Patents

Literature

404results about How to "Reduce welding workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

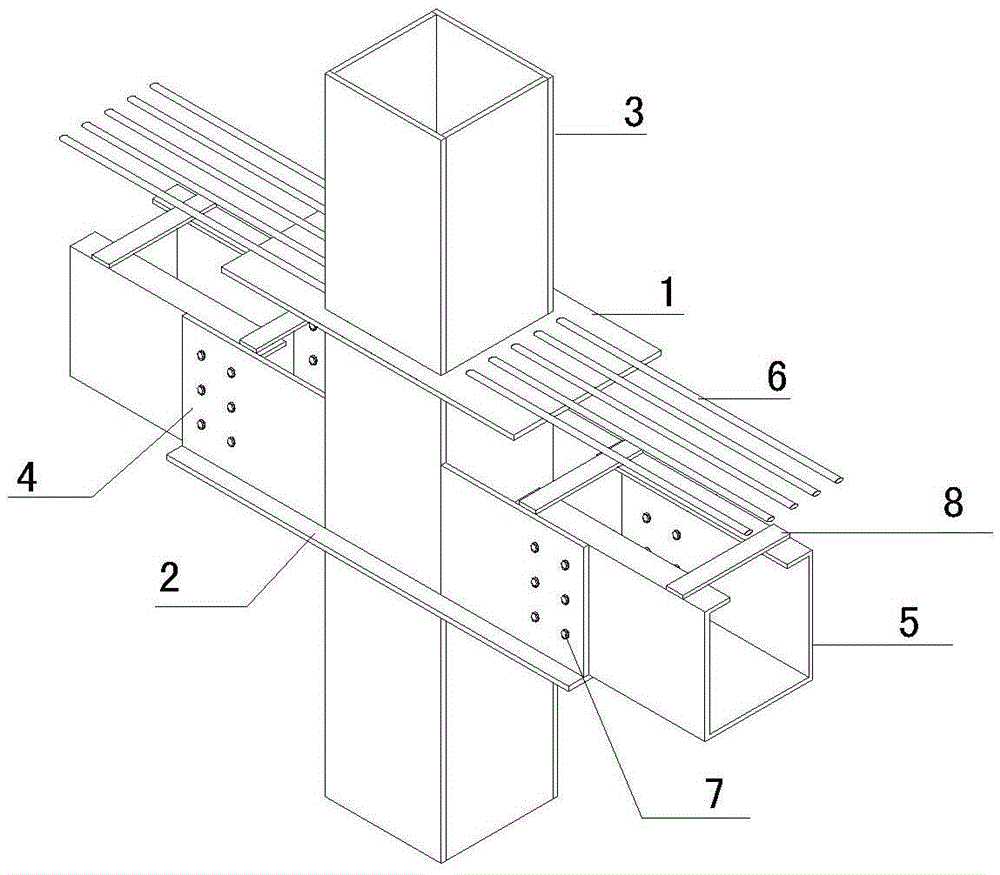

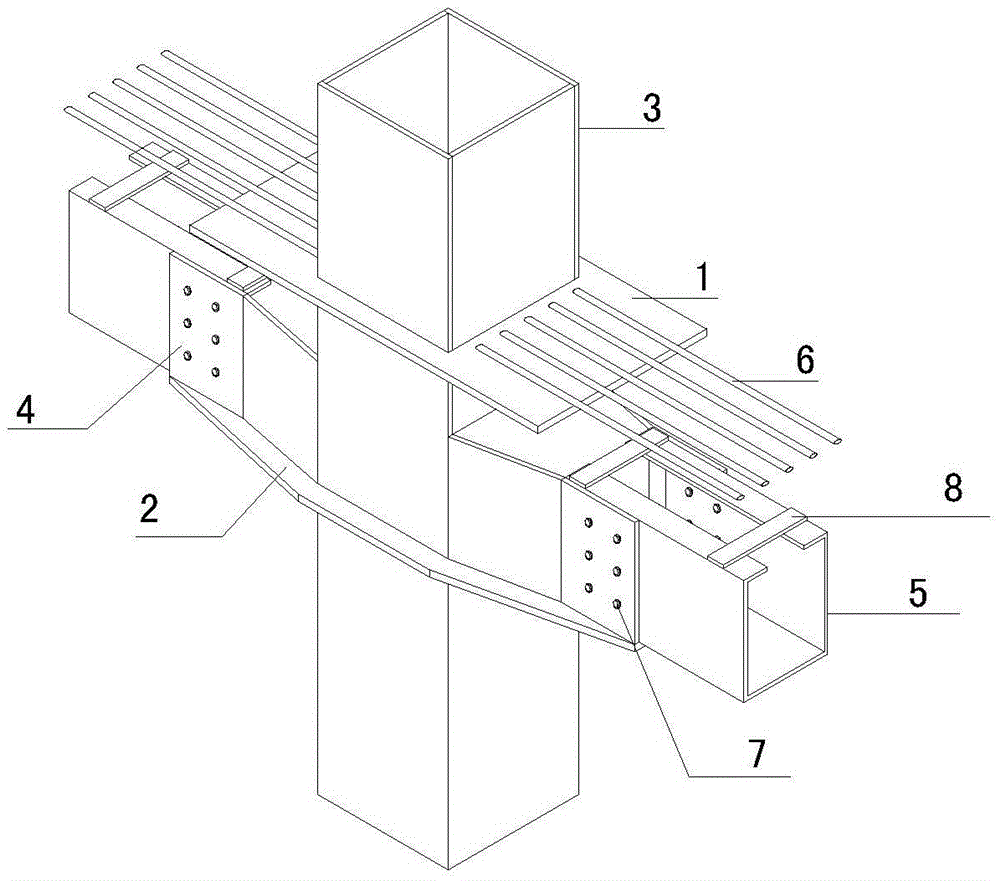

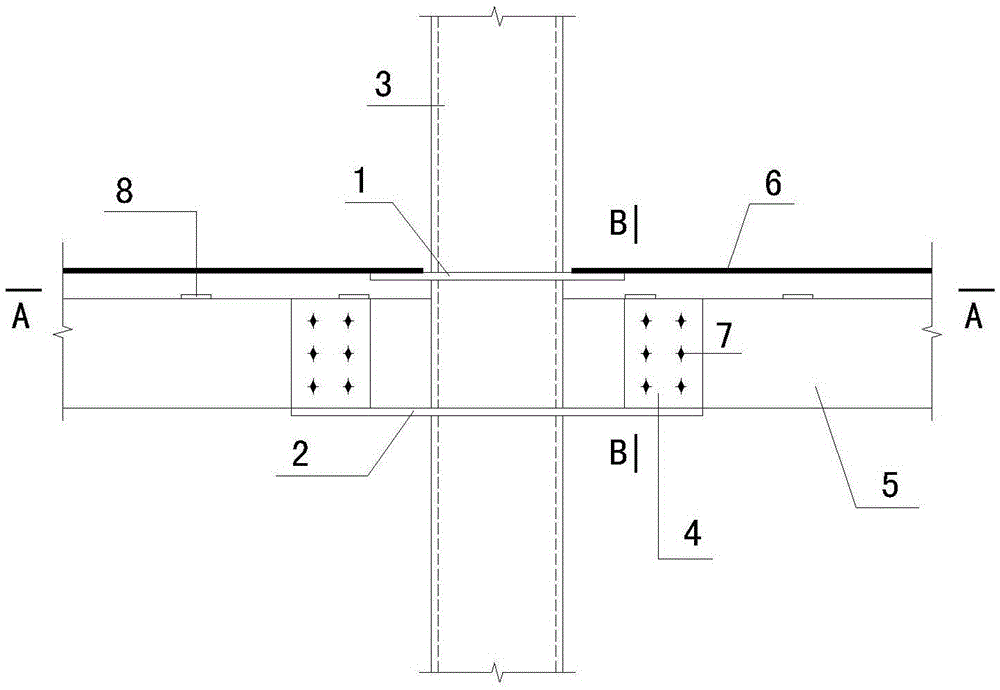

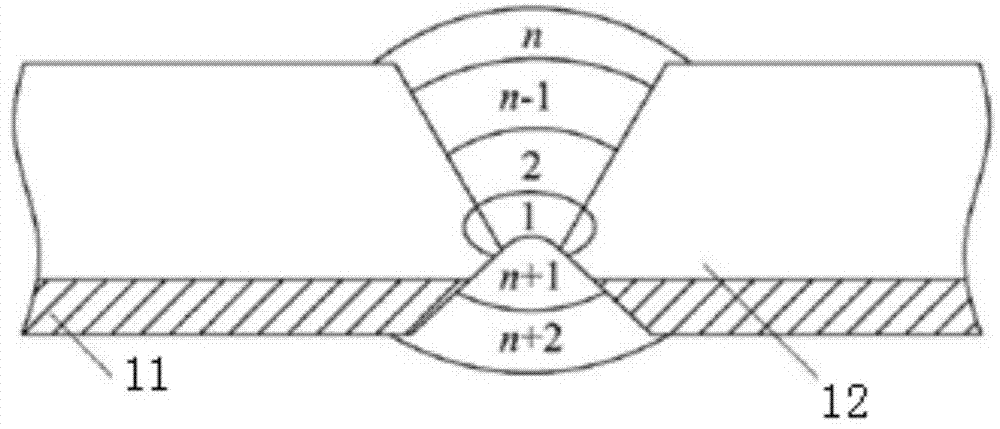

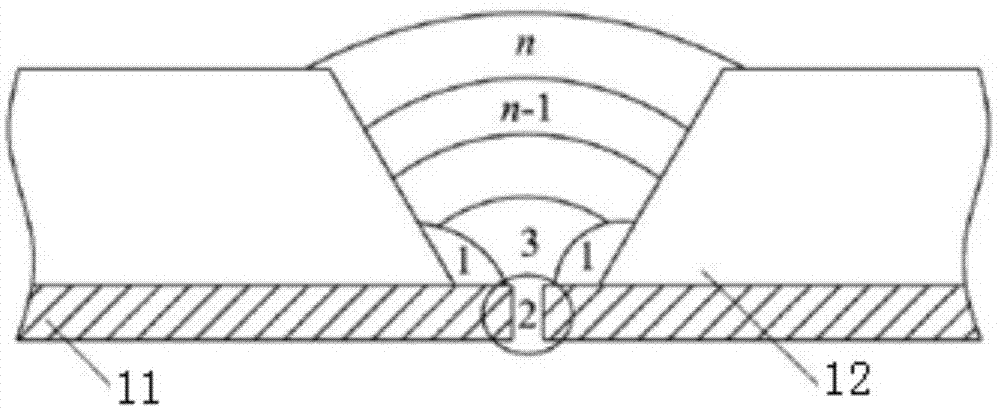

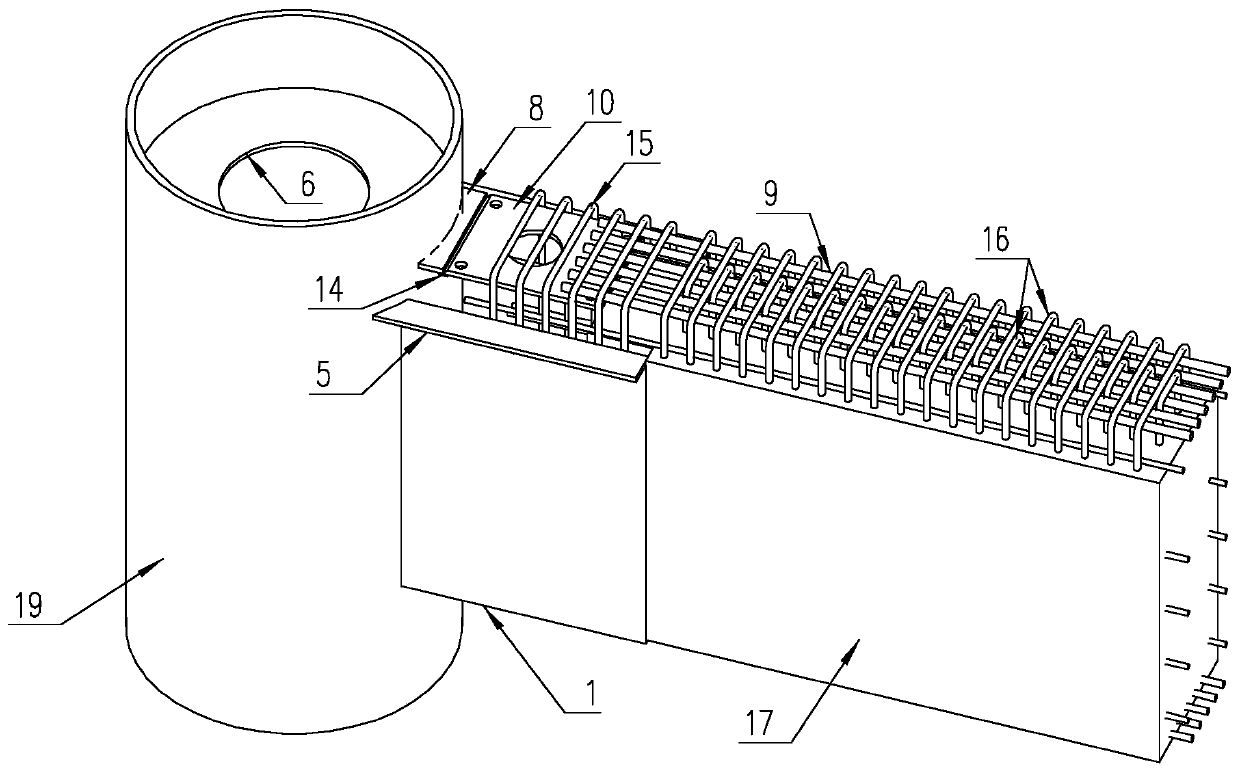

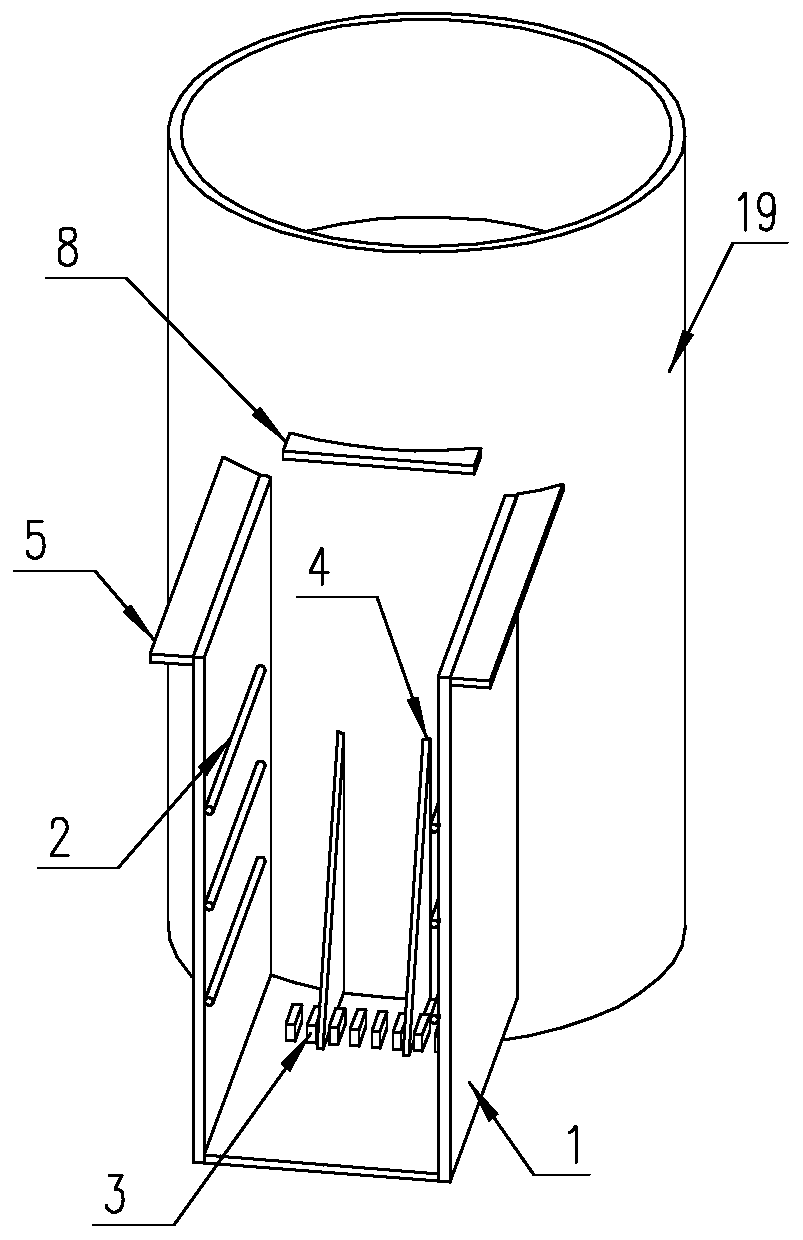

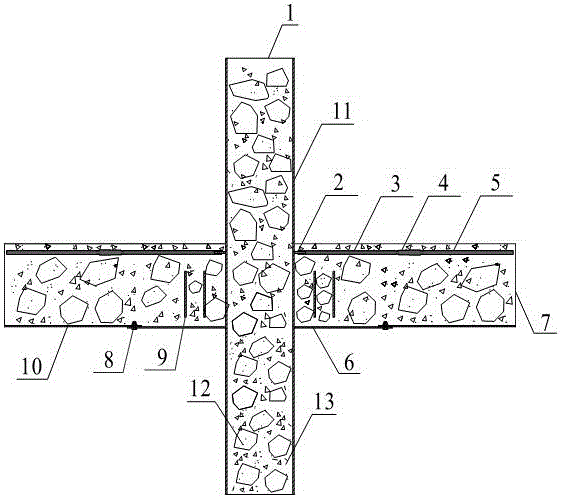

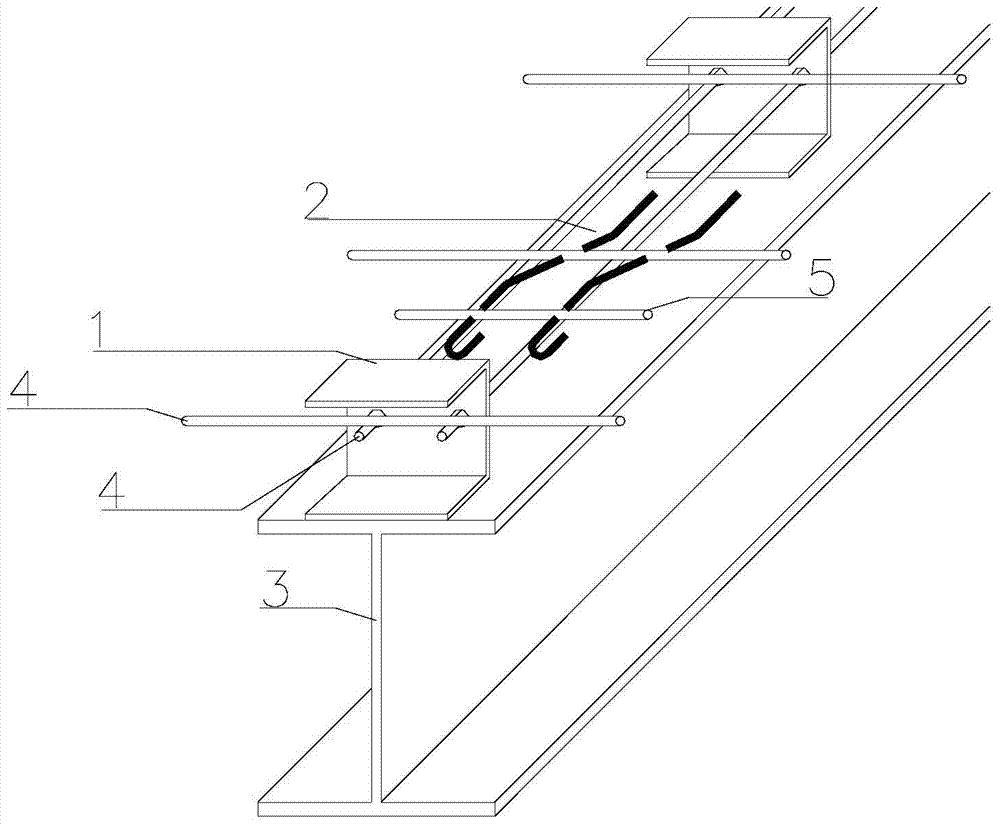

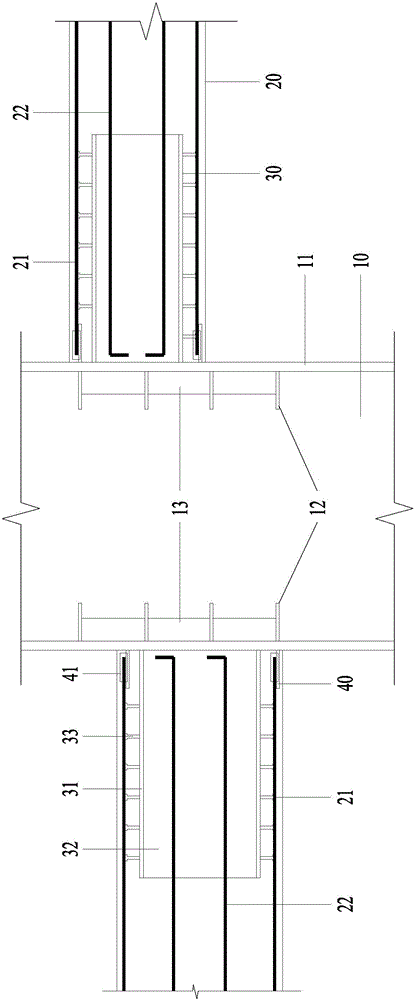

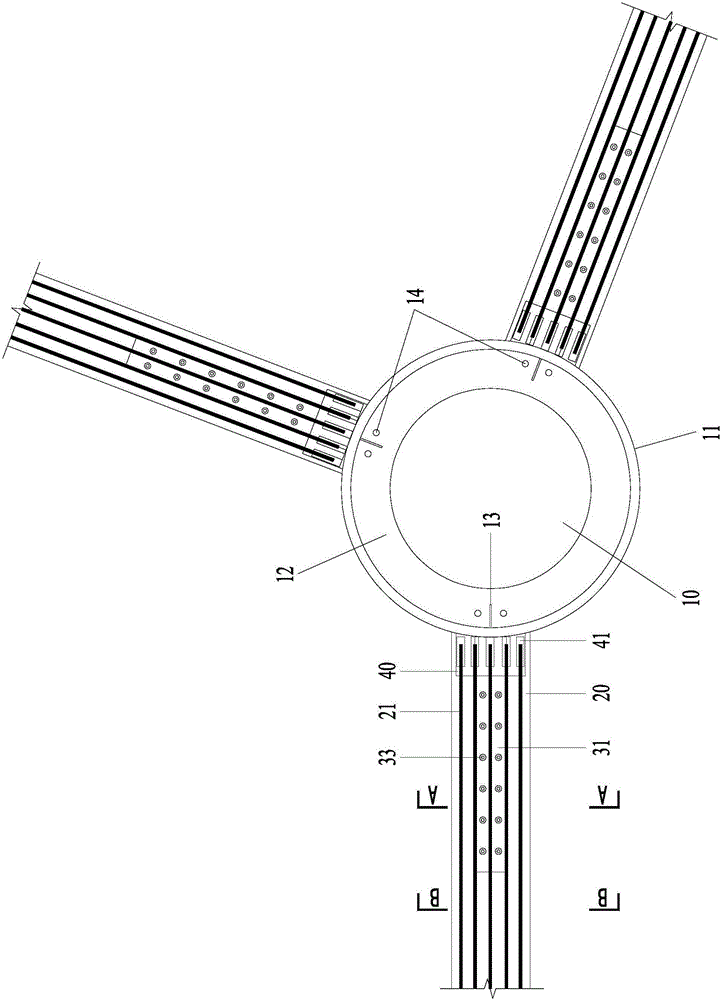

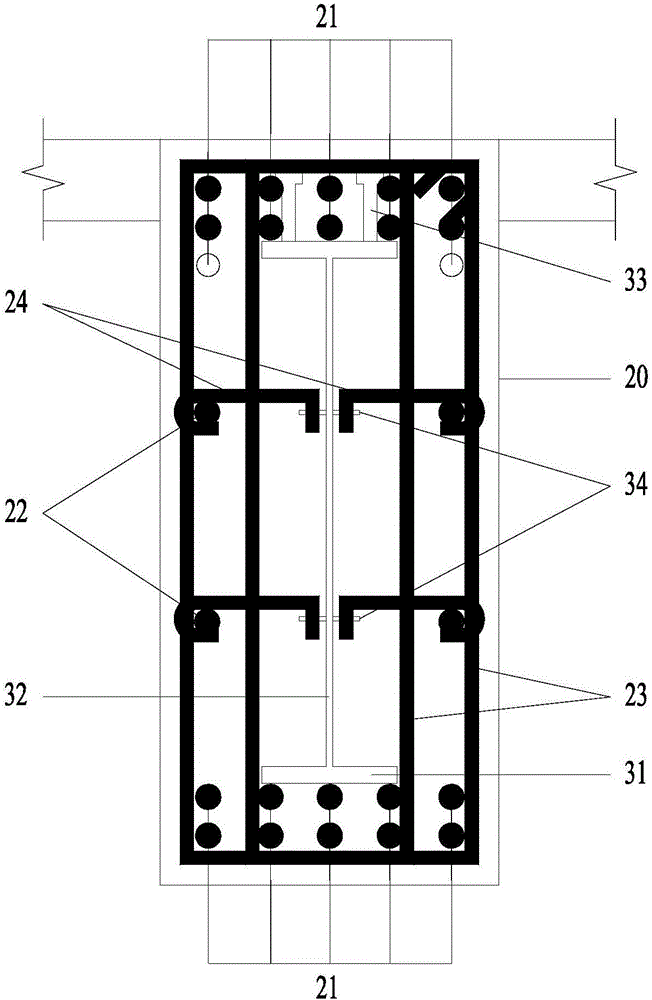

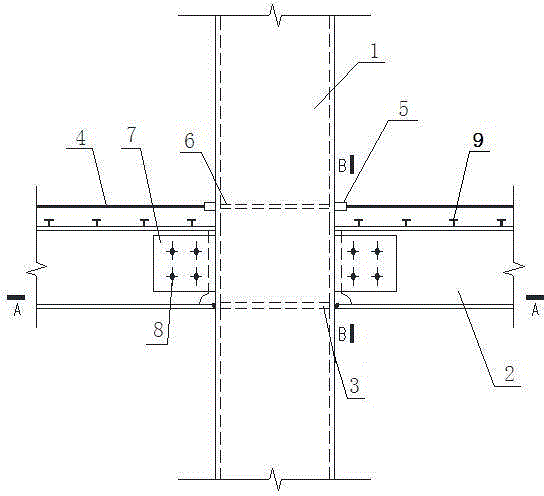

Steel-encased concrete composite beam-steel pipe column connection joint

InactiveCN105569191AReduce welding workloadEasy constructionBuilding constructionsSteel tubeBending moment

The invention discloses a steel-encased concrete composite beam-steel pipe column connection joint and a manufacturing method thereof. The joint comprises a steel pipe column, an upper through partition plate, a lower through partition plate, a lateral connection plate and the like; the upper through partition plate and the lower through partition plate are arranged on the steel pipe column in a transverse penetrating mode; hogging moment reinforcing steel bars are welded to the two ends of the end face of the upper through partition plate, the lower through partition plate and the lateral connection plate form a U-shaped device on the column side, and the U-shaped device can be made into a uniform cross-section or a variable cross-section form according to beam-column cross section size; a steel-encased girder is directly placed in the U-shaped device and connected with the U-shaped device through high-strength bolts. The steel-encased concrete composite beam-steel pipe column connection joint has the advantages that the welding work of the whole U-shaped device can be completed in a factory, a steel-encased girder bottom plate and a lateral plate are connected with the joint through high-strength bolts, the site welding work amount is greatly reduced, and construction and assembling are facilitated; the hogging moment reinforcing steel bars are directly welded to the upper through partition plate, the situation that steel pipe bearing capacity is weakened due to trepanning in the side wall of a steel pipe can be reduced, and force transfer is definite.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD +1

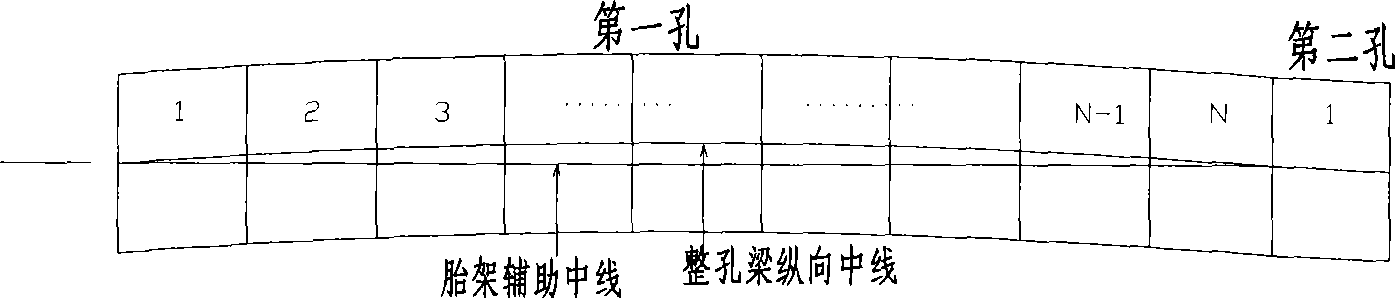

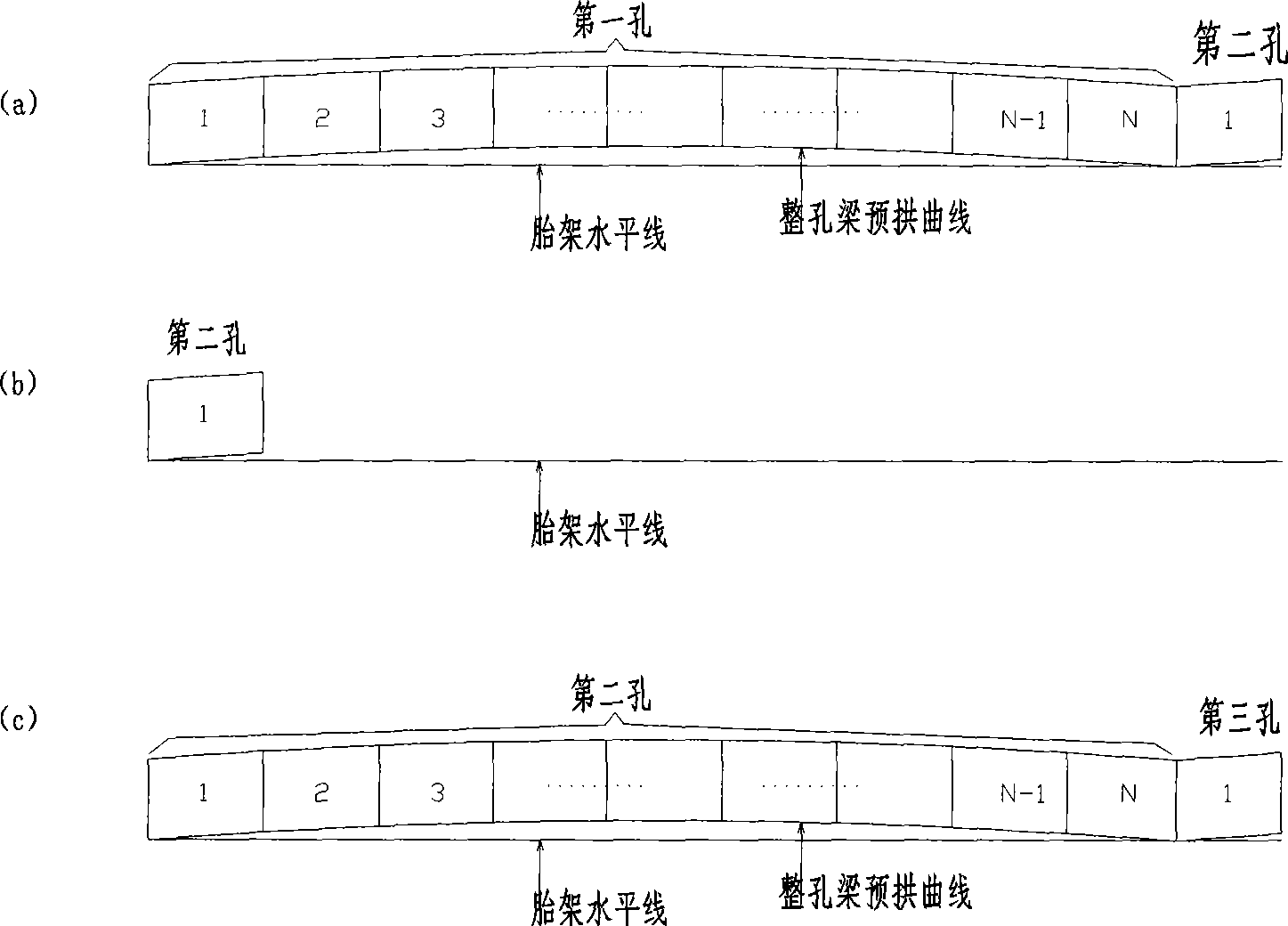

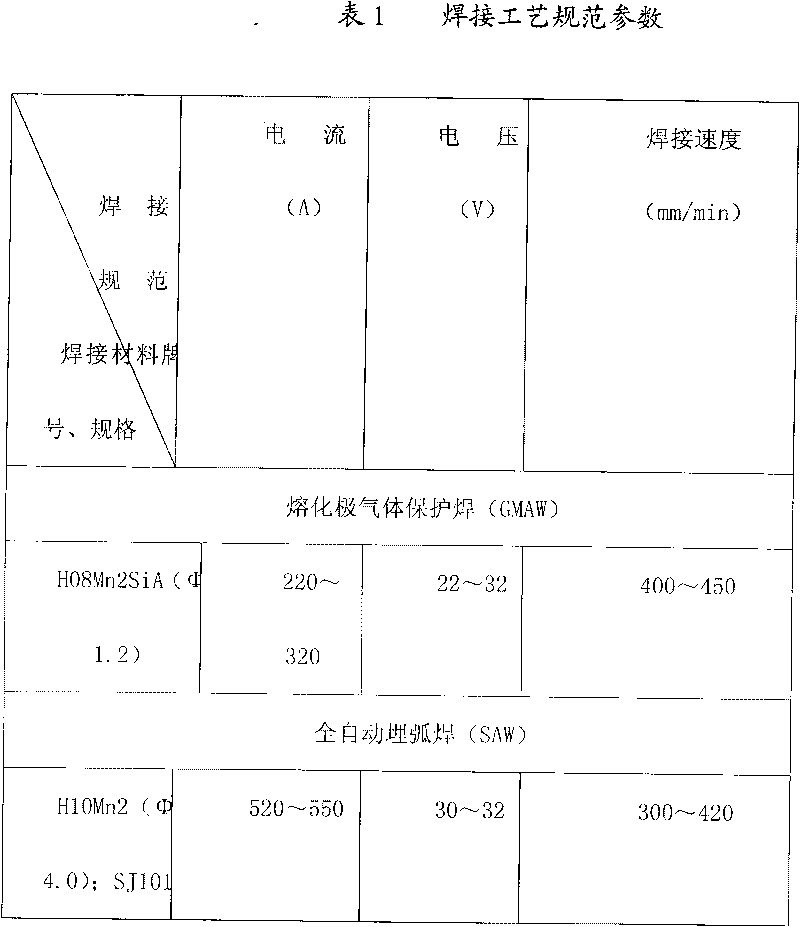

Long continuous structural steel box beam or combination box beam construction method

InactiveCN101368373AReduce welding workloadSatisfy \"Light Large Span\"Bridge erection/assemblyBridge materialsButt weldingEngineering

The invention discloses a long continuous steel box girder or combined box girder construction method, including the following steps: 1, segment division and plate unit division; 2, butt welding the fulcrum segmental box girders and standard segmental box girders at a prefabrication plant, namely, pre-splicing the segmental box girders of a full span box girder and the first box girder segment of the adjacent span box girder through long line method on a segmental box girder molding bed on which plane curves and pre-camber are arranged; marking the box girder segments, taking away the segmental box girders of the full span box girder, leaving the first box girder segment of the adjacent span box girder, and continuing to splice and weld the segmental box girders of the rest full span box girders; 3, generally assembling the full span box girders in the prefabrication plant. The invention adopts full span prefabrication and arrangement to construct a long continuous steel box girder or combined box girder, thus greatly reducing welding work load at the site. The invention ensures that the adjacent spans close smoothly after the steel girders are arranged and meets the requirements of light large span, precast assembly and quick construction.

Owner:CHINA MAJOR BRIDGE ENG

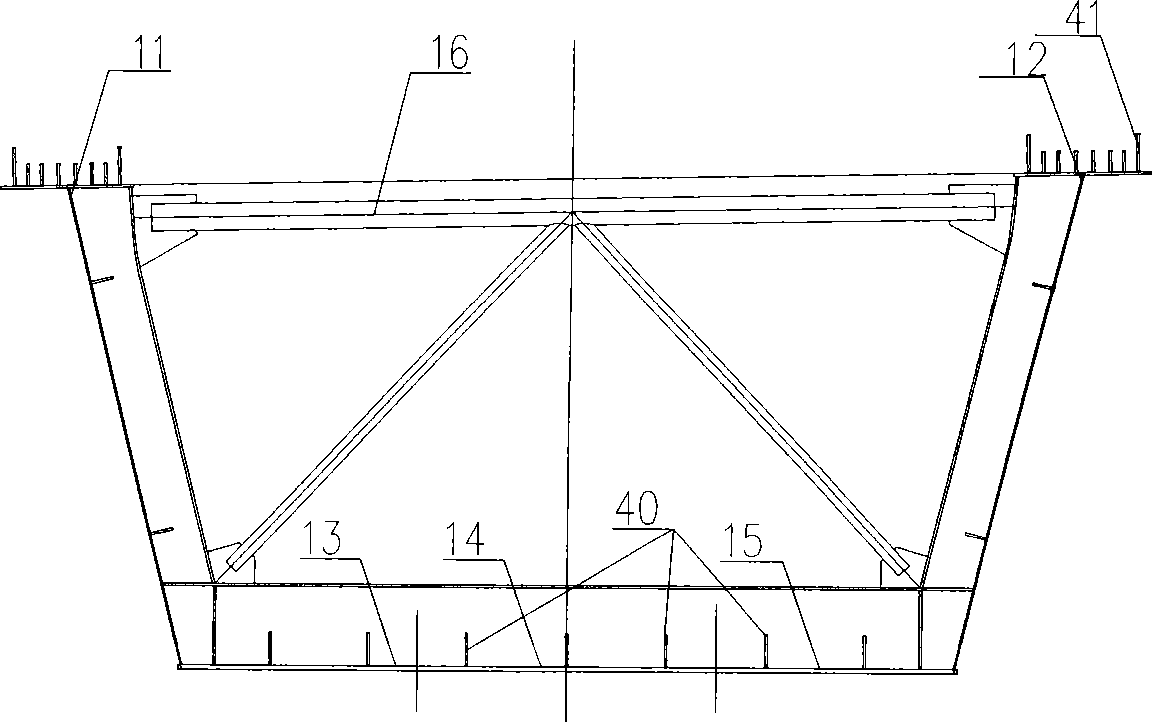

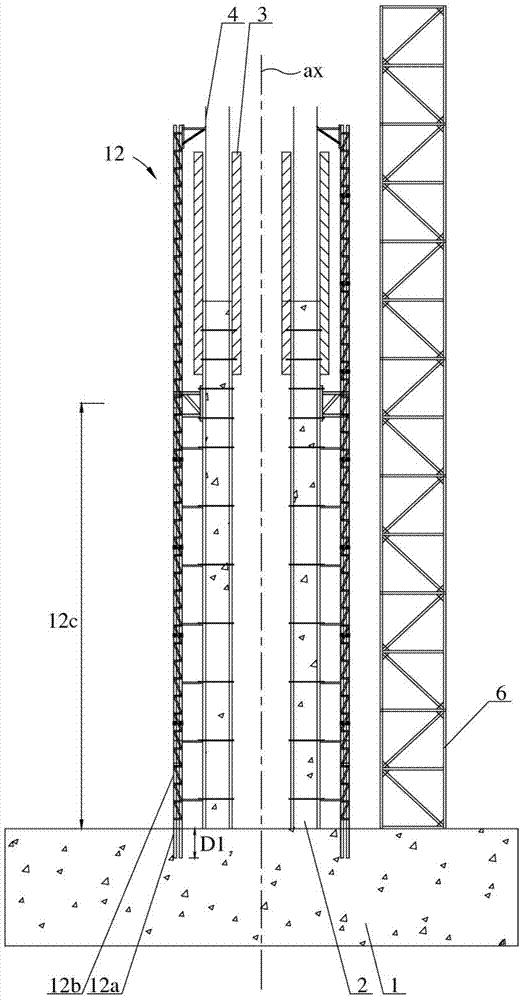

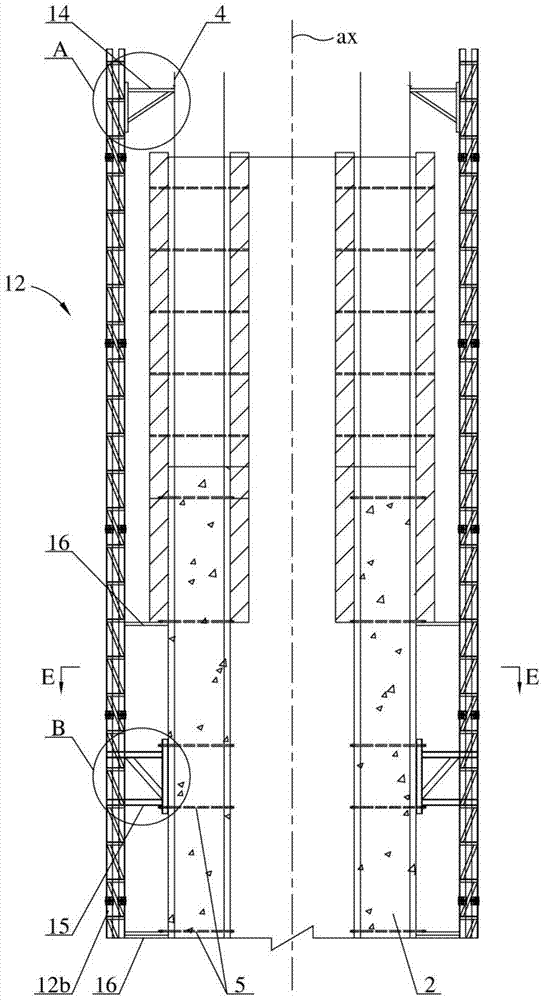

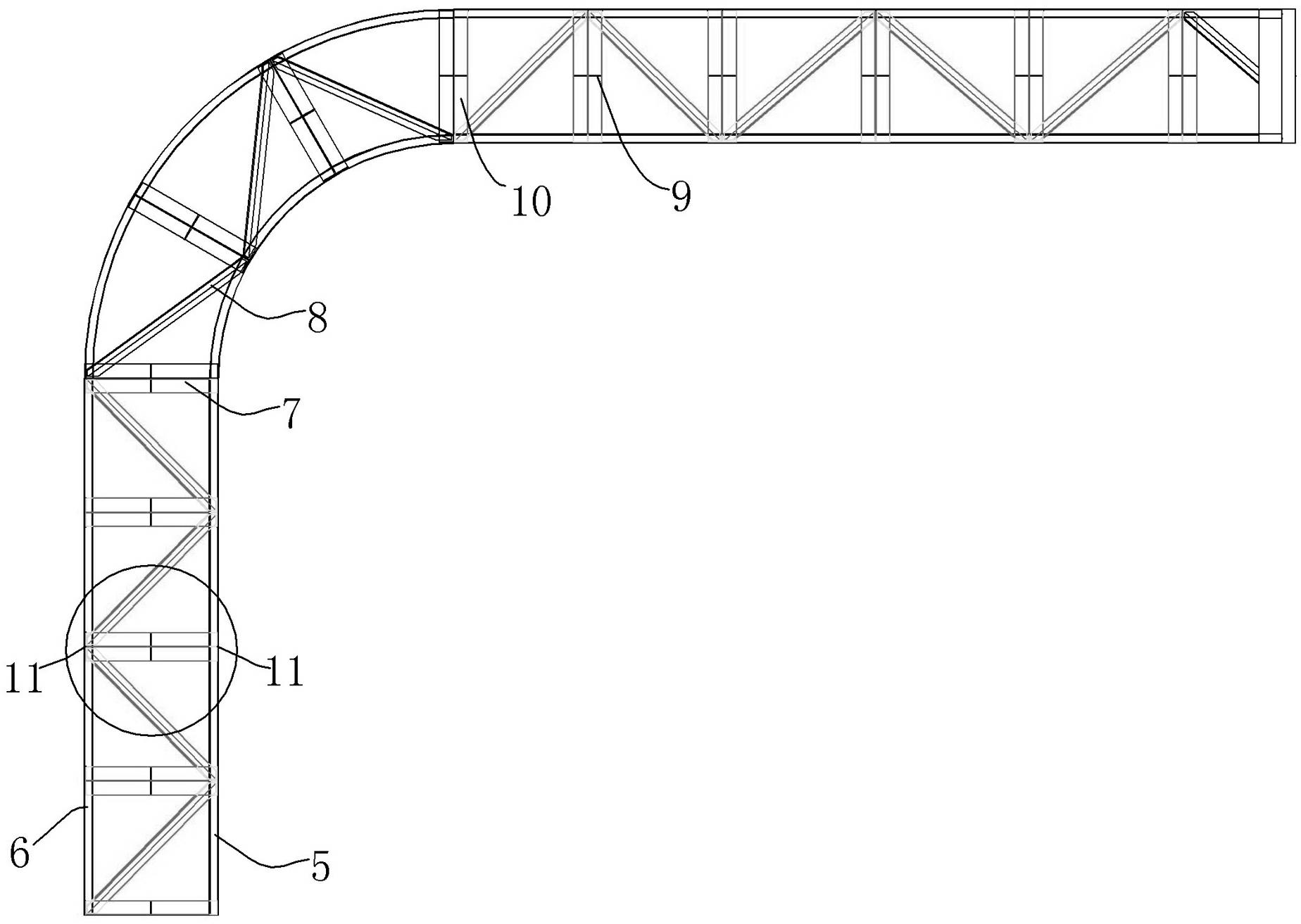

Stiff framework and method for constructing bridge tower column by means of same

ActiveCN103614967AImprove stabilityPrecise positioningBridge structural detailsBridge erection/assemblyEngineeringRebar

The invention provides a stiff framework and a method for constructing a bridge tower column by means of the stiff framework, and relates to the technical field of methods for erecting or assembling bridges. The problems that an existing stiff framework is arranged in a tower column, structural steel consumption is high and concrete in the tower column easily cracks are resolved. The stiff framework comprises framework main bodies enclosing the outer side of the tower column, a plurality of transverse rods and a steel bar positioning supporting arm device; each framework main body is composed of a stiff framework pre-buried section and a plurality of stiff framework standard sections, and multiple stiff framework standard sections connected in a head-to-end mode along the axis form a stiff framework unit. The method comprises the steps that firstly, the stiff framework pre-buried sections and the standard sections are prefabricated; secondly, a formwork and the framework main bodies are erected, and main reinforcement is positioned through the steel bar positioning supporting arm device; thirdly, the formwork and the framework main bodies continue to be erected, then the main reinforcement is positioned through the steel bar positioning supporting arm device, and the formwork and the framework main bodies are disassembled after being constructed; fourthly, the tower column is fixedly connected with the transverse rods through the stiff framework standard sections; the third step and the fourth step are repeated, and the stiff framework is disassembled after pouring is completed.

Owner:SHANGHAI MUNICIPAL CONSTR

Efficient butt-joint laser welding method for laminated duplex-metal composite material

InactiveCN103878484ARealize one-time welding forming technologyGuaranteed Performance CharacteristicsWelding/soldering/cutting articlesWorkpiece edge portionsMolten bathMetallic materials

The invention discloses an efficient butt-joint laser welding method for a laminated duplex-metal composite material. The efficient butt-joint laser welding method comprises the steps that a base layer retaining layer is arranged at the portion, close to one side of a composite layer, of a base layer to form an I-type groove; the characteristic that in the laser penetration-type welding process, liquid metal at the upper portion and liquid metal at the lower portion inside a molten bath conduct Marangoni convection at the respective positions under the action of metal vapor friction and the temperature gradient, and little convection exchange happens between the liquid metal at the upper portion and liquid metal at the lower portion is used for being matched with the laminated characteristic of the laminated duplex-metal composite material, and the performance characteristics of two metal materials in a weld joint are ensured. The efficient butt-joint laser welding method has the advantages that one-time butt-joint welding forming of metal of the composite layer and some metal of the base layer is achieved, the working procedures of sealing and welding of a transition layer during a traditional composite board or composite pipe butt-joint welding are omitted, and the depth and the width of the remaining groove in the base layer are reduced, in other word, the welding amount of the base layer is reduced.

Owner:XI AN JIAOTONG UNIV

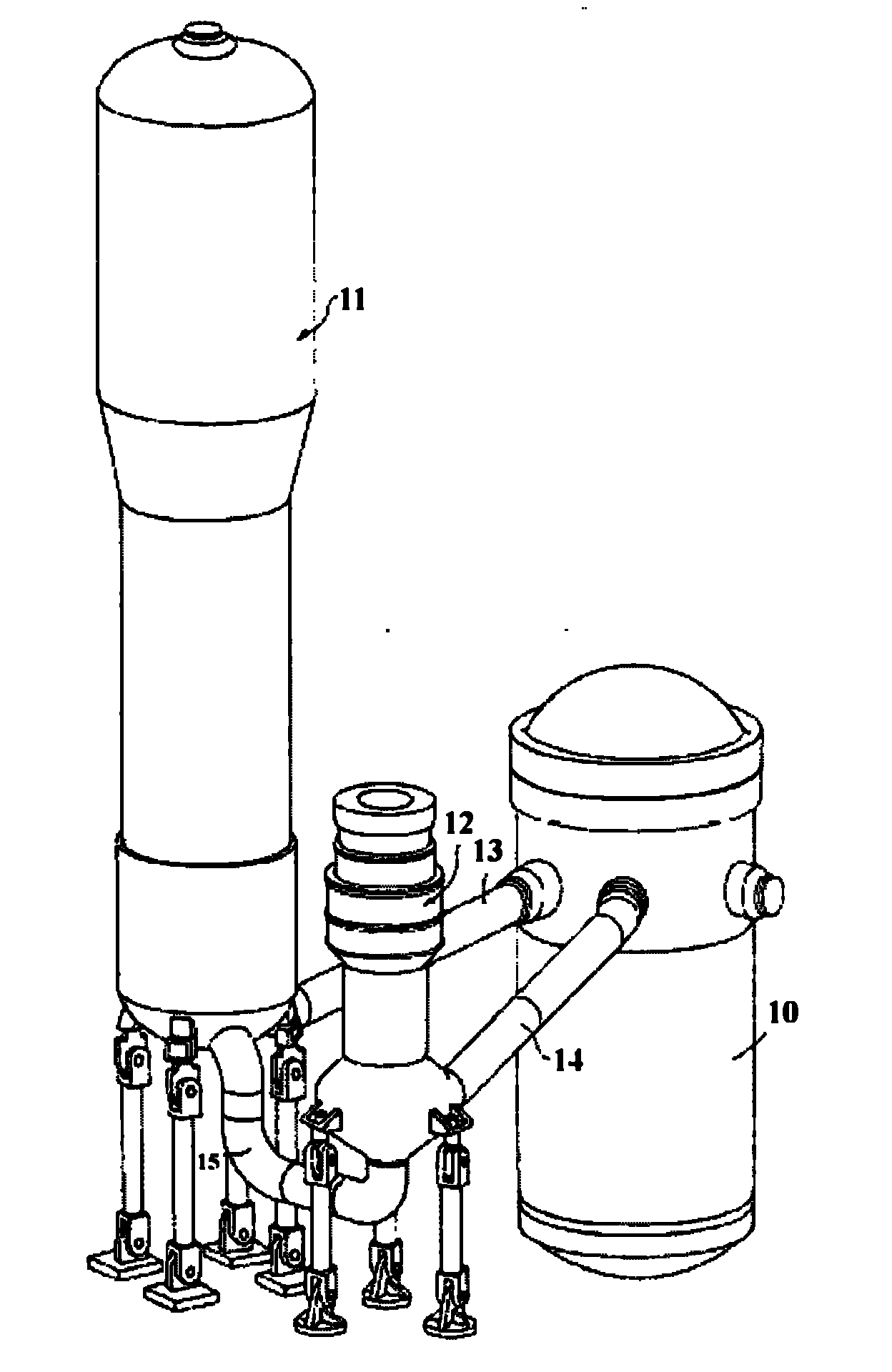

Method for mounting main pipeline and main loop of pressurized water reactor nuclear power station steam generator

ActiveCN101839467AAvoid inconvenienceEasy to controlNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention discloses a method for mounting a main return loop of a nuclear power station pressurized water reactor coolant system, which is characterized in that: a main pipeline heat section bend (16) and a main pipeline transition section bend (17) are welded at a loop nozzle of a lower seal end of the used steam generator (1); during mounting, a welding line (9) between a main pipeline heat section (13) and the main pipeline heat section bend (16) on the lower part of the steam generator (11) and a welding line (2) between the main pipeline heat section (13) and a reactor pressure container (10) can be assembled and welded simultaneously. In addition, the working amount for a welding line (5) is reduced during mounting. The mounting method can better control and guarantee the assembling and welding quality, improve the working efficiency, reduce the mounting time, and shorten the construction period.

Owner:CHINA NUCLEAR POWER ENG CO LTD

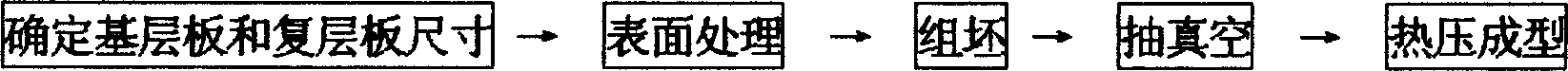

Processing method of press forming soldering high rolling composite blank

InactiveCN1686653AReduce welding workloadReduce edge lossWelding/cutting media/materialsAuxillary arrangementsManufacturing technologyDetackifier

A technology for making the combined blank includes providing the basic metal plate and additional metal plate, cleaning their surfaces, putting two additional metal plates between two basic ones, putting solder between the basic and additional metal plates, putting the high-temp detackifier between two additional metal plates, welding sealing plates on their periphery while pressing, drilling holes, vacuumizing, heating, hot pressing and cooling.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

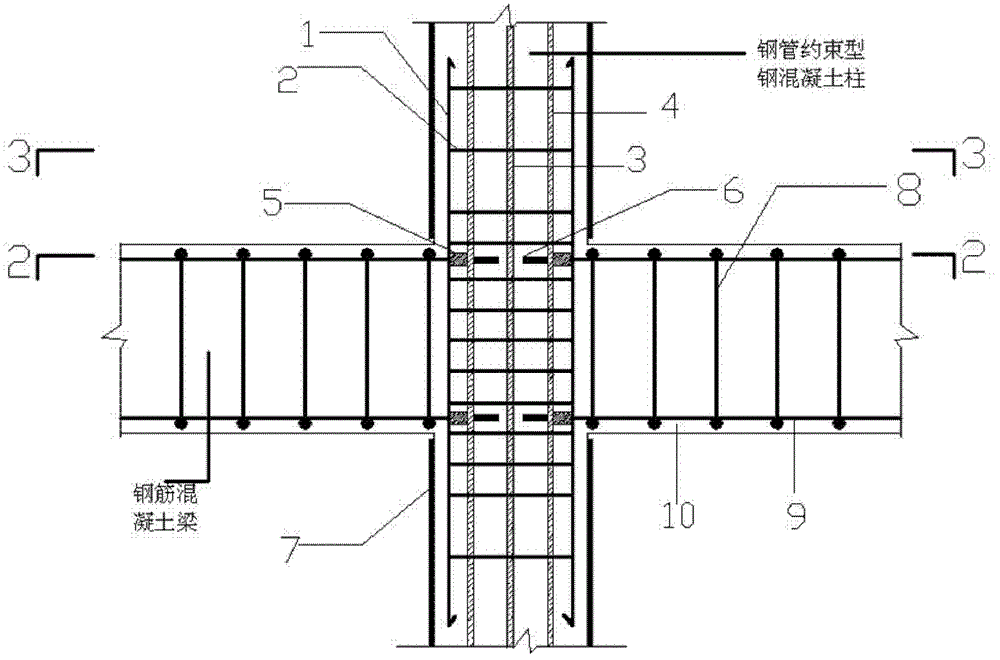

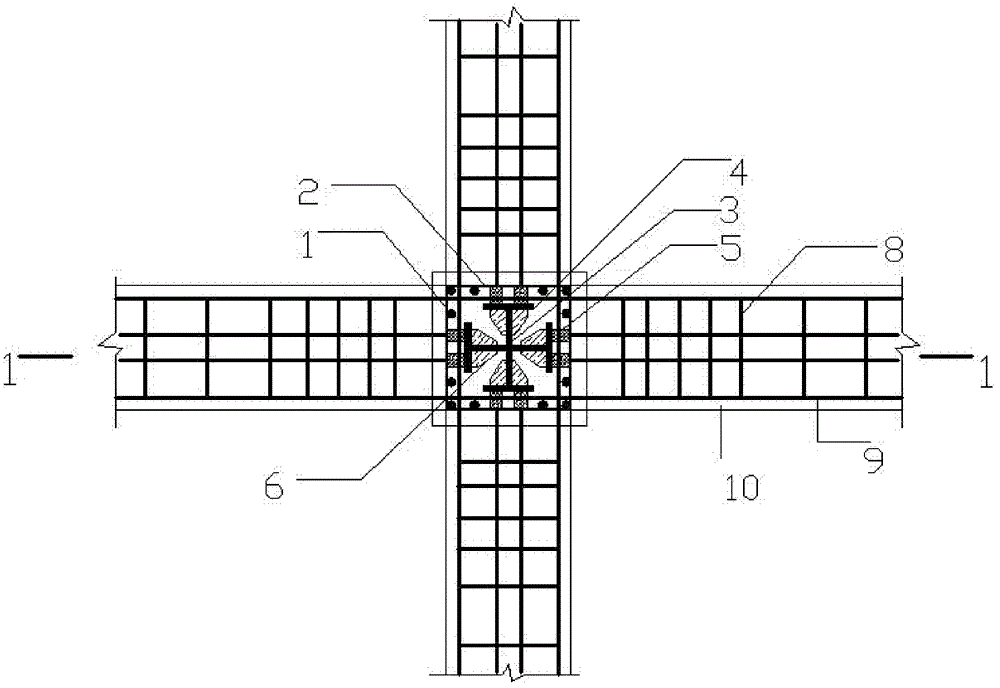

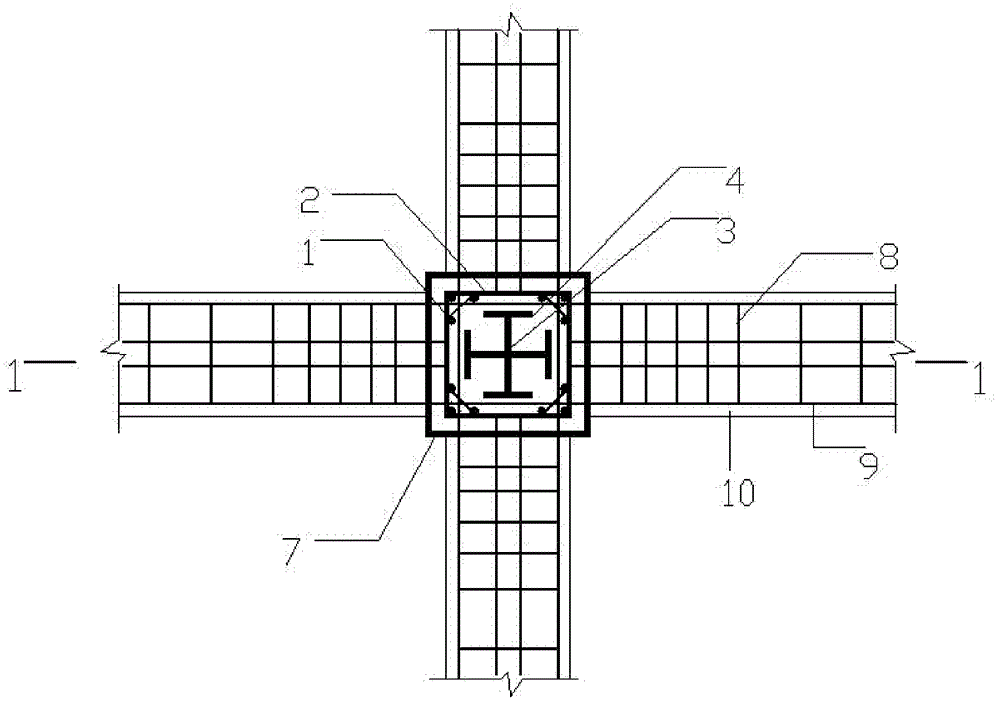

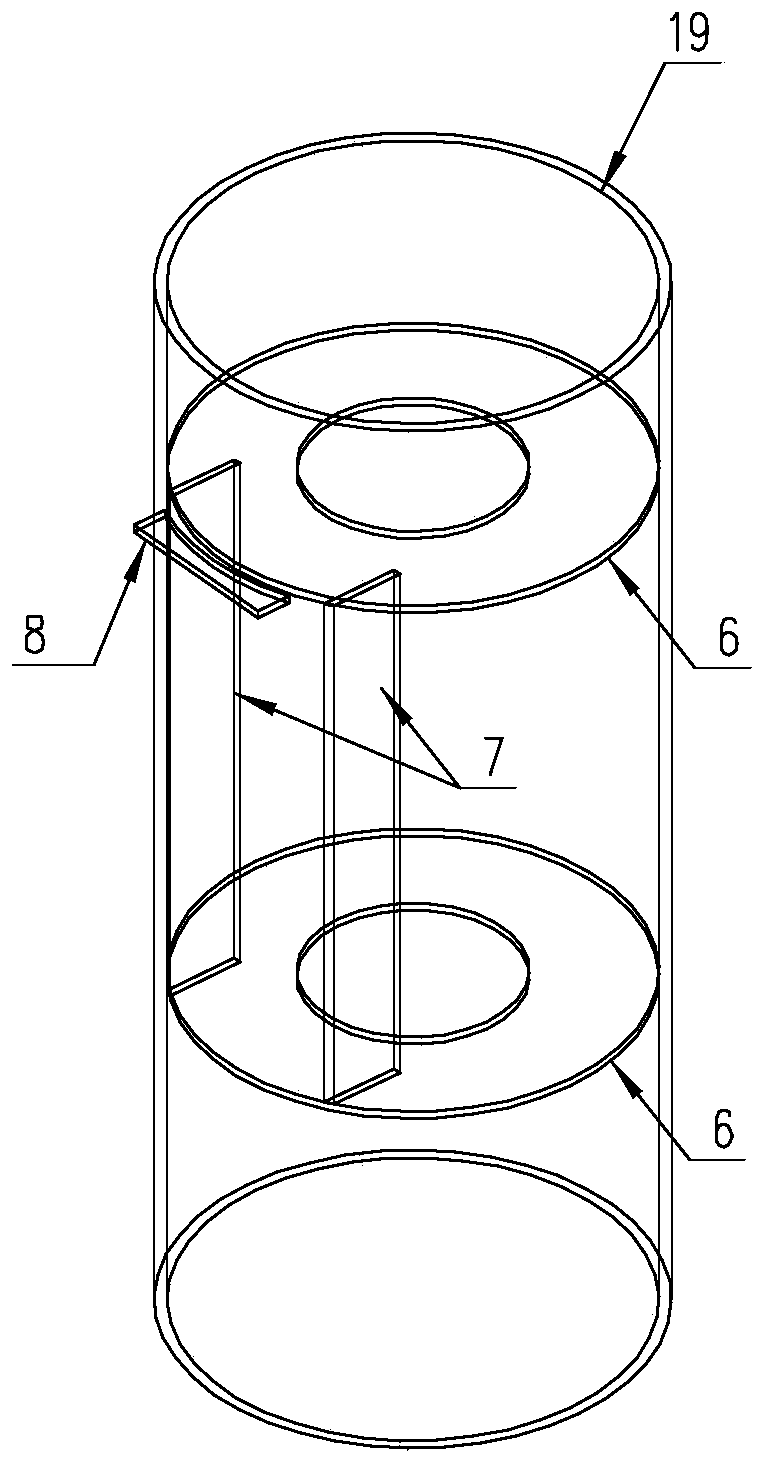

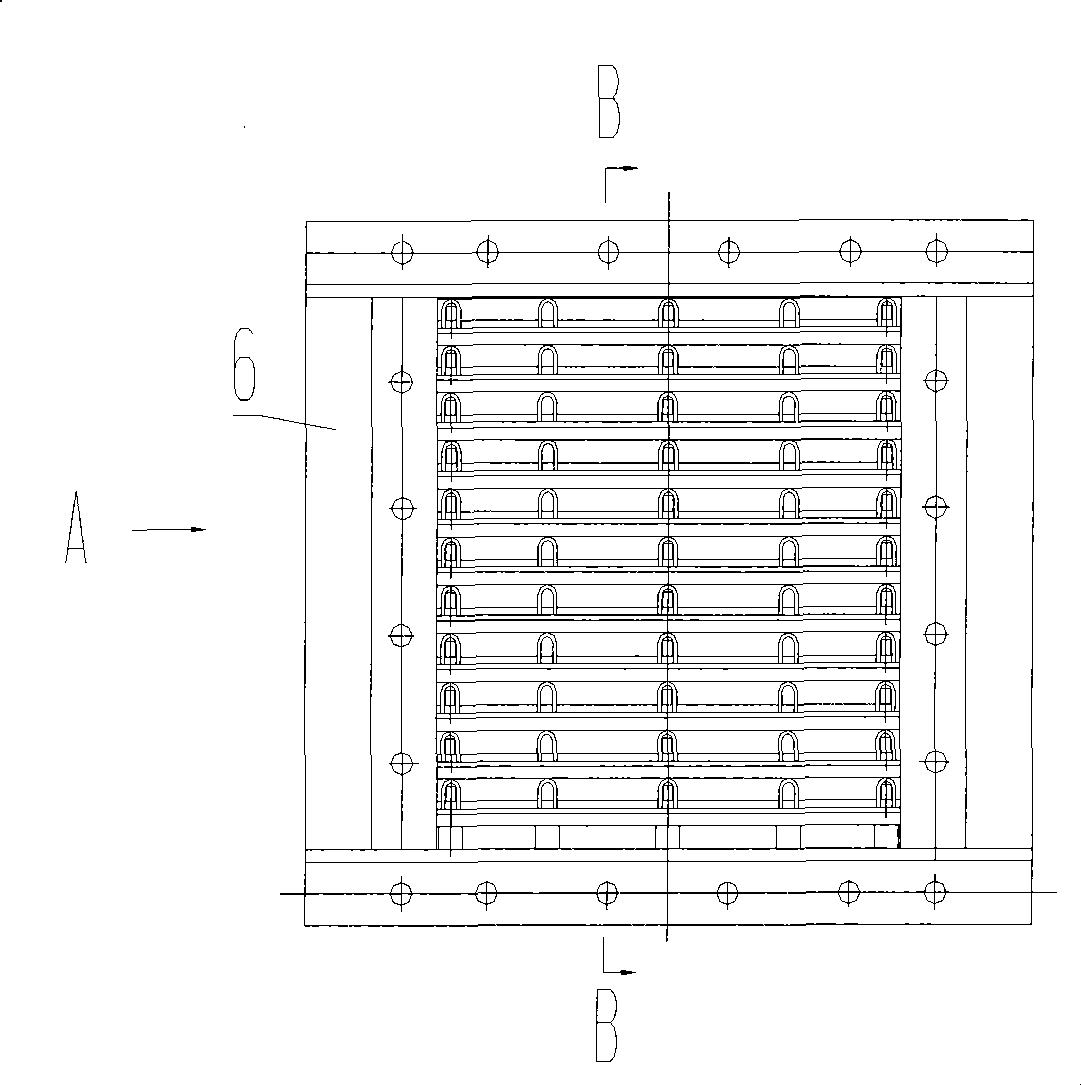

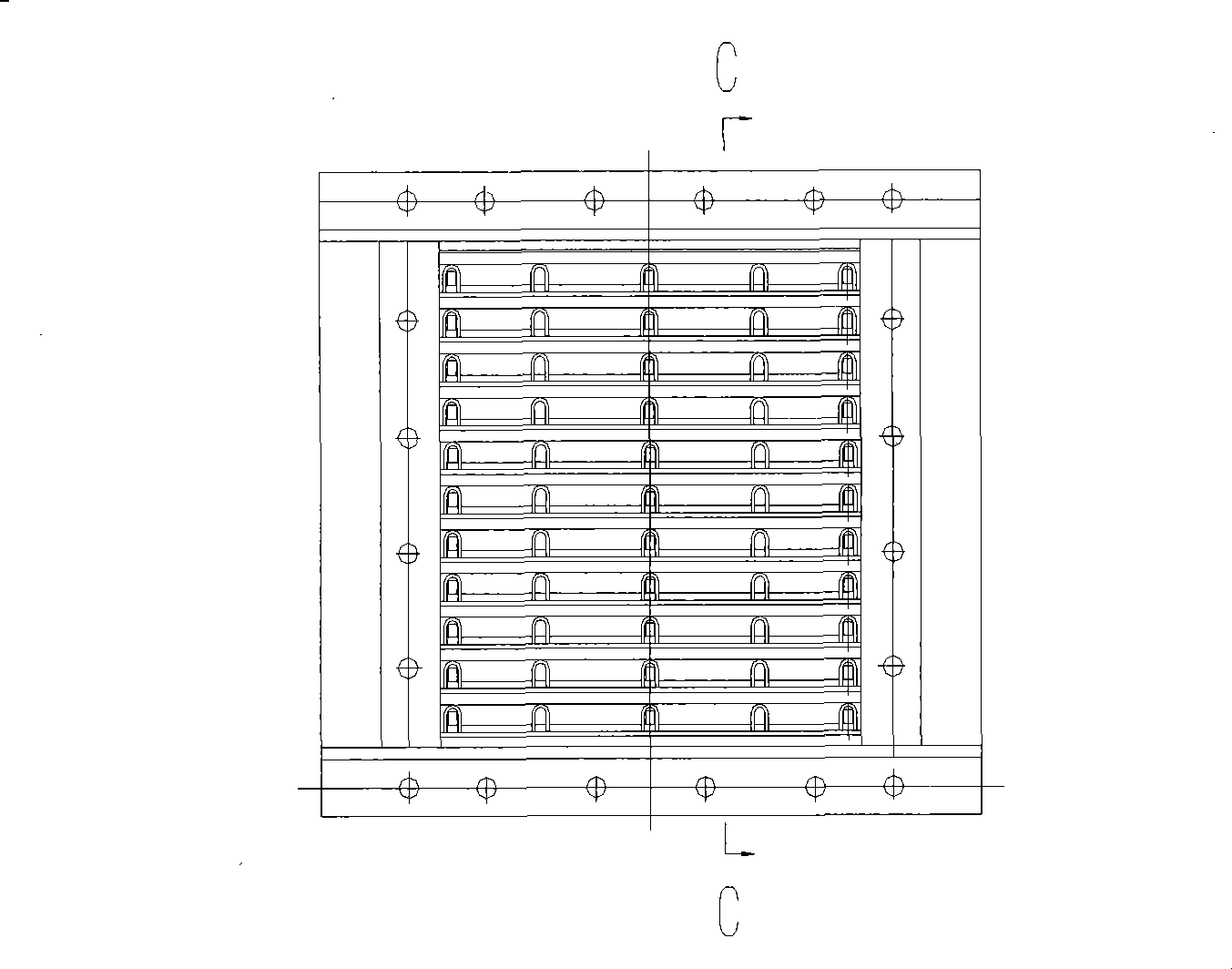

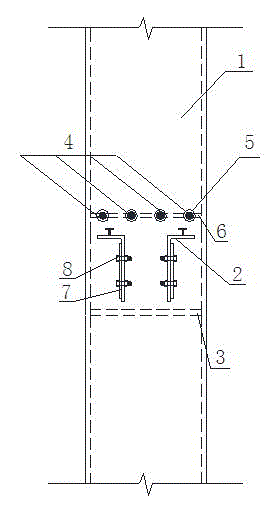

Joint structure of steel-pipe-restraining steel concrete columns and reinforced concrete beams

InactiveCN103061416AImprove integrityReliable deliveryBuilding constructionsReinforced concreteRebar

The invention relates to a joint structure of steel-pipe-restraining steel concrete columns and reinforced concrete beams. The joint structure is characterized in that a profile steel is in a cross structure and is formed by a profile steel web (3) and profile steel flanges (4) through welding. At joints, sleeves (5) are welded on the outer sides of the profile steel flanges (4) of sides of the profile steel, and stiffening ribs (6) are welded on the inner sides of the profile steel flanges (4) corresponding to the sleeves (5). Gaps are arranged between steel pipes (7) at the joints, and the profile steel penetrates through the joints from bottom to top in a continuous mode. Vertical connection steel bars (1) are inserted in the inner sides of the upper segment and the lower segment of the steel pipes (7) arranged at the joints. Columnar stirrups (2) are used for being bound with the vertical connection steel bars (1) to form a reinforcement cage. A part of beam main ribs (9) in a beam penetrate through continuously from sides of the profile steel flanges (4), and the part of the beam main ribs (9) are connected with the sleeves (5) welded on the outer sides of the profile steel flanges (4) in a welding mode. The joint structure is good in mechanical property, simple in design, convenient to construct, and low in cost, and has no special requirement on welding.

Owner:YANGTZE UNIVERSITY

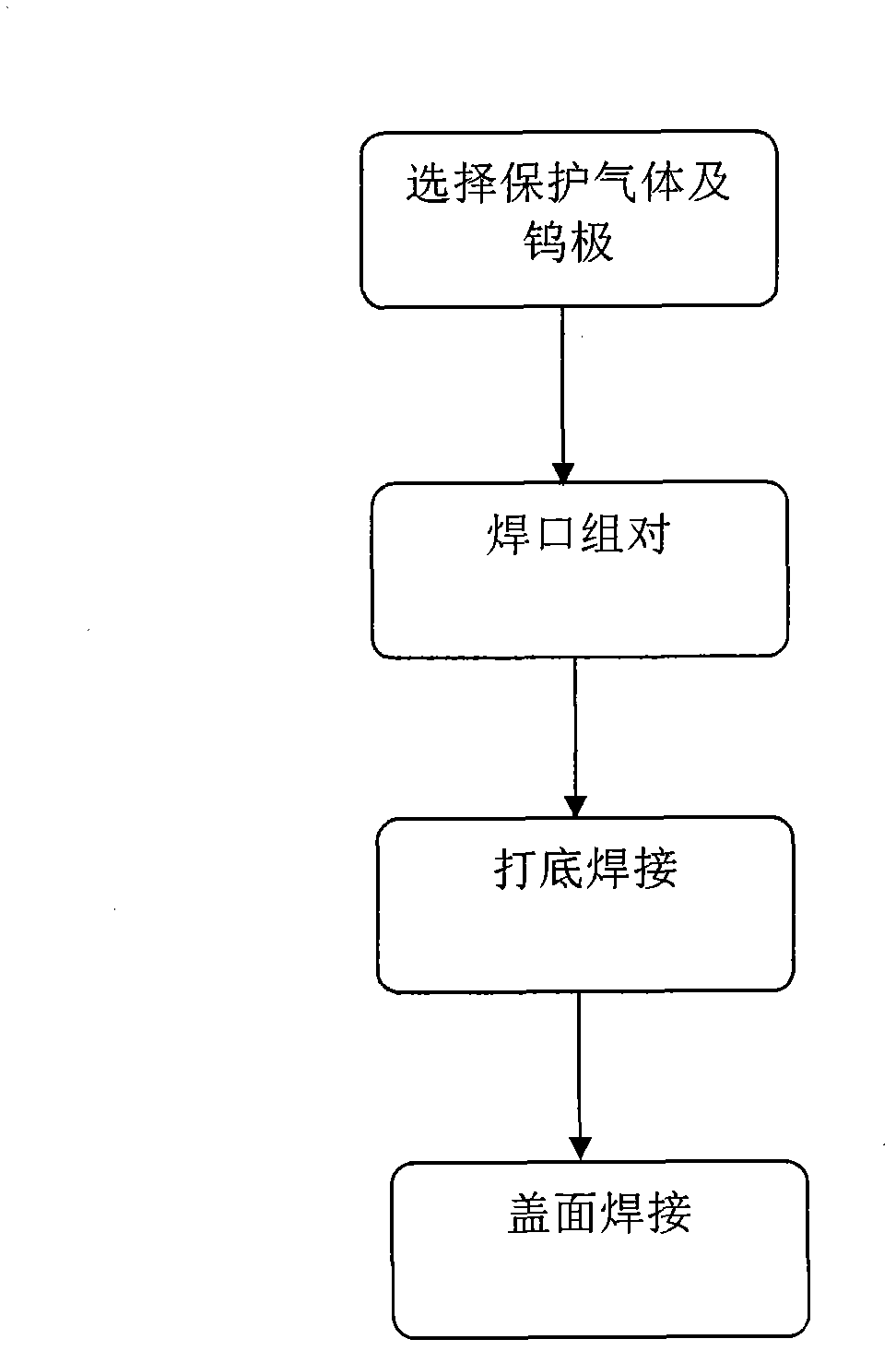

Method for welding cut surface butt joint formed by thin welding base materials

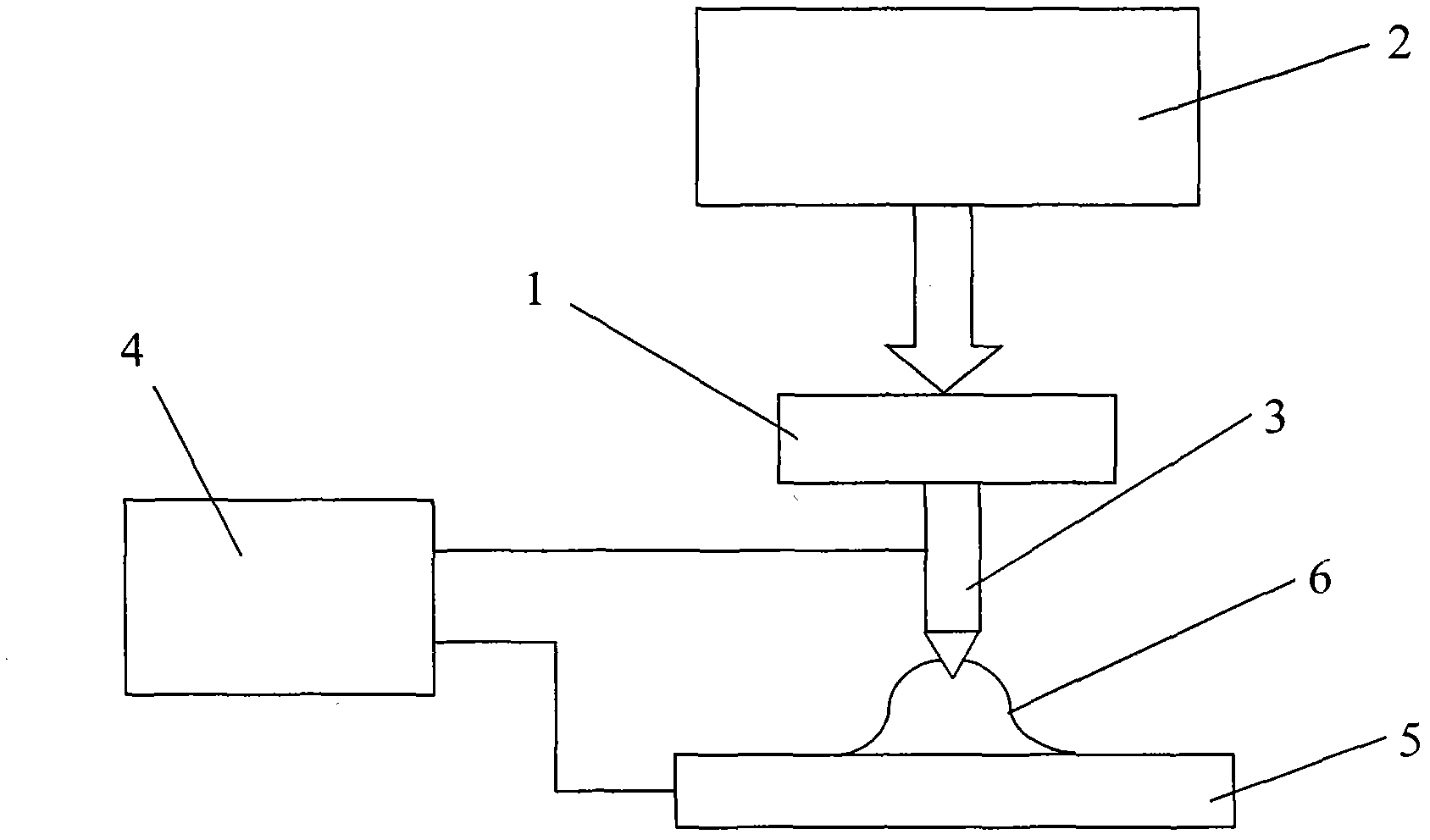

ActiveCN102699545AReduce process stepsReduce consumptionArc welding apparatusSignal onFilling materials

The invention relates to a method for a welding cut surface joint formed by assembling cut surface ports, in particular to a method for welding a cut surface butt joint formed by thin welding base materials in nuclear power engineering, and aims to solve the problems that the machining period of tubes and welding period are relatively long, the welding cost is high, and part of the materials are not completely welded in the prior art. According to the method, the thickness of each welding base material is less than or equal to 6.0mm. The method comprises the following steps of: selecting protective gas and a tungsten electrode; assembling craters; overlapping an ultrasonic electrical signal on pulse welding current to generate a stable ultrasonic- tungsten inert gas (TIG) combined weld electric arc by taking ultrasonic waves and TIG combined electric arc welding machine as a welding power supply of automatic welding equipment, and performing backing welding on the surface butt joints without feeding wires; performing cosmetic welding, and finishing welding. By the welding method, the processing step of forming a groove is eliminated, so that the welding workload, the consumption of welding filling materials and the welding cost are reduced, and the welding efficiency is improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

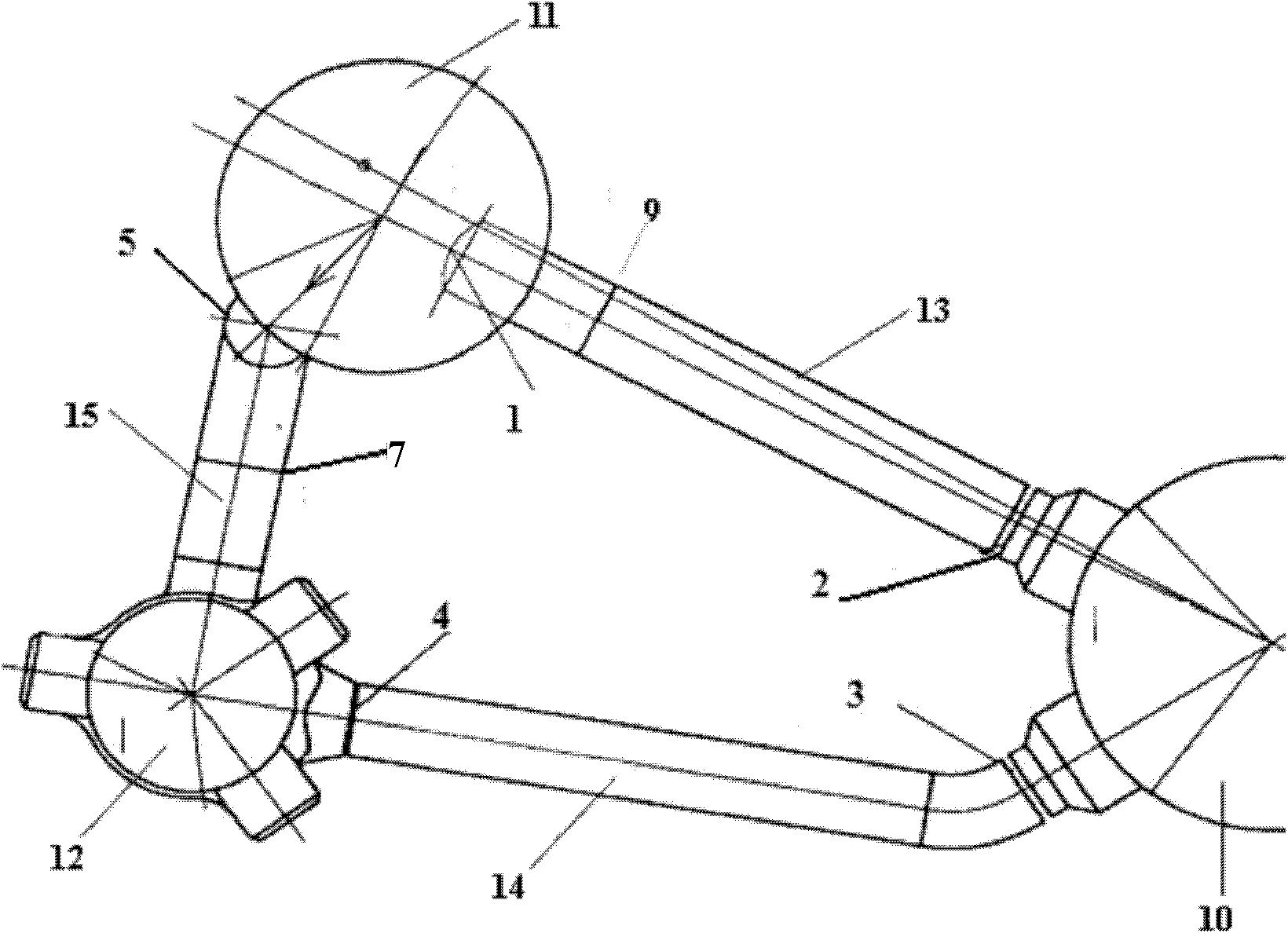

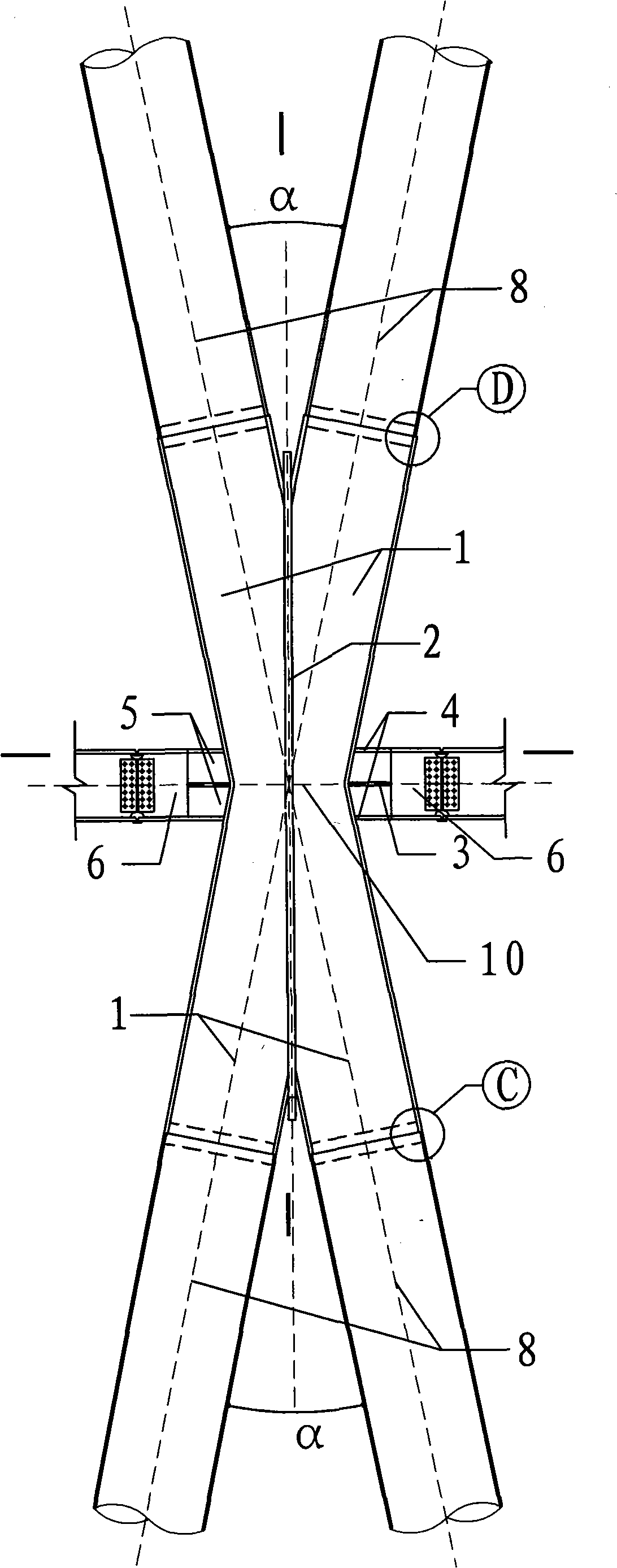

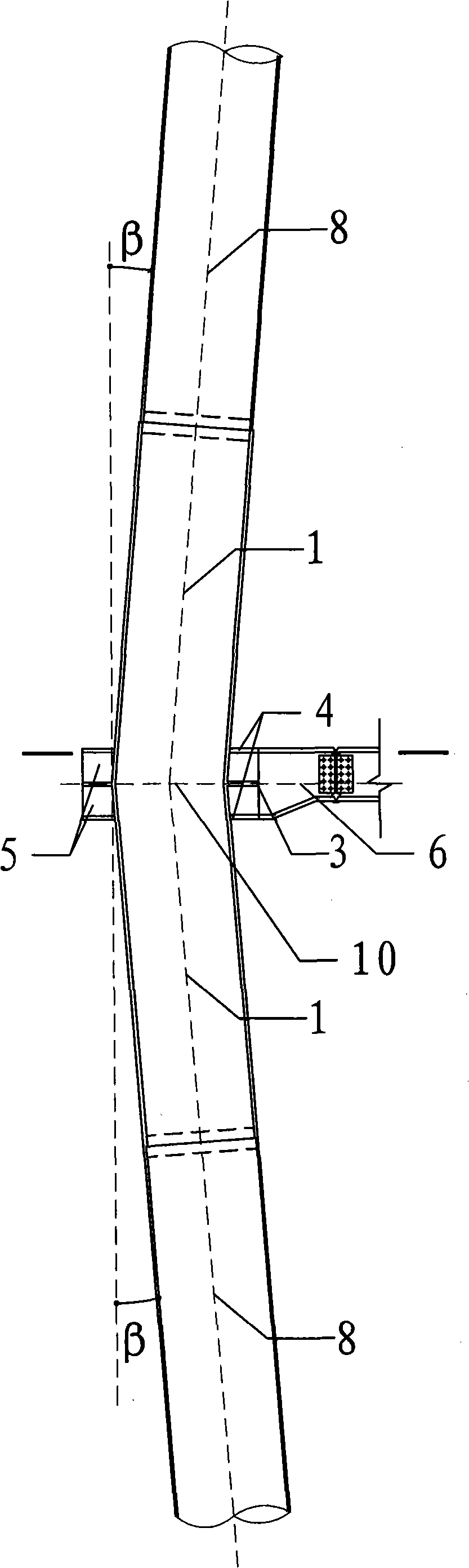

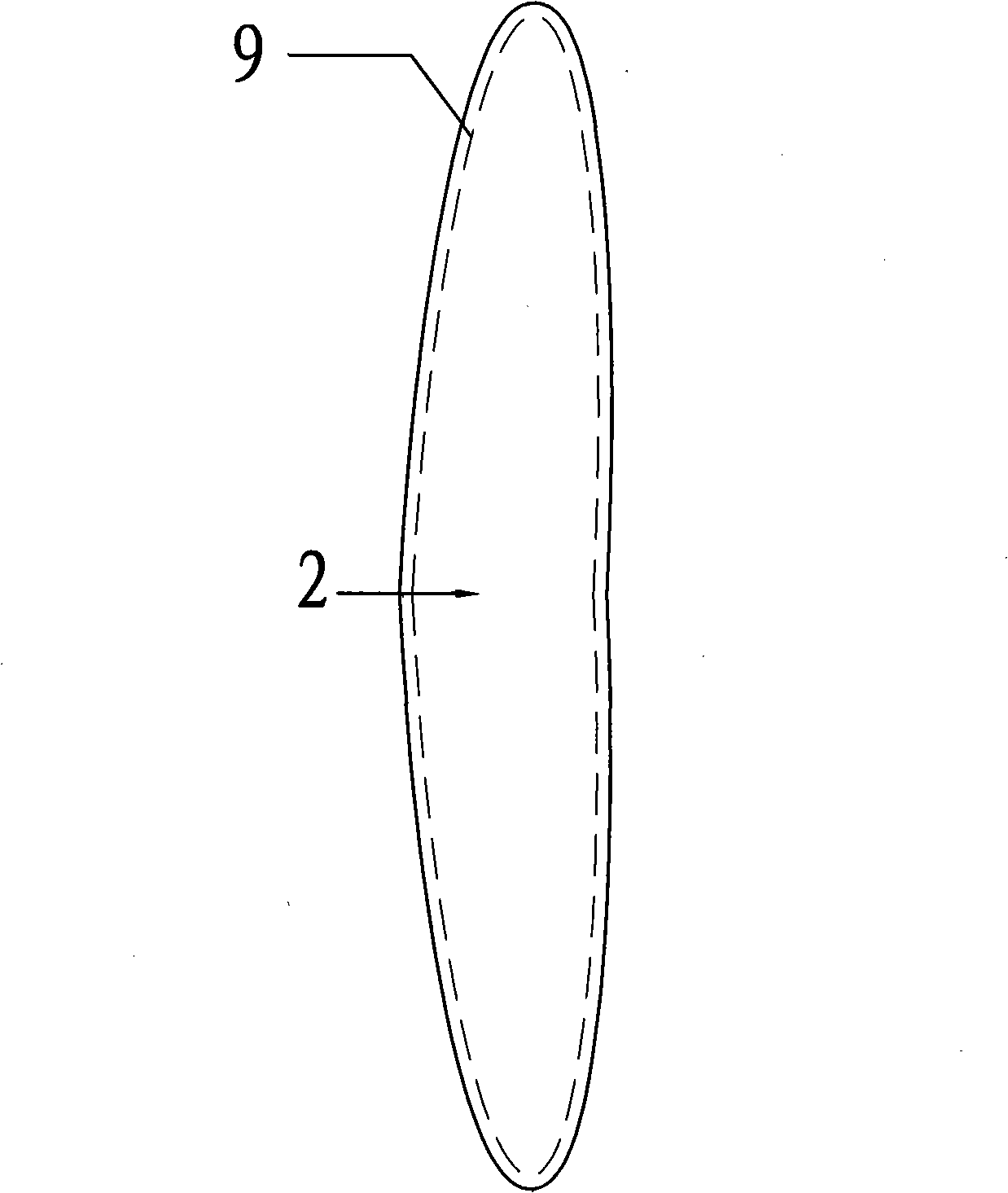

Steel tube concrete diagonal frame column spatial tubular joint and its manufacture method

InactiveCN101260689APower transmission is clearActive connectionBuilding constructionsSteel tubeMaterials science

The invention provides an oblique grid column spatial joint for a concrete-filled steel tube and a manufacture method thereof, wherein, four round steel tubes of the joint are crossed at the position of an oval connecting plate, and welding connections are adopted among the four round steel tubes and between the round steel tubes and the oval connecting plate; a circumferential reinforcing plate consists of at least two annular steel plates, is welded on the four round steel tubes on the welded joint of a central plane; two annular plates parallel to the circumferential reinforcing plate are respectively welded on round steel tubes above and under the circumferential reinforcing plate; stiffener plates are welded between the circumferential reinforcing plate and the annular plates in uniform distribution; and joint extending brackets are welded on the annular plates. The manufacture method of the joint comprises the welding among the round steel tubes and the connecting plate, and the welding of the circumferential reinforcing plate, the annular plates and the stiffener plates. The joint has the advantages of clear force transfer, high bearing capacity, light weight, good performance and convenient construction, can effectively connect an upper oblique grid column and a lower oblique grid column so as to realize the spatial intersection of the joint of the concrete-filled steel tube column, and have excellent engineering application foreground.

Owner:SOUTH CHINA UNIV OF TECH

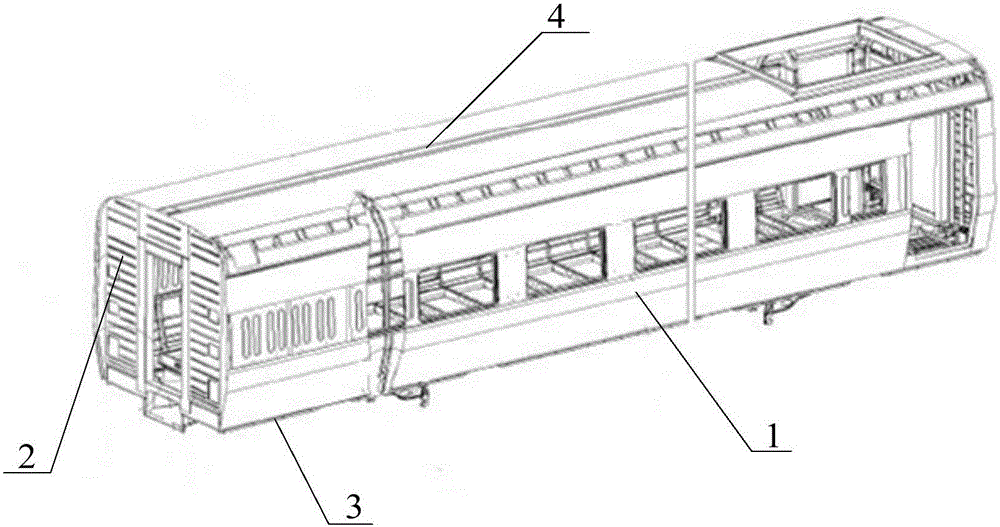

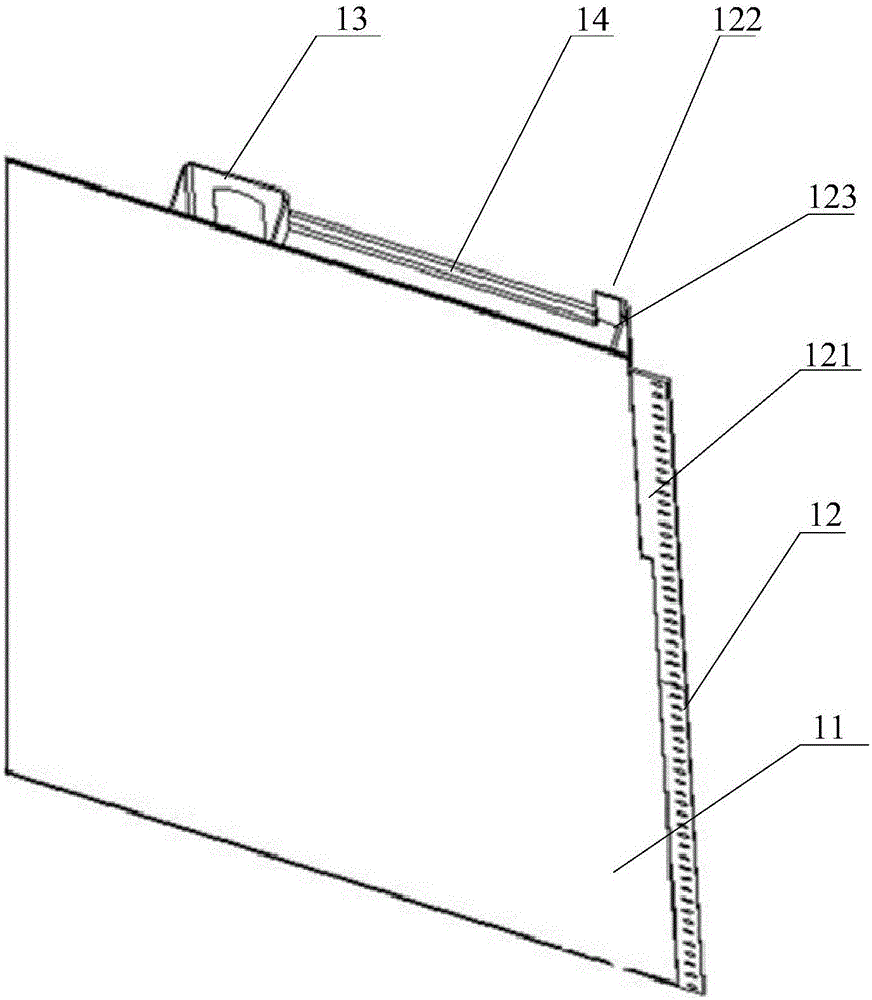

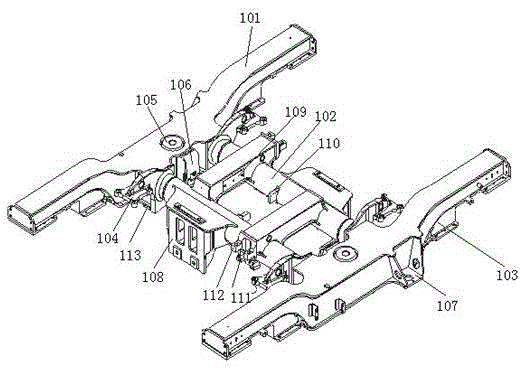

Vehicle body of railroad vehicle and railroad vehicle

ActiveCN106080629AGuaranteed verticalityReduce welding workloadAxle-box lubricationRailway bodiesWall plateConcave surface

The invention provides a vehicle body of a railroad vehicle and the railroad vehicle. The vehicle body of the railroad vehicle comprises a lateral wall, an end wall, a bottom frame and a roof, wherein the lateral wall comprises a Z-shaped end stand column; the end wall comprises a U-shaped end corner column; one part, far away from an end wall plate, on the bottom surface of the U-shaped end corner column is provided with a concave surface; an end face, welded with a lateral wall plate, of the Z-shaped end stand column is overlapped on the concave surface; the overlapping amount of overlapping the end face, welded with the lateral wall plate, of the Z-shaped end stand column on the concave surface is determined according to a deviation amount of the length of the bottom frame in the direction of the lateral wall and the length of the lateral wall; the Z-shaped end stand column is connected with the concave surface through a welding manner. According to the vehicle body of the railroad vehicle and the railroad vehicle, provided by the invention, the perpendicularity of the end wall installation can be guaranteed, the welding working amount of connecting the vehicle body can be reduced and the working efficiency of welding is improved.

Owner:CRRC TANGSHAN CO LTD

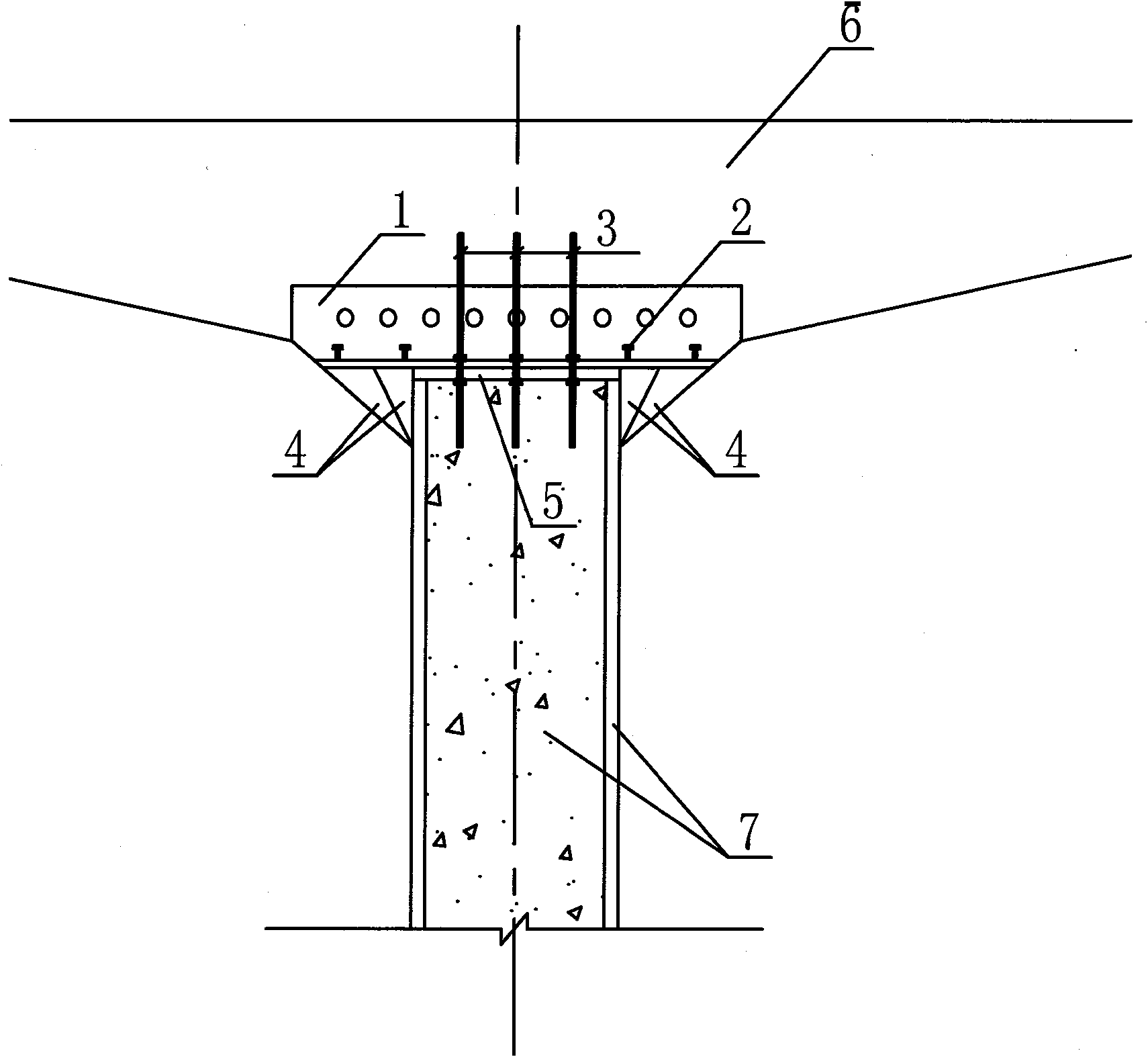

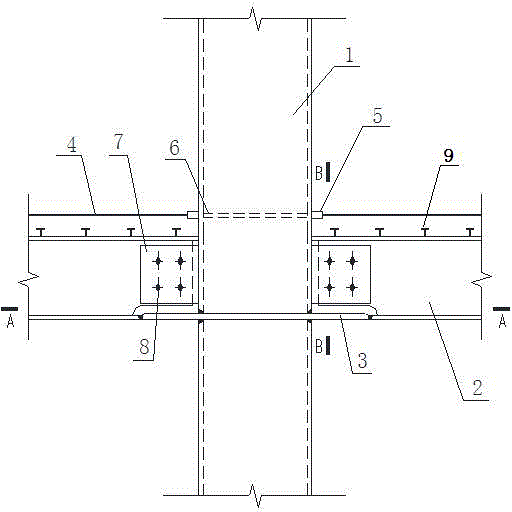

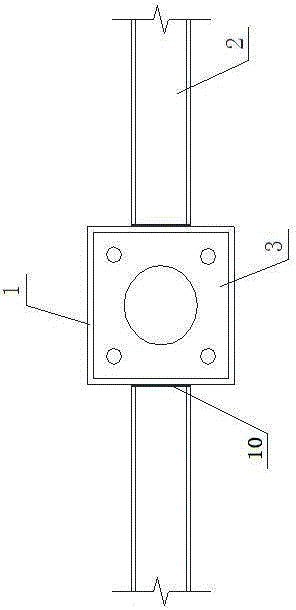

Connection structure for concrete-filled circular steel tubular pier column and concrete cover beam

InactiveCN101818478AReduce welding workloadEasy constructionBridge structural detailsSteel platesSteel tube

The invention discloses a connection structure for a concrete-filled circular steel tubular pier column and a concrete cover beam. The connection structure comprises a reverse T-shaped steel beam, the concrete cover beam and the concrete-filled circular steel tubular pier column, wherein the reverse T-shaped steel beam is pre-buried at the lower end of the concrete cover beam. The connection structure is characterized by also comprising a steel tubular cover plate and a riveting rib with a nut, wherein the steel tubular cover plate is welded with the upper end of the concrete-filled circular steel tubular pier column; the hole on the web plate of the reverse T-shaped steel beam is connected with the concrete; a flange plate of the T-shaped steel beam is fixedly connected with the steel tubular cover plate through the riveting rib with the nut; and the two ends of the riveting rib with the nut are embedded in the concrete cover beam and the concrete-filled circular steel tubular pier column. The connection structure needs no complex arrangement of reinforcement, and each component can be processed in the factory and assembled on site. Only welding of a triangular supporting steel plate and the steel tubular cover plate is needed on site so as to ensure small workload and definite force transferring path. The connection structure has the advantages of simple and quick construction during the implementation.

Owner:HOHAI UNIV

Back-contact solar cell module

InactiveCN102723380AImprove electrical performanceIncrease electric powerPhotovoltaic energy generationSemiconductor devicesElectricityInterconnection

The invention discloses a back-contact solar cell module. The back-contact solar cell module comprises a first cell, a second cell and a third cell which are connected in series and are adjacent, the back surface of each cell is provided with at least one group of back electrode array and at least one group of hole metal electrode array, the number of the back electrode array on each cell is equal to that of the hole metal electrode array, the electrode distribution structures of adjacent cells are the same, the hole metal electrode array of the first cell is directly connected with the back electrode array on the second cell which is adjacent to the first cell through a flow guidance piece in a broken line or curve way, and the hole metal electrode array of the second cell is directly connected with the back electrode array on the third cell which is adjacent to the second cell through the flow guidance piece in the broken line or curve way. According to the back-contact solar cell module disclosed by the invention, a confluence piece adopted by the traditional back-contact cell in interconnection is omitted, not only is a series welding step omitted and is the welding work amount greatly reduced, but also the electric performance and the total power of the back-contact solar cell module are increased, and the back-contact solar cell module has unexpected technical effect.

Owner:CSI CELLS CO LTD +1

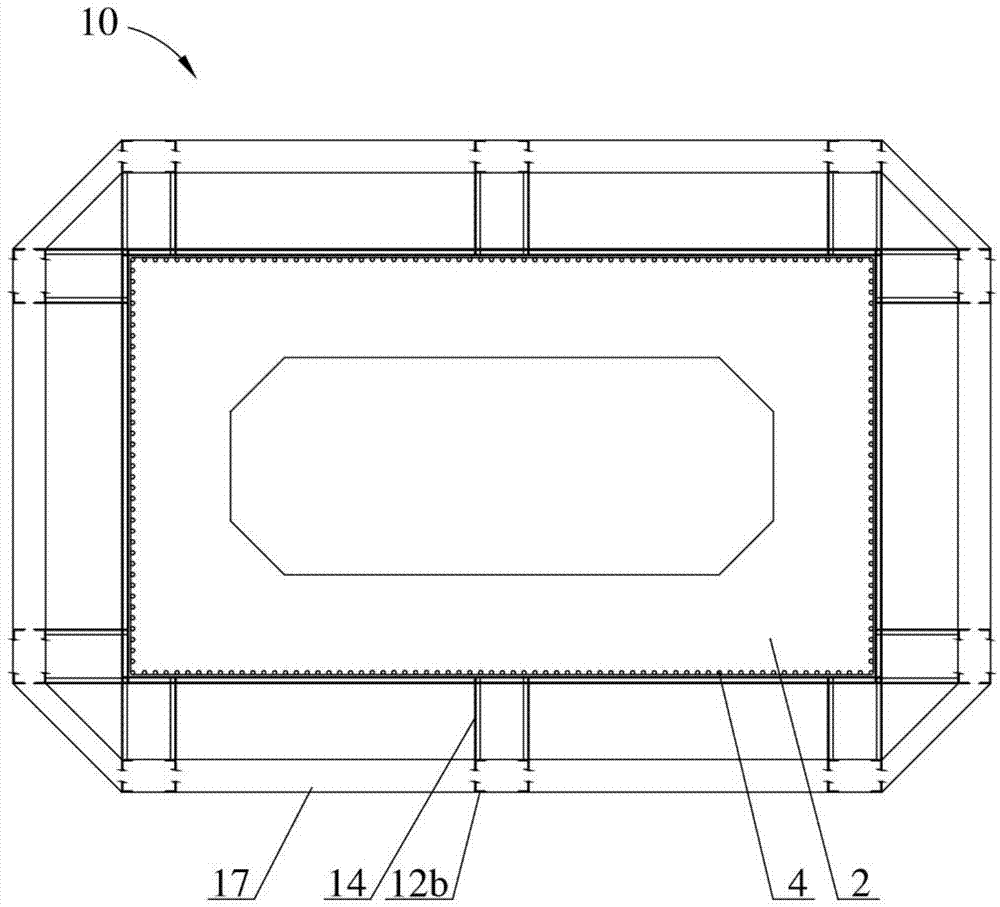

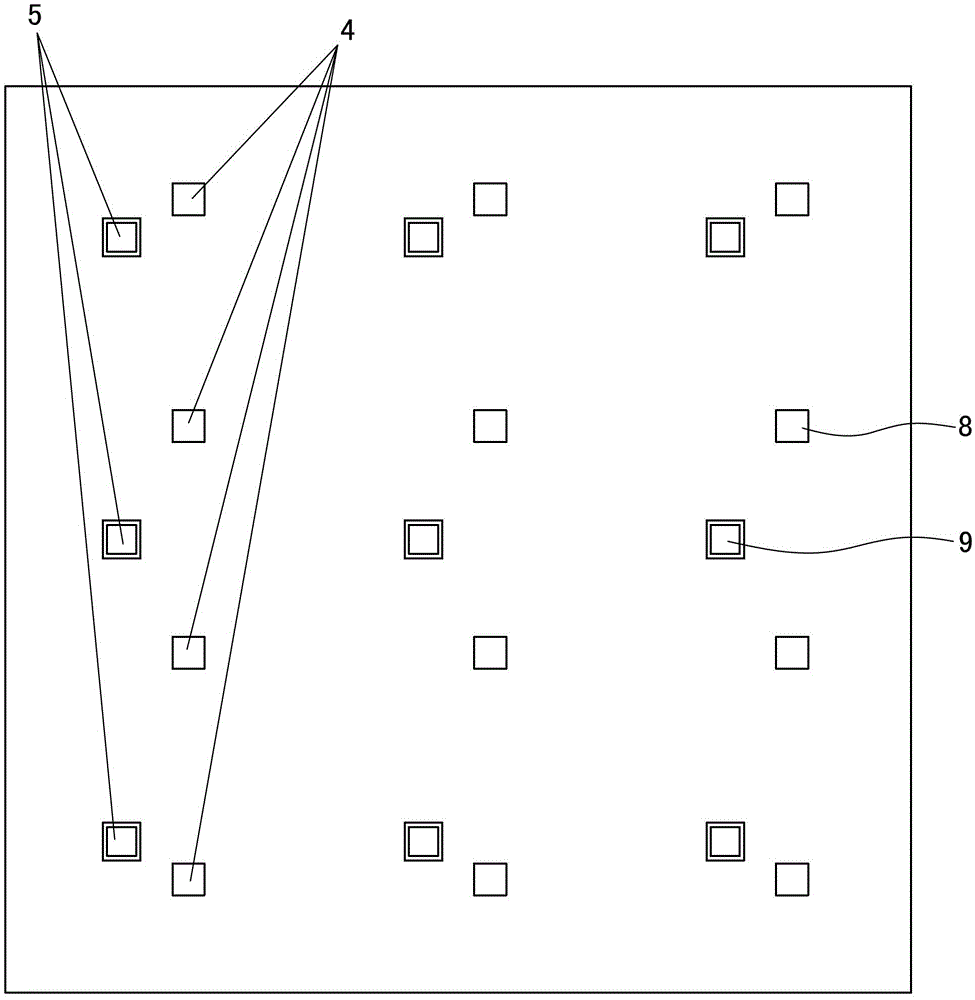

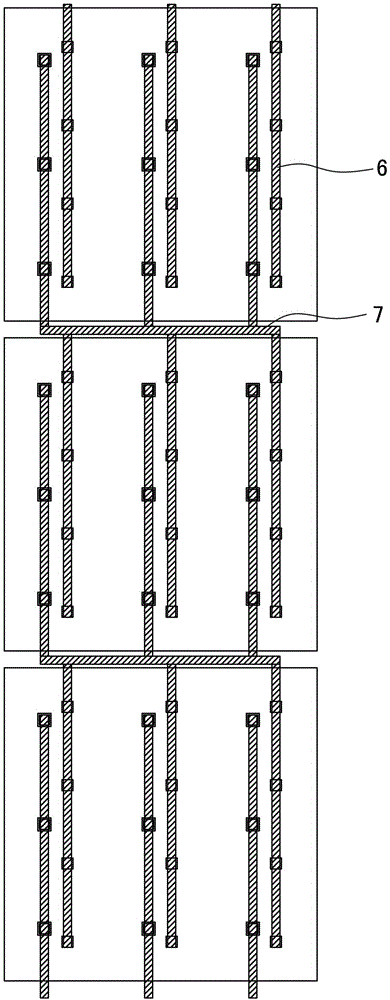

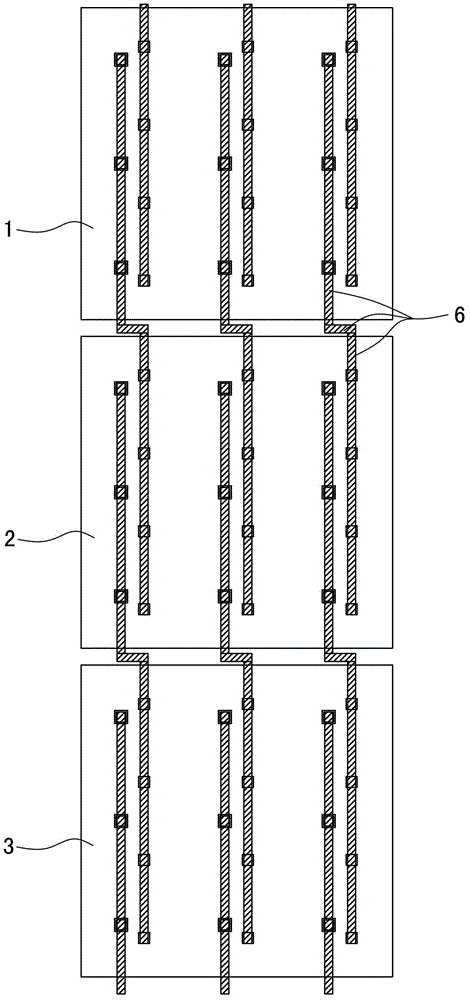

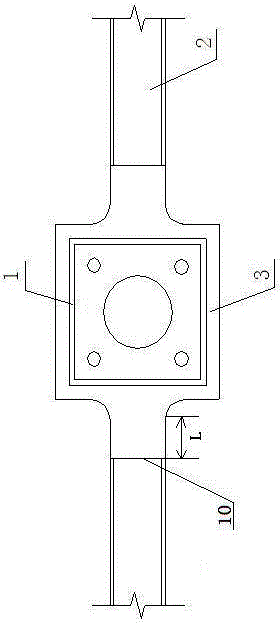

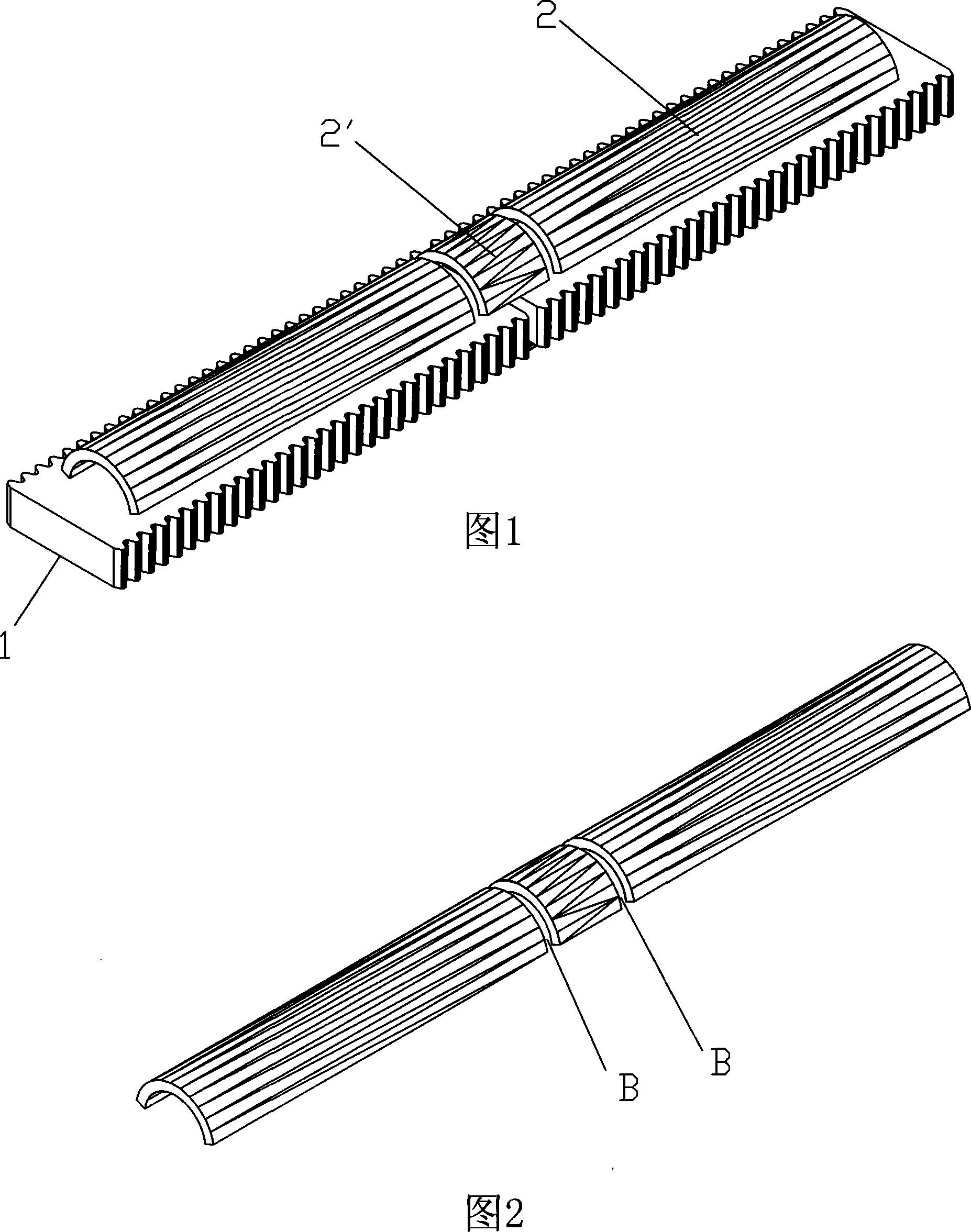

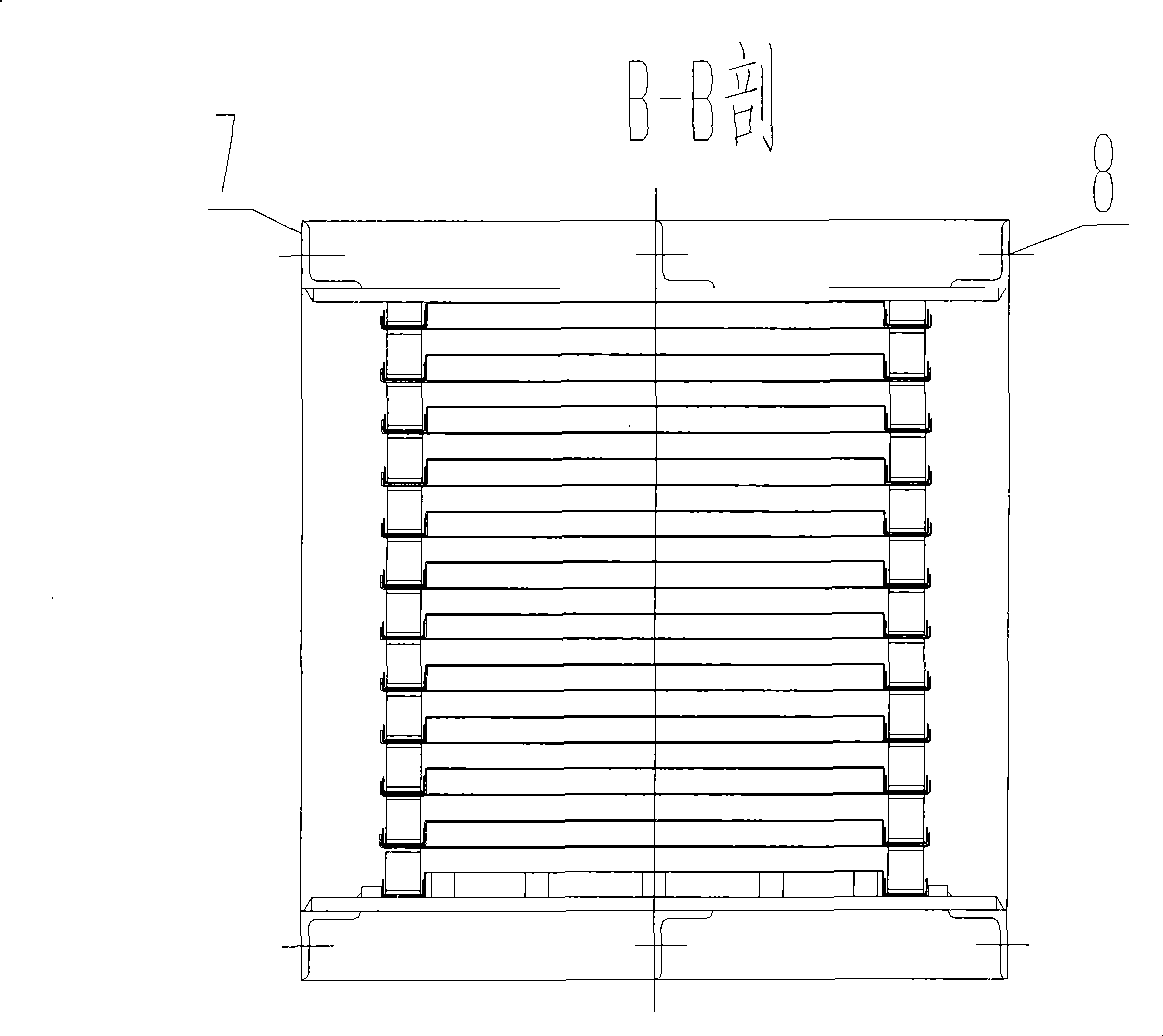

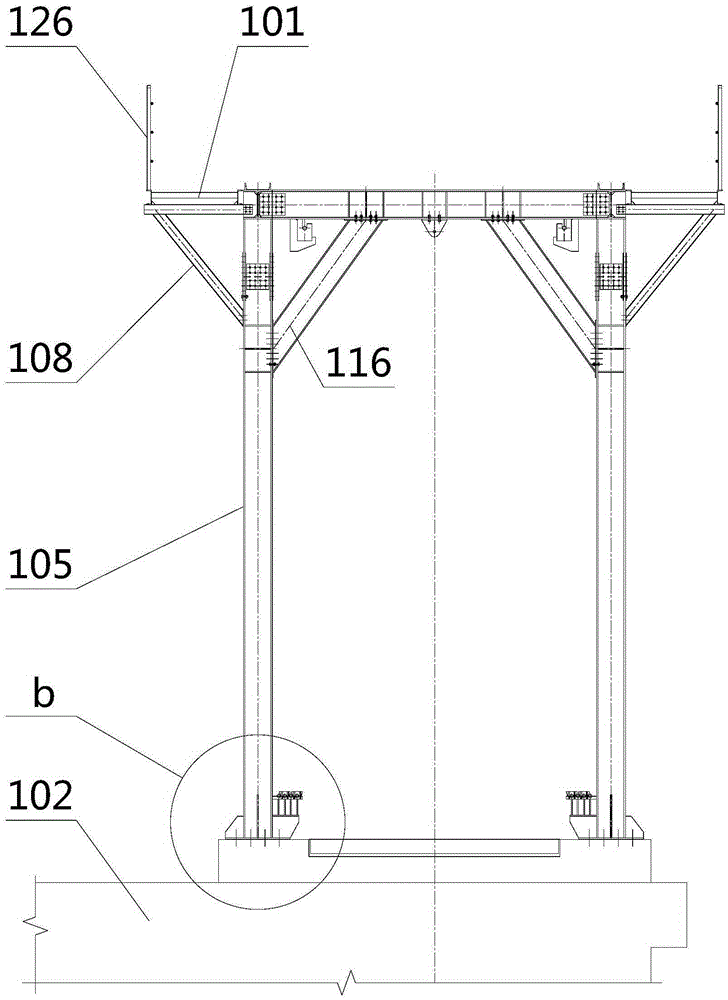

Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

The invention discloses a steel pipe concrete column-precast concrete superposed beam assembly type building connection node. The steel pipe concrete column-precast concrete superposed beam assembly type building connection node comprises a steel pipe concrete column and a precast concrete superposed beam, wherein the outer wall of the steel pipe concrete column is provided with a U-shaped steel tank and a prewelded outer ring steel plate in a welded manner, the prewelded outer ring steel plate is horizontally arranged and located above the U-shaped steel tank, the U-shaped steel tank is provided with a bottom plate and side plates, the bottom plate is provided with bottom steel bar clamping buckle devices, and the tops of the side plates are provided with upper flanges being folded outwards; and the precast concrete superposed beam is installed inside the U-shaped steel tank in an inserted manner, the bottom of the precast concrete superposed beam is connected with the bottom steel bar clamping buckle devices in a clamped manner, the top of the precast concrete superposed beam is welded to the prewelded outer ring steel plate, a mutual plug-in mounting area of the precast concretesuperposed beam and the U-shaped steel tank is a superposed area, and concrete is poured into the superposed area after lap joint and assembly of the precast concrete superposed beam. The steel pipeconcrete column-precast concrete superposed beam assembly type building connection node is convenient and fast to install without bolts and mold supporting, and the production and construction efficiency can be effectively improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

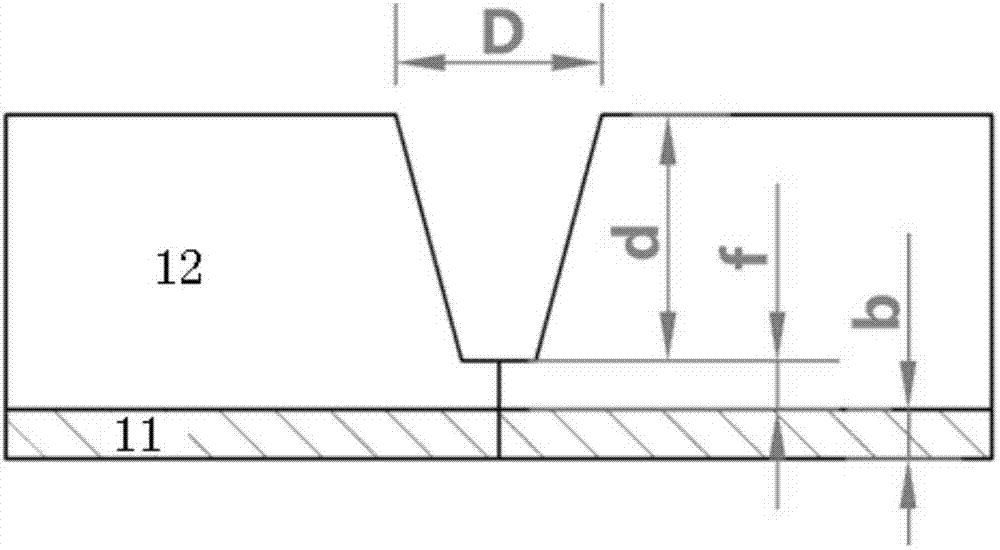

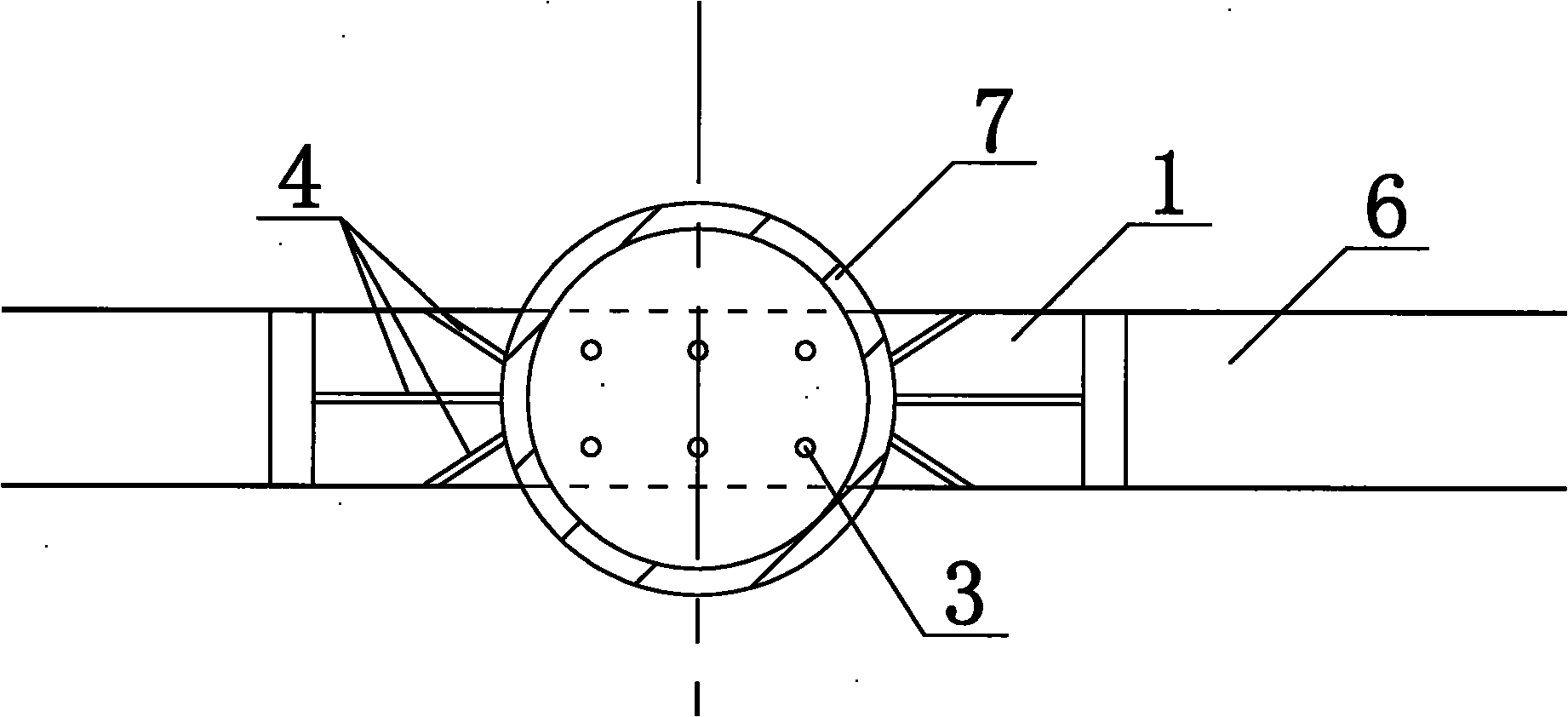

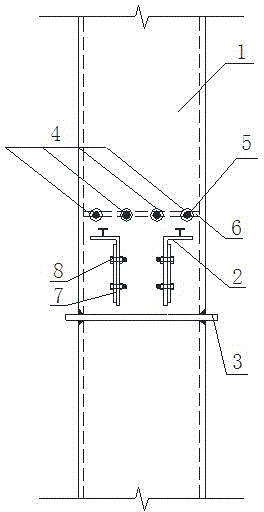

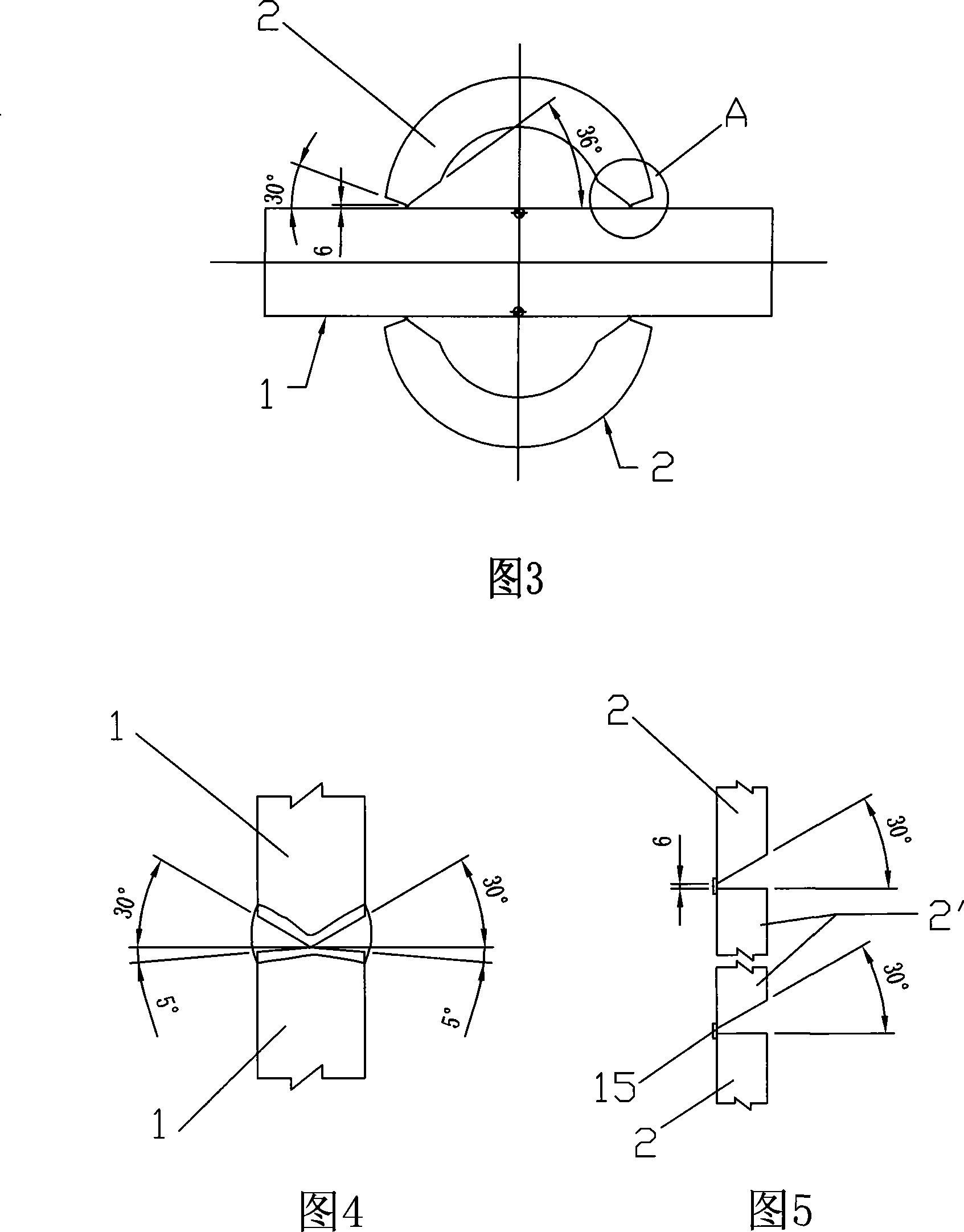

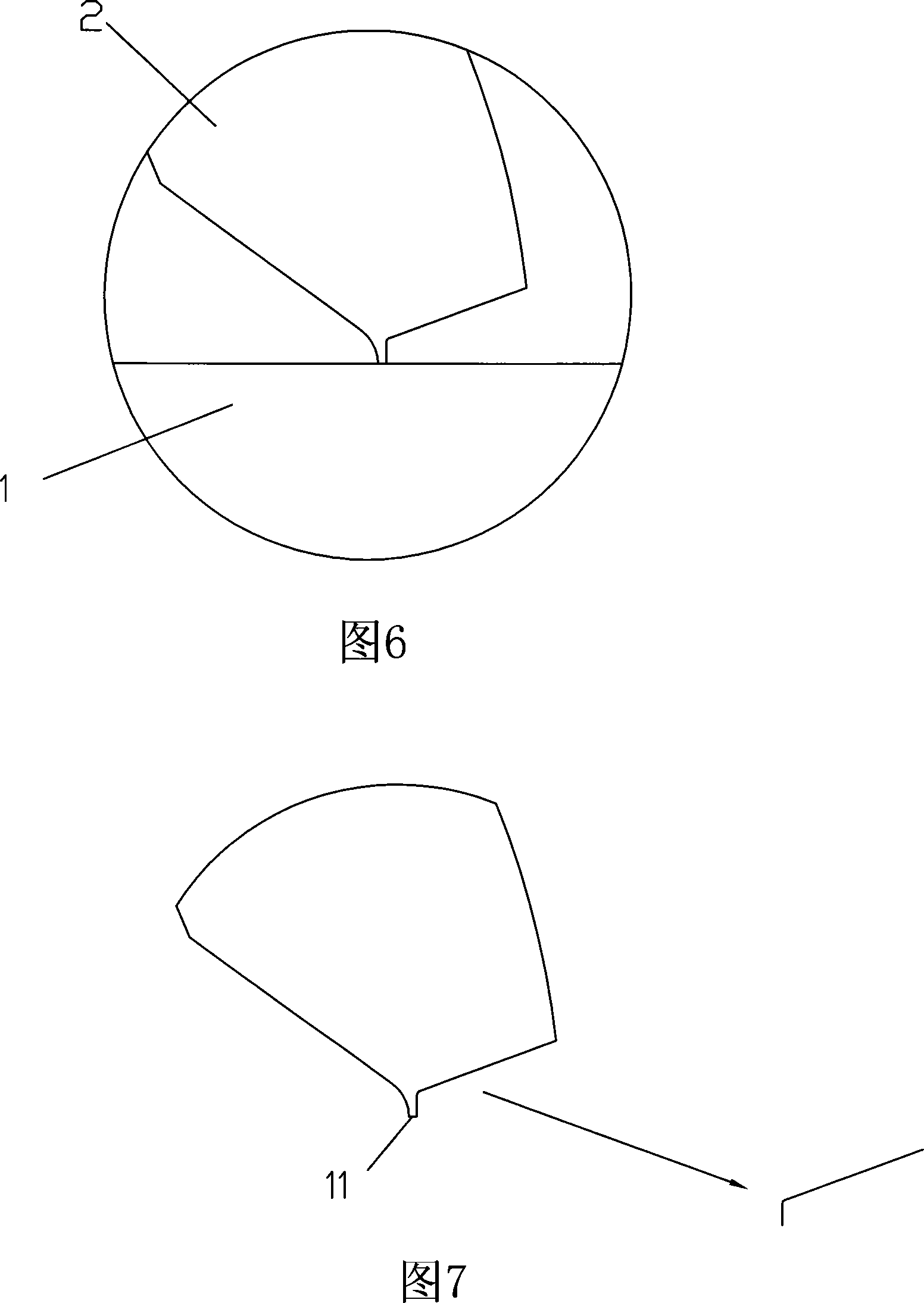

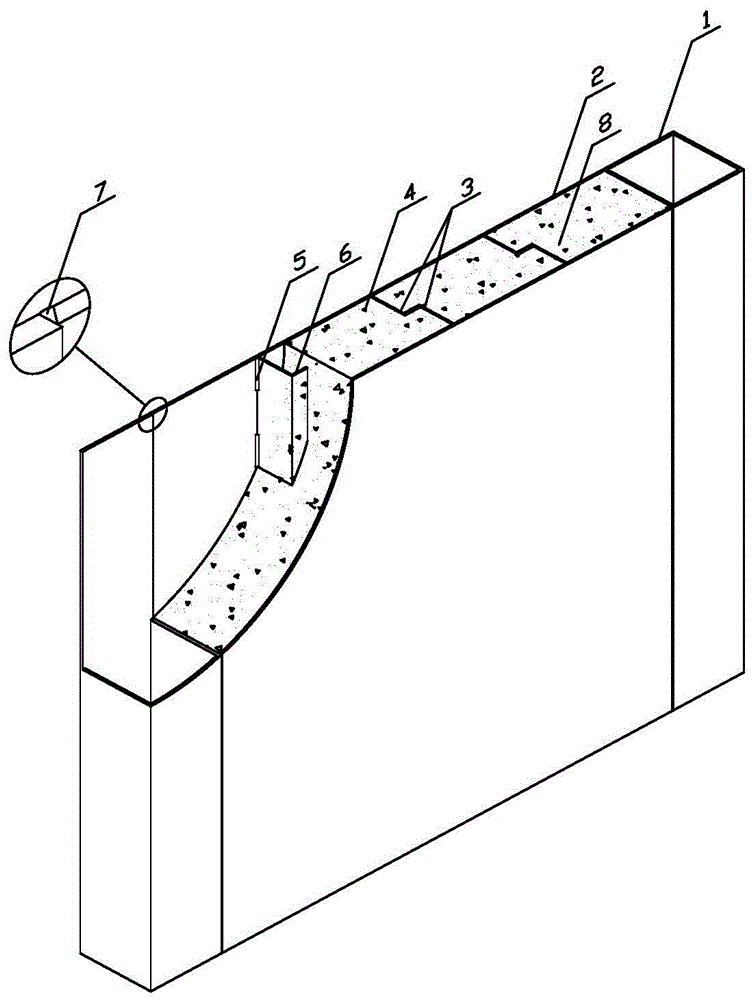

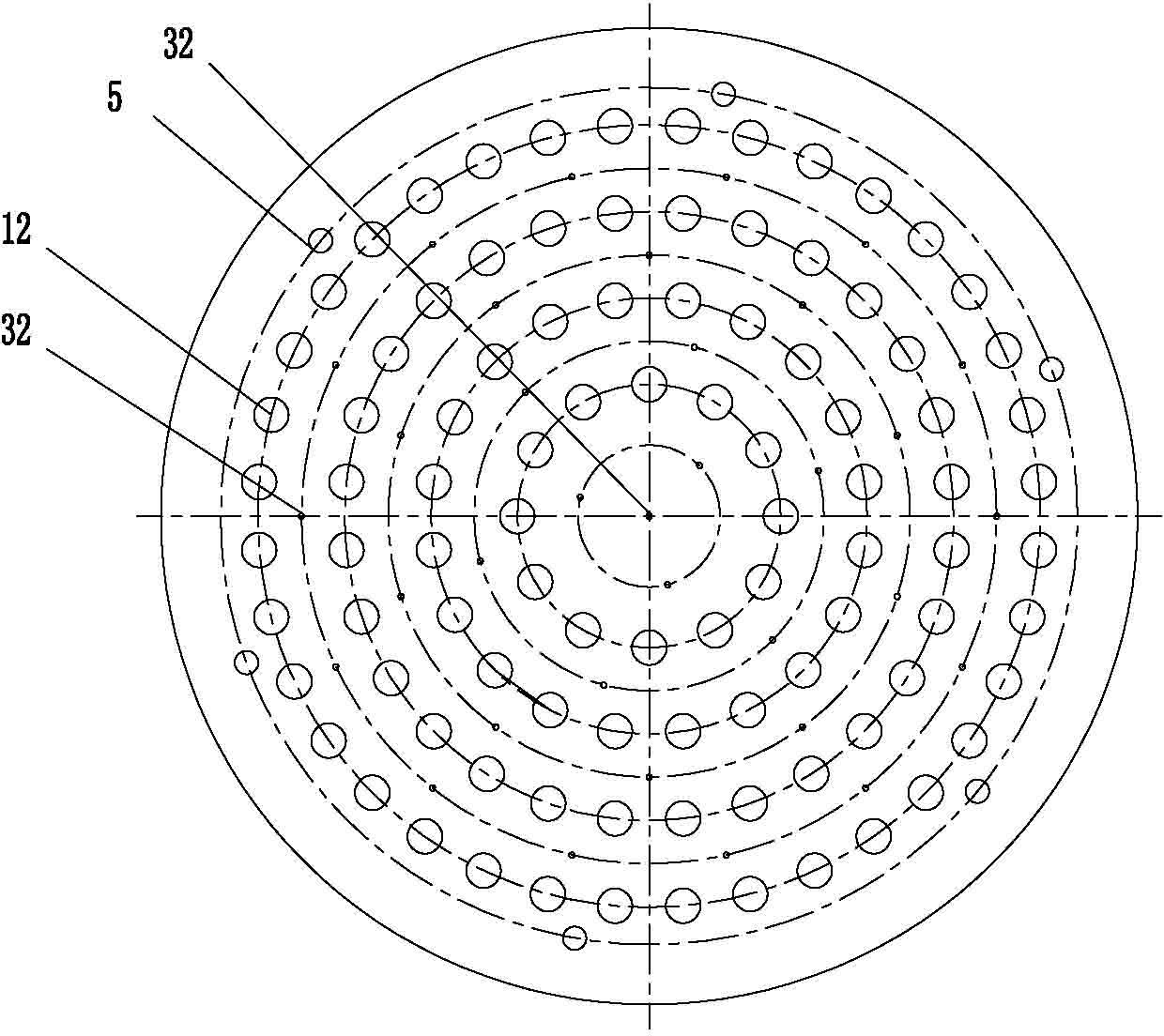

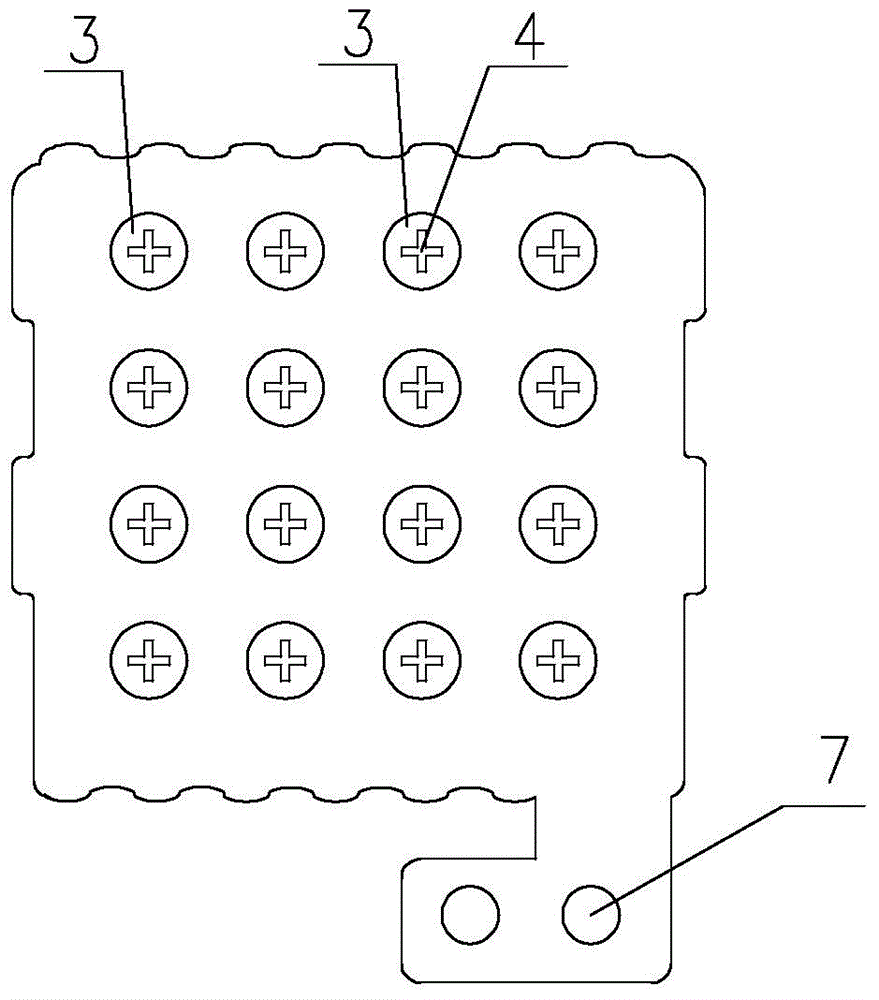

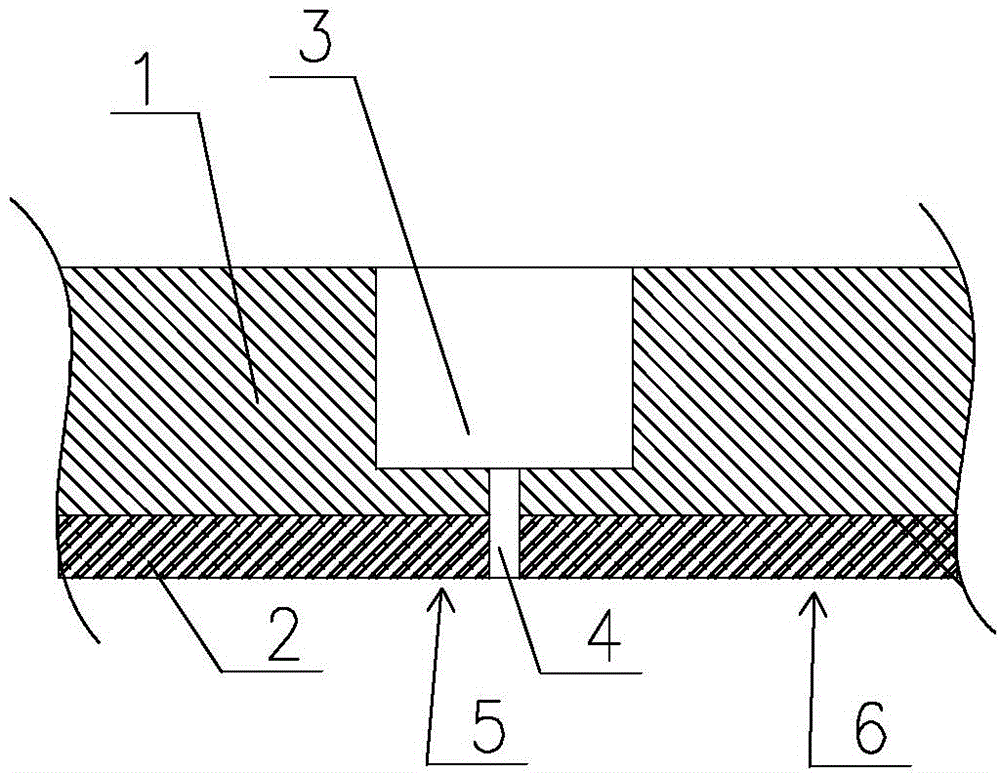

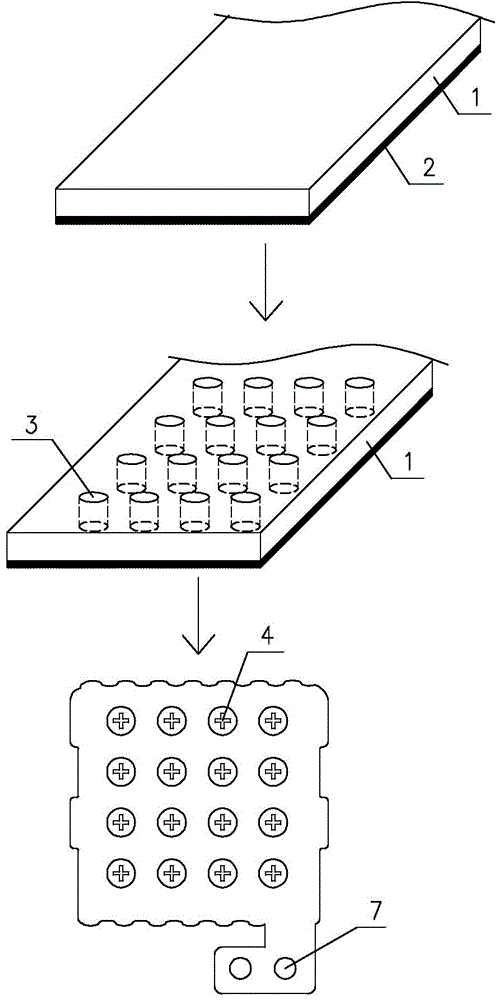

Connecting node for steel pipe concrete post and outside U-shaped steel and concrete composite beam

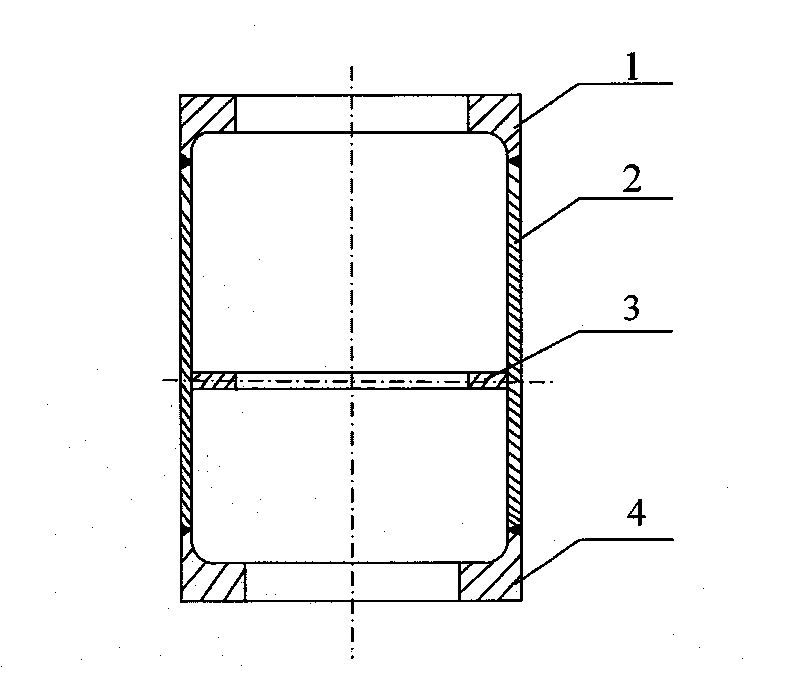

The invention provides a connecting node for a steel pipe concrete post and an outside U-shaped steel and concrete composite beam. In order to prevent the lamellar tearing of the steel pipe walls and the outer surface deformation of a post wall plate, a penetrating separation plate penetrating through steel pipes is arranged in the steel pipes arranged in a position of a composite beam bottom plate; the steel pipes are broken in a position of the penetrating separation plate; the upper steel pipe and the lower steel pipe are connected with the upper end surface and the lower end surface of the penetrating separation plate through butt-jointed welding seams with grooves; a U-shaped steel bottom plate is connected with the penetrating separation plate by the butt-jointed welding seams after the amputation; the welding seams cannot easily crack; the connection intensity is high; and the anti-seismic performance is good. The two opposite ends of the steel pipes in the length direction of the composite beam are correspondingly provided with sleeves capable of being movably connected with the end parts of negative reinforcement steel bars; and the sleeves are welded with the outer walls of the steel pipes. The structural form has the advantages that the weakening on the carrying force of the steel pipes due to the hole forming in the side walls of the steel pipes can be reduced; meanwhile, the welding workload is reduced; the construction is convenient; and the assemblage can be conveniently realized. In order to effectively transfer the load, a horizontal reinforcement plate is fixedly welded in a position, corresponding to the sleeves, of an inner cavity of the steel pipes.

Owner:SHANDONG JIANZHU UNIV

Joint connection of regeneration cubage concrete combination beam-column and construction method thereof

ActiveCN106522381ASolve delivery difficultiesReduce deliveryBuilding constructionsConcrete beamsRebar

The invention discloses joint connection of a regeneration cubage concrete combination beam-column. A square steel pipe regeneration cubage concrete column, a U-shaped steel-encased regeneration cubage concrete beam, a U-shaped steel connecting piece of which a bottom plate is weakened locally and the single end is widened, a steel connecting plate with a groove, and a short reinforcing bar of which the single end is provided with a thread are included. The invention further provides a construction method of joint connection of the regeneration cubage concrete combination beam-column. According to joint connection of the regeneration cubage concrete combination beam-column and the construction method thereof, on the one hand, as no core penetrating component exists in a joint core area, the problem that large-dimension waste concrete block throwing construction is difficult is solved, moreover, the procedures of rebar binding, formwork assembling, formwork disassembling and the like can be decreased by adopting a U-shaped steel-encased part, construction is convenient and rapid, and the building industrialized requirement is met; and on the other hand, by arranging the U-shaped steel connecting piece of which the bottom plate is weakened locally and the single end is widened, and the short reinforcing bar of which the diameter is smaller than that of a longitudinal rebar on the upper portion of the beam and the single end is provided with the thread, the end of the beam is formed into a plastic hinge through yielding at first so that a large amount of earthquake energy can be consumed, and the overall anti-seismic property of the structure is improved.

Owner:SOUTH CHINA UNIV OF TECH

Construction welding method for main chord pipe inside platform legs

ActiveCN101225653AImprove accessibilityEliminate negative effectsArtificial islandsUnderwater structuresArchitectural engineeringWorkload

The invention discloses a construction welding method for a major side pipe in a pile leg, comprising a plurality of connecting sections composed of a plurality of semicircle plates and rack plates. The welding procedure is described as follows: a. the two side semicircle plates are welded with the rack plate into the form of a unilateral U-shaped groove joint, with the semicircle plate positioned in the middle of the rack plate and shorter than the rack plate; b. the terminals of the two sections of rack plate are welded into the form of an unsymmetrical X groove joint; c. a filling semicircle plate is filled in between two connecting sections of semicircle plates in the form of a V-shaped groove joint through welding. The construction welding method for a major side pipe in a pile leg has the advantages that the accessibility of the welding construction is enhanced while the welding joint is reduced; workload is decreased while work efficiency is enhanced and mechanical properties of the welding joint are improved. After welding procedure evaluating test, every index of the mechanical properties of the welding joint meets the requirements of a classification society.

Owner:DALIAN SHIPBUILDING IND

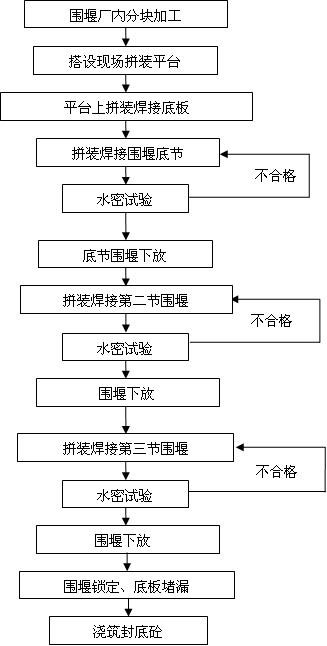

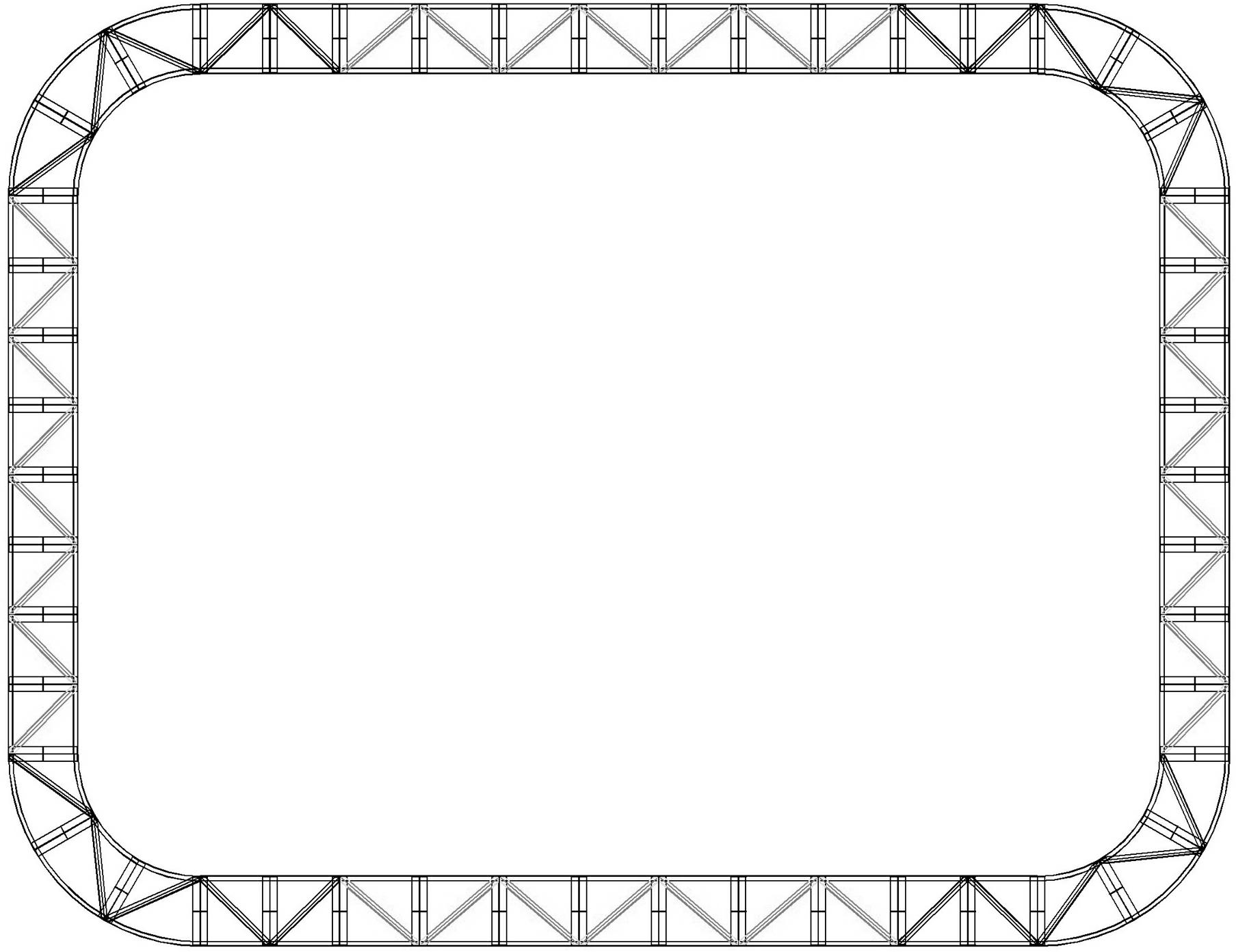

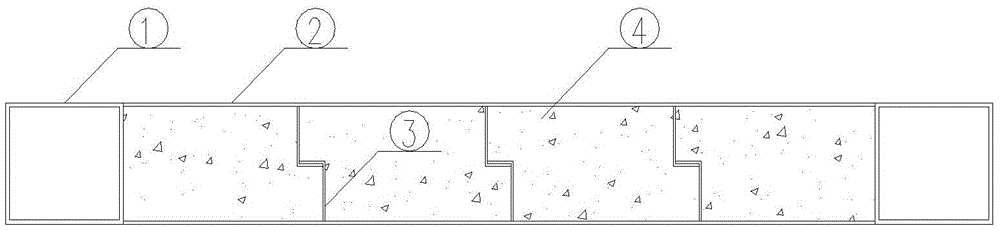

Double-wall cofferdam with partitioned cabins

InactiveCN102587398AReasonable forceImprove stress resistanceFoundation engineeringDouble wallCofferdam

The invention discloses a double-wall cofferdam with partitioned cabins. The whole cofferdam has a rectangular structure formed by connecting an inner wall board, an outer wall board and a base board, wherein a rectangular annular cavity is formed between the inner wall board and the outer wall board; partitioning boards are arranged in the longitudinal direction and used for partitioning the cavity into a plurality of independent cabins; a plurality of flat linkage inclined rods parallel to the base board are symmetric about the partitioning plates and arranged at the diagonal positions of the adjacent cabins; each cabin has an independent stable structure, so that the stable structure of the whole cofferdam is formed; therefore, the whole cofferdam is rationally stressed and has relatively high compression strength and distortion resistance; and the partitioned cabin type structure replaces the conventional truss structure, so that the assembly and manufacturing process of the cofferdam is simplified, the number of the specifications of the used materials is small, workpieces are uniform and easy to machine, site mounting is facilitated, a large number of truss connection rods are not used, the loss of steel materials is reduced, and the cost is saved.

Owner:中铁二十二局集团第一工程有限公司 +1

Mixed shear connector

InactiveCN103572839AReduced brittle propertiesImprove ductilityBuilding constructionsRebarFloor slab

The invention discloses a mixed shear connector which comprises channel steel connectors and bent-up steel bar connectors, wherein the channel steel connectors and the bent-up steel bar connectors are arranged in a floor slab and distributed on a steel beam alternately; the channel steel connectors are suitable for being arranged at the beam end; preformed holes are formed in ventral plates of the channel steel connectors; and reinforcement bars in reinforced nets in the floor slab penetrate through the preformed holes. According to the mixed shear connector, the channel steel connectors and the bent-up steel bar connectors are distributed on the steel beam at intervals, so that joint shear of the bent-up steel bar connectors and the channel steel connectors is realized, cooperative work of the steel beam and the concrete floor slab is guaranteed, and the structure bearing capacity is improved.

Owner:NANJING UNIV OF TECH

Pull-joint type double-steel-plate composite shear wall

The invention discloses a pull-joint type double-steel-plate composite shear wall, comprising steel pipe columns (steel pipe columns or concrete-filled steel tube columns) respectively arranged at the two ends, a pair of steel plates and at least one pull-joint type connecting piece. The pull-joint type connecting piece is firstly connected with the steel plates by staggered and intermittent one-side fillet welds in a welding way, and then a whole is assembled; the pull-joint type double-steel-plate composite shear wall has the advantages that the composite shear wall is simple in pull-joint structure, has a flat wall surface, and is less in welding workload, easy to operate and convenient to assemble; the stress performance of the composite shear wall is seldom affected by the welding quality since weld joints are positioned at construction parts; the composite shear wall is economical and safe; the steel plates and concrete are strong in cooperative work capability. A straight hook L shape, a sickle hook shape or hump hook shape can be adopted as the pull-joint way of the connecting piece, the pull-joint position can be positioned at the middle or side part of the thickness of the composite wall, and the pull-joint way is flexible and changeable, so that different engineering stress and use requirements are met. Riffled plates can be used as the wallboard steel plates and the pull-joint type connecting piece, so that the binding action between the wall steel plates and the concrete is effectively improved, and the co-working between steel components and the concrete is guaranteed.

Owner:HEFEI UNIV OF TECH +1

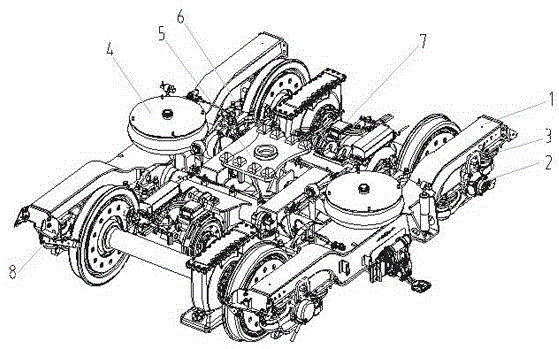

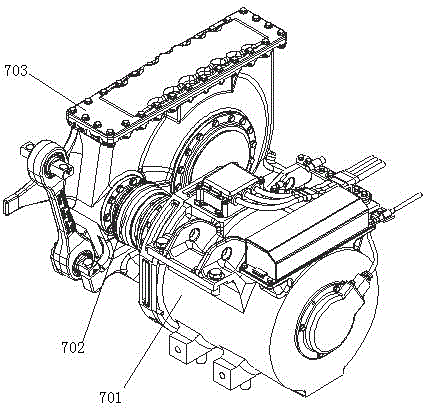

Bogie for A-type broad-gauge metro vehicle

The invention discloses a bogie for an A-type broad-gauge metro vehicle. The bogie comprises a frame, a wheelset and axle box device, a primary suspension device, a secondary suspension device, a central traction device, a foundation brake device, a driving device and a rim lubrication device. The bogie is characterized in that the frame has a large lateral span, the primary suspension adopts a rubber spring, the secondary suspension adopts an air spring, a secondary vertical damper and a horizontal damper to reduce vibration and impact, so that a passenger sits more conformably, two traction rods are adopted between a vehicle body and the bogie for transferring traction and braking force, and the foundation brake device adopts a wheel mounted type disc brake unit. The bogie meets requirements for a Brazil 1A metro project contract, and the bogie for the A-type broad-gauge metro vehicle, which meets requirements for a dual-mode signal system, is researched for the first time; the gauge is 1600 mm and the axle load is 17.5 tons; the bogie has the advantages of high operation quality and convenience for maintenance and can be widely applied to the foreign market.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

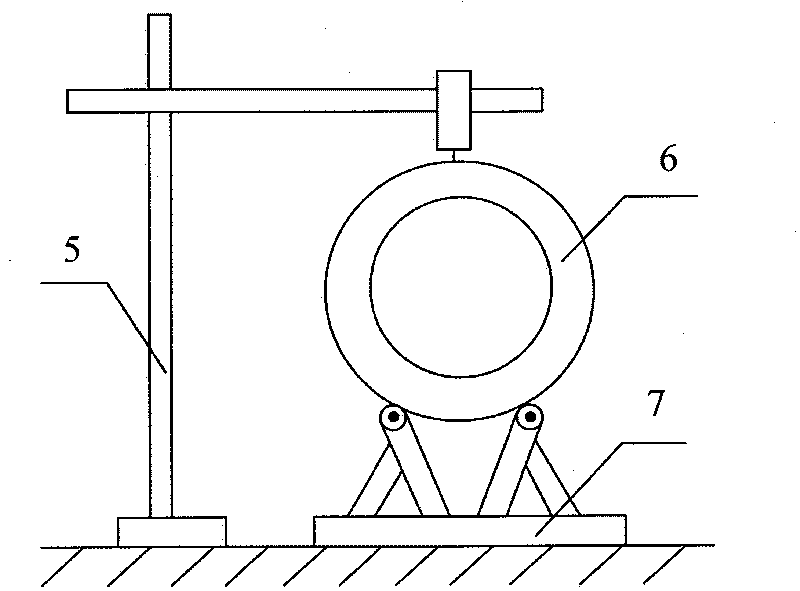

Manufacturing process for main shaft of large water turbine

InactiveCN101761541AIncrease productivityReduce manufacturing costShaftsHydro energy generationWater turbineStress relieving

The invention relates to a manufacturing process for a main shaft of a large water turbine. The main shaft is divided into two sections along the length direction, and each shaft body is divided into two cylindrical bodies subjected to cold-press molding by using a 3000 ton level oil press. The cylindrical bodies are welded to form a shaft body, and submerged-arc welding is adopted for the longitudinal welding of the shaft body. After welding, an intermediate stress relief heat treatment is performed on the single shaft body. The two shaft bodies assembled and welded by using a method of narrow-gap submerged arc welding. After being welded, the inner circle of the shaft body is machined to a size in accordance with the drawing. The welding line between the shaft body and the flange I and between the shaft body and the flange II are welded by using the narrow-gap submerged arc welding. After welding, a final stress relief heat treatment is performed on the main shaft. UT, MT flaw detections are performed on the welding line to realize final machining of the main shaft. The invention has the advantages of reasonable and brief assembling process, high production efficiency, low cost and the like.

Owner:HARBIN ELECTRIC MASCH CO LTD

Connecting structure of concrete-filled steel tube column and reinforced concrete beam

ActiveCN105735468AImprove the bending capacityIncreased shear capacityBuilding constructionsReinforced concreteSteel bar

The invention discloses a connecting structure of a concrete-filled steel tube column and a reinforced concrete beam. The connecting structure comprises the concrete-filled steel tube column made of a steel tube and concrete and the reinforced concrete beam made of a reinforcing steel bar and concrete; a boom extending steel beam is welded on the outer side surface of the steel tube and consists of flanges and a web plate; pull and tie plates parallel to the flanges are symmetrically welded on the two sides of the web plate; bar penetration holes are formed in the pull and tie plates; the reinforcing steel bar comprises longitudinal bars arranged on the upper side and the lower side, lumbar bars arranged on the left side and the right side, a first stirrup connected onto the longitudinal bars and the lumbar bars in a bundling manner and a pull and tie bar with two ends respectively colluded on the crossed lumbar bars and the first stirrup; one end of the reinforced concrete beam is inserted into the boom extending steel beam; the pull and tie bar is cut into two sections by the web plate of the boom extending steel beam, and the cut ends of the pull and tie bar are inserted into the bar penetration holes. Through the overlap joint of the reinforcing steel bar and the boom extending steel beam, the anchorage and the force transmission of the reinforcing steel bar are realized. The connecting structure disclosed by the invention has the advantages of being strong in bending and shear bearing capacity, small in welding workload, simple in mounting process and convenient and quick to construct.

Owner:筑博设计股份有限公司

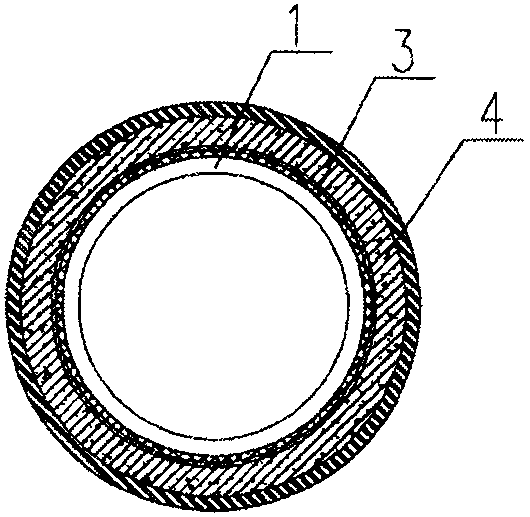

Non-welded plate type heat exchanger

ActiveCN101464105AEasy to manufactureLow costStationary plate conduit assembliesEngineeringHeat exchanger

The invention relates to the technology of heat exchangers, particularly a weldless plate-type heat exchanger. A plurality of fluid passages are formed by a plurality of heat exchange plates 1 which are vertically placed in a rectangularly (90 DEG) staggered manner, wherein, the openings of adjacent fluid passages among the fluid passages are mutually staggered at an angle of 90 DEG to form hot fluid passages and cold fluid passages; upward right-angled fold edges are formed on the two symmetric sides of each heat exchange plate 1, and right-angled double-fold edges are formed on the other two corresponding sides so as to form L-shaped fold edges; each two vertically adjacent heat exchange plates are placed in a rectangularly (90 DEG) staggered manner, that is, the downward L-shaped fold edge of an upper heat exchange plate is correspondingly placed between the upward right-angled fold edges of a lower heat exchanges plate, and the upward rectangular (90 DEG) fold edge of the lower heat exchange plate serves the function of limiting to the L-shaped fold edge of the upper heat exchange plate; a sealing gasket 5 is arranged between the lower heat exchange plate and the upper exchange plate; a flexible sealing layering 3 is arranged between each two adjacent heat exchange plates; and a support strip 2 is arranged between the passage formed by the upper heat exchange plate and thelower heat exchange plate.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

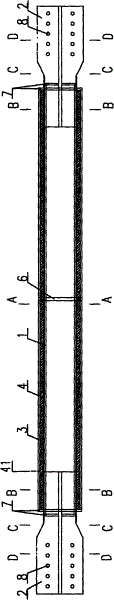

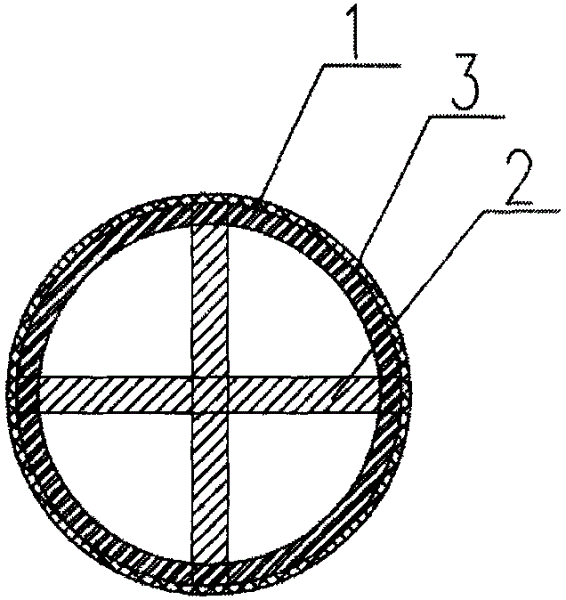

Buckling restrained brace with steel pipe concrete sleeved on round pipe as inner core

InactiveCN102619292AConvenient sourceEasy to processBridge structural detailsShock proofingBuckling-restrained braceMetallurgy

The invention discloses a buckling restrained brace with steel pipe concrete sleeved on a round pipe as an inner core. The buckling restrained brace consists of an inner core steel supporting component, an unbonded material layer and an externally coated steel pipe concrete component, wherein inner core steel supporting component is a cylindrical steel pipe; the unbonded material layer is coated on the outer wall of the cylindrical steel pipe; the externally coated steel pipe concrete component is a tubular component; a clearance is formed between the unbonded material layer and the inner side wall of the externally coated steel pipe concrete component; cross connecting steel plates are fixedly welded in the two ends of the cylindrical steel pipe and extend outwards along the axial direction of the cylindrical steel pipe; and the diameter of the extending sections is more than the inner diameter of the cylindrical steel pipe. The middle part of the inner pipe is a restrained yield section, the parts, reinforced by the cross connecting steel plates, at the end parts of the inner pipe are restrained non-yield section, and the externally extending parts are non-restrained non-yield sections. The material of the inner pipe is convenient to select, the inner pipe is convenient to machine and low in welding workload; and the outer pipe conveniently supports a die and is convenient to pour, low in weight and low in comprehensive cost. Therefore, the buckling restrained brace can be applied to civil buildings, industrial buildings, public buildings, bridge engineering and the like.

Owner:上海丹木钢结构技术有限公司

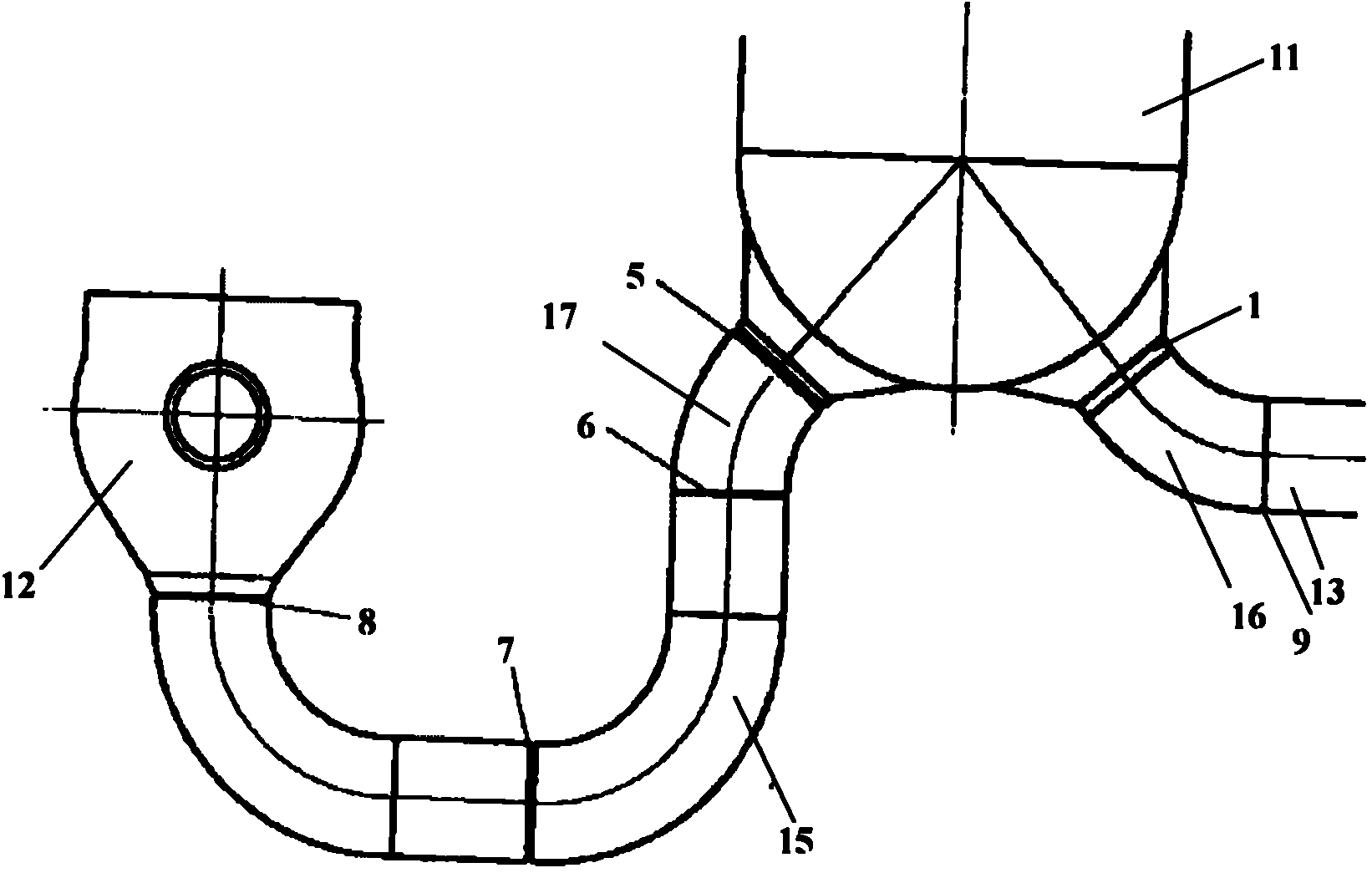

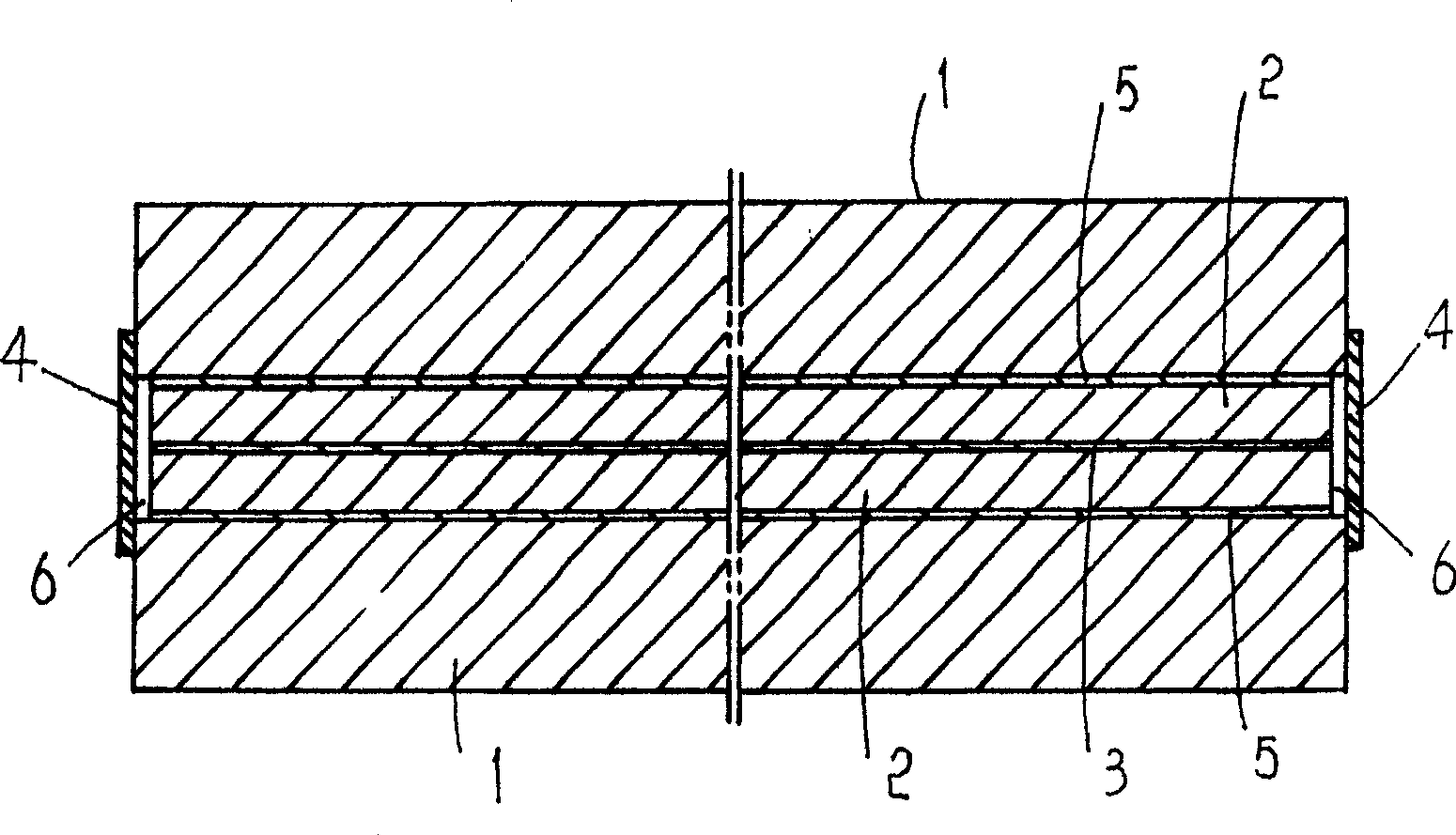

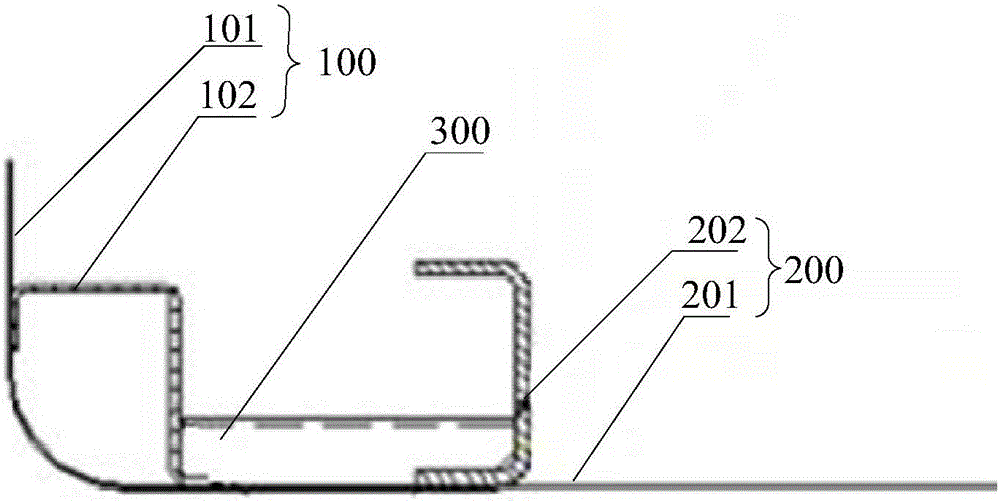

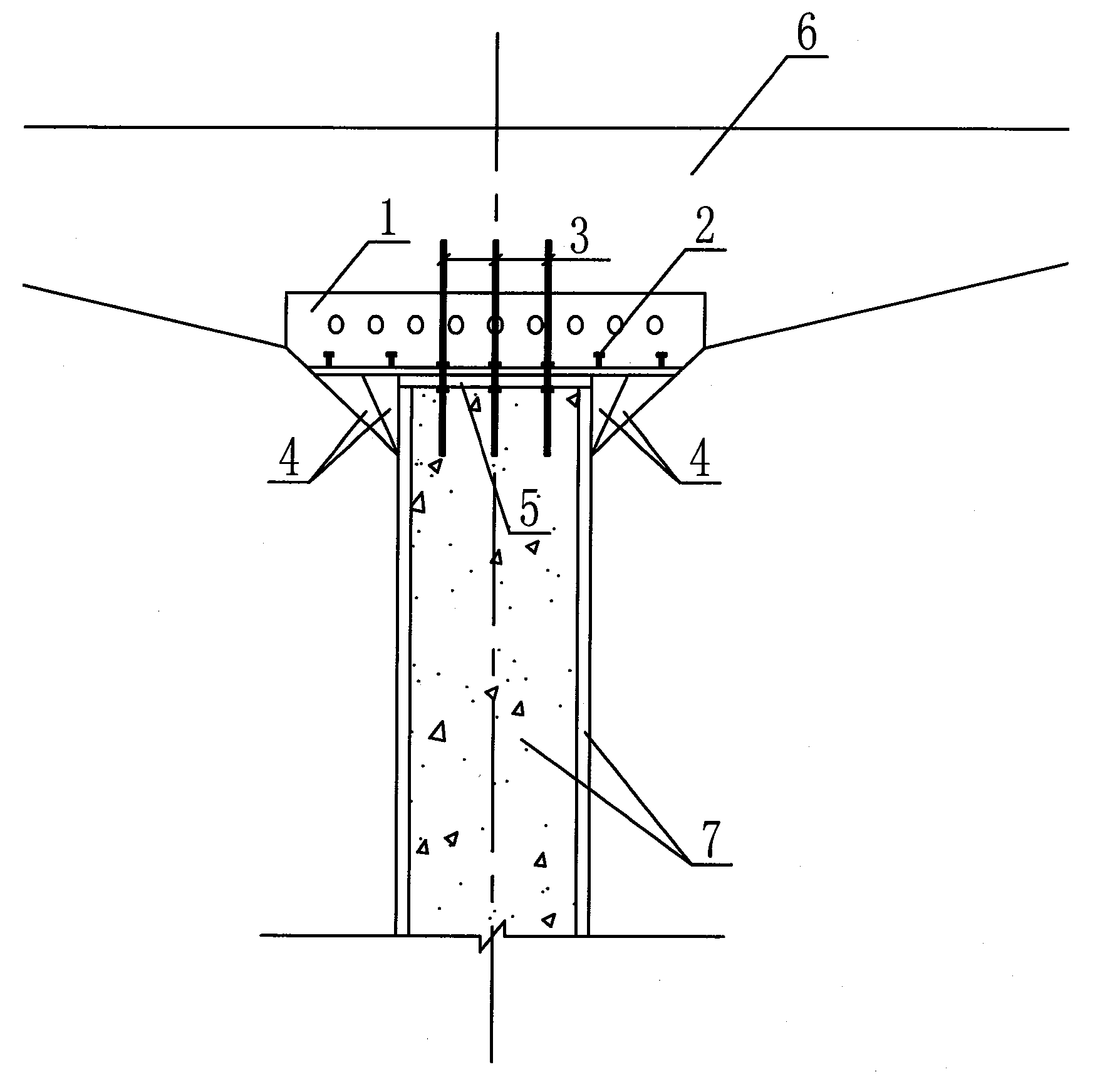

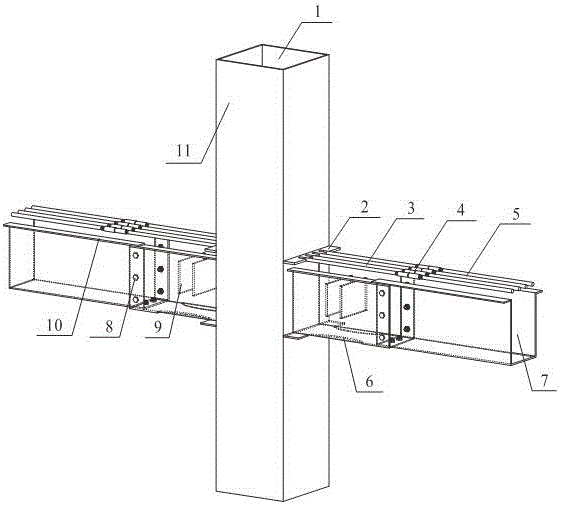

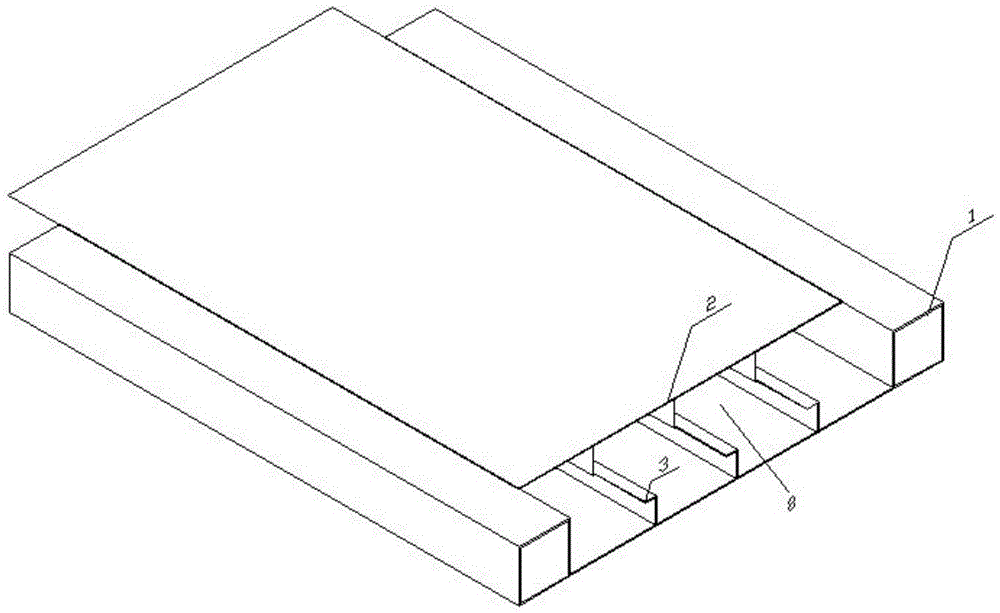

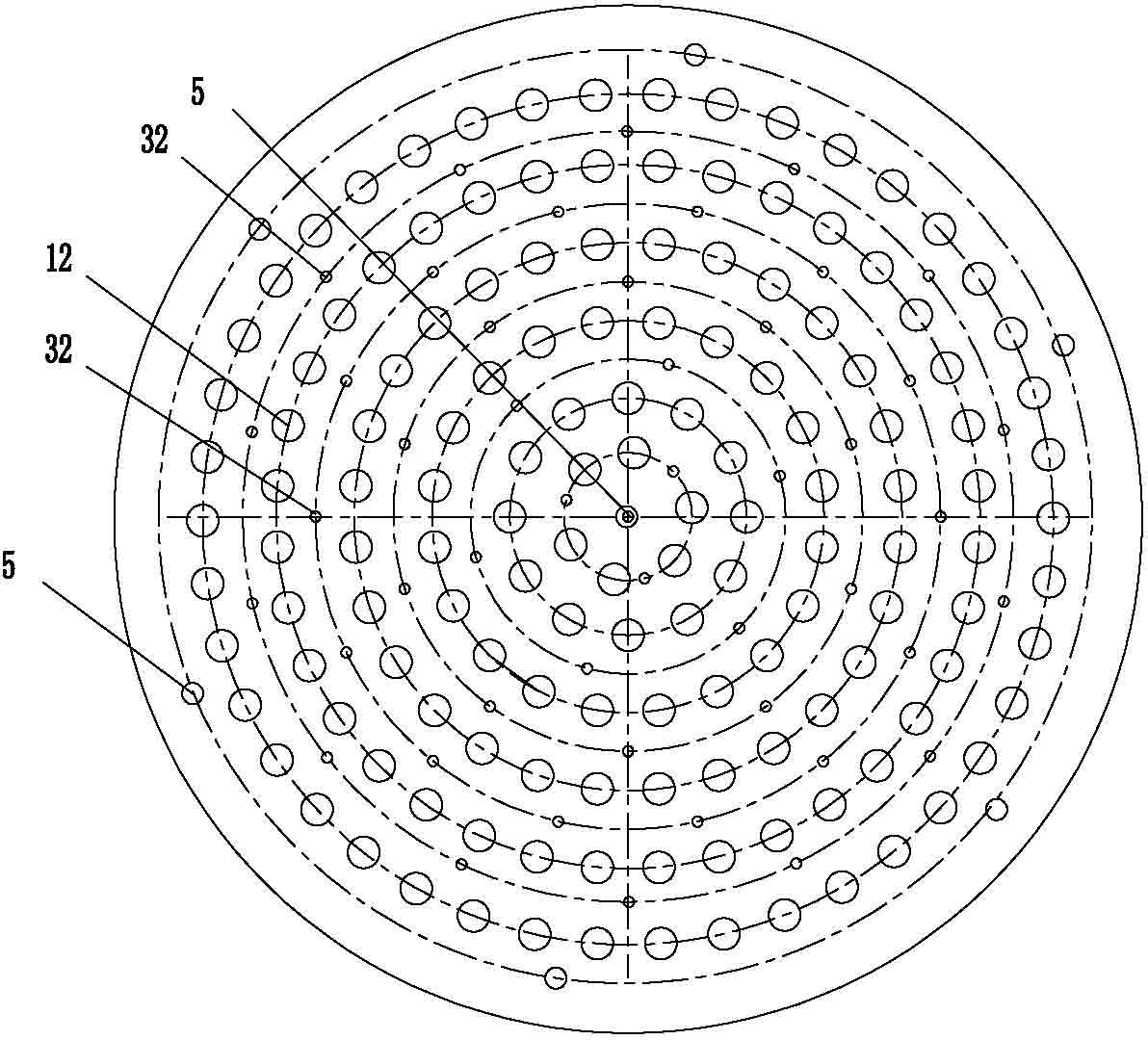

Connection joint of concrete filled steel tubular column and enclosed U-shaped steel concrete composite beam

InactiveCN104912196ASave materialReduce welding workloadBuilding constructionsSteel tubeBending moment

The invention provides a connection joint of a concrete filled steel tubular column and enclosed U-shaped steel concrete composite beam; in order to save materials and solve the problem that since a connection plate at the connection part of a composite beam bottom plate and a steel pipe outwards extends, an indoor corner has a convex angle to influence the beautiful sense, an inner partition plate is arranged at a position corresponding to a U-shaped steel bottom plate in the steel pipe, and the periphery of the inner partition plate is welded with the inner wall of the steel pipe. Sleeves which are movably connected with the end parts of hogging moment reinforcing steel bars are correspondingly arranged at two relative ends in the steel pipe along the length direction of the composite beam respectively; and the sleeves are welded with the outer wall of the steel pipe. The joint is capable of relieving the condition that the bearing capacity of the steel pipe is weakened due to hole forming in the side wall of the steel pipe; the welding workload is reduced; construction is facilitated; and assembly is realized. In order to effectively transmit a load, a horizontal stiffening plate is fixedly welded at positions corresponding to the sleeves in an inner cavity of the steel pipe, and the welding workload in field is reduced; a U-shaped steel side plate is connected with the wall of the steel pipe by adopting high-strength bolts through connection plates; the connection plates are connected with the wall of the steel pipe by angle welding; and welding is completed in a factory.

Owner:SHANDONG JIANZHU UNIV

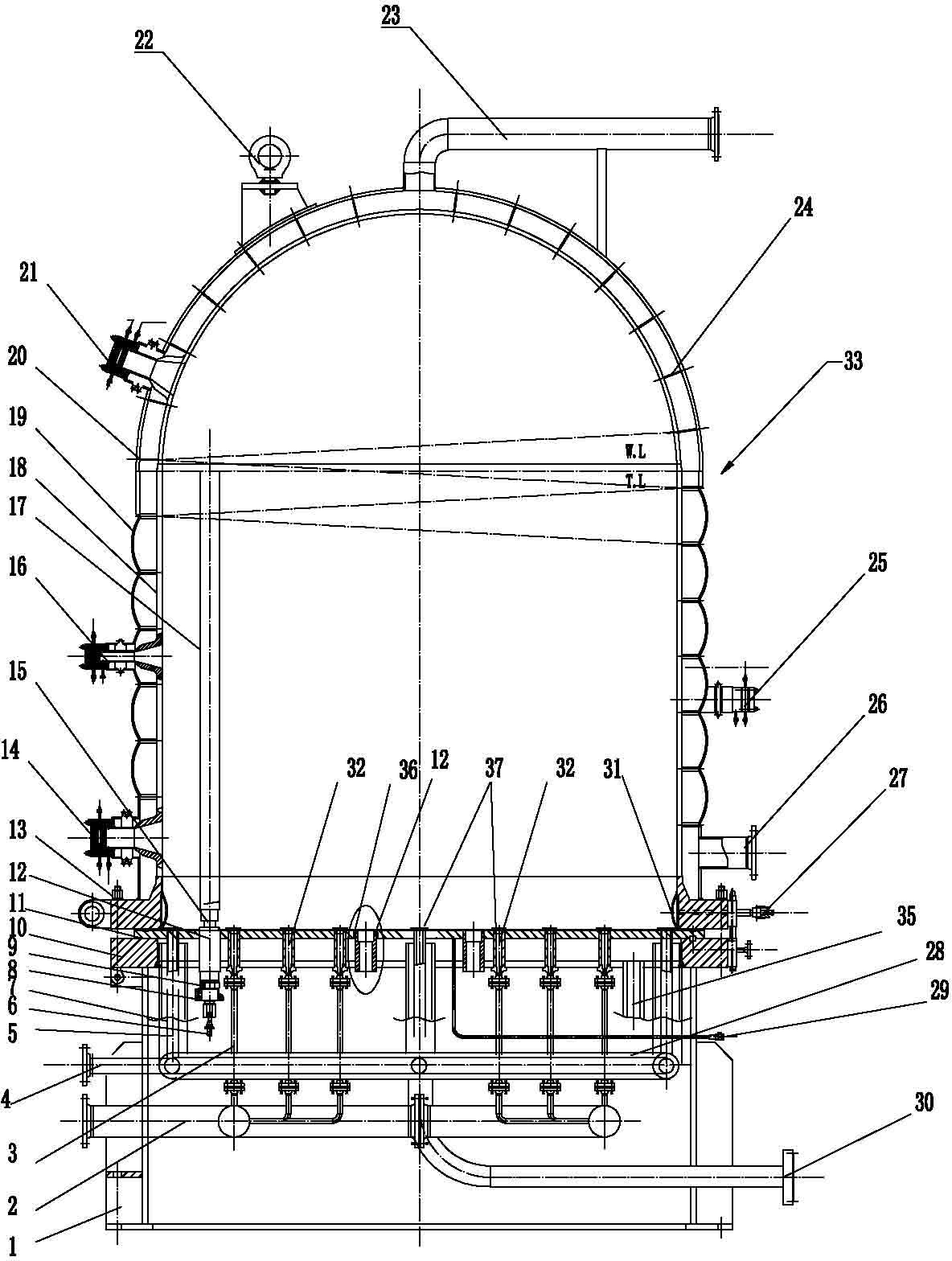

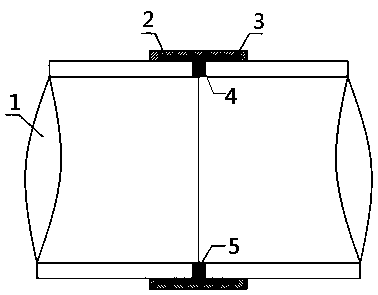

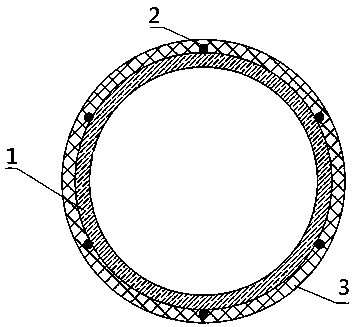

Uniform temperature type polysilicon reducing furnace

ActiveCN102424387AAvoid depositionEffective cooling systemChemical industrySilicon compoundsCooling effectEngineering

An uniform temperature type polysilicon reducing furnace comprises a bearer (1), a water jacket tube plate (10) and a furnace body (33), wherein the water jacket tube plate (10) is installed on the bearer (1); and the furnace body (33) is installed on the water jacket tube plate (10) through a flange. The uniform temperature type polysilicon reducing furnace is characterized in that the furnace body (33) is composed of a furnace cylinder inner wall (18), arc-shaped furnace outer cylinder (19) and a spherical furnace outer cylinder (20), wherein the furnace cylinder inner wall (18) facing the furnace chamber is provided with a thermoreflectance coating; Spirally arranged shoe plates (24) are installed both between the furnace cylinder inner wall (18) and the arc-shaped furnace outer cylinder (19) and between the furnace cylinder inner wall (18) and the spherical furnace outer cylinder (20). The bottom of the arc-shaped furnace outer cylinder (19) is provided with a cooling water outletand inlet (26) for cooling the furnace body (33). The cooling water between the furnace cylinder inner wall (18) and the arc-shaped furnace outer cylinder (19) and the spherical furnace outer cylinder (20) spirally rises to a steam outlet (23) arranged at the top of the furnace body and is discharged out of the furnace body (33). The joint of an electrode sleeve (12) and a water jacket tube plate(10) is provided with a silk screen or semicircular capillary cooling component (36). The furnace core space outlets of a raw material gas nozzle (32) and a tail gas outlet duct (5) are provided withporous or cancellate filter mantles (37). The furnace provided by the invention has advantages of large size, good cooling effect of the thick tube plate, uniform furnace velocity field and temperature field and remarkable energy-saving effect.

Owner:江苏中圣压力容器装备制造有限公司

Connection method for installation of large-diameter pipe

ActiveCN110645418AReduce brittlenessReduce welding workloadPipe laying and repairRigid pipesEpoxyGlass fiber

The invention relates to the field of engineering construction for pipe installation, in particular to a connection method for installation of a large-diameter pipe. A circular seam of a metal steel pipe connector is full-welded to form a composite connector in the circumferential direction according to the characteristic of small axis stress of the large-diameter engineering pipeline, namely a ribbed plate is adopted for the connector or the local circular seam of the connector is welded to counteract the influence generated when the axis of the pipe is pulled; then, a flexible glass fiber reinforced plastic connector is formed on the outer wall of the connector by means of epoxy and glass wool cloth or carbon fiber cloth to assist in axis stress of the pipe, prevent pipe seepage and meetthe requirement for linear temperature stretchable deformation of the pipe; gaps in the inner wall of the connector are filled with epoxy asphalt filler to be trimmed and smoothened under the condition that the protection of a pipe coating is not destroyed, so that unstressed butt joint of the connector is completed to form composite connector connection; and through such connector connection, the capacity to resist temperature stretchable deformation in the axis direction can be improved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Conductive connecting piece for battery and preparation method of conductive connecting piece

ActiveCN104638265AImprove cooling effectReduce welding workloadContact member manufacturingCurrent conducting connectionsMetal stripsPower battery

The invention relates to a conductive connecting piece for a battery and a preparation method of the conductive connecting piece. The conductive connecting piece is made of a laminated composite metal material; a concave part is formed in the back side of a resistance spot welding area in the conductive connecting piece; the laminated composite metal material comprises a copper layer and a first corrosion-resisting easily welded metal layer which is compounded on a first side of the copper layer; the front side of the resistance spot welding area is positioned on the first corrosion-resisting easily welded metal layer. The preparation method comprises the following steps: S1, preparing a copper-based laminated composite metal strip material; S2, selectively etching the copper-based laminated composite metal strip material so as to form the concave part; and S3, performing stamping molding on the etched copper-based laminated composite metal strip material, thereby preparing the conductive connecting piece. The conductive connecting piece is easy to weld, good in conductivity, high in production efficiency and low in cost, and also can meet high magnification and large-capacity application places such as a power battery.

Owner:YULIN NORMAL UNIVERSITY

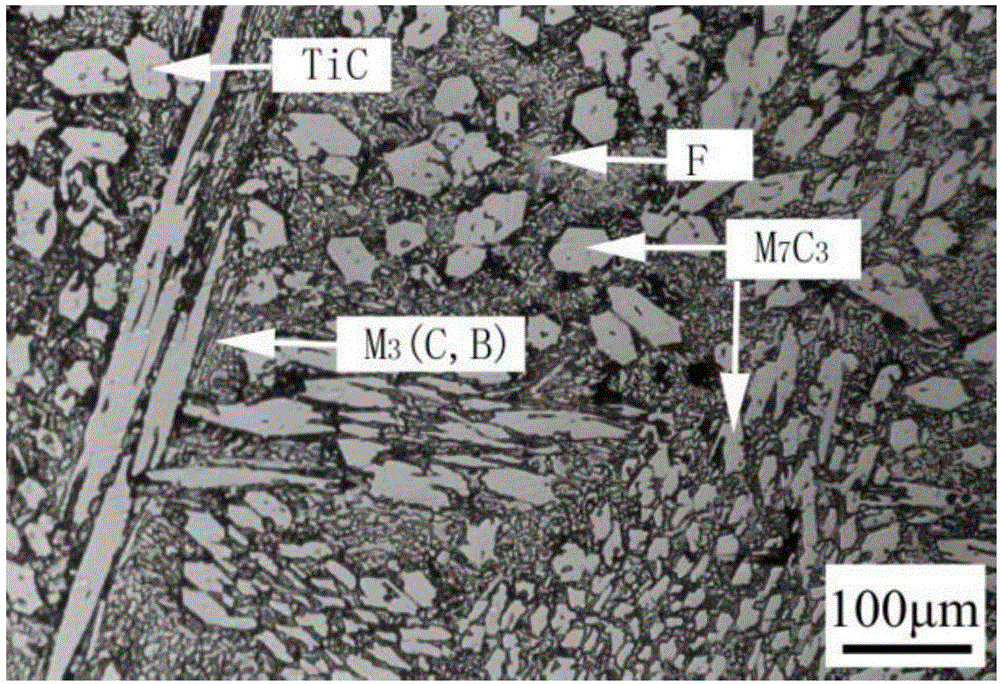

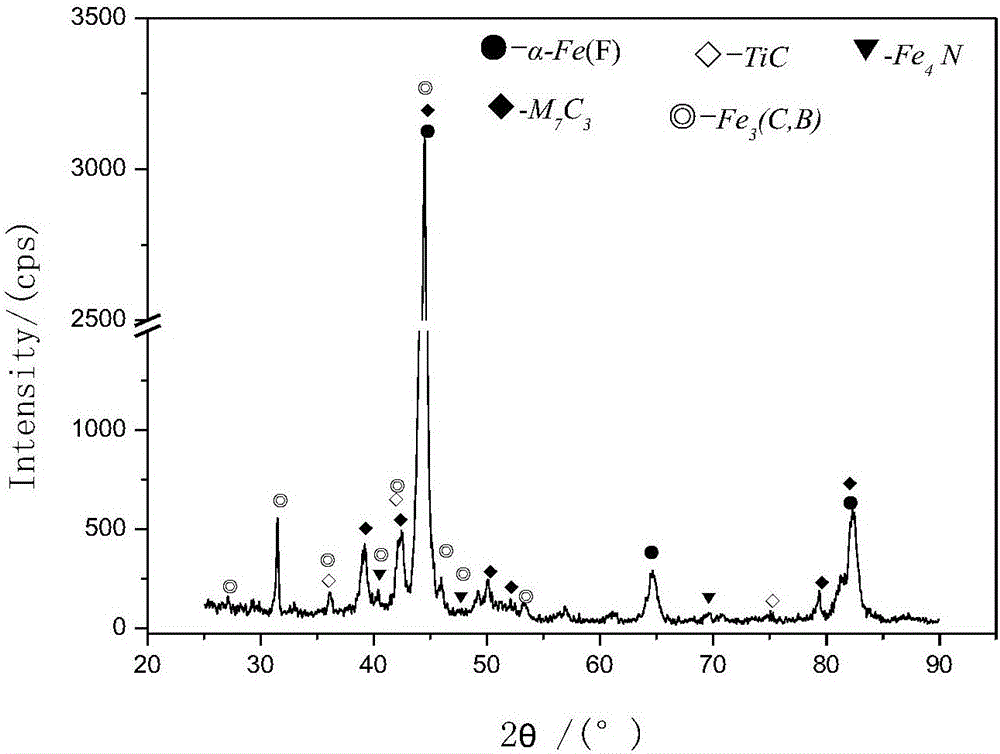

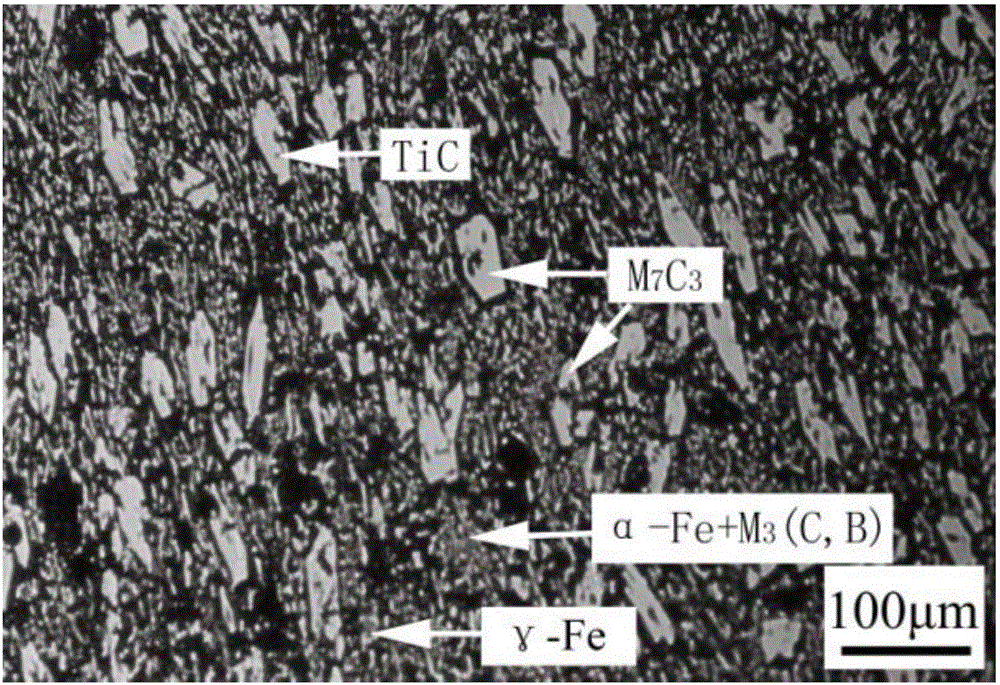

Pre-prepared alloy powder type flux-cored wire and self-protection open arc surfacing welding method of high-chromium alloy

ActiveCN106041361AIncreased welding deposition efficiencyRemarkable effect of energy saving and consumption reductionArc welding apparatusWelding/cutting media/materialsHigh carbonFerrosilicon

The invention discloses a pre-prepared alloy powder type flux-cored wire and a self-protection open arc surfacing welding method of a high-chromium alloy. The adopted technical scheme lies in that a cold rolled thin steel strip manufactured through low-carbon steel H08A as an outer coating, high carbon ferro-chrome, ferrosilicon, graphite and other metal powder are blended inside the coating to form a powder core of the flux-cored wire, and high carbon ferro-chrome, ferroboron, ferrosilicon and reduced iron powder are blended to form pre-prepared alloy powder; and before welding, the alloy powder is placed on a welding bead in advance, the surfacing welding current control value is set, a regulating melt mode combined with the mass of the pre-prepared alloy powder type flux-cored wire is set, a nonhomogeneous melt containing liquid high carbon ferro-chrome atom clusters formed through melting high carbon ferro-chrome particles is formed, and the concretionary high-chromium alloy which adopts the liquid high carbon ferro-chrome atom clusters as component donors, nucleates and grows into primary M7C3 abrasion-resistance phases is formed. According to the method, the problems that the source of components of surfacing welding alloys is single and the chromium content of the surfacing welding alloys is not liable to increase are solved, and the method is widely applied to surfacing welding manufacturing and repairing of parts with the requirement of abrasive wear resistance.

Owner:XIANGTAN UNIV

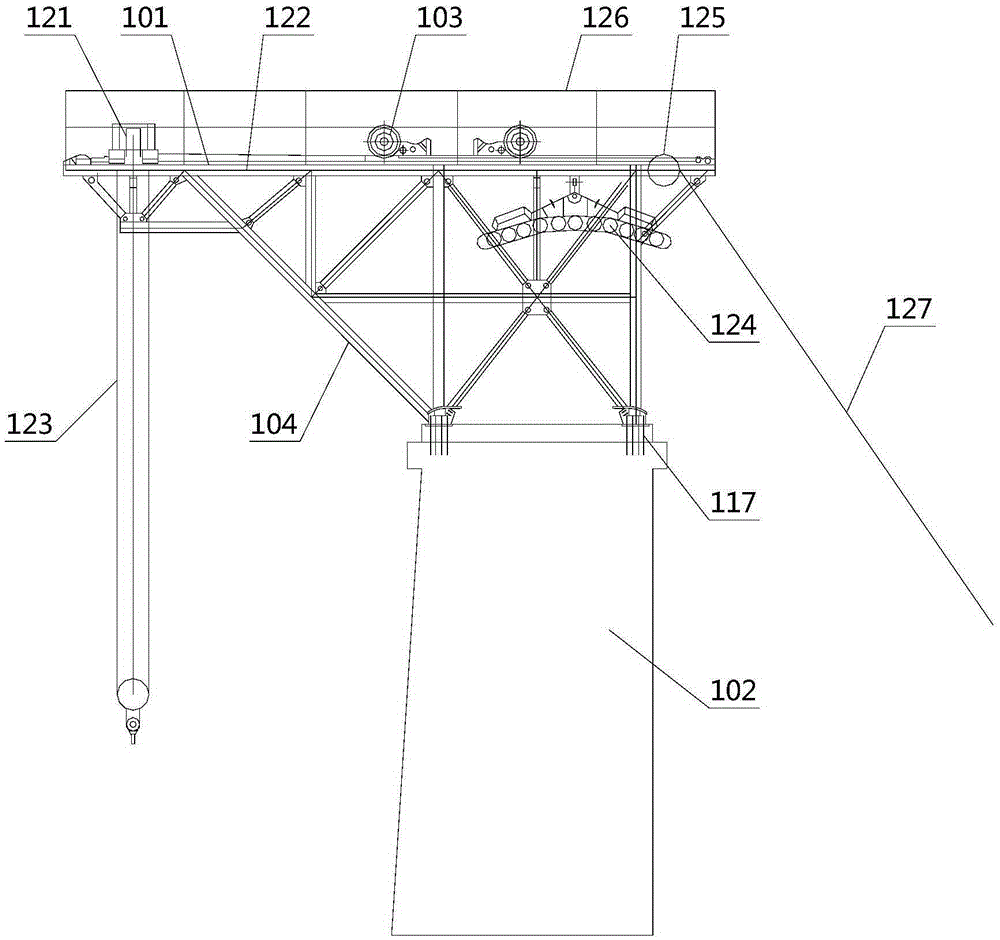

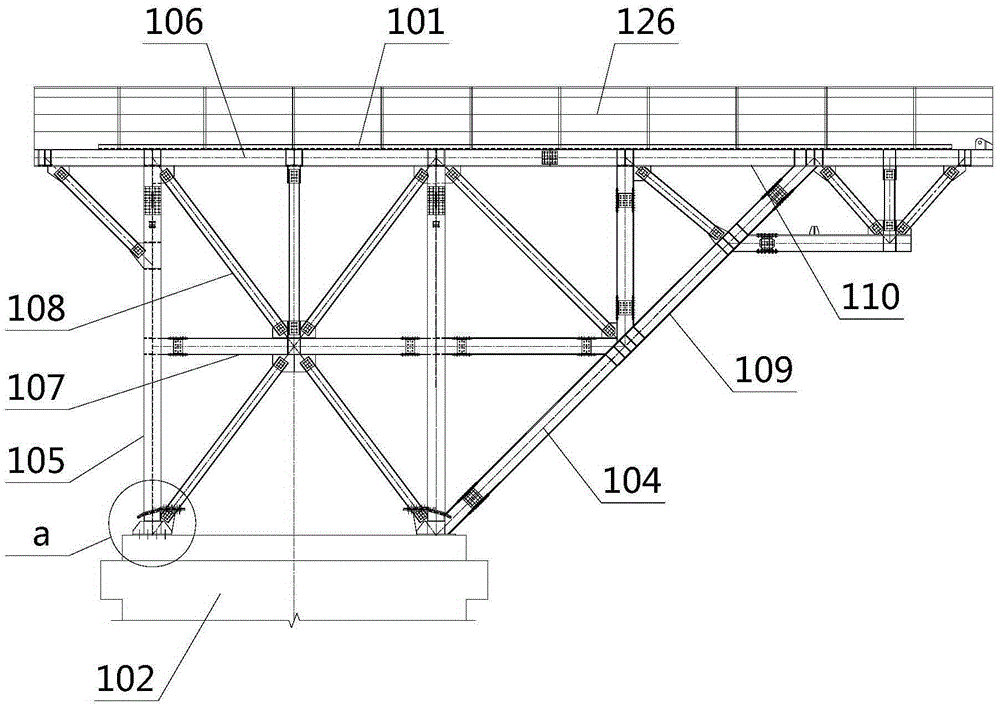

Multifunctional portal device of suspension bridge pillar top

ActiveCN105386411AStructural stress safetySimplify construction difficultyBridge erection/assemblyTraction systemTower

The invention provides a multifunctional portal device of a suspension bridge pillar top, and belongs to the field of construction devices of suspension bridges. The multifunctional portal device of the suspension bridge pillar top comprises a field mounted portal body, wherein the field mounted portal body comprises a supporting truss system, a working platform, a catwalk turning cable saddle, a lifting system and a traction system; the working platform is connected to the upper end of the supporting truss system; the lower end of the supporting truss system is anchored to the suspension bridge pillar top through an anchoring system; and the catwalk turning cable saddle, the lifting system and the traction system are respectively connected with the supporting truss system. The multifunctional portal device of the suspension bridge pillar top is provided with the field mounted portal body, a portal is divided into different blocks which are assembled on a tower top, requirements on field hoisting are met, conveying, mounting and machining can be facilitated further, construction installation is simplified, the different blocks of the portal can be combined with the catwalk turning cable saddle at the tower top, the portal is stressed safely, effects of the portal can be fully achieved in various stages of installation construction of an upper structure of the suspension bridge, and multifunction of the portal is fulfilled really.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com