Multi-sleeper type long rail laying machine set and rail laying method thereof

A technology of long rails and units, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of difficult training of crew members, unguaranteed safety of rail passing, and high failure rate of hydraulic system, so as to improve the efficiency of ballastless laying operations, Avoid on-line over-track transportation and facilitate freight transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

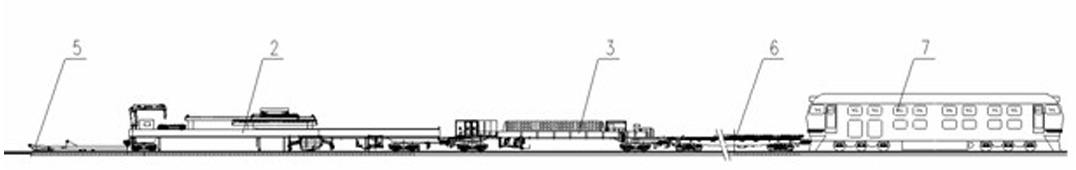

[0065] About the laying of the Dao Dao bed track, such as attachment figure 1 Show.

[0066] The rail paving unit is arranged in the direction of the rail paving: Long Steel Rail Tractor 1. Host 2, auxiliary machine 3, a rail pillow transport vehicle carrier with rail pillow transport vehicle 6, locomotive 7.

[0067] Construction according to the following process:

[0068] 1. Preparation

[0069] (1) Chang Steel Tractor 1 enter the rail label scene in advance; Host 2 and Auxiliary 3 push from locomotive 7 to the line to be paved, park at about 0.5m from the rail rail, connect the pipeline of the unit, start the engine, start the engine, start the engine, start, start the engine, start the engine, and start the engine.The hydraulic system is pressed, and the gear of the steering frame driver is closed;

[0070] (2) Put the front -end track traction device 13 on the front -end track traction device with the built -in car 2; make the host 2 self -ride on the track traction device 1...

Embodiment 2

[0091] About the laying of the rails of Wuyao Dao bed, such as attachment figure 2 Show.

[0092] Construction according to the following process:

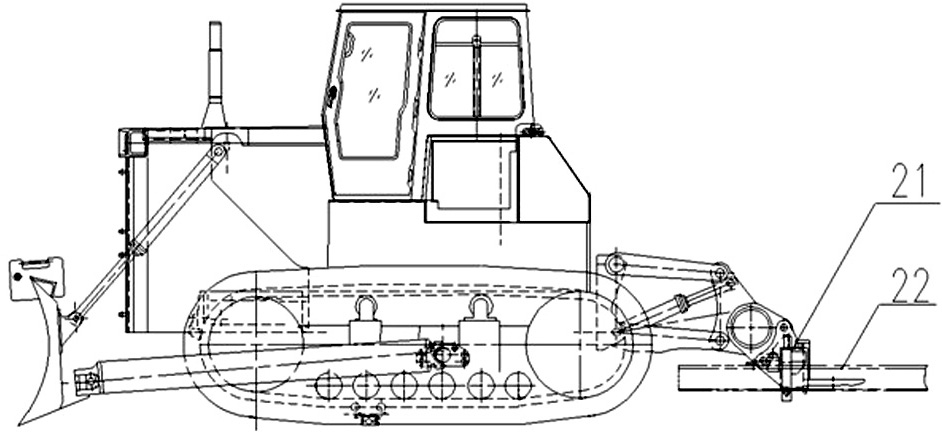

[0093] The rail paving unit is arranged in order in the direction of the rail paving: Wuyao Rail Panel 5, Host 2, Aid Aircraft 3, Rail Pillow Transporter Group 6, locomotive 7.

[0094] (1) Hang the tracked traction device 13 to the host 2 with a trailer 12, so that the front end of the host 2 front -end steering gear 17 supports the rails of the paved rails.Parking at 0.5m from the rail paved;

[0095] (2) In every 10M of the no -Dao Dao bed, the roller is preset every 10m;

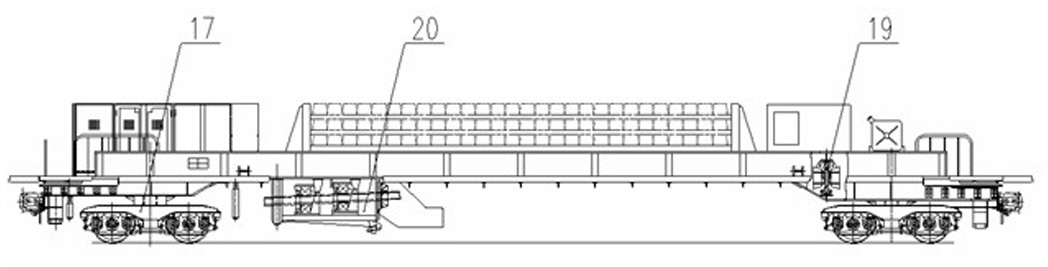

[0096](3) Long steel rails are dragged out of the pillow rail transport vehicle group 4 from the pillow rail transport vehicle 2, and split to the sides of the car body through the rails and enter the rail push mechanism 20;

[0097] (4) The rail push agency 20 drives the steel rail, and pushes the rail to the front end of the host 2 through the guide roller gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com