Precast slab type ballastless track structure

A ballastless track and prefabricated slab technology, applied in tracks, roads, buildings, etc., can solve the problems of complex stress on bridges and track systems, expensive finishing of track slabs, and complicated construction operations, and achieve a clear transmission path of structural mechanics. , to meet the high smoothness and high stability, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

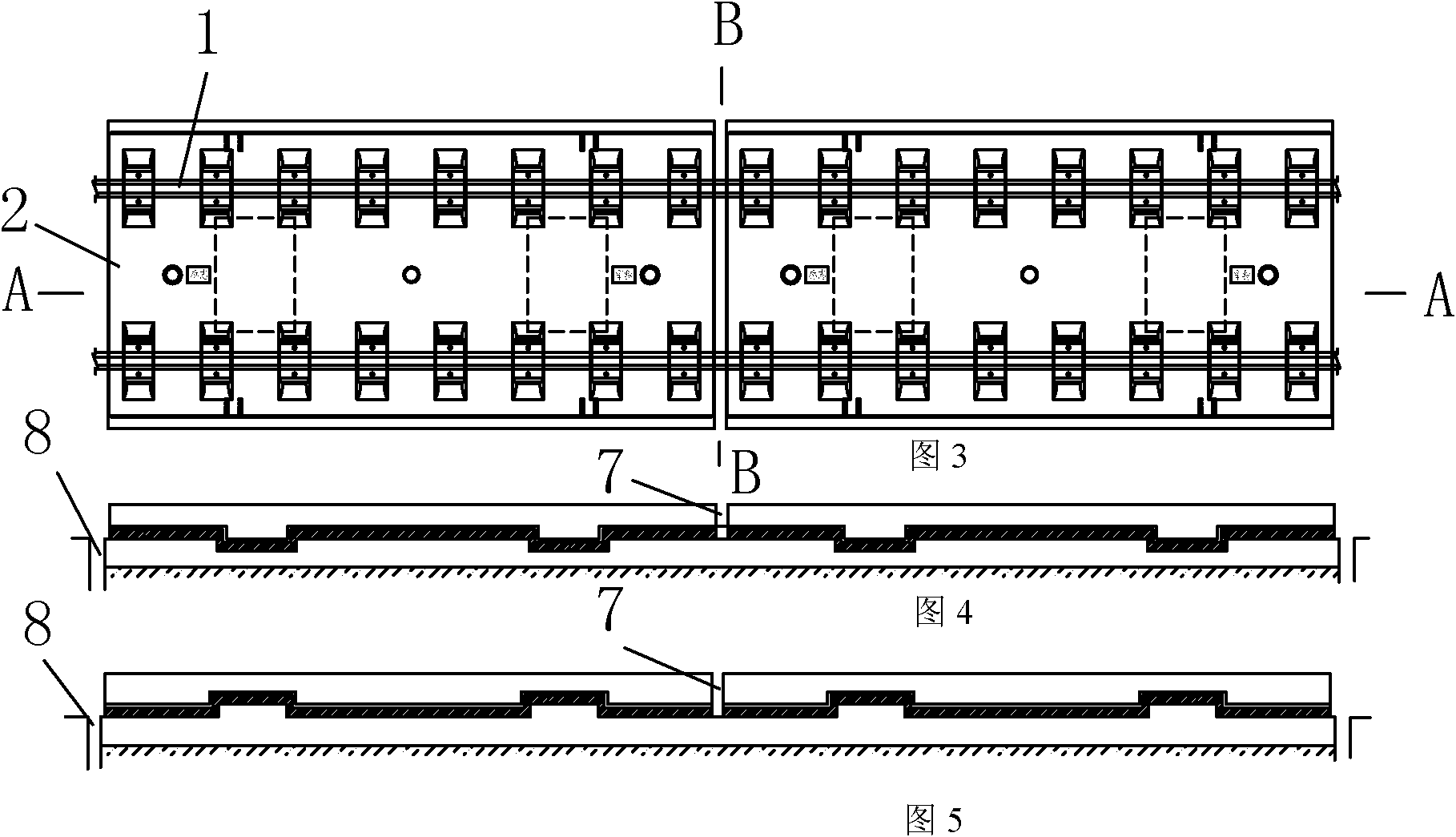

[0061] Embodiment 1: see image 3 , Figure 4 and Figure 6 . This embodiment is composed of a steel rail 1, a fastener, a prefabricated track slab 2, an adjustment layer 3, and a reinforced concrete base 4. Wherein, the prefabricated track slab 2 is located on the base 4, and self-compacting concrete is filled between the base and the track slab as an adjustment layer 3, and steel mesh sheets are arranged therein. The prefabricated track slab 2 has a unit block structure along the longitudinal direction, and transverse gaps 7 are provided between adjacent prefabricated track slab units. The base 4 is also a unit block structure in the longitudinal direction, and a transverse gap 8 is provided between adjacent base units. Each base unit is provided with at least one prefabricated track plate unit. The base unit of this embodiment is provided with two A prefabricated track slab unit. The transverse gaps 7 between adjacent prefabricated track slab units and the transverse g...

Embodiment 2

[0068] Example 2: see image 3 , Figure 5 and Figure 6 . This embodiment is basically the same as Embodiment 1, except that a groove 6 is provided on the lower surface of the prefabricated track plate 2, and a boss 5 is set on the base 4 corresponding to the groove 6 on the prefabricated track plate. 5 cooperates with groove 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com