Robot for disposing dangerous goods and ammunition

A technology for robots and dangerous goods, applied in the field of robotics, can solve the problems of small grasping weight, limited working range and scope, and complex structure of high-performance robots, and achieves high grasping weight, wide operating range, and large output torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

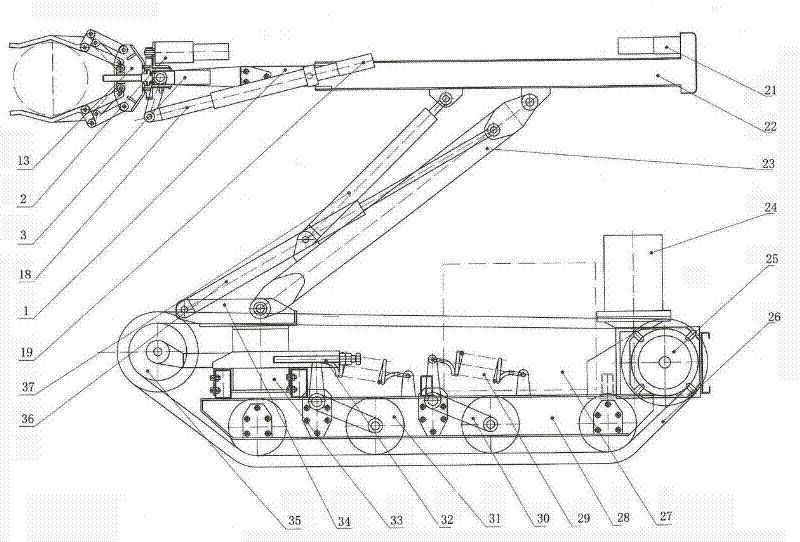

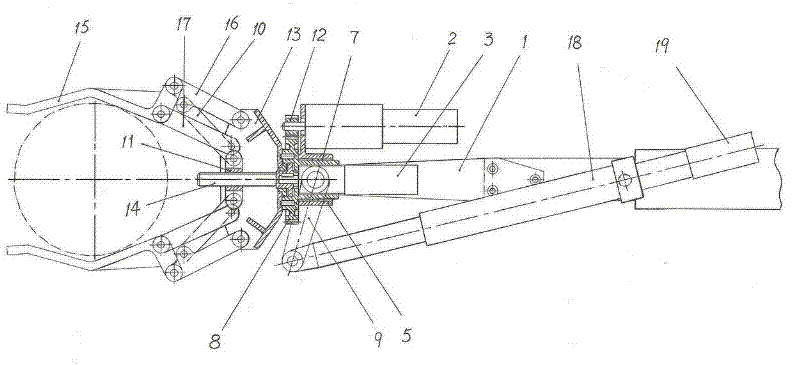

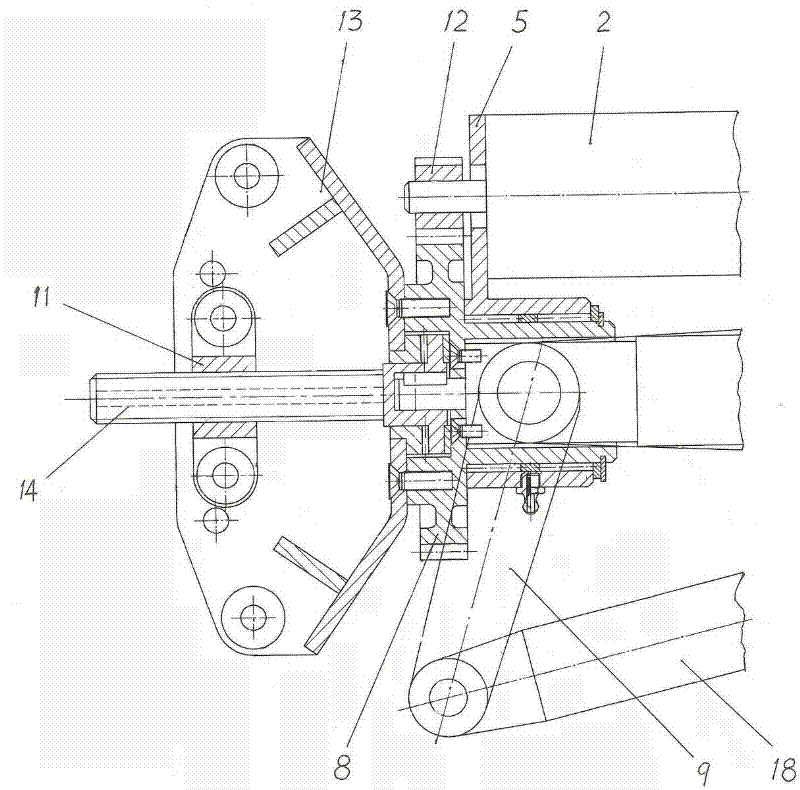

[0031] Such as figure 1 Shown, robot of the present invention comprises three main parts of car body, mechanical arm and manipulator.

[0032] Wherein, vehicle body is provided with vehicle frame 28, and rotary platform 34 is housed on vehicle frame 28, and the rotary oil cylinder 33 that controls rotary platform rotation is housed in the bottom of rotary platform 34. On the vehicle frame 28, crawler type running gear is also housed. The crawler type traveling mechanism comprises main driving wheel 25, from driving wheel 35, walking crawler belt 26, load-bearing wheel 31 and walking drive motor 24 etc., and the wheel axle on main driving wheel 25, from driving wheel 35 and load-bearing wheel 31 is installed on respectively by bearing. On the frame 28. The walking drive motor 24 is powered by a lithium power battery pack 27, and drives the main drive wheel 25 to rotate through a worm gear reducer, thereby driving the robot to travel by the walking crawler belt 26.

[0033] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com