Patents

Literature

101results about How to "Improve blasting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

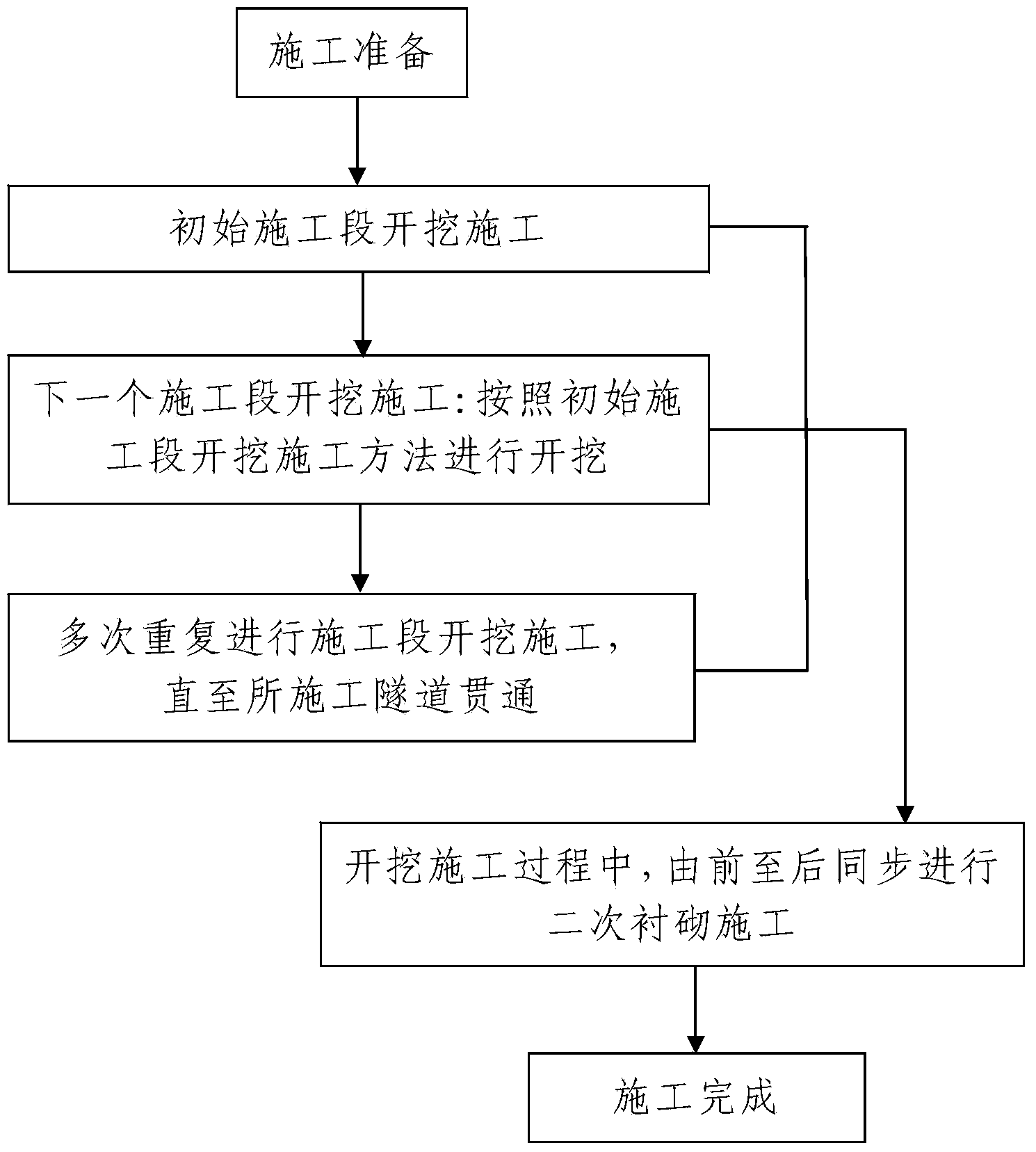

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

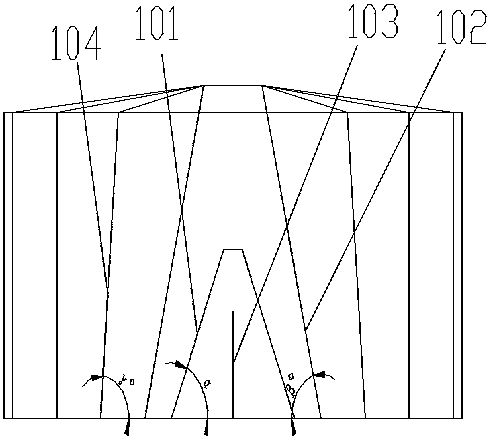

Coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure and method

InactiveCN108225137AIncrease the speed of excavationImprove energy utilizationBlastingShaped chargeStructure of the Earth

The invention relates to the field of shaped-charge water-pressure smooth blasting, in particular to a coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure and method. The coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure is characterized in that rock breaking holes are formed in the center line of a section of a rock roadway; cutting holes are symmetrically formed in two sides of the rock breaking holes; secondary cutting holes are formed in one side of the cutting holes; tertiary cutting holes are formed in one side ofthe secondary cutting holes; auxiliary holes are formed in one side of the tertiary cutting holes; peripheral holes are formed in the outer sides of the auxiliary holes; and bottom holes are formed inthe bottoms of the peripheral holes. The invention further provides the coalmine rock roadway excavation shaped-charge water-pressure smooth blasting method. Through the coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure and method provided by the invention, the big rock occurrence ratio can at least be obviously reduced; the coalmine rock roadway excavation speed can be improved by adoption of shaped-charge water-pressure blasting; and meanwhile, the explosive energy utilization ratio can be improved, the smooth blasting quality can be improved, and underground blasting dust can be efficiently reduced.

Owner:HENAN SUNHO COAL & POWER CO LTD

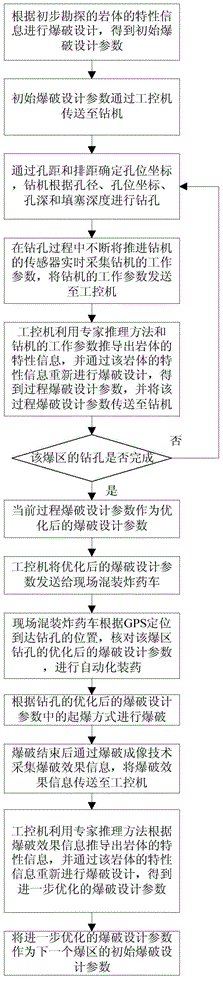

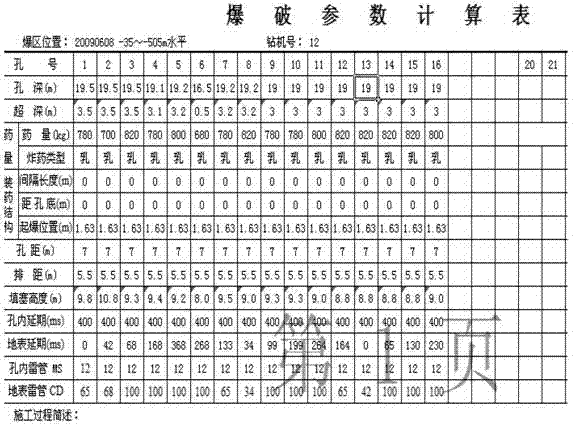

Digitized surface blasting operation method

ActiveCN104596371AEliminate the problem that the blasting quality cannot be guaranteedLow costBlastingBlast effectsEngineering

The invention relates to a digitized surface blasting operation method. The digitized surface blasting operation method includes the following step that according to preliminarily explored rock mass characteristic information, a blasting design is conducted, and an initial blasting design parameter is obtained; according to the initial blasting design parameter, drilling is conducted, during the drilling process, working parameters of a driller are constantly collected, and an industrial personal computer utilizes a specialist inference method and the working parameters of the driller to deduce rock mass characteristic information; according to the rock mass characteristic information, blasting is redesigned, and a process blasting design parameter is obtained; according to the process blasting design parameter, the drilling continues to be conducted, and the processes are repeated until the drilling is finished; according to an optimized blasting design parameter, blasting is conducted, blasting effect information is collected through a blasting imaging technology after the blasting is finished, the industrial personal computer utilizes the specialist inference method to deduce rock mass characteristic information based on the blasting effect information, the blasting is redesigned, and a further optimized blasting design parameter is obtained and taken as an initial blasting design parameter of a next blasting area.

Owner:SHANXI JIANGYANG ENG BLASTING CO LTD

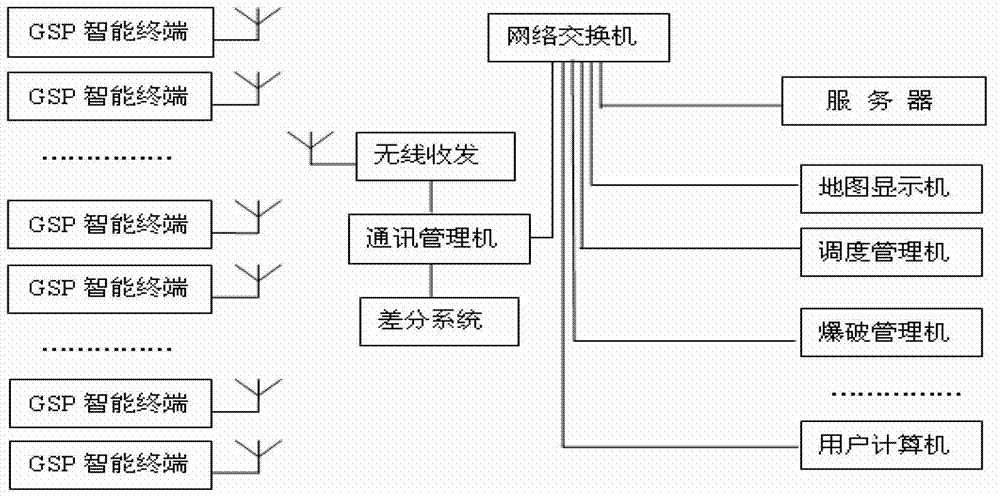

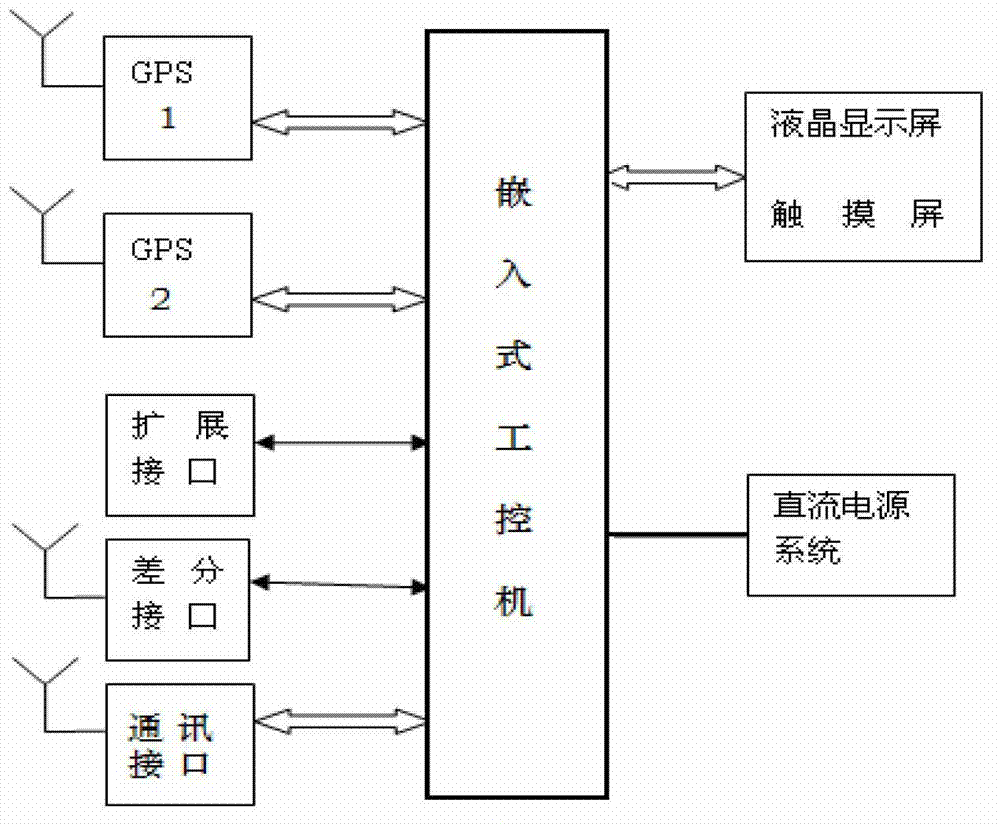

High-accuracy global system positioning (GPS) geared drill automatic hole arrangement system

ActiveCN102927865AGuaranteed horizontal positioning accuracyImprove blasting qualityBlastingComputer terminalDouble frequency

The invention provides a high-accuracy global system positioning (GPS) geared drill automatic hole arrangement system and belongs to the technical field of open-cast mining digitization drilling and blasting. The high-accuracy GPS geared drill automatic hole arrangement system comprises an intelligent terminal, a double-frequency GPS module, a GPS differential station, a computer network and a terminal computer of a scheduling control center, a GPS differential station, intelligent terminal host computer software and scheduling control center software. The high-accuracy GPS geared drill automatic hole arrangement system has the advantages of eliminating various factors which are hidden and uncontrollable and influence drilling and blasting quality in traditional drilling and blasting process, high and new technology available now is used to improve traditional process, and therefore refine course management and digital control course are achieved.

Owner:BEIJING SOLY TECH

Back break control method for tunnel

ActiveCN110132084AImprove blasting qualityImprove blasting effectBlastingTunnelsStructure of the EarthEngineering

The invention provides a back break control method for a tunnel. The method comprises the following steps: first, further optimizing original blasting parameters according to a surrounding rock condition determined by advance geology forecast and construction site investigation; then letting out a hole distributing position accurately according to the optimized blasting parameters; and finally, drilling, cleaning the hole, and charging an explosive, and connecting a detonating network to blast. The blasting parameters of an excavated smooth face of a conventional stone tunnel is optimized according to the type of the surrounding rock determined jointly by advance geology forecast combined with construction site investigation around by finely adjusting the drilling parameter and the charging structure by means of existing common materials such as a fire work material and a water bag, so that the blasting quality of full face excavation of the tunnel is improved, a back break phenomenonin conventional full face blasting of the tunnel is reduced to the maximum extent, and targets that the blasting effect is good, the quality safety is guaranteed, the construction cost is controlled effectively and the steps are circular and convenient in sandy slate tunnel excavation penetrating a belt of folded strata are achieved.

Owner:陕西路桥集团有限公司

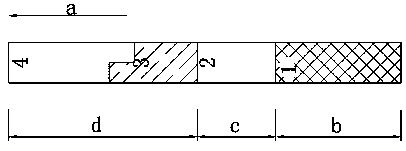

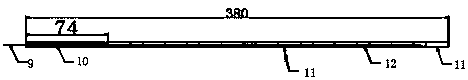

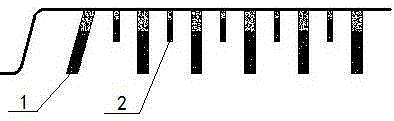

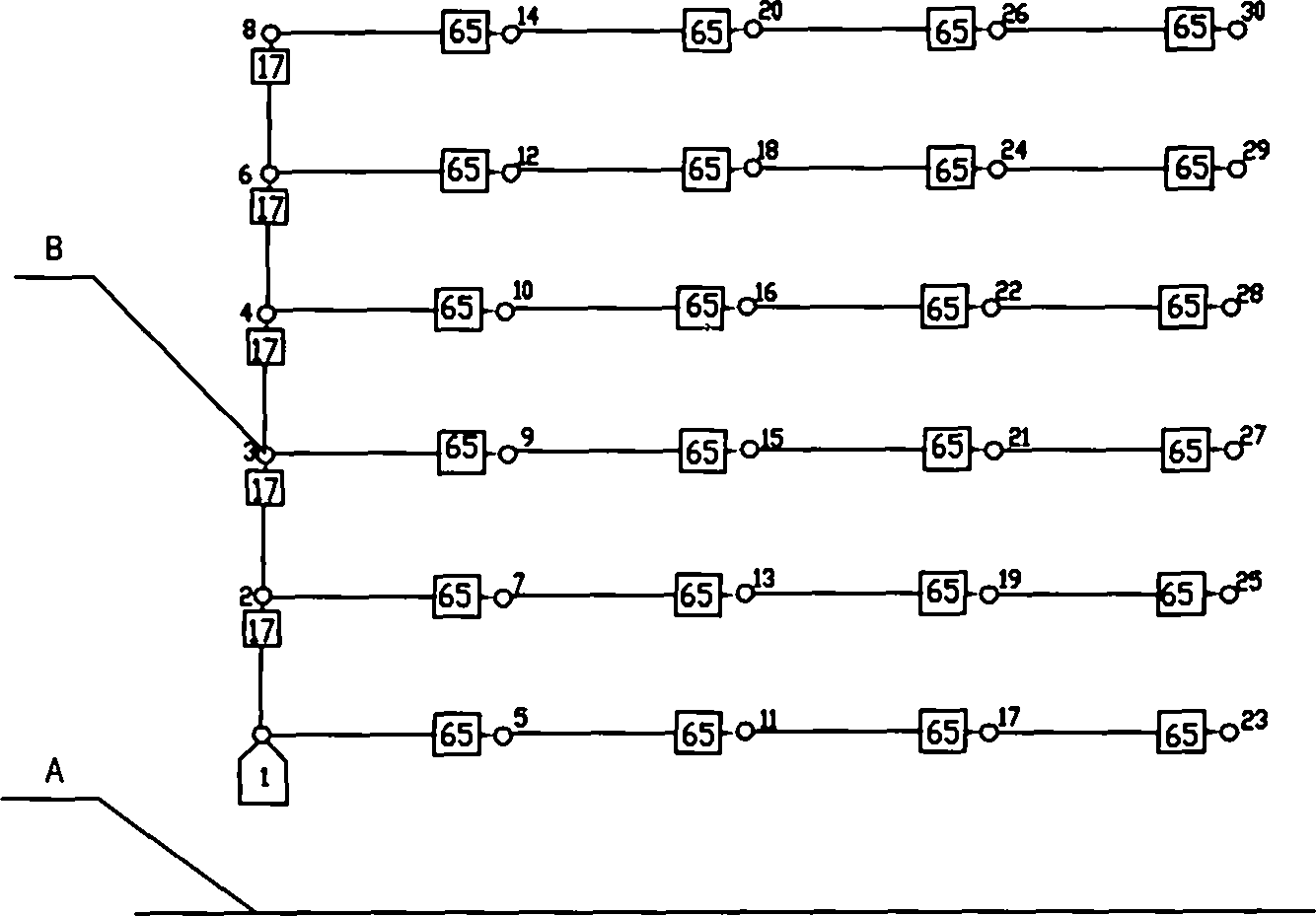

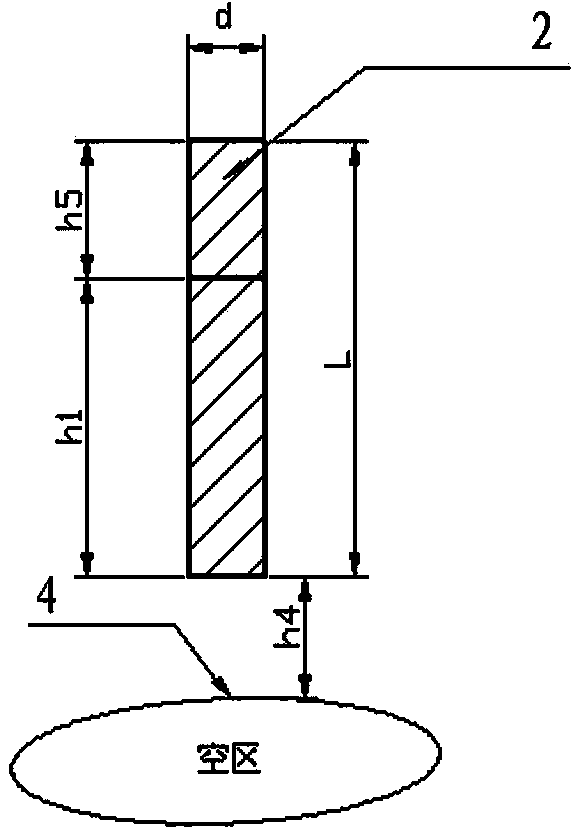

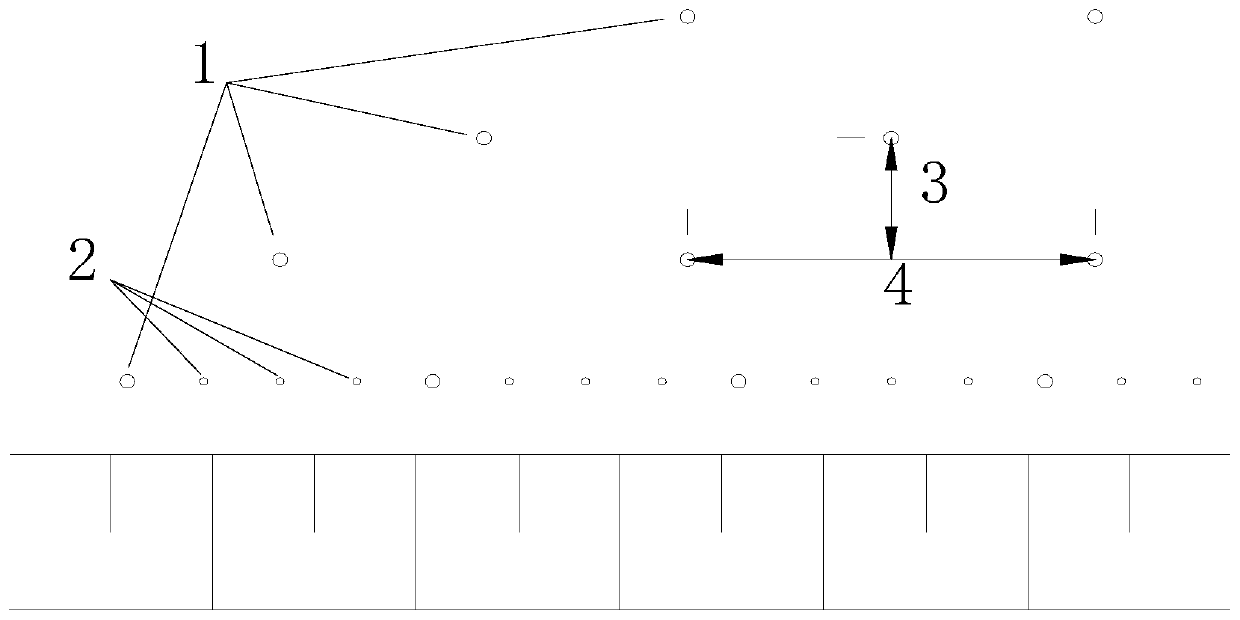

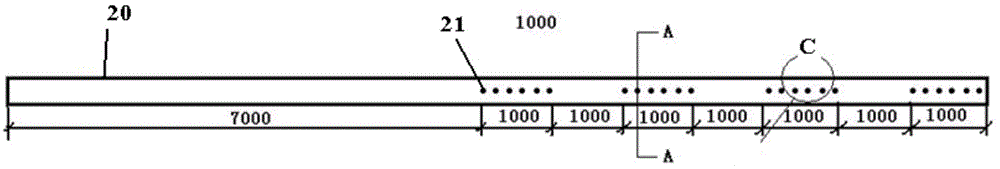

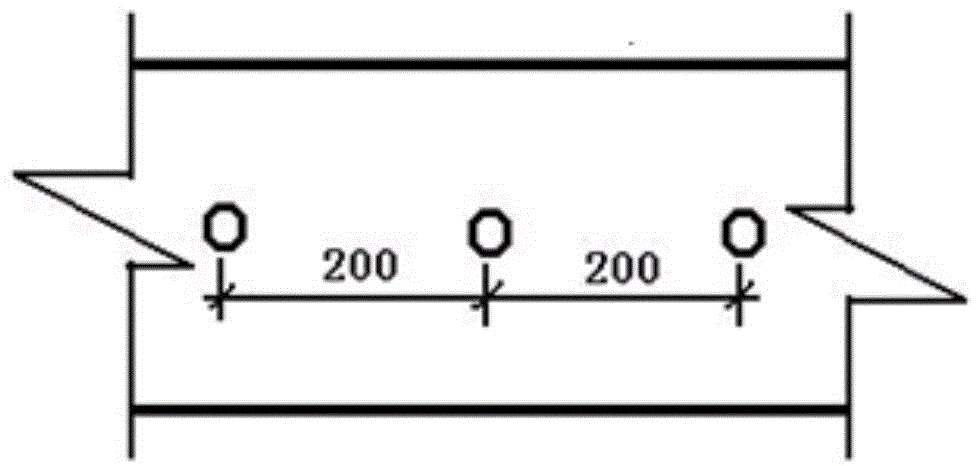

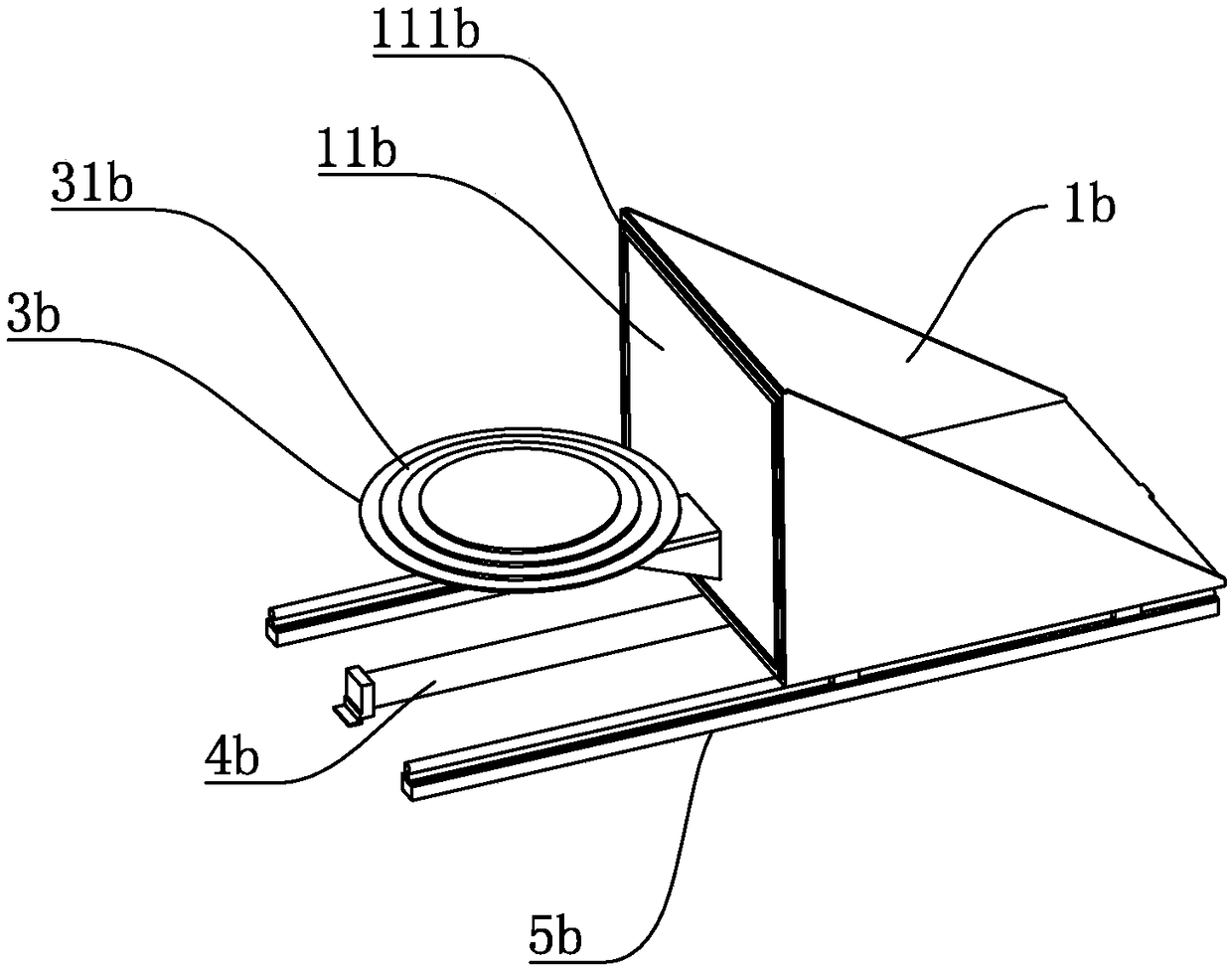

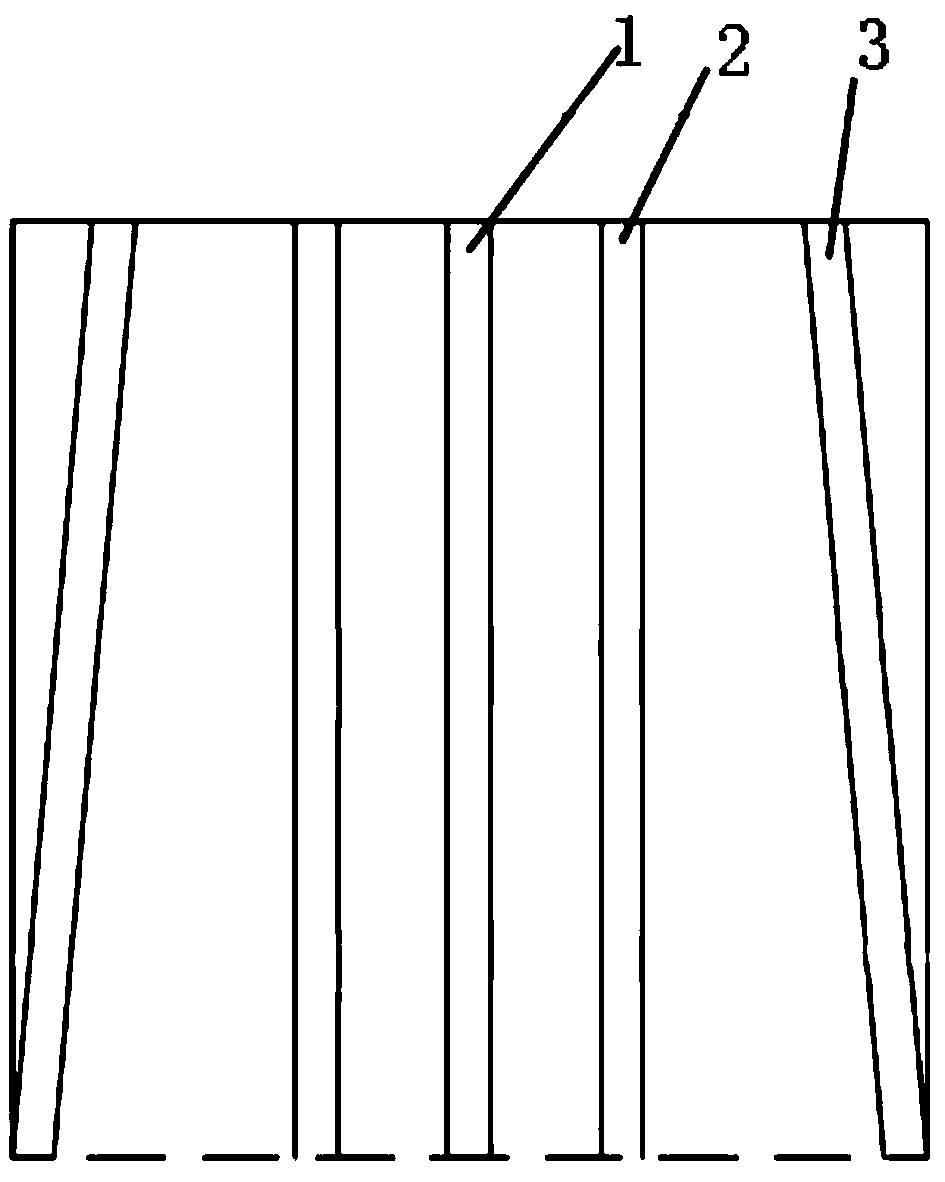

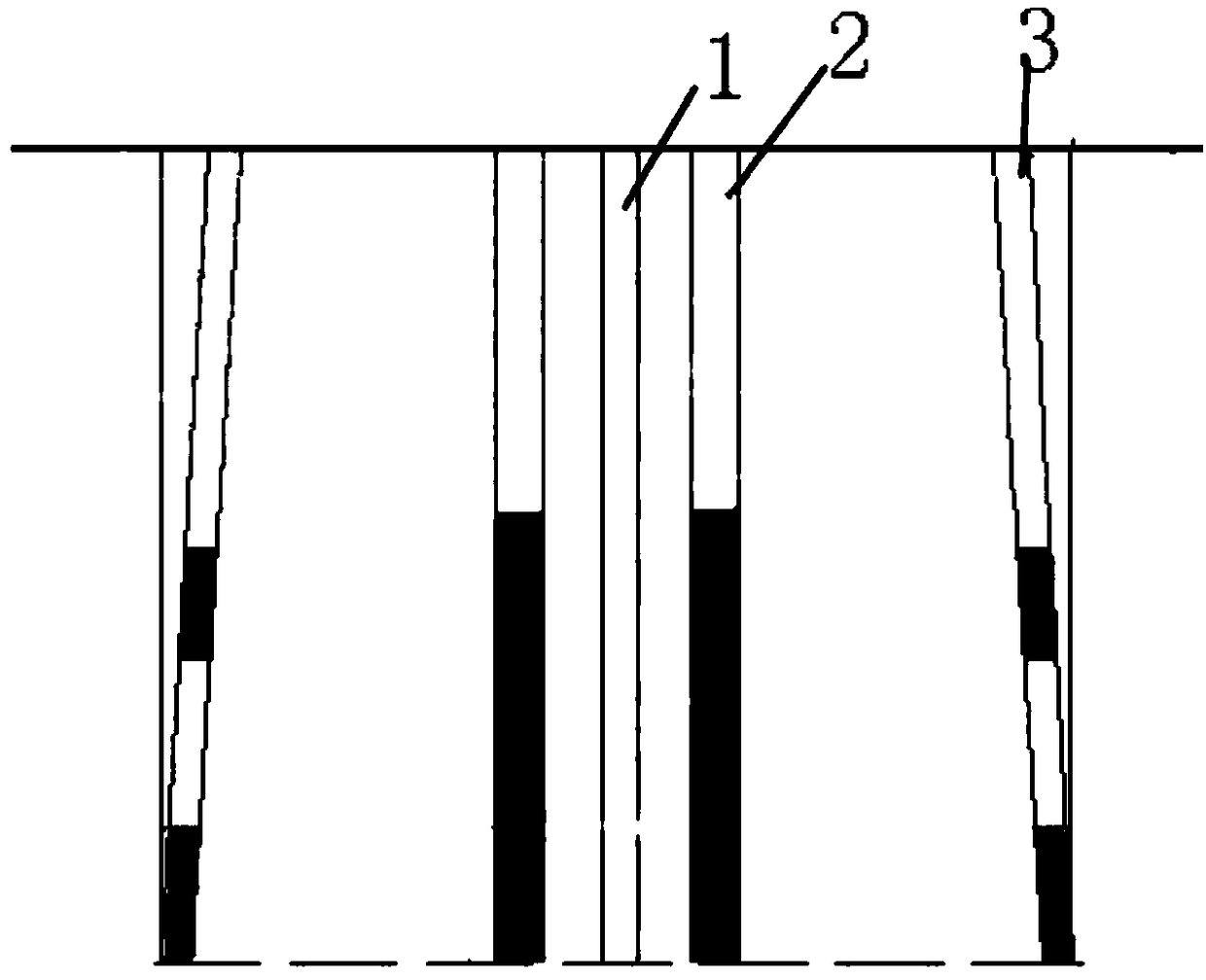

Blasting method capable of improving step deep-hole blasting quality by using auxiliary blasthole

The invention belongs to the technical field of blasting methods, and particularly relates to a blasting method capable of improving step deep-hole blasting quality by using an auxiliary blasthole, which comprises the following steps: determining the auxiliary blasthole, determining the depth of the auxiliary blasthole, selecting different explosives for the blasthole, and determining the detonation mode. The auxiliary blasthole 2 is arranged between the deep-hole blastholes, thereby solving the problem of overhigh bulk rate on the step upper part due to the overhigh blasthole blockage length, overlow charging center of gravity and other conditions in production. The vertical blasthole-oblique blasthole combination mode is adopted to effectively improve the blasting quality on the premise of not influencing the perforation-blasting combined efficiency. According to the principle that the diameter of the blasthole should be approximate to or slightly greater than the limit diameter of the explosive, different explosives are selected for the auxiliary blasthole 2 and main blasthole 1, thereby creating ideal detonation conditions for the explosives and enhancing the energy utilization efficiency of the explosives.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

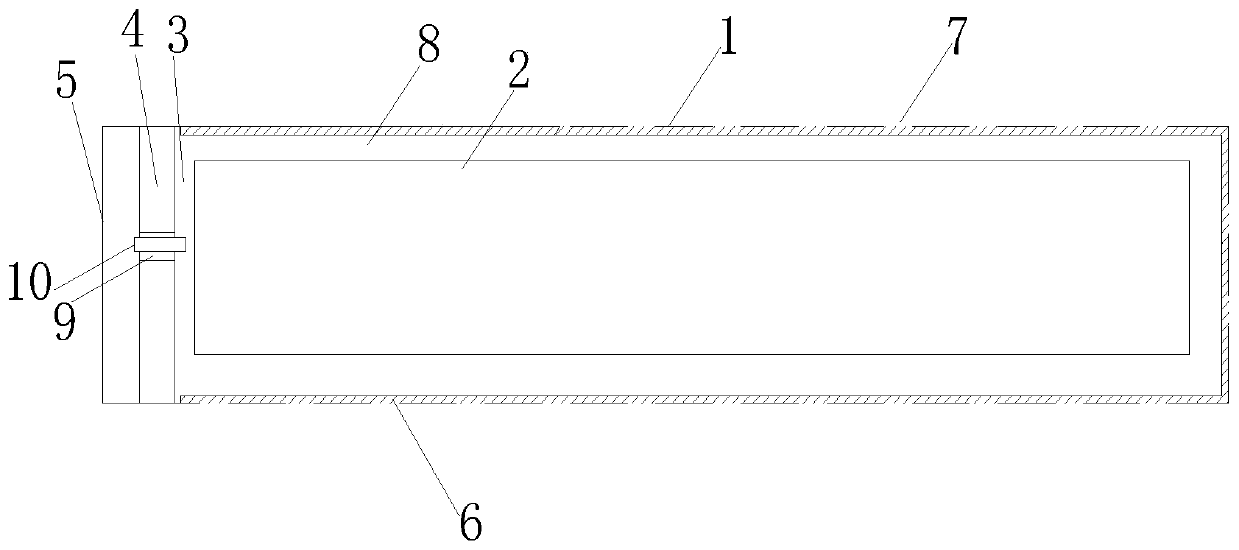

Sand blasting machine

ActiveCN106078533AAdjustable angleAccurate in and outBlast gunsAbrasive feedersSand blastingSpray nozzle

The invention discloses a sand blasting machine, which comprises a sand blasting chamber. The sand blasting chamber comprises a feeding hole for feeding and discharging workpieces, and spray nozzles arranged in the sand blasting chamber; the spray nozzles are fixed on a spray nozzle drive mechanism; a feeding mechanism capable of driving the workpieces to feed and discharge is matched on the feeding hole; the spray nozzle drive mechanism comprises at least one swinging mechanism arranged in the sand blasting chamber; each swinging mechanism is provided with one spray nozzle and is driven by a first drive part to swing to the left and right; the feeding mechanism comprises a placement platform used for placing workpieces and a second drive part; and the placement platform comprises at least one positioning table used for placing the workpieces, and a sealing plate arranged behind the positioning table and matched with the feeding hole of the sand blasting chamber. A plurality of swinging mechanisms are arranged in the sand blasting chamber, and a plurality of spray nozzles can swing to blast sand on the workpieces when being used for blasting sand, so that a uniform and efficient sand blasting effect is realized; and in addition, the workpieces can be quickly fed and discharged in the sand blasting chamber through the feeding mechanism, so that the sand blasting efficiency of the workpieces is further improved.

Owner:宁波精益微型轴有限公司

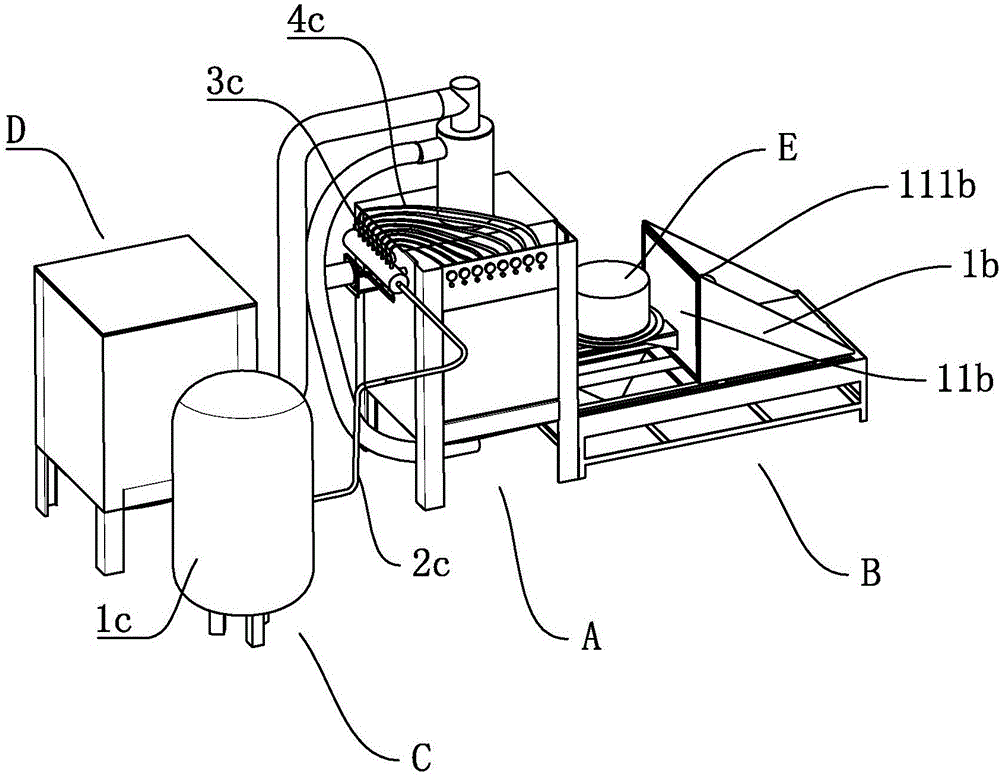

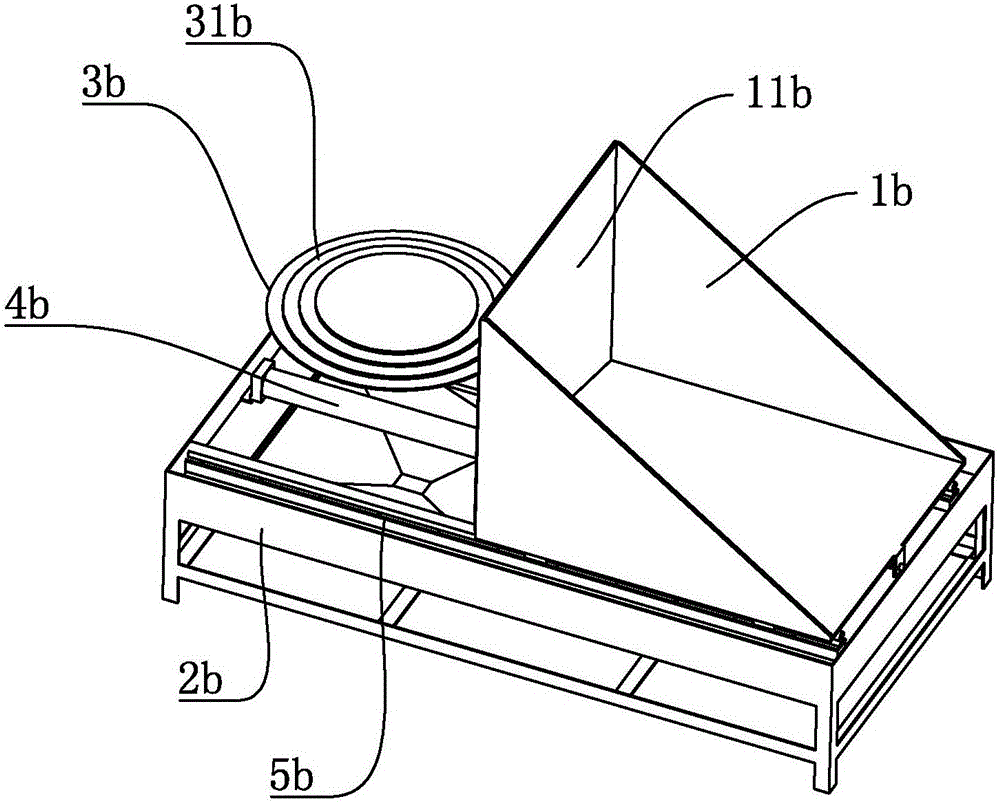

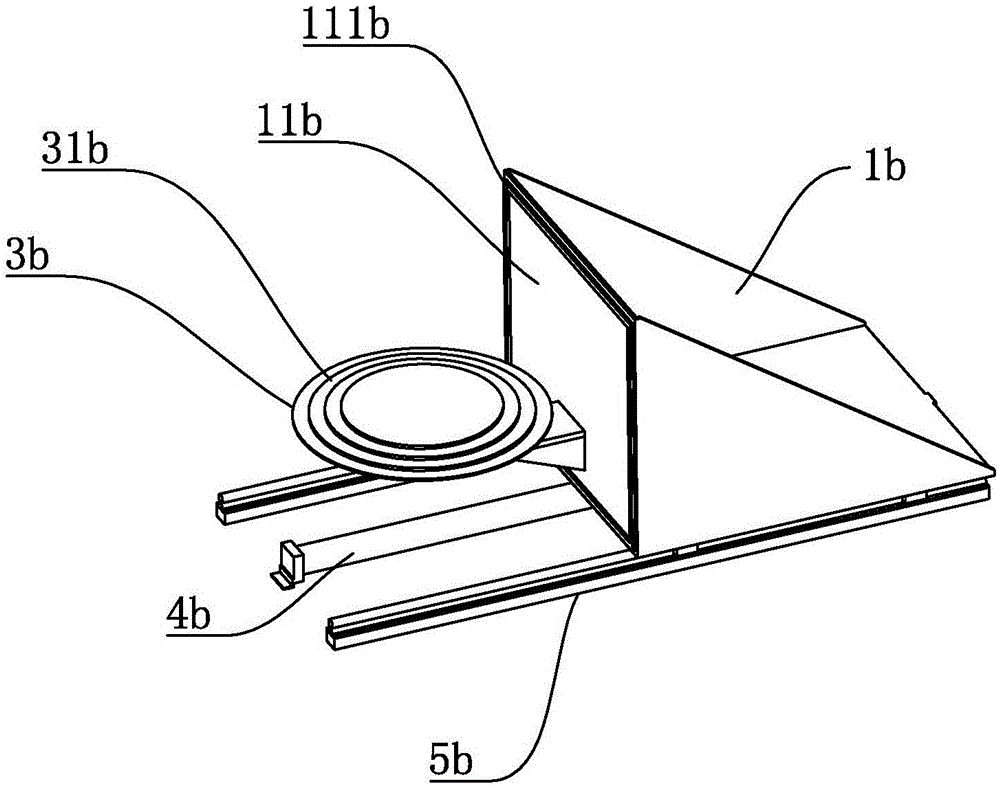

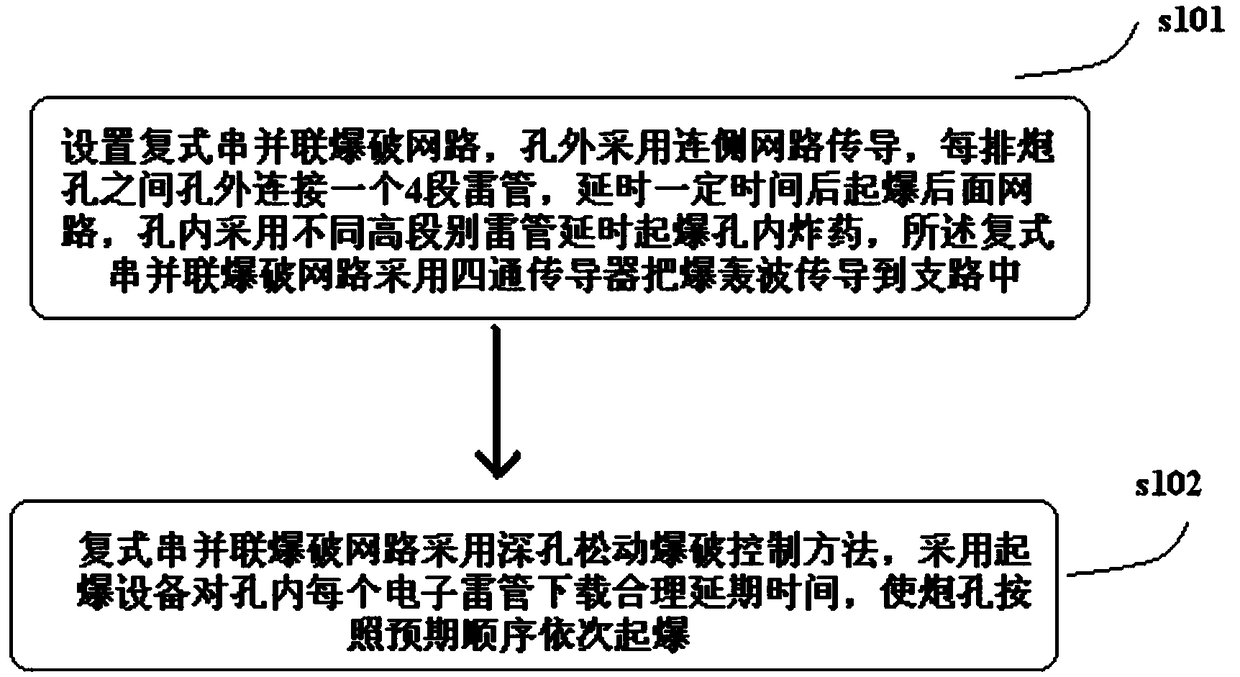

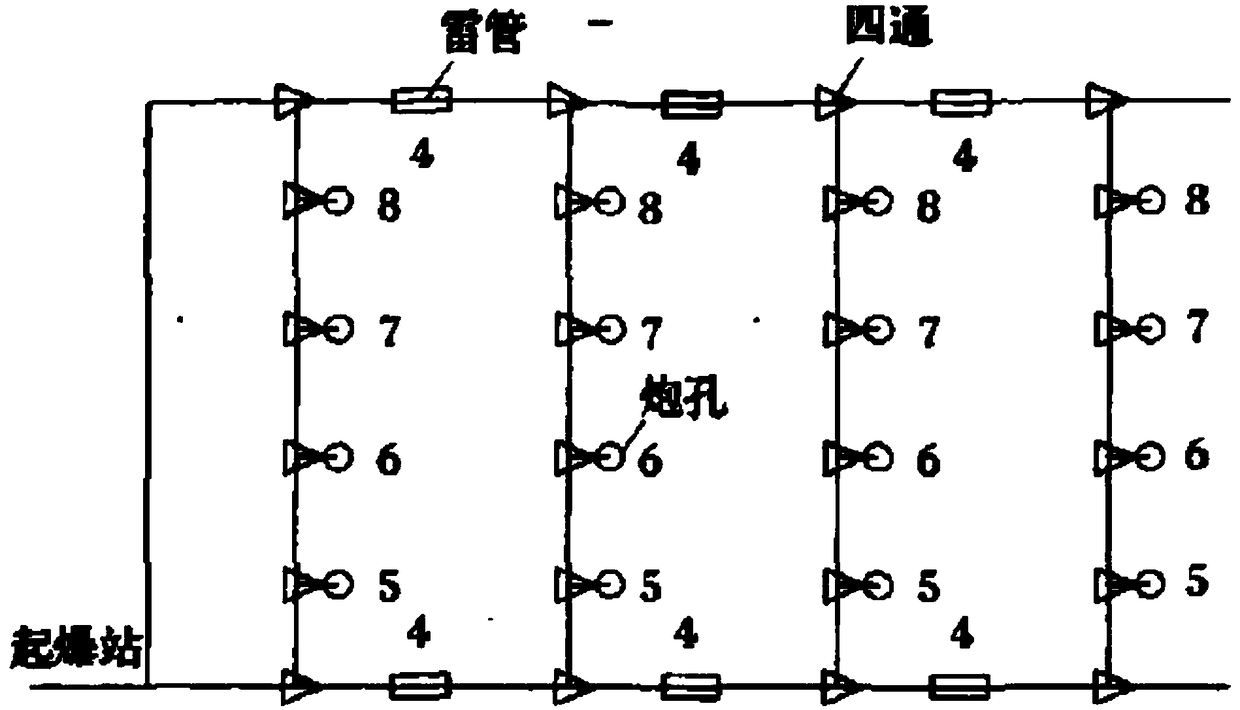

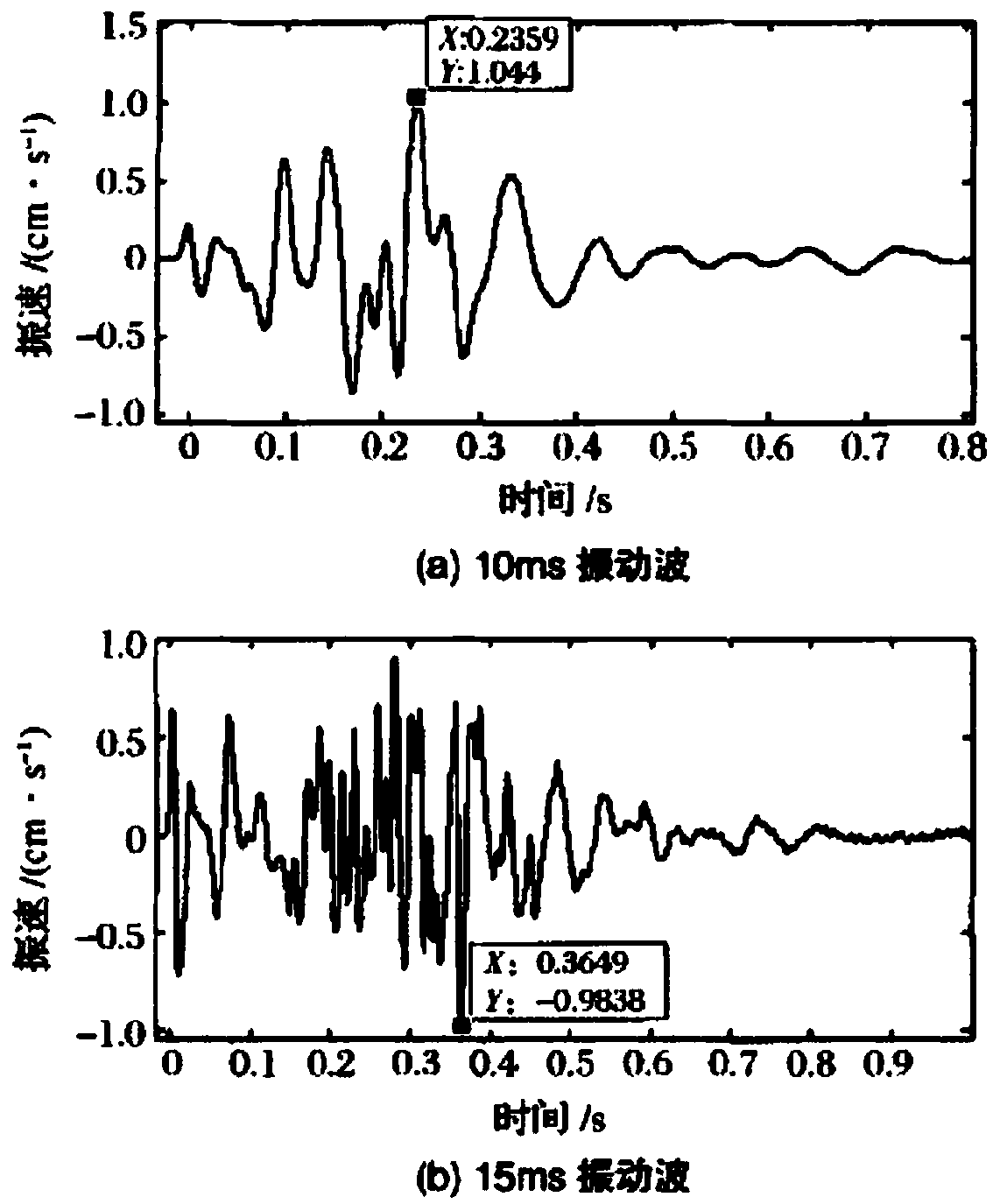

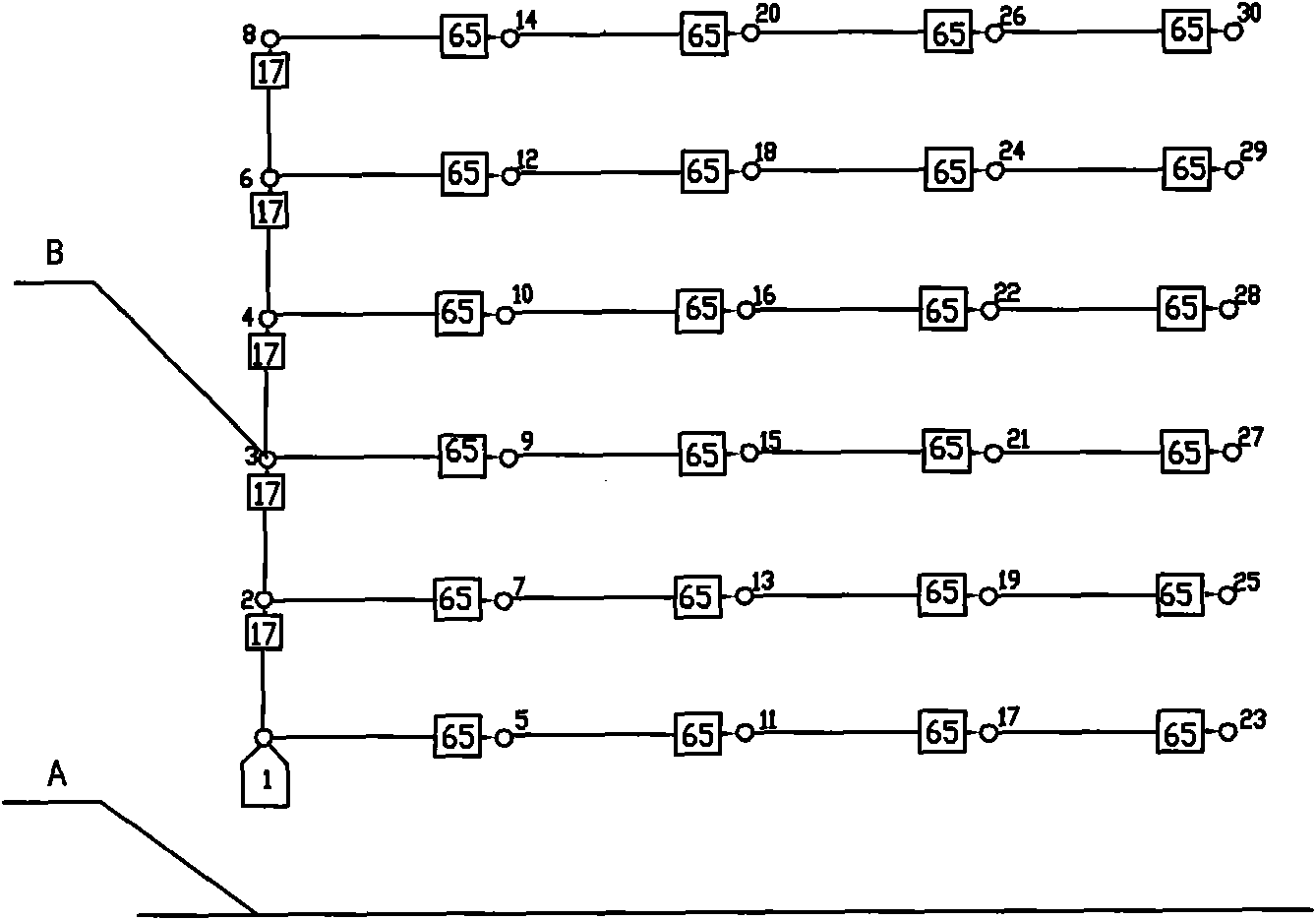

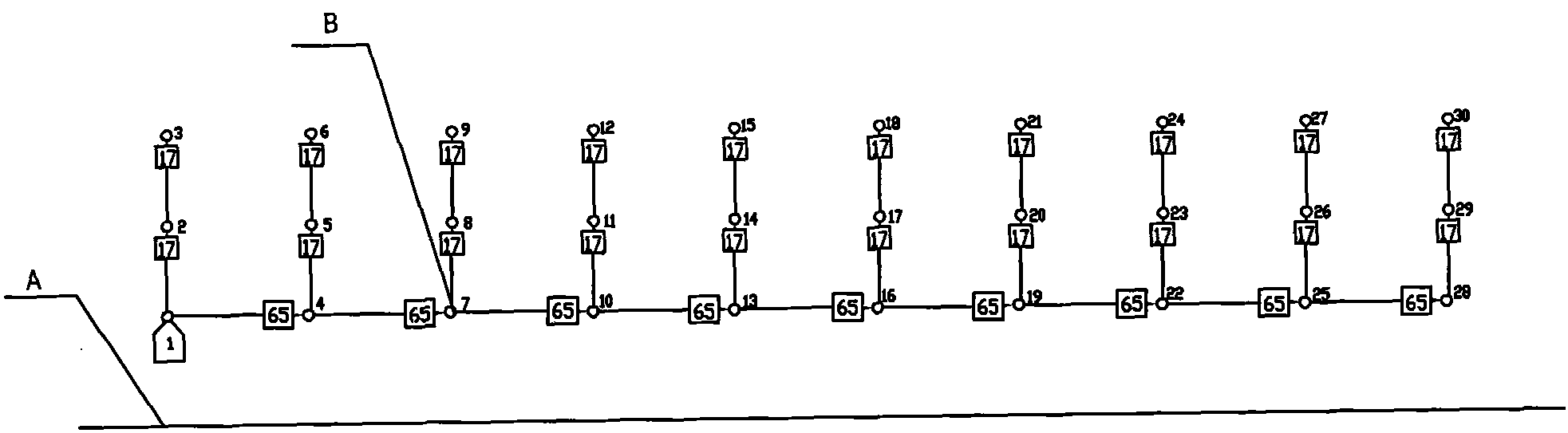

Detonation control method for reducing blast vibration

InactiveCN109115061AReduce blasting vibration effectsImprove blasting qualityBlastingDetonatorDetonation

The invention provides a detonation control method for reducing blast vibration. The detonation control method for reducing blast vibration comprises the steps of (1) setting a compound series-parallel blasting network, adopting a connected side network for conducting outside holes, connecting a 4-section detonator outside holes between each row of blast holes, detonating a back network after delaying for a certain time, adopting detonators with different high sections for delaying to detonate explosives in the blast holes, and enabling the compound series-parallel blasting network to adopt afour-way conductor for conducting a detonation wave into a branch circuit; and (2) enabling the compound series-parallel blasting network to adopt a long hole loose blasting control method, adopting detonation equipment for downloading reasonable delay time for each electronic detonator in each hole, and sequentially detonating the blast holes according to the expected sequence. According to the method, the blasting quality can be improved, the blasting vibration effect is reduced, the one-time blasting scale is expanded, and the reliability of the high-precision millisecond nonel detonators and millisecond delay blasting networks inside and outside the holes can be improved, so that the large-scale blasting can be realized, and the blasting construction progress is accelerated.

Owner:CHANGAN UNIV +1

Slope expansion and blasting method for mining deep concave open-pit mine by stages

InactiveCN102116156AEasy to operateImprove blasting qualityUnderground miningBlastingDetonatorDetonation

The invention relates to a slope expansion and blasting method for mining a deep concave open-pit mine by stages. The method comprises the following steps: sequentially performing hole distribution design of deep holes, perforation construction, setting of primer detonators in the deep holes and the construction of charging explosive in the deep holes, performing time delay detonation design of the detonators in a surface network, connecting the detonators in blast holes with the detonators in the surface network, and detonating, and the method is characterized in that, under the condition that the width of the slope expansion part is greater than 20 meters, the hole distribution design of the deep holes is used for designing the blast holes in a control row of a blasting area to be vertical to a bench crest of a main stope, the time delay detonation design of the detonators in the surface network is used for designing the detonation sequence to hole-by-hole differential detonation, and the time delay detonation design of the detonators in the surface network is used for designing delay time of the detonators to enable the inter-hole detonator time delay to be shorter than the inter-row detonator time delay. Under the condition that the width of the slope expansion part is smaller than 20 meters, the hole distribution design of the deep holes is used for designing the blast holes in the control row of the blasting area to be parallel to the bench crest of the main stope, and the time delay design of the detonator is used for designing the delay time of the detonators to enable the inter-hole detonator time delay to be longer than the inter-row detonator time delay. The method is strong in operability, safe, practical and reliable.

Owner:ANSTEEL GRP MINING CO LTD

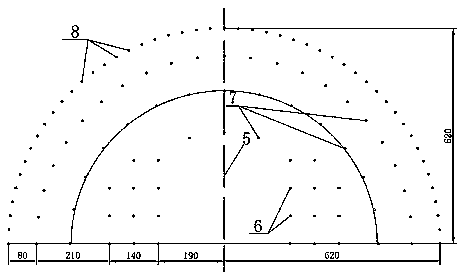

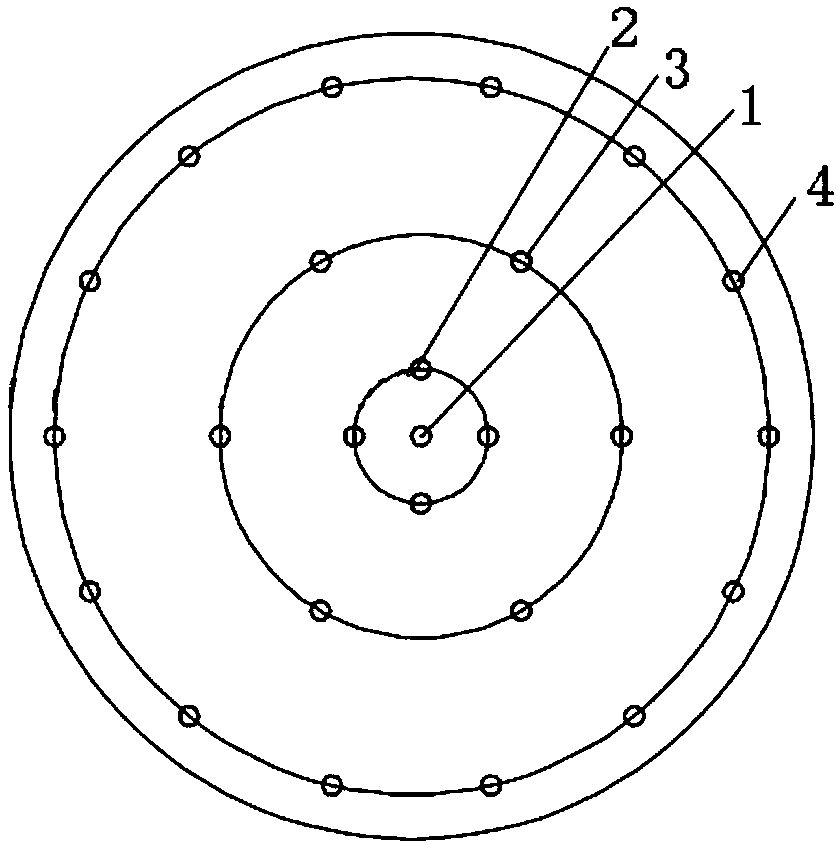

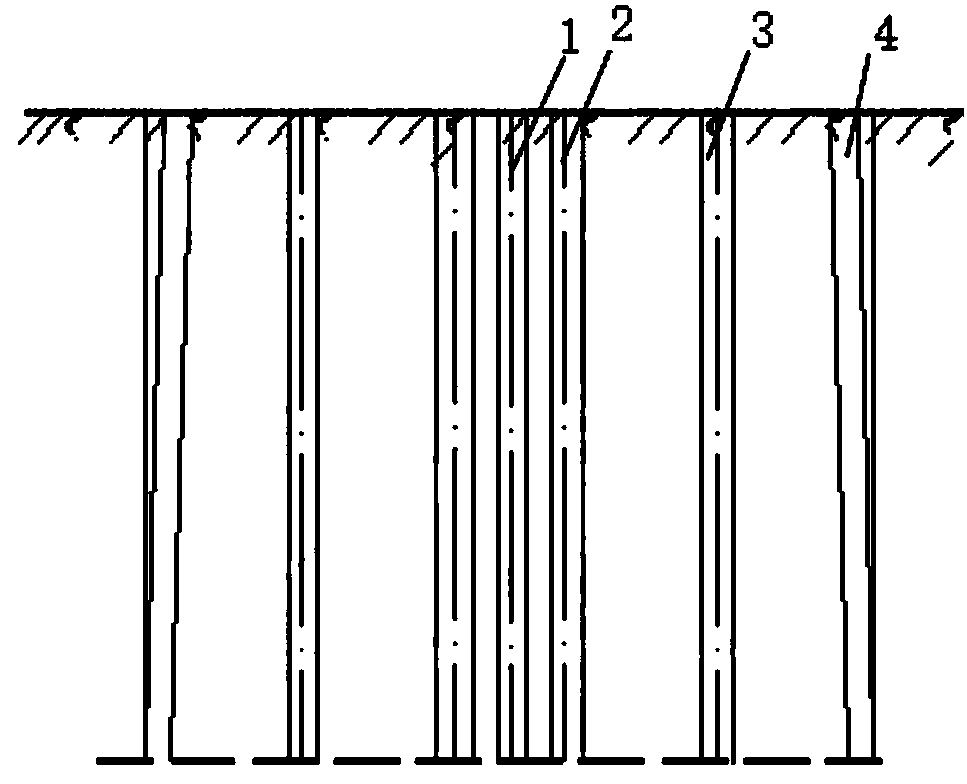

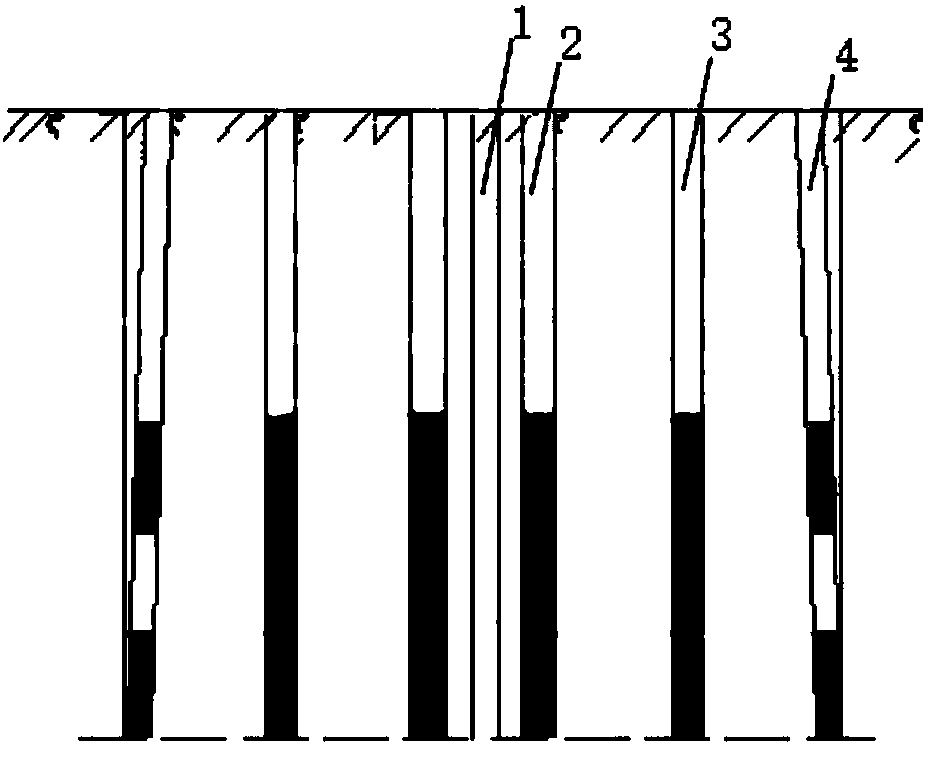

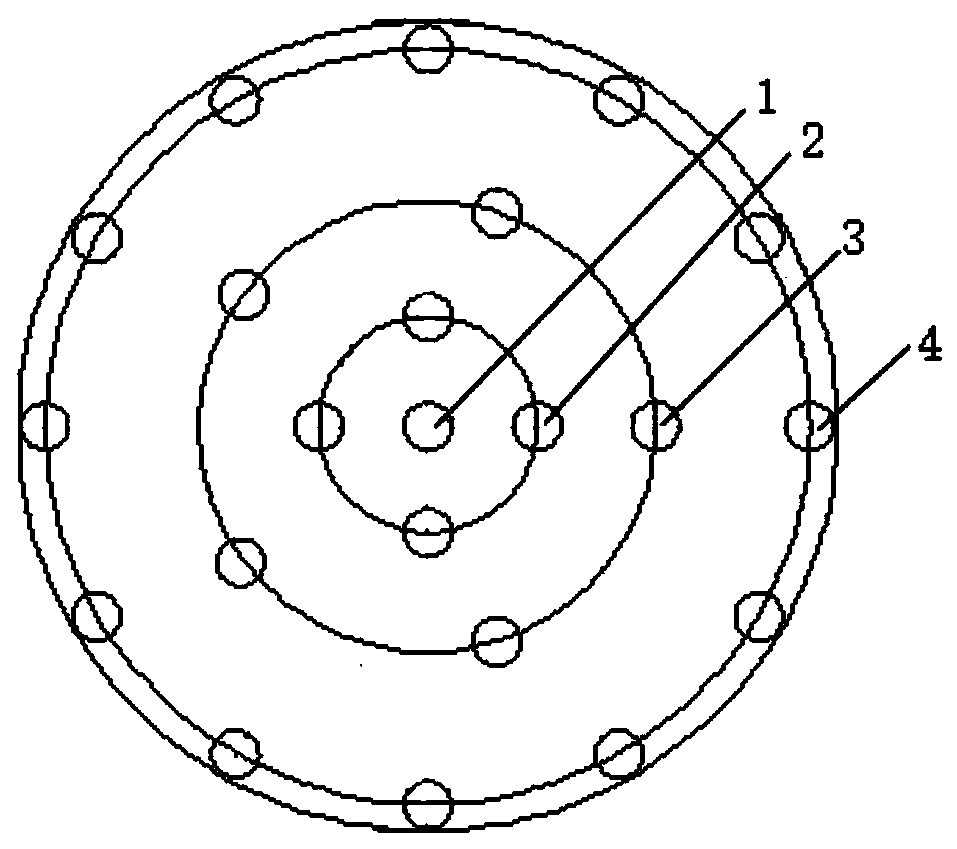

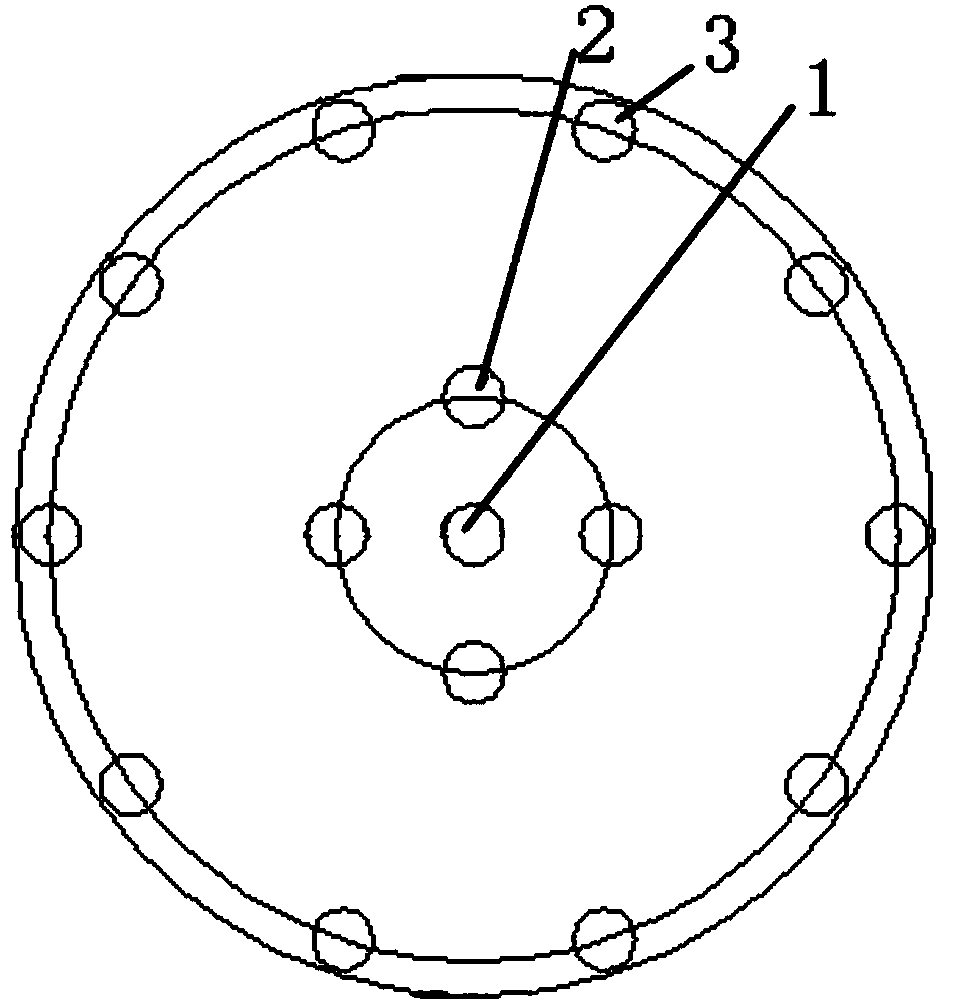

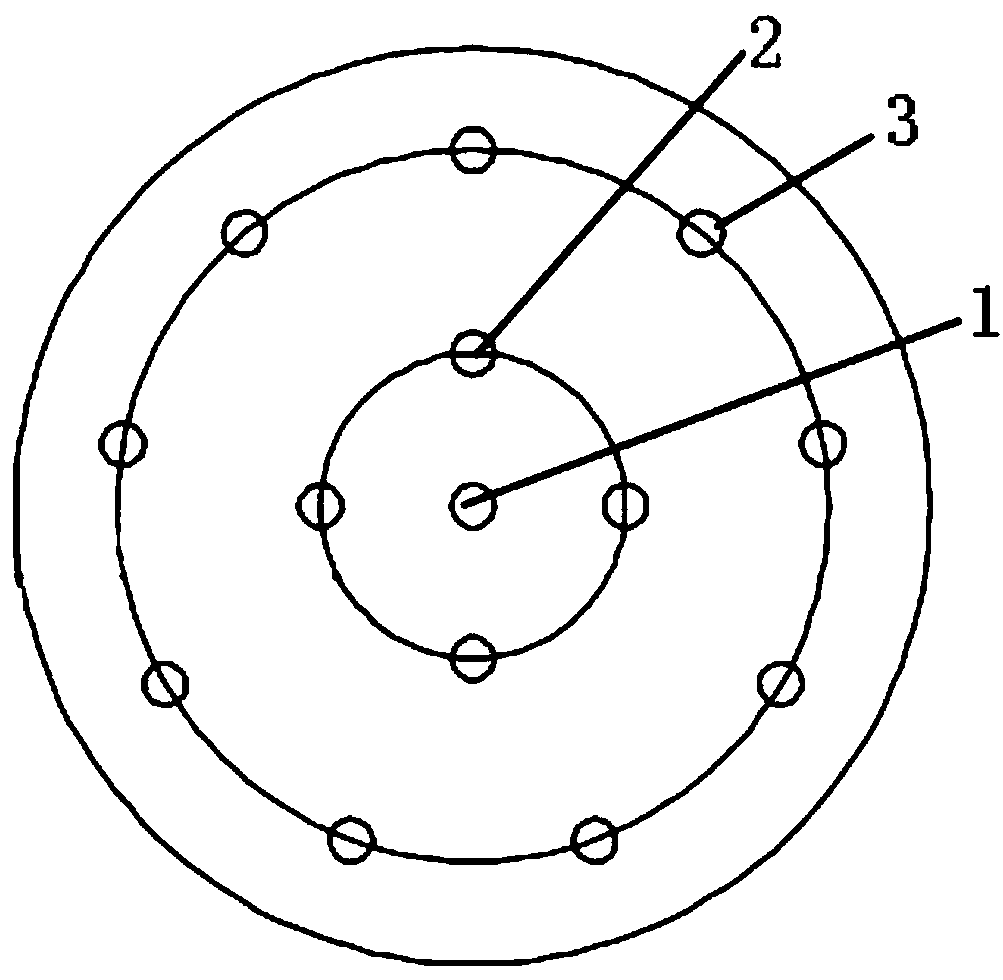

Blasting method for bridge cylindrical pile base with pile base diameter of 1.7-1.9 m

The invention relates to a blasting method for a bridge cylindrical pile base with the pile base diameter of 1.7-1.9 m. The blasting method includes the steps of drilling holes, loading explosive materials, blocking a cannon opening and triggering blasting. According to a hole drilling method, a central hole is vertically formed along a central line of the cylindrical pile base, a cannon opening inner ring with a radius of 0.13-0.17 m is formed with the central line of the cylindrical pile base as the center, a cannon opening middle ring with a radius of 0.43-0.47 m is formed, a cannon openingouter ring with a radius of 0.78-0.82 m is formed, and 4 vertically formed cutting holes are evenly distributed in the cannon opening inner ring, 6 vertically formed auxiliary holes are evenly distributed in the cannon opening middle ring, and 14 obliquely formed peripherical holes are evenly distributed in the cannon opening outer ring; the included angle between the central axis of each peripherical hole and the vertical direction is arccot10-arccot12, and the distance between the top of each peripherical hole and the central hole is smaller than that between the bottom of each periphericalhole and the central hole. The blasting quality is high, the construction efficiency is high, and the blasting cost is low.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

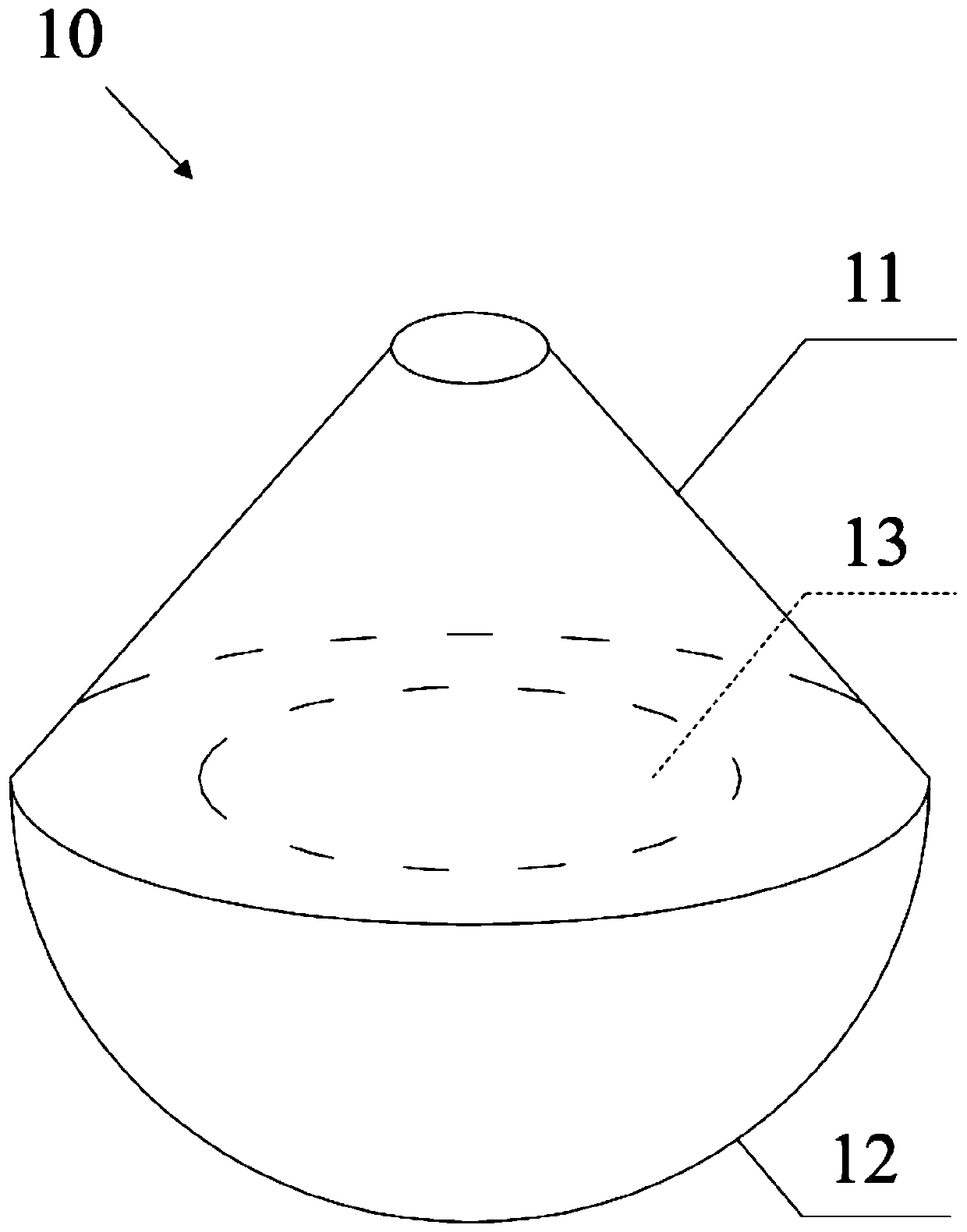

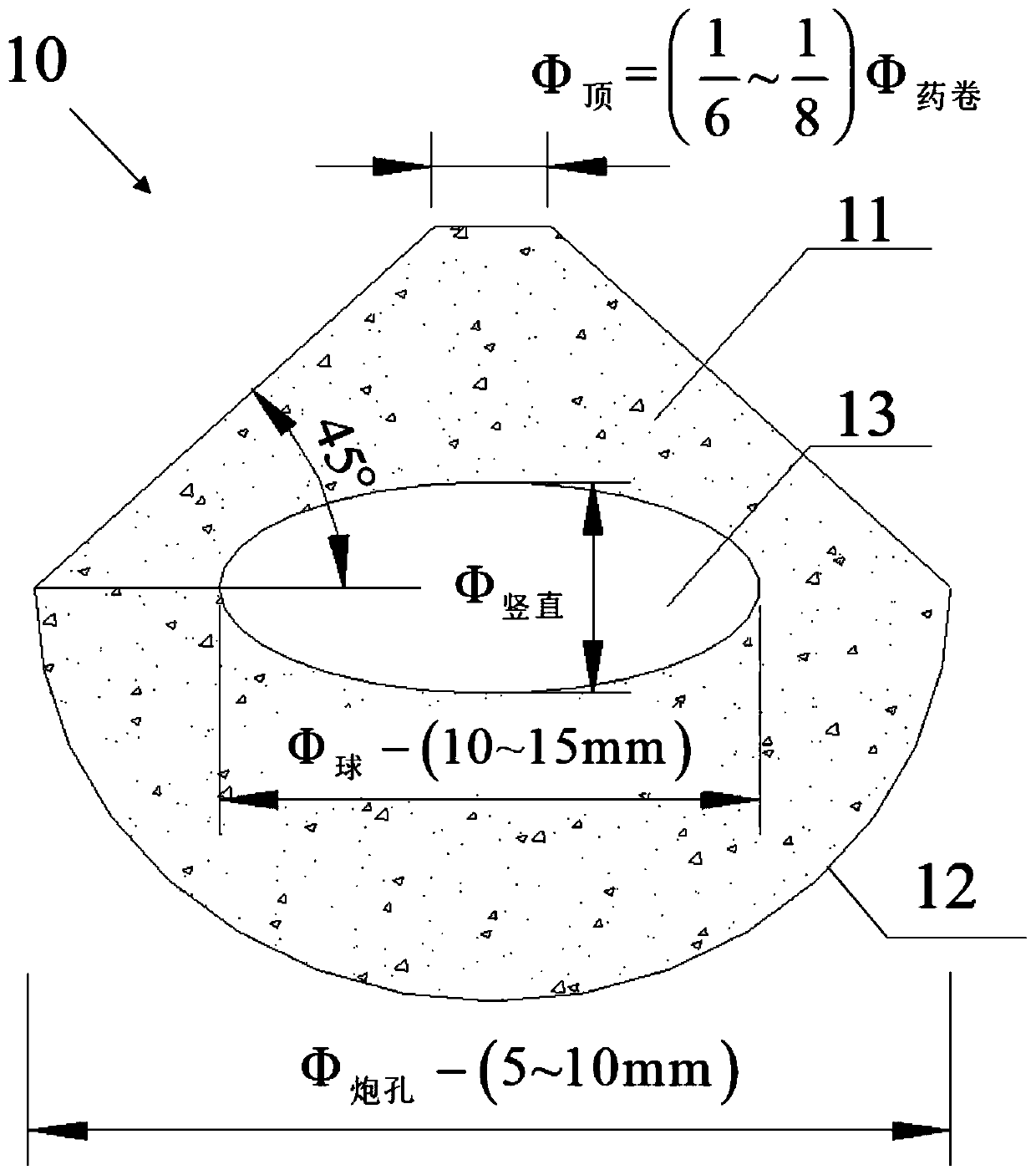

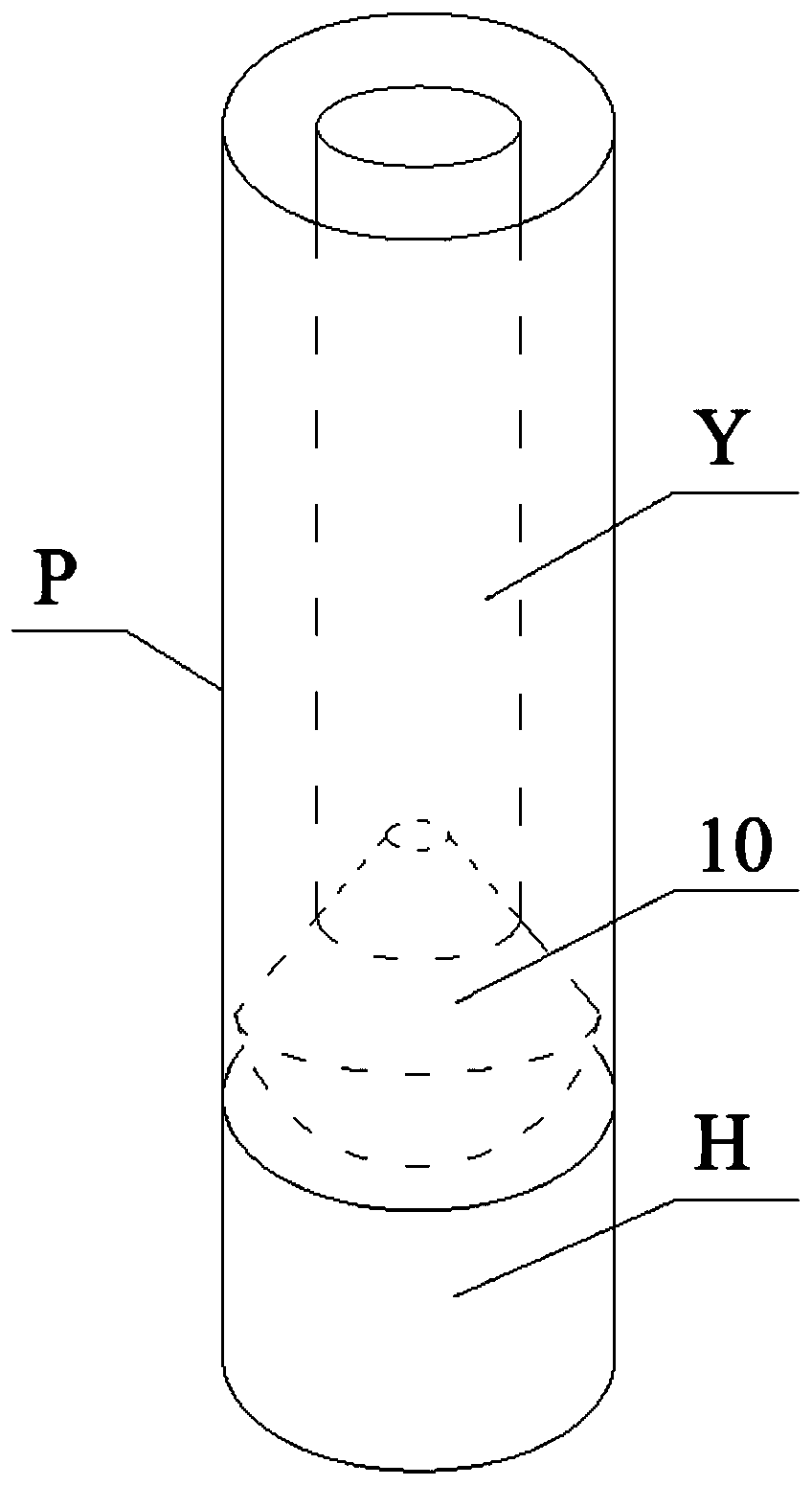

High-wave resistance orientation resistance sliding combination energy dissipation body applied to rock foundation excavation forming

ActiveCN109870086AIncrease lateral blast fragmentationControl damage depthBlastingShock waveRound table

The invention provides a high-wave resistance orientation resistance sliding combination energy dissipation body applied to rock foundation excavation forming. The high-wave resistance orientation resistance sliding combination energy dissipation body applied to the rock foundation excavation forming is characterized by comprising a round table, a hemispheroid and flat inflatable cavities, whereina bus has an angle of 45 degrees with the bottom surface; the upper surface of the hemispheroid is fixedly connected with the bottom surface of the round table, the lower surface of the hemispheroidarches downwards to form a semi-spherical shape, and the diameter is equal to the bottom surface diameter of the round table; and the flat inflatable cavities are formed in the round table and the hemispheroid and in an ellipsoid shape, an interface of the round table and the hemispheroid is used as a symmetric surface, the length direction is the horizontal direction in which the symmetric surface is located, and the width direction is the perpendicular direction in which the axis lines of the round table and the hemispheroid are located. According to the high-wave resistance orientation resistance sliding combination energy dissipation body applied to the rock foundation excavation forming, the operability of energy dissipation body site construction is high, various perpendicular holescan be combined to perform construction, complete reflection of exploded shock waves can be realized, lateral exploding crushing of a cannon hole is effectively increased, cannon bottom damage is avoided, and the foundation surface excavation construction efficiency and exploding quality are greatly improved; and the high-wave resistance orientation resistance sliding combination energy dissipation body applied to the rock foundation excavation forming is particularly applied to excavation forming of a rock foundation surface in the condition of containing water monitor holes.

Owner:WUHAN UNIV

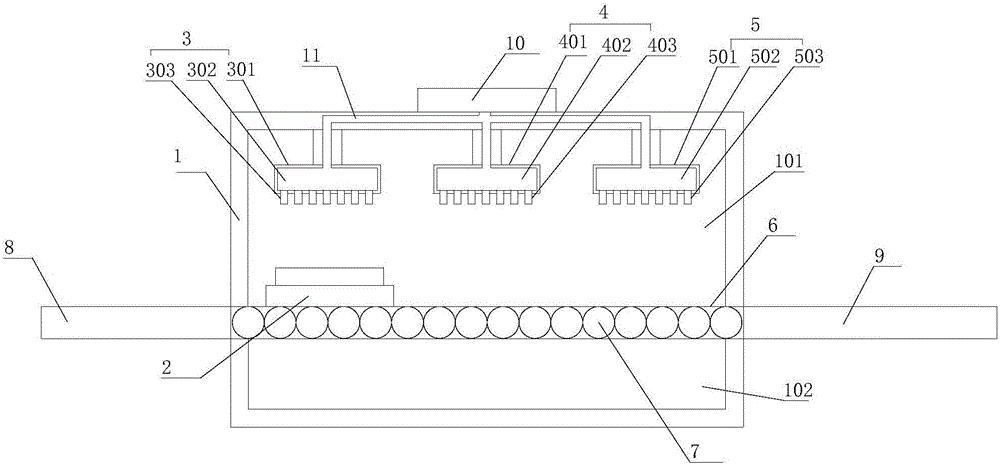

Sand blasting device for motor train unit air compressor crankcase casting mold machining

InactiveCN106425884ARealize continuous blastingImprove sandblasting work efficiencyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingInductor

The invention proposes a sand blasting device for motor train unit air compressor crankcase casting mold machining. The sand blasting device comprises a sand blasting box, an object carrying plate for placing workpieces, a first sand blasting module, a second sand blasting module, a third sand blasting module, a first inductor, a second inductor, a third inductor and a controller; a separation plate is horizontally arranged in the sand blasting box; a conveying roller set for conveying the object carrying plate is arranged between a feed end and a discharge end of the separation plate; the first inductor is used for monitoring the in-place condition of the object carrying plate and sending monitored signals to the controller; the second inductor is used for detecting the in-place condition of the object carrying plate and sending monitored signals to the controller; the third inductor is used for detecting the in-place condition of the object carrying plate and sending monitored signals to the controller; and the first sand blasting module, the second sand blasting module and the third sand blasting module are mounted at the top end of the sand blasting box in sequence. The sand blasting device is universal in sand blasting and high in sand blasting quality, and improves the sand blasting efficiency of a motor train unit air compressor crankcase casting mold.

Owner:LAIAN KELAIXING IND CO LTD

Method for mining thick ore body through segmental ore breaking and subsequent cemented filling

InactiveCN107130962AEnsure safety and stabilityPrevent weatheringUnderground chambersUnderground miningShotcreteMesh reinforcement

The invention discloses a method for mining a thick ore body through segmental ore breaking and subsequent cemented filling. The method comprises the following steps: 1) dividing the ore body into a plurality of segments along the vertical direction of the ore body; 2) dividing the ore body into a plurality of stopes in each segment along the trend of the ore body; 3) arranging rock drilling roadways along a direction perpendicular to the trend of the ore body in each stope, wherein the rock drilling roadways penetrate the ore body and extend to the hanging wall rock of the ore body; 4) supporting the rock drilling roadways formed in the step 3): a, spraying concrete onto the wall surfaces of the roadways; b, knocking anchor poles into the two sides and the tops of the roadways; c, fixedly laying steel mesh reinforcement onto the two sides of the roadways; and d, spraying a 100-mm-thick layer of concrete onto the surfaces of the steel mesh reinforcement; and 5) carrying out mining: a, mining the ore body from hanging segment to footwall segment successively; and b, mining every stope in each segment in such a manner that primary mining is carried out on odd or even stopes at first and then secondary mining is carried out on the rest stopes.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

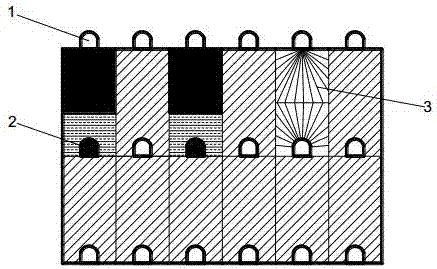

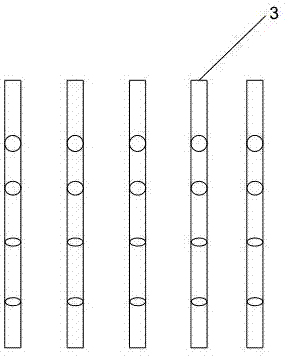

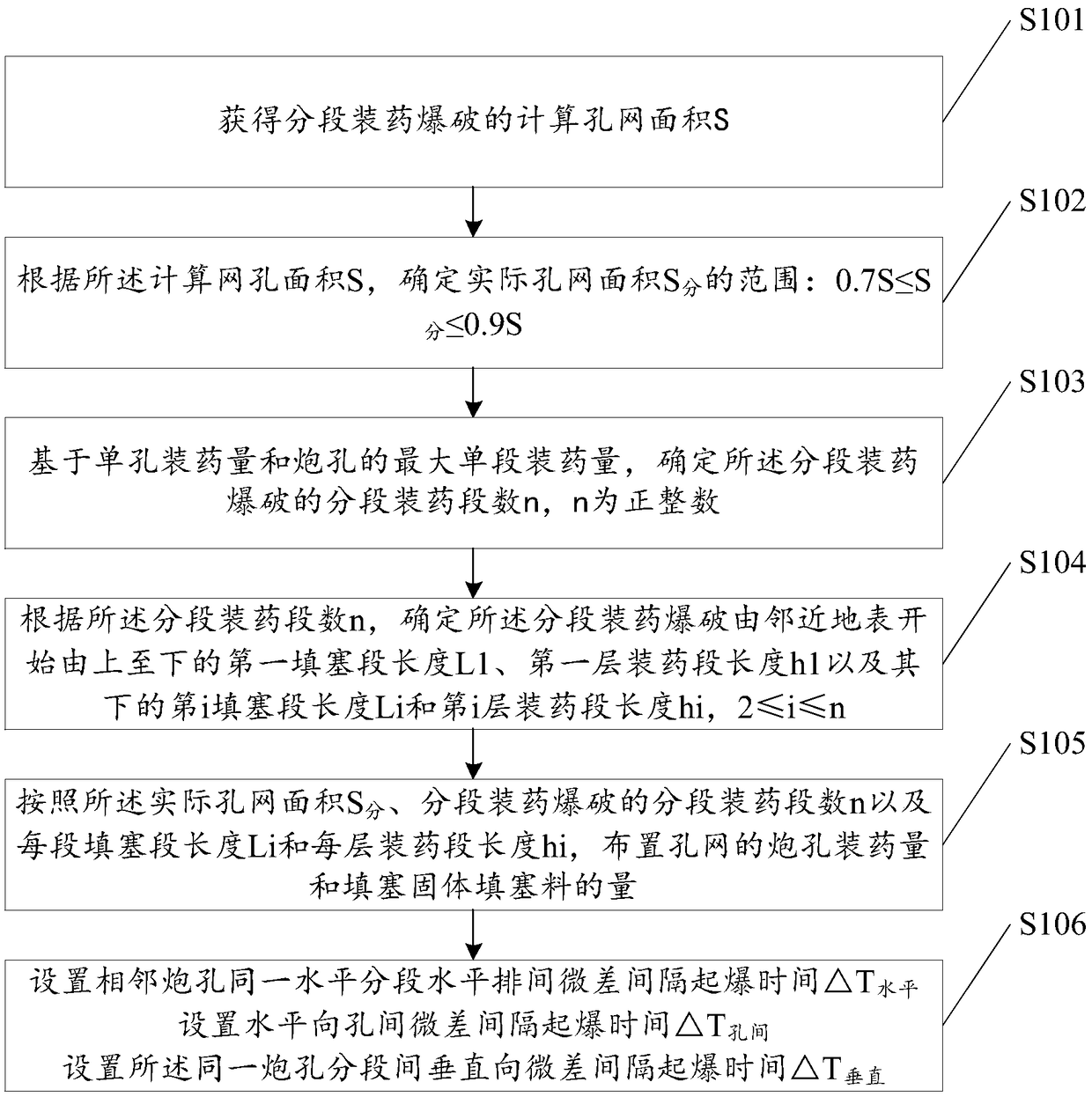

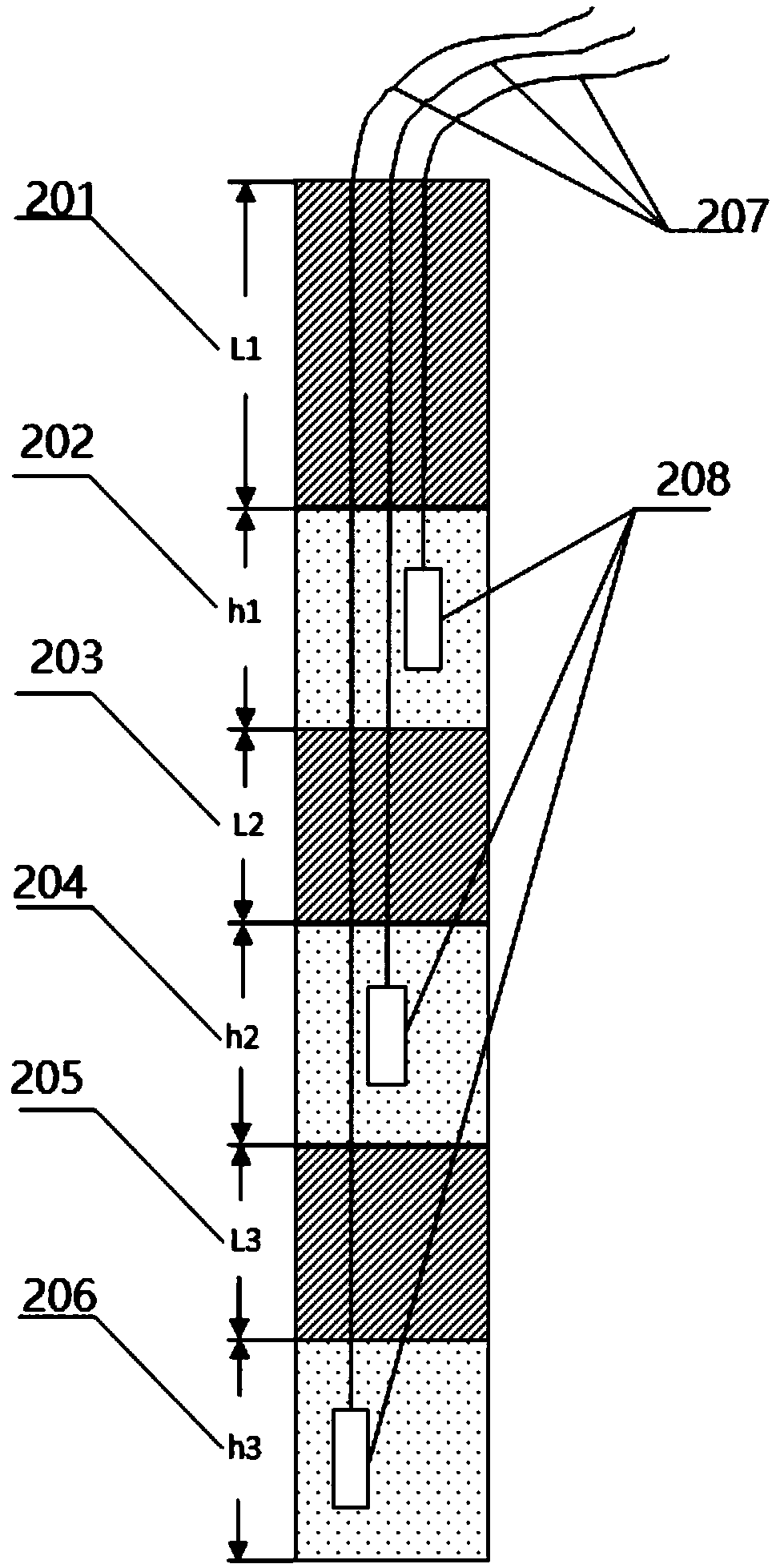

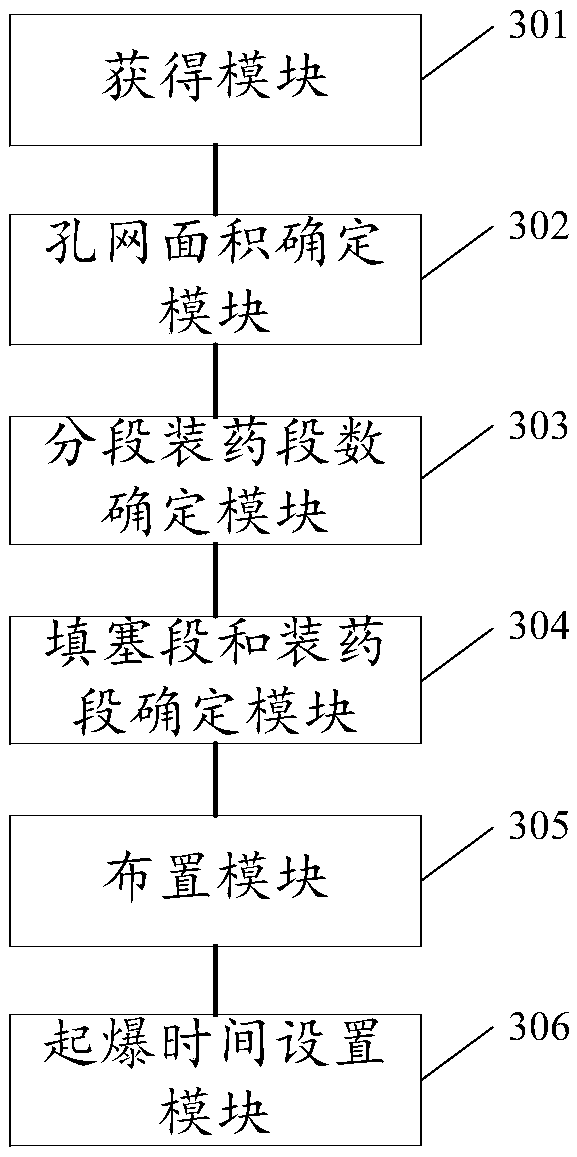

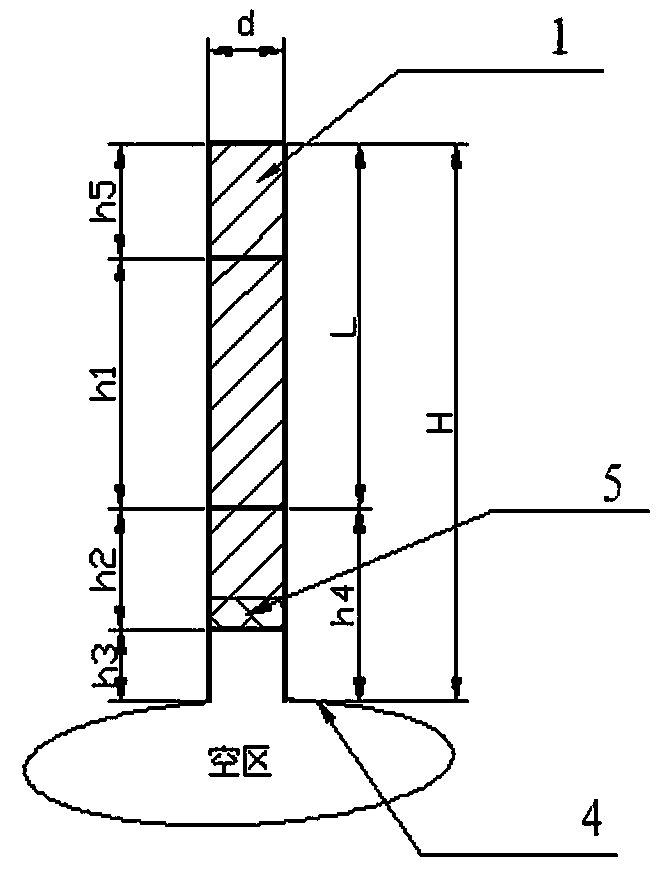

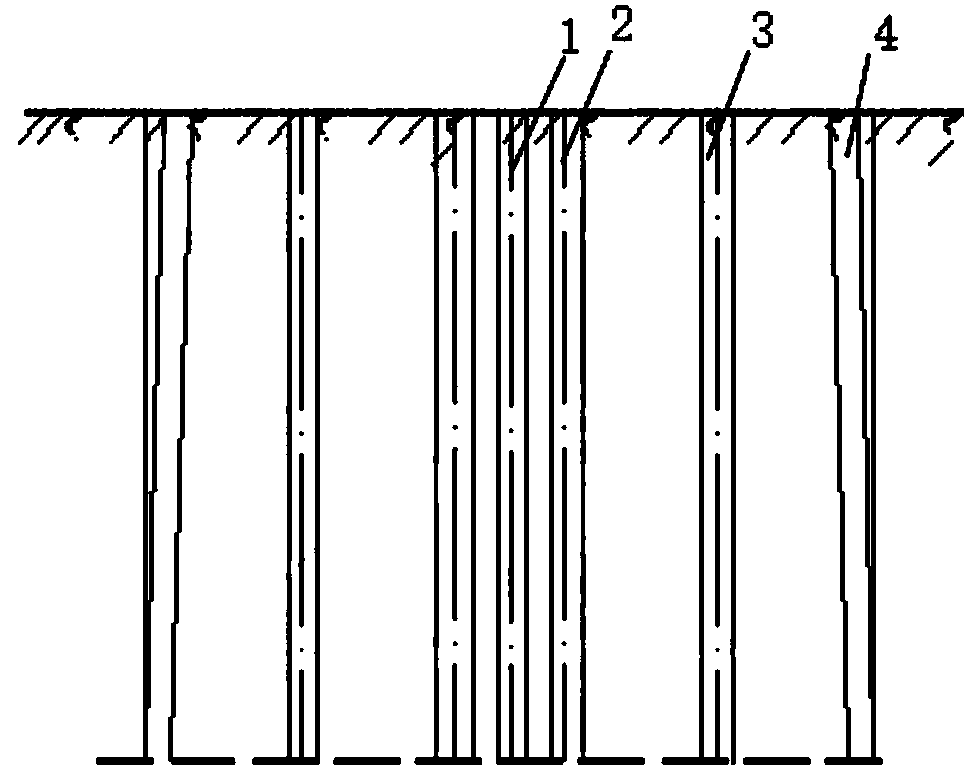

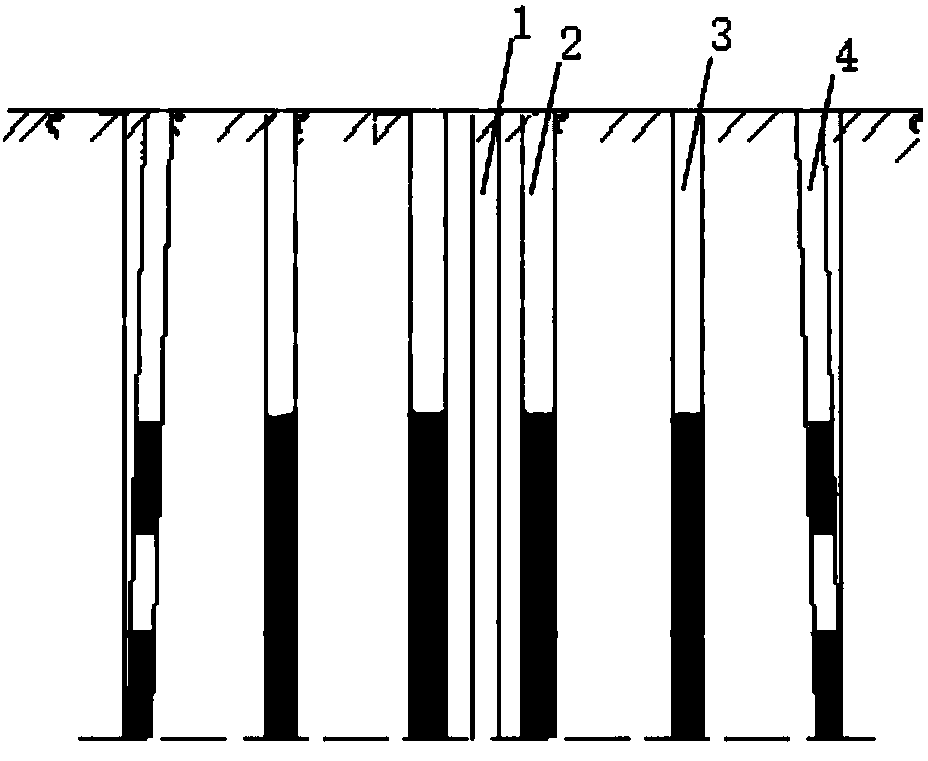

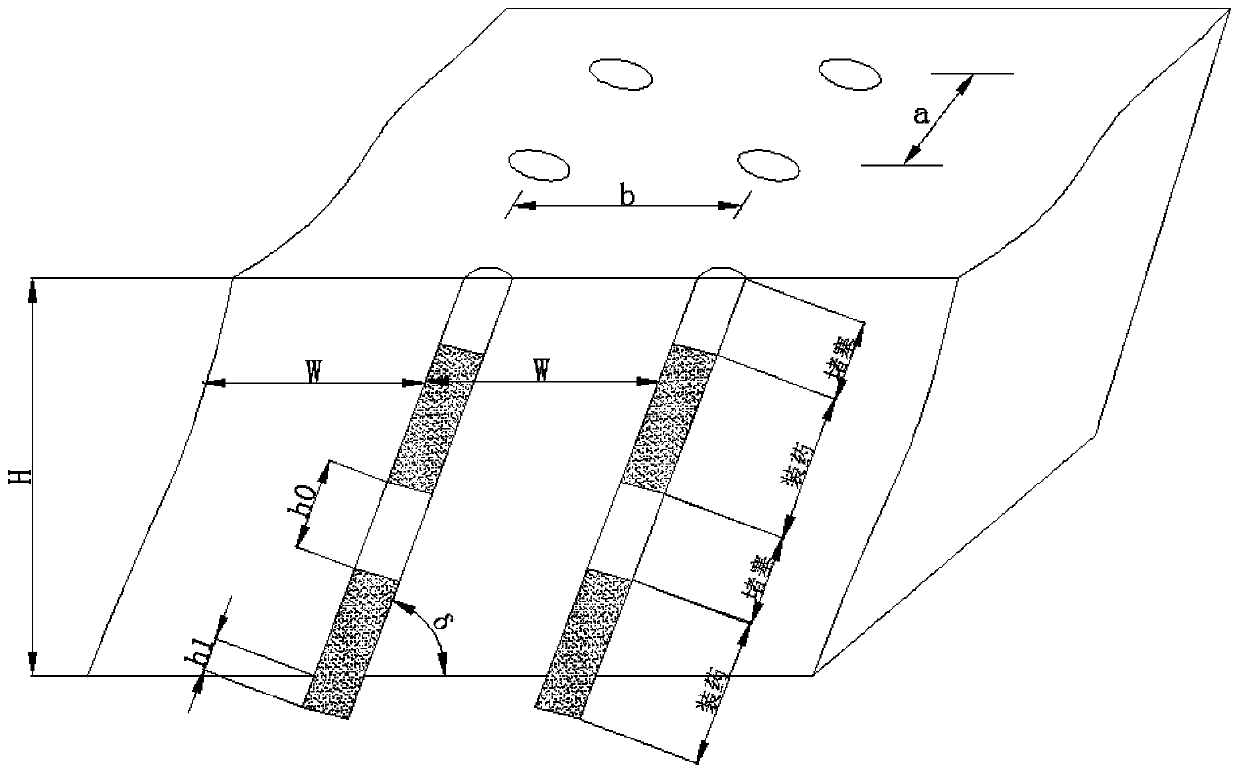

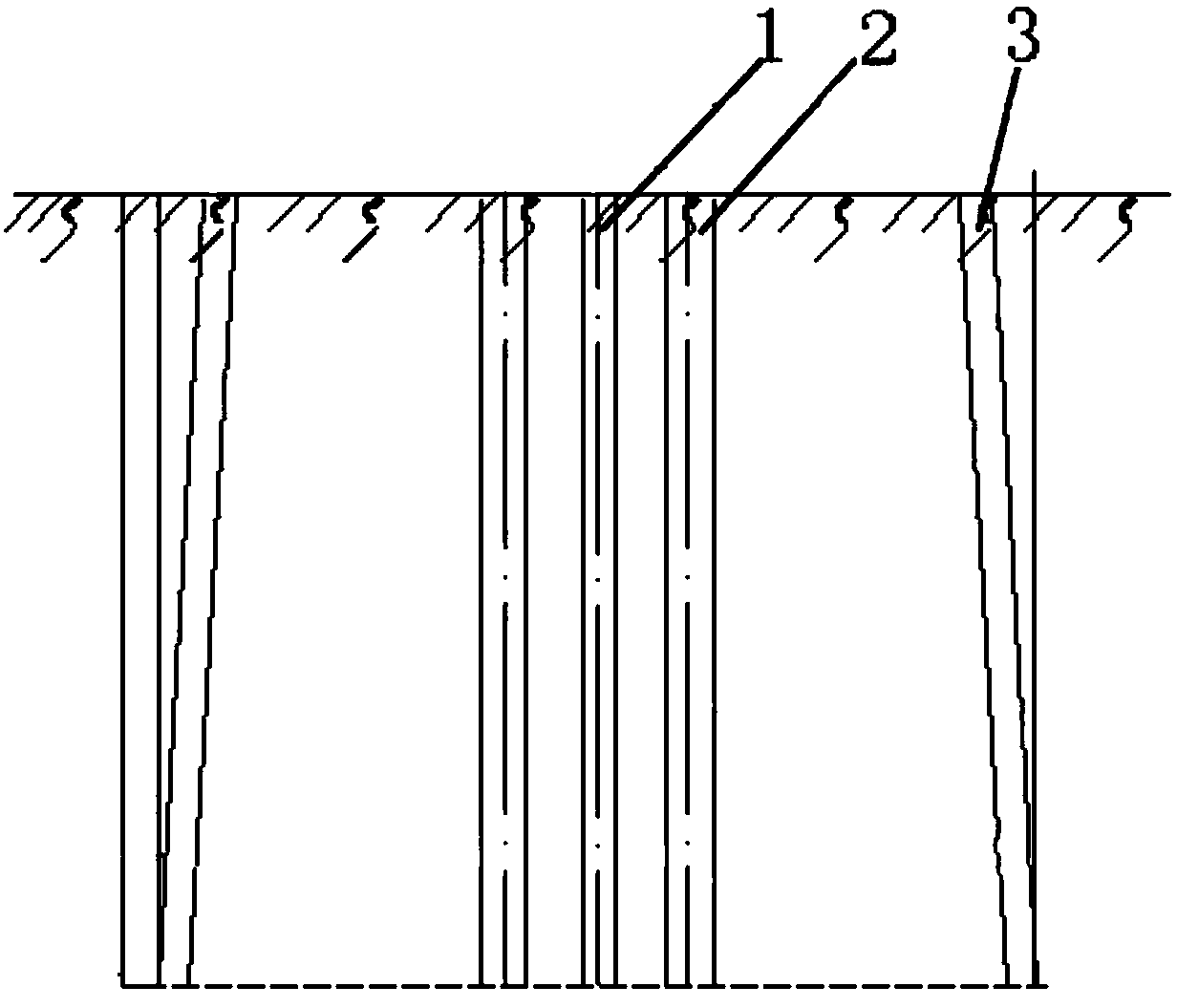

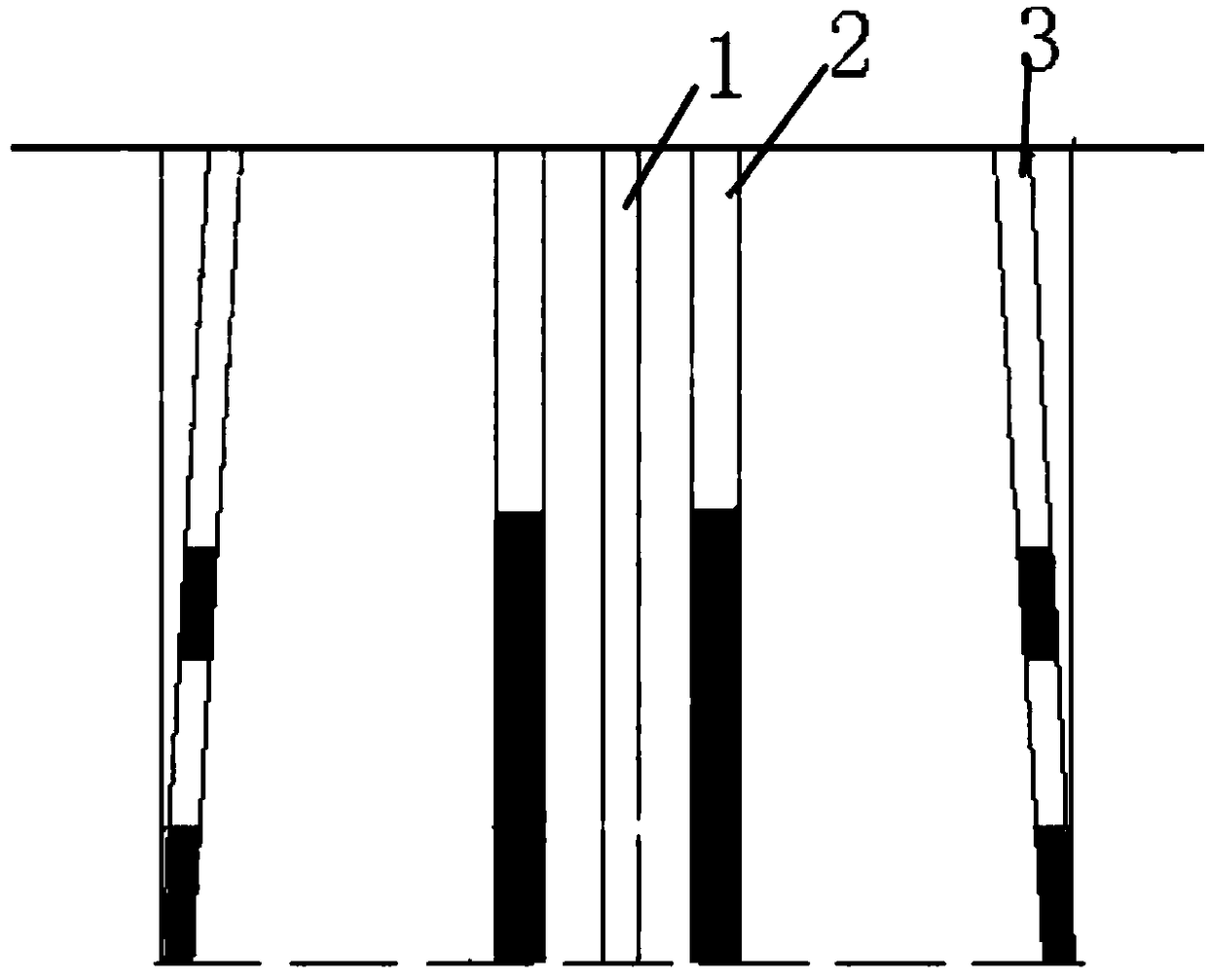

Segmented blasting method and device for medium-depth holes

The invention relates to the technical field of blasting processes, in particular to a segmented blasting method and device for medium-depth holes. The method includes the steps of determining the range of an actual hole net area S, wherein S is equal to or greater than 0.7 S and equal to or smaller than 0.9 S; on the basis of the single-hole explosive payload and the maximum single-segment explosive payload of a blasthole, determining the segmented explosive loading segment number of segmented explosive loading and blasting, and according to the segmented explosive loading segment number, determining the length L1 of a first filling segment, the length h1 of a first layer explosive loading segment, the length Li of the ith filling segment under the first layer explosive loading segment and the length hi of the ith layer explosive loading segment during segmented explosive loading and blasting, wherein the first filling segment, the first layer explosive loading segment, the ith filling segment and the ith layer explosive loading segment are sequentially disposed at the position close to the earth surface from top to bottom; setting the blasthole explosive payload of a hole net andthe quantity of solid fillers for filling according to the parameters above and setting short-delay interval blasting time of every two adjacent blastholes in each horizontal segment among horizontalrows and the short-delay interval blasting time among horizontal holes; according to the calculation value of the short-delay interval blasting time of one blasthole segment in the vertical direction, setting the actual value of the short-delay interval blasting time of the blasthole segment in the vertical direction to be 1.2-1.3 times higher than the calculation value. Therefore, the blasting quality is improved.

Owner:SHOUGANG CORPORATION

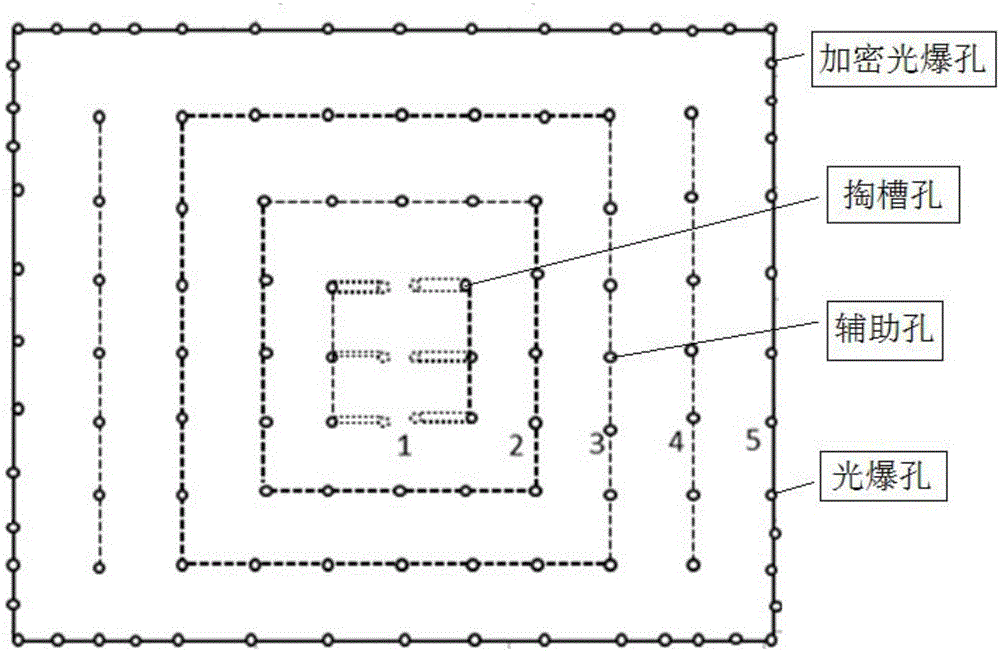

Rectangular tunnel full-section blasting excavation construction method

InactiveCN105953670AImprove blasting qualityMeet the design requirementsBlastingEncryptionDrilling and blasting

The invention discloses a rectangular tunnel full-section blasting excavation construction method. The rectangular tunnel full-section blasting excavation construction method comprises the following steps that drilling and blasting are designed through the smooth blasting principle; cut holes, auxiliary holes, smooth blasting holes and encryption smooth blasting holes are sequentially formed from inside to outside and are blasted one by one according to the smooth blasting requirements; and a standard designed rectangular section is formed finally. The rectangular tunnel full-section blasting excavation construction method is applied to construction, except that a rectangular-section tunnel is constructed according to the smooth blasting requirements, gap narrowing measures are taken for the blast holes in the corners, and thus the smooth blasting effect is improved; and on-site quality inspection shows that the formed section size of the rectangular tunnel meets the design requirement, and the rock surface flatness is smaller than the deviation value required by the specification.

Owner:杨毅

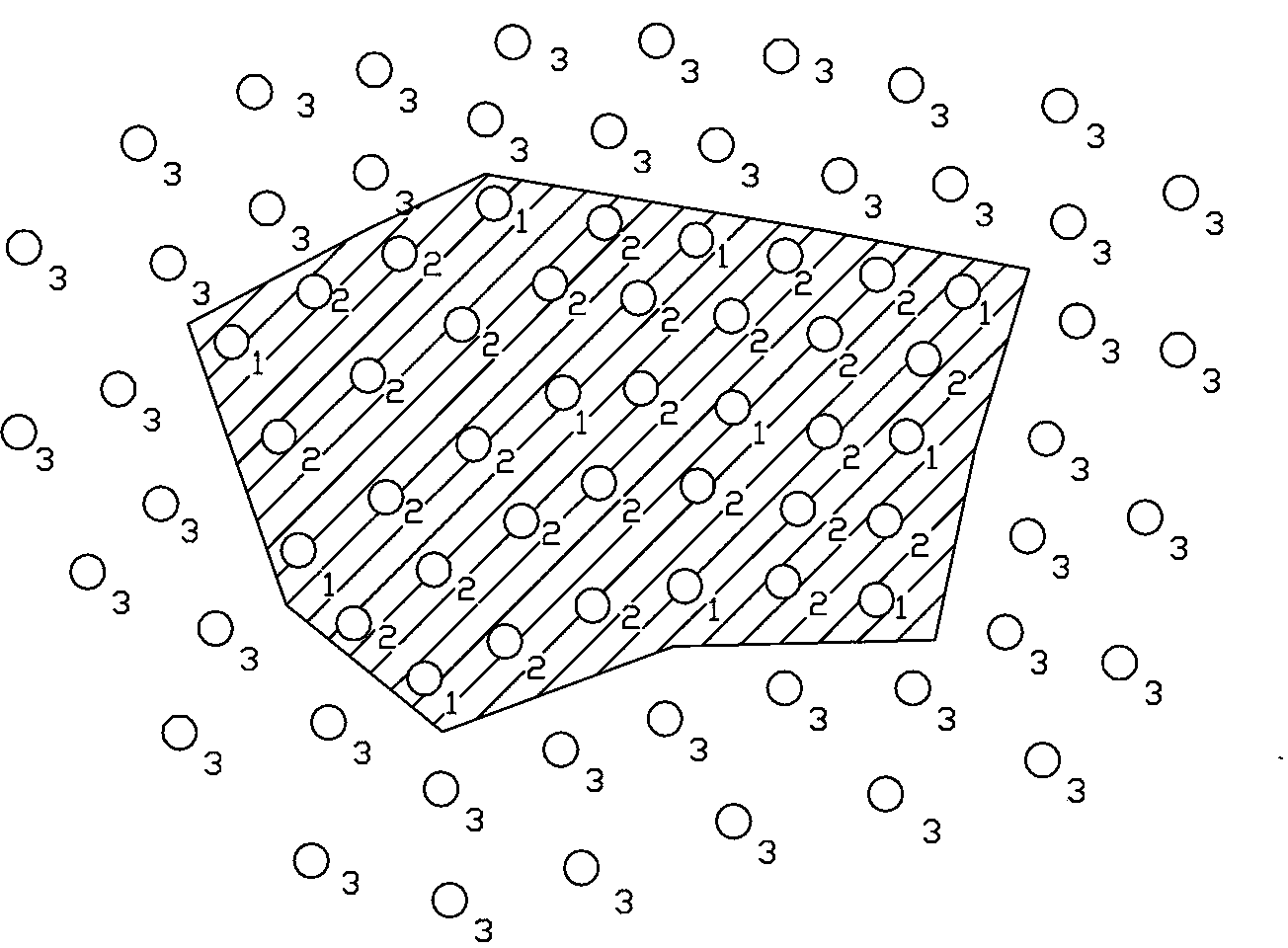

Explosion method for open-cast mining underground goaf position

Owner:ANSTEEL GRP MINING CO LTD

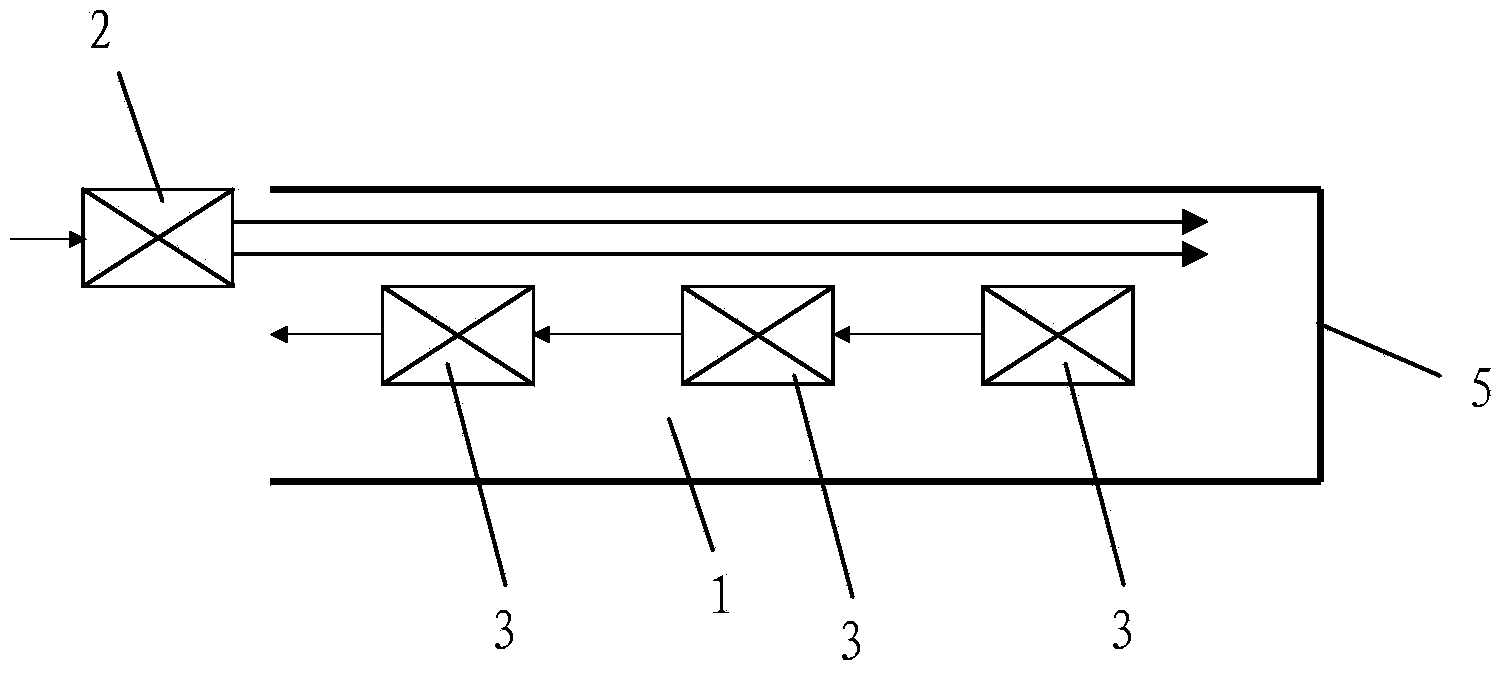

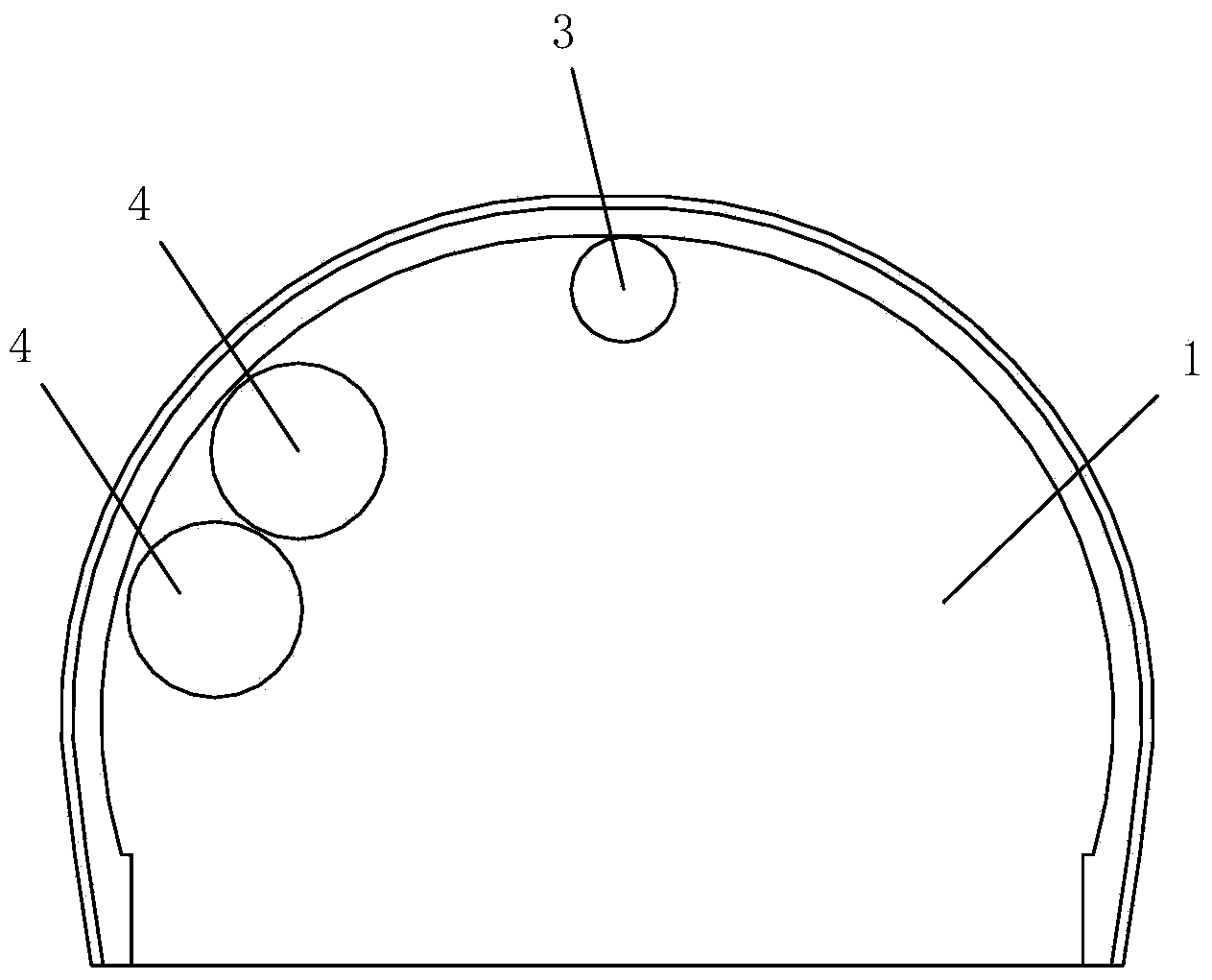

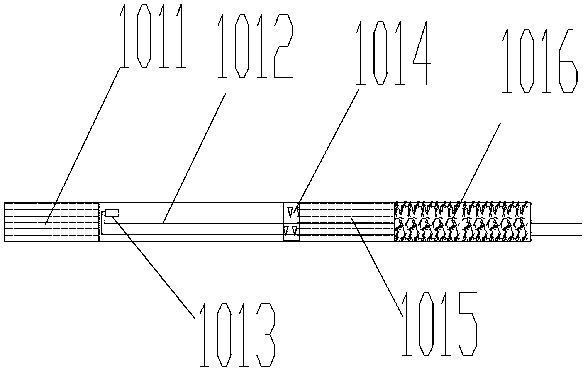

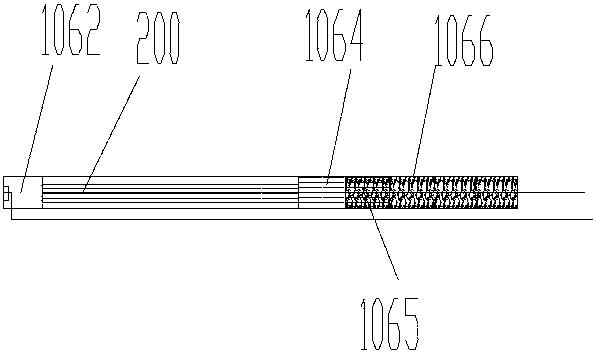

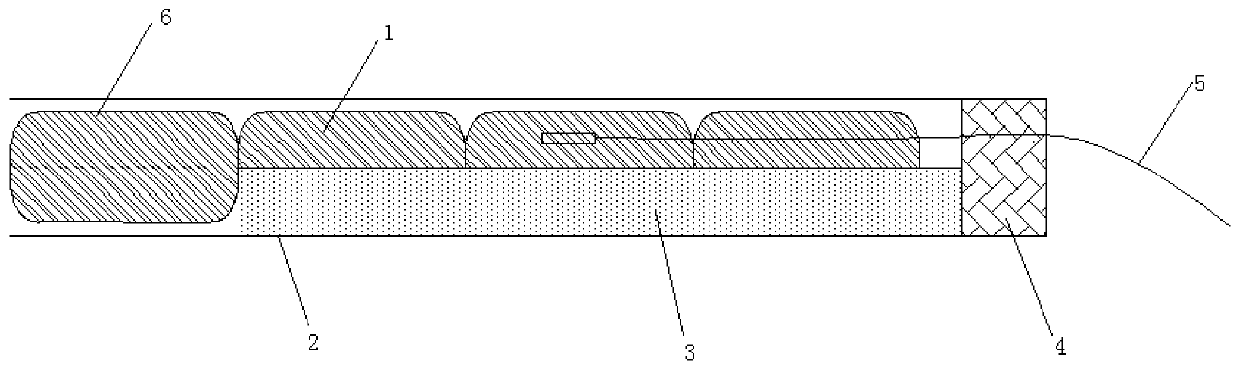

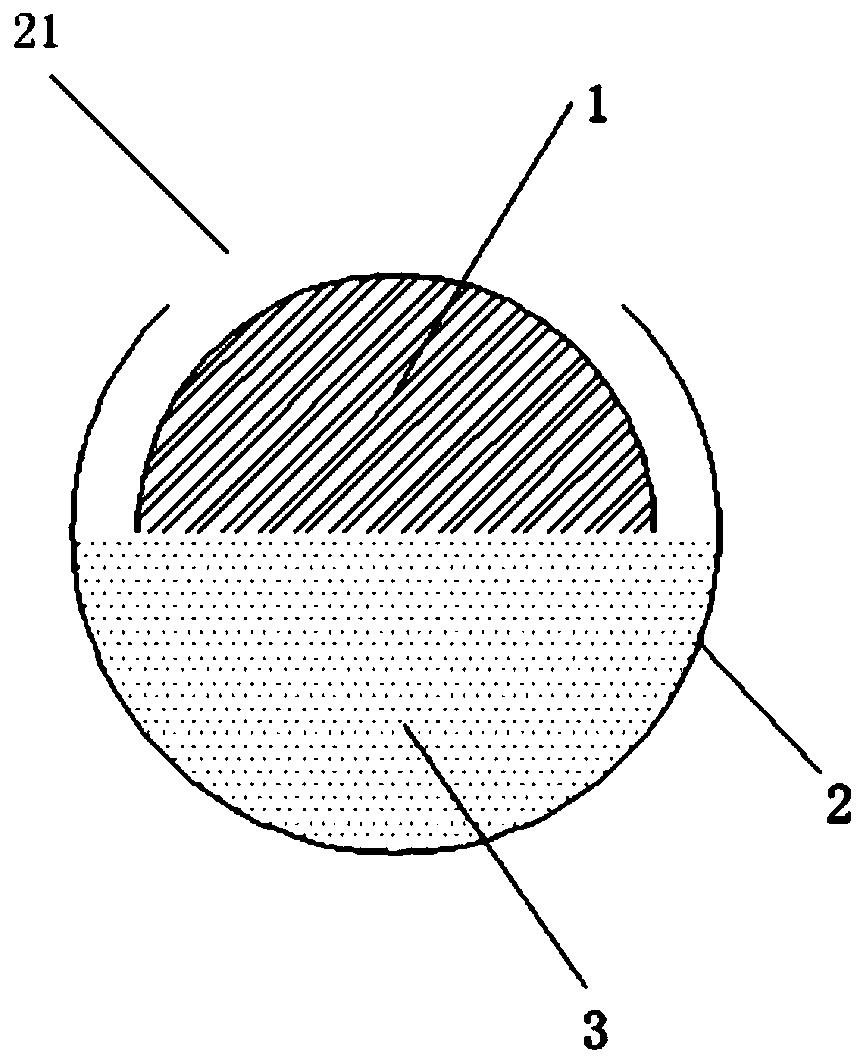

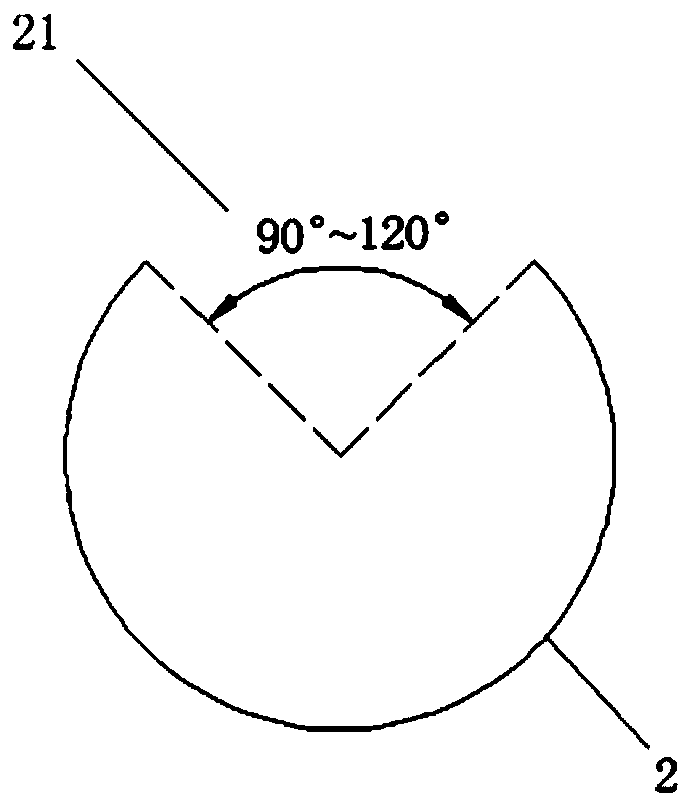

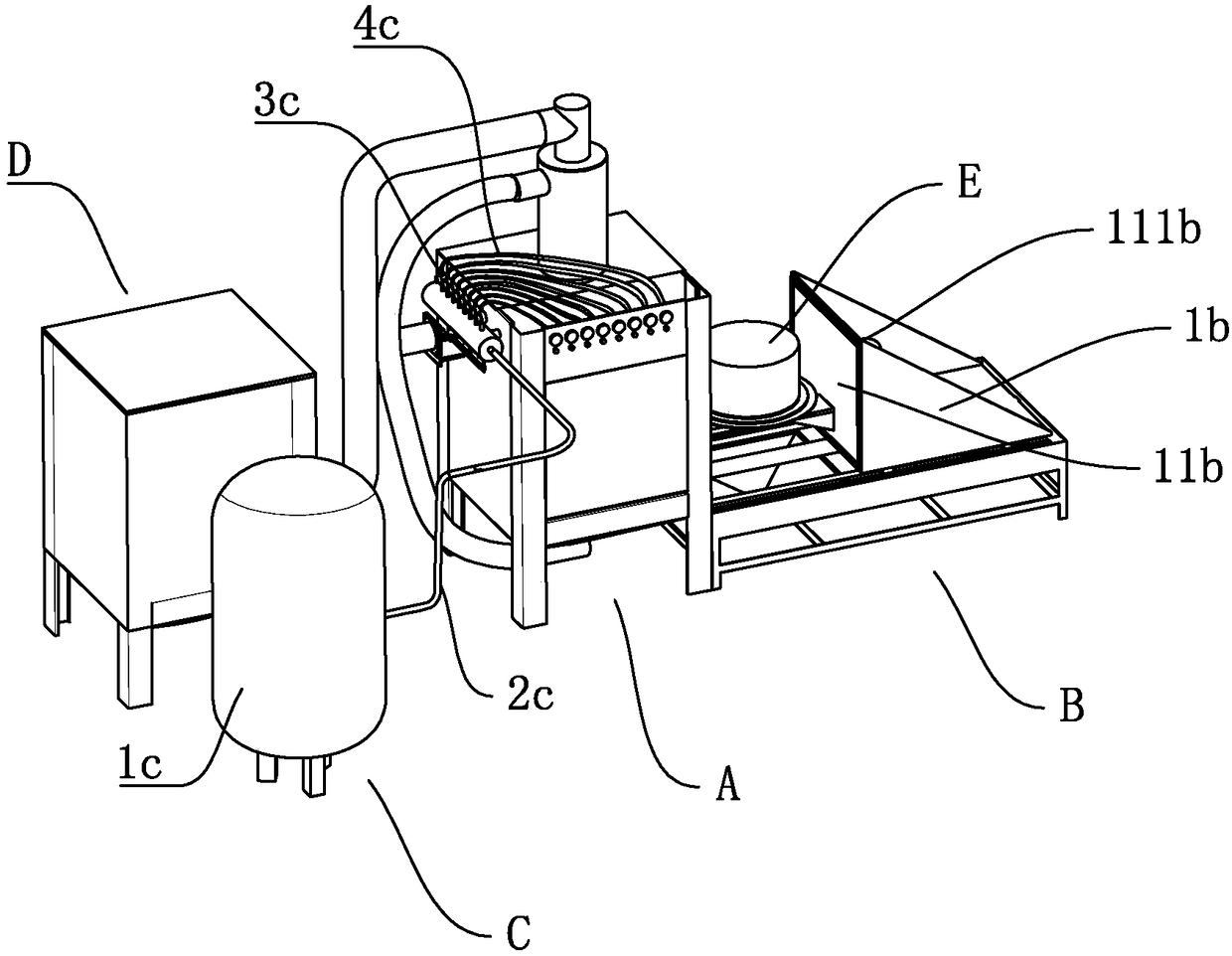

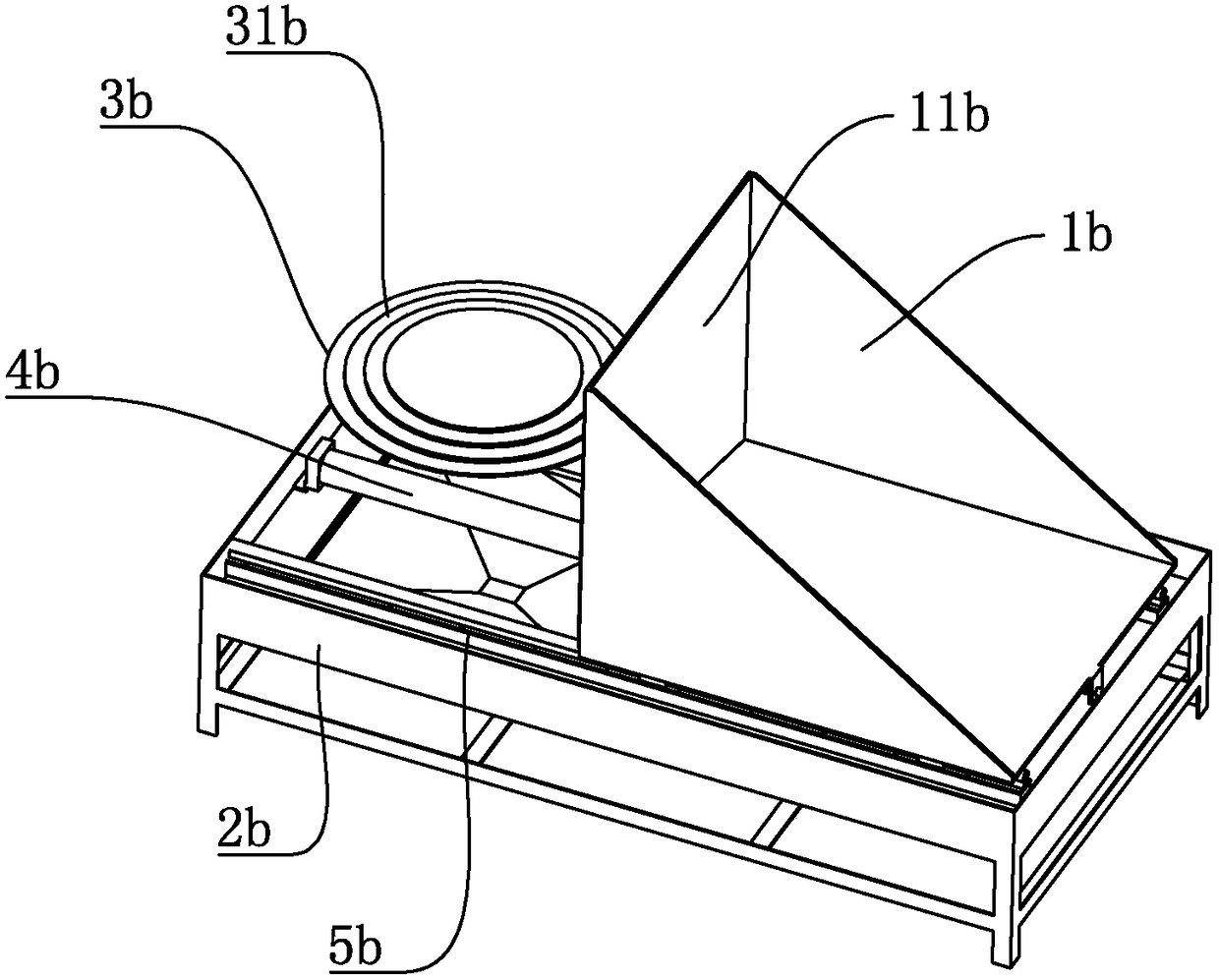

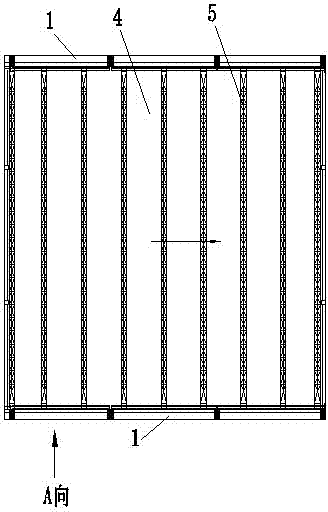

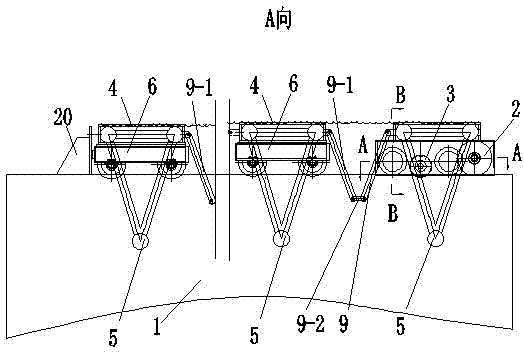

System and method for charging peripheral hole in smooth blasting of tunnel

The invention provides a system and a method for charging a peripheral hole in smooth blasting of a tunnel. The system comprises an elastic C-shaped pipe, curing foam, an explosive cartridge and a detonating apparatus, wherein the length of the C-shaped pipe is matched with the length of the to-be-charged peripheral hole; the curing foam is coated to the inner wall of the C-shaped pipe, the explosive cartridge fills the C-shaped pipe and is positioned by an elastic constraining force of the C-shaped pipe, and the detonating apparatus is inserted into the explosive cartridge. When the peripheral hole is charged, the C-shaped pipe filled with the explosive cartridge and the detonating apparatus is plugged into the peripheral hole and the outer wall of a part, coated by the curing foam, of the C-shaped pipe is attached to a hole wall, located on one side of a surrounding rock, of the peripheral hole. The system provided by the scheme plays roles of buffering the pressure to protect the wall and guiding energy release, so that the detonating damage to the surrounding rock is reduced effectively, the crushing action to an excavated rock body is enhanced, and differentiated action of peripheral hole blasting is achieved. The system and the method are particularly suitable for excavating the tunnel with a joint crushed zone.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

High sublevel double-hexagon caving mining method

InactiveCN109356581AHigh recovery rateReduce depletionDisloding machinesUnderground miningMineralogy

The invention belongs to the technical field of mining, and particularly relates to a high sublevel double-hexagon caving mining method. The method comprises the following steps of 1, preliminary mining cutting; 2, rock drilling; 3, exploding and ore breaking; and 4, ore removing. The method integrates the advantages of the sublevel caving without sill pillar method, the block stoping method, thehigh-end wall drawing method and other methods, and therefore the recovery rate of pure ore is improved, and the problem of excessive loss and dilution is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

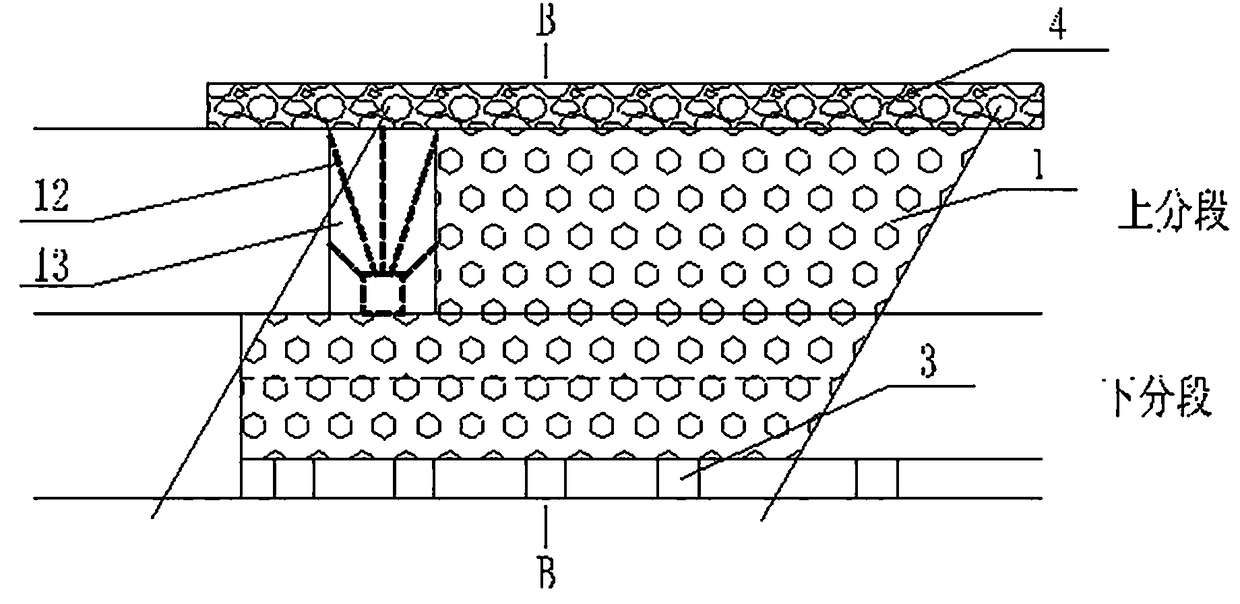

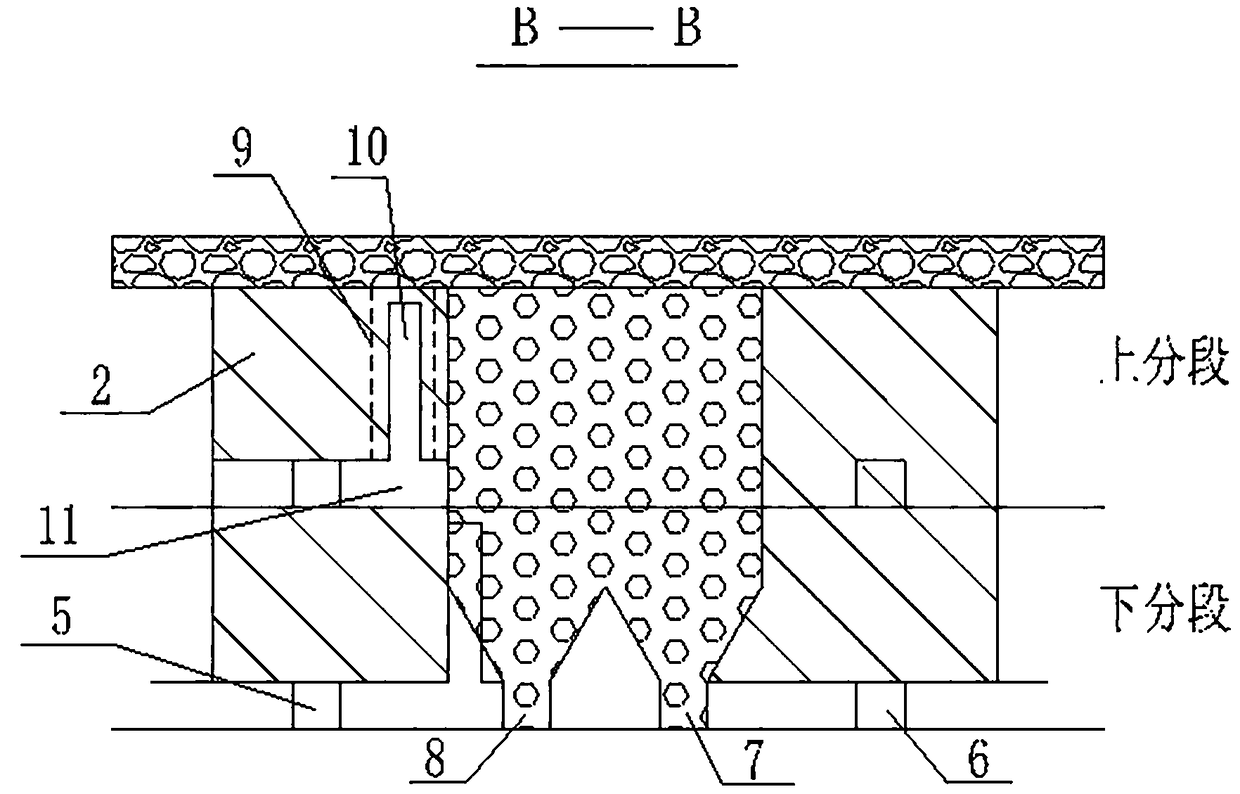

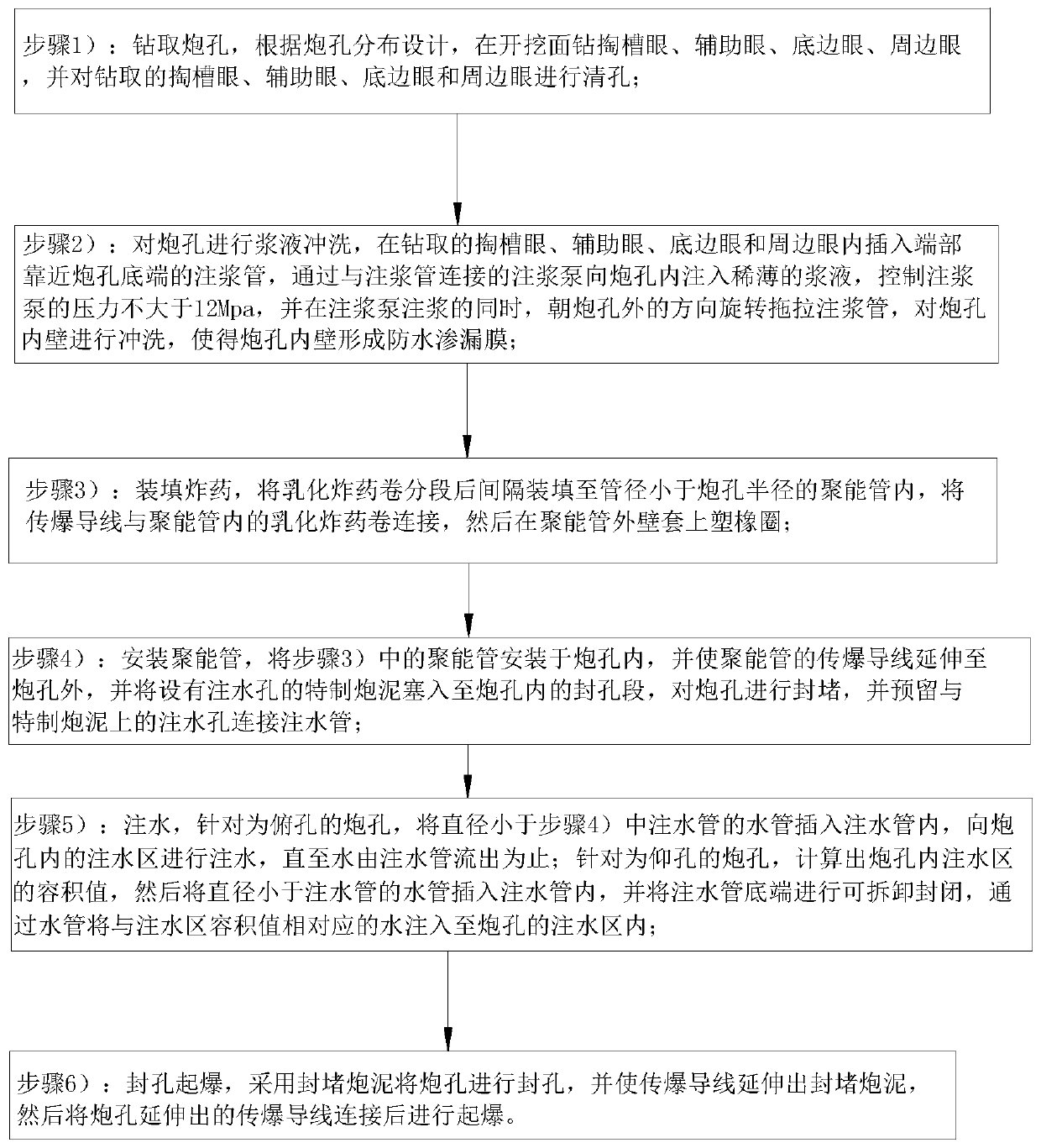

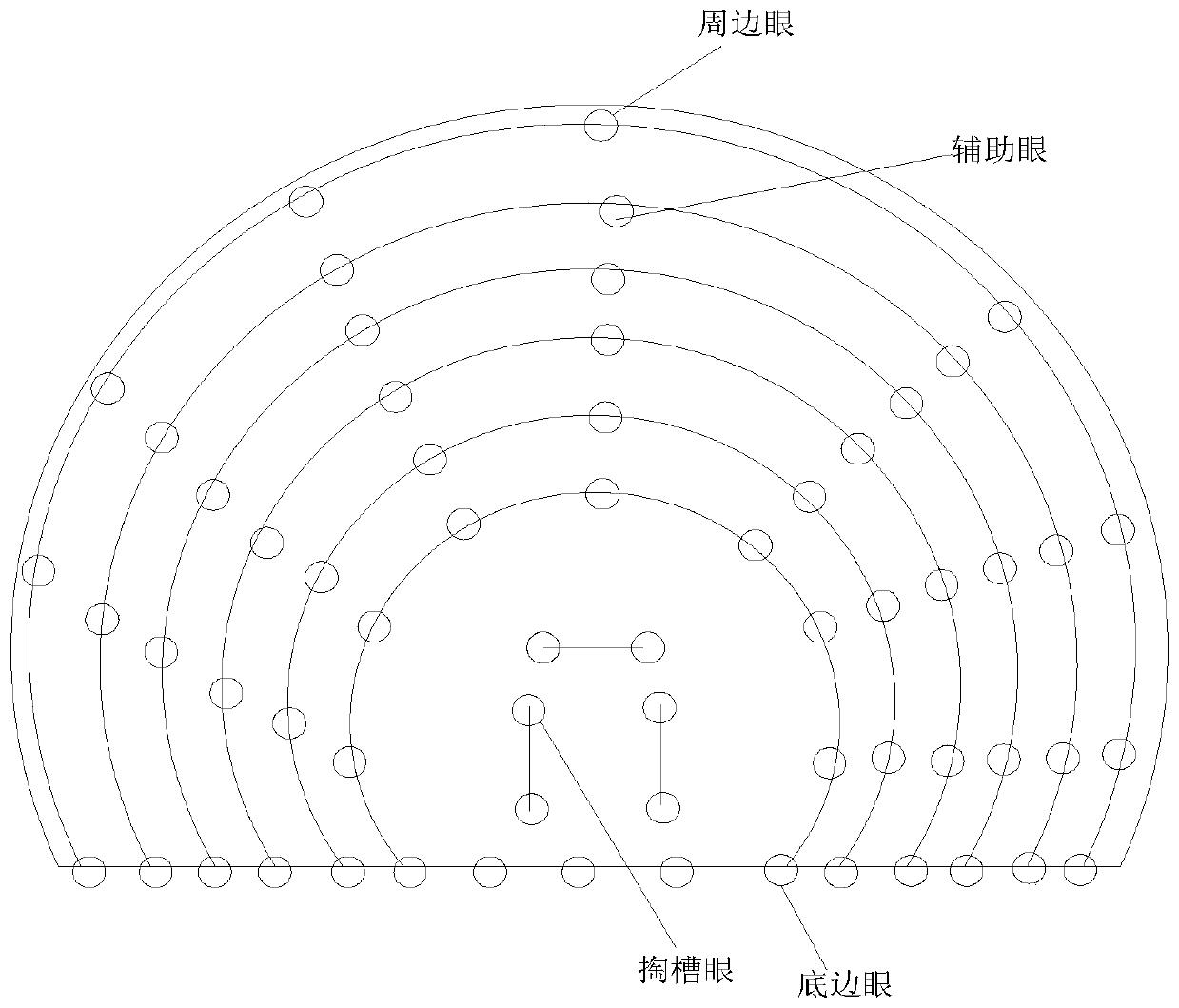

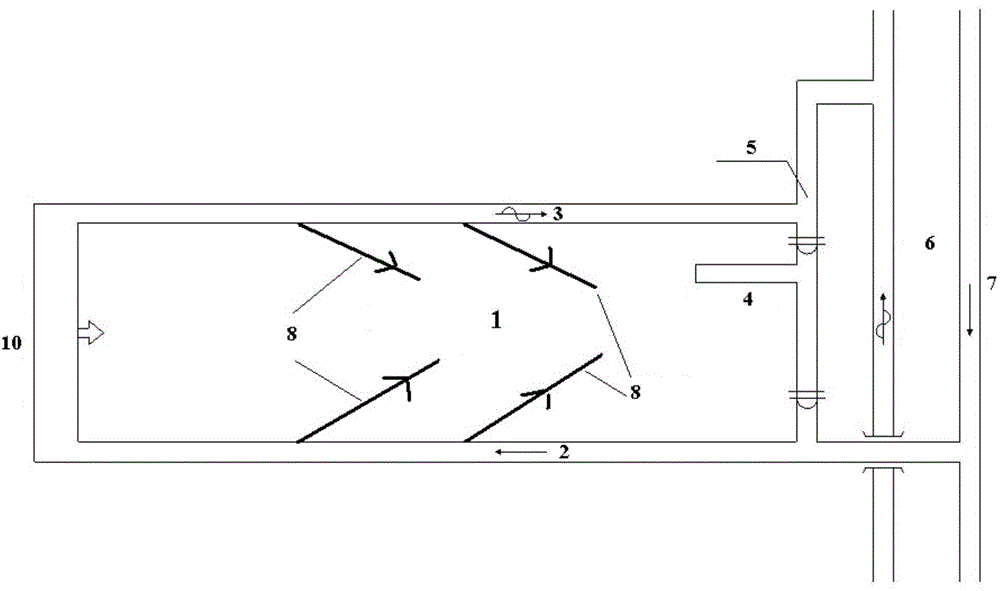

Hydraulic blasting construction method for joint fissure development rock mass tunnel

ActiveCN111536839AEven blasting energy transferImprove blasting qualityBlastingStructural engineeringTEX-explosive

The invention discloses a hydraulic blasting construction method for a joint fissure development rock mass tunnel, and relates to the technical field of tunnel blasting engineering. The hydraulic blasting construction method is characterized by comprising the following steps that 1) a blast hole is drilled; 2) the inner wall of the blast hole is washed by adopting specially-made slurry; 3) the energy gathering pipe is filled with explosives at intervals; 4) the energy gathering pipe is installed in the blast hole, the blast hole is plugged by adopting special stemming, and a water injection pipe is reserved; 5) water is injected, the blast hole is filled with the water by using the water injection pipe; and 6) the hole is sealed by adopting the plugging stemming, and an explosion propagation wire is connected for detonation. For a joint fissure development rock mass, joint fractures on the inner wall of the blast hole can be blocked, water injected into the blast hole is prevented from being lost in a blasting preparation stage, coupled medium water evenly transfers explosion energy to be acted on rock, the coupling effect of explosives and the water is improved, the blast hole utilization rate and the blasting efficiency are improved, the explosive use amount is reduced, the dust concentration of an operation site after blasting can be reduced, the operation site environmentis improved, meanwhile, the construction efficiency is high, and the cost is low.

Owner:CHONGQING JIAOTONG UNIVERSITY

Detonation method of bridge cylinder pile foundation with pile foundation diameter ranging from 1.4 m to 1.6 m

The invention relates to a detonation method of a bridge cylinder pile foundation with the pile foundation diameter ranging from 1.4 m to 1.6 m. The detonation method comprises the steps of hole drilling, explosive charging, blasthole opening blocking and detonation. The hole drilling method is that a center empty hole is vertically formed along the center line of the cylinder pile foundation, thecenter line of the cylinder pile foundation is the center, a blasthole inner ring is formed with the radius being 0.13 m-0.17 m, a blasthole middle ring is formed with the radius being 0.33 m-0.37 m,a blasthole outer ring is formed with the radius being 0.63 m-0.67 m, four vertically-arranged grooving holes are evenly distributed on the blasthole inner ring, five vertcialy-arranged assisting holes are evenly formed in the blasthole middle ring, and twelve inclined perimeter holes are evenly distributed on the blasthole outer ring; included angles formed between the central axes of the perimeter holes and the vertical direction are arccot10-arccot12, and the distances between hole tops of the perimeter holes and the center empty hole are smaller than the distances between hole bottoms ofthe perimeter holes and the center empty hole. The detonation method is high in detonation quality, high in construction efficiency and low in detonation cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

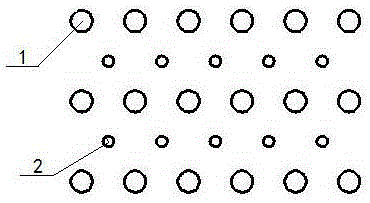

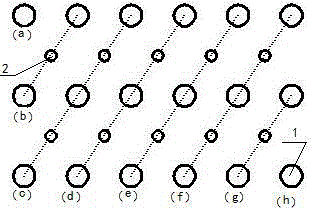

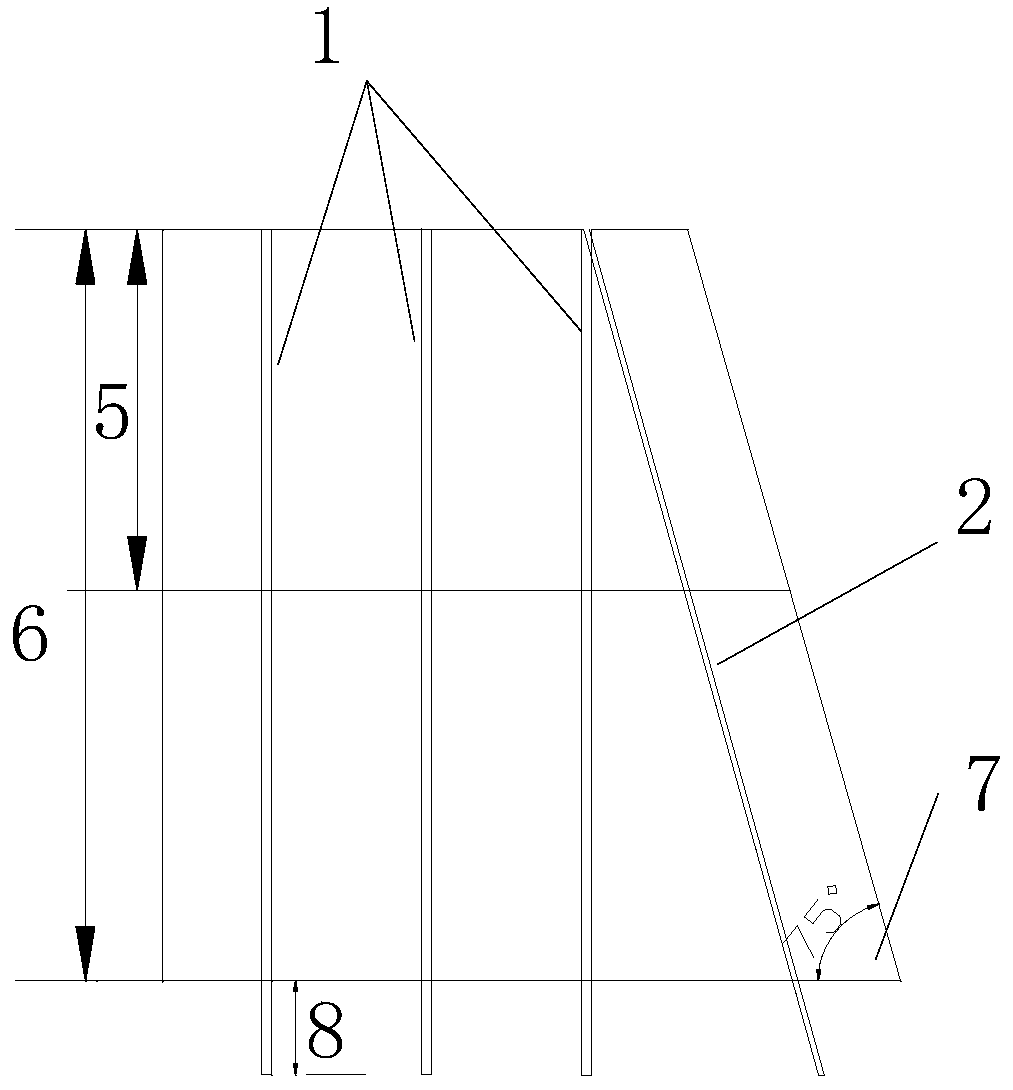

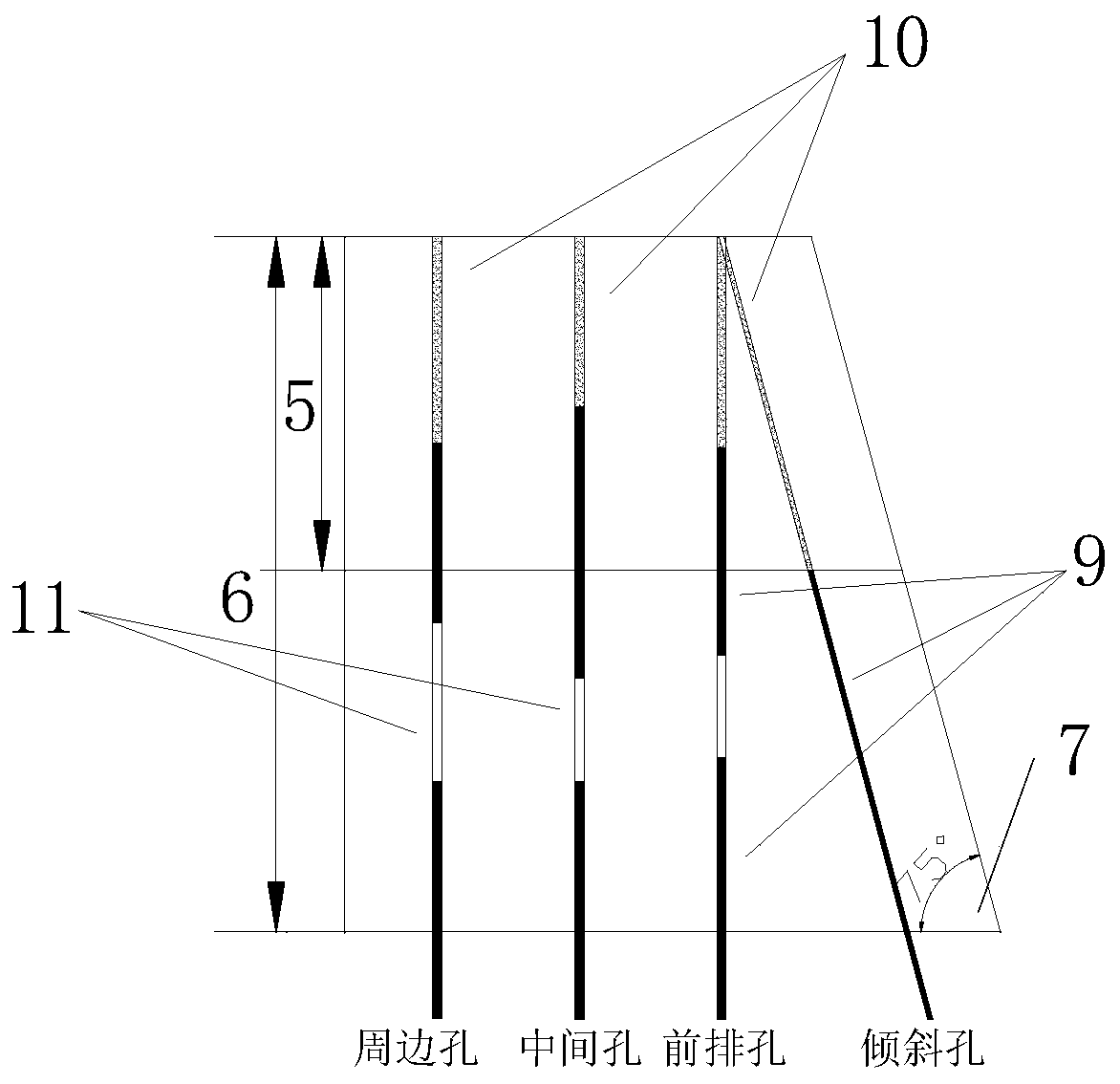

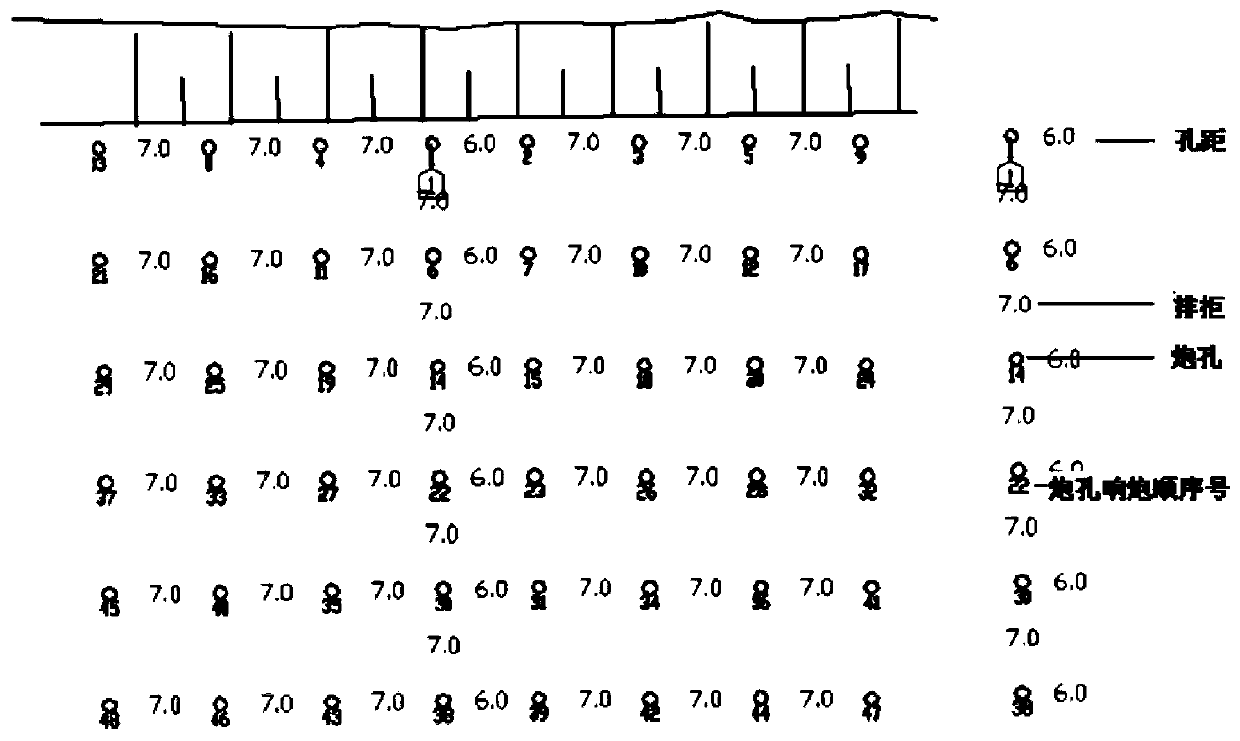

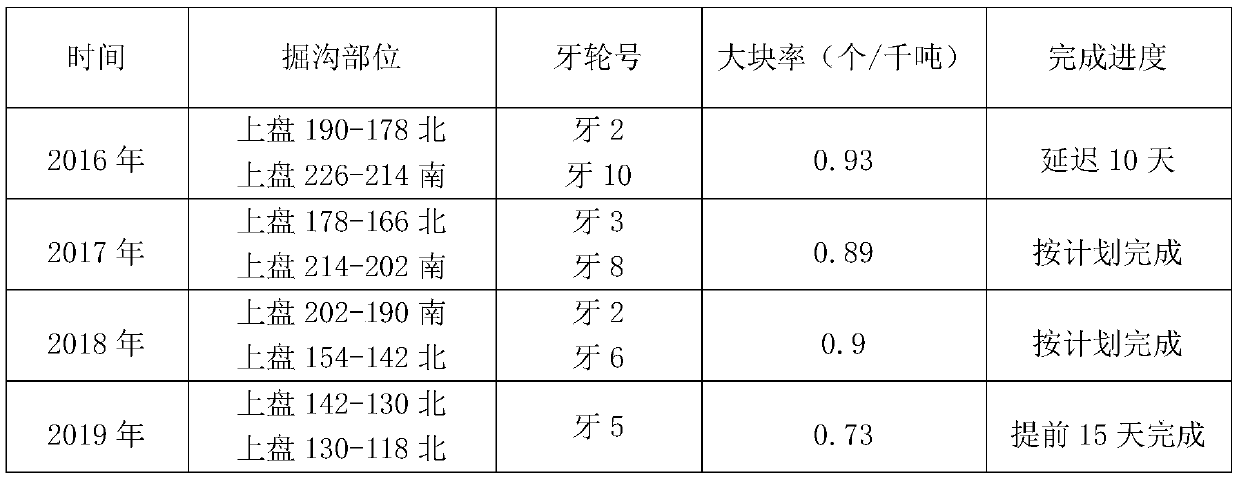

24m high step slope expansion blasting method for open pit mine

PendingCN111307003AGuaranteed perforation efficiencyImprove blasting qualityBlastingOpen-pit miningMining engineeringStructural engineering

The invention discloses a 24m high step slope expansion blasting method for an open pit mine. On a basis of considering advantages and disadvantages of a rotary drill and a down-the-hole drill fully,a way of combination operation of the rotary drill, the pore diameter of which is 310 mm, and the down-the-hole drill, the pore diameter of which is 165 mm, is adopted for hole arrangement. The methodcomprises a specific measure of adding 3-4 165 mm inclined holes parallel to a step slope between two front row 310 mm vertical holes. The method reduces a front row resistance line of high step blasting effectively and guarantees the perforating efficiency of the drills to the maximum extent, so that blasting economy is rationalized.

Owner:BAOTOU IRON & STEEL GRP

Strip mine deep hole ditch digging detonation method

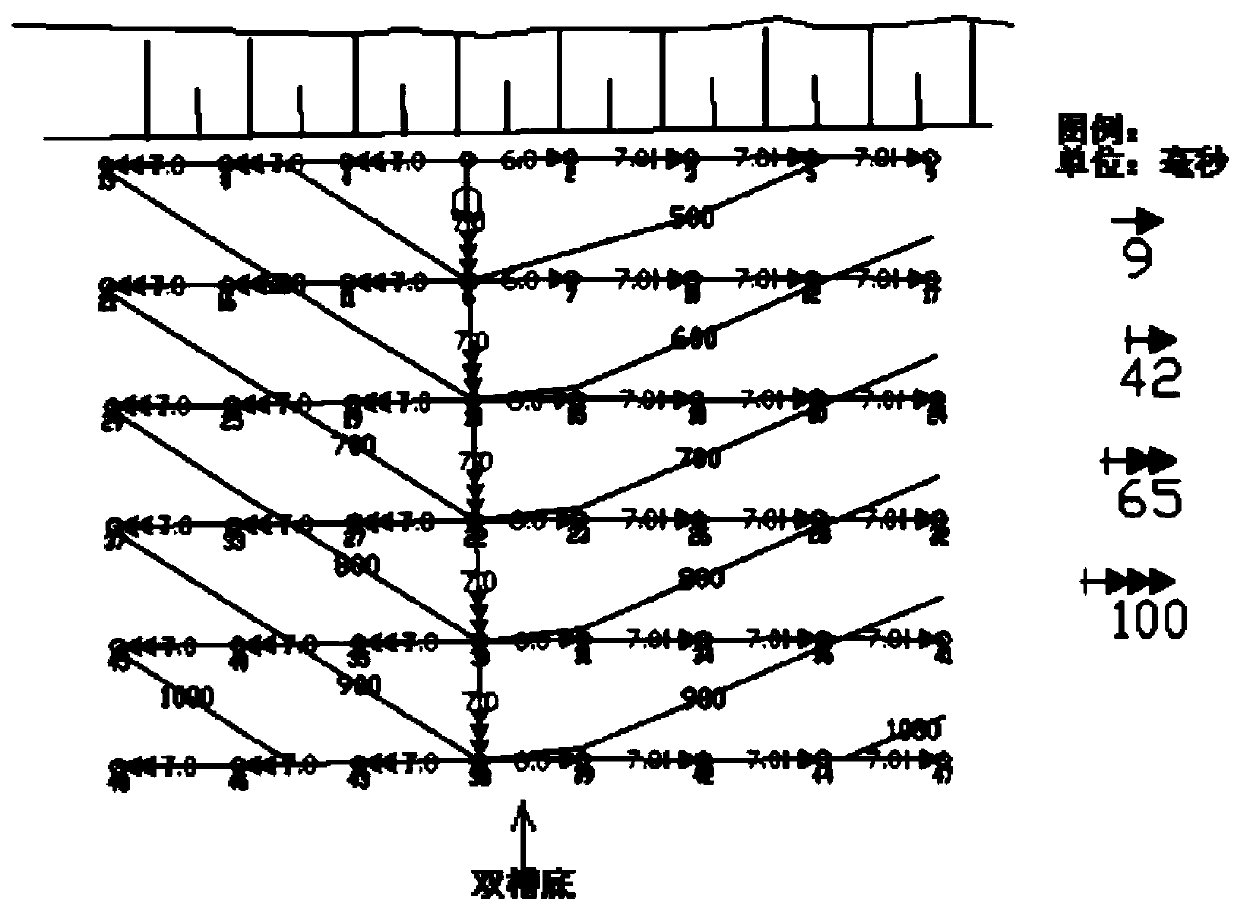

InactiveCN111207638AImprove blasting qualityImprove mining efficiencyBlastingOpen-pit miningDetonationMining engineering

The invention discloses a strip mine deep hole ditch digging detonation method. The distance between two lines of holes in the middle of a detonation area is smaller than the line distance by 0.8-1 m;the V-shaped double-groove-bottom form is adopted in the two lines of the middle according to the detonation sequence; and the V-shaped double-groove-bottom form is a detonation sequence that middletwo blast holes are detonated at the same time, and then blast holes on two wings are successively detonated. The strip mine deep hole ditch digging detonation method has the advantages that detonation backlash is controlled within 7 m, the detonation quality is effectively improved, and the mining efficiency is improved.

Owner:BENGANG STEEL PLATES

Loose blasting excavation construction method of intermediary weathered sandstone stratum rock

The invention discloses a loose blasting excavation construction method of an intermediary weathered sandstone stratum rock, and relates to the technical field of rock blasting construction methods. The loose blasting excavation construction method of the intermediary weathered sandstone stratum rock comprises the following steps that (1) a drilling machine working field is leveled; (2) hole distribution and medicine loading are conducted; (3) network connection is conducted; (4) safety alert is blasted; and (5) blast firing blasting is conducted. In the step (2), blast hole distribution technical parameters on districts with the digging depth less than 5 meters and districts with the digging depth great than 5 meters are accurately calculated, thus the blasting parameters are strictly controlled, the technical parameters comprise a blast hole inclined angle, a blast hole diameter, a step height, blast hole depth, the minimum resistance line, over-drilling depth of blast hole bottom, ablocking length, blast hole distance, blast array pitch, the medicine loading amount of each blast hole. The loose blasting excavation construction method of the intermediary weathered sandstone stratum rock has the advantages that blasting power control is precise and accurate, the blasting quality is high, and stability of a roadbed slope and safety of houses and personnel nearby can be ensured.

Owner:CHINA MCC5 GROUP CORP +1

Method for preventing and treating coal and gas outburst by explosion

The invention provides a method for preventing and treating coal and gas outburst by explosion. The method comprises the following steps of drilling a hole; forming at least one guiding hole for guiding an explosion energy spreading direction in a wall of a guide tube; sequentially mounting at least one blasting charge with a priming device inside on the bottom of the inner wall of the guide tube from bottom to top; enabling the guiding holes and one of the blasting charges to be positioned on the same portion of the guide tube; guiding a blasting fuse out of the guide tube after the priming devices of the various blasting charges are connected in series through the blasting fuse; injecting water in the drilled hole until water reaches an opening of the hole; slowly and stably inserting the guide tube fixed with the blasting charges and a cement cannon in the drilled hole filled with the water; detonating the various blasting charges so that fractures are generated in coal bodies of a specific region according to a certain extension direction by blasting charge explosion energy and destruction and earthquake effects and under the guiding effect of the guiding holes, and a gas extracting channel is formed; starting gas extracting equipment at regular intervals; and extracting gas outwards through a gas extracting channel so as to reduce gas outburst risks. The method has the advantages of wide application range, low construction cost and good convenience in construction.

Owner:SHANDONG UNIV OF SCI & TECH +2

a sandblasting machine

ActiveCN106078533BAchieve recyclingIncrease profitBlast gunsAbrasive feedersSand blastingSpray nozzle

The invention discloses a sand blasting machine, which comprises a sand blasting chamber. The sand blasting chamber comprises a feeding hole for feeding and discharging workpieces, and spray nozzles arranged in the sand blasting chamber; the spray nozzles are fixed on a spray nozzle drive mechanism; a feeding mechanism capable of driving the workpieces to feed and discharge is matched on the feeding hole; the spray nozzle drive mechanism comprises at least one swinging mechanism arranged in the sand blasting chamber; each swinging mechanism is provided with one spray nozzle and is driven by a first drive part to swing to the left and right; the feeding mechanism comprises a placement platform used for placing workpieces and a second drive part; and the placement platform comprises at least one positioning table used for placing the workpieces, and a sealing plate arranged behind the positioning table and matched with the feeding hole of the sand blasting chamber. A plurality of swinging mechanisms are arranged in the sand blasting chamber, and a plurality of spray nozzles can swing to blast sand on the workpieces when being used for blasting sand, so that a uniform and efficient sand blasting effect is realized; and in addition, the workpieces can be quickly fed and discharged in the sand blasting chamber through the feeding mechanism, so that the sand blasting efficiency of the workpieces is further improved.

Owner:宁波精益微型轴有限公司

Blasting method for bridge cylindrical pile foundation with pile foundation diameter of 1.1-1.3m

The invention relates to a blasting method for a bridge cylindrical pile foundation with a pile foundation diameter of 1.1-1.3m. The blasting method comprises the steps of drilling, filling explosives, blocking a blast hole and detonating, wherein the drilling step comprises the following steps of: vertically forming a central bull hole along a central line of the cylindrical pile foundation, forming a blast hole inner ring with a radius of 0.13-0.17m by taking the central line of the cylindrical pile foundation as a center, forming a blast hole outer ring with a radius of 0.48-0.52m by takingthe center line of the cylindrical pile foundation as the center, uniformly distributing four slotting holes which are vertically distributed in the blast hole inner ring, and uniformly distributing10 peripheral holes which are formed in an inclined mode in the blast hole outer ring, wherein included angles between the center axes of the peripheral holes and the vertical direction are arccot10-arccot12, and distances from the hole tops of the peripheral holes to the hollow bull hole are smaller than those from the hole bottoms of the peripheral holes to the hollow bull hole. The blasting method is high in blasting quality, is high in construction efficiency, is low in blasting cost, further can alleviate damages, on a pile hole protective wall, of blasting vibrations and flying rocks, and prevents the flying rocks from damaging construction equipment.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

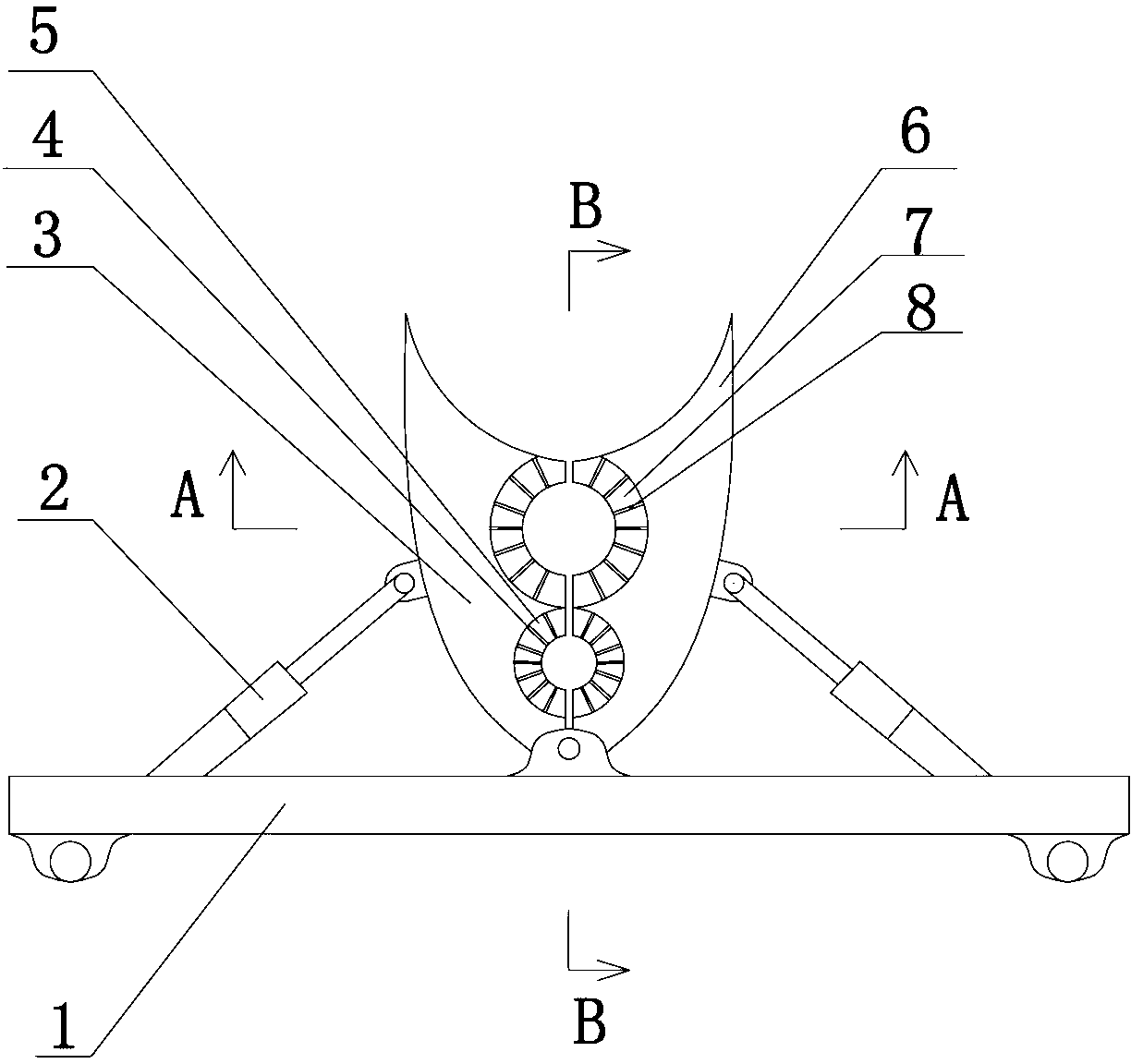

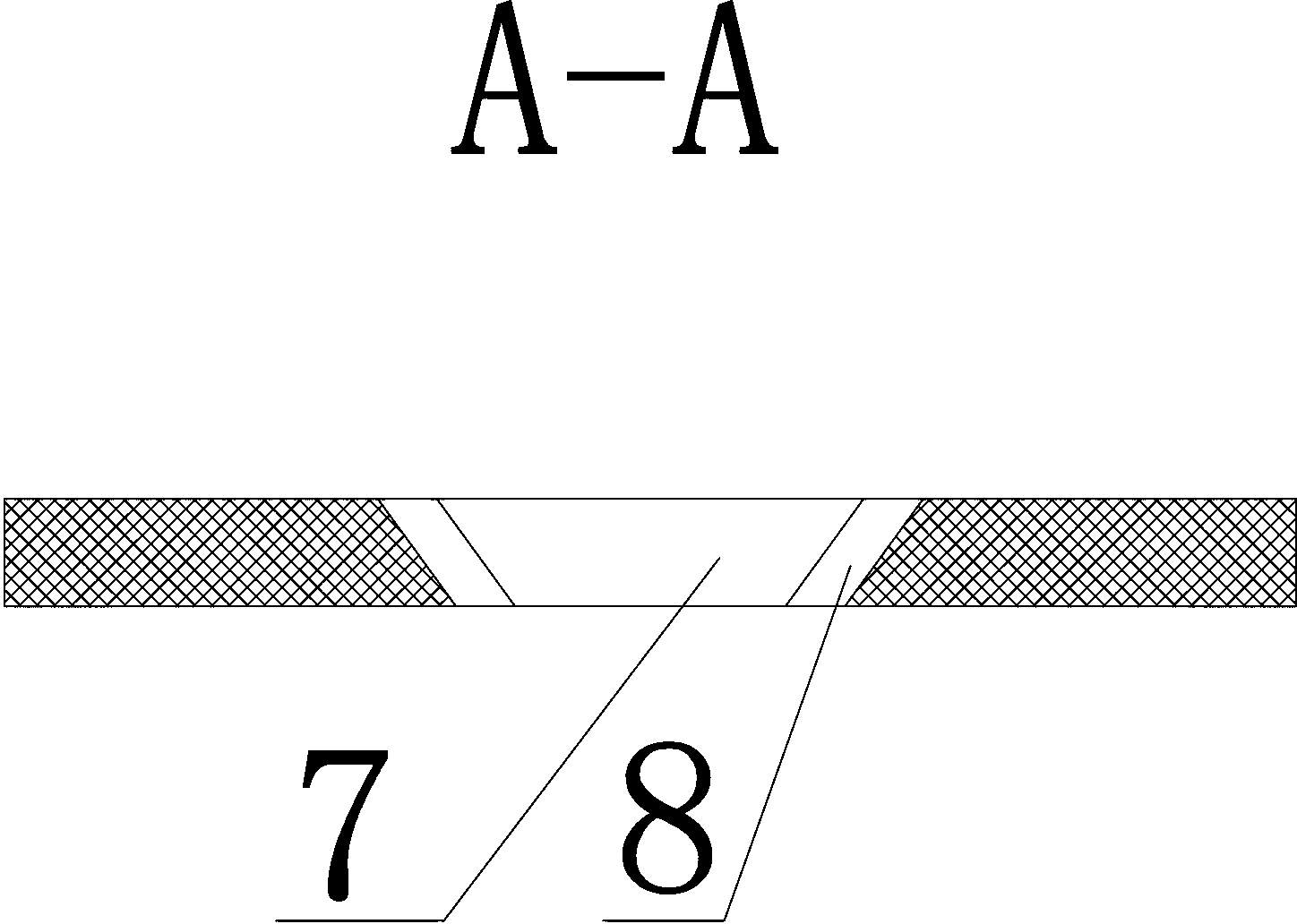

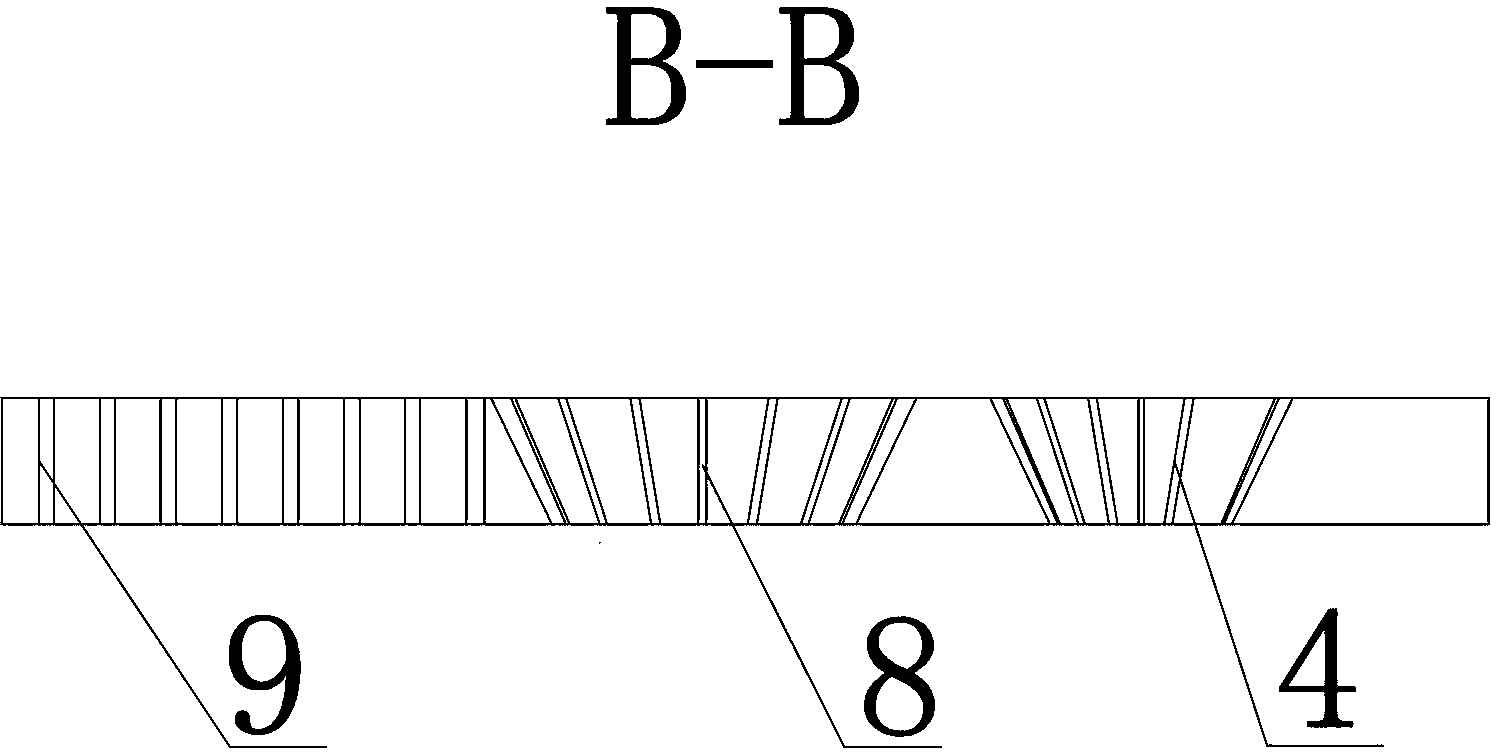

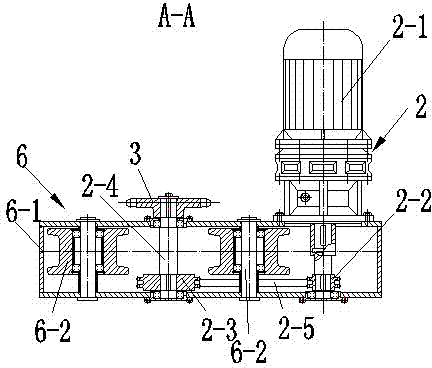

Crab-claw type filling device for filling slag into mine blast holes

ActiveCN102706227AImprove safety and reliability performanceImprove blasting qualityBlastingSlagEngineering

The invention discloses a crab-claw type filling device for filling slag into mine blast holes. The crab-claw type filling device is characterized in that a scraping plate device is arranged at the front part of a driving vehicle; a blast-hole-filling auxiliary protecting device is arranged in the slag-filled blast holes; the scraping plate device consists of a support fixed at the front of the driving vehicle and a double-arm crab-claw type scraping plate hinged with the middle part of the support and connected with a hydraulic driving system; the double-arm crab-claw type scraping plate is formed by hinging two symmetrical crab-claw scraping plates; crushing jaws are arranged at the front parts of the crab-claw scraping plates; a forehead opening of each crushing jaw is provided with a group of meshing teeth III; the middle and the tail of each crab-claw scraping plate are respectively provided with a semicircular hopper surface I and a semicircular hopper II with different diameters; and the semicircular hopper surface I and the semicircular hopper surface II are respectively provided with a group of meshing teeth I and a group of meshing teeth II. The crab-claw type filling device disclosed by the invention has the advantages that higher efficiency and higher quality for the filling work of the blast holes are achieved, the safety, reliability and the blasting quality of the mine blasting are effectively improved and the labor intensity of workers is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Blasting method for bridge cylindrical pile foundation with diameter being 0.8-1 m

InactiveCN108061492AReduce consumptionTake advantage ofBlastingExcavationsExplosive materialBuilding construction

The invention relates to a blasting method for a bridge cylindrical pile foundation with the diameter being 0.8-1 m. The blasting method includes the steps of hole drilling, explosive material charging, blast hole opening blocking and detonating. According to the step of hole drilling, a central empty hole is vertically formed along the central line of the cylindrical pile foundation, a blast holeinner circle is formed with the central line of the cylindrical pile foundation as the center and with the radius of 0.13-0.17 m, a blast hole outer circle is formed with the central line of the cylindrical pile foundation as the center and with the radius of 0.33-0.37 m, four vertical grooving holes are evenly distributed in the blast hole inner circle, and nine inclined peripheral holes are evenly distributed in the blast hole outer circle. The included angle between the central axis of the peripheral holes and the vertical direction is arccot 10-arccot 12, and the distance from the tops ofthe peripheral holes to the central empty hole is smaller than the distance from the bottoms of the peripheral holes to the central empty hole. According to the blasting method for the bridge cylindrical pile foundation with the diameter being 0.8-1 m, blasting quality is high, construction efficiency is high, blasting cost is low, damage of blasting shock and flying stones to a pile hole protective wall can be reduced,, and flying stones are prevented from damaging construction equipment.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Roof structure of sandblasting room

The invention discloses a roof structure of a sandblasting room. The roof structure of the sandblasting room comprises a wall body and also comprises a driving mechanism, a transmission chain wheel, a flexible tarpaulin, a plurality of trusses, a plurality of trolleys, a sliding rail, a chain rail and a hinge structure; the sliding rail and the chain rail are fixedly connected onto the upper portion of the wall body; the driving mechanism is in transmission connection with the transmission chain wheel; the driving mechanism and the transmission chain wheel are fixedly connected onto the first trolley; the transmission chain wheel is meshed with the chain rail in a transmission mode; two ends of the plurality of trusses are fixedly connected with the corresponding trolleys respectively; the plurality of trusses are hinged to each other through the hinge structure; the trolleys are in rolling connection with the sliding rail; the flexible tarpaulin is fixedly connected with the plurality of trusses. According to the roof structure of the sandblasting room, the sealing effect is good, the pollution to the external environment in the process of sandblasting is avoided, and the efficiency and the quality of the sandblasting are improved.

Owner:常州钢构建设工程有限公司

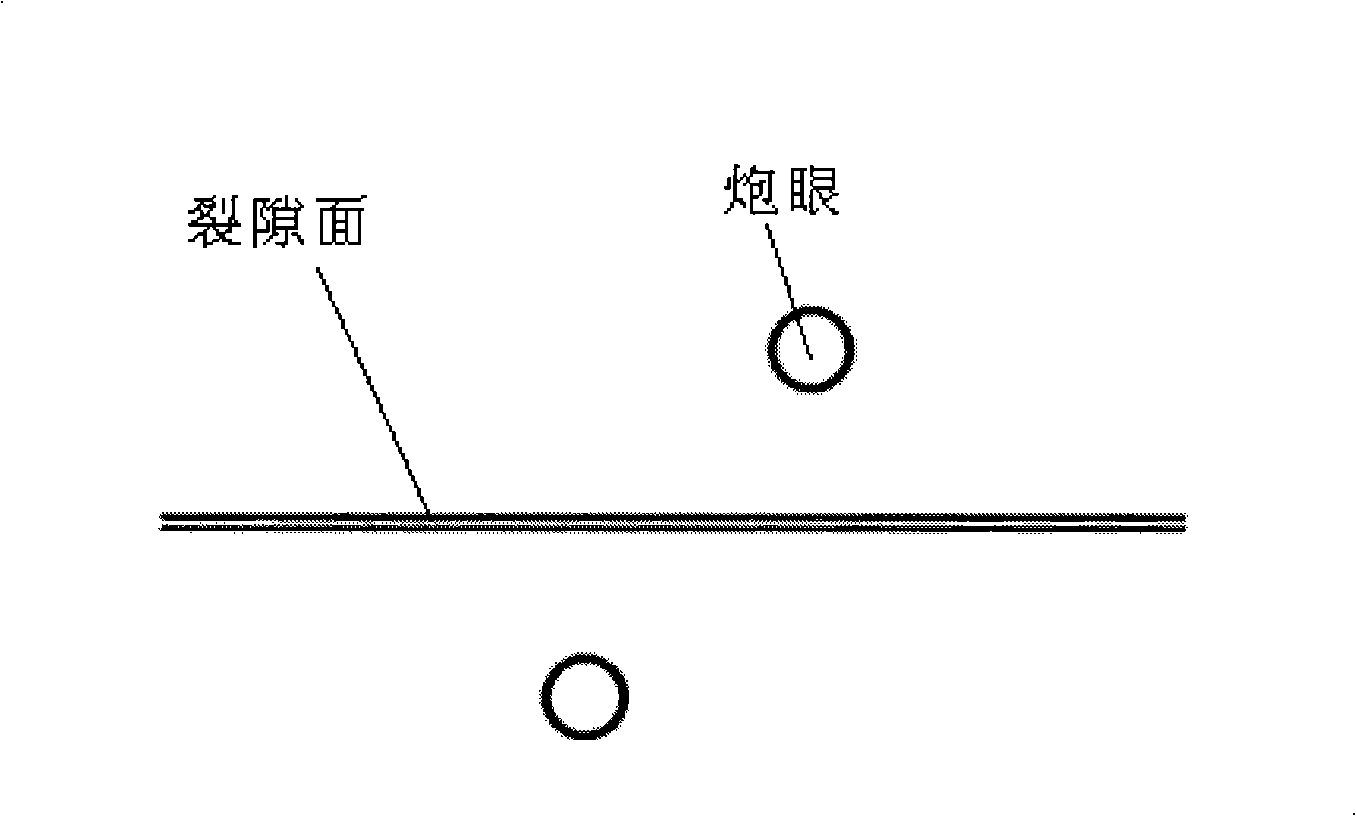

Crack rock laneway molding control method

The invention discloses a cranny rock mass laneway forming and control method. A working surface is provided with periphery shot holes. When the working surface has a bigger fissure plane, the included angle between the connecting line of the two periphery shot holes of the two sides of the fissure plane and the fissure plane ranges from 45 degree to 90 degree, and the periphery shot holes on the two sides of the fissure plane are arranged symmetrically and are chiseled in parallel as much as possible. When the detonation is performed, the detonation tier number is increased and the explosive load of the complete section is decreased, particular the explosive load of the single detonation section. Therefore, the effect of smooth surface blasting is greatly improved, the traced hole rate is up to more than 85 percent, the laneway smooth surface blasting quality is improved, the laneway overexcavation quantity is reduced, the laneway forming regularity is guaranteed, the gunning material is reduced and the stability of the laneway rock mass is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com