Existing railway reinforcement construction method in jacking process of box body

A construction method and line technology, applied in the field of existing line reinforcement construction during box jacking, can solve the problems of increasing personnel, driving safety, affecting the stability of existing lines, and long construction work time, etc., and achieve the expected increase The effects of leaving space, reducing the depth of the planing trench, and reducing the amount of reinforcement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The existing line reinforcement construction method in the box body jacking process provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 1 — Figure 8 As shown, the existing line reinforcement construction method in the box body jacking process provided by the present invention includes the following steps carried out in order:

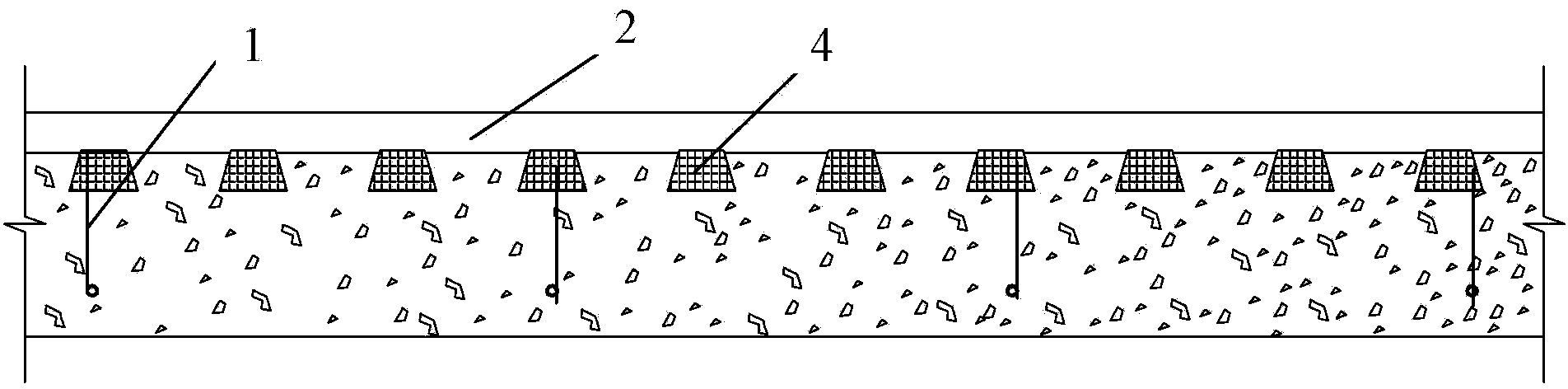

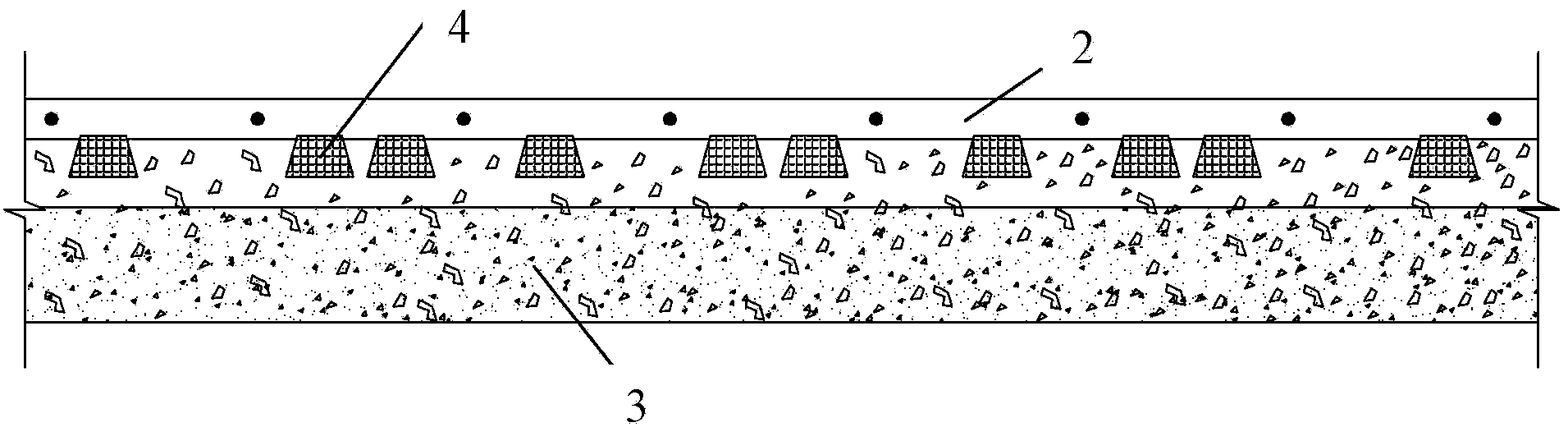

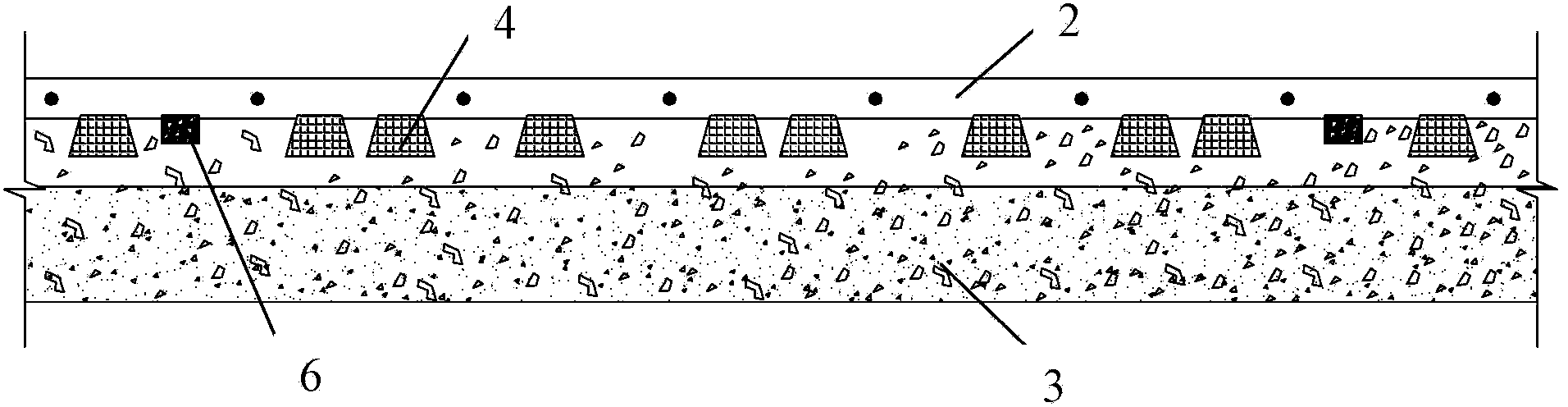

[0020] 1) Firstly, grout the ballast under the existing track in the area to be jacked. The method is to drive a plurality of grouting pipes 1 vertically into the ballast bed in the area at intervals with a pneumatic pick. The lower end is 60cm away from the bottom surface of the rail 2, with a distance of 2m, and then the grouting liquid is injected through the grouting pipe 1 by a grouting pump, and the grouting range is controlled from 30cm from the bottom surface of the rail 2 to the bottom of the ballast bed to form a reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com