Patents

Literature

96results about How to "Reduce blasting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

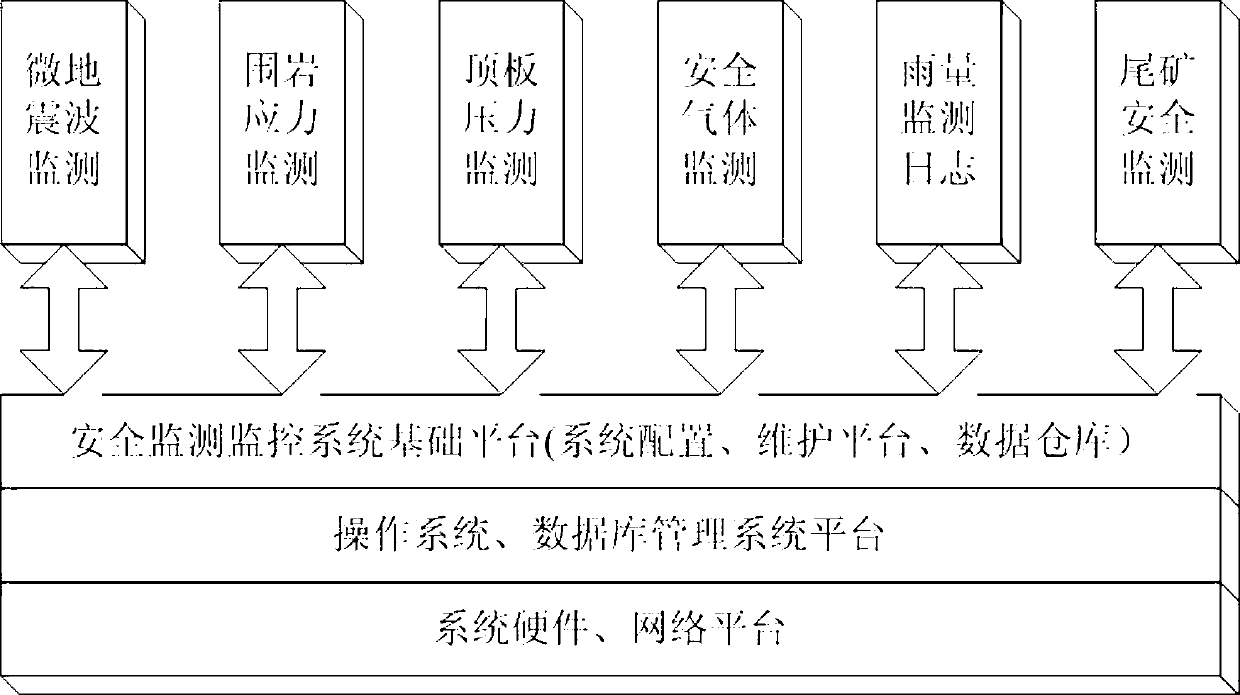

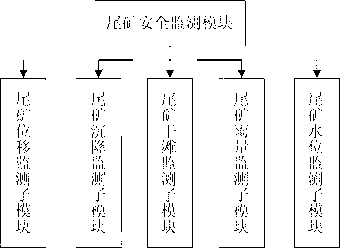

Digital mine safety monitoring and inspecting system

InactiveCN102999873AReduce outputSafe and efficient productionData processing applicationsInformation processingRelational system

The invention provides a digital mine safety monitoring and inspecting system which sequentially comprises four layers, namely a system hardware and network platform, an operation system and database management system platform, a safety monitoring and inspecting system base platform and a safety monitoring and inspecting system software platform, wherein in the four layers, the lower layer provides service for the upper layer and provides interactive connectors. The digital mine safety monitoring and inspecting system is integrally constructed on the hardware platform and network platform, and interaction between the digital mine safety monitoring and inspecting system and a bottom layer hardware facility and a monitoring and inspecting system is achieved through an operation system and a database management system, the interactive information is processed and stored in the safety monitoring and inspecting system base platform in distributing mode, and the safety monitoring and inspecting system software platform at the highest layer achieves scanning and processing on the interactive information through different functional subsystems and issues control information to the operation system and database management system platform through the safety monitoring and inspecting system base platform. The digital mine safety monitoring and inspecting system has the advantages of being capable of achieving safety monitoring, safety alarm and safety control on mines.

Owner:SHANDONG GOLD GROUP

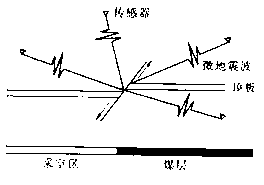

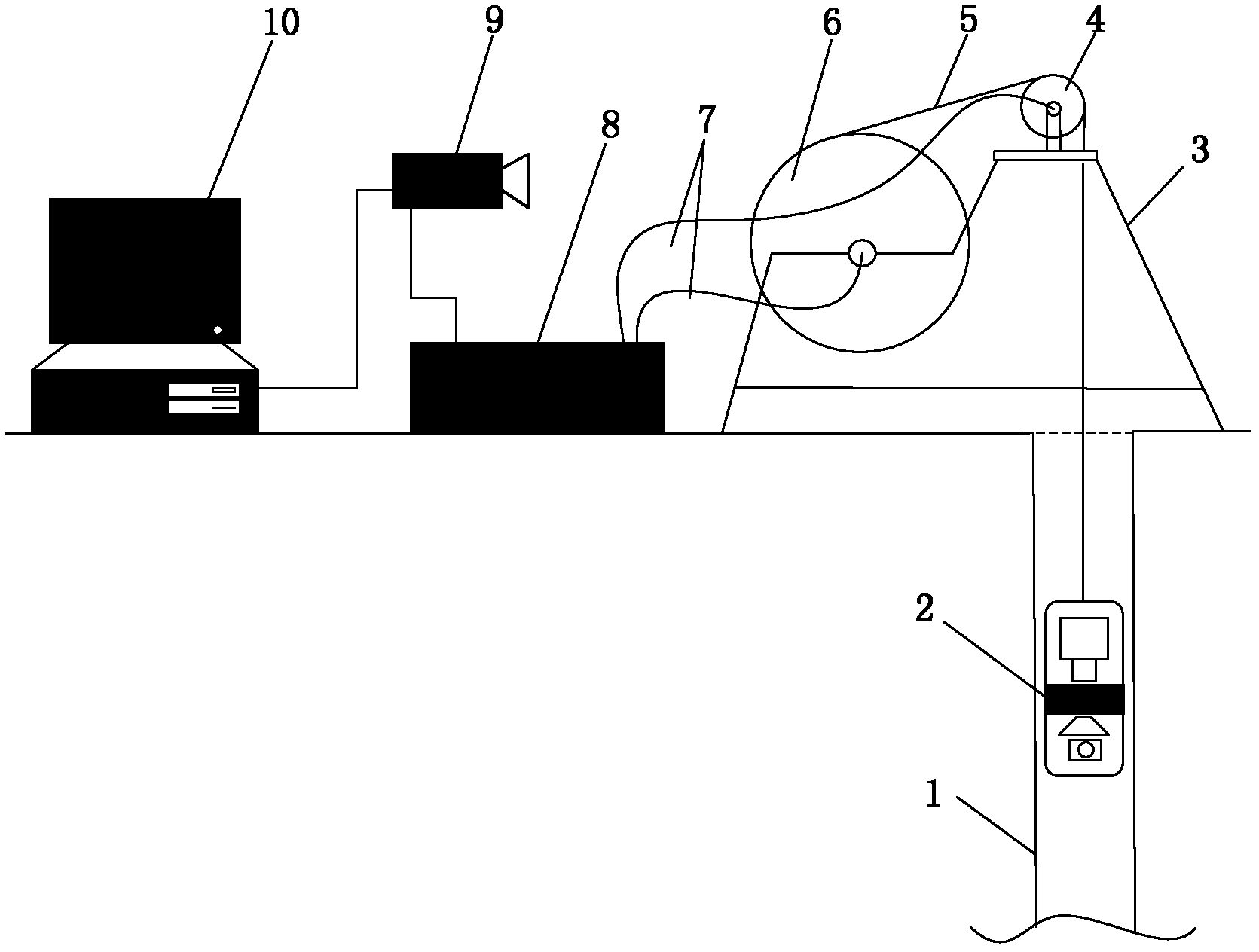

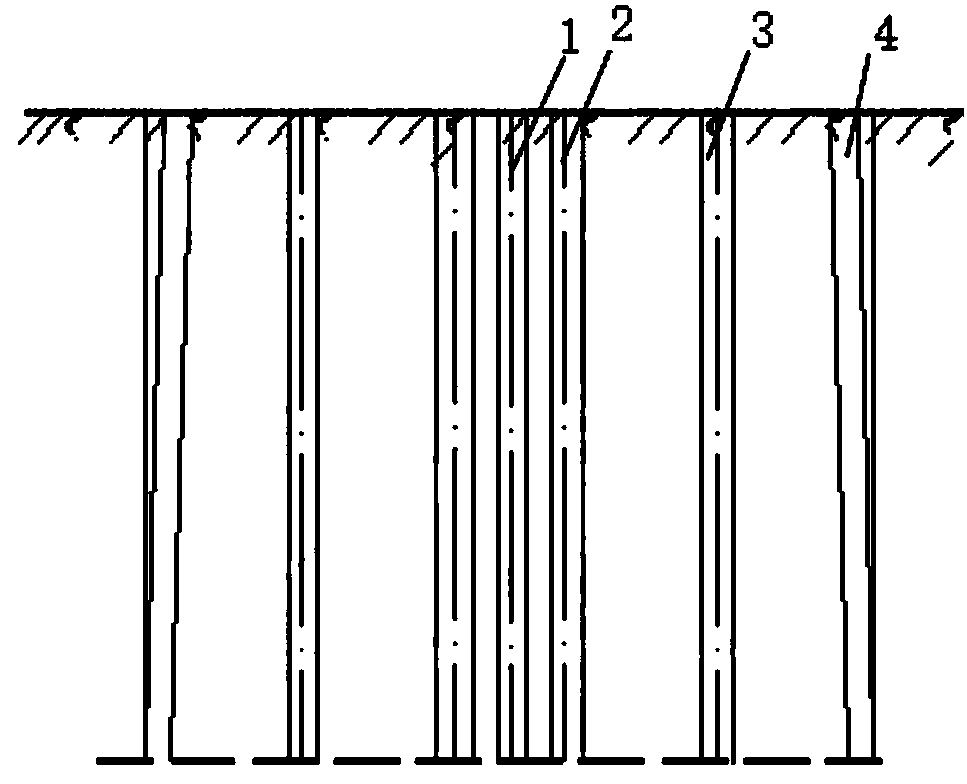

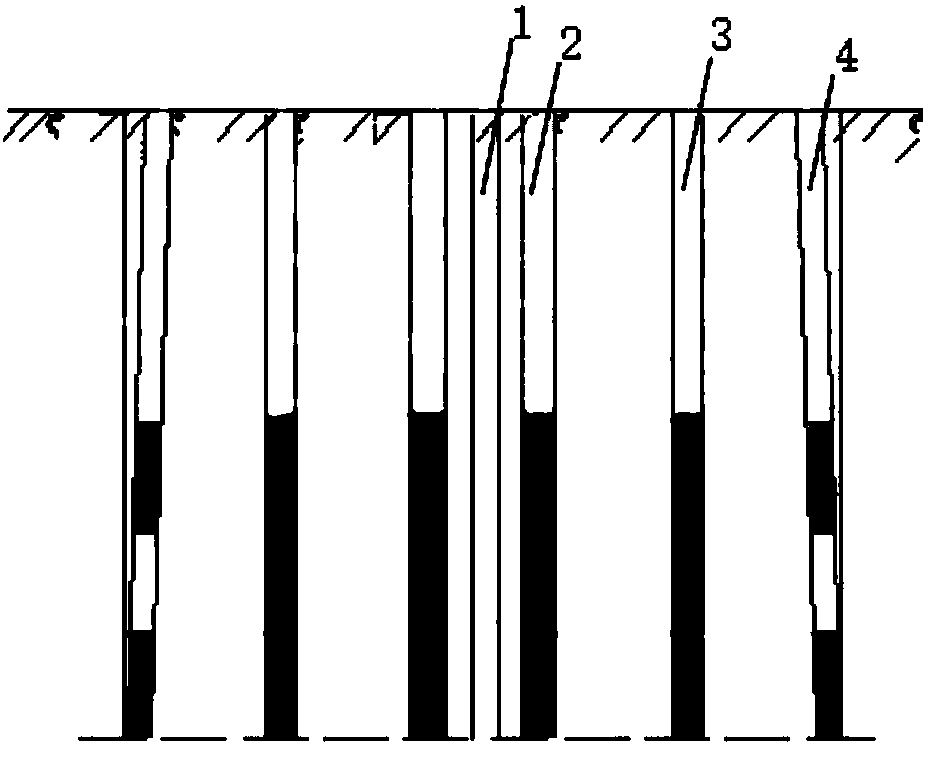

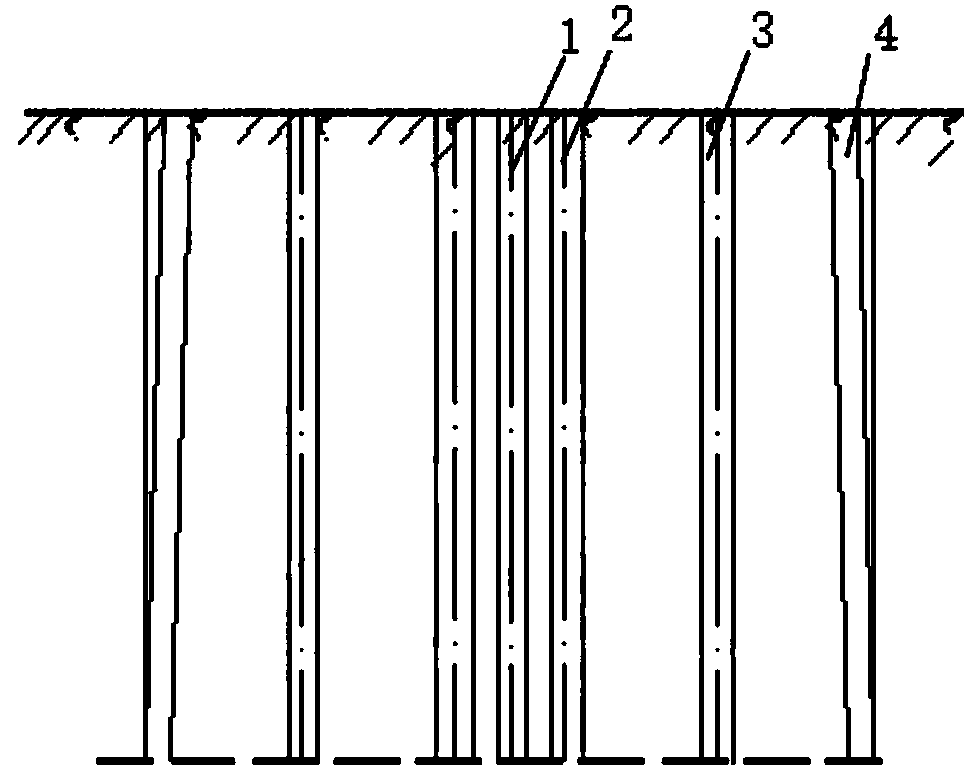

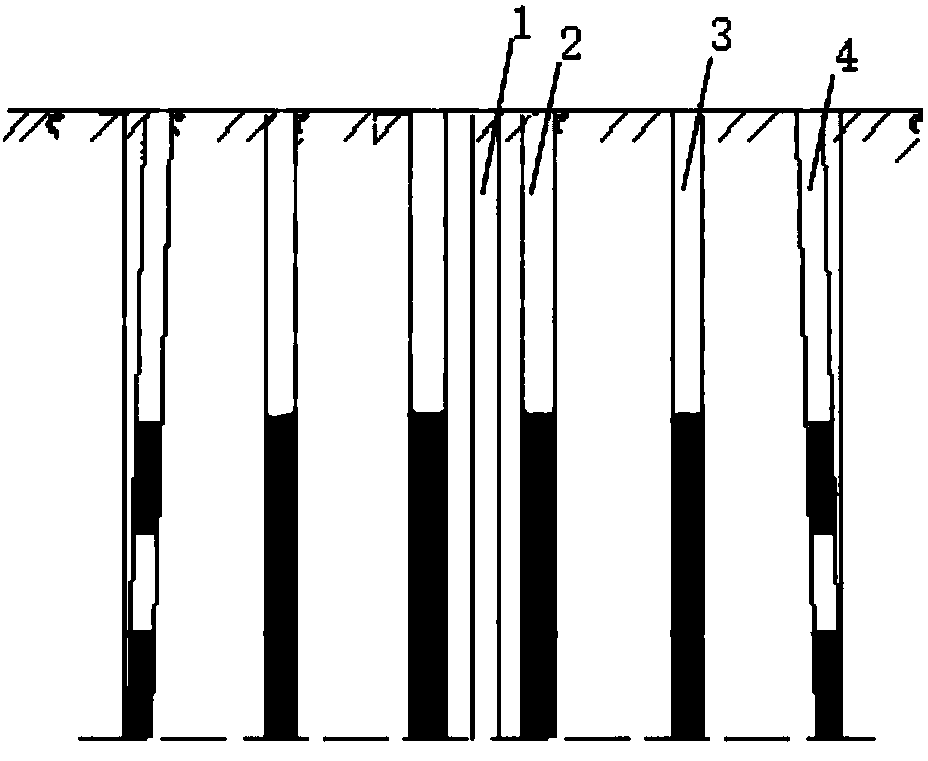

Deep-hole blasting construction technology in fractured rocks

The invention discloses a deep-hole blasting construction technology in fractured rocks. The technology comprises the following steps: firstly finding out information such as joint fracture occurrence in the inner wall of a blasting hole, development degree, space position by utilizing a drilling camera shooting technology; and then carrying out optimization design for blasting parameters, such as explosive load of a blasting hole, explosive load structure, the length of an explosive roll, blasting sequences according to the storage condition of the joint fracture in each blasting hole, thus the aim to improve the blasting effect, reduce the effect of blasting quality by the fracture and reduce the blasting cost is realized. The technology provided by the invention is especially suitable for a medium-deep hole blasting construction technology of soft cracked crocks of joint fracture of underground metal ores, the effect degree for blasting quality by joint fracture of the crocks can be reduced effectively, the damage to surrounding rocks by the blasting shock is reduced, the damage caused by shock waves to surrounding drill holes is reduced, and the blasting cost is saved.

Owner:CENT SOUTH UNIV

Bamboo-chip smooth wall protection blasting method for joint fissure mud rock slope

InactiveCN101900519AEasy processing and installationSafe and reliableBlastingExcavationsState of artStructural engineering

The invention relates to a bamboo-chip smooth wall protection blasting method for a joint fissure mud rock slope. The method comprises the following steps of: binding cartridges in certain distance to form a wall protection cartridge on a wall protection device, arranging the wall protection device back to the rock on the reserved rock side, inserting the wall protection cartridge into a light blasting hole, reserving certain clearance between the cartridge and four walls of the blasting hole, and performing smooth wall protection blast. Compared with the prior art, the method has the advantages of low cost, good effect, safety, reliability, strong practicability and the like.

Owner:TONGJI UNIV

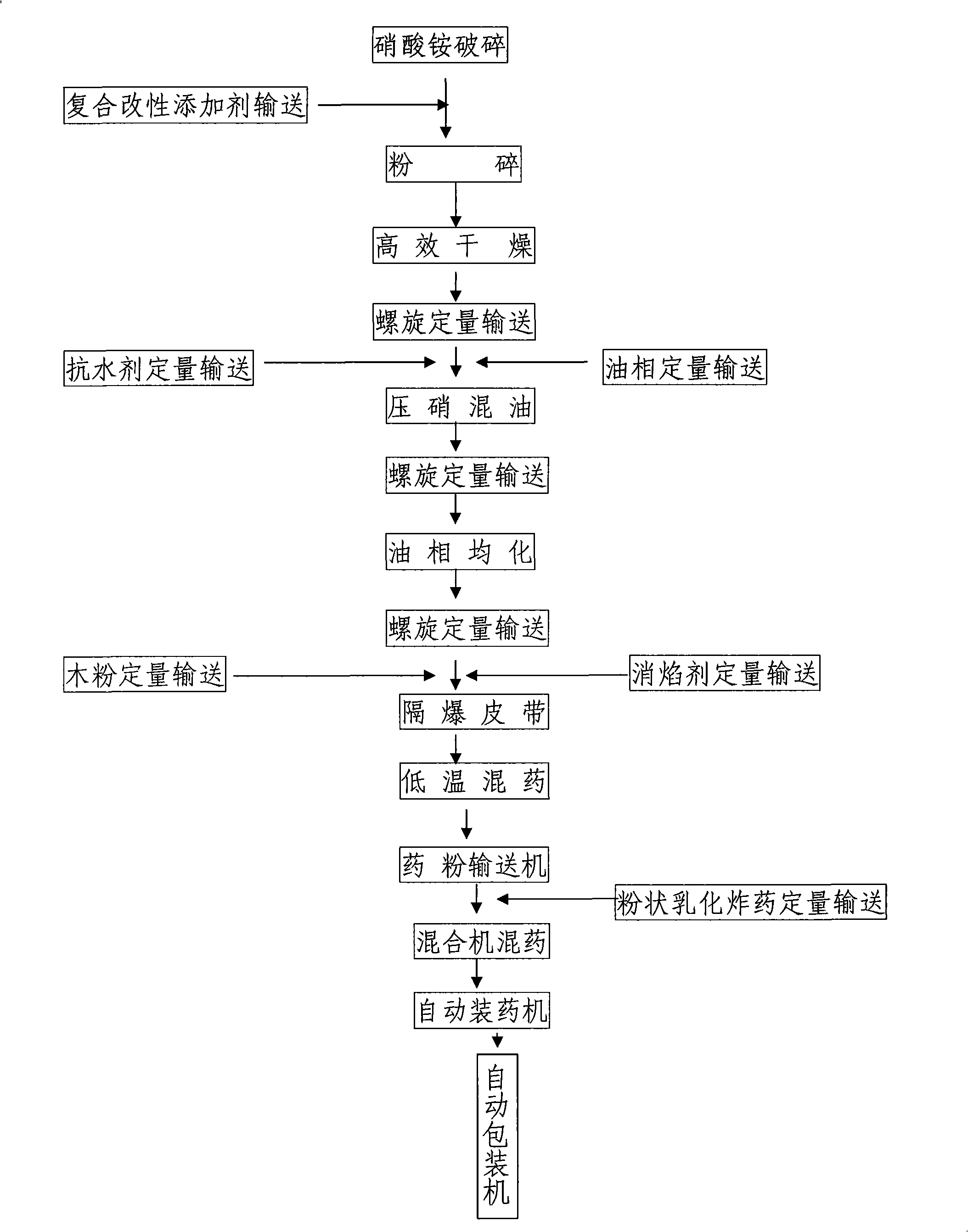

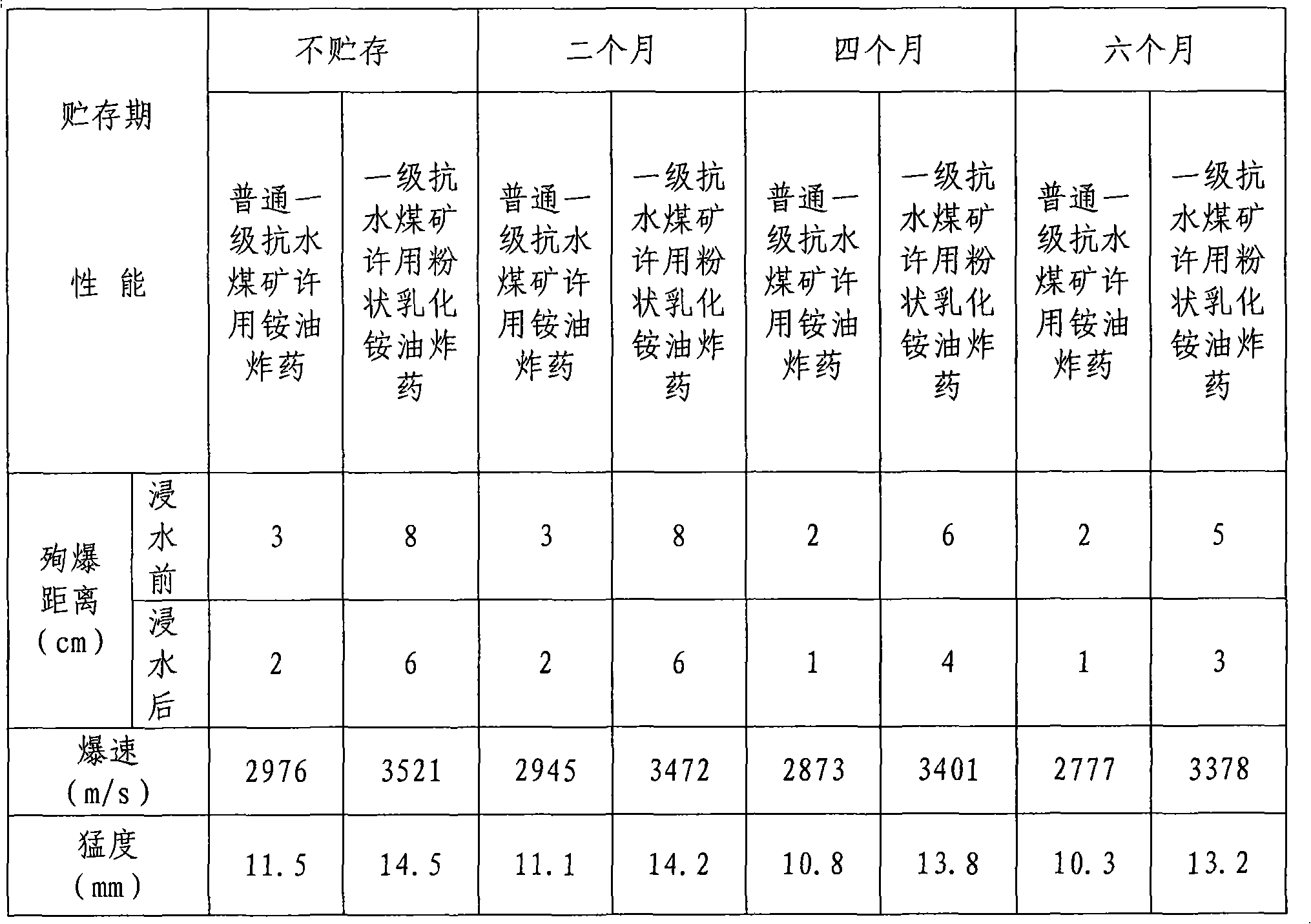

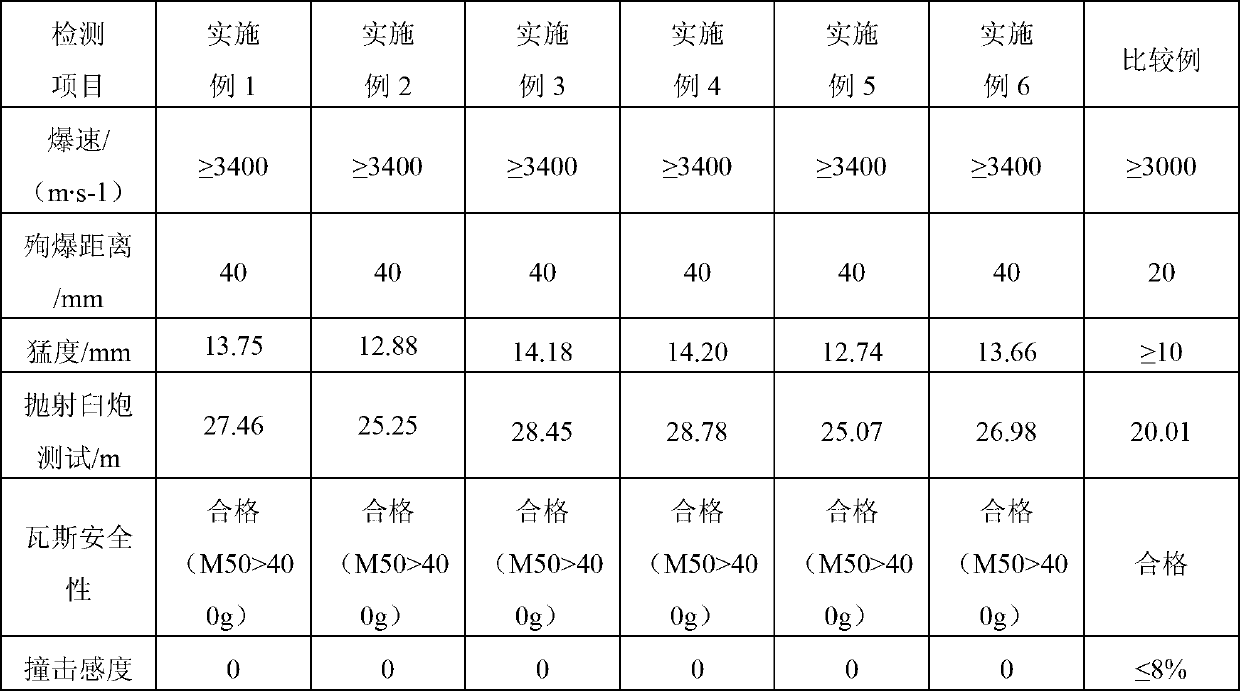

Coal mine admissible powdery emulsifying ammonium nitrate fuel explosive and preparing process thereof

ActiveCN101323552AGood explosive performanceGood storage stabilityExplosive working-up apparatusEmulsion explosiveFuel oil

The invention discloses a powdery emulsion ammonium nitrate fuel oil explosive allowed to be used in coal mines and a preparation technology thereof, which is compounded and prepared by using rock powdery emulsion explosive which has good characteristics of high sensitivity to initiation, high detonation velocity and high explosive grading, to mix with ammonium nitrate fuel oil explosive containing a certain amount of flame inhibitor, wherein, the rock powdery emulsion explosive accounts for 28 percent to 32 percent of the total weight of the explosive and the fire-resistant ammonium nitrate fuel oil explosive accounts for 68 percent to 72 percent of the total weight of the explosive. The rock powdery emulsion explosive is an industrial explosive like powder formed from water-in-oil type latex base material which is sprayed and dried. The rock powdery emulsion explosive can be mixed into ordinary ammonium nitrate fuel oil explosive to replace trinitrotoluene and plays a sensitization role in the explosive to increase the explosive performance of compound explosive. The grade I and the grade II explosive prescriptions of the invention are respectively applicable to the excavating working faces of low-methane rock or low-methane coal beds and mines and the preparation technology thereof is applicable to the discontinuous or continuous automatic production of the powdery emulsion ammonium nitrate fuel oil explosive used in the coal mines.

Owner:LIAONING HONGSHAN CHEM

High performance on-site mixed emulsified explosive

InactiveCN101475423AImprove oxygen balanceImprove powerExplosive working-up apparatusExplosive AgentsEmulsion explosive

The invention relates to a high-performance emulsion explosive mixed and loaded on the spot. Ammonium nitrate and sodium nitrate are thrown into a crusher, are crushed, are sent to a melting pot filled with water according to mixture ratio, are heated to a temperature of between 70 and 80 DEG C and are kept at the temperature to prepare a water phase solution; an emulsifier, diesel oil and engine oil are pumped to a mixing tank and are fully stirred to prepare an oil phase solution; an explosive mixing and loading vehicle is driven to a blasting scene and is hung with a power takeoff device; when the pressure of a hydraulic pump is not less than 10 MPa, the water phase solution and the oil phase solution are automatically pumped to an emulsifier of the explosive mixing and loading vehicle according to proportion of 94:6; after emulsification, a sensitizing agent is added into a mixing device according to mixture ratio and is mixed to form medicine slurry; the medicine slurry is pressed to a hose reel by the pressure of a screw pump; the density and the temperature of the explosive are measured; and after the density and the temperature are qualified, the explosive is loaded to a blast hole for blasting. The high-performance emulsion explosive has high efficiency and a simple formula, reduces a packaging link, has low production cost and low blasting cost, reduces labor intensity of operators and field workers and is safe and reliable.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

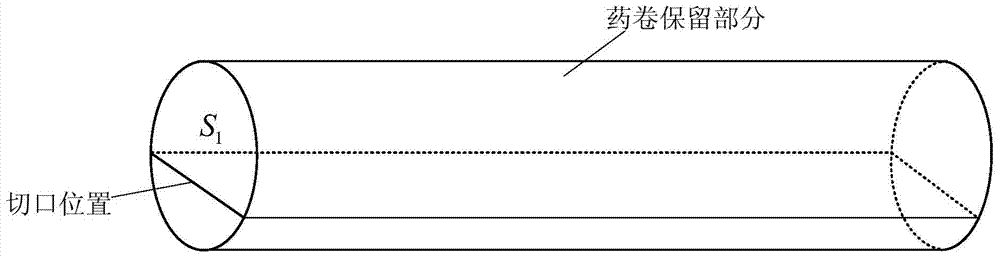

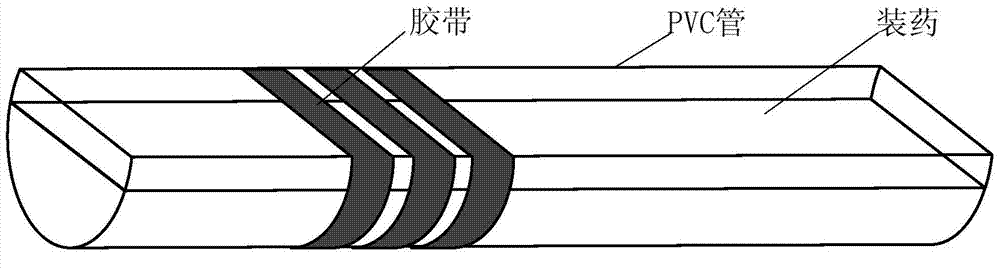

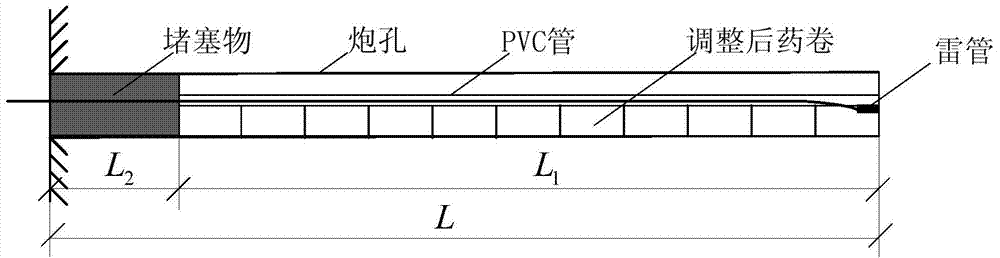

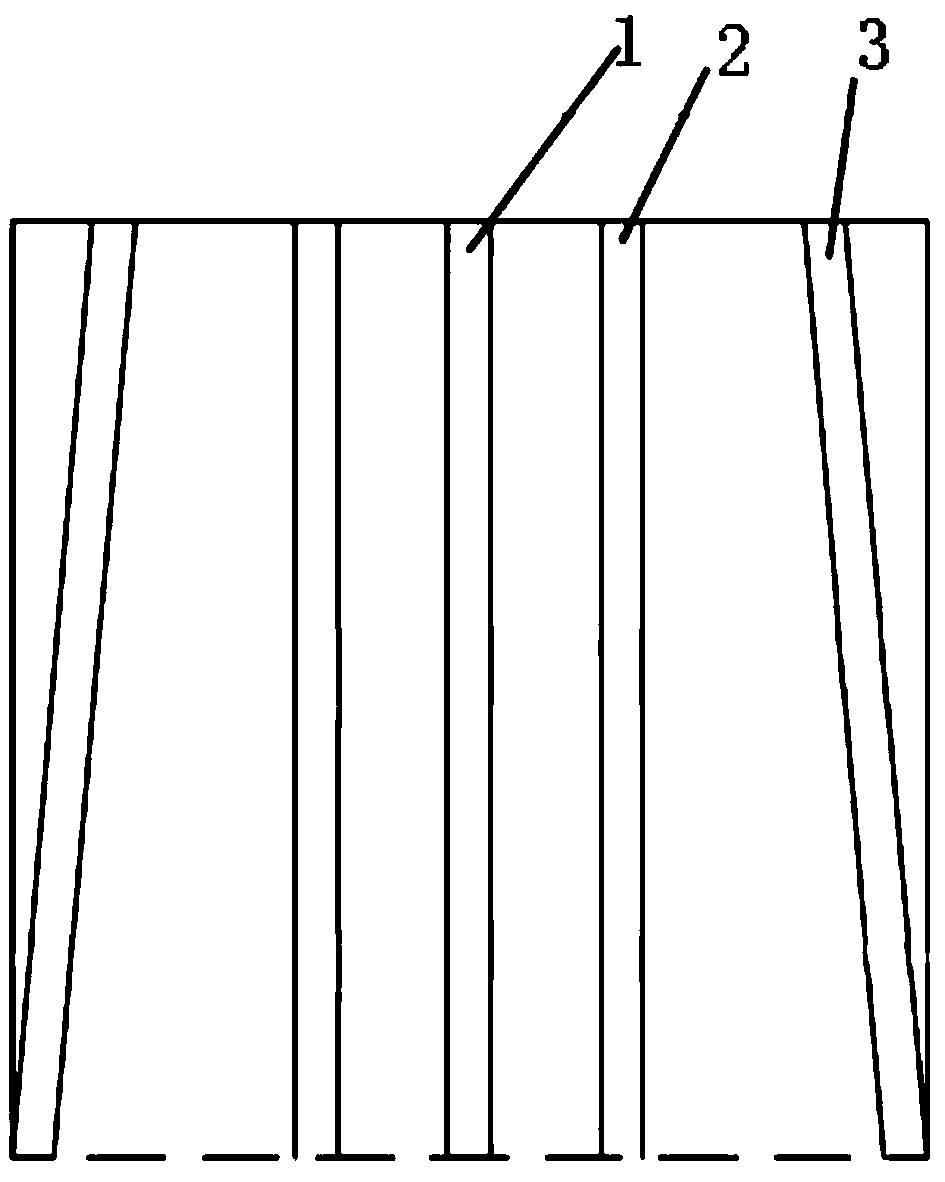

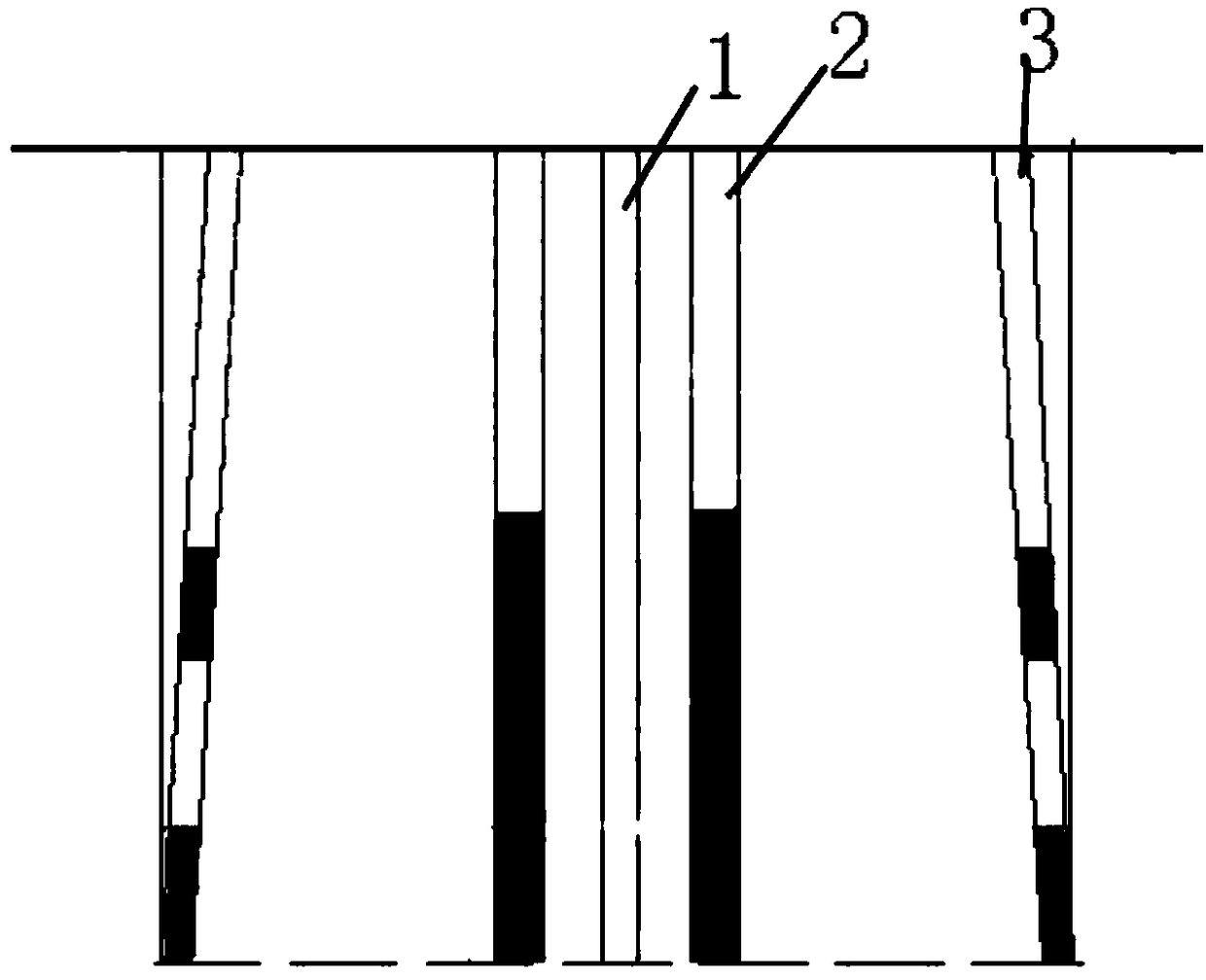

Method for peripheral hole non-coupling continuous loading

The invention relates to a method for peripheral hole non-coupling continuous loading. According to the method, under the condition that spaced loading and detonation of a detonating cord are not adopted, the feature that emulsion explosives can be conveniently shaped is made use of and non-coupling continuous loading is achieved in the axial direction of a blast hole by regulating the loading diameter through a PVC pipe and in strict accordance with the designed peripheral hole cord loading density. Reversed detonation of a hole bottom blasting cap is used for achieving the aim of smooth detonation. Compared with a traditional method, non-coupling continuous loading is carried out on a peripheral hole, so that explosive energy in the hole can be distributed more evenly. Local damage to the wall of the hole by a cartridge bag is controlled and the smoothing effect is more obvious. Meanwhile, due to the fact that reversed detonation of a hole bottom is adopted, a detonating cord does not need to be arranged on the peripheral hole, the cost of smooth detonation is greatly reduced. In addition, the PVC pipe has good flexibility, the PVC pipe serves as an auxiliary material to make a loading body, and the method is suitable for blast hole loading of different depths and easy and convenient to operate.

Owner:SHANDONG UNIV OF SCI & TECH

Primary blasting well forming method for middle guide well

InactiveCN108374661AVarious construction methodsHigh security riskBlastingShaft sinkingDetonatorSludge

The invention relates to the field of tunnel engineering, and discloses a primary blasting well forming method for a middle guide well. The method includes the steps: (1) performing measuring and positioning to determine the wellhead position of a vertical well; (2) mechanically digging a wellhead of the vertical well; (3) reversely digging the bottom of the vertical well upwards; (4) according toa blasting design lofting blast hole position of the middle guide well: performing lofting to form 2m*2m middle guide well position of the vertical well by the aid of a total-station instrument, andlabeling the position of the blast hole position; (5) completely drilling a blast hole by a down-the-hole drill once; (6) plugging the bottom of the blast hole; (7) filling the blast hole with explosive; (8) plugging an upper opening of the blast hole with blast sludge after the blast hole is plugged by the explosive; (9) line connecting and explosion initiating, connecting starting detonators inthe blast holes in a clustering manner, and performing differential initiation of non-electric millisecond detonators. The method has the advantages that construction safety is improved, potential safety hazards are reduced, and life safety of construction staff is guaranteed.

Owner:浙江省隧道工程集团有限公司

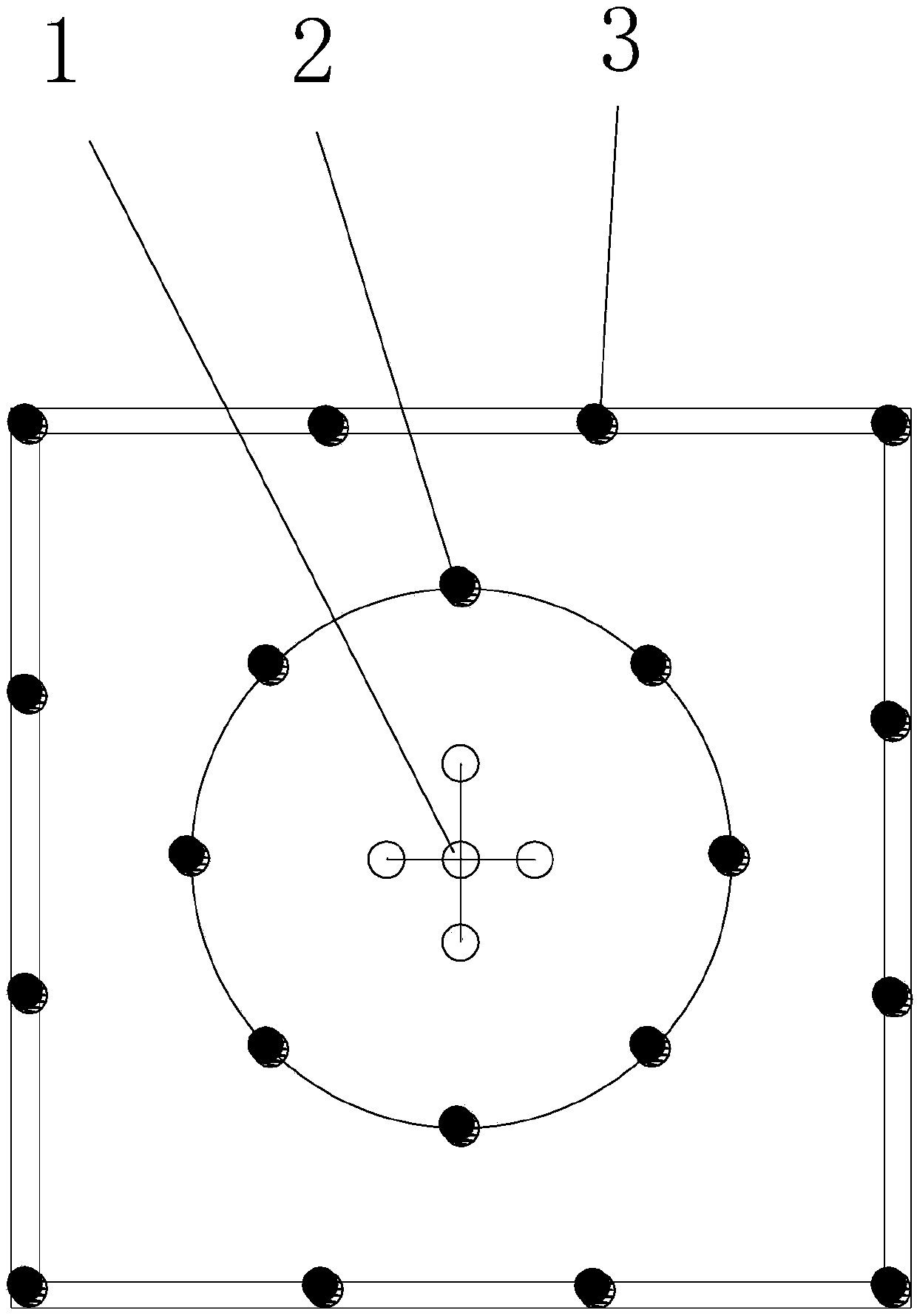

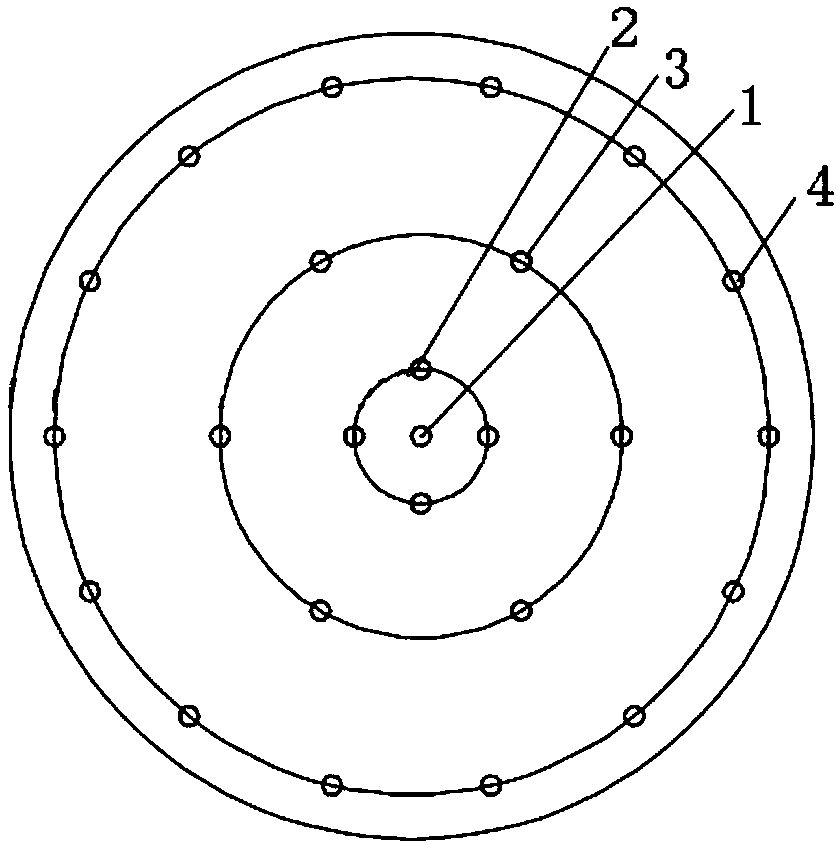

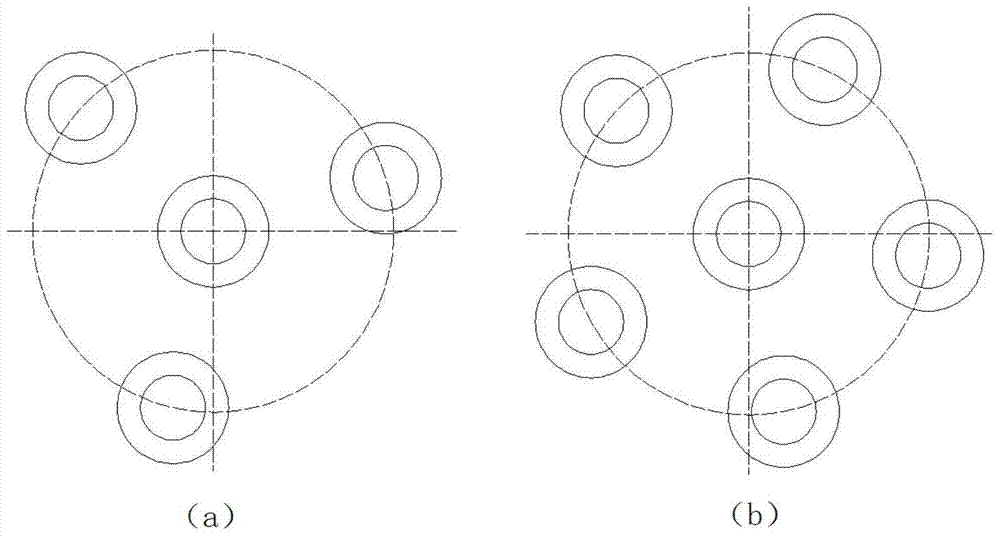

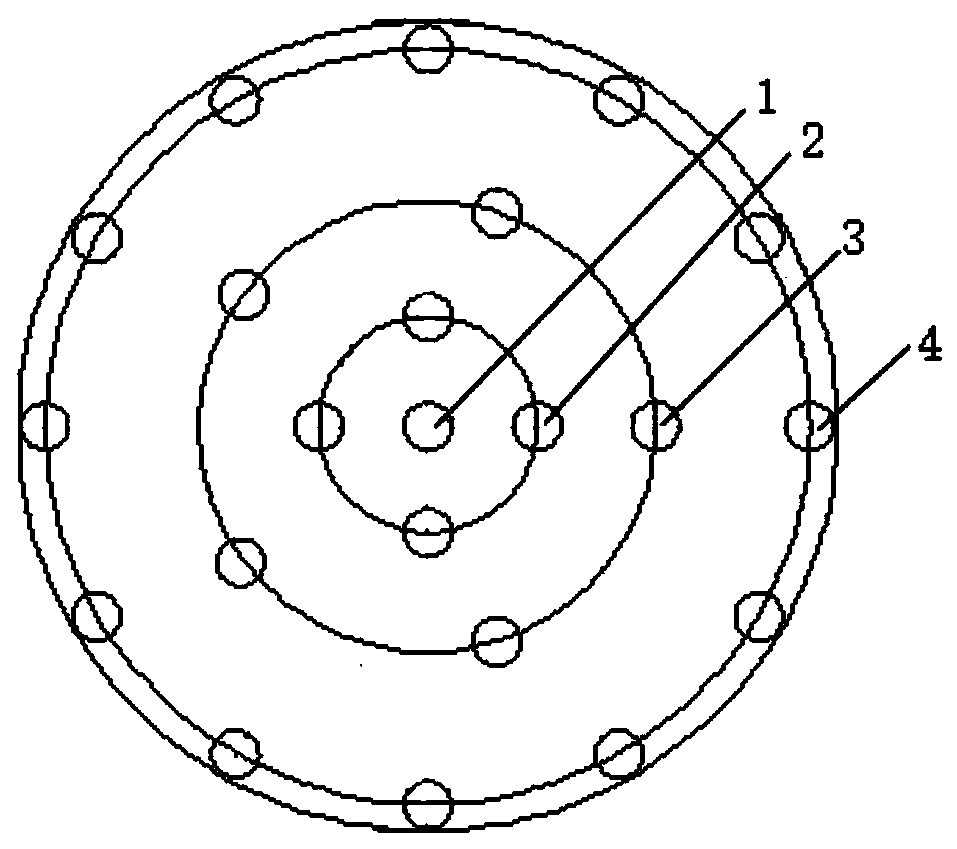

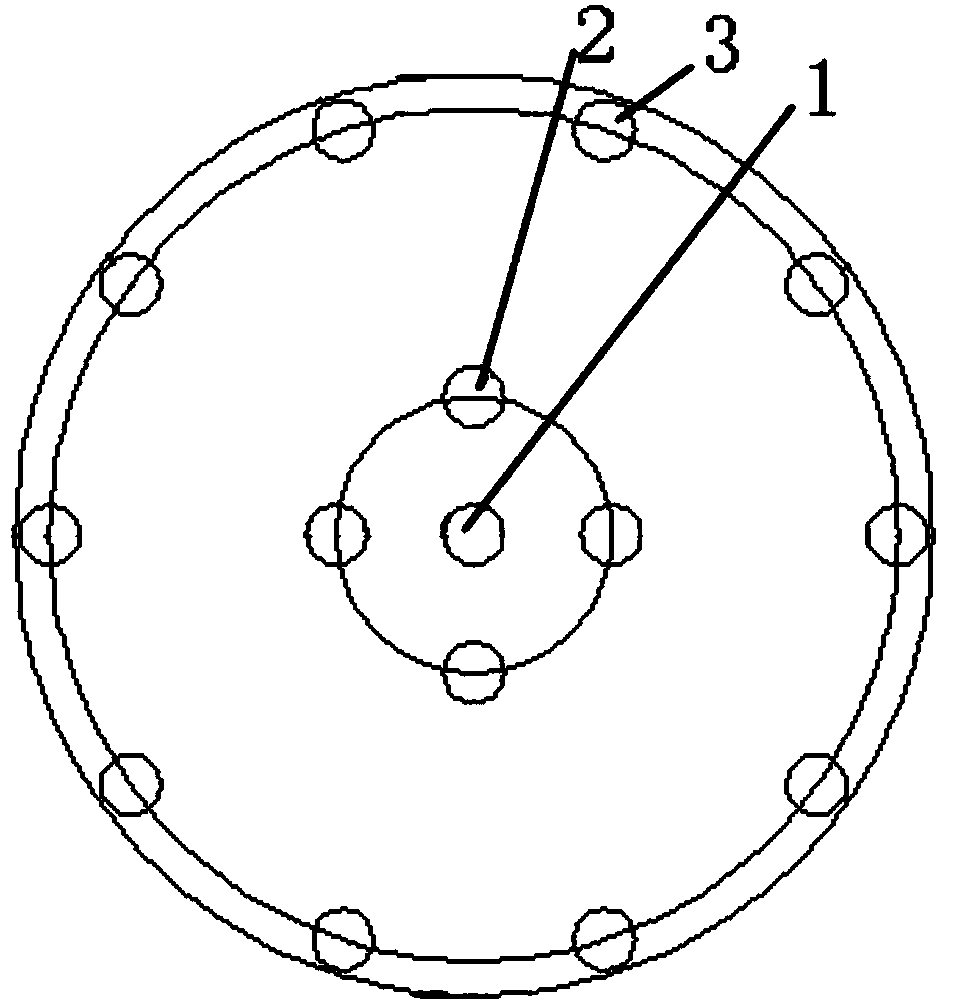

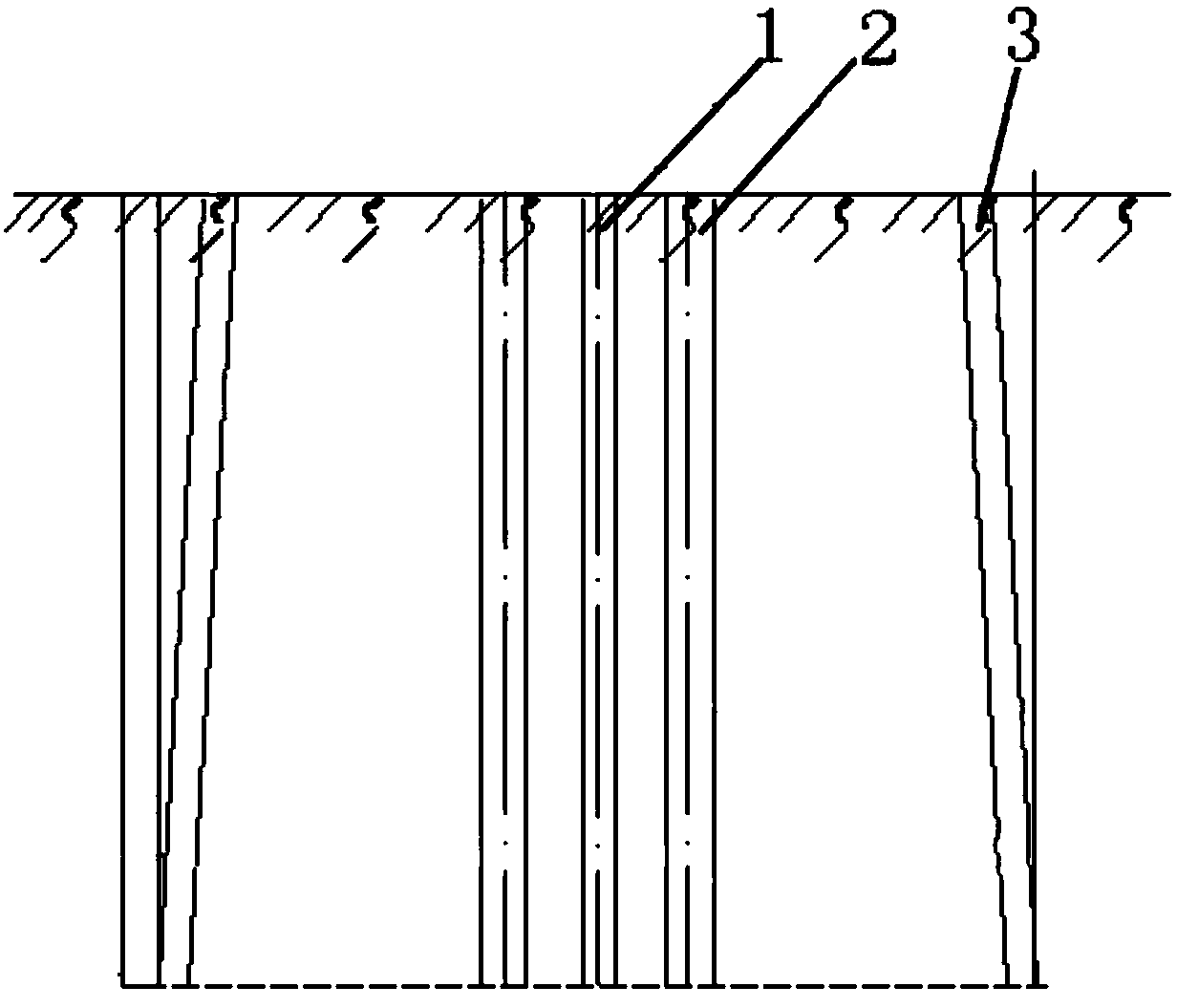

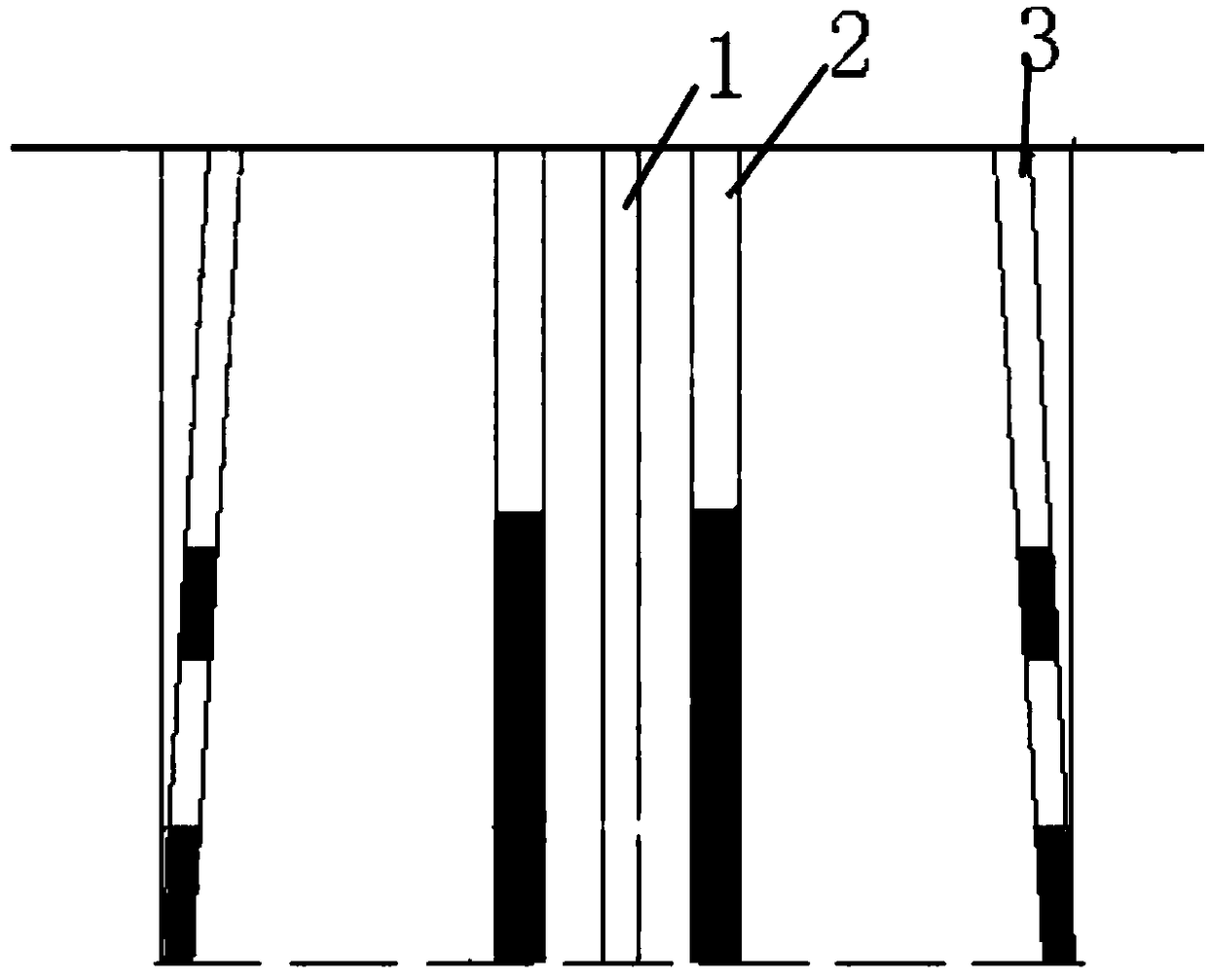

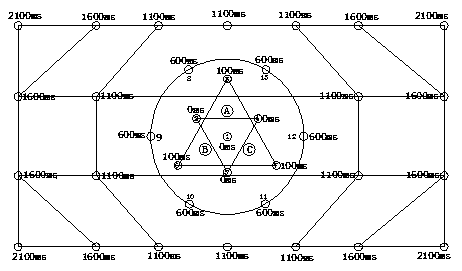

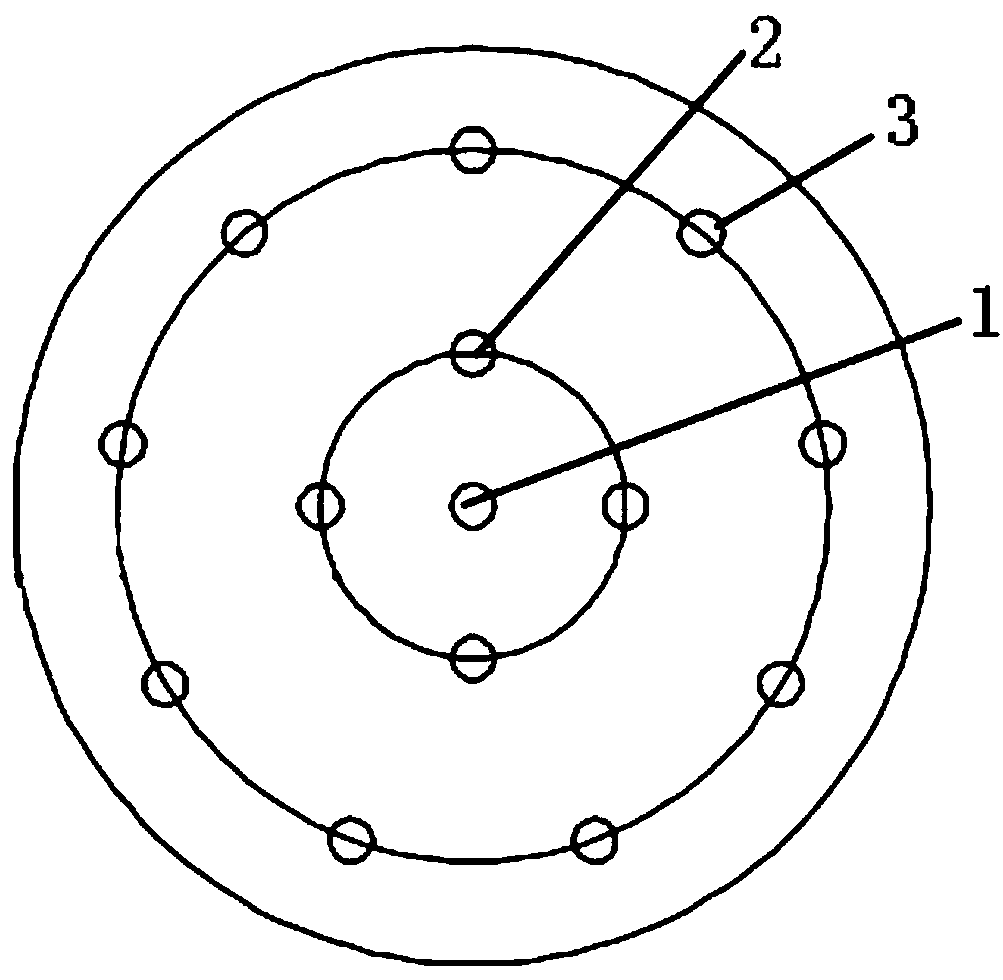

Blasting method for bridge cylindrical pile base with pile base diameter of 1.7-1.9 m

The invention relates to a blasting method for a bridge cylindrical pile base with the pile base diameter of 1.7-1.9 m. The blasting method includes the steps of drilling holes, loading explosive materials, blocking a cannon opening and triggering blasting. According to a hole drilling method, a central hole is vertically formed along a central line of the cylindrical pile base, a cannon opening inner ring with a radius of 0.13-0.17 m is formed with the central line of the cylindrical pile base as the center, a cannon opening middle ring with a radius of 0.43-0.47 m is formed, a cannon openingouter ring with a radius of 0.78-0.82 m is formed, and 4 vertically formed cutting holes are evenly distributed in the cannon opening inner ring, 6 vertically formed auxiliary holes are evenly distributed in the cannon opening middle ring, and 14 obliquely formed peripherical holes are evenly distributed in the cannon opening outer ring; the included angle between the central axis of each peripherical hole and the vertical direction is arccot10-arccot12, and the distance between the top of each peripherical hole and the central hole is smaller than that between the bottom of each periphericalhole and the central hole. The blasting quality is high, the construction efficiency is high, and the blasting cost is low.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

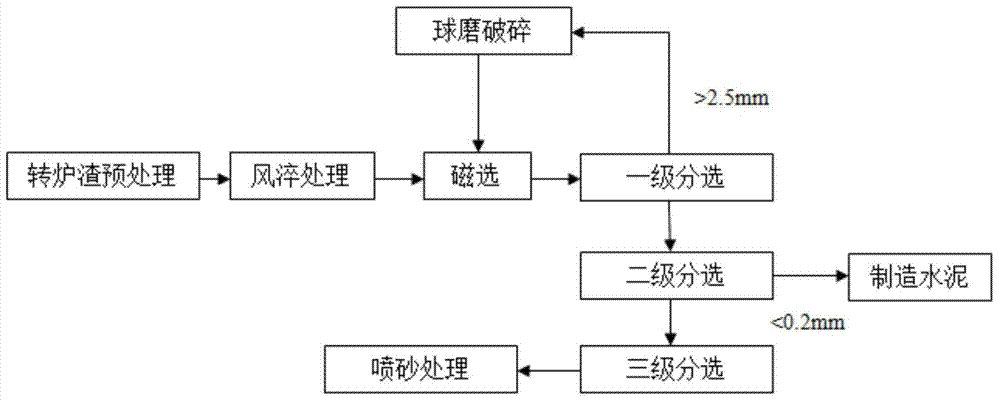

Method for sandblasting surface of workpiece by utilizing steelmaking converter slag

ActiveCN103707204ARealize resource utilizationGood yieldAbrasion apparatusManufacturing convertersSteelmakingThree level

The invention discloses a method for sandblasting the surface of a workpiece by utilizing steelmaking converter slag, and belongs to the technical field of comprehensive utilization of the steelmaking converter slag. The method comprises the following steps: 1, converter slag pretreatment: adding a flux into a converter at the final converter steelmaking stage to carry out converter slag pretreatment; 2, converter slag air quenching treatment: sending liquid converter slag into an air quenching treatment station through a slag tank vehicle, allowing the liquid converter slag to flow out of a tundish, blowing through air injected through a Laval nozzle, and crushing to particles; 3, converter slag sorting treatment: carrying out three-level sorting of the obtained magnetically-separated converter slag particles; and 4, sandblasting, wherein sandblasting nozzles comprise a center nozzle and circumferential nozzles, 3-5 circumferential nozzles are uniformly distributed in the periphery of the center nozzle, and each of the center nozzle and the circumferential nozzles is a Venturi nozzle. The steelmaking converter slag has the advantages of good abrasive crushing resistance, benefiting for the recycle, realization of the circulating frequency reaching 10, and great reduction of the sandblasting cost as a sandblasting abrasive.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

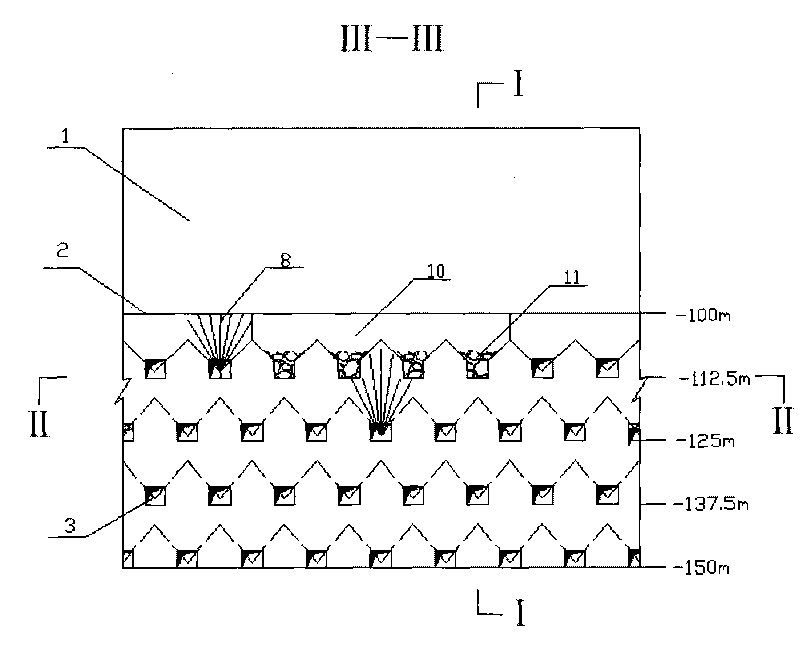

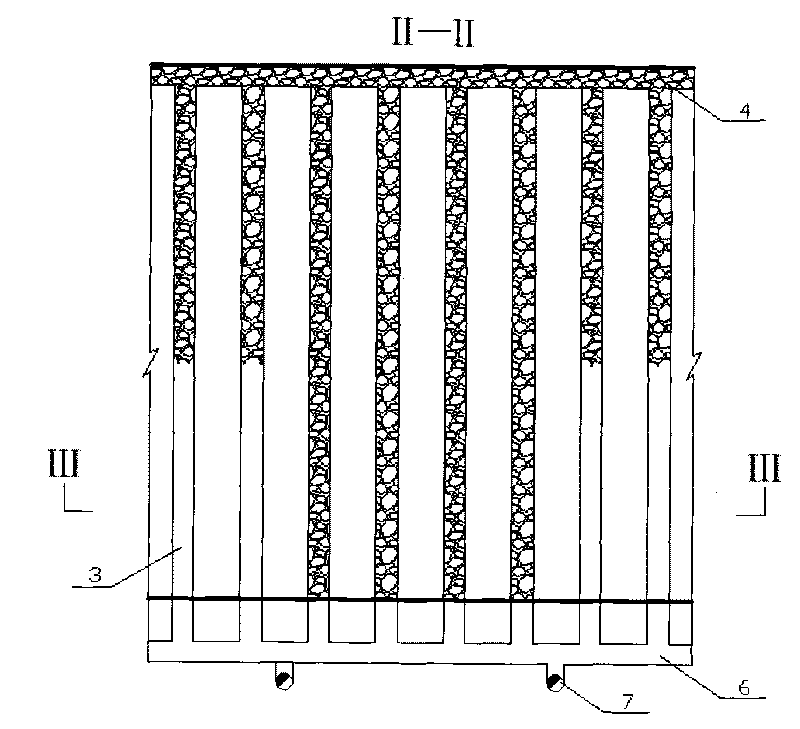

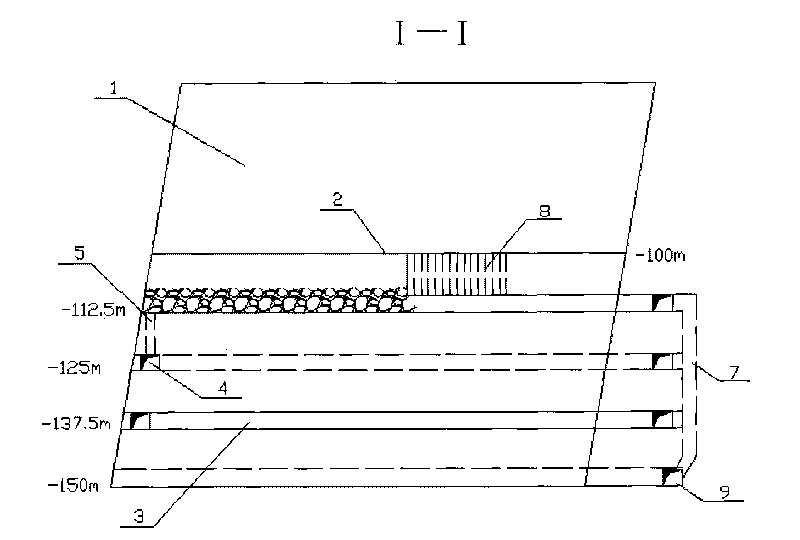

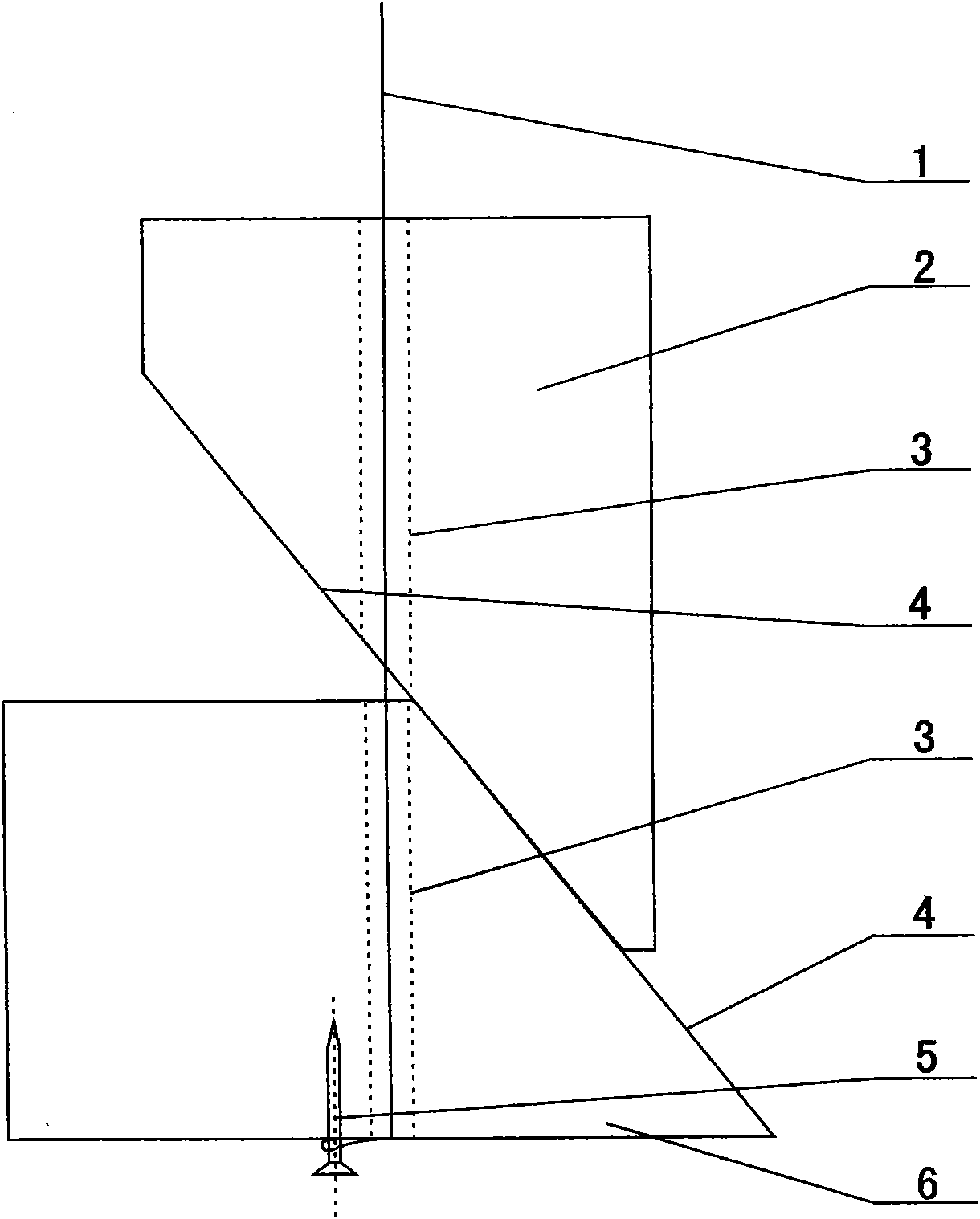

Covering layer forming method of blind ore bodies

The invention discloses a covering layer forming method of blind ore bodies with stable and massive roof surrounding rocks applying a bottom pillar-free subsection collapse method. The method can obviously reduce the work quantity of caving, has low caving cost and a little ore dilution, and improves the production efficiency and economic benefit of mines. The key points of the technical scheme are as follows: a first subsection mining tunnel is distributed in an ore body, and continuous gobs provided after the first subsection mining are used for inducing the roof rocks to collapse; and with the performing of the mining work, the areas of the gobs are expanded continuously, when the areas of the gobs reach the critical exposed area, the roof rocks at the gobs are unstable gradually and collapsed under the effects of stress and gravity so as to form a covering layer. When the first subsection mining tunnel distributes blast holes, the ore bodies among the access roads are required to be thoroughly collapse so as to cut off the support of the roof surrounding rocks completely and form continuous gobs with exposed area. The forming method is applicable to forming the covering layer of more stable and massive blind ore bodies of the roof surrounding rocks.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of ammonium nitrate fuel oil explosives with different densities, and ammonium nitrate fuel oil explosives with different densities

InactiveCN103193562ASatisfy the demand of detonation speedMeet needsNon-explosive/non-thermic compositionsParticulatesFuel oil

The invention relates to explosives, and especially relates to a preparation method of ammonium nitrate fuel oil explosives with different densities, and ammonium nitrate fuel oil explosives with different densities. According to the invention, density is regulated by adding a particulate physical density regulating agent with particle size of 0.5-5.0mm and a bulk density of 0.03-0.30g / cm<3> during an ammonium nitrate fuel oil explosive preparation process. With the method, the density of porous particulate ammonium nitrate fuel oil explosive can be regulated to 0.3-0.95g / cm<3>, such that a porous particulate ammonium nitrate fuel oil explosive with detonation velocity of 1600-3600m / s can be obtained; or the density of heavy ammonium nitrate fuel oil explosive can be regulated to 0.3-1.25g / cm<3>, such that a heavy ammonium nitrate fuel oil explosive with detonation velocity of 1800-5000m / s can be obtained. Therefore, demands of different lithologies on different explosive detonation velocities can be satisfied, and demands of different blast-holes on different explosives can be satisfied.

Owner:QINGDAO TARGET MINING SERVICES

Prepn process of sand blasting ceramic nozzle

The preparation process of sand blasting ceramic nozzle includes adding (W, Ti)C solid solution into B4C substrate and small amount of Si sintering assistant and hot pressed sintering with in-situ chemical reaction between B4C and (W, Ti)C to produce B4C / TiB / W2B5. The B4C base sand-blasting ceramic nozzle produced through the said process has high compactness, strength and toughness high than those of B4C ceramic one, sintering temperature reduce to below 1900 deg.c, short sintering time and high erosion and wear resistance.

Owner:SHANDONG UNIV

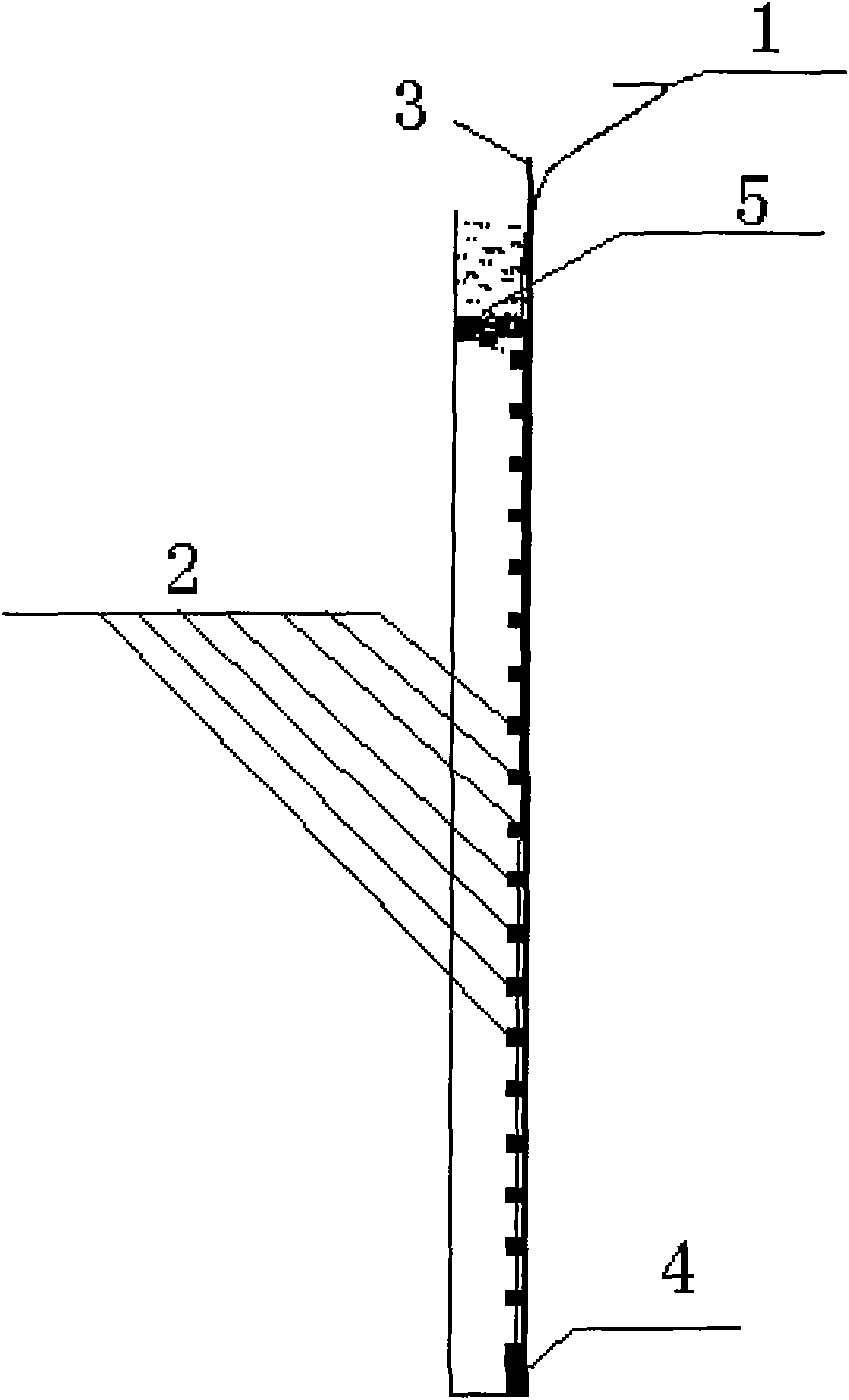

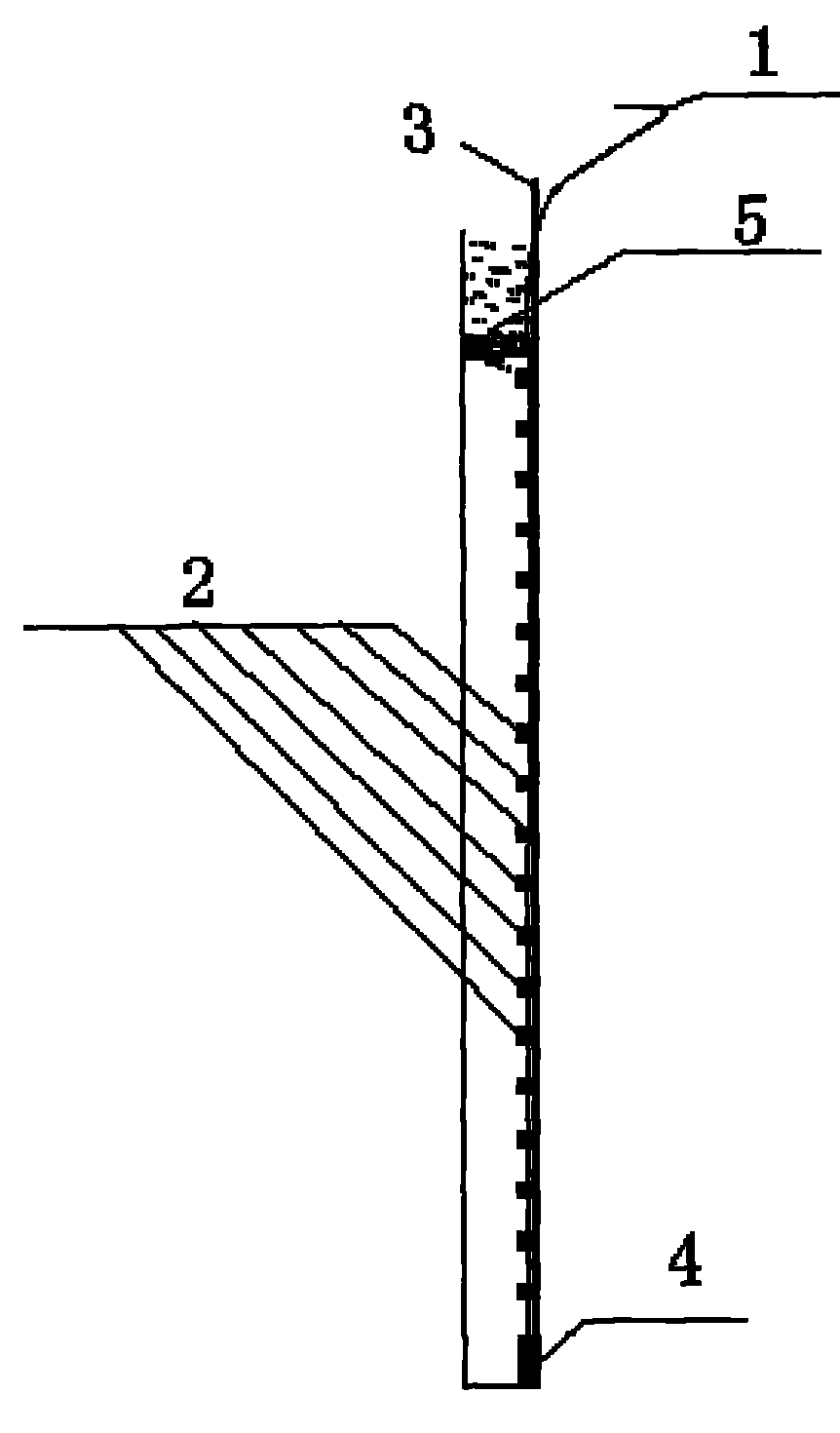

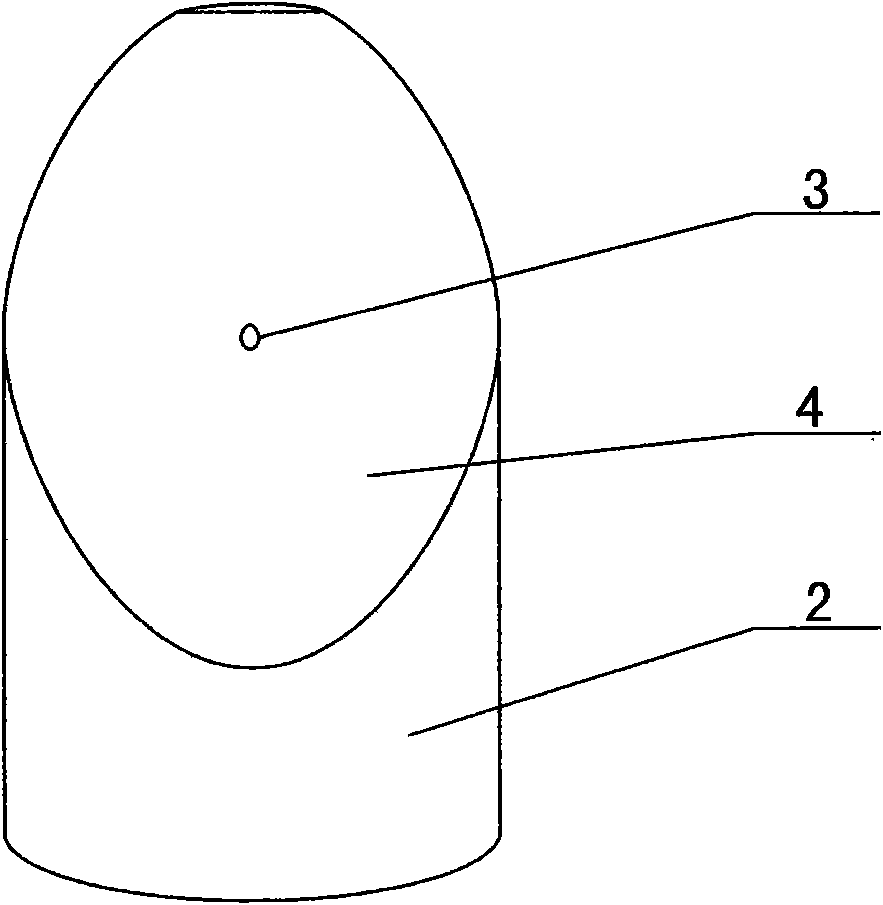

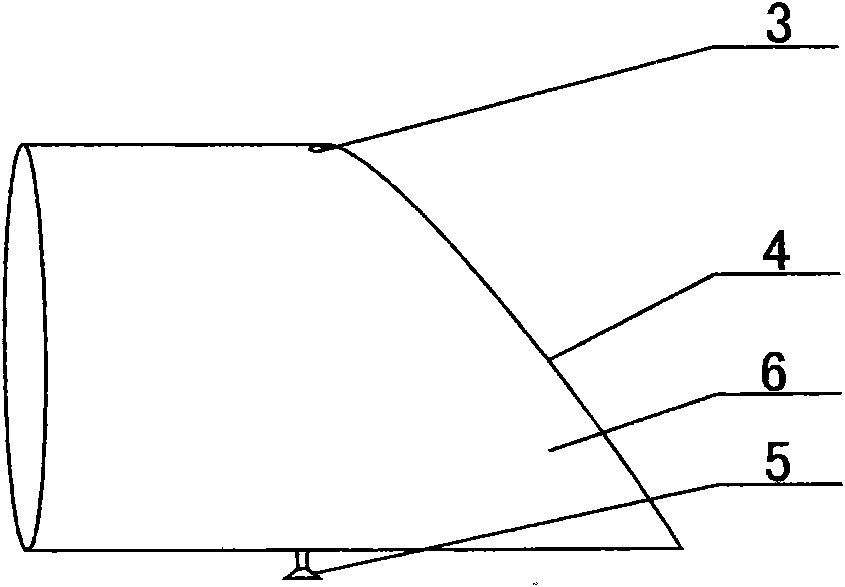

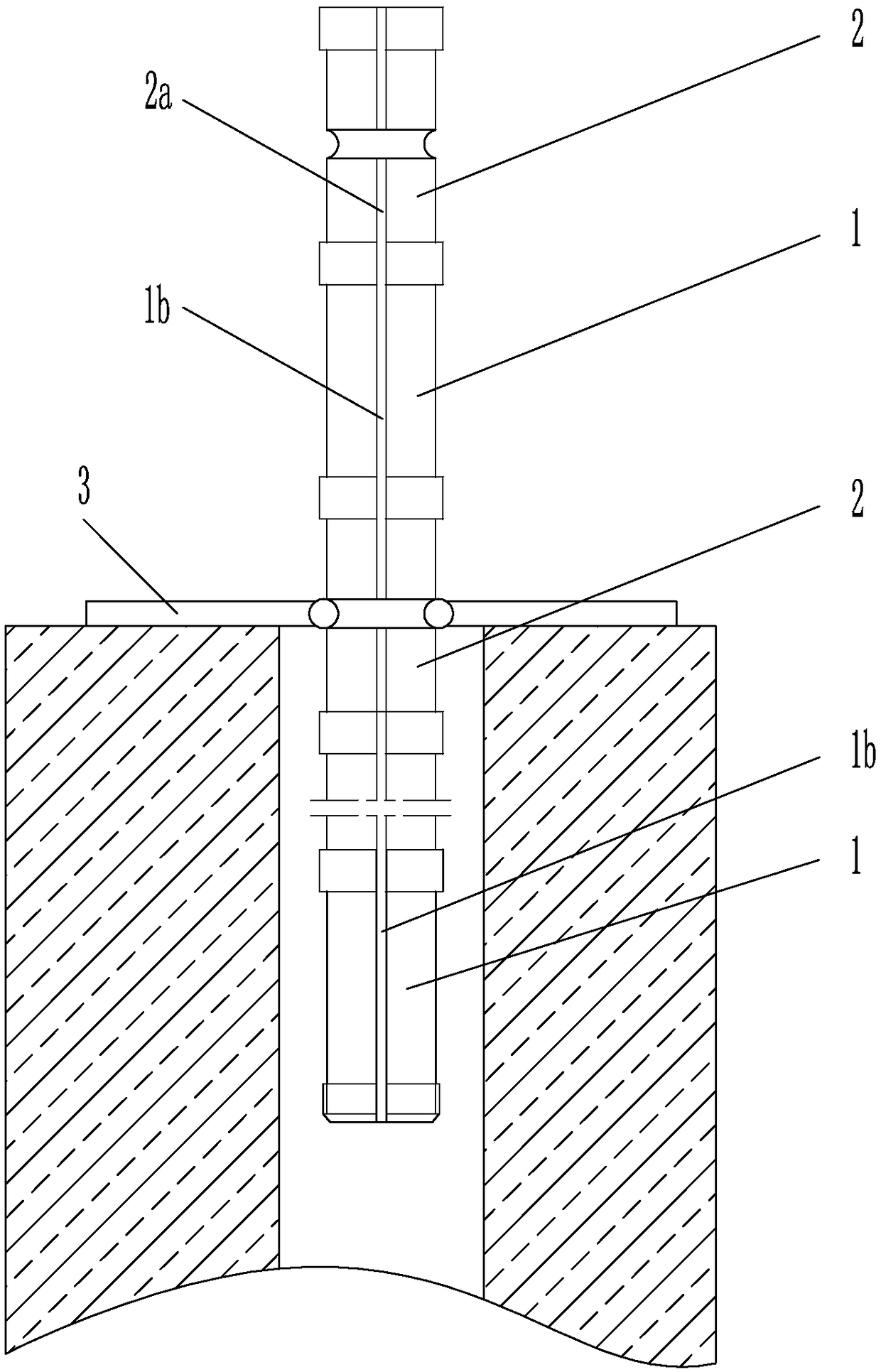

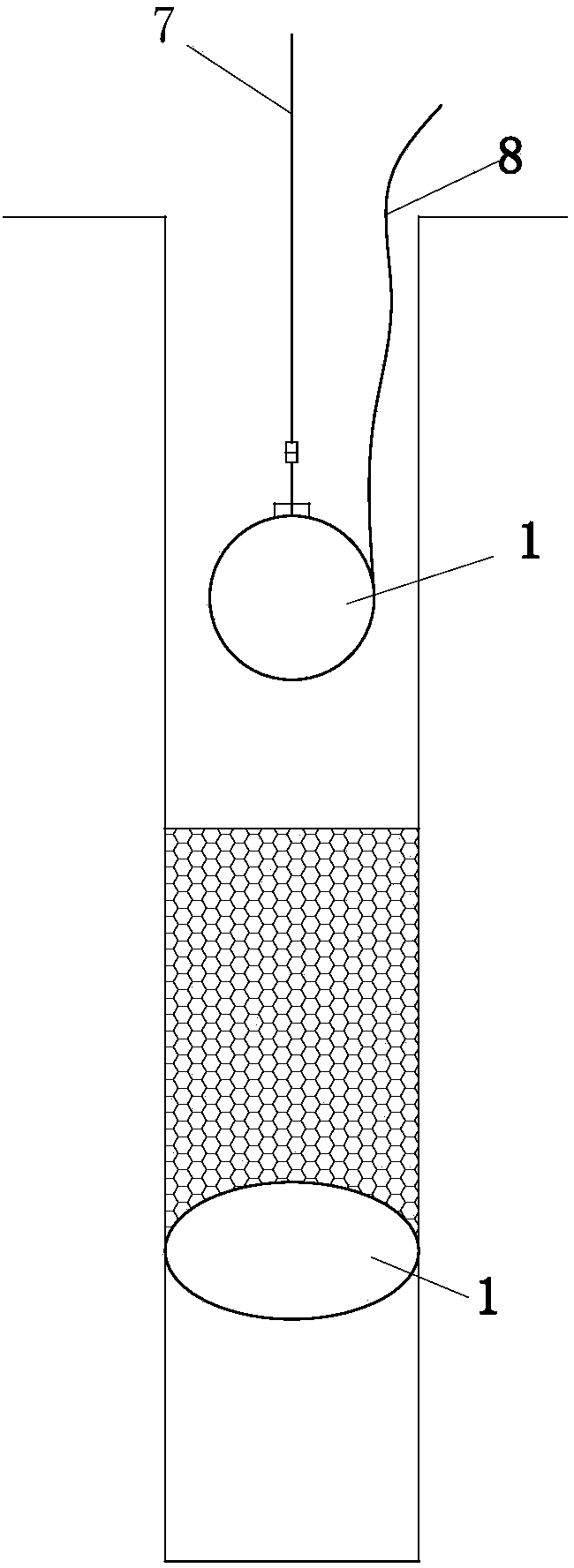

Open pit mined-out area through hole plug and through hole plugging method thereof

ActiveCN101967976APrevent secondary useSolve the problem of difficult hole pluggingUnderground miningSurface miningEngineeringMaterial Perforation

The invention relates to a hole plug, in particular to an open pit mined-out area through hole plug and a through hole plugging method thereof. The upper end of an upper wood wedge (2) is a plane, the lower end of the upper wood wedge (2) is an inclined plane (4), and an iron wire (1) through hole (3) is formed from the center of the upper end plane of the upper wood wedge to the center of the lower end inclined plane; and one end of a main wood wedge (6) is a plane, the other end of the main wood wedge (6) is an inclined plant, and an iron wire through hole is formed from the upper part of the main wood wedge (6) to the lower part of the wood wedge (6), an iron nail (5) is arranged on any side of a through hole in the lower part of the wood wedge (6), and the lower end of the iron wire is fixedly connected with the iron nail and then the iron wire passes through the through hole in the main wood wedge and the through hole in the upper wood wedge. The open pit mined-out area through hole plugging method comprises following steps: pretreating the through hole; measuring hole diameter; making a plug; mounting the plug; filling explosive; and exploding. In the invention, the trees influencing exploitation in during mining area exploitation are fully used, the waste is changed into valuable materials, explosive is saved, explosion cost is saved, and through hole plugging time and labor force are reduced.

Owner:CHINA MOLYBDENUM

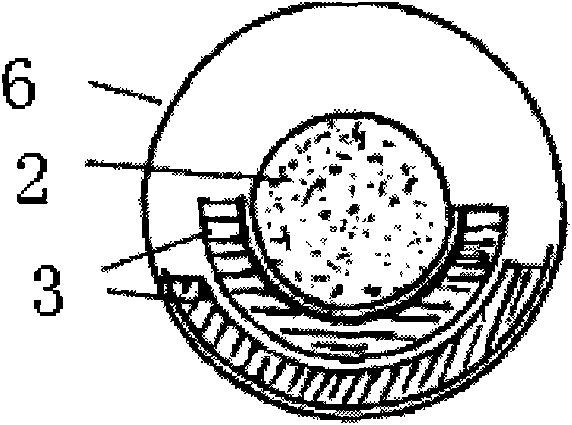

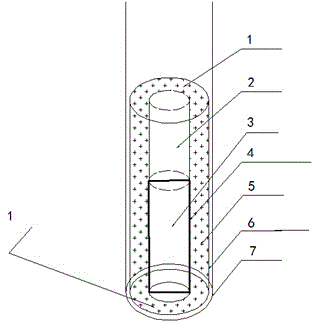

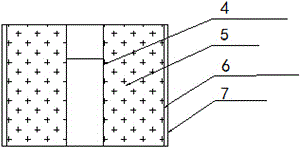

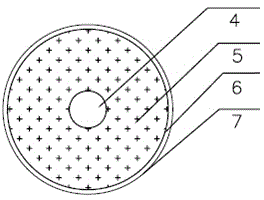

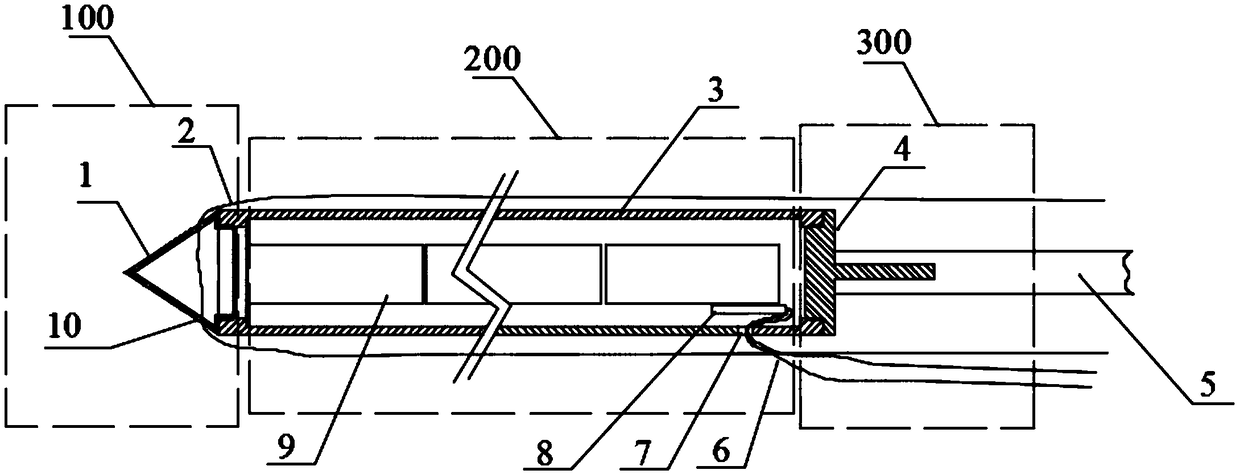

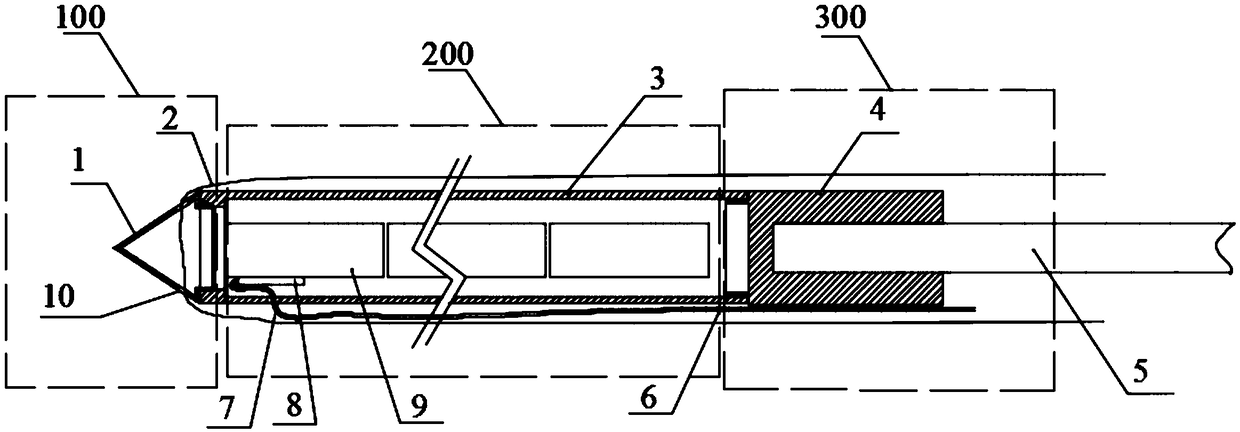

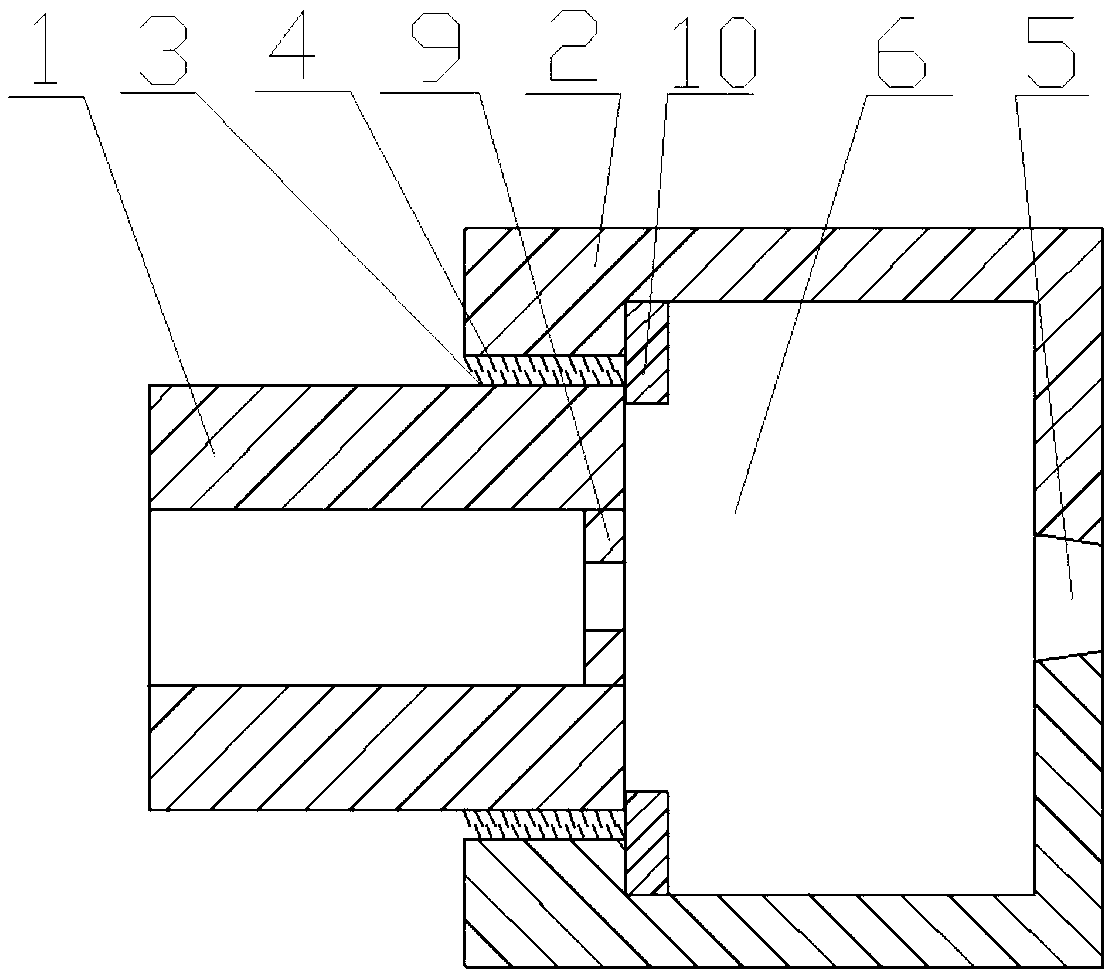

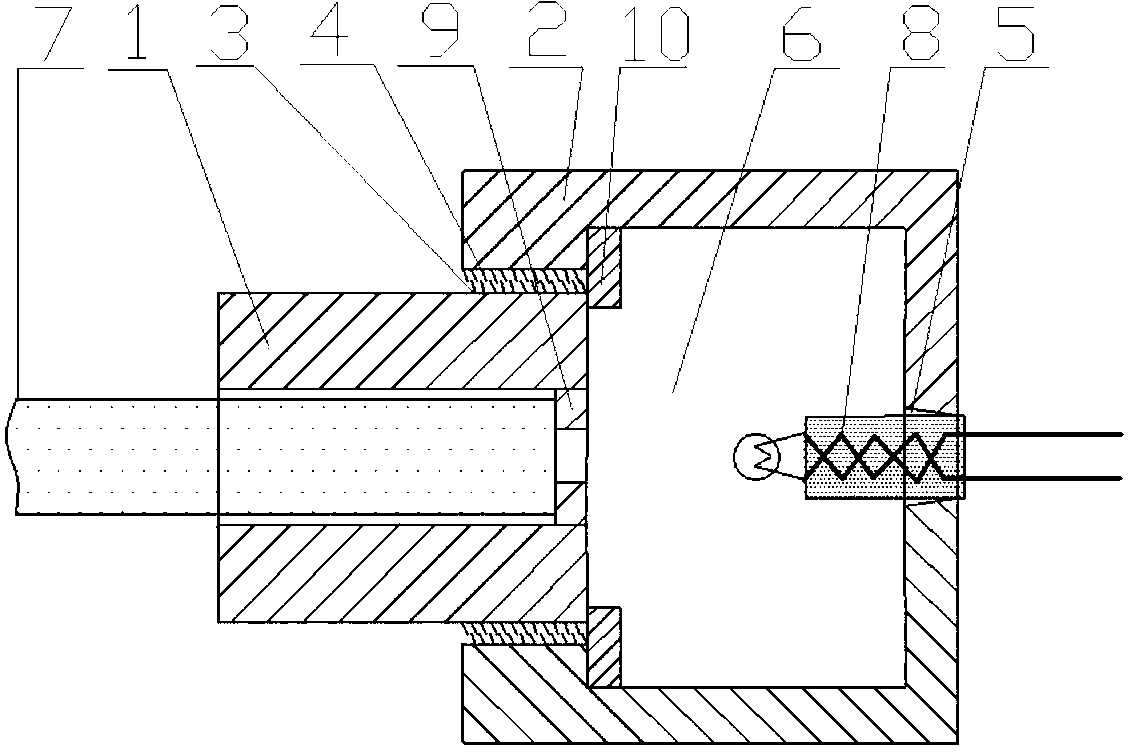

Radial vacuum spaced charging device with active pressure relief

ActiveCN104897013AReduce unit consumptionInitial peak pressure reductionBlastingEngineeringDielectric layer

The invention discloses a radial vacuum spaced charging device with active pressure relief, and the radial vacuum spaced charging device comprises an outer cavity (6). The radial vacuum spaced charging device is characterized in that a vacuum dielectric layer (5) is arranged between the outer cavity (6) and an inner cavity (4), both ends of the vacuum dielectric layer (5) are sealed by sealing plates (1), the inner cavity (4) is filled with explosives (3), and an air dielectric layer (2) is arranged above the explosives (3). According to the radial vacuum spaced charging device, the problem that an ideal blasting effect cannot be achieved due to great pulverization effect of rocks in a pulverization area, large early energy consumption and non-ideal effective utilization rate of explosive energy because the explosive energy cannot be effectively discharged in time after explosion due to narrow sealed space in a blast hole by utilizing water or air as spaced media in the prior art is solved.

Owner:GUIZHOU UNIV

Pre-split blasting combined explosive charging method, explosive charging structure and auxiliary device

ActiveCN109059693AGuaranteed charging qualityEfficient and fast chargingBlastingEngineeringElectrical and Electronics engineering

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

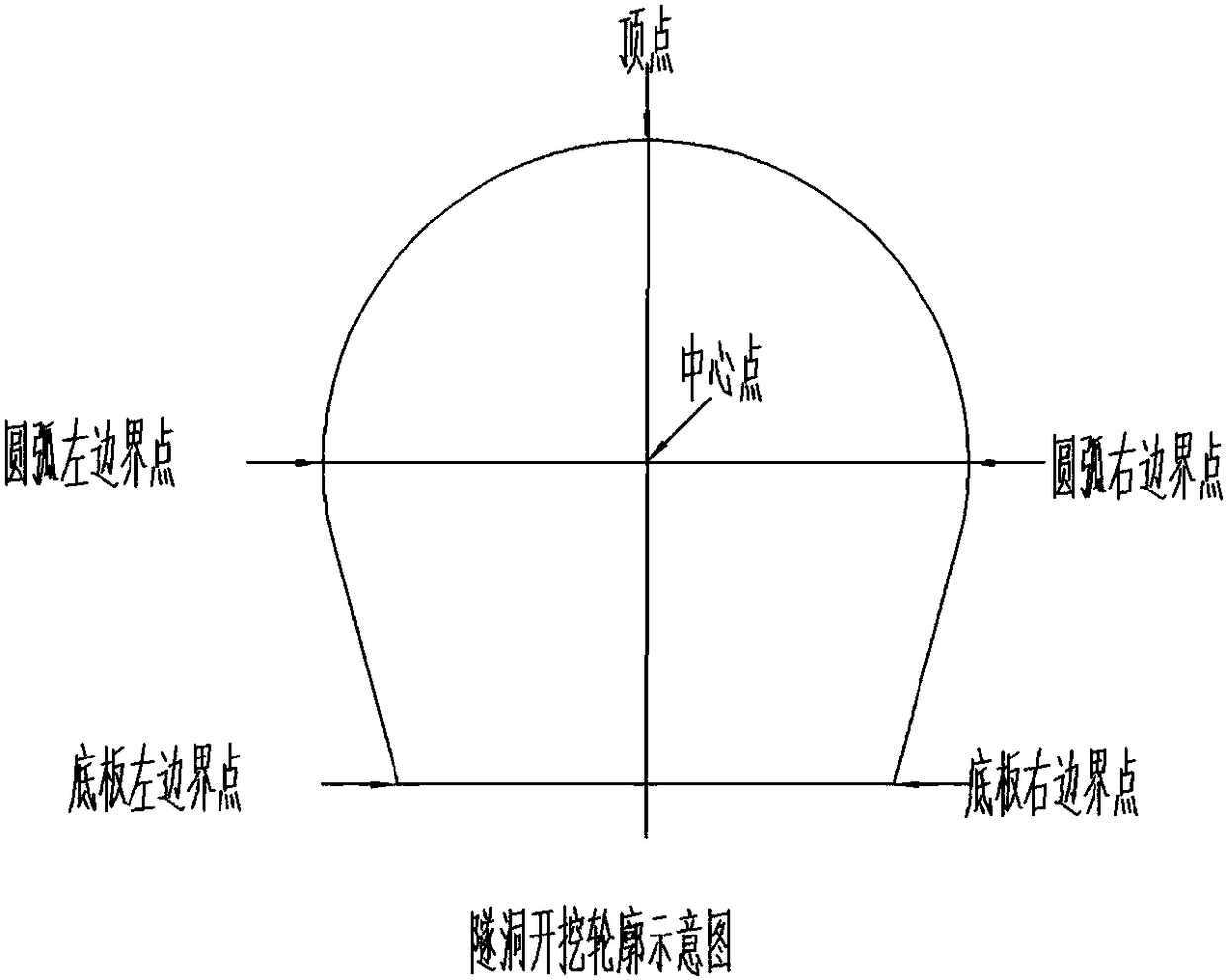

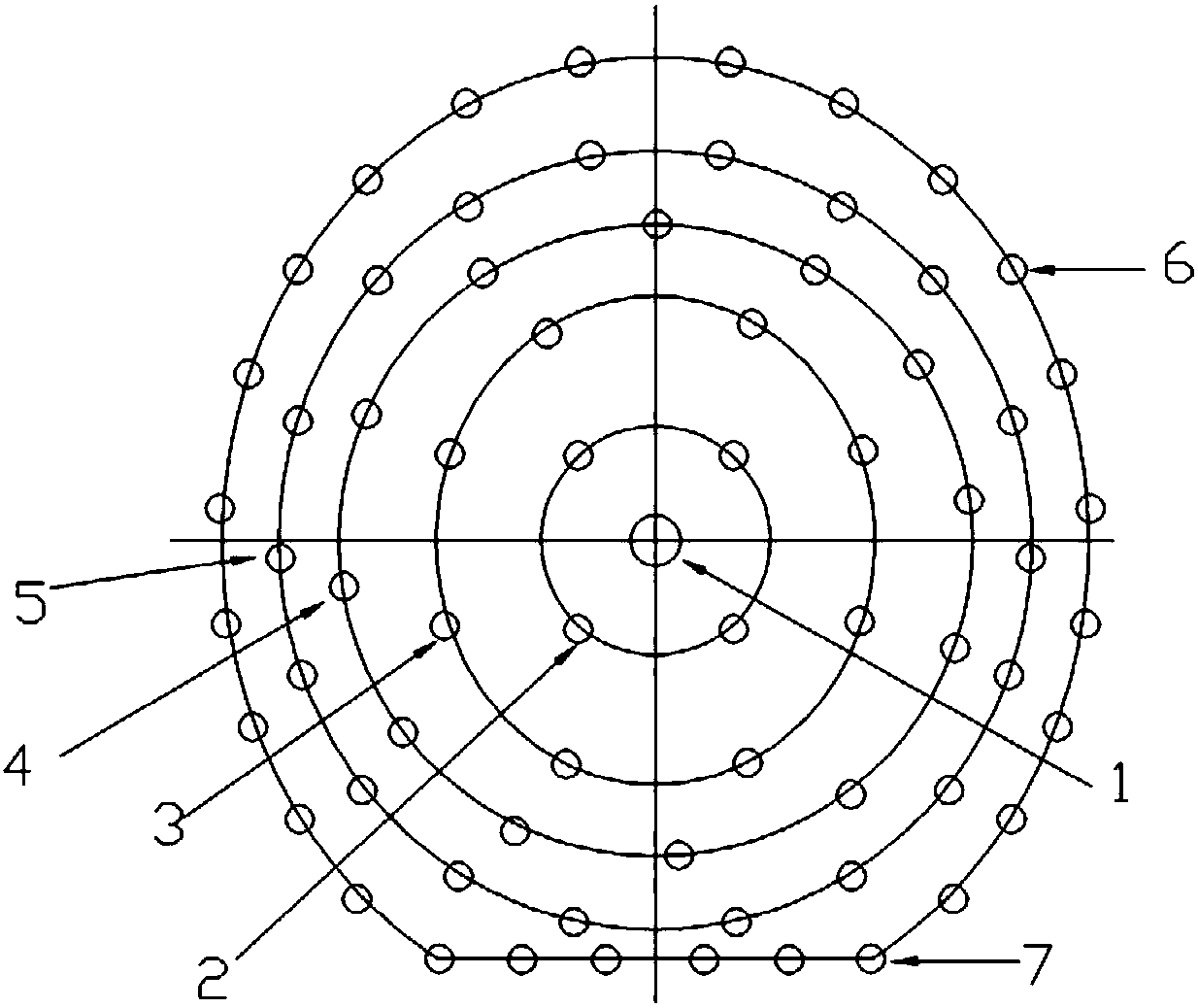

Water delivery tunnel whole-section one-time blasting forming construction method

The invention discloses a water delivery tunnel whole-section one-time blasting forming construction method. The water delivery tunnel whole-section one-time blasting forming construction method comprises following steps that firstly, a blasting center hole, a breaking-in hole, an auxiliary hole, a periphery hole and a bottom plate hole are determined in the face of a tunnel, and drilling is carried out on the corresponding position; secondly, an ammonium nitrate fuel oil mixture is loaded in blast holes of the breaking-in hole and the auxiliary hole, a continuous coupling charging structure is adopted, hydrogel explosive is arranged in blast holes of the periphery hole and the bottom plate hole, and a continuous non-coupling charging structure is adopted; thirdly, explosive non-electric millisecond detonators are connected to form a blast network, and connected to the position outside the holes, and blasting excavation is achieved. The ammonium nitrate fuel oil mixture is adopted to serve as main blasting explosive, the hydrogel explosive serves as the auxiliary detonating explosive, in combination with the non-electric millisecond detonators, the blasting sequence is strictly controlled, the blasting effect and the construction proceed are improved, combination of the ammonium nitrate fuel oil mixture and the hydrogel explosive is adopted, the cost of each meter of a footageblasting device is reduced obviously, and the blasting cost can be effectively reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

High-power water gel explosive applicable to coal mine and manufacturing method thereof

ActiveCN102942428AGood chemical inhibition effectImprove securityBlastingExplosivesAluminium powderReducer

The invention provides a high-power water gel explosive applicable to a coal mine. The high-power water gel explosive comprises the following substances in parts by weight: 30-45 parts of 75-86% nitric acid-methylamine water solution, 28-38 parts of powdery ammonium nitrate, 7-14 parts of sodium nitrate, 5-12 parts of efficient blast reducer, 0.1-1.5 parts of aluminium powder, 0.6-1.4 parts of sesbania powder, 1-3 parts of air bubble carriers, 0.2-0.4 part of cross-linking agent and 0.1-0.3 part of fluorizating protein. The power of the water gel explosive achieves the level of an existing second-stage water gel explosive applicable to the coal mine, and the safety meets the requirement of the existing second-stage water gel explosive applicable to the coal mine, so that the water gel explosive provided by the invention can be used for obviously improving the embrasure utilization ratio and lowering the blasting cost during high gas coal mine blasting operation.

Owner:ANHUI UNIV OF SCI & TECH +1

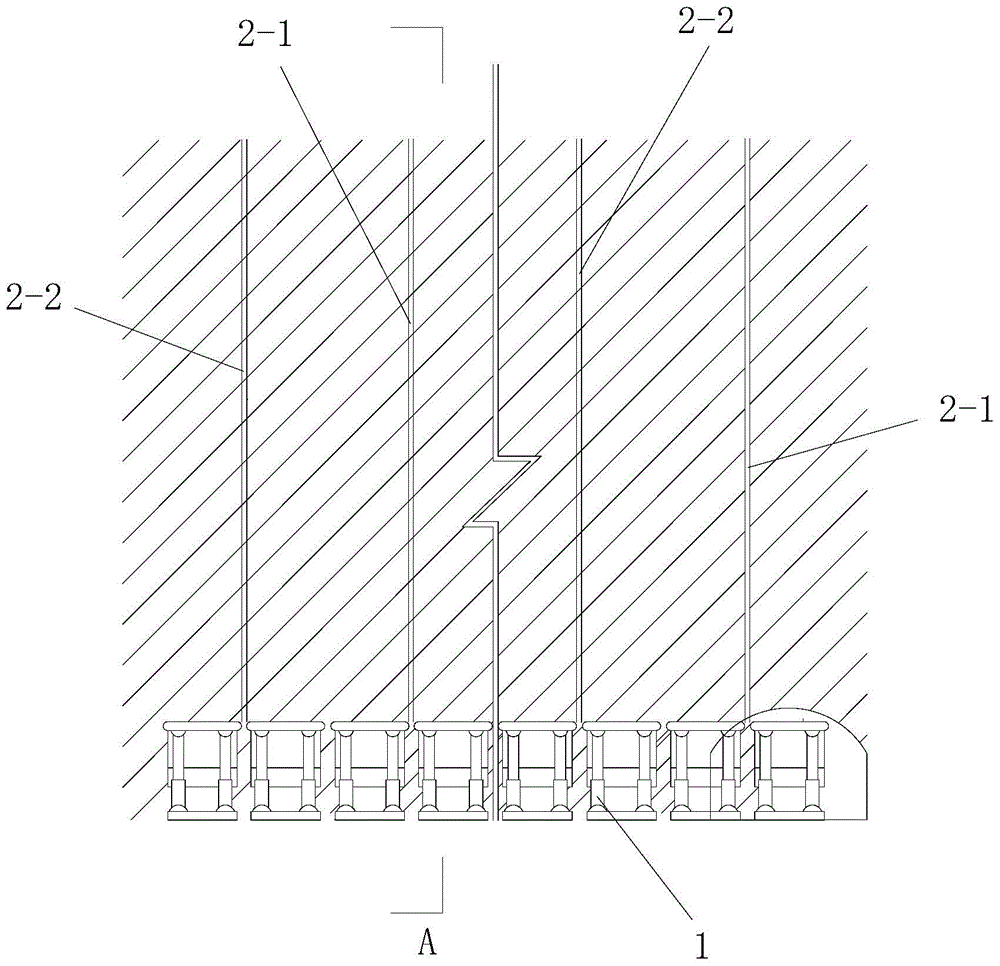

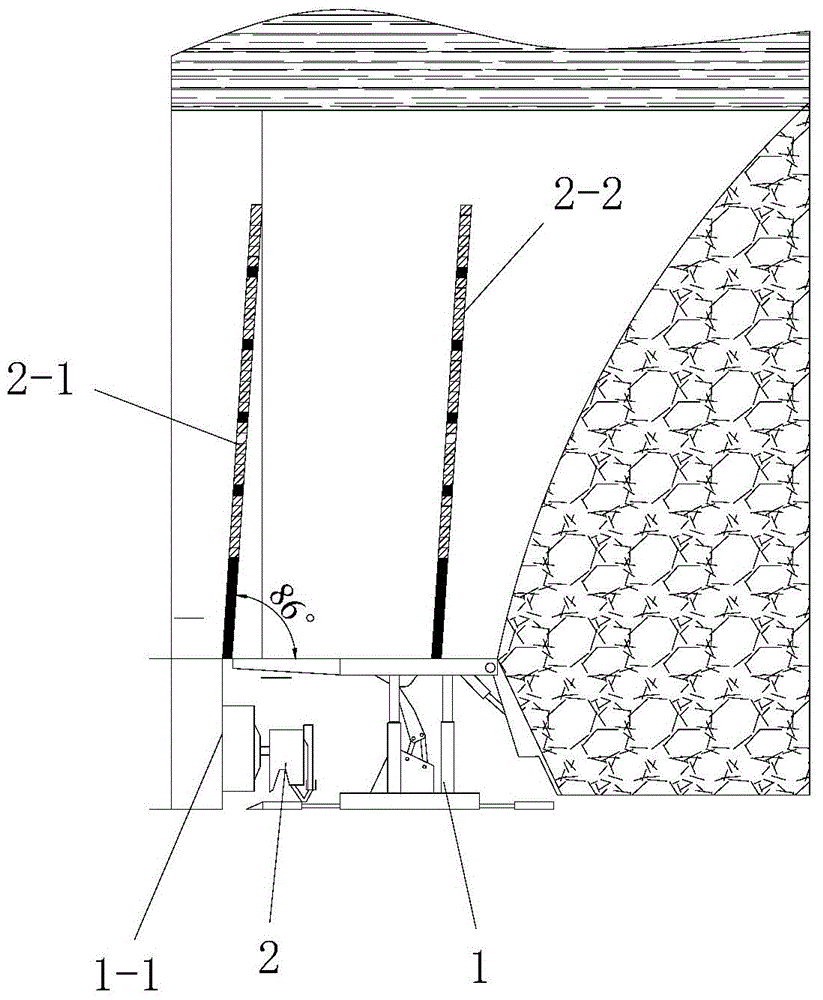

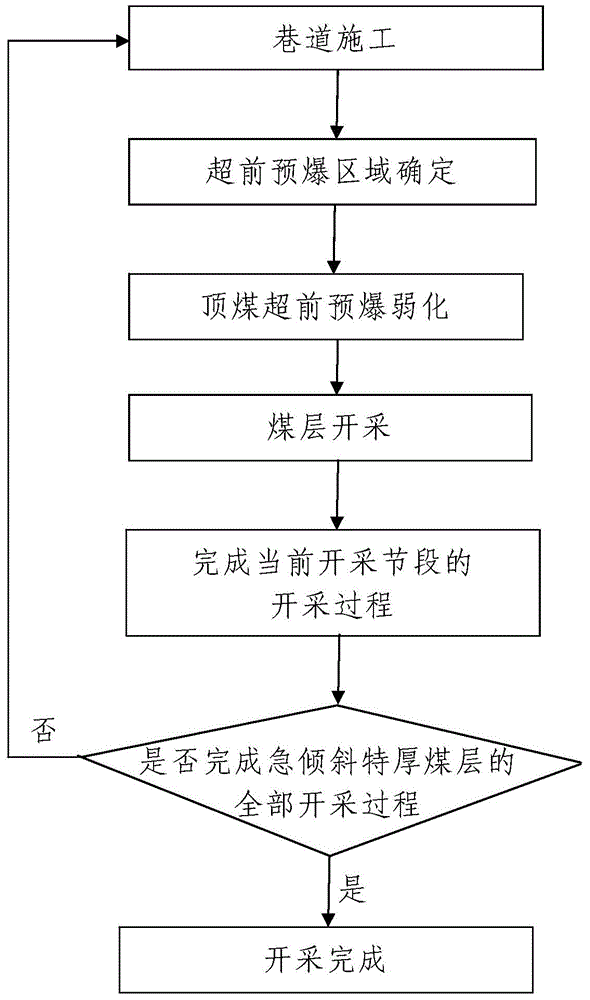

Steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening

InactiveCN104879128AThe process steps are simpleReasonable designUnderground miningSurface miningDetonationCoal

The invention discloses a steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening. The steep-dip ultra-thick coalbed mining technique includes exploiting steep-dip ultra-thick coalbed from back to front along coalbed bearing in several exploiting periods. In one of the exploiting period, the steps include firstly, constructing a roadway; secondly, weakening top-coal advancing pre-detonation, to be specifically, 201, determining a coalbed to be detonated; 202, drilling blast holes from an intake airflow road by a drilling machine; 203, charging and sealing the blast holes; 204, detonating for the first time; 205, detonating for the second time; thirdly, exploiting the coalbed; fourthly starting the next exploiting period; repeating the fourth step for many times until the steep-dip ultra-thick coalbed is completely exploited. The steep-dip ultra-thick coalbed mining technique is simple in steps, reasonable in design, high in exploitation efficiency and working-face recovery ratio, and good in using effect, and the problem that an existing mining technique is complicated, low in working-face recovery ratio and low in exploitation efficiency and causes many potential safety hazards is solved.

Owner:XIAN UNIV OF SCI & TECH

Deep-shallow hole combined blasting method

InactiveCN101551218ASolve the problem of easy large ballast explosionImprove subsequent digging efficiencyBlastingEngineering

The invention provides a deep-shallow hole combined blasting method, relating to an engineering blasting method. The invention aims to provide a deep-shallow hole combined blasting method for reducing the ratio of large blasting block at the plugging section of blasting hole, and following technical solution is used to realize the invention aim, comprising following steps: (1) drilling the deep blasting hole according to the parameters of the designed blasting hole mesh; (2) drilling a blasting hole of small diameter at the centre of every four adjacent deep blasting holes by a min-driller, the depth of the small blasting hole is a little less than the plugging length of the deep blasting hole; (3) plugging the blasting hole ports after finishing the hole drilling to prepare for filling drugs. The invention is primarily applied to engineering blast.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

Detonation method of bridge cylinder pile foundation with pile foundation diameter ranging from 1.4 m to 1.6 m

The invention relates to a detonation method of a bridge cylinder pile foundation with the pile foundation diameter ranging from 1.4 m to 1.6 m. The detonation method comprises the steps of hole drilling, explosive charging, blasthole opening blocking and detonation. The hole drilling method is that a center empty hole is vertically formed along the center line of the cylinder pile foundation, thecenter line of the cylinder pile foundation is the center, a blasthole inner ring is formed with the radius being 0.13 m-0.17 m, a blasthole middle ring is formed with the radius being 0.33 m-0.37 m,a blasthole outer ring is formed with the radius being 0.63 m-0.67 m, four vertically-arranged grooving holes are evenly distributed on the blasthole inner ring, five vertcialy-arranged assisting holes are evenly formed in the blasthole middle ring, and twelve inclined perimeter holes are evenly distributed on the blasthole outer ring; included angles formed between the central axes of the perimeter holes and the vertical direction are arccot10-arccot12, and the distances between hole tops of the perimeter holes and the center empty hole are smaller than the distances between hole bottoms ofthe perimeter holes and the center empty hole. The detonation method is high in detonation quality, high in construction efficiency and low in detonation cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

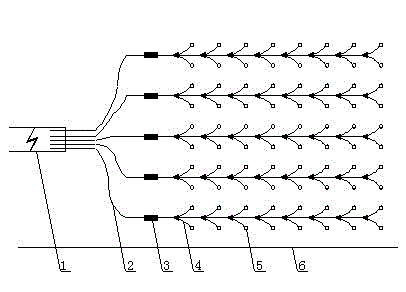

Non-electric coupling multi-section differential detonating circuit

The invention relates to a non-electric coupling multi-section differential detonating circuit. The technical scheme is as follows: a primary circuit detonating cord (2) is arranged between every two rows of blast holes (5) in a working surface; hole inlet branch circuit detonating tubes(4), nonel detonators and cartridge bags are packed into each row of the blast holes (5); two blast holes (5) which take a primary circuit detonating cord (2) as a symmetric axis are in cluster parallel connection with the primary circuit detonating cord (2) through the hole inlet branch circuit detonating tubes(4) in the holes; each primary circuit detonating cord (2) is in cluster parallel connection with a trigger device (1); a primary circuit millisecond delay detonator (3) is arranged on each primary circuit detonating cord (2); each circuit millisecond delay detonator (3) is subjected to differential accumulation according to the delay time of 100-200 ms sequentially; nonel detonators among every 1-3 blast holes (5) are subjected to differential accumulation according to the delay time of 25-50 ms; and the delay time of nonel detonators of two symmetric blast holes (5) which are cluster parallel connection with each primary circuit detonating cord (2) is 25-50 ms. The non-electric coupling multi-section differential detonating circuit has the characteristics as follows: the detonation is reliable, and the detonating circuit is economically feasible.

Owner:WUHAN UNIV OF SCI & TECH

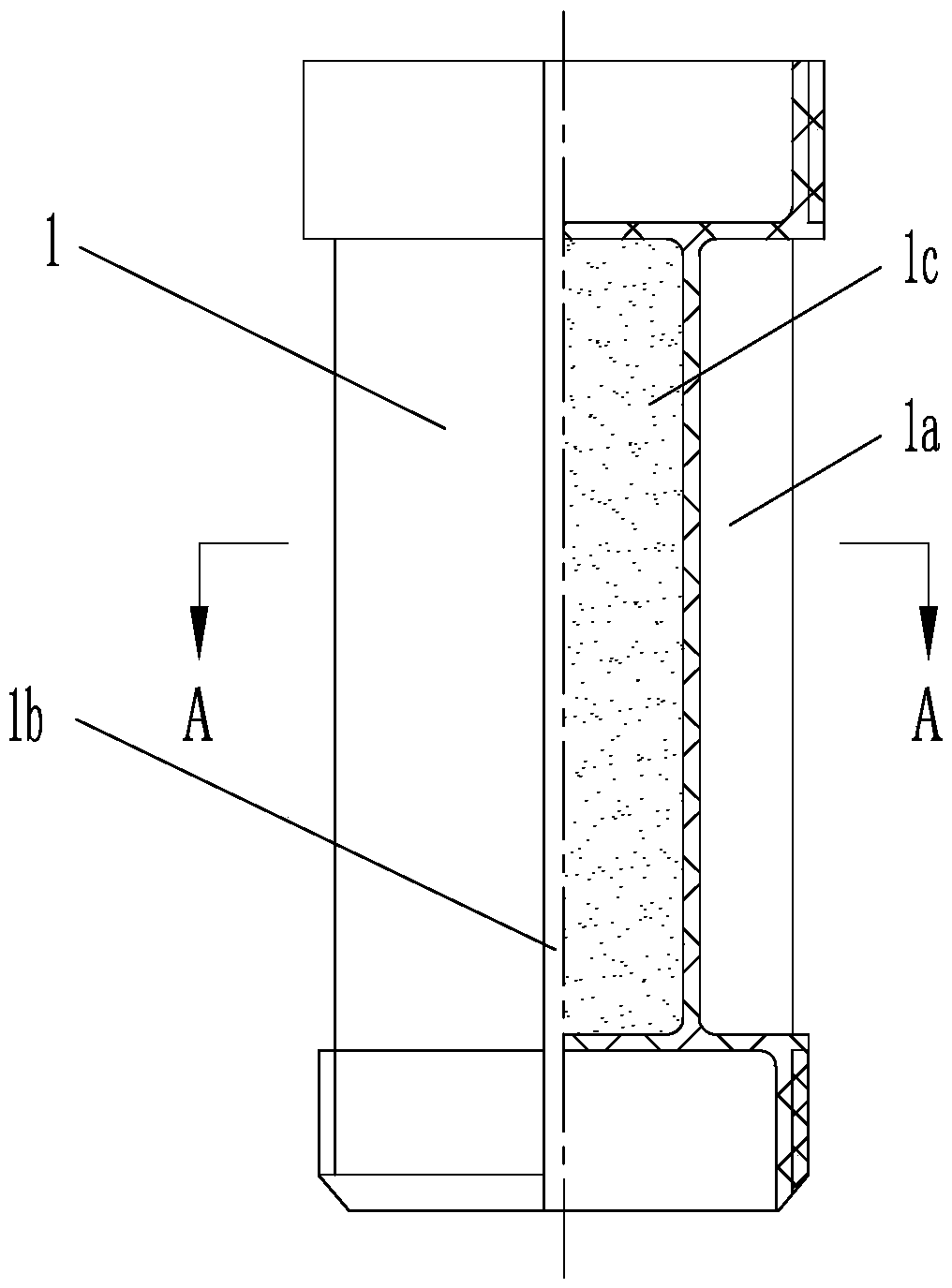

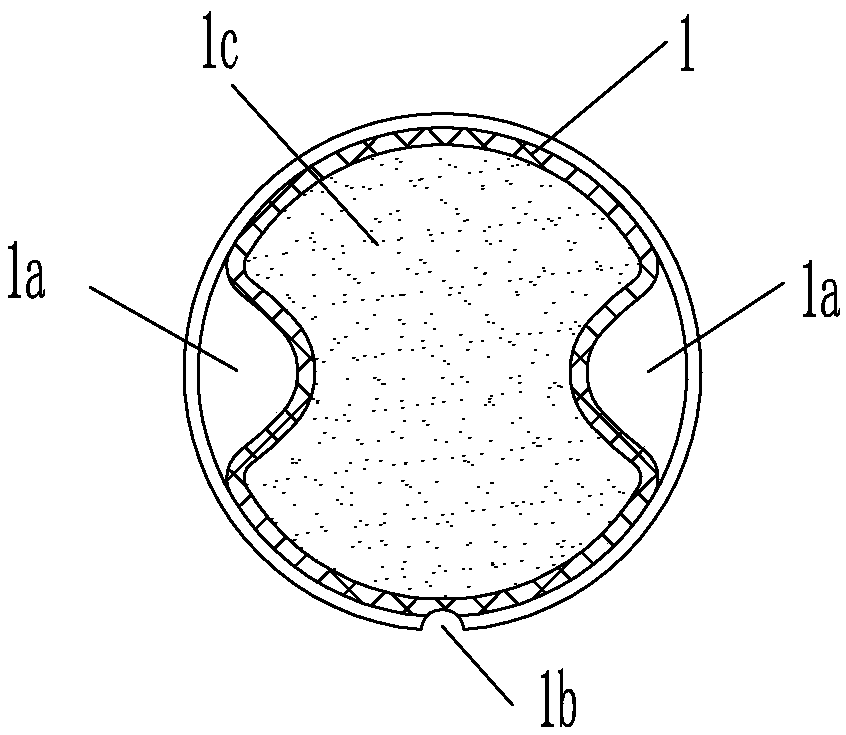

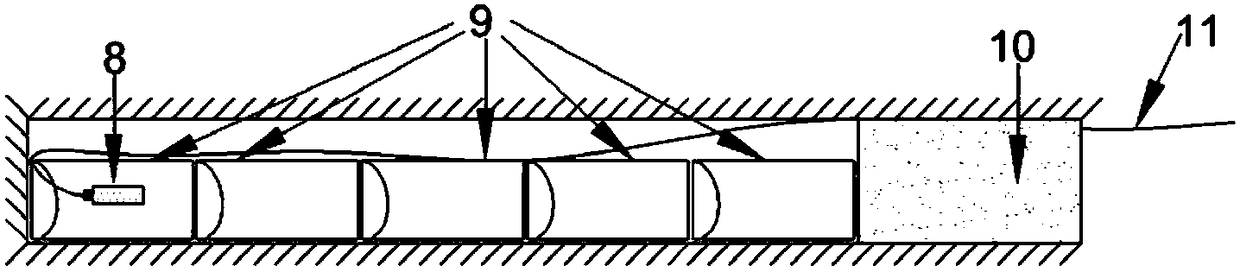

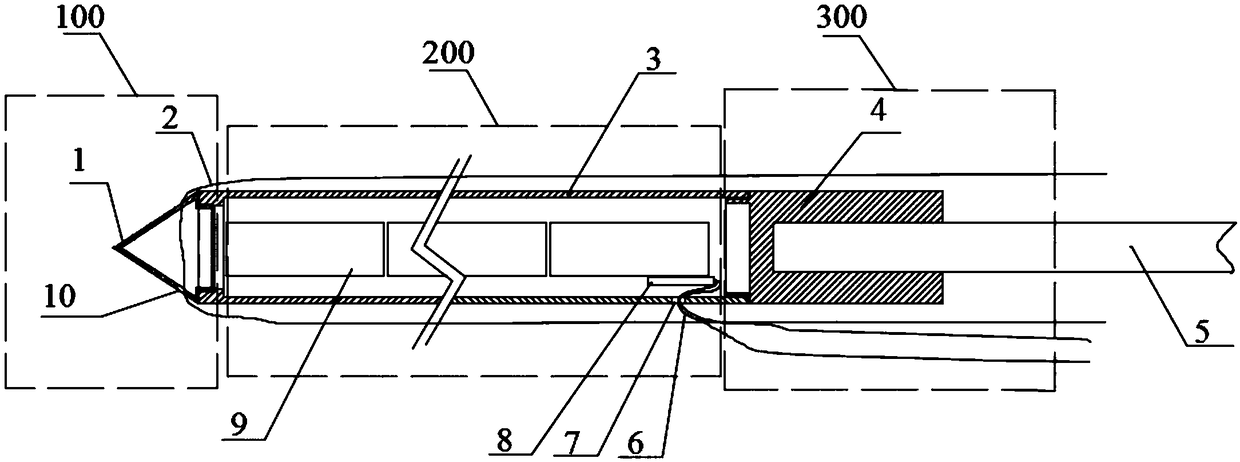

Deep hole blasting explosive cartridge

The invention discloses a deep hole blasting explosive cartridge. The deep hole blasting explosive cartridge comprises a front guide device, a powder charging device and a powder feeding device. The front guide device is a hollow taper end cap, the side wall of the taper end cap is symmetrically provided with two through holes, an oil wire rope penetrates through the through holes, and half of theoil wire rope is larger than the hole depth of a drill hole. The powder charging device comprises a hollow cylindrical powder charging cylinder, the taper end cap is connected to one end of the powder charging cylinder, the powder charging cylinder is provided with a laryard hole, the powder charging cylinder is internally provided with a plurality of stick dynamites and a detonating detonator, and a laryard of the detonator penetrates through the laryard hole and extends to the outer end of the drill hole. The powder feeding device comprises a tail end cap connected to the other end of the powder charging cylinder, and the other end of the tail end cap is provided with a groove or a protrusion matched with a powder feeding rod. According to the deep hole blasting explosive cartridge, powder charging is convenient and stable, powder can be precisely fed to a preset position, the success rate of explosion of loosening explosive powder is increased, the loosening blasting cost is reduced, and the deep hole blasting explosive cartridge is conveniently taken out when misfire detonation of the explosive powder occurs.

Owner:CHINA UNIV OF MINING & TECH

Exciter for detonating tube

The invention discloses an exciter for a detonating tube. The exciter for the detonating tube comprises a fixed part and an inserting part, wherein an inner thread is arranged at one end of the fixed part, and a fixed hole is formed in the other end of the fixed part. The fixed hole and the inner thread are communicated through a cavity. The inserting part is a circular cylinder, wherein an axis core is provided with a through hole. An outer thread which corresponds to the inner thread is arranged outside the inserting part, and the through hole of the inserting part is communicated with the cavity. According to the exciter for the detonating tube, a shock wave principle is utilized, and an electric firing component is placed inside a sealed cavity. A high-temperature shock wave is generated in the cavity by detonating the electric firing component, and thereby the detonating tube is detonated, and a detonator is set off. The exciter for the detonating tube is easy to achieve and capable of being reused, and thereby the detonating cost can be lowered.

Owner:SHANXI HUHUA GRP

Blasting method for bridge cylindrical pile foundation with pile foundation diameter of 1.1-1.3m

The invention relates to a blasting method for a bridge cylindrical pile foundation with a pile foundation diameter of 1.1-1.3m. The blasting method comprises the steps of drilling, filling explosives, blocking a blast hole and detonating, wherein the drilling step comprises the following steps of: vertically forming a central bull hole along a central line of the cylindrical pile foundation, forming a blast hole inner ring with a radius of 0.13-0.17m by taking the central line of the cylindrical pile foundation as a center, forming a blast hole outer ring with a radius of 0.48-0.52m by takingthe center line of the cylindrical pile foundation as the center, uniformly distributing four slotting holes which are vertically distributed in the blast hole inner ring, and uniformly distributing10 peripheral holes which are formed in an inclined mode in the blast hole outer ring, wherein included angles between the center axes of the peripheral holes and the vertical direction are arccot10-arccot12, and distances from the hole tops of the peripheral holes to the hollow bull hole are smaller than those from the hole bottoms of the peripheral holes to the hollow bull hole. The blasting method is high in blasting quality, is high in construction efficiency, is low in blasting cost, further can alleviate damages, on a pile hole protective wall, of blasting vibrations and flying rocks, and prevents the flying rocks from damaging construction equipment.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

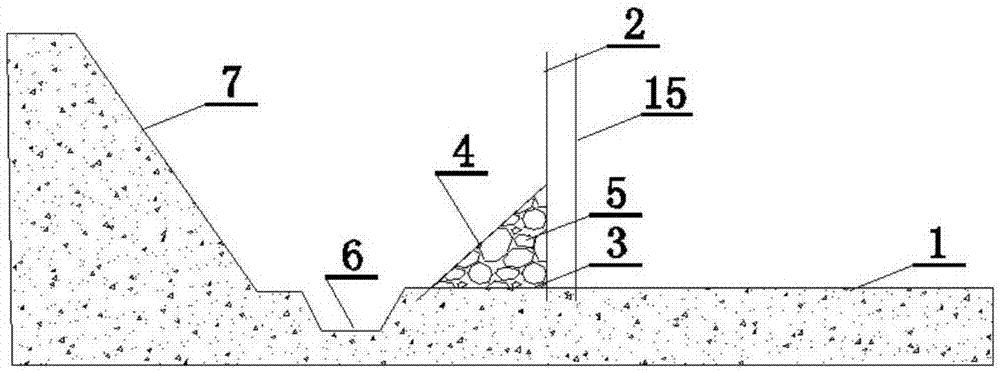

High and steep slope blasting comprehensive protection device and method

ActiveCN107421405AAvoid harmEasy to cleanClimate change adaptationBlastingSocial benefitsEconomic benefits

The invention relates to the technical field of engineering blasting, in particular to a high and steep slope blasting comprehensive protection device and method. The device comprises a first protection device body, a second protection device body and a spraying dust preventing device; the first protection device body comprises a first fixed supporting frame, a steel channel bottom frame and an inclined supporting frame; a triangular space is formed among the first fixed supporting frame, the steel channel bottom frame and the inclined supporting frame; the triangular space is filled with a protective bag; the second protection device body comprises a second fixed supporting frame and a protective net; and the spraying dust preventing device comprises a spraying pipe and a spraying head. The high and steep slope blasting comprehensive protection device is simple in structure, easy to operate, low in cost and convenient to construct, guarantees that blasting of a high and steep slope is fast and effectively performed, economic construction is accelerated, and an important role is achieved for creating good economic benefits, environmental benefits and social benefits.

Owner:中铁十九局集团矿业投资有限公司

Deep hole dust suppression blasting method in strip mine

The invention discloses a deep hole dust suppression blasting method in a strip mine. The method includes the following steps of firstly, designing a hole pattern and arranging holes; secondly, punching holes; thirdly, detecting and measuring blast holes before explosives are loaded; fourthly, filling the explosives; fifthly, placing water bags; and sixthly, connecting a network and initiating theblasting. By means of the deep hole dust suppression blasting method in the strip mine, the dust concentration is reduced after blasting, and the environmental protection is facilitated; safety is improved, and the blasting vibration and flying rock are obviously reduced; zero bottom rock is produced, the top bulk rate is reduced, and the cost for secondary disposing bottom rock and top bulk is saved; and the consumption of the explosives is reduced, and the blasting cost is reduced.

Owner:冀东海天水泥闻喜有限责任公司

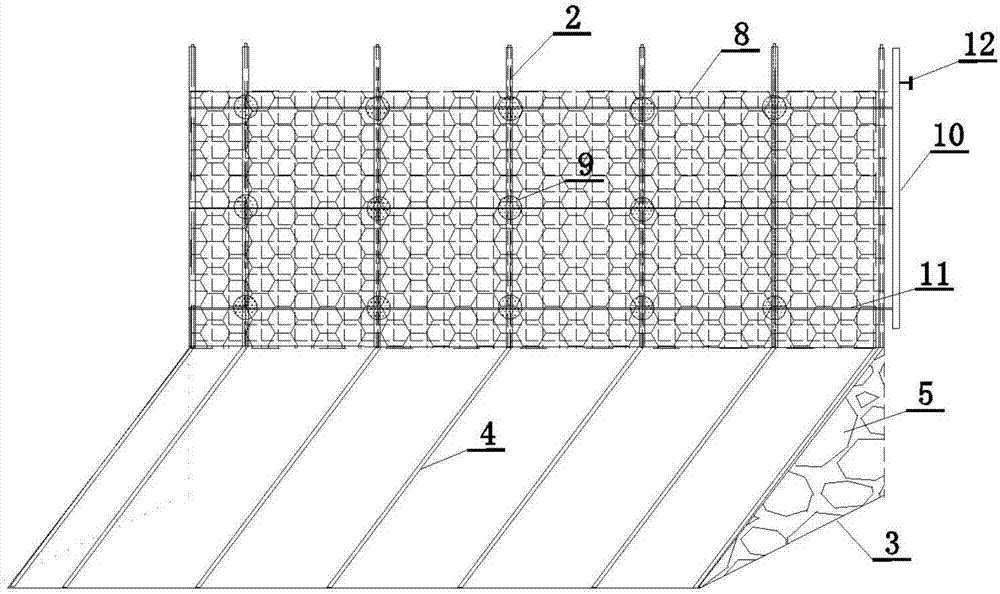

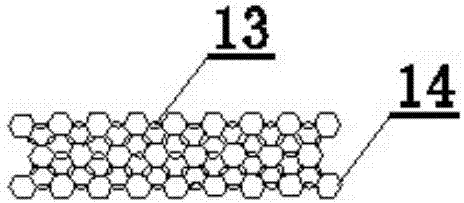

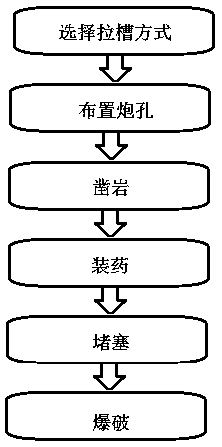

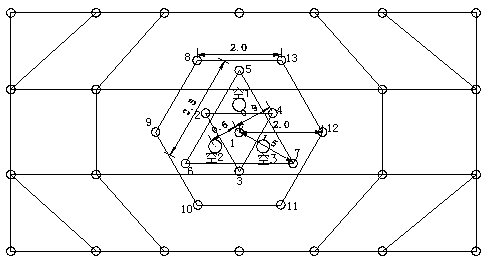

Light well-free deep hole slot broaching blasting method

ActiveCN109373843AReduce blasting costsShorten the blasting cycleUnderground miningBlastingEngineeringDeep hole

The invention belongs to the technical field of underground mine blasting and in particular relates to a light well-free deep hole slot broaching blasting method. Through six steps of selecting a slotbroaching mode, arranging a blasthole, drilling rocks, charging powder, blocking and blasting, a blasting method of slot broaching blasting is carried out directly by means of a compensation space provided by a large diameter empty hole without tunneling a light well in a stope by adopting a large diameter deep hole blasting post mining filling mining method, so that the blasting cost is loweredand the blasting period is shortened.

Owner:SHAANXI METALLURGICAL DESIGN & RES INST CO LTD

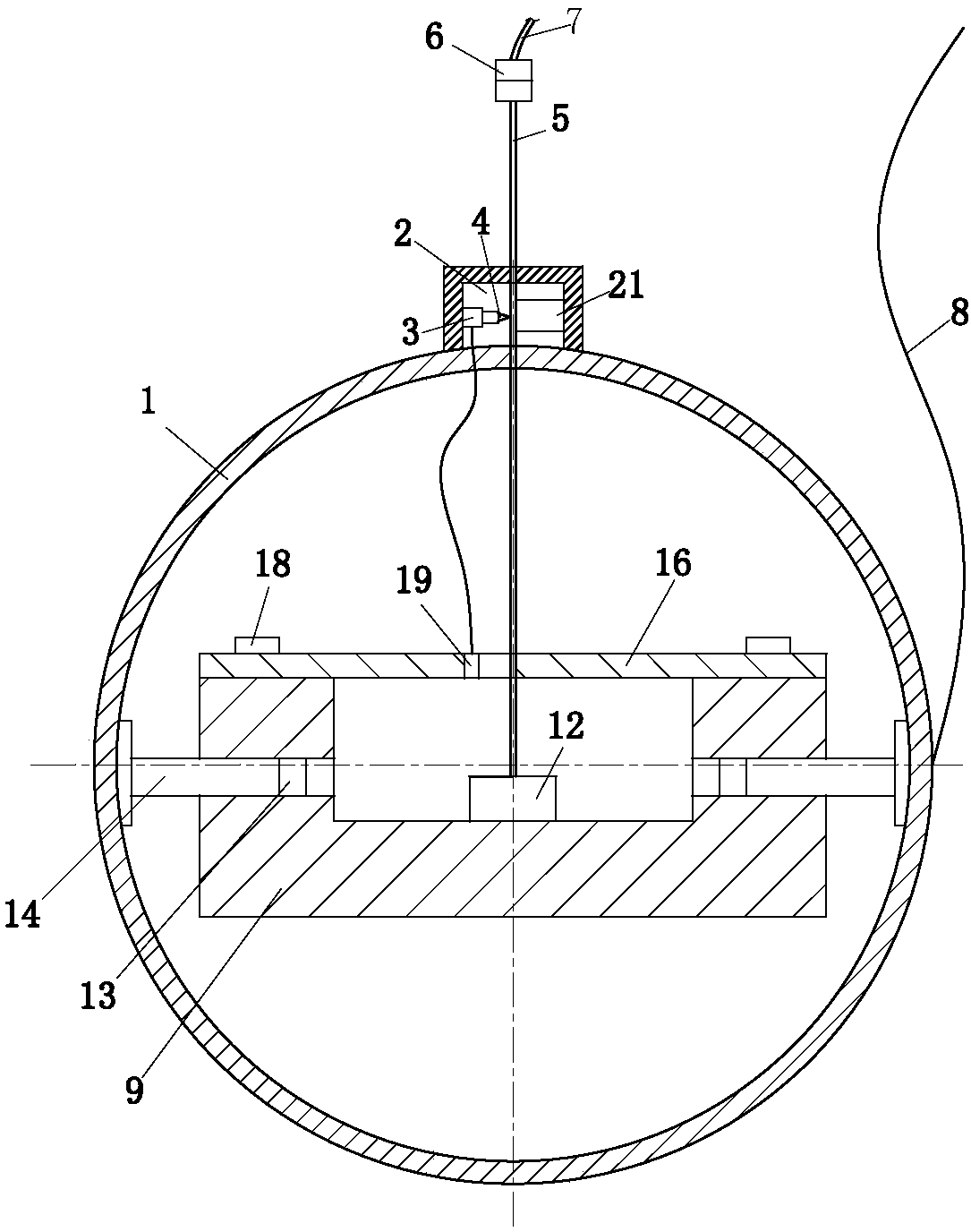

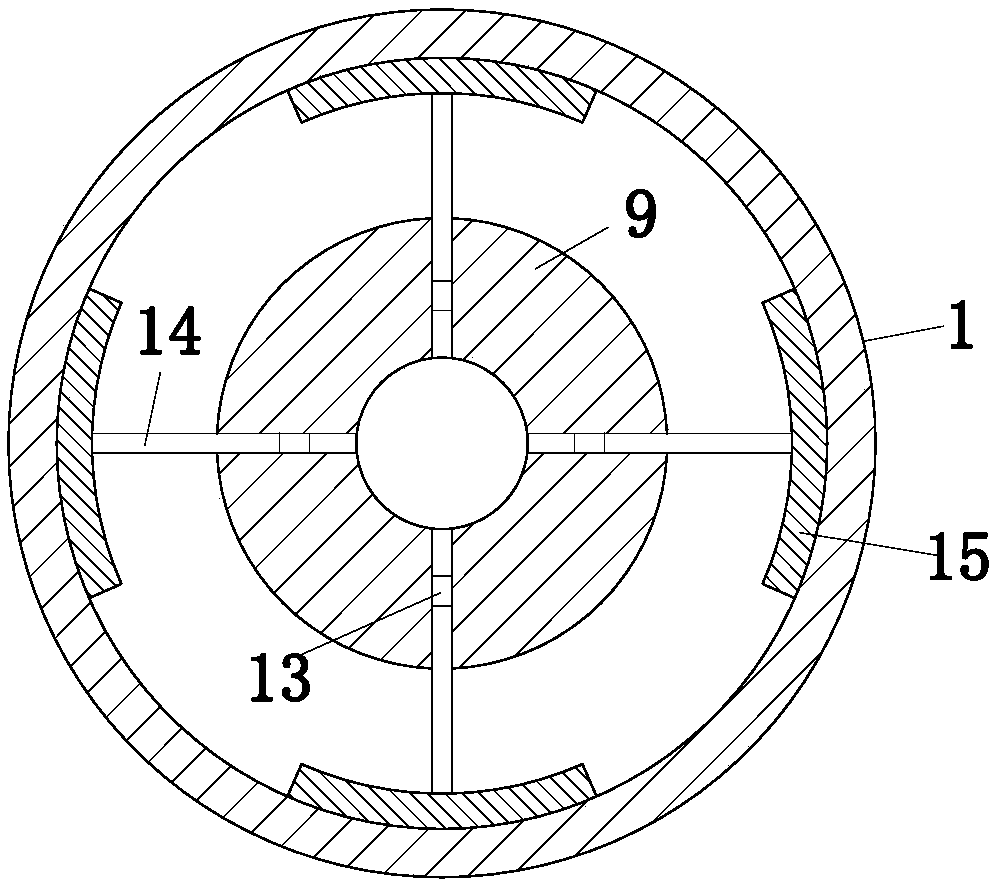

Blast hole spaced charging device for engineering blasting

The invention belongs to the technical field of blasting, and particularly relates to a blast hole spaced charging device for engineering blasting. The blast hole spaced charging device comprises a shell which is a sphere, the top of the shell is provided with a sealed chamber, a cylinder is mounted on the left inner wall of the sealed chamber, and the cylinder is connected with a cutter; one endof a trigger wire penetrates through the sealed chamber and extends into the shell, and the trigger wire is connected with a placing wire through an explosion-proof connecting box; a disc is horizontally arranged at the center position of the shell, piston holes are formed in the circumference of the disc, a groove is formed in the center of the upper surface of the disc and communicates with thepiston holes, and a gas releasing device is arranged in the groove; a piston and a piston rod are arranged in each piston hole, and supporting plates are connected with the piston rods and glued to the inner wall of the shell; and a sealing end cover is arranged on the upper surface of the shell, and an air guide hole is formed in the sealing end cover and is connected with the cylinder through anair pipe. The blast hole spaced charging device is mainly applicable to spacing of blast holes in open-air coal seams, and the condition that explosives are detonated can be effectively avoided, so that the safety of blasting is improved.

Owner:西安鹏程爆破工程有限公司

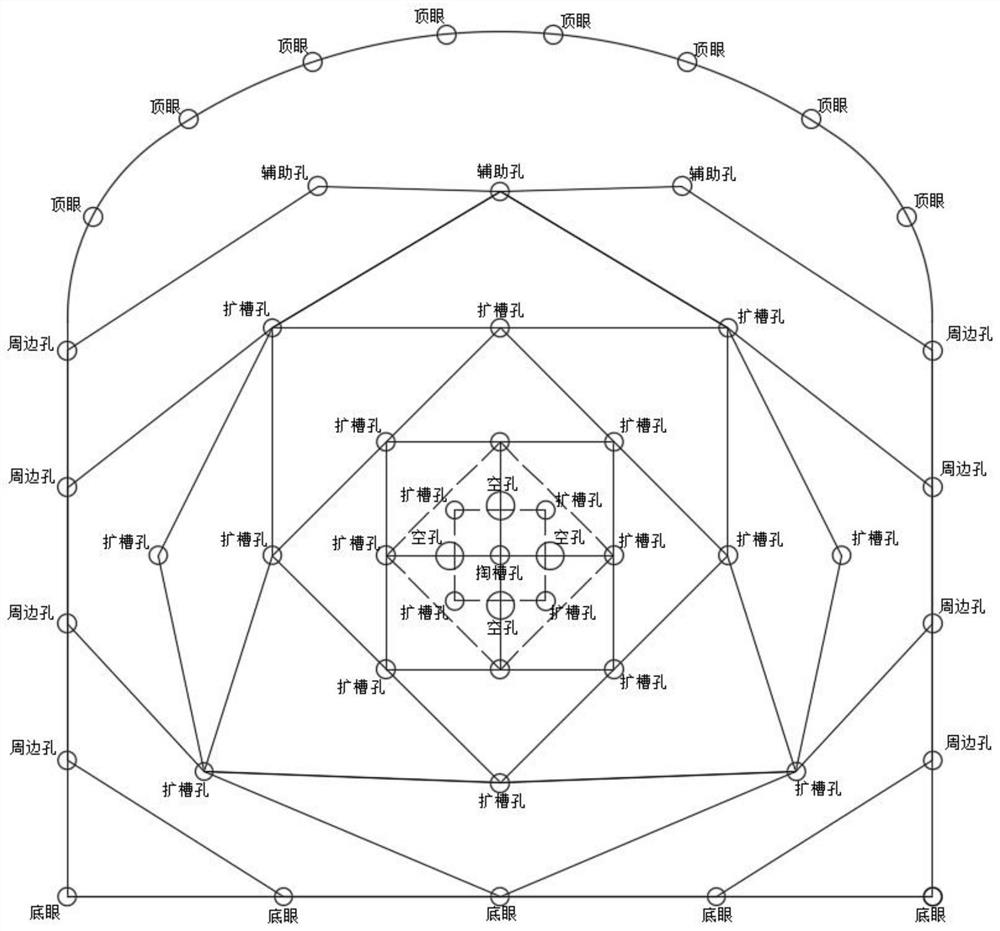

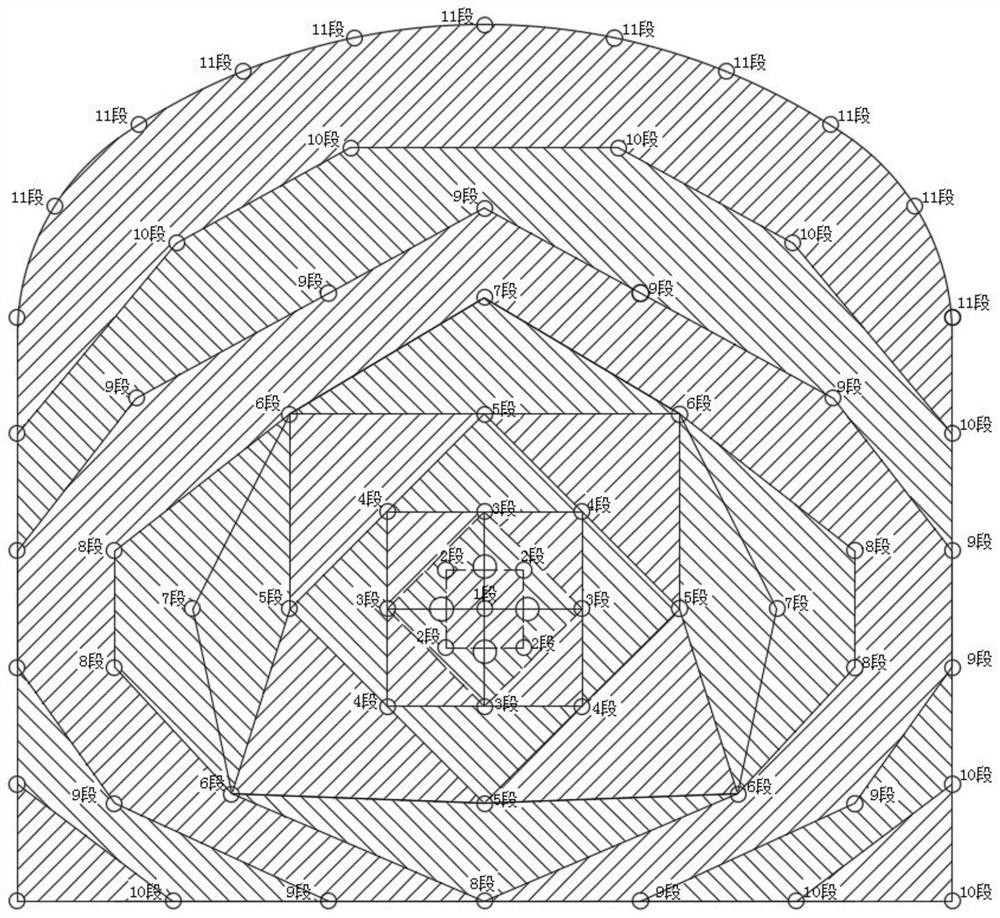

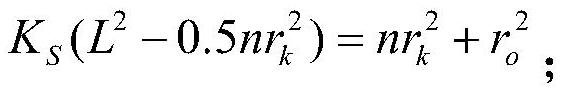

Simple smooth blasting drilling and charging method for medium-hard rock

PendingCN114485304AReduce in quantityReduce consumptionConstructionsReciprocating drilling machinesDetonatorExplosive Agents

The invention relates to the technical field of mining, and discloses a simple smooth blasting drilling and charging method for medium-hard rock, which comprises the following operation steps: S1, rock drilling: firstly, drilling four empty holes, arranging a section of slotting hole in the center of the four empty holes, forming an expanded slot cavity between a section of expanded slot hole and each empty hole after the section of expanded slot hole is blasted, and arranging a section of expanded slot hole in the middle of each empty hole; four three-section groove expanding holes are formed in the periphery of the opposite angles of the groove cavity; the second section, the third section, the fourth section and the fifth section are alternately arranged in a square mode and a rhombus mode in sequence, the third section of other blast holes are positioned, peripheral holes are symmetrically formed in the left side and the right side of the outermost side of the expanded slotted hole, a bottom hole is formed in the bottom of the outermost side of the expanded slotted hole, an auxiliary hole is formed in the top of the outermost side of the expanded slotted hole, and a top hole distributed in an arc shape is formed in the top of the auxiliary hole; s4, the blast holes are filled with coiled explosives; and S5, blasting: according to the principle that detonators at the same section position are loaded in each group of slot expanding holes, detonator section positions are gradually increased in sequence for charging. According to the method, the number of drilled holes is small, the drilling and charging time is short, the blasting success rate is high, and the blasting cost is low.

Owner:ANHUI KAIFA MINING IND

Blasting method for bridge cylindrical pile foundation with diameter being 0.8-1 m

InactiveCN108061492AReduce consumptionTake advantage ofBlastingExcavationsExplosive materialBuilding construction

The invention relates to a blasting method for a bridge cylindrical pile foundation with the diameter being 0.8-1 m. The blasting method includes the steps of hole drilling, explosive material charging, blast hole opening blocking and detonating. According to the step of hole drilling, a central empty hole is vertically formed along the central line of the cylindrical pile foundation, a blast holeinner circle is formed with the central line of the cylindrical pile foundation as the center and with the radius of 0.13-0.17 m, a blast hole outer circle is formed with the central line of the cylindrical pile foundation as the center and with the radius of 0.33-0.37 m, four vertical grooving holes are evenly distributed in the blast hole inner circle, and nine inclined peripheral holes are evenly distributed in the blast hole outer circle. The included angle between the central axis of the peripheral holes and the vertical direction is arccot 10-arccot 12, and the distance from the tops ofthe peripheral holes to the central empty hole is smaller than the distance from the bottoms of the peripheral holes to the central empty hole. According to the blasting method for the bridge cylindrical pile foundation with the diameter being 0.8-1 m, blasting quality is high, construction efficiency is high, blasting cost is low, damage of blasting shock and flying stones to a pile hole protective wall can be reduced,, and flying stones are prevented from damaging construction equipment.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com