Patents

Literature

518 results about "Drilling and blasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drilling and blasting is the controlled use of explosives and other methods such as gas pressure blasting pyrotechnics, to break rock for excavation. It is practiced most often in mining, quarrying and civil engineering such as dam, tunnel or road construction. The result of rock blasting is often known as a rock cut.

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

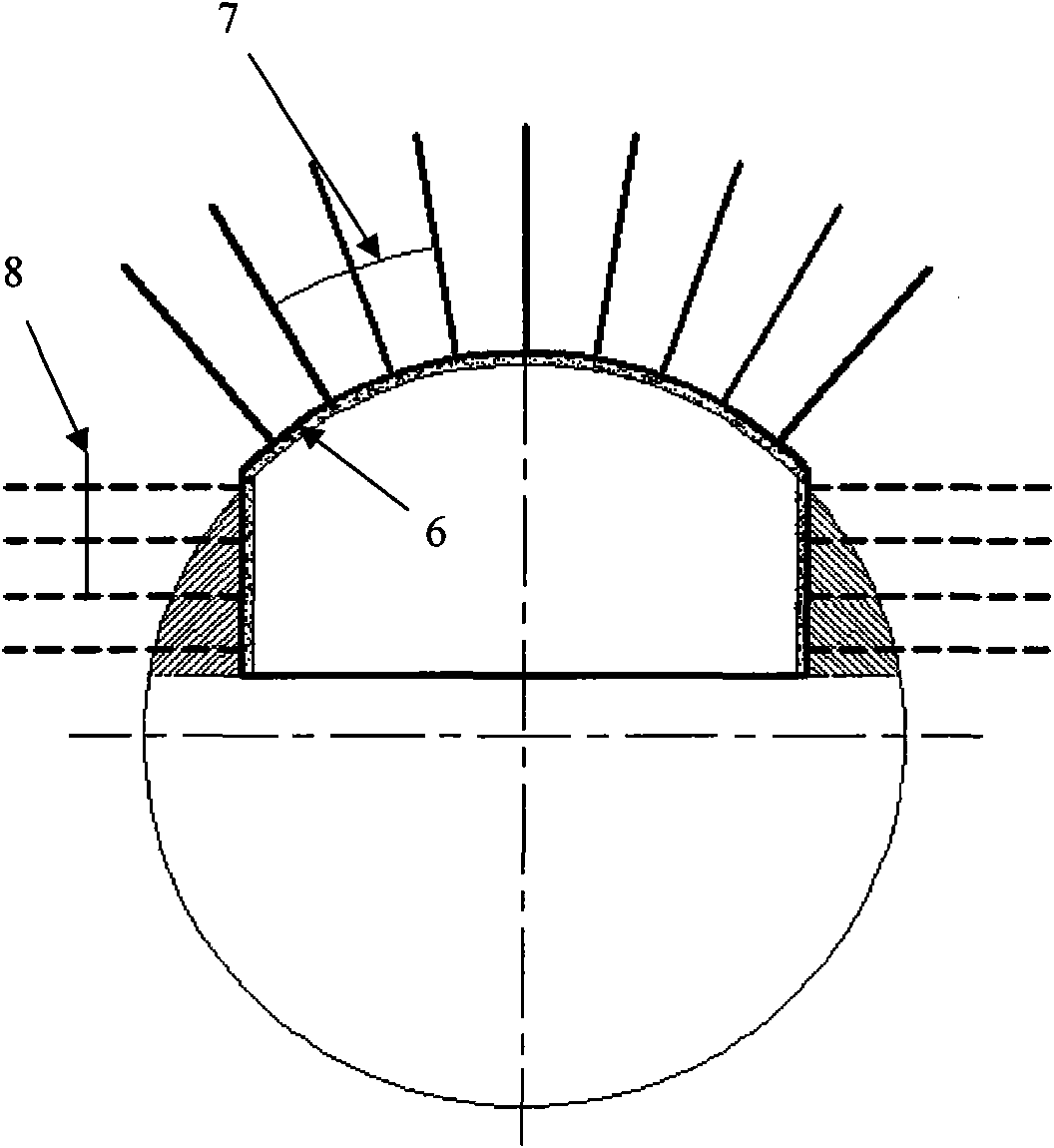

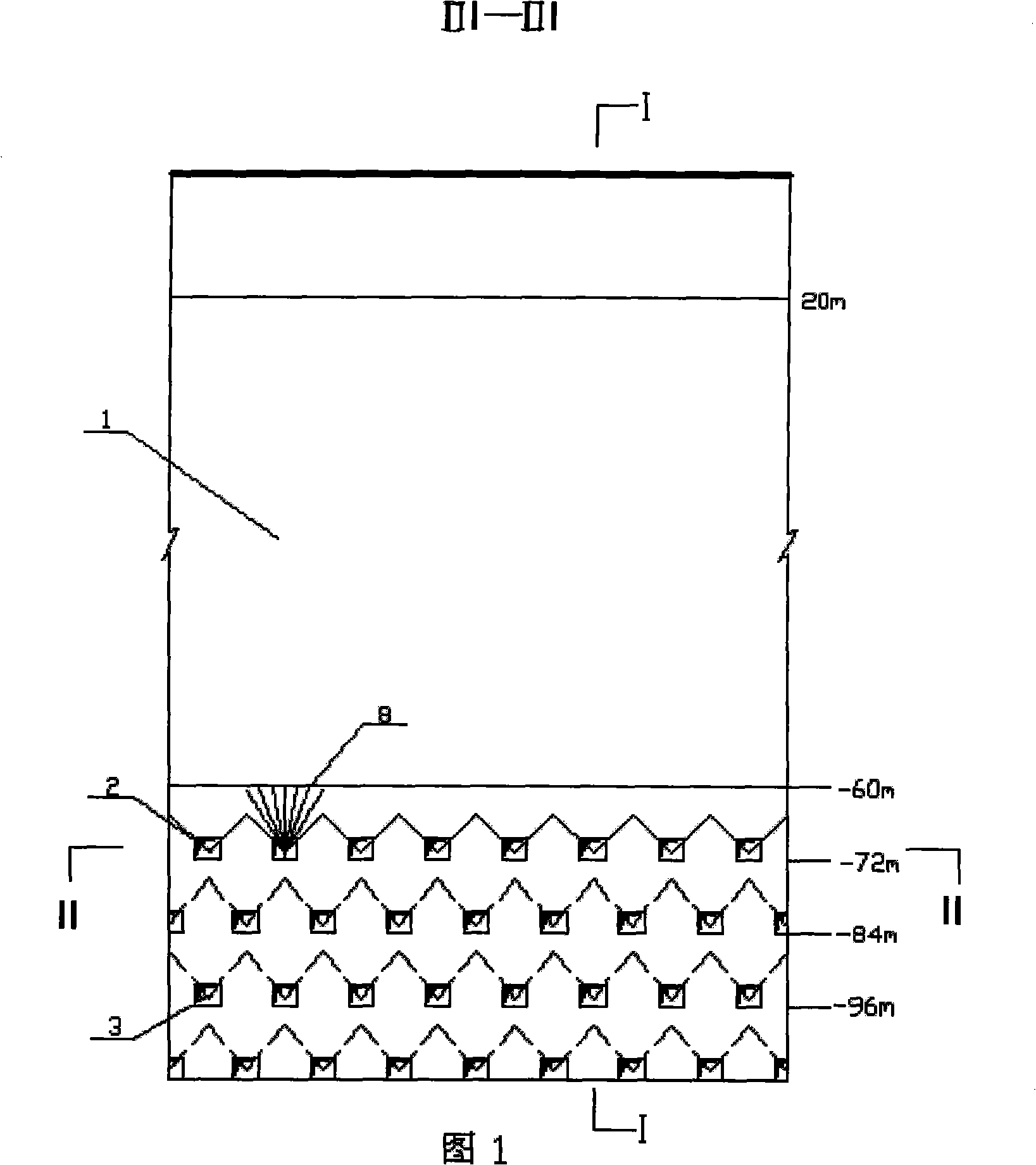

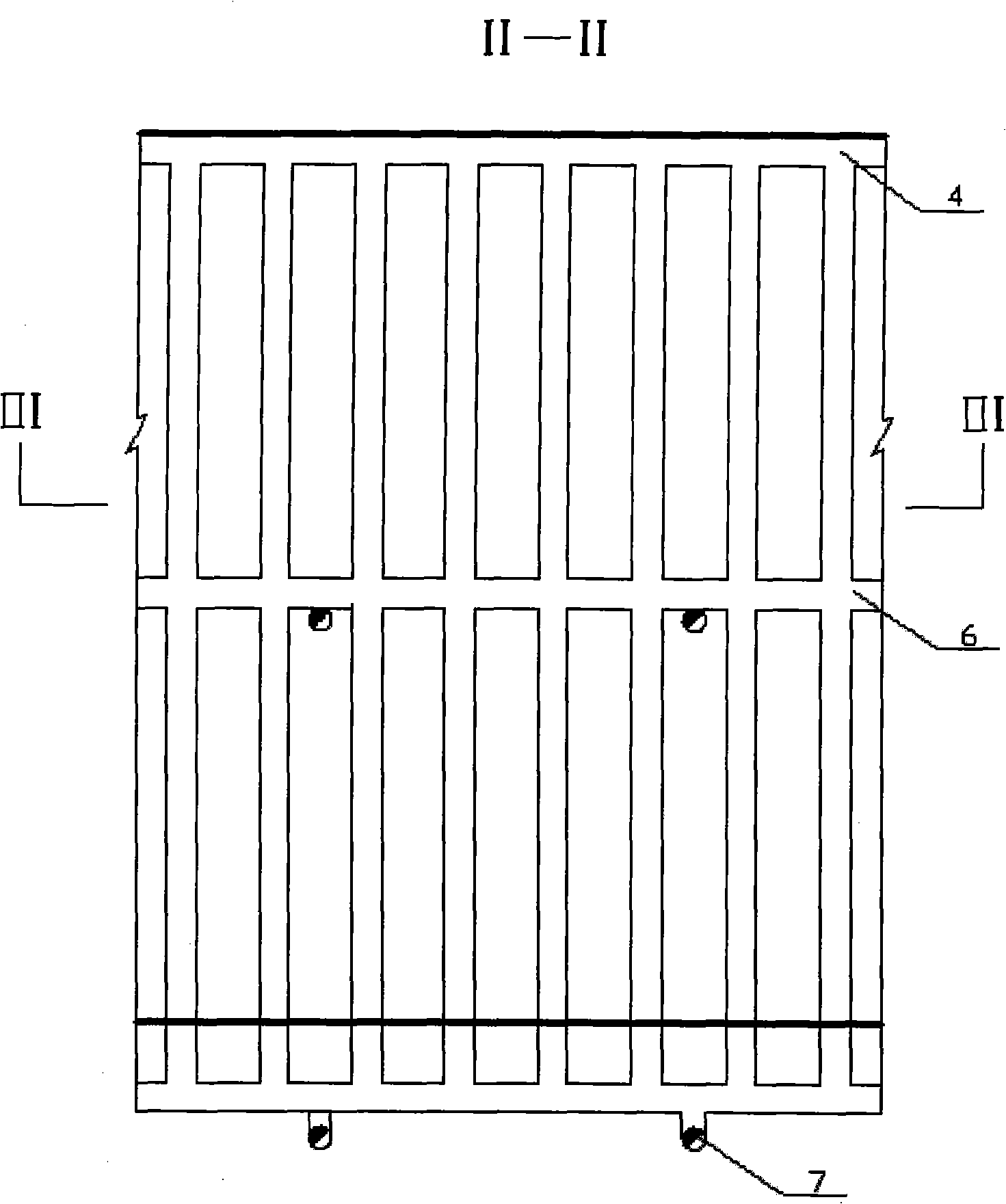

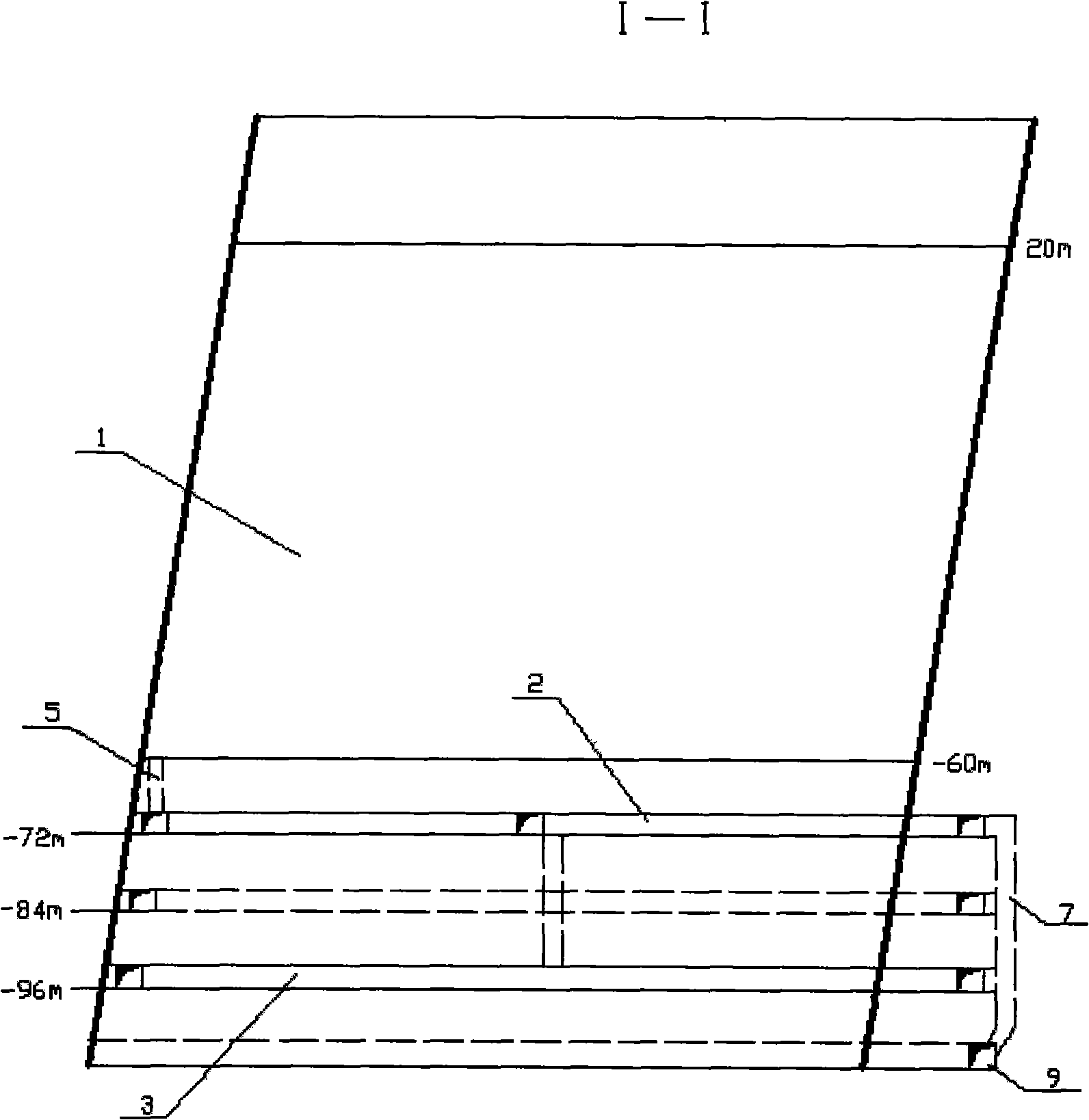

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

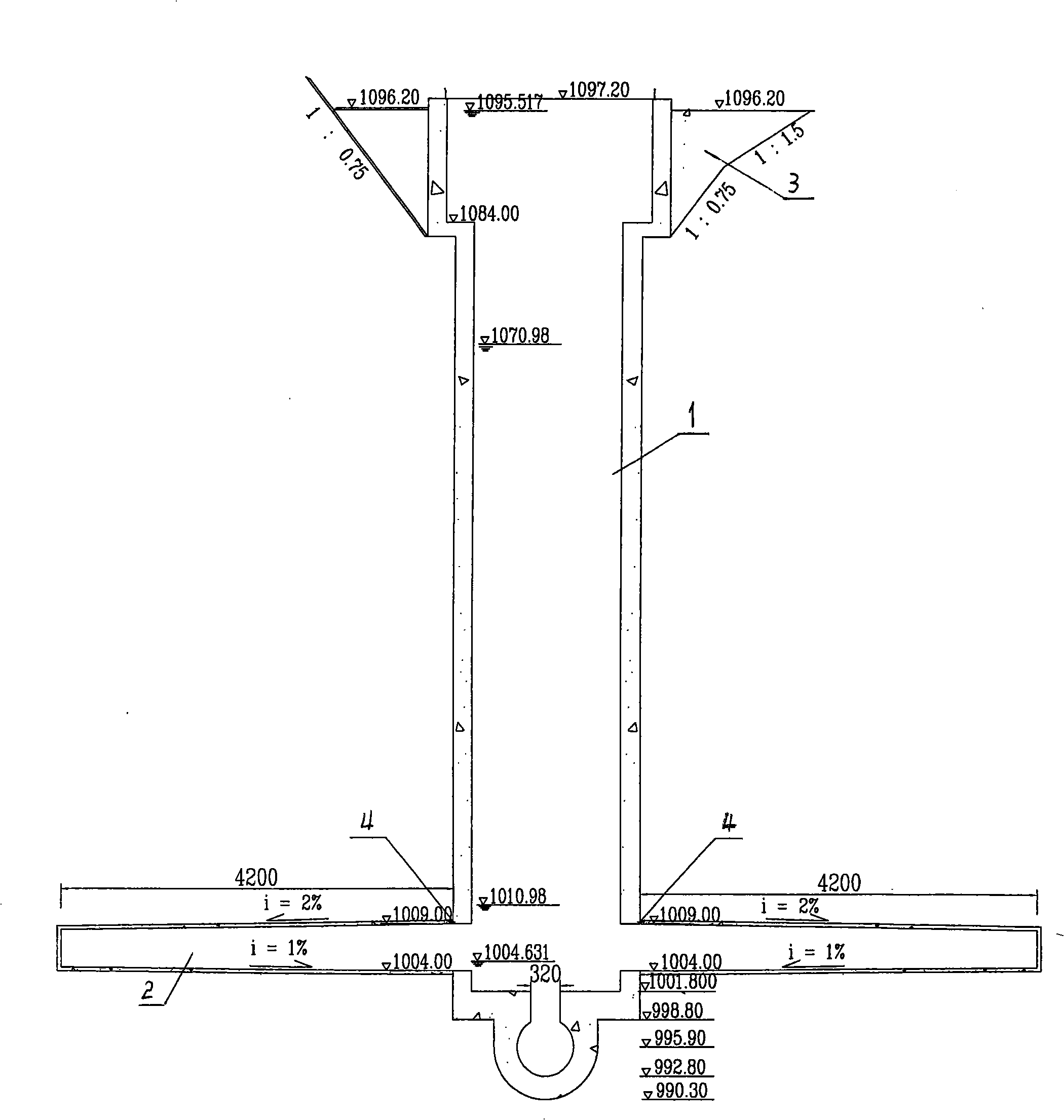

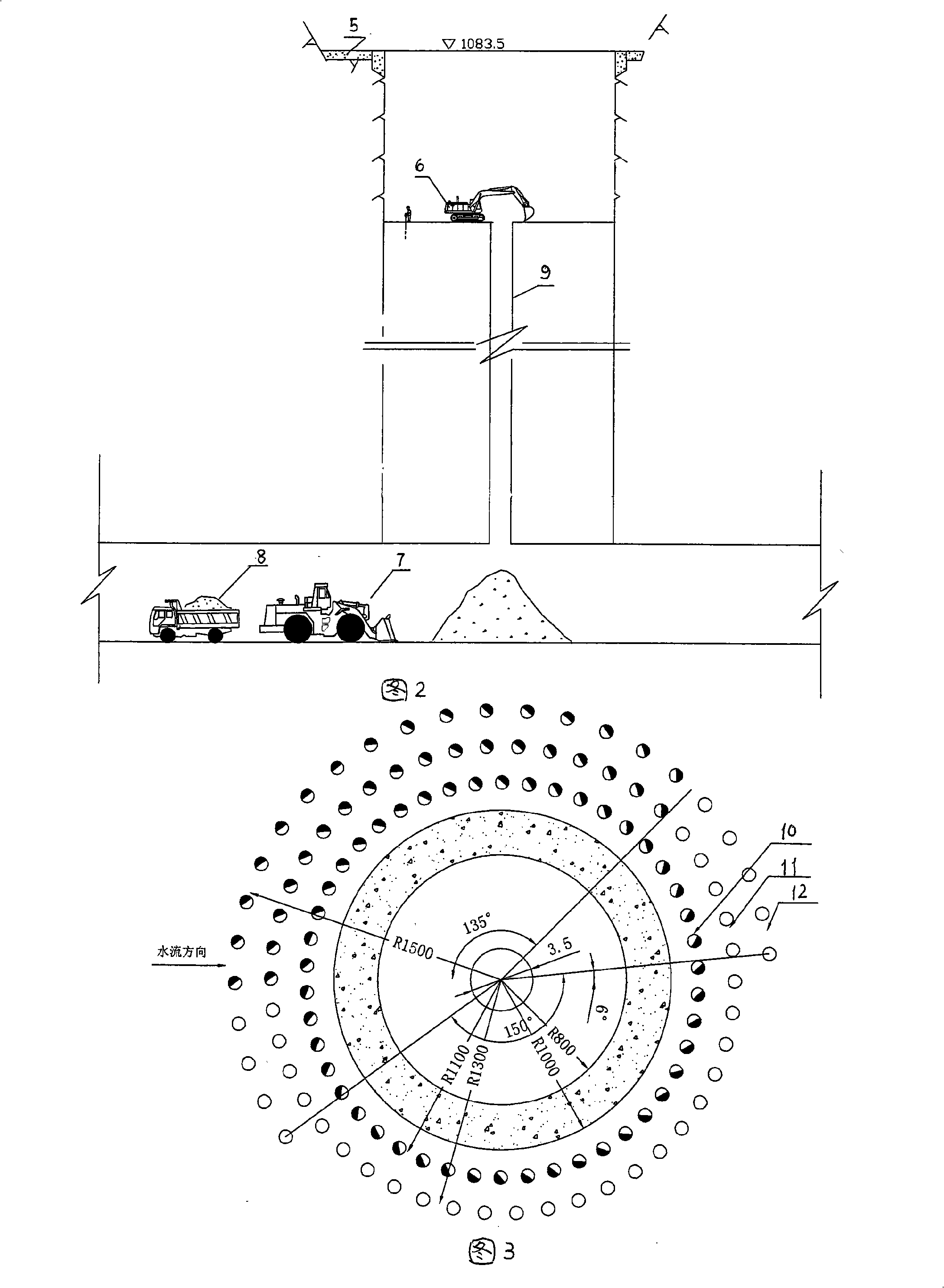

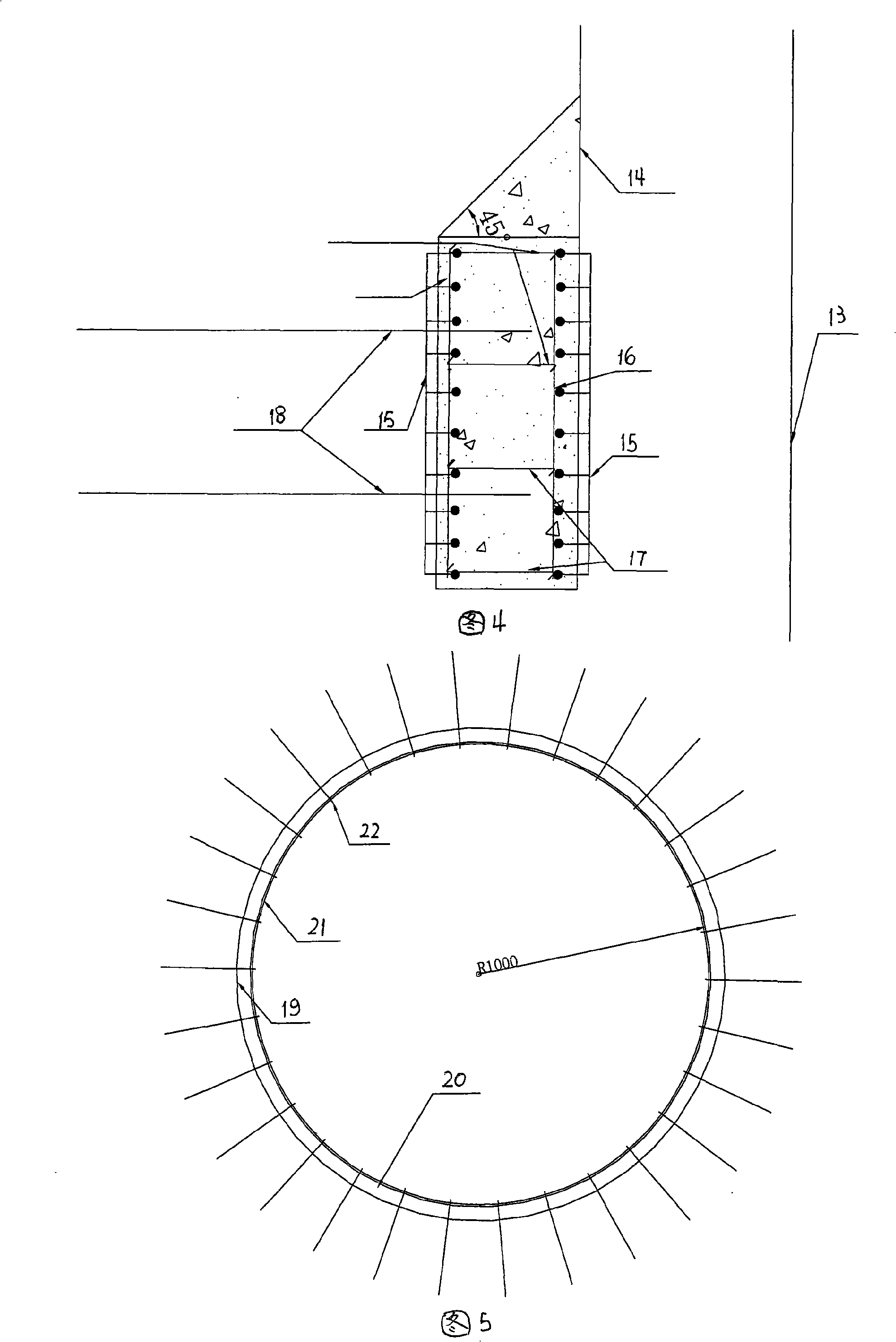

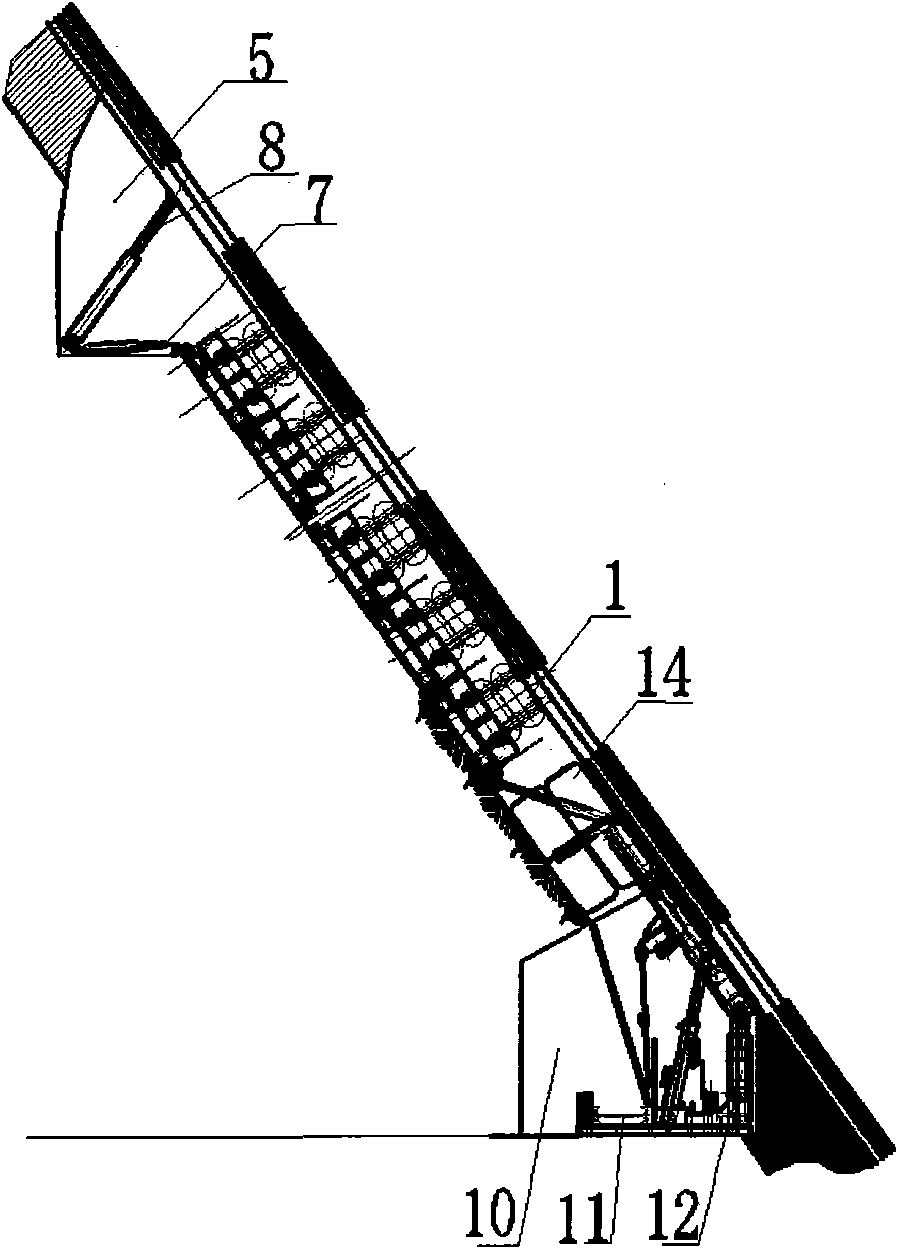

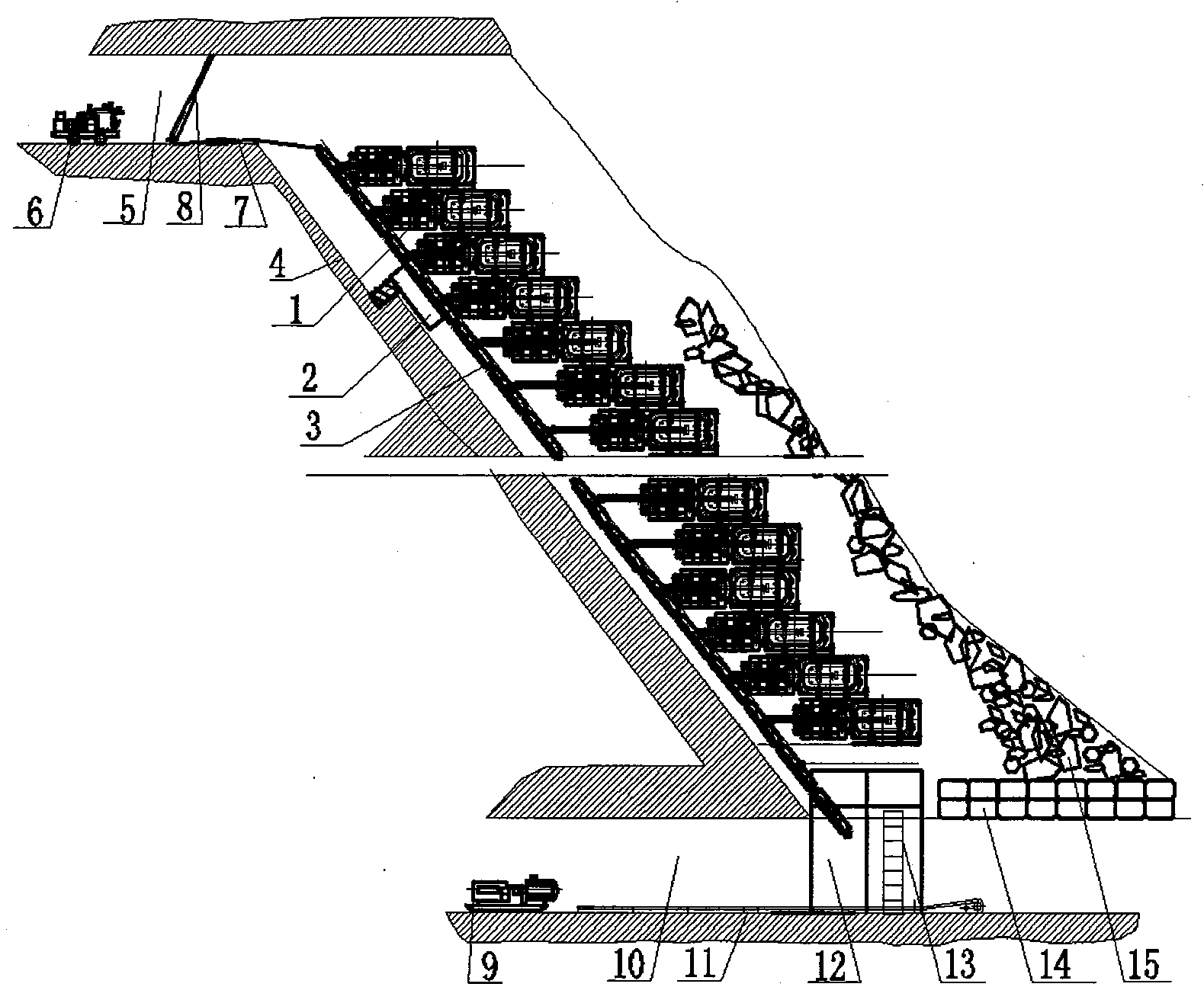

Construction method of hydroelectric power station surge chamber vertical shaft under soft rock geological condition

ActiveCN101349064ASimple designEnsure safetyArtificial islandsUnderwater structuresSteam-electric power stationGeomorphology

The invention relates to a method for constructing a drilled shaft of a surge chamber in a hydropower station under the condition of weak rock geology; the excavation diameter of the drilled shaft is more than or equal to 20 meters; and the depth of the drilled shaft is more than or equal to 50 meters. The method comprises the following steps: firstly, a safe prestress reinforcing measure is adopted; a prestress anchor rope is arranged in a side slope of the drilled shaft; the deep rock holes in the periphery of the drilled shaft are subjected to consolidation and grouting; the periphery of the drilled shaft is cast with reinforced concrete for locking a mouth, etc; the construction sequence of excavating the drilled shaft comprises that: a raise-boring machine drills a guide hole of phi 216 millimeters from top to bottom; the raise-boring machine enlarges and excavates a small guide well of phi 1, 400 millimeters; a slag slipping guide well of phi 2, 500 millimeters is enlarged and excavated manually from bottom to top; and the slag slipping guide well is enlarged and excavated from top to bottom. The slag slipping guide well is excavated by manual drilling and blasting; slag is naturally slipped and mechanically loaded in the bottom of the well; a large well is enlarged and excavated through drilling and blasting by a manual air drill; and the skimmed slag in a hydraulic backhoe well slips to the bottom of a passage through the slag slipping guide well and is mechanically loaded in the bottom of the well. The construction method has the characteristics of having reasonable construction arrangement, alternately and simultaneously carrying out a plurality of construction types and saving the construction period.

Owner:SINOHYDRO BUREAU 5 +1

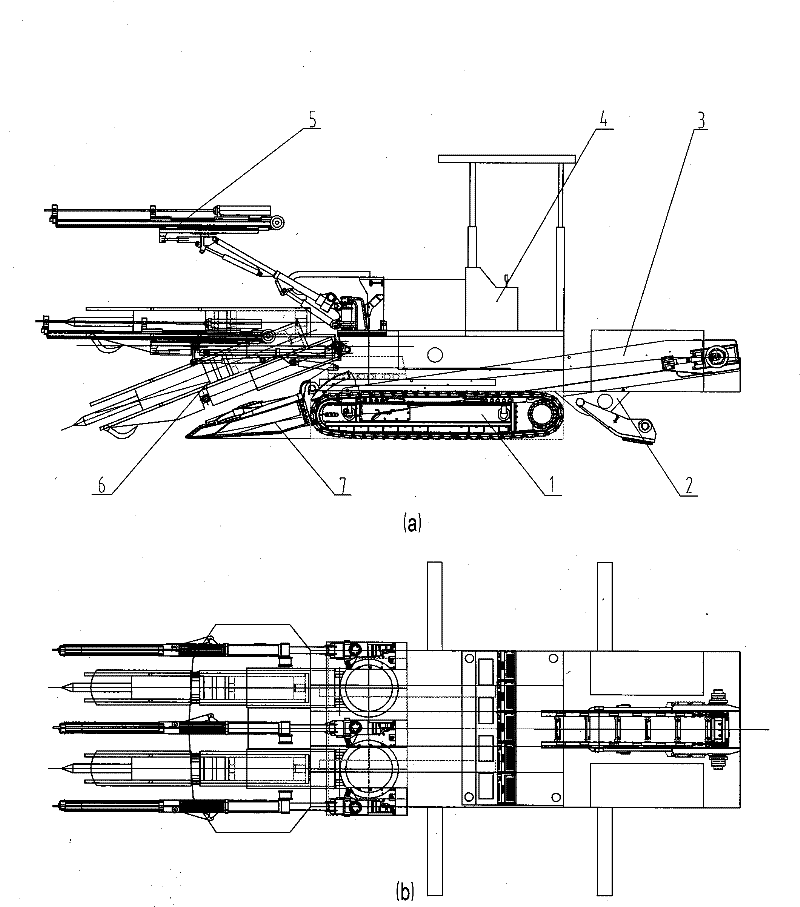

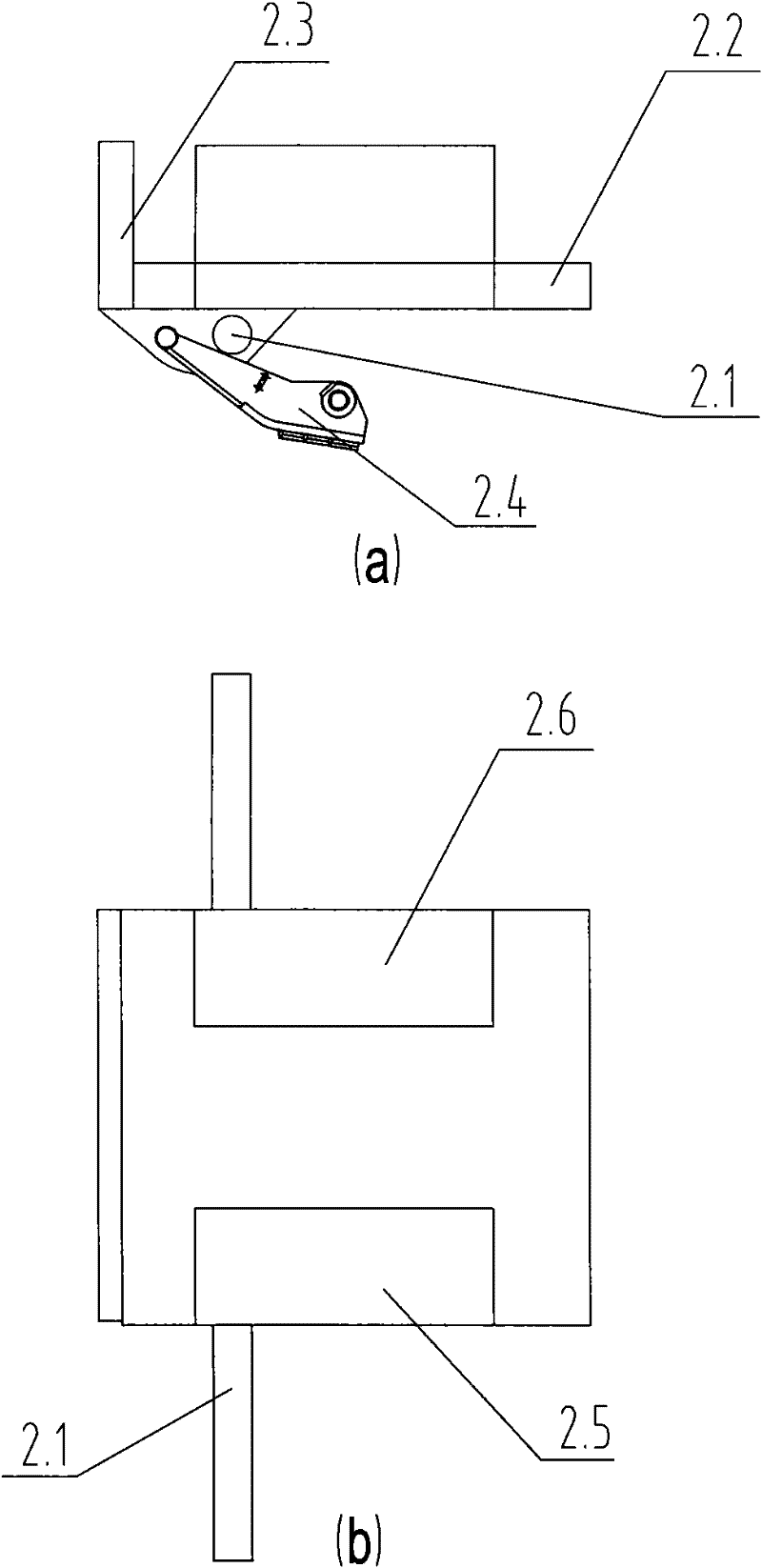

A hard rock hydraulic crushing roadheader

The invention relates to hard rock excavation equipment, in particular to a hard rock hydraulic crushing type excavation machine. It integrates the functions of drilling, rock breaking, material collection, transportation, walking and dust removal, and can realize fast and efficient excavation of all-rock roadways above f10 and above. The roadheader includes a running part, a rear support part, a transport part, a main body part, a rock drilling part, a rock breaking part and a shoveling part. Part, the rear part of the body part is provided with a rear support part and a transport part. The invention can solve the problems of low operation efficiency, harsh working environment and the like existing in the prior art. The whole equipment can realize the efficient, safe and high-quality rapid excavation of the whole hard rock roadway, replacing the more dangerous drilling and blasting method commonly used in hard rock excavation and the comprehensive excavation method with low efficiency in hard rock excavation.

Owner:SANY HEAVY EQUIP

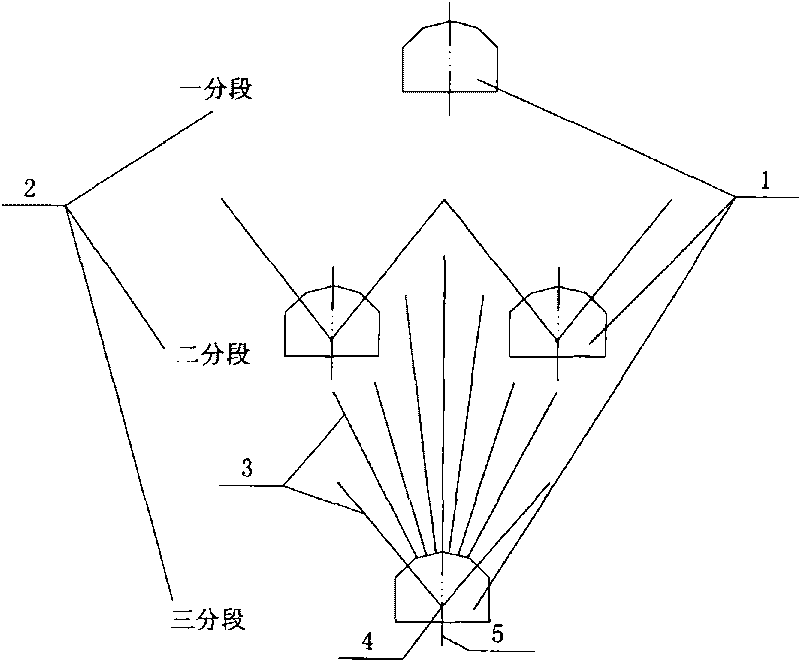

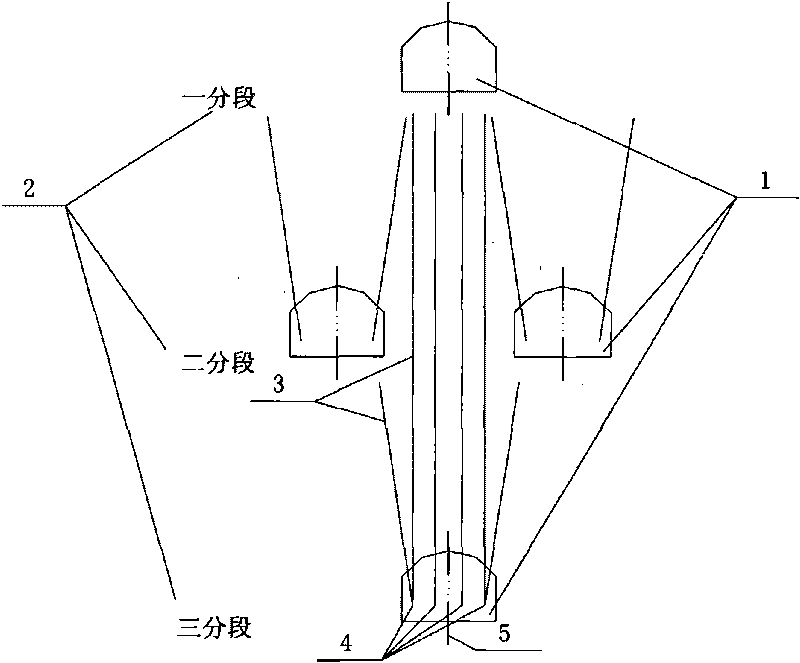

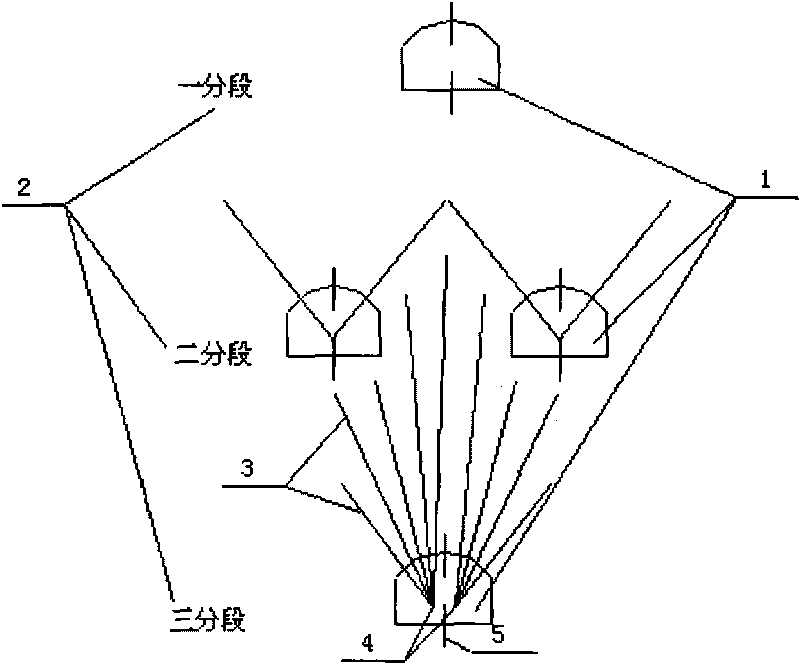

Deep hole arranging method in mining

InactiveCN101737050AReduce densityNot much densityUnderground miningSlitting machinesDepth directionDrill

The invention relates to a deep hole arranging method in mining, which comprises the following steps of: arranging deep holes in mining in a sectional plan stoping route according to certain row-to-row distances and hole concentration coefficients, and carrying out deep hole construction in mining by adopting an air operated or hydraulic drill jambo, wherein the deep hole arrangement in mining of 2-3 rock drilling centers is adopted according to the working mechanism and the working parameter of rock drilling equipment, and at least one hole in adjacent holes is not perpendicular to a horizontal surface when fan-shaped holes are arranged according to the 2-3 rock drilling centers. The invention enables the concentration degrees of the holes on the depth direction to differ slightly, i.e. the densities of the holes at hole mouths and hole bottoms differ a little. Under the condition of a certain ore caving range, the deep hole arranging method is beneficial to reducing the quantity of the holes and saving the rock drilling and blasting cost in mining, thereby improving the ore caving quantity of the holes in unit length.

Owner:宝钢集团上海梅山有限公司

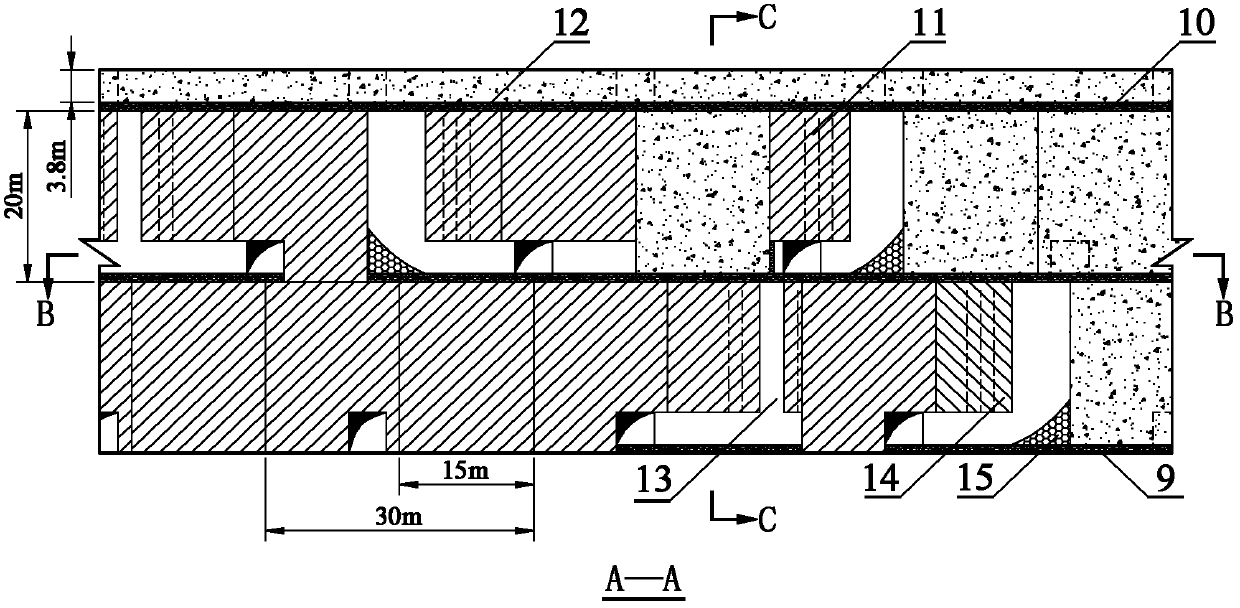

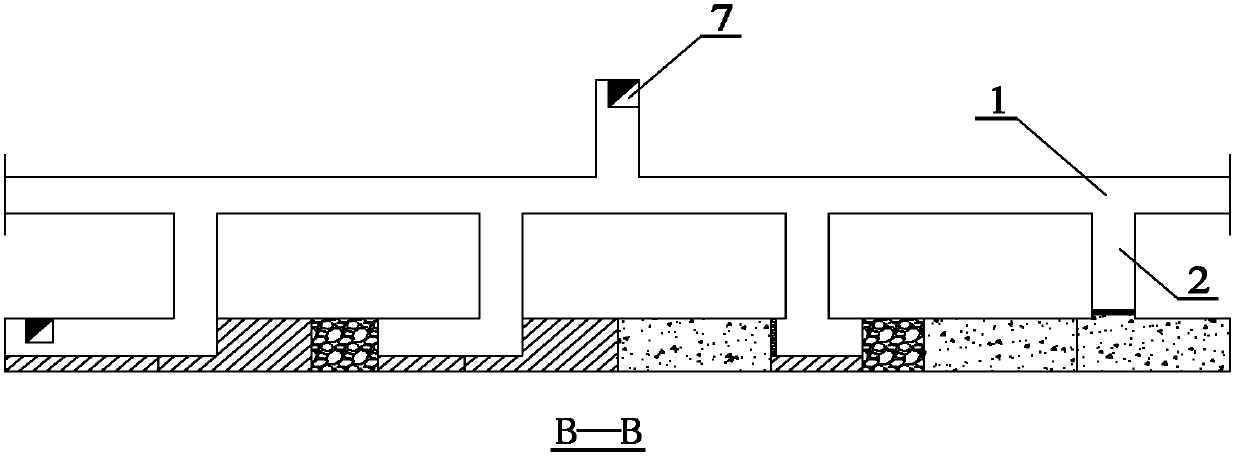

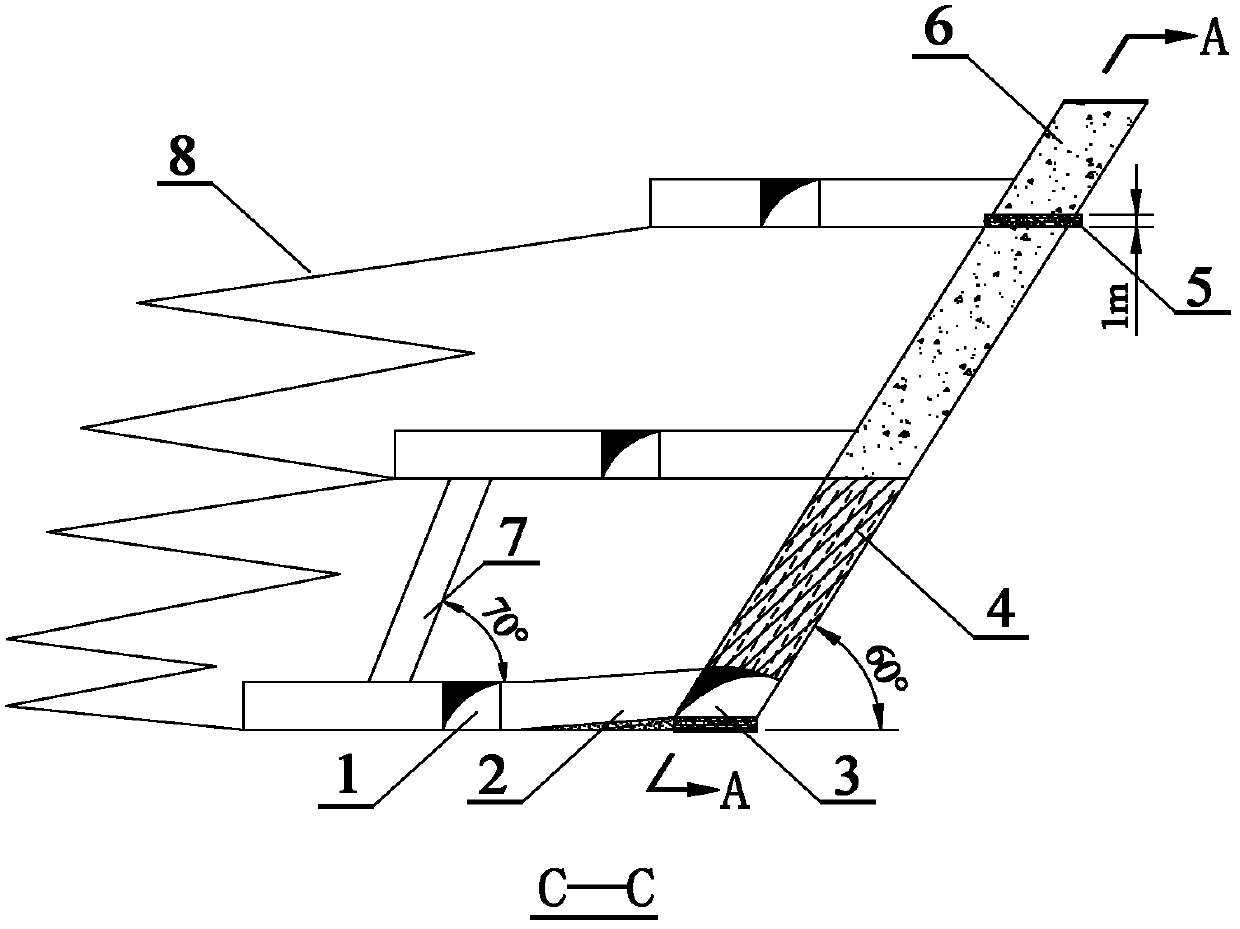

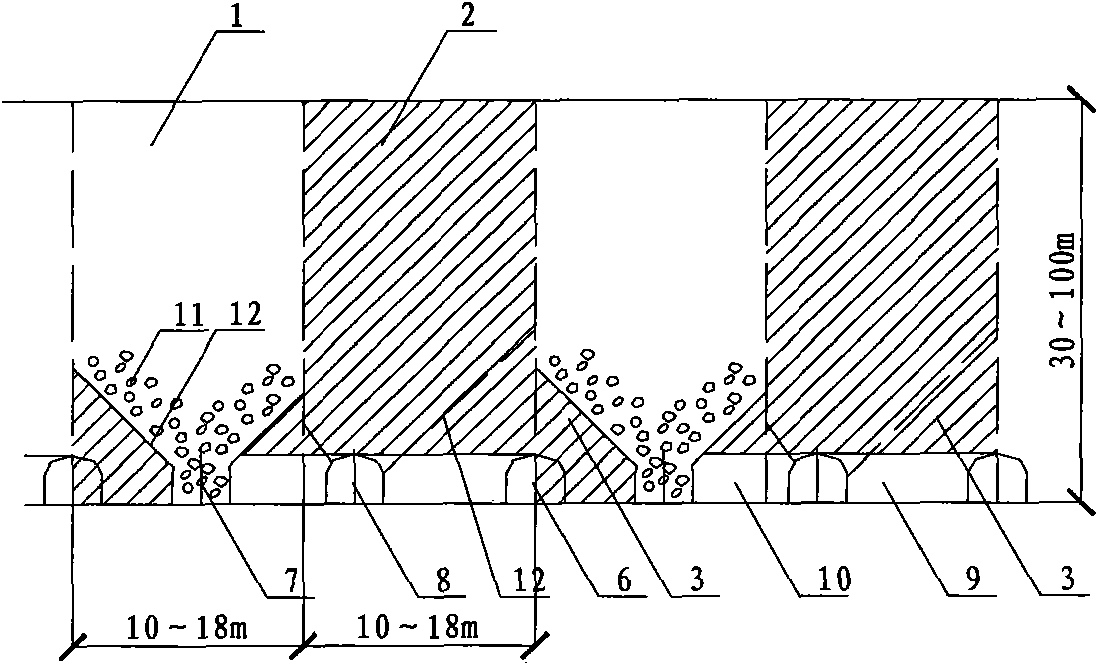

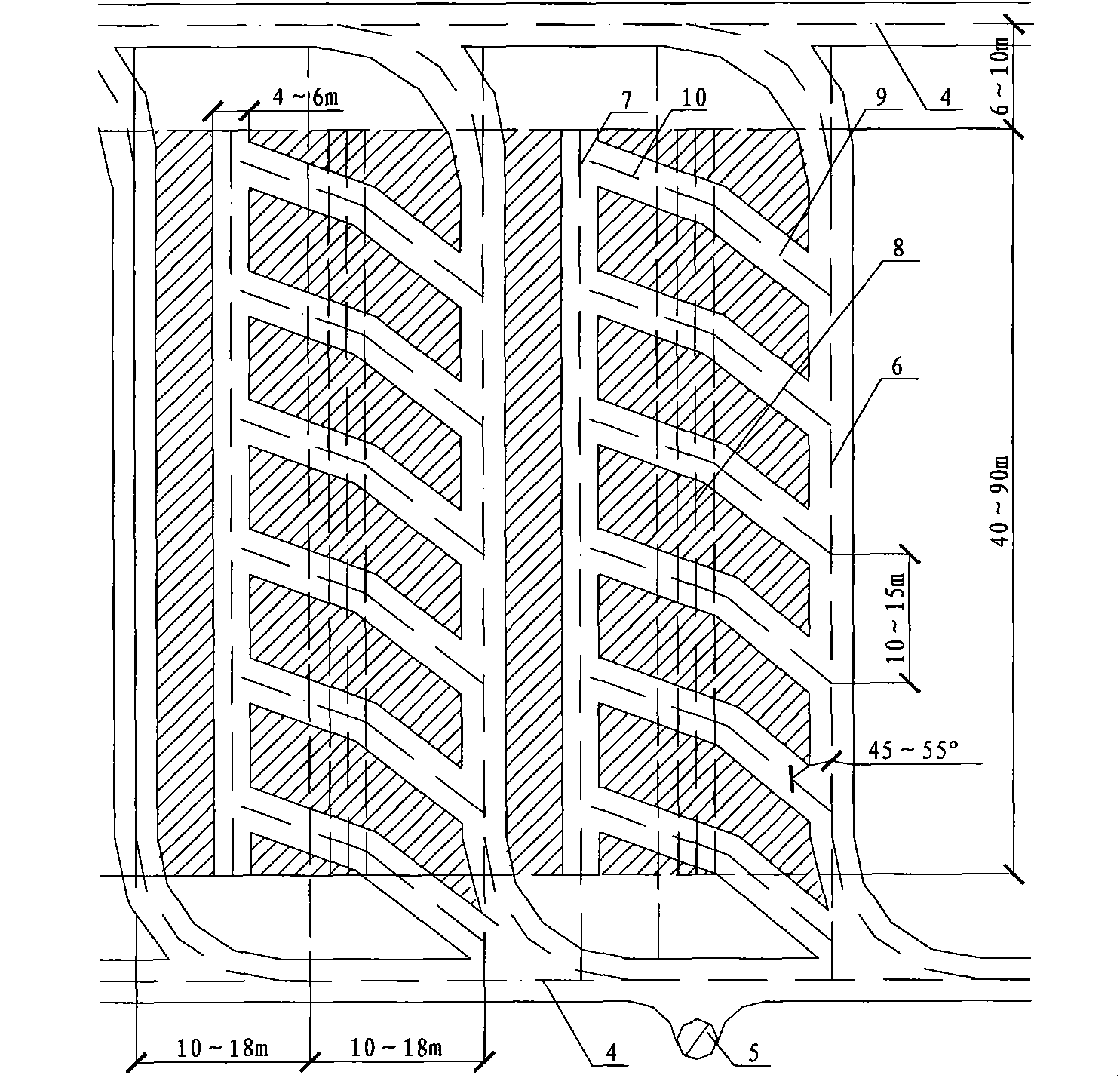

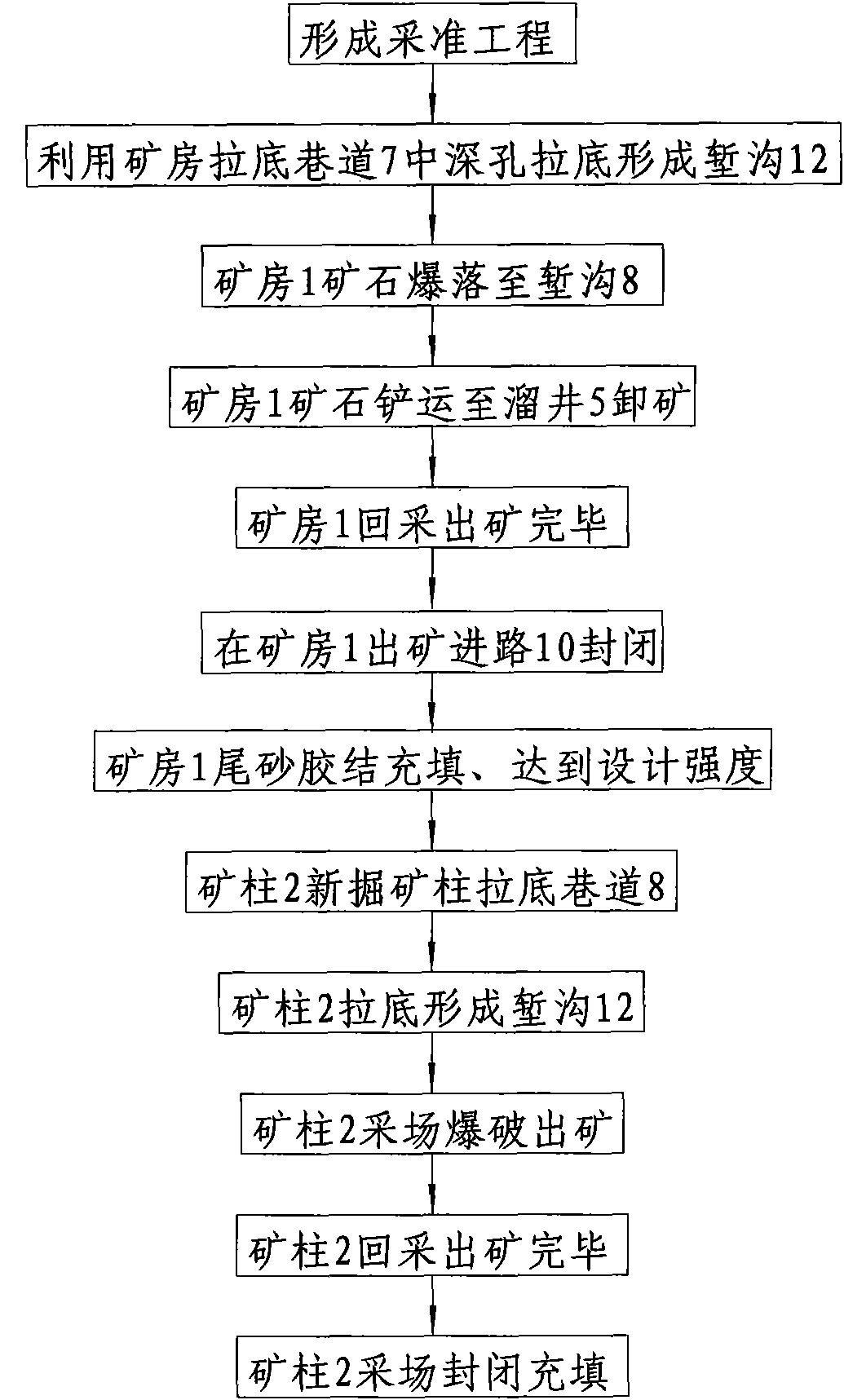

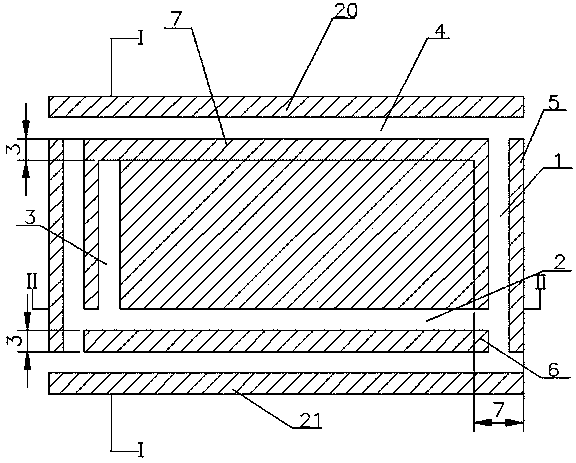

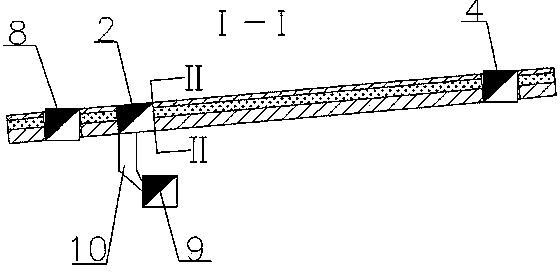

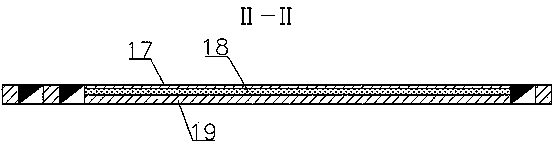

Stope bottom structure suitable for underground two-step mining and production process thereof

ActiveCN102011589ASmall amount of workAvoid secondary excavationUnderground miningSurface miningStructure of the EarthEngineering

The invention discloses a stope bottom structure suitable for underground two-step mining and a production process thereof. An underground stope is divided into a room stope and a pillar stope. Bottom pillars are reserved according to the bottom structure forms. Along-vein travelling roadways (4) and across-vein ore-drawing roadways (6) are utilized to handle the ores. The blasting ores (11) in the stope are blasted and fall in trenches (12). A scraper pours the ores into an ore pass (5) via a common ore-drawing drift (9) and a room ore-drawing drift (10). After tailing-cemented filling of the room of the stope, new pillar undercutting roadways (8) are driven in the bottom pillars (3) during mining the pillar stope. The trenches (12) for room mining are formed through drilling and blasting and undercutting. The goafs formed after mining and ore-drawing of pillars (2) are filled. The stope bottom structure can serve two stopes, reduce the quantities and support quantity, reduce the mining and development ratio of mining, improve the stability and save the mining cost and preparation time of two-step mining.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

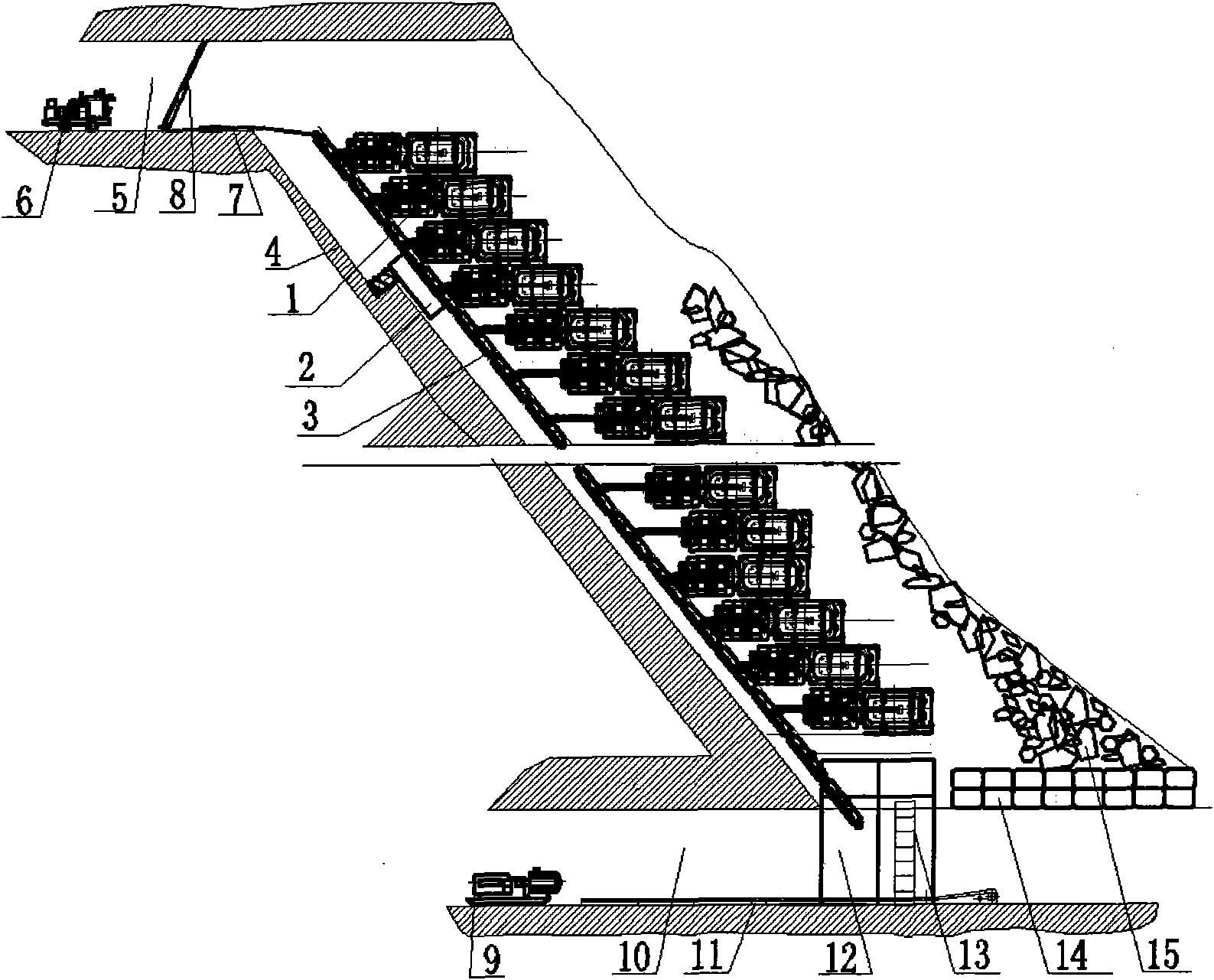

Coal mining method for high-dipping low seam

InactiveCN101942999AAchieve mechanical propertiesIncrease productionUnderground miningSurface miningLongwall miningMining engineering

The invention relates to a coal mining method for a high-dipping low coal seam by long-wall mining. The method comprises the following steps of: supporting a roof by a self-advancing air bag support; arranging a working surface in a mode of advancing to the dip; mining coal by drilling and blasting or using an off-pan shearer; transporting the coal in a mode of gravity haulage; filling a goaf with gangue or sand; and filling a lower end with gangue bags, precast concrete blocks or solidified macromolecular foaming slurry. The coal mining method has the advantages of realizing mechanical coal mining for the high-dipping low coal seam, improving the yield per unit and efficiency of the working surface, effectively protecting the exploited ground, improving the recovery rate of mines, and guaranteeing the coal seam mining safety.

Owner:TIANDI SCI & TECH CO LTD

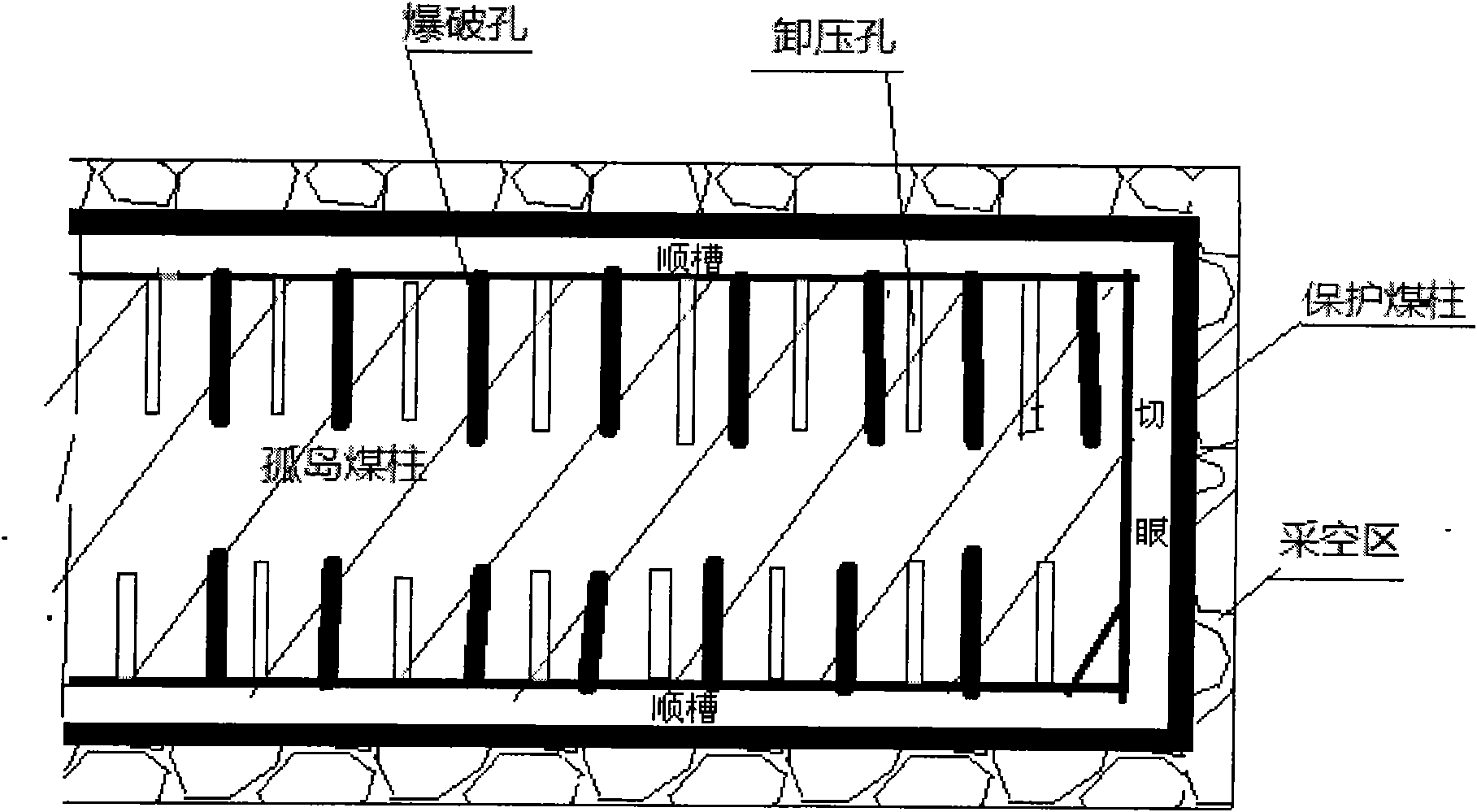

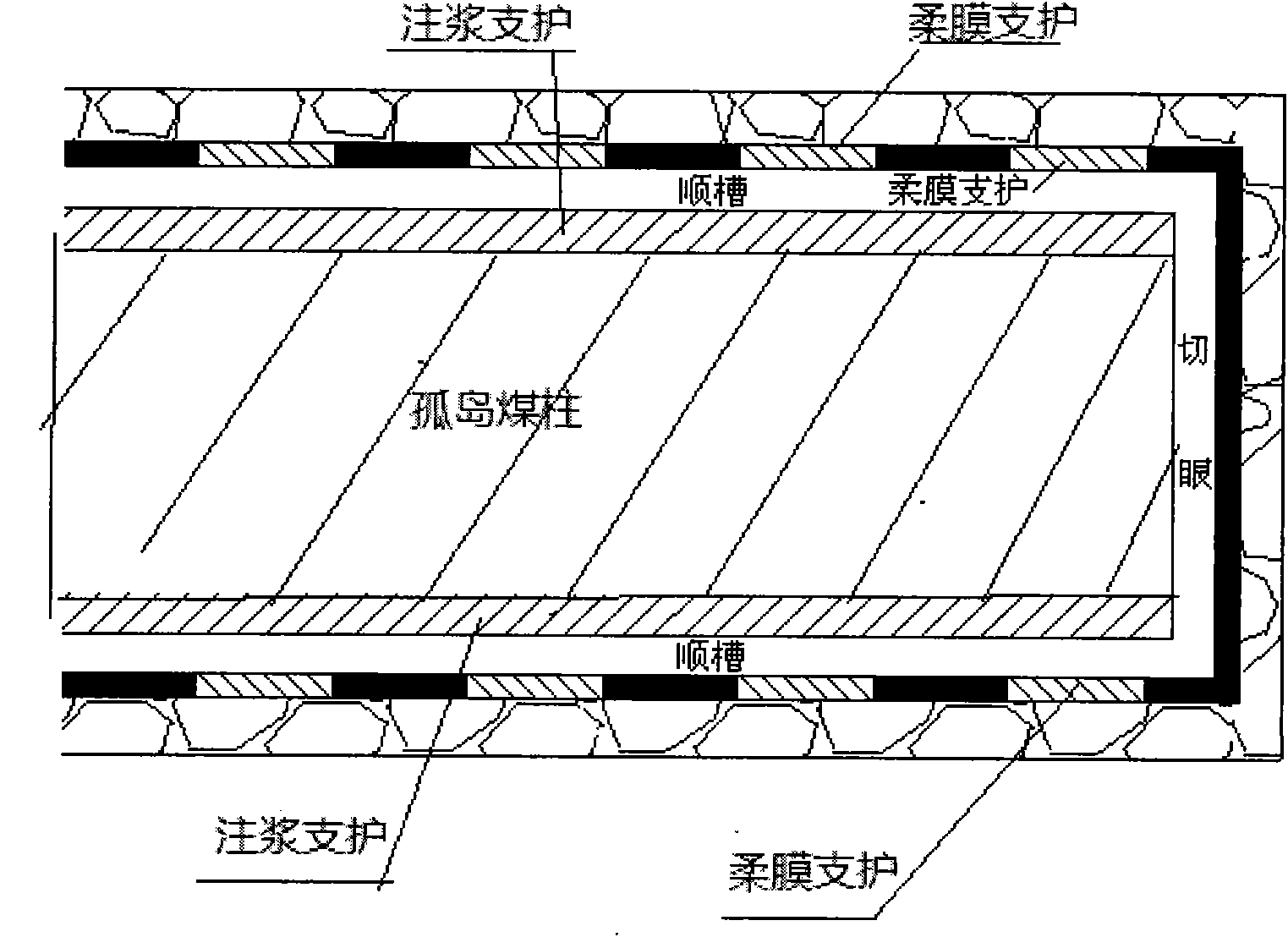

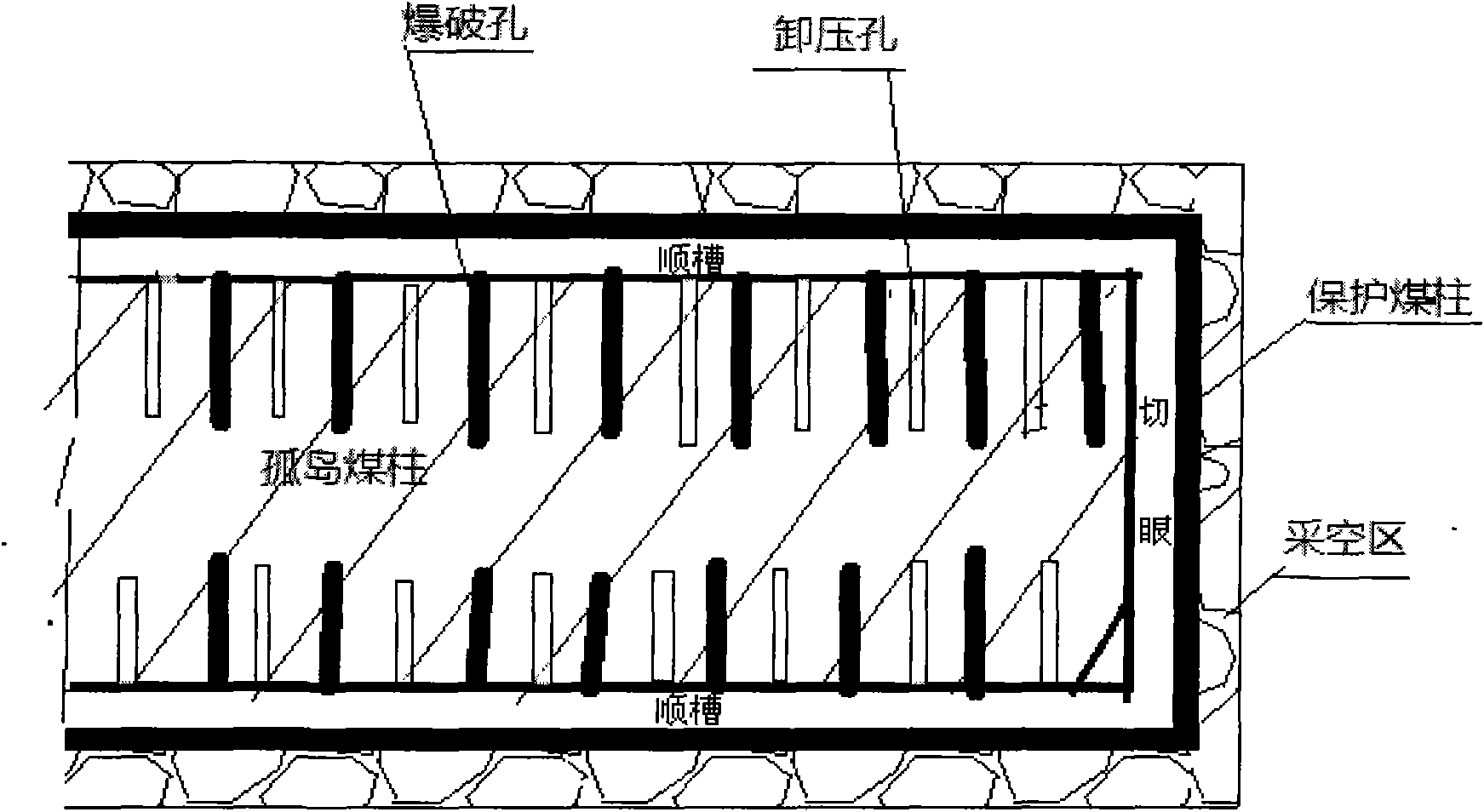

Control method for coal mine insular coal pillar crossheading rock burst

InactiveCN102322262AHigh strengthAct as a protective wallUnderground chambersUnderground miningDistressingCoal pillar

The present invention discloses a control method for coal mine insular coal pillar crossheading rock burst. According to the method, firstly, roadways of a coal mine insular coal pillar are dug and arranged on an upper crossheading, a lower crossheading and a coal face cut; treatments of drilling and blasting distressing are performed on inner side walls of the upper crossheading and the lower crossheading; then, a treatment of interval strong supporting is performed on outer side walls of goaf sides of the upper crossheading and the lower crossheading; finally, a treatment of grouting is applied on the inner side walls of the upper crossheading and the lower crossheading to reinforce the support, wherein the upper crossheading and the lower crossheading are subjected to the blasting distressing. With the present invention, the drilling and the blasting distressing are adopted, the ground pressure of the coal pillar is released, such that the coal body with the impact trend is transformed in the coal body with the weak impact trend; the strong supporting is performed for both side walls, such that the strength of the coal body from the coal wall of the roadway to the deep roadway is improved, the protection wall effect is provided for the roadway, and the safeties of the workers are protected.

Owner:SHANDONG UNIV OF SCI & TECH

Rock burst control method for deep tunnel excavation by adopting TBM (Tunnel Boring Machine)

InactiveCN101915104AReduce the risk of rockburstsRockburst Risk EliminationTunnelsTunnel boring machineUtilization rate

The invention relates to a rock burst prevention method for deep tunnel excavation by adopting a TBM (Tunnel Boring Machine), aiming to solve the technical problem on lowering or eliminating the rock burst danger of the TBM in a strong-rock-burst tunnel section in an excavation process, improving the equipment utilization rate of the TBM and accelerating a construction schedule by means of pretreating a wall rock for the TBM to excavate. The rock burst prevention method for the deep tunnel excavation by adopting the TBM adopts the technical scheme comprising the following steps of: (a) excavating a pilot tunnel with the size smaller than the excavation contour line of the TBM in the strong-rock-burst tunnel section through which the TBM needs to pass for excavation by adopting a drilling and blasting method and monitoring microseisms before the TBM enters the potential strong-rock-burst tunnel section; and (b) releasing the stress of a strong-rock-burst part in the excavation process of the pilot tunnel and a part with potential rock-burst danger shown by microseismic monitoring. The invention is mainly used for deep hydraulic tunnels and deep traffic tunnels with high rock burst danger.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

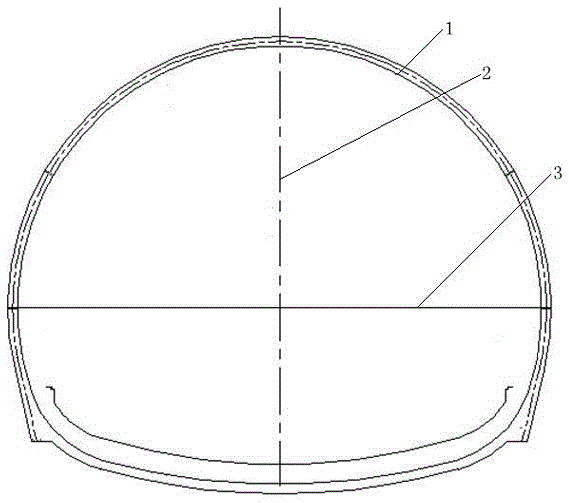

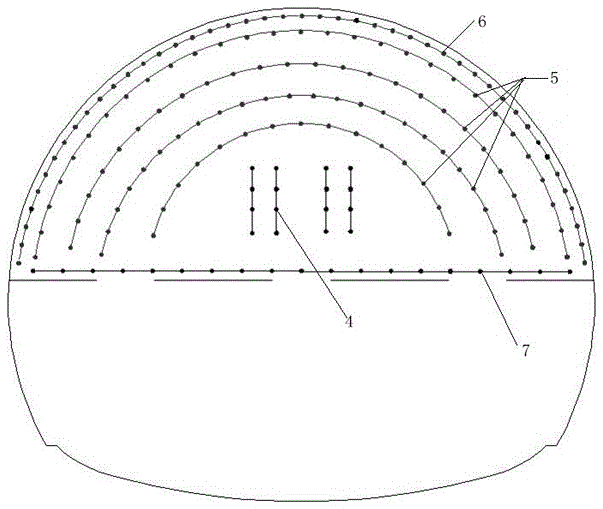

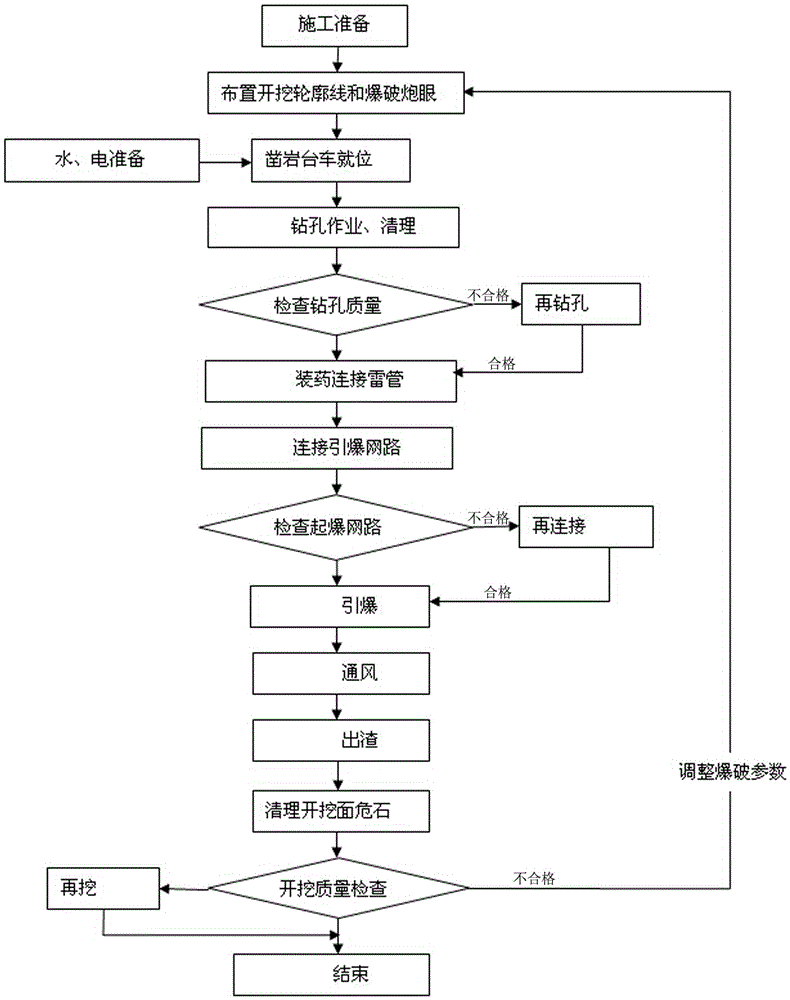

Method for carrying out bench cut method construction in IV-grade surrounding rocks by using three-arm drill jumbo

InactiveCN105605996APrecise positioningDrilling and blasting footage shortenedBlastingRock cuttingDrilling and blasting

The invention belongs to the technical field of tunnel rock mass construction, and particularly relates to a method for carrying out bench cut method construction in IV-grade surrounding rocks by using a three-arm drill jumbo. According to the method for carrying out bench cut method construction in the IV-grade surrounding rocks by using the three-arm drill jumbo, which is disclosed by the invention, a construction section is excavated by adopting smooth blasting; the characteristics of rapidness, positioning accuracy and safety of the three-arm drill jumbo are sufficiently utilized; drilling time is short; an extrapolation angle is easy to control; a drilling and blasting footage of the construction section is shortened; each cycle of drilling and blasting numbers are reduced; and particularly, the three-arm drill jumbo is used for carrying out drilling and blasting for the first time in the excavating process of an upper bench, and manual drilling and blasting are adopted on a lower bench, so that the rapid and accurate drilling operation is achieved, cycle operation time is reduced, and when drilling and blasting quality and operation efficiency are improved, the operation environment is improved, thereby improving integral efficiency of tunnel construction.

Owner:CCCC TUNNEL ENG

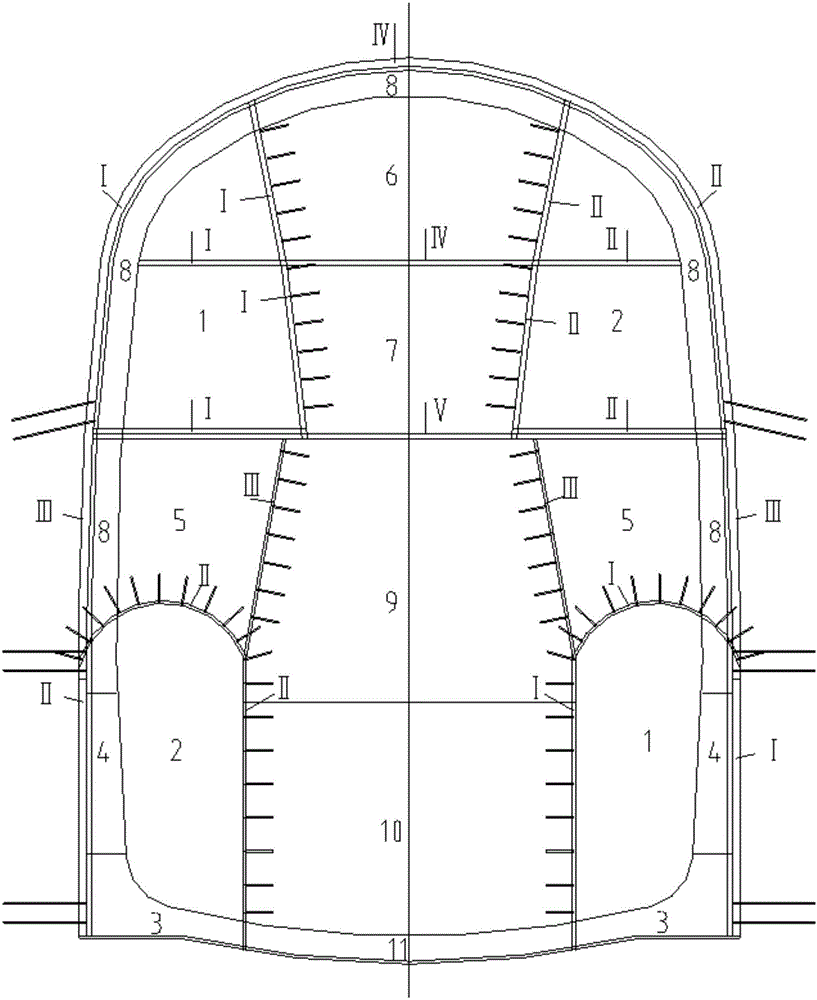

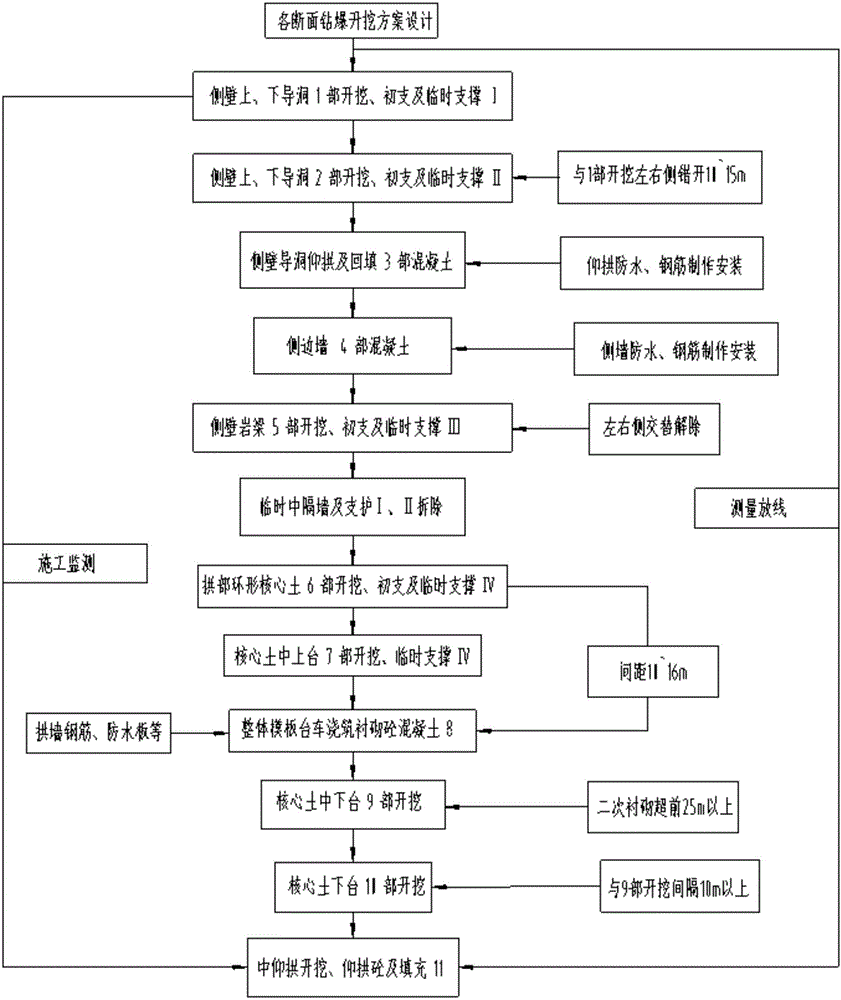

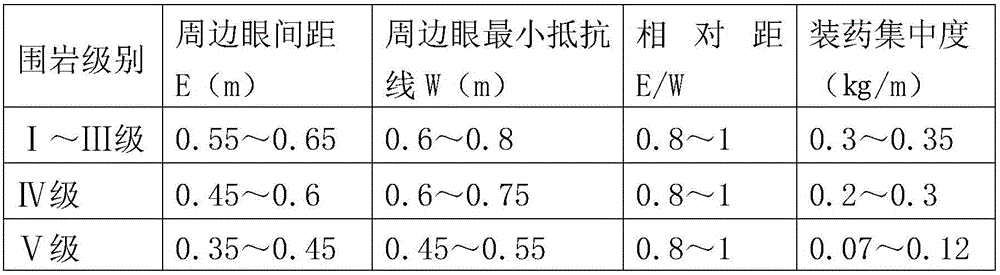

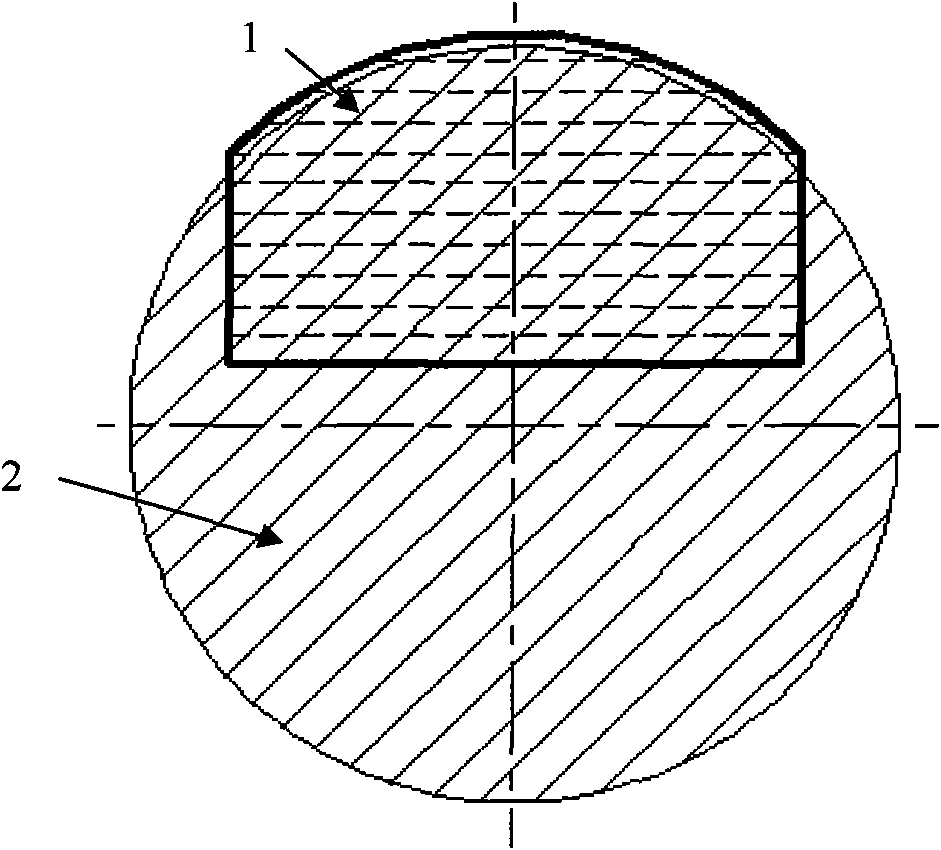

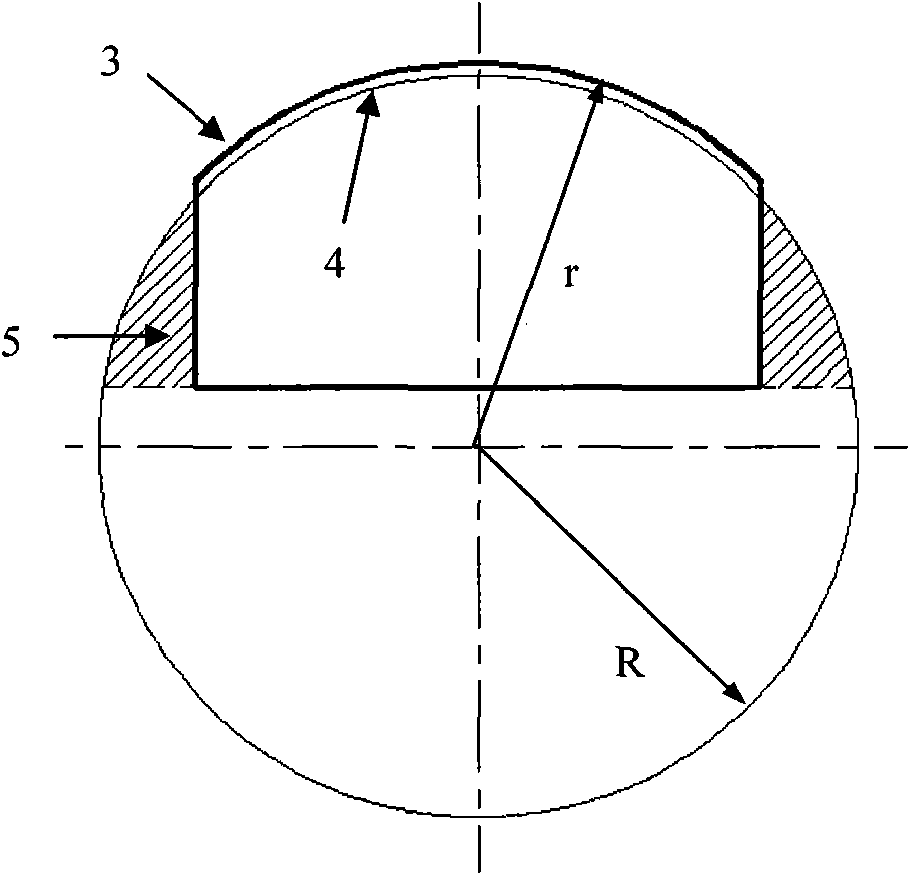

Construction method for excavating upper drift heading and lower drift heading in two side walls of ultra-large subsurface tunnel

InactiveCN106643361AReduce unit consumptionReduce the impactBlastingDrilling and blastingBuilding construction

The invention provides a construction method for excavating an upper drift heading and a lower drift heading in the two side walls of an ultra-large subsurface tunnel and belongs to the technical field of construction engineering. The method comprises the steps of drilling and blasting scheme design; construction requirements meeting of drilling and blasting design; blasting parameter selection; surveying and setting out; excavation of the upper pilot tunnel portion and the lower pilot tunnel portion of the two side walls; removal of reserved rock beam portions; excavation of an annular core soil portion of an arch portion; and excavation of core soil middle-upper steps, middle-lower steps and lower steps. Compared with a traditional two-side-wall drift heading method, according to the method, the way of excavating the upper drift heading and the lower drift heading at the same time is adopted, and the characteristics of the large-section tunnel can be fully utilized; a working face which can be excavated is increased; tunnel excavation conducted at the early stage is accelerated; and the construction period is effectively shortened. According to the method, reserved rock beams are utilized, so that horizontal support strength and global stability are effectively enhanced; horizontal convergence deformation and arch top settlement of the tunnel are decreased; and safety of buildings on the upper portion of the tunnel is guaranteed. According to the construction method, after the high side walls are constructed by means of the bottom of a lower pilot tunnel of the tunnel, backfilling is conducted, the height of a second lining construction section of the tunnel is reduced, and the construction problem of an ultra-large-section formwork trolley is solved.

Owner:CHINA CONSTR EIGHTH ENG DIV

United method for tunneling super-strong or strong rock burst hole section of TBM construction tunnel

InactiveCN101915105AReduce risk of strong or severe rockburstsGuaranteed driving speedUnderground chambersTunnel liningSocial benefitsHigh stress

The invention relates to a united method for tunnelling a super-strong or strong rock burst hole section of a TBM construction tunnel by sufficiently utilizing the flexibility of the construction control measures of the drilling and blasting method and the advantages of TBM rapid tunneling,, aiming at overcoming the limitation that the traditional TBM tunneling method cannot be used for dealing with super-strong or strong rock burst. The united method is characterized by comprising the steps of designing an excavated section by an upper guide hole drilling and blasting method, excavating the section by the upper guide hole drilling and blasting method, supporting by surrounding rocks, and TBM whole section tunneling and supporting. The united method solves the problem that the traditional construction excavation technology cannot be used for effectively pretreating super-strong or strong rock burst risk in the process of high-stress tunnel TBM tunneling, guarantees the safety of TBM equipment and construction staff, ensures the tunneling speed of TBM, and has strong economical benefit and social benefit. The invention is suitable for the TBM excavation construction of high-stress tunnels, such as various water conservancy and hydropower tunnels, traffic tunnels, and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Large dead zone residual ore recovery method

InactiveCN101403304AHigh recovery rateImprove safety conditionsUnderground miningBlastingSpelunkingRecovery method

The invention relates to a recovery method of residual ores in a large mined out space. The method comprises the steps of sublevel caving method without sill pillar, rock drilling and blasting in an inlet passage and ore removal; and is characterized in that: forced caving and induced inbreak are adopted by ore break down, a recycling inlet passage is arranged at the bottom of the mined out space, residual orebody inside and at the periphery of the mined out space to be recycled is divided into an induced inbreak area and a forced caving area from top to bottom, the continuous mined out space formed after the blasting is utilized to induce the inbreak of the ore at the upper part, and the recycling inlet passage is arranged in the ore body at the lower part of the mined out space. The method solves the problems of poor safety condition and low recovery rate and the like of the traditional residual ore recovery in the mined out space, realizes high degree of safety, low production cost and high recovery rate and the like of the residual ore recovery, and improves the production efficiency and economic efficiency of mines.

Owner:KUNMING UNIV OF SCI & TECH

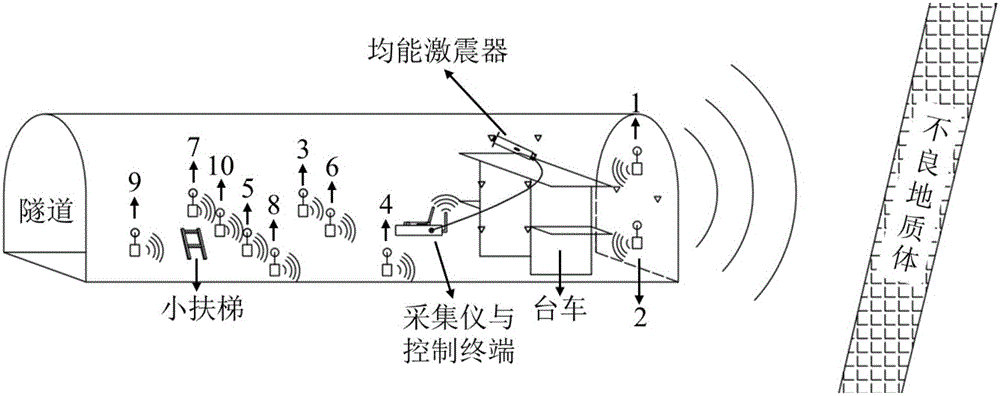

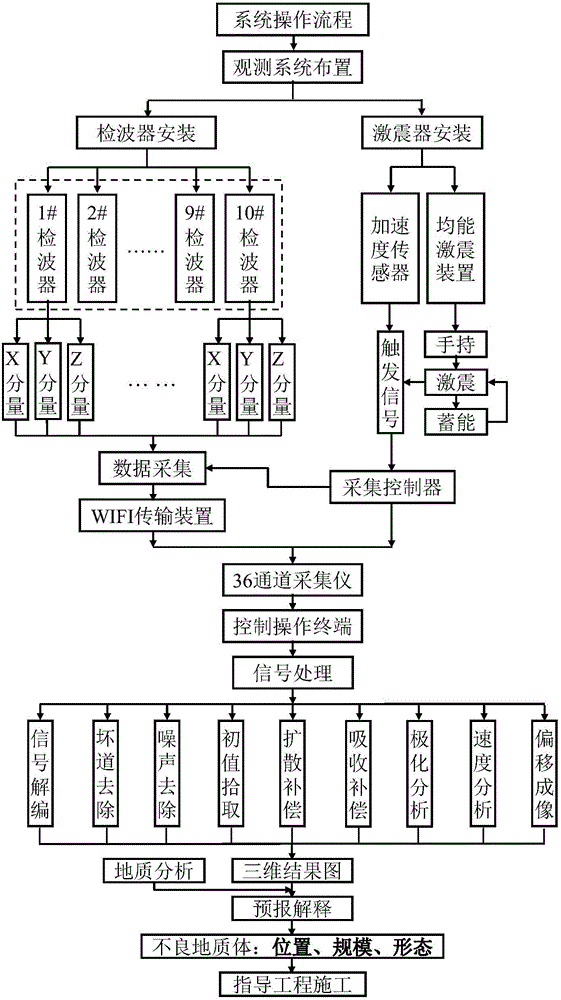

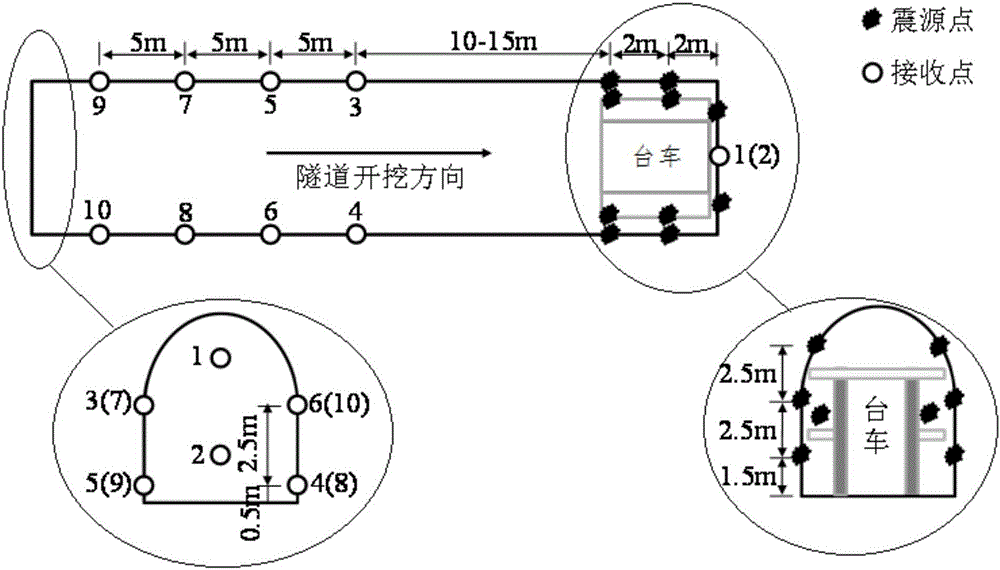

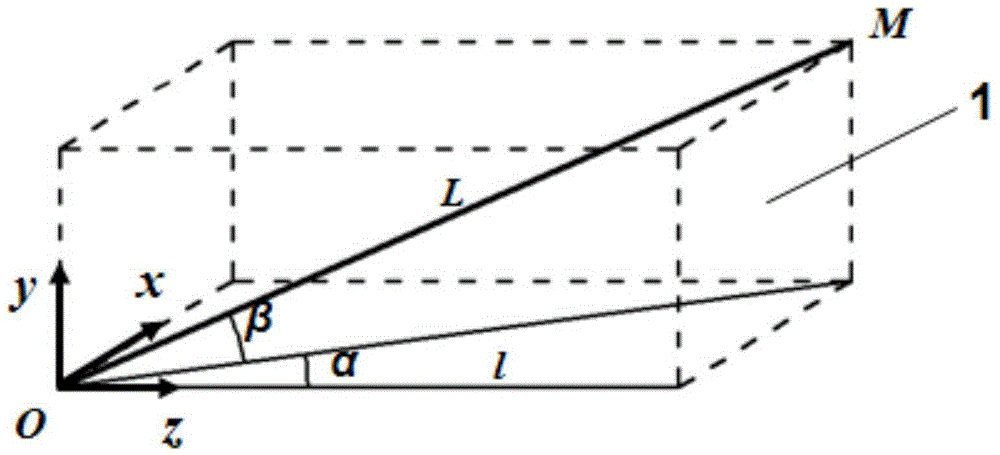

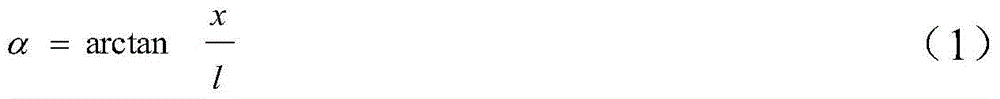

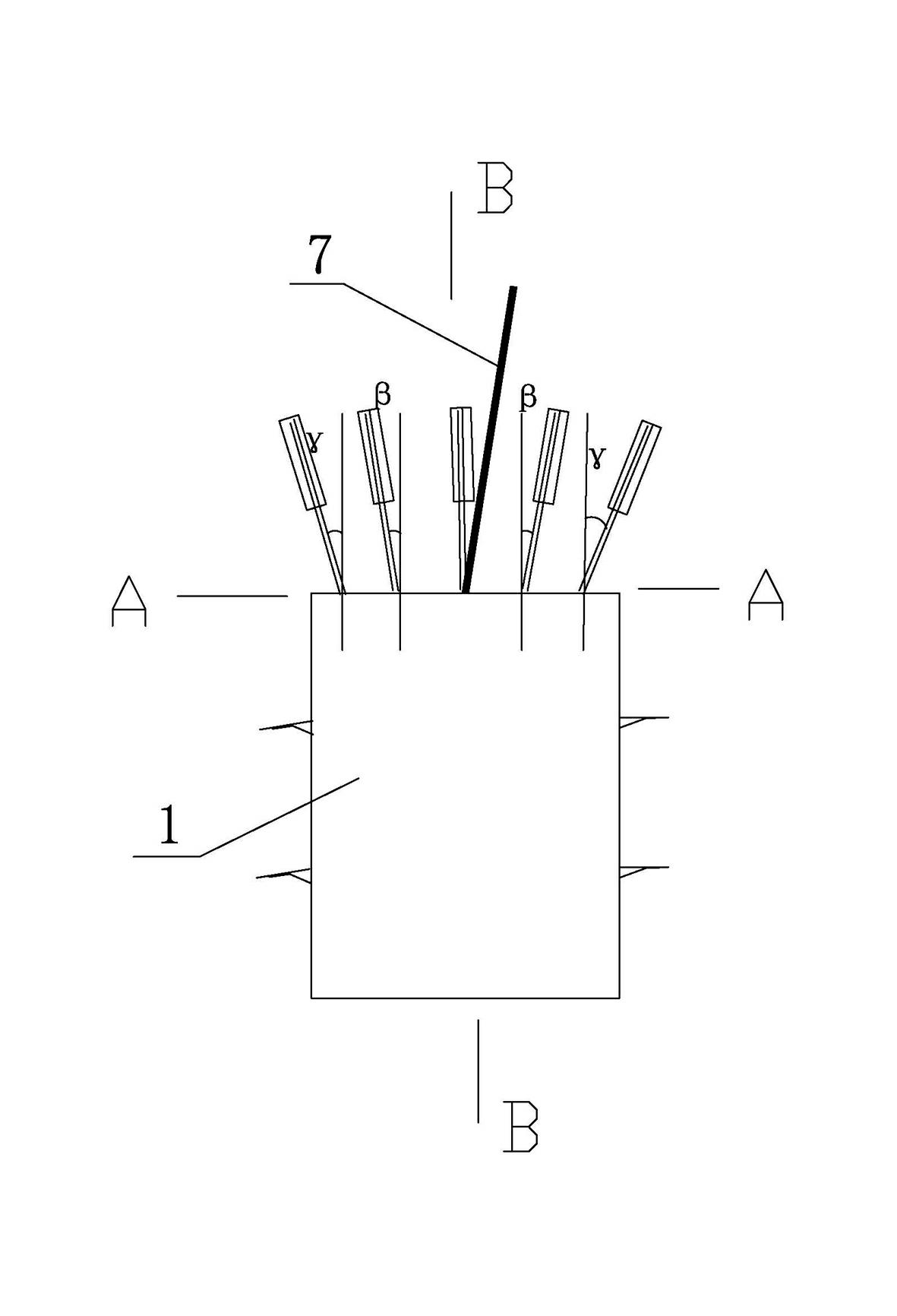

Tunnel three-dimensional seismic wave advanced detection space observation system and tunnel three-dimensional seismic wave advanced detection space observation method

ActiveCN105974465AShock fastQuick installationSeismic signal receiversSeismic signal transmissionEqualizationObservation system

The invention discloses a tunnel three-dimensional seismic wave advanced detection space observation system and a tunnel three-dimensional seismic wave advanced detection space observation method. The tunnel three-dimensional seismic wave advanced detection space observation system mainly comprises a full-space observation system, a sensor quick mounting method and an energy equalization vibration device. In a channel which is excavated according to a drilling and blasting method, taking regard of a field space condition, a full-space three-dimensional space observation system which adapts field quick arrangement is designed. The spatial resource of a tunnel face and a trolley platform resource can be sufficiently utilized. On condition that no external large-size machinery is utilized, quick mounting and field detection can be realized. Furthermore the number of hammering points is increased. Three-dimensional spatial arrangement of the hammering points is enlarged. Arrangement and detection of the observation system are finished. Furthermore the invention provides two geophone mounting manners, namely a viscose glue mounting manner and a bolt splicing manner, thereby adapting with quick mounting and coupling of the geophone in a water environment and a no-water environment can be adapted. Based on the two geophone mounting manners, the invention provides a data processing and interpretation system. The tunnel three-dimensional seismic wave advanced detection space observation system and the tunnel three-dimensional seismic wave advanced detection space observation method can realize quick detection and provide high safety insurance for tunnel project construction.

Owner:山东百廿慧通工程科技有限公司

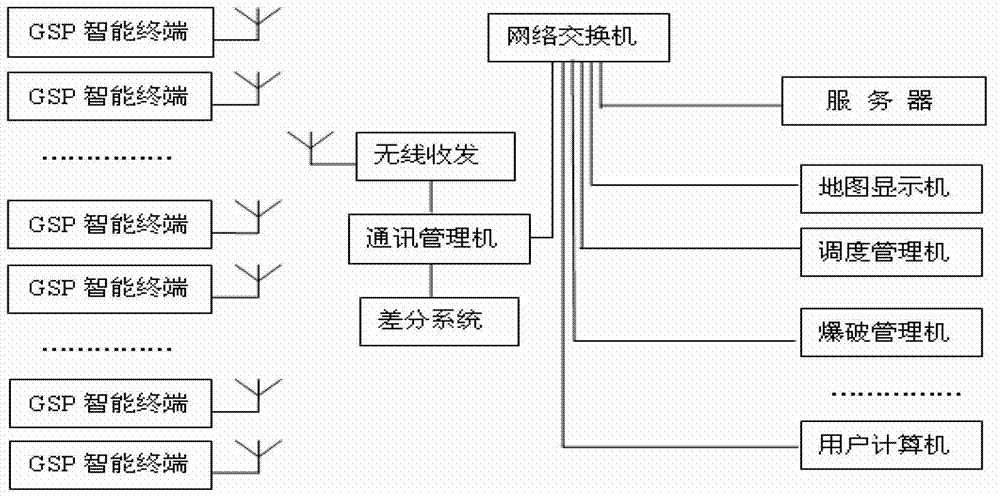

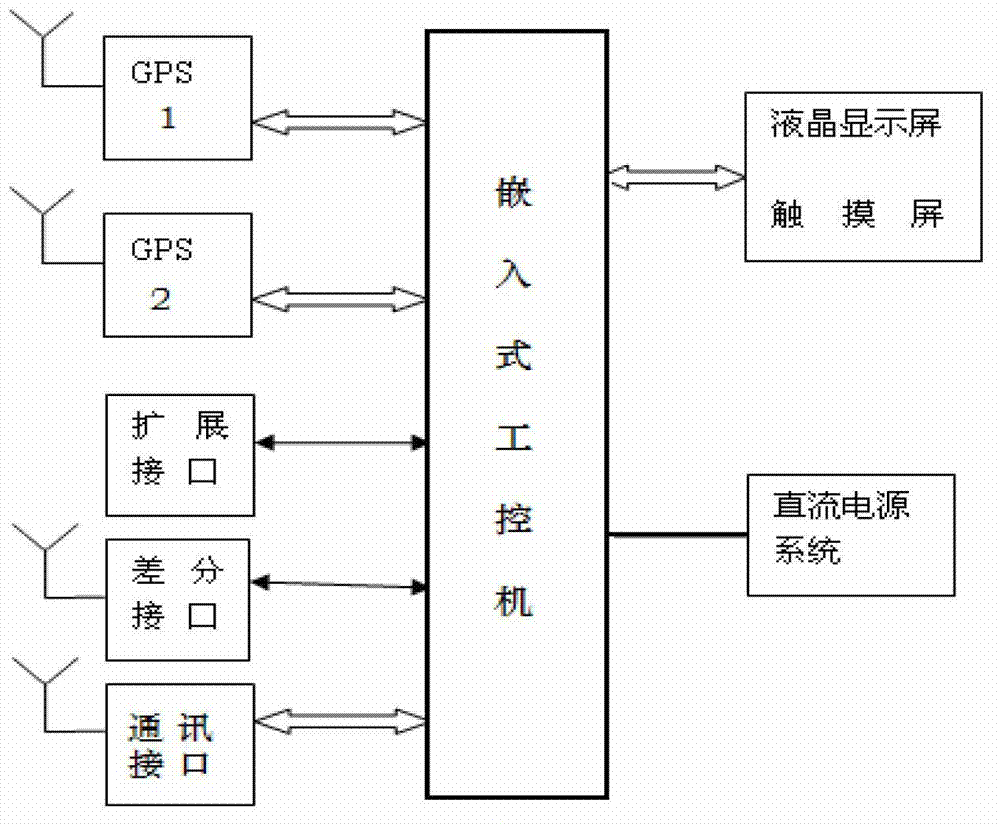

High-accuracy global system positioning (GPS) geared drill automatic hole arrangement system

ActiveCN102927865AGuaranteed horizontal positioning accuracyImprove blasting qualityBlastingComputer terminalDouble frequency

The invention provides a high-accuracy global system positioning (GPS) geared drill automatic hole arrangement system and belongs to the technical field of open-cast mining digitization drilling and blasting. The high-accuracy GPS geared drill automatic hole arrangement system comprises an intelligent terminal, a double-frequency GPS module, a GPS differential station, a computer network and a terminal computer of a scheduling control center, a GPS differential station, intelligent terminal host computer software and scheduling control center software. The high-accuracy GPS geared drill automatic hole arrangement system has the advantages of eliminating various factors which are hidden and uncontrollable and influence drilling and blasting quality in traditional drilling and blasting process, high and new technology available now is used to improve traditional process, and therefore refine course management and digital control course are achieved.

Owner:BEIJING SOLY TECH

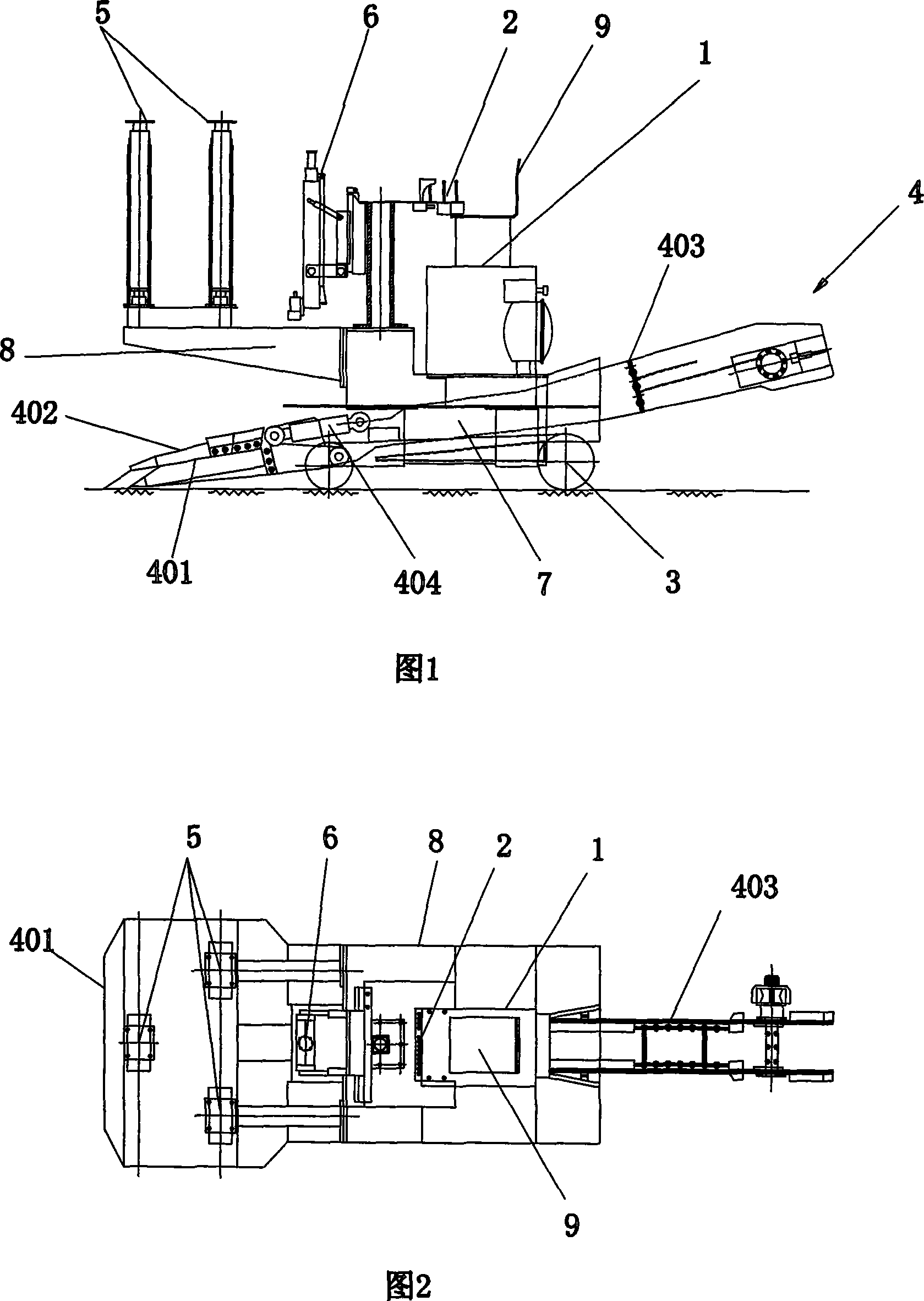

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

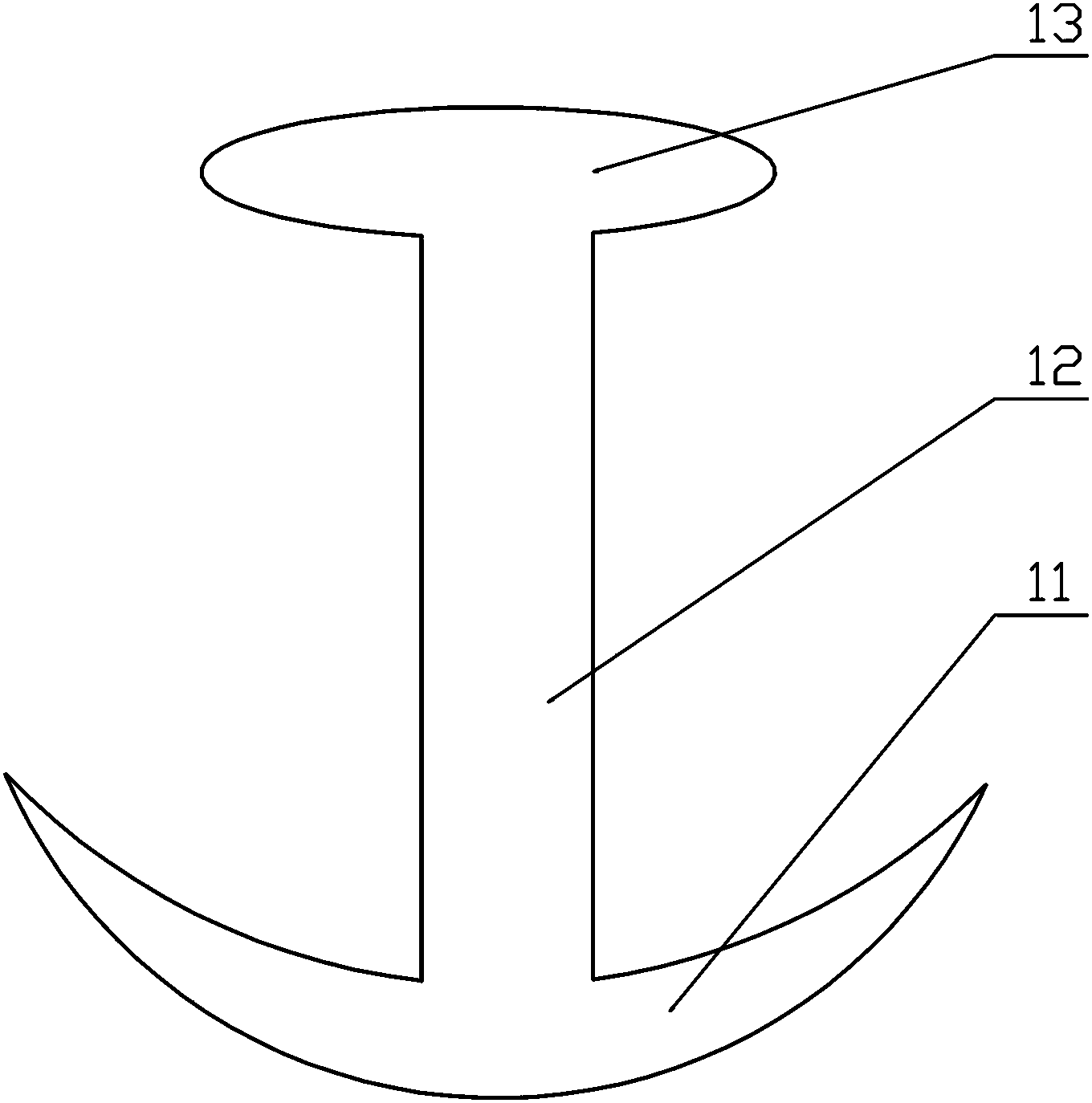

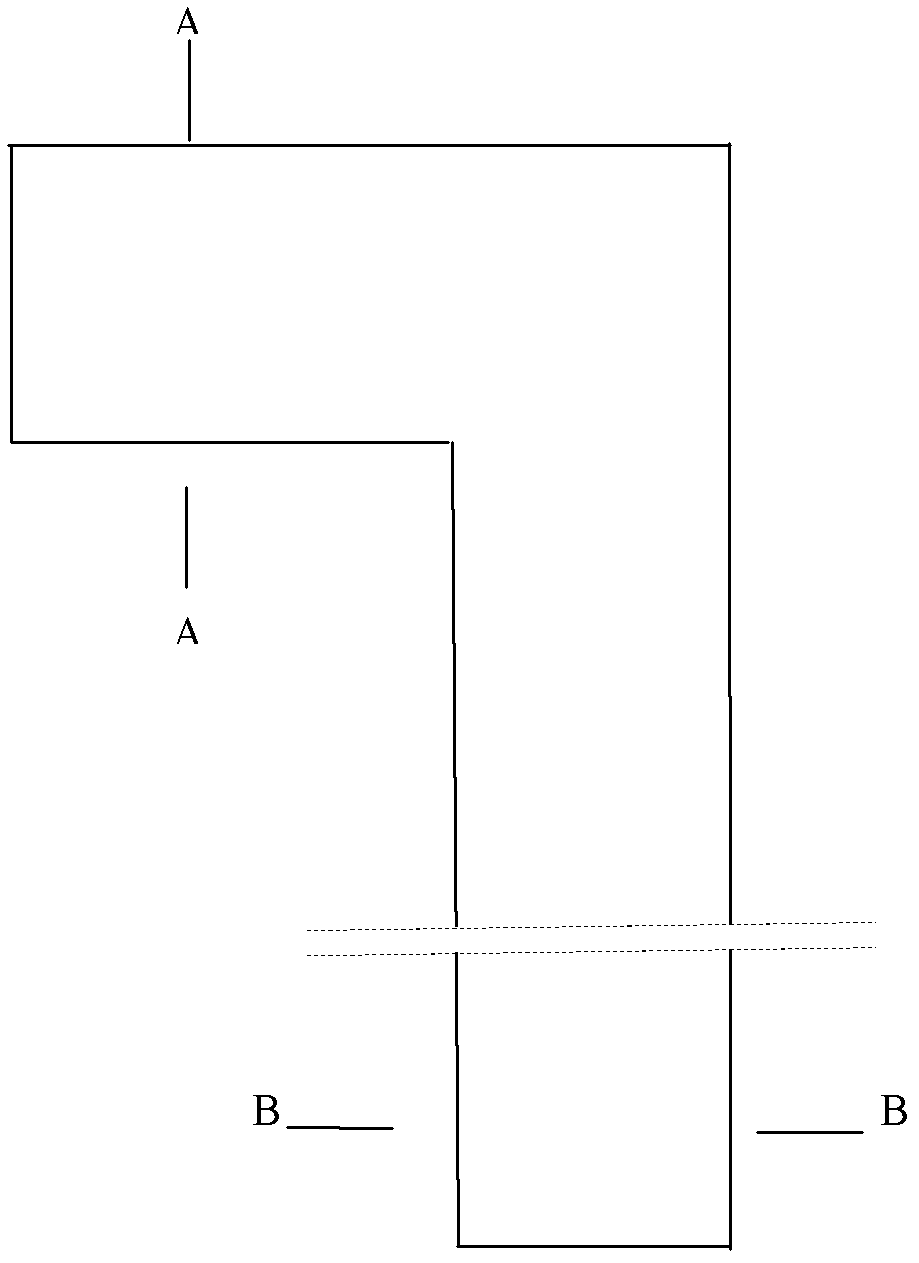

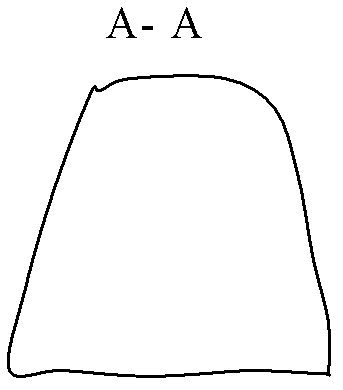

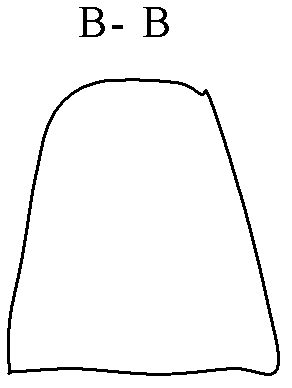

Blasthole plug and method

InactiveCN103453808AAvoid enteringSolve the problem of poor blocking effectBlastingDetonatorEngineering

Disclosed is a blasthole plug. A concave arc-shaped part is arranged at the front end of the plug and thinned gradually from the axis to the edge, a longitudinal section of the concave arc-shaped part is in a shape a concave arc, the diameter of the concave arc-shaped part is larger than that of a blasthole, the diameters of the rest parts of the plug are smaller than that that of the blasthole, and the height of the plug is larger than the diameter of the blasthole. A method for drilling and blasting by the blasthole plug includes the steps: firstly, charging after drilling to form the blasthole; secondly, mounting a detonator and leading out a detonator lead; thirdly, mounting the concave arc-shaped portion into the blasthole downwards; fourthly, filling drilling dust for compaction. Through the steps, the drilling dust is adopted to plug the blasthole. The drilling dust can be prevented from entering a charging section; in addition, due to one-way mobility, large resistance can be obtained during blasting, and thereby a blasting effect is better.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

Loading method suitable for field mixed loading of explosive and tool used for method

The invention relates to a loading method suitable for field mixed loading of explosive and a tool used for the method. The loading method suitable for the field mixed loading of the explosive comprises the following steps: 1) putting constituted detonated explosive into an explosive forming bag, introducing a detonating fuse connected with the detonated explosive out of the explosive forming bag, and binding a load bearing rope with a load bearing belt of the explosive forming bag; 2) enabling an explosive conveying hose to extend into the bottom of the explosive forming bag from an explosive conveying hole of the explosive forming bag, and fixing the rope and a detonating fuse on the hole of a blasthole by a load bearing rod after the explosive forming bag is taken into place; and 3) starting a mixed loading truck for the explosive, injecting the explosive into the explosive forming bag, removing an antistatic locating rod out of the blasthole when the length of an injected explosive section reaches the requirement of a user, and taking out the explosive conveying hose after the explosive loading amount reaches a designed volume to finish the explosive loading operation of the position. The loading method suitable for the field mixed loading of the explosive can be widely used for loading a fracture rock blasthole and an air interval outline blasthole under various conditions that explosive mixed loading is adopted for ground drilling and blasting, such as mines, traffic, hydroelectric power and the like.

Owner:GUANGDONG HONGDA BLASTING +1

A high-efficiency, safe and environmentally-friendly mining method for irregular strip-shaped distribution of poor and shallow buried seams

InactiveCN102278115AIncrease production capacityEasy to manageMaterial fill-upOpen-pit miningEcological environmentLand resources

The invention discloses a high-efficiency, safe and environment-friendly mining method for irregular strip-shaped thin and shallow buried mine seams. The mining method adopts the method of arranging mining pits along the direction of the mine seam, and Stripping and mining by step-by-step open-air step blasting in sequence, drilling, blasting and transportation are arranged in steps. The drilling, blasting, and transportation operations have high production efficiency and are safer than other mining methods. The stripped waste rock is backfilled to the first mining area. The mined-out area of the section saves land resources, protects the natural environment, saves transportation costs, reduces comprehensive mining costs, reduces energy consumption, and reduces waste rock discharge. The invention solves the problems of backward mining planning, low production efficiency, unsafe production, valuable land occupied by dumps, environmental pollution by dumps, high transportation energy consumption, high mining costs and living environment caused by mining in traditional open-pit mining projects. and environmental pollution and other technical issues.

Owner:汉通控股集团有限公司

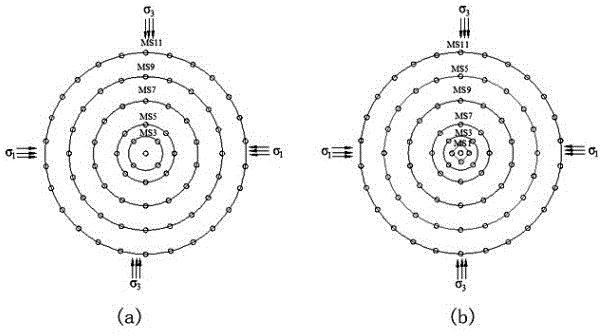

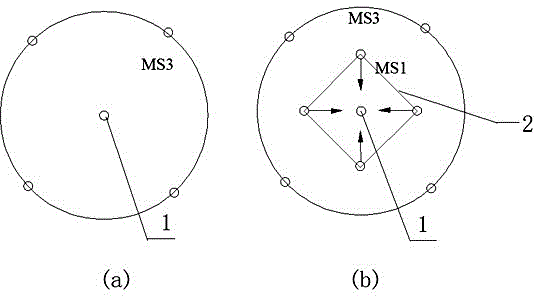

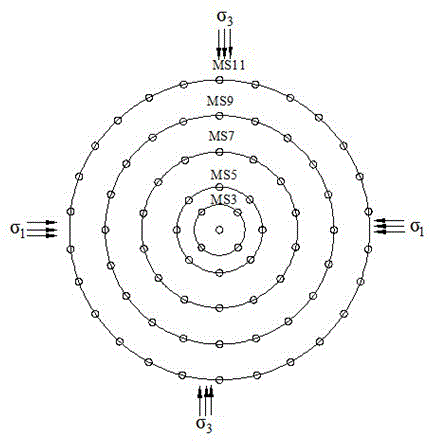

Deep-buried tunnel blasting excavation effect control method

The invention discloses a deep-buried tunnel blasting excavation effect control method. The method comprises the steps that 1, the main stress level and direction of the heading face of a tunnel to be excavated are determined before blasting excavation; 2, according to the drilling and blasting design scheme with single fire dynamite as a core control index, blast holes are formed and explosive payload is designed on the heading face of the tunnel to be excavated; 3, a circle of conical cutting holes pointing to a center hollow hole of an original cutting hole section is added into the formed original cutting hole section, and breaking holes in the outmost circle are used as buffer holes; 4, on the basis of the excavation blasting design scheme, blasting internetworking is carried out on the blast holes except for the conical cutting holes; 5, blasting is carried out by the adoption of a micro-differential blasting method. The deep-buried tunnel blasting excavation effect control method can control excavation disturbance evoked by deep rock strain energy transient release and blasting loads at the same time so as to achieve active control over the deep rock damage and rock blast, and can be widely applied for control over blasting excavation and deep blasting mining disturbance of deep-buried underground engineering in the hydraulic and hydroelectric engineering field, the traffic field, the mine field and the like.

Owner:WUHAN UNIV

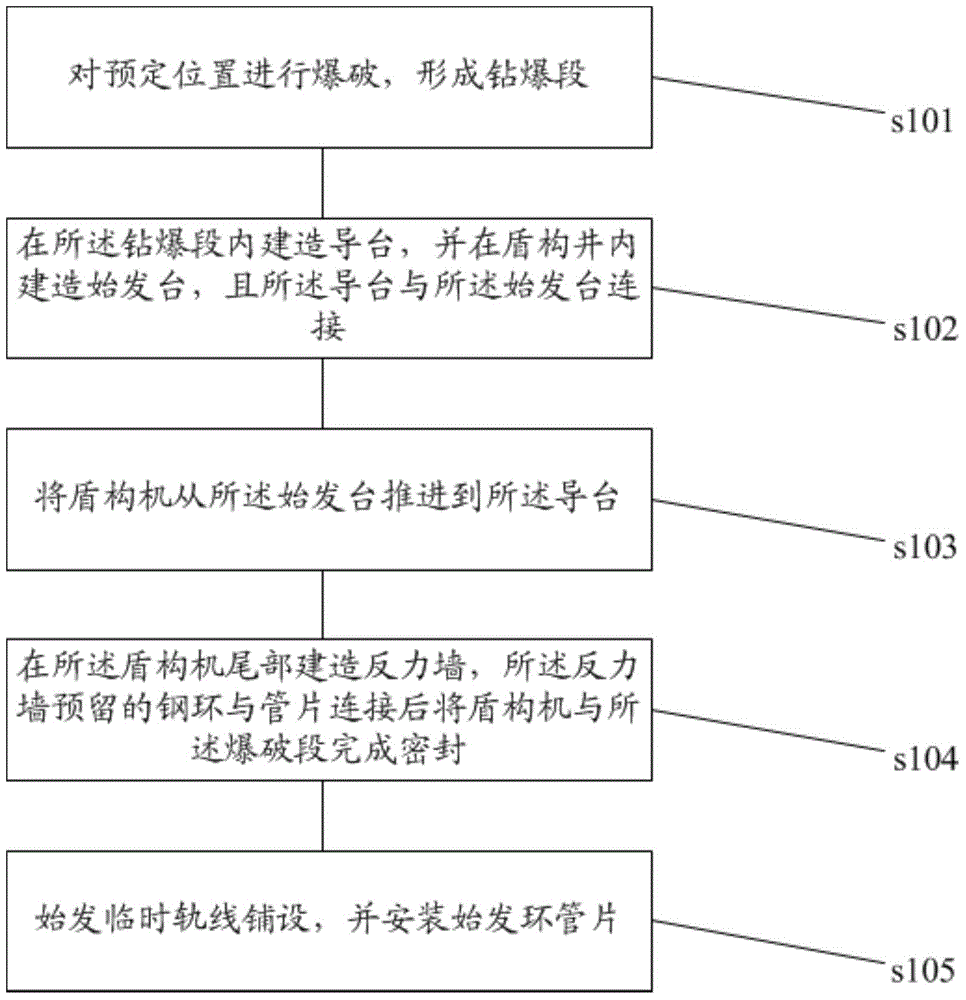

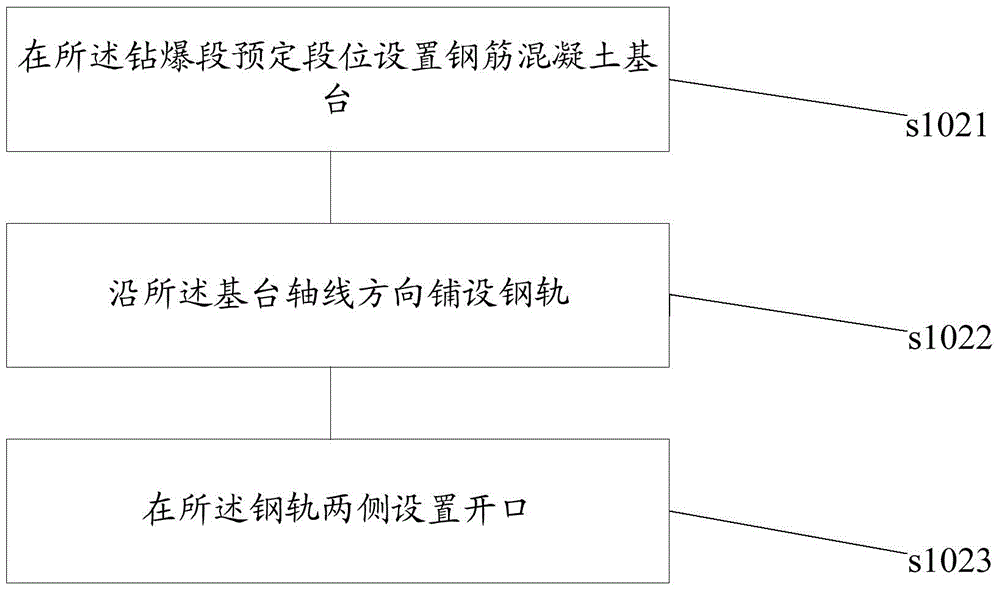

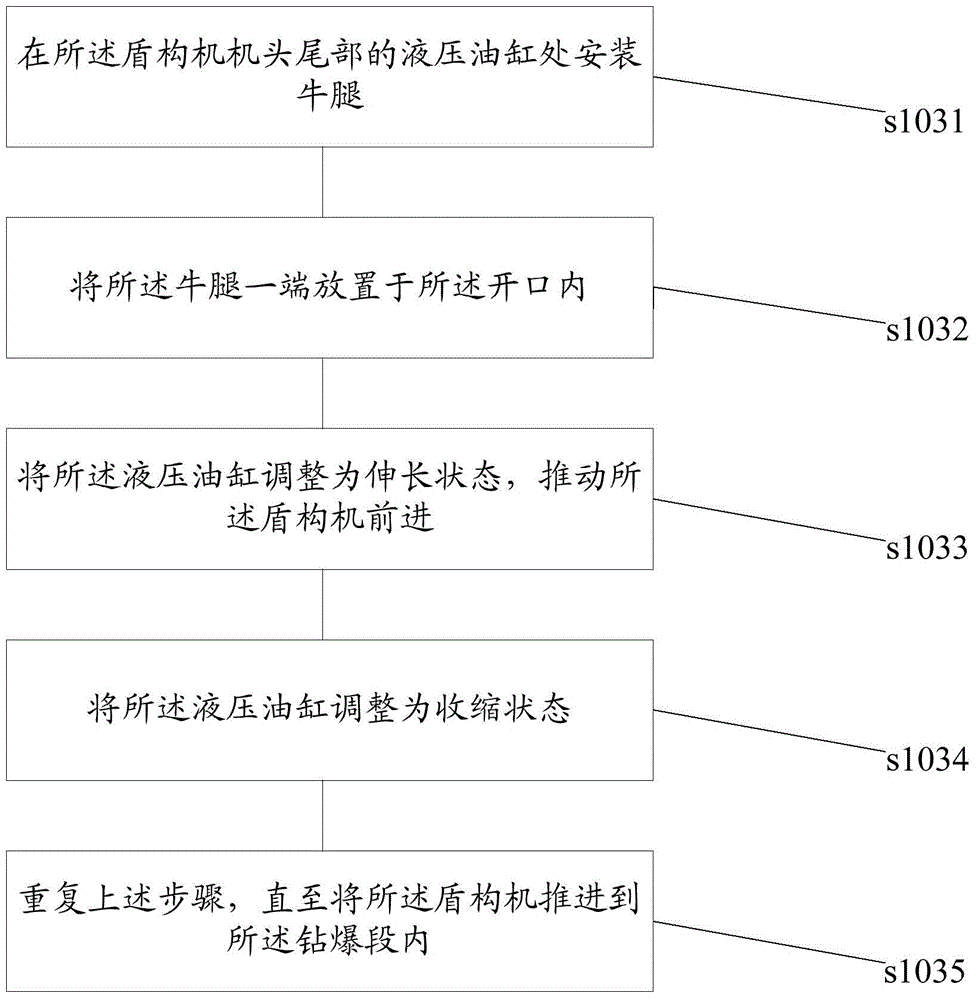

Method for in-tunnel starting of shield tunneling machine

InactiveCN104695968AEasy constructionReduce engineering costsUnderground chambersTunnel liningEngineeringShield tunneling

The invention discloses a method for in-tunnel starting of a shield tunneling machine. The method comprises the following steps: exploding preset positions to form a drilling and exploding section; constructing a guiding station in the drilling and exploding section, and constructing a starting station in a shield well, wherein the guiding station and the starting station are connected; propelling the shield tunneling machine from the starting station to the guiding station; constructing a reaction wall at the tail of the shield tunneling machine, wherein a steel ring preserved for the reaction wall is connected with a segment, so as to seal the shield tunneling machine and an exploding section; paving a starting temporary orbit, and mounting a starting circular segment. According to the method, when the geological condition is complex, the drilling and blasting section can be formed through exploding, the starting station and the guiding station are arranged in the shield well as well as the drilling and blasting section, the shield tunneling machine can be directly propelled into the guiding station of the drilling and blasting section, and the reaction wall is arranged at the tail of the shield tunneling machine and provides a direction force for the shield tunneling machine, so that the in-tunnel starting of the shield tunnel machine can be finished. The method provided by the invention is suitable for complex geological conditions and limited construction spaces.

Owner:HENAN INST OF ENG

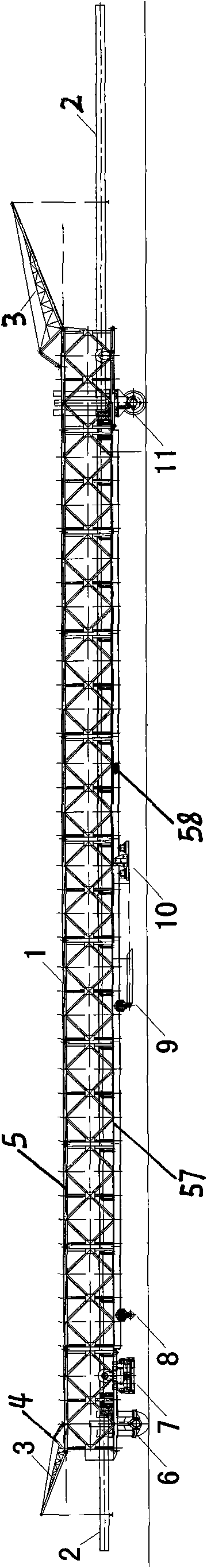

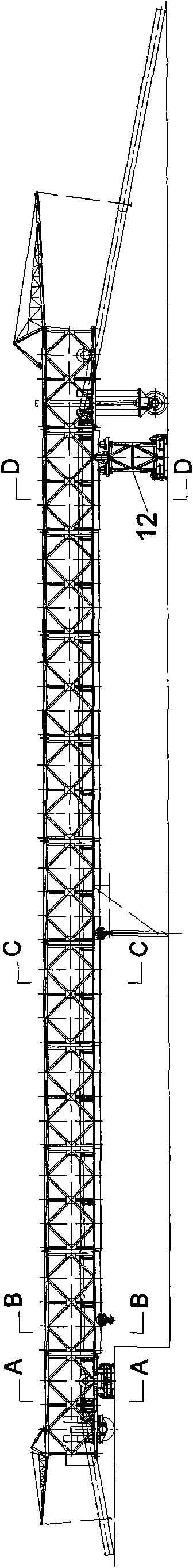

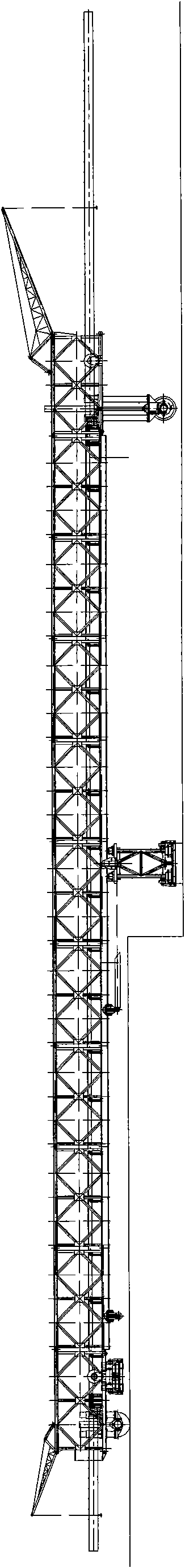

Multifunctional fabricated hydraulic drive moveable trestle

ActiveCN101598025AMeet the excavation construction requirementsAdaptableUnderground chambersTunnel liningDrive wheelSteering wheel

The invention provides a multifunctional fabricated hydraulic drive moveable trestle, relating to a hydraulic drive moveable trestle used for various excavation constructions carried out by various tunnel or cavity drilling and blasting methods. The trestle comprises a main trestle and approach trestles positioned on both ends of the main trestle, wherein, the main trestle comprises a transverse beam and trusses connected to both sides of the transverse beam, the upper and the lower ends of the trusses are respectively provided with upper chord members of the main trestle and lower chord members of the main trestle. The invention has the technical scheme that a steering wheel is installed on the front end of the main trestle, a driving wheel and a rear supporting device are installed on the rear end of the main trestle, and lifting mechanisms are arranged on the steering wheel and the driving wheel. Moveable tracks are installed on the lower chord members of the main trestle between the steering wheel and the rear supporting device; concrete slicking devices, fixing devices for inverted arch templates, front supporting devices and lengthwise moved idler pulleys for front support are installed on the moveable tracks, and drawing mechanisms are installed on the lower chord members of the main trestle on the left and the right sides of the trestle. The trestle is suitable for various excavation constructions of public roads, railroads, water diversion, flood discharge, anti-aircraft defense, and the like by the tunnel or cave drilling and blasting methods, and meets the requirements of simultaneous construction, namely the tunnel or cave excavation and the pouring of concrete for the bottom inverted arch.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

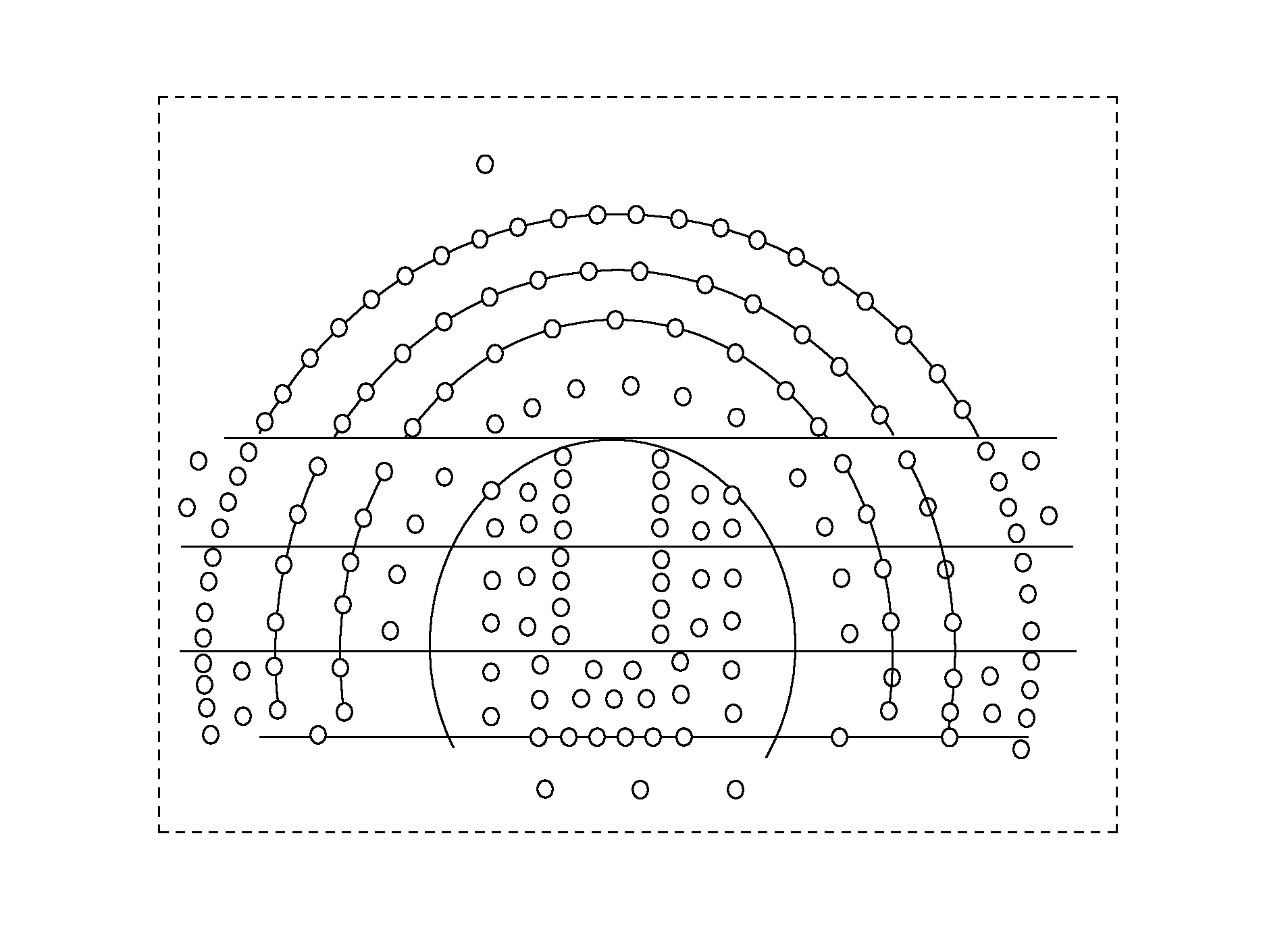

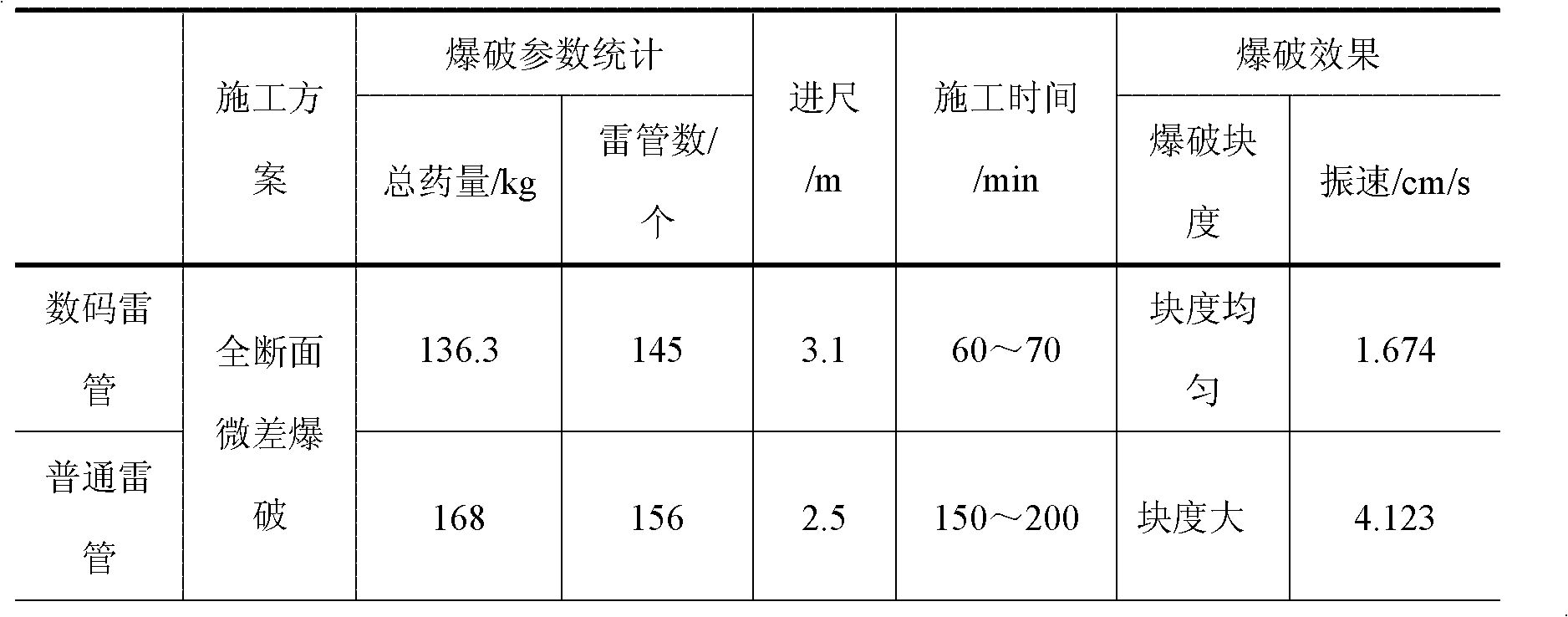

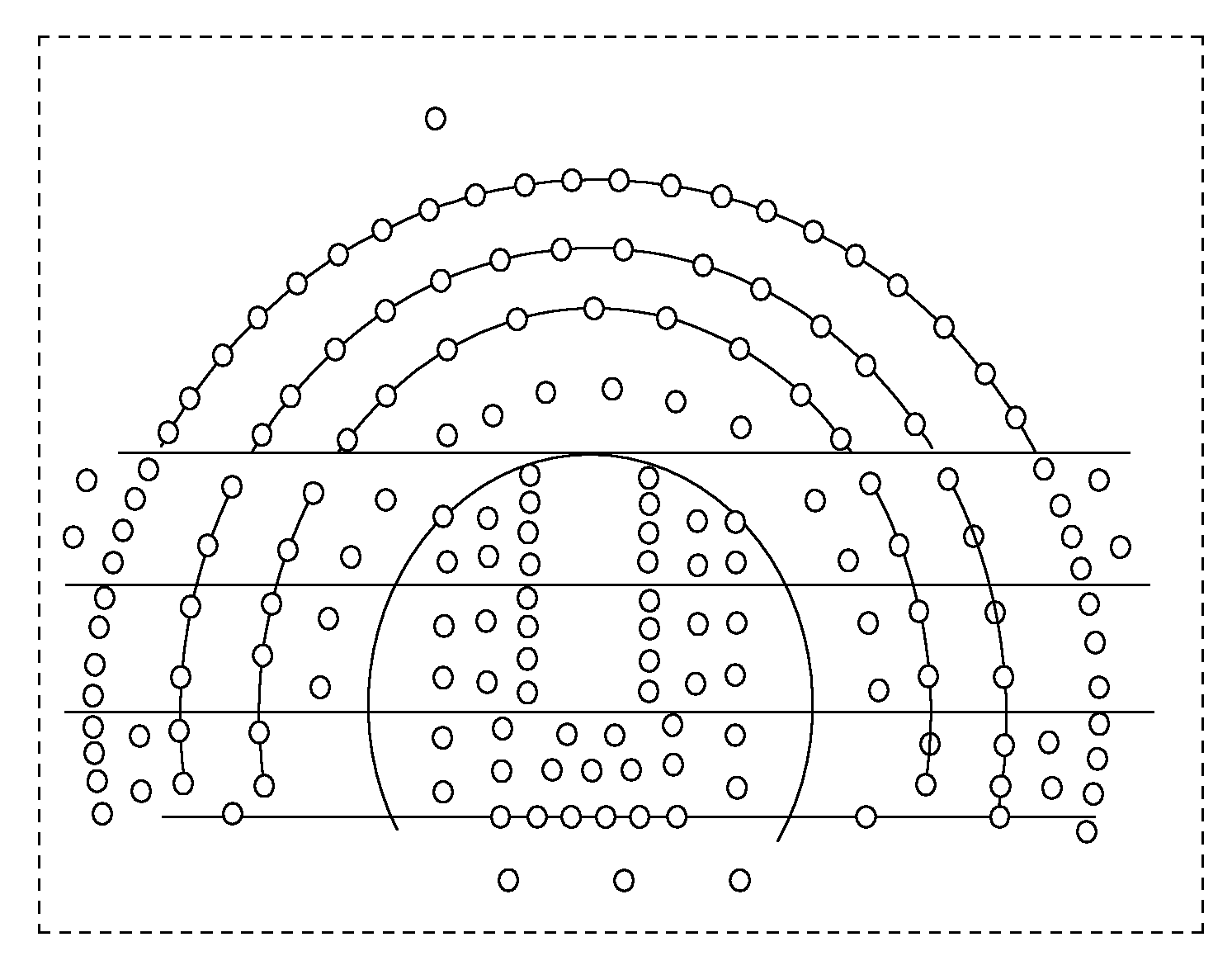

Method for implementing full-face smooth blasting construction by using digital detonators

InactiveCN102305580AIncreased explosion fragmentationImprove the glossy effectBlastingDetonatorDetonation

The invention relates to a method for implementing a full-face smooth blasting construction by using digital detonators. The method comprises the following steps: (1) designing a blasting construction plan; (2) carrying out trial blasting; (3) numbering digital detonators; (4) setting delay blasting times for the digital detonators; (5) installing the digital detonators; (6) carrying out web connection; and (7) carrying out a digital detonator detonation process. Compared with a common blasting method, by using the method provided by the invention, the blasting fracture is increased by 40%, and the smooth effect is increased by 30%, the full-face blasting can be performed, and the circulation footage is increased; a blasting vibration control effect is obvious; and the construction cost is higher than that of the construction using a drilling and blasting method, but compared with other methods, the construction cost advantage is obvious, therefore, the method provided by the invention has remarkable social and economic benefits.

Owner:BEIJING JIAOTONG UNIV

Excavation deviation processing method of raise-boring machine for deep vertical shaft

InactiveCN105298499AGuaranteed verticalityHigh strengthShaft sinkingShaft raisingPilot holeBottom pressure

The invention discloses an excavation deviation processing method of a raise-boring machine for a deep vertical shaft. The method includes the steps that the position of a pilot hole tail end drill is determined according to the drill stem deviation angle, the vertical shaft height and other parameters, and a mucking pilot shaft and a muck discharging channel are formed through expanding excavation; then, after the mucking pilot shaft is formed, the vertical shaft is excavated in a drilling and blasting mode, and when the mucking pilot shaft deviates and loses the mucking function or mucking is unsmooth, expanding excavation is performed on the part between the vertical shaft and the mucking pilot shaft so that the mucking pilot shaft can perform mucking effectively and smoothly; after exaction is completed, the deviation expanding excavation part is backfilled so that the verticality of the vertical shaft can be guaranteed and the requirement of pressure steel pipe installation for the verticality of the vertical shaft can be met. According to the method, under the condition that a pilot hole deviates, it is guaranteed that the mucking pilot shaft performs mucking effectively, and the verticality of the vertical shaft is also guaranteed; in pressure vertical shaft or surge shaft construction in water conservancy and hydropower engineering, the method has the advantages of reducing repeated drilling extraction of a pilot hole, shortening the construction period and improving the strength of a backfilled region behind a pressure steel pipe at the bottom of a pressure vertical shaft, and therefore the method can be widely applied to small-diameter deep vertical shaft or inclined shaft construction with a short construction period.

Owner:SINOHYDRO BUREAU 7 CO LTD

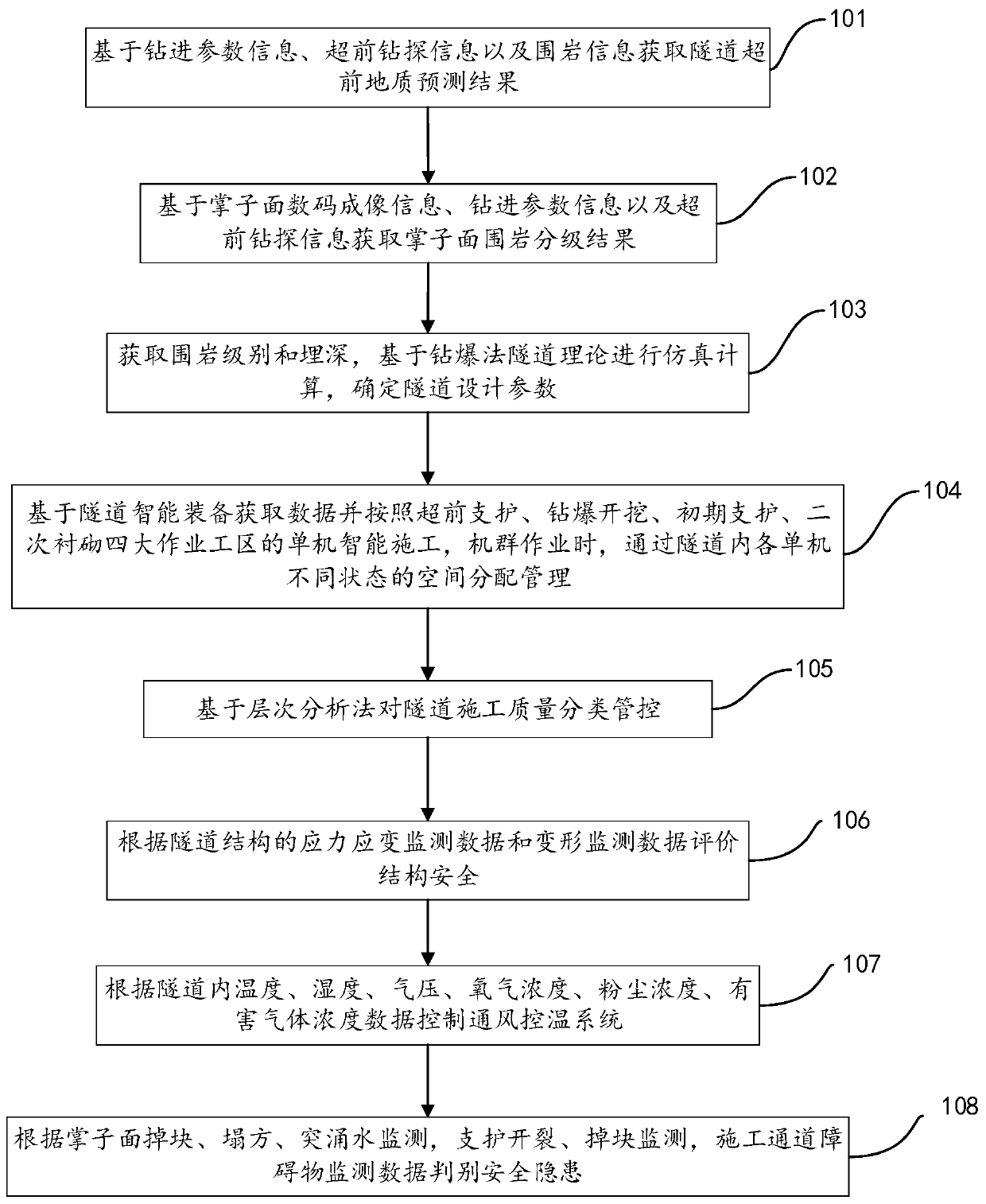

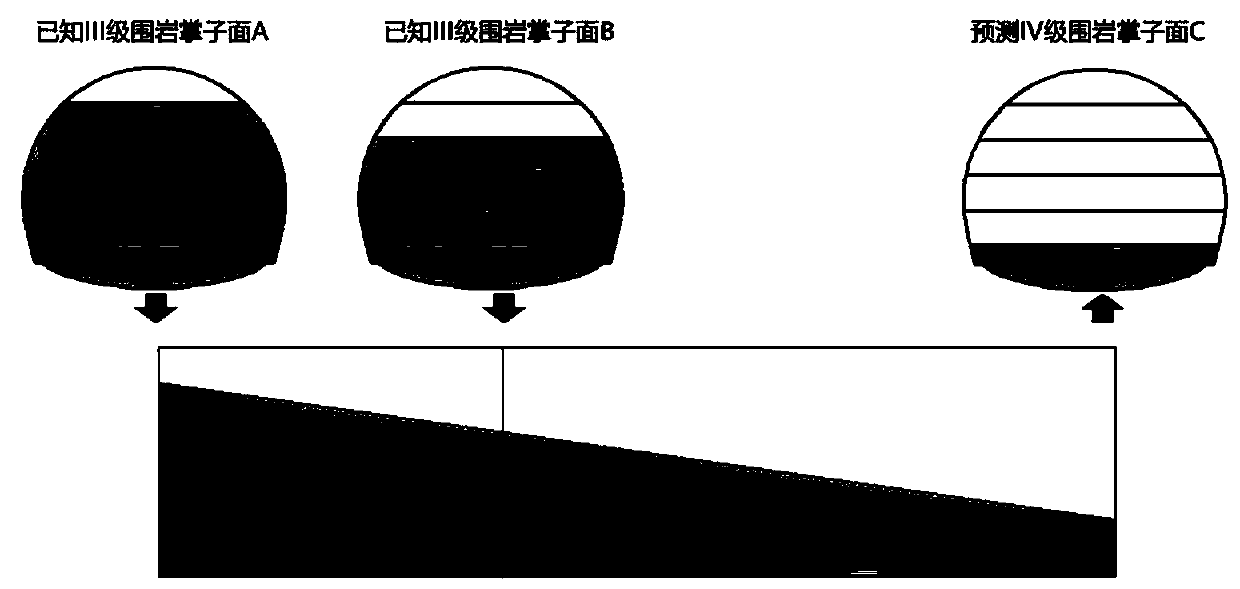

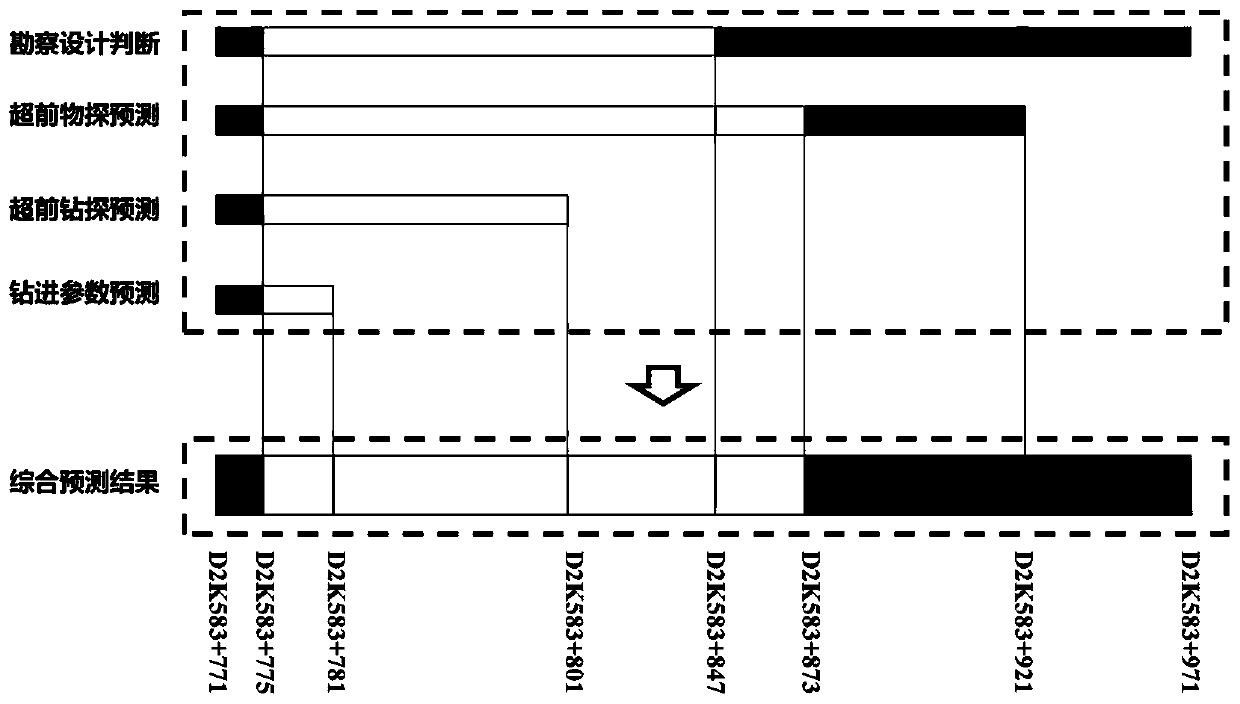

Intelligent construction method for tunnel through drilling and blasting method

InactiveCN111553000AReduce investmentImprove quality and efficiencyGeometric CADDesign optimisation/simulationArchitectural engineeringIntelligent management

The invention provides an intelligent construction method for a tunnel through a drilling and blasting method, and belongs to the field of tunnel engineering. The intelligent construction method for atunnel through a drilling and blasting method integrates a drilling and blasting method tunnel face front surrounding rock intelligent prediction method, a tunnel face surrounding rock intelligent grading method, an intelligent design method, an intelligent construction method and an intelligent construction quality control method. Intelligent prediction of surrounding rock in front of the tunnelface, intelligent grading of the surrounding rock on the tunnel face, intelligent design, intelligent construction and intelligent management and control of construction quality and efficient collaborative management are achieved; investment of constructors can be effectively reduced; construction quality and construction efficiency are improved; and potential risks in the tunnel construction process are reduced.

Owner:SOUTHWEST JIAOTONG UNIV

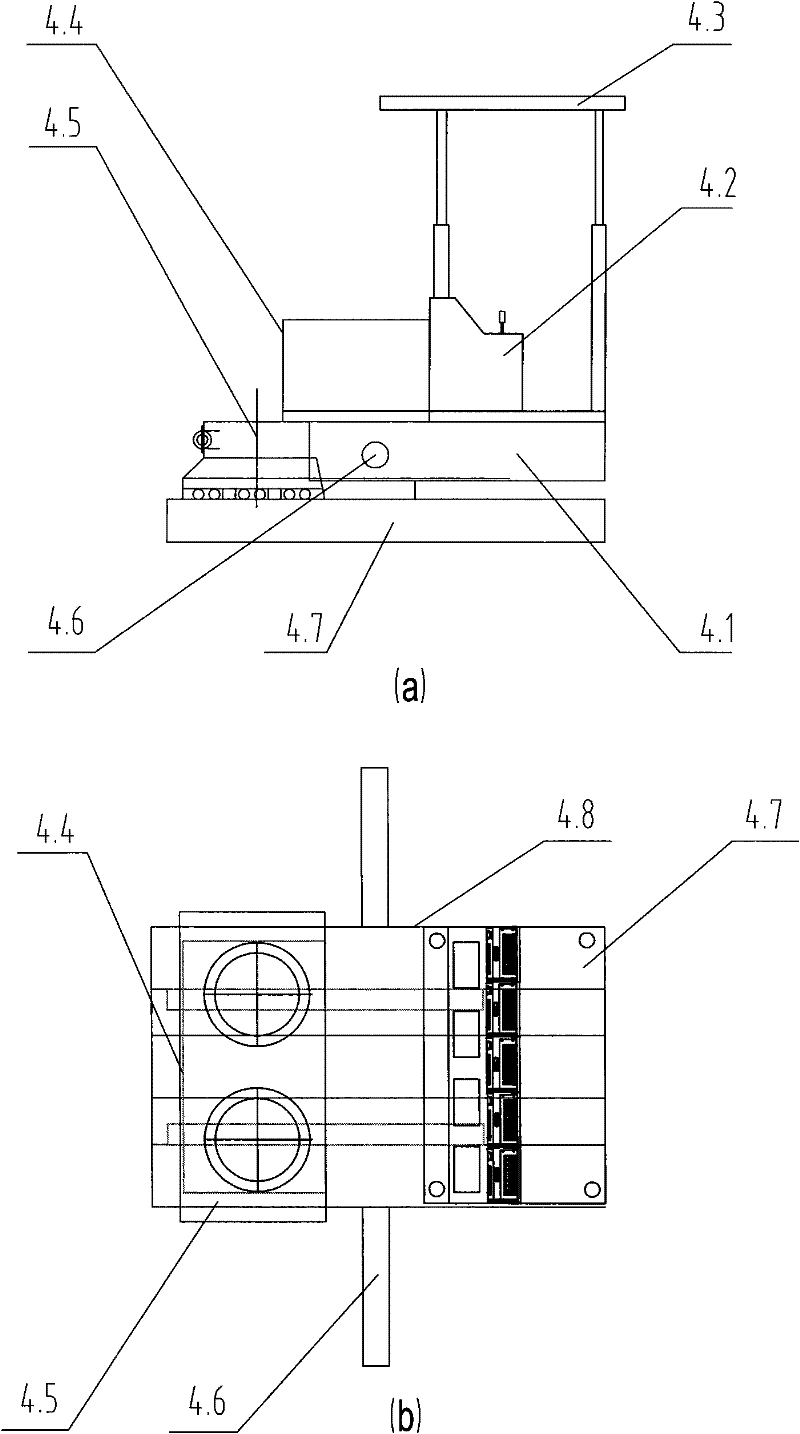

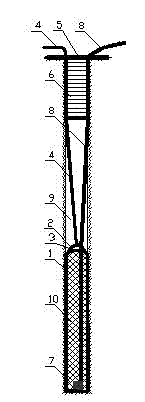

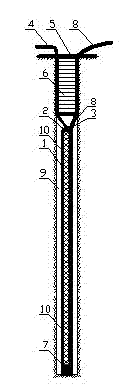

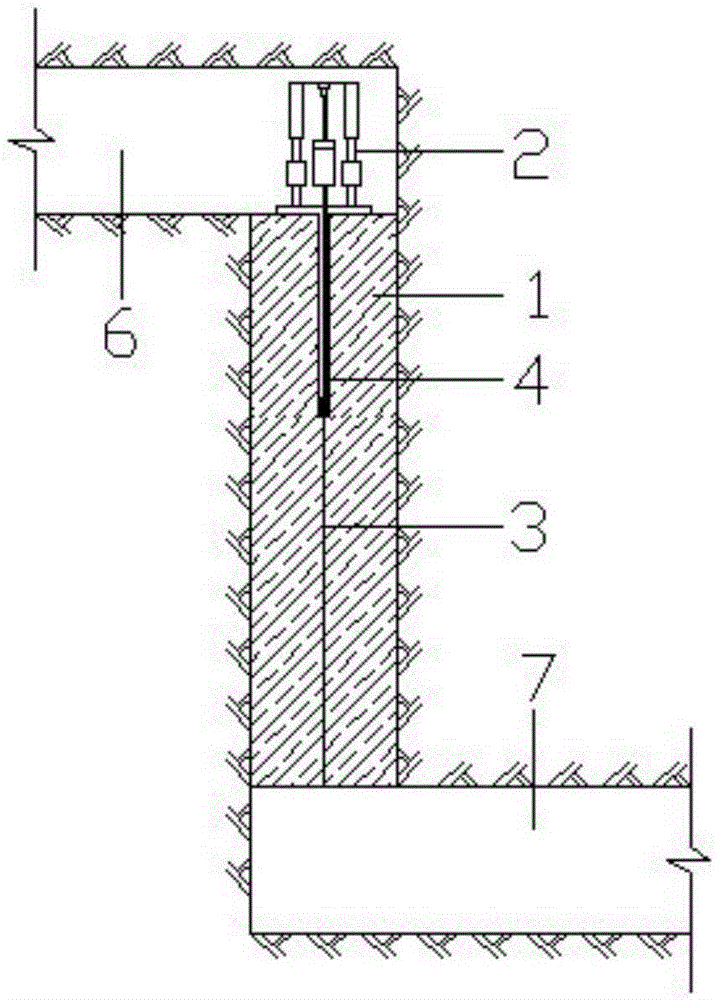

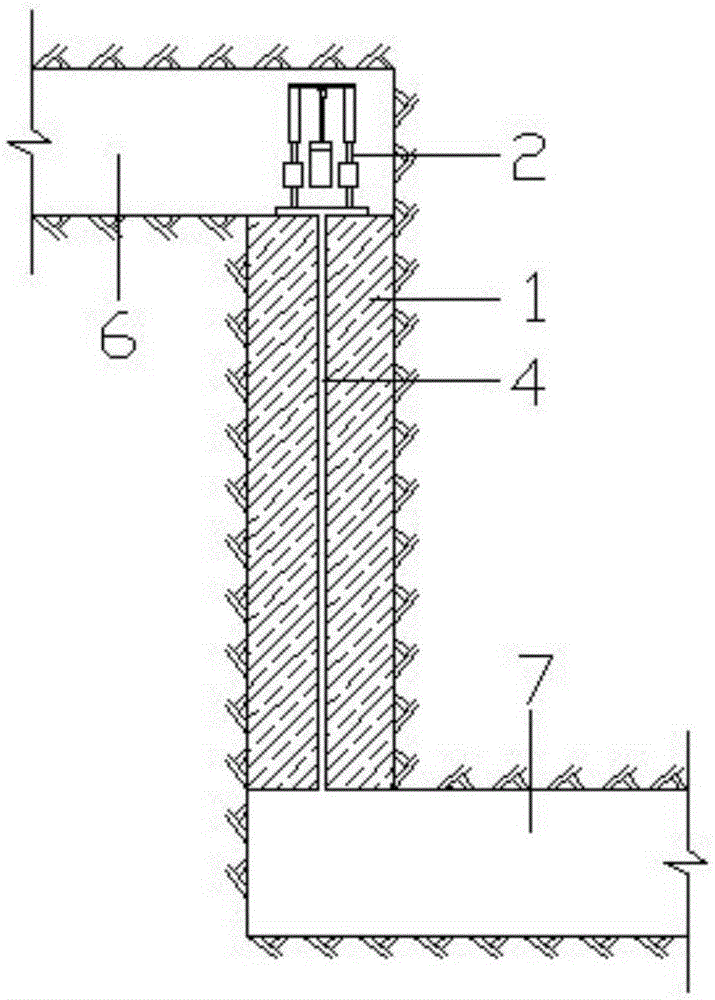

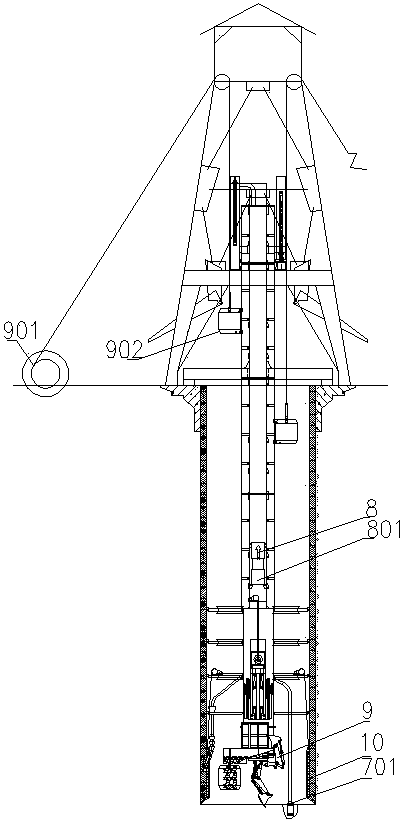

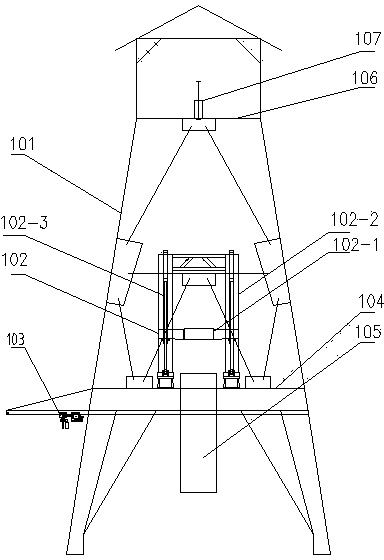

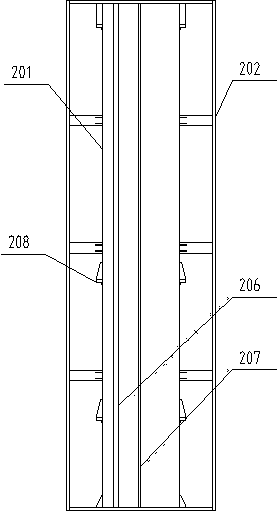

Novel drilling and blasting method vertical shaft drilling machine

The invention discloses a novel drilling and blasting method vertical shaft drilling machine. The machine mainly comprises a derrick, a numerical control umbrella drill, a loading machine, an equipment suspension system, a drainage system, a ventilation system, a slag discharge system, a shaft wall casting system, a shaft bottom hanging scaffold, a hydraulic station and a control room, wherein the equipment suspension system comprises a center vertical column, a vertical column lifting mechanism and a sealing flatcar; the center vertical column is connected with the vertical column lifting mechanism, and extends underground; the lower part of the center vertical column is connected with the shaft bottom hanging scaffold; the derrick and the sealing flatcar are mounted in a shaft mouth; the vertical column lifting mechanism is fixed and mounted on the derrick; the loading machine is mounted at the lower end of the center vertical column; the numerical control umbrella drill is mounted in the center vertical column; and the hydraulic station, the drainage system and the control room are mounted on the shaft bottom hanging scaffold. The machine adopts the reinforced derrick and the equipment suspension system, so that the equipment connection is reliable, and the construction is safer. The construction of the numerical control umbrella drill needs no shaft lifting, and is full-automatically controlled, so that the construction efficiency is improved; the slag loading efficiency of the loading machine is higher; the operation is more convenient; and the slag discharge efficiency is further improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

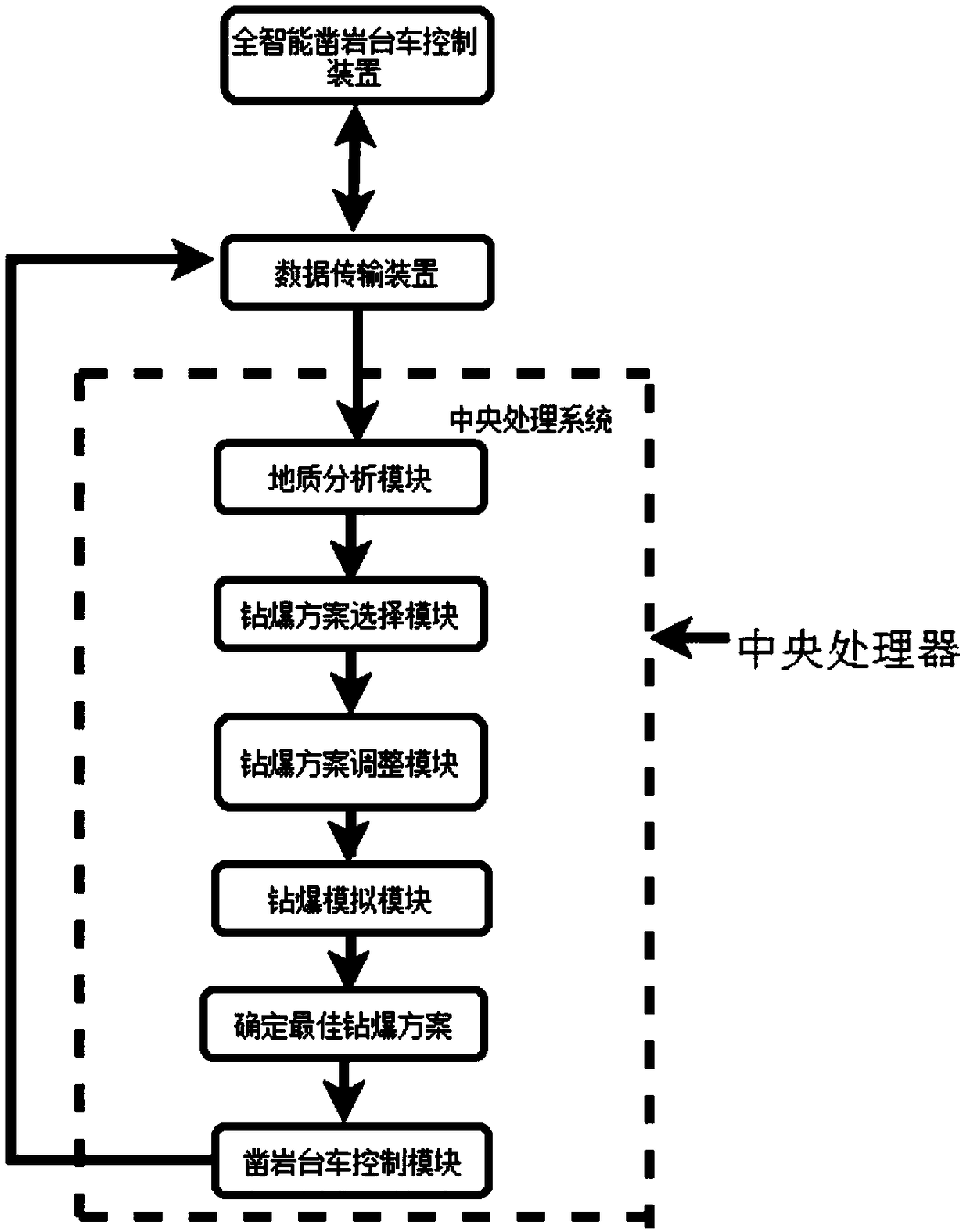

Method for overbreak-underbreak control of tunnel based on building information modeling (BIM)

ActiveCN108930539AEasy to controlRealize intelligent automation managementGeometric CADBlastingLS-DYNAComputer science

The invention discloses a method for overbreak-underbreak control of a tunnel based on building information modeling (BIM). According to the method, a full intelligent drill jumbo is connected with acentral processing unit of a user terminal, the precise positioning and multi-arm synchronous attitude adjustment of the drill jumbo are realized in the tunnel, multiple-drilling-arm automatic operation is achieved, and the peripheral contour of the tunnel and the positions of positioning boreholes are measured automatically. Geological analysis is carried out by combining advanced level drillinggeological exploration data with BIM technology analysis, according to drilling and blasting design matched with the implanted drilling and blasting design scheme, in cooperation with the constructionexperience of blasting personnel, the drilling and blasting design scheme is dynamically adjusted, and an LS-DYNA program is combined to perform drilling and blasting simulation, so that the best drilling and blasting program is formulated. The drill jumbo performs drilling according to the scheme, overbreak-underbreak is controlled strictly, and the intelligent and automatic management of personnel and machineries at a tunnel excavation construction site is realized, so that the control of overbreak and underbreak of the tunnel is achieved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

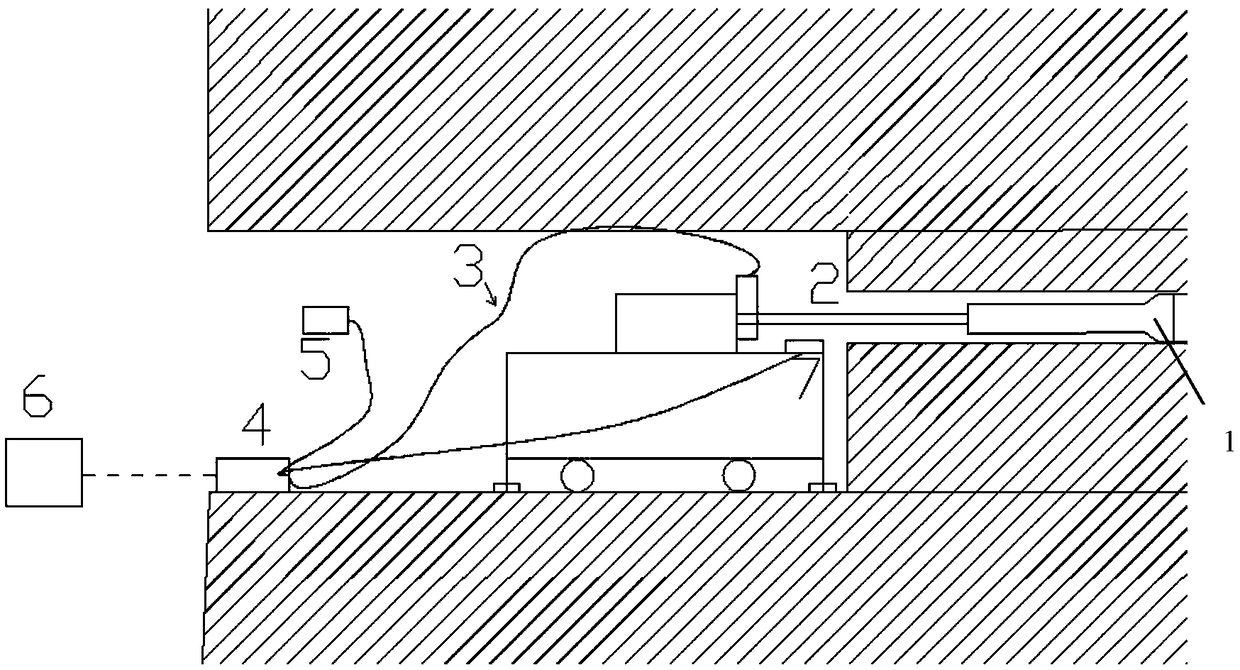

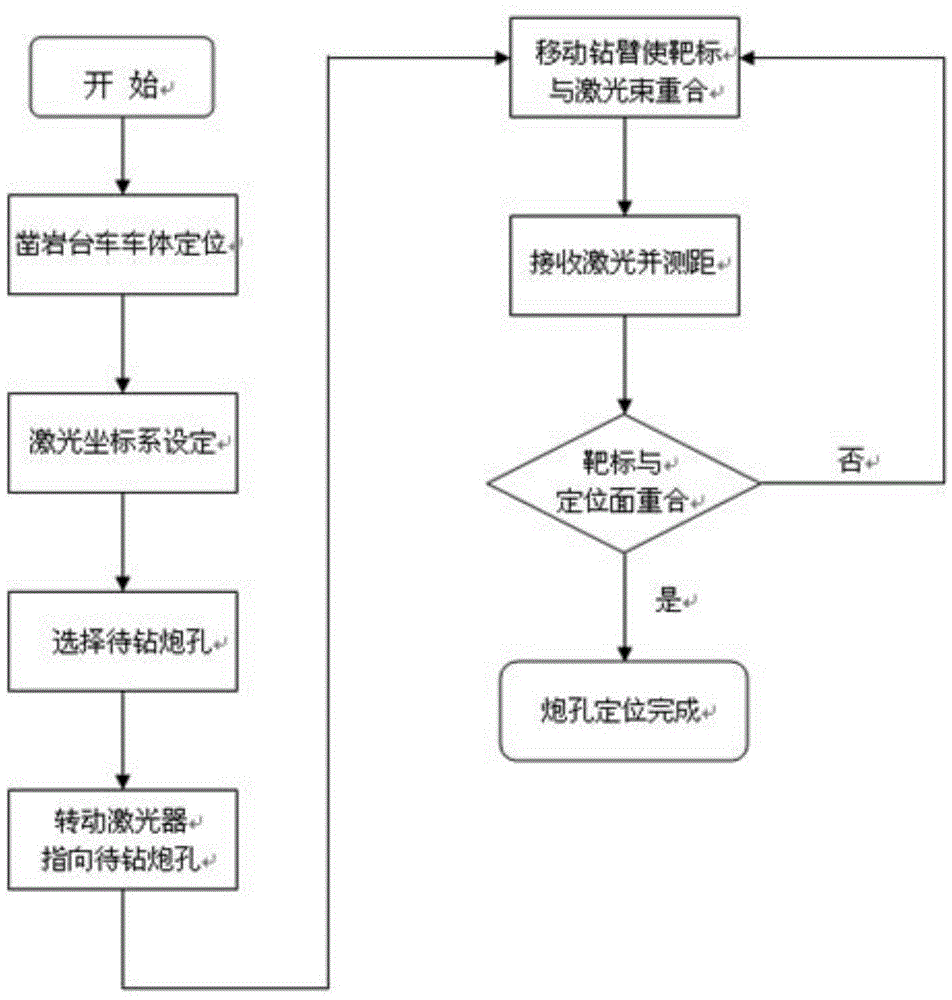

Drill jumbo blast hole laser ranging and positioning method

InactiveCN104536008APrecise positioningEasy to operateElectromagnetic wave reradiationLaser rangingLaser target

The invention belongs to the field of laser measurement and relates to a drill jumbo blast hole laser ranging and positioning method. A device used in the drill jumbo blast hole laser ranging and positioning method comprises an industrial laser ranging sensor, a laser target, a high-precision omni-directional cloud deck and a touch screen and PLC all-in-one machine. The drill jumbo blast hole laser ranging and positioning method is applied to drill jumbo blast hole positioning in a mine drilling and blasting method. The drill jumbo blast hole laser ranging and positioning method has the advantages that the positioning process is not affected by the actual fracture surface condition of a roadway, the blast hole position is accurately positioned, operation is easy, and working efficiency is high.

Owner:DALIAN UNIV OF TECH

Stress unloading, water injecting and drilling and blasting method for longitudinal structure surface structural strong rockburst regions

ActiveCN102692164AReduce the degree of energy accumulationThe degree to which energy accumulation is eliminatedBlastingTunnelsStructure of the EarthDrilling and blasting

The invention relates to a stress unloading, water injecting and drilling and blasting method for longitudinal structure surface structural strong rockburst regions. The invention aims to solve the longitudinal structure surface structural strong rockburst problem in the process of tunneling deep-buried tunnels (tunnels and roadways). The technical scheme is that the stress unloading, water injecting and drilling and blasting method for the longitudinal structure surface structural strong rockburst regions is characterized by comprising the following steps of: a, drilling a group of blast holes which are uniformly and symmetrically distributed in an excavation surface; b, cleaning the excavation surface by clean water once every 10 minutes, and filling water in each blast hole during the period; c, filling explosive at the bottom of top holes, filling the explosive at the bottom of middle holes, filling the explosive in side holes, and filling the explosive at the bottom of bottom holes; d, firstly blasting the top holes, the side holes and the bottom holes, then blasting the middle holes, and de-slagging after blasting; and e, sequentially repeating the steps a, b, c and d until the excavation surface fully penetrates through the whole longitudinal structure surface. The method is suitable for underground engineering such as hydropower engineering, traffic and mine, and is especially suitable for the longitudinal structure surface structural strong rockburst regions.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

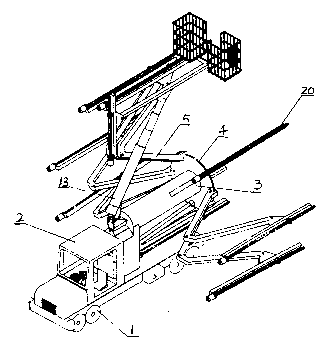

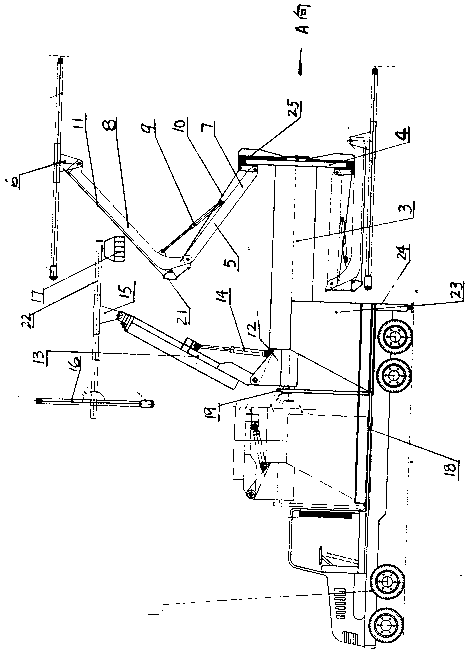

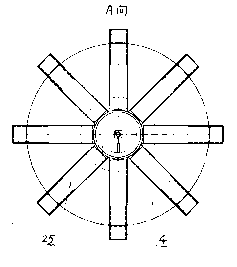

Thousand-palm compound wagon drill

ActiveCN103075098AImprove working environmentImprove efficiencyUnderground chambersTunnel liningEngineeringDrill

The invention discloses a thousand-palm compound wagon drill. A wheel type or crawler-type carrying tool is used for carrying multiple types of equipment; an engine which is used for driving the carrying tool to move and can be used for supplying power to a hydraulic device of the carrying equipment is arranged; the carrying tool is provided with a cab; a control device for the carrying equipment is arranged in the cab; a plurality of groups of drilling and blasting devices are arranged on a chassis of the carrying tool; and auxiliary attachments are arranged. The thousand-palm compound wagon drill is characterized in that: the drilling and blasting device is provided with a horizontal tube support (3) which can be moved forwards and backwards; the tube support is supported by using the chassis; one front end of the tube support is fixedly connected with a palm type end face; a plurality of groups of drill hammer drilling fingers are arranged on the palm type end face along the circumferential edge of a circular disk (4), so that supporting, positioning and propelling of a drill hammer are realized; and a rotary crane boom is arranged at the back end of the tube support, so that initial lining and spraying anchorage delivery operation of tunnels are completed.

Owner:四川千手机械科技有限公司

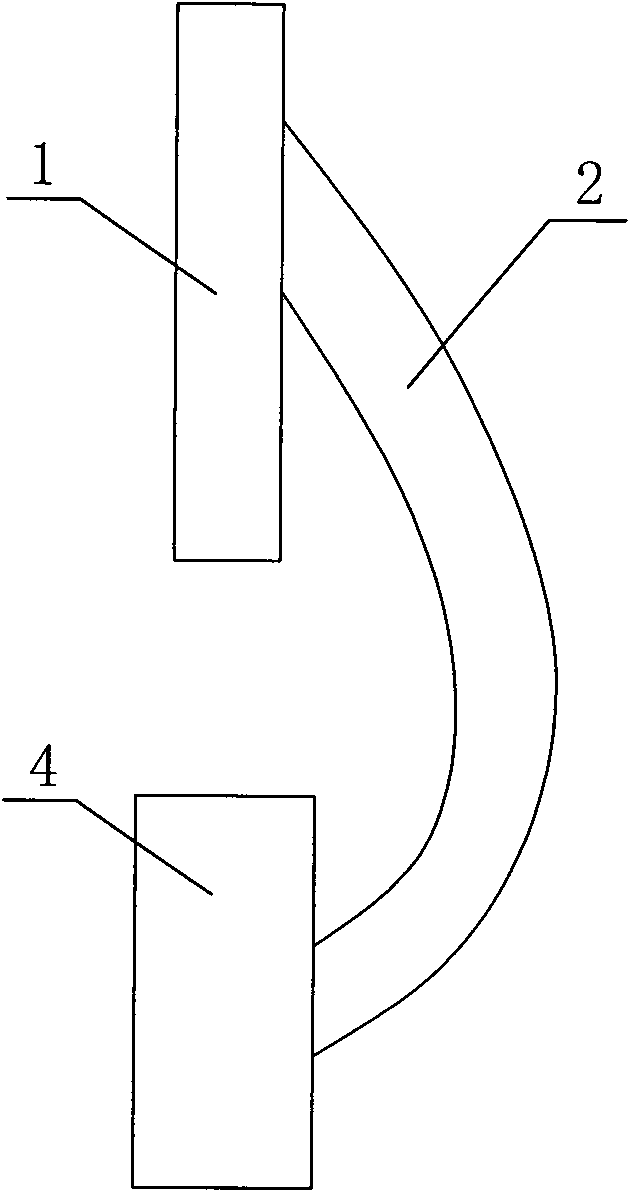

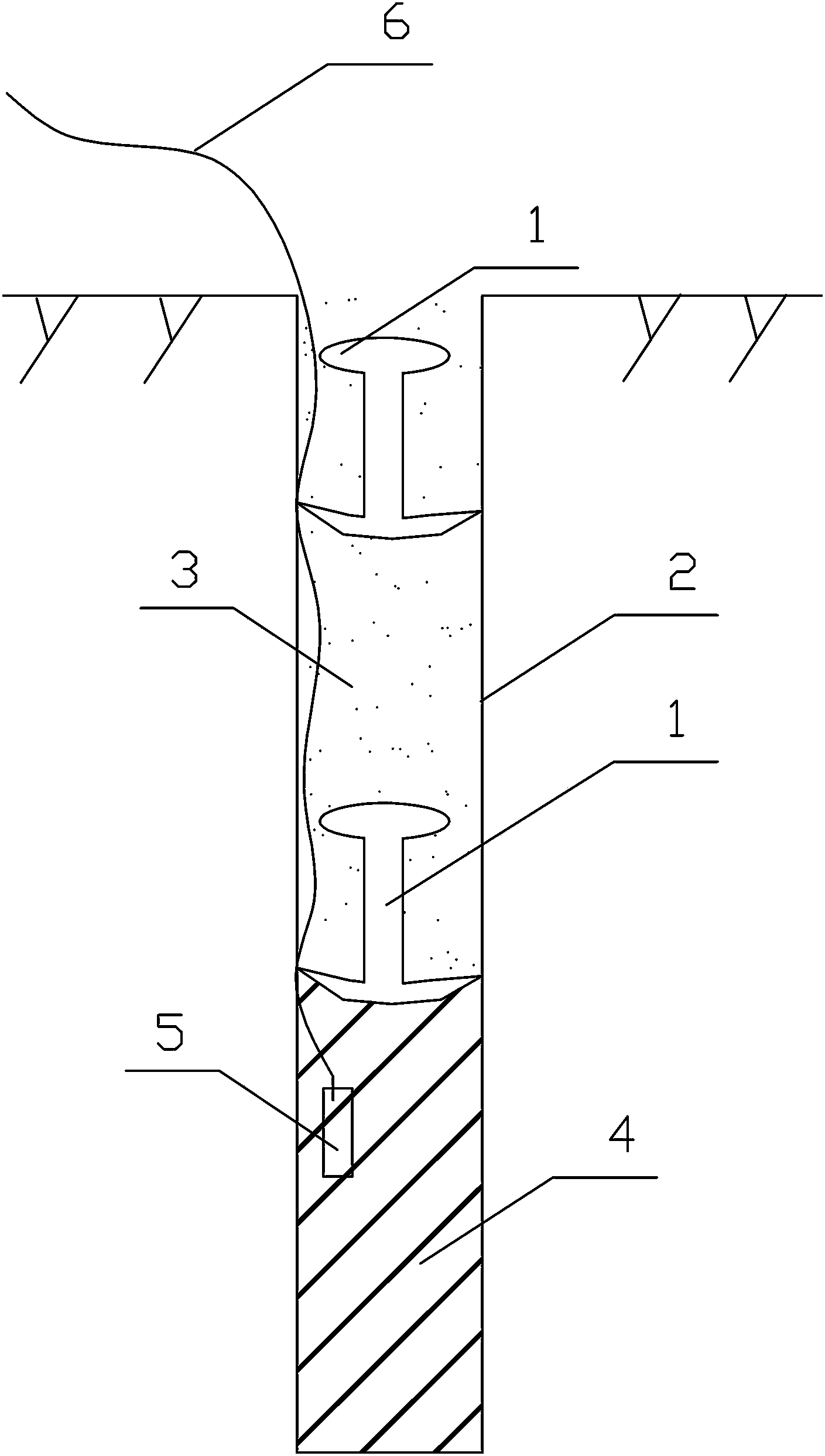

Mining method for multilayer fragile gently-inclined extra-narrow ore vein

The invention discloses a mining method for a multilayer fragile gently-inclined extra-narrow ore vein. According to the method, mining areas are divided along the ore body trend; mining area columns (5) are reserved among the mining areas; a mine slope (1) is arranged in each mining area column (5); one vein following combined roadway is arranged in the inclination direction every 20m to 40m; vein following cutting roadways (2) and cutting mine slopes (3) are excavated at the end part of a chamber in the trend direction and the inclination direction; and a first layered ore vein, a rock sandwich layer and a second layered ore vein are totally excavated in one step along the vein following cutting roadways (2) and the cutting mine slopes (3). In the backstopping process, different drilling and blasting parameters are adopted at the first layered ore vein, the rock sandwich layer and the second layered ore vein, rocks among the ore veins can be removed; the problem of ore mixing into the rocks is solved; and the ore dilution is reduced. The method provided by the invention is particularly applicable to the mining of the underground metal mine multilayer fragile gently-inclined extra-narrow ore vein and the ore vein easy to crush due to blasting disturbance; the simultaneous recovery of the multilayer ore vein is realized; and the problem of personnel operation and equipment operation space limitation is solved through full thickness mining.

Owner:河南发恩德矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com