Primary blasting well forming method for middle guide well

A technology for pilot wells and detonating tubes is applied in the field of one-shot blasting of medium pilot wells, which can solve the problems of construction progress, difficult safety, low safety system, and many processing procedures, so as to enrich technologies and construction methods, reduce blasting costs, and reduce blasting costs. The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

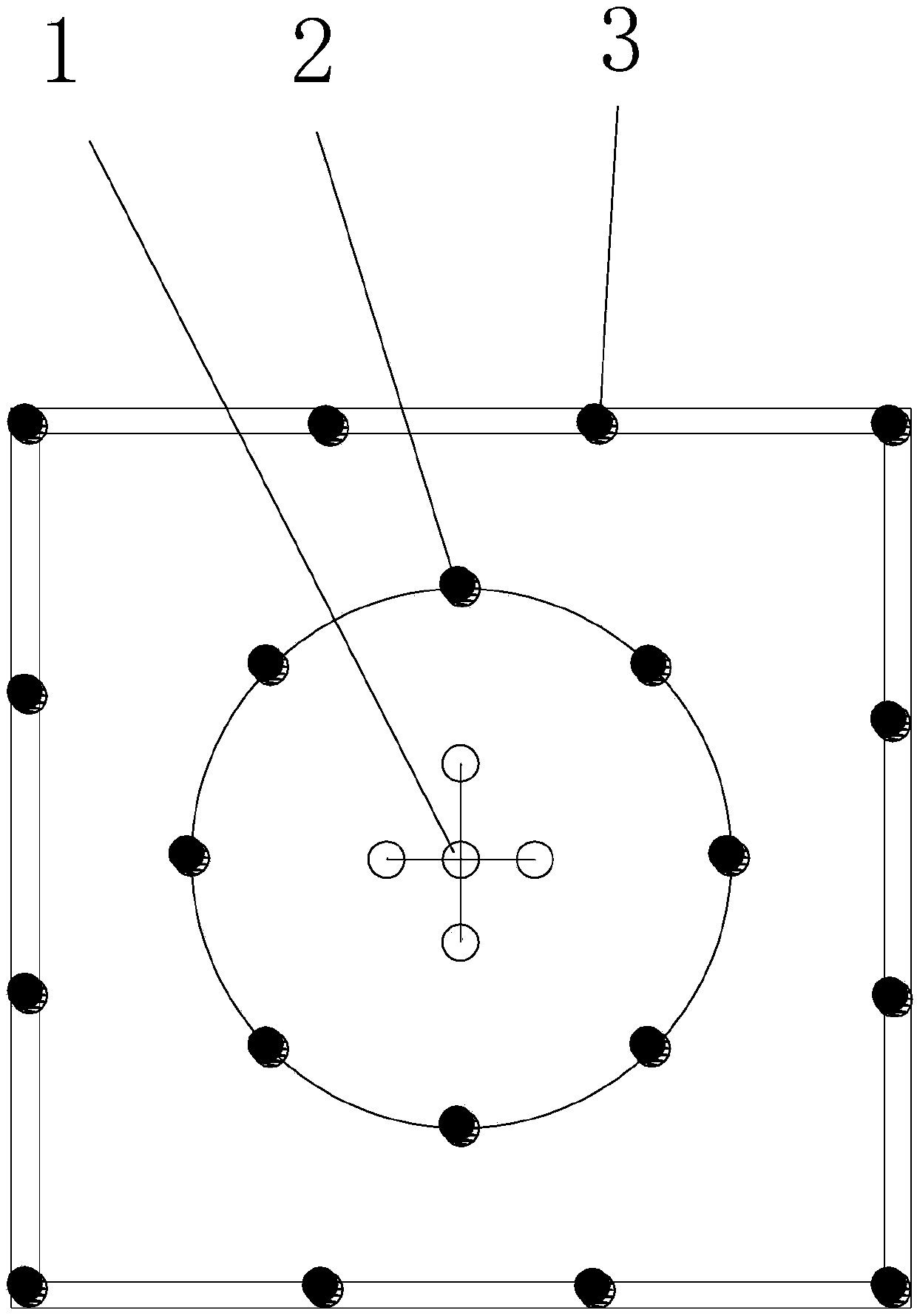

[0026] A kind of blasting well formation method of intermediate guide well, such as figure 1 shown, including the following steps:

[0027] (1) Measurement and positioning to determine the wellhead position of the shaft;

[0028] (2) Mechanical excavation at the shaft mouth: use excavators and picks to excavate the upper section of the shaft, clean up the site, level it, excavate the strong weathered layer, break it mechanically and clean it;

[0029] (3) Back digging at the bottom of the shaft: back digging at the bottom of the shaft for a cycle. The cycle refers to drilling, charging, connection, blasting and inspection after blasting. The height is 2.3m. Drilling, hole diameter 43mm, hole depth 2.3m, detonating tube connection, non-electric millisecond detonating detonator differential detonation;

[0030] (4) Stakeout blasthole position according to the blasting design of the pilot shaft: use the total station to stake out the position of the pilot shaft in the 2m×2m ver...

Embodiment 2

[0039] With embodiment 1, difference is that in step (3), height 2m, hole depth 2m; The distance between the holes is 0.1m; then cut the hole 2, the diameter of the blast hole The distance between the holes is 0.4m; the peripheral hole 3 is finally drilled, and the diameter of the blast hole is Hole spacing 0.4.

Embodiment 3

[0041] With embodiment 1, difference is that in step (3), height 2.5m, hole depth 2.5m; The distance between the holes is 0.2m; then cut the hole 2, the diameter of the blast hole The distance between the holes is 0.6m; finally, the peripheral holes 3 are drilled, and the diameter of the blast hole is The hole distance is 0.6m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com