Corrugated steel web prefabricated assembly

A corrugated steel web, prefabricated assembly technology, applied in the erection/assembly of bridges, bridge materials, bridges, etc., can solve the problems of poor performance of the connection parts in the assembly construction, the large influence of the assembly error of the connection parts, and the restriction of the popularization and application of the assembly process. , to achieve the effect of reasonable stress, enhanced stiffness and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

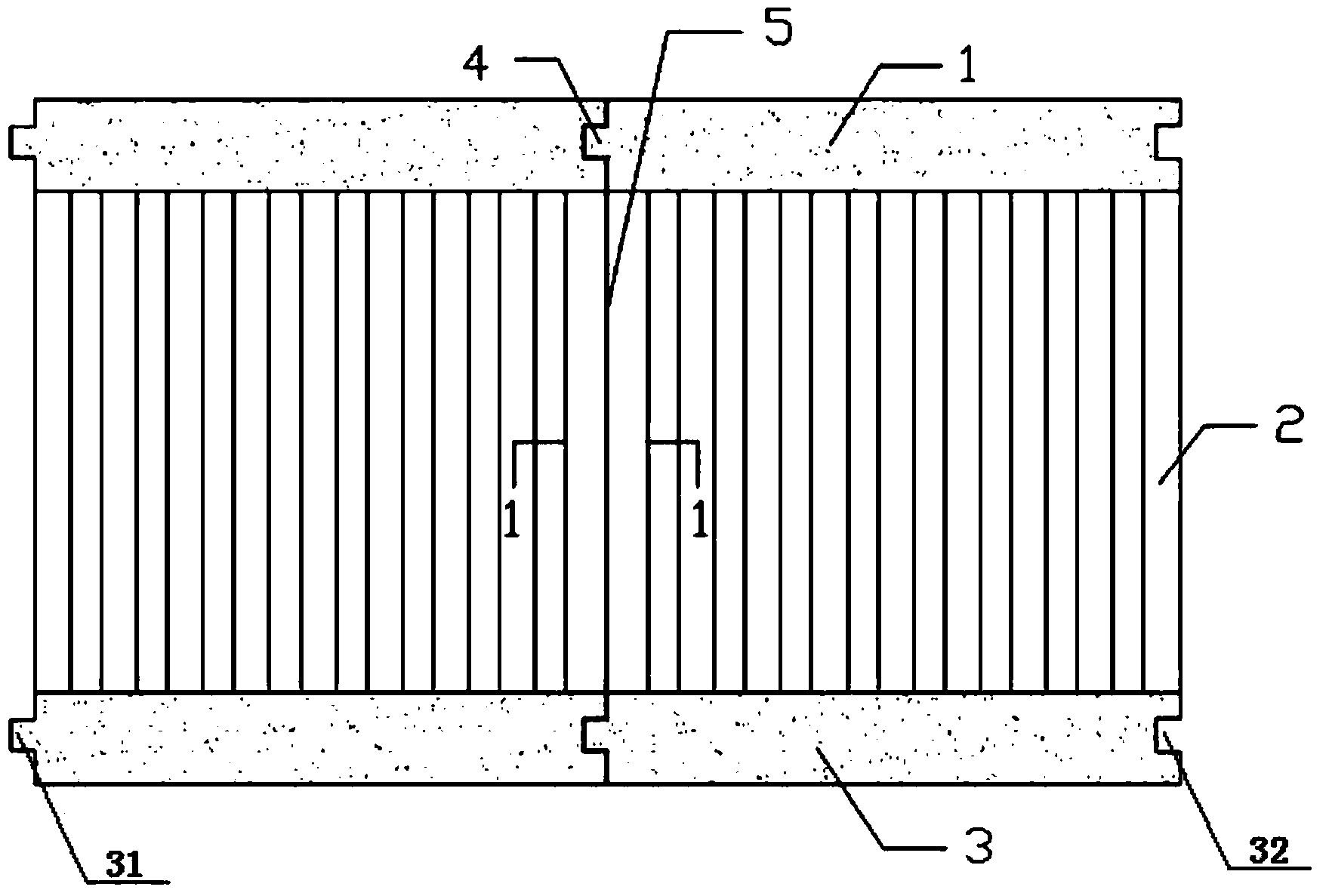

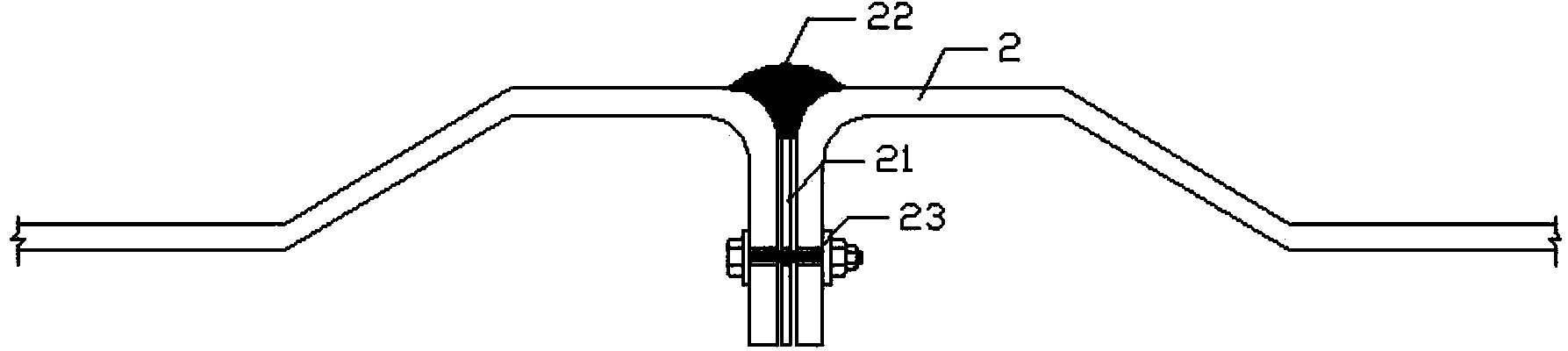

[0019] Such as figure 1 , figure 2 The schematic diagram of the prefabricated assembled structure of corrugated steel webs of the present invention includes a reinforced concrete top plate 1, a corrugated steel web 2, a reinforced concrete bottom plate 3, and a prefabricated segment 6, wherein a plurality of corrugated steel webs 2 are arranged on the reinforced concrete top plate 1 and the reinforced concrete floor 3 form a prefabricated segment 6 . Two adjacent prefabricated segments 6 are fixed by concrete hinges 4 and connectors 5 .

[0020] Wherein the concrete hinge 4 is a combined structure, and a protrusion 31 is provided on the same side of the reinforced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com