Patents

Literature

102 results about "Ground roller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ground rollers are a small family of non-migratory near-passerine birds restricted to Madagascar. They are related to the kingfishers, bee-eaters and rollers. They most resemble the latter group, and are sometimes considered a sub-family of the true rollers.

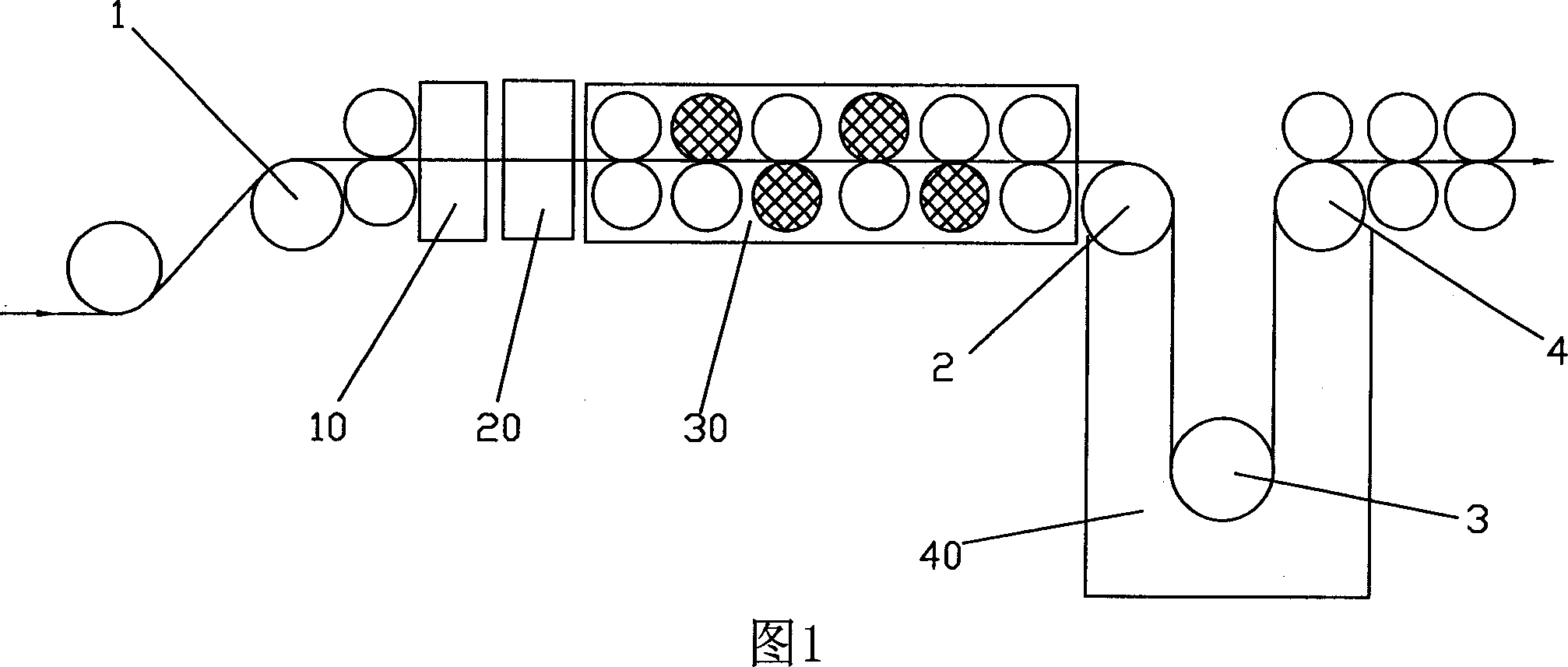

Method and apparatus for preventing band-steel electrolyzing cleaner running from offset and coiling leakage

ActiveCN101029414AImprove deviationOvercoming Coil Overflow ChallengesElectrolysis componentsWork treatment devicesGround rollerPulp and paper industry

A method for preventing band steel electrolyzed cleaner set running from offset and overflow is optimized. The band steel electrolyzed cleaner set consists of unwind section, cleaning section and tension coiling section, roller's shaped is optimized designed. Cleaning section entrance, exist grounding roller and front steering roller of coiler adopt sinusoidal curved roller and medium projected, roller material is chromium plated on surface; front steering roller of silicon-coated slot for cleaning section contacting liquid, submerged roller of silicon-coated slot and submerged roller of spraying slot adopt sinusoidal curved roller and medium projected; roller-side rubber, ring-opening slot and rear steering roller of silicon-coated slot adopt planar roller, roller-side material, ring-opening slot, front steering roller of silicon-coated slot and coiling section roller are sinusoidal curved roller and medium projected, roller side is made of polyurethane urea ring-opening slot. It's simple and convenient.

Owner:BAOSHAN IRON & STEEL CO LTD

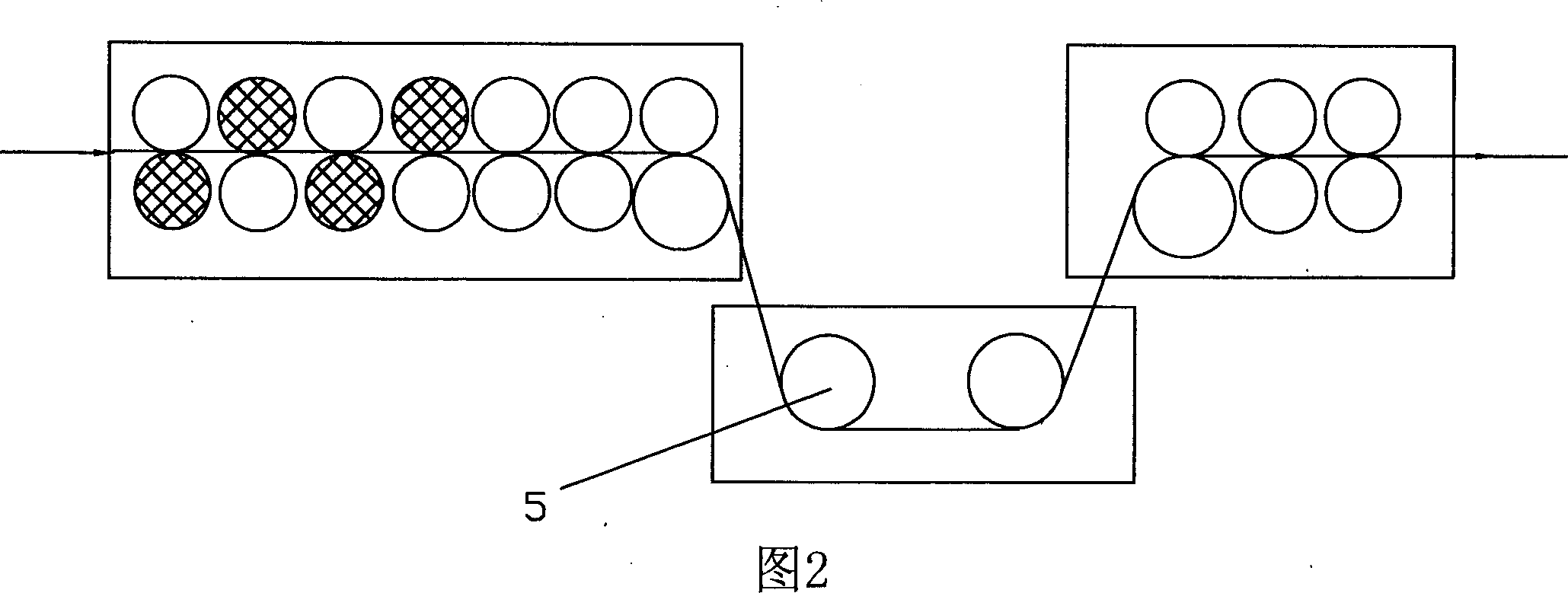

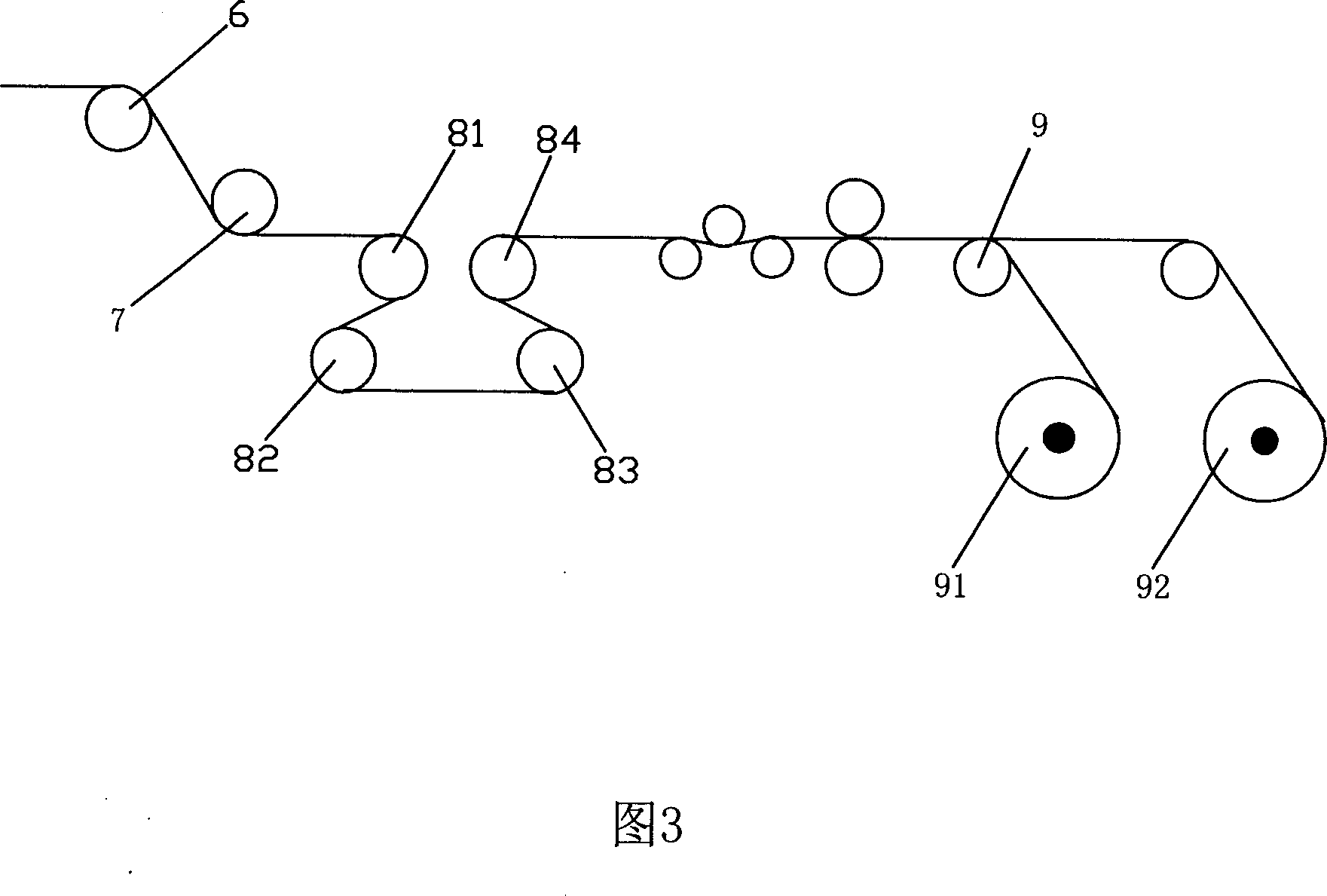

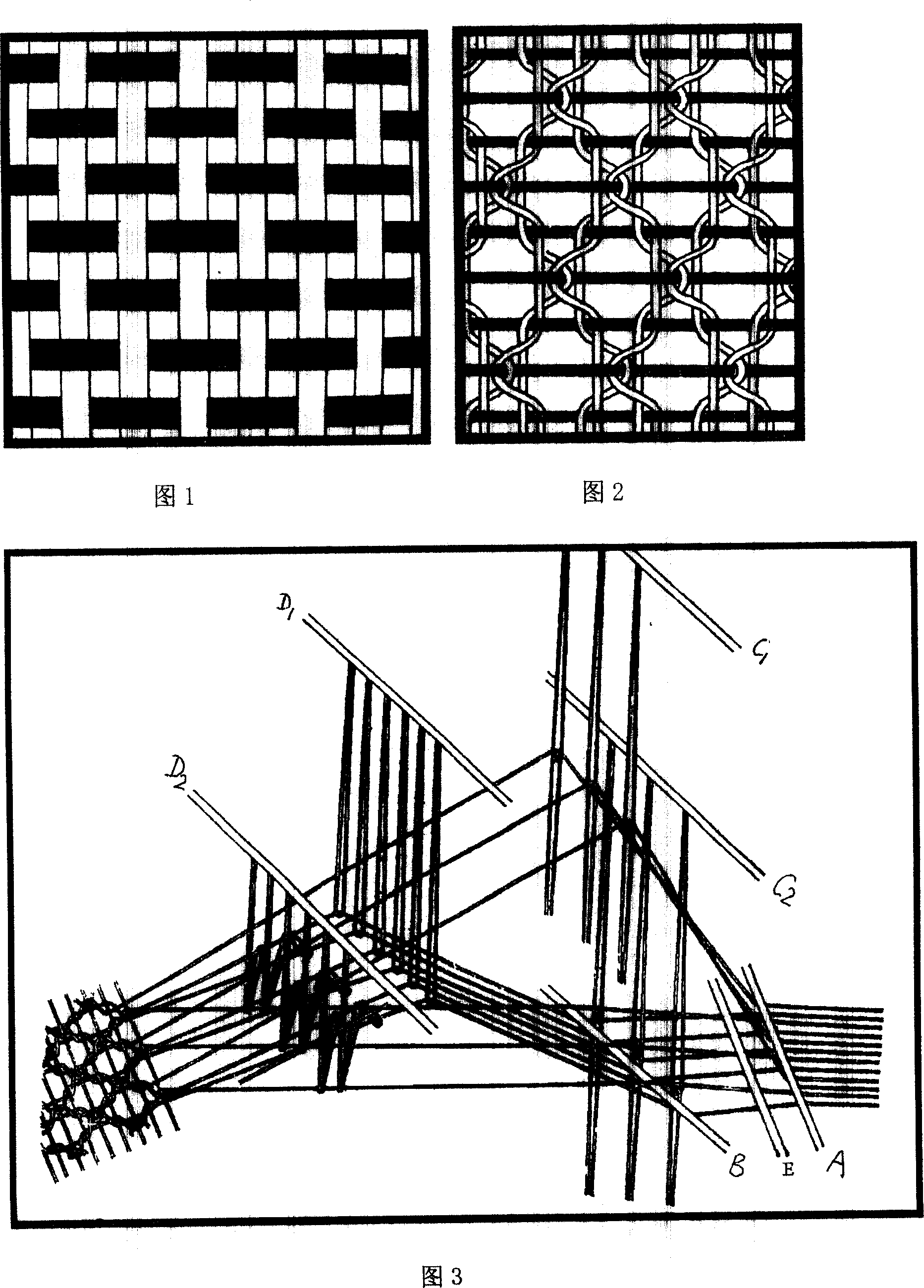

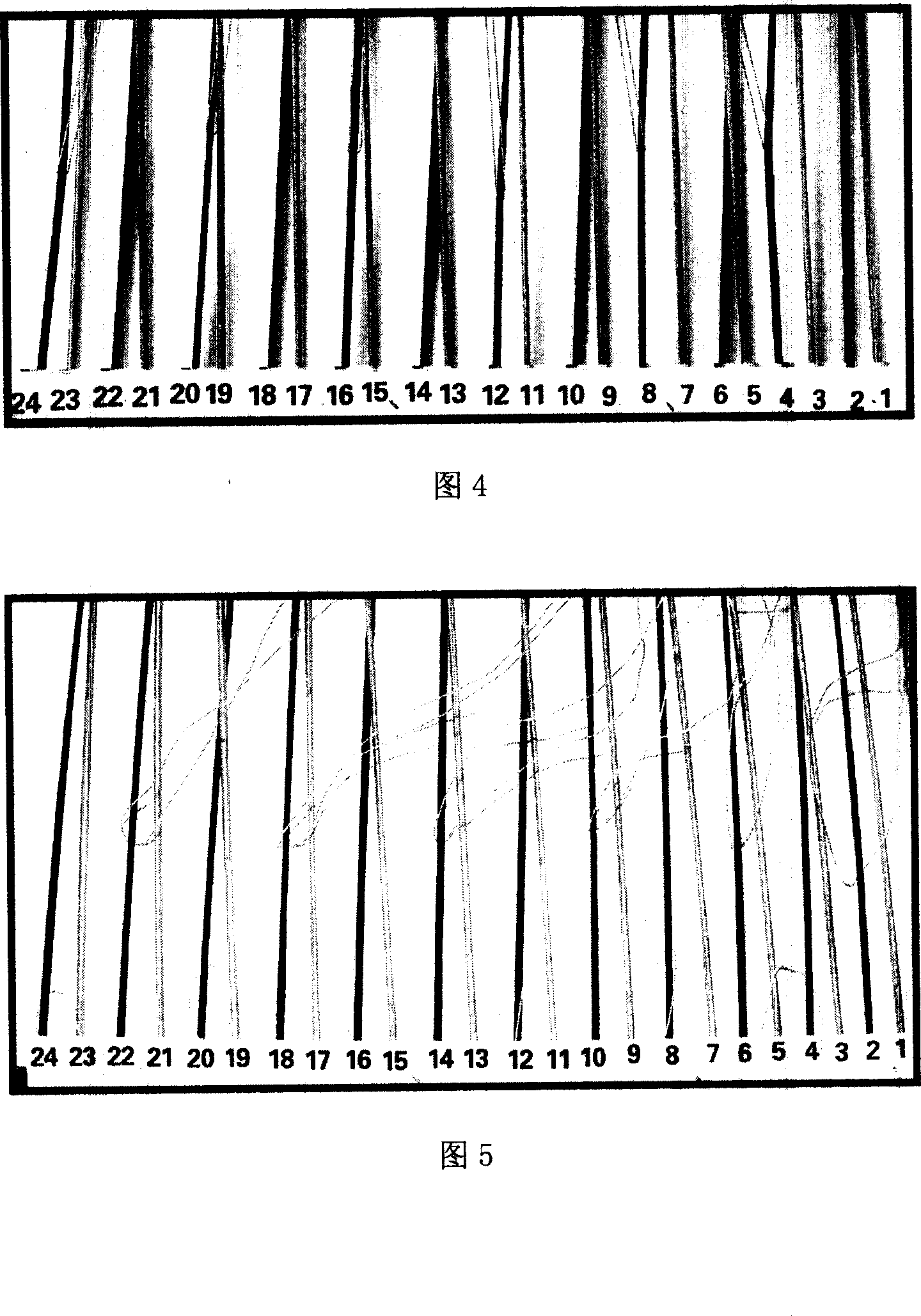

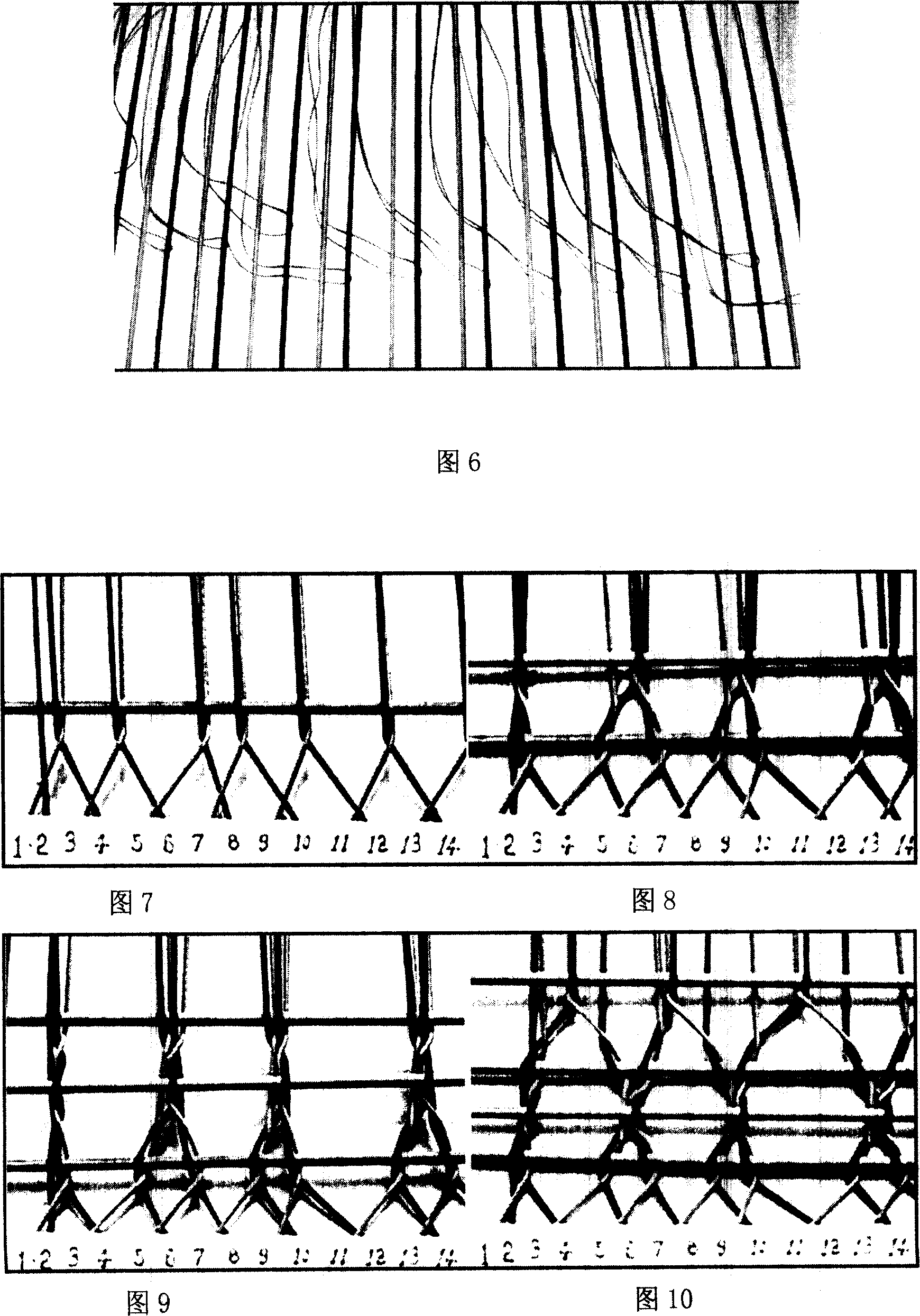

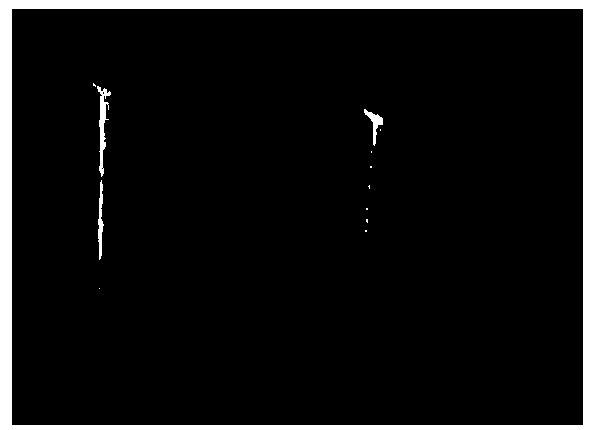

Device and method for weaving four-and-complexgauze

InactiveCN101016670AConducive to carry forwardImprove protectionLeno shedding mechanismGauze-woven fabricsGround rollerEngineering

The invention discloses a method for producing four-warp winder, characterized in that the invention comprises following steps that preparing half heald roller, using two half heald rollers and two ground rollers to form an integral spinning device, using half heald roller as opening device, the invention can avoid weft blade in weaving and use four wraps as one group, while one shuttle is two-wrap winder, one shuttle is four-wrap winder, and four shuttles as one circle, to obtain the four-wrap winded fabric.

Owner:NANJING YUNJIN RES INST

Production method of precise tapered roller

InactiveCN103821828AHigh precisionRaise the potentialBearing componentsGround rollerSurface roughness

The invention discloses a production method of a precise tapered roller. The method comprises the following steps: 1, preprocessing: carrying out cold heading processing of light tensioned steel wires to form a roller blank; 2, soft buffing processing: carrying out soft buffing of the external diameter of the roller blank, carrying out two-step grinding processing on two centerless grinders, and carrying out soft buffing of the end surfaces of the roller blank; 3, heat treatment and hard grinding: carrying out hard grinding of the external diameter of the surface processed roller on a centerless grinder; 4, base surface: carrying out spherical base surface processing of the fine ground roller on a spherical base grinder; 5, fine finishing: carrying out final grinding of the external diameter on the centerless grinder; and 6, superfinishing: carrying out superfine crown processing of the fine finished roller to obtain the finished tapered roller. A detection result shows that all indexes of the tapered roller obtained in the invention can stably reach national standard (GB / T25767-2010) II level standards, and the rolling surface roughness, the spherical base surface jumping SDW and the circularity of the tapered roller can reach national standard I level standards, and the bus of the external diameter of the roller has a crown form.

Owner:SHANDONG DONGE STEEL BALL GRP

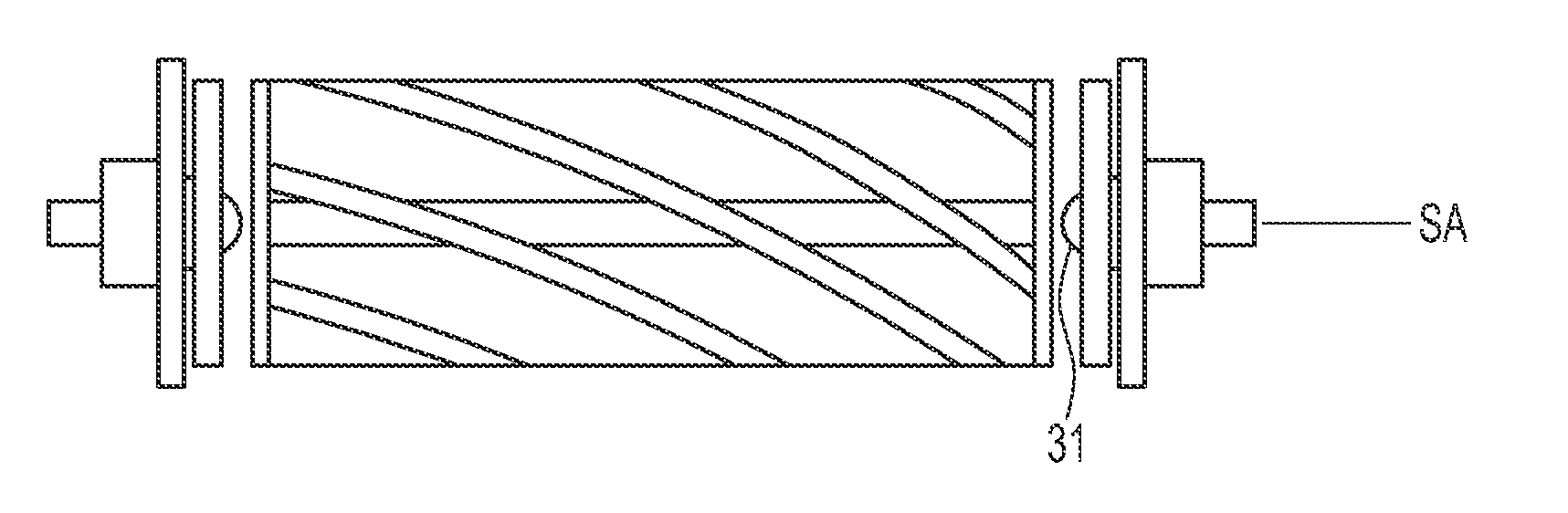

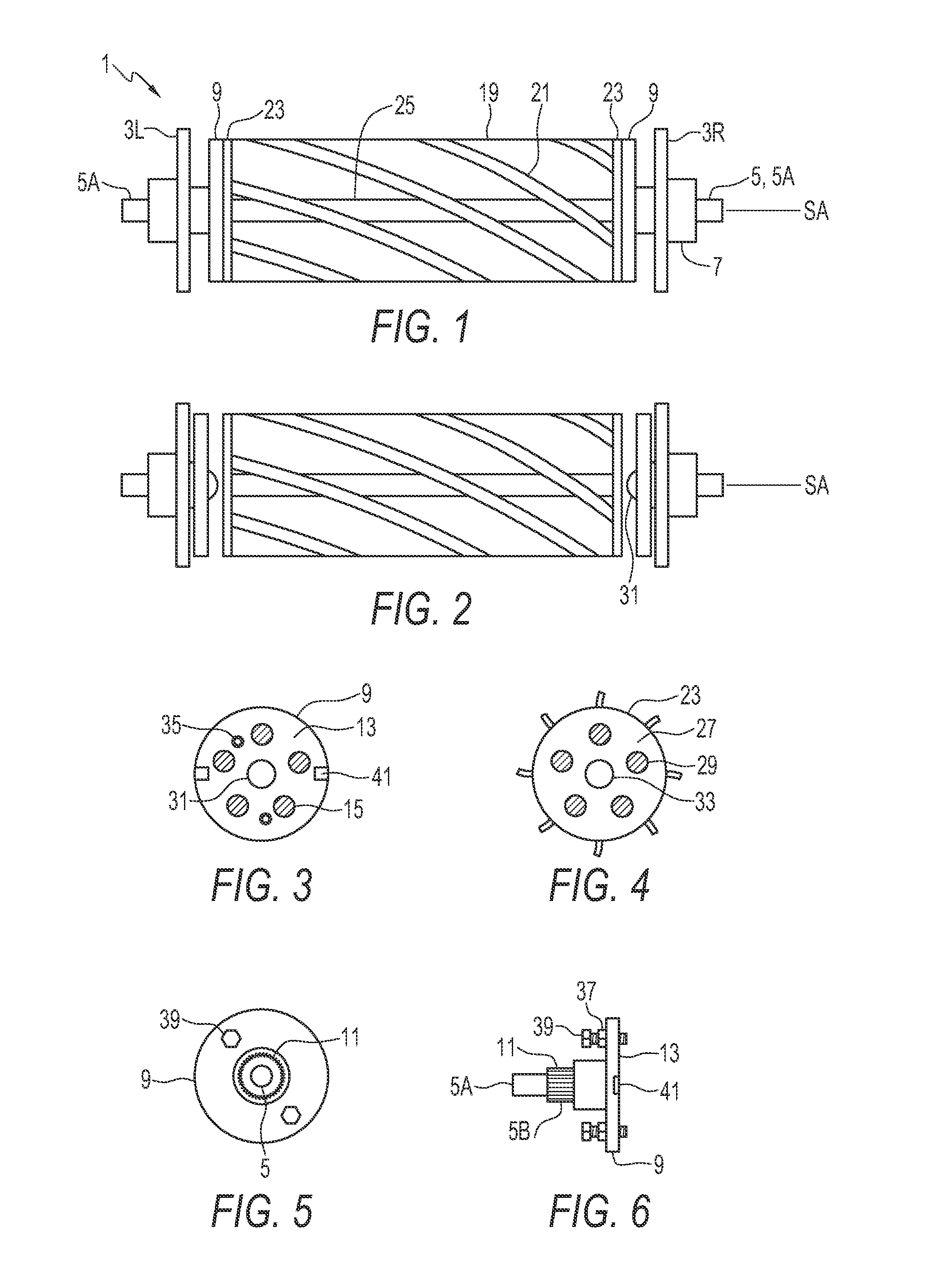

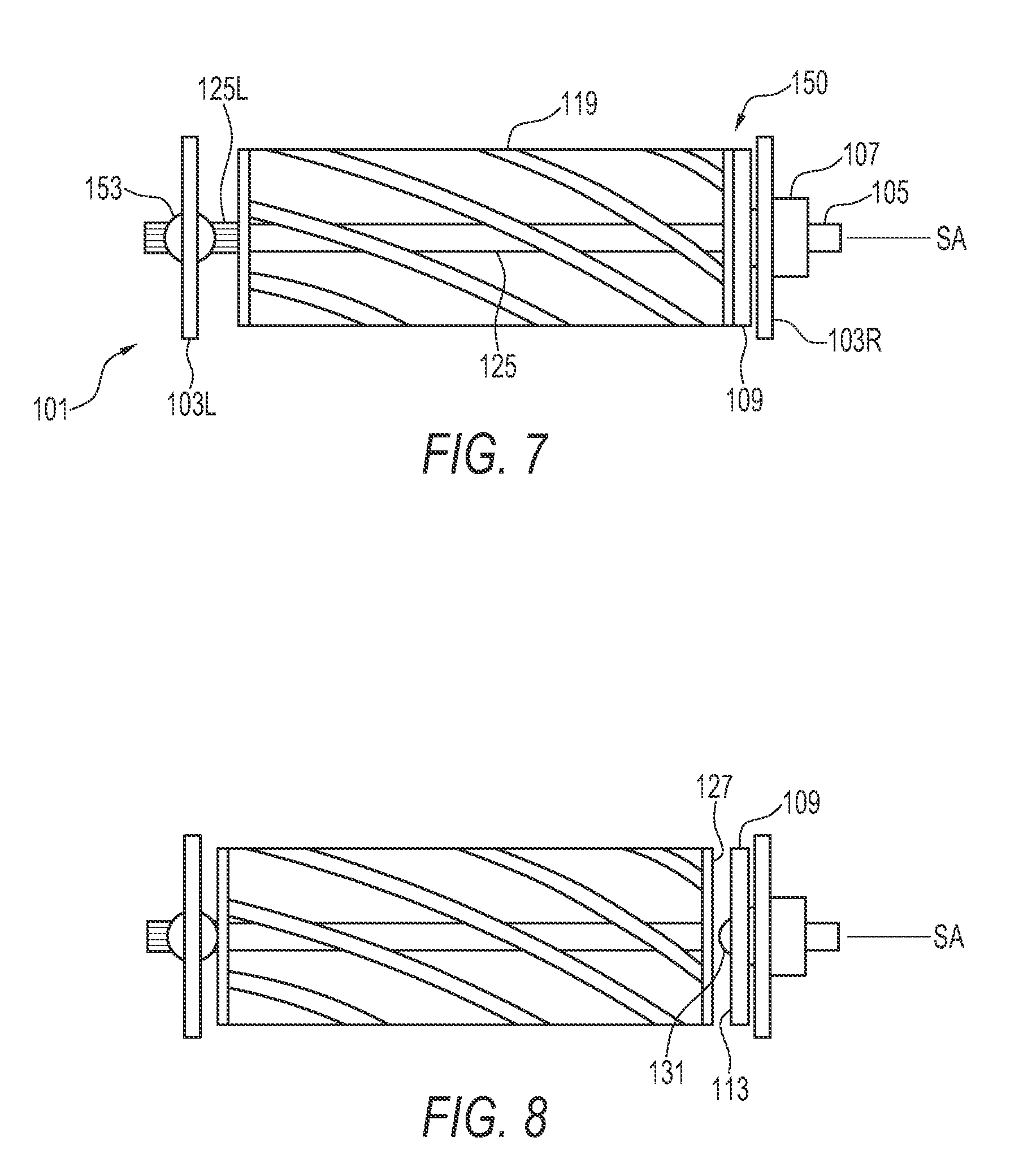

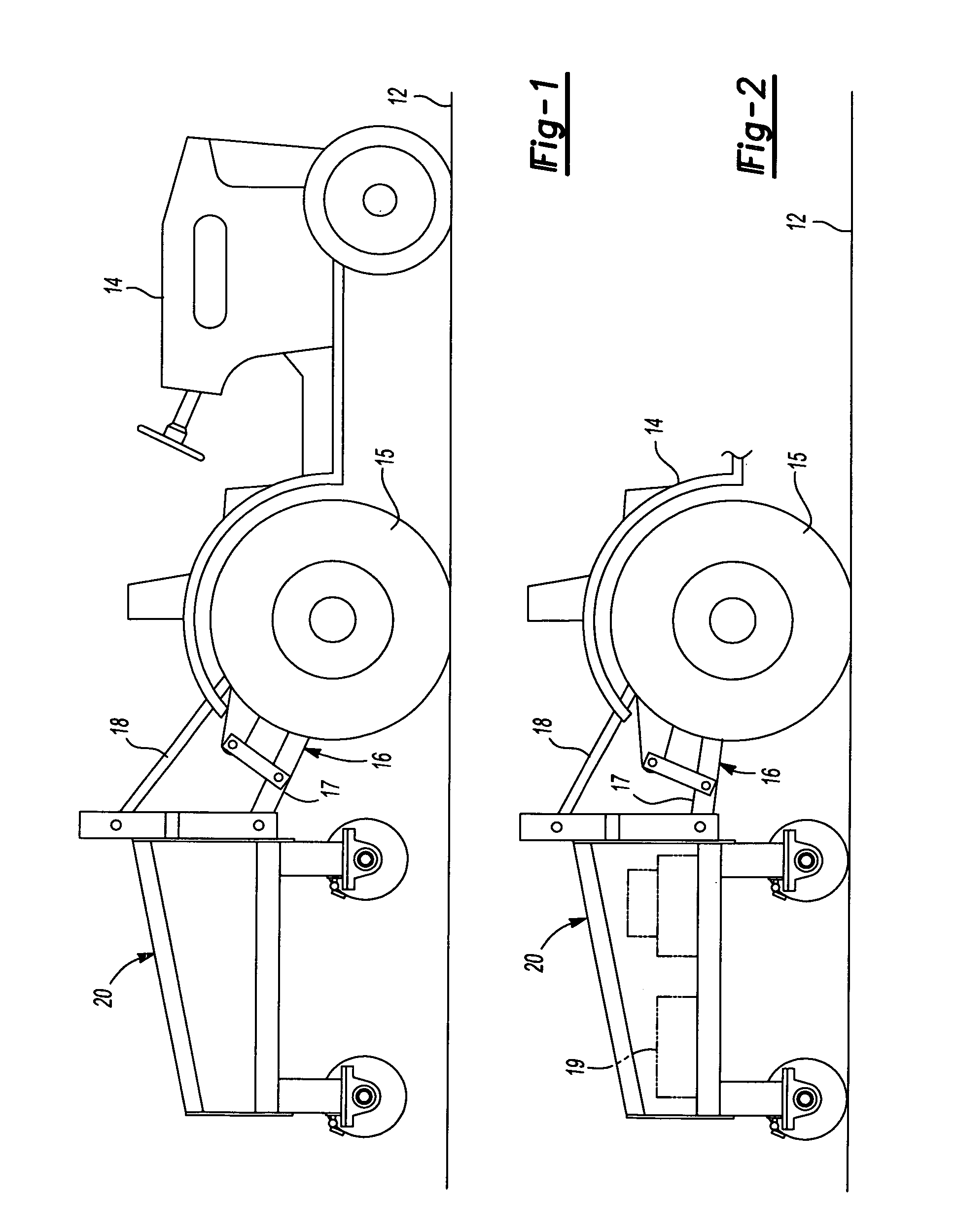

Magnetic drive connection for a reel mower

InactiveUS20120017559A1Reduce harmInsufficient magnetic forceMowersGround rollerMagnetic tension force

A rotating mechanical apparatus, such as would be used in a reel mower assembly, comprises a drive member rotatably mounted in a frame about a shaft axis. The drive member has a drive face. A driven member has a driven shaft rotatably supported in the frame about the shaft axis, and a driven face. A projection extends outward from one of the drive face and the driven face and into a corresponding recess in the other. Magnets force the drive face against the driven face such that the driven shaft rotates with the drive member. One of the drive face and the driven face are movable along the shaft axis to disengage the projection from the recess. A height adjustment mechanism moves ground rollers closer together or farther apart to vary cutting height.

Owner:BUCHKO JEFFREY

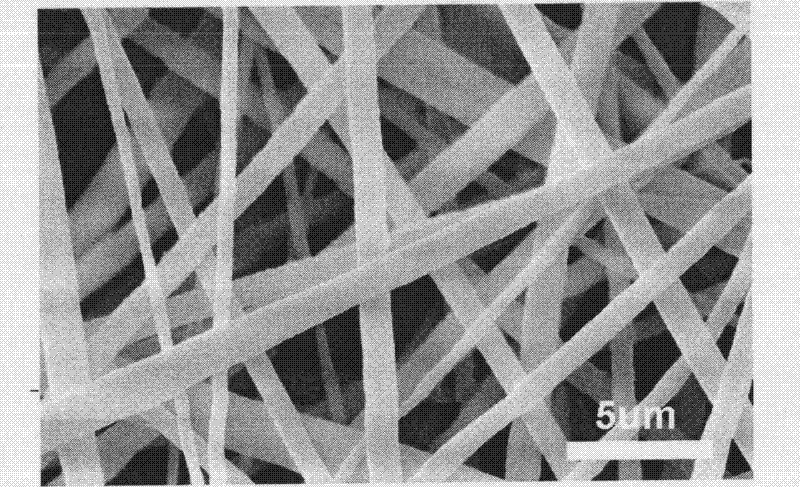

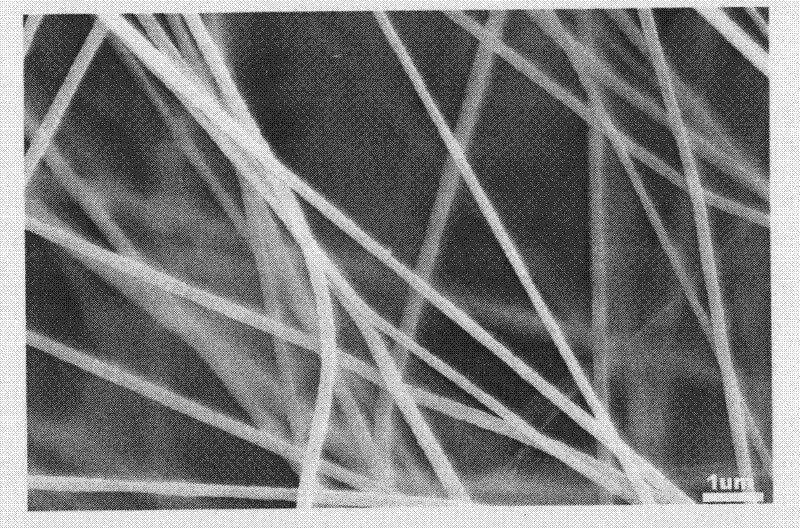

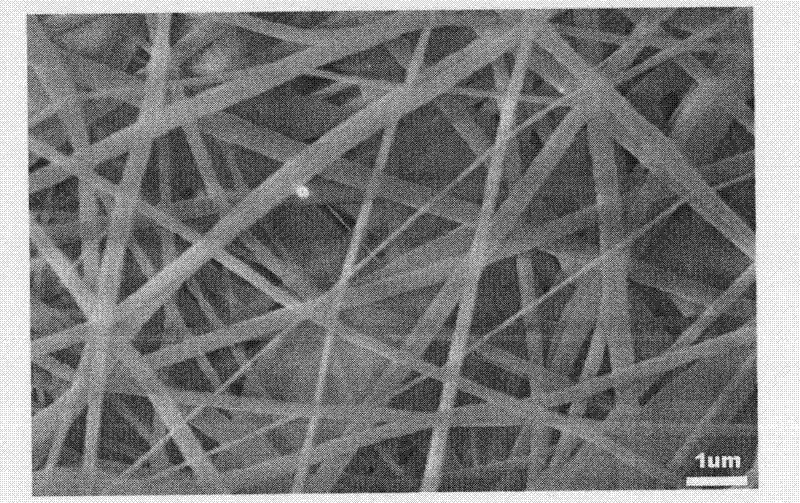

Polysulphone nanometer fiber polymer membrane and preparation method as well as application thereof

InactiveCN102240511AHigh porosityLarge specific surface areaSemi-permeable membranesDispersed particle filtrationGround rollerFiber

The invention relates to a polysulphone nanometer fiber polymer membrane and a preparation method as well as application thereof. The preparation method comprises the following steps: placing a polysulphone spinning solution in an injector of a static spinning device; spinning under the conditions that temperature is 18-30 DEG C and humidity is 35-65%; injecting the spinning solution into a spinning nozzle at a speed of 0.5-5 ml / h under the action of an injection pump; applying a 12-20kV direct-current high-voltage electric field between the spinning nozzle and a grounded roller receiver so as to obtain a nanometer fiber polymer membrane from the roller receiver; and finally drying to obtain the polysulphone nanometer fiber polymer membrane provided by the invention. The diameter of the polysulphone nanometer fiber in the membrane provided by the invention is 300-700 nanometers; the porosity between the polysulphone nanometer fibers is 45-75%; and an aperture of pore formed between the polysulphone nanometer fibers is 1-8 microns. The polysulphone nanometer fiber polymer membrane provided by the invention can be used for preparing a filtering material for filtering grains in the air or a support material of an ultra-filtrated, nano-filtrated or reverse osmosis membrane.

Owner:BEIJING SHOUKE PENBO TECH DEV

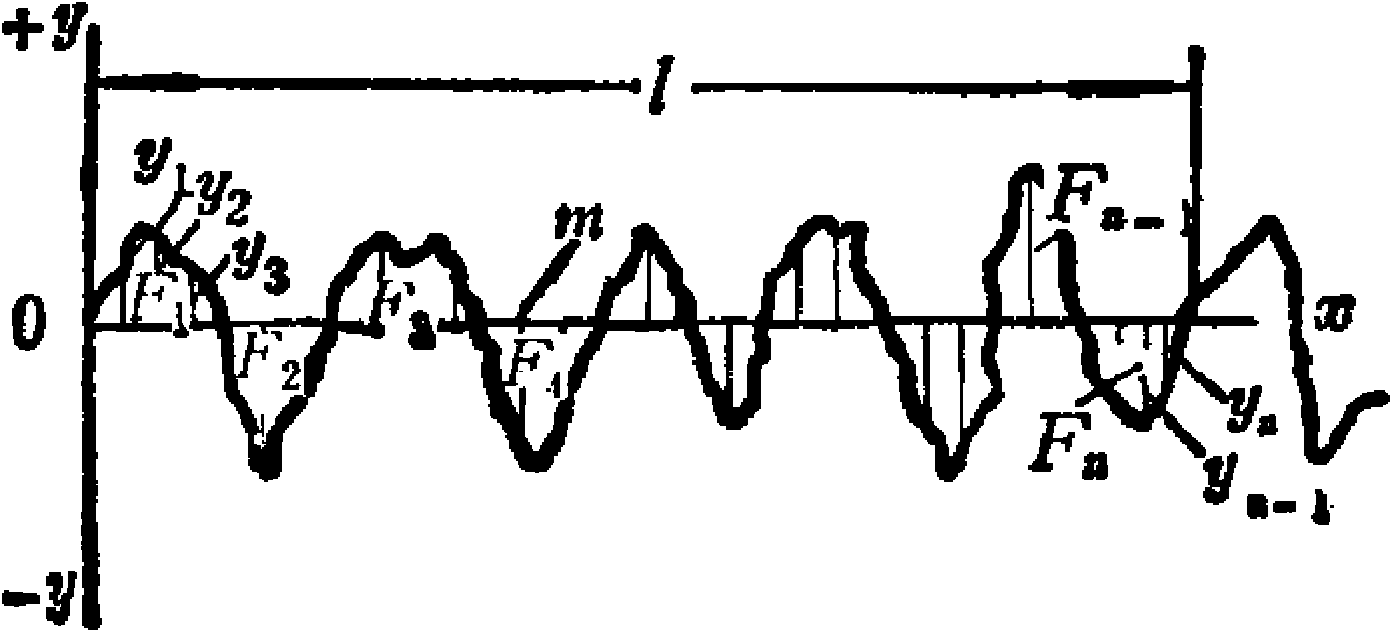

Method for controlling aluminium strip material periodic thickness difference

InactiveCN101502850AOptimize the grinding processHigh precision of thickness differenceMeasuring devicesMetal rolling arrangementsGround rollerMaterials science

The invention discloses a method for controlling periodic thickness difference in producing aluminum alloy strop, the control method comprises grinding a roller and implementing a pressure test on the ground roller; the roller grinding comprises: putting the roller upon a grinder on the basis of a bearing location for grinding to obtain the roller having accurate roller-type parameter and accurate basic circle run-out parameters; the pressure test for the ground roller comprises: mounting the roller on a rolling mill, measuring total rolling force deviation of the roller, judging fluctuation situation of the pressure at both sides of the roller: a, uniform pressure fluctuation at the both sides represents that the roller is qualified; b, non-uniform pressure fluctuation at the both sides represents checking the grinding parameters of the roller. The invention can accurately evaluate the condition of thickness distribution in the entire length direction of the aluminum strip and correctly judge the thickness of coil to control the quality.

Owner:SOUTHWEST ALUMINUM GRP

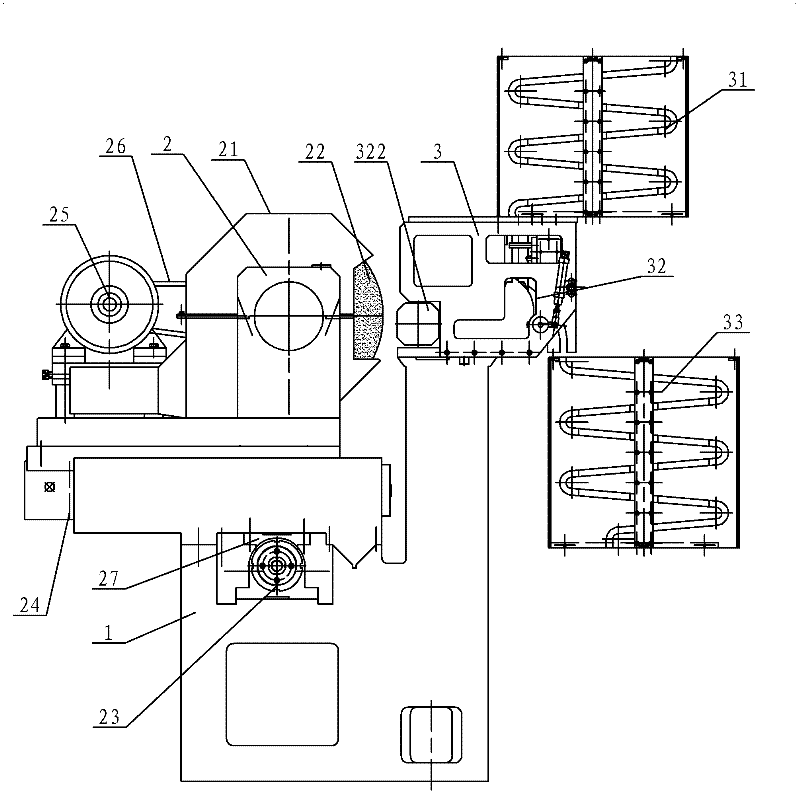

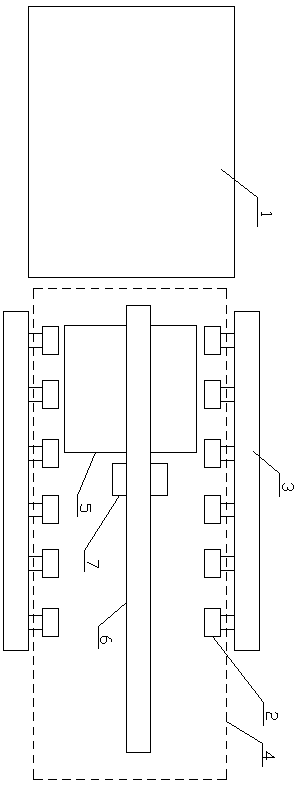

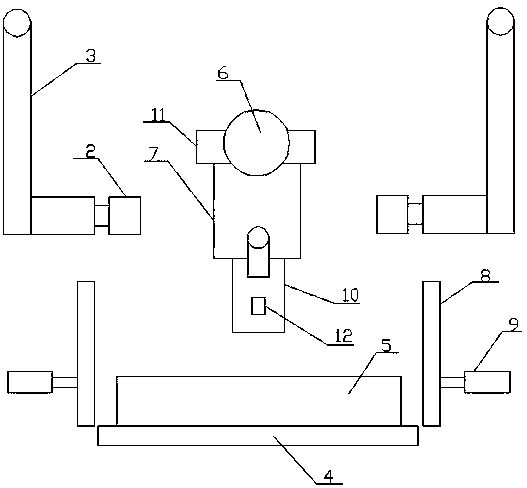

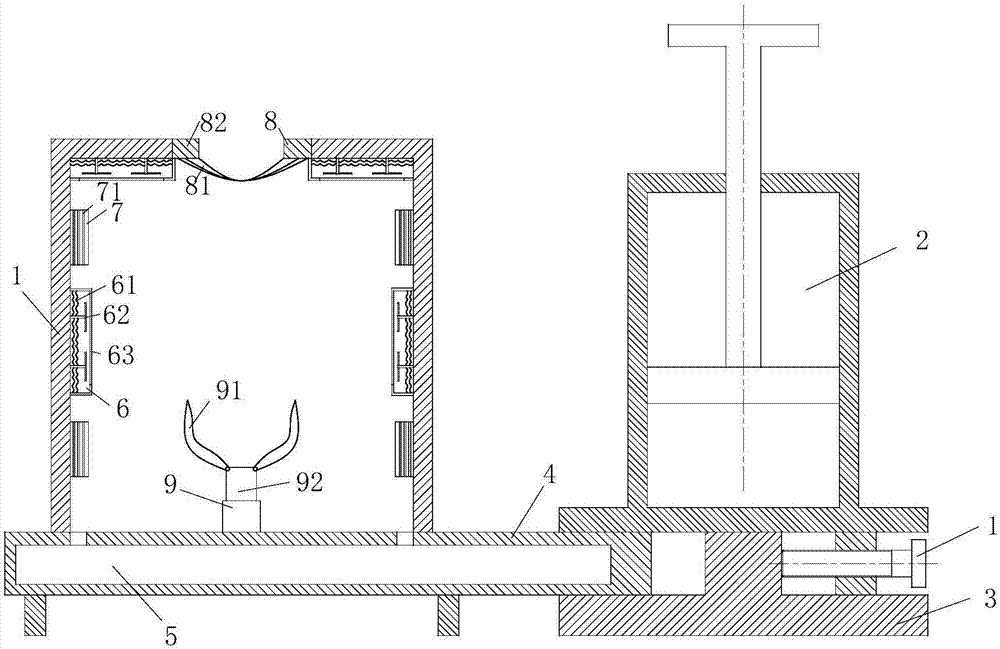

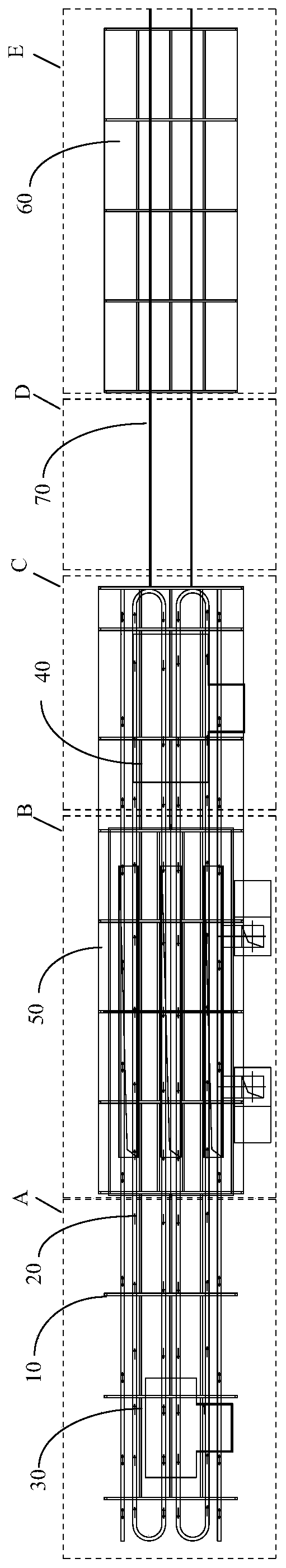

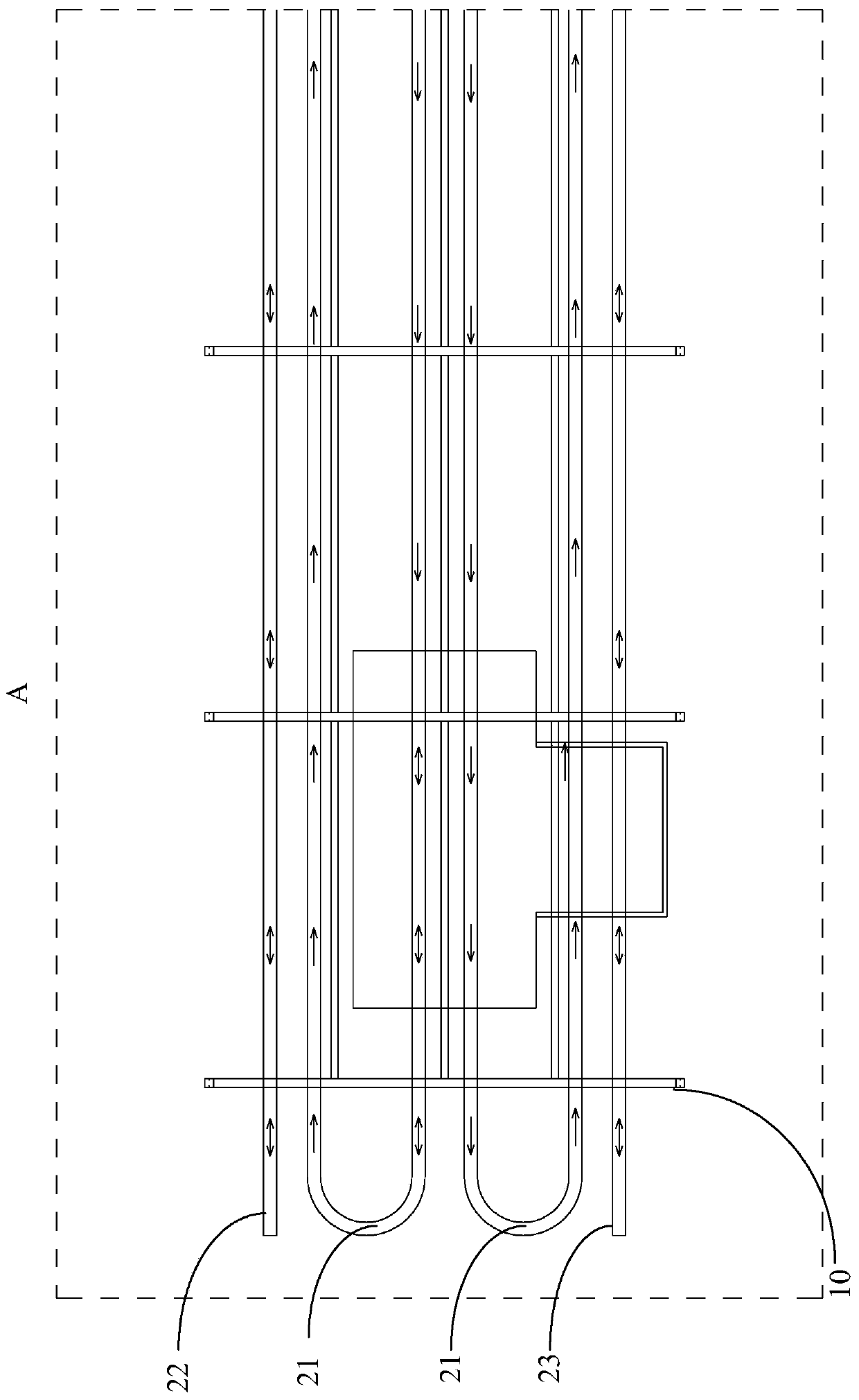

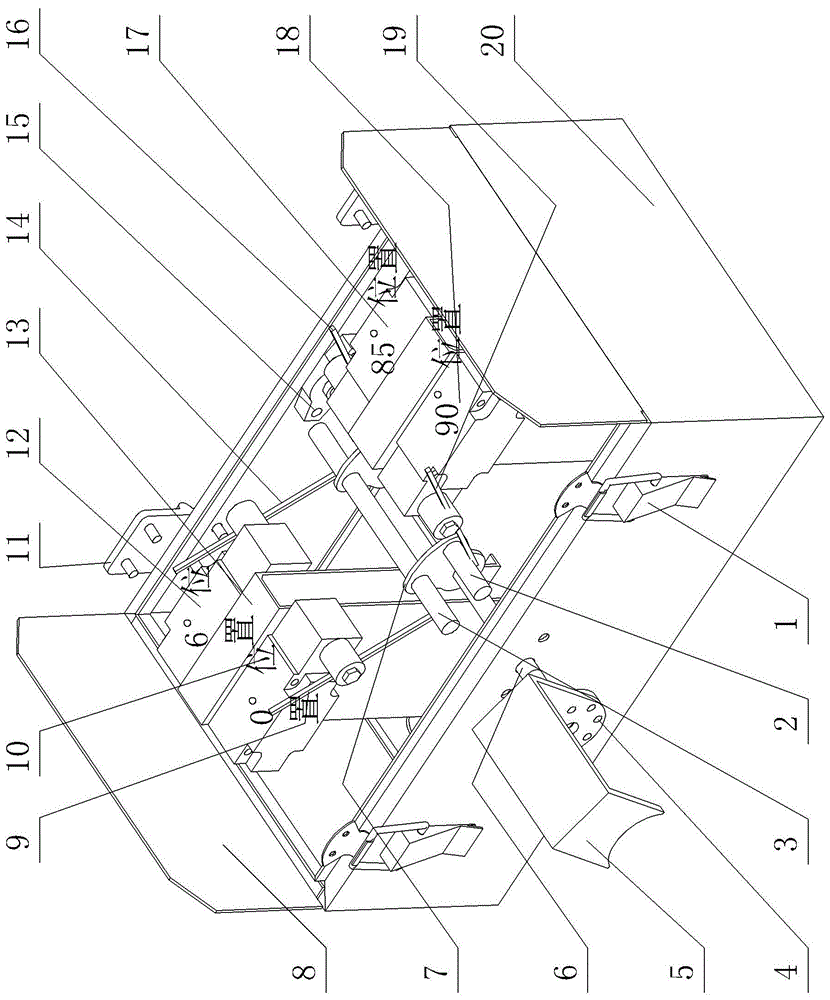

Full-automatic wide grinding wheel roller grinding machine

InactiveCN102416586AEven by forceImprove stabilityRevolution surface grinding machinesGround rollerReciprocating motion

The invention discloses a full-automatic wide grinding wheel roller grinding machine, which comprises a bed, a grinding device, an automatic loading and unloading device and a system control device, wherein the grinding device is arranged on one side of the upper part of the bed, and the automatic loading and unloading device is arranged on the other side of the bed; the grinding device comprises grinding wheel heads; a base is arranged on the lower part of the grinding wheel heads; a servo motor a capable of allowing the base to move to and fro along a Z axis is arranged on the lower part of the base and in the bed; a servo motor b capable of allowing the grinding wheel heads to move to and fro along an X axis is arranged between the base and the grinding wheel heads; a grinding wheel is arranged between the grinding wheel heads; and a servo motor c capable of allowing the grinding wheel to rotate is arranged on one side of the grinding wheel. The bed is fixed on the ground or a platform, and both the grinding device and the automatic loading and unloading device are fixed on the bed, so that the reciprocating motion of a workbench is avoided, the stability of the whole machine is enhanced, vibration in the reciprocating motion is reduced and the roughness requirement of a ground roller is ensured; and linkage of the grinding wheel heads moving along the X axis and the base moving along the Z axis is realized, so that the position of the grinding wheel can be adjusted and the grinding precision is ensured.

Owner:安徽尚美电气科技有限公司

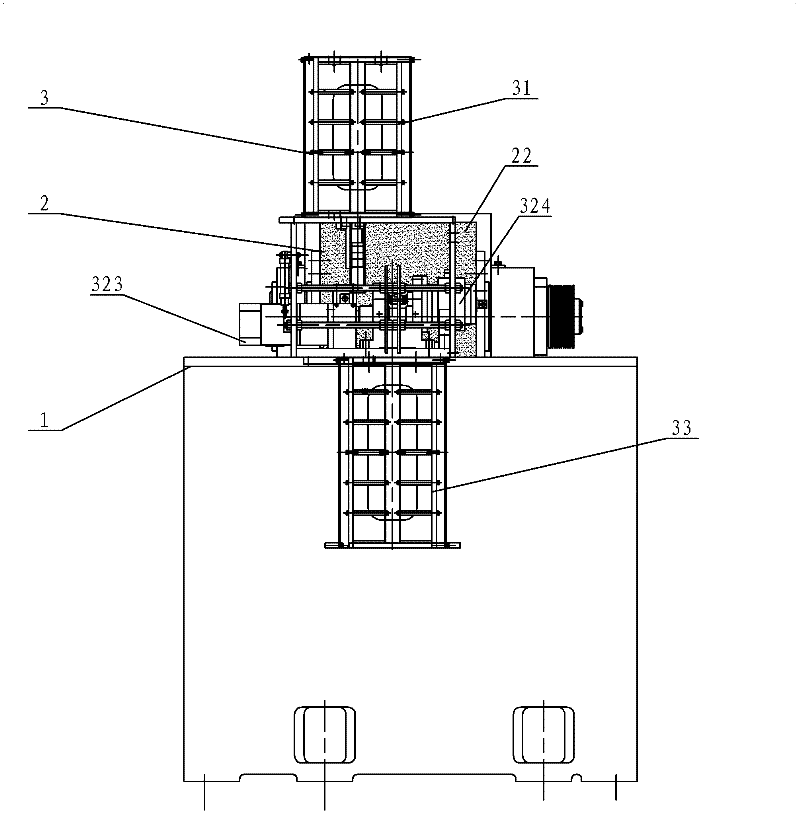

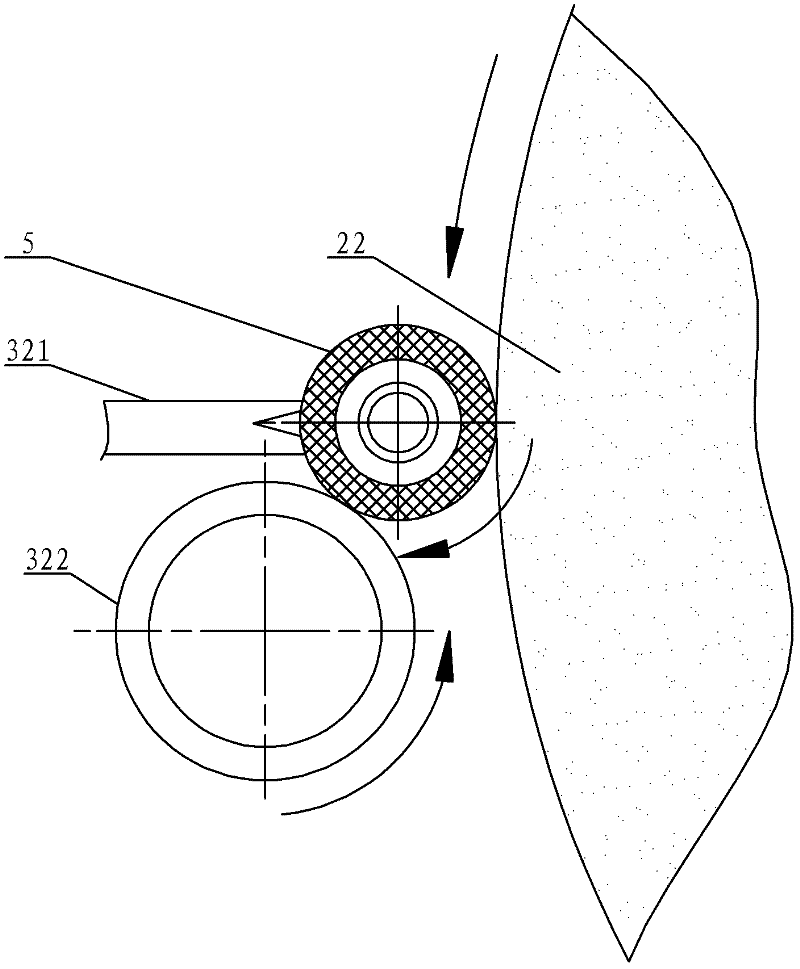

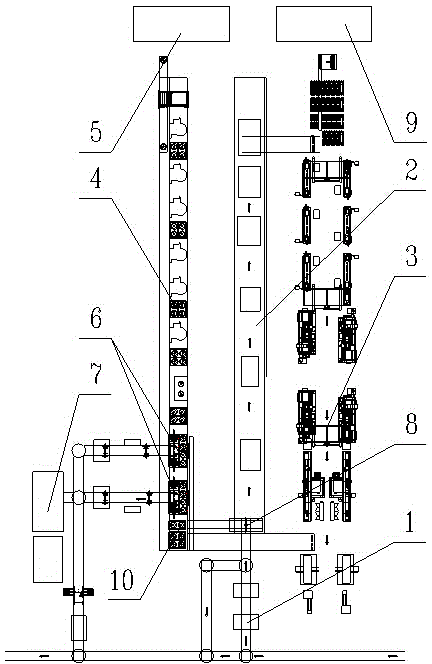

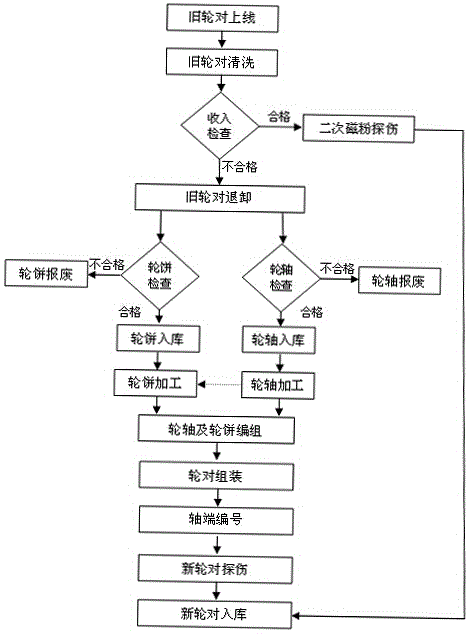

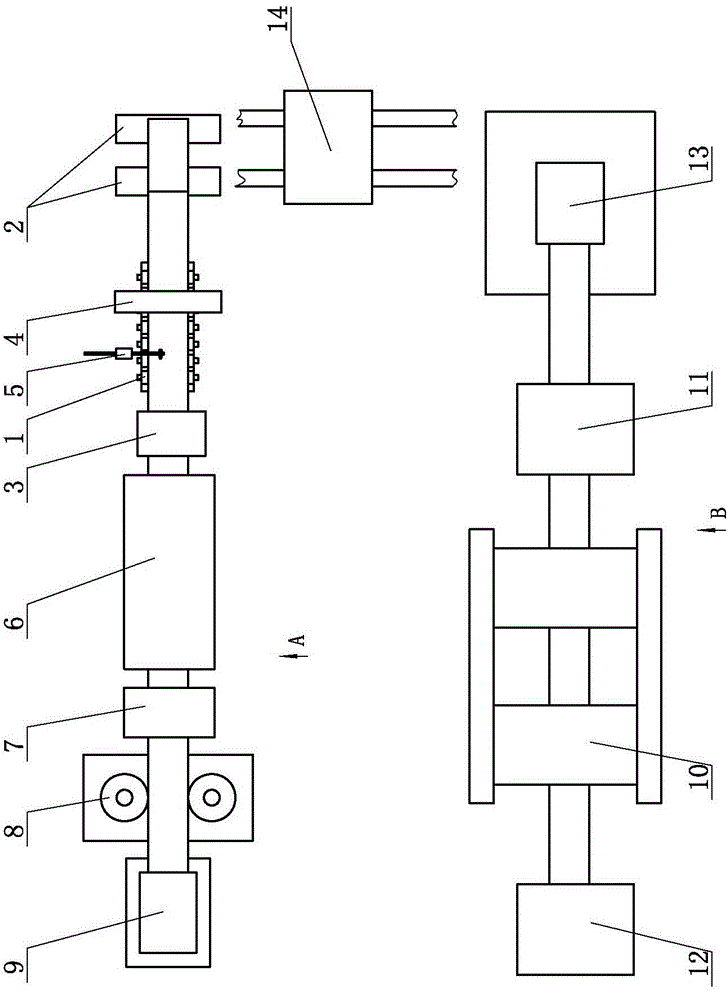

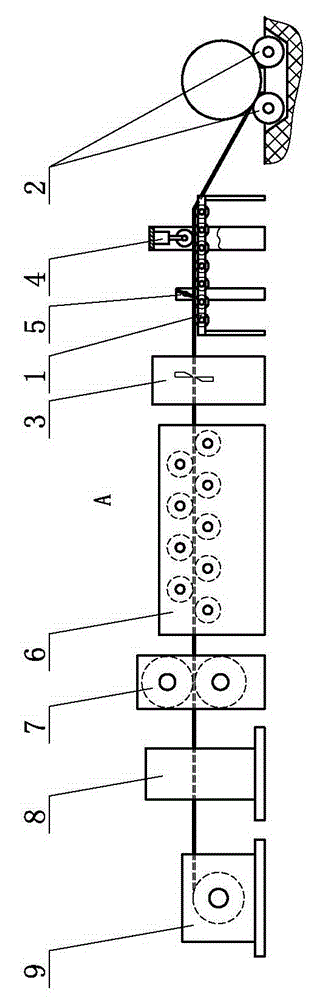

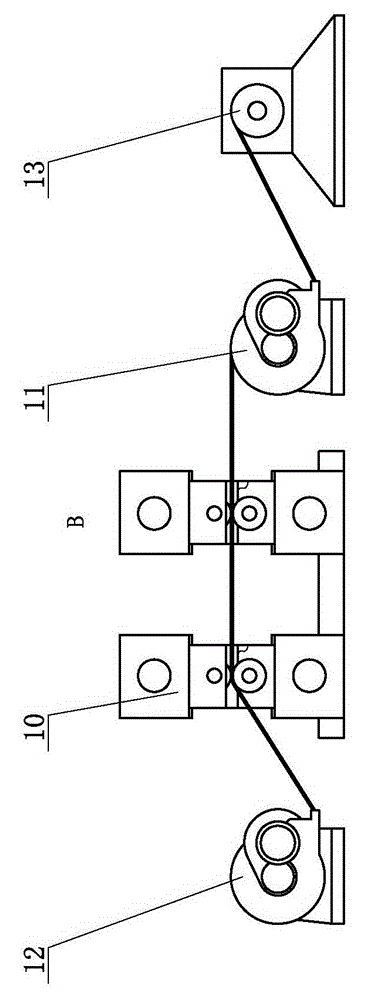

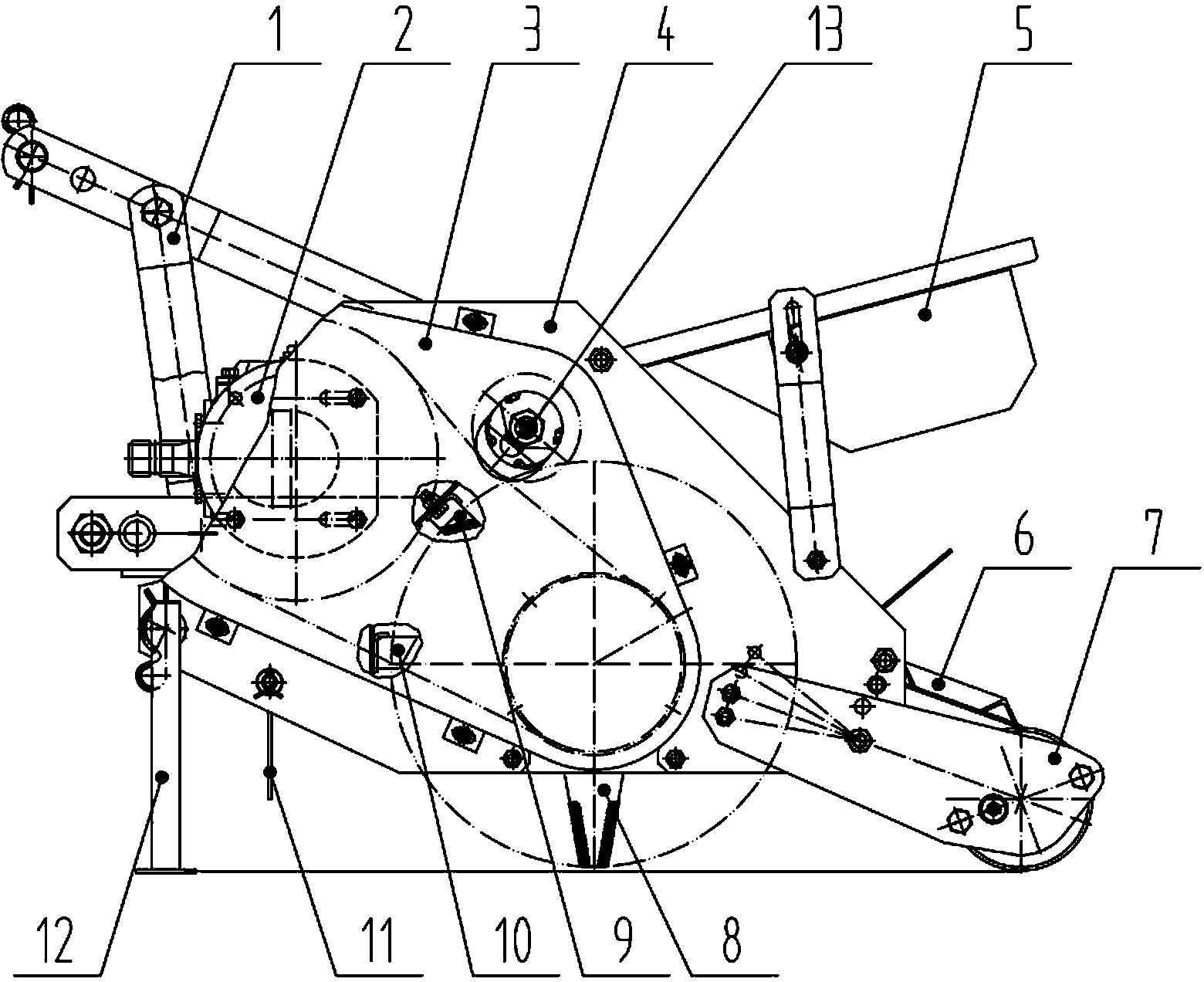

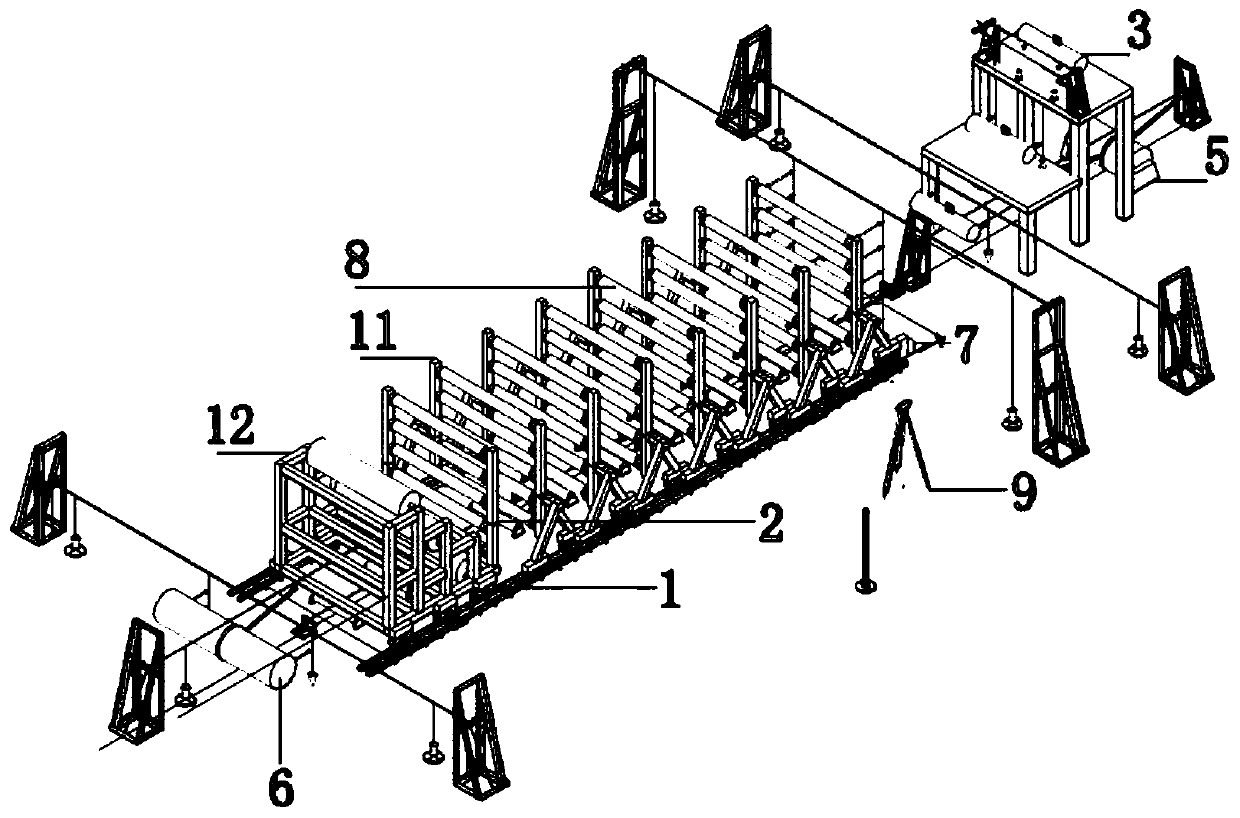

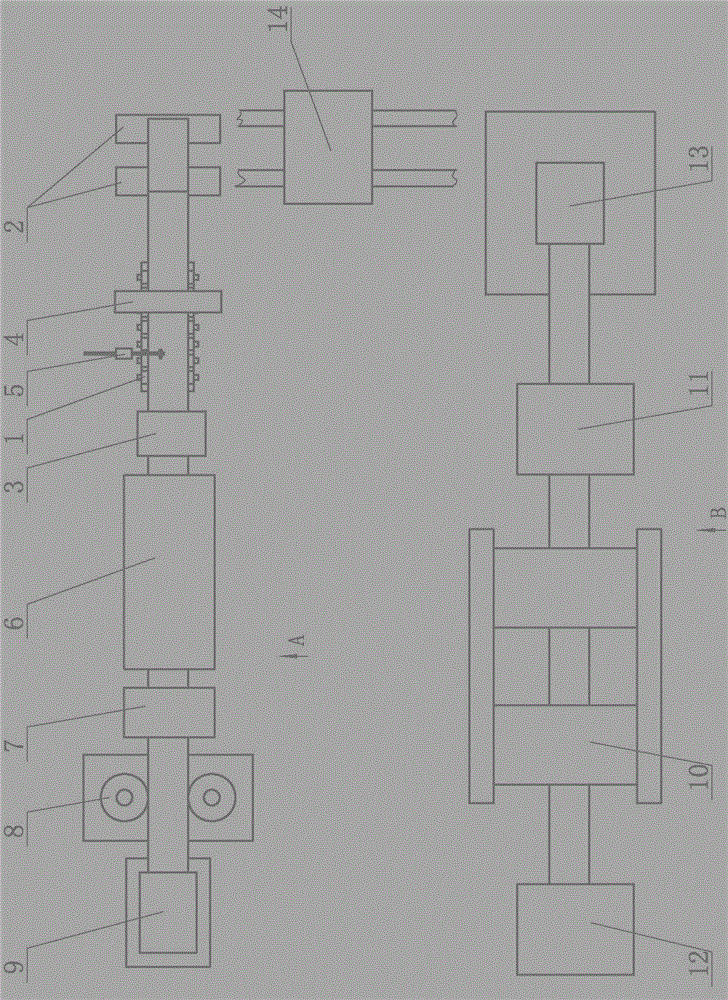

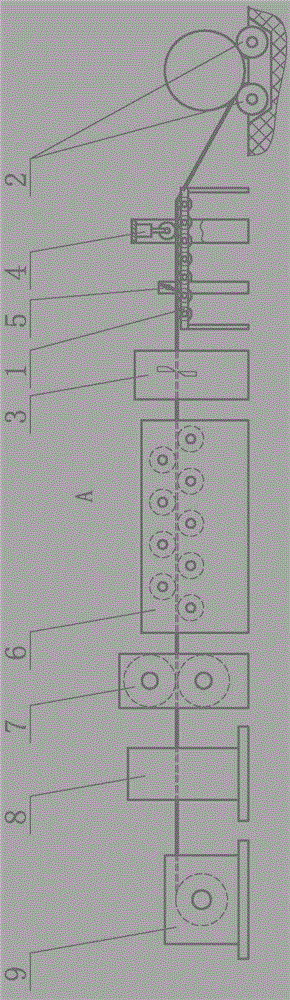

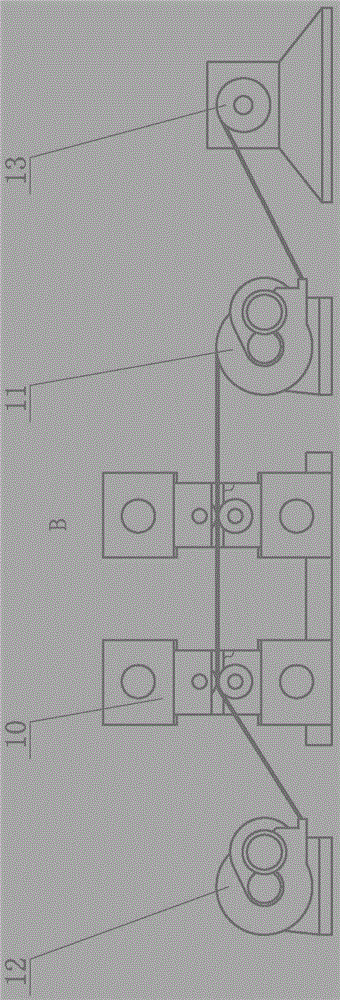

Wheel axle overhauling system

ActiveCN104528310ASmall footprintImprove compatibilityMechanical conveyorsGround rollerSmall footprint

The invention discloses a wheel axle producing and overhauling system. The system is characterized by comprising a used wheel set storage inspection conveyer line 1, a wheel axle inspection conveyer line 2, a wheel axle machining conveyer line 3, a wheel cake machining conveyer line 4, a wheel cake blank storage warehouse 5, a wheel set assembling machine 6, a new wheel set storage warehouse 7, a wheel set discharging machine 8 and a wheel axle blank storage warehouse 9. The system has the advantages that occupied space is small and compatibility is high compared with a ground roller way or roller conveyer line, digital management and matching of a wheel axle workshop are facilitated, automation degree is high, original ground type workshop traveling cranes and workshop people and forklift channels are reserved on the premise that three-dimensional conveyance is achieved, and occupied area is small.

Owner:江西速升智能装备有限公司

Device and method suitable for improving yield of welding leading tape of double-stander cold rolling mill

The invention relates to a device and a method suitable for improving yield of a welding leading tape of a double-stander cold rolling mill. The method comprises the steps of rotating ground rollers to uncoil a qualified coil; conveying the end part of a steel coil to a welding position after uncoiling the qualified coil; coiling a leading tape coil upwards to a leading tape uncoiler, conveying the leading tape coil to a transverse cutting shear after centering the leading tape coil by using centering vertical rollers and straightening the leading tape coil by using a straightening machine, and shearing off an unqualified leading tape head; conveying the leading tape head to the welding position; welding the leading tape head with the end part of the steel coil by using a welding machine; reversely rotating the ground rollers to carry out recoiling; bundling a recoiled big coil, and conveying the recoiled big coil to a double-stander rolling device through an double-stander; uncoiling the steel coil by using a steel coil uncoiler, wherein an uncoiled steel belt penetrates the space between mill rolls of a double-stander reversable mill, and two upper mill rolls of the double-stander reversable mill are both lifted; and coiling two ends of the steel belt by using a steel belt coiling machine, and starting rolling after the mill rolls of the double-stander reversable mill fall. According to the device and the method, the cold rolling efficiency of an iron and steel enterprise can be increased, a narrow leading tape can be used, and the production cost is relatively low.

Owner:JIGANG INT ENG & TECH CO LTD

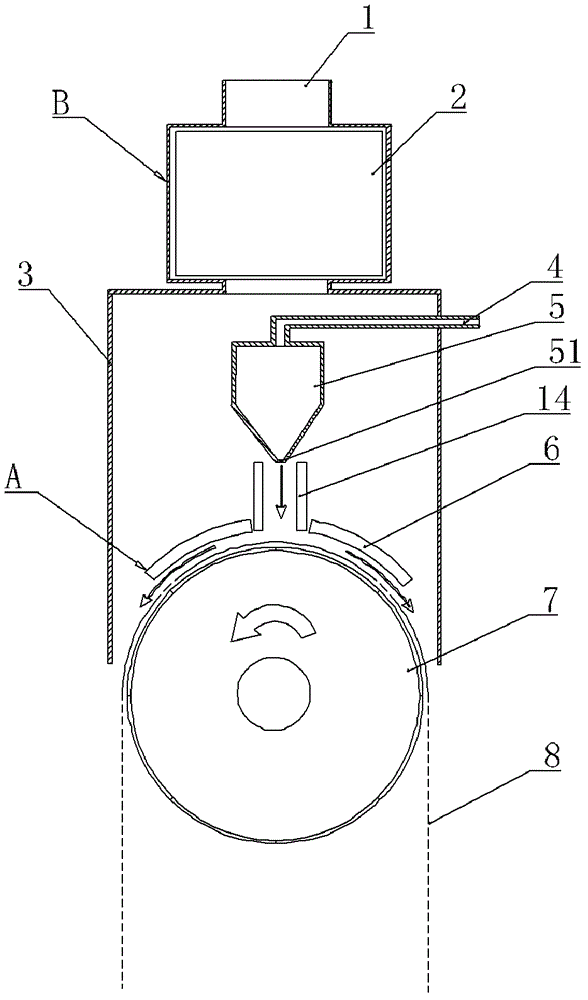

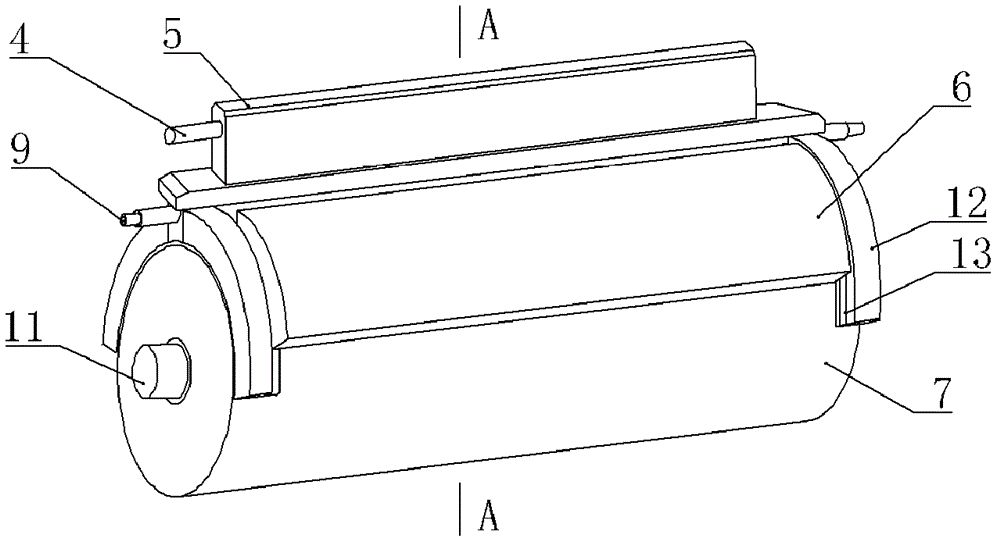

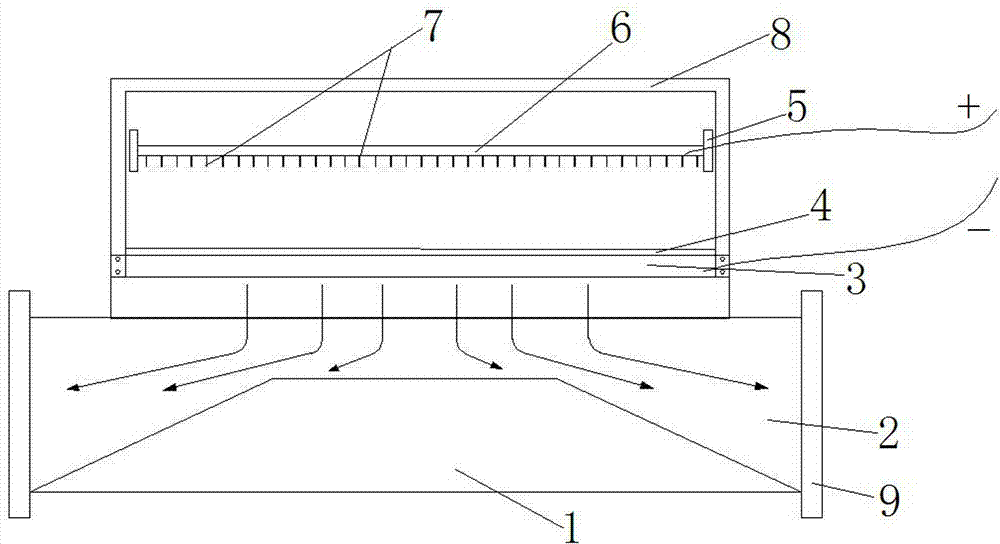

Barrier discharge plasma surface treatment system for large-breath medium

InactiveCN102869180AImprove adhesionStrong van der Waals forcePlasma techniqueGround rollerCatalytic decomposition

The invention discloses a barrier discharge plasma surface treatment system for a large-breath medium, comprising an ozone absorbing device arranged above a barrier discharge plasma treatment component. The barrier discharge plasma treatment component comprises a grounding roller, an electrode plate and a gas transmission device, wherein the two ends of a spindle of the grounding roller are rotationally supported on a machine frame, a pair of electrode plates with arc surfaces coaxial with the grounding roller is mounted on the grounding roller, equal discharge intervals are formed between the electrode plates and the peripheral surface of the grounding roller, and a water cooling channel is arranged in each electrode plate, and the circulating water ports connected with the two ends of the electrode plate are arranged in the corresponding electrode plate; and the gas transmission device is mounted between the two electrode plates. The barrier discharge plasma surface treatment system is strong in treatment strength, long in treatment timeliness, also has the ability of ozone absorption or catalytic decomposition, is applicable to most of large-breath packaging materials such as metal, thin film, leather and the like, and can realize the online plasma surface treatment at different speeds.

Owner:中国印刷科学技术研究所

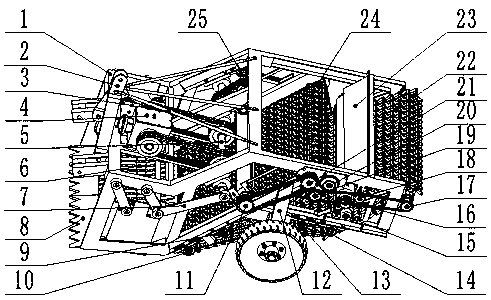

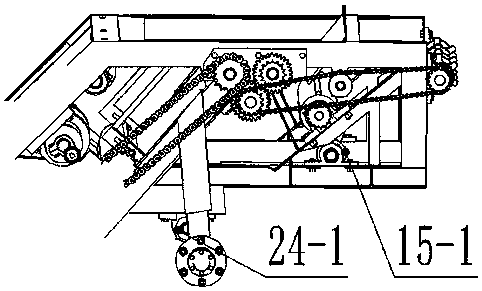

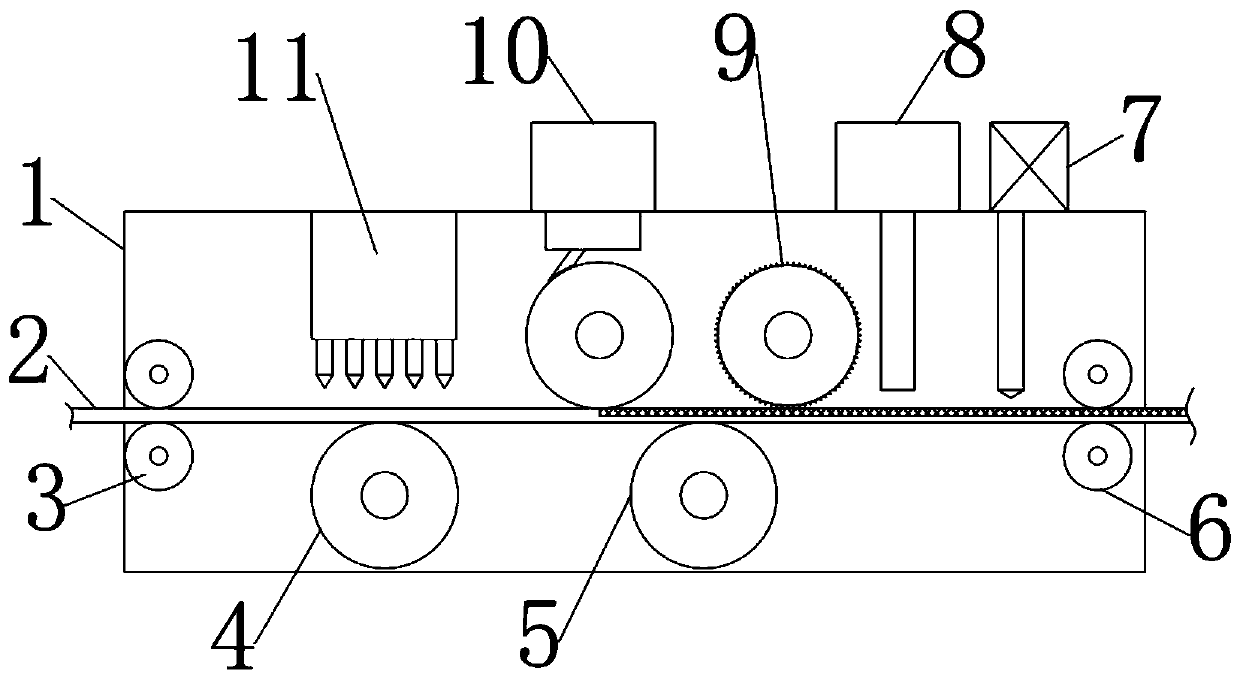

Excavator for Chinese medicinal herbs

PendingCN108541441AReduce excavation costsHigh degree of mechanizationDiggersMedicinal herbsGround roller

The invention provides an excavator for Chinese medicinal herbs. The excavator comprises a frame and a transmission system, wherein the frame is provided with a roller shaft; two ends of the roller shaft are respectively provided with a ground roller; the frame is provided with a hanging device; the front end of the frame is provided with a soil shoveling mechanism; a vibrating sieve device is arranged at the rear of the soil shoveling mechanism and connected with the frame through a crank rocker mechanism; the frame located at the rear of the vibrating sieve device is obliquely provided witha front soil-sieving conveying device; the frame located at the rear of the front soil-sieving conveying device is obliquely provided with a rear soil-sieving conveying device; the frame located abovethe central part of the front soil-sieving conveying device is provided with a first pressure roller device which matches with the front soil-sieving conveying device; and the frame located above thecentral part of the rear soil-sieving conveying device is provided with a second pressure roller device which matches with the rear soil-sieving conveying device. The excavator provided by the invention is a Chinese medicinal herb excavating and harvesting combined machine which can complete a plurality of processes like deep loosening, soil sieving and soil-herb separation by one time.

Owner:GANSU AGRI UNIV

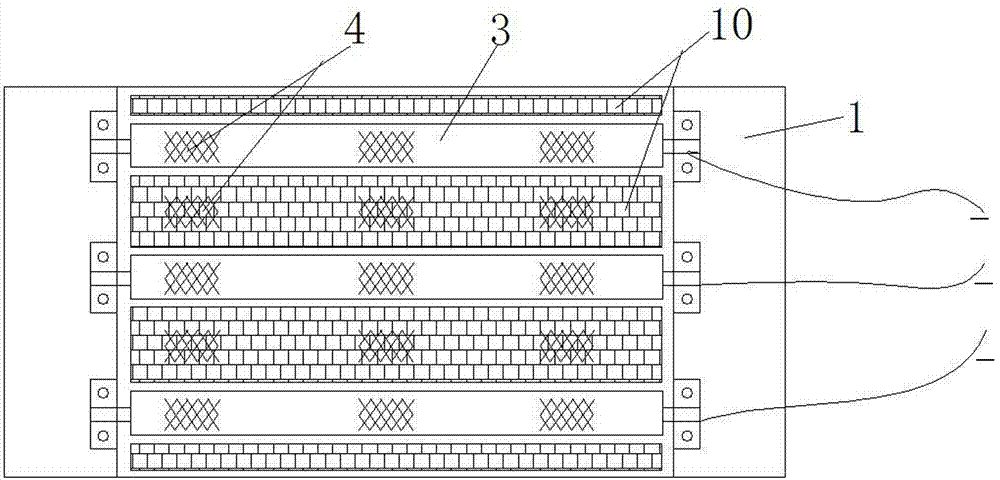

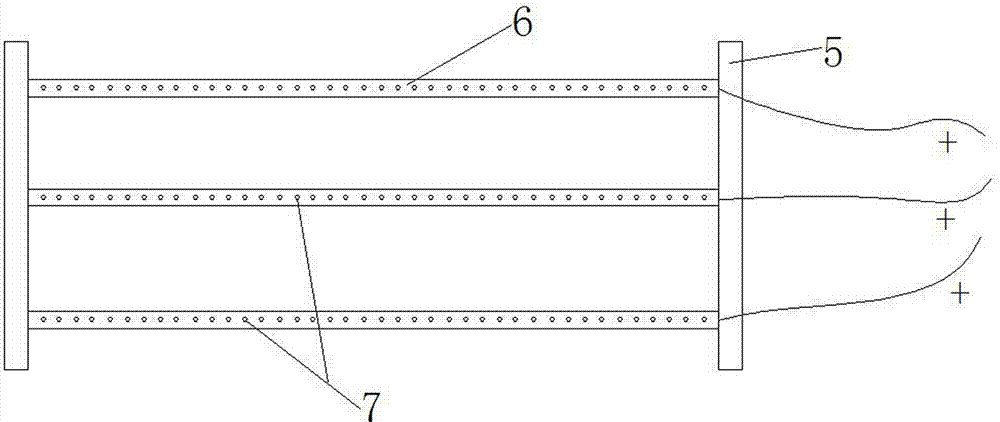

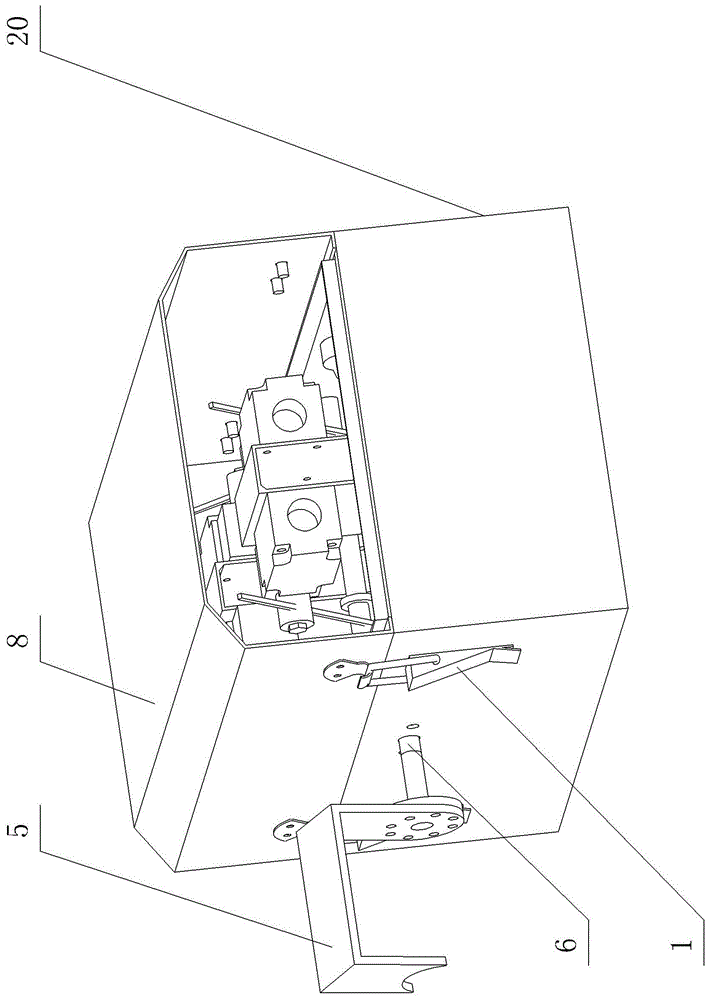

Online electret receiving device of non-woven fabric

ActiveCN104328515ACompact structureReduce volumeArtificial thread manufacturing machinesFilament/thread formingGround rollerEngineering

The invention relates to an online electret receiving device of a non-woven fabric, which is suitable for online electrets of the non-woven fabrics including anti-bonding fabrics, needle-punched non-woven fabrics, melt-blow filtering fabrics and the like which are made of high-molecular polymers. The online electret receiving device comprises an insulating box body, a plurality of static grounding rollers, an insulating air inlet network board, a nylon web curtain, an electret board mounting bracket and a plurality of electret boards, wherein the insulating box body is internally provided with a ventilating duct; connection flanges are arranged on the two sides of the insulating box body and the static grounding rollers are mounted at the upper part of the insulating box body; the static grounding rollers are connected with a cathode of a matched high-voltage static generator; the insulating air inlet network board is paved between the static grounding rollers; the nylon web curtain is arranged at the upper parts of the insulating grounding rollers and the insulating air inlet network board; the electret board mounting bracket is mounted at the upper part of the insulating box body; the electret boards are mounted on the electret board mounting bracket; the electret boards are connected with an anode of the high-voltage static generator; the electret boards are provided with a plurality of high-voltage static electret needles.

Owner:江苏金美达新材料有限公司

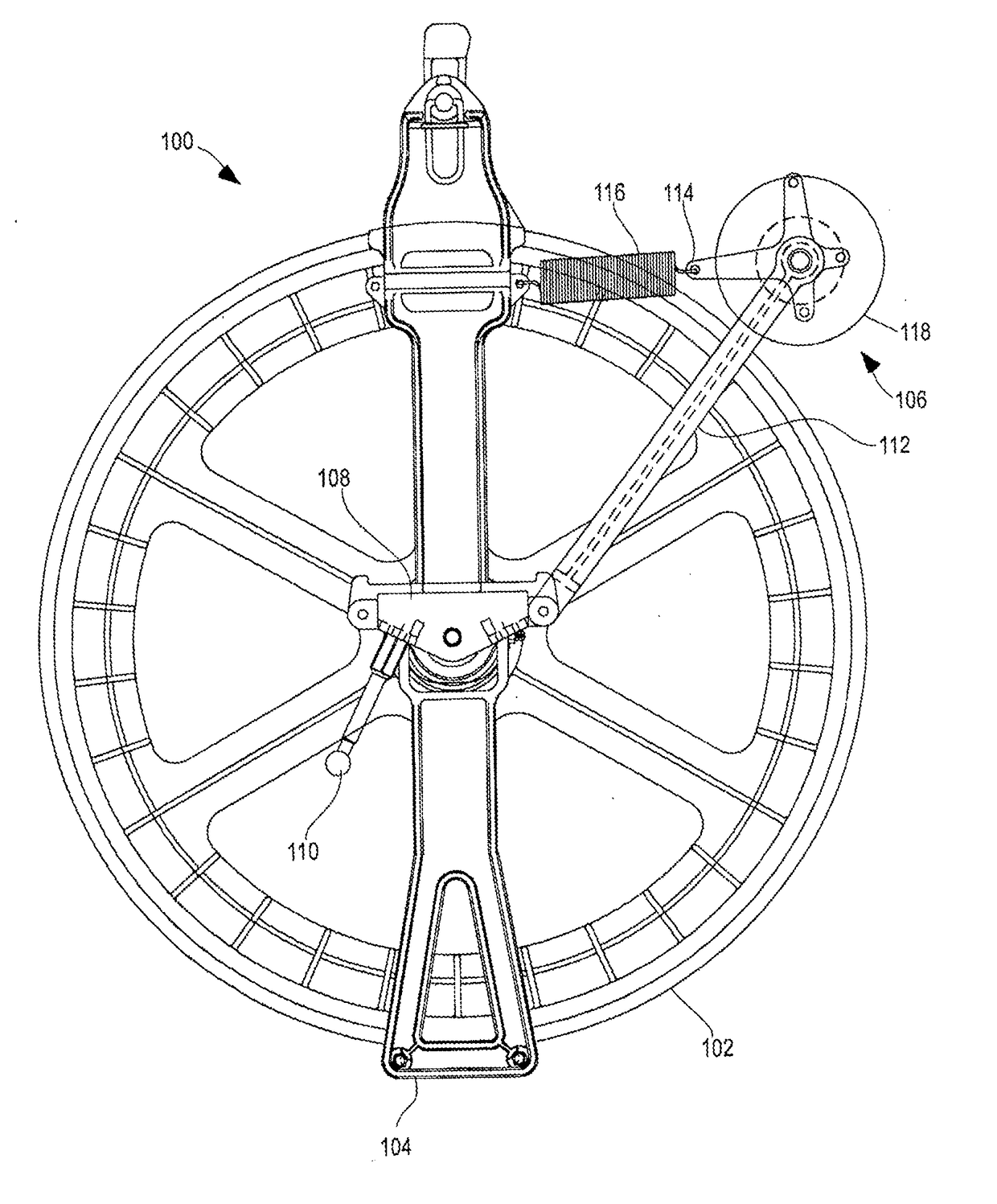

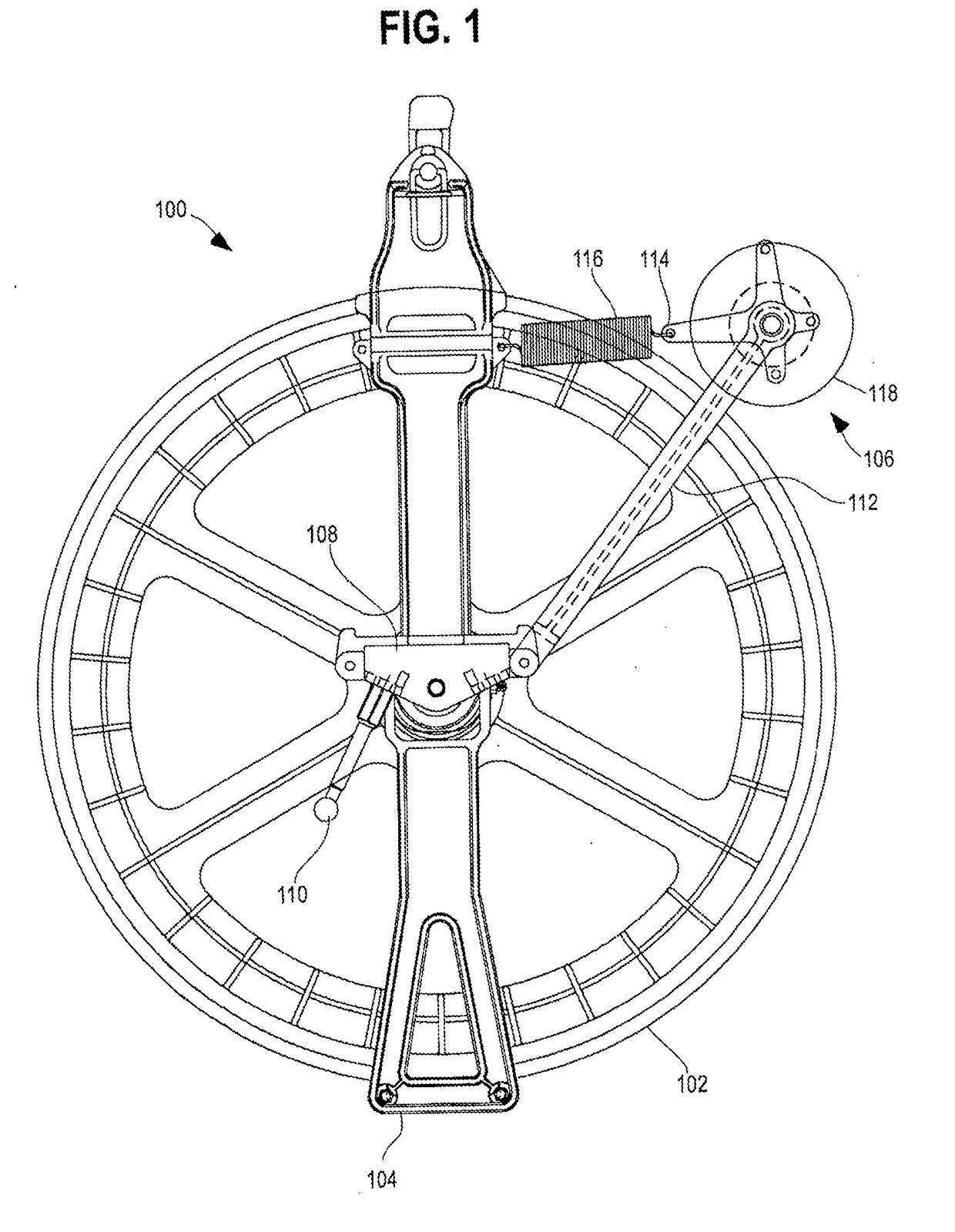

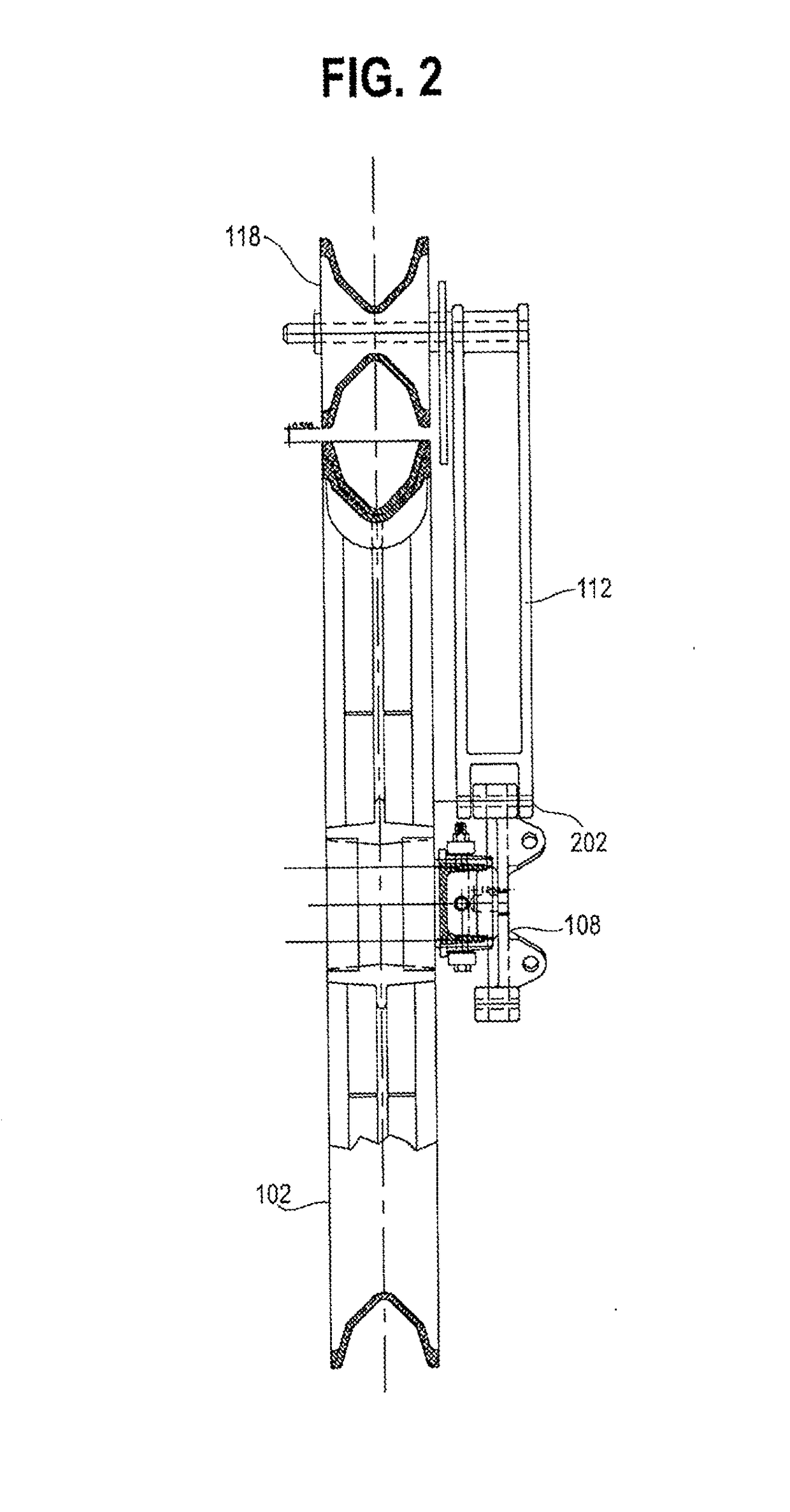

Ground roller assembly

InactiveUS20180242438A1Electrostatic chargesApparatus for overhead lines/cablesGround rollerElectrical conductor

The present disclosure provides a ground roller assembly for grounding electrical current induced in a conductor during installation of high power transmission lines. The ground roller assembly may include a mounting bracket having a plurality of pivot points spaced away from a mounting aperture, and an integrally formed tongue projecting outwardly away from an upper edge of the mounting bracket. A support arm may be coupled to one of the plurality of pivot points positioned proximate to a side edge of the mounting bracket. A sheave configured to receive an electrical conductor may be attached to an end of the support arm opposite the mounting bracket

Owner:MACLEAN POWER LLC

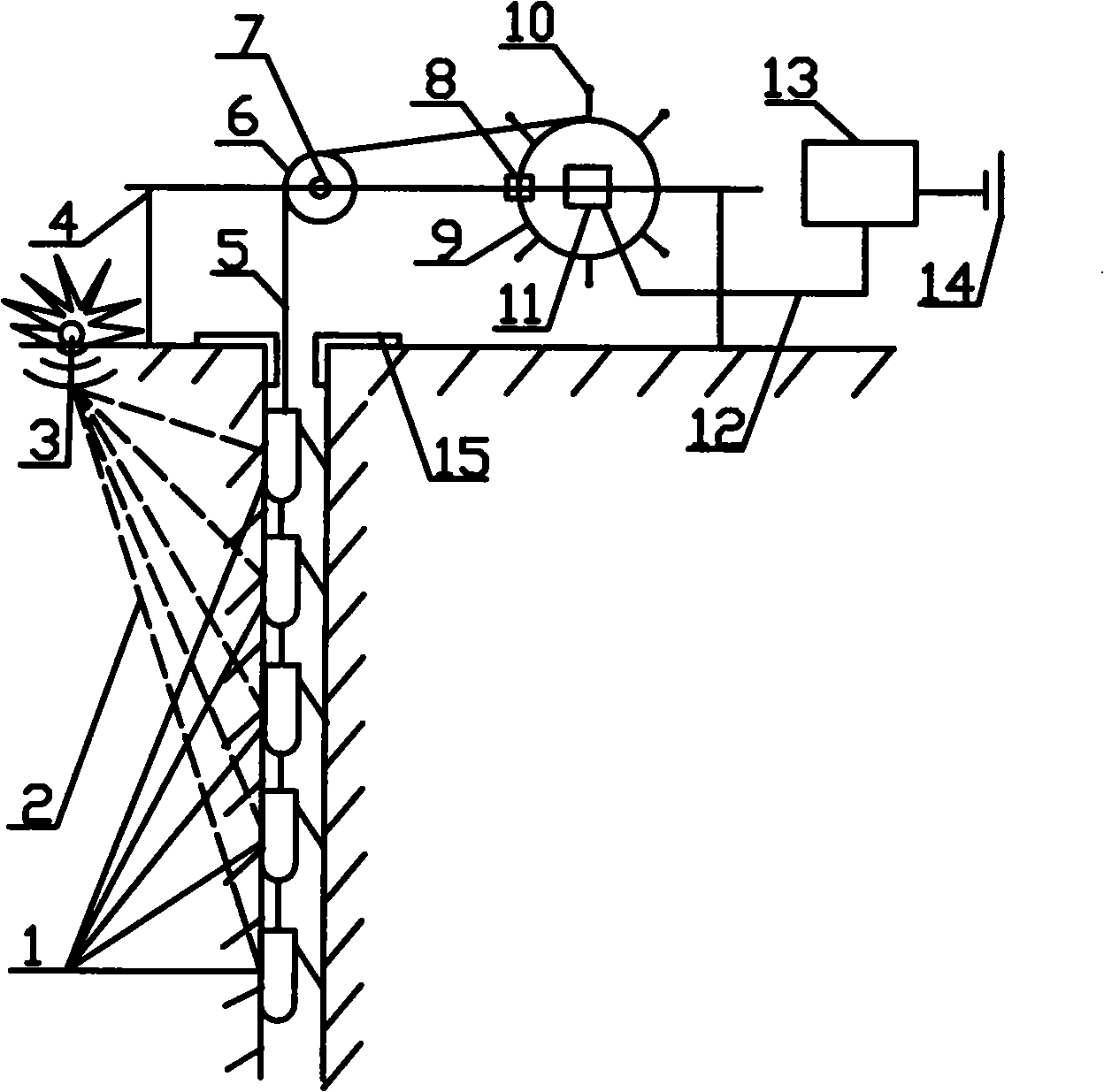

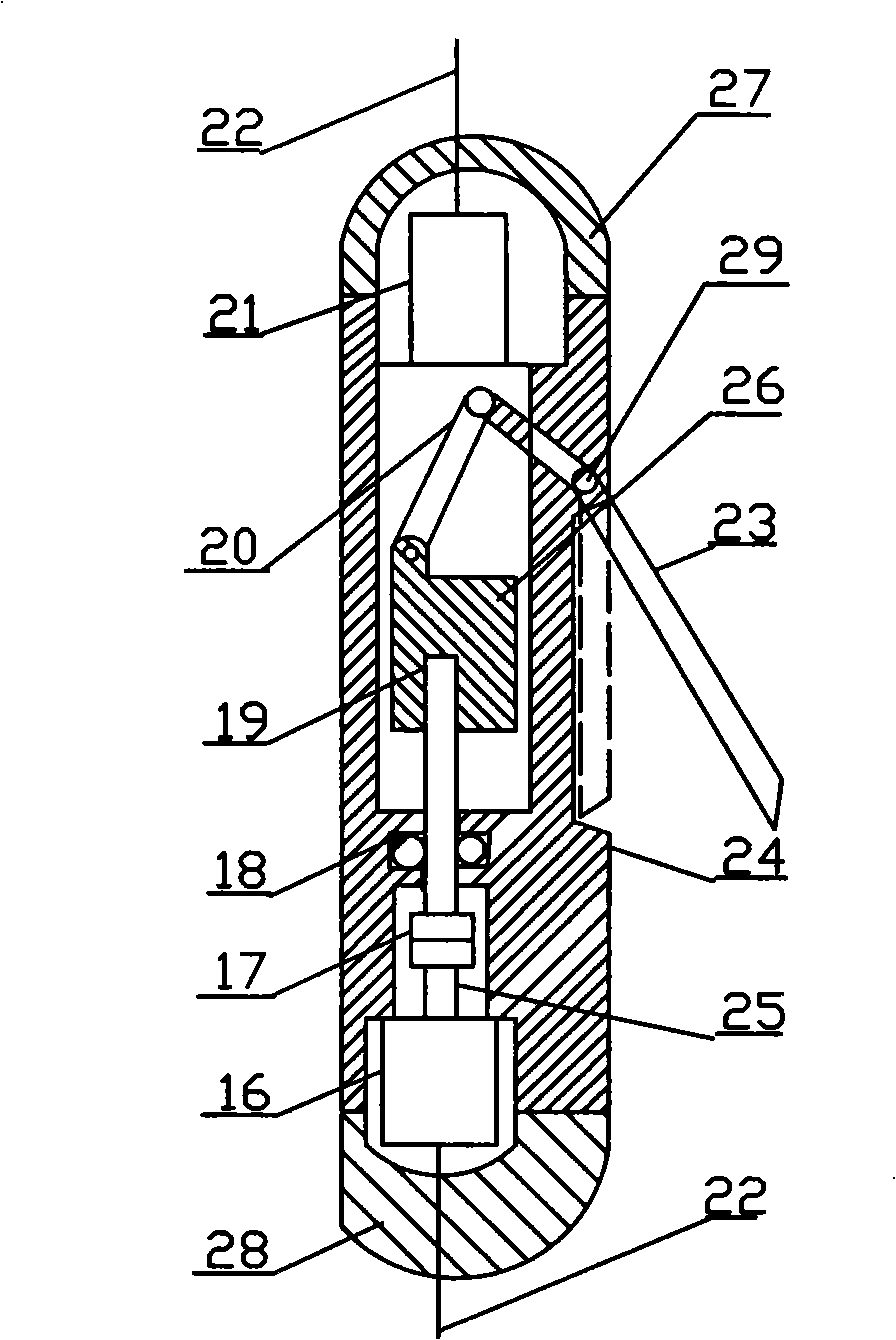

Method for down-hole multilevel micrologging for oil prospecting and electric coupler

InactiveCN101338670AHigh precisionClose and firm contactSeismic energy generationBorehole/well accessoriesGround rollerElectric cables

The present invention provides a method used for petroleum exploration downhole multi-grade micrologging and an electric coupler. An electric cable which can bear pull is used for connecting the electric coupler in series and putting the electric coupler into a well; after the depth requirement is achieved, the support leg of the electric coupler is stretched by supplying power and is contacted with a well wall stratum closely and stably; then a surface source is exploded to produce earthquake wave; the earthquake wave is transmitted into a wave detector in the electric coupler by the support leg; data are returned to a control recording instrument on the ground by the electric cable, and the collection of stratum data is achieved. The support leg of the electric coupler is controlled to close by reverse power supply and is departed from the well wall stratum, the electric coupler drives a ground roller to rotate, the electric coupler is sent to the next stratum for collecting, and the multi-grade micrologging construction is achieved.

Owner:王国忠 +2

Auxiliary examination method for weaving texture defect on surface of roller

InactiveCN101972781AReduce finishingReduce reflectivityMeasuring devicesMetal rolling arrangementsGround rollerPulp and paper industry

The invention discloses an auxiliary examination method for a weaving texture defect on the surface of a roller. The method comprises the step of: polishing a ground roller surface by using sandpaper, wherein the surface is the roller surface besides rolling width. In the method, after polishing the ground roller surface by using the sandpaper, the smooth finish and the reflection rate of the roller surface are reduced so that the grinding texture on the roller surface can be observed clearly. Because the polished surface is the roller surface besides the rolling width, the surface quality of a belt material cannot be affected by the polished roller surface. The auxiliary examination method for the weaving texture defect provided by the invention is simple to operate, can rapidly discover whether the ground roller surface has a texture with a depth, and can improve the accuracy of stripe judgment of the roller surface by comparing with a standard sample of a product.

Owner:SOUTHWEST ALUMINUM GRP

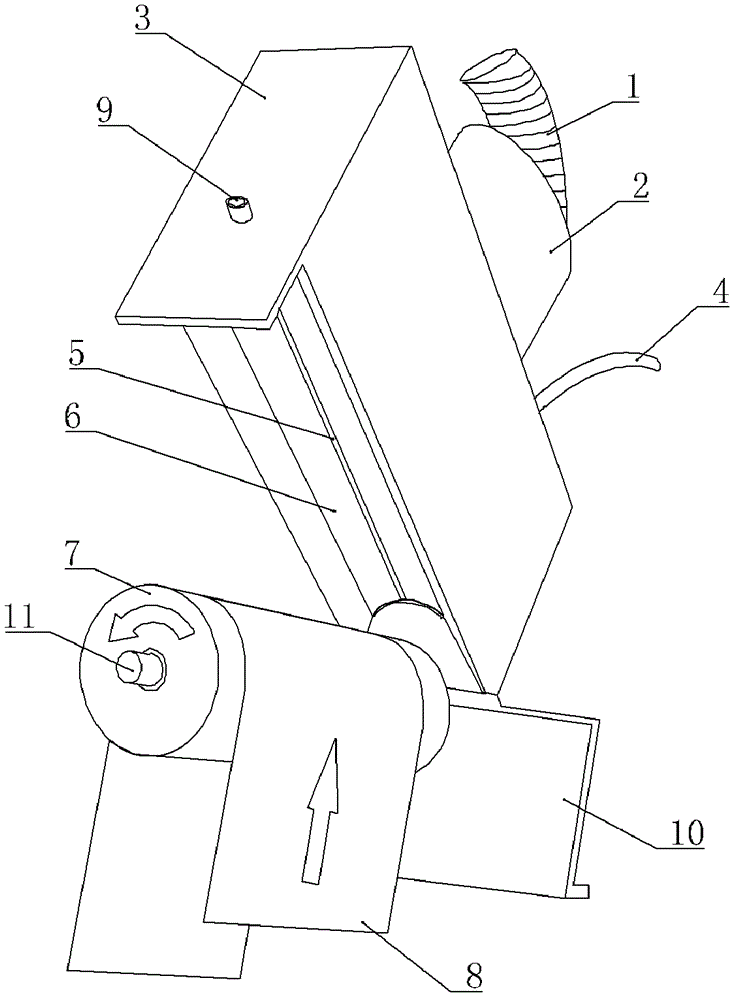

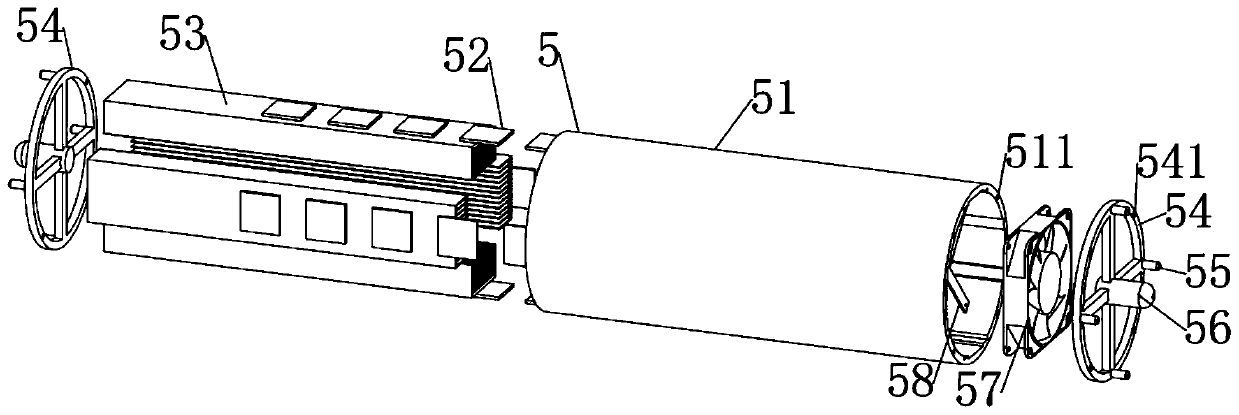

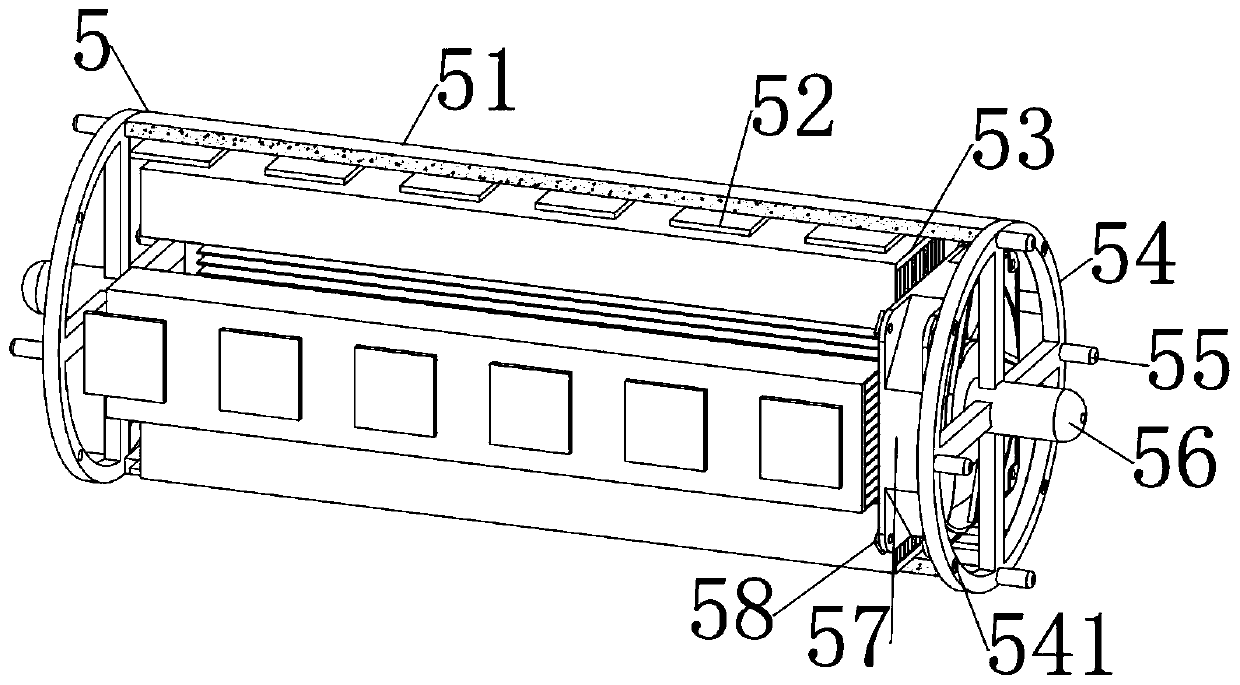

Straw secondary chopping and spilling machine

ActiveCN104012251ASolve the uniformity of spreadingSolve for uniformityCrop conditionersMowersGround rollerEngineering

The invention relates to a processing device for straws of crops, in particular to a straw secondary chopping and spilling machine. A machine frame is integrally in a rhombus shape. A suspension frame is connected to the top on the left side of the machine frame, and supporting legs are connected to the bottom of the machine frame. A spreader plate assembly, a chopping knife shaft assembly and a grass blocking curtain are arranged at the upper right portion of the machine frame, the bottom of the machine frame and the position in front of the supporting legs respectively. The middle of the front face and the middle of the back face of the machine frame are provided with an upper stationary knife row and a lower stationary knife row respectively from top to bottom. A transmission box assembly is located inside the portion, on one side of the suspension frame, of the machine frame. The transmission box assembly is in driving connection with a ground roller assembly through a belt. A belt wheel protection cover is arranged outside the belt, a tension device is arranged on the upper portion of the belt, one side of the ground roller assembly extends out of the lower right portion of the machine frame, and a scraping fender is arranged on the top of the ground roller assembly. The straw secondary chopping and spilling machine has the advantages that straws chopped by a combine harvester can be sucked to be chopped and spilled for the second time, evenness of spilling of the chopped straws of the crops is achieved, and the problems that stubbles are high and bottoms are not flush after the straws of the crops are cut, and grass and soil are stuck to the ground rollers easily are solved.

Owner:黑龙江红兴隆机械制造有限公司

Plastic coating and film laminating device

PendingCN110004769AGood adhesionControl the amount of coatingPaper/cardboardPhysical paper treatmentGround rollerRefrigeration

The invention relates to the technical field of plastic coating and film laminating processing for instant film attaching, in particular to a plastic coating and film laminating device which comprisesa device body. A feeding guide rail, a corona device, a grounding roller, a plastic coating device, a cooling roller, a puncture roller, a film laminating device, a thickness gauge and a dischargingguide roller are sequentially arranged in the device body in the advancing direction of workpieces. A driving device and a patch board which are matched with the cooling roller are arranged on the side wall of the device body. A refrigerating assembly is arranged on the cooling roller. By means of the cooling roller, the workpieces are rapidly cooled, and upwarp and corrugated edges can hardly happen during the plastic coating of the surfaces of the workpieces; the conductive rail matched with a conductive column is arranged on the surface of the patch board, the patch board and the rollers are all made of copper, the driving device drives a main shaft to rotate, the conductive column keeps fitting the conductive rail though a spring, the copper has excellent self lubricity, the rotation of the rollers is realized, and meanwhile semiconductor refrigeration sheets and a draught fan in the rollers are powered.

Owner:中山市旭森涂层材料有限公司

Plate stacking and automatic beating mechanism

PendingCN107902422AIncrease spacingAccurate whereaboutsConveyorsStacking articlesGround rollerEngineering

The invention discloses a plate stacking and automatic beating mechanism. The plate stacking and automatic beating mechanism comprises a transporting belt for moving plates, and the left side and theright side of the tail end of the transporting belt are both connected with roller shafts. The roller shafts are fixedly mounted on swinging frames, and the distance between the left roller shaft andthe right roller shaft is adjusted through swinging of the swinging frame. The roller shafts and the transporting belt are consistent in height, a rail is arranged on the ground between the left roller shaft and the right roller shaft, and a trolley is arranged on the rail. A supporting rod is arranged above the rail, and a vertically-downward baffle is arranged on the supporting rod. The plates falling on the trolley are slapped, and thus the plates on the trolley are tidy and orderly.

Owner:安徽戎发冲压机器人有限公司

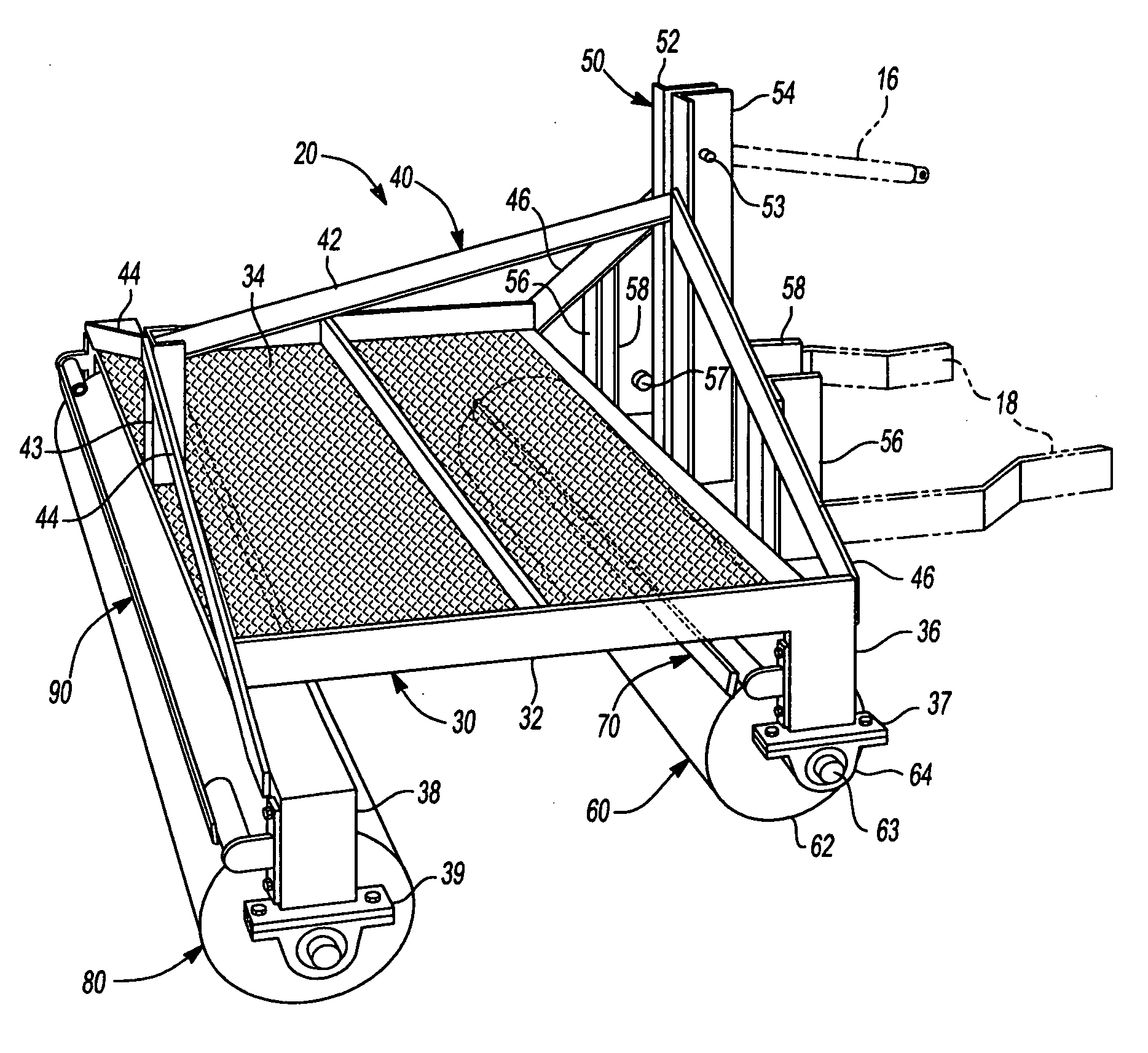

Ground roller

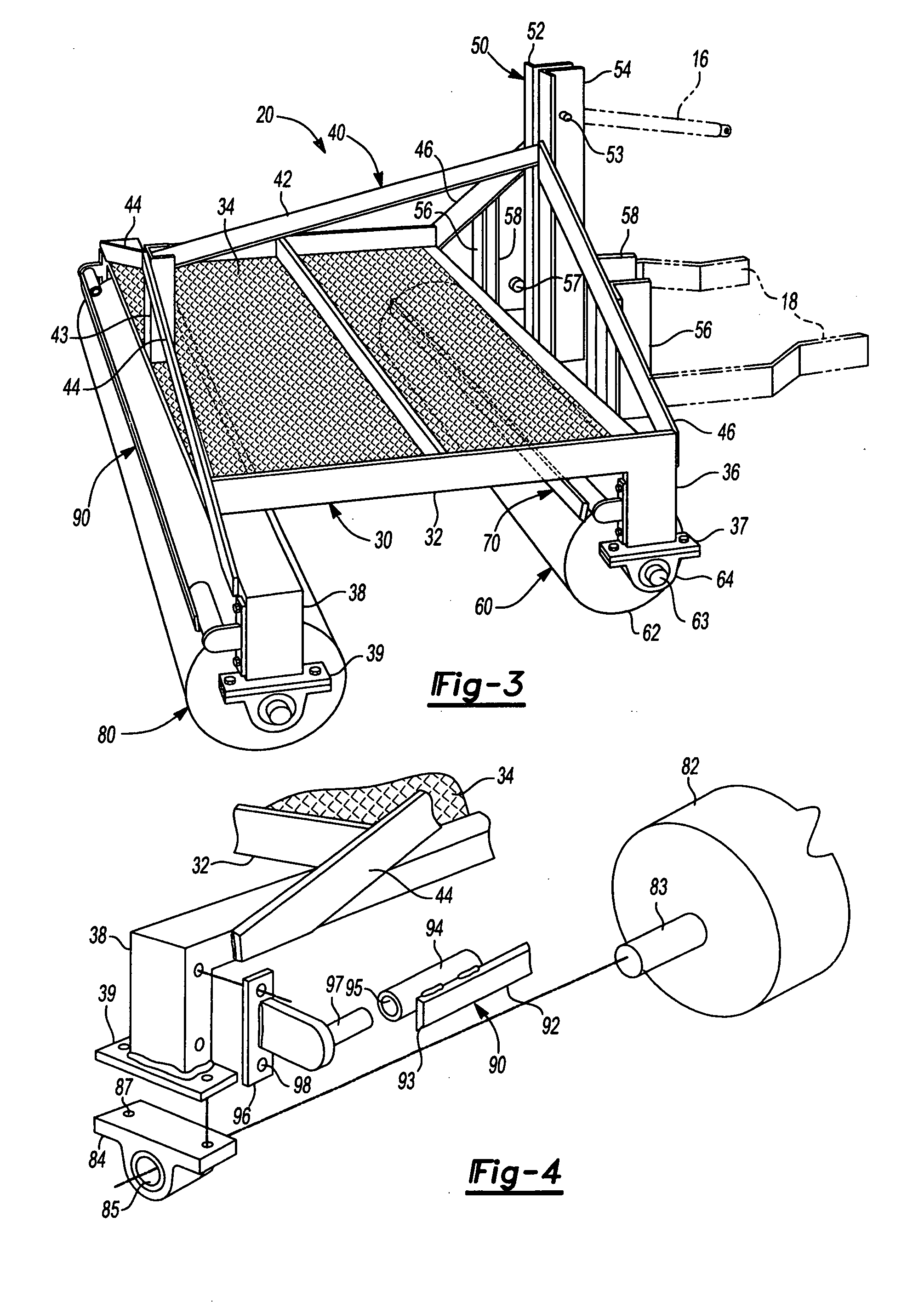

InactiveUS20090226259A1Increase compacting forcePrevent buildupAgricultural rollersRoads maintainenceGround rollerEngineering

A ground roller for compacting and leveling ground, includes a frame having a front and a rear with one or more cylindrical rollers rotatably journaled to a plurality of roller supports affixed to a bottom portion of the frame. A hitch structure is affixed to the front of the frame for connecting to a three point hitch of a tractor.

Owner:COMEAU MICHAEL +1

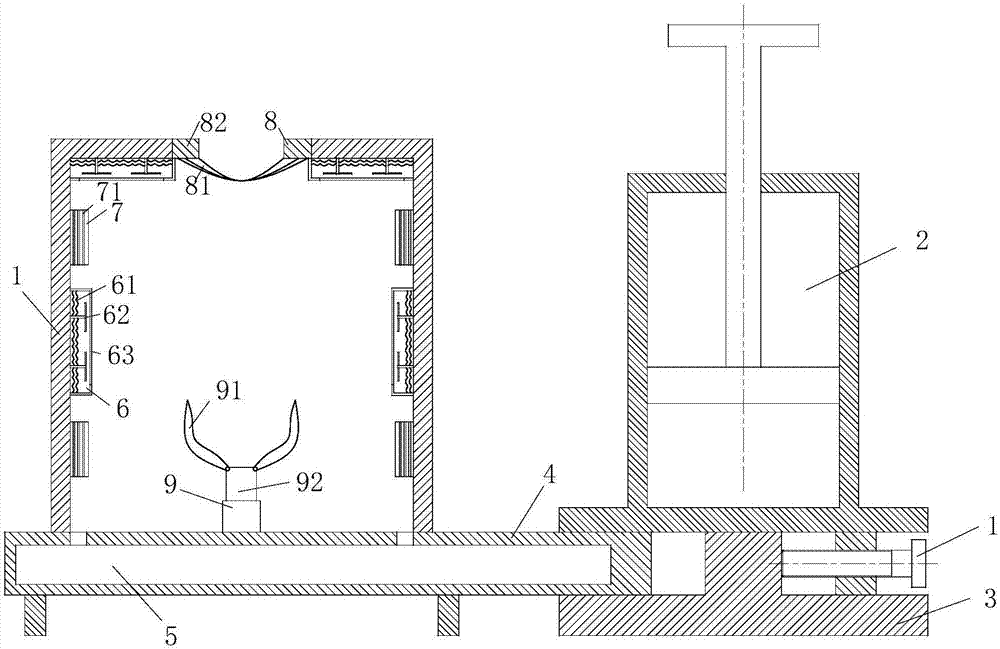

Medical ground roller cleaning and disinfecting equipment

The invention belongs to the technical field of medical equipment, and particularly relates to medical ground roller cleaning and disinfecting equipment. The medical ground roller cleaning and disinfecting equipment comprises a shell, a cylinder, a supporting base, a rotating bracket, a cleaning hole, a dirty water collecting box, drying unit, a disinfecting unit, a silica gel closing door and a clamping unit, wherein the shell is fixedly mounted on the rotating bracket; the cylinder is used for supporting a medical bed; the supporting base is used for fixing the cylinder and enabling the rotating bracket to rotate around the cylinder; the rotating bracket is used for driving the shell to rotate around the supporting base; the drying unit is used for blow-drying cleaned medical bed casters; the disinfecting unit is used for disinfecting the blow-dried medical bed casters; the silica gel closing door has the function of avoiding splashing of water inside the shell during cleaning; the dirty water collecting box is used for storing dirty water after cleaning; the clamping unit is used for regulating and controlling the medical bed casters. The medical ground roller cleaning and disinfecting equipment can clean and disinfect the medical bed casters alone; meanwhile, the medical ground roller cleaning and disinfecting equipment performs blow-drying and disinfecting operations at the same time under collaboration of the drying unit and the disinfecting unit, so that the time is saved.

Owner:山东润蒙应急救援装备有限公司

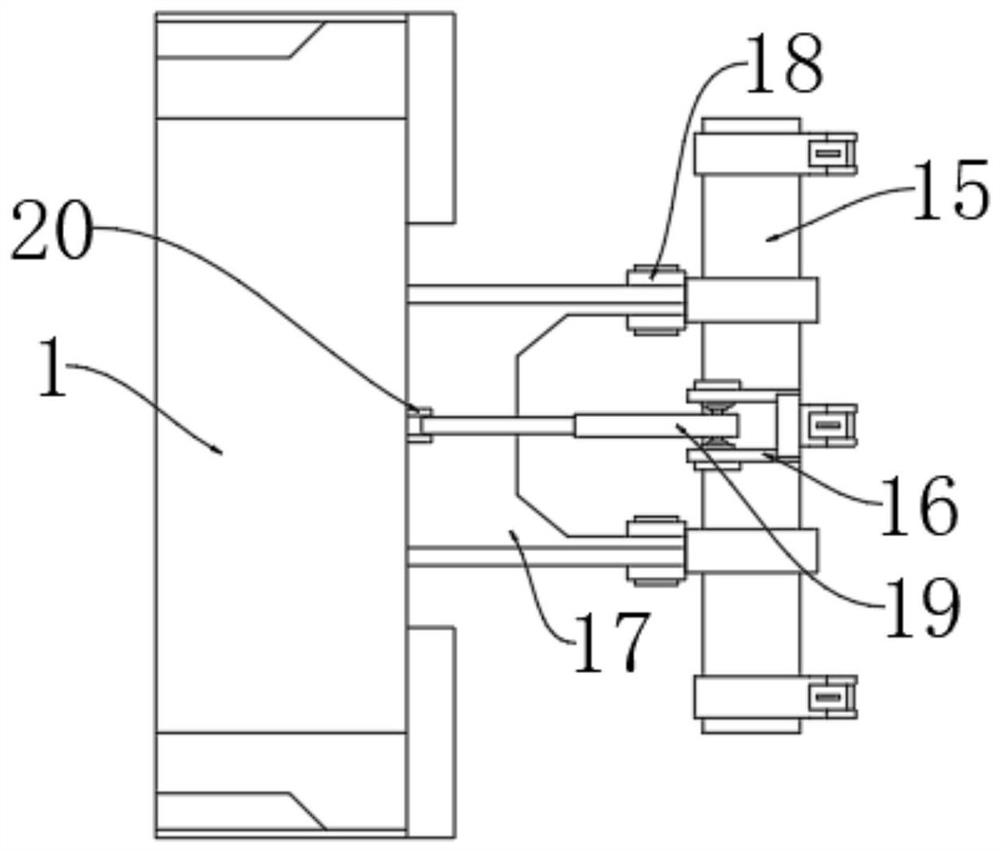

Pneumatic transfer platform

The invention relates to a car transfer platform for mining wells, in particular to a pneumatic transfer platform. The pneumatic transfer platform comprises a box body, a pneumatic motor, a rotary disc, a bearing guide rail, a car arrester, a movable rail and a ground roller, wherein the box body is connected with a transmission box of which the lower side is provided with a drive gear; a roller wheel group is installed in the box body; the rotary disc is borne at the upper side of the roller wheel group; a gear ring is installed at the lower side of the rotary disc; the outer edge of the rotary disc is matched with the inner edge of the press cover arranged at the upper side of the box body by a manner of sliding; the car arrester is installed between the two bearing rails which are installed at the upper side of the rotary disc; a fixed rail and an adjustable rail are installed on the press cover and the seats arranged at the periphery of the press cover; the fixed rail is connected with the movable rail; and the rotary disc is provided with a rotary handle. Compared with the prior art, the roller wheel group bears the rotary disc, so that the friction rate of the pneumatic transfer platform is low, and the mining cars can be easily driven by the bearing rail on the rotary disc to rotate at any angle; and the fixed rail is connected with the movable rail, so that the rail can switch the angles at any time, and the mining cars can flexibly rotate at the corners in roadways and the parking lots. The pneumatic transfer platform has high transportation efficiency.

Owner:TANGSHAN MENGLI MACHINERY EQUIP

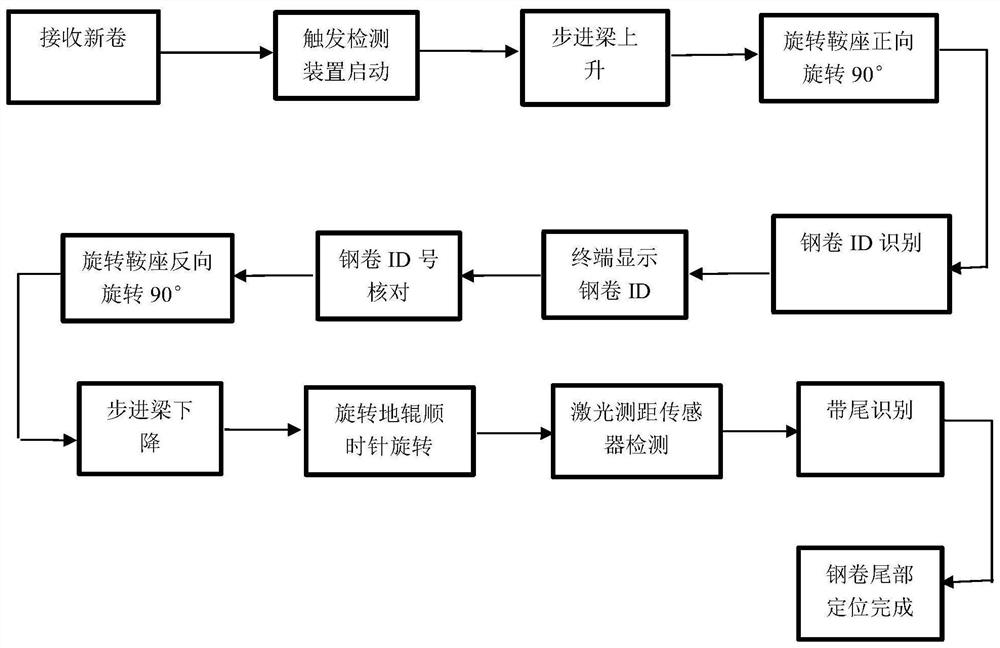

Steel coil tail and steel coil ID automatic identification structure and method

PendingCN112257707AAchieve a streamlined effectImprove automation production efficiencyGuiding/positioning/aligning arrangementsCharacter and pattern recognitionHydraulic motorGround roller

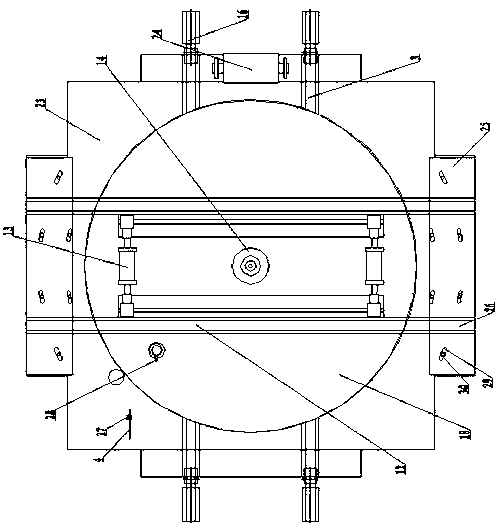

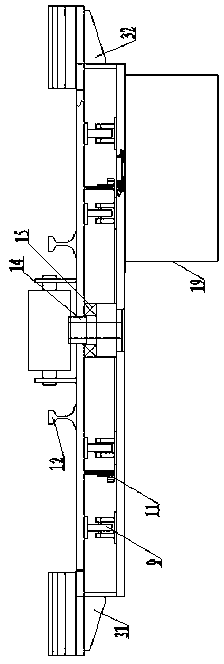

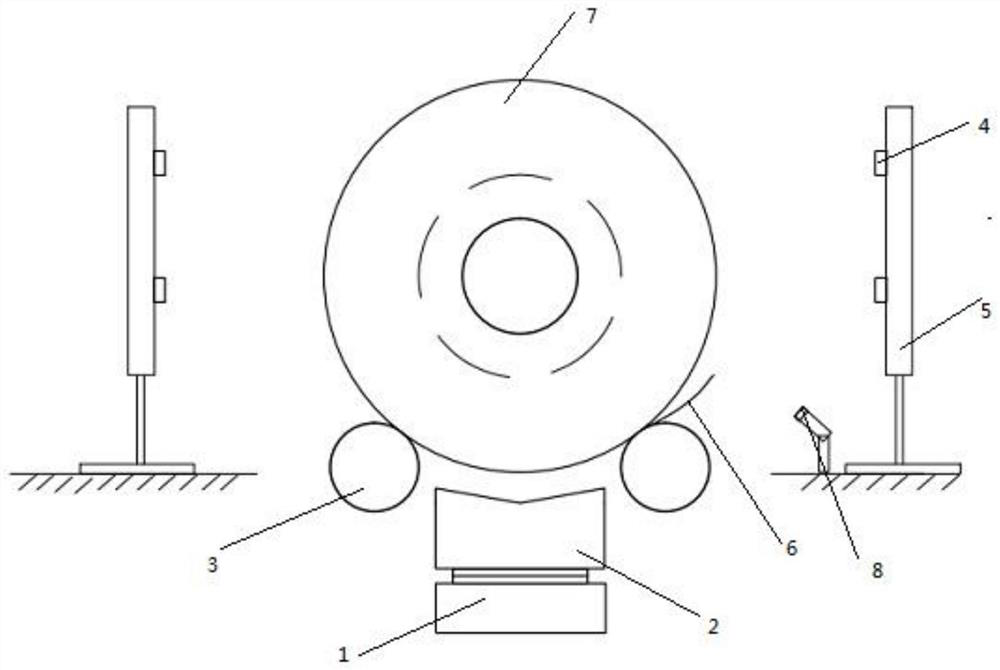

The invention discloses a steel coil tail and steel coil ID automatic identification structure and method. The automatic identification structure comprises a walking beam, a rotary saddle and a set ofrotary ground roller saddles, wherein the rotary saddle and the rotary ground roller saddles are arranged above the walking beam, the rotary saddle is connected with a hydraulic motor, and the rotaryground roller saddles are arranged above the rotary saddle and symmetrically arranged at two ends of the rotary saddle; cameras are installed on the two sides of the rotary saddle respectively, the cameras are installed on camera supports, a positioning sensor is installed on one side of the rotary ground roller saddle, the cameras and the positioning sensor are connected with a control system ofthe walking beam, the rotary saddle is controlled to rotate forwards by 90 degrees, and the cameras conduct scanning to obtain the ID of the steel coil; and the positioning sensor scans the outer ring of the steel coil to position the strip tail along with the clockwise rotation of the rotary ground roller saddle, so that the full-automatic operation is realized, the operation efficiency is improved, and the risk of mixed steel production accidents caused by human errors is avoided.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

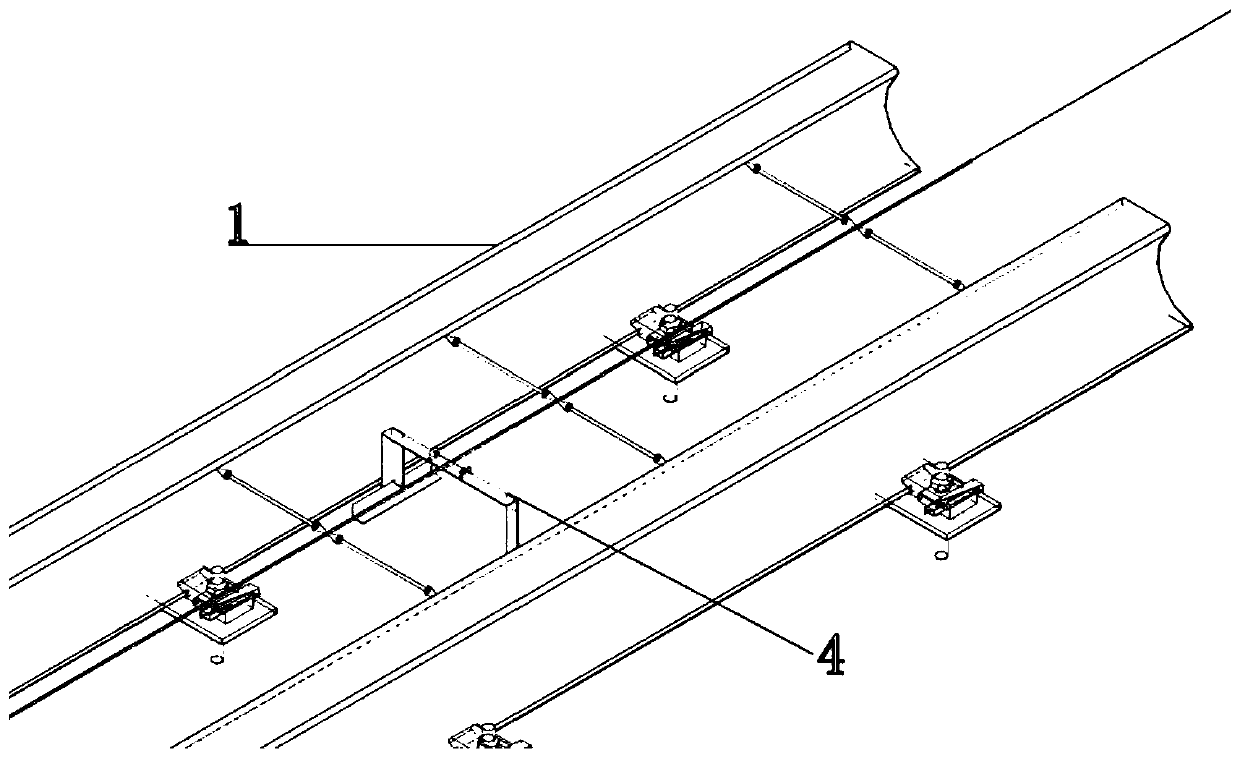

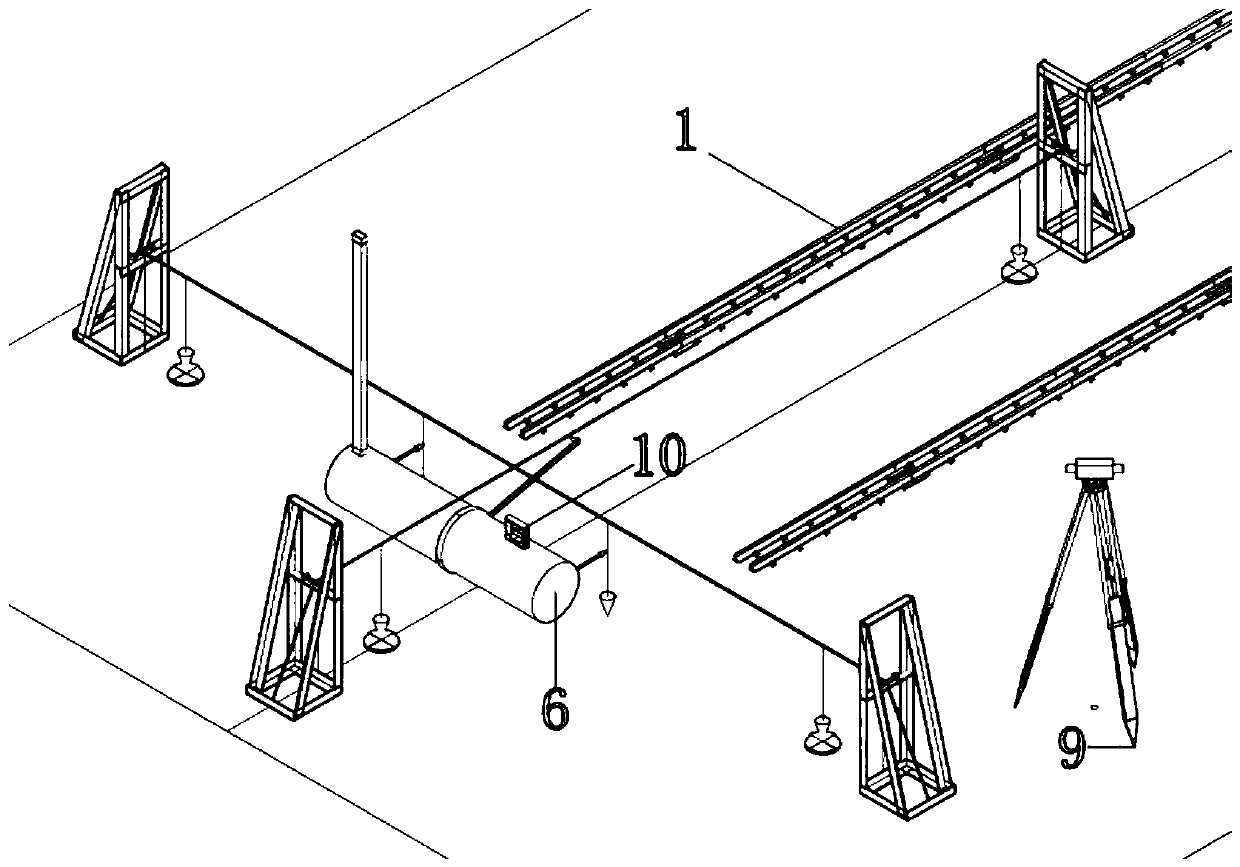

Method for mounting and adjusting running deviation of cold-rolled horizontal loop

ActiveCN110193521ASolve the installationSolve the adjustmentFlexible work arrangmentsMetal rolling arrangementsGround rollerControl line

The invention relates to a method for mounting and adjusting a running deviation of a cold-rolled horizontal loop. The method comprises the following steps that firstly, accurate adjustment is conducted on looping car rails, ground rollers, a deviation correcting roller and a loop transmission device; the accurate adjustment is conducted on looping car carrier rollers; and finally the carrier rollers are checked and adjusted in the threading operation, during the mounting and measurement paying-off process of the equipment in the loop, all control lines are arranged to complete at one step byusing a total station according to an inspection item. According to the method, key technical problems in the mounting and operation deviation adjustment of the cold-rolled horizontal loop are effectively solved, the mount speed is high, and the construction efficiency is high.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Container house production line and container house production process

PendingCN110630045ALow costImprove reliabilitySpecial buildingSpray boothsProduction lineGround roller

The invention provides a container house production line and a container house production process. The container house production line comprises a polishing device and a spraying device which are arranged in sequence. A plurality of transfer ground rollers are arranged between the polishing device and the spraying device. After being polished through the polishing device, a workpiece is moved intothe spraying device through the transfer ground rollers. According to the container house production line, the transfer ground rollers are directly arranged between the polishing device and the spraying device, so that the workpiece transfer efficiency is improved, and assembly work is achieved. Meanwhile, the transfer ground rollers are low in cost, high in reliability and capable of being applied in a large scale. It needs to be pointed out that through the arrangement of the transfer ground rollers, the transfer efficiency is high, the occupied area is small, and the space utilization rateis increased.

Owner:河北浩石集成房屋有限公司

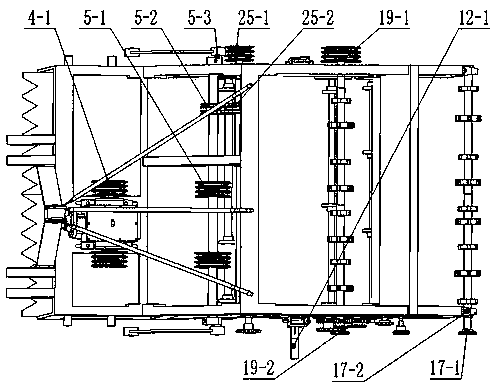

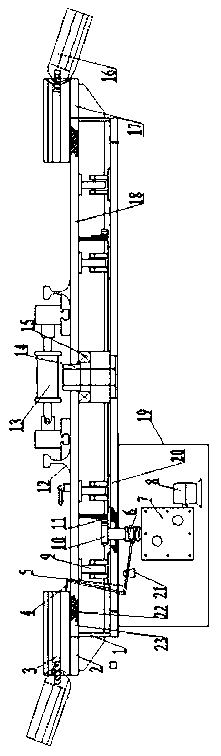

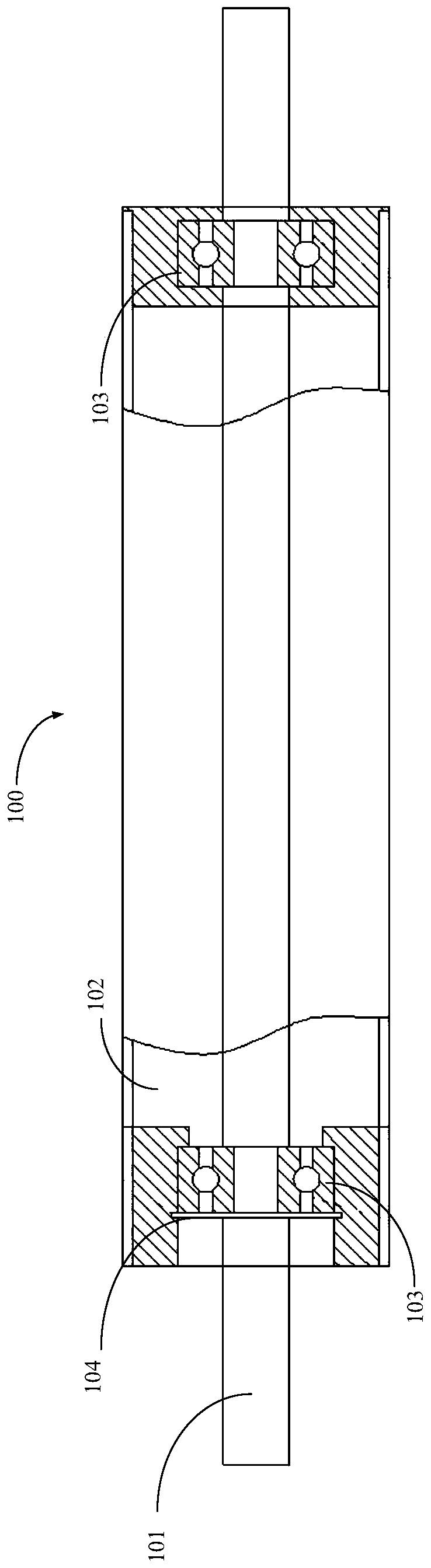

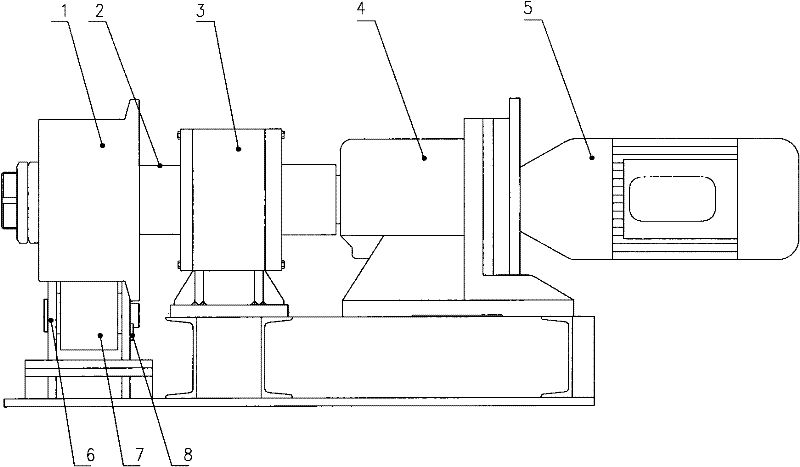

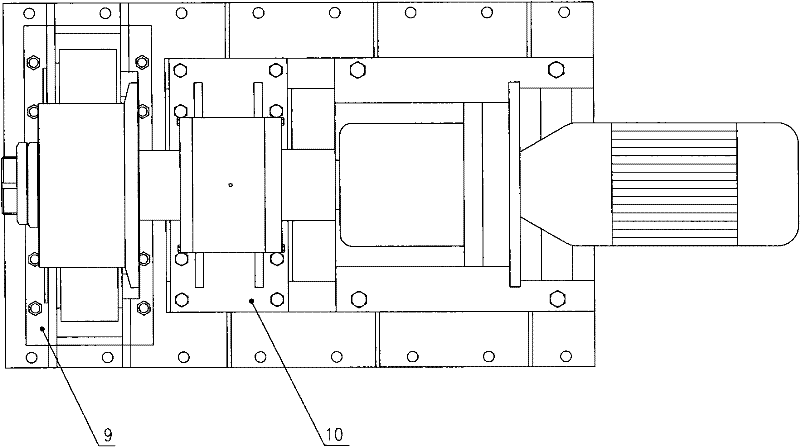

Ground roller type coiling and uncoiling device

InactiveCN102476766ASolve the problem of single use environmentSimple structureGround rollerEngineering

The invention relates to a ground roller type coiling and uncoiling device which comprises friction wheels, limiting sleeves for the friction wheels, a bearing base, a speed reducer, a motor, a supporting wheel shaft, a supporting wheel set, a shaft end baffle, a supporting wheel base and a coiling and uncoiling base. The ground roller type coiling and uncoiling device is used for realizing the positive and negative rotation of a hose storage cylinder and is capable of braking; the hose storage cylinder has a full load weight of 150 tons, a diameter of 7 meters, a width of 3.62 meters and a 15m / min speed for coiling and uncoiling the hose; the ground roller type coiling and uncoiling device is provided with four friction wheels; and the four friction wheels are all driven by the speed reducer of the motor and are used for driving a braking device. When the ground roller type coiling and uncoiling device is used, the supporting of a bracket of the hose storage cylinder is unnecessary; the ground roller type coiling and uncoiling device is capable of normally running in stormy waves, is simple in structure and is small in occupied area; the problem of a single use environment of a traditional ground roller type coiling and uncoiling device is solved; and the dual demand of usage on the sea and on the land is met.

Owner:NEPTUNE OFFSHORE ENG DEV

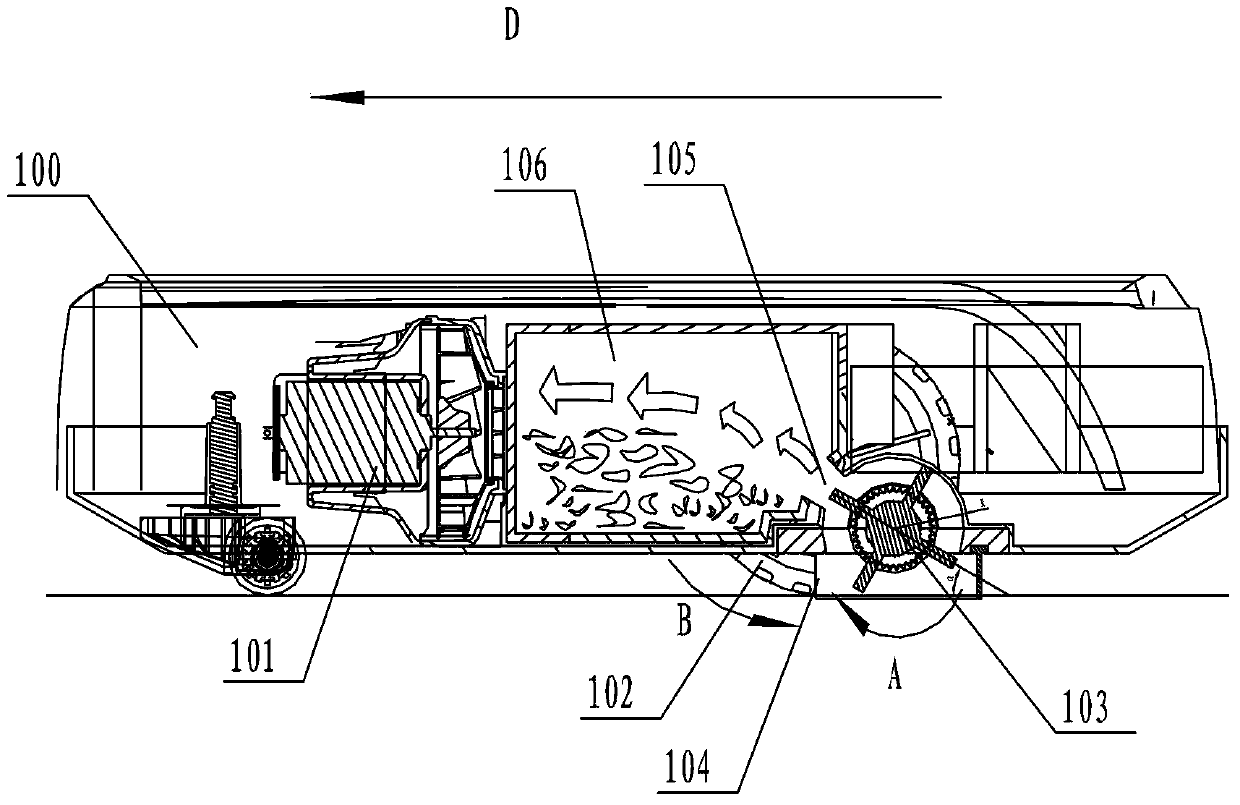

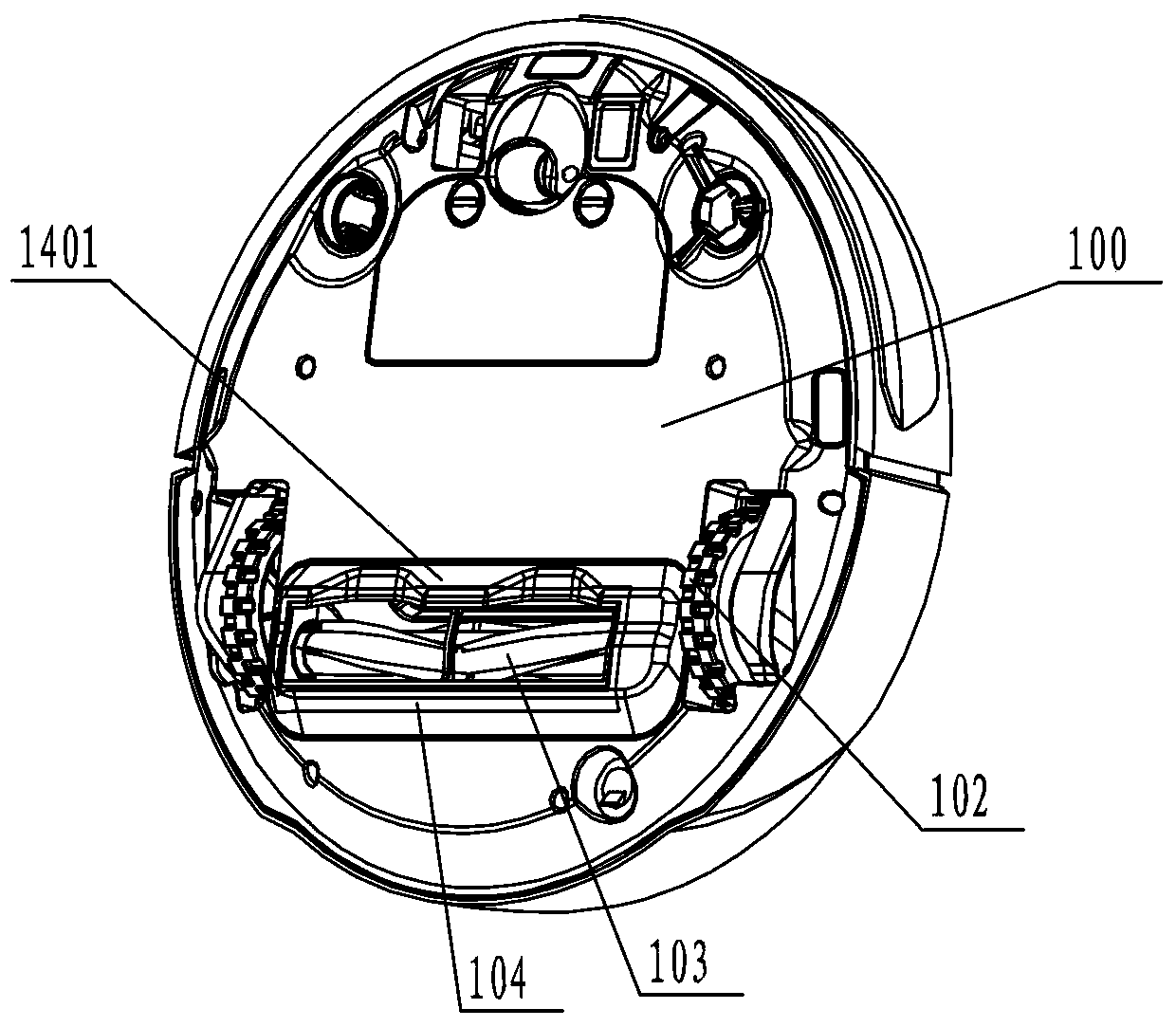

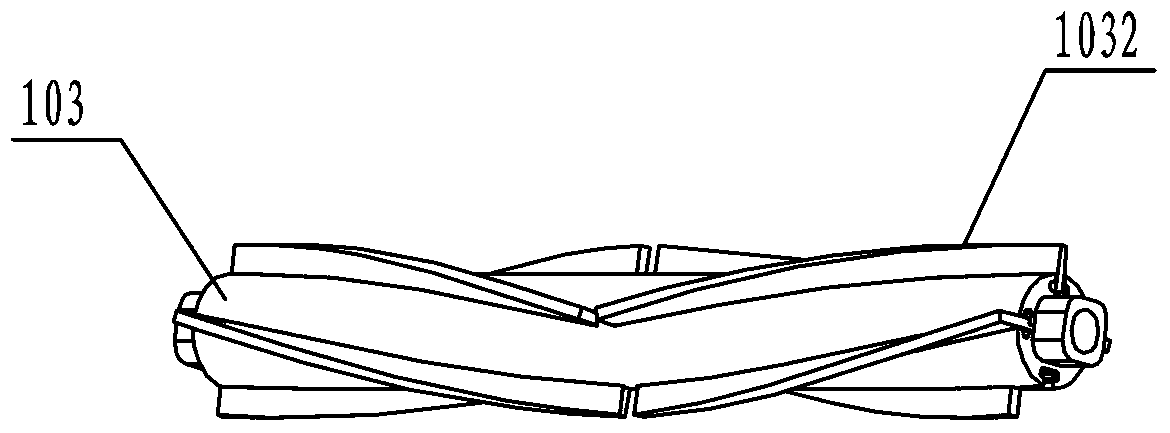

cleaning robot

ActiveCN104224054BEasy accessSimple structureSuction cleanersMachine detailsGround rollerDrive wheel

A cleaning robot, the roller brush (103) is arranged at the dust suction port (104), the dust is cleaned by the roller brush, and is sucked by the dust suction motor (101) through the dust collection channel (105) Collected in the dust collection chamber (106); assuming that the direction of travel of the cleaning robot during the cleaning operation is the front, the rotation direction (A) of the roller brush is opposite to the rotation direction (B) of the driving wheel when the cleaning robot advances. The middle position of the front side of the dust suction port on the body extends from the shell to the surface to be cleaned to form a flange (1041); the roller brush is provided with spirally arranged bristles (1032), and as the roller brush rotates, the ends of the bristles The contact point with the surface to be cleaned moves from the end of the roller brush to the middle, so that the dust gathers towards the middle of the front side of the suction port. The size of the garbage particles to be cleaned in the present invention is not limited by the size of the gap between the roller brush body and the ground. The bristles on the roller brush are set in a "V"-shaped spiral structure, which cooperates with the flange structure on the front side of the dust suction port, and the cleaning efficiency is high. .

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

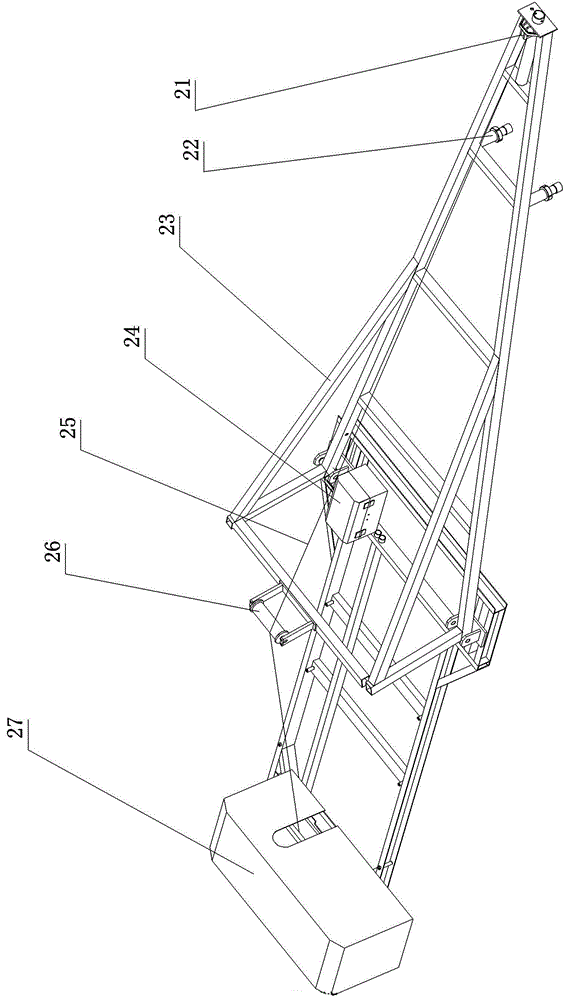

Arresting net lifting device

PendingCN106742020AHigh mechanical strengthReduce frictional resistanceArresting gearJet aeroplaneGround roller

The invention belongs to the technical field of III type airplane arresting nets and particularly relates to an arresting net lifting device. The arresting net lifting device does not damage steel wire ropes and facilitates ascending and descending of a net frame. The device comprises a net frame, a net frame lifting motor and a net frame base, and is structurally characterized in that the rear end of the net frame is connected with the front end of the net frame base through a rotary shaft, the net frame lifting motor is arranged at the rear end of the net frame base, upward supporting rods are disposed on the two sides of the rear end of the net frame, a cross beam is arranged between the supporting rods on the two sides, an installation base is arranged in the middle of the cross beam, vertical supporting plates are arranged on the two sides of the installation base, and a nylon ground roller is arranged between the upper ends of the supporting plates.

Owner:辽宁东鹰航空装备科技股份有限公司

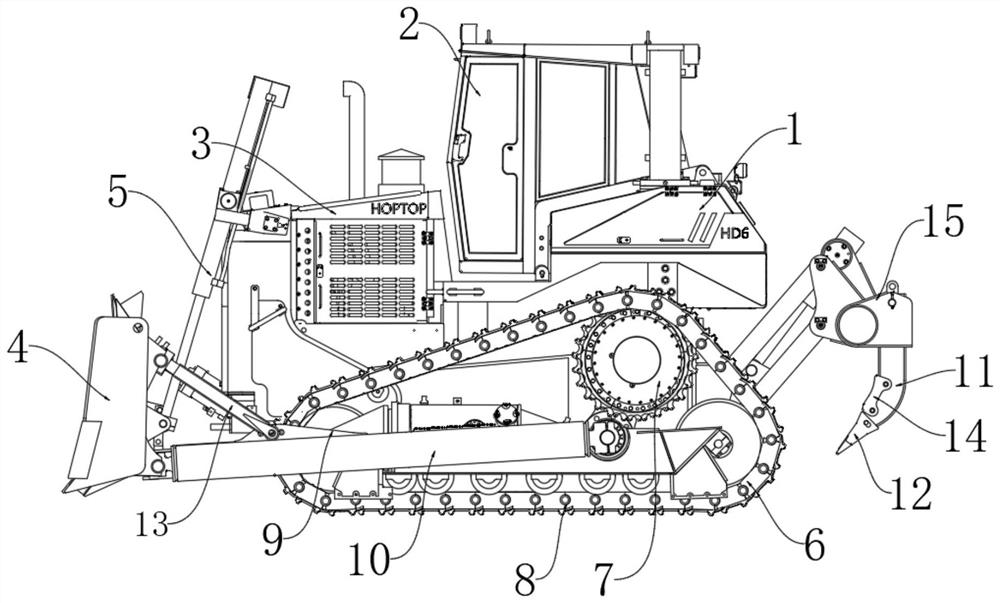

Hydrostatic bulldozer applying high-drive structure

PendingCN112195990AExtended service lifeEliminate shock loadsMechanical machines/dredgersGround rollerEngineering

The invention discloses a hydrostatic bulldozer applying a high-drive structure, relates to the technical field of bulldozers, and aims to solve the problems that an existing bulldozer is heavy in operation, poor in flexibility, extremely hard for operators to work, low in engineering machinery energy utilization rate and not energy-saving and environment-friendly. A cab is arranged at the upper end of a high-drive bulldozer body, an advancing crawler belt is arranged at the lower end of the cab, an engine compartment is arranged at one side of the cab, a lifting oil cylinder is arranged at one side of the engine compartment, a bulldozing hopper is arranged at the lower end of the lifting oil cylinder, and an inclined oil cylinder is arranged on one side of the bulldozing hopper; and a grounding supporting plate is arranged at the lower end of the bulldozing hopper, an auxiliary grounding roller is arranged in the grounding supporting plate, and a scarifier is installed at the tail ofthe high-drive bulldozer body.

Owner:江苏汉推重工有限公司

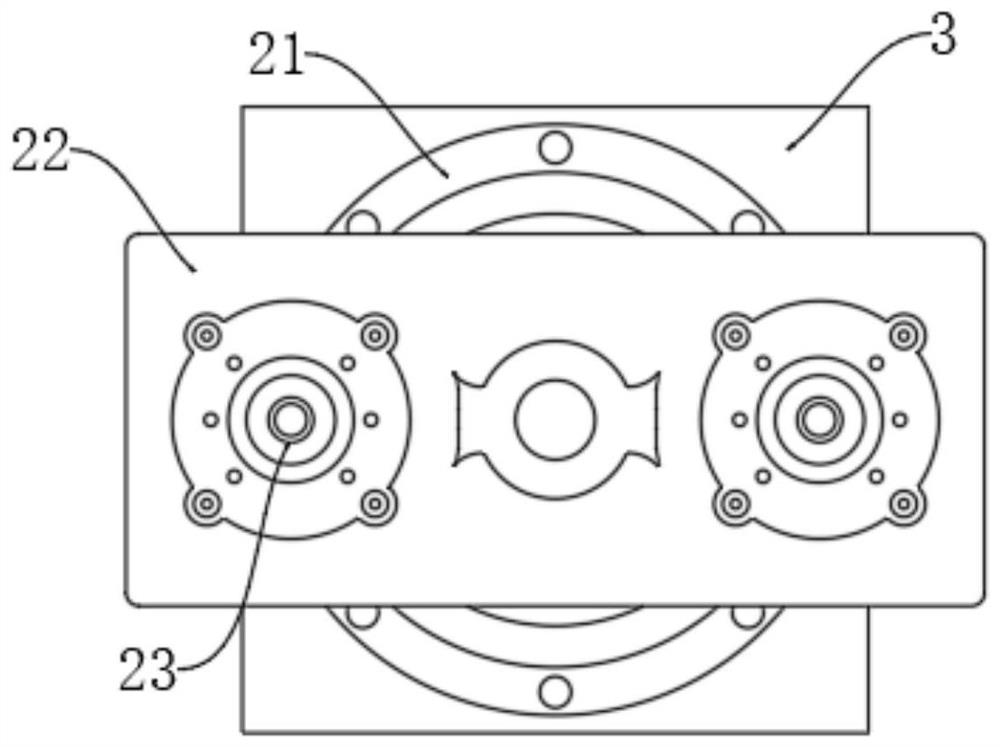

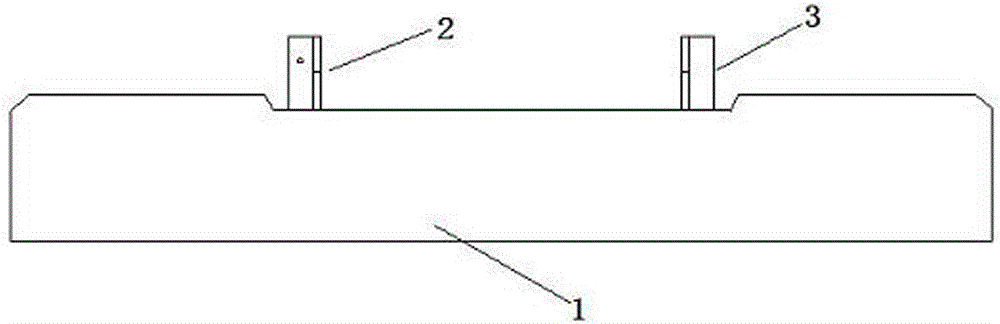

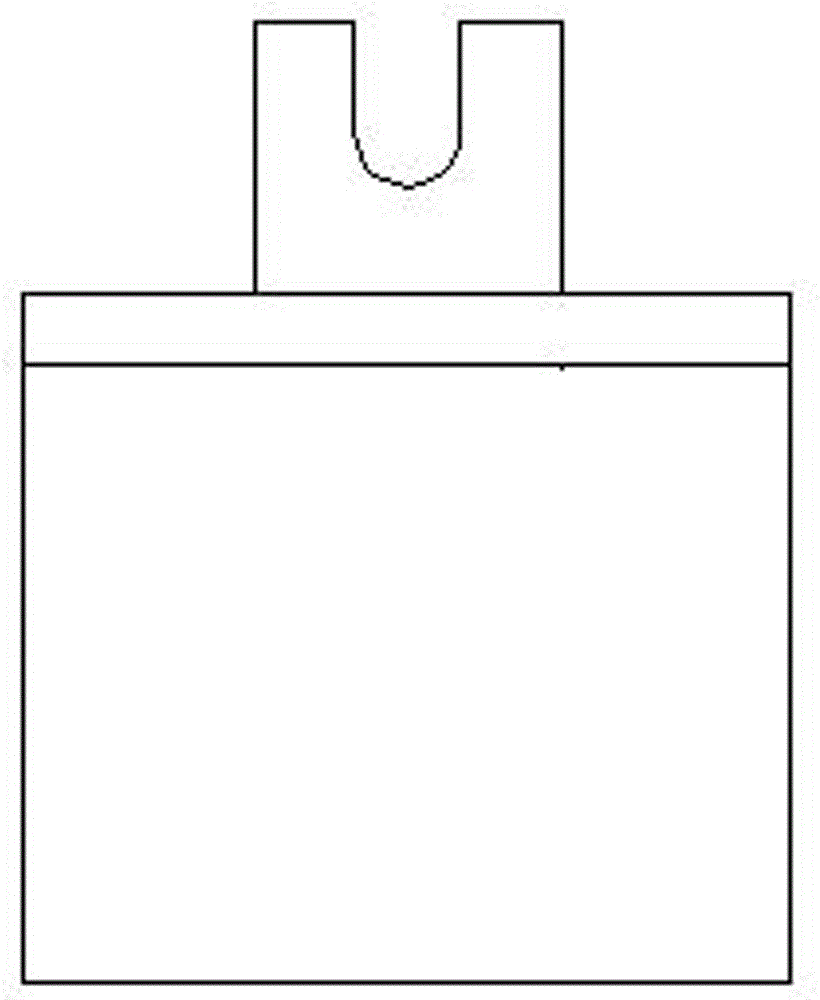

Composite cement road plate ground roller bracket

InactiveCN105926377AHigh strengthImprove stabilityEarth drilling and miningMovable tracksGround rollerEngineering

The invention provides a composite cement road plate ground roller bracket, and relates to the technical field of use equipment in coal mine equipment installation. The composite cement road plate ground roller bracket is characterized by comprising a cement road plate (1), a ground roller bracket (2) and a ground roller bracket (3), wherein the ground roller bracket (2) and the ground roller bracket (3) are respectively arranged on the cement road plate (1); the ground roller bracket (2) and the ground roller bracket (3) are arranged on the same horizontal line; the ground roller bracket (2) is in an opening type; the ground roller bracket (3) is in a jack type. The composite cement road plate ground roller bracket has the characteristics that the cost is low; the intensity, the stability and the firmness are good; the mounting and the dismounting of the ground roller are convenient; the work efficiency is improved; the labor cost is reduced, and the like.

Owner:合肥慧林建材有限公司

Applicable to the device and method for improving the yield of welding leaders for double-stand cold rolling mills

The invention relates to a device and a method suitable for improving yield of a welding leading tape of a double-stander cold rolling mill. The method comprises the steps of rotating ground rollers to uncoil a qualified coil; conveying the end part of a steel coil to a welding position after uncoiling the qualified coil; coiling a leading tape coil upwards to a leading tape uncoiler, conveying the leading tape coil to a transverse cutting shear after centering the leading tape coil by using centering vertical rollers and straightening the leading tape coil by using a straightening machine, and shearing off an unqualified leading tape head; conveying the leading tape head to the welding position; welding the leading tape head with the end part of the steel coil by using a welding machine; reversely rotating the ground rollers to carry out recoiling; bundling a recoiled big coil, and conveying the recoiled big coil to a double-stander rolling device through an double-stander; uncoiling the steel coil by using a steel coil uncoiler, wherein an uncoiled steel belt penetrates the space between mill rolls of a double-stander reversable mill, and two upper mill rolls of the double-stander reversable mill are both lifted; and coiling two ends of the steel belt by using a steel belt coiling machine, and starting rolling after the mill rolls of the double-stander reversable mill fall. According to the device and the method, the cold rolling efficiency of an iron and steel enterprise can be increased, a narrow leading tape can be used, and the production cost is relatively low.

Owner:JIGANG INT ENG & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com