A treatment method for the external cable shielding layer of a conductive slip ring for a three-axis precision turntable

A processing method and conductive slip ring technology, which is applied in the direction of cable installation, disassembly/armored cable equipment, cable installation devices, etc., can solve the problem of increasing diameter size, difficulty in threading, and excessive thickness of cable shielding layer processing position, etc. problem, to achieve the effect of solving the problem of over-thickness, strengthening the shielding effect, and improving the anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

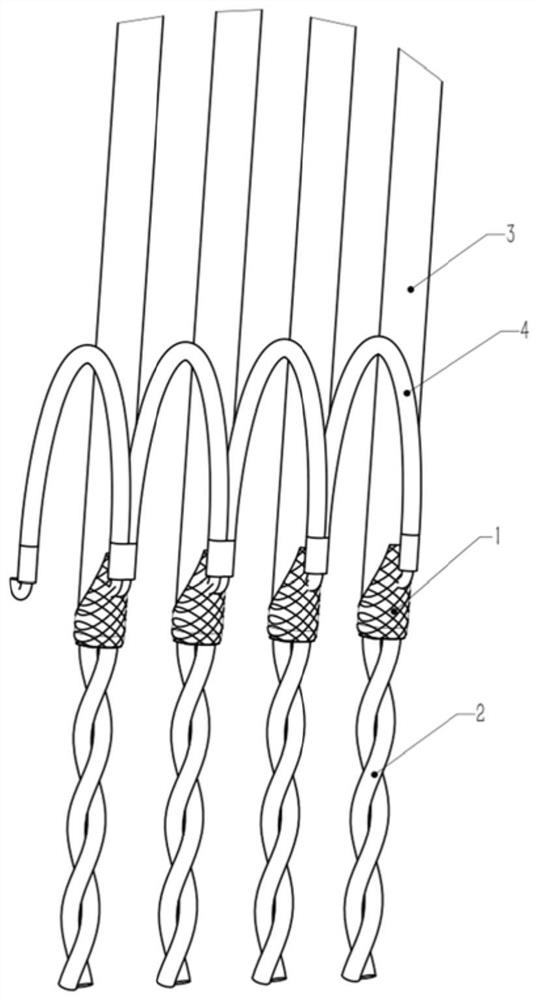

[0021] The invention provides a method for processing the external cable shielding layer of a conductive slip ring for a three-axis precision turntable, comprising the following steps:

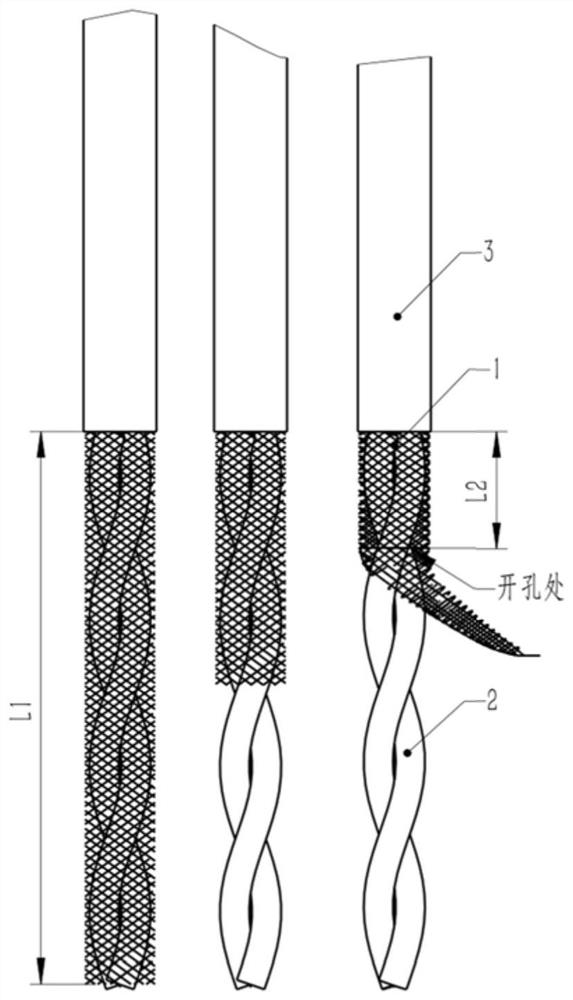

[0022] Step 1, cutting and stripping the outer insulating layer 3 of the shielded cable, so that the wire mesh shielding layer 1 is exposed;

[0023] Step 2: arrange and cut the wire mesh shielding layer 1, and pick out the free end of the lower section of the wire core 2 from the side of the wire mesh shielding layer 1, so that the lower section of the wire core 2 is exposed outside the wire mesh shielding layer 1, and open The wire mesh shielding layer 1 below the hole is superimposed on the side of the core 2; the shielded cable after the hole is opened is as follows: figure 1 shown;

[0024] Step 3: T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com