Patents

Literature

467 results about "Track bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The track bed or trackbed is the groundwork onto which a railway track is laid. Trackbeds of disused railways are sometimes used for recreational paths or new light rail links. According to Network Rail, the trackbed is the layers of ballast and sub-ballast above a prepared subgrade/formation (see diagram). It is designed primarily to reduce the stress on the subgrade.

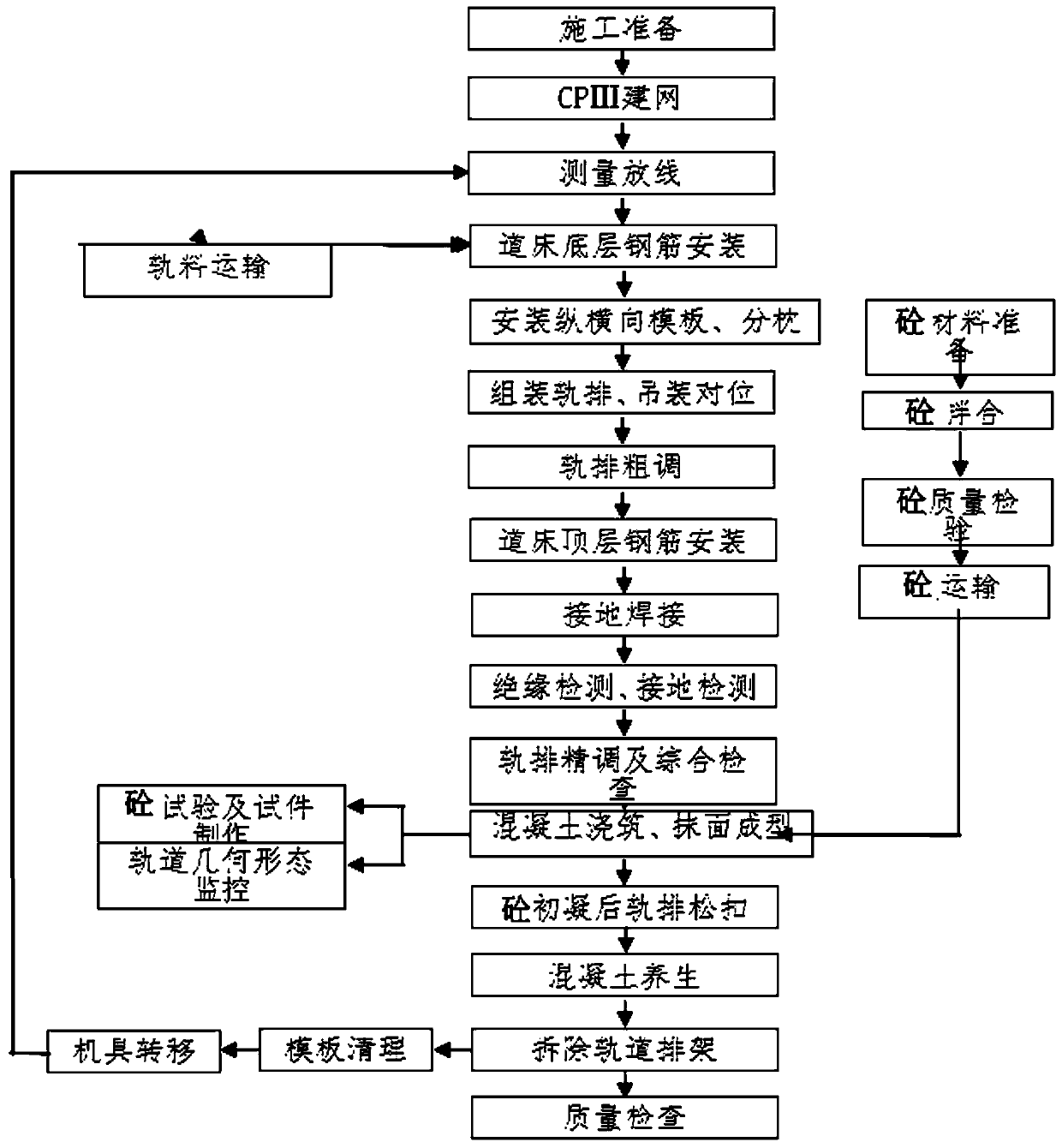

Construction method for two-block unballasted track bed board

InactiveCN101503870AAchieve precise positioningTooling system is simpleRailway track constructionEngineeringRebar

The invention relates to a construction method for a double-block-type ballastless track bed slab, which comprises the following steps: 1, clearing a base surface and performing construction lofting; 2, placing a bottom layer of reinforcing steel bars, and laying sleepers; 3, mounting a tool track and adjusting the sleepers; 4, assembling track panels; 5, coarsely adjusting the track panels; 6, binding the reinforcing steel bars and performing earthing welding; 7, mounting templates and finely adjusting the track; 8, casting concrete into the track bed slab; 9, loosening adjusting devices and fasteners, and curing the concrete; and 10, relocking the tool track and completing the measurement. The construction method has the advantages that: the tool track is adopted as a detection standard, so the precise positioning of the track is realized; a frock system is simple, is easy to process and manufacture, has wide commonality, and is not only suitable for construction of the track bed slab in a subgrade section but also suitable for construction of the track bed slab in a bridge section; the construction process is simple and quick, and various working procedures are easily carried out by flow construction; and the construction cost is low, so the construction investment is effectively saved.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

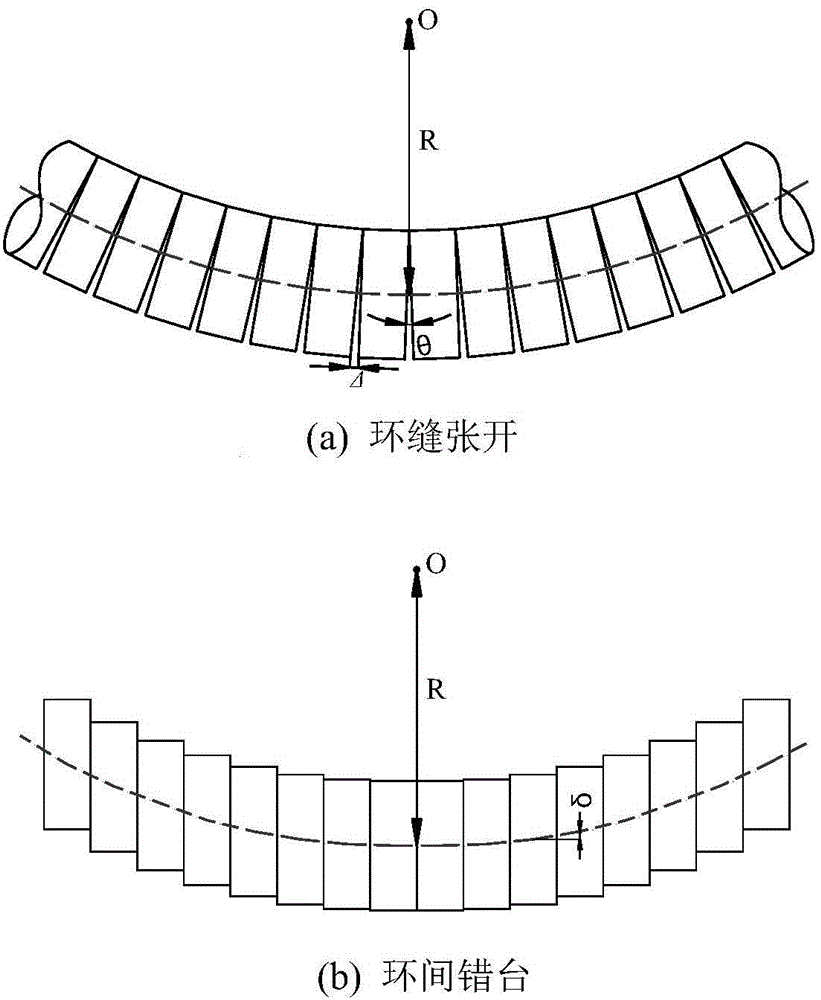

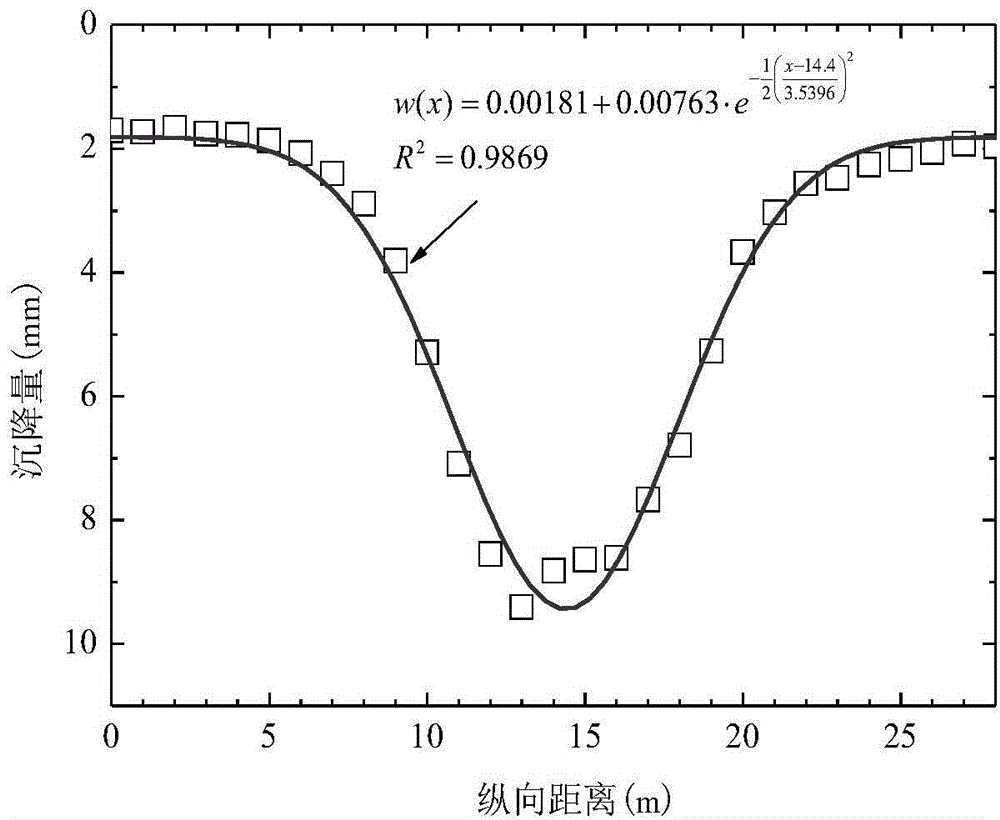

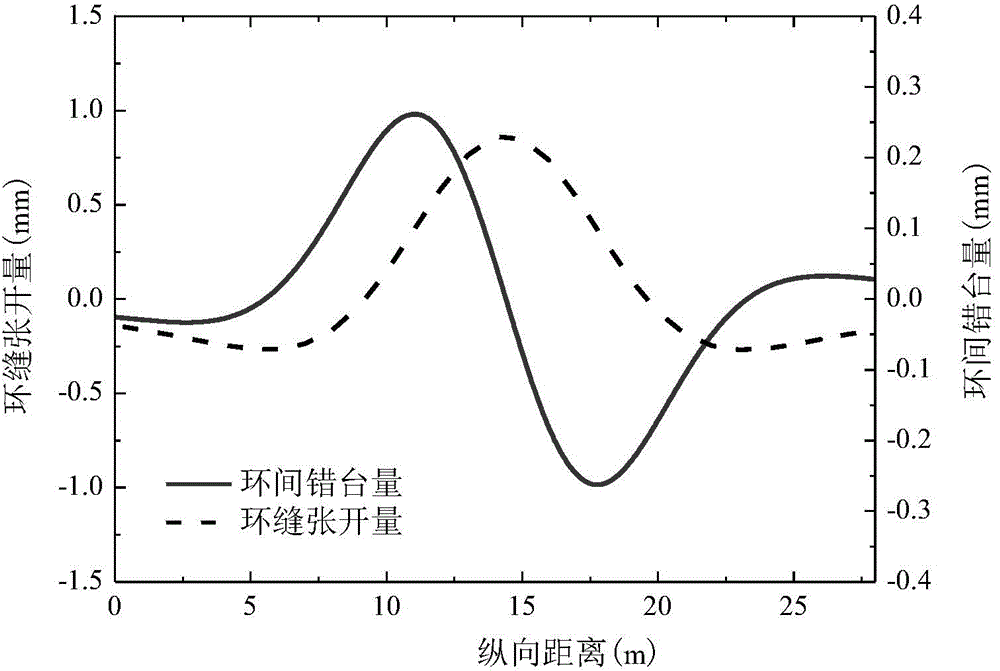

Method for determining capability of resisting slab staggering and expanding deformation of joints between shield tunnel lining rings

InactiveCN104537162AAccurate calculationSimple methodSpecial data processing applicationsShear stiffnessEngineering

The invention provides a method for determining the capability of resisting slab staggering and expanding deformation of joints between shield tunnel lining rings. The method comprises the steps that firstly, the design information of a shield tunnel is obtained; secondly, the longitudinal equivalent bending rigidity and the longitudinal equivalent shearing rigidity of a Timoshenko beam tunnel model are determined by combining the lining design information of the tunnel and the design information of the shield tunnel; thirdly, measuring points are embedded in a track bed of the tunnel, and the settlement volumes of all the longitudinal lining rings of the tunnel are determined; fourthly, fitting is conducted on settlement monitoring values of the tunnel through the Gaussian curve, a fitting equation of a settlement curve is obtained, and the range of the influence of a settlement funnel is judged; fifthly, rotating angles of the lining rings of the tunnel are determined by using the fitting equation of the settlement curve and combining the longitudinal equivalent bending rigidity and the longitudinal equivalent shearing rigidity of the tunnel; sixthly, the expansion amount of the joints of the rings and / or the slab staggering amount between the rings are / is determined. The method is simple, practical, convenient to popularize and suitable for determining the capability of resisting slab staggering and expanding deformation of the joints between the shield tunnel lining rings.

Owner:SHANGHAI JIAO TONG UNIV

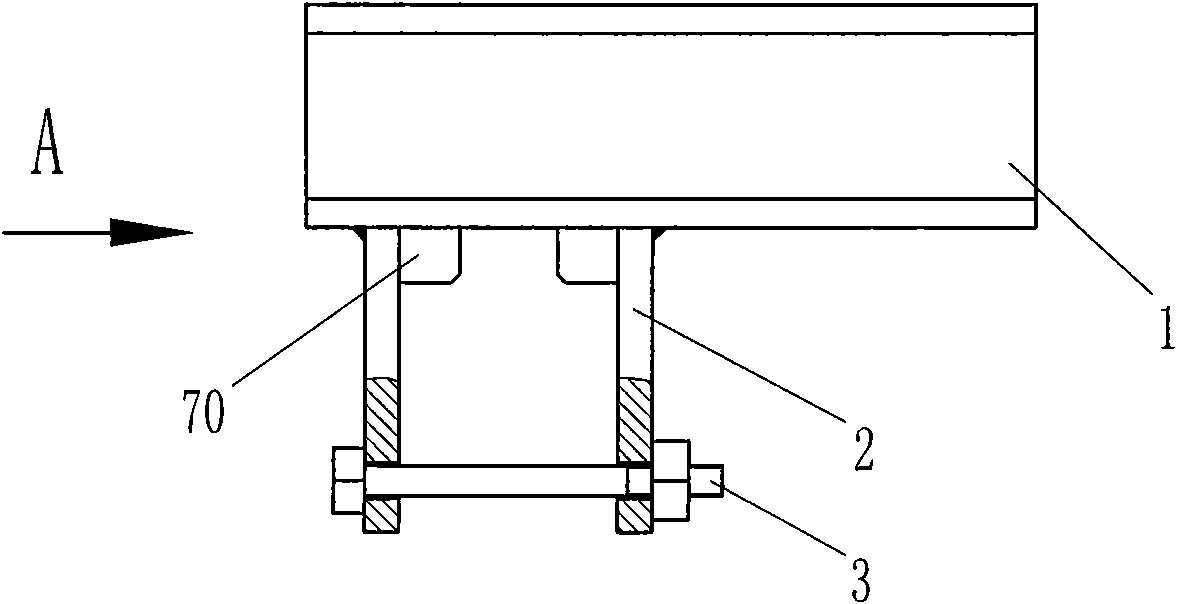

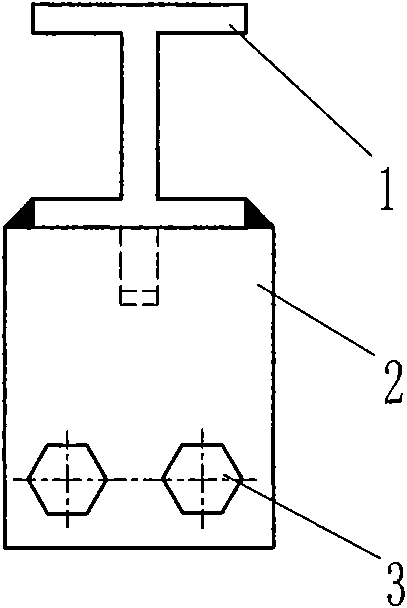

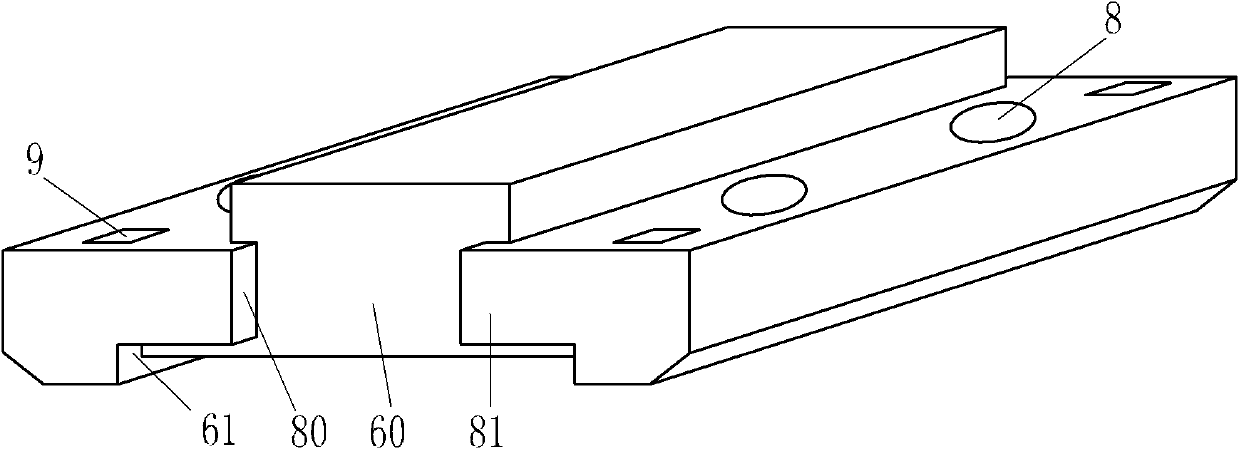

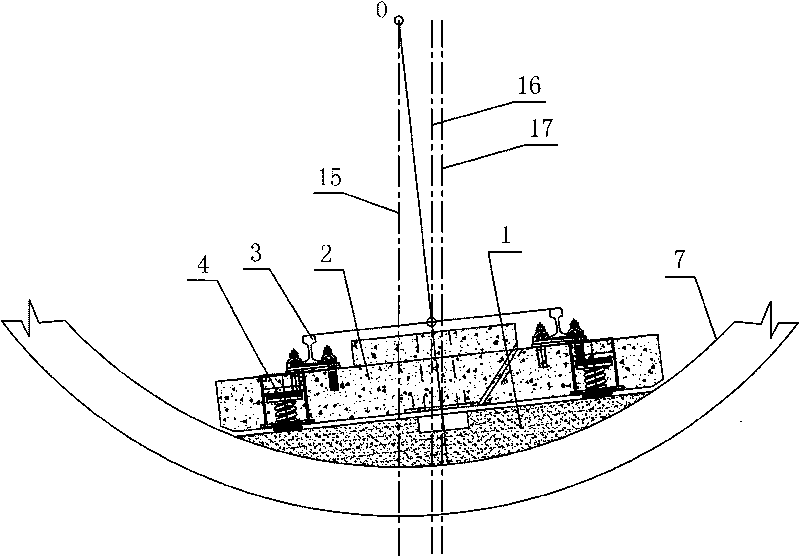

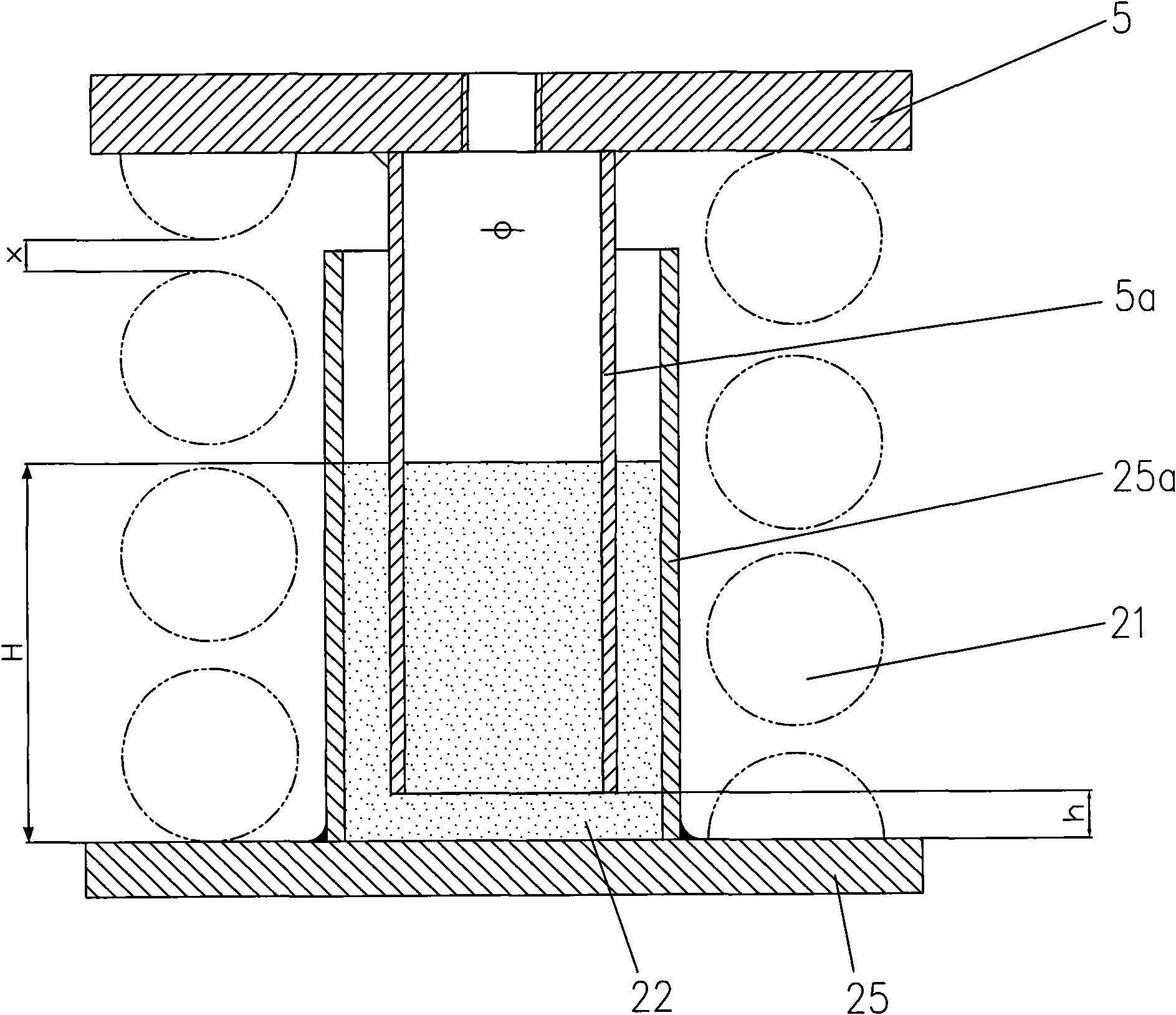

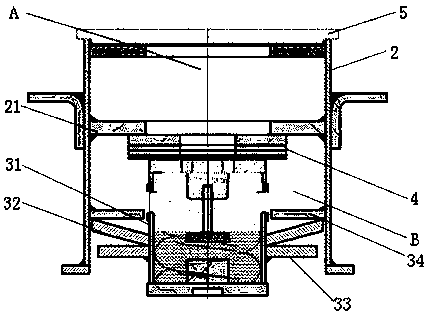

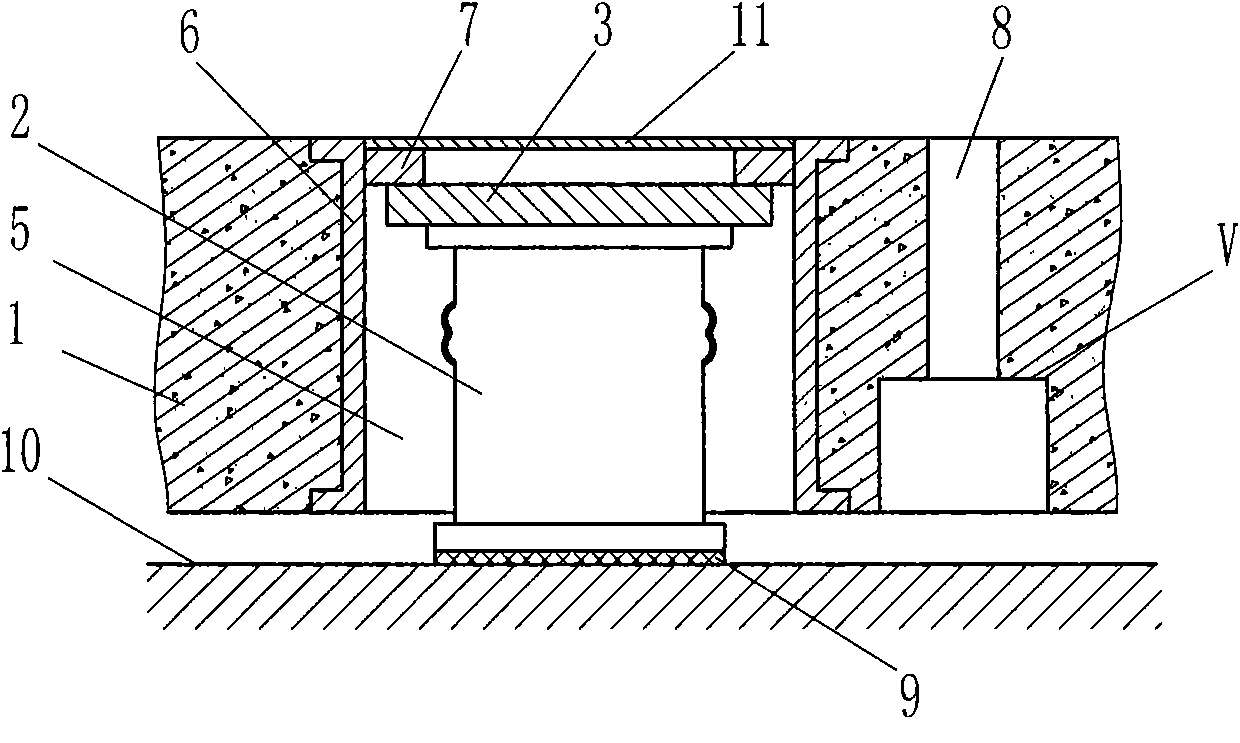

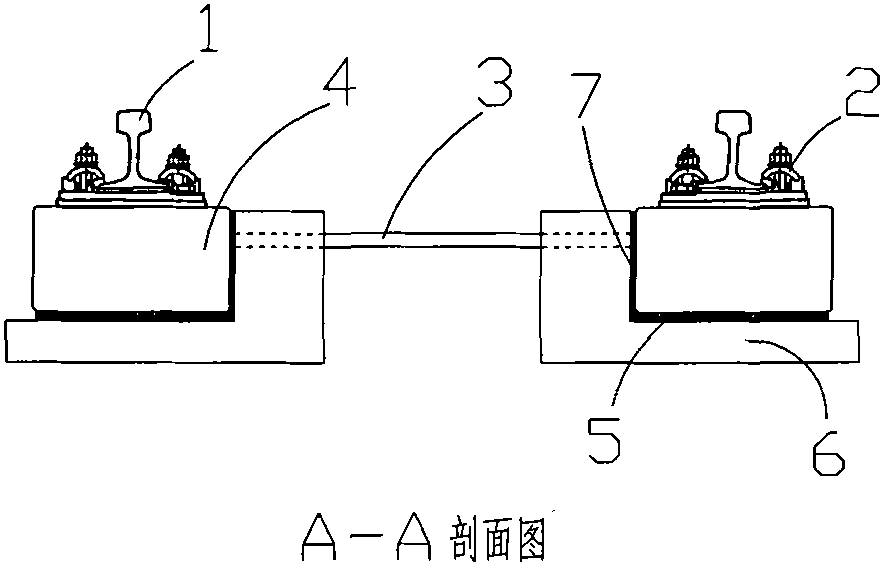

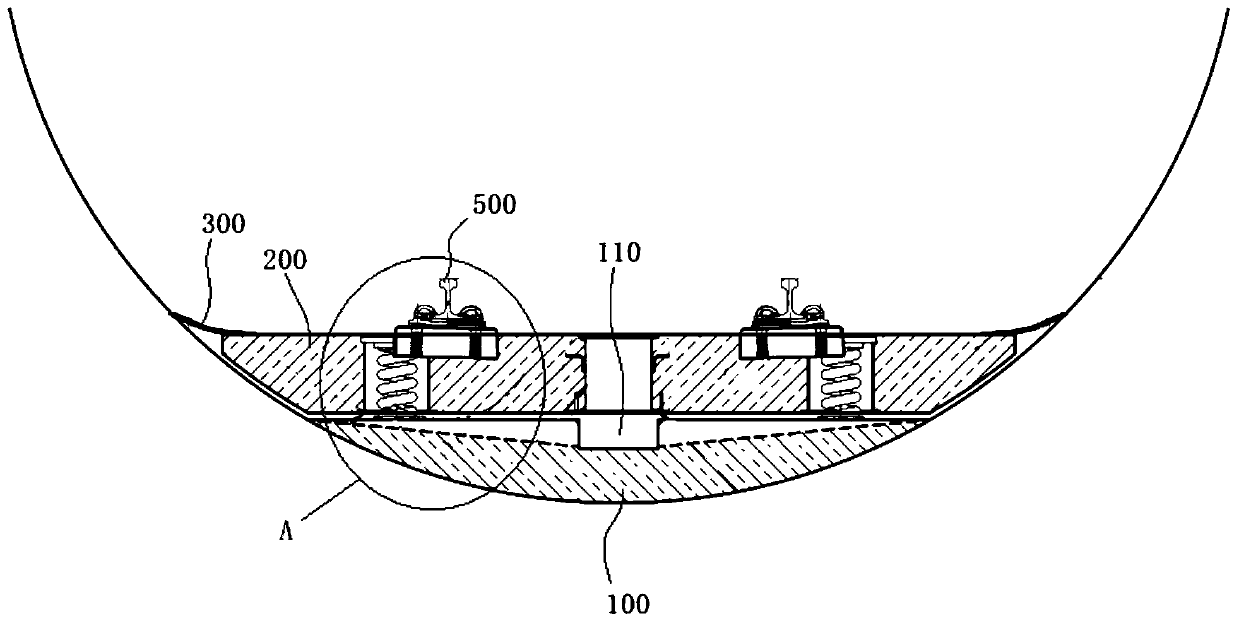

Built-in type floating track bed and method and device for lifting same

The invention relates to a track bed and a method and a device for lifting the same. The floating track bed is lifted by using a carrying beam which can be connected with a steel rail or floating plate through a locking clamp or hanging clamp as the support of the force of the working jack, thus the defect existing in the prior art that the floating track bed is lifted by using a lifting baffle block as the support of the force of the working jack is overcome. The device and the method have a lower requirement for the lifting space in and above a vibration isolating device and are more applicable. In addition, the device has simple structure, convenient operation, reliable performance and high work efficiency and can be widely used for lifting the built-in type floating structure, particularly the built-in type floating track bed and maintaining and replacing the vibration isolating device thereof in the later period.

Owner:尹学军

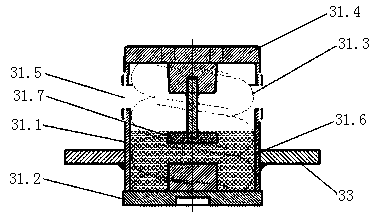

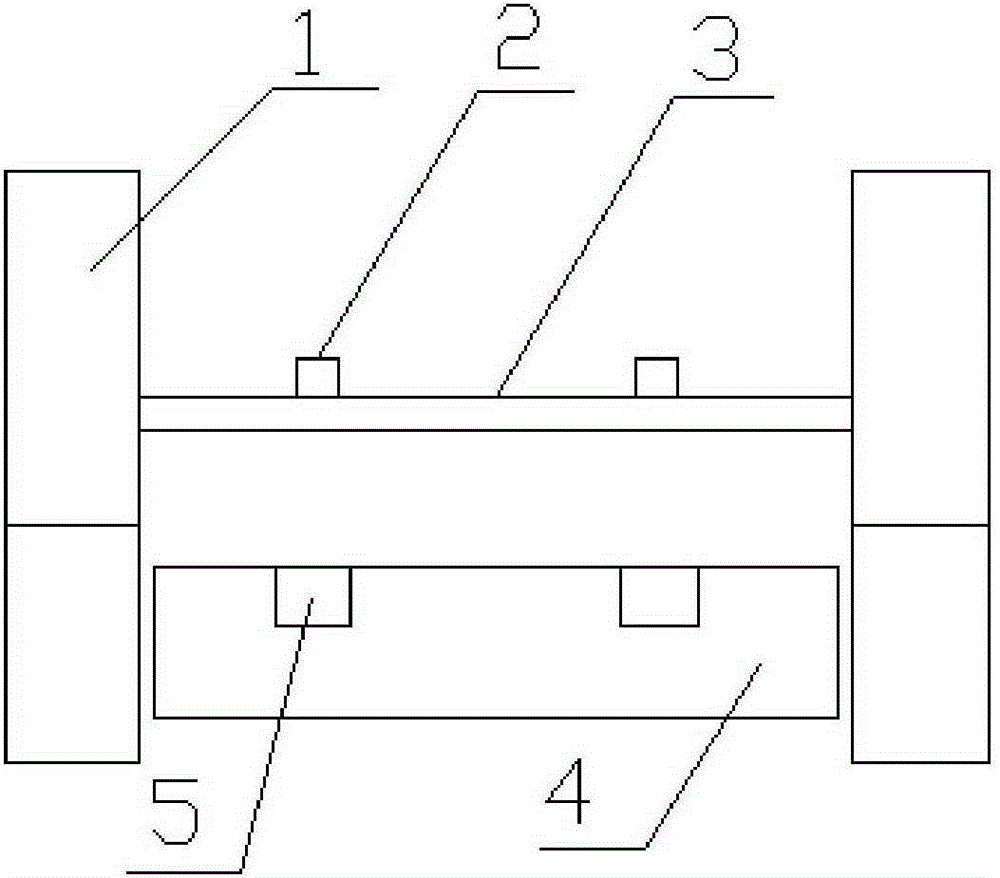

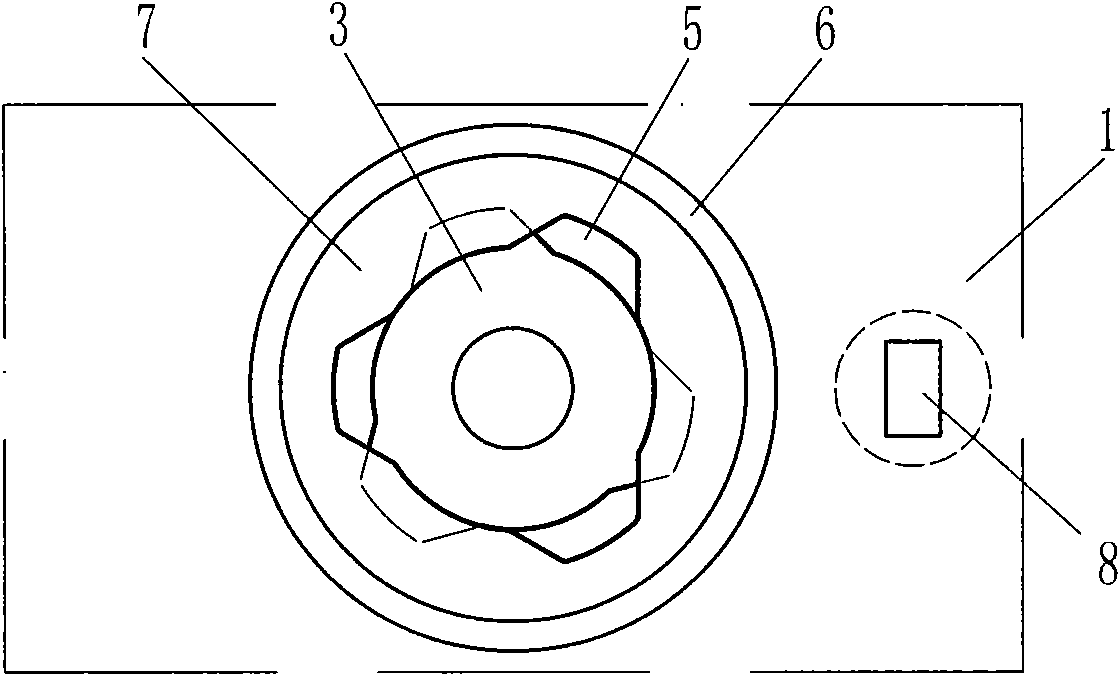

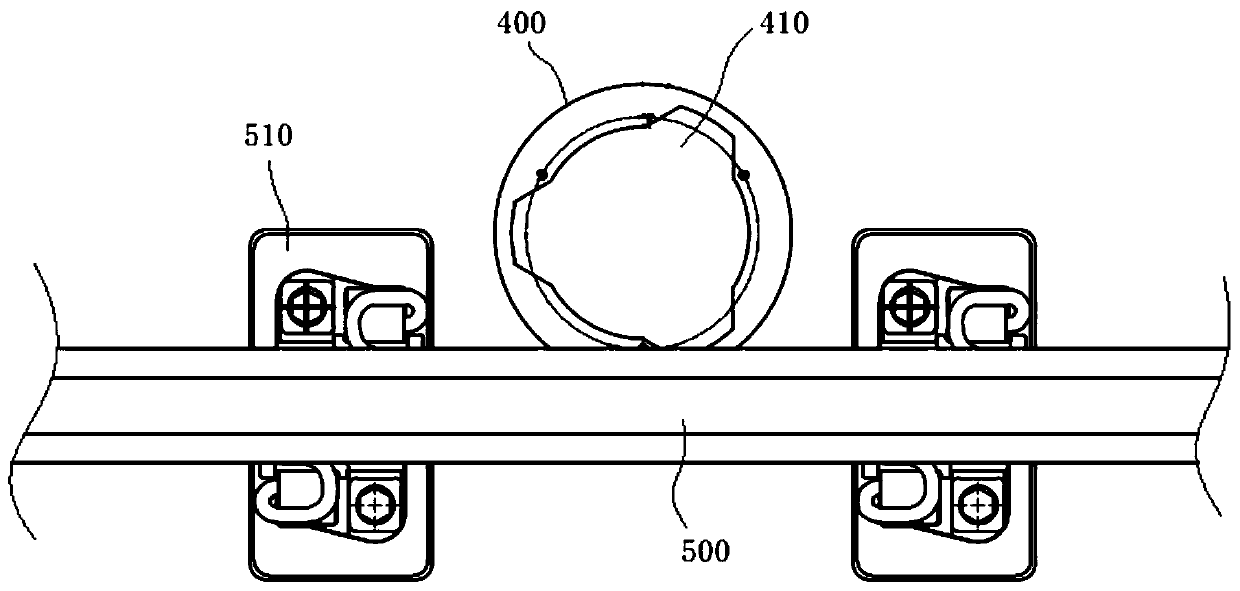

Slab end isolation mounting device for floating track bed

The invention belongs to the field of vibration control and relates to a slab end isolation mounting device for supporting a floating slab in a floating track bed. The slab end isolation mounting device comprises a top slab, a bottom slab, an elastic element and a damping element, wherein the elastic element and the damping element are arranged between the top slab and the bottom slab. The slab end isolation mounting device is characterized in that the top slab is provided with a slab end horizontal limiting device; the slab end horizontal limiting device comprises a slab end transverse limiting device or / and a slab end lengthwise limiting device. The slab end isolation mounting device and a prefabricated short slab in the length of 1.2-8m form the structure of the floating track bed together, the prefabricated production and lifting construction of the floating slab are possible, and the prefabricated short slab is limited lengthwise and transversely through the slab end horizontal limiting device, so that the stability and safety of the structure of the floating track bed in the travelling process are guaranteed, the construction speed is greatly improved, the construction period is further shortened, the construction difficulty is reduced, and the production cost is saved. The isolation mounting device is high in practicability, safe, reliable and high in cost performance and has a wide market application prospect.

Owner:GERB QINGDAO VIBRATION CONTROL +1

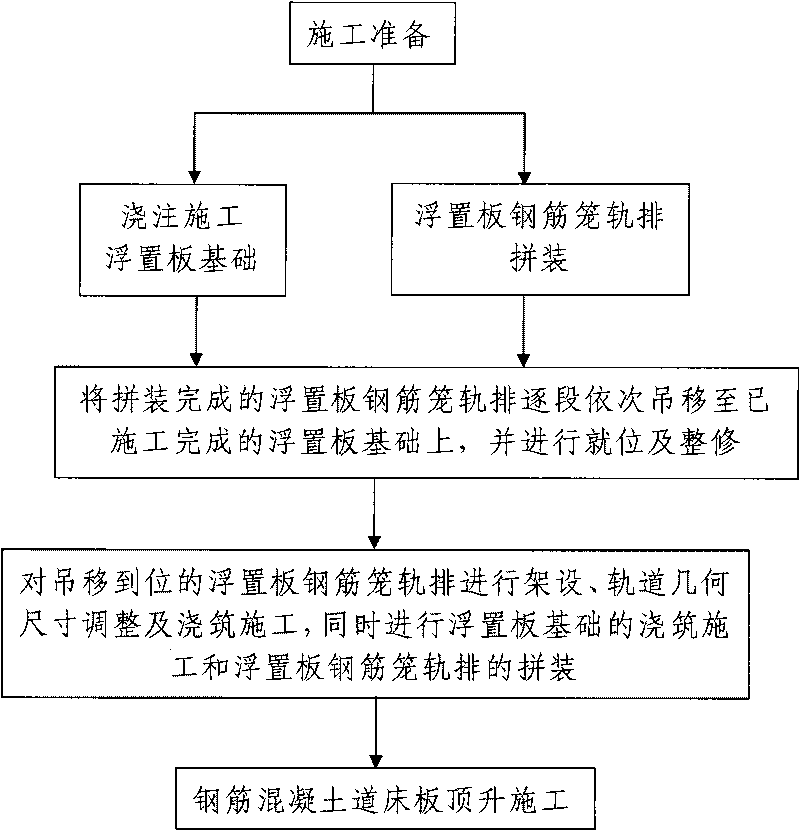

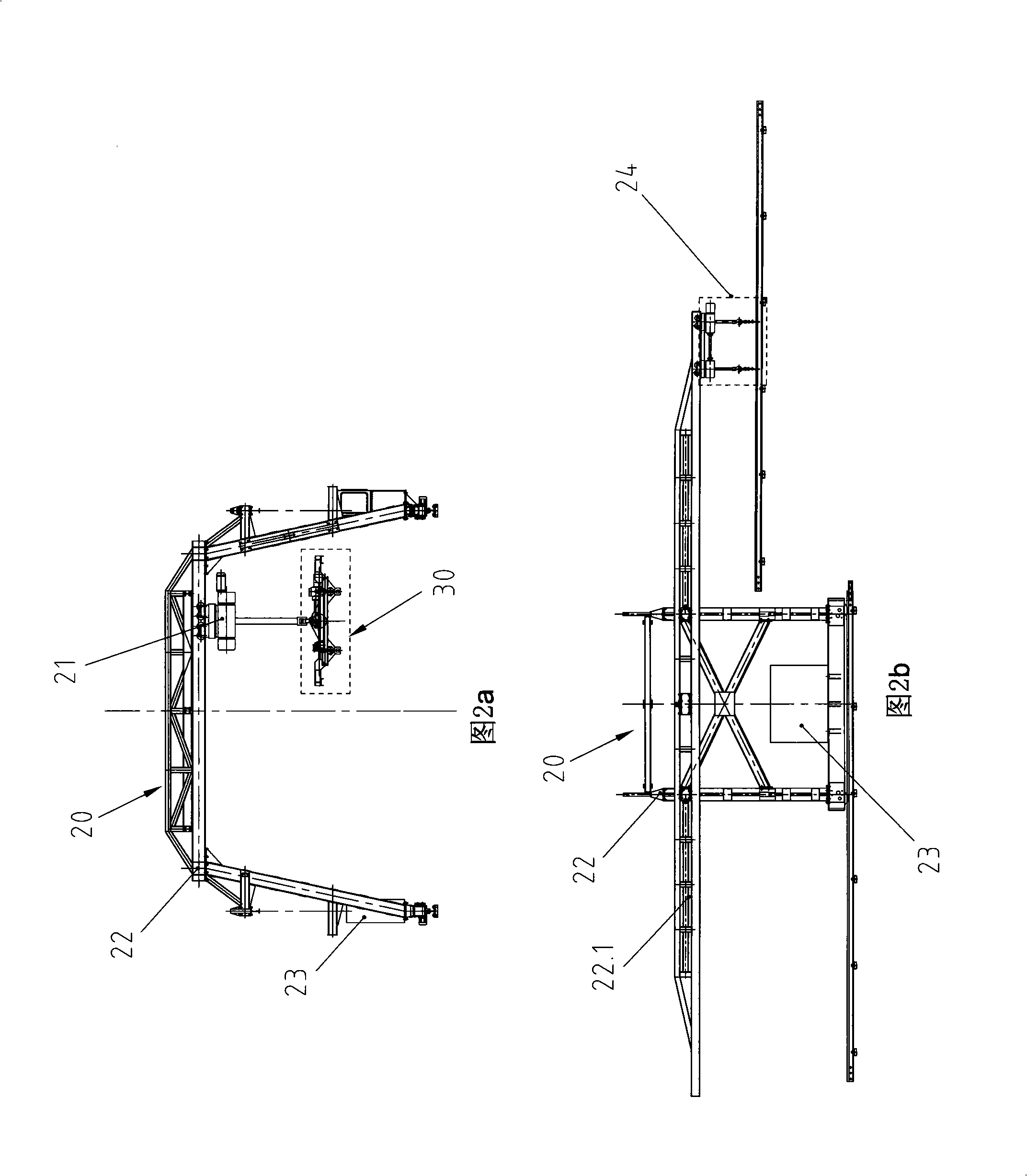

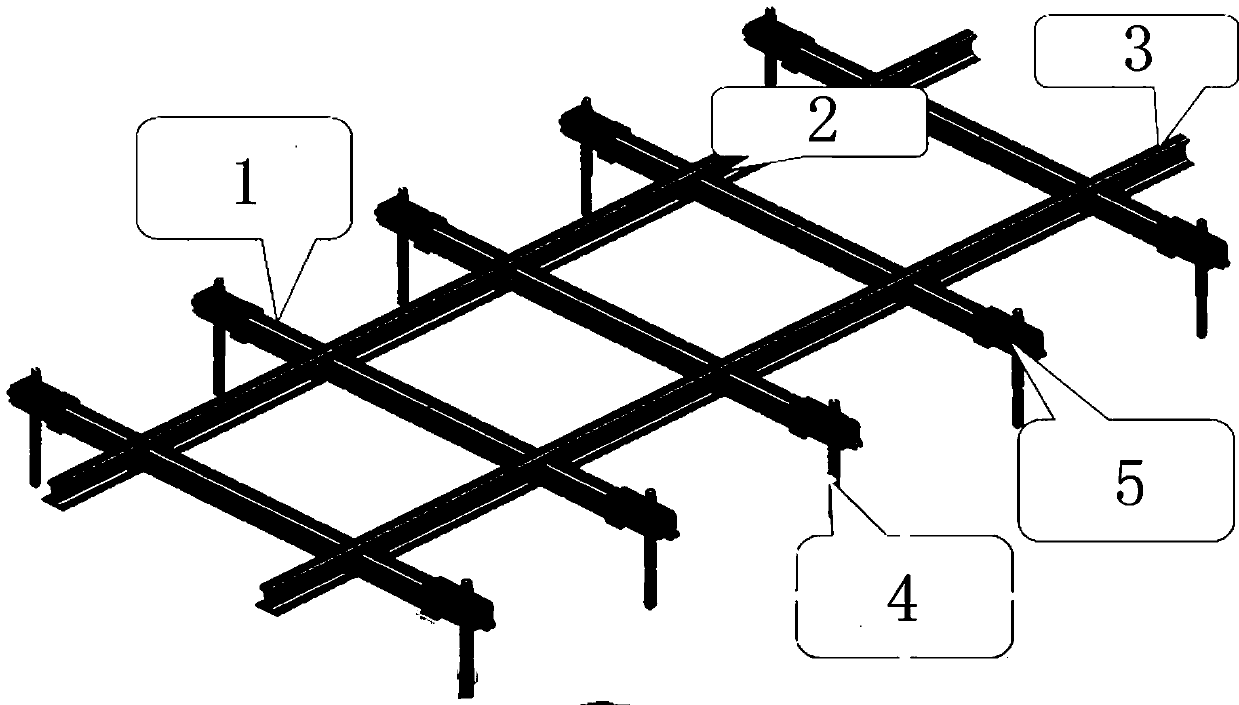

Steel reinforcement cage track skeleton method construction process of steel spring floating plate track

ActiveCN101701439AInnovative designReasonable designRailway track constructionReinforced concreteRebar

The invention discloses a steel reinforcement cage track skeleton method construction process of steel spring floating plate track, which comprises the following steps of: 1. preparing construction; 2. pouring and constructing a floating plate foundation and simultaneously assembling a floating plate steel reinforcement cage track skeleton; 3. sequentially hoisting the assembled floating plate steel reinforcement cage track skeleton to the constructed floating plate foundation by sections and positioning and trimming; 4. carrying out erection, track geometric dimension adjustment and pouring construction on the hoisted floating plate steel reinforcement cage track skeleton and carrying out floating plate foundation pouring and floating plate steel reinforcement cage track skeleton assembly so as to ensure that three processes of the floating plate foundation pouring construction, the floating plate steel reinforcement cage track skeleton section assembly and concrete track bed plate pouring construction are simultaneously and continuously carried out respectively; and 5. carrying out reinforced concrete track bed plate lifting construction. The invention has reasonable design, simple construction step, time and manpower saving and high construction efficiency and can effectively solve the practical problems of high construction difficulty and high technical requirement, complicated construction procedures and low construction speed of the floating plate track.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

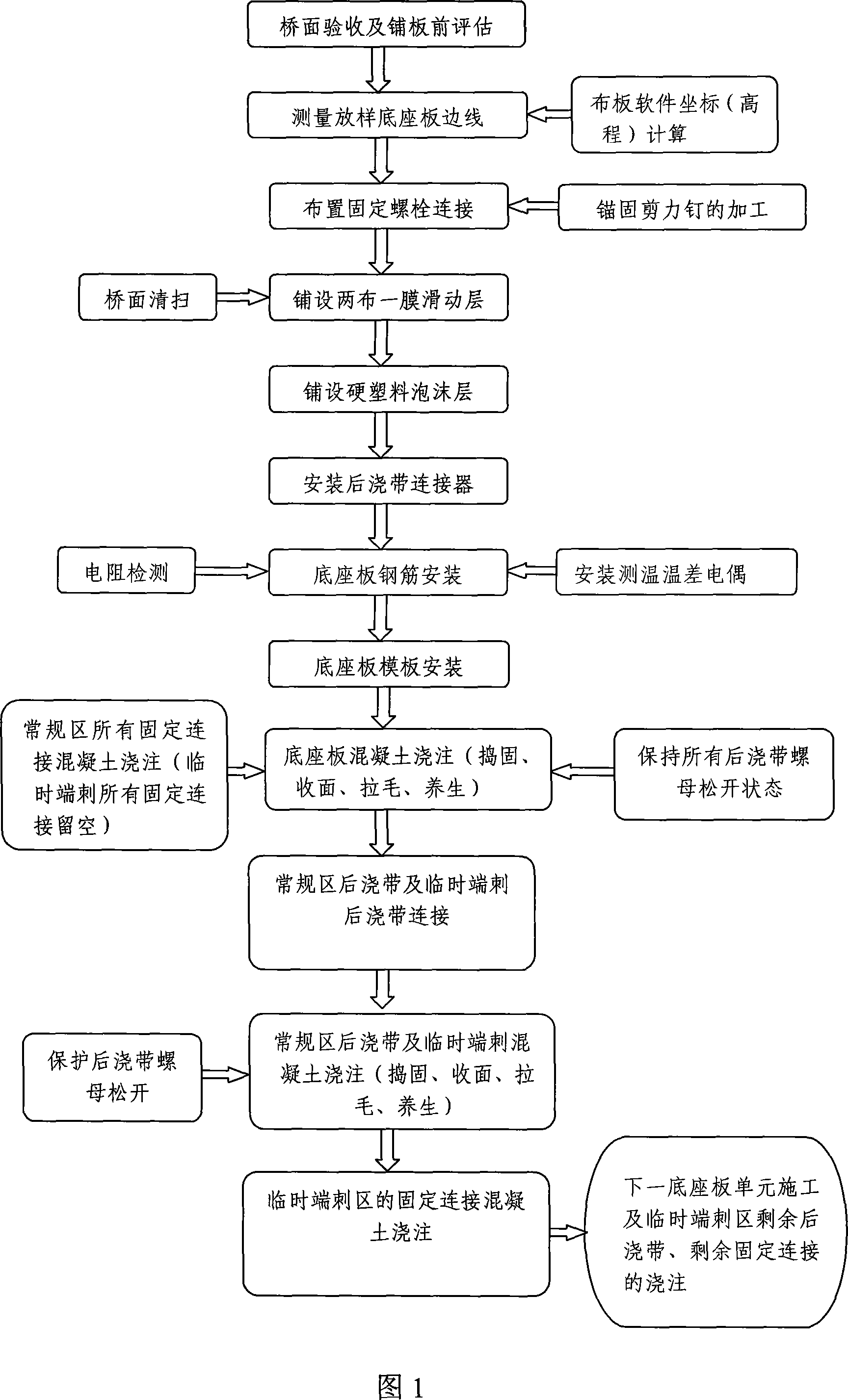

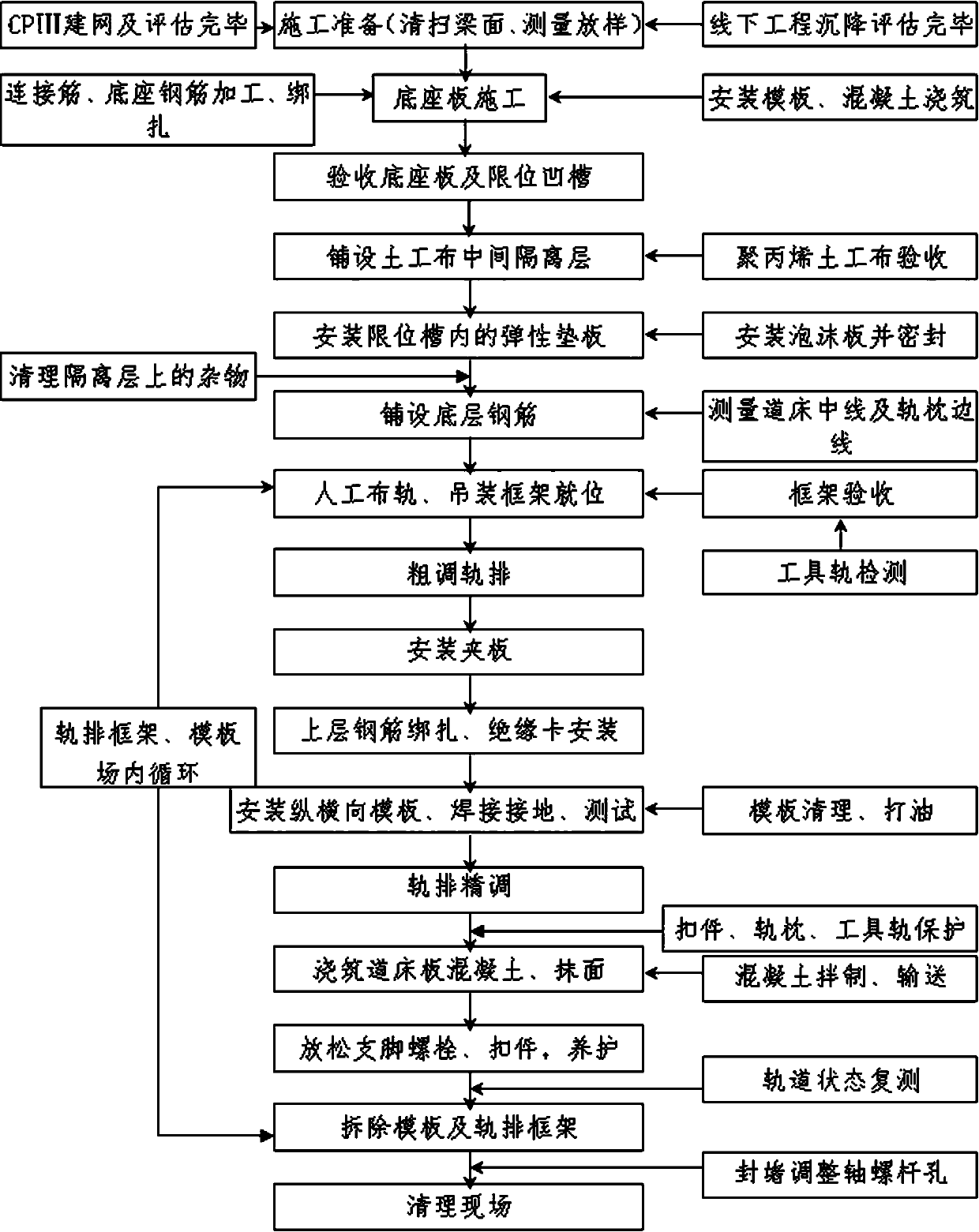

Unballasted track bed plate construction method

ActiveCN101195983ASolve technical difficulties in constructionImprove construction qualityRailway track constructionArchitectural engineeringBridge deck

The invention relates to a construction method of the bottom seat plate of the ballastless track, which belongs to a construction process method of tracks. The purpose of the invention is to provide a reliable construction method of the bottom seat plate of the ballastless track on bridges to meet the quality and accuracy requirement of the bottom seat plate of the ballastless track. The construction method comprises the following steps: step one, firstly, the bridge floor is checked and accepted and assessed before planking; secondly, the stakingout connecting line of the bottom seat plate is measured; thirdly, the connection of the fixed bolt is arranged; fourthly, a sliding layer with two cloth and one film is laid on the bridge floor of the box-beam bridge; step two, a hard plastics foam layer is laid on the two ends of the beam slot; step three, a post casting strip connector is installed; step four, firstly, tooth socket welding studs are installed; secondly, bottom seat plate reinforcing bars are installed; step five, bottom seat plate mould plates are installed; step six, the concrete of the bottom seat plate is cast; step seven, the cast post casting strip and the welding stud tooth socket are fixedly connected, and the connection of the bottom seat plates is completed.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

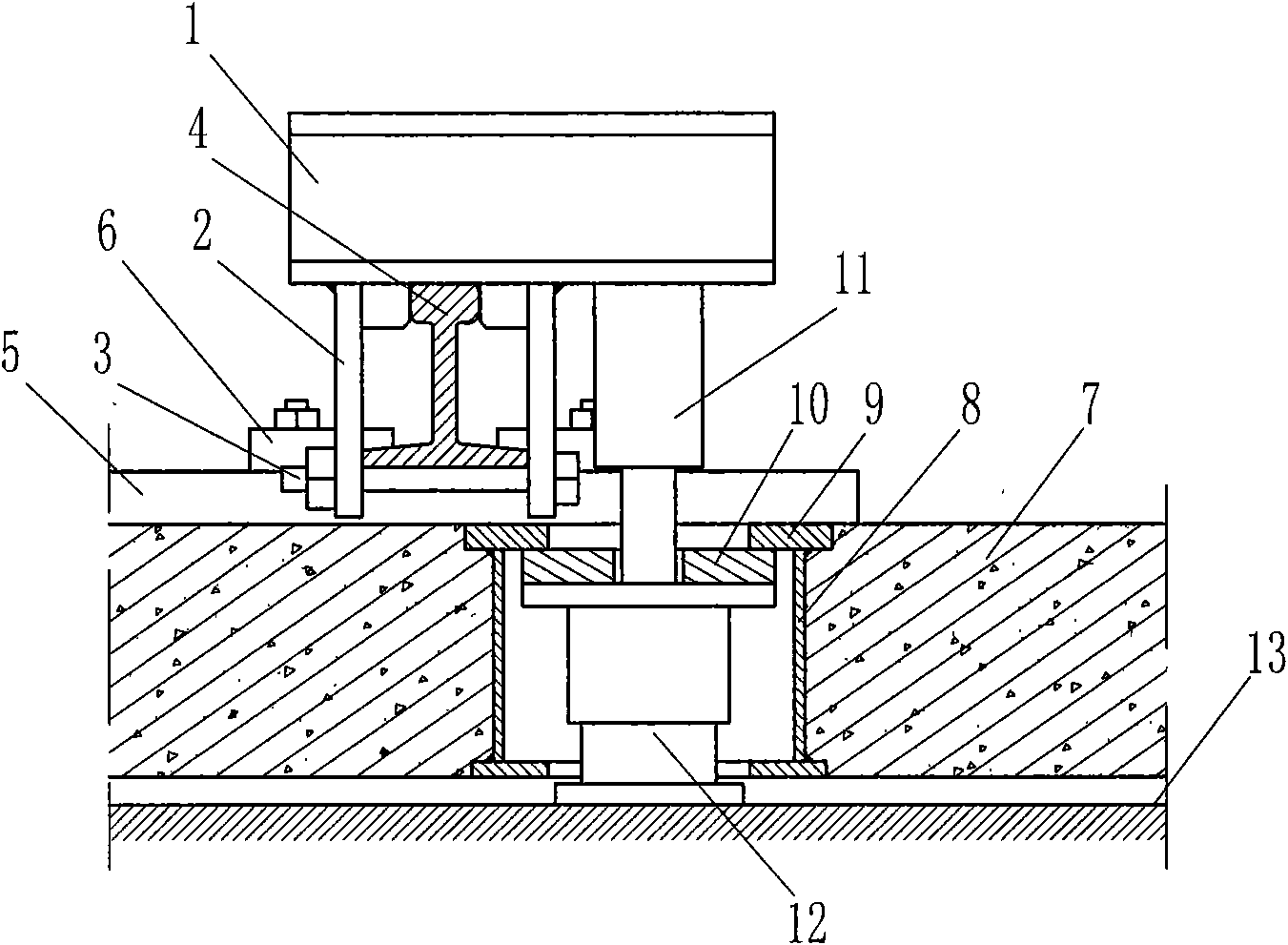

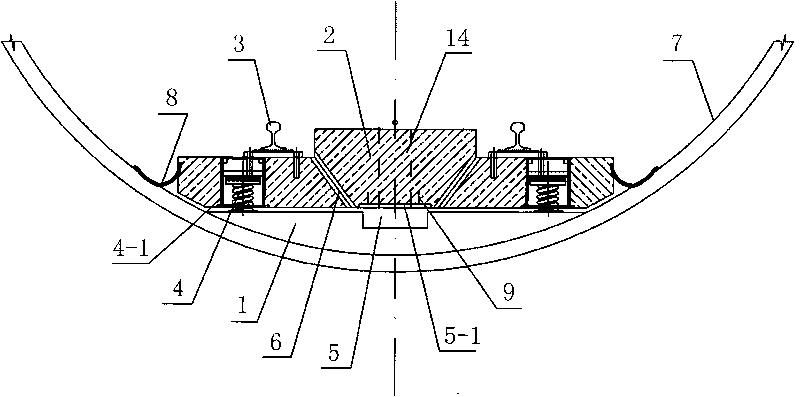

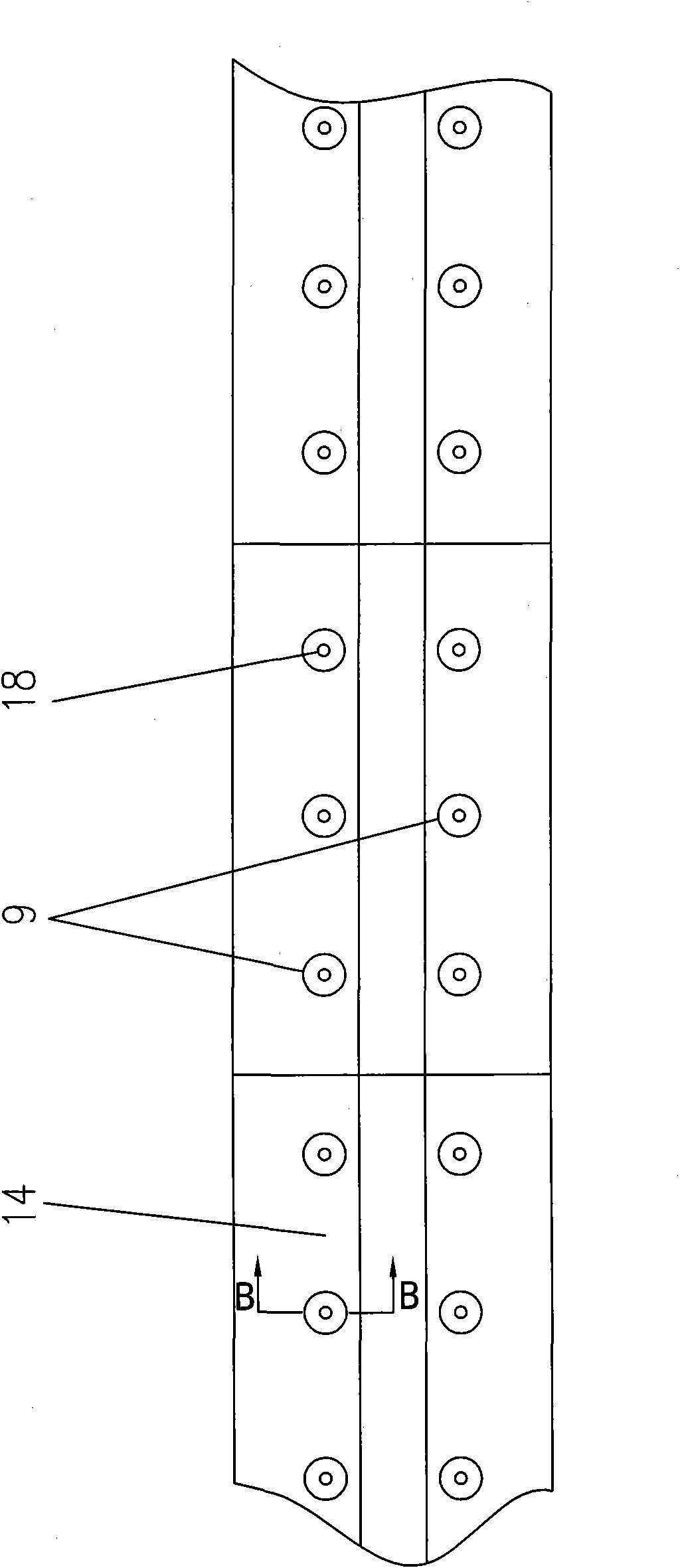

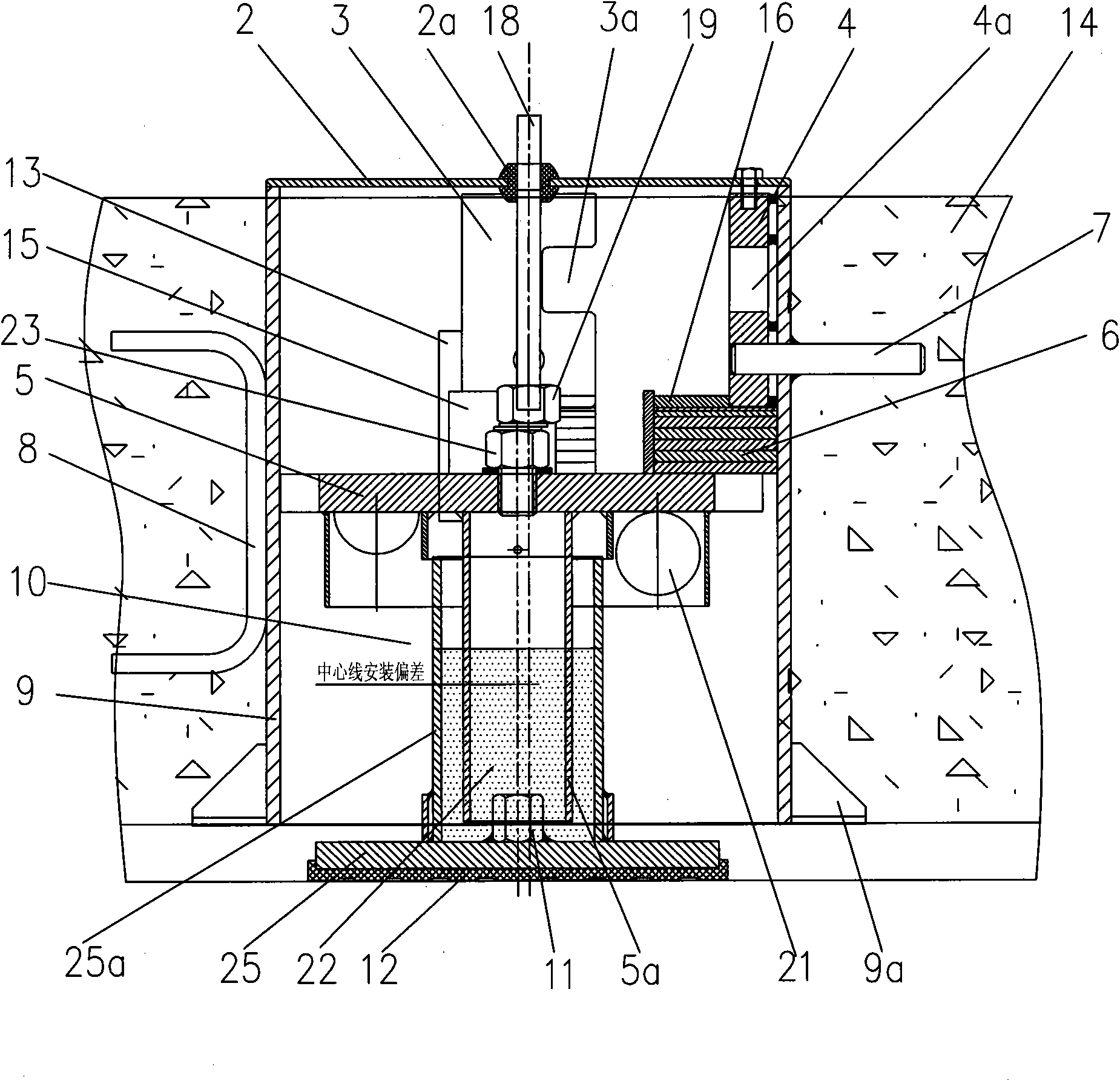

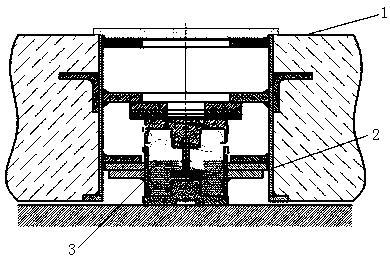

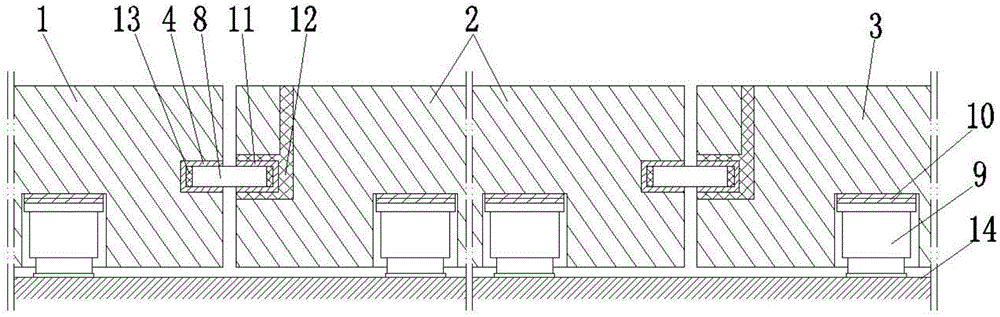

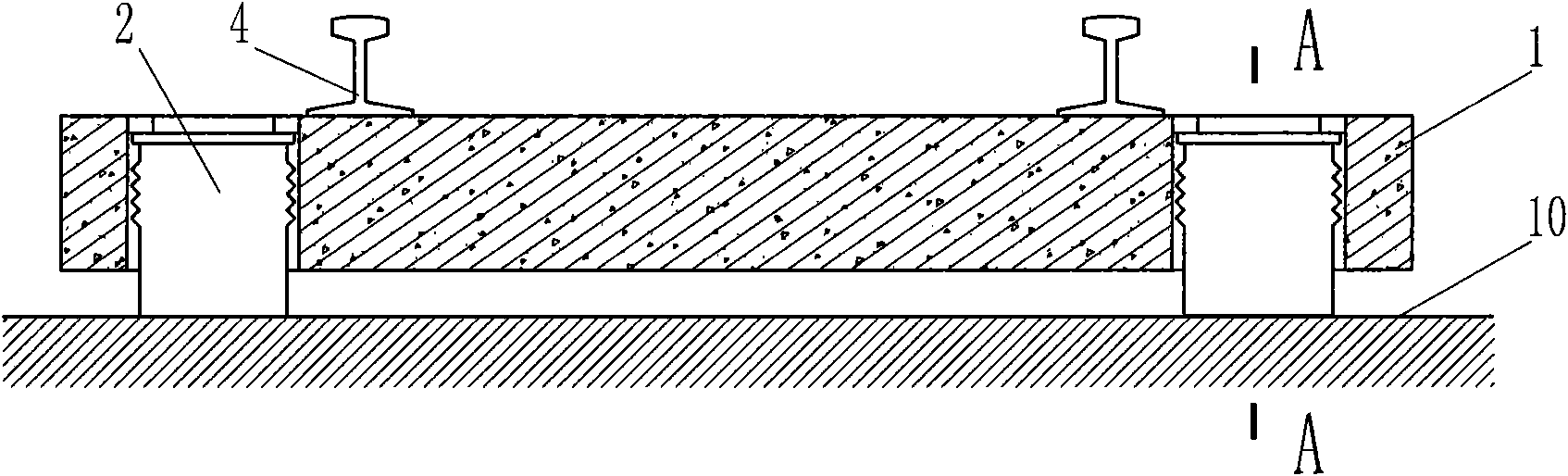

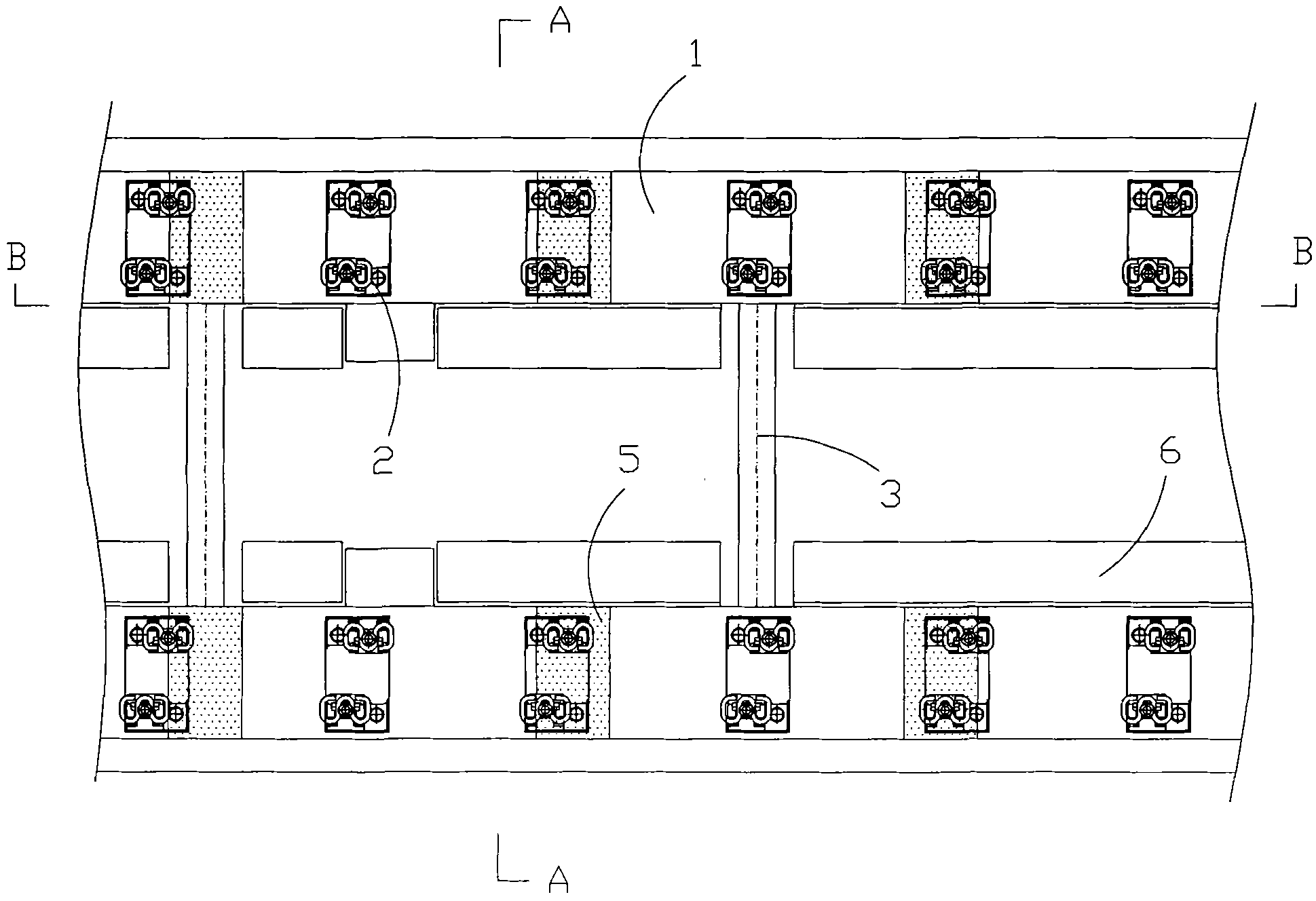

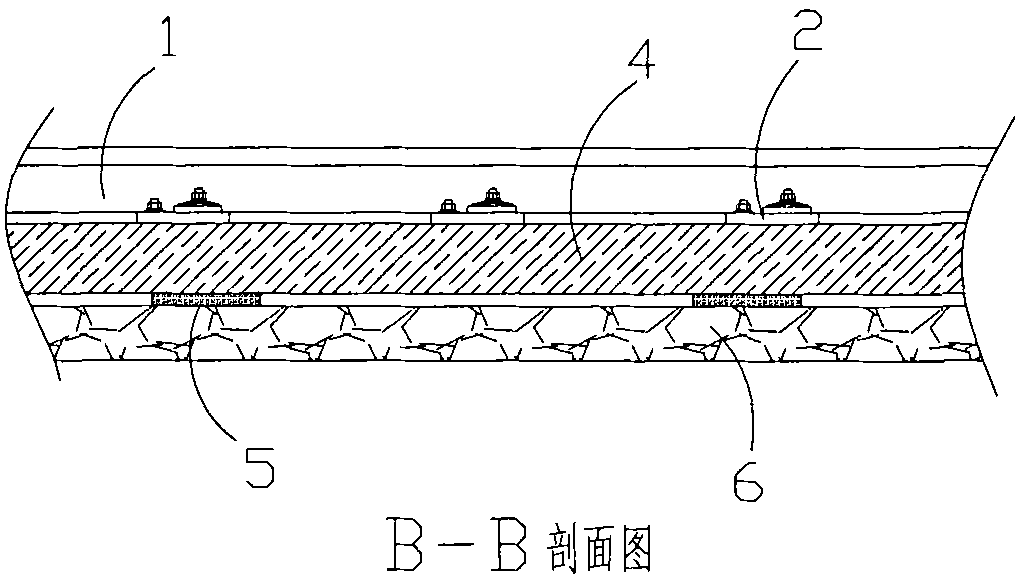

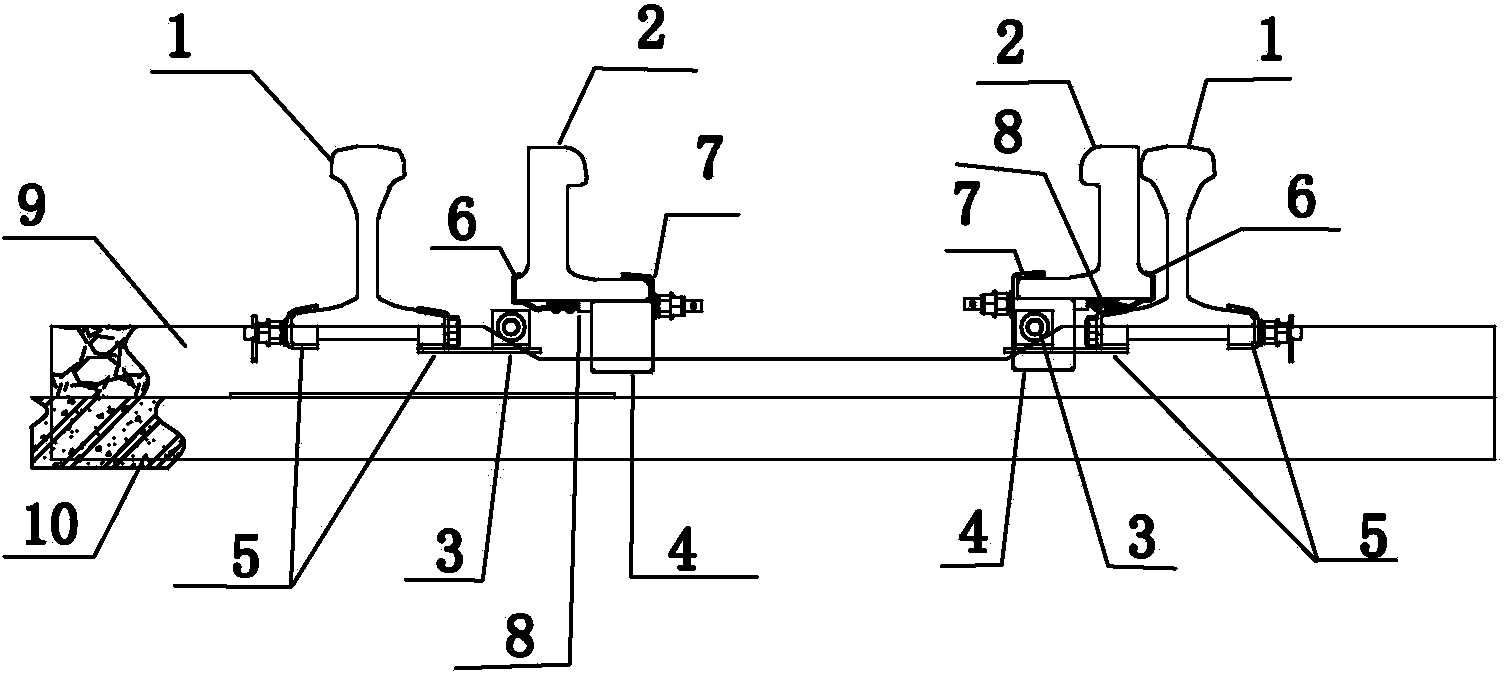

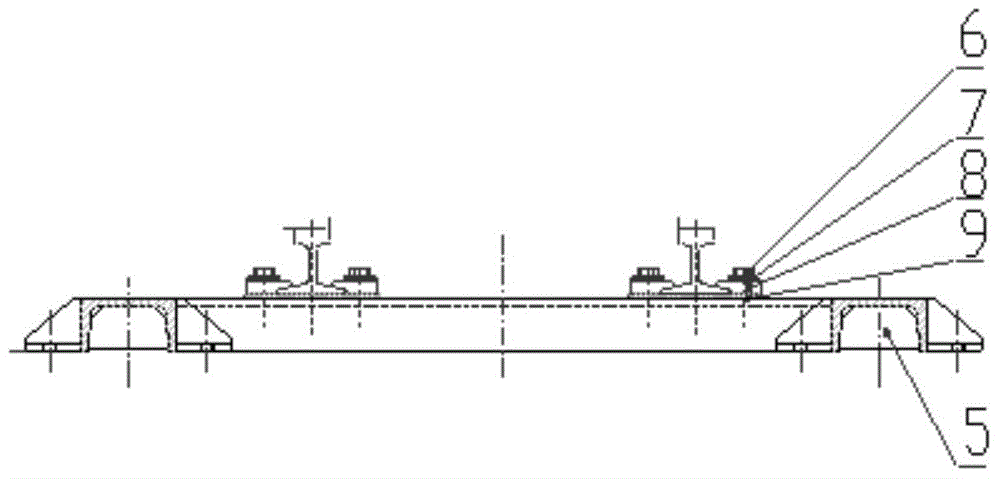

Vibration isolating support structure of damping spring floating track bed and installation method thereof

ActiveCN101775762AReduce dosageGood vibration reduction effectRail fastenersFatigue fracturesEngineering

The invention discloses a vibration isolating support structure of a damping spring floating track bed and an installation method thereof, which comprises a pre-buried sleeve (9) and a vibration isolator component (10). The pre-buried sleeve (9) is cast in a floating plate type track bed body (14) as a whole, bearing convex tables (3, 4 and 17) are fixedly arranged in the pre-buried sleeve (9), a pre-buried anchor bar (8) which extends into the bed body is arranged outside of the pre-buried sleeve (9), and the vibration isolator component (10) is arranged in the pre-buried sleeve (9) and can support the floating plate type track bed body (14) and isolate the vibration of the floating plate type track bed body (14) through the pre-buried sleeve (9). The vibration isolating support structure can provide emergency safety measures under the extreme condition, so that when the fatigue fracture of a large quantity of support springs occurs suddenly, the local settlement of the floating plate type track bed can be limited within the safety limit range of a few millimeters, thereby preventing the spring breakage accident to endanger the safe running of trains, and greatly improving the security coefficient of the floating plate type track bed.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

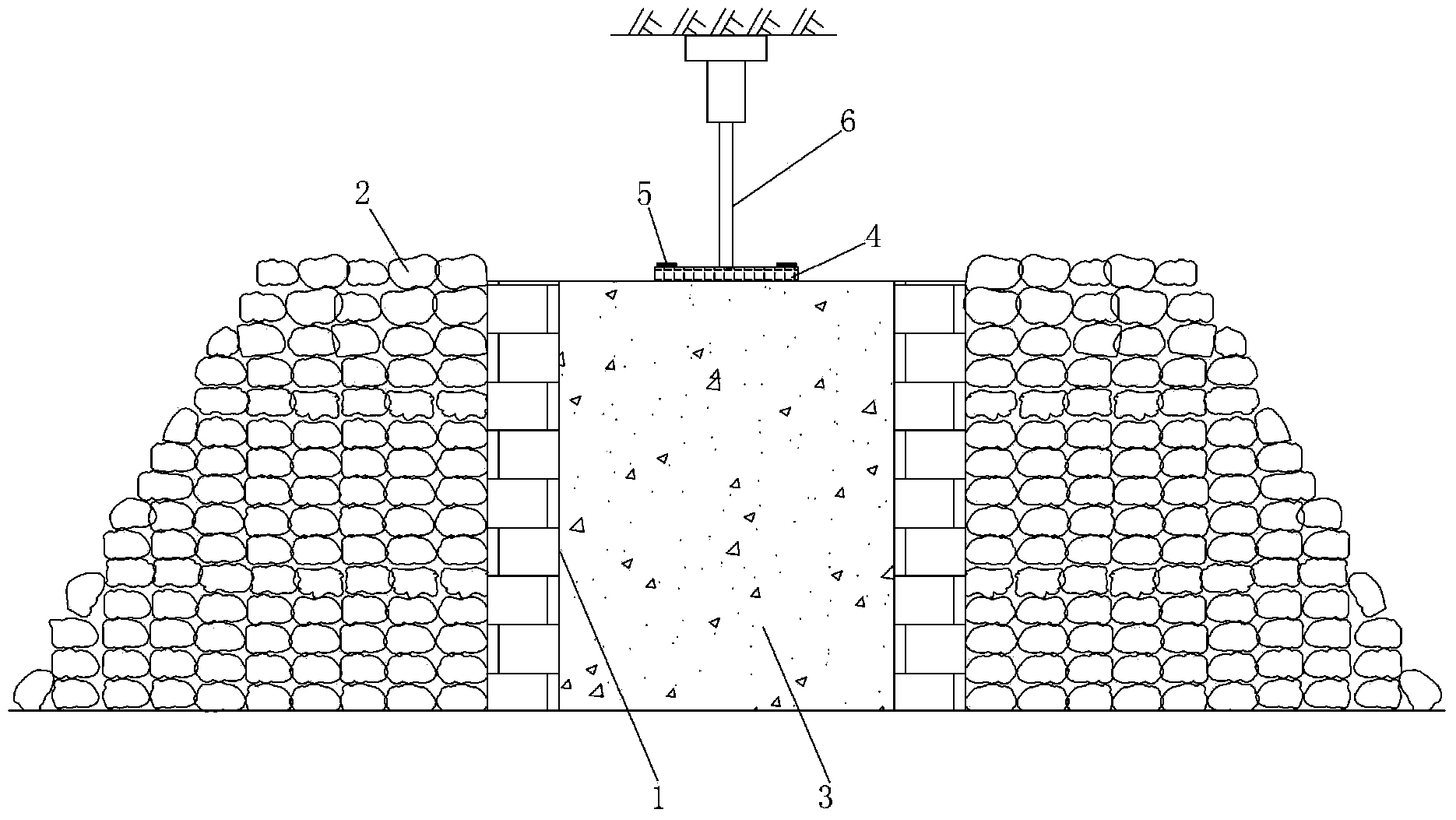

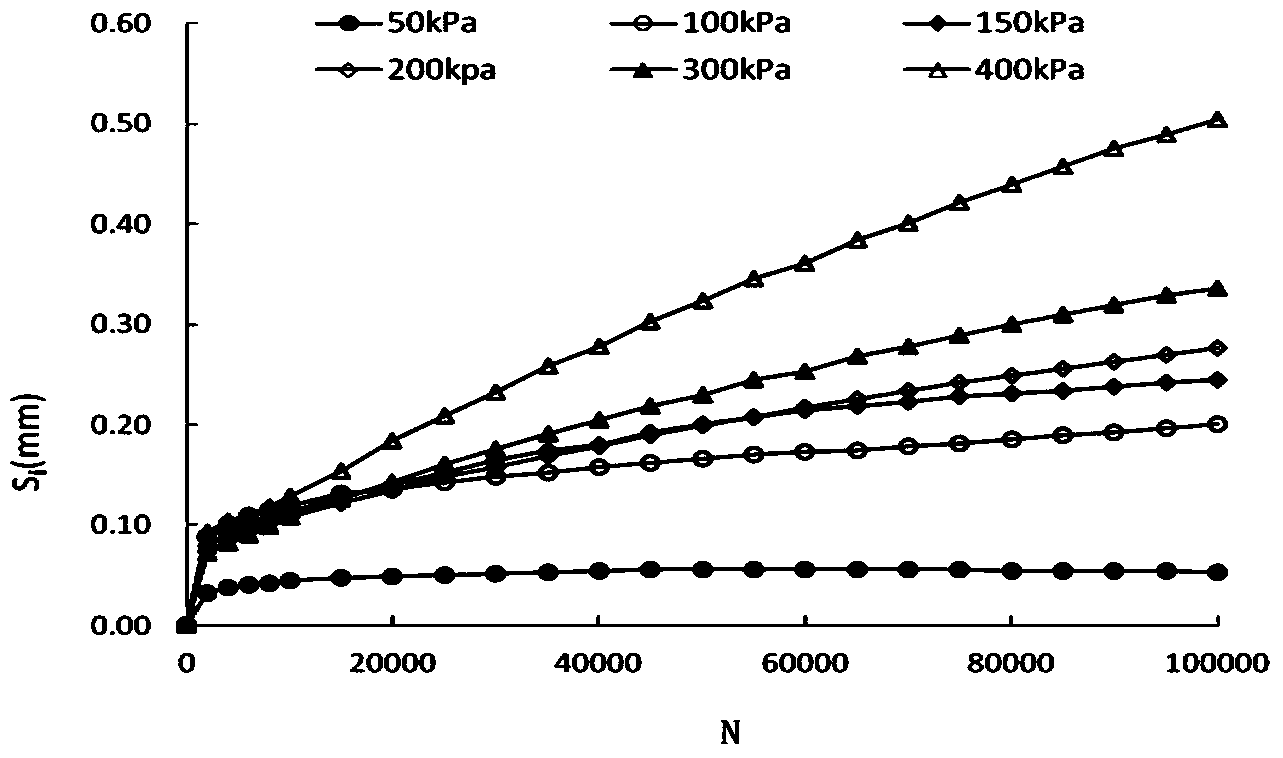

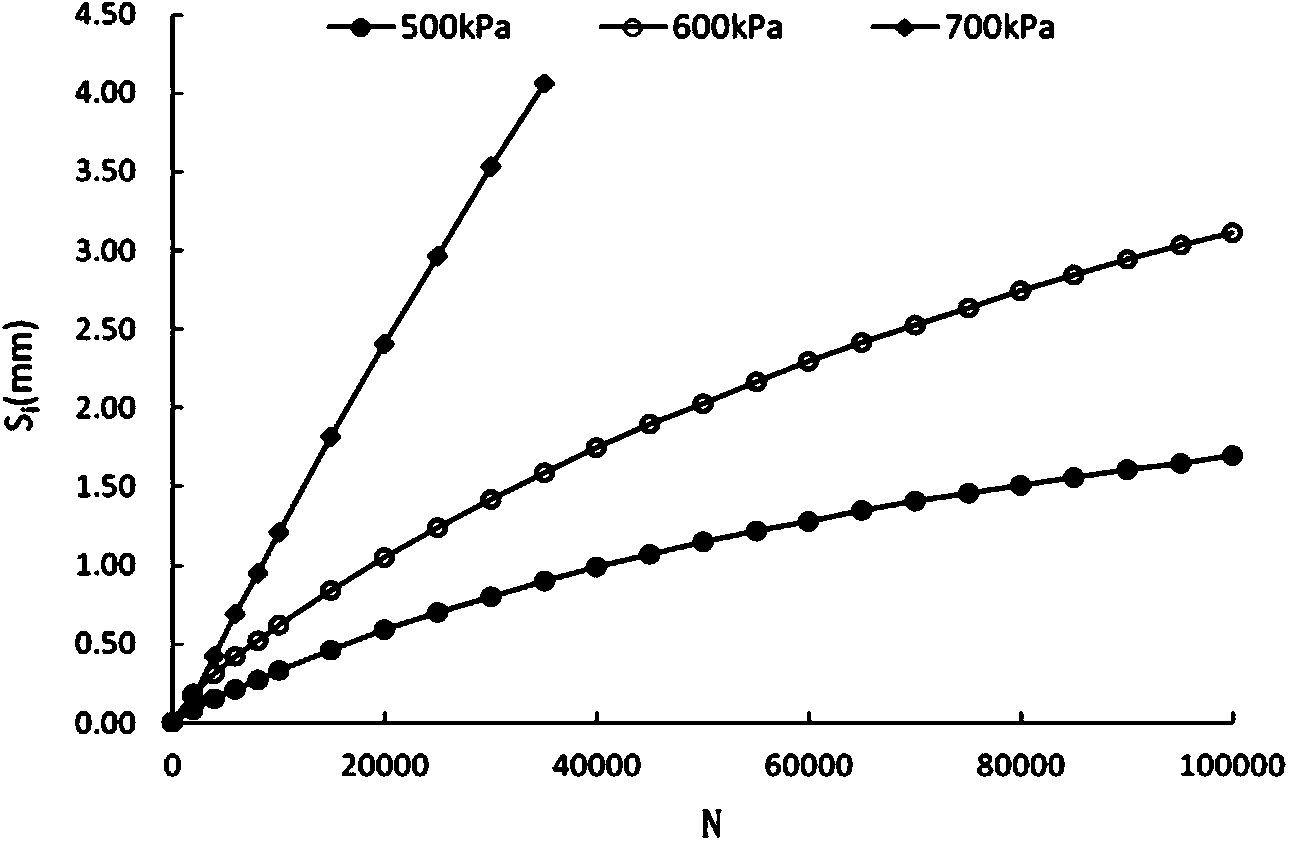

Method for measuring load threshold of geotechnical packing accumulated deformation state under cyclic loading

ActiveCN104020063AGuaranteed test accuracyReduce testing workloadMaterial strength using repeated/pulsating forcesBrickNegative power

The invention relates to a method for measuring load thresholds of geotechnical packing accumulated deformation states under cyclic loading. According to the method, brick walls and sand bags are adopted to construct a filling model, so as to form a testing system along with loading equipment and a displacement sensor, and a cyclic loading test is performed on the filling model, so as to obtain a changing curve of accumulated deformation with loading times; then the changing curve of segmented single loading average deformation with the loading times is obtained through calculation, and a negative power function as shown in the specification is adopted to fit, so as to obtain a relation curve of a power exponent Pi value with the change of load levels; a function relation between the Pi value and the load levels is obtained by virtue of cubic polynomial regression, and the corresponding load levels when P is equal to 2, 1 and 0 are obtained through back calculation, so as to be used as the load thresholds delta t1, delta t2 and delta t3 for distinguishing different evolution states of the accumulated deformation, wherein an experimental basis is respectively provided for design and maintenance of ballastless and ballast track bed structures of railways by the delta t1 and delta t2. The method has the advantages of convenience in model manufacturing, low cost, simplicity in operation and clear distinguishing criterion, and the obtained load thresholds are accurate and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

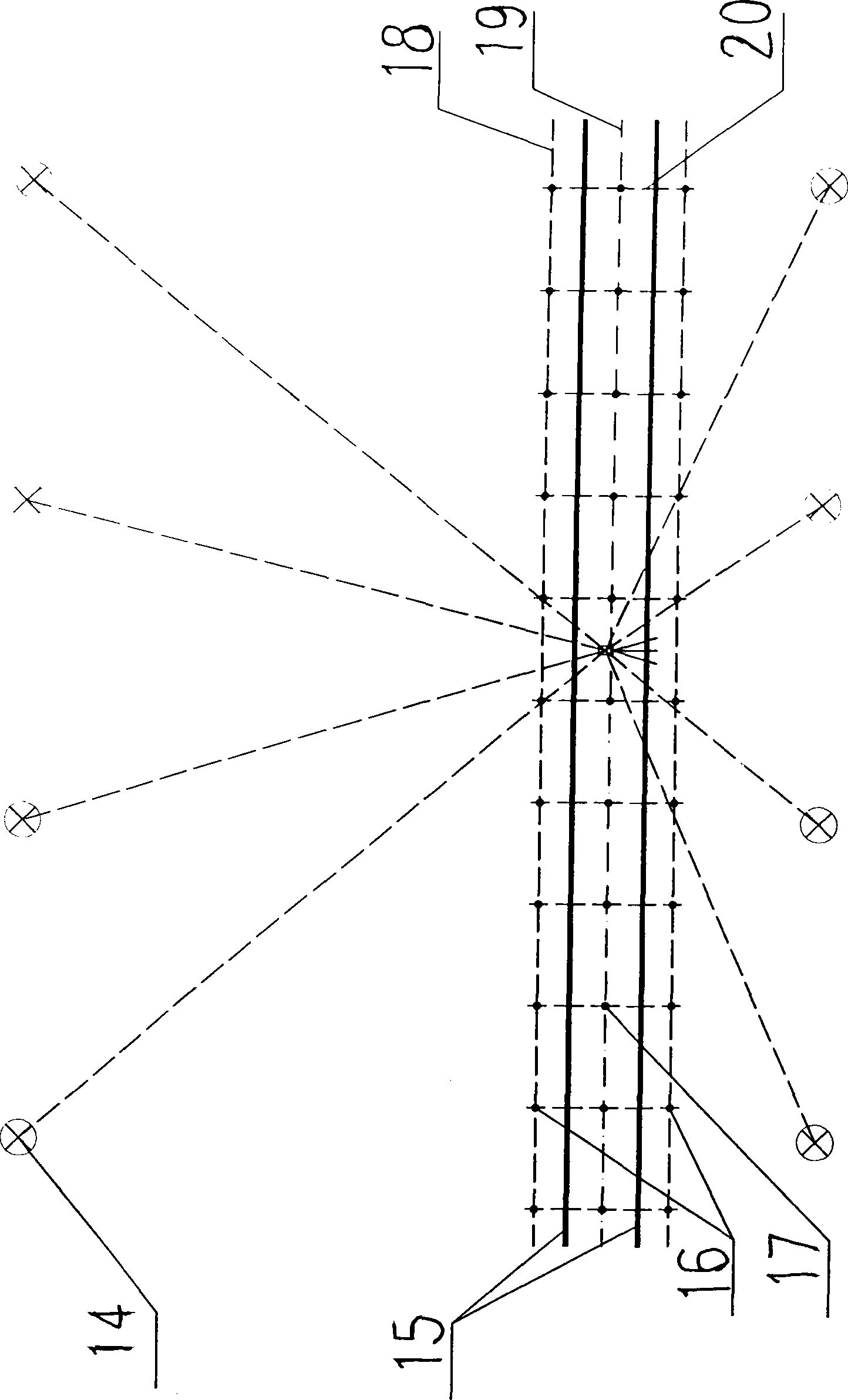

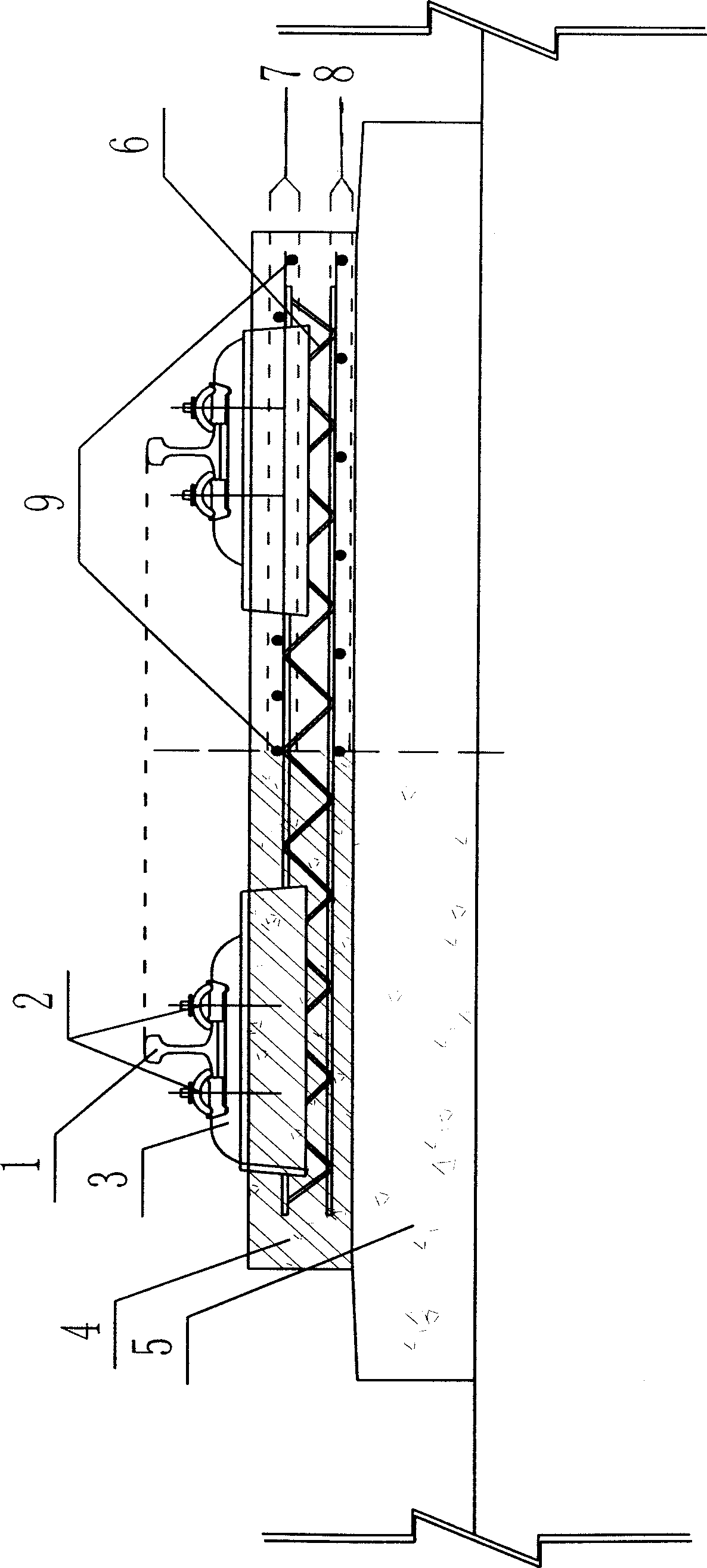

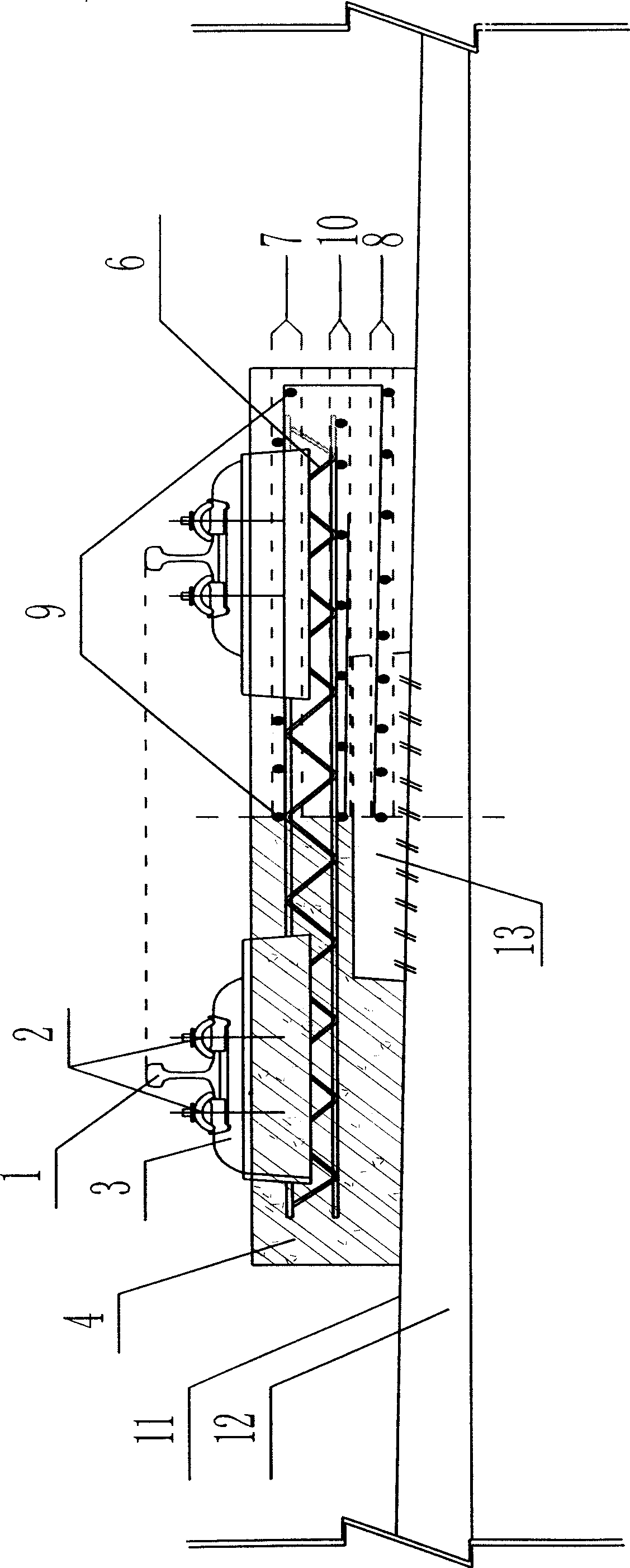

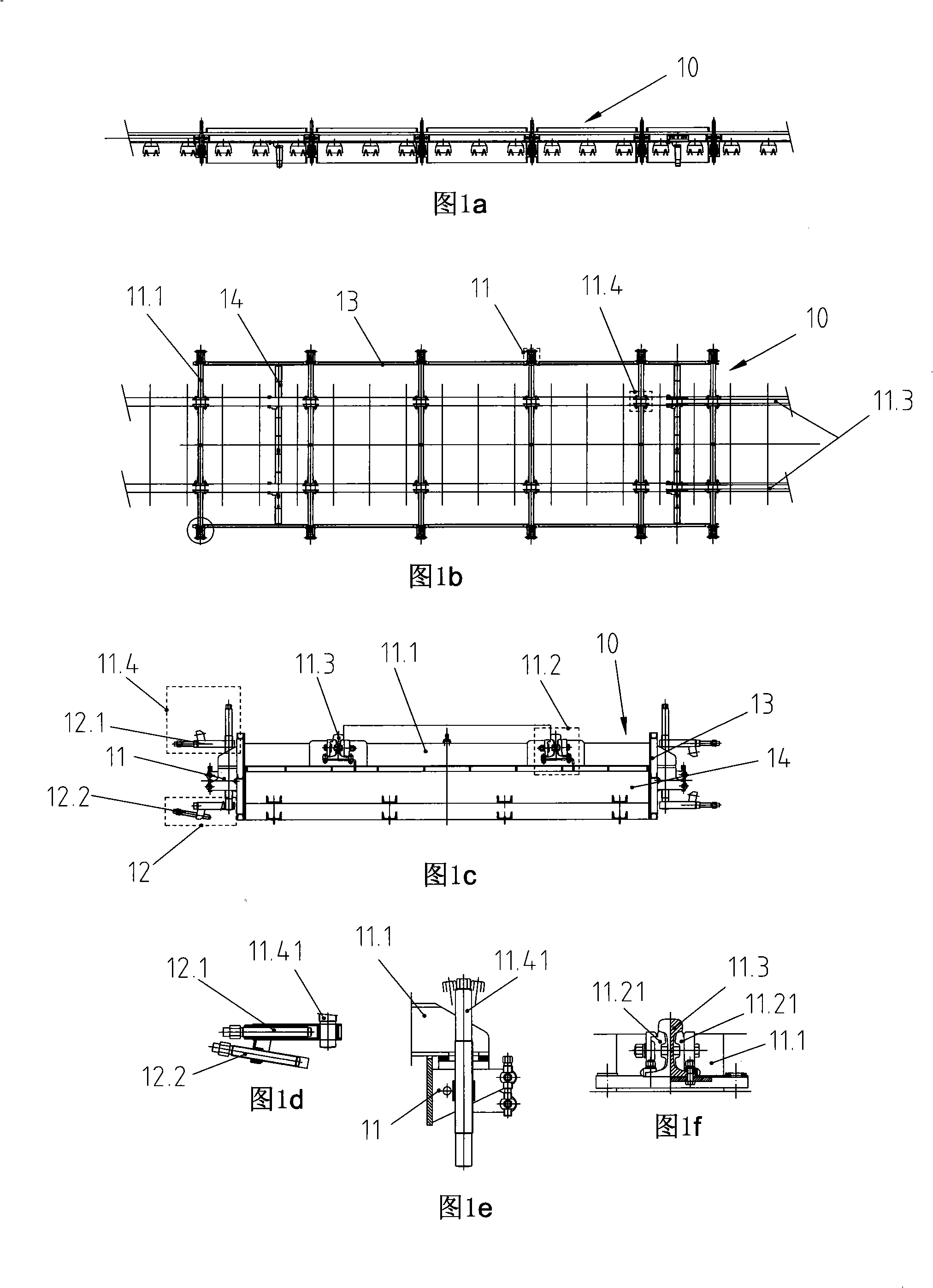

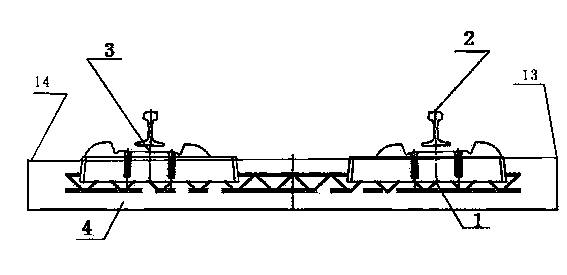

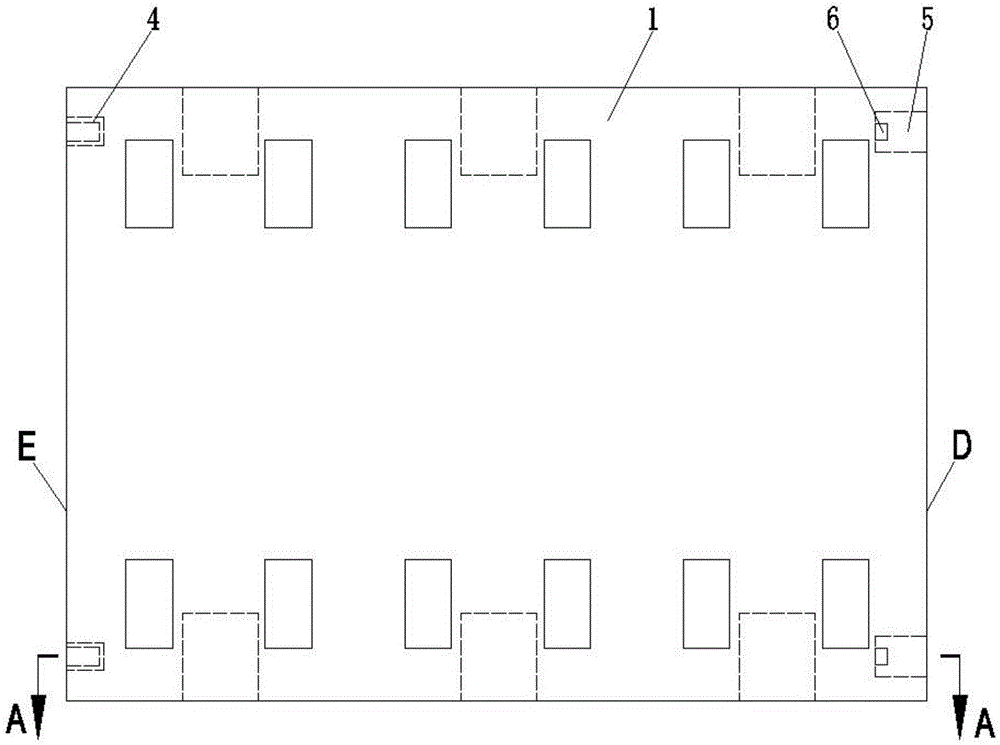

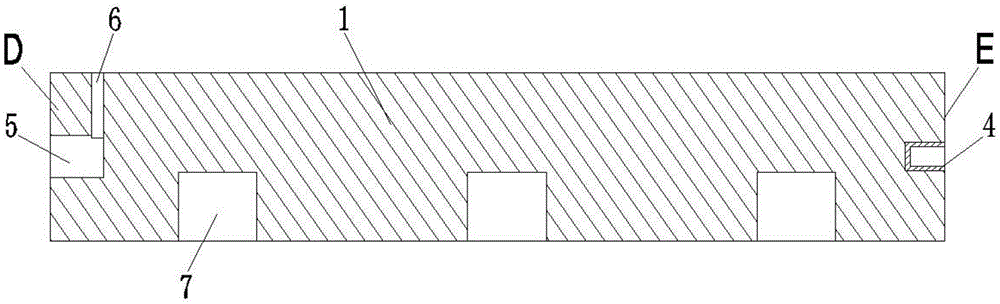

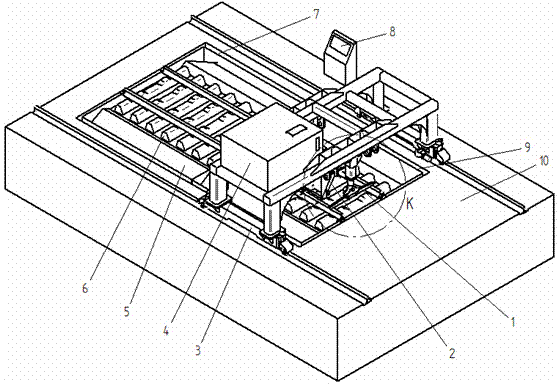

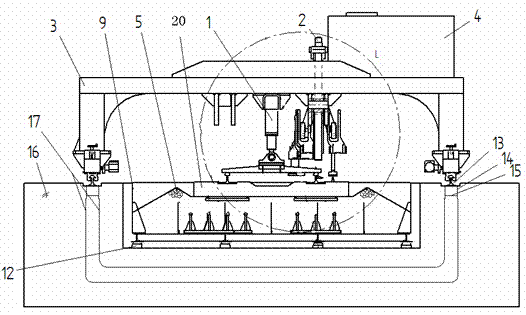

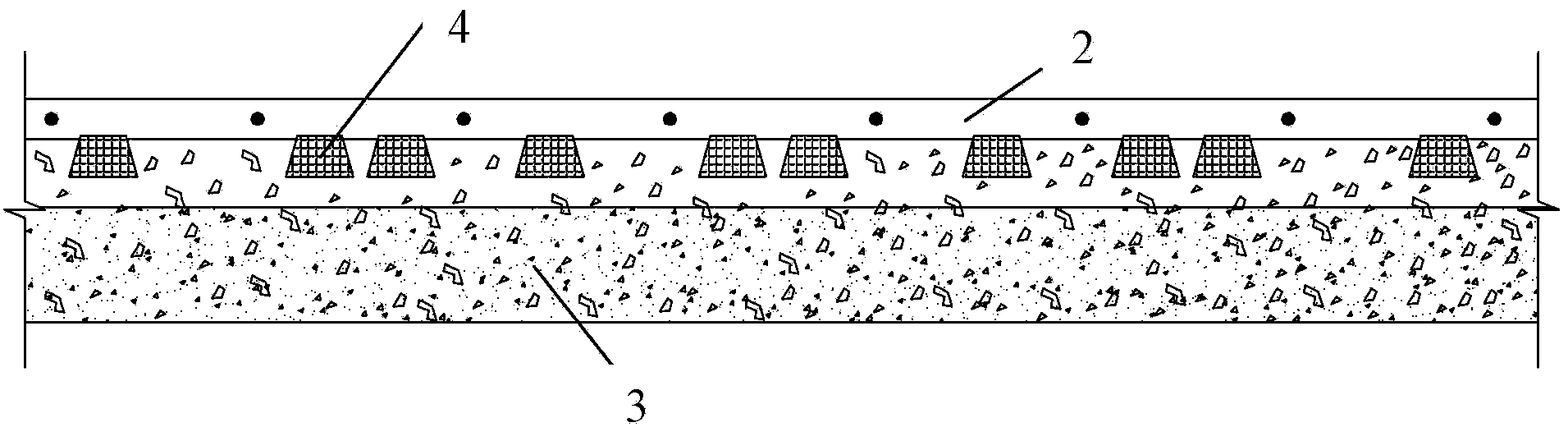

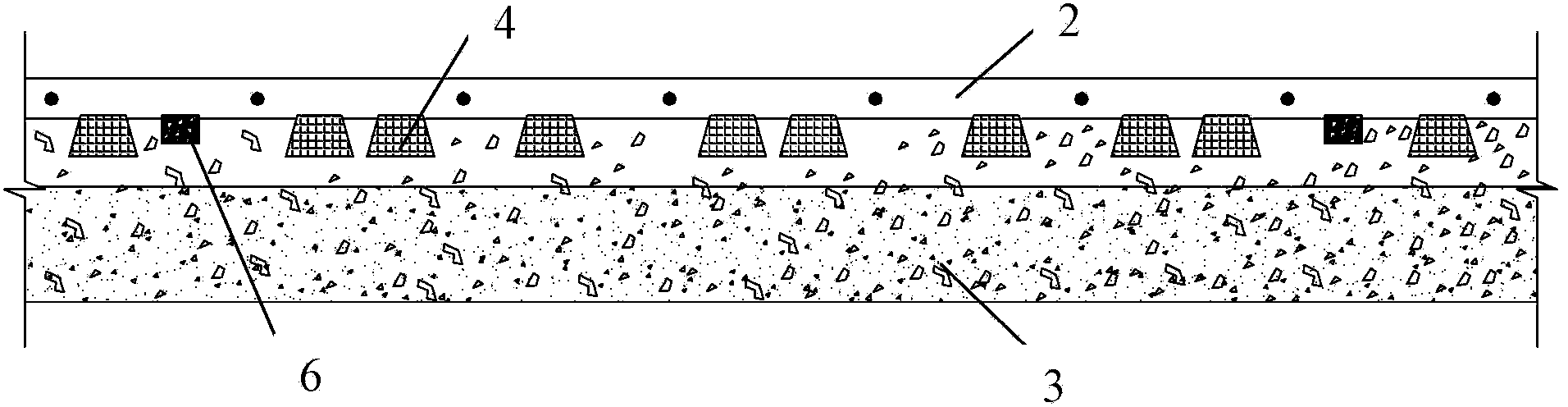

Construction apparatus of double-block ballastless track and construction process

ActiveCN101289828AAccurate and reliable spacingSimplify operating proceduresRailway track constructionMeasuring apparatusSurface finishMovable type

The invention discloses construction equipment and a construction process for a double block type unballasted track, belonging to the railway track construction field. The construction equipment comprises combined type track panels which are matched to use, a proper motion type paver, a multifunctional electric control lifting device, a movable type mechanical sleeper distribution assembly platform and a shunting swing bridge; under the conditions of meeting the construction quality and the construction efficiency, the construction equipment has the advantages of small number of device categories, simple equipment operation, high construction efficiency and low cost of the outfit. The construction process comprise the following steps: the transverse template mounting, the sleeper distribution and the track panel assembly, the coarse adjustment of track panels, the track bed reinforcing fabric seizing and the grounding welding, the connection and the accurate adjustment of the track panels, the vertical template mounting, the track bed concrete pouring and the surface finishing and forming, the curing and the track panel disassembly, reentering the circle; the process has the advantages of simple process and fast speed; therefore, the invention can completely meet requirements of high standard, high accuracy and high efficiency in the construction of the unballasted track.

Owner:北京铁五院工程机械有限公司 +2

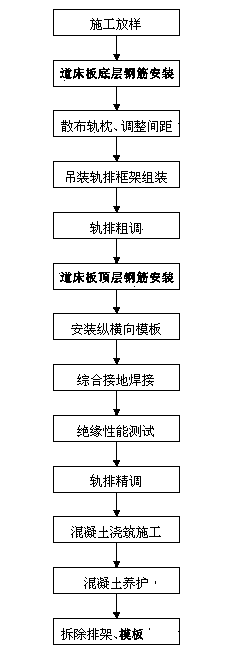

Ballastless track construction method with sleepers arranged firstly and rail panel assembled later

InactiveCN103643603AReduce land occupationImprove transition efficiencyRailway track constructionEngineeringRebar

A ballastless track construction method with sleepers arranged firstly and rail panel assembled later comprises the steps of construction layout, installation of steel bars at a bottom layer of a track bed, dispersion of the sleepers and spacing adjustment, assembly of hoisted rail panel frames, coarse adjustment of rail panels, installation of steel bars at top layers of track bed boards, installation of longitudinal and transverse formworks, comprehensive grounding welding, insulating property test, fine adjustment of the rail panels, concrete pouring construction, concrete curing and removal of bent frame molds. According to the construction method, a method that a gantry crane is used for assembling the rail panels on a mobile assembly platform is changed, a method that the sleepers are arranged firstly and the rail panels are assembled later on a construction operation surface is adopted directly, the usage of the mobile assembly platform is canceled, the problem of land occupation of the mobile assembly platform is solved, and the field change efficiency of other machines, tools and equipment is improved, in addition, a crane instead of the gantry crane is used for matching assembly, so that the gantry crane is mainly used for transferring other light machines, tools and equipment, the safety of transferring hoisting is improved, the continuous construction is guaranteed, the effective utilization rate of the gantry crane is increased, and the construction efficiency is improved.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP +1

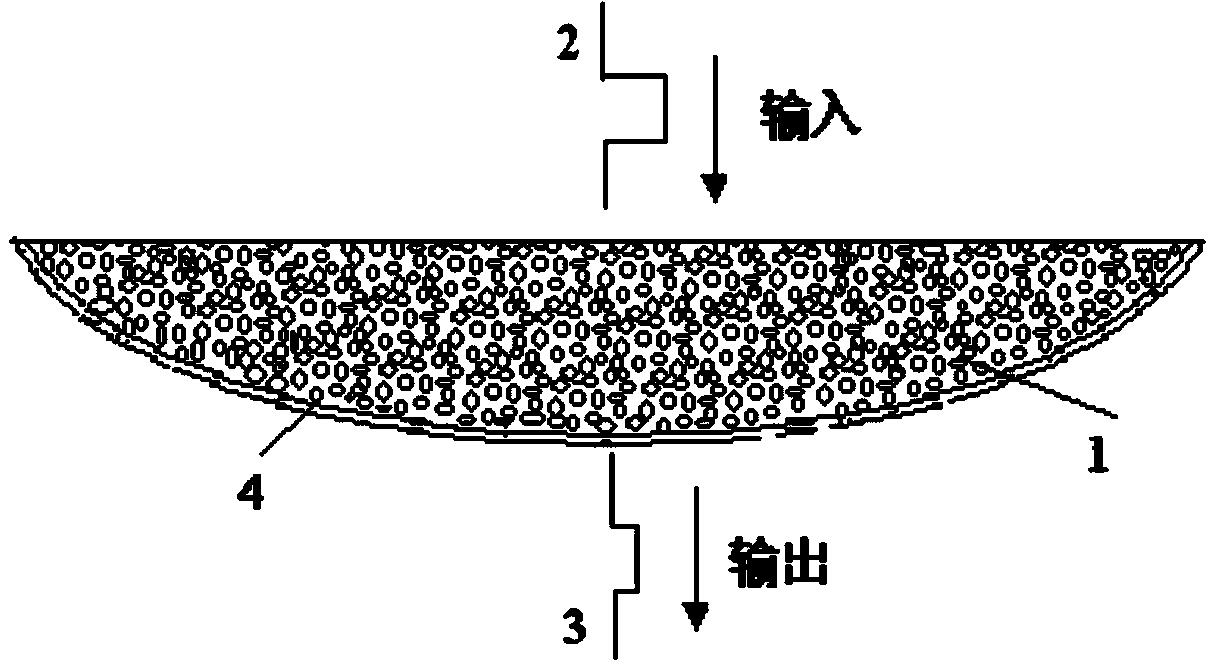

Metro shock absorption and vibration isolation elastic mixed light track bed

ActiveCN103981777AVibration impact isolation and reductionSmall transmitted energyBallastwayPolystyreneStructural engineering

The invention discloses a metro shock absorption and vibration isolation elastic mixed light track bed. The metro shock absorption and vibration isolation elastic mixed light track bed comprises an elastic light concrete layer, wherein the elastic light concrete layer is arranged at the bottom of a metro track bed and used as a base track bed, and pouring material of the elastic light concrete layer comprises a mixture of concrete and expandable polystyrene (EPS) particles. According to the metro shock absorption and vibration isolation elastic mixed light track bed, the mixture of the concrete and the EPS particles is used, the EPS particles have the functions of : 1) absorbing vibration waves and vibration energy, which are generated during the running process of a metro train; 2) generating small transmission energy for an elastic light track bed base layer by being mixed with the concrete due to the fact that wave impedance differences of the EPS particles and the concrete are large. Accordingly, a small part of the vibration energy of the metro train can be transmitted to a metro tunnel lining or a metro duct piece, and furthermore vibration influences on ground and a foundation are weakened.

Owner:SOUTHEAST UNIV

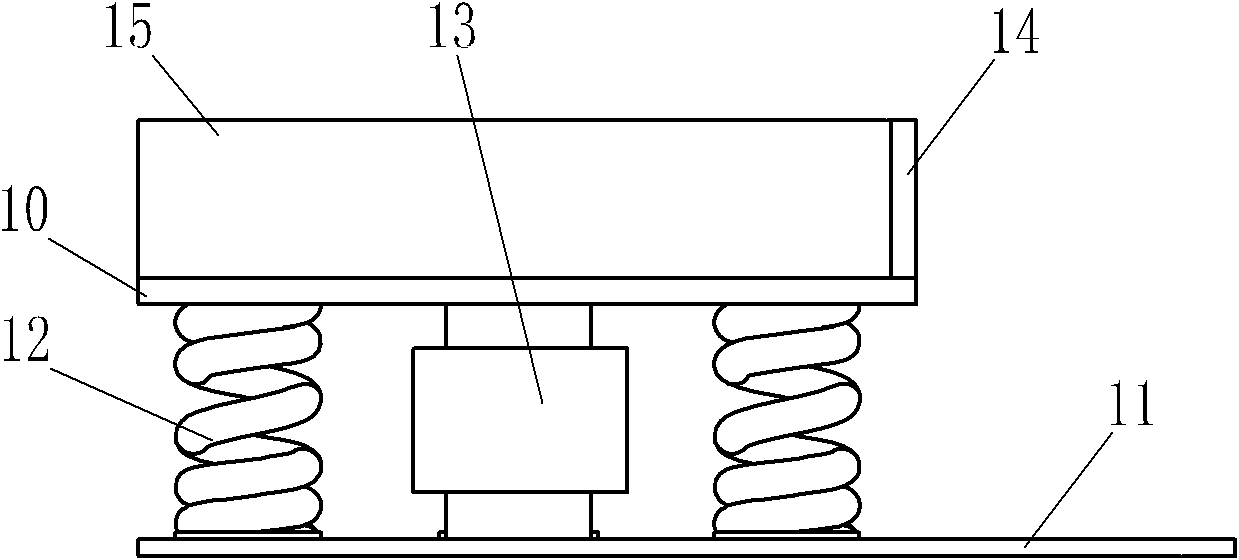

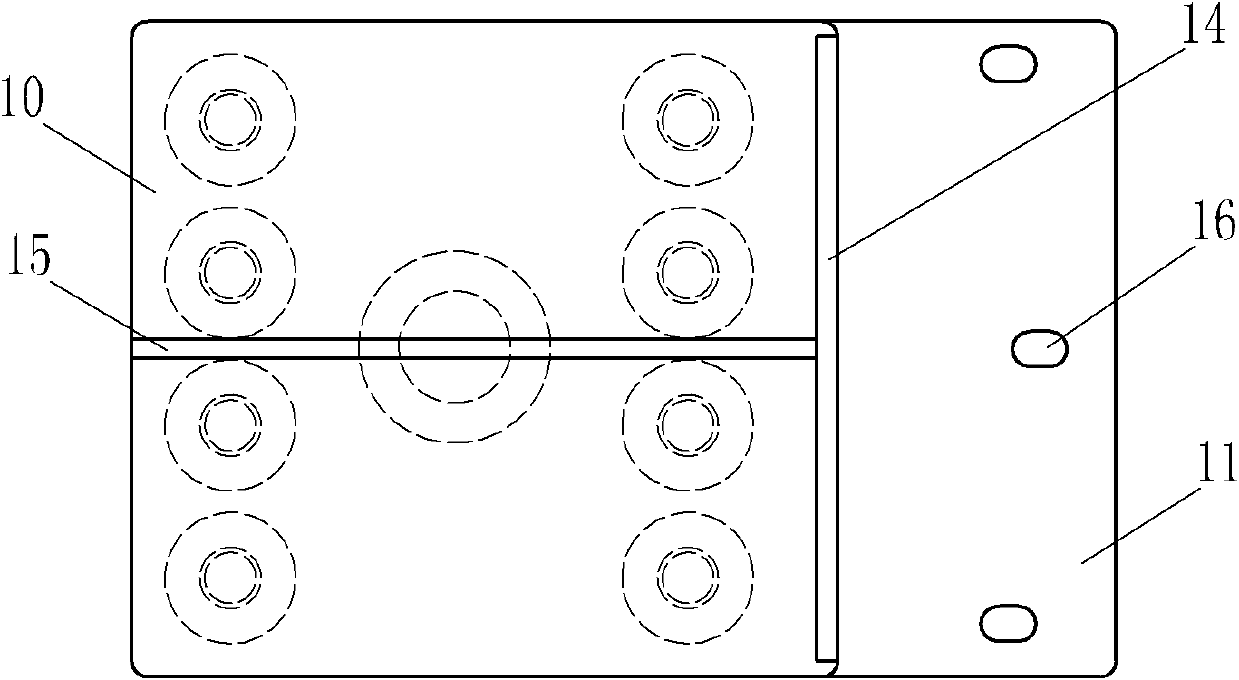

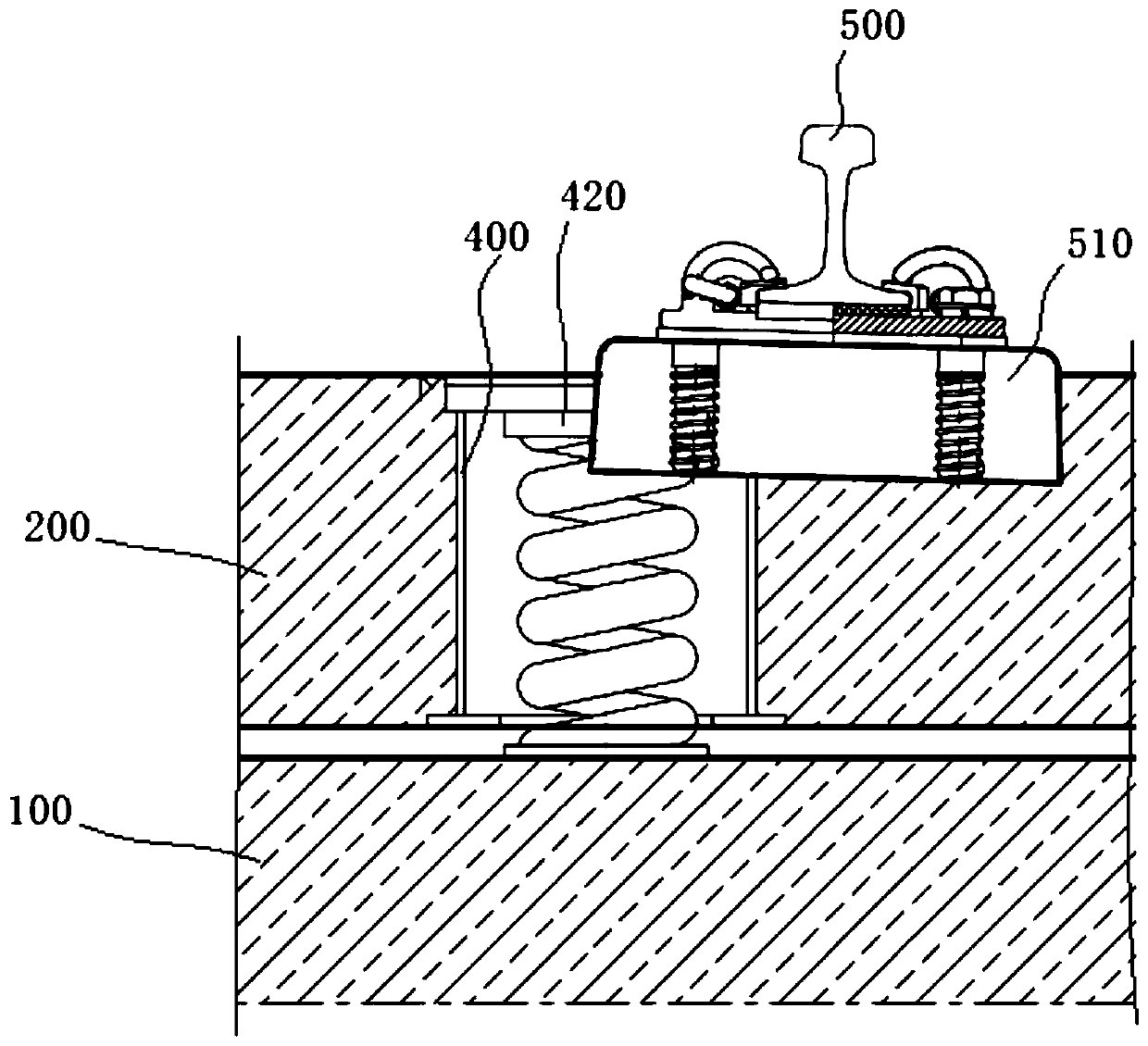

Quasi-zero stiffness vibration isolator floating slab track bed and design method thereof

ActiveCN108411713ADoes not affect the bearing capacityStability is not affectedBallastwayIsolation effectEngineering

The invention discloses a quasi-zero stiffness vibration isolator floating slab track bed. The quasi-zero stiffness vibration isolator floating slab track bed is characterized by comprising floating slabs and vibration isolating assemblies disposed in the floating slabs. The vibration isolating assemblies are arranged in the length direction of the floating slabs at intervals. The vibration isolating assemblies comprise outer sleeves cast in the floating slabs and quasi-zero stiffness vibration isolators installed in the outer sleeves. Heightening gaskets for adjusting the height of the floating slabs are arranged between the quasi-zero stiffness vibration isolators and the outer sleeves in a padded mode, the top portions of the outer sleeves are covered with insulating cover plates. According to the quasi-zero stiffness vibration isolator floating slab track bed, the quasi-zero stiffness vibration isolators are arranged in the floating slab track bed, the bearing capacity and stability of a floating slab track are not affected, and the floating slab track bed has the advantages of high bearing capacity, small deformation capability, good low-frequency vibration isolation effect and large vibration isolation frequency range. The low-frequency vibration component of the floating slab track bed is effectively suppressed, and the low-frequency vibration isolation of the floating slab track is realized. The invention further provides a design method of the quasi-zero stiffness vibration isolator floating slab track bed.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

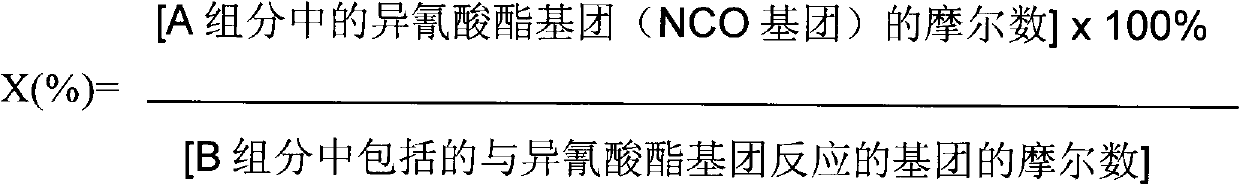

Testing method of tensile adhesive strength of flexible polyurethane foam material for polyurethane solidification track bed

InactiveCN104122203ATrue reflection of cohesionReliable principleUsing mechanical meansMaterial analysisAdhesiveEngineering

The invention relates to a testing method of the tensile adhesive strength of a flexible polyurethane foam material for a polyurethane solidification track bed. The method mainly comprises the following steps: (1) erecting two cylinder railway ballast specimens oppositely and concentrically with an interval between the two specimens of 20mm, and sealing a cavity between the two specimens with kraft paper and an adhesive tape; (2) pouring the stirred double-component polyurethane slurry into the cavity, and dismounting the seal and cutting excessive foam bodies after the slurry reacts to expand in volume and is solidified, hardened and maintained for a period of time; (3) coating adhesives at two sides of the bonding specimens, and pasting positioning base plates to two sides of the specimens; (4) linking a tensile steel plate with pull rods to the positioning base plates by fastening bolts; (5) testing the bonding strength of the flexible polyurethane foam material and railway ballast stones along the tensile direction. According to the invention, the bonding strength of the flexible polyurethane material and the railway ballast stones is tested by adopting a sandwiched bonding specimen, and the testing method has the characteristics of reliable principle, convenience in installation and accuracy in measurement.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Damping vibration-isolating compound track bed for metro and construction method thereof

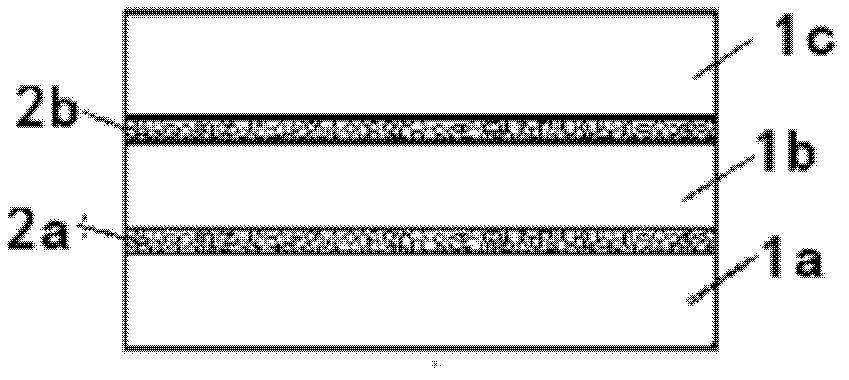

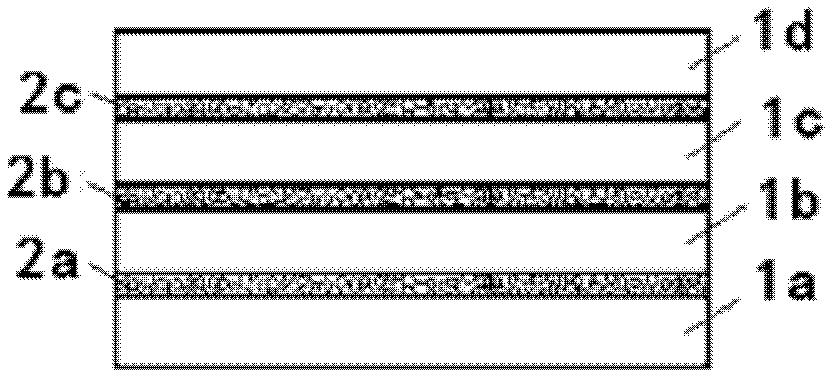

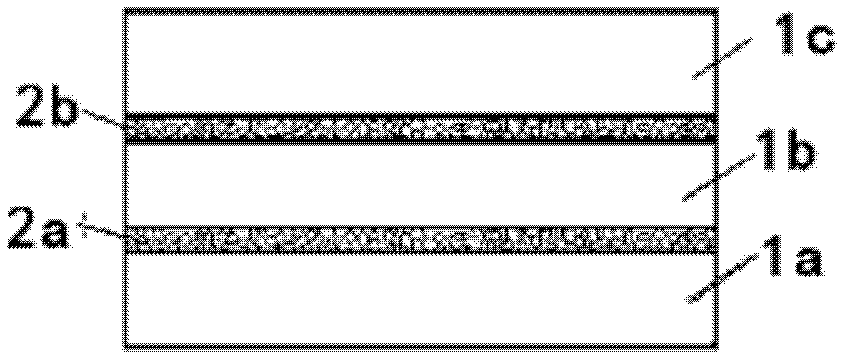

The invention relates to a damping vibration-isolating compound track bed for a metro and a construction method thereof. The track bed comprises concrete layers and EPS (Expanded Poly Styrol) layers which are arranged at intervals, wherein the quantity of the concrete layers is three or four; the quantity of the EPS layers is two or three; the top layer and the bottom layer are both concrete layers; the EPS layers and the poured concrete layers are fixed by small steel chisels; the concrete layers meet the C35 standard; a demand on the density of the EPS layers is 12-15kg / m<3>; and a grain size of EPS grains is 1-2mm. The damping vibration-isolating compound track bed meets the demands on strength and long-term stability, has certain elasticity, has an obvious damping vibration-isolating function and has the energy attenuation above 50-60dB.

Owner:SOUTHEAST UNIV

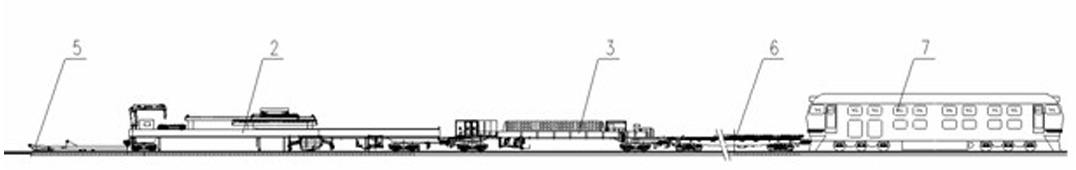

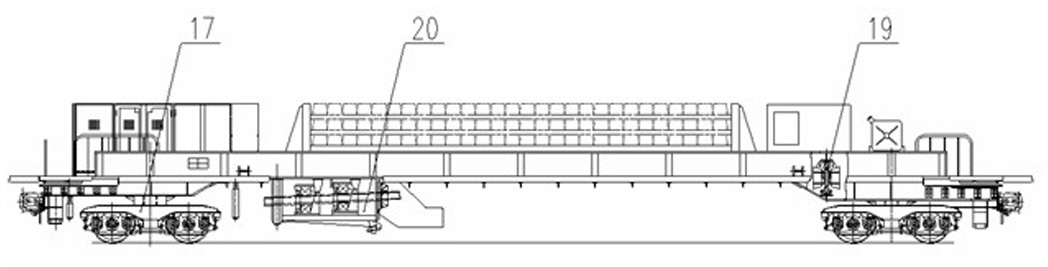

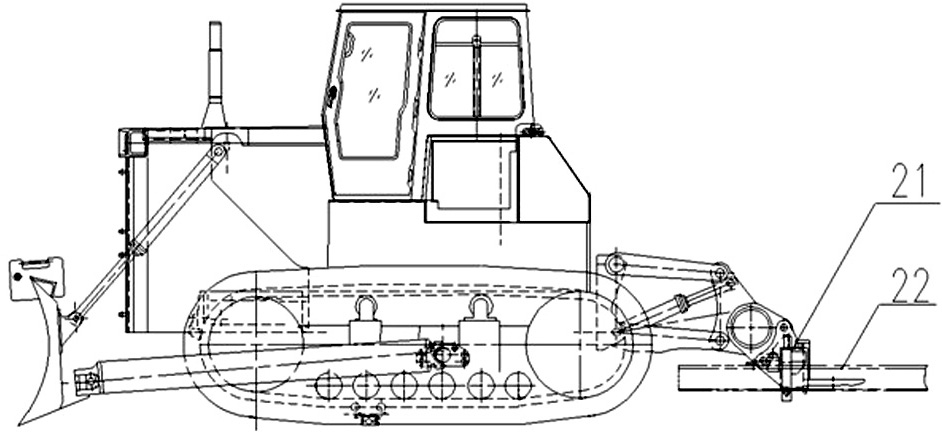

Multi-sleeper type long rail laying machine set and rail laying method thereof

ActiveCN102071606AGood value for moneyLow maintenanceRailway track constructionMarine engineeringTrackway

The invention discloses a multi-sleeper type long rail laying machine set and a rail laying method, wherein the multi-sleeper type long rail laying machine set comprises a long rail tractor, a ground roller, a main machine, an auxiliary machine and sleeper carriers, and is characterized in that: when a ballast track bed rail is laid, the multi-sleeper type long rail laying machine set is sequentially provided with the long rail tractor, the main machine, the auxiliary machine, a sleeper carrier group loading with the sleeper carriers and a locomotive along the rail laying direction; and when a ballastless track bed rail is laid, the multi-sleeper type long rail laying machine set is sequentially provided with a ballastless track bed laying device, the main machine, the auxiliary machine, the sleeper carrier group and the locomotive along the rail laying direction. The machine set can satisfy the requirements on laying a long rail of 500m and the sleeper at once under the condition of ballast track bed and ballastless track bed laying, and meanwhile, the cost performance of a construction method is obvious, and the operation efficiency and laying quality are as good as those of a single sleeper continuous laying method.

Owner:株洲长远智造股份有限公司 +1

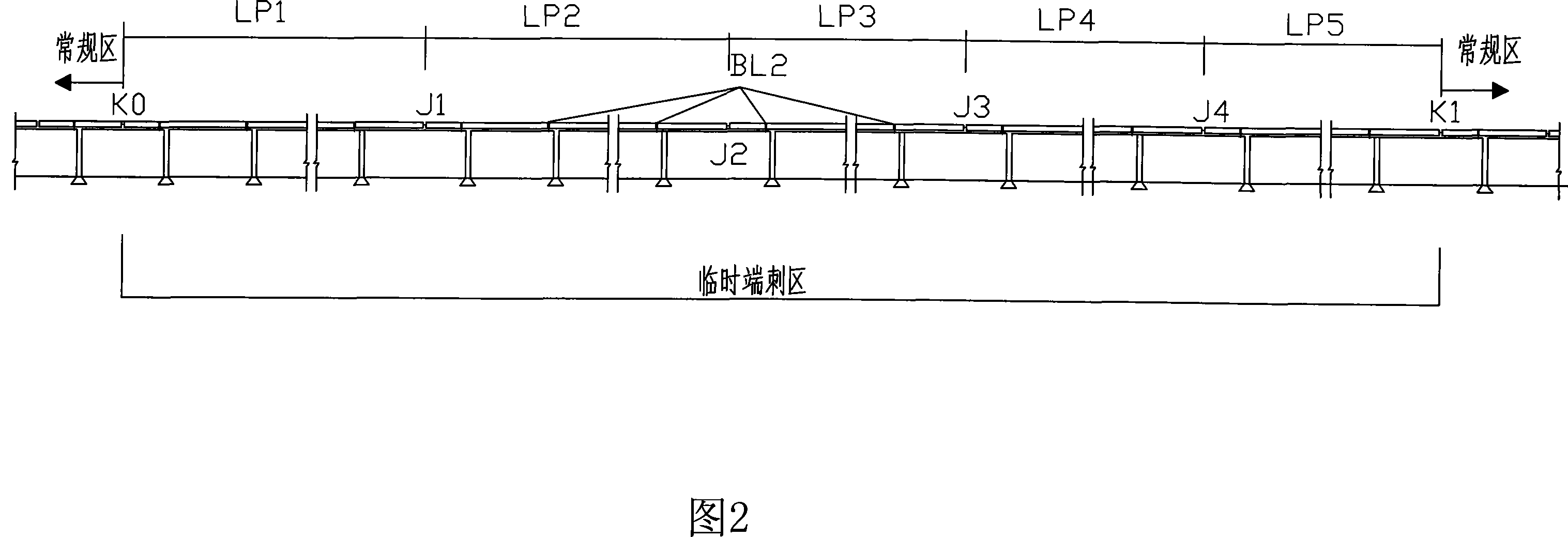

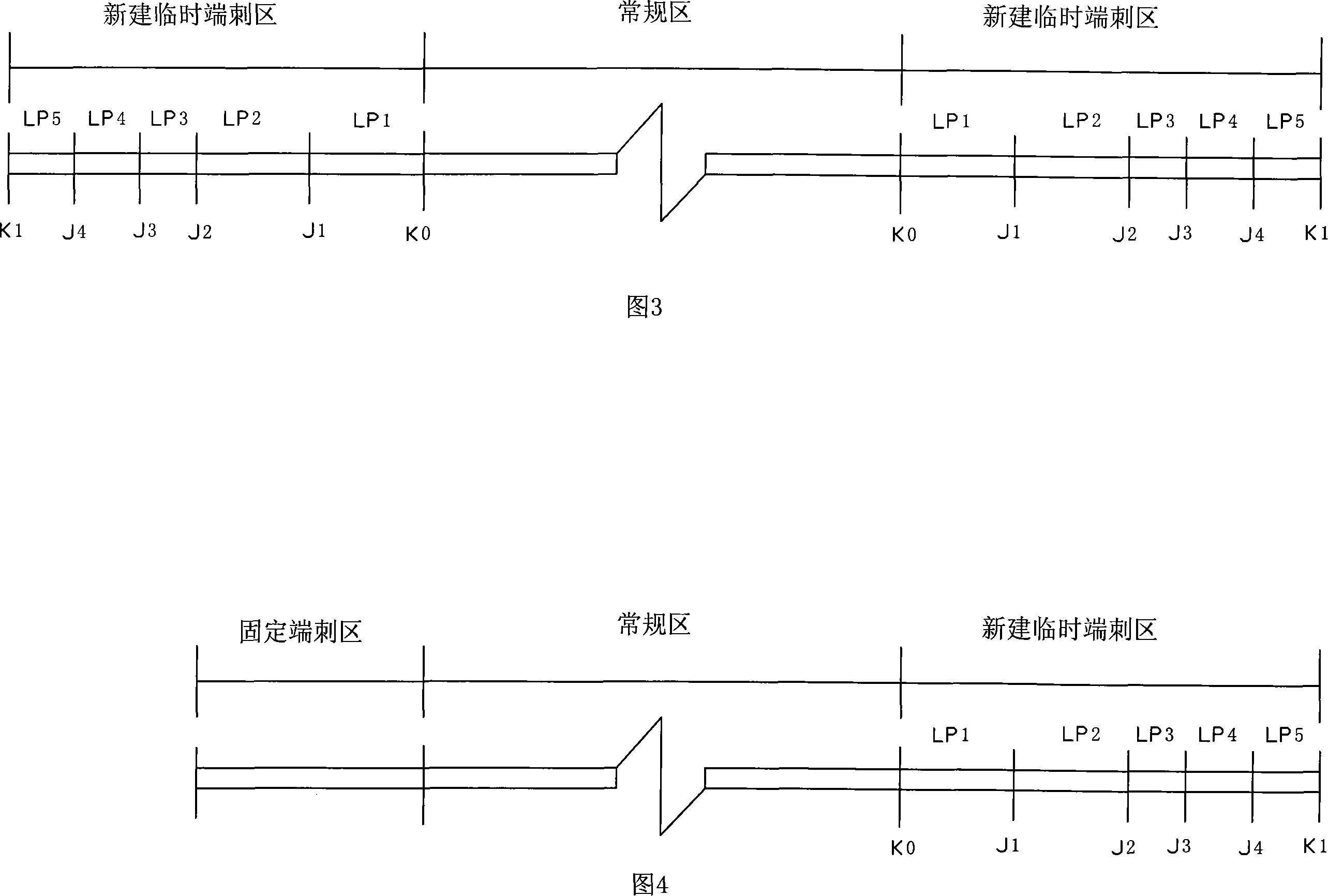

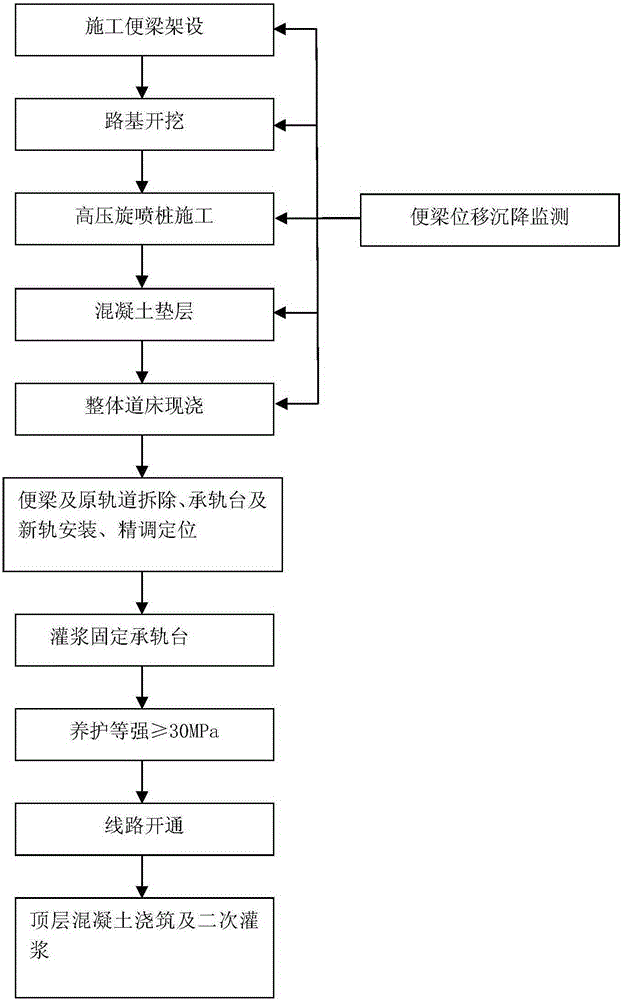

Monolithic track bed construction process for remodeling ballast track subgrade into ballastless track

A monolithic track bed construction process for remodeling a ballast track subgrade into a ballastless track is characterized by comprising the following steps that a monolithic track bed is cast in place under an auxiliary girder; a track supporting platform mounting groove and a line pipe reserved pipe are reserved during casting; after the monolithic track bed is cast to reach the design strength, the auxiliary girder and an existing track are removed; a track supporting platform is mounted in the track supporting platform mounting groove; and after the track is finely adjusted and fixed, a grouting material is grouted to fix the track supporting platform, wherein the grouting material for fixing the track supporting platform is a high strength non-shrinkage grouting material. The monolithic track bed construction process for remodeling the ballast track subgrade into the ballastless track, provided by the invention is advantaged in that the construction time is greatly reduced, the cost is reduced, resources are saved, the track bed does not need to be integrally pushed and the process is safe and reliable because the monolithic track bed is cast in place under the auxiliary girder. And meanwhile, as the high strength non-shrinkage grouting material is adopted, the grouting operation can be finished within one skylight point and the use strength can be reached to open the line directly within one skylight point.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP +1

Easy-to-assemble floating track bed precast slab and application thereof

ActiveCN105484109AAchieve connectionReduce the difficulty of assemblyBallastwayEngineeringRail transit

The invention relates to an easy-to-assemble floating track bed precast slab and an application thereof, which belong to the field of rail transit. According to the invention, the easy-to-assemble floating track bed precast slab can conveniently establish reliable connection with an adjacent floating slab and can smoothly transmit a shear force and improve the force born on the floating slab; and meanwhile, the integrality of a floating track bed structure can be also effectively enhanced, the adaptability of the easy-to-assemble floating track bed precast slab is enhanced and the service life of the easy-to-assemble floating track bed precast slab is prolonged. According to the invention, the easy-to-assemble floating track bed precast slab comprises a precast slab body, wherein the middle part of a connecting end of one side of the precast slab body is fixedly provided with locating guide sleeves; the middle part of a connecting end of the other side of the precast slab body is correspondingly provided with join-assembling holes; the locating guide sleeves and the join-assembling holes are respectively arranged in a longitudinal direction of a track; at least two locating guide sleeves are arranged; the number of the join-assembling holes is as same as that of the locating guide sleeves; a grouting passage is formed in the precast slab body; one end of the grouting passage is communicated with the bottoms of the join-assembling holes; and the other end of the grouting passage is open in the upper surface of the precast slab body. The easy-to-assemble floating track bed precast slab, provided by the invention, is mainly used for the construction of rail transit.

Owner:GERB QINGDAO VIBRATION CONTROL +1

Floating track bed, jacking device and jacking method thereof

ActiveCN101845776AThe jacking method is simple and easyThe jacking method is safe and reliableRailway tracksLifting devicesMarine engineeringElastic vibration

The invention relates to the field of track traffic, in particular to a track bed and a jacking device used when the track bed is jacked. The floating track bed comprises a floating plate, a gasket and an elastic vibration isolator, wherein a pre-reserved through hole or a side groove for accommodating the elastic vibration isolator and the gasket is arranged on the floating plate, and the floating plate is supported on the elastic vibration isolator through the gasket; an articulating hole for jacking is arranged on the floating plate and is of a ladder hole, and the interface of the upper hole and the lower hole of the ladder hole forms a retaining shoulder; and the size of the upper aperture is smaller than the size of the lower aperture. The floating track bed has simpler structure, requires lower requirements for the thickness of the floating plate and the jacking space, and stronger practicality, is more favorable for reducing cost when not affecting the vibration isolating efficiency, prolongs service life, and has more higher performance-price ratio and very broad market application prospects.

Owner:尹学军

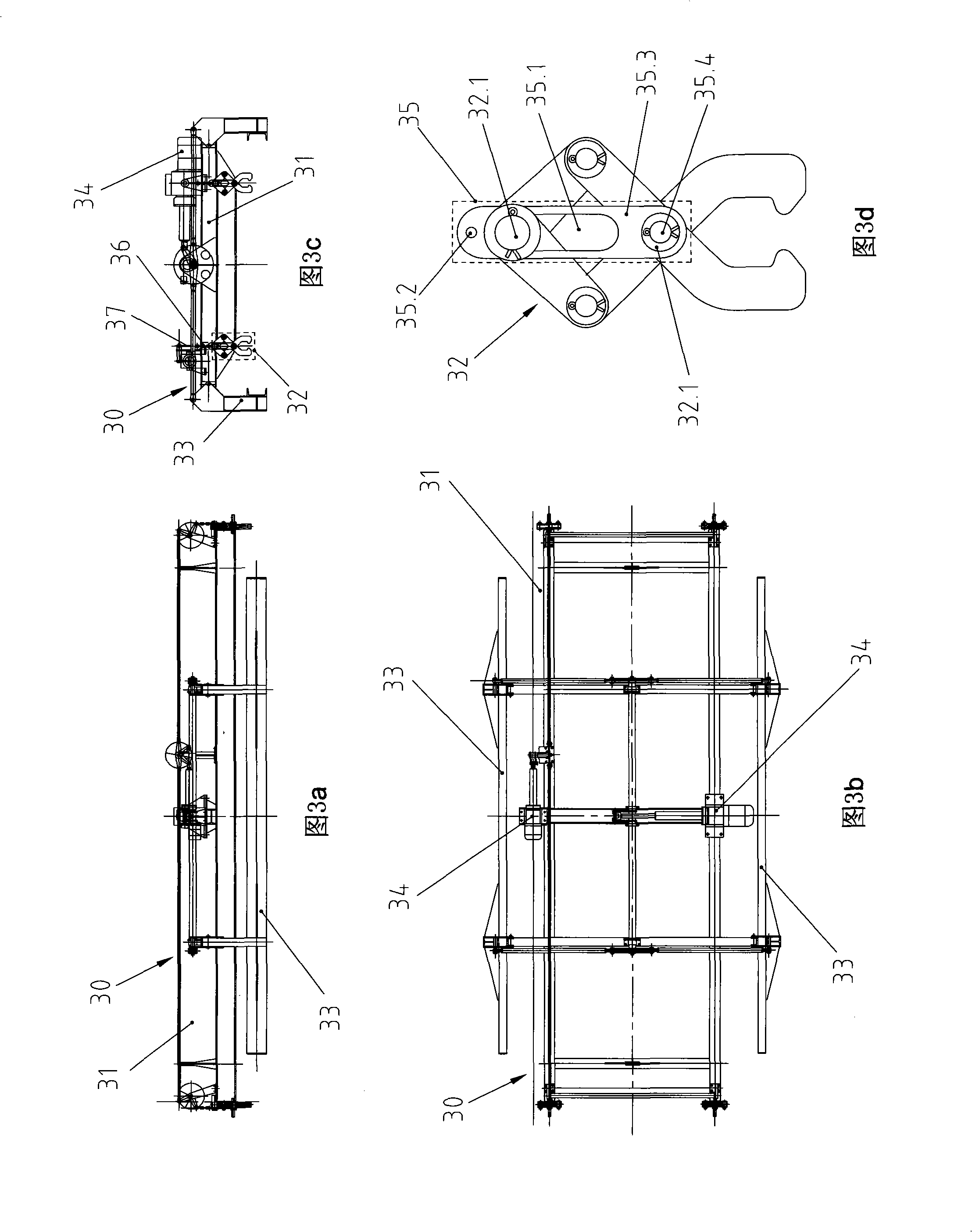

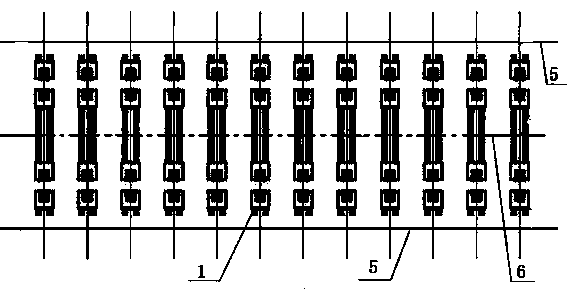

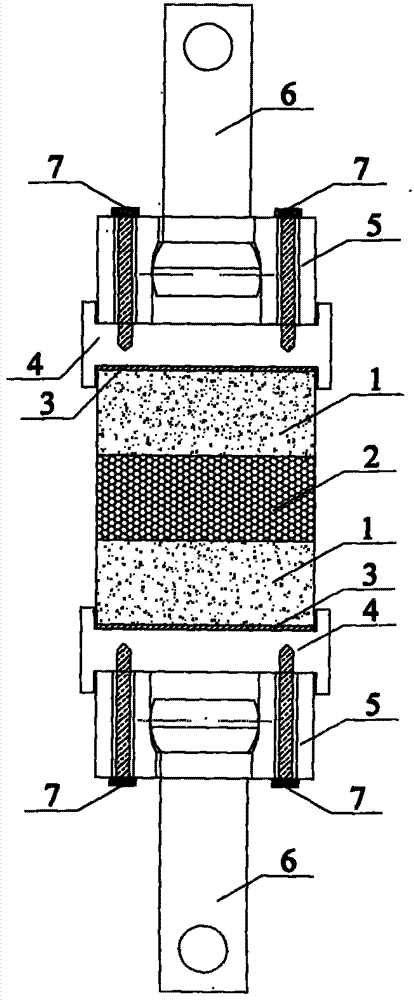

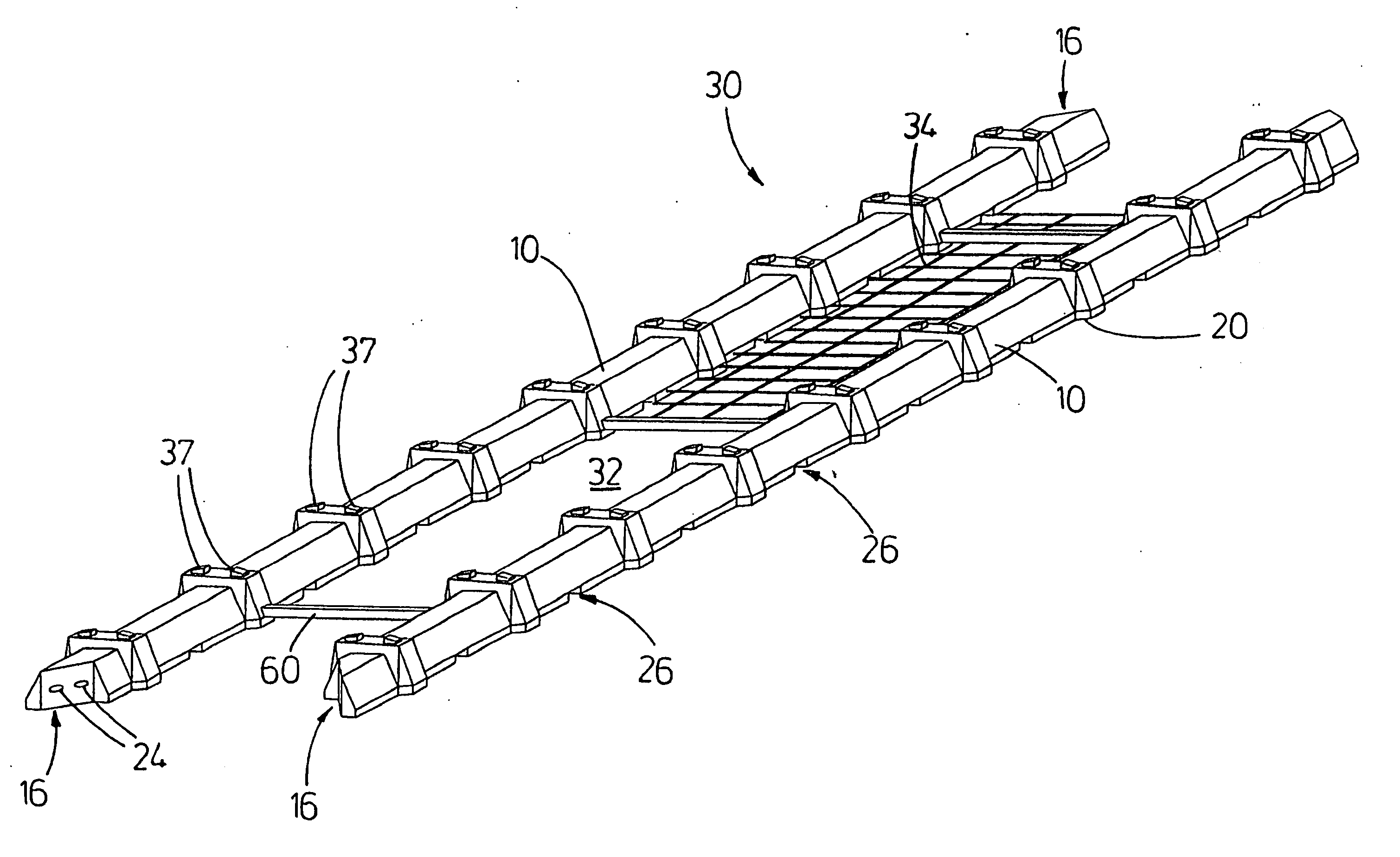

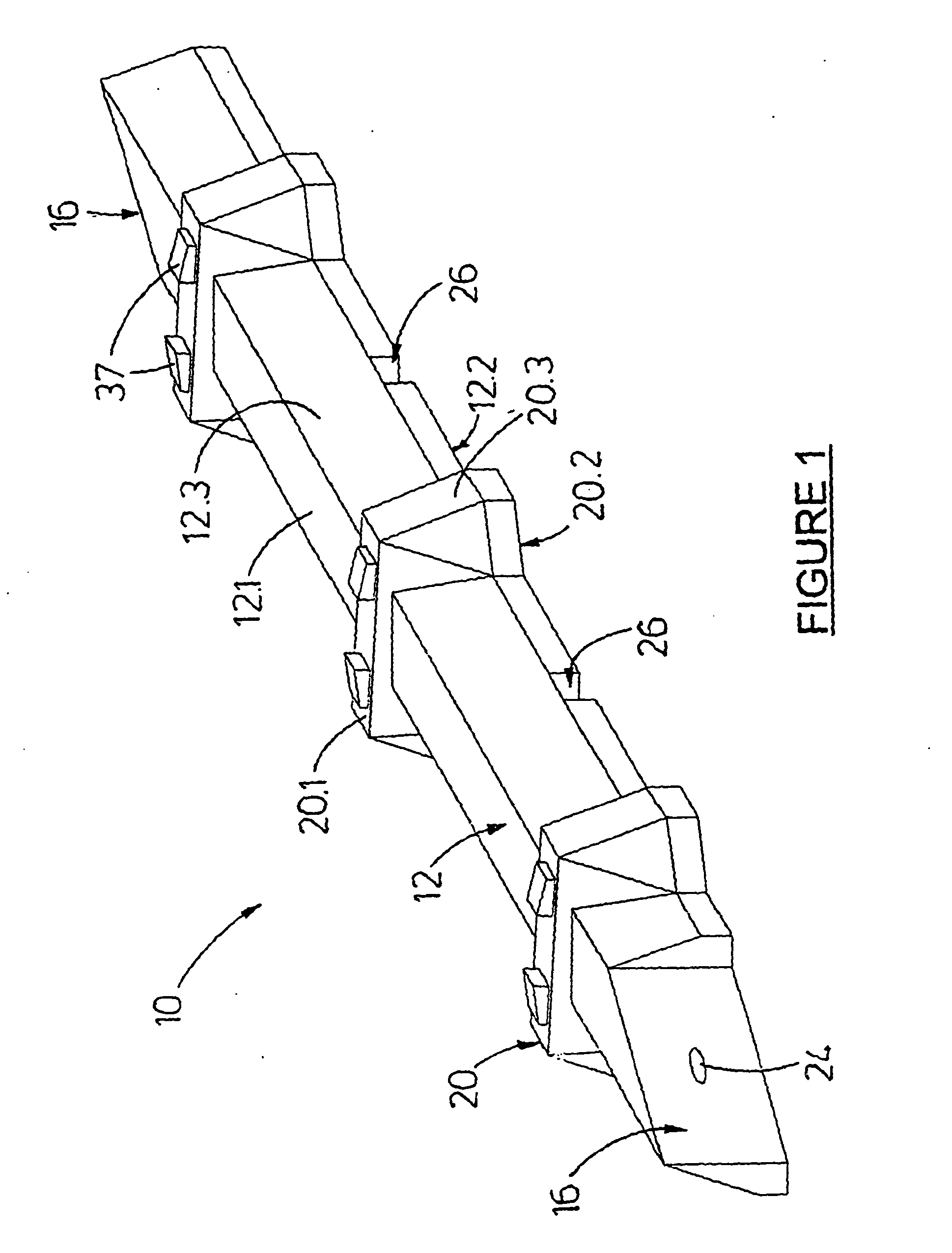

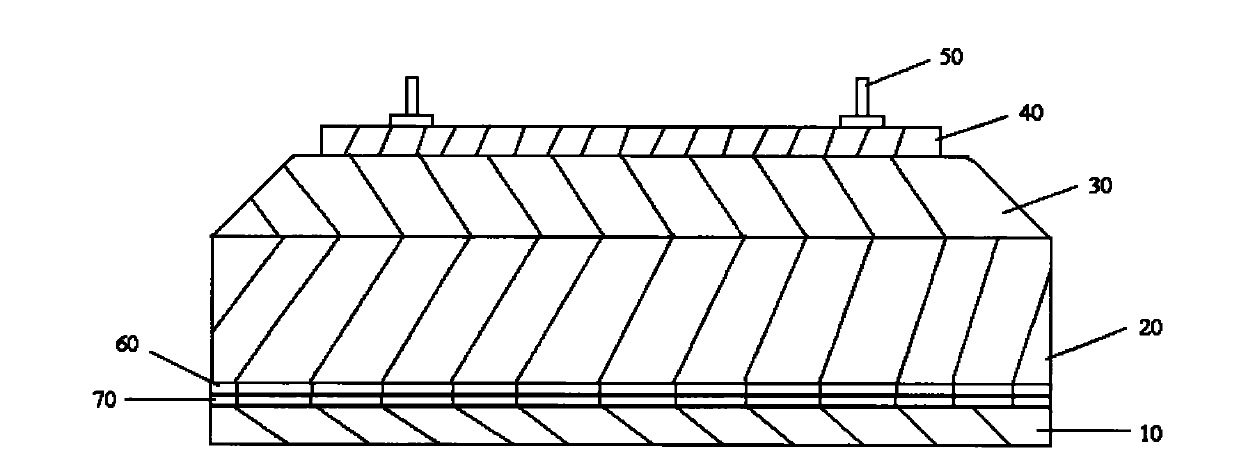

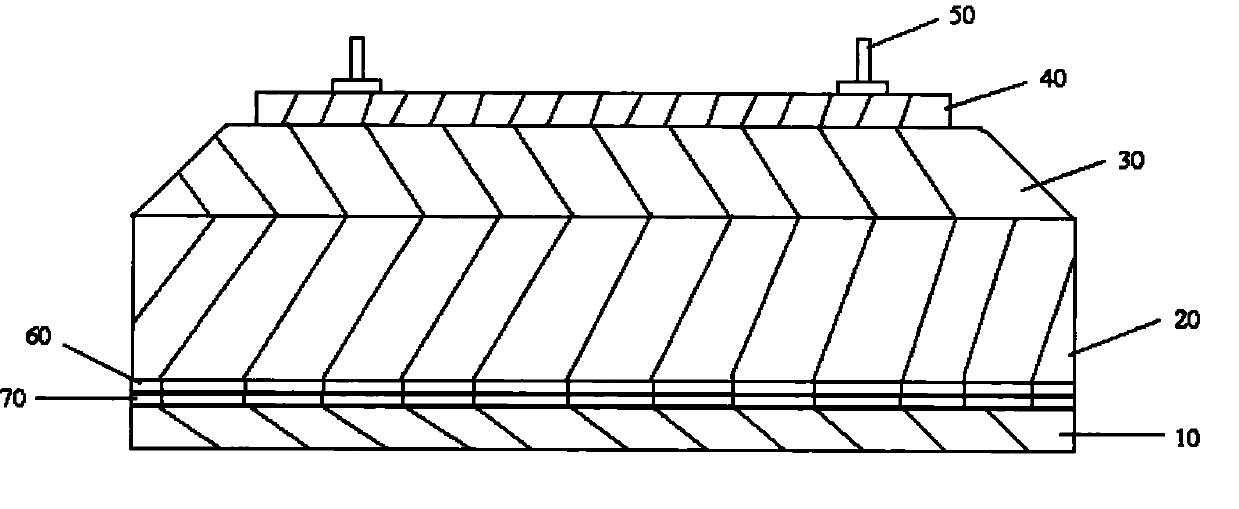

Rail sleeper and ballast-free track structure

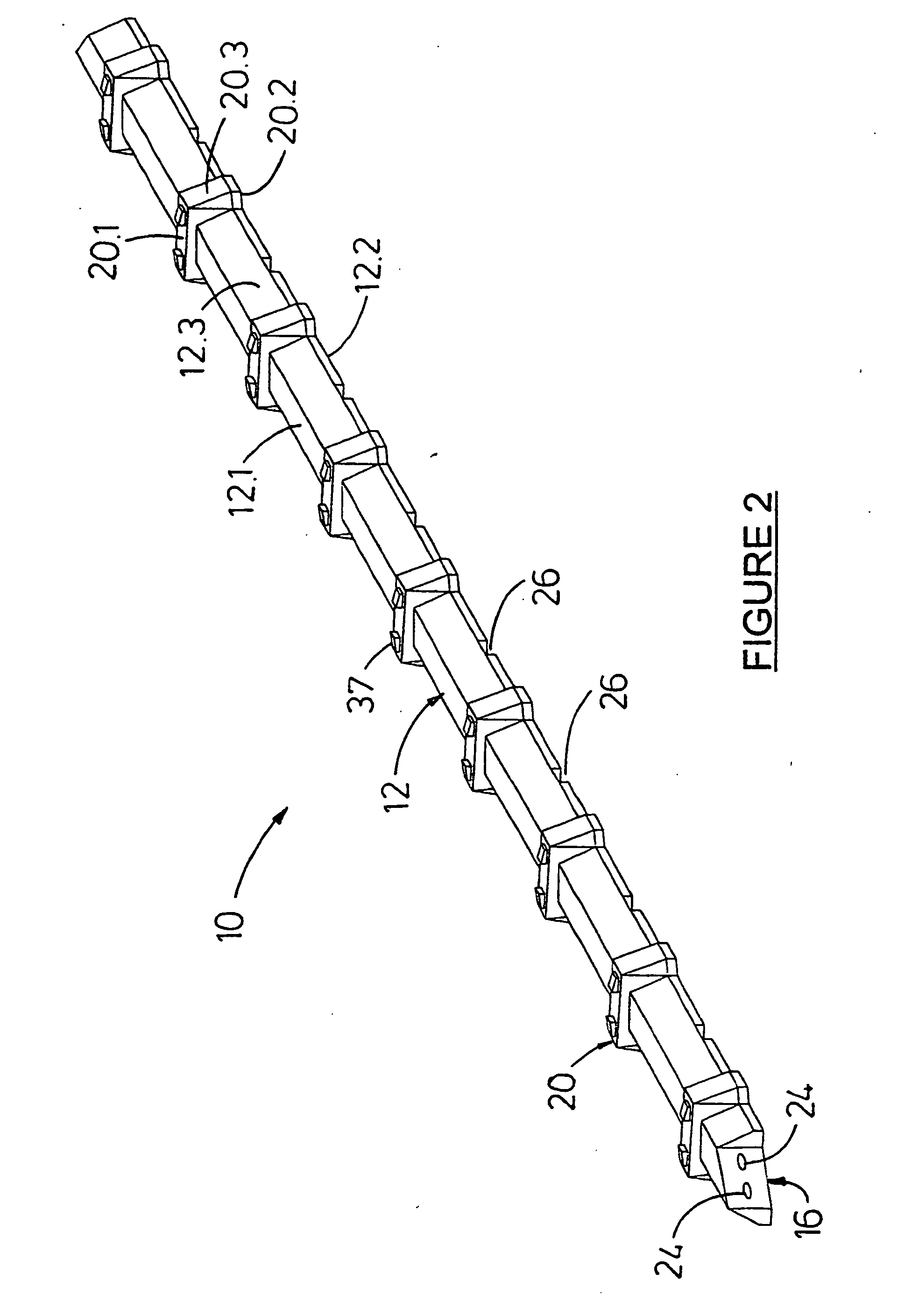

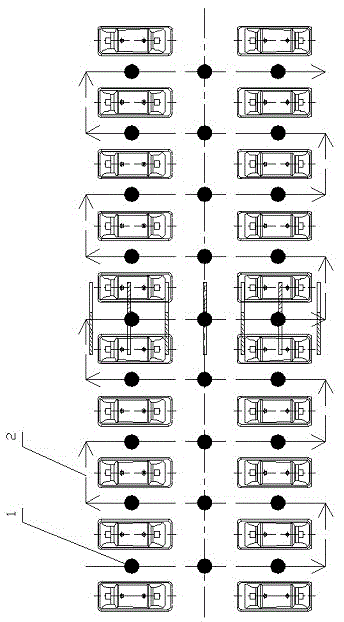

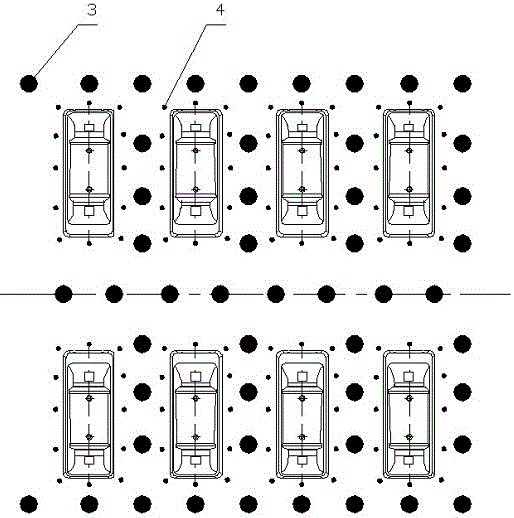

InactiveUS20050252985A1Facilitate rapid installationEasy to replaceBallastwayRail fastenersEngineeringMechanical engineering

According to one aspect of the invention there is provided a prefabricated rail sleeper [10] suitable for use in erecting a track structure [30]. The rail sleeper [10] comprises an elongate body portion [12] for supporting rails [14], the body portion [12] including a top surface [12,1], a bottom face [12.1] and at least two side faces [12.3], and terminating at least at one end thereof in a transition joint formation [16] dimensioned matingly to engage a complimentarily dimensioned transition joint formation [16] of an adjacent rail sleeper [10] in use so as to form a substantially continuous track structure. The sleeper [10] also includes a series of block formations [20], each of which is at least partially outwardly flared and extending beyond the side faces [12.3] of the body portion [12] so as to increase shear interlock of the sleeper [10] with the track bed to reduce longitudinal creep; as well as a series of transverse drainage ducts [26] extending underneath the rail sleeper [10] for allowing rainwater drainage between different side faces [12.3] of the body portion [12] and away from the rail sleeper. The invention extends to a ballast-free track structure [30] comprising at least two rail sleepers [10] according to the invention wherein the sleepers are located in spaced parallel orientation on a ballast-free track bed so as to define a centre drain [32] between the sleepers; and including a mesh [34] located between the sleepers [10] for reinforcing the centre drain [32].

Owner:HIGHFLYER INVESTMENTS & TRADING 6

Method for controlling cracks of double-block type ballastless track bed slabs

The invention discloses a method for controlling cracks of double-block type ballastless track bed slabs. The method includes steps of pouring concrete back and forth among double-block type sleepers according to 'Z'-shaped paths; vibrating the concrete, in other words, performing a secondary vibrating process in procedures for pouring the concrete of double-block type track bed slabs according to slump and the initial setting time of the concrete, performing press polish on plastered surfaces, performing rough screeding by the aid of wood float after the concrete is filled into forms, secondarily plastering the surfaces 2 hours after the concrete is filled into the forms, and performing tertiary press polish on the plastered surfaces 4 hours after the concrete is filled into the forms; loosening vertical screw adjusters, fish plates and fasteners, in other words, loosening vertical adjusting screws 4.5 hours after the concrete is plastered on the surfaces, loosening the corresponding fish plates from two sides of a pouring starting end, timely loosening the fasteners by the aid of a bolt fastening machine after bolts of the fish plates are loosened, and removing connection; spraying maintenance liquid. The cracks of the ballastless track bed slabs can be reduced in construction procedures, so that trains can assuredly run safely, economically and quickly. The method has the advantages of simplicity in process, convenience in operation and easiness in construction. Besides, the construction quality of the ballastless track bed slabs can be improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

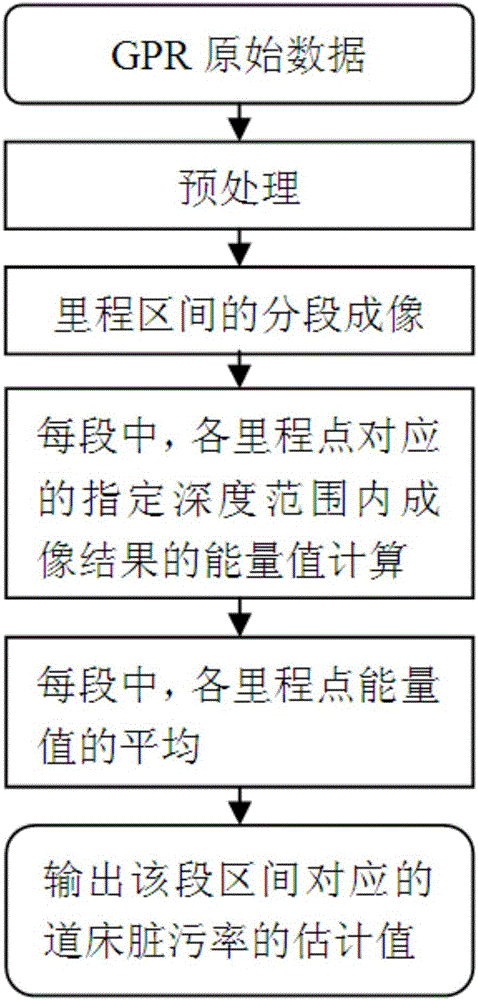

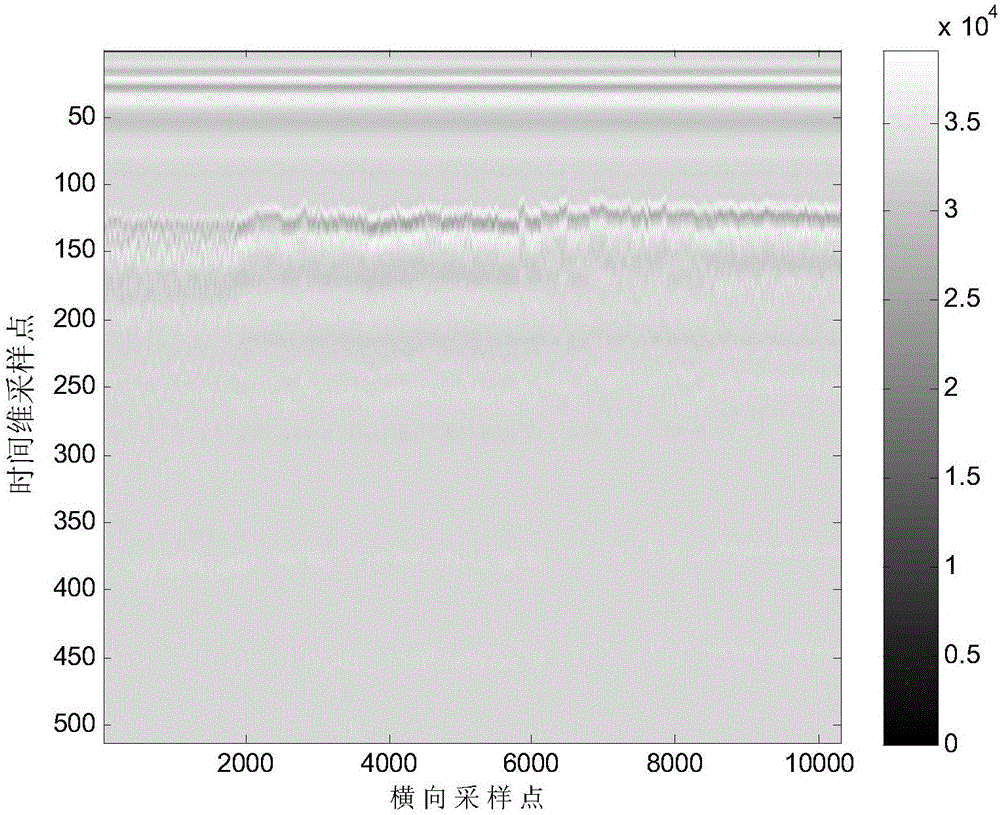

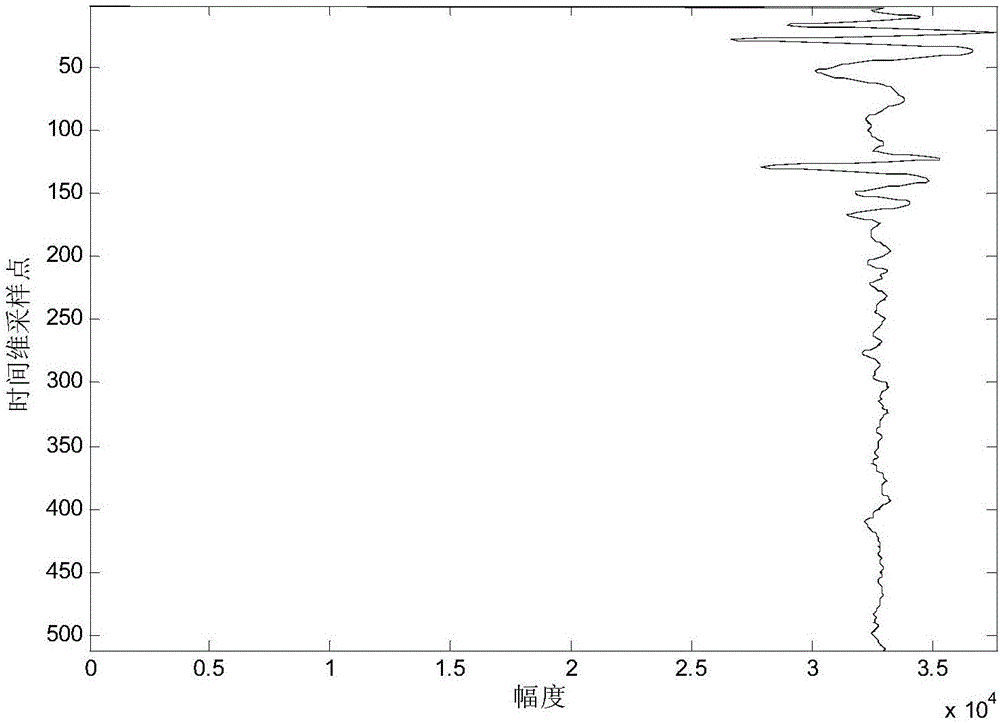

Method for inversing railway base track bed contamination rate by using ground penetrating radar

ActiveCN106338729AAvoid influenceAvoid problems with big ups and downsDetection using electromagnetic wavesRadio wave reradiation/reflectionOriginal dataIn vehicle

The invention discloses a method for inversing railway base track bed contamination rate by using a ground penetrating radar. The method includes the following steps that: original data acquired by a vehicle-mounted ground penetrating radar are preprocessed; sectional imaging is performed on the pre-processed data according to track mileage intervals, so that two-dimensional imaging results of each section interval can be obtained; imaging results of a certain set depth interval at mileage points in each section interval are extracted; the energy values of the imaging results of the depth interval are calculated, and are adopted as railway base track bed contamination rates corresponding to the mileage points; and the railway base track bed contamination rates corresponding to the mileage points in each section interval are averaged, and an obtained result is adopted as the estimated value of the railway base track bed contamination rate of the corresponding section interval. The method of the invention has the advantages of high calculation speed and low relative error.

Owner:CENT SOUTH UNIV

Construction method of ladder-shaped track in urban track traffic

InactiveCN101967782ASimple processImprove construction efficiencyRailway track constructionEngineeringNoise reduction

The invention discloses a construction method of a ladder-shaped track in urban track traffic, which is characterized by comprising the following steps of: firstly, before ensuring ladder-shaped sleepers in position, completely adhering parts located among sections of vibration reduction members by using cystosepiments according to the thicknesses the same with those of a bottom vibration reduction pad and a side cushion pad respectively at the bottom part and the side part of the ladder-shaped sleeper; hoisting the ladder-shaped sleepers adhered with the cystosepiments in position, arranging brackets to ensure that the ladder-shaped sleepers are erected by the brackets, installing buckle accessories on the ladder-shaped sleepers, and laying steel rails and arranging a rail state; then placing support concrete with a vertical mold; and after the placing of the support concrete is completed, manually removing the cystosepiments to form the ladder-shaped track in a floating state. In the invention, the whole track bed is integrally formed, the process is simple, the construction efficiency is high, the ladder-shaped sleepers can effectively float, and the performances of vibration reduction and noise reduction are effectively ensured.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Turnout rail creeping amount monitoring device

ActiveCN104109991AAdapt to conductivityAdapt to requirementsMeasuring apparatusCommunication interfaceRemote control

The invention provides a turnout rail creeping amount monitoring device. Turnout rails comprise turnout stock rails and turnout switch rails, two creeping amount detection assemblies are installed on the same cross section of the turnout rails, the creeping amount detection assemblies comprise magnetic metal fixedly installed on the turnout switch rails and electrical vortex sensors fixedly installed on the turnout stock rails, and the lateral surfaces, close to the turnout stock rails, of the magnetic metal serve as creeping amount measuring reference surfaces. The turnout rail creeping amount monitoring device further comprises a collection device and a processor, and the processor is in communication connection with a remote control terminal through a communication interface. The turnout rail creeping amount monitoring device has the advantages that the device is fixed to the rail bottoms by using cold end clamping units and elastic clamping units, and no holes need to be drilled in the rails for installation; the creeping reference surfaces move along with the switch rails, the movement space of the creeping reference surfaces is located in existing space between the rail bottoms and the ground, and track beds do not need to be damaged; measurement errors are small.

Owner:HANGZHOU HUIJING TECH

Cyclic loading tamping teststand for indoor crushed stone ballast track beds

ActiveCN104198310AImplement cyclic loadingAchieving a tamping testUsing mechanical meansMaterial strength using repeated/pulsating forcesMarine engineeringTrackway

The invention relates to a cyclic loading tamping teststand for indoor crushed stone ballast track beds, and belongs to the technical field of railway engineering blast track bed detection. The cyclic loading tamping teststand comprises a cyclic loading apparatus, a tamping apparatus, a movable loading vehicle, a loading hydraulic system, a ballast track bed, a track panel, a ballast box I, a power supply, a ballast box II, a groundwork and ground pit system, a track bed detection system, a system damping apparatus and a vehicle walking track. The cyclic loading tamping teststand performs cyclic loading tests to simulate loading effect of a train on a ballast track bed and simulate tamping operation of the crushed stone ballast track bed, performs test analysis and test research on track bed compactness. The cyclic loading tamping teststand is capable of simulating operation of a train with the shaft weight of 0.5-35 ton and the speed per hour of 40-350 Km / h on a ballast track, performing real-time testing and monitoring and acquiring data. During tamping simulation operation, the cyclic loading tamping teststand is capable of realizing the tamping frequency variation scope of 15 Hz-60 Hz and realizing multi-station operation with high testing precision and high testing efficiency, satisfies indoor repeatability test demands, and is strong in anti-interference capability.

Owner:KUNMING UNIV OF SCI & TECH

Construction method of ballastless tracks of tunnel group of heavy haul railway

ActiveCN110541329AAdvanced technologyHigh precisionBallastwayRailway track constructionRailway tunnelRebar

The invention relates to a construction technology of a heavy haul railway, specifically relates to a construction method of ballastless tracks of a tunnel group of a heavy haul railway. According tothe characteristics of high requirement on the construction precision of a ballastless track bed and difficulty in control in the construction of the ballastless tracks, the principle of near laying and convenience in precision control is adopted; a double-block sleeper is hung and placed to a position to be laid near a construction track bed plate; after key processes of steel bar binding, trackpanel assembly, comprehensive grounding, track coarse adjustment and the like are carried out, the geometric dimension of the tracks is finely adjusted by using a track inspection trolley measuring system, so that the design precision requirement is met, and finally, the track bed concrete is poured for one-step forming. The technology has the characteristics of being simple and convenient to operate, safe, practical, accurate in track geometric dimension, quick to position and the like.

Owner:CHINA RAILWAY SIXTH GROUP +2

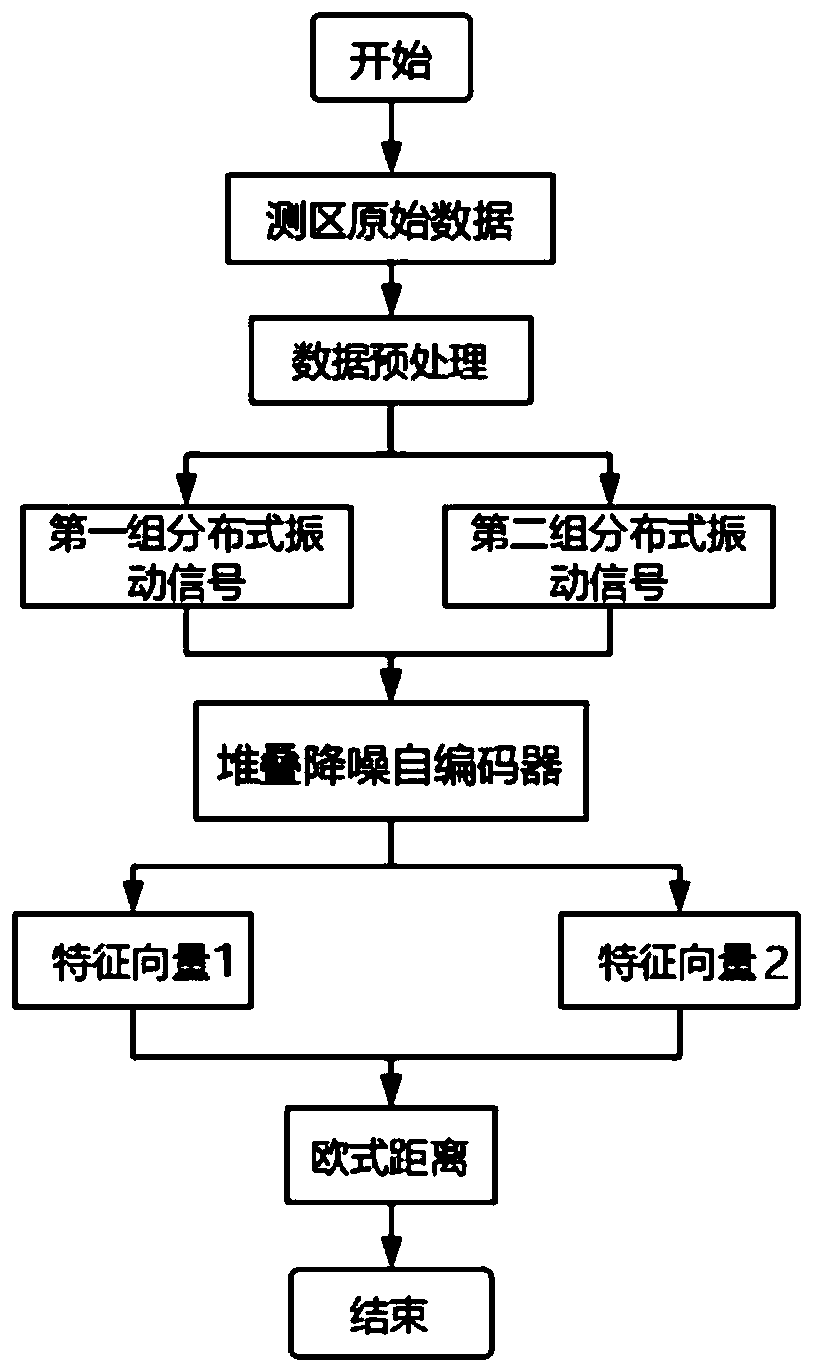

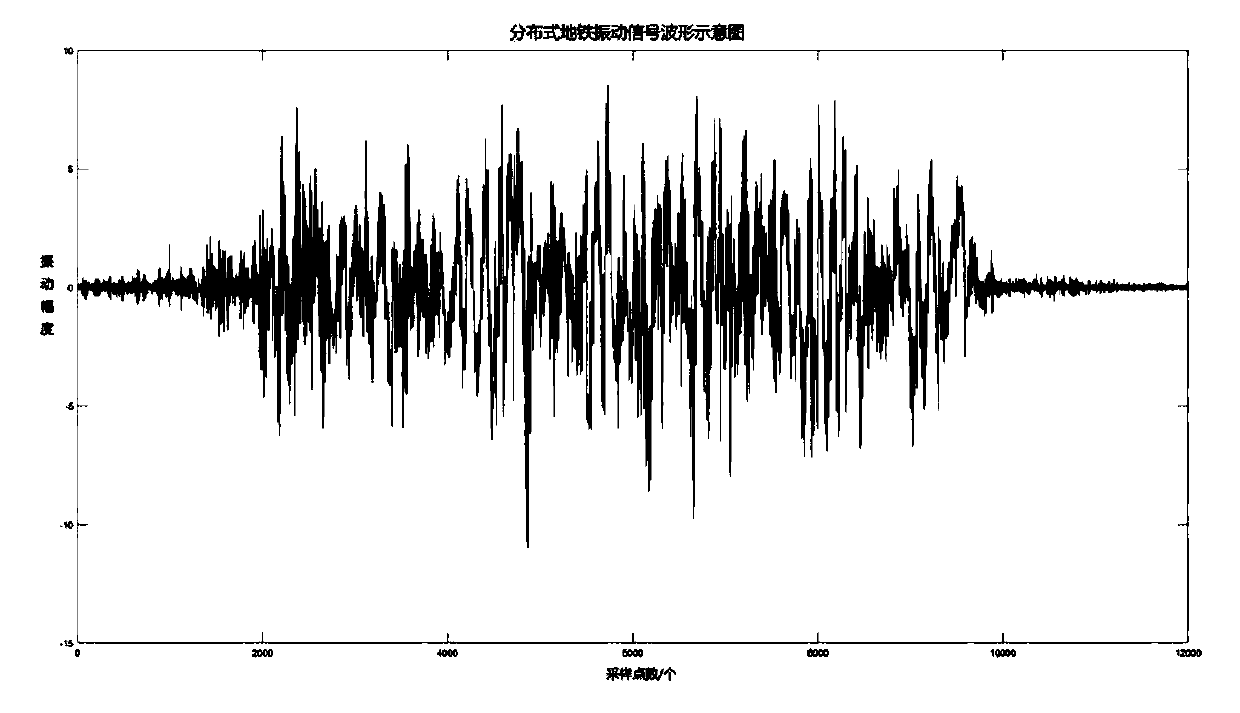

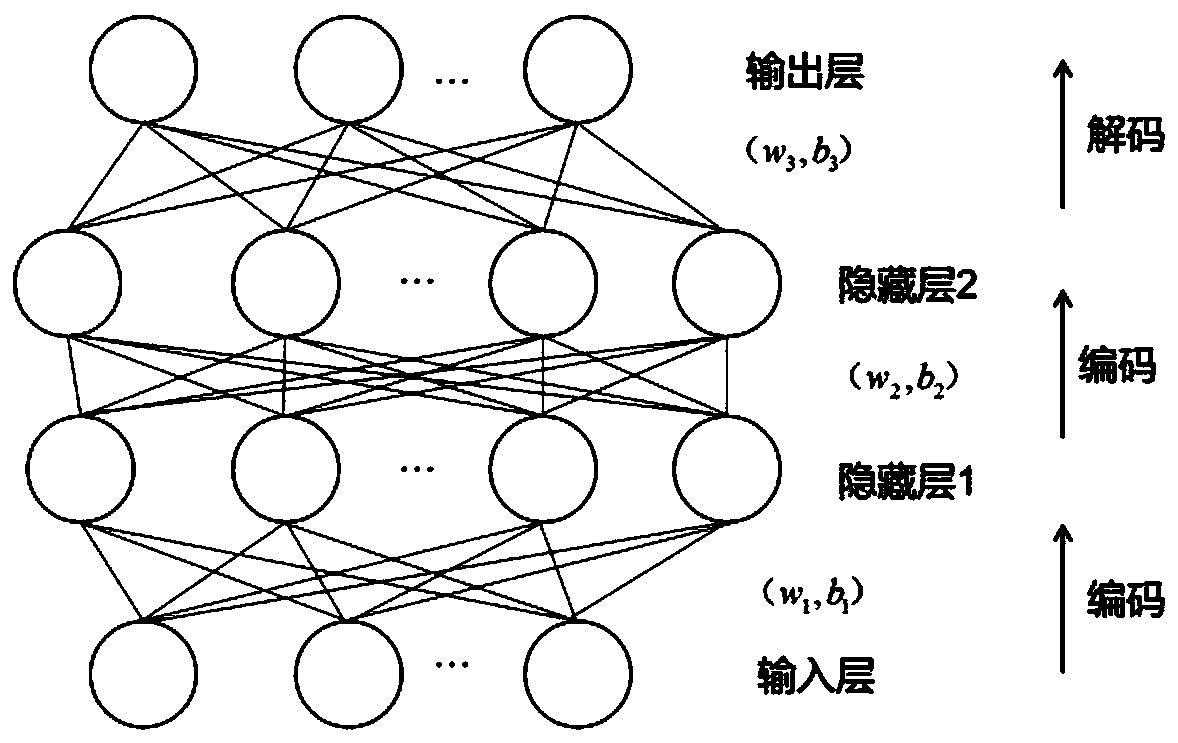

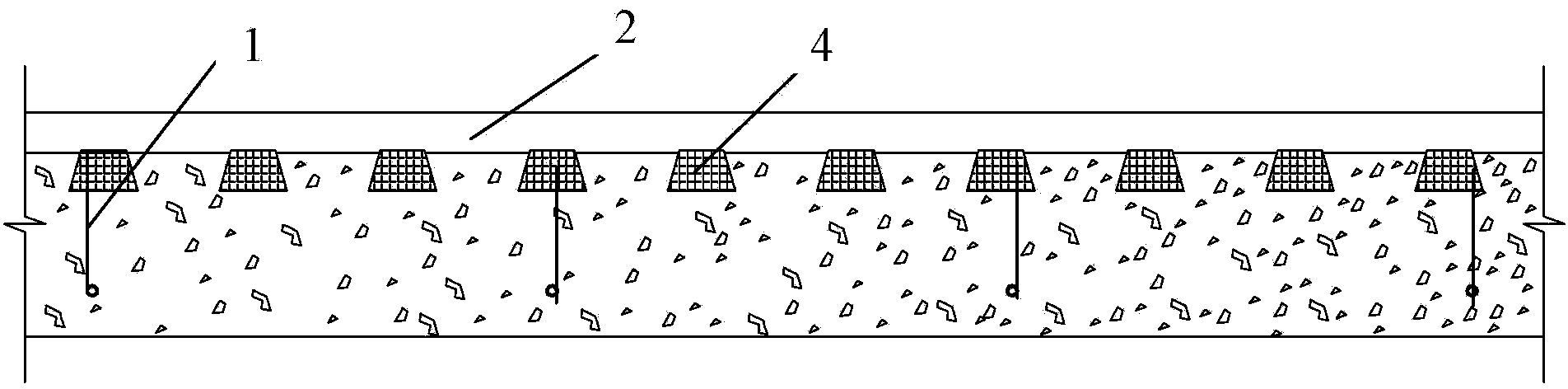

Subway distributed vibration signal similarity determination method

ActiveCN110751108AEffective extraction of local location featuresSpatial distance measurement is convenientSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionPattern recognitionTest sample

The invention discloses a subway distributed vibration signal similarity determination method, which comprises the following steps: 1) collecting vibration response of structural parts including a track bed and a tunnel wall along a subway tunnel through an optical fiber sensor, and obtaining an original monitoring vibration data set; 2) carrying out signal preprocessing on the original monitoringvibration data set, and extracting a distributed vibration signal data set excited by a subway coming vehicle; 3) normalizing the distributed vibration signal data set, and dividing the normalized distributed vibration signal data set into a training sample subset and a test sample subset; 4) constructing an SDAE network model; training an SDAE model by using the training sample and the test sample; 5) selecting two groups of vibration signals, respectively inputting the signals into the SDAE model, and then extracting the feature representation of the last middle layer of the SDAE model to form two groups of feature matrixes. According to the method, the local position features contained in the signals are extracted, the vibration signal similarity is expressed through the spatial distance between the feature matrixes, and the method is simple and reliable.

Owner:WUHAN UNIV OF TECH

Existing railway reinforcement construction method in jacking process of box body

An existing railway reinforcement construction method in the jacking process of a box body comprises the following steps: performing grouting treatment to railway ballast below an existing railway positioned in a to-be-jacked area, moving concrete sleepers, penetrating wooden ties among the concrete sleepers, mounting locking tracks, forming a beam arranging ditch, penetrating a beam, mounting a longitudinal beam, and the like. The method provided by the invention has the following advantages: the operation of renewing concrete sleepers is reduced, so that the damage to the original road bed / track bed is reduced, and the stability of the road bed is high; the depth of a dug ditch and the work amount of reinforcement are reduced, the construction period and the on-line operation time are shortened, and the risk of personnel safety and running of an existing railway is lowered; grouting solidification can effectively reduce the problem that vibration is caused when a train passes, so that railway ballast rolls into the ditch, and then repeated operation can be avoided; insulating boards of 3 cm in thickness and H-steel of 45 cm in height are arranged at the lower part of a steel rail, so that the reserved space is enlarged, a treatment space is provided for the rising phenomenon that possibly occurs when the box body is jacked, and running safety of the existing railway can be ensured.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

Polyurethane railway track bed and its production method and application

InactiveCN102561114AAccurately increment or decrement densityPrecisely increase or decrease hardnessBallastwayEngineeringSubgrade

The invention relates to a polyurethane railway track bed, a production method of the polyurethane railway track bed and a railway facility comprising the polyurethane railway track bed. The polyurethane railway track bed comprises a railway subgrade and a moulded polyurethane layer, and the moulded polyurethane layer is disposed on the railway subgrade. The moulded polyurethane layer is laid on the railway subgrade, so that the strict requirement of the field polyurethane pouring method on field pouring environment can be omitted, and the moulded polyurethane layers different in density and / or hardness can be produced and laid on the railway subgrade according to actual needs of different railway track beds.

Owner:COVESTRO DEUTSCHLAND AG

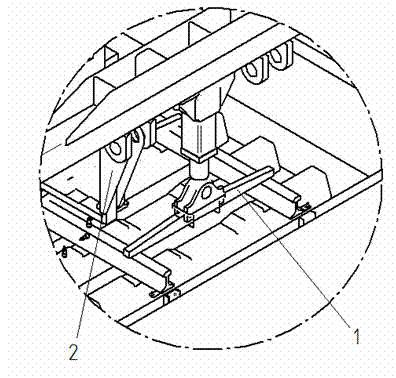

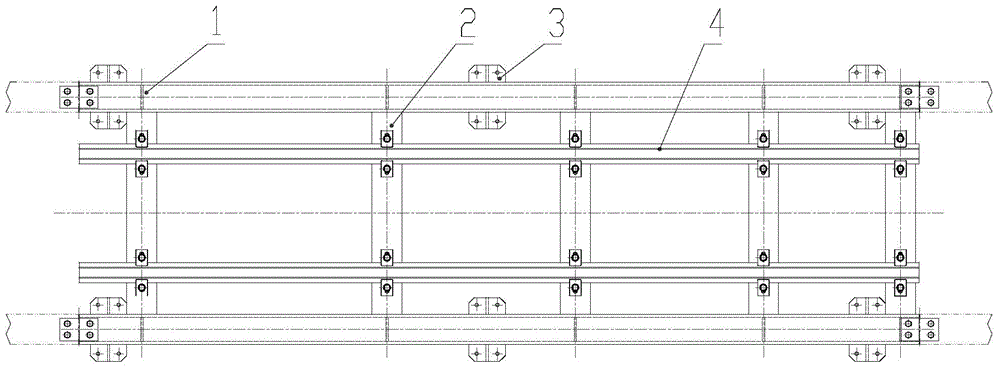

Modularized steel structure track bed with adjustable gauge

InactiveCN104894925AEasy to assemble and installBallastwayMoving rail partsSteel frameModular structure

The invention relates to a modularized steel structure track bed with an adjustable gauge. The modularized steel structure track bed is formed by sequentially splicing by adopting a modularized structure, and adjacent modules are connected through a connecting plate by bolts; the modules comprise longitudinal groove steel frames and lateral groove steel frames, which are mutually connected vertically, wherein the longitudinal groove steel frames are arranged on both sides of each of tracks, a distance is regulated according to the gauge of the tracks, and the longitudinal groove steel frames are mounted on a track bed mounting base through basic connecting seats; the tracks are fixedly connected to the lateral groove steel frames. Compared with the prior art, the modularized steel structure track bed disclosed by the invention can determine the gauge according to specific application, then selects the tracks with the corresponding gauges and the track bed modules, the modules are sequentially connected together in the longitudinal direction through the connecting plate to form the required track length, and the basic connecting seats are connected with the track bed mounting bases or other devices through bolts in the vertical direction and the lateral direction so as to have the function of regulation; the modularized steel structure track bed is convenient to assemble and mount.

Owner:TONGJI UNIV

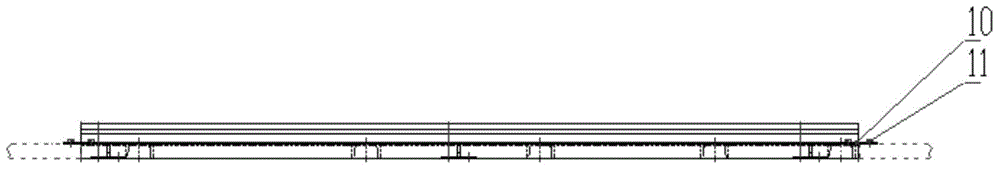

Steel spring floating slab monolithic track bed construction method based on track engineering

PendingCN110700023AImprove working conditionsImprove affordabilityRail fastenersTrackwayArchitectural engineering

The invention discloses a steel spring floating slab monolithic track bed construction method based on track engineering, which comprises the following steps: S1, installing a walking rail in a tunnel, and pouring a support base body at the bottom of the tunnel; s2, manufacturing a floating slab reinforcement cage , arranging vibration isolator assemblies on the reinforcement cage at intervals, and fixing steel rails to the top of the reinforcement cage; s3, laying an isolation layer on the supporting base body, placing the floating slab reinforcement cage on the isolation layer and calibrated, and then conducting concrete pouring to form a ballast bed; and s4, after the ballast bed reaches the designed strength, lifting the ballast bed to the designed height through a vibration isolator assembly. According to the technical scheme, the beneficial effects are as follows: the reinforcement cage is manufactured in a prefabricated mode, ground operation with a larger operation space can beselected, large-batch manufacturing can be conducted at the same time, the operation efficiency can be improved, jacking can be conducted after ballast bed pouring is completed, a ballast bed has certain elasticity, impact force generated by vehicles can be absorbed in the operation process, and the service life of a rail is prolonged.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com