A method for installing the cutter beam long axis hole cutter bracket of cutter suction dredger

The technology of a cutter suction dredger and its installation method is applied in the direction of mechanically driven excavators/dredgers, etc., which can solve the problems of long production cycle, difficulty in meeting high efficiency requirements, and low efficiency, so as to reduce processing difficulty, The effect of reducing work complexity and coordination difficulty and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for installing a cutter beam long axis hole cutter support of a cutter suction dredger, comprising the following steps:

[0016] A. Mark the twist point seat, and draw the horizontal centerline, longitudinal centerline and horizontal positioning line respectively;

[0017] B. Carry out lines on the general section of the hull, draw horizontal lines, rib position lines and transverse positioning lines respectively;

[0018] C. Hoist the hinge point seat, hoist the hinge point seat on the general section of the hull for positioning, and align with the horizontal line, rib position line and transverse positioning line respectively;

[0019] D. Weld the twist point seat to the general section of the hull;

[0020] E. After installing the twist point seat on the hull, install the twist shaft and the twist cover.

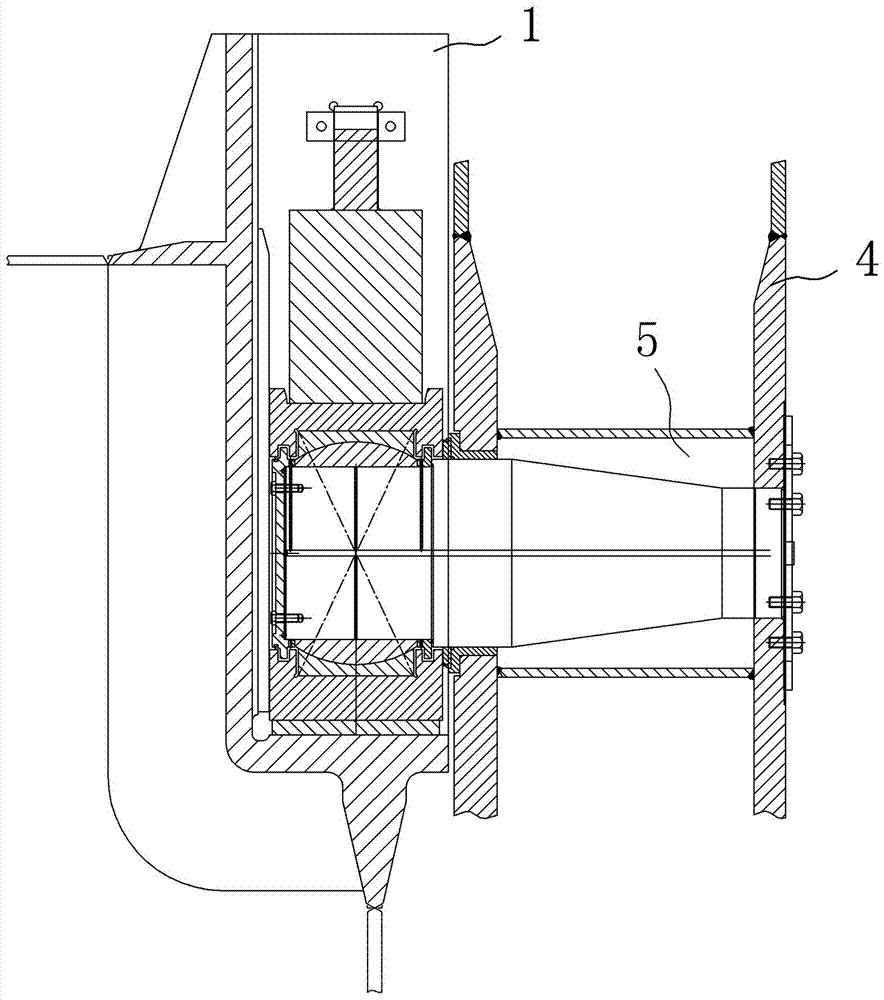

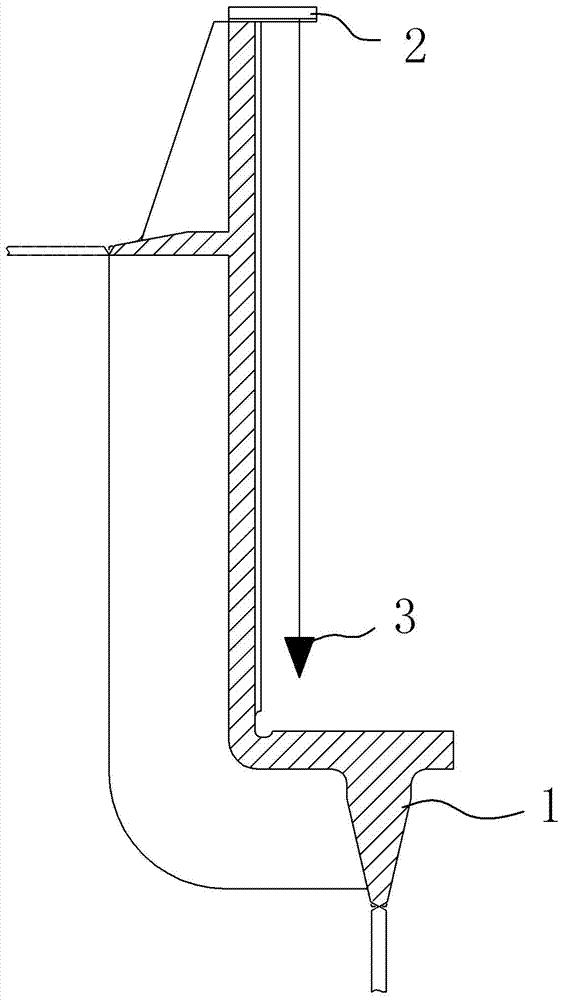

[0021] Such as figure 1 As shown, there is a long axis hole 5 on the reamer beam 4, and the reaming point seat 1 is installed at the long axis hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com