A construction technique for closing the superstructure of a ship without allowance

A technology of superstructure and construction technology, which is applied in the direction of ship construction, ship parts, ships, etc. It can solve the problems that other work cannot be carried out smoothly, affect the quality of ship construction, and consume a lot of working time, so as to reduce the difficulty of operation, protect the structure, The effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Such as Figure 1-5 shown.

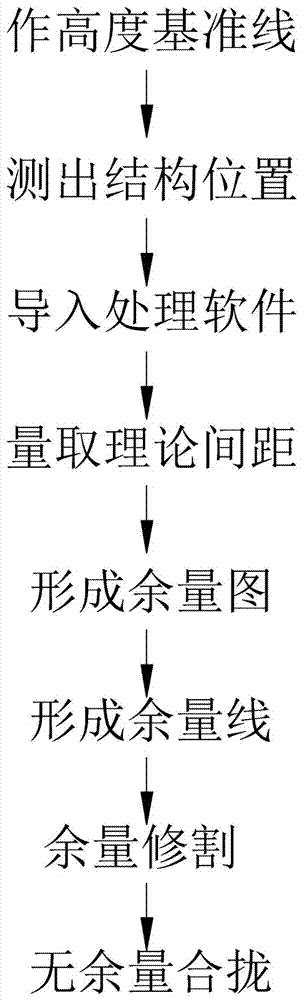

[0017] A construction technique for closing a ship superstructure without allowance, comprising the following steps:

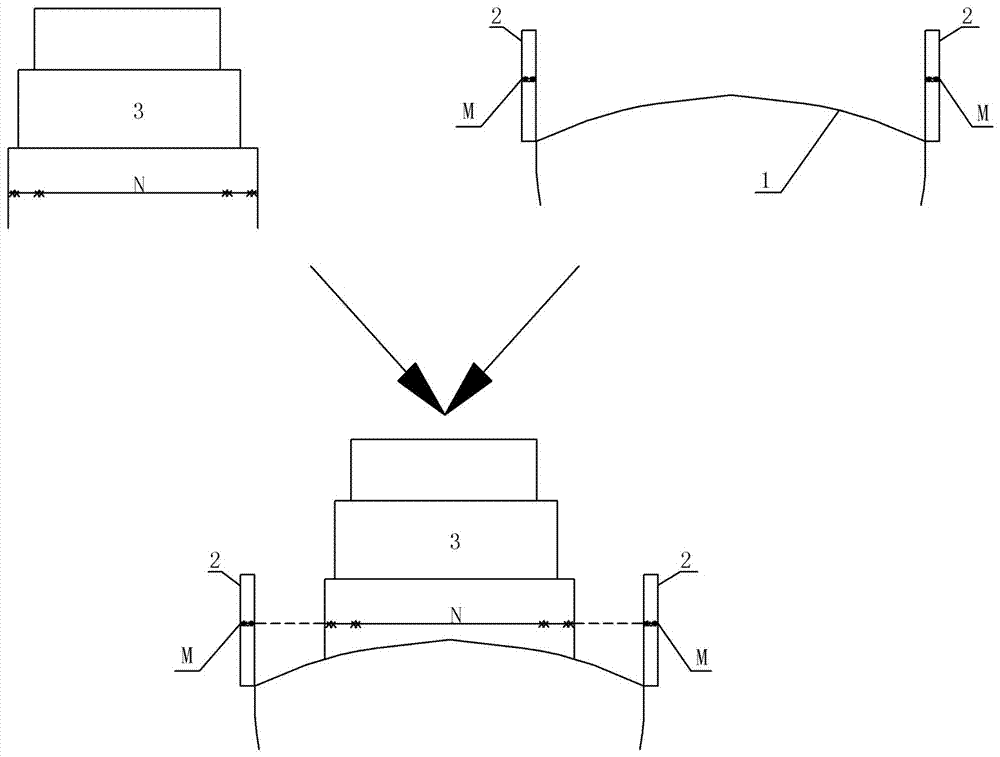

[0018] A. Make a height reference line, including erecting a mark post 2 marked with a height M on the main hull 1, and at the same time, draw a height line N on the general section 3 of the superstructure, and the height of the height line N is consistent with the height M marked on the mark post ;Such as figure 1 shown;

[0019] B. Measure the position of the structure docked with the superstructure general section on the main hull; if figure 2 shown;

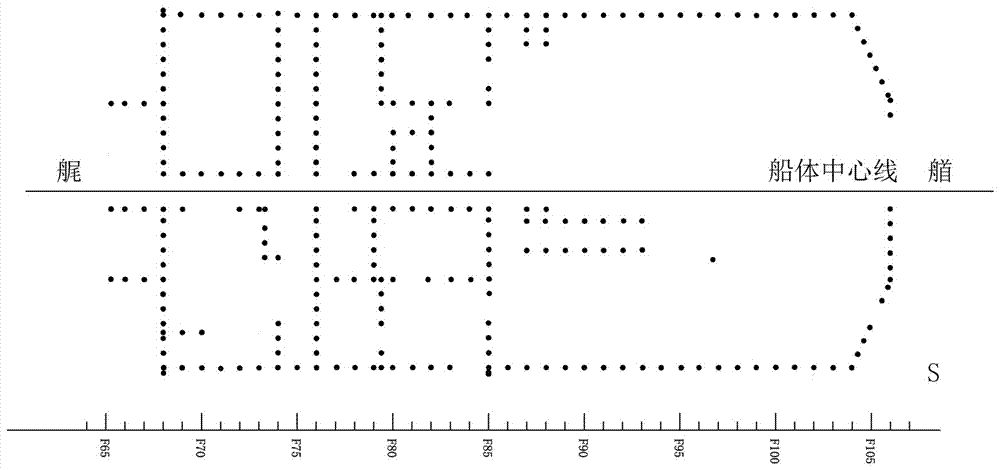

[0020] C, import the measured structural position data into processing software, such as the CAD software used in this embodiment, connect each structural position point with a spline curve according to the hull structure; as image 3 shown;

[0021] D, put the height reference line into the theoretical position of the hull coordinate system of step C, then measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com