Crack rock laneway molding control method

A cracked rock mass and control method technology, applied in the field of rock roadway excavation, can solve problems such as poor roadway formation regularity, reduced roadway smooth surface blasting quality, poor stability of roadway surrounding rock, etc., and achieve the effect of improving blasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

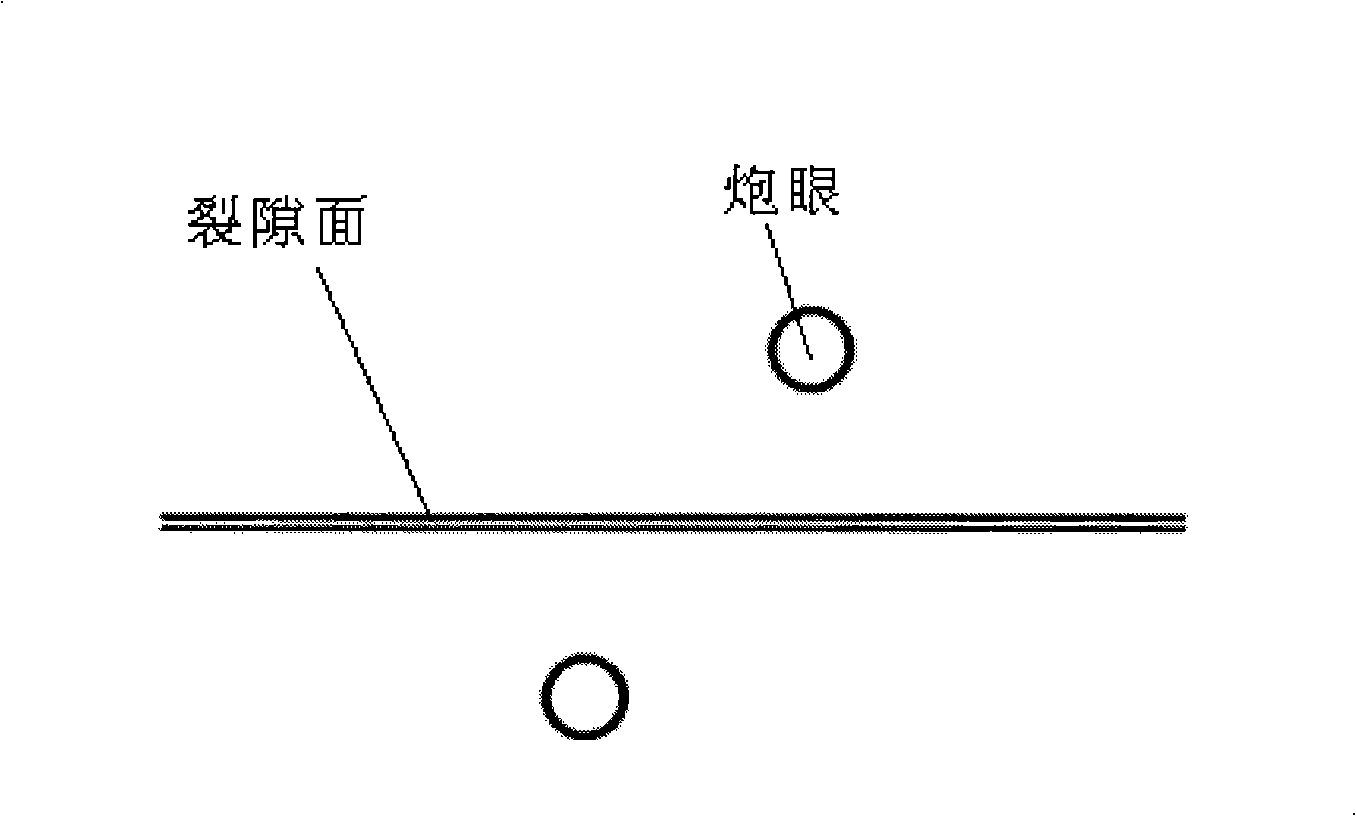

[0007] The method for controlling the formation of cracked rock mass roadway of the present invention, its preferred specific implementation is as follows figure 1 As shown, when peripheral blastholes are arranged on the working face, when the working face encounters a fracture surface, especially a relatively large fracture surface, the angle between the line connecting the two peripheral blastholes on both sides of the fracture surface and the fracture surface is 45 °~90°, may be 60°, 75°, etc., or other angles.

[0008] When laying holes around the perimeter, it is possible to arrange the blastholes symmetrically on both sides of the crack surface as far as possible to ensure the forming effect around the roadway. The symmetrical arrangement mentioned here does not refer to absolute symmetry in mathematics, but refers to the The distance from the blast hole on the side to both sides of the fracture surface is equal.

[0009] The peripheral eyes on both sides of the fractur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com