Patents

Literature

5050results about "Bridge materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

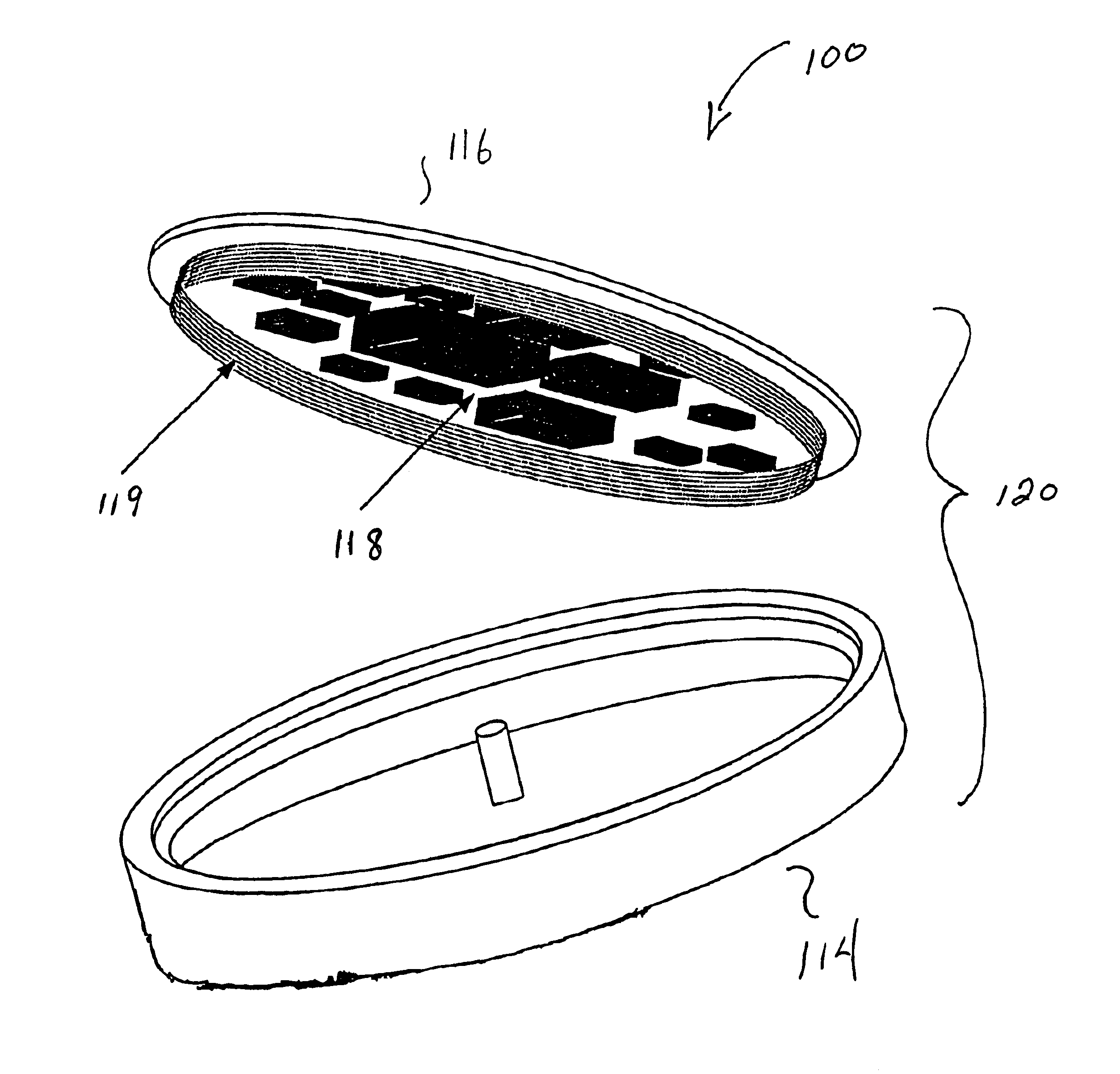

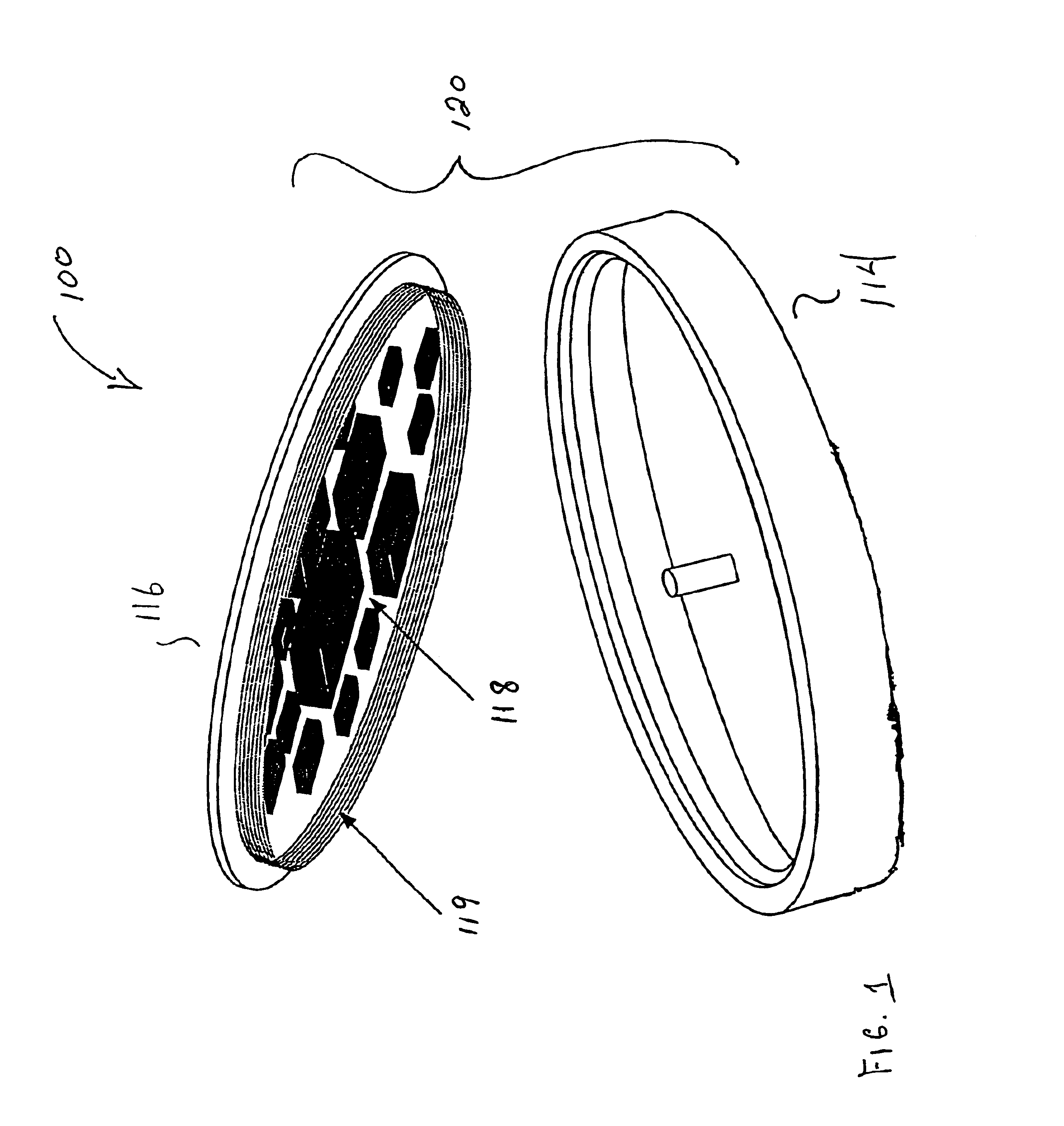

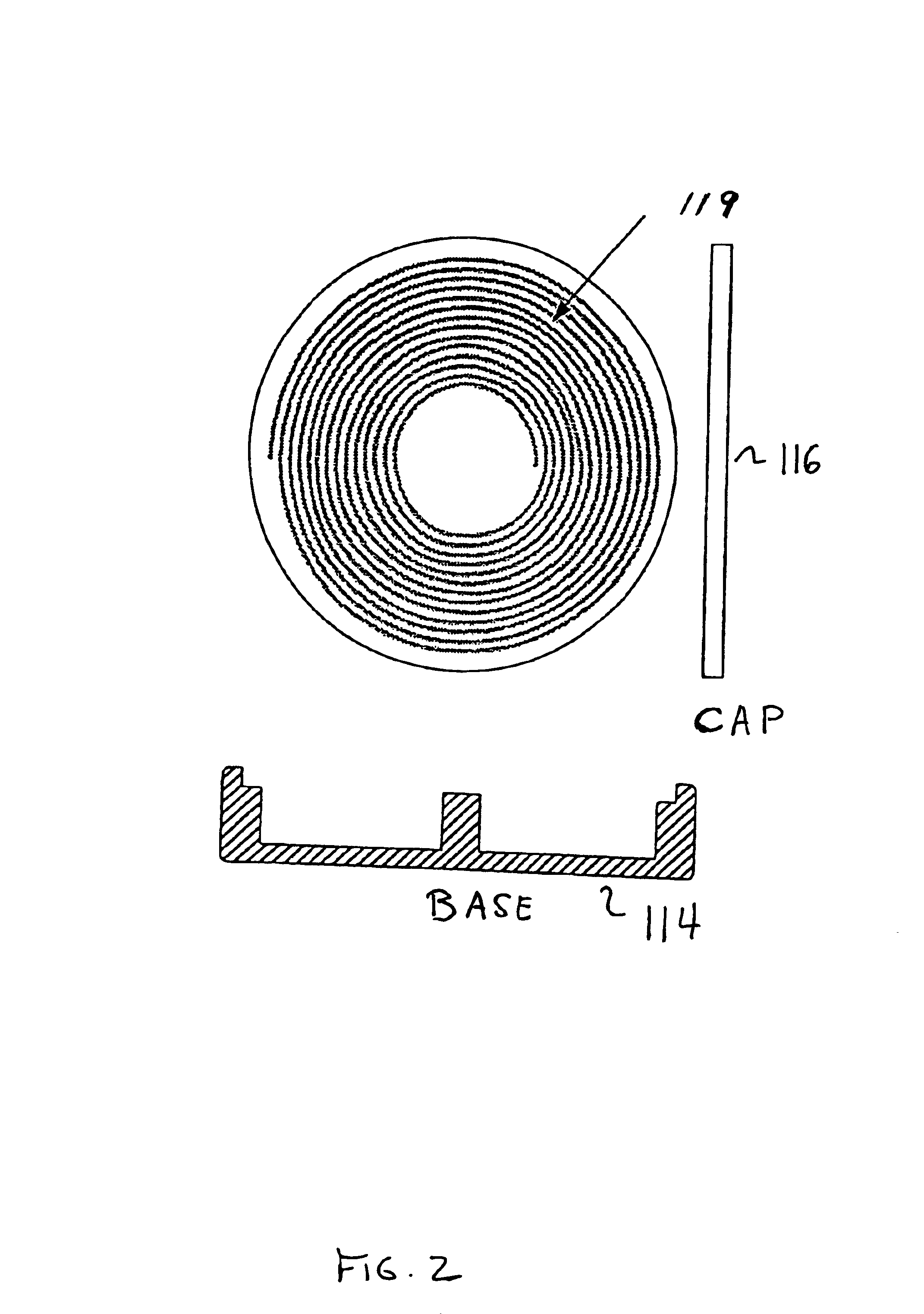

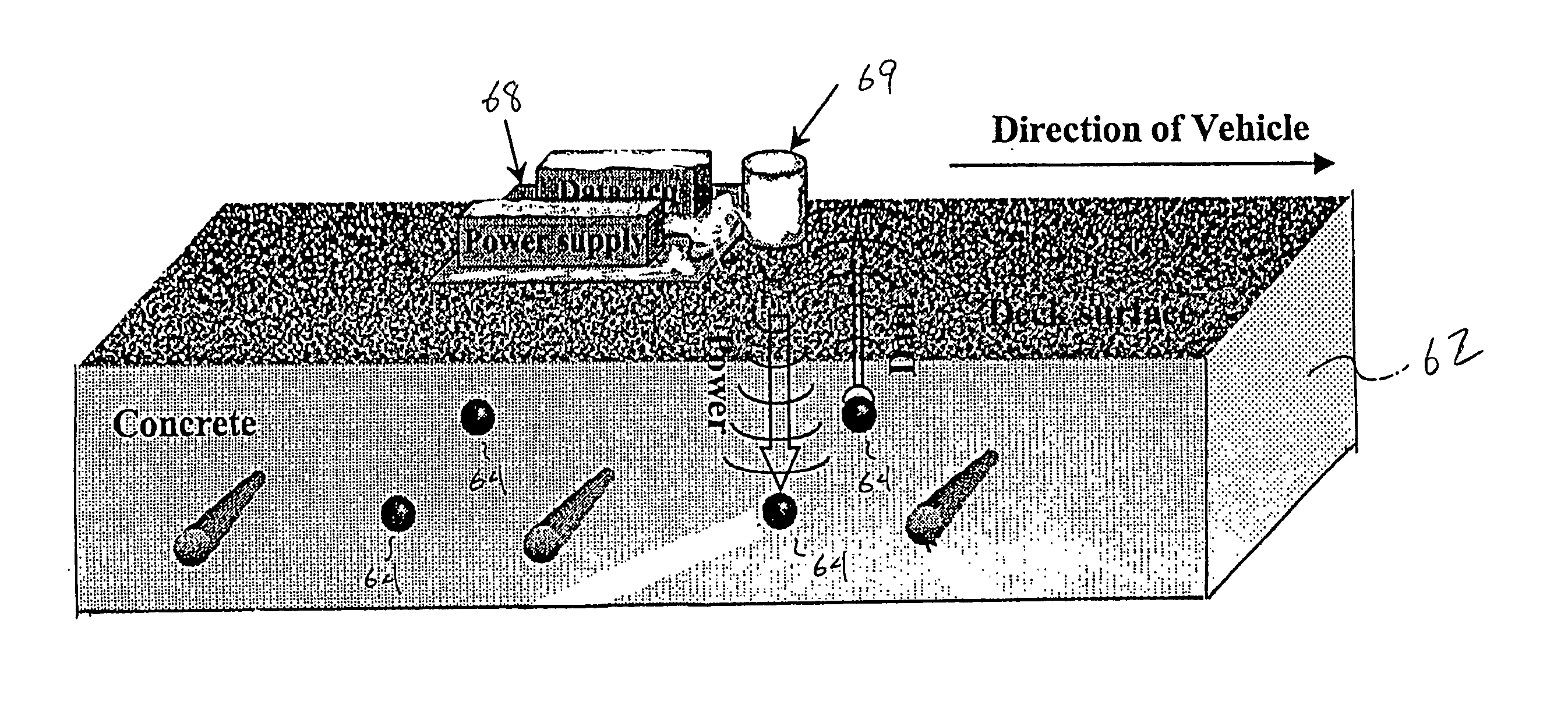

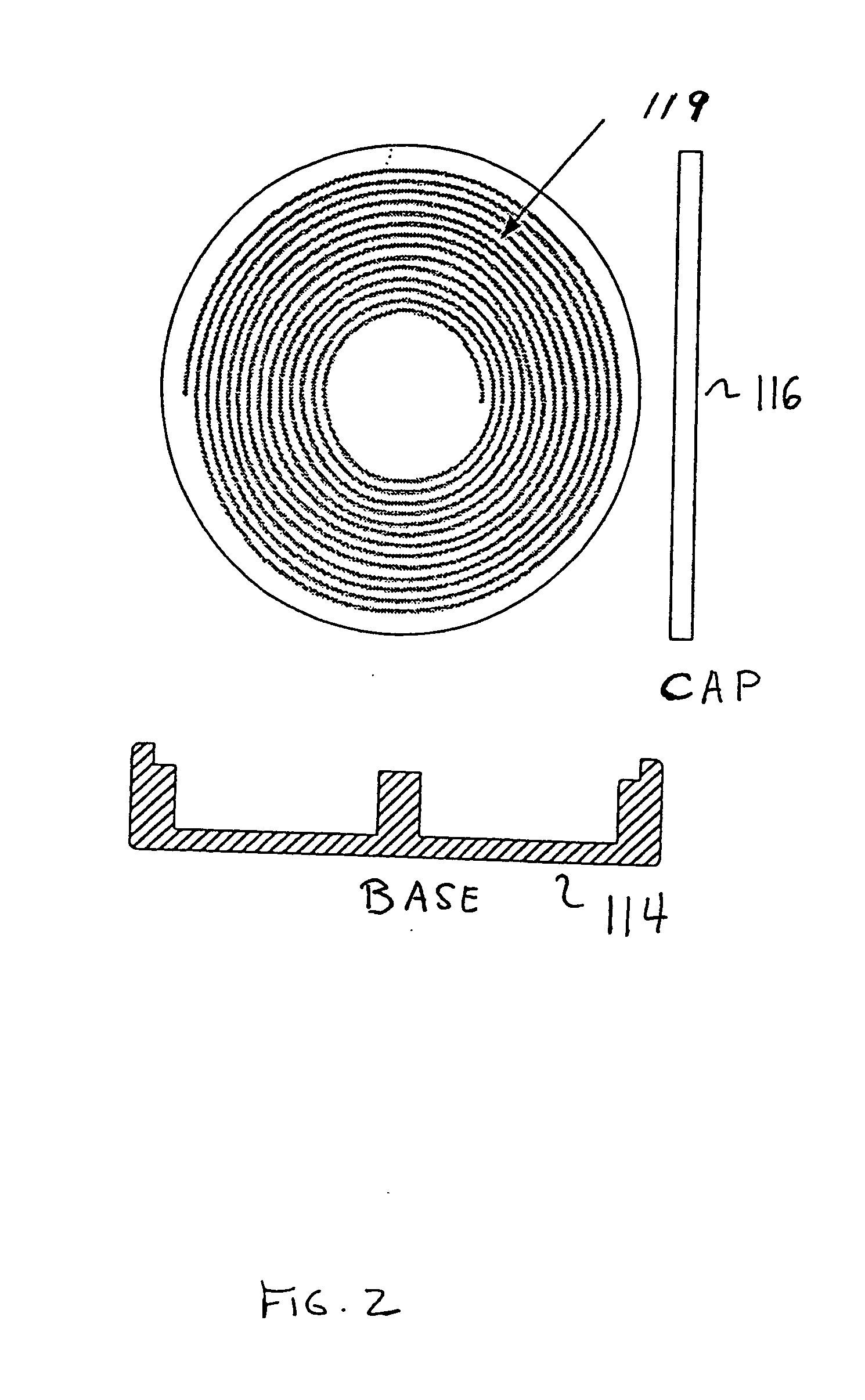

Wireless multi-functional sensor platform, system containing same and method for its use

InactiveUS6796187B2Small sizeLow costElectric signal transmission systemsForce measurementLine sensorTransmitted power

A multi-functional sensor system for simultaneously monitoring various parameters such as the structural, chemical and environmental conditions associated with a medium to be monitored, e.g., bridges, high-rise buildings, pollution zones, is provided wherein the system includes at least a plurality of wireless multi-functional sensor platforms embedded in the medium in which an interrogation unit transmits power and receives responses. Each wireless multi-functional sensor platform includes multiple channels for accommodating a plurality of sensor types to simultaneously monitor the parameters associated with the medium. Thus, the wireless sensor platforms are formed to include those sensor types which are considered germane to the intended medium to be monitored.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

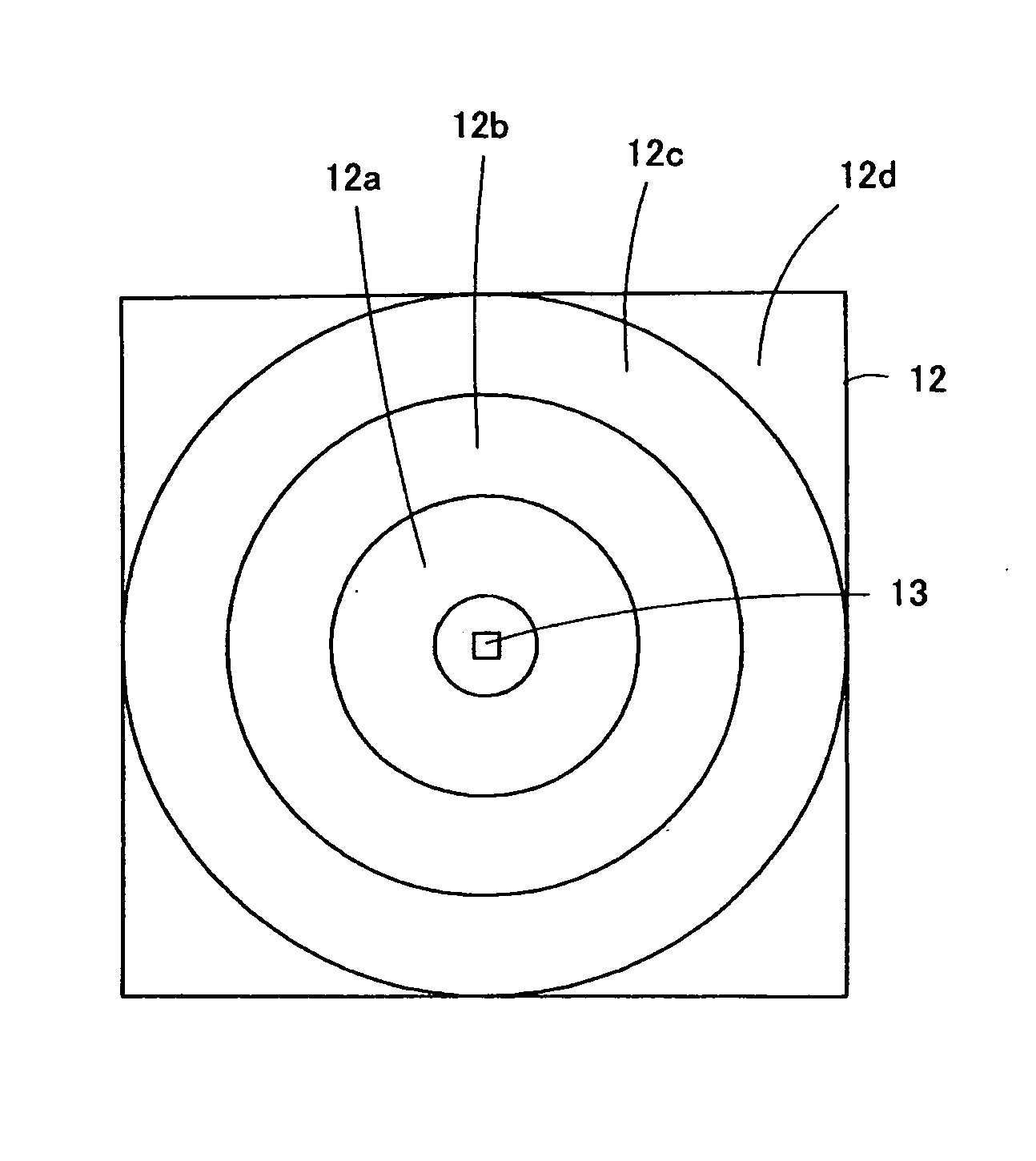

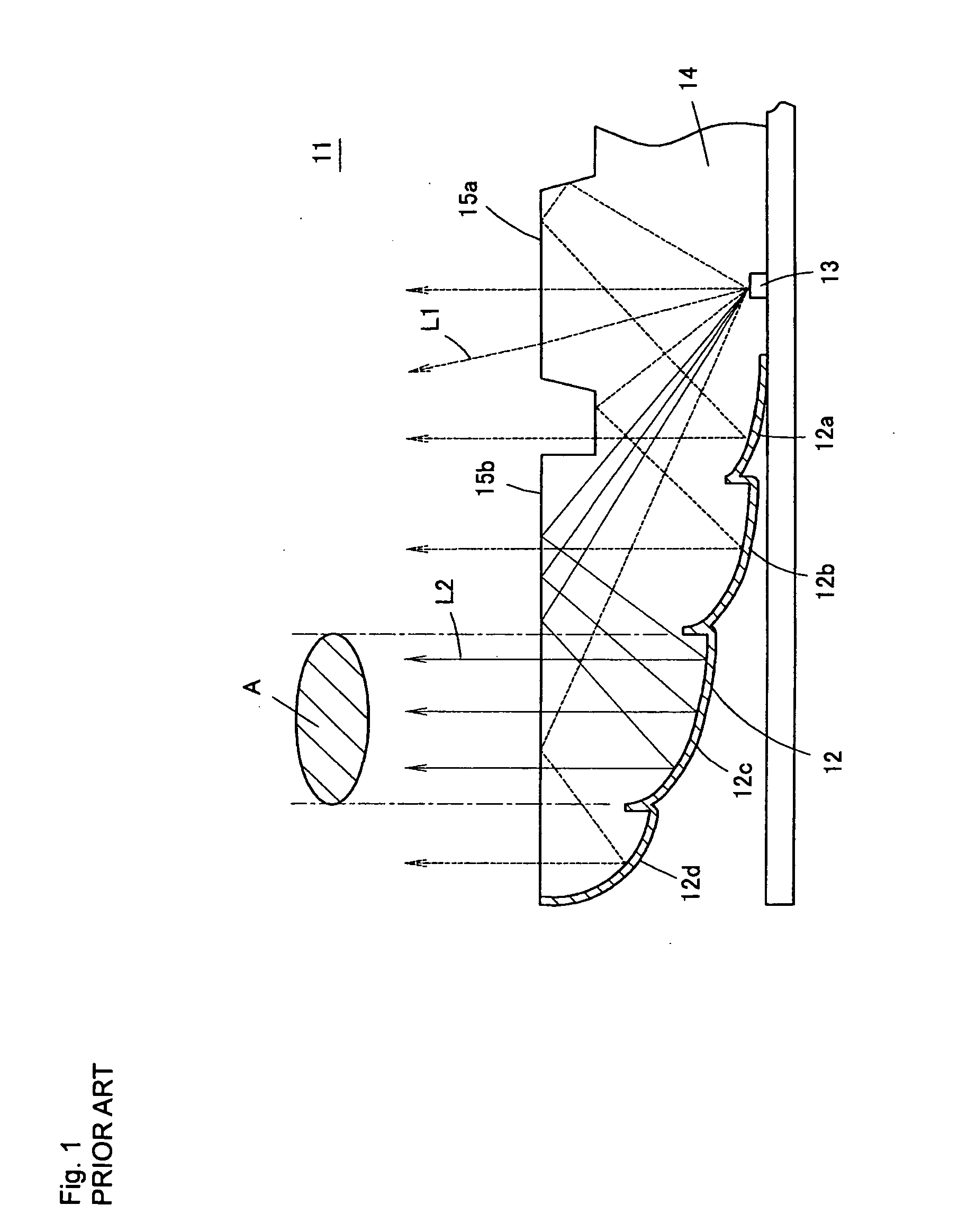

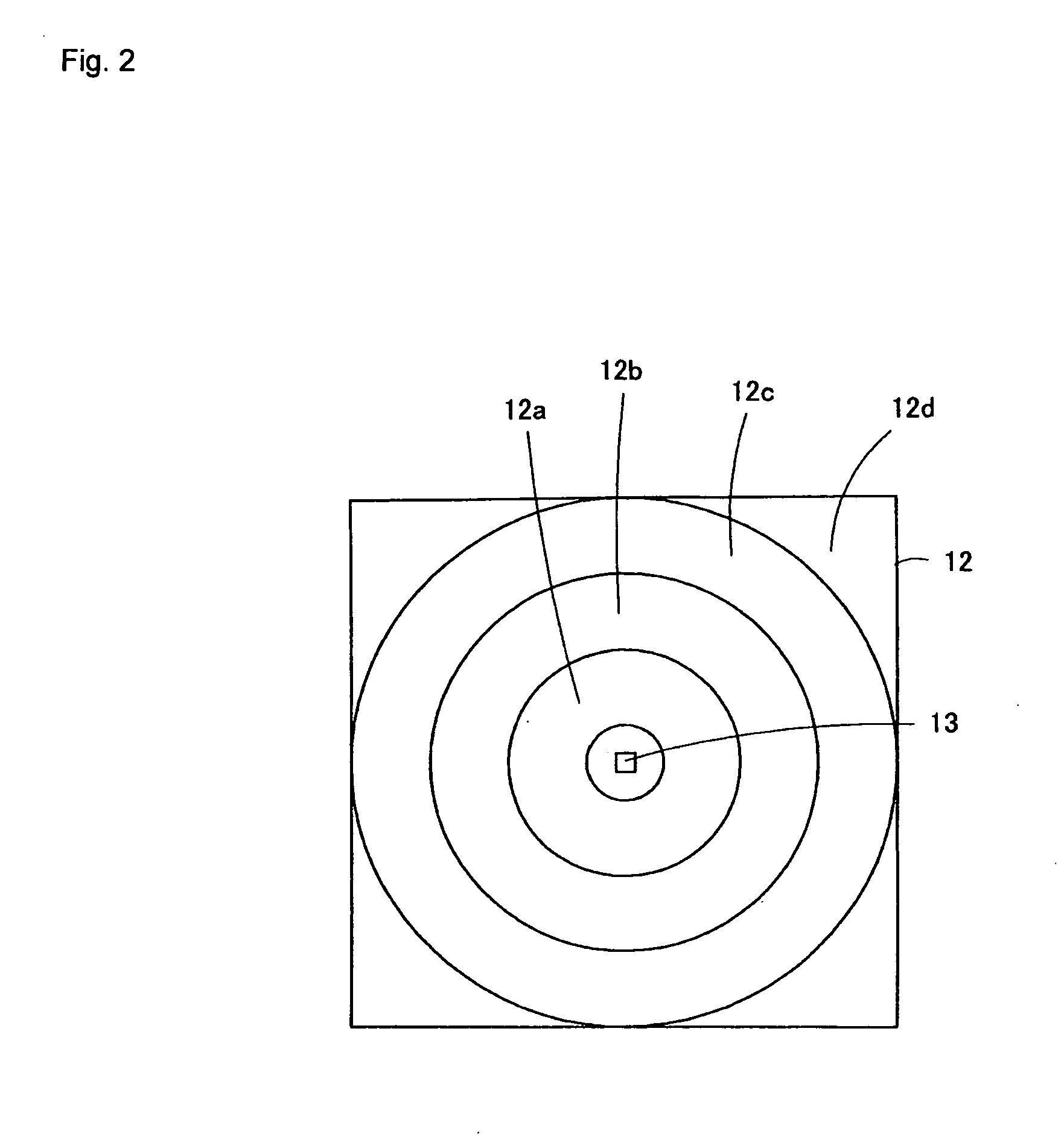

Luminescent light source and luminescent light source array

ActiveUS20060158899A1Division increaseNarrowing pitch interval of reflection areaMirrorsPoint-like light sourceLight reflectionLight emitting device

To provide a luminescent light source that can increase the number of divisions of a reflecting mirror without reducing pitch interval of reflection areas. A luminescent light source comprises a reflecting mirror for reflecting light, a mold unit arranged on a light reflection surface of the reflecting mirror, and light emitting devices of three luminescent devices of red, blue and green that are placed in the central part and output light to the mold unit. In the reflecting mirror, rectangular reflection areas are arranged vertically and horizontally in a grid.

Owner:ORMON CORP

Wireless multi-funtional sensor platform, system containing same and method for its use

InactiveUS20040004554A1Electric signal transmission systemsForce measurementLine sensorTransmitted power

A multi-functional sensor system for simultaneously monitoring various parameters such as the structural, chemical and environmental conditions associated with a medium to be monitored, e.g., bridges, high-rise buildings, pollution zones, is provided wherein the system includes at least a plurality of wireless multi-functional sensor platforms embedded in the medium in which an interrogation unit transmits power and receives responses. Each wireless multi-functional sensor platform includes multiple channels for accommodating a plurality of sensor types to simultaneously monitor the parameters associated with the medium. Thus, the wireless sensor platforms are formed to include those sensor types which are considered germane to the intended medium to be monitored.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

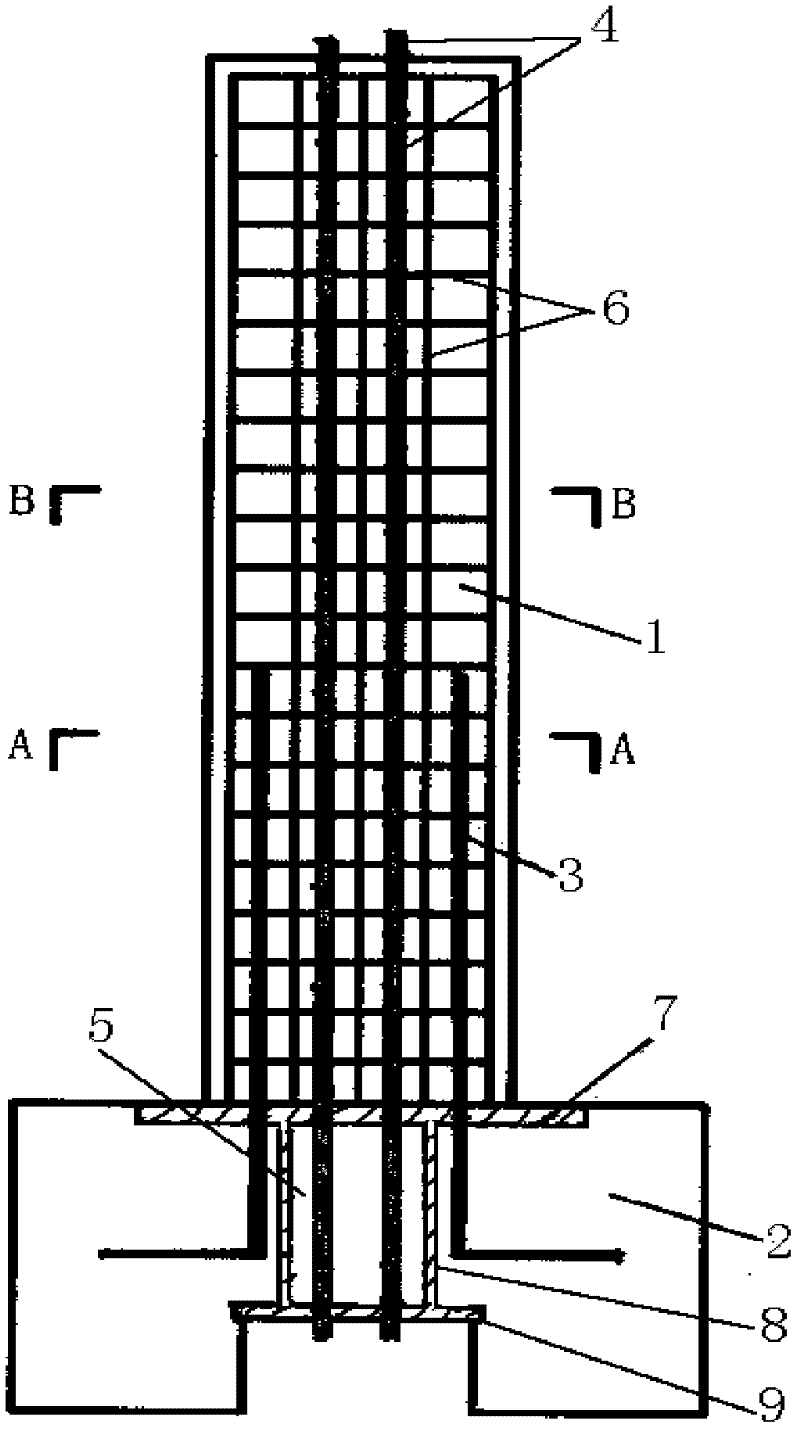

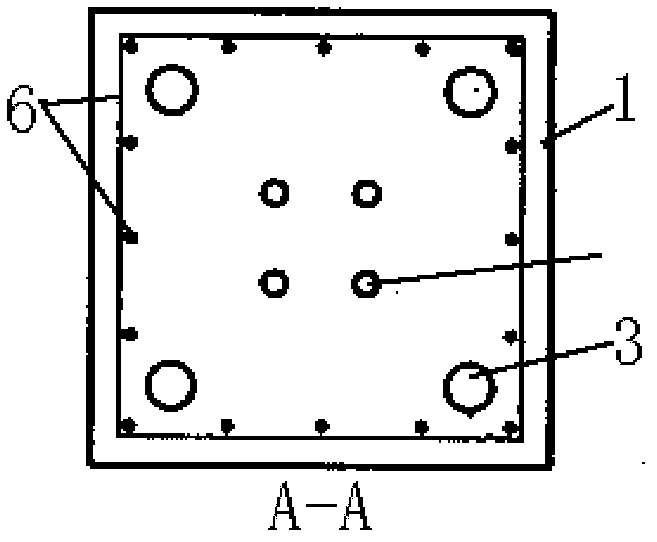

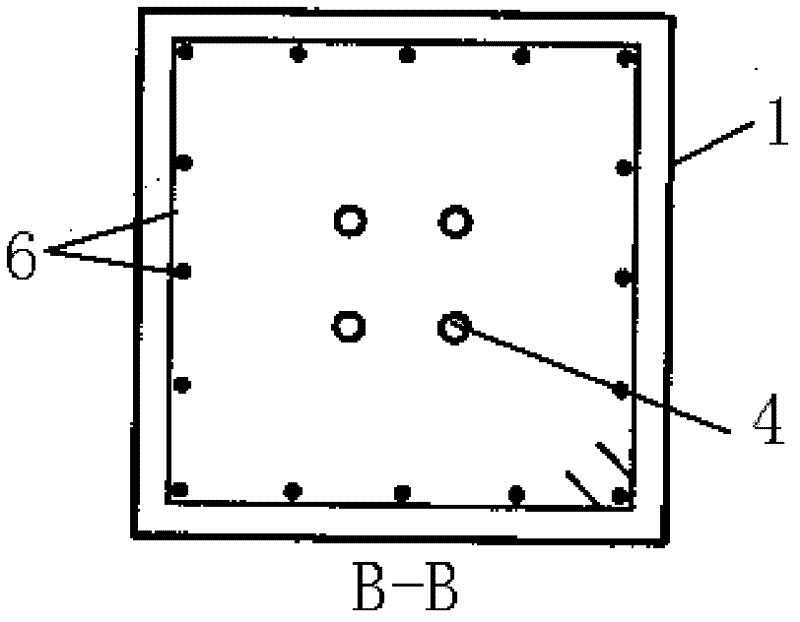

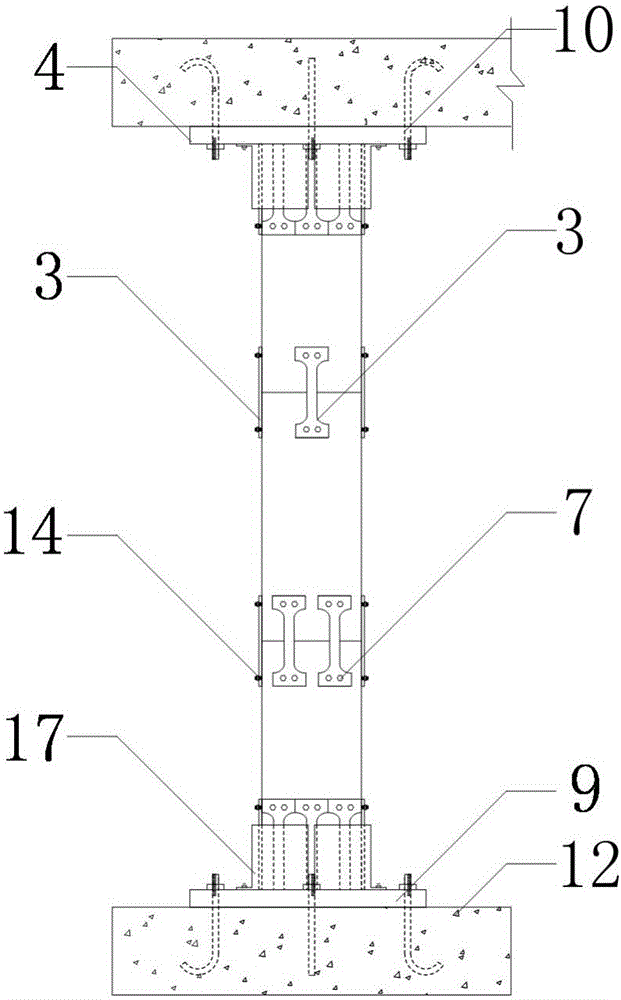

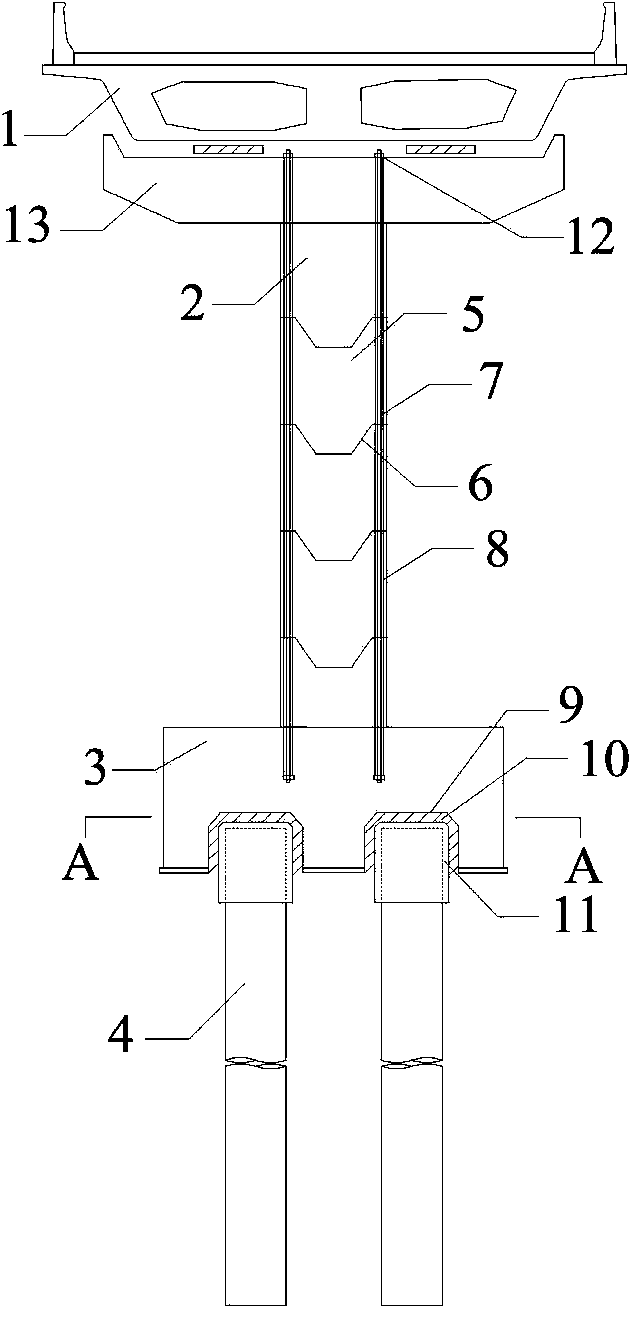

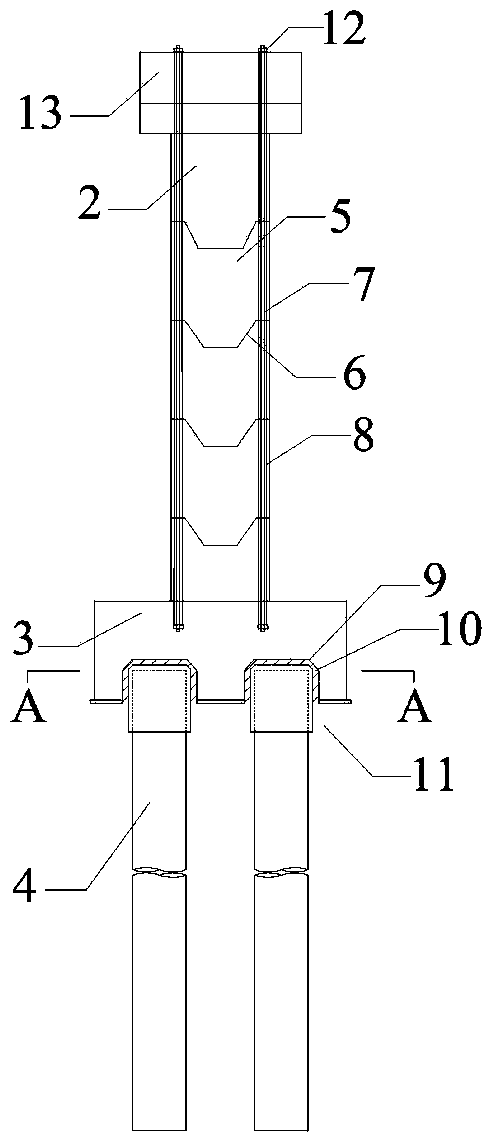

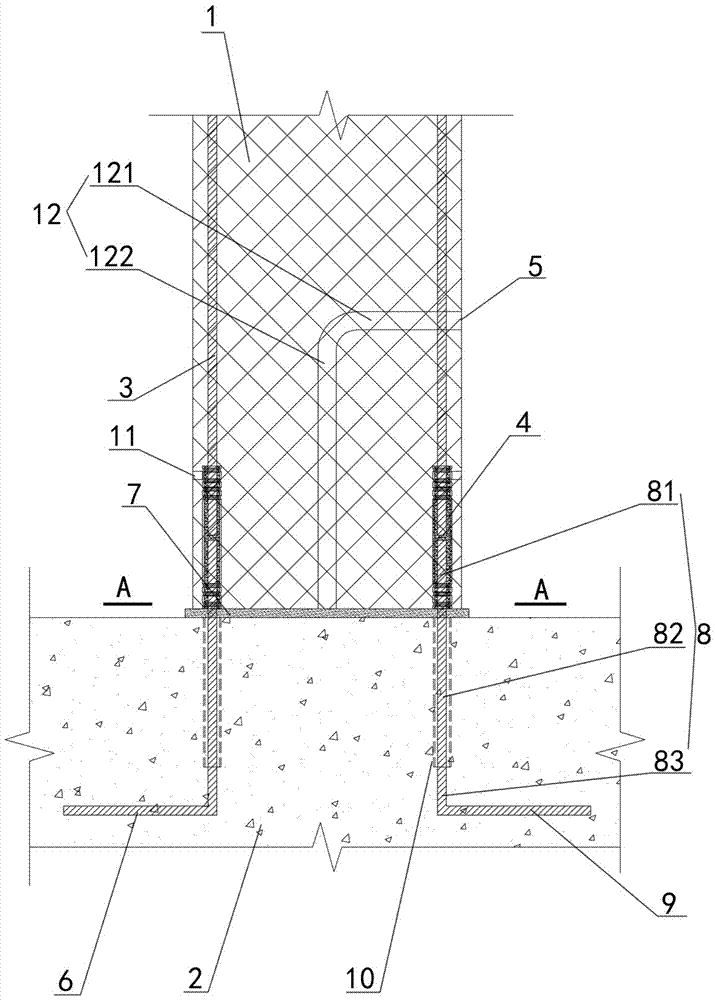

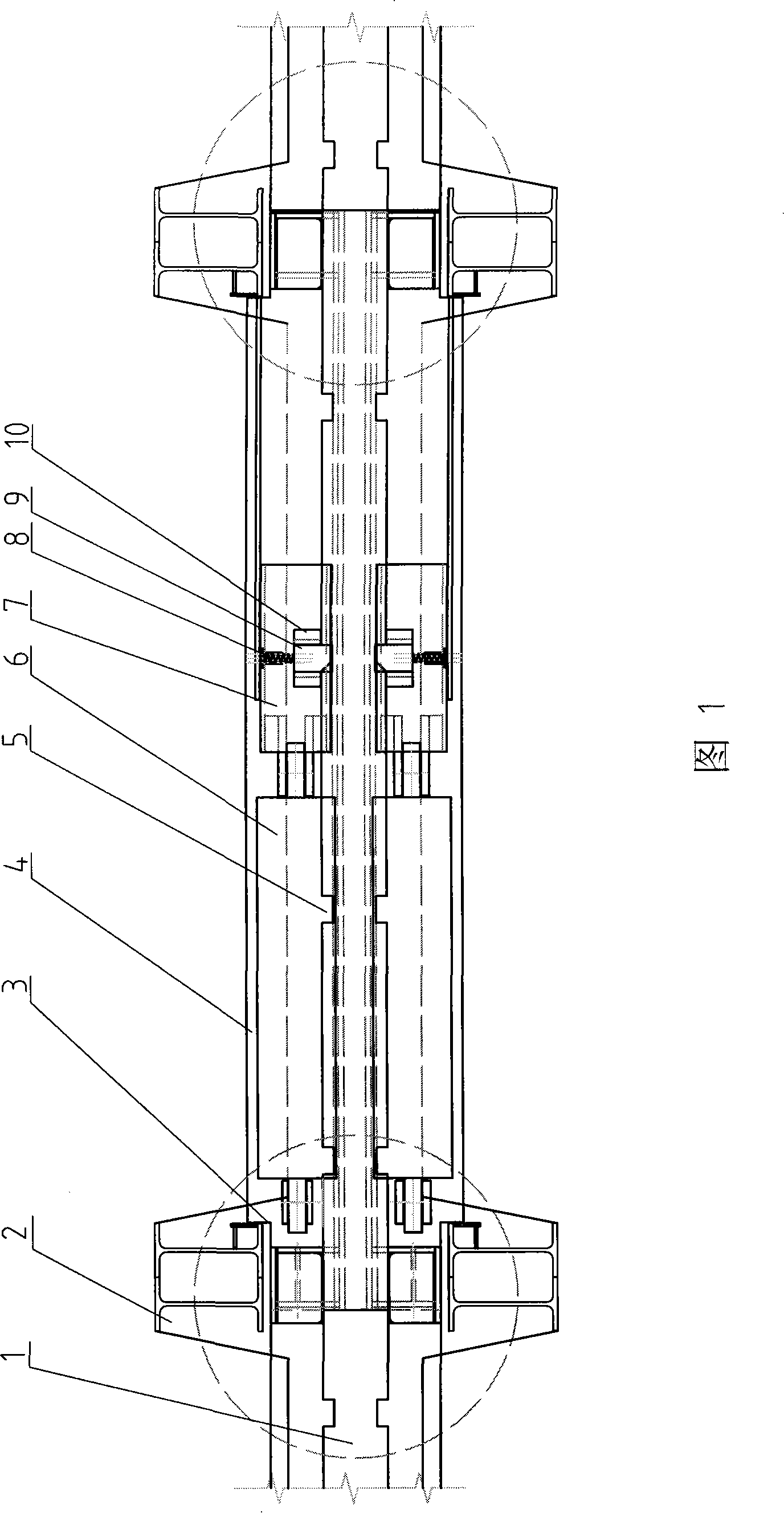

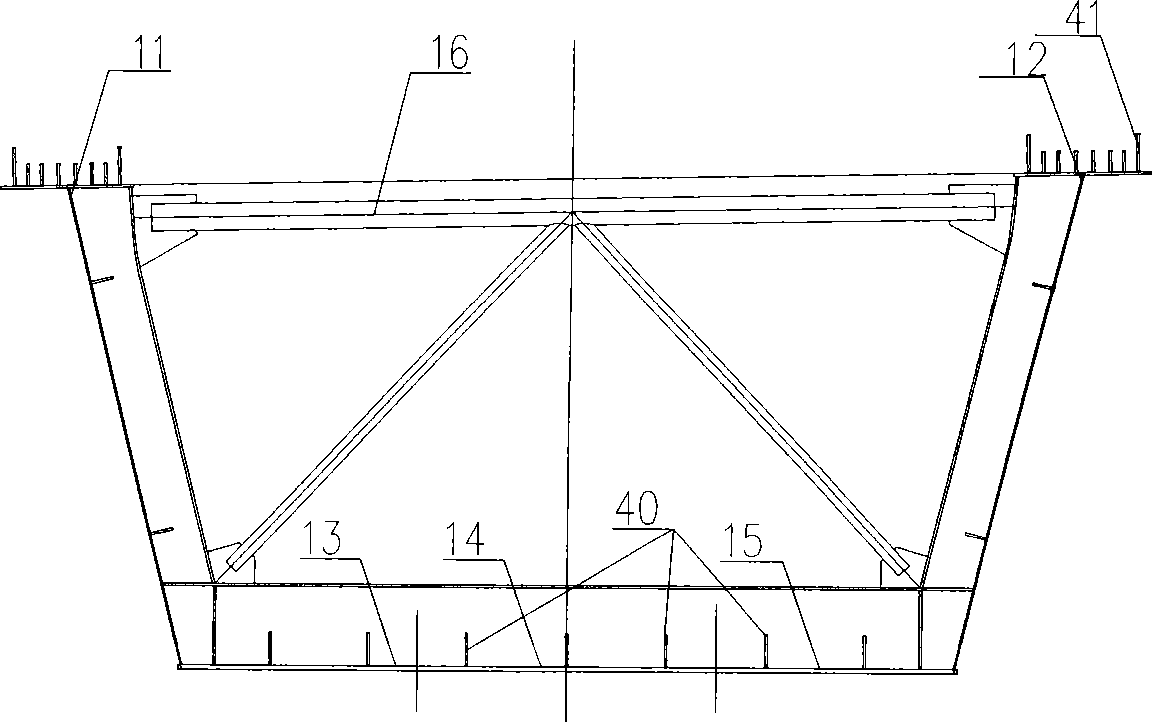

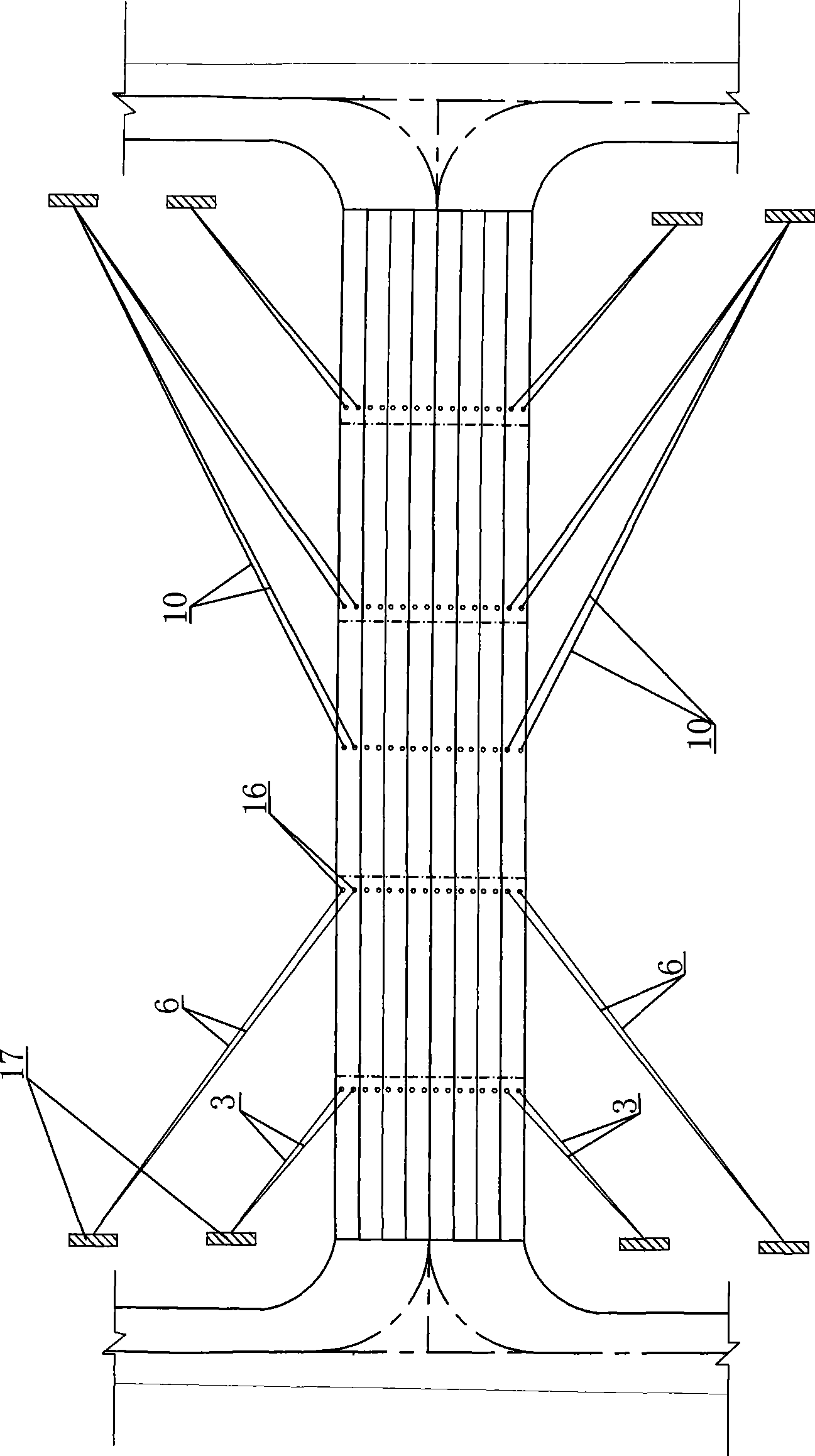

Self-resetting pier column structural system with built-in energy dissipation assembly and implementing method for self-resetting piper column structural system

InactiveCN102409606ASufficient ductility and energy dissipation capacityStrong enoughBridge structural detailsBridge erection/assemblyBridge engineeringResidual deformation

The invention discloses a self-resetting pier column structural system with a built-in energy dissipation assembly and an implementing method for the self-resetting pier column structural system, and belongs to the field of bridge engineering. The self-resetting pier column structural system consists of a pier column, a bridge abutment, energy dissipation steel bars, non-adhesion prestressed steel bars with an elastic resetting function and an embedded part; in the novel pier column structural system capable of effectively reducing residual deformation and ensuring sufficient energy dissipation, a pier is connected with the bridge abutment through the energy dissipation steel bars and the non-adhesion prestressed steel bars. Compared with the conventional pier column node, the self-resetting pier column structural system has the advantages that: the non-adhesion prestressed steel bars are positioned in the axle center of the pier column, a self-resetting restoring force can be generated, and the problem that the conventional pier has large residual deformation under the action of an earthquake load and cannot serve people any longer can be solved well; the self-resetting pier column structural system is flexible in design and definite in structural stress; the pier is ensured to have sufficient strength and rigidity; and the self-resetting pier column structural system can be implemented by a prefabricating or on-site pouring method, is easy and convenient to construct, and is an advanced and practical novel pier column system.

Owner:TSINGHUA UNIV

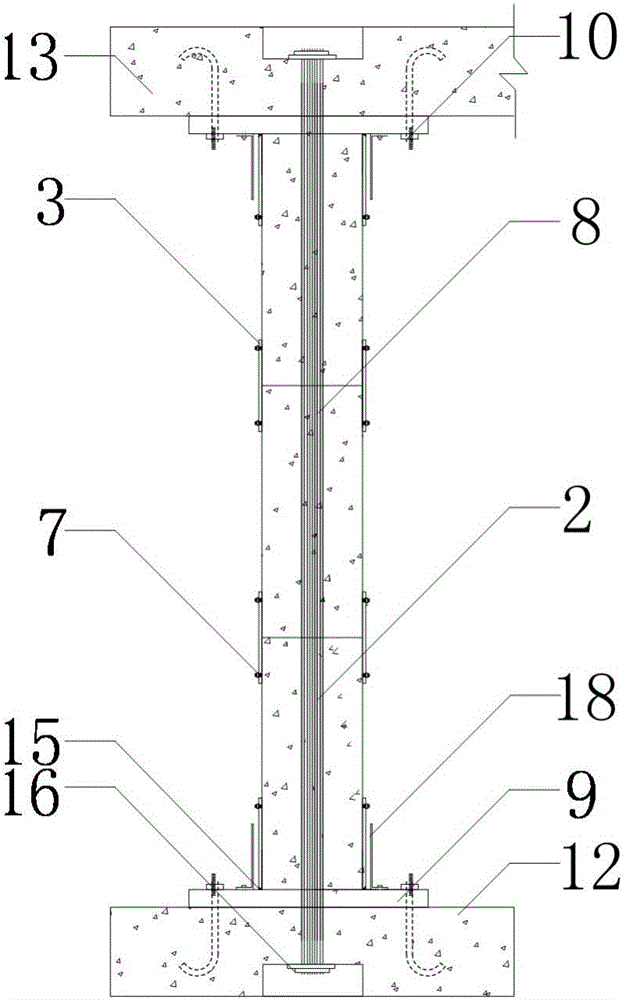

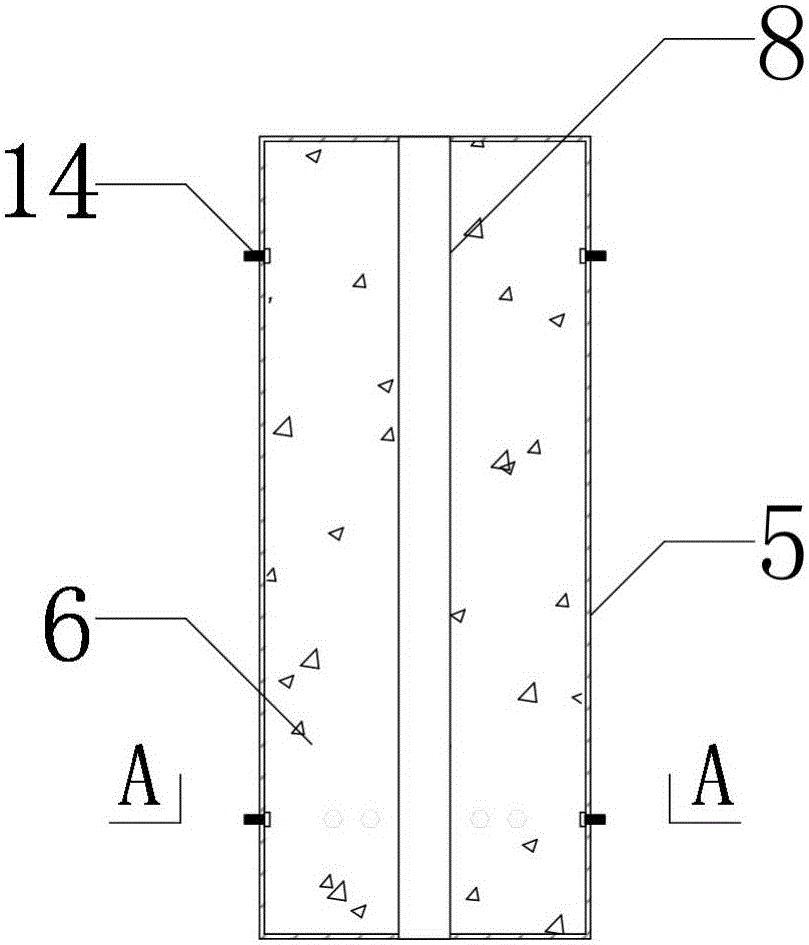

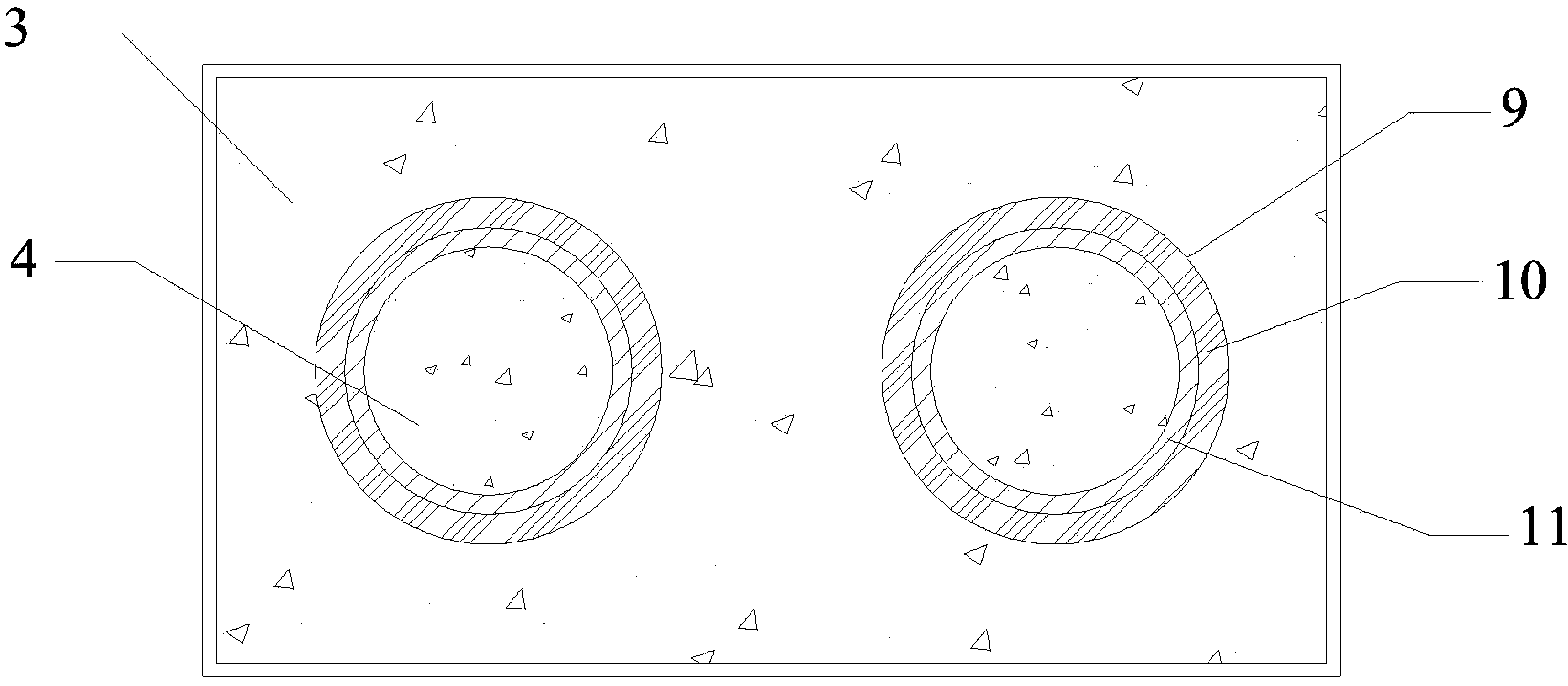

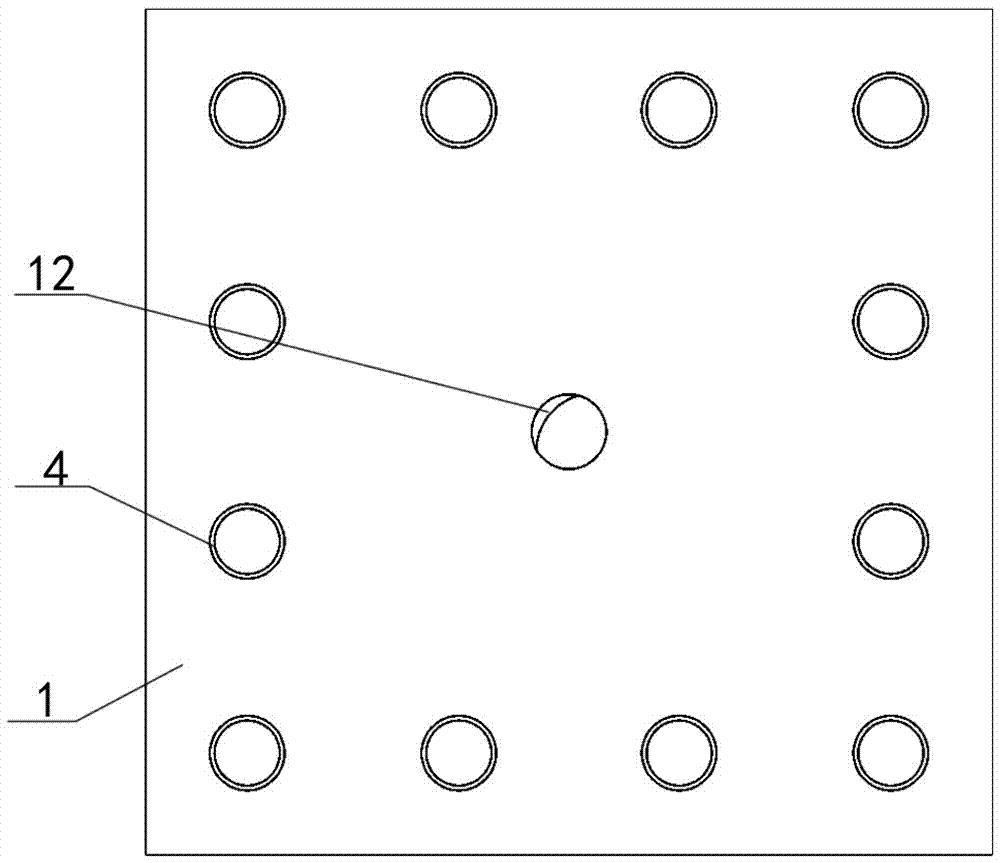

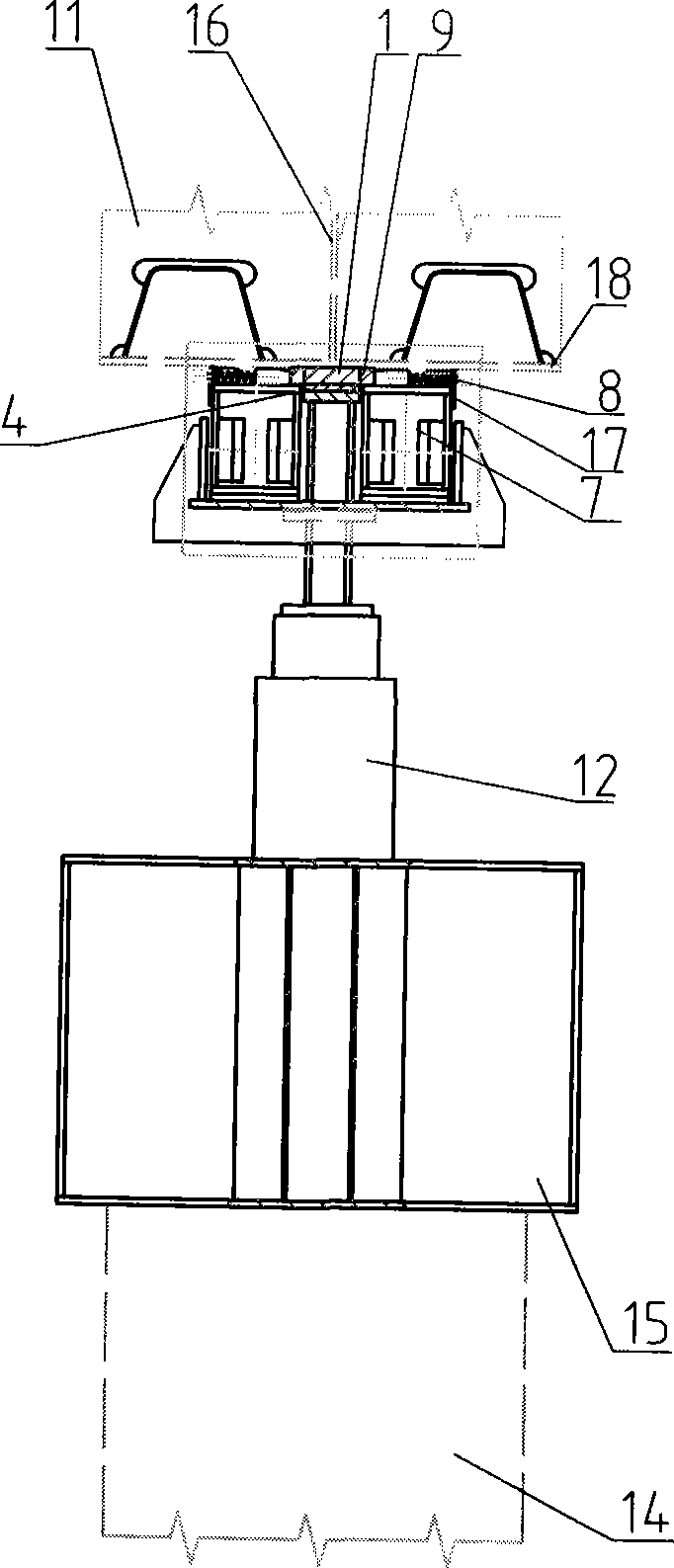

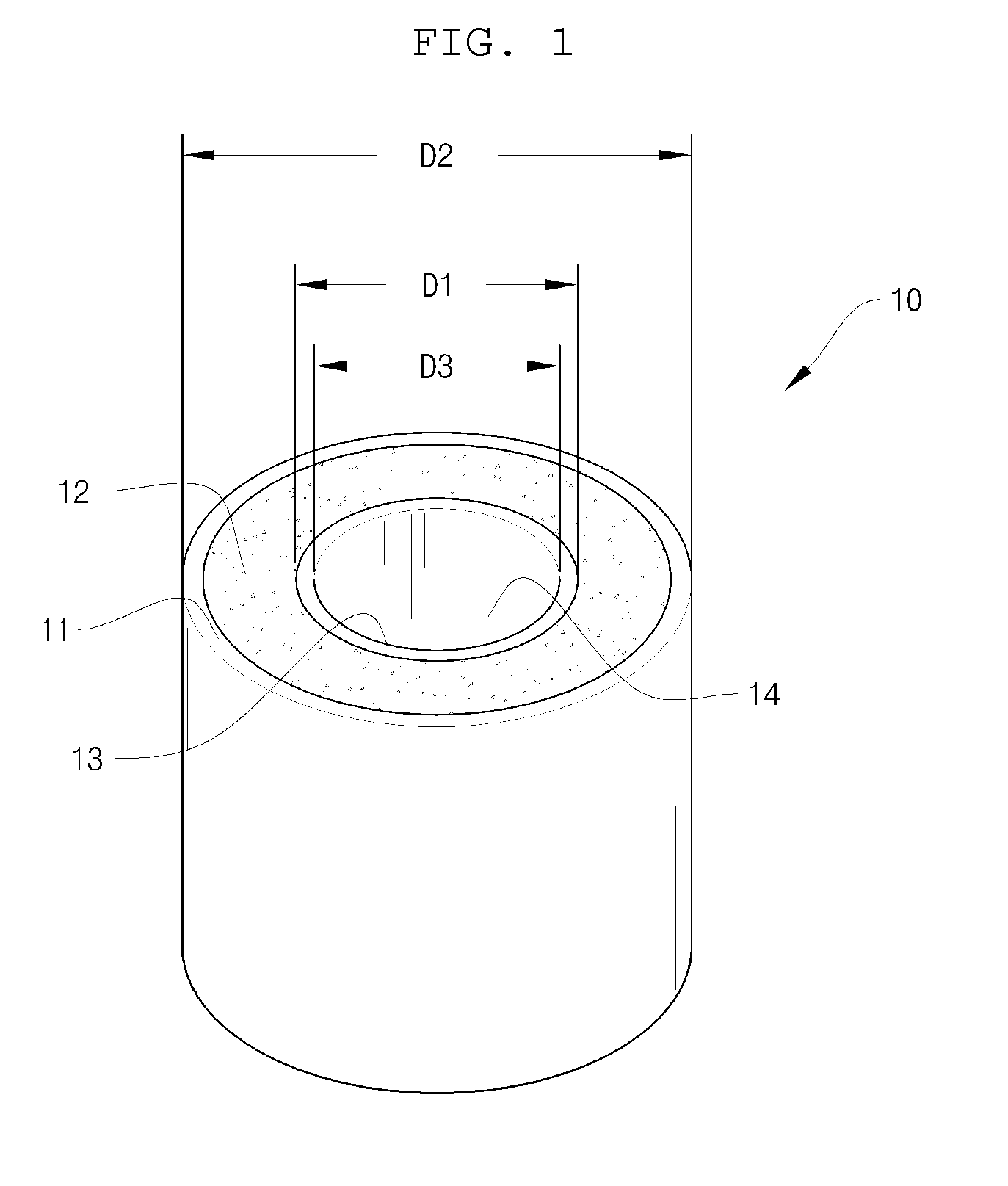

Damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and manufacturing method thereof

ActiveCN105908621ASmall residual displacement after earthquakeImprove bearing capacityBridge structural detailsBridge erection/assemblyBridge engineeringHigh energy

The invention discloses a damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and a manufacturing method thereof, and belongs to the field of bridge engineering. An exposed node connecting piece consists of a foot plate, anchor bolts, end connecting plates and buckling restraining sleeves. A connecting plate is mounted between prefabricated steel pipe concrete sections through high-strength bolts; the exposed node connecting piece is connected with each of a cover beam and a bearing platform by utilizing the anchor bolts, and is connected with a prefabricated steel pipe concrete section through the high-strength bolts relying on the end connecting plates. A pre-stressed tendon penetrates through a section prefabricated steel pipe concrete pier; the two ends of the pre-stressed tendon are respectively anchored to the interiors of the bearing platform and the cover beam by using anchorage devices. The energy consumption-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier disclosed by the invention has the characteristics of small post-seismic residual displacement, high energy consumption capacity, controllable energy consumption, high assembling degree, convenience and quickness in construction process, greenness, high efficiency, energy conservation, environment friendliness, easiness in factory production, convenience and quickness in construction, and the like; the construction period of the pier can be remarkably shortened.

Owner:BEIJING UNIV OF TECH

Semiconductor chip production method, semiconductor device production method, semiconductor chip, and semiconductor device

ActiveUS20050009329A1Less susceptible to metal contaminationLess susceptible to contaminationSemiconductor/solid-state device detailsSolid-state devicesDevice formDevice material

A semiconductor chip production method including the steps of: forming a front side recess in a semiconductor substrate; depositing a metal material in the front side recess to form a front side electrode electrically connected to a functional device formed on the front surface; removing a rear surface portion of the semiconductor substrate to reduce the thickness of the semiconductor substrate to a thickness greater than the depth of the front side recess; forming a rear side recess communicating with the front side recess in the rear surface of the semiconductor substrate after the thickness reducing step; and depositing a metal material in the rear side recess to form a rear side electrode electrically connected to the front side electrode for formation of a through-electrode.

Owner:ROHM CO LTD

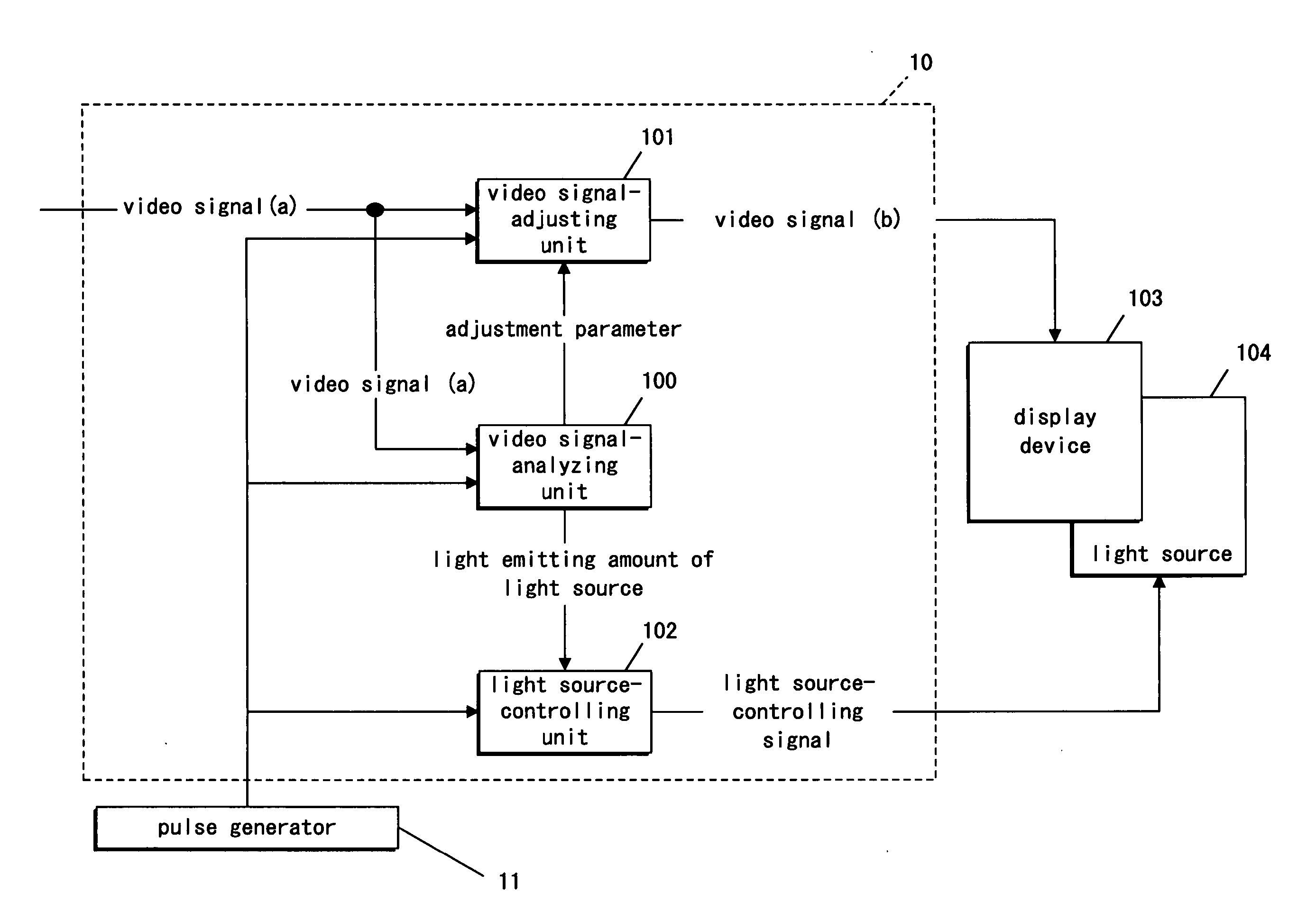

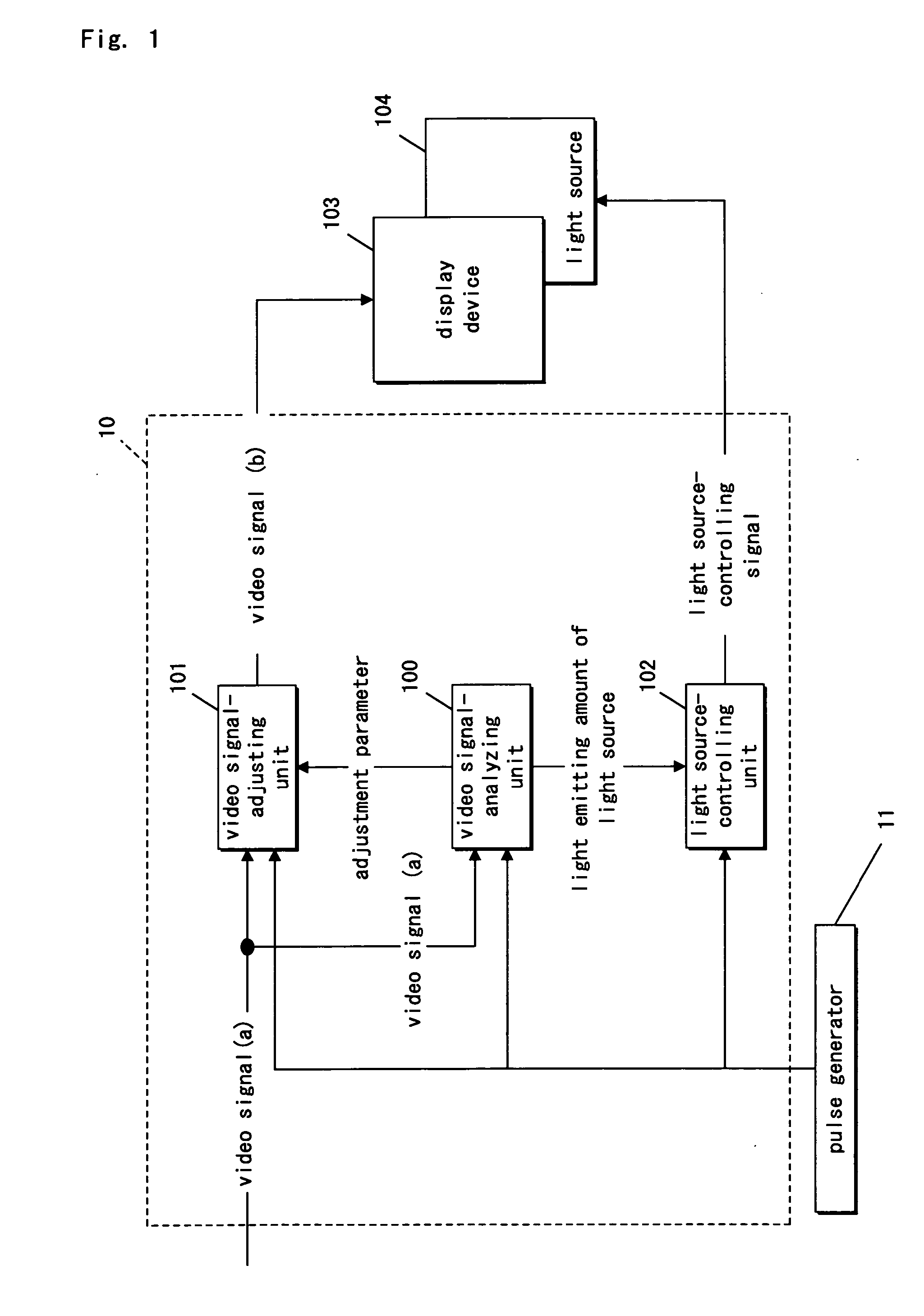

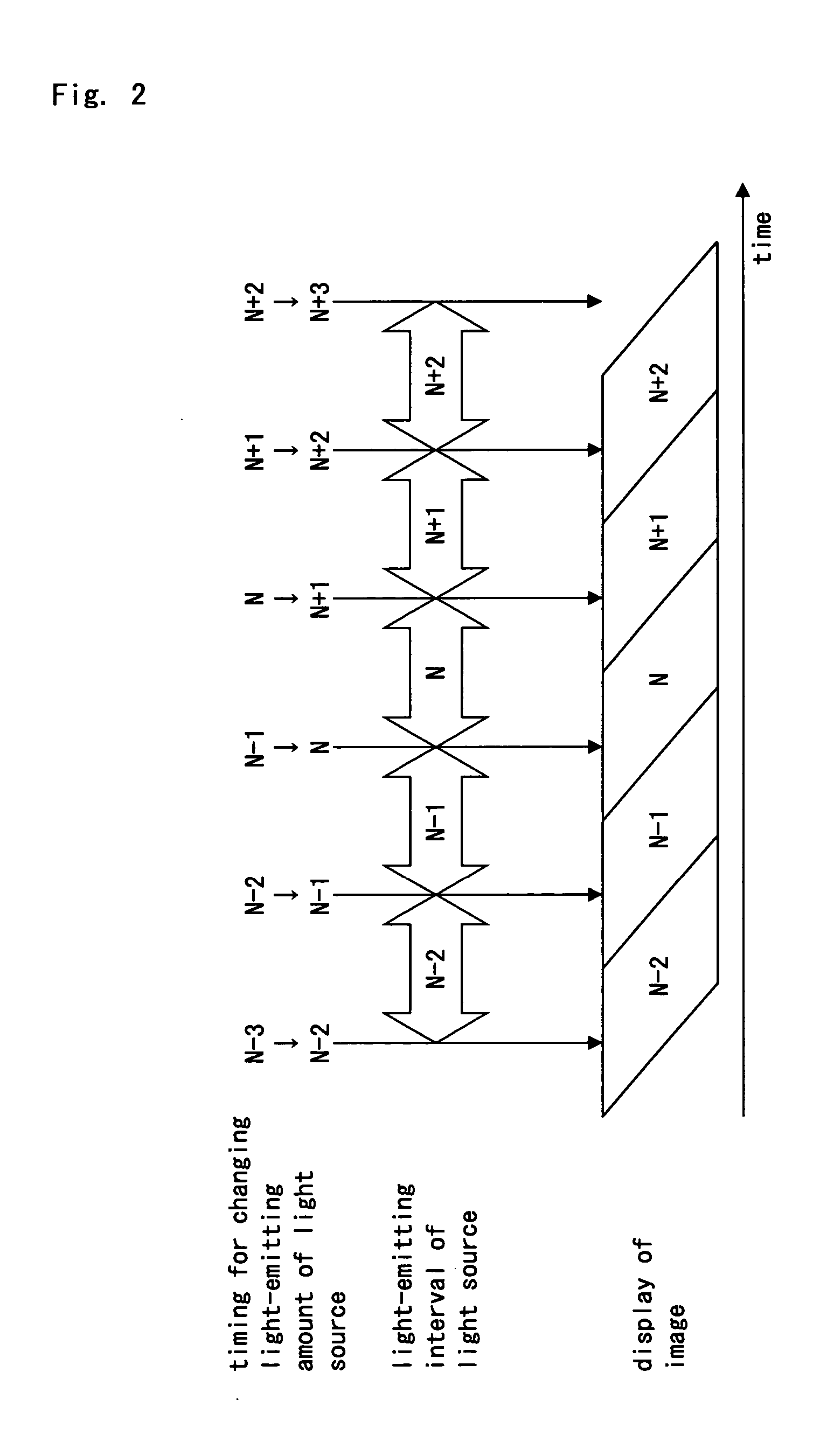

Display method, display controller, and display apparatus

ActiveUS20040207609A1Improve display qualityCathode-ray tube indicatorsBridge structural detailsImaging qualityComputer graphics (images)

A display controller including a video signal-analyzing unit, a video signal-adjusting unit operable to receive a video signal, to adjust the video signal in accordance with adjustment parameter information, and to feed the adjusted video signal into a display device, and a light source-controlling unit operable to feed a light source-controlling signal into a light source in accordance with light source light-emitting amount information. The video signal-analyzing unit allows timing in which the display device displays a picture in accordance with the adjusted video signal from the video signal-adjusting unit to be synchronized with timing in which the light source changes a light-emitting amount in response to the light source-controlling signal from the light source-controlling unit. As a result, such two different timings are held in a proper relationship with one another, and degradation in image quality is suppressed, which otherwise would result from a change in the light source to become dark and bright. This feature realizes high-quality video display.

Owner:PANASONIC CORP

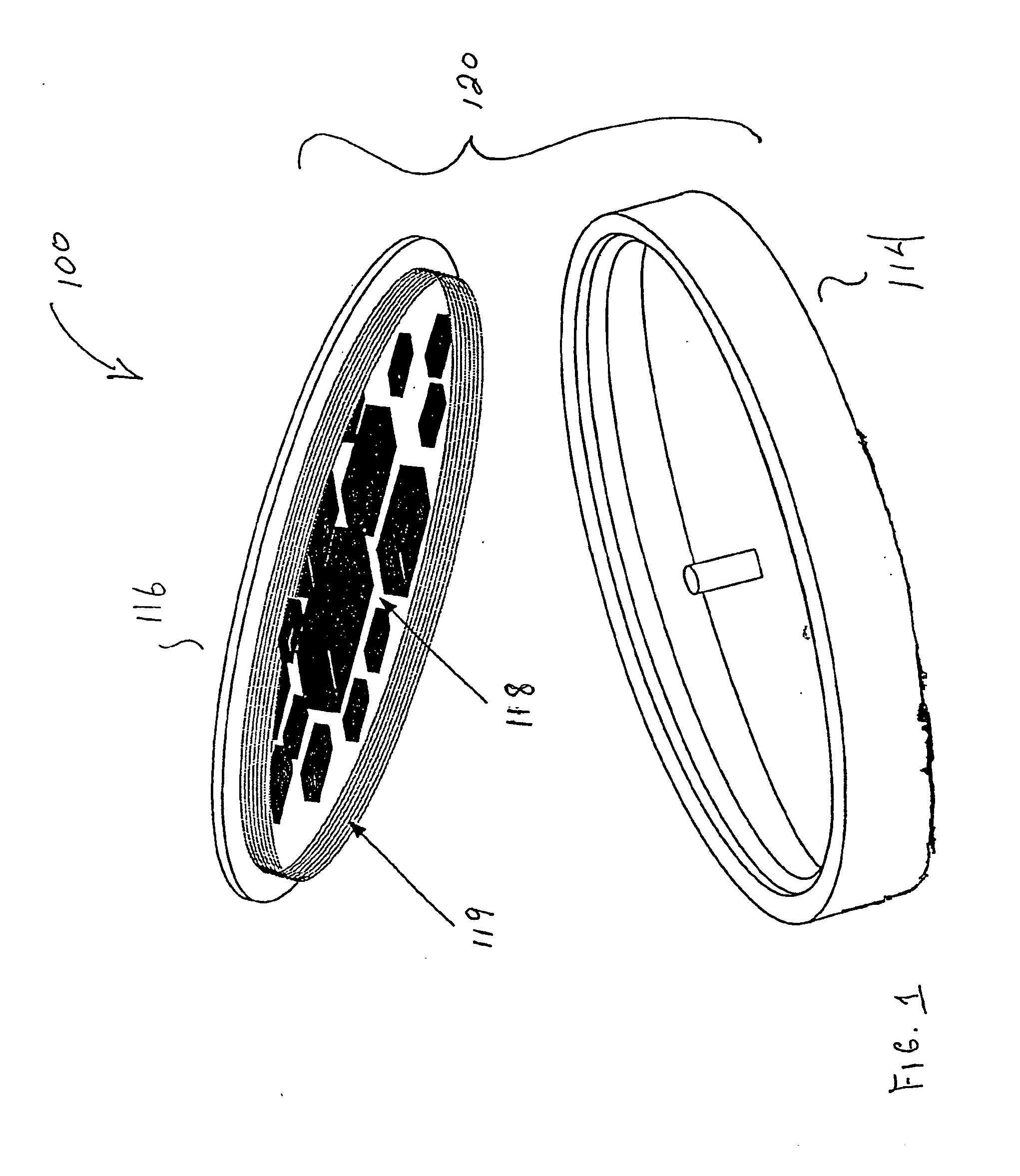

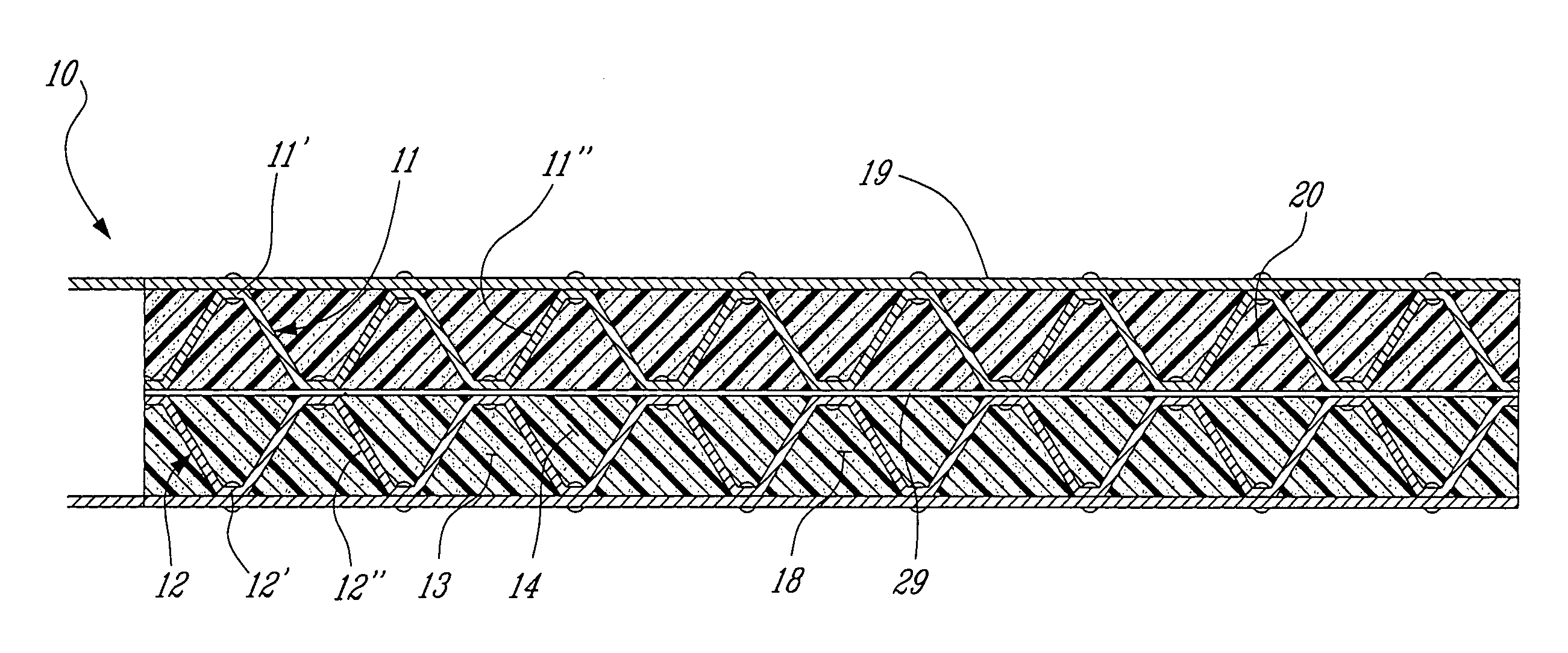

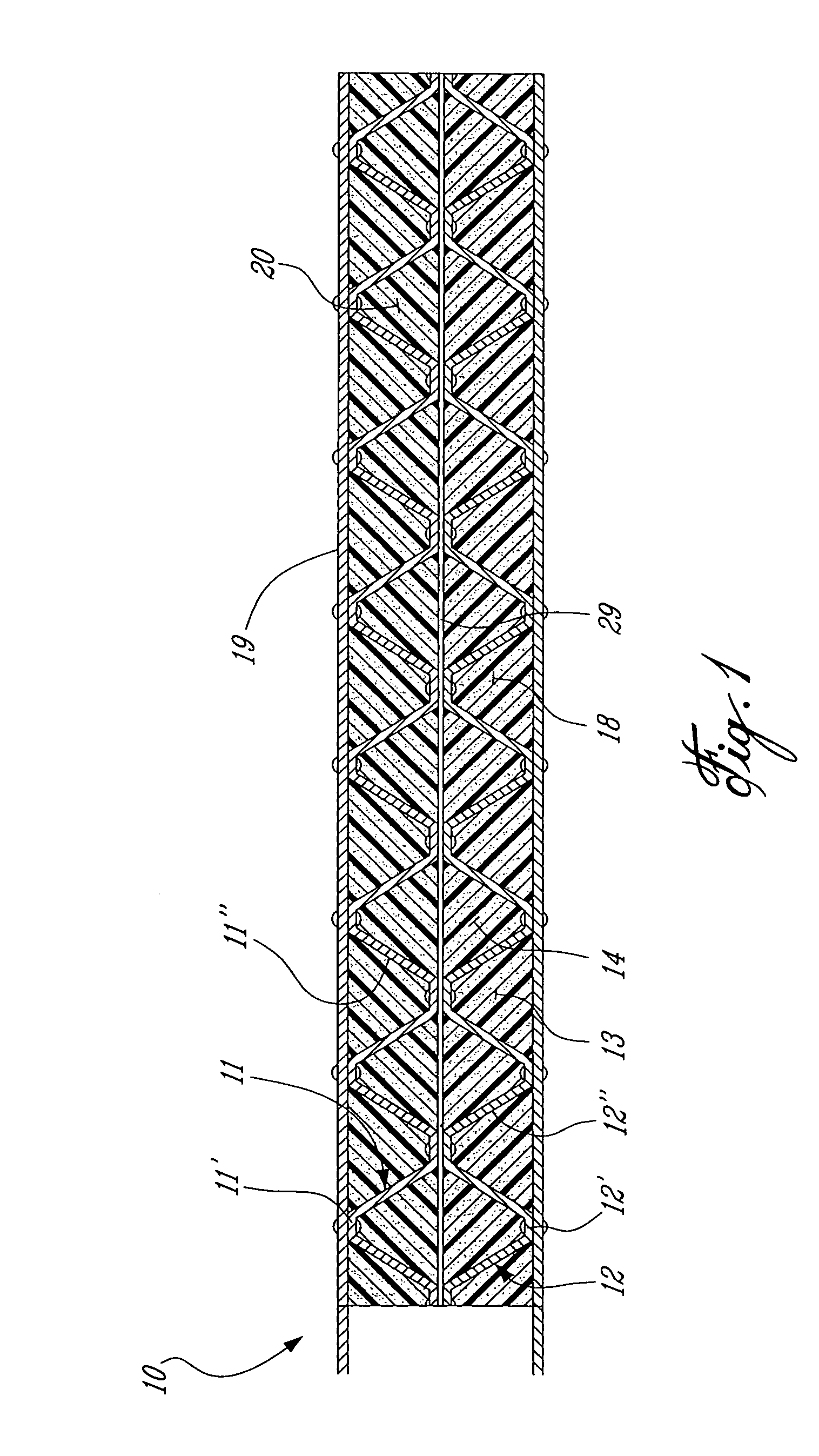

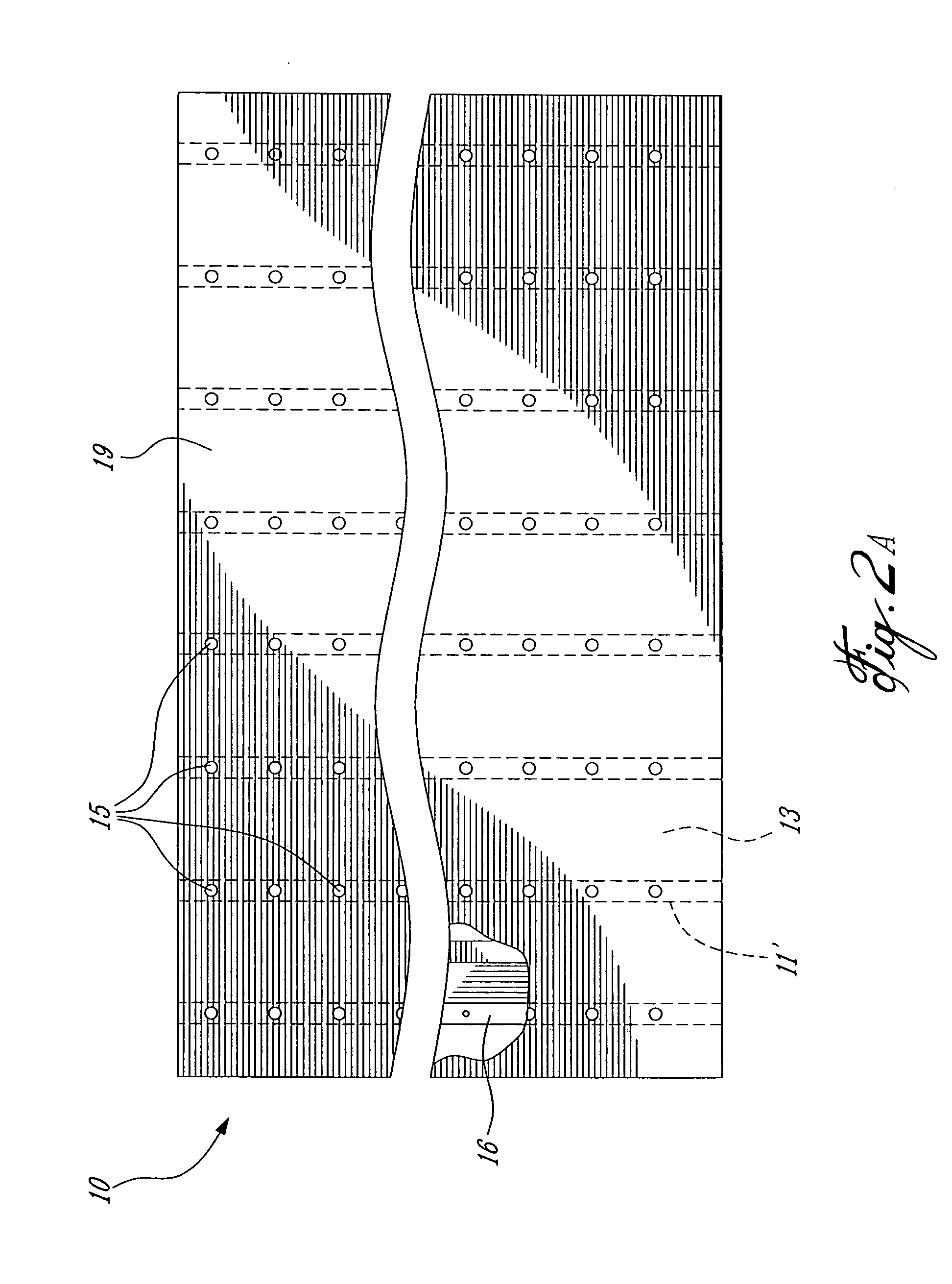

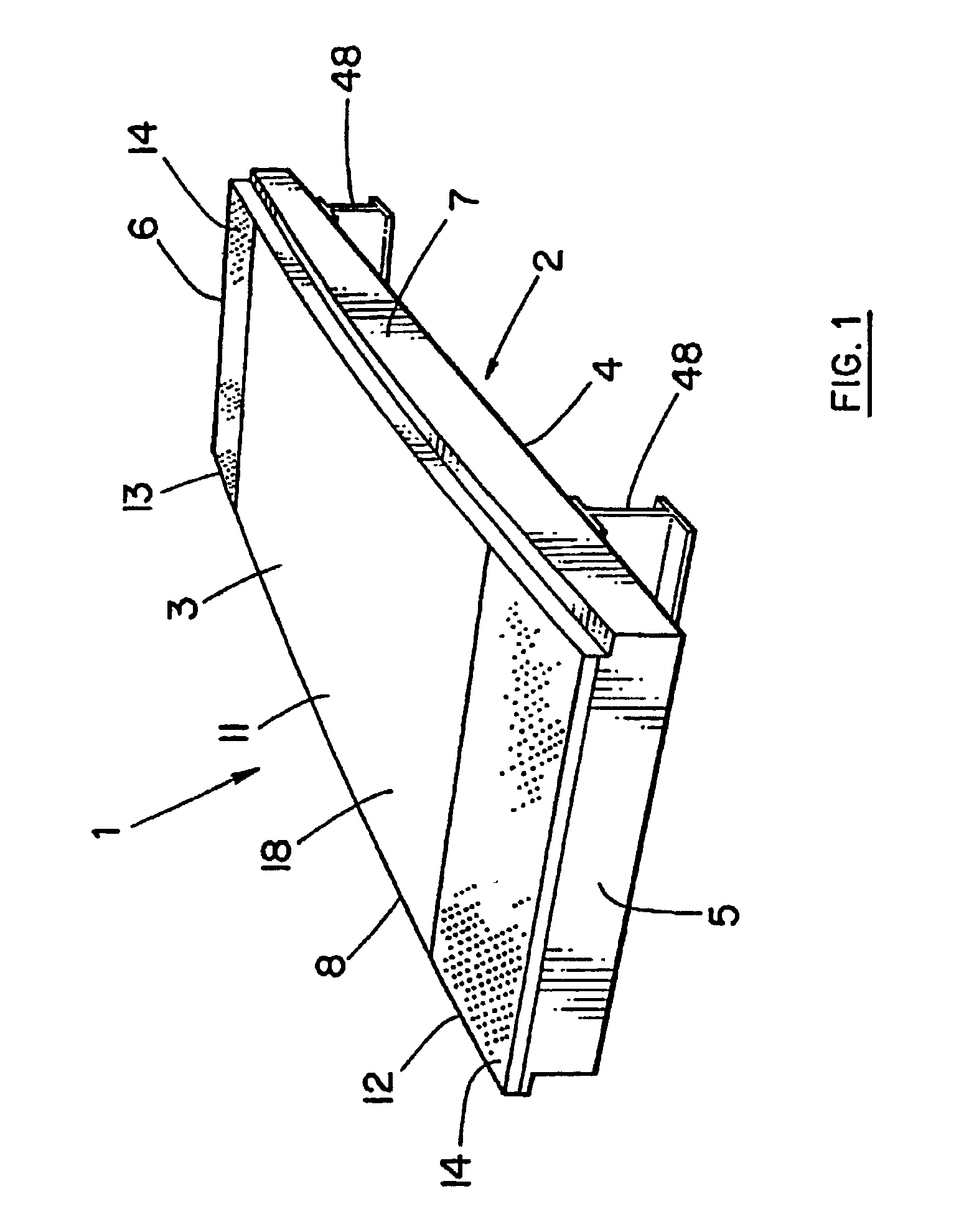

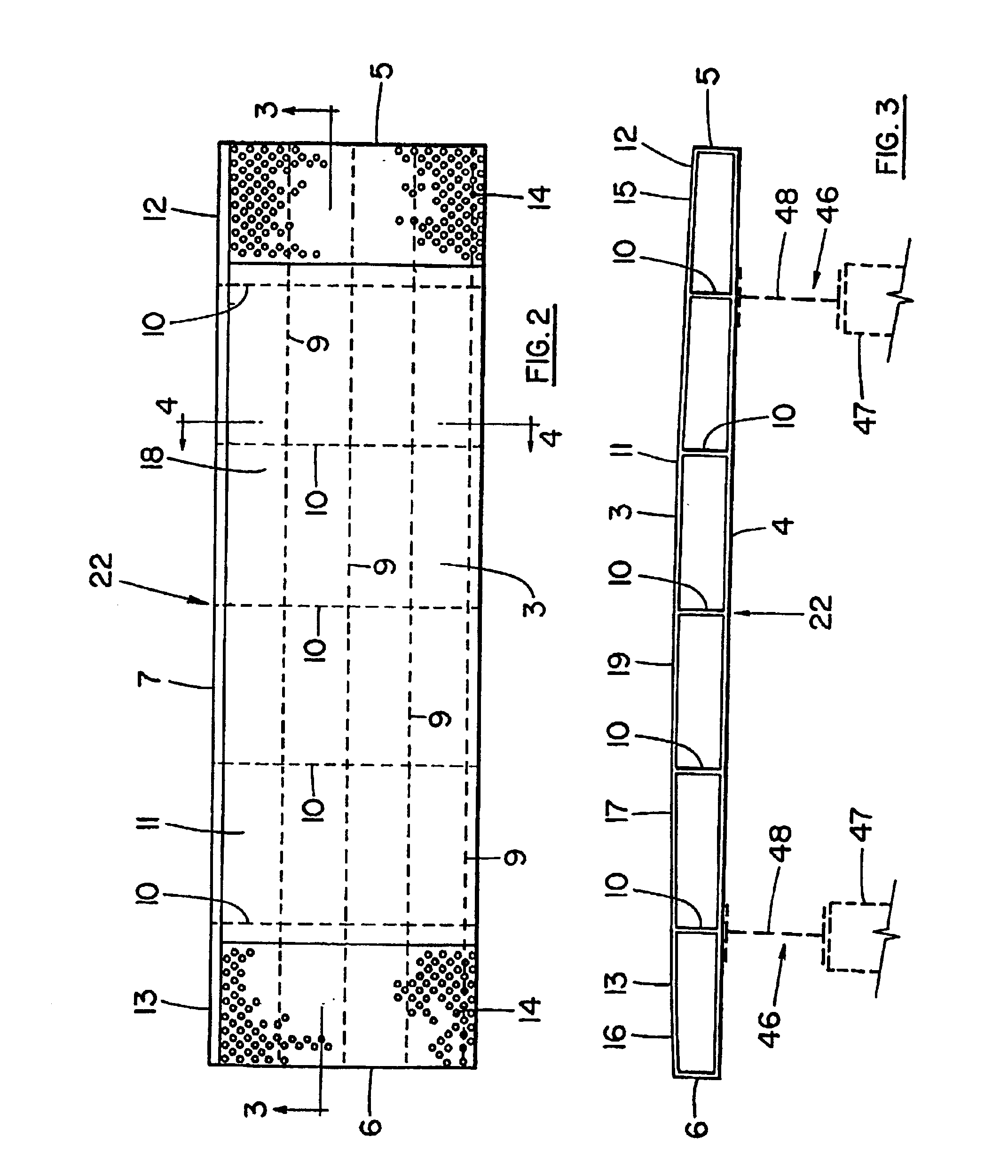

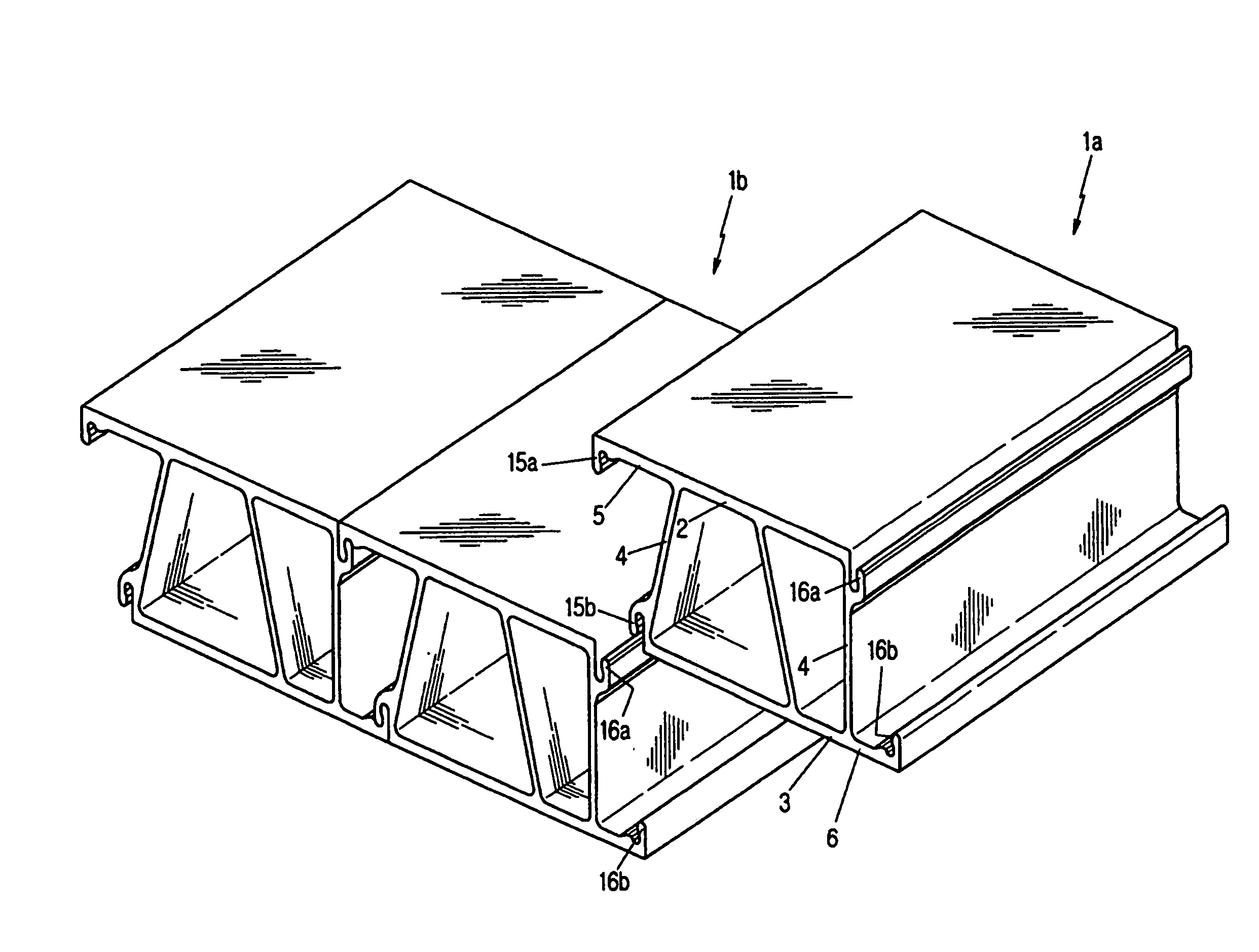

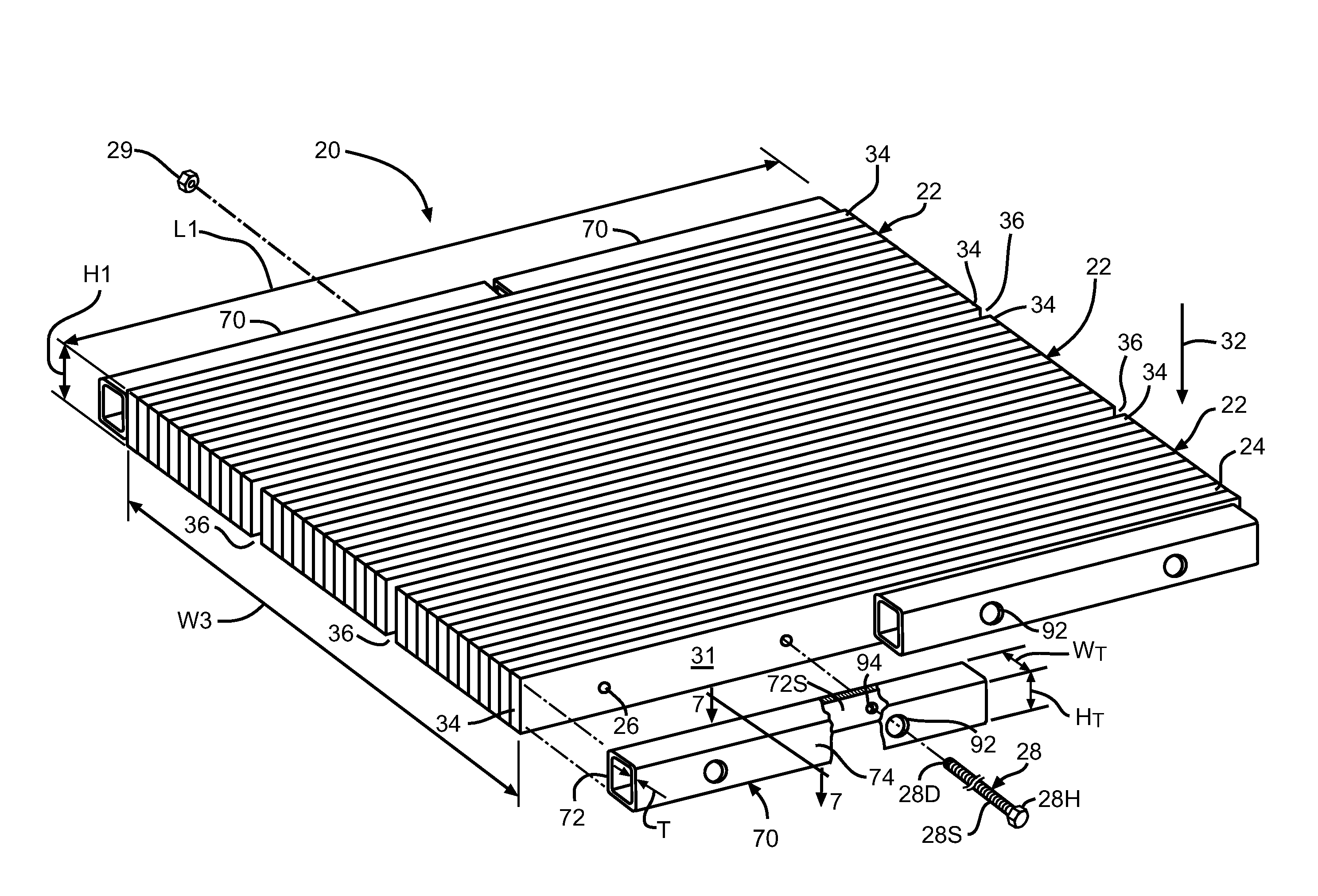

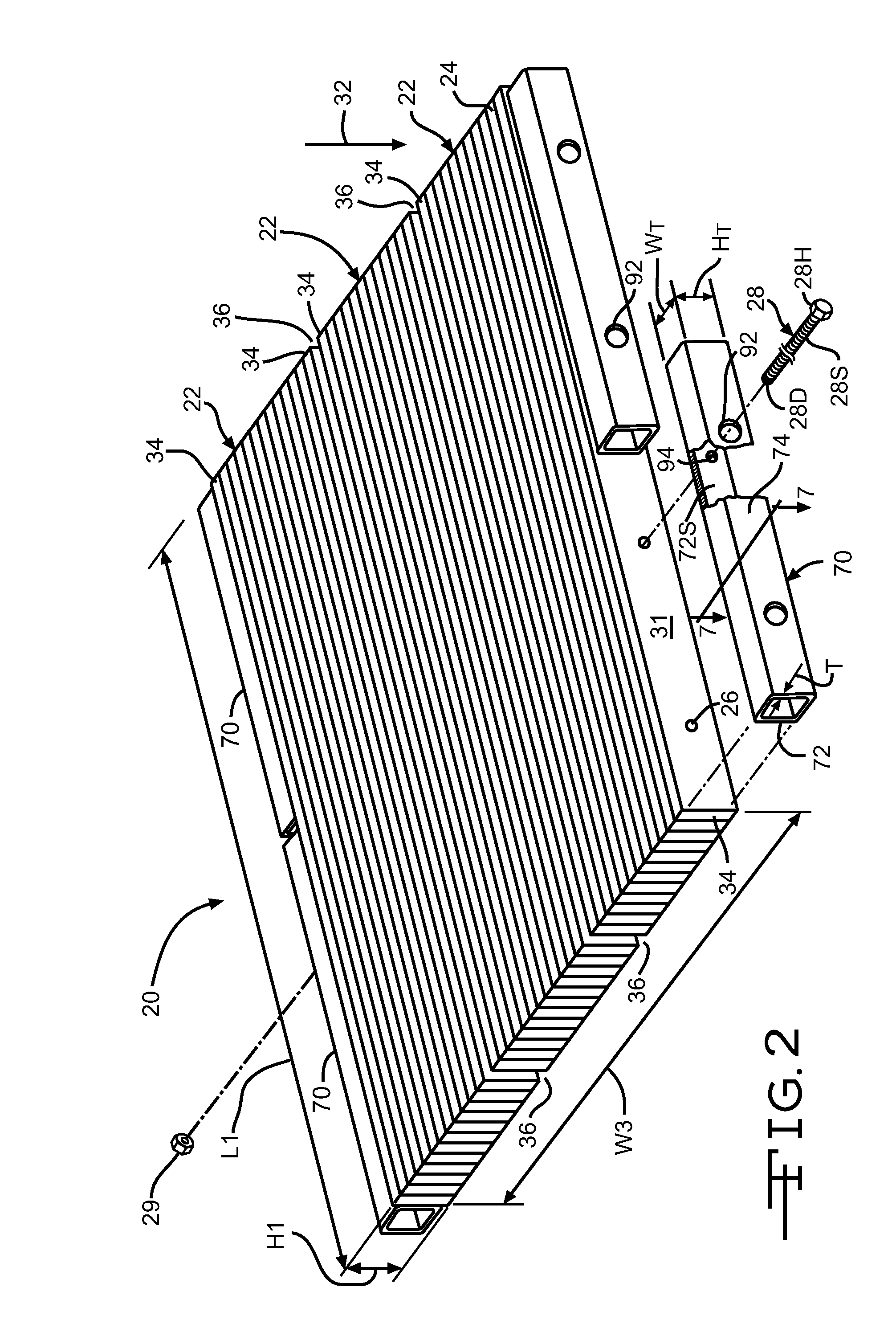

Fiber reinforced thermoplastic composite panel

InactiveUS20080078038A1Increased durabilityHigh fatigueSynthetic resin layered productsBridge structural detailsGlass fiberFilling materials

A fiber reinforced thermoplastic composite panel is described. One use of the panel is to construct bridge decks although the panel may have several other uses. It comprises two flat plates formed of commingled glass fiber reinforced polypropylene secured in spaced parallel relationship to a core. The core is formed by either two corrugated sheets interconnected together along connecting ridge sections or else by a plurality of elongated FRP channel members disposed transversely between the flat plates. The corrugated sheets or channel members form hollow core spaces between the two flat plates and the core material and these hollow spaces are filled with a filler material to add stability to the panel. Both the flat plates and the core material are formed of commingled glass fiber reinforced polypropylene (FRP).

Owner:BORAZGHI HOSSEIN

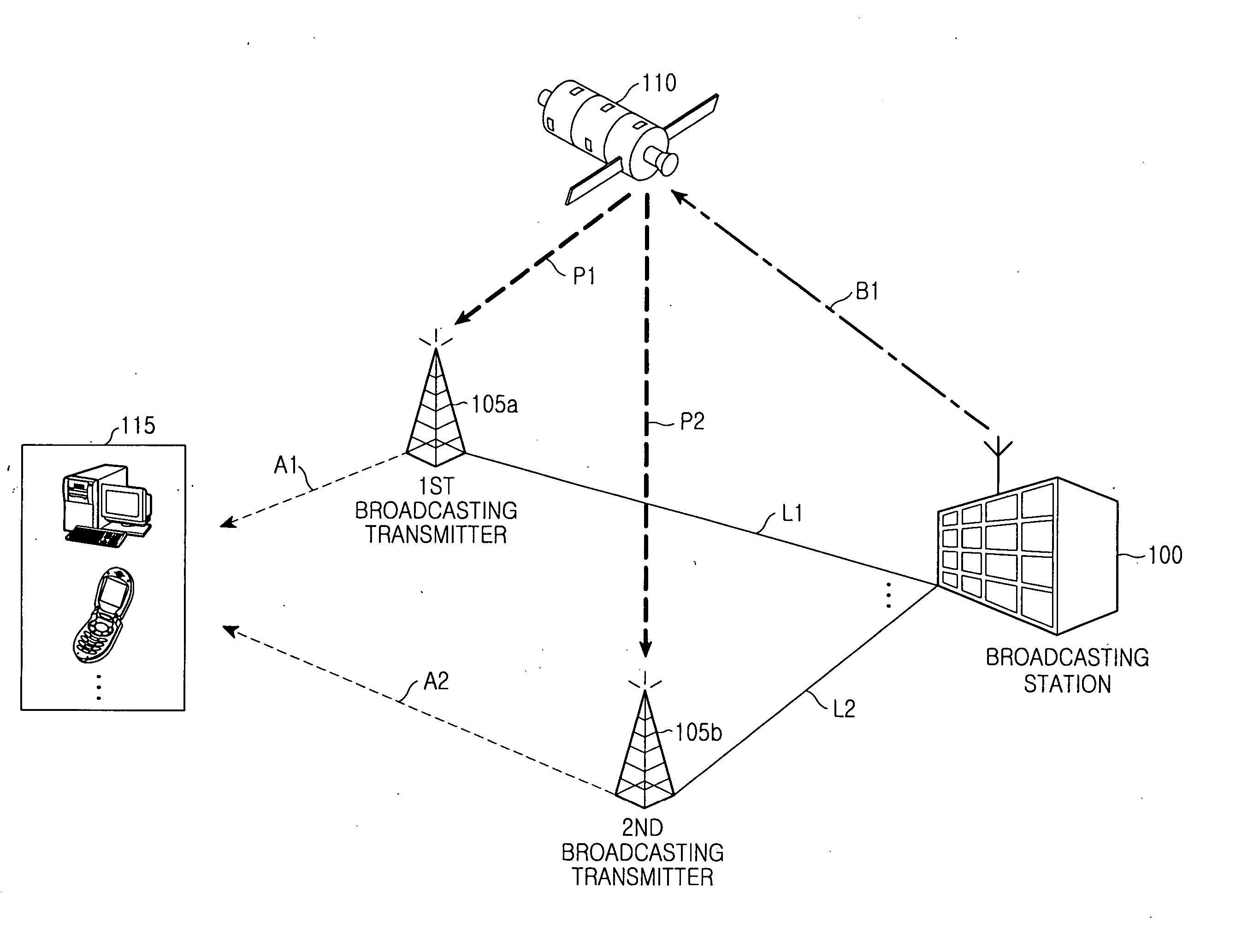

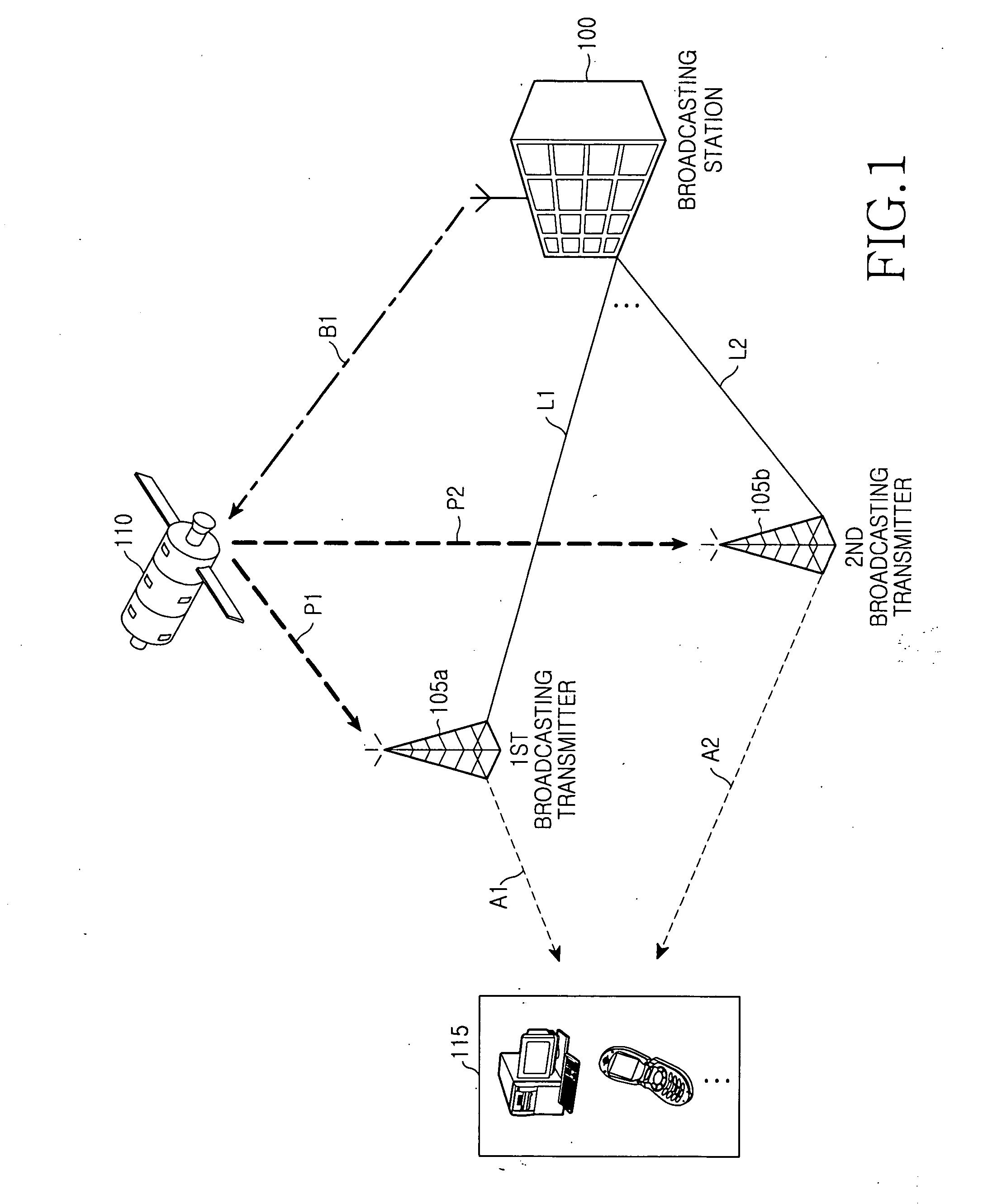

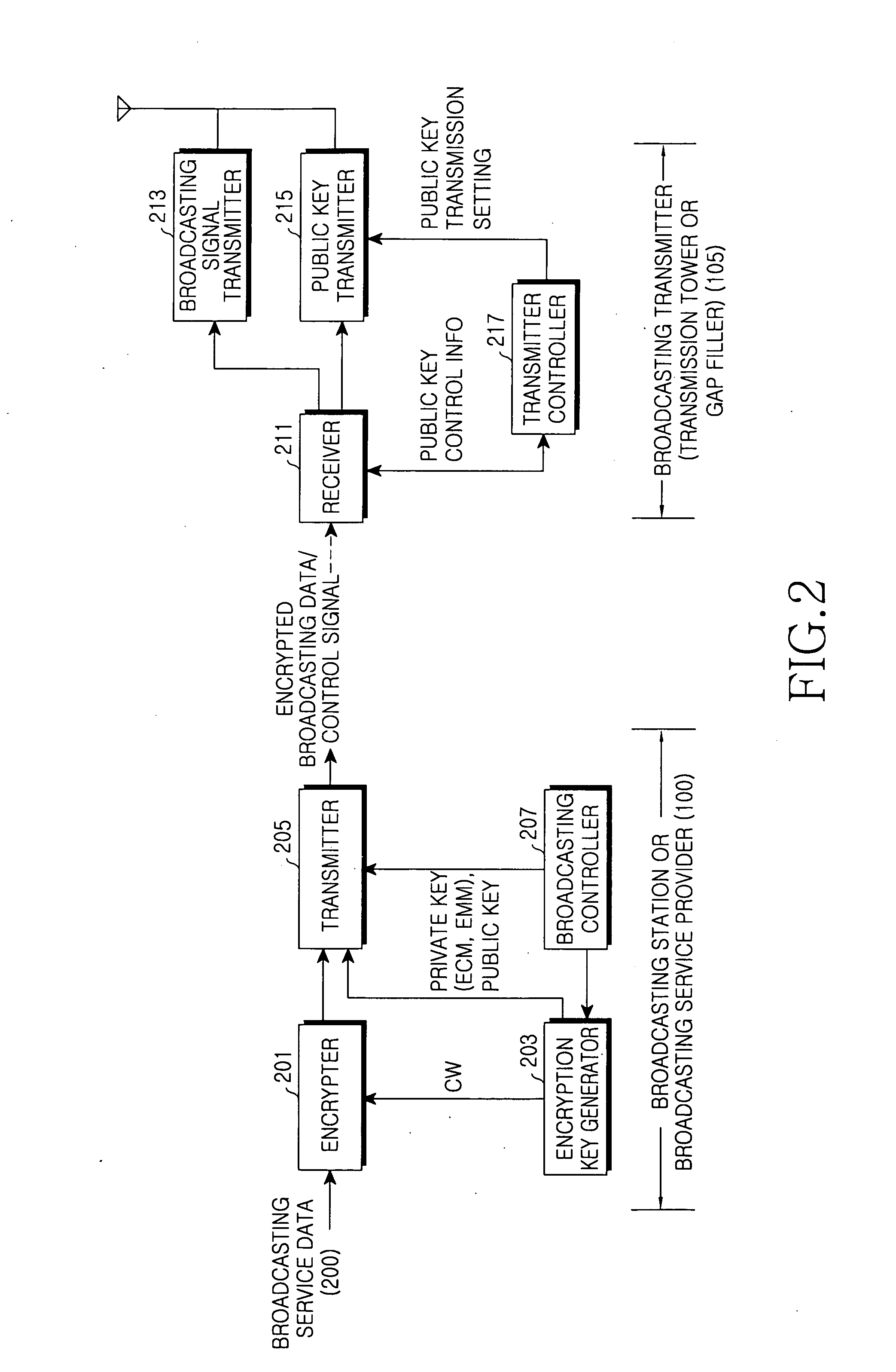

Apparatus, method and system for providing a broadcasting service in a digital broadcasting system with a single frequency network

InactiveUS20060233359A1Key distribution for secure communicationPublic key for secure communicationConditional access systemsDigital broadcasting

An apparatus, method, and system for providing a broadcasting service in a Digital Multimedia Broadcasting (DMB) system with a Single Frequency Network (SFN). Networks of shadow and non-shadow regions can be distinguished in the digital broadcasting system. A conditional access system can be used in the shadow region. A terminal can select a service network. A broadcasting providing server encrypts broadcasting service data, generates private and public keys into which predetermined encryption keys are divided to decrypt the encrypted broadcasting service data, sets at least one broadcasting transmitter for transmitting the private key and / or at least one broadcasting transmitter for transmitting the public key, and provides the encryption keys along with the encrypted broadcasting service data. Broadcasting transmitters transmit the encrypted broadcasting service data received from the broadcasting providing server and the private key using the SFN. At least one of the broadcasting transmitters further transmits the public key.

Owner:SAMSUNG ELECTRONICS CO LTD

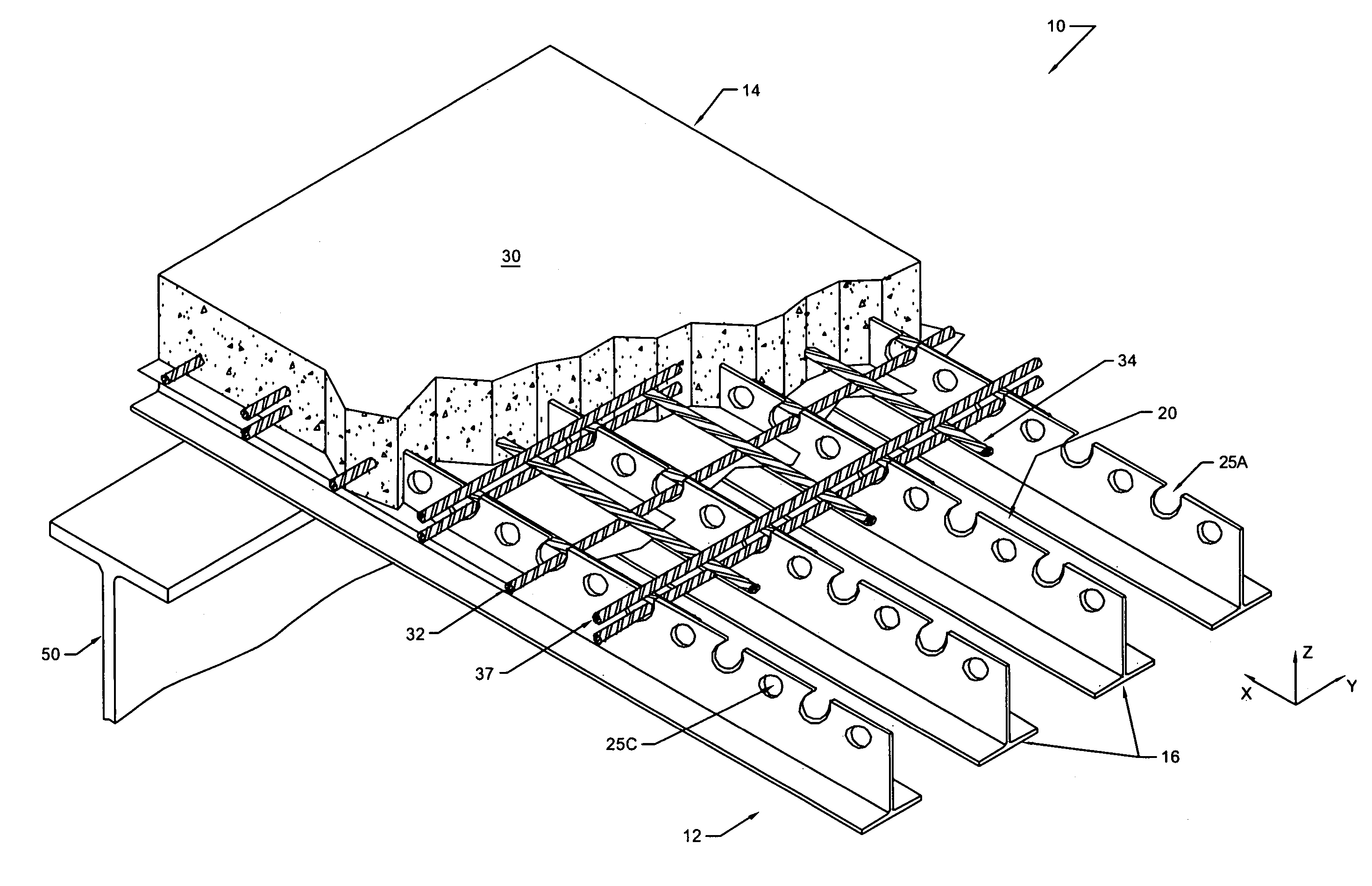

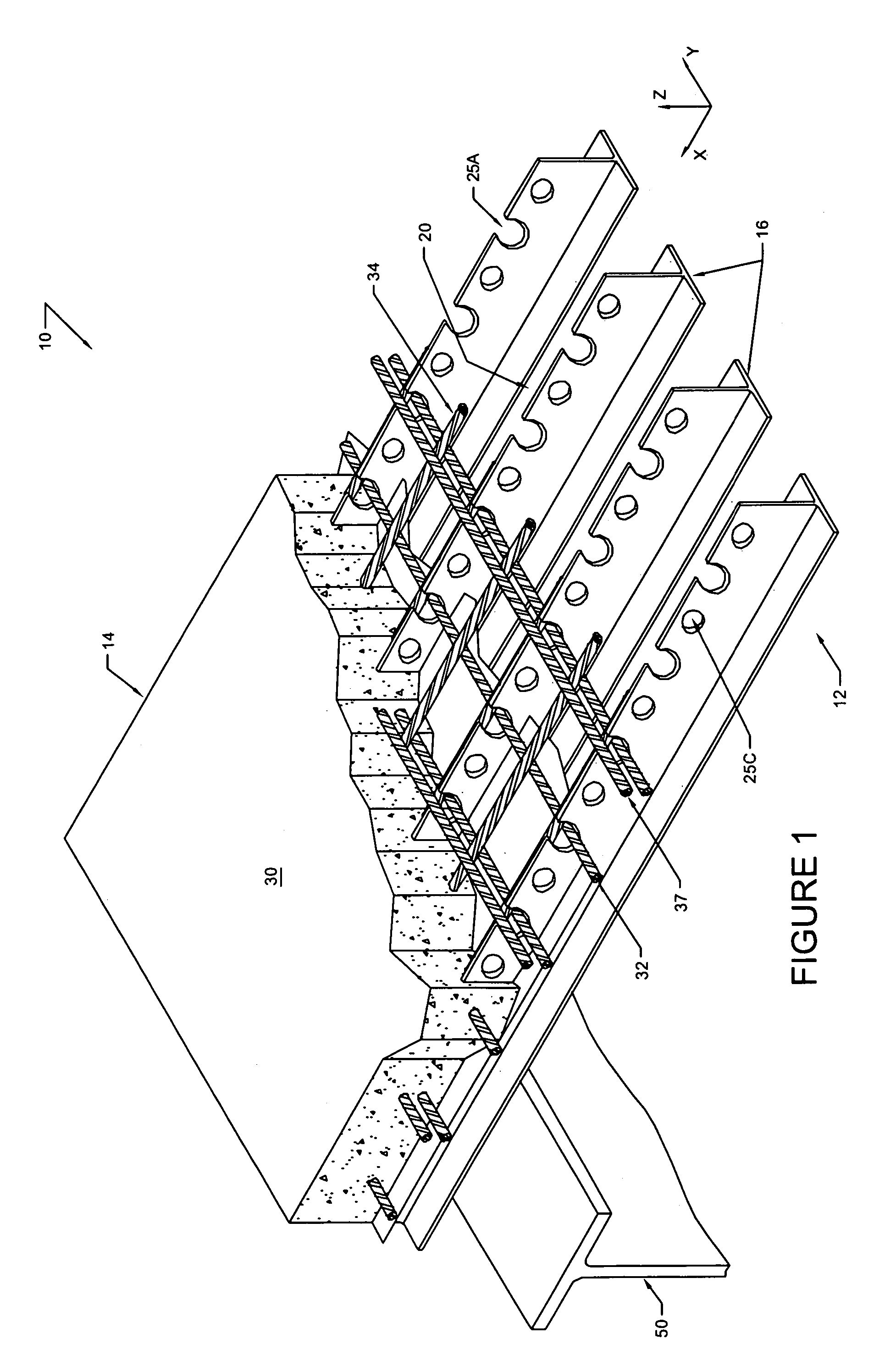

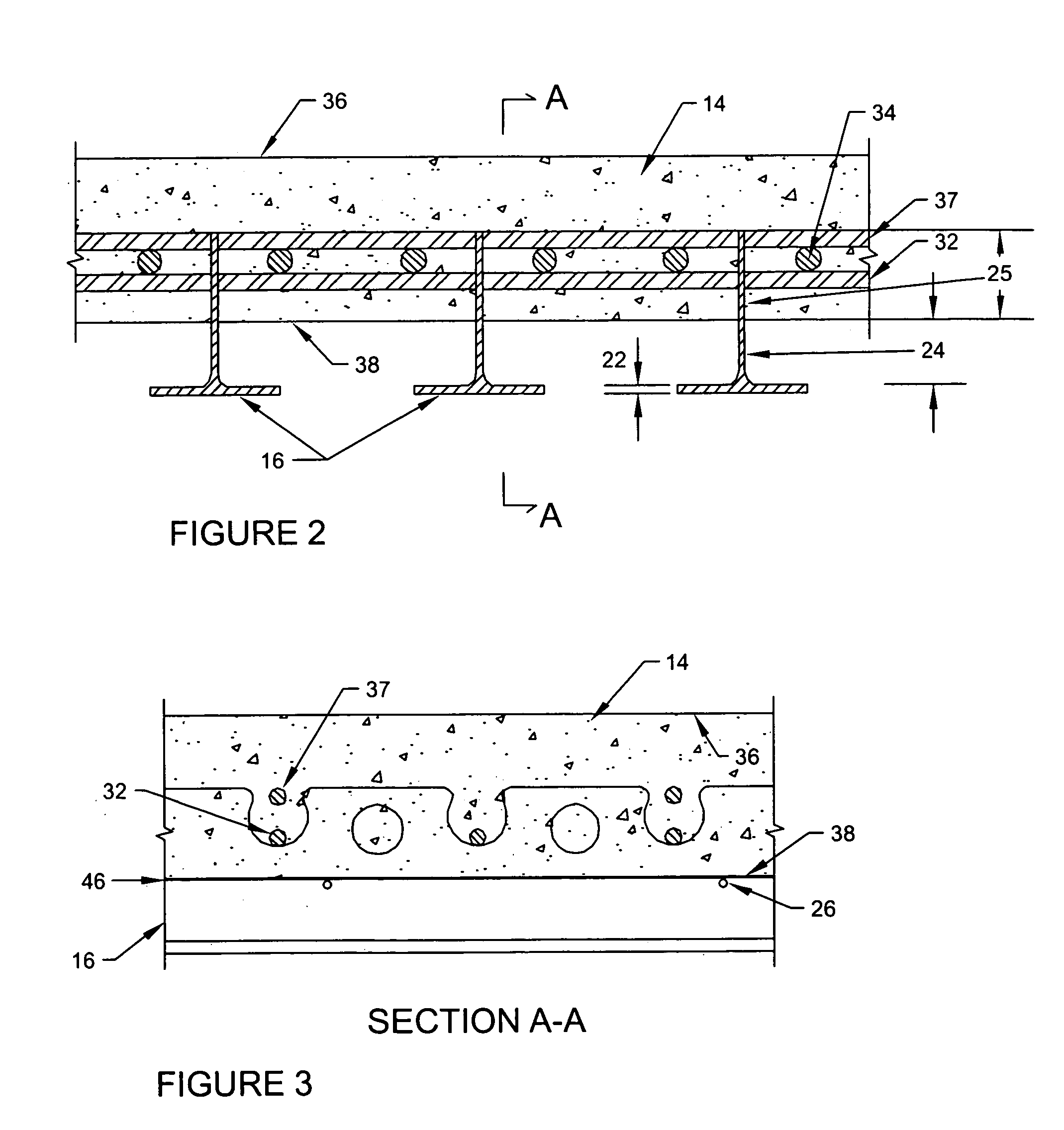

Prestressed or post-tension composite structural system

InactiveUS7197854B2Improved shear connectionEliminates some of the punching and all of the weldingFloorsBridge structural detailsGratingFloor slab

A prestressed or post-tensioned composite structural system for bridge floors, road beds, pedestrian walkways, building floors, building walls, or similar structural elements. The structural system comprises a composite structure comprising an unfilled grating as a base component, and a prestressed, post-tensioned reinforced concrete slab as a top component. The base grating component is preferably a plurality of main bearing bars without any distribution bars or tertiary bars. The upper portions of the main bearing bars are embedded in the concrete component permitting horizontal shear transfer and creating a composite deck structure which maximizes the use of tensile strength of steel and the compressive strength of concrete.

Owner:D S BROWN

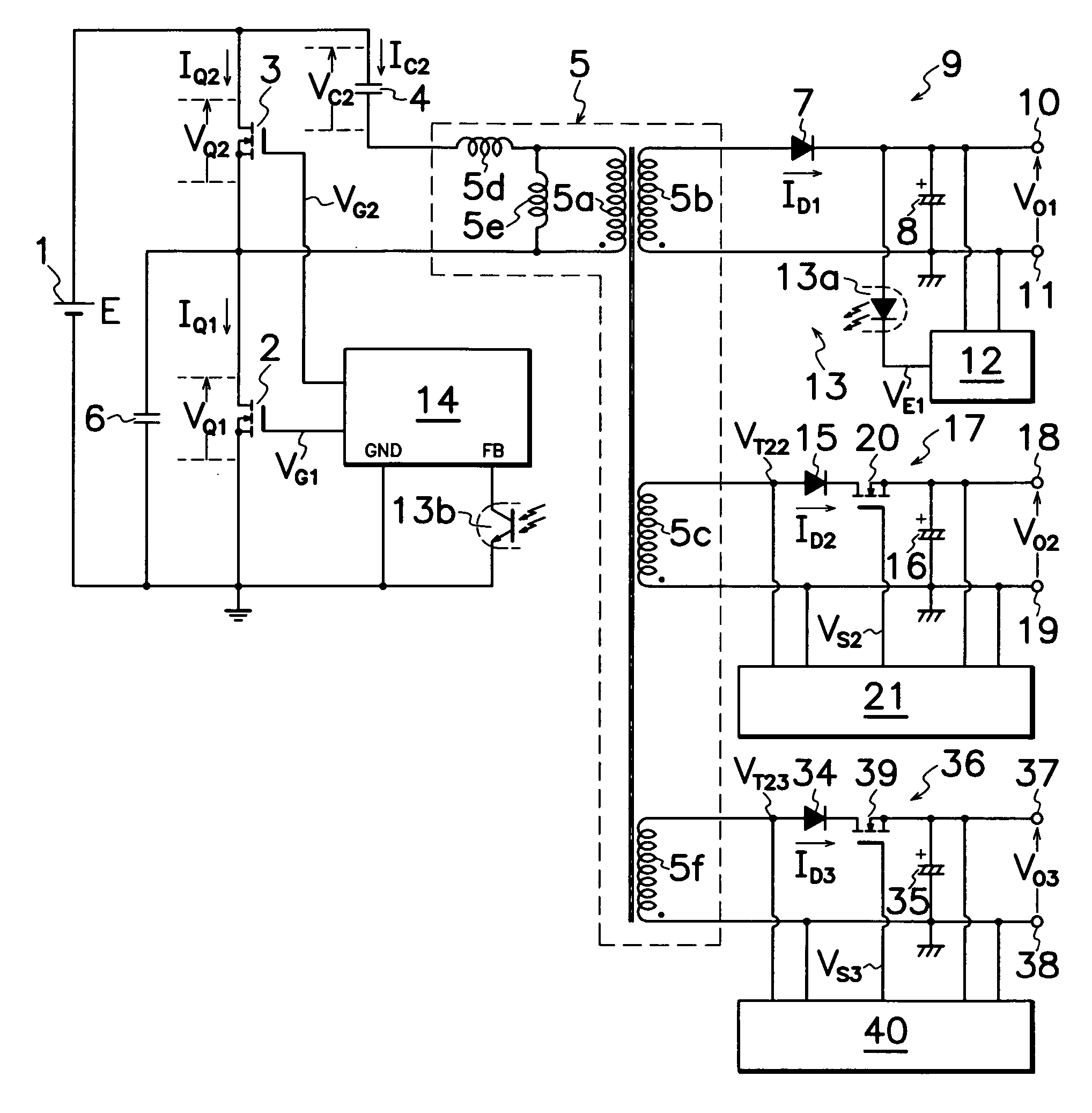

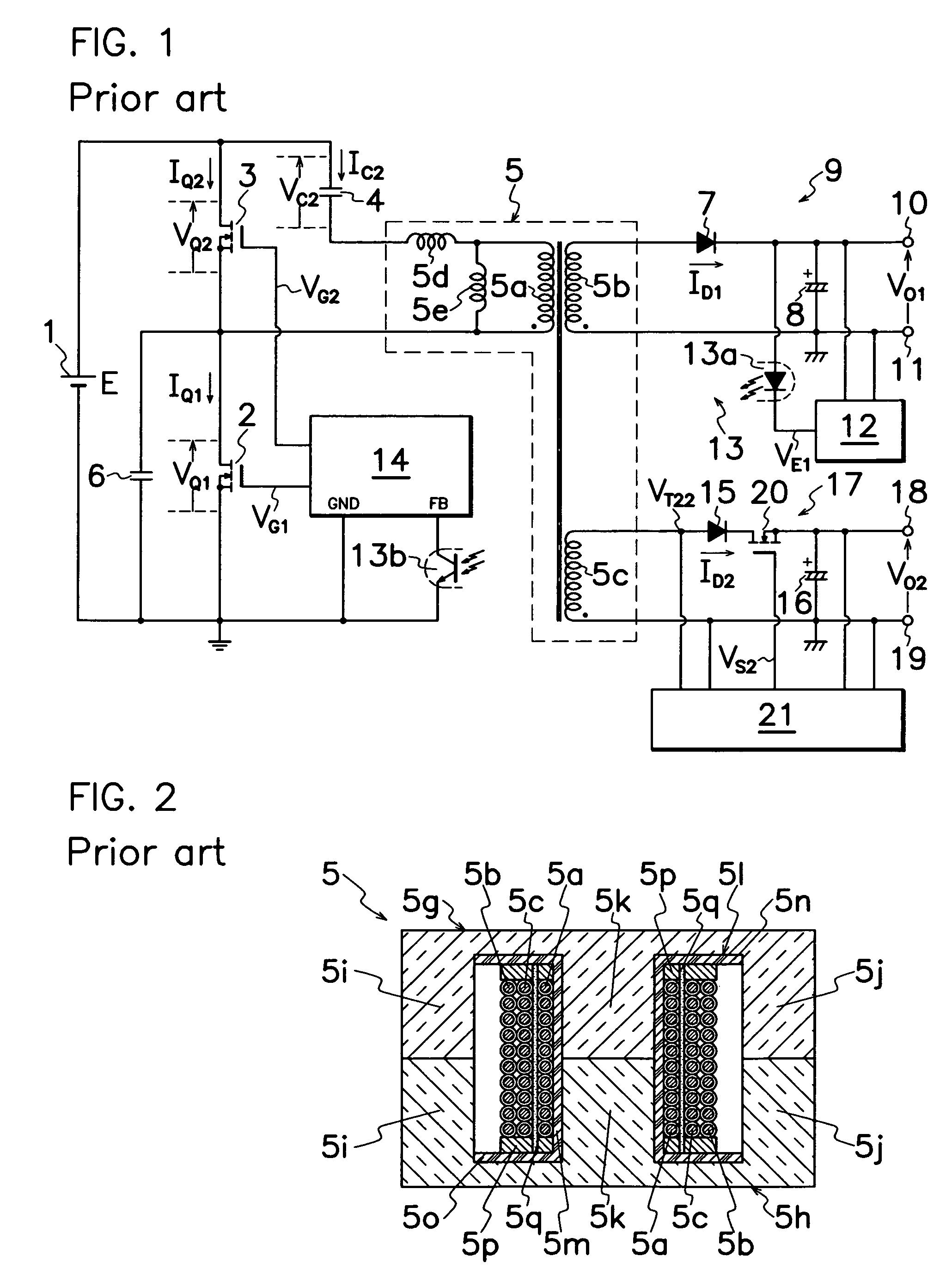

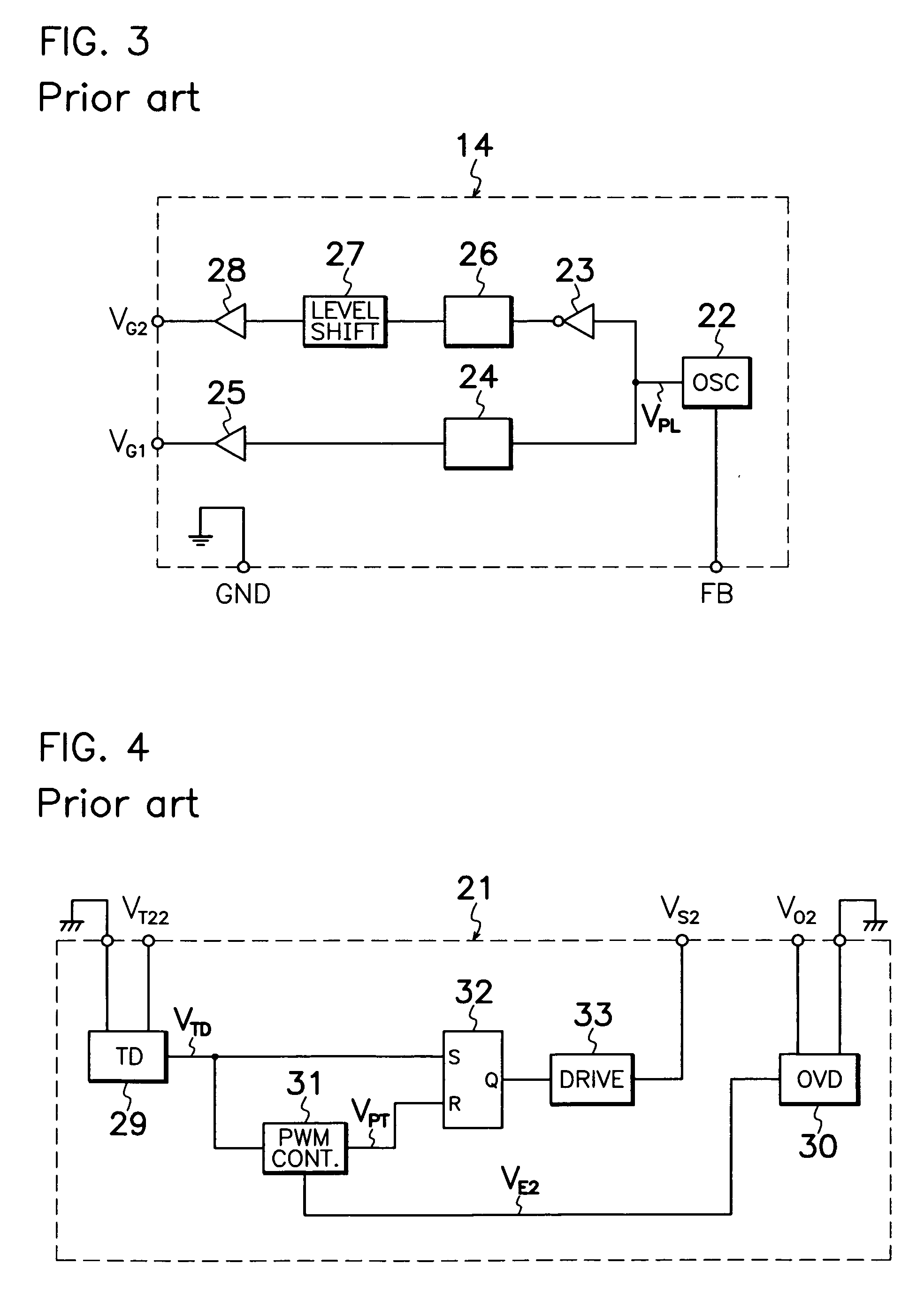

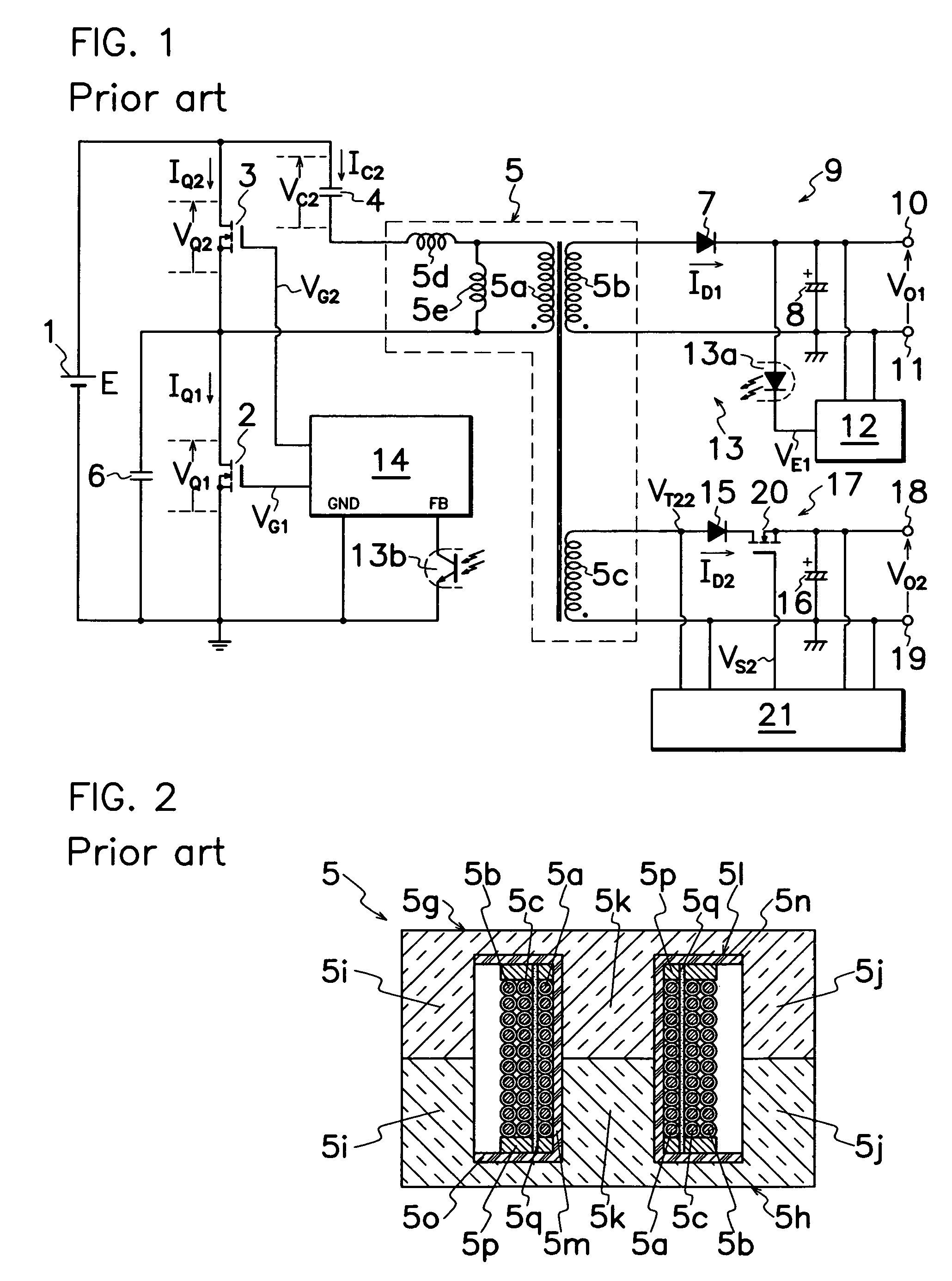

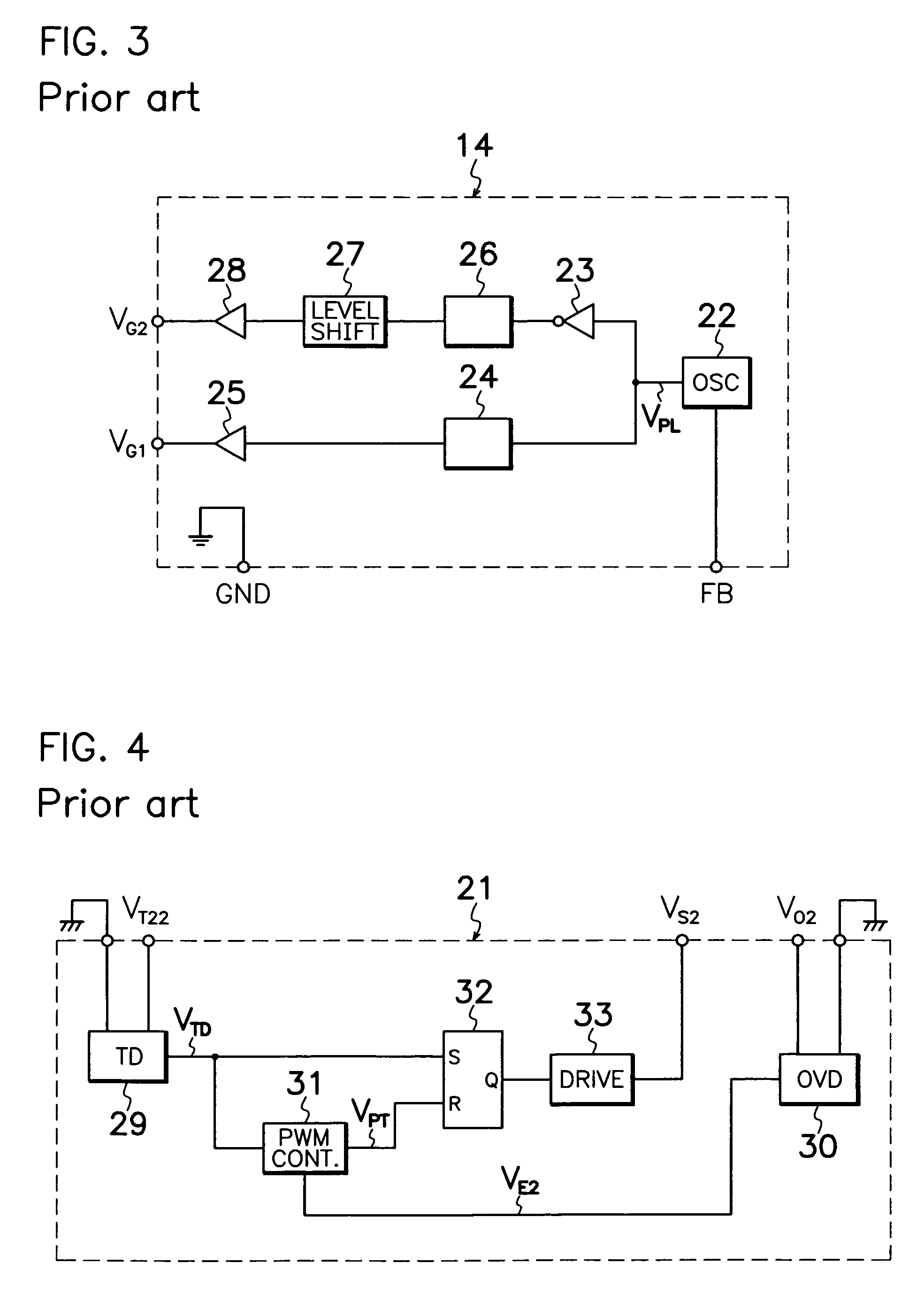

DC-DC converter of multi-output type

InactiveUS20060158908A1Reduce, attenuate or relax serge voltageDc network circuit arrangementsAc-dc conversion without reversalElectric forceDc dc converter

A DC-DC converter of multi-output type is provided wherein a primary winding 5a is wound around core halves 5g, 5h of a transformer 5 between first and second secondary windings 5b, 5c of transformer 5 also concentrically wound around core halves 5g, 5h to form an electromagnetic sparse coupling between first and second secondary windings 5b, 5c. When on-off operation of first and second primary MOS-FETs 2, 3 generates first and second DC outputs VO1, VO2, the electromagnetic sparse coupling can reduce, attenuate or relax serge voltage induced on first secondary winding 5b. This restrains or controls potential increase in first output voltage VO1 resulted from serge voltage through first rectifying smoother 9 under the light- or no-load condition to control fluctuation in second output voltage VO2 through second rectifying smoother 17 without restricting transmission of electric power from the primary to the secondary side making use of feedback control to primary control circuit 14 in order to generate stable first and second DC output voltages VO1 and VO2 throughout the entire loaded and unloaded range.

Owner:SANKEN ELECTRIC CO LTD

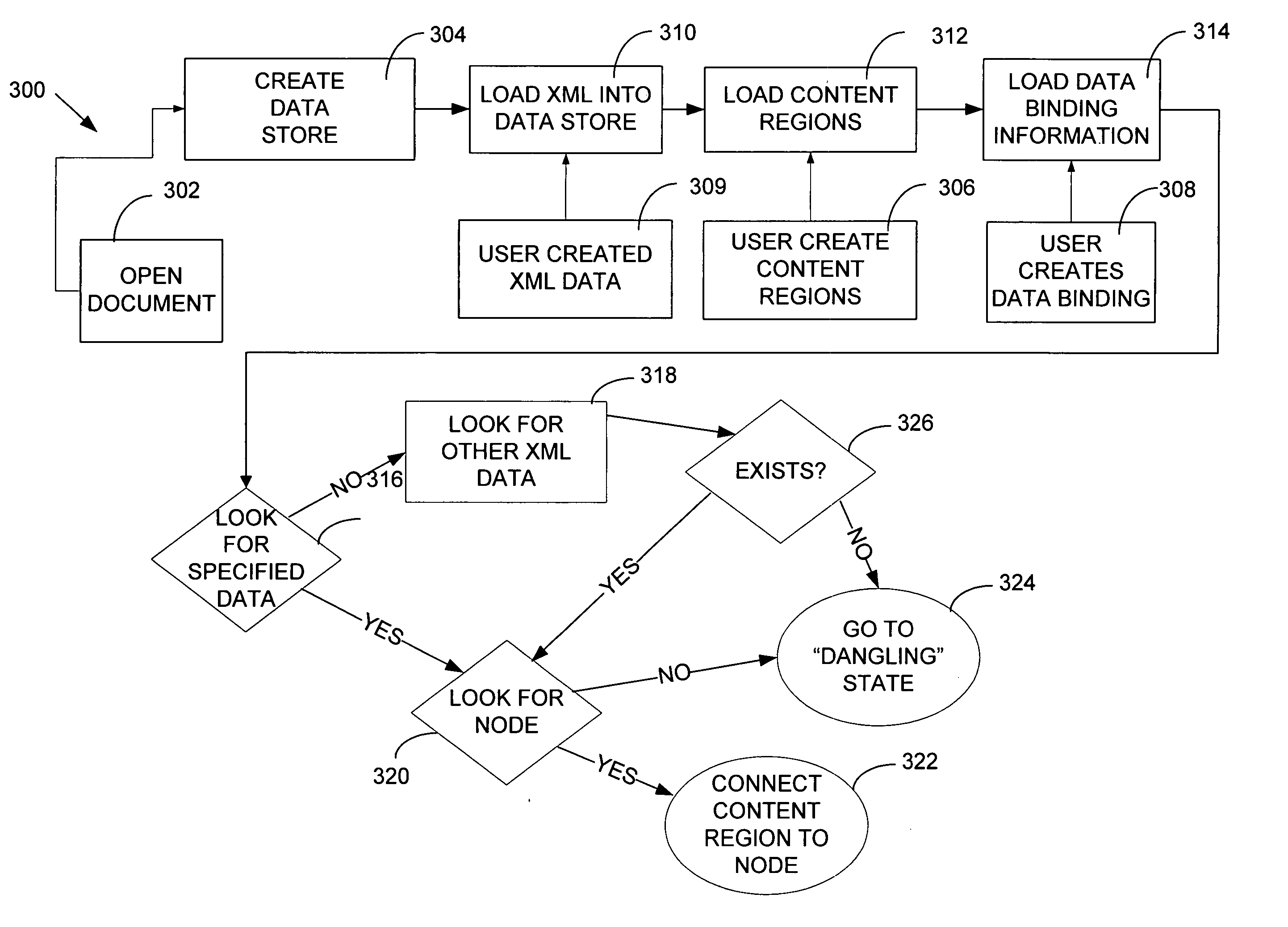

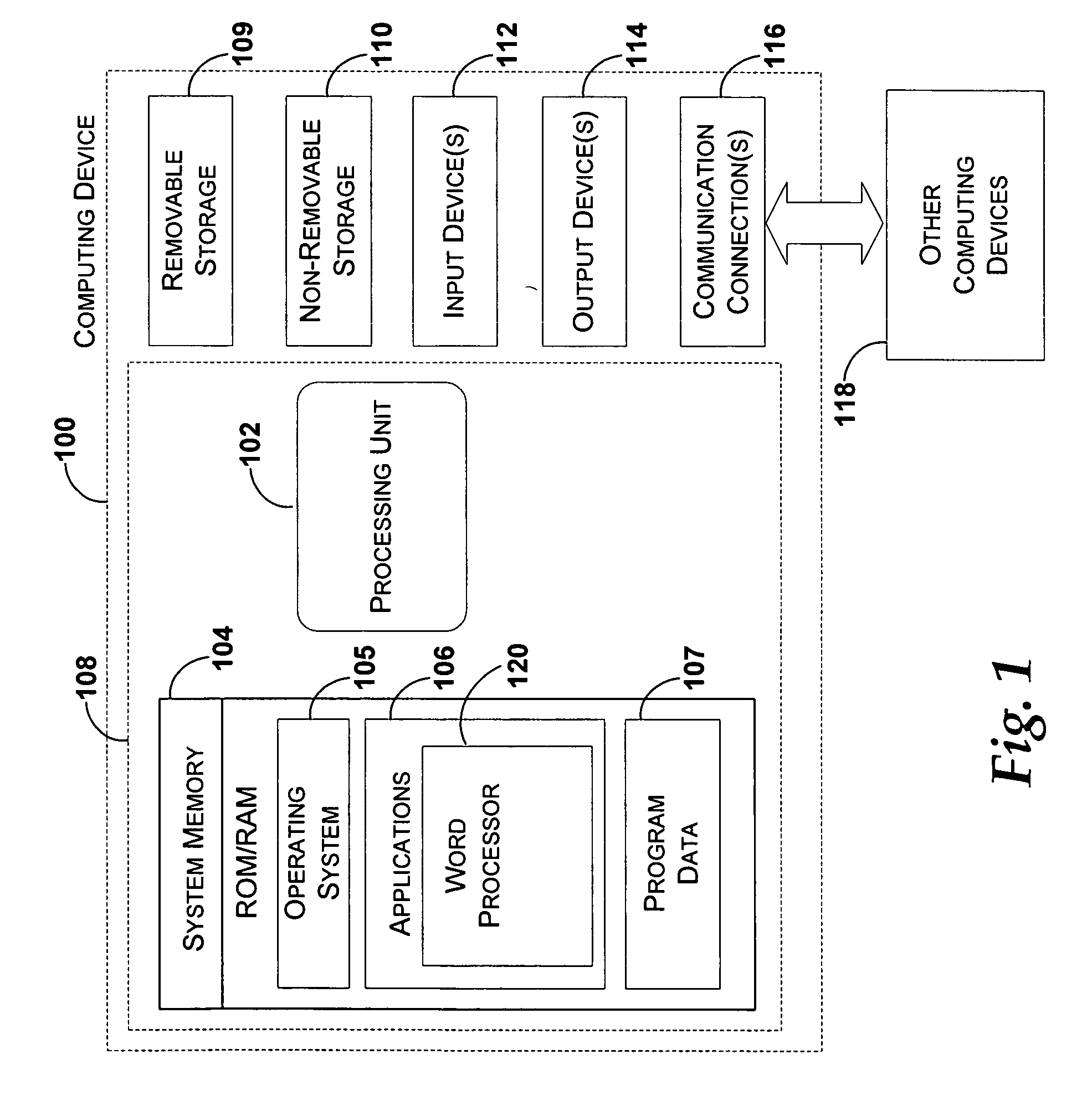

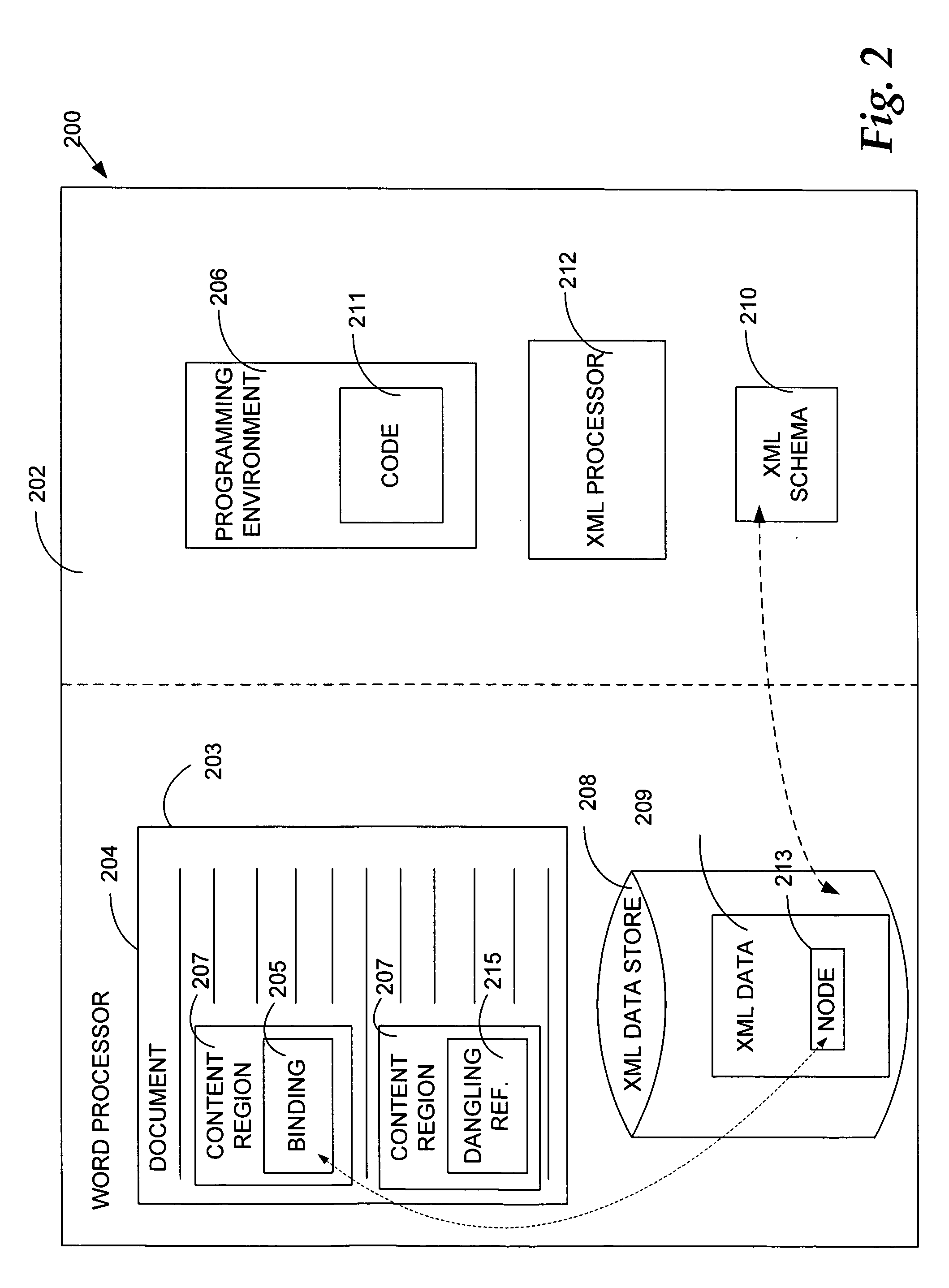

Programmability for binding data

InactiveUS20060195783A1Simplifying and streamlining application developmentSimplify the development processMultiprogramming arrangementsNatural language data processingWord processingData store

An object model allows code to be developed using a programming environment to access the functionality of an application, in a word processing application, for example. The object model may be used to manipulate one or more data bindings in an application. Code may also be developed using a programming environment for reacting to changes, in either direction, of a content region or a node in XML data associated with one or more data bindings. Code may be developed to define data bindings between file content and content within data in a data store. Additionally, code may be developed that reacts to changes within a bound region of a file or within a data store, trapping or intercepting events, such as edits, additions, deletions, etc.

Owner:MICROSOFT TECH LICENSING LLC

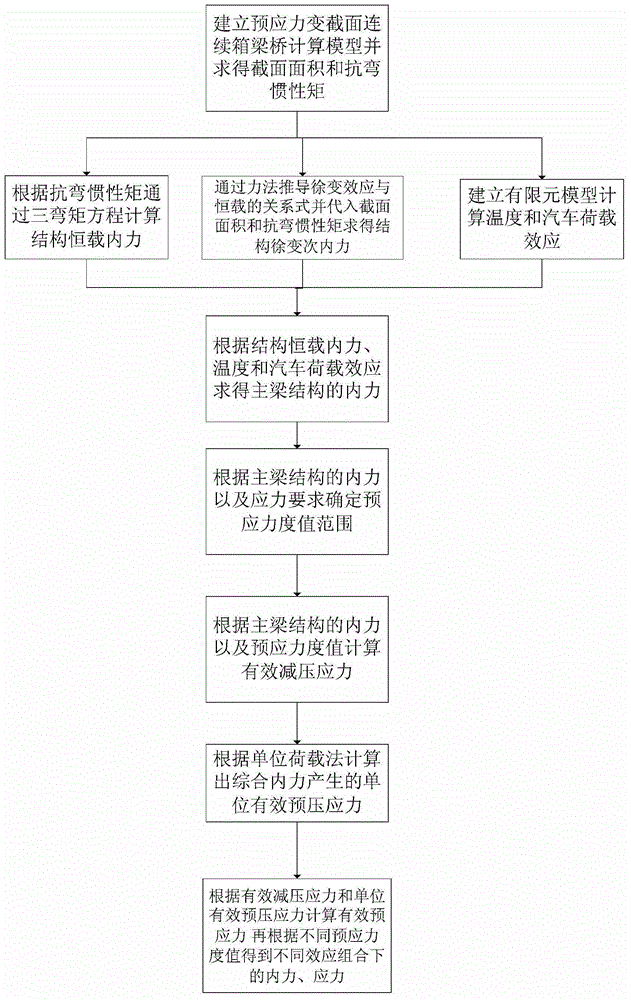

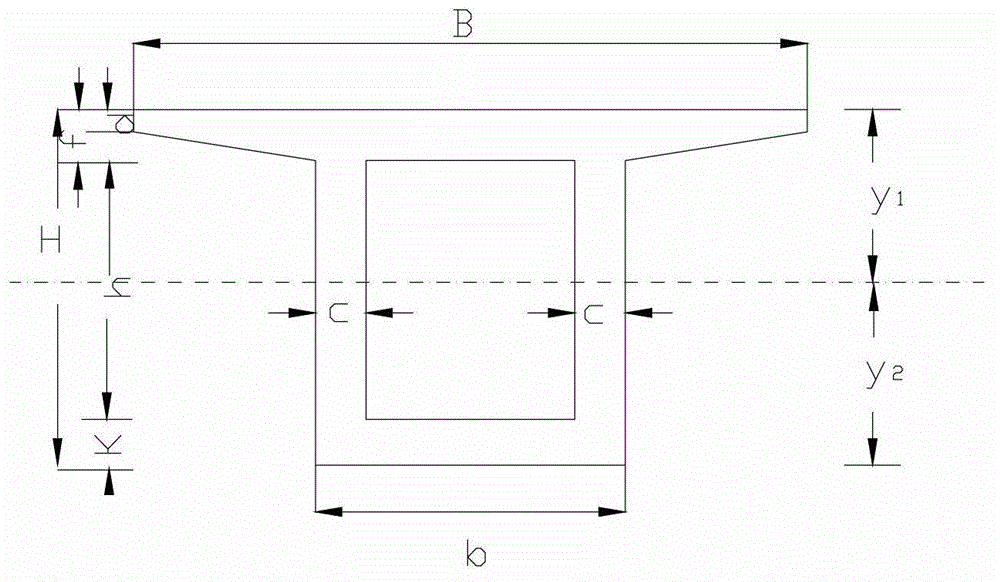

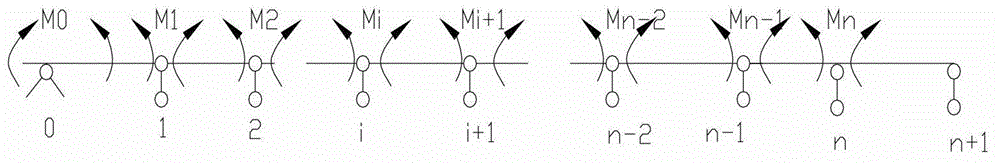

Design method for longitudinal pre-stressing tendons of variable-cross-section pre-stressed concrete continuous bridge

InactiveCN103065035ADevelop longitudinal prestressDevelopment of Analytical Computational MethodsSpecial data processing applicationsBridge materialsStress ratioPre stressing

The invention discloses a design method for longitudinal pre-stressing tendons of a variable-cross-section pre-stressed concrete continuous bridge. The optimization design method for the longitudinal pre-stressing tendons of the pre-stressed concrete continuous bridge is built based on the design principle of the pre-stressed degree and through combining an analytic method with a finite element method and compressively considering dead load and live load action effects. A three moment equation of the variable-cross-section pre-stressed concrete continuous box girder bridge is established to solve the internal force of the structure under the action of the self weight on the basis of the average bending moment method. A calculation formula of pre-stressed effective pre-pressure is built through a load equal effect method and a unit load method; a creep effect calculation formula is built through a force method; the temperature effect and the automobile load effect are calculated through the finite element method; and a variable-cross-section statically indeterminate structure pre-stressing tendon reinforcement calculation formula is obtained through combination of the stress ratio with the definition of the competitive pre-stressed degree.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for constructing segmental prefabricating and assembling swing foundation pier

ActiveCN104343080AReduce the impactShort construction periodBridge structural detailsBridge materialsRubber materialEngineering

The invention relates to a method for constructing a segmental prefabricating and assembling swing foundation pier. The pier is assembled by prefabricated segments, and a bearing platform is hinged to a foundation. Except for the uppermost end connected with a cover beam and the bottom end connected with the bearing platform, the middle segments of the pier are same in shape and size. The oblique section of the upper part of the middle pier prefabricated segment slopes and is hollowed into a groove, namely a prefabricated segment groove; the bottom of the middle pier prefabricated segment is manufactured into a bulge with a corresponding shape, namely a prefabricated segment convex slot; the prefabricated segment groove and the prefabricated segment convex slot can realize the assembly of upper and lower pier prefabricated segments and forms the contact connecting surface of the segmental pier. The bottom of the pier is fixedly connected with the bearing platform, and the upper part of the pier is fixedly connected with the cover beam. After the prefabricated segments are assembled, a prestressed cable in a prepared channel is tensioned and anchored. A gap between a pile head and the contact surface of a prepared hole in the bottom of the bearing platform is filled with a rubber material or other elastic materials. The method has the advantages of short construction period, small environmental influence, good vibration isolation effect under earthquake and high anti-seismic property of whole structure.

Owner:BEIJING UNIV OF TECH

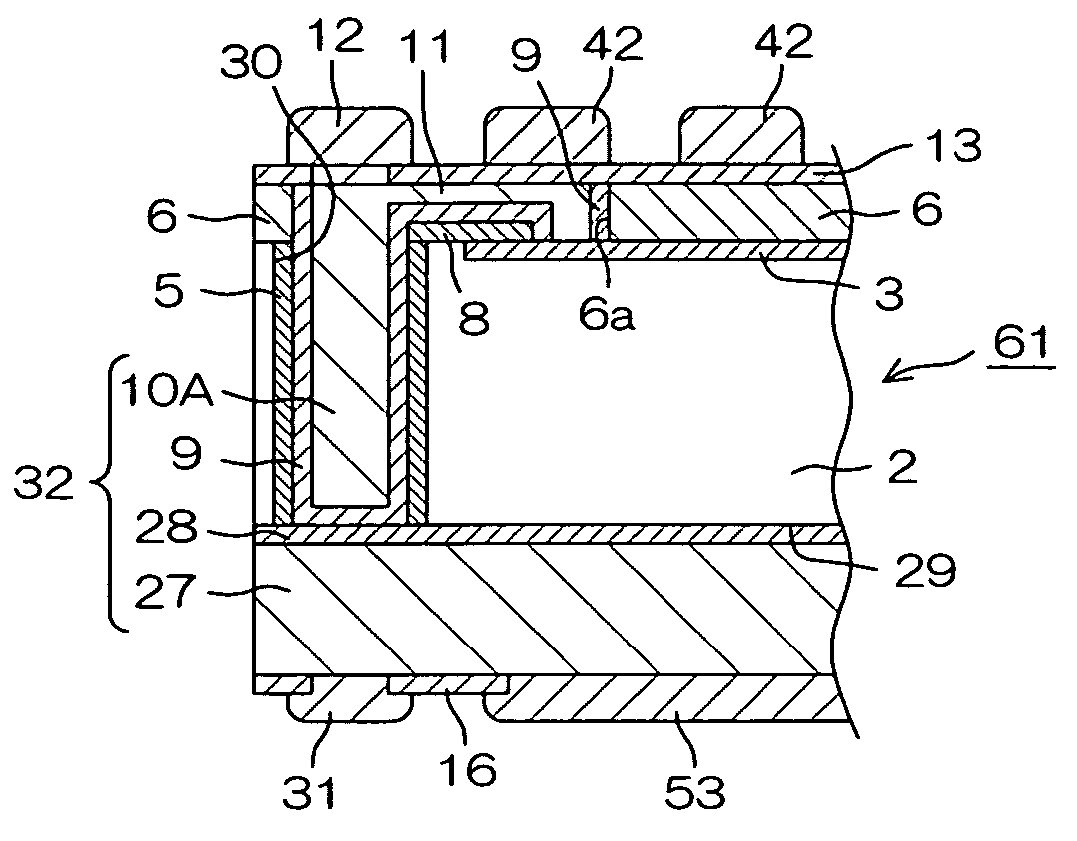

Assembled joint node for column base and construction method

PendingCN107299641AImprove seismic performanceImprove abilitiesStrutsWallsReinforced concrete columnRebar

Provided is an assembled joint node for a column base and a construction method thereof. The assembled joint node for the column base can be used in a prefabricated reinforced concrete column, a reinforced concrete foundation, a column anchorage longitudinal rib, a grouting sleeve and a foundation anchor steel bar, wherein the foundation anchor steel bar is connected with the column anchorage longitudinal rib through a crack pouring material, and the grouting sleeve is filled full with the crack pouring material; a spliced seam of the reinforced concrete foundation and the prefabricated reinforced concrete column is also filled with the crack pouring material, and the foundation anchor steel bar comprises a vertical part and a horizontal part; the vertical part comprises an upper anchorage section, which extends beyond the upper surface of the reinforced concrete foundation, a middle no-bonding section, which is embedded in the reinforced concrete foundation, and a lower anchorage section; the outside of the middle no-bonding section is provided with an isolation suite which is used for isolating the the middle no-bonding section and preventing the middle no-bonding section from being bonded with concrete; the top surface of the isolation suite is aligned with the upper surface of the reinforced concrete foundation. According to the assembled joint node for the column base and the construction method of the assembled joint node, the deformation capability and the mechanical property of the node at the column base in an assembled structure, the construction is efficient, and the seismic performance is good.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

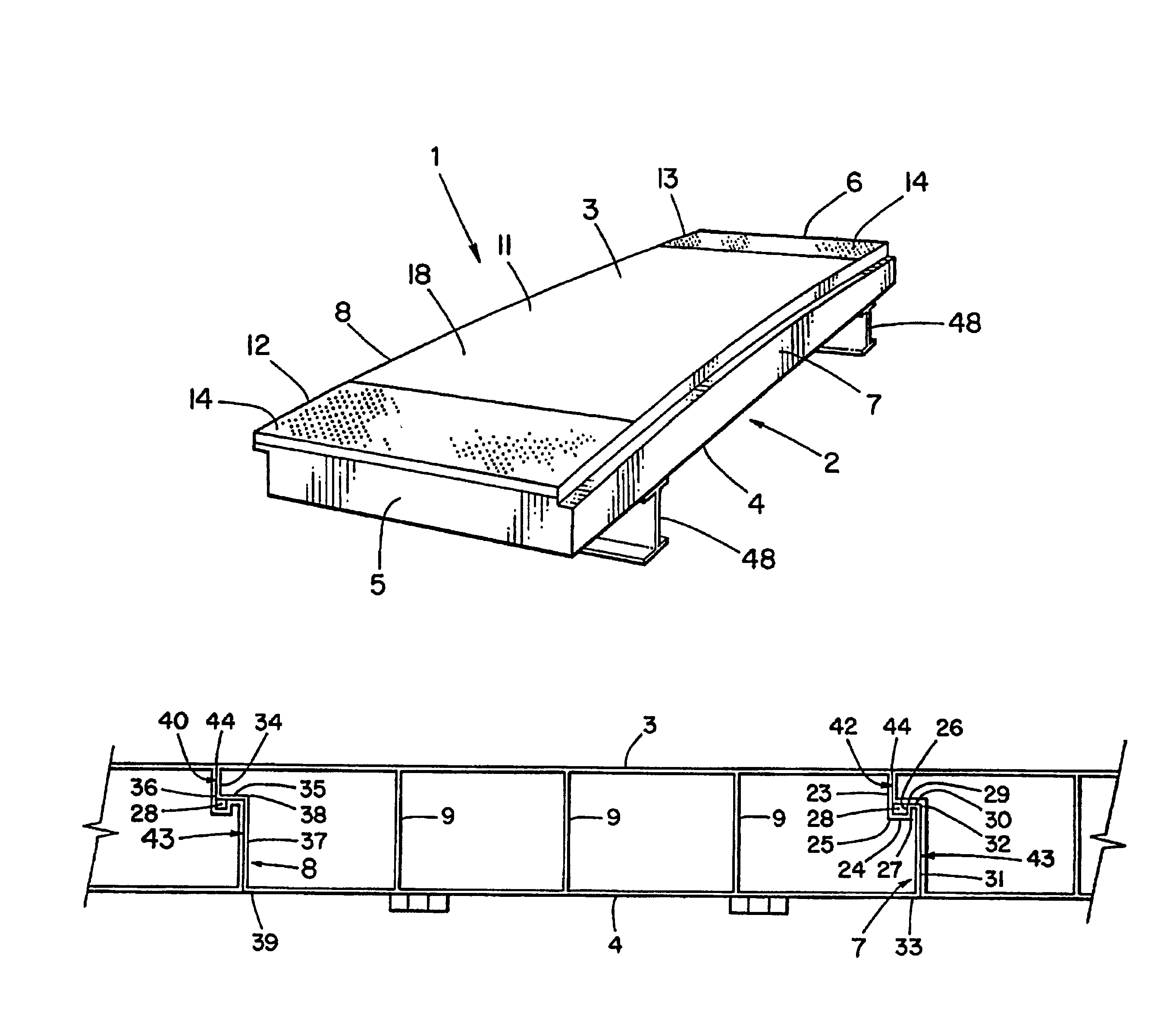

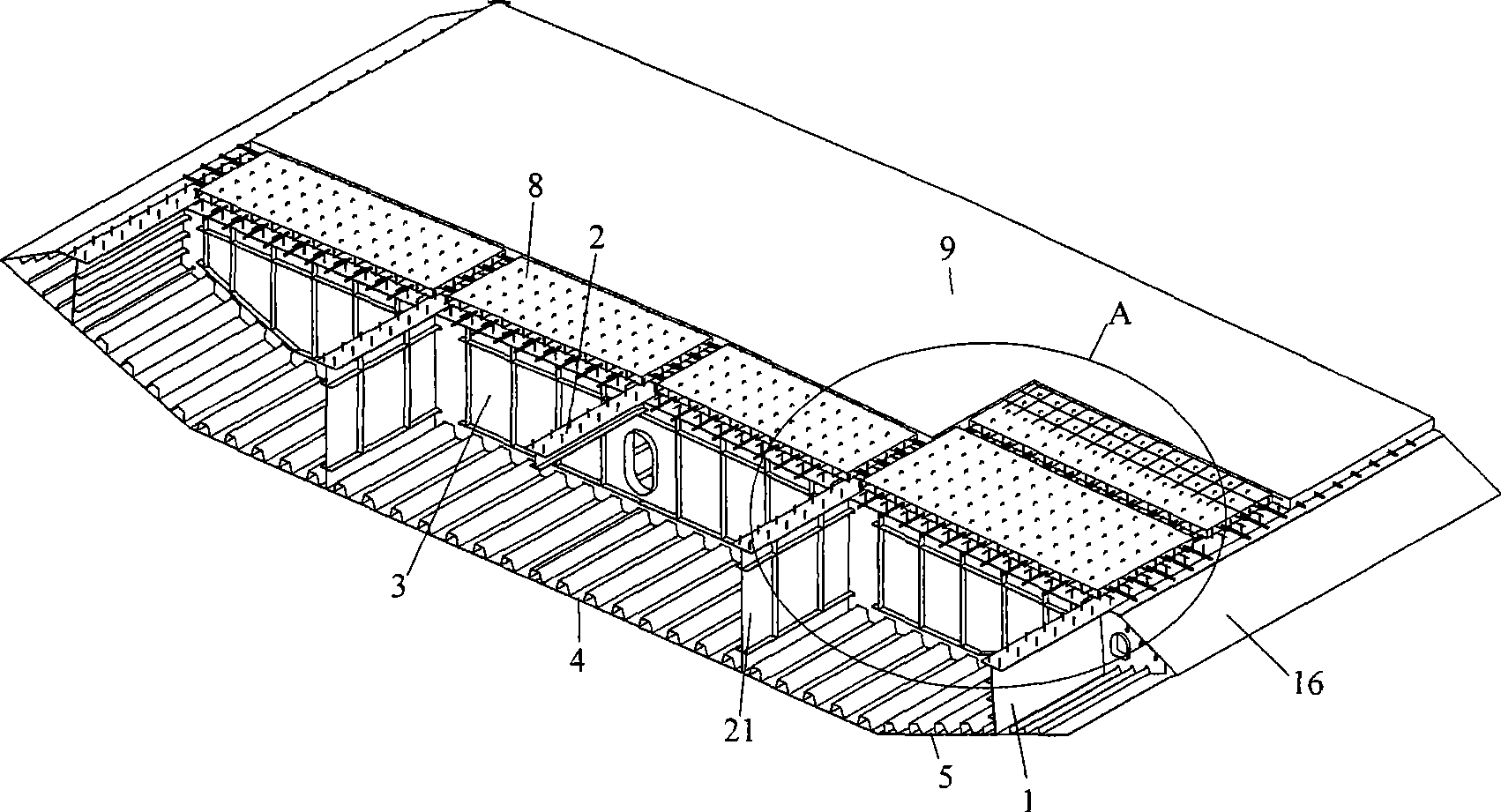

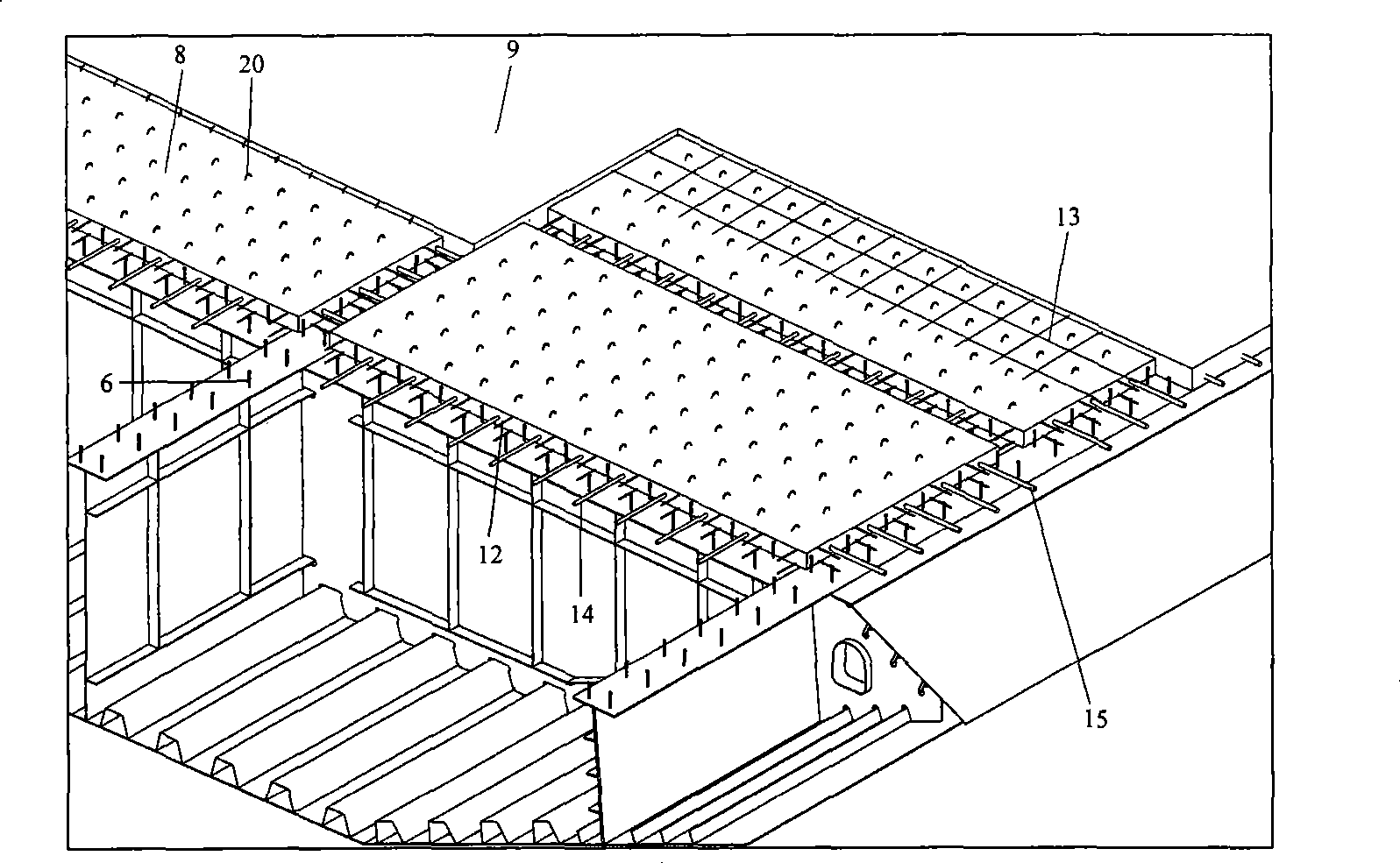

Transit boarding platform panel

InactiveUS6895622B2Prevent standing poolPromote precipitationRefuge islandsPaving detailsExtremity PartPrecipitation

A transit boarding platform panel comprising a base portion formed from a reinforced composite polymer. The base portion has a top deck and a bottom plate, a first end, a second end, a first side and second side. Between the top deck and bottom plate are a series of internal longitudinal and cross support members. The top deck has a central section and opposite end sections. Detectable warning tiles are mounted to the top surfaces of the end sections. The top surface of the central section has a slip resistant surface. Positive drainage is provided by the top deck to facilitate runoff of any precipitation and prevent standing pools of water. Positive drainage is further provided by the interface between adjacent panels utilizing a ship lap configuration with a drainage channel beneath the joint between adjacent panels.

Owner:ASTRA CAPITAL

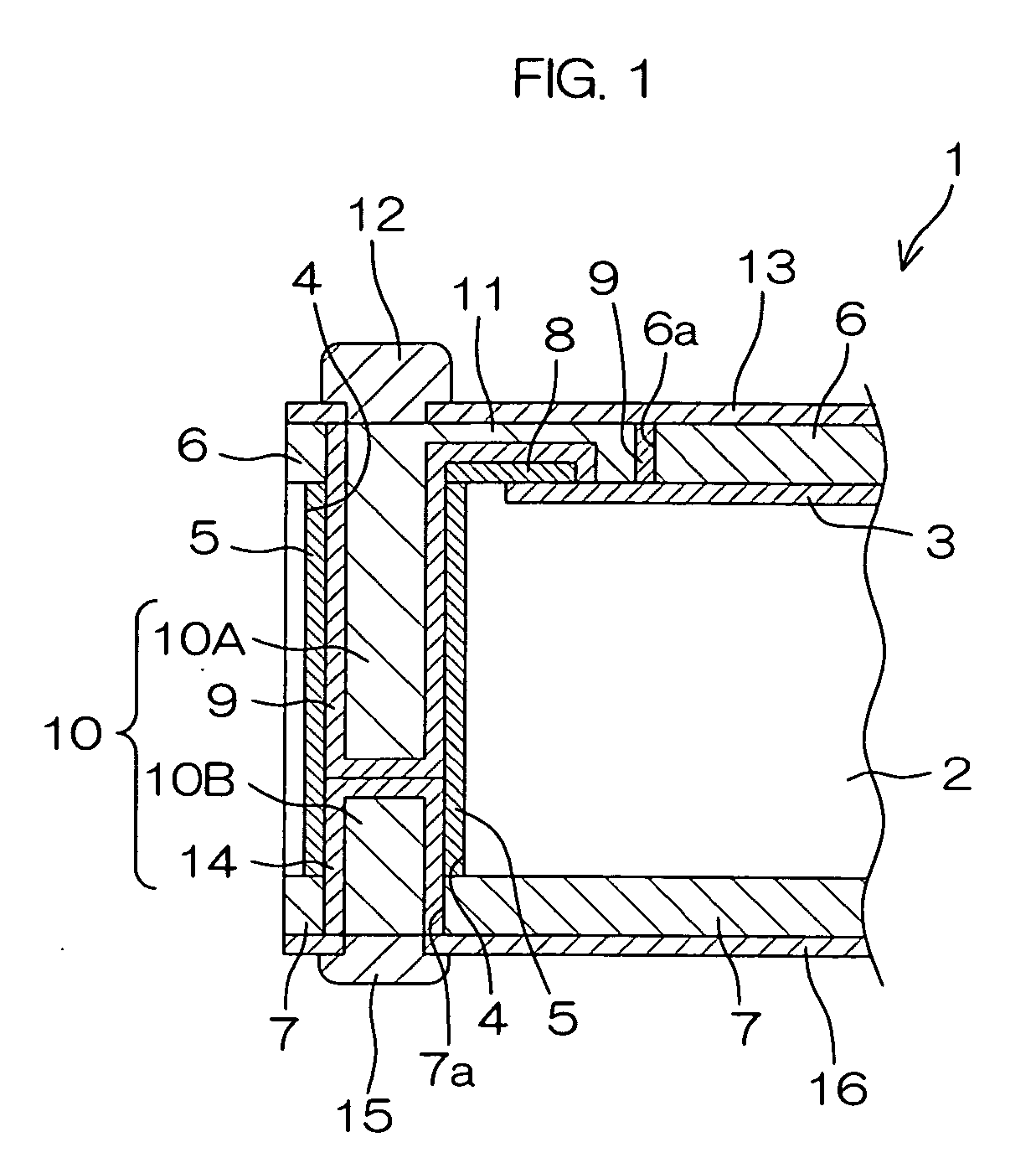

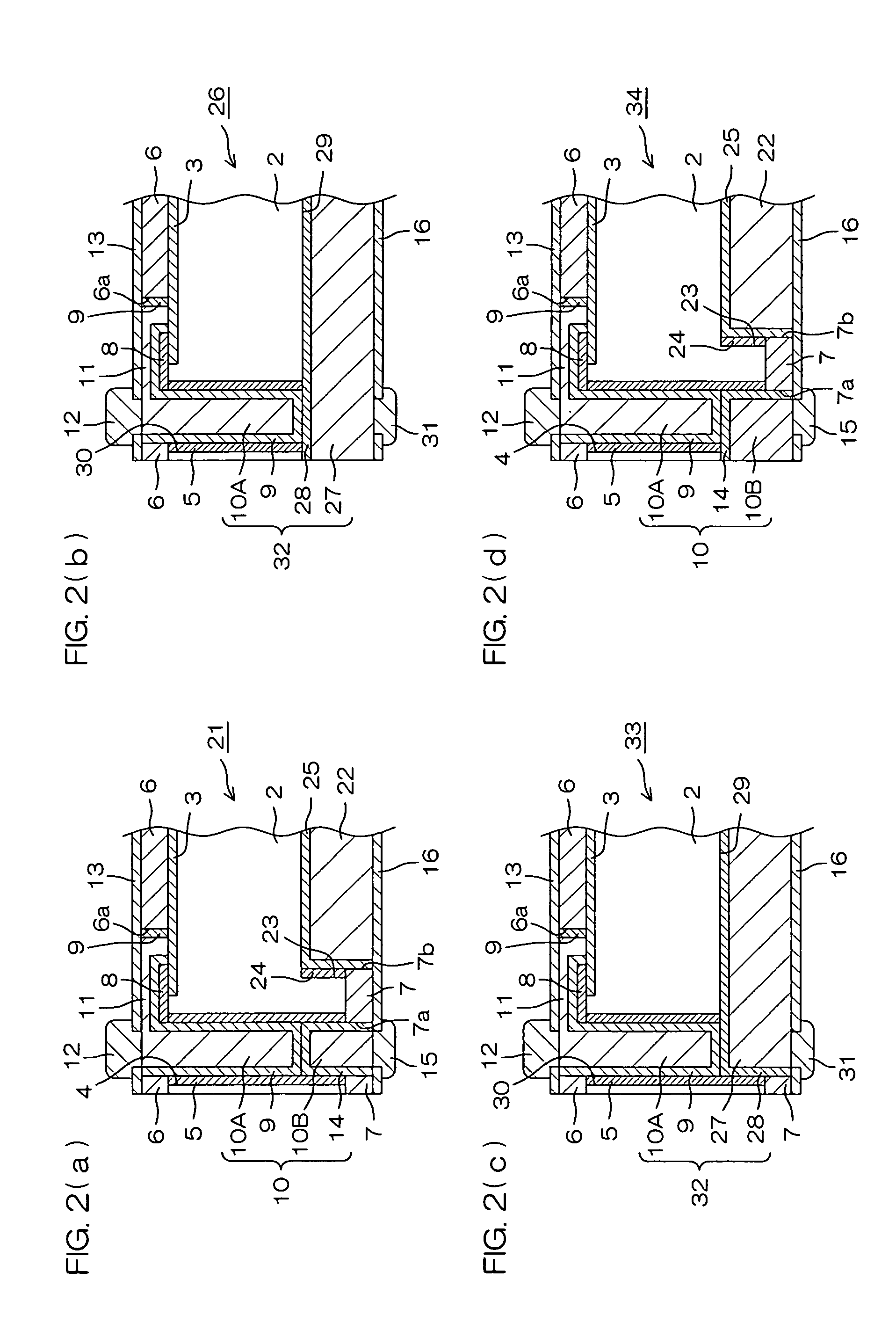

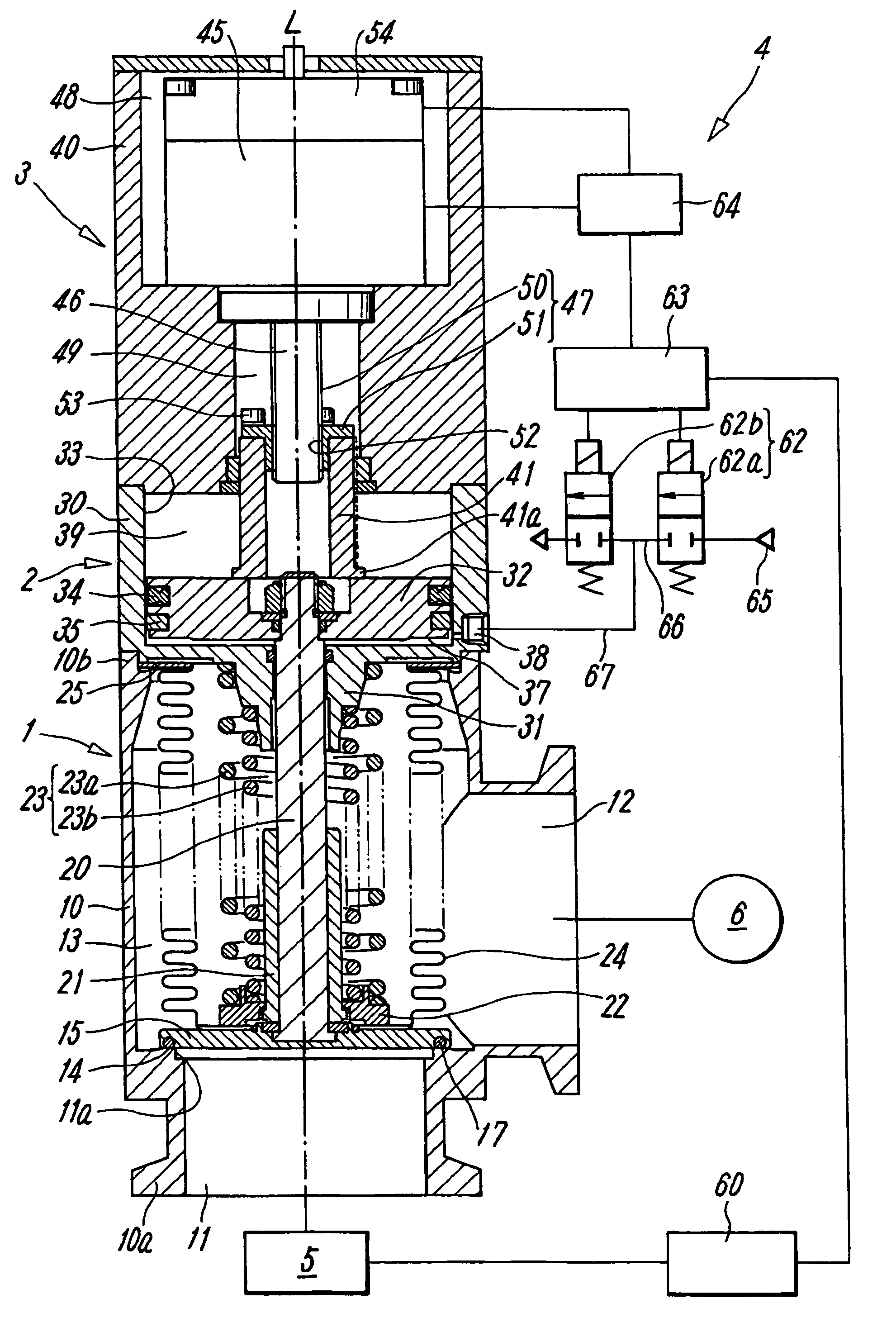

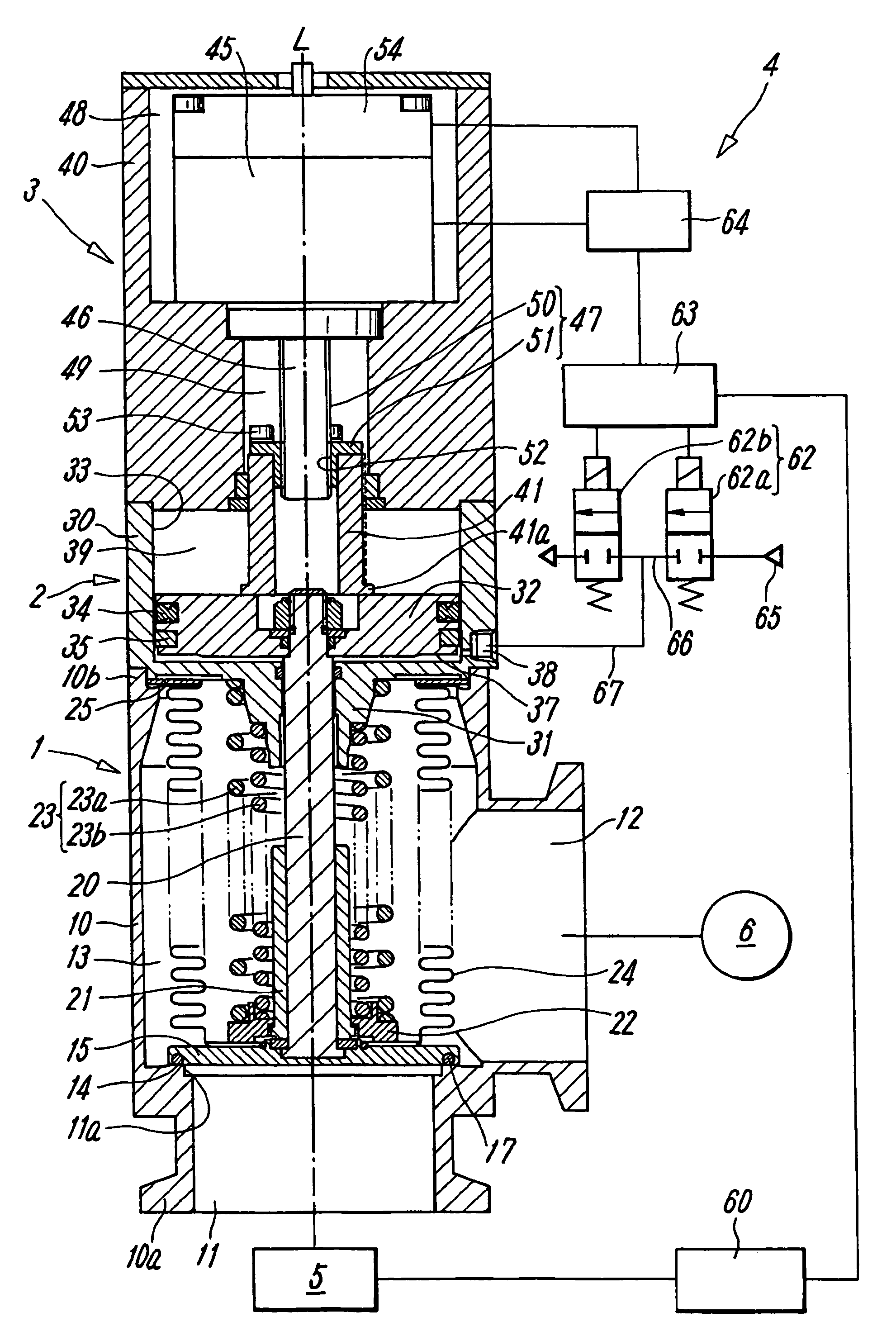

Vacuum regulating valve

ActiveUS7117886B2Quickly and accurately regulatedHighly controllableOperating means/releasing devices for valvesFluid pressure control using electric meansMotor controllerControllability

A vacuum regulating valve has high controllability, wherein the opening of a valving member can be quickly and accurately controlled by using a small and inexpensive electric motor. In accordance with a signal indicative of a pressure set value and a pressure signal from the pressure sensor, the main controller in the valve control section outputs a signal for setting the opening of the valving member to a motor controller that controls the electric motor, and performs control to cause a pilot fluid to be supplied to a pressure receiving chamber of the piston, thereby causing the piston to move to the position of abutment with the stopper.

Owner:SMC CORP

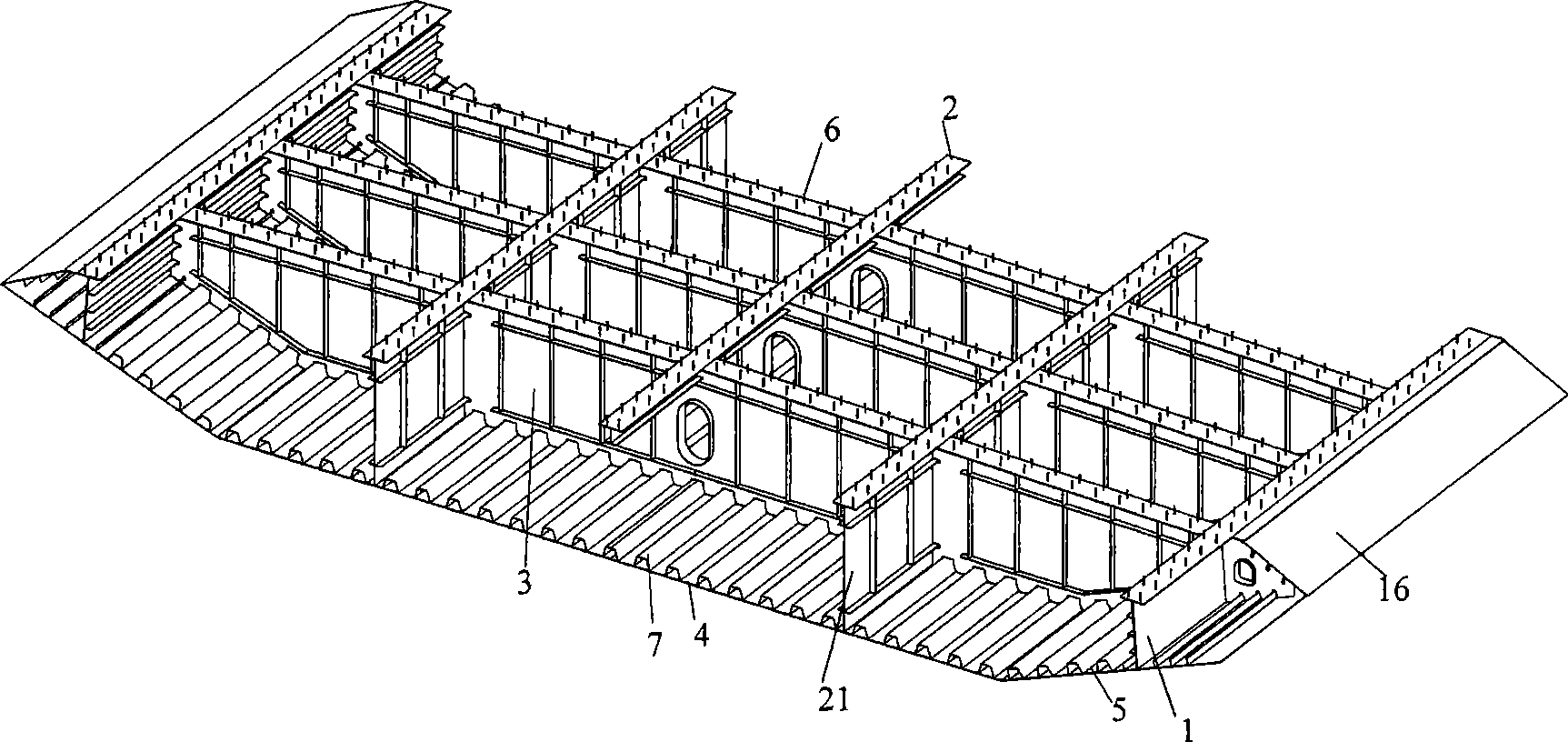

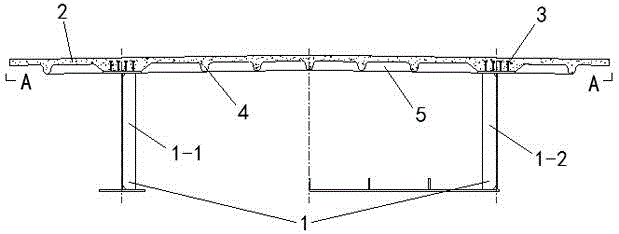

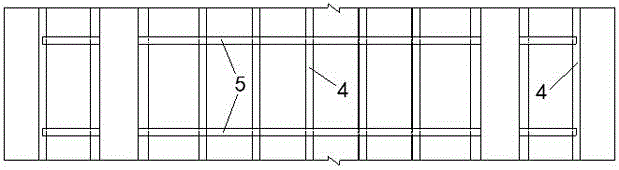

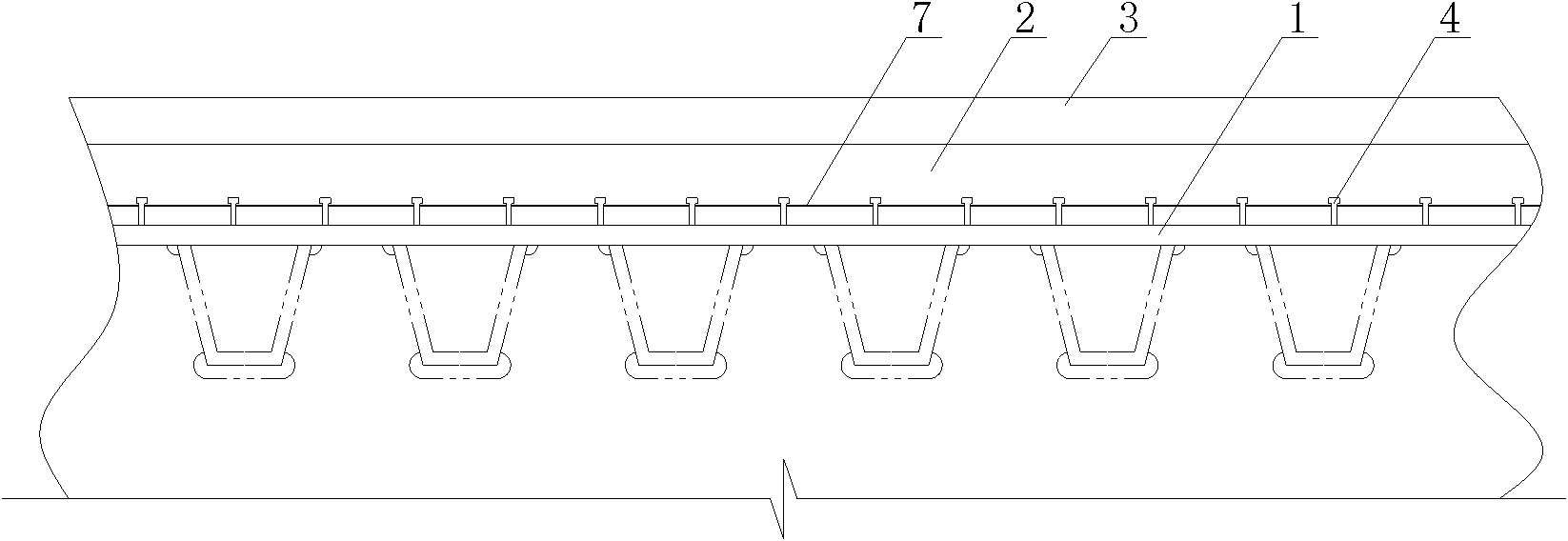

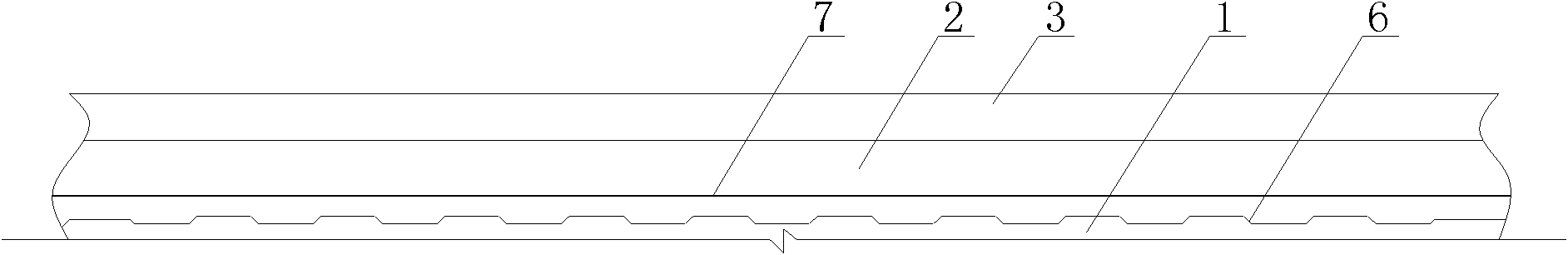

Streamline steel-concrete folding case beam

InactiveCN101413247AIncreased torsional stiffnessImprove wind resistanceBridge materialsBridge engineeringCable stayed

The invention discloses a streamlined steel-concrete superimposed box girder, which relates to the technical field of bridge engineering and is used for a long-span bridge girder. Two sides of the superimposed box girder are provided with tuyere structures, and a bridge panel adopts a superimposed structure consisting of prefabricated concrete slabs and a post-poured concrete layer. When the box girder is in use, the superimposed box girder is a streamlined single-box single-chamber or single-box multi-chamber cross section; the tuyere structures are polygonal open thin-walled structures; and longitudinal-transverse prestress is applied in the superimposed bridge panel. The box girder effectively improves the torsional rigidity and wind-resistant stability of the section of the girder, remarkably improves the integrity and durability of the bridge panel, and expands the application of superimposed girders in cable-stayed bridges and other long-span bridges.

Owner:CCCC HIGHWAY CONSULTANTS

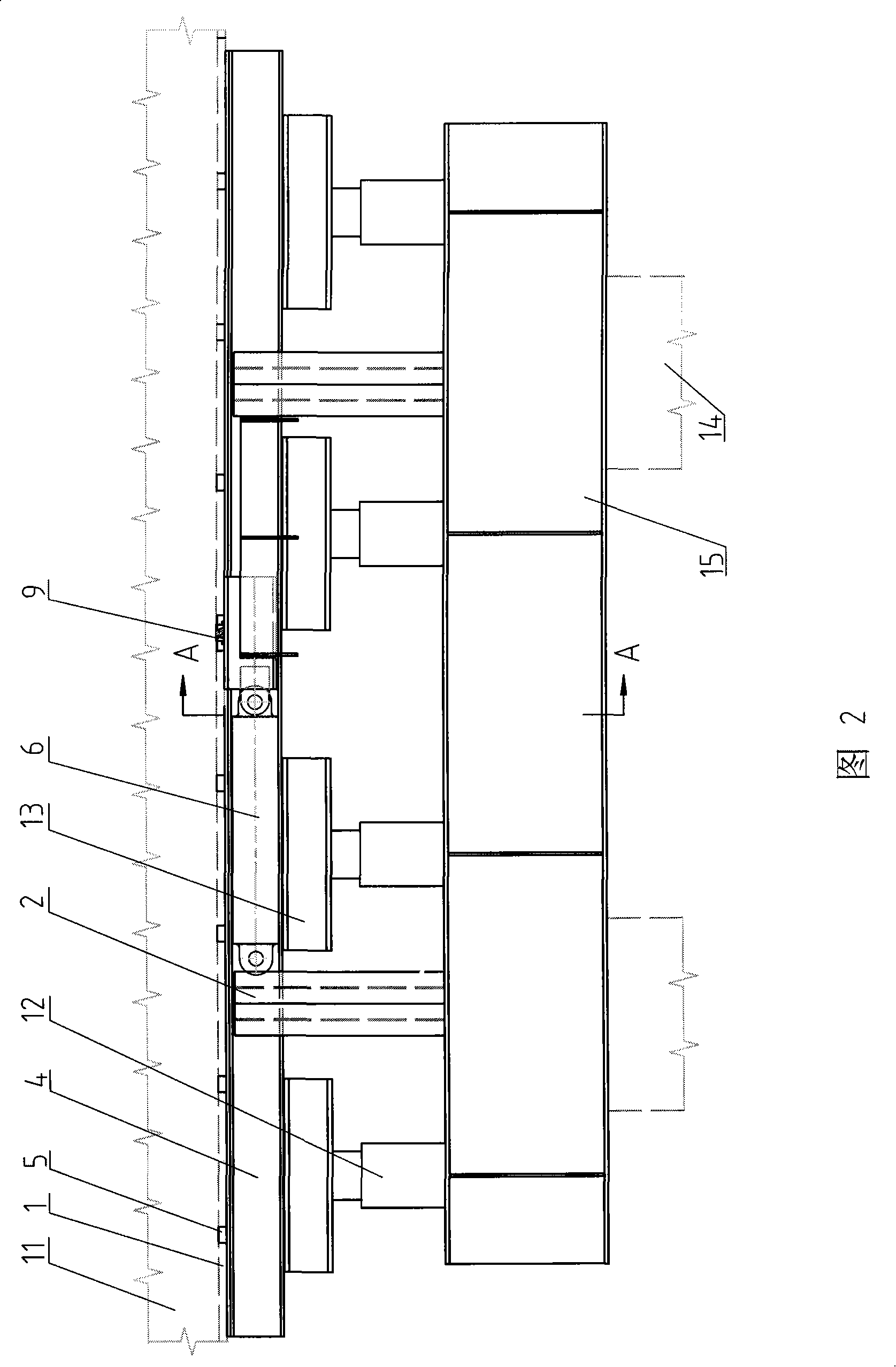

Method for construction of multi-point integral top pulling steel case beam

ActiveCN101250855AReduce width sizeImprove work efficiencyBridge erection/assemblyBridge materialsBridge engineeringPiston rod

The invention discloses a construction method of a multi-point whole incremental launching steel box girder, which belongs to the field of bridge engineering. The construction method uses a dental plate with a tooth socket, which is arranged on a steel box girder and a guiding beam web plate, a jacking force is supplied by an incremental launching jack, wherein a piston rod of the incremental launching jack is equipped with a slider, on which a spinous block with an inclined plane and a control spring are arranged, the inclined plane is arranged on the side of the incremental launching jack, the steel box girder and the guiding beam are applied with the jacking force through the push travel of the incremental launching jack, and the spinous block withdraws from the tooth socket during the return to enter into a next push travel. The construction method also supplies the support and adjusts the elevation of corresponding points through lifting-up the jack, simultaneously the incremental launching jack and the upper portion of the incremental launching jack are all equipped with a displacement sensor and a pressure sensor to collect information, thereby controlling an incremental launching process. The construction method has less consumption of steel material, a support reaction and a thrust force are capable of being controlled, and the problem of the rotation angle of the steel box girder is capable of being excellently solved.

Owner:SHANDONG LUQIAO GROUP

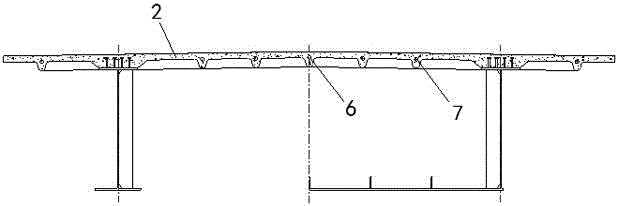

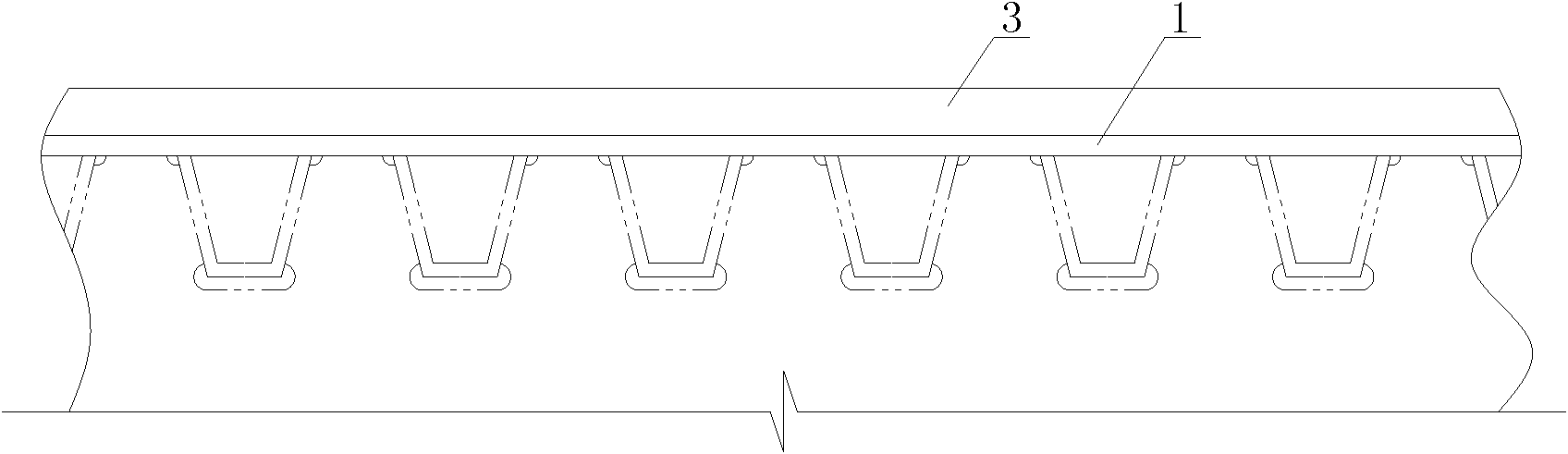

Steel-super high performance concrete composite beam based on ribbed plate type bridge deck and construction method

InactiveCN104831617AReasonable forceHigh strengthBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention discloses a steel-super high performance concrete composite beam based on a ribbed plate type bridge deck and a construction method. The construction method includes the following steps that step1, steel beams are machined, manufactured and installed; step2, shearing force connecting parts are welded; step3, the super high performance concrete bridge deck is constructed; step4, a guardrail or an anti-collision wall is constructed; step5, bridge deck pavement is constructed, wherein the super high performance concrete bridge deck and the steel beams are fixed through the shearing force connecting parts, the cross section or / and the longitudinal section of the super high performance concrete bridge deck is / are of a ribbed plate structure, and pre-stressed reinforcements can be arranged on a longitudinal rib region or / and a transverse rib region. The composite beam is reasonable in stress, high in strength and capable of substantially reducing the structure dead weight, effectively avoiding defects at a hogging moment region of a composite continuous beam and bringing tensile strength, compressive strength and high durability of super high performance concrete into full play; the composite beam has the advantages of being small in building height, high in rigidity, small in dead weight, good in durability, crack resistance and fatigue resistance and the like, and has great practical value and good economic benefits.

Owner:FUZHOU UNIV

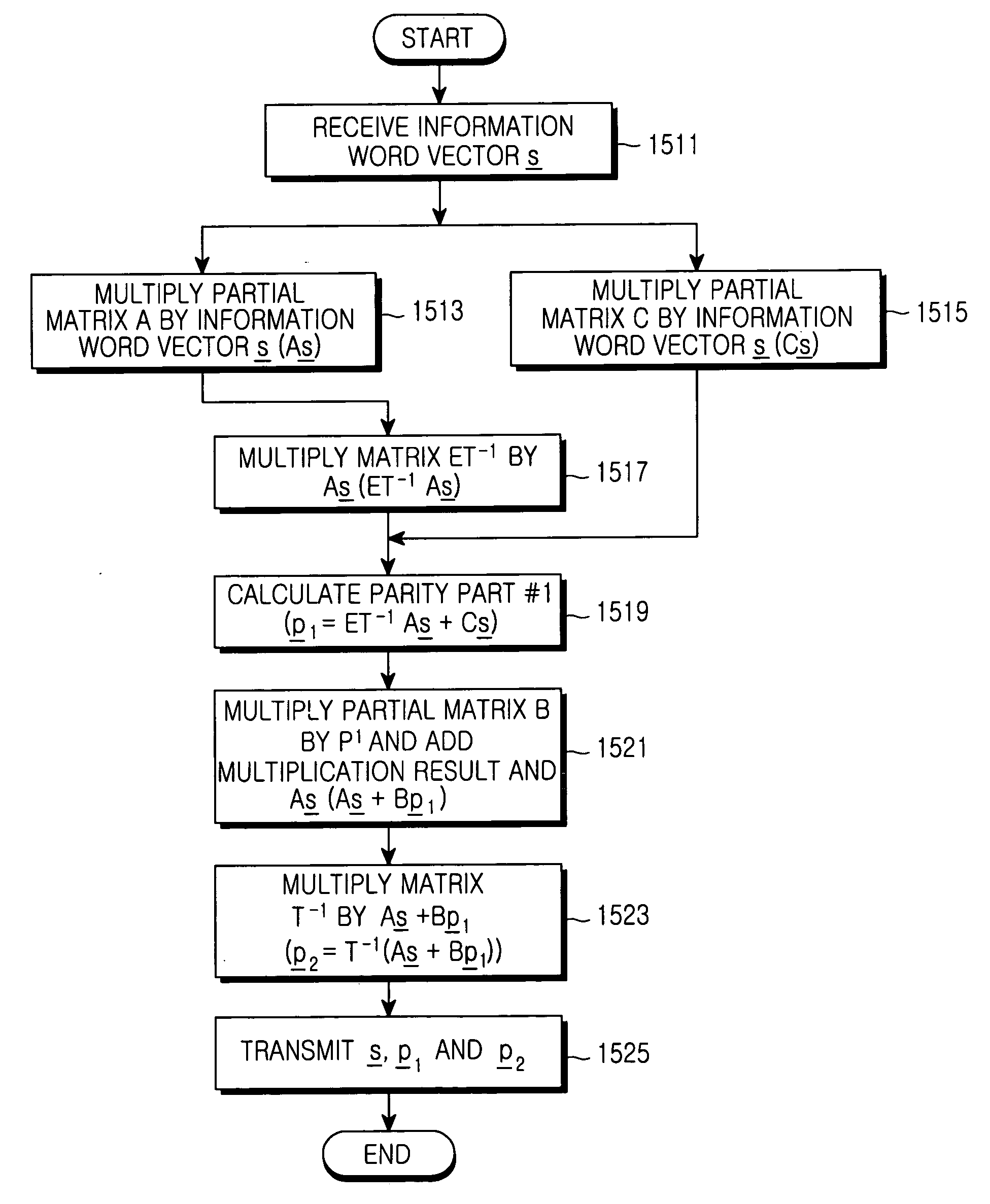

Apparatus and method for coding/decoding block low density parity check code with variable block length

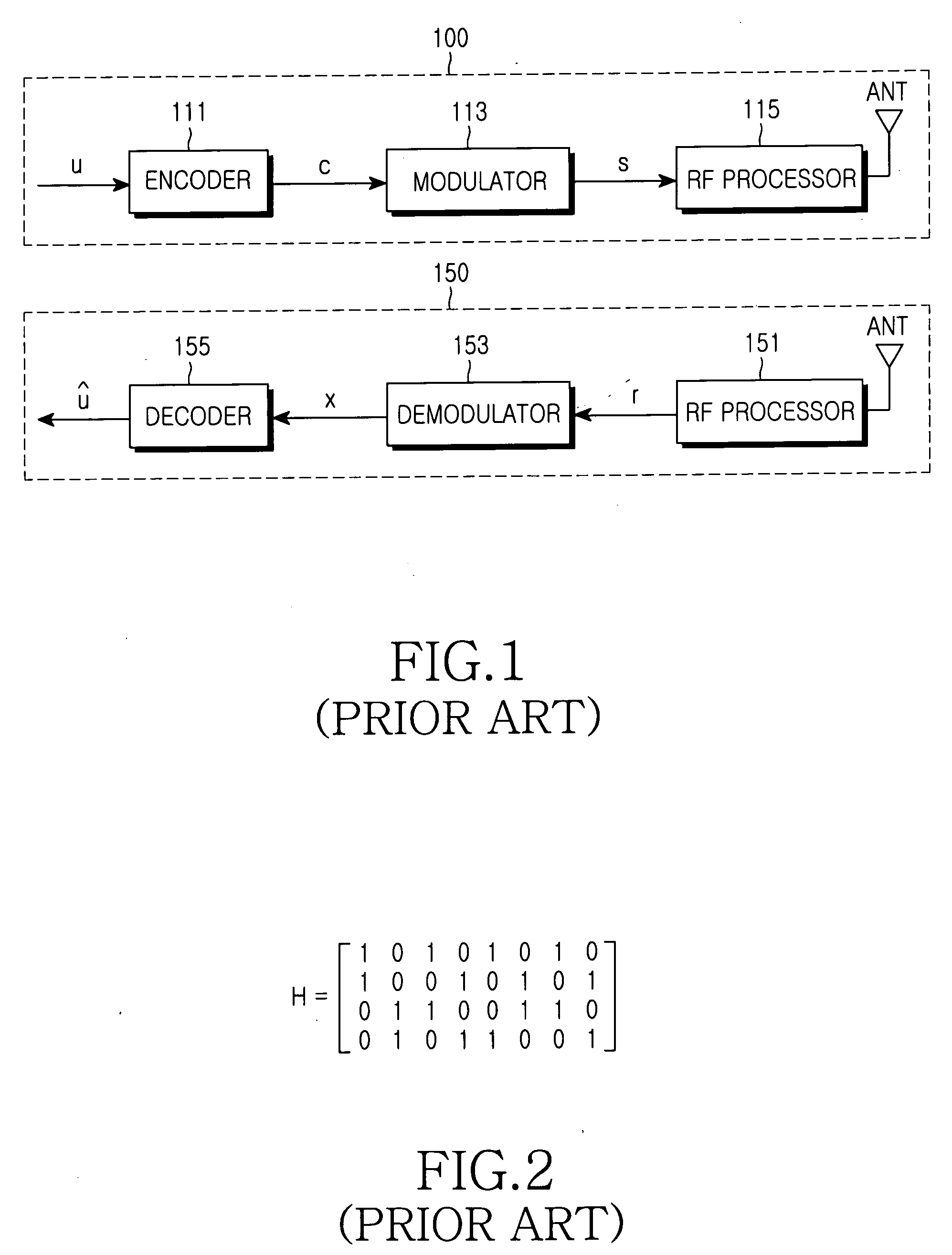

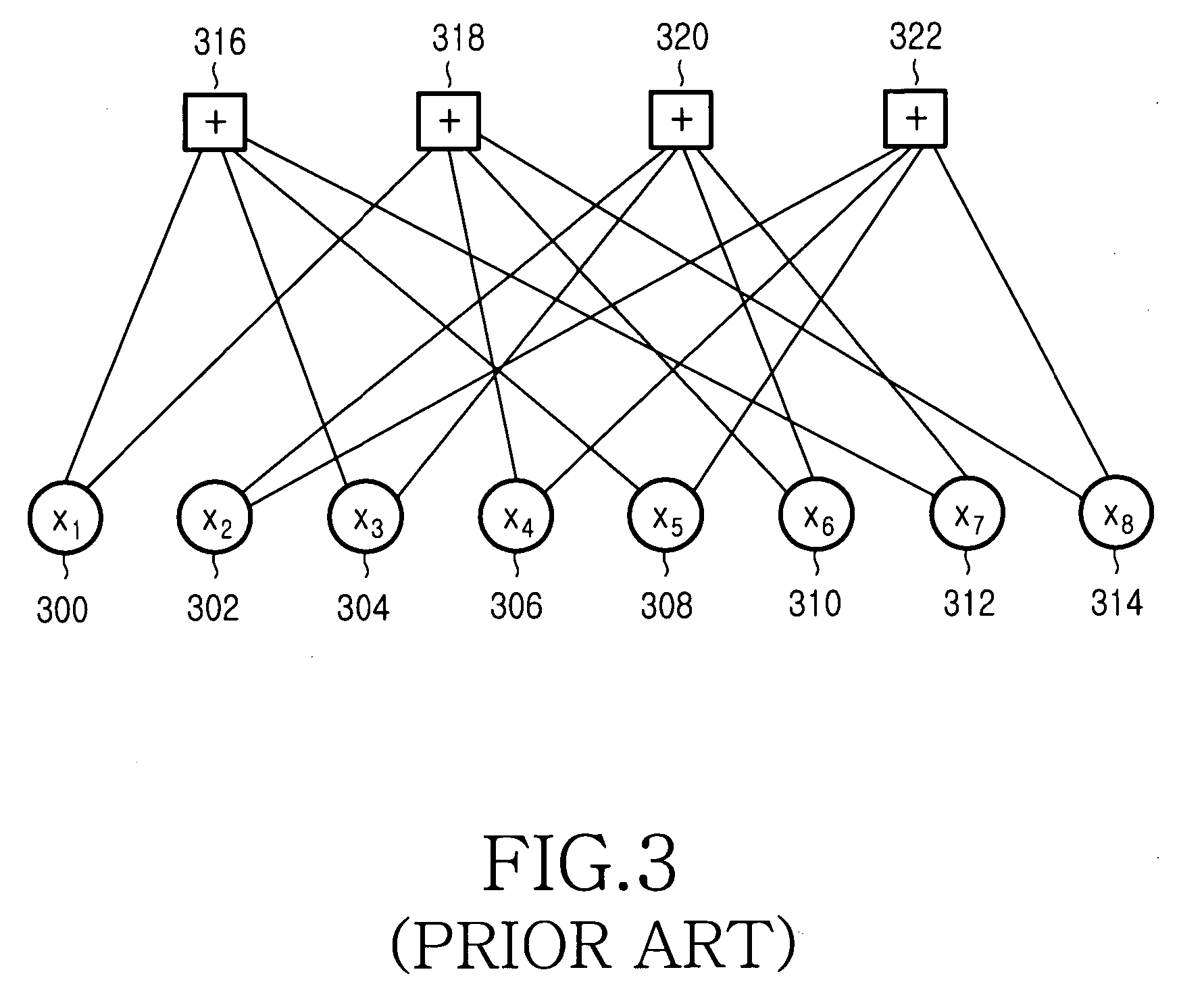

ActiveUS20060036925A1Minimize complexityError correction/detection using multiple parity bitsCode conversionTheoretical computer scienceParity-check matrix

Disclosed is a device and procedure for coding a block low density parity check (LDPC) code having a variable length. The a device and procedure includes receiving an information word; and coding the information word into a block LDPC code according to a first parity check matrix or a second parity check matrix depending on a length to be applied when generating the information word into the block LDPC code.

Owner:NOKIA TECHNOLOGLES OY

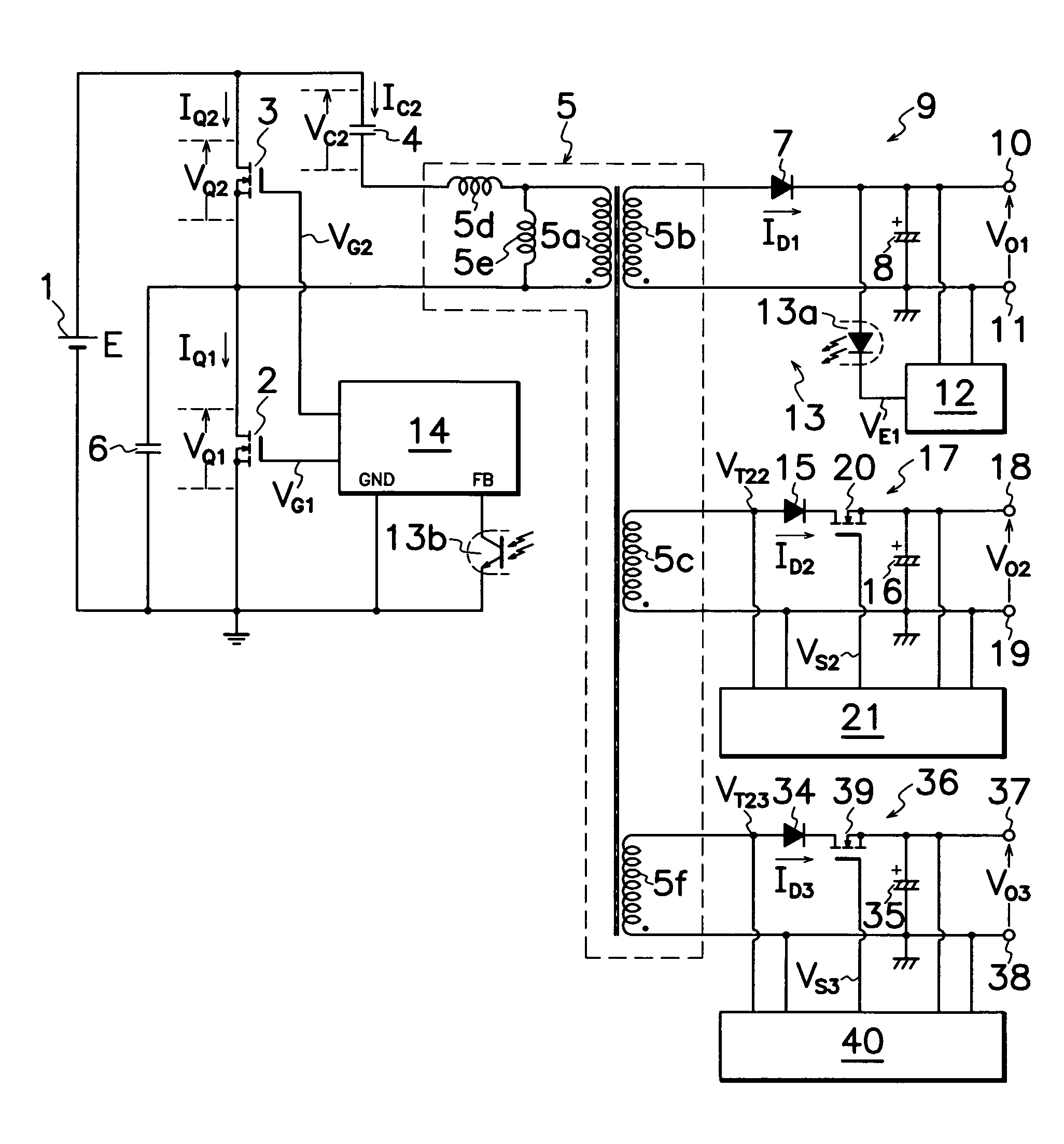

DC-DC converter of multi-output type

InactiveUS7304867B2Reduce, attenuate or relax serge voltageDc network circuit arrangementsAc-dc conversion without reversalDc dc converterCoupling

A DC-DC converter of multi-output type is provided wherein a primary winding 5a is wound around core halves 5g, 5h of a transformer 5 between first and second secondary windings 5b, 5c of transformer 5 also concentrically wound around core halves 5g, 5h to form an electromagnetic sparse coupling between first and second secondary windings 5b, 5c. When on-off operation of first and second primary MOS-FETs 2, 3 generates first and second DC outputs VO1, VO2, the electromagnetic sparse coupling can reduce, attenuate or relax serge voltage induced on first secondary winding 5b. This restrains or controls potential increase in first output voltage VO1 resulted from serge voltage through first rectifying smoother 9 under the light- or no-load condition to control fluctuation in second output voltage VO2 through second rectifying smoother 17 without restricting transmission of electric power from the primary to the secondary side making use of feedback control to primary control circuit 14 in order to generate stable first and second DC output voltages VO1 and VO2 throughout the entire loaded and unloaded range.

Owner:SANKEN ELECTRIC CO LTD

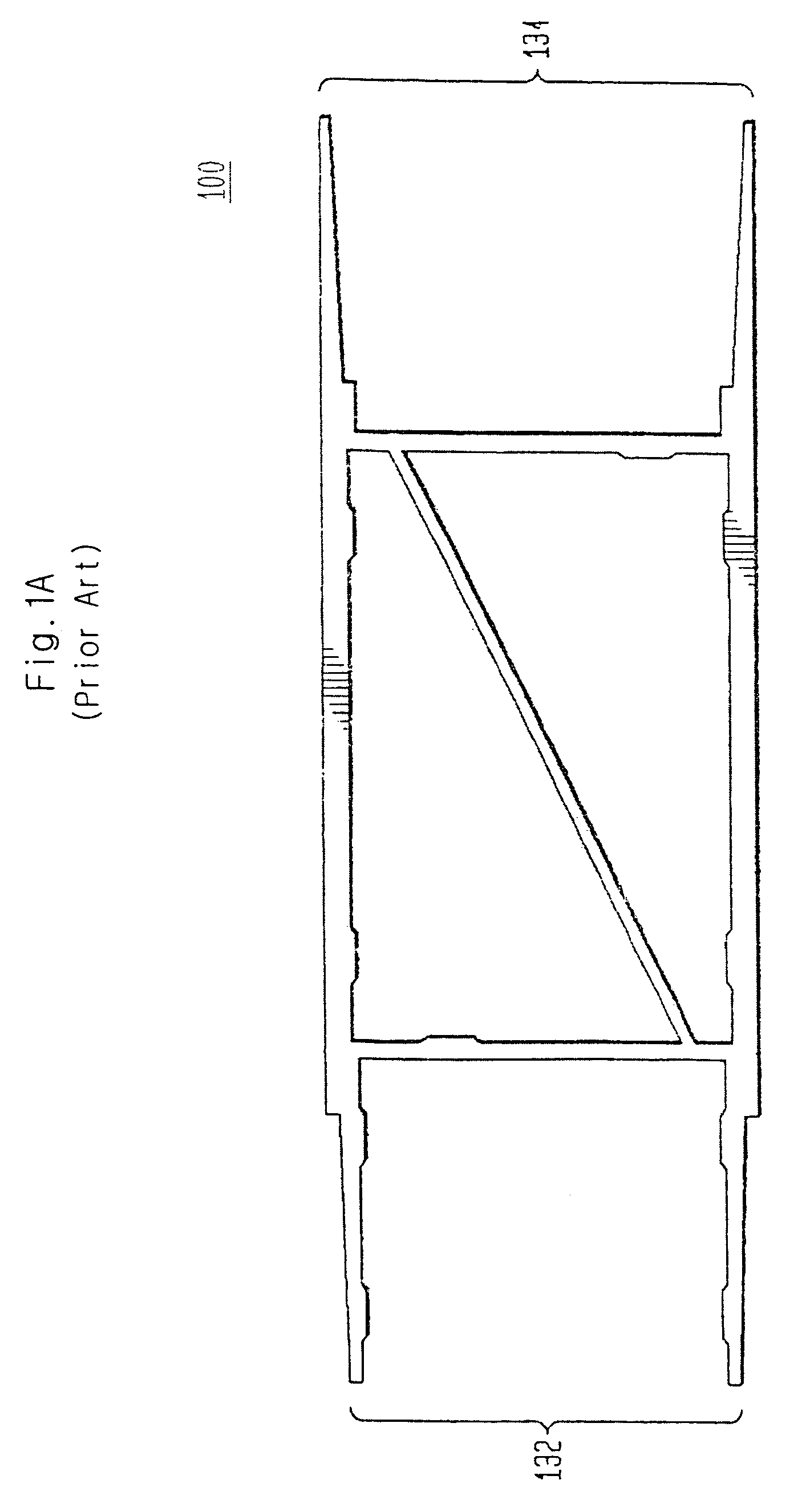

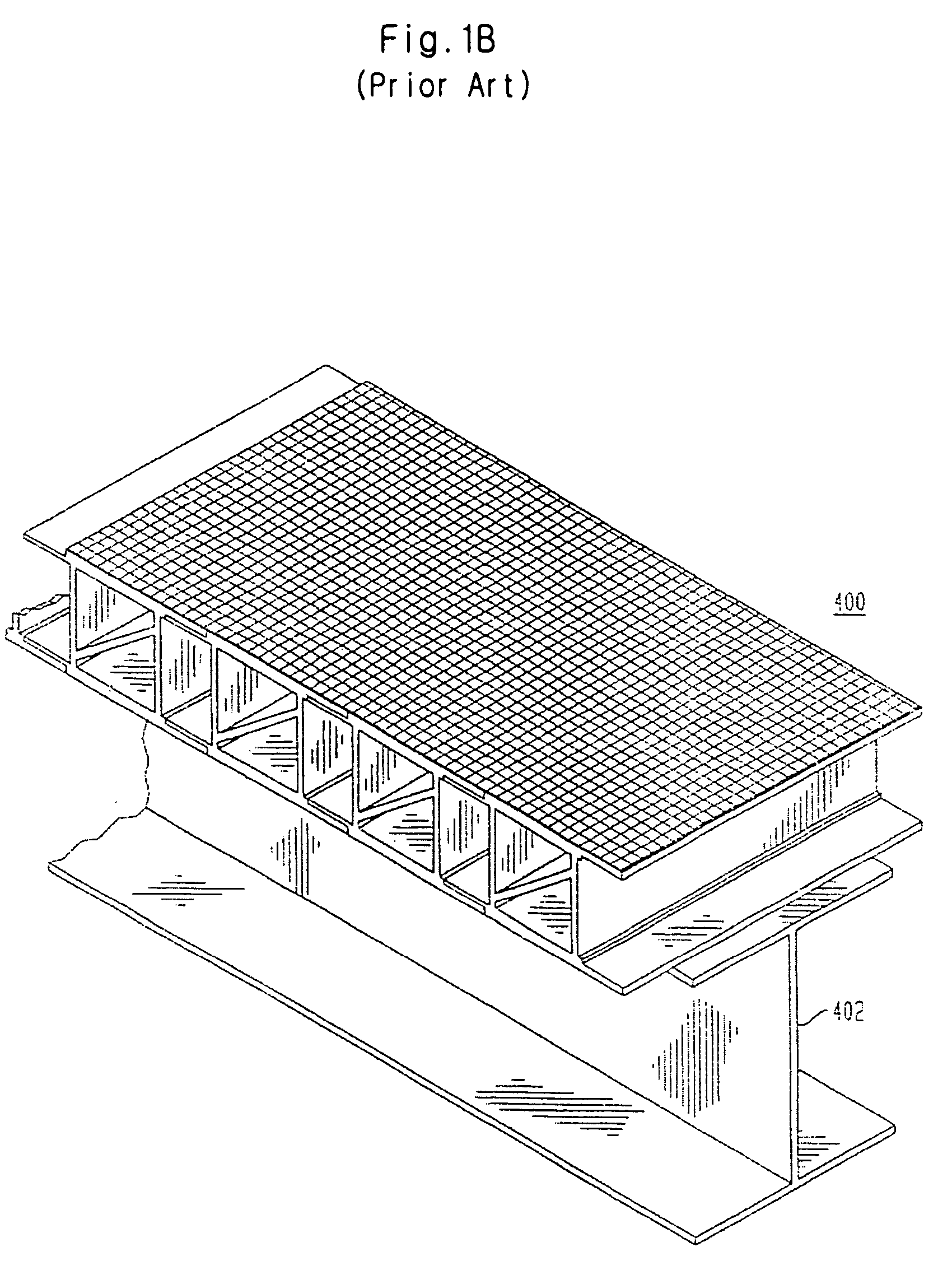

Fiber reinforced polymer composite bridge deck of tubular profile having vertical snap-fit connection

InactiveUS7131161B2Quality improvementImprove workabilitySingle unit pavingsTemporary pavingsBridge deckEngineering

Owner:LEE SUNG WOO

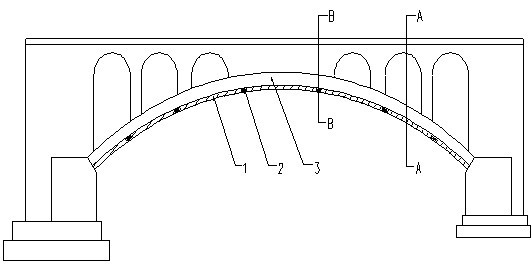

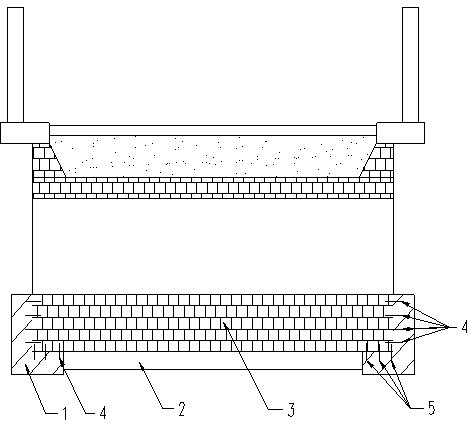

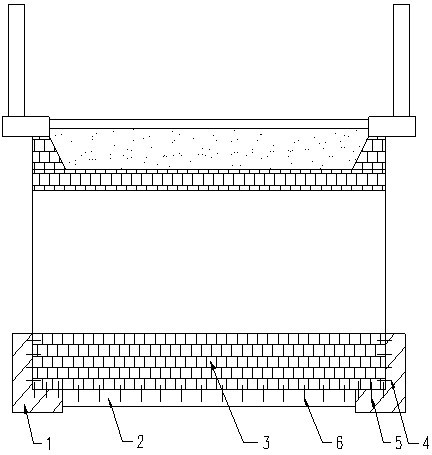

Reinforcing method of masonry arch bridge

InactiveCN102322026AReduce dosageImprove bearing capacityBridge erection/assemblyBridge strengtheningReinforced concreteEngineering

The invention discloses a reinforcing method of a masonry arch bridge, which comprises the following steps of: a, planting ribs on an arch ring of the arch bridge along the cambered surface direction of the arch bridge; b, planting ribs at the position close to the two sides, on the circular arc surface of the arch ring along the cambered surface direction of the arch bridge; and c, forming symmetrically distributed reinforced concrete ribs along the distribution direction of the planted ribs in the step a and the step b in a way of casting molding, wherein the cross section of the reinforcedconcrete ribs is L-shaped. The reinforced concrete ribs which are of integral structures are formed along the two sides of the arch ring in the way of planting the ribs and casting concrete, then load can be directly transferred to an arch base through the symmetrically distributed reinforced concrete ribs of which the cross section is L-shaped, and the stress to the reinforced concrete ribs is equal to that to a ribbed arch bridge. When the method is compared with the method of singly increasing the area of the arch ring, the dependence on the primary arch ring is smaller, even the primary arch ring can be supported, the damage to the primary arch ring is small, the requirement of increasing the loading capacity of the masonry arch bridge is met, and the damage to the primary old arch ring is avoided to the maximal degree.

Owner:CHONGQING JIAOTONG UNIVERSITY

Steel and ultra-high performance concrete combined bridge deck structure

InactiveCN101858052AChange structureChange work statusBridge structural detailsBridge materialsBridge deckRebar

The invention relates to a bridge deck structure of a steel bridge, in particular to a steel and ultra-high performance concrete combined bridge deck structure, comprising a steel bridge deck, an ultra-high performance concrete layer is coated above the steel bridge deck, a bridge deck pavement layer is coated above the ultra-high performance concrete layer, and the ultra-high performance concrete layer is internally provided with reinforced bars. The steel and ultra-high performance concrete combined bridge deck structure has the advantages of small construction height, large stiffness, good binding performance between combined layers, good durability, good fatigue resistance, little vehicle impact and the like.

Owner:HUNAN UNIV

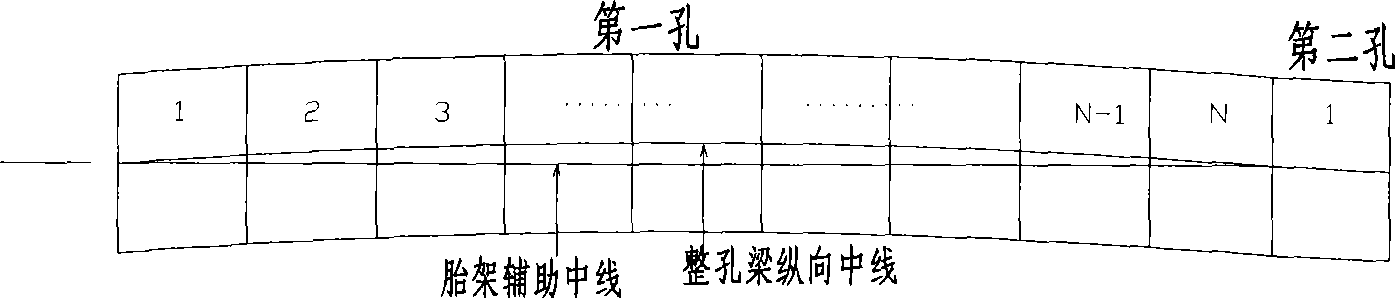

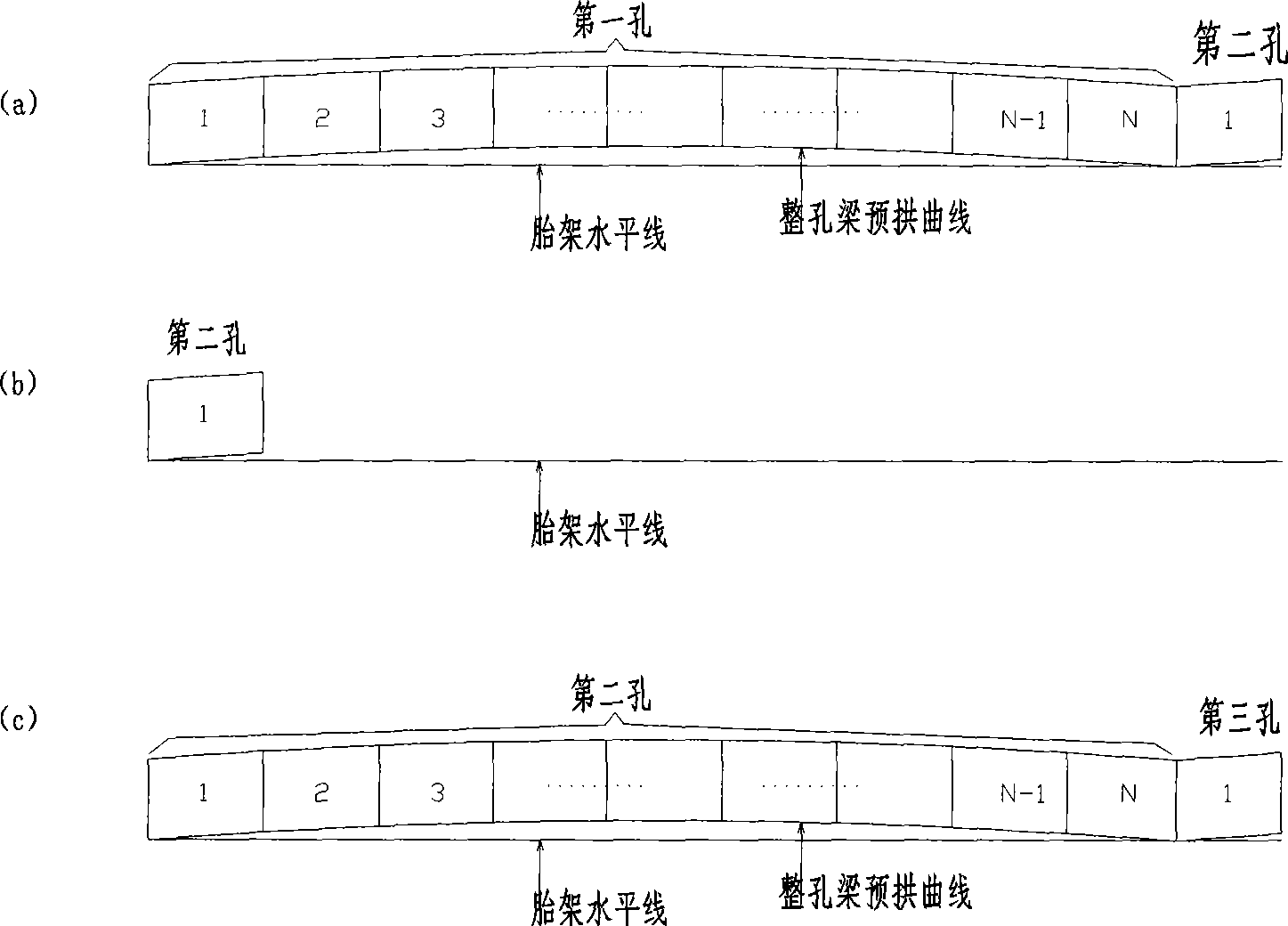

Long continuous structural steel box beam or combination box beam construction method

InactiveCN101368373AReduce welding workloadSatisfy \"Light Large Span\"Bridge erection/assemblyBridge materialsButt weldingEngineering

The invention discloses a long continuous steel box girder or combined box girder construction method, including the following steps: 1, segment division and plate unit division; 2, butt welding the fulcrum segmental box girders and standard segmental box girders at a prefabrication plant, namely, pre-splicing the segmental box girders of a full span box girder and the first box girder segment of the adjacent span box girder through long line method on a segmental box girder molding bed on which plane curves and pre-camber are arranged; marking the box girder segments, taking away the segmental box girders of the full span box girder, leaving the first box girder segment of the adjacent span box girder, and continuing to splice and weld the segmental box girders of the rest full span box girders; 3, generally assembling the full span box girders in the prefabrication plant. The invention adopts full span prefabrication and arrangement to construct a long continuous steel box girder or combined box girder, thus greatly reducing welding work load at the site. The invention ensures that the adjacent spans close smoothly after the steel girders are arranged and meets the requirements of light large span, precast assembly and quick construction.

Owner:CHINA MAJOR BRIDGE ENG

Reinforced laminated support mat

Owner:ANTHONY HARDWOOD COMPOSITES

Method for mounting box arch bridge

ActiveCN101519864ASimplified installation procedureReduce engineering costsBridge erection/assemblyArch-type bridgeT-beamAbutment

The invention discloses a method for mounting a box arch bridge. The method comprises the following steps: (1) excavating earth and stone work of a main arch abutment, and mounting a cable system; (2) pouring concrete of the main arch abutment and haunch; (3) hoisting the haunch; (4) mounting a bent on the arch; (5) mounting a T beam; and (6) constructing a bridge floor system. In haunch hoisting, after a first arch rib is mounted, a knotted rope used for stabilizing the haunch is detached, and the knotted rope is used for mounting a second haunch, and the like, so that all haunches can be mounted by the first knotted rope. The method simplifies mounting program of the box arch bridge, and greatly saves construction cost.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

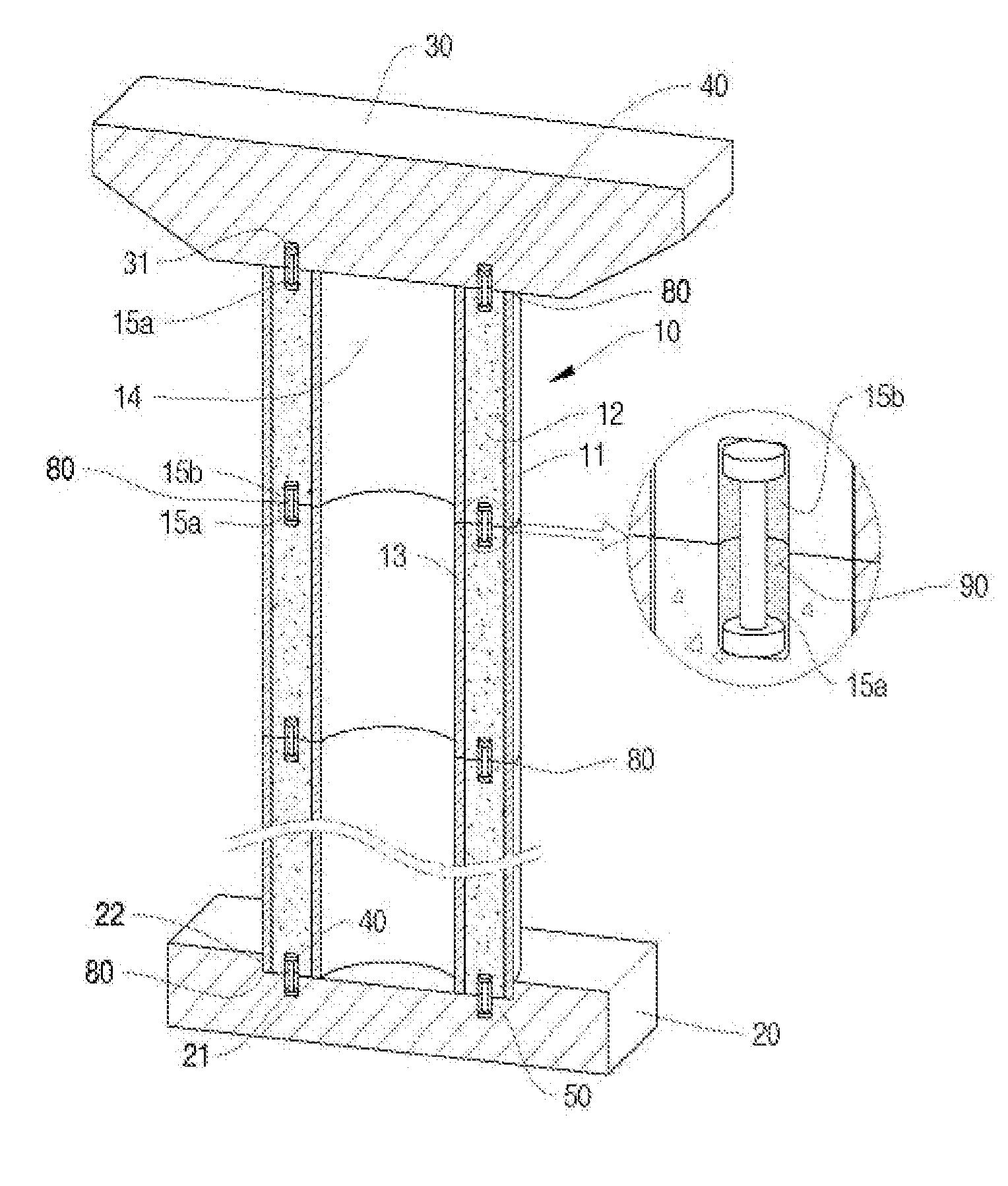

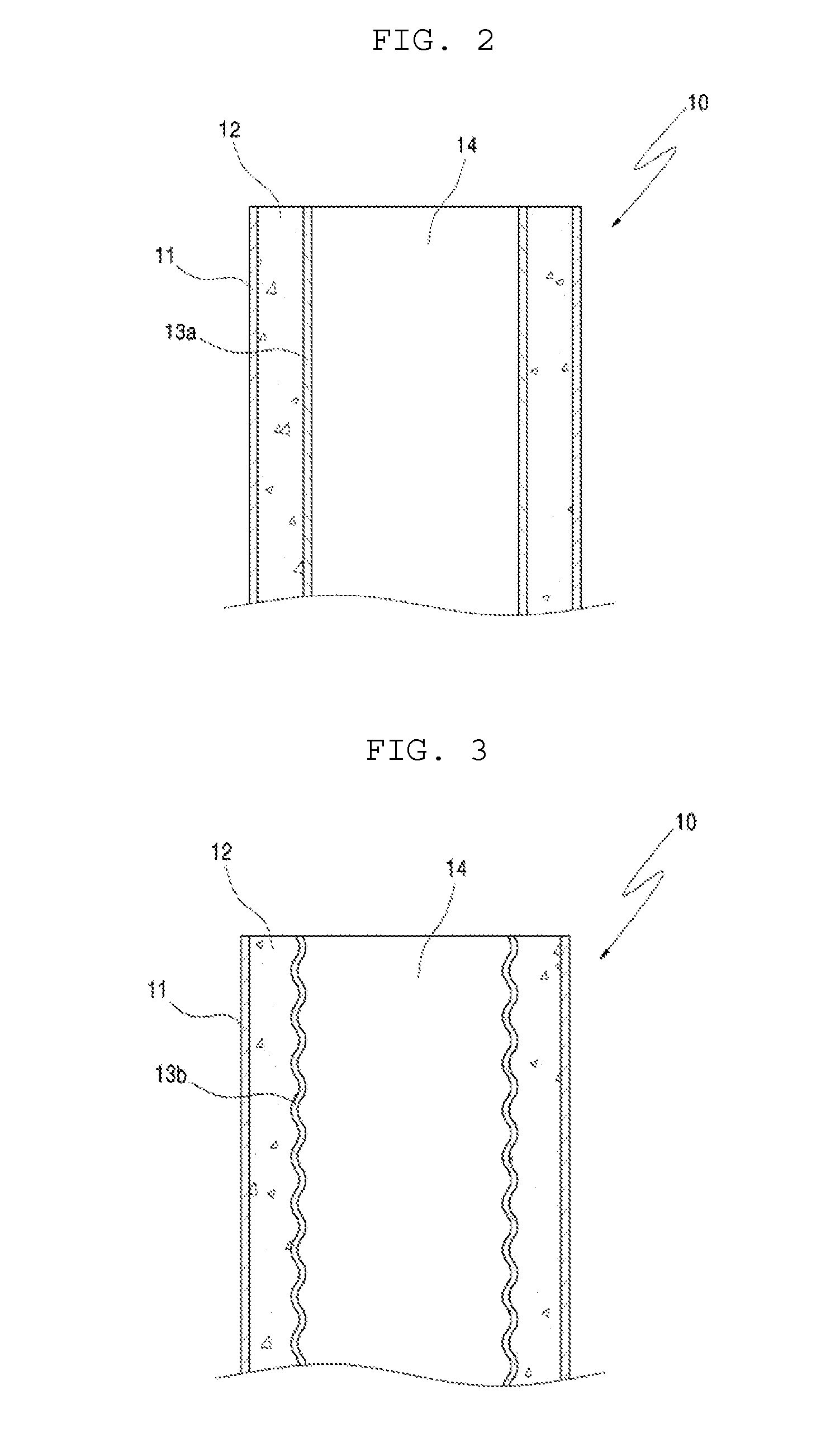

Modular Column System Using Internally Confined Hollow Column Unit and Method of Constructing the Same

A modular column system and a method of constructing the same are constructed by stacking at least one precast unit between a foundation section and a coping section. The precast unit makes use of an internally confined hollow column unit fabricated in advance, and joint sections between the precast units are firmly formed. Thereby, the modular column system can realize a short construction period and economy because reinforcement bars and forms are not used, as well as high resistance to bending moment and reduction in cross section and self-weight of the precast unit, and thus the modular column system can provide easier and more economical assembly, and prevent brittle fracture of the joint section between the precast units.

Owner:HANBAT NAT UNIV IND ACADEMIC COOPERATION FOUND

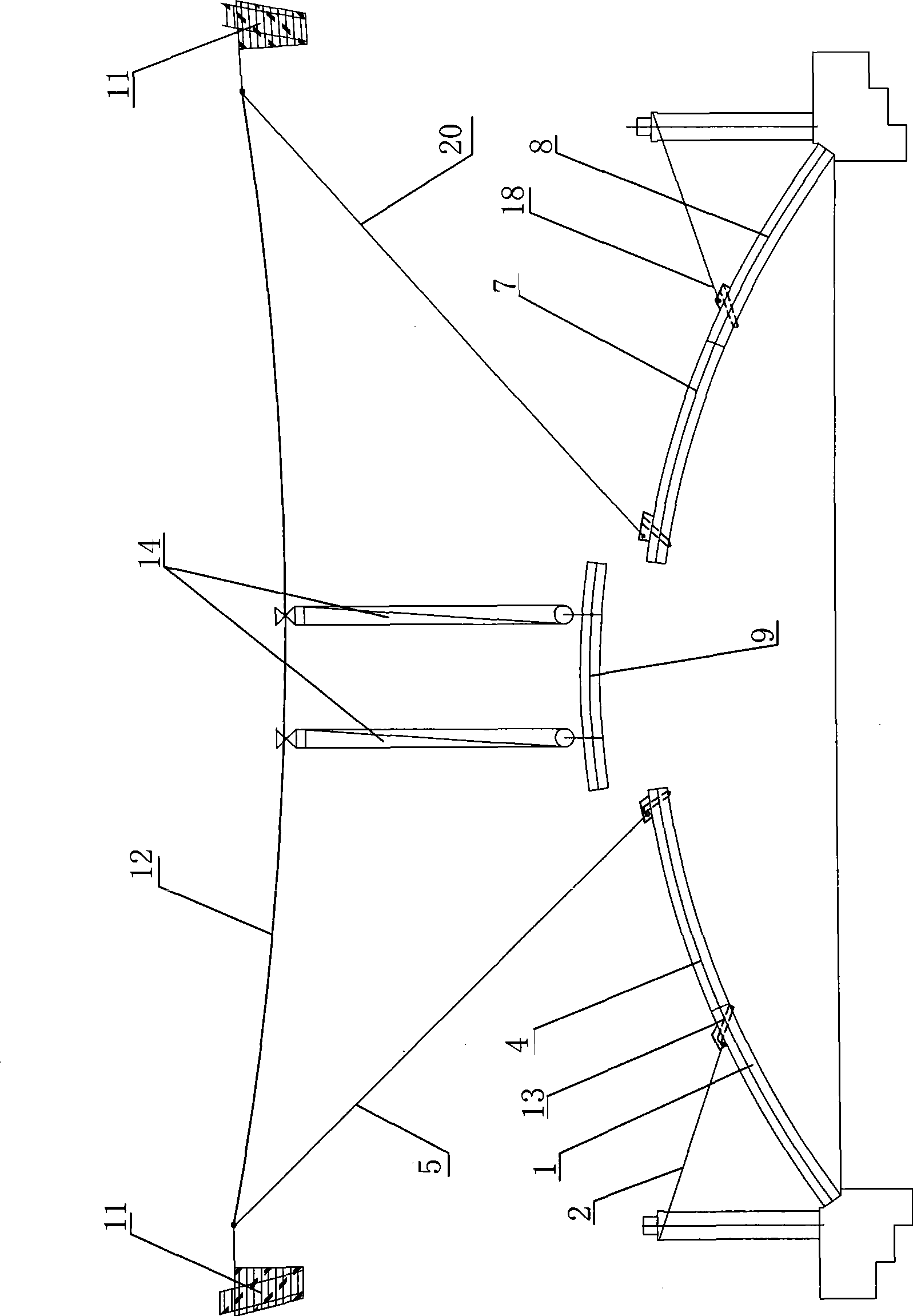

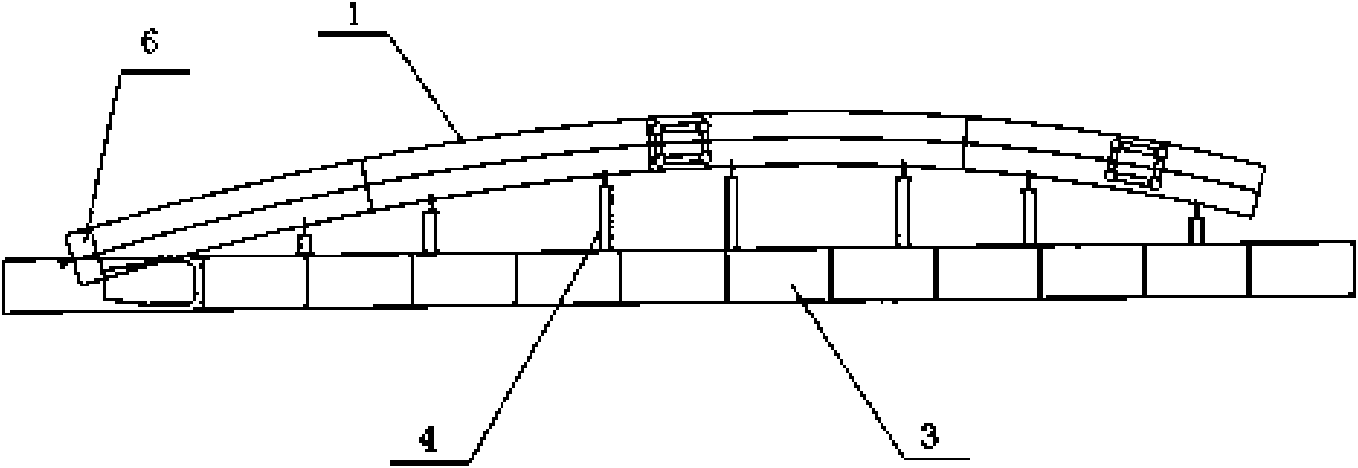

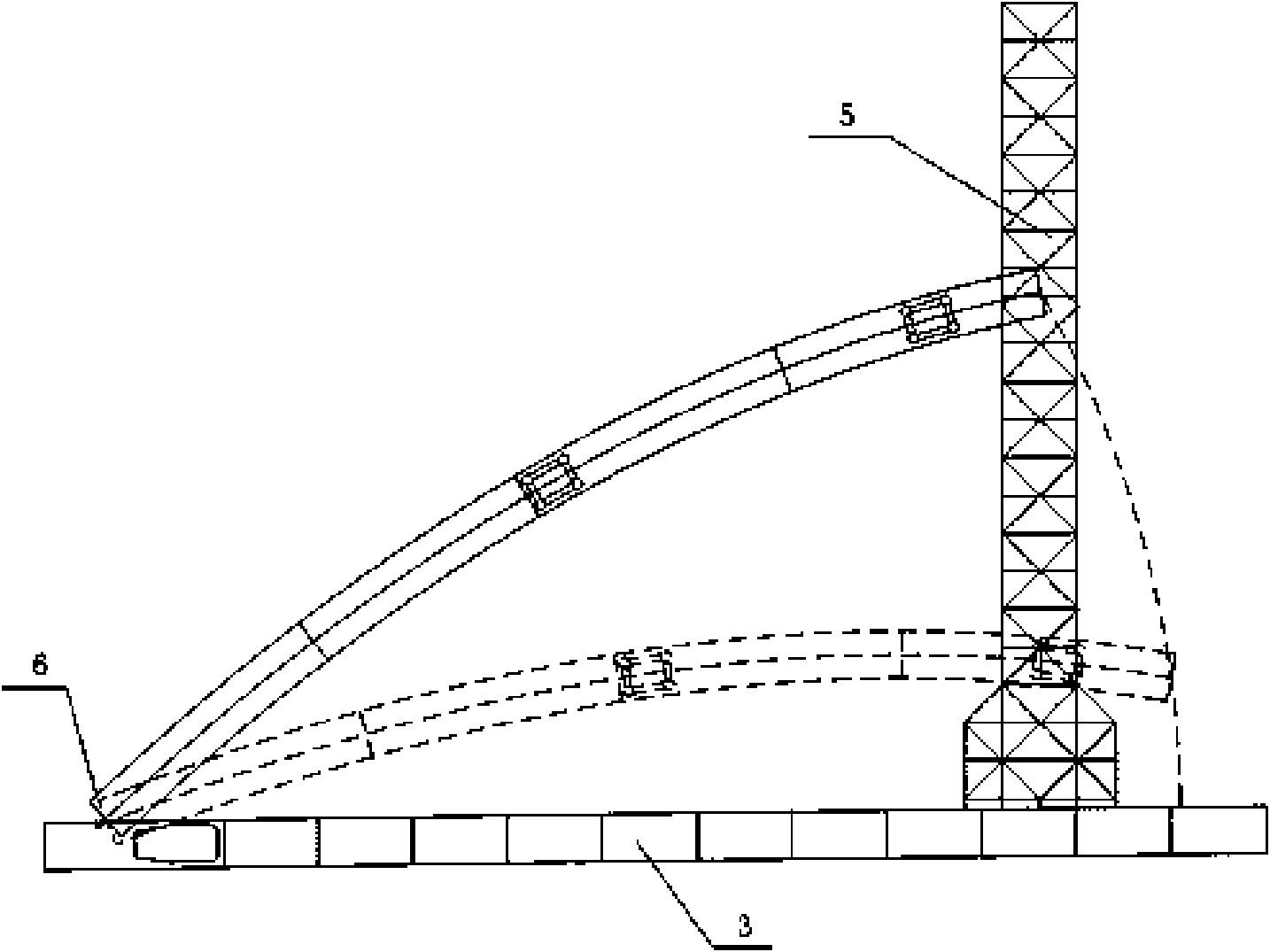

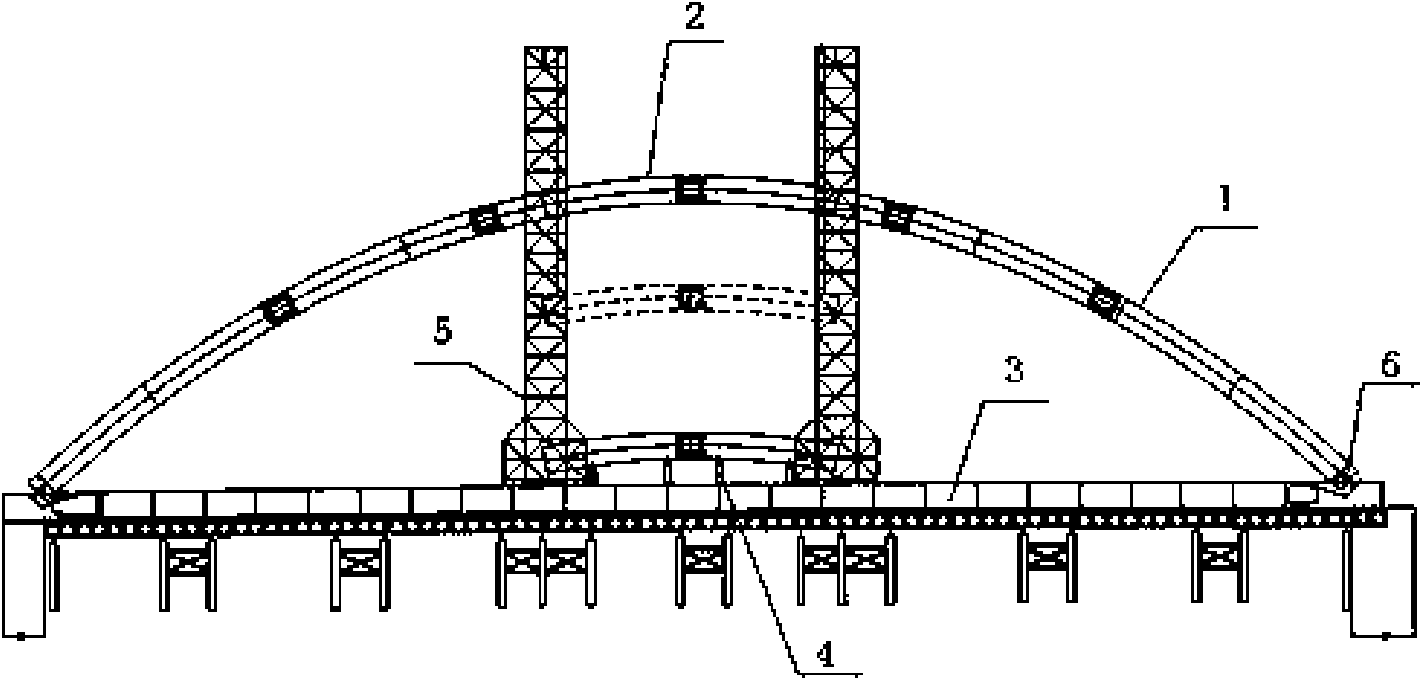

Steel tube arch rib vertical lifting method

ActiveCN101672011AReduce construction investmentThe structural force is clearBridge erection/assemblyArch-type bridgeButt jointTower

The invention discloses a steel tube arch rib vertical lifting method, which comprises the following steps: separating the steel tube arch rib into two side sections and middle-section closure sections, taking an arch hinge of a side section arch springing as a rotating point and vertically lifting the two side sections of the steel tube arch rib, adopting a temporary support for respectively stabilizing the two side sections on two lifting towers after reaching a set position; lifting the middle-section closure sections of the steel tube arch rib which is butt-jointed and closed with the twoside sections; the side sections and the middle-section closure sections can be split into two to four pieces of processing sections; the maximum weight of all sections is less than 20 tons; and all the sections can be assembled and welded on the spot before lifting. The steel tube arch rib vertical lifting method has the beneficial effects that the method has little constructional investment, clear structural force, shortcut and convenient construction process, and effectively solves the technical problem that the steel-tube arch is transferred and assembled into in a hoisting section in theconstruction process of a little span, low height and first-beam and post-arch arch bridge and the section of the steel-tube arch is arranged in place.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com