Basement outer wall single-side steel formwork supporting system and construction method thereof

A basement external wall and support system technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, and the processing of building materials, etc., which can solve the problem of high labor intensity for construction personnel and work efficiency Low-level problems, to achieve the effect of high turnover times, easy control of verticality, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

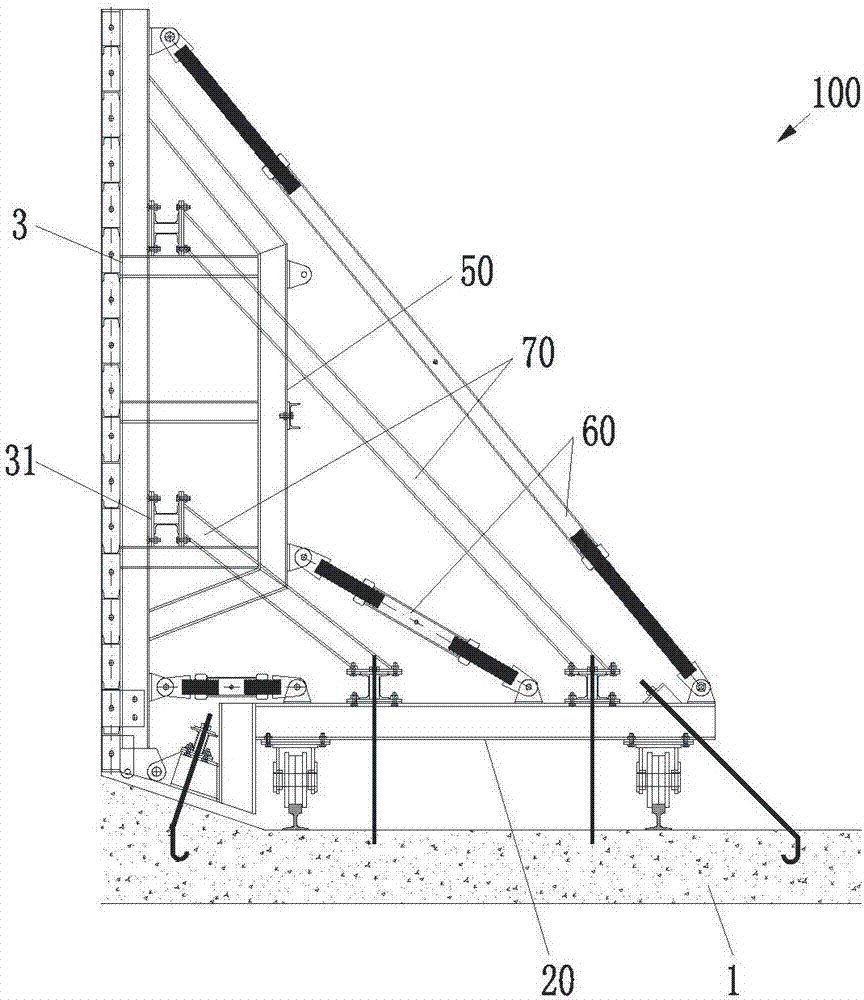

[0028] Embodiment 1: In this embodiment, the construction of an underground project is taken as an example. The steel formwork 3 for the exterior wall of the basement is spliced by a plurality of standard plates with a specification of 2000mm (length) × 4200mm (height). The horizontal back ribs, vertical back ribs constitute the skeleton and the panel connected with the frame bolts. The panel is a cold-rolled steel plate with a thickness of 5mm. The size of the panel needs to be adjusted according to the actual situation of the basement exterior wall 2. The ribs are all made of channel steel, the distance between two adjacent horizontal back ribs is 250mm, the distance between two adjacent vertical back ribs is 2m, and the two adjacent standard plate bolts are connected as a whole.

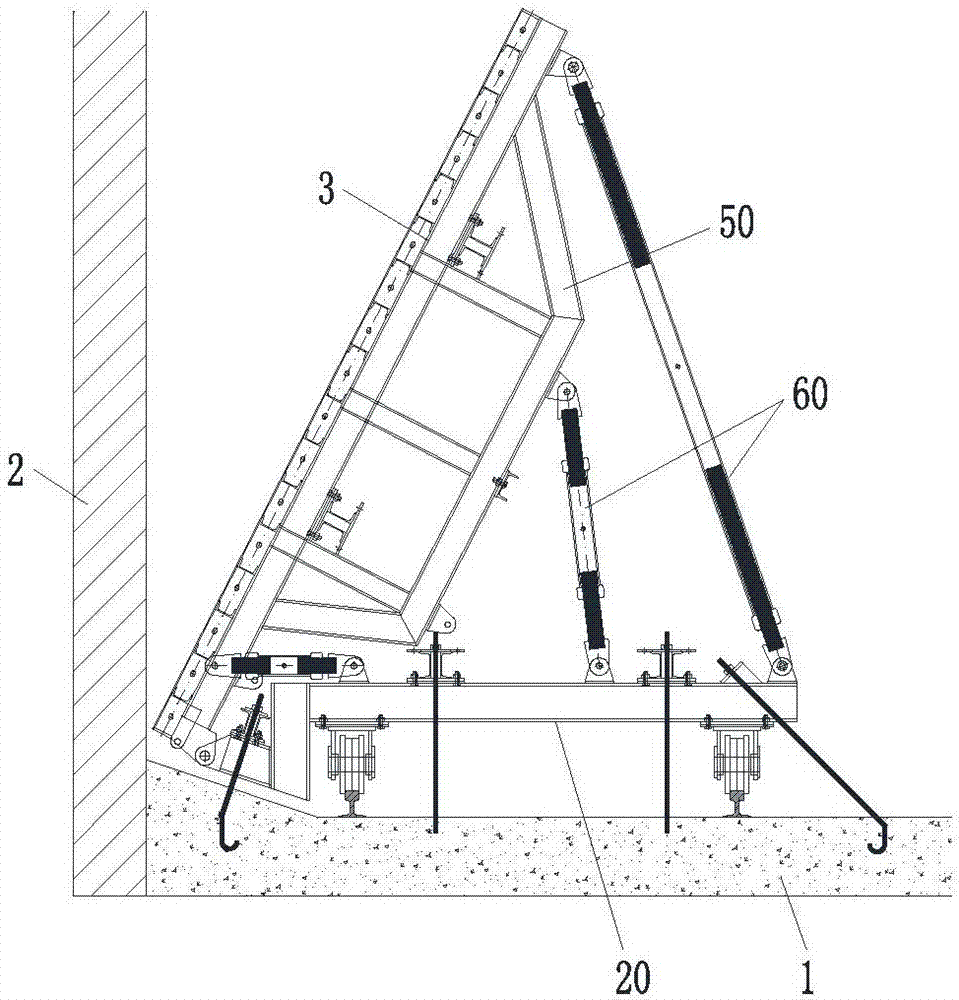

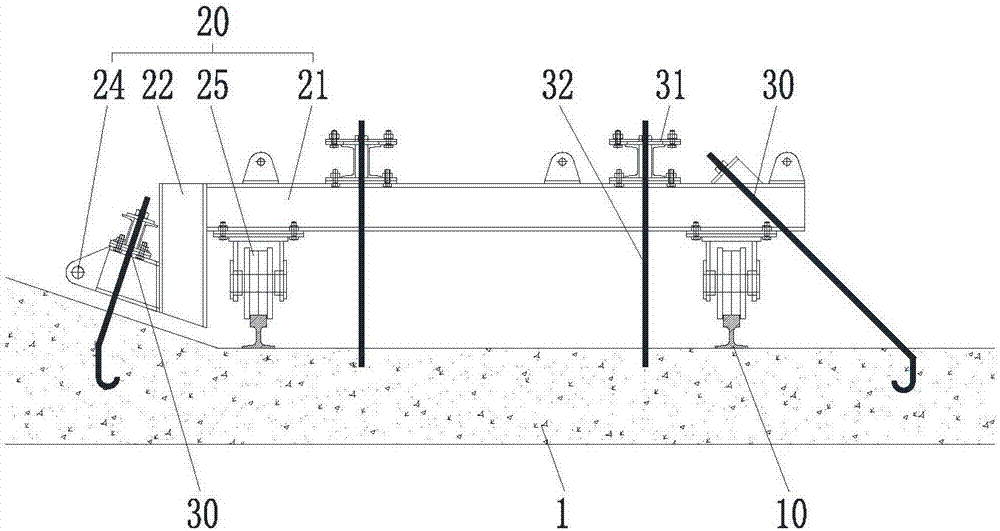

[0029] Combine below Figure 1 to Figure 6 Illustrate the single-side steel formwork support system for the basement exterior wall of the present invention, which includes a pair of rails 10 lai...

Embodiment 2

[0038] Embodiment 2: Combination Figure 1 to Figure 5 Illustrate the construction method of the basement exterior wall unilateral steel formwork support system of the present invention, concrete steps are as follows:

[0039] S1: Bind the steel bars of the exterior wall of the basement and check and accept it. A pair of rails 10 are pre-embedded on the foundation floor 1. The head bolts assemble and connect the exterior wall steel formwork 3 and the support truss 50 into a whole and hoist them to the construction site. After the installation base 20 and the support truss 50 are in place, connect the adjustment rod 60 between the base 20 and the support truss 50 and the diagonal brace 70, install the ground anchor assembly 30 to firmly fix the base 20 on the foundation floor 1, and when the ground anchor assembly 30 is pre-embedded, it is necessary to pull the wire through to ensure that the ground anchor assembly 30 on the same side is on the same straight line, ensuring that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com