Patents

Literature

127results about "Shaft raising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

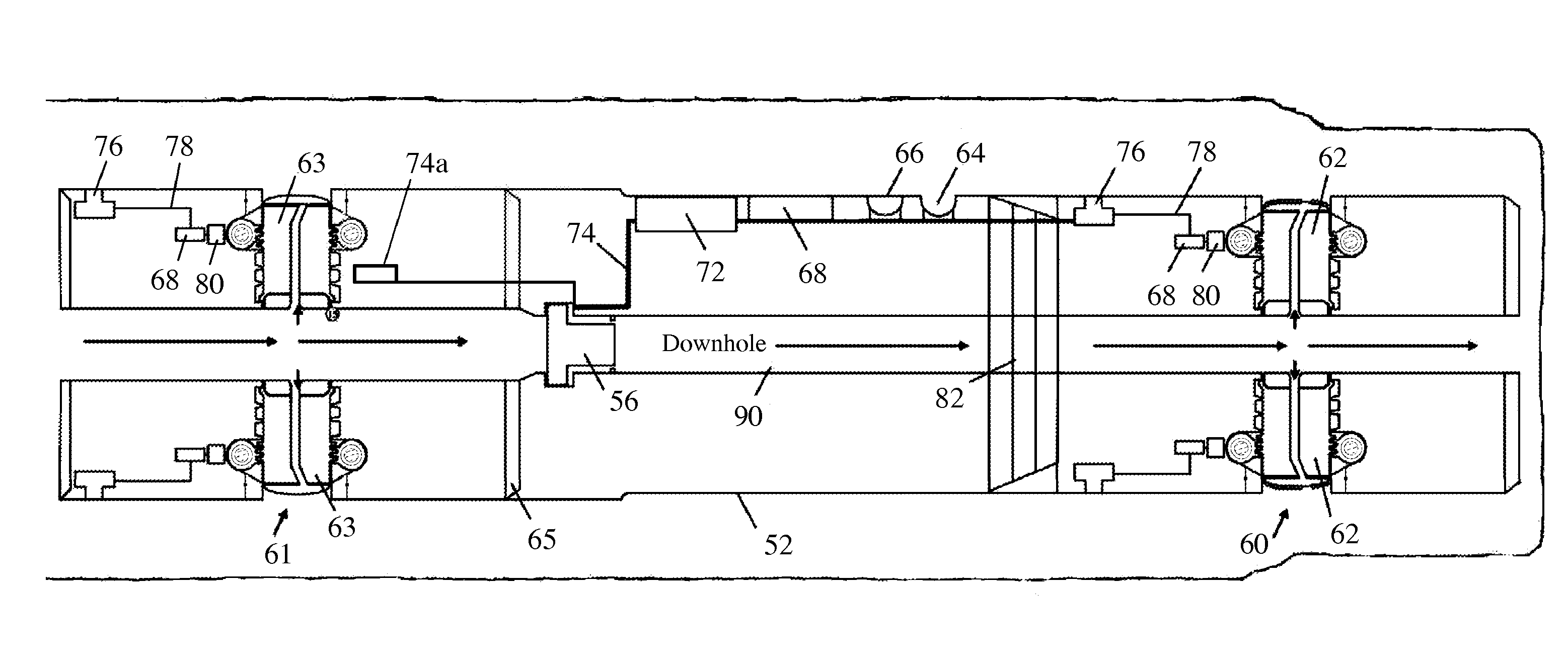

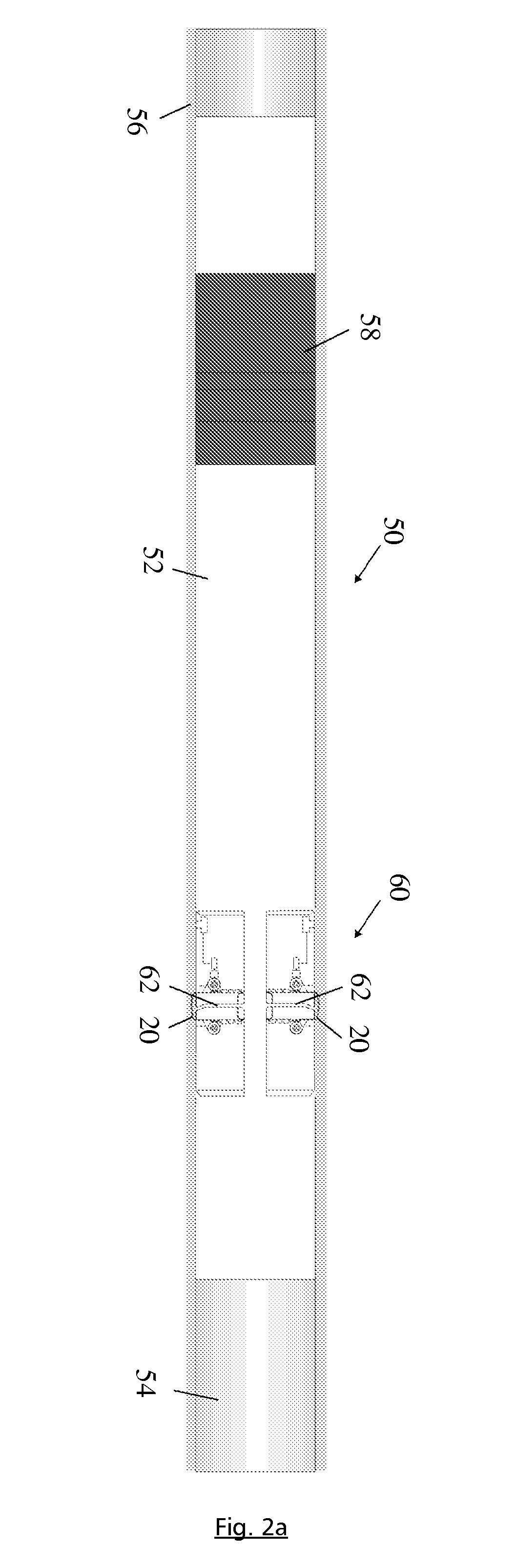

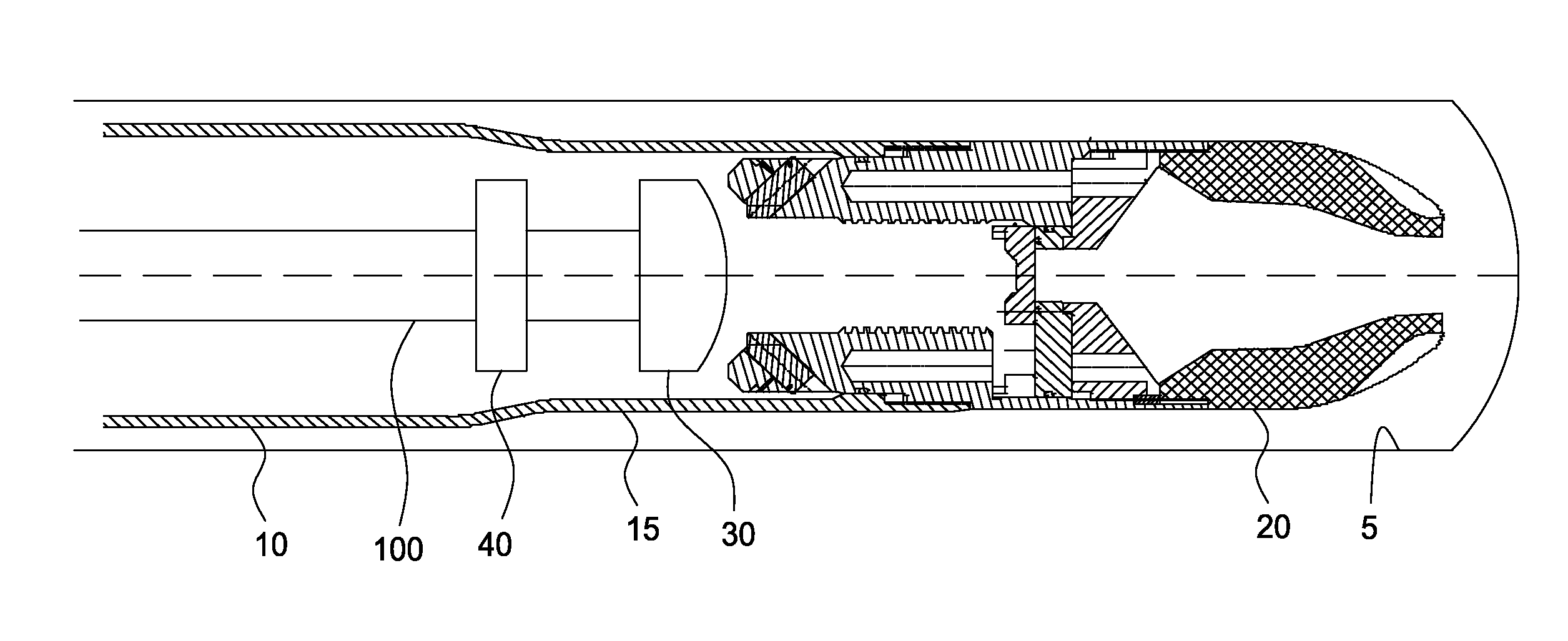

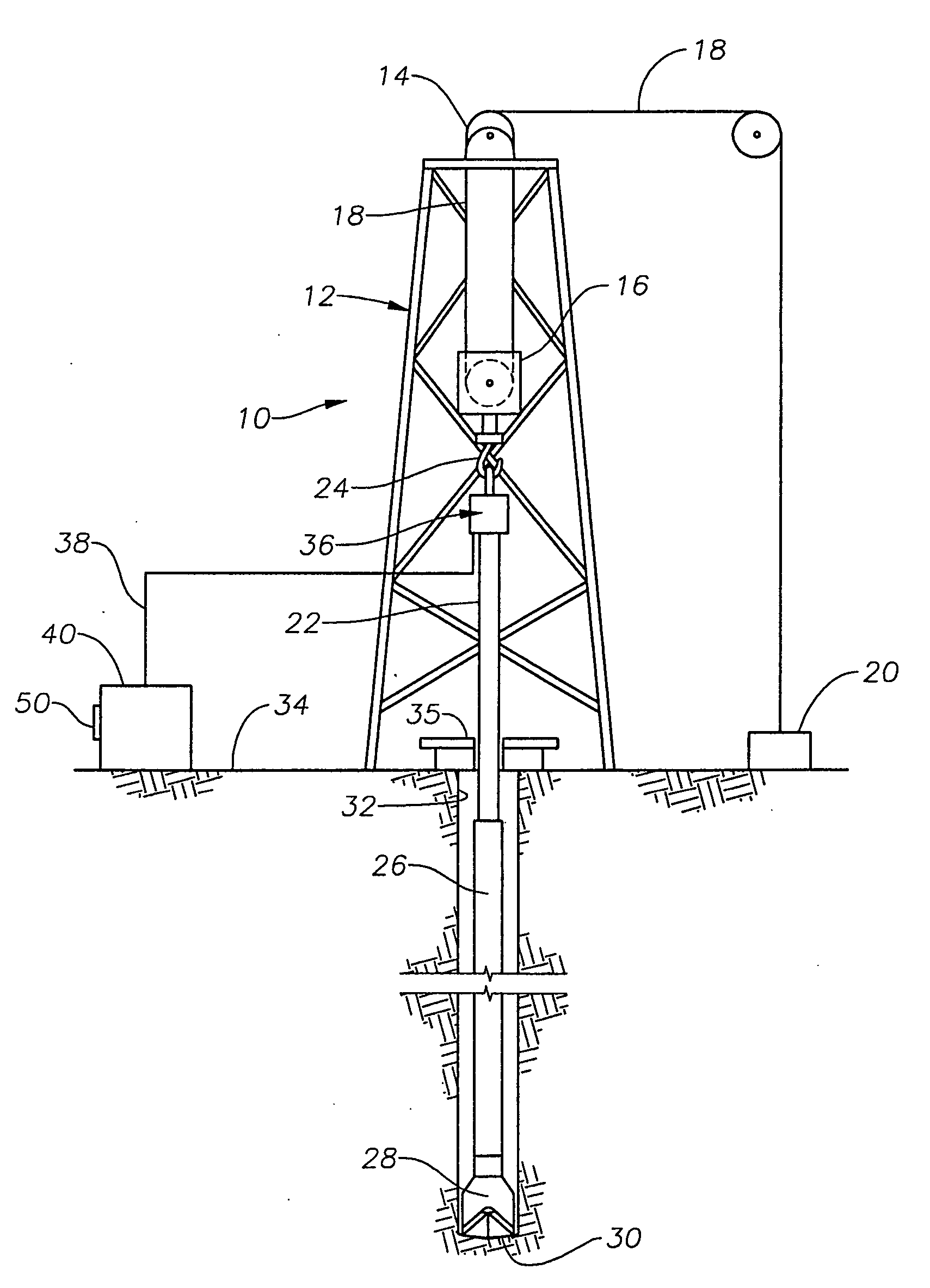

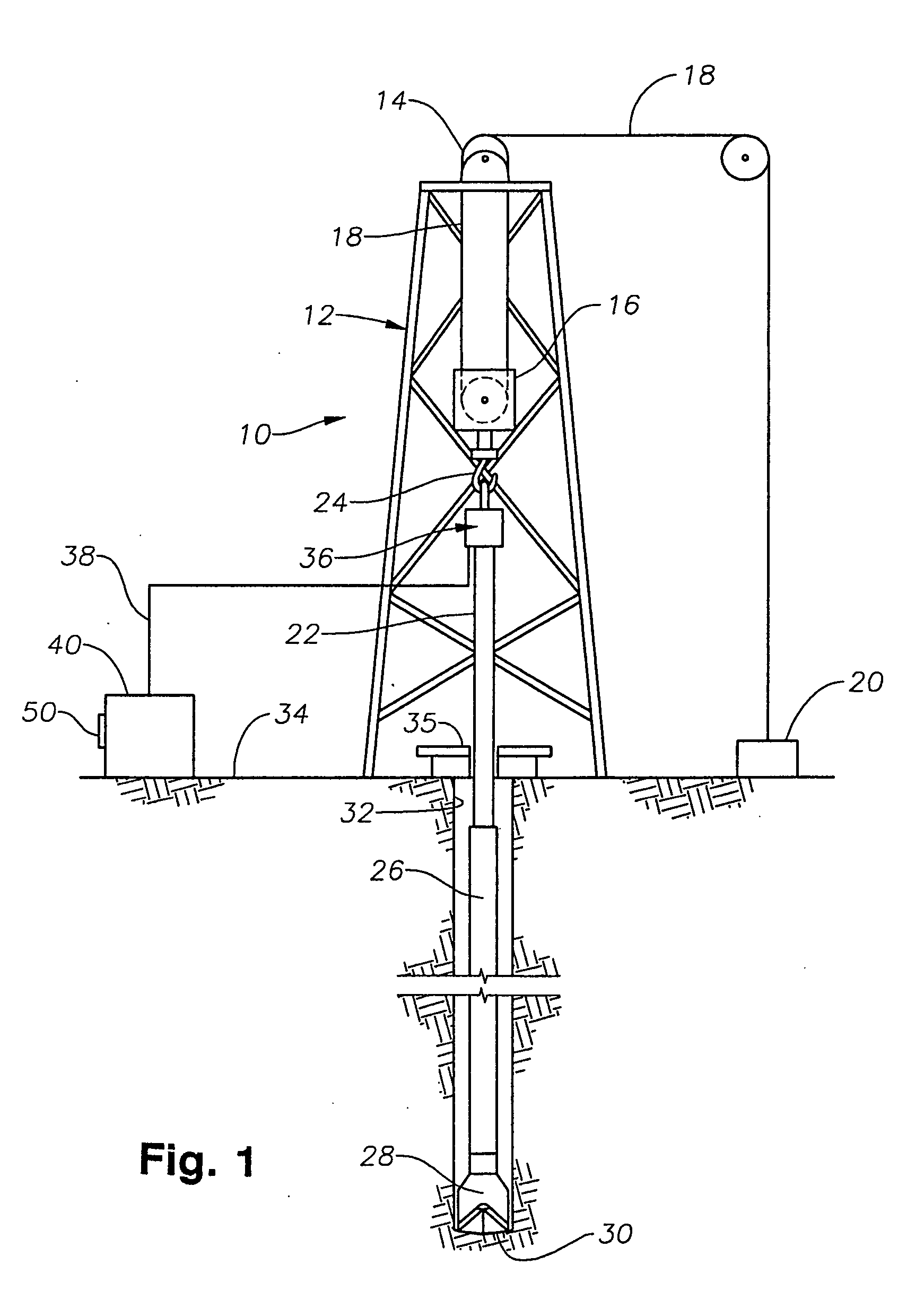

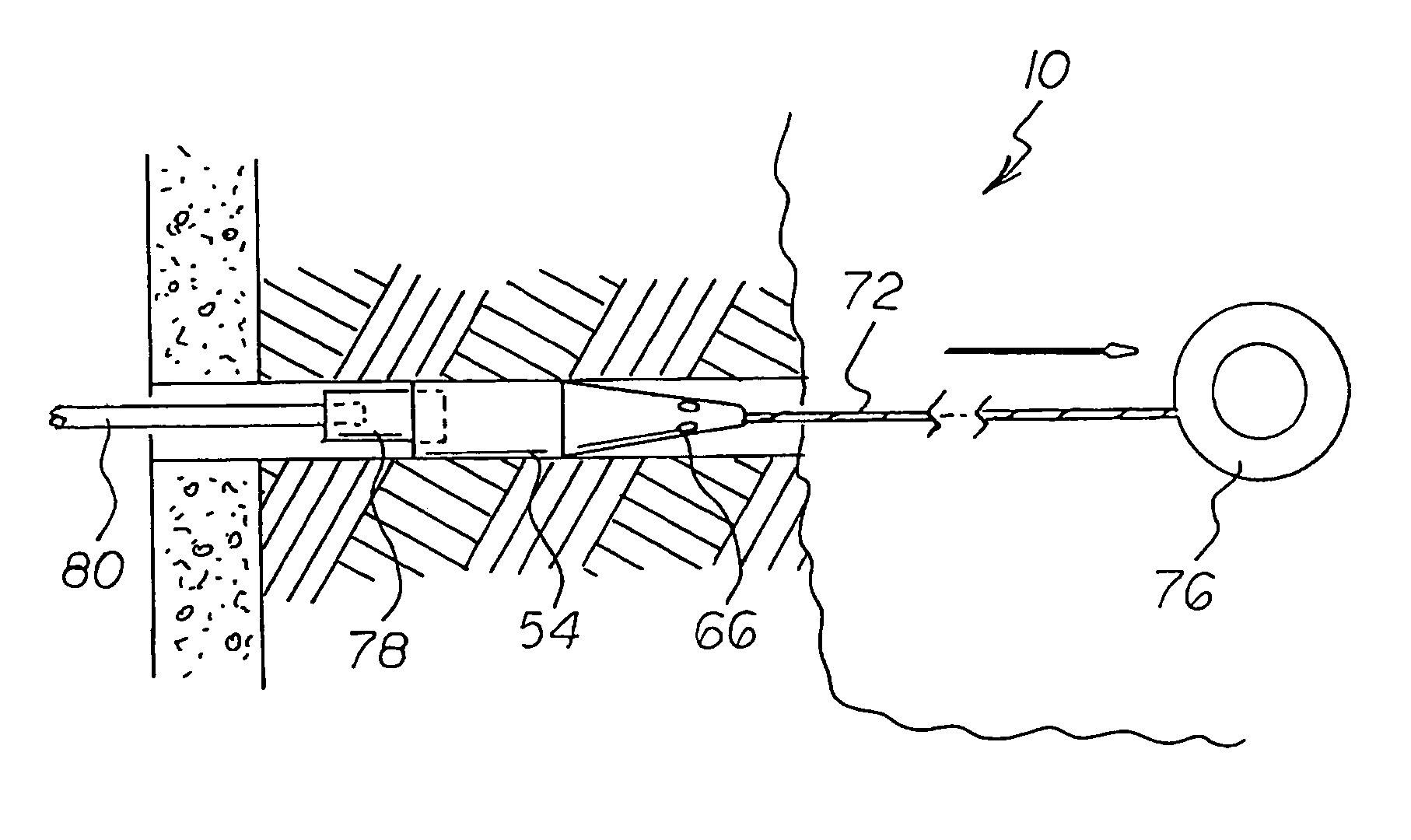

Expansion and sensing tool

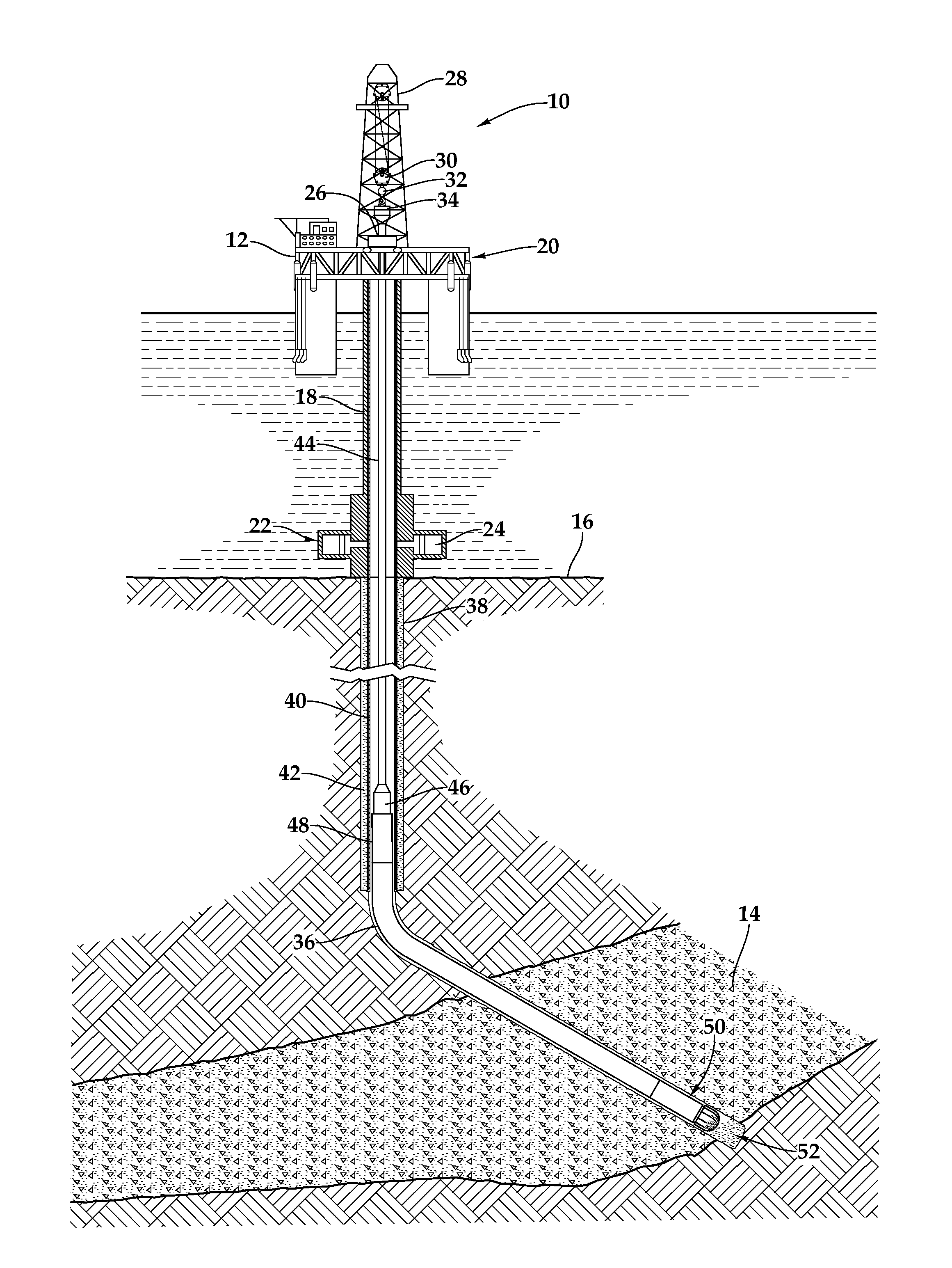

ActiveUS20110247878A1Enter exactlyImprove drilling efficiencyBiocideDrill bitsEngineeringOil and natural gas

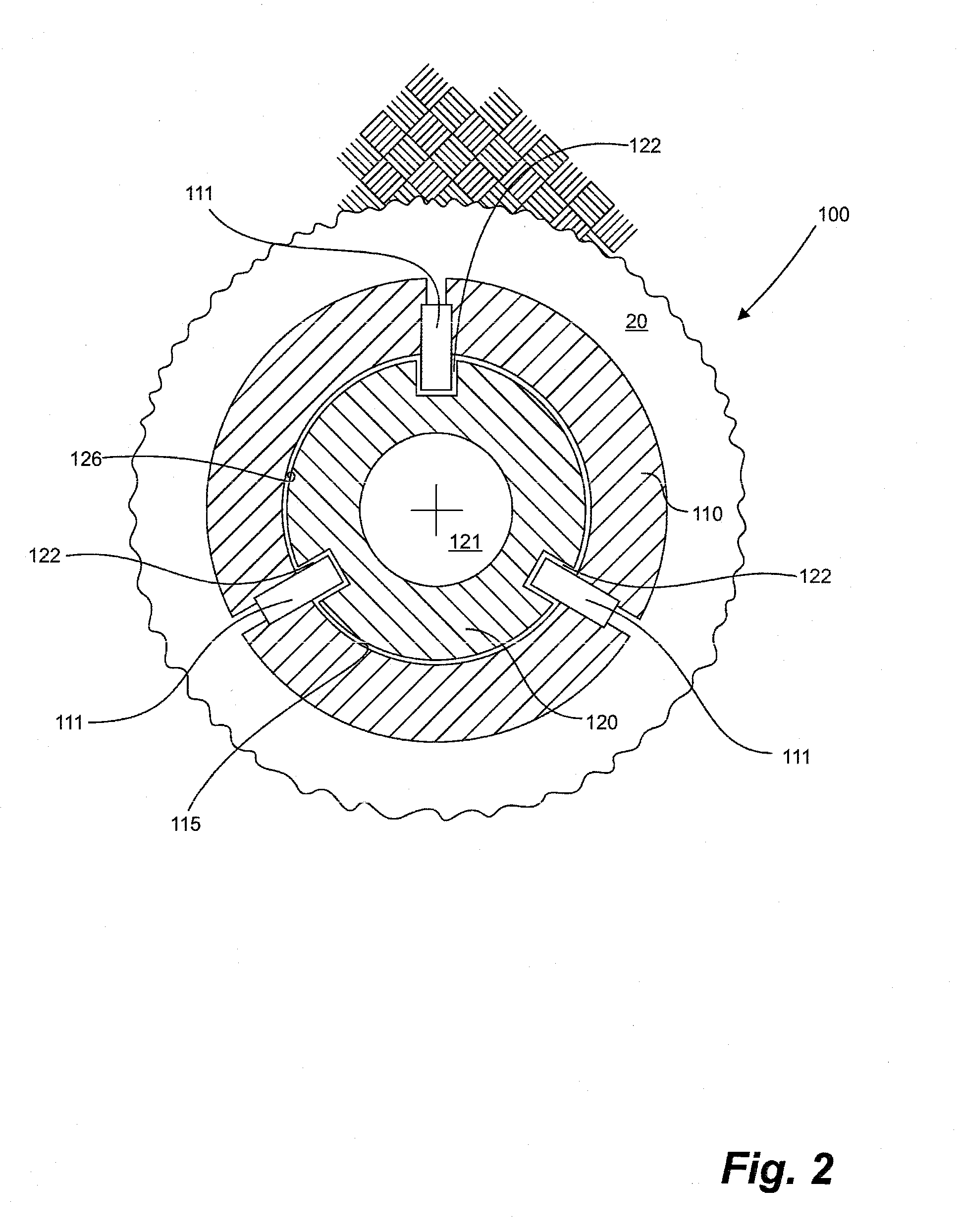

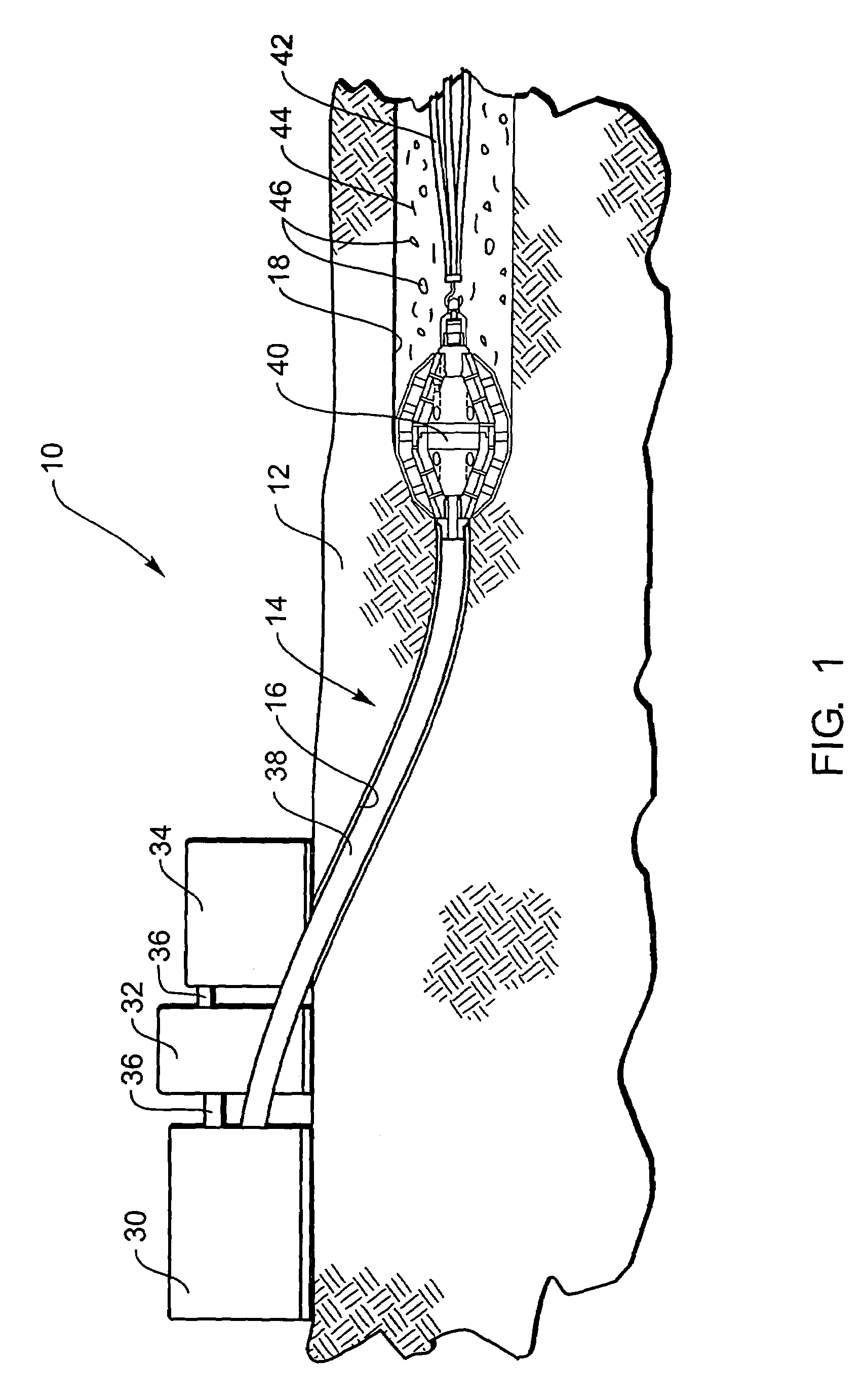

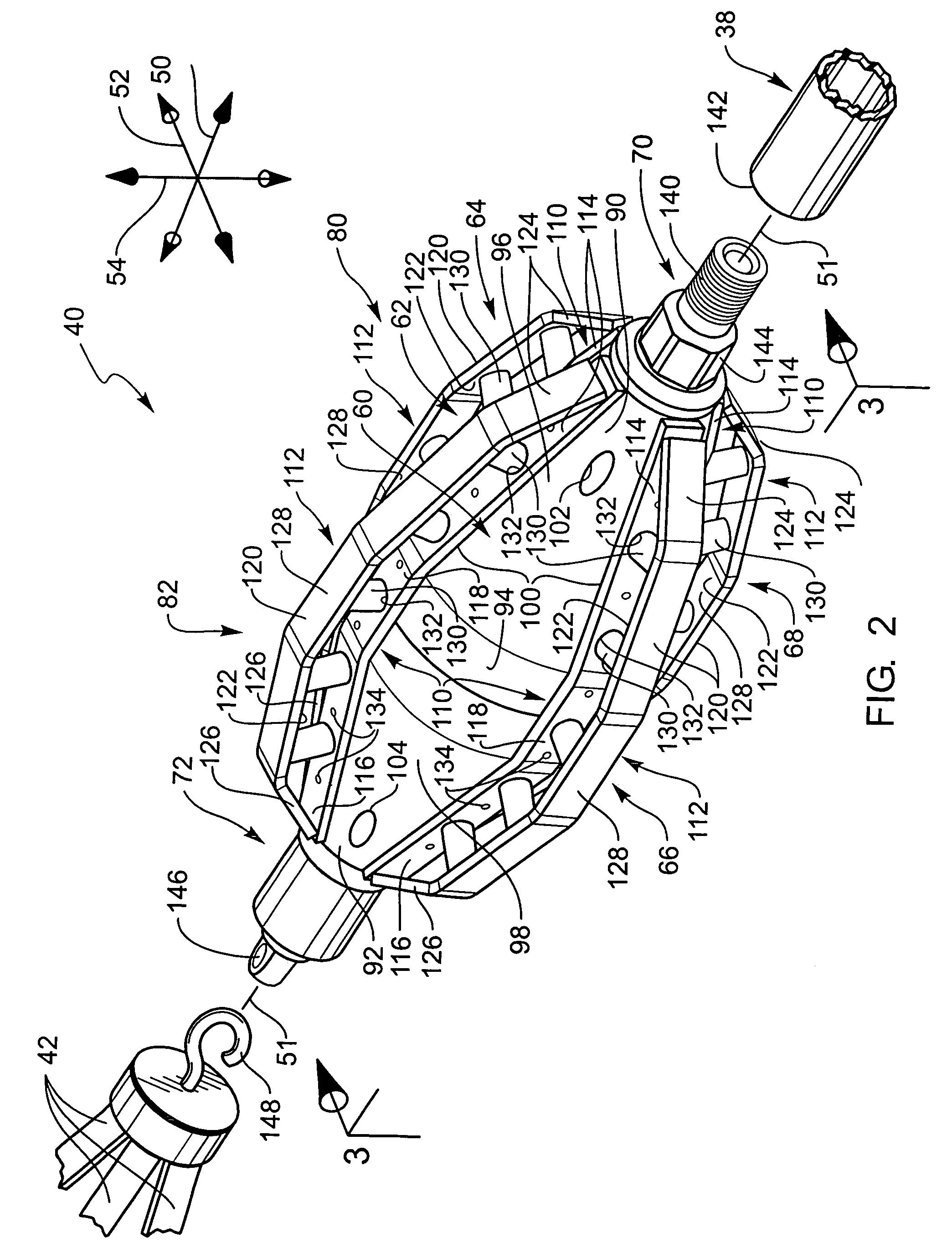

An expansion and sensing tool (50) comprising a tool body, cutter blocks and sensors with means for attachment to a drilling support and rotation which permits simultaneous underreaming and measurement of the diameter of a wellbore (40) drilled by an oil and gas rig (10) and characterized by radially extendable cutter blocks (62) incorporating positional sensors (80) adapted to measure the position of the cutter block relative to the tool, and vibration sensor means (76) to measure vibration and underreaming dynamics wellbore dimension in real-time, all of which are inter-linked by a means of communication using receivers, sensors and microprocessors to deliver a desired wellbore depth by simultaneously comparing and correlating measured vibration data and optimizing underreaming parameters. The tool may be optionally configured with calliper or stabilizer means directly or indirectly connected to the underreamer.

Owner:SMART REAMER DRILLING SYST LTD

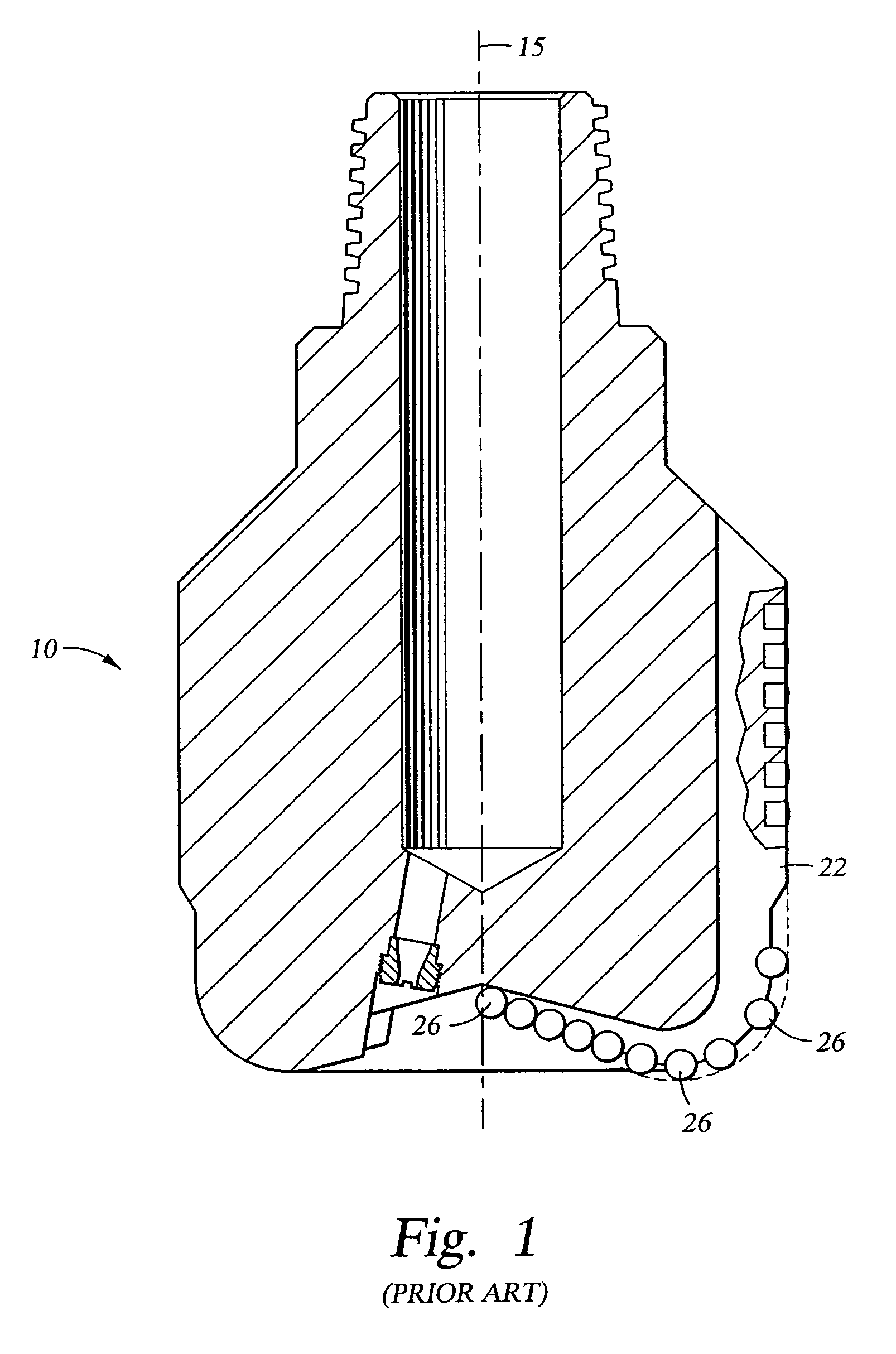

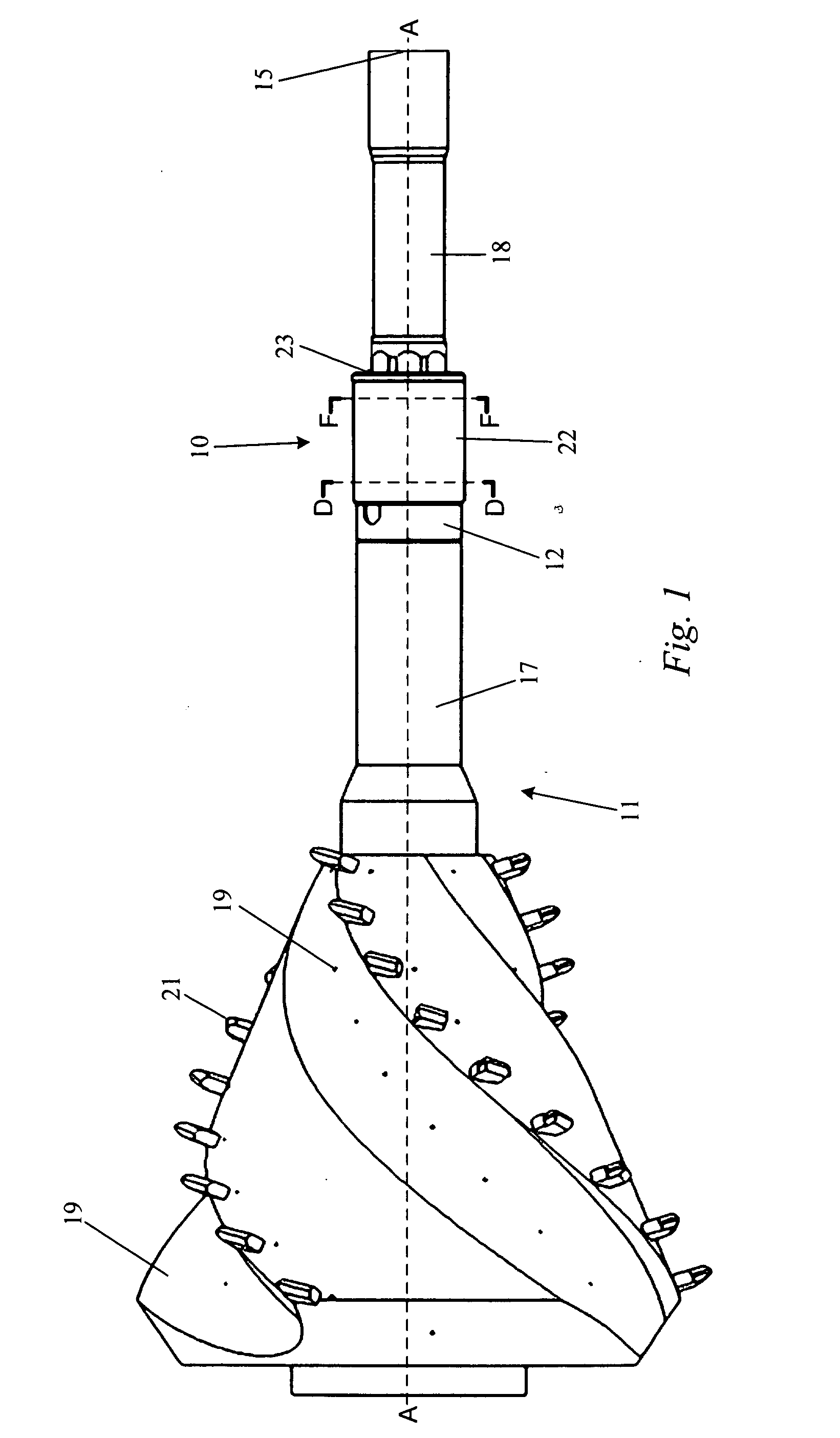

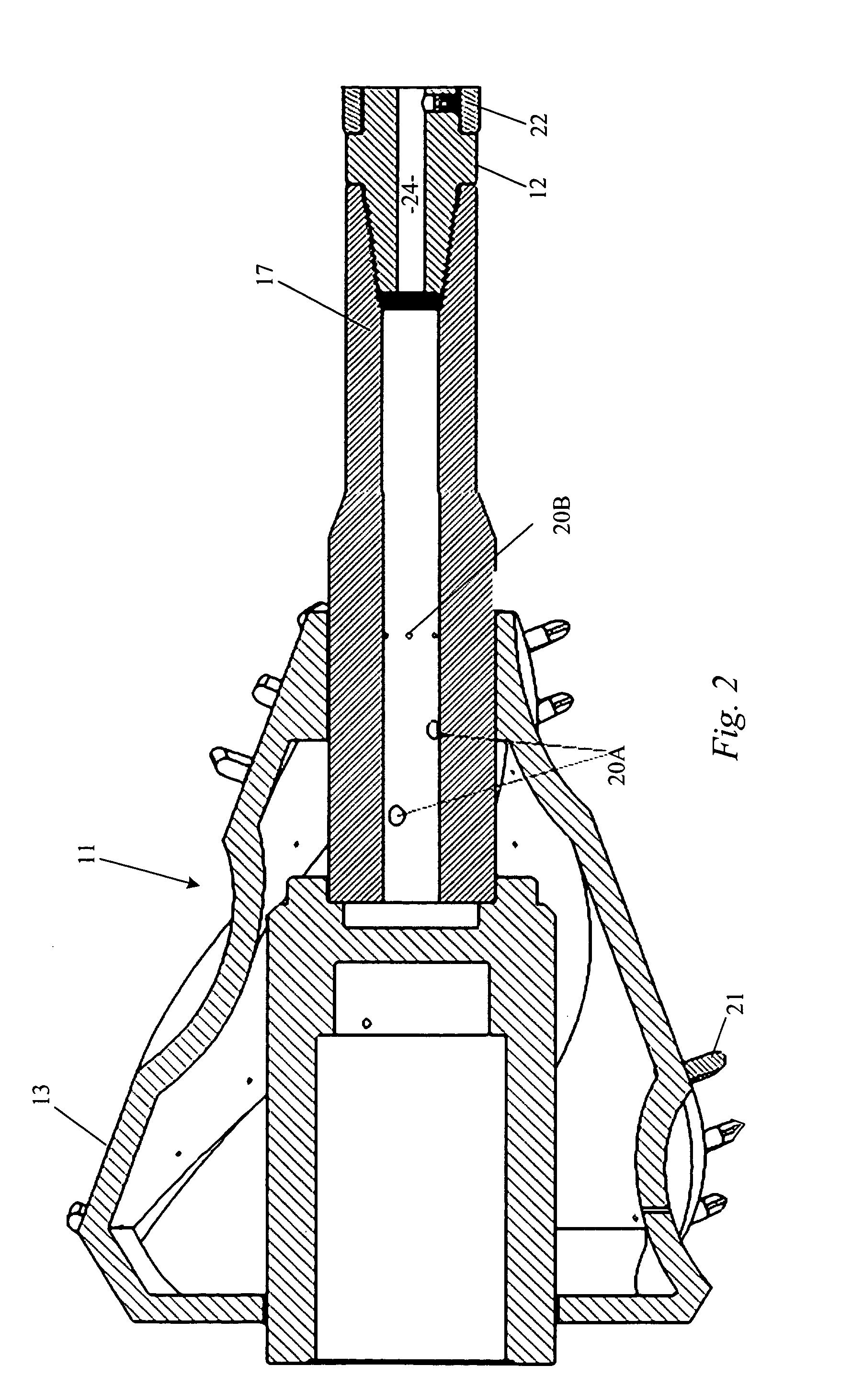

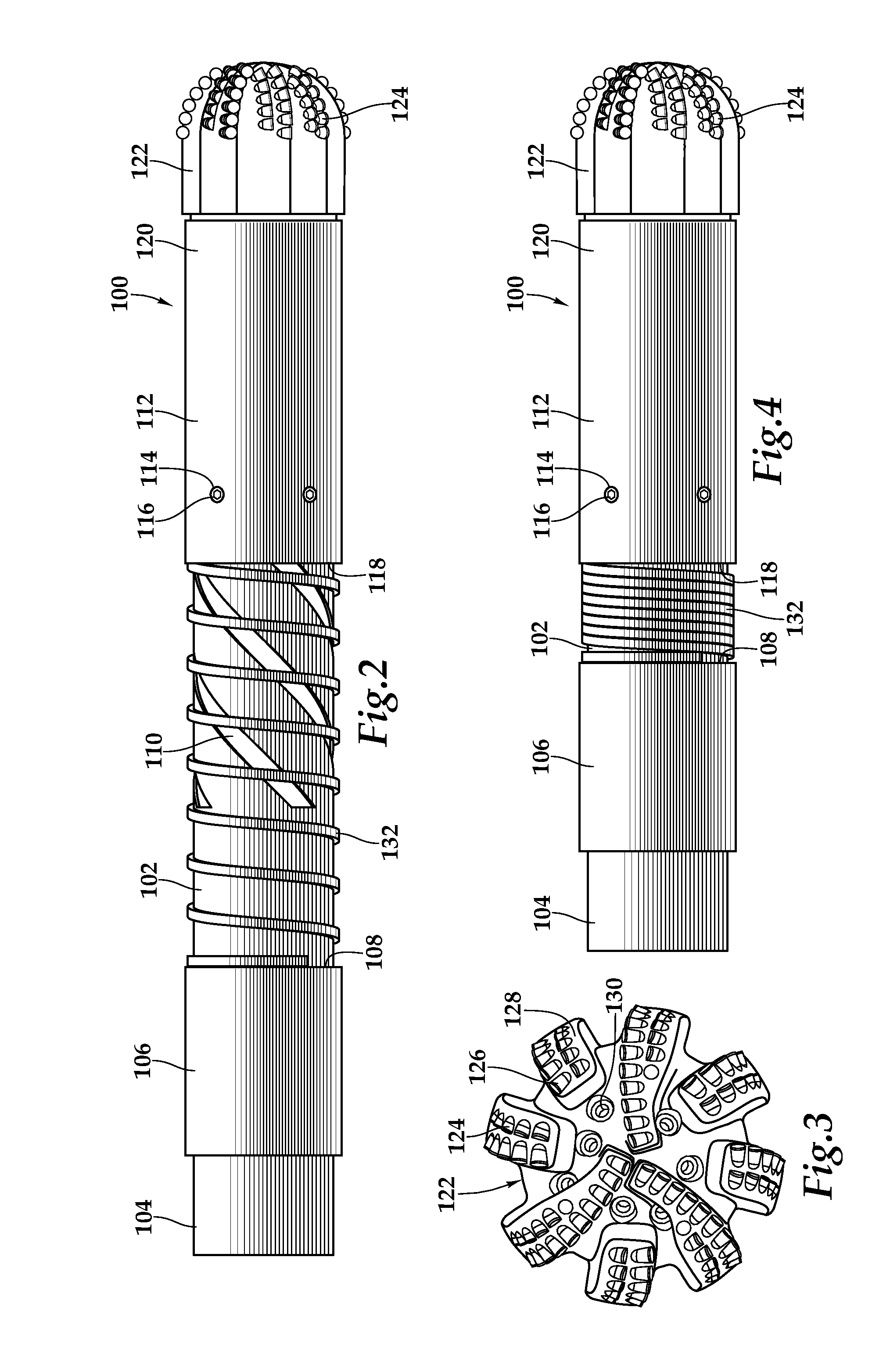

Fixed blade fixed cutter hole opener

A hole opener including a tool body having upper and lower ends. The upper and lower ends may be coupled to adjacent drilling tools. At least two blades are formed on the tool body and are arranged so that the hole opener is positioned concentric with a wellbore, and cutting elements are located on the blades. The at least two blades and the cutting elements are arranged to increase a diameter of a previously drilled wellbore.A hole opener including a tool body having upper and lower ends. The upper and lower ends may be coupled to adjacent drilling tools. At least two blades are formed on the tool body and are arranged so that the hole opener is positioned concentric with a wellbore, and cutting elements are located on the blades. The hole opener includes a pilot hole conditioning section. The pilot hole conditioning section includes at least two pilot blades formed on the tool body in a position axially ahead of the blades. The pilot blades include a taper at a downhole end and gage pads positioned at selected diameters. At least one cutting element is disposed on the pilot blades.

Owner:SMITH INT INC

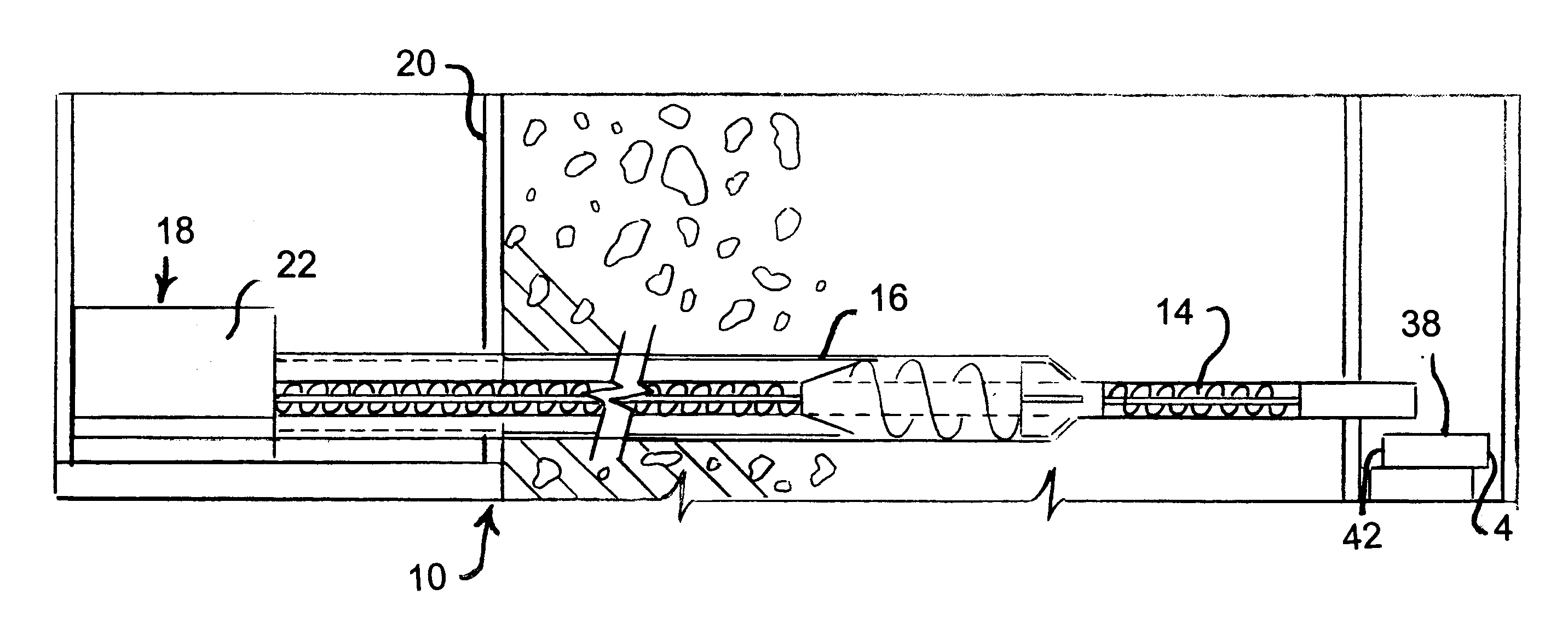

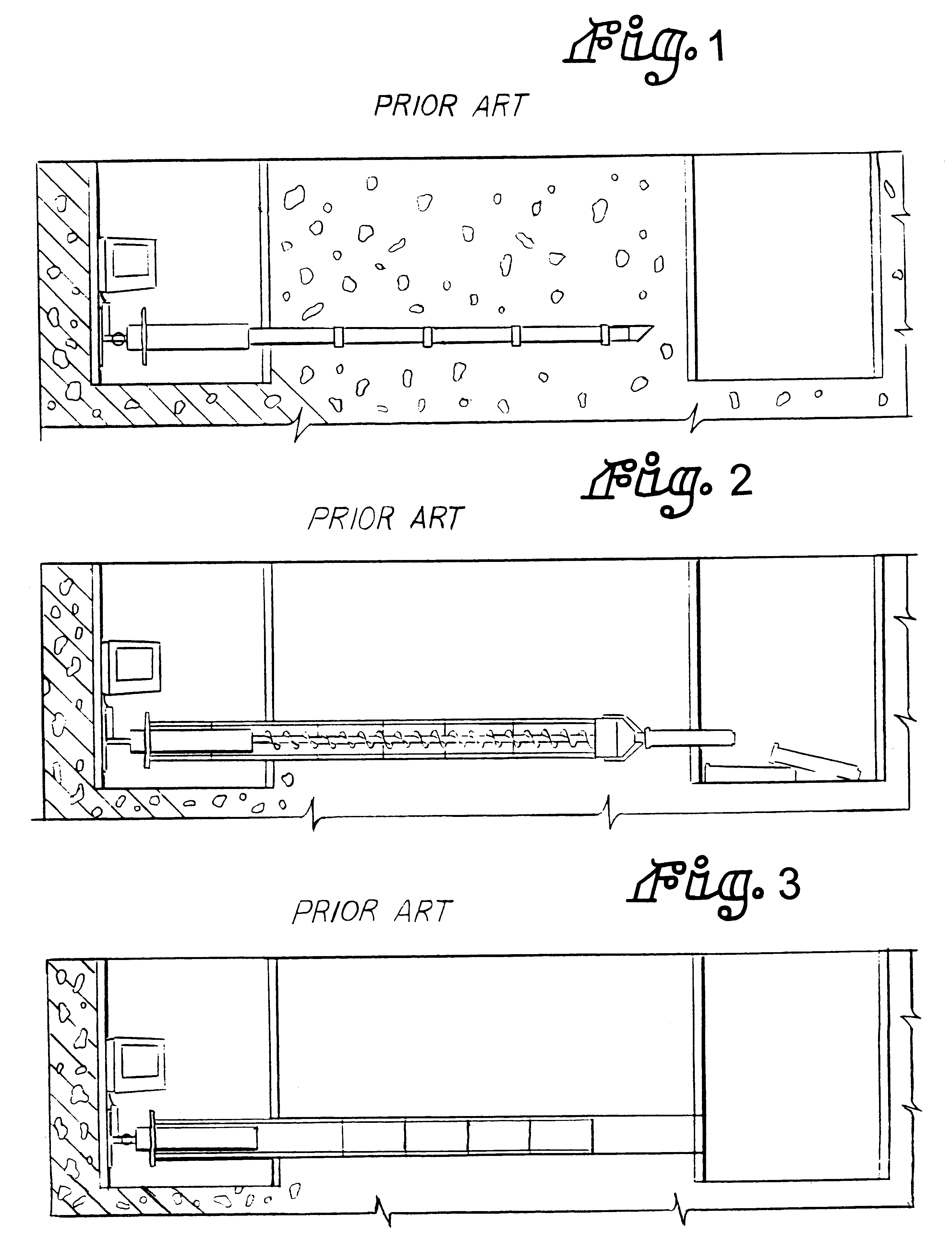

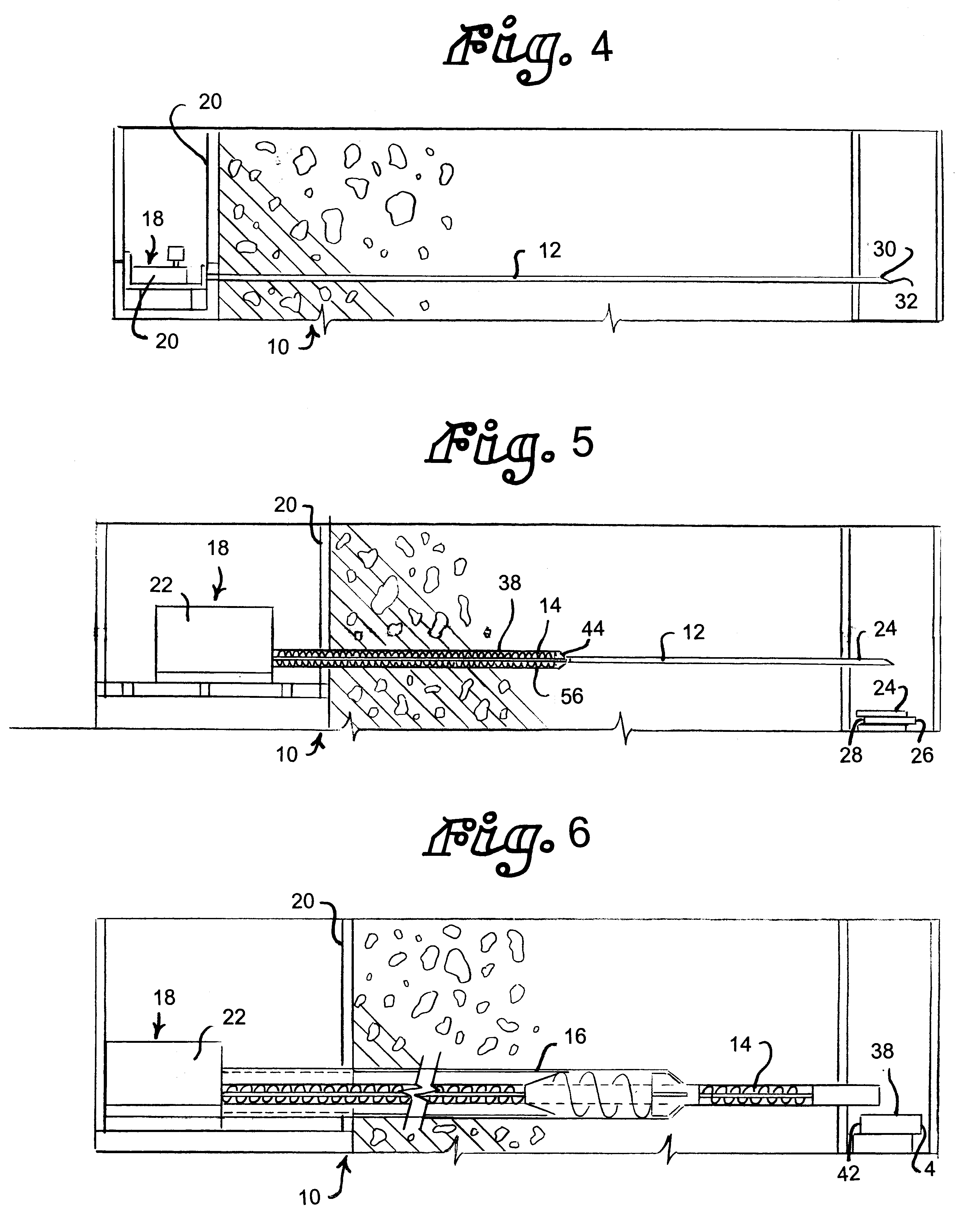

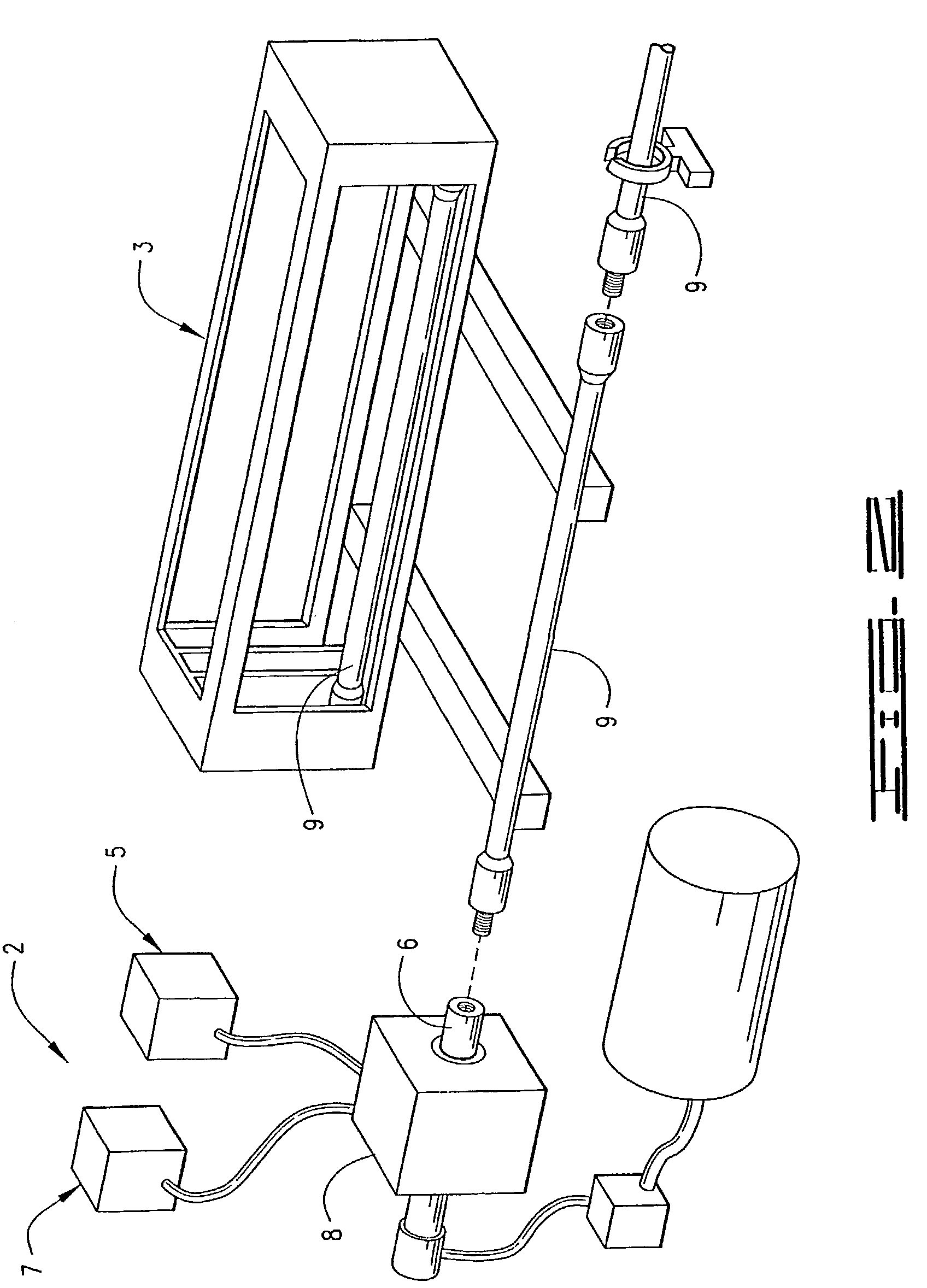

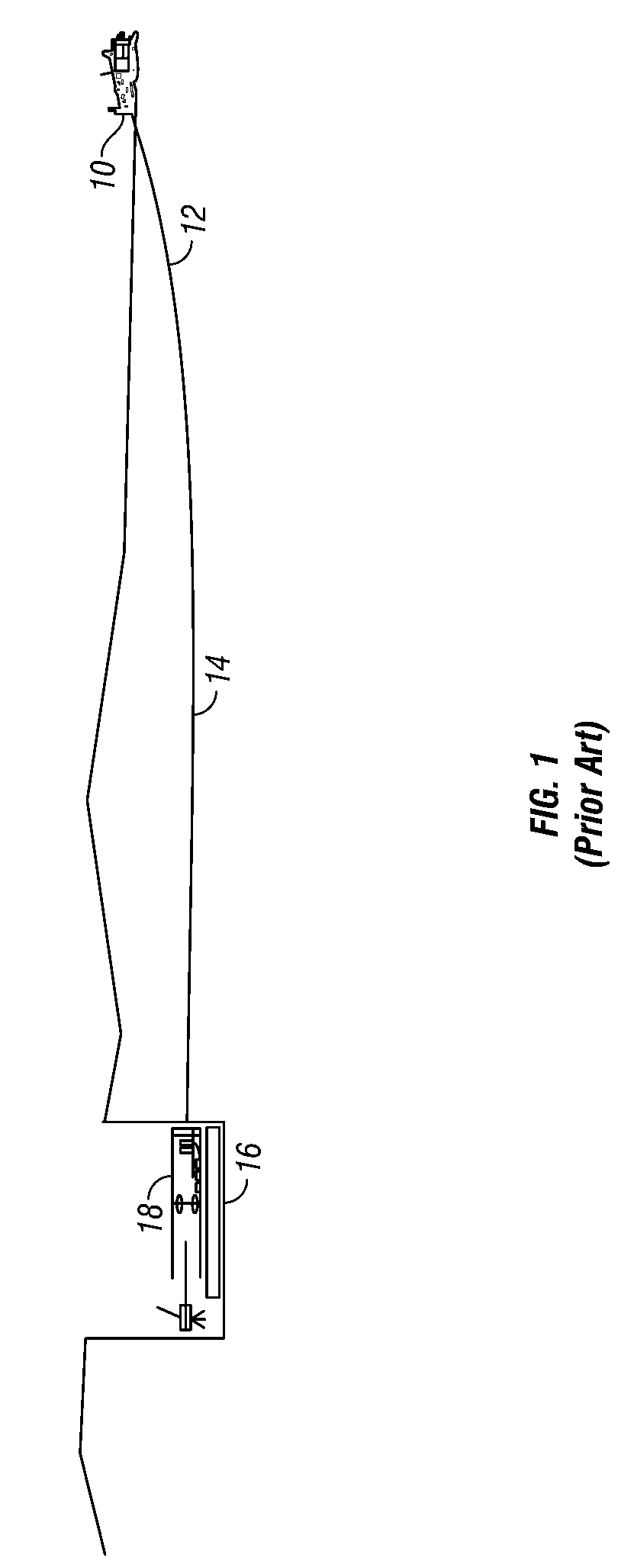

Apparatus and method for pilot-tube guided auger boring

An apparatus and method for trenchless, underground emplacement of man-sized product pipe between first and second shaft locations is disclosed. The apparatus comprises a pilot tube assembly having a pilot tube segment and a steering head mounted to the pilot tube segment. The steering head is configured to operatively guide the pilot tube assembly from the first shaft location to the second shaft location. The apparatus further comprises an intermediate sleeve assembly having an intermediate sleeve segment and an intermediate cutting head mountable to the pilot tube assembly and to the sleeve segment. The intermediate cutting head has a diameter substantially greater than the diameter of the pilot tube assembly and is configured to be operably guided by the pilot tube assembly. An enlarging assembly of the apparatus comprises a drive sleeve segment and an enlarging cutting head mounted to the intermediate sleeve assembly and to the drive sleeve segment. The enlarging cutting head has a diameter substantially larger than the diameter of the intermediate sleeve assembly and the drive sleeve segment. The enlarging cutting head and the drive sleeve segment are operably guidable by the intermediate sleeve assembly. A drive assembly successively advances the pilot tube assembly, the intermediate sleeve assembly, the trailing assembly, and product pipe from the first shaft location to the second shaft location.

Owner:EXACTGRADE UNDERGROUND INFRASTRUCTURE

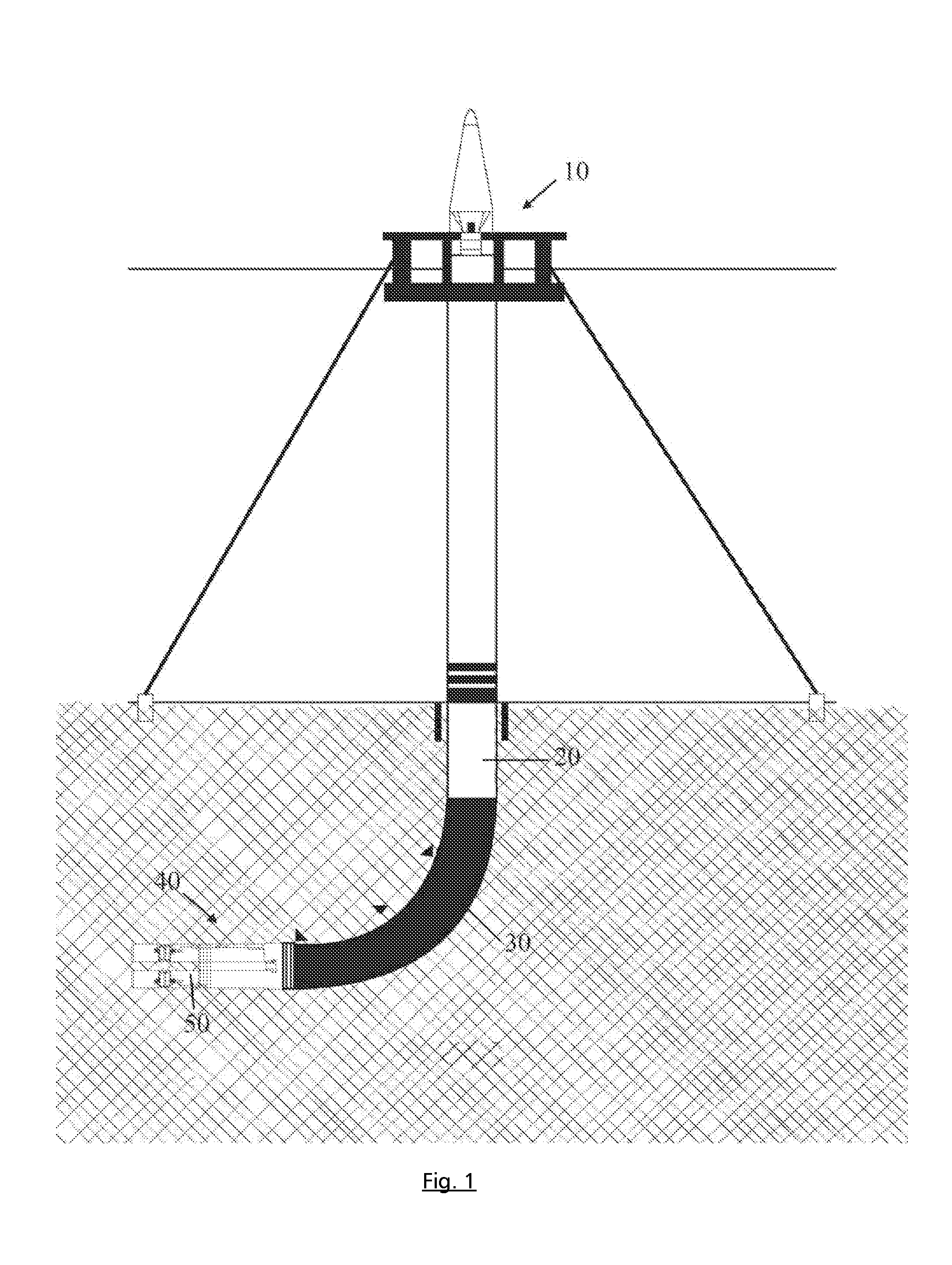

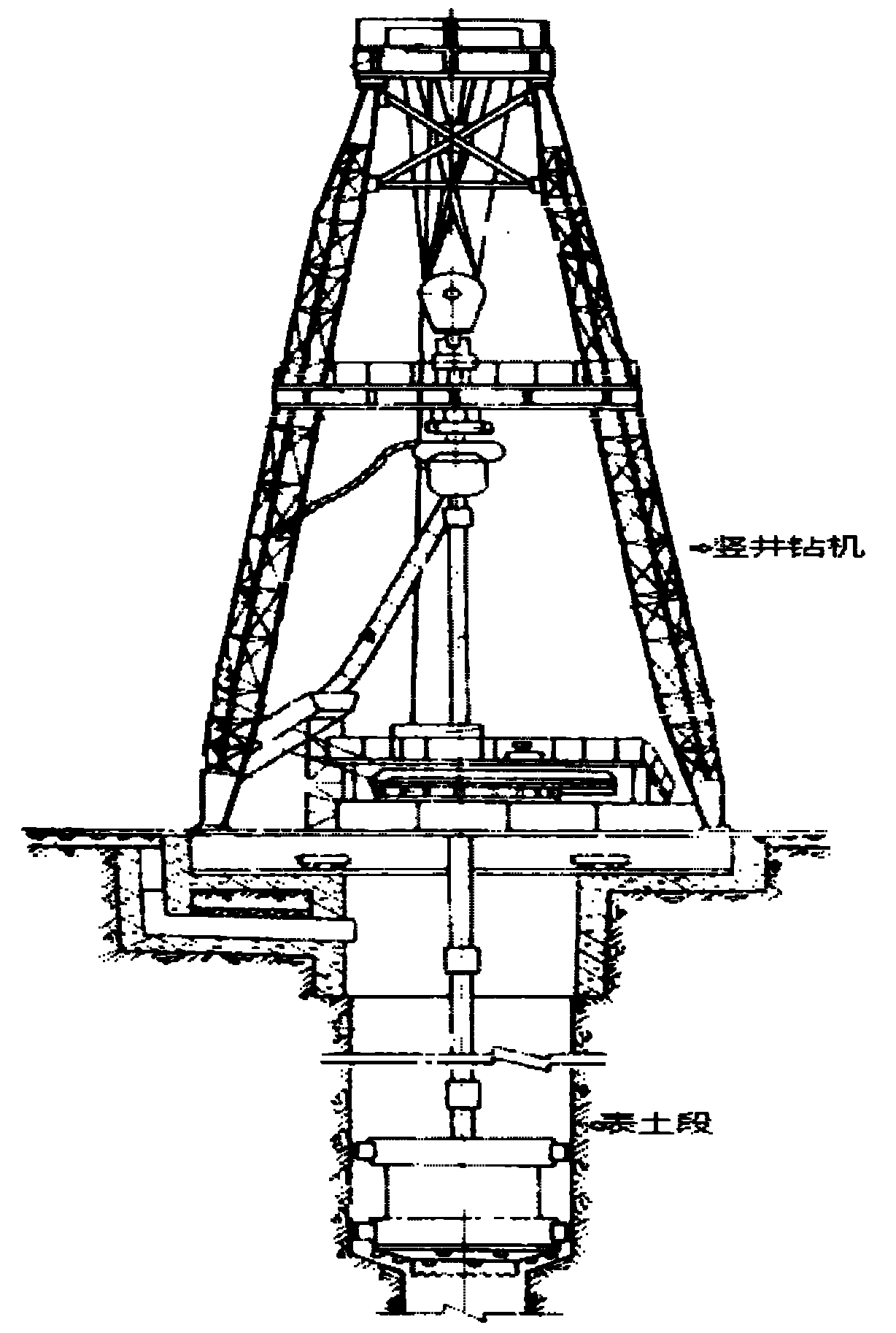

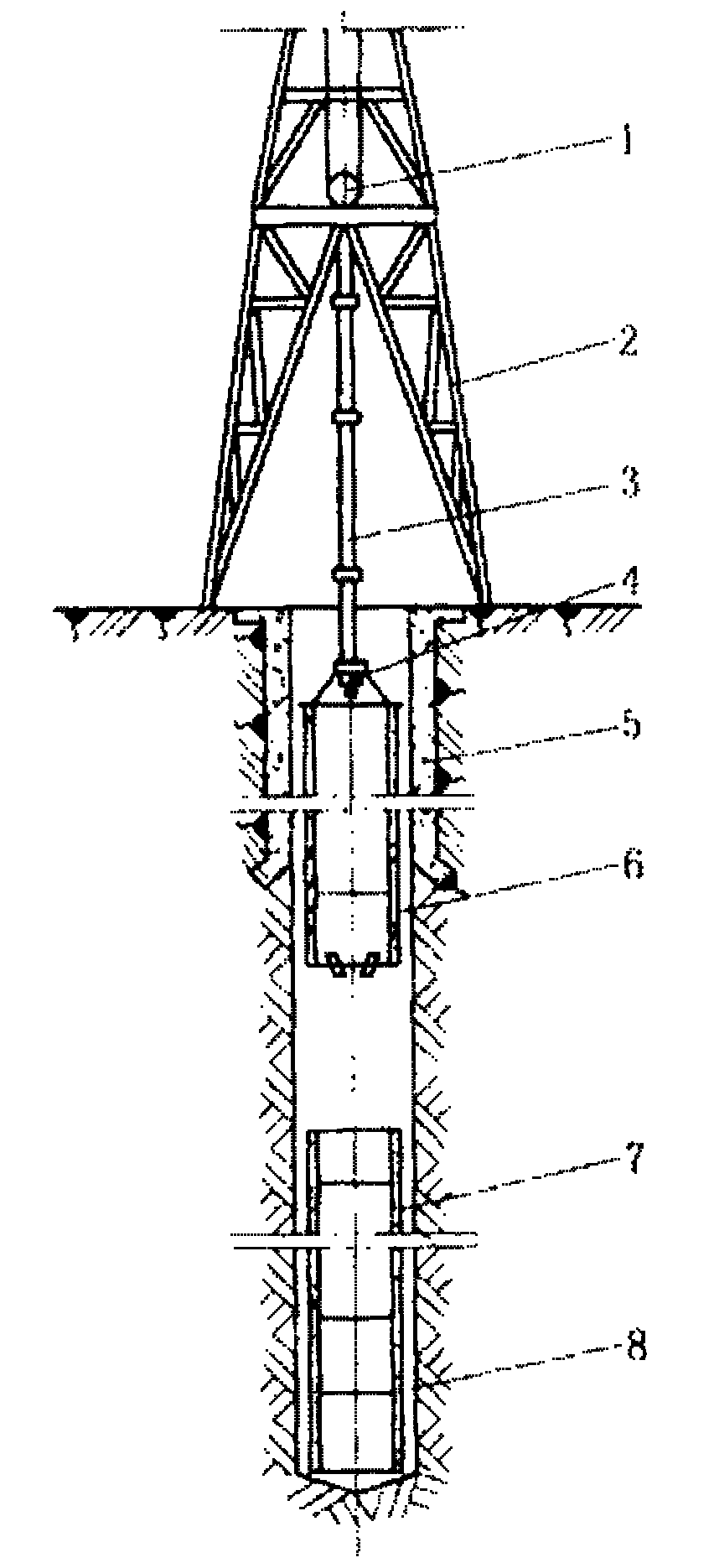

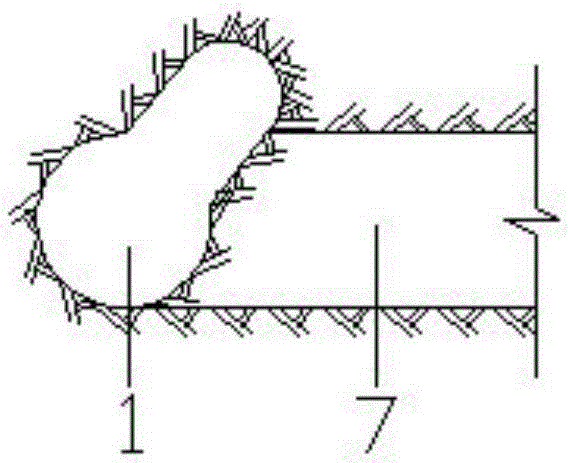

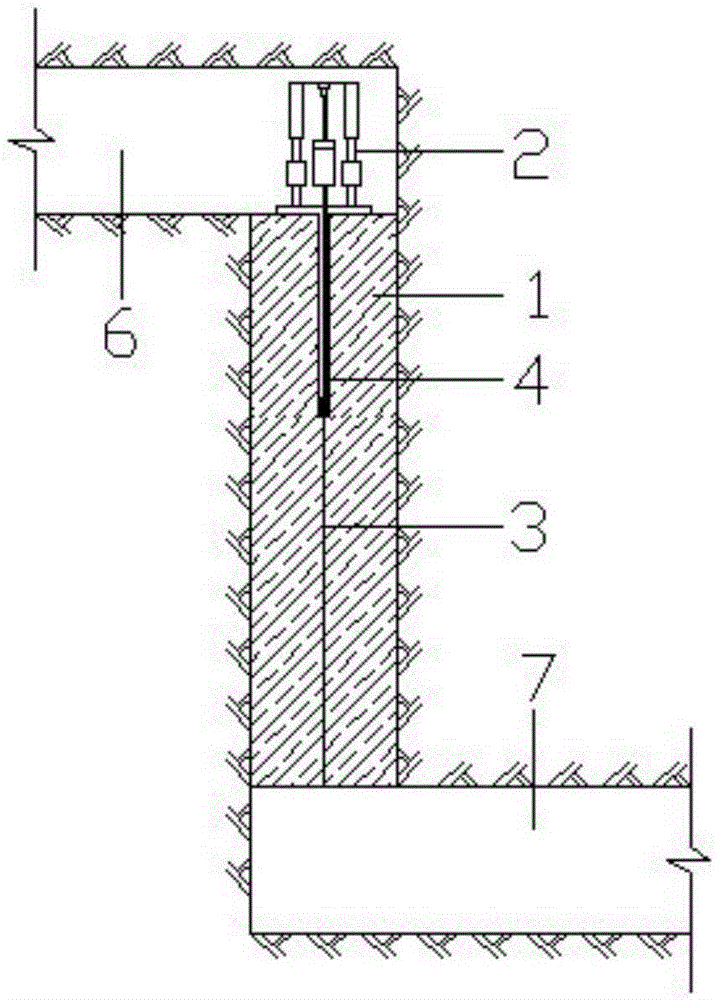

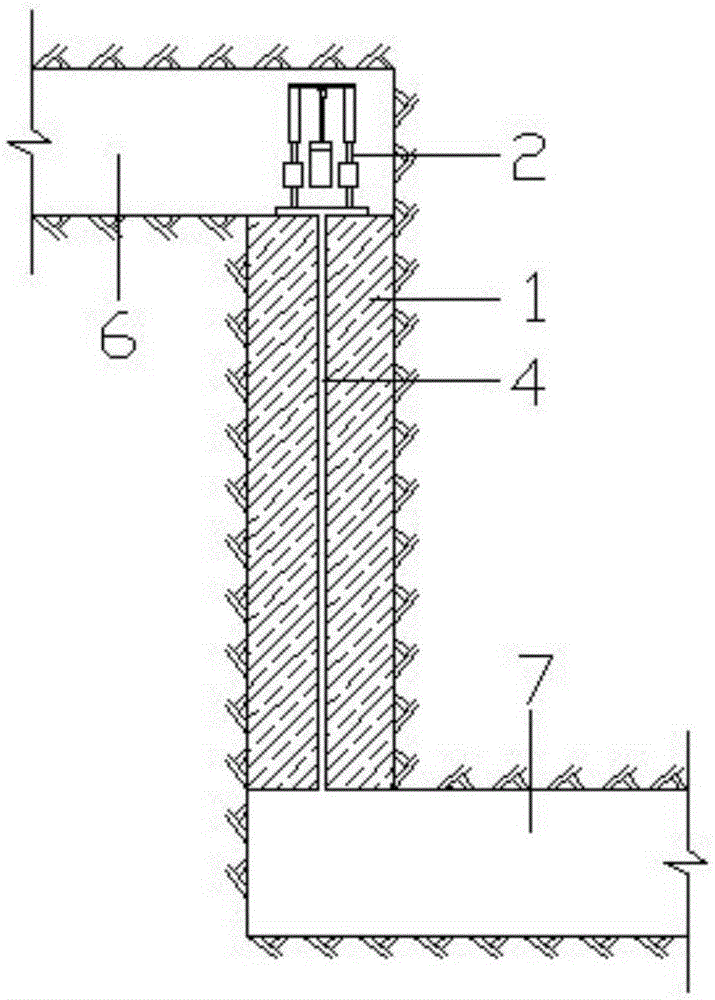

Comprehensive shaft sinking method of positive and raising boring for vertical shaft

InactiveCN102493809AReduce construction costsFast well formationShaft sinkingShaft raisingBedrockWell drilling

The invention discloses a comprehensive shaft sinking method of positive and raising boring for a vertical shaft, which comprises the following steps: drilling into a bedrock section by utilizing a vertical shaft drill machine, forming surface soil section well holes, discharging rock-debris-containing slurry produced during the well drilling process to the ground at high speed through air lifting; prefabricating sections of well walls on the ground; adding counter weight water in the drill well, slowly sinking the sections of well walls to the surface soil section well holes by utilizing buoyancy force of slurry to the well walls in the drill well, and sequentially welding the well walls to the surface soil section well holes; filling grout between the well walls and the rock sides on the outer sides of the well walls, filling cement paste in the lowest layer, then alternatively filling upwards the cement paste and rubbles layer by layer, and obtaining a surface soil section drill well; selecting a suitable raise-bore drilling machine according to practical requirements of the diameter and depth of a bed rock section shaft; lowering the raise-bore drilling machine and fixing the raise-bore drilling machine at the bottom of the surface soil section drill well; inversely expanding the holes by utilizing the raise-bore drilling machine to form bing-holes; and the diameter of the bing-holes is enlarged to preset shaft diameter. The comprehensive shaft sinking method of the positive and raising boring for the vertical shaft greatly improves well forming speed of shaft sinking and is safe, reliable and low in construction cost.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Apparatus and methods of milling a restricted casing shoe

A method of removing a restriction in a tubular located in a well includes providing a drilling assembly with a drill bit and a reamer, the reamer having a cutting structure for removing the restriction; drilling through a lower portion of the tubular; expanding the reamer at a location below the restriction; and urging the reamer back toward the restriction to remove the restriction.

Owner:WEATHERFORD TECH HLDG LLC

Bore hole reaming apparatus and method

Owner:PUTNAM SAMUEL W

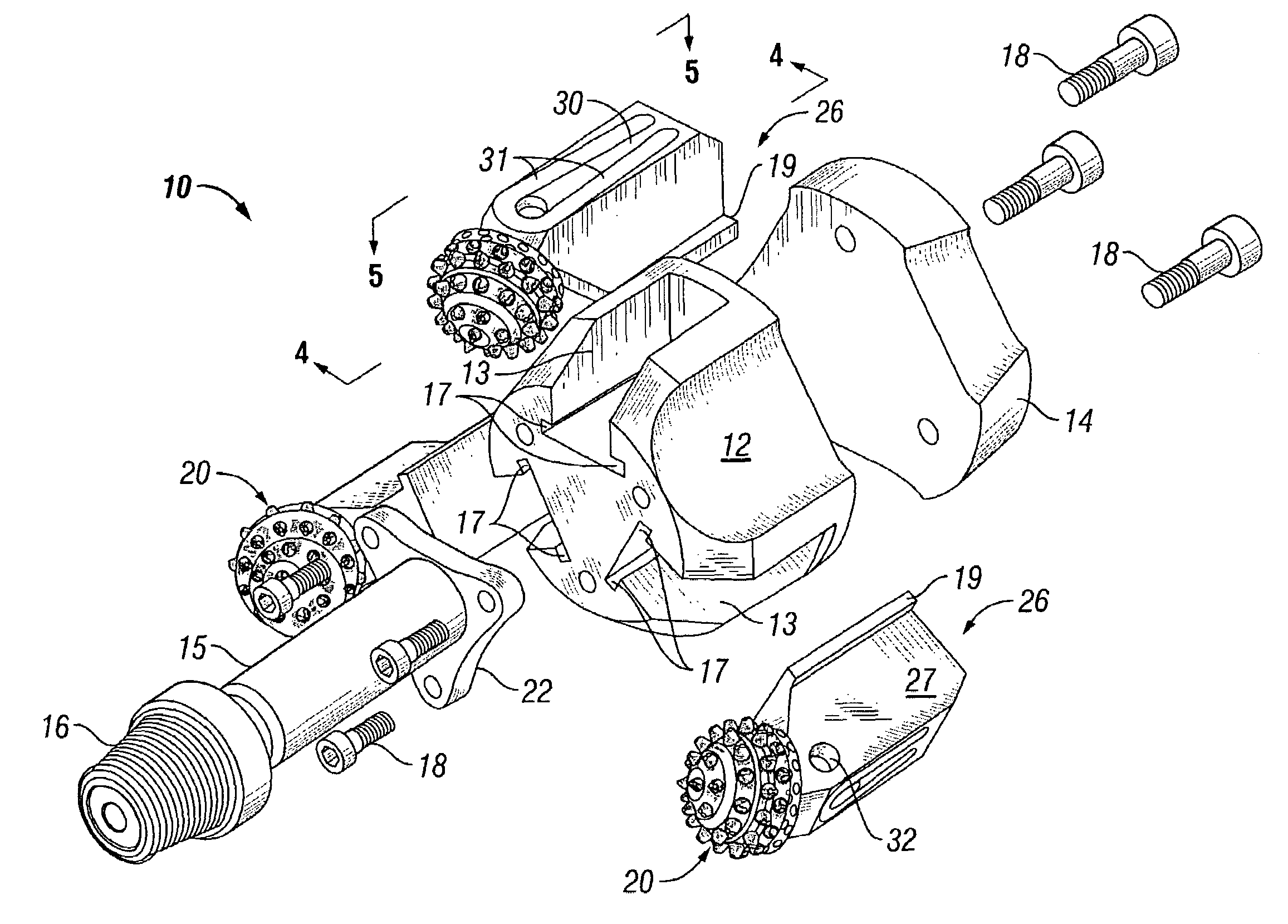

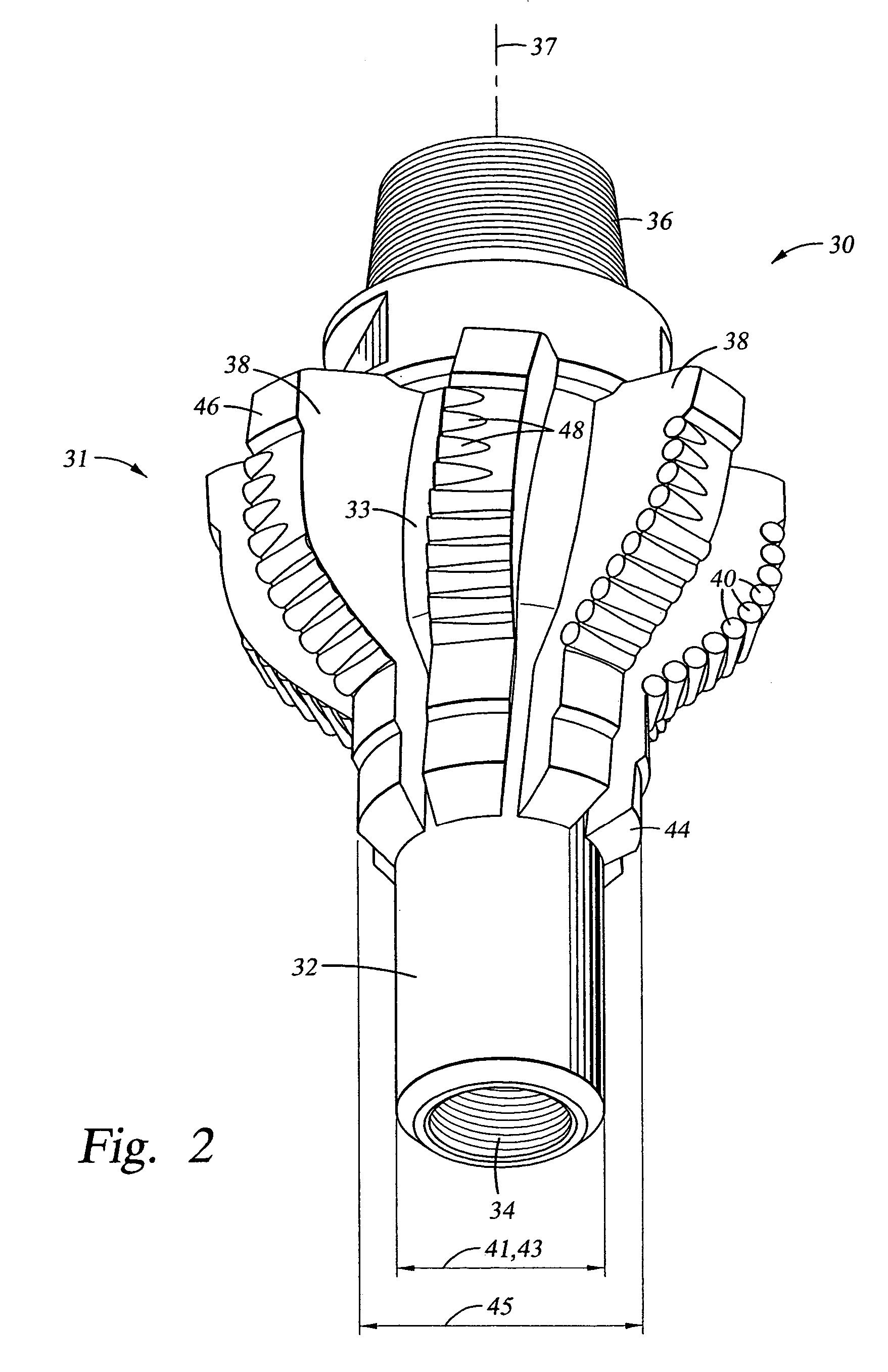

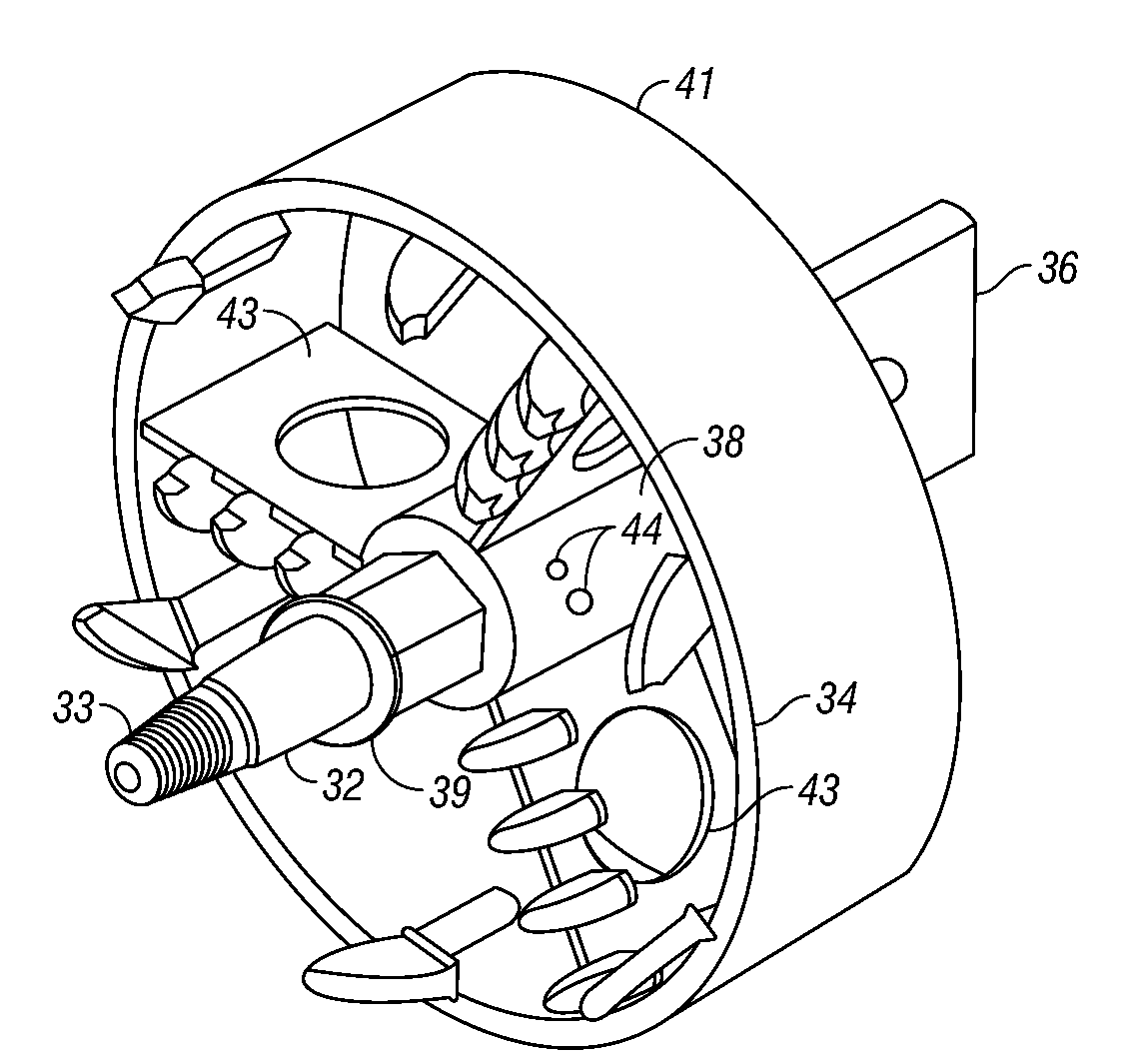

Downhole tool leg retention methods and apparatus

A back reamer includes a drive stem configured to support a main reamer body, the main reamer body including a plurality of receptacles, and a plurality of cutting leg assemblies in positive locking engagement with the plurality of receptacles to restrict radial movement of the cutting leg assemblies.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

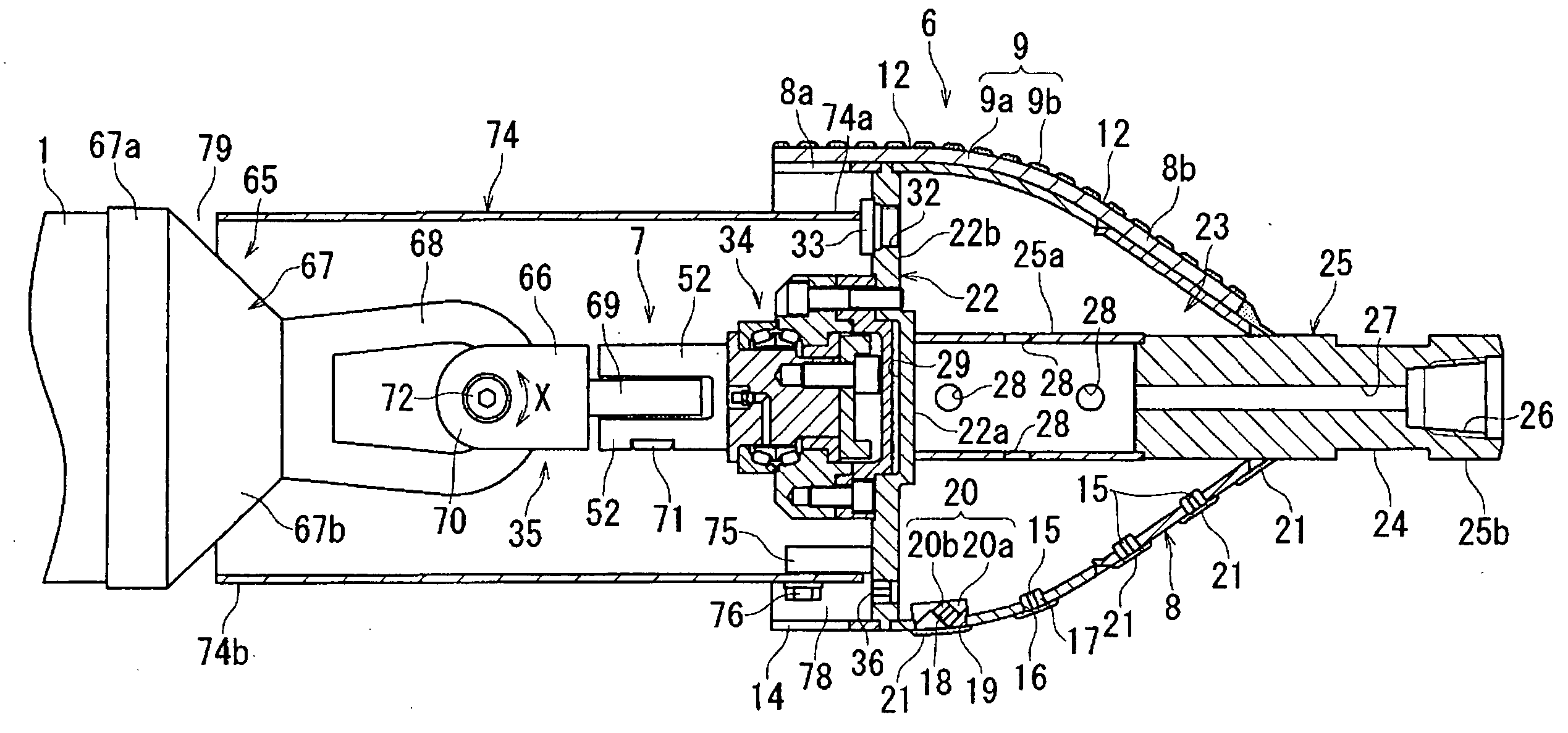

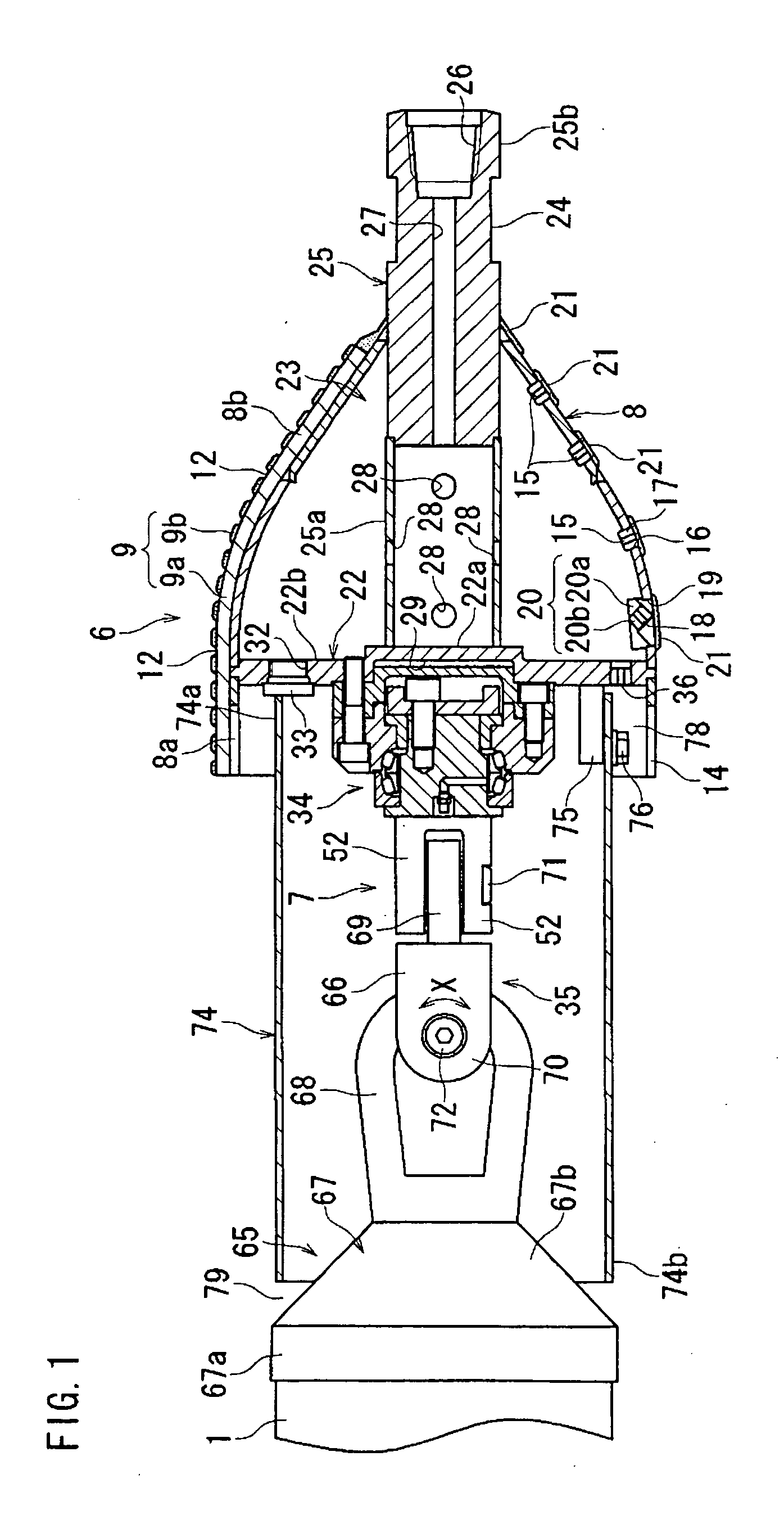

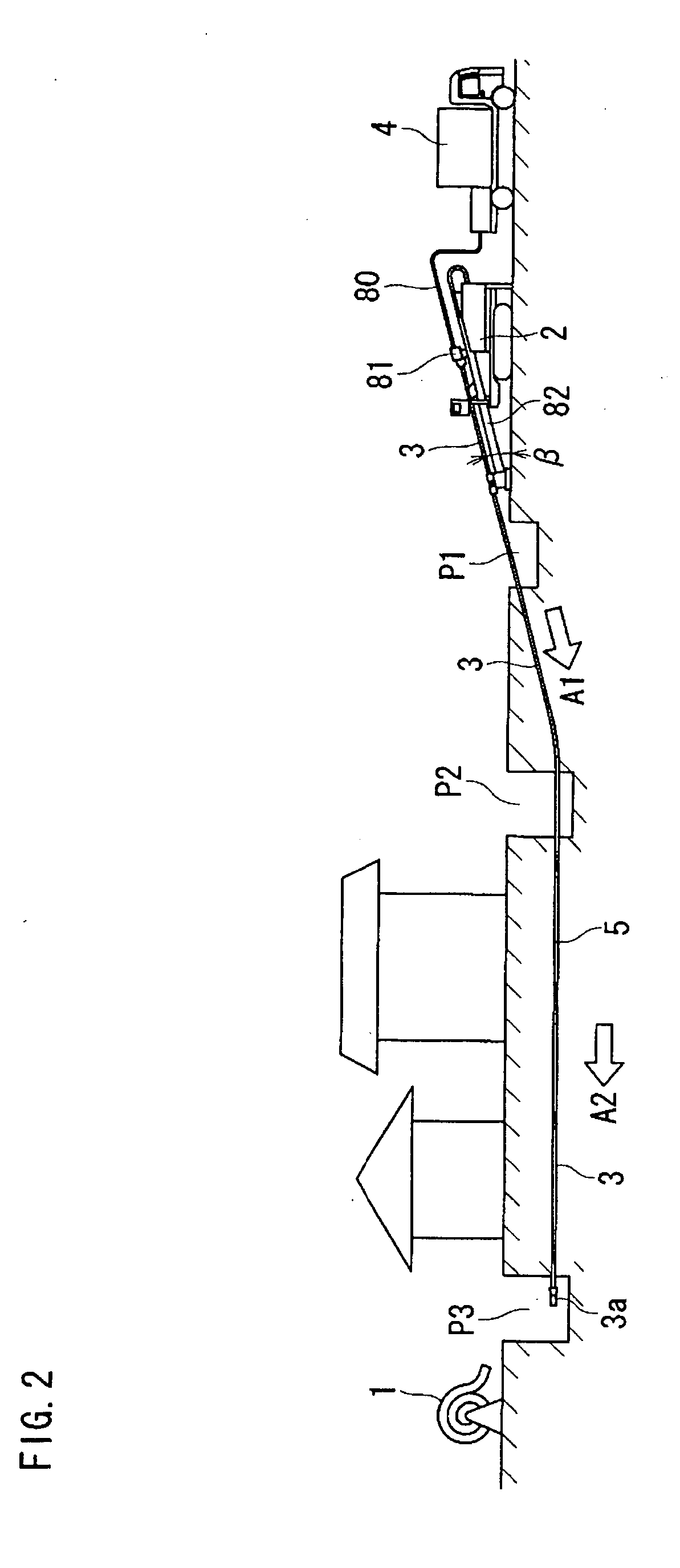

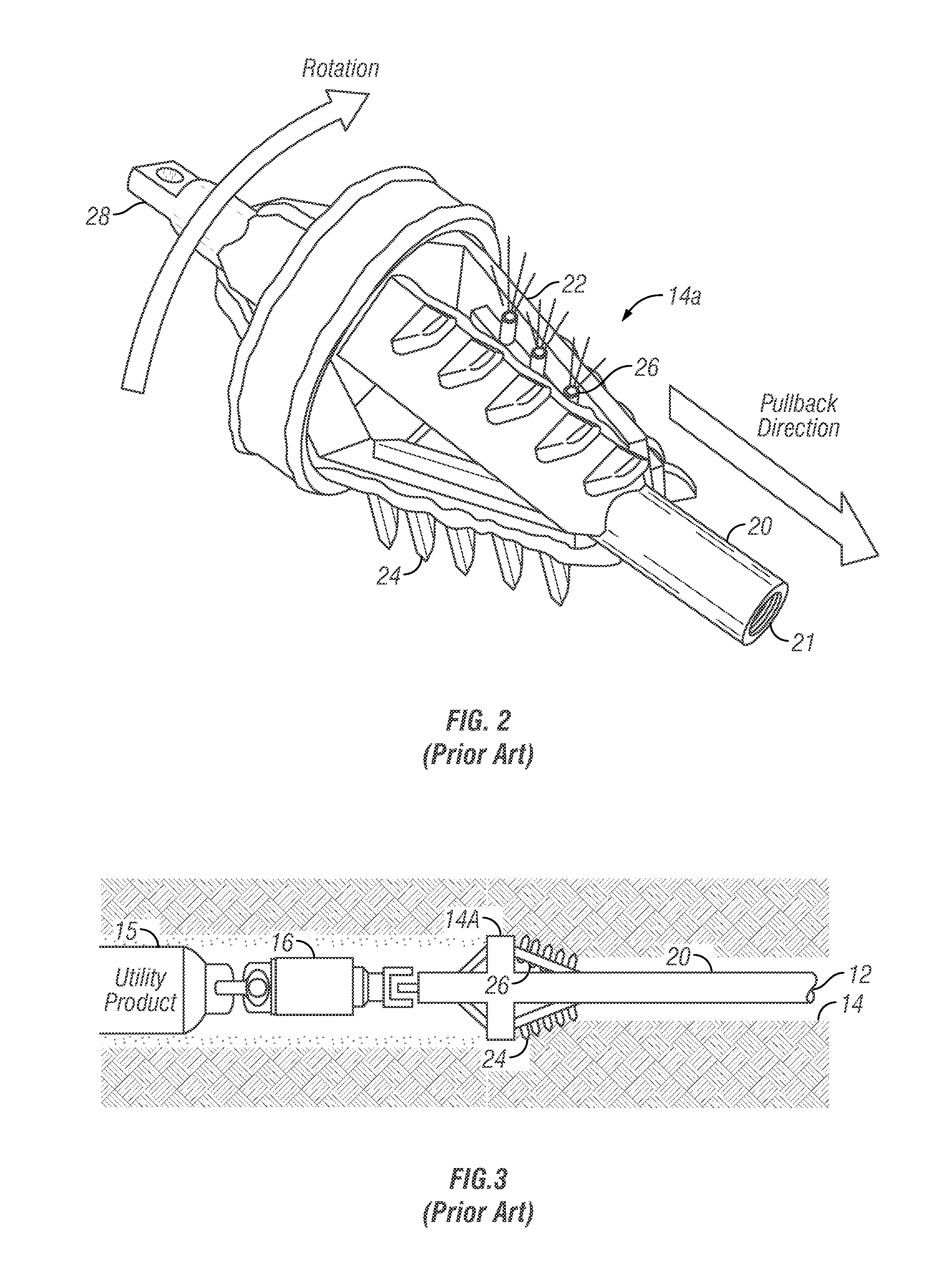

Reamer apparatus for ground boring machine

The invention provides a reamer apparatus for a ground boring machine that is capable of restricting increase in drawing resistance when performing drawing of a buried pipe by using a reamer and of efficiently performing drawing operations of the buried pipe without degrading properties such as flexibility and rotatability. The reamer apparatus includes a reamer main body of substantially hollow conical shape that reduces in diameter towards a drawing side, and a rod connecting portion that provided at a narrow diameter end portion of the reamer main body and connected with a rod. The reamer main body is connected to a buried pipe through a coupling structure disposed on an opposite side to the rod connecting portion. The coupling structure has a Swivel joint that allows rotation of the reamer main body with respect to the buried pipe, wherein a main portion of the Swivel joint is substantially accumulated in the reamer main body.

Owner:KOMATSU LTD

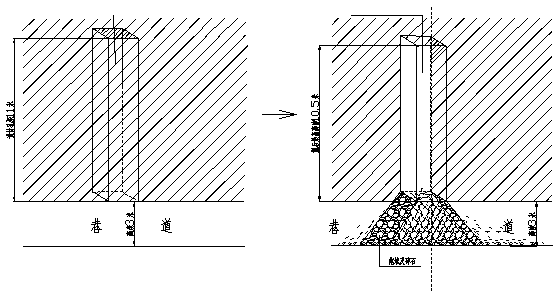

'|'-shaped free surface holing one-step well completion technology

ActiveCN103306679AImprove recovery rateReduce the number of constructionBlastingShaft raisingBuilding constructionEngineering

The invention discloses a '|'-shaped free surface holing one-step well completion technology, which comprises the following steps: (1) confirming the holing way and arranging blasting holes, wherein holing holes and peripheral holes and assistant holes are formed in the position needed to complete the well at the end part of a mining roadway, the number of the holing holes is 8, and the total number of the peripheral holes and the assistant holes is 9; and the specific way is that four hollow holes are longitudinally formed in the center line at the end part in a '|'-shaped manner to be taken as a blasting initial free surface and compensation space, four explosive filling holes are formed in the periphery of the four hollow holes under a principle to the benefit of the forming of the groove cavity and not to mutually blast, and the nine peripheral holes and assistant holes are formed in the periphery of the groove cavity; (2) drilling; (3) filling explosive; and (4) blasting. The technology can reduce the lose of the ore, improves the ore recovery rate, can also guarantee the blasting quality, reduces the construction number of the blasting holes, reduces the groove-pulling blasting times, reduces the explosive consumption, relieves the labor intensity of the blaster, improves the safety performance, reduces the manufacturing cost, and meanwhile can also be directly used for constructing vertical wells.

Owner:安徽马钢矿业资源集团姑山矿业有限公司 +1

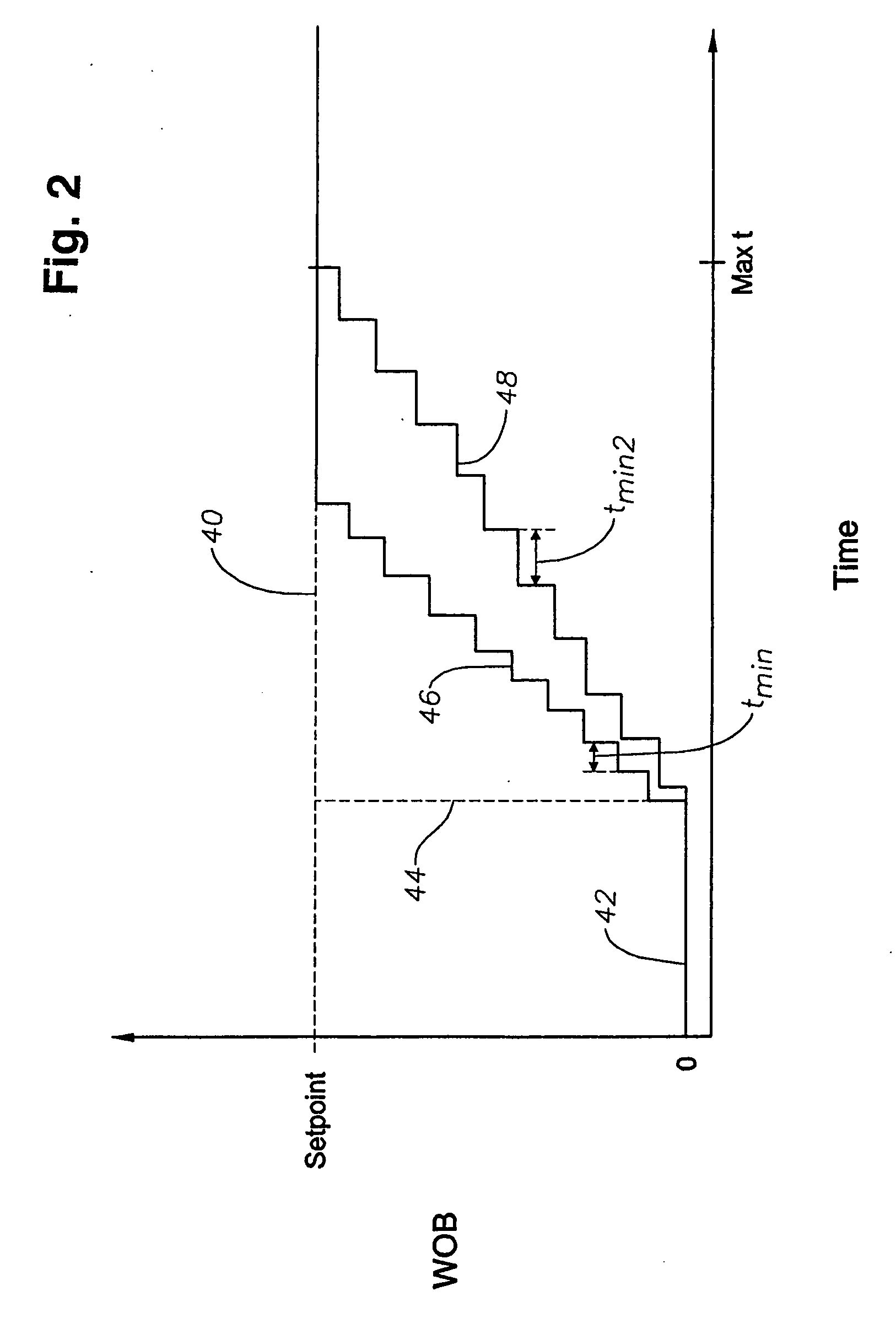

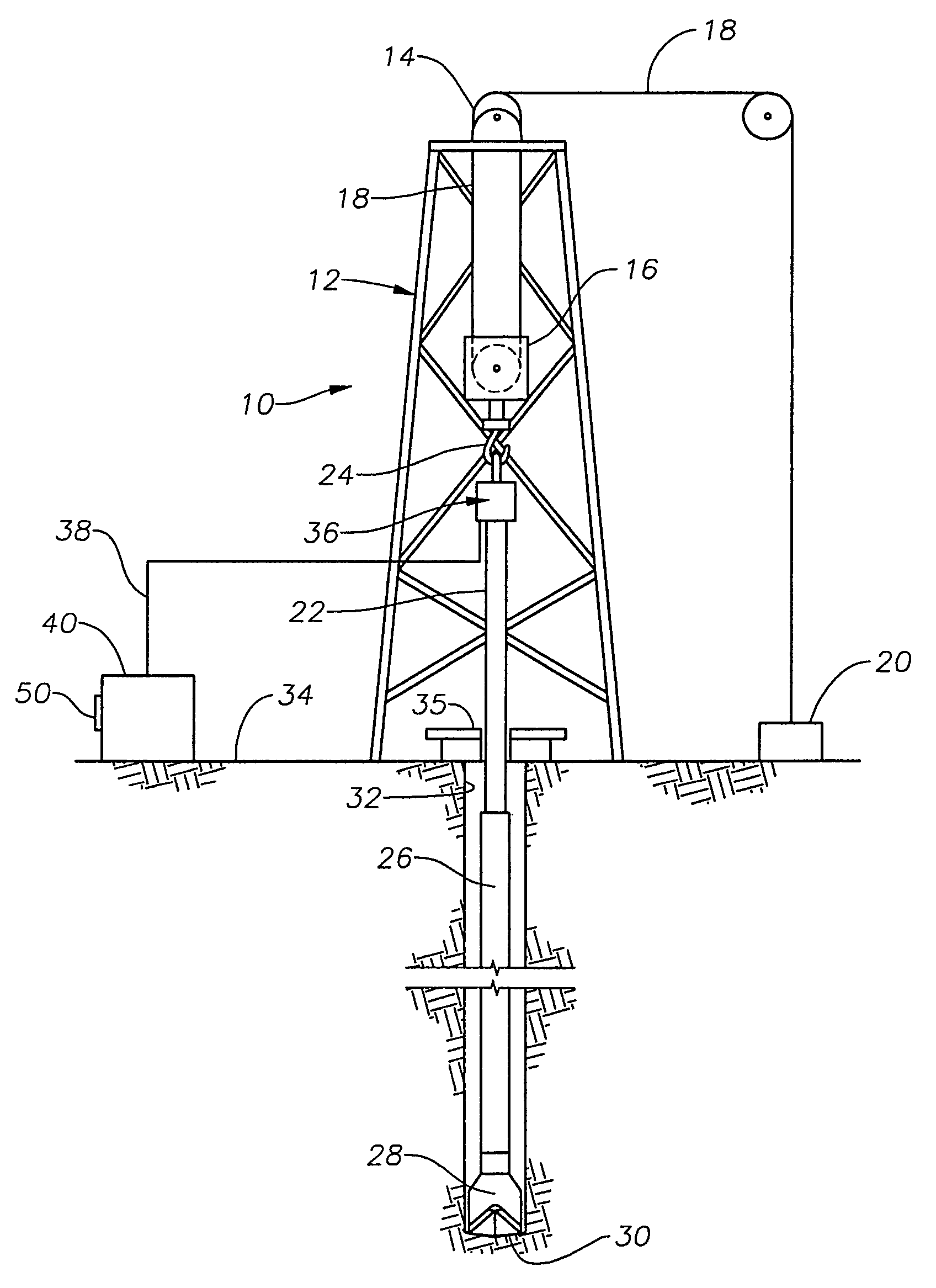

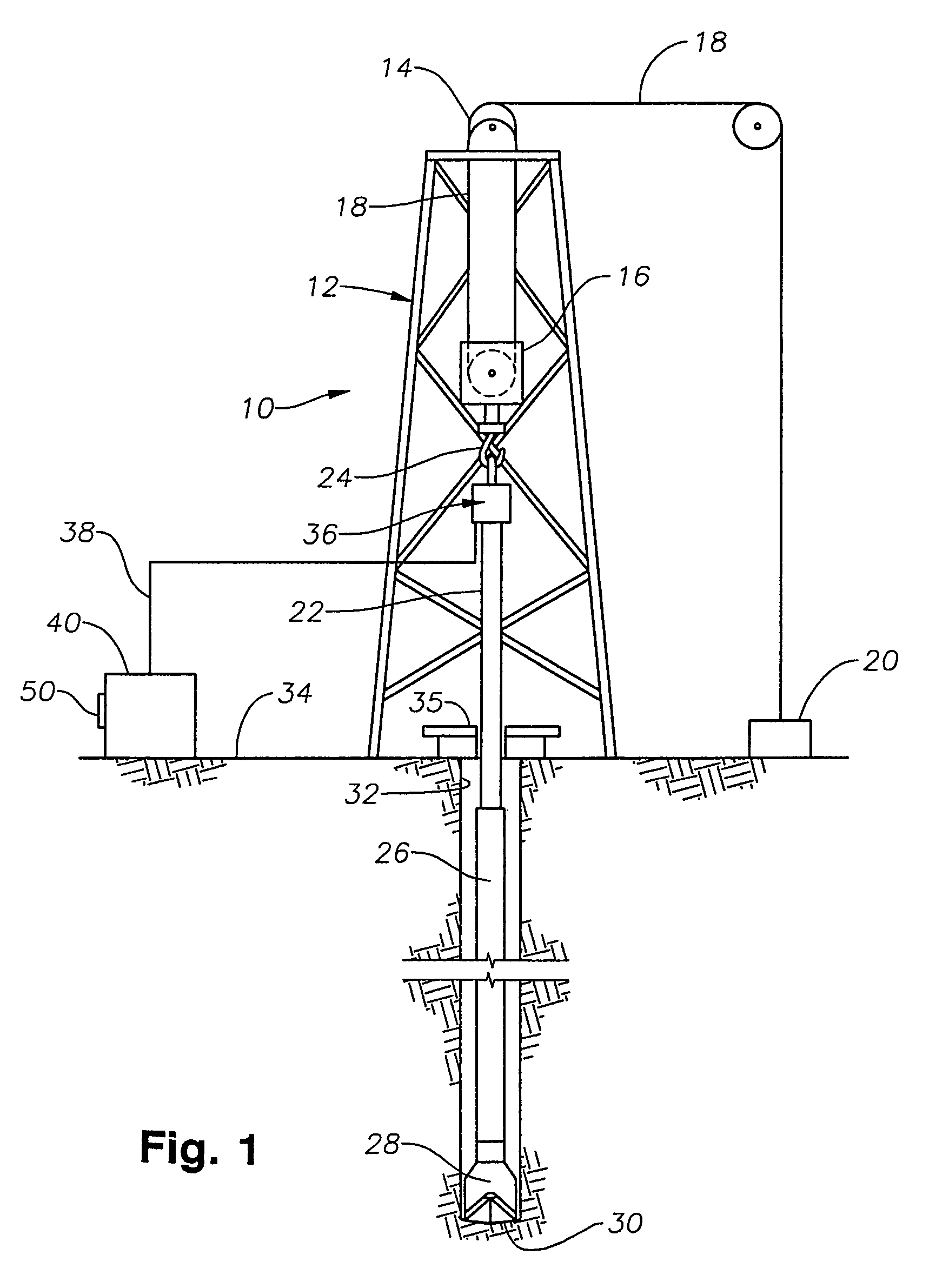

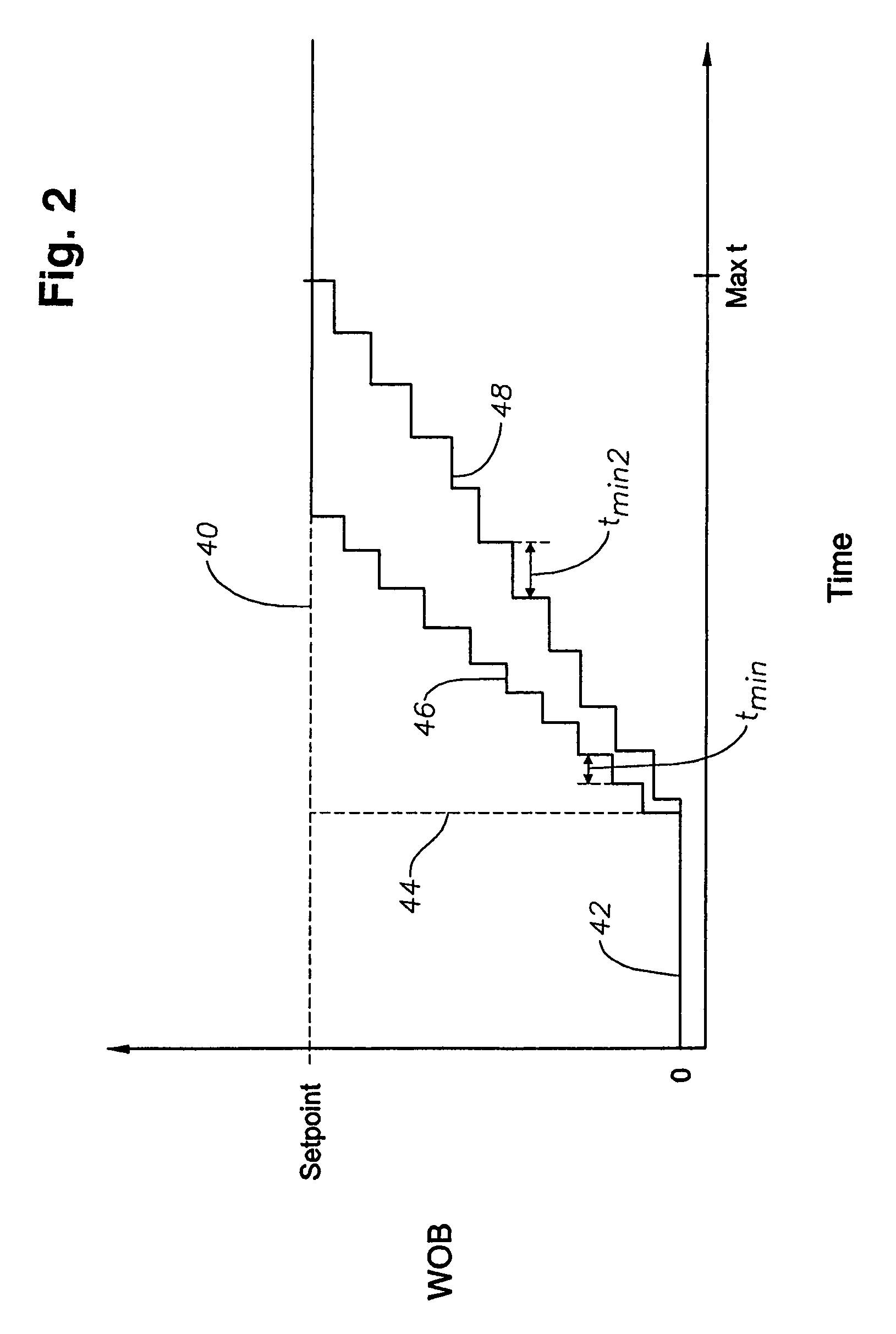

Autoreaming systems and methods

Methods and systems for controlling movement of a bit of a drilling assembly during reaming of an already-drilled hole; the methods, in certain aspects, including determining a ream speed for downward movement of the bit in the hole, moving the bit downward in a hole at said ream speed, determining a time period for deceleration of the bit to the hole bottom, determining a value for a target drilling parameter for drilling beyond the bottom of the hole, decelerating the bit (linearly or non-linearly) for the time period, and achieving the value for the target drilling parameter when the bit reaches the bottom of the hole.

Owner:VARCO I P INC

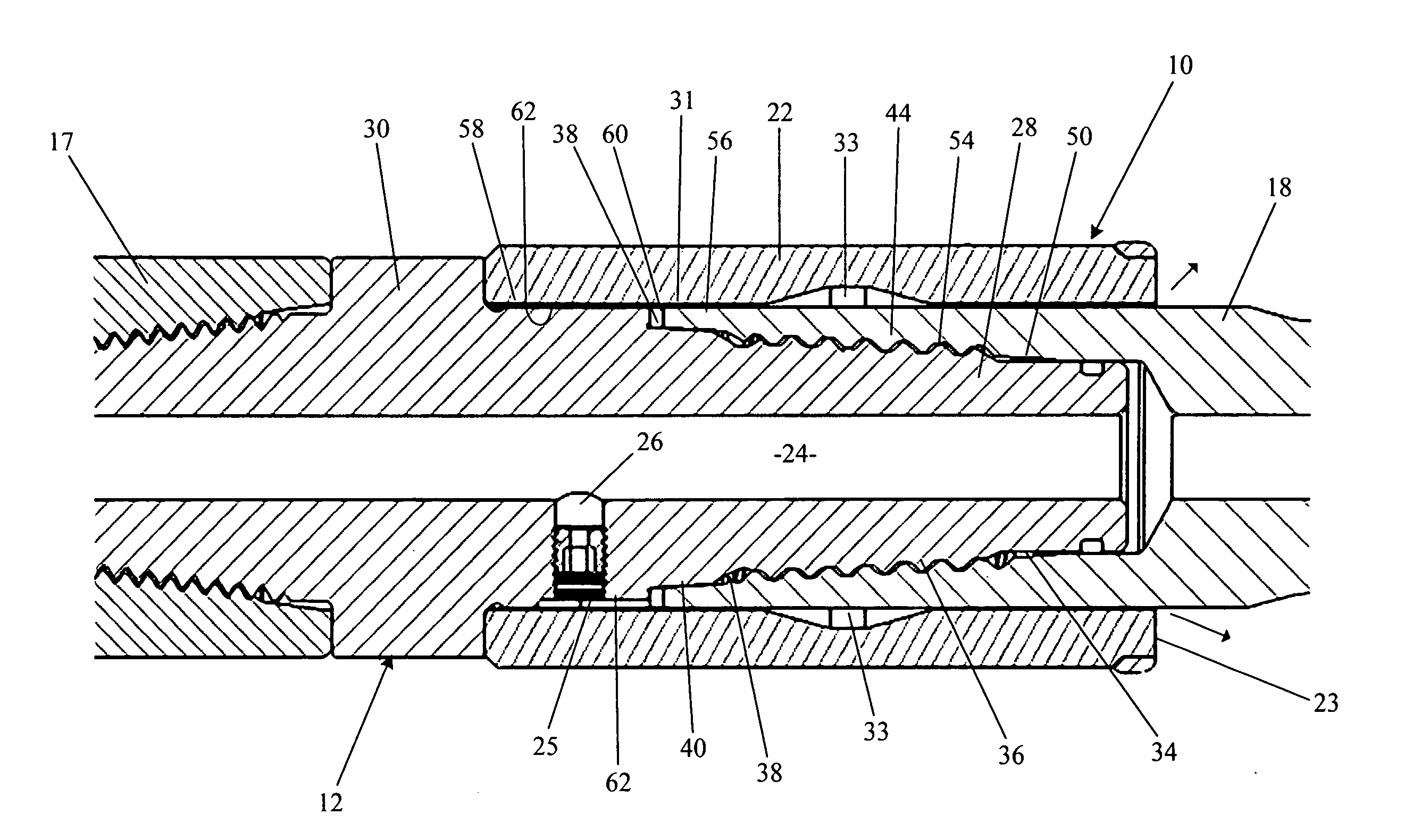

Joint for use in back reaming

A joint according to the invention for connecting a pair of members rotatable about a common axis end to end. A sleeve has a non circular profile on an inner surface thereof whereby the sleeve can be slidably mounted on non circular exterior surfaces of the first and second members when such surfaces are brought into alignment by rotation of one member relative to the other in a manner effective to pass torque from one member to the other by means of the non circular surfaces. A fluid release passage includes a radial port that extends from the first longitudinal fluid supply passage to a clearance between the sleeve and the first member, which clearance communicates with a second clearance between the sleeve and the second member, which second clearance has a discharge opening.

Owner:CHARLES MACHINE WORKS

Excavation deviation processing method of raise-boring machine for deep vertical shaft

InactiveCN105298499AGuaranteed verticalityHigh strengthShaft sinkingShaft raisingPilot holeBottom pressure

The invention discloses an excavation deviation processing method of a raise-boring machine for a deep vertical shaft. The method includes the steps that the position of a pilot hole tail end drill is determined according to the drill stem deviation angle, the vertical shaft height and other parameters, and a mucking pilot shaft and a muck discharging channel are formed through expanding excavation; then, after the mucking pilot shaft is formed, the vertical shaft is excavated in a drilling and blasting mode, and when the mucking pilot shaft deviates and loses the mucking function or mucking is unsmooth, expanding excavation is performed on the part between the vertical shaft and the mucking pilot shaft so that the mucking pilot shaft can perform mucking effectively and smoothly; after exaction is completed, the deviation expanding excavation part is backfilled so that the verticality of the vertical shaft can be guaranteed and the requirement of pressure steel pipe installation for the verticality of the vertical shaft can be met. According to the method, under the condition that a pilot hole deviates, it is guaranteed that the mucking pilot shaft performs mucking effectively, and the verticality of the vertical shaft is also guaranteed; in pressure vertical shaft or surge shaft construction in water conservancy and hydropower engineering, the method has the advantages of reducing repeated drilling extraction of a pilot hole, shortening the construction period and improving the strength of a backfilled region behind a pressure steel pipe at the bottom of a pressure vertical shaft, and therefore the method can be widely applied to small-diameter deep vertical shaft or inclined shaft construction with a short construction period.

Owner:SINOHYDRO BUREAU 7 CO LTD

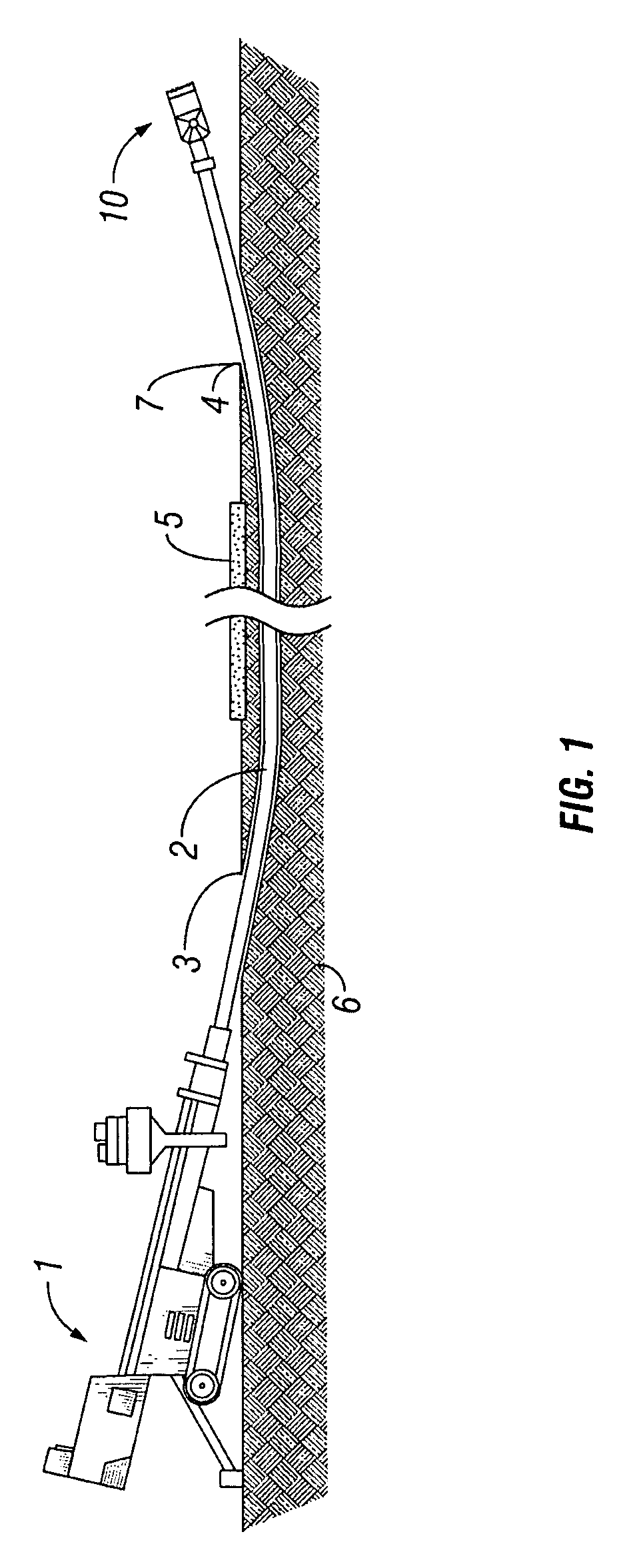

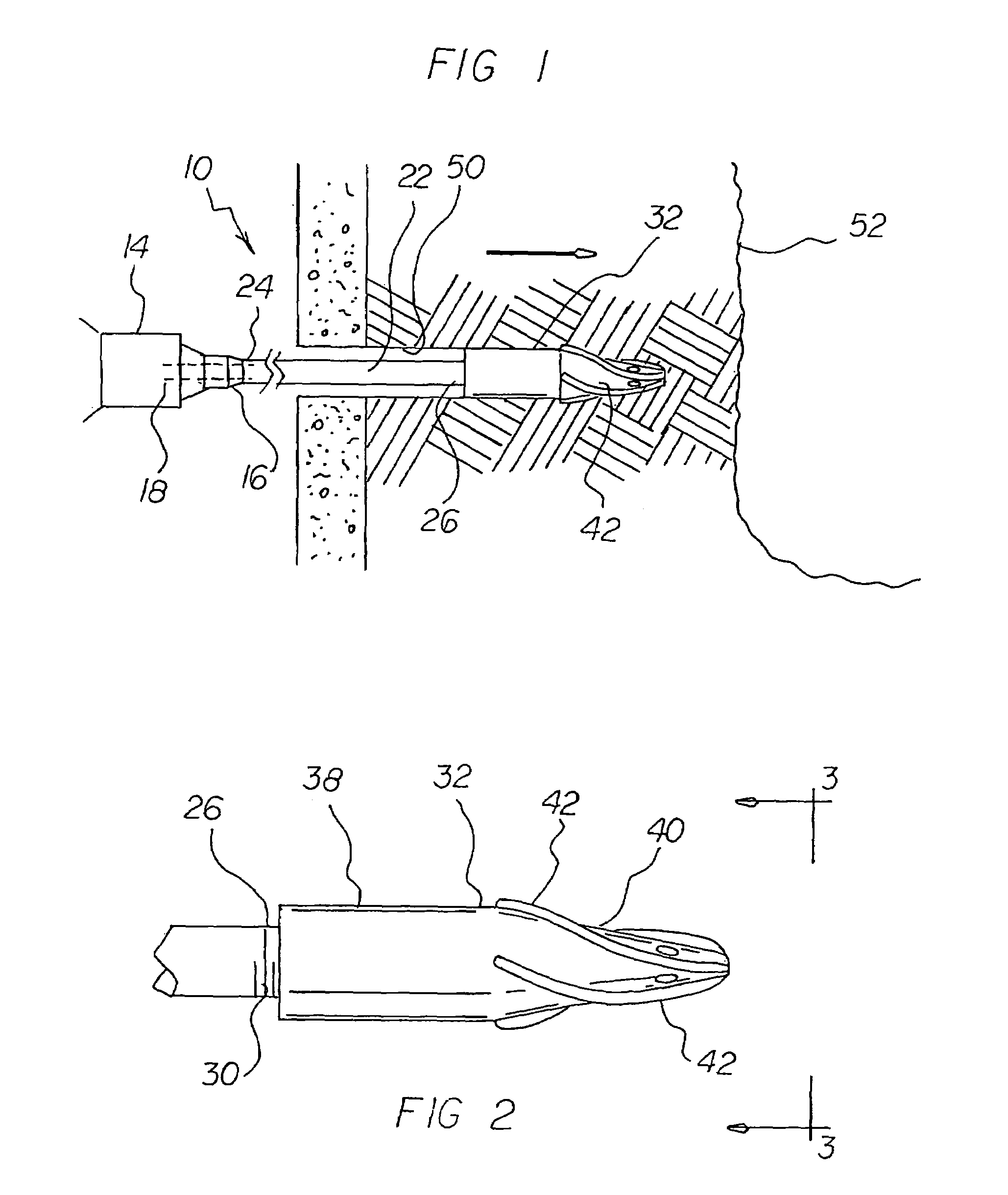

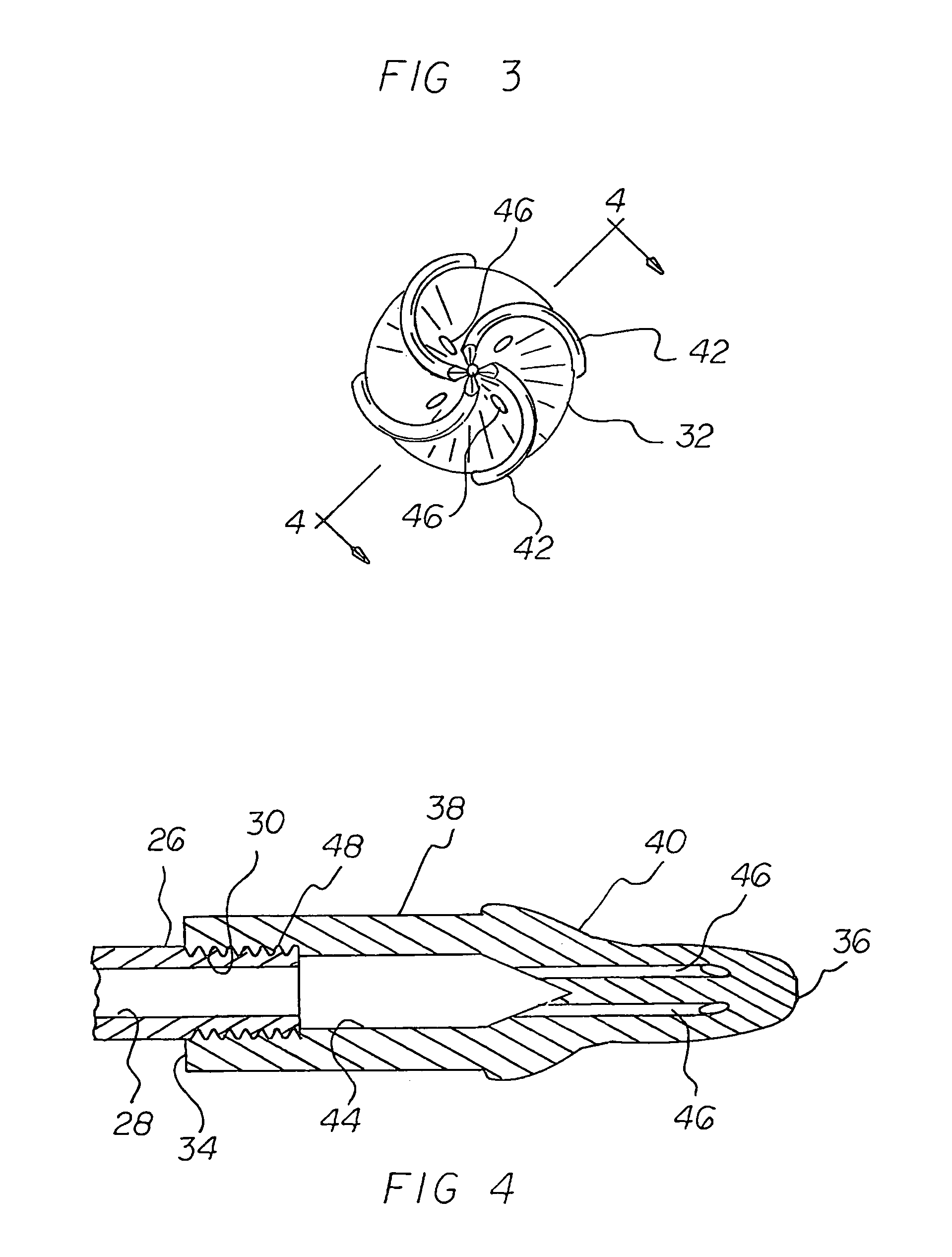

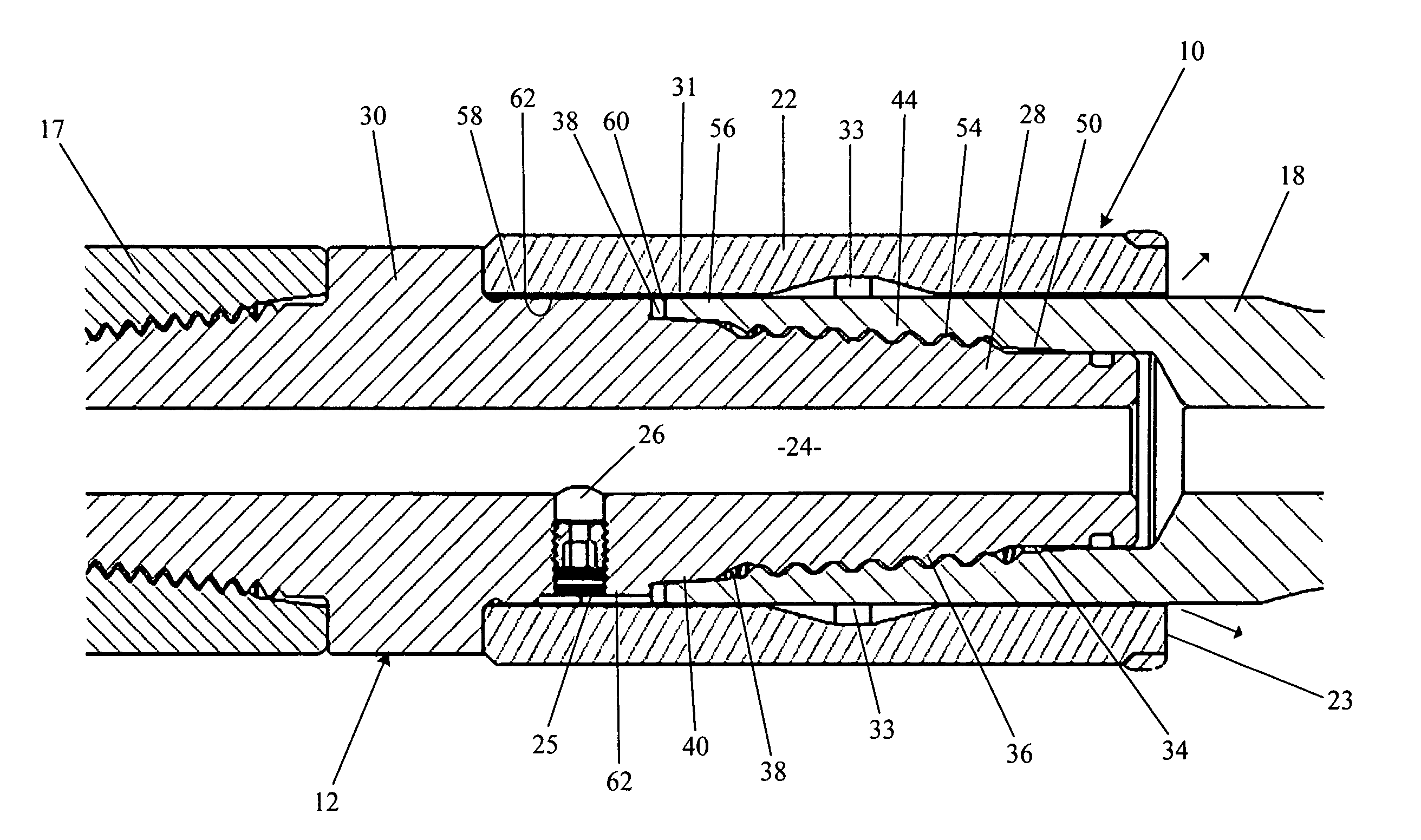

Boring and conduit/pipe system

InactiveUS7131790B1Easy and efficient to manufactureDurable and reliable constructionPipe laying and repairDrill bitsEngineeringScrew thread

Owner:CORDOVES JORGE L

Methods and Apparatus for Expanding Tubular Members

A method for sealing a hole in a tubular in a wellbore comprising: (A) locating the tubular patch adjacent the hole; (B) (i) plastically expanding a first portion of the tubular patch above the hole into annular sealing engagement with the tubular to form a first annular seal and (ii) plastically expanding a second portion of the tubular patch below the hole in the tubular into annular sealing engagement with the tubular or the open hole to form a second annular seal thereby sealing the hole in the tubular. The patch may be a corrugated tube prior to expansion in order to pass through restrictions and may have a section with an increased wall thickness including a resilient seal.

Owner:SCHLUMBERGER TECH CORP

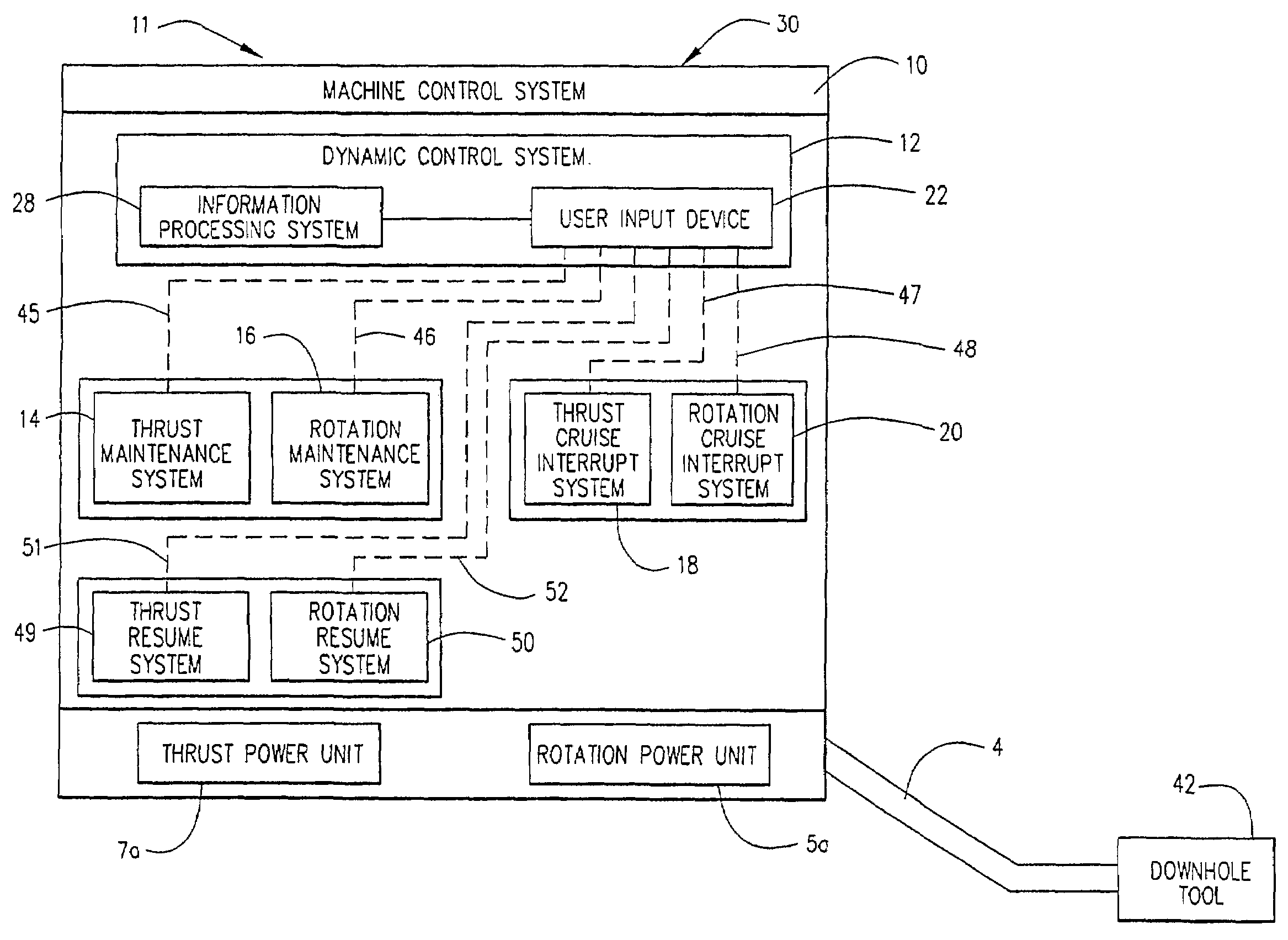

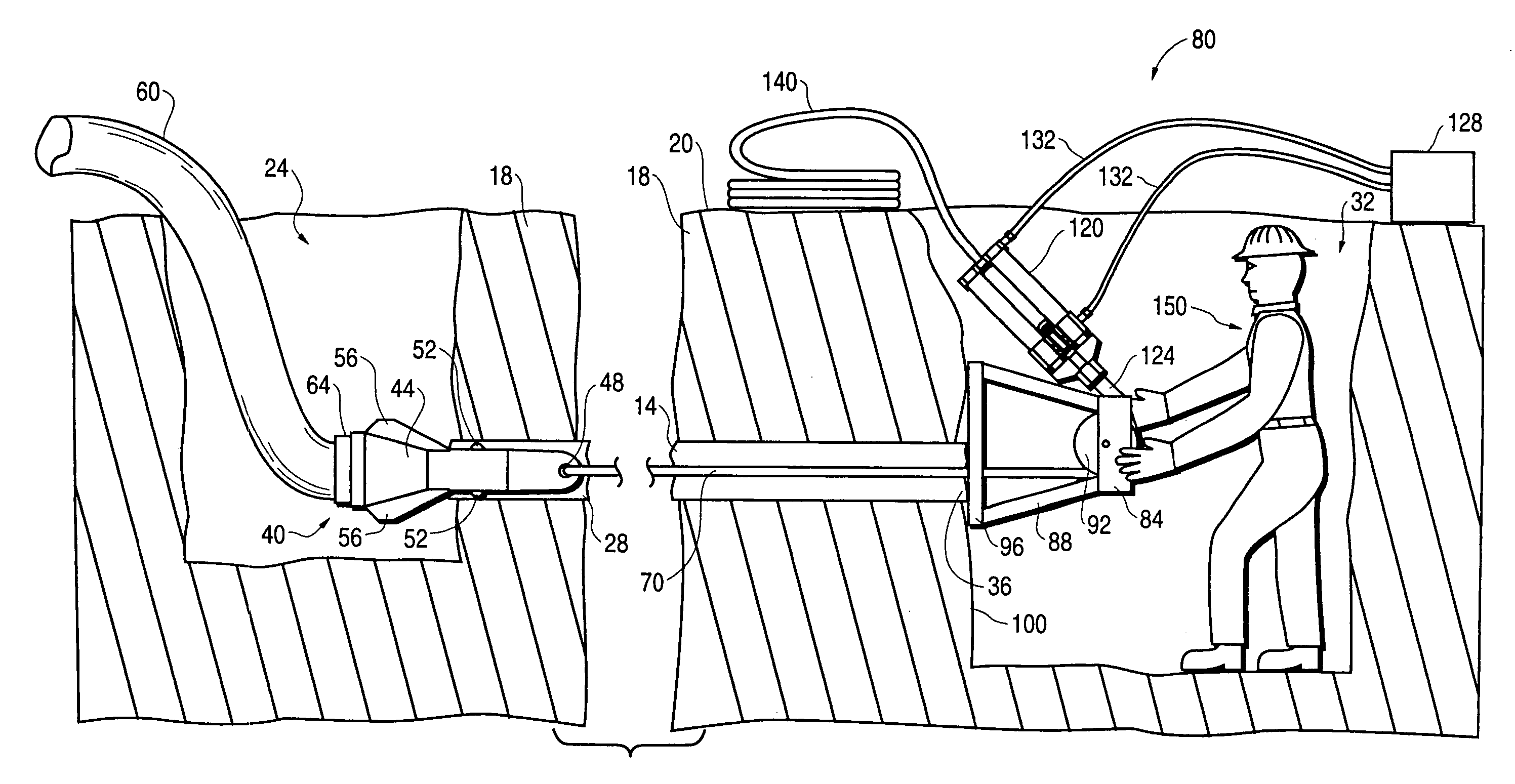

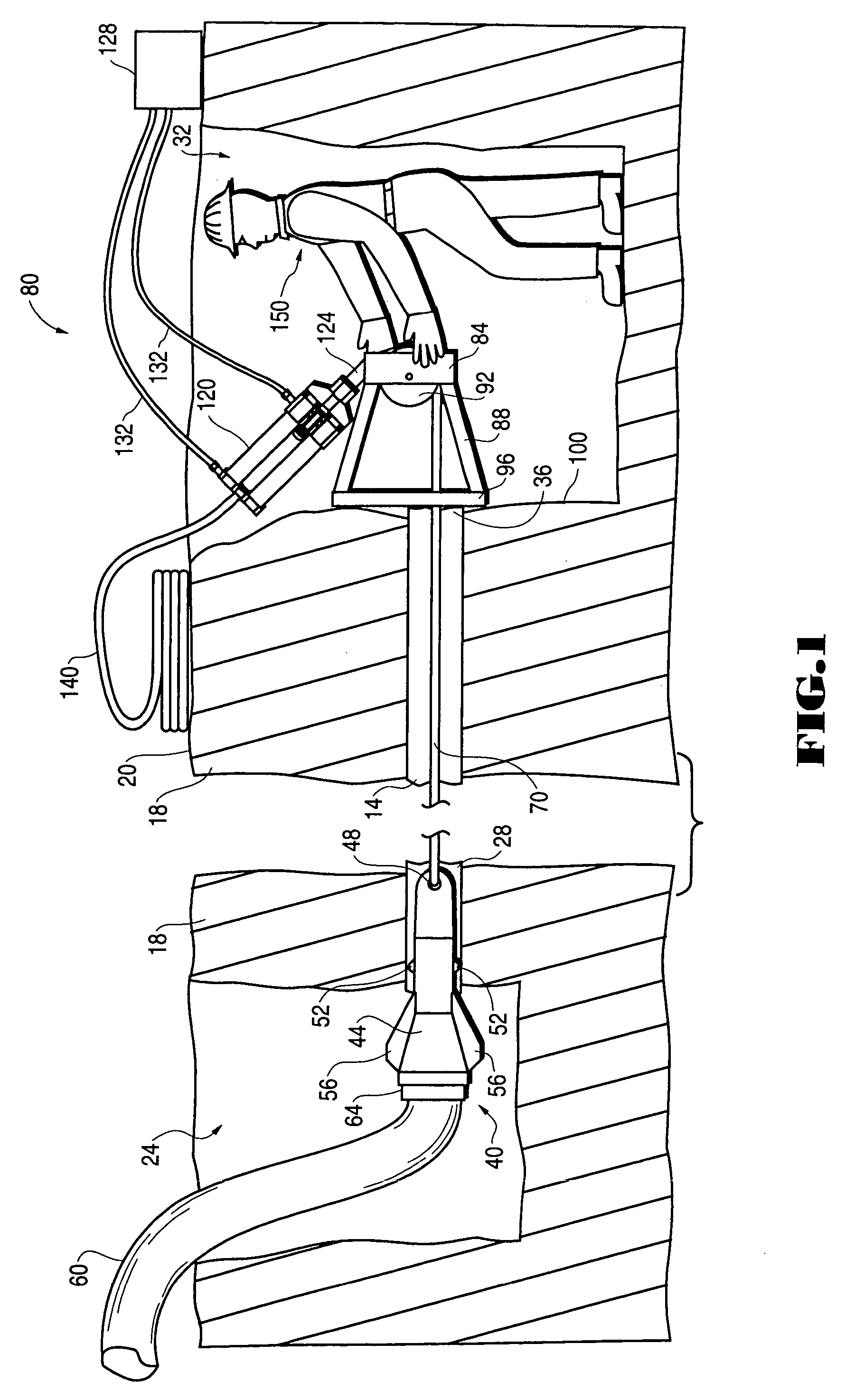

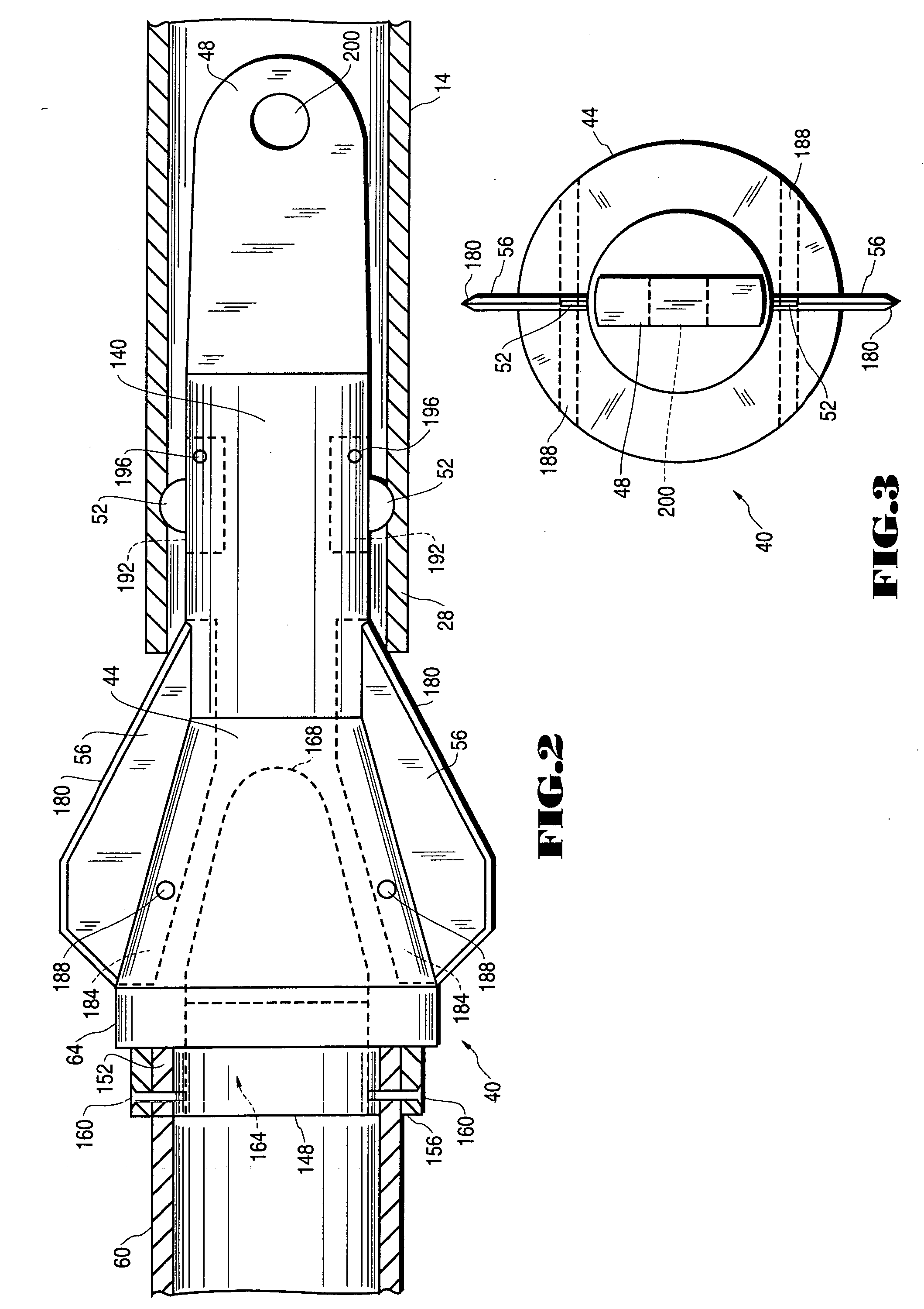

Apparatus and method for maintaining control of a drilling machine

An apparatus is provided for maintaining control of a machine which produces thrust, rotation or other outputs in response to input signals. The apparatus has two distinct parts, namely the operator input portion and the output portion. The operator input portion consists of the primary thrust, rotation and other output control, and the input signal generation, signal maintenance and signal resume control. Through these controls, the operator enters the desired operation at conditions and levels for rotation, thrust, and other input signals. The output portion consists of an information processing and control portion and the power units for rotation, thrust and other outputs generated from the machine. The information processing and control system interprets all of the desired operational conditions and levels from the input portion and sends commands to the thrust, rotation and other power units to produce the desired outputs in response to the input signals.

Owner:CHARLES MACHINE WORKS

Autoreaming systems and methods

Methods and systems for controlling movement of a bit of a drilling assembly during reaming of an already-drilled hole; the methods, in certain aspects, including determining a ream speed for downward movement of the bit in the hole, moving the bit downward in a hole at the ream speed, determining a time period for deceleration of the bit to the hole bottom, determining a value for a target drilling parameter for drilling beyond the bottom of the hole, decelerating the bit (linearly or non-linearly) for the time period, and achieving the value for the target drilling parameter when the bit reaches the bottom of the hole.

Owner:VARCO I P INC

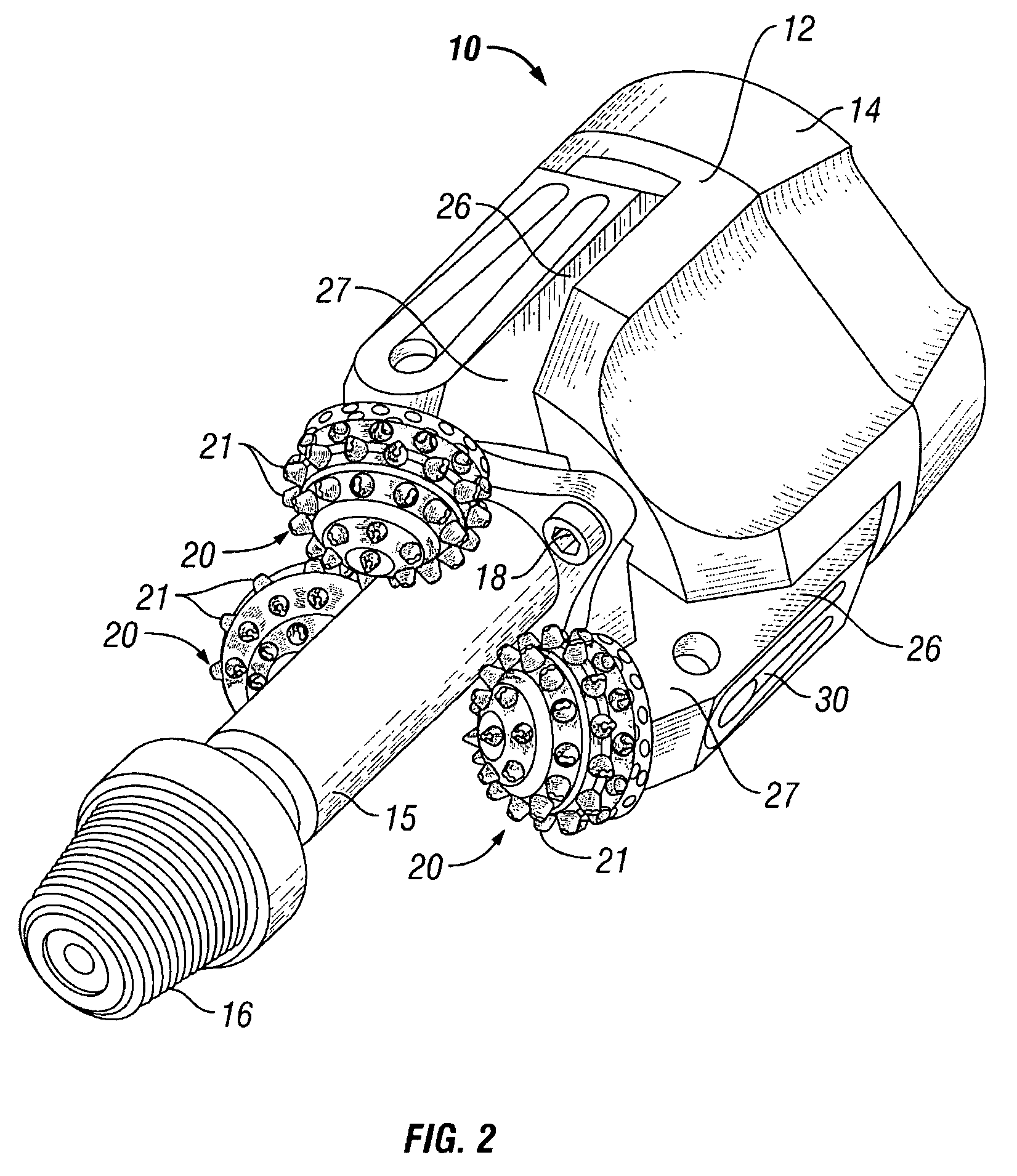

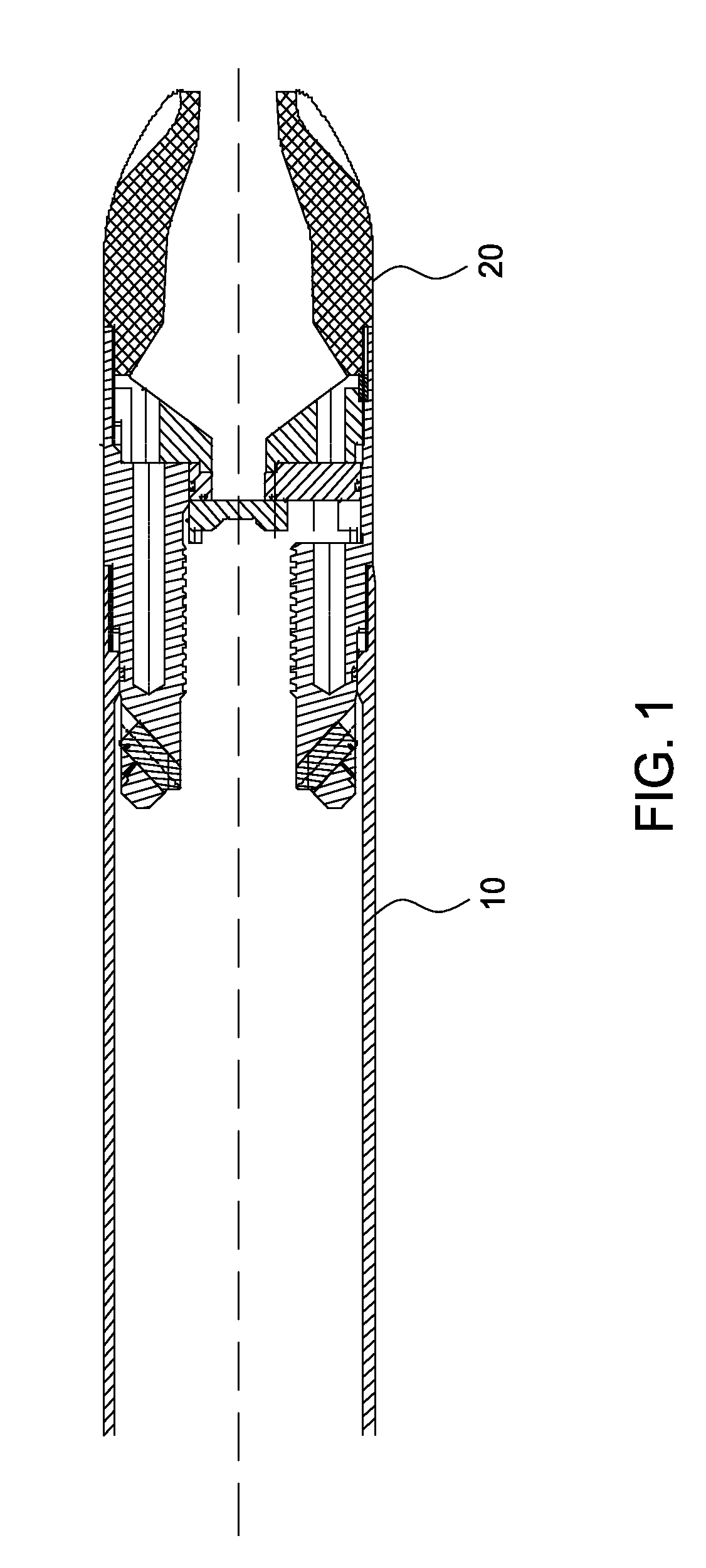

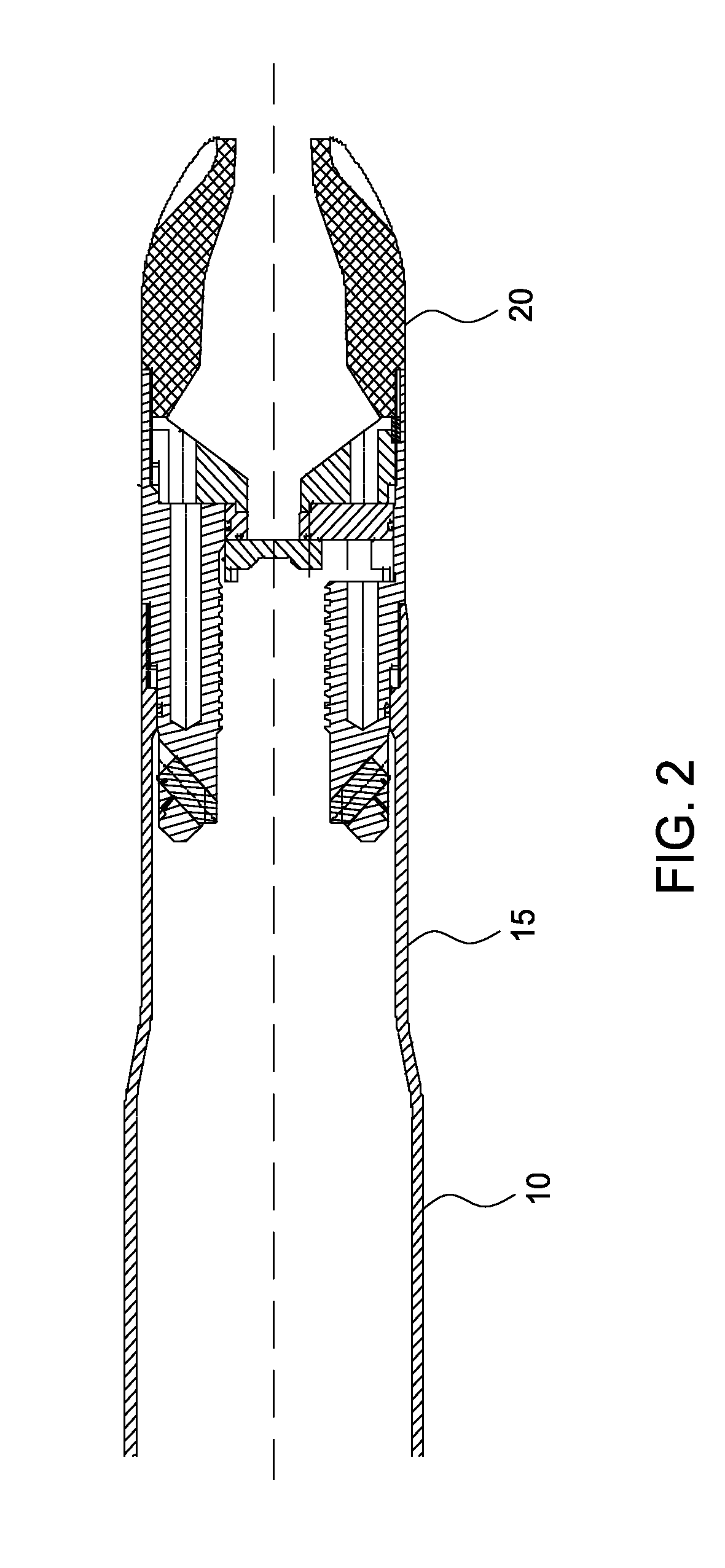

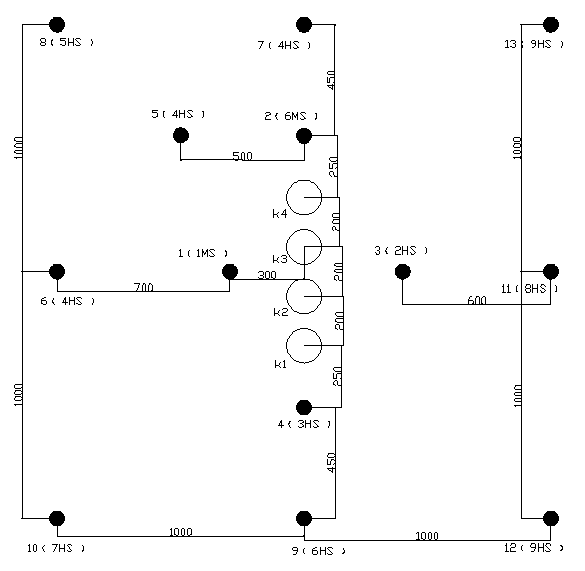

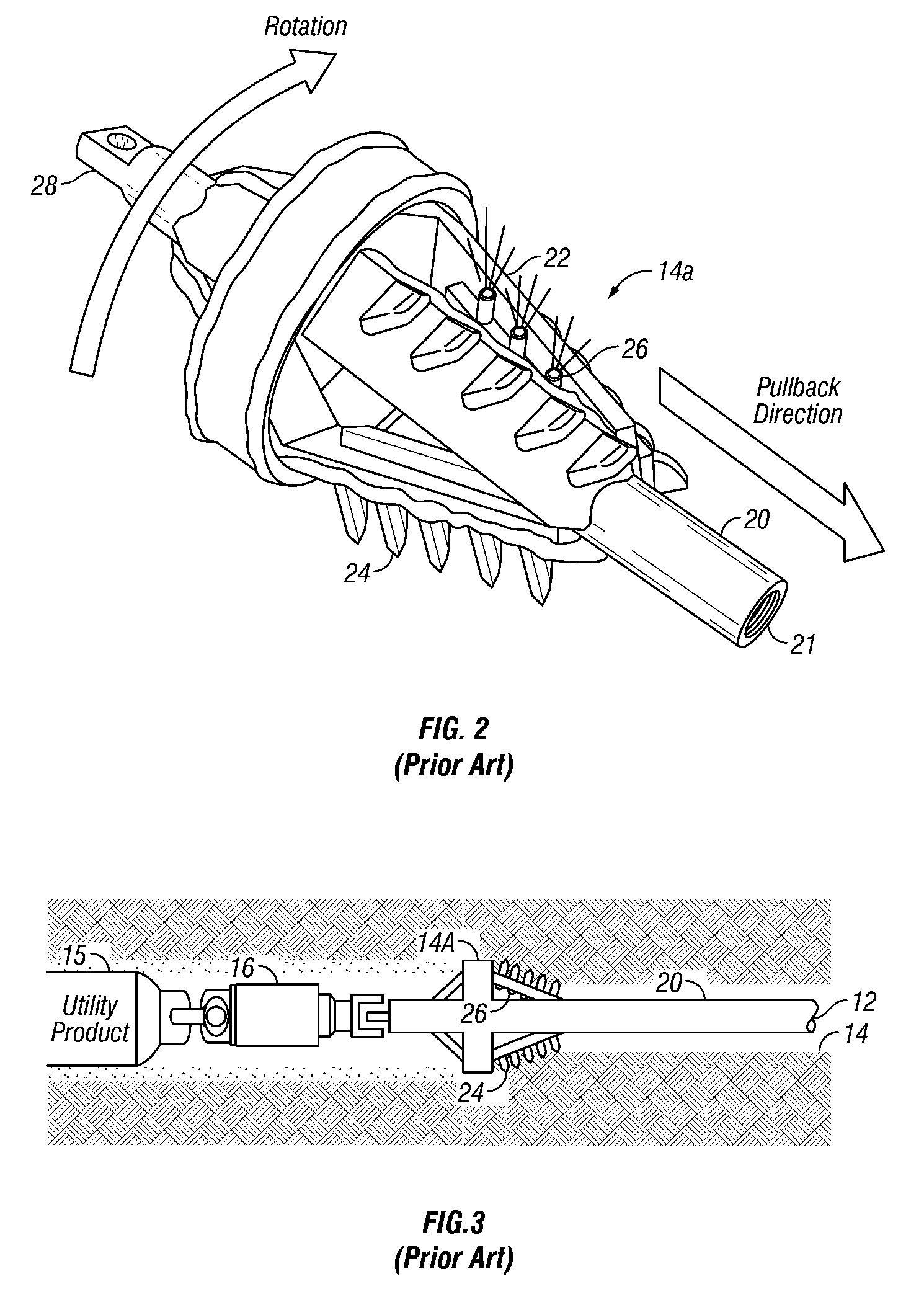

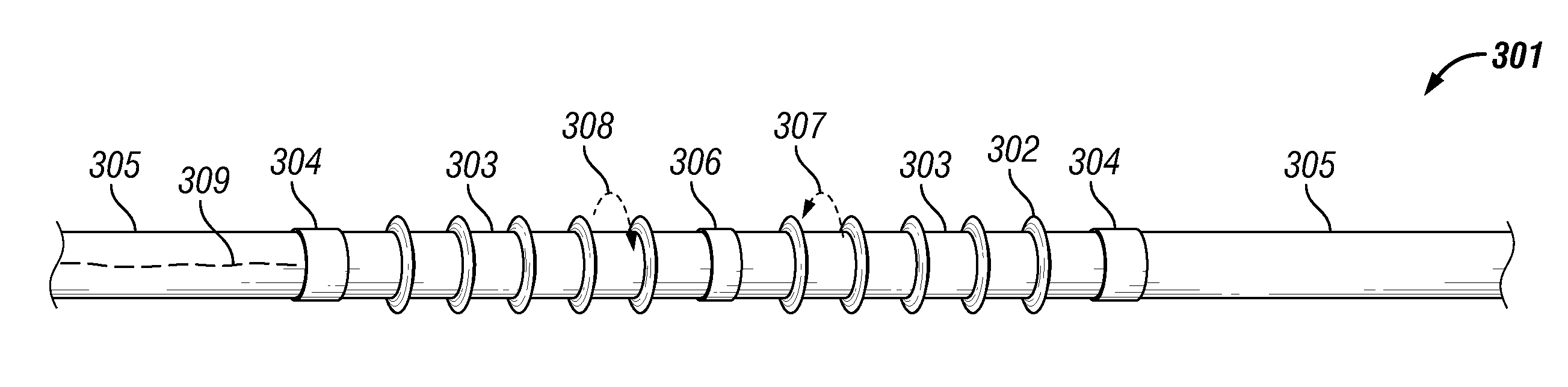

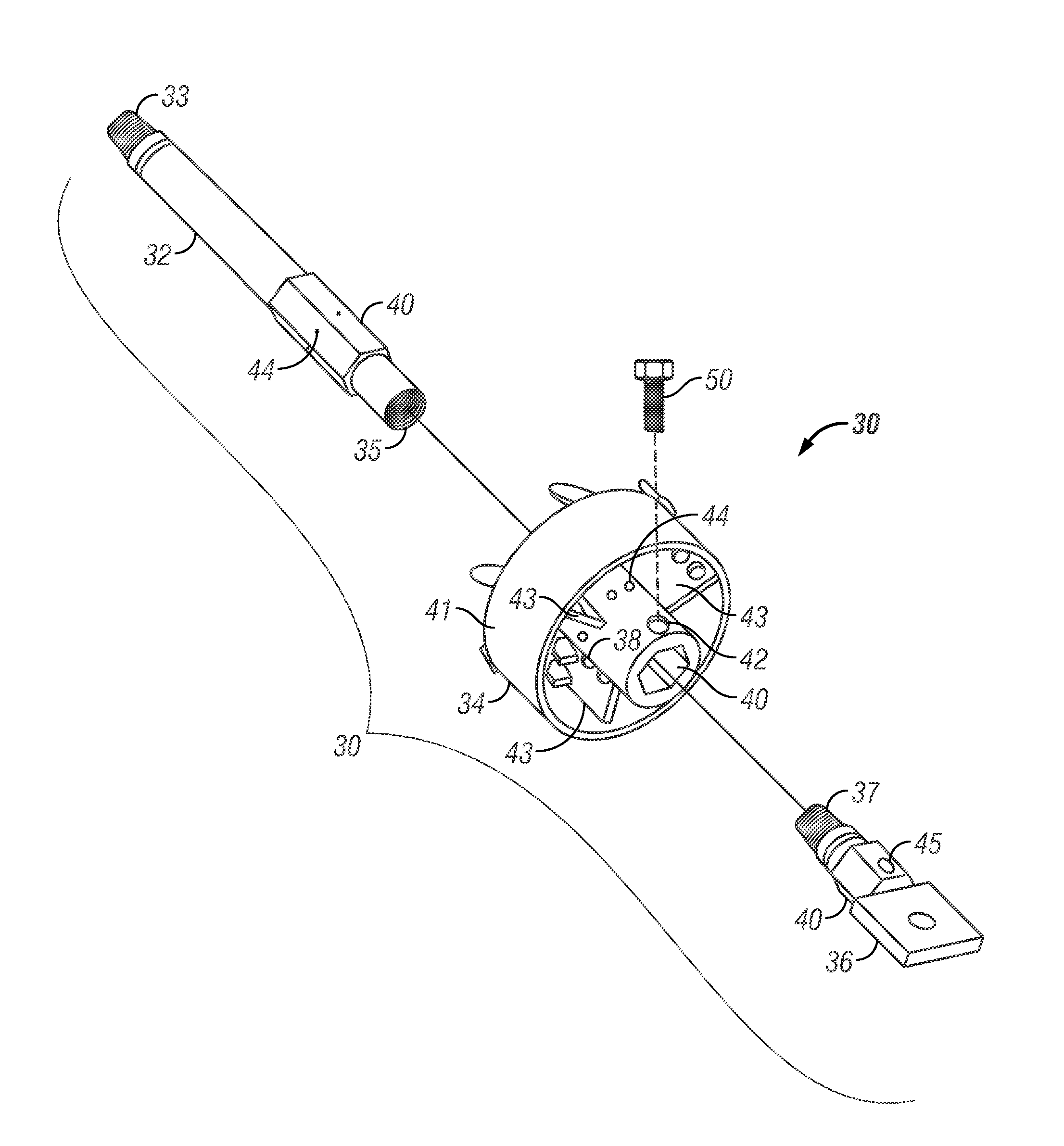

Sectional back reamer for horizontal directional drilling

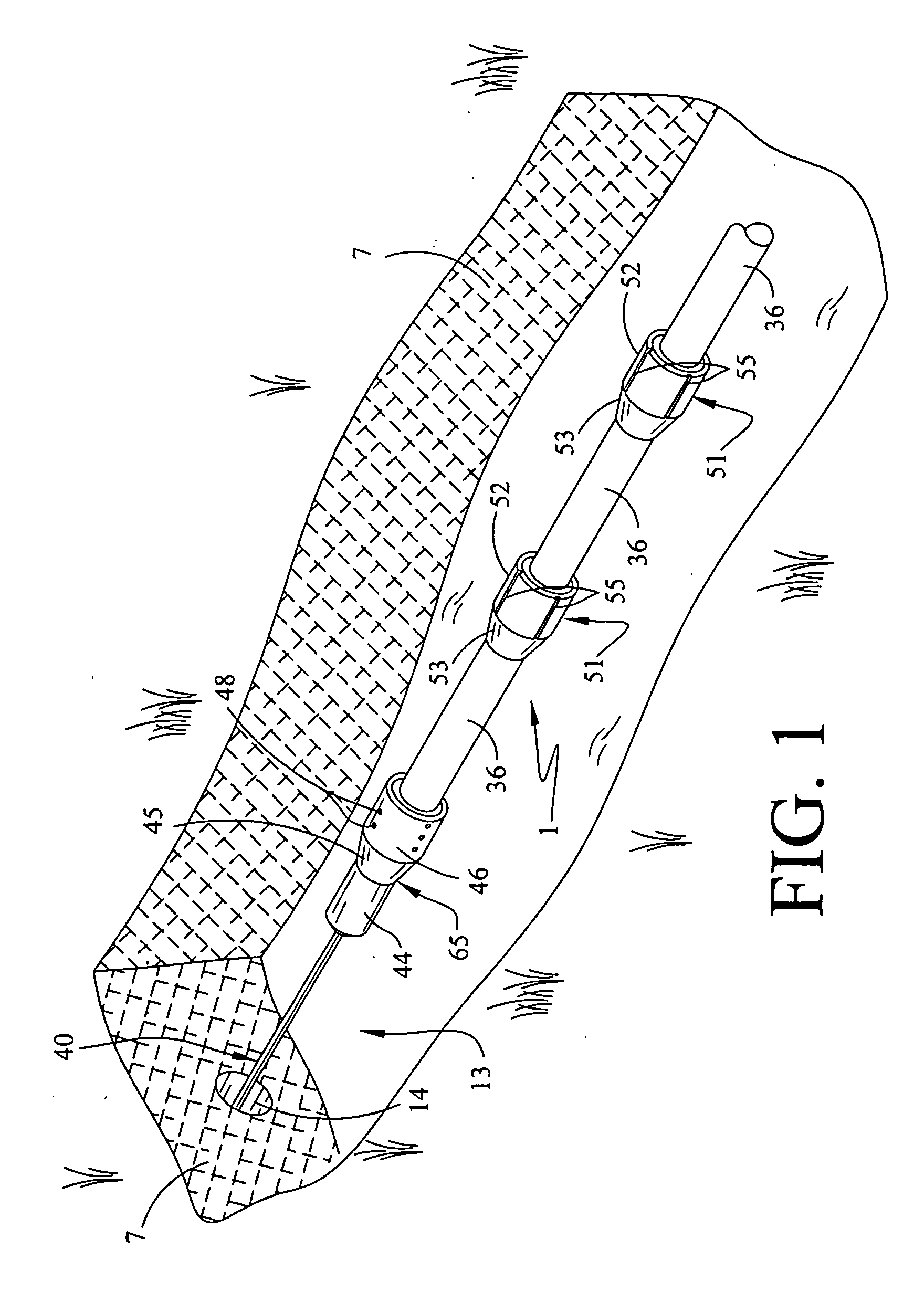

ActiveUS20090250266A1Easy and fast assemblySmall sizeArtificial islandsPipe laying and repairEngineeringReamer

An improved back reamer for horizontal directional drilling is provided with multiple components which can be quickly and easily assembled and disassembled before and after the back reaming process. The reamer includes a main shaft connectable to the drill string, a reamer head removably mounted on the main shaft, and a pull tab removably attached to the main shaft. The components are much lighter than prior art one-piece reamers, and thus improves safety to the installer and operator during the horizontal drilling operation.

Owner:DIMITROFF TED R

Wellbore obstruction clearing tool and method of use

A wellbore obstruction-clearing tool connected to the bottom of a tubing string, such as casing, utilizes a sleeve which is axially and rotationally moveable in response to axial reciprocation of a tubing string to engage and clear obstructions in the wellbore. Fluid is discharged through the casing and the tool to engage the obstructions and to convey debris through the annulus to surface. Thus, the obstructions are cleared from the wellbore, permitting the casing to be advanced, without the need to rotate the casing.

Owner:LONGHORN CASING TOOLS

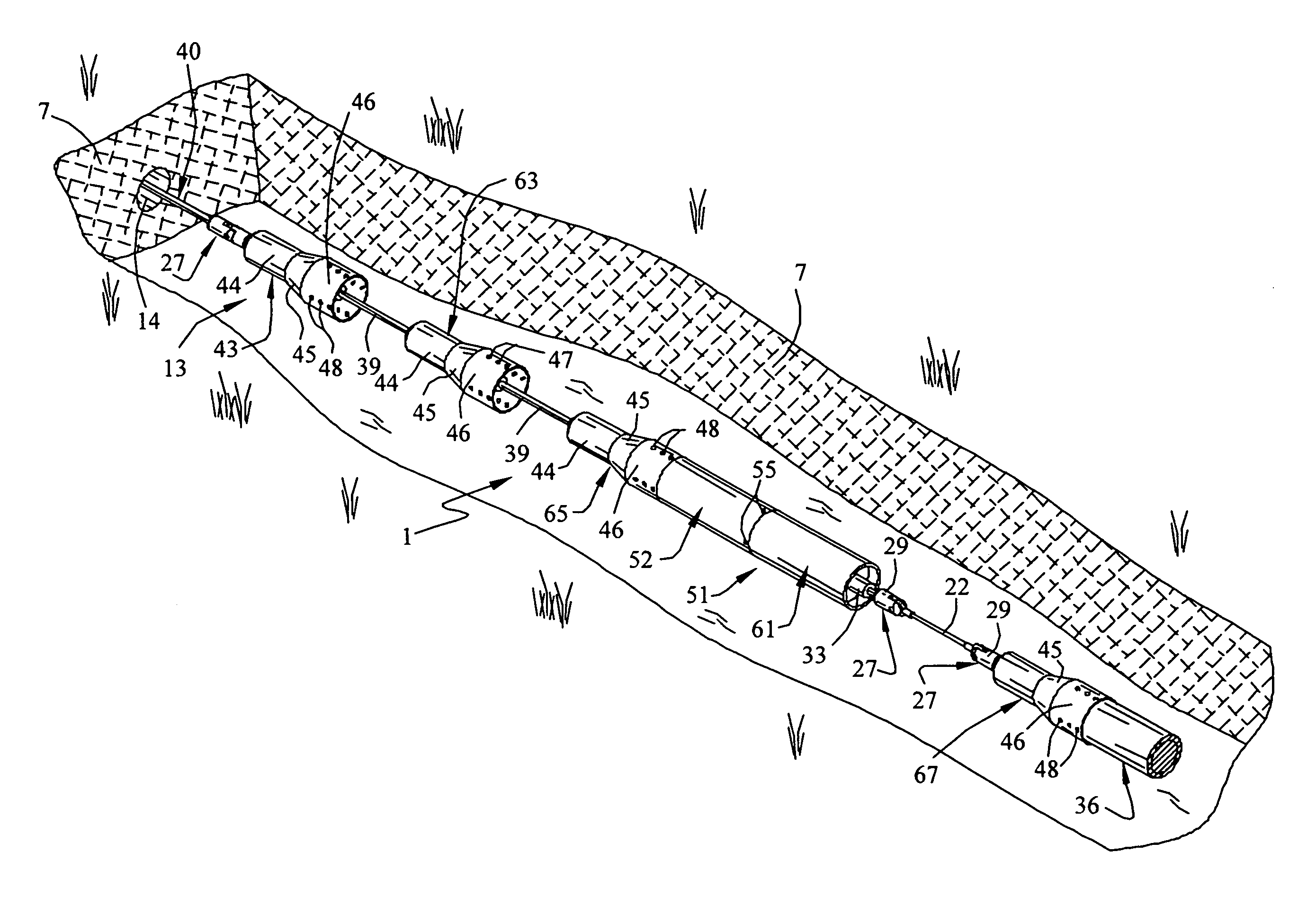

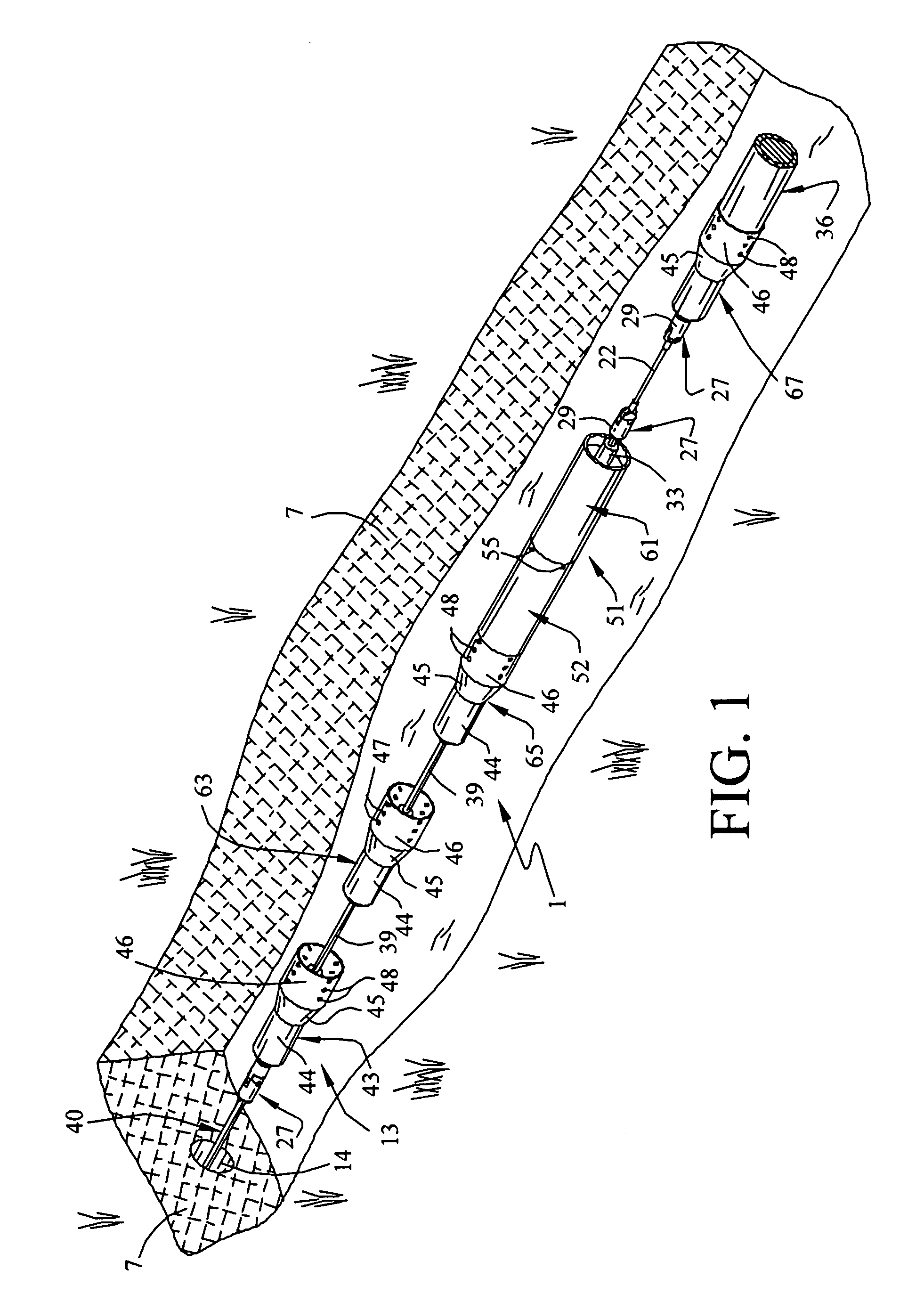

Bore hole sleeve reaming apparatus and method

InactiveUS20080296066A1Reduce frictionExcessive tensile strainEarth drilling toolsDrill bitsEngineeringDrill hole

A bore hole sleeve reaming apparatus which is characterized by one or more subterranean bore clearing devices or sleeves for use with one or more clearing or bursting heads attached to a pull rod or cable and a pulling apparatus. One or more tapered sleeves are attached in spaced-apart relationship to a string of tandem-mounted plastic pipe when the clearing or bursting head or heads are attached to the pipe string to be pulled through the bore hole. The tapered sleeves are designed to straighten bore irregularities and clean, smooth and free the bore hole from collapsing earth, roots and / or rock and broken pipe and facilitate pulling the pipe string through the bore hole with minimum friction on the pipe string. The clearing sleeve elements are sequentially pulled through the bore hole with the clearing or bursting head(s) and pipe string from an entry pit using a pull rod or cable and a pulling apparatus is seated in a corresponding exit pit spaced from the entry pit and receives the opposite end of the pull rod or cable. A method for clearing and cleaning a subterranean pilot bore or tunnel, which includes the steps of placing one or more clearing or bursting heads in an entry pit; connecting the clearing or bursting head(s) to a pulling apparatus using a rod or cable; connecting a string of typically plastic pipe to the clearing or bursting head(s); mounting at least one tapered clearing sleeve on the pipe string; and operating the pulling apparatus to pull the clearing or bursting head(s), pipe string and clearing sleeve or sleeves through the pilot bore, pipe or tunnel and clean, smooth and free the resulting bore from collapsing earth and other debris.

Owner:PUTNAM SAMUEL W

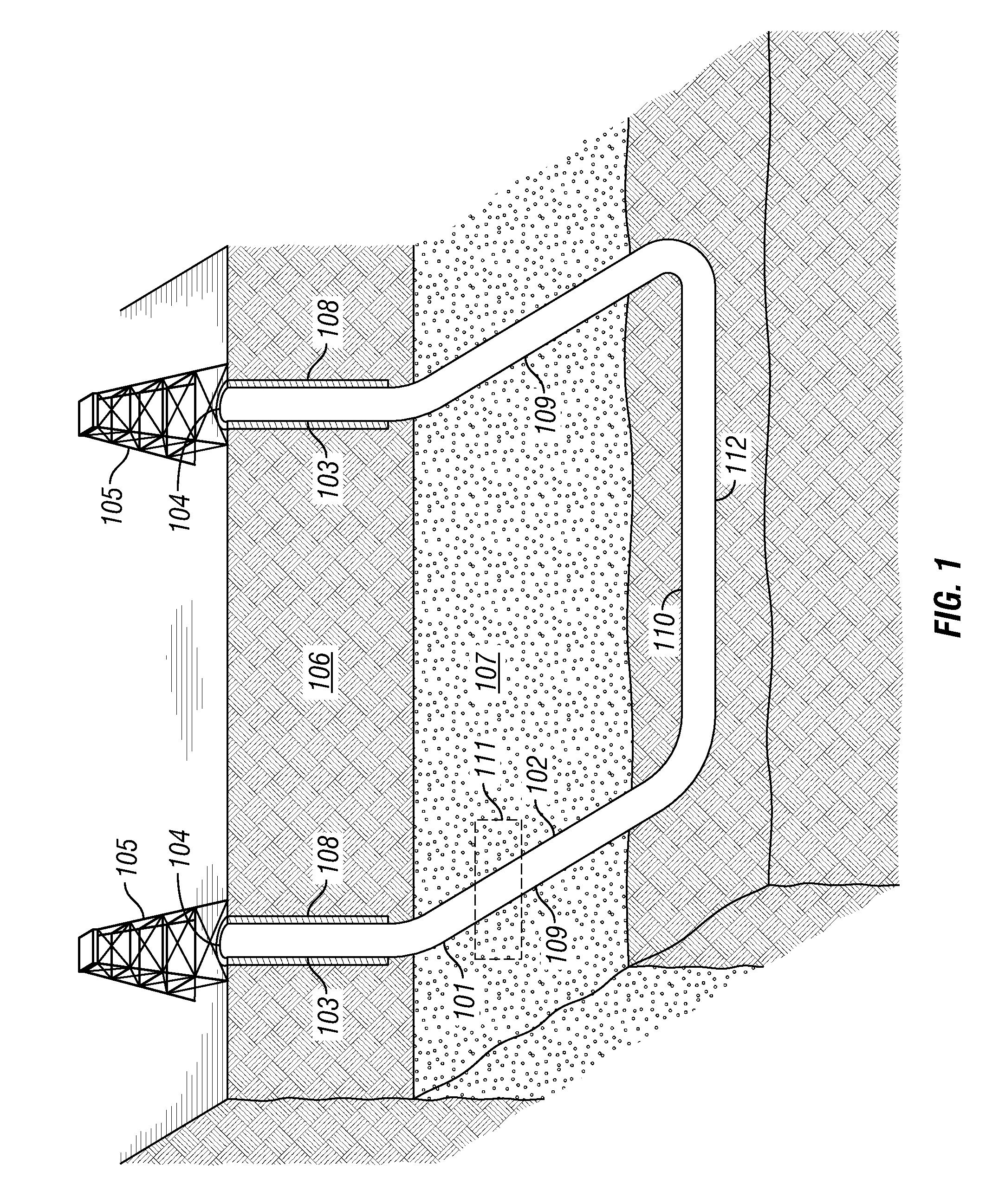

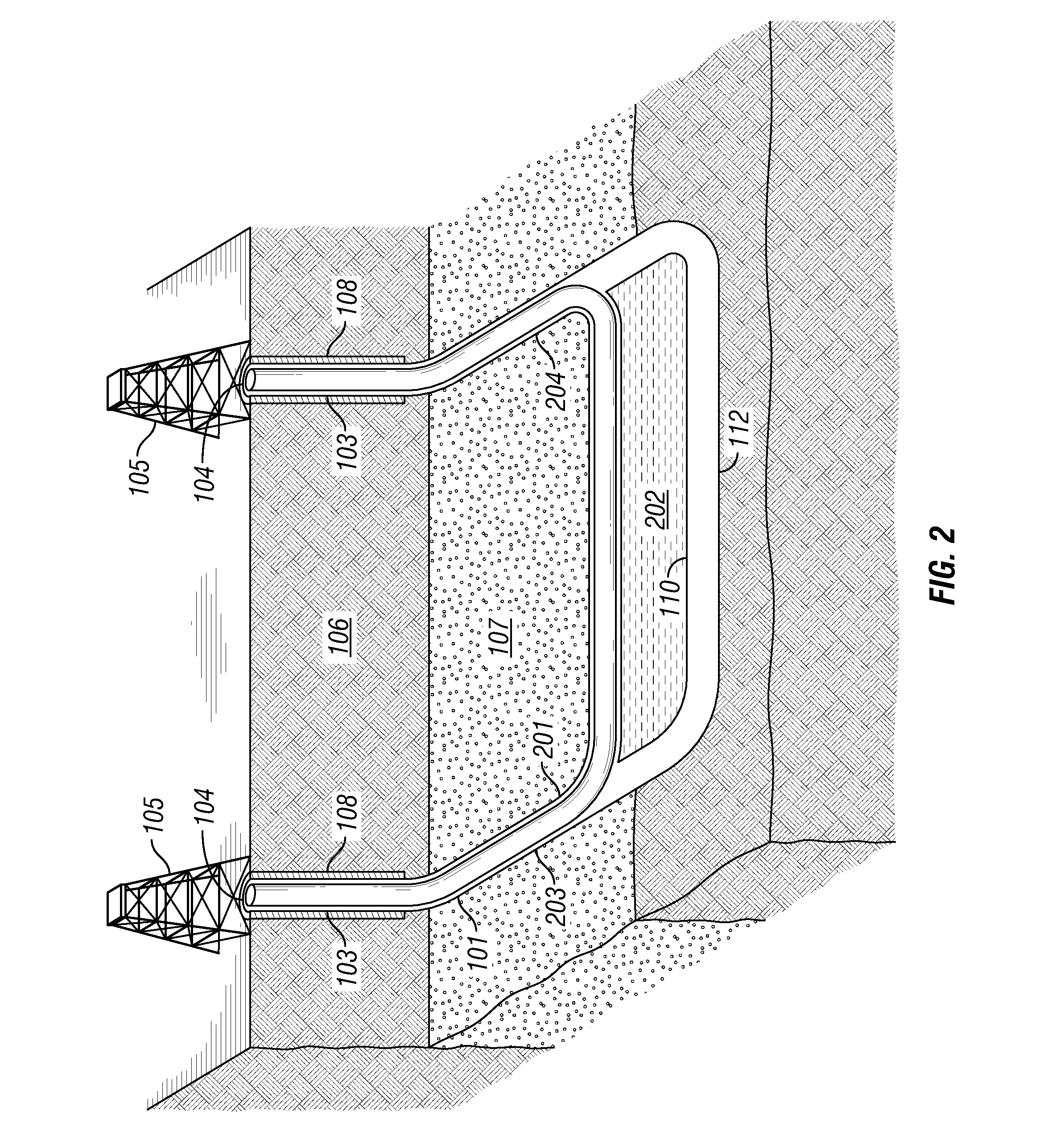

Mechanized slot drilling

InactiveUS20150096806A1Create quicklyMinimizing bend curvatureEarth drilling toolsDrill bitsEngineeringMechanical engineering

A system and method are provided for providing access to surfaces within a formation is provided, the method including: providing a wellbore from a first surface location to a second surface location; inserting into the wellbore a cylindrical cutting assembly connected to at least two wellbore tubulars, one of the wellbore tubular extending to each of the first surface location and the second surface location; and rotating the radial cylindrical cutting element.

Owner:SHELL OIL CO

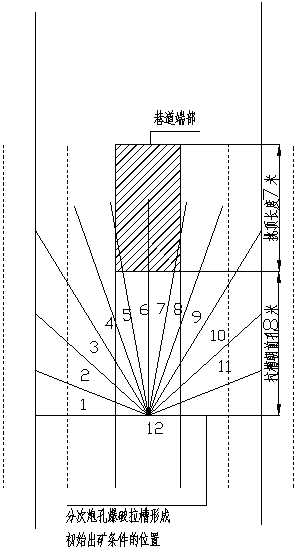

Primary blasting well forming method for middle guide well

InactiveCN108374661AVarious construction methodsHigh security riskBlastingShaft sinkingDetonatorSludge

The invention relates to the field of tunnel engineering, and discloses a primary blasting well forming method for a middle guide well. The method includes the steps: (1) performing measuring and positioning to determine the wellhead position of a vertical well; (2) mechanically digging a wellhead of the vertical well; (3) reversely digging the bottom of the vertical well upwards; (4) according toa blasting design lofting blast hole position of the middle guide well: performing lofting to form 2m*2m middle guide well position of the vertical well by the aid of a total-station instrument, andlabeling the position of the blast hole position; (5) completely drilling a blast hole by a down-the-hole drill once; (6) plugging the bottom of the blast hole; (7) filling the blast hole with explosive; (8) plugging an upper opening of the blast hole with blast sludge after the blast hole is plugged by the explosive; (9) line connecting and explosion initiating, connecting starting detonators inthe blast holes in a clustering manner, and performing differential initiation of non-electric millisecond detonators. The method has the advantages that construction safety is improved, potential safety hazards are reduced, and life safety of construction staff is guaranteed.

Owner:浙江省隧道工程集团有限公司

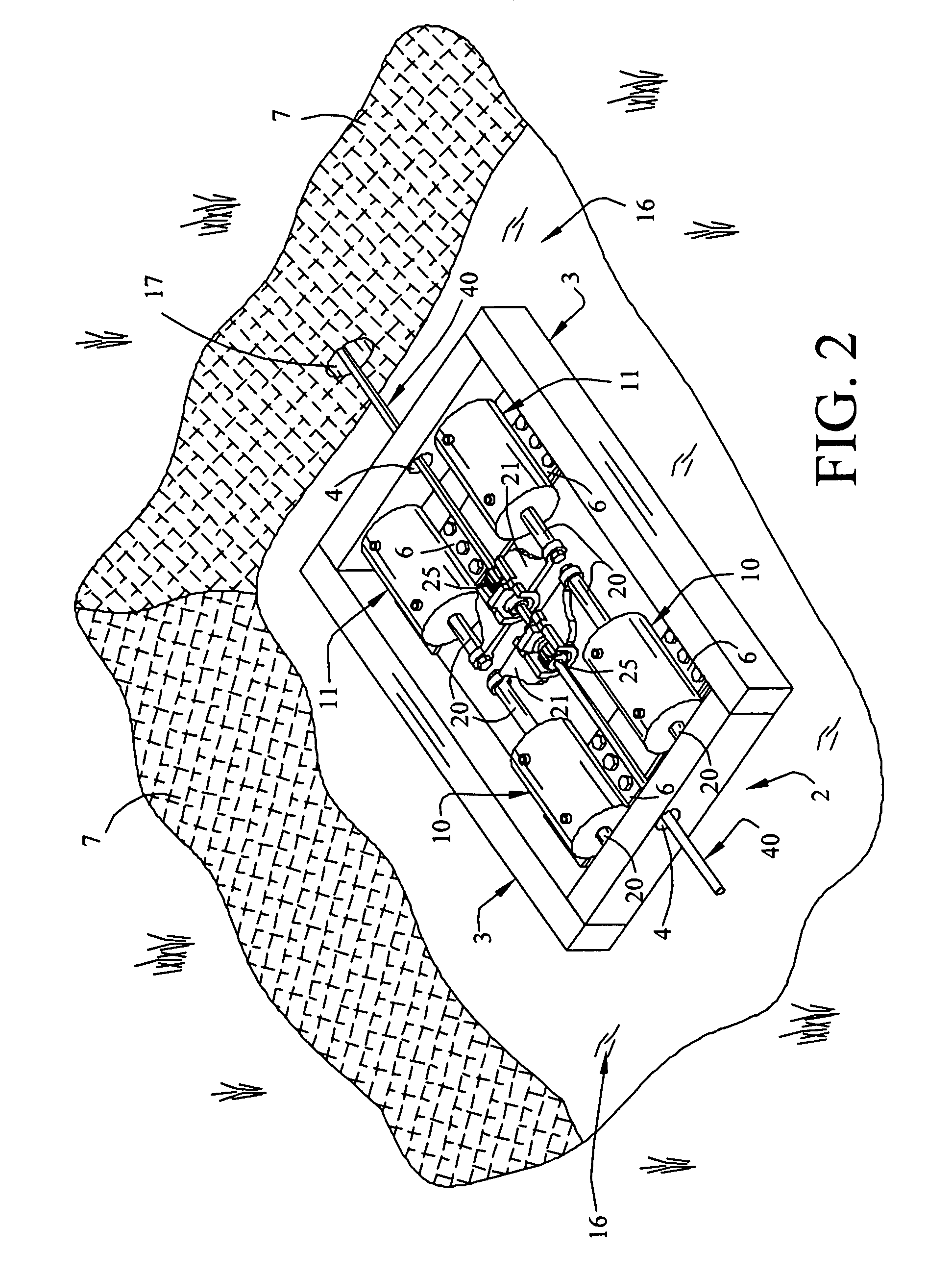

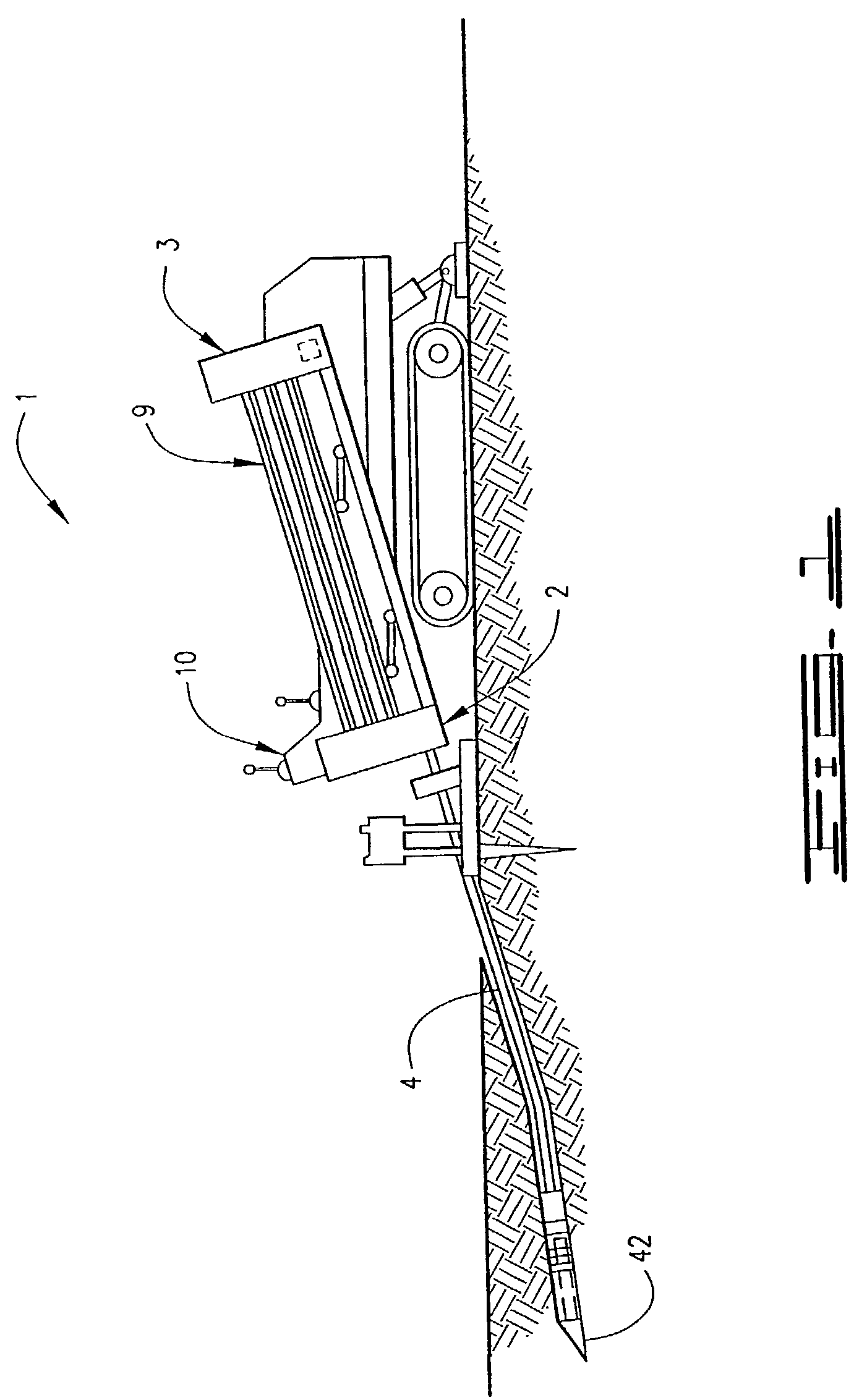

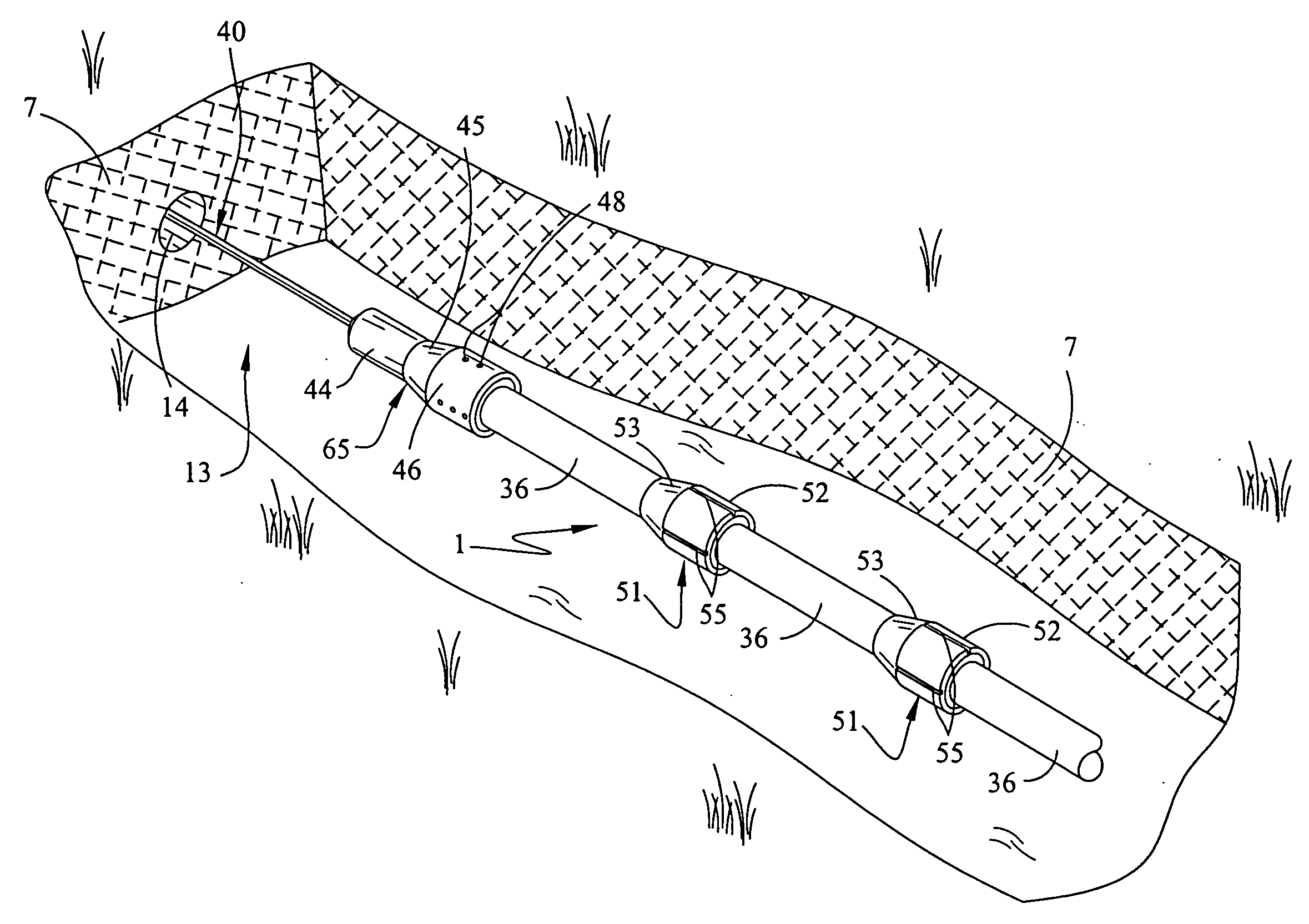

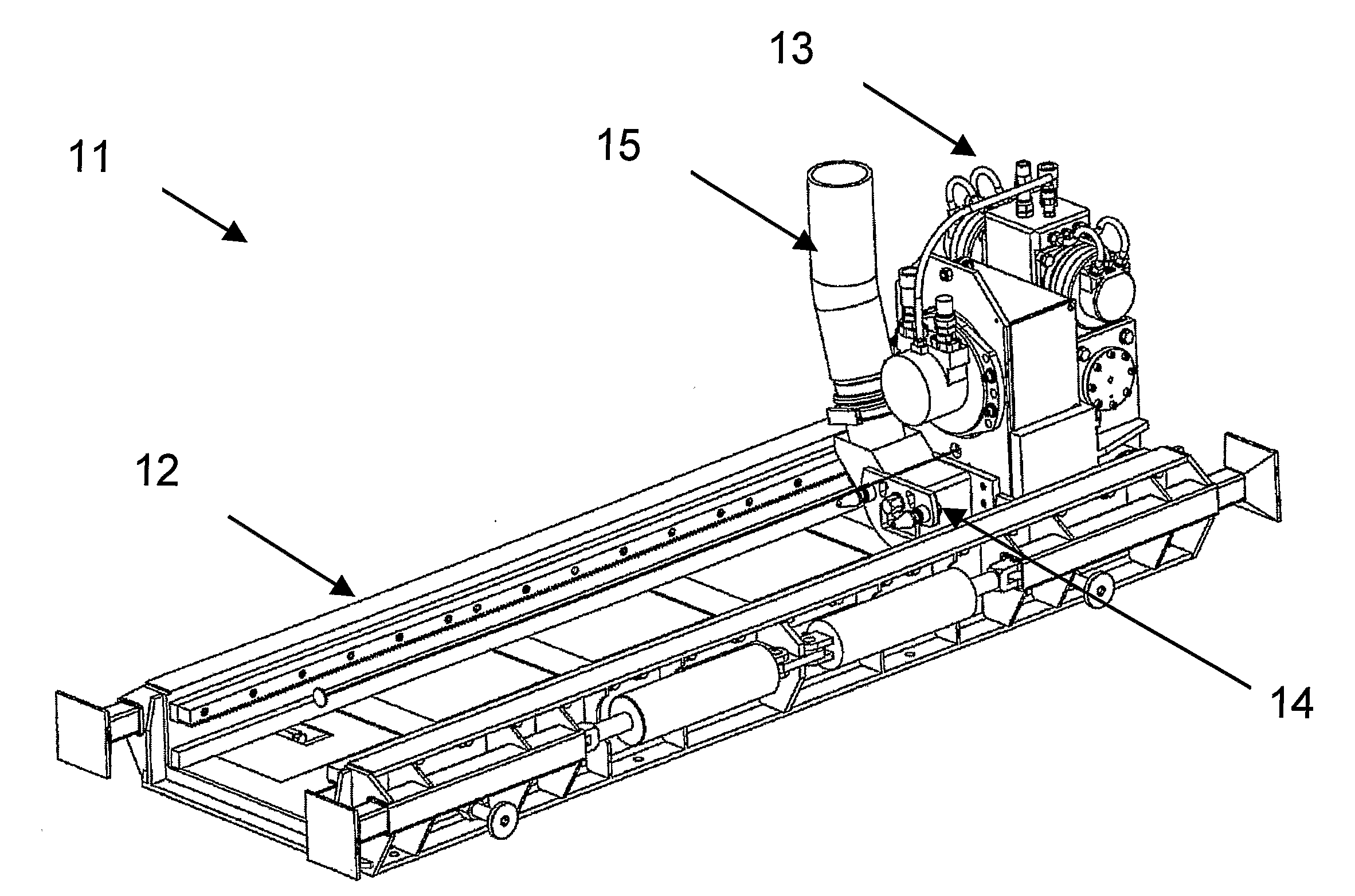

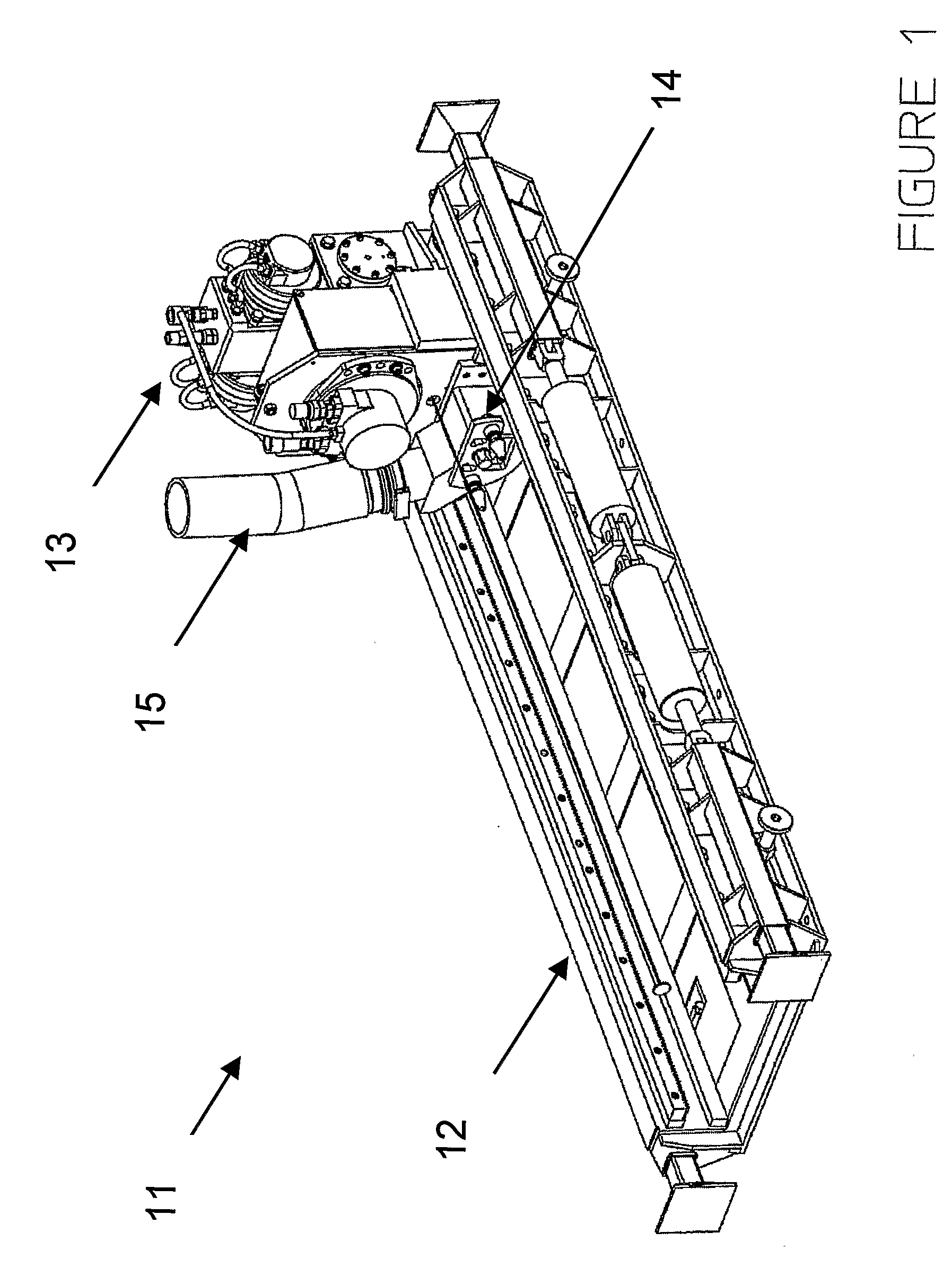

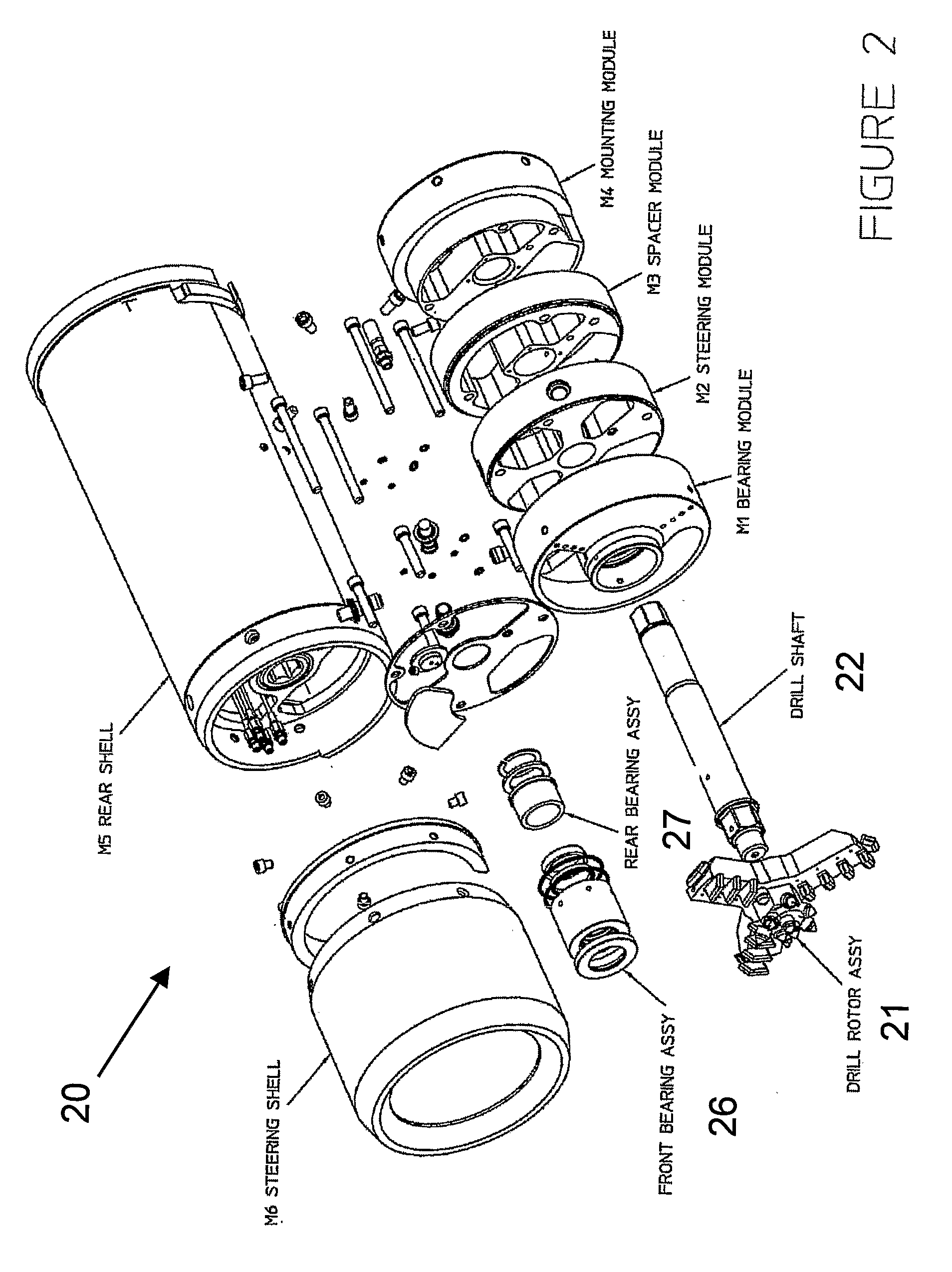

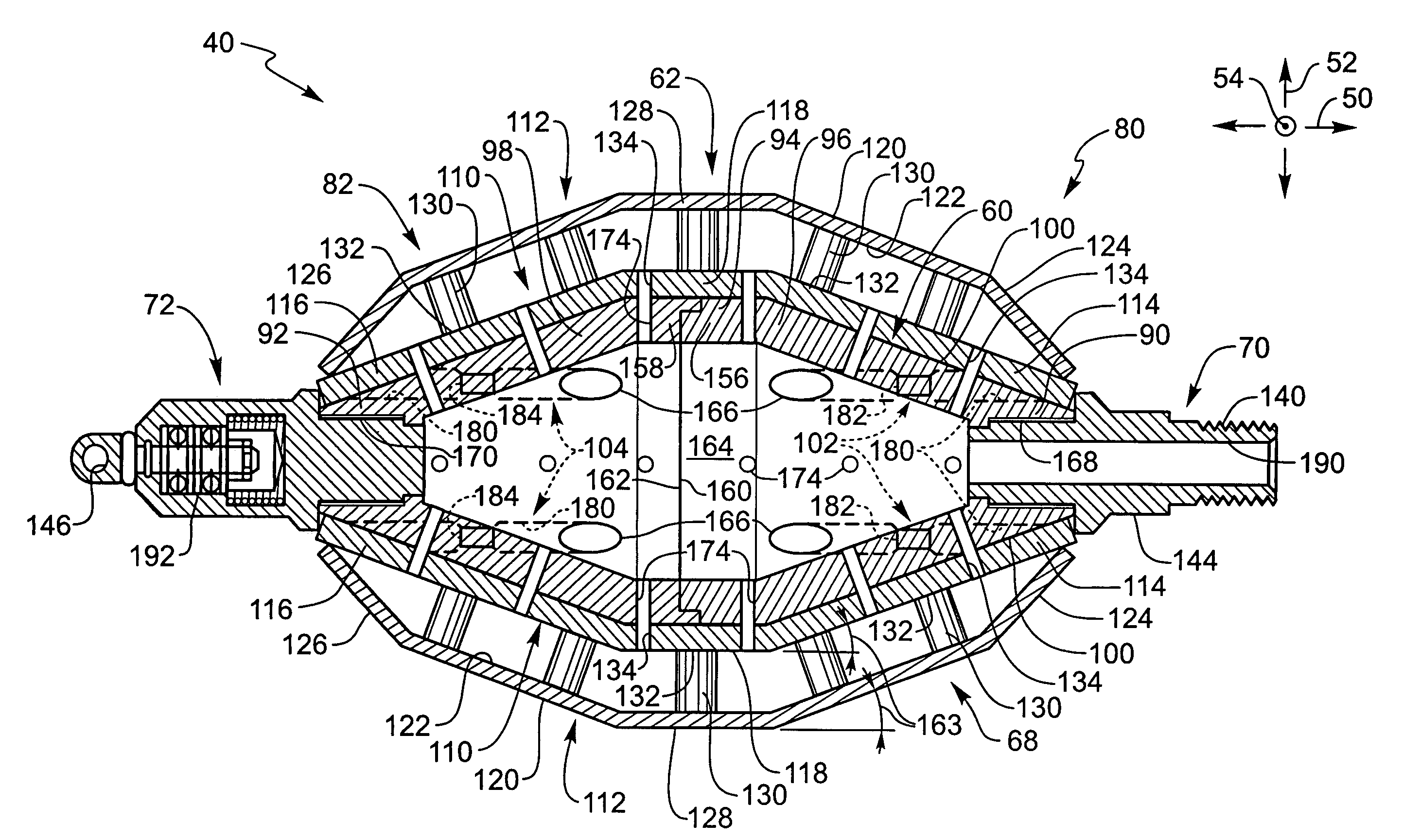

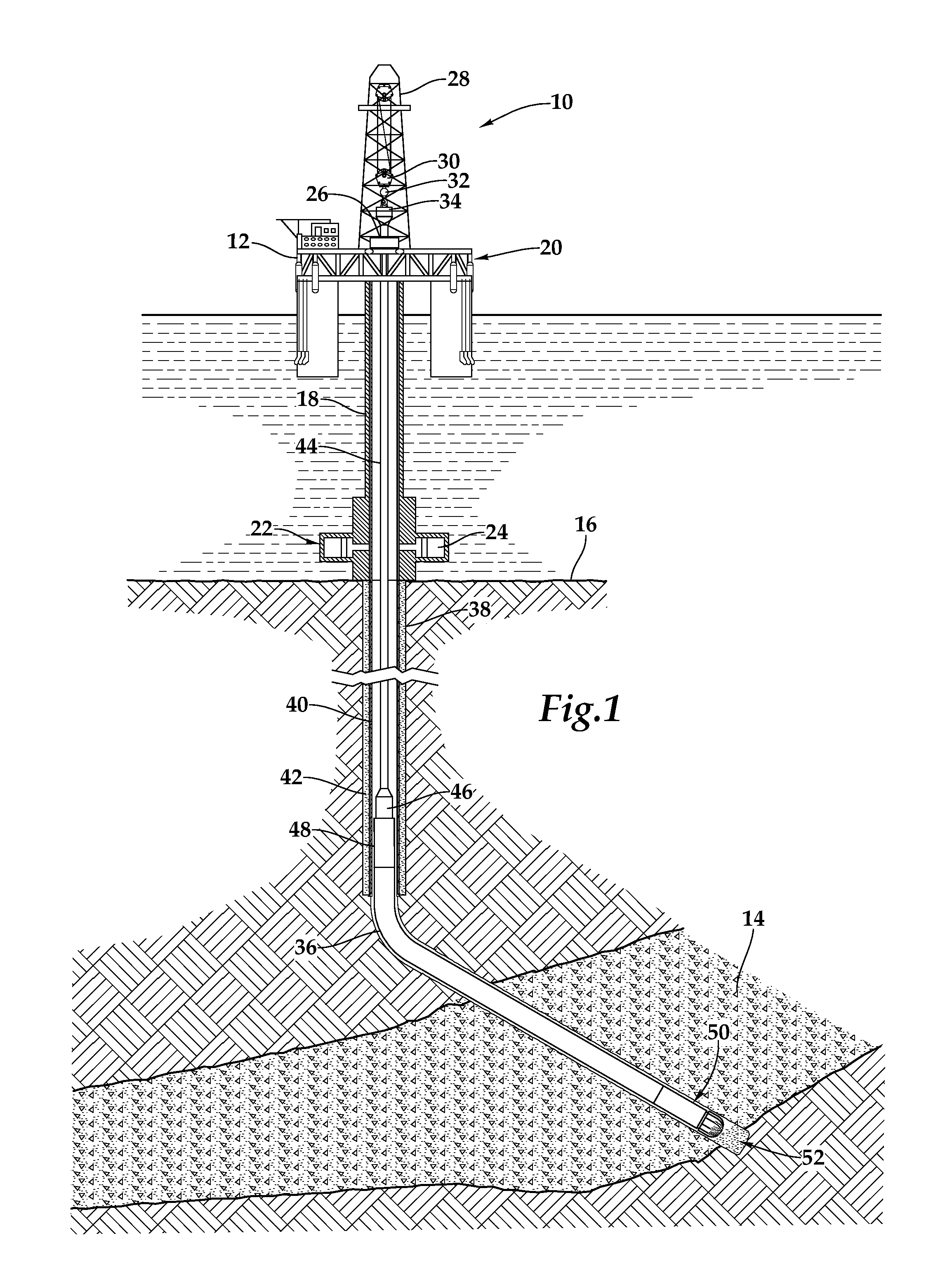

Microtunnelling system and apparatus

ActiveUS20090301783A1Increase the areaMaximize the machines ability to remove spoilDrilling rodsUnderground chambersCircular discAbutment

A microtunnelling apparatus and system that includes an external drive system having rotational and linear thrust drive means, a drill head section having drill rotor and drill rod and connecting to intermediate drill rods allowing extension of the boring hole created by the drill head section driven by the drive system. The drill head includes a modular construction having a plurality of circular disc like elements, a bearing module, a steering module, a spacer module, and a mounting module, for axial alignment and abutment and mounting within a cylindrical steering shell. Directional steering of the drill head includes a plurality of substantially radially extending channels in steering module, each with an hydraulically movable protuberance movable by control means to redirect the outer steering casing and thereby redirect the drill head section mounted on the distal end of the drill rods.

Owner:VERMEER MFG CO

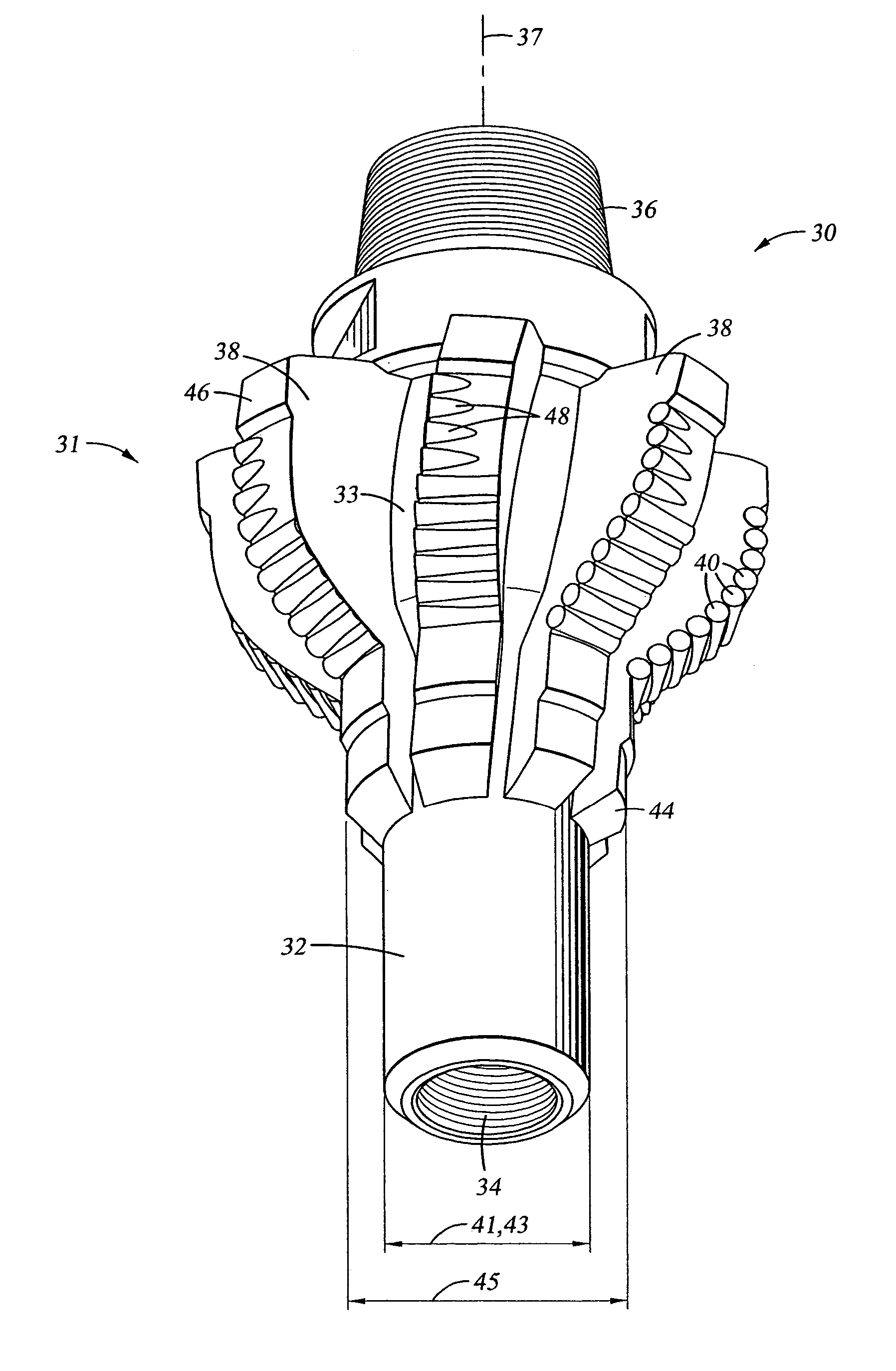

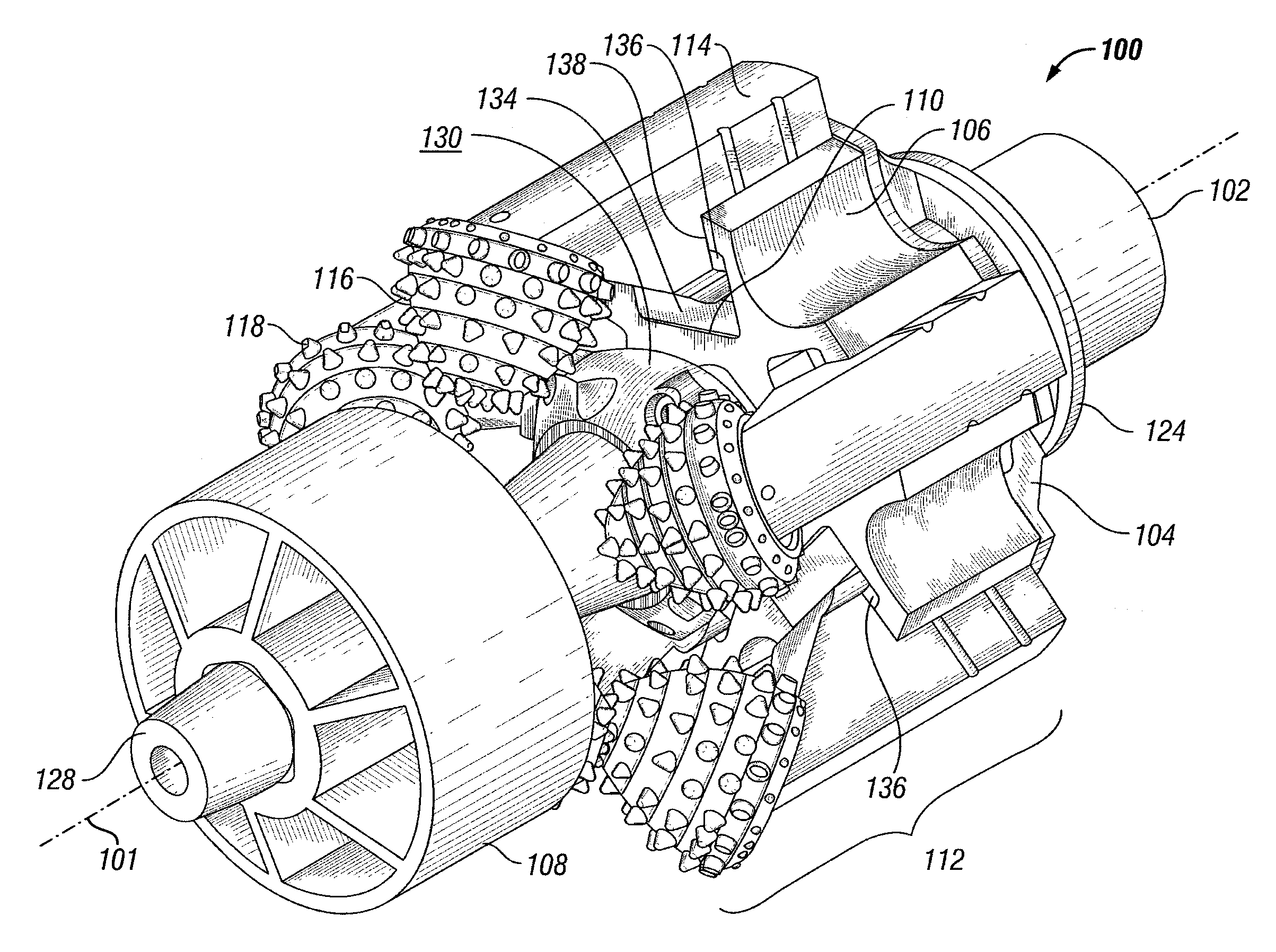

Hole reaming apparatus and method

An enhanced reaming apparatus and method are disclosed. A reaming assembly may have a motor and a pump that provide linear force, torsional force, and pressurized drilling fluid to a reamer to cause the reamer to enlarge the bore of a pilot hole. The reamer may have a body and a plurality of blade assemblies that cooperate to define two substantially symmetrical, oppositely oriented reaming sections. Each blade assembly may have an inner blade attached to the body and an outer blade extending outward from the body. Hard cutting elements may be used in place of the outer blade. The blade assemblies may be field-replaced, or the orientation of the reamer may be reversed to enhance the life of the reamer. The reamer has jets and circulation openings that release the drilling fluid into the bore to facilitate penetration and remove cuttings.

Owner:XTECH INDS INT

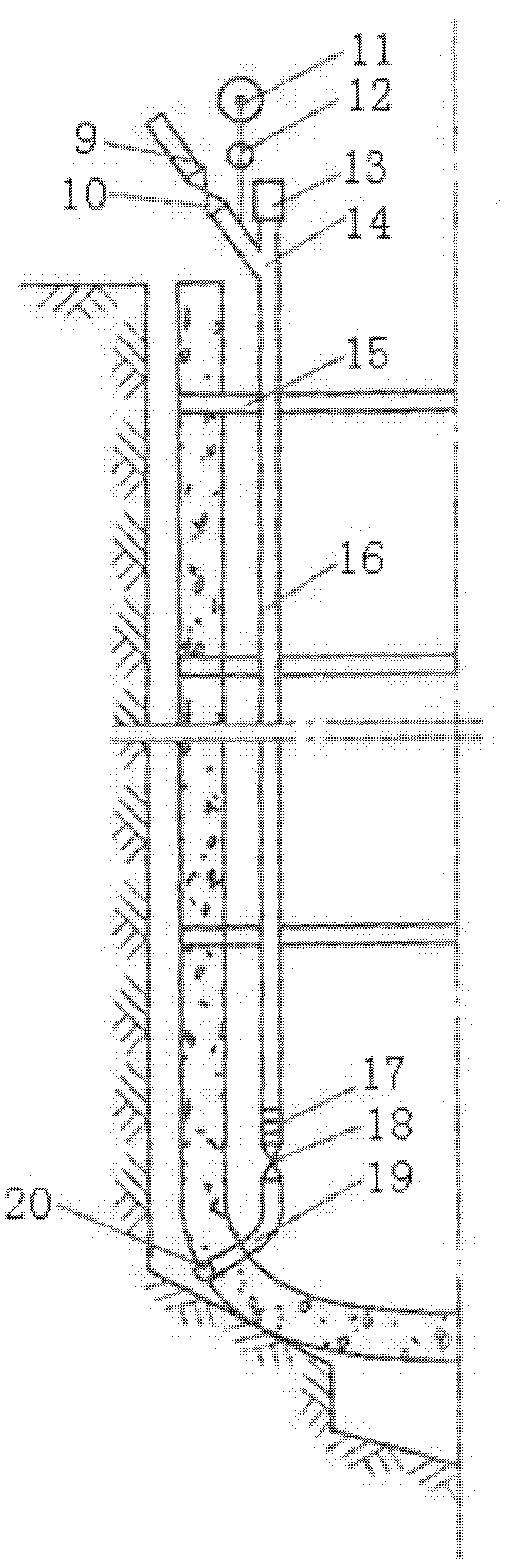

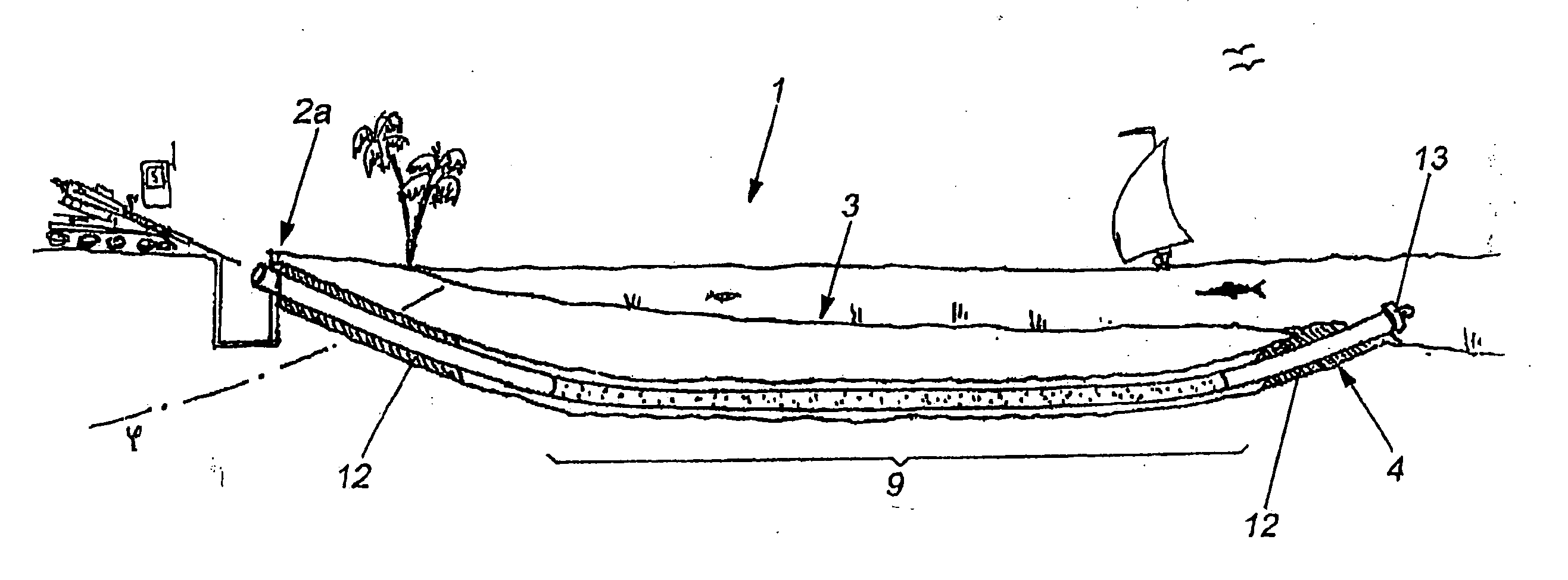

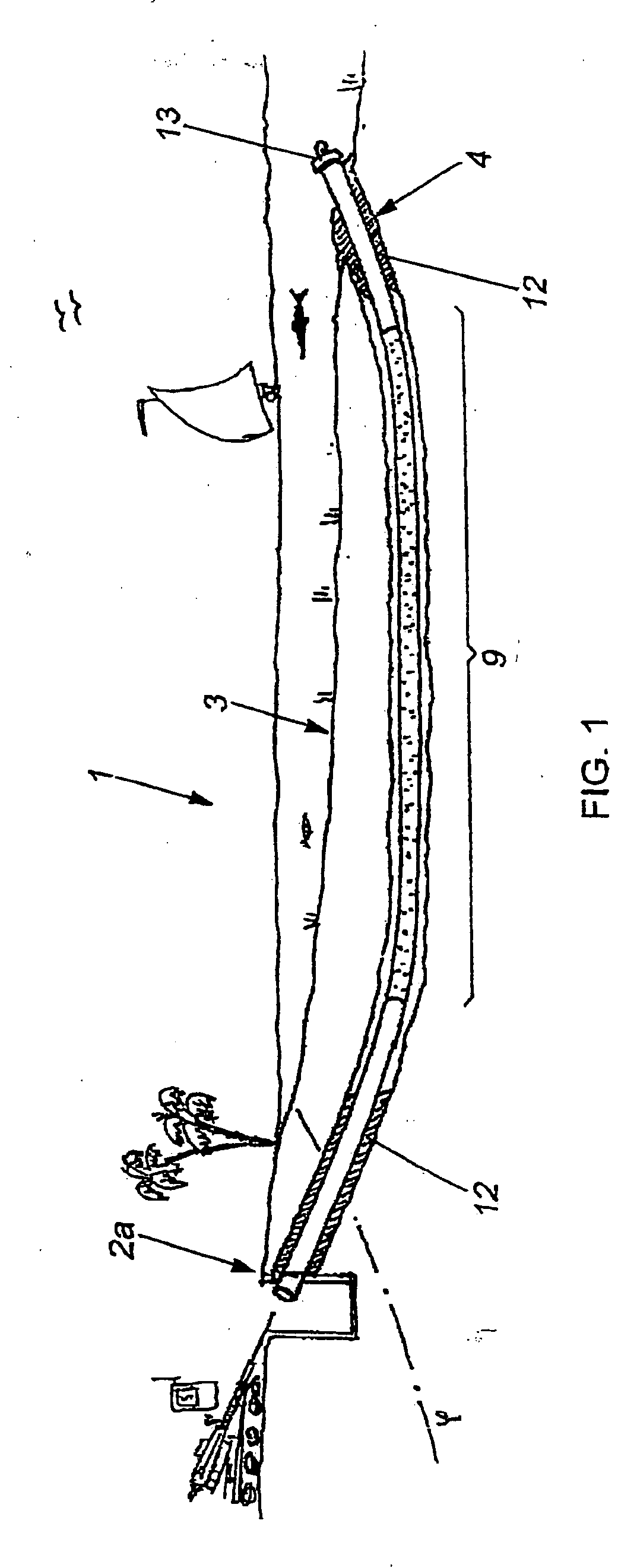

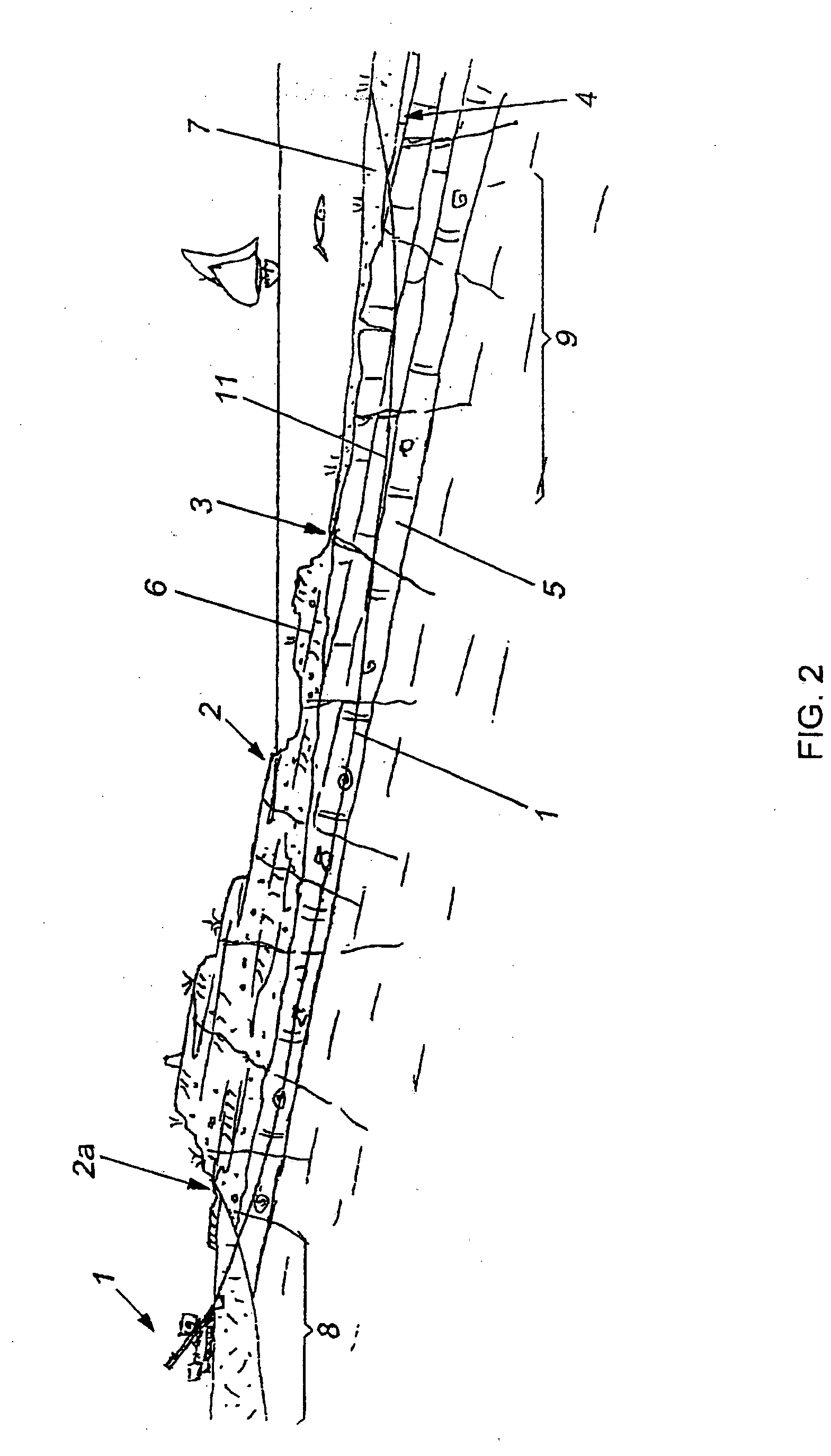

Procedure for Installing Horizontal Drains for Uptake of Sea Water

A procedure for the installation of horizontal drains for uptake of seawater of the type of those that use guided horizontal drilling (GHD) with widening by means of reamers and use of drilling muds for consolidation of the drilled galleries, and subsequent installation of drains, characterized in that the guided horizontal drilling (GHD), of single or multiple holes, is carried out from behind the coastline and directed towards the sea, crossing predetermined submerged productive strata; in the boreholes drilled, tubular drains are introduced, with grooves or holes only in stretches that correspond to predicted productive areas, remaining closed in the other sections; the space between the hole and the drain is sealed in the non-productive parts.

Owner:CATALANA DE PERFORACIONS

Device and method for trenchless replacement of underground pipe

The basic features of the invention include a pipe parting mole, a length of cable that is engagable to the mole, a cable pulling device and a cable pulling device engagement means that provides a mounting structure for the cable pulling device. The cable pulling device engagement means generally includes a reaction plate and a structure for removably engaging the cable pulling device therewithin. A cable pulling frame may be advantageously used to facilitate the removal of the cable from a relatively small hole that is created at the pulling end of the pipe.

Owner:CARTER ROBERT WARD +1

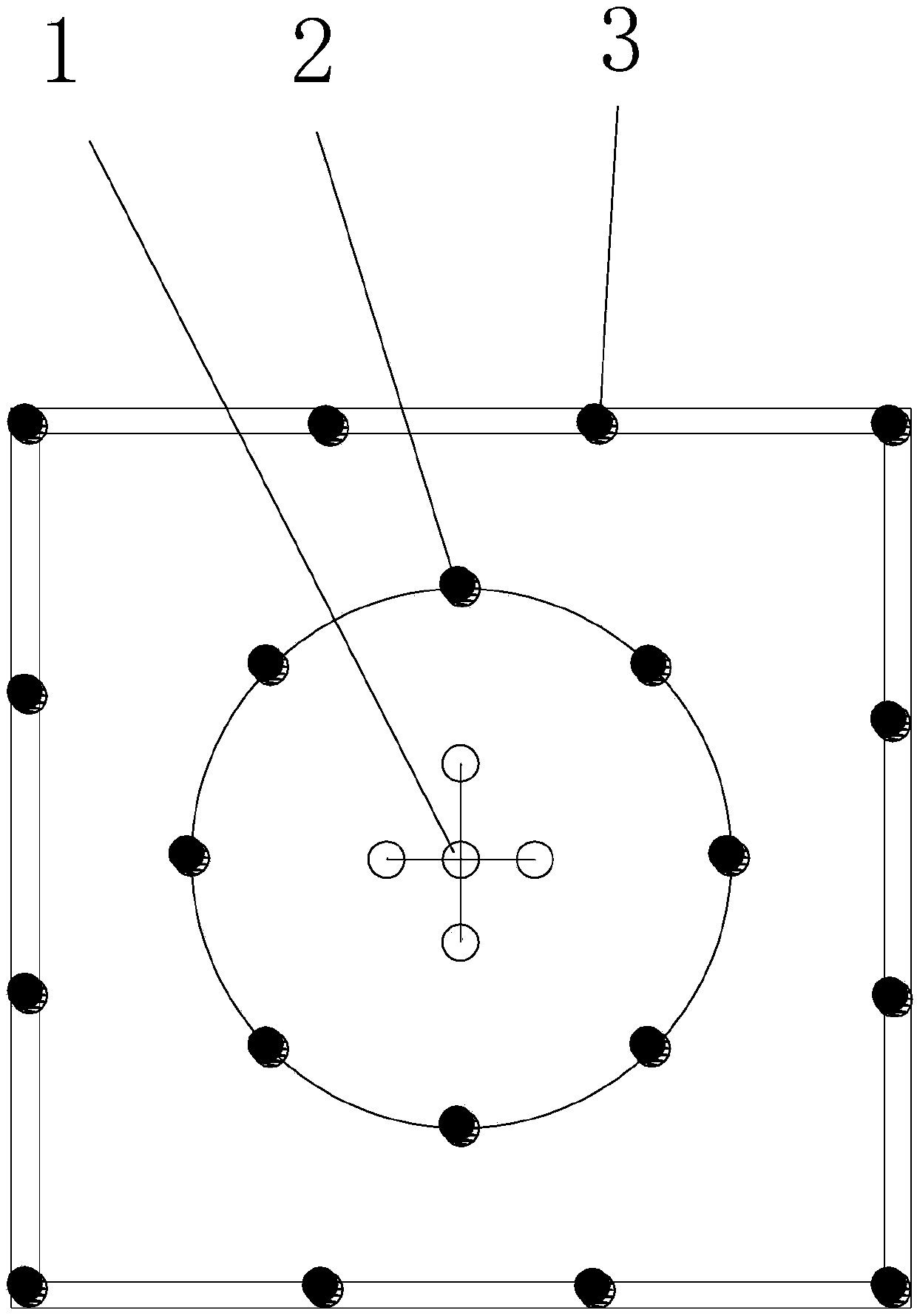

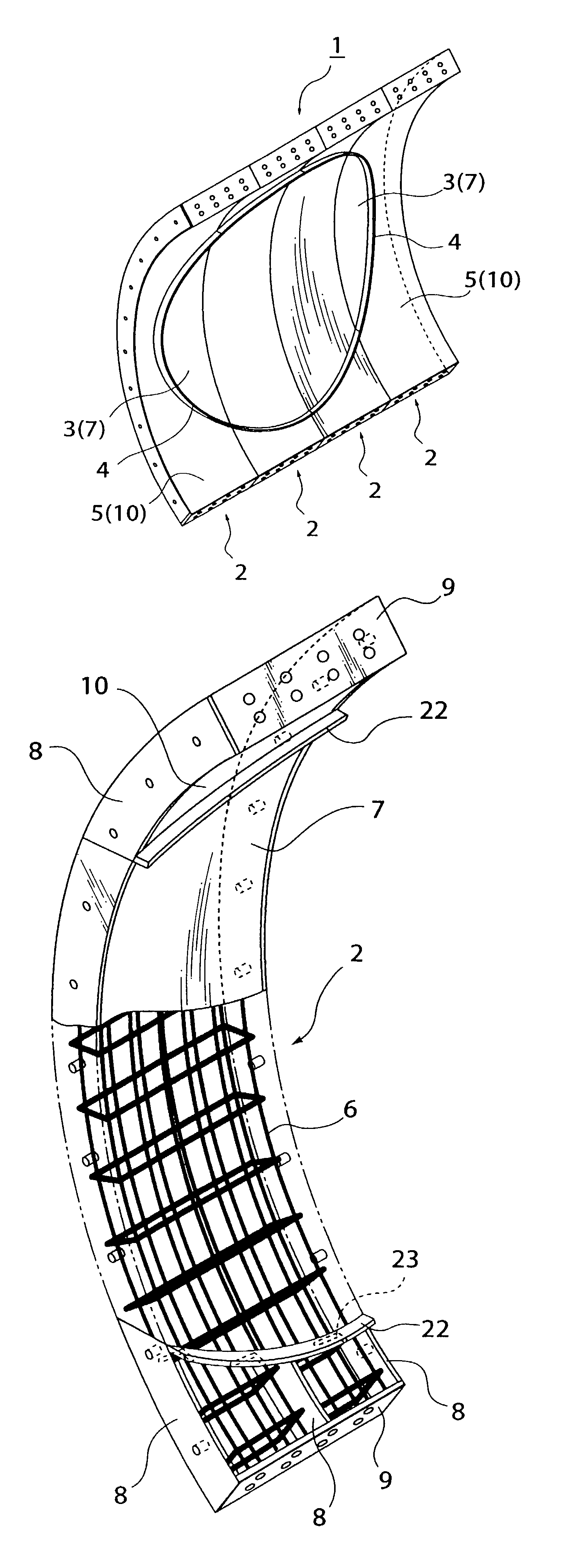

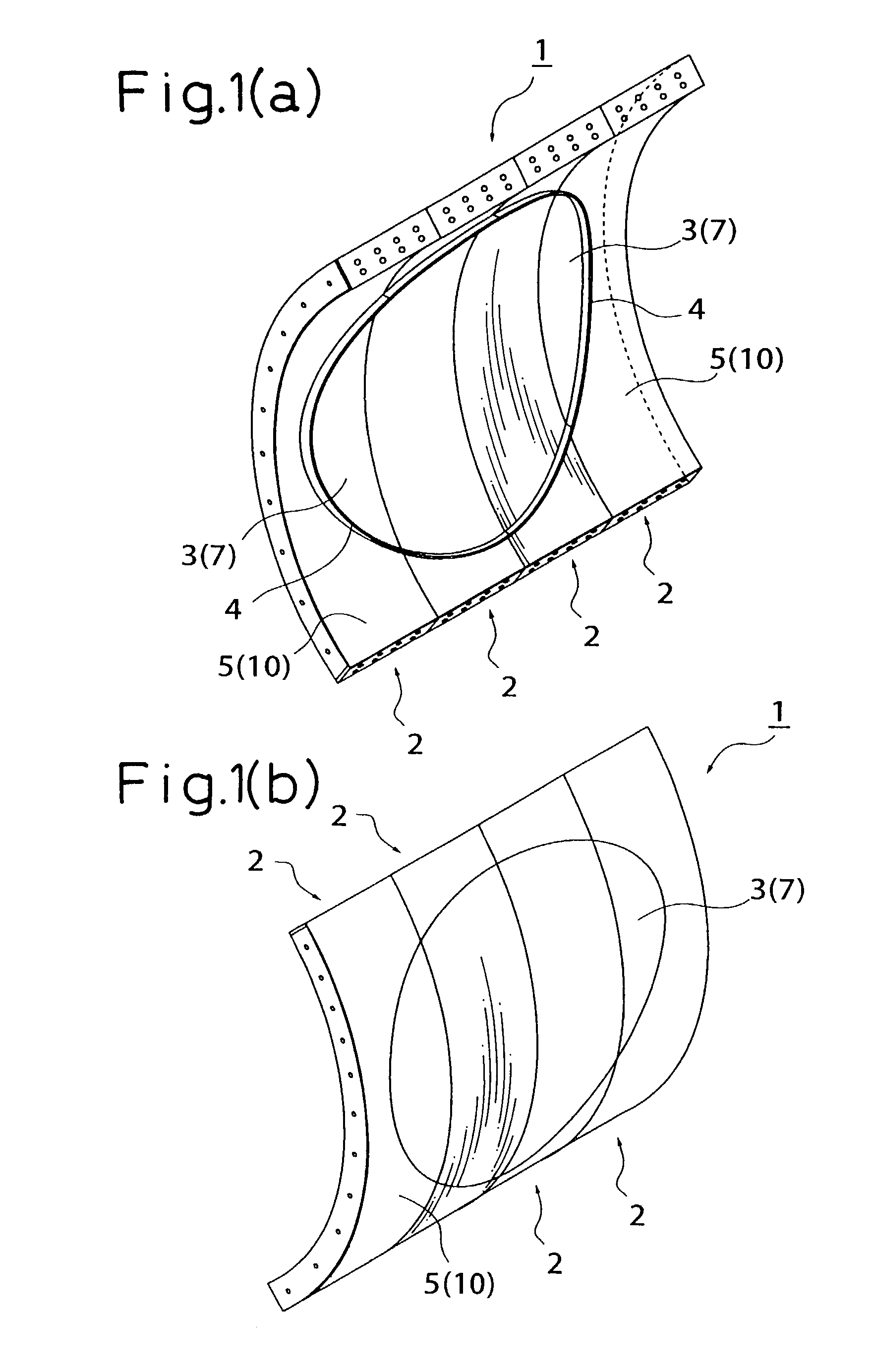

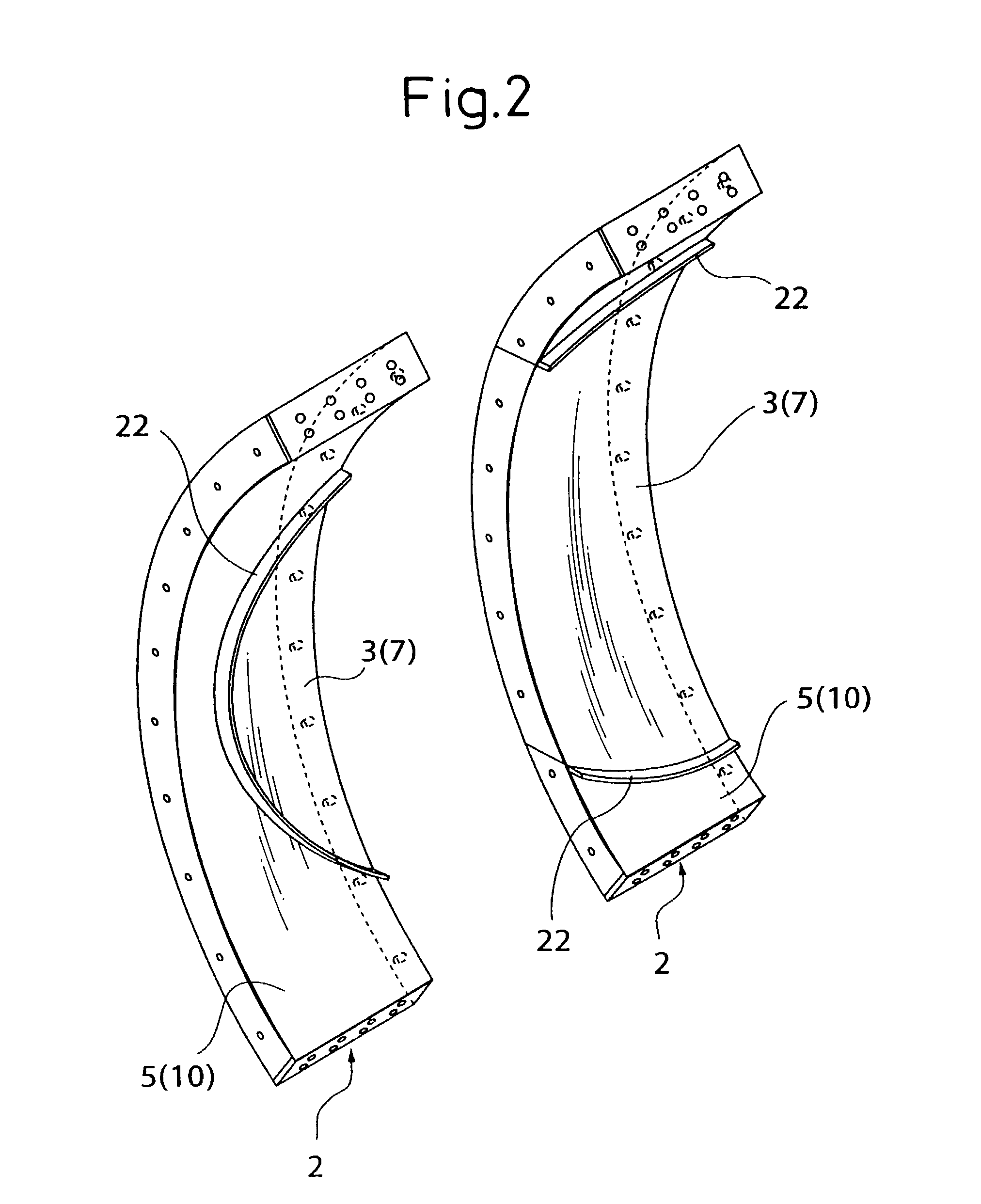

Easily-cuttable tunnel segment structure

InactiveUS7004679B2Easy to cutEasily-cuttable tunnel segment structureArtificial islandsUnderground chambersShield machineSegment structure

The present invention relates to a novel easily-cuttable tunnel segment structure used for the departure of a shield machine from a main tunnel to a branch tunnel or the return to the main tunnel from the branch tunnel, and provides an easily-cuttable tunnel segment structure 1 constructed by connecting a plurality of easily-cuttable tunnel segment pieces 2 in the longitudinal direction of a tunnel, wherein at least an easily-cuttable area 3 is formed by concrete 7 in which easily-cuttable reinforcement members are arranged, and a join disposed at least in the easily-cuttable area 3 in the longitudinal direction has an easily-cuttable join structure.

Owner:NIPPON STEEL CORP +2

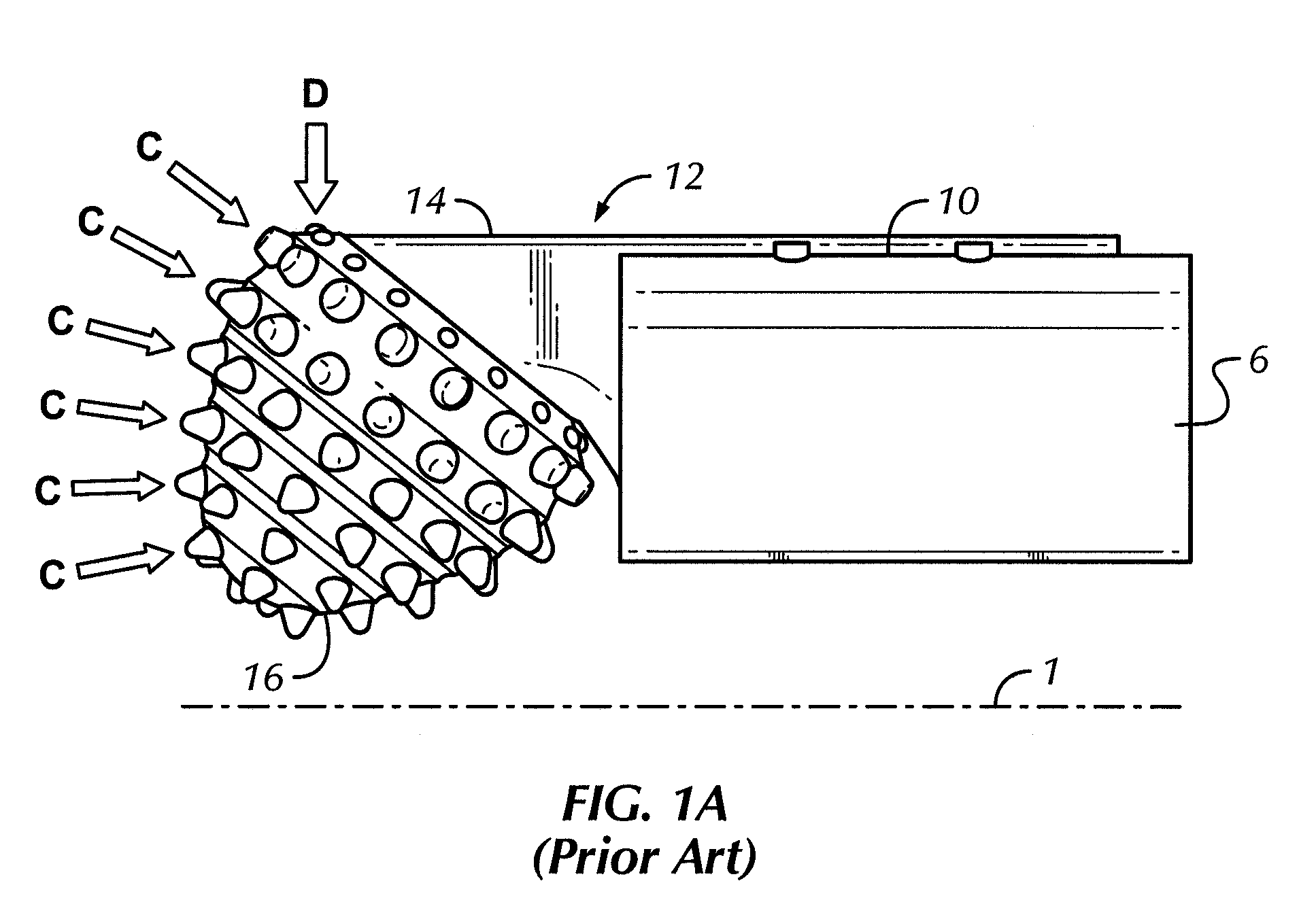

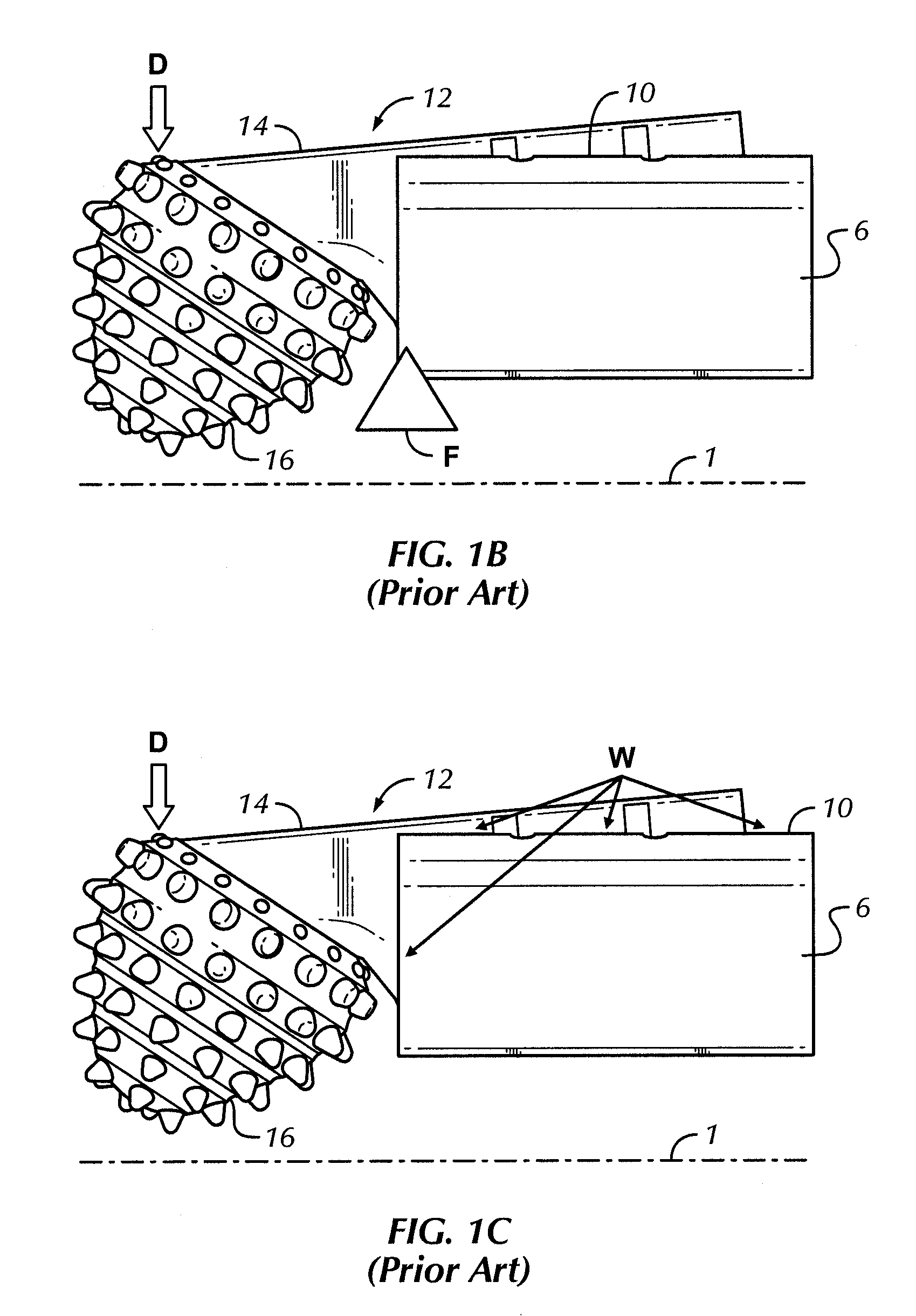

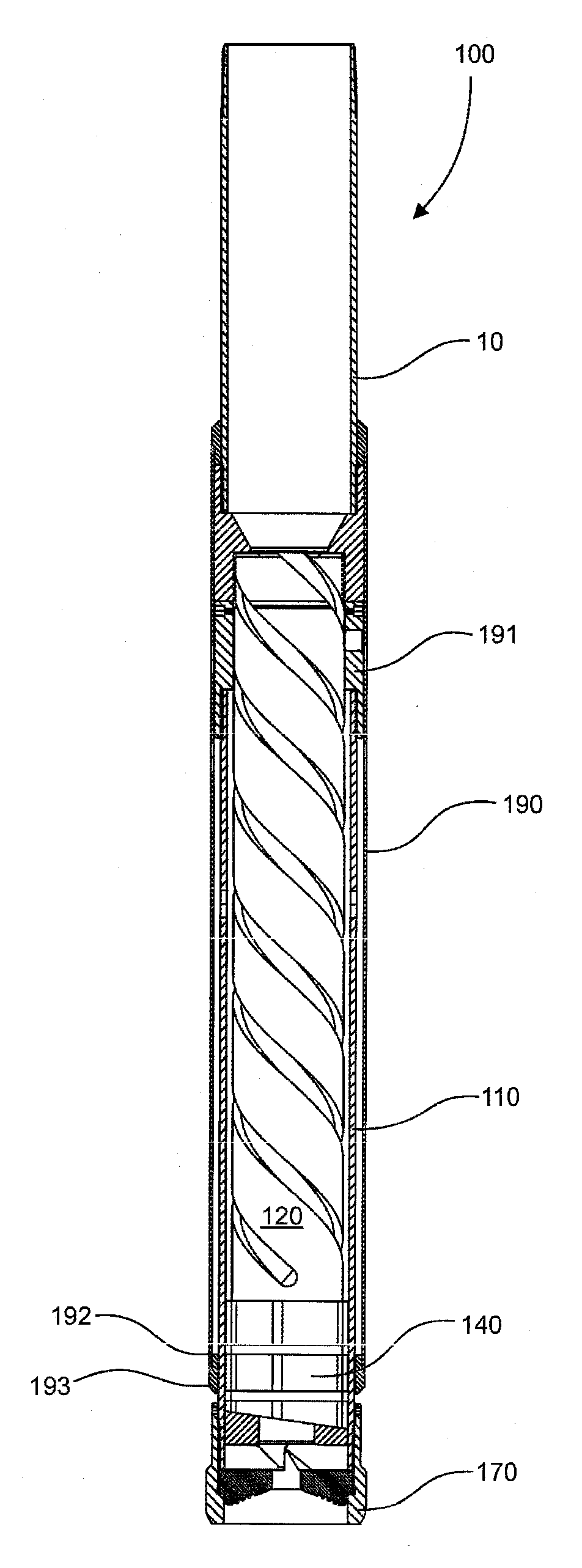

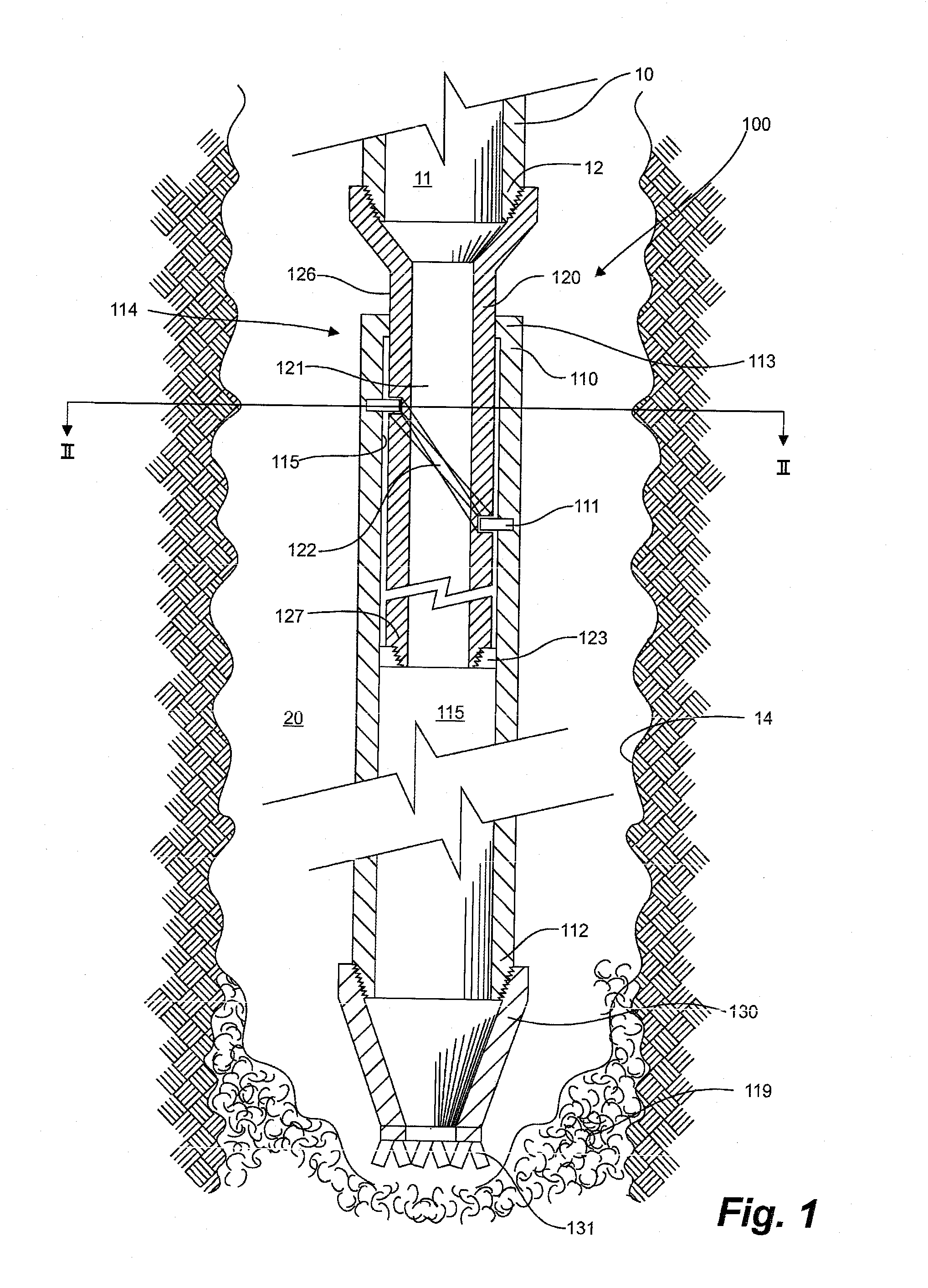

Apparatus and Method for Reaming a Wellbore During the Installation of a Tubular String

An apparatus for reaming a wellbore without rotating a tubular string that is extendable to a surface. A mandrel (102) is coupled to a downhole end of the tubular string. The mandrel (102) has at least one groove (110) in a sidewall portion thereof. A sleeve (112) is operably associated with the mandrel (102) such that longitudinal travel of the mandrel (102) relative to the sleeve (112) shifts the sleeve (112) between extended and contracted positions relative to the mandrel (102). A reamer shoe (122) is coupled to a downhole end of the sleeve (112). At least one coupling device (116) is operably associated with the sleeve (112) and extendable into the at least one groove (110) such that longitudinal travel of the mandrel (102) relative to the sleeve (112) caused the sleeve (112) to rotate relative to the mandrel (102), thereby rotating the reamer shoe (122).

Owner:HALLIBURTON ENERGY SERVICES INC

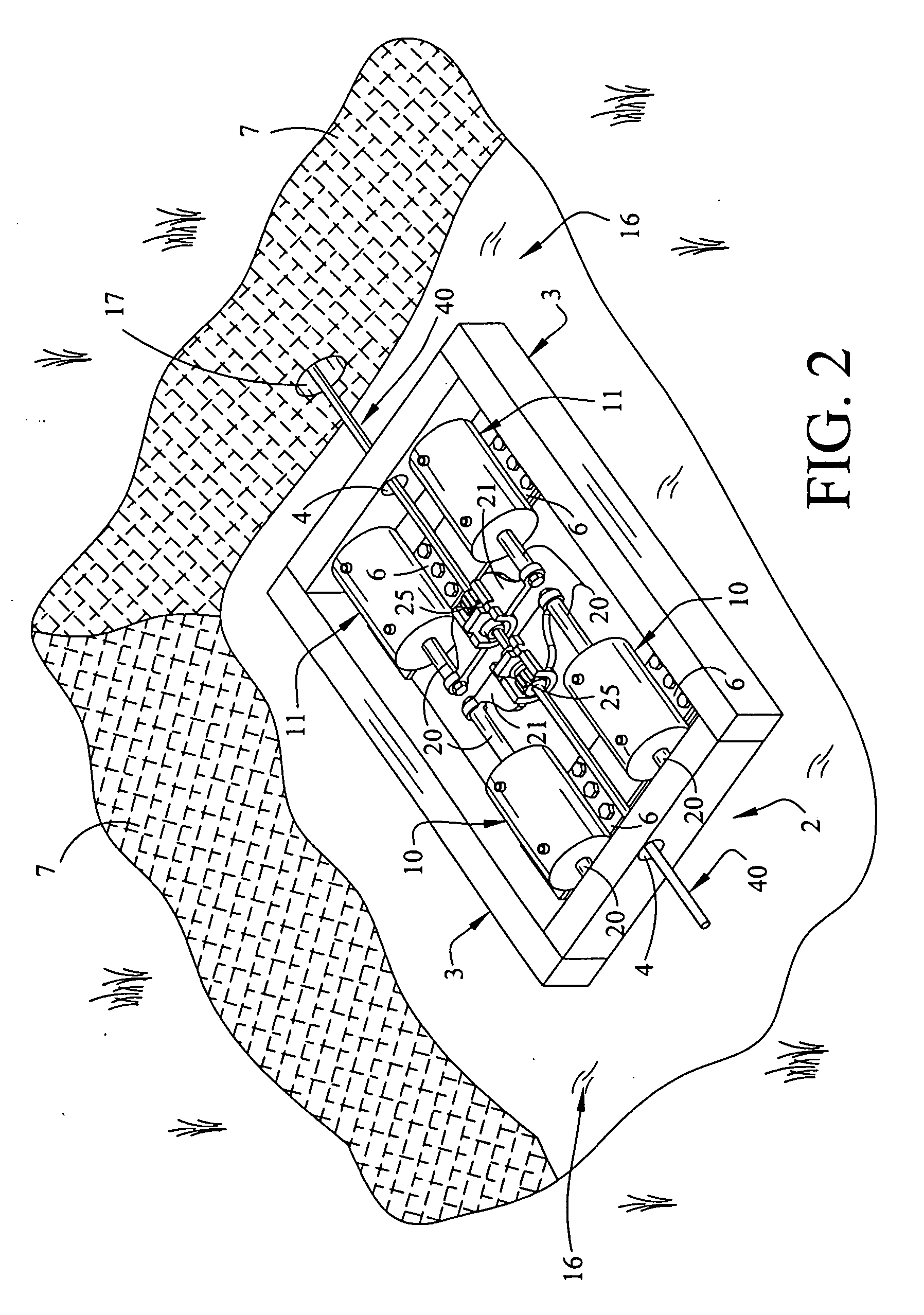

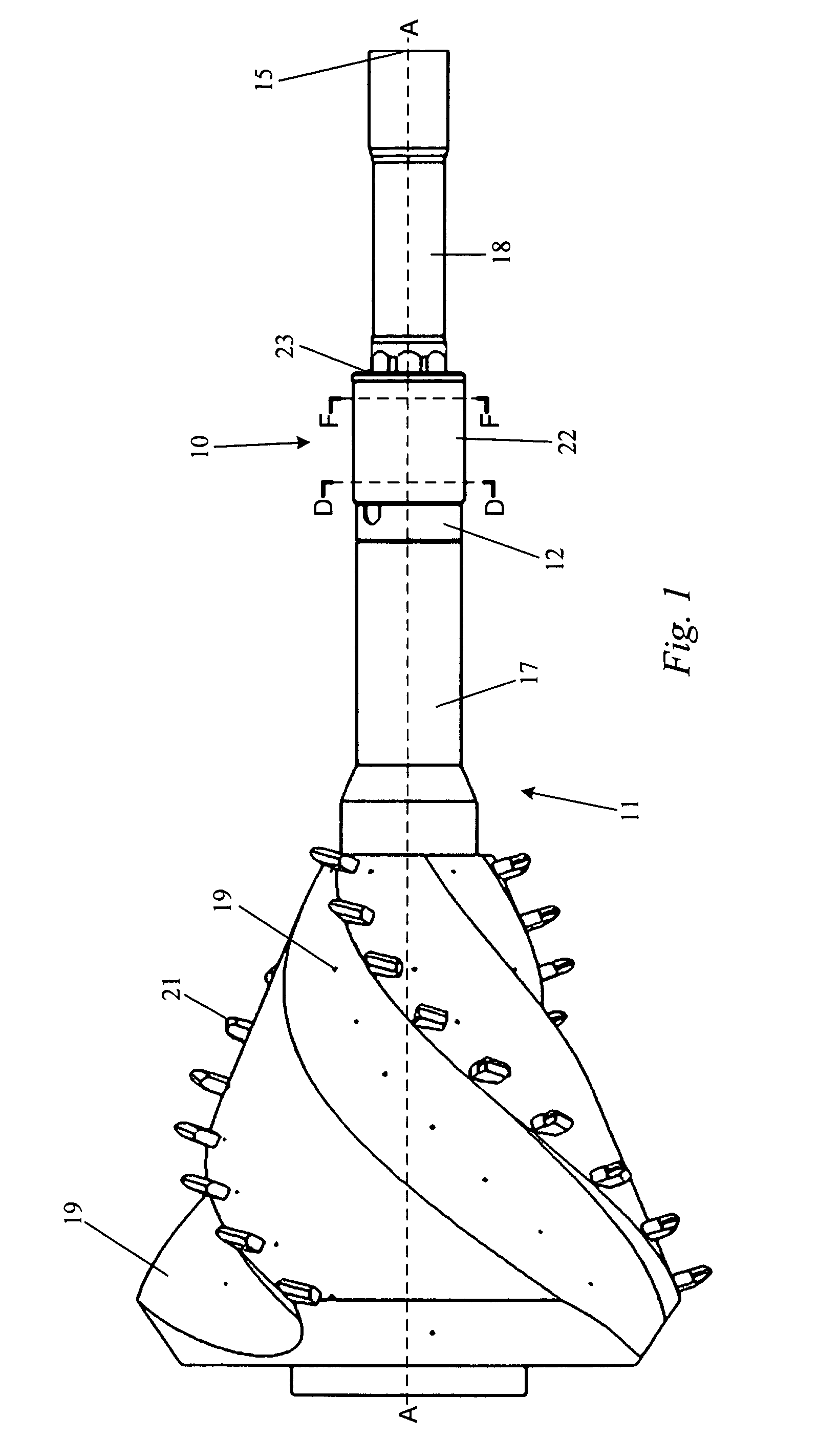

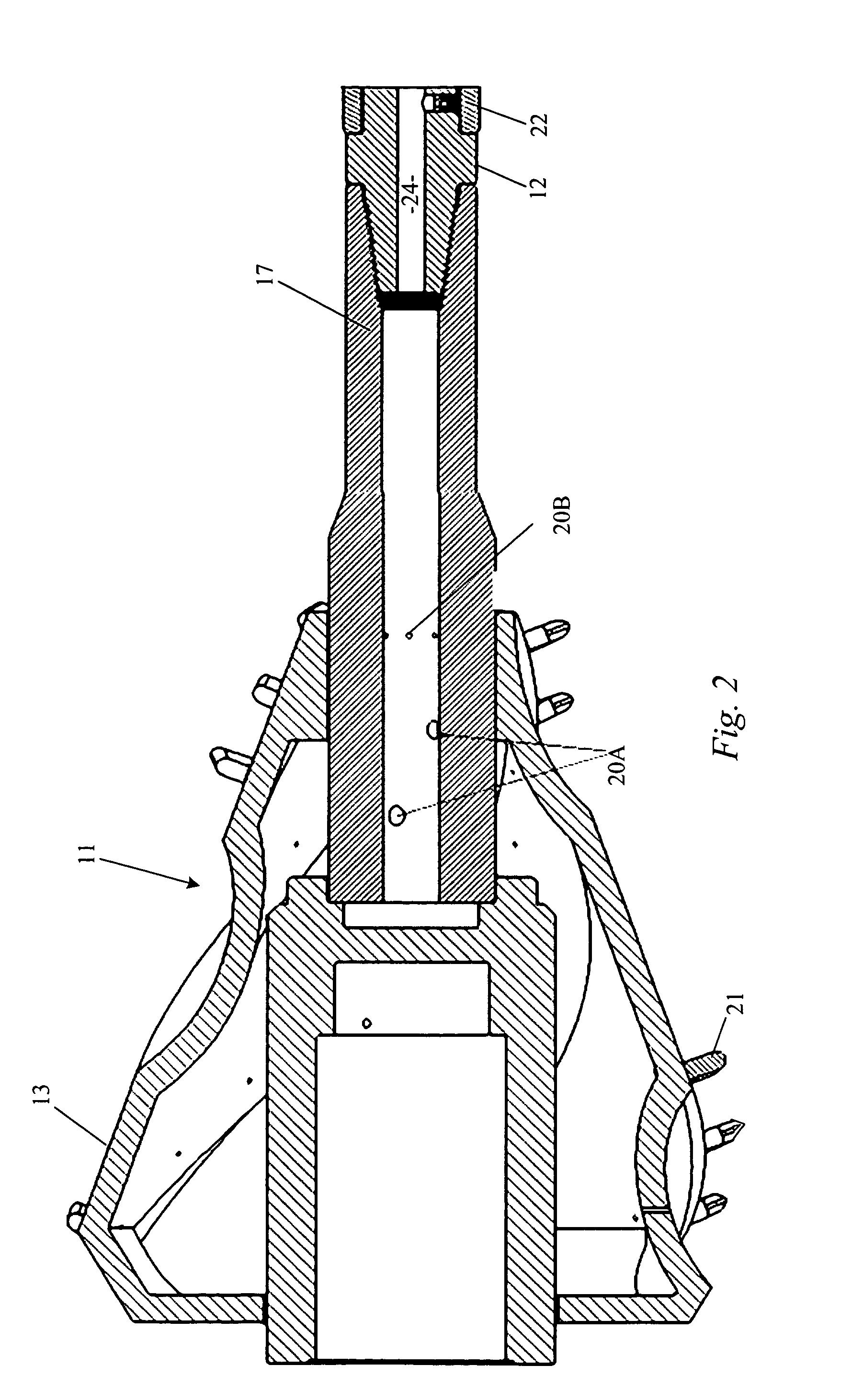

Sectional back reamer apparatus and method for horizontal directional drilling

ActiveUS8365841B2Easy and fast assemblySmall sizeArtificial islandsPipe laying and repairCouplingEngineering

An improved back reamer for horizontal directional drilling is provided with multiple components which can be assembled and disassembled before and after the back reaming process. The reamer includes a main shaft connectable to the drill string, a reamer head removably mounted on the main shaft, and a pull tab removably attached to the main shaft. Faceted couplings between the reamer shaft and head, and between the reamer head and pull tab preclude rotation between the components.

Owner:DIMITROFF TED R

Joint for use in back reaming

A joint according to the invention for connecting a pair of members rotatable about a common axis end to end. A sleeve has a non circular profile on an inner surface thereof whereby the sleeve can be slidably mounted on non circular exterior surfaces of the first and second members when such surfaces are brought into alignment by rotation of one member relative to the other in a manner effective to pass torque from one member to the other by means of the non circular surfaces. A fluid release passage includes a radial port that extends from the first longitudinal fluid supply passage to a clearance between the sleeve and the first member, which clearance communicates with a second clearance between the sleeve and the second member, which second clearance has a discharge opening.

Owner:CHARLES MACHINE WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com