A curtain motor end tamper-resistant structure

A technology of anti-dismantlement and curtains, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of destroying the working accuracy and safety of motors, disassembly damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

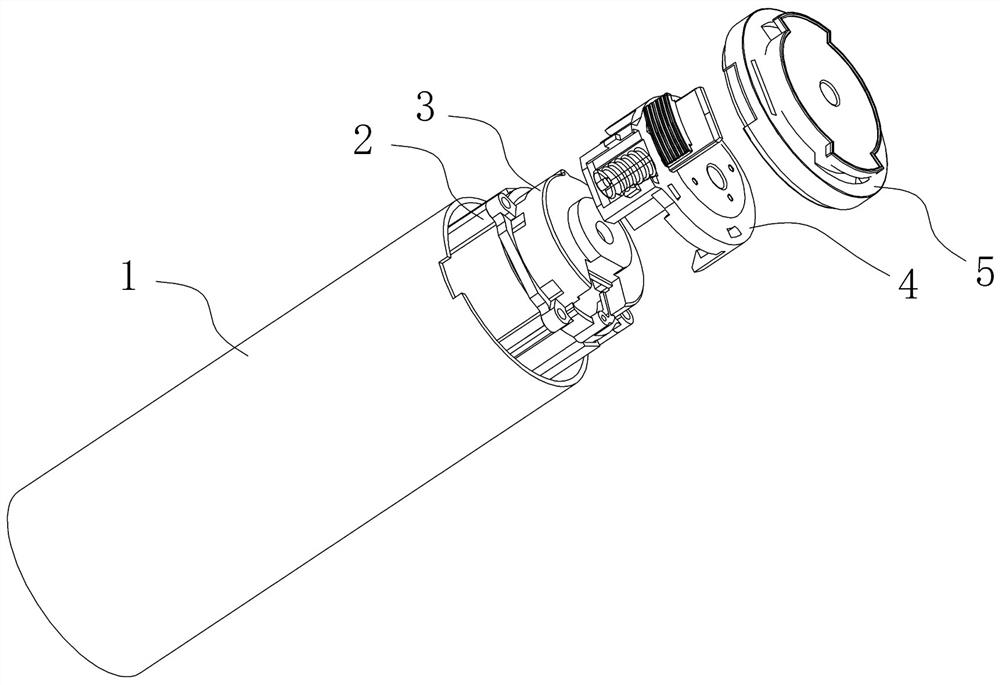

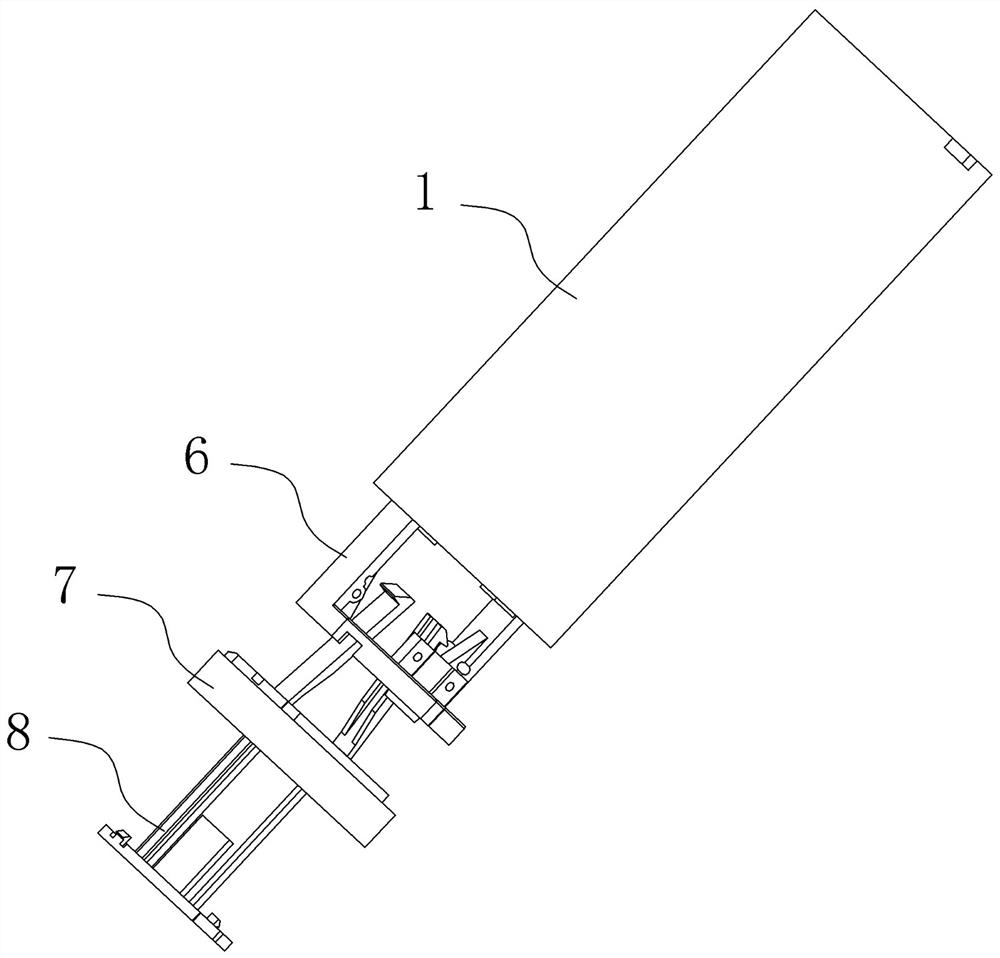

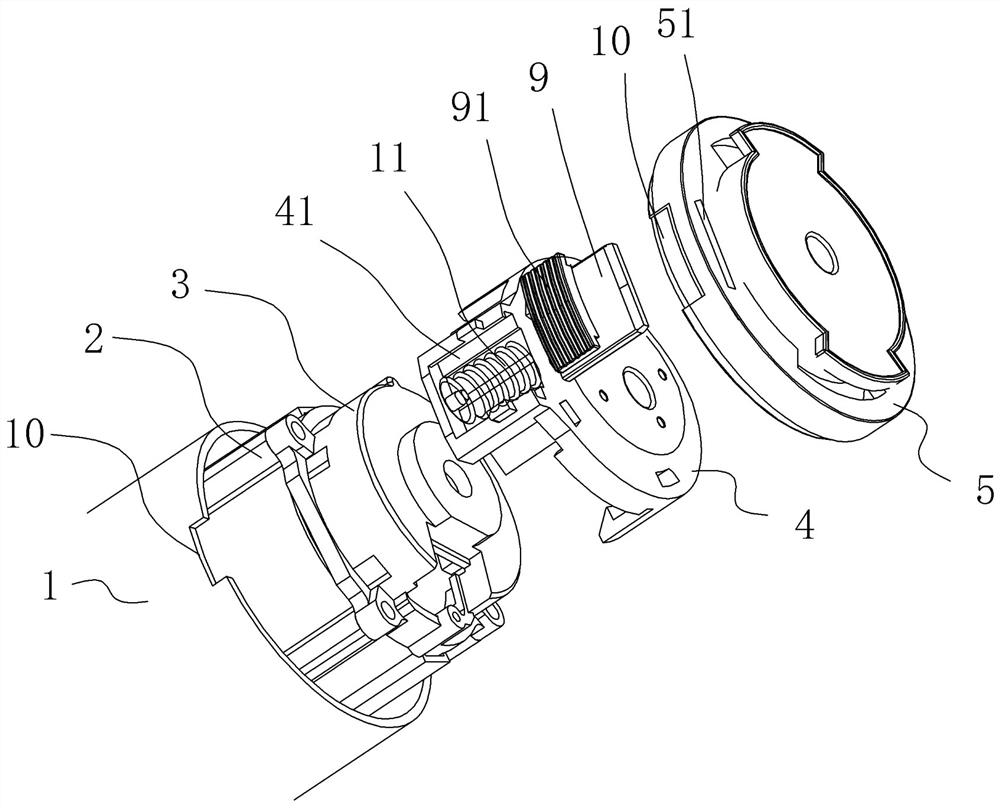

[0012] An anti-disassembly structure for a curtain motor, comprising a base 2 arranged in a housing 1, a driving motor 3 fixedly installed in the base, and an end of the housing opposite to the rotating shaft of the driving motor is provided on the outside of the driving motor and connected to the base. The adapter buckle 4, the front end cover 5 is installed on the outside of the adapter buckle; the end of the machine base facing away from the front end cover is provided with a mounting seat 6, the mounting seat is provided with a block 61, and the outward end of the mounting seat is provided with an internal connection. The seat groove 62 is also equipped with a rear end cover 7, and the rear end cover is provided with a draw-in groove 71 opposite to the seat groove, and the rear end cover is positioned at the side of the draw-in groove to pass through the seat groove and extend to the block. Card bar 72, the end of card bar is provided with the hook 73 that engages and fixes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com