Mortar and putty constructability detecting device

A detection device and constructional technology, applied in the direction of measuring device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as loss and inaccurate detection, achieve convenient operation, ensure building quality, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

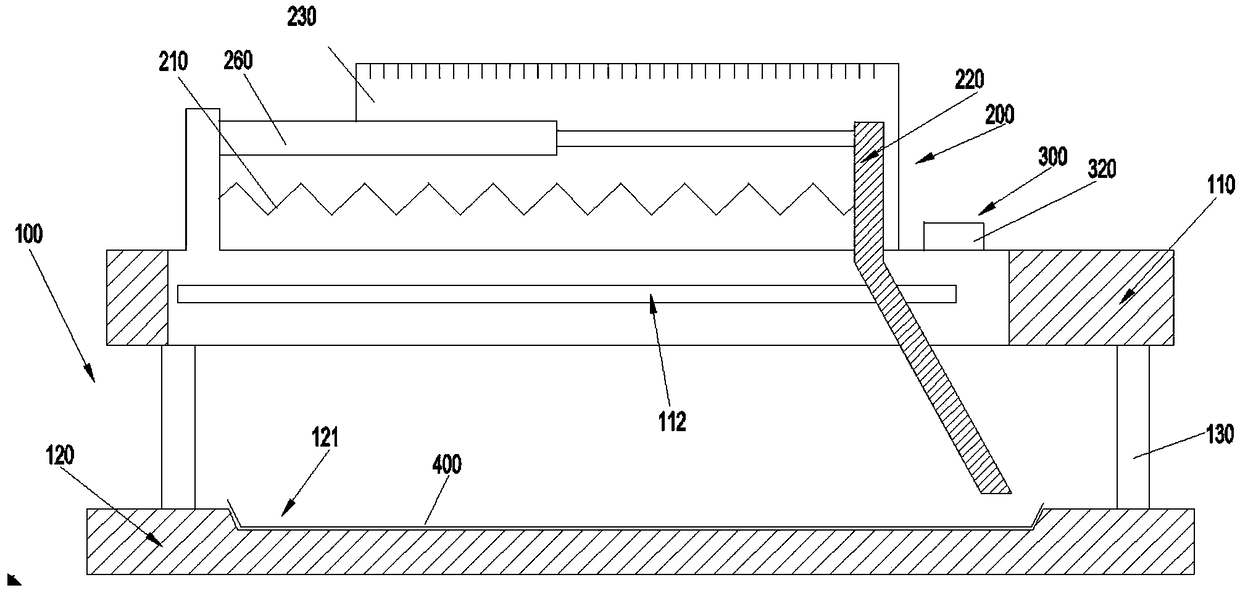

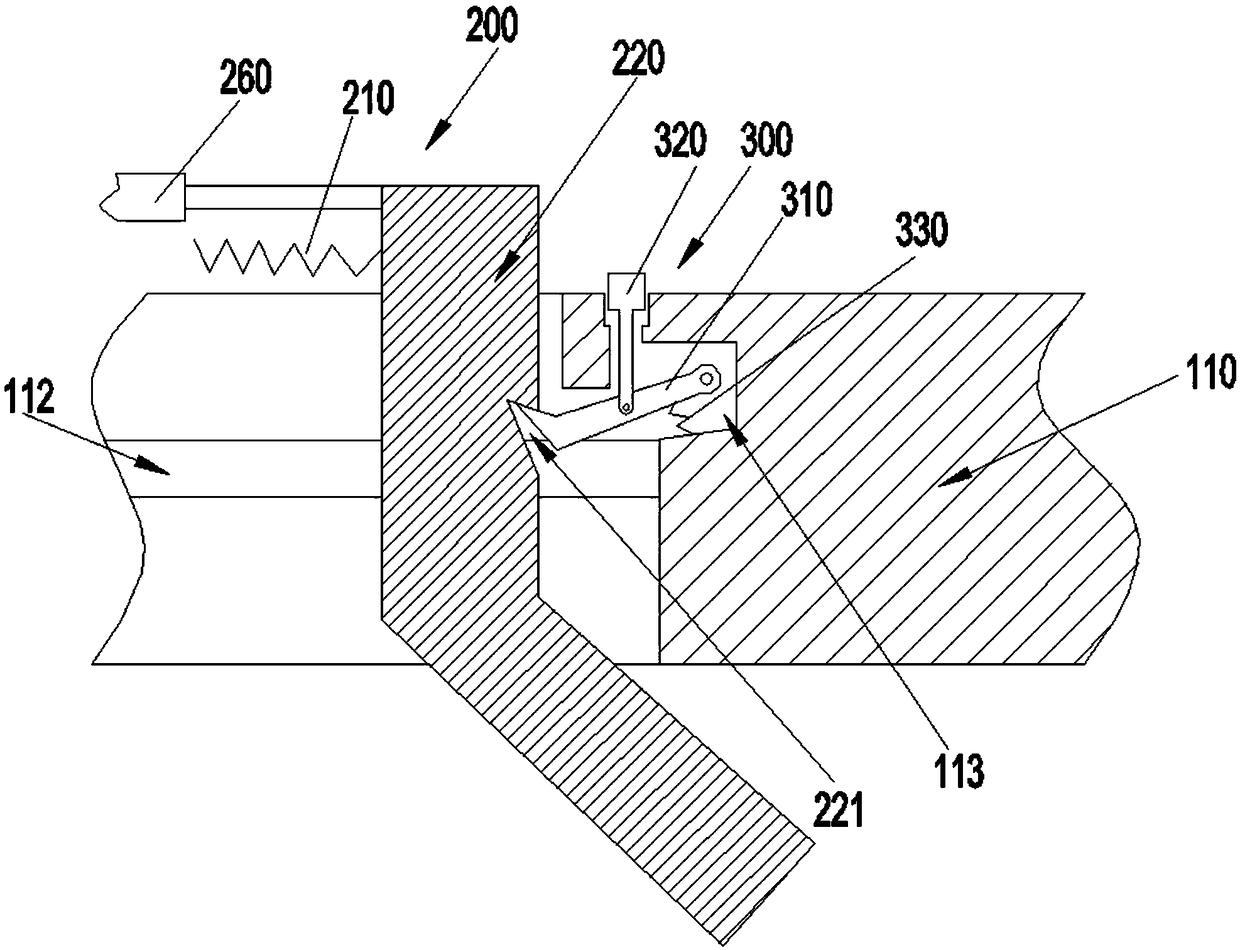

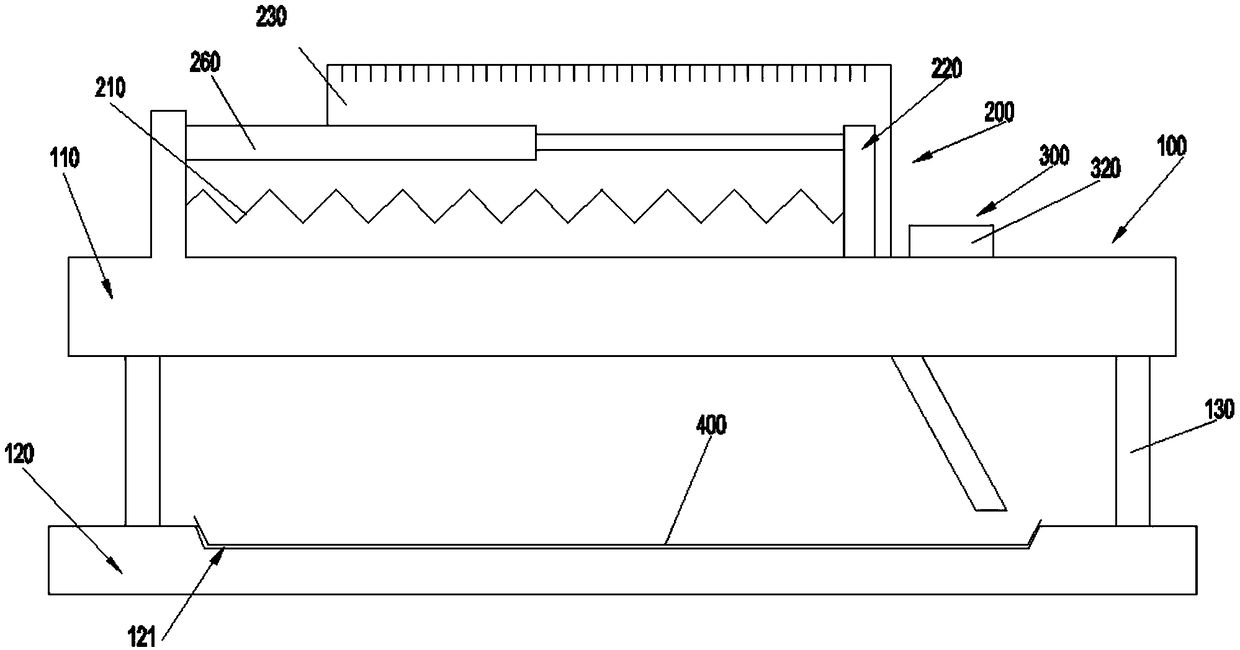

[0026] This embodiment provides a kind of mortar and putty constructability detection device, such as Figure 1-Figure 3 As shown, a bracket 100 and a measurement assembly 200 are included.

[0027] The bracket 100 includes an upper plate 110 , a lower plate 120 and a connecting rod 130 . The upper plate 110 and the lower plate 120 are connected as one by the connecting rod 130 , so that the upper plate 110 is disposed above the lower plate 120 with a detection gap between them. The upper plate 110 is provided with a slot, and the two side walls of the slot are respectively provided with a dovetail slot, and the two dovetail slots both extend from one end of the slot to the other end.

[0028] The measurement assembly 200 includes a tension spring 210 , a slide plate 220 and a scale 230 . One end of the tension spring 210 is connected to the upper plate 110, and its connection point is located at one end of the slot; the upper part of the sliding plate 220 passes through the...

Embodiment 2

[0034] This embodiment provides a kind of mortar and putty constructability detection device, such as figure 1 , figure 2 with Figure 4 As shown, a bracket 100 and a measurement assembly 200 are included.

[0035] The bracket 100 includes an upper plate 110 , a lower plate 120 and a connecting rod 130 . The upper plate 110 and the lower plate 120 are connected as one by the connecting rod 130 , so that the upper plate 110 is disposed above the lower plate 120 with a detection gap between them. The upper plate 110 is provided with a slot, and the two side walls of the slot are respectively provided with a dovetail slot, and the two dovetail slots both extend from one end of the slot to the other end.

[0036] The measurement assembly 200 includes a cylinder 240 , a slide plate 220 and a tension gauge 250 . One end of the cylinder 240 is connected to the upper plate 110 , and its connection point is located at one end of the slot; the other end of the cylinder 240 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com