Strip mine deep hole ditch digging detonation method

An open-pit mine and deep-hole technology, which is applied in the mining, blasting, and earthwork drilling of open-pit mines, can solve the problems of reducing blasting efficiency, reducing blasting area, and increasing blasting costs, so as to improve blasting quality and mining efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

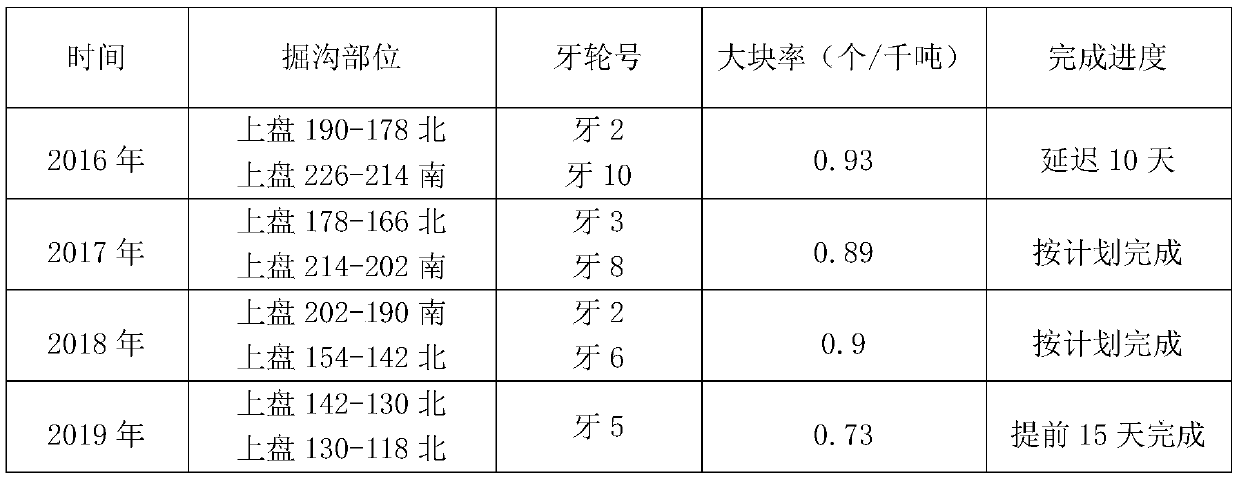

Examples

Embodiment Construction

[0012] Explanation of terms:

[0013] Ditto: A horizontal trench excavated in an open-pit mine to establish a bench or the initial working line of a bench. Ditch opening in open-pit mines is a preparation project for open-pit mining.

[0014] Open-pit mining: the operation form of mining metal ore, coal and other non-metallic ore deposits from the surface through downward step stripping.

[0015] Explosion area: the scope of the explosion area.

[0016] Step Height: The vertical distance between the bottom face of a step and the plane of the top of the step.

[0017] Ditch: A trench excavated for the establishment of a bench line.

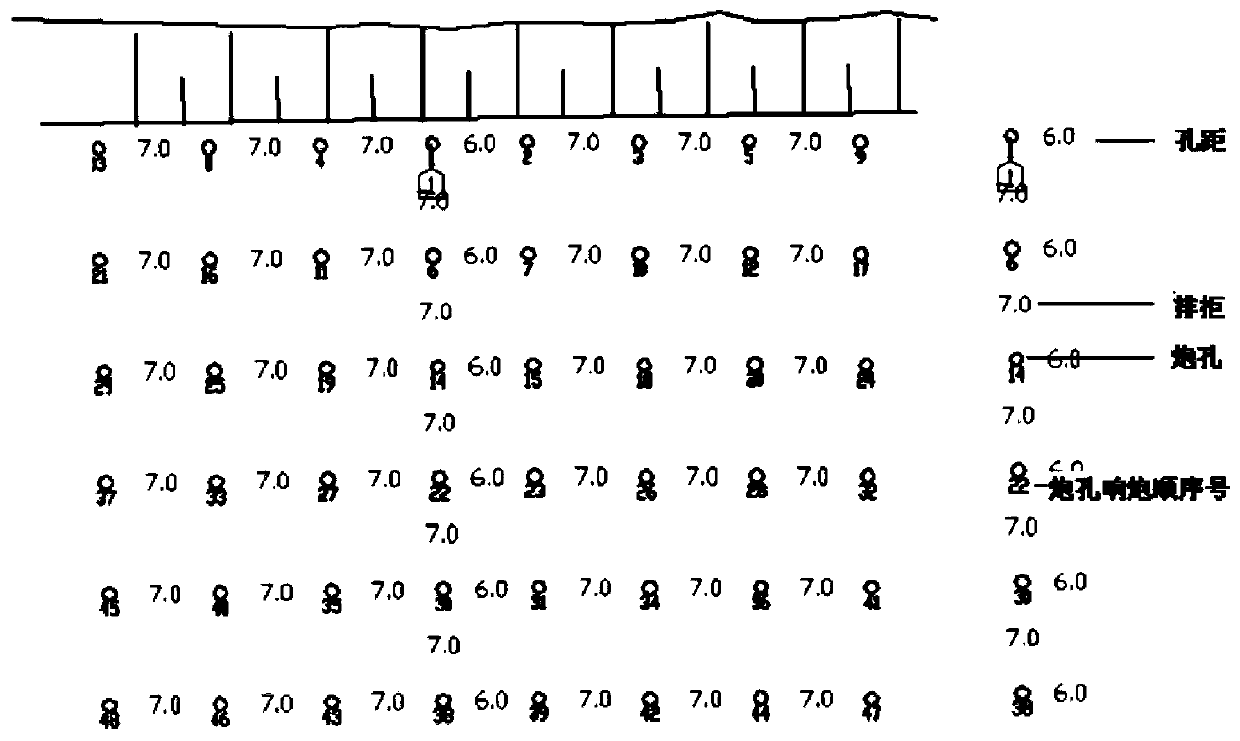

[0018] (Bunker Hole) Row Distance: The distance between rows of gun holes.

[0019] (Bunker Hole) Hole Distance: The distance between the blast hole and the hole.

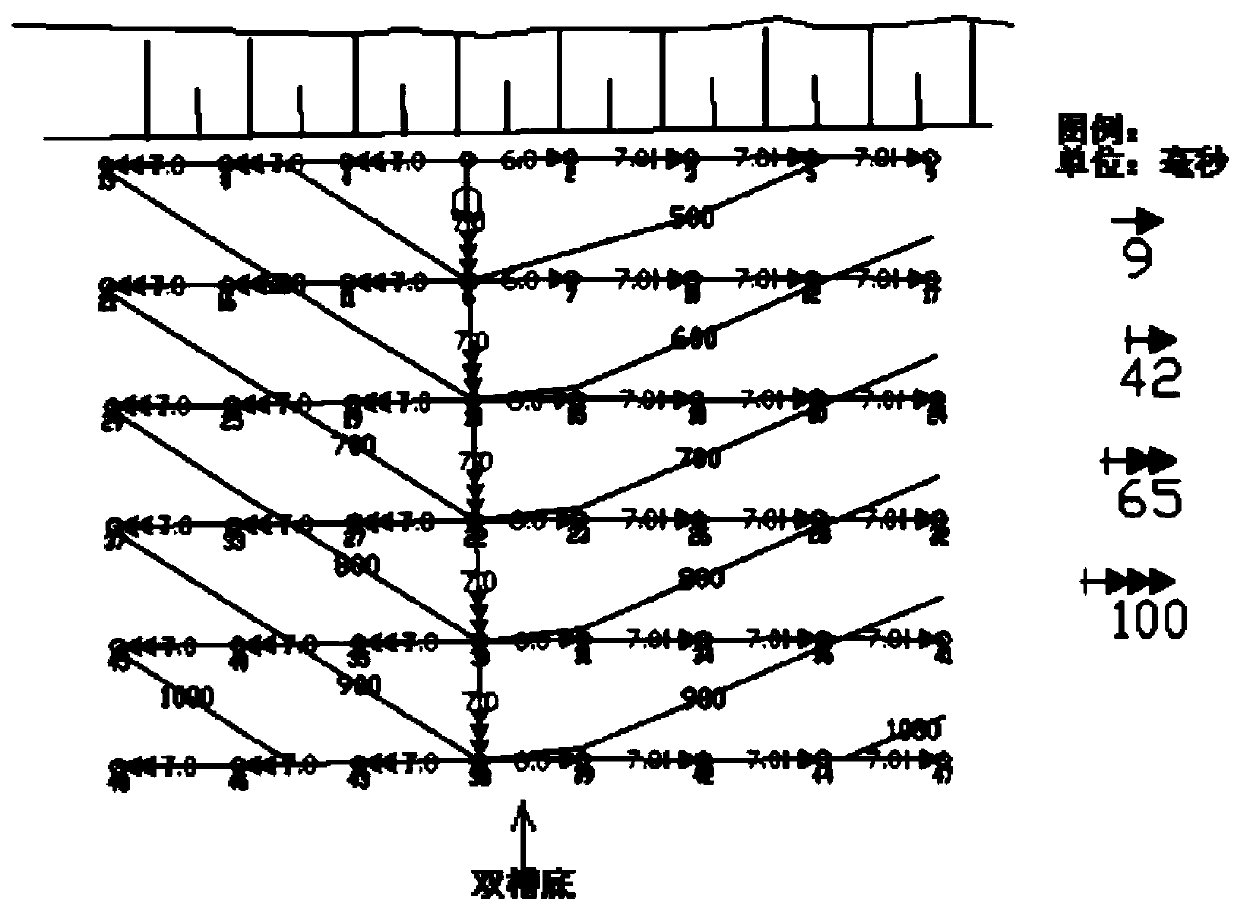

[0020] The V-shaped detonation sequence refers to a detonation sequence in which the single blast hole in the middle is blasted first, and the blast holes on the two wings are blas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com