Comprehensive advance geological detection system carried by tunnel boring machine

A tunnel boring machine and geological detection technology, which is applied in the field of comprehensive advanced geological detection system, can solve the problems of complex electromagnetic environment, narrow space, false alarms, etc., and achieve the effect of improving detection efficiency and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below through specific examples and accompanying drawings. It should be pointed out that what is disclosed below is only a preferred embodiment of the present invention, and certainly cannot limit the scope of rights of the present invention with this. Under the premise of departing from the principle of the present invention, those skilled in the art can also make some improvements and modifications, and these improvements and modifications should also be regarded as the protection scope of the present invention.

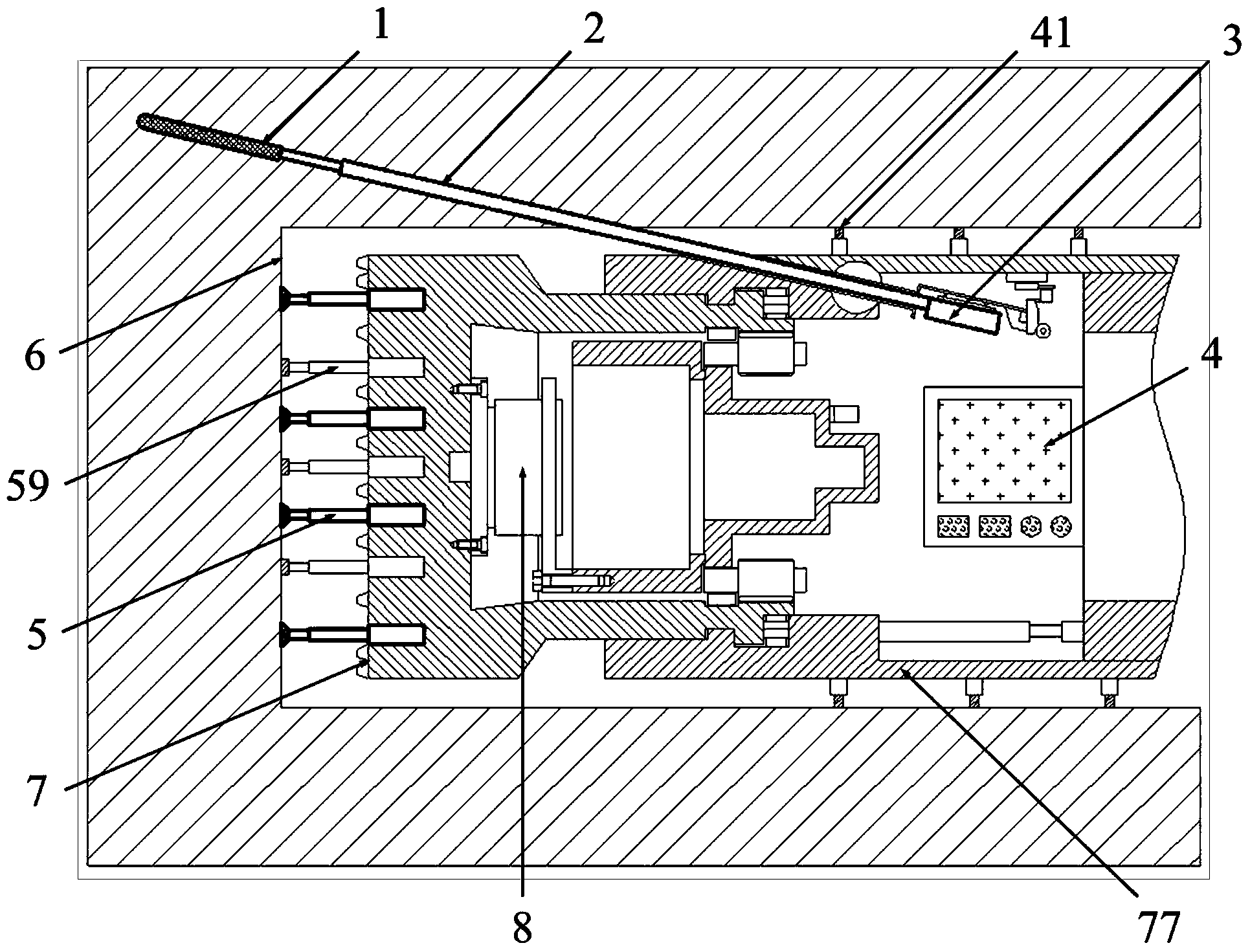

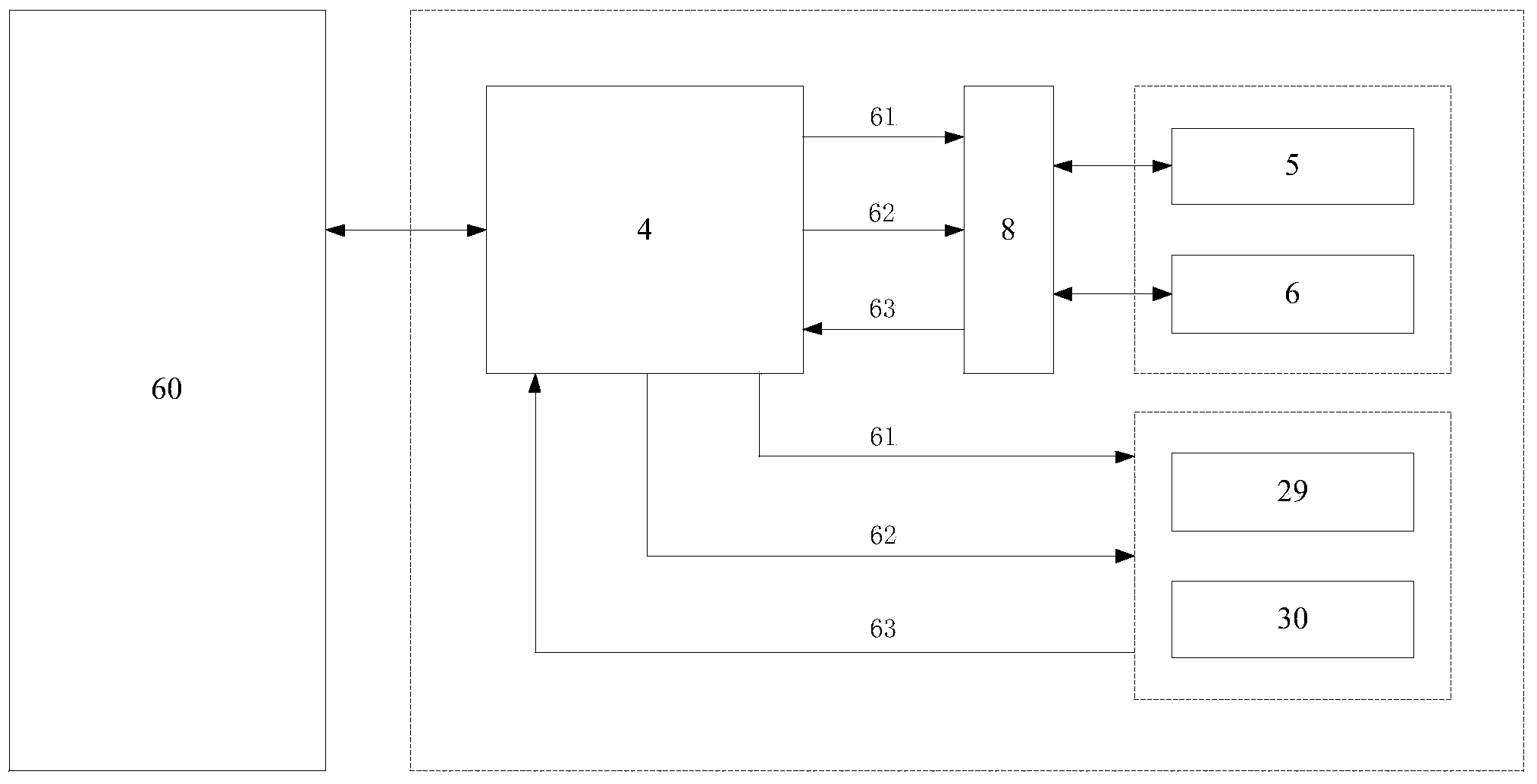

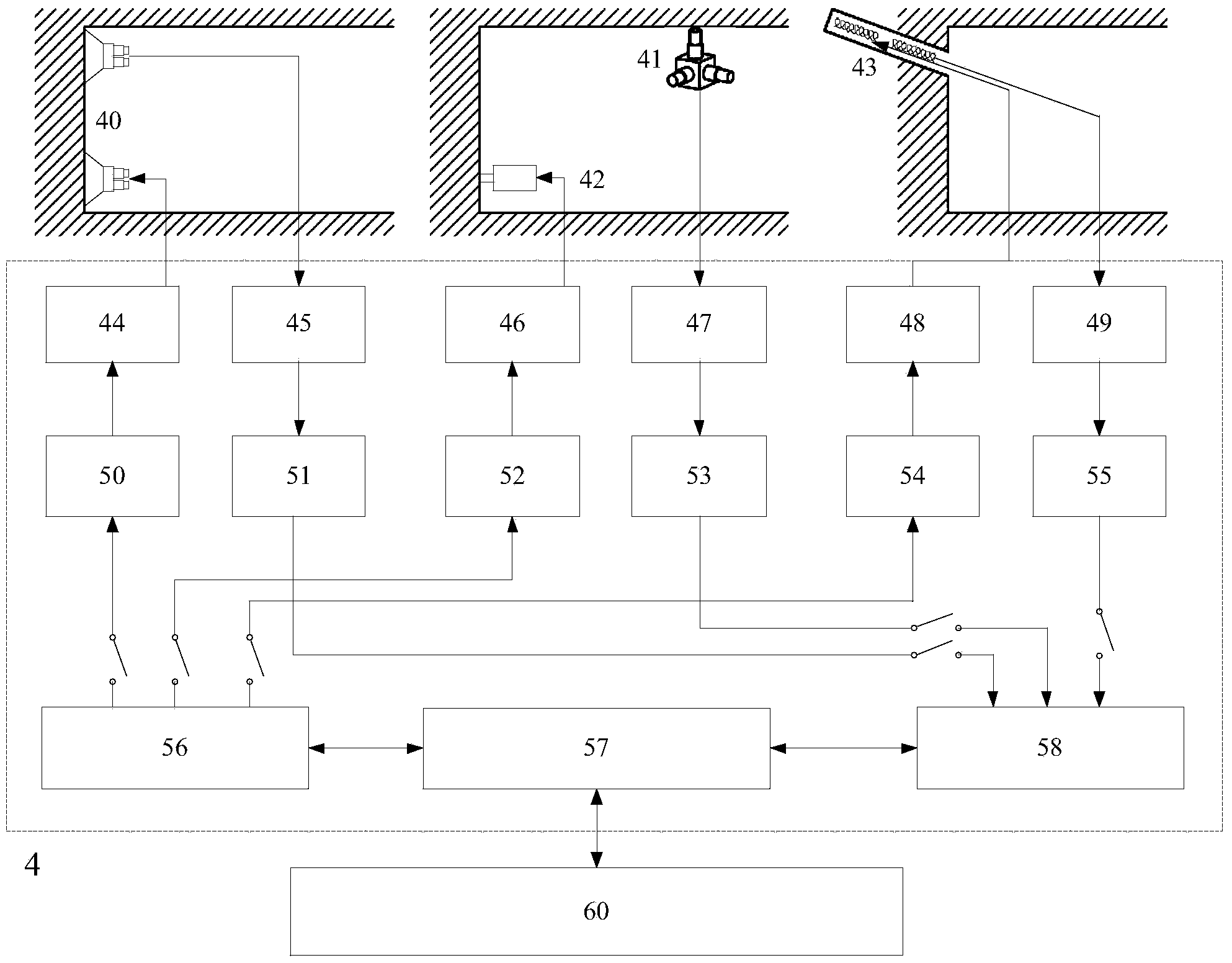

[0046] figure 1 The overall cross-sectional view of the comprehensive advanced geological detection system carried by the tunnel boring machine 68. The comprehensive advanced geological detection system carried by the tunnel boring machine 68 mainly includes four parts, which are the multi-functional combined host 4 and the excitation polarization on the cutterhead 7. The detection device 5 and the seismic wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com