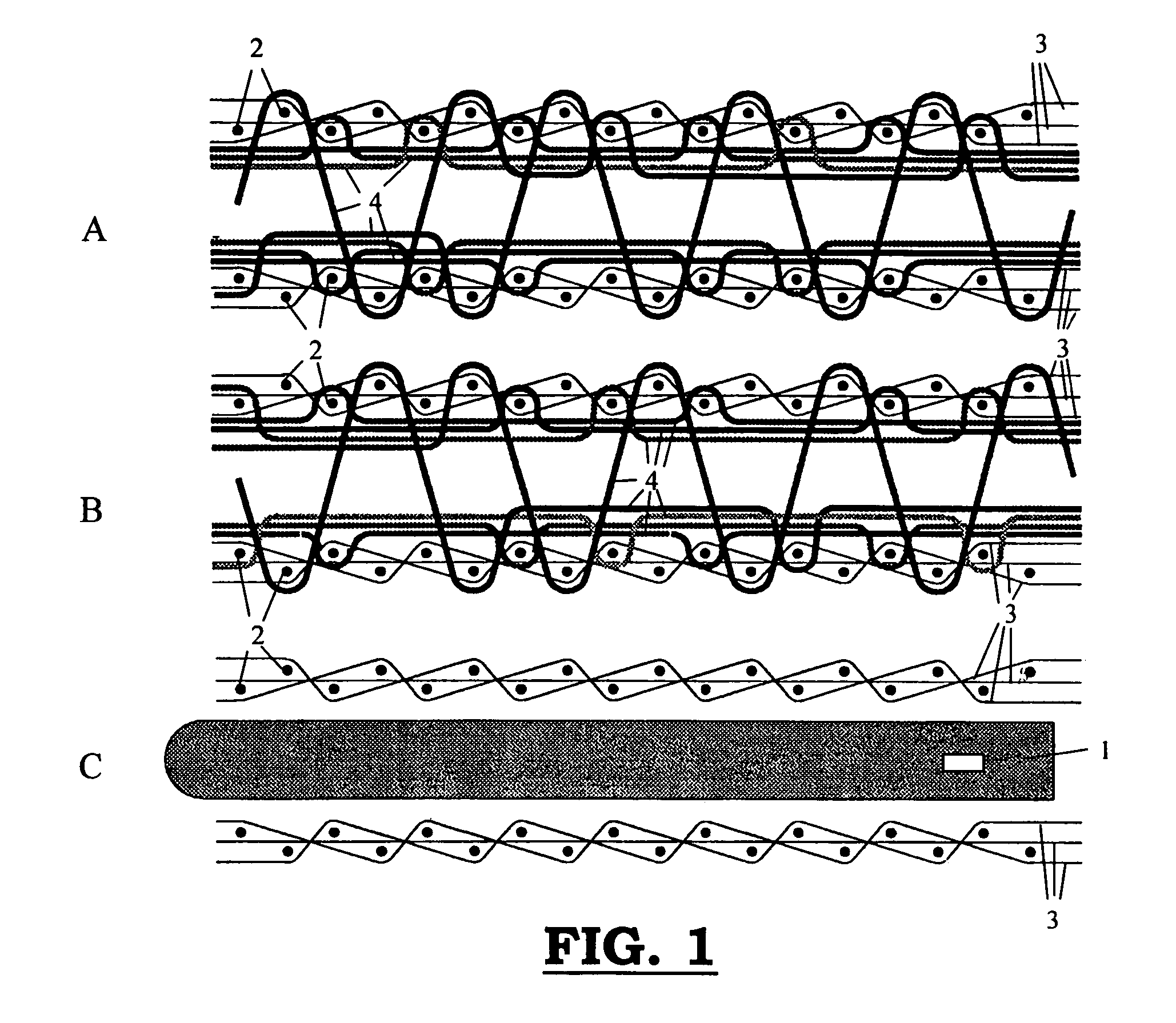

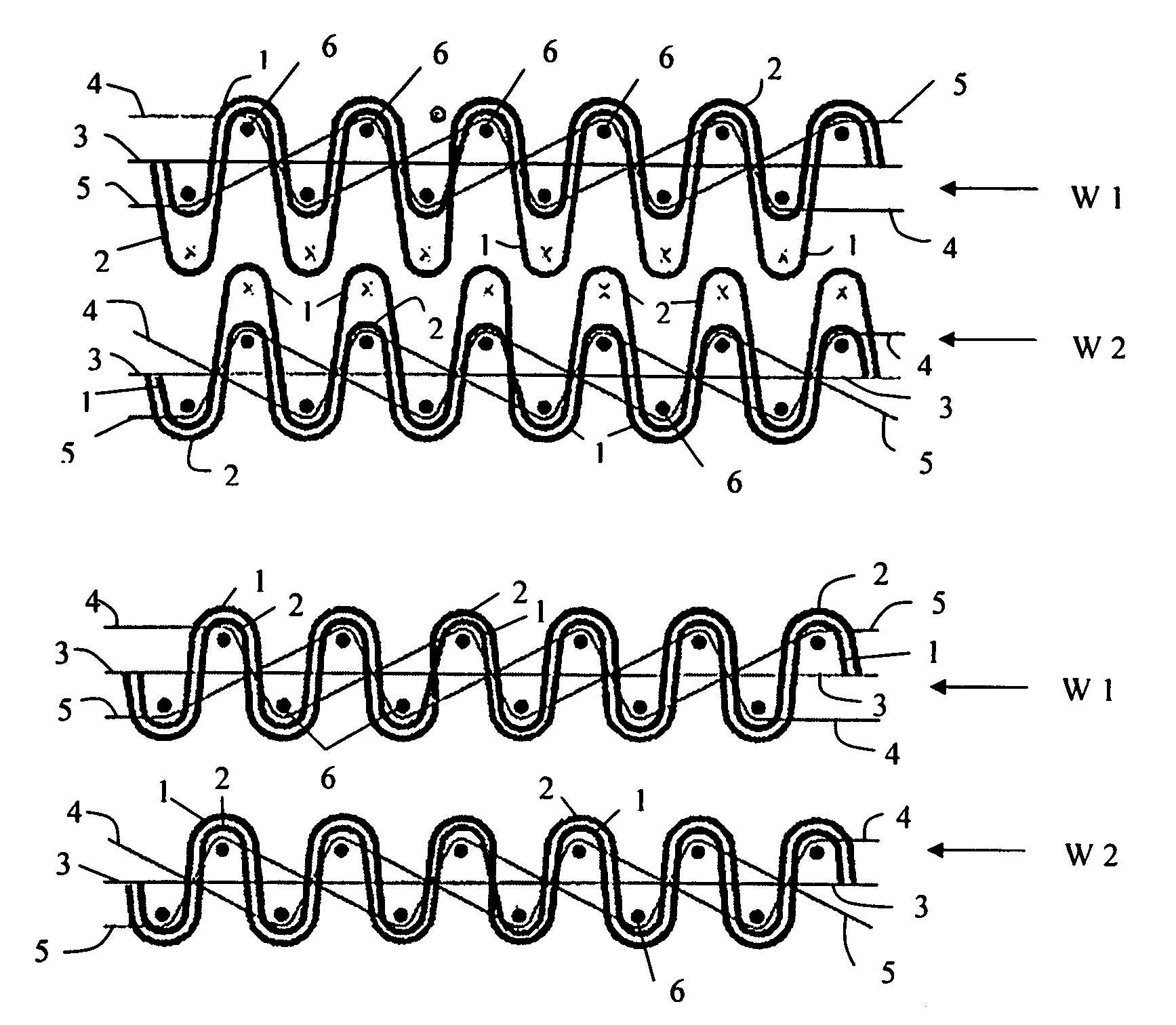

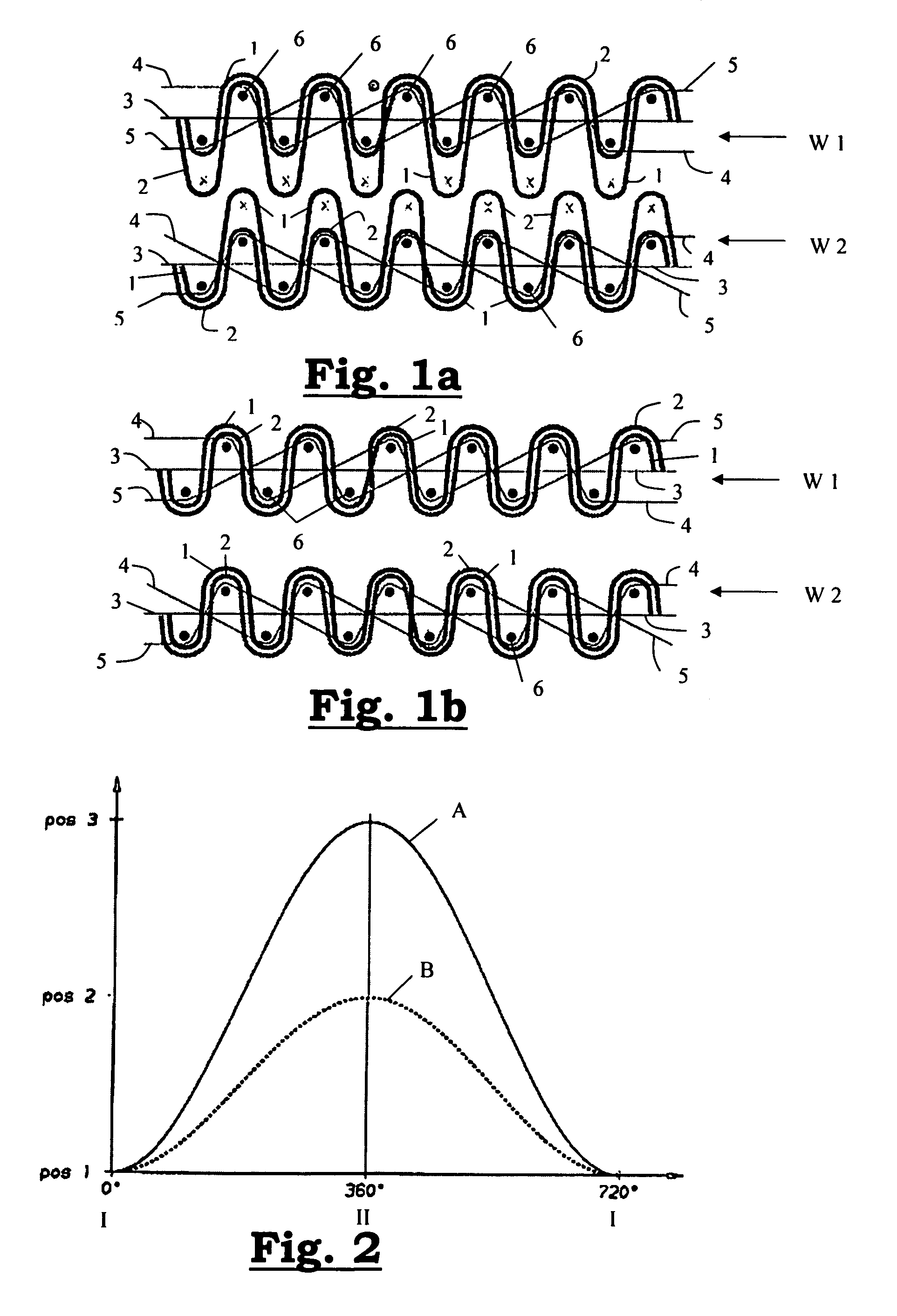

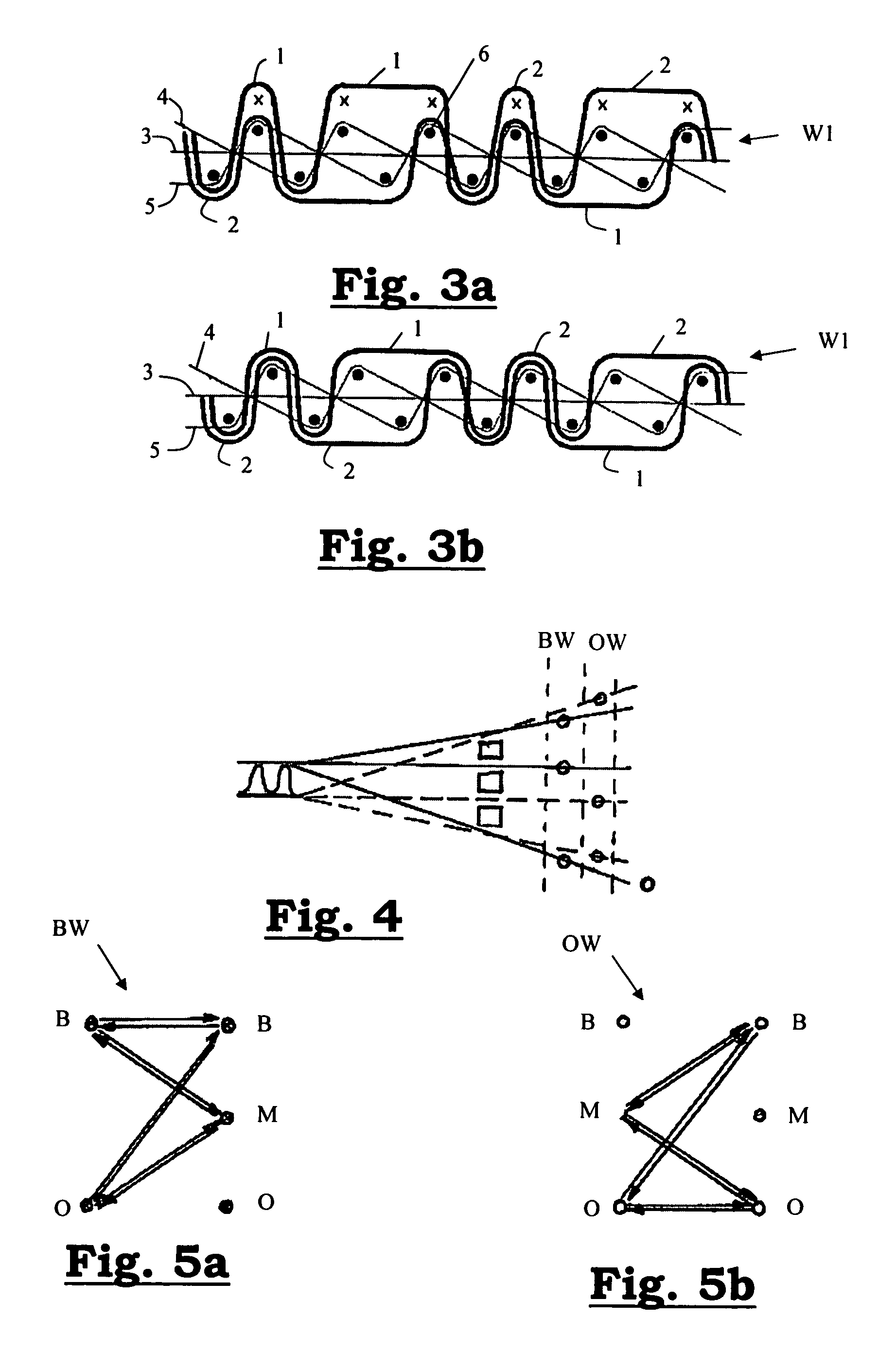

Method for weaving face-to-face fabrics, fabric woven according to such a method and face-to-face weaving machine for carrying out such a method

ActiveUS7240698B2Attractive aestheticallyKeep distancePile-fabric loomsAuxillary apparatusYarnEngineering

On the one hand, the invention relates to a method for weaving face-to-face fabrics on a face-to-face weaving machine, the fabrics (10),(20) consisting of weft yarns (2), ground warp yarns (3) and pile warp yarns (4), and one or several spacers (1) being provided in order to keep the fabrics (10),(20) at a distance during the weaving process, and a weaving reed being provided, comprising reed dents (A),(B),(C) through which the said ground warp yarns (3) and pile warp yarns (4) are extending, and through which the spacers (1) are extending every two or more reed dents (A),(B),(C), wherein the pile warp yarns (4) and the spacers (1) are separated from one another in the respective reed dents (A),(B),(C). On the other hand, the invention relates to a fabric woven in accordance with such a method and a face-to-face weaving machine designed to carry out such a method.

Owner:N V MICHEL VAN DE WIELE

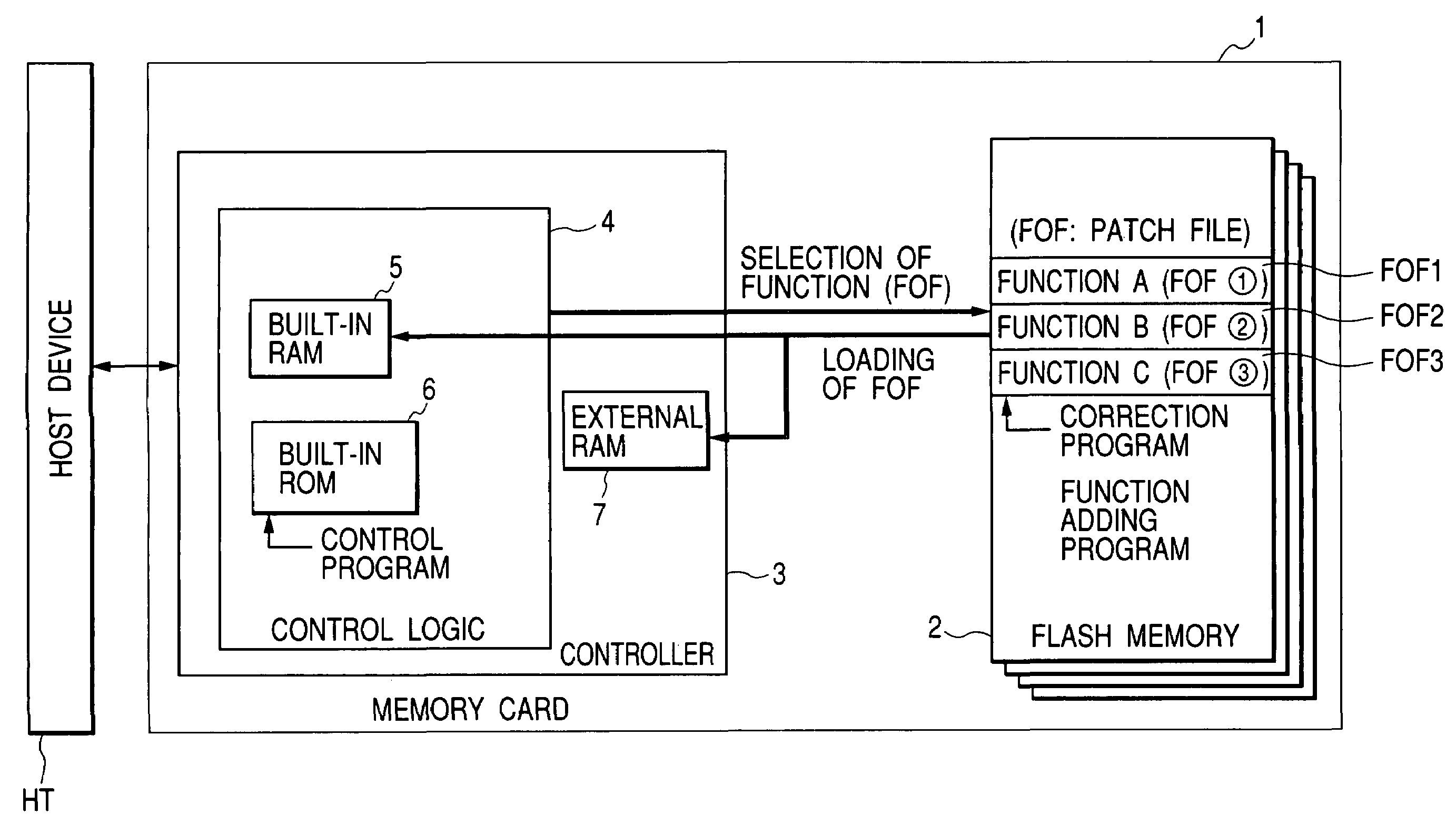

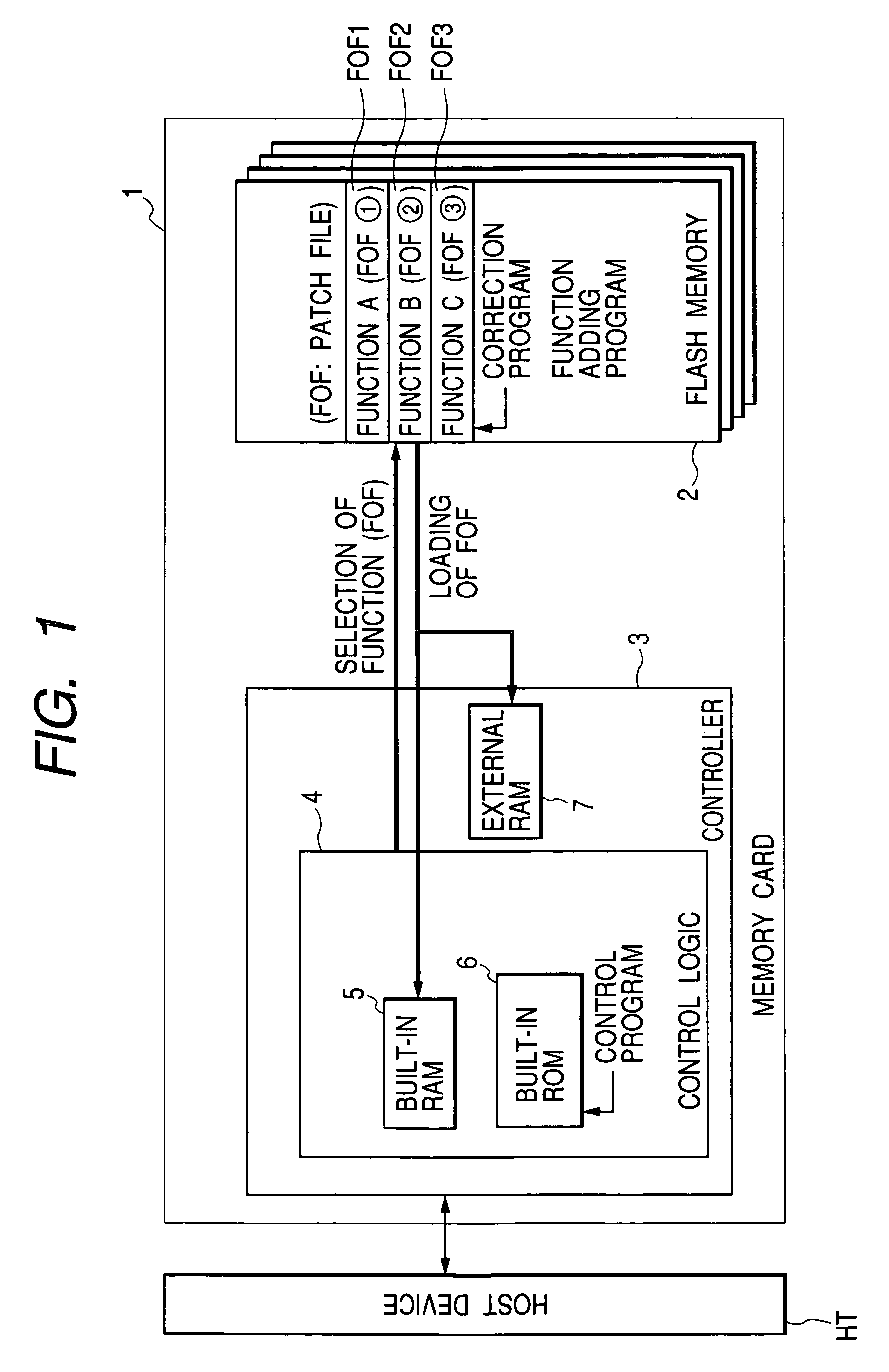

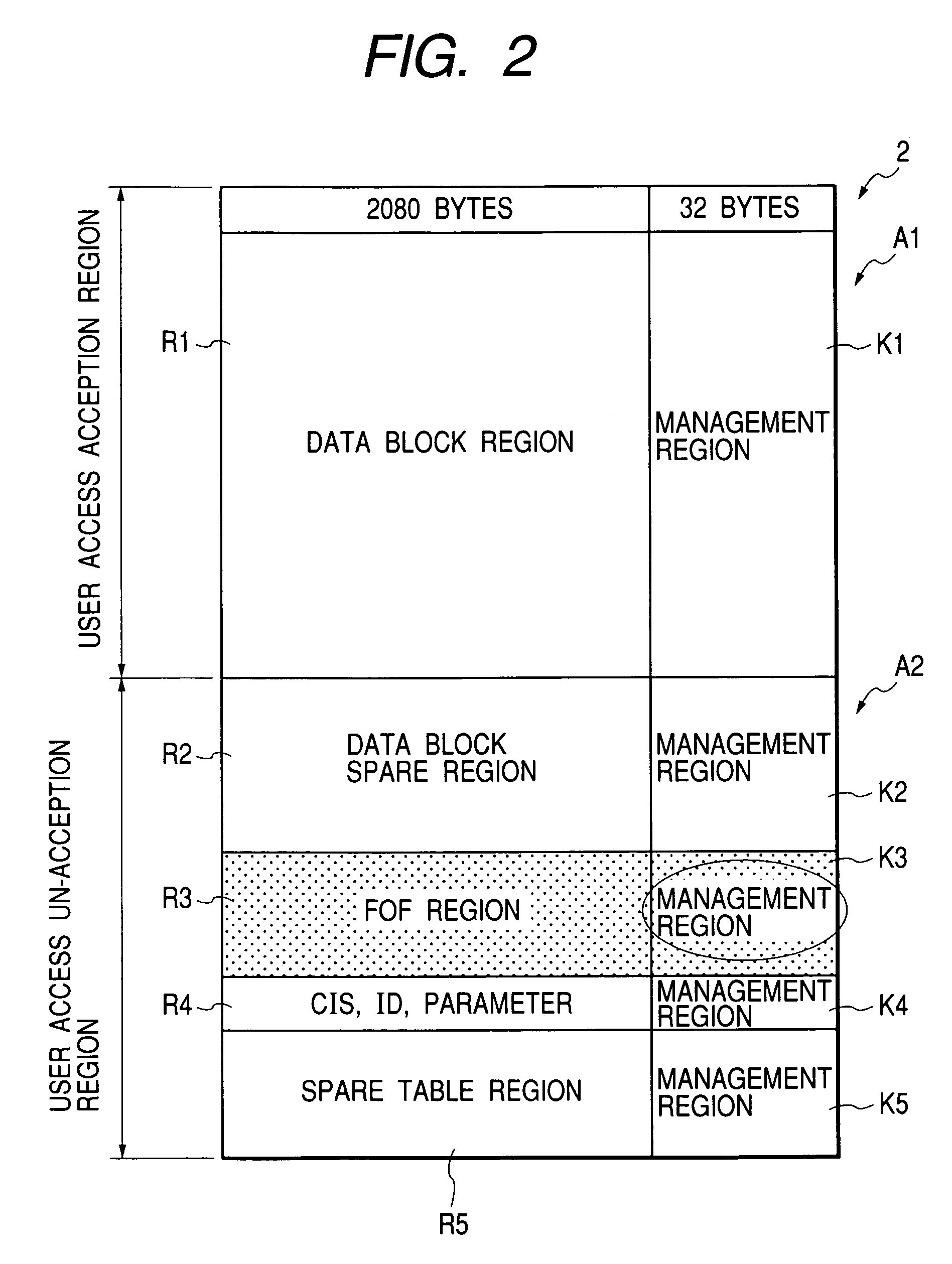

Nonvolatile memory card

The present invention provides a nonvolatile memory card in which a program is added, modified, changed, or the like by selecting arbitrary firmware on a flash memory from a plurality of pieces of firmware on flash memories. In a memory card, in addition to a program stored in a built-in ROM, firmware on flash memories as programs for adding, changing, modifying, or the like of a function such as a patch program are stored. Firmware on a flash memory which is desired to be made valid is set in a parameter sector or the like and is loaded into an external RAM, and the CPU of a control logic executes a process.

Owner:RENESAS ELECTRONICS CORP

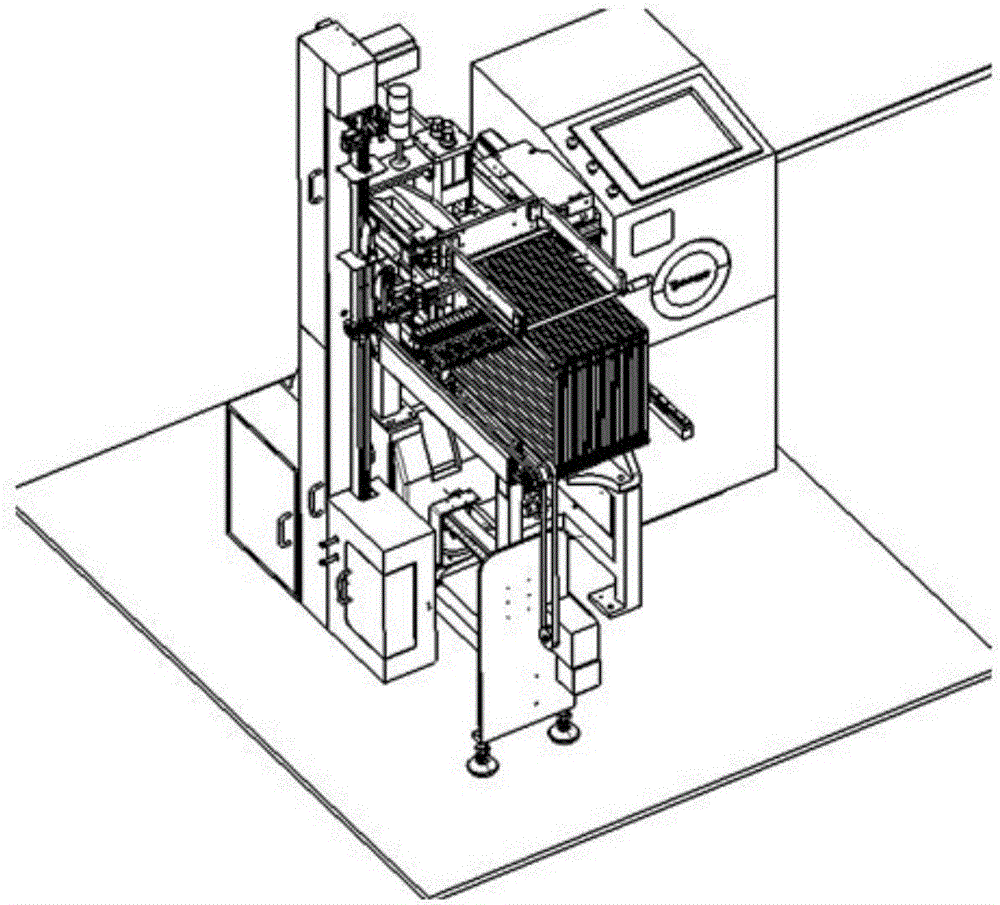

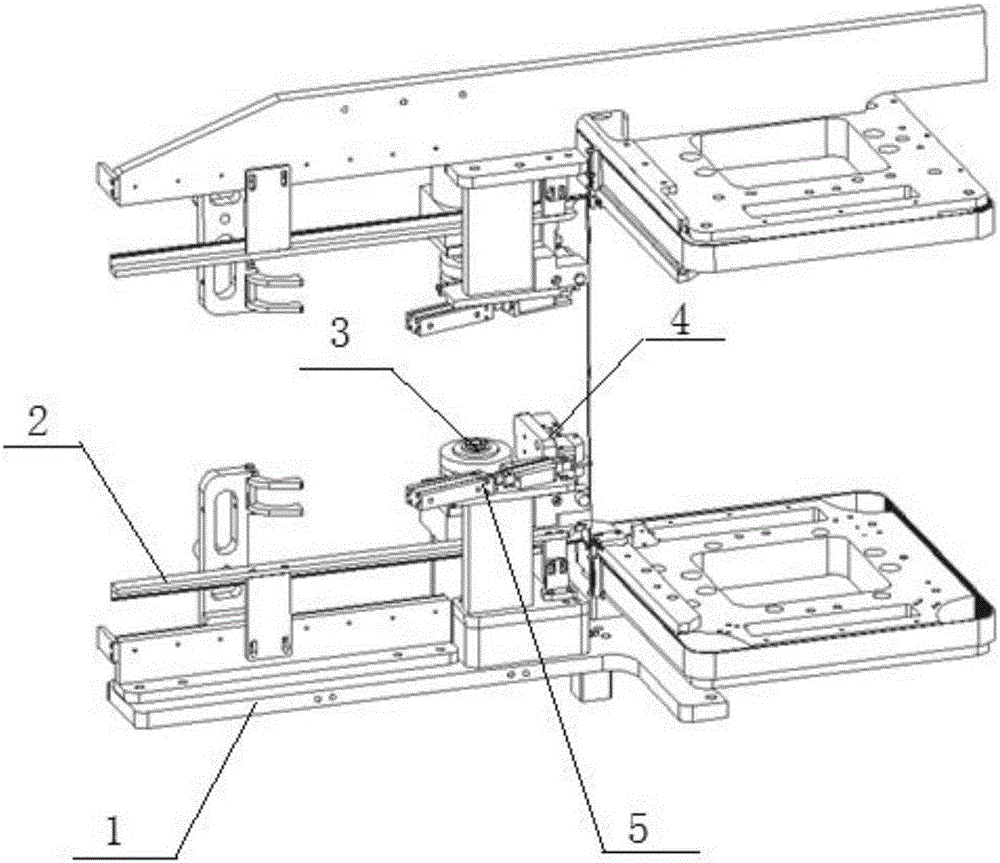

Automatic yarn drafting equipment

The invention relates to automatic yarn drafting equipment suitable for sample looms. The automatic yarn drafting equipment comprises a heddle feeding mechanism mounted on a rack, a heddle conveying mechanism, a yarn feeding mechanism, a yarn hooking mechanism, a reed feeding mechanism and a heddle arranging mechanism, the heddle feeding mechanism stores heddle at a heddle storage place at a time and conveys the same to a corresponding process position of the automatic yarn drafting equipment for single heddle separation, the reed feeding mechanism and the heddle arranging mechanism are at tail-end workstations of the equipment, and the heddle penetrates among workstations; the heddle conveying mechanism conveys the heddle which is separated successfully to the workstations for working, the yarn feeding mechanism conveys yarn equal in length at a yarn storage place to the top end of the equipment, the yarn hooking mechanism utilizes an arrow belt to hook vertical yarn at a yarn feeding workstation into the heddle and steel reeds and stores ends of the yarn at the tail end of the yarn hooking mechanism, the reed feeding mechanism orderly conveys the steel reeds, each steel reed gap allows 1-3 yarns to penetrate, and the heddle arranging mechanism sequentially arranges the heddle which successfully penetrate the yarns according to a set sequence.

Owner:JIANGYIN TONGYUAN TEXTILE MACHINERY

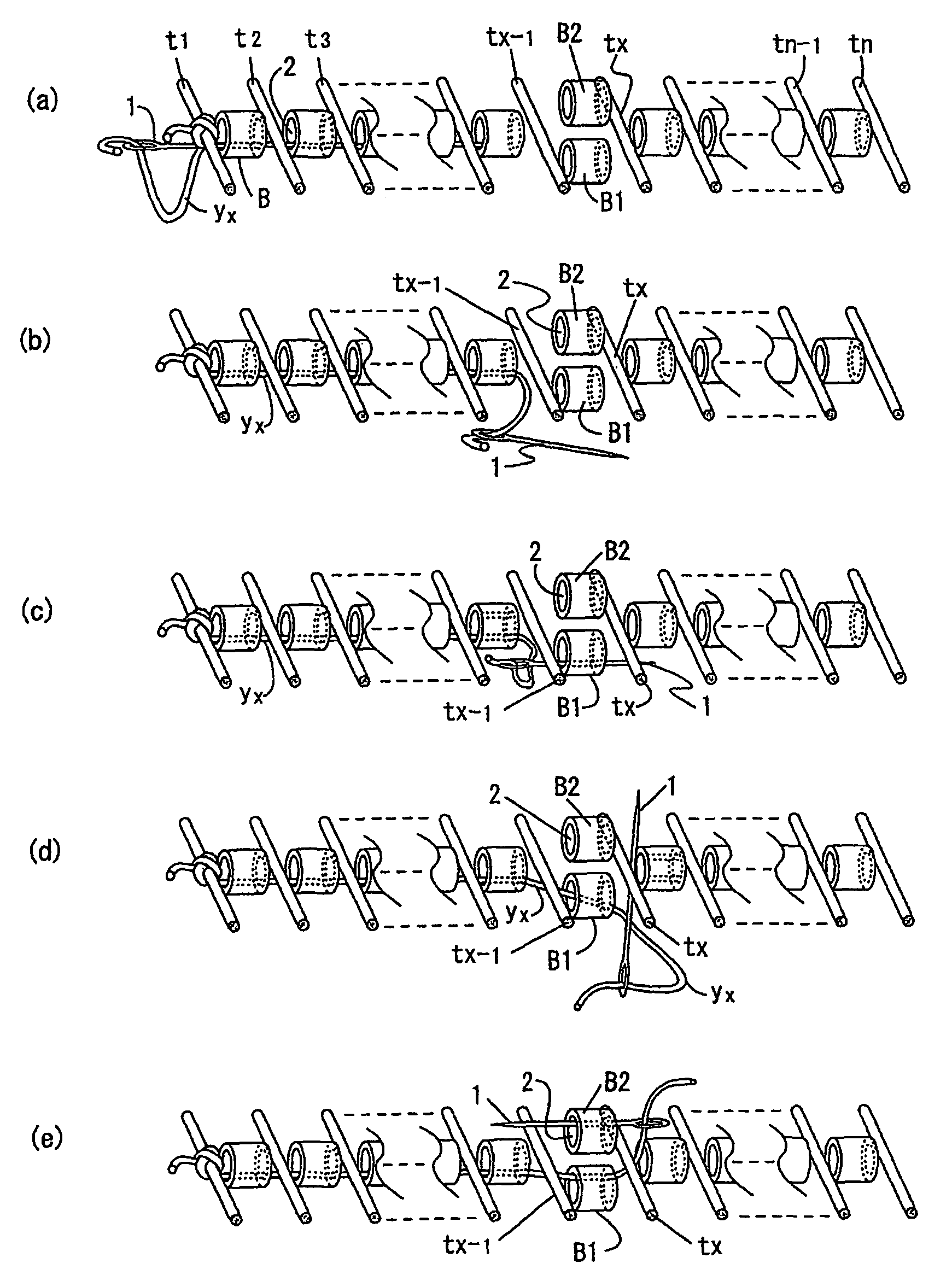

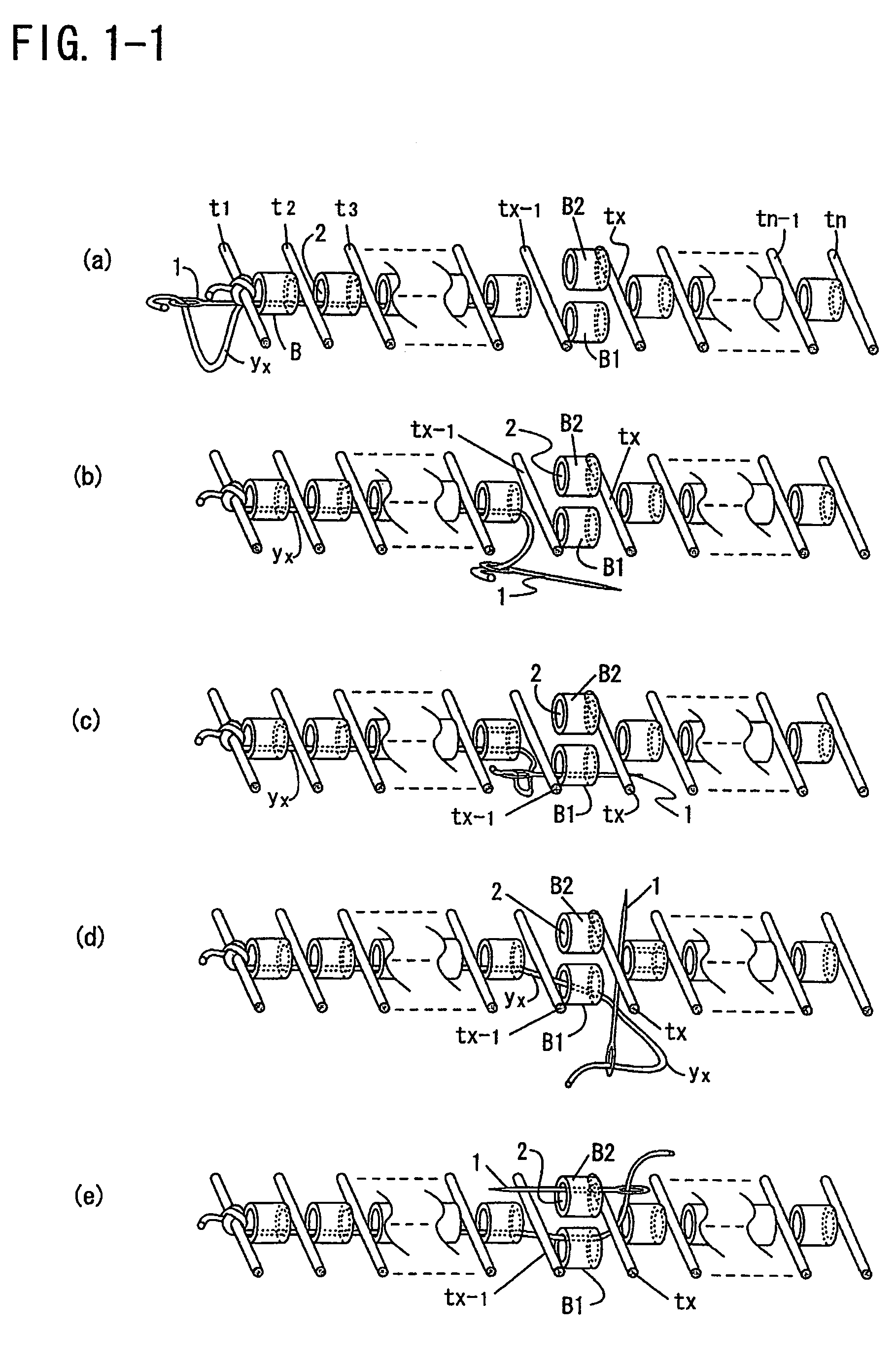

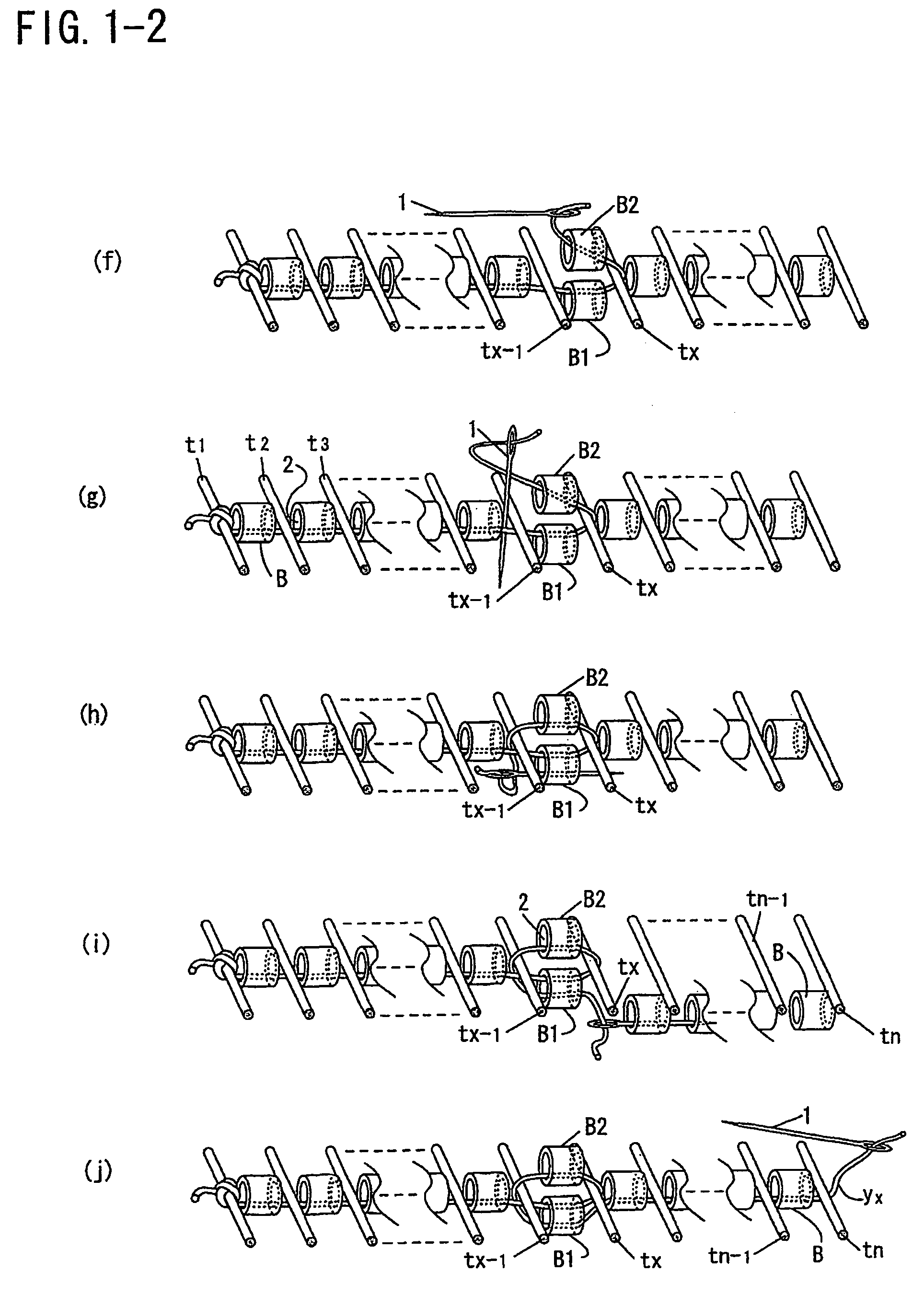

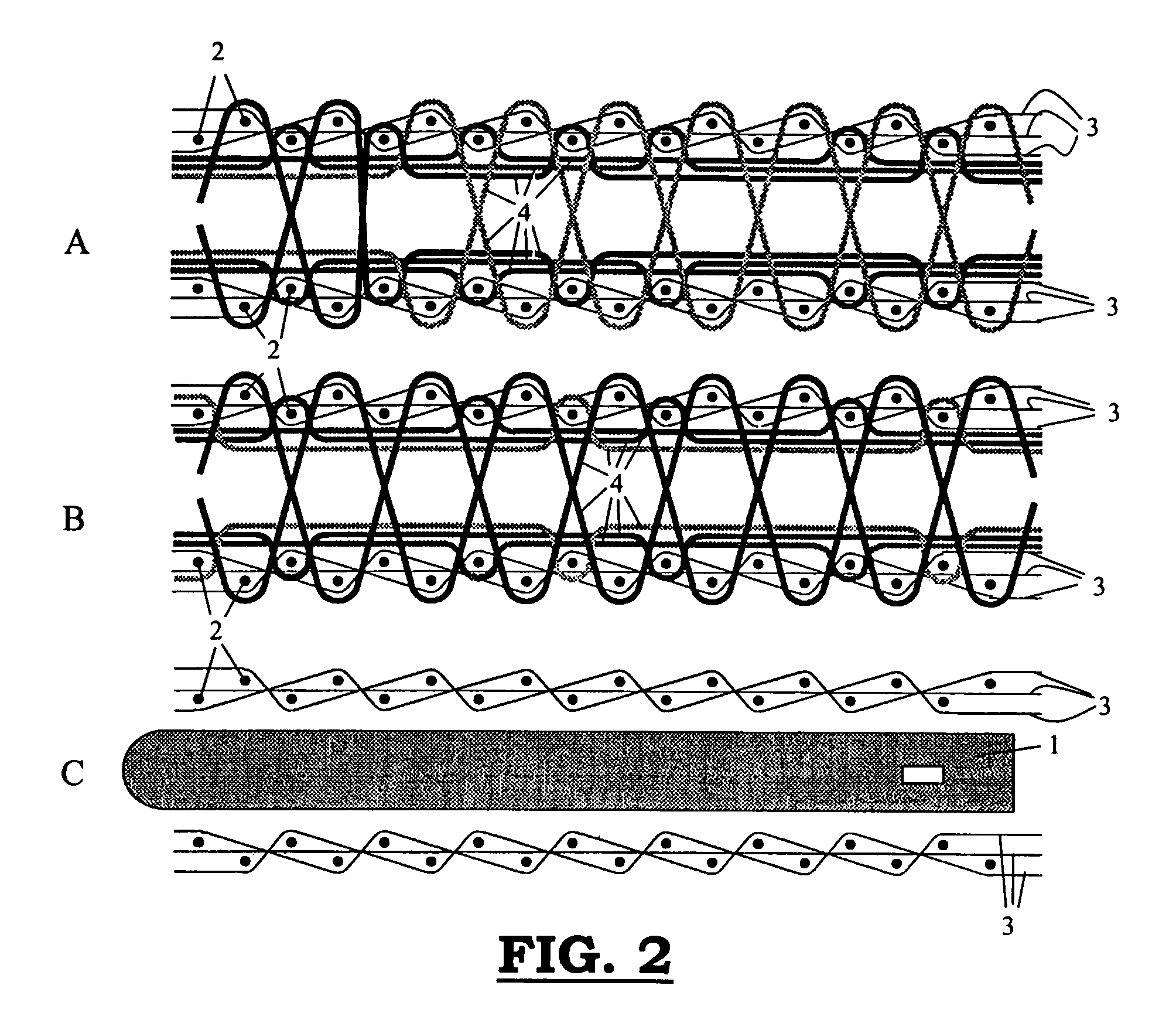

Method and system for weaving fabrics with two useable sides

This invention relates to a method and to a system for weaving fabrics with two useable sides (W1), (W2), in which per operating cycle one weft thread (6) is inserted, and in which each fabric comprises a first figure warp thread (1) and a second figure warp thread (2) that, in a number of operating cycles, are positioned together alternately above and below the weft insertion level, so that, at both fabric sides, these figure warp threads (1), (2) are bound over the same weft threads (6), while running above one another, and in which the mutual position (upper or lower position) taken up by the first figure warp thread (1) and the second figure warp thread (2) in each fabric (W1), (W2) during the weaving process is determined selectively according to a previously defined figure pattern, preferably by positioning the first (1) and second figure warp threads (2) in a first shed (I) at a first level (POS. 1) at one side of the weft insertion level and in a second shed (II), selectively on a different second level (POS. 2) and third level (POS. 3), at the other side of the weft insertion level. The invention also relates to fabrics (W1), (W2) woven according to such method.

Owner:VAN DE WIELE MICHEL

Weaving loom panel support structure for jacquard selectors

A loom and a weaving mechanism of the Jacquard type for forming the shed in the loom wherein the weaving mechanism is associated with a harness including harness cords secured to heddles. The harness cords are controlled by electric actuators mounted to two panels extending above the heddles and between which a compartment is formed in which a control unit for supplying and monitoring the operation of the actuators is housed.

Owner:STAUBLI FAVERGES SA

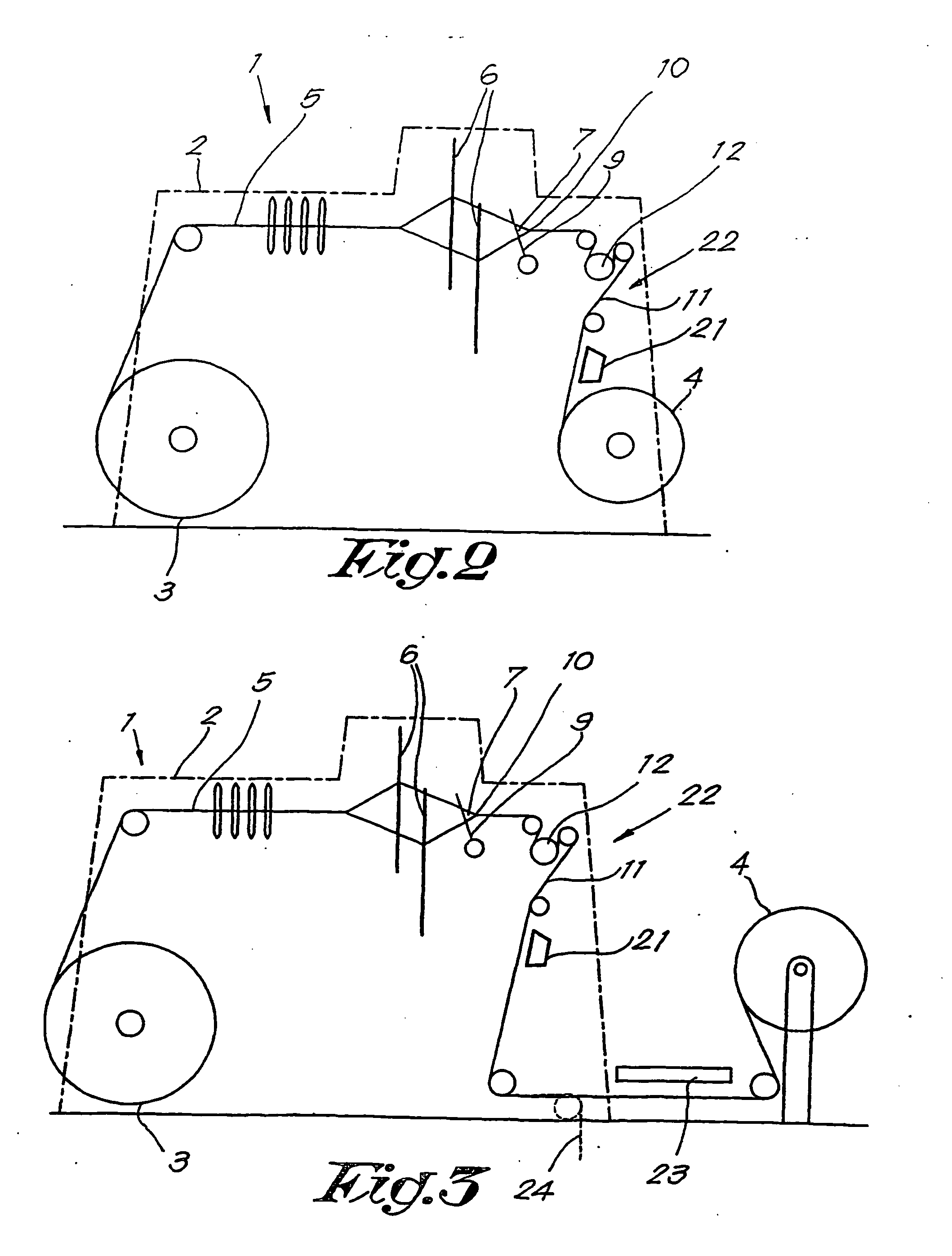

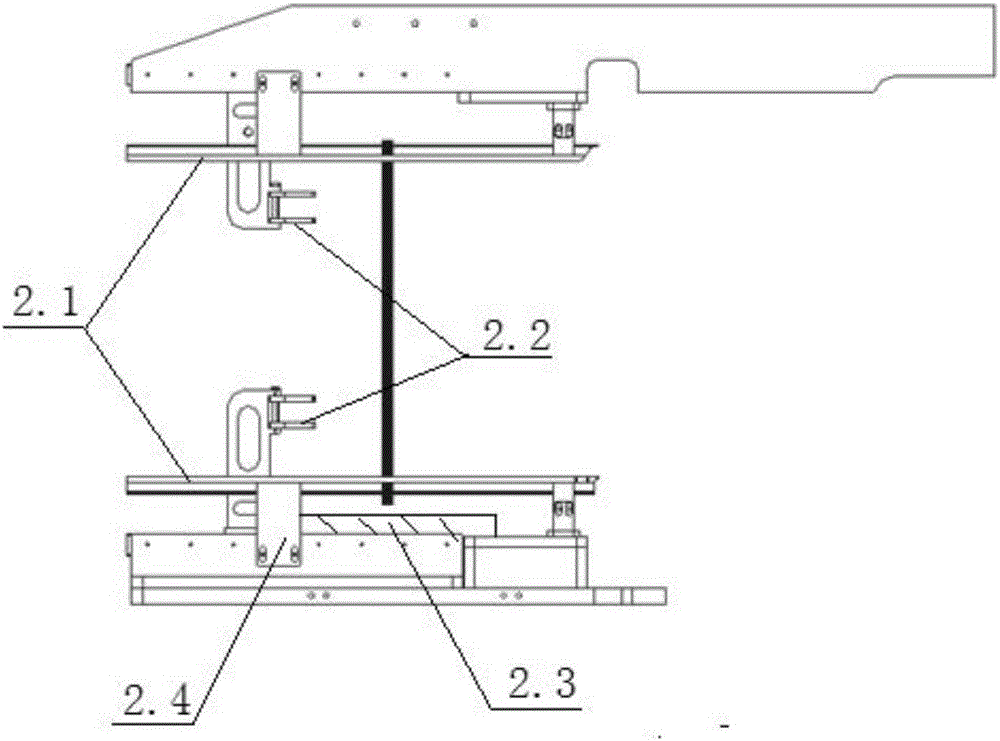

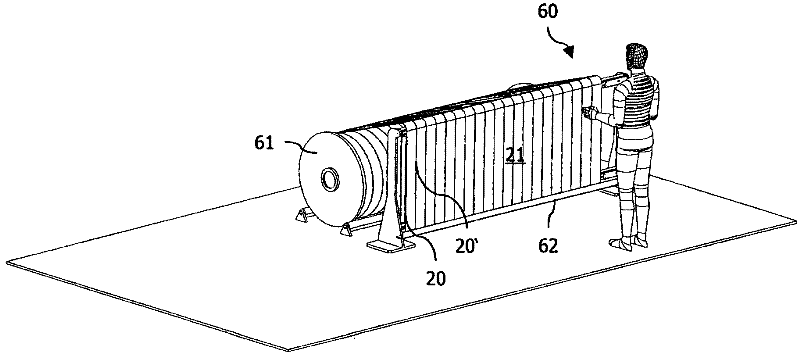

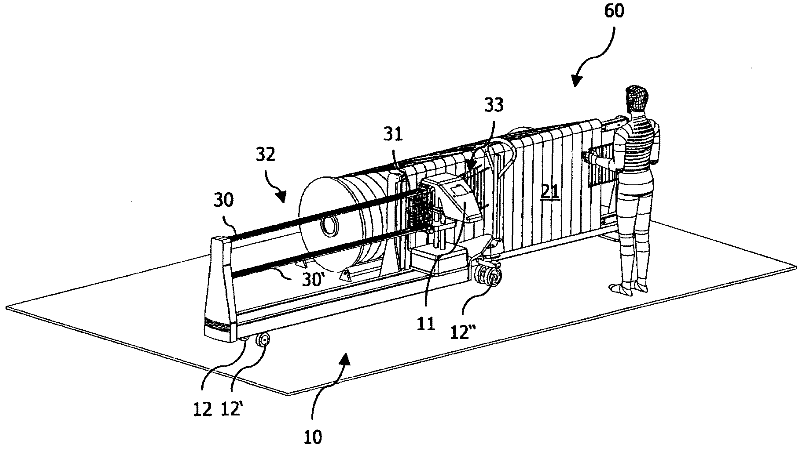

Movable threading unit

InactiveCN102292485AFlexible threadingFlexible useAuxillary apparatusWoven fabricsYarnComputer module

The invention relates to a movable drawing-in unit (10) for threading individual warp threads (20) of a weaving warp thread into elements of a weaving implement, comprising: at least one feeding device (33, 43, 51) , in order to provide the elements of the weaving appliance; at least one receiving device (32, 42, 51) for receiving the elements of the weaving appliance with the threaded warp yarn (20); passing through the module (11) , the passing-through module is configured to separate an element from at least one providing device (33, 43), for grabbing a corresponding warp thread (20), for threading the warp thread (20) Into separate elements and for elements with threaded warp threads (20) to be positioned on a receiving device (32, 42), wherein for the threading of each warp thread (20), the threading unit (10) is movable in space.

Owner:普费菲孔斯陶布里股份公司

Hybrid three-dimensional woven/laminated struts for composite structural applications

ActiveUS7943535B2High damage toleranceImprove propertiesSewing-machine elementsLoomsFiberEngineering

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies. The first and second end portions can have through thickness reinforcements comprising reinforcement fibers that traverse through the independent woven layers and the bias plies, locking them together.

Owner:ALBANY ENGINEERED COMPOSITES

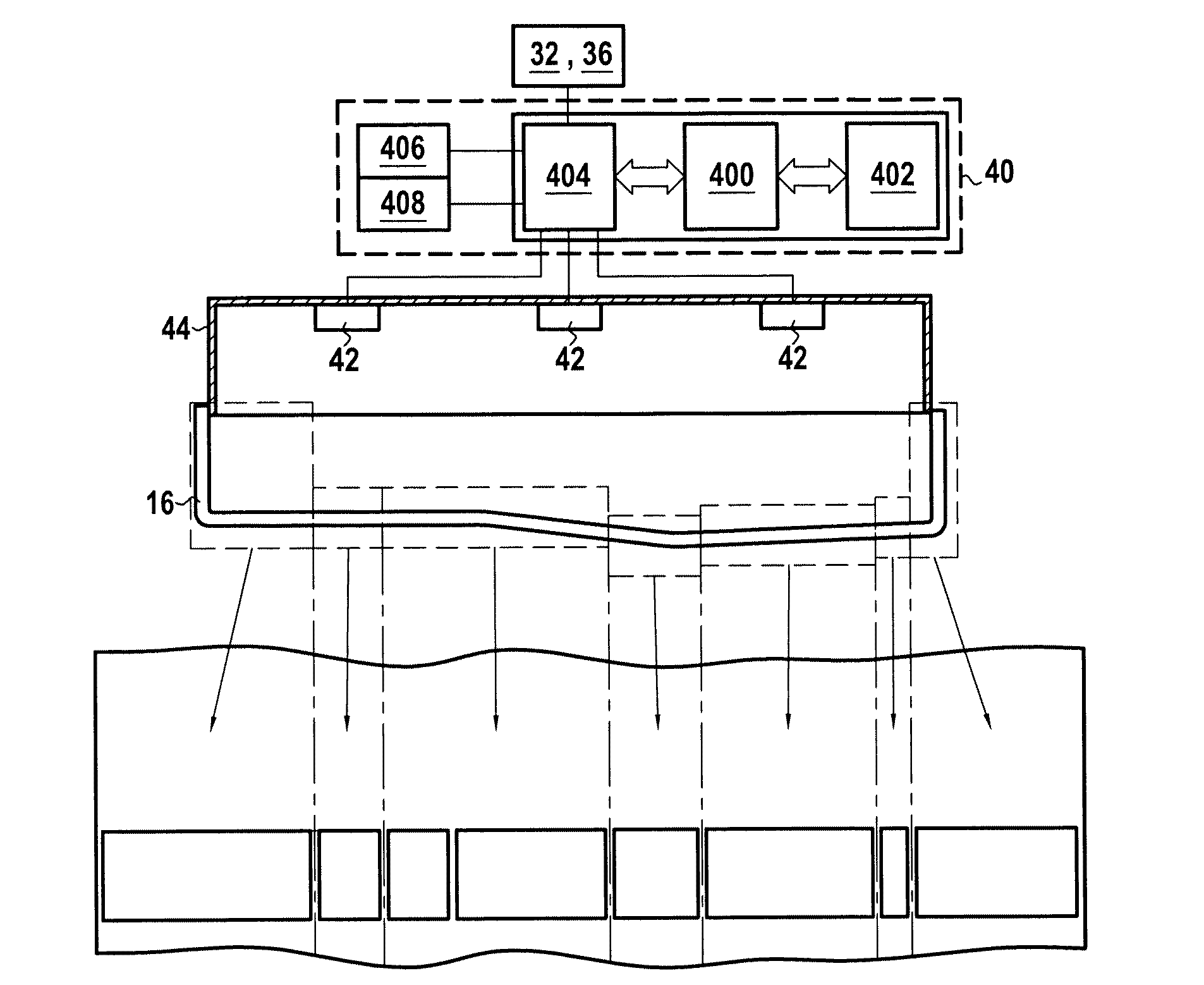

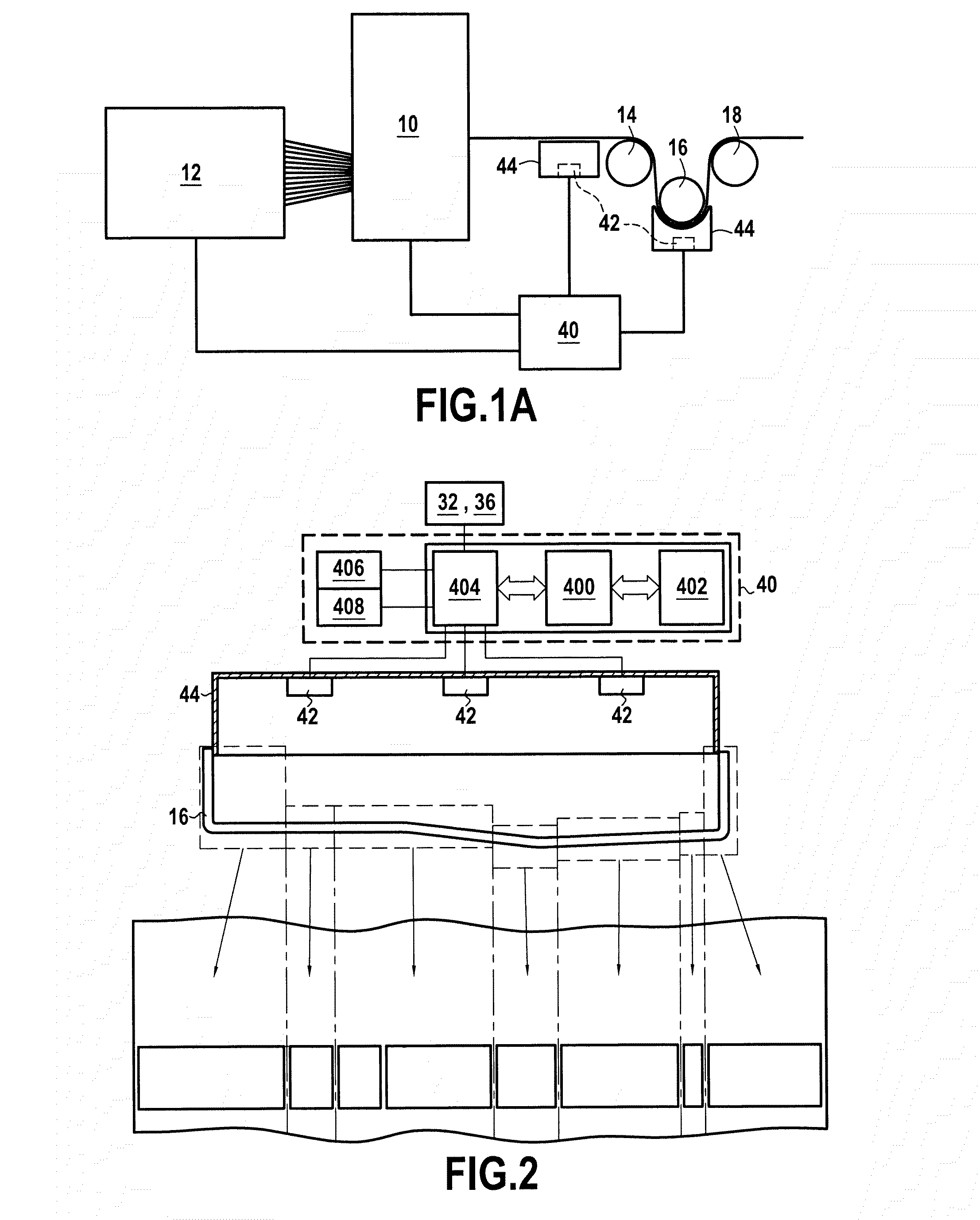

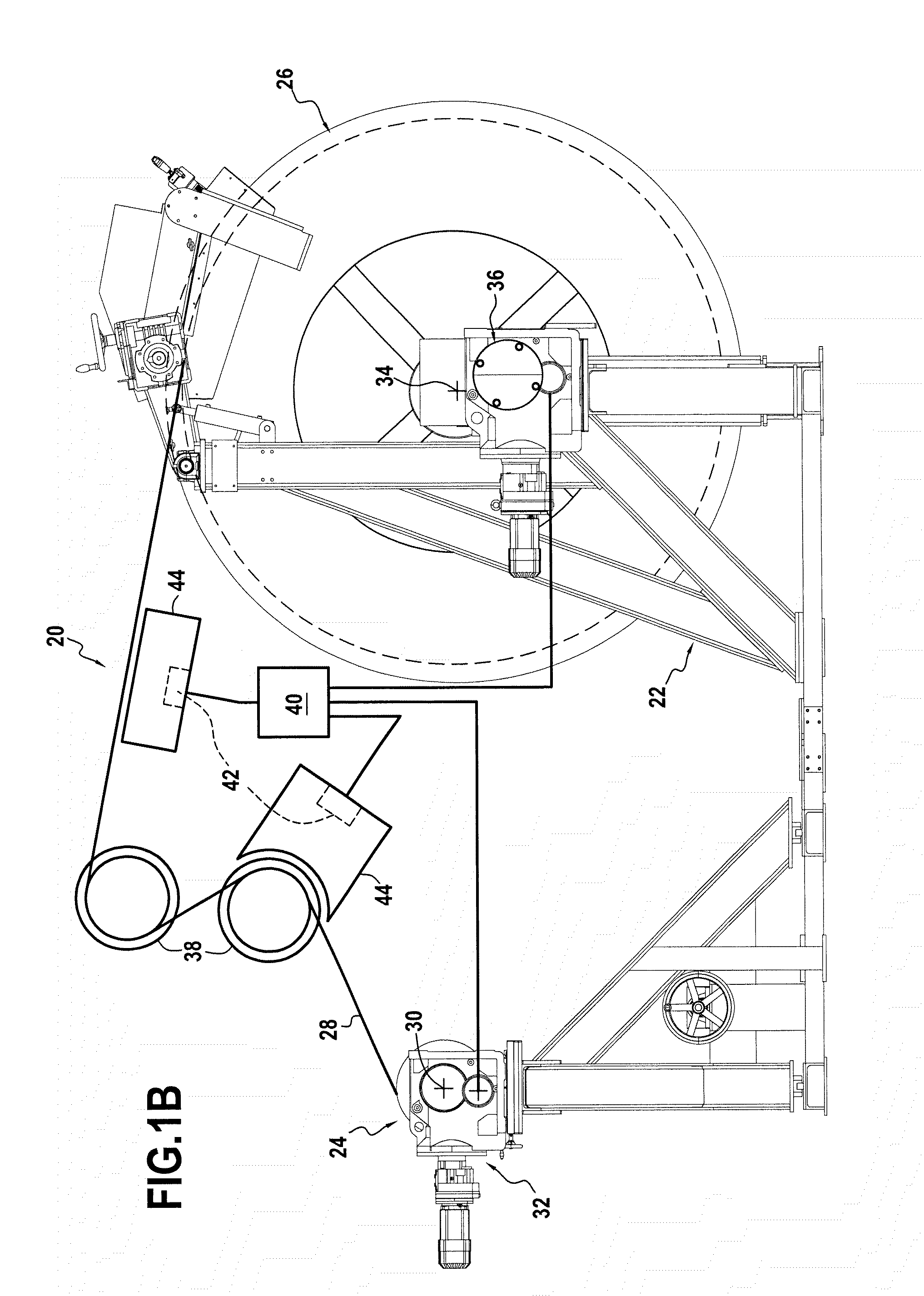

Machine for weaving or winding a fiber texture and enabling anomalies to be inspected by image analysis

ActiveUS20160077019A1Reduce needMonitor qualityInvestigating composite materialsInspecting textilesFiberComputer vision

A machine for weaving or winding a fiber preform on a mandrel having an axis of rotation that is substantially horizontal and that serves to receive the preform, the machine having a plurality of cameras pointing towards the underside of the fiber preform in order to scan the hidden face of the fiber preform and acquire images of the hidden face; an image analysis module for processing these images of the hidden face of the fiber preform in a plurality of adjacent scan windows, and for extracting weaving patterns therefrom and comparing them with reference weaving patterns previously stored in the module; a motor for driving the mandrel in rotation about its axis of rotation; and a control unit for stopping rotation of the mandrel if the result of the comparison reveals a difference of appearance between the two weaving patterns.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

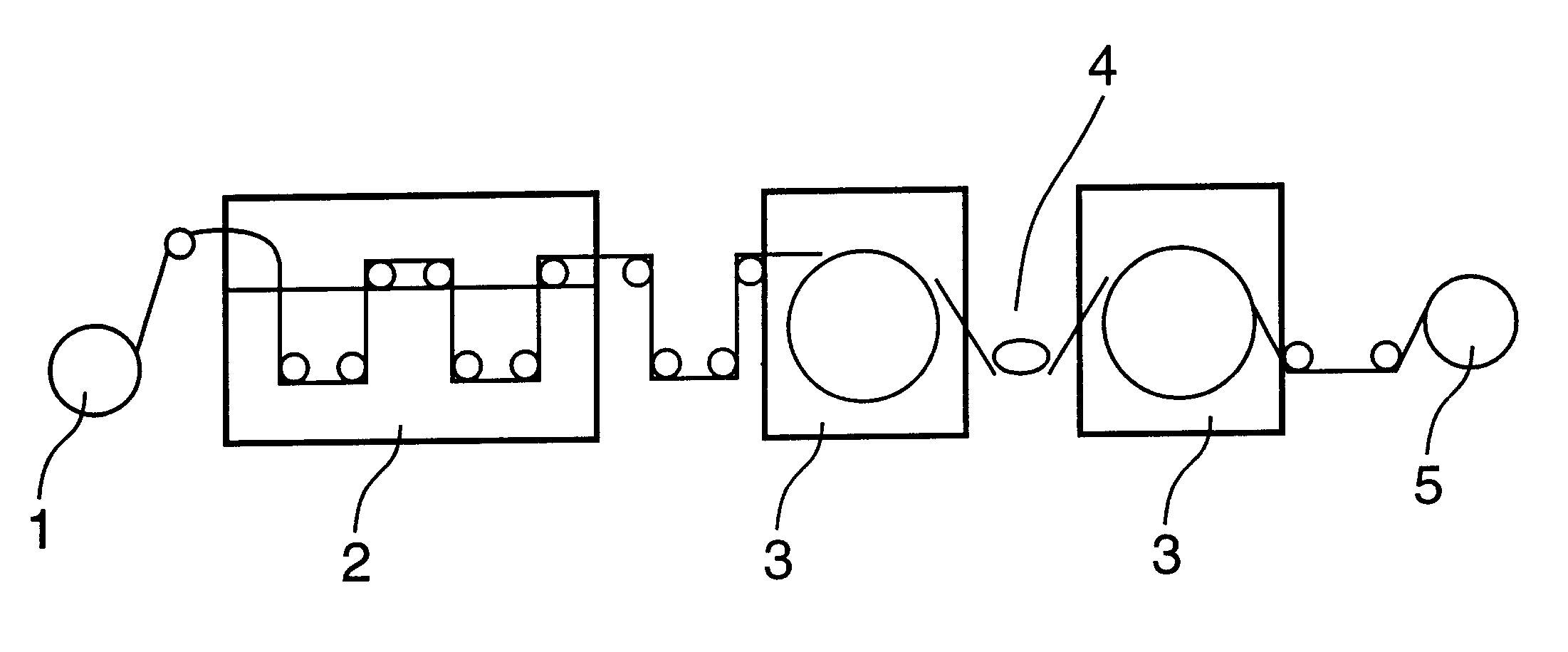

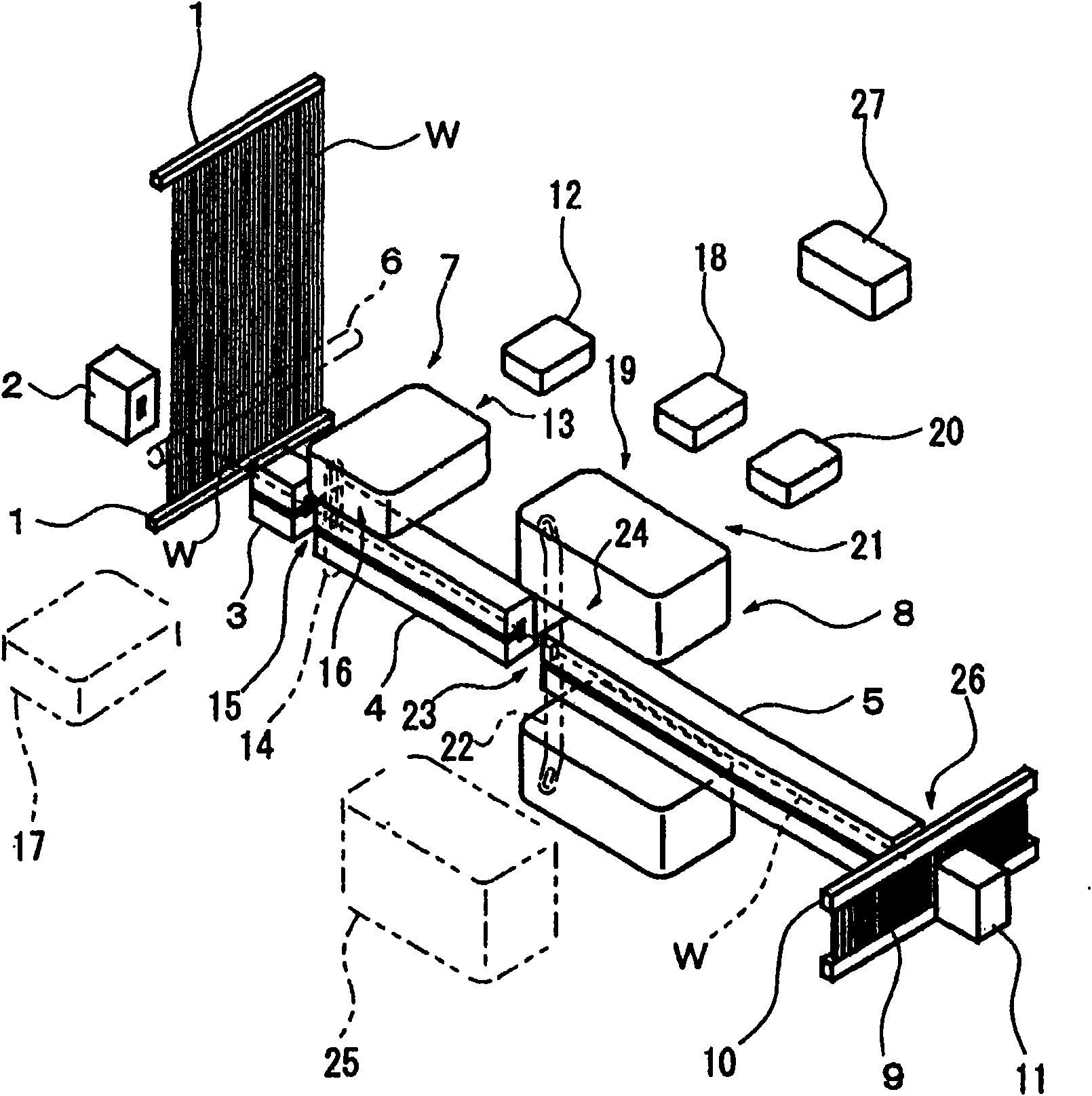

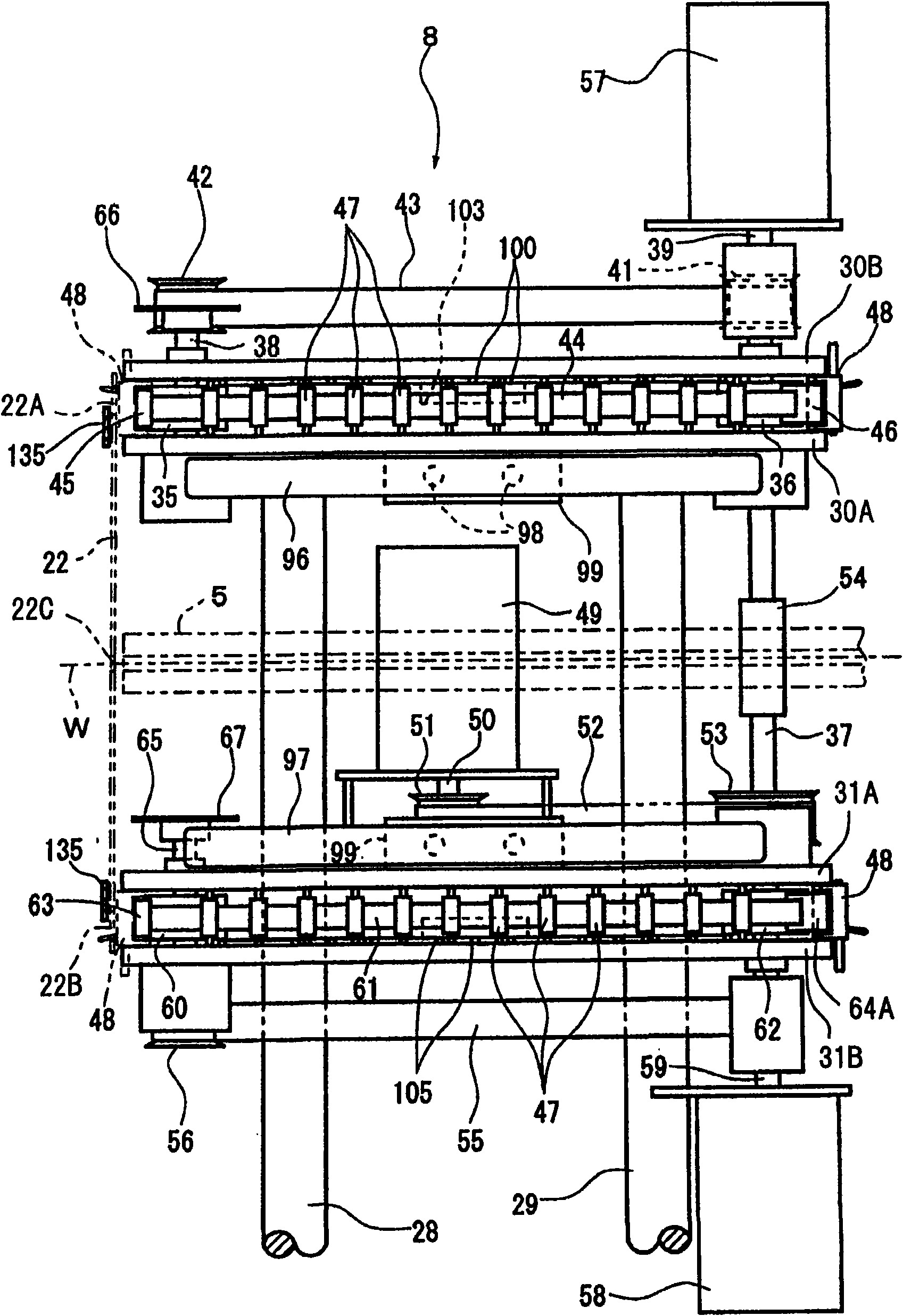

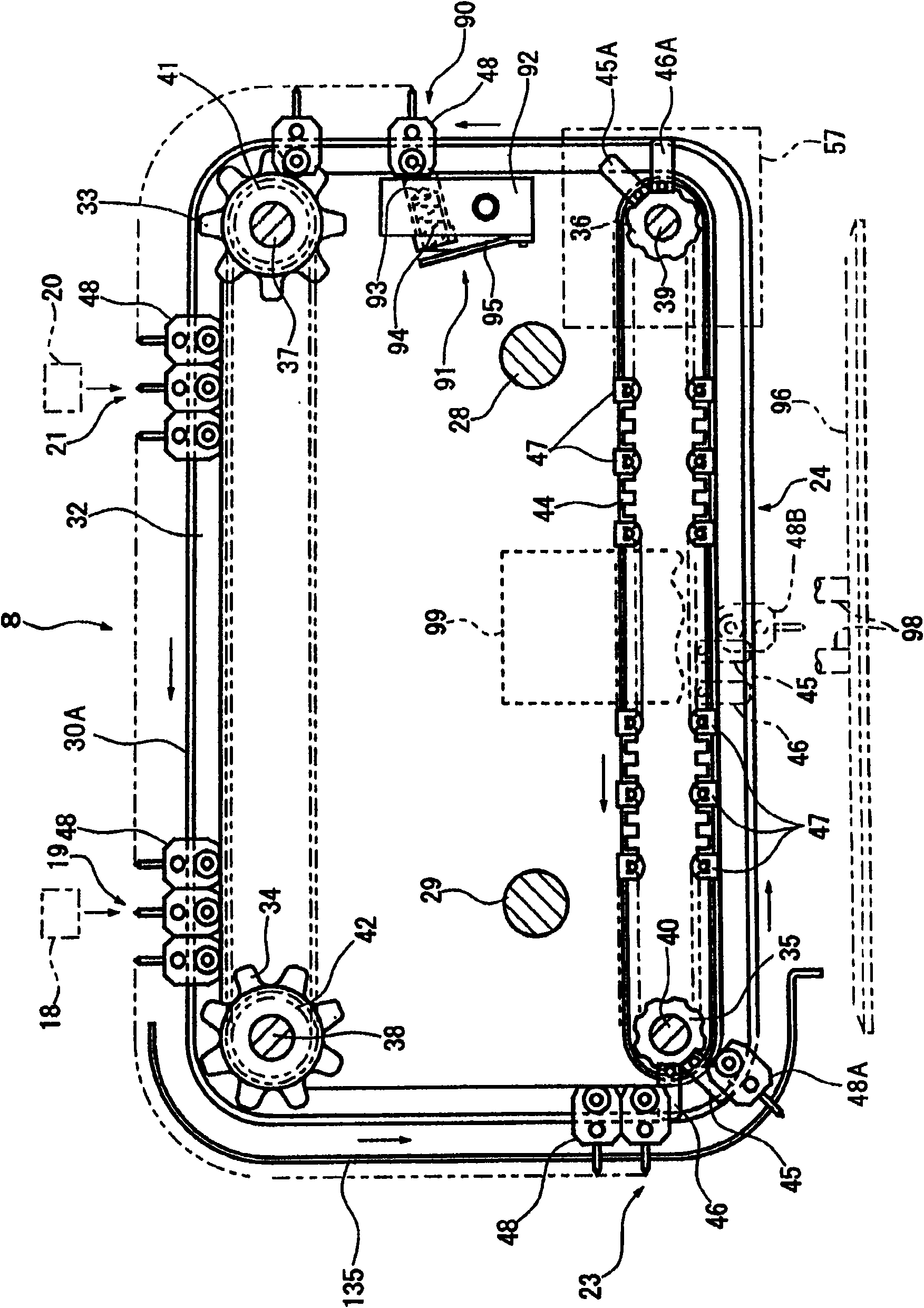

Drawing in machine

A drawing in machine comprises a plurality of laths, a lath memory and a transporting mechanism. The transporting mechanism receives the laths separated from the lath memory at the heddle supplying position, and transports the heddle to the warp leading position, and transports to the lath popping position through the lath led with warps. The transporting mechanism comprises a plurality of loaders, loader guides, transporting mechanisms of constant pitch and transporting mechanisms of non-constant pitch. The loaders fix the independent lath and can be movably arranged on the loader guides. The loader guides lead the loader having lath to the warp leading position. The transporting mechanisms of constant pitch transport the loader from the heddle supplying position to the warp leading position by instant pitch. The transporting mechanisms of non-constant pitch transport the loader from the warp leading position to the lath popping position by instant pitch.

Owner:TOYOTA IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com