Excavation deviation processing method of raise-boring machine for deep vertical shaft

A raise drilling rig and processing method technology, applied in vertical well equipment, well sinking, earthwork drilling and other directions, can solve the problems of reducing slagging capacity, delaying construction period, failing to produce slag, etc., and achieve shortening construction period, strengthening strength, Reduces the effect of repeated drilling of pilot holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the contents of the present invention And adjustments also belong to the protection scope of the present invention.

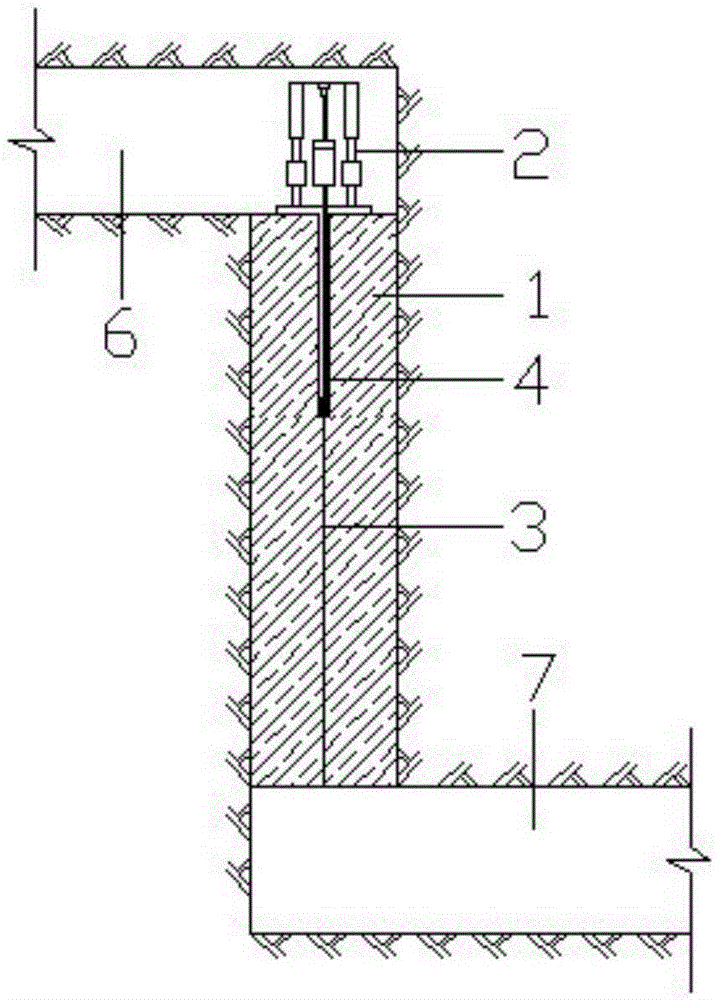

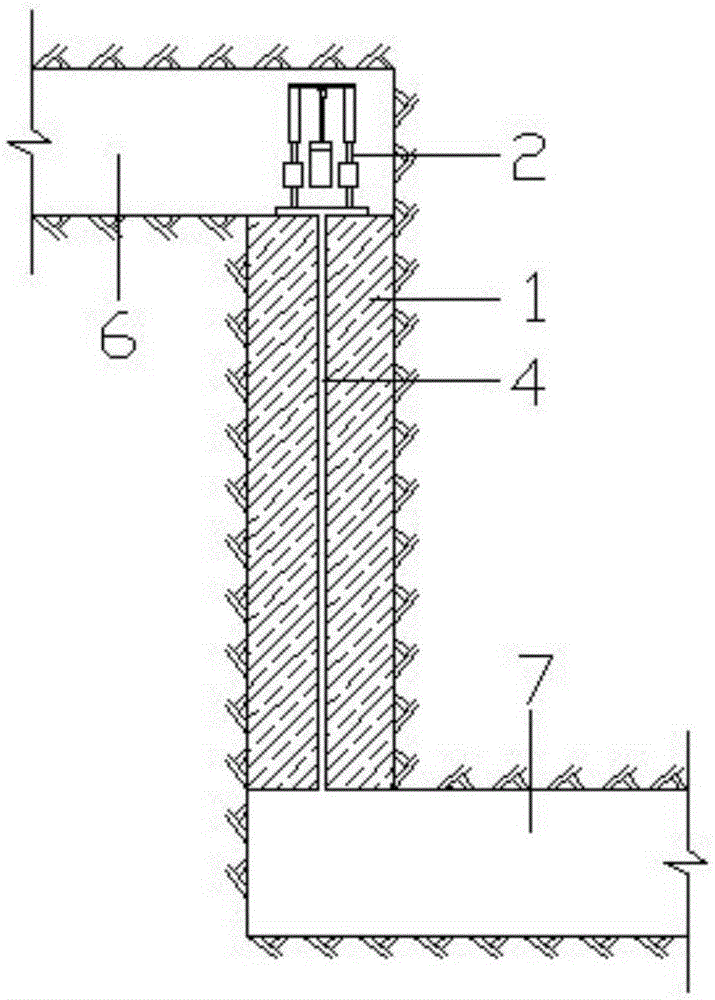

[0027] combine Figure 1 to Figure 16 .

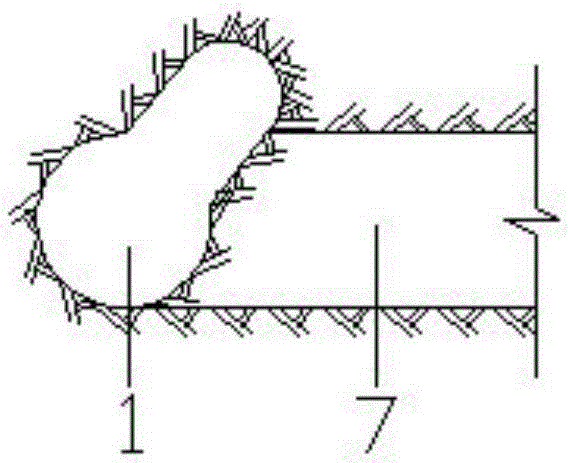

[0028] The process of excavating a vertical shaft using a raise drilling rig: when the upper level hole 6 and the lower level hole 7 are excavated during the excavation of the vertical shaft 1, use the raise drilling rig 2 to excavate from the top of the vertical shaft 1 in the upper level hole 6 The center line 3 drills the pilot hole 4 from top to bottom, and the position of the drill bit can be calculated according to the inclination angle of the drill pipe, the length of the drill pipe, and the depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com