Conductive connecting piece for battery and preparation method of conductive connecting piece

A technology of conductive connecting sheet and battery, applied in conductive connection, battery electrode, contact manufacturing and other directions, can solve the problems of unfavorable welding stability, increase production cost and equipment cost, etc., achieve low cost, high production efficiency, easy welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

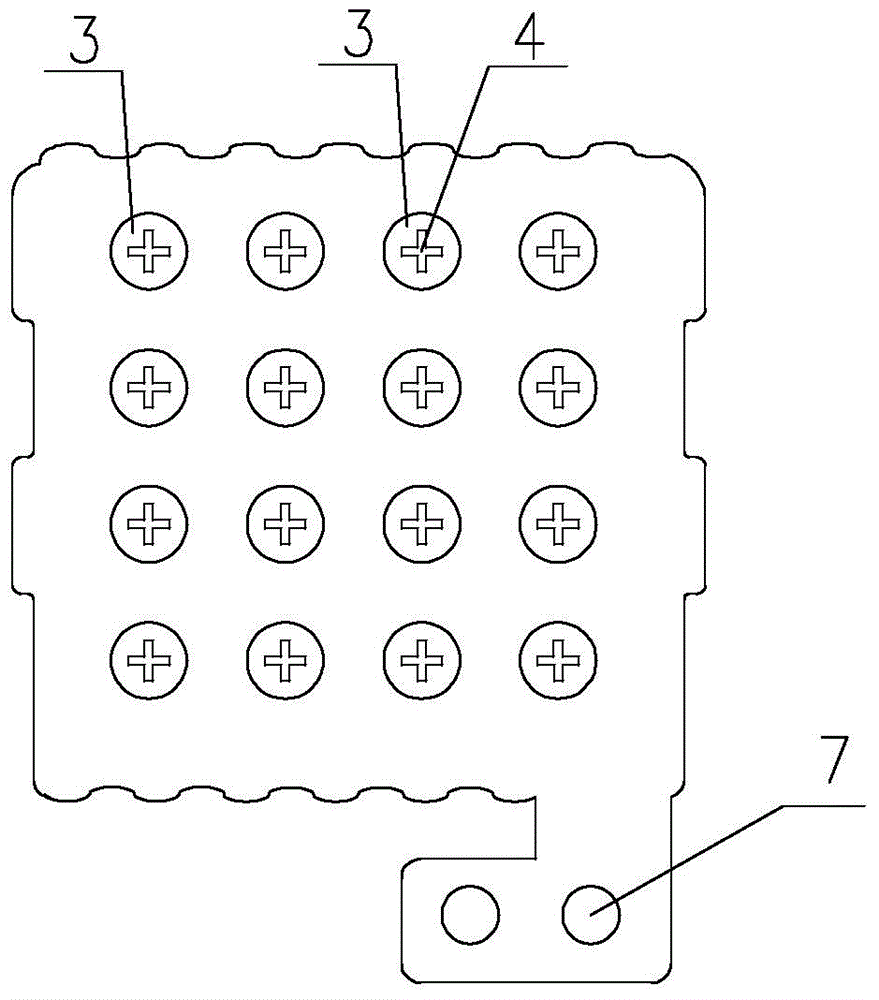

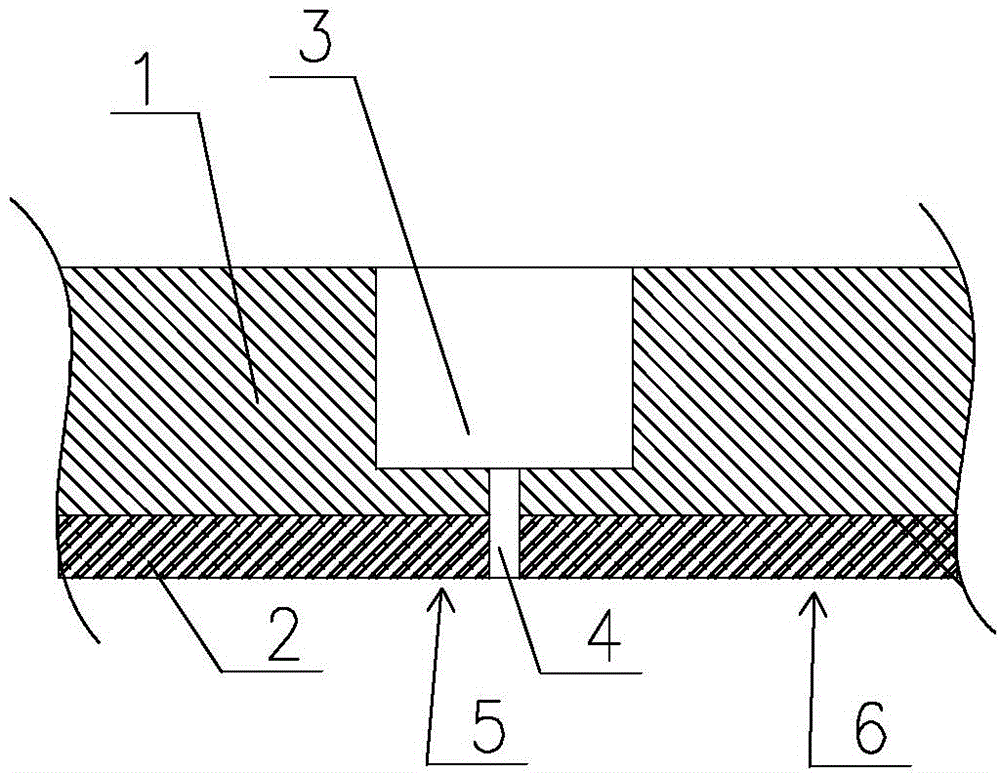

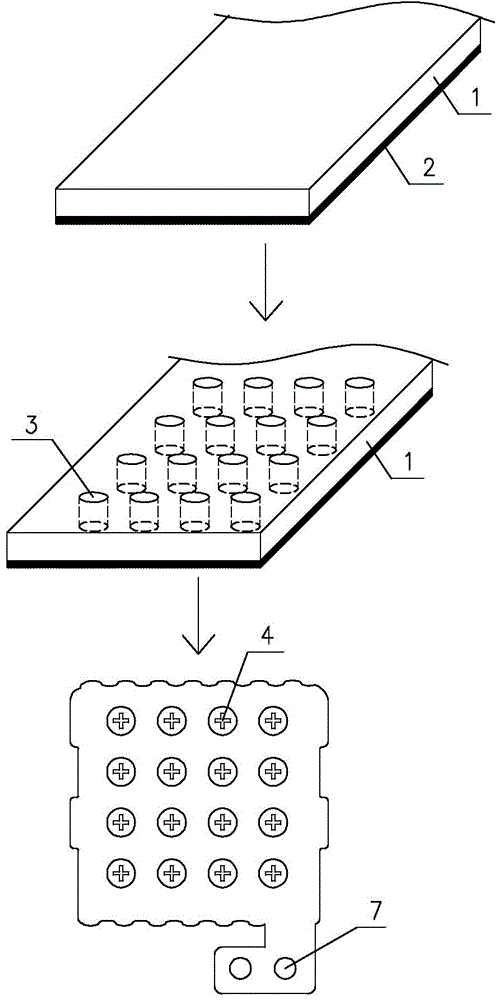

[0032] figure 1 It schematically shows the structure of the conductive connecting sheet for the battery in Example 1. The conductive connecting sheet for the battery is a conductive connecting sheet that can connect 4*4 18650 batteries, and the overall thickness is 0.3 mm. figure 2 The cross-sectional structure of the conductive connecting sheet is schematically shown in . In the figure, 1 is the copper layer, 2 is the first corrosion-resistant and easy-to-solder metal layer, 3 is the recess, 4 is the cross-shaped welding seam, 5 is the resistance spot welding area, 6 is the non-resistance spot welding area, and 7 is the tab hole on the top.

[0033] see figure 1 and figure 2 , The conductive connecting sheet is a conductive connecting sheet made of a layered composite metal, and the layered composite metal includes a copper layer 1 and a first corrosion-resistant and easy-soldering metal layer 2 compounded on the first surface of the copper layer 1 . The area on the condu...

Embodiment 2

[0044] The conductive connecting sheet for the battery is a conductive connecting sheet that can connect 4*4 18650 batteries, and the overall thickness is 0.5mm.

[0045] Its shape is the same as that of the conductive connecting piece in Example 1, but its material (namely, the composition and structure of the layered composite metal constituting the conductive connecting piece) is different.

[0046] In Embodiment 2, the layered composite metal constituting the conductive connecting piece includes a copper layer and a first corrosion-resistant and easily-soldering metal layer compounded on the first surface of the copper layer, and the first corrosion-resistant and easily-soldering metal layer is a nickel layer.

[0047] The specific process of preparing the conductive connecting sheet is basically similar to that of Example 1, including the following steps:

[0048] S1. Prepare a copper-based layered composite metal strip. The 0.8mm (thickness)*110mm (width) N6 pure nickel...

Embodiment 3

[0054] The battery conductive connecting sheet is a conductive connecting sheet that can connect 4*4 18650 batteries, and the overall thickness is about 0.5mm. Its shape is the same as that of the conductive connecting piece in Example 2, but the material (ie, the composition and structure of the layered composite metal constituting the conductive connecting piece) is different.

[0055] In Example 3, the layered composite metal constituting the conductive connecting sheet not only includes a copper layer and a first corrosion-resistant and easy-soldering metal layer compounded on the first surface of the copper layer, but also a second corrosion-resistant metal layer compounded on the second surface of the copper layer. etch the solderable metal layer. The first corrosion-resistant and solderable metal layer and the second corrosion-resistant and solderable metal layer are nickel layers.

[0056] One of its preparation methods is basically the same as the method in Example 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com