Blasting method for bridge cylindrical pile foundation with diameter being 0.8-1 m

A technology for cylindrical piles and bridges, used in blasting, excavation, infrastructure engineering, etc., can solve the problems of high blasting cost, poor blasting quality, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for blasting a cylindrical pile foundation of a bridge with a pile foundation diameter of 0.9 m, comprising the following steps:

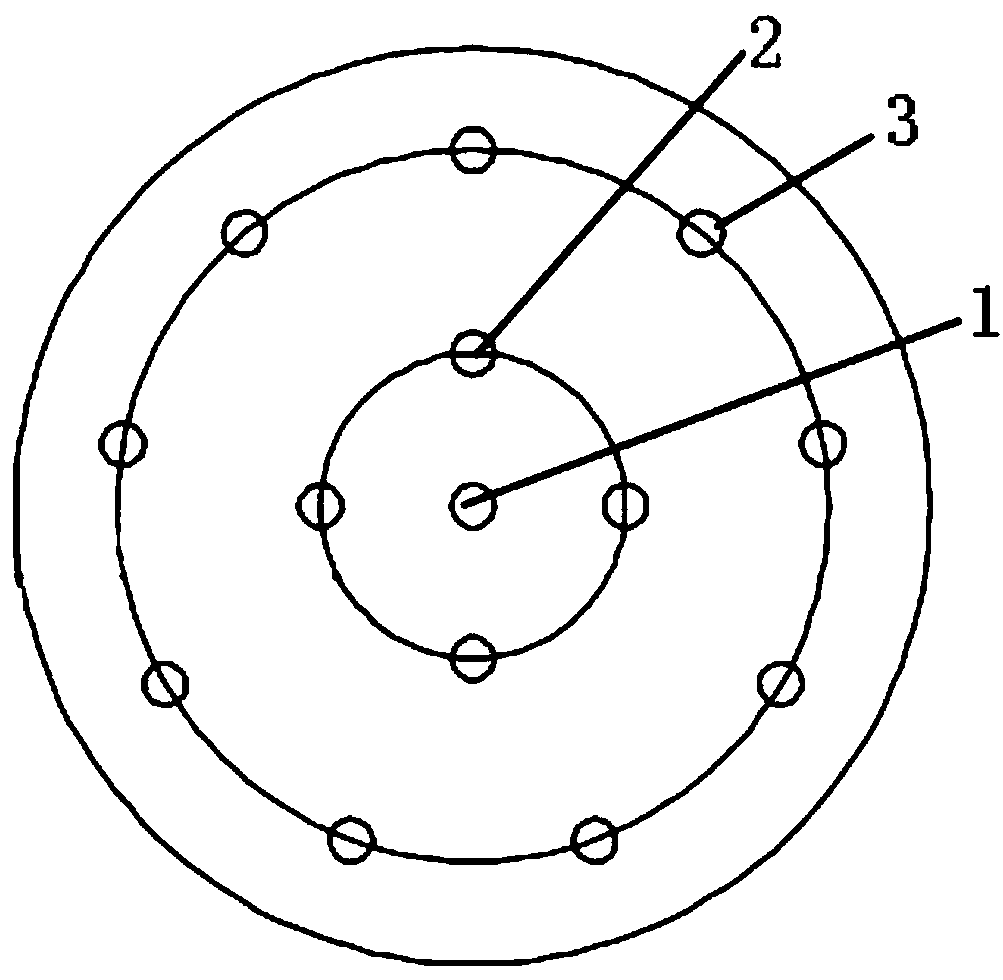

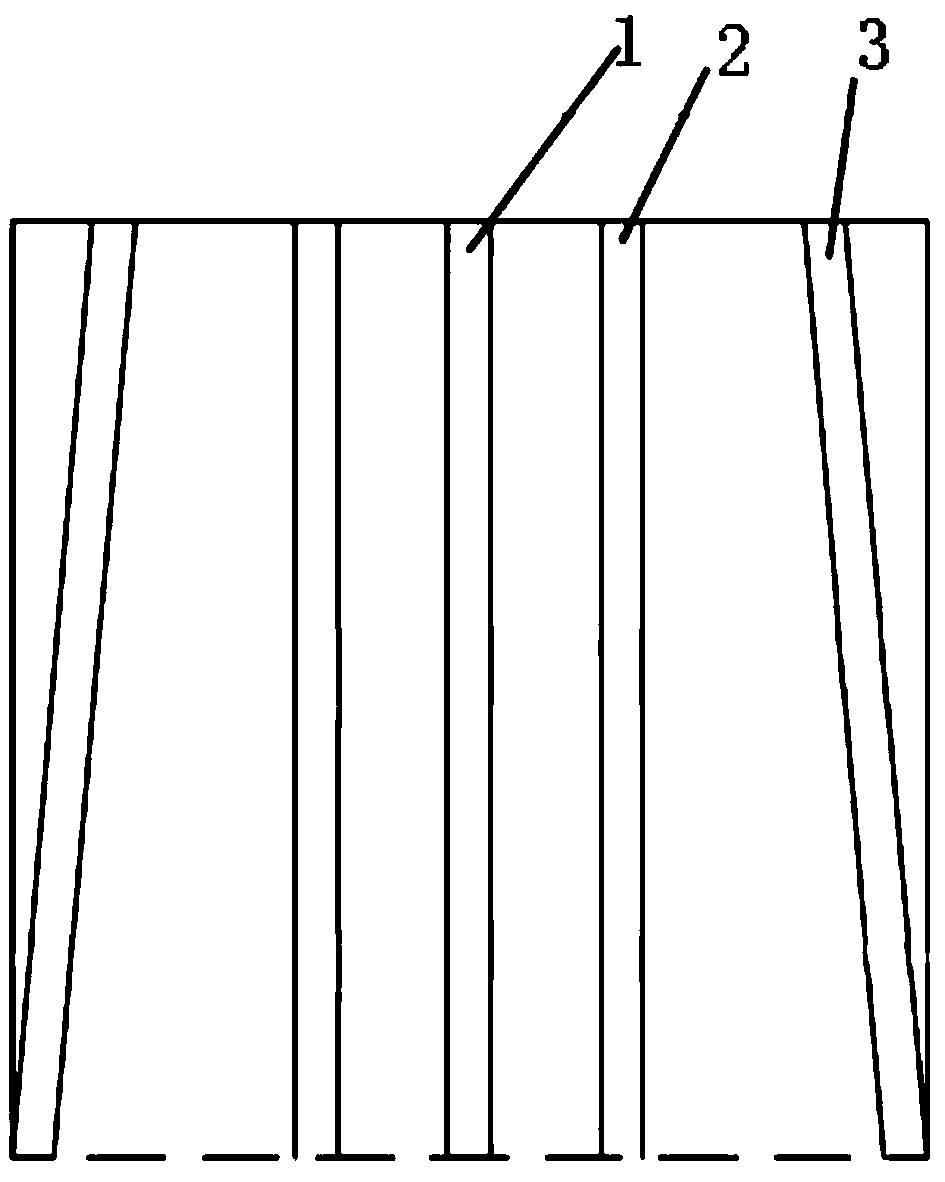

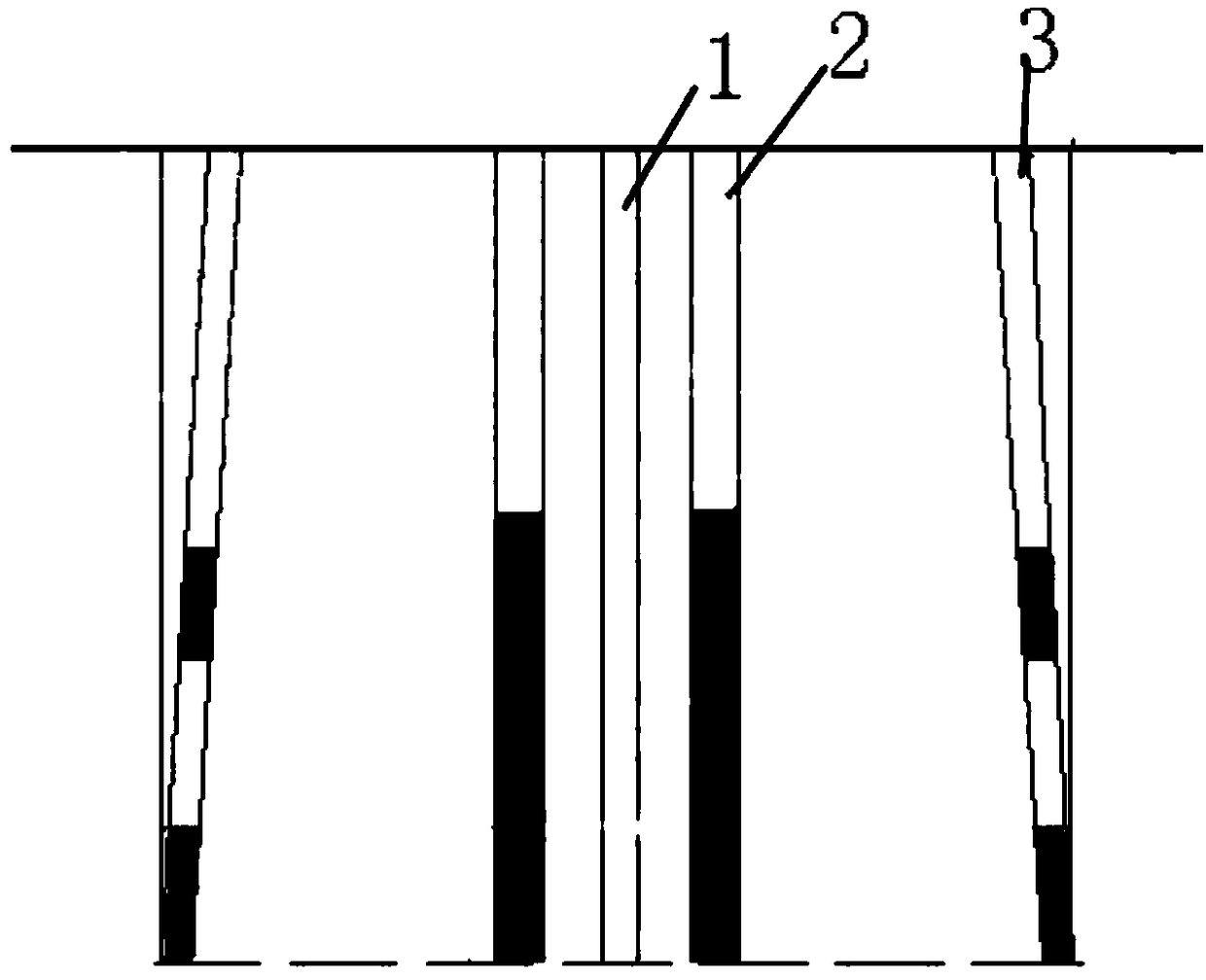

[0029] Drilling: such as figure 1 with figure 2 As shown, a central hollow hole 1 is vertically arranged along the centerline of the cylindrical pile foundation, and the inner ring of the blast hole is formed with the centerline of the cylindrical pile foundation as the center and with a radius of 0.15m. The outer ring of the blast hole is formed as a radius, and 4 vertically arranged cut holes 2 are evenly distributed on the inner ring of the blast hole, and 9 peripheral holes 3 arranged obliquely are evenly distributed on the outer ring of the blast hole; The included angle between the central axis of the peripheral hole 3 and the vertical direction is arccot12, and the distance from the top of the peripheral hole 3 to the central hole 1 is smaller than the distance from the bottom of the peripheral hole...

Embodiment 2

[0035] This embodiment provides a method for blasting a cylindrical pile foundation of a bridge with a diameter of 1 m, comprising the following steps:

[0036] Drilling: such as figure 1 with figure 2 As shown, a central hole 1 is arranged vertically along the centerline of the cylindrical pile foundation, and the inner circle of the blast hole is formed with the centerline of the cylindrical pile foundation as the center and with a radius of 0.17m. The outer ring of the blast hole is formed as a radius, and 4 vertically arranged cut holes 2 are evenly distributed on the inner ring of the blast hole, and 9 peripheral holes 3 arranged obliquely are evenly distributed on the outer ring of the blast hole; The included angle between the central axis of the peripheral hole 3 and the vertical direction is arccot11, and the distance from the top of the peripheral hole 3 to the central hole 1 is smaller than the distance from the bottom of the peripheral hole 3 to the central hole ...

Embodiment 3

[0042] This embodiment provides a method for blasting a cylindrical pile foundation of a bridge with a pile foundation diameter of 0.8 m, comprising the following steps:

[0043] Drilling: such as figure 1 with figure 2 As shown, a central hole 1 is arranged vertically along the centerline of the cylindrical pile foundation, and the inner circle of the blast hole is formed with the centerline of the cylindrical pile foundation as the center and with a radius of 0.13m. The outer ring of the blast hole is formed as a radius, and 4 vertically arranged cut holes 2 are evenly distributed on the inner ring of the blast hole, and 9 peripheral holes 3 arranged obliquely are evenly distributed on the outer ring of the blast hole; The included angle between the central axis of the peripheral hole 3 and the vertical direction is arccot10, and the distance from the top of the peripheral hole 3 to the central hole 1 is smaller than the distance from the bottom of the peripheral hole 3 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com