Movable threading unit

A technology of drawing-in and drawing-in machine, which is applied to auxiliary equipment for weaving, fabrics, textiles, etc., can solve the problems of high initial cost, large capacity, unused utilization, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

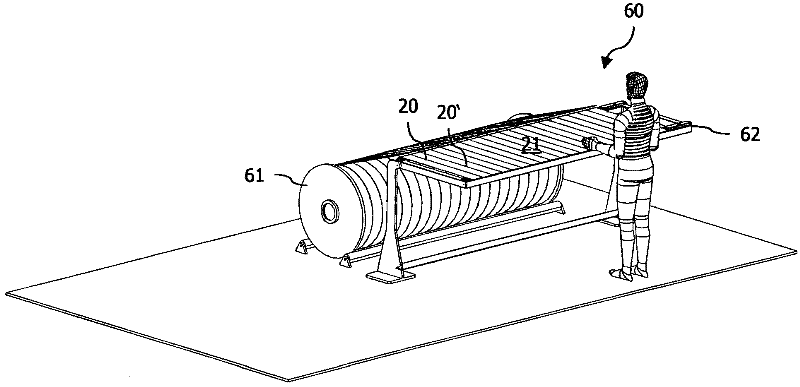

[0035] figure 1 A perspective view of the clamping unit 60 is shown in the ready position, said clamping unit comprising the warp thread layer 21 of the warp beam 61 inserted into said clamping unit. The generally stationary clamping unit 60 has a thread frame 62 rotatable in a vertical or horizontal line for clamping a warp thread layer 21 of individual warp threads 20 , 20 ′ coming from a warp beam 61 . The width corresponds at least to the widest warp thread layer 21 to be processed. The yarn frame 62 has a device for applying tension to the warp yarn layer 21 required for processing. The clamping unit 60 can be additionally provided with a support 70 for the reed on the side of the yarn frame 62, such as Figure 7 As shown in , each warp thread 20, 20 can be threaded into the reed simultaneously during the drawing-in process.

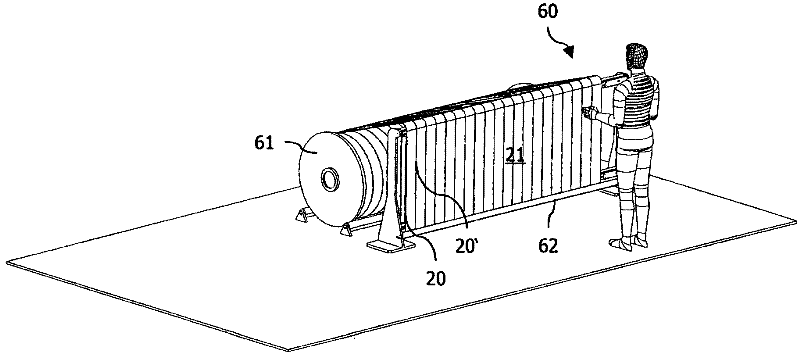

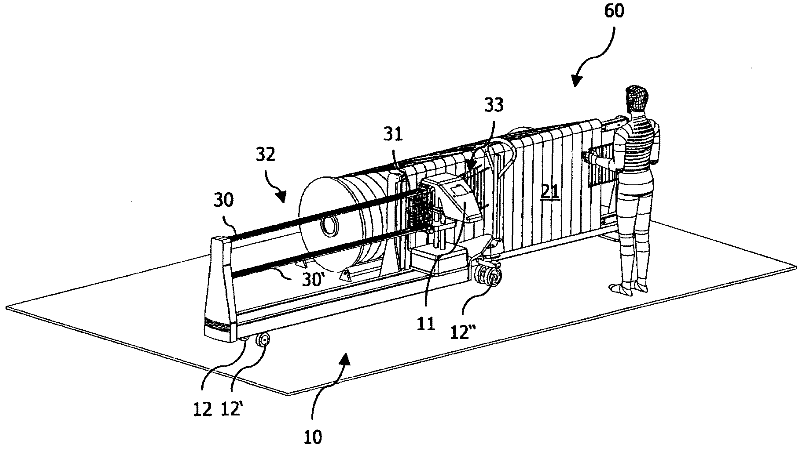

[0036] figure 2 show figure 2The clamping unit 60 is in the threading position for positioning the threading unit 10 according to the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com