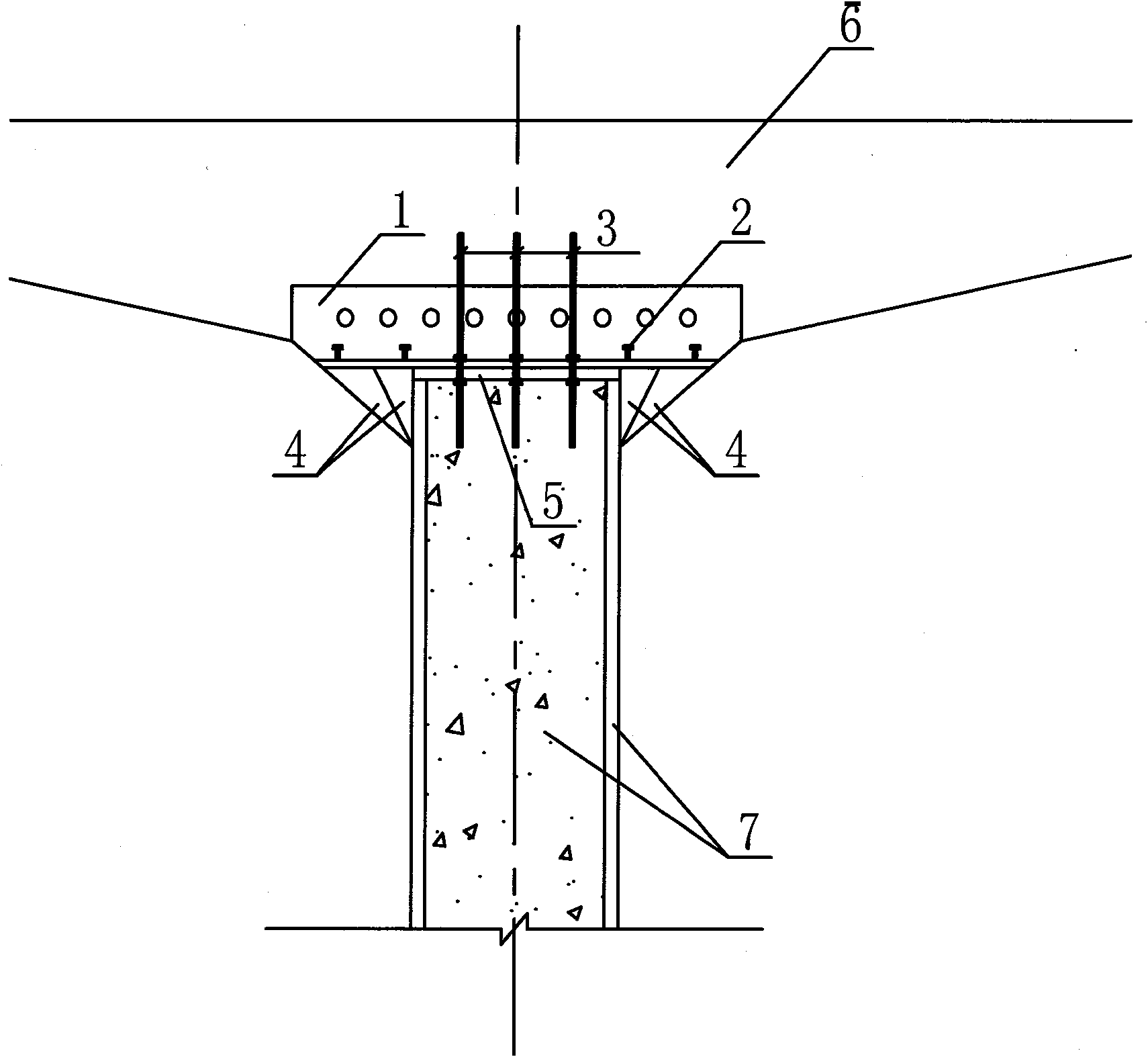

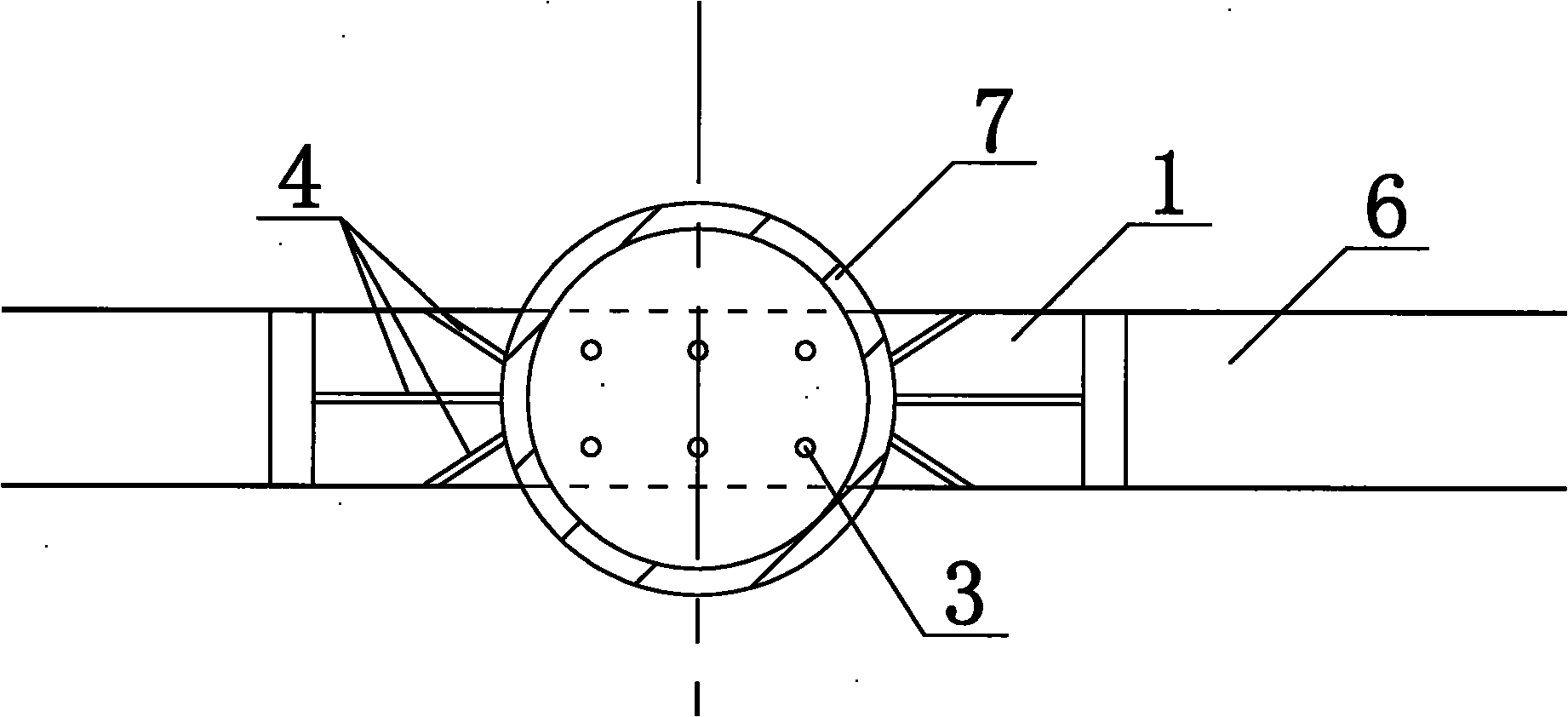

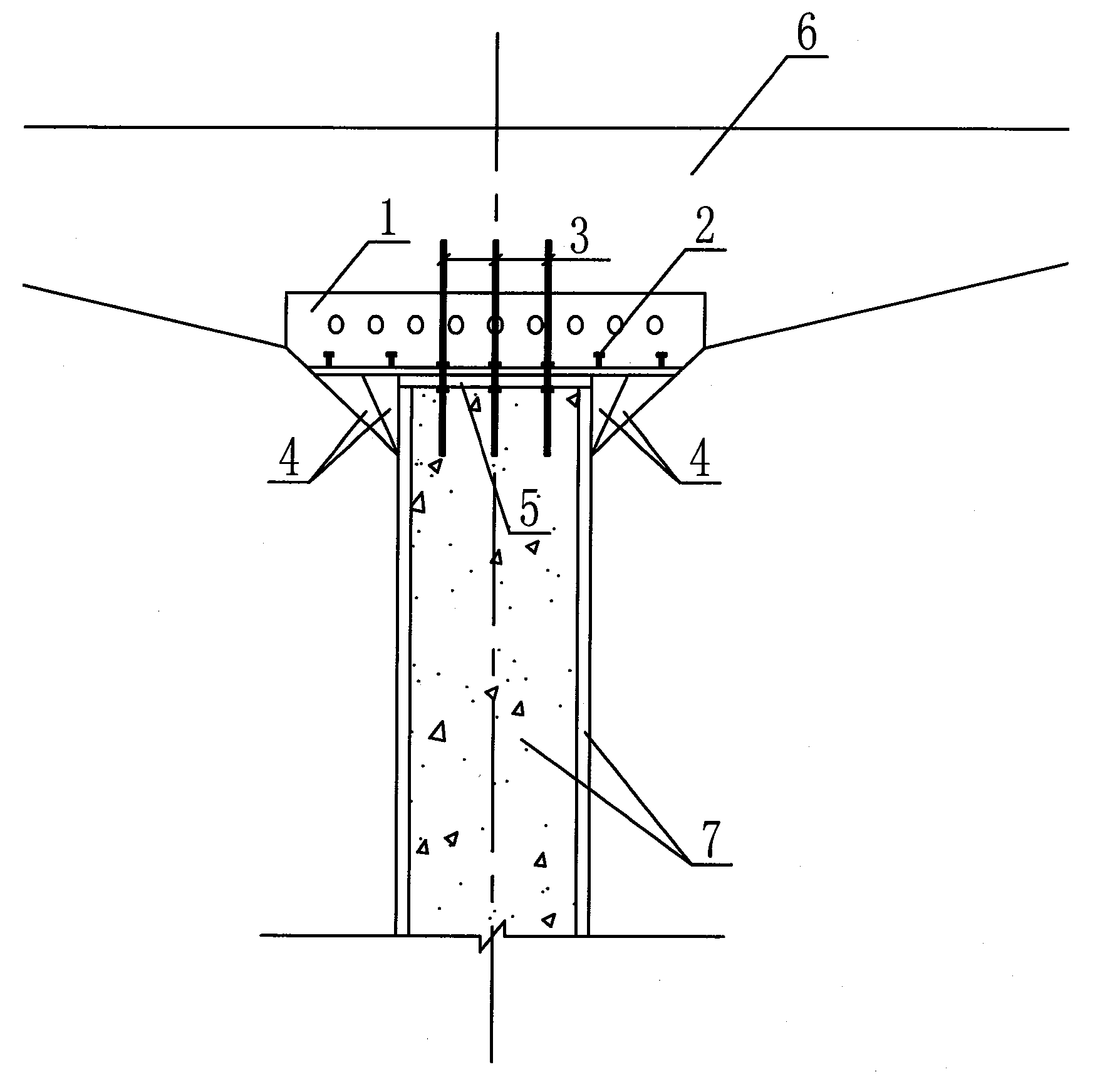

Connection structure for concrete-filled circular steel tubular pier column and concrete cover beam

A technology for steel pipe concrete and connection structures, which is applied in bridges, bridge parts, bridge construction, etc., and can solve the problems of complex stress on pier nodes and inapplicability, and achieve clear force transmission paths, small welding workload, and reasonable structural stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The composition of the connection structure of the present invention is mainly composed of an inverted T-shaped steel beam with a hole web, rivets 2, rivet bars with nuts 3, a triangular support steel plate 4, a steel pipe cover plate 5, a concrete cover beam 6, and a steel pipe concrete pier column 7 composition. Its main features are as follows: First, the concrete cover beam 6 and the inverted T-shaped steel beam 1 can be effectively connected by welding the rivets 2 on the web and flange of the hole, and the arrangement of the holes and rivets is determined according to the specific bearing capacity requirements. The second is that the steel pipe cover plate 5 is welded to the steel pipe concrete pier column 7, and the steel pipe cover plate 5 and the flange of the inverted T-shaped steel beam 1 are connected by the rivet bar 3 bolts with nuts, and the rivet bar extends into the concrete of the steel pipe concrete pier column 7 And in the concrete cover beam 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com