High-accuracy global system positioning (GPS) geared drill automatic hole arrangement system

A roller cone drilling rig, high-precision technology, applied in blasting and other directions, can solve problems such as uneven bottom, harsh shovel operation environment, and unguaranteed blasting depth consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

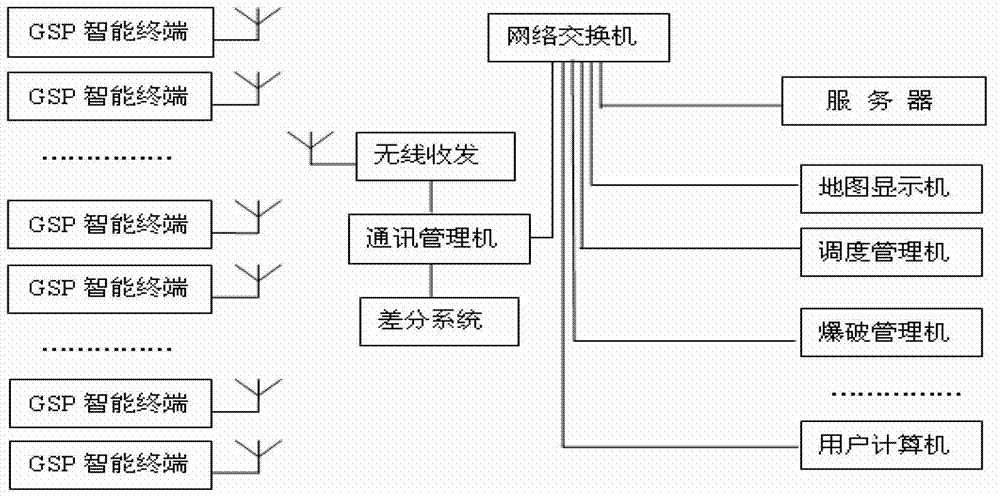

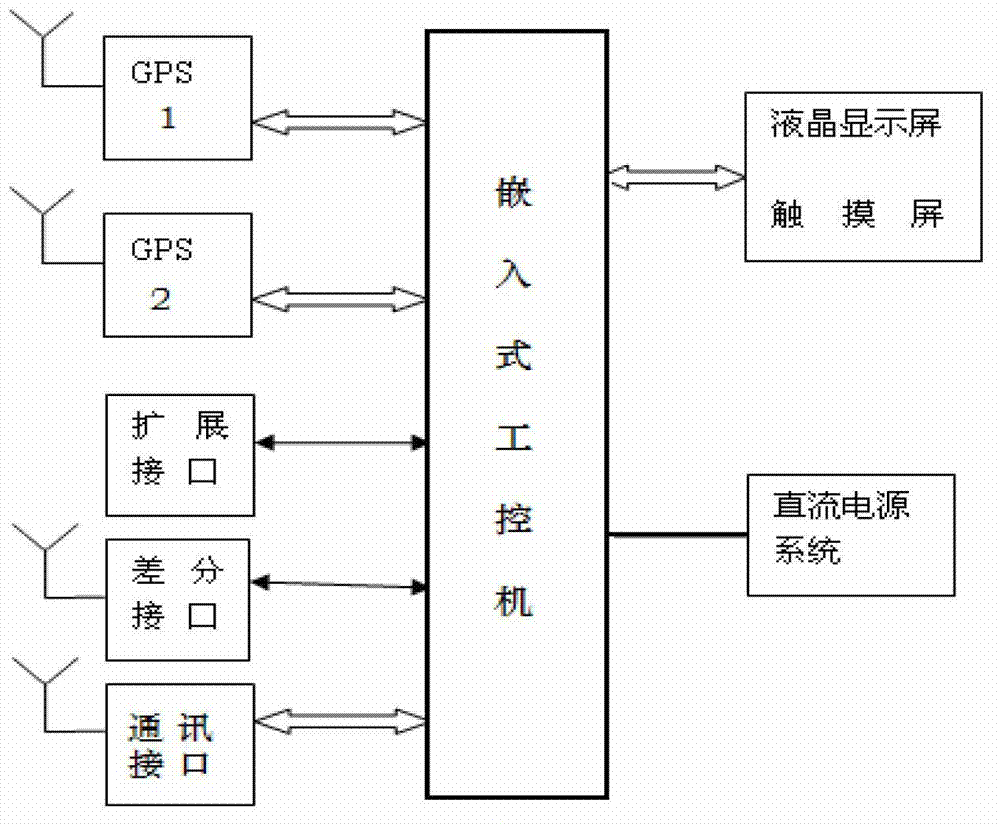

Method used

Image

Examples

Embodiment Construction

[0119] 1. Introduction to Shuichang Iron Ore of Shougang Mining Company

[0120] The system officially started operation at the Shuichang Iron Mine of Shougang Mining Company at the end of 2009. The Shuichang Iron Mine of Shougang Mining Company is located at the junction of Qian’an City and Qianxi County in Tangshan City, Hebei Province. The mining area covers an area of 19.55 km2. It was completed and put into operation in 1969. It has been continuously mined for more than 40 years, and a total of about 310 million tons of ore have been mined. Currently, the total annual mining and stripping volume is 56 million tons, the ore is 11 million tons, and the raw ore processing capacity is 18 million tons. It is one of the largest open-pit iron mines in Asia. Currently, 6 YZ-55 drilling rigs and 1 45-R drilling rig are in use.

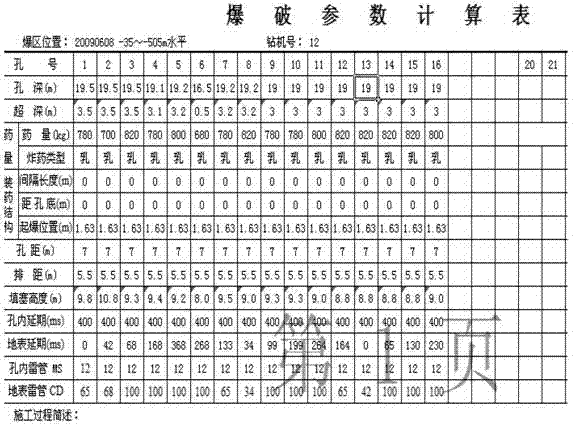

[0121] 2. Perfect and improve the existing Blast-Code computer blasting design software design

[0122] (1) Improve blasting design work

[0123] Sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com