Patents

Literature

259results about How to "Reasonable structural stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

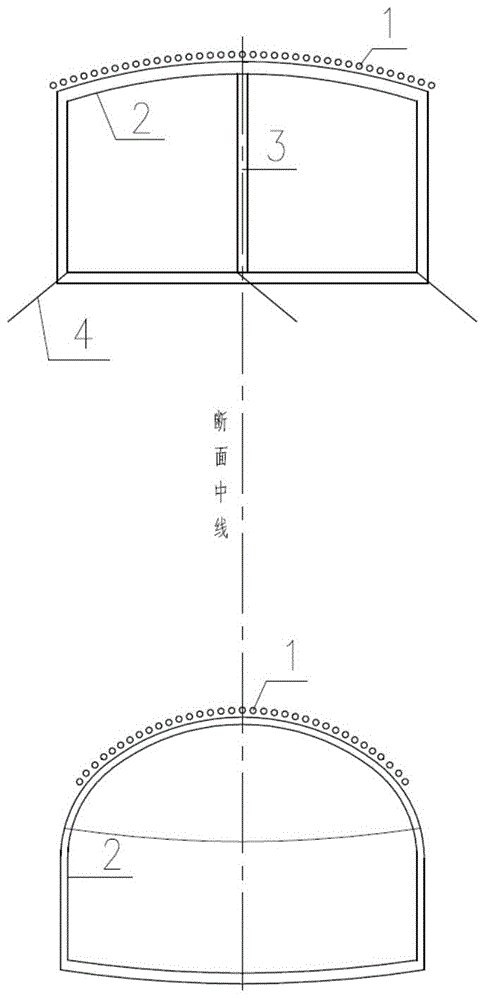

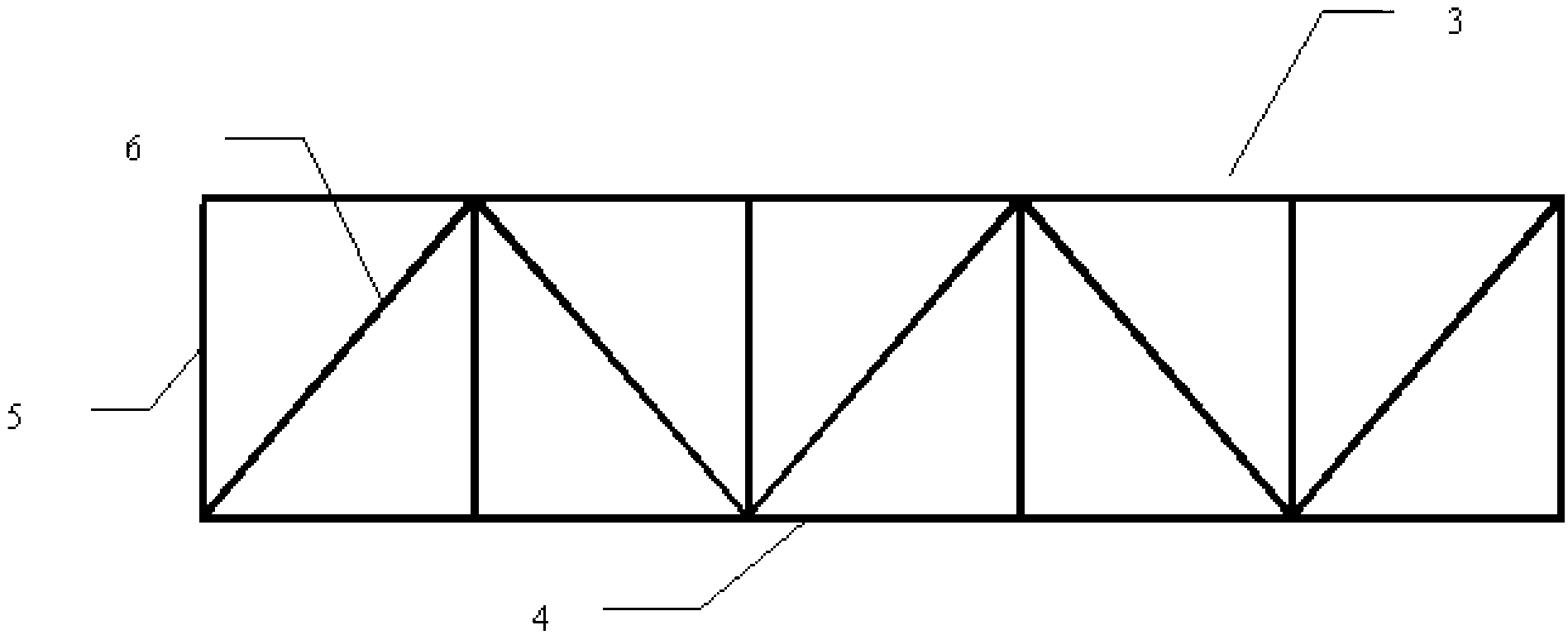

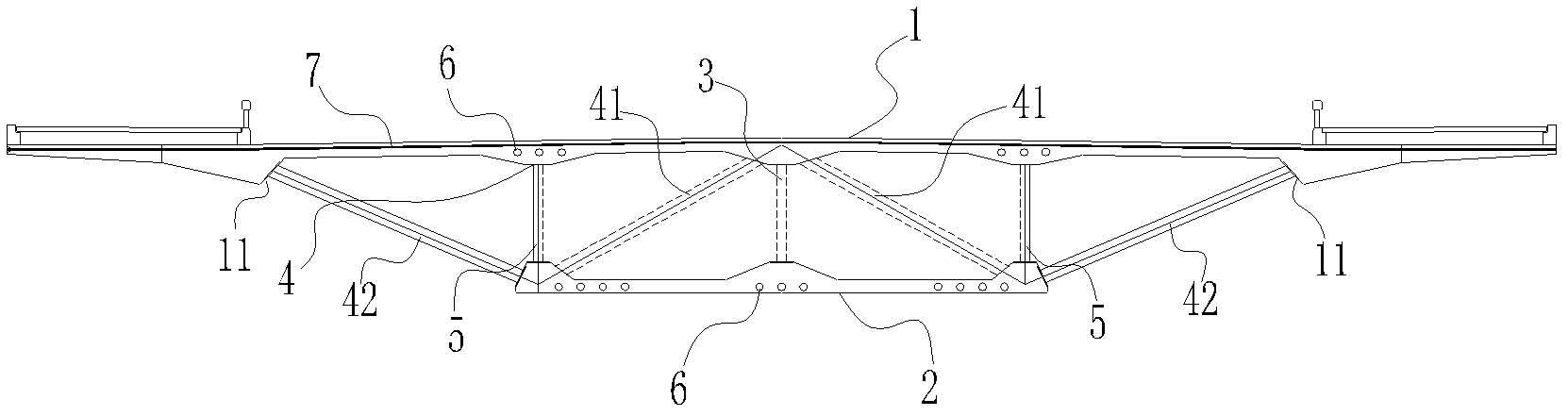

Precast slab type ballastless track structure

InactiveCN102182120ACorrect geometryEfficient deliveryRailway tracksTemperature stressHigh intensity

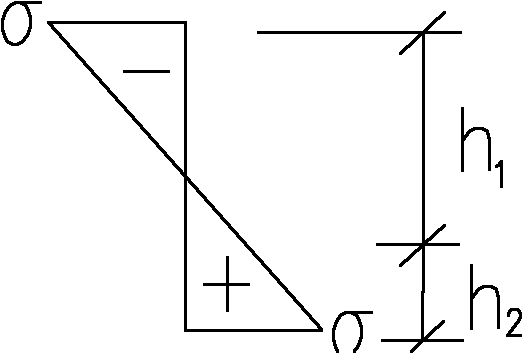

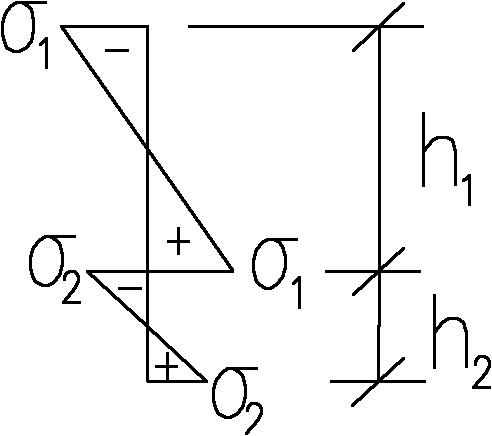

The invention discloses a precast slab type ballastless track structure. The structure comprises a steel rail (1), fasteners, a precast track slab (2), an adjusting layer (3) and a base (4). The structure is characterized in that: the bottom of the track slab is provided with limiting lug bosses (5) or limiting grooves (6), and the number of the limiting lug bosses (5) or the limiting grooves (6) is single or many. The structure has reasonable stress and good stability and durability, and can fully exert the functions of high strength and high rigidity of the track slab, lighten the longitudinal temperature stress of the track slab and meet the requirements of high smoothness and high stability of rail transit such as railways, light rails, subways and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

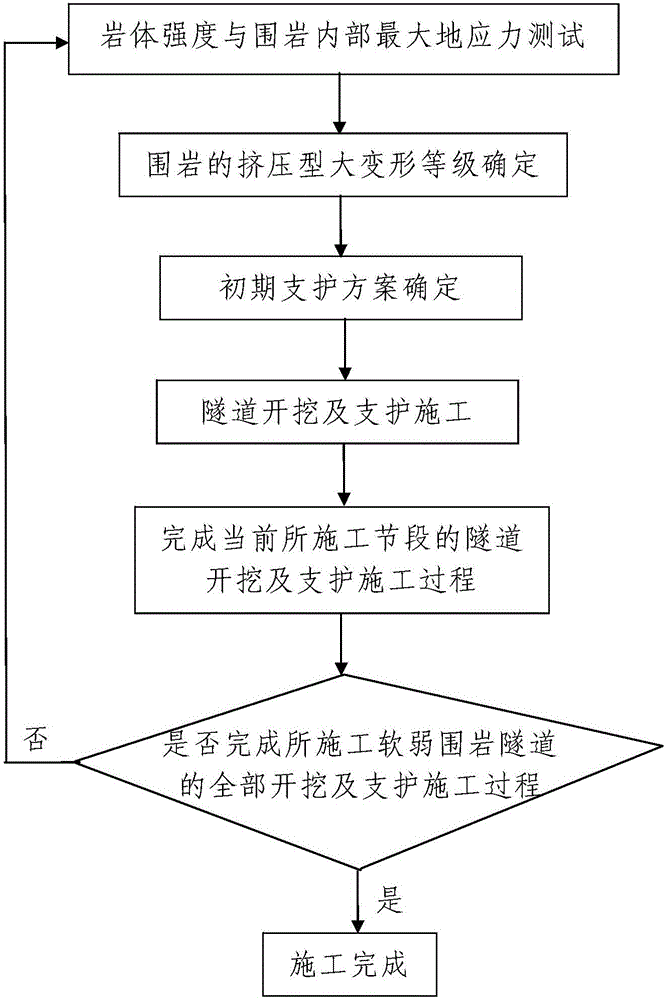

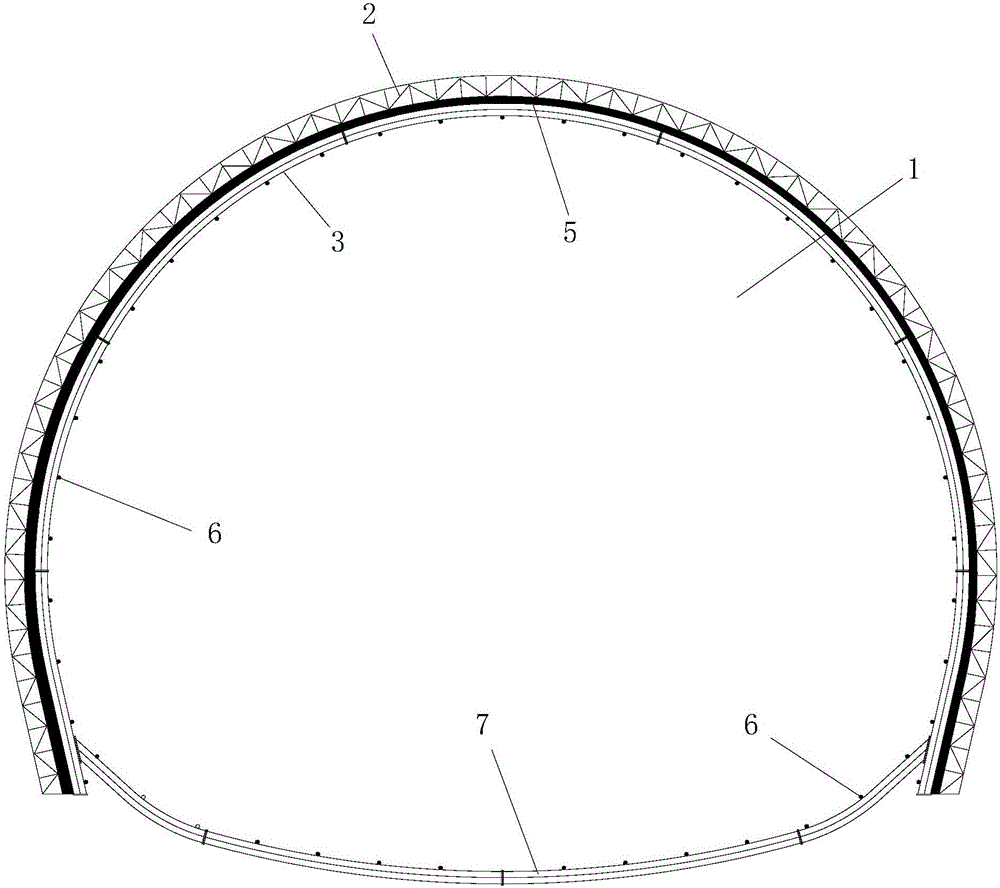

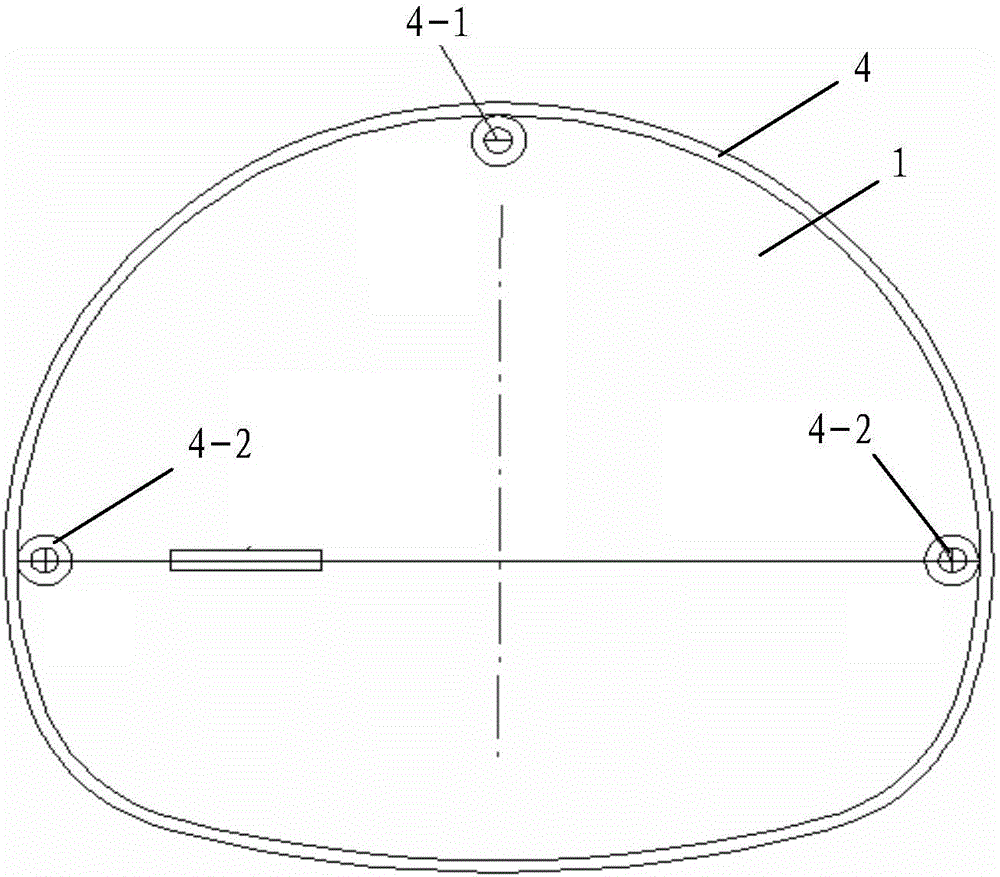

High ground stress weak surrounding rock tunnel excavation and support construction method

ActiveCN105156118AThe method steps are simpleReasonable designUnderground chambersTunnel liningSteel frameRock tunnel

The invention discloses a high ground stress weak surrounding rock tunnel excavation and support construction method. Excavation and support construction are conducted on a weak surrounding rock tunnel to be constructed in multiple sections from rear to front in the longitudinal extension direction of the tunnel. The method comprises the steps that 1, rock body strength and the maximum ground stress inside surrounding rock are tested; 2, the extrusion-type large-deformation level of the surrounding rock is determined; 3, a primary support scheme is determined, wherein the primary support scheme is determined according to the determined extrusion-type large-deformation level, and the primary support scheme is a profile steel frame support scheme or a grid steel frame and cover arch combined support scheme; 4, tunnel excavation and support construction are conducted; 5, excavation and support construction of the next section are conducted; 6, the fifth step is repeated for many times till the whole excavation and support construction process of the weak surrounding rock tunnel to be constructed is completed. According to the high ground stress weak surrounding rock tunnel excavation and support construction method, the steps are simple, the design is reasonable, construction is convenient, the use effect is good, the tunnel excavation and support construction process of the high ground stress weak rock tunnel can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

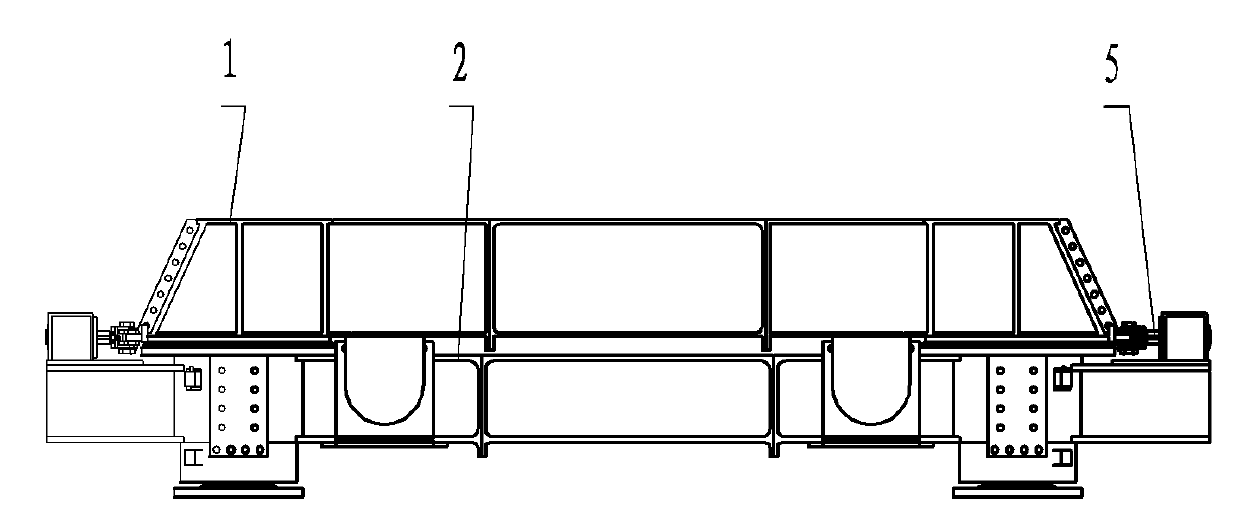

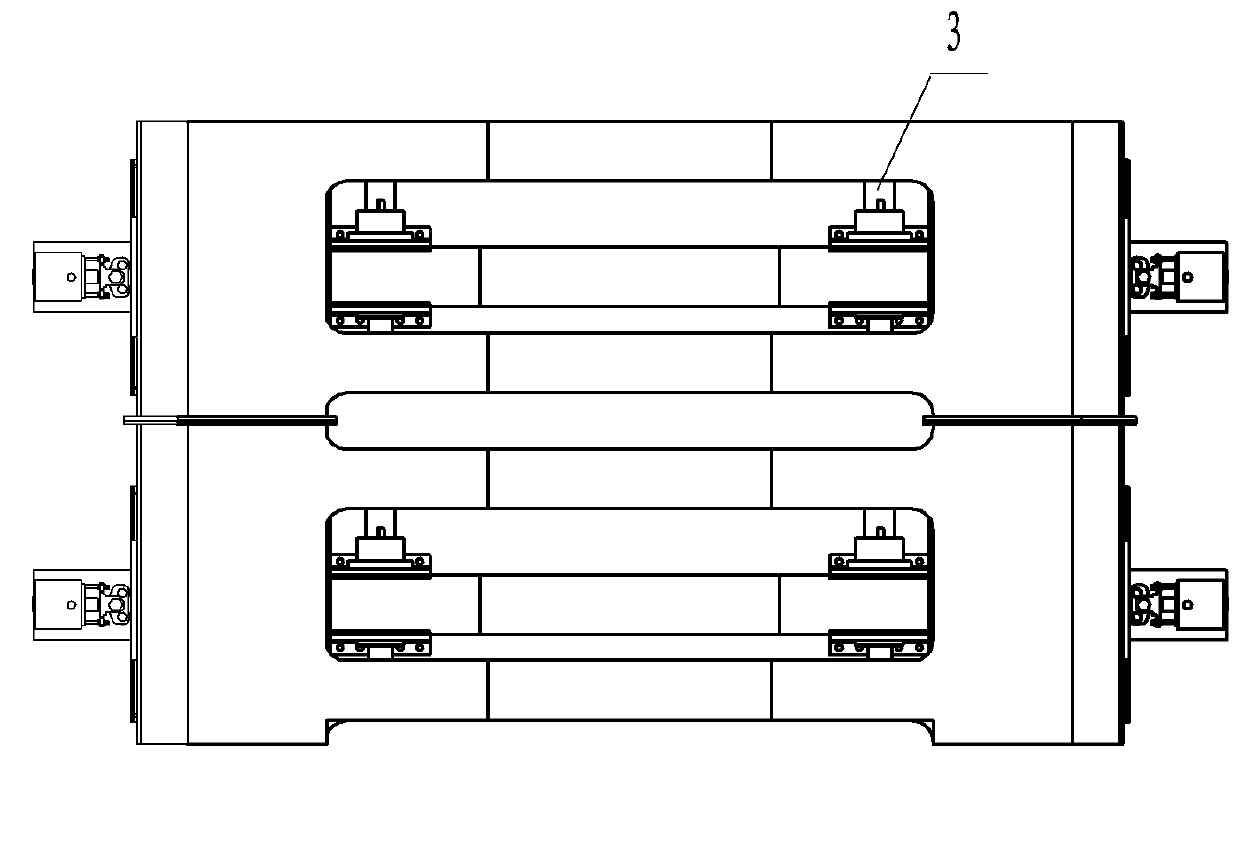

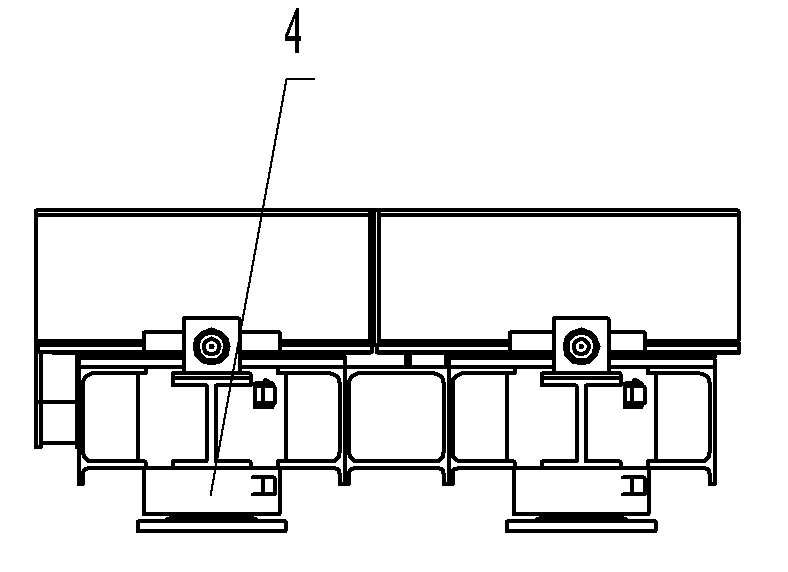

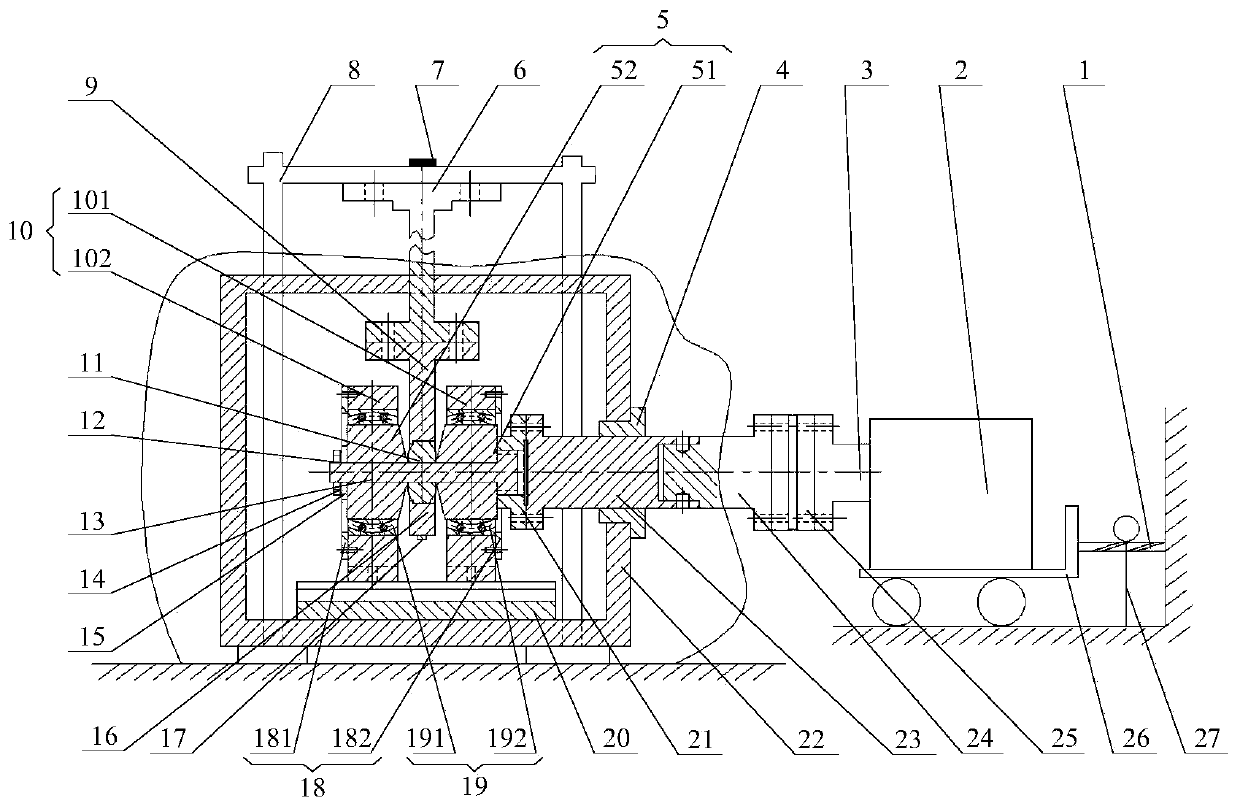

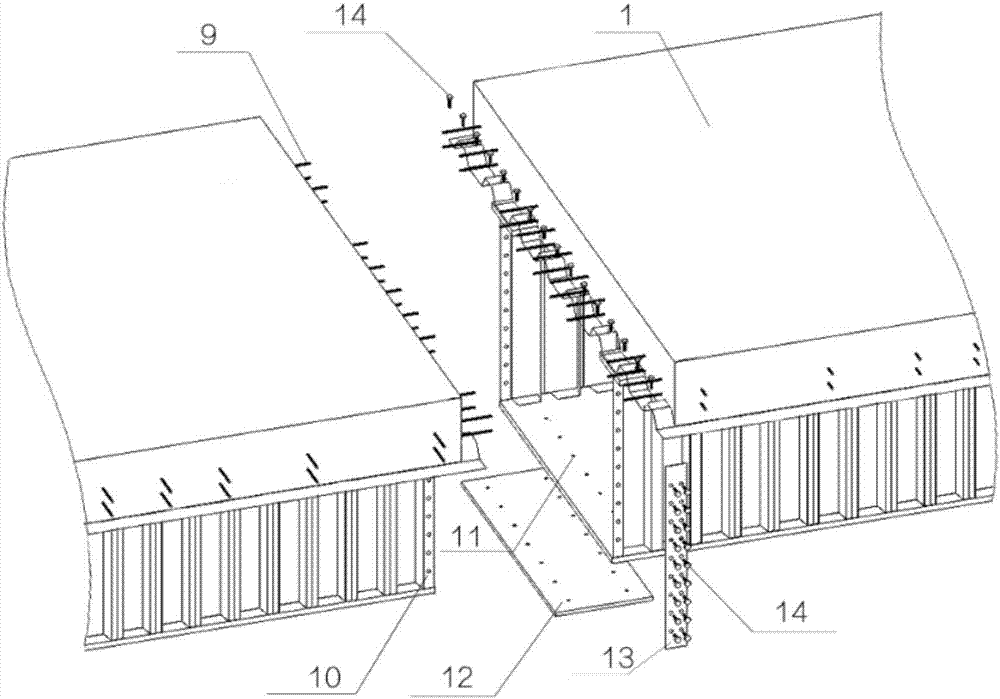

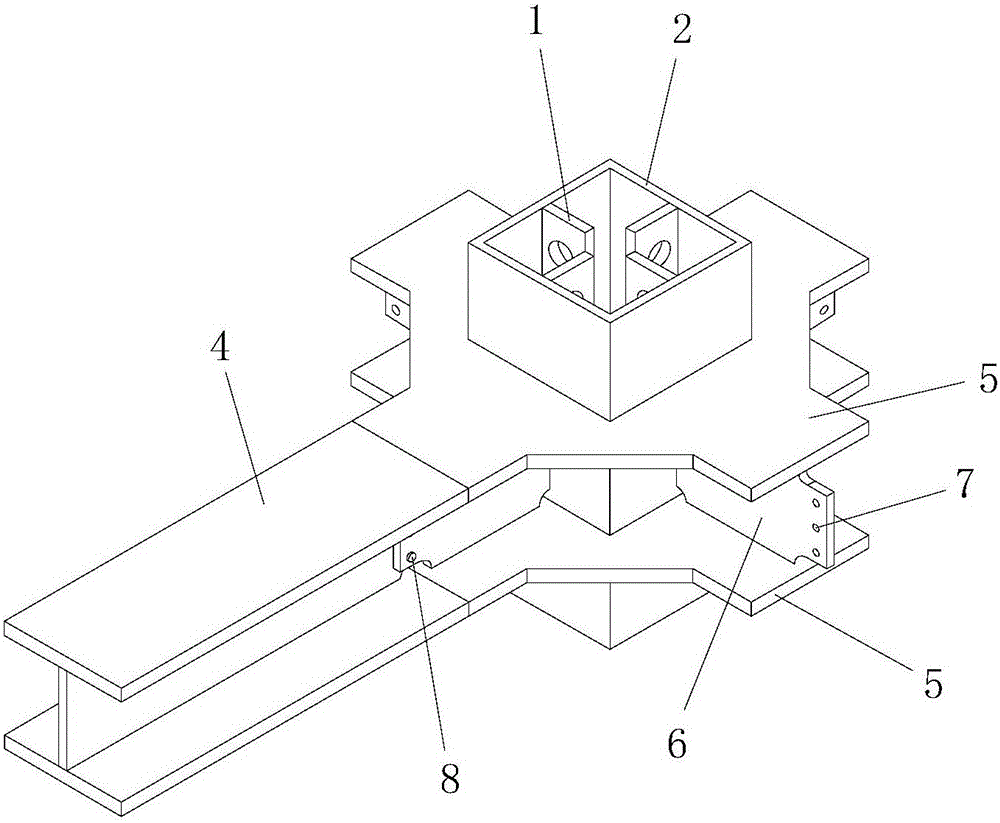

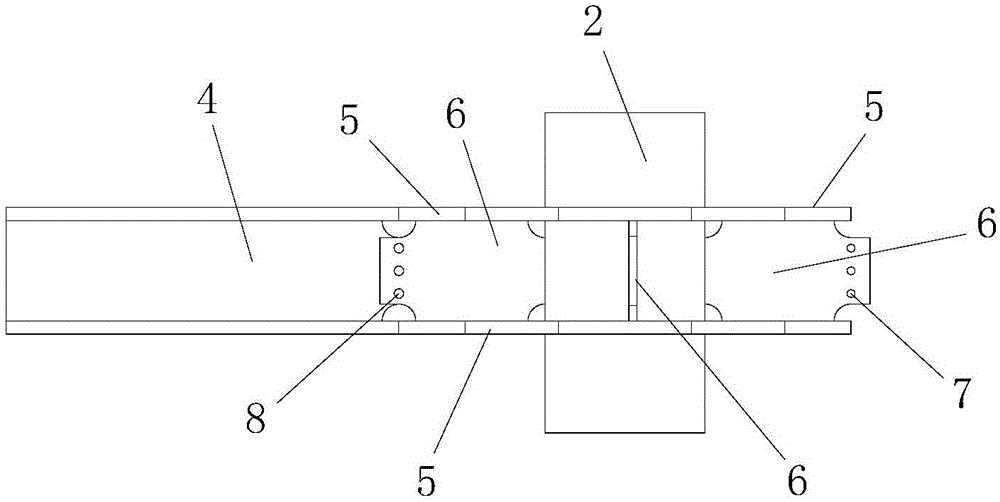

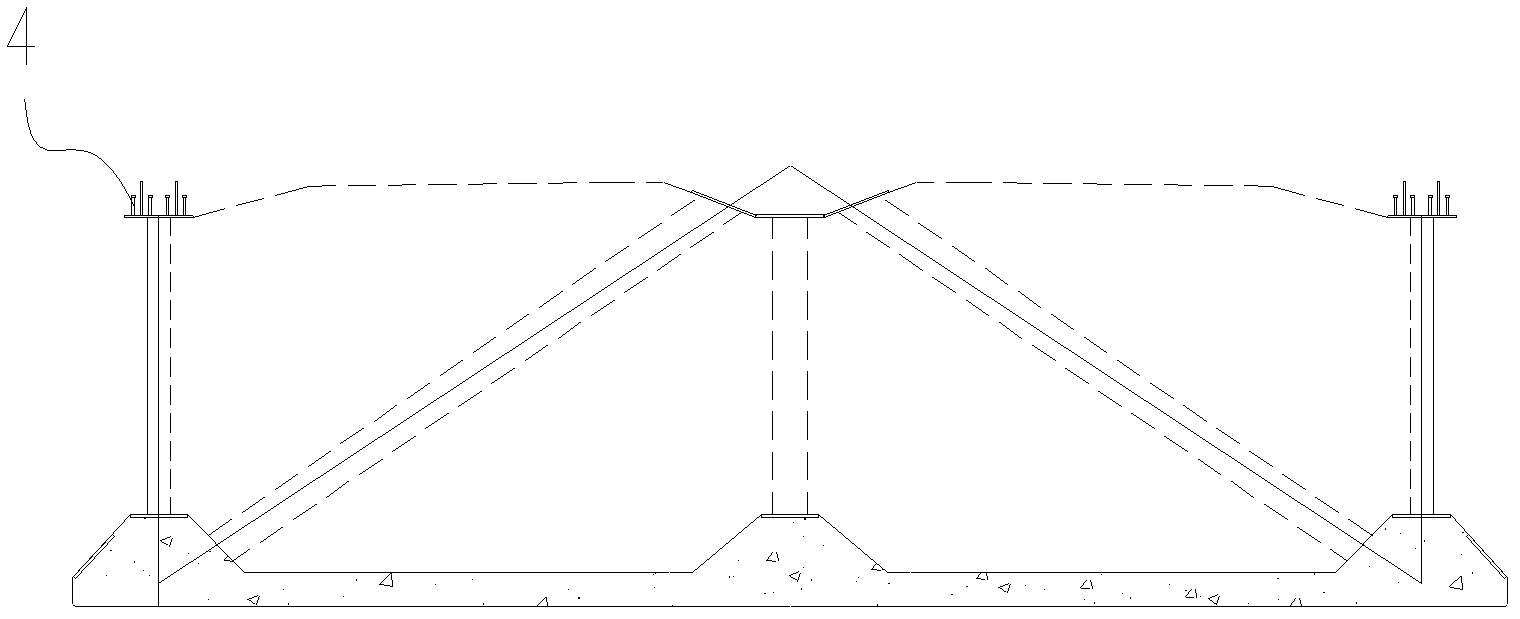

Walking type incremental launching device and bridge incremental launching construction method using same

ActiveCN102199915AThe overall structure is compactGuaranteed stability and securityBridge erection/assemblyBridge materialsMechanical engineeringBuilding construction

The invention provides a walking type incremental launching device. The device comprises a slide box, a slideway, a translation jack, a jacking jack and a deviation-rectifying jack assembly, wherein the slide box comprises slide box body units and slide box body connectors connecting the slide box body units; the slide box body units are movably connected by bolts; the slide box body units and the slide box body connectors are movably connected by bolts; the slide box body connectors are movably connected by bolts; the slideway comprises slideway body units and slideway body connectors; the slideway body units are movably connected by bolts; the slideway body units and the slideway body connectors are movably connected by bolts; the slideway body connectors are movably connected by bolts; the whole slide box is put on the slideway and is of an up-down structure; the jacking jack is installed in a jacking jack installation barrel on the slideway; the translation jack is installed on a translation jack installation plate on the slideway; and the deviation-rectifying jack assembly is installed on a deviation-rectifying jack installation rack on the slideway. Used in a method for bridge incremental launching construction, the device has the characteristics of strong generality, convenience in construction and low cost.

Owner:LIUZHOU OVM MACHINERY

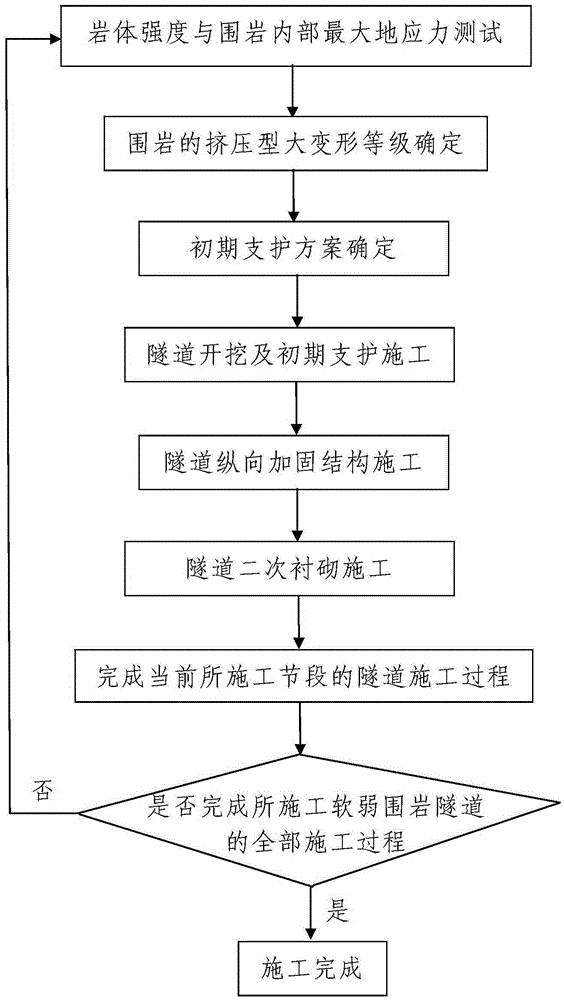

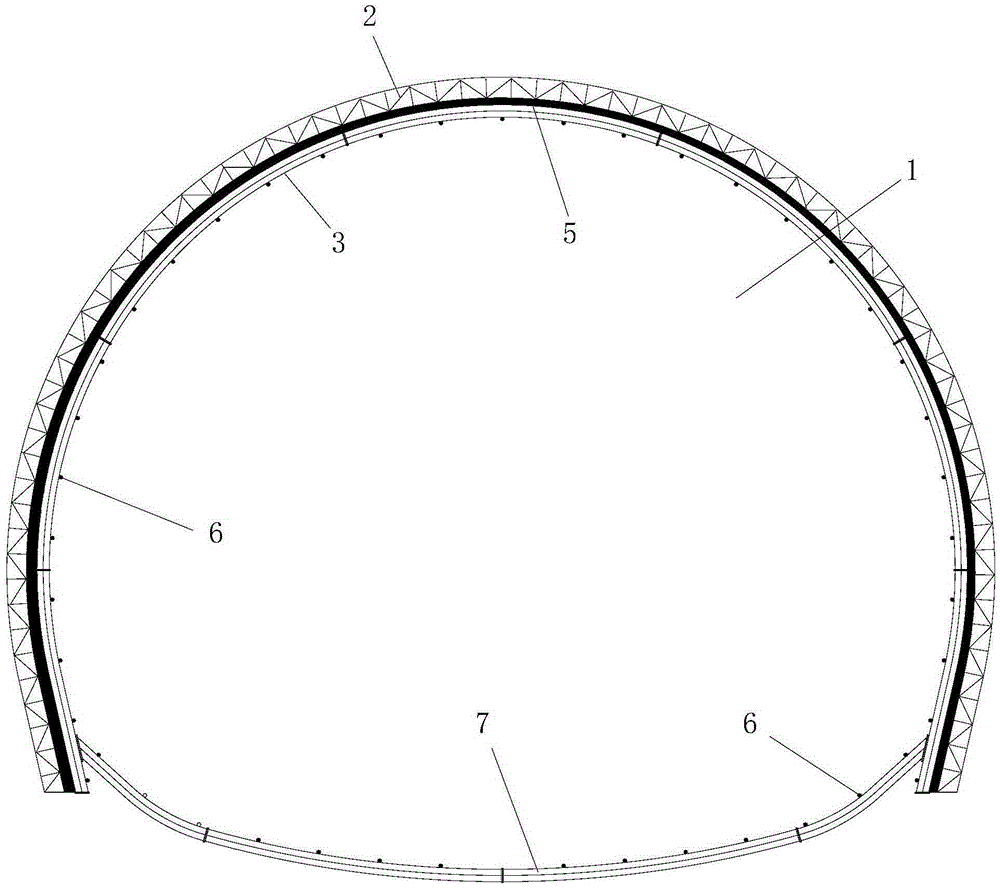

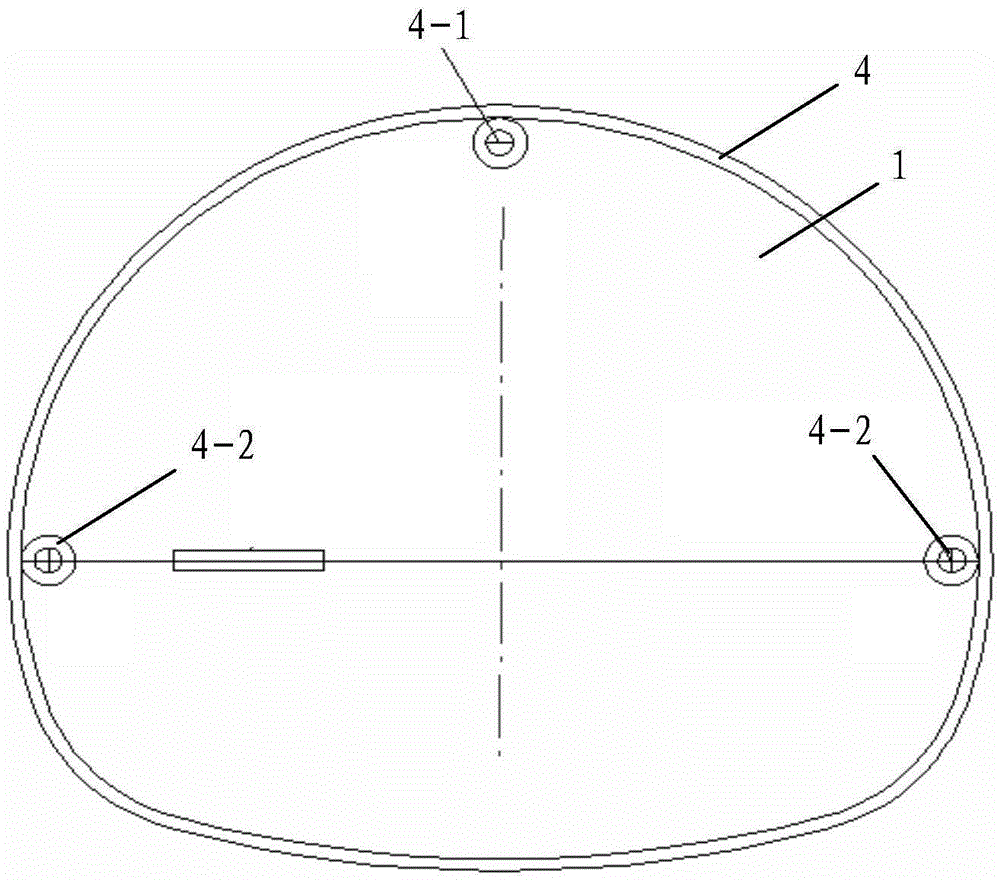

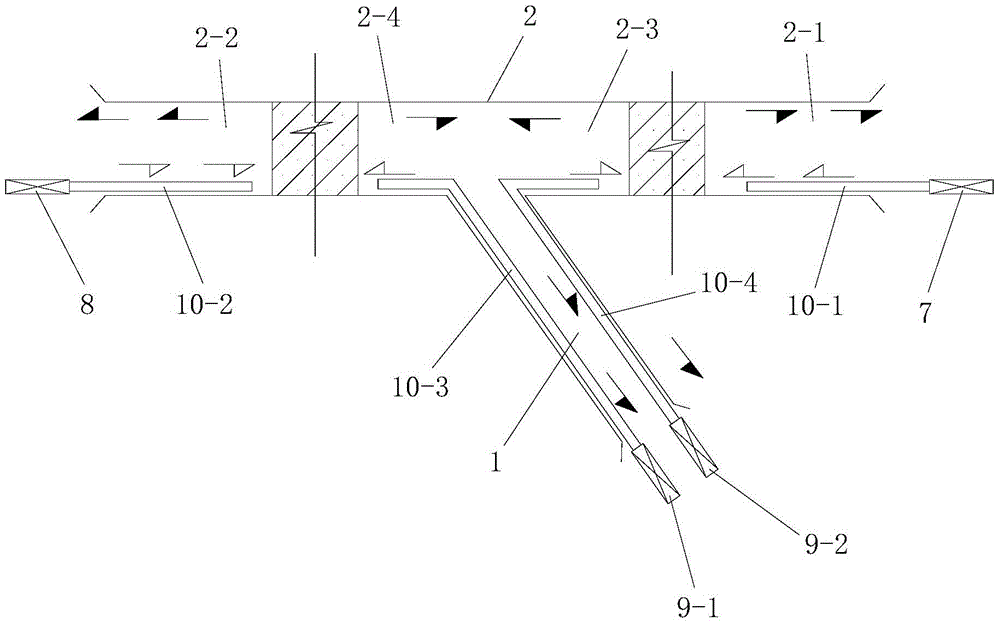

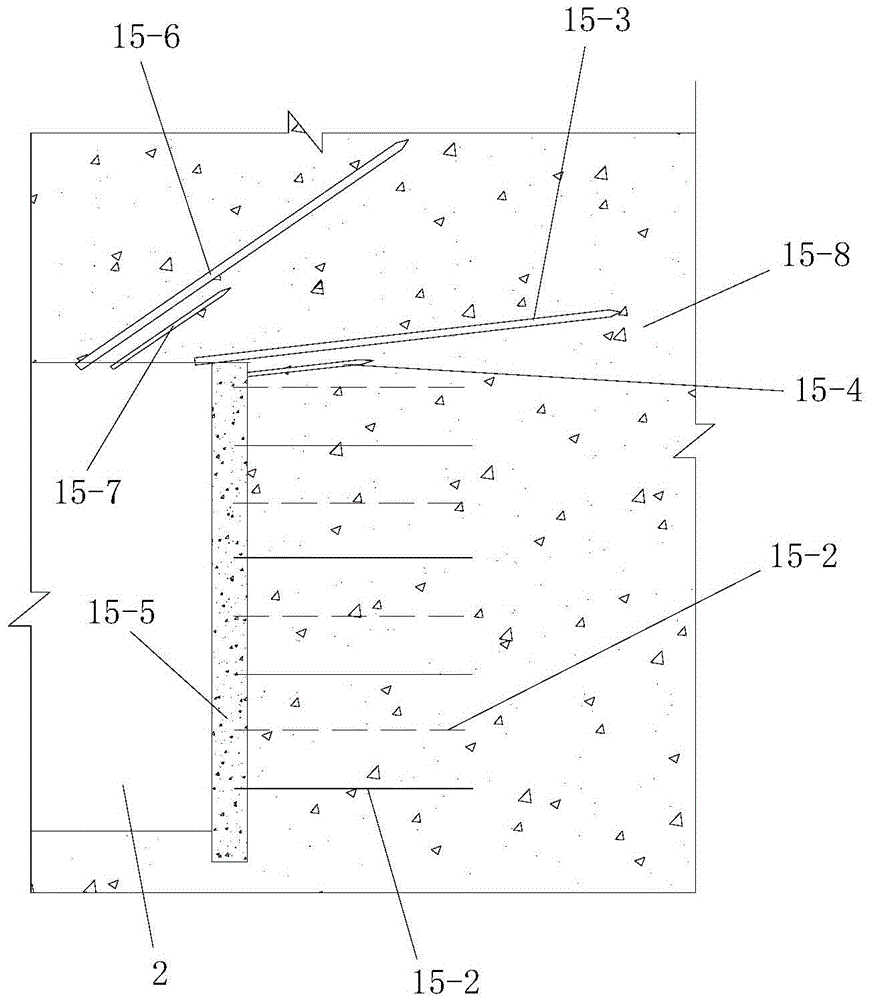

Large-deformation control construction method for high ground stress weak surrounding rock tunnel

ActiveCN105401947AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructure of the EarthRock tunnel

The invention discloses a large-deformation control construction method for a high ground stress weak surrounding rock tunnel. A plurality of segments are arranged in the longitudinal extending direction of the tunnel from back to front to construct the constructed weak surrounding rock tunnel. The method comprises the steps that firstly, the rock strength and surrounding rock interior maximum ground stress test is carried out; secondly, the large extrusion deformation grade of the surrounding rock is determined; thirdly, a primary support scheme is determined; fourthly, tunnel excavation and primary support construction are carried out; fifthly, longitudinal tunnel strengthening structure construction is carried out; sixthly, tunnel secondary lining construction is carried out; seventhly, construction of the next segment is carried out according to the first step to the sixth step; and eighthly, the seventh step is repeated many times till the whole construction process of the constructed weak surrounding rock tunnel is finished. According to the method, the steps are simple, the design is reasonable, construction is convenient, and the using effect is good. The tunnel construction process of the high ground stress weak surrounding rock tunnel can be easily, conveniently and rapidly finished, the construction process is safe and reliable, and the large deformation of the weak rock can be effectively controlled.

Owner:CHINA RAILWAY 20 BUREAU GRP

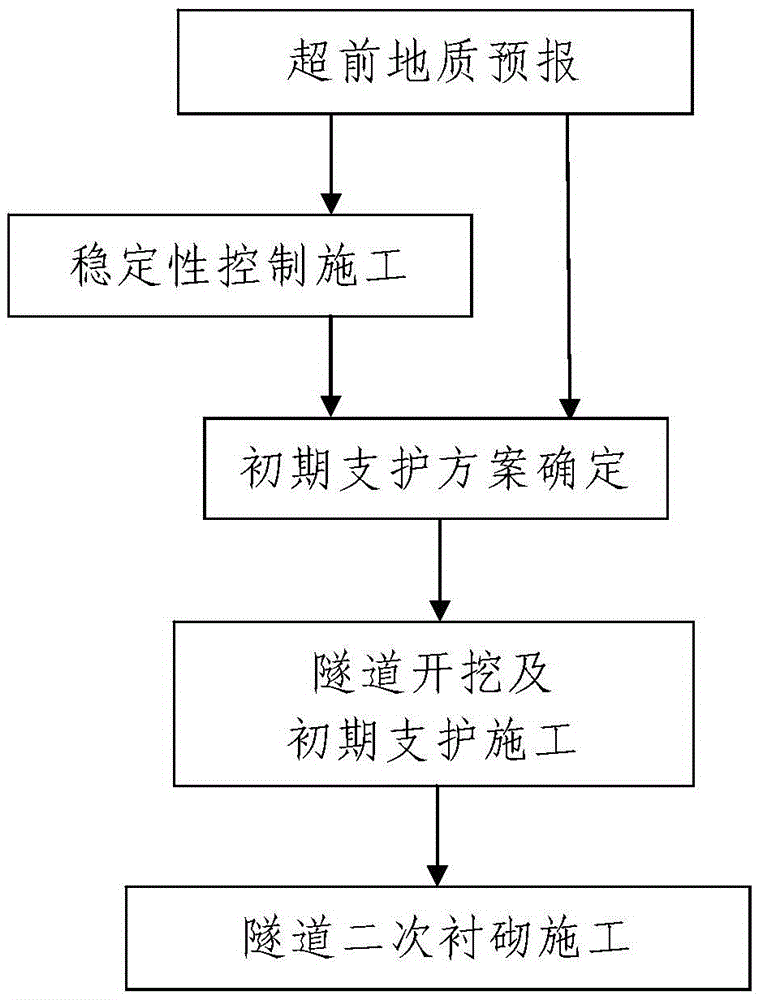

Water-rich weak surrounding rock long-and-big tunnel construction method

The invention discloses a water-rich weak surrounding rock long-and-big tunnel construction method. The method includes that a tunnel inclined shaft is arranged on one side of a main tunnel of a tunnel to be constructed, the main tunnel is divided into a tunnel entry section, a tunnel exit section and a middle connecting section connected between the tunnel entry section and the tunnel exit section, the middle connecting section is divided into an inclined shaft assisting construction entry section and an inclined shaft assisting construction exit section, and each of the tunnel entry section, the tunnel exit section, the inclined shaft assisting construction entry section and the inclined shaft assisting construction exit section is divided into multiple sections for construction. A construction method of each section includes: step 1, performing geological forecasting in advance, and when a debris flow formation exists ahead, entering a step 2, or else, entering a step 3; step 2, performing stability control construction; step 3, determining a primary supporting scheme; step 4, excavating the tunnel, and performing primary supporting construction; step 5, performing secondary lining construction on the tunnel. The water-rich weak surrounding rock long-big tunnel construction method is simple in step, reasonable in design, simple and convenient to construct, good in using effect, capable of meeting construction requirements of water-rich weak surrounding rock long-and-big tunnels, short in construction period and safe in construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

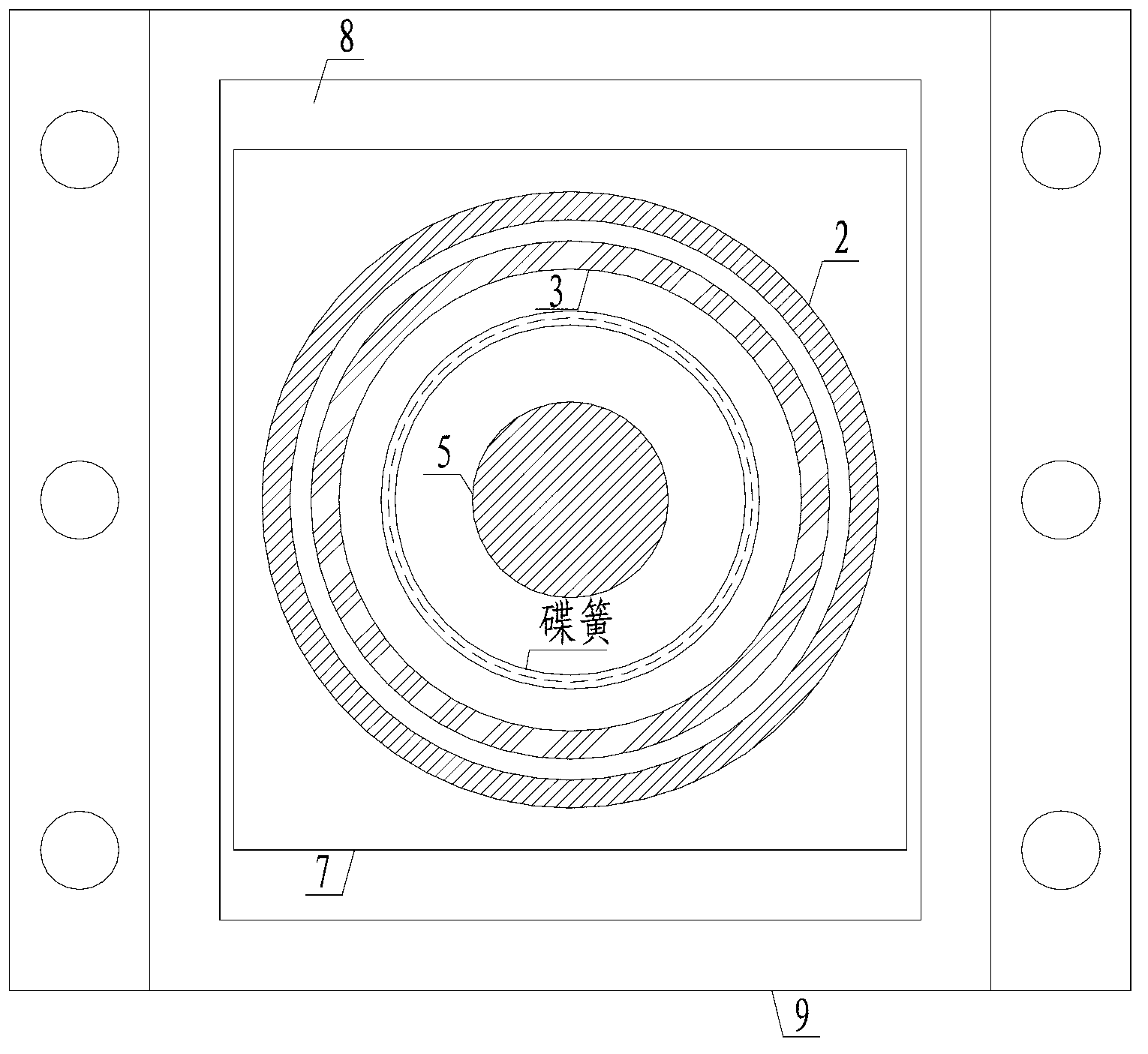

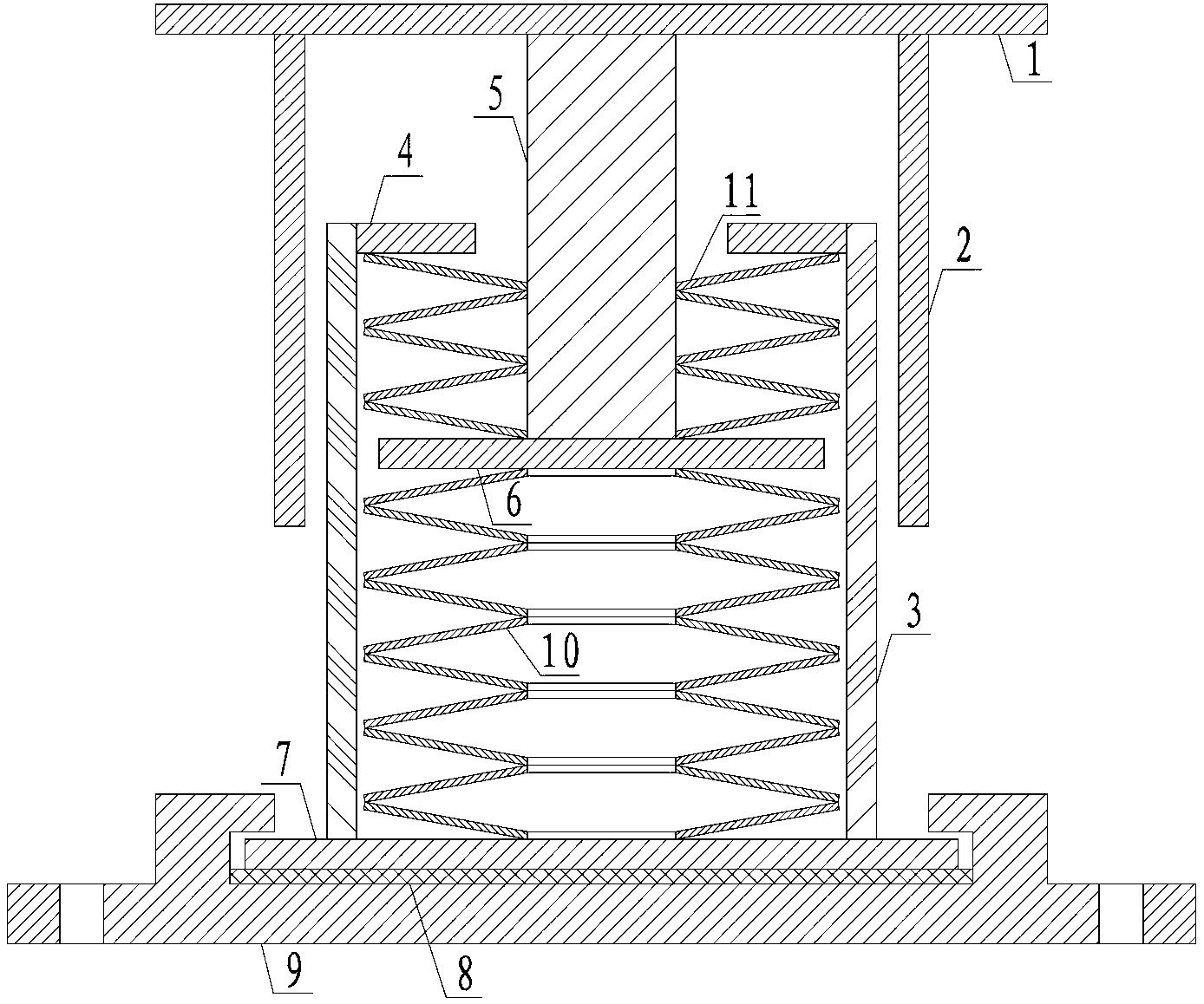

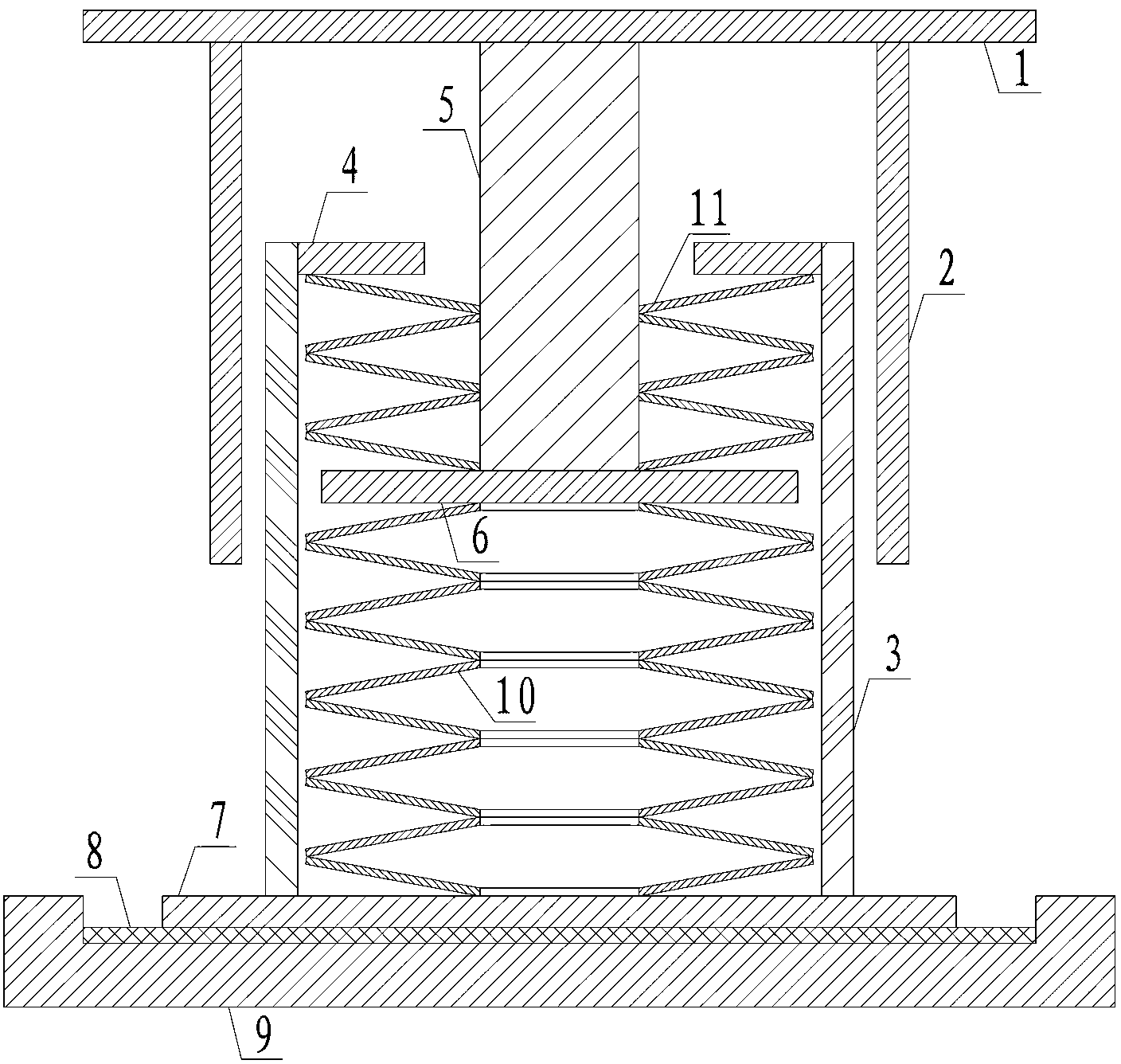

Tension-compression elastic support

InactiveCN103225259AAchieving horizontal fixationReasonable structural stressBridge structural detailsTension compressionWear resistant

The invention provides a tension-compression elastic support which comprises a support top plate, an outer casing, an inner casing, an annular baffle, a steel core pillar, a spring partition plate, a steel sliding plate, a wear-resistant plate, a support bottom plate, an upper layer disk spring set and a lower layer disk spring set. The specification and the quantity of disk springs selected in the support are controlled, so that the elastic stiffness required by a structural design is provided, and the bearing capacity and deformation requirements of the support can be balanced; the tension-compression elastic support can be widely applied to the field of engineering design; the design problem that can be solved by large-scale design alteration before can be solved at very small cost; the structural design is more flexible; the stress is more reasonable; and the construction cost of engineering is lowered.

Owner:DALIAN UNIV OF TECH

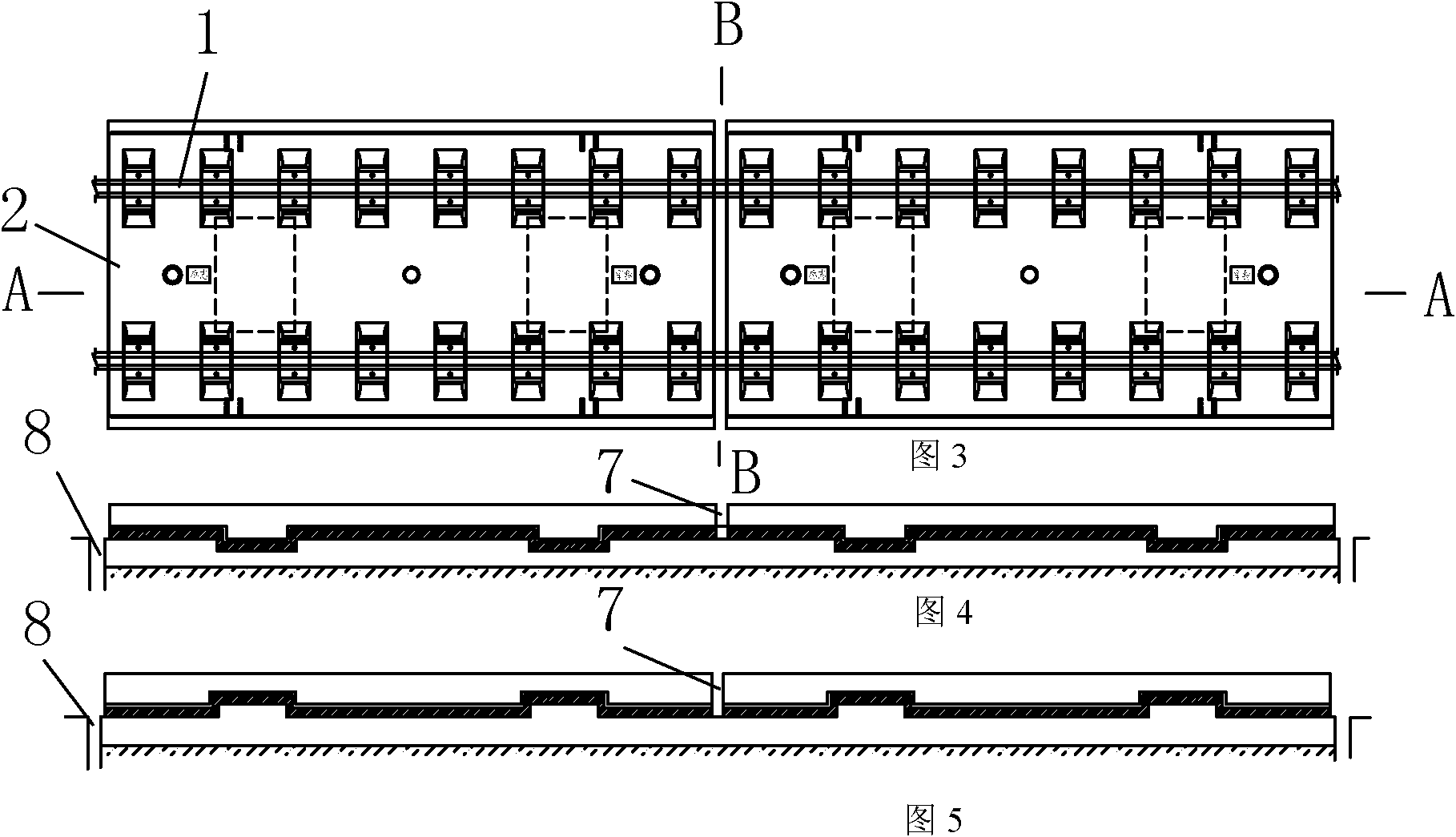

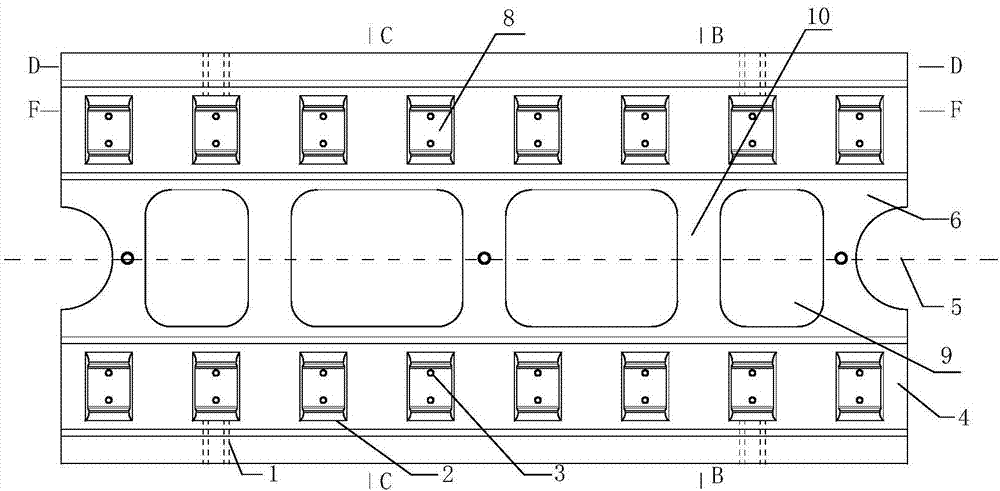

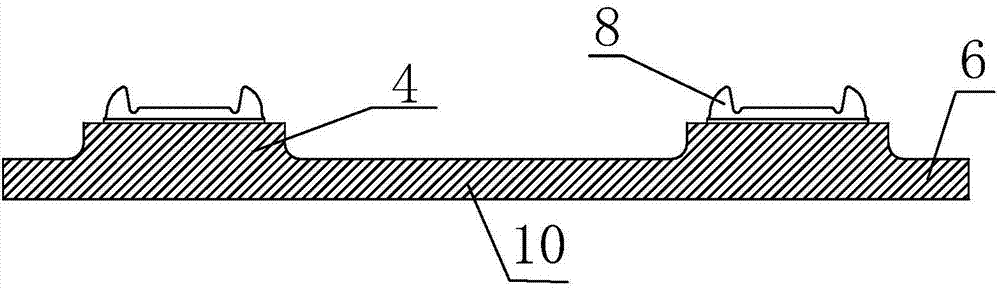

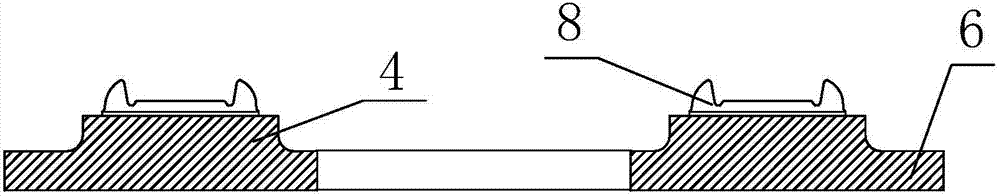

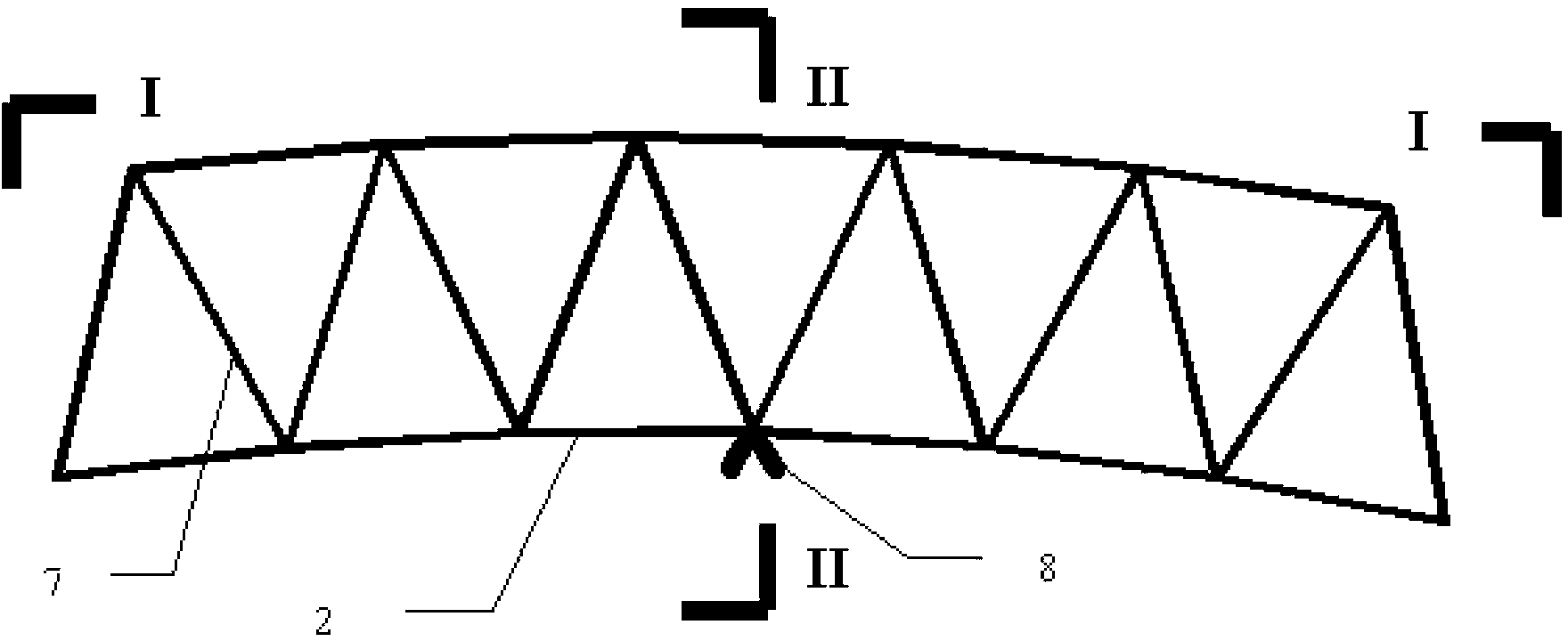

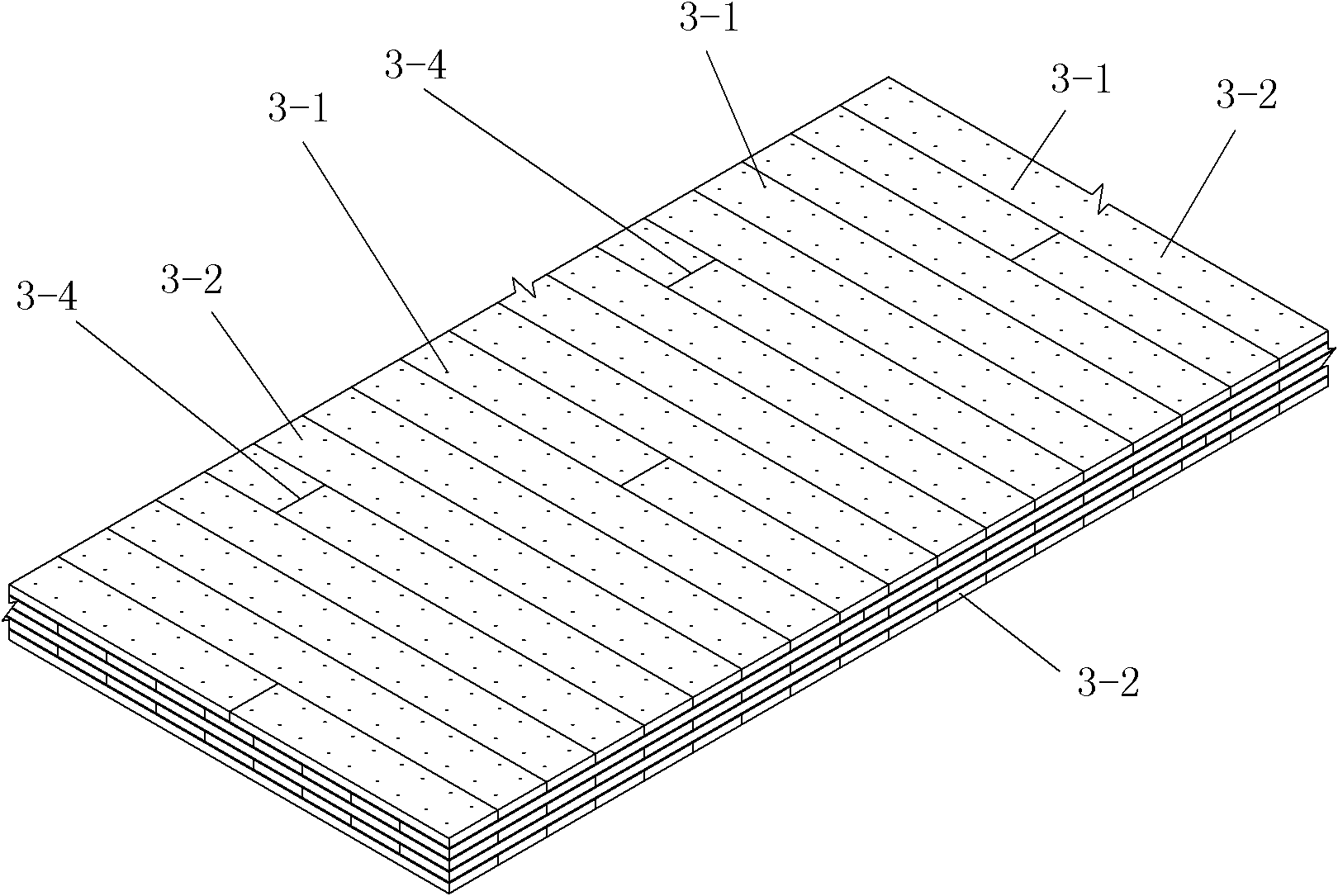

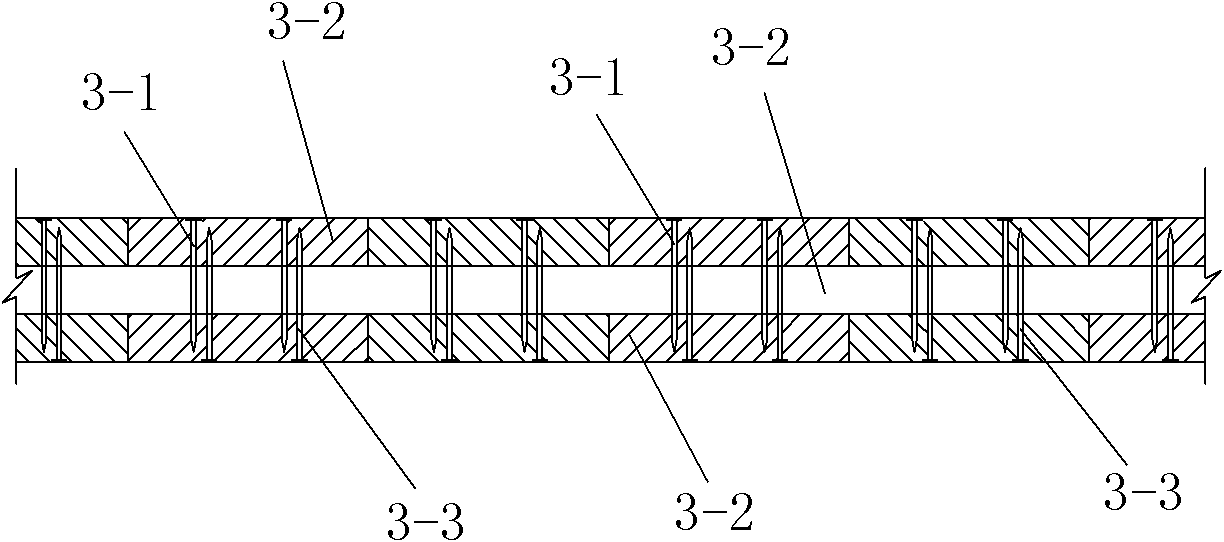

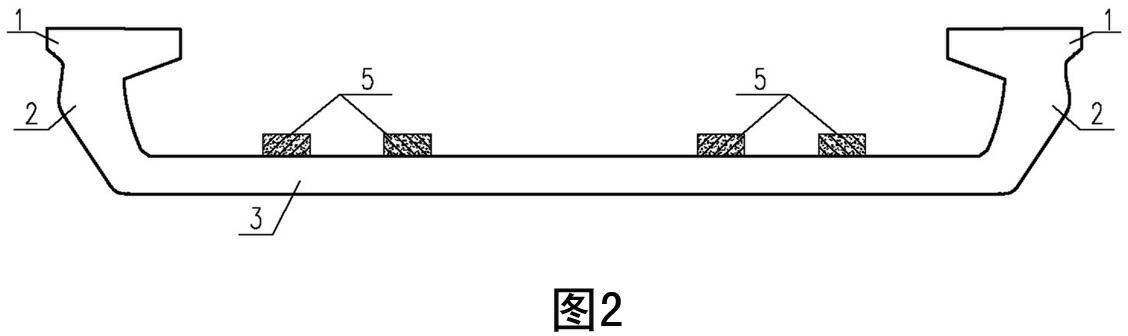

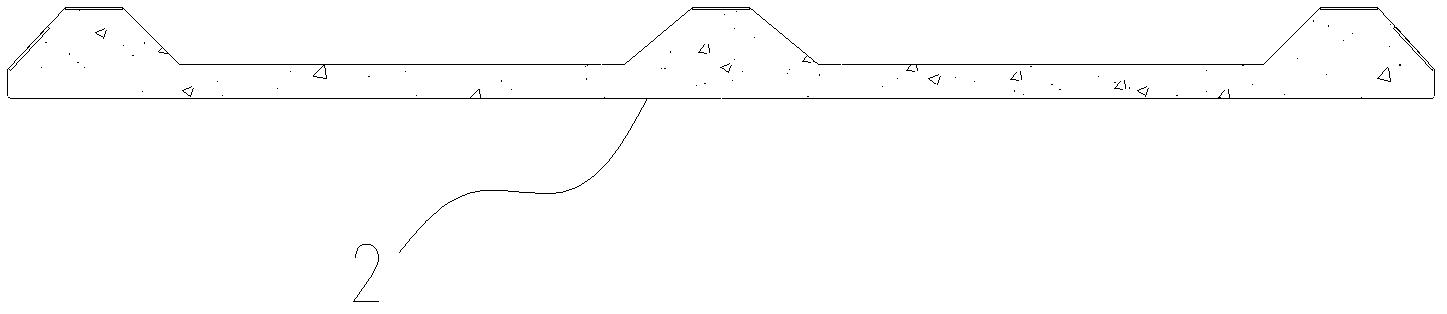

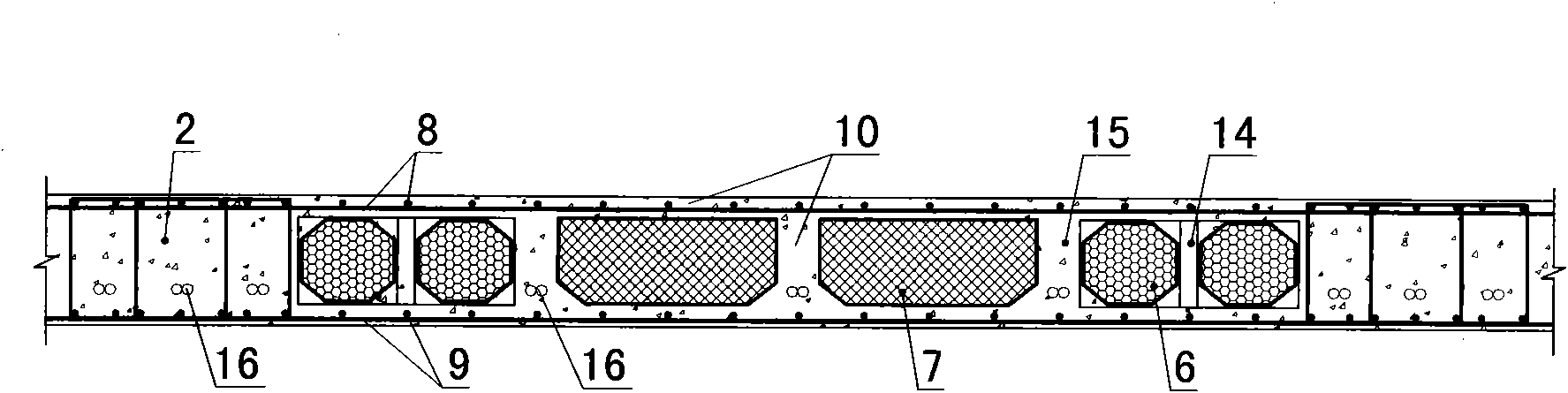

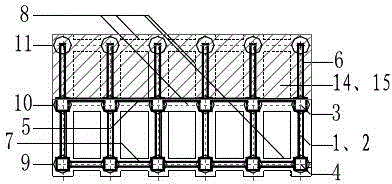

Thickened frame type ballastless track plate

Provided is a thickened frame type ballastless track plate. The track plate comprises a base plate, bosses and track bearing tables. The base plate is of a cuboid, the two bosses are symmetrically arranged on one face of the base plate along the axis of the cuboid in the length direction, and the track bearing tables are evenly distributed in the length direction of the upper surfaces of the bosses. A through hole is formed in the base plate and is located between the two bosses symmetrically arranged on the base plate, and a frame structure connected between the two bosses through a transverse reinforcement concrete structure is formed. The thickened frame type ballastless track plate can effectively reduce track plate warping caused by temperature stress, eliminate a pull cracking phenomenon, and enhance running safety and comfort. The thickened frame type ballastless track plate is reasonable in structural stress, light, high in structural strength and capable of effectively improving the stress condition of a sleeper structural system, prolonging the service life of the structure and optimizing rack circuit parameters, improves the circuit transmission characteristic of a resonant track, can be directly and effectively connected with a current high-speed railway CRTS-I ballastless track plate, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

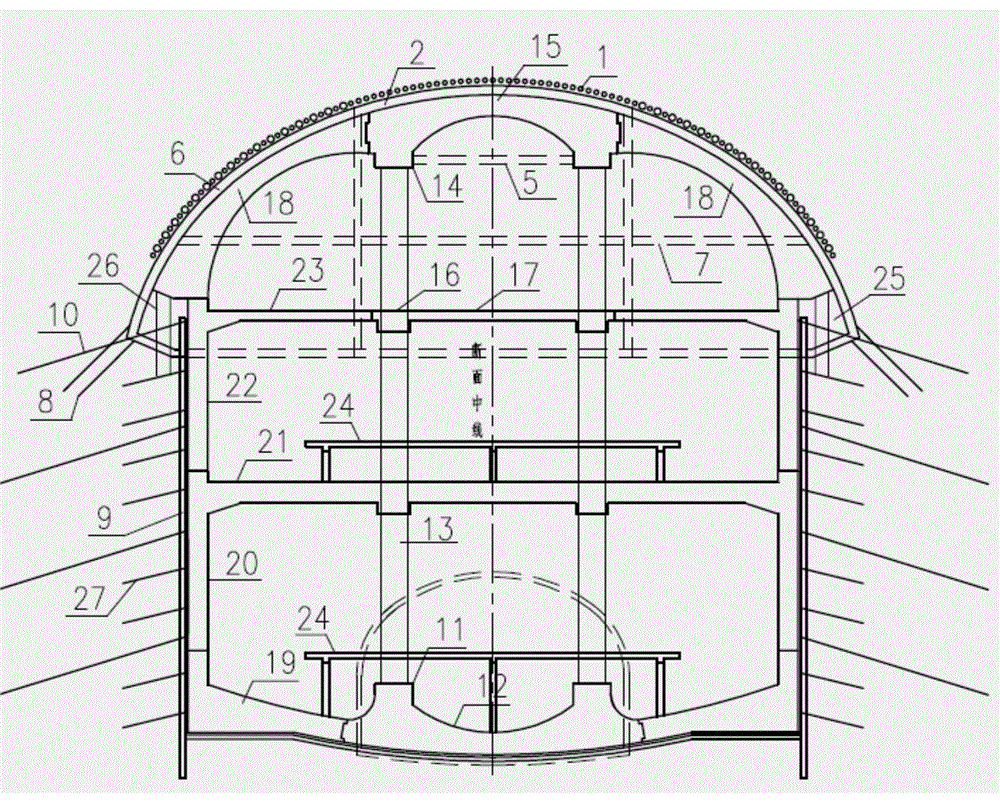

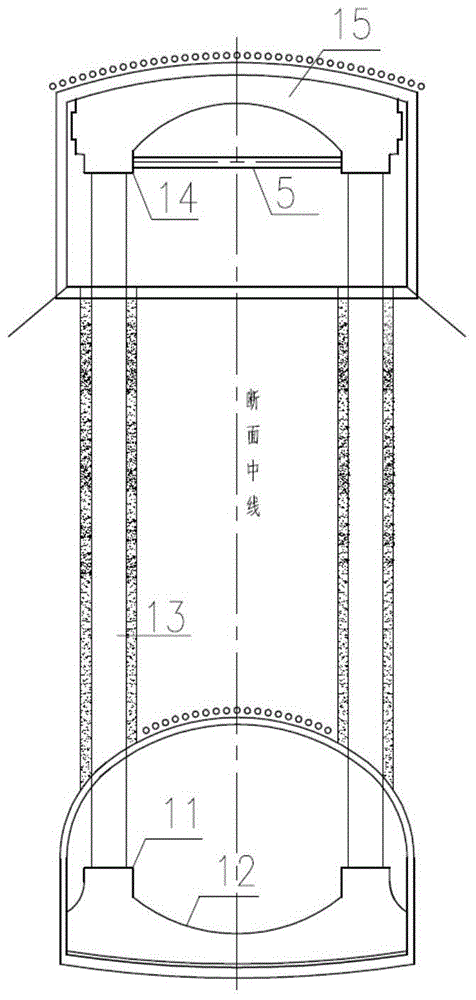

Rock stratum underground excavation three-story subway station umbrella cover structure and construction method thereof

ActiveCN106337686AReasonable structural designImprove stabilityUnderground chambersTunnel liningReinforced concreteSubway station

The invention belongs to the technical field of design and construction of tunnel and underground engineering and especially relates to a rock stratum underground excavation three-story subway station umbrella cover structure and a construction method thereof. The structure comprises a main arc structure and a reinforced concrete inverted arch. an underground two-story side wall and an underground three-story side wall are installed between the main arc structure and the reinforced concrete inverted arch. The main arc structure comprises an arch portion second lining middle segment and arch portion second lining side segments; the arch portion second lining side segments are positioned at two sides of the arch portion second lining middle segment; the reinforced concrete inverted arch comprises an inverted arch second lining middle segment and inverted arch second lining side segments; the top of the inverted arch second lining middle segment is provided with two bottom girders; the bottom of the arch portion second lining middle segment is provided with two top girders; steel-pipe columns are installed between the top girders and the bottom girders. The structure and the method of the invention is suitable for supporting structure and construction of weak rock stratum dug three-story subway station and large sections of underground space; the structure has good stability and increased construction efficiency.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

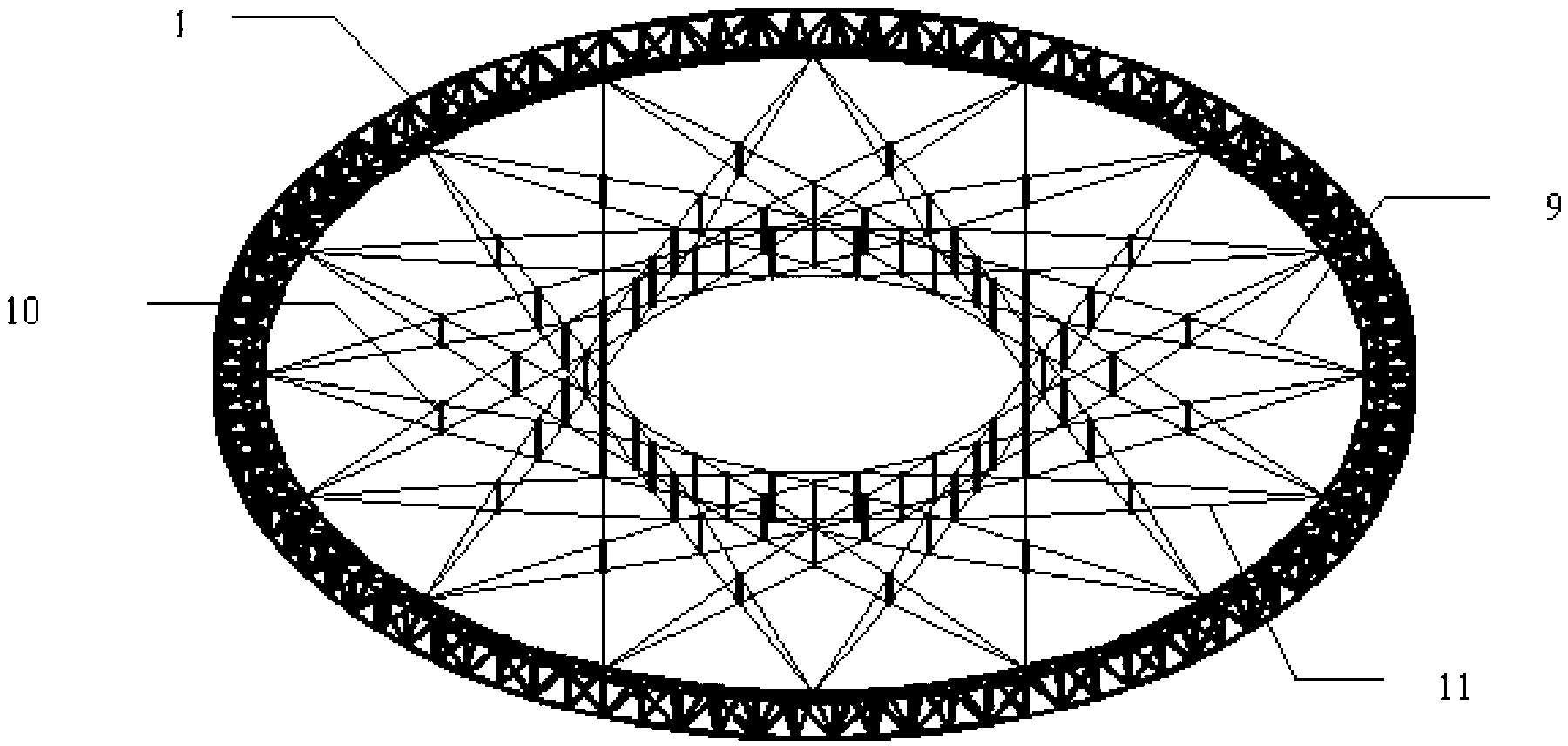

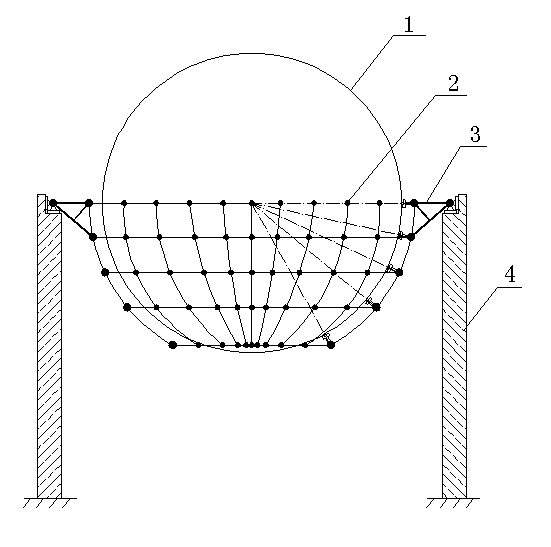

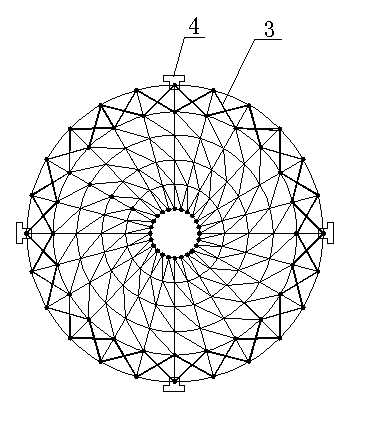

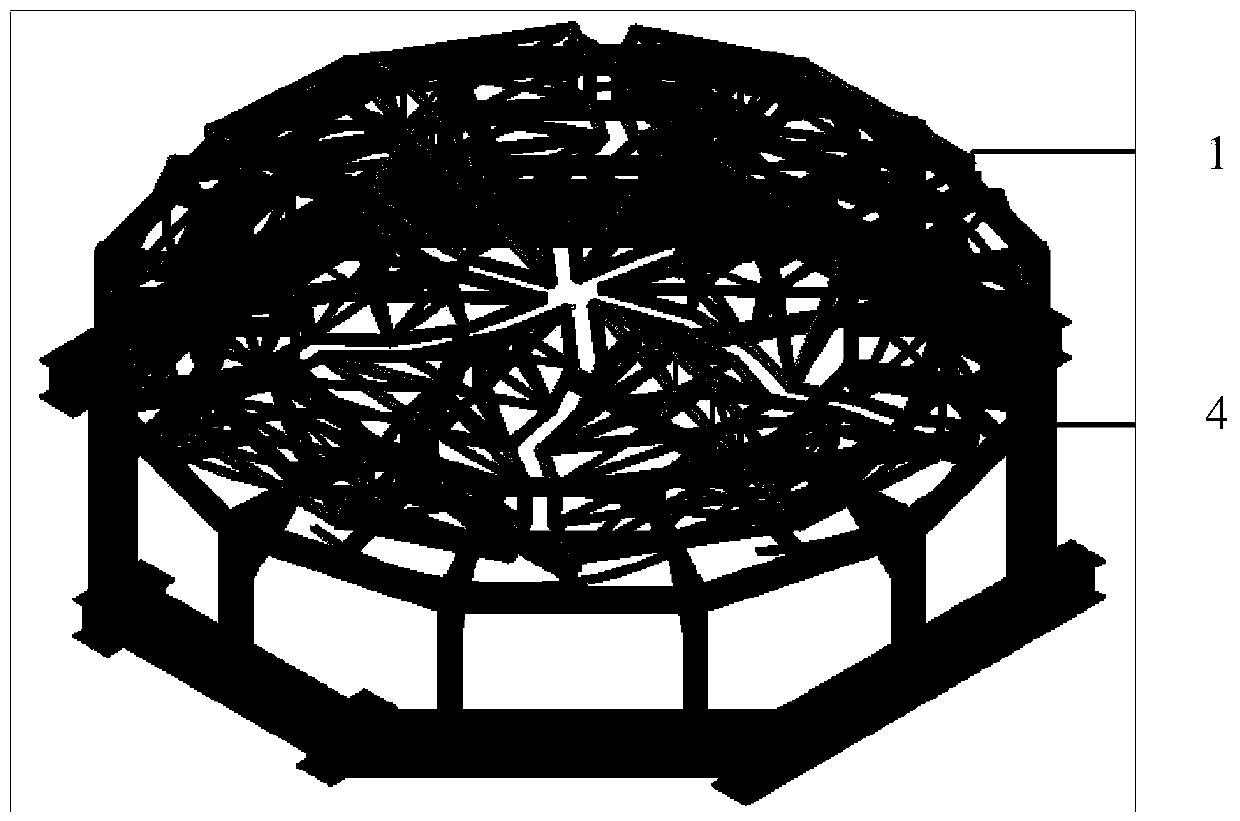

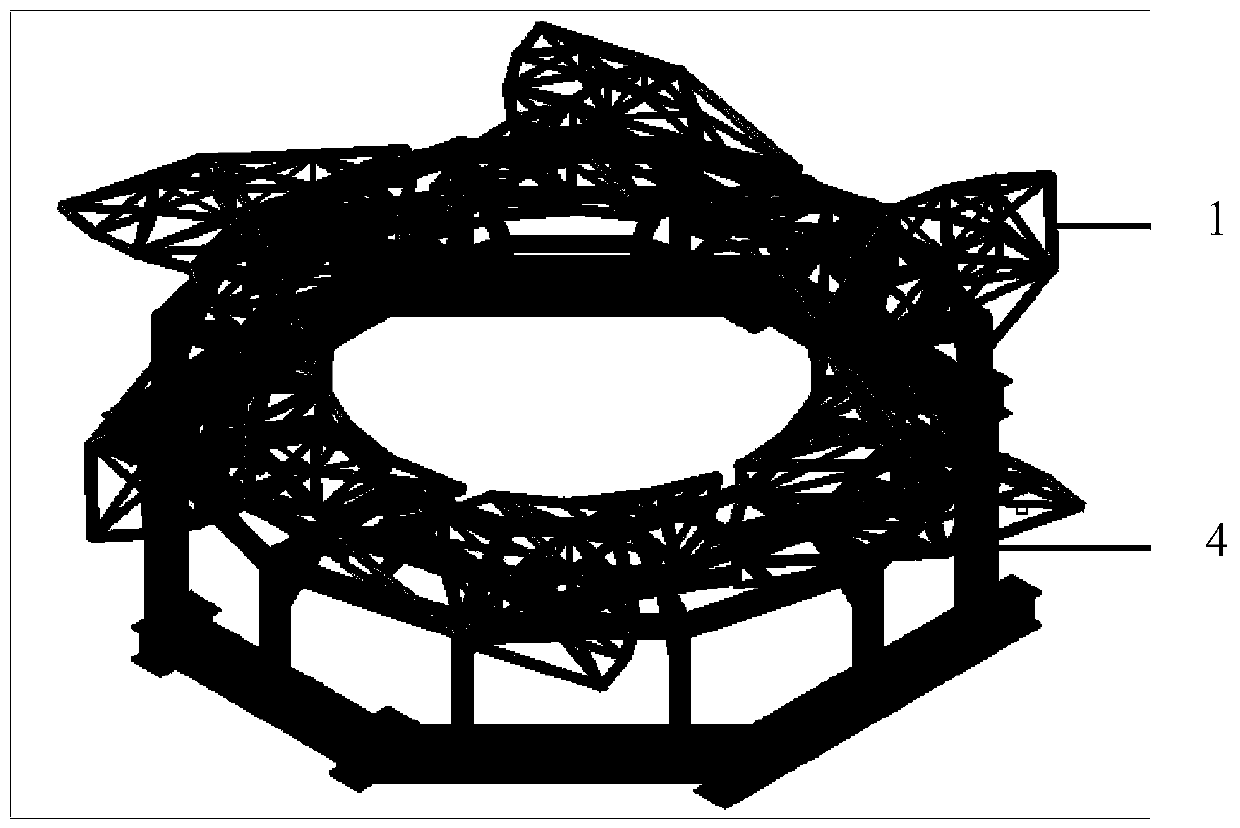

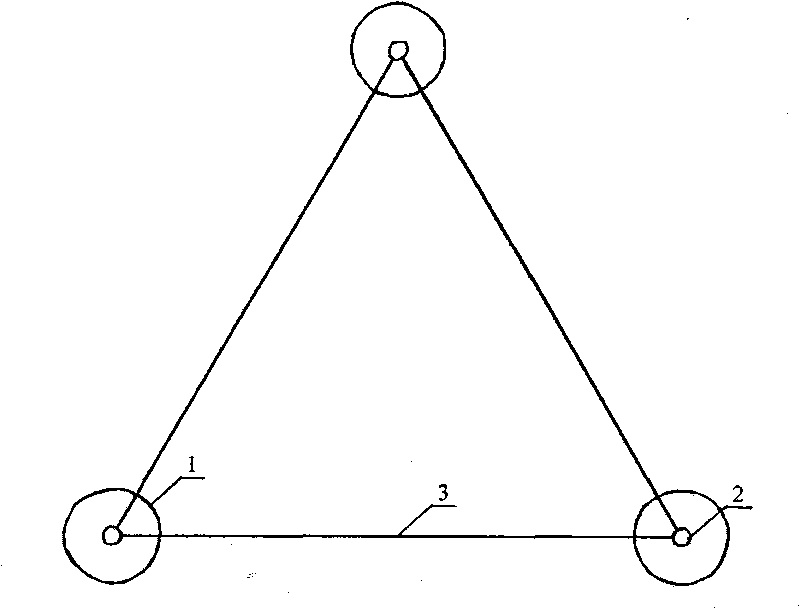

Annular cross cable truss structure

InactiveCN103074938ANovel structureReasonable structural stressBuilding roofsStructural elementHorizontal force

The invention relates to an annular cross cable truss structure, belonging to the field of a spatial cable truss structure. The structure comprises an annular stressed truss part, and a cable truss system part, wherein the cable truss system part consists of an upper string stabilizing cable, a support rod and a lower string bearing cable; a fish-bellied cable truss, stressed on a plane, is formed by connecting an upper string cable, a lower string cable and the support rod; and the annular cross cable truss structure, which has good spatial stress performance, is formed by arranging a plurality of plane fish-bellied cable trusses in an annular and cross way; the upper string cable and the lower string cable are and fixed at an ear plate of the annular stressed truss through anchorages at cable ends; and the stressed truss provides constraint to balance the horizontal force in the cables. The annular cross cable truss structure provided by the invention has the advantages of novel structure form, rational structure stress, less structure parts, strong collapse resistance, and attractive architectural style and can automatically maintain stable outside a surface, and moreover, the annular cross cable truss structure is convenient to manufacture and install, thus, the structure has stronger practical values.

Owner:BEIJING UNIV OF TECH

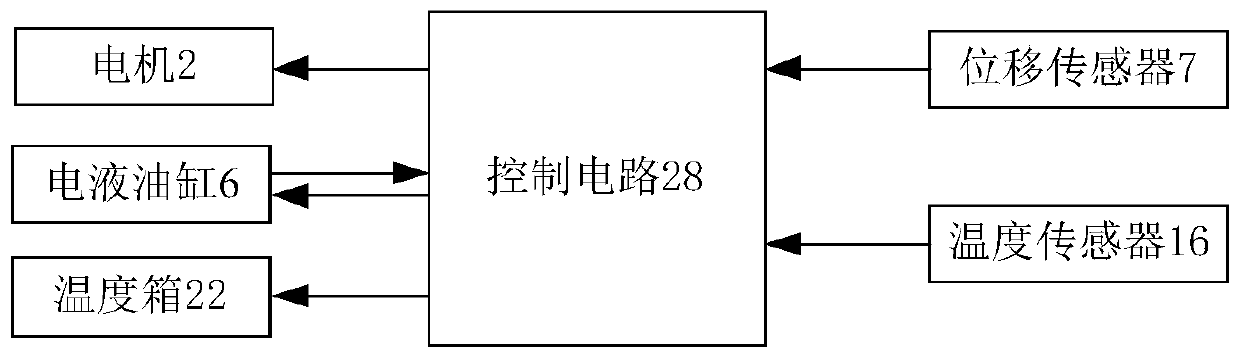

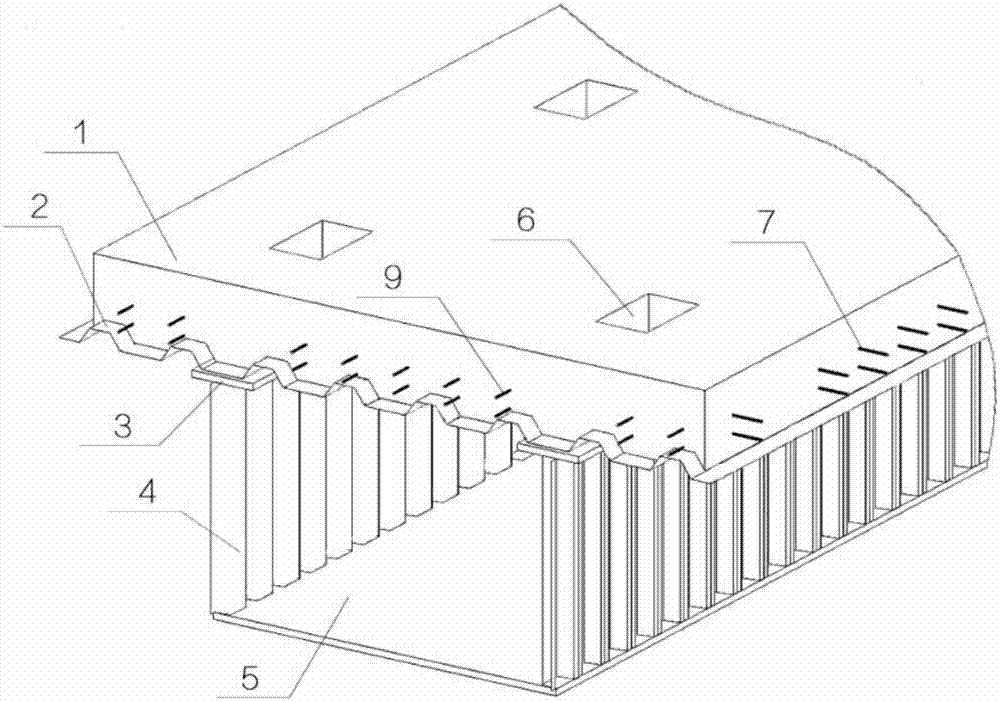

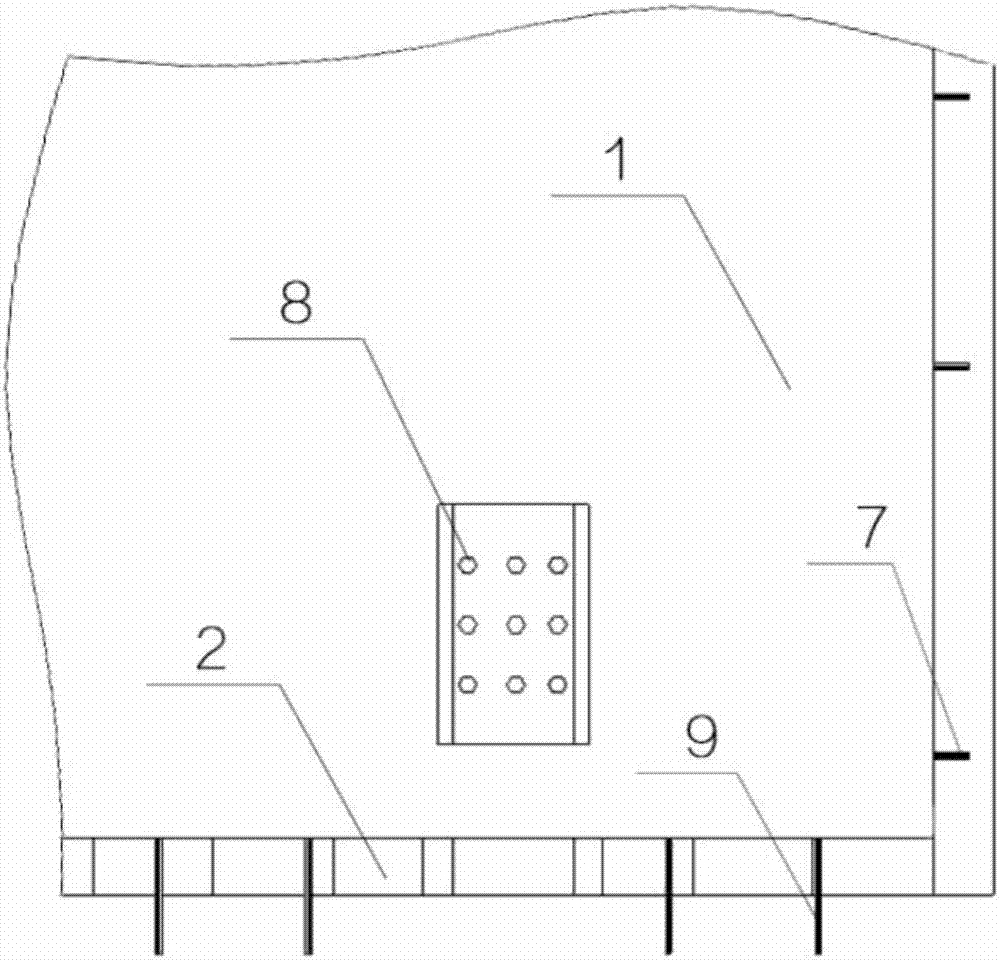

Joint bearing low-temperature wear test system and assembly method thereof

ActiveCN110243602AEasy to disassembleImprove general performanceMachine bearings testingInvestigating abrasion/wear resistanceTemperature controlRadial stress

The invention provides a joint bearing low-temperature wear test system. The system comprises a base, a temperature box, a radial stress subsystem, a power subsystem, a temperature control subsystem, a wear measurement subsystem and a clamp subsystem. The clamp subsystem comprises a pushing block, a loading plate, an accompanying test bearing seat, a mandrel, an accompanying test bearing, an end cover and a locking part, which are independent detachable parts; the mandrel, the pushing block or the loading plate can be replaced to realize clamping in a life test of joint bearings with different diameters, so that the utilization rate and the universality of a test clamp are improved; and in addition, the clamp subsystem adopts the structural design improvement that a single-side flange is added to an inner hole of the loading plate, the thickness of the pushing block is reduced, the flange and the end cover cooperatively fix the accompanying test bearing, and the like, so that the mandrel deformation or breakage easily caused in the joint bearing wear test process is effectively avoided.

Owner:CHINA AERO POLYTECH ESTAB

Fabricated steel-profiled steel sheet concrete combined board small box girder

The invention discloses a fabricated steel-profiled steel sheet concrete combined board small box girder, and belongs to the field of civil engineering. The invention solves the problem of long construction time of the field pouring of the existing steel-concrete combined box girder. The small box girder comprises a steel box and profiled steel sheet concrete combined bridge panels; two rectangular box structures formed by corrugated steel web plates are welded on the surface of the steel bottom plate; upper steel braces are arranged on the upper edge end faces of the corrugated steel web plates, and the profiled steel sheet concrete combined bridge panels are arranged on two upper steel braces; the profiled steel sheet concrete combined bridge panel is formed by pouring and prefabricating concrete on the profiled steel plate with a reinforcing mesh; multiple reserve holes are arranged on the concrete board, and stud groups are welded in the reserve holes; concrete is poured in the reserve holes. Through the prefabrication and overall assembly of components, the small box girder can meet the demand of bridge construction of a modernized city, thus the construction influence on surrounding environment is reduced, the fast construction with few people is realized.

Owner:HARBIN INST OF TECH

Steel frame reinforced column and reinforcing method thereof

InactiveCN101839074AReasonable structural stressImprove structural bearing capacityStrutsBuilding repairsSheet steelSteel frame

The invention relates to a steel frame reinforced column and a reinforcing method thereof. The steel frame reinforced column is characterized in that sealing reinforcing steel plates are welded between two flanges at two sides of an H-shaped steel frame column along the overall length of the column, are arranged in pair at two side openings of the H-shaped steel frame column and are welded with two flanges at the opening of the H-shaped steel frame column, and two sealing reinforcing steel plates adjacent up and down are mutually welded. In the invention, the reinforcing steel plates are prefabricated into parts in advance, are directly hoisted to the position during construction, pass through the steel column in over length along the direction of a weak shaft of the H-shaped steel frame column and are welded in pair, thereby enabling the structure stress of the steel reinforced column to be more reasonable and the structural bearing of an original building to be enlarged and satisfying the structural bearing stress requirement. By adopting the construction method of the invention, the original structure can be used for reinforcing the frame steel column of the original steel structure without being disassembled, thereby not influencing the normal work in the original building. All the reinforcing steel plates can be precast in factories, thereby not only shortening the time limit for a project and reducing the construction cost but also ensuring project quality and satisfying the requirement of building extension.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving

InactiveCN103306531AGood energy dissipation and shock absorptionGood wind resistanceBulk storage containerShock proofingRebarReinforced concrete

The invention relates to a reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving. The system comprises combined spherical tanks, reticulated shell-annular truss frame-irregular-shaped combination column combined supports, a rubber ball-damper shock-absorbing energy consumption device, wherein annular truss frames are encircled outside the reticulated shells, and are connected with the irregularly-shaped combination columns; the combined spherical tanks are arranged on the reticulated shell-annular truss frame-irregularly-shaped combination column combined supports; the rubber ball-damper shock-absorbing energy consumption device is arranged between the reticulated shell pitch points and the combined spherical tanks; the rubber ball- damper shock-absorbing energy consumption device is composed of dampers and rubber balls; the rubber balls are arranged at one ends of the dampers; concave slide tracks are arranged on the outer walls of the combined spherical tanks; the rubber balls are positioned in the concave slide tracks; the other ends of the dampers are fixed with the pitch points of the reticulated shells; the irregularly-shaped combination columns are composed of solid-web section steel and reinforced concrete; the solid-web section steel is placed in the reinforced concrete; an L-shaped support seat is arranged at the top ends of the combination columns. The system can move slightly in any direction under the strong shock or the strong wind, and has excellent energy consumption shock-absorbing performance and wing resistance.

Owner:NORTHEAST GASOLINEEUM UNIV

Prefabricated assembled box culvert and construction method thereof

InactiveCN102418319AImprove construction progressQuality assuranceGround-workRc framesArchitectural engineering

The invention discloses a prefabricated assembled box culvert and a construction method thereof. The box culvert is in an assembled structure and consists of a reinforced concrete culvert body, wing walls, a foundation and deformation joints, wherein the culvert body of the box culvert is in an integral closed-type reinforced concrete framework structure formed by combining transition culvert joints, non-standard culvert joints and standard culvert joints. The culvert body and the wing walls adopt assembly and construction. By utilizing the prefabricated assembled box culvert, batch production can be performed in a factory, field assembly is realized, the construction progress of the culvert is accelerated, the construction period is shortened and the quality of the culvert is ensured. Therefore, the problems of long culvert construction period and difficult control on the quality during the current road construction can be solved.

Owner:新疆交通科学研究院有限责任公司

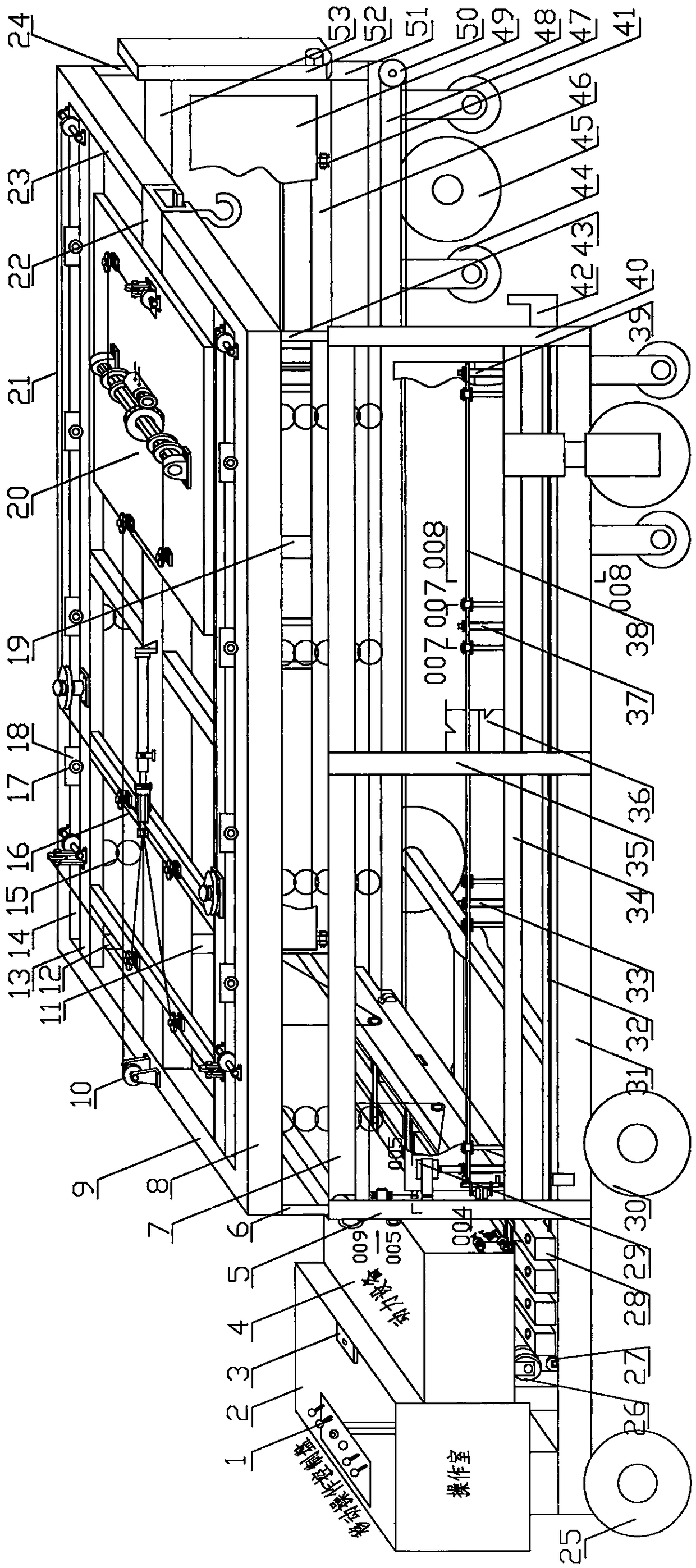

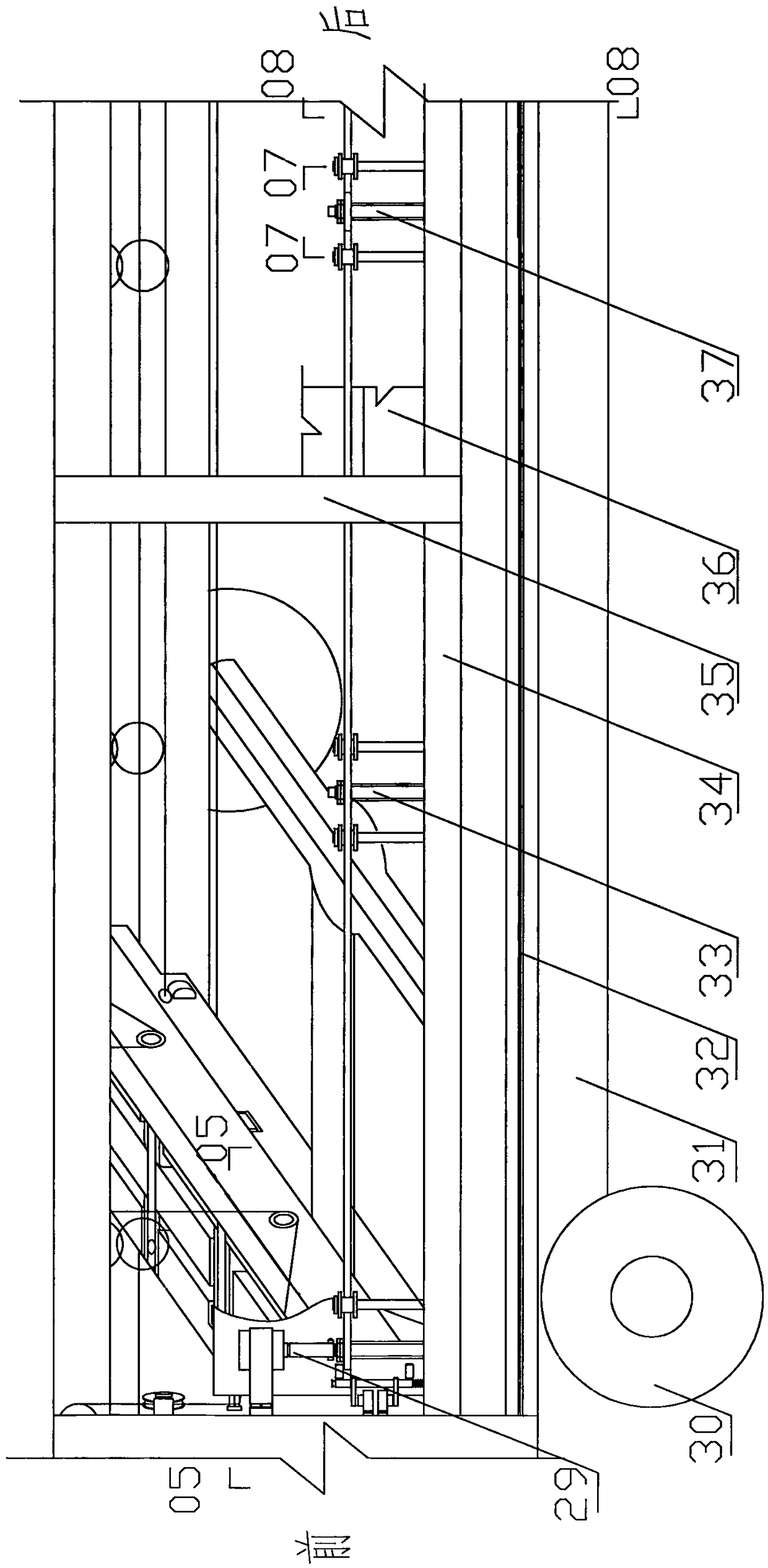

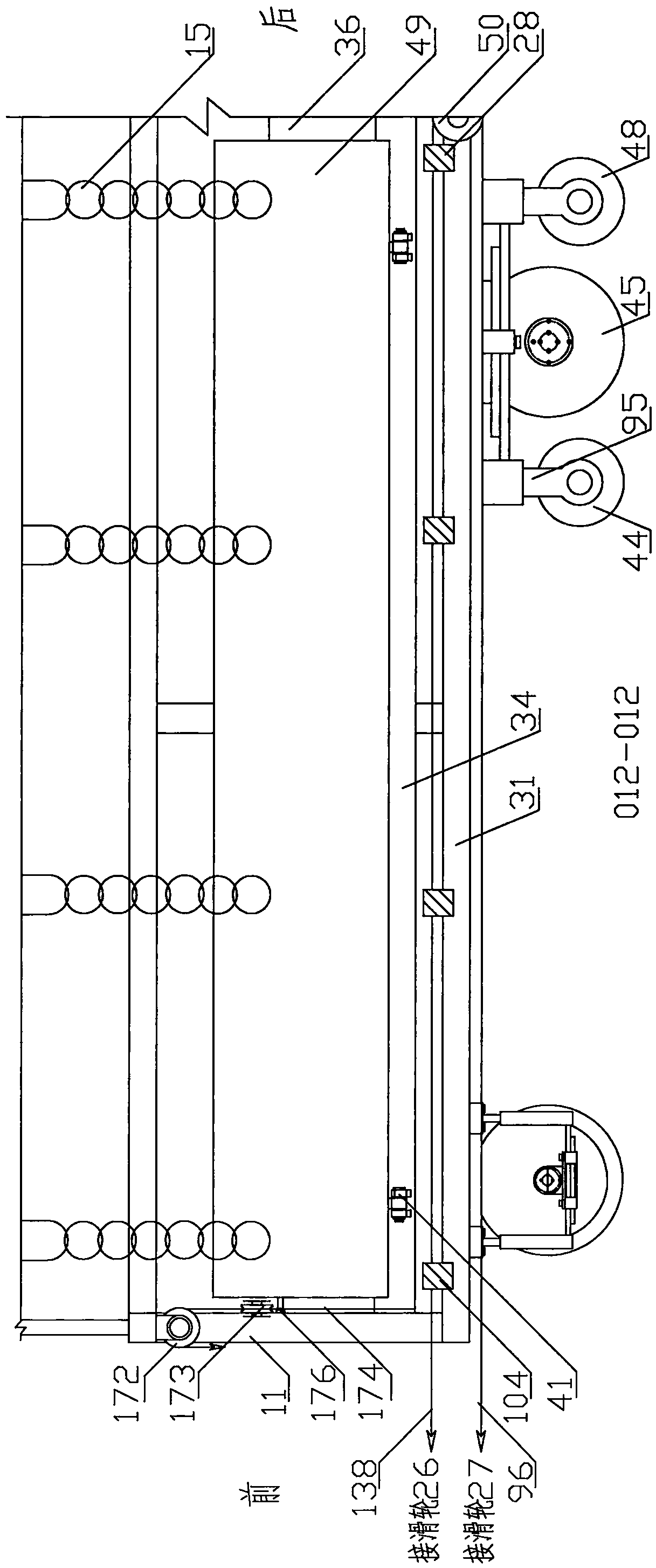

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

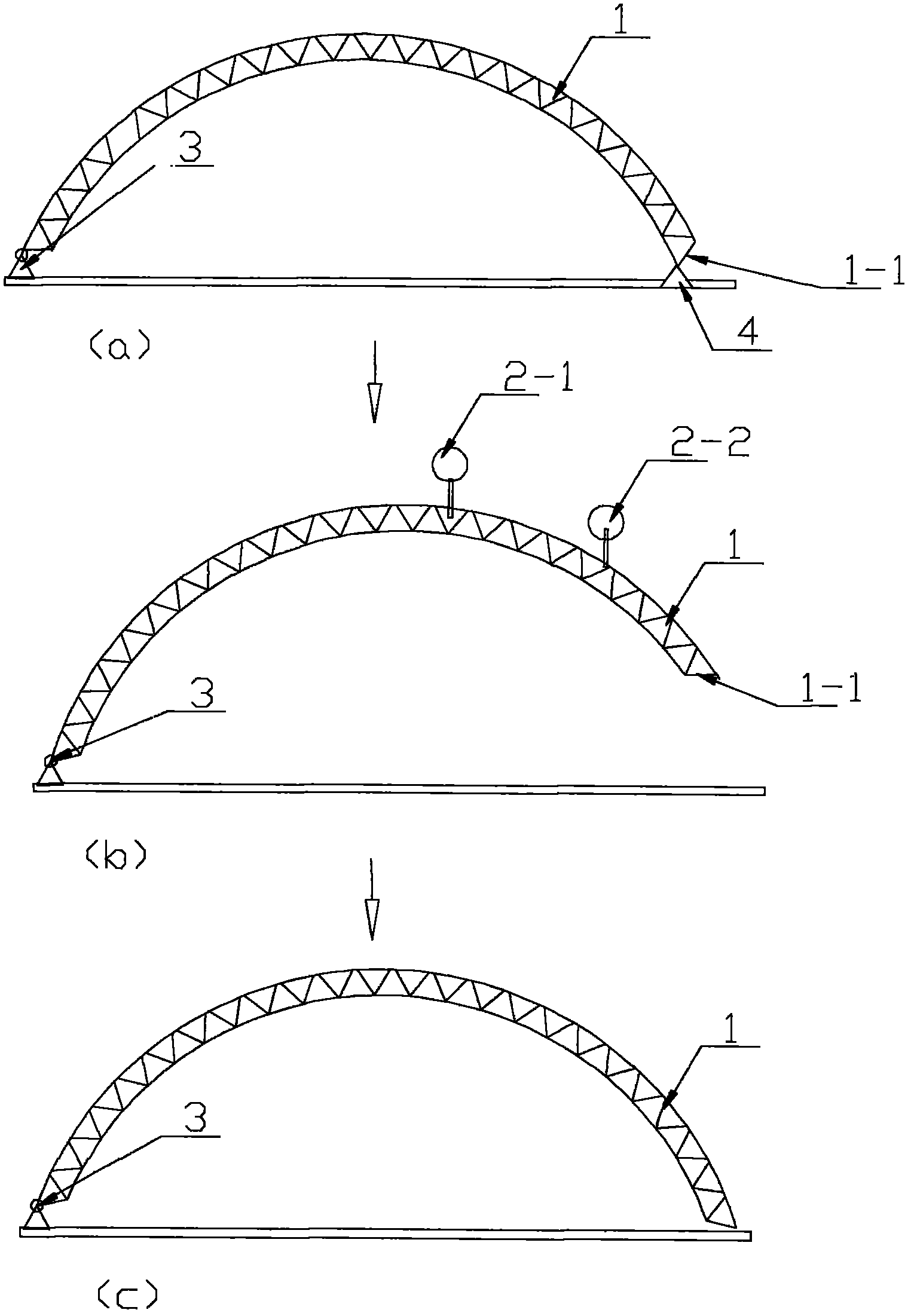

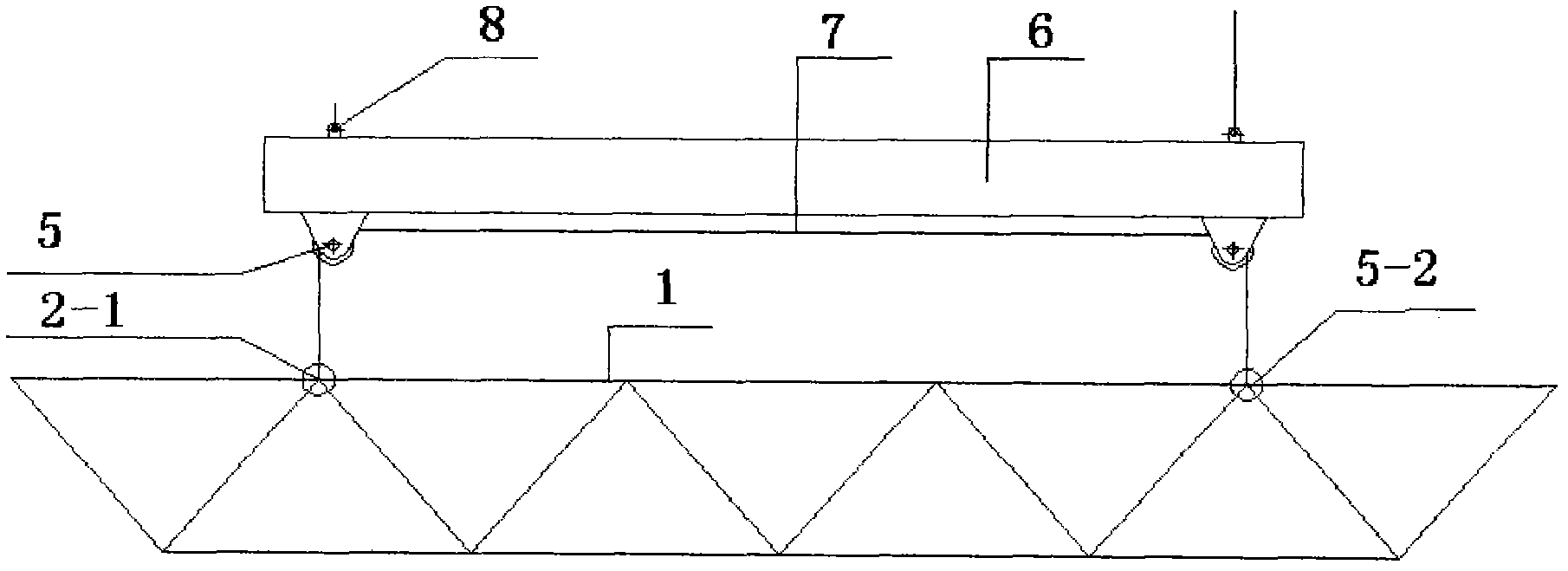

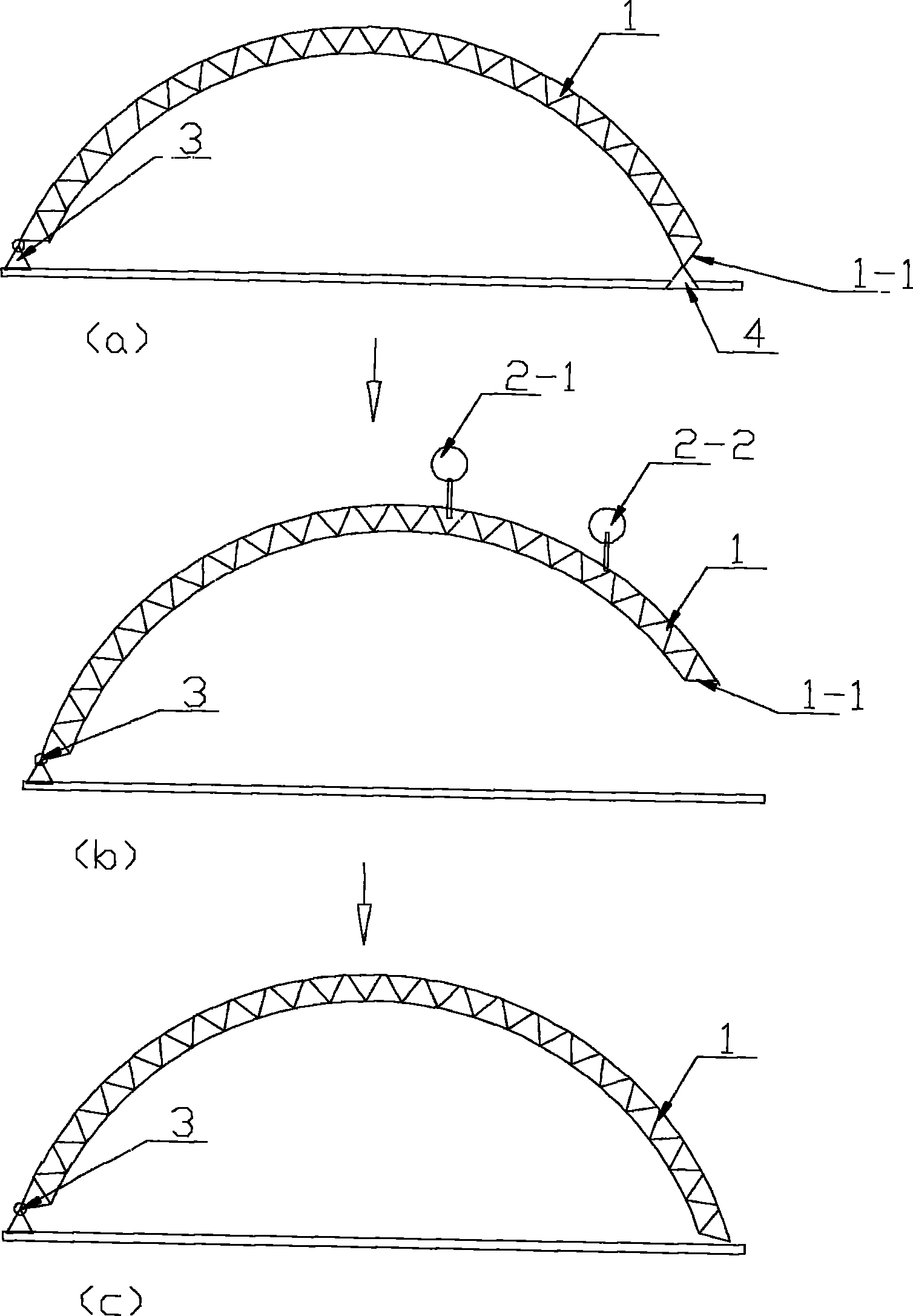

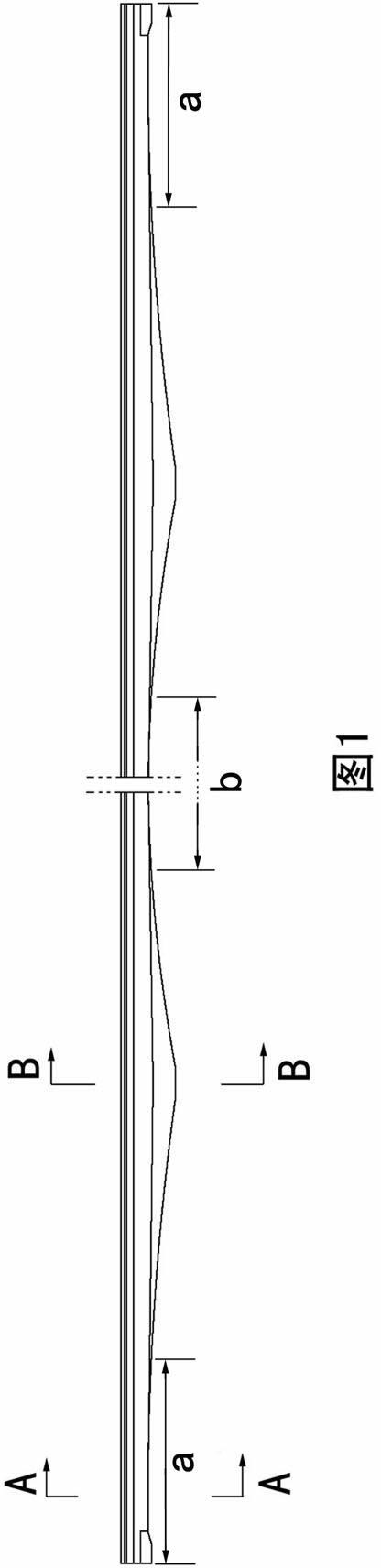

Rotary lifting construction method for cylindrical reticulated shell

InactiveCN102465602AOvercome weaknessReasonable structural stressBuilding material handlingRotating hingeBuilding construction

The invention relates to a rotary lifting construction method for a cylindrical reticulated shell, and relates to a building construction method. The rotary lifting construction method comprises the following steps of: (1) splicing the cylindrical reticulated shell (1) on the ground; (2) supporting one end of the spliced cylindrical reticulated shell (1) by using a rotating hinge (3), and supporting a spliced extension operating surface (1-1) at the other end of the spliced cylindrical reticulated shell (1) by using a temporary support (4); (3) lifting the cylindrical reticulated shell (1) by using a lifter, so that the cylindrical reticulated shell (1) rotates around the rotating hinge (3), and continuing to splice the cylindrical reticulated shell (1) on the spliced extension operating surface (1-1); and (4) performing the lifting process and the splicing process alternately, so that the cylindrical reticulated shell (1) extends along the direction of an arc line until the cylindrical reticulated shell (1) reaches a designed position. By the rotary lifting construction method, the key problem of the forming of a cylindrical surface in the installation construction process of a cylindrical reticulated shell structure is solved, and an installation construction method without a support is provided.

Owner:WUHU TIANHANG TECH GRP

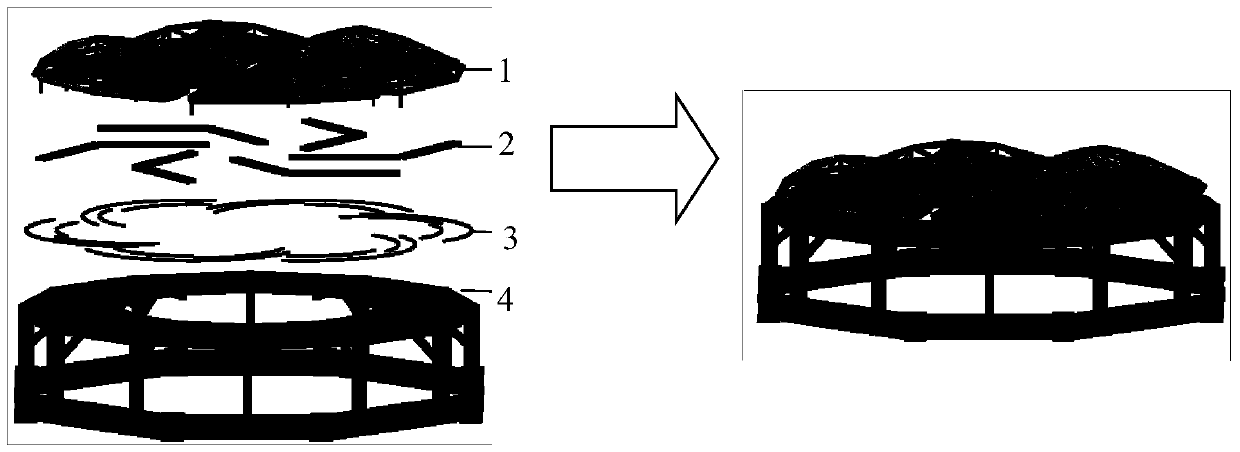

Radial whole retractable roof structure

InactiveCN103590525AEasy synchronization controlReduce layoutBuilding roofsDegrees of freedomEngineering

The invention relates to a radial whole retractable roof structure. The radial whole retractable roof structure comprises movable roofs, transmission connecting rods and fixed roofs. A whole retractable roof only has one degree of freedom and is radially wholly opened and closed in the opening and closing processes, the movable roofs are connected together through the transmission connecting rods to form a whole, the movable roofs move along rails arranged on the fixed roofs through universal balls to achieve the retractable functions. A variable height intersection truss system is adopted in the movable roofs to form a space stress structural system, and then the dead weight of the movable roofs is reduced. The rails are of a circular arc shape and reasonably arranged, and therefore the rails are prevented from being exposed out of a visual field when the roof is opened. Joints for connecting the movable roofs, the transmission connecting rods and the universal balls are designed, and rotation between the movable roofs and the transmission connecting rods can be achieved to further achieve the retractable function. The radial whole retractable roof structure is novel in retractable mode, reasonable in structure stress, convenient to drive and control, and good in application prospect.

Owner:SOUTHEAST UNIV

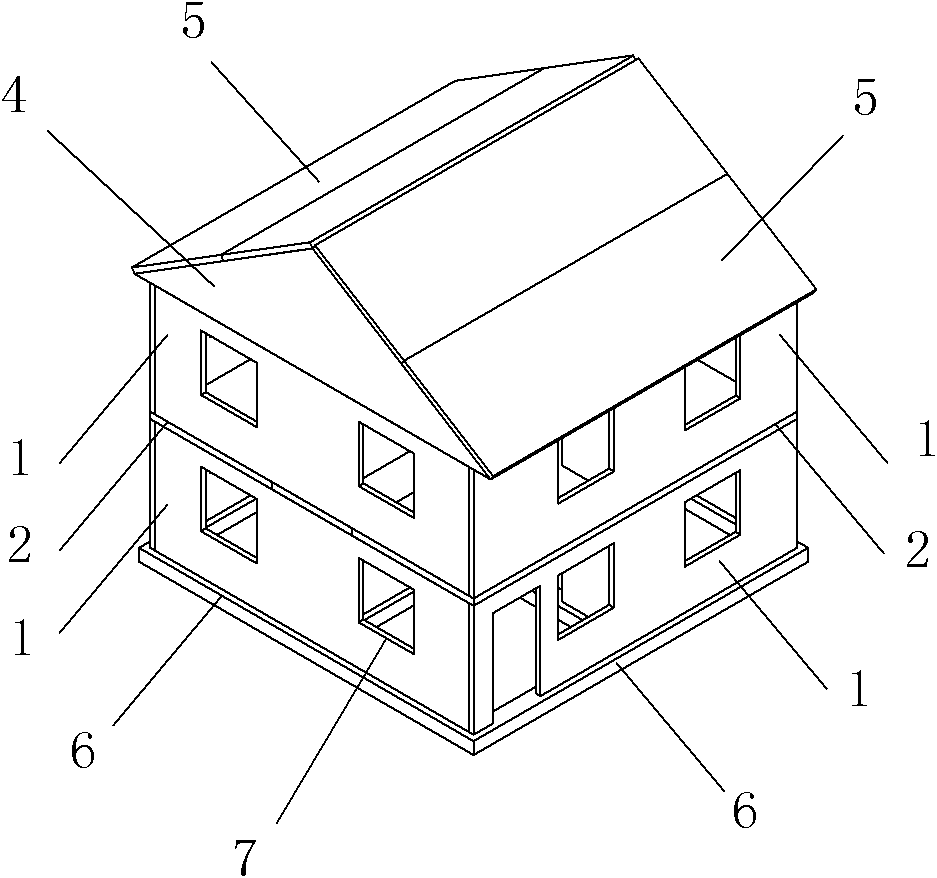

Wooden structure house and building process thereof

InactiveCN102174859ASimple structureClear mechanical propertiesRoof covering using slabs/sheetsBuilding roofsBasementOn board

The invention discloses a wooden structure house and a building process thereof. The wooden structure house comprises a house main body structure and a roof structure, wherein every floor of the house main body structure comprises a plurality of wall bodies 1; the adjacent floors are separated by a floor plate; the wall bodies 1 and the floor plate are an integrated composite board or are formed by splicing a plurality of composite boards arranged on the same plane; the integrated composite board is formed by piling a plurality of layers of wooden boards with same shapes and sizes; and the wooden board is formed by splicing a plurality of wooden plate strips which are arranged on the same plane. The building process comprises the following steps of: 1, on-site constructing foundation and basement, factory-prefabricating and transporting the integrated composite boards; and 2, using the prefabricated composite boards to assemble the wooden structure house on the spot. The wooden structure house in the invention is simple in construction process, controllable in construction quality, low in input investment, rational in structural stress of the built house, beautiful in shape, wide in application range and convenient for prefabricating the integrated boards and suspending on the spot.

Owner:杨岳华

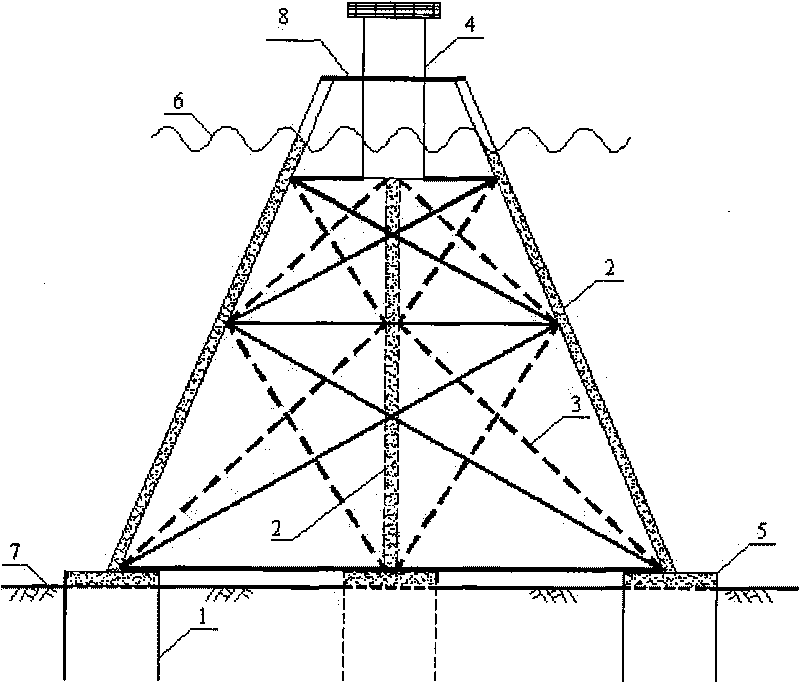

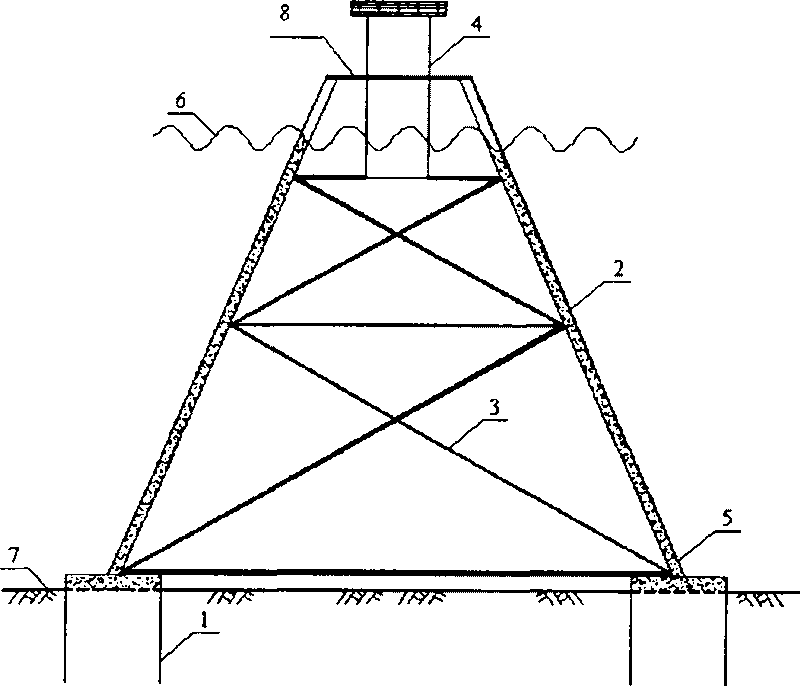

Space truss multi-barrel base of offshore wind power unit

InactiveCN101761090APress down verticallyImprove carrying capacityArtificial islandsFoundation engineeringElectricityBarrel Shaped

The invention discloses a space truss multi-barrel base of an offshore wind power unit, which mainly comprises a connecting cylinder, three suction barrels arranged in a triangle shape or four suction barrels arranged in a quadrangle shape, and support pillars the number of which is the same as that of the suction barrels, wherein each suction barrel is fixedly connected with the connecting cylinder through the corresponding support pillar; and a support member with a truss structure is connected between every two support pillars. The invention is of an integrated structure which consists of a space truss system and a multi-suction-barrel base, transfers the overturning load suffered by the whole base into vertical underdraught and up-pull load on single-barrel base, fully utilizes the superiority of multi-barrel base for bearing vertical load, has the advantages that the bearing load of the structure is reasonable, and solves the difficulties that the construction cost of the offshore wind power unit is high and the construction is complicated.

Owner:ZHEJIANG UNIV +1

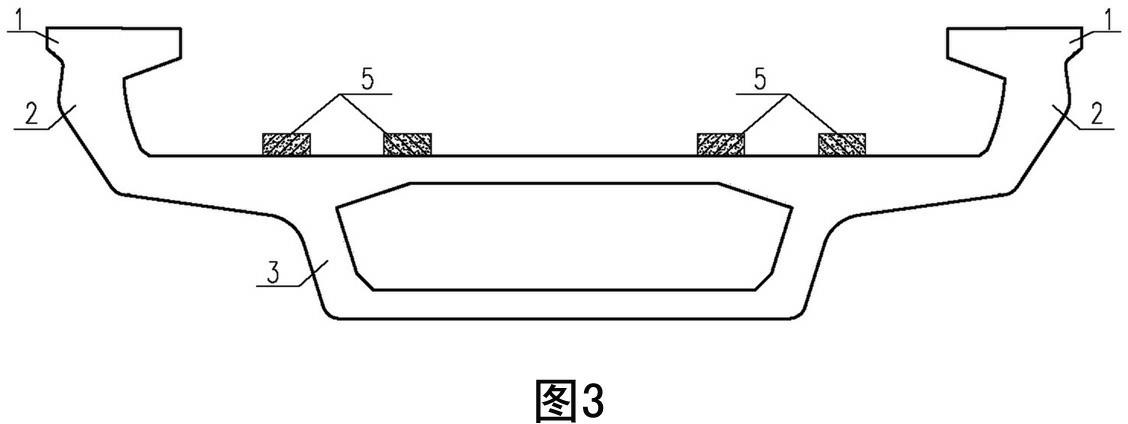

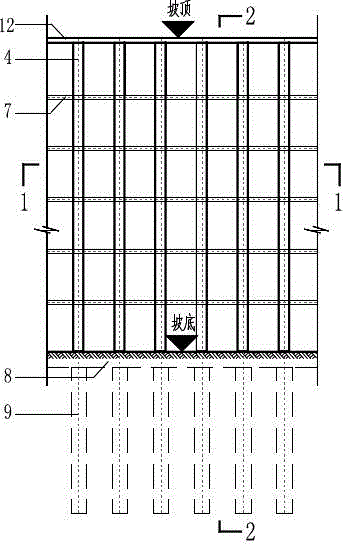

Urban rail transit continuous basin beam

The invention relates to an urban railway traffic continuous basin type beam. A beam body of the continuous basin type beam is a passage which has the basin-shaped cross section and is formed by connecting a support bottom plate, upper web plates and wing edge plates, the upper web plates are arranged at both sides of the support bottom plate, the wing edge plates are arranged at the tops of the upper web plates, at least two pairs of rail carrying tables are arranged on the support bottom plate, a power supply device, power supply cable support bodies and communication signal cable grooves are fixedly connected in the length direction of the beam body, the span of the beam body is 40m to 80m, the support bottom plate of the beam body at the side fulcrum region section and the middle spanflat and straight section is in a single layer, the rest support bottom plate of the beam body is in a closed opening box shape, in addition, the lower surface of the single-layer support bottom plate of the side fulcrum region section and the middle span flat and straight section is in smooth transition connection with the bottom surface of the box shape. The beam is arranged at the crossed transition line region section or a place required to span a large node, the urban railway traffic continuous basin type beam belongs to a bridge structural form integrating the thin-wall opening U-shapedbeam and the closed opening box-shaped beam into a whole, the problems that the ordinary railway traffic U-shaped beam cannot span large node and cannot be applied to the crossed wire transition region section are solved, and the application range of the U-shaped beam is enlarged.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

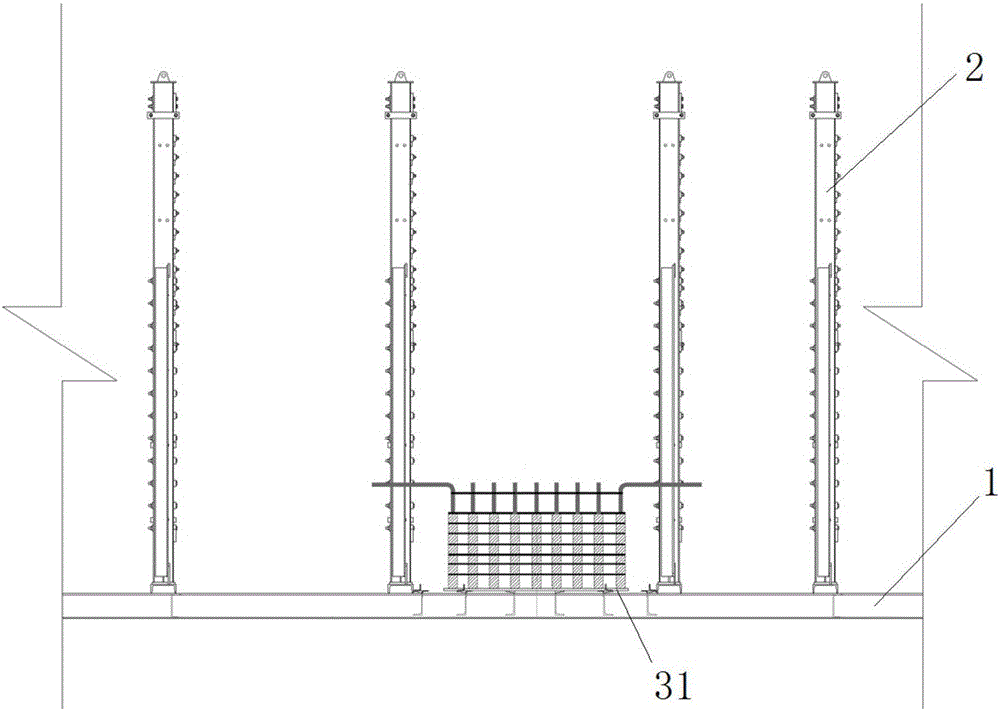

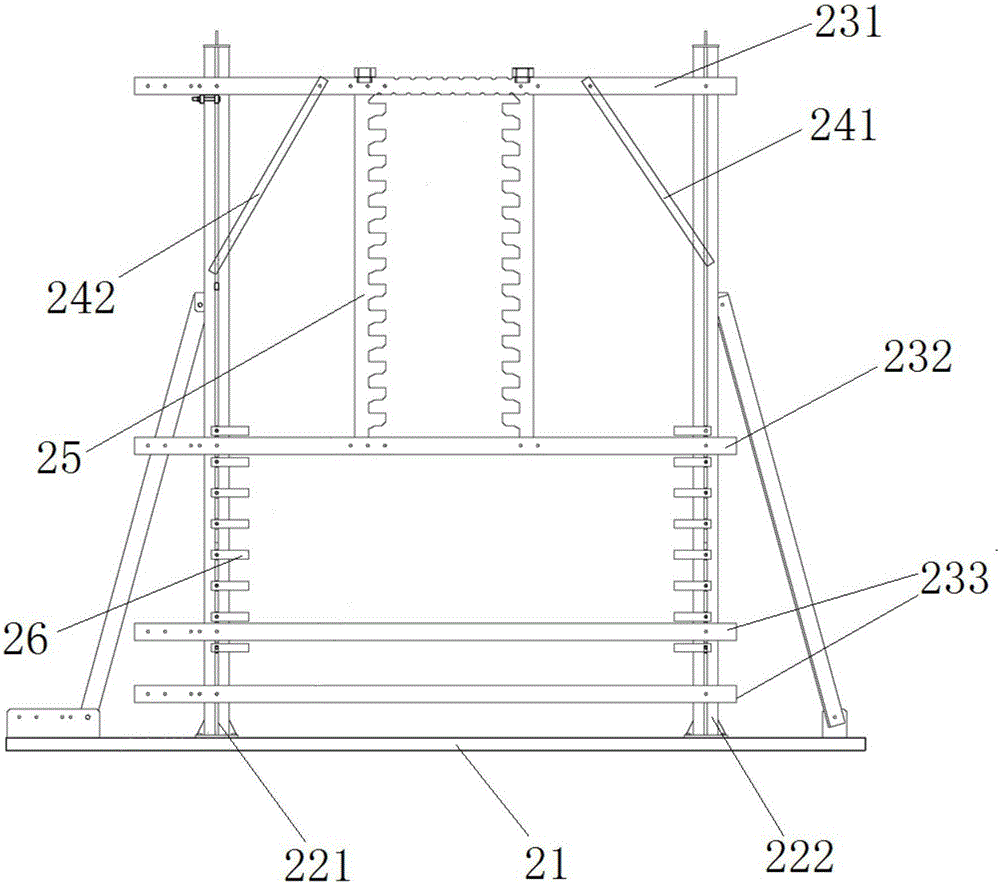

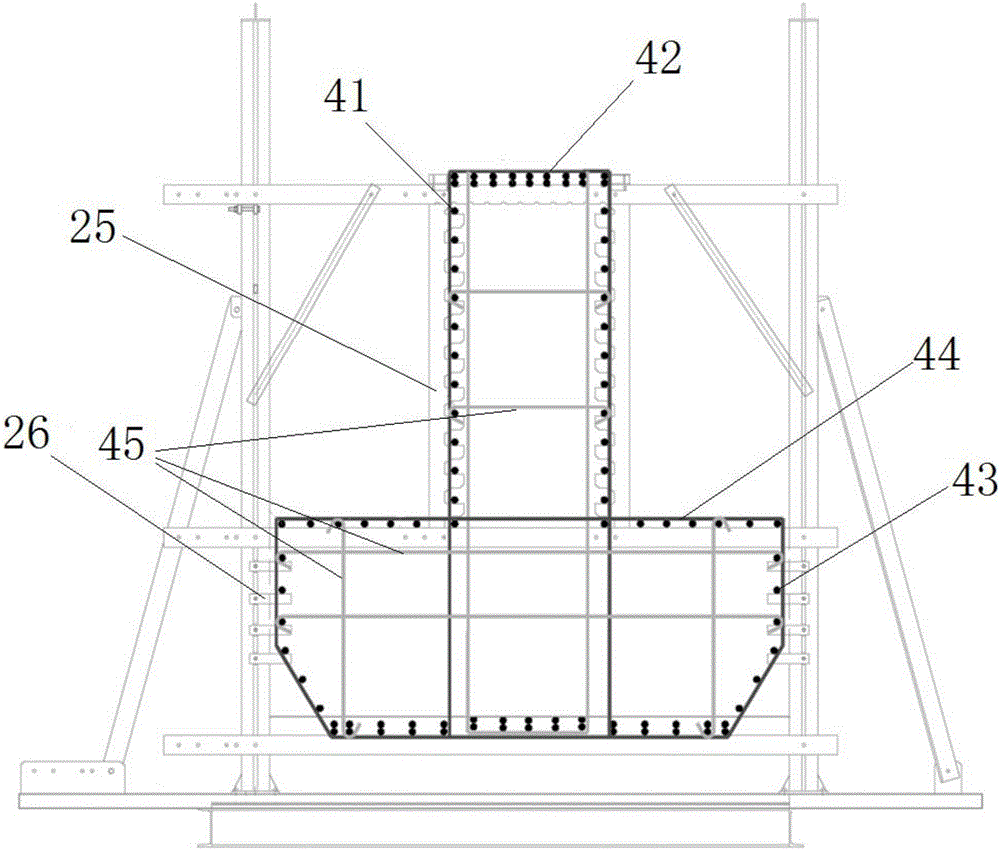

Prefabricated cover beam steel bar jig frame and manufacturing method of prefabricated cover beam reinforcement cage

ActiveCN105951579AImprove manufacturing precisionImprove manufacturing speedBridge structural detailsBridge erection/assemblyRebarManufacturing quality

The invention relates to a prefabricated cover beam steel bar jig frame and a manufacturing method of a prefabricated cover beam reinforcement cage and belongs to the technical field of bridge structure construction. According to the main technical scheme, the prefabricated cover beam steel bar jig frame comprises an underframe, a plurality of positioning frames and a grouting sleeve positioning disc; the multiple positioning frames are distributed on and connected to the underframe; main reinforcement positioning structures are arranged on the positioning frames and used for positioning main reinforcements in the prefabricated cover beam reinforcement cage; and the grouting sleeve positioning disc is arranged on the underframe and used for positioning an end grouting sleeve of the prefabricated cover beam reinforcement cage. The manufacturing method of the prefabricated cover beam reinforcement cage comprises the step that the prefabricated cover beam reinforcement cage is manufactured through the prefabricated cover beam steel bar jig frame. The prefabricated cover beam steel bar jig frame and the manufacturing method of the prefabricated cover beam reinforcement cage are mainly used for precisely positioning steel bars and the embedded end grouting sleeve of the prefabricated cover beam reinforcement cage, and the splicing precision and manufacturing quality of the prefabricated cover beam reinforcement bars are effectively improved.

Owner:SHANGHAI NO 4 CONSTR +1

Steel pipe concrete column-steel beam outer separation plate type node structure and construction method thereof

ActiveCN105714939ASimple structureReasonable designBuilding material handlingShock proofingStress concentrationSeismic resistance

The invention discloses a steel pipe concrete column-steel beam outer separation plate type node structure and a construction method thereof. The node structure comprises a steel pipe concrete column, a steel beam located on the outer side of the steel pipe concrete column, and a beam column connection structure connected between the steel pipe concrete column and the steel beam; the steel pipe concrete column and the steel beam are arranged vertically; the steel pipe concrete column comprises a rectangular steel pipe column, four groups of open vertical ribs and a core concrete structure; the beam column connection structure comprises an upper external separation plate and a lower external separation plate; and the outer end of the upper part of the steel beam is fixedly connected with the upper external separation plate, and the outer end of the lower part of the steel beam is fixedly connected with the lower external separation plate. The construction method of the node structure comprises the following steps: step 1, assembling and welding the open vertical ribs and the rectangular steel pipe column; step 2, welding the beam column connection structure; step 3, connecting the steel beam; and step 4, pouring concrete. The steel pipe concrete column-steel beam outer separation plate type node structure is reasonable in structure, simple and convenient to construct, good in use effect and clear in force transmission; stress concentration and deformation concentration problems of a steel pipe concrete column-steel beam node can be effectively alleviated, and the seismic resistance is good.

Owner:CHANGAN UNIV

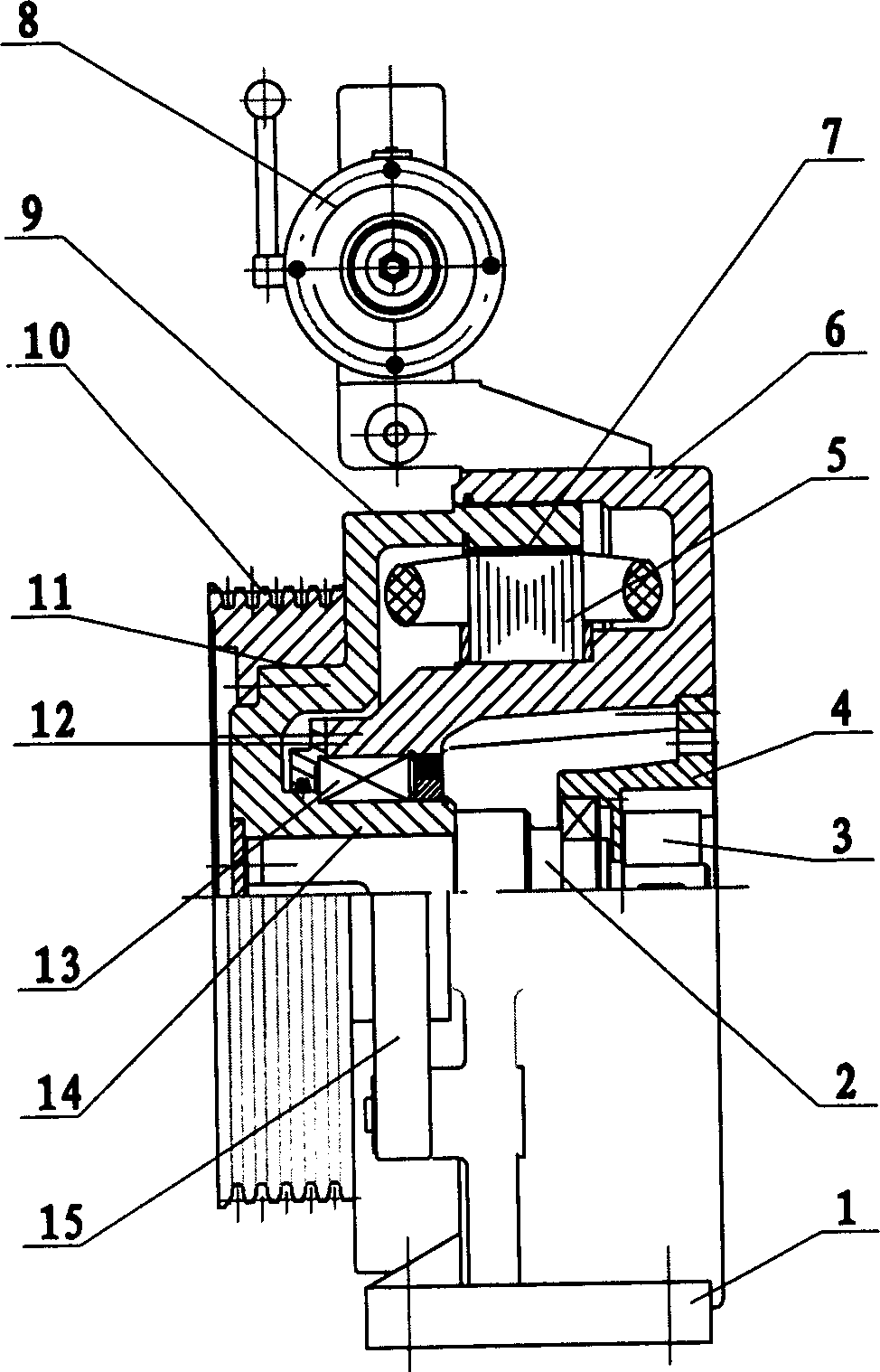

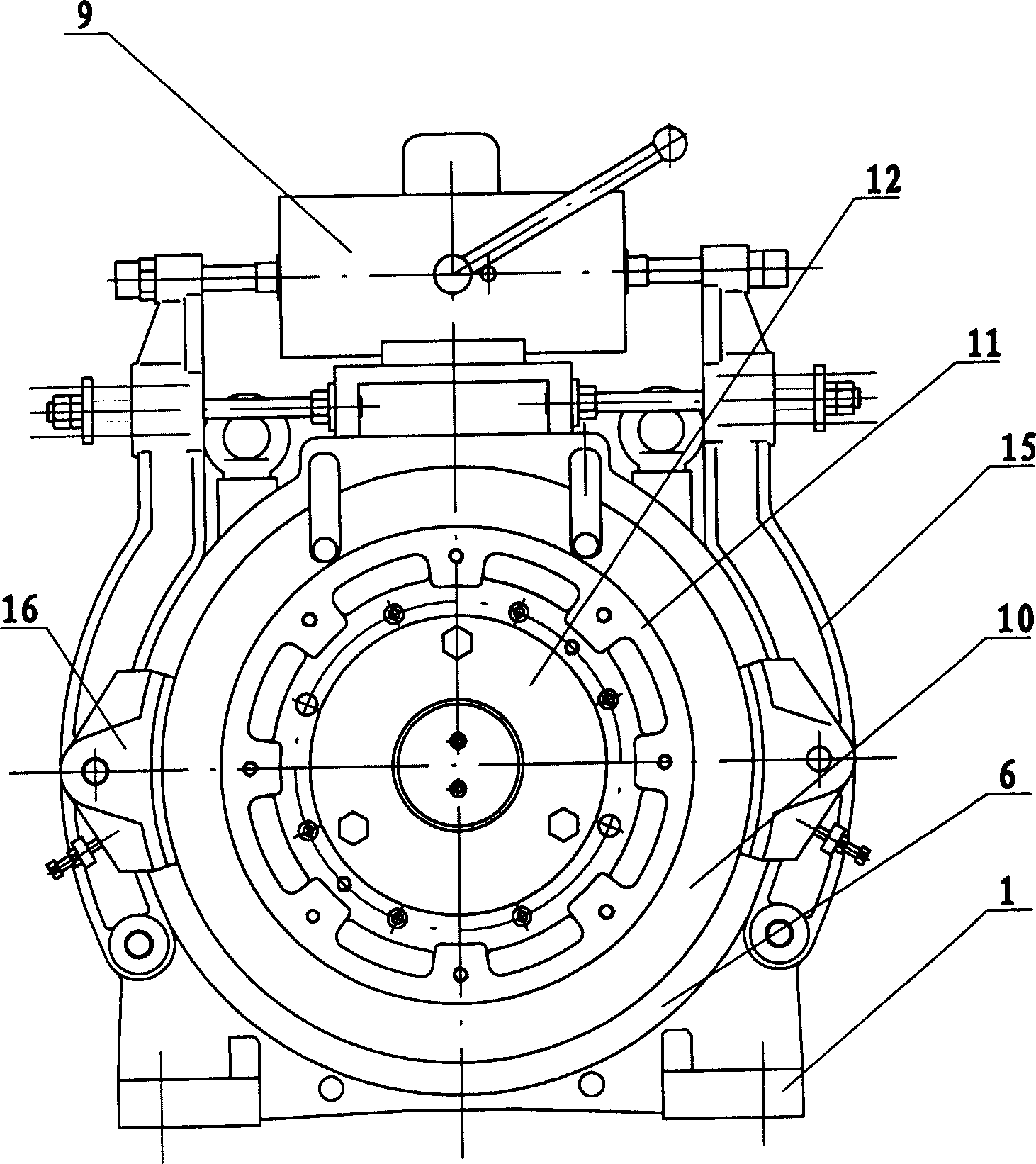

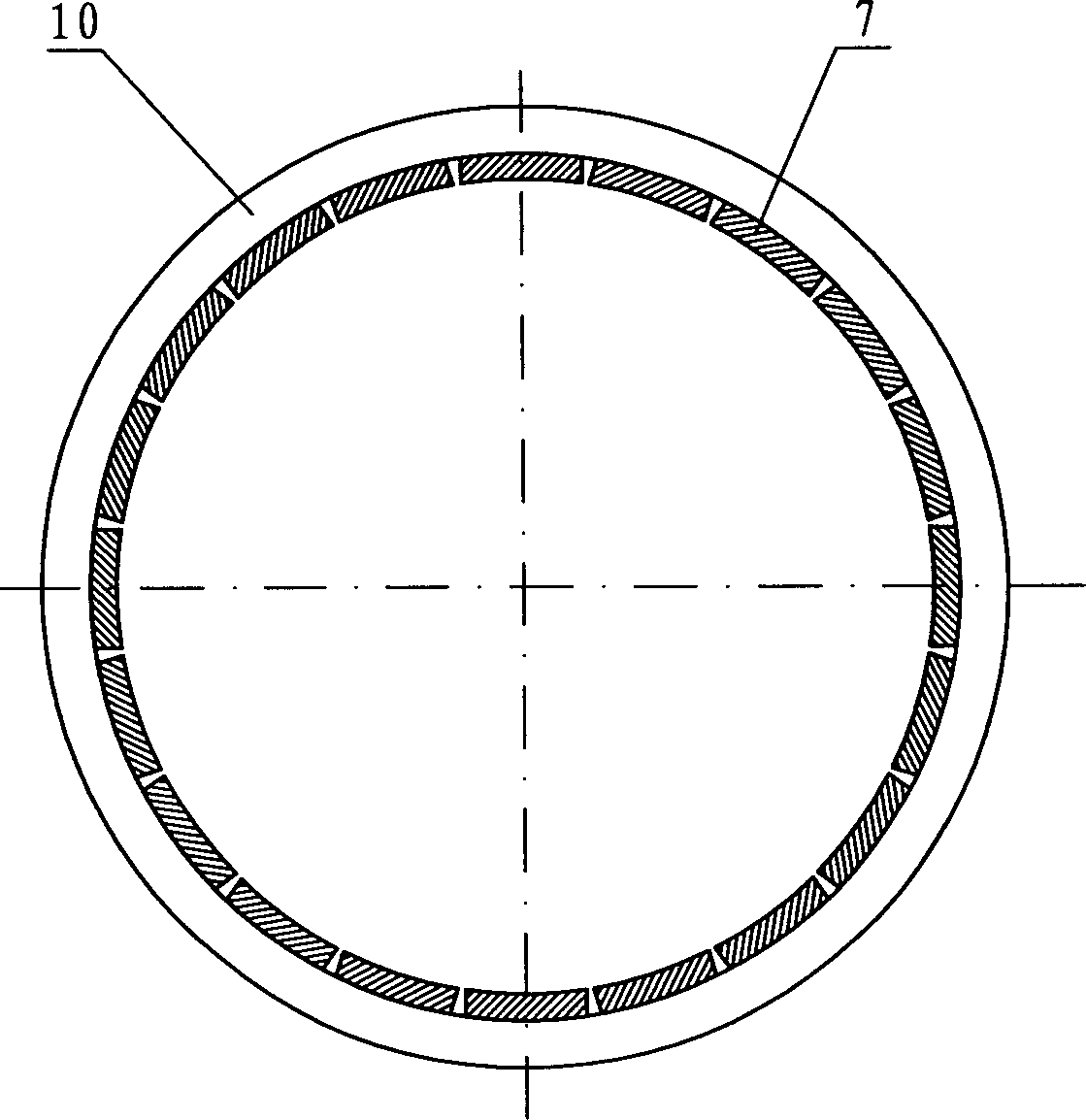

Synchronous gearless permanent-magnet draw machine

InactiveCN1387300ASimple structureCompact structureMechanical energy handlingSynchronous machines with stationary armatures and rotating magnetsGear wheelBrake shoe

A permanent magnet synchronous towing machine without gear wheel includes the stator, rotor and the brake equipment. The stator frame, the stator case and the shoring cover are cast as a whole. Arc type permanent magnets are affixed to the inner side of the rotor wall along the direction of circle. Shaft is mounted on the axle hole of the axle housing of the rotor. The iron cords are pressed to the outer side of the shorting cover along direction of the circle. The rotation coder is positioned on the back end of the shaft. The stretch type electromagnetic brake providing thrust in bi-directional is mounted between two brake arms on the base. The brake shoes with hinge jointed on the brake arms are fitted on the symmetrical two sides of the outer wall of the rotor. The towing wheel is fixed on the circular bead of the end part.

Owner:沈阳蓝光驱动技术有限公司

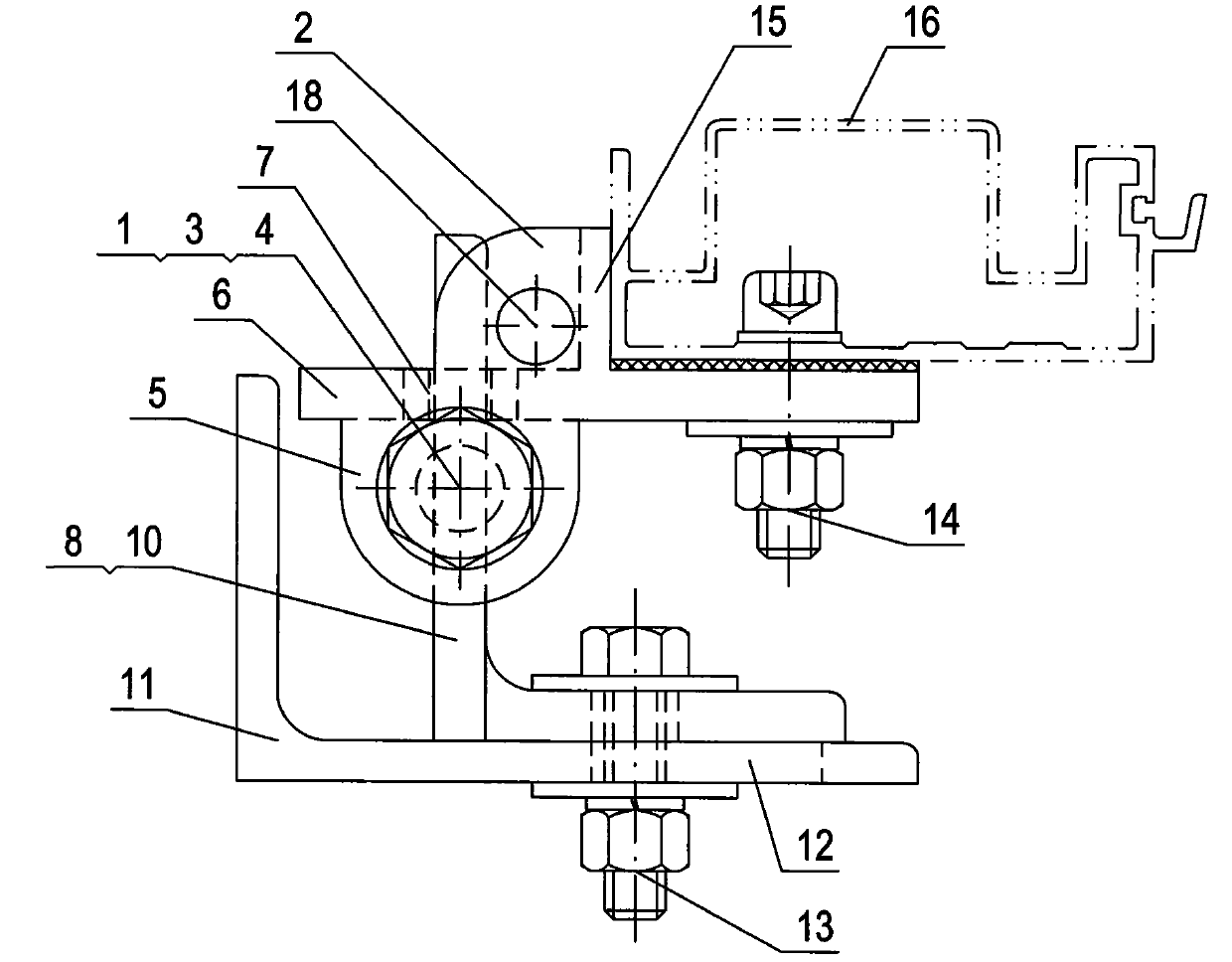

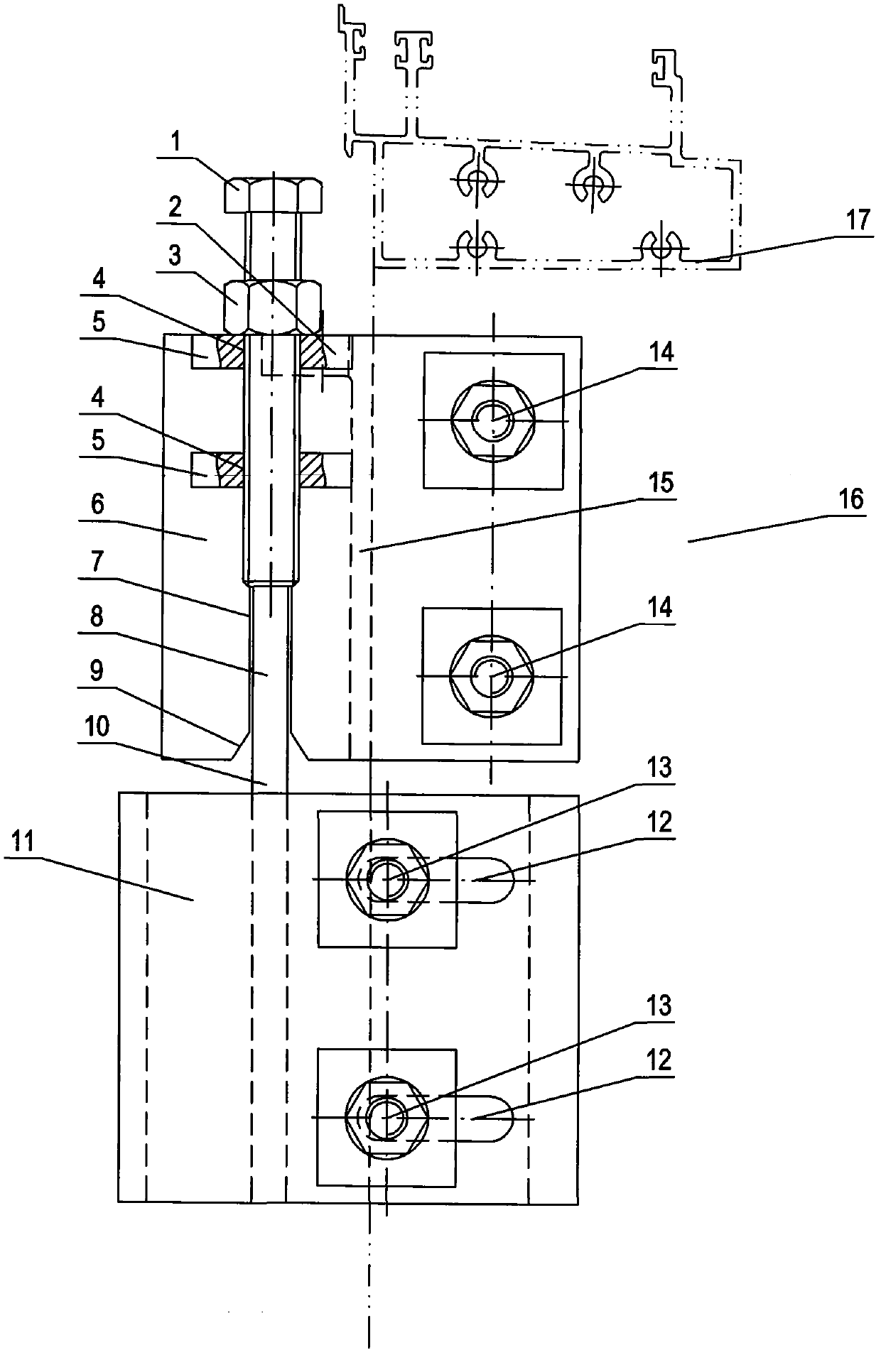

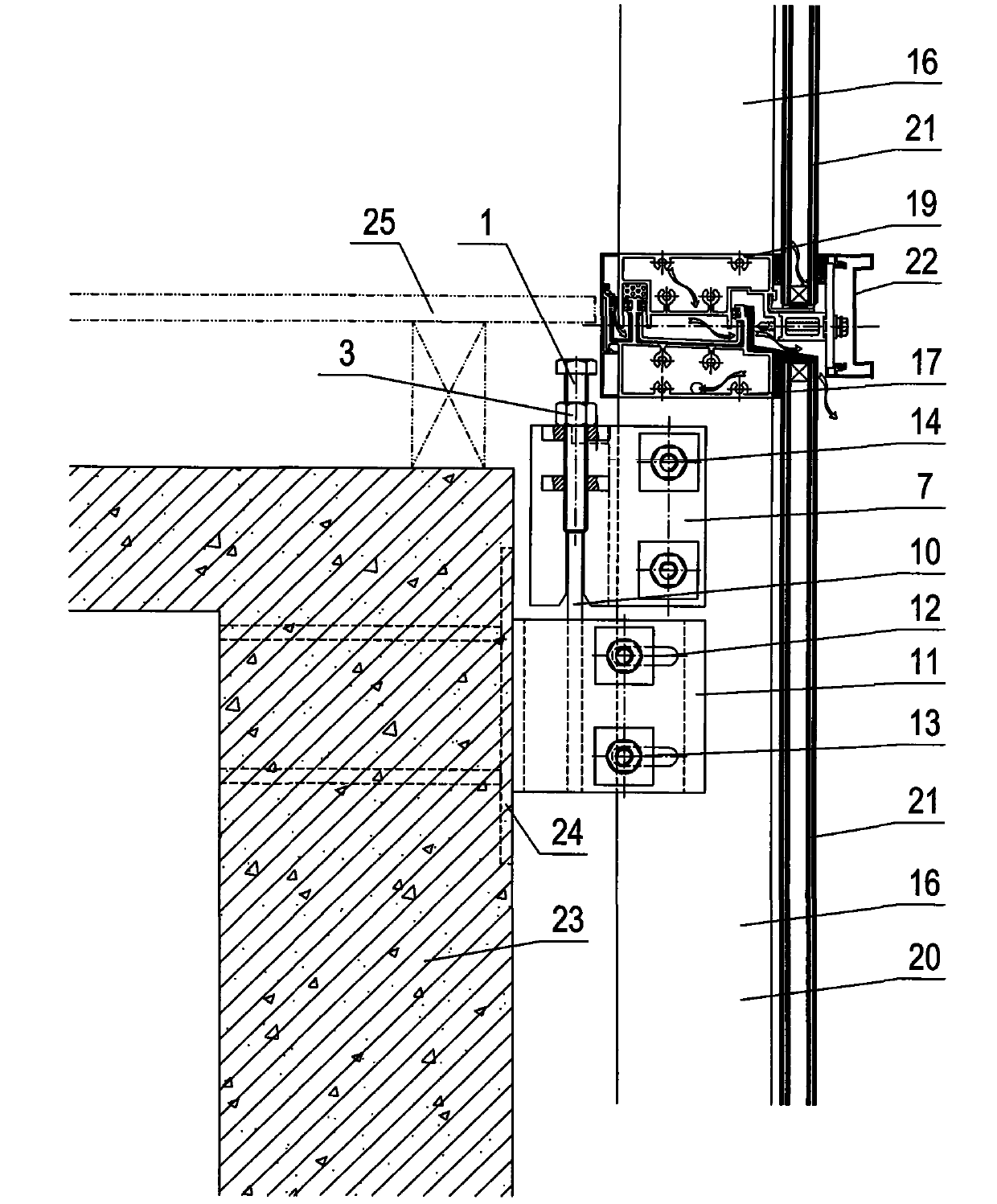

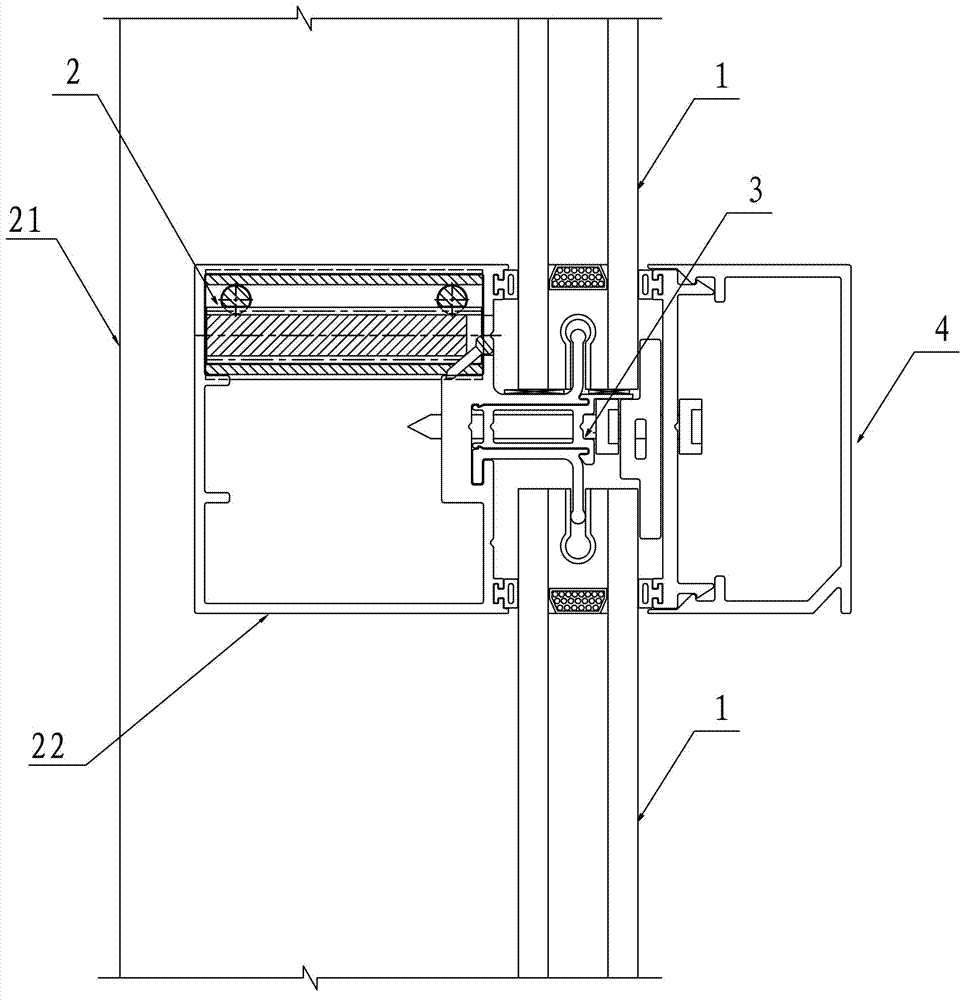

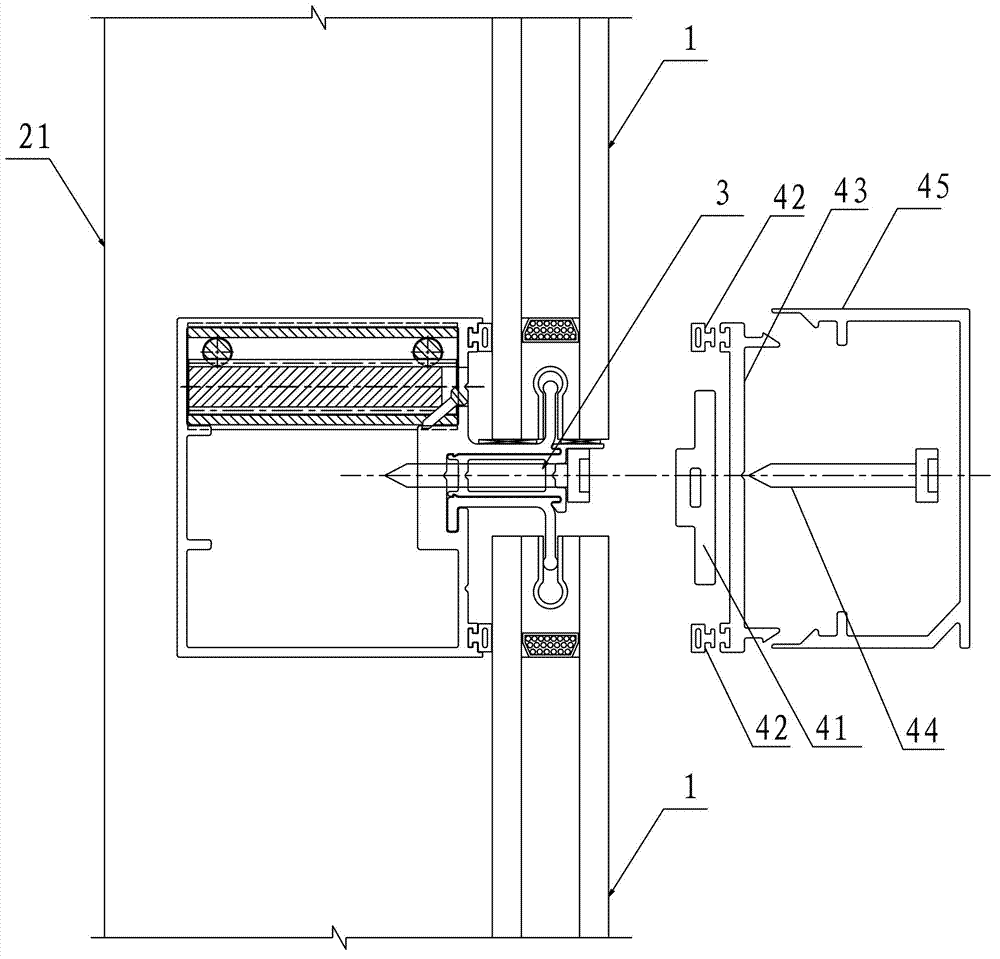

Force bearing device three-dimensionally adjusted and positioned by unitized curtain wall

The invention relates to a force bearing device three-dimensionally adjusted and positioned by a unitized curtain wall, comprising bearing bolts, a No.1 bracket, a No.2 bracket, a No.3 bracket and a unitized curtain wall vertical wooden stick, wherein the bearing bolts are installed in a tapped hole; the tapped hole is arranged on a bearing flange which is arranged on the No.1 bracket; one end of the No.1 bracket is connected with the unitized curtain wall vertical wooden stick by the inside hexagonal bolt of a cheese head, and the other end is connected with the No.2 bracket by the cooperation of a horizontal slot and a transverse flange; one edge of the No.2 bracket is connected with the No.1 bracket by the cooperation of the horizontal slot and the transverse flange, and the other edge of the No.2 bracket is connected with the No.3 bracket by connecting bolts; one edge of the No.3 bracket is welded with an embedded piece on a main body structure; and the other edge of the No.3 bracket is connected with the No.2 bracket by the connecting bolts. The invention has high strength, small volume, simple processing working procedure and high efficiency, has obvious advantage on the occasions with narrow installation space and is suitable for all unitized curtain wall to install and use.

Owner:WUXI HENGSHANG DECORATION ENG CO LTD

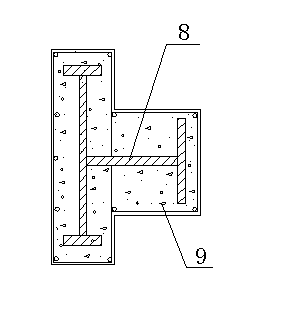

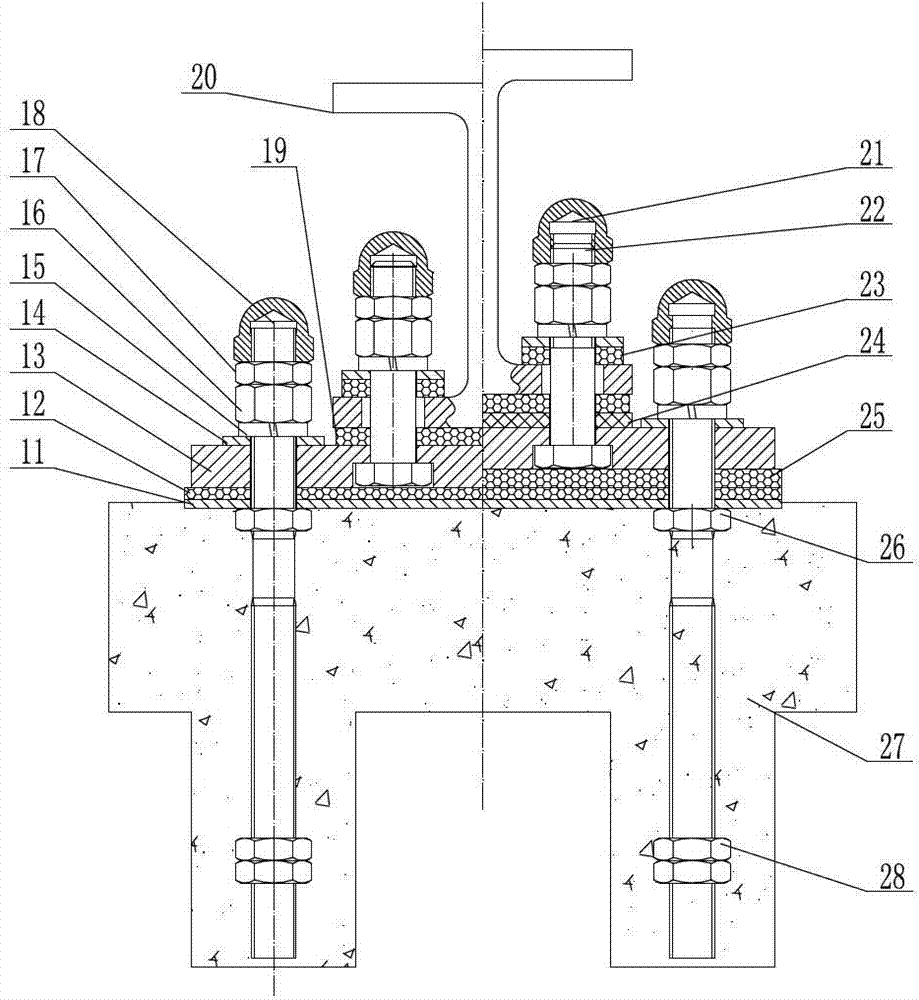

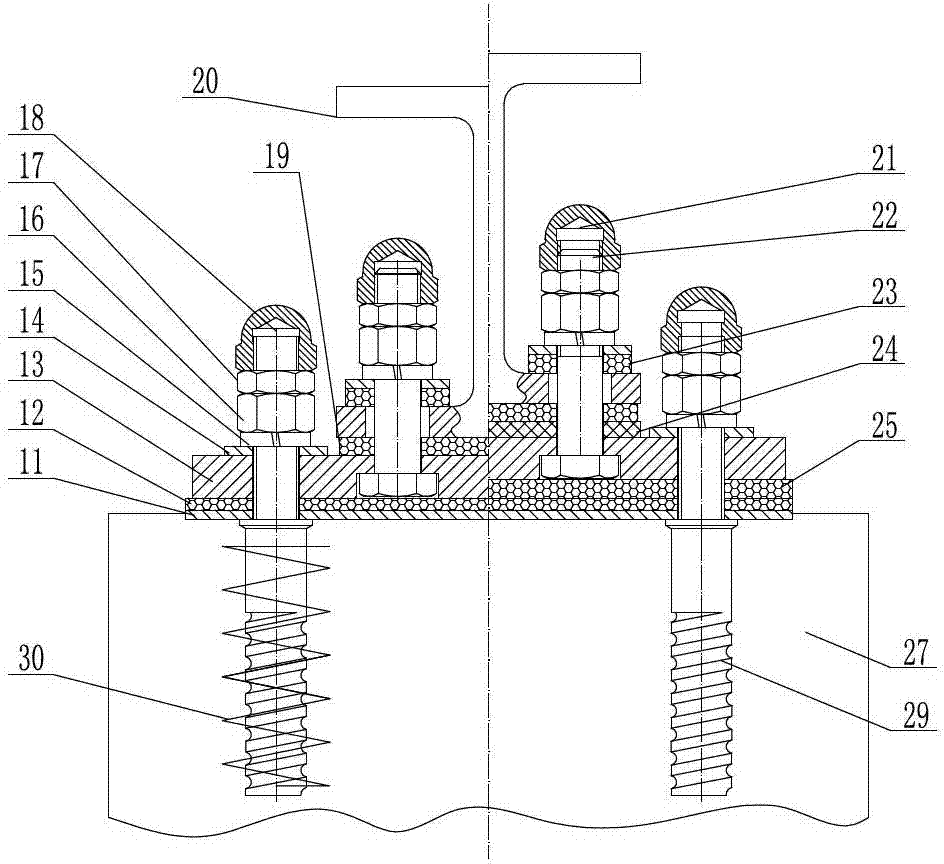

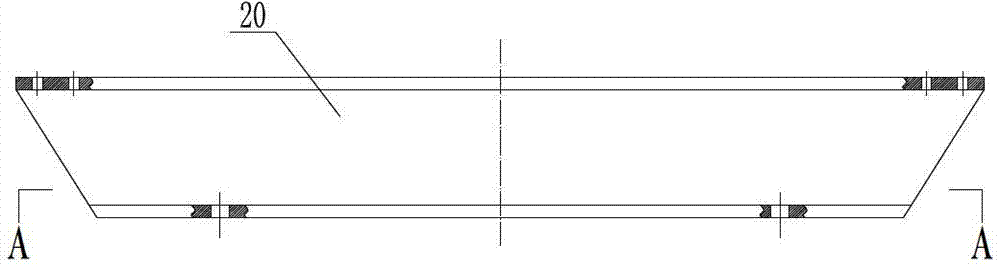

Elastic split type fastener of medium and low speed magnetic suspension rail

ActiveCN102852056AAchieve horizontal stepless adjustmentOvercoming Rough Adjustment NeedsRailway tracksVibration attenuationLow speed

An elastic split type fastener of a medium and low speed magnetic suspension rail has enough strength and buckling pressure, has large rail vertical, transverse and longitudinal adjusting capacity simultaneously provides rail elasticity and achieves bidirectional vibration attenuation. The elastic split type fastener comprises two groups of connection bolt assemblies arranged transversely at intervals and two groups of anchoring bolt assemblies transversely arranged at intervals, wherein the connection bolt assemblies integrate an H-shaped steel pillow with a connection board, vibration attenuation gaskets are arranged on the contact surfaces of the connection bolt assemblies and the H-shaped steel pillow, an under-pillow elastic cushion plate is arranged between a base plate of the H-shaped steel pillow and the connection board, and connection bolt long round holes extending along the circuit direction and used for enabling the upper portions of the connection bolt assemblies to penetrate through are arranged on the bottoms on two sides of the H-shaped steel pillow; and the anchoring bolt assemblies integrate the connection board and a support rail table, the lower portions of the anchoring bolt assemblies are connected with the support rail table in anchoring mode, a buffering cushion plate is arranged between the connection board and an iron cushion plate at the top surface of the support rail table, and anchoring bolt long round holes extending along the direction perpendicular to the circuit and used for enabling the upper portions of the anchoring bolt assemblies to penetrate through are arranged on the connection board.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Large cantilever wave-purlin combined PC bridge and manufacture method thereof

ActiveCN102425099AMake up for stress resistanceMake up for stiffnessBridge structural detailsBridge erection/assemblyPurlinCantilever

The invention relates to a large cantilever wave-purlin combined PC bridge and a manufacture method thereof. The bridge comprises a concrete top plate and a concrete bottom plate, wherein two wavelike steel webs are arranged between the concrete top plate and the concrete bottom plate, the bottom ends of the two wavelike steel webs are respectively connected to two sides of the concrete bottom plate, the upper ends of the two wavelike steel webs are connected with the concrete top plate, an included angle between each wavelike steel web and the concrete bottom plate is not less than 90 degrees, vertical steel purlin pipes placed between the concrete top plate and the concrete bottom plate are arranged between the two wavelike steel webs, and steel purlin web inclined struts are arranged between the concrete top plate and the concrete bottom plate. The steel purlin web inclined struts are formed into a top plate large cantilever, the pulling stress is reduced, and the resistance to pressure is increased, so that the defects of no resistance to pressure and small torsional rigidity in the wavelike steel webs are remedied; the transverse flexural rigidity of the wavelike steel webs is good, and the longitudinal shearing rigidity is large, so that the defects of small transverse flexural rigidity and small longitudinal shearing rigidity of the steel purlin web inclined struts are remedied; and the large cantilever wave-purlin combined PC bridge has the advantages of light self weight, template bracket saving, convenience for construction, shortened construction period and low cost..

Owner:SHENZHEN UNIV +1

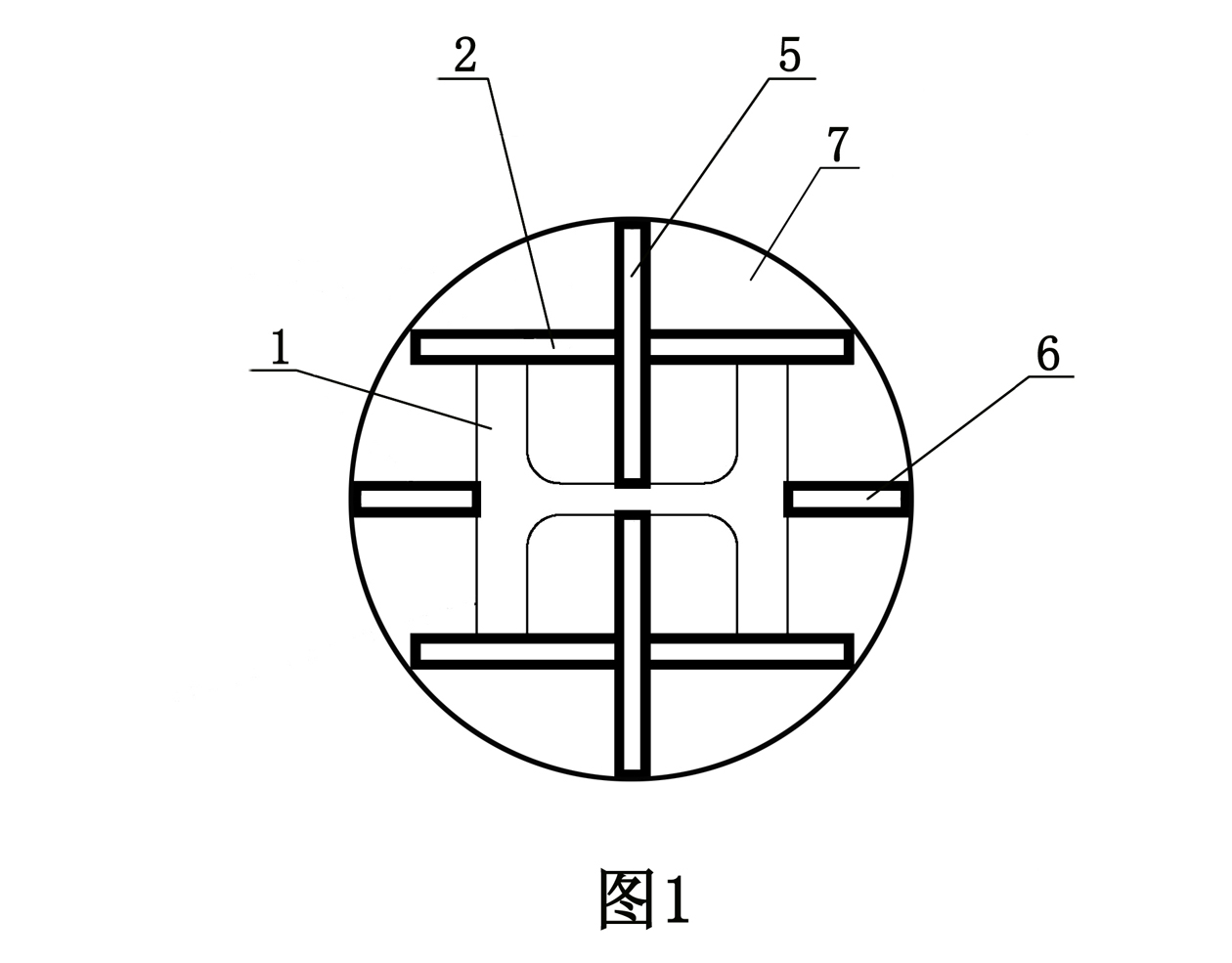

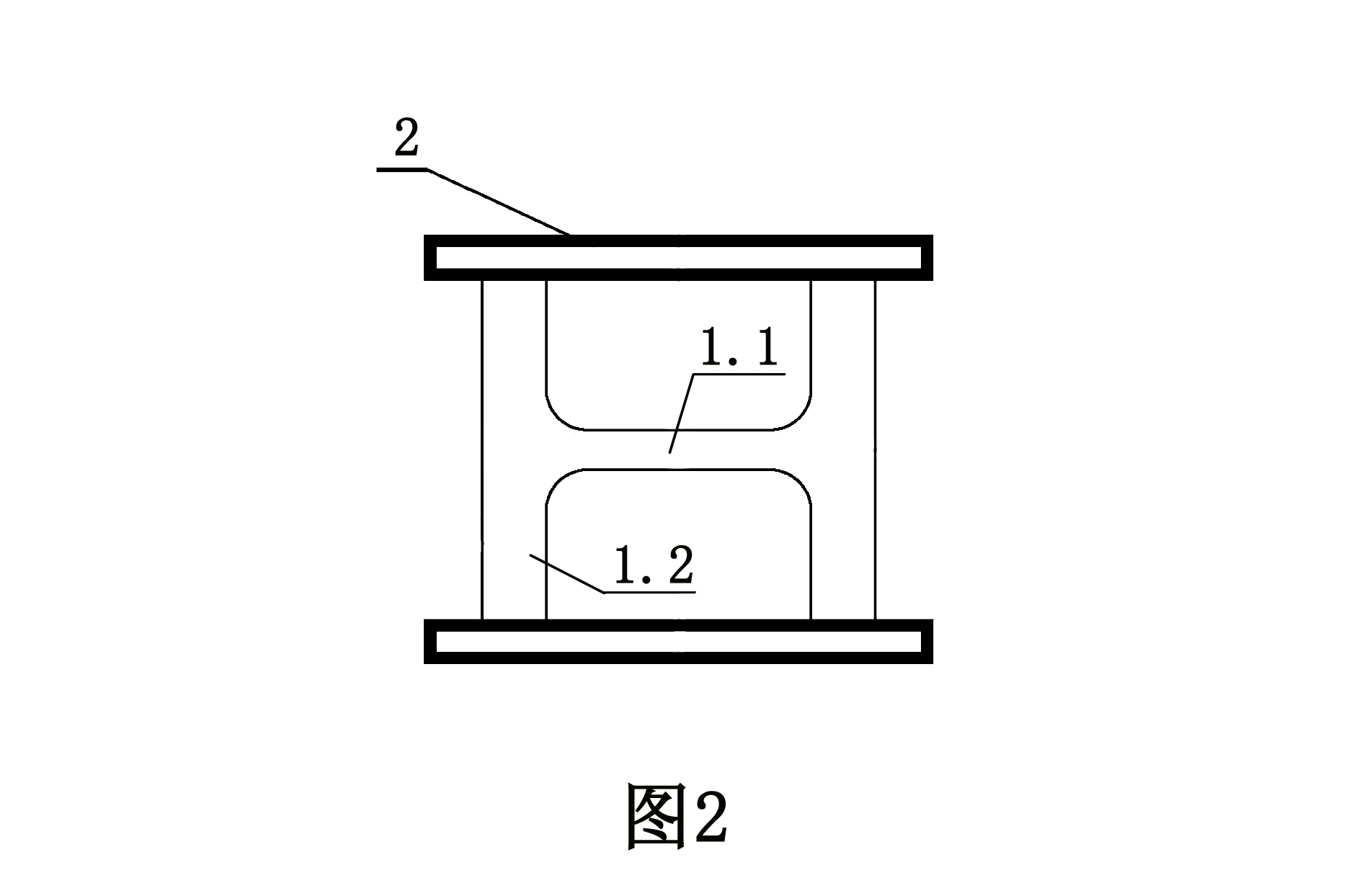

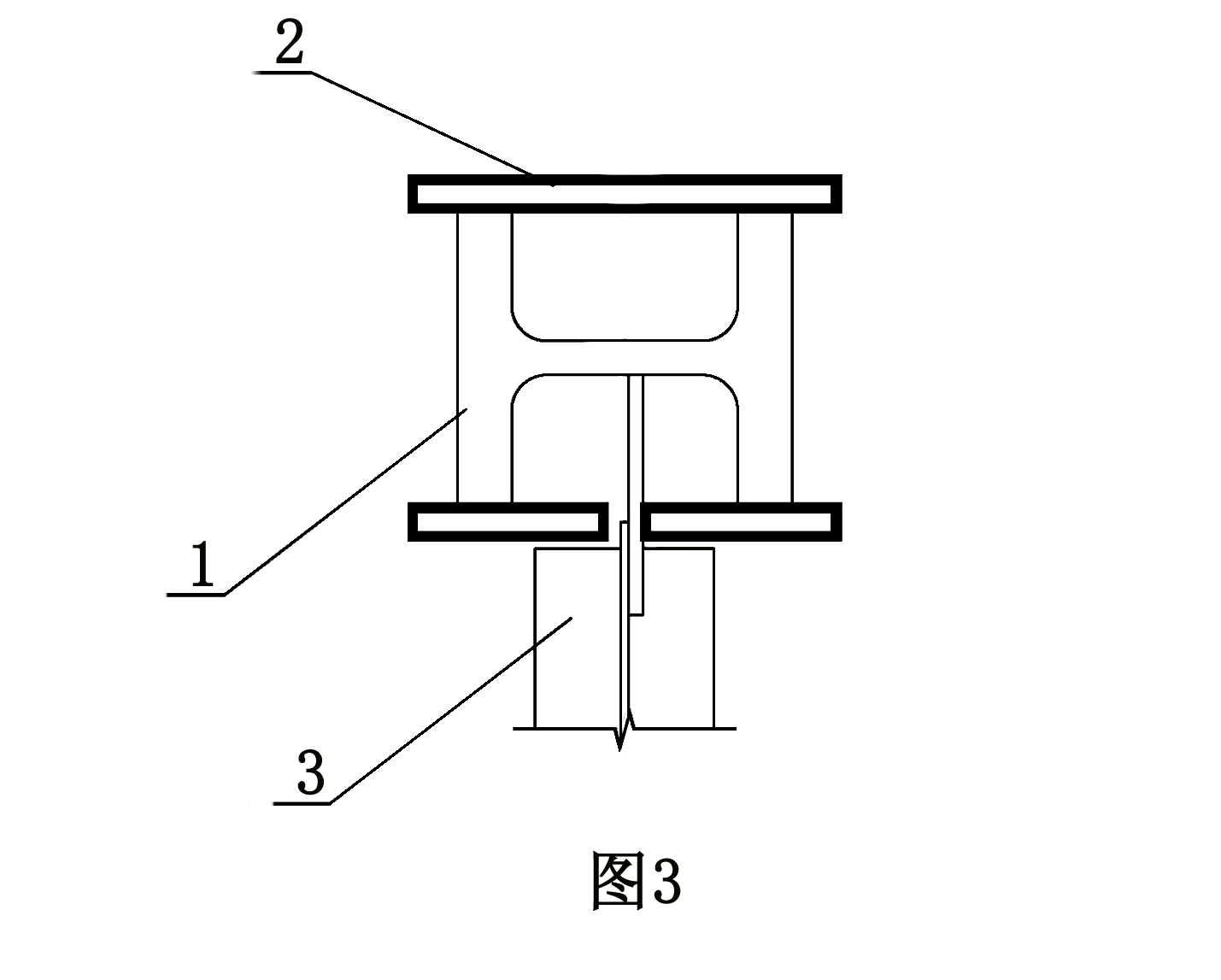

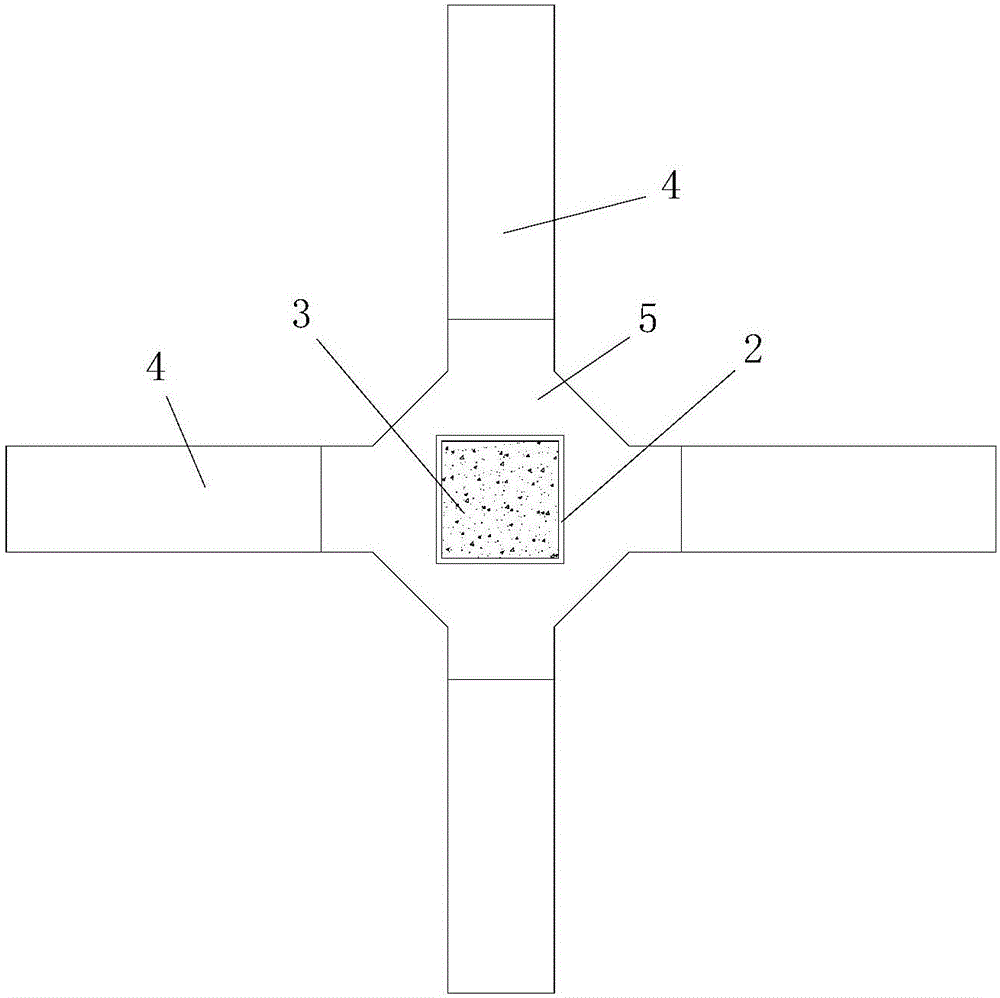

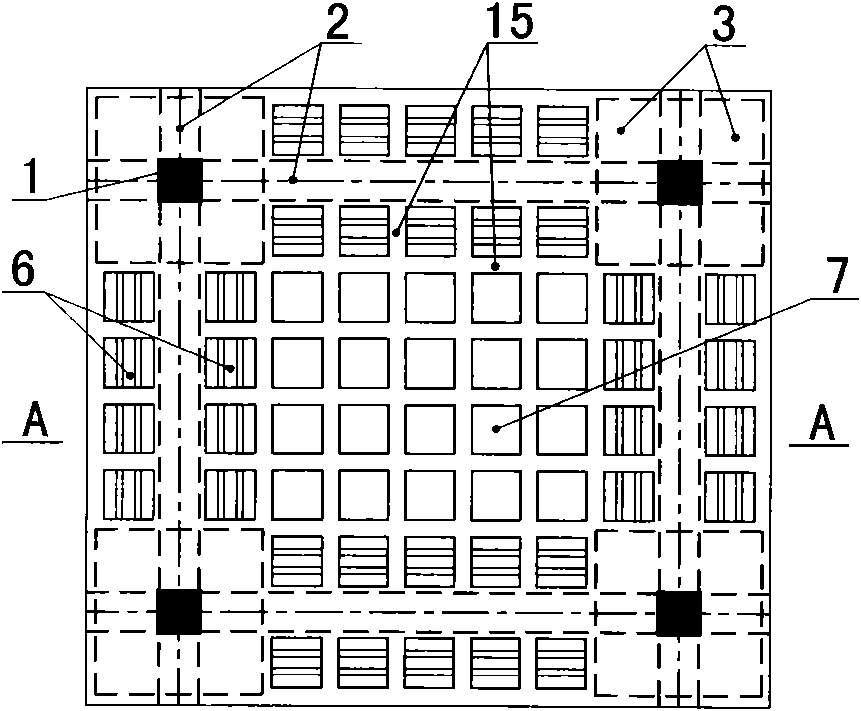

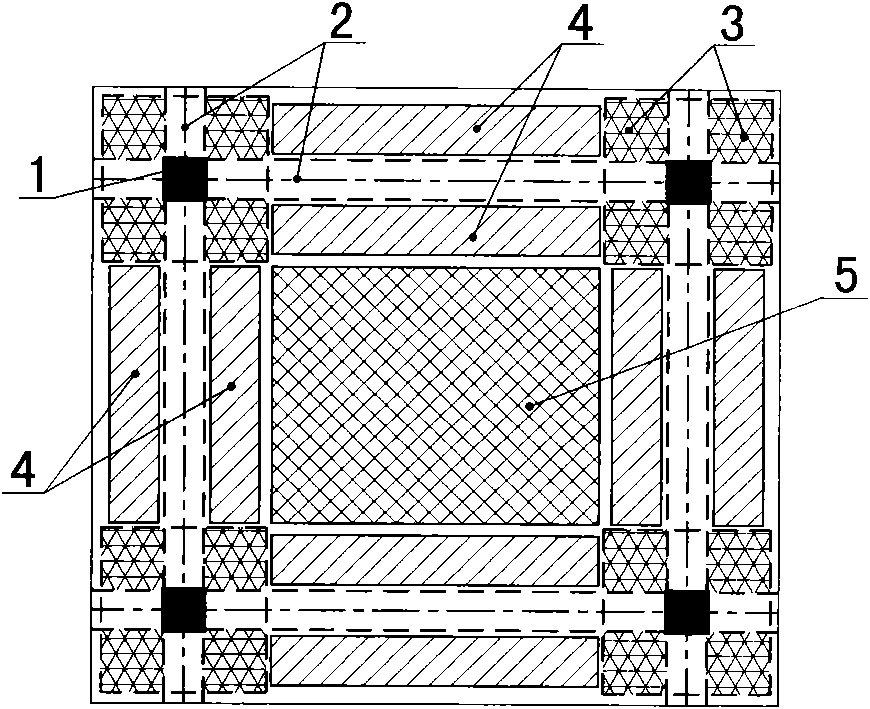

Slab-column structure hollow slap with mixed use of filling rod and filling box

The invention relates to a slab-column structure hollow slap with mixed use of a filling rod and a filling box, and belongs to the field of general building constructions. The hollow slap comprises a column (1), a beam (2), a column side solid area (3), a beam side hollow area (4) and a central hollow area (5), and is characterized in that: a filling rod combined block (6) is arranged in the beamside hollow area (4); the orientation of the filling rod combined block (6) in the beam side hollow area (4) is accordant with the direction of the beam (2) which is adjacent to the filling rod combined block (6); the filling box (7) is arranged in the central hollow area (5); and the filling rod combined block (6) and the filling box (7) are positioned between an upper layer steel bar (8) and a lower layer steel bar (9) and are permanently embedded in concrete (10). A hollow floor provided by the invention is reasonably stressed along with a high hollow ratio, and the structure of the hollowfloor also has high reliability, earthquake resistance and cracking resistance, so the hollow floor has high economical efficiency and practicability.

Owner:宁夏千弓预应力技术工程有限公司

Supporting steel frame of high altitude large-span cantilever structure mold frame

InactiveCN102454292AReasonable structural stressIncrease stiffnessForms/shuttering/falseworksFloor slabEconomic benefits

The invention discloses a supporting steel frame of a high altitude large-span cantilever structure mold frame. The supporting steel frame comprises a floor slab, a supporting frame and a cantilever beam, wherein the supporting frame is of triangular shape; the lower end of the triangular supporting frame is mounted on an embedded iron piece on a lower floor slab; the upper end of the triangular supporting frame is provided with the cantilever beam; and one end of the cantilever beam penetrates in an anchoring ring mounted on an upper floor slab and is wedged through a wooden wedge. The supporting steel frame of the high altitude large-span cantilever structure mold frame, disclosed by the invention, has the advantages of reasonable stress, high rigidity, strong bearing force at the cantilever end, large cantilever span, strong bearing force, large rigidity of the frame body and capability of effectively ensuring the integral stability and construction safety of the large-span cantilever structure mold frame. The steel frame can be integrally spliced on the site in advance and has the advantages of lightweight frame body, convenience for mounting and detaching and labor and time conservation. The supporting steel frame can be recycled for multiple times, obtains better economic benefits and is worthy of being generalized.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

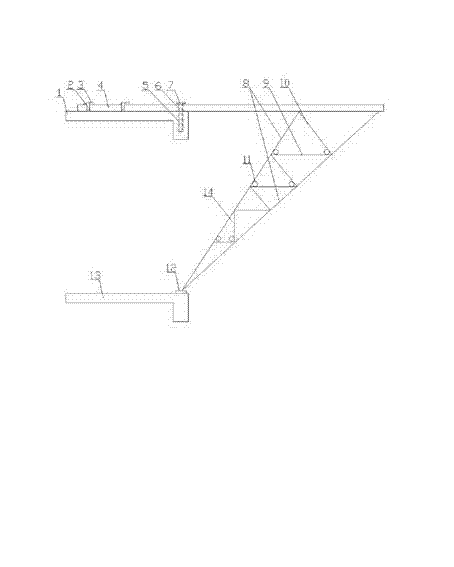

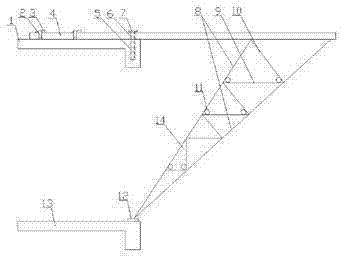

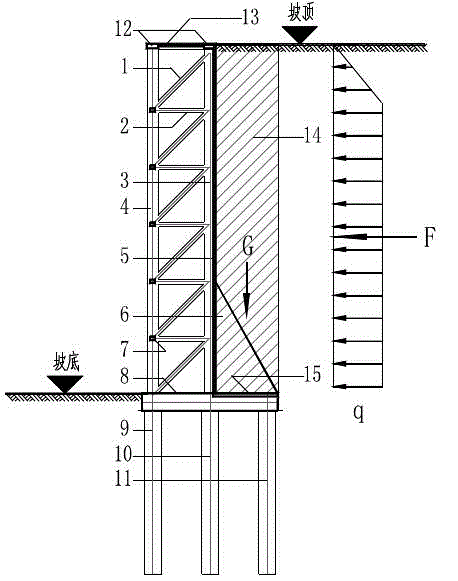

Truss type retaining wall

ActiveCN104652475ASimple structureHigh material utilizationArtificial islandsUnderwater structuresCantileverRetaining wall

The invention discloses a truss type retaining wall. The upper end of a lower part pile foundation is connected with an upper part truss structure through a bearing platform beam; the upper part truss structure comprises upper chord stand columns, lower chord stand columns, horizontal web girders, inclined web girders, transverse connecting beams and retaining plates; wherein the lower chord stand columns are connected through the transverse connecting beams to form a grid structure; each upper chord stand column is connected with the corresponding lower chord stand column through a plurality of horizontal web girders and a plurality of inclined web girders; every two adjacent upper chord stand columns are connected through the retaining plates to form an integrated retaining wall. The invention relates to a vertically placed cantilever truss structure system, which mainly utilizes the rationality and the stability of stress of truss triangular structure arrangement to improve the bearing capability and the lateral migration resisting ability of a retaining structure. Meanwhile, the overturning moment of a vertical truss retaining structure is balanced by utilizing the weight G of anti-pressure soil on the upper part of the bearing platform. According to the truss type retaining wall provided by the invention, the material intensity can be fully utilized, and the material utilization ratio is improved, and the construction cost of the foundation is reduced.

Owner:CHONGQING UNIV +1

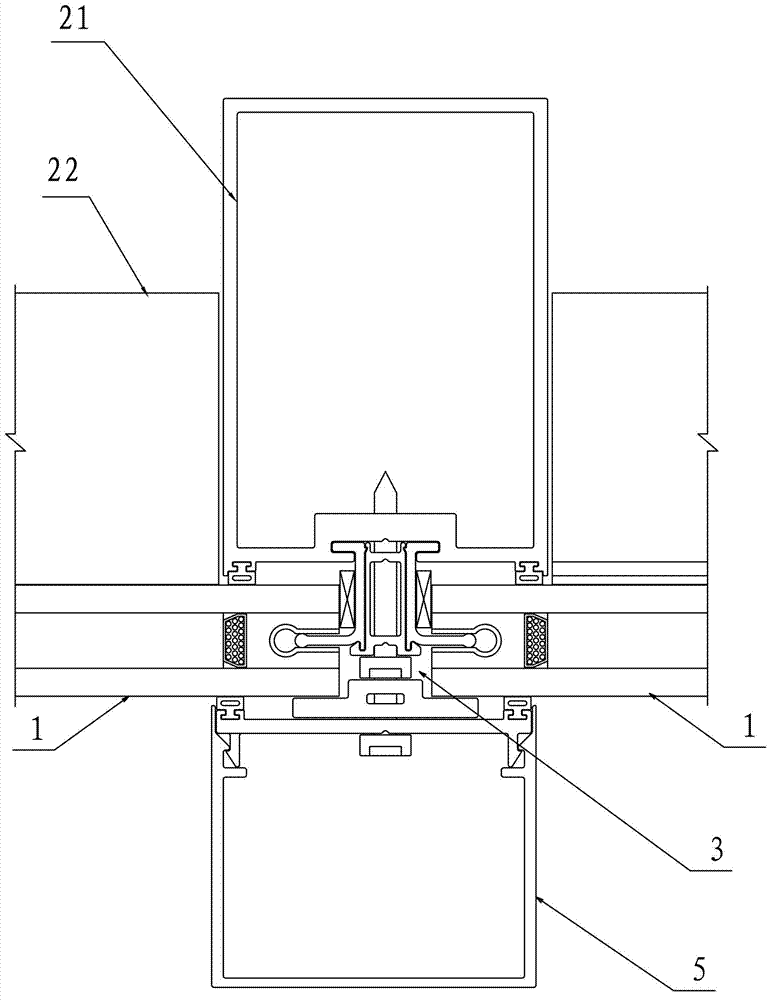

Curtain wall

InactiveCN102776971ASave materialAvoid secondary environmental pollutionWallsStructural engineeringEngineering

The invention mainly discloses a curtain wall. The curtain wall comprises hollow glass, upright columns and crossbeams, wherein the upright columns are connected with the crossbeams through first connecting joints to form a main structure body, and the hollow glass is connected with the crossbeams through second connecting joints. The hollow glass is assembled on the second connecting joints to form a hidden frame type curtain wall system. The novel curtain wall with the structure innovates the structure of the conventional curtain wall, initiates a new structure of a hidden frame type curtain wall in a curtain wall system, is reasonable in structure stress, is clean and elegant in appearance, and is safe and flexible to assemble.

Owner:ZHEJIANG BAOYE CURTAIN WALL DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com